Patents

Literature

189results about How to "No reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

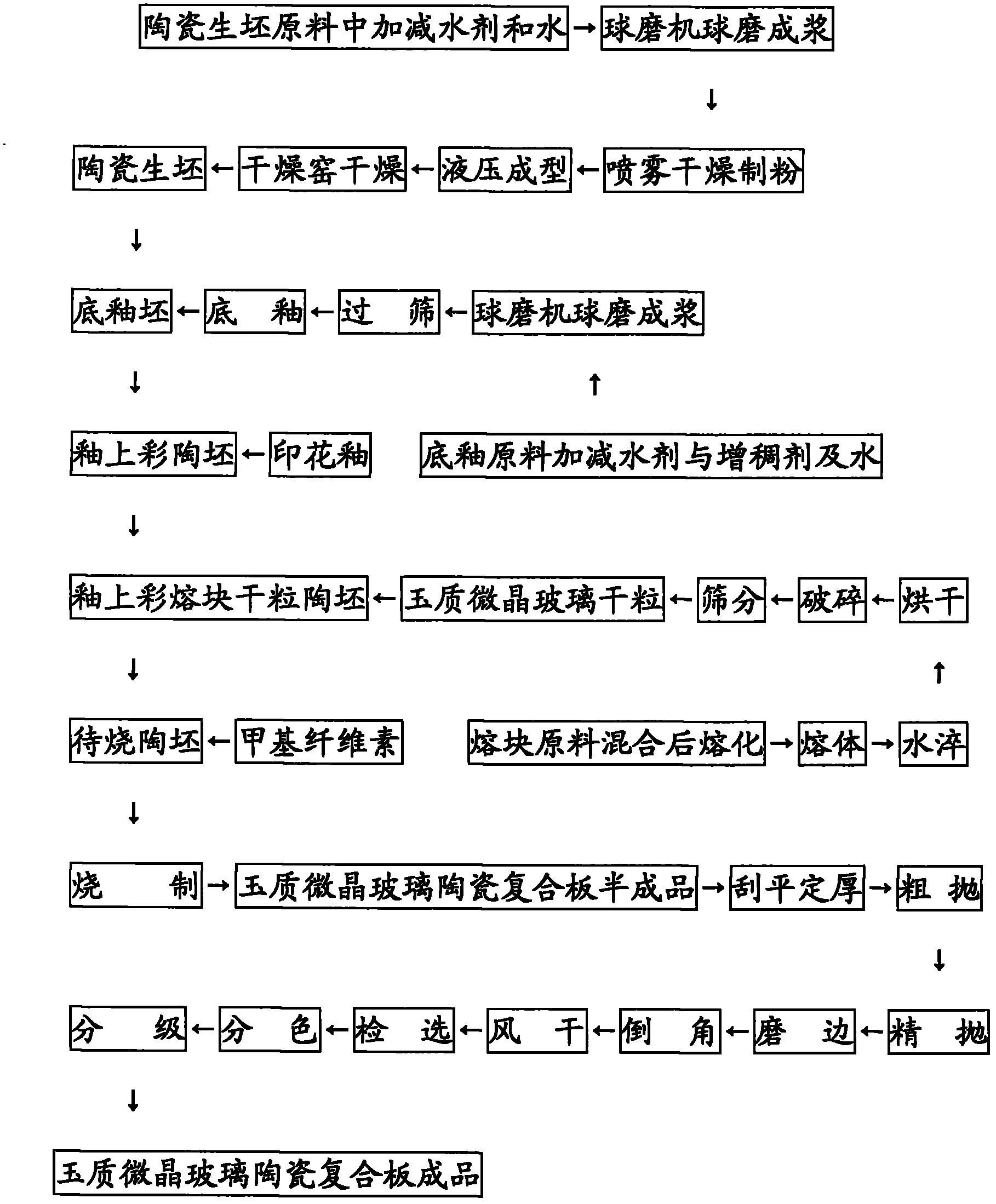

Method for preparing jadeite microcrystal glass ceramic composite board

The invention relates to a method for preparing a jadeite microcrystal glass ceramic composite board, and relates to the technical field of building materials. The method comprises the following steps of: on the basis of a key technology of 'jadeite microcrystal glass clinker dry granules obtained by selecting materials within a preset range of product ingredients', applying a ground coat on a ceramic blank to obtain a ground coat blank, and printing textile printing glaze on the ground coat blank to obtain an over-glaze colored ceramic blank; applying the jadeite microcrystal glass clinker dry granules on the over-glaze colored ceramic blank to obtain over-glaze colored clinker dry granular greenware, spraying methylcellulose for fixing to obtain greenware to be fired; and firing the greenware to be fired to obtain a semi-finished product, strickling, calibrating thickness, polishing coarsely, polishing finely, edging, chamfering, airing, sorting, performing color separation, and grading to prepare a finished product of the jadeite microcrystal glass ceramic composite board. The method is used for producing jadeite microcrystal glass ceramic composite boards, and adapts to a primary or secondary sintering process; and the product is high in quality, high in surface strength and wear resistance and wide in application range, and has a unique jadeite texture and a high comprehensive benefit.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

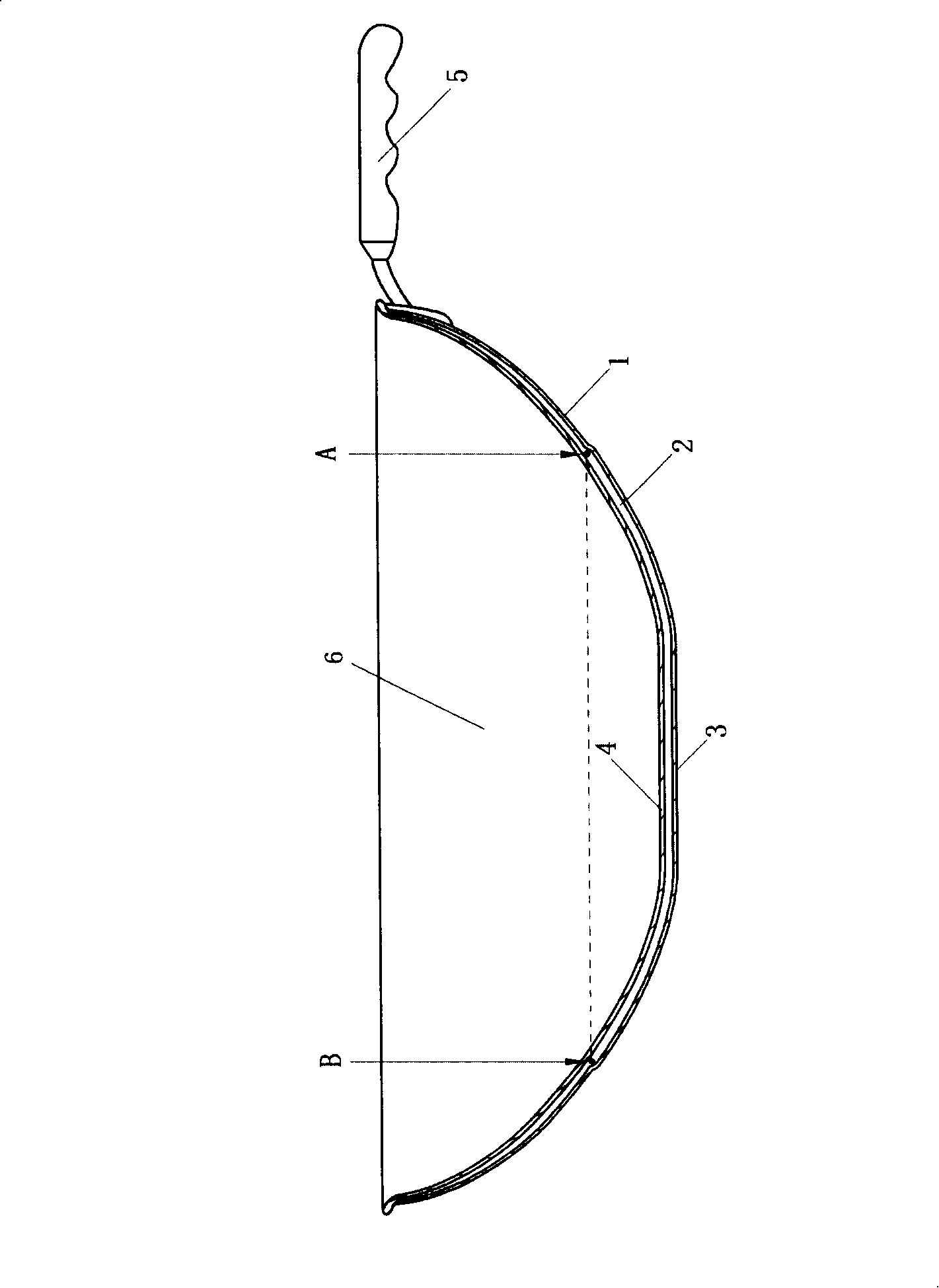

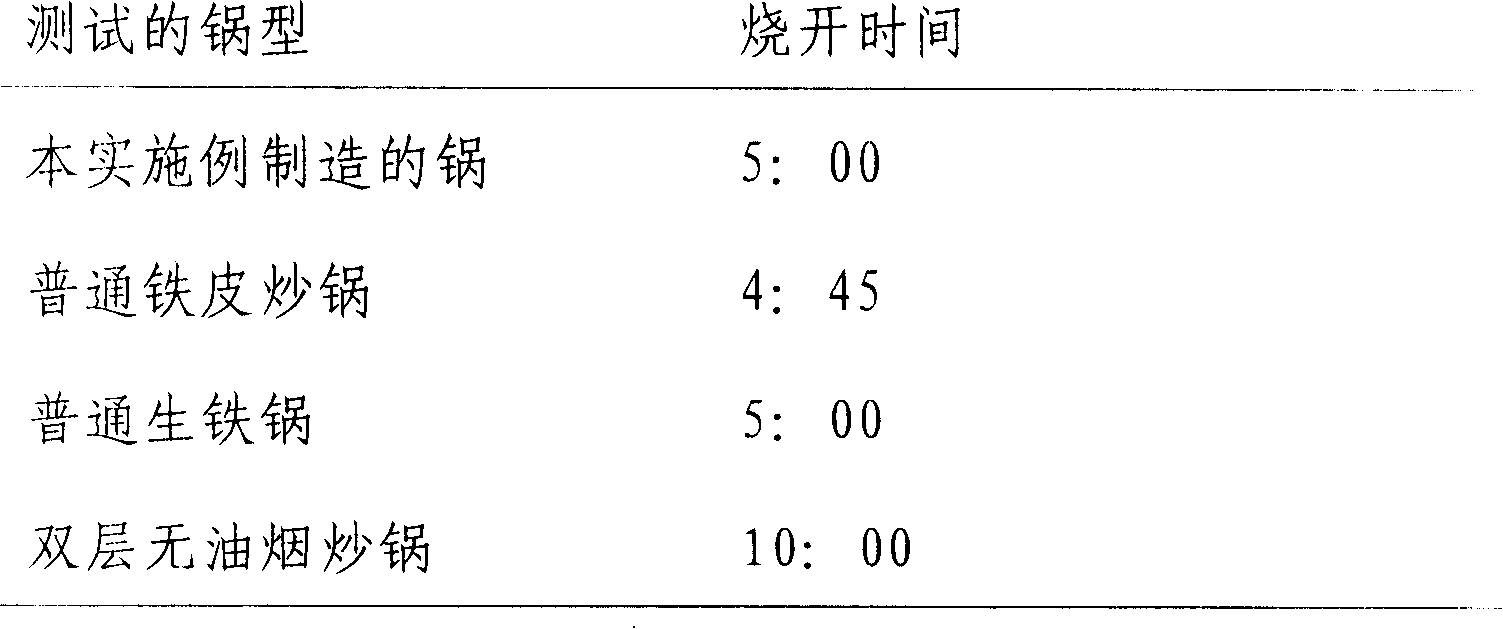

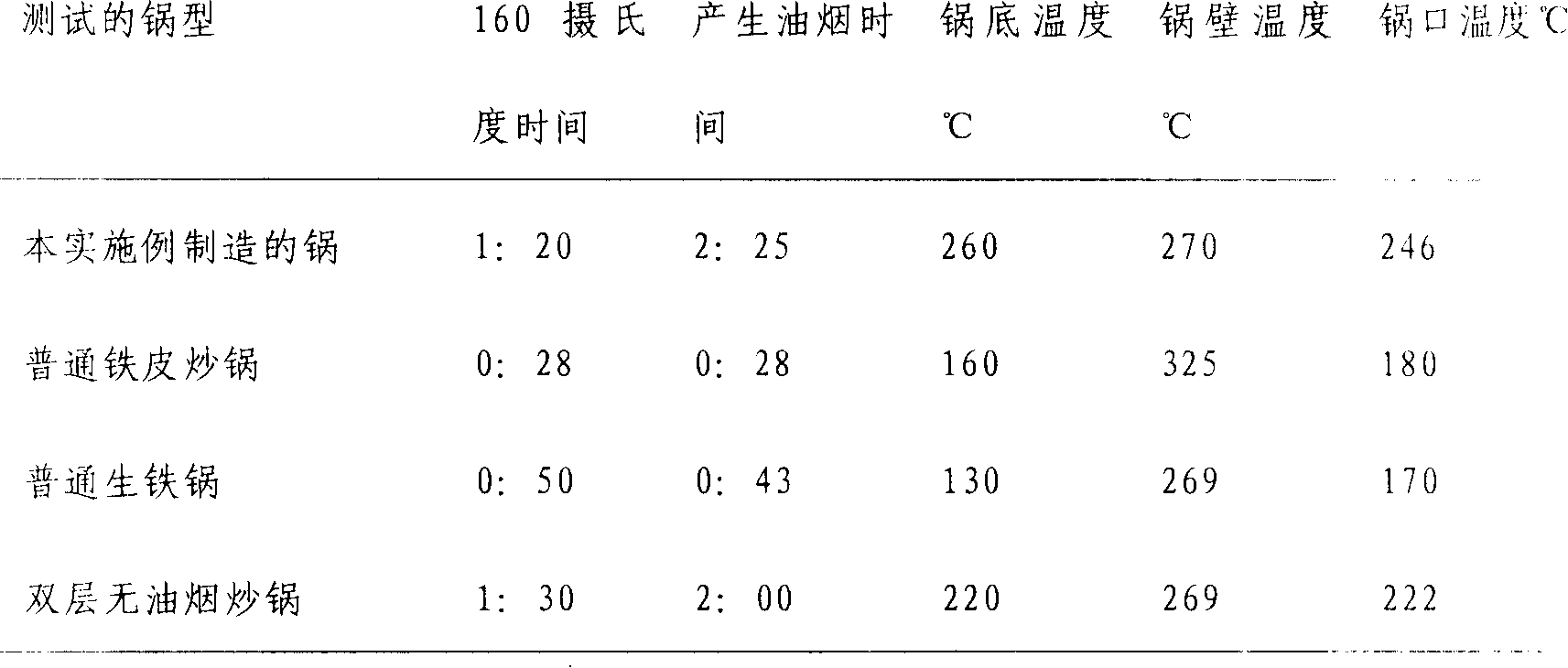

Zisha ware ceramal non-cooking fume non-stick pan and preparation method thereof

InactiveCN101190097AGood non-stickAvoid direct contactCooking-vessel materialsHardnessWear resistance

The invention relates to a purple clay pottery alloy non-stick cookware without oil smoke and a preparation method thereof. The purple clay pottery alloy non-stick cookware without oil smoke comprises a cookware body and a cookware handle, wherein, the cookware body takes aluminium alloy as a substrate, the outer surface of the substrate of the cookware body is provided with a pottery crystal layer, and the inner surface of the substrate is provided with a purple clay pottery layer. The purple clay pottery alloy non-stick cookware without oil smoke of the invention consists of the non-stick purple clay pottery layer, the substrate of the cookware body and the pottery crystal layer, so the cookware is heated uniformly and does not generate partial high temperature when in use, thus generating no oil smoke when cooking dishes; in addition, the purple clay pottery layer avoids the direct contact between food and the aluminium alloy substrate, and improves surface hardness considerably, thus leading the cookware body to have more wear resistance and adhesion resistance, resist high temperature and be safe and non-toxic to the human body.

Owner:胡金高

Alumina titanate ceramica lift tube preparation method

The invention relates to a preparation method of ceramic materials; the raw materials used in the method comprises alumina powder, titanium oxide powder, synthetic material of aluminium titanate and stabilizing agents, wherein, the stabilizing agents comprise magnesium oxide, silica dioxide, ferric oxide, chromium dioxide and zirconium oxide. The conditions of the preparation process are as follows: firstly, the raw material and water carry out ball milling and pulping by a wet method; secondly, the slurry is granulated and dried into powder with the water content to be less than 2 percent; thirdly, isostatic pressing molding is carried out; fourthly, the powder is sintered into a lift tube of aluminium titanate ceramics under the conditions that the sintering temperature is 1,480 to 1,550 DEG C, the sintering time is 20 to 30 hours and the sintering atmosphere is oxidizing atmosphere; wherein, alumina powder, titanium oxide powder, stabilizing agents and water carry out ball milling and pulping by the wet method and granulation to prepare particle size, then the synthetic material of aluminium titanate is prepared by sintering. The product prepared by the method is characterized by low price, non-infiltration of alumina melt, no reaction, high intensity, strong thermal shock resistant capability, no slag during the using process, long service life, etc.

