Patents

Literature

106 results about "Phase formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

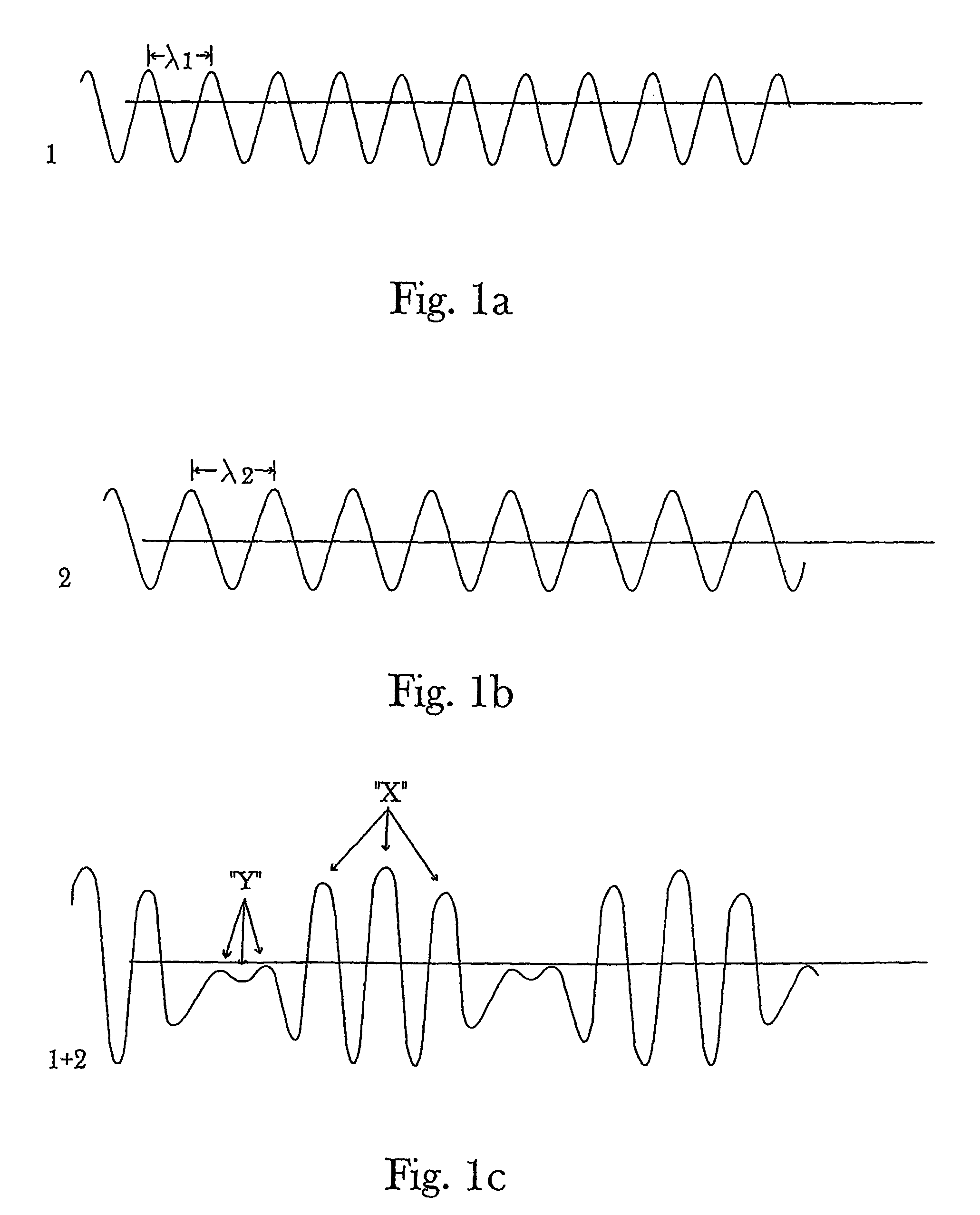

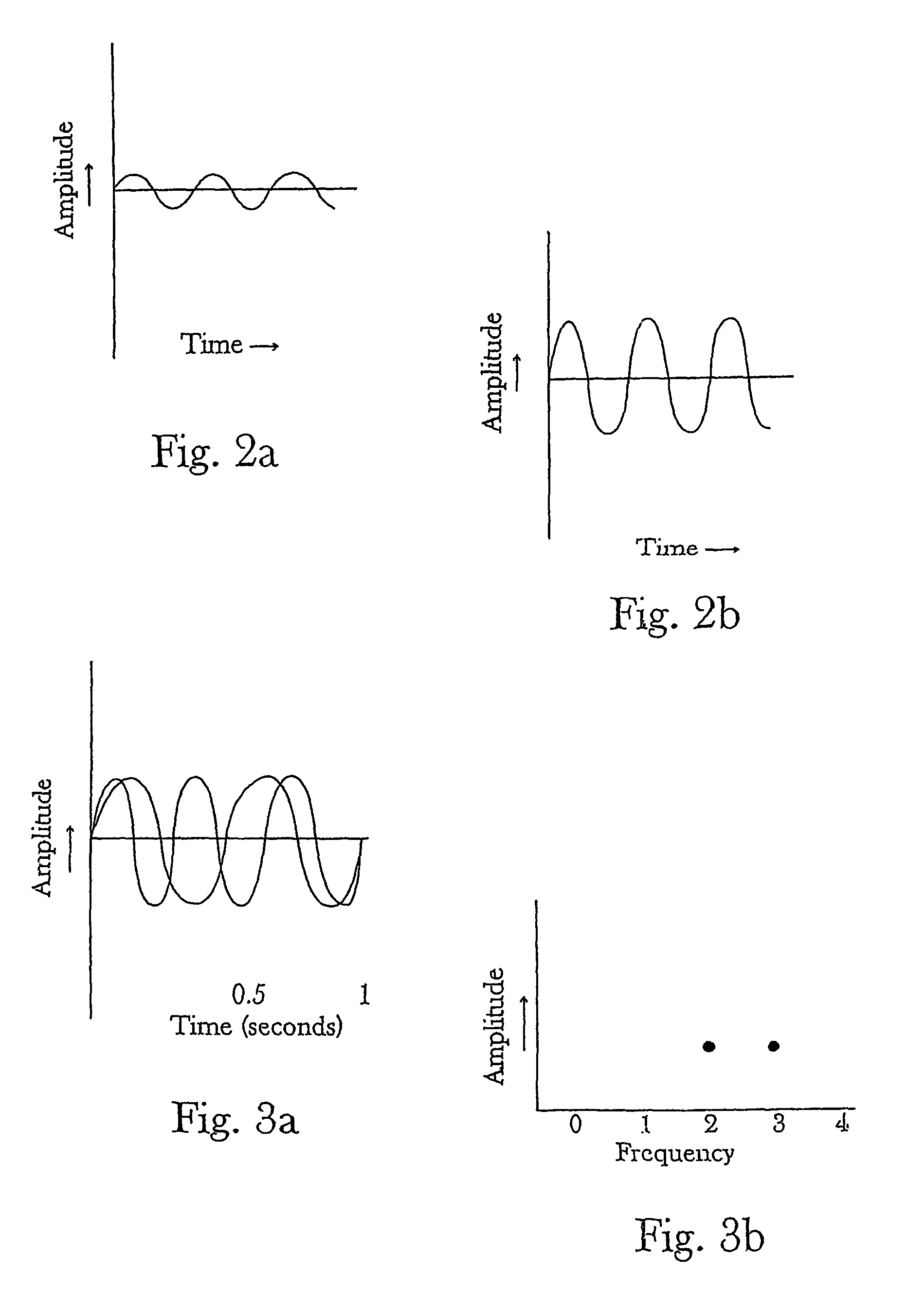

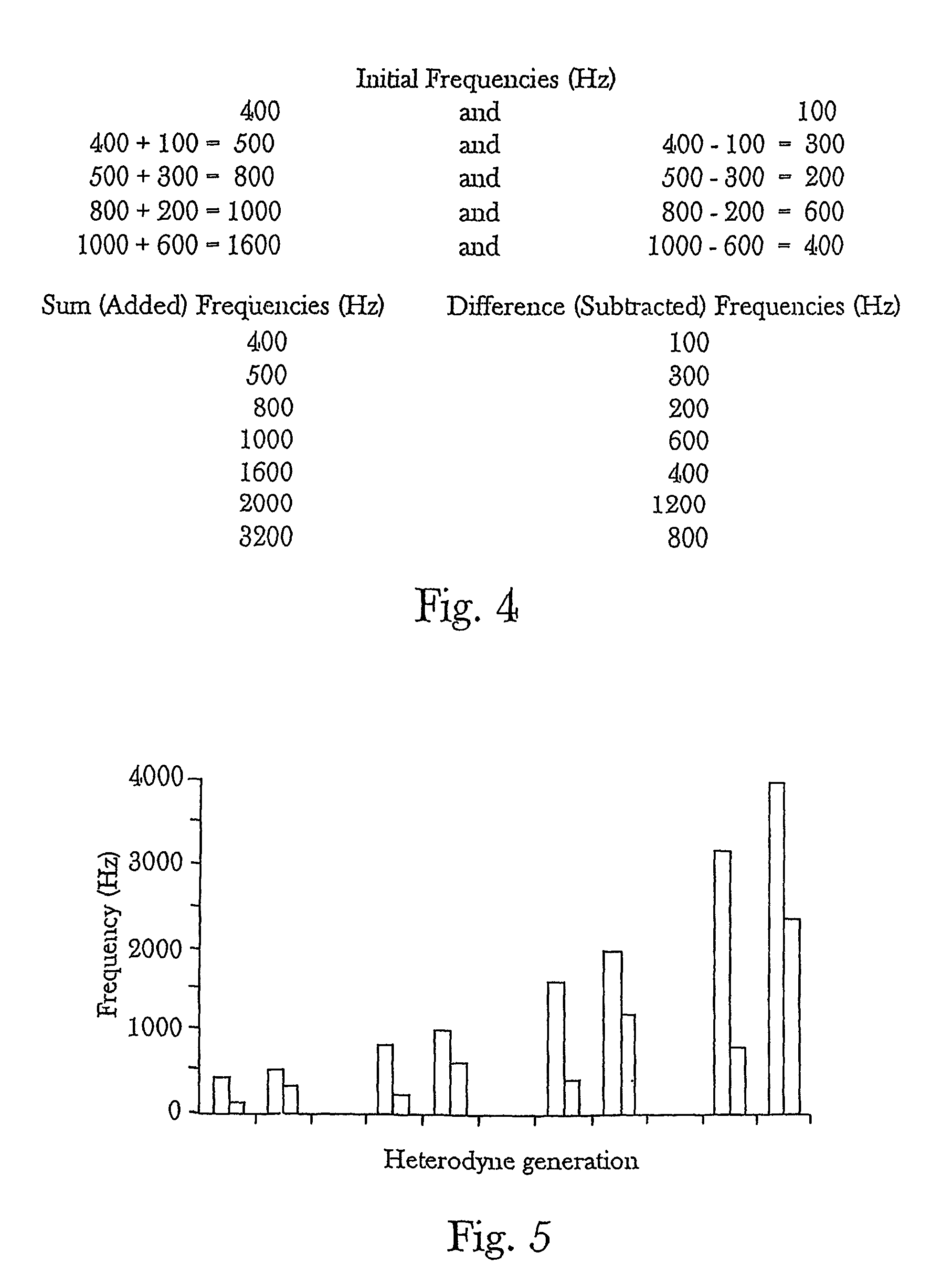

Methods for controlling crystal growth, crystallization, structures and phases in materials and systems

InactiveUS20060037177A1Growth inhibitionExisting techniquePolycrystalline material growthOxygen/ozone/oxide/hydroxidePhase formationEnergy regulation

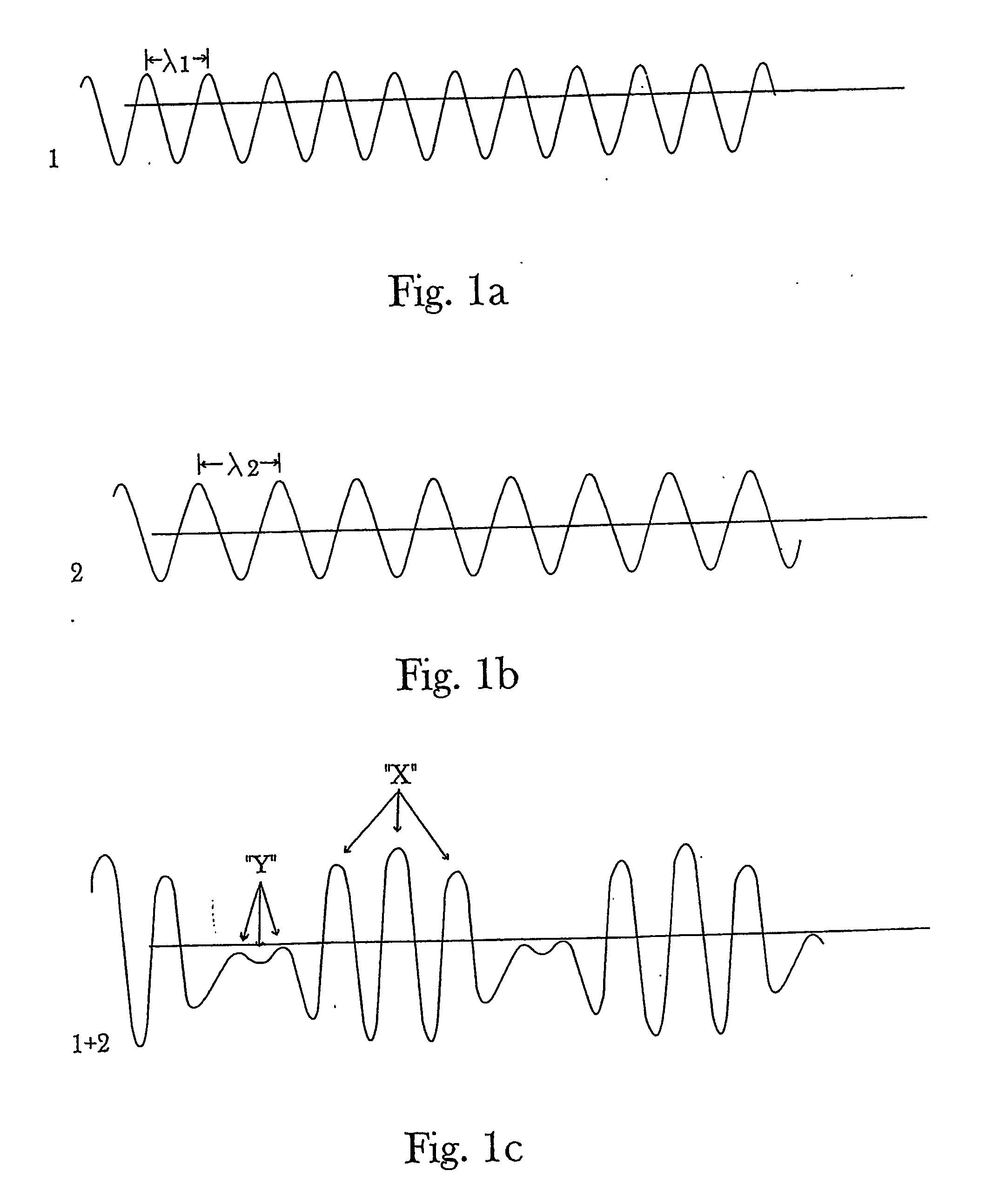

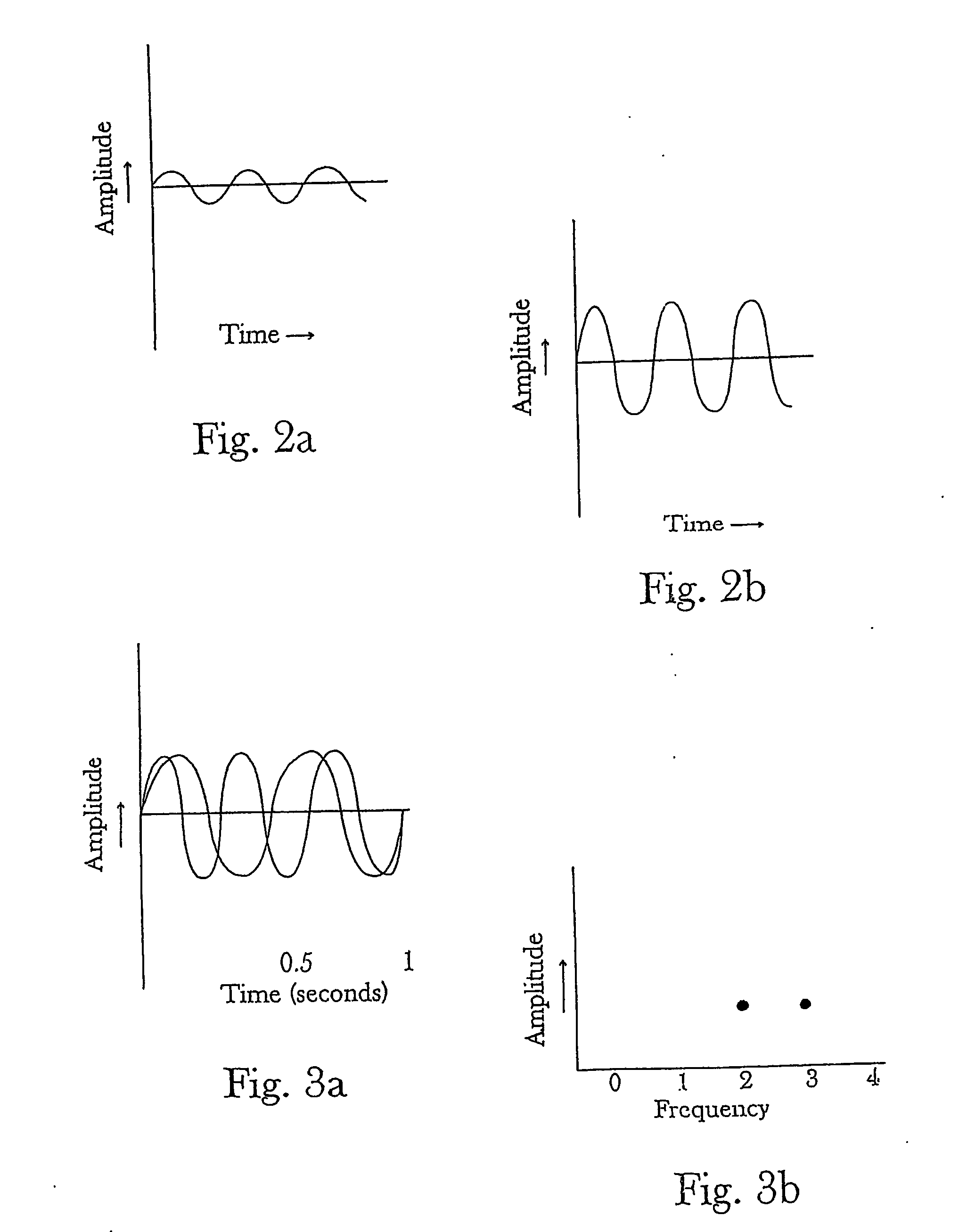

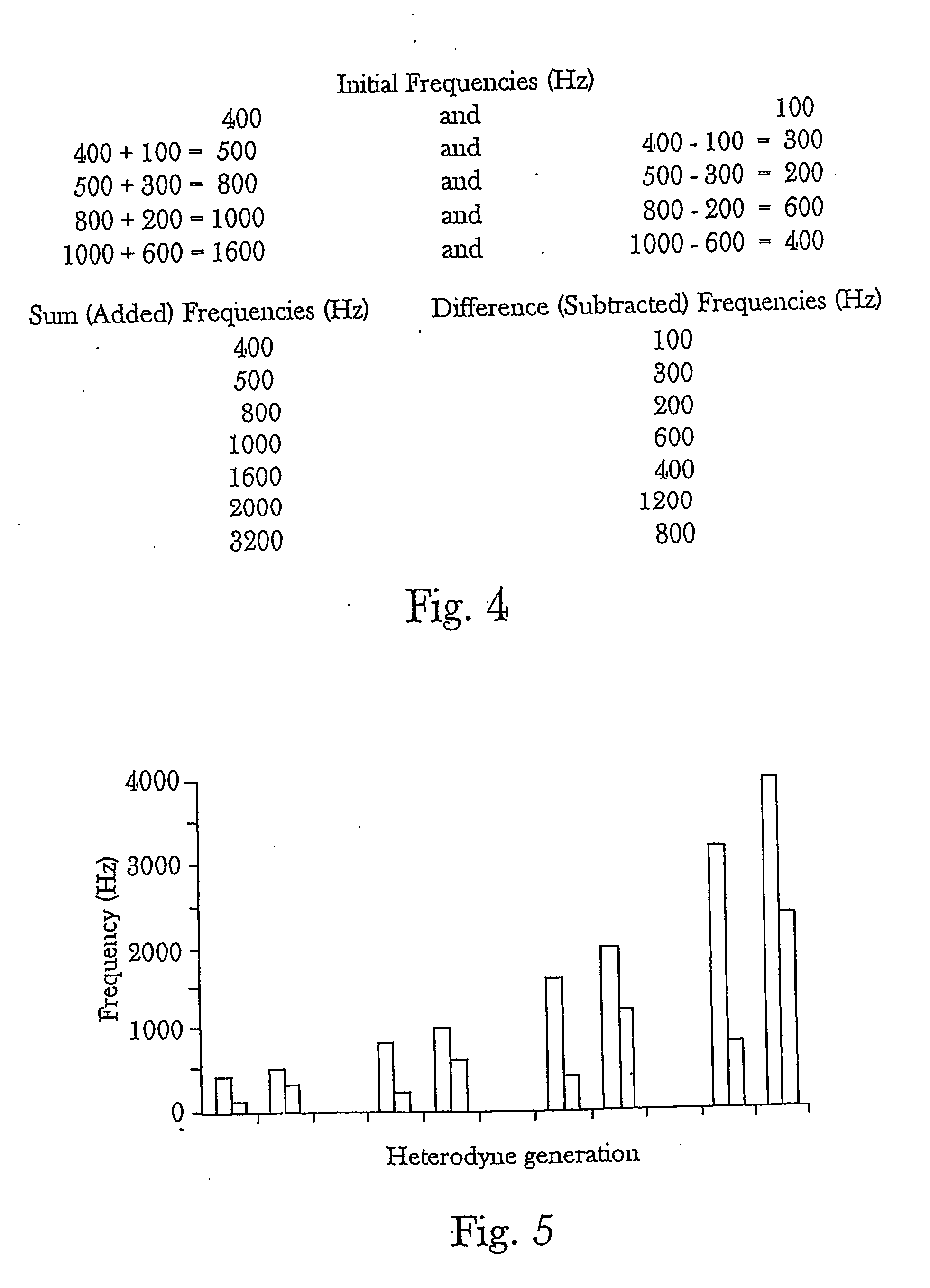

This invention relates to novel methods for affecting, controlling and / or directing various crystal formation, structure formation or phase formation / phase change reaction pathways or systems by exposing one or more components in a holoreaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a crystallization reaction system. In a second aspect of the invention, at lest one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other (or all) crystallization reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

