Patents

Literature

82 results about "Lattice thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lattice thermal conductivity strongly affects the applications of materials related to thermal functionality, such as thermal management, thermal barrier coatings and thermoelectrics. In order to understand lattice thermal conductivity more...

Dynamic thermal interface material

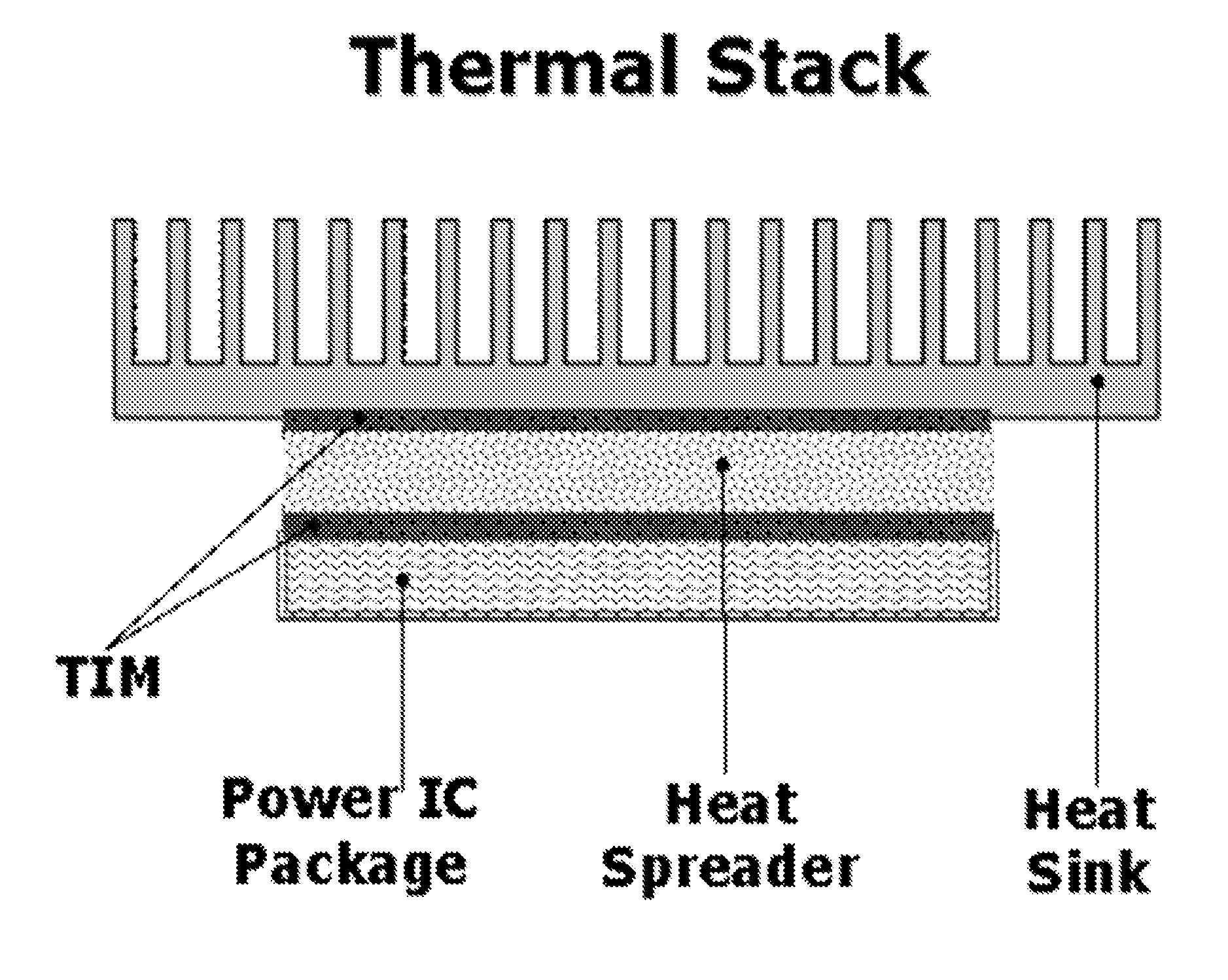

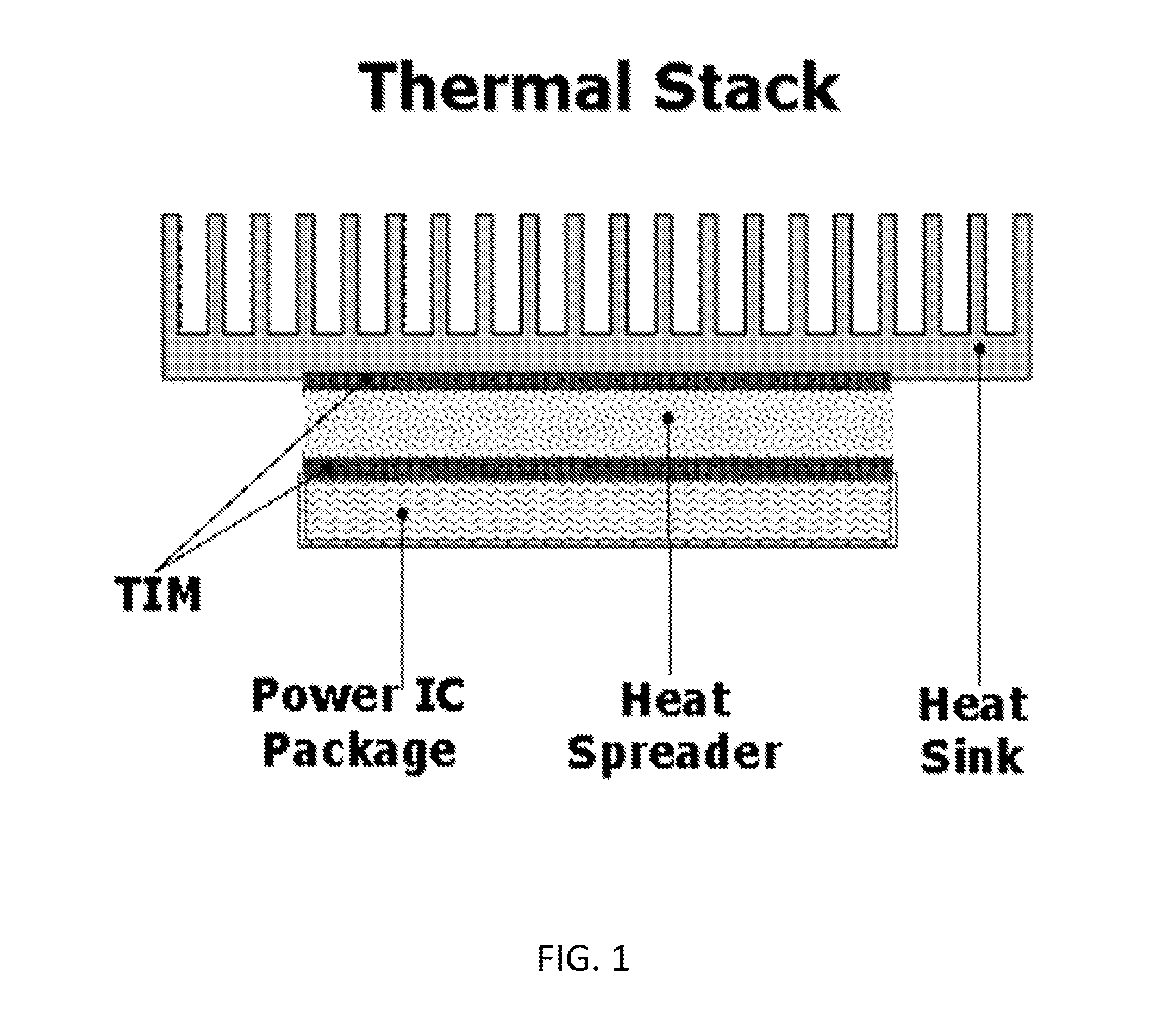

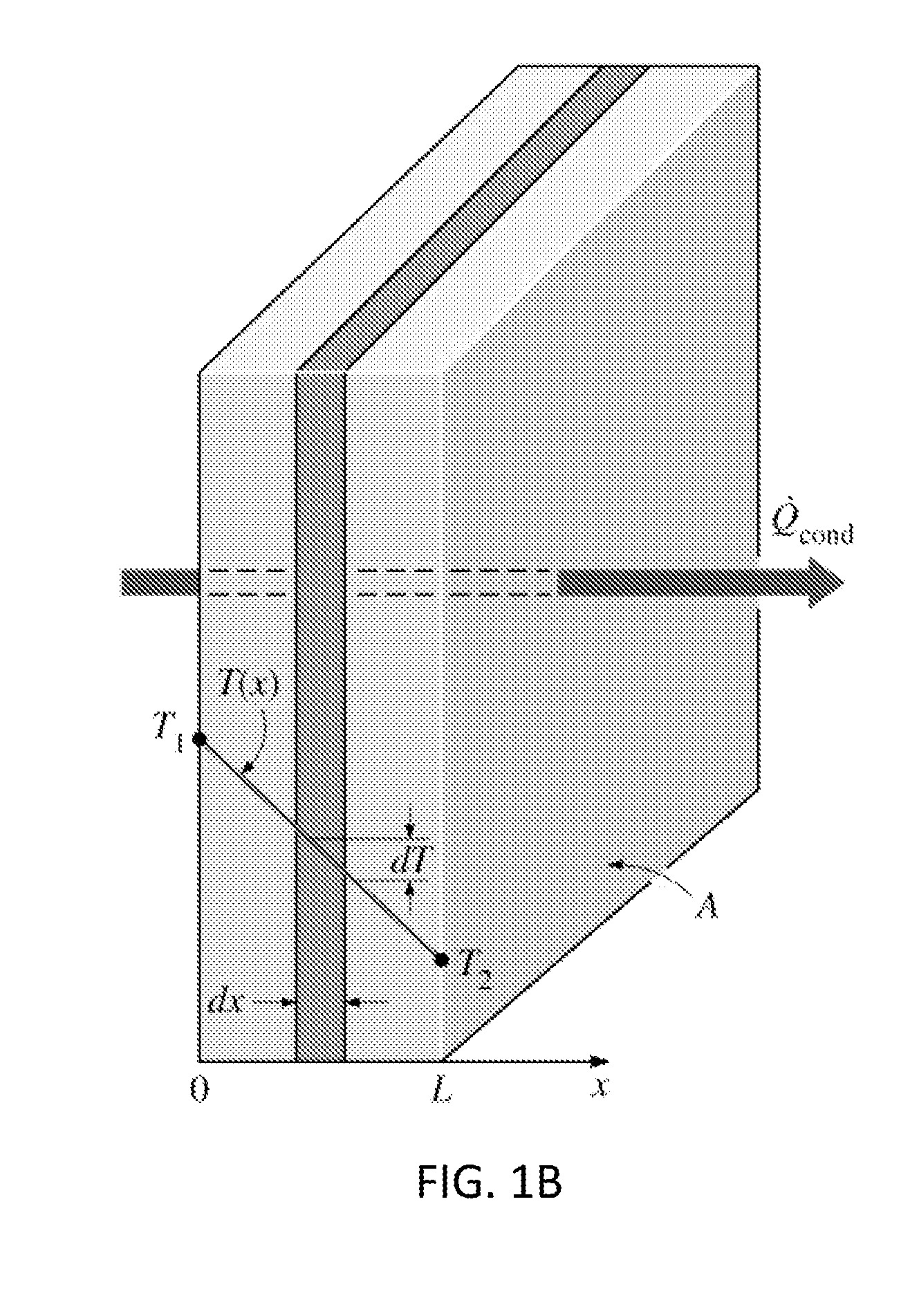

InactiveUS20140345843A1High densityImproving CNT and nGP interactionSemiconductor/solid-state device detailsSolid-state devicesLattice thermal conductivityCarbon nanotube

Aspects of the invention provide compositions that include carbon nanotubes dispersed within nanographite particles, and that have useful thermal properties. Certain compositions have high thermal conductivities (e.g., high thermal conductivities at ambient temperature). Certain compositions have a temperature dependent thermal conductivity that reversibly increases with temperature. Certain compositions are useful for heat transfer and can be used as thermal interface material, for example, in the context of computer and / or power generating devices.