Owner:DONGYING XINKEXINTETAO

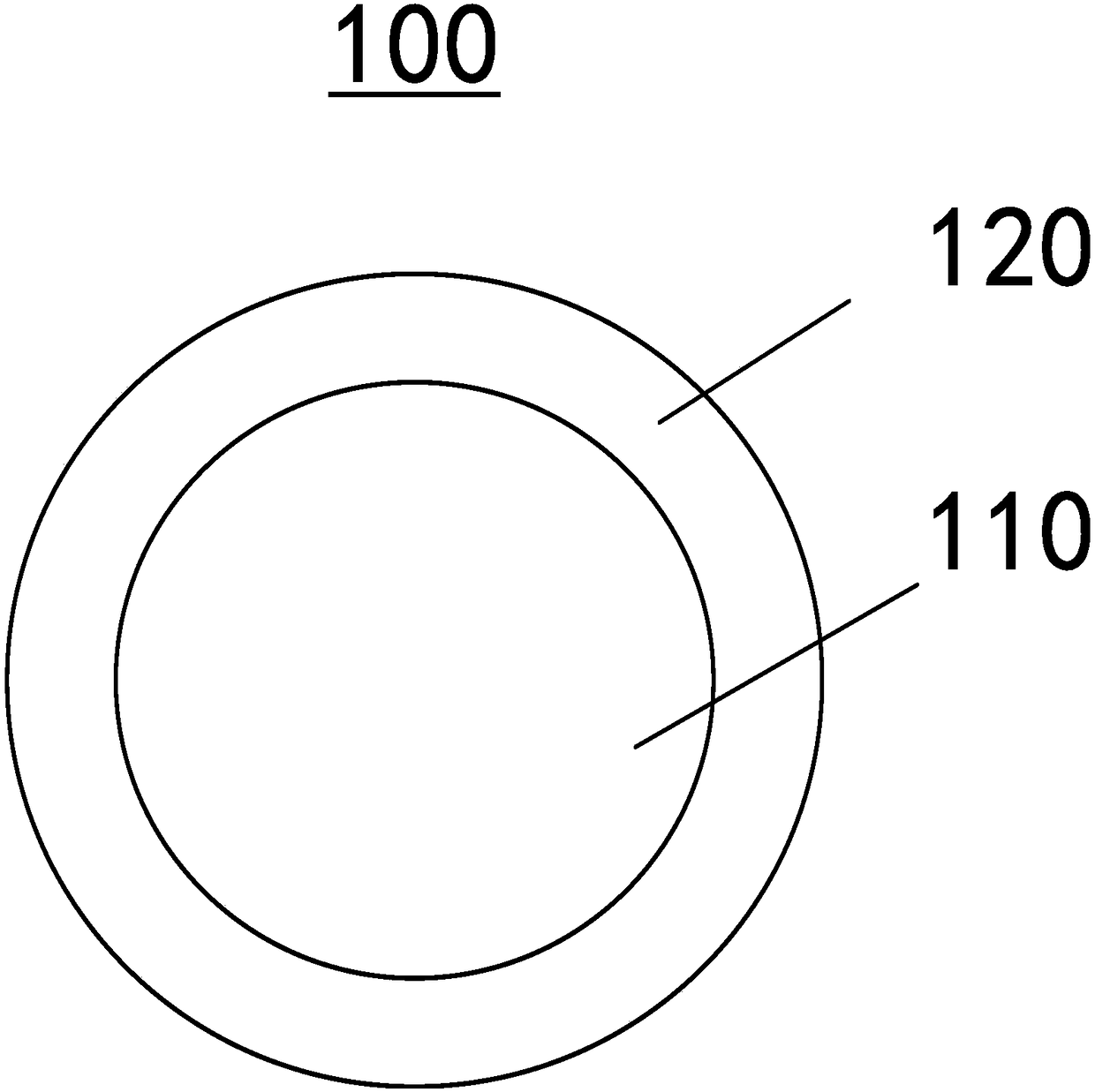

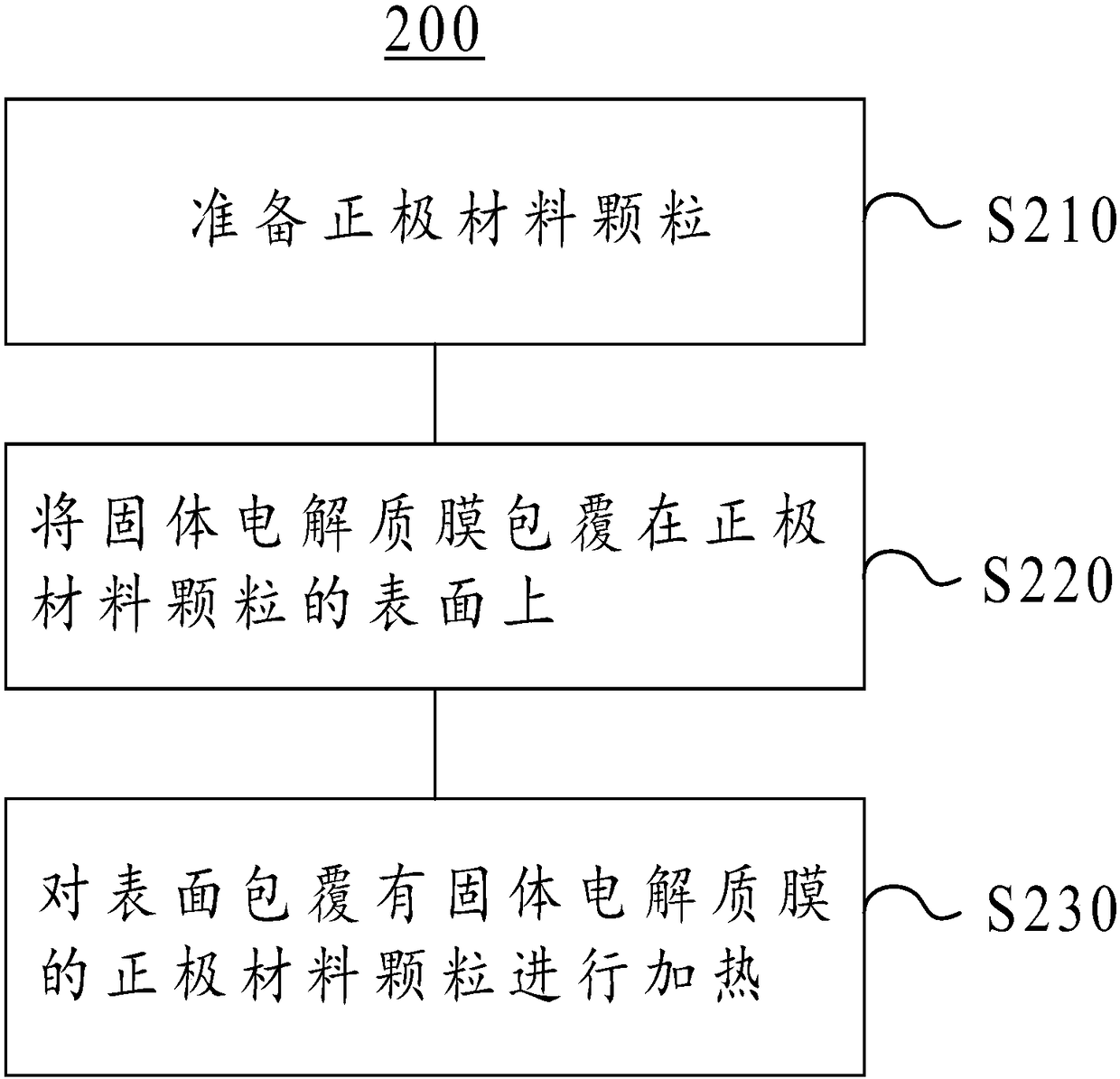

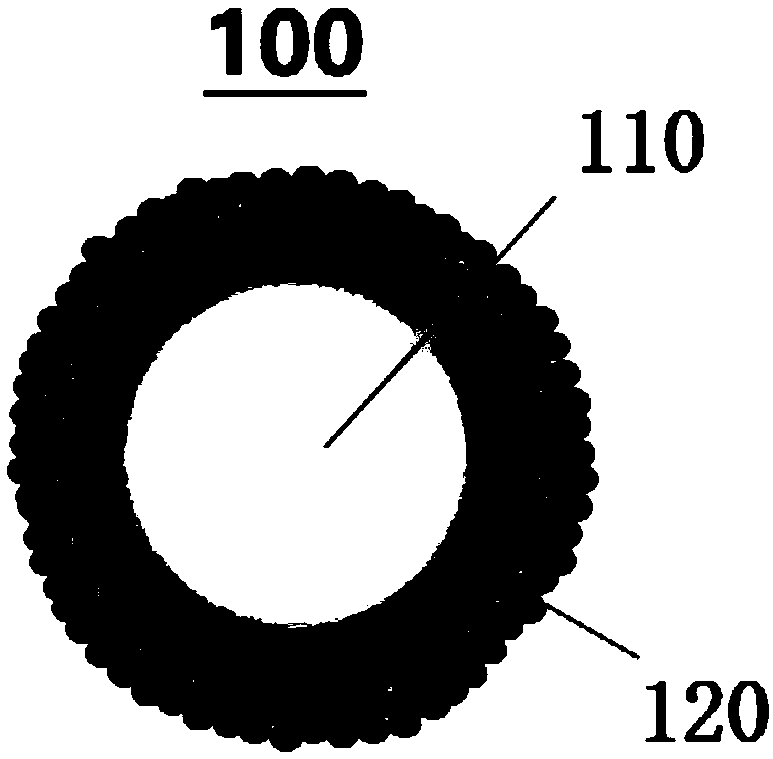

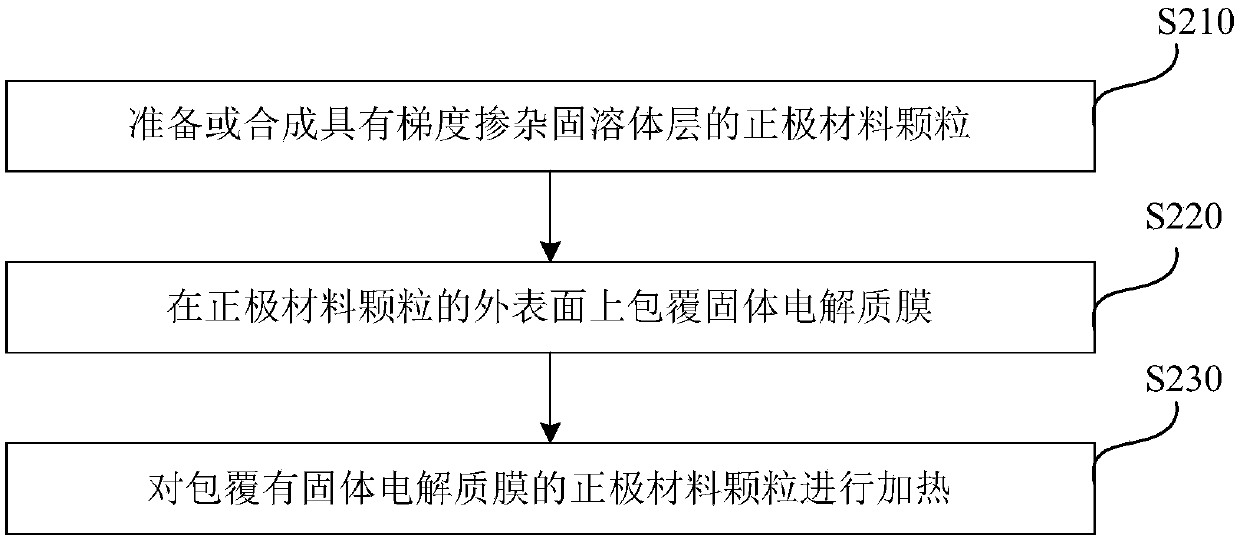

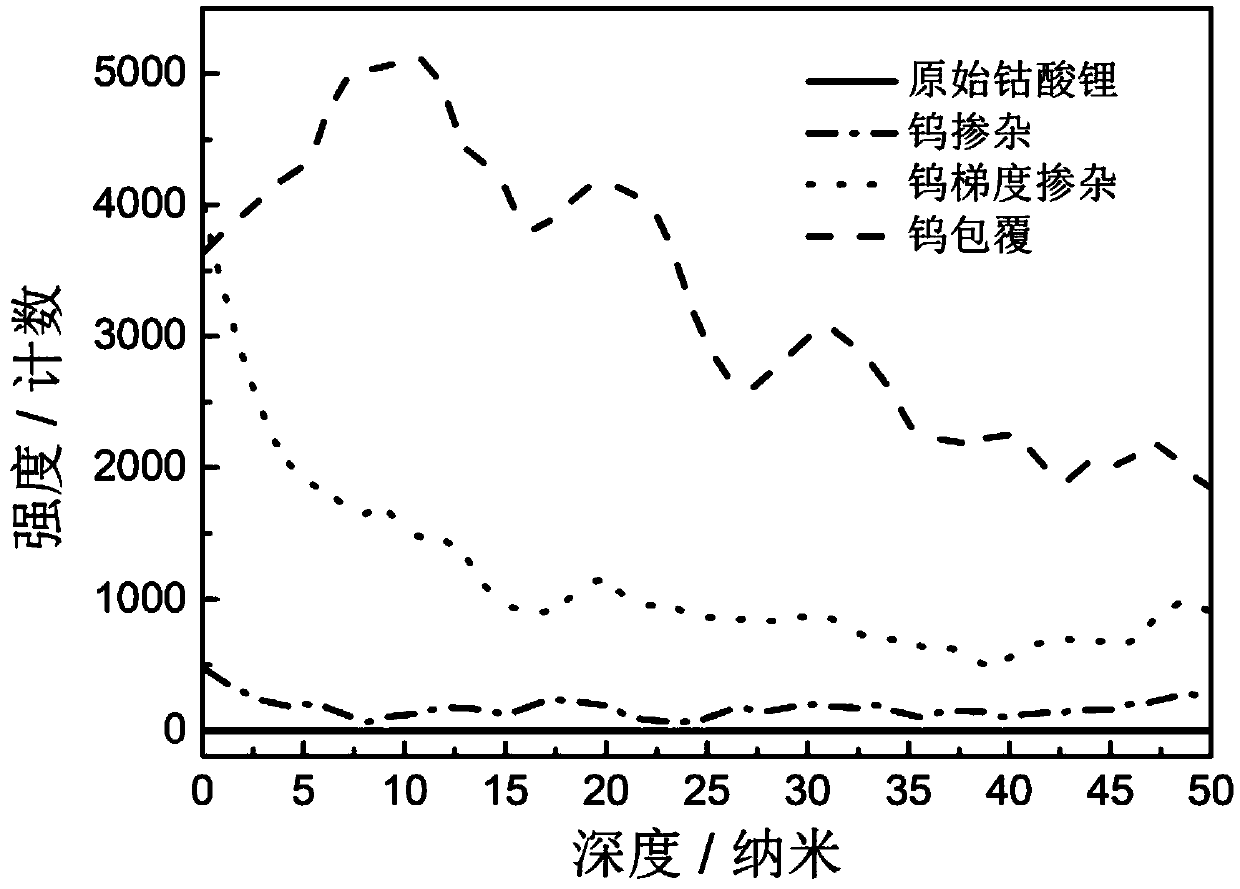

Lithium ion battery positive electrode material and preparation method thereof

InactiveCN108448055ASimple and easy way to make cathode material for lithium-ion batteriesSimple methodNon-aqueous electrolyte accumulator electrodesAmorphous phaseDissolution

The invention relates to a lithium ion battery positive electrode material and a preparation method thereof. According to an embodiment, the lithium ion battery positive electrode can comprise a positive electrode material particle and a solid electrolyte film, wherein the solid electrolyte film is coated on an outer surface of the positive electrode material particle, is a continuous film havingthickness within a range of 1-50 nanometers and comprises an amorphous phase and a crystal phase which coexist, the grain size is within a range of 1-40 nanometers, and no new phase is formed betweenthe solid electrolyte film and the positive electrode particle. By the lithium ion battery positive electrode material, the electrochemical stability can be improved, meanwhile, the problems of volumeexpansion of the positive electrode particle and dissolution-out of transition metal can be prevented, and thus, the lithium ion battery positive electrode material has the advantages of high electrochemical stability, favorable cycle property, high structure stability, good high-voltage performance, high safety and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