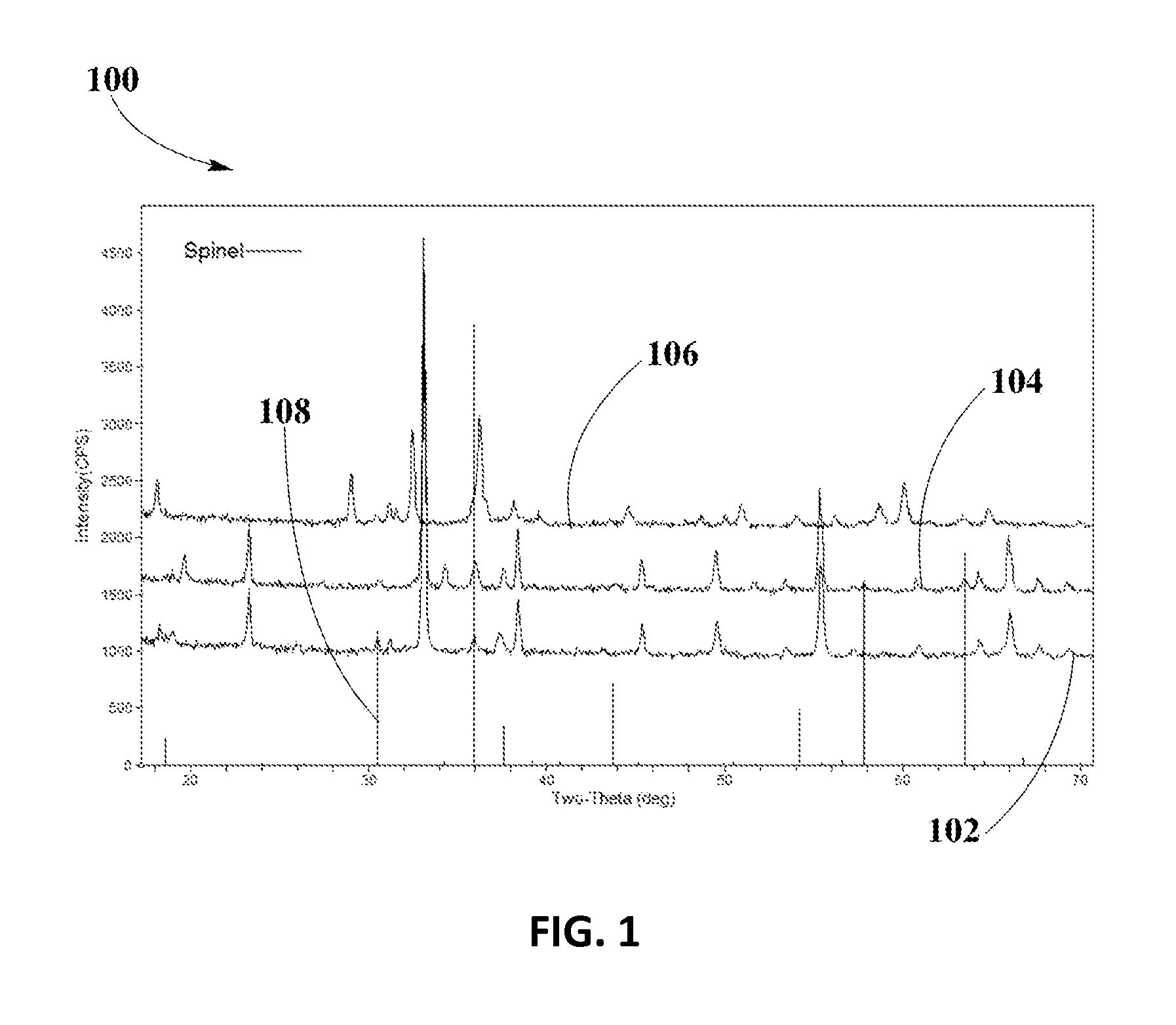

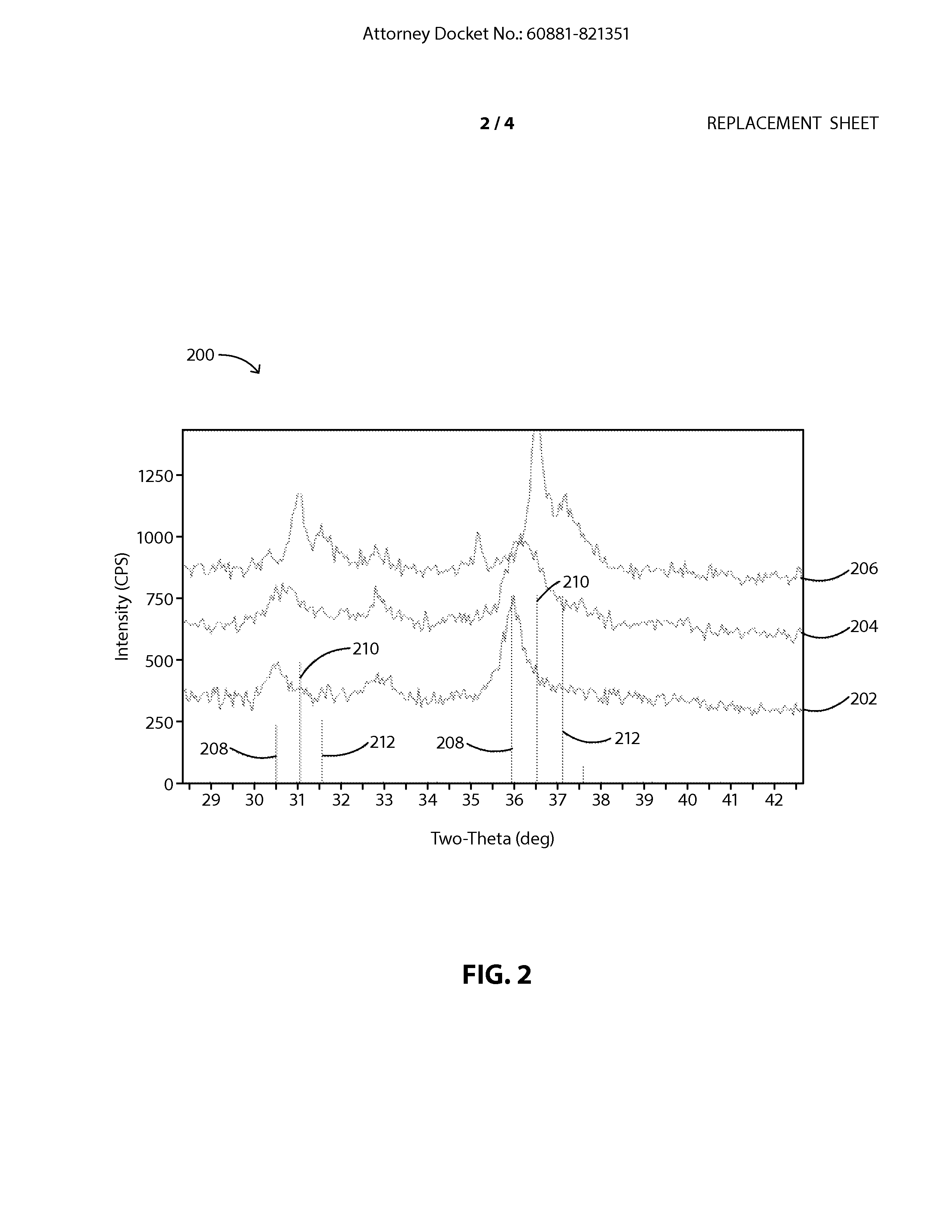

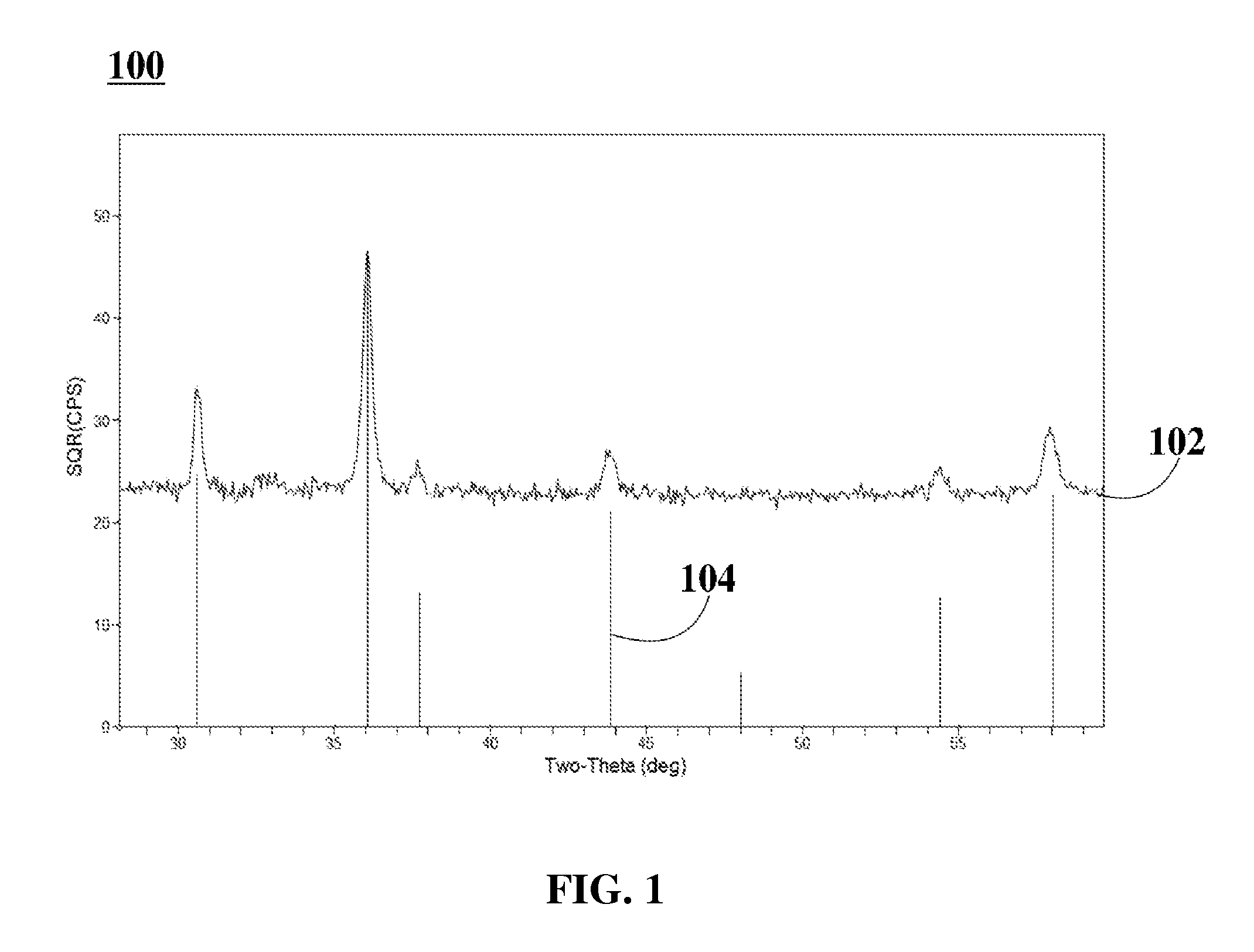

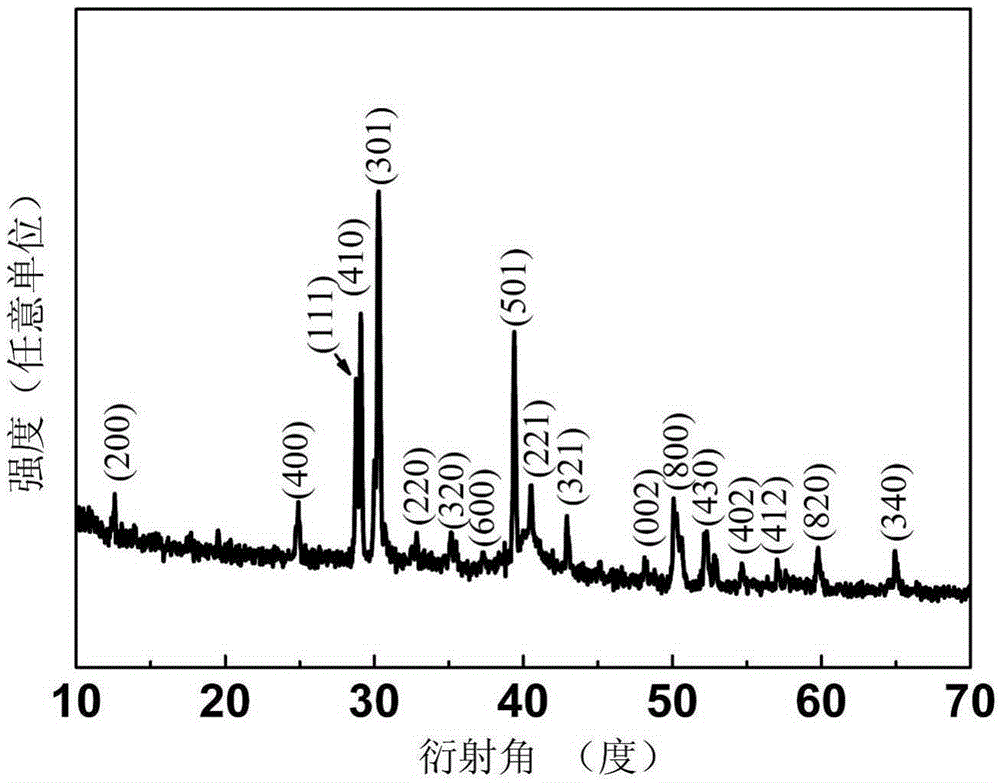

Formation and Stability of Cu-Mn Spinel Phase for ZPGM Catalyst Systems

InactiveUS20140271388A1Optimal spinel phase formation phaseOptimal phase phase stability propertyCombination devicesInternal combustion piston enginesPhase formationSpinel

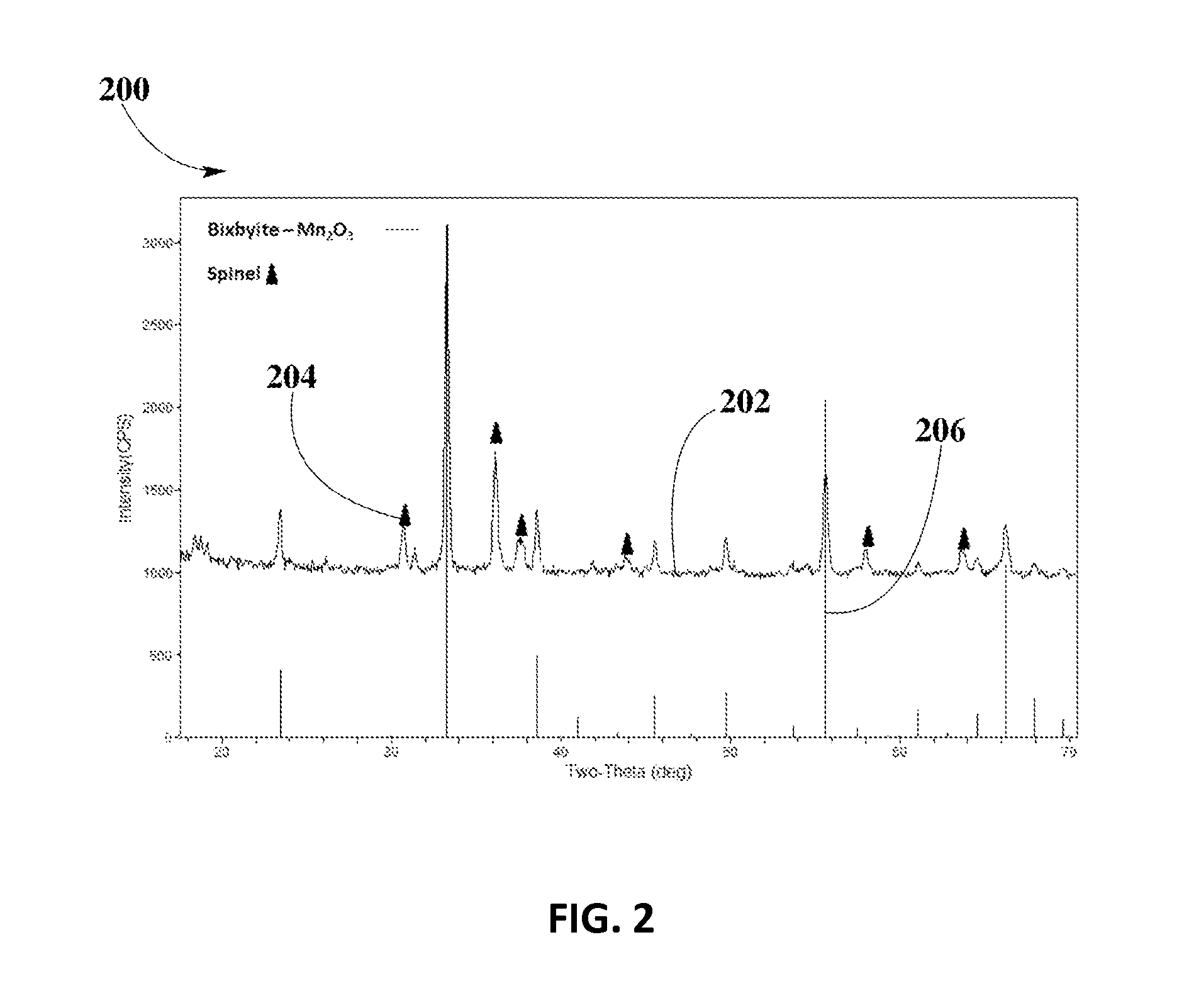

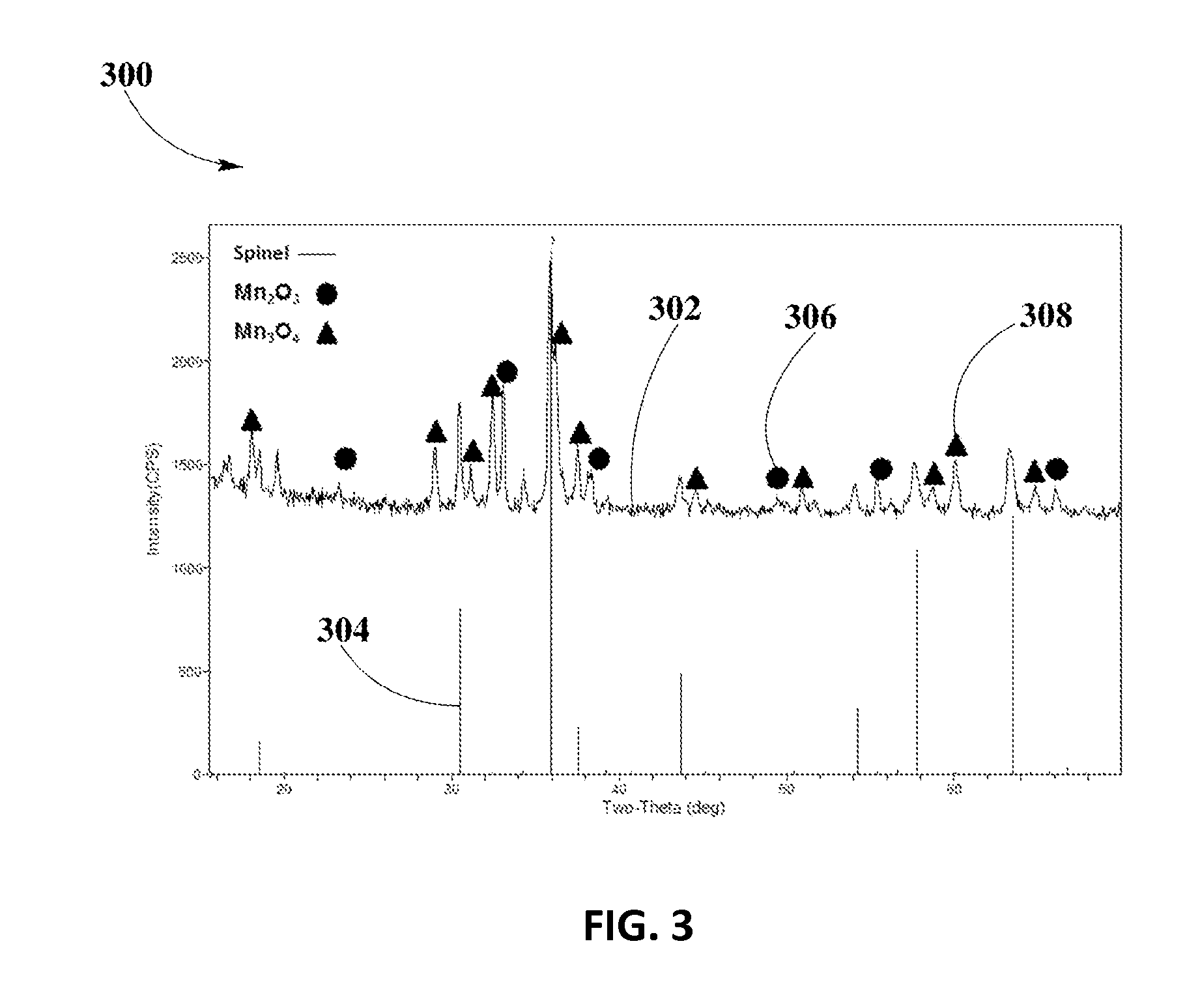

Optimized Cu—Mn spinel compositions, with optimal spinel phase formation and phase stability properties, for a plurality of ZPGM catalysts in underfloor and closed-loop coupled catalyst applications are disclosed. Plurality of Cu—Mn spinel compositions are prepared with variations of molar ratios. Effect of calcination temperature is analyzed to determine spinel phase formation and phase stability, as well as the effect of calcination temperature on lattice parameter of spinel, as correlated to spinel phase formation and phase stability of optimal Cu—Mn spinel compositions disclosed. Disclosed Cu—Mn spinels with enhanced spinel phase formation and phase stability may be suitable for ZPGM catalyst systems used in a vast number of TWC applications.

Owner:CLEAN DIESEL TECHNOLOGIES

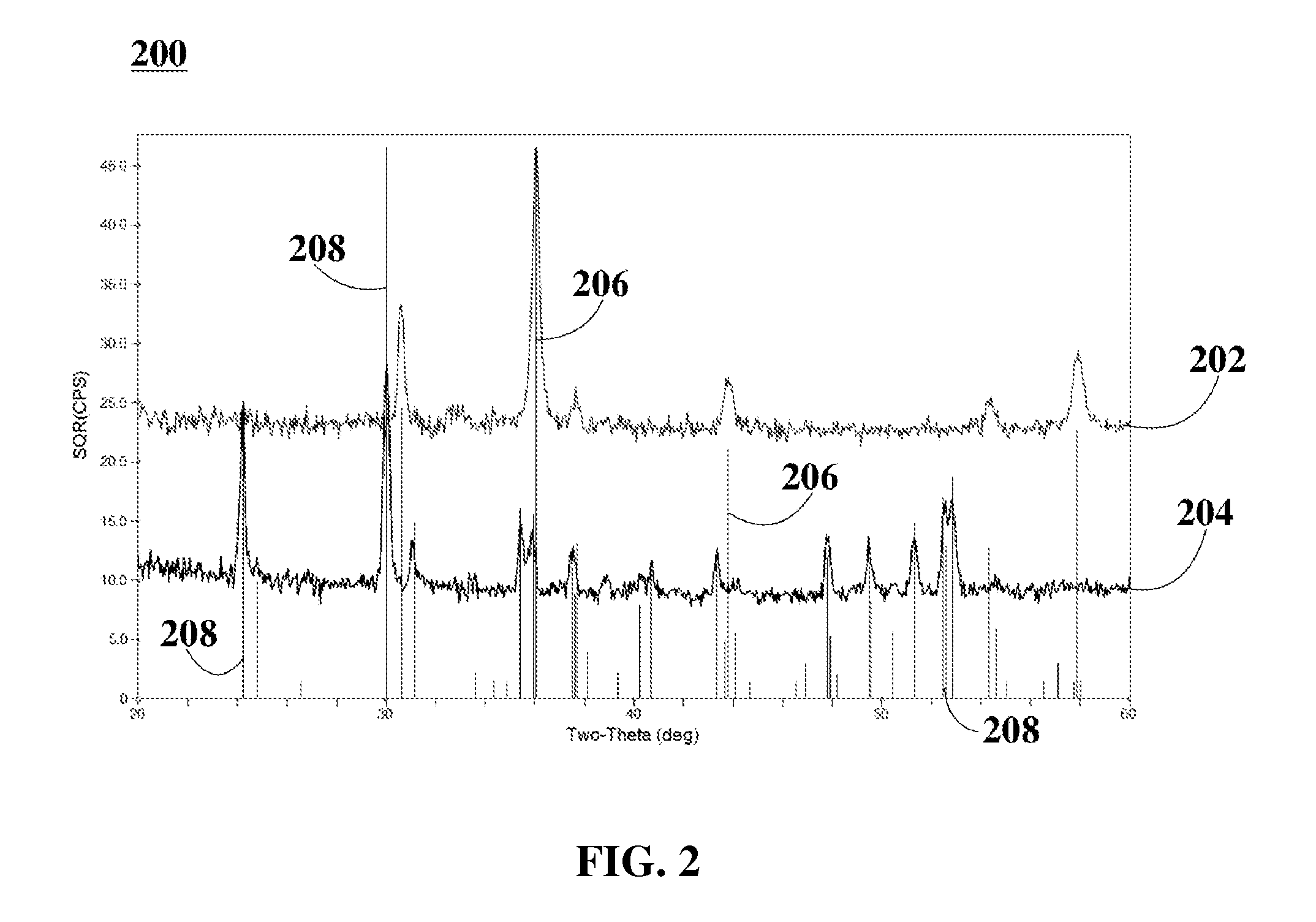

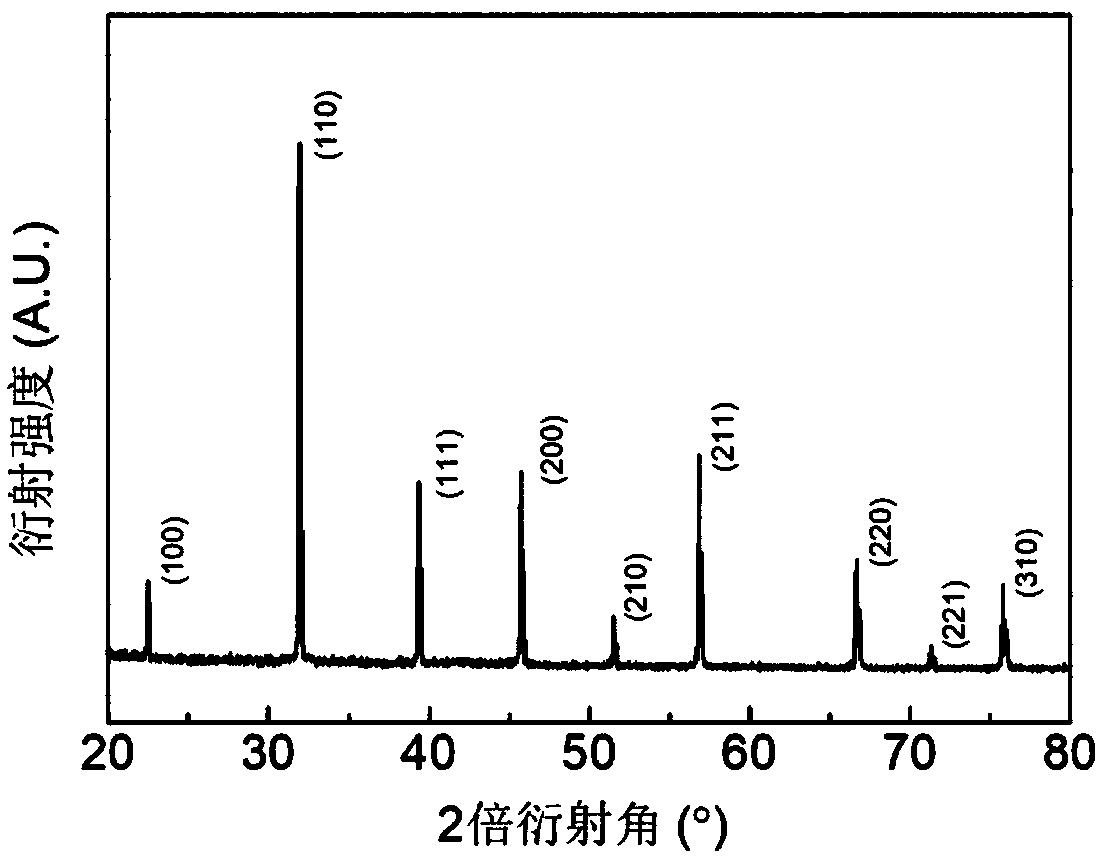

Phase Stability of Lanthanum-Manganese Perovskite in the Mixture of Metal Oxides

InactiveUS20150182954A1Gas treatmentMaterial analysis using wave/particle radiationPhase formationCordierite

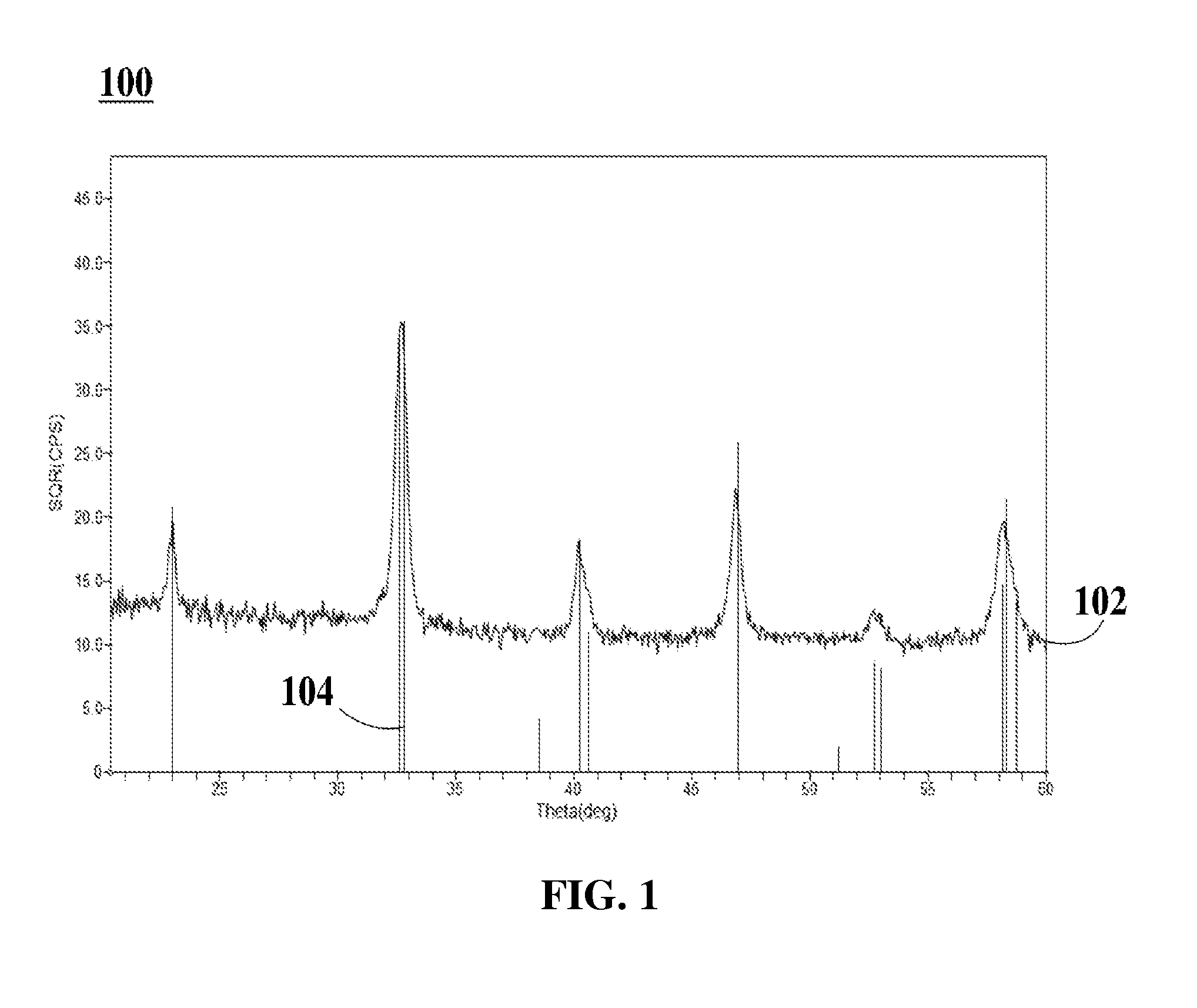

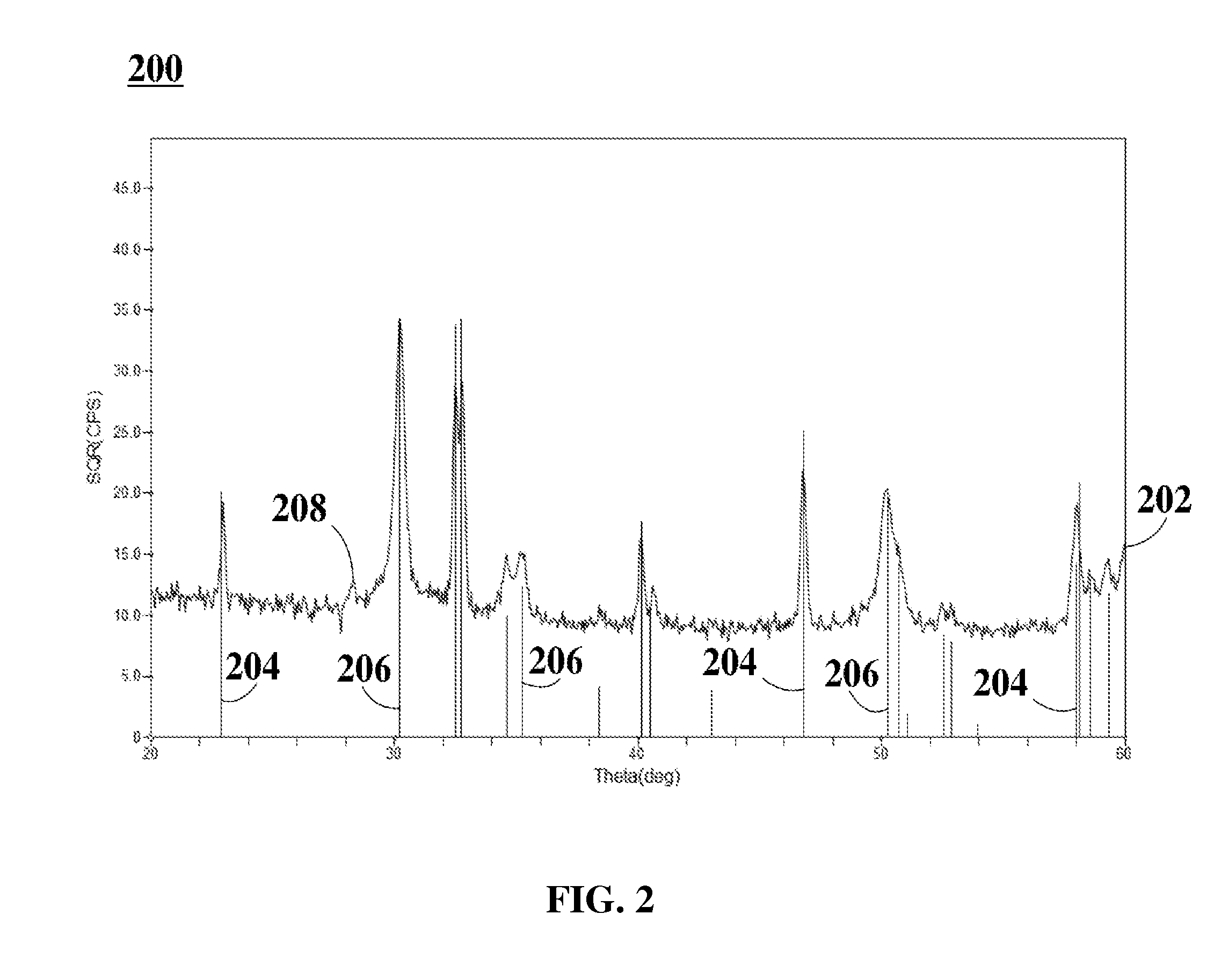

The present disclosure describes ZPGM material compositions including LaMnO3 perovskite structure mixed with a plurality of support oxide powders to develop suitable ZPGM catalyst materials. Bulk powder ZPGM catalyst compositions are produced by physically mixing bulk powder LaMnO3 perovskite with different support oxide powders calcined at about 1000° C. XRD analyses are performed for bulk powder ZPGM catalyst compositions to determine La—Mn perovskite phase formation and phase stability for a plurality of temperatures to about 1000° C. ZPGM catalyst material compositions including La—Mn perovskite structure mixed with doped zirconia, La2O3, cordierite, and ceria-zirconia support oxides present phase stability, which can be employed in ZPGM catalysts for a plurality of DOC applications, thereby leading to a more effective utilization of ZPGM catalyst materials with high thermal and chemical stability in DOC products.

