Patents

Literature

122 results about "Skutterudite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

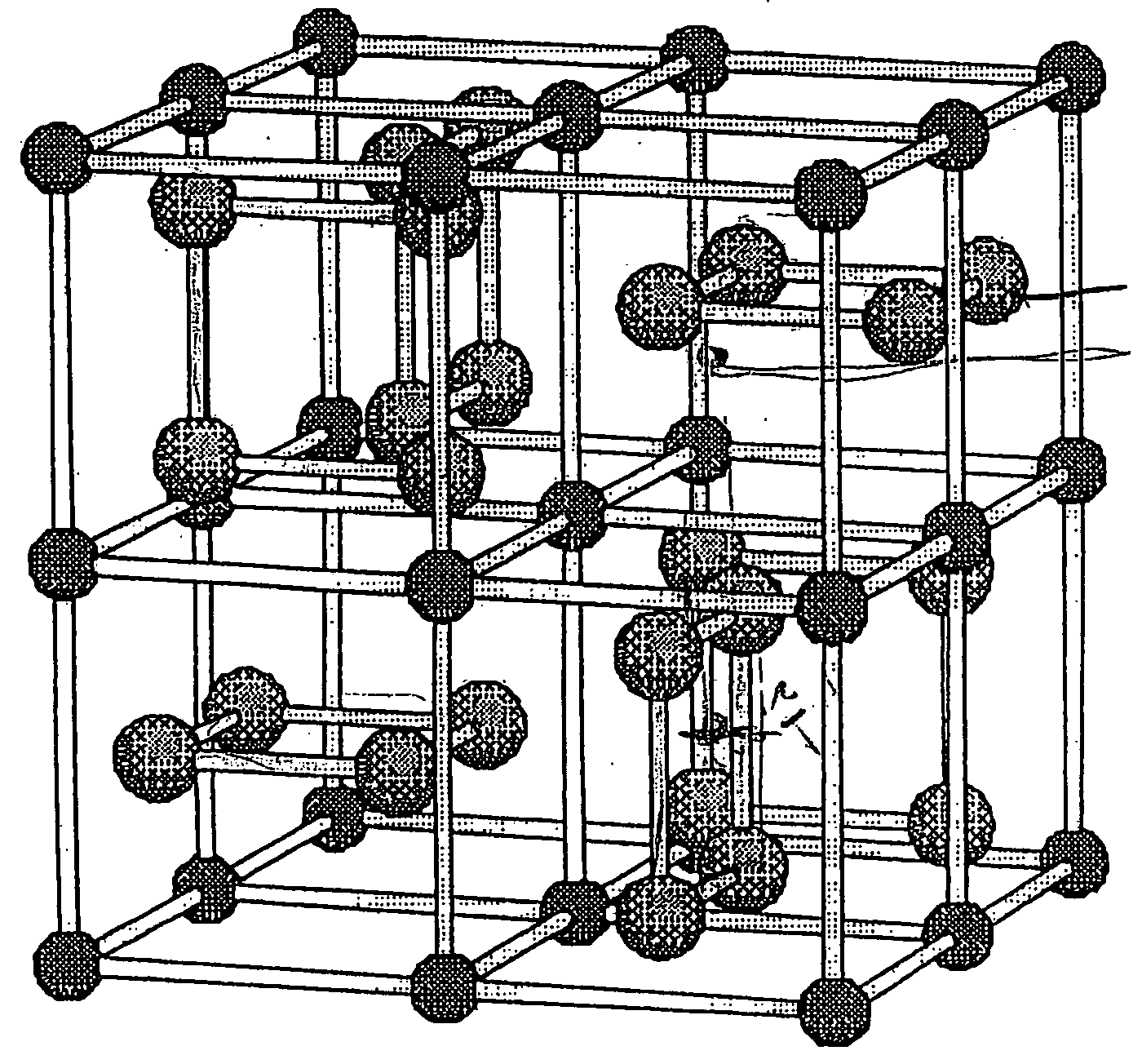

Named after the city of Skotterud, Norway, skutterudite is a cobalt arsenide mineral containing variable amounts of nickel and iron substituting for cobalt with a general formula: CoAs₃. Some references give the arsenic a variable formula subscript of 2-3. High nickel varieties are referred to as nickel-skutterudite, previously chloanthite. It is a hydrothermal ore mineral found in moderate to high temperature veins with other Ni-Co minerals. Associated minerals are arsenopyrite, native silver, erythrite, annabergite, nickeline, cobaltite, silver sulfosalts, native bismuth, calcite, siderite, barite and quartz. It is mined as an ore of cobalt and nickel with a by-product of arsenic.

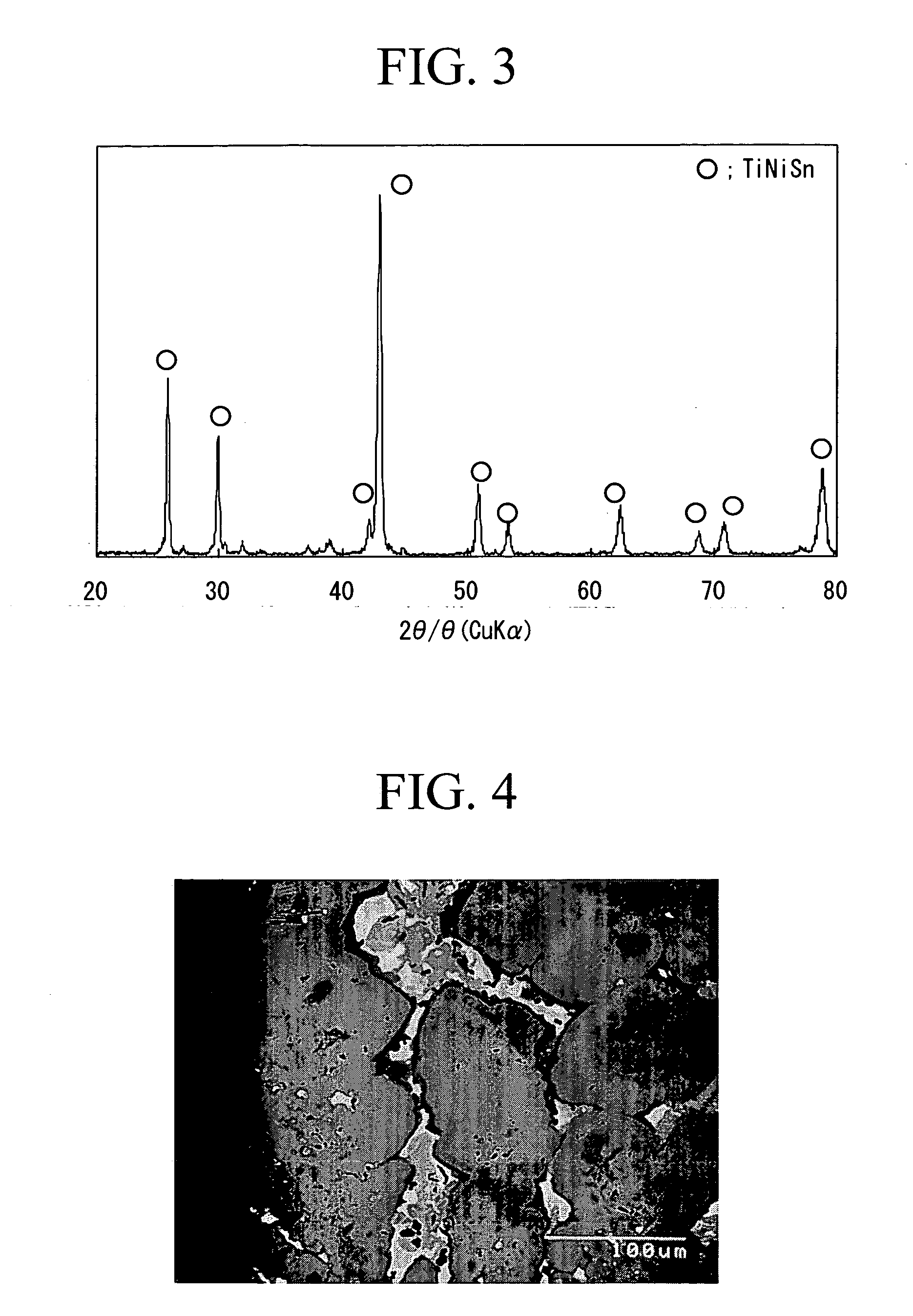

Process for producing thermoelectric semiconductor alloy, thermoelectric conversion module, thermoelectric power generating device, rare earth alloy, producing process thereof, thermoelectric conversion material, and thermoelectric conversion system using filled skutterudite based alloy

InactiveUS20070034245A1Improve power generation efficiencyEffective measure against global warmingThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSkutteruditeSemiconductor alloys

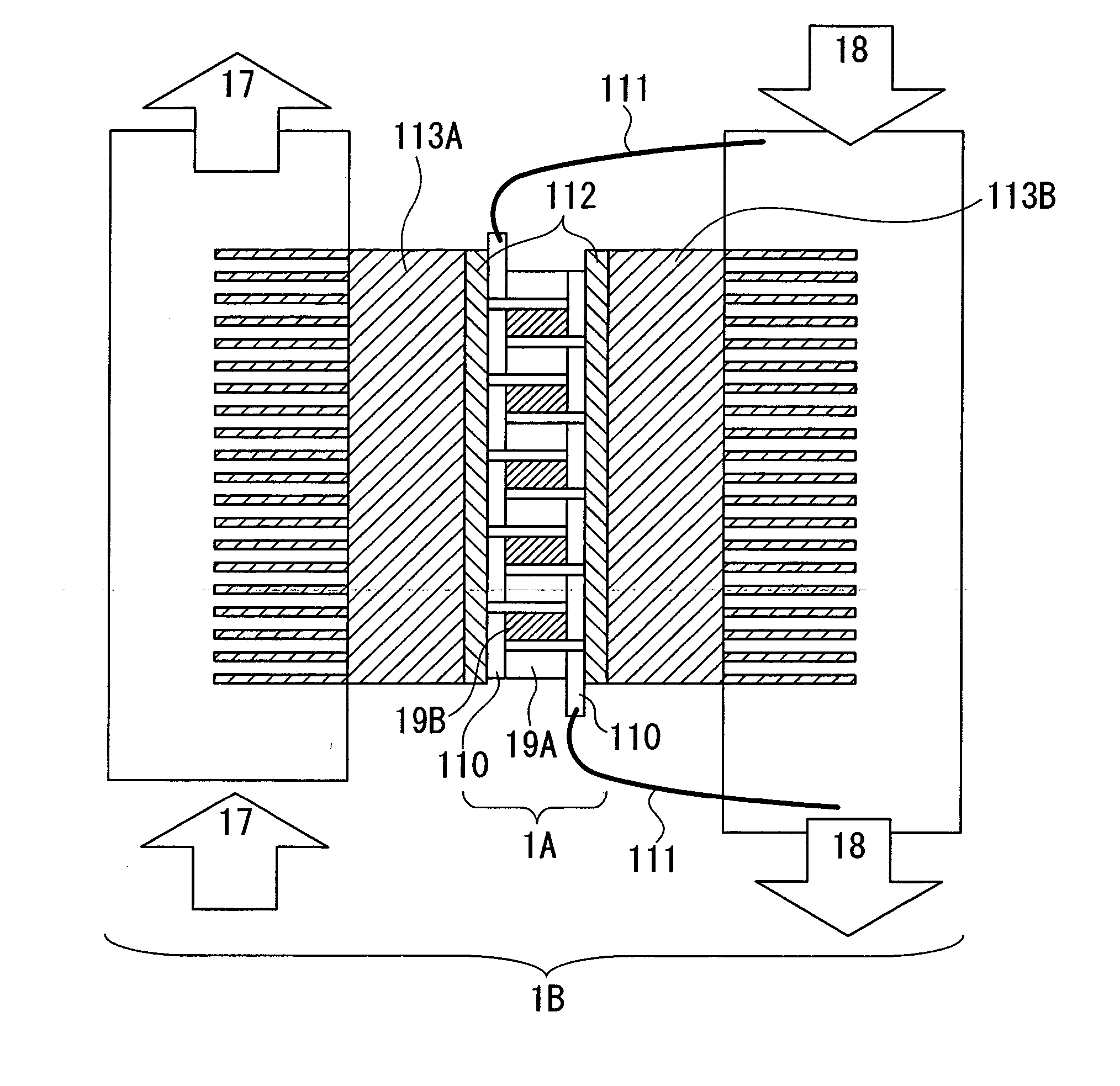

The present invention is a process for producing a rare earth alloy including heating a raw material alloy which is compounded so as to have a composition represented by the formula: A3−XBXC (wherein A and B each is at least one member selected from transition metals consisting of Fe, Co, Ni, Ti, V, Cr, Zr, Hf, Nb, Mo, Ta and W, and C is at least one member selected from Group 13 or 14 elements consisting of Al, Ga, In, Si, Ge and Sn) to be a molten ally, and quench-solidifying the molten alloy at a cooling rate of 1×102 to 1×103° C. / sec.

Owner:SHOWA DENKO KK

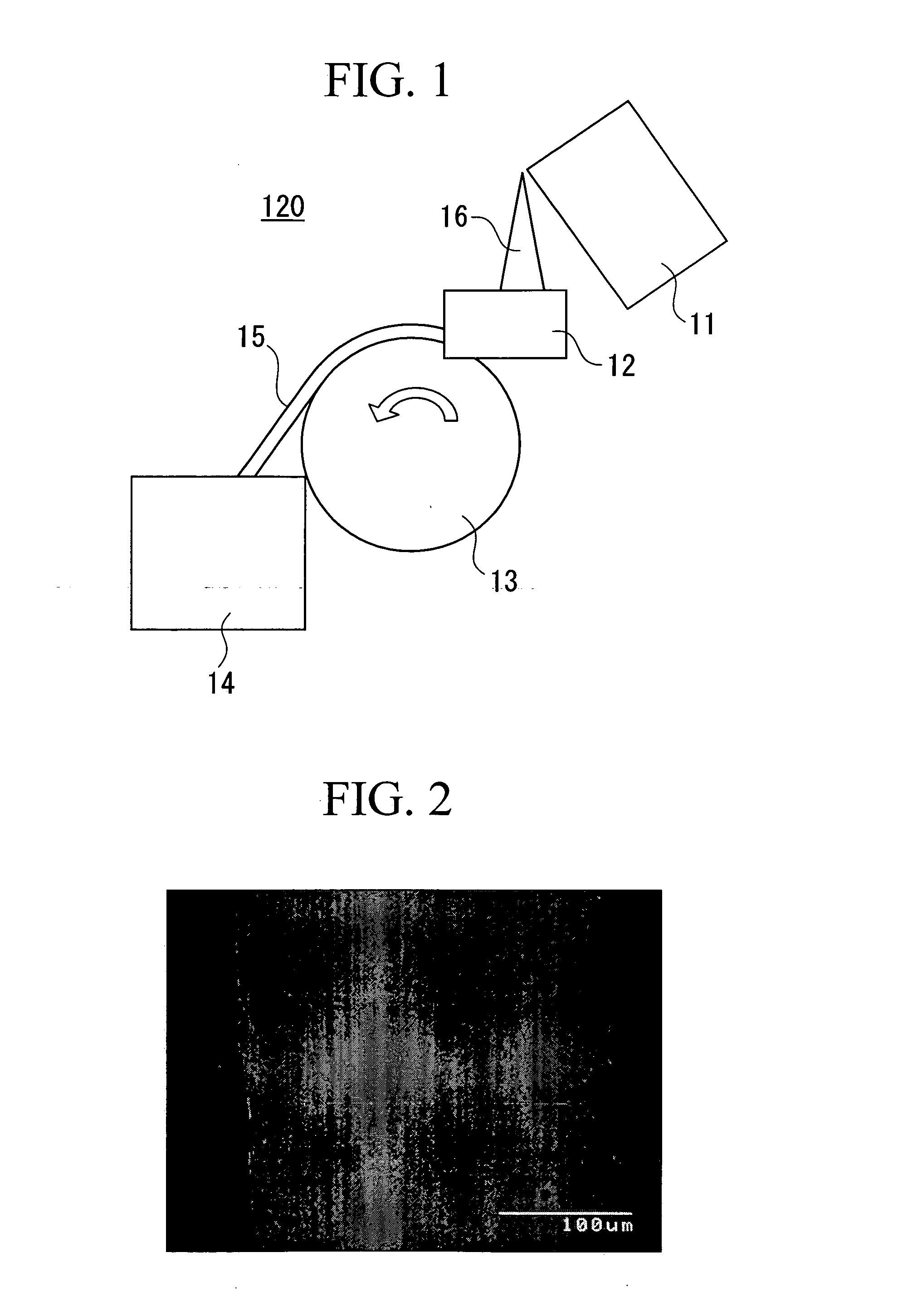

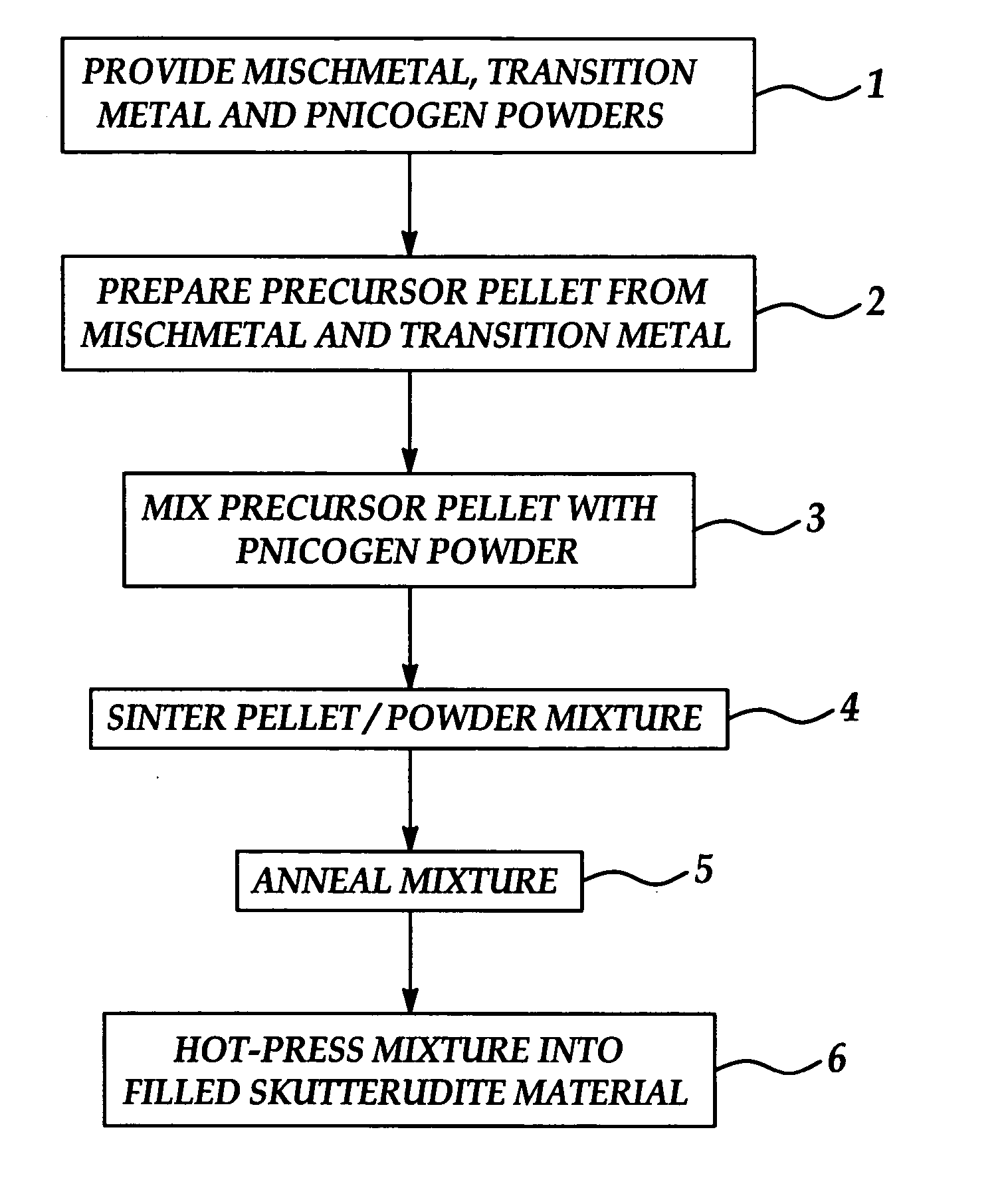

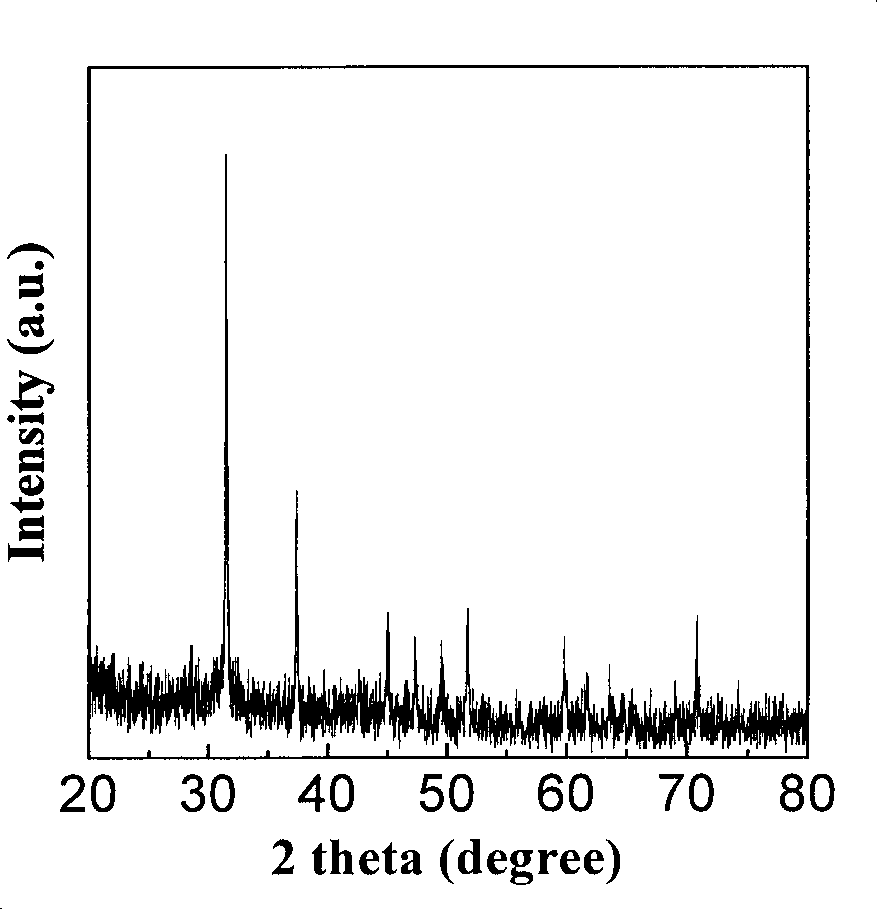

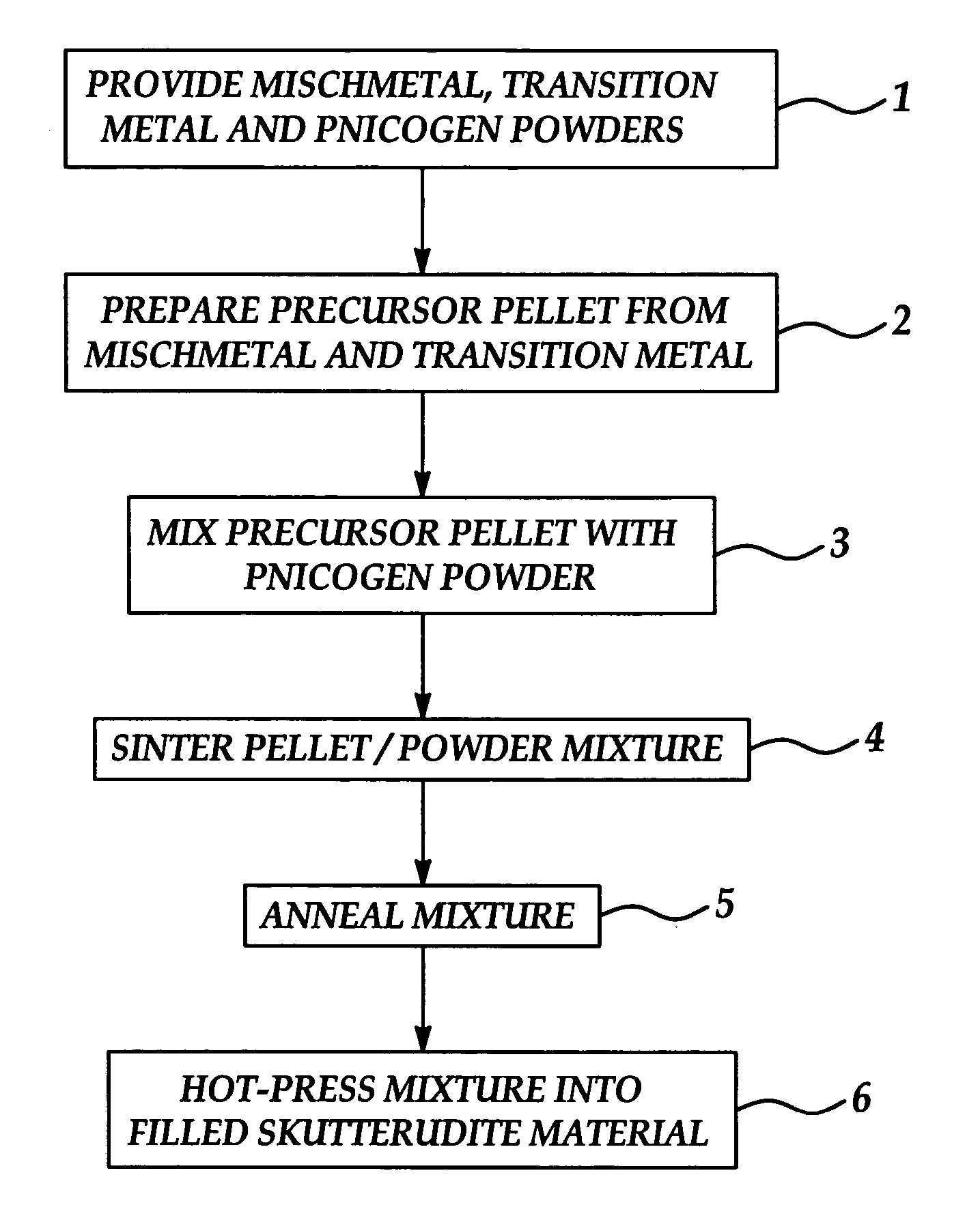

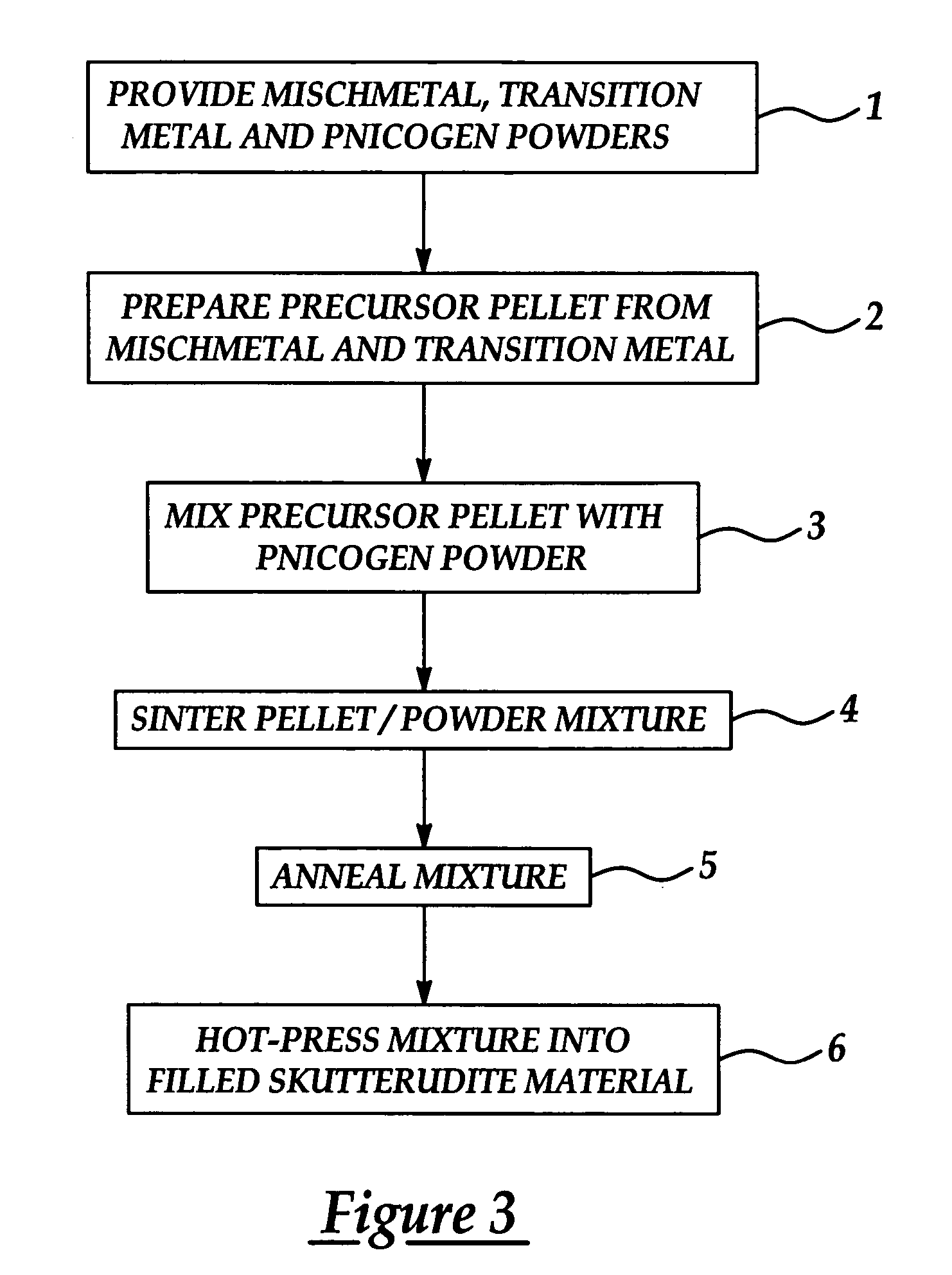

Filled skutterudites for advanced thermoelectric applications

ActiveUS20060016470A1Suitable for useThermoelectric device manufacture/treatmentThermoelectric device junction materialsMischmetalRare-earth element