Owner:ANCHOR SCI

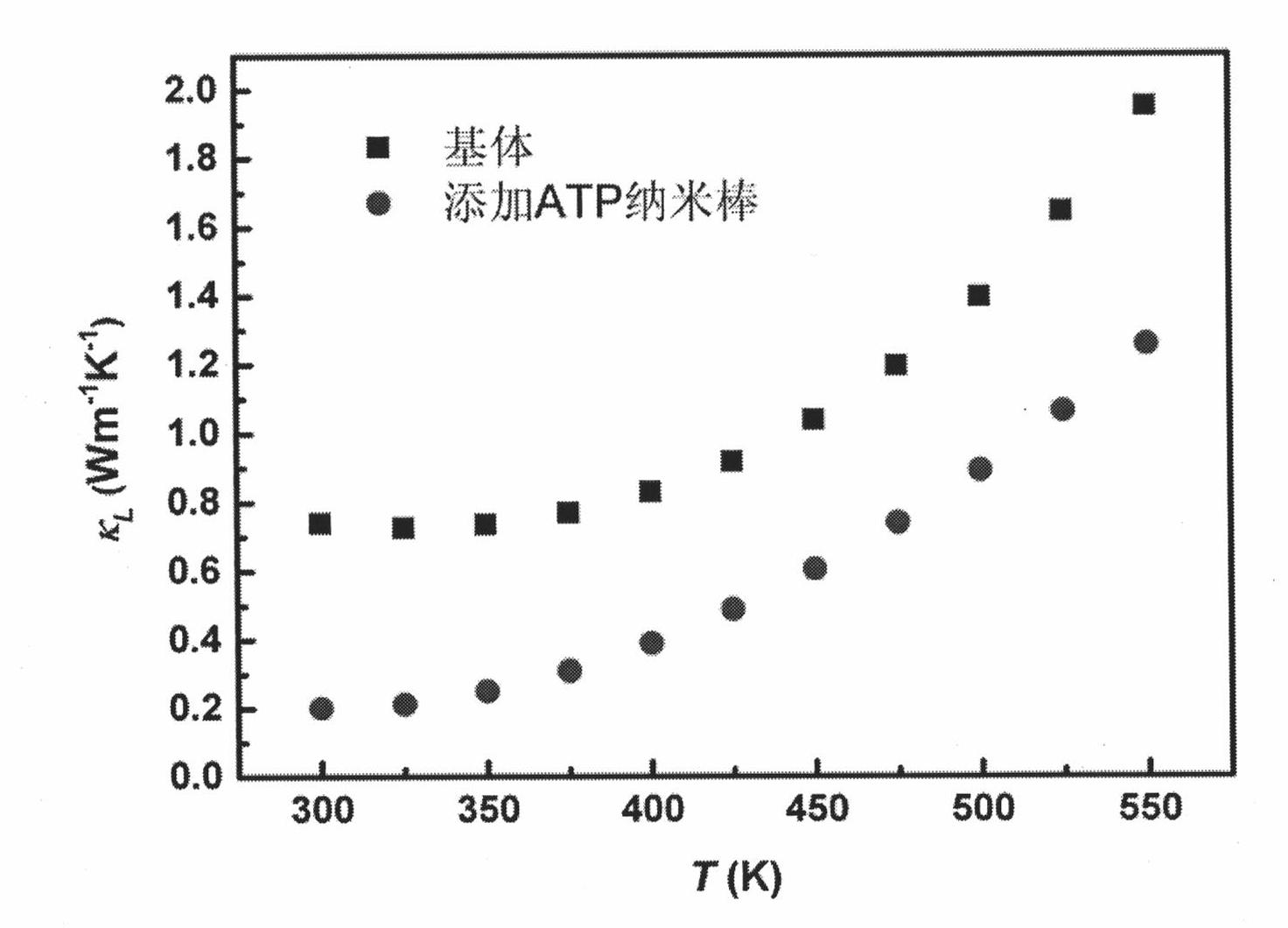

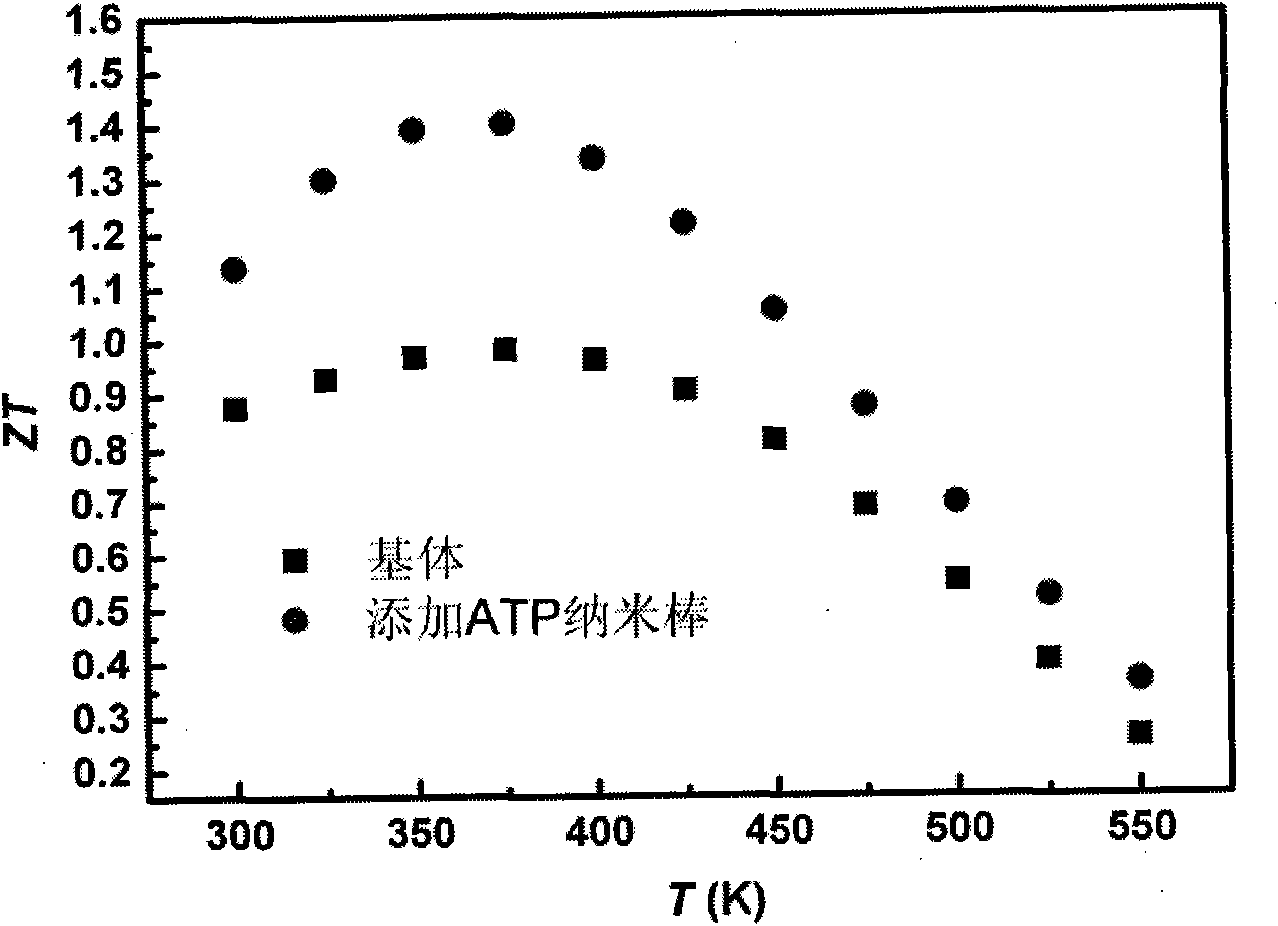

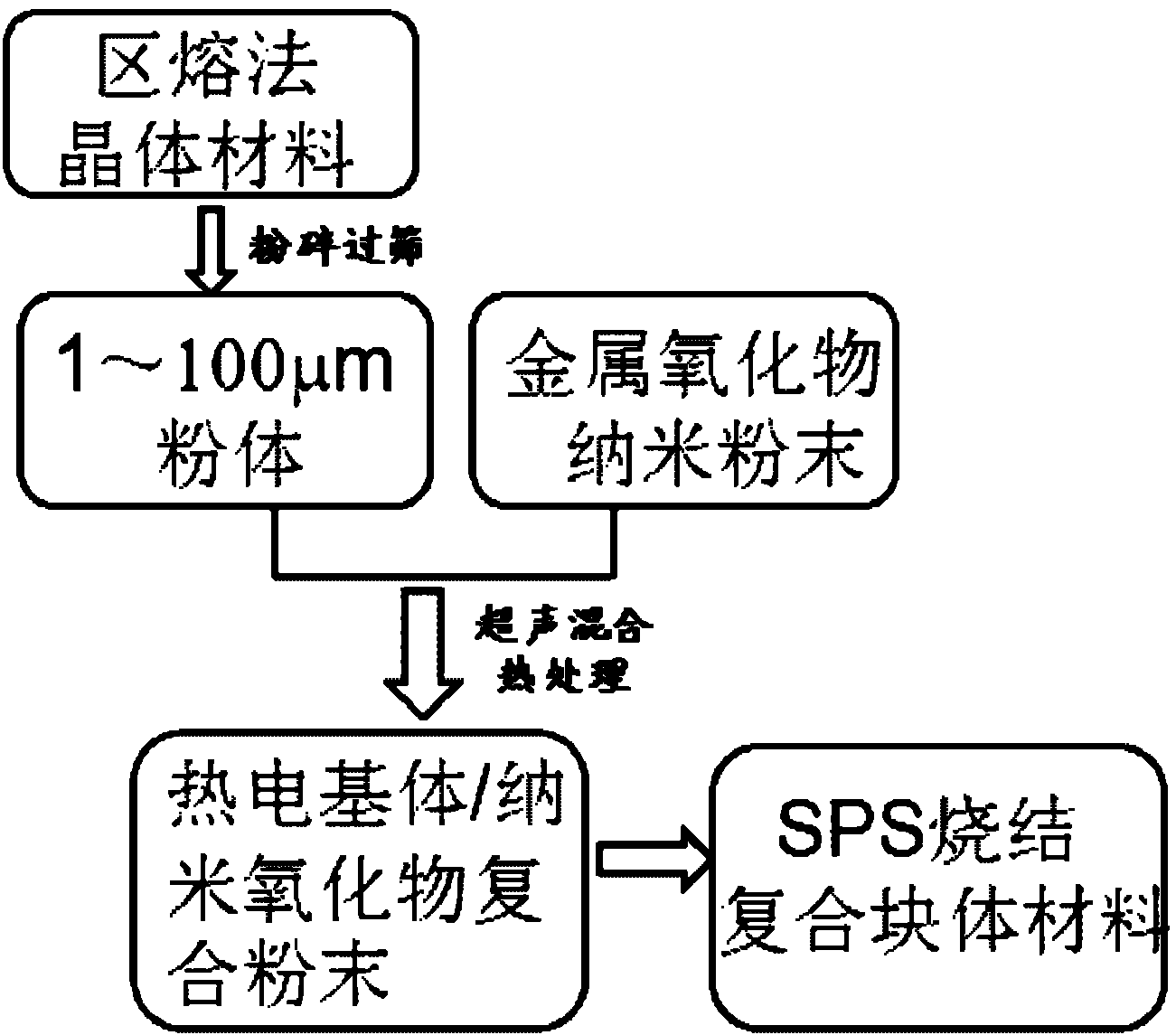

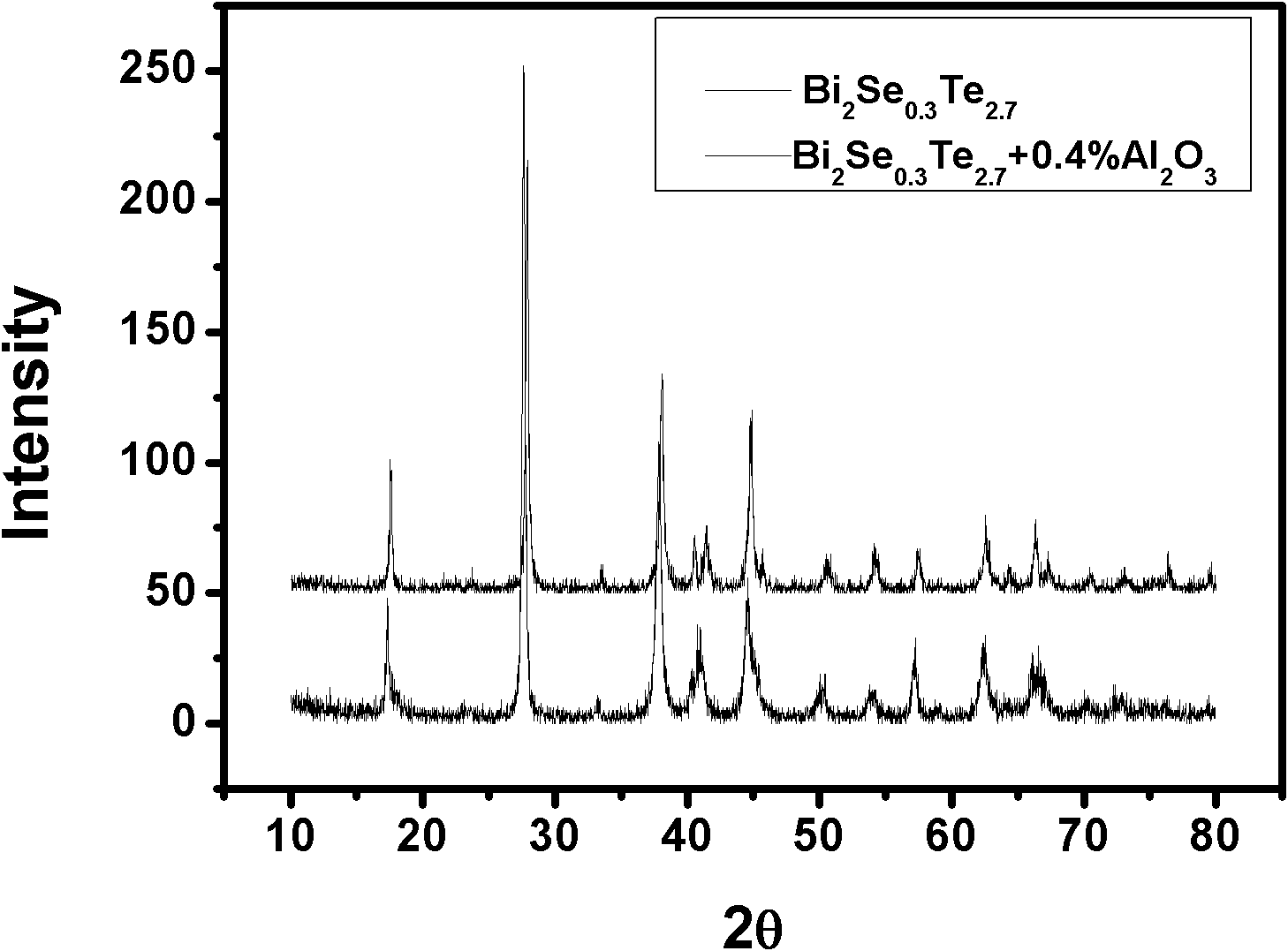

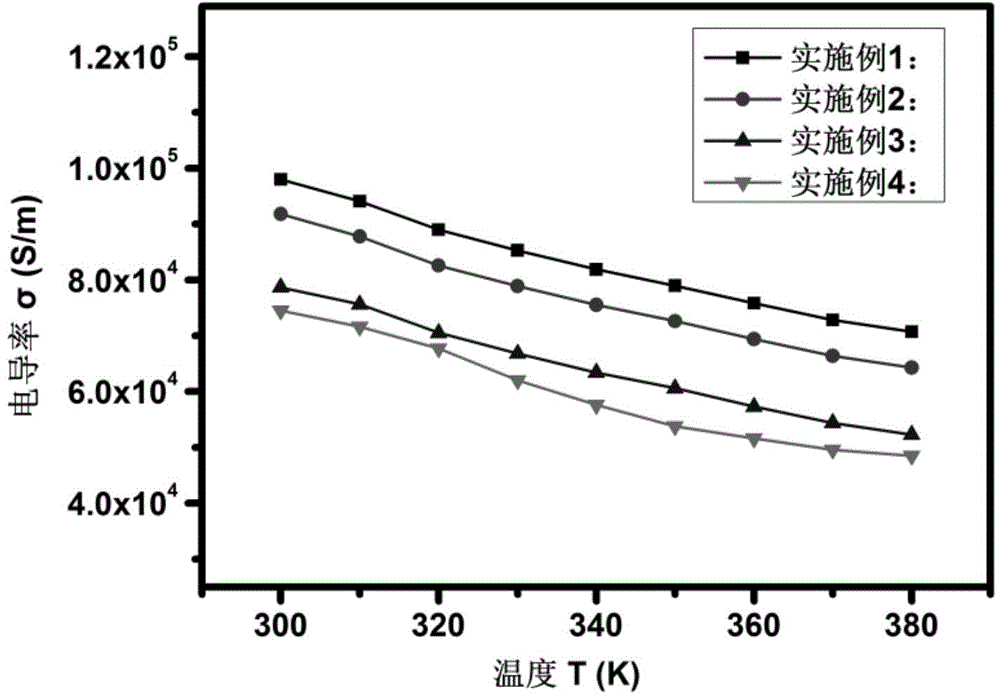

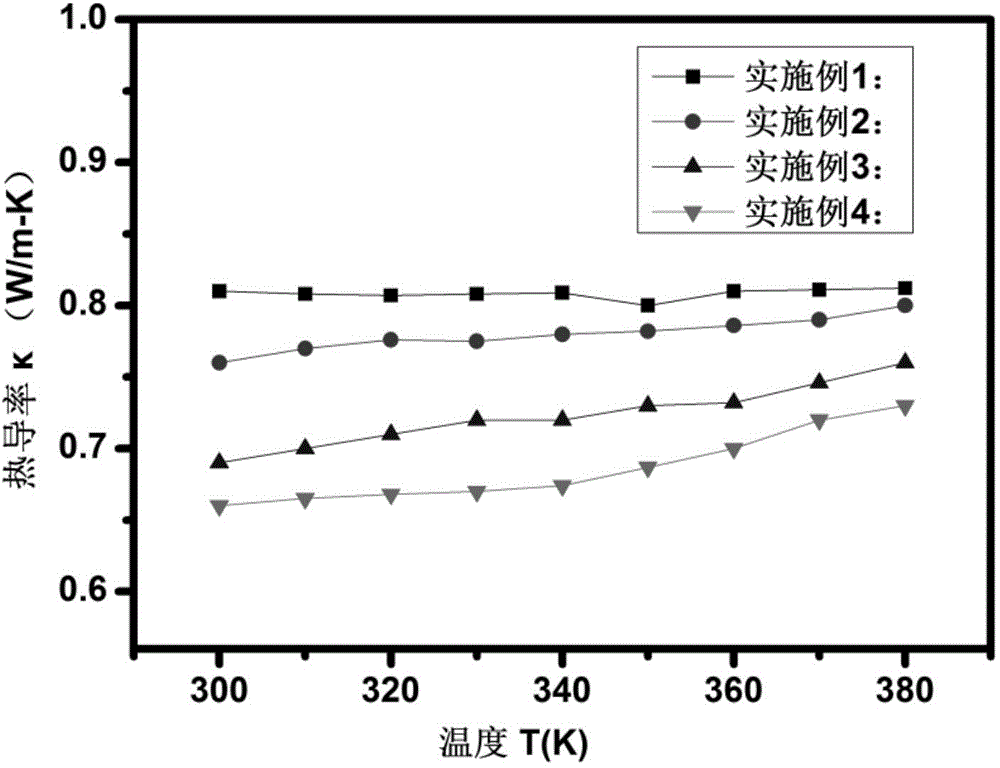

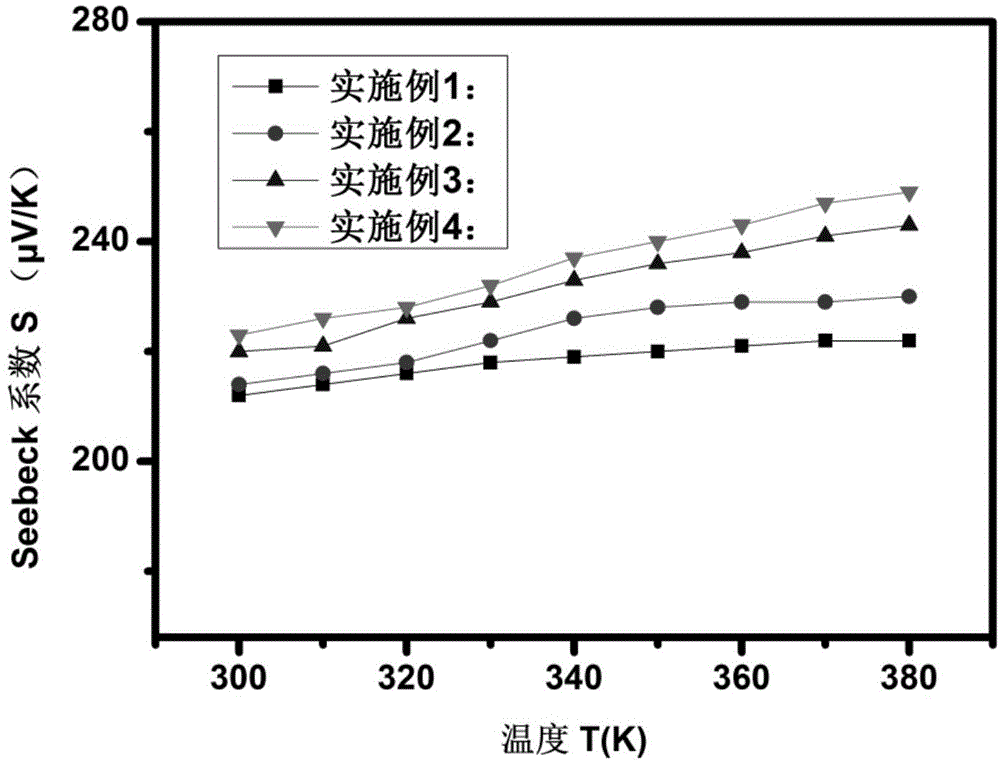

Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

ActiveCN101994155ALower lattice thermal conductivityReduced lattice thermal conductivity κ

<sub>L</sub>Polycrystalline material growthBy zone-melting liquidsBismuth tellurideCarbon nanotube

The invention discloses a nanophase doped bismuth telluride-based thermoelectric material and a preparation method thereof. The bismuth telluride-based thermoelectric material is characterized in taking the bismuth telluride-based thermoelectric material containing a tellurium element, a bismuth element and a doped chemical element, as a matrix. The doped nanophase is a one-dimensional nanophase,and the weight of the one-dimensional nanophase accounts for 0.01-5 percent of the weight of the matrix. Attapulgite or a zinc oxide nanowire or a single-wall carbon nanotube or a multi-wall carbon nanotube is preferable to the one-dimensional nanophase. Compared with the prior art, in the bismuth telluride-based thermoelectric material, the lattice heat conductivity within the whole temperature zone range is reduced, thereby a ZT value is greatly improved and the thermoelectric performance of the bismuth telluride-based thermoelectric material is improved. The preparation method is simple and easy to implement, and compared with other methods of balling milling or liquid phase and the like, impurities are not easy to introduce in the preparation method so that the one-dimensional nanophase is evenly staggered and distributed in the matrix and the mechanical property of the material is effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Filled skutterudite-base thermoelectrical composite material and its prepn

ActiveCN1888105ALower lattice thermal conductivityDoes not affect electrical transmission performanceMolten stateMechanical crushing

The present invention relates to filled skuterudite-base thermoelectrical composite material and its preparation process, and belongs to the field of thermoelectrical material preparing technology. The thermoelectrical composite material has the composition of IyA4B12 / zIOx, where I is one of Yb, Eu, Ce, La, Nd, Ca and Sr; A is Sb or its mixture with one of Ge, Sn, Te and Se; B is Co or its mixture with Fe or Ni; y is the amount of I element, y+z=m, and m is greater than the filling limit of filling atom. The thermoelectrical composite material is prepared through first smelting process to produce block material, the subsequent mechanical crushing and grinding to obtain powder, and the final fast sintering with pulse DC current to form compact block. The material has lowered lattice heat conductivity, maintained electric transmission performance and raised thermoelectrical conversion performance.

Owner:中科西卡思(苏州)科技发展有限公司

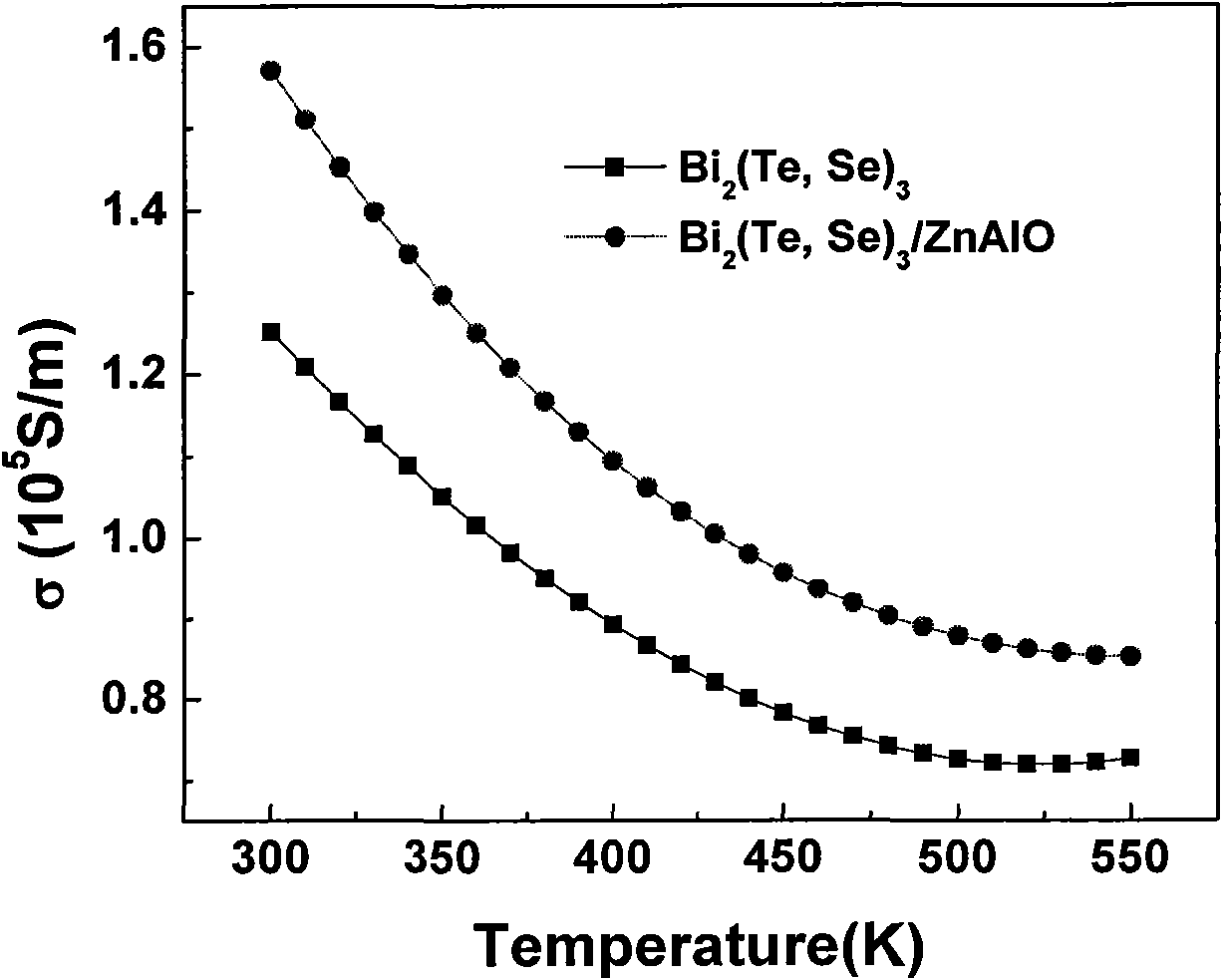

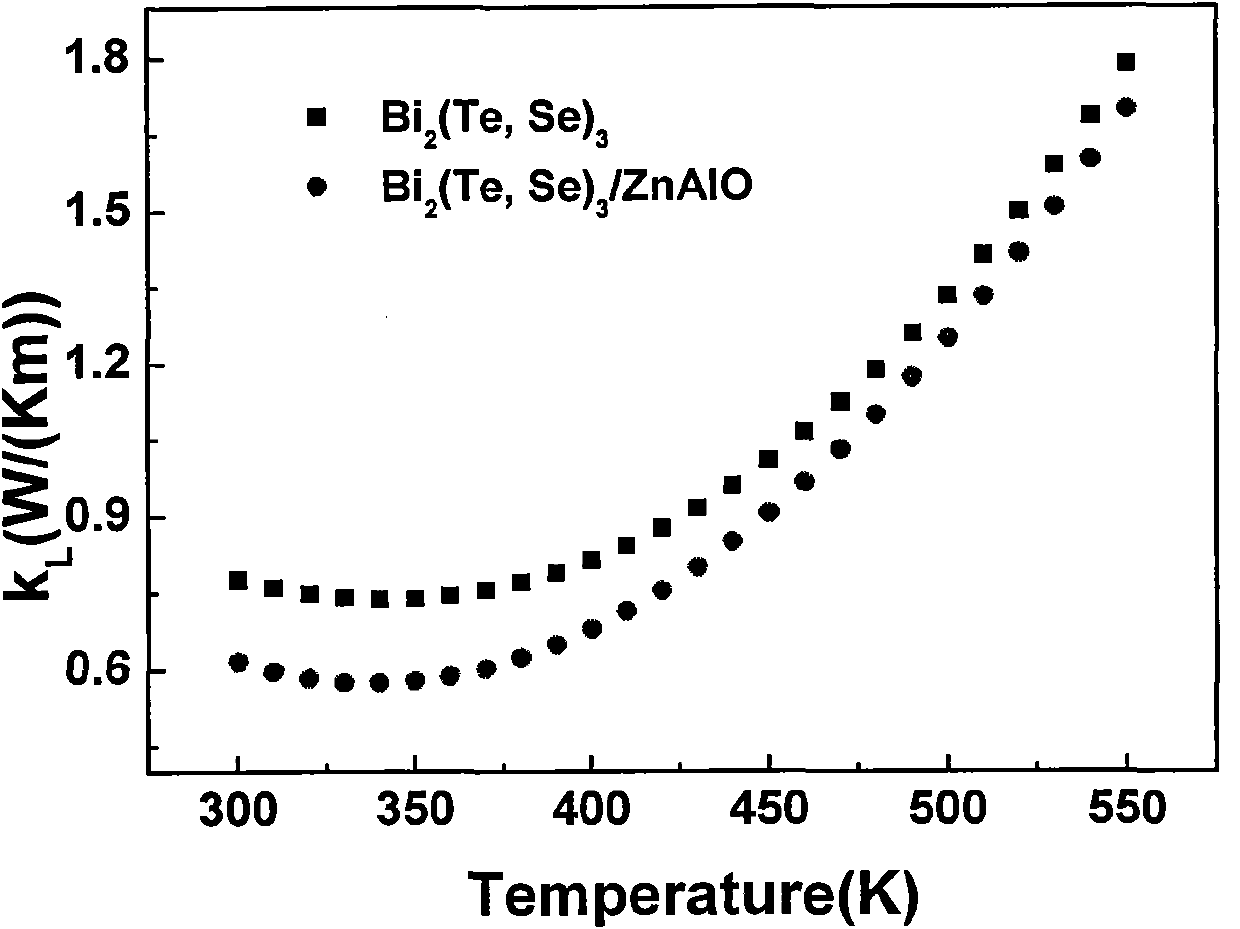

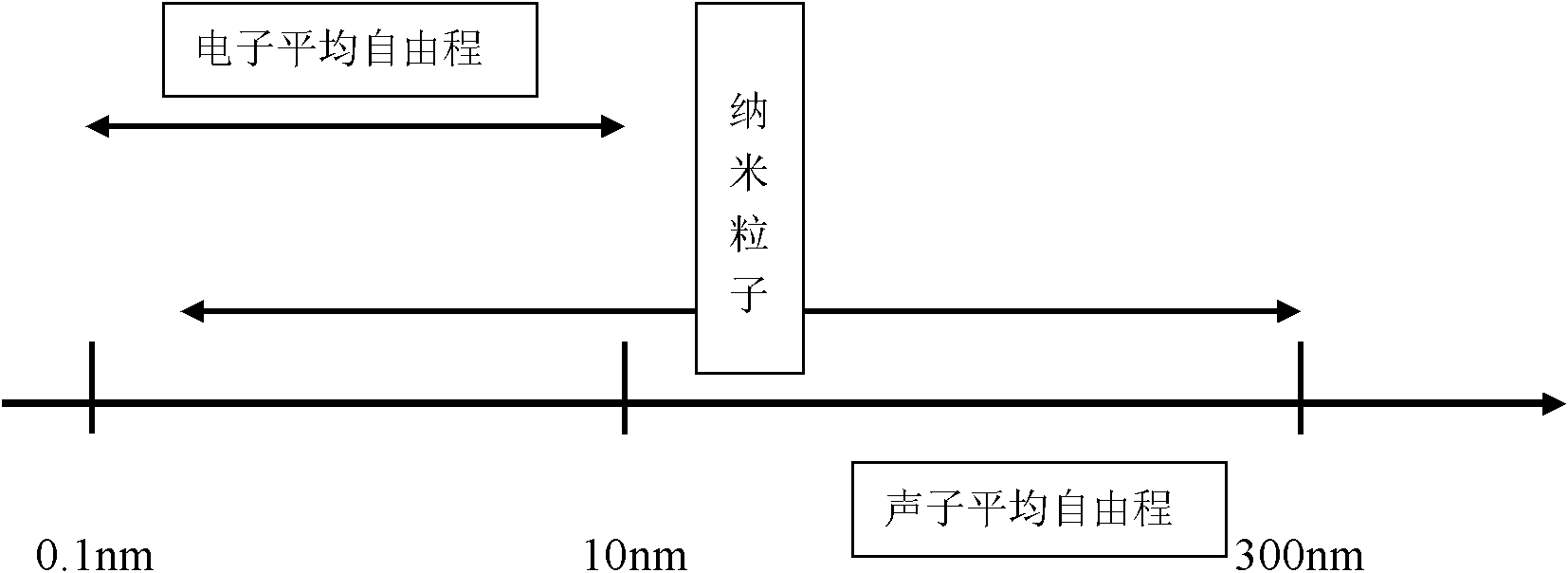

Nanoparticle composite bismuth telluride-based thermoelectric material and preparation method thereof

ActiveCN102024899ALower lattice thermal conductivityImprove thermoelectric figure of merit ZTThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention discloses a nanoparticle composite bismuth telluride-based thermoelectric material and a preparation method thereof. In the nanoparticle composite bismuth telluride-based thermoelectric material, a bismuth telluride thermoelectric material is used as a substrate, and nanoparticles are mixed in the substrate, wherein the nanoparticles are electrical-conduction oxide nanoparticles. Compared with the prior art, since the electrical-conduction oxide nanoparticles are used as a second phase and compounded with a bismuth telluride-based alloy substrate; on one hand, the electrical-conduction oxide nanoparticles can enhance the selective scattering to low-frequency phonons so that the crystal lattice heat conductivity of the bismuth telluride-based thermoelectric material can be effectively reduced, and on the other hand, the electrical-conduction oxide nanoparticles can improve the electrical conductivity of the material on the other hand, therefore, an integral regulation and control effect improves the thermoelectric figure of merit ZR of the bismuth telluride-based thermoelectric material so that the thermoelectric property of the bismuth telluride-based thermoelectric material is optimized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

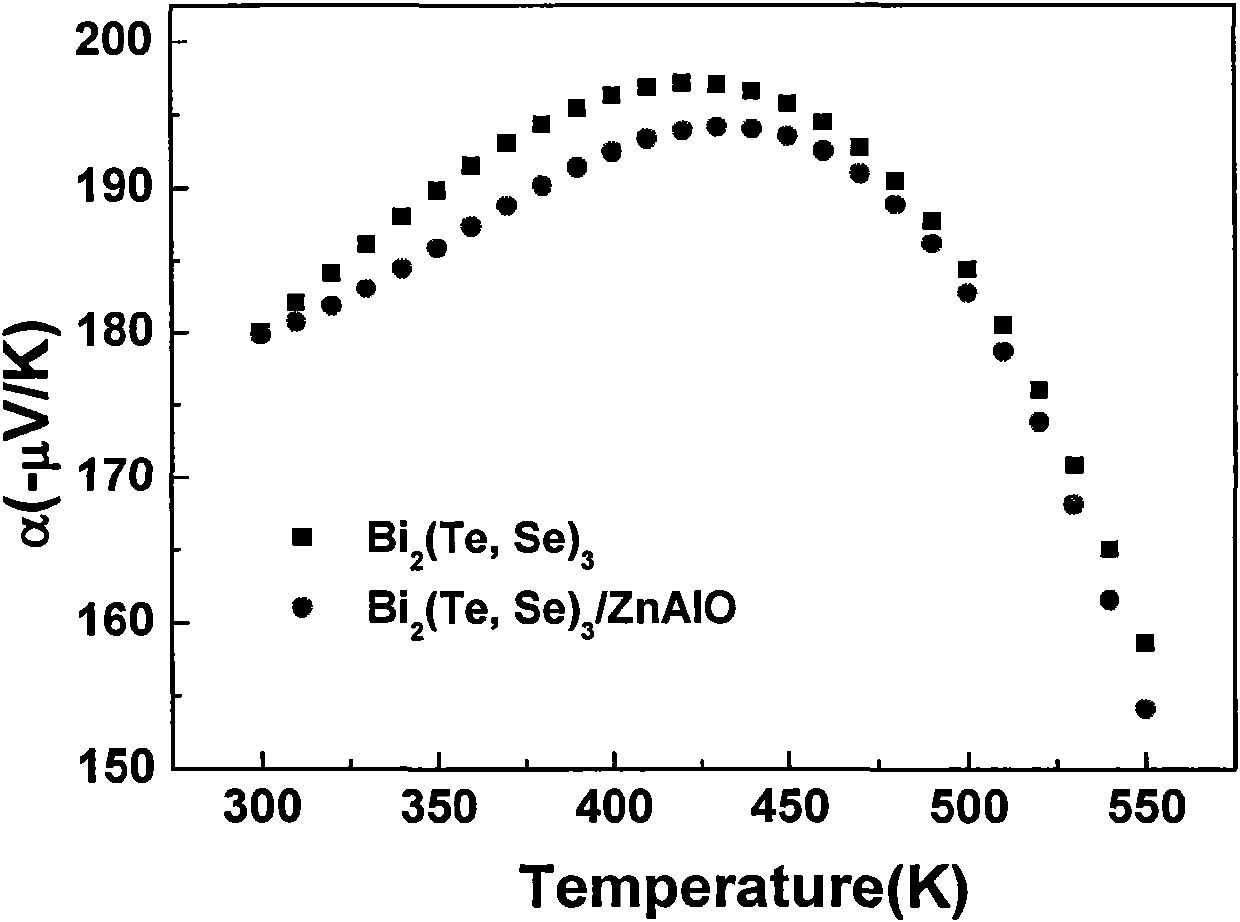

High-performance thermoelectric composite material and preparation method thereof

ActiveCN102339946AImprove Seeback coefficientLow thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention relates to a high-performance thermoelectric composite material and a preparation method thereof, belonging to the field of thermoelectric materials. The composite material consists of two phases. A first phase is n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3, and a second phase is nanometer powder of a metallic oxide. The nanometer powder of the metallic oxide accounts for 0.05-10% in terms of the total weight of the thermoelectric composite material. According to the preparation method provided by the invention, the n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3 powder is ultrasonically mixed with the nanometer oxide, and discharge plasma sintering is carried out on the mixture to obtain a dense block material. Compared with the bismuth-telluride-based thermoelectric base material, under the condition that the electric conductivity of the thermoelectric base material is maintained to be unchanged basically in the invention, the high-performance thermoelectric composite material, provided by the invention, achieves the advantages of obviously reduced lattice heat conductivity and increased Seeback coefficient, and therefore the thermoelectric performance of the material can be greatly improved.

Owner:中科西卡思(苏州)科技发展有限公司

Argyrodite thermoelectric material and preparation method thereof

InactiveCN106098923AImprove thermoelectric performanceLow thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsArgyroditeSlow cooling

The invention relates to an argyrodite thermoelectric material, the chemical formula of which is Ag8Sn(1-x)NbxSe6, x=0-0.05. The preparation method of the argyrodite thermoelectric material is characterized by, with simple substances being raw materials, carrying out material blending according to stoichiometric ratio of the chemical formula; after vacuum packaging, melting reaction quenching and thermal treatment quenching, grinding ingots into powders; and carrying out vacuum high-temperature hot-pressure sintering, and after slow cooling, obtaining a block material, which is the argyrodite thermoelectric material. Compared with the prior art, the high-performance thermoelectric material, which is low in heat conduction and high in thermoelectric performance, is prepared, and the method for preparing the thermoelectric material, which is high in density, high in mechanical strength and high in thermoelectric performance, is explored; the thermoelectric material has very low lattice thermal conductivity (0.2-0.4 W / m.K) in a whole-temperature range; when the temperature is 900 K, thermoelectric peak of the thermoelectric material reaches 1.2; when the temperature is 300-850 K, the average thermoelectric figure of merit zTave of the thermoelectric material is infinity-0.8; and the argyrodite thermoelectric material is a potential thermoelectric material.

