Lithium ion battery cathode material and preparation method thereof and lithium battery

A technology for lithium ion batteries and cathode materials, applied in the field of materials, can solve the problems of low doping amount, inability to suppress side reactions on the surface of materials, and influence on the electrochemical performance of materials, so as to achieve a simple and easy method of reducing dosage and impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

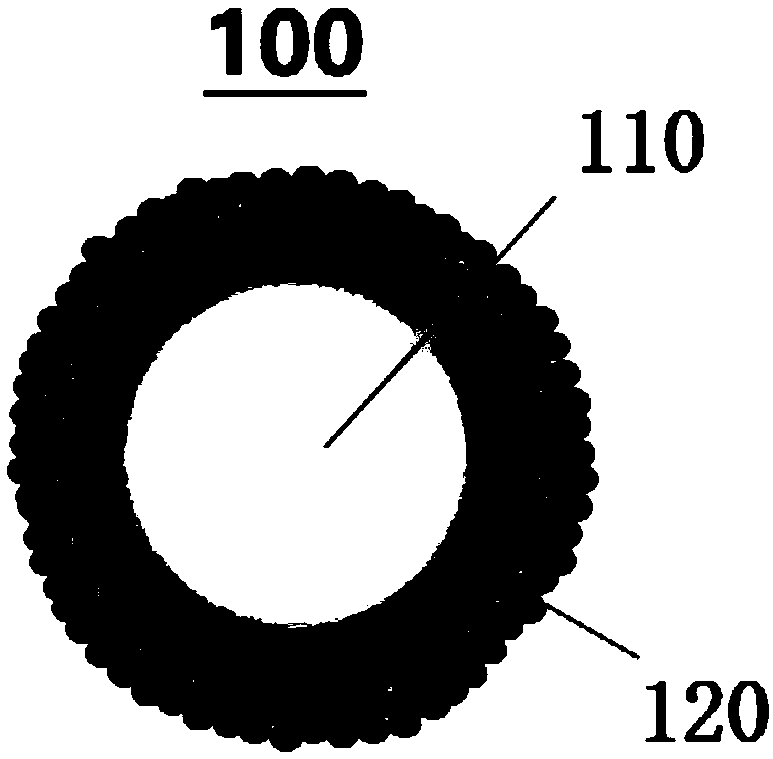

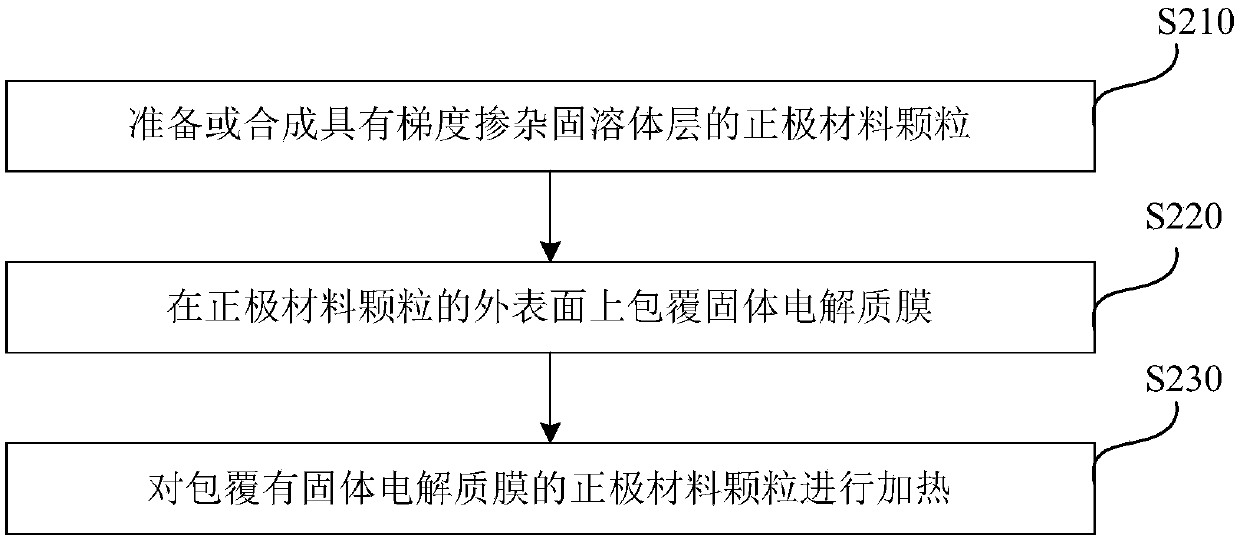

[0041] The preparation method of lithium ion battery cathode material of the present invention comprises:

[0042] Synthesizing positive electrode material particles with a gradient doping solid solution on the surface, the doping elements are 4d and 5d metals, and the positive electrode material particles include a positive electrode material precursor or a positive electrode material after phase formation;

[0043] Coating a solid electrolyte membrane on the surface of the positive electrode material particles, the solid electrolyte membrane includes an electrolyte material precursor or a phase-formed electrolyte material;

[0044] Heating the positive electrode material particles or the positive electrode material precursor, the heating temperature is in the range of 300-1200°C;

[0045] The positive electrode material particles coated with the solid electrolyte membrane are heated, and the heating temperature is in the range of 50-500°C.

[0046] specific figure 2 It is...

