Patents

Literature

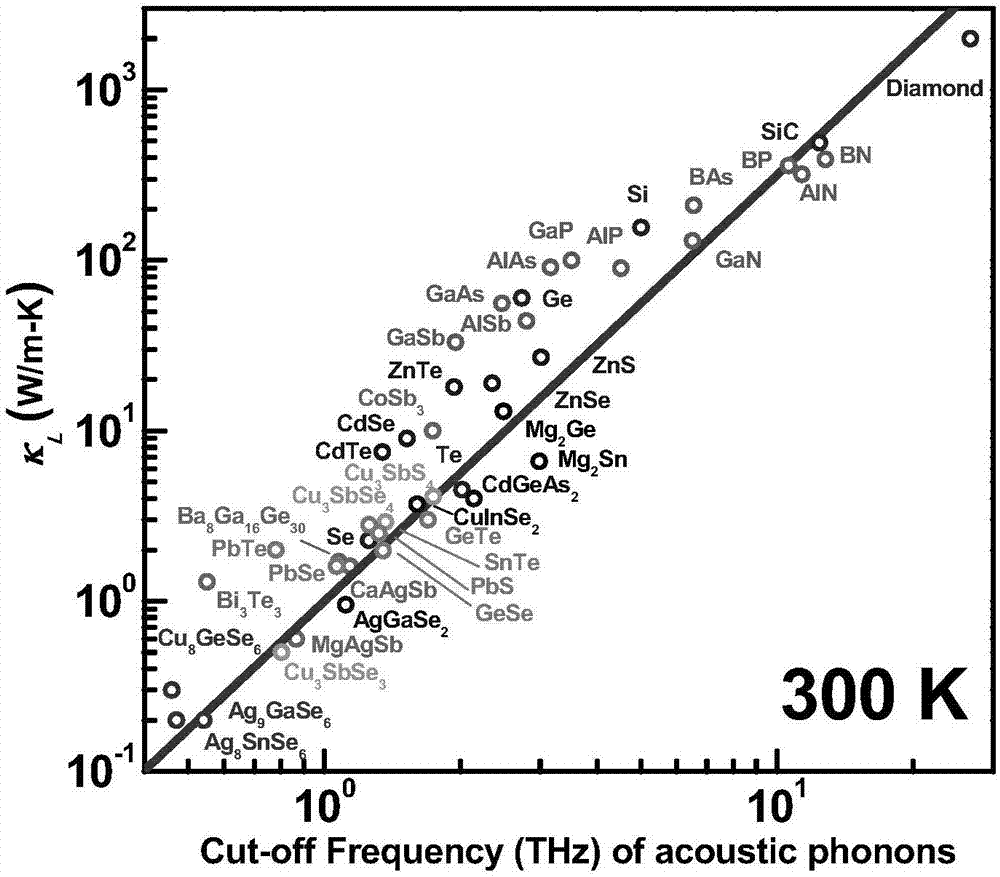

90results about How to "Lower lattice thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