Owner:TONGJI UNIV

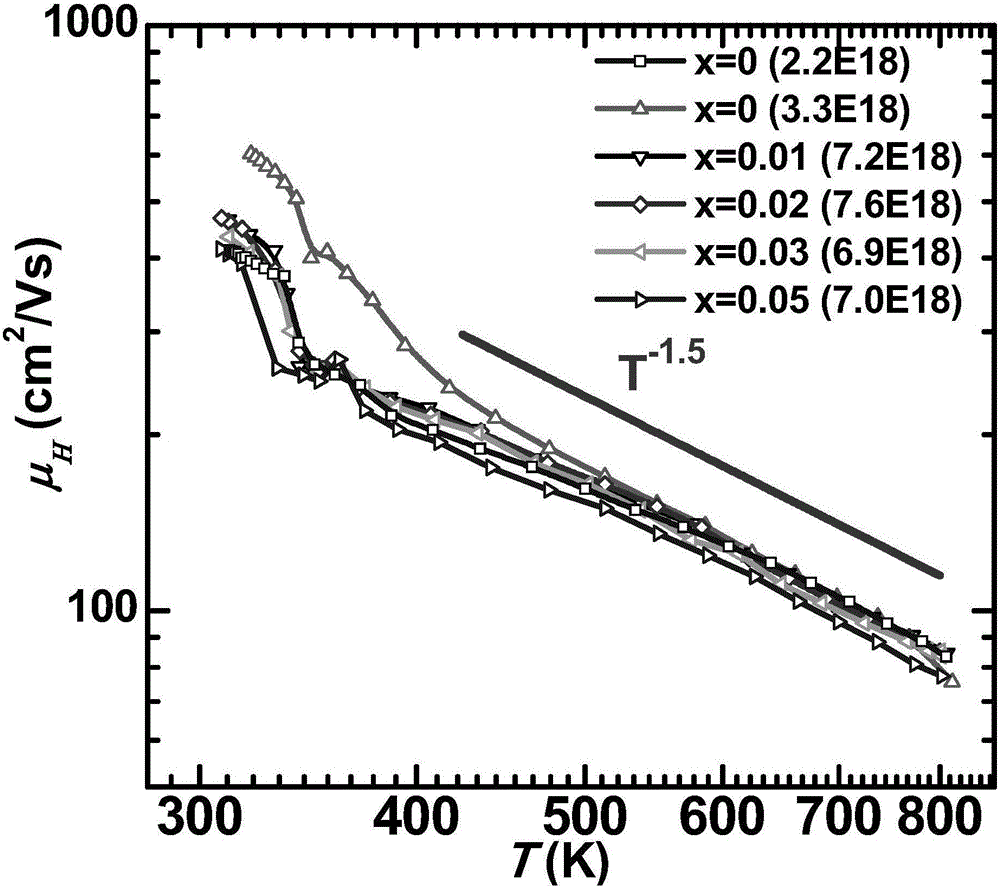

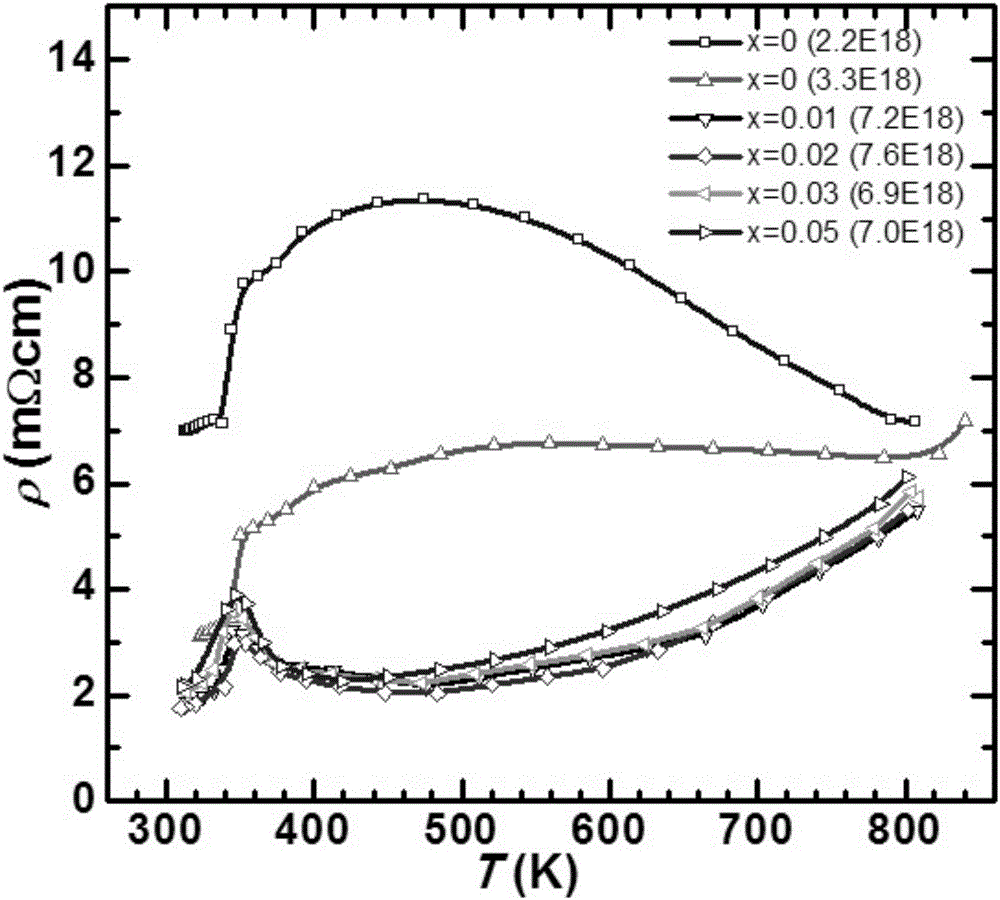

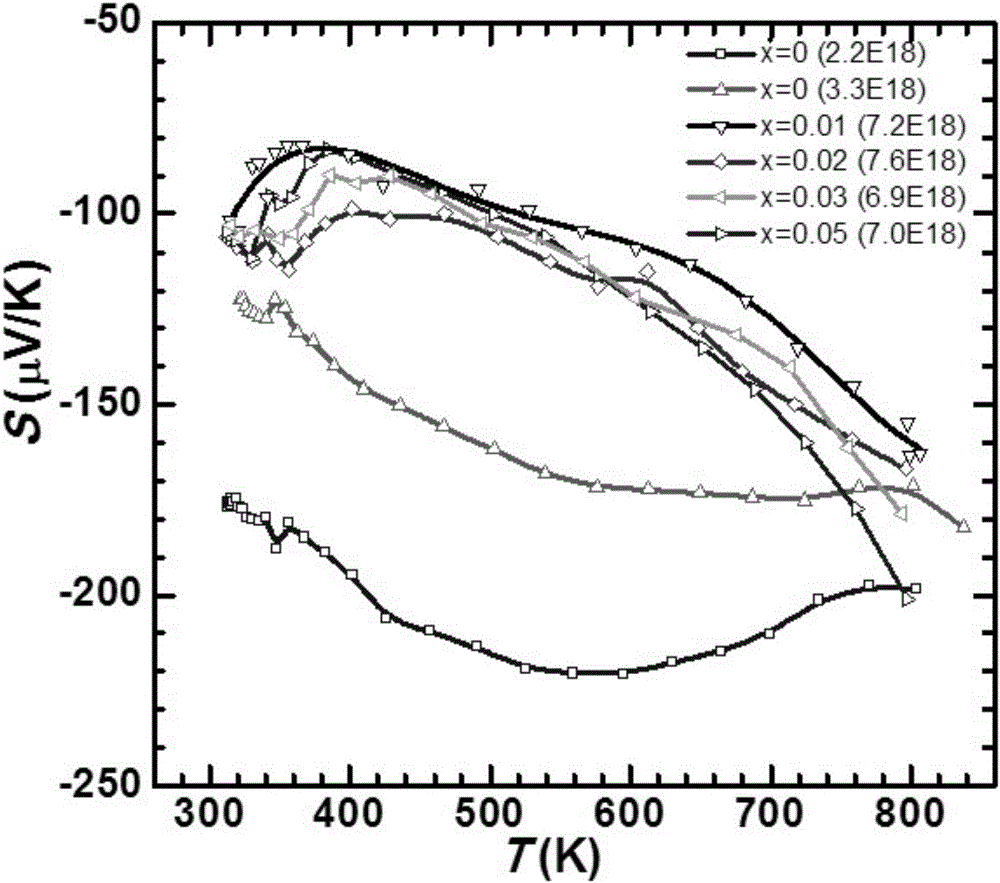

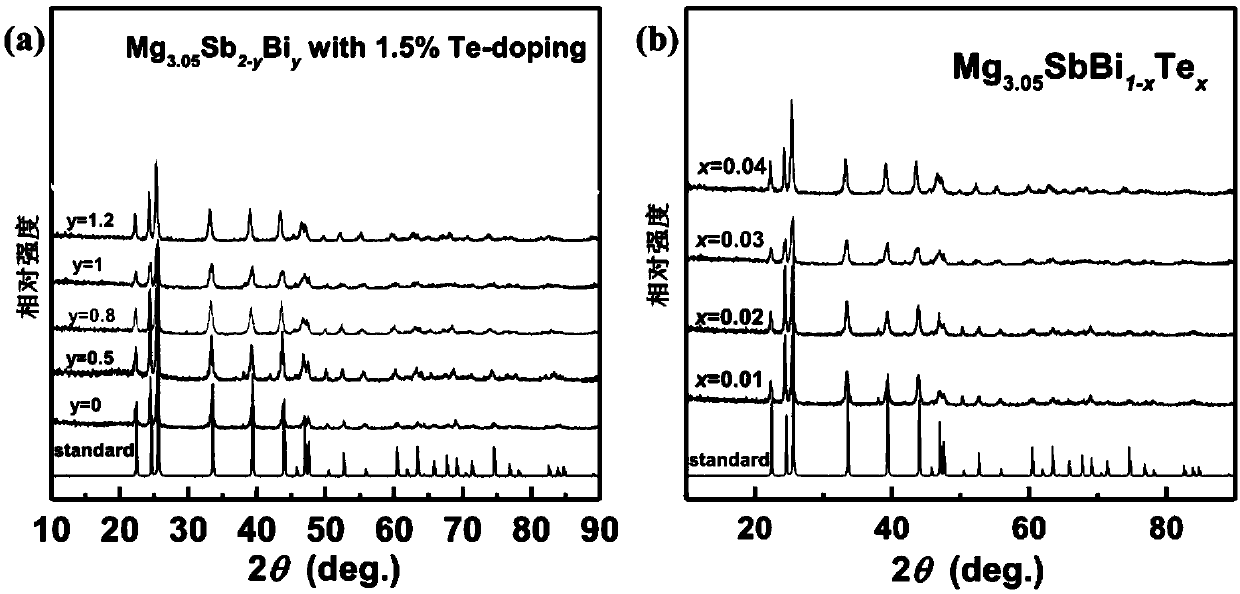

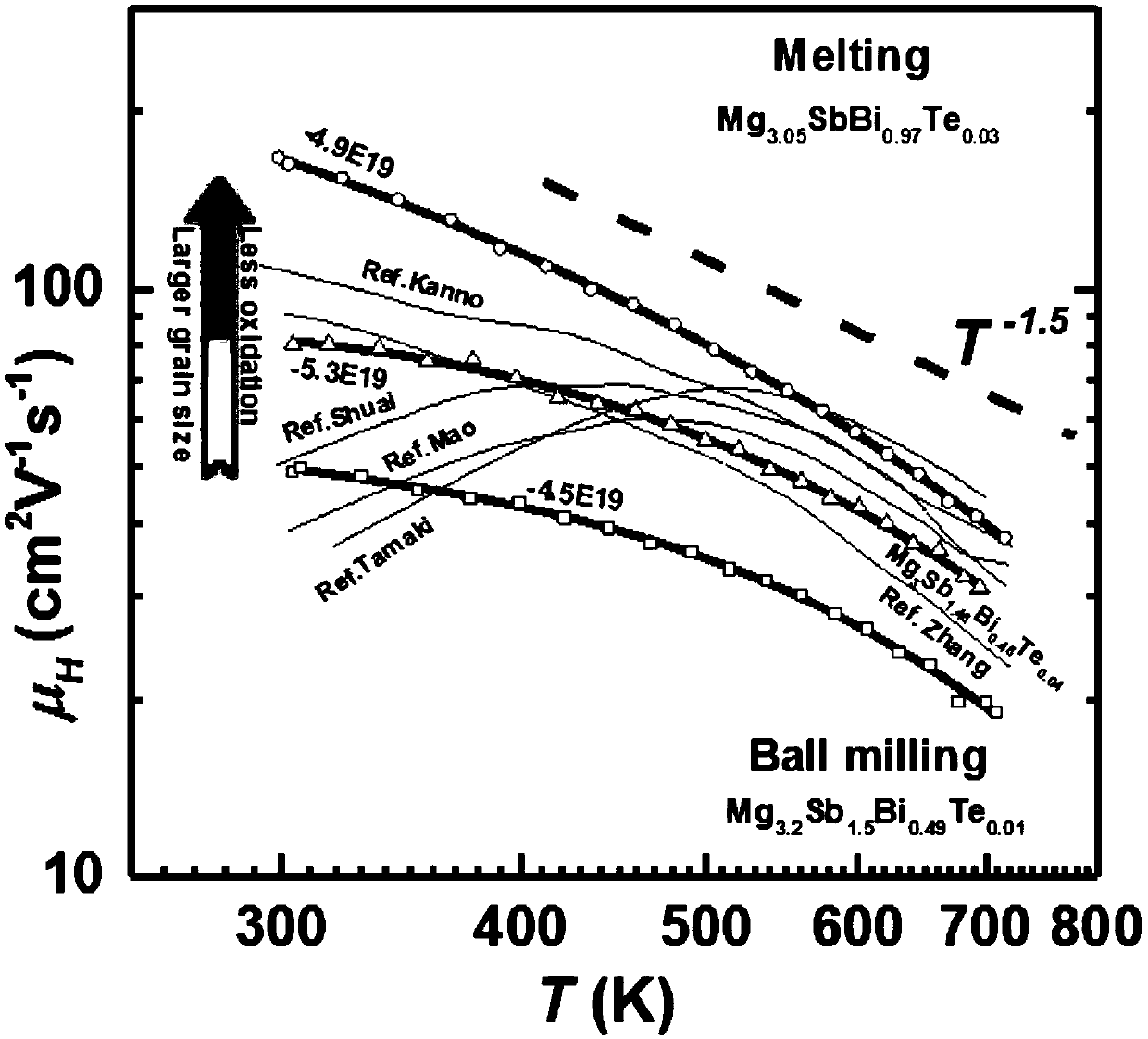

N-type antimony trimagnesium alloy thermoelectric material with high mobility and preparation method thereof

ActiveCN109616568AIncrease the carrier concentrationImprove mobilityThermoelectric device manufacture/treatmentThermoelectric device junction materialsTe elementSlow cooling

The invention relates to an N-type antimony trimagnesium alloy thermoelectric material with high mobility and a preparation method thereof. The chemical formula of the thermoelectric material is Mg<3.05>Sb<2-x-y>Bi<y-x>Te<x>, wherein x is more than 0 but less than or equal to 0.04, and y is more than 0 but less than or equal to 1.5. The thermoelectric material takes a high-pure element as a raw material, material is prepared according to a stiochiometric ratio in the chemical formula, the raw material is grinded to form powder after vacuum package by a tantalum pipe, high-temperature melting and annealing thermal treatment, and the thermoelectric material is obtained after vacuum hot-press sintering and slow cooling. Compared with the prior art, the tellurium doping is improved by solid solution of antimony trimagnesium, negative ion electrons are introduced, and simultaneous control of carrier concentration and lattice thermal conductivity is achieved; and meanwhile, the content of magnesium oxide in an N-type Mg3Sb2 alloy crystal boundary is reduced by tantalum package melting, so that higher mobility than that of traditional document is shown. The simple and controllable technology can be widely applied to various thermoelectric materials, particularly materials with a large amount of intrinsic defects, and a new method is provided for improving the thermoelectric performance.

Owner:TONGJI UNIV

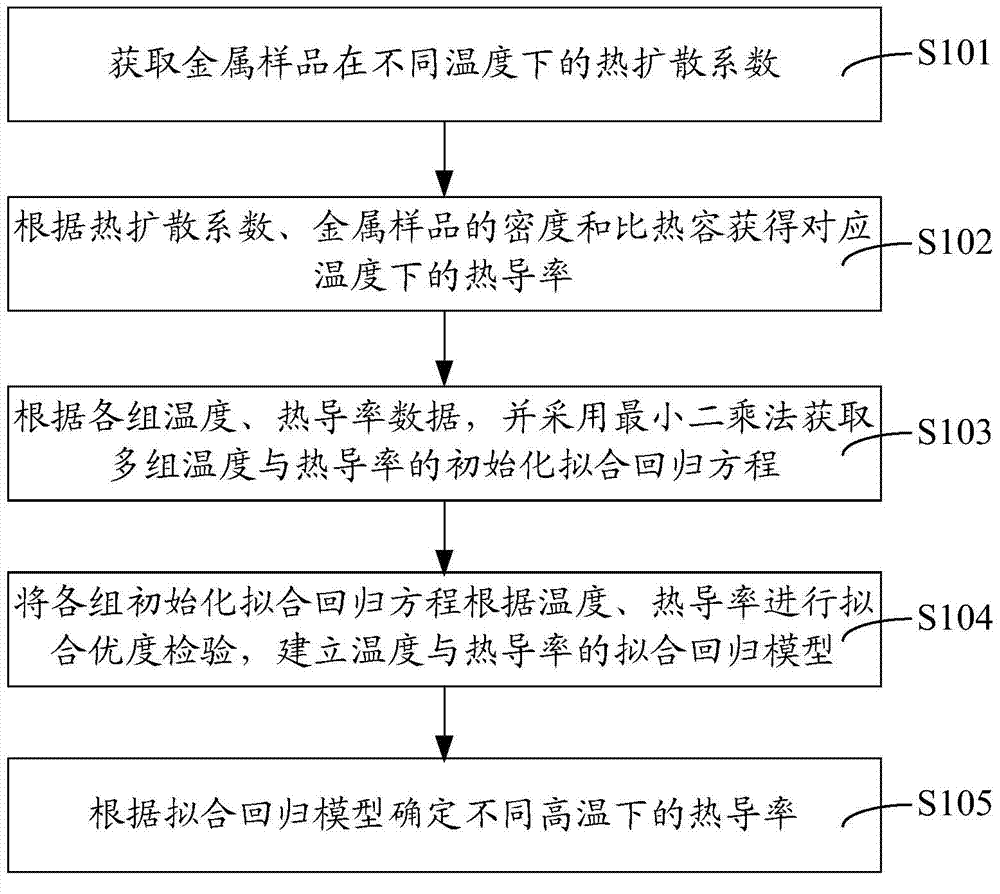

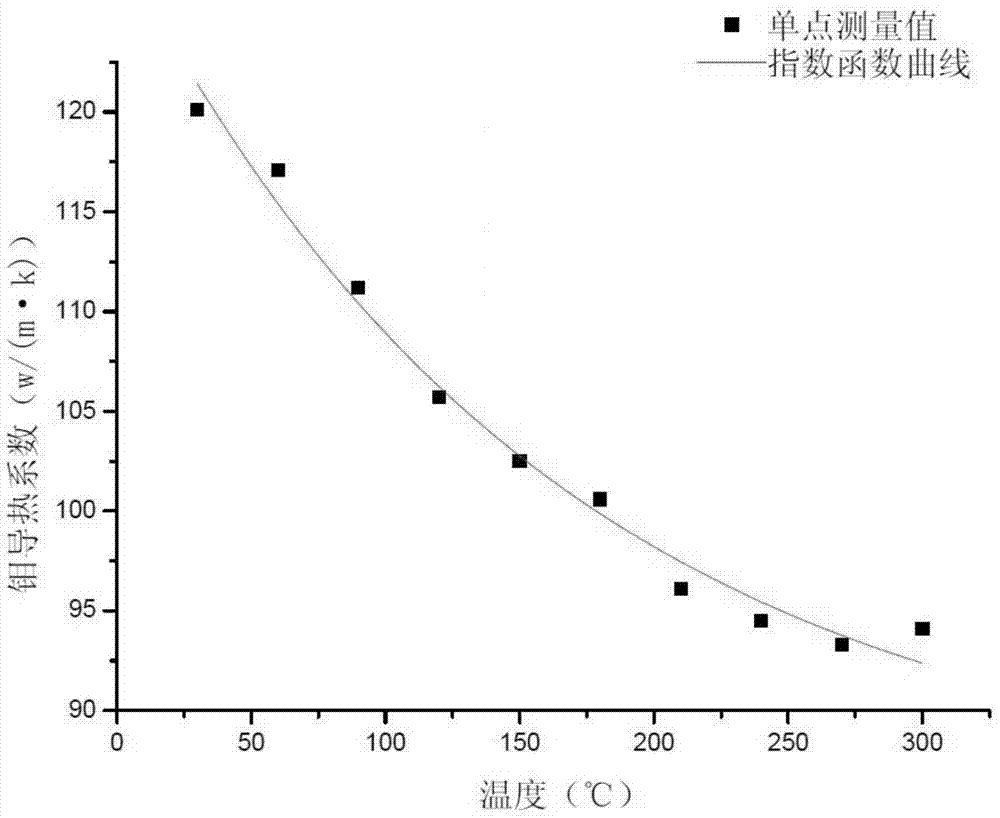

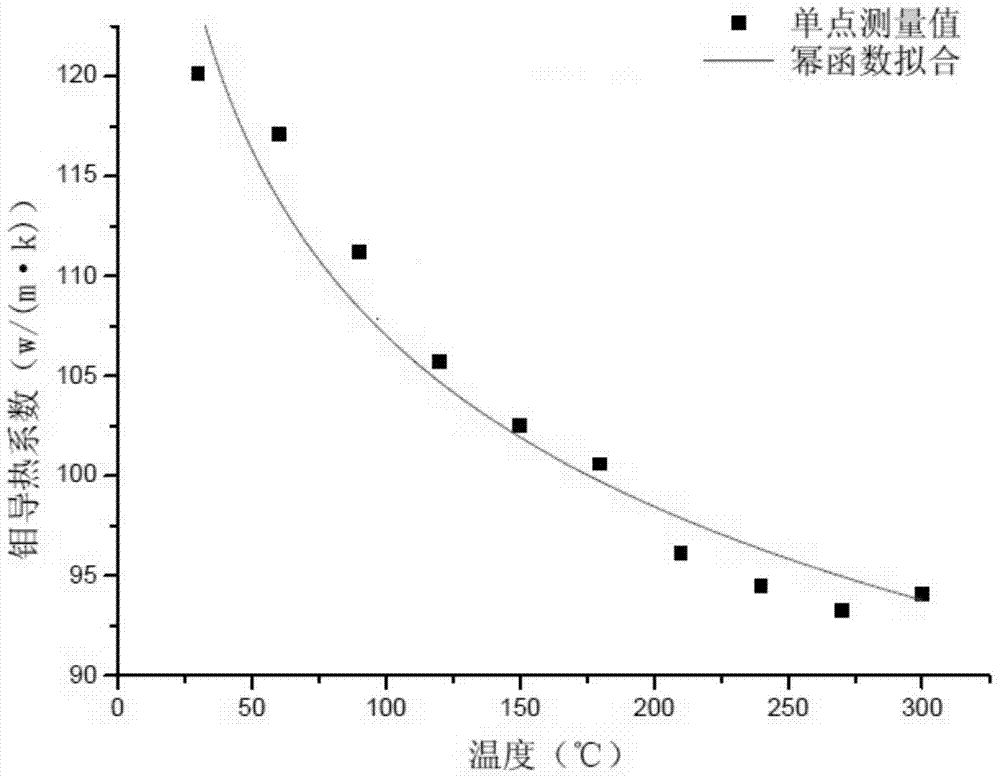

Measuring method for thermal conductivity of metal at high temperature

ActiveCN103940845AImprove accuracyImprove measurement accuracyMaterial heat developmentDiffusionThermal diffusion coefficient

The invention provides a measuring method for thermal conductivity of metal at high temperature. The measuring method comprises the following steps: acquiring thermal diffusion coefficients of a metal sample at different temperatures, wherein the temperatures refer to temperatures except the oxidizing temperature of the metal sample; acquiring thermal conductivity at a corresponding temperature according to the thermal diffusion coefficients and the density and specific heat capacity of the metal sample; acquiring a plurality of groups of initialization fitting regression equation of the temperatures and thermal conductivity according to each group of temperature and thermal conductivity data; subjecting each group of initialization fitting regression equation to test of goodness of fit according to the temperatures and thermal conductivity and establishing a fitting regression model of the temperatures and thermal conductivity; and determining thermal conductivity at different high temperatures according to the fitting regression model. With the method provided by the invention, thermal conductivity of metal at high temperature can be obtained, and accuracy of the obtained thermal conductivity is high.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

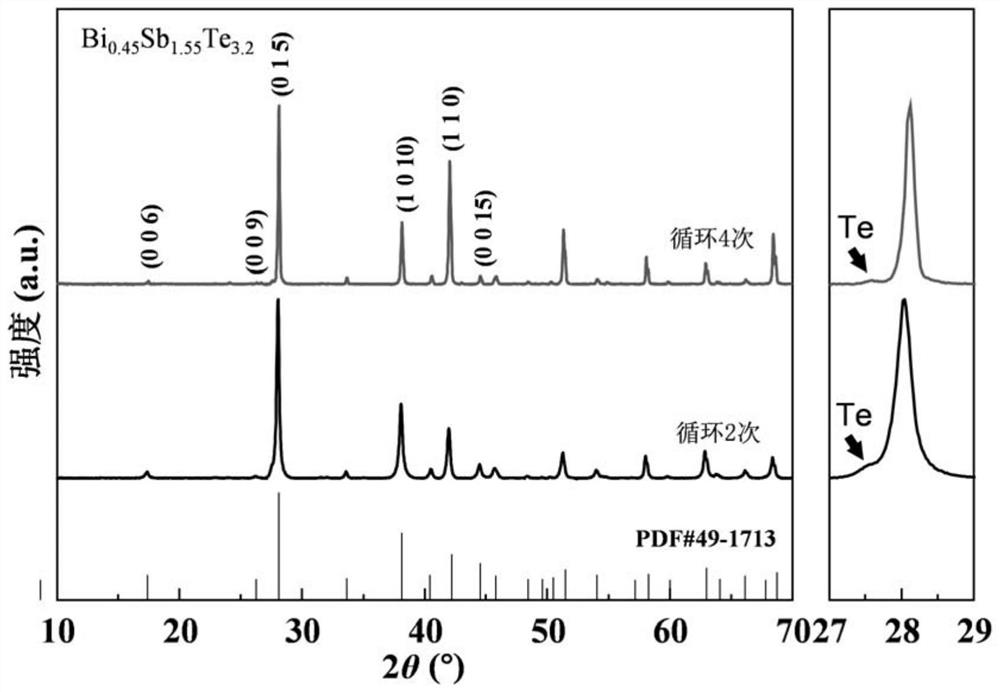

Non-stoichiometric bismuth telluride-based thermoelectric material and preparation method thereof

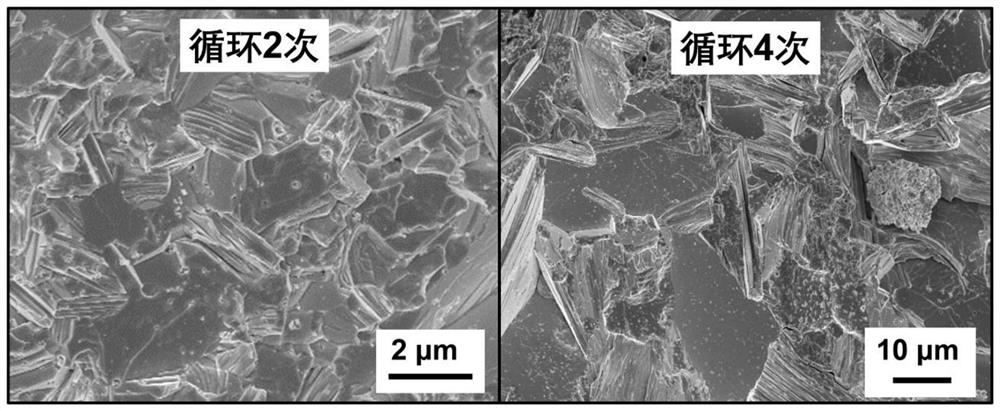

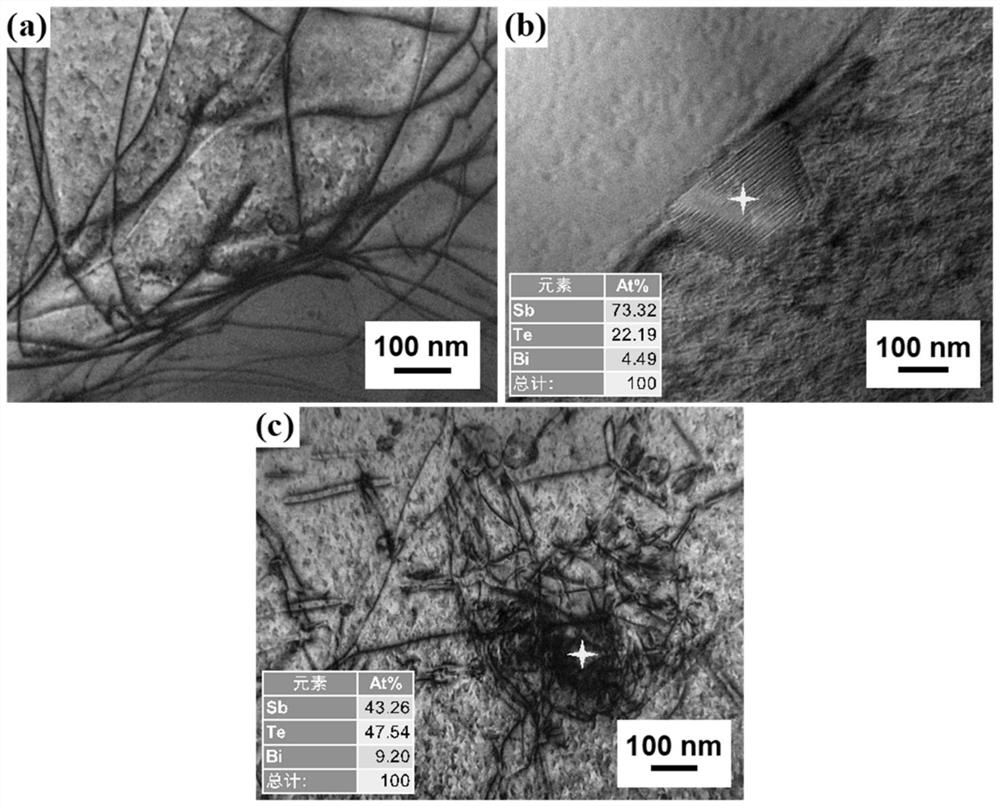

ActiveCN112028632AImprove electrical performanceLower lattice thermal conductivityThermoelectric device junction materialsChemical compositionBismuth telluride

The invention belongs to the technical field of energy materials, and particularly relates to a non-stoichiometric bismuth telluride-based thermoelectric material and a preparation method thereof. Thematerial disclosed by the invention has a chemical composition shown as the following general formula: BixSb2xTe3+y, and the preparation method comprises the following steps: firstly, weighing Bi simple substance powder, Sb simple substance particles and Te simple substance powder raw materials according to the chemical composition of the general formula, carrying out ball milling treatment to obtain powder, and carrying out cyclic discharge plasma sintering treatment on the obtained powder for 1-5 times to obtain a block sample. The bismuth telluride-based thermoelectric material prepared bythe method is good in crystallinity and compact in structure, and compared with a sample prepared by a traditional mechanical alloying and sintering combined method, the bismuth telluride-based thermoelectric material is obviously increased in grain size and introduces a large number of dislocations, so that the electrical property is improved, the lattice thermal conductivity is reduced, and thethermoelectric property is excellent. Meanwhile, the preparation method is simple and convenient to operate, short in period, free of high-temperature risk and low in energy consumption, and has a wide application prospect.