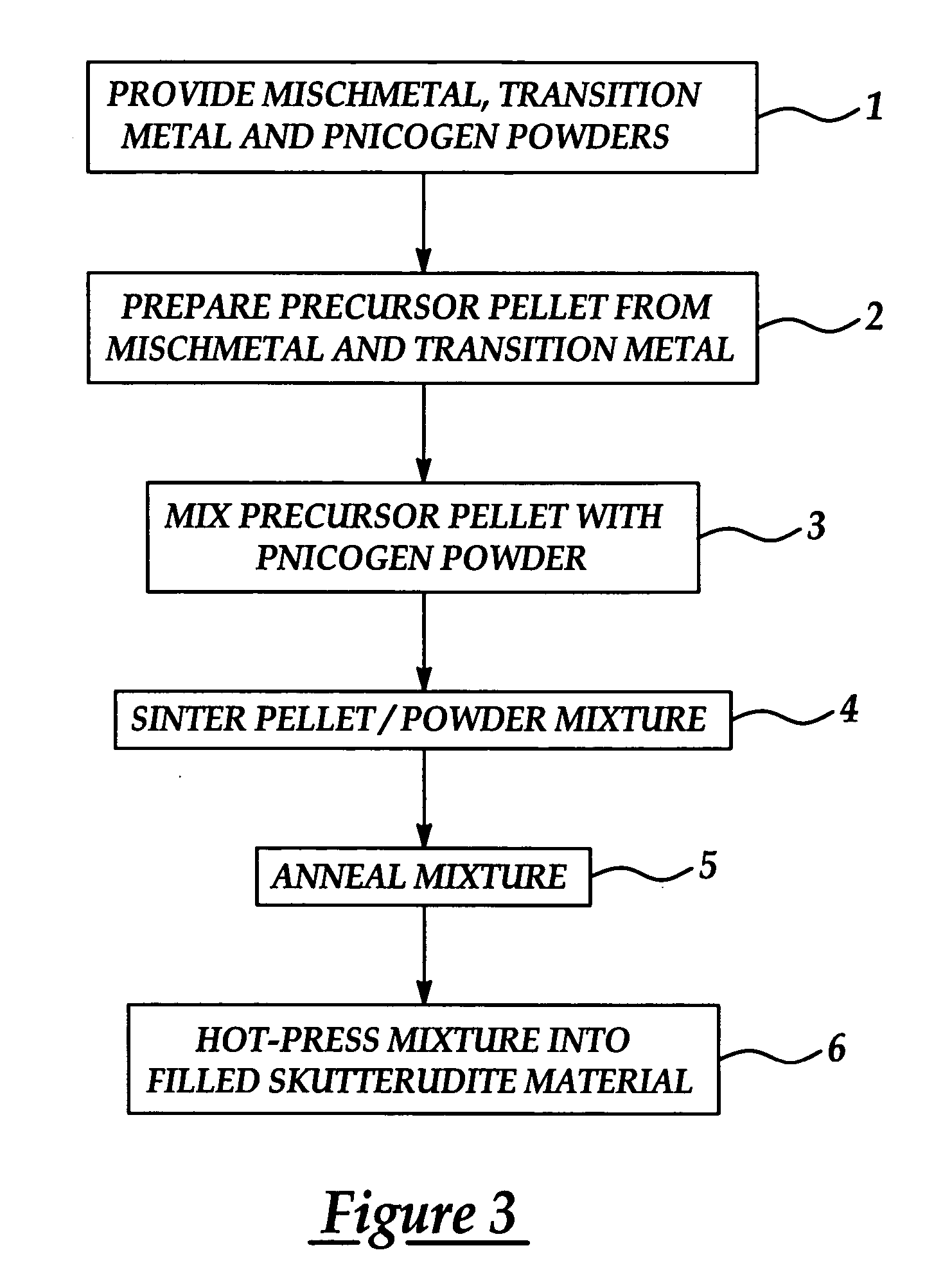

A low-cost filled skutterudite for advanced thermoelectric applications is disclosed. The filled skutterudite uses the relatively low-cost mischmetal, either alone or in addition to rare earth elements, as a starting material for guest or filler atoms.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for preparing skutterudite base thermoelectric block body material

The invention discloses a preparation method of a skutterudite group thermoelectricity lump material, which adopts the combination of solvent thermosynthesis and vacuum melting. In the skutterudite MSb3, M equals to Co, Rh, and Ir, comprising the skutterudite MSb3; M bits or Sb bits-doped MSb3; Ag, Cu, Zn, Cd, Pb, Sn, Ga or In-filled MSb3; doped and filled MSb3 and MSb3 which is compounded with a second phase. The preparation method comprises the steps of: material blending, thermal reaction of the solvent, washing, thermal treatment and sealing melting. The invention discloses a preparation method of a skutterudite group thermoelectricity lump material compounded with the second phase, when adopting the method, second phase nano powder such as ZrO2 with the mass percentage of 0.05 percent to 5 percent is added for supplement in the step of the material blending. Compared with the existing commonly used spark plasma sintering or hot pressed sintering after simple substance mechanical alloying, or the plasma sintering or the hot pressed sintering after long-time high temperature solid phase reaction of the simple substance materials, the obtained materials are more compact and lower in cost.

Owner:TONGJI UNIV

High performance thermoelectric materials and their method of preparation

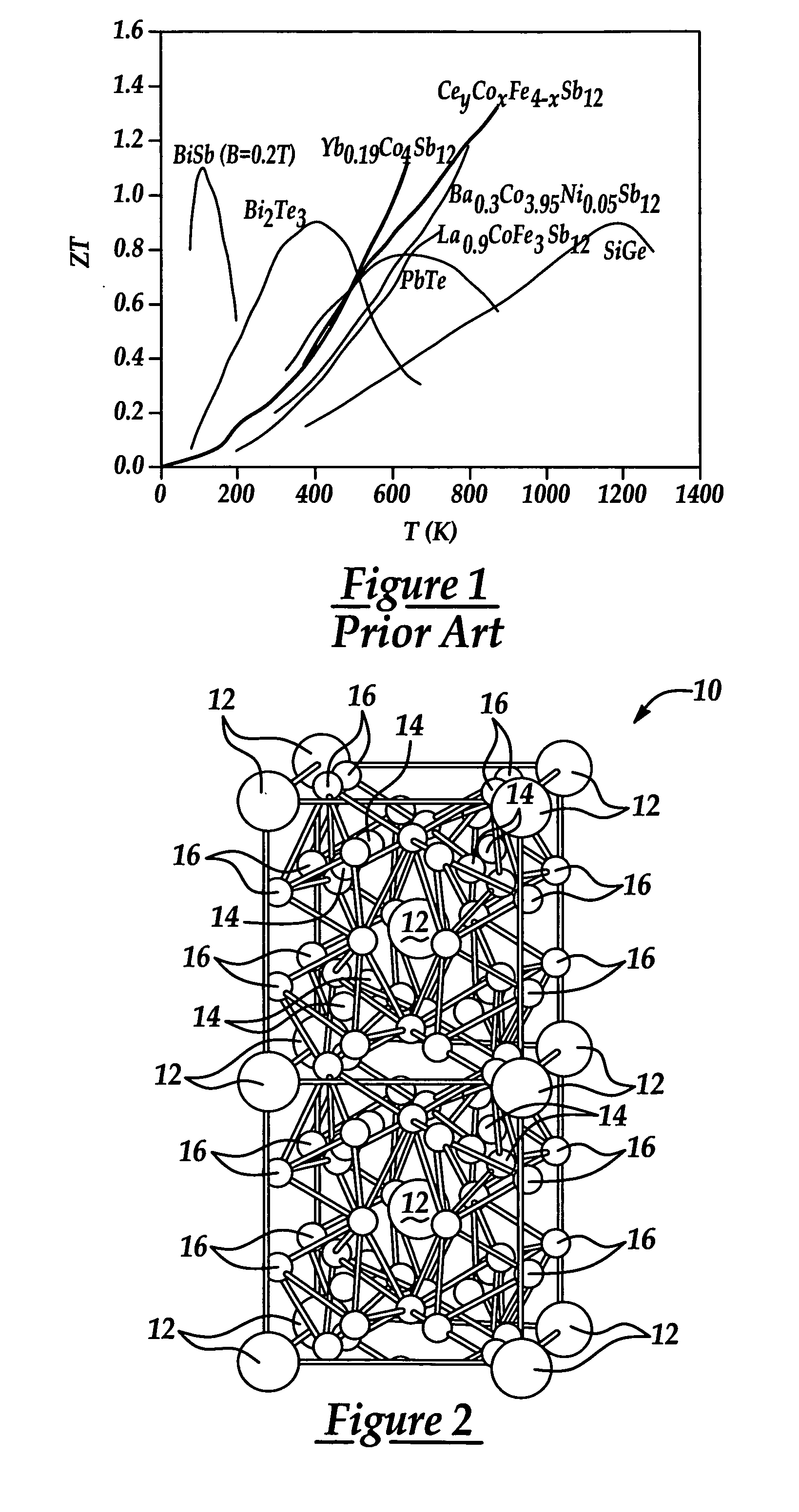

InactiveUS20050229963A1High quality factorCobalt compoundsMetal/metal-oxides/metal-hydroxide catalystsIndiumSkutterudite

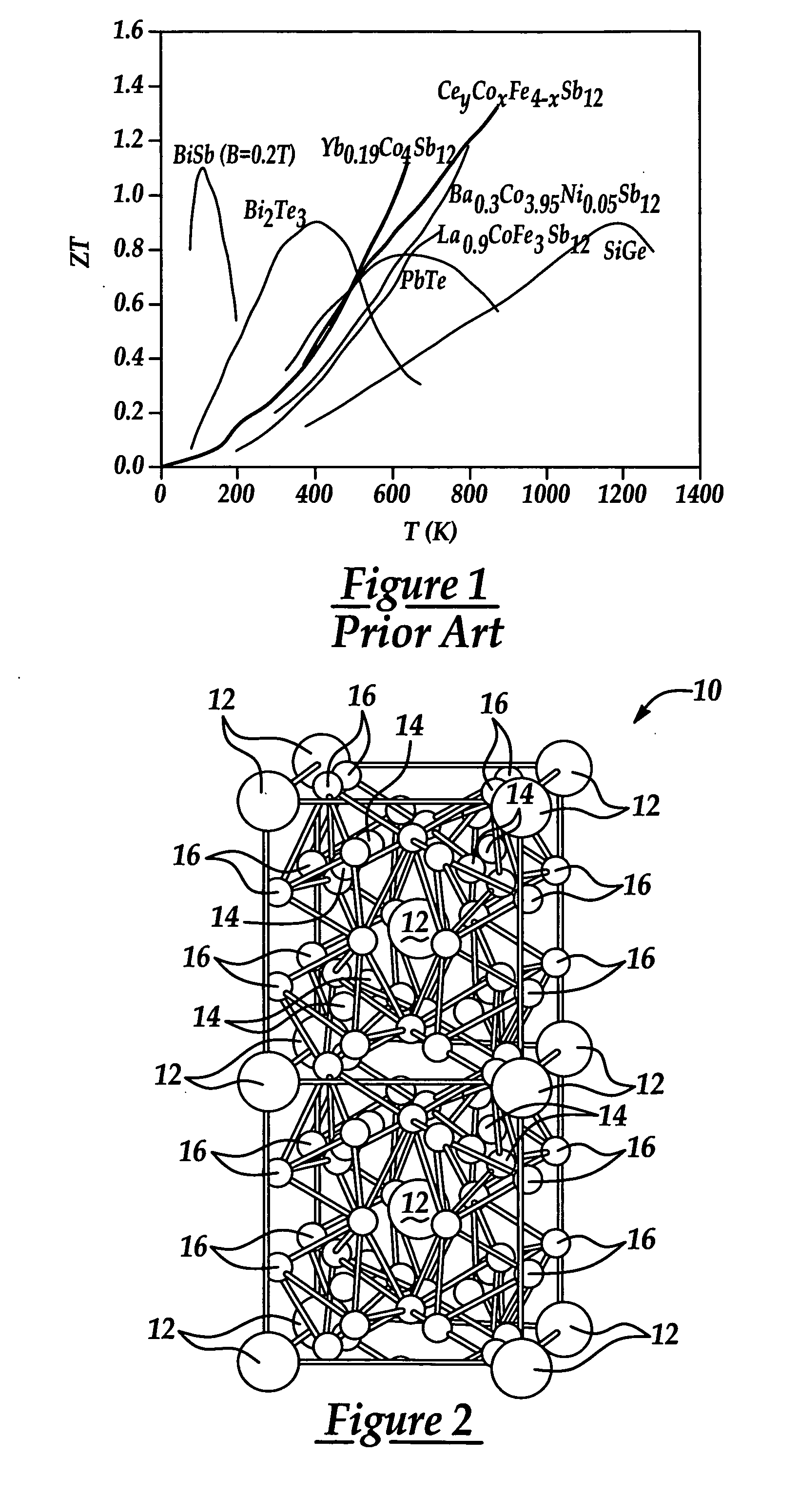

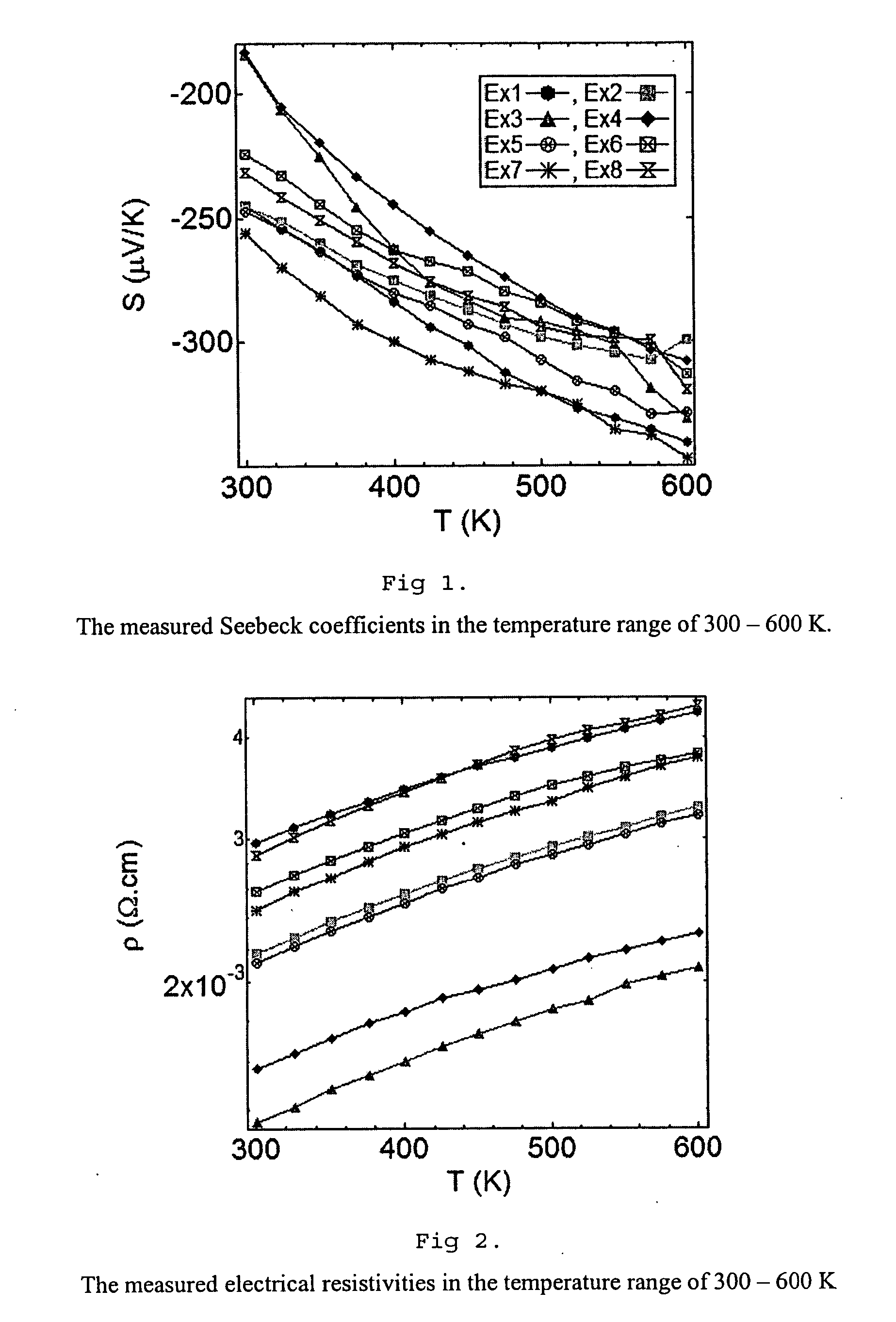

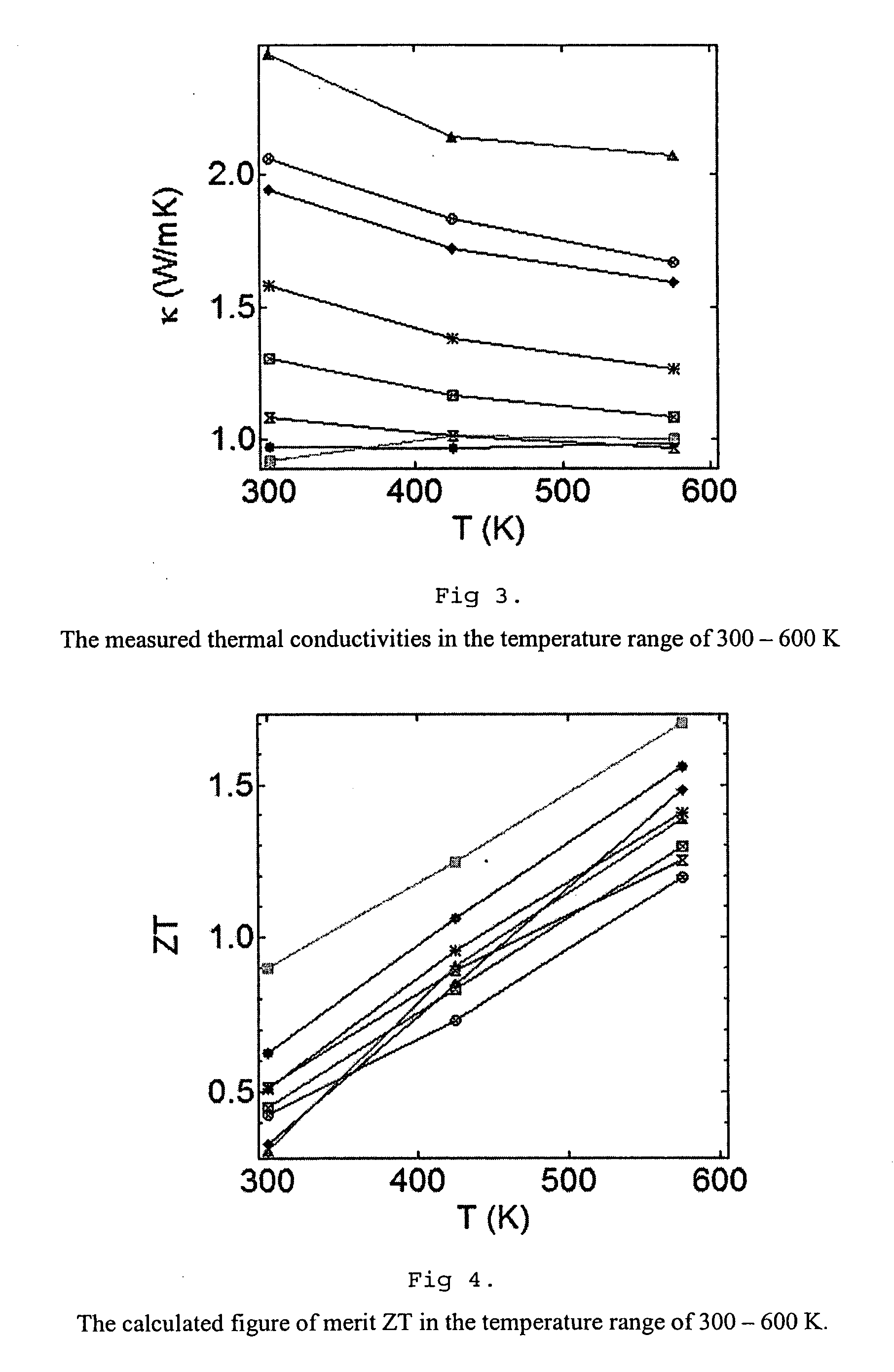

The present invention provides an indium-doped CO4Sb12 skutterudite composition in which some Co on the cubic lattice structure may be replaced with one or more members of the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt; some Sb on the planar rings may be replaced by one or more members of the group consisting of Si, Ga, Ge and Sn; and a second dopant atom is selected from a member of the group consisting of Ca, Sc, Zn, Sr, Y, Pd, Ag, Cd, Ba, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu. The composition is useful as a thermoelectric material. In preferred embodiments, the composition has a figure of merit greater than 1.0. The present invention also provides a process for the production of the composition, and thermoelectric devices using the composition.

Owner:EI DU PONT DE NEMOURS & CO

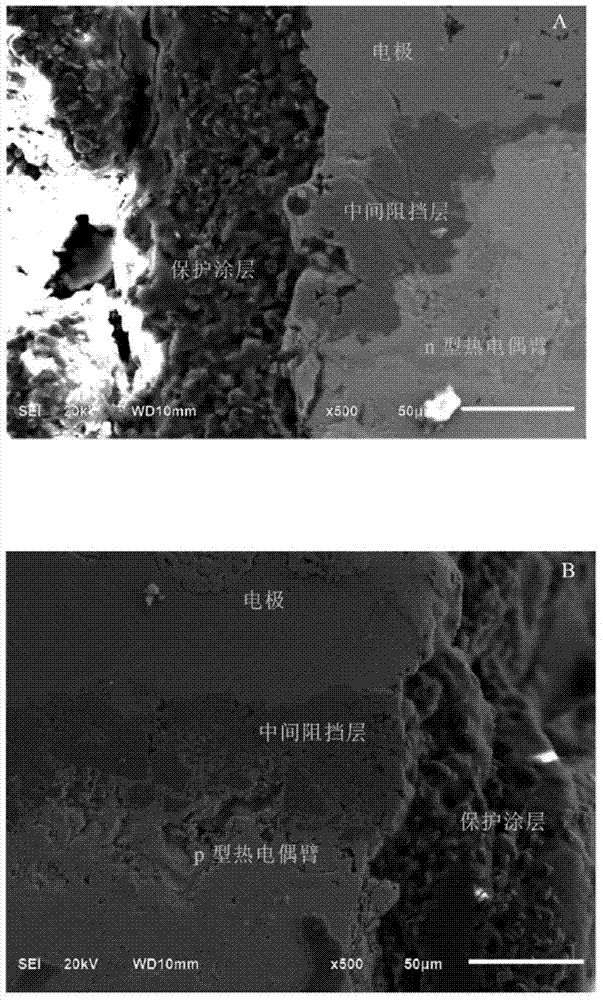

Skutterudite based thermoelectric material, thermal protection coating for devices and preparation method thereof

ActiveCN103146301AImprove heat resistance durabilityThickness is easy to controlCoatingsThermoelectric device detailsSkutteruditeMaterials science

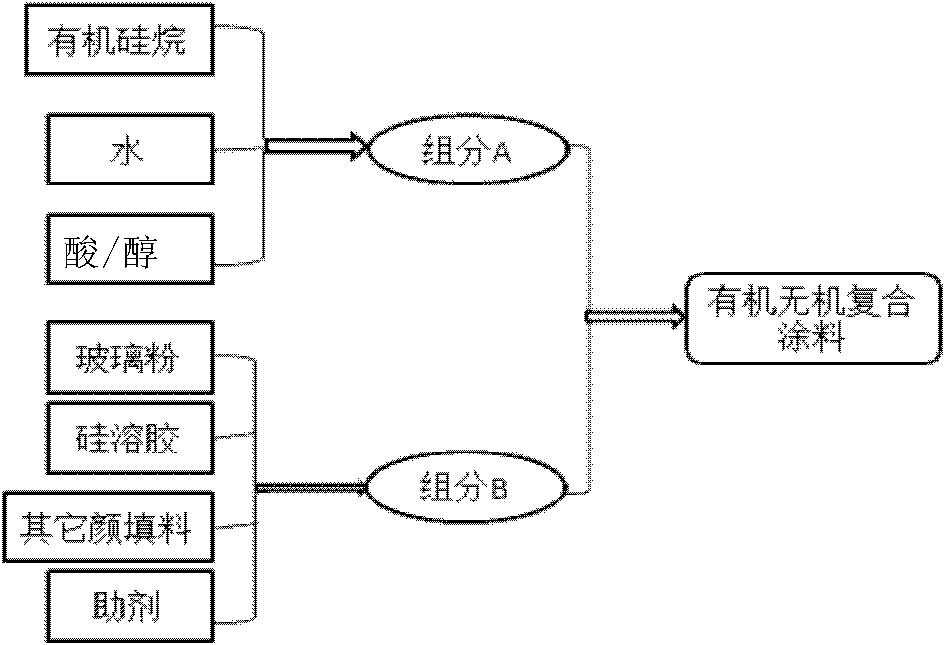

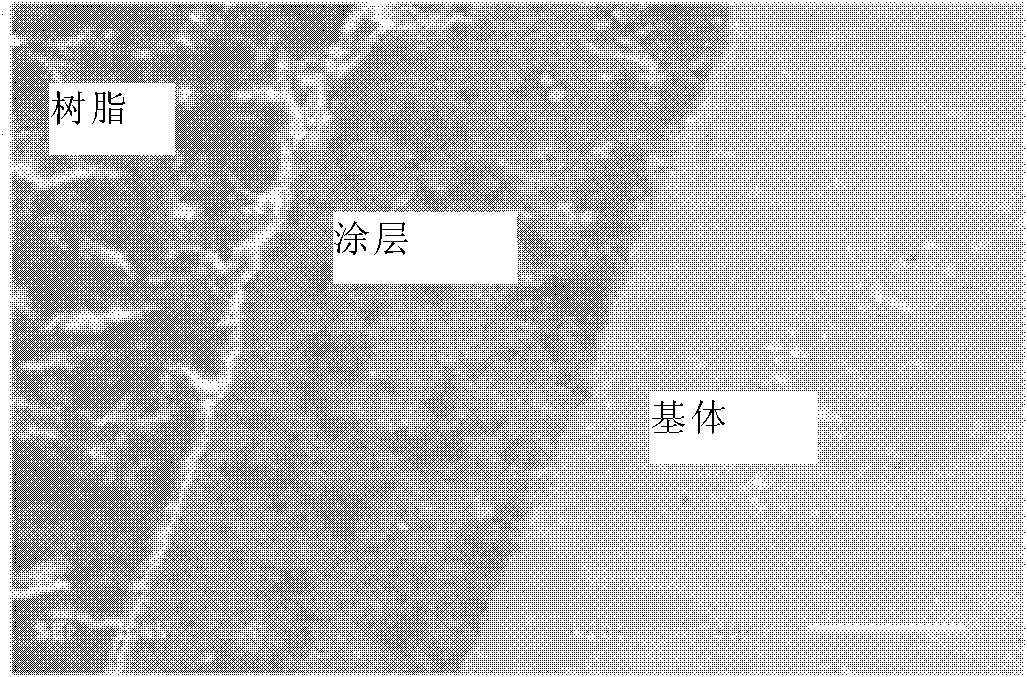

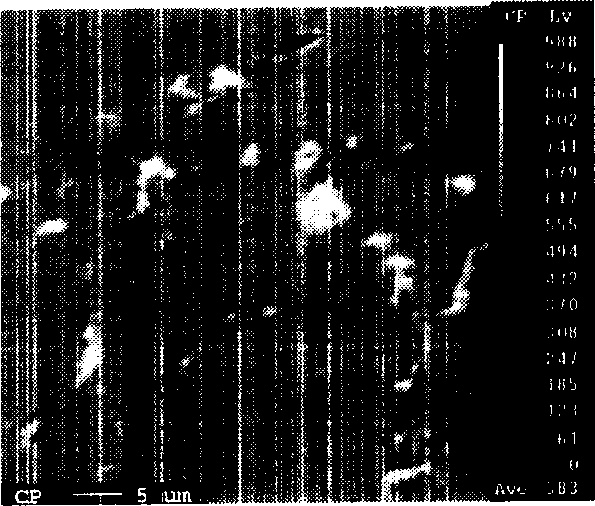

The invention relates to a skutterudite based thermoelectric material, a thermal protection coating for devices and a preparation method thereof. The skutterudite based thermoelectric material and the thermal protection coating for the devices comprise the following components: 20-80 weight parts of organosilane, 3-60 weight parts of silica sol, 3-55 weight parts of glass powder and 3-50 weight parts of water. The invention further provides the preparation method of the skutterudite based thermoelectric material and the thermal protection coating for the devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