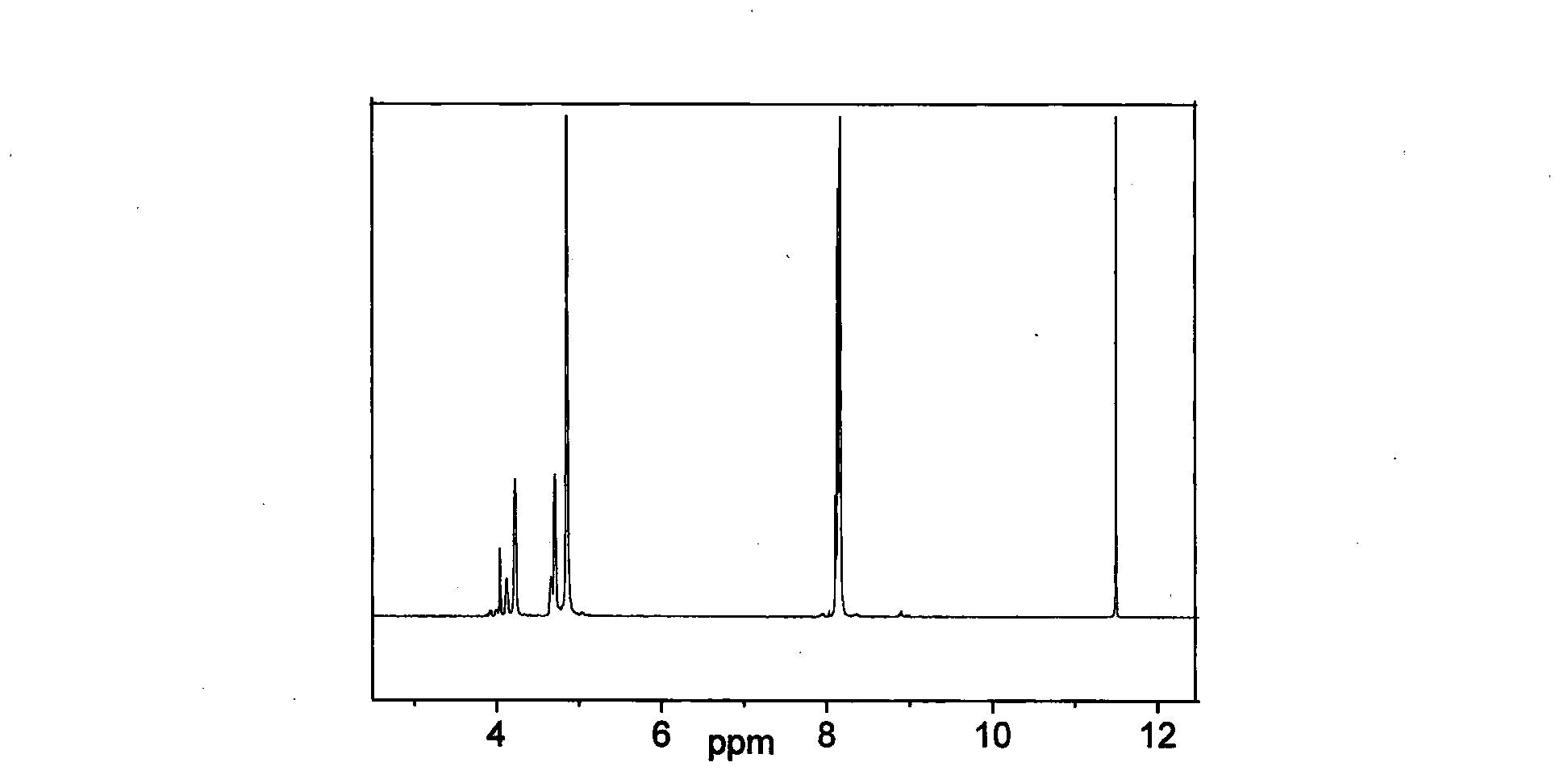

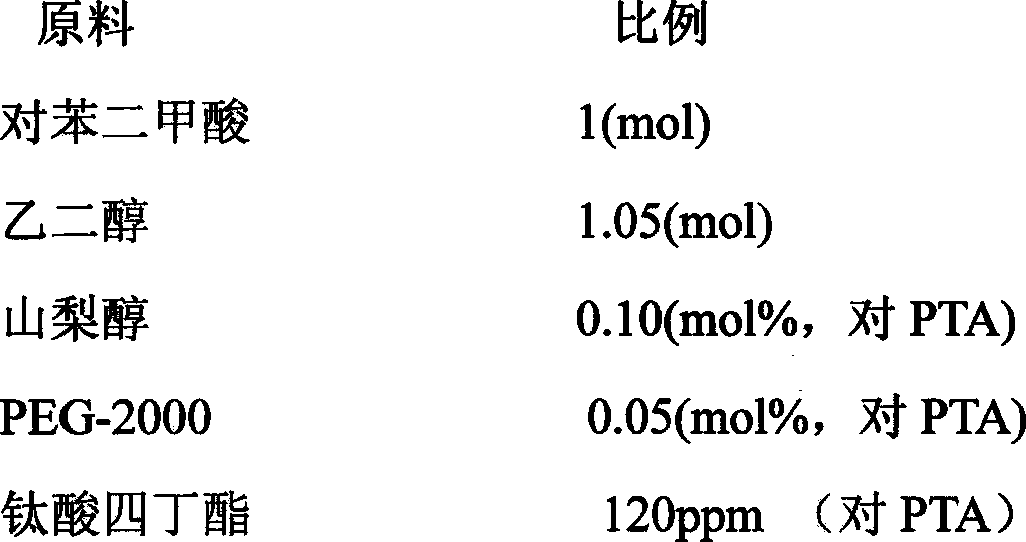

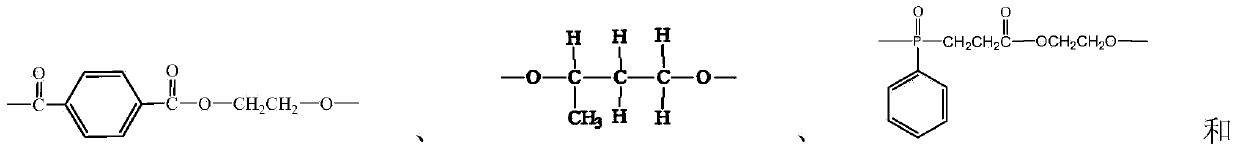

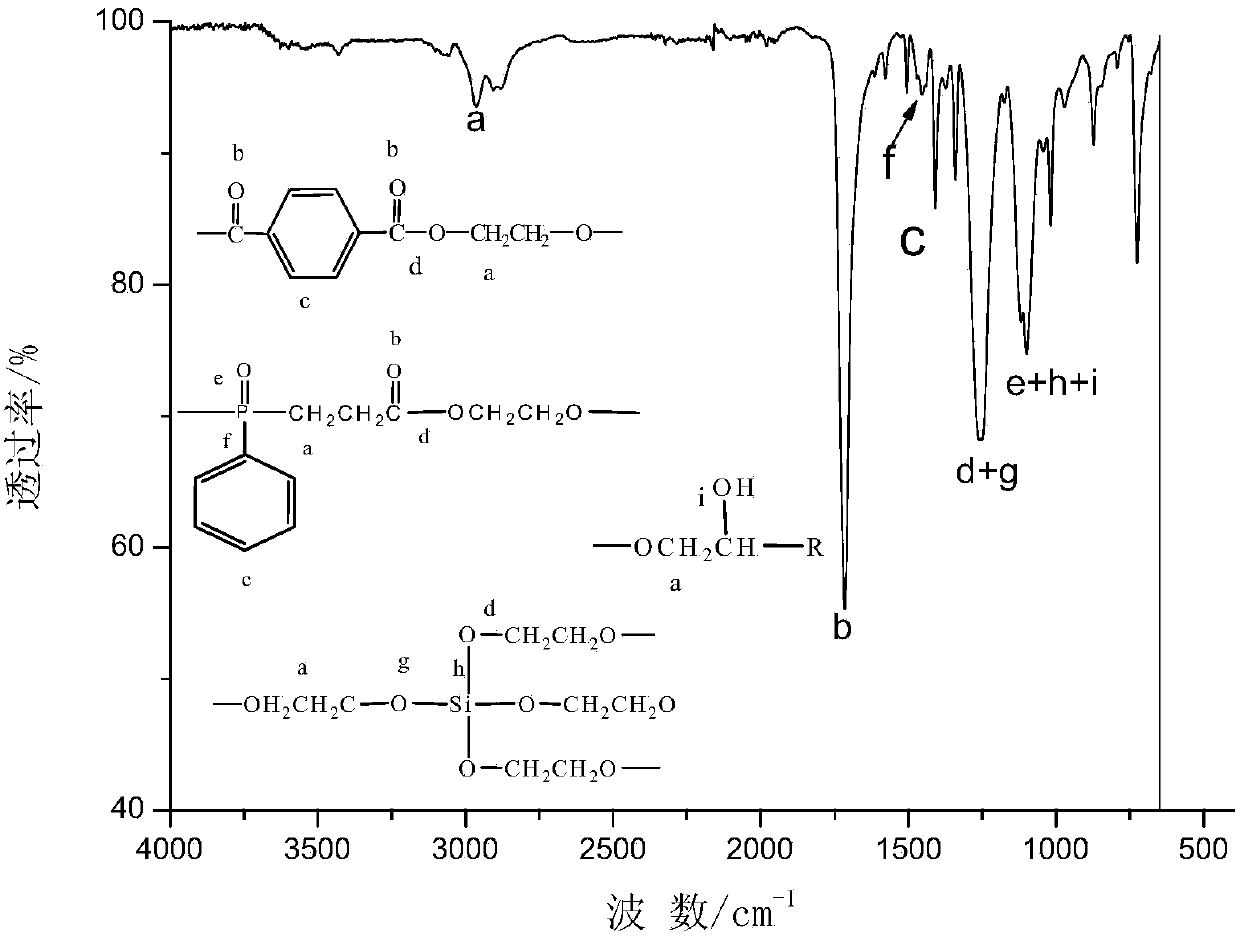

Preparation method for multi-functional hydrophilic polyester fibers

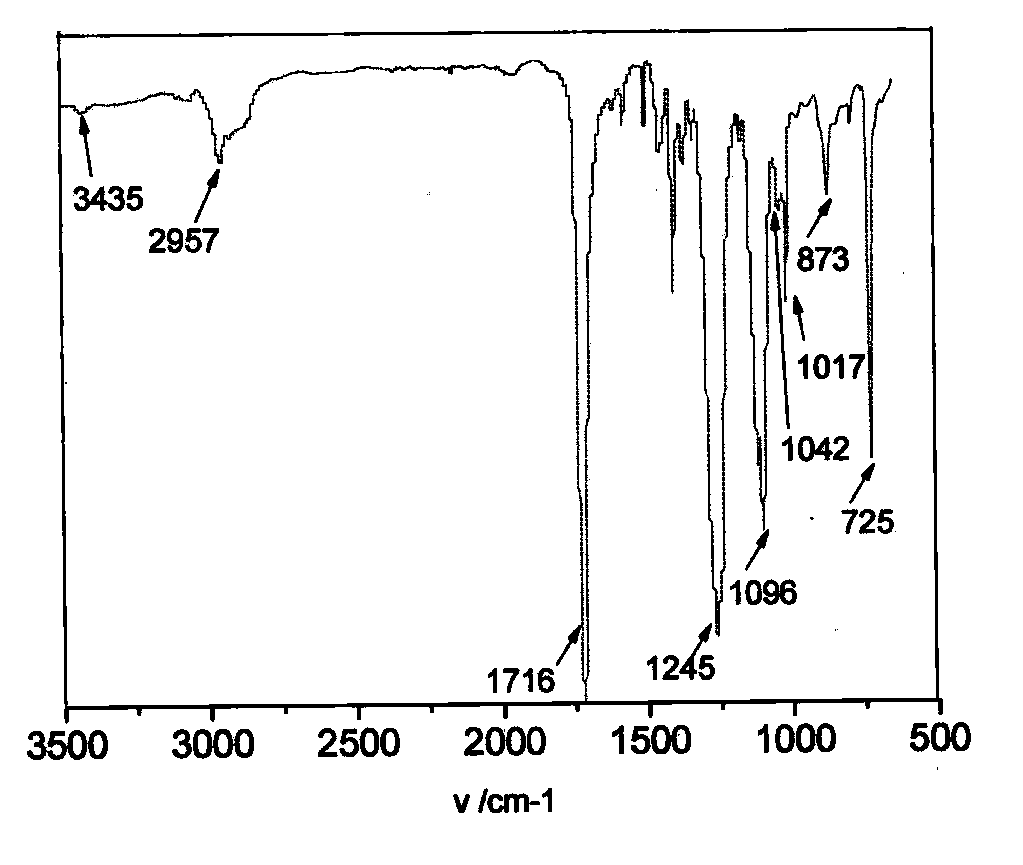

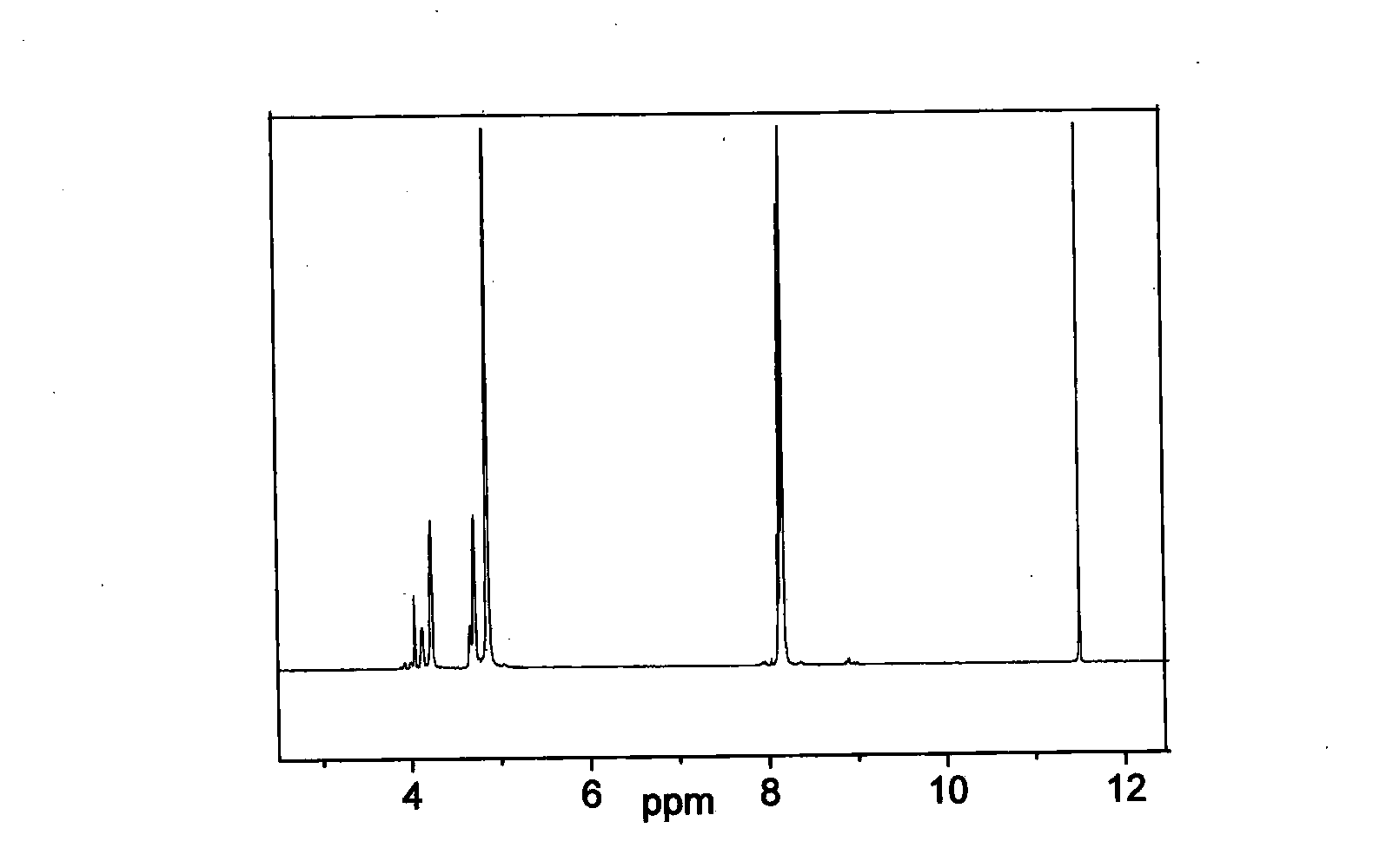

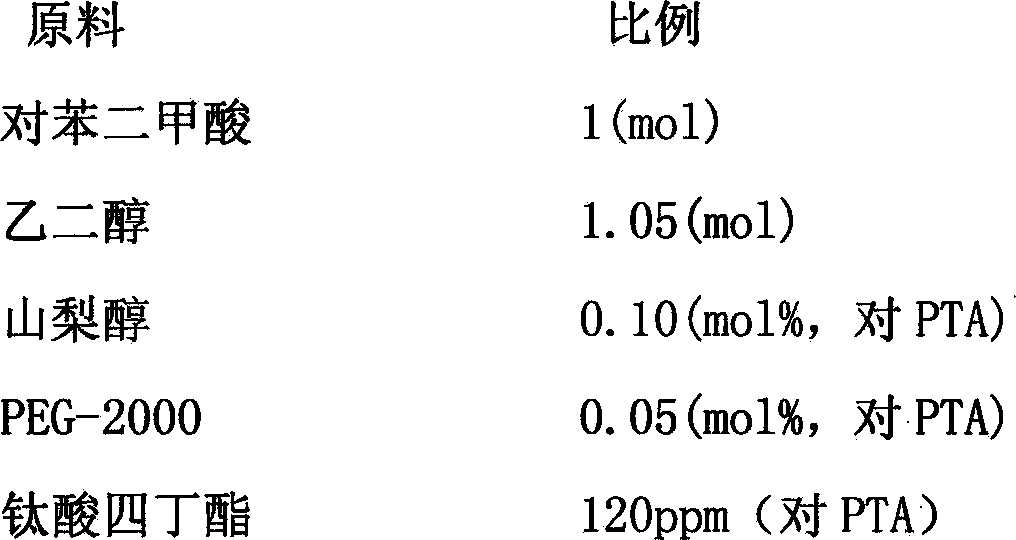

ActiveCN103820878AImprove hydrophilicityNo reactionMonocomponent polyesters artificial filamentArtifical filament manufacturePolyethylene glycolEthylene glycol

The invention provides a preparation method for multi-functional hydrophilic polyester fibers. The method is characterized by specifically comprising the following steps: firstly, mixing terephthalic acid with ethylene glycol to prepare a paste; adding into an esterfying reactor to carry out first esterfying reaction; when the collecting quantity of byproducts reaches 82-95% of a theoretical value, adding sorbitol and polyethylene glycol to carry out second esterfying reaction; after finishing esterfying reaction, performing polycondensation reaction on obtained esterfied products so as to obtain a hydrophilic polyester chip; secondly, preparing nanometer coffee carbon powder; thirdly, preparing nanometer bamboo charcoal powder containing an ultraviolet resistor; fourthly, performing fusing granulation on the nanometer bamboo charcoal powder containing the ultraviolet resistor and the hydrophilic polyester chip so as to obtain functional master batch; fifthly, performing fusing spinning on the functional master batch and the hydrophilic polyester chip so as to obtain the multi-functional hydrophilic polyester fibers. The multi-functional hydrophilic polyester fibers have great hydrophilic performance and continuously have the functions of the ultraviolet resistor and the bamboo charcoal for a long term.

Owner:江苏三联新材料股份有限公司

Hydrophilic polyester fiber containing coffee carbon and preparation method of hydrophilic polyester fiber

ActiveCN103820879AFine structureEffective absorptionMonocomponent polyesters artificial filamentArtifical filament manufactureChemistryPolyester

The invention provides a hydrophilic polyester fiber containing coffee carbon and a preparation method of the hydrophilic polyester fiber. The hydrophilic polyester fiber containing coffee carbon is characterized by comprising a hydrophilic polyester fiber body and nanoscale coffee carbon powder scattered in the hydrophilic polyester fiber body. The hydrophilic polyester fiber containing coffee carbon is good in hydrophilicity, can be used for deodorizing, warming and is dried quickly, and brings touch sensation of enjoying refreshing and comfort to consumers.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

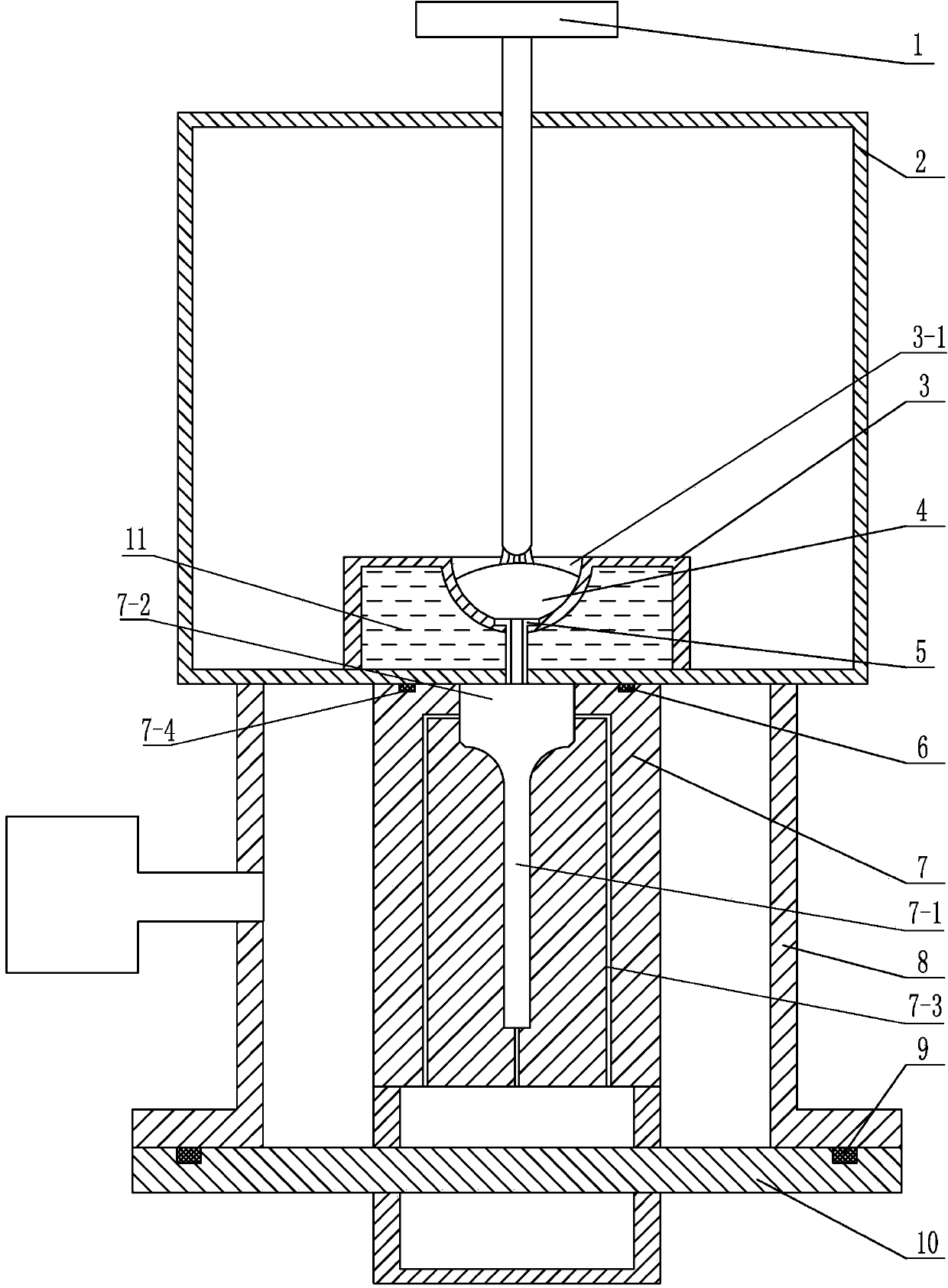

Method for casting and forming TiAl-based alloy vent valve

The invention provides a method for casting and forming a TiAl-based alloy vent valve, and relates to casting methods for the TiAl-based alloy vent valve. The technical problems that gravity casting of an existing TiAl-based alloy vent valve can not enable mold filling to be conducted smoothly, inner quality can not be guaranteed, a centrifugal casting method is complex in process, the material utilization rate is low, the casting process is too complex, and the surface quality is poor are solved. The method mainly comprises the steps that first, the prior art is used for manufacturing a metal mold of the vent valve; second, the metal valve of the vent valve in the first step is placed in a suction casting chamber of a smelting furnace, and the metal mold of the vent valve is mounted on a mold seat; third, a graphite suction port is mounted on a water cooling crucible; fourth, a TiAl-based alloy pig which is smelted in advance is placed in a suction casting crucible of a vacuum arc melting furnace, and overheating melt is obtained by smelting; fifth, a vacuum system of a suction casting chamber of the vacuum arc melting furnace is opened, a suction casting button is opened, suction casting, mold filling and cooling are conducted, and a casting is obtained. The method is used for preparing TiAl-based alloy vent valve castings.

Owner:HARBIN INST OF TECH

Praseodym or praseodym-europim doped strontium lithium silicate yellow-red fluorescent powder and preparation method thereof

