Method for casting and forming TiAl-based alloy vent valve

A casting forming and exhaust valve technology, which is applied in the casting field of TiAl-based alloy castings, can solve the problems of centrifugal casting method, such as complex process, difficult internal quality assurance, complex casting process, etc., to avoid process and tedious process, and dimensional accuracy And the effect of high surface finish and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

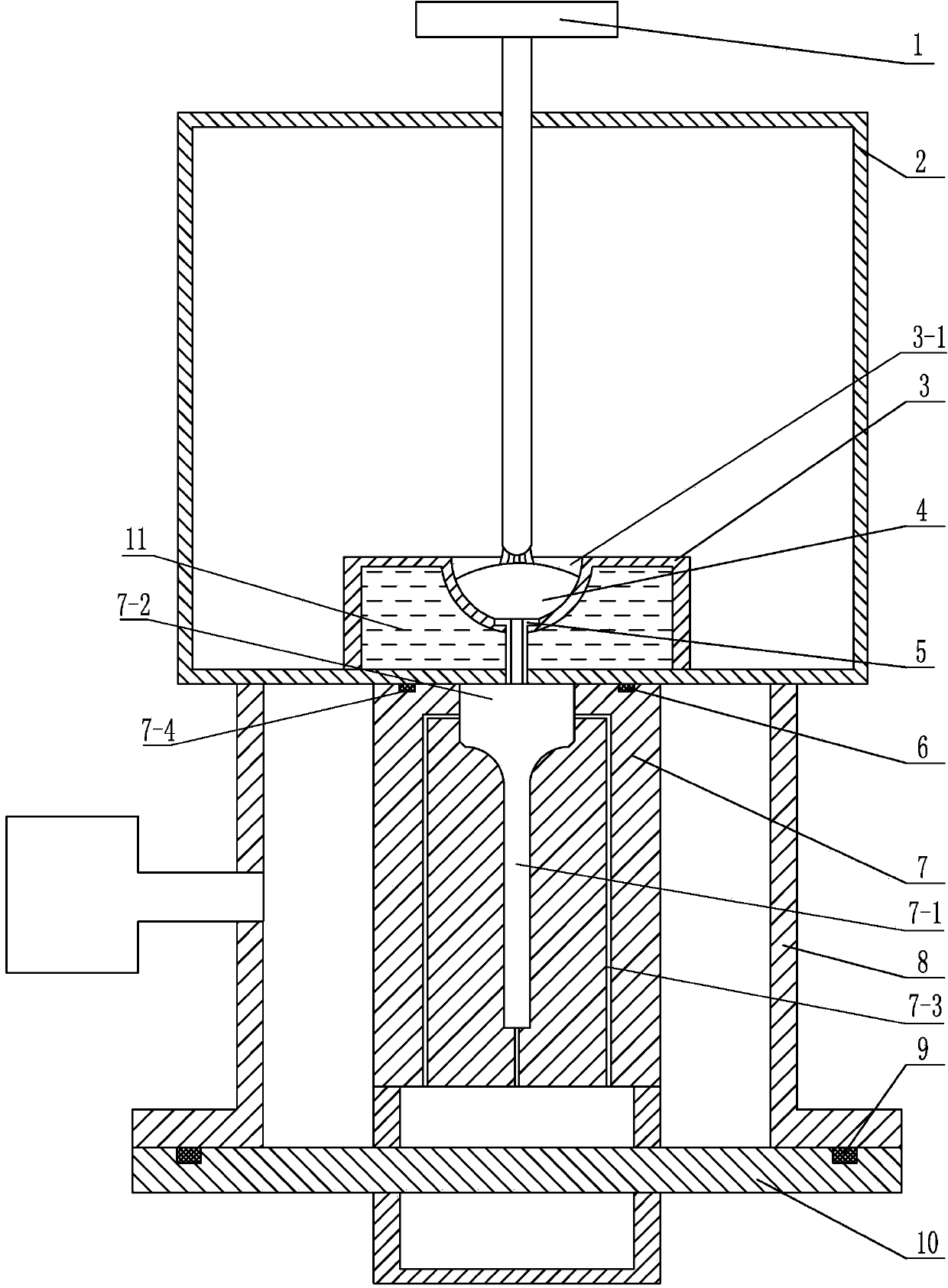

[0017] Specific implementation mode one: combine figure 1 Explain that the casting method of a TiAl-based alloy exhaust valve in this embodiment is carried out according to the following steps:

[0018] Step 1, manufacture the exhaust valve metal mold 7, the middle part of the exhaust valve metal mold 7 is processed with a cavity 7-1, the interior of the exhaust valve metal mold 7 is processed with two exhaust passages 7-3, two exhaust The channels 7-3 are arranged side by side on both sides of the cavity 7-1, the upper end of the exhaust channel 7-3 communicates with the cavity 7-1, the lower end of the exhaust channel 7-3 is against the bottom of the mold 7, and the bottom of the mold 7 There is an annular sealing groove 7-4 on the upper surface, and the gate 7-2 of the exhaust valve metal mold 7 is located in the annular sealing groove 7-4;

[0019] Step 2: Install the first sealing ring 9 on the mold base 10, install the second sealing ring 6 in the annular sealing groove...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step three, a graphite suction port with a diameter of 5 mm is selected. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step four, in step four, the TiAl-based alloy ingot melted in advance is put into the suction casting crucible 3 of the vacuum arc melting furnace, and then the melting chamber 2 is pumped Vacuum to 0.1Pa ~ 0.4Pa. Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com