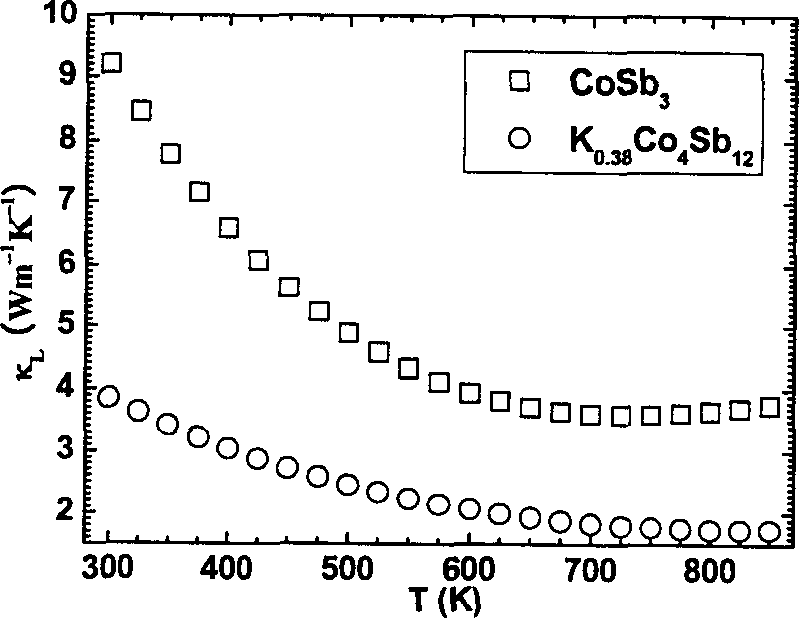

Filled skutterudite-base thermoelectrical composite material and its prepn

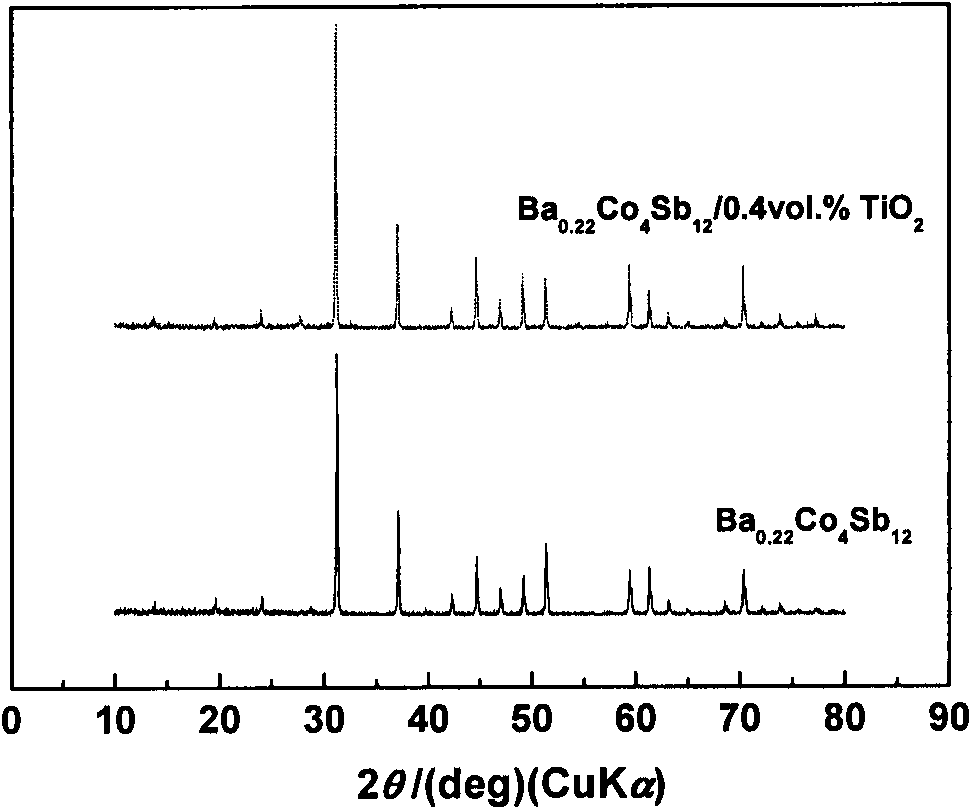

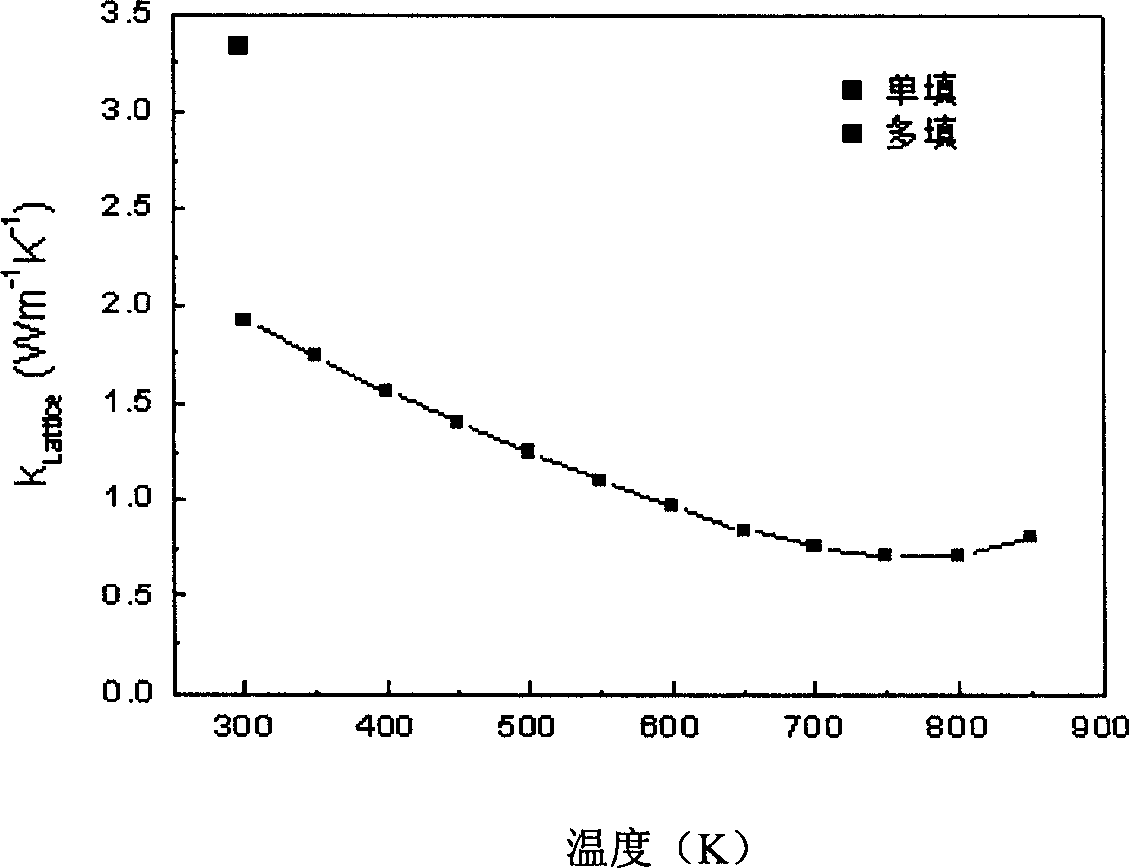

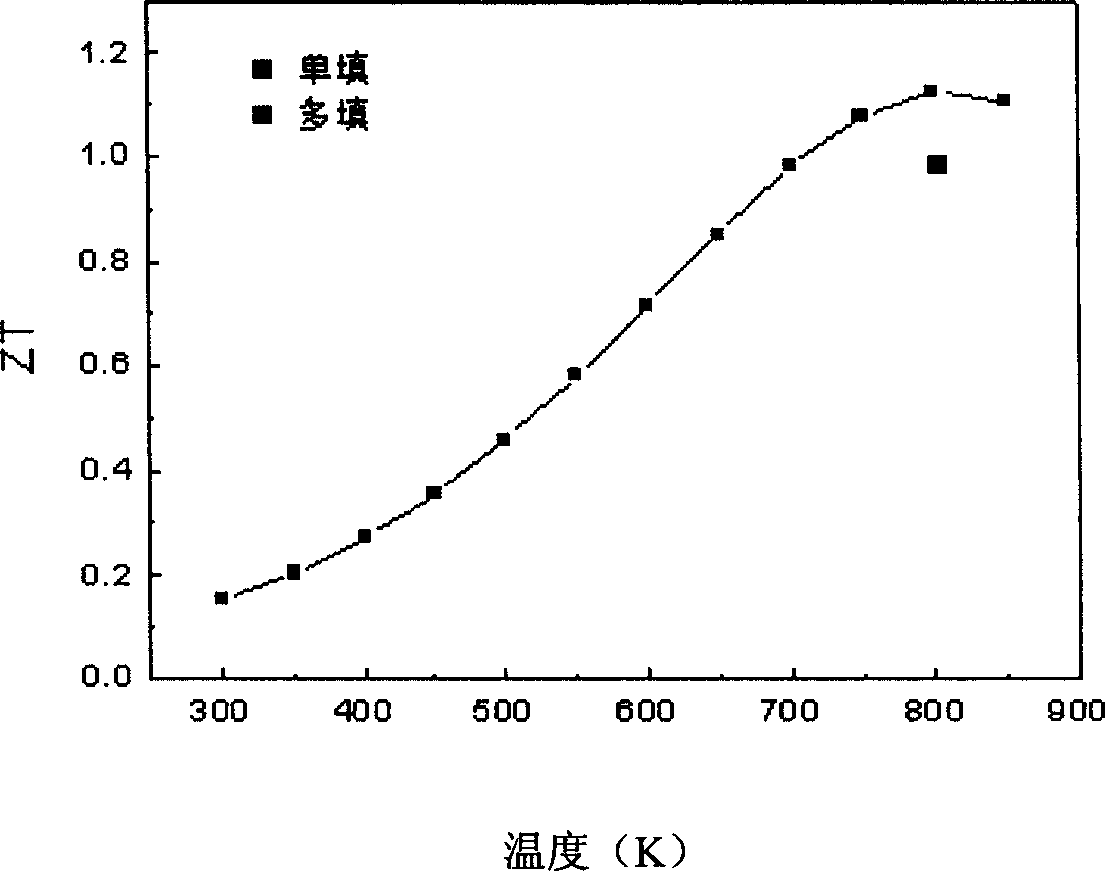

ActiveCN1888105ALower lattice thermal conductivityDoes not affect electrical transmission performanceMolten stateMechanical crushing

The present invention relates to filled skuterudite-base thermoelectrical composite material and its preparation process, and belongs to the field of thermoelectrical material preparing technology. The thermoelectrical composite material has the composition of IyA4B12 / zIOx, where I is one of Yb, Eu, Ce, La, Nd, Ca and Sr; A is Sb or its mixture with one of Ge, Sn, Te and Se; B is Co or its mixture with Fe or Ni; y is the amount of I element, y+z=m, and m is greater than the filling limit of filling atom. The thermoelectrical composite material is prepared through first smelting process to produce block material, the subsequent mechanical crushing and grinding to obtain powder, and the final fast sintering with pulse DC current to form compact block. The material has lowered lattice heat conductivity, maintained electric transmission performance and raised thermoelectrical conversion performance.

Owner:中科西卡思(苏州)科技发展有限公司

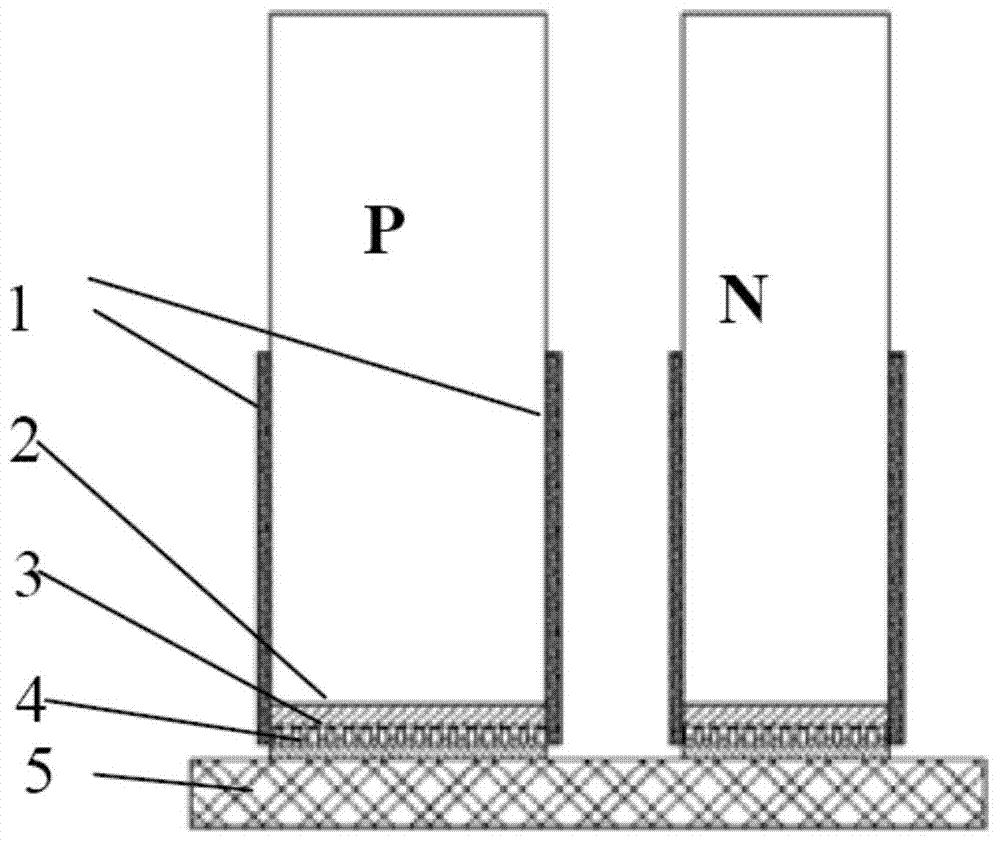

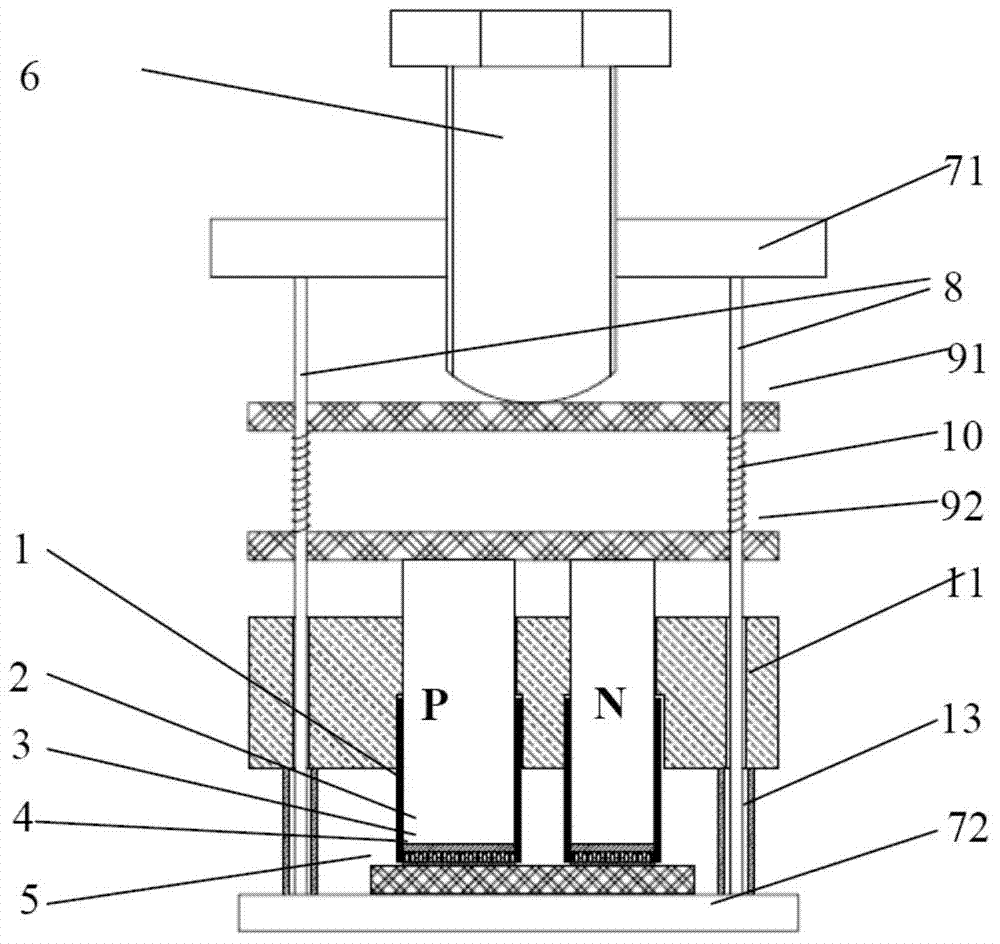

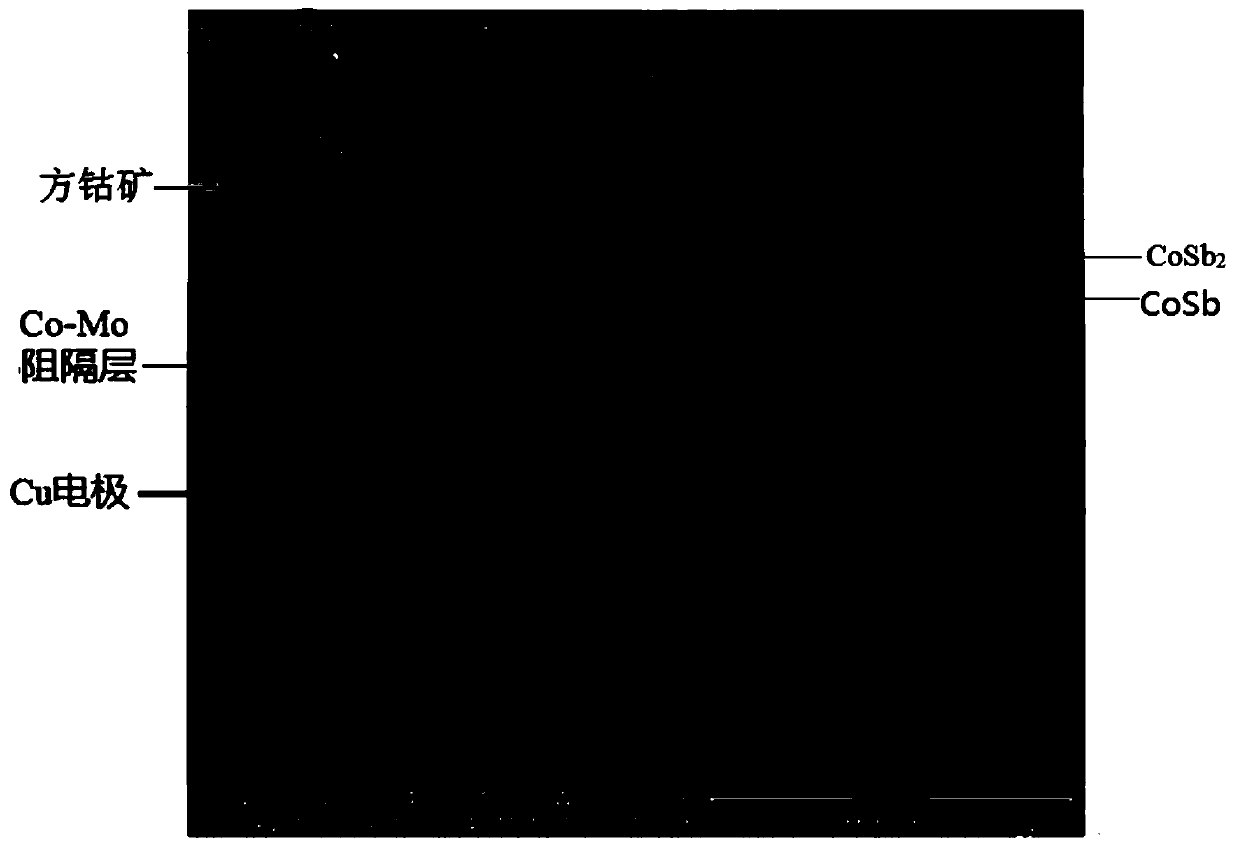

Electrode and packaging material for skutterudite thermoelectric unicouple component and step method connection technology

ActiveCN103531704APrevent oxidationReduce thermal stress matchingThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSkutteruditeProtection layer

The invention provides a coating for a thermoelectric unicouple component. The thermoelectric unicouple component comprises a high-temperature end and a low-temperature end; the coating is a glass protection layer, and the high-temperature end of the thermoelectric unicouple component is coated with the coating; and the glass softening temperature of the glass protection layer is close to the electrode welding temperature of the high-temperature end of the thermoelectric unicouple component. The invention further provides the corresponding thermoelectric unicouple component and a preparation method of the thermoelectric unicouple component.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Pyroelectric material with quadruple skutterudite structure and preparation method thereof

InactiveCN101350394AIncrease the doping concentrationLow thermal conductivityThermoelectric device junction materialsSkutteruditeGroup element

A pyroelectric material of a quaternary skutterudite structure and a method for preparing the material, the chemical formula of the material is that CoSb3+delta-x-yXxYy, wherein the X is Se or Te, the Y is Ge or Sn, the delta is Sb compensation, and the x and the y are respectively the doping quantity of the X and the Y. The material is characterized by simultaneously doping IVB group and VIB group elements into CoSb3, and the material utilizes the charge compensation between the IVB group and the VIB group elements to increase the whole doping concentration, and introduces more point defect scatterings to reduce the heat conductivity. Under a proper condition, a CoX1.5Y1.5 phase can be separated from a Co-Sb-X-Y basal body and 'nanometer points' can be formed, and the additional scattering action can be generated to the phonon transport. The invention adopts the method of combining the mechanical alloying and the spark discharging plasma sintering, and prepares Co-Sb-X-Y quaternary materials with high pyroelectricity, and the non-dimensional value ZT of the material can reach 1.1 at 550 DEG C.

Owner:TSINGHUA UNIV

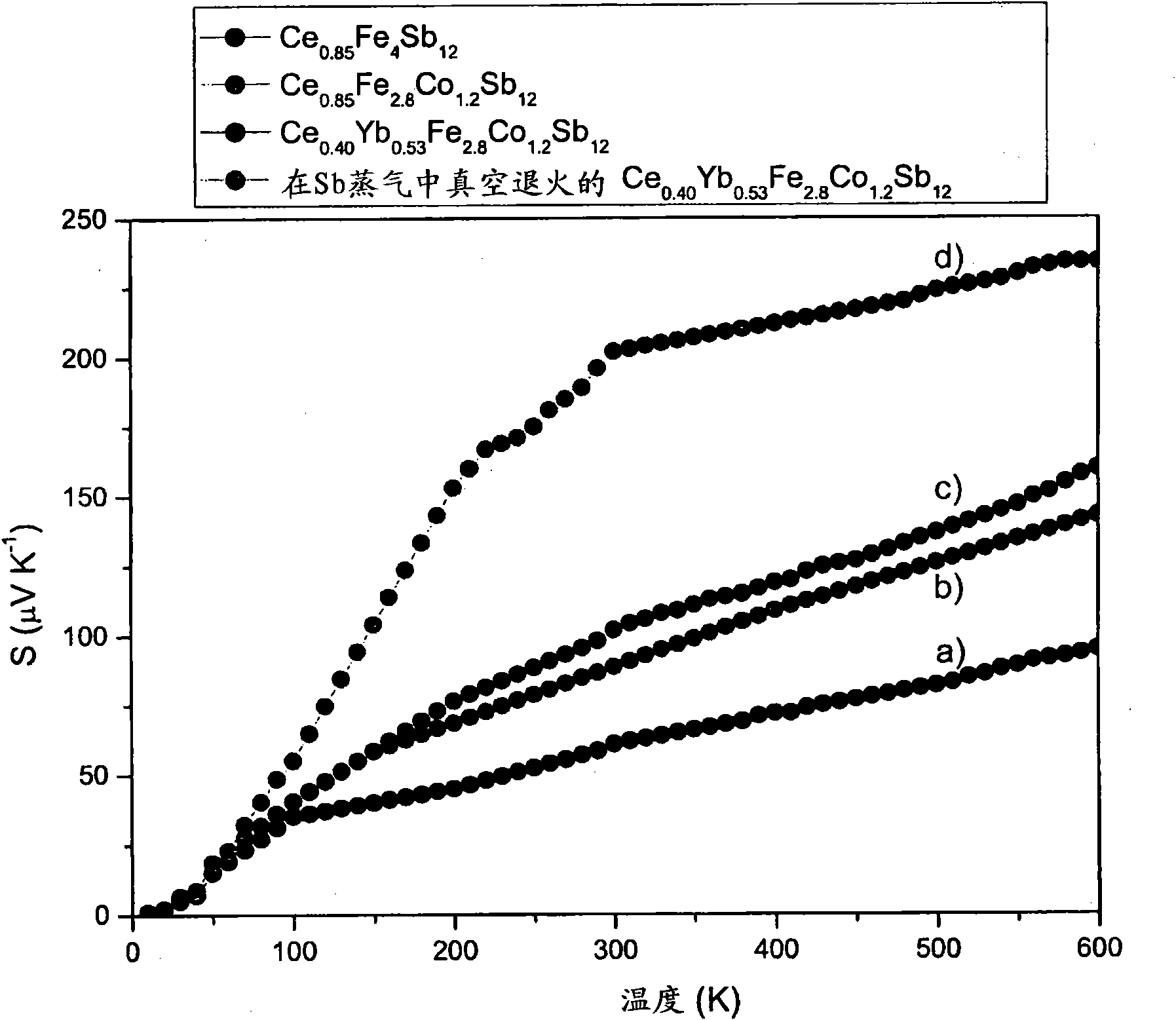

Method for preparing p-type filling type skutterudite compound thermoelectric material

InactiveCN101693962AOmit premeltingPrevent deviationThermoelectric device junction materialsSkutteruditeArgon atmosphere

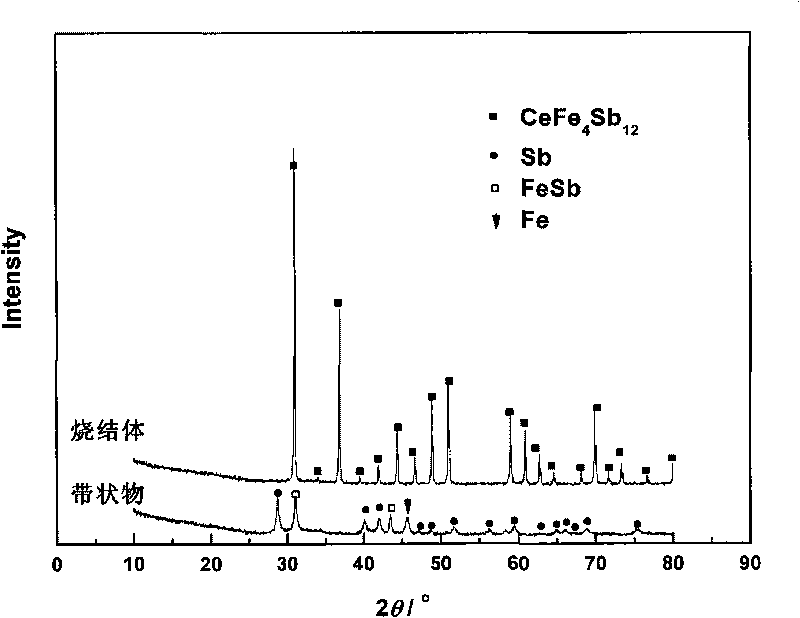

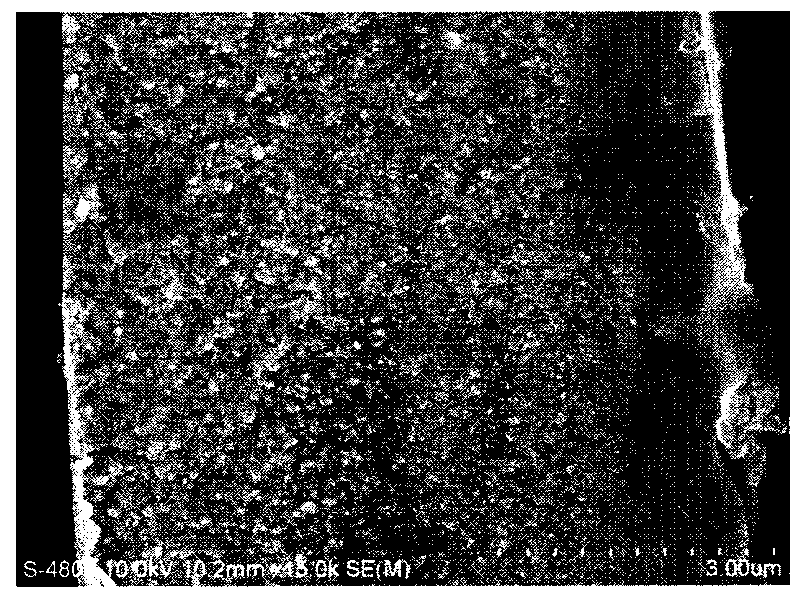

The invention belongs to the field of new energy materials, and particularly relates to a method for preparing filling type skutterudite thermoelectric compound. A method for preparing the p-type filling type skutterudite compound thermoelectric material comprises the following steps: firstly, taking high-purity granule type M, Fe, Co and Sb as starting reaction materials, weighing reaction raw materials in an Ar gas glove box according to the chemical formula MFe4-xCoxSb12+y, wherein 0<=x<=3, 0<=y<=1.0, mixing the high purity granule type M, Fe, Co and Sb, then, pressing into columnar blocks under the pressure of 300 to 400MPa, secondly, melting columnar blocks, swinging melted welding flux in argon atmosphere, obtaining belt-shaped products, thirdly, sintering in vacuum through a discharge plasma sintering method after coarsely grinding and pressing the belt-shaped products tightly, and obtaining single-phase compact p-type filling type skutterudite compound thermoelectric material. The method for preparing p-type filling type skutterudite compound thermoelectric material has the characteristics of simple technique, short reaction time, low energy consumption, excellent repeatability, and the like.