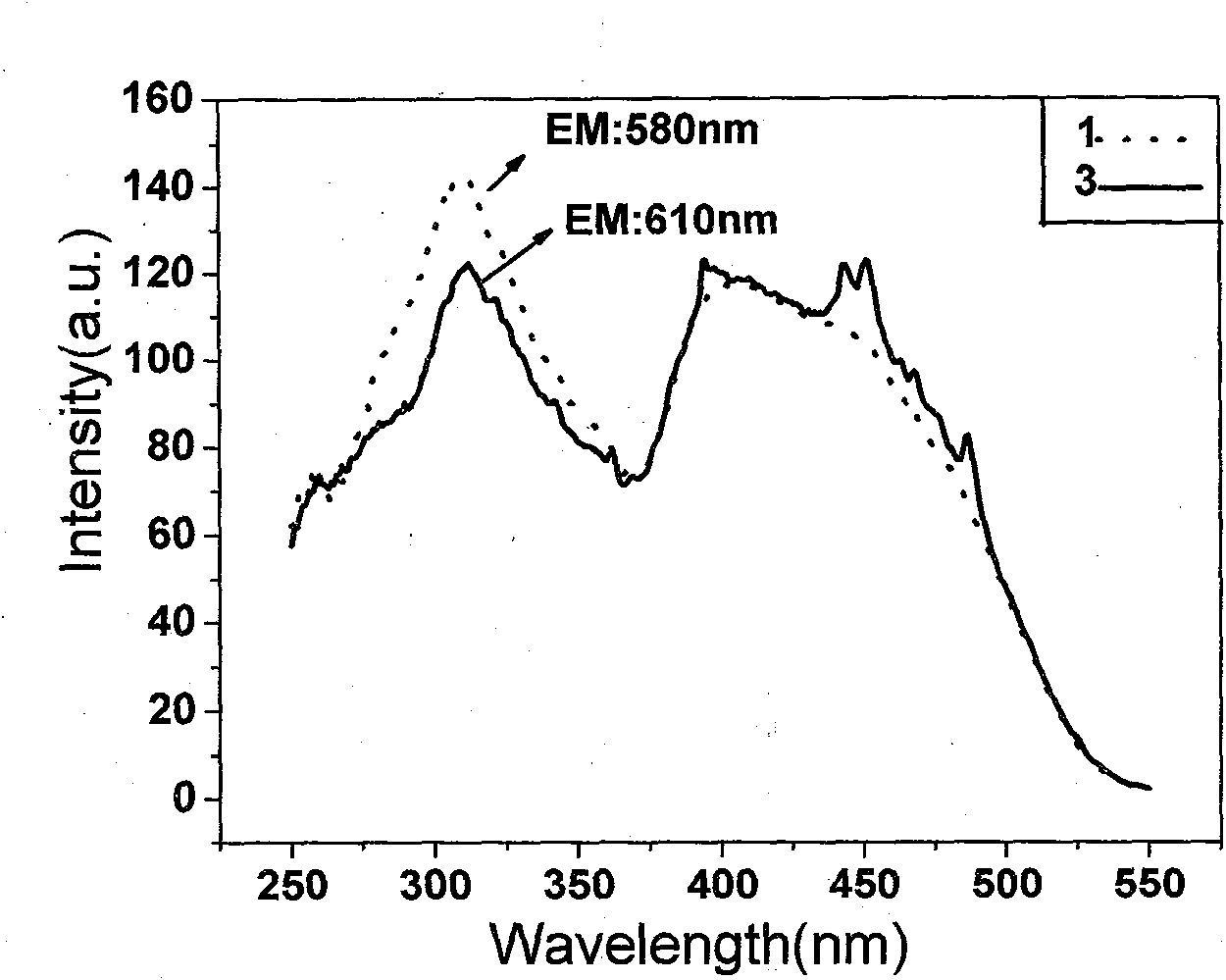

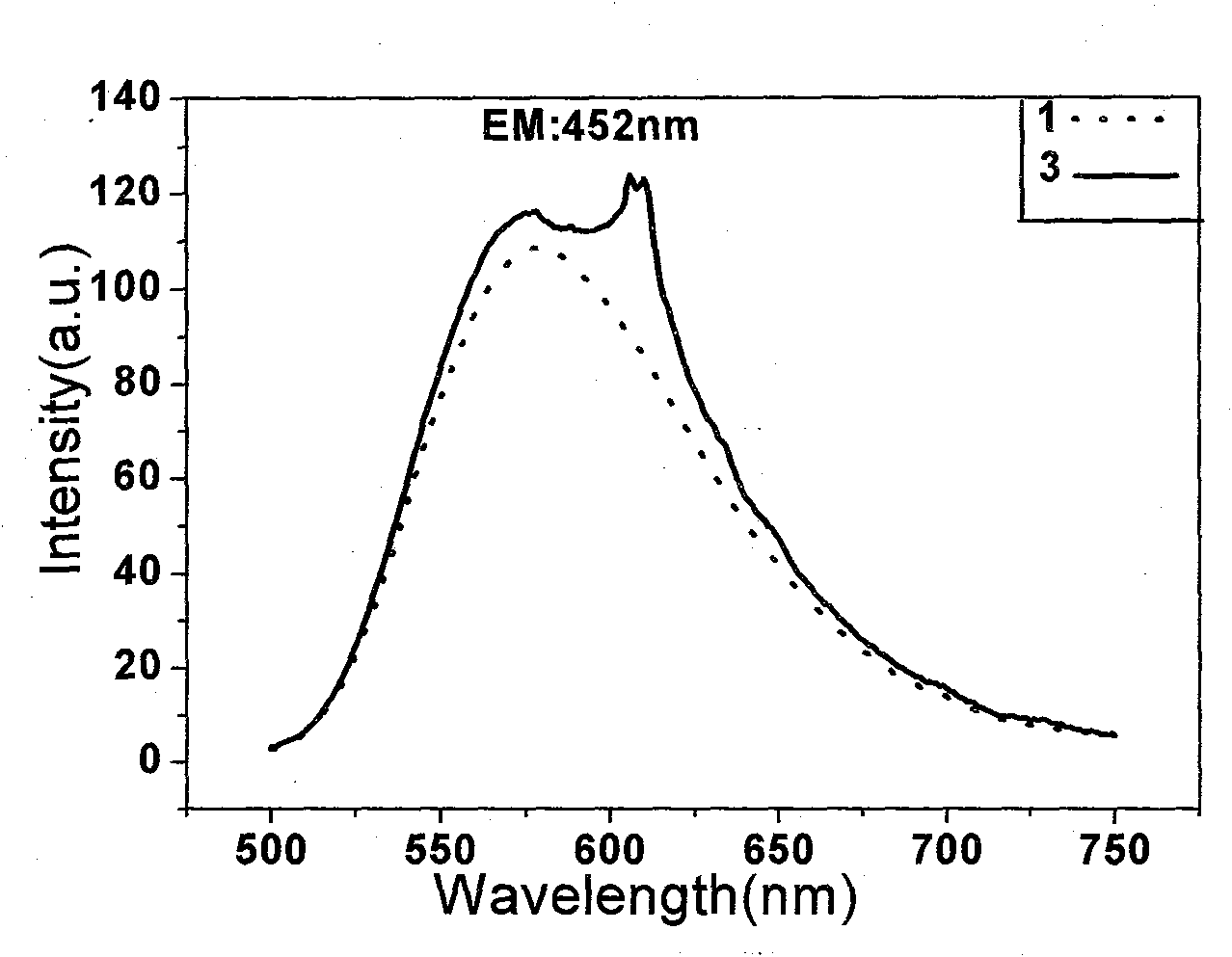

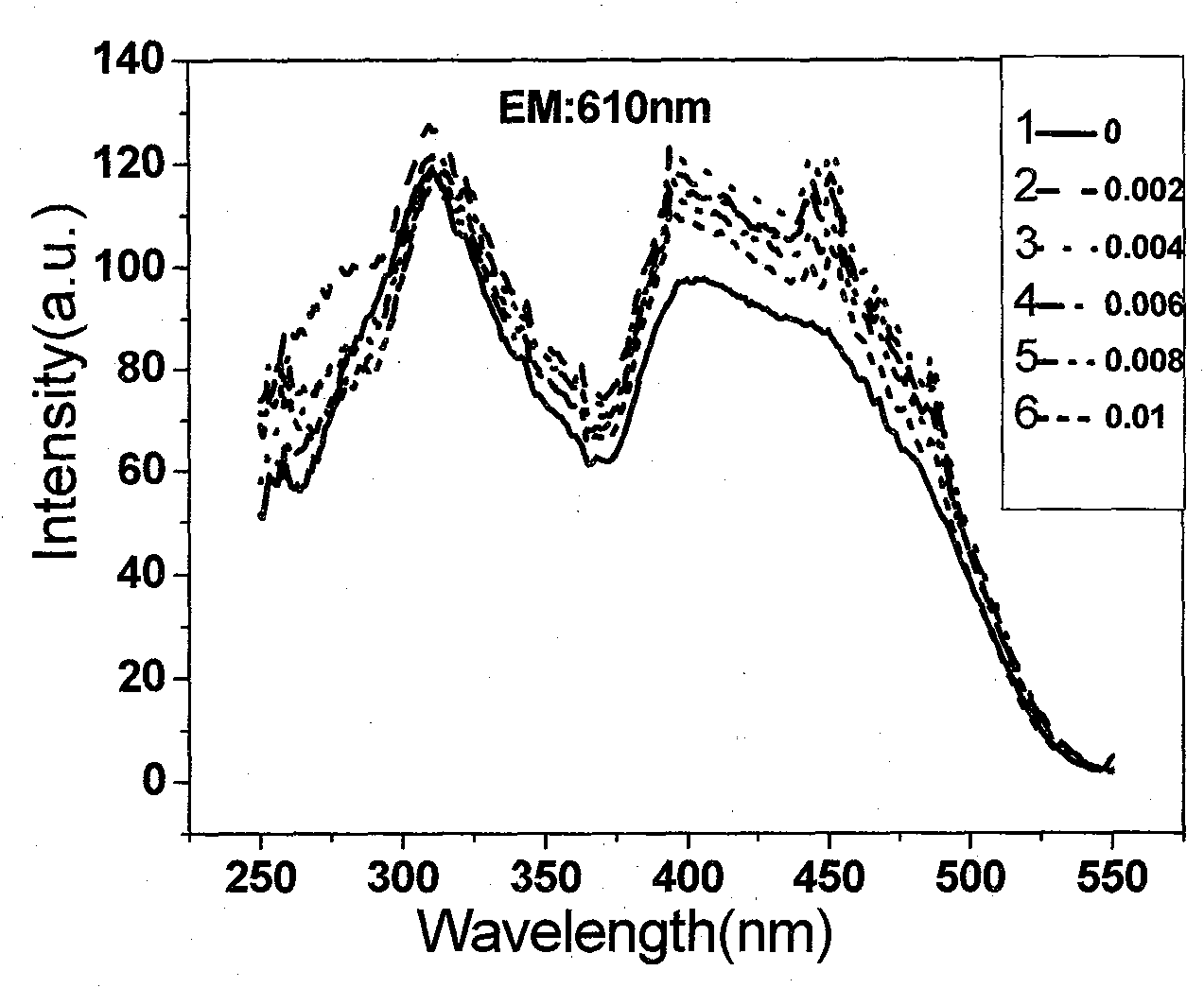

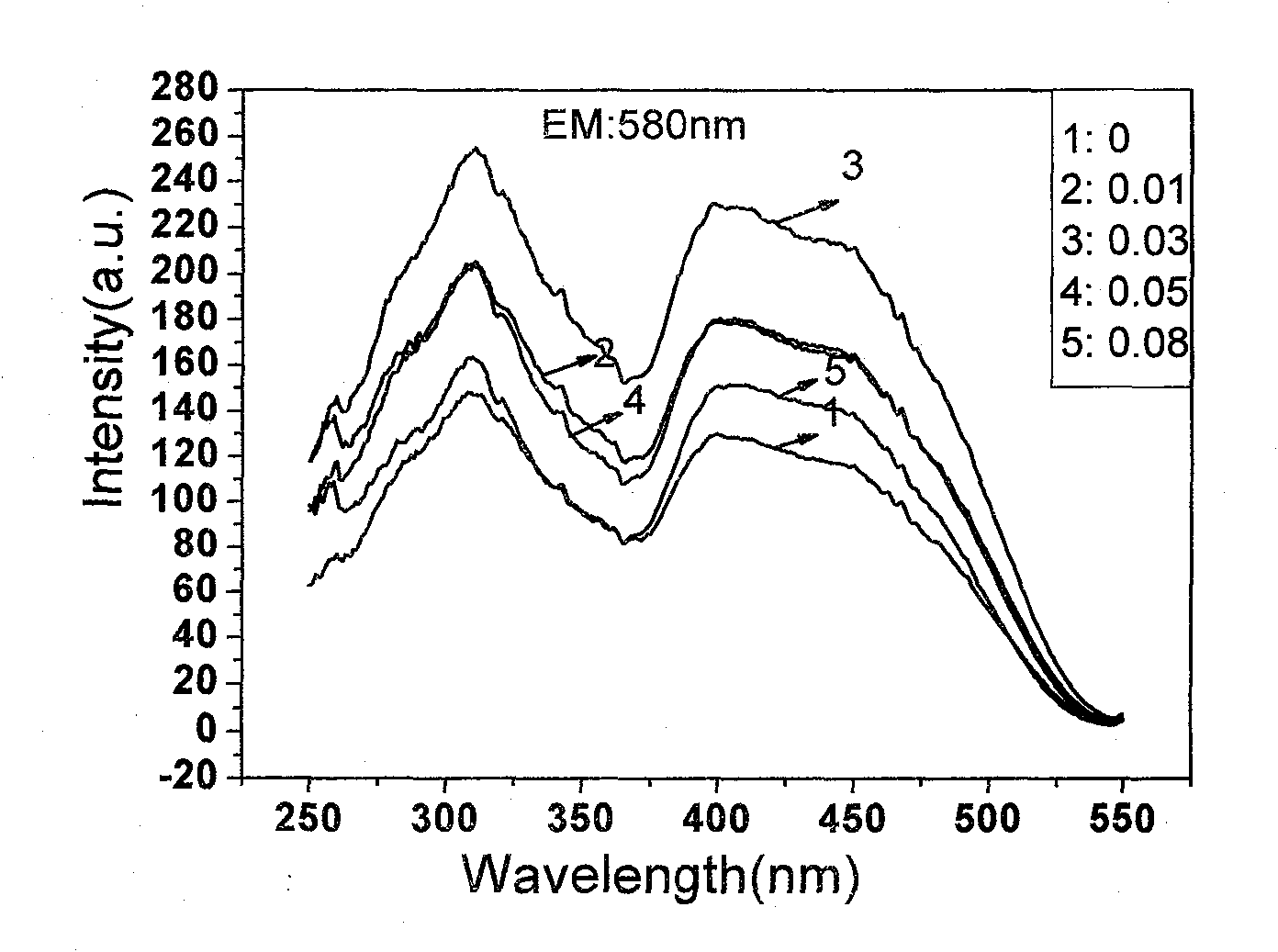

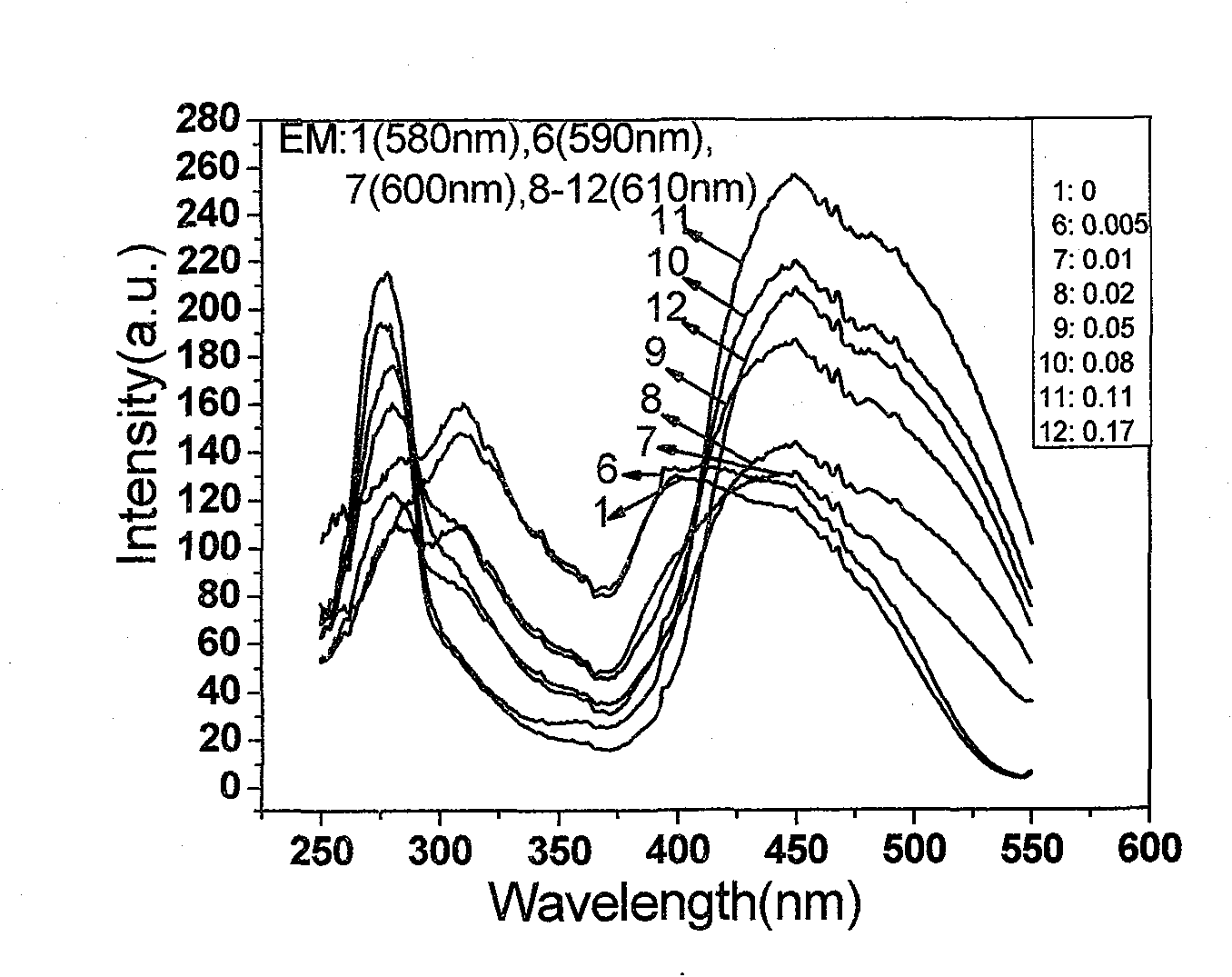

InactiveCN101818062AWide range of excitation wavelengthsImprove luminous performanceLuminescent compositionsBroadband transmissionEuropium

The invention relates to praseodym or praseodym-europim doped strontium lithium silicate yellow-red fluorescent powder and a preparation method thereof. The fluorescent powder utilizes strontium lithium silicate as a medium, can be effectively triggered by blue light with the wavelength of 400-500nm by codope of the praseodym and europium, and has a doublet broadband transmission characteristic (the main peaks are respectively 580nm and 610nm); and the fluorescent powder can be triggered by blue light with the wavelength of 440-490nm to transmit strong red fluorescence (the main peak is a narrow band of 610nm) by single dope of praseodym. The chemical composition of the fluorescent powder has a general formula as Li2Sr1-x-ySiO4:xEu2+, yPr3+, wherein x is no less than 0 and no more than 0.02, so is y. The excitation spectrum of the fluorescent powder has good matching with a blue light LED chip, so the fluorescent powder can be used in assembly of a white light LED with a high color rendering index; and the preparation process is easy to control, and the basic equipment of the current fluorescent powder plants can be used for realizing industrialized production, thus the fluorescent powder is novel and has application potential.

Owner:NANCHANG UNIV

Artificial crystal synthesizing mica and its preparation technology

The present invention relates to artificial crystal synthetic mica and its preparation process. Its raw material composition includes (by wt%) 33%-37% of quartz, 28%-31% of magnesium oxide, 9%-12% of aluminium oxide, 18%-21% of potassium fluorosilicate and 0.3%-0.4% of potassium carbonate. Its preparation process includes the procedures of preparing raw materials, processing in container and melting, etc.

