High-performance thermoelectric composite material and preparation method thereof

A composite material and thermoelectric technology, which is applied in the direction of thermoelectric device lead-out wire materials, thermoelectric device manufacturing/processing, etc., can solve the problems of low thermoelectric performance and low mechanical strength at high temperature end, so as to improve thermoelectric performance and reduce crystal lattice Thermal conductivity, effect of improving process workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

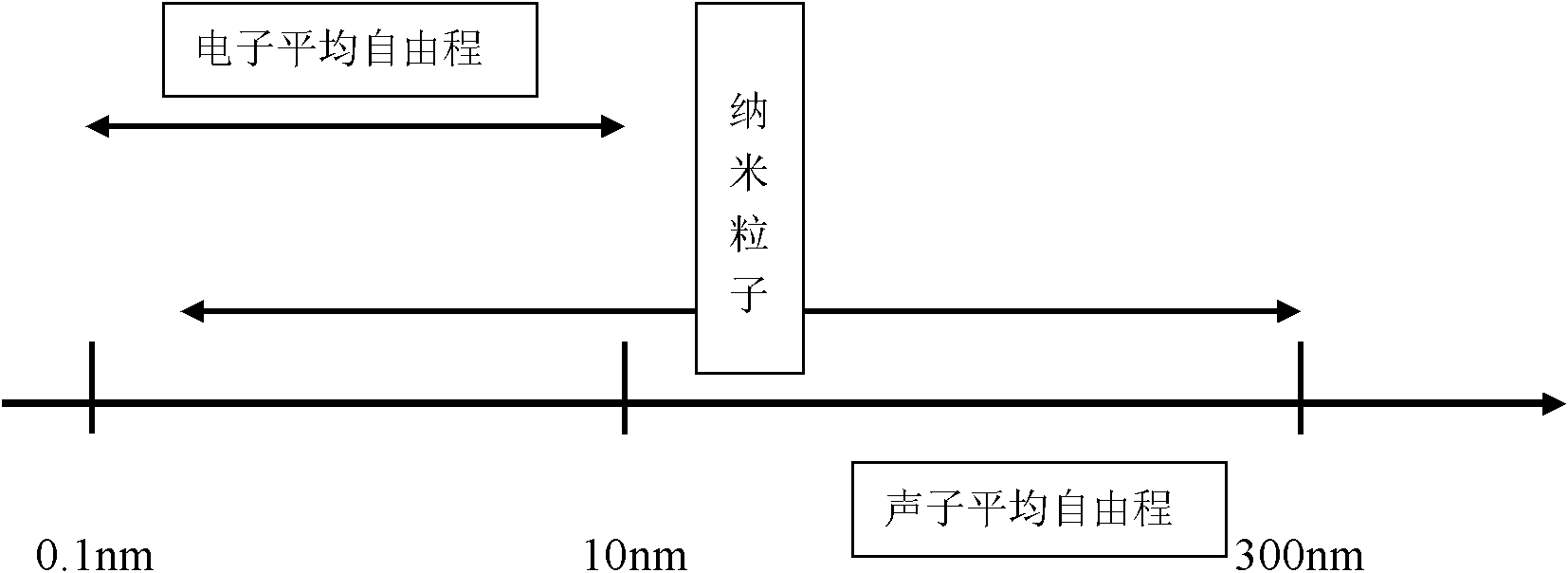

Problems solved by technology

Method used

Image

Examples

Embodiment 1

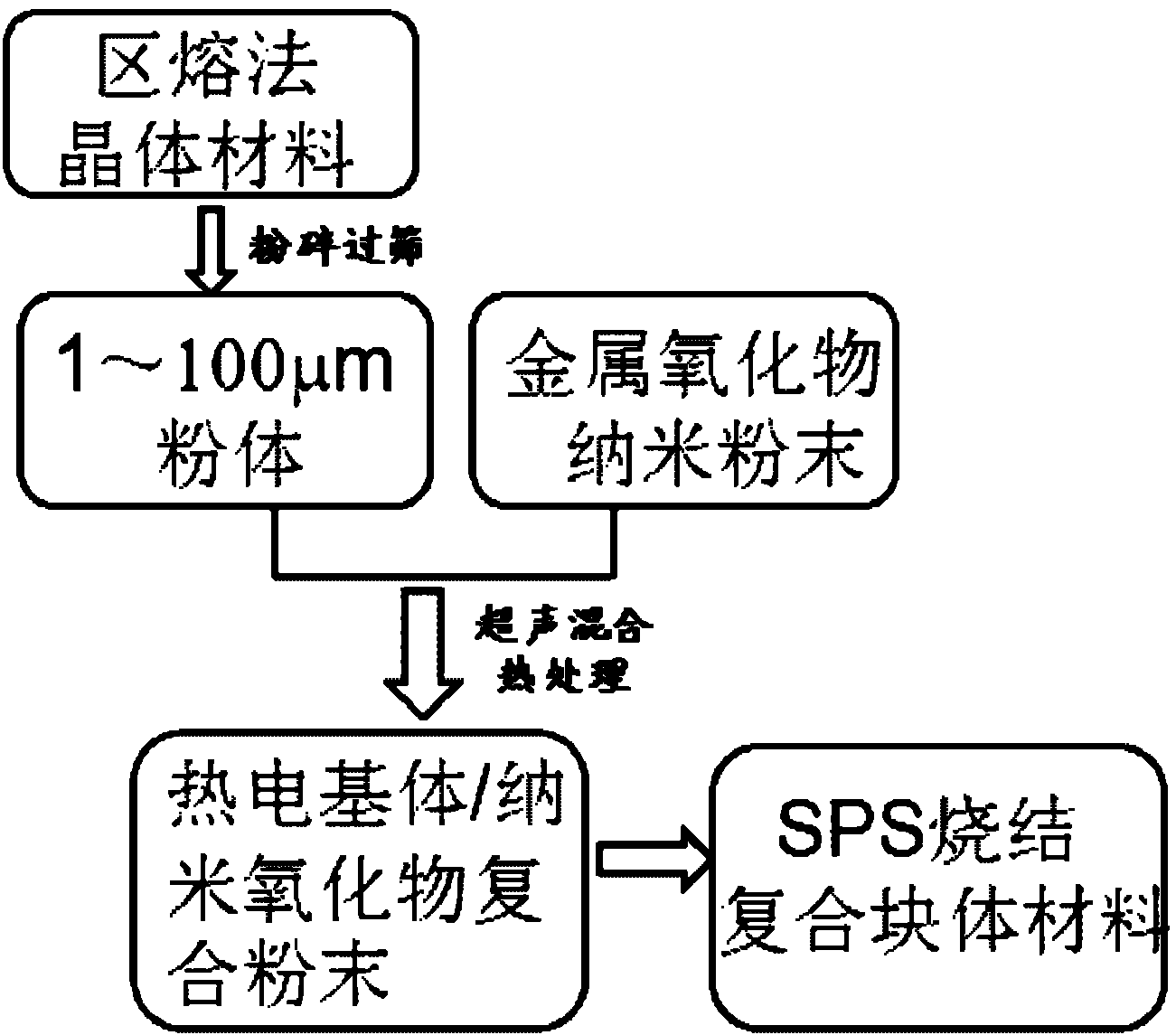

[0030] Embodiment 1: component is Bi 2 Se 0.3 Te 2.7 n-type matrix powder

[0031] Firstly, oriented polycrystalline rods of the above components were obtained by zone melting growth. The zone melting growth conditions were melting temperature 700°C, temperature gradient 25°C / mm, and growth rate 2.5mm / h. After the surface part of the polycrystalline rod is removed, it is crushed and sieved, and a steel container is used as a crushing tool, and the crushing process is protected by an inert atmosphere such as argon. After crushing, use a standard nylon sieve to sieve the powder to obtain the initial powder with the required particle size distribution, and select the powder with a particle size of 1-100 μm.

[0032] Using a graphite mold, SPS sintering was performed under vacuum conditions. The sintering temperature is 440°C, the heating rate is 100°C / min, the holding time is 10min, and the applied pressure is 60MP. The bending strength of the obtained sintered body is close...