Owner:WUHAN UNIV OF TECH

Graphene compounded with stibine cobalt base skutterudite thermoelectric material and preparation method of material

ActiveCN102931335AReduce the temperatureShorten the timeThermoelectric device manufacture/treatmentThermoelectric device junction materialsRare-earth elementAlkaline earth metal

The invention relates to a graphene compounded with stibine cobalt base skutterudite thermoelectric material and a preparation method of the graphene compounded with stibine cobalt base skutterudite thermoelectric material. The chemical general expression of the material is MxCo 4 Sb 12 / graphene, wherein x is greater than or equal to 0 and less than or equal to 1, M is one of a rare earth element, alkali earth metal, alkali metal, Ga and Tl, and the content of the graphite olefine is less than 3%. The preparation method comprises the following steps of: (1) weighing M, cobalt and antimony, then mixing with a carbon nanometer pipe, and carrying out ball milling under inert gas shielding; and (2) placing the obtained substances in a graphite jig, and carrying out discharge plasma sintering under the inert gas shielding, thus obtaining the graphene compounded with stibine cobalt base skutterudite thermoelectric material. The graphene compounded with stibine cobalt base skutterudite thermoelectric material and the preparation method of the graphene compounded with stibine cobalt base skutterudite thermoelectric material have the advantages of simple preparation technology, short preparation time, easiness in control, good repeatability, low cost and good industrialization prospect; and the obtained material has a good pyroelectricity property.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

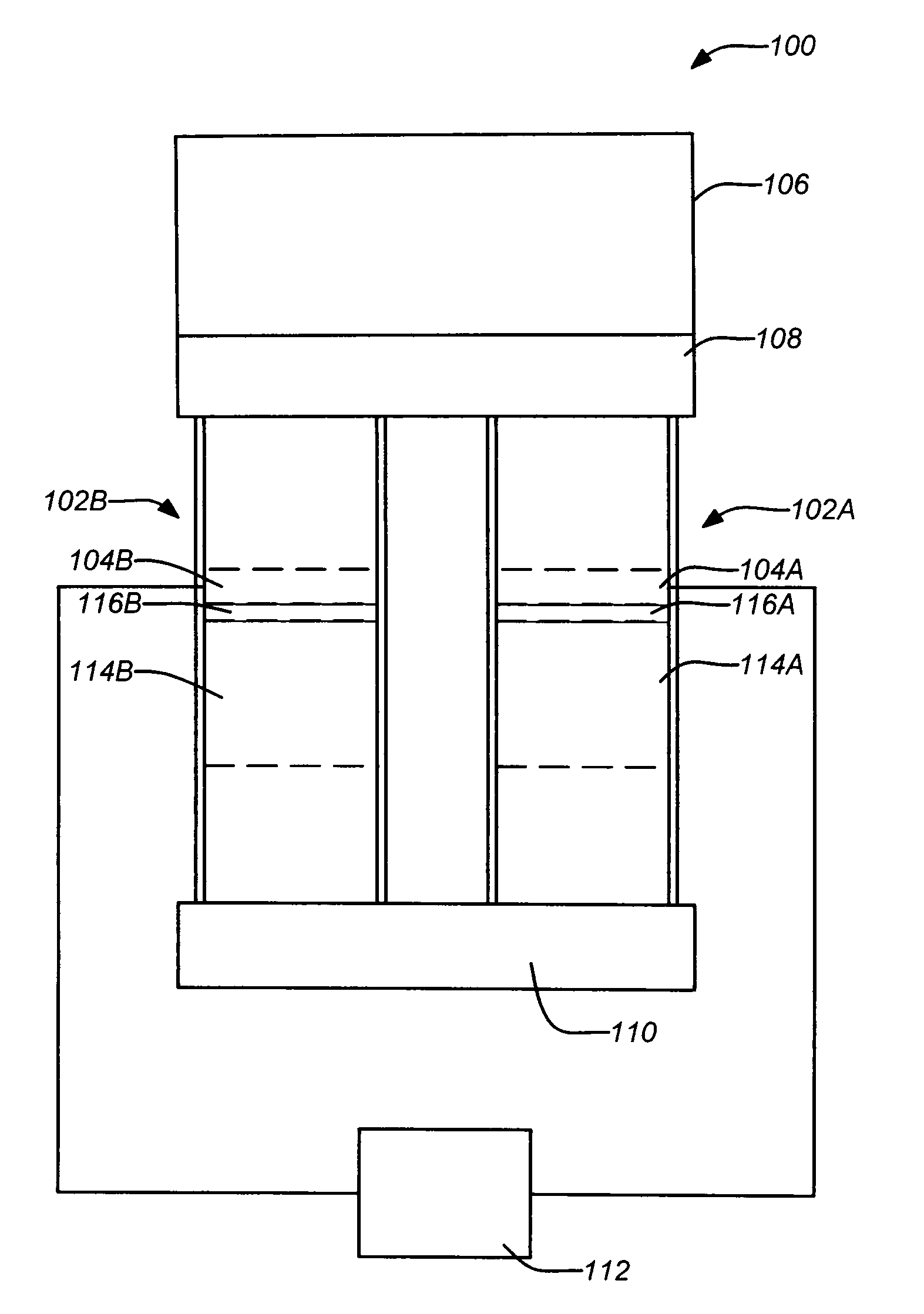

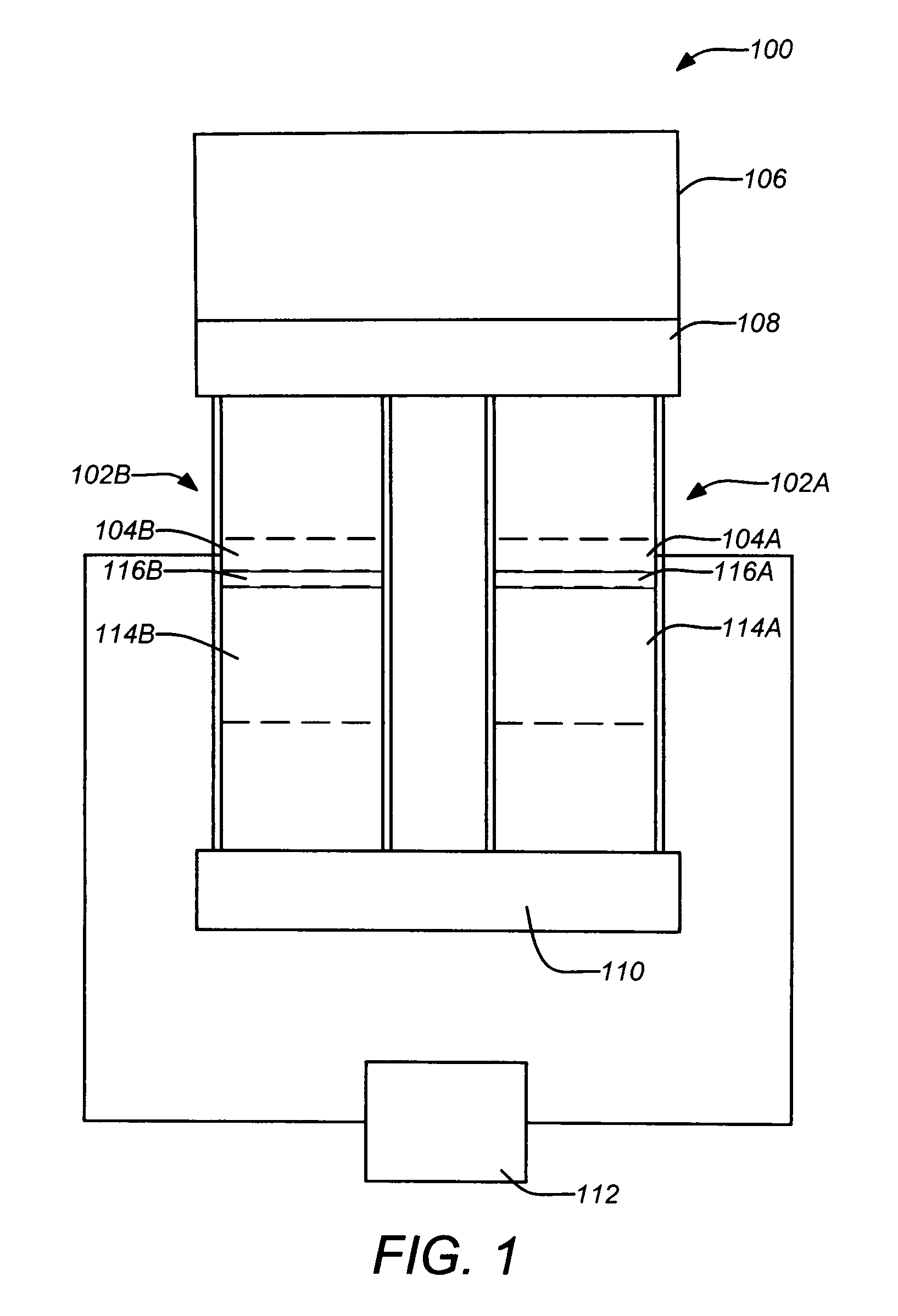

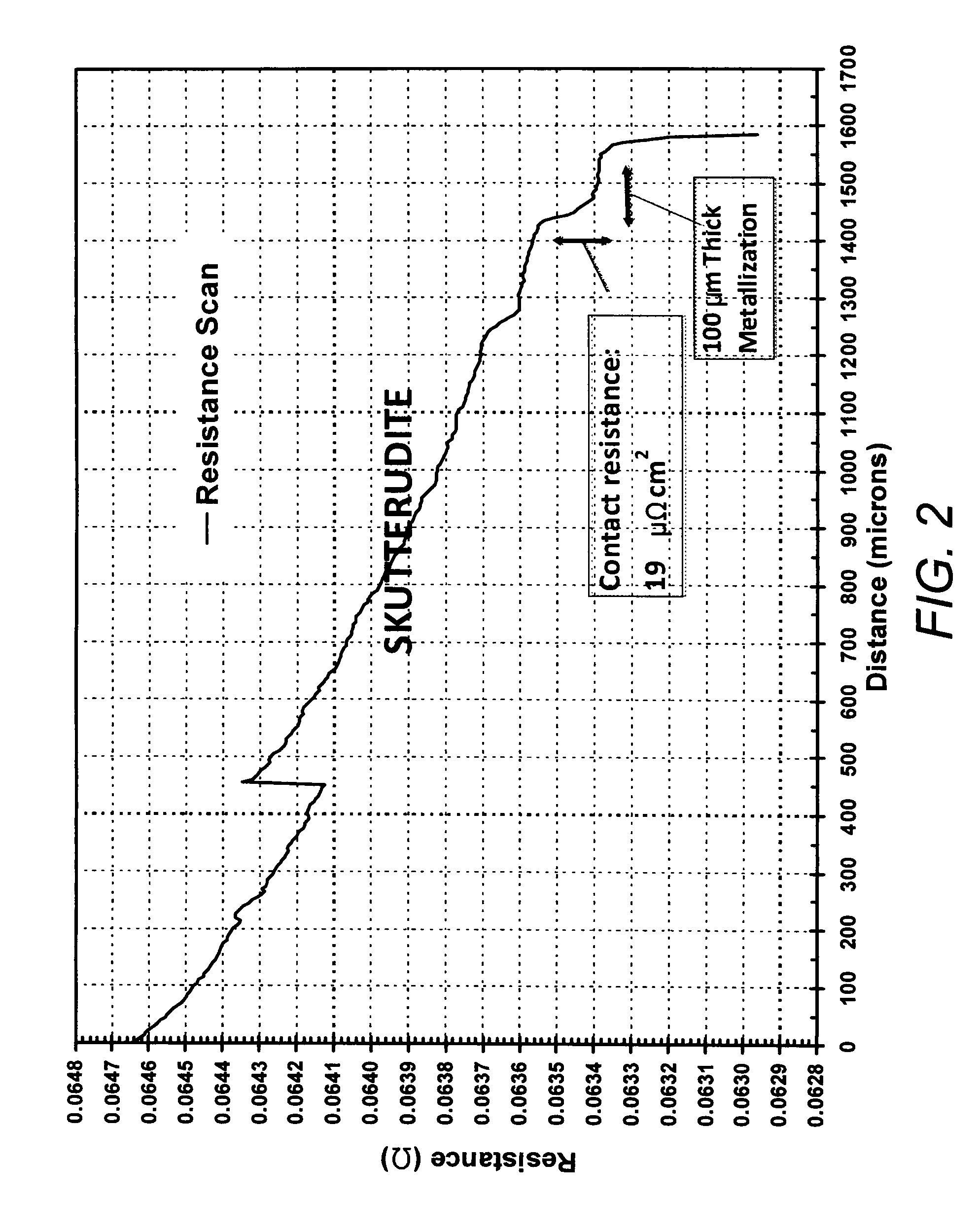

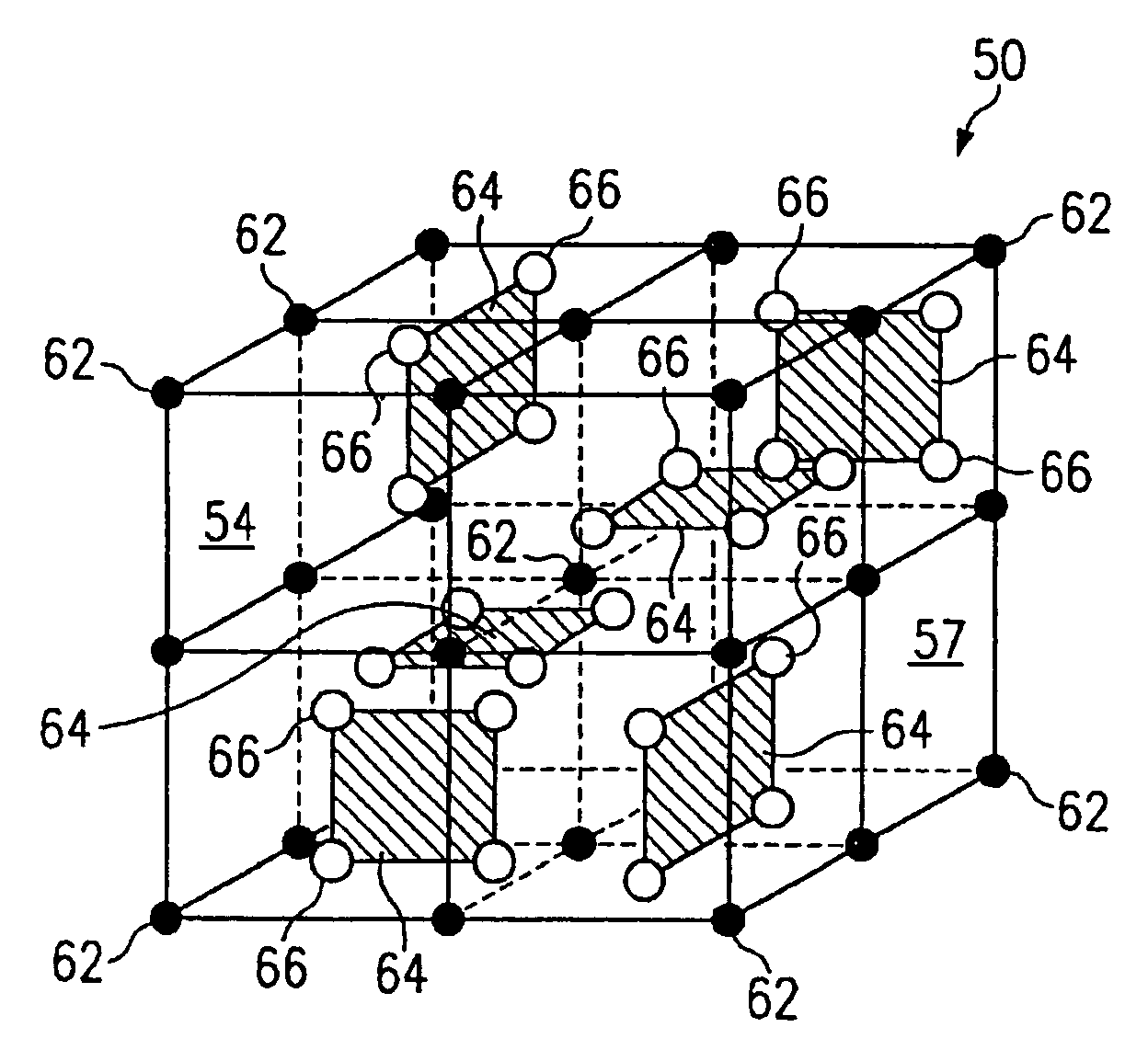

Electrical contacts for skutterudite thermoelectric materials

InactiveUS20120006376A1Avoid rapid degradationInhibited DiffusionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHafniumYttrium

A thermally stable diffusion barrier for bonding skutterudite-based materials with metal contacts is disclosed. The diffusion barrier may be employed to inhibit solid-state diffusion between the metal contacts, e.g. titanium (Ti), nickel (Ni), copper (Cu), palladium (Pd) or other suitable metal electrical contacts, and a skutterudite thermoelectric material including a diffusible element, such as antimony (Sb), phosphorous (P) or arsenic (As), e.g. n-type CoSb3 or p-type CeFe4−xCoxSb12 where the diffusible element is Sb, to slow degradation of the mechanical and electrical characteristics of the device. The diffusion barrier may be employed to bond metal contacts to thermoelectric materials for various power generation applications operating at high temperatures (e.g. 673 K or above). Some exemplary diffusion barrier materials have been identified such as zirconium (Zr), hafnium (Hf), and yttrium (Y).