Owner:王新成

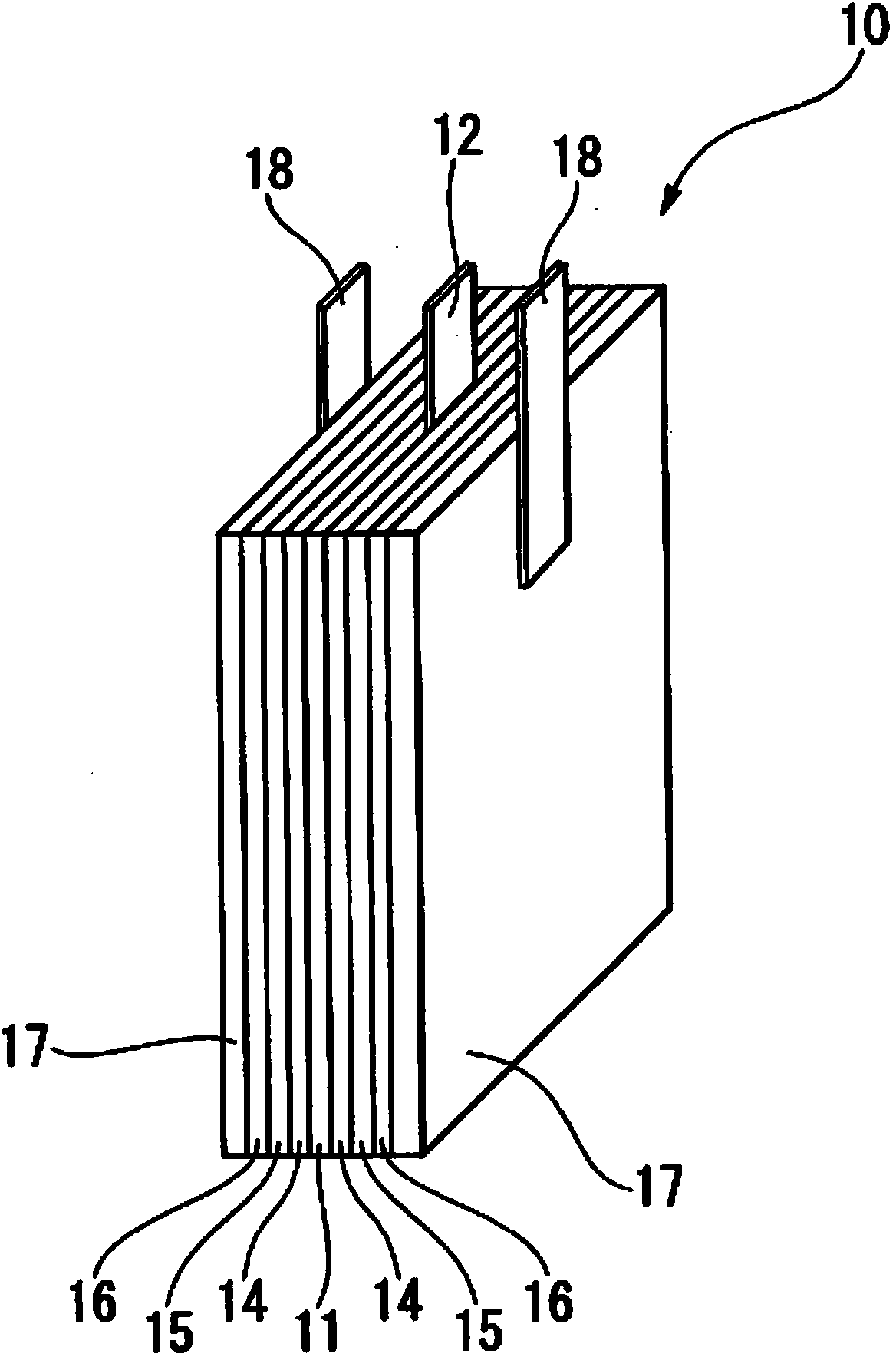

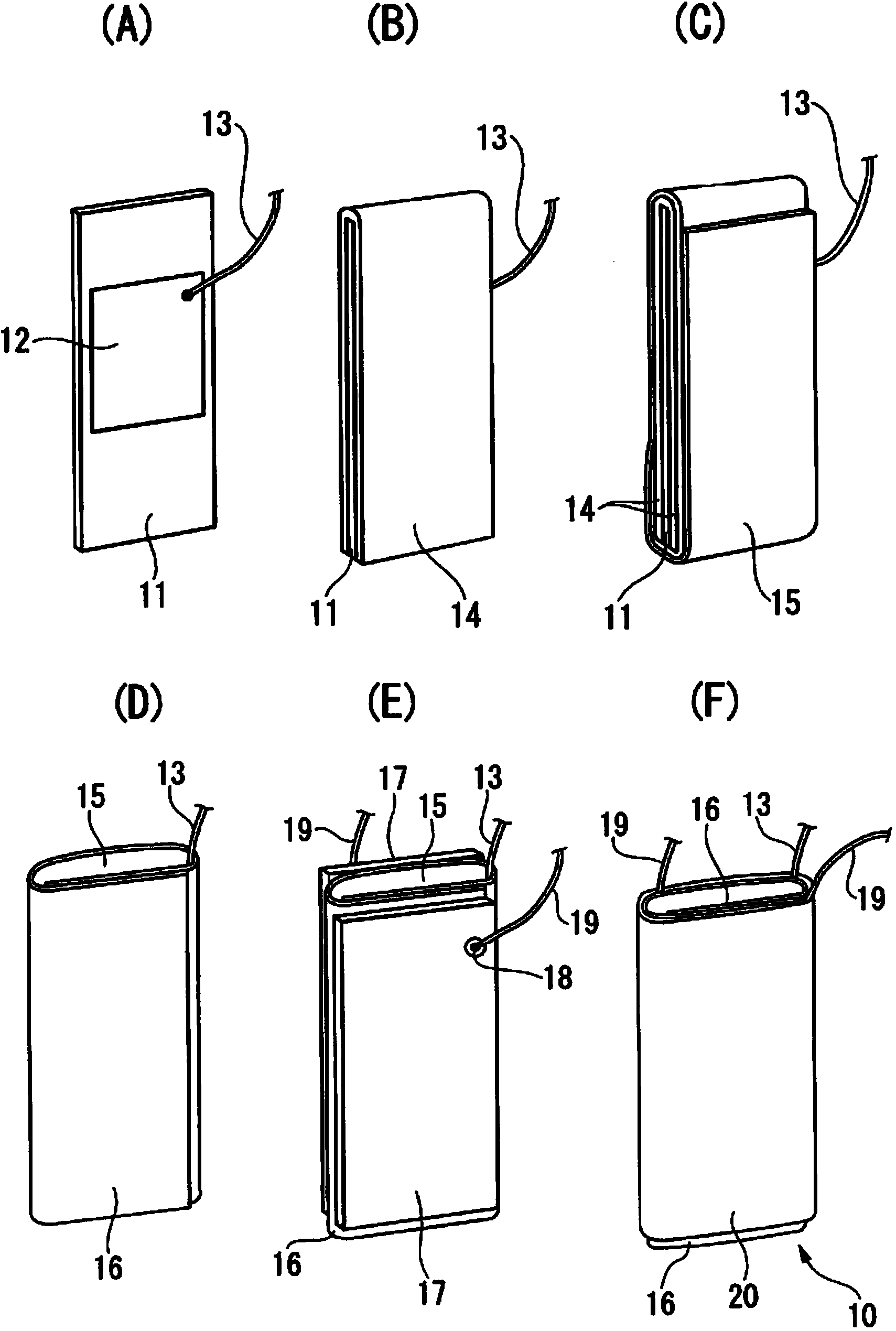

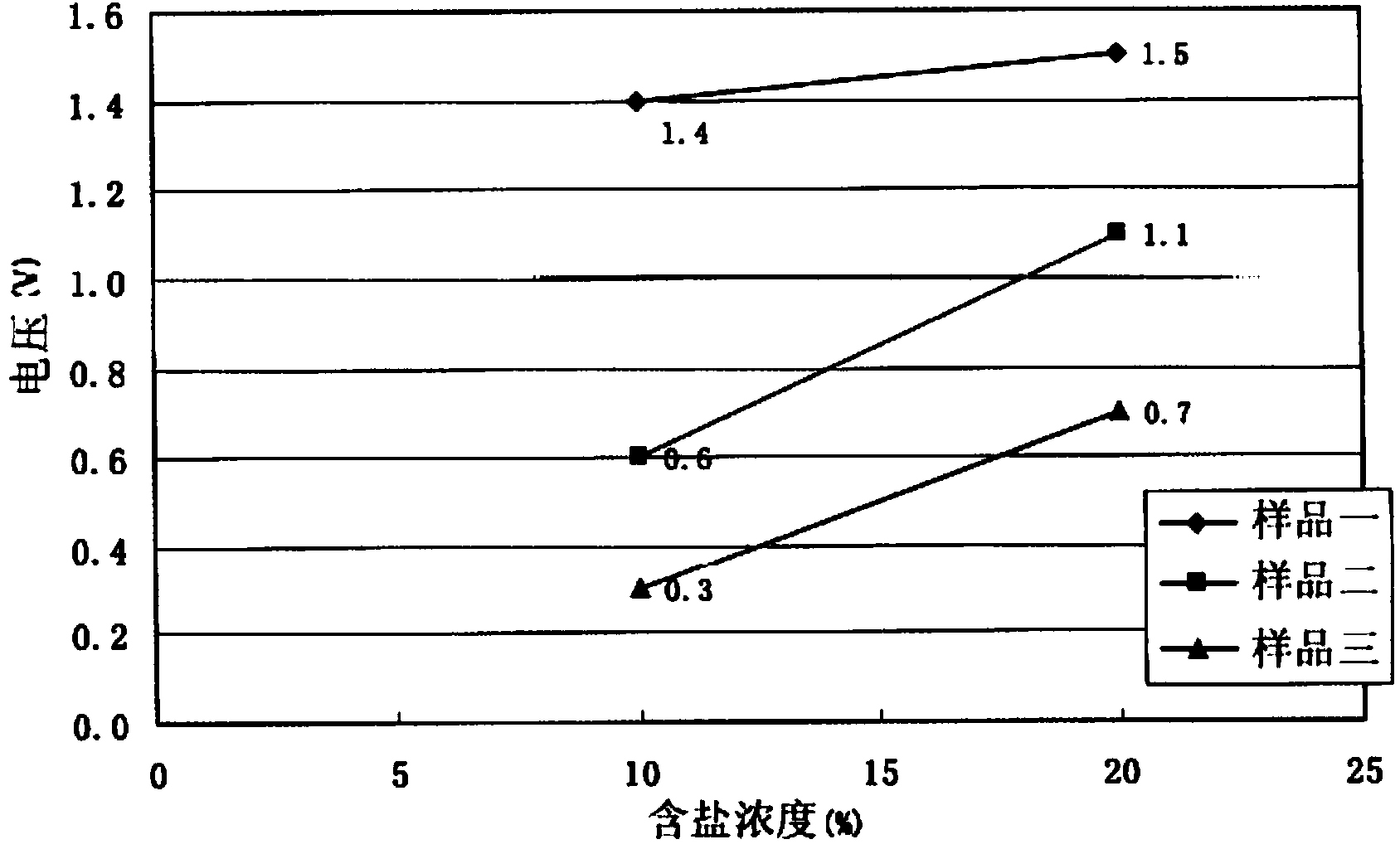

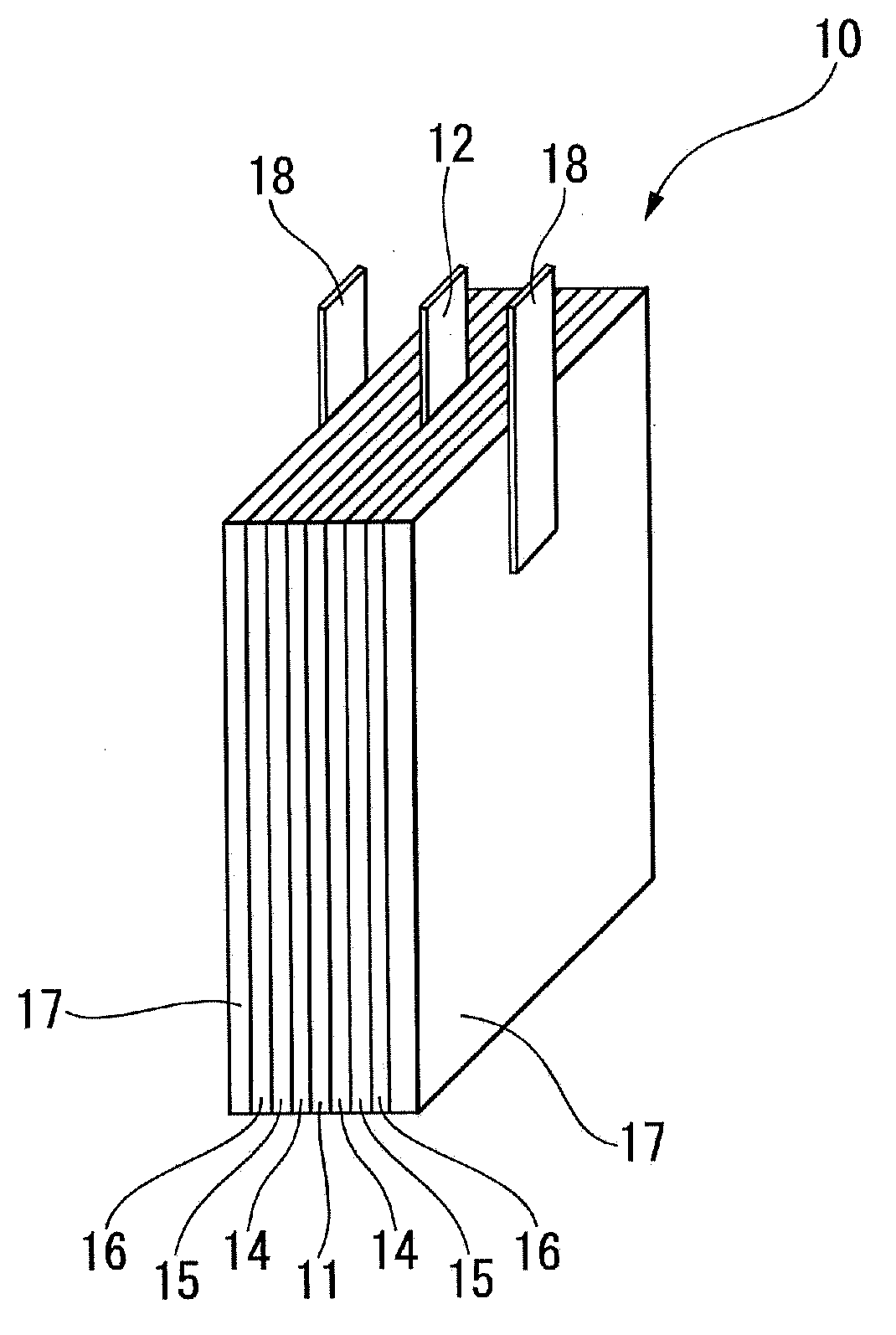

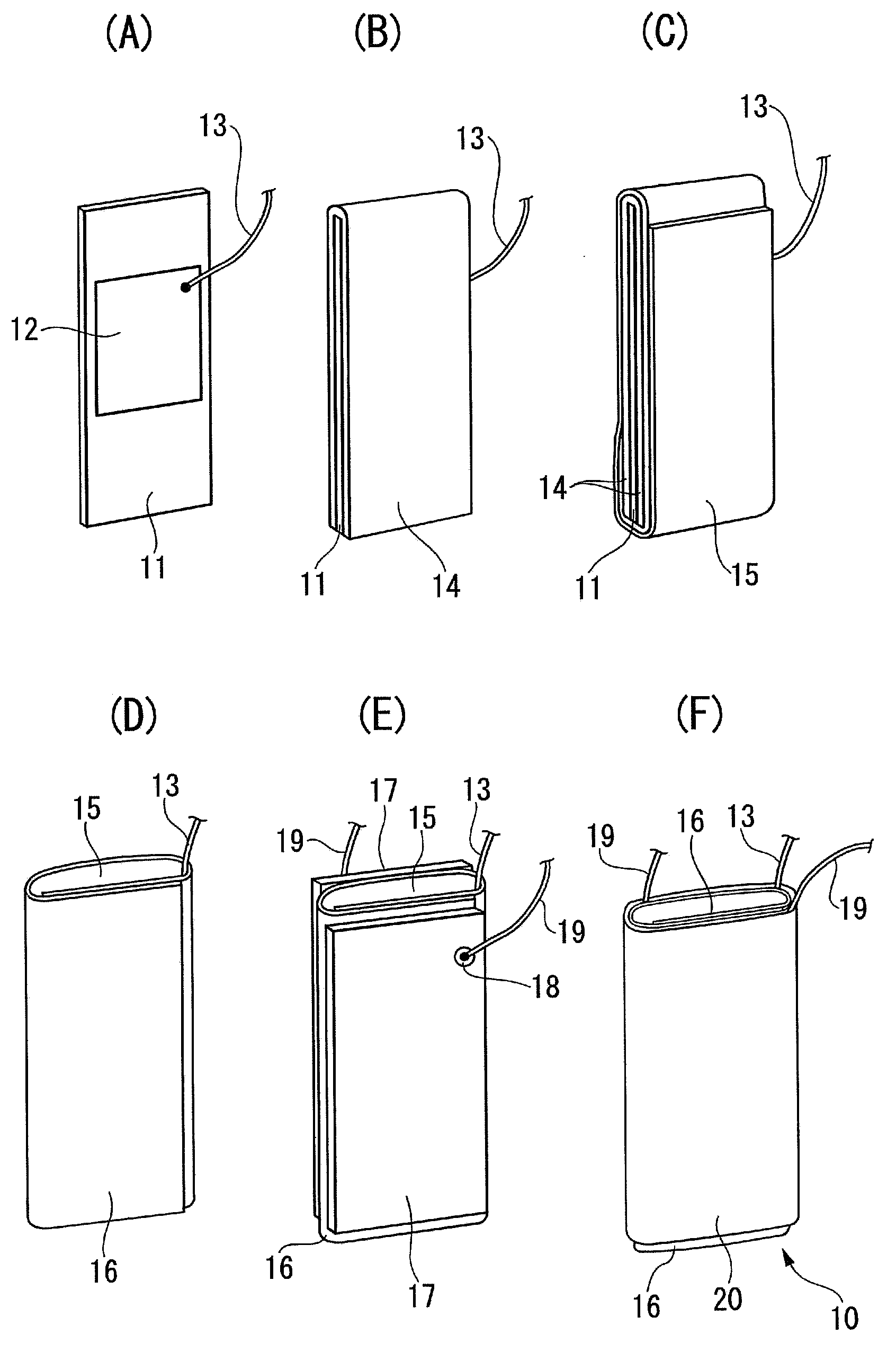

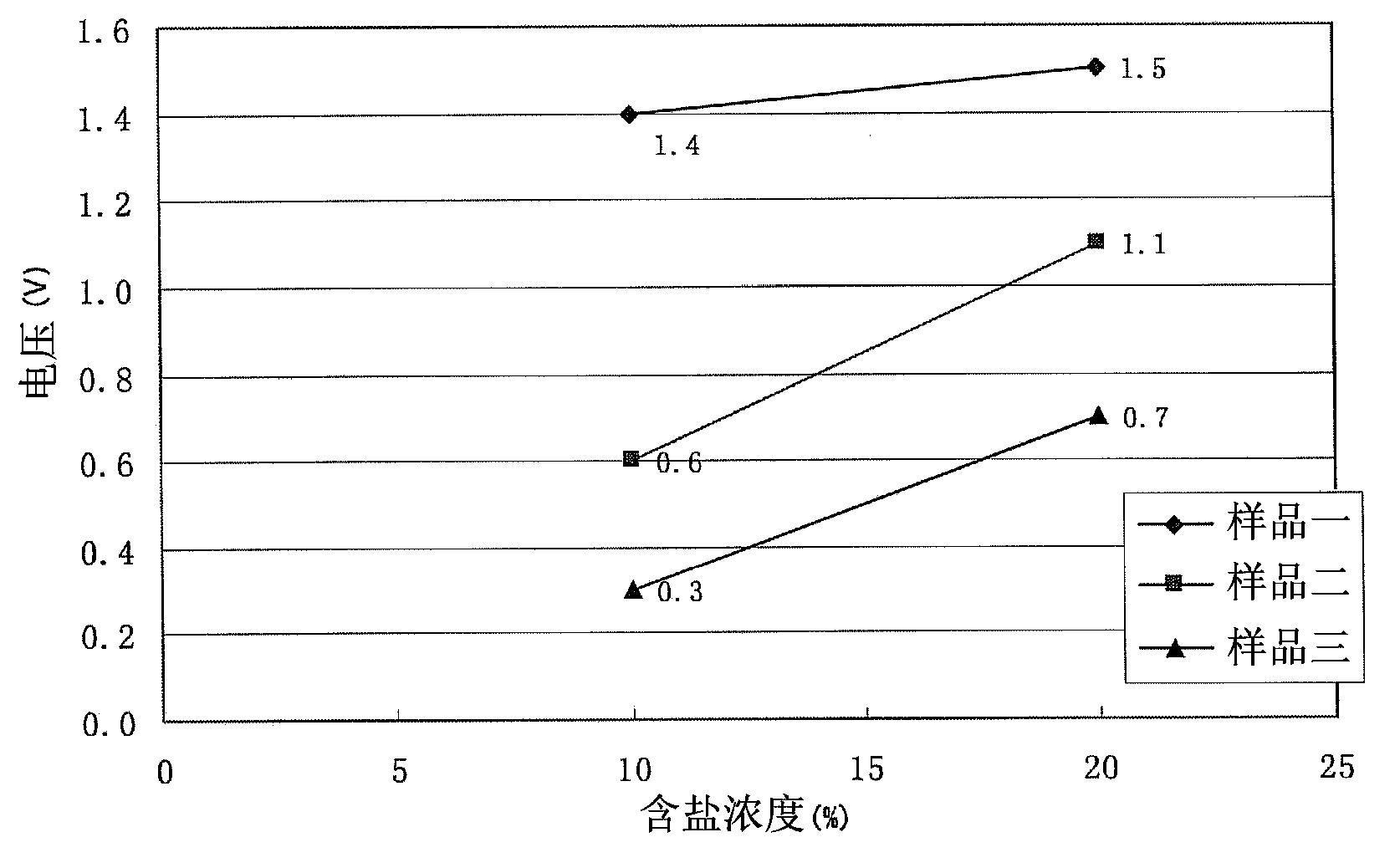

Portable water battery element and water battery device comprising the same

InactiveCN103618096AStrong temperature adaptabilityEasy to store and transportDeferred-action cellsPrimary cell electrodesWater batteryThermal contraction

The invention discloses a portable water battery element and a water battery device comprising the same. The portable water battery element is composed of a carbonized cloth forming the anode, an anode extraction electrode electrically connected with the carbonized cloth, a salt-containing cloth tightly connected with the carbonized cloth, a piece of water-absorbing paper tightly connected with the salt-containing cloth, a cathode metal piece closely connected with the water-absorbing paper and forming the cathode, a cathode extraction electrode electrically connected with the cathode metal piece, and thermal contraction pipes pressing the carbonized cloth, anode extraction electrode, salt-containing cloth, water-absorbing paper, cathode metal piece and cathode extraction electrode. The water battery element and the water battery device comprising the same can be preserved for a long time and are convenient for storage and transportation; the water battery device can quickly supply power only by injecting water or other electrolytic driving liquid or other neutral liquid, and the voltage and current characteristics at initial and long-term usage are very good. In addition, the invention has the advantages of simple production process, low manufacturing cost, wide application and no pollution to the environment.

Owner:浙江源茂金诺科技有限公司

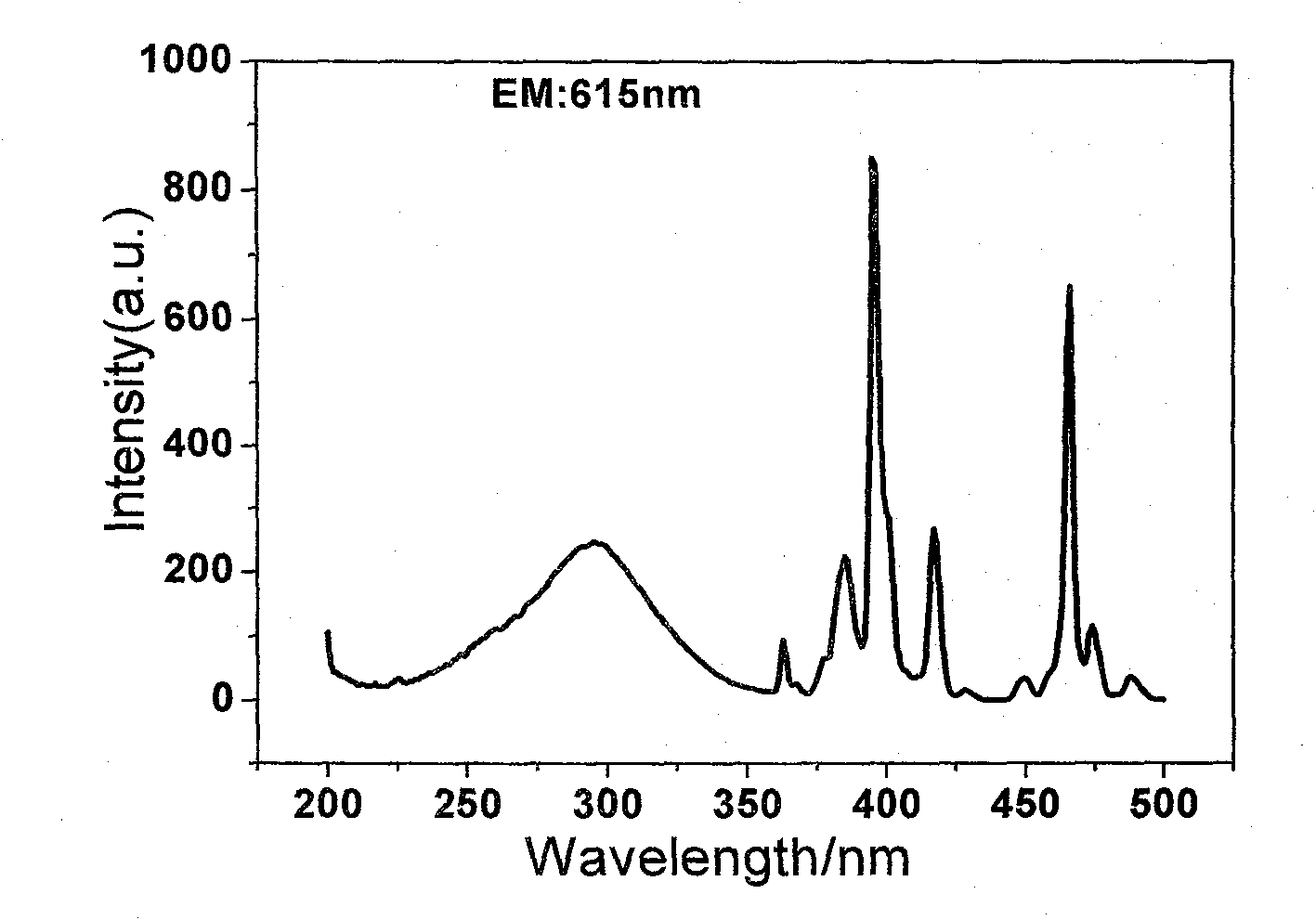

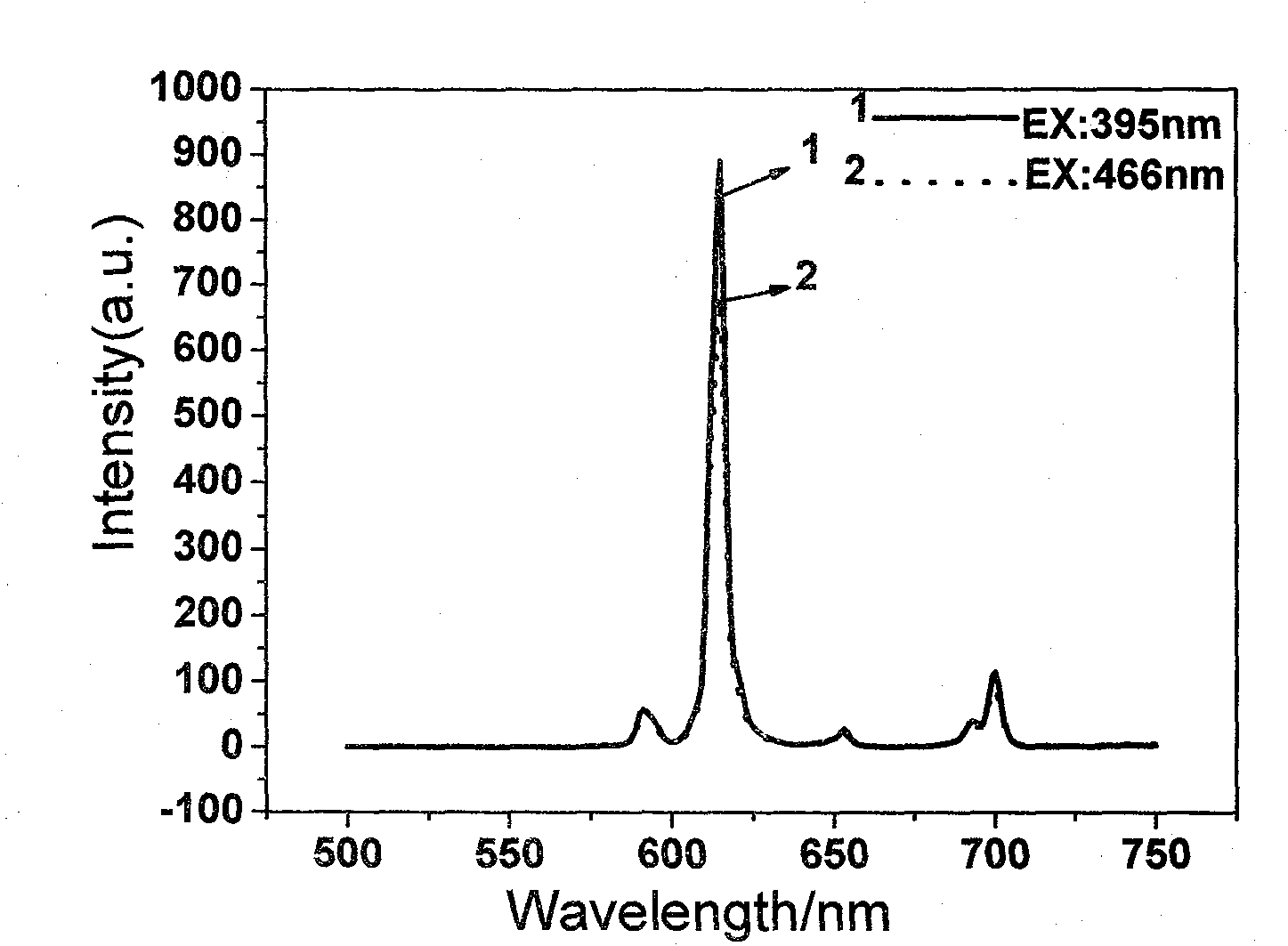

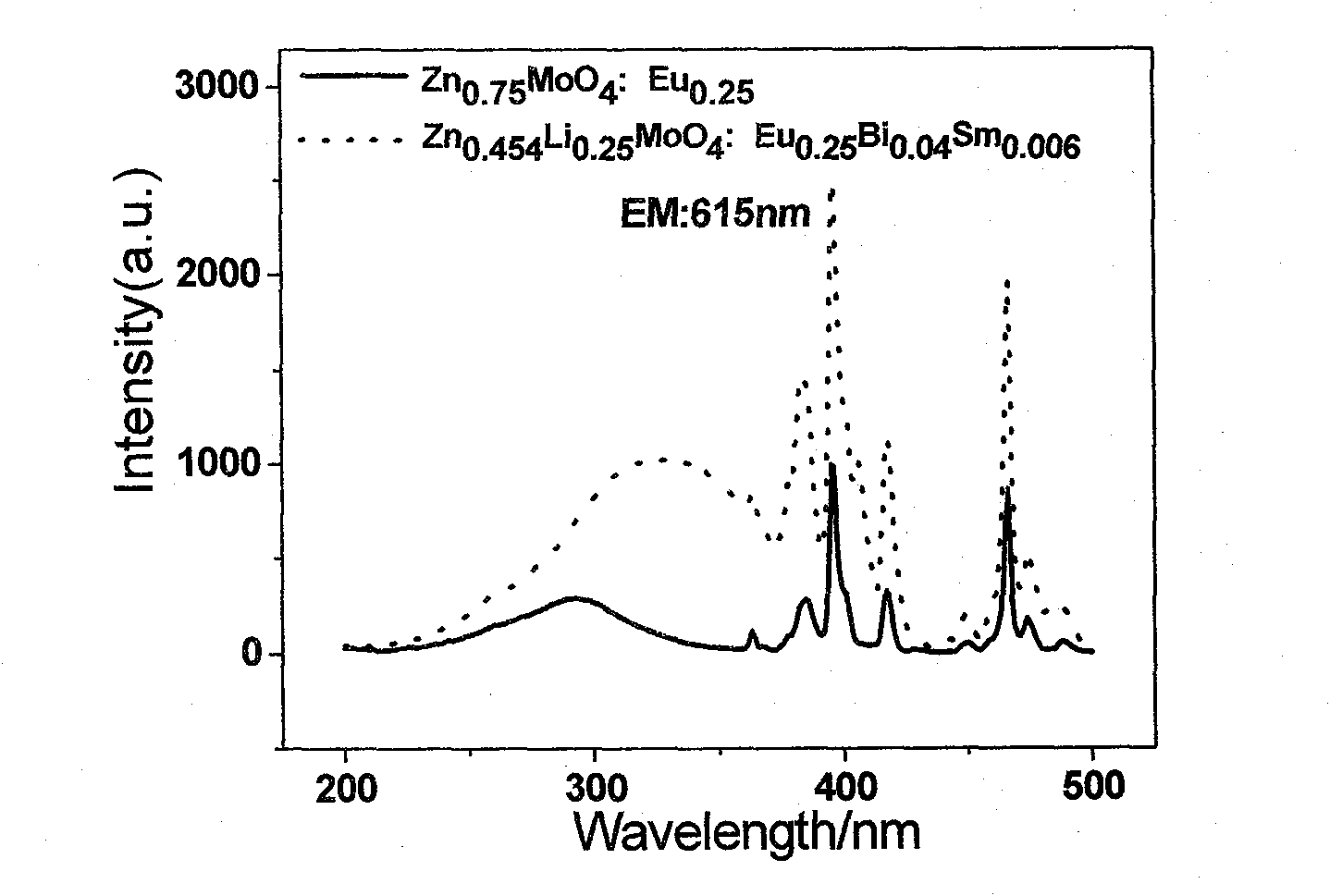

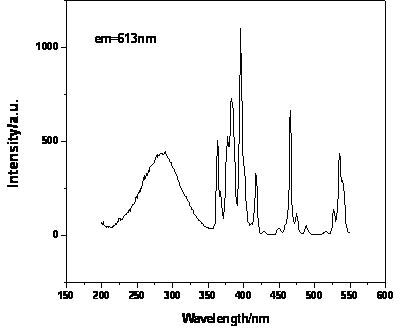

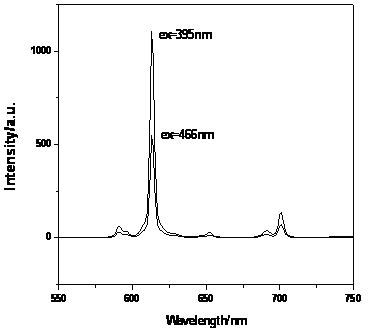

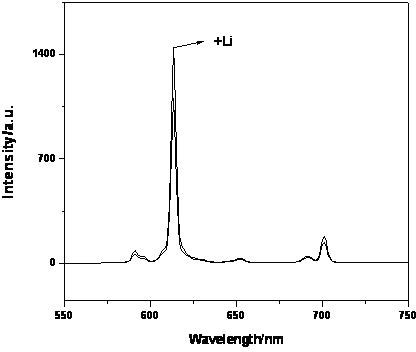

Red fluorescent powder capable of being simultaneously effectively excited by near ultraviolet and blue LED light