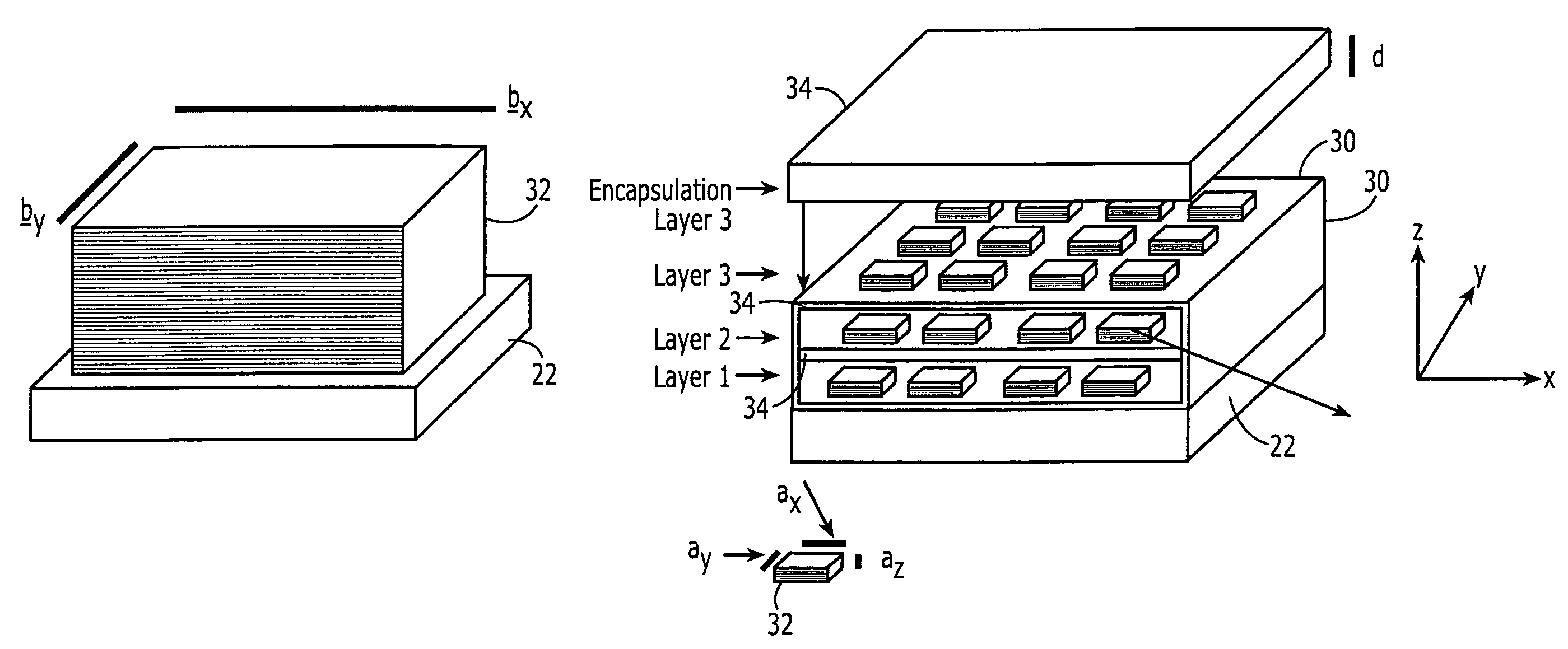

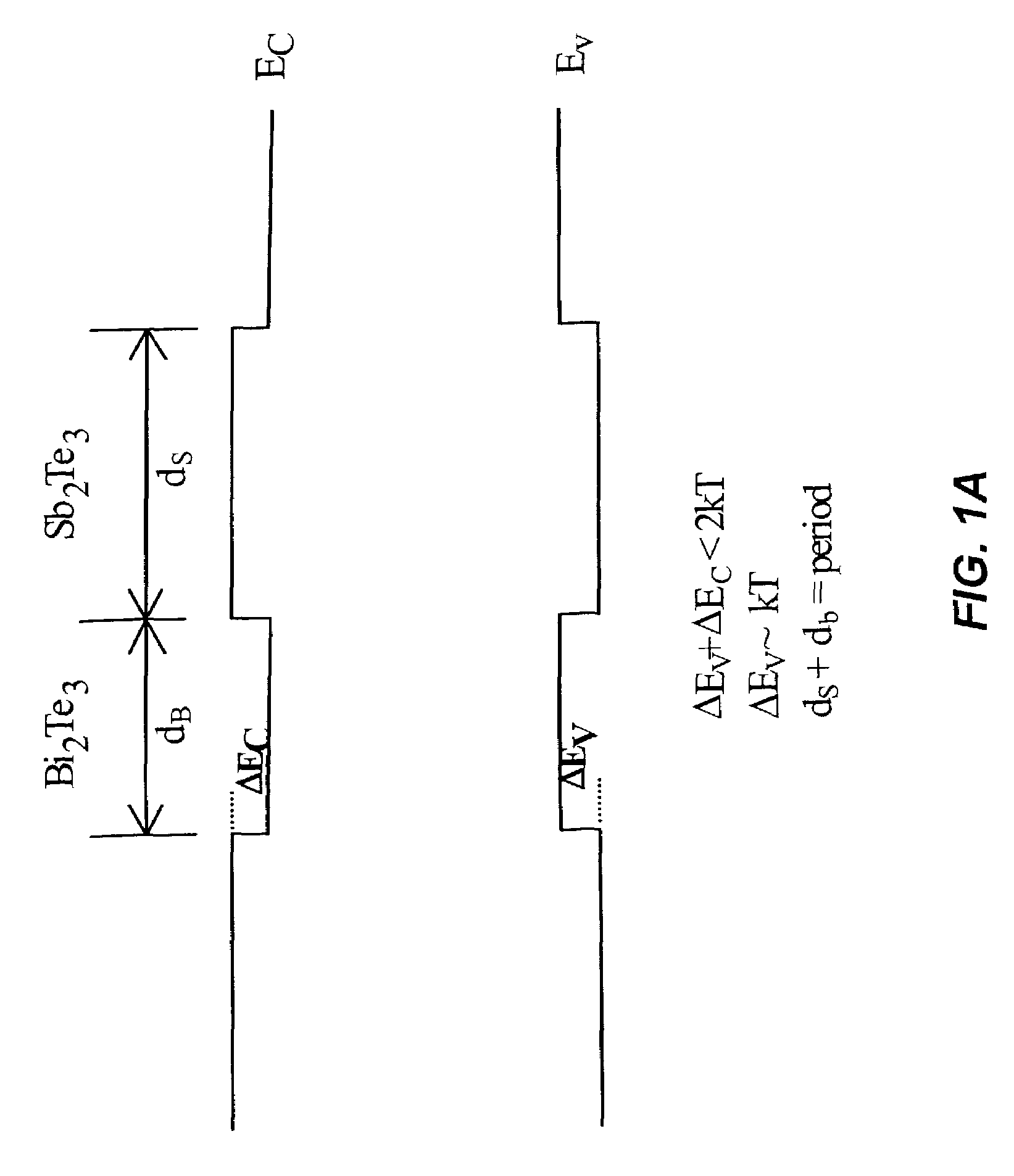

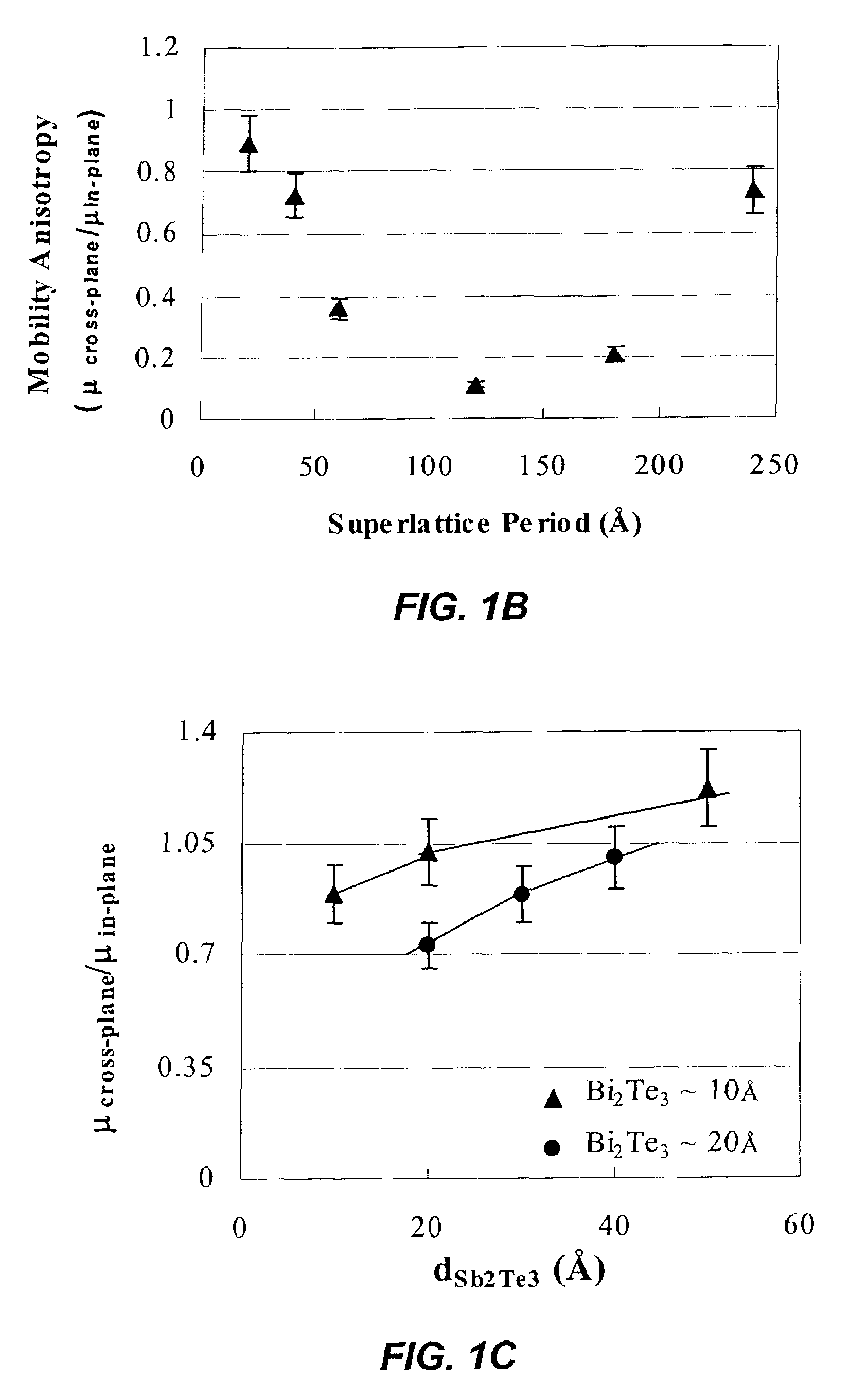

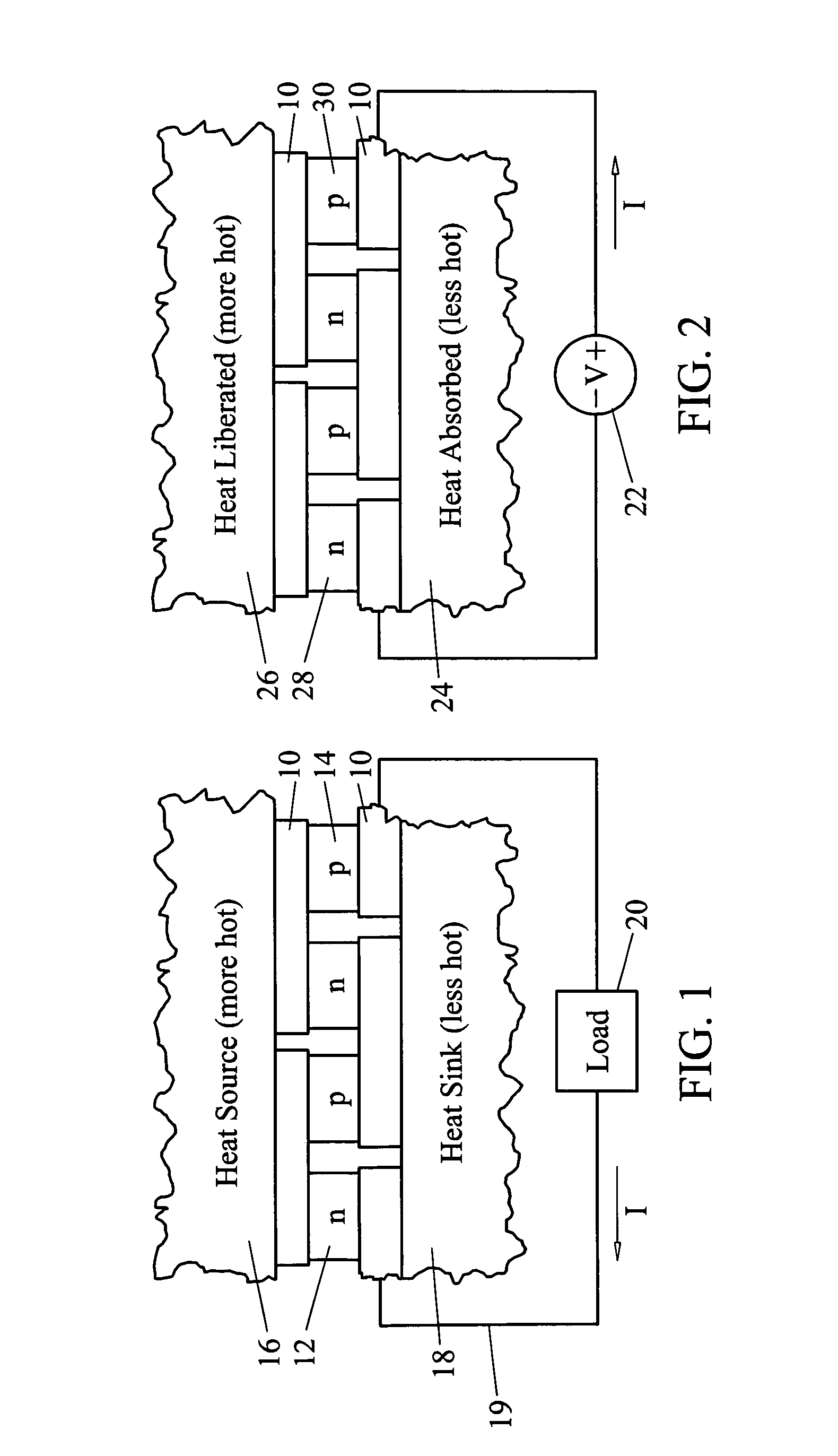

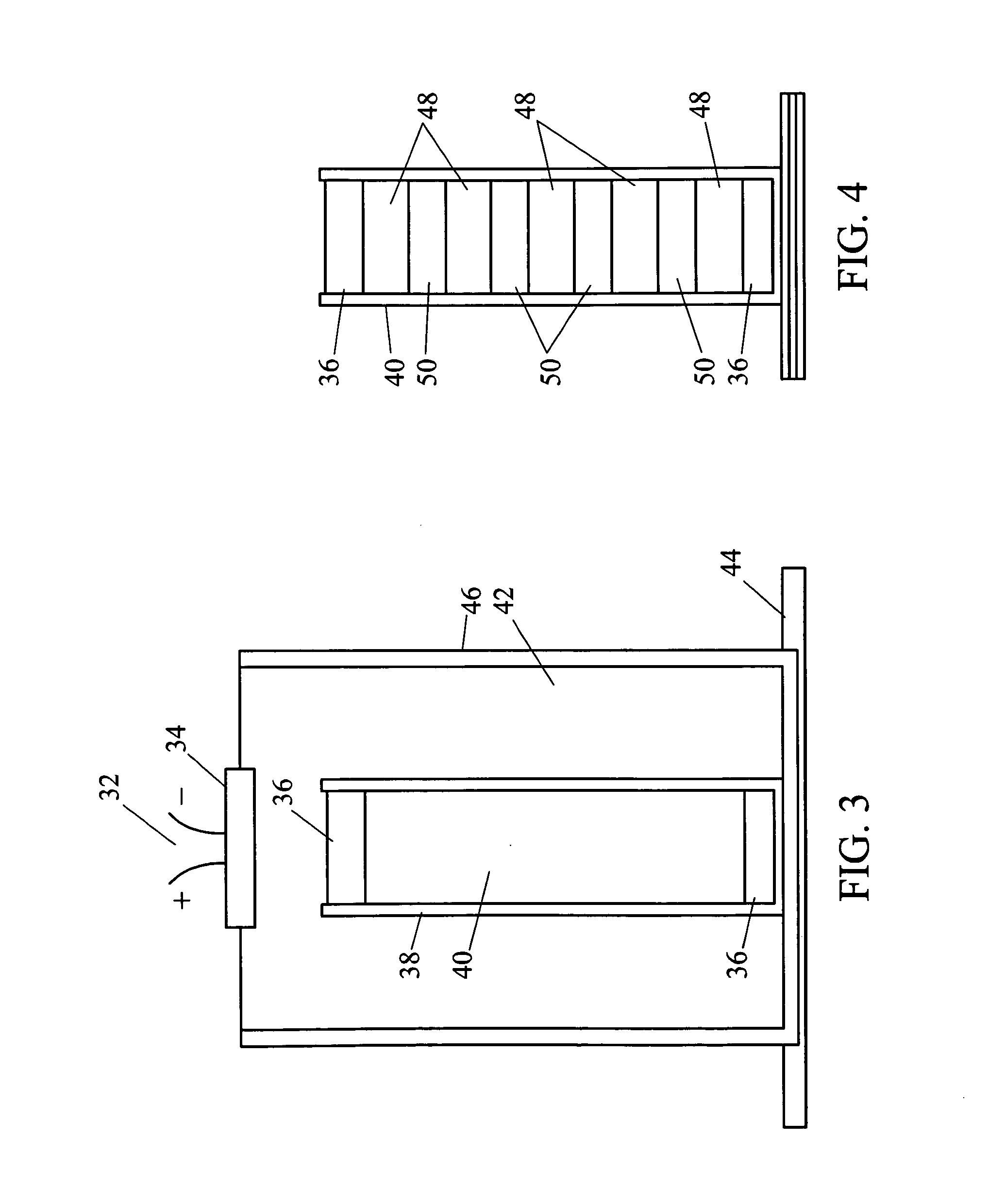

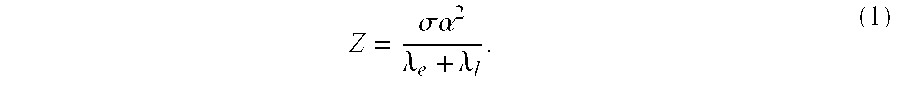

Phonon-blocking, electron-transmitting low-dimensional structures

ActiveUS7342169B2Lower lattice thermal conductivityImprove ZTThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentLattice mismatchCharge carrier

A thermoelectric structure and device including at least first and second material systems having different lattice constants and interposed in contact with each other, and a physical interface at which the at least first and second material systems are joined with a lattice mismatch and at which structural integrity of the first and second material systems is substantially maintained. The at least first and second material systems have a charge carrier transport direction normal to the physical interface and preferably periodically arranged in a superlattice structure.

Owner:LAIRD THERMAL SYST INC

Preparation method of bismuth telluride based bulk nano crystalline thermoelectric material

InactiveCN101786162ASimple processLess investmentThermoelectric device manufacture/treatmentMicrowaveBismuth telluride

The invention relates to a bismuth telluride based bulk nano crystalline thermoelectric material and preparation method thereof. The technical scheme includes that: firstly simple substance powder with mass percent more than 99.99% is taken as raw material, burdening is carried out according to the chemical formula (SbxBi1-x)2Te3 or Bi2(SeyTe1-y)3, wherein x is more than or equal to 0.75 and less than or equal to 0.85, y is more than or equal to 0.04 and less than or equal to 0.06, mixing to be uniform is carried out, and then ball milling is carried out by a ball mill, thus obtaining bismuth telluride base alloy nano powder; secondly, the bismuth telluride base alloy obtained in the first step is loaded into a graphite mould or ceramic mould to be sintered in a micro wave irradiation pressure sintering device; temperature rises to 300-550 DEG C by heating under the condition that the pressure applied to the powder is 10-40MPa, and then heat preservation is carried out for 10-60min under the condition that the pressure applied to the powder is 30-60MPa, thus obtaining the bismuth telluride based bulk nano crystalline thermoelectric material. The invention has the characteristics of less investment, low production cost, simple technology and short period; and the obtained bismuth telluride based bulk nano crystalline thermoelectric material has high performance.