Embodiment 2

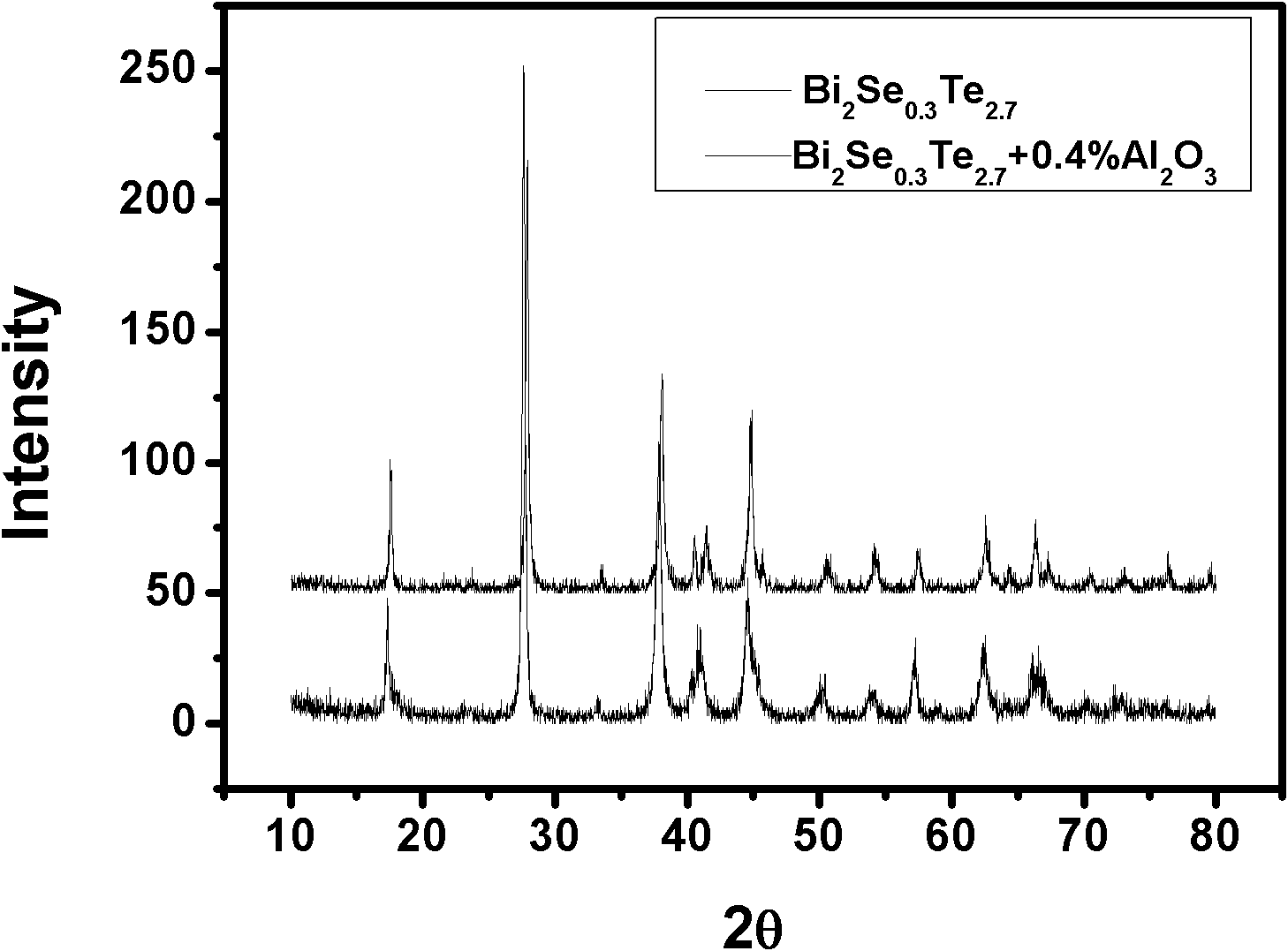

[0033] Embodiment 2: component is Bi 2 Se 0.3 Te 2.7 n-type matrix powder+0.4wt.%Al 2 o 3 nano powder

[0034] Firstly, oriented polycrystalline rods of the above components were obtained by zone melting growth. The zone melting growth conditions were melting temperature 700°C, temperature gradient 25°C / mm, and growth rate 2.5mm / h. After the surface part of the polycrystalline rod is removed, it is crushed and sieved, and a steel container is used as a crushing tool, and the crushing process is protected by an inert atmosphere such as argon. After crushing, use a standard nylon sieve to sieve the powder to obtain the initial powder with the required particle size distribution, and select the powder with a particle size of 1-100um.

[0035] Ultrasonic mixing of the matrix powder and metal oxide nanopowder obtained above, the liquid medium used for ultrasonic mixing is ethanol solution, polyethylene glycol is used as a dispersant, and ultrasonic mixing is performed for 0.5h...

Embodiment 3

[0037] Embodiment 3: component is Bi 2 Se 0.3 Te 2.7 n-type matrix powder+0.2wt.%Al 2 o 3 nano powder

[0038] Firstly, oriented polycrystalline rods of the above components were obtained by zone melting growth. The zone melting growth conditions were melting temperature 650°C, temperature gradient 20°C / mm, and growth rate 3mm / h. After the surface part of the polycrystalline rod is removed, it is crushed and sieved, and a steel container is used as a crushing tool, and the crushing process is protected by an inert atmosphere such as argon. After crushing, use a standard nylon sieve to sieve the powder to obtain the initial powder with the required particle size distribution, and select the powder with a particle size of 1-100um.

[0039] Ultrasonic mixing of the matrix powder and metal oxide nano-powder obtained above, the liquid medium used for ultrasonic mixing is ethanol, polyethylene glycol is used as a dispersant, and ultrasonic mixing is carried out for 2 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com