InactiveCN101928562AWide range of excitation wavelengthsGood luminous effectLuminescent compositionsChemical compositionPhotochemistry

The invention discloses red fluorescent powder capable of being simultaneously effectively excited by near ultraviolet and blue LED light. In the red fluorescent powder, ZnMoO4 is taken as a substrate, Eu3+ is taken as an activation center, and one or more of Li+, Na+, K+, Rb+ and Ag+ are taken as charge compensators, and one or more of Bi3+, Sm3+, Gd3+, Sc3+, Y3+, La3+, Gd3+ and Yb3+ with proper concentration are introduced to partially replace Zn so as to improve the absorption of the Eu3+ under the excitation at 395 nm and 466nm. The chemical composition general formula of the red fluorescent powder is Zn1-2x-y-zAxByMoO4:EuxBizSmw, wherein A is one or more of Li, Na, K, Rb and Ag; B is one or more of Sc, Y, La, Gd and Yb; and x is more than or equal to 0.05 and less than or equal to 0.4, y is more than or equal to 0 and less than or equal to 0.1, z is more than or equal to 0 and less than or equal to 0.1, and w is more than or equal to 0 and less than or equal to 0.05. The invention is applied to the preparation of the red fluorescent powder capable of being simultaneously effectively excited by the near ultraviolet and blue LED light.

Owner:NANCHANG UNIV

Europium-doped hydrated zinc molybdate high-efficient red fluorescent powder and preparation method thereof

InactiveCN102277162APromote absorptionImprove luminous brightnessGas discharge lamp usageLuminescent compositionsMolybdateRare earth ions

The invention relates to europium-doped hydrated zinc molybdate high-efficient red fluorescent powder and a preparation method thereof. The main crystalline phase of the fluorescent powder is zinc dimolybdate pentahydrate (or calcium, gadolinium and other alkaline earth or rare earth metal replacing parts of zinc); and during synthesizing, batching is carried out according to a general formula of A1-x-yMoO4:EuxBy. The preparation method comprises the following steps of: reacting the prepared zinc-containing and zinc-substituted ionized calcium and rare earth ion solution with an alkali metal or ammonium molybdate under appropriate conditions; regulating PH (Potential of Hydrogen) to completely precipitate; filtering directly or filtering after aging for a period of time, and washing the precipitate; and drying at a normal temperature to finish the preparation. According to the invention, the preparation method is simple and easy to operate; moreover, the red fluorescent powder has a good luminous effect and stable physical and chemical properties, can be well matched with near-ultraviolet and blue-light LED (Light Emitting Diode) chips, and can be used as red fluorescent powder of a novel high-efficient white-light LED.

Owner:NANCHANG UNIV

Paddy rice tillering-promoting, lodging-resisting, and yield-increase-assisting multifunctional fertilizer and application method thereof

ActiveCN103360164AFormulation ScienceVersatileFertilising methodsFertilizer mixturesWater contentUniconazole

The invention relates to a paddy rice tillering-promoting, lodging-resisting, and yield-increase-assisting multifunctional fertilizer and an application method thereof. According to the invention, uniconazole, amine hexanoate, calcium chloride, magnesium sulfate, zinc sulfate, borax, EDTA-Fe, EDTA-Mn, EDTA-Cu, silicon fertilizer, and bentonite are crushed and sieved; the mixture is sufficiently mixed by stirring, and is uniformly delivered into a fertilizer granulator; preliminary granulation is carried out according to a round-disk granulation method; the granules are uniformly delivered into a multi-level granular fertilizer round polishing machine, and granulation is carried out again; drying is carried out, such that a water content is below 10%, such that formed granular fertilizer is obtained. Before paddy rice transplantation and before soil preparation before seeding, the fertilizer is uniformly mixed with a composite fertilizer or fine soil, and the mixture is used for application. After paddy rice transplantation, and during a reviving period, the fertilizer is uniformly mixed with a urea fertilizer, and the mixture is used for application. The fertilizer provided by the invention has the advantages of scientific formula, comprehensive functions, simple application, low residue in soil, and safety to succeeding crop. The granular fertilizer is convenient for packaging and transportation, and can be conveniently mixed with other fertilizers. The fertilizer has a substantial effect. With the fertilizer, paddy rice effective tillering can be increased by 2-5 pieces / group, yield can be increased by 10-20%, plant height is substantially reduced, and lodging resistance is improved.

Owner:武汉盛大神农生物工程有限公司

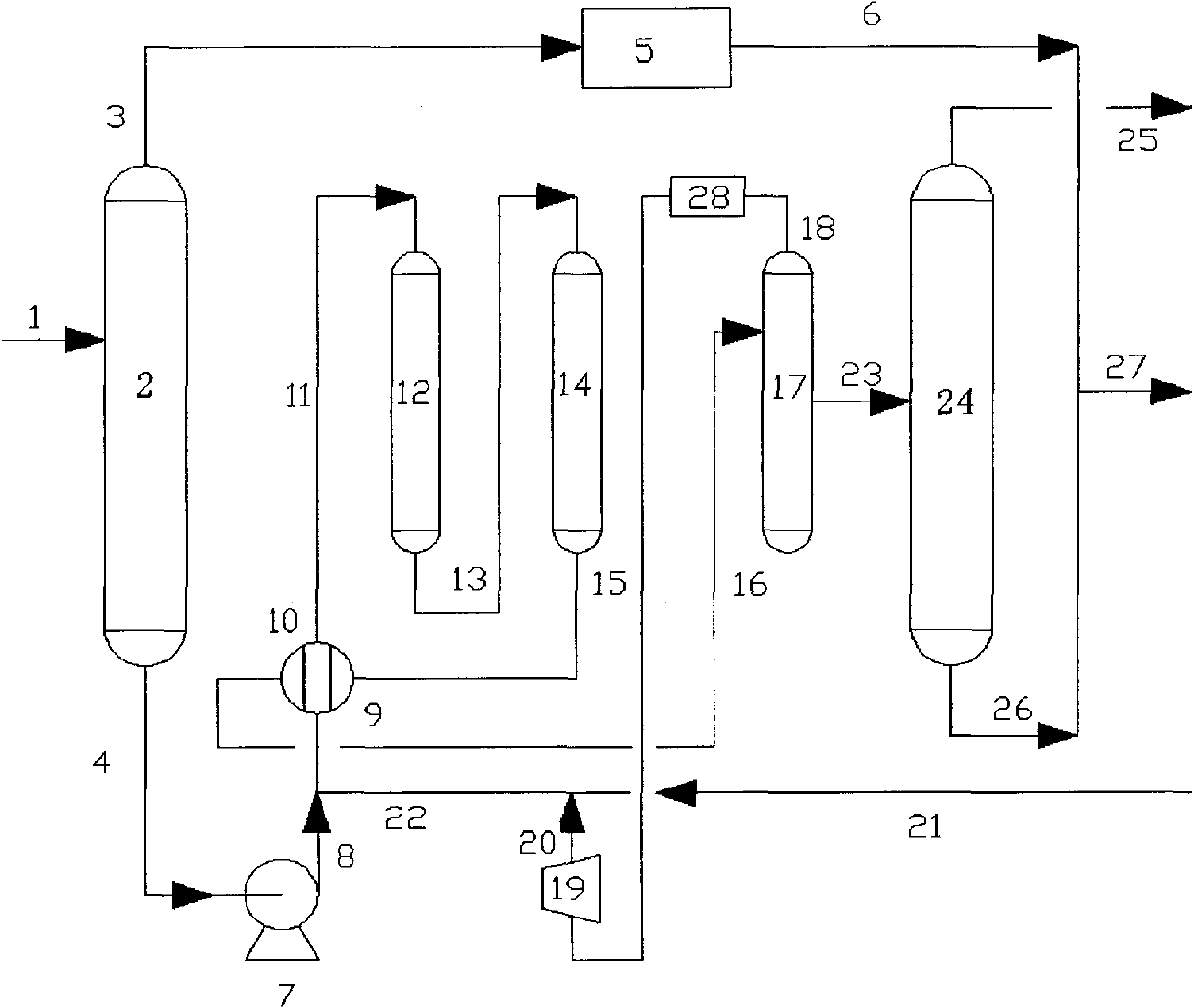

Process method for reducing olefins by hydrogen desulfurization of catalytic gasoline

InactiveCN102199448AReduce contentBoost octaneTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a process method for reducing olefins by the hydrogen desulfurization of catalytic gasoline, which comprises the following steps of: cutting gasoline into a light distillate and a heavy distillate at the cutting point of between 60 and 80 DEG C; contacting the heavy distillate and hydrogen with an octane value restoration catalyst to perform an isomerization reaction, an aromatization reaction and a building-up reaction; and contacting reaction effluents which are not separated with a selective hydrogen desulfurization catalyst to perform a hydrogen desulfurization reaction, and separating hydrogenated generation oil to obtain light hydrocarbons and gasoline distillates, wherein hydrogen-enriched gas is recycled, the octane value restoration catalyst is used for loading one or two VIB or VIII group metal as active ingredients by taking one or more of aluminum oxides or molecular sieves as a carrier, an aid is one or two oxides in IIB groups or lanthanide series, the selective hydrogen desulfurization catalyst takes the aluminum oxides as the carrier, Mo and Co as active metal and one or more of Ce, Mg, K, P and F as the aid, the olefin content is less than 20 volume percent, the sulfur content is less than 50 micrograms / gram, and research octane number (RON) is improved by 1.5 to 2 units.

Owner:PETROCHINA CO LTD

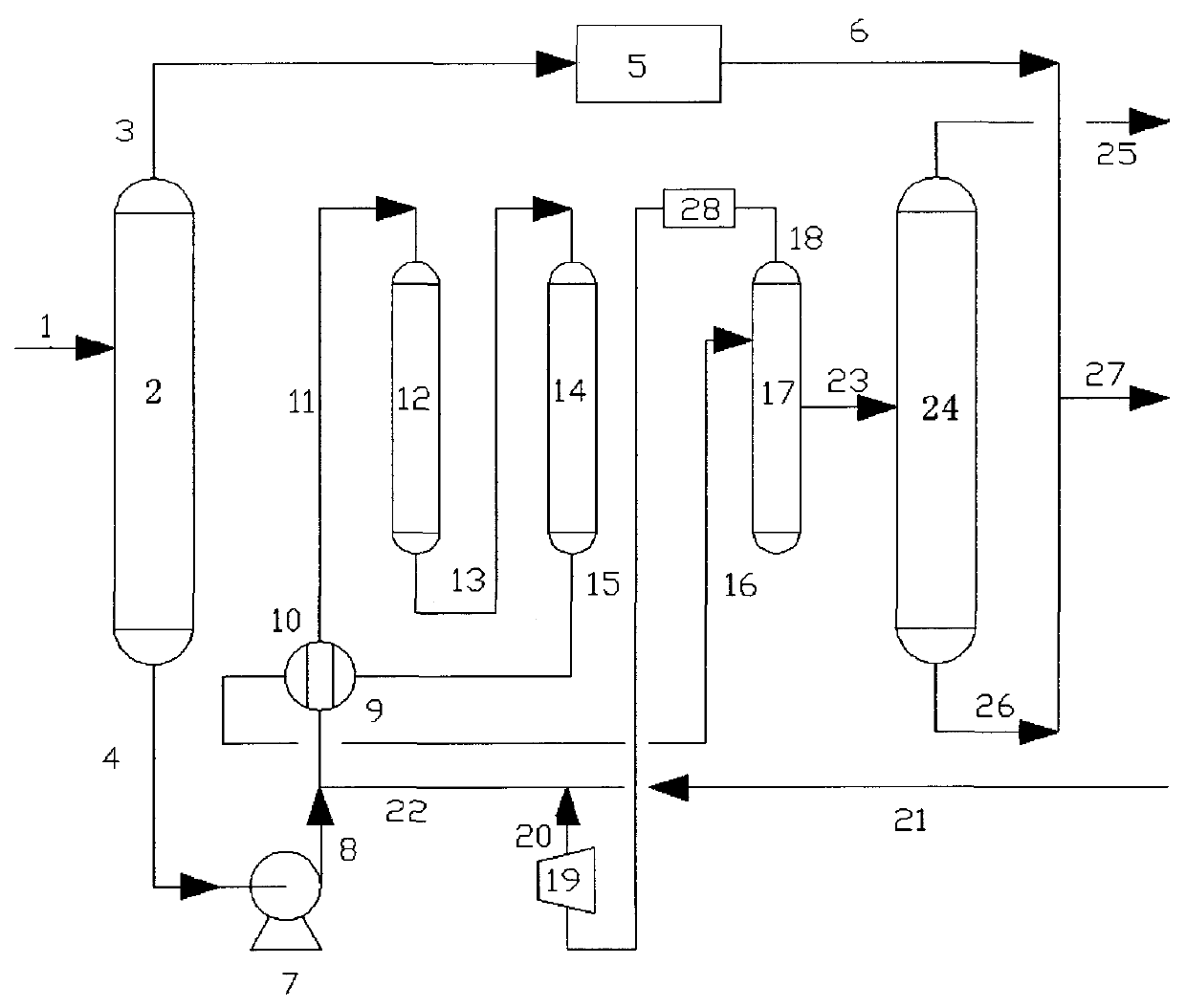

Resource recycling device and process of dichloromethane tail gas

PendingCN107803100ATake advantage ofReduce dosageGas treatmentDispersed particle separationCirculating pumpVacuum pump

The invention discloses a resource recycling device and process of dichloromethane tail gas. According to the device, the bottom of an absorption tower is connected with an absorbent heat exchanger through an absorption tower kettle extraction pump; the absorbent heat exchanger is connected to the upper part of an desorption tower; the absorbent heat exchanger is connected with an absorbent primary cooler; the bottom of a falling film evaporator is connected with the lower part of the desorption tower; the bottom of the desorption tower is connected with the top of the falling film evaporatorthrough a falling film circulating pump; a desorption tower top condenser is connected with the top of the desorption tower; the desorption tower top condenser is connected with the top of a desorption tower top receiving tank; the top of the desorption tower top receiving tank is connected with an after-pumping receiving tank through a vacuum pump; the vacuum pump is connected with the desorptiontower top condenser; the top of the after-pumping receiving tank is connected with an after-pumping condenser; and the top of the after-pumping condenser is connected to the lower part of the absorption tower. The device provided by the invention is simple in structure, convenient in operation, and high in solvent recovery rate; dangerous waste is not generated; the environment-friendly requirement can be met; the emission is safe; and resource recycling is realized.

Owner:烟台国邦化工机械科技有限公司

Sialon complex phase ceramic lift tube and production method thereof

The invention relates to a sialon composite ceramic lift tube and a preparation method thereof. The weight percents of the raw materials forming the composite ceramic lift tube are: 25-50 percent of silicon nitride, 15-30 percent of quartz, 5-20 percent of aluminum dioxide, 0.01-0.1 percent of yttria, 20-40 percent of carborundum, 1-10 percent of zirconia, 0.01-0.06 percent of acrylamide, 0.001-0.005 percent of N, N'-methylenebisacrylamide, 0.1-0.7 percent of polymethacrylic acid amine and 0.05-0.2 percent of ammonium persulfate. The preparation method comprises: adding pre-mix liquid to a ball mill in advance, adding the silicon nitride, the quartz, the yttria, the aluminum dioxide, the carborundum and zirconia in sequence and ball-milling for 15-30 hours; adding the ammonium persulfate to the sizing agent, vacuumizing by a vacuum agitator and injecting into a mold to be solidified; demolding, drying and sintering at the temperature of 1300-1600 DEG C to obtain the finished product. The sialon composite ceramic lift tube is characterized by long service life, high strength, strong thermal shock resistance and low cost, which is not infiltrated or reacted with aluminum melt.