Owner:WUHAN UNIV OF SCI & TECH

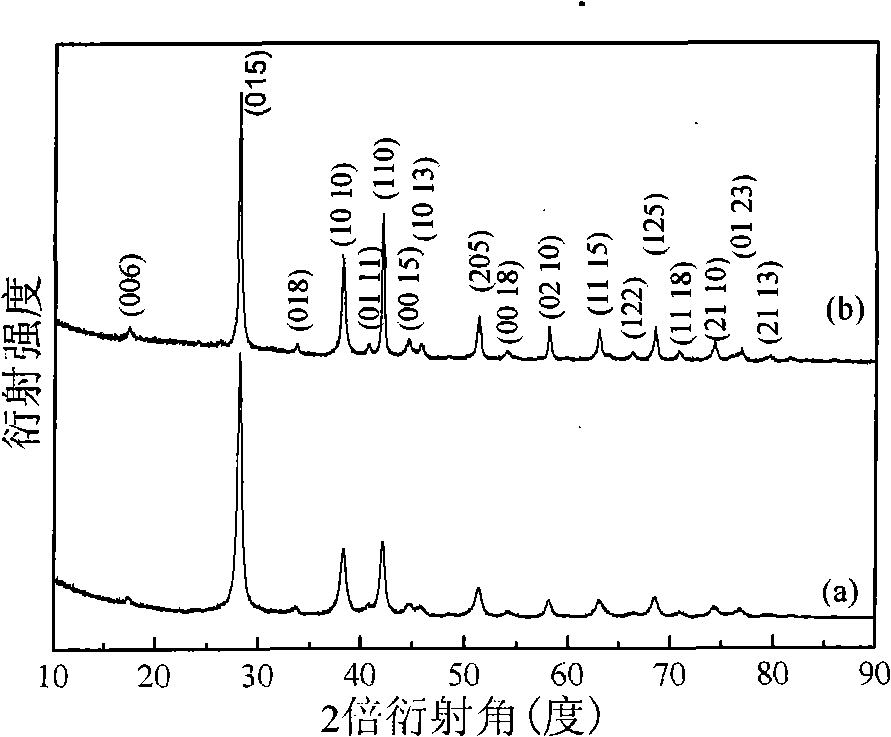

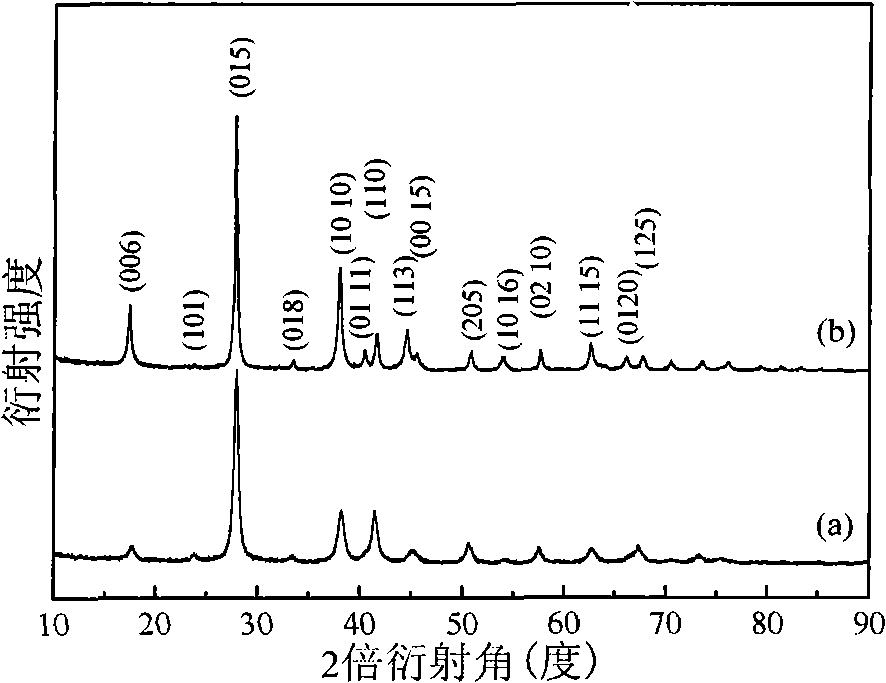

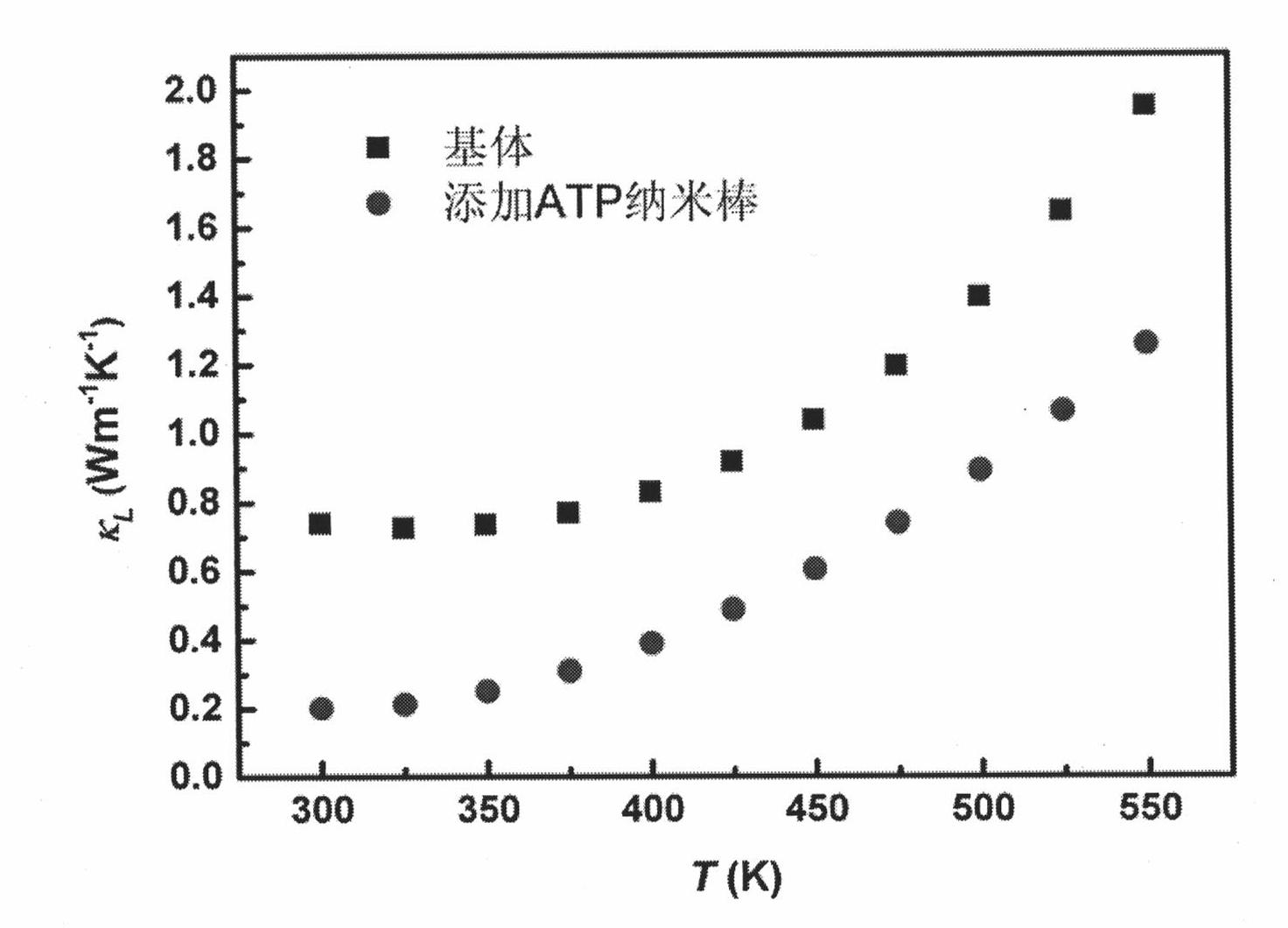

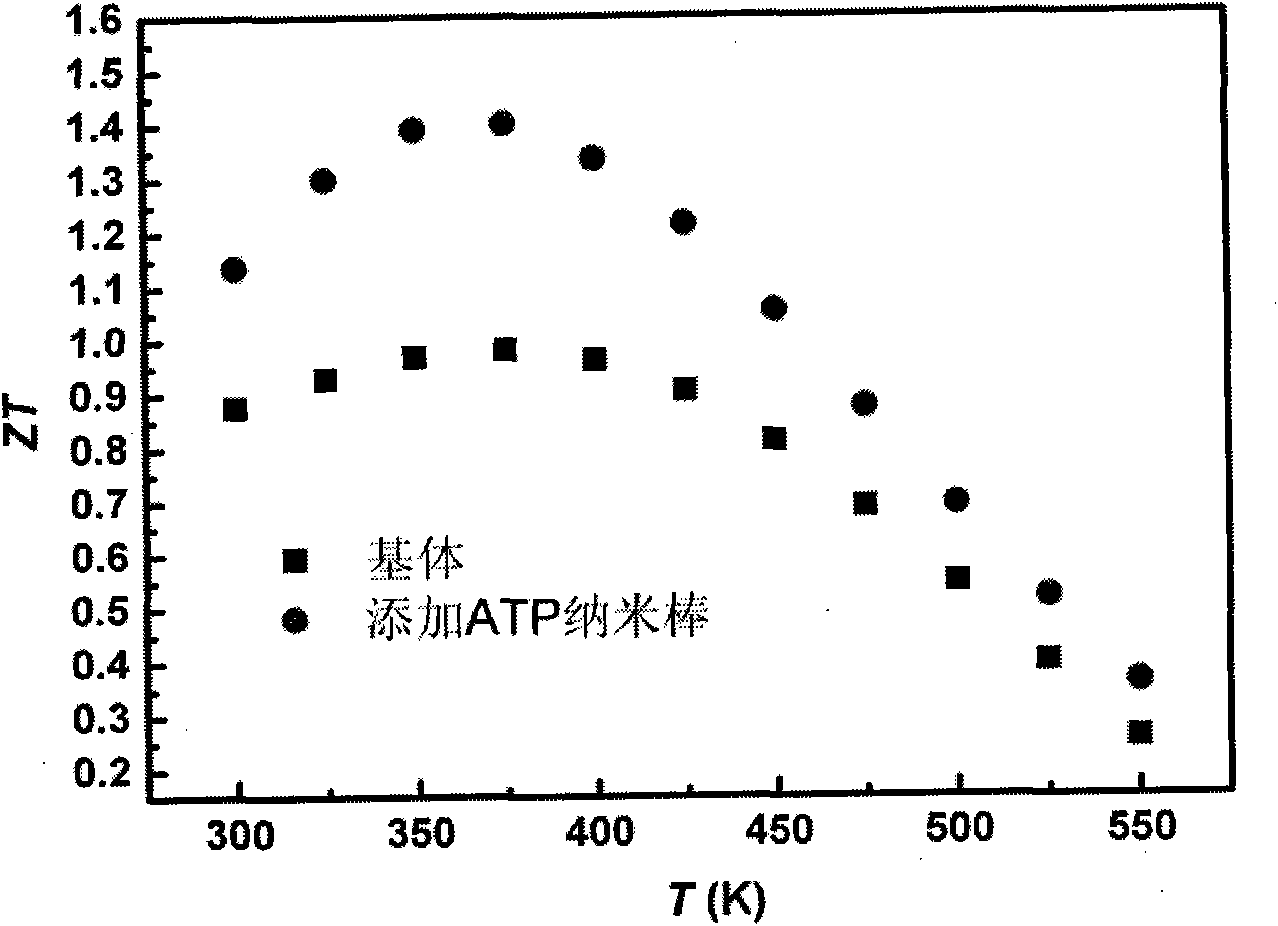

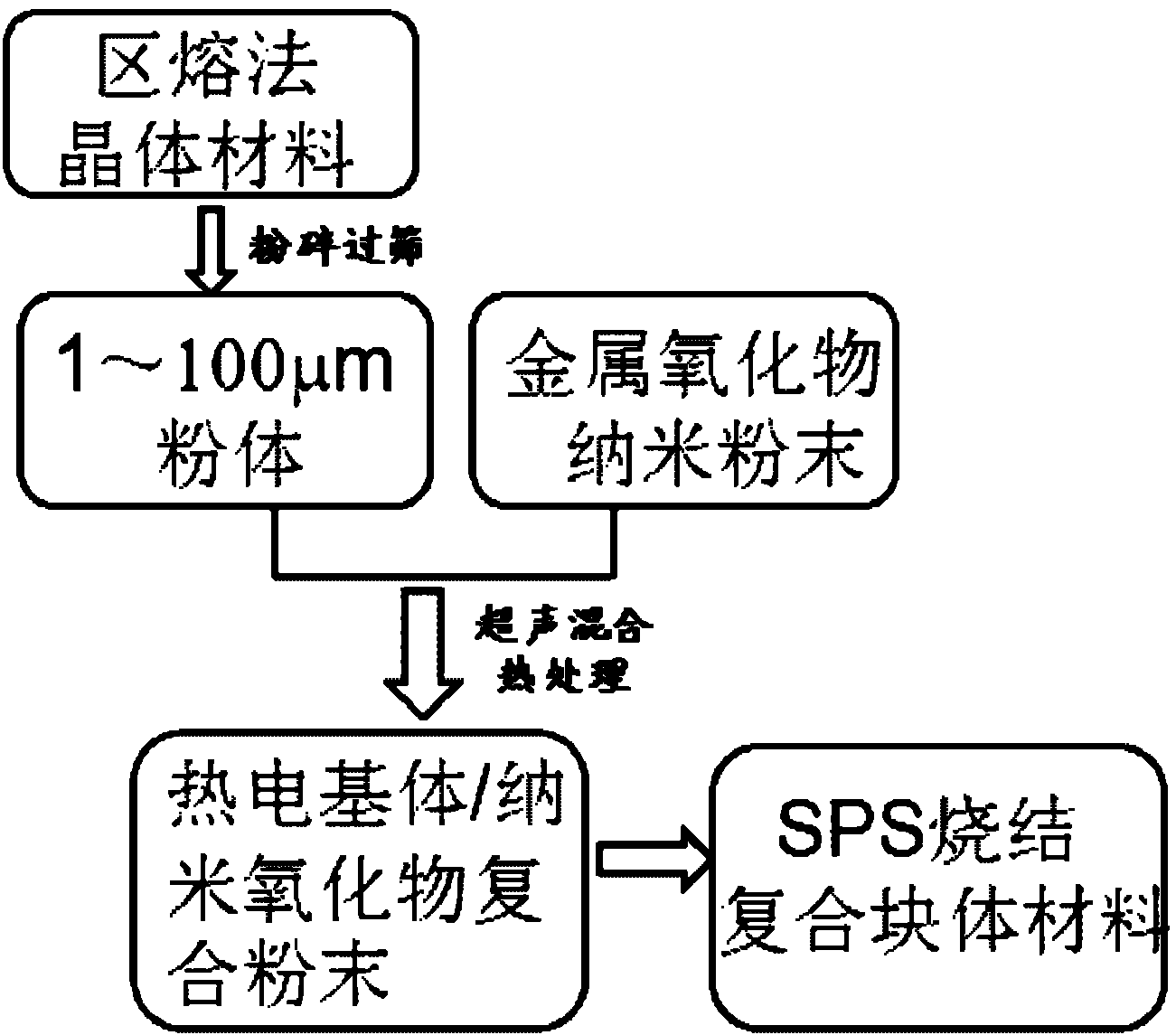

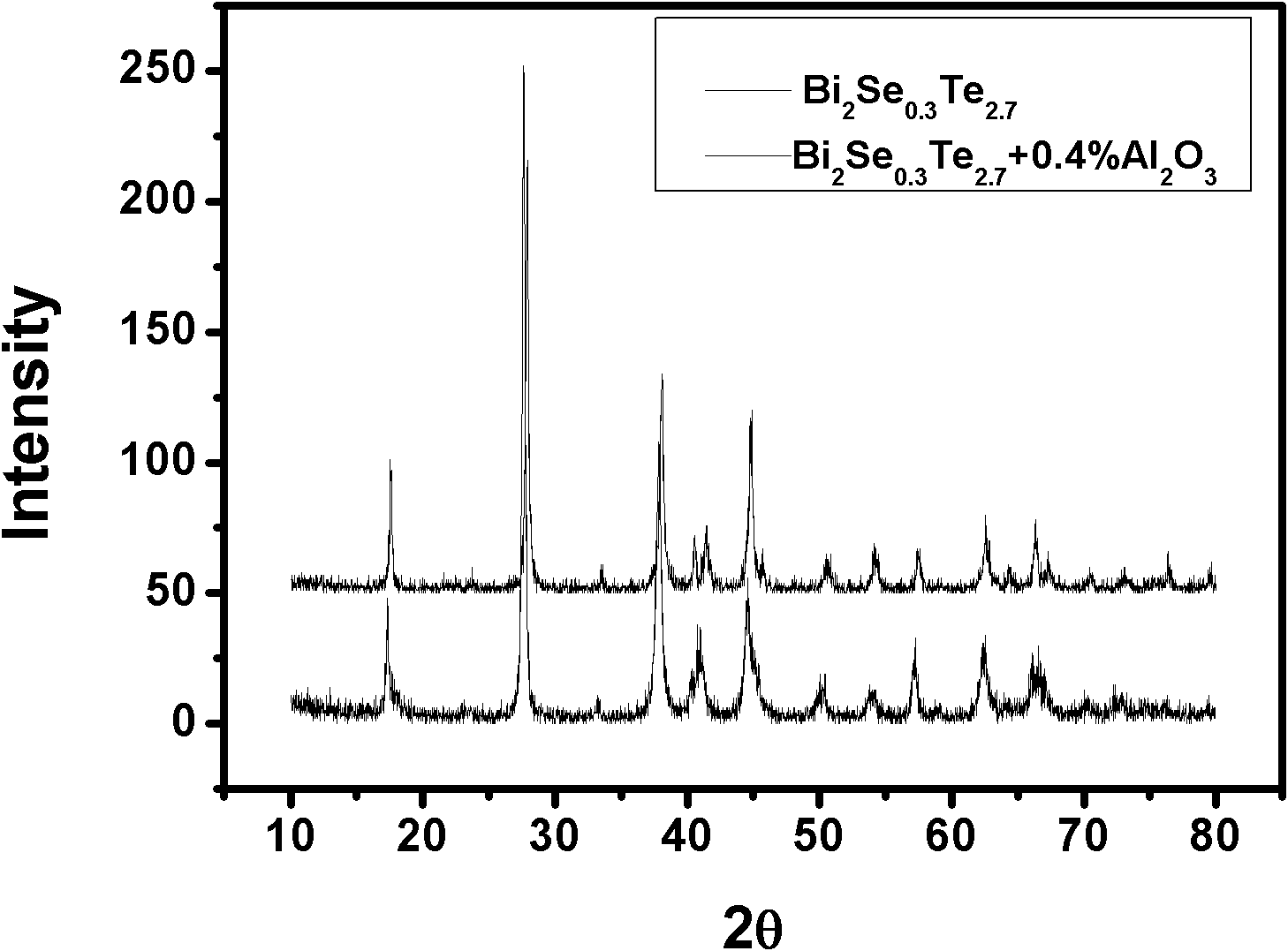

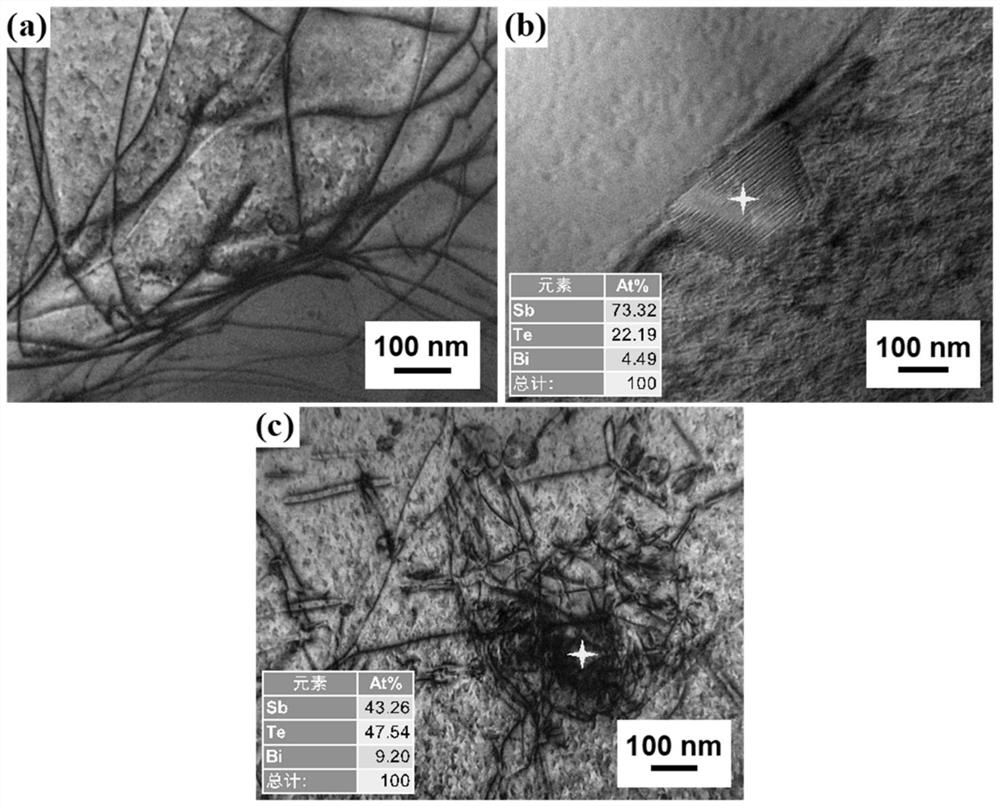

Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

ActiveCN101994155ALower lattice thermal conductivityReduced lattice thermal conductivity κ

<sub>L</sub>Polycrystalline material growthBy zone-melting liquidsBismuth tellurideCarbon nanotube

The invention discloses a nanophase doped bismuth telluride-based thermoelectric material and a preparation method thereof. The bismuth telluride-based thermoelectric material is characterized in taking the bismuth telluride-based thermoelectric material containing a tellurium element, a bismuth element and a doped chemical element, as a matrix. The doped nanophase is a one-dimensional nanophase,and the weight of the one-dimensional nanophase accounts for 0.01-5 percent of the weight of the matrix. Attapulgite or a zinc oxide nanowire or a single-wall carbon nanotube or a multi-wall carbon nanotube is preferable to the one-dimensional nanophase. Compared with the prior art, in the bismuth telluride-based thermoelectric material, the lattice heat conductivity within the whole temperature zone range is reduced, thereby a ZT value is greatly improved and the thermoelectric performance of the bismuth telluride-based thermoelectric material is improved. The preparation method is simple and easy to implement, and compared with other methods of balling milling or liquid phase and the like, impurities are not easy to introduce in the preparation method so that the one-dimensional nanophase is evenly staggered and distributed in the matrix and the mechanical property of the material is effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

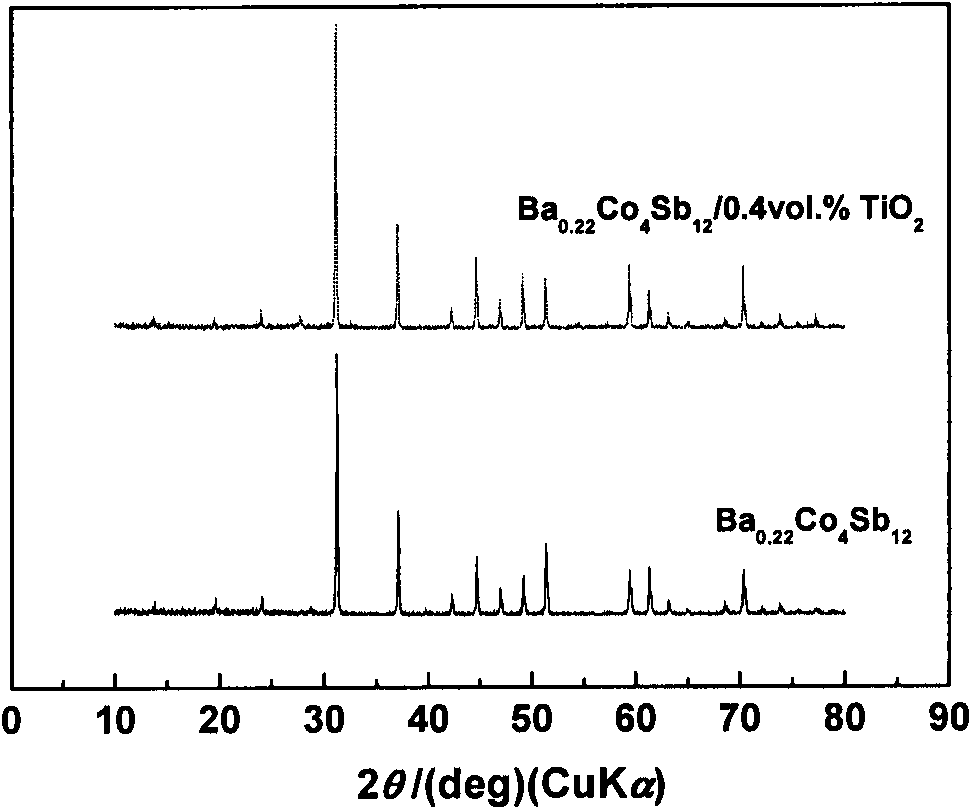

Filled skutterudite-base thermoelectrical composite material and its prepn

ActiveCN1888105ALower lattice thermal conductivityDoes not affect electrical transmission performanceMolten stateMechanical crushing

The present invention relates to filled skuterudite-base thermoelectrical composite material and its preparation process, and belongs to the field of thermoelectrical material preparing technology. The thermoelectrical composite material has the composition of IyA4B12 / zIOx, where I is one of Yb, Eu, Ce, La, Nd, Ca and Sr; A is Sb or its mixture with one of Ge, Sn, Te and Se; B is Co or its mixture with Fe or Ni; y is the amount of I element, y+z=m, and m is greater than the filling limit of filling atom. The thermoelectrical composite material is prepared through first smelting process to produce block material, the subsequent mechanical crushing and grinding to obtain powder, and the final fast sintering with pulse DC current to form compact block. The material has lowered lattice heat conductivity, maintained electric transmission performance and raised thermoelectrical conversion performance.