Owner:CALIFORNIA INST OF TECH

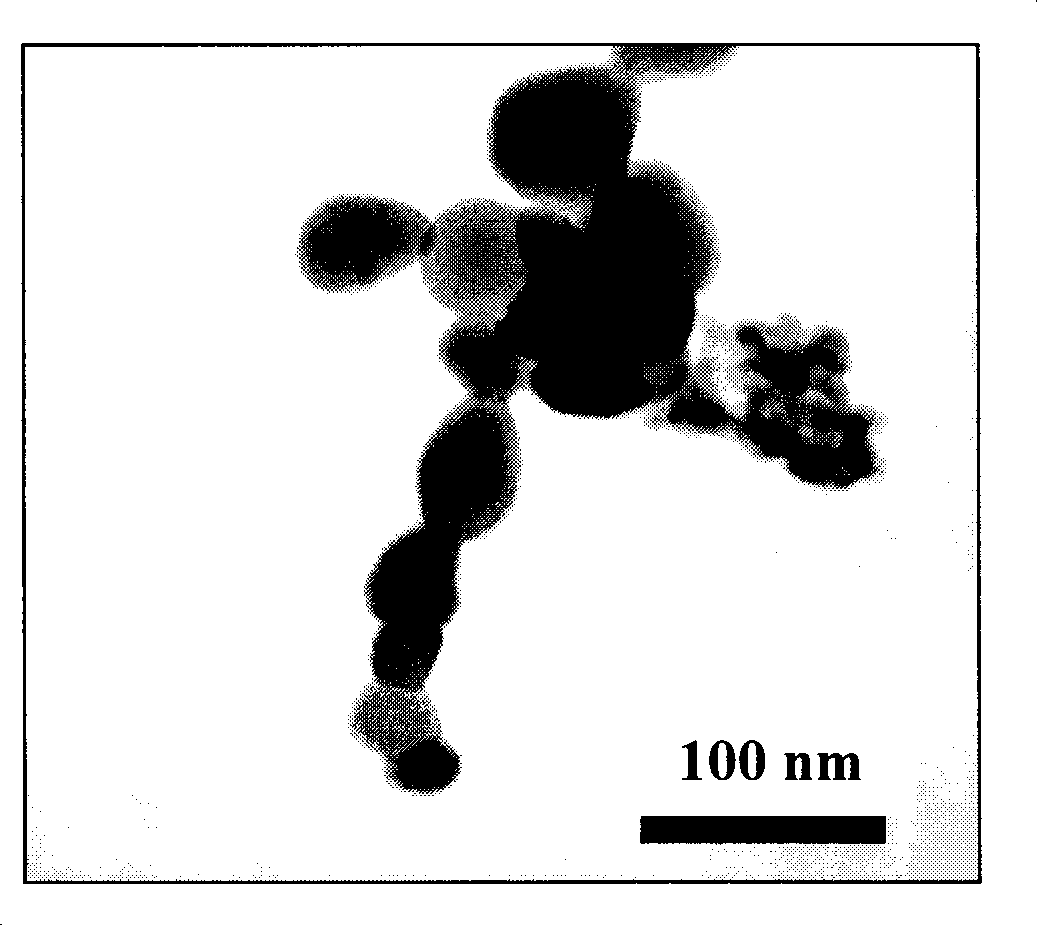

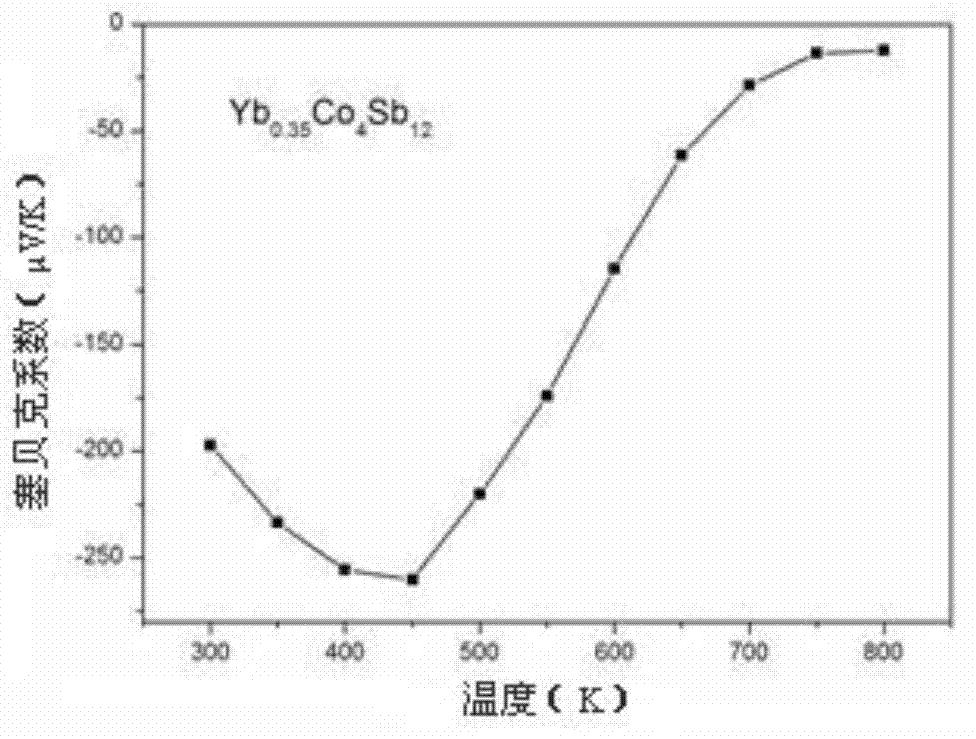

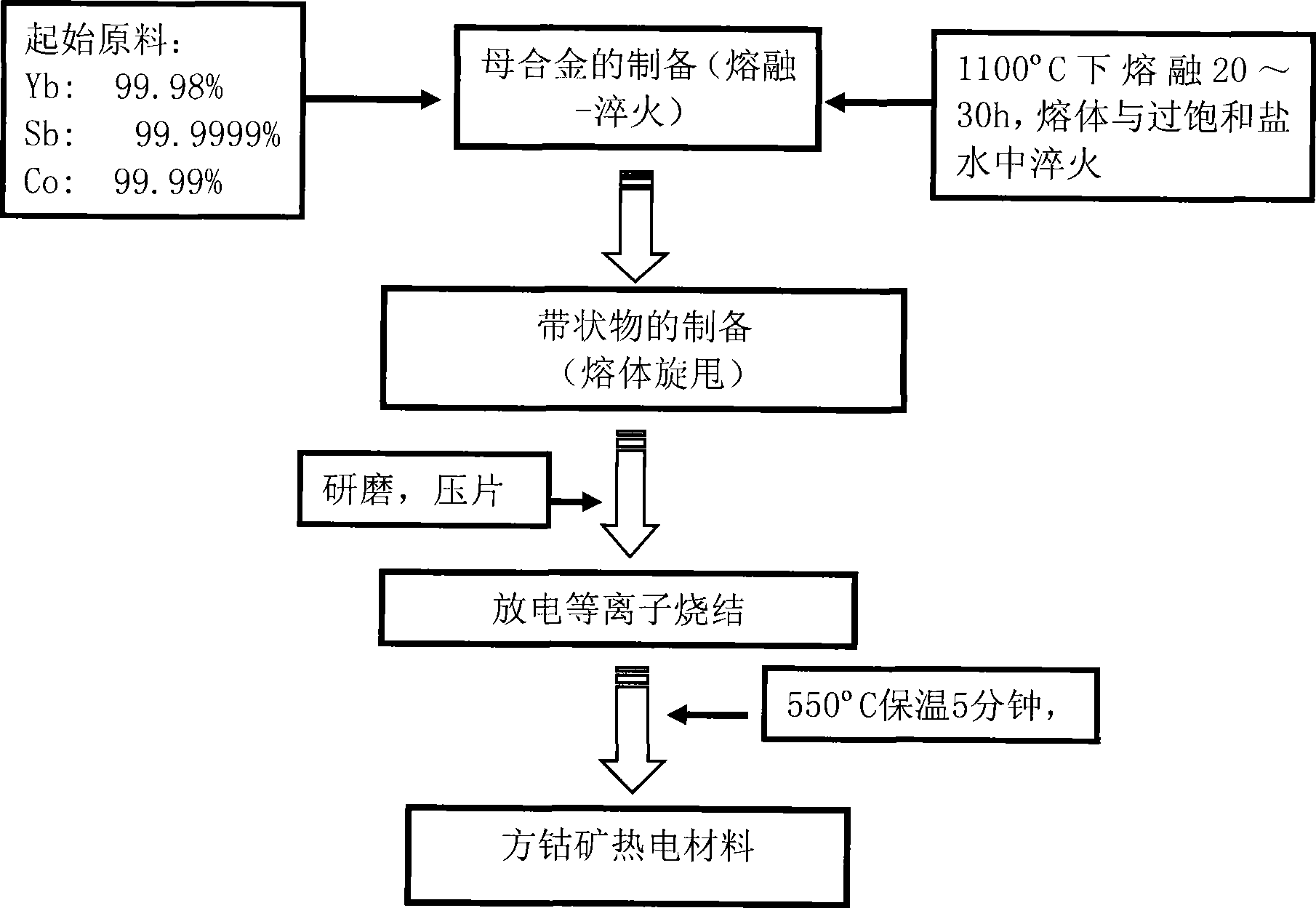

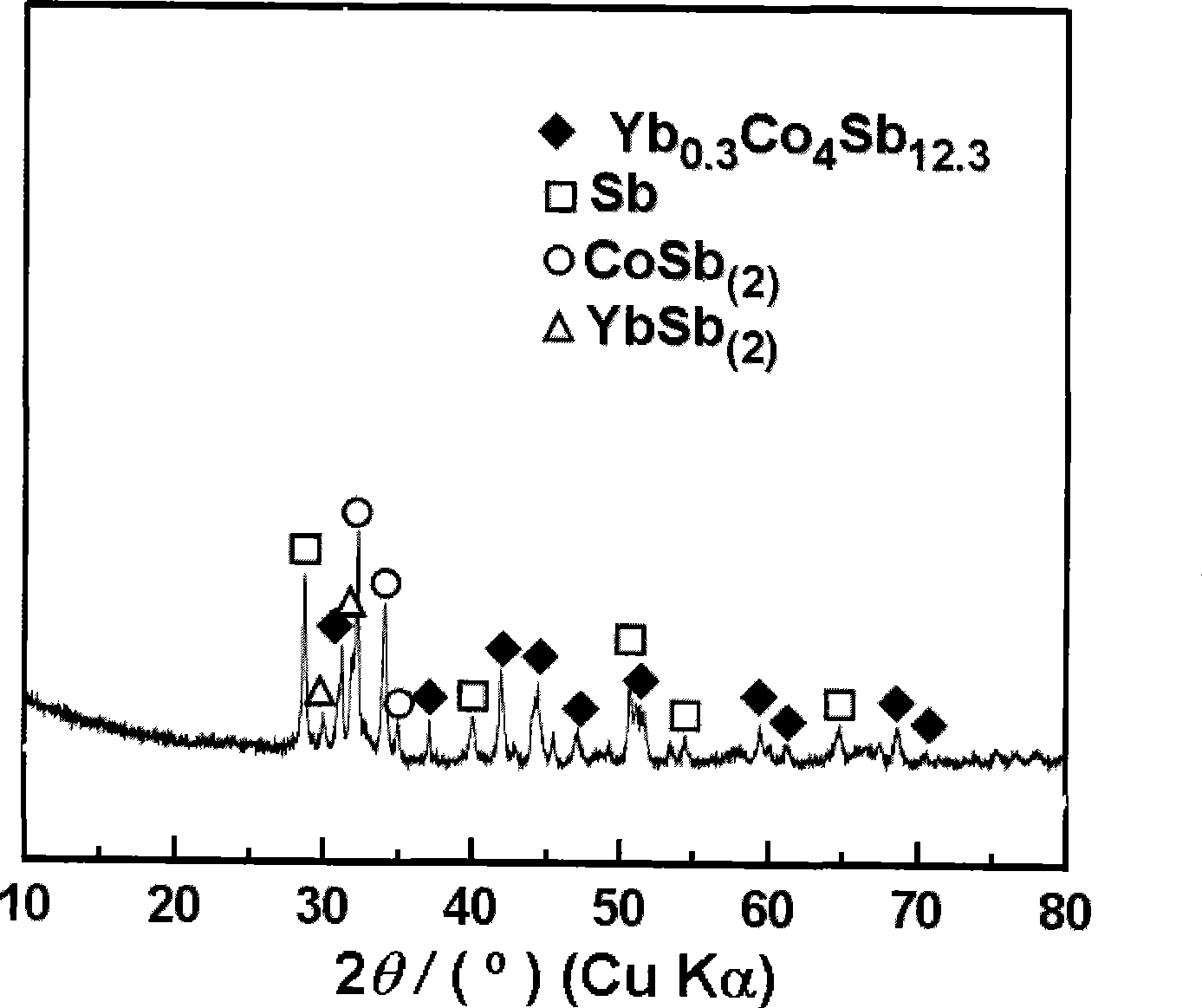

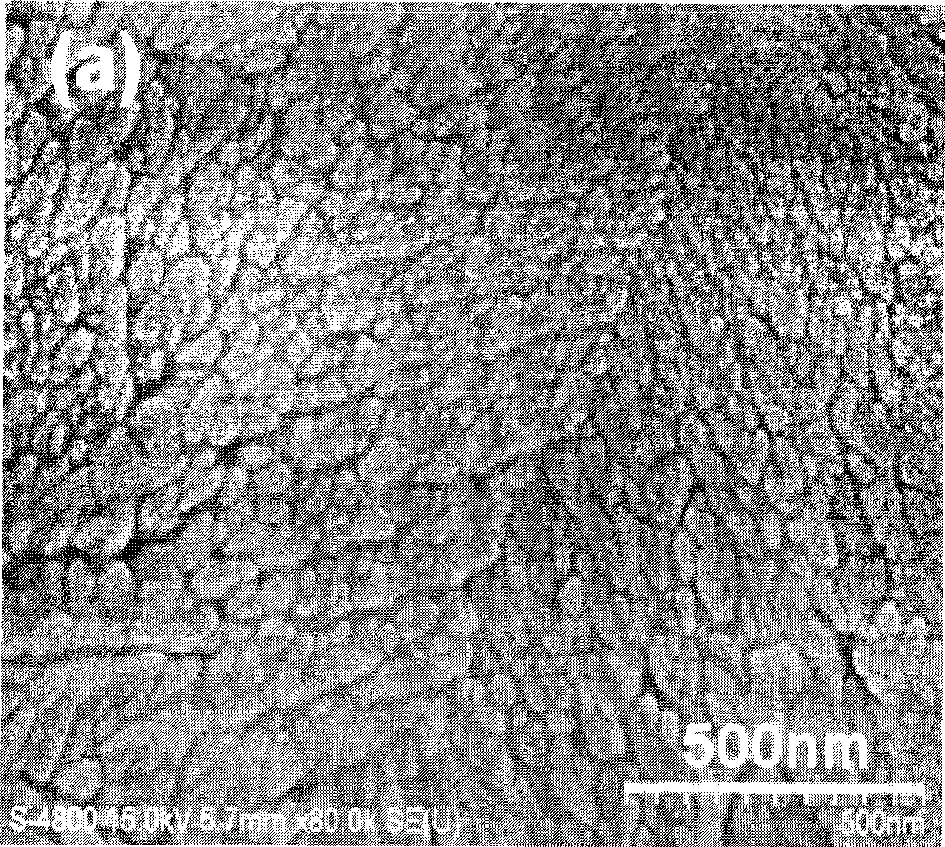

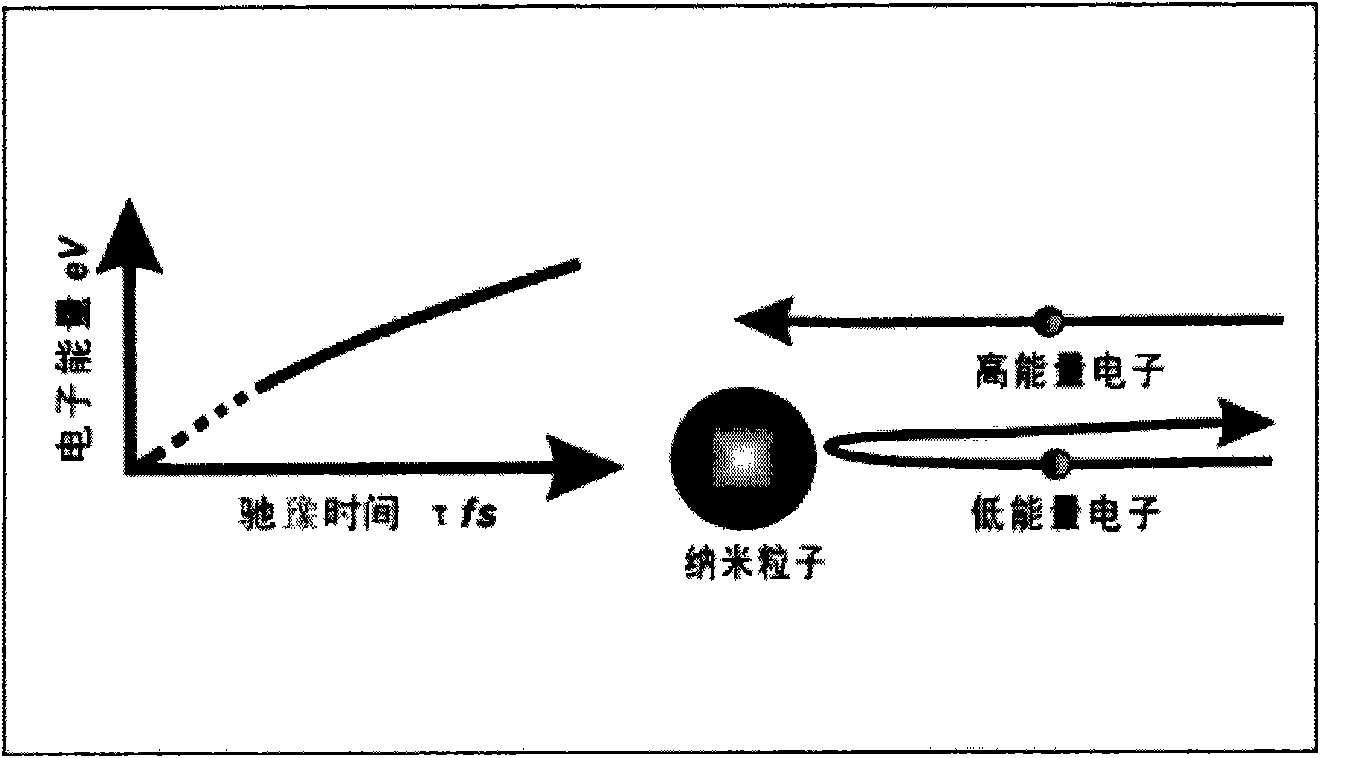

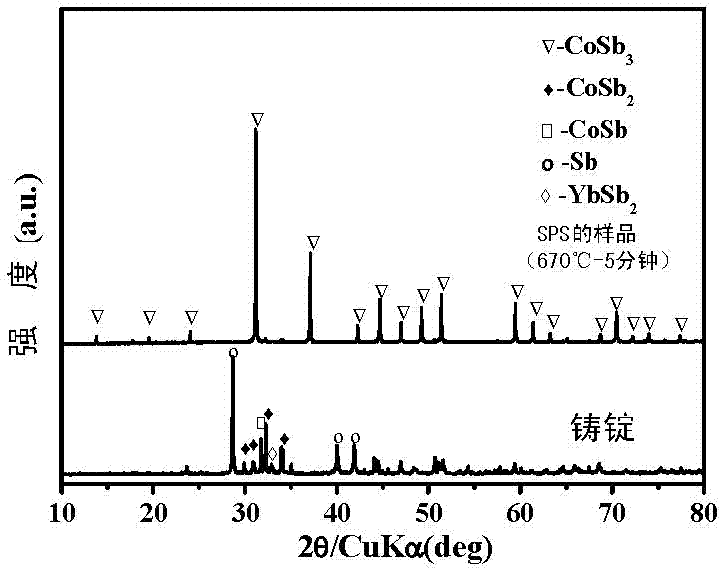

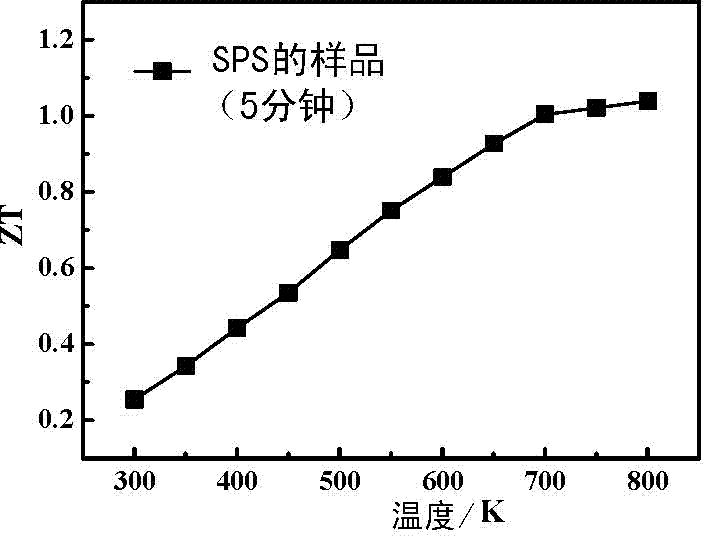

Rapid preparation of high performance nanostructured filling type skutterudite thermoelectric material

InactiveCN101435029AShort manufacturing cycleImprove thermoelectric performanceSkutteruditeSalt water

The invention relates to a preparing method of thermoelectric compound, in particular to a fast preparing method of filled type skutterudite thermoelectric material with high performance nanostructure. The invention is characterized in that the method comprises the following steps: 1) batching: granular Yb, granular Co and granular Sb are used as starting materials and weighed according to the chemical formula Yb0.3Co4Sb12.3; 2) preparing master alloy: the granular Yb, the granular Co and the granular Sb are mixed, then put into a melting furnace, heated slowly to 1100 DEG C by adopting rate of temperature increase of 2 DEG C / min and melted for 20 to 30h so as to obtain melt; the melt is quenched in supersaturated salt water so as to obtain the master alloy; 3) the master alloy is carried out cleaning processing, placed in an induction heating furnace to be melted to melt and then rotatablely throws the melt so as to obtain a strap product with an amorphous / nanocrystalline composite structure; and 4) the strap product with the amorphous / nanocrystalline composite structure is ground, tableted and then sintered by using discharging plasma so as to obtain filled type skutterudite thermoelectric material with high performance nanostructure. The method has short preparation period, low energy consumption, simple and easy-control technique, safety and no pollution.

Owner:WUHAN UNIV OF TECH

Method for producing a thermoelectric intermetallic compound

InactiveCN101952466AImprove figure of meritThermoelectric device junction materialsCompound aPhase formation

A method for producing an intermetallic compound, the method comprising: (1) providing components A, B and X; and forming by solid state reaction of components A, B and X an intermetallic compound having a filled skutterudite structure and formula of AaBbXc; (2) melting the intermetallic compound having a filled skutterudite structure produced in step (1) in the presence of additional X; and (3) annealing the intermetallic compound of step (2) in the presence of additional X at a temperature equal to, or greater than the phase formation temperature of the intermetallic compound.

Owner:BIOMETRIC TECH SOLUTIONS

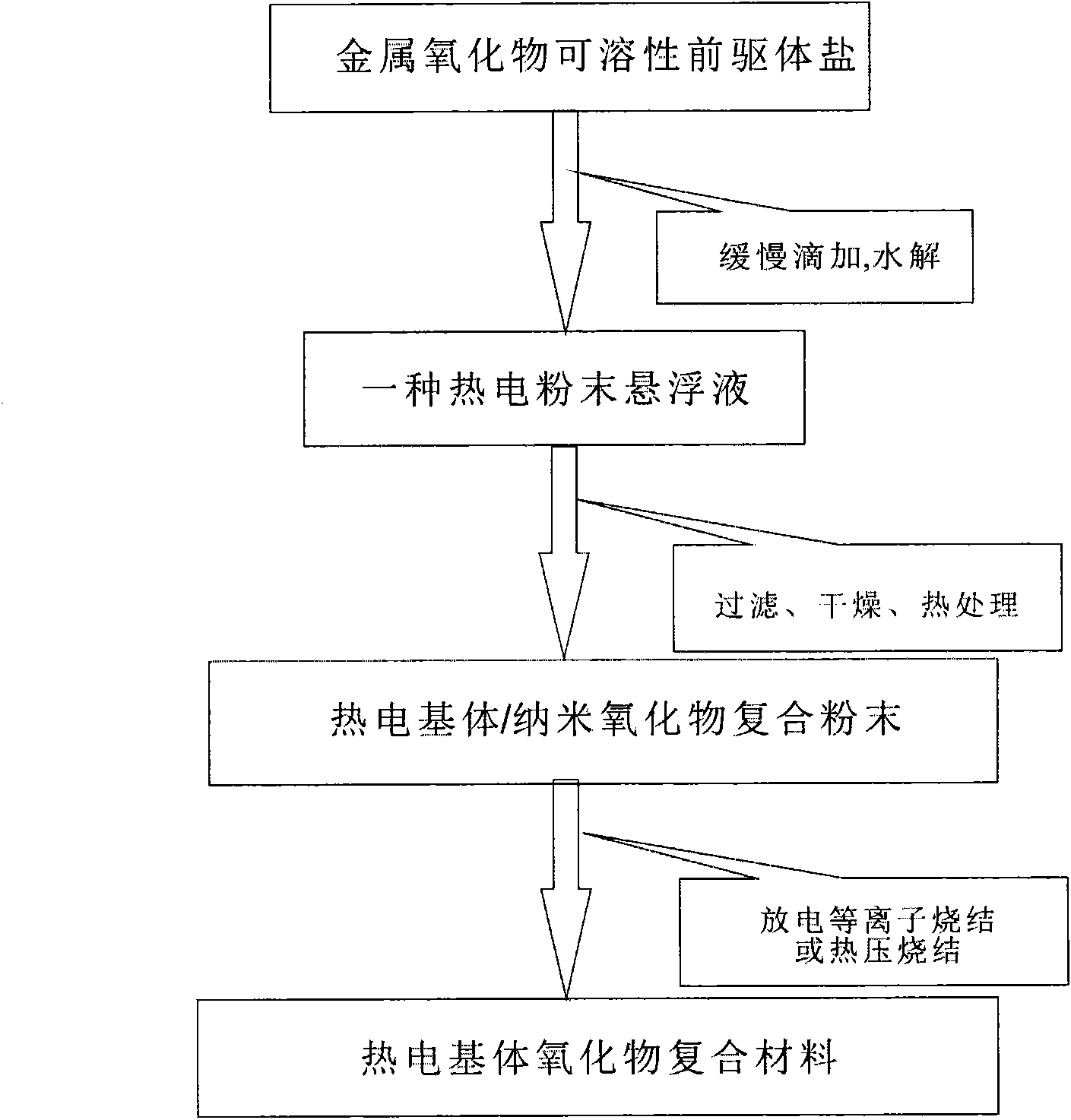

Thermoelectric composite and preparation method thereof

InactiveCN101942577ALower lattice thermal conductivityImprove thermoelectric performanceMaterial nanotechnologyThermoelectric device manufacture/treatmentLiquid mediumSkutterudite

The invention provides a preparation method of a composite, comprising: providing a suspension of a solid thermoelectric material which disperses in a liquid medium, wherein the solid thermoelectric material is filled and / or doped with skutterudite, half-Heusler alloy, a cagelike material and other thermoelectric ordered alloy or thermoelectric disordered alloy or a thermoelectric intermetallic compound; contacting the suspension with a solution formed by dissolving a metallic oxide precursor into solvent to obtain a reaction mixture; forming a metallic oxide by hydrolyzing the metallic oxide precursor in the presence of water; obtaining the compound of the metallic oxide and the solid thermoelectric material which are evenly dispersed in liquid phase; and separating the compound of the metallic oxide and the solid thermoelectric material from the liquid phase to obtain the separated composite. The invention can dramatically improve the thermoelectric performance of the composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