Owner:TSINGHUA UNIV

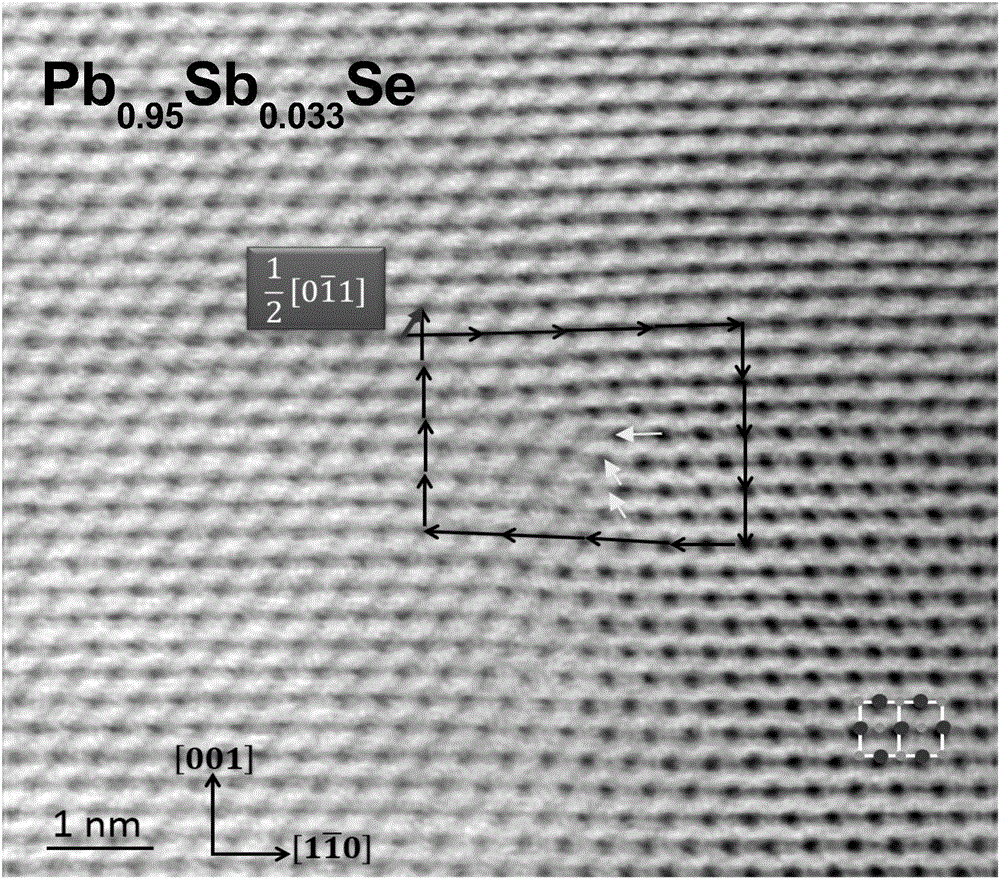

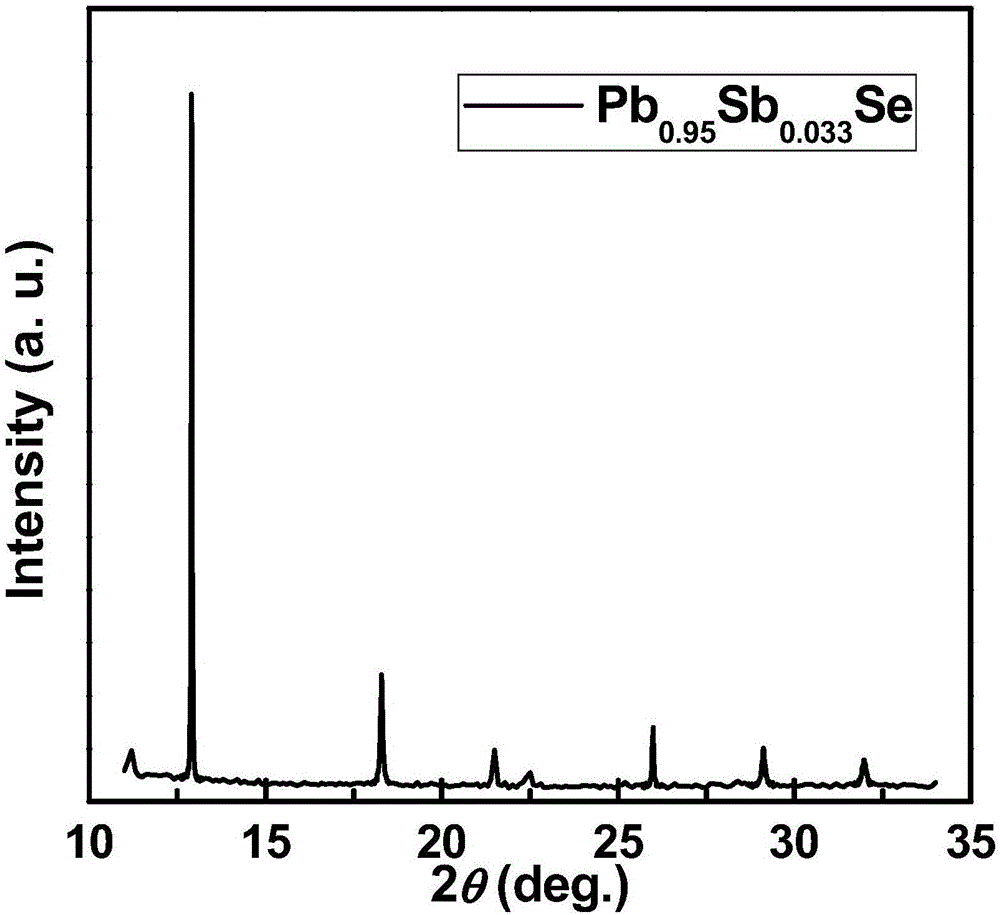

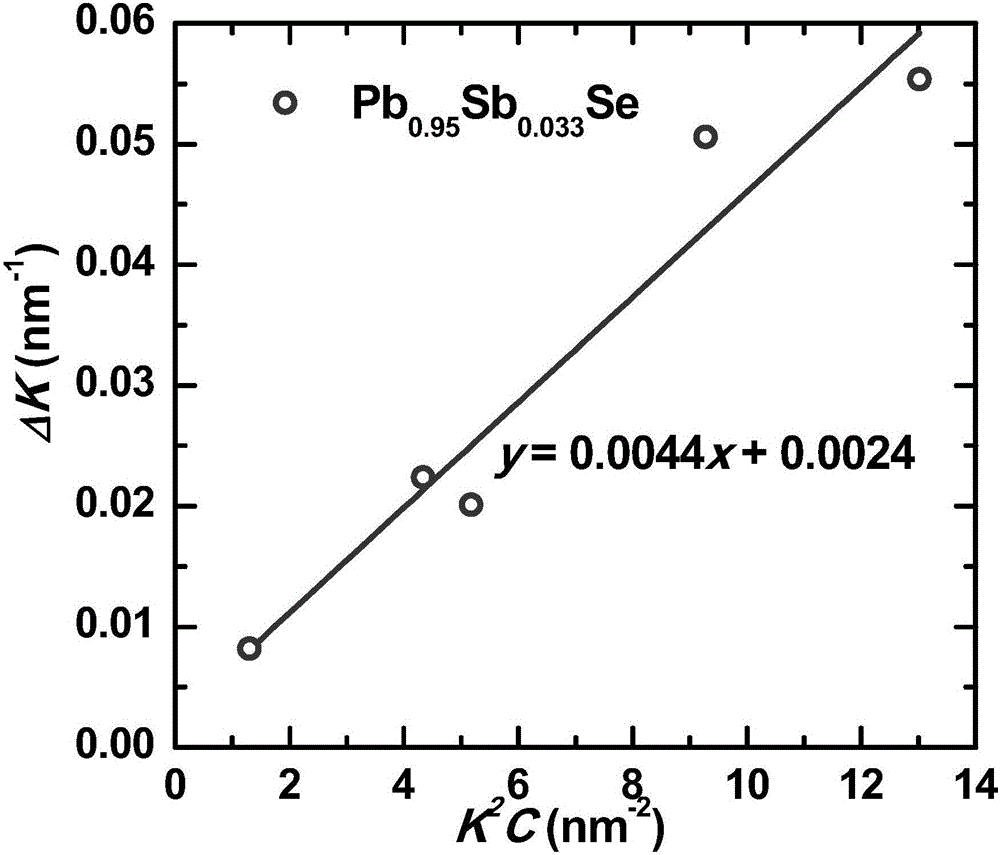

Sulfur-group lead-compound thermoelectric material and preparation method thereof

InactiveCN106711317AEffect on mechanical propertiesEmpty space engineering method is simpleThermoelectric device manufacture/treatmentThermoelectric device junction materialsIntermediate frequencyDislocation

The invention relates to a sulfur-group lead-compound thermoelectric material and a preparation method thereof. The chemical formula of the sulfur-group lead-compound thermoelectric material is Pb(1-x)Sb(2x / 3)Se, wherein the x is larger than 0 and is less than 0.09. According to the preparation method, a high-purity simple substance is used as a raw material; batching is carried out based on a stoichiometric ratio in the chemical formula; after vacuum packaging, high-temperature melting, and annealing heat treatment are carried out, grinding is carried out to obtain powder; vacuum hot pressing sintering and slow cooling are carried out to obtain a sheet type block material that is a lead selenide material based on target components. A controllable preparation method of forming a dislocation structure by introducing a Pb positive ion vacancy structure is designed; and because a high-density transgranular dislocation structure is introduced into the material, intermediate-frequency phonons can be scattered effectively, so that the lattic thermal conductivity, less than 0.4W / m-K, of the material, can be reduced substantially. According to the prepared novel high-performance thermoelectric material based on Pb(1-x)Sb(2x / 3)Se, the zT value reaches 1.6 on the condition of 900K, wherein the zT value is a highest value of the existing PbSe system terminal. Therefore, the sulfur-group lead-compound thermoelectric material is a novel thermoelectric material with great large-scale application potential.

Owner:TONGJI UNIV

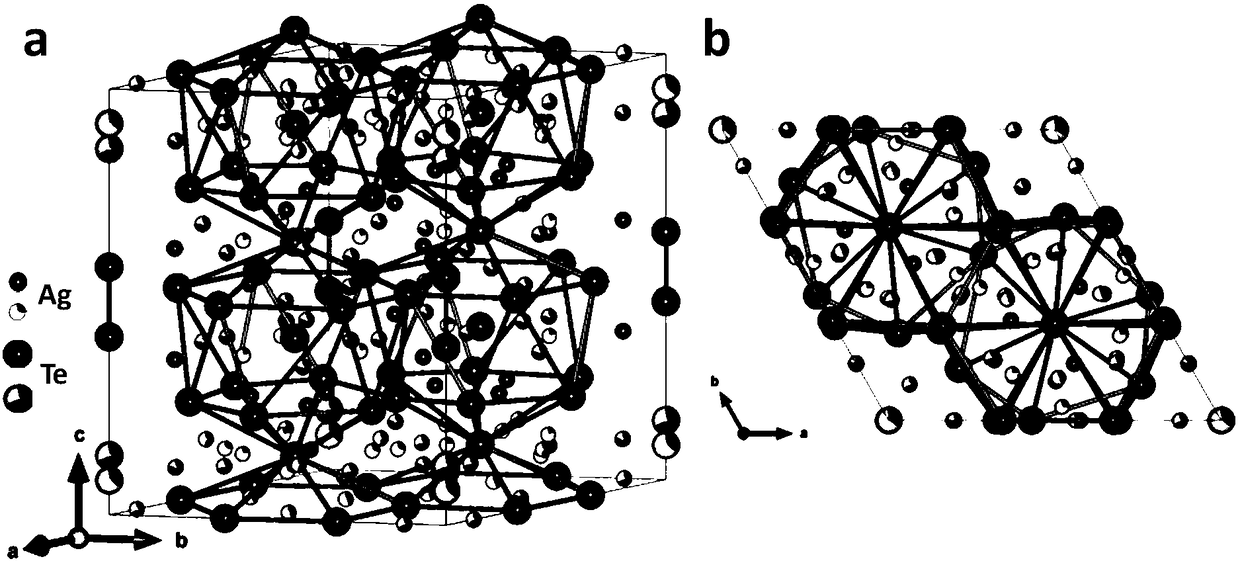

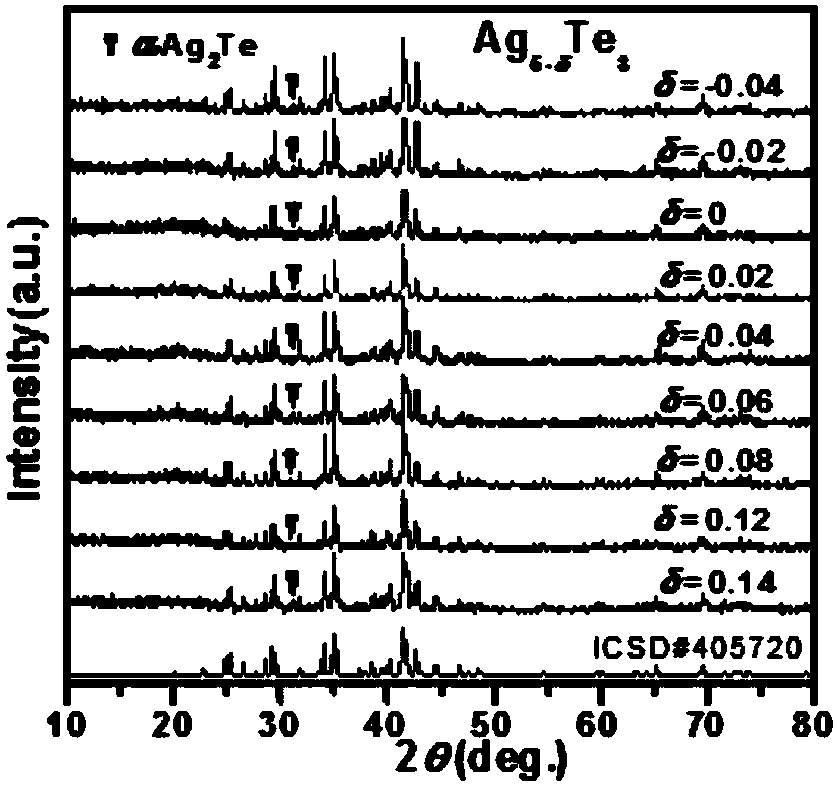

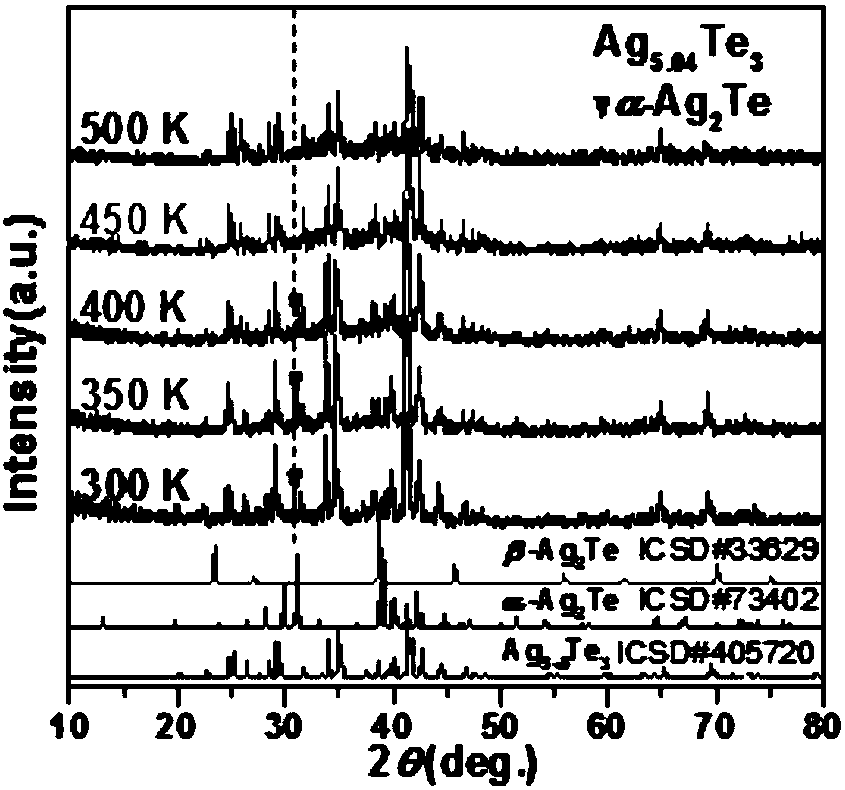

High-performance silver-tellurium compound thermoelectric semiconductor material and preparation method thereof

InactiveCN108346736AHigh densityImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsHot pressingLattice thermal conductivity

The invention relates to a high-performance silver-tellurium compound thermoelectric semiconductor material and a preparation method thereof. The chemical formula of the silver-tellurium compound thermoelectric semiconductor material is Ag5-xTe3, wherein x satisfies a relational expression that -0.04<=x<=0.14. According to the preparation of the silver-tellurium compound thermoelectric semiconductor material, high-purity simple substances are adopted as raw materials; the materials are selected according to a stoichiometric ratio in the above chemical formula; and the materials are subjected to vacuum encapsulation, high-temperature melting, annealing and heat treatment, and obtained substances are ground into powder, and the powder is subjected to vacuum hot-pressing and sintering, and slow cooling, so that a sheet-like block material is obtained, the sheet-like block material is a target product. Compared with the prior art, the thermoelectric semiconductor material of the inventionproduced by using the preparation method of the invention has the advantages of extremely low thermal conductivity and high thermoelectric performance; the lattice thermal conductivity of the thermoelectric material is as low as 0.18 to 0.25W / m.K in a full temperature range; the thermoelectric figure of merit of the thermoelectric material reaches 1.0 when temperature reaches 650K; and the thermoelectric material has a great potential. With the invention adopted, a preparation process for obtaining a high-quality polycrystalline sample is explored.

Owner:TONGJI UNIV

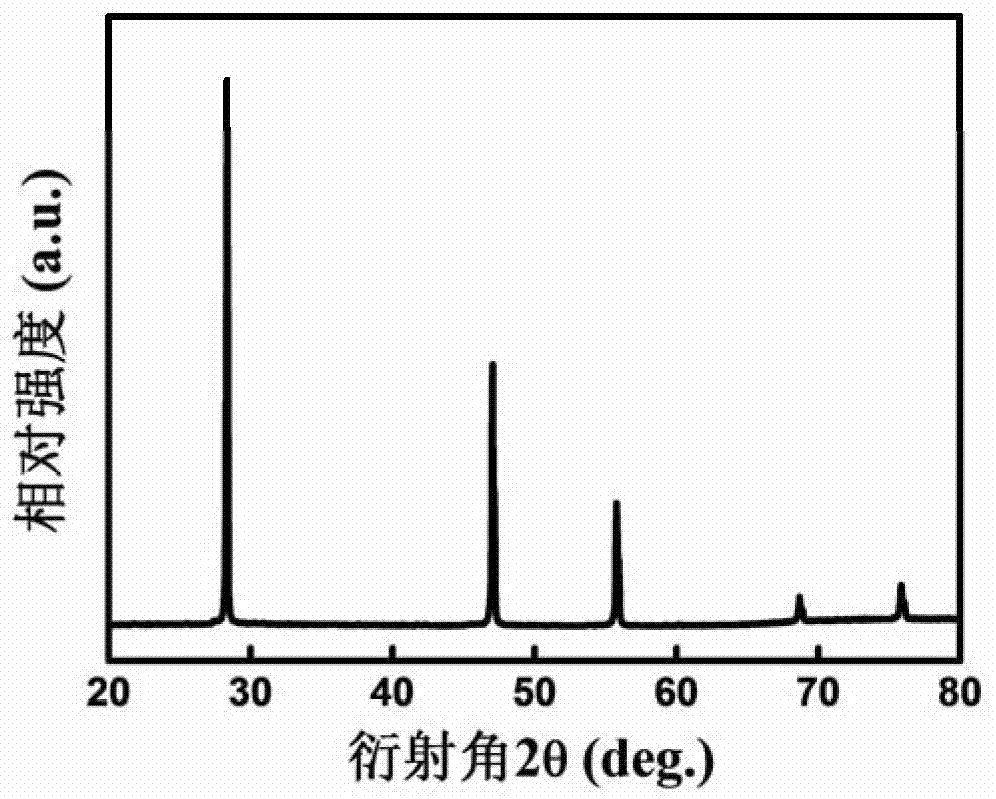

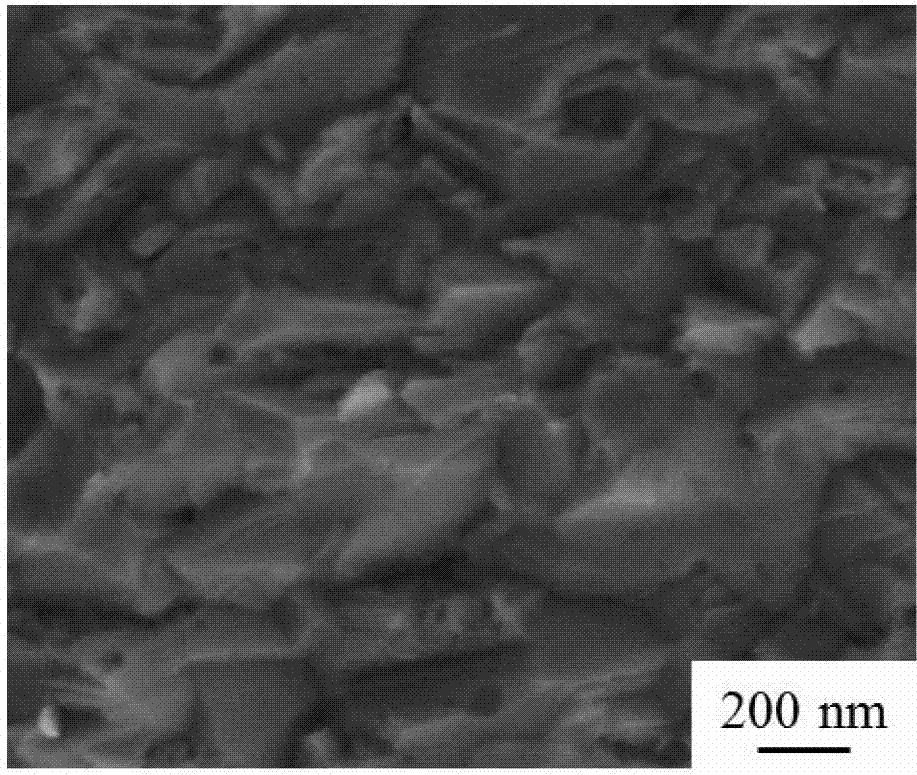

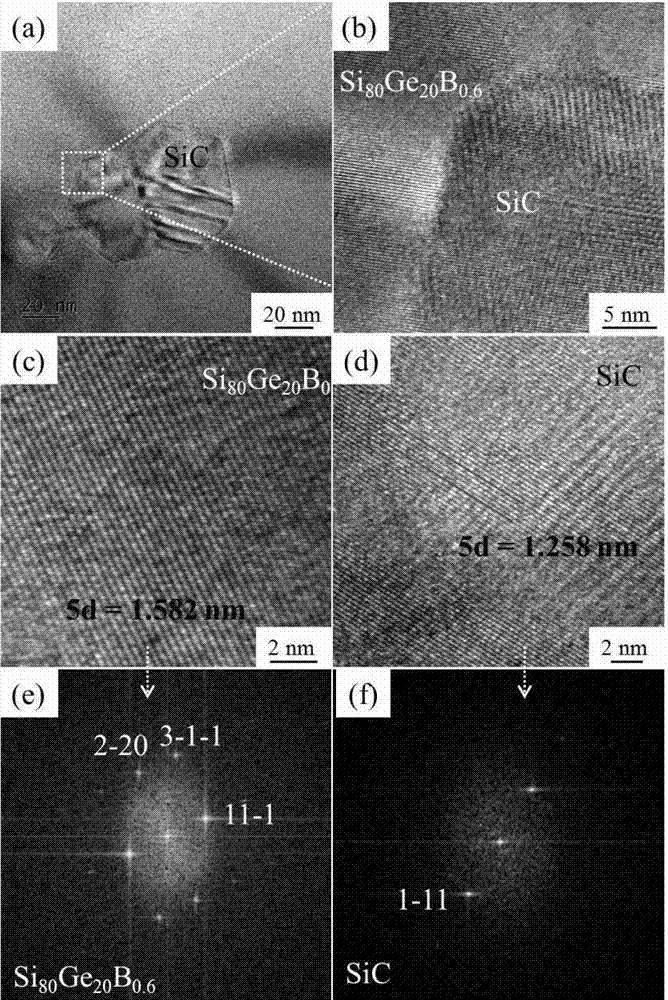

Nano SiC/P-type silicon germanium alloy-based thermoelectric composite material and preparation method thereof

ActiveCN107123729ALower lattice thermal conductivityImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsPower factorLattice thermal conductivity

The invention relates to a Nano SiC / P-type silicon germanium alloy-based thermoelectric composite material and a preparation method thereof. The thermoelectric composite material is composed of P-type silicon germanium alloy and Nano SiC particles uniformly dispersed on the grain boundary and / or inside the grains of the P-type silicon germanium alloy. The chemical formula of the P-type silicon germanium alloy is Si(80)Ge(20)B(x), wherein 0.2<=x<=2.0. The volume percentage of the Nano SiC particles is 0.3-2.0% that of the P-type silicon germanium alloy. The Nano SiC particles and the P-type silicon germanium alloy are composited to prepare the thermoelectric composite material. The lattice thermal conductivity of the material is reduced significantly on the premise that the power factor does not change much. The thermoelectric property of the material in the whole range of temperature is improved. In addition, the preparation method provided by the invention is simple and fast, has high utilization ratio of raw materials, and has a good industrialization prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