Owner:DONGYING XINKEXINTETAO

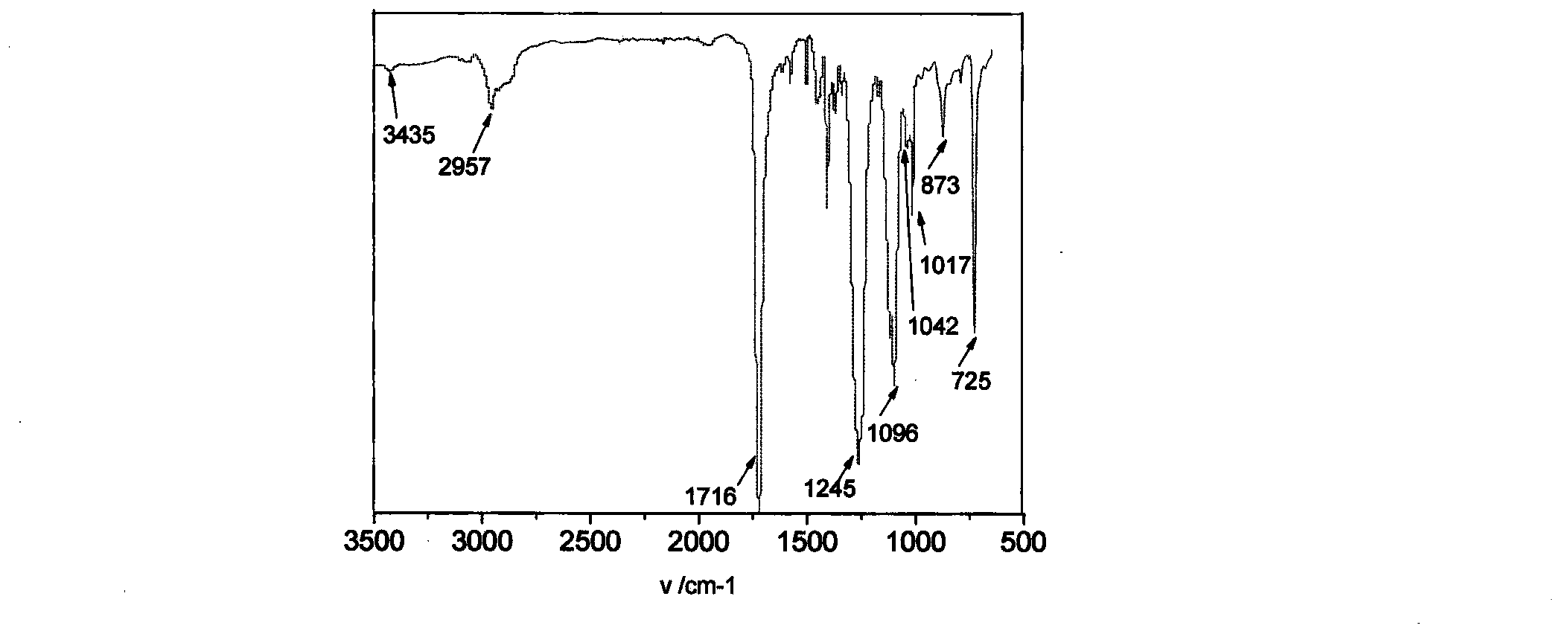

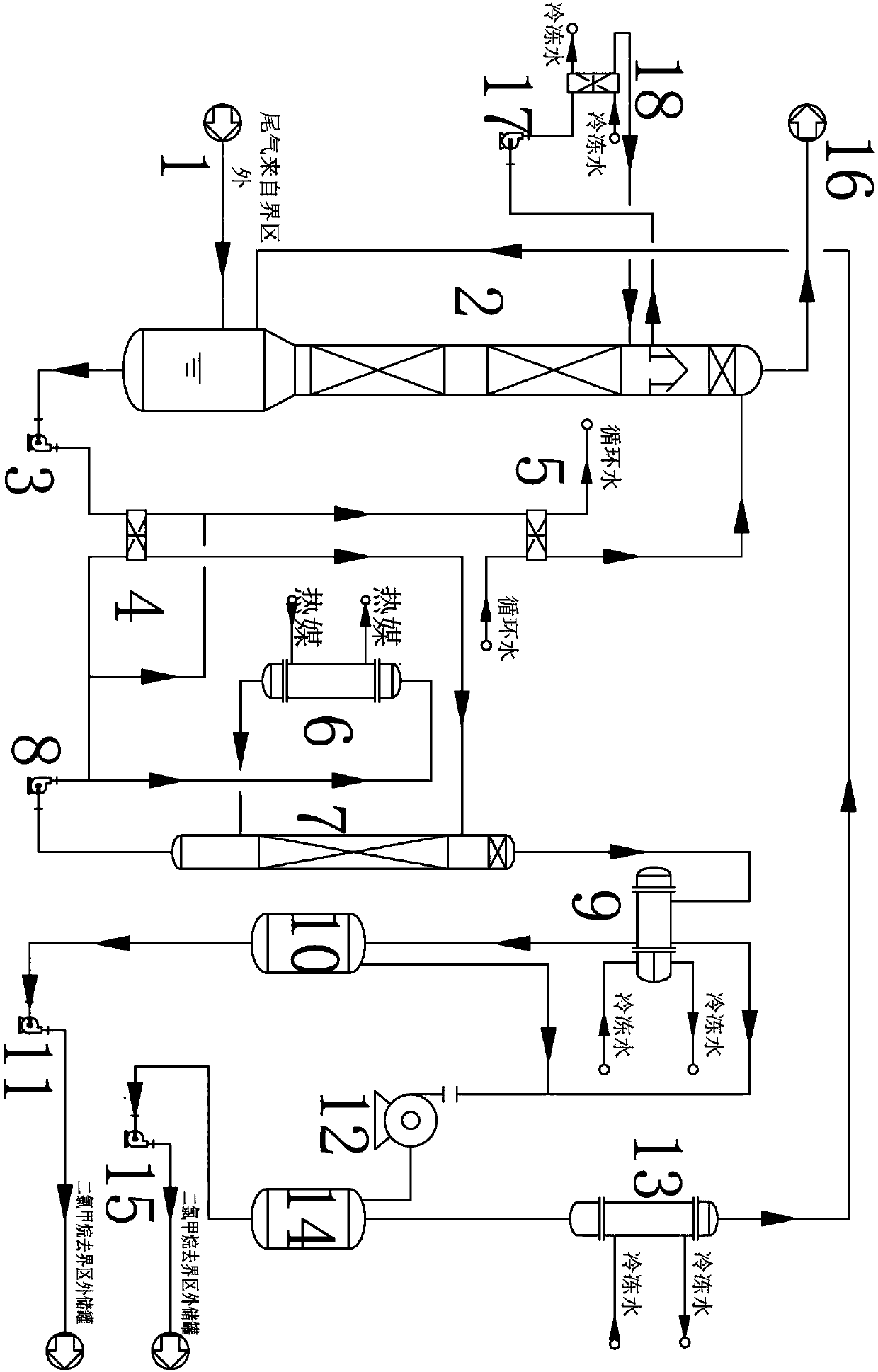

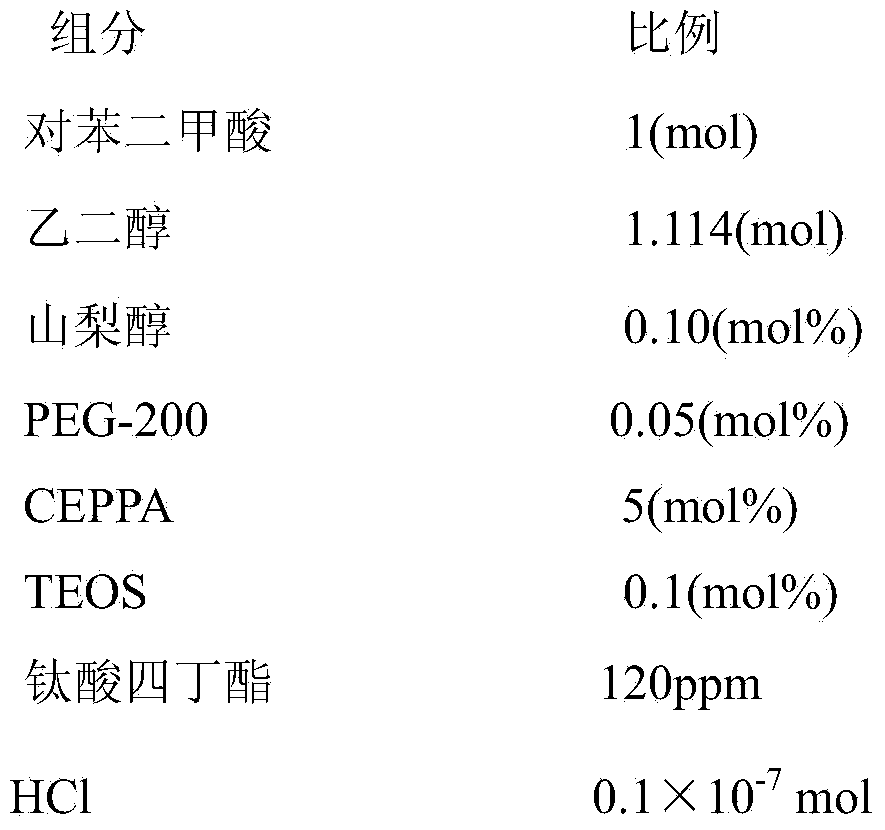

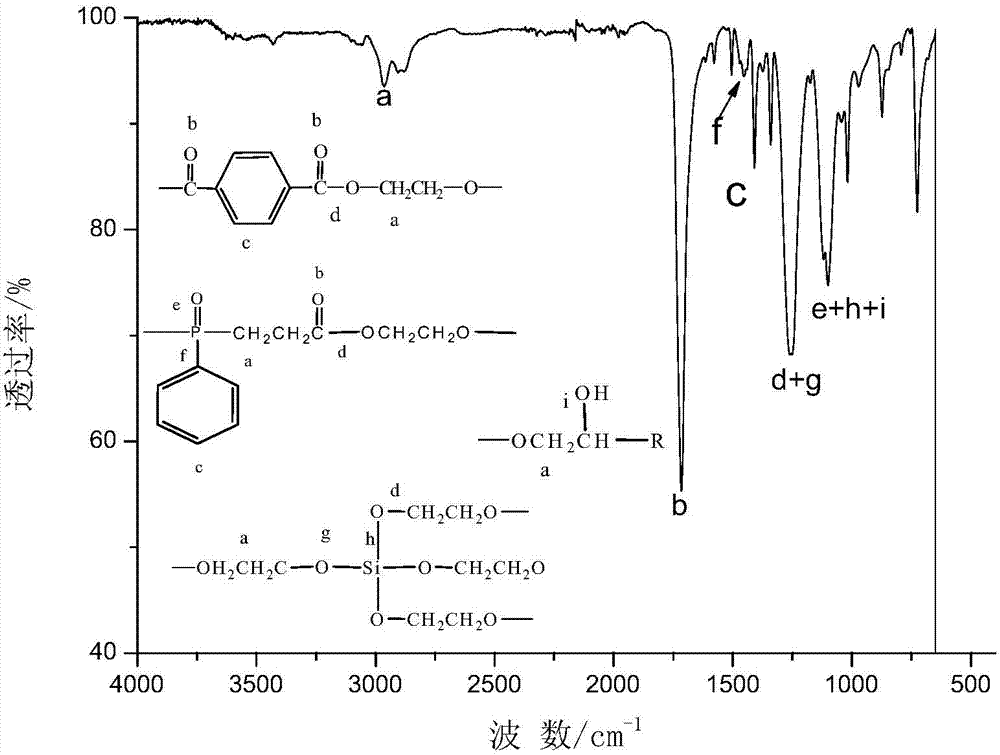

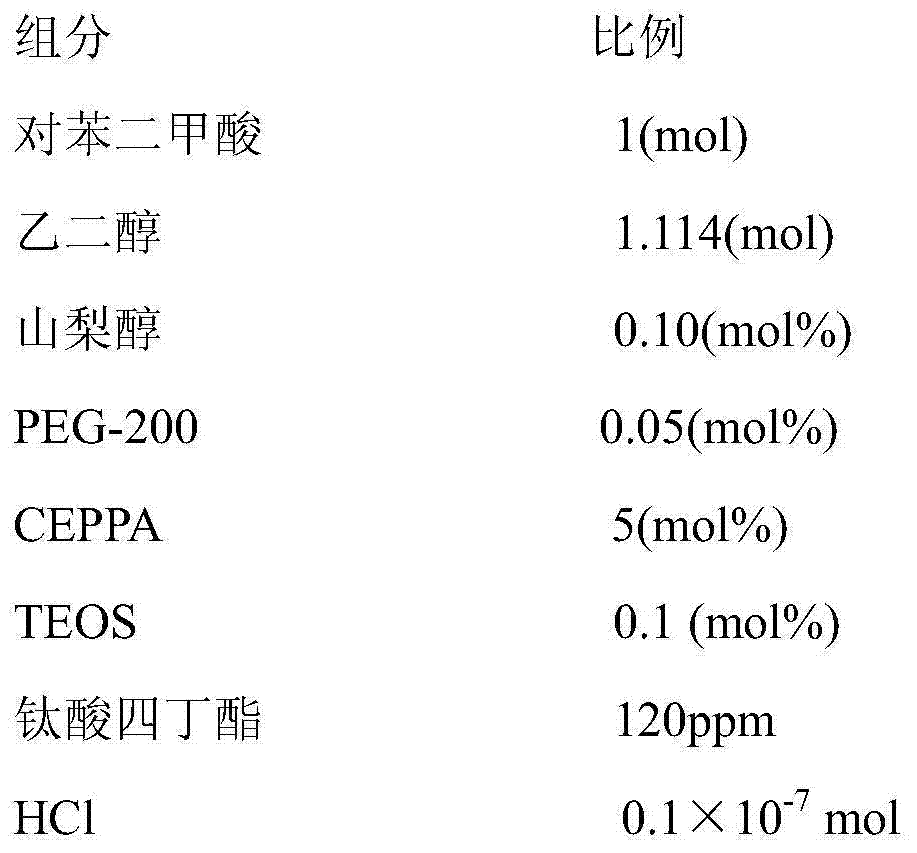

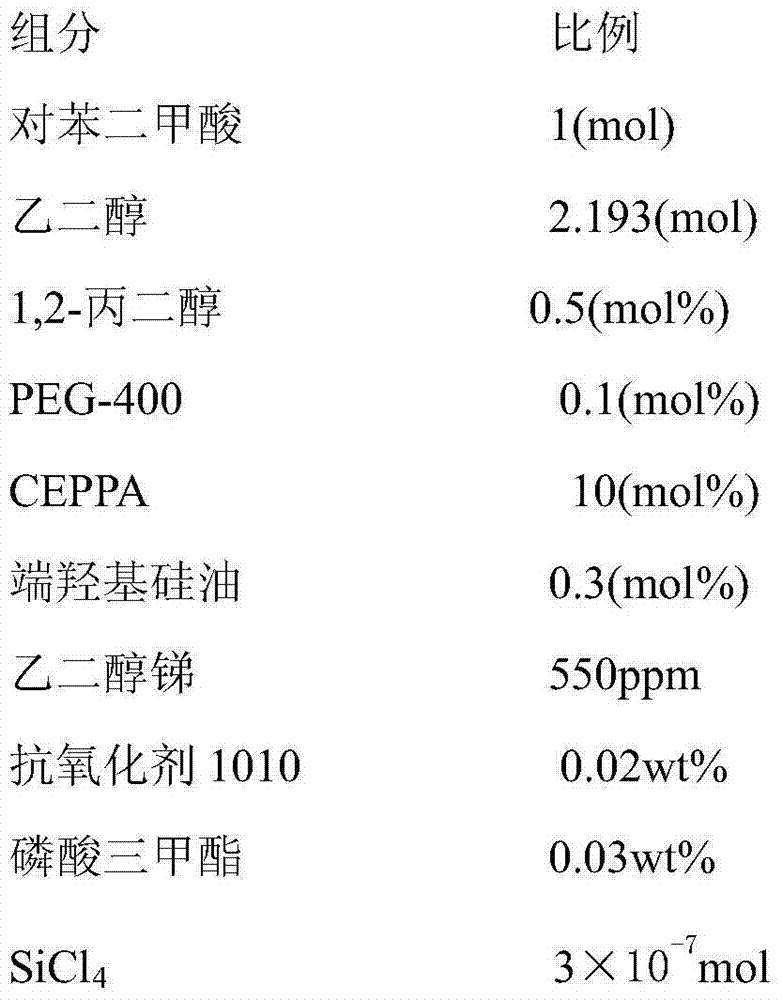

Preparation method of high-hydrophilicity flame-retardant polyester fiber

ActiveCN103628173AImprove hydrophilicityNo reactionArtificial filament heat treatmentMonocomponent copolyesters artificial filamentPolyesterPolymer science

The invention relates to a preparation method of high-hydrophilicity flame-retardant polyester fiber, which comprises the steps of (1) enabling a copolymer flame retardant to react with polyalcohol to obtain CEPPA (carboxethyl phenylphosphinic acid)-polyalcohol; (2) enabling hydroxyl-terminated siloxane to react with ethylene glycol in the presence of a catalyst to obtain a hydroxyl-terminated siloxane-ethylene glycol solution; (3) preparing slurry, and adding the prepared slurry into an esterification reaction kettle to perform a first esterification reaction; (4) when the quantity of the collected byproducts reaches 82-95% of the theoretical value, adding polyalcohol, sodium sulfo bis(hydroxyethyl) isophthalate (SIPE) and polyethylene glycol (PEG) to perform a second esterification reaction; (5) after the esterification reaction, adding the products obtained by the steps (1) and (2) into a reaction kettle, and after the condensation polymerization reaction, performing melt spinning to obtain the high-hydrophilicity flame-retardant polyester fiber. The limit oxygen index of the polyester fiber prepared by the method provided by the invention is over 30%, the moisture regain is 0.6-2.0%, and the fiber has relatively high moisture regain and is comfortable to wear.

Owner:DONGHUA UNIV

Lithium ion battery cathode material and preparation method thereof and lithium battery

InactiveCN110767896AStress reliefImprove stabilityLi-accumulatorsElectrolyte layer coatingChemical physicsPhysical chemistry

The invention relates to a lithium ion battery cathode material and a preparation method thereof and a lithium battery. The lithium ion battery cathode material comprises cathode material particles and an inorganic solid electrolyte membrane covering the outer surface of the cathode material particles; doping elements are distributed on the surface of the cathode material particles from outside toinside to form a gradient solid solution layer, and the concentration of the doping elements in the gradient solid solution layer gradually decreases from the surface to the inside; the doping elements are 4d and 5d metals; the outer surface of the cathode material particles is covered with the inorganic solid electrolyte membrane, the inorganic solid electrolyte membrane is a continuous membranehaving a thickness of 1 to 200 nm, the inorganic solid electrolyte membrane comprises an amorphous phase and a crystalline phase that coexist, and the crystalline grain size is in a range of 1 to 40nm. The lithium ion battery cathode material has the advantages of high electrochemical stability, high voltage resistance, good cycle performance, strong structural stability, high safety, and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

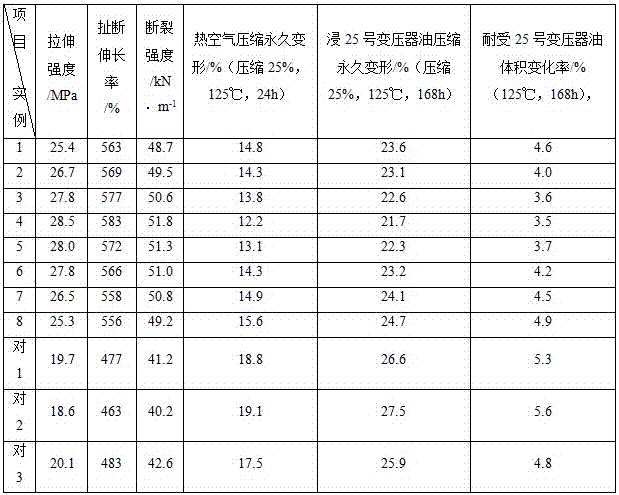

Rubber material for sealing ring of transformer and preparation method of rubber material

ActiveCN106883472AGood oil resistanceImprove wear resistanceBuilding insulationsRubber materialCross-link

The invention belongs to the technical field of sealing materials and particularly relates to a rubber material for a sealing ring of a transformer and a preparation method of the rubber material. The rubber material is prepared from the following raw material in parts by weight: 50-70 parts of nitrile rubber, 20-30 parts of acrylic rubber, 5-10 parts of epichlorohydrin rubber, 3-8 parts of wood fibers, 5-10 parts of nanometer titania, 15-25 parts of a fortifier, 1-5 parts of an anti-aging agent, 1-3 parts of an accelerate, 1-3 parts of sulfur, 3-6 parts of zinc oxide, 4-8 parts of stearic acid, 3-6 parts of asphalt, 1-3 parts of chlorinated paraffin, 10-15 parts of a plasticizer and 5-15 parts of a cross-linking agent. The rubber material for the sealing ring of the transformer is high in strength, small in compressive deformation and excellent in anti-aging performance.

Owner:国网河南省电力公司方城县供电公司

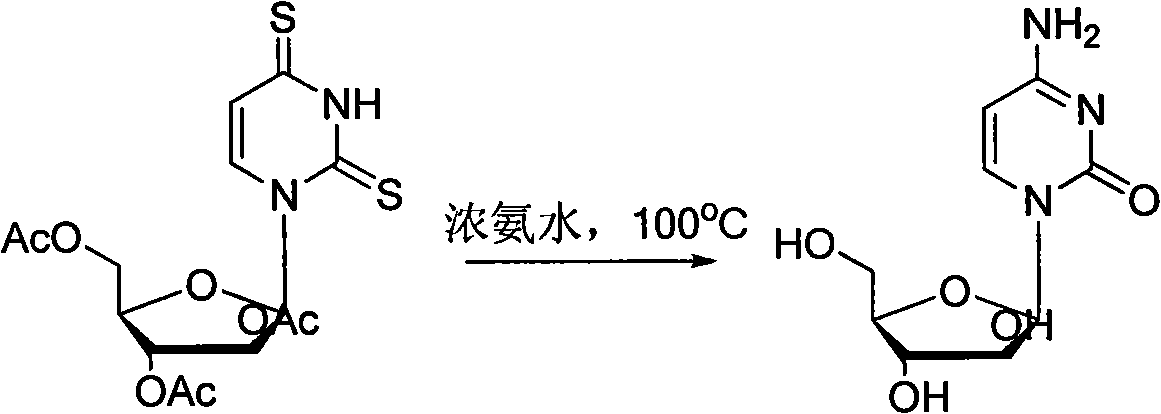

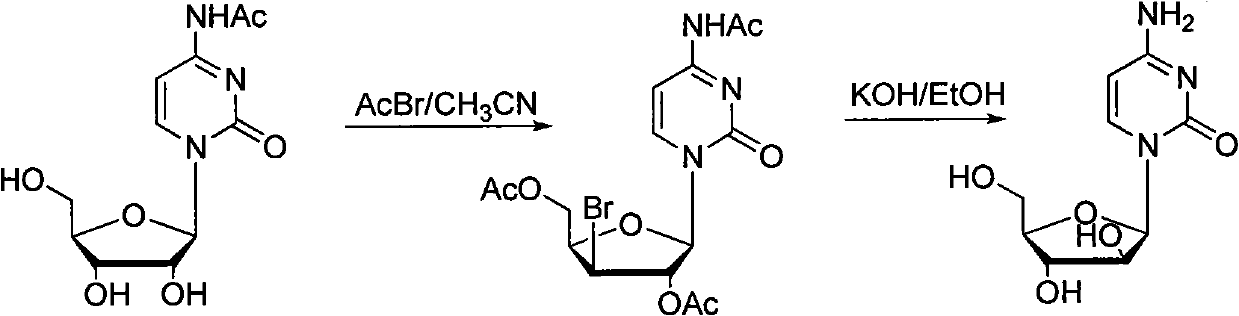

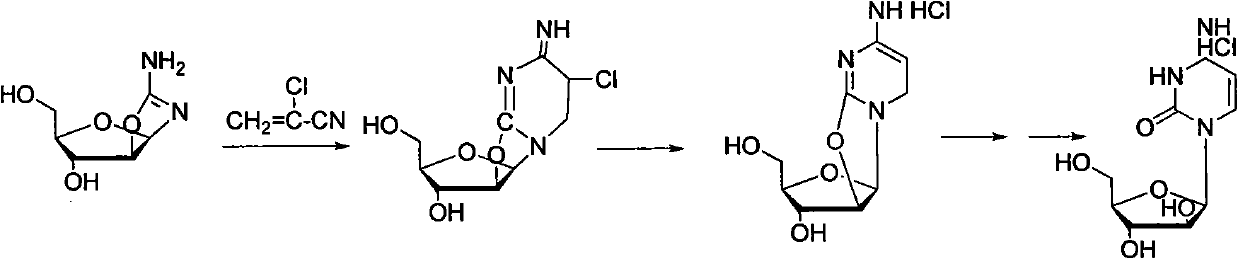

Technology for producing cytarabine through chemical synthesis method

InactiveCN101948492ARaw materials are cheap and easy to getReduce process stepsSugar derivativesSugar derivatives preparationCytarabineChemical synthesis

The invention discloses a technology for producing cytarabine through a chemical synthesis method, relating to a synthesis technology of an organic compound and aiming to provide a technology for producing the cytarabine through the chemical synthesis method, which has the advantages of cheap and available raw material, simple reaction condition, low cost, environmental protection and high yield. Based on the solving technical scheme, the technology for producing the cytarabine through the chemical synthesis method has a synthetic route which comprises the following synthesis steps of: firstly, reacting the cytarabine (1) used as a starting raw material with hexamethyldisilazane (HMDS) for 10-80h under the pressure of 5-20kg and at the temperature of 70-160 DEG C, cooling, stirring and vacuum concentrating a reaction system, and removing and recovering redundant hexamethyldisilazane to obtain an intermediate (II), wherein the dosage of the hexamethyldisilazane is 2-10 times larger than the weight of the cytarabine; secondly, dissolving the intermediate (II) into a proper solvent, and cooling or stirring to prepare crude cytarabine. The invention is used for preparing an anticancer drug.

Owner:HENAN NORMAL UNIV +1

Preparation method of sodium chlorite

InactiveCN103159178AThe reaction process is easy to controlNo reactionChlorous acidSodium chlorateChlorous acid

The invention discloses a preparation method of sodium chlorite. The preparation method comprises the following steps of (1) enabling sodium chlorate solution to react with hydrochloric acid to generate chlorine dioxide gas and chlorine; (2) leading chlorine dioxide gas and chlorine into sodium chlorite solution to further react, so as to generate chlorine dioxide gas; (3) leading the chlorine dioxide gas into sodium hydroxide solution, and adding hydrogen peroxide to react, so as to generate sodium chlorite at the same time; (4) crystallizing and drying sodium chlorite prepared in the step (3) to obtain a final product, wherein the concentration of the sodium chlorate solution in the step (1) is 25-33%, the concentration of hydrochloric acid solution in the step (1) is 31%, and the molar ratio of the hydrochloric acid to chlorous acid in the step (1) is (1-1.5) to 2. The preparation method of sodium chlorite disclosed by the invention does not utilize concentrated sulfuric acid of which the concentration is over 95%, is easy in control of the reaction process, not drastic in reaction, higher in safety coefficient, low in cost, and suitable for industrial large-scale application at the same time.

