Method for producing a thermoelectric intermetallic compound

A technology of intermetallic compounds and mixtures, applied in the field of thermoelectrics, can solve problems such as reducing the magnitude of k1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

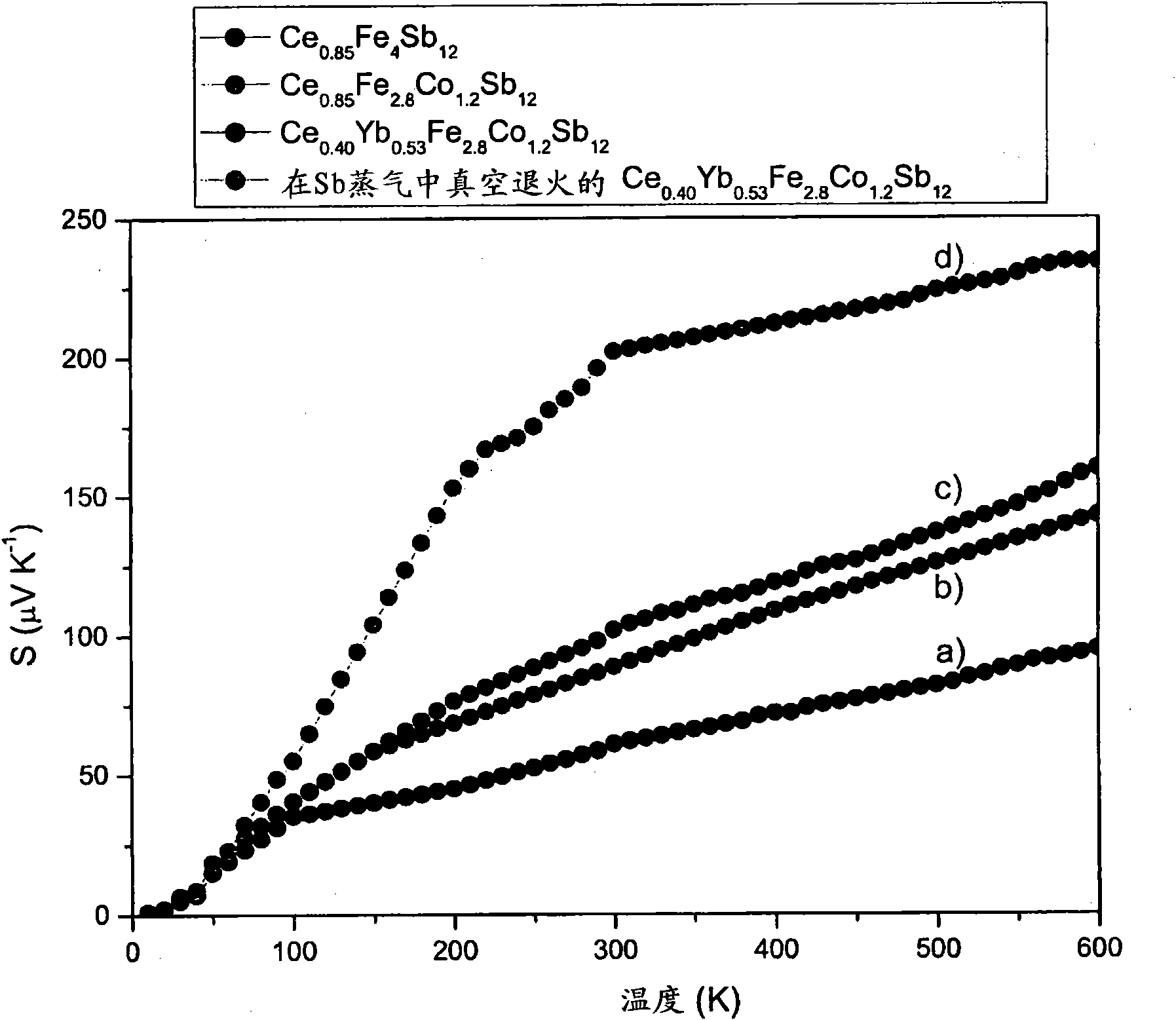

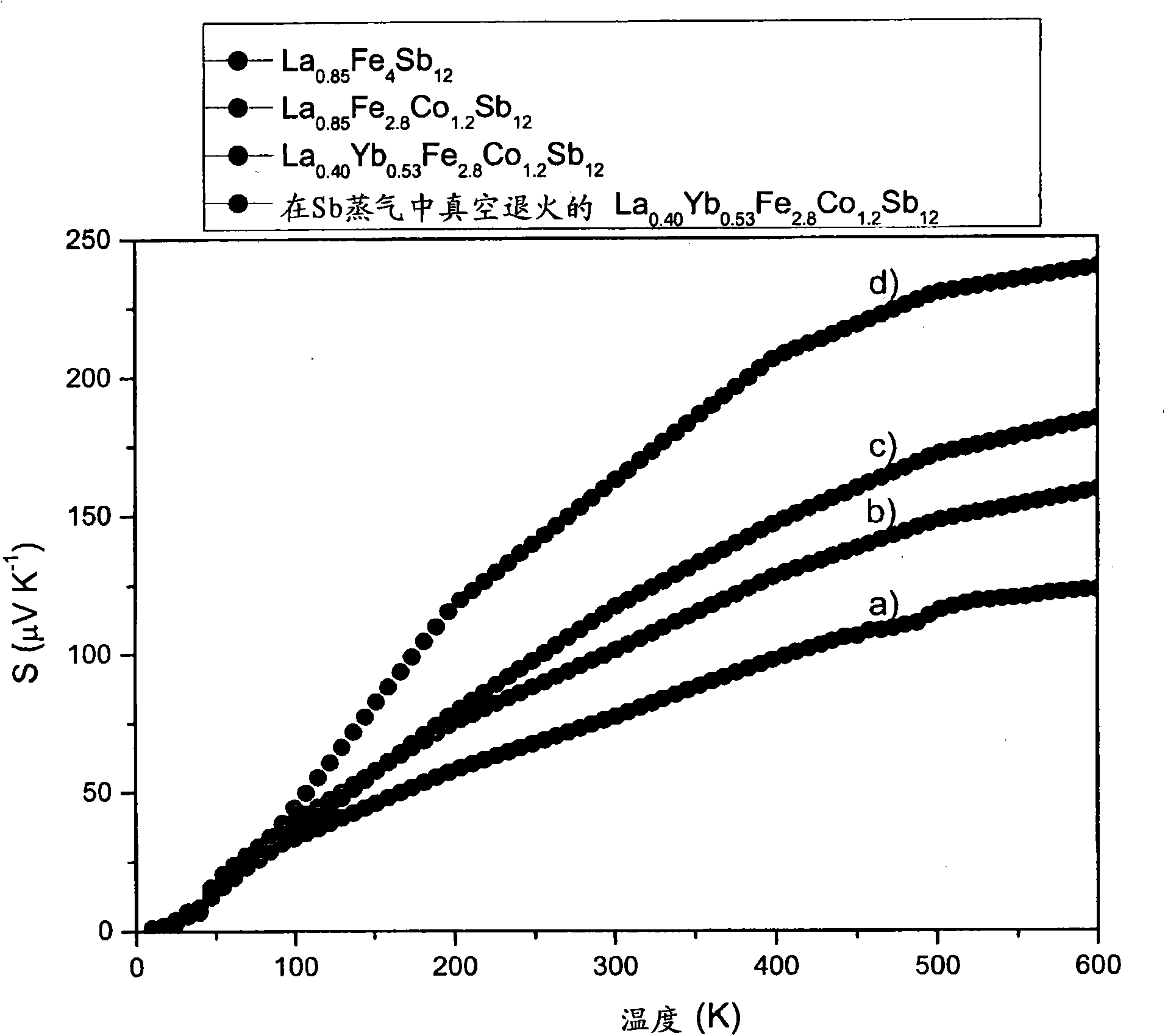

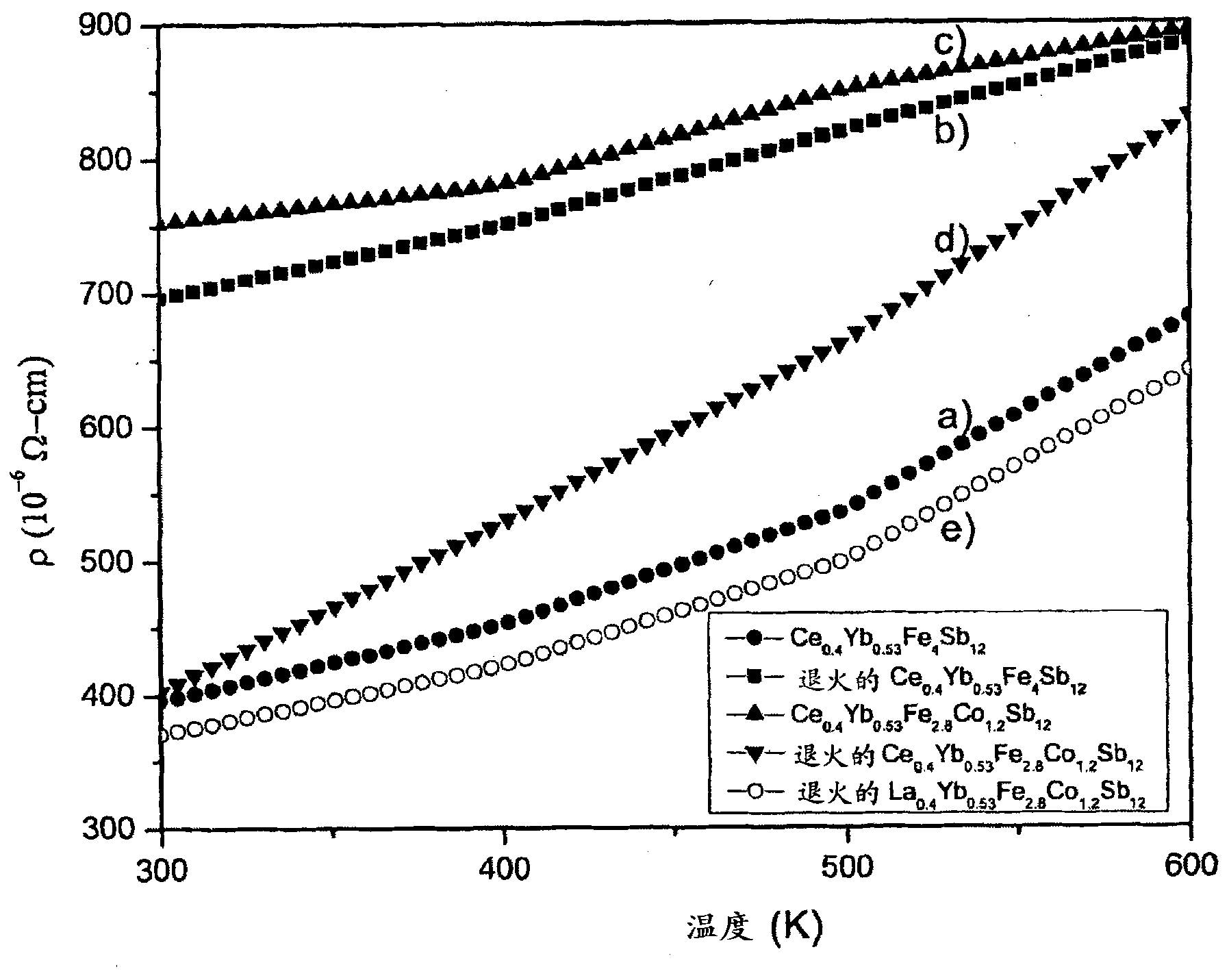

[0122] Compound Z was synthesized from high-purity starting ingots of La, Ce, Yb, Fe, Co, and Sb purchased from Sigma Aldrich 1-x Yb x Fe 4 Sb 12 and Z 1-x Yb x Fe 3.9 co 0.01 Sb 12 (Z = Ce, La). The stoichiometric mixture of these reactants is then sealed in a vacuum (-6 mbar) in a quartz tube. The sample was then heated very slowly to 400°C at a ramp rate of 0.5° / min. The samples were kept at this temperature for 48 hours. Then the temperature was raised to 700°C for one week. Finally, the sample was quenched to room temperature.

[0123] Each of the resulting samples was then pressed into pellets and induction melted. Excess Yb and Sb were added before melting. The resulting dense pellets were then annealed at 700°C for 24 hours.

[0124] Phase formation was confirmed by X-ray powder diffraction and microscopy / compositional analysis was performed using SEM / EDX techniques. The measurement of resistance as a function of temperature is performed using the DC fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com