Owner:中科西卡思(苏州)科技发展有限公司

High-performance thermoelectric composite material and preparation method thereof

ActiveCN102339946AImprove Seeback coefficientLow thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention relates to a high-performance thermoelectric composite material and a preparation method thereof, belonging to the field of thermoelectric materials. The composite material consists of two phases. A first phase is n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3, and a second phase is nanometer powder of a metallic oxide. The nanometer powder of the metallic oxide accounts for 0.05-10% in terms of the total weight of the thermoelectric composite material. According to the preparation method provided by the invention, the n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3 powder is ultrasonically mixed with the nanometer oxide, and discharge plasma sintering is carried out on the mixture to obtain a dense block material. Compared with the bismuth-telluride-based thermoelectric base material, under the condition that the electric conductivity of the thermoelectric base material is maintained to be unchanged basically in the invention, the high-performance thermoelectric composite material, provided by the invention, achieves the advantages of obviously reduced lattice heat conductivity and increased Seeback coefficient, and therefore the thermoelectric performance of the material can be greatly improved.

Owner:中科西卡思(苏州)科技发展有限公司

Argyrodite thermoelectric material and preparation method thereof

InactiveCN106098923AImprove thermoelectric performanceLow thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsArgyroditeSlow cooling

The invention relates to an argyrodite thermoelectric material, the chemical formula of which is Ag8Sn(1-x)NbxSe6, x=0-0.05. The preparation method of the argyrodite thermoelectric material is characterized by, with simple substances being raw materials, carrying out material blending according to stoichiometric ratio of the chemical formula; after vacuum packaging, melting reaction quenching and thermal treatment quenching, grinding ingots into powders; and carrying out vacuum high-temperature hot-pressure sintering, and after slow cooling, obtaining a block material, which is the argyrodite thermoelectric material. Compared with the prior art, the high-performance thermoelectric material, which is low in heat conduction and high in thermoelectric performance, is prepared, and the method for preparing the thermoelectric material, which is high in density, high in mechanical strength and high in thermoelectric performance, is explored; the thermoelectric material has very low lattice thermal conductivity (0.2-0.4 W / m.K) in a whole-temperature range; when the temperature is 900 K, thermoelectric peak of the thermoelectric material reaches 1.2; when the temperature is 300-850 K, the average thermoelectric figure of merit zTave of the thermoelectric material is infinity-0.8; and the argyrodite thermoelectric material is a potential thermoelectric material.