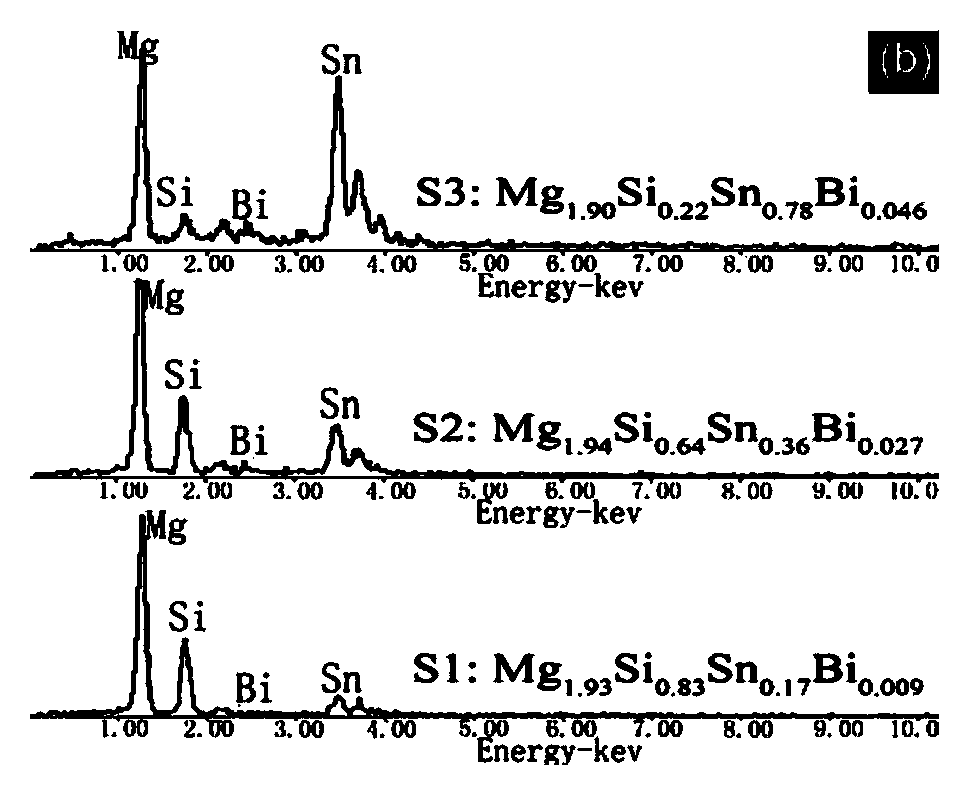

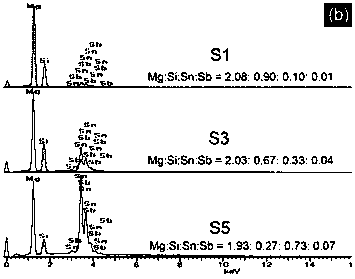

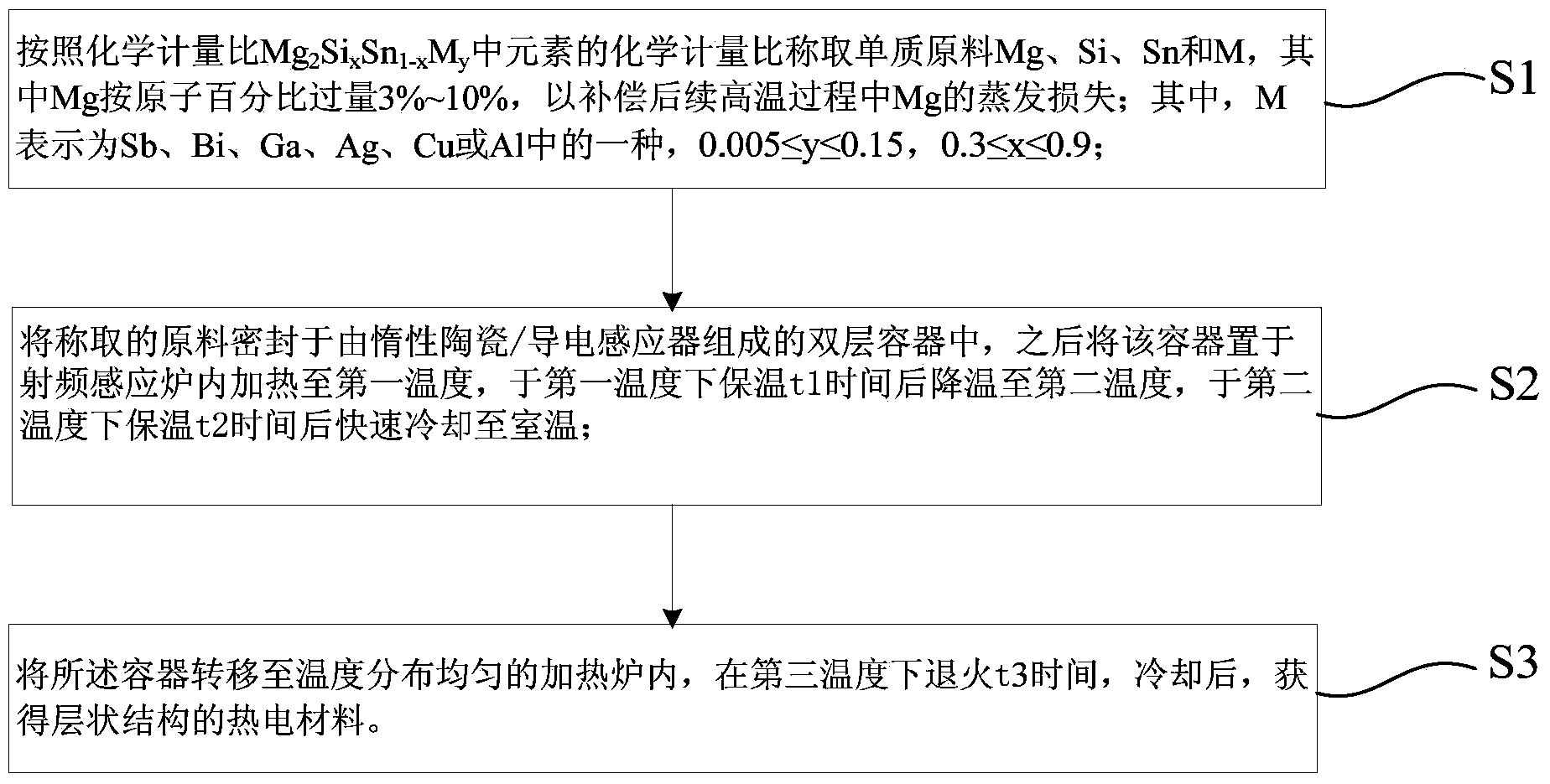

Mg-Si-Sn-based nano-composite thermoelectric material and preparation method thereof

InactiveCN104109785AReduced ionization scattering centerImprove conductivityLattice thermal conductivityNanocomposite

The invention provides a Mg-Si-Sn-based nano-composite thermoelectric material and a preparation method thereof. The Mg-Si-Sn-based nano-composite thermoelectric material has a layered structure, and the chemical general formula of the Mg-Si-Sn-based nano-composite thermoelectric material is Mg2SixSn1-xMy, wherein M is a doping element and is one selected from Sb, Bi, Ga, Ag, Cu and Al, x is not less than 0.3 and not more than 0.9, and y is not less than 0.005 and not more than 0.15; the structures of all layers have different Mg:Si:Sn atom mole content ratios and different M doping concentrations; and the structure of each of all the layers comprises a Mg-Si-Sn matrix and a Mg-Si-Sn nanometer grain second phase dispersed in the matrix to form a coherent interface or a semi-coherent interface. The Mg-Si-Sn-based nanocomposite thermoelectric material has a coherent interface and a modulation-doped structure, so the Mg-Si-Sn-based nanocomposite thermoelectric material has the advantages of low thermal conductivity of lattices, and good thermoelectricity performance, and can be widely used in the fields of spaceflight, national defense, automotives and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

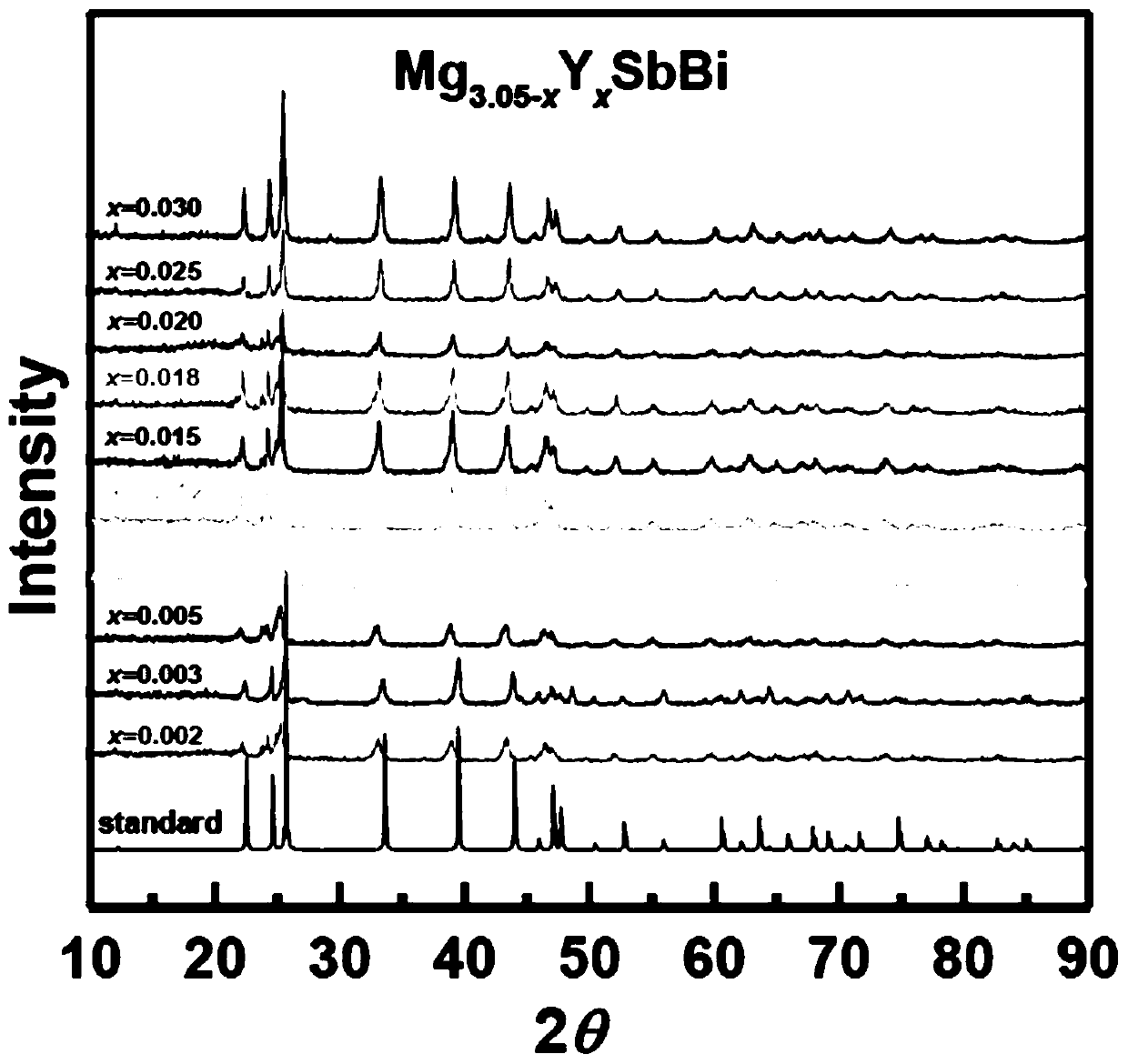

N-type Mg3Sb2 alloy thermoelectric material and preparation method thereof

The invention relates to an n-type Mg3Sb2 alloy thermoelectric material and a preparation method thereof. The chemical formula of the alloy thermoelectric material is YxMg3.05-xSbBi, wherein x is greater than or equal to 0.002 and less than or equal to 0.03; the method is characterized by comprising the steps of taking high-purity simple substance as a raw material; proportioning according to the stoichiometric ratio in the chemical formula; carrying out vacuum packaging on a tantalum tube, high-temperature melting, annealing and heat treatment; cutting into pieces with the size of 3 mm; and performing vacuum hot-pressing sintering and slowly cooling to obtain the alloy thermoelectric material. Compared with the prior art, the method has the advantages that doping of the yttrium is improved by carrying out solid-solution on magnesium bismuthide, anion electrons are introduced, so that the carrier concentration and the lattice heat conductivity can be simultaneously regulated and controlled, and meanwhile, the content of magnesium oxide in the grain boundary of the N-type Mg3Sb2 alloy is reduced by utilizing tantalum packaging smelting, so that the high migration rate is achieved.

Owner:TONGJI UNIV

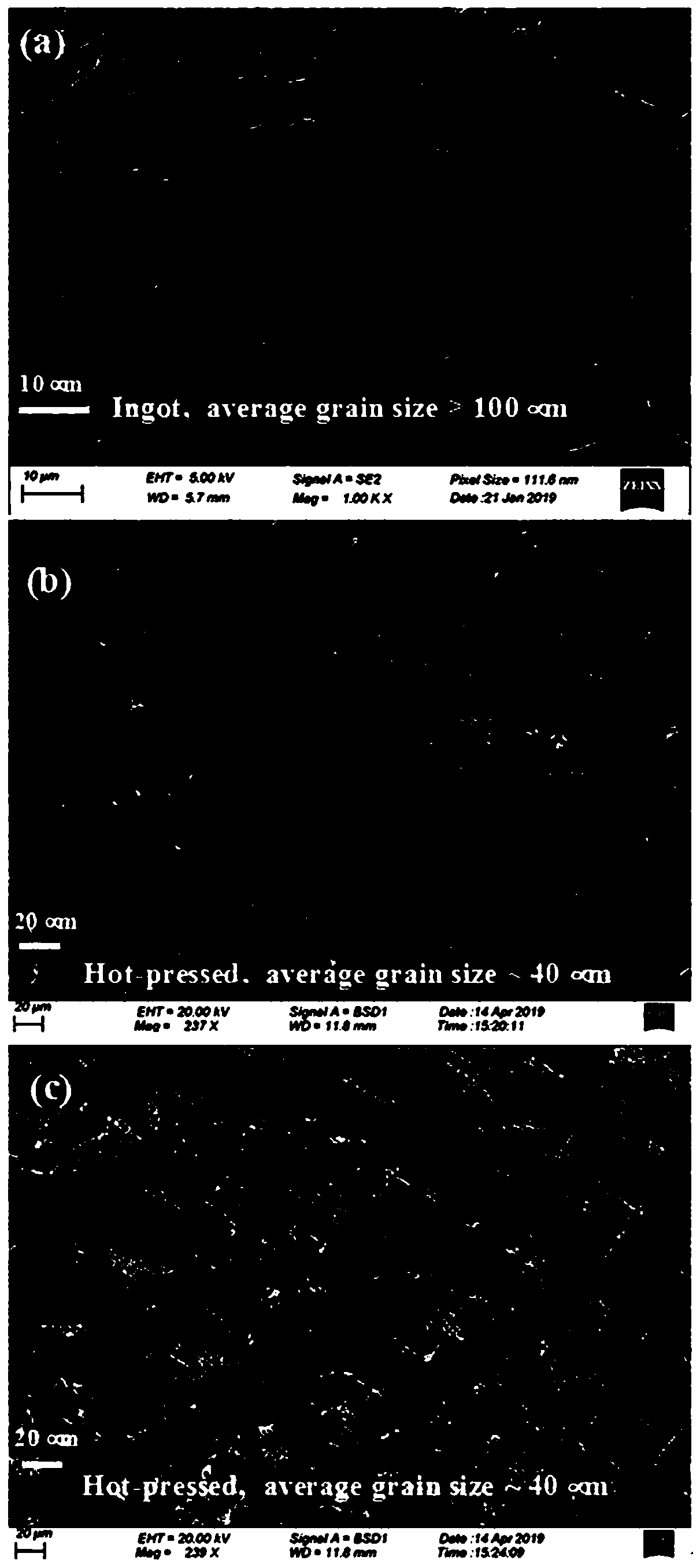

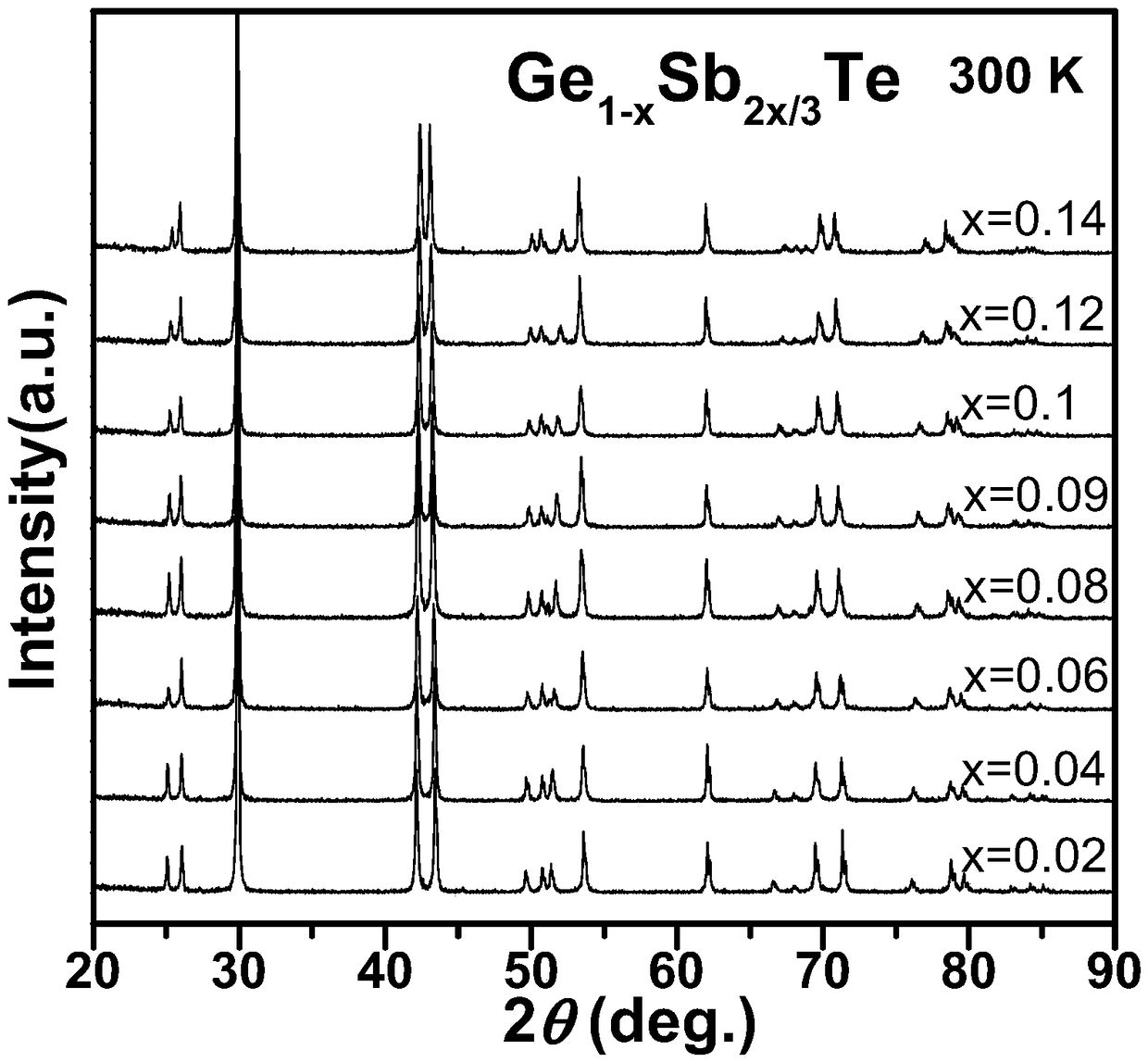

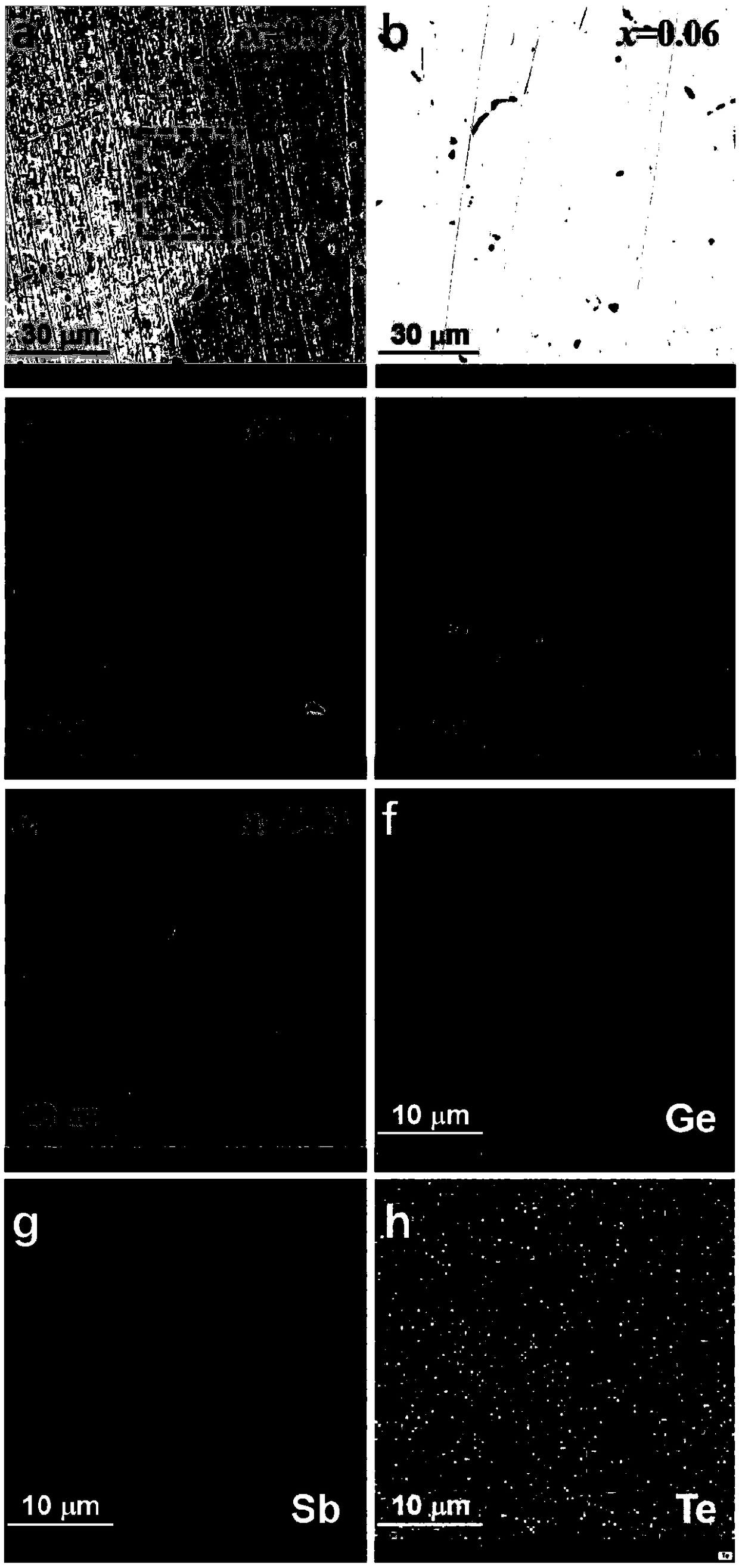

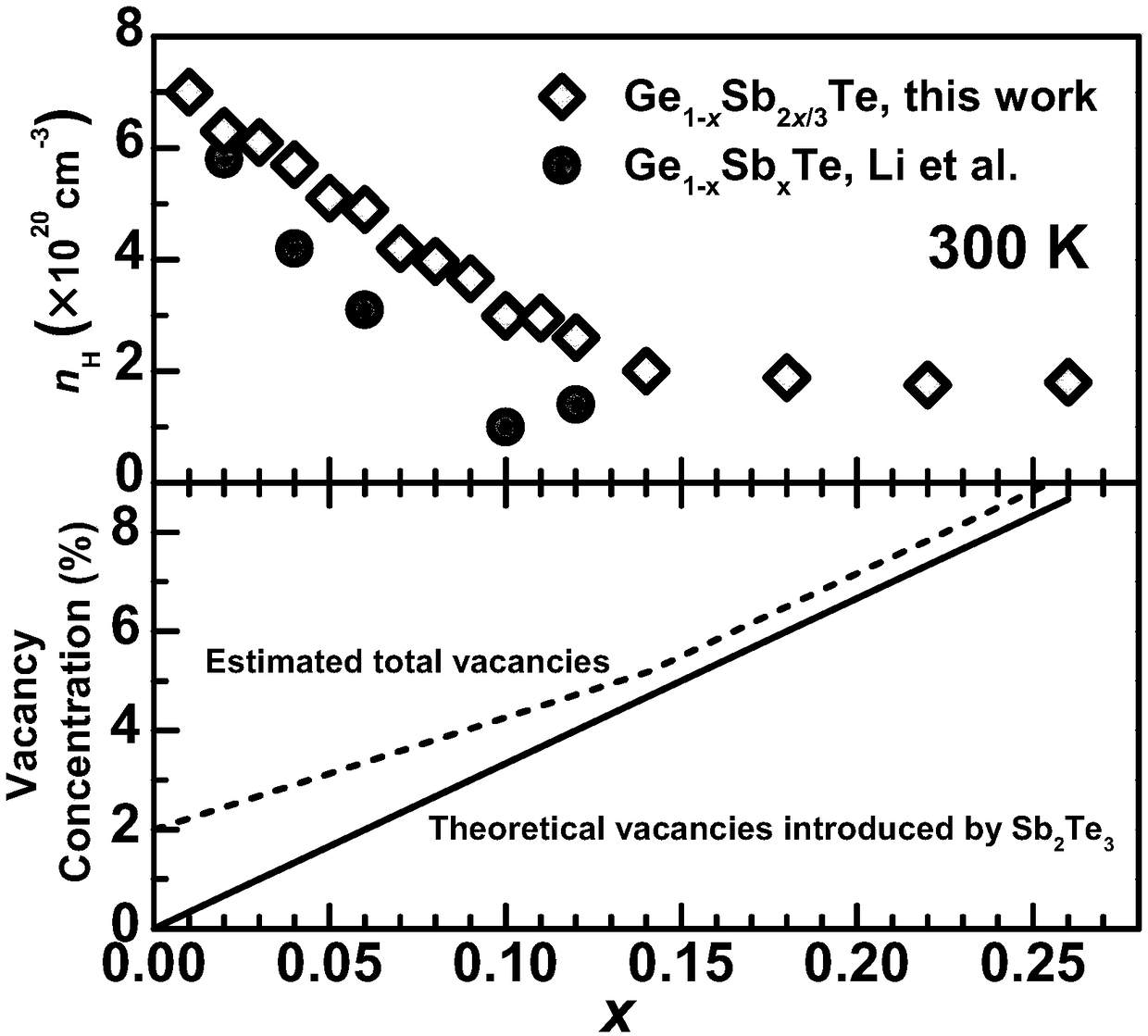

Novel GeSbTe compound thermoelectric material having high concentration vacancy and preparation method thereof

InactiveCN108735888AReduce carrier concentrationReduce concentrationThermoelectric device manufacture/treatmentThermoelectric device junction materialsHigh concentrationState of art

The invention relates to a novel GeSbTe compound thermoelectric material having a high concentration vacancy and a preparation method thereof, wherein the thermoelectric material has a chemical formula of Ge1-xSb2x / 3Te, x is greater than 0 and less than or equal to 0.14; by using the high purity element as raw material, the novel GeSbTe compound thermoelectric material is obtained through grindinginto powder, vacuum hot pressing sintering and slow cooling after vacuum encapsulation, high temperature melting, and annealing heat treatment by dosing according to the stoichiometric ratio in the chemical formula. Compared with the prior art, the introduction of cationic vacancies enables simultaneous regulation of carrier concentration and lattice thermal conductivity. This simple and controllable technique may be widely applied to various thermoelectric materials, especially the materials with a large number of intrinsic defects, which provides a new approach to improving thermoelectric performance.

