Filling in thermoelectric material of cobalt stibide based skutterudite by alkali-metal atom, and preparation method

A technology for filling cobalt antimonide-based and thermoelectric materials, which is applied in the direction of thermoelectric device node lead-out materials, etc., can solve the problems of difficult preparation, strong corrosion, etc., and achieve the effect of solving difficult preparation, low cost, and improved thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

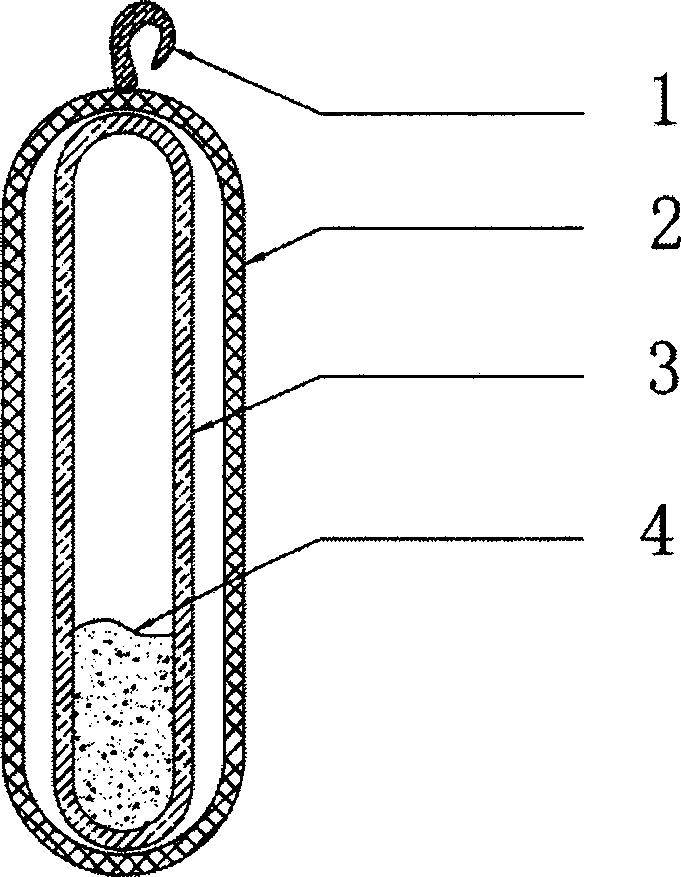

Image

Examples

Embodiment 1

[0027] Example 1: Ky co 4 Sb 12 Material

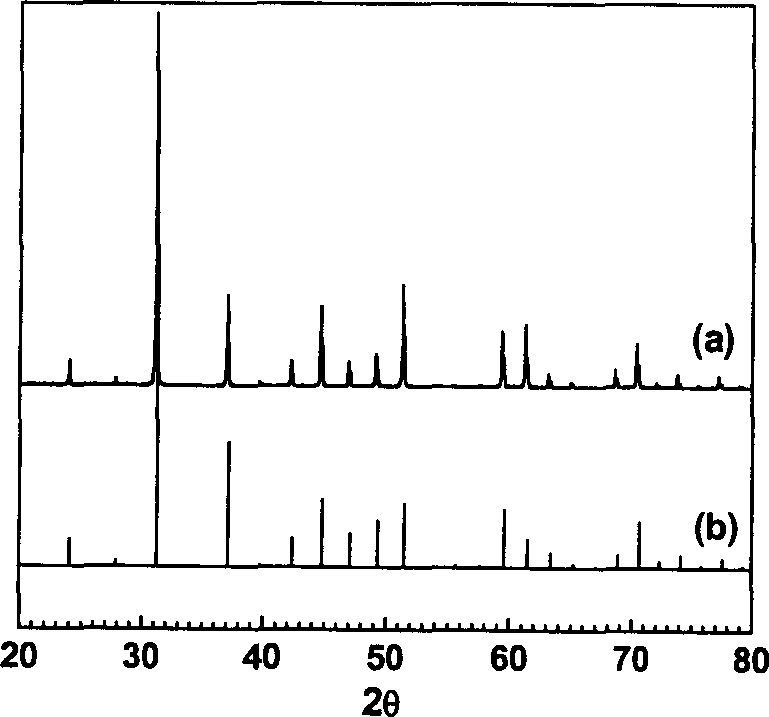

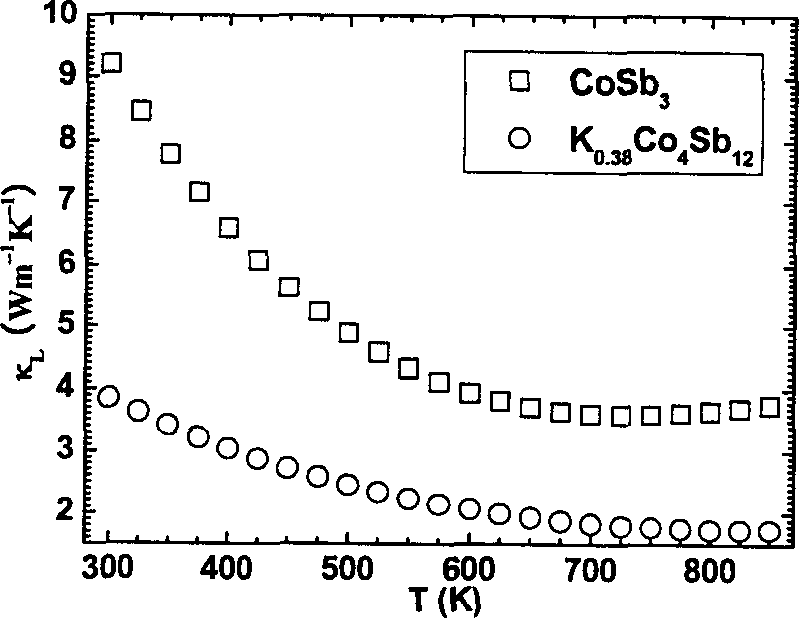

[0028] The metal raw materials K, Co, and Sb were mixed according to the molar ratio of 0:4:12 and 0.5:4:12 respectively, and double-layer packaged into a vacuum carbon-coated quartz tube, and the packaged raw materials were melted together with the quartz ampoule at 1150 ° C for 30 minutes After quenching in air, the obtained ingot was ground into powder and then heat-treated at 800°C for 1 hour. X-ray diffraction analysis of the obtained powder showed that the synthesized material was pure phase K y co 4 Sb 12 For the skutterudite material, the resulting loading was 0.38. The X-ray diffraction pattern illustrates the obtained K 0.38 co 4 Sb 12 The material is well crystalline and of high purity (see figure 2 ). The obtained powder was sintered by SPS at 450° C. for 25 minutes with a pressure of 100 MPa. Thermal conductivity tests show that the lattice thermal conductivity of potassium-filled skutterudite materials is sign...

Embodiment 2

[0029] Example 2: Na y co 4 Sb 12 Material

[0030] The metal raw materials Na, Co, and Sb are dosed according to the molar ratio of 0:4:12 and 0.6:4:12, and double-packed into a carbon-coated quartz tube filled with a small amount of inert gas. After melting at low temperature for 30 hours, it was quenched in water. The obtained ingot was ground into powder and then heat-treated at 400°C for 100 hours. X-ray diffraction analysis of the obtained powder showed that the synthesized material was pure phase Na y co 4 Sb 12 The skutterudite material, resulting in a fill of 0.5. Na prepared by this method 0.5 co 4 Sb 12 and CoSb 3 Good crystallinity and high purity (see Figure 5 ). The obtained powder was sintered by SPS at 750° C. for 10 minutes with a pressure of 30 MPa. Thermal conductivity tests show that the lattice thermal conductivity of sodium-filled skutterudite materials is very low (see Image 6 ); by measuring the electrical conductivity and the Seebeck coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com