Owner:CLEAN DIESEL TECHNOLOGIES

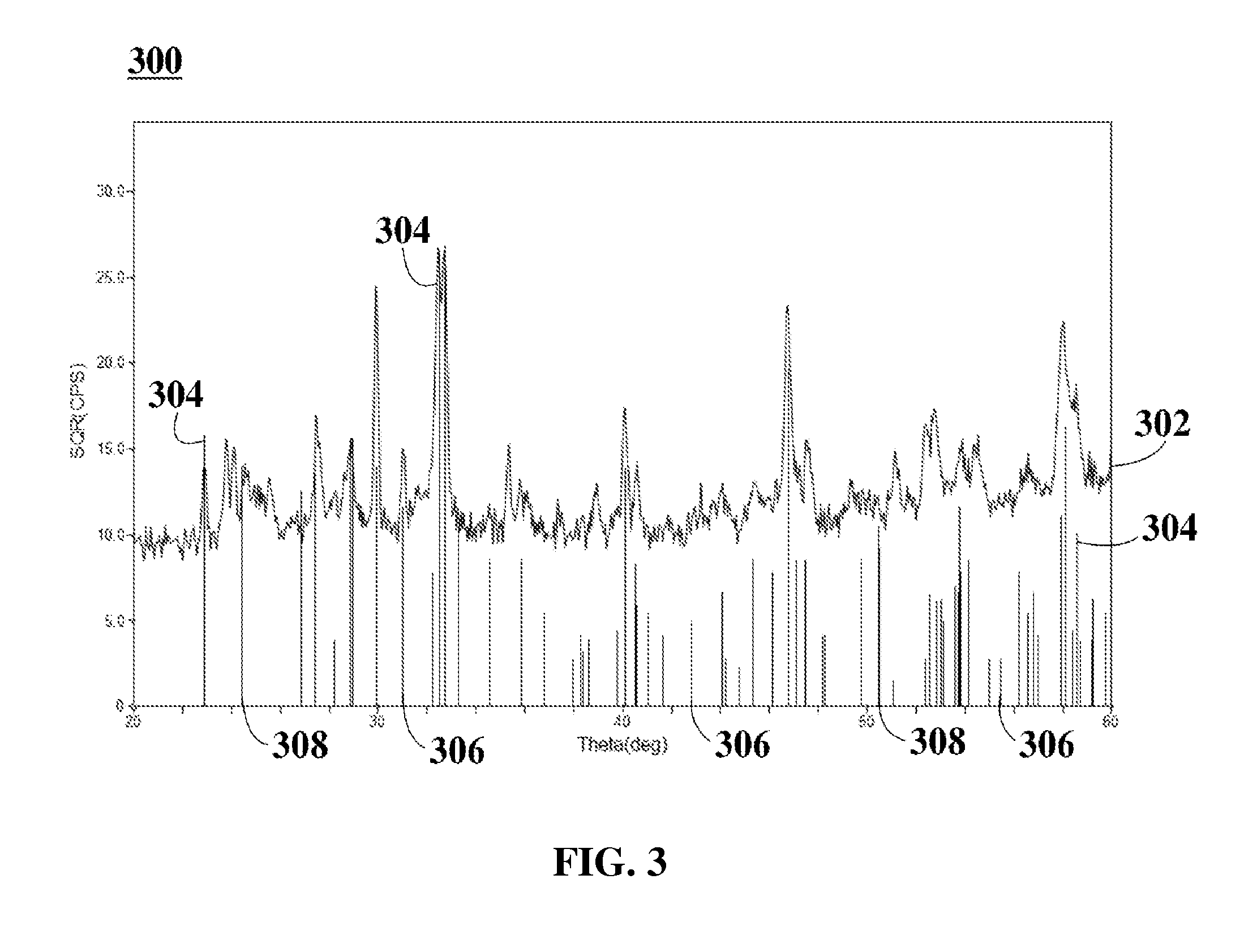

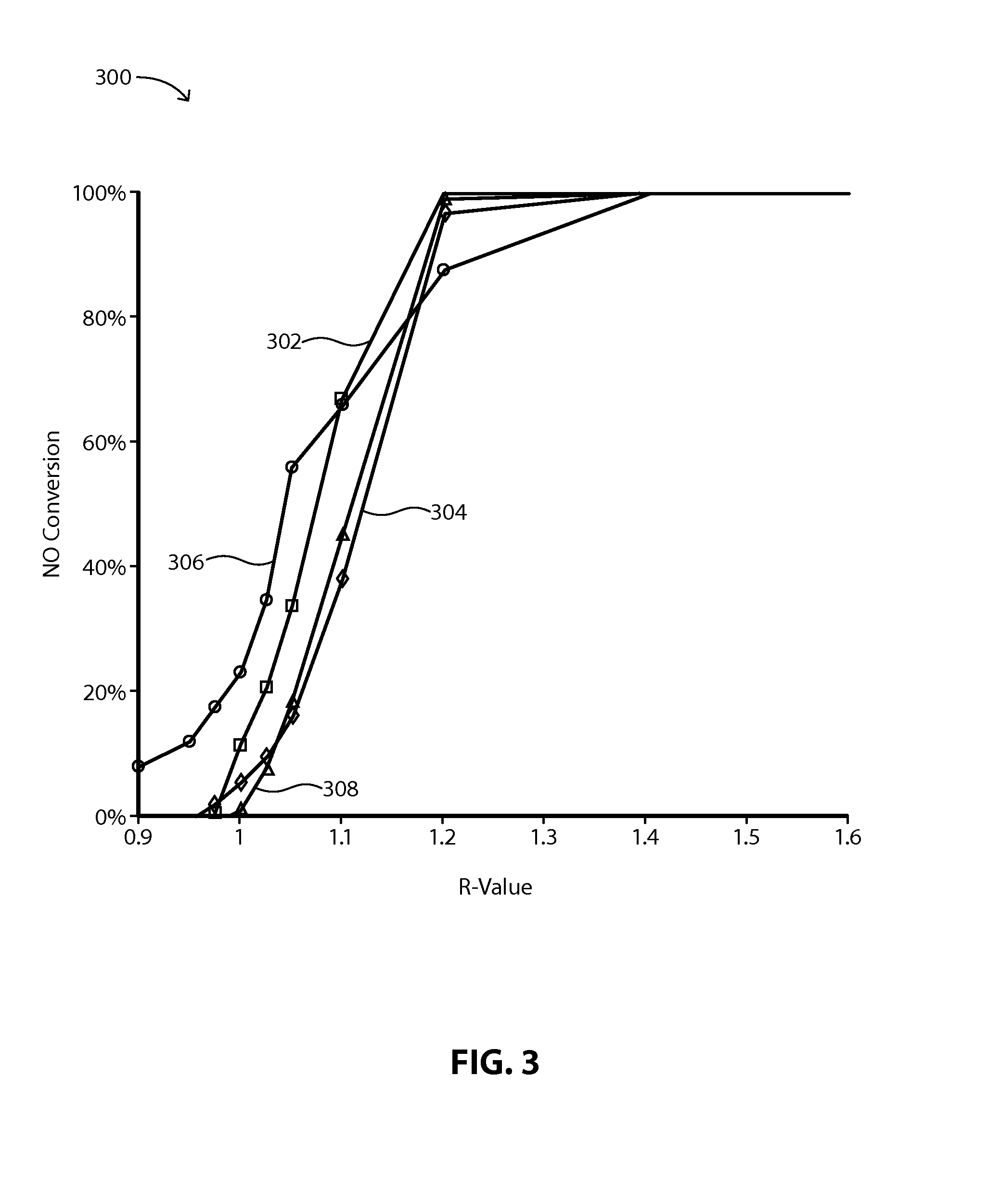

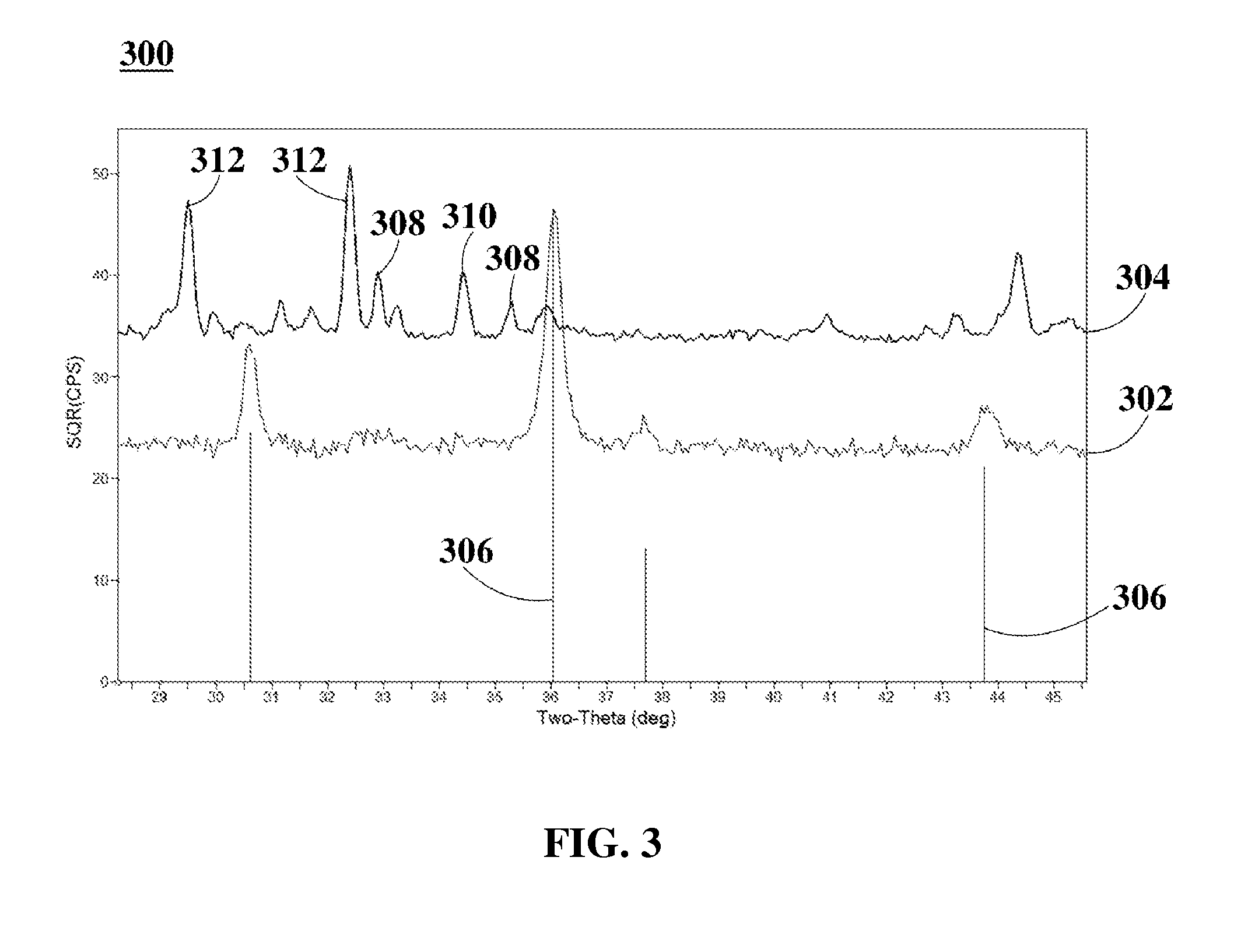

Influence of Type of Support Oxide on Stability of Copper-Manganese Zero-PGM Catalyst

InactiveUS20150352529A1Internal combustion piston enginesHeterogenous catalyst chemical elementsPhase formationActivity measurements

Variations of metal oxide materials used as support oxide for Cu—Mn spinel powder for ZPGM TWC applications are disclosed. Bulk powder catalyst samples of Cu—Mn spinel structure on MgAl2O4, Al2O3-9% BaO, Al2O3—SrO, Al2O3—CeO, CeO2—ZrO2 support oxides and among others are prepared using incipient wetness method. BET-surface area analysis is performed for selected support oxides before and after deposition of Cu—Mn spinel to analyze thermal stability. XRD analysis is performed for bulk powder catalyst samples to investigate Cu—Mn spinel phase formation, and phase stability for a plurality of temperatures to about 1000° C. Activity measurements under isothermal steady state sweep test condition may be performed under rich condition to lean condition for different aging temperature at about 800° C. and about 1000° C. Catalytic activity of samples may be compared to analyze the influence that selected support oxides may have on thermal stability and TWC performance of ZPGM materials for a plurality of TWC applications.

Owner:CLEAN DIESEL TECHNOLOGIES

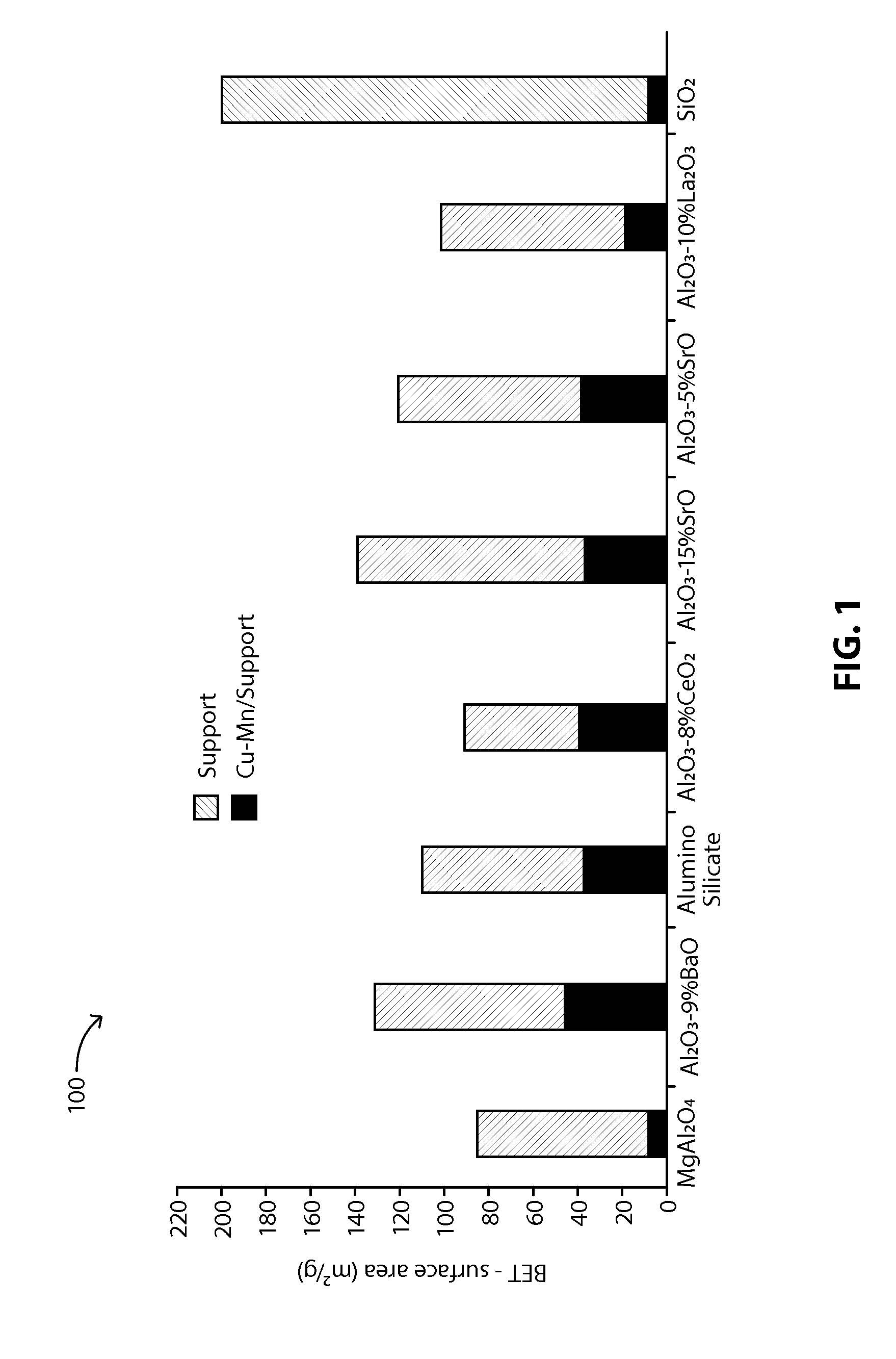

Phase Stability of Copper-Manganese Spinel Oxide within a Mixture of Metal Oxides

InactiveUS20150182951A1Material analysis using wave/particle radiationMolecular sieve catalystsPhase formationSpinel

The present disclosure describes ZPGM material compositions including a CuMn2O4 spinel structure mixed with a plurality of support oxide powders to develop suitable ZPGM catalyst materials. Bulk powder ZPGM catalyst compositions are produced by physically mixing bulk powder CuMn2O4 spinel with different support oxide powders calcined at about 1000° C. XRD analyses are performed for bulk powder ZPGM catalyst compositions to determine Cu—Mn spinel phase formation and phase stability for a plurality of temperatures to about 1000° C. ZPGM catalyst material compositions including CuMn2O4 spinel mixed with La2O3, cordierite, and ceria-zirconia support oxides exhibit phase stability, which can be employed in ZPGM catalysts for a plurality of TWC applications, thereby leading to a more effective utilization of ZPGM catalyst materials with high thermal and chemical stability in TWC products.

Owner:CLEAN DIESEL TECHNOLOGIES

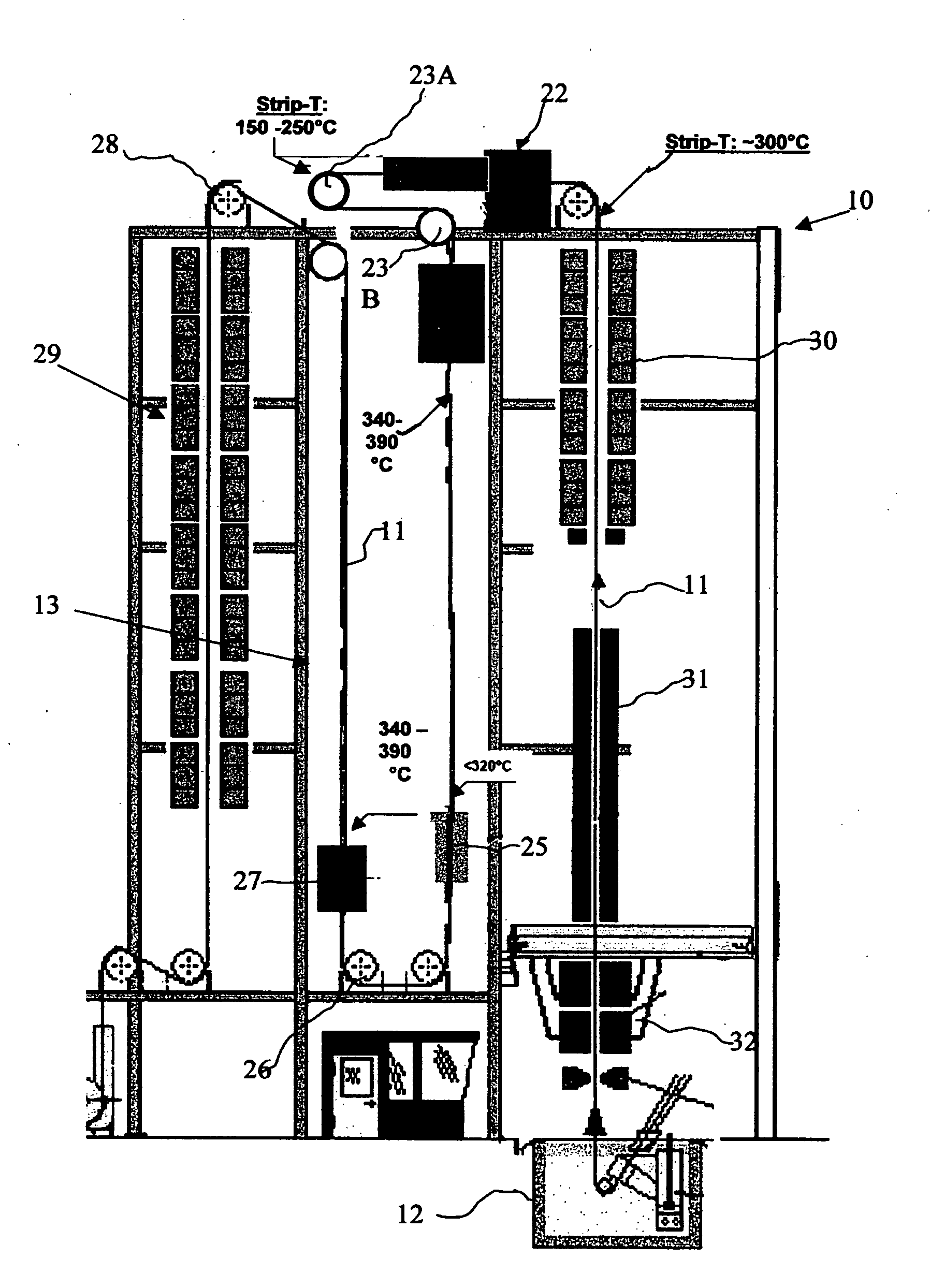

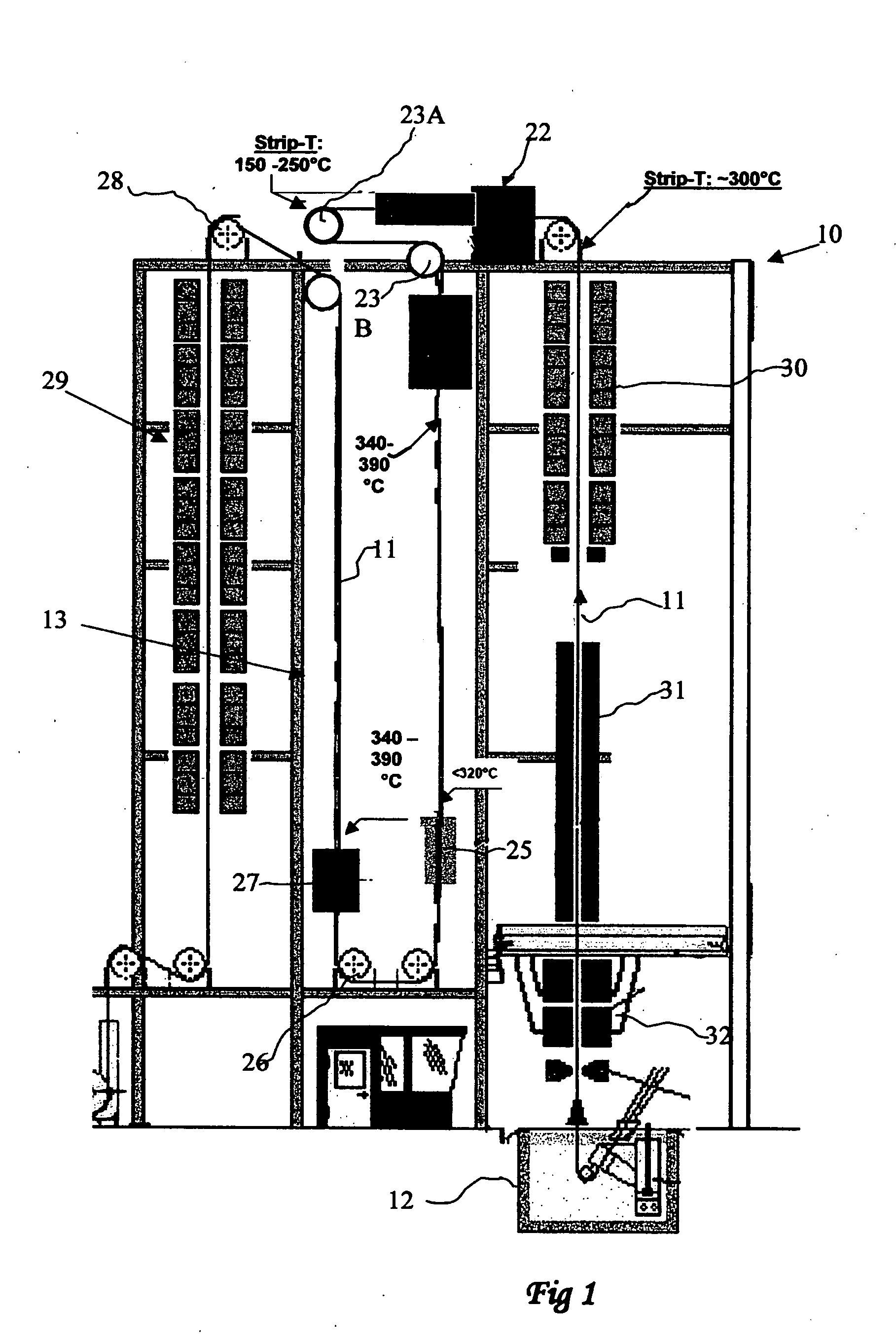

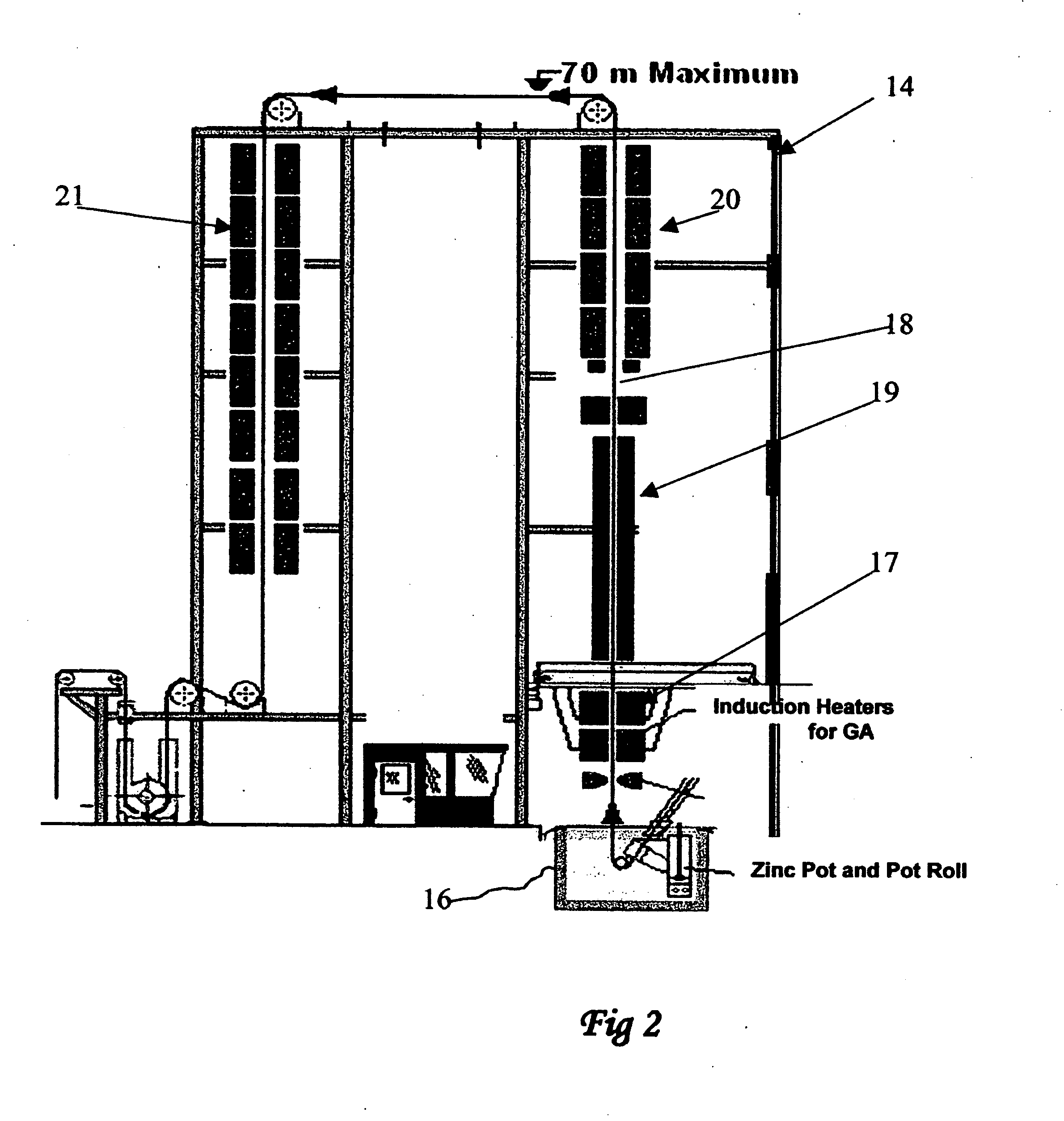

Method and apparatus for improved formability of galvanized steel having high tensile strength

InactiveUS20090065103A1Good molding effectHigh tensile strengthHot-dipping/immersion processesLiquid surface applicatorsCooling towerPhase formation

The present invention is directed to a method and apparatus of producing a dual-phase galvanized steel strip with improved formability while maintaining a high tensile strength. The present invention comprises a step of cooling and a step of reheating. In the cooling step, the galvanized steel strip has a temperature reduction of from about 300° C. to about 150° C.-250° C. This step of cooling should cool to a maximum extent of about 150° C. different between the initial temperature and the final temperature. This cooling may be accomplished by a hot water quench, or the use of a cooling tower, or other means. The step of reheating should follow the step of cooling. The step of reheating should heat the galvanized steel strip to a temperature of about 340°-390° C. This reheating causes the martensite in the galvanized steel strip to be tempered at a relatively low temperature, which reduces the Fe—Zn phase formation in the GI-coating.