Owner:TONGJI UNIV

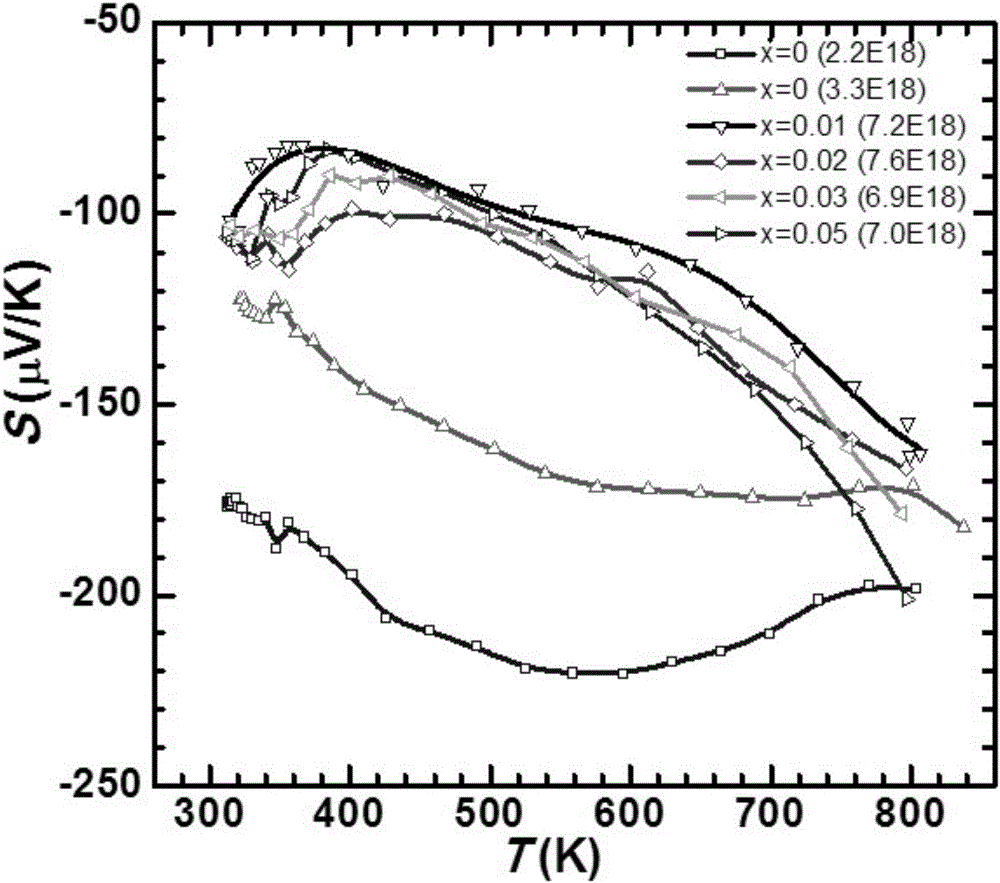

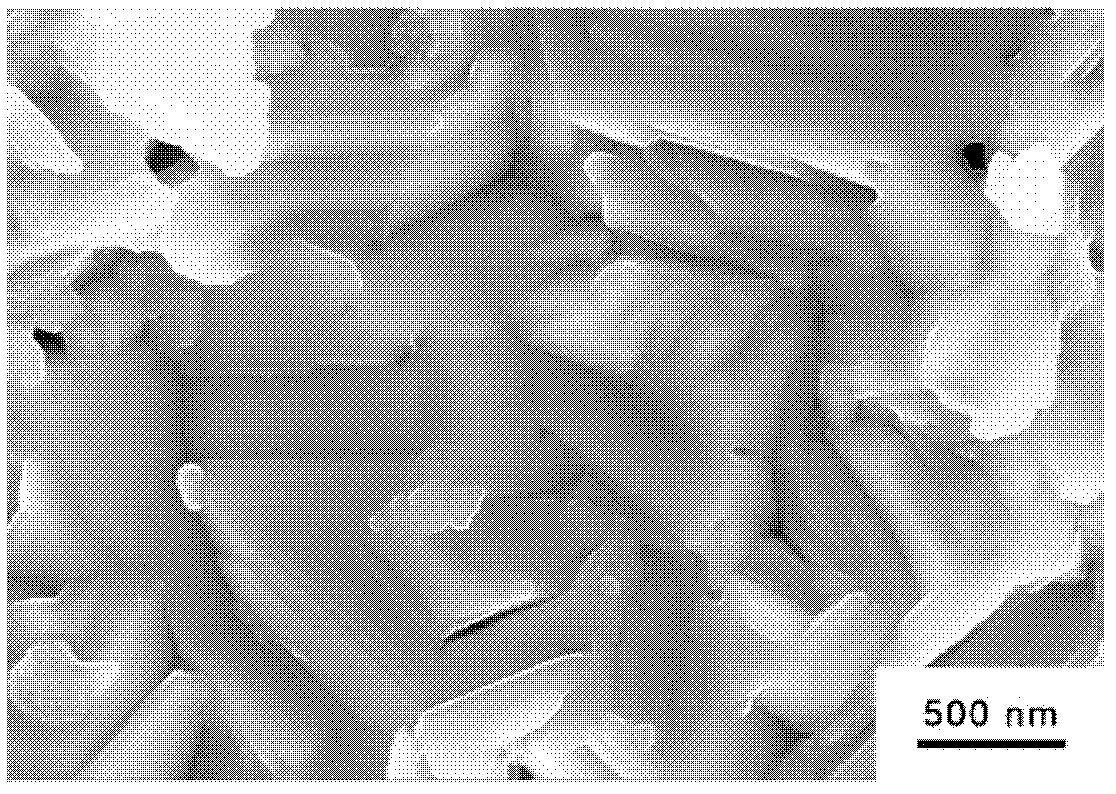

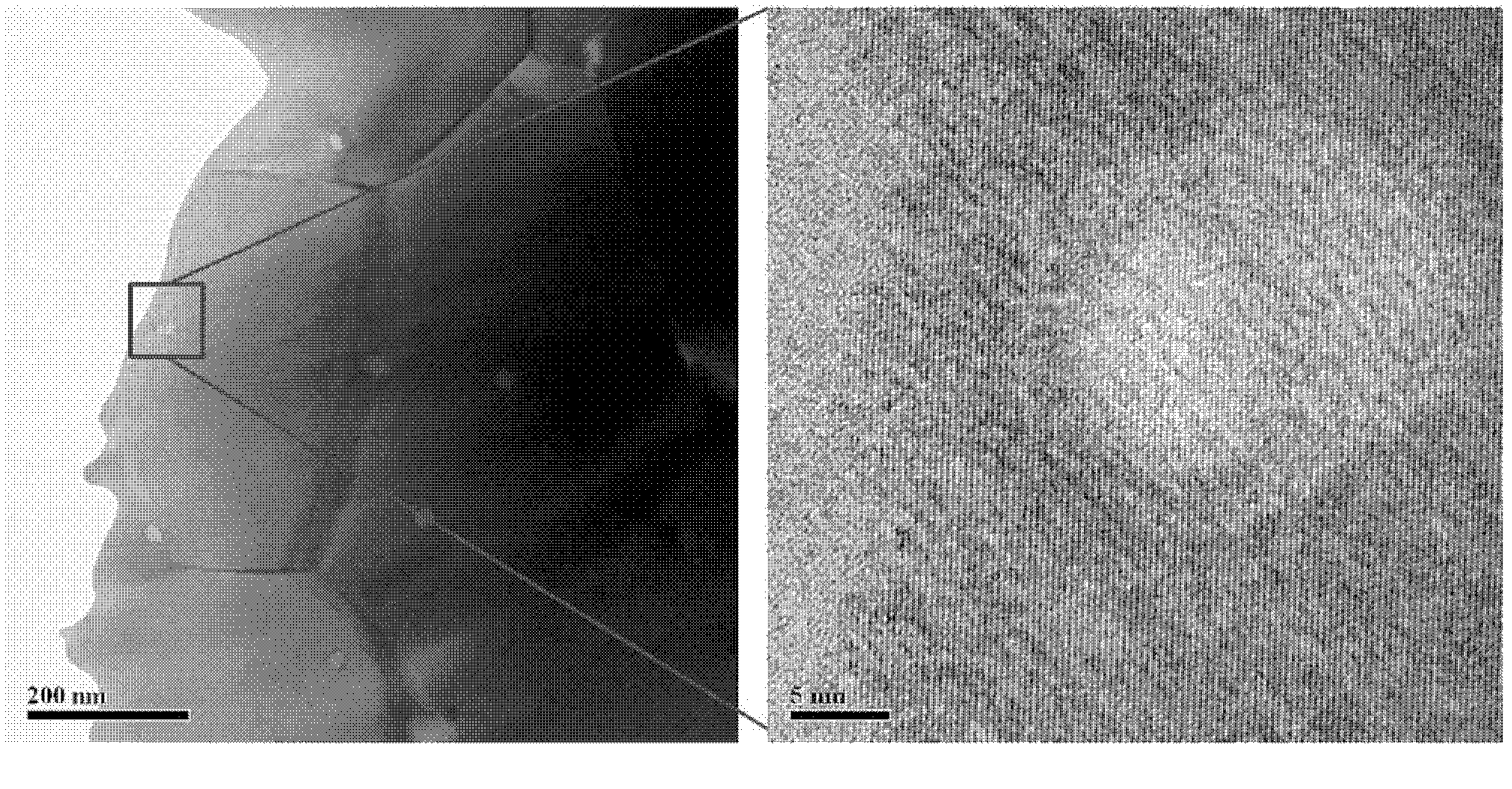

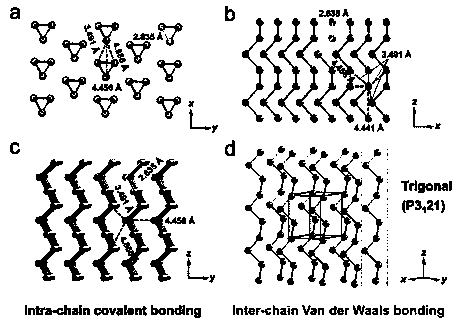

A Trace Cu-doped Bi2S3-Based Thermoelectric Material

InactiveCN102280570AControl stoichiometric ratioPrecise control of stoichiometric ratioThermoelectric device junction materialsMetallurgyElectric properties

The invention belongs to the technical field of energy materials and in particular relates to a trace Cu-doped Bi2S3-based thermoelectric material. In the thermoelectric material, metal simple substance Bi and Cu powder with the purity of 99.99 percent and simple substance S powder serve as raw materials, the thermoelectric material is prepared according to a chemical general formula of CuxBi2-xS3, wherein x is mole fraction of a Cu component and x is more than or equal to 0.001 and less than or equal to 0.05, and the thermoelectric material is prepared into a block material by combining a discharge plasma sintering technology and a mechanical alloying method. By the method, the trace Cu-doped Bi2S3-based block thermoelectric material can be easy and convenient to prepare, trace Cu is introduced into a Bi2S3 lattice, the carrier concentration of a sample is improved, a power factor is optimized, a Cu-S nano deposition coherent with a substrate structure is formed, and the thermal conductivity is greatly reduced; therefore, the thermoelectric performance of the Bi2S3-based block material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