Owner:TONGJI UNIV

Method for preparing elemental tellurium based composite pyroelectric material

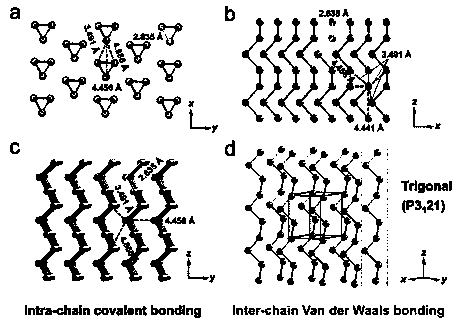

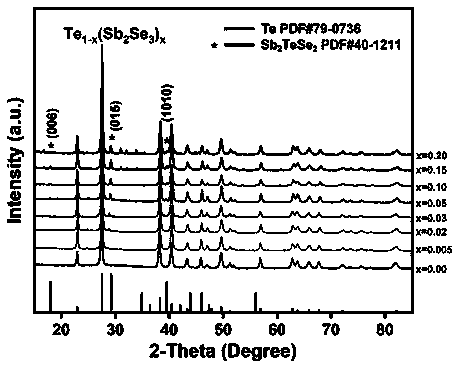

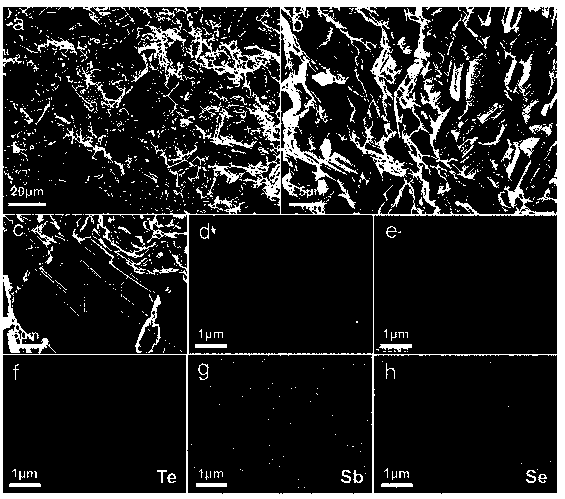

InactiveCN110698203AGood heat transfer performanceOptimize spaceThermoelectric device manufacture/treatmentThermoelectric device junction materialsVertical tubeElectric properties

The invention relates to a method for preparing an elemental tellurium based composite pyroelectric material and belongs to the field of pyroelectric materials. The pyroelectric material is characterized by having a chemical formula of Te1-x(Sb2Se3)x, wherein x is not smaller than 0 and not greater than 0.2. The preparation method disclosed by the invention comprises the following steps: weighingvarious raw material ingredients according to a mole fraction proportioning ratio of the chemical formula, and encapsulating Te cakes, Sb powder and Se powder into a carbon-plated quartz tube throughvacuum encapsulation; then, smelting the quartz tube in a vertical tube type furnace; then, carrying out annealing treatment; and finally, grinding an obtained cast ingot into fine powder, then, carrying out spark plasma sintering, so as to obtain dense mass which has very low thermal conductivity and relatively high pyroelectric properties, wherein the pyroelectric Q-value reaches 0.95. Accordingto the method, the pyroelectric properties of the elemental tellurium based composite pyroelectric material are improved through a smelting process, an annealing process and a spark plasma sinteringprocess. Compared with the prior art, the method has the advantages that through introducing an antimony selenide component, the cooperated optimization of carrier concentration and lattice thermal conductivity is achieved, and the process flow is simple and controllable and is low in cost.

Owner:TAIYUAN UNIV OF TECH

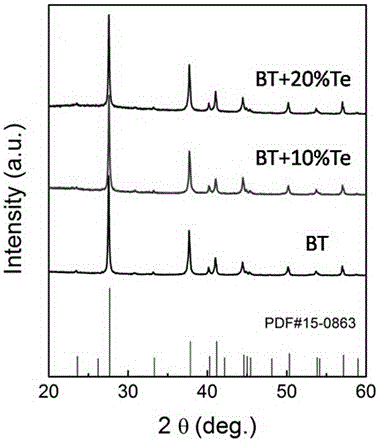

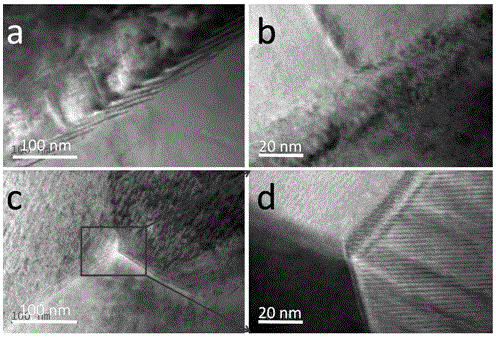

Method for reducing thermal conductivity of bismuth telluride polycrystal lattice

InactiveCN106283173ASimple methodEasy to operatePolycrystalline material growthFrom solid stateBismuth tellurideLattice thermal conductivity

The invention relates to a method for reducing thermal conductivity of a bismuth telluride polycrystal lattice and belongs to the technical field of energy materials. According to the method, bismuth telluride powder is prepared in a mechanical alloying method and is mixed with Te with an additional mass ratio of 5-30% and then undergoes secondary ball milling, and powder with bismuth telluride and simple substance tellurium evenly mixed with each other is obtained. The mixed powder is placed in a graphite die, and a spark plasma sintering process is adopted to perform sintering for 0-30 min at 450-580 DEG C to prepare bismuth telluride polycrystalline blocks. In the spark plasma process, since Te has a low melting point and is liquified completely and since Te is extruded out of the graphite die under the pressure effect, plenty of dislocations are reserved in bismuth telluride blocks, and the lattice thermal conductivity of a material is reduced through introduction of plenty of dislocations. The method is simple in process and easy to operate, and the thermal conductivity is reduced vey obviously.

Owner:KUNMING UNIV OF SCI & TECH

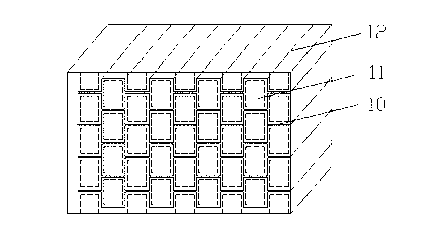

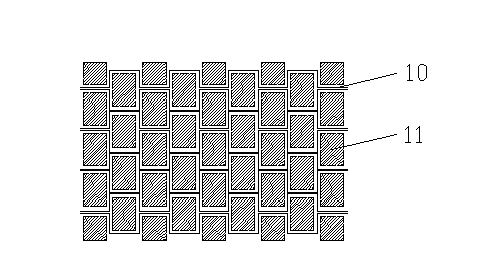

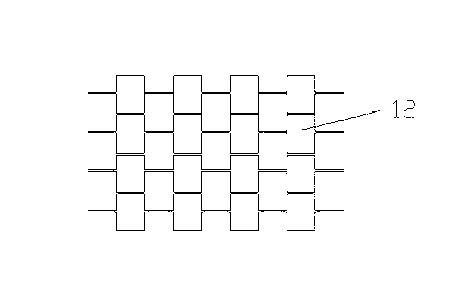

Three-dimensional net-shaped high thermal conductivity graphite framework structure and manufacture method thereof

InactiveCN103108531AHigh mechanical strengthImprove thermal conductivityCooling/ventilation/heating modificationsStructure of the EarthLattice thermal conductivity

A three-dimensional net-shaped high thermal conductivity graphite framework structure comprises at least two layers of graphite heat conduction films (12) and is characterized in that the number of connection points between every two adjacent layers of the graphite heat conduction films (12) is more than 5, and the distance between the every two connection points is more than 1mm. The thermal conductivity of the graphite heat conduction films (12) is 400-2400W / mK, and the thickness of each graphite heat conduction film (12) is 5-100 microns. The three-dimensional net-shaped high thermal conductivity graphite framework structure has very high thermal conductivity on the three-dimensional direction, and heat conduction materials have high thermal conductivity and strong mechanical strength. The requirement of fast heat conduction can be met, and the design requirement of a certain mechanical structure can be met. The three-dimensional net-shaped high thermal conductivity graphite framework structure can serve as a framework to be used with other materials in a compound mode, and whole thermal conductivity is improved.

Owner:ZHENJIANG BROWAH TECH

NbFeSb-based high-entropy thermoelectric material, preparation method thereof and thermoelectric device

InactiveCN107946449ALarge lattice distortionLower lattice thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsLattice thermal conductivityMo element

The invention discloses a NbFeSb-based high-entropy thermoelectric material, a preparation method thereof and application thereof. The chemical formula of the NbFeSb-based high-entropy thermoelectricmaterial is Nb1-xMxFeSb1-ySny, x=0.1 to 0.8, y=0 to 0.3, and M comprises any 4 to 5 elements in V, Ti, Hf, Zr, Sc, Y, Ta and Mo elements. The preparation method comprises the steps of weighing and taking pure metal raw materials according to a stoichiometric ratio of the elements contained in the NbFeSb-based high-entropy thermoelectric material and carrying out melting and annealing treatment anddischarge plasma sintering. The NbFeSb-based high-entropy thermoelectric material of the invention has a low lattice thermal conductivity. The process conditions of the preparation method of the NbFeSb-based high-entropy thermoelectric material are easy to control, the stability of microtopography and physicochemical properties of the prepared NbFeSb-based high-entropy thermoelectric material areensured, the efficiency of preparation is high, and the production cost is reduced.

Owner:SHENZHEN UNIV

Method for preparing (Bi0.8Sb0.2)2Te3 nano thermoelectric material

InactiveCN103555986AImprove Seebeck coefficientImprove thermoelectric performanceMaterial nanotechnologyThermoelectric device manufacture/treatmentMass ratioScattering effect

The invention discloses a method for preparing a (Bi0.8Sb0.2)2Te3 nano thermoelectric material. The method comprises the following steps of (1) mixing a Bi2Te3 powder material and a Sb2Te3 powder material, and performing mechanical alloying treatment, thereby obtaining a ball-milling material; (2) taking a small part of ball-milling material, putting the ball-milling material into an alumina burning boat of a vacuum atmosphere furnace, filling mixed gas of argon and hydrogen, raising the temperature for performing vapor deposition, and collecting a powder material deposited on an alumina plate, thereby obtaining a vapor deposition material; (3) mixing the ball-milling material and the vapor deposition material according to a mass ratio of 5:1, and performing high-frequency heating and rapid hot press molding, thereby obtaining the (Bi0.8Sb0.2)2Te3 nano thermoelectric material. According to the preparation method, the electronic state density nearby a Fermi level is improved and controlled, and a Seebeck coefficient of the thermoelectric material is improved. Moreover, with nano-scale micro-defects, a scattering effect on phonons is enhanced, the lattice thermal conductivity of the thermoelectric material is reduced, and the thermoelectric performance of the material is greatly improved.

Owner:HENAN UNIV OF URBAN CONSTR

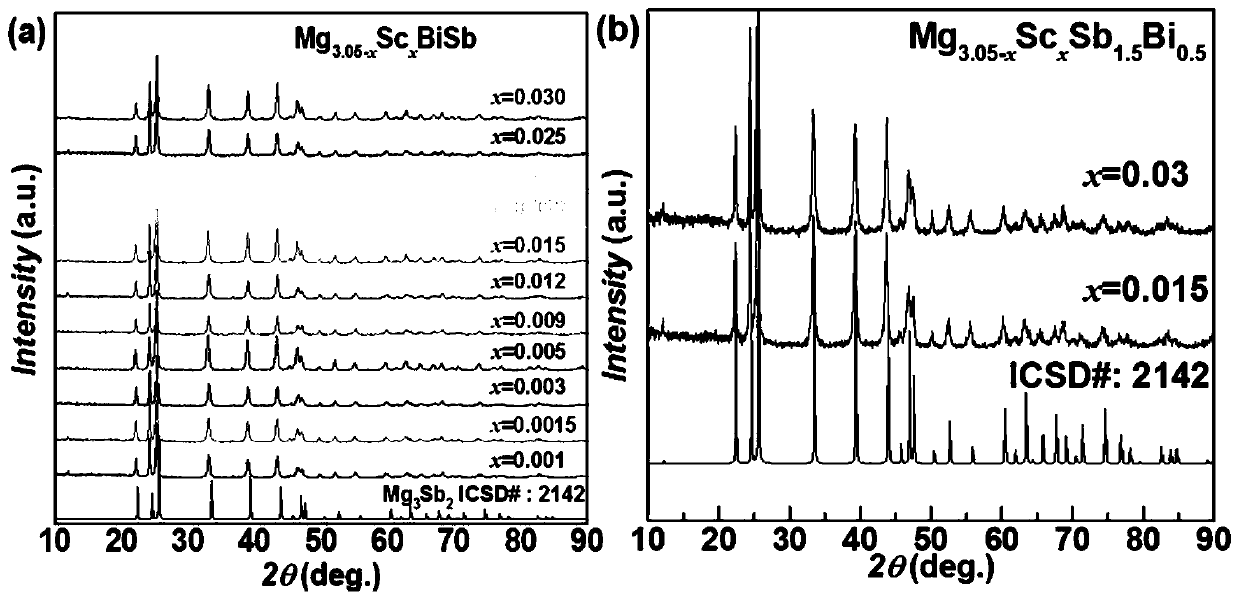

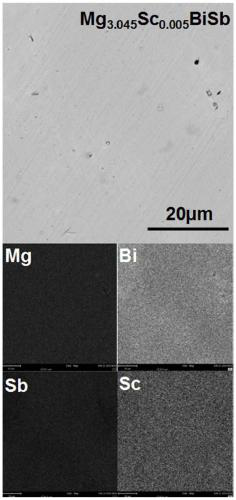

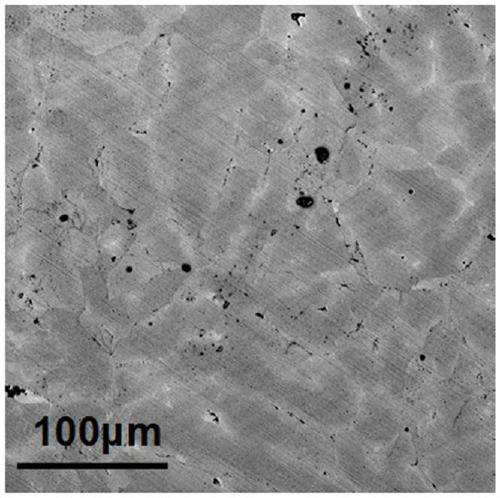

N-type antimonous trimagnetite scandium-doped alloy thermoelectric material and preparation method thereof

InactiveCN111057884AAvoid missingReduced enrichmentThermoelectric device junction materialsLattice thermal conductivityAlloy

The invention relates to an N-type antimonous trimagnetite scandium-doped alloy thermoelectric material and a preparation method thereof. The chemical formula of the thermoelectric material is Mg<3.05-x>Sc<x>Sb<2-y>Bi<y>, wherein y is greater than 0 and less than or equal to 1, and x is greater than 0 and less than or equal to 0.03. Compared with the prior art, cationic electrons are introduced byimproving scandium doping through the solid solution of bismuth trimagnetite, so that carrier concentration and lattice thermal conductivity are regulated and controlled at the same time; the contentof magnesium oxide in the grain boundary of N-type Mg3Sb<2> alloy is reduced through tantalum packaging smelting, so that high mobility is shown. The simple and controllable technology can be widelyapplied to various thermoelectric materials, especially materials with a large number of intrinsic defects, and therefore, a new method is provided for improving thermoelectric performance.

Owner:TONGJI UNIV

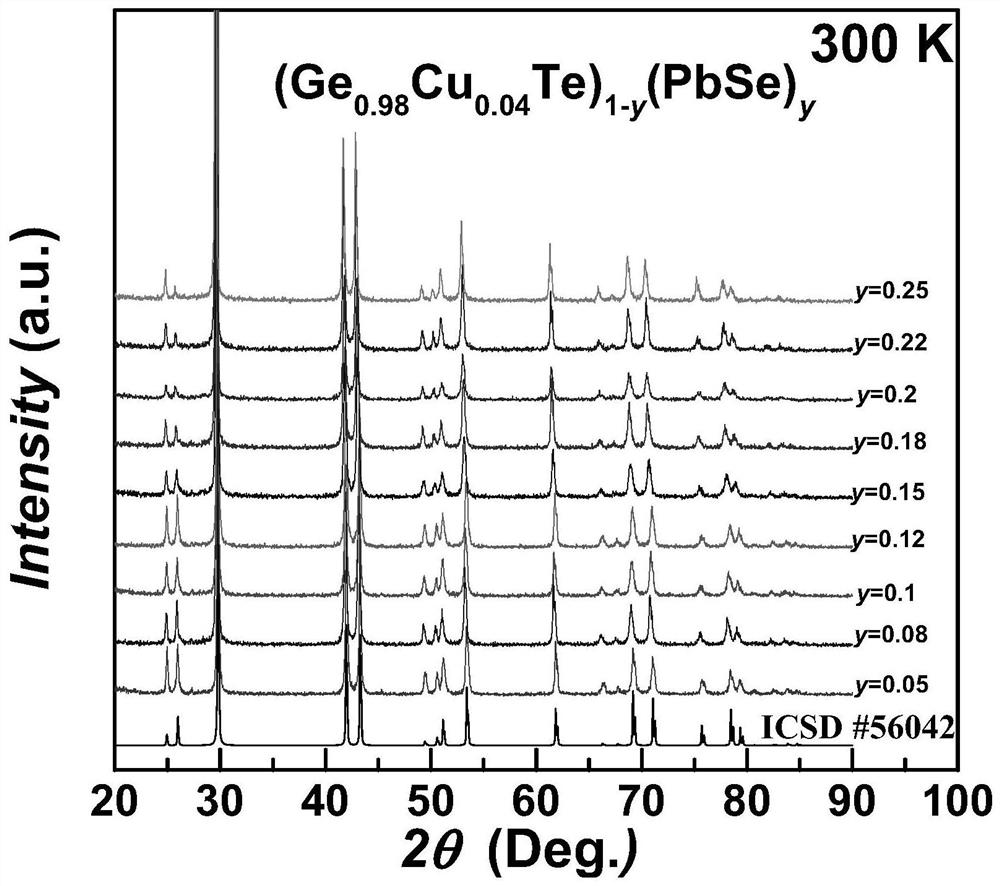

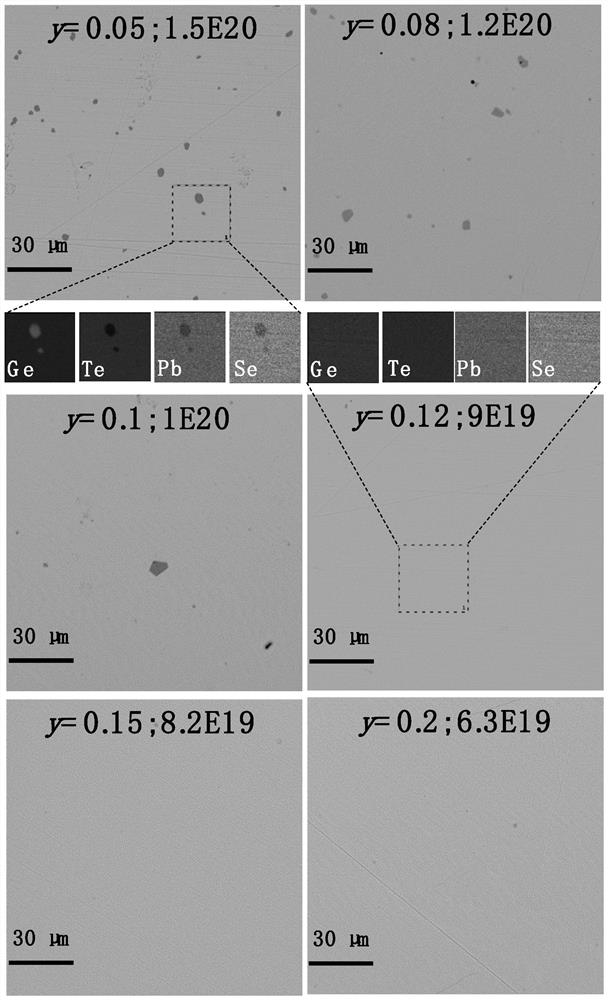

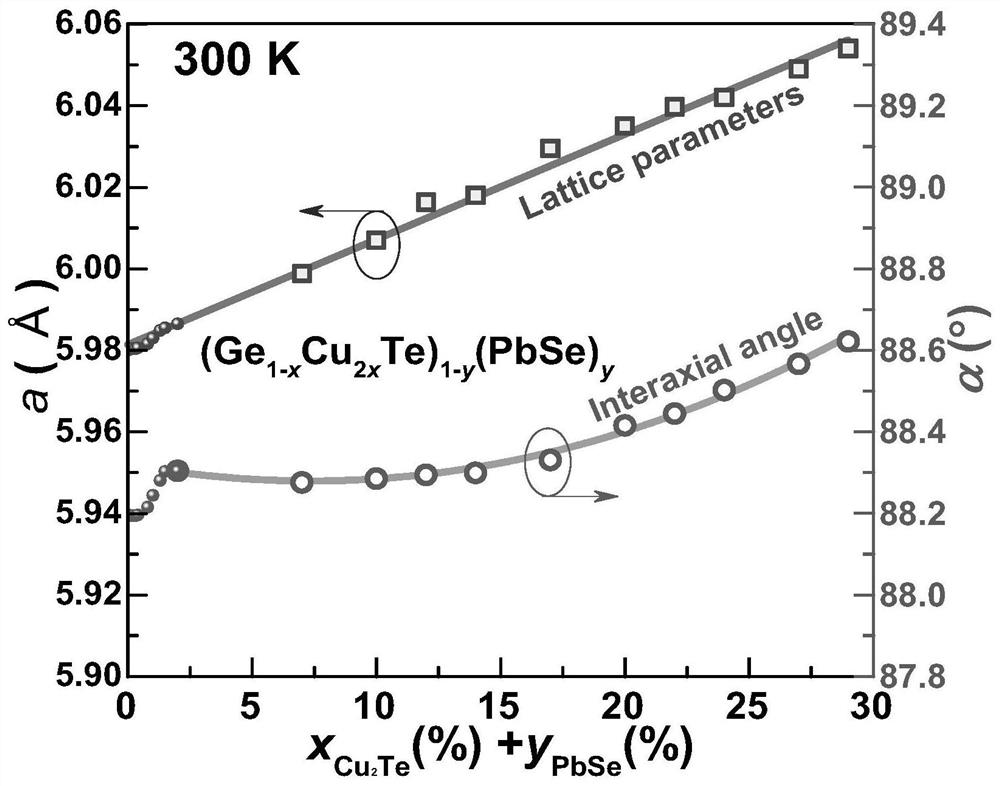

Novel germanium telluride based thermo-electric material with high thermo-electric performance and preparation method thereof

ActiveCN112661122ALow thermal conductivityIncrease scatteringSelenium/tellurium compundsThermoelectric device junction materialsGermanium tellurideLattice thermal conductivity

The invention relates to a novel germanium telluride based thermo-electric material with high thermo-electric performance and a preparation method thereof. The chemical expression of the novel germanium telluride based thermo-electric material is (Ge<1-x>Cu<2x>Te)<1-y>(PbSe)<y>, wherein x is equal to 0.02, and y is greater than or equal to 0 and less than or equal to 0.25. The preparation method comprises the following steps: taking a metal simple substance as a raw material, proportioning according to a stoichiometric ratio, carrying out vacuum packaging, high-temperature melting, annealing heat treatment and quenching to obtain a cast ingot, grinding the cast ingot into powder, and carrying out vacuum hot pressing to obtain a flaky material, namely the target component: the novel germanium telluride based thermo-electric material. Compared with the prior art, the thermo-electric material provided by the invention creates a new record of zT peak value and average zT (the peak value zT reaches 2.5 at 600-800K, and the average zT of the working temperature is greater than 1.5), and is a material with optimal thermo-electric performance in GeTe at present, which is higher than other known p-type thermo-electric materials; through defect regulation and control in GeTe, the optimization of carrier concentration and the reduction of lattice thermal conductivity are realized, and the high thermo-electric performance with record-ability is obtained.

Owner:TONGJI UNIV

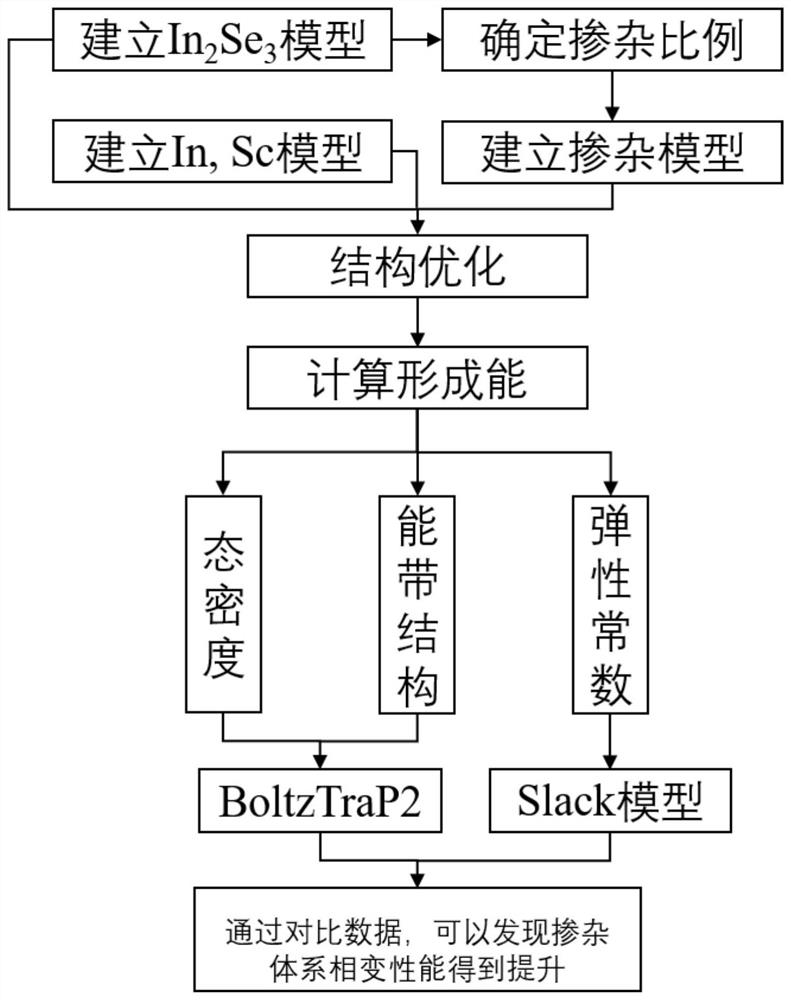

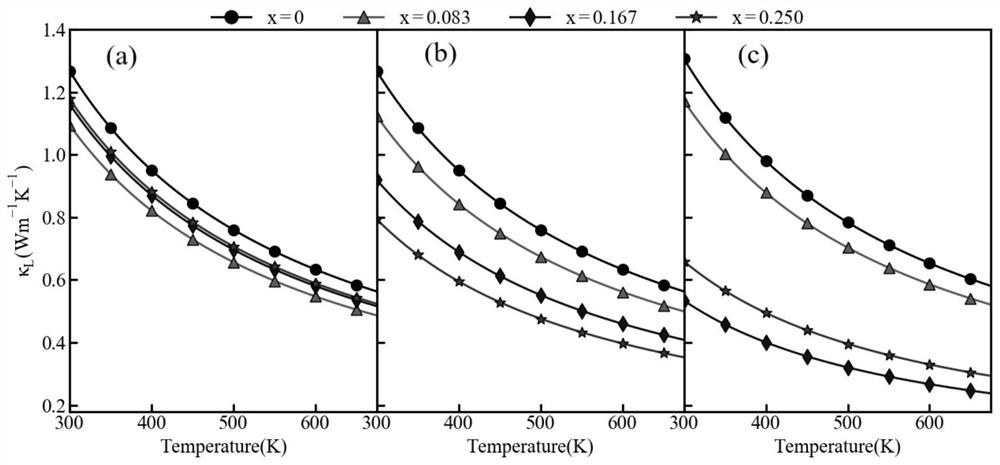

Method for improving multi-value storage characteristic of In2Se3 phase change material

InactiveCN111785831AImprove resistivity contrastStable and reliable multi-value storageElectrical apparatusDigital storageOctahedronChemical physics

The invention discloses a method for improving the multi-value storage characteristic of an In2Se3 phase change material. The method comprises the following steps: constructing crystal models of an alpha phase and a beta phase of In2Se3; respectively replacing tetrahedral In atoms and octahedral In atoms in the alpha phase with Sc in proportion to form an alpha-phase tetrahedral doping system model and an octahedral doping system model; replacing the octahedral In atoms in the beta phase with Sc in proportion to form a beta-phase octahedral doping system model; establishing models of elementalIn and elemental Sc; optimizing the model; calculating the doping formation energy of the alpha phase and the beta phase; calculating the total energy, the state density, the energy band structure and the elastic constant of the optimization model; calculating the electrical conductivity and the electronic thermal conductivity; calculating the relationship between the lattice thermal conductivityand the temperature; and comparing the thermal conductivity and the electrical conductivity before and after doping to obtain the phase change material with better performance. Metal elements meetinga certain condition are doped into the metal oxide, so the storage performance of the metal oxide can be improved.