Owner:SIPPOLA PERTTI J

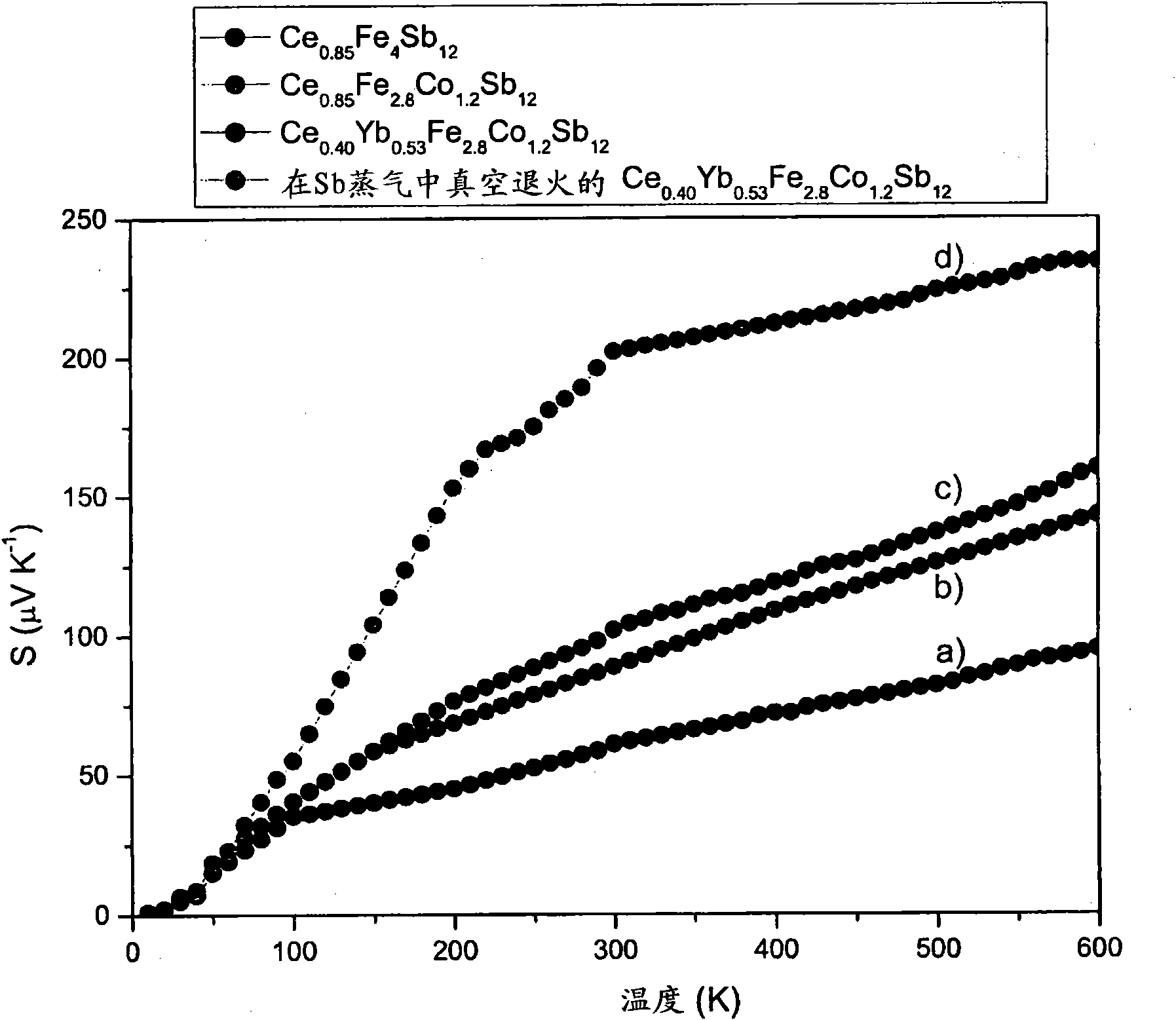

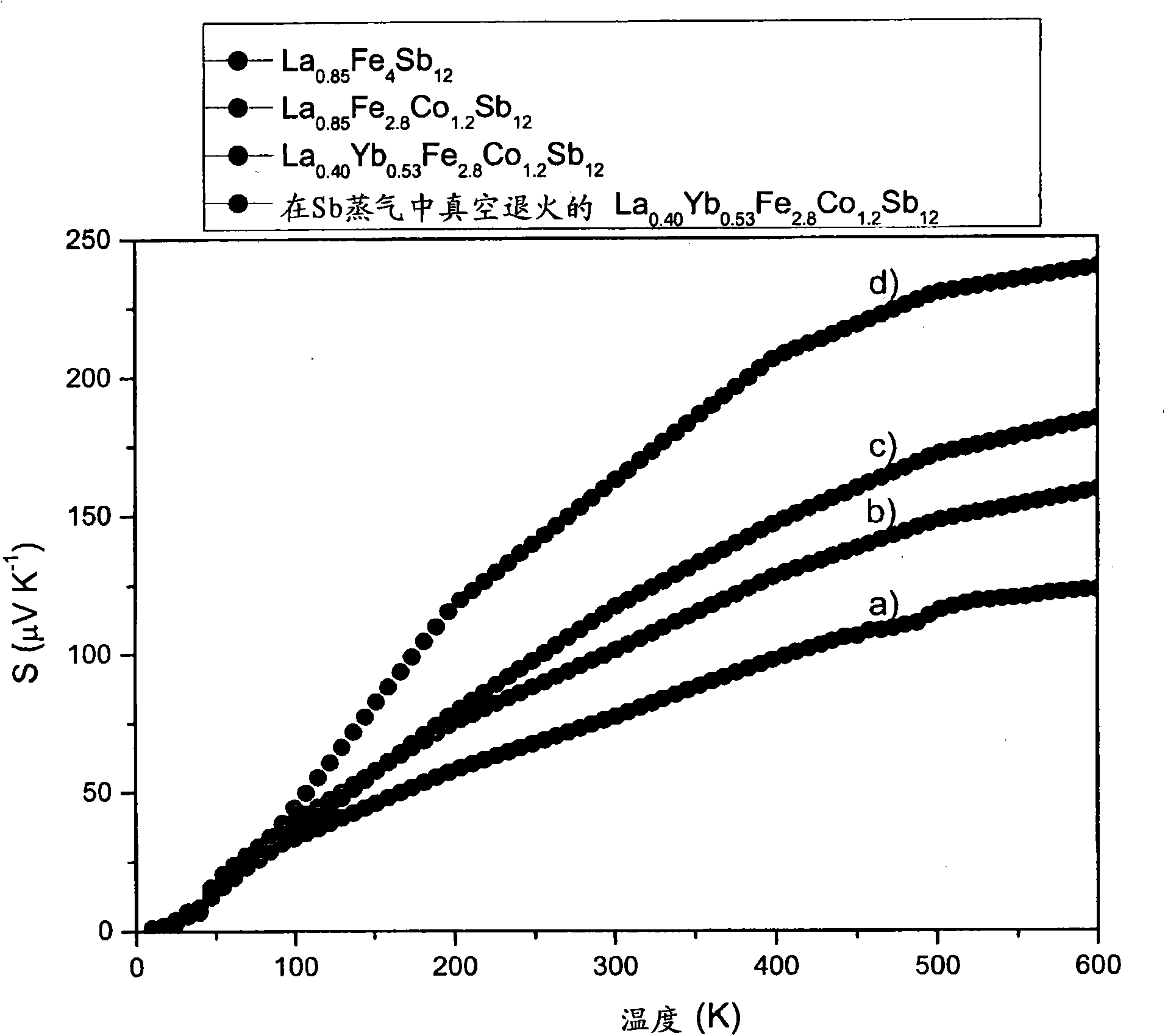

Method for producing a thermoelectric intermetallic compound

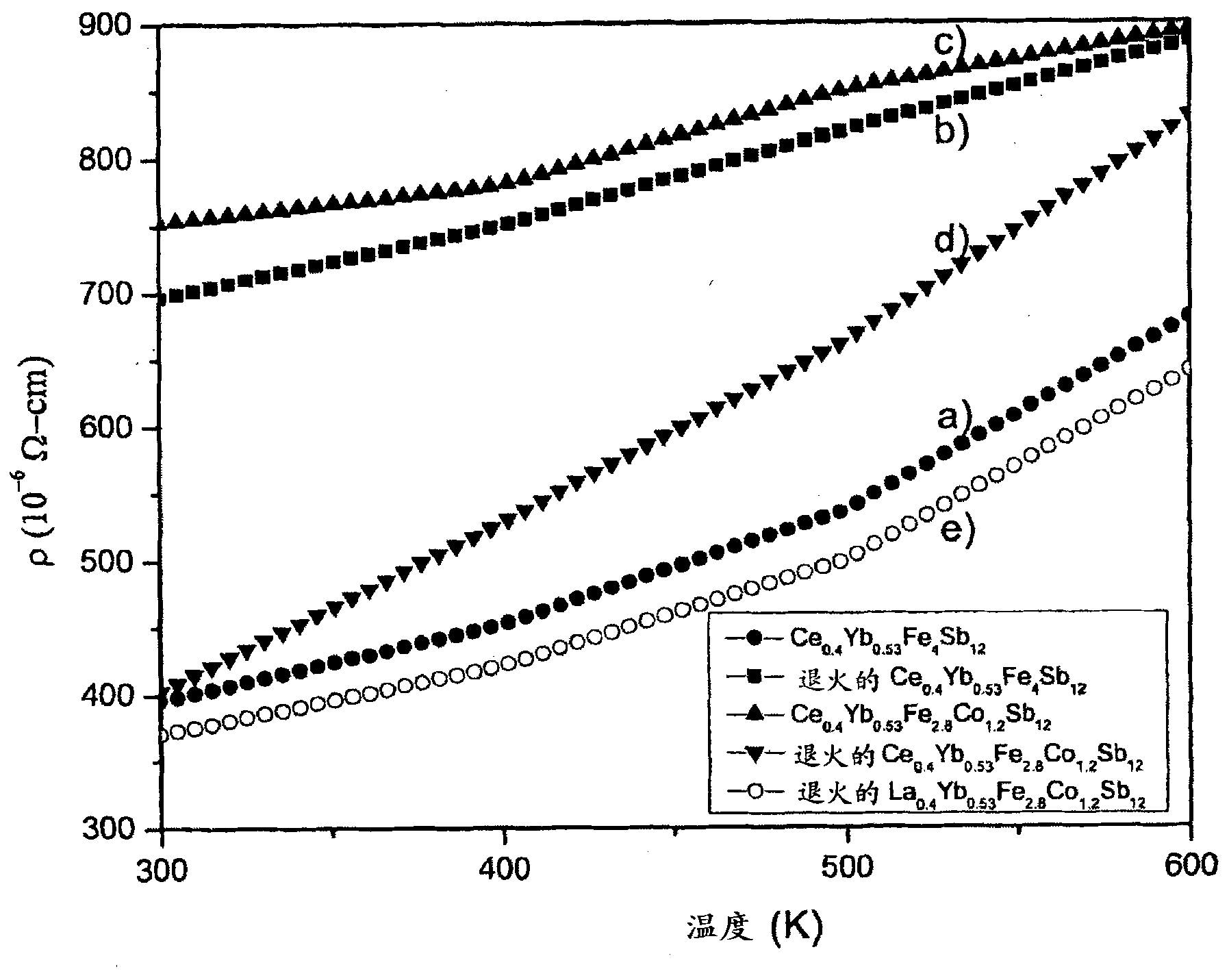

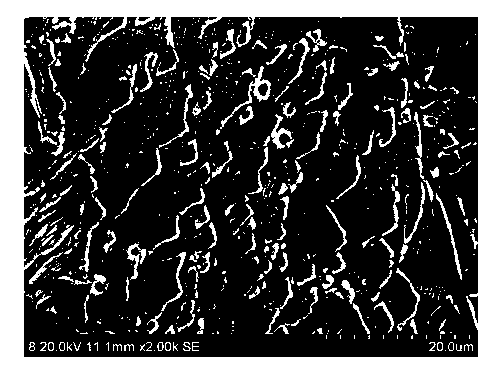

InactiveCN101952466AImprove figure of meritThermoelectric device junction materialsCompound aPhase formation

A method for producing an intermetallic compound, the method comprising: (1) providing components A, B and X; and forming by solid state reaction of components A, B and X an intermetallic compound having a filled skutterudite structure and formula of AaBbXc; (2) melting the intermetallic compound having a filled skutterudite structure produced in step (1) in the presence of additional X; and (3) annealing the intermetallic compound of step (2) in the presence of additional X at a temperature equal to, or greater than the phase formation temperature of the intermetallic compound.

Owner:BIOMETRIC TECH SOLUTIONS

Laser sintering synthesis method of ceramic-particle-reinforced nickel-aluminum-based composite

InactiveCN102876926AEasy to control speedPlay a role in strengthening the matrixNumerical controlPhase formation

The invention belongs to the technical field of material processing and particularly relates to a laser sintering synthesis method of a ceramic-particle-reinforced nickel-aluminum-based composite. The technical scheme includes that the laser sintering synthesis method includes the steps: mixing nickel powder with aluminum powder according to the atomic ratio of Ni to Al of 3:1, adding tungsten concentrate powder accounting for 0.5-2wt% of the total weight of nickel-aluminum mixed powder, performing ball milling to obtain uniformly-mixed mixed powder, compacting the mixed powder to a cylindrical compact, placing the compact on a numerically-controlled machine tool, starting a CO2 laser machine with the laser powder of 900-1200W for laser radiation for 10-20s, and lighting the surface of the compact to enable the compact to generate self-propagating reaction, so that the ceramic-particle-reinforced nickel-aluminum-based composite by laser sintering synthesis is obtained. According to the laser sintering synthesis method, matrix reaction, reinforced phase formation and metal-based composite preparation are combined together, and the reinforced ceramic phase subjected to in-situ synthesis enables high-temperature mechanical properties of a nickel-aluminum intermetallic compound to be obviously improved and enhanced.

Owner:LIAONING TECHNICAL UNIVERSITY

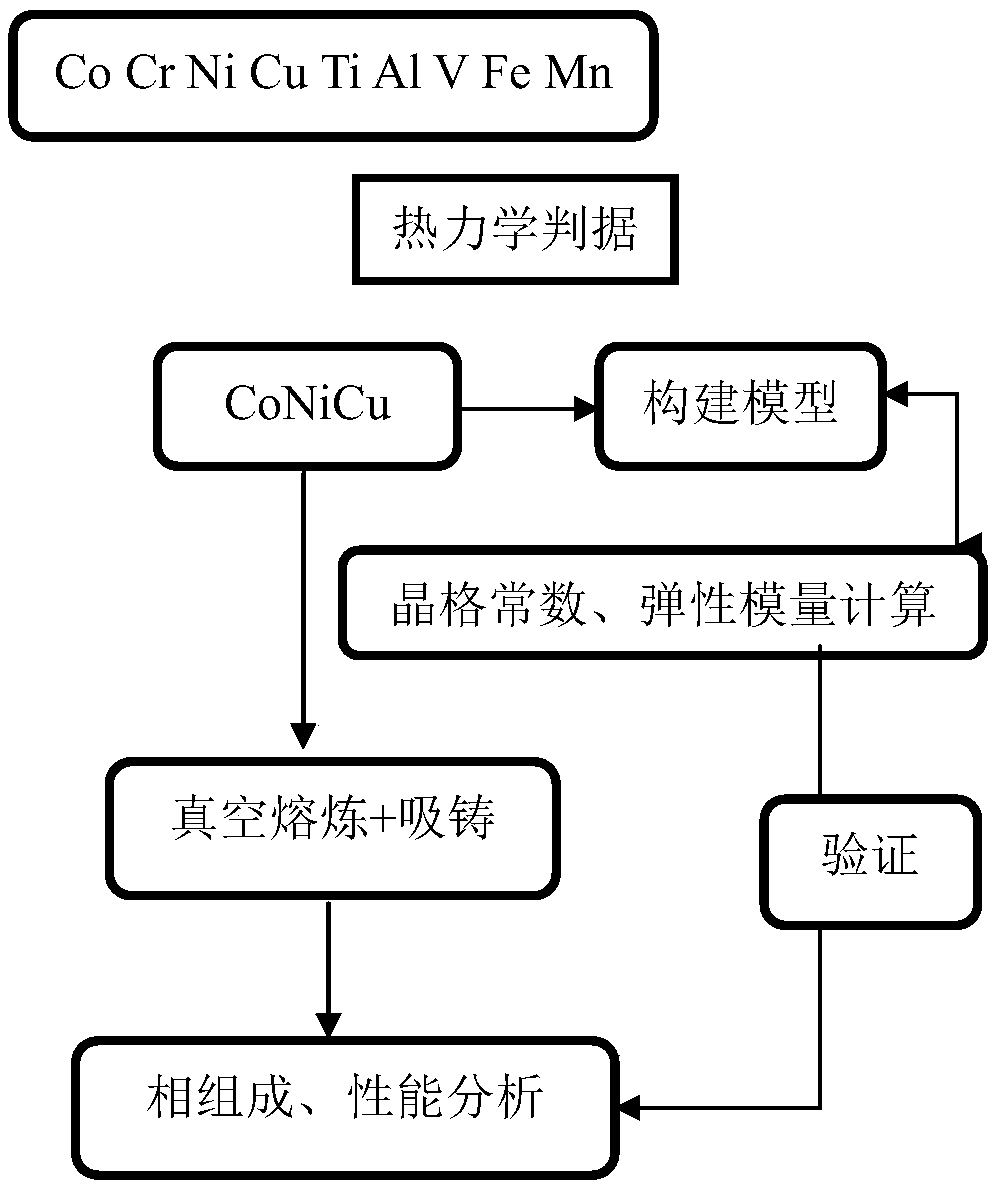

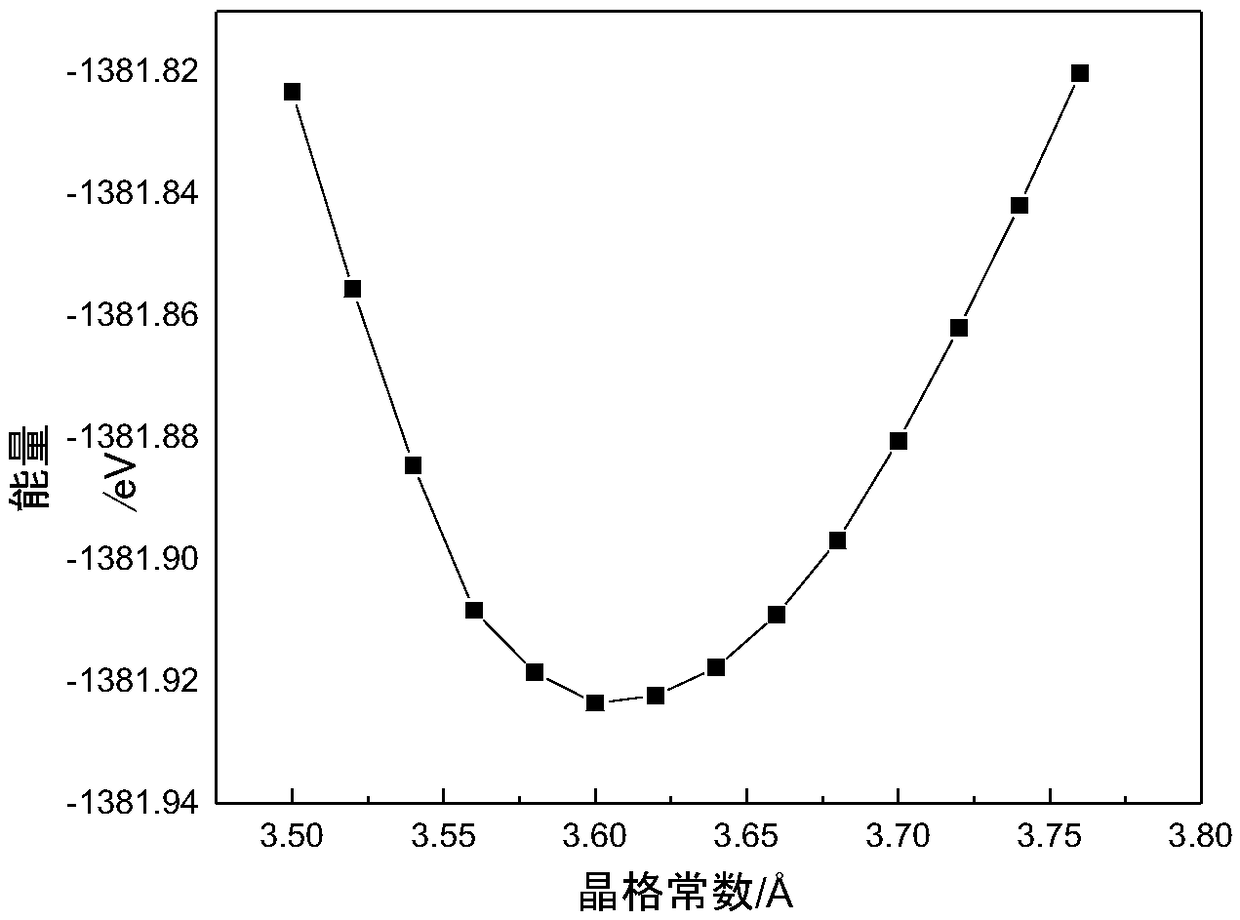

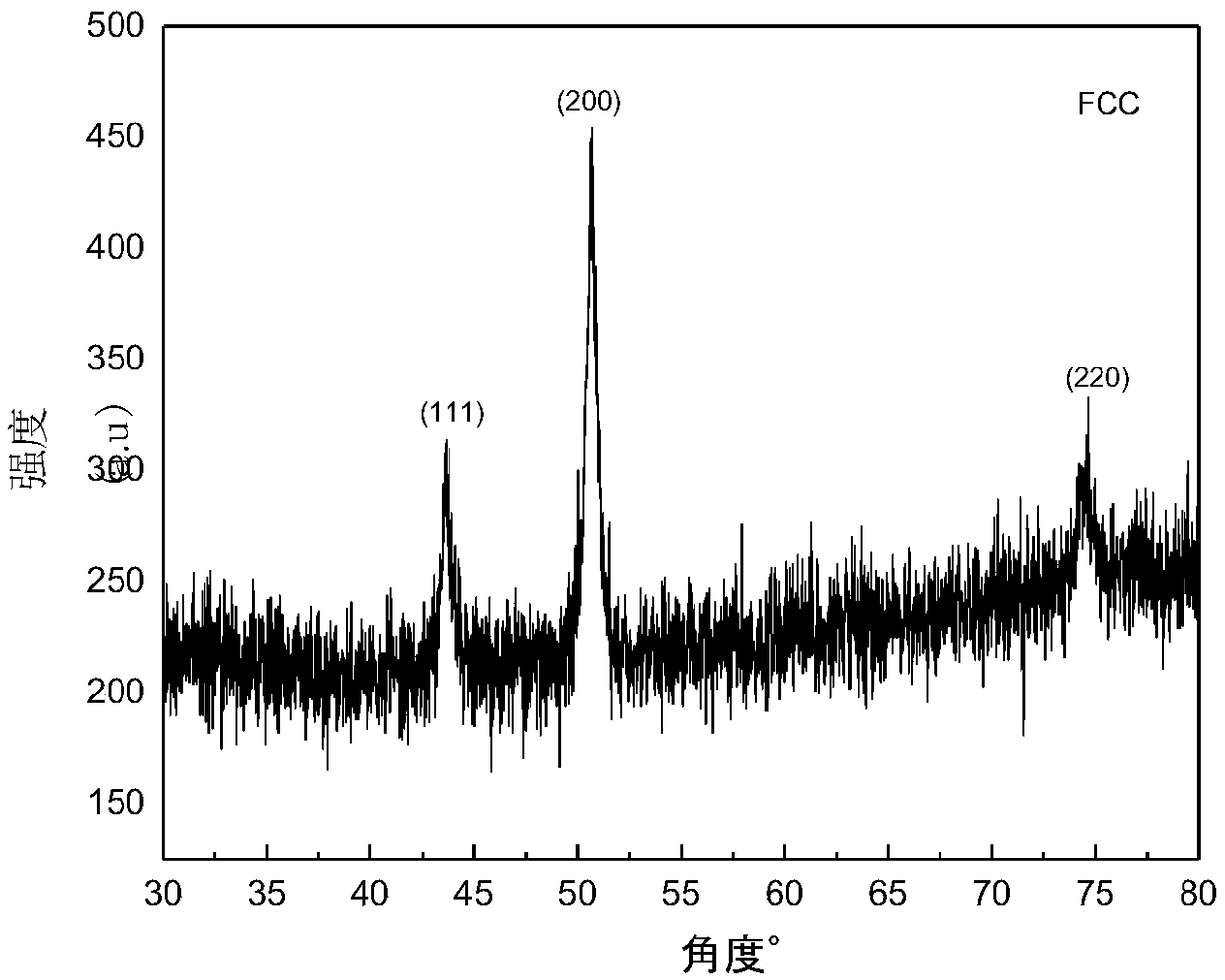

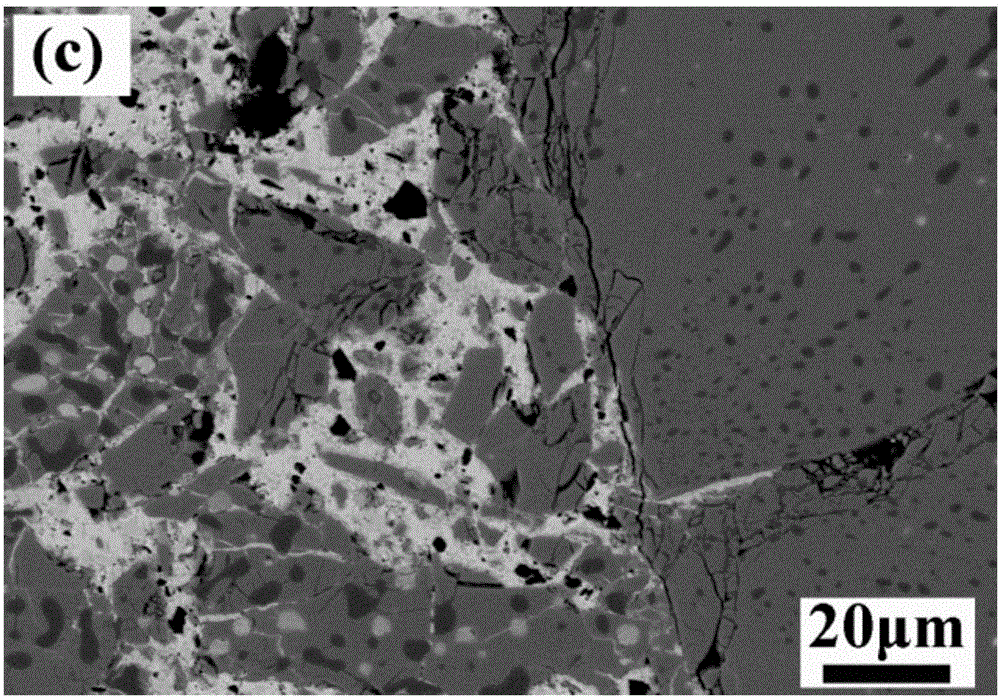

High-strength face-centered cubic structure medium-entropy alloy and preparation method thereof

The invention discloses a high-strength face-centered cubic structure medium-entropy alloy and a preparation method thereof. The CoNiCu medium-entropy alloy comprises Co, Ni and Cu elements; a resultof respective comparison of different medium-entropy alloys in electron concentration and mixing enthalpy according to the Gibbs free energy and the phase formation law of the alloy shows that the CoNiCu medium-entropy alloy has the tendency to form a single-phase FCC structure, a CoNiCu medium-entropy alloy model is constructed based on the tendency, and the alloy is predicted to be a ductile material by a first-principles technique. The preparation method of the alloy comprises the following steps: batching, vacuum melting, suction casting, homogenization annealing and solid solution treatment. Co, Cr, and Cu with a purity of 99% or more are selected and are proportioned according to an equimolar ratio or an approximately equimolar ratio, the proportioned raw materials are placed in a vacuum smelting furnace and are multiply smelted, suction casting molding is carried out after the components are uniform, and the obtained casting undergoes homogenization annealing and solid solutiontreatment to obtain the CoNiCu medium-entropy alloy having a single face-centered cubic structure and having a room temperature compressive strength of above 1600 MPa and a compression ratio of above20%.