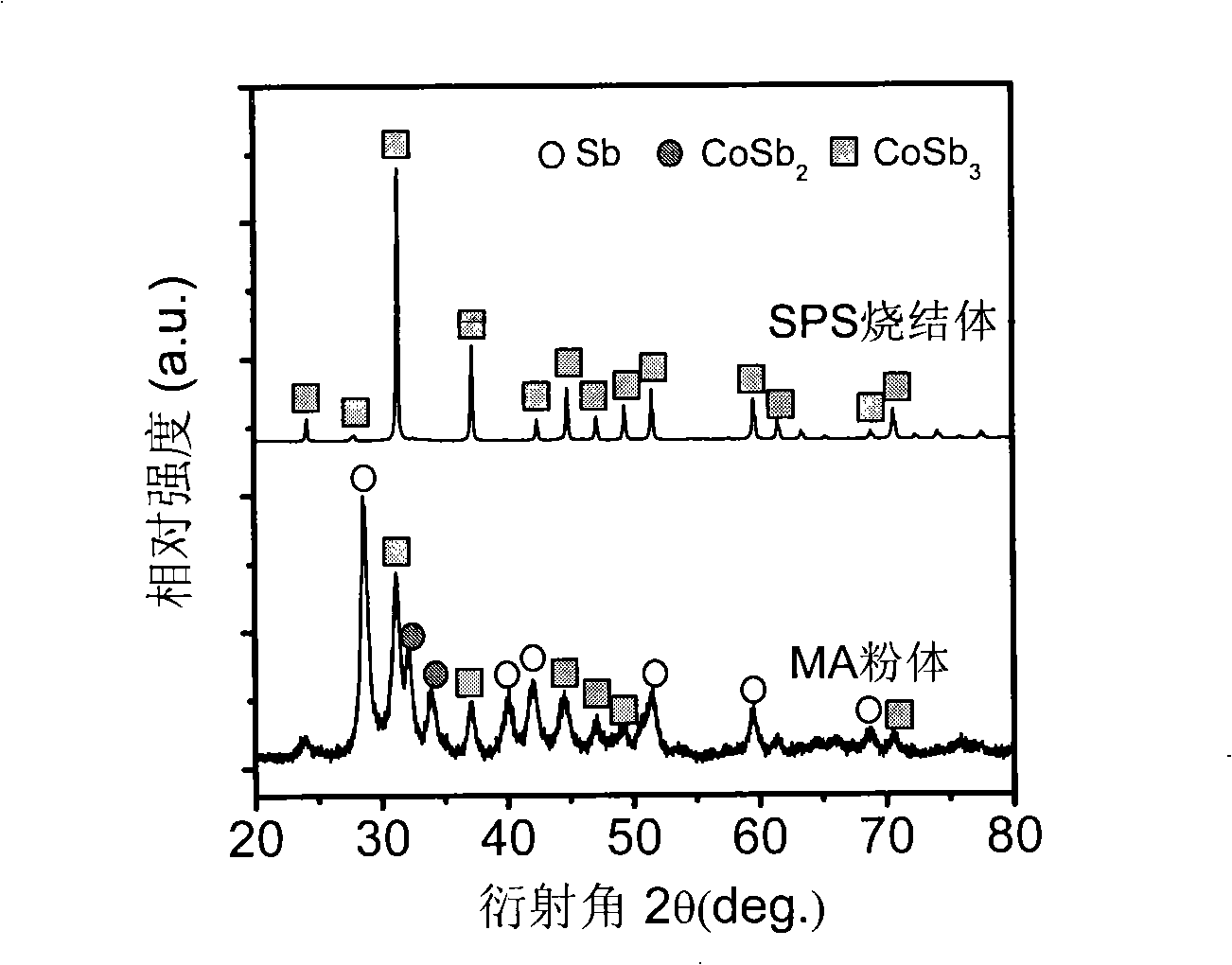

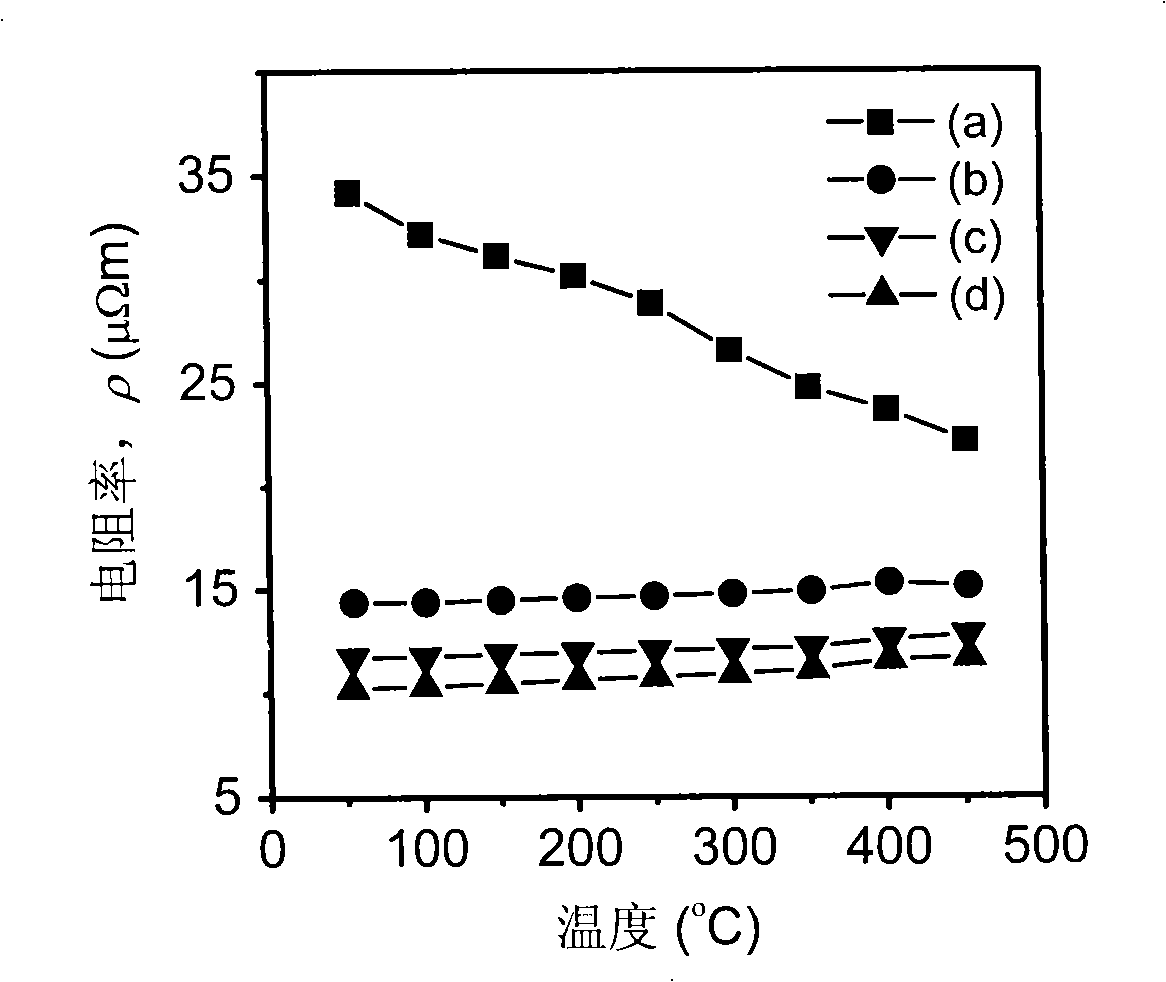

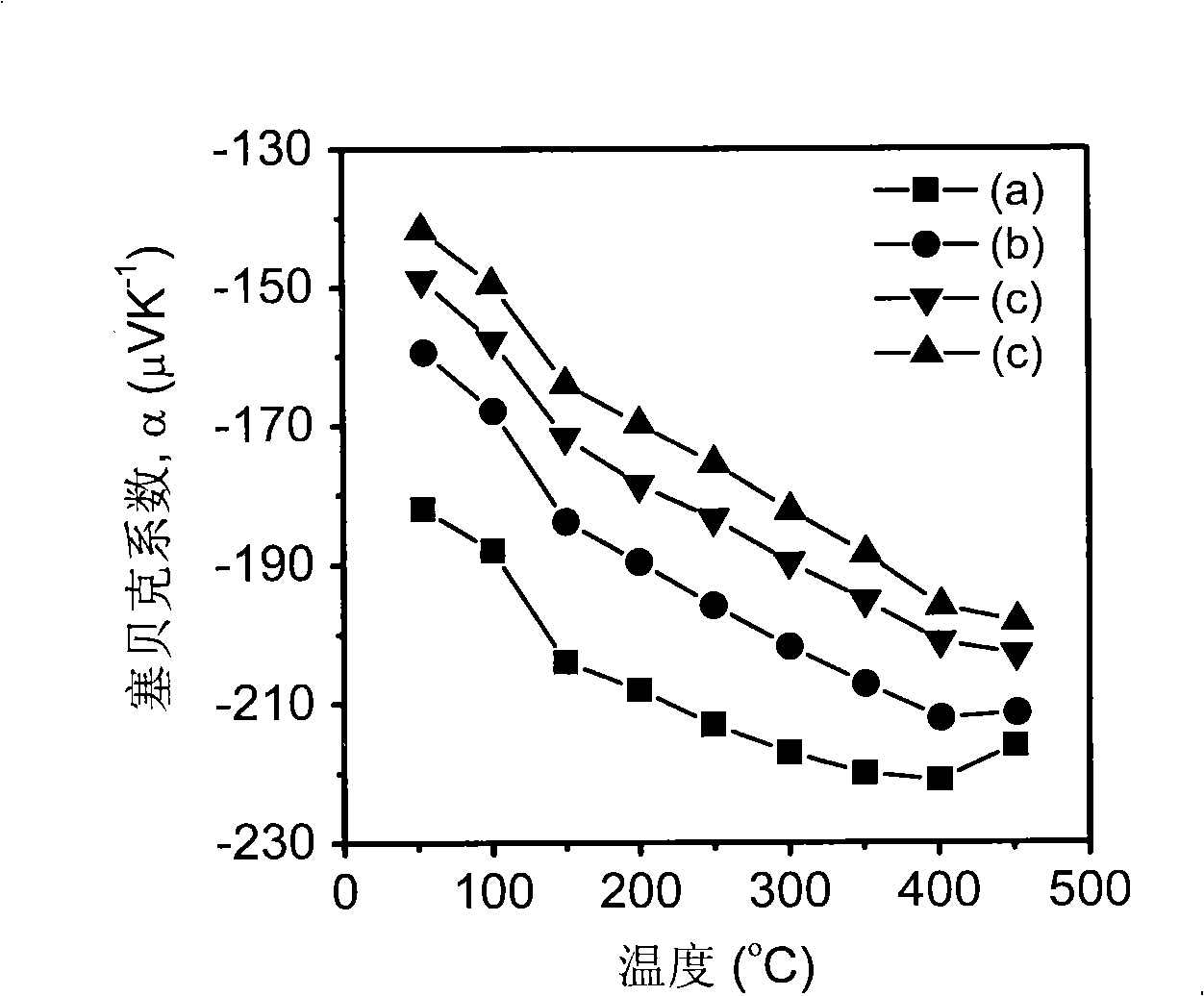

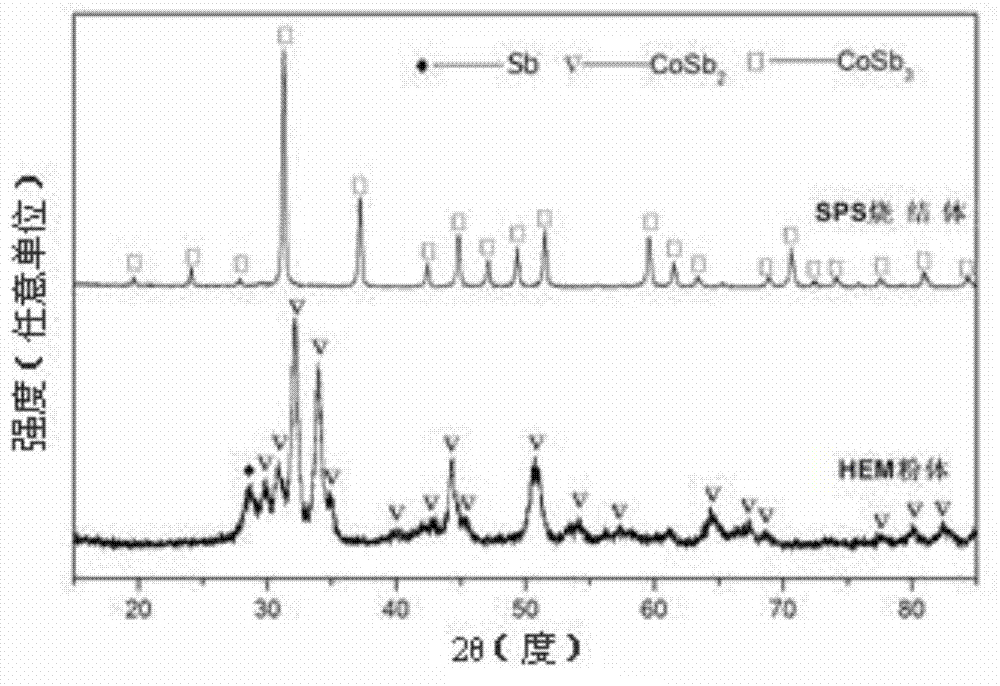

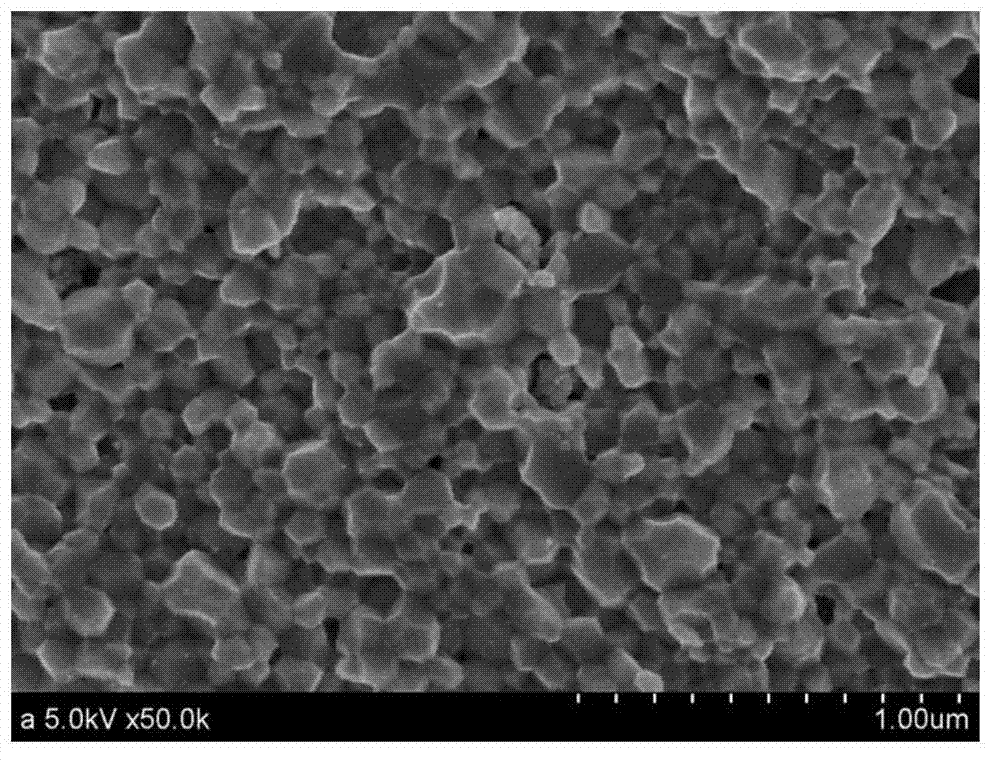

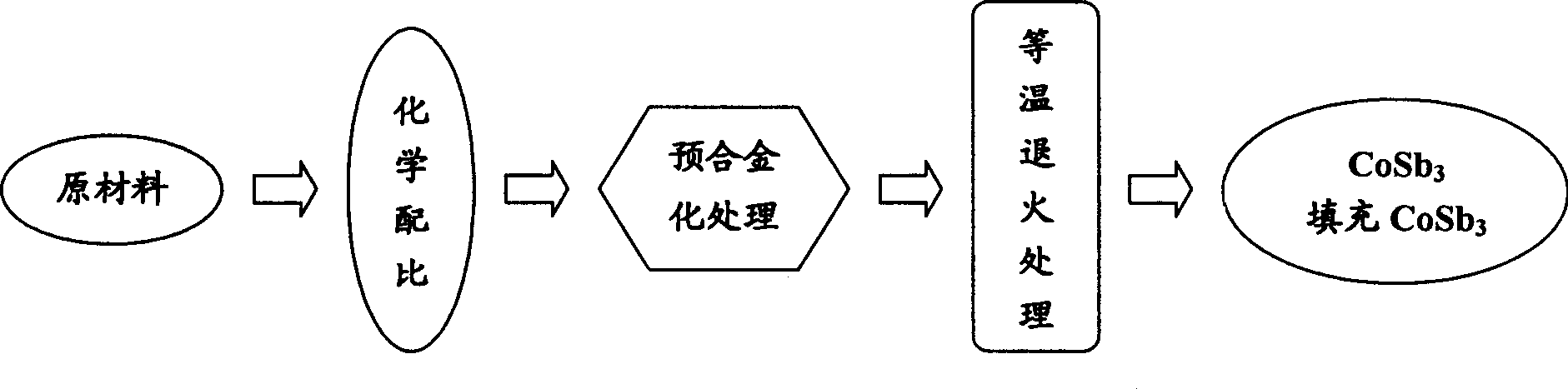

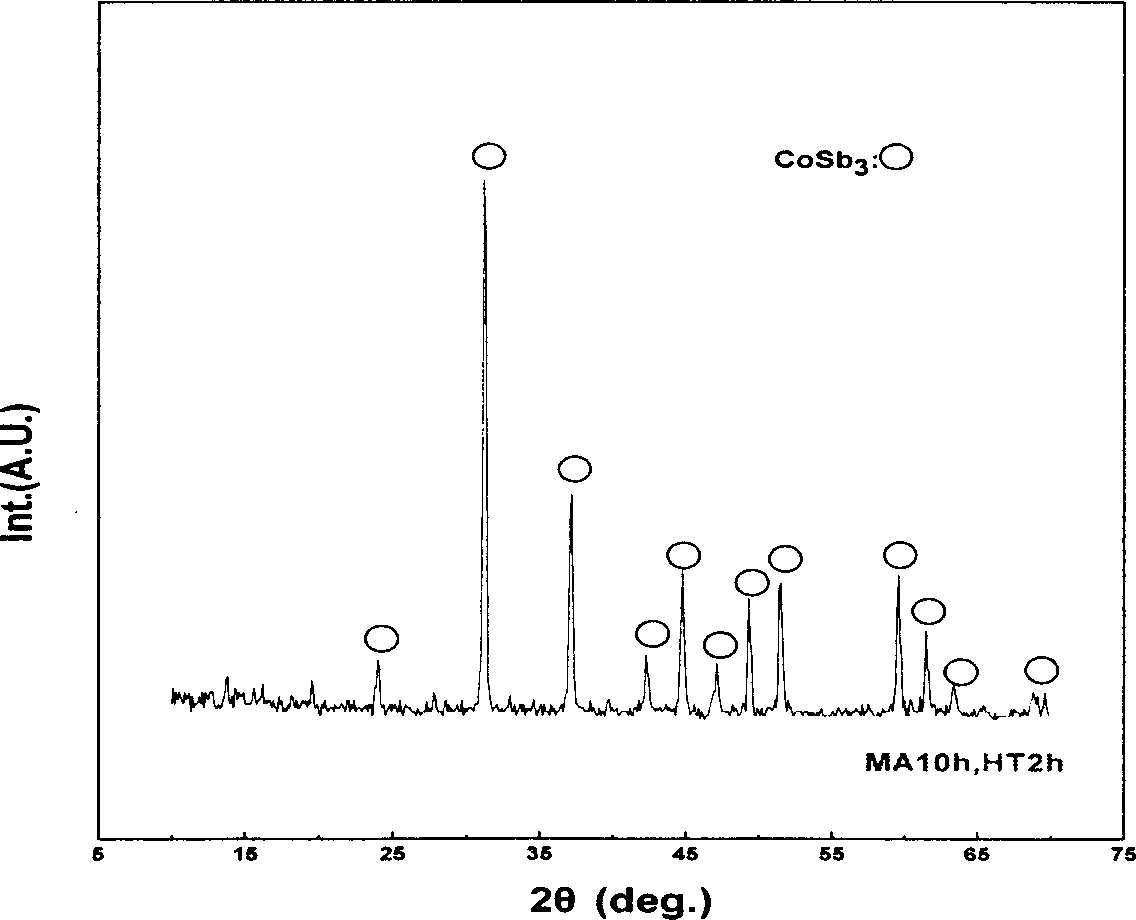

Co-Sb series skutterudite compound thermoelectric material preparation method

There is a manufacturing method of Co-Sb serial cobalt compound thermoelectricity materials, the steps is: óƒ mechanism alloy process: the materials atomic proportion is Co:Sb=1:3, then the material powder is blended with grinding ball to carry on high energy ball grinding process, the weight proportion of ball material is 10:1í½20:1, the rotate speed is 180í½350 revolution / minute, the time is 8í½11 hours under protective gas. ó equal temperature quenching process: the material is equal temperature quenching processed under the protection vacuum or inert gases, the temperature is: 923í½1023K, the time is :1-3 hours. The invention uses two segment processing method, then the material is quenching processed and gets the CoSb3 compound with a short time.

Owner:HUAZHONG UNIV OF SCI & TECH

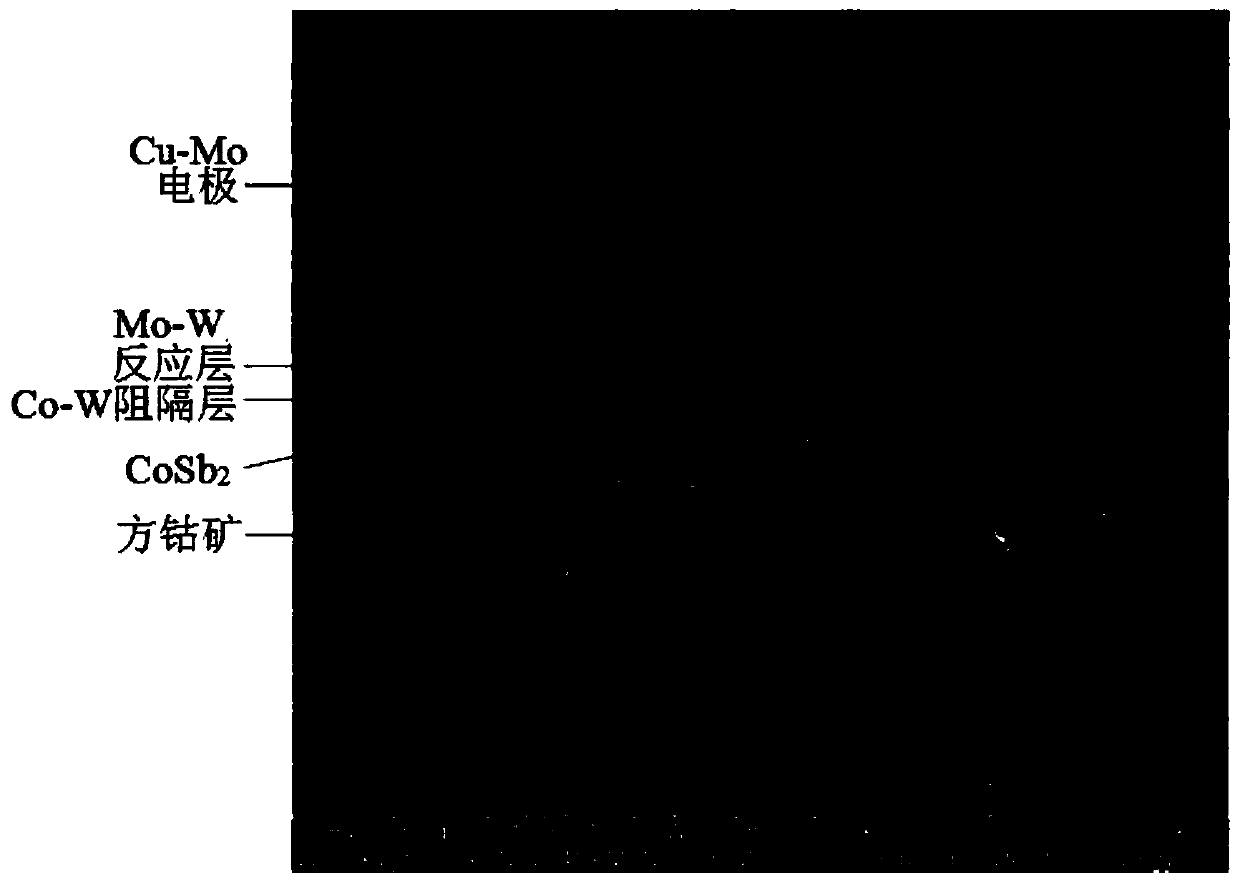

Rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929AImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusSkutteruditeElectroplating

The invention discloses a rapid diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The method aims to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with an electrode. The method comprises the steps of takingan electrode, cleaning a to-be-welded surface, electroplating an alloy barrier layer on the surface of the to-be-welded surface of the electrode, cleaning the to-be-welded surface of the skutteruditethermoelectric material, and performing diffusion welding. The barrier layer is prepared on the electrode side through an electroplating method, diffusion welding is achieved between the barrier layerand the skutterudite thermoelectric material under the relatively low pressure and at the relatively low temperature, element diffusion of weld joint elements and skutterudite does not exist in the process, and Sb element volatilization and element diffusion can be prevented. The method is suitable for welding the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

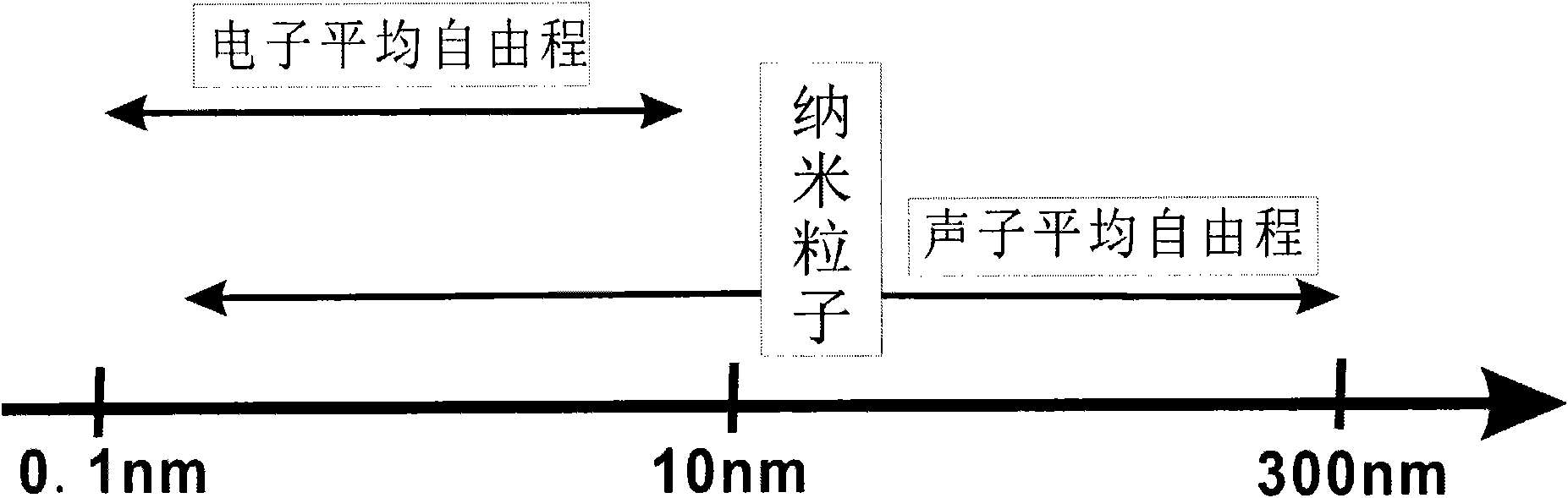

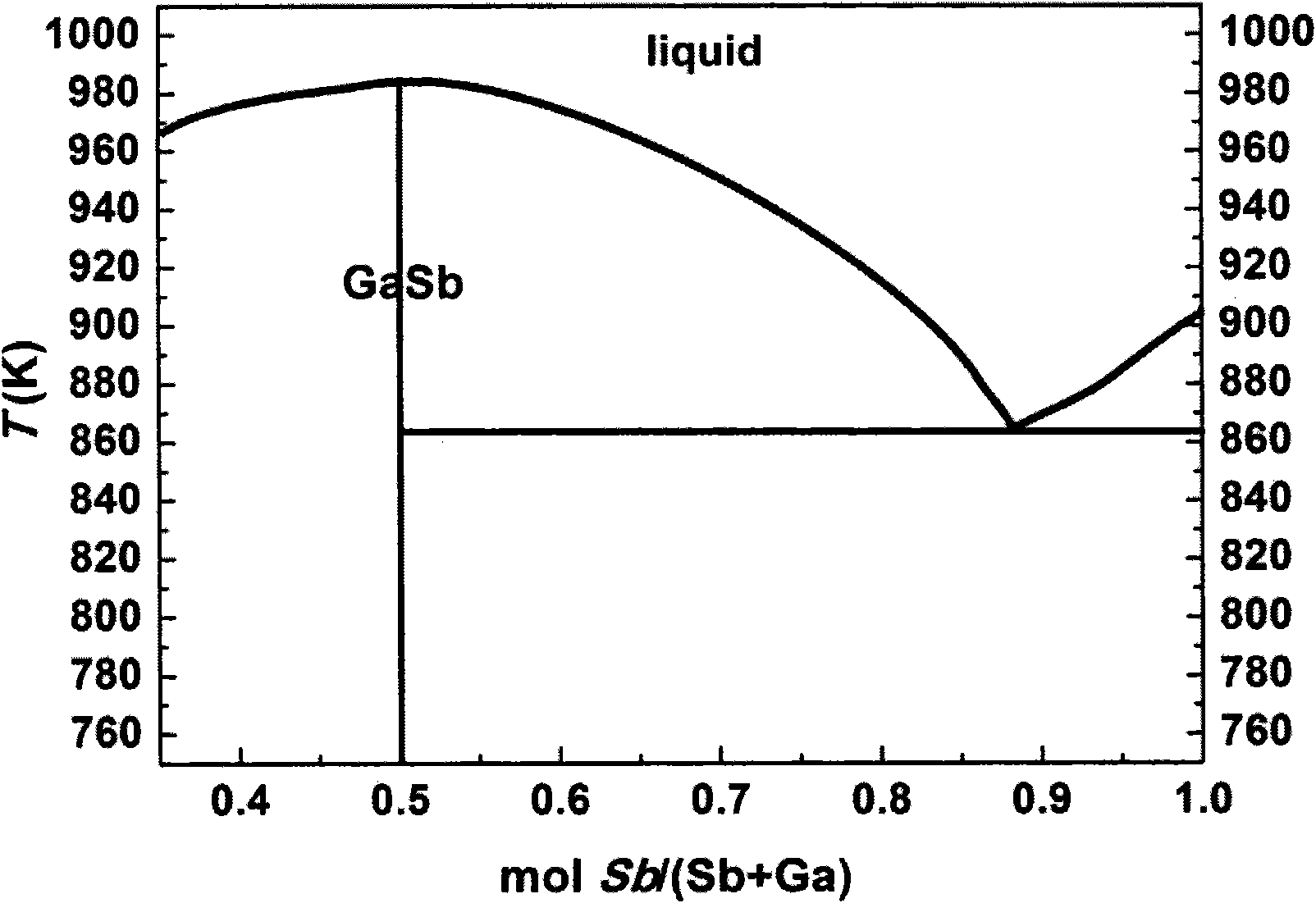

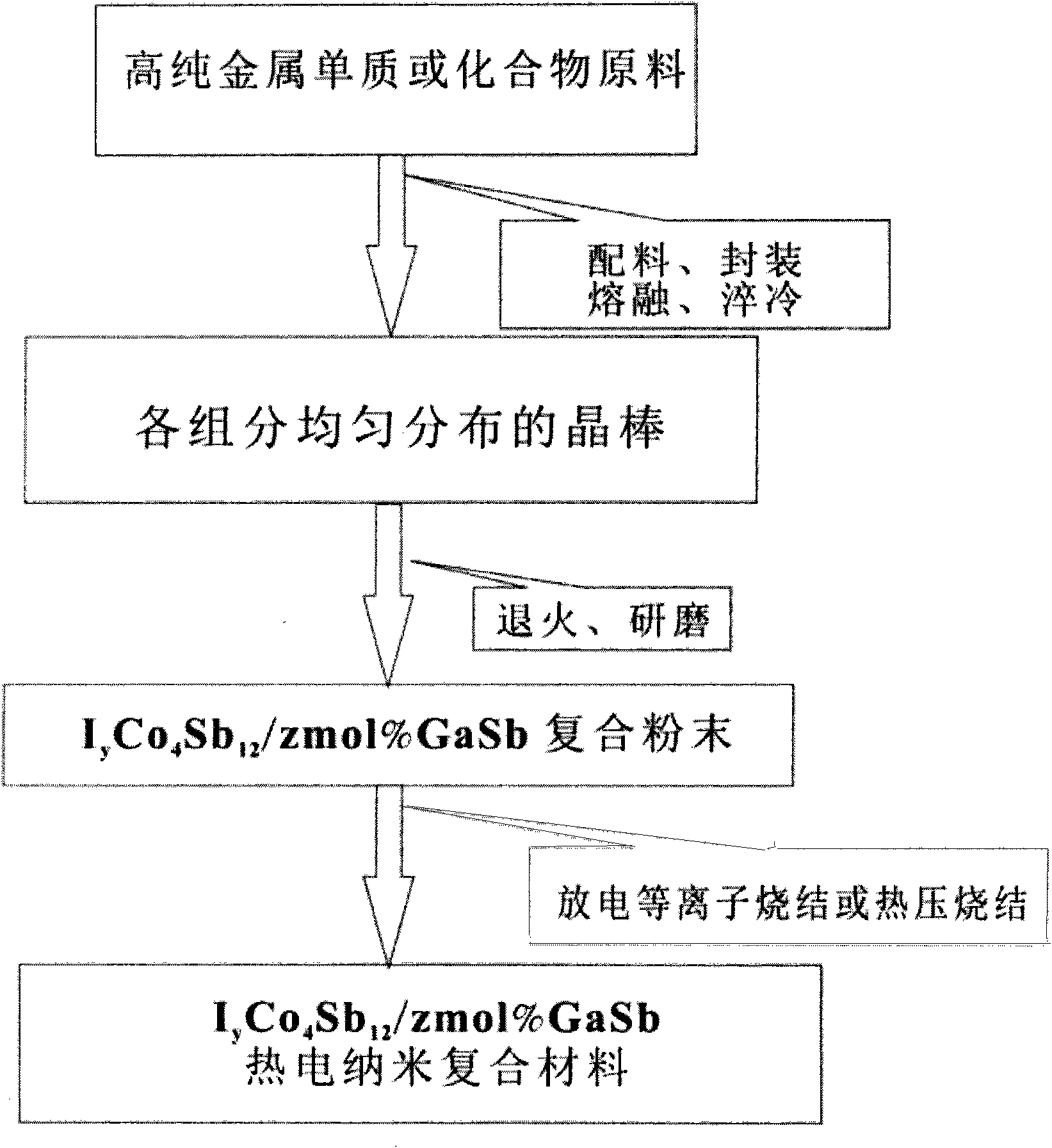

Composite material of skutterudite filling substrate and preparation method thereof

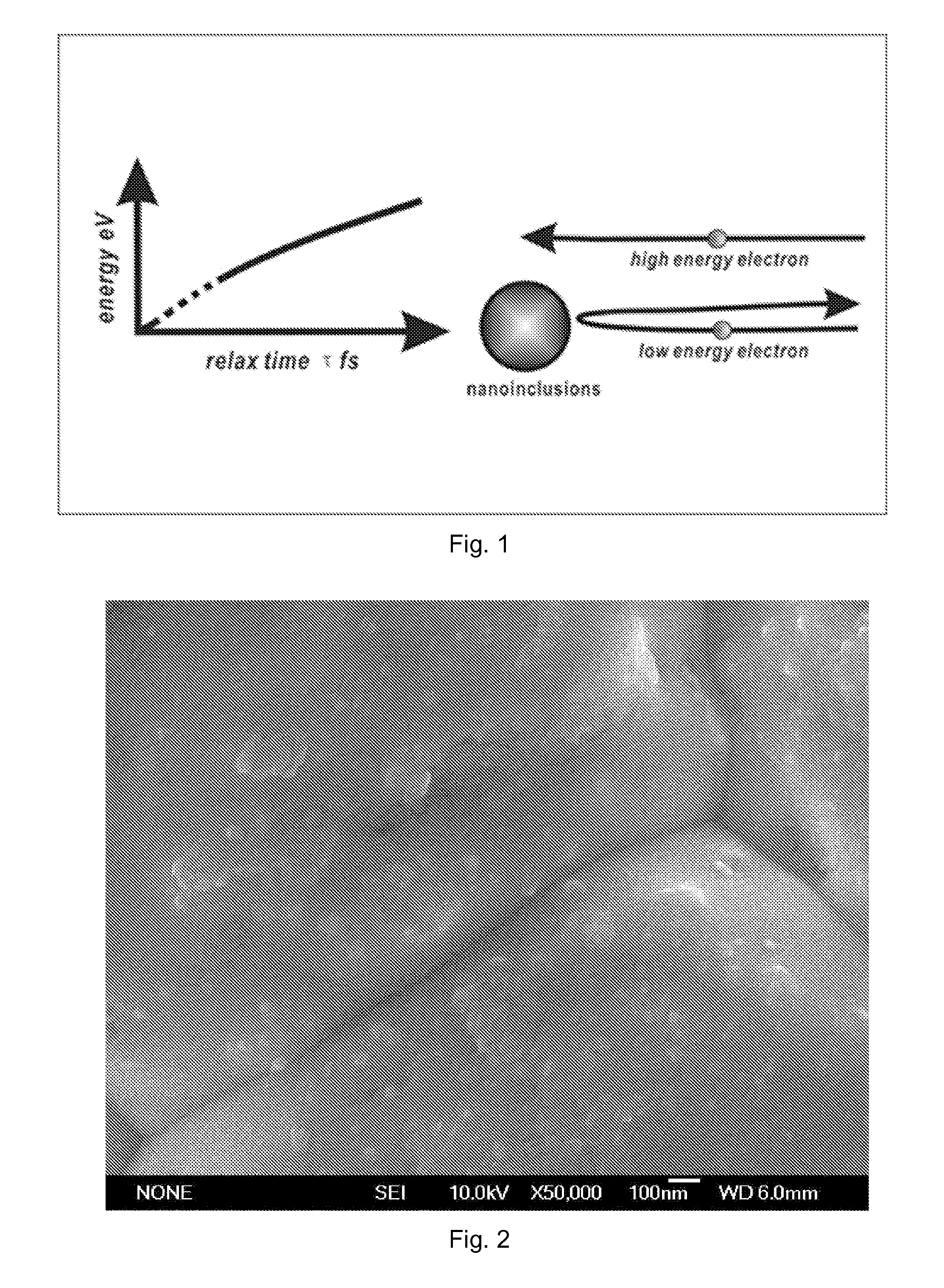

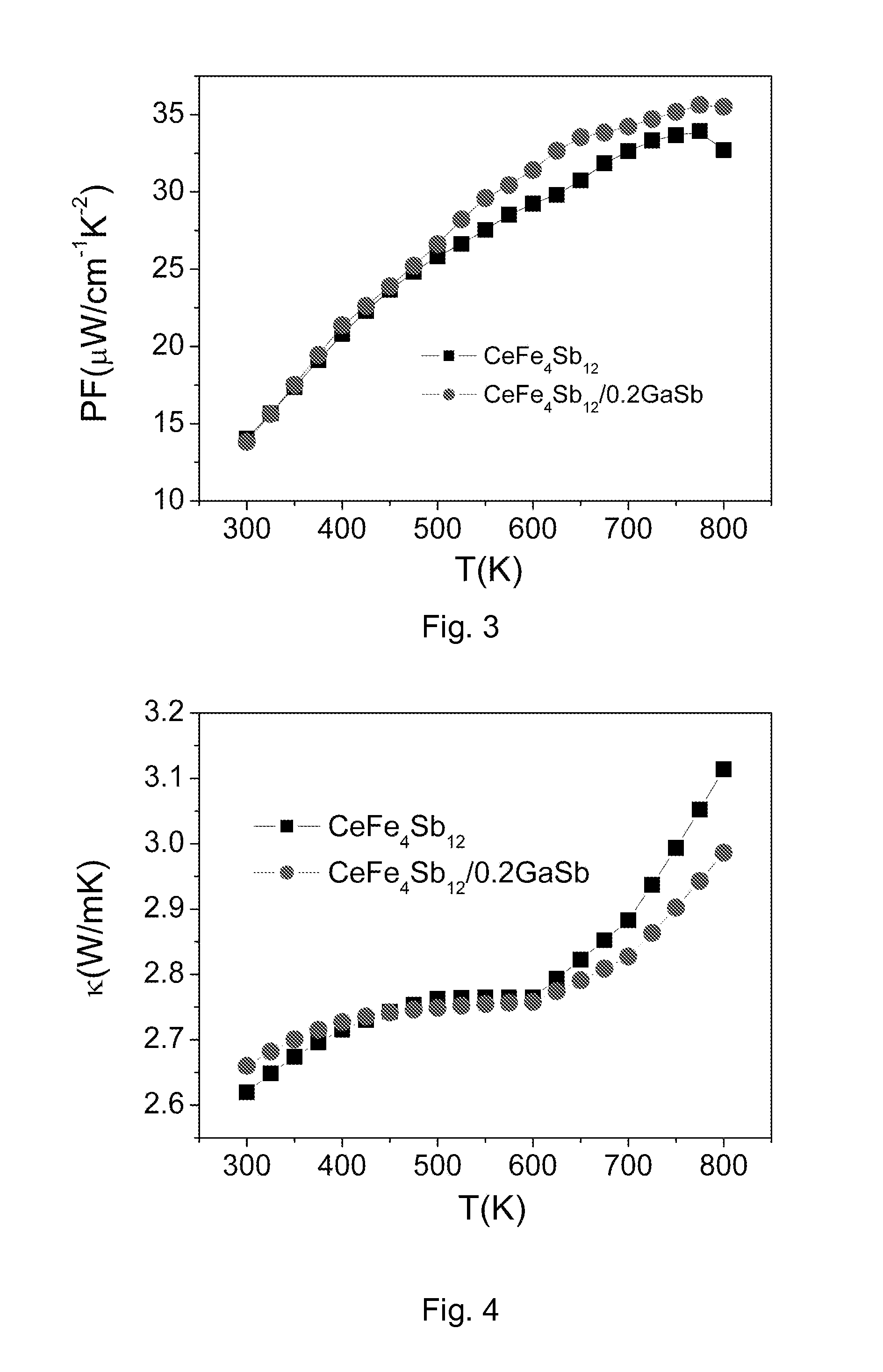

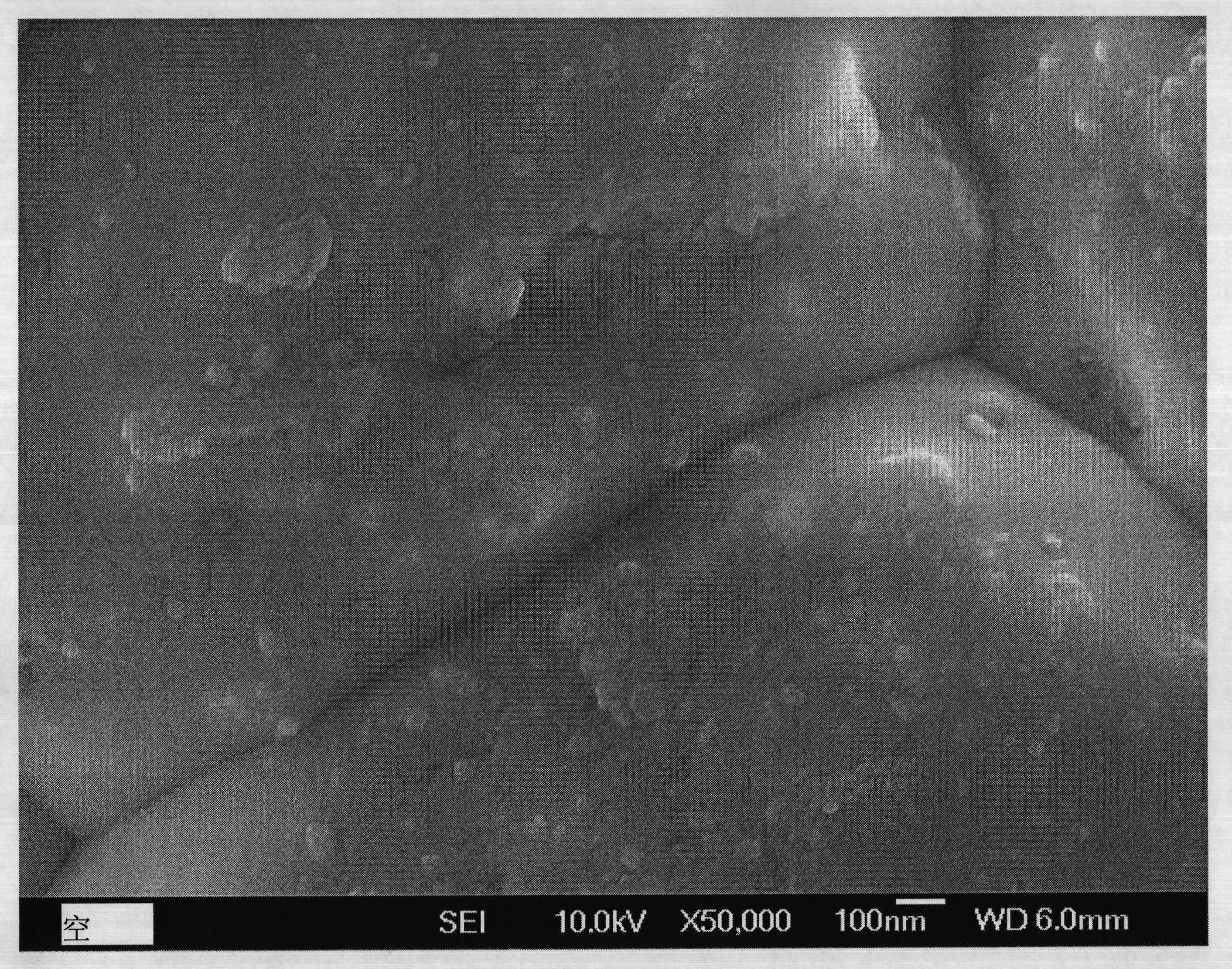

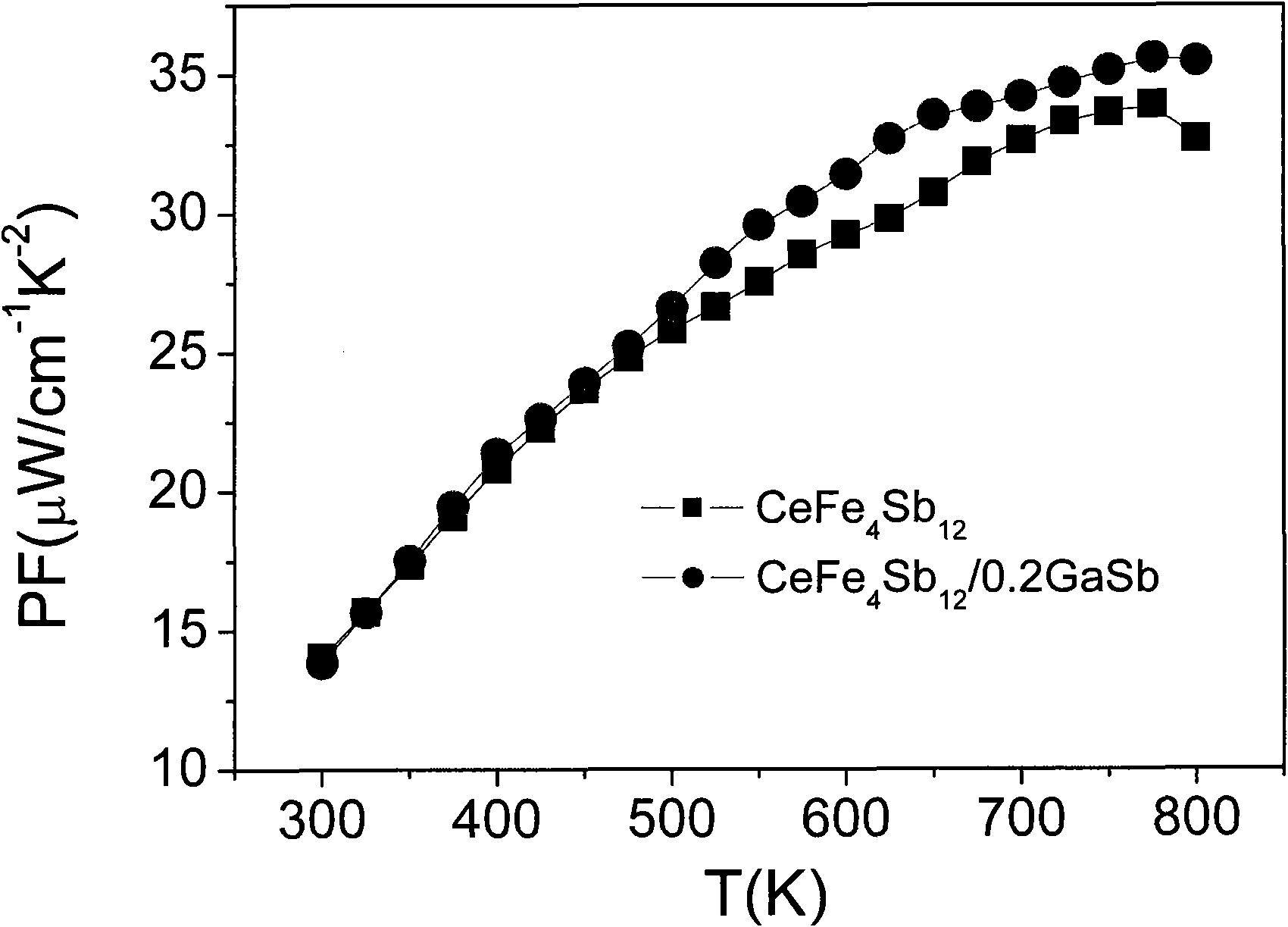

InactiveCN102031416AImprove Seebeck coefficientLow thermal conductivityMaterial nanotechnologyGallium/indium/thallium compoundsCompound aSkutterudite