Embodiment 1

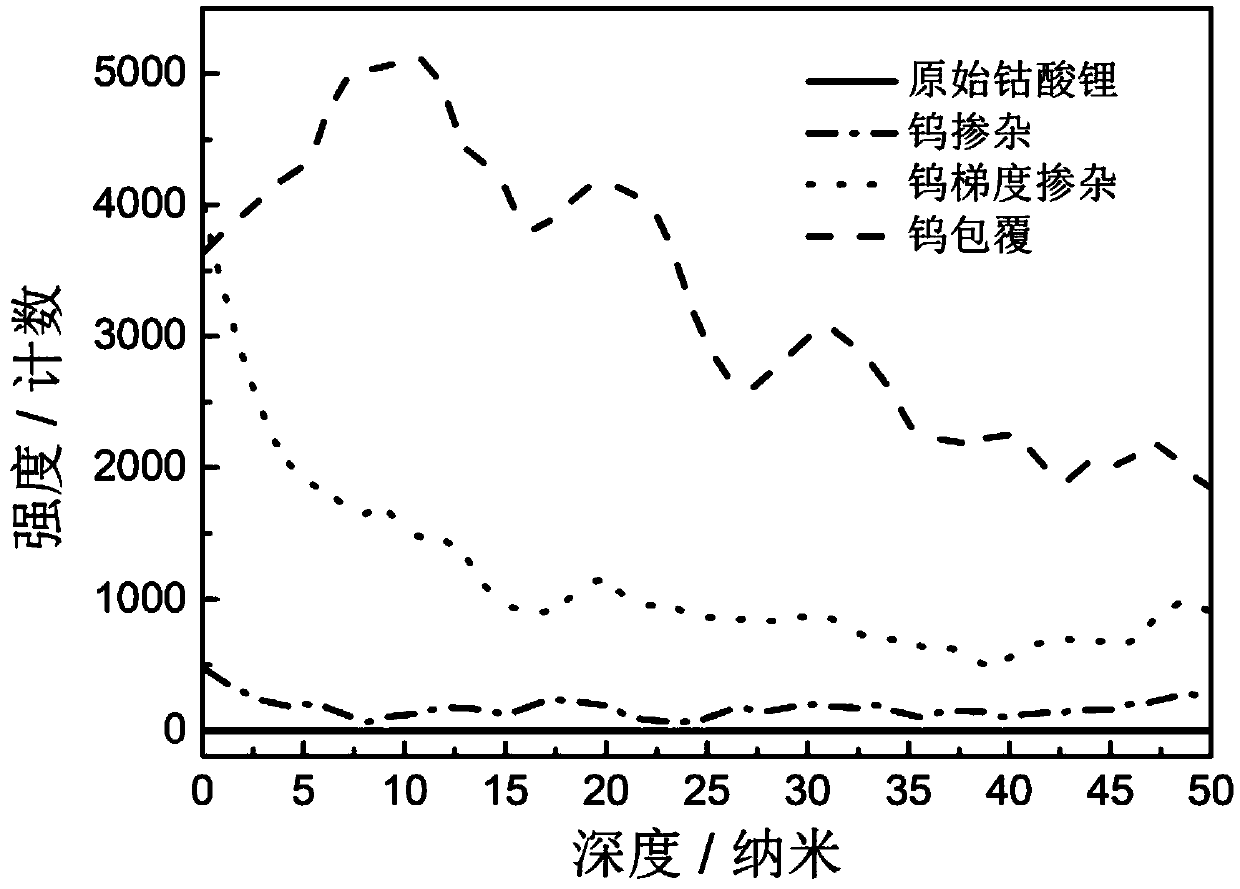

[0057] Ultra-thin Li 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 Preparation of (LATP)-coated W gradient-doped lithium cobalt oxide materials.

[0058] Nano WO 3 Precursor and micron-scale lithium cobalt oxide precursor Co 3 o 4 , Li 2 CO 3 Ball milling at 300 rpm for 1 hour to obtain a uniformly mixed precursor mixture. The resulting mixture was packed in Al 2 o 3 Place the crucible in a muffle furnace, raise the temperature to 500°C at a heating rate of 2°C / min, keep at 500°C for 5 hours, cool to room temperature naturally, and take out the crucible. After grinding the obtained powder with an agate mortar for 2 h, the obtained mixture was loaded again in Al 2 o 3 The crucible was placed in a muffle furnace, and the temperature was raised to 1100 °C at a heating rate of 3 °C / min, and then kept at 1100 °C for 15 hours, then naturally cooled to room temperature, and the crucible was taken out. A positive electrode material with a gradient doped solid solution layer on the surface...

Embodiment 2

[0062] Preparation of Li by Atomic Layer Deposition 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 Preparation of (LATP)-coated W gradient-doped ternary materials.

[0063] Nano WO 3 The precursor and the micron-scale ternary cathode material were ball milled at a speed of 300rpm for 1 hour to obtain a uniformly mixed cathode material and WO 3 mixture. The resulting mixture was packed in Al 2 o 3 The crucible was placed in a muffle furnace, and the temperature was raised to 700°C at a heating rate of 3°C / min. After holding at 700°C for 10 hours, it was naturally cooled to room temperature, and the crucible was taken out to obtain a gradient-doped lithium cobaltate cathode material.

[0064] Spread 1g of gradient-doped positive electrode particles on the substrate, using LATP raw materials Li2CO3, Al2O3, TiO2 and NH4H2PO4 as targets, in a vacuum of 10 -2 torr, voltage 24V, Ar atmosphere, depositing 28 seconds, 8 seconds, 64 seconds and 12 seconds respectively, different raw materials wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com