Owner:SOUTHEAST UNIV

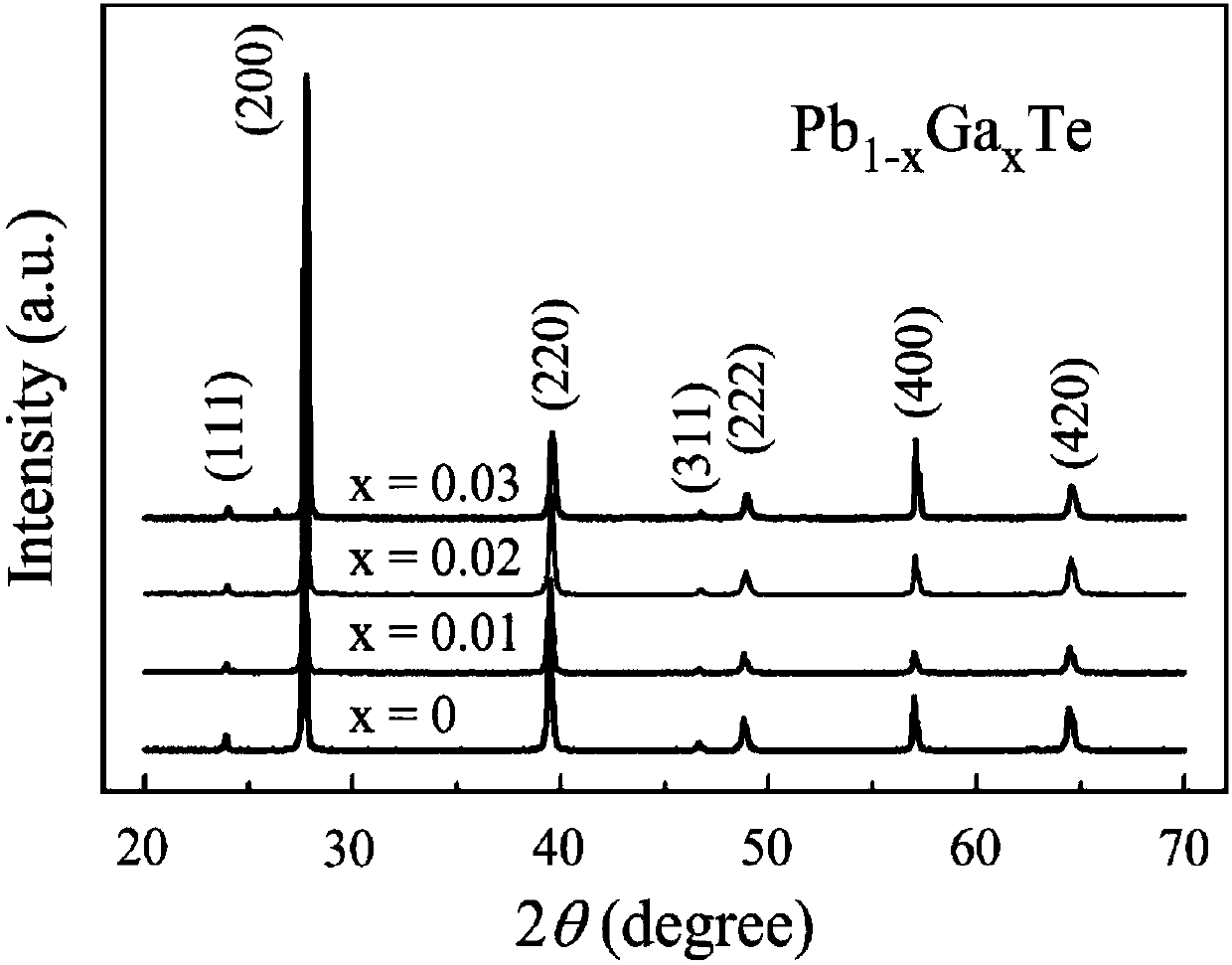

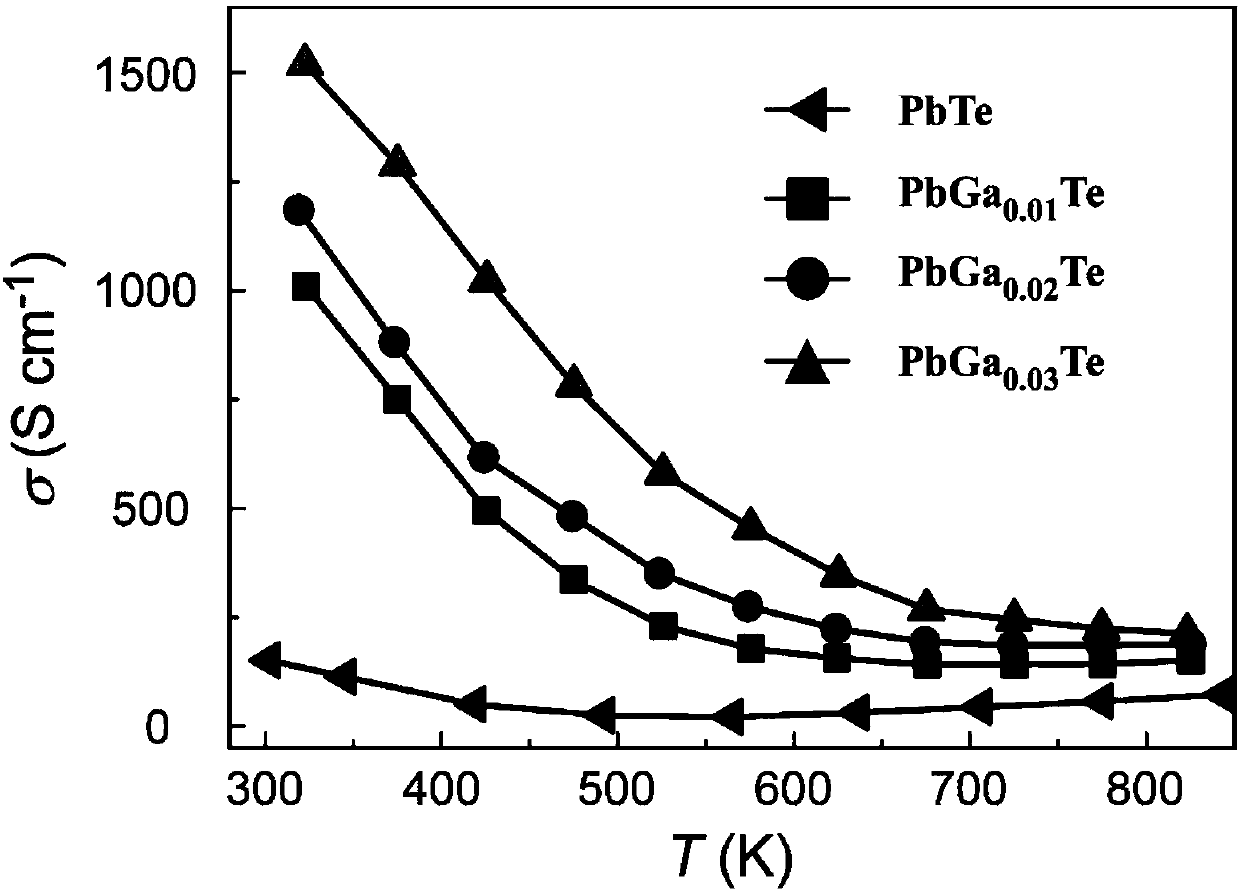

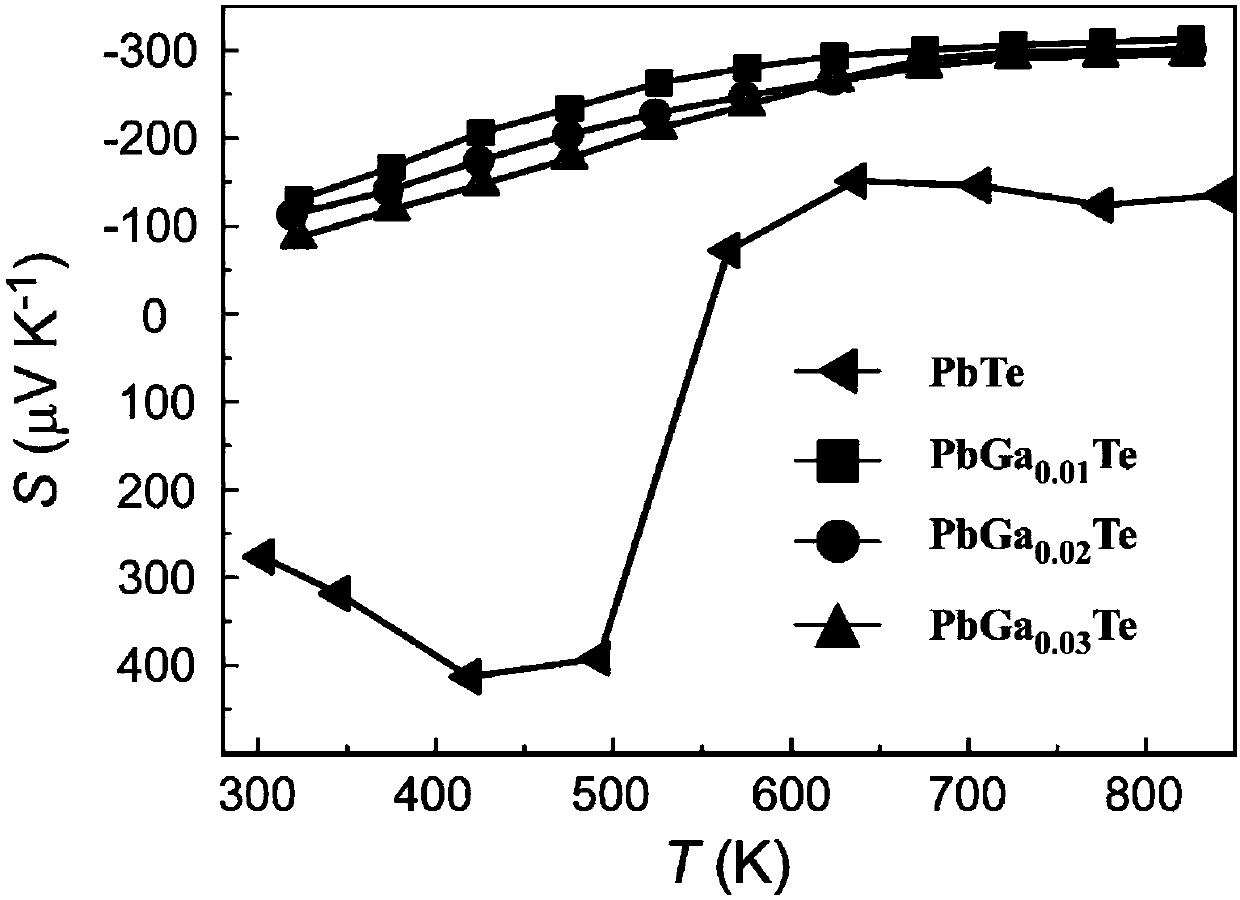

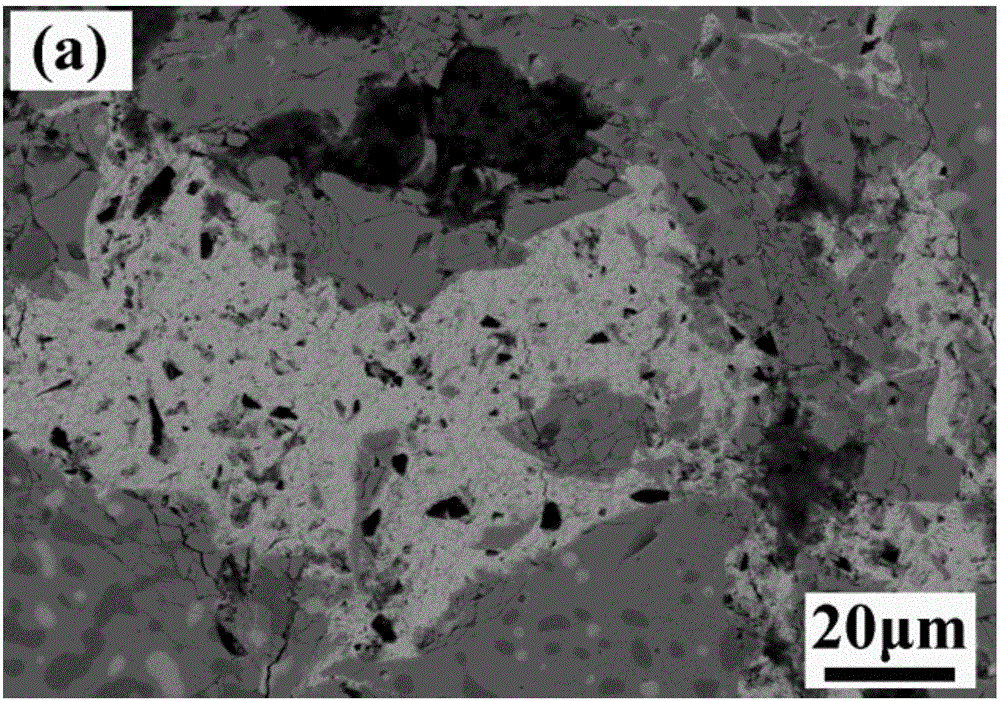

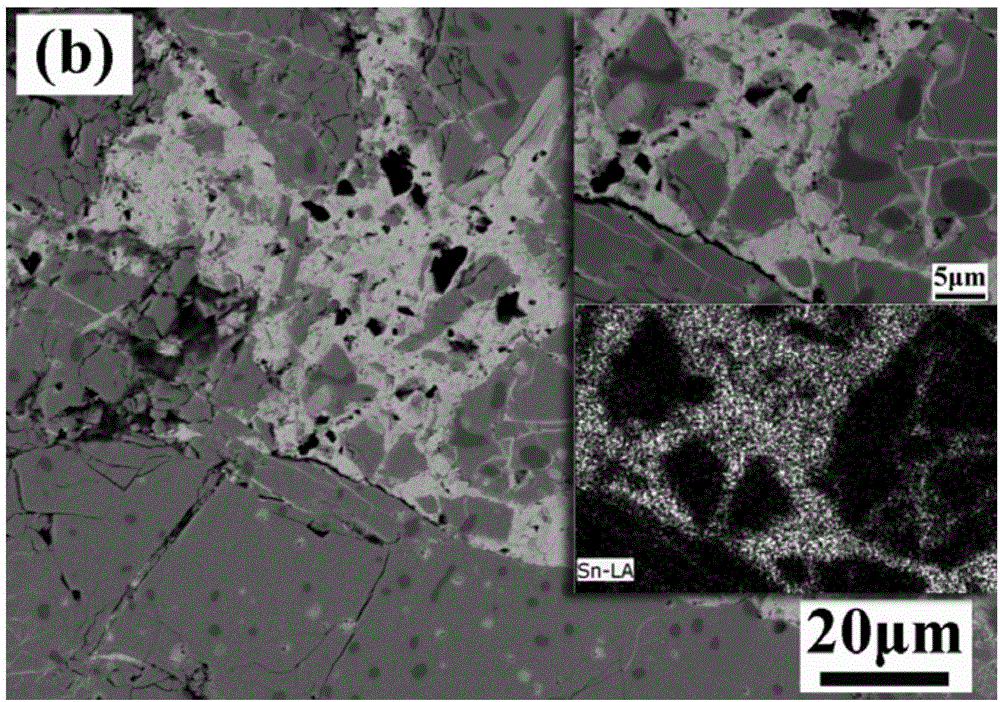

Method for effectively enhancing PbTe thermoelectric performance based on Ga element doping

ActiveCN107565011AImprove thermoelectric performanceHigh crystallinityThermoelectric device manufacture/treatmentThermoelectric device junction materialsPhase formationGa element

The invention belongs to the field of material, and relates to a method for effectively enhancing PbTe thermoelectric performance based on Ga element doping. Pb powder, Te powder and Ga blocks are weighed and taken according to the element proportion of 1:x:1-x, wherein the value of x is taken as 0.01-0.05; and the mixture is ground, mixed and compacted into a piece and then put in a quartz tube to perform vacuum pumping and tube sealing, and sintering and discharge plasma sintering are performed in turn so that the Ga-doped PbTe compound thermoelectric material can be obtained. According to the method for enhancing the PbTe thermoelectric figure of merit based on Ga element doping, the method can be used for preparation of the PbTe doped sample and enhancement of the performance so that the process operation is easy and the repeatability is high. According to the method, the phase formation degree, the compactness and the microstructure of the PbTe compound can be controlled by adjusting the temperature increasing and decreasing rate, the phase formation temperature, the thermal preservation time and other process parameters so that the controllability is high; and the prepared Gadoped PbTe compound has the characteristics of high degree of crystallization, less impurity, high compactness, low thermal conductivity and high thermoelectric performance.

Owner:SICHUAN UNIV

Hard phase forming alloy powder, wear resistant sintered alloy, and production method for wear resistant sintered alloy

InactiveUS20100008812A1Low costImprove wear resistance and corrosion resistancePhase formationWear resistant

A hard phase forming alloy powder, for forming a hard phase dispersed in a sintered alloy, consists of, by mass %, 15 to 35% of Mo, 1 to 10% of Si, 10 to 40% of Cr, and the balance of Co and inevitable impurities. A production method, for a wear resistant sintered alloy, includes preparing a matrix forming powder, the hard phase forming alloy powder, and a graphite powder. The production method further includes mixing 15 to 45% of the hard phase forming alloy powder and 0.5 to 1.5% of the graphite powder with the matrix forming powder into a raw powder. The production method further includes compacting the raw powder into a green compact having a predetermined shape and includes sintering the green compact. A wear resistant sintered alloy exhibits a metallic structure in which 15 to 45% of a hard phase is dispersed in a matrix. The hard phase consists of, by mass %, 15 to 35% of Mo, 1 to 10% of Si, 10 to 40% of Cr, and the balance of Co and inevitable impurities.

Owner:HITACHI POWDERED METALS COMPANY

Method for obtaining alkali metal salt aqueous solution of aromatic dihydroxy compound from waste aromatic polycarbonate

InactiveUS7750057B2Short timeReduce energy costsOrganic chemistryOrganic compound preparationPhase formationOrganic solvent

There is provided a method for obtaining an aqueous solution of an alkali metal salt of an aromatic dihydroxy compound by decomposing a waste aromatic polycarbonate by an alkali metal hydroxide aqueous solution. The method comprises (1) a dissolution step of dissolving a waste aromatic polycarbonate in a chlorinated hydrocarbon solvent, (2) a decomposition step of adding an alkali metal hydroxide aqueous solution to this solution to decompose the aromatic polycarbonate, (3) a re-dissolution step of adding water to this decomposed solution to dissolve a solid, (4) a two phase formation step of leaving the treated solution obtained in the step (3) to stand to form an organic solvent phase (organic phase) and an aqueous solution phase (aqueous phase), and (5) a separation / collection step of separating the aqueous phase from the organic solvent phase and collecting the aqueous phase.

Owner:TEIJIN KASEK KK

La-Fe based magnetic refrigeration composite material and preparation method thereof

ActiveCN106381133AReduce crackingImprove magnetocaloric performanceHeat-exchange elementsMagnetic materialsPorosityHigh density

The invention discloses a La-Fe based magnetic refrigeration composite material and a preparation method thereof. The method includes the steps of: subjecting a La-Fe based magnetic refrigeration material with good phase formation to mechanical grinding and screening out 180-250micrometer thick main phase particles and fine main phase powder less than 45micrometer; mixing two La-Fe based magnetic refrigeration materials with different particle sizes according to different weight ratios, then adding metal tin powder accounting for 9%-1% of the total weight, and mixing the substances evenly; and carrying out hot embossing processing forming, thus obtaining the La-Fe based magnetic refrigeration composite material. The main phase involved in the invention is composed of multiple components, the particle size difference of the components is greater than 4 times to reduce porosity, therefore high density, high strength and high magnetocaloric performance La-Fe based magnetic refrigeration composite material can be obtained, and a good solution is provided for the problems of large hardness, great brittleness, difficult processing forming and the like in La-Fe based magnetic refrigeration materials.

Owner:SOUTH CHINA UNIV OF TECH

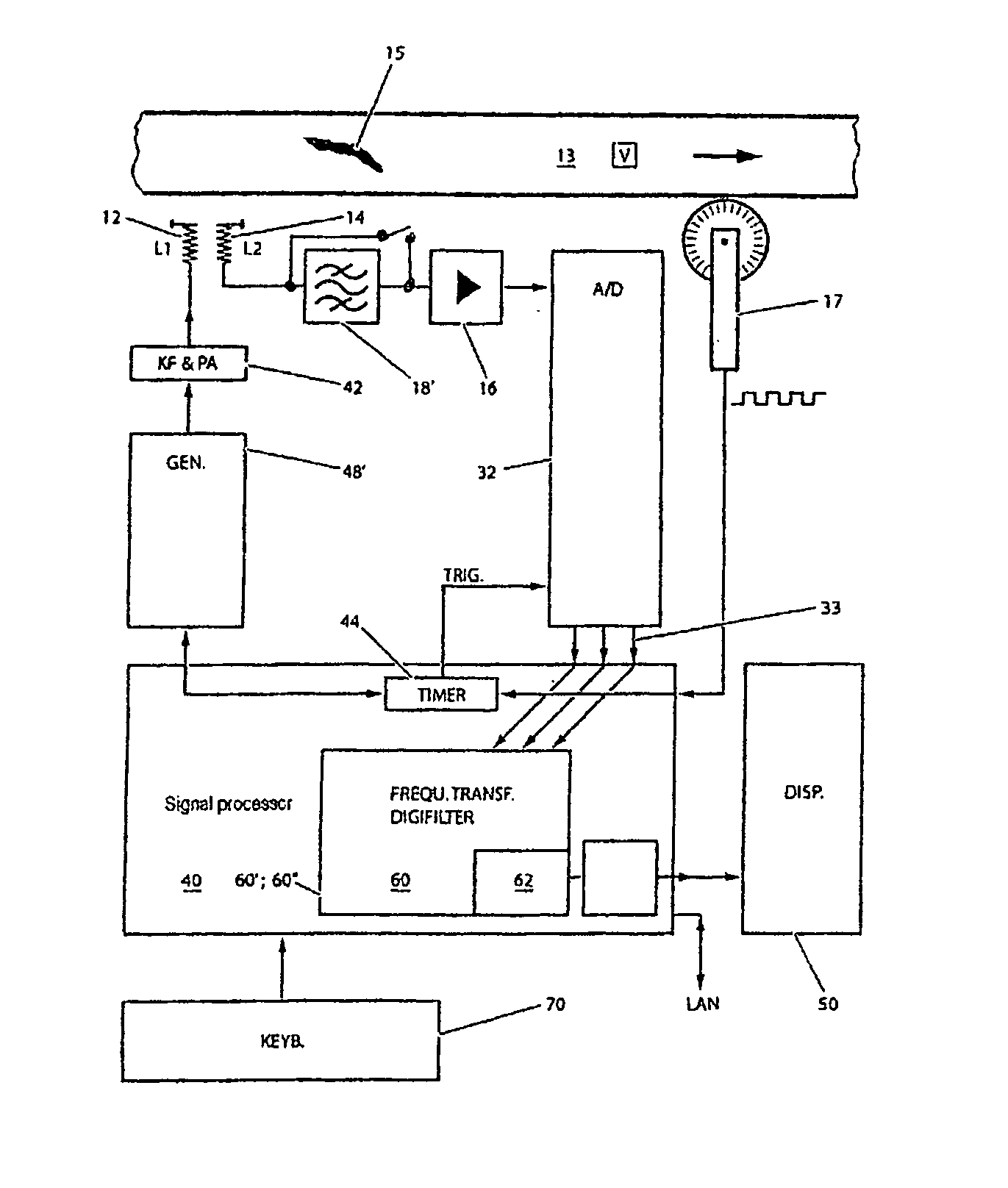

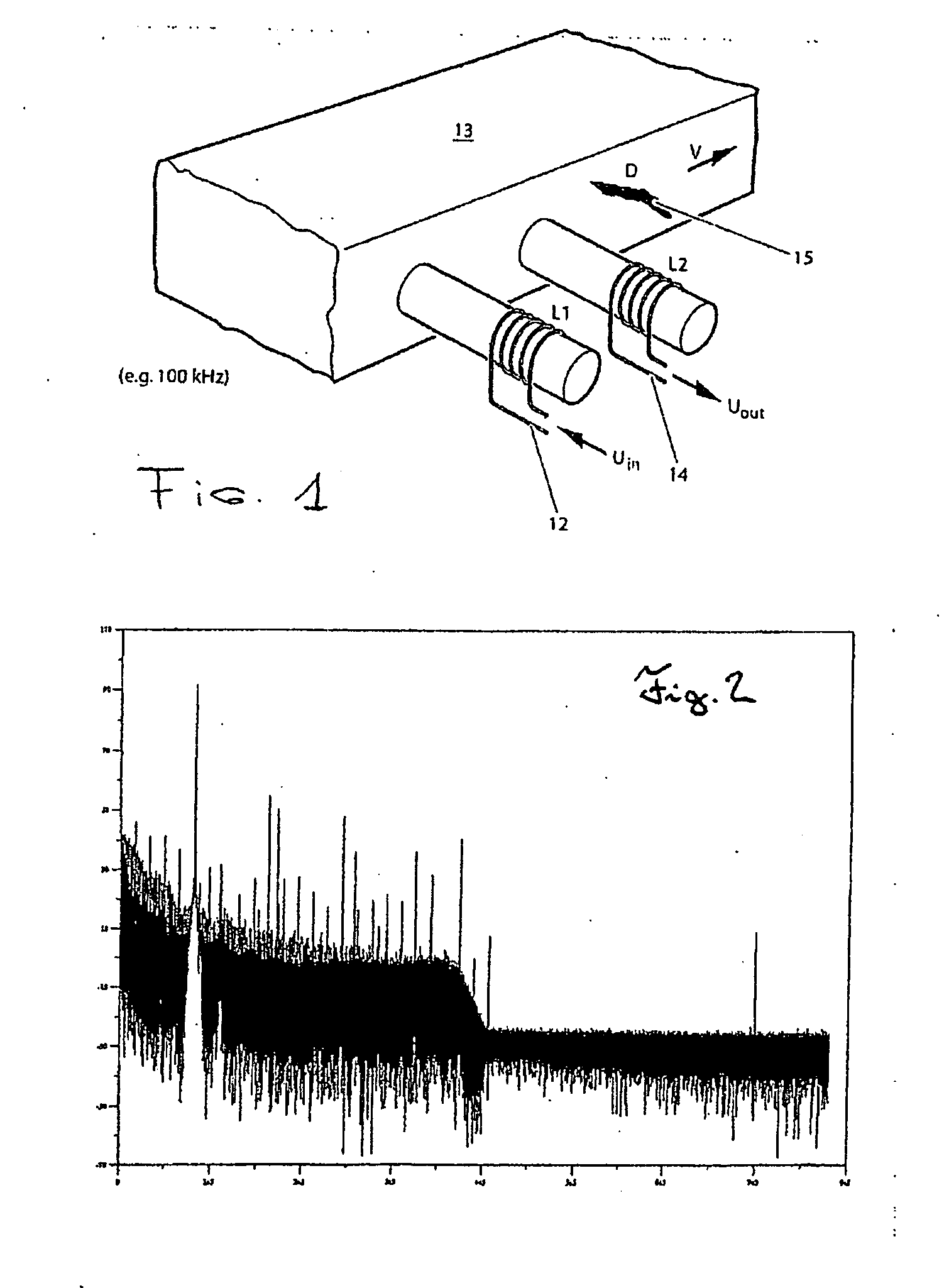

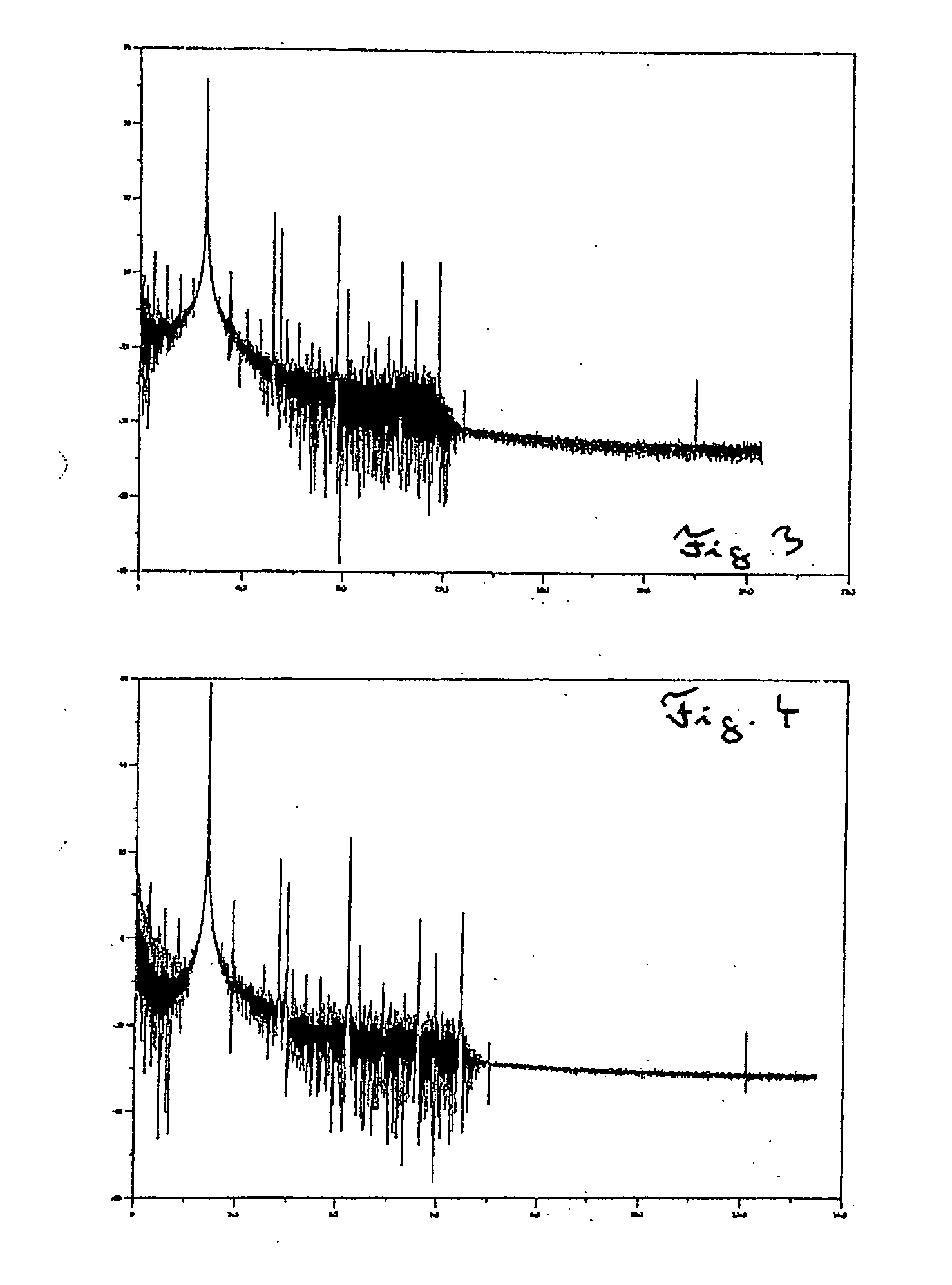

Device and Method for Detecting Flaws on Objects or Locating Metallic Objects

ActiveUS20070242758A1Precise and reliable measurements-asLower energy requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesModulated-carrier systemsPhase formationHarmonic

Apparatus and associated method for identifying defects on objects provide for—under computer driving—the AC voltage energization of at least one transmitting coil to be simultaneously effected by a carrier signal, and for an essentially amplitude-modulated received signal to be received by means of at least one receiving coil; what is carried out, furthermore, is a demodulation not only of the carrier signal contained in the received signal by means of magnitude and phase formation, but also a demodulation of the harmonics of the carrier which are contained in the received signal, likewise by means of respectively associated magnitude and phase formation, to be precise preferably by using a Fourier or wavelet transformation method.