The invention provides a composite material. The composite material comprises a skutterudite filling substrate shown as the following formula (I): IyCo4Sb12 (1), wherein I is at least one of Yb, Eu, Ce, La, Nd, Ba and Sr, and y is less than 1 and not more than 0.05. The composite material further comprises GaSb particles distributed in the skutterudite filling substrate, wherein the composite material contains 0.05-5 mol% GaSb particles. Compared with the thermoelectric material substrate without compounding a nanometer GaSb phase, the Seebeck coefficient of the composite material is improved to a large extent, the total heat conductivity is slightly reduced, the thermoelectric performance index ZT value is greatly increased in the whole high temperature and low temperature zone range, and the thermoelectric conversion efficiency of the material is greatly improved. The composite material has simple process and favorable industrialization prospect and is easy to control.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

P-type skutterudite material and method of making the same

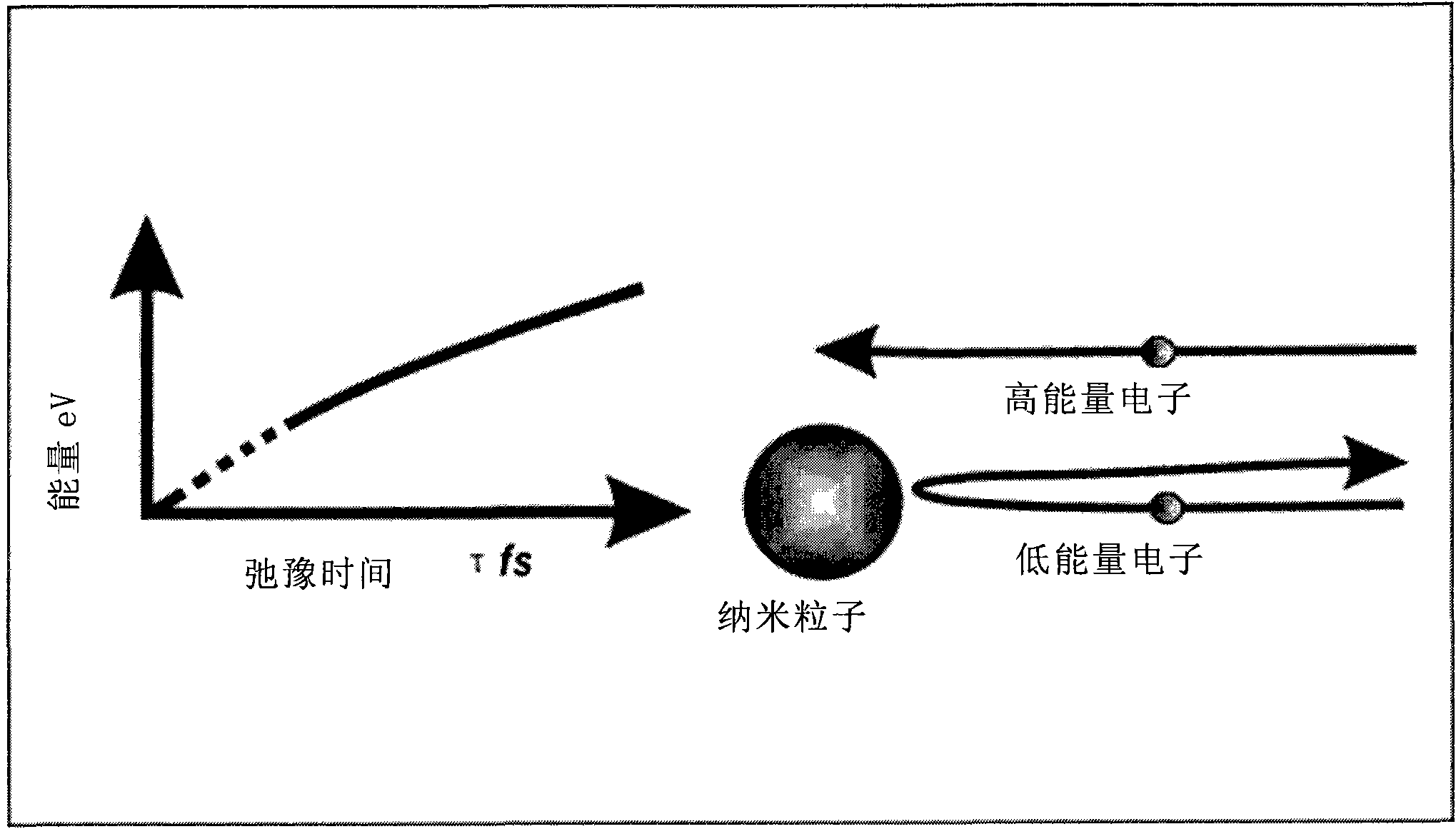

InactiveUS20130323110A1Improve power factorLow thermal conductivityThermoelectric device junction materialsDopantSkutterudite

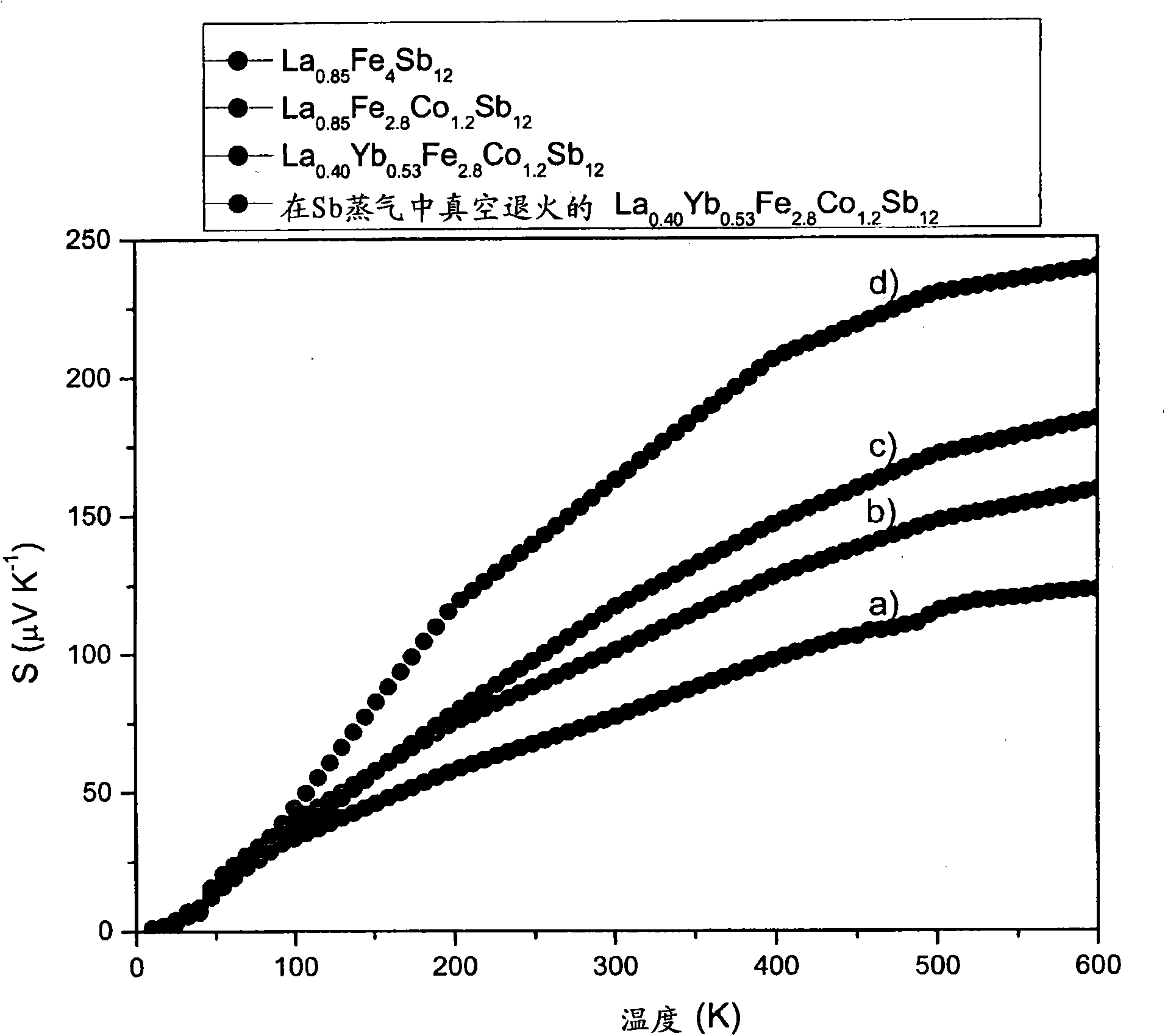

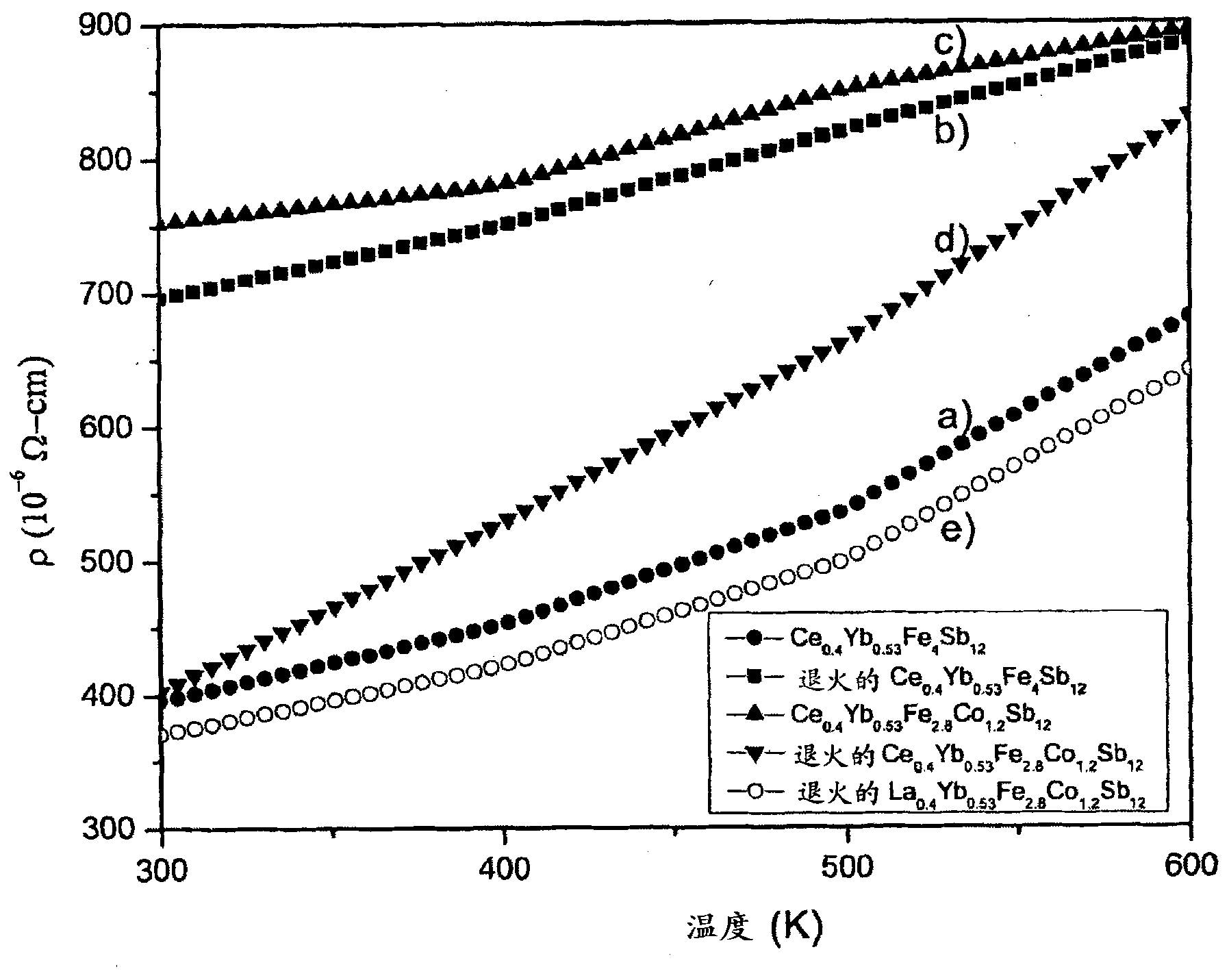

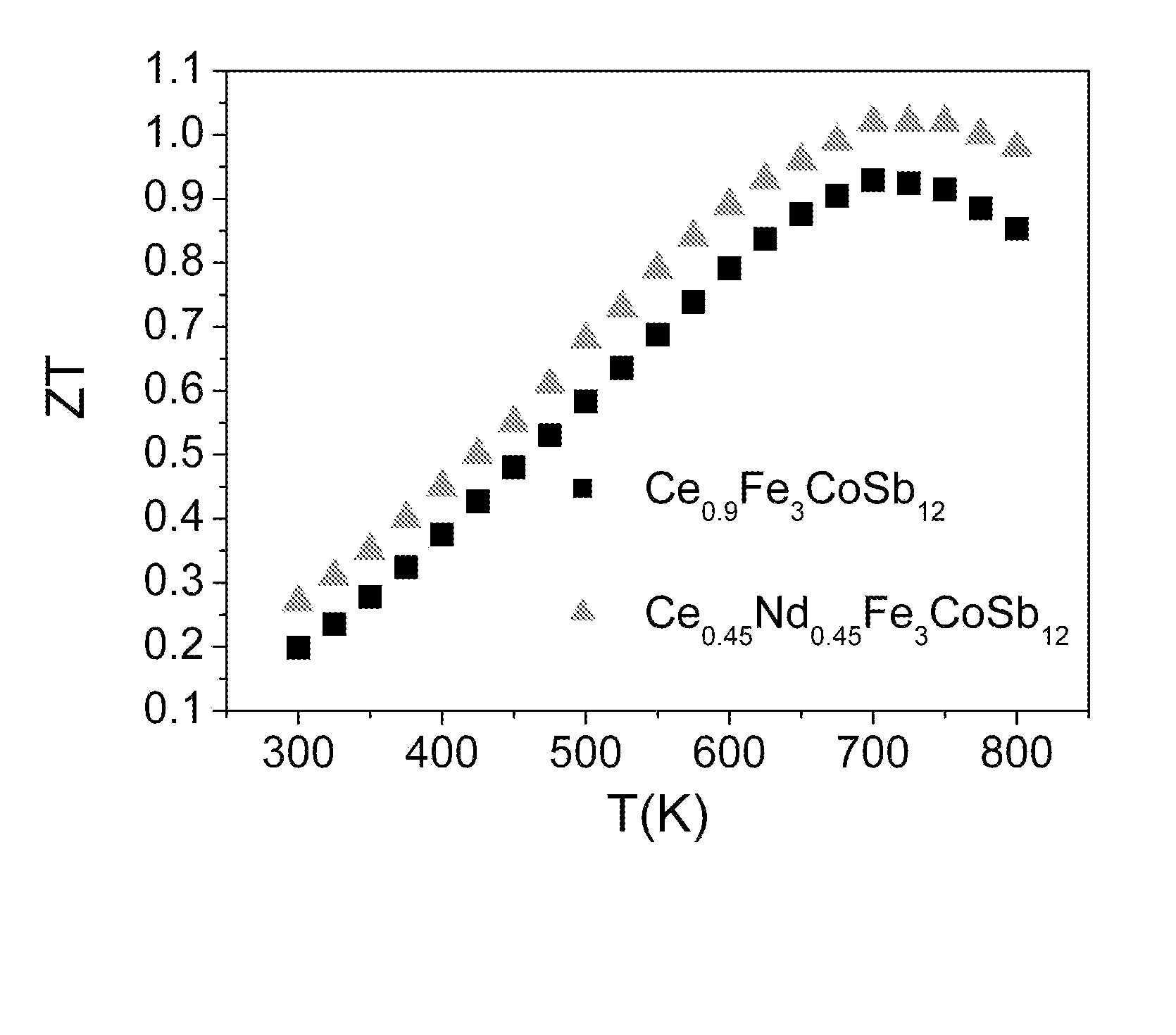

The disclosure relates to a p-type skutterudite material and a method of making the same, comprising providing a p-type skutterudite material having a general formula: IyFe4-xMxSb12 / z(J) wherein I represents one or more filling atoms in a skutterudite phase, the total filling amount y satisfying 0.01≦y≦1; M represents one or more dopant atoms with the doping amount x satisfying 0≦x≦4; J represents one or more second phases with the molar ratio z satisfying 0≦z≦0.5; wherein second phase precipitates are dispersed throughout the skutterudite phase.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

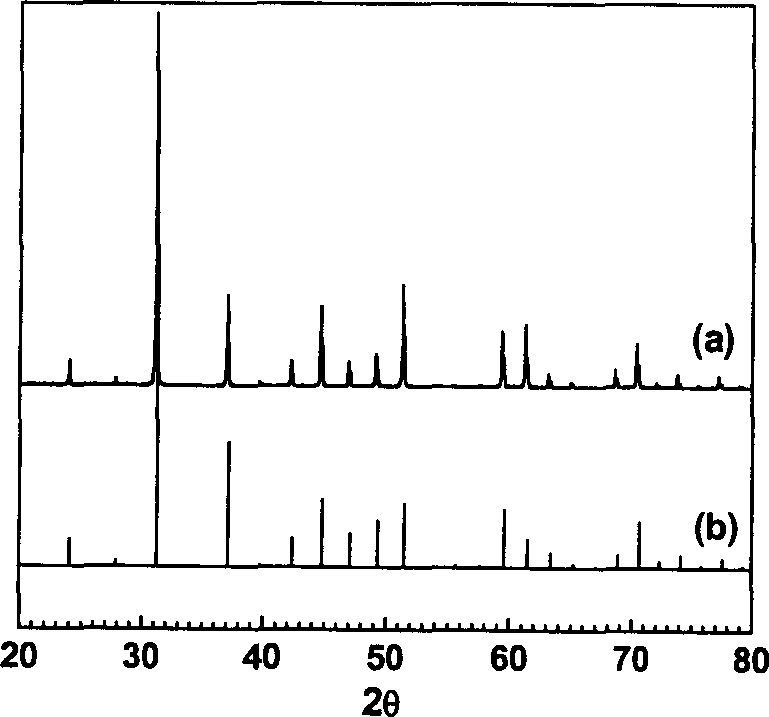

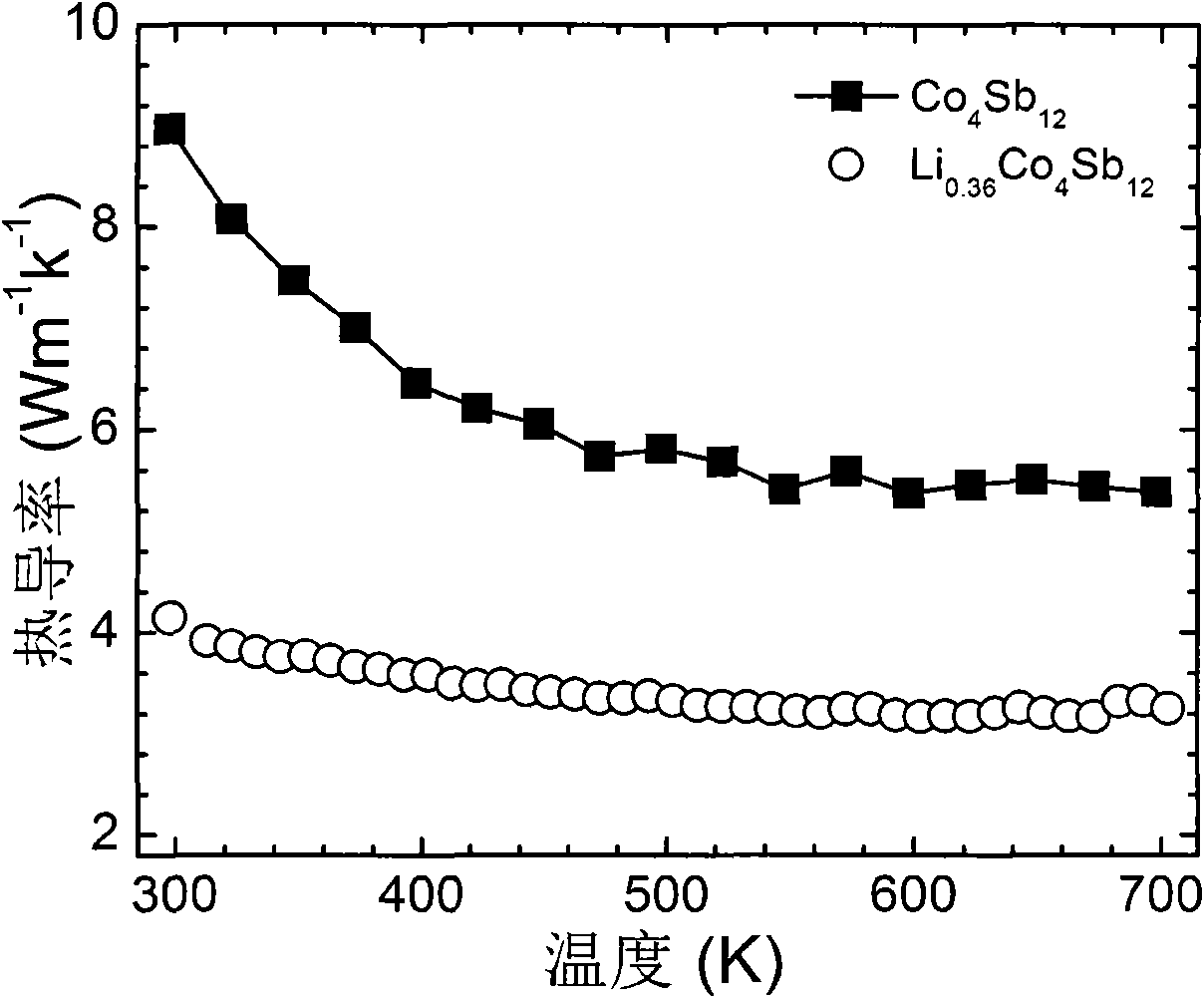

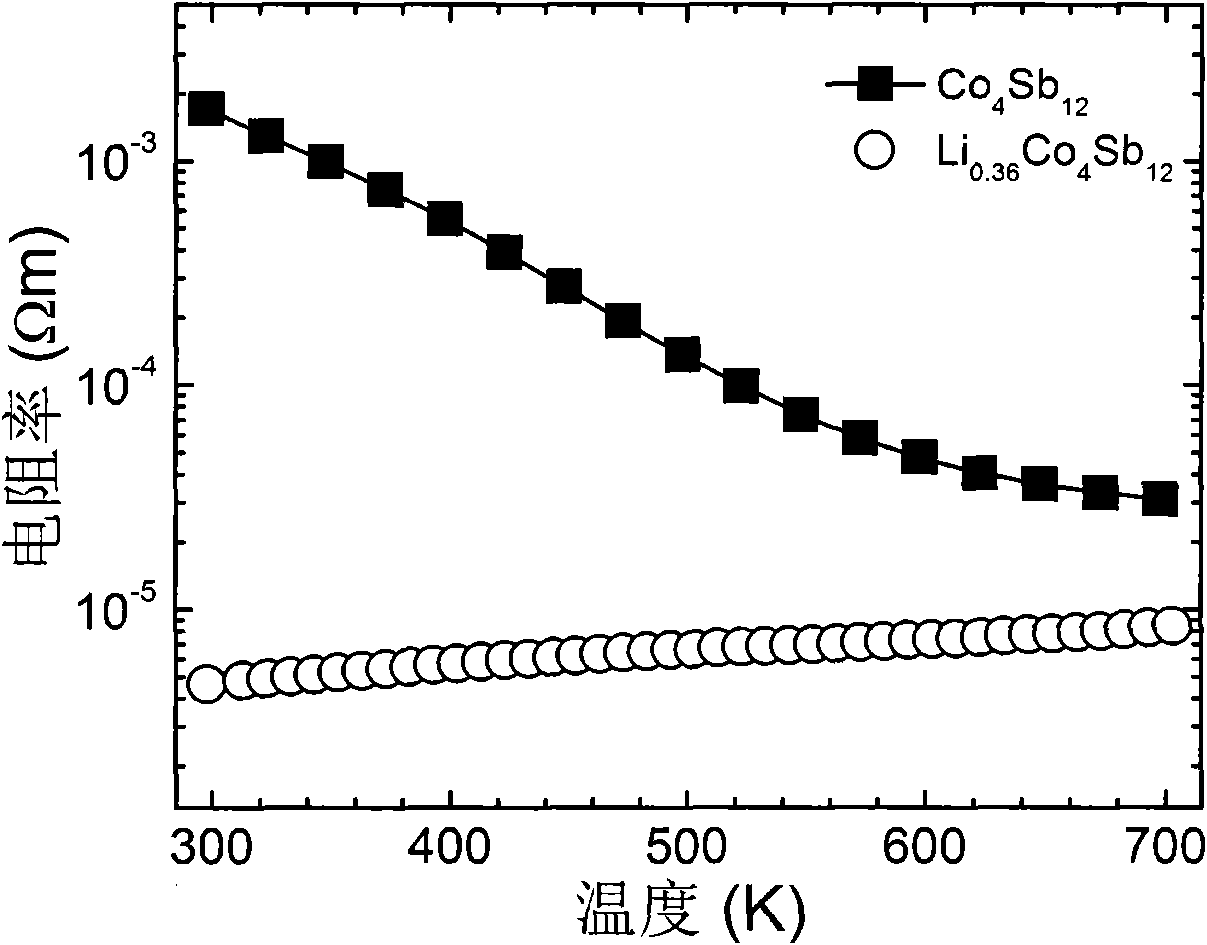

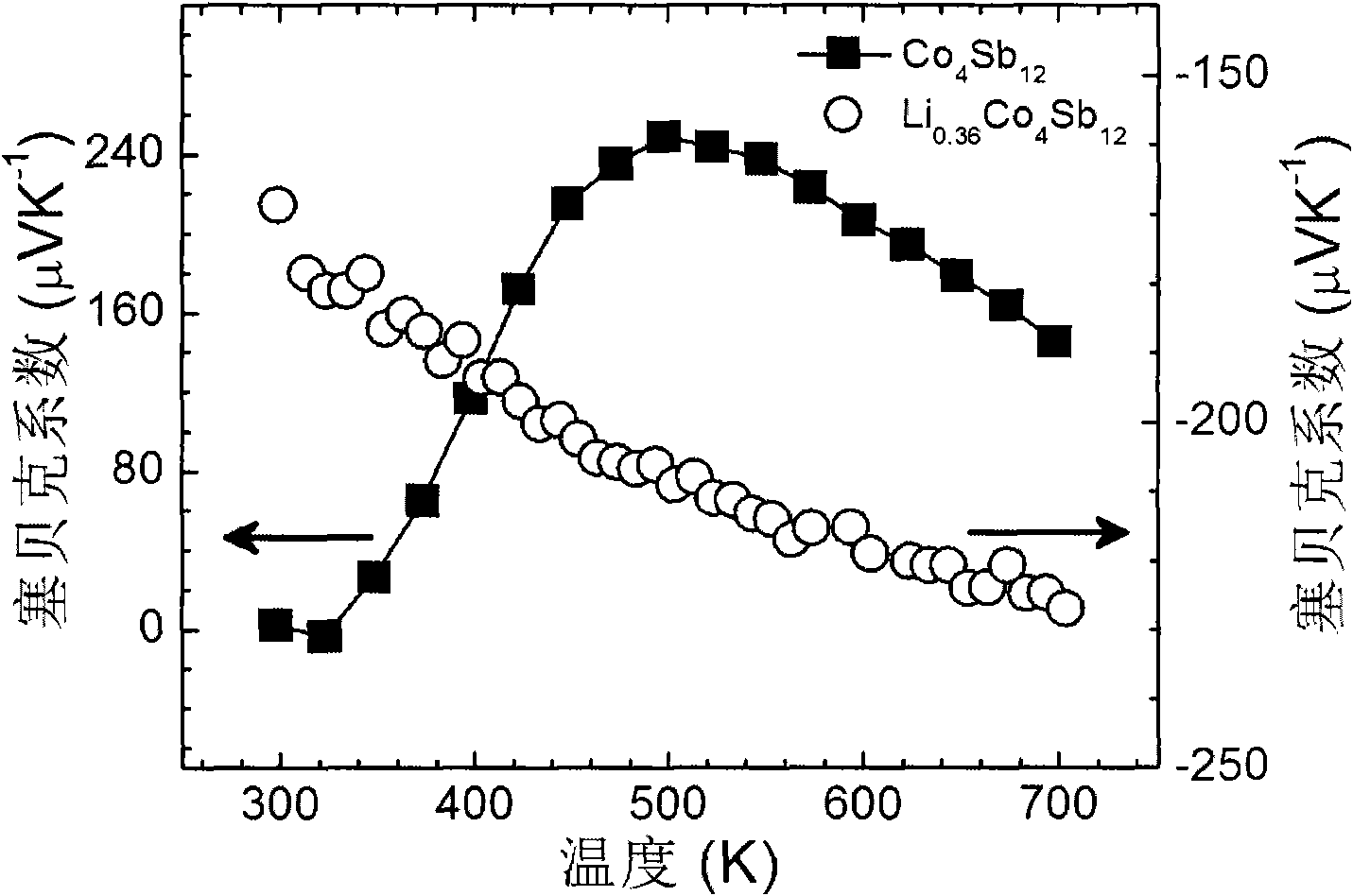

Filling in thermoelectric material of cobalt stibide based skutterudite by alkali-metal atom, and preparation method

ActiveCN1916211ASolve preparation difficultiesSolve the problem of strong corrosionThermoelectric device junction materialsMolten stateCobalt

This invention relates to a method for preparing alkali-metal-filled cobalt-antimonide-based thermoelectric material having high filling amount and excellent thermoelectric property. The thermoelectric material has a general chemical formula of AyCo4Sb12, wherein y is within 0-1, and A is at least one of Li, Na, K and Rb. The method comprises: (1) preparing metal raw materials with purities higher than 99% according to a stoichiometric ratio of Ay+y'Co4Sb12, wherein y' is within 0-0.5y and y within 0-1; (2) mixing and filling into a carbon-coated quartz tube in vacuum or inert atmosphere; (3) heating to 950-1200 deg.C for melting, and reacting completely; (4) quenching in air or quenching liquid oil (oil or water) to obtain AyCo4Sb12 crystal rod; (5) grinding into powder, mixing uniformly and tableting; (6) performing thermal treatment in inert atmosphere, grinding into powder, placing into a graphite mold, and rapidly sintering by plasma-discharging sintering to obtain compact block. The method has such advantages as simple process and low cost, and the obtained alkali-metal-filled cobalt-antimonide-based thermoelectric material has excellent thermoelectric properties.