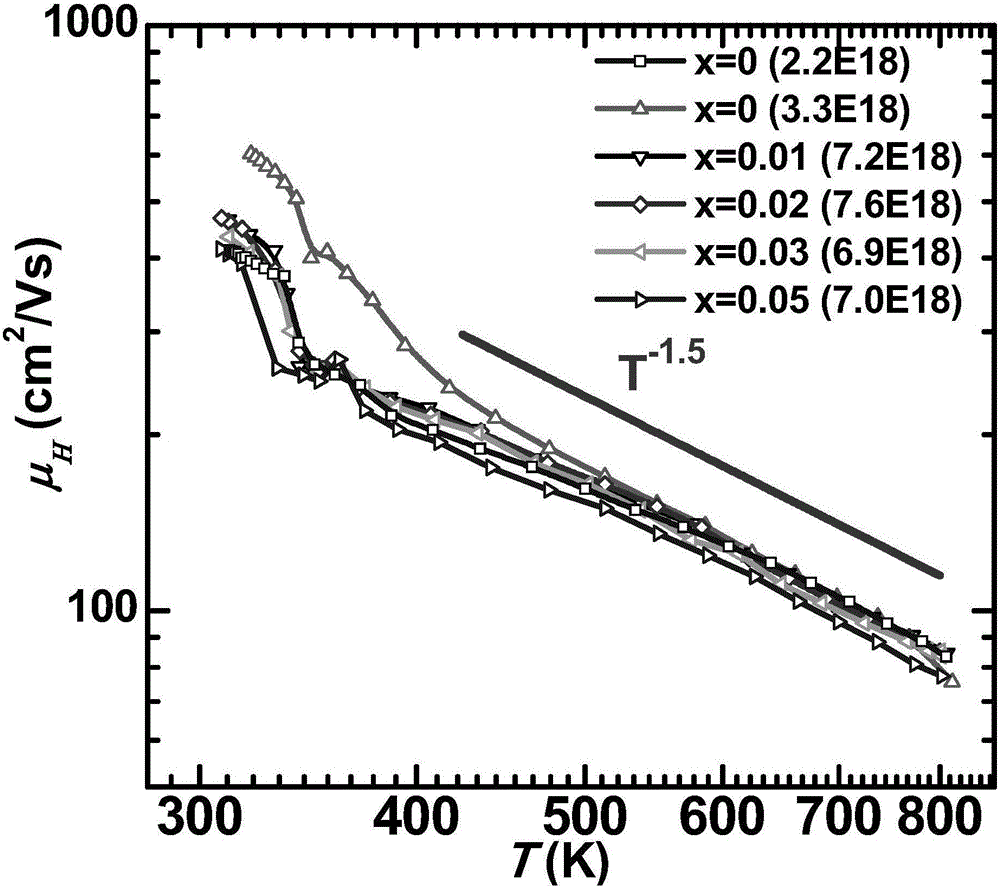

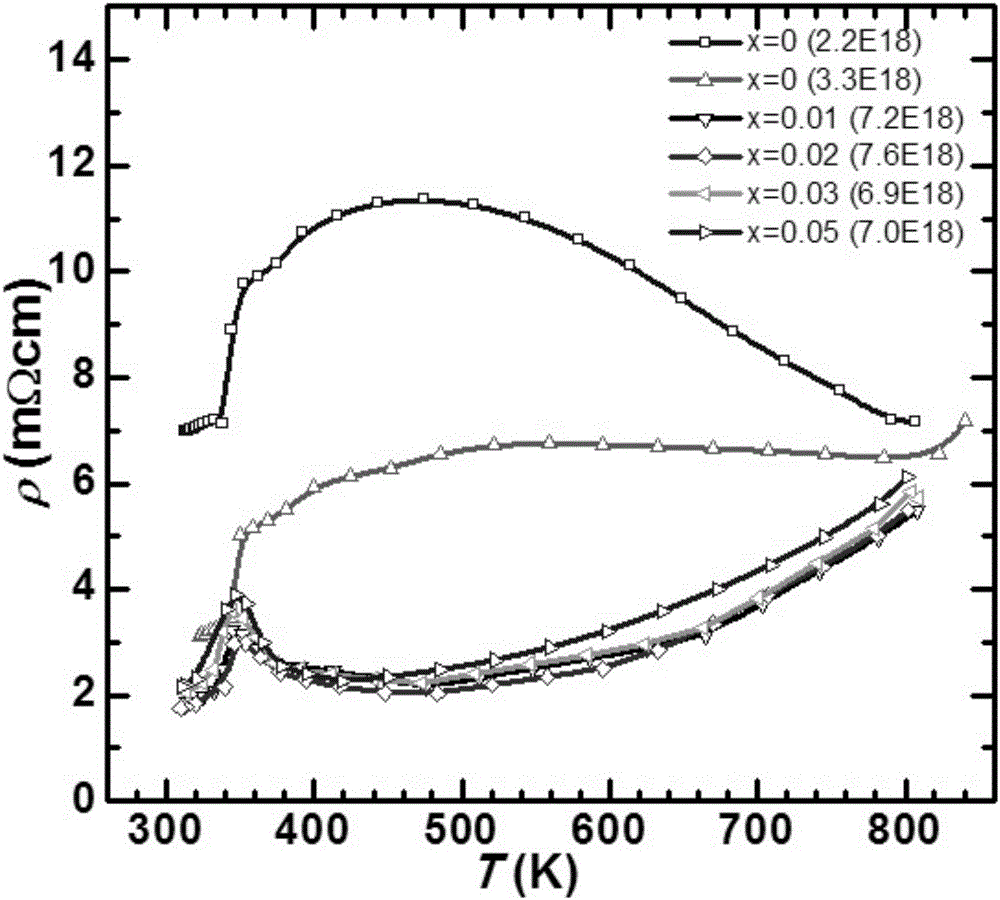

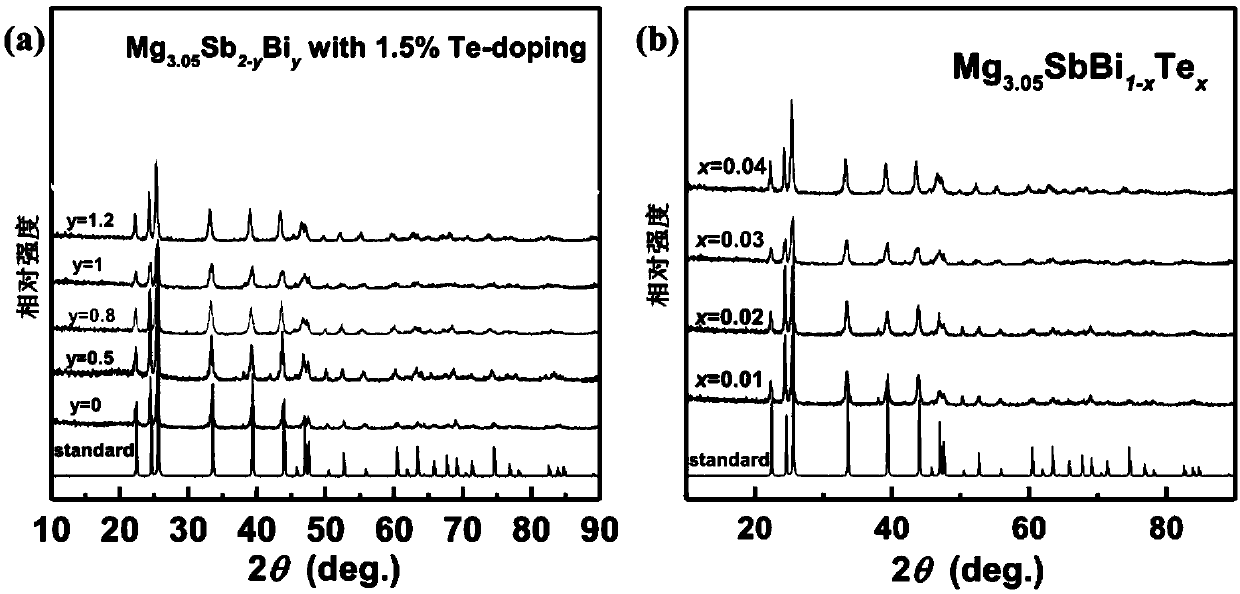

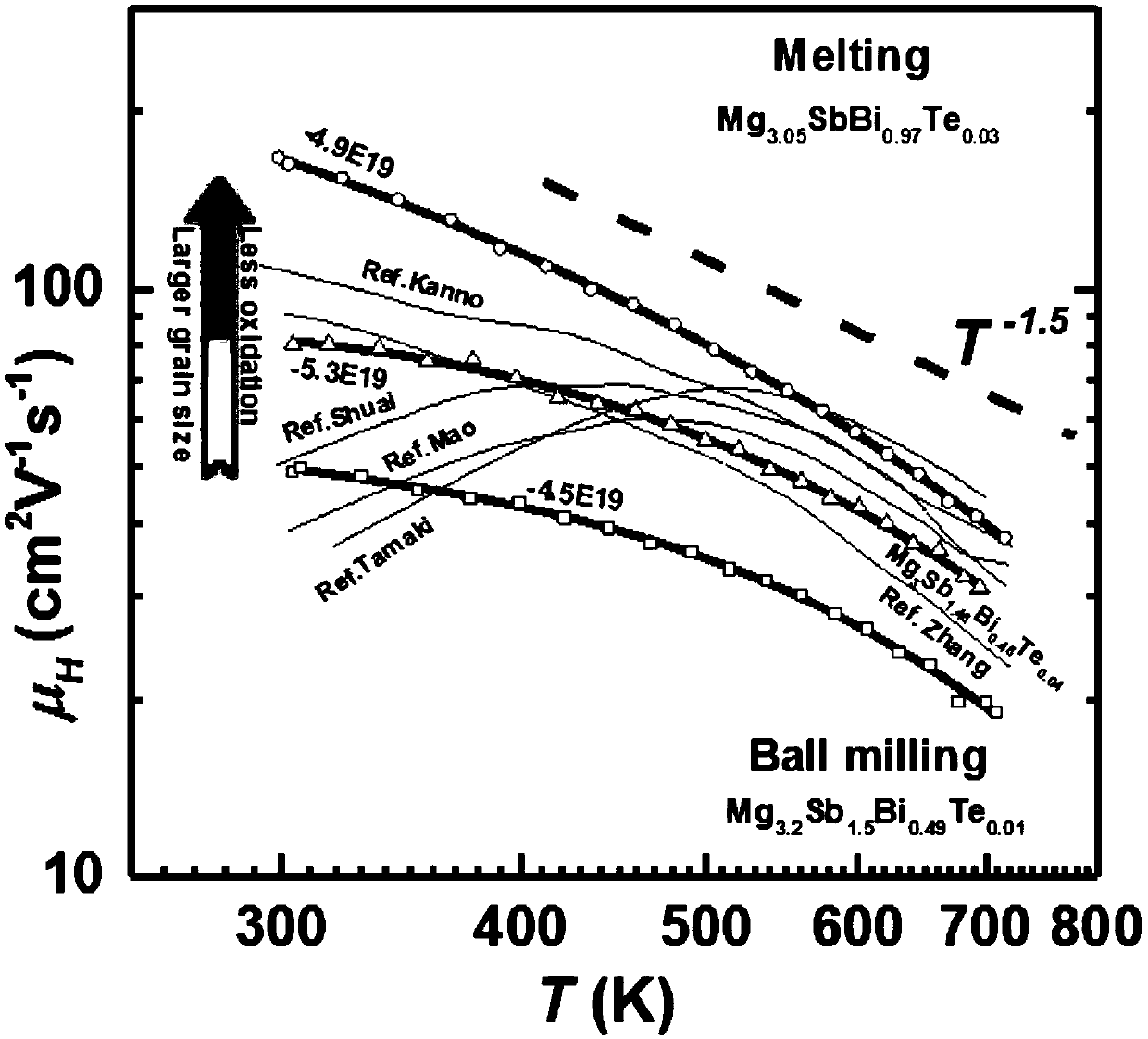

N-type antimony trimagnesium alloy thermoelectric material with high mobility and preparation method thereof

ActiveCN109616568AIncrease the carrier concentrationImprove mobilityThermoelectric device manufacture/treatmentThermoelectric device junction materialsTe elementSlow cooling

The invention relates to an N-type antimony trimagnesium alloy thermoelectric material with high mobility and a preparation method thereof. The chemical formula of the thermoelectric material is Mg<3.05>Sb<2-x-y>Bi<y-x>Te<x>, wherein x is more than 0 but less than or equal to 0.04, and y is more than 0 but less than or equal to 1.5. The thermoelectric material takes a high-pure element as a raw material, material is prepared according to a stiochiometric ratio in the chemical formula, the raw material is grinded to form powder after vacuum package by a tantalum pipe, high-temperature melting and annealing thermal treatment, and the thermoelectric material is obtained after vacuum hot-press sintering and slow cooling. Compared with the prior art, the tellurium doping is improved by solid solution of antimony trimagnesium, negative ion electrons are introduced, and simultaneous control of carrier concentration and lattice thermal conductivity is achieved; and meanwhile, the content of magnesium oxide in an N-type Mg3Sb2 alloy crystal boundary is reduced by tantalum package melting, so that higher mobility than that of traditional document is shown. The simple and controllable technology can be widely applied to various thermoelectric materials, particularly materials with a large amount of intrinsic defects, and a new method is provided for improving the thermoelectric performance.

Owner:TONGJI UNIV

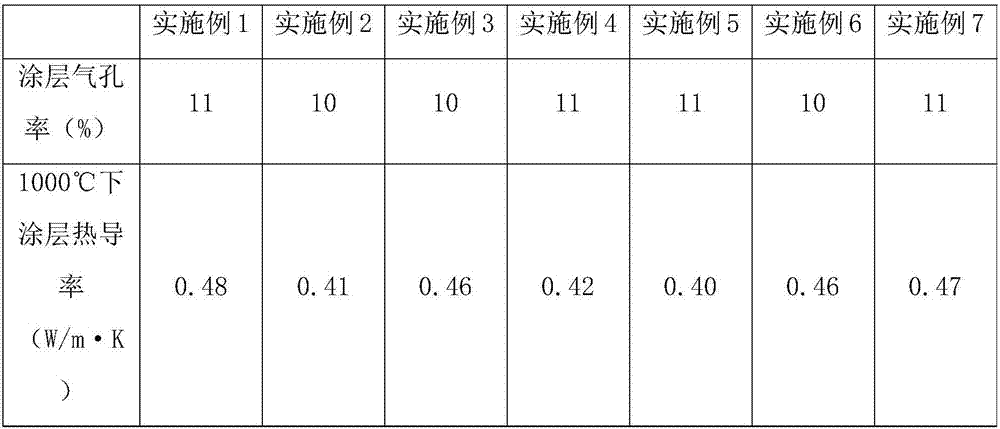

Shining thermal barrier coating system of rare earth niobate based on defective fluorite structure and preparation method of shining thermal barrier coating system

InactiveCN106967953ALow thermal conductivityImprove oxygen barrier performanceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

Owner:乐延伟

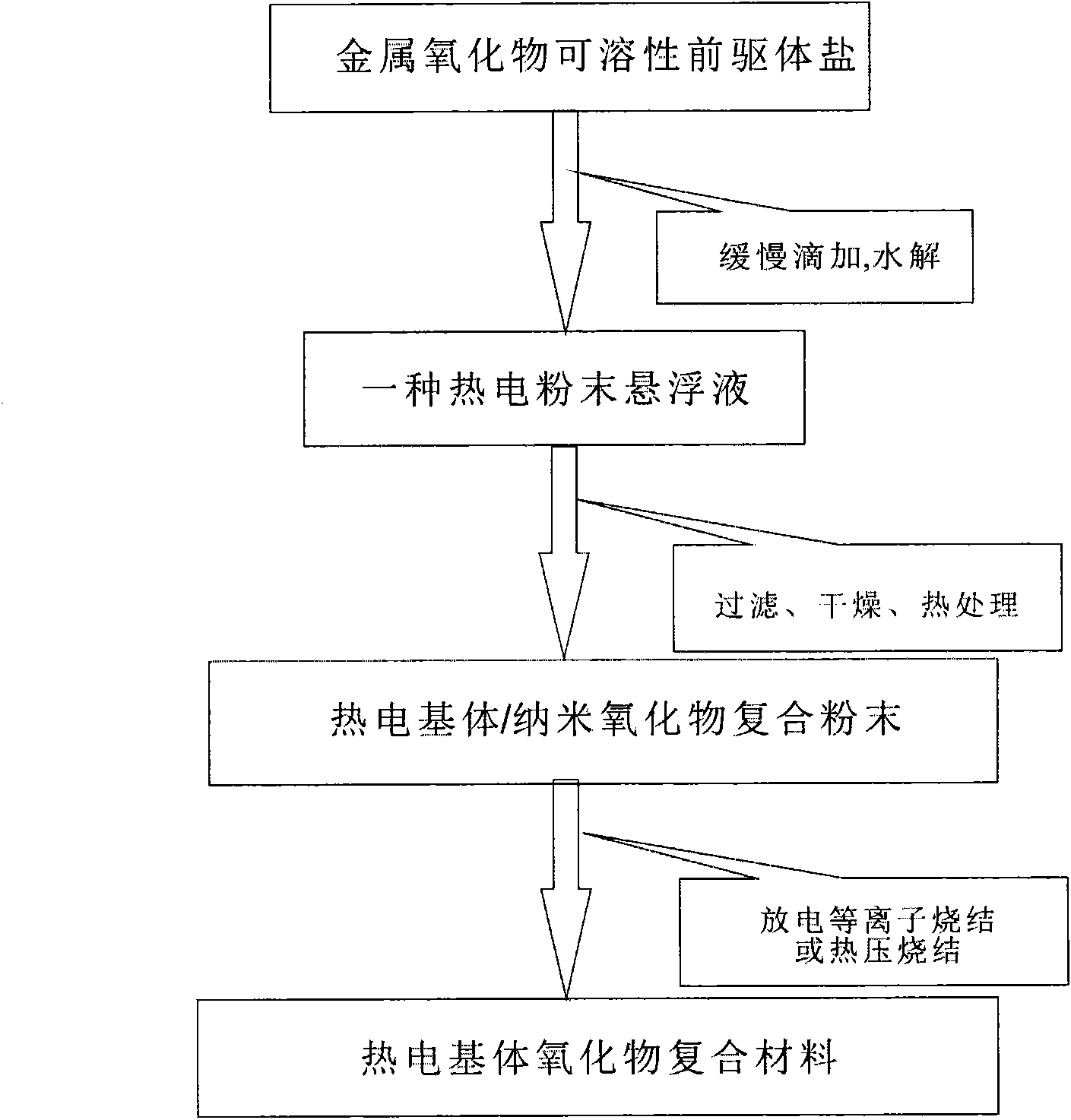

Thermoelectric composite and preparation method thereof

InactiveCN101942577ALower lattice thermal conductivityImprove thermoelectric performanceMaterial nanotechnologyThermoelectric device manufacture/treatmentLiquid mediumSkutterudite

The invention provides a preparation method of a composite, comprising: providing a suspension of a solid thermoelectric material which disperses in a liquid medium, wherein the solid thermoelectric material is filled and / or doped with skutterudite, half-Heusler alloy, a cagelike material and other thermoelectric ordered alloy or thermoelectric disordered alloy or a thermoelectric intermetallic compound; contacting the suspension with a solution formed by dissolving a metallic oxide precursor into solvent to obtain a reaction mixture; forming a metallic oxide by hydrolyzing the metallic oxide precursor in the presence of water; obtaining the compound of the metallic oxide and the solid thermoelectric material which are evenly dispersed in liquid phase; and separating the compound of the metallic oxide and the solid thermoelectric material from the liquid phase to obtain the separated composite. The invention can dramatically improve the thermoelectric performance of the composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

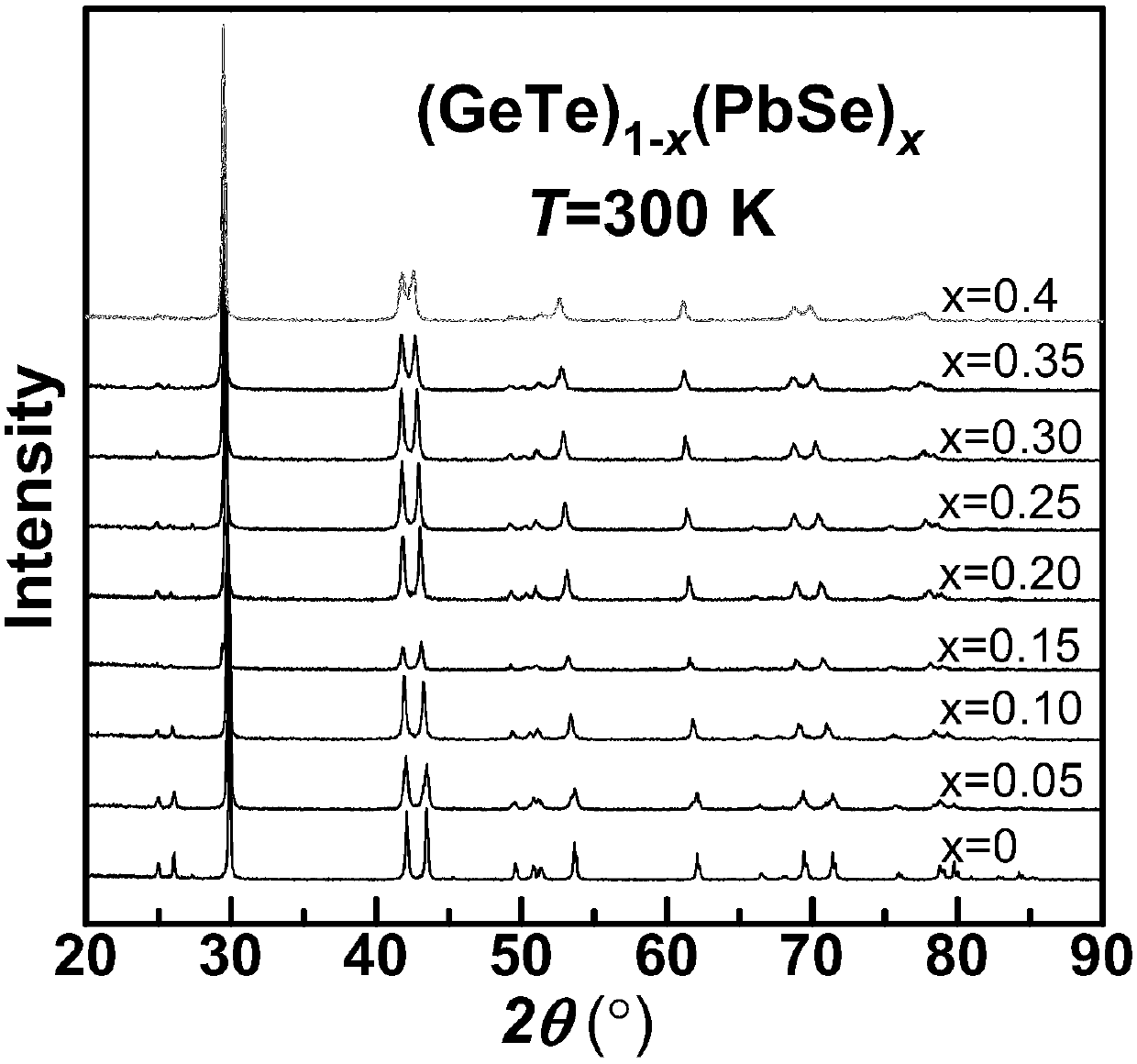

Alloy thermoelectric semiconductor material and fabrication method thereof

ActiveCN107799646ALower lattice thermal conductivityImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsSemiconductor materialsAlloy