Owner:PRUTECHNIK DIETER BUSCH AG

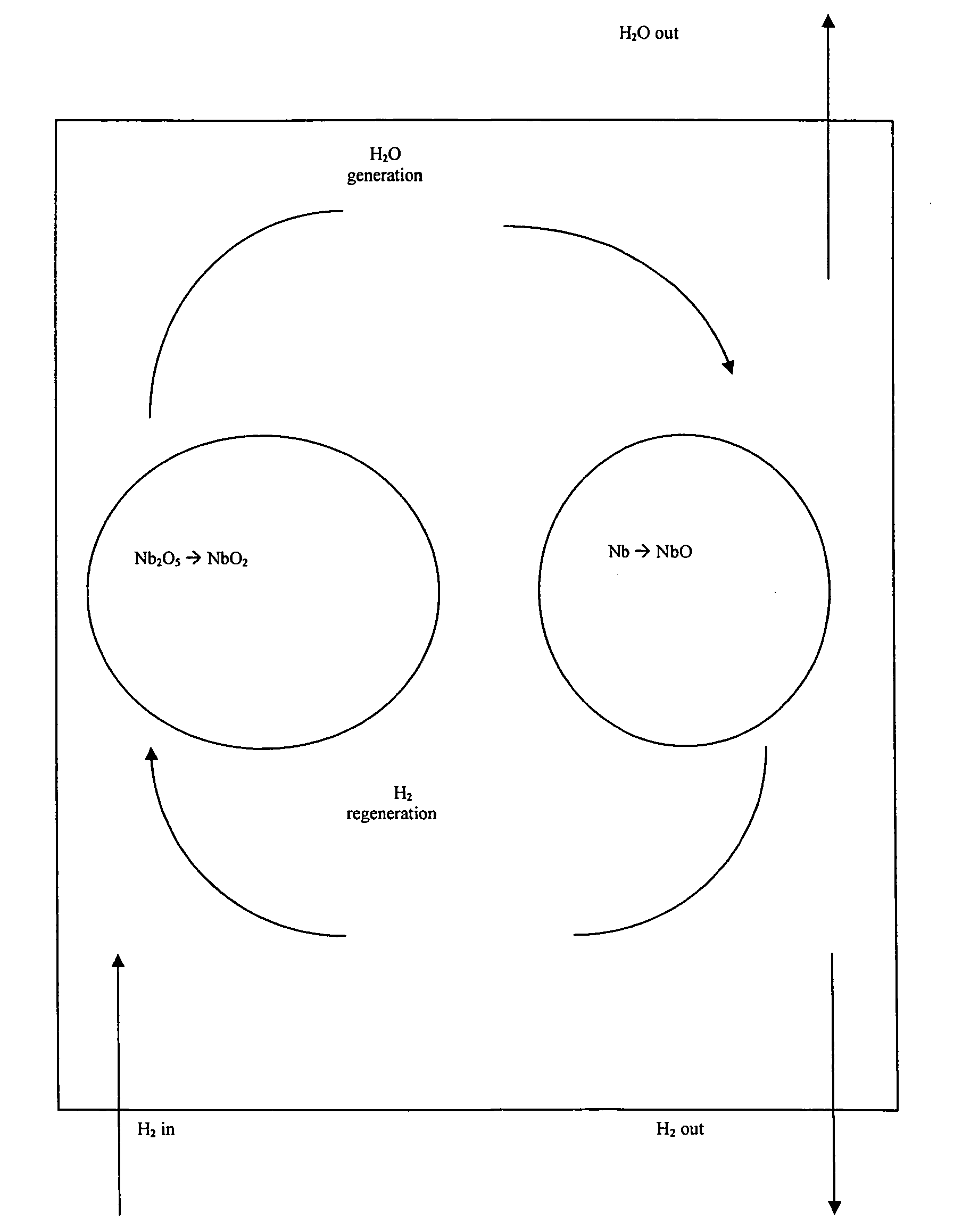

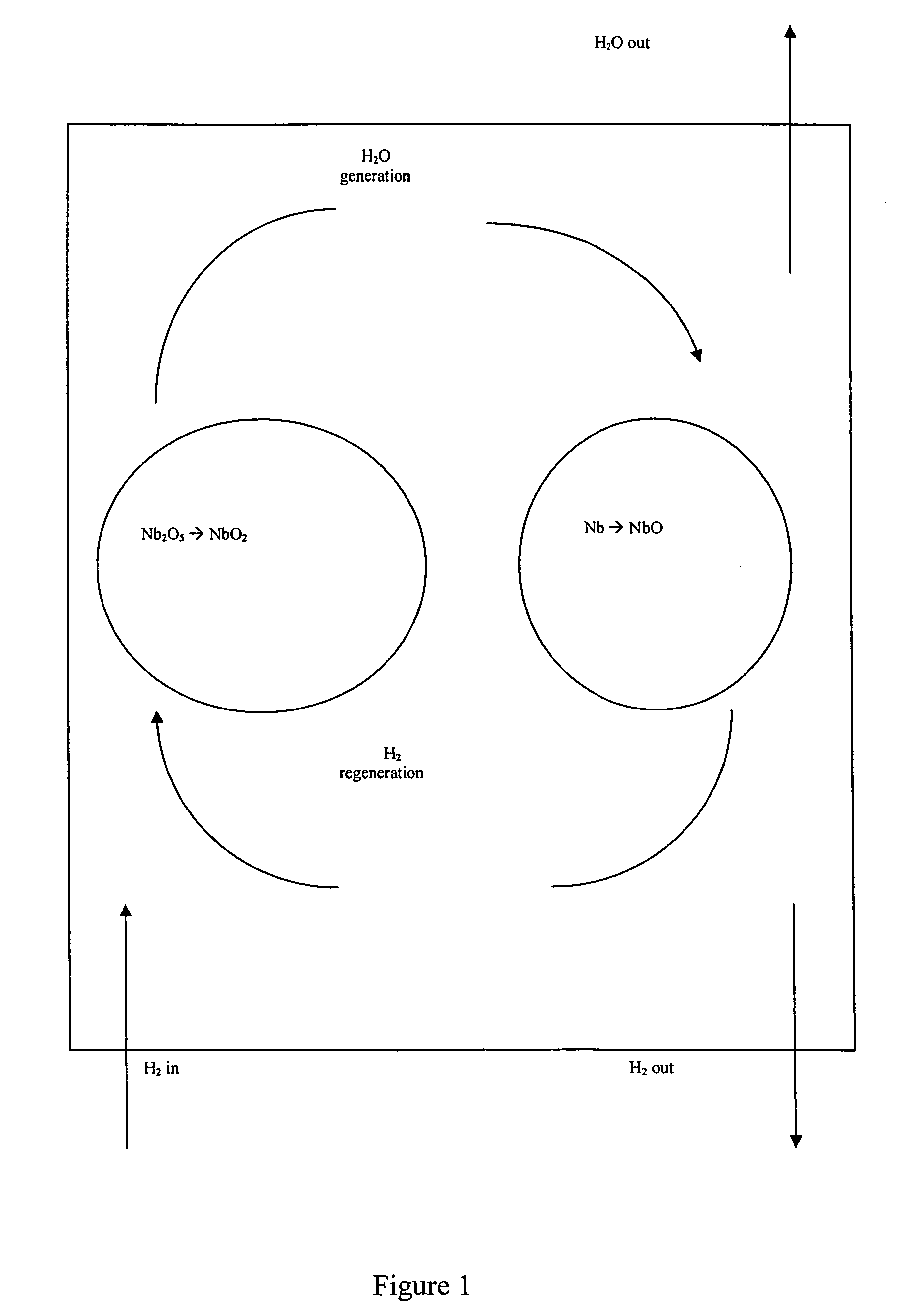

Phase formation of oxygen reduced valve metal oxides and granulation methods

ActiveUS7655214B2Uniform phase formationOxide/hydroxide preparationLiquid electrolytic capacitorsPhase formationOxygen

Valve metal suboxides having a primary suboxide phase and optionally a secondary suboxide phase, a valve metal phase, and / or at least one tertiary suboxide phase can be present in varying amounts. Also disclosed is anodes and capacitors containing the valve metal suboxides of the present invention. Also, a method to prepare a valve metal suboxide is further described which includes granulating one or more of the starting materials individually or together and / or granulating the final product.

Owner:GLOBAL ADVANCED METALS USA

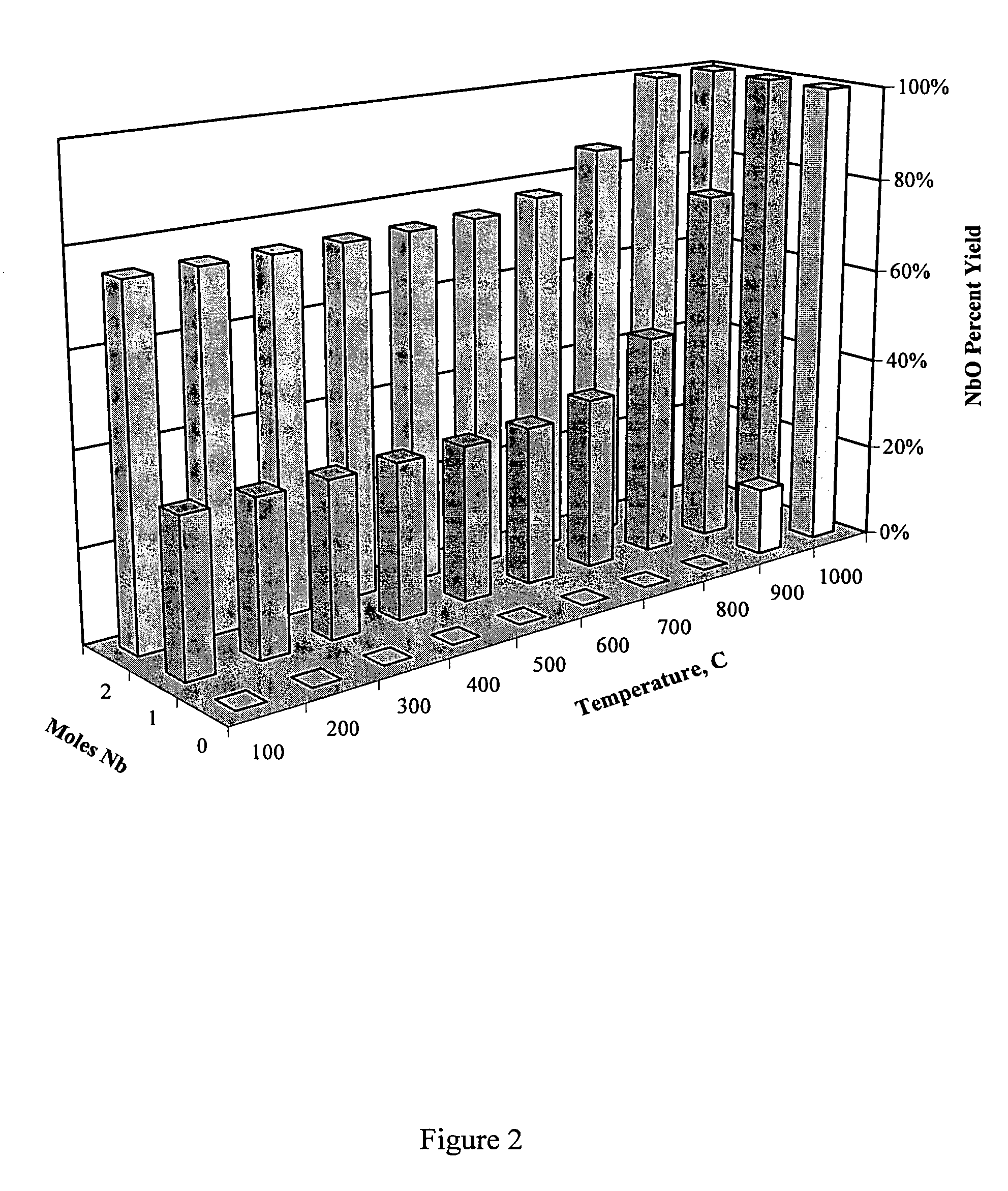

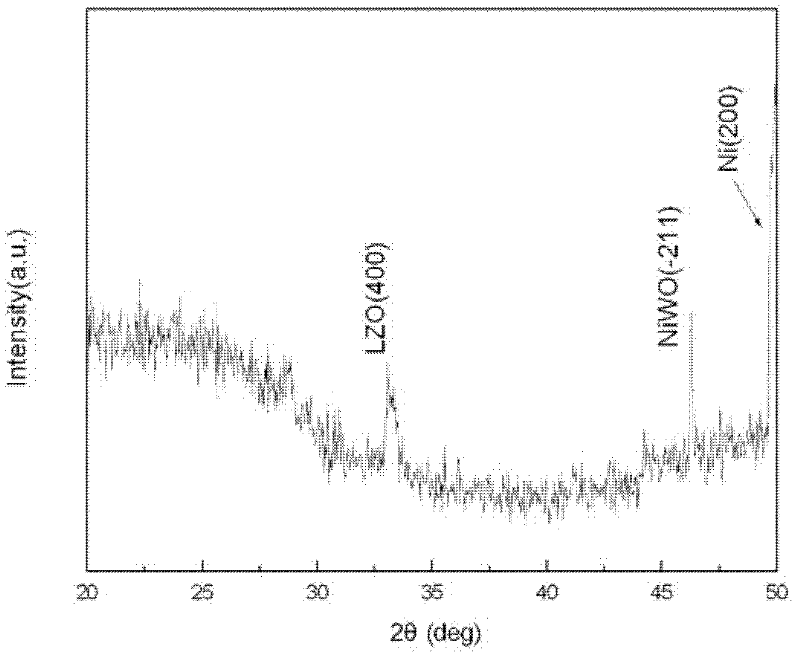

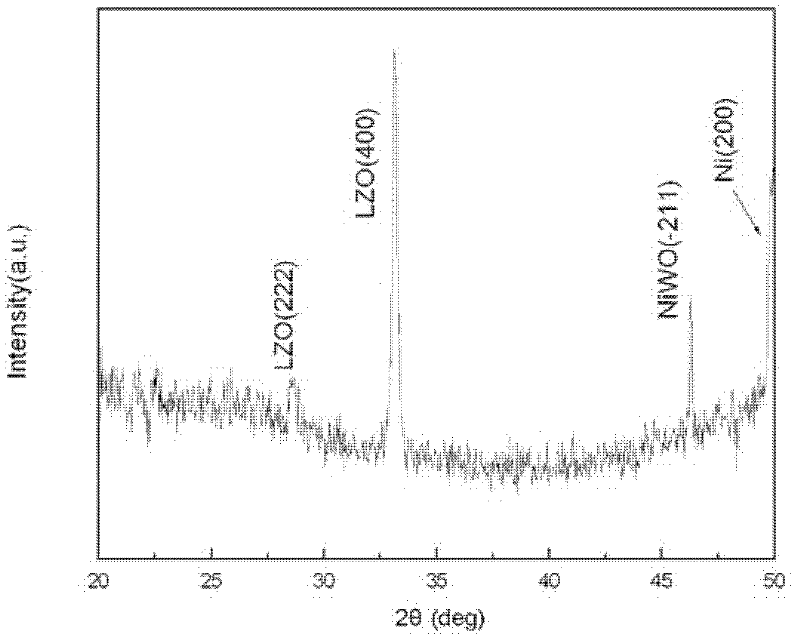

Method for preparing lanthanum-zirconium oxide La2Zr2O7 buffer layer thin film of high-temperature superconducting coating conductor on biaxially textured NiW alloy substrate

InactiveCN102509764AImprove qualityFunction effectivelySuperconductor device manufacture/treatmentPhase formationElectrical conductor

The invention discloses a method for preparing a lanthanum-zirconium oxide La2Zr2O7 buffer layer thin film of a high-temperature superconducting coating conductor on a biaxially textured NiW alloy substrate. The method comprises the following steps of: dissolving lanthanum nitrate La(NO3)3.6H2O and zirconium nitrate Zr(NO3)4.5H2O in ethylene glycol monomethyl ether to form an anhydrous solution; adding polyethylene glycol 20000 (PEG-20000) into the anhydrous solution to prepare colloid with a high film-forming property; and coating the colloid on the biaxially textured NiW alloy substrate, and placing the biaxially textured NiW alloy substrate in a sintering furnace for sintering and phase formation to obtain the La2Zr2O7 buffer layer thin film of the high-temperature superconducting coating conductor. The method is low in manufacture cost; the La2Zr2O7 thin film with high quality can be easily prepared; and a buffer layer of the coating conductor can effectively function.

Owner:SOUTHWEST JIAOTONG UNIV

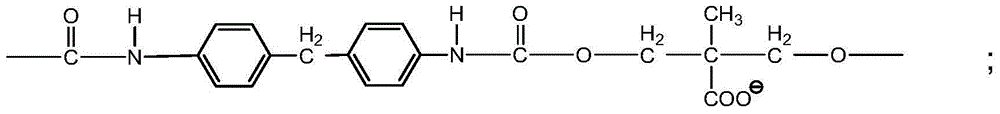

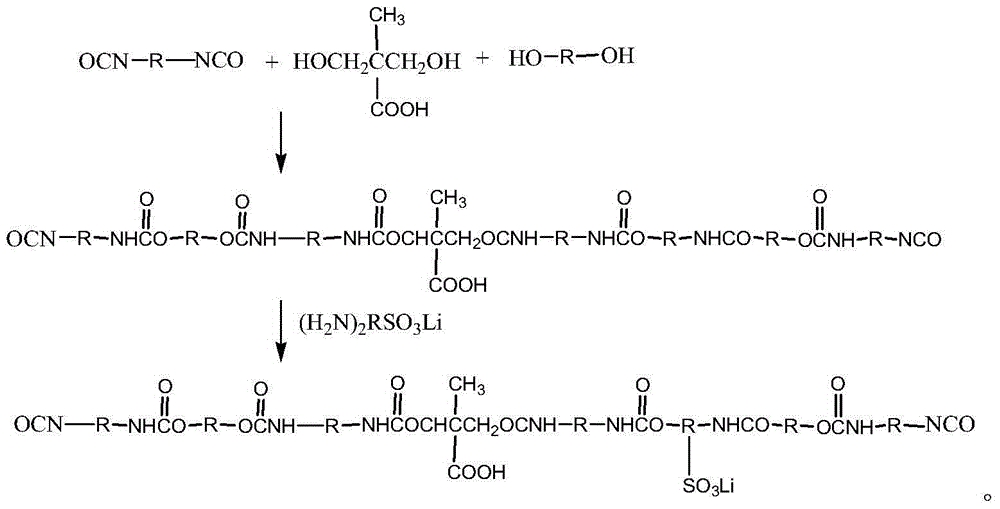

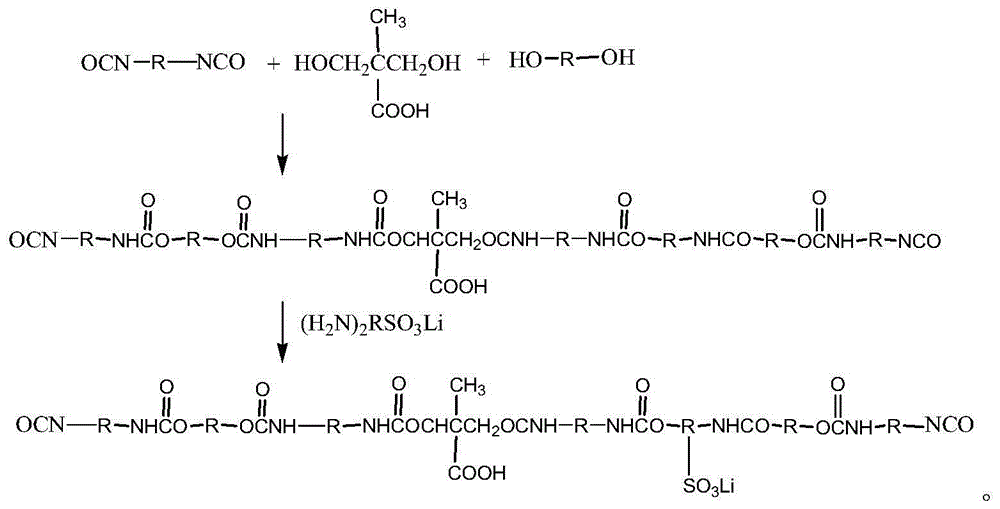

Preparation method and application of high lithium salt concentration aqueous polyurethane ionomer

ActiveCN104966847AImprove conductivityHigh mechanical strengthSecondary cellsPhase formationPolymer science

The present invention discloses a preparation method and application of a high lithium salt concentration aqueous polyurethane ionomer, the method comprises the following steps: S1, an aqueous polyurethane prepolymer is prepared from polyurethane hard segments and polyurethane soft segments in accordance with the proportion; and S2, diamido-sulfonate lithium is used for high lithium salt processing of the aqueous polyurethane prepolymer to obtain the high lithium salt concentration aqueous polyurethane ionomer, the conductivity of aqueous polyurethane can be significantly improved by high lithium ion concentration, due to differences in polarity, the polyurethane hard segments and polyurethane soft segments have the tendency to respective phase formation, the phase separation phenomenon provides an ideal environment for ion conduction; a graphene polymer electrolyte-based lithium-ion battery can be further prepared from the aqueous polyurethane ionomer, the graphene polymer electrolyte-based lithium-ion battery can be widely used in mobile phones, computers and other electronic products, automobiles, electric bicycles and other vehicles, and also can be used in aerospace fields and the like which requires high energy density, long cycle life and small volume.

Owner:济南恒元光电科技有限公司

Anti-corrosive hybrid sol-gel film on metallic substrates and method of producing the same

InactiveUS20110091654A1Improve corrosion resistanceSilicon organic compoundsAlkali metal silicate coatingsColloidal silicaPhase formation

This invention relates to a method of preparing anti-corrosive hybrid sol-gel film coating on zinc or zinc alloy coated metallic substrates comprising the steps of preparing a mixture of sol-gel from hydrolisable silicon alkoxides, sodium venadate solution combined with colloidal silica in a beaker and vigorously stirred; adding within 20 seconds of two separated phase formation between silica precursors and colloidal silica acetic acid or dilute nitric acid as a catalizer to initiate hydrolysis reaction of silicon alkoxides and condensation reaction in the sol gel composition, continuously stirring the mixture for about 24 hours to form a single phase solution, applying the solution on cleaned zinc or zinc alloy coated metal substrates to form a transparent sol-gel coating film and drying the coated substrates at 50° to 200° C. for 10 to 60 minutes.

Owner:TATA STEEL

Methods for controlling crystal growth, crystallization, structures and phases in materials and systems

InactiveUS7972390B2Growth inhibitionExisting techniquePolycrystalline material growthOxygen/ozone/oxide/hydroxidePhase formationEngineering

This invention relates to novel methods for affecting, and / or directing various crystal formation, structure formation or phase formation / phase change reaction pathways or systems by exposing one or more components in a holoreaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a crystallization reaction system. In a second aspect of the invention, at least one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other (or all) crystallization reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

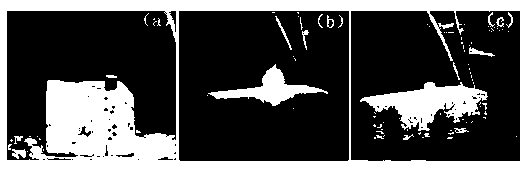

Method of welding metallic glass with crystalline metal by high-energy beam

ActiveUS20100275655A1Improve joint strengthRestriction welding conditionElectron beam welding apparatusWelding/soldering/cutting articlesWide areaPhase formation

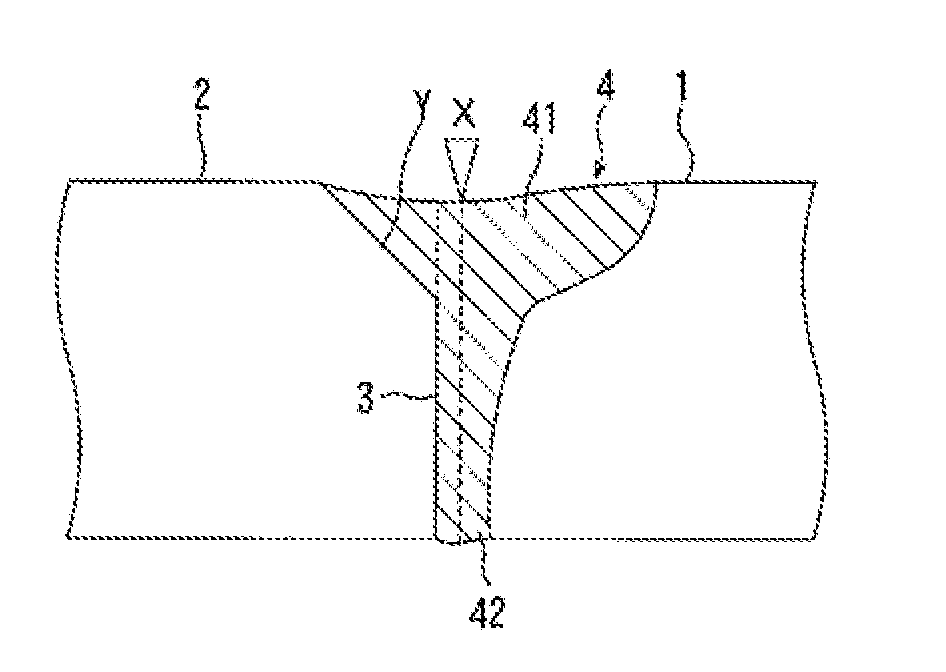

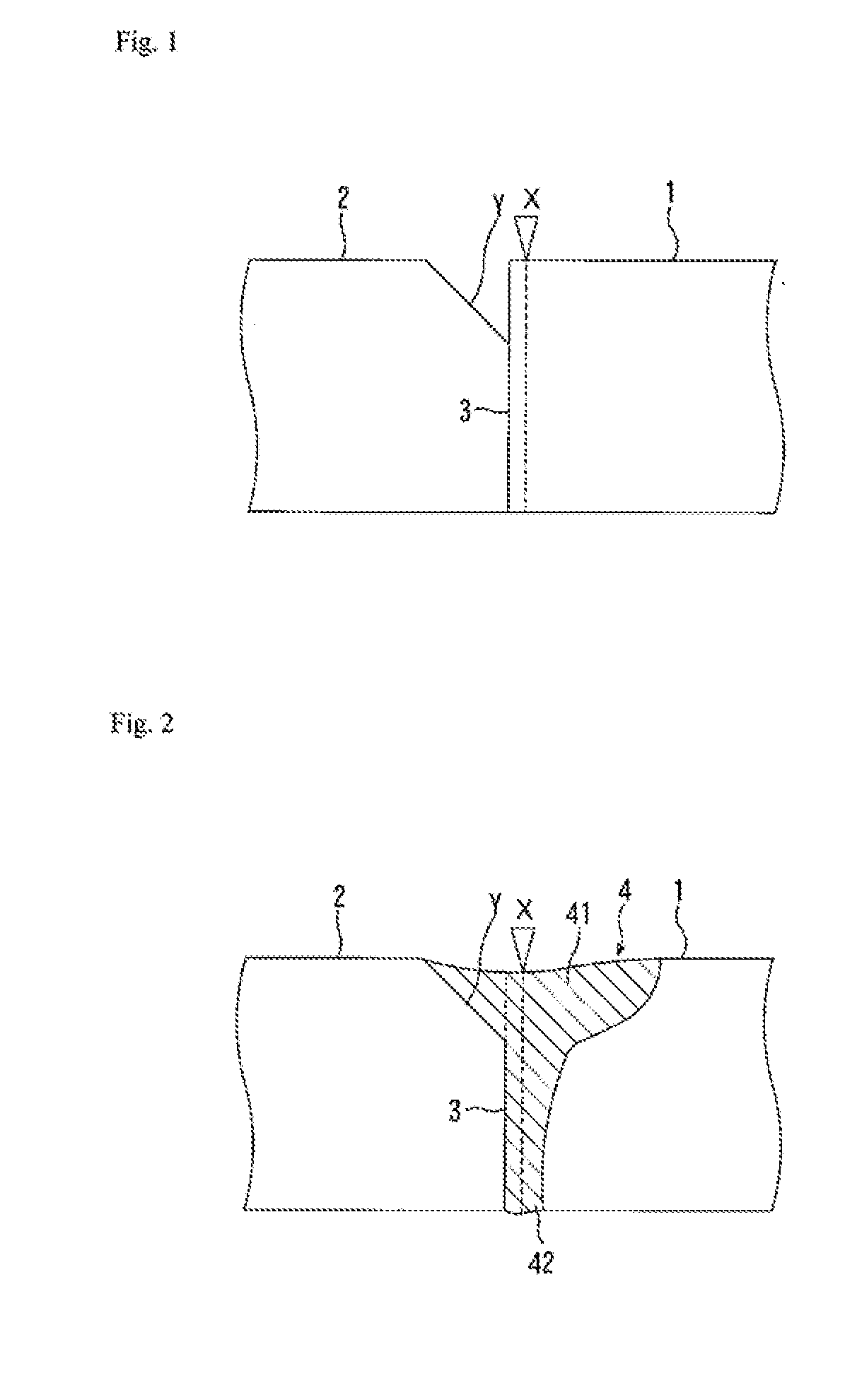

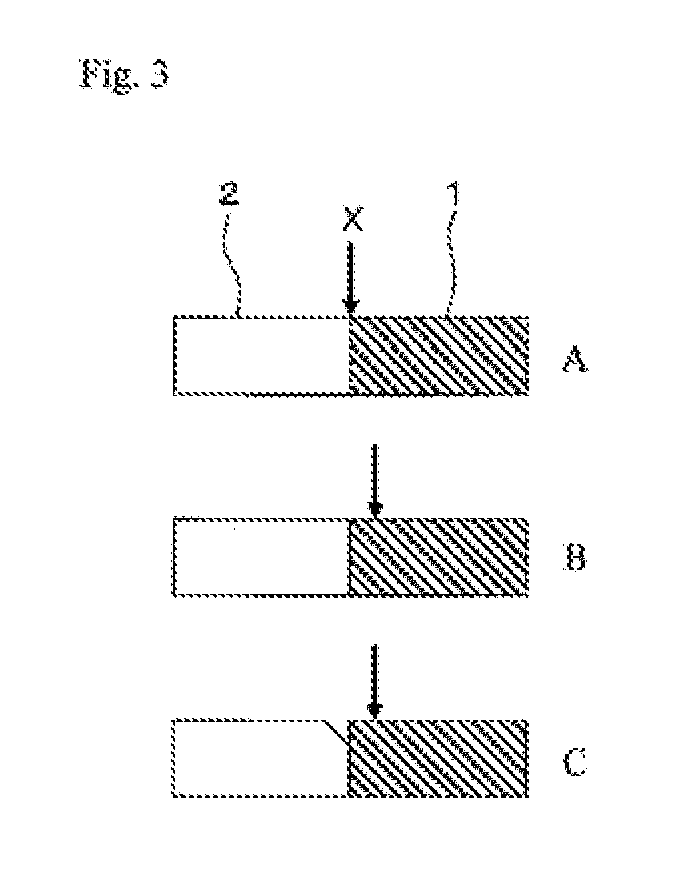

[Problems] To provide a method of welding a metallic glass and a crystalline metal by shifting a high-energy beam scan area from a butting face thereof to the metallic glass side, to fall within a composition range required for glass phase formation of a metallic glass base material in a simplified assured manner.[Means for Solving Problems] In a welding method for weldingly joining a metallic glass and a crystalline metal together by scanning a high-energy beam in a position shifted from a butt interface between the metallic glass and the crystalline metal toward the metallic glass, it is intended to provide a technique for allowing a composition of a melt zone formed around a welding interface to fall within a composition range required for forming a glass phase in the metallic glass to be joined, in a simple and more reliable manner. A metallic glass (1) and a crystalline metal (2) are butted against each other to define a groove space (Y) over a groove formed on the side of the crystalline metal (2). Then, electron beam welding is performed in a position shifted from the butt interface toward the metallic glass (1) to form a melt zone (4) which has a composition for forming an amorphous metallic glass, and comprises a top fused sub-region (41) and a lower fused sub-region (42), wherein the top fused sub-region has a relatively wide area including the groove space (Y) defined adjacent to an upper end of the butt interface and on the side of the crystalline metal, and the lower fused sub-region extends from the top fused sub-region to reach bottom surfaces of the metallic glass and the crystalline metal, while being narrowingly tapered in a downward direction.