Owner:WUHAN UNIV OF TECH

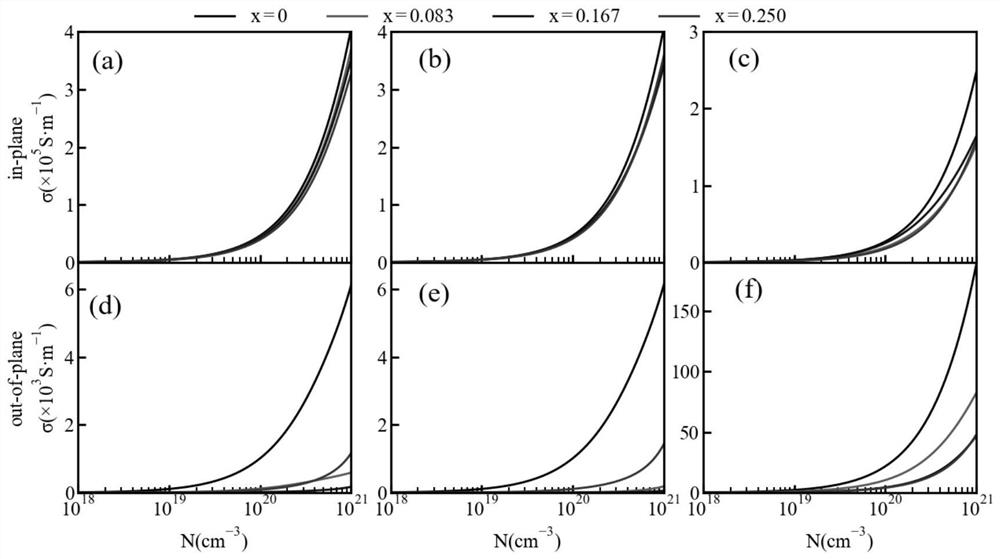

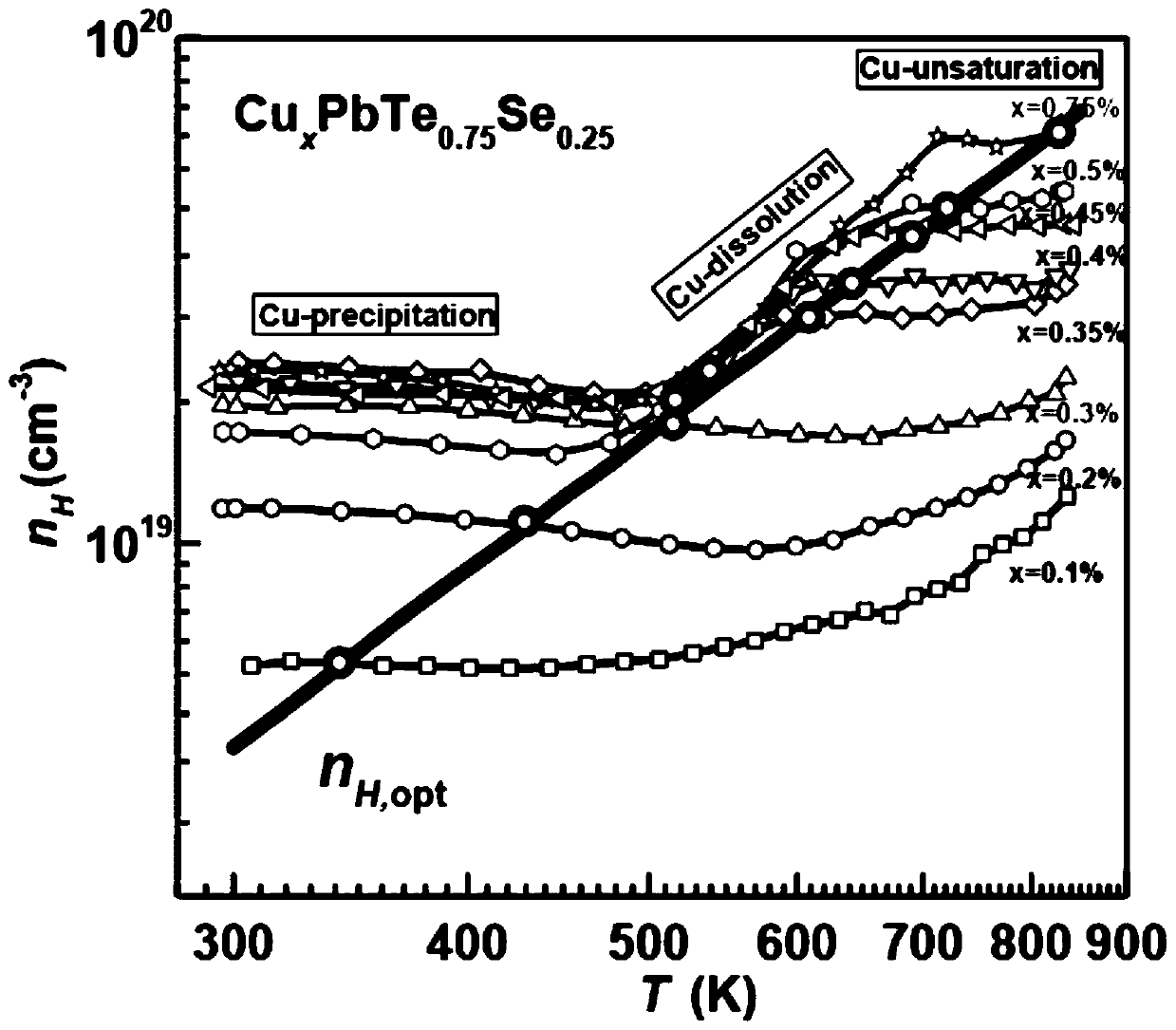

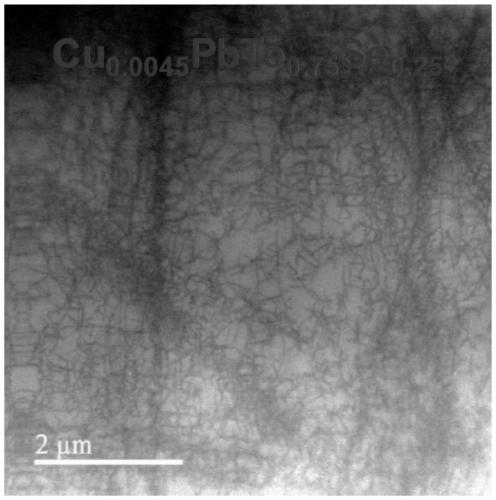

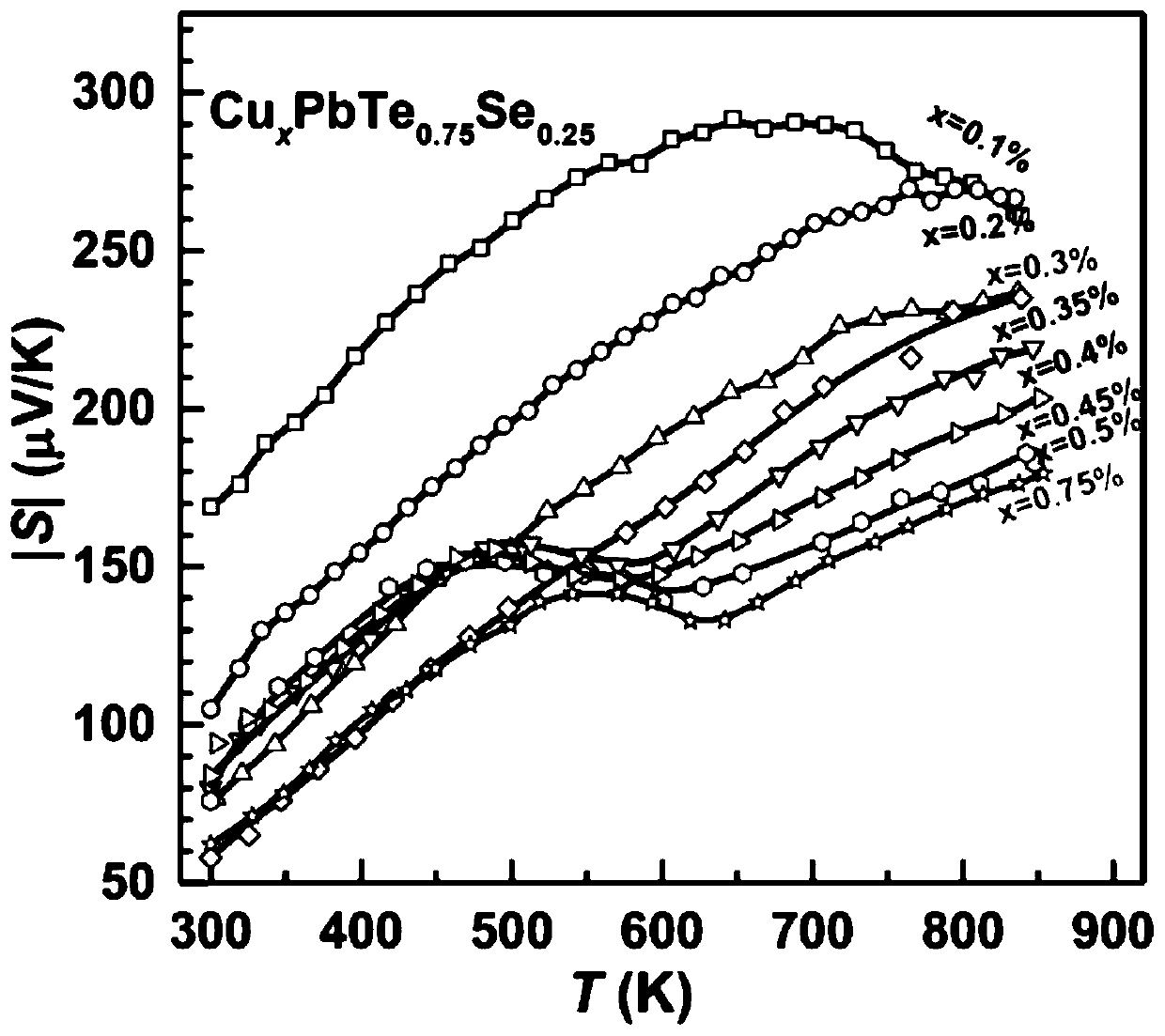

High-performance PbTe-based N-type thermoelectric material and preparation method thereof

PendingCN111200055AAchieving Spontaneous Dynamic OptimizationImprove solubilityThermoelectric device manufacture/treatmentThermoelectric device junction materialsHigh densityPhysical chemistry

The invention relates to a high-performance PbTe-based N-type thermoelectric material and preparation thereof. The chemical formula of the thermoelectric material is CuxPbTe0.75Se0.25, wherein x is greater than 0 and less than or equal to 0.75%. Compared with the prior art, by using heterovalent interstitial copper atom doping, electrons can be released at interstitial positions after copper atomsenter crystal lattices, and the carrier concentration is adjusted, so that the material shows the properties of an N-type semiconductor. Due to the fact that the added interstitial copper atoms havethe solubility which is continuously increased along with the temperature in a PbTe0.75Se0.25 material system, the carrier concentration which is increased along with the temperature rise can be obtained in the temperature rise process, dynamic optimization of the carrier concentration is achieved, and the electrical transport performance of the material is enhanced. Besides, high-density intragranular dislocations can be introduced into the material due to aggregation of the interstitial copper atoms, and remarkable lattice strain can be introduced into the material due to the dislocation defects, so that the lattice thermal conductivity of the material is greatly reduced, and the thermal performance of the material is greatly optimized.

Owner:TONGJI UNIV

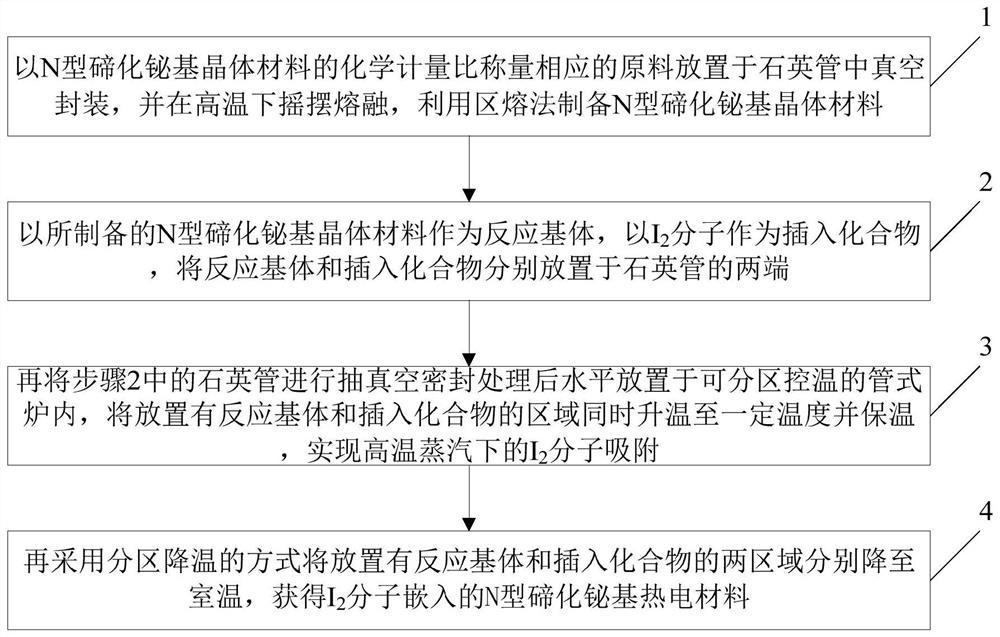

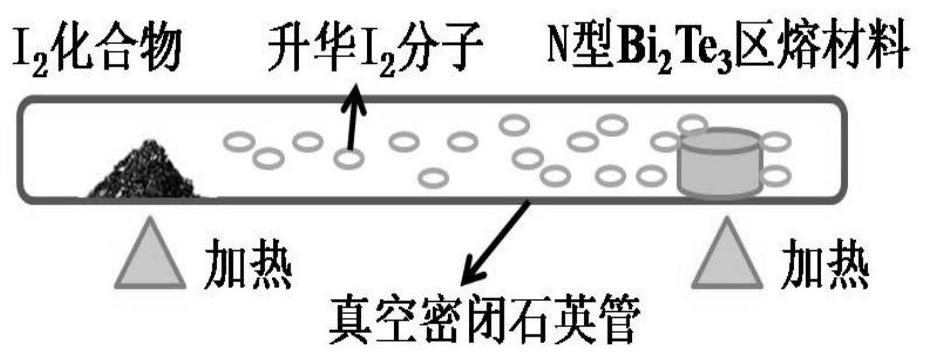

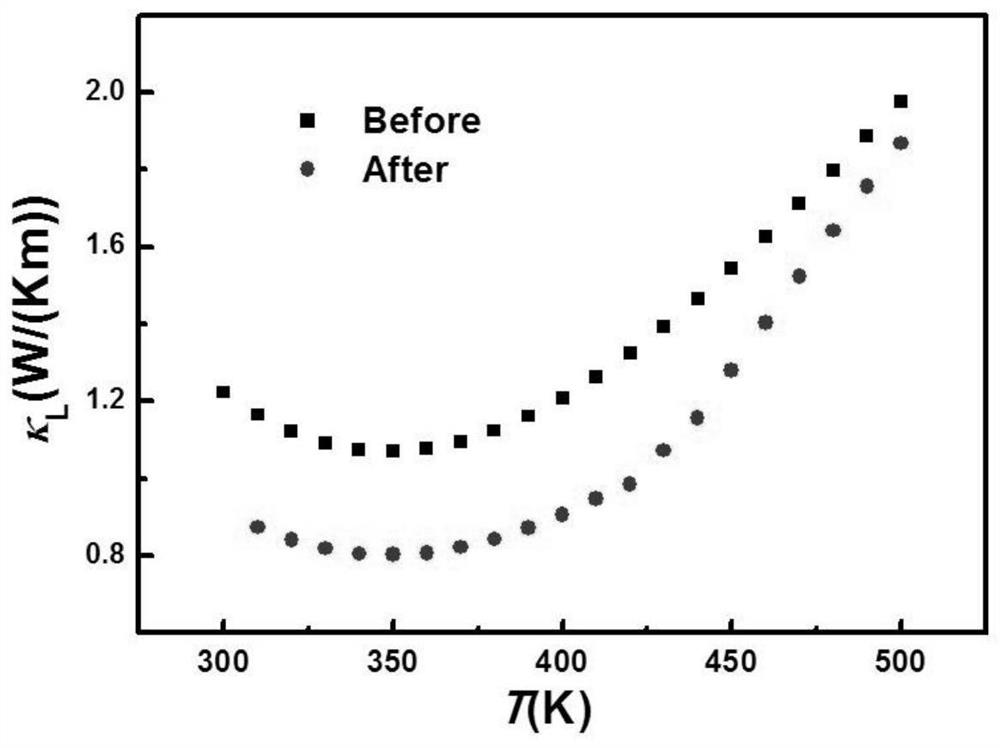

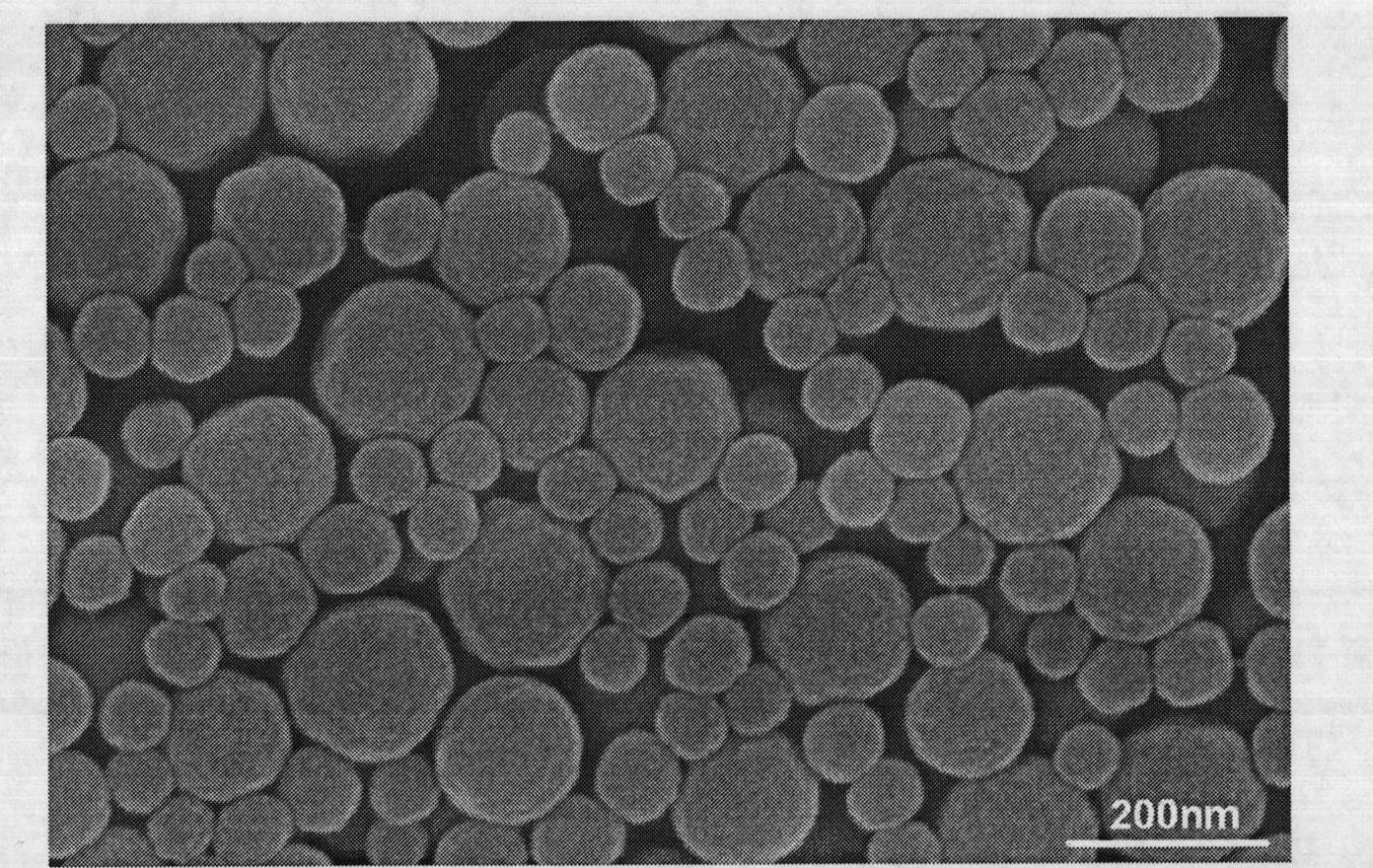

A kind of preparation method of n-type bismuth telluride-based thermoelectric material

InactiveCN108550689BGuaranteed electrical performanceLow thermal conductivityThermoelectric device with dielectric constant thermal changeBismuth tellurideMolecular adsorption

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

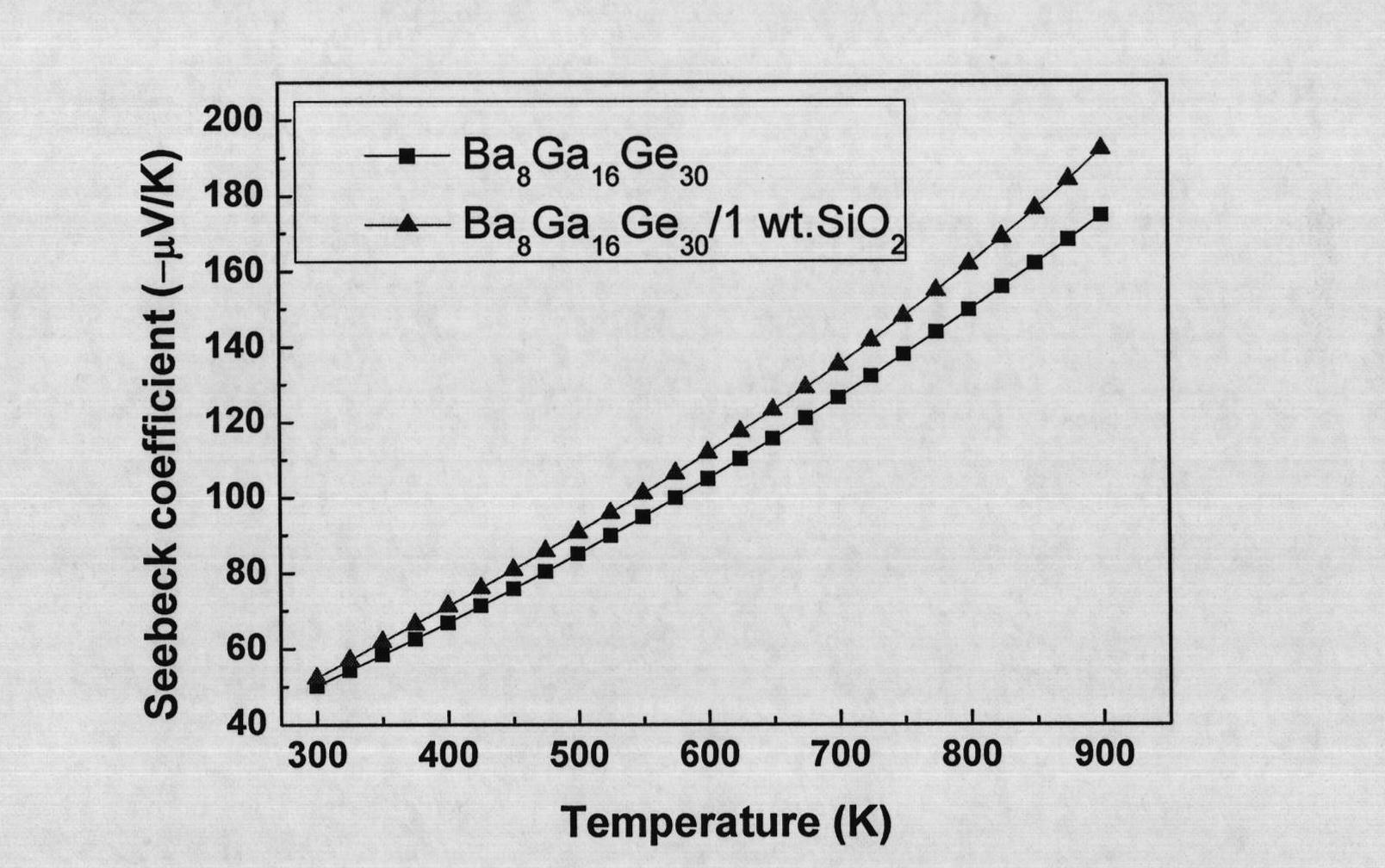

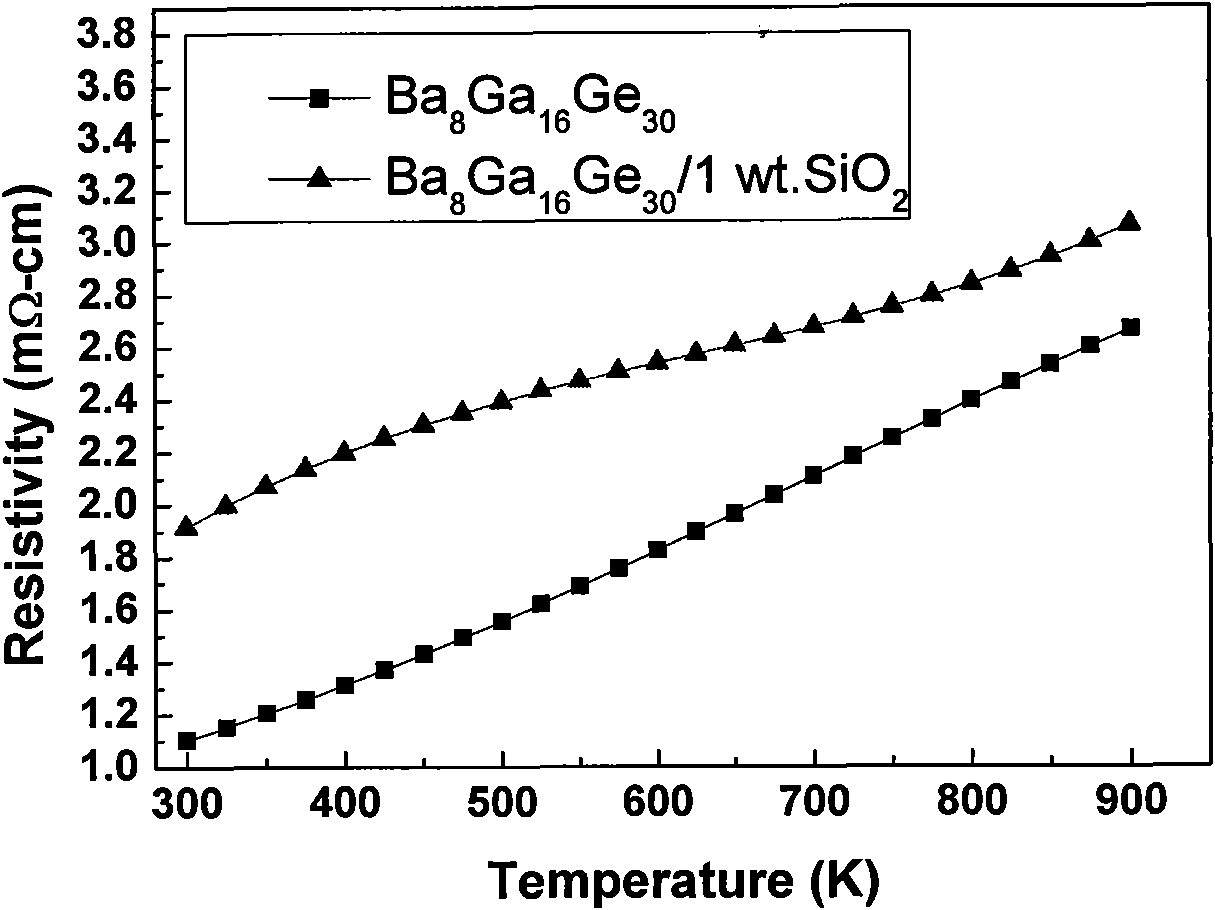

SiO2 nanoparticle composite cage compound thermoelectric material and preparation method thereof