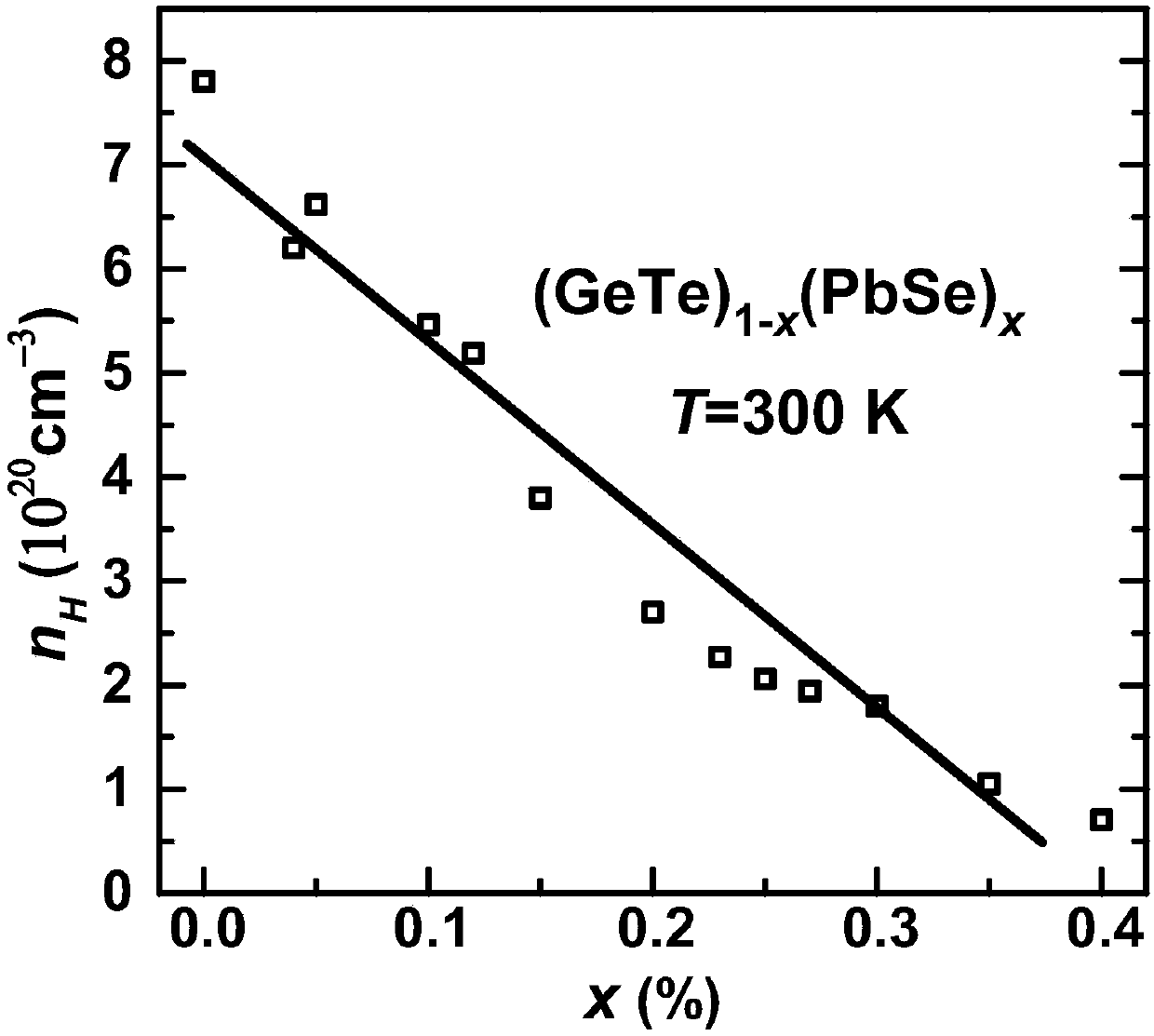

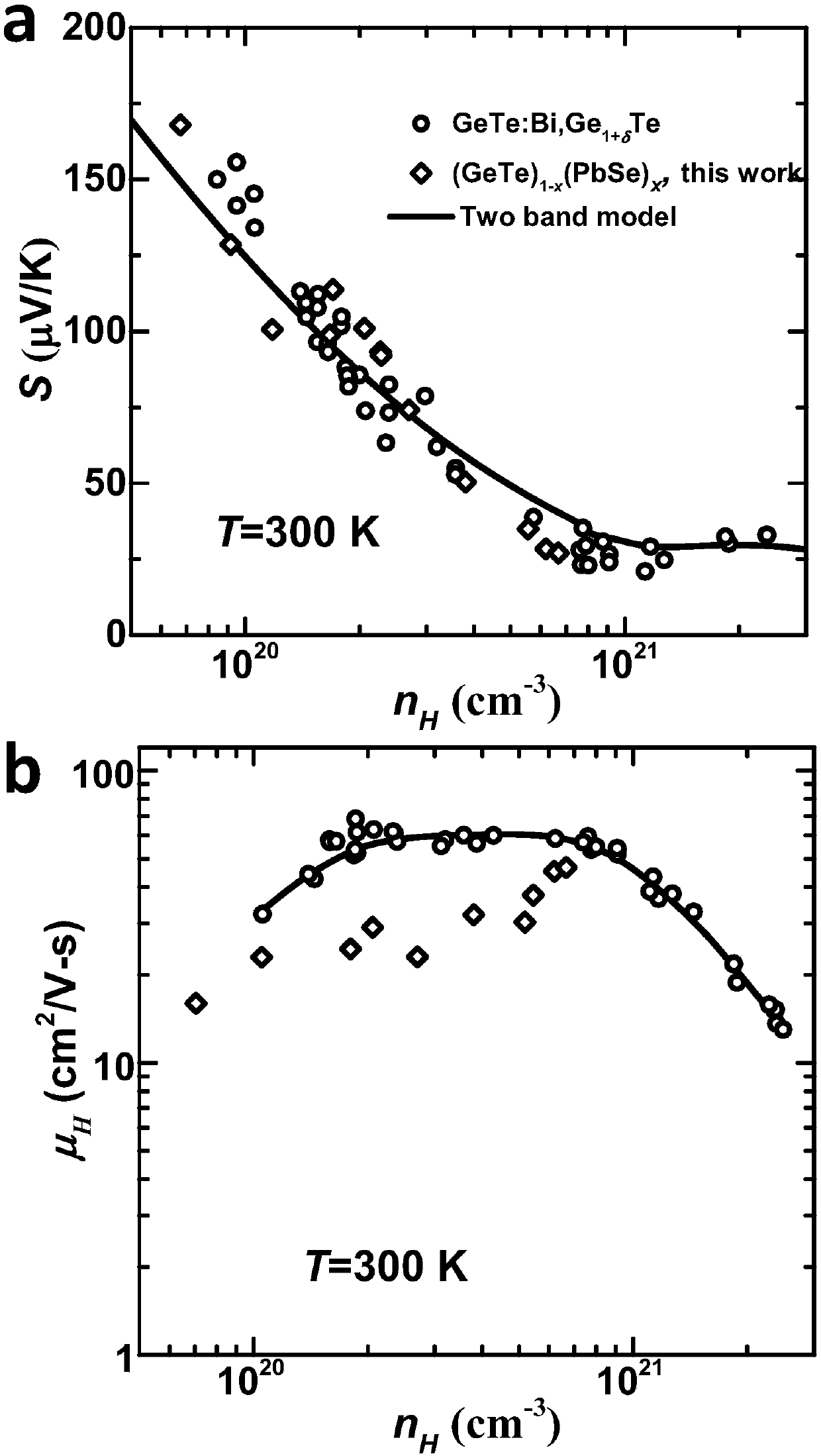

The invention relates to an alloy thermoelectric semiconductor material and a fabrication method thereof. The chemical formula of the alloy thermoelectric semiconductor material is (GeTe)<1-x>(PbSe)<x>, and x is more than 0 but less than0.4. During fabrication, simple elements Ge, Te, Pb and Se are sequentially loaded in a quartz ampoule from small to large and are packaged after vacuumizing, andthe steps of melting quenching, annealing quenching and hot-press sintering are sequentially performed to finally fabricate the alloy thermoelectric semiconductor material. Compared with the prior art, substitution of the elements (Ge / Pb and Te / Se) in the main group are performed on positions of a negative ion and a positive ion in a GeTe material, the large-range control of carrier concentrationis achieved, the carrier concentration level of the GeTe material is optimized, meanwhile, the thermoelectric merit figure of the material is also increased by point defect introduced by element substitution, the lattice thermal conduction of the material is substantially reduced as well as the carrier concentration is regulated, and a new idea is provided for improvement of thermoelectric performance of a GeTe-based thermoelectric material and same-type material.

Owner:TONGJI UNIV

Non-stoichiometric bismuth telluride-based thermoelectric material and preparation method thereof

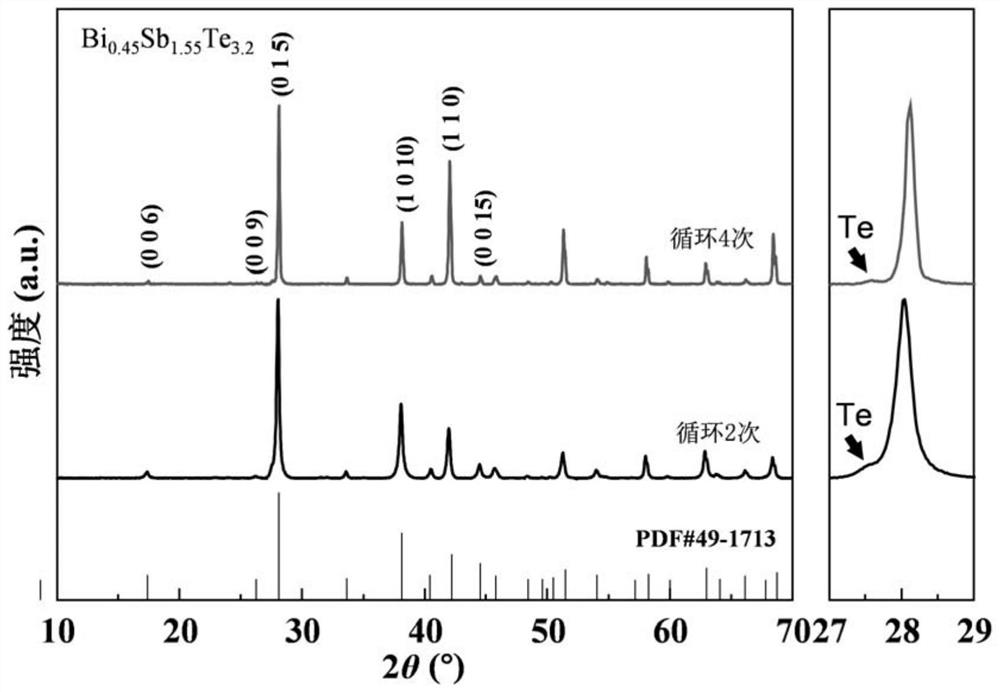

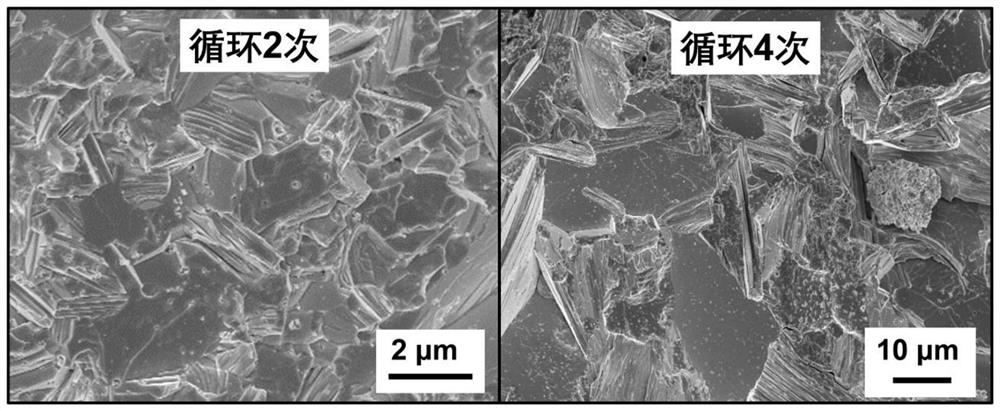

ActiveCN112028632AImprove electrical performanceLower lattice thermal conductivityThermoelectric device junction materialsChemical compositionBismuth telluride

The invention belongs to the technical field of energy materials, and particularly relates to a non-stoichiometric bismuth telluride-based thermoelectric material and a preparation method thereof. Thematerial disclosed by the invention has a chemical composition shown as the following general formula: BixSb2xTe3+y, and the preparation method comprises the following steps: firstly, weighing Bi simple substance powder, Sb simple substance particles and Te simple substance powder raw materials according to the chemical composition of the general formula, carrying out ball milling treatment to obtain powder, and carrying out cyclic discharge plasma sintering treatment on the obtained powder for 1-5 times to obtain a block sample. The bismuth telluride-based thermoelectric material prepared bythe method is good in crystallinity and compact in structure, and compared with a sample prepared by a traditional mechanical alloying and sintering combined method, the bismuth telluride-based thermoelectric material is obviously increased in grain size and introduces a large number of dislocations, so that the electrical property is improved, the lattice thermal conductivity is reduced, and thethermoelectric property is excellent. Meanwhile, the preparation method is simple and convenient to operate, short in period, free of high-temperature risk and low in energy consumption, and has a wide application prospect.