Owner:NAT UNIV CORP KUMAMOTO UNIV +1

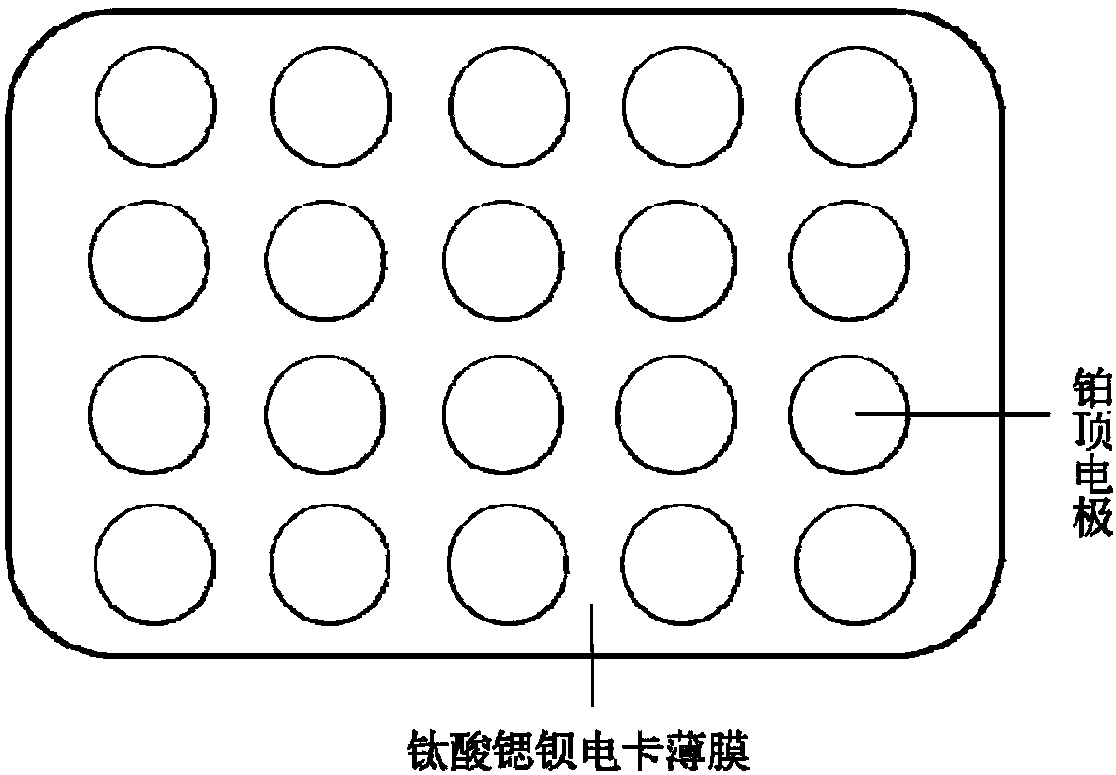

Flexible electric card refrigeration device

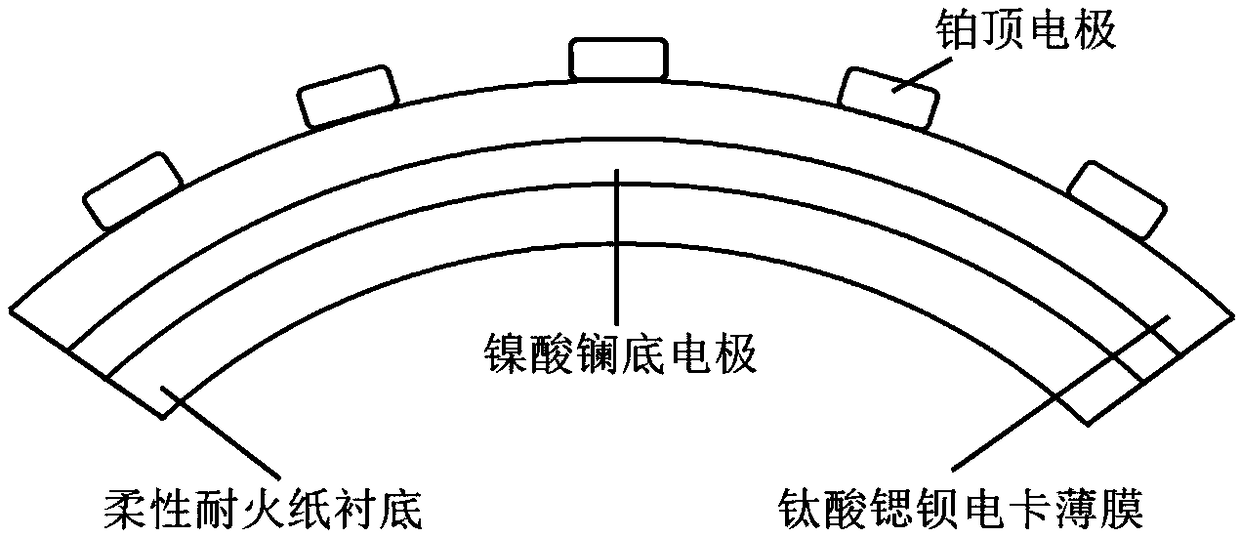

ActiveCN108573940AImprove flexibilityReduce loadSemiconductor/solid-state device detailsSolid-state devicesPhase formationBarium strontium titanate

The invention discloses a flexible electric card refrigeration device which comprises a flexible refractory paper substrate, a strontium nickelate bottom electrode layer, a barium strontium titanate electric card film layer and a platinum top electrode. The flexibility of the device is achieved by replacing a traditional rigid substrate with the novel flexible refractory paper substrate. The refractory paper can withstand high temperatures above 1000 DEG C, and can realize in-situ phase formation of the electrode and the electric card film. According to the invention, the preparation method issimple and low-costed, and the prepared device has the advantages of high refrigeration coefficient, noise prevention and small size, and can be widely used in the fields of submarine refrigeration components, robot heat dissipation, fire safety, medical treatment and health, wearable smart clothing, artificial intelligence and the like.

Owner:NANJING UNIV OF SCI & TECH

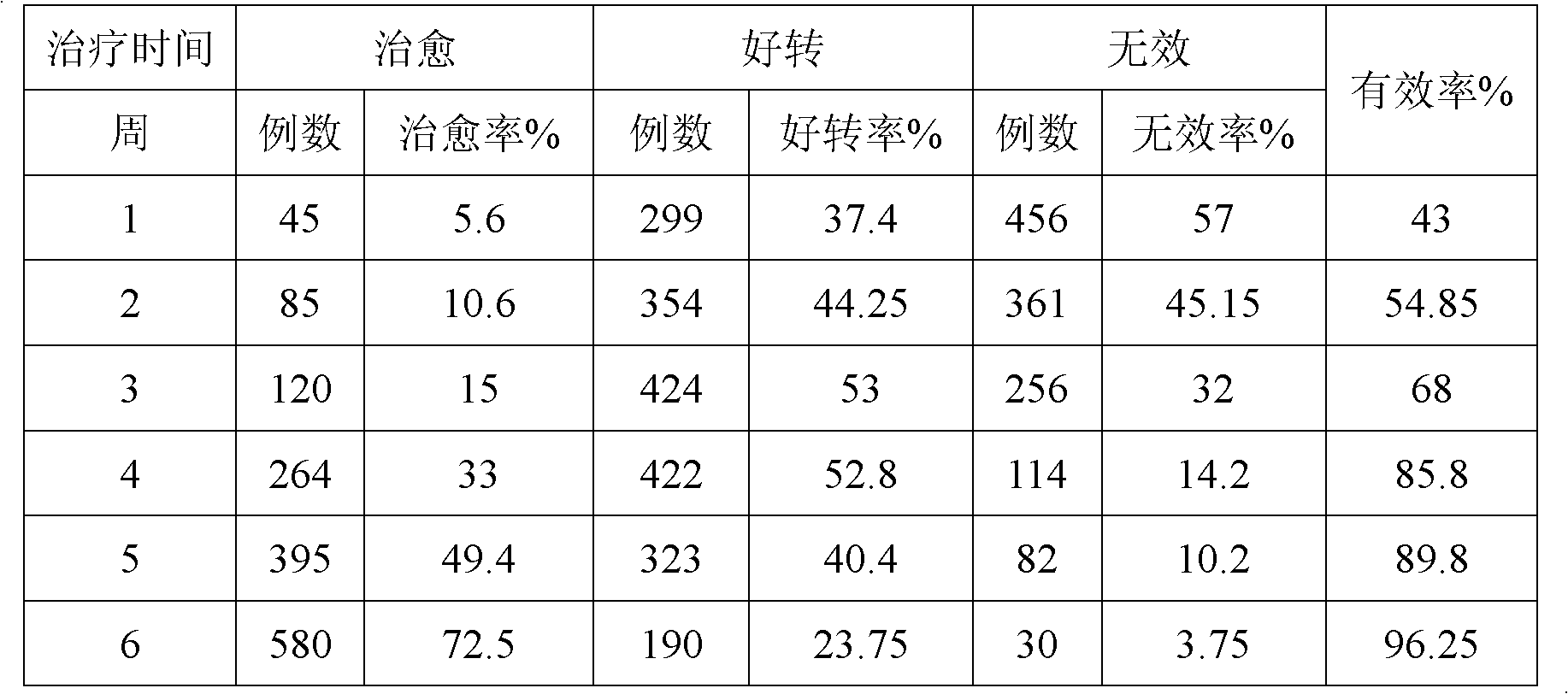

Antithrombotic and thrombosis-eliminating preparation

ActiveCN102198181AReduce viscosityPrevent coagulationCardiovascular disorderLeech/worm material medical ingredientsPhase formationClinical trial

The invention relates to an antithrombotic and thrombosis-eliminating preparation, which is characterized by being prepared from the following raw material medicines in part by weight: 30 to 60 parts of astragalus, 3 to 6 parts of leech, 10 to 20 parts of safflower, 10 to 20 parts of red paeony root, 5 to 15 parts of root of red-rooted salvia and 10 to 20 parts of peach kernel. Compared with the prior art, the antithrombotic and thrombosis-eliminating preparation has the advantages that: based on the acute phase formation characteristics and pathological change of ishemic stroke, a compound Chinese medicine with effects of scattering and eliminating stasis, promoting dieresis and diminishing swelling is used to treat acute ishemic stroke; and lots of clinic tests prove that the antithrombotic and thrombosis-eliminating preparation has obvious treatment effects of preventing blood clotting, dissolving blood clots, expanding blood capillaries, relieving arteriospasm, lowering blood viscosity, improving flowing speed of microcirculating blood.

Owner:海城市中医院

Method for preparing superconducting layer of high-temperature superconducting coated conductor by depositing fluorine-free chemical solution

InactiveCN101857429AReduced current carrying capacityStable stateSuperconductors/hyperconductorsSuperconductor devicesElectrical conductorPhase formation

The invention discloses a method for preparing a superconducting layer of a high-temperature superconducting coated conductor by depositing fluorine-free chemical solution. The method comprises the following steps of: a, preparation of precursor solution; b, the preparation of coating colloid; c, coating and drying; d, wet-type decomposition heat treatment, namely placing a substrate with a film into a tubular finance; rising the temperature to be between 100 and 150 DEG C from room temperature at the speed of 1-5DEG C / min under the protection of an argon atmosphere; introducing a mixed gas of water vapor and argon with the dew point of between 10 to 20 DEG C into the furnace to form a wet argon protective atmosphere; rising the temperature to be between 450 and 500 DEG C at the speed of 0.25 to 1.5DEG C / min; keeping the temperature for 0.5 to 2 hours; cooling to the room temperature in the argon atmosphere; and e, phase formation and heat treatment to obtain the superconducting layer. The critical current density of the superconducting layer of the high-temperature superconducting coated conductor prepared by the method is up to the same magnitude order as the that of the superconducting layer prepared by a fluorine-containing method; the superconducting layer has a high-degree biaxially texture and a flat and dense surface; and the method is easy to prepare a thicker superconducting layer and has the characteristics of low cost, simple process and suitability of large-scale industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

Phase formation agent for liquid-liquid-liquid tri-phase system

InactiveCN1806881AEasy to separateRealize recyclingLiquid solutions solvent extractionInorganic saltsPhase formation

The invention relates the phase former of liquid-liquid-liquid triple systems, comprising 7-20wt% copolymer of epoxyethane and epoxypropane, 7-20wt% inorganic salt and 10-40wt% organic solvent. The copolymer is block copolymer the weight average molecular weight of which is 1000-10000, comprising 40-85% epoxyethane block, or random copolymer the weight average molecular weight of which is 800-10000, comprising 50-85% epoxyethane. The invention can be used in separating filter liquor containing the biofermentation system, industrial waste water, and the complicated system containing the miscible liquids of organic synthesis product. The invention reaches the purification of phase-forming polyaromatics, reduces the cost, shortens the nature difference of organic phase and intermediate phase, and simplifies the technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

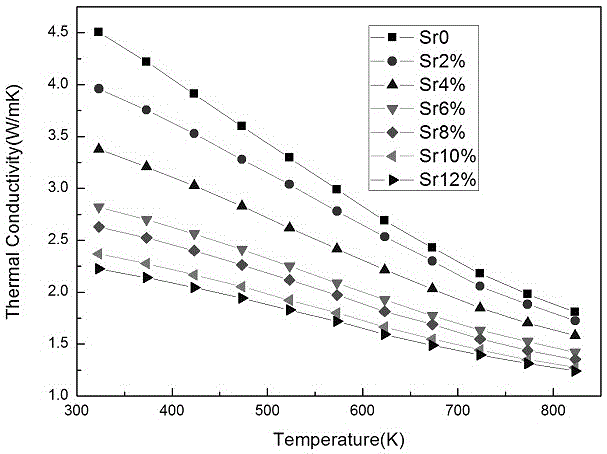

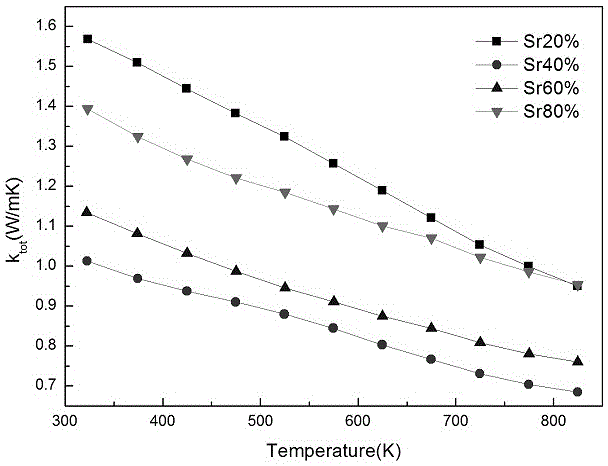

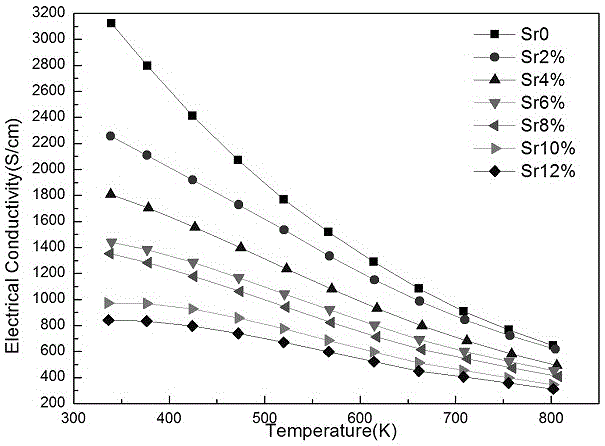

Composite PbSe-based thermoelectric material doped with Sr and Na and preparation method thereof

InactiveCN105140383ALow thermal conductivityIncreased ZT valueThermoelectric device junction materialsThermoelectric materialsPhase formation

The invention discloses a composite PbSe-based thermoelectric material doped with Sr and Na and a preparation method thereof. The preparation method comprises the steps of firstly weighing Pb, Sr, Na and Se according to a stoichiometric ratio of Pb<0.98-x>Sr<x>Na<0.02>Se, mixing Pb, Sr, Na and Se, carrying out vacuum tube sealing smelting, and completing a phase formation stage of the phase. A sample after heat treatment is ground and put into a graphite die, and powder is manufactured into a block sample by adopting a rapid hot-pressing sintering technology, thereby being capable of acquiring a Pb<0.98-x>Sr<x>Na<0.02>Se thermoelectric material. Compared with traditional hot-pressing sintering, the preparation method disclosed by the invention has the advantages of uniform heating, high temperature rising speed, short sintering time and the like, and the sintered sample is obvious in performance variation. The thermal conductivity of the material is greatly reduced after being doped with Sr and Na, the Seebeck coefficient is increased, and a thermoelectric material with a high ZT value is acquired.

Owner:SHANGHAI UNIV

Surface active agent, and its preparing method and use

InactiveCN1470317ADecrease critical micelle concentration valueHarm reductionTransportation and packagingMixingEpoxyPhase formation

The invention refers to a kind of active agent and the manufacturing method, and the application that the active agent is used as degreasing agent in triple oil extraction. The invention synthesizes primary alcohol into branch jubeite alcohol through jubeite reaction, then epoxy froming, sulphonating and neutralizing, forms a negative ion surface active agent which contains some non-ion surface active agent. The agent can form micro-latex with the oil without the aid surface active agent, decreases the interfacial tension between water and oil greatly. The invention synthesizes hydrophobe base group with 12~18 carbon and surface active agent with different EO number, researches the interfacial tension between it and the raw oil and simulative oil, and acquires prominent surface active agent system.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

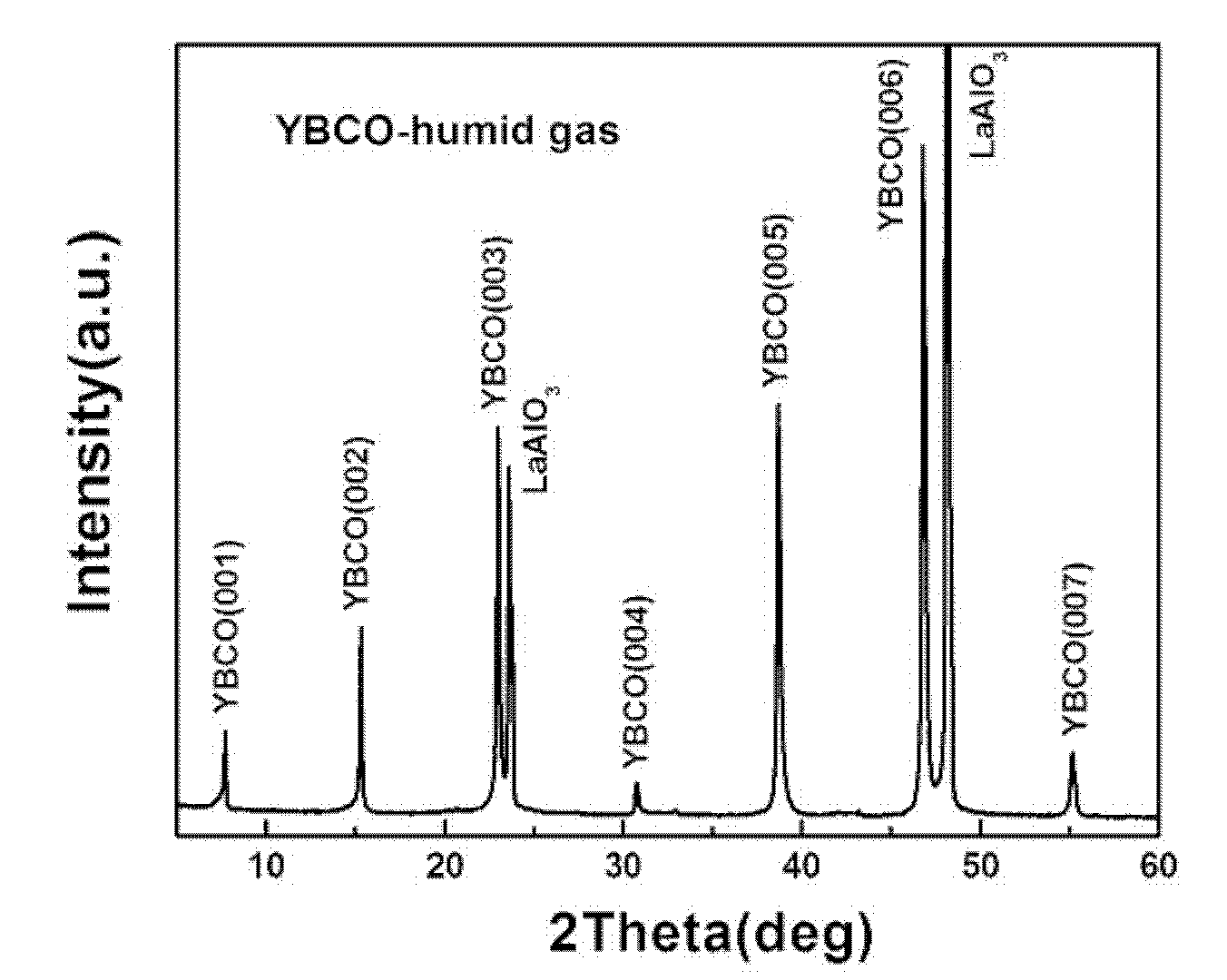

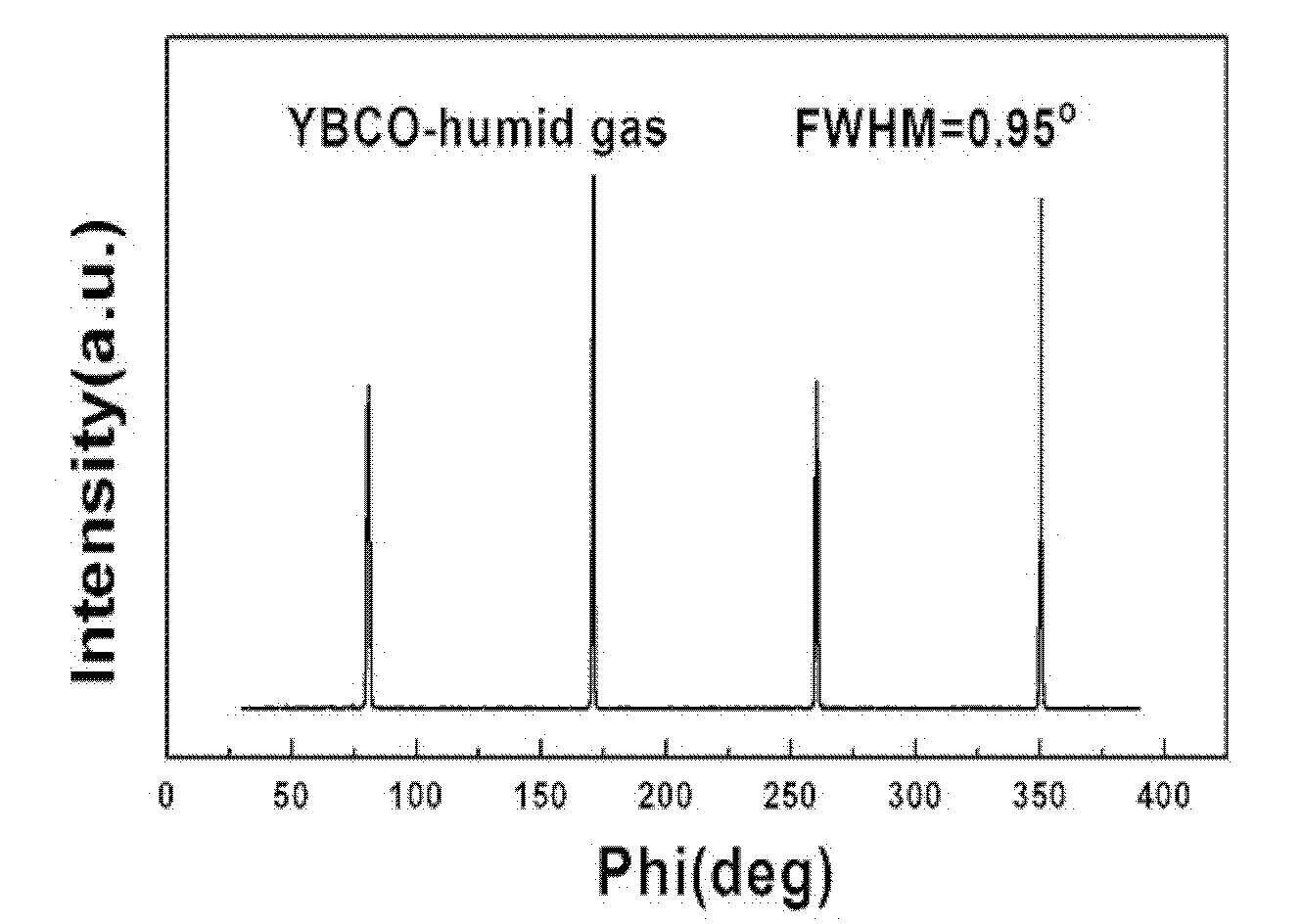

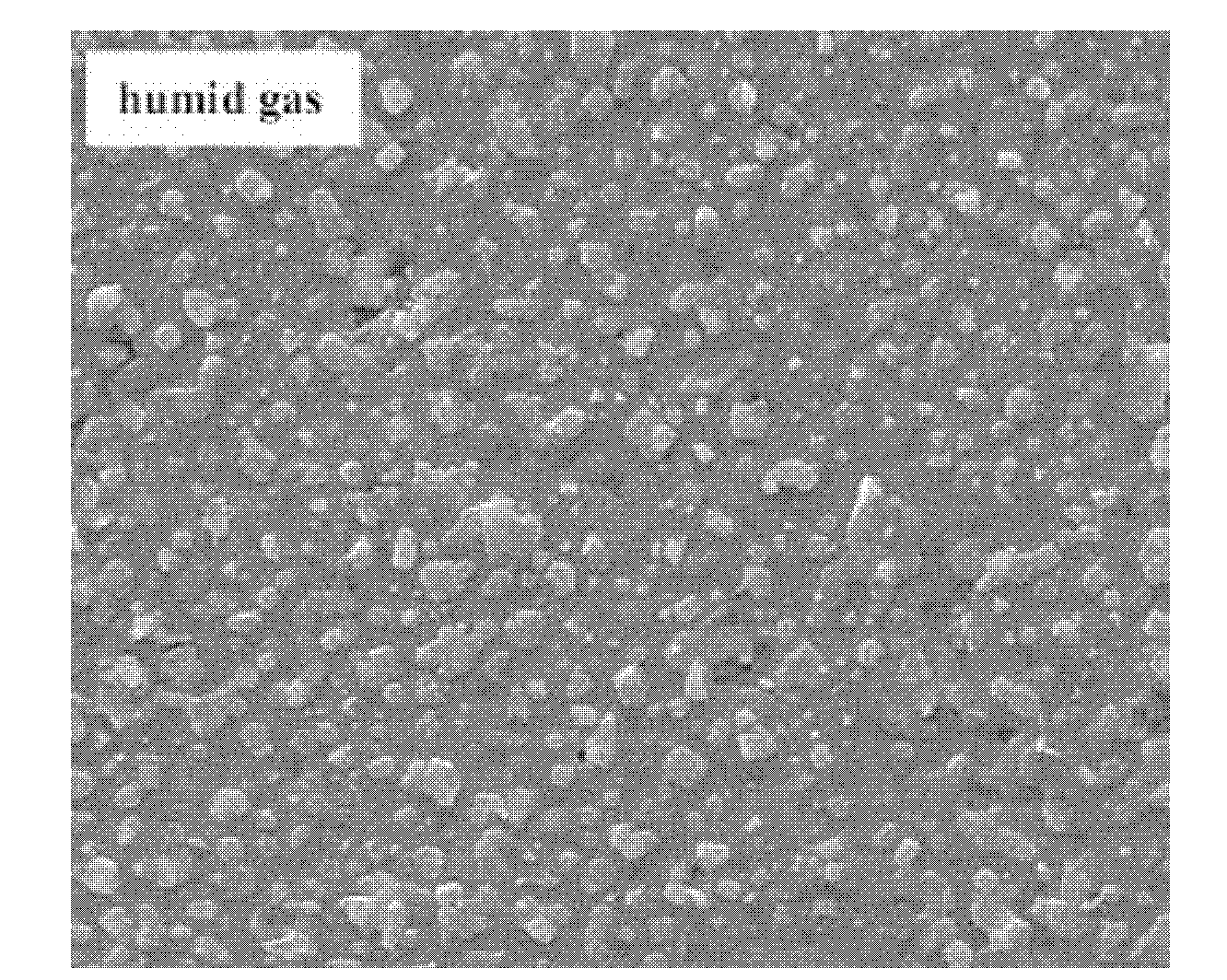

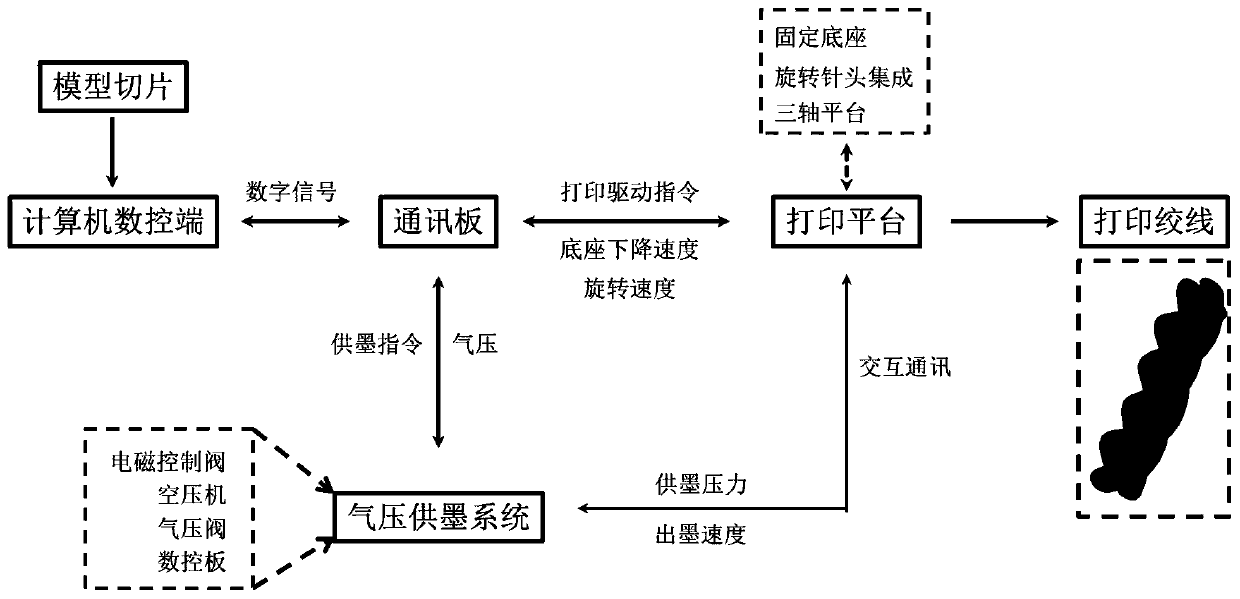

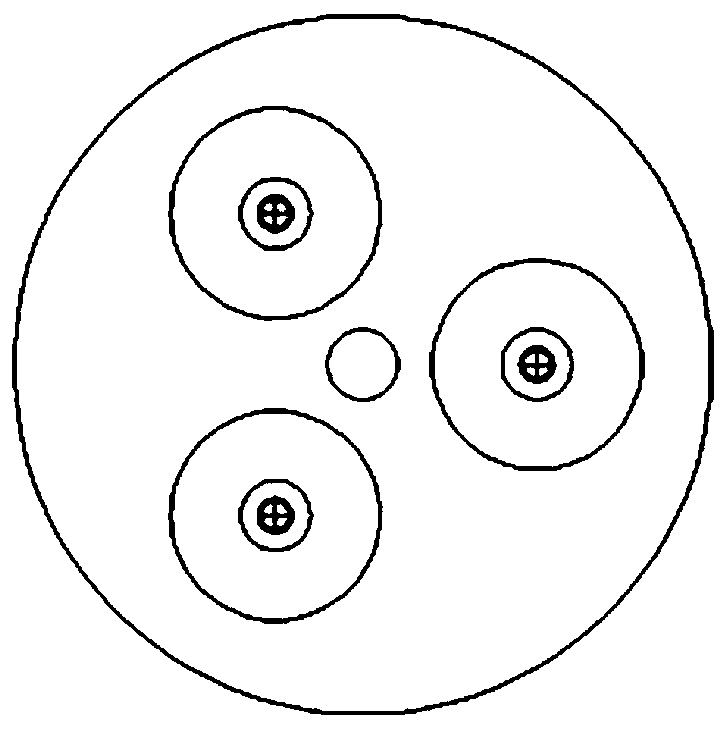

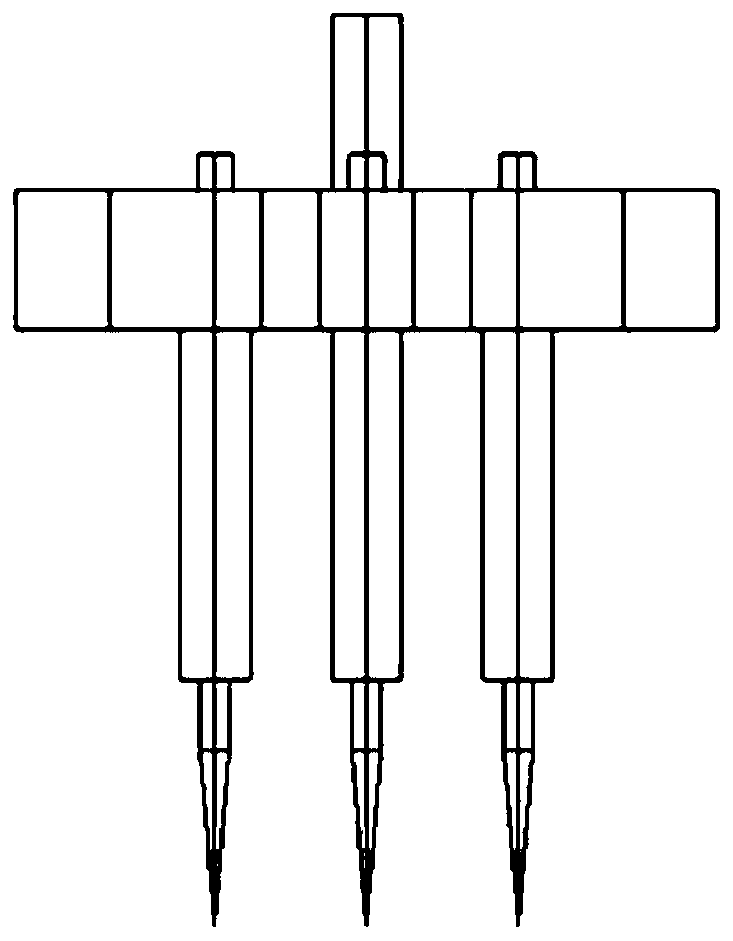

Method for preparing superconducting yttrium barium copper oxide (YBCO) twisted wire through 3D printing

ActiveCN110634615ARealize the filamentization processRealize integrated designAdditive manufacturing apparatusSuperconductors/hyperconductorsMicro nanoYttrium barium copper oxide

The invention discloses a method for preparing a high-temperature superconducting yttrium barium copper oxide (YBCO) twisted wire through 3D printing. The method comprises four steps of firstly, preparing a nanoscale superconducting powder precursor, then preparing printing slurry with proper viscosity and supporting characteristics, then utilizing CAD three-dimensional modeling, exporting STL format model data, and utilizing professional software for slicing, achieving one-step molding stranded wire preparation with low current loss through a twisted printing nozzle, and finally, the printedstranded wires are subjected to the processes of plastic removal, phase formation, oxygen supplementation, packaging and the like to form the practical superconducting stranded cable. The method is advantaged in that the application of the direct writing type 3D printing advanced technology in the aspect of high-temperature superconducting wires is realized for the first time, the micro-nano superconductive core wire is prepared through 3D printing, the fine wire process of the core wire is achieved, integrated design of materials and structures is achieved, the preparation process of the high-temperature superconducting wire is simplified, current-carrying performance and production efficiency of the high-temperature superconducting wire are improved, and production cost is reduced.