Owner:中科西卡思(苏州)科技发展有限公司

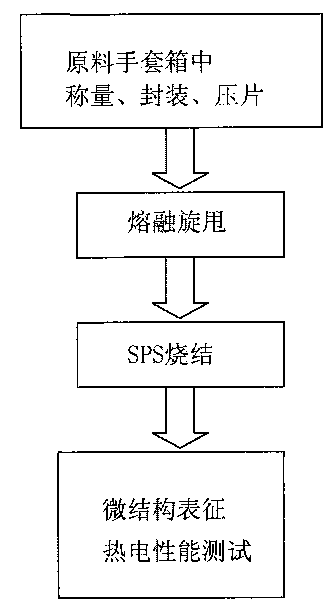

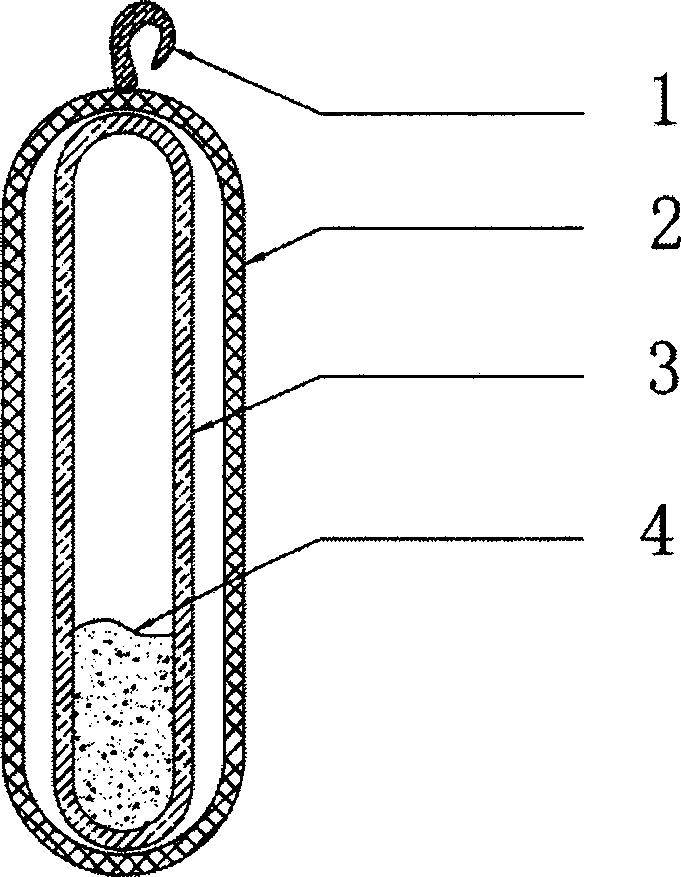

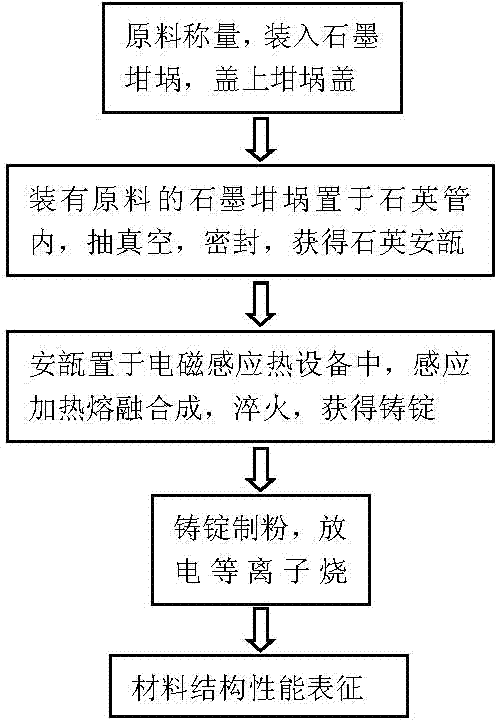

Preparation method of thermoelectric material of skutterudite

The invention relates to a preparation method of a thermoelectric material of skutterudite. The preparation method comprises the following steps: 1) weighing a pure metal serving as a raw material according to a chemical formula of the thermoelectric material of the skutterudite; 2) vacuum sealing the raw material, then adopting electromagnetic induction heating to obtain a uniformly mixed melt, and quenching the melt to obtain an ingot; and 3) grinding the ingot prepared in step 2) into powder, and carrying out spark plasma sintering on the ingot powder to obtain the thermoelectric material of the skutterudite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

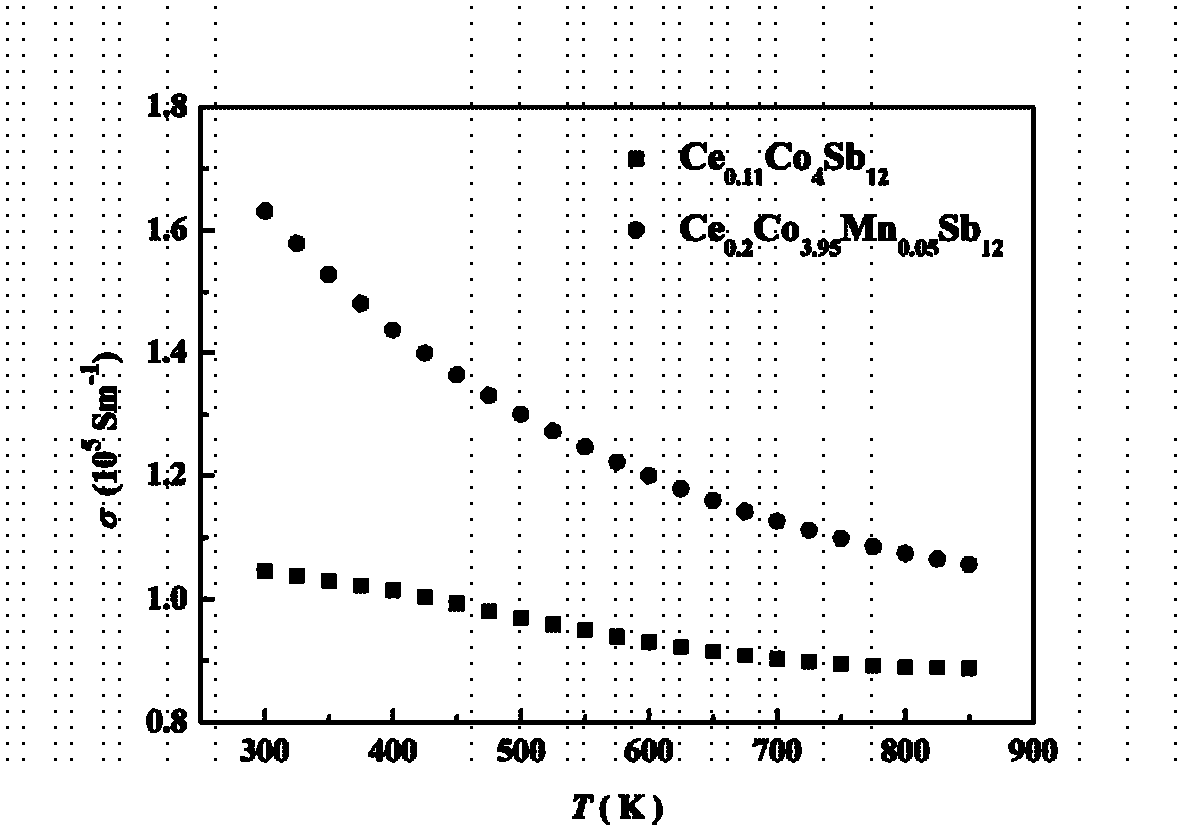

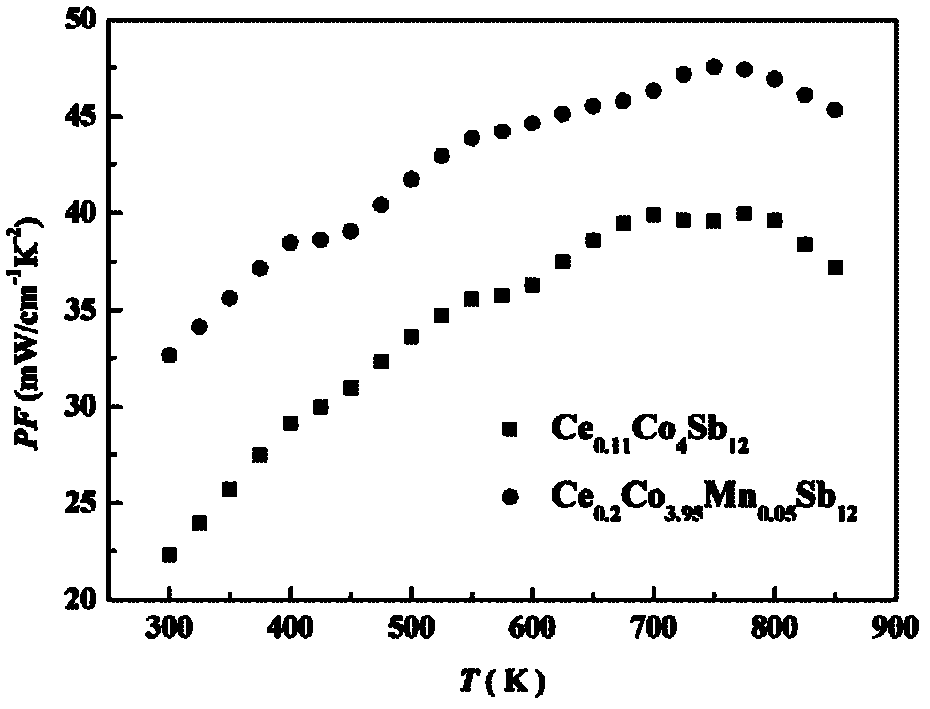

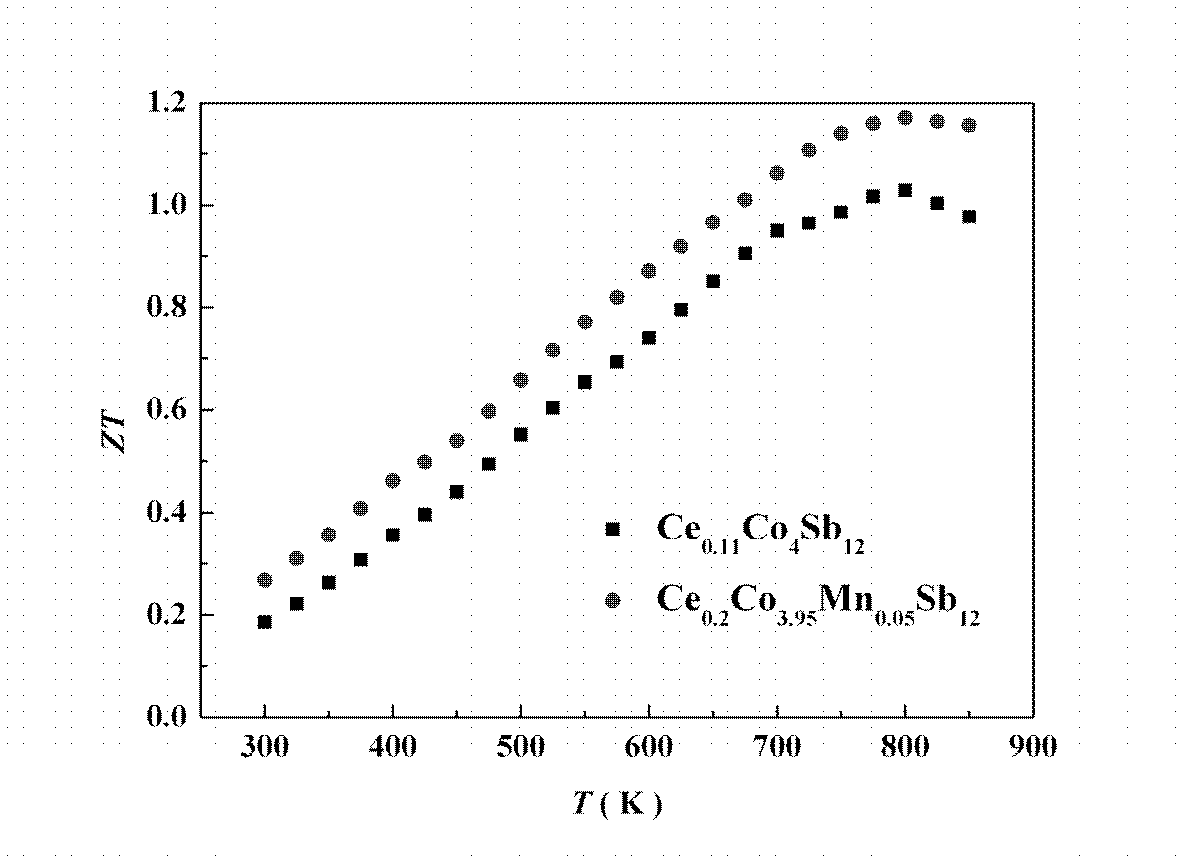

Hole compensation type skutterudite thermoelectric material and preparation method therefore

ActiveCN102881814AIncrease filling volumeHigh conductanceIron compoundsCobalt compoundsSkutteruditeElectron number

The invention relates to a hole compensation type skutterrudite thermoelectric material and a preparation method of the hole compensation type skutterudite thermoelectric material. The hole compensation type skutterudite thermoelectric material is shown in the following description: RyA(4-x)BxSb12 / z NC, wherein x is equal to or greater than 0.01 and equal to or less than 0.5, y is equal to or greater than 0.01 and equal to or less than 1 and z is equal to or greater than 0% and equal to or less than 10%; R is selected from at least one of the following group of elements: Ca, Ba, La, Ce, Pr, Nd and Yb; A is selected from at least one of the following group of elements: Fe, Co and Ni; B is selected from at least one of the following group of transition metal elements: Ti, V, Cr, Mn, Fe, Nb, Mo, Tc and Ru, and electron number of the element B is less than that of the element A; and NC is in phase II, wherein z is mole% in the phase II of the thermoelectric material. The invention also provides the preparation method of the hole compensation type skutterrudite thermoelectric material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

High-pressure synthesis preparation method of high-performance densification filled skutterudite thermoelectric material

InactiveCN102650005ASimple processHigh pressure synthesis parameters are easy to controlThermoelectric device manufacture/treatmentSkutteruditeHigh density

The invention discloses a high-pressure synthesis preparation method of a high-performance densification filled skutterudite thermoelectric material, which is characterized in comprising the following steps that 1) reaction raw materials with correspondent doses are mixed and subjected to cold press molding according to a chemical proportion for the planned synthesized filled skutterudite thermoelectric material; 2) primary high-pressure synthesizing is carried out, wherein the pressure range is 1 to 6GPa, the reaction temperature is 700 to 900 DEG C, the time is 10 to 120 minutes, the raw materials are mixed to be reacted with one another to primarily generate a transition product, and an obtained product is uniformly ground and subjected to cold press molding after being cooled and decompressed; 3) secondary high-pressure synthesizing is carried out, wherein the pressure range is 1 to 5 GPa, the reaction temperature is 550 to 650 DEG C, the time is 30 to 60 minutes, the synthesized filled shutterudite material is subjected to grinding, acidifying, drying and cold press molding after being cooled and decompressed; and 4) the final block thermoelectric material is obtained by adopting a high-pressure sintering or an electric spark discharging technology. The prepared product has high density, good mechanical machining performance and excellent thermoelectric performance, and the dimensionless thermoelectric figure of merit (ZT) is generally higher than 1. At the same time, the method and the device have simple process, take less time, save energy and have excellent industrialized production and an application prospect.

Owner:YANSHAN UNIV

Filled antimony-based square cobalt mineral compound and its production

The structural formula of filled antimony-based square cobalt mineral compound is RxM4Sb12-yDy; R represents filled atom element, M represents VIII-B family transient metal elements, D represents doped elements, 0 C22C 12 / 00 C22C 1 / 00 B22F 9 / 16 0 6 2 2007 / 4 / 13 101074463 2007 / 11 / 21 000000000 Zhejiang Univ. 310027 Zhao Xinbing Mi Jianli Zhu Tiejun tangyin yi 33212

Owner:ZHEJIANG UNIV

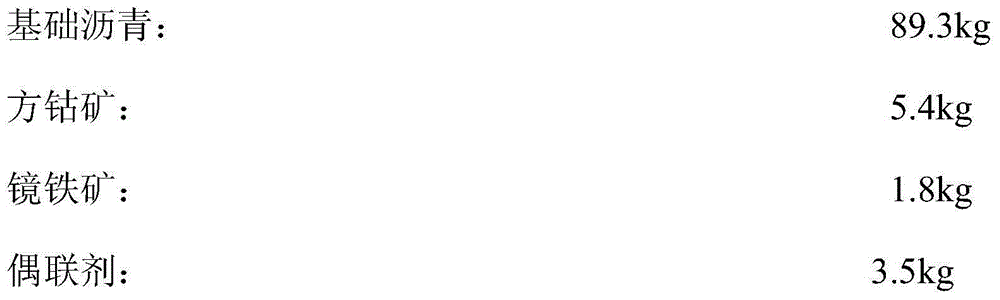

Modified asphalt with flame retardance and hot-mix emission reduction functions

ActiveCN103554932AImprove flame retardant performanceGood hot mix emission reduction effectBuilding insulationsRoad surfaceButadiene-styrene rubber

The invention discloses an asphalt pavement material with flame retardance and hot-mix emission reduction functions. The asphalt pavement material is prepared from the following raw materials in percentage by mass: 70-90% of base asphalt, 5-17.5% of skutterudite, 1.5-5.5% of specularite and 2.5-7% of coupling agent, wherein the total mass percentage of the raw materials is 100%; the base asphalt is common pavement petroleum asphalt, or asphalt modified with SBS (styrene-butadiene-styrene), SBR (styrene-butadiene copolymer), EVA (ethylene-vinyl acetate) and the like; the coupling agent is a titanate coupling agent, a silane coupling agent and the like. By adopting the material disclosed by the invention, the prepared asphalt has relatively good flame retardance, the emission of harmful gases such as asphalt fume, CO and NO2 generated in the asphalt heating and asphalt mixture construction processes can be remarkably reduced, and the asphalt has the advantages that the material source is wide, the cost is low, the preparation process is simple and the like.

Owner:王朝辉

P-type skutterudite material and preparation method thereof

ActiveCN102373348AIncreased maximum theoretical conversion efficiencyHigh thermoelectric figure of meritThermoelectric device manufacture/treatmentThermoelectric device junction materialsSkutteruditeChemistry

The invention relates to a p-type skutterudite material and a preparation method thereof. The invention provides the p-type skutterudite material which has a chemical formula as represented by IyFe4-xMxSb12 / z(phi), wherein, I is one kind or more kinds of filling atoms in a skutterudite phase, the filling amount y of the filling atoms is no less than 0.01 and no more than 1, M is one kind or more kinds of dopant atoms, the dopant amount x of the dopant atoms is no less than 0 and less than 4, phi is one kind or more kinds of second phases, the molar ratio z of phi is no less than 0 and no morethan 0.5, and second phase sediment disperses in the skutterudite phase. The invention also provides the preparation method for the p-type skutterudite material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

High performance thermoelectric materials and their method of preparation

InactiveUS7723607B2High quality factorThermoelectric device with peltier/seeback effectCobalt compoundsDopantSkutterudite

The present invention provides an indium-doped Co4Sb12 skutterudite composition in which some Co on the cubic lattice structure may be replaced with one or more members of the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt; some Sb on the planar rings may be replaced by one or more members of the group consisting of Si, Ga, Ge and Sn; and a second dopant atom is selected from a member of the group consisting of Ca, Sc, Zn, Sr, Y, Pd, Ag, Cd, Ba, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu. The composition is useful as a thermoelectric material. In preferred embodiments, the composition has a figure of merit greater than 1.0. The present invention also provides a process for the production of the composition, and thermoelectric devices using the composition.

Owner:EI DU PONT DE NEMOURS & CO

Formation of thermoelectric elements by net shape sintering

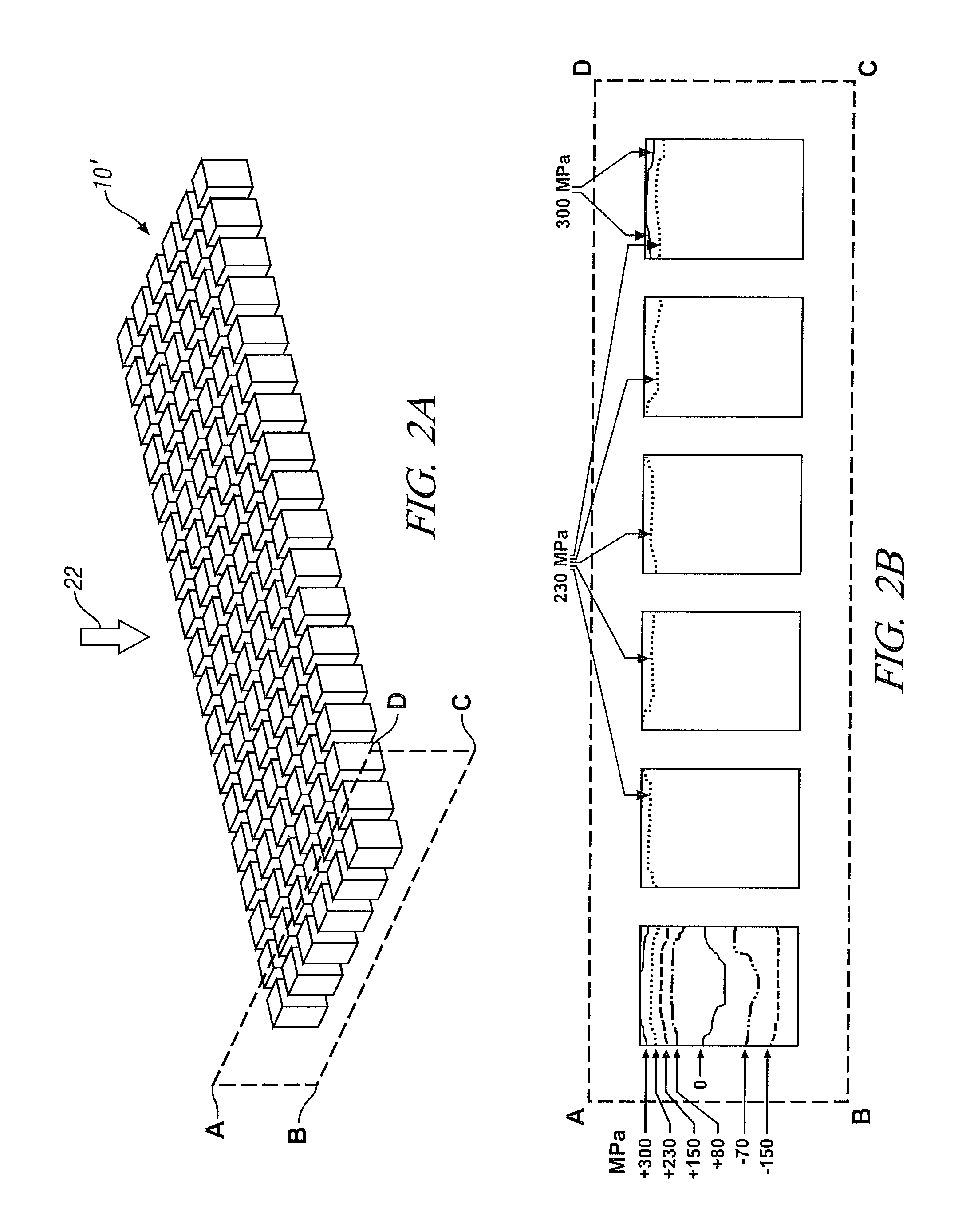

InactiveUS20110297203A1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSkutteruditeThermoelectric element

Practices are described for preparing fine-grain, stress-tolerant, brittle, doped semiconductor thermoelectric elements better suited to withstand thermal and mechanical loads without cracking or fracture. Preparation entails net shape powder processing of substantially isotropic thermoelectric compounds such as skutterudites under conditions which promote reduction of the largest grain sizes in a grain size distribution. Nearly three-fold improvements in fracture strength over conventionally-processed thermoelectric elements are observed. The net shape powder processing is adapted for the ready incorporation of the net shape thermoelectric elements into a thermoelectric device.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Filled skutterudites for advanced thermoelectric applications

ActiveUS7648552B2Suitable for useThermoelectric device manufacture/treatmentAlkaline accumulator electrodesMischmetalRare-earth element

Owner:GM GLOBAL TECH OPERATIONS LLC

Multiple filling skutterudite thermoelectric material and preparation process thereof

This invention relates to a multi filled skutterudite thermoelectric material. Its characteristic is filling of two or more than two metal atoms I in the hole of skutterudite AB3 crystal icosahedron, the ratio of I:A:B is y:4;:12. In the equation, A represents one or two of Fe, Co and Ni, B is one or two of S6, Se and Fe, I is two or more than two of K, Na, Ca, Sr, Ba, Yb, Ce, La or Ou, y is the sum padding whose volume is met to 0.05-1. The production process of the thermoelectric material includes feeding, melting and quenching, it has the characteristic such as simple processes, low cost and being suitable to produce.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Alloy electrode for skutterudite thermoelectric element and preparation method thereof

ActiveCN106299099AImprove conductivityGood welding performanceThermoelectric device manufacture/treatmentThermoelectric device detailsChemical platingSkutterudite

The invention relates to an alloy electrode for a skutterudite thermoelectric element and a preparation method thereof. The alloy electrode provided by the invention is an alloy electrode deposited at two end parts of the skutterudite thermoelectric element. The alloy electrode is made of a Ni-Mo alloy or a Ni-W alloy, wherein the molar percentage content of Mo in the Ni-Mo alloy is 10%-40%, the molar percentage content of W in the Ni-W alloy is 5%-40%. In the invention, the selected electrode material is a Ni(Mo) or Ni(W) alloy electrode prepared through an electroplating or chemical plating method. The alloy electrode is good in conductivity and excellent in weldability, the coefficient of thermal expansion of a Ni-containing electrode can be adjusted through substances with a small coefficient of thermal expansion such as Mo and W, and the difference between the electrode material and a skutterudite thermoelectric material in coefficient of thermal expansion is reduced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com