Owner:TSINGHUA UNIV

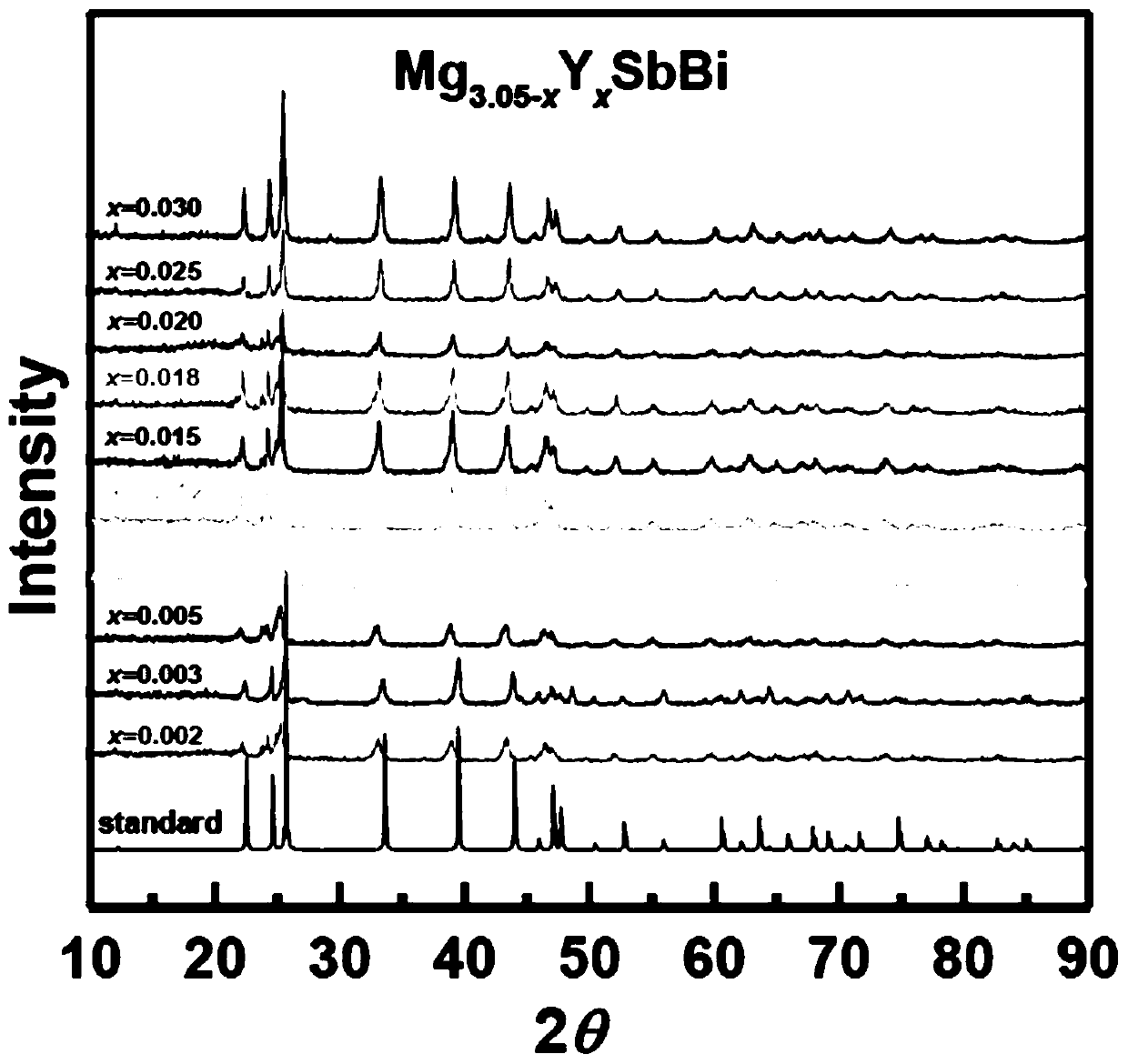

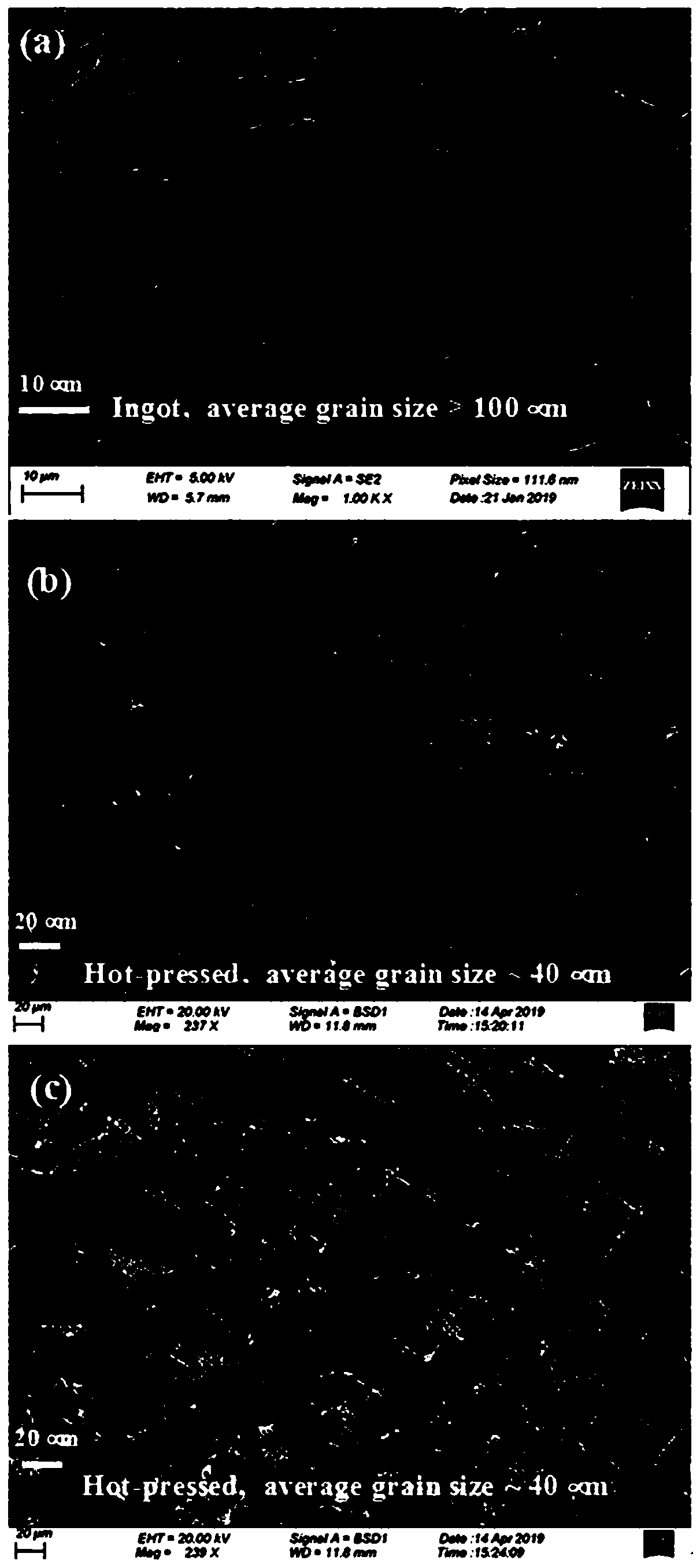

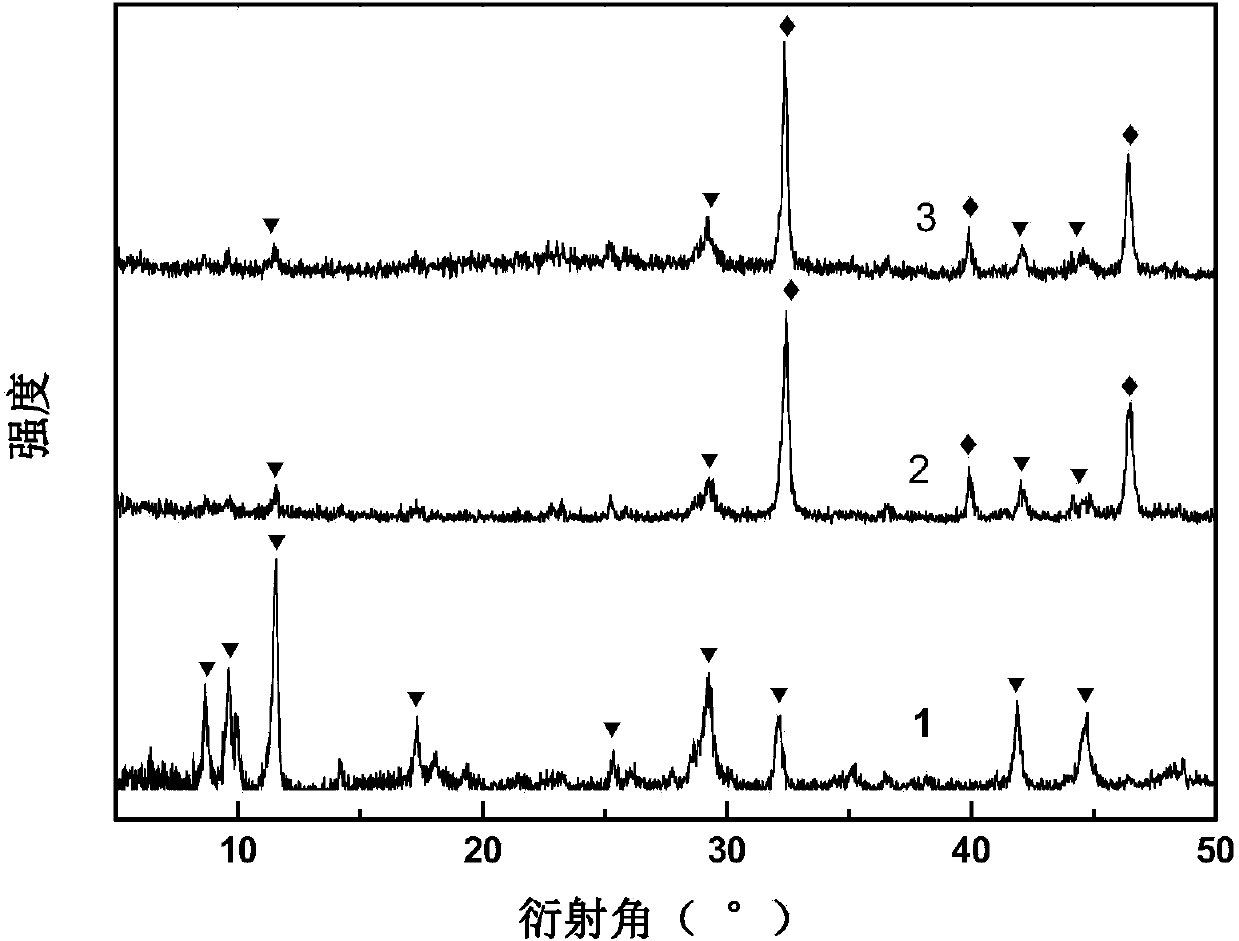

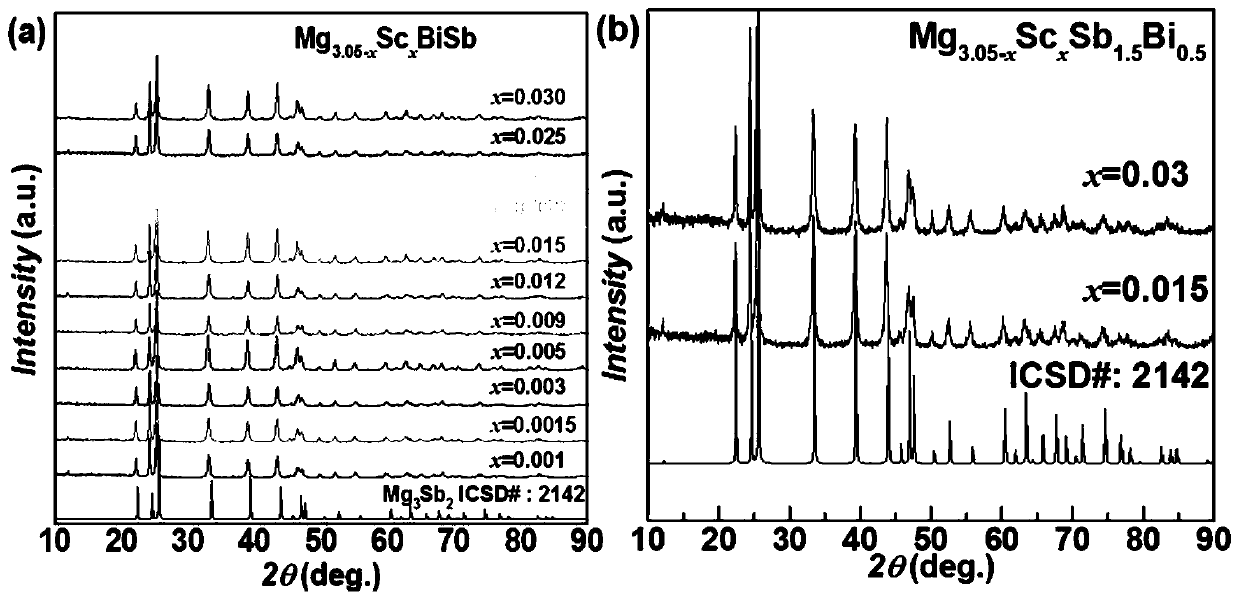

N-type Mg3Sb2 alloy thermoelectric material and preparation method thereof

The invention relates to an n-type Mg3Sb2 alloy thermoelectric material and a preparation method thereof. The chemical formula of the alloy thermoelectric material is YxMg3.05-xSbBi, wherein x is greater than or equal to 0.002 and less than or equal to 0.03; the method is characterized by comprising the steps of taking high-purity simple substance as a raw material; proportioning according to the stoichiometric ratio in the chemical formula; carrying out vacuum packaging on a tantalum tube, high-temperature melting, annealing and heat treatment; cutting into pieces with the size of 3 mm; and performing vacuum hot-pressing sintering and slowly cooling to obtain the alloy thermoelectric material. Compared with the prior art, the method has the advantages that doping of the yttrium is improved by carrying out solid-solution on magnesium bismuthide, anion electrons are introduced, so that the carrier concentration and the lattice heat conductivity can be simultaneously regulated and controlled, and meanwhile, the content of magnesium oxide in the grain boundary of the N-type Mg3Sb2 alloy is reduced by utilizing tantalum packaging smelting, so that the high migration rate is achieved.

Owner:TONGJI UNIV