Owner:LANZHOU UNIVERSITY

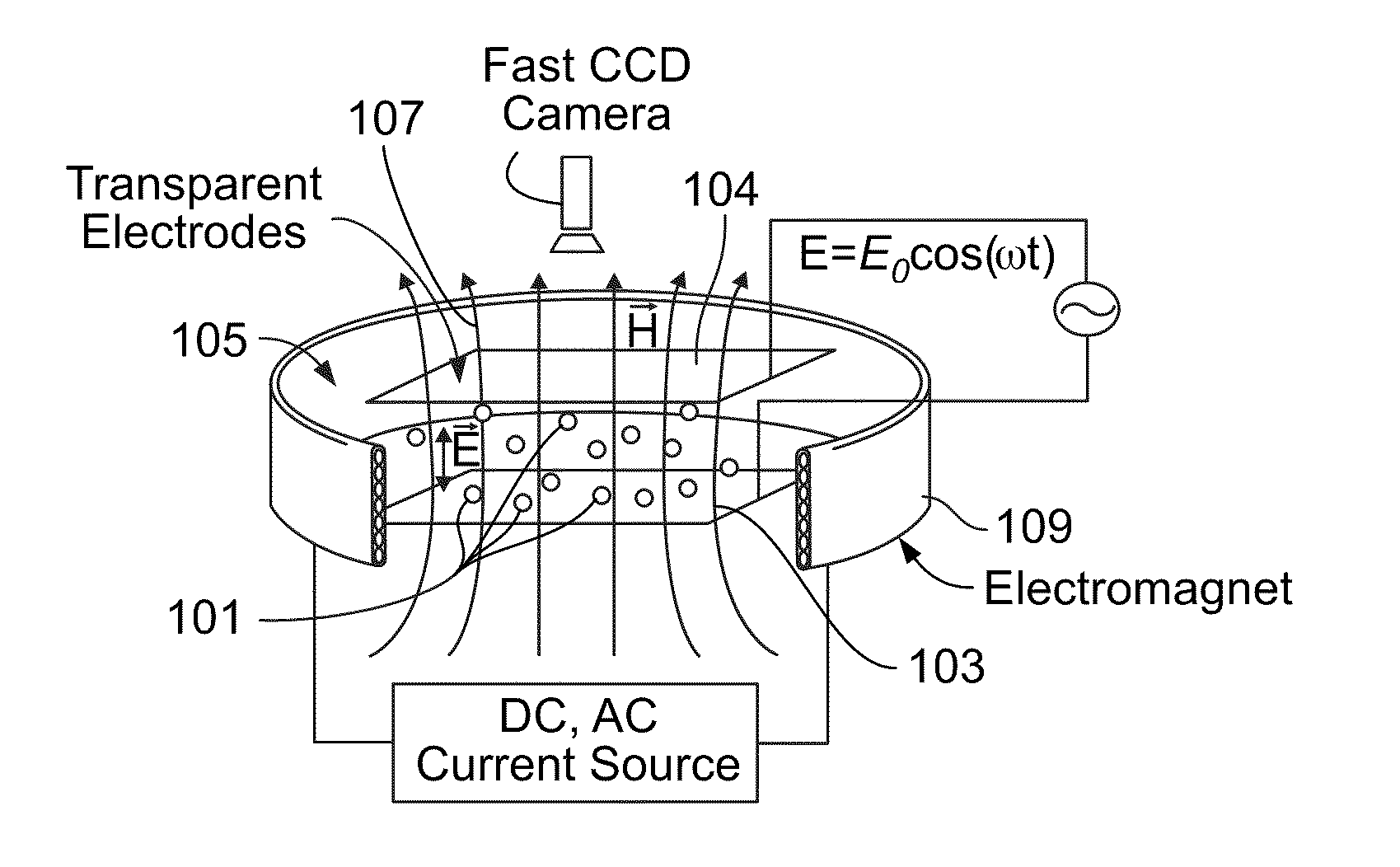

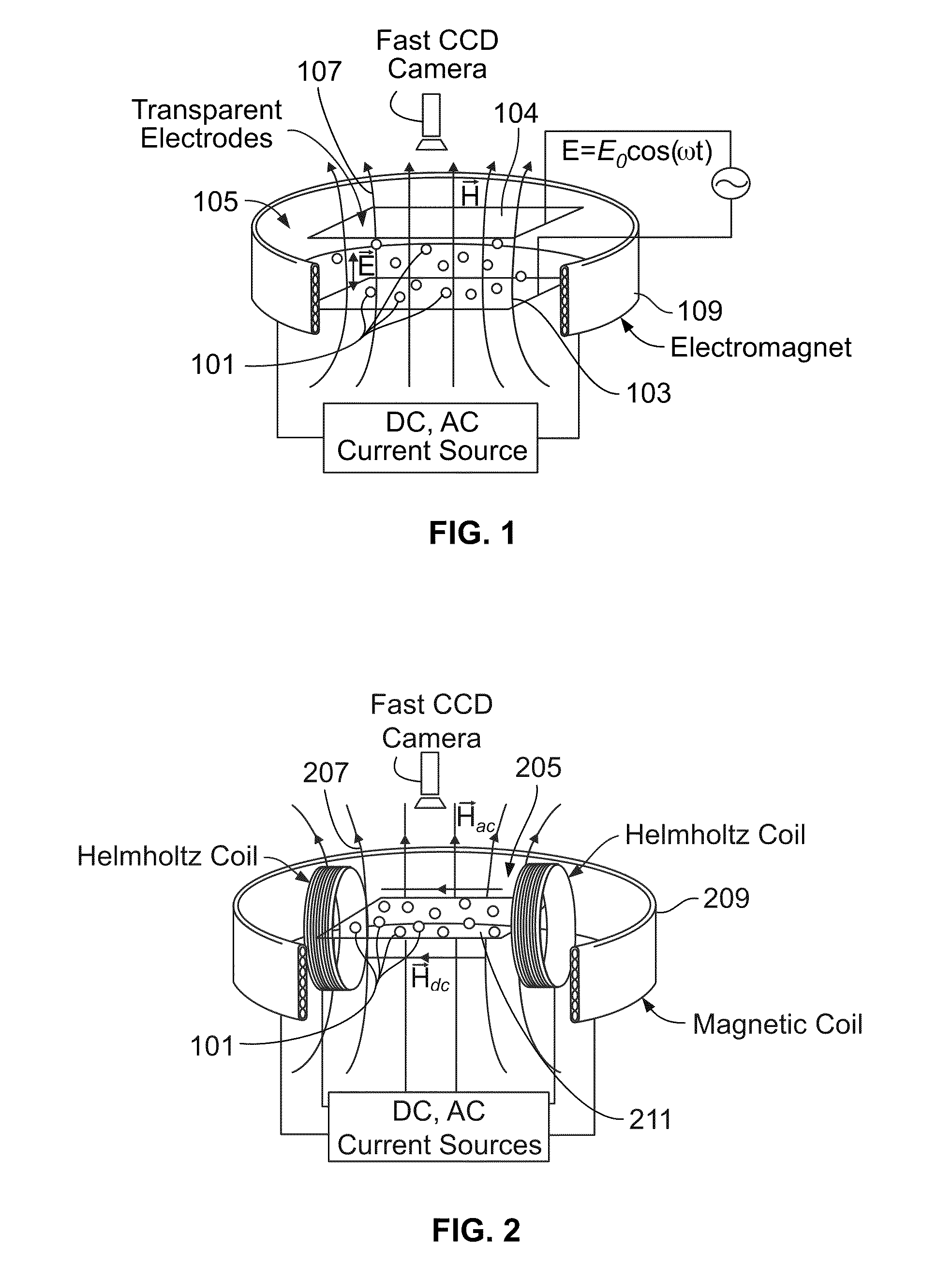

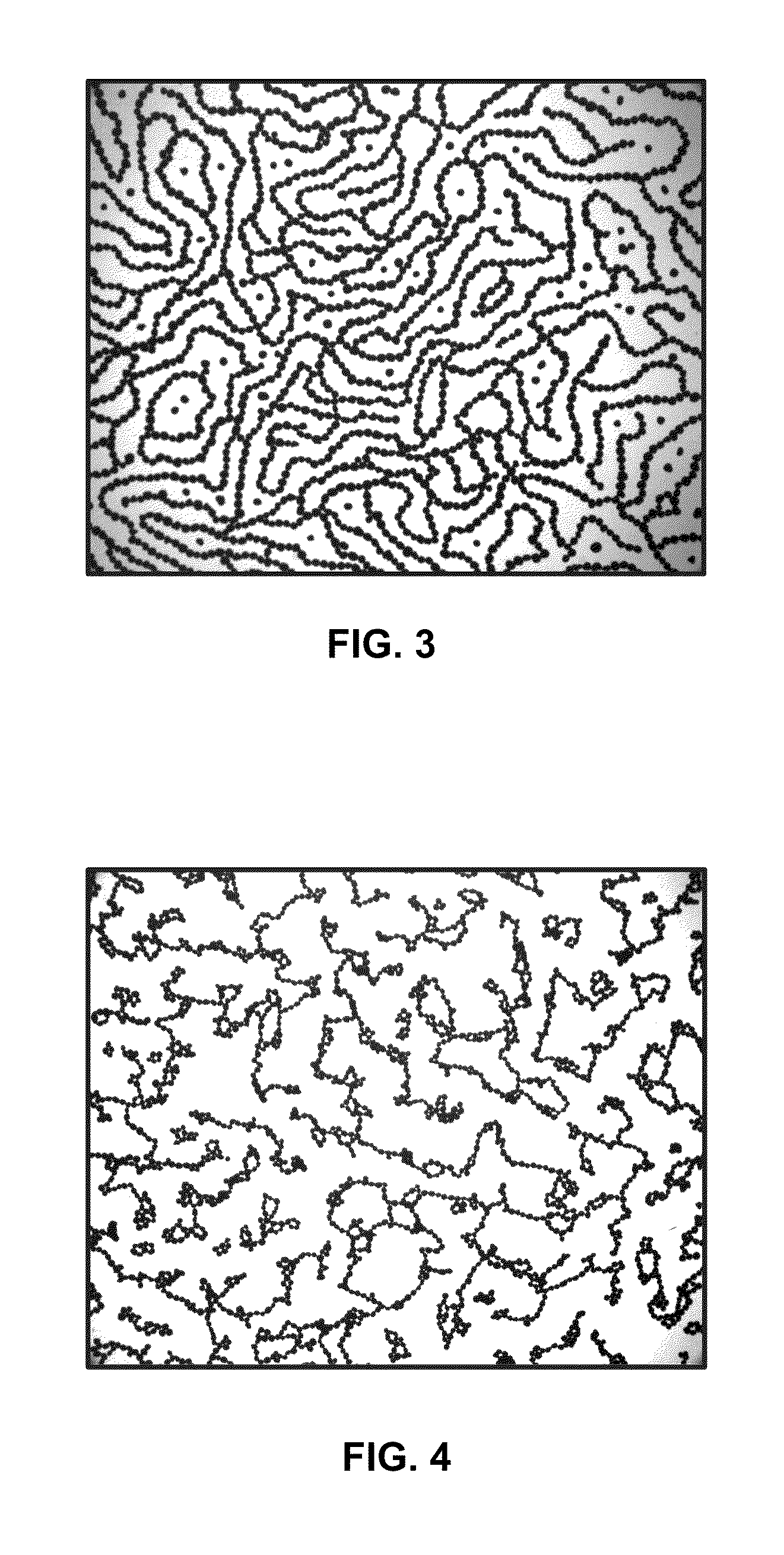

Systems and methods for creation of conducting networks of magnetic particles through dynamic self-assembly process

InactiveUS7875187B2Easy to controlElectrostatic separatorsFatty/oily/floating substances removal devicesPhase formationMicroparticle

Self-assembly of magnetic microparticles in AC magnetic fields. Excitation of the system by an AC magnetic field provides a variety of patterns that can be controlled by adjusting the frequency and the amplitude of the field. At low particle densities the low-frequency magnetic excitation favors cluster phase formation, while high frequency excitation favors chains and netlike structures. For denser configurations, an abrupt transition to the network phase was obtained.

Owner:UCHICAGO ARGONNE LLC

Method for preparing copper antimony sulfide solar cell light-absorbing layer film

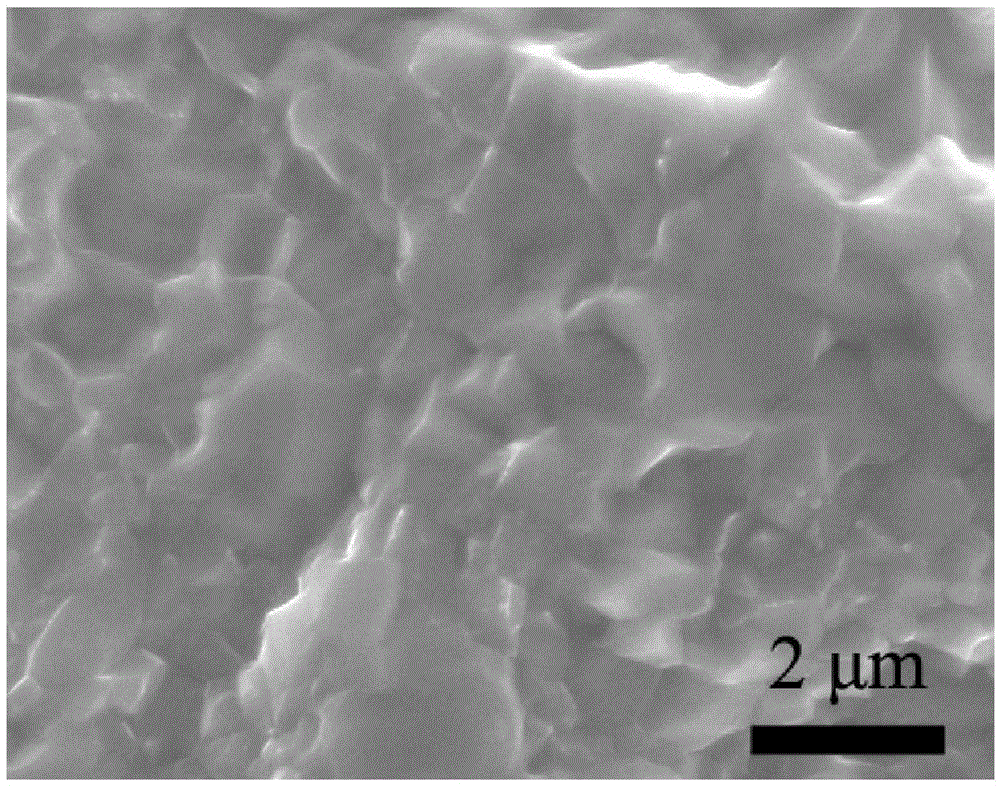

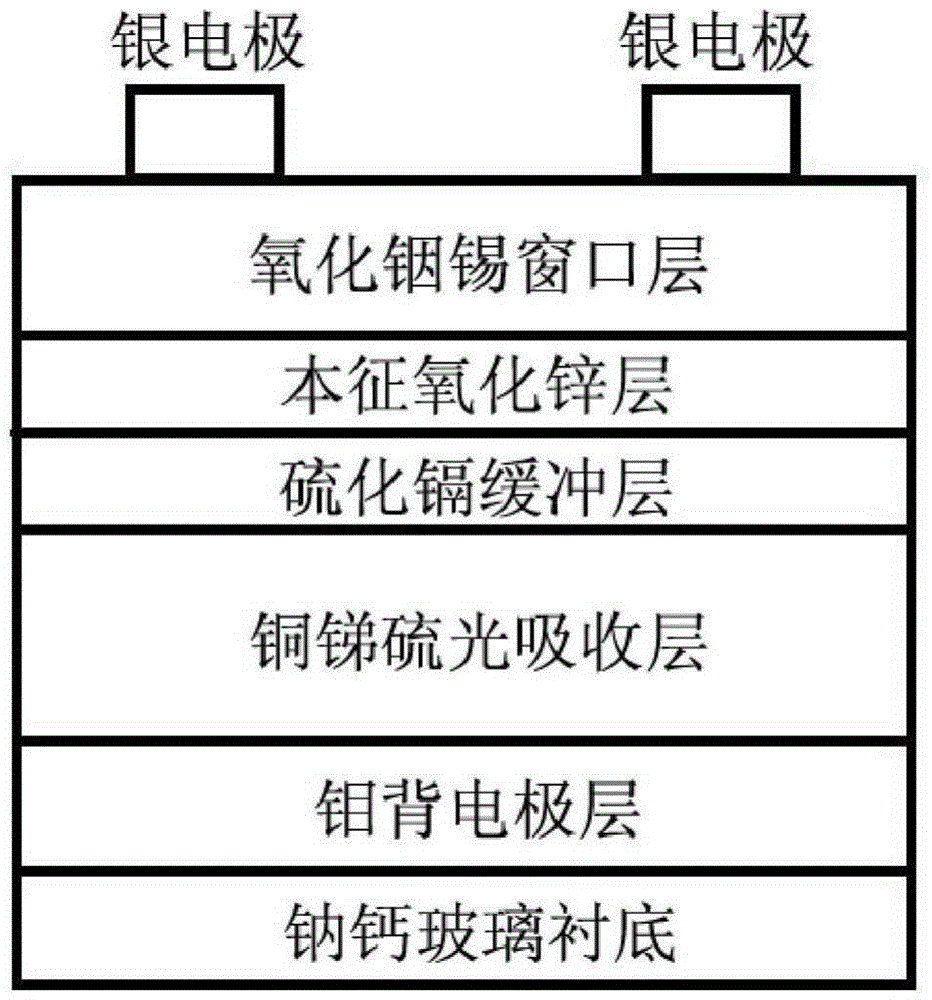

InactiveCN105390373AHigh crystallinitySmall sizeFinal product manufactureSemiconductor/solid-state device manufacturingPhase formationSurface layer

The present invention discloses a method for preparing a copper antimony sulfide solar cell light-absorbing layer film. Light-absorbing layer copper antimony sulfide is prepared by stree-step multi-source co-evaporation deposition process, the anti-evaporation of antimony sulfide is effectively compensated, a film composition is precisely controlled, the crystallinity of the film is improved, film bottom is in antimony, the film adhesion is enhanced, a surface layer is rich in antimony, the generation of a surface layer rich copper phase is inhibited, and the leakage current of a solar cell is reduced. Compared with a chemical method, the method of the invention has the advantages that the crystallinity and component controllability of the copper antimony sulfide is improved, the miscellaneous phase formation is suppressed, the carrier recombination of a space charge region is reduced, and the improvement of cell efficiency is facilitated.

Owner:HEFEI UNIV OF TECH

Rare-earth magnesium alloy solidification process comparison heat analysis method

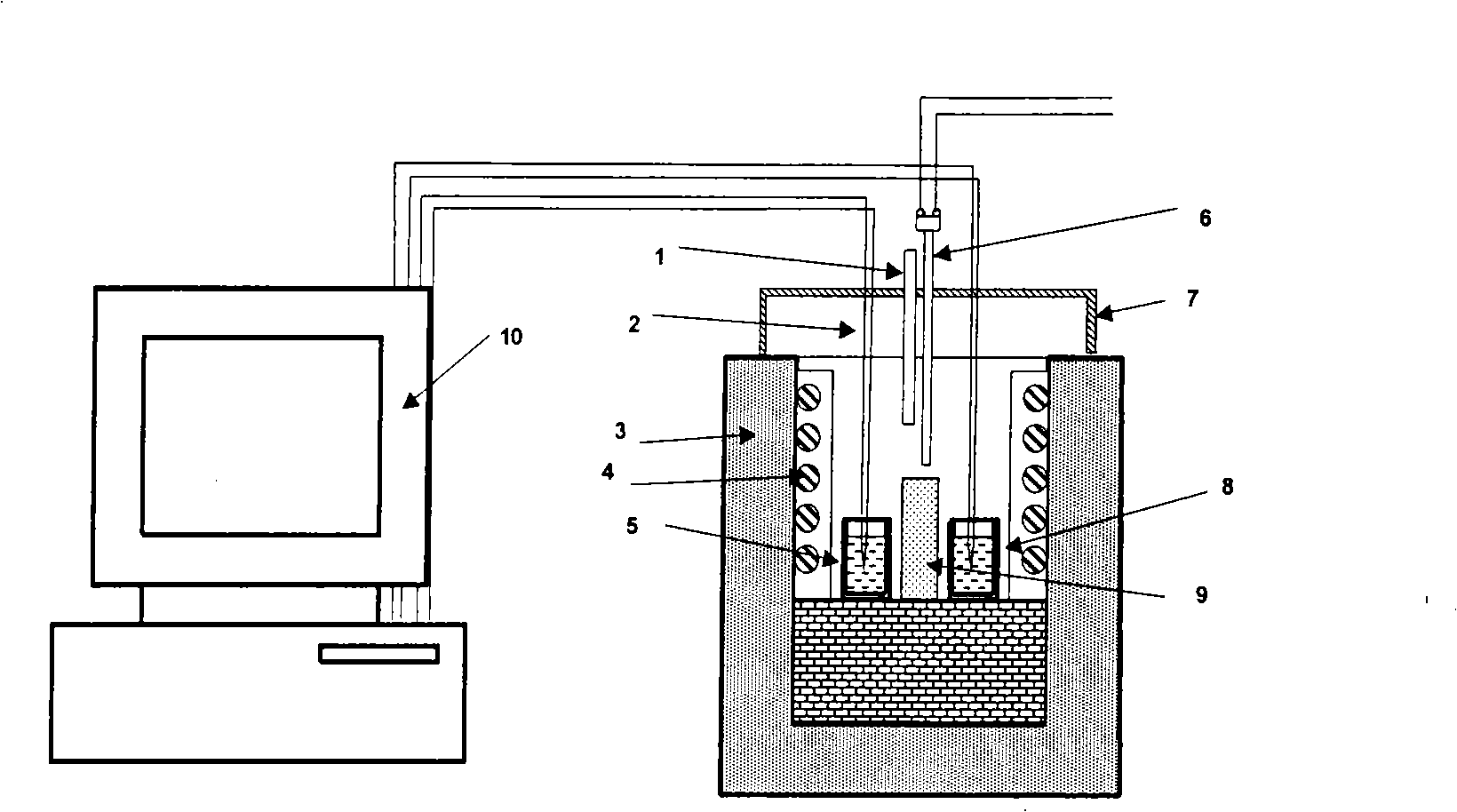

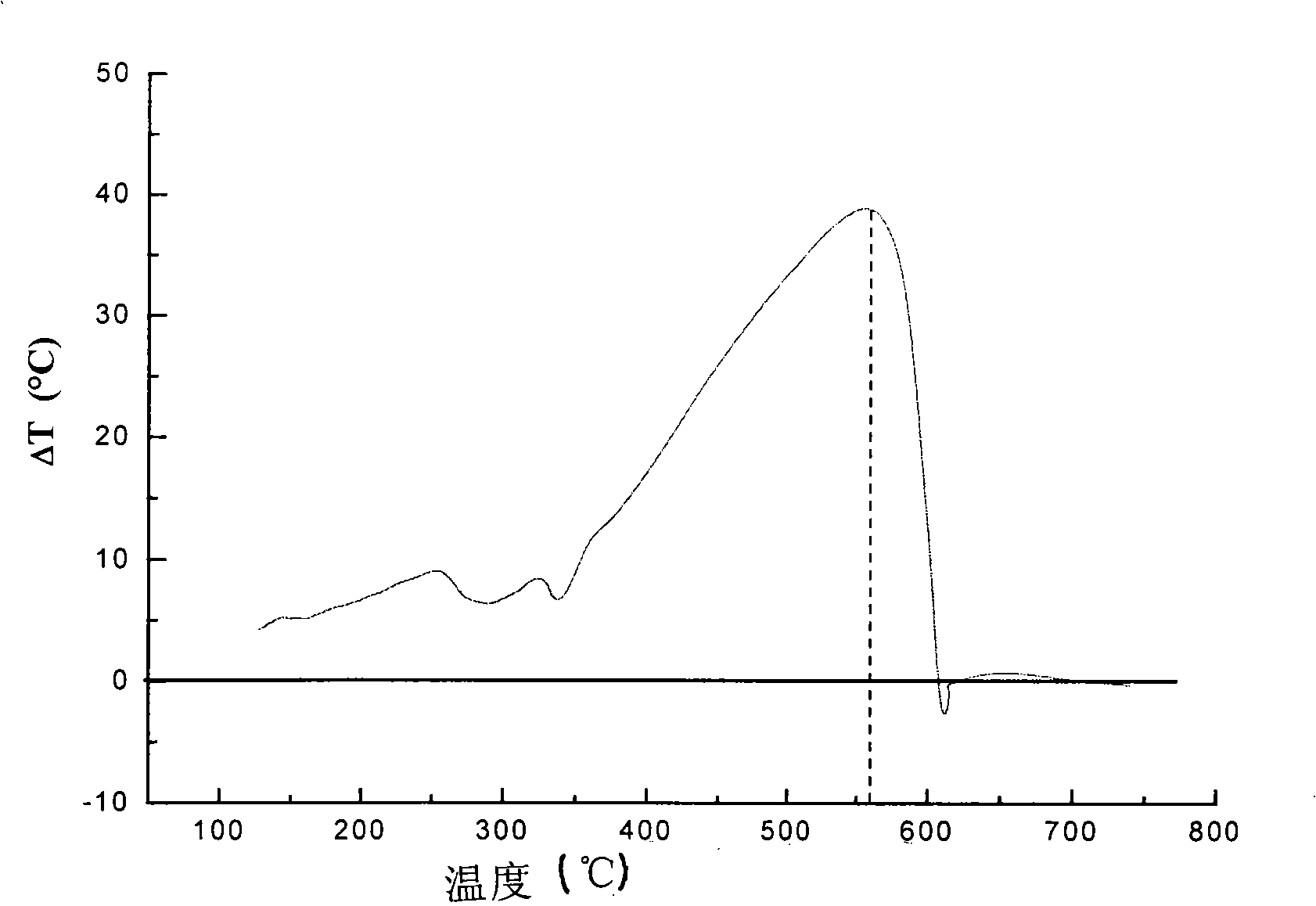

InactiveCN101308106AAccurate measurementPracticalInvestigating phase/state changeReference samplePhase formation

The invention relates to a rare earth magnesium alloy solidification process comparison and thermal analysis method, which comprises the following steps that: (1) a rare earth magnesium alloy (ZA52-xNd, x=1, 2, 4, 6) and a reference magnesium alloy (ZA52) are put into crucibles having the same size respectively; (2) each alloy is heated in a resistance furnace to be melted, the heating and cooling processes are implemented under the protection of (SF6+CO2) mixed gases until samples in the two crucibles are melted thoroughly and the temperature approaches 720 DEG C; and (3) the power of the resistance furnace is turned off, and fused masses in the crucibles are cooled along with the furnace; and the cooling temperature is recorded every 0.05 second, and solidification cooling curves of the samples to be detected and reference samples are obtained through the corresponding software processing. The method in the invention can accurately measure the rare earth magnesium alloy new phase formation temperature range and is practical.

Owner:厦门火炬特种金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com