Owner:常州和方环保科技有限公司

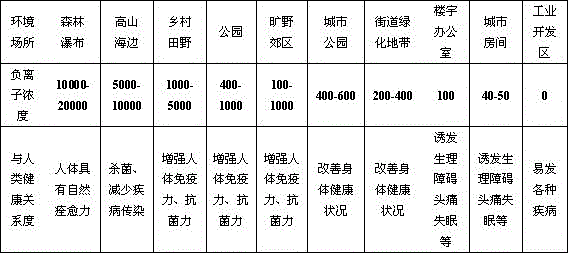

Ceramic brick with negative ion function and production method thereof

InactiveCN106747667AWith negative ion functionNegative ion function is goodEdge grinding machinesPolishing machinesBrickMetallurgy

The invention discloses a ceramic brick with a negative ion function and a production method thereof. The ceramic brick is characterized in that a negative ion additive is added into a ceramic layer. The production method comprises the following steps of (1) preparing a ceramic brick blank; (2) preparing a ceramic material with high-temperature ceramic forming property; (3) applying the ceramic material onto the surface of the blank, forming a ceramic layer, and drying; (4) printing, decorating, forming a printing and decorating layer, and drying; (e) firing; (f) grinding edges. The ceramic brick and the production method have the beneficial effects that the problems of low releasing concentration of negative ions and consumption of a large amount of negative ion powder for increasing releasing concentration of negative ions in the prior art are solved, and the economic and environment-friendly production method of the ceramic brick with the negative ion health function is provided.

Owner:HANGZHOU NABEL CERAMIC

High-hydrophilic flame-retardant polyester and preparation method thereof

The invention relates to high-hydrophilic flame-retardant polyester and a preparation method thereof. The flame-retardant polyester comprises terephthalic acid, polyatomic alcohol, a copolymerization fire retardant and hydroxyl-terminated siloxane. The preparation method comprises the steps as follows: 1), the copolymerization fire retardant is reacted with the polyatomic alcohol, so that a reaction product CEPPA-polyatomic alcohol is obtained; 2), the hydroxyl-terminated siloxane is reacted with ethylene glycol under the effect of a catalyst, so that a hydroxyl-terminated siloxane-ethylene glycol solution is obtained; 3), a slurry is prepared, and the prepared slurry is added to an esterification reaction kettle for first esterification reaction; 4), when the collection amount of a by-product reaches 82%-95% of a theoretical value, the polyatomic alcohol, 5-sodium sulfo bis(-hydroxyethyl) isophthalate (SIPE) and PEG (polyethylene glycol) are added, and second esterification reaction is performed; and 5), after the esterification reaction, products obtained in the step 1) and the step 2) are added to the reaction kettle, and condensation polymerization is performed, so that the high-hydrophilic flame-retardant polyester is obtained. The high-hydrophilic flame-retardant polyester has a higher flame-retardant function and a higher hydrophilic function.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

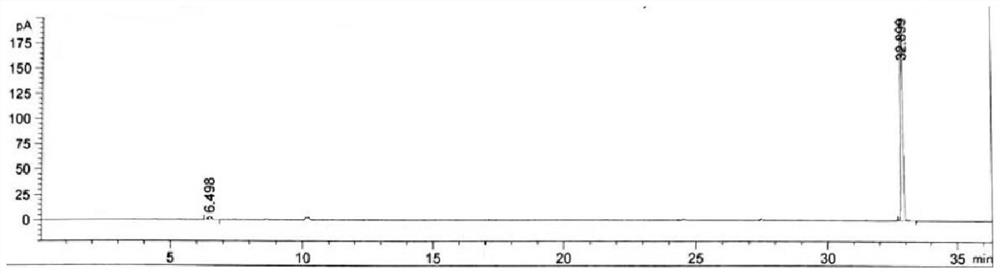

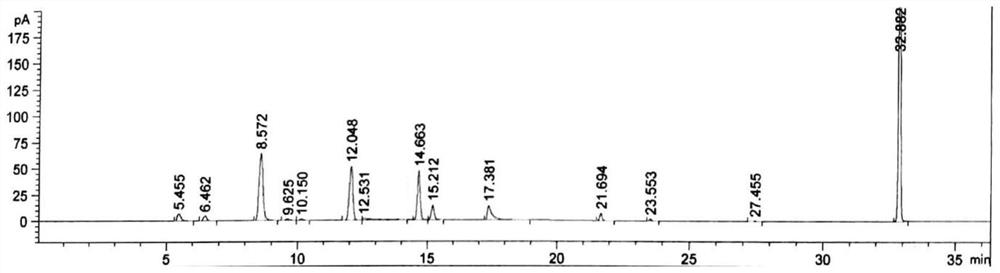

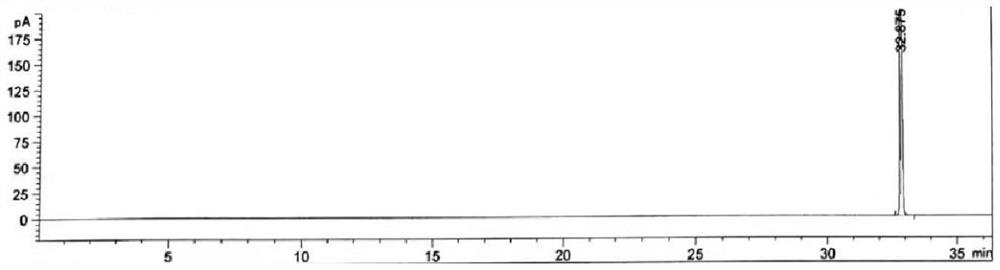

Method for detecting fluorobromomethane residues in bulk drugs

PendingCN111751455ANo reactionPrevent volatilizationComponent separationVapor phase chromatographyPhysical chemistry

The invention discloses a method for detecting fluorobromomethane residues in bulk drugs. The invention provides a method for detecting bromofluoromethane, and relates to a method for determining bromofluoromethane residues in API, which adopts gas chromatography, takes DB-624 as a chromatographic column and carrier gas as helium, adopts a headspace sample injection method for sample injection, adopts a column temperature programmed heating method, and selects a hydrogen flame ionization detector as a detector. The method has the beneficial effects that the headspace temperature is reduced to25-30 DEG C for detection, fluorobromomethane detected at the temperature can be completely vaporized, so that fluorobromomethane is prevented from reacting, volatilization of fluorobromomethane during direct sample introduction is avoided, and the detection precision is guaranteed.

Owner:TIANJIN PHARMA GROUP CORP

Thermoplastic elastomer composite material

The invention relates to a thermoplastic elastomer (TPE) composite material, which consists of a polyolefin thermoplastic elastomer (TPO), a styrene thermoplastic elastomer (SBC) and a polyurethane thermoplastic elastomer (TPU), wherein each 100 weight portions of the thermoplastic elastomer (TPE) comprise 30 to 70 portions of the polyolefin thermoplastic elastomer (TPO), 1 to 50 portions of the styrene thermoplastic elastomer (SBC) and 1 to 50 portions of the polyurethane thermoplastic elastomer (TPU). The material has stable chemical properties, is difficult to decompose after being processed, has no smog, and does not pollute the environment due to production of carbon dioxide after burning treatment; and a transfusion system manufactured does not need to be added with low molecular compounds such as a stabilizer, a lubricant and pigment. The thermoplastic elastomer (TPE) composite material has a reasonable formula, stable performance and good flexibility, elasticity and toughness, does not pollute the environment when being destroyed, and is a special material which can be used for mass production of portable thermoplastic elastomer transfusion systems in a cleaning shop.

Owner:威海威高创新有限公司

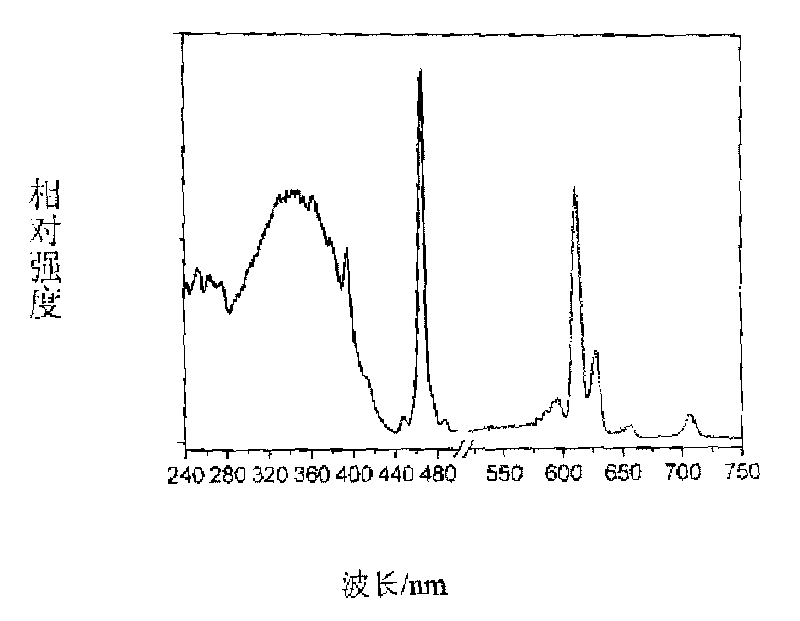

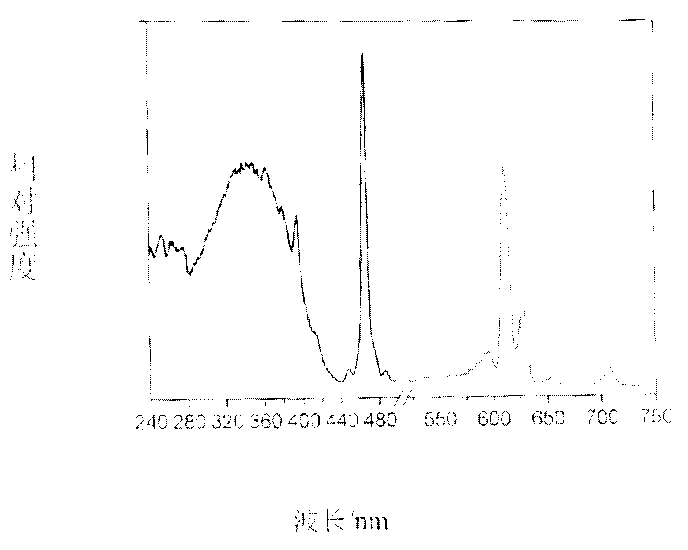

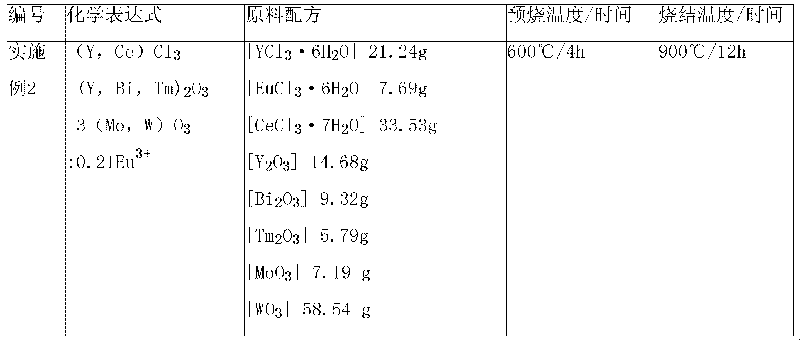

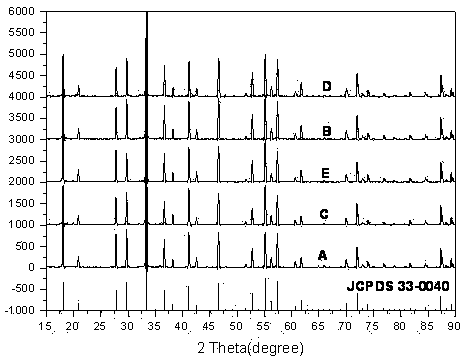

Red fluorescent powder excitated by near-ultraviolet broadband and preparation method thereof

ActiveCN101709216AHigh color purityStable physical and chemical propertiesLuminescent compositionsLuminous intensityUltraviolet lights

The invention discloses red fluorescent powder excitated by near-ultraviolet broadband and a preparation method thereof. The chemical expression of the red fluorescent powder is R1R23-R32O3-3R4O3:xEu3+, wherein R1 is one, two or more of Y3+, La3+, Gd3+, Pr3+, Sm3+ and Bi3+, and R2 is one, two or three of Cl-, Br- and I-; R3 is one, two or more of La3+, Gd3+, Y3+, Pr3+, Sm3+, Bi3+, Tm3+ and Dy3+; R4 is W6+ or / and Mo6+; and x is equal to 0.005-2.0. The preparation process comprises the steps of preparing a raw material of powder, preparing a mixture material, prefiring, sintering and postprocessing. The red fluorescent powder presents broadband excitation and sharp peak transmission to near-ultraviolet light, and red has high luminescence intensity and good color purity.

Owner:山东格新精工有限公司

Method for improving luminescent intensity and stability of synthesized YAG (yttrium aluminum garnet):Ce fluorescent powder

InactiveCN103666472AHigh luminous intensityImprove luminescence stabilityLuminescent compositionsDispersityCerium

The invention belongs to the technical field of rare earth luminescent materials, and mainly relates to a method for obviously improving the luminescent intensity and stability of synthesized YAG (yttrium aluminum garnet):Ce fluorescent powder. The main process comprises the following steps: mixing raw materials according to composition requirements, and calcining at 1400-1700 DEG C to obtain YAG:Ce raw fluorescent powder; performing ball milling dispersion on the YAG:Ce raw fluorescent powder in an acidic water medium, filtering, and drying to obtain surface-acidic raw fluorescent powder; adding cosolvent, uniformly mixing, and performing reducing calcination in hydrogen gas and hydrogen-nitrogen mixed gas at 1400-1600 DEG C for 2-50 hours; and performing furnace cooling to room temperature under the protection of a reducing atmosphere, washing with water, performing grinding dispersion, filtering, washing, and drying to obtain the fluorescent powder. The acid treatment on the surface of the YAG:Ce fluorescent powder can guarantee the cerium reducing effect in the subsequent high-temperature calcination process and improve the dispersity of the YAG fluorescent powder. Thus, the YAG:Ce powder produced by the invention has the characteristics of high luminescent intensity, less luminance decrease, favorable dispersity and stability and the like. The YAG:Ce powder is suitable for synthesis of new fluorescent powder, and can be also used for reforming and upgrading waste fluorescent powder.

Owner:YIZHENG SENTAI CHEM

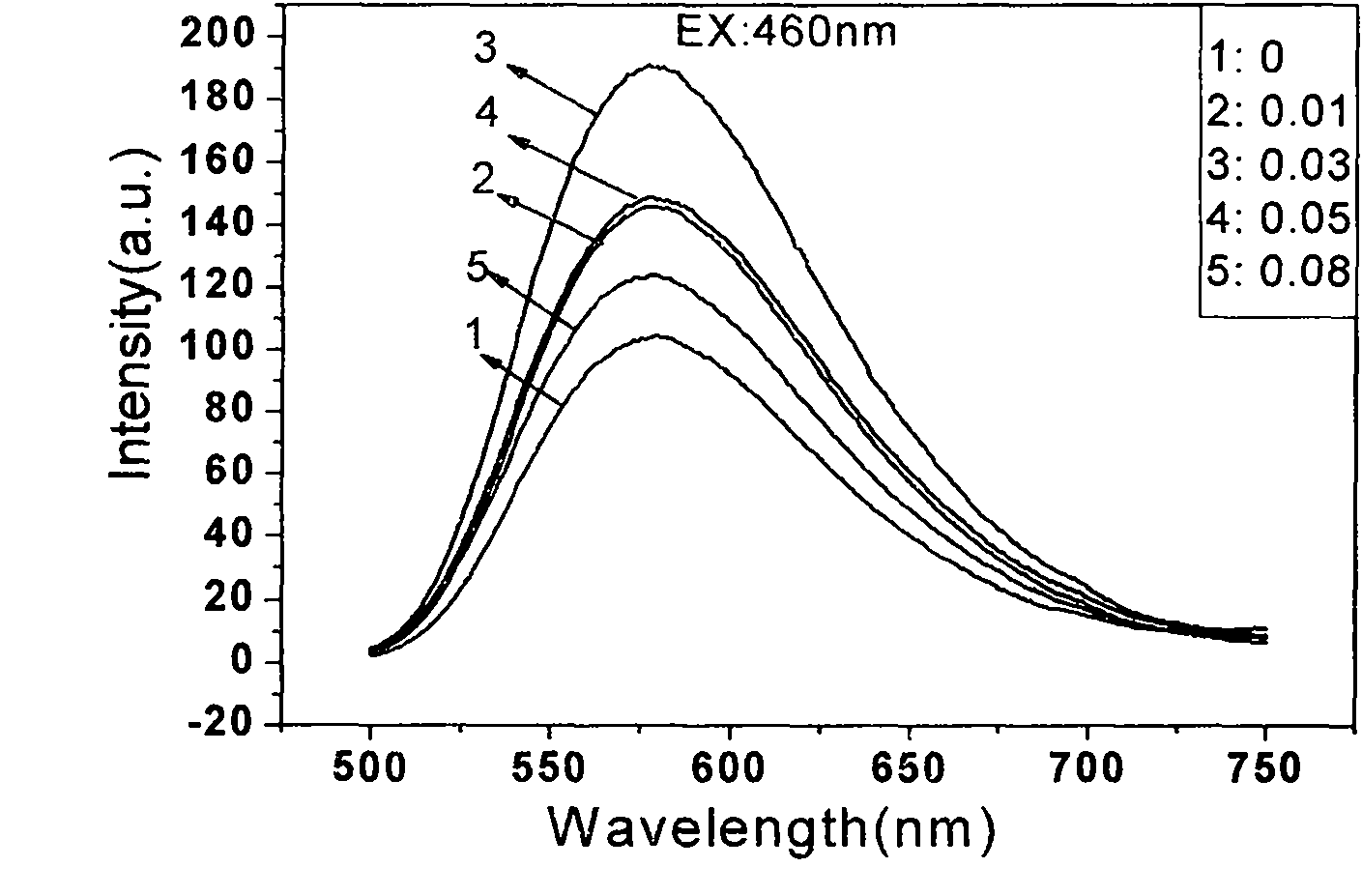

Fluorescent powder capable of being effectively excited by blue light and preparation method thereof

ActiveCN101812297APromote absorptionHigh luminous intensityLuminescent compositionsChemical compositionUltraviolet lights

The invention belongs to the technical field of rare earth luminescent materials, and in particular relates to fluorescent powder capable of being effectively excited by blue light and a preparation method thereof. The general formula of chemical compositions of the fluorescent powder is Li2Sr1-z(SiO4)1-0.75x-0.5y(M1O4)x(M2O4)y:zEu2+, wherein M1 refers to P; M2 refers to S; x is more than or equal to 0 and less than or equal to 0.2; y is more than or equal to 0 and less than or equal to 0.3; and z is more than or equal to 0 and less than or equal to 0.01. The preparation method comprises the following steps of: correctly weighing raw materials in a stoichiometric ratio of the general formula, uniformly mixing the raw materials fully, and pre-sintering the raw materials into a high temperate furnace at the temperature of between 400 and 800 DEG C for 1 to 12 hours; and sintering the pre-sintered raw materials in the reducing atmosphere at the temperature of between 700 and 1,000 DEG C for 1 to 10 hours. The fluorescent powder can be effectively excited by the blue light between 400 and 550nm, intense fluorescence-emission of which the main peak is about 580 to 610nm is obtained, and the fluorescent powder can be matched with a blue LED chip and is used for assembling white LEDs. Meanwhile, the fluorescent powder also can be excited by ultraviolet light between 250 and 280nm to emit intense red fluorescence. The fluorescent powder prepared by the invention has stable chemical properties, the preparation process is easily controlled, and the industrial production can be realized by utilizing basic equipment in the current fluorescent powder plants. Therefore, the fluorescent powder is new fluorescent powder with application potential.

Owner:瑞金市工业投资发展有限公司

Composite binder for preparing sintered porous body of silicon carbide powder and using method thereof

The invention discloses a composite binder for preparing a sintered porous body of silicon carbide powder and a using method thereof. The composite binder comprises the components of aluminium metaphosphate and polyvinyl alcohol. The using method of the composite material comprises the following steps: firstly adding silicon carbide powder into water solution of the aluminium metaphosphate with the concentration of 0.007 to 0.056g / ml, drying at the temperature of 200 DEG C, sieving, then adding water solution of the polyvinyl alcohol with the concentration of 0.035 to 0.14g / ml, drying at the temperature of 80 DEG C, sieving, then die-pressing and molding, sintering and obtaining the porous body of silicon carbide; and the adding amount of the aluminium metaphosphate is 0.5 to 4wt% of thatof the silicon carbide powder, and the adding amount of the polyvinyl alcohol is 0.5 to 2wt% of that of the silicon carbide powder. The obtained molded blank of the silicon carbide has smooth surfaceand good molding quality. After being sintered for 3h at the temperature of 80 DEG C, the obtained porous body of the silicon carbide has high strength and good high temperature resistance.

Owner:CENT SOUTH UNIV

Portable water battery components and water battery device comprising same

InactiveCN103682385AImprove temperature adaptabilityNo reactionCurrent conducting connectionsCell lids/coversEngineeringMetal

A power supply device, in particular a portable water battery component and a water battery device comprising same. The water battery component comprises a carbonized cloth constituting a positive electrode, a positive electrode lead-out electrode electrically connected to the carbonized cloth, a salt-containing cloth closely connected to the carbonized cloth; a absorbent paper closely connected to the salt-containing cloth, a negative electrode metal piece closely connected to the absorbent paper and constituting a negative electrode, a negative electrode lead-out electrode electrically connected to the negative electrode metal piece, and a heat-shrinkable tube compressing the carbonized cloth, the positive electrode lead-out electrode, the salt-containing cloth, the absorbent paper, the negative electrode metal piece, and the negative electrode lead-out electrode against each other. The water battery device comprises a shell, wherein the shell is internally provided with one or more of the foregoing battery components, and the shell is provided with water injection holes for injecting water into the shell; thus the absorbent paper of water battery component absorbs water.

Owner:ECO BATTERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com