ActiveCN101979688AEnabling regulated electrical transport propertiesRegulating electrical transport propertiesThermoelectric device manufacture/treatmentThermoelectric device junction materialsNano sio2Lattice thermal conductivity

The invention relates to the technical field of thermoelectric materials and discloses a SiO2 nanoparticle composite cage compound thermoelectric material and a preparation method thereof. In the invention, 50 to 300 nanometer SiO2 nanoparticles are mixed with a cage compound, the regulation of the electron transport performance of the cage compound thermoelectric material and the considerable reduction of lattice thermal conductivity are realized by adding a proper amount of the SiO2 nanoparticles, and finally the hermoelectric property of the cage compound thermoelectric material is improved. In addition, the preparation method of the SiO2 nanoparticle composite cage compound thermoelectric material is simple and easy to implement, overcomes the drawbacks of introducing other impurities easily and preventing the mixed second-phase particles from dispersing and agglomeration easily of the traditional preparation method, and makes the nano SiO2 particles uniformly dispersed and mixed with the cage compound thermoelectric material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

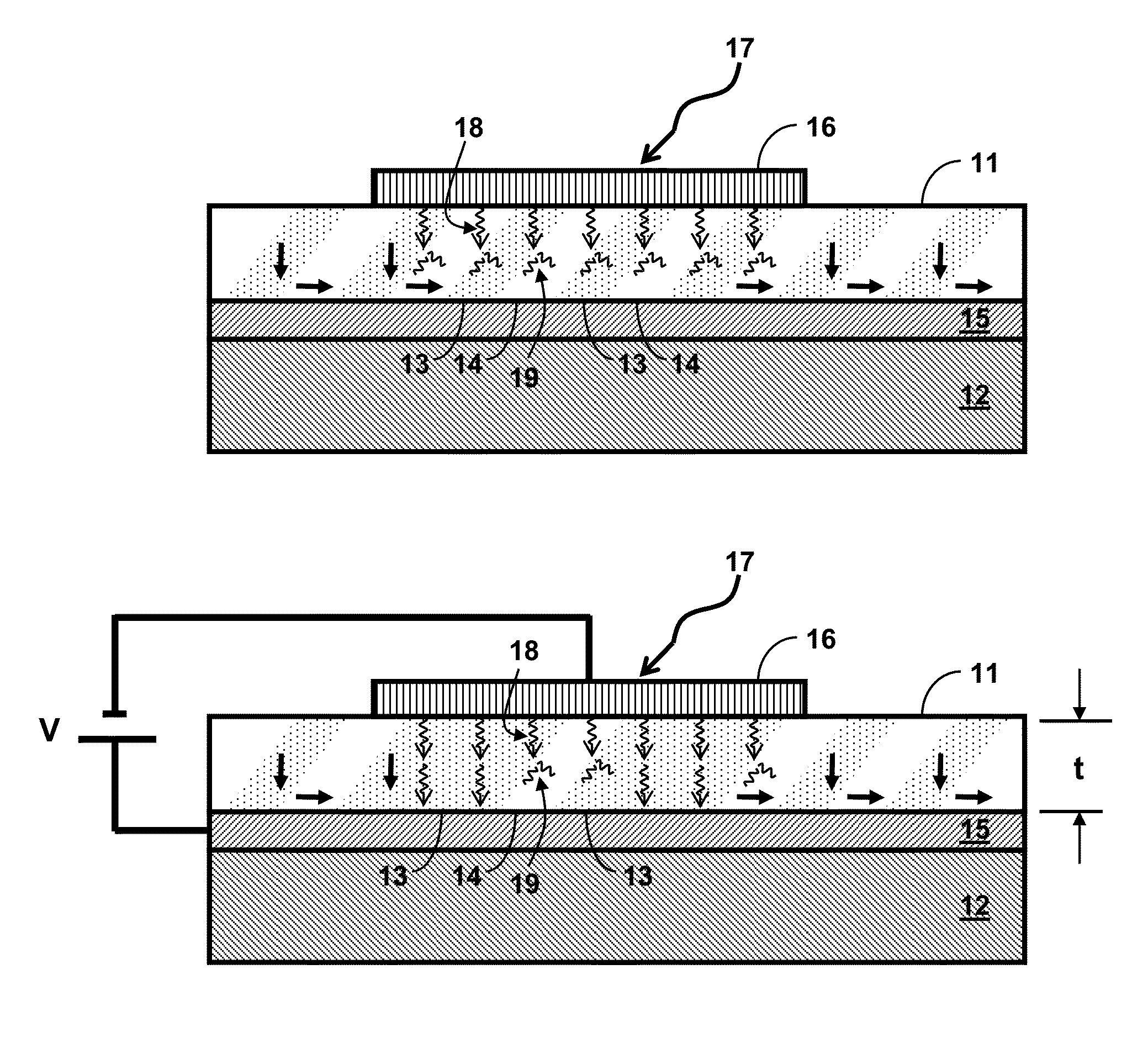

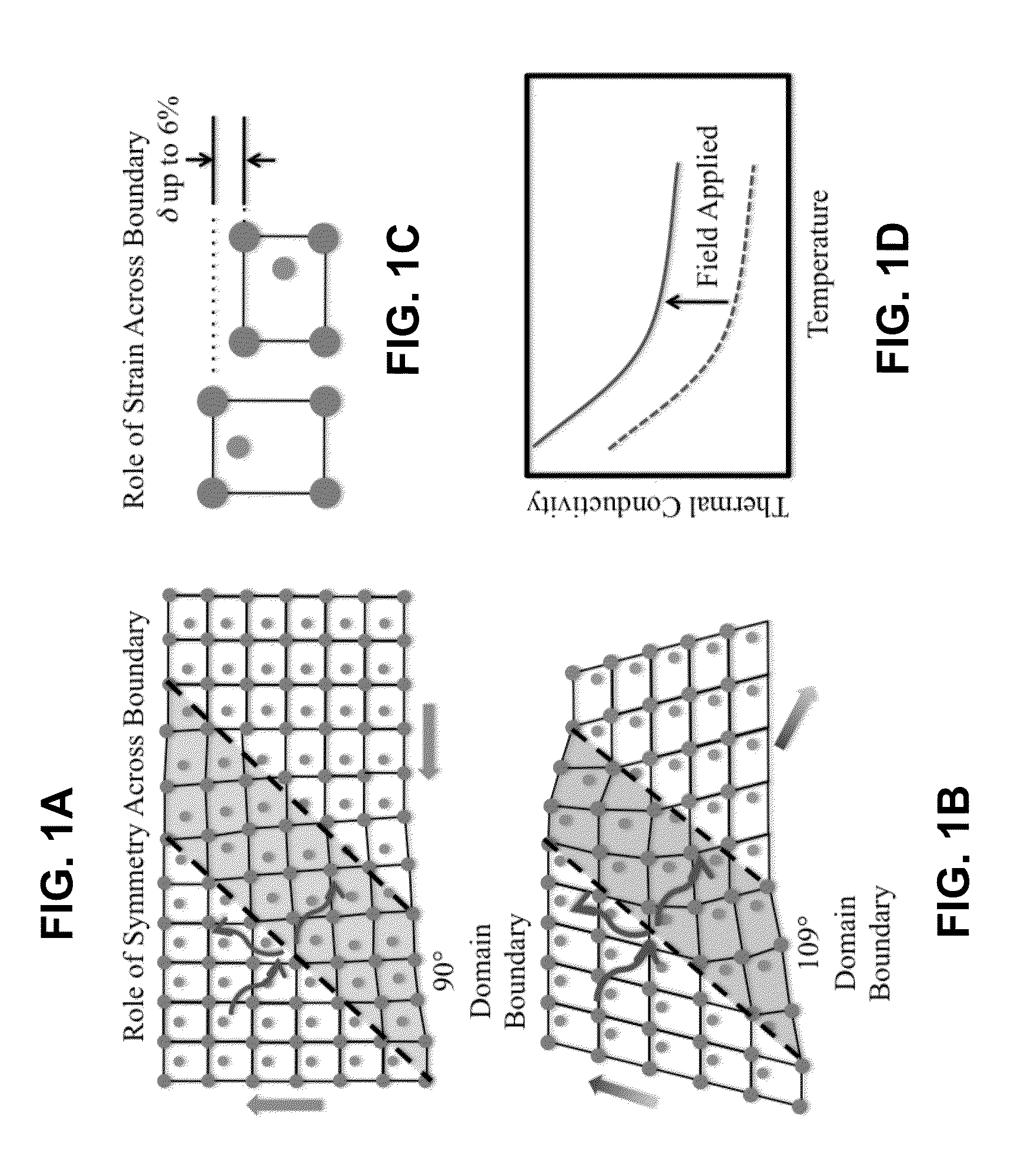

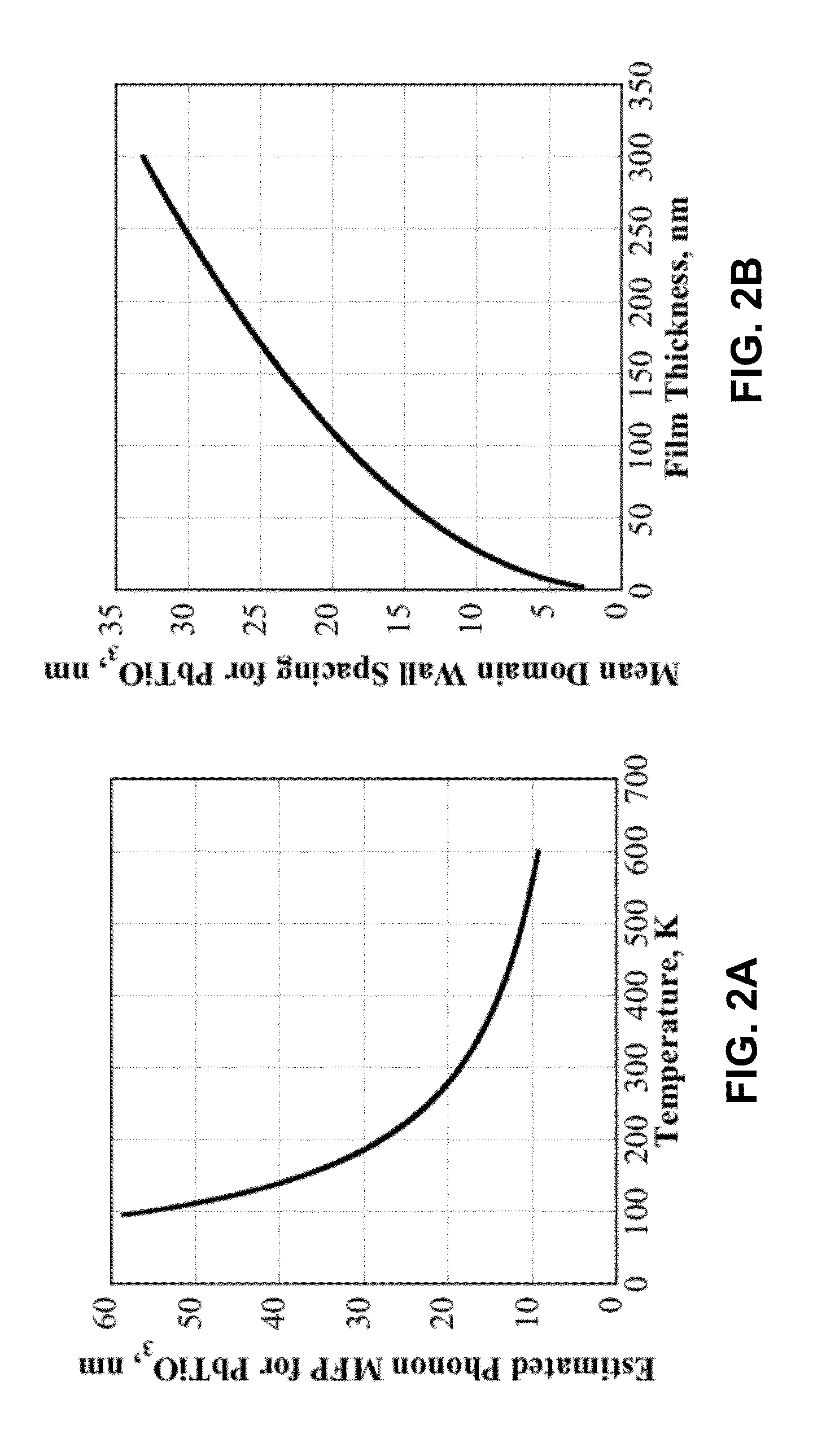

Voltage tunability of thermal conductivity in ferroelectric materials

ActiveUS9255347B2Low thermal conductivityReduce conductivityPolycrystalline material growthDecorative surface effectsThermal energyDirect effects

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

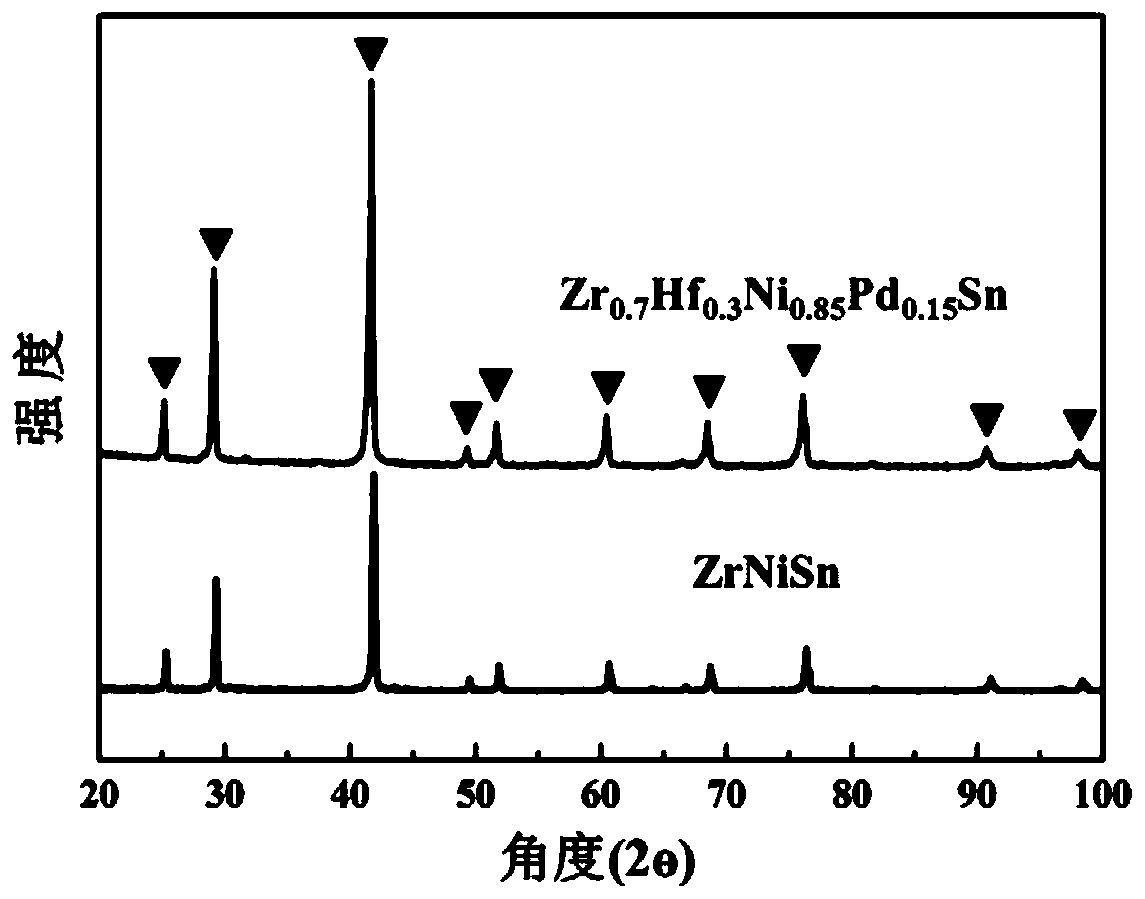

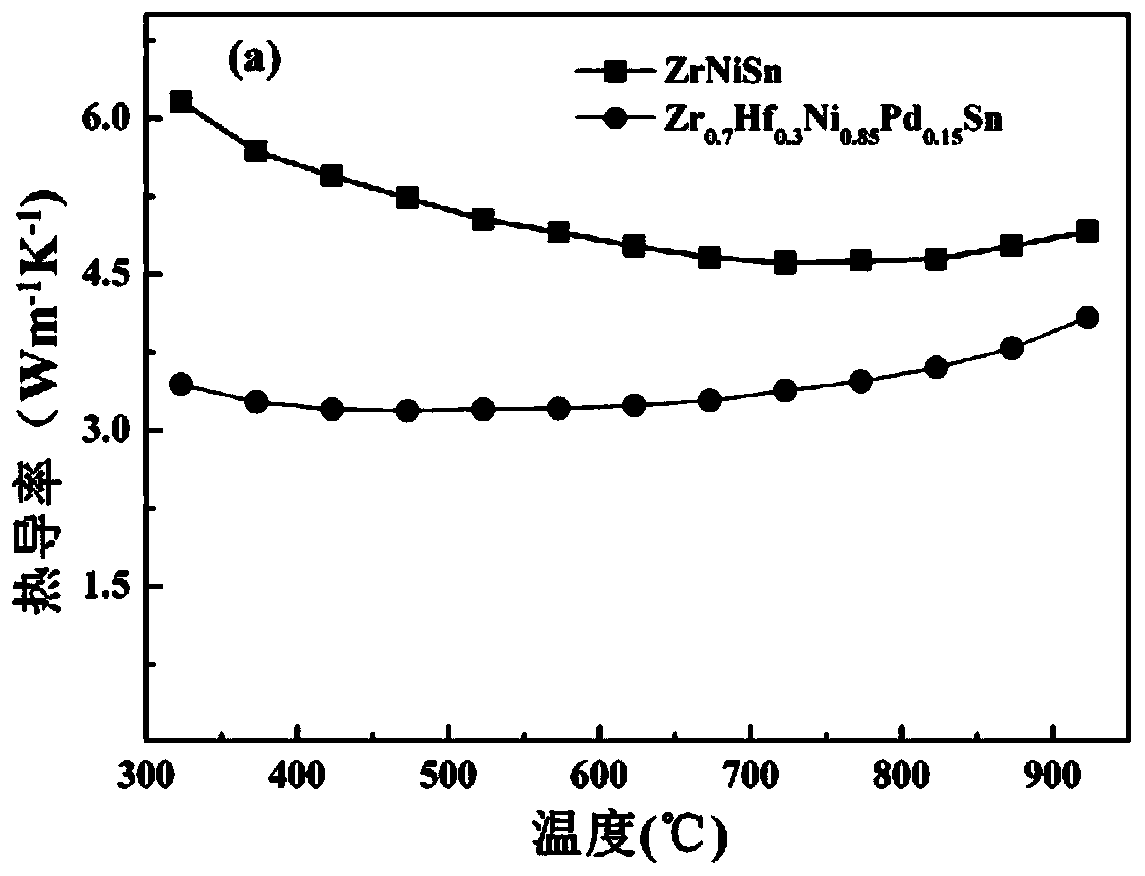

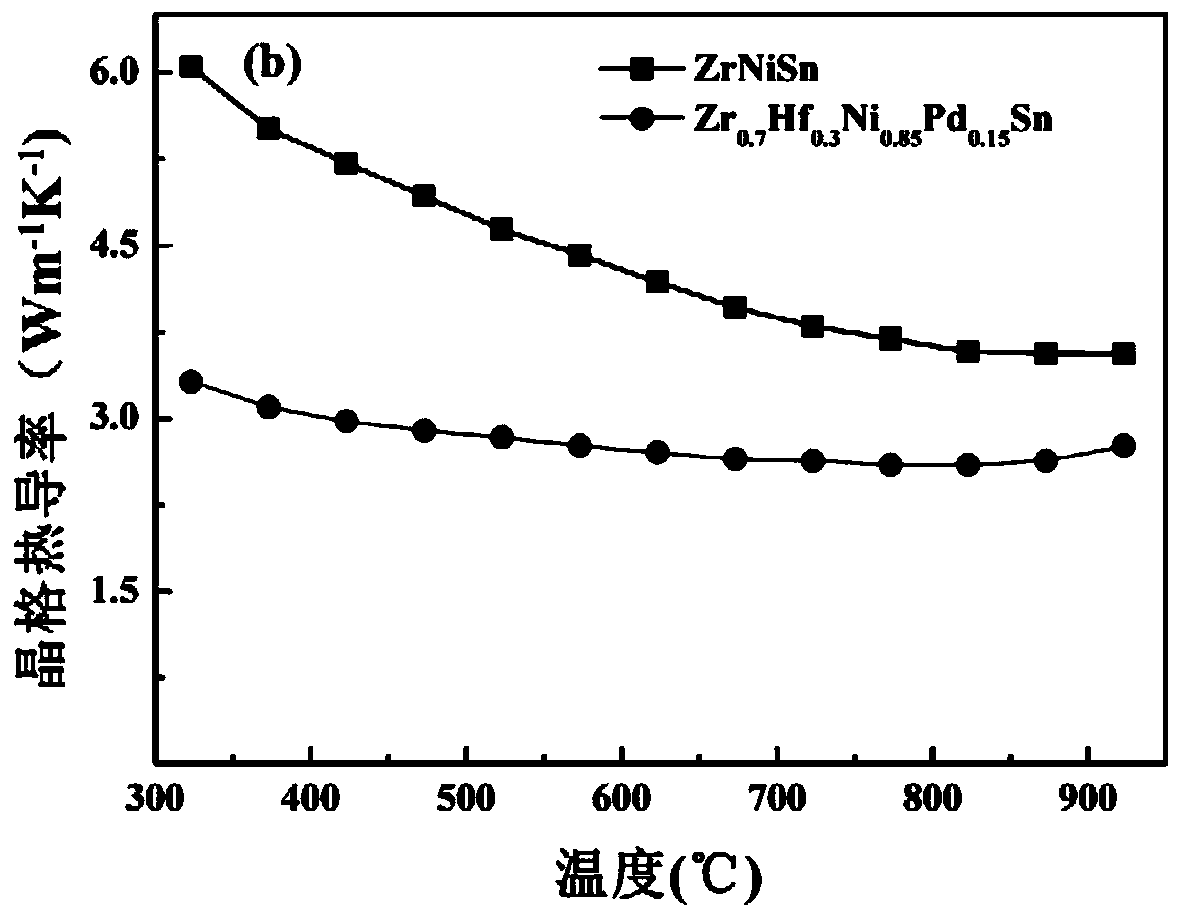

High entropy Half-Heusler thermoelectric material with low lattice thermal conductivity and preparation method thereof

ActiveCN110592459ASolid solubility of major elementsLower lattice thermal conductivityThermoelectric device manufacture/treatmentTransportation and packagingLattice thermal conductivityMixed materials

The present invention provides a high entropy Half-Heusler thermoelectric material with a low lattice thermal conductivity and a preparation method thereof. The general formula of the high entropy Half-Heusler thermoelectric material with the low lattice thermal conductivity is ZrxHf1-xNiyPd1-ySn, wherein x=0.6-0.8, and y=0.8-0.9. The preparation method of the high entropy Half-Heusler thermoelectric material with the low lattice thermal conductivity comprises the following steps: proportioning and mixing the materials according to the general formula Zr0.7Hf0.3Ni0.85Pd0.15Sn, placing the mixed materials in a magnetic suspension smelting furnace for smelting, grinding and drying an ingot obtained by smelting to obtain powder, and sintering the powder by adopting a discharge plasma sintering technology to obtain the high entropy Half-Heusler thermoelectric material with the low lattice thermal conductivity. The high entropy Half-Heusler thermoelectric material has the low lattice thermal conductivity and high ZT value.

Owner:DALIAN UNIV OF TECH

ZrNiSn-based high-entropy thermoelectric material and preparation method thereof and thermoelectric device

InactiveCN108048725ALarge lattice distortionLower lattice thermal conductivityLattice thermal conductivityChemical measurement

The invention discloses a ZrNiSn-based high-entropy thermoelectric material and a preparation method and application thereof. The chemical formula of the ZrNiSn-based high-entropy thermoelectric material is Zr<1>-<x>M<x>Ni<1>-<y>Co<y>Sn<1>-<z>Sb<z>, wherein x=0.2-0.8, y=0-0.2, and z=0-0.3; and M comprises any 4-5 elements of V, Nb, Hf, Ti, Sc, Y, Ta and Mo. The preparation method comprise the steps that all pure metal raw materials are weighed and taken according to the stoichiometric ratio of the elements contained by the ZrNiSn-based high-entropy thermoelectric material, and the steps of smelting treatment, annealing treatment and discharging plasma sintering are conducted. The ZrNiSn-based high-entropy thermoelectric material has the low lattice thermal conductivity; the technological condition of the preparation method of the ZrNiSn-based high-entropy thermoelectric material is easy to control, stability of microstructure and physicochemical properties of the prepared ZrNiSn-basedhigh-entropy thermoelectric material is ensured, the preparation efficiency is high, and the production cost is reduced.

Owner:SHENZHEN UNIV

Novel Zintl phase thermoelectric material and preparation method thereof

ActiveCN110218888AReduce conductivityImprove thermoelectric performanceElectricityLattice thermal conductivity

The invention discloses a novel Zint1 phase thermoelectric material. The chemical formula of the novel Zintl phase thermoelectric material is YbMg2Sb2, the novel Zintl phase thermoelectric material isa pure-phase hexagonal crystal structure, the width of a forbidden band calculated by the energy band structure is 1.23 eV, the YbMg2Sb2 thermoelectric material is doped with Na, the chemical formulais Yb1-xNaxMg2Sb2, Mg2Sb2, and x is greater than or equal to 0 and less than or equal to 0.025. Na is doped at the position of Yb, so that the concentration of carriers is increased, and meanwhile, the thermal conductivity of lattices is reduced, the thermoelectric performance is improved, and the highest thermoelectric optimal value is reached when the temperature is 77K. The novel Zintl phase thermoelectric material is prepared, the electricity and the heat transportation performance are optimized simultaneously through Na doping, and the novel Zintl phase thermoelectric material has an application potential. The development of the Zintl phase thermoelectric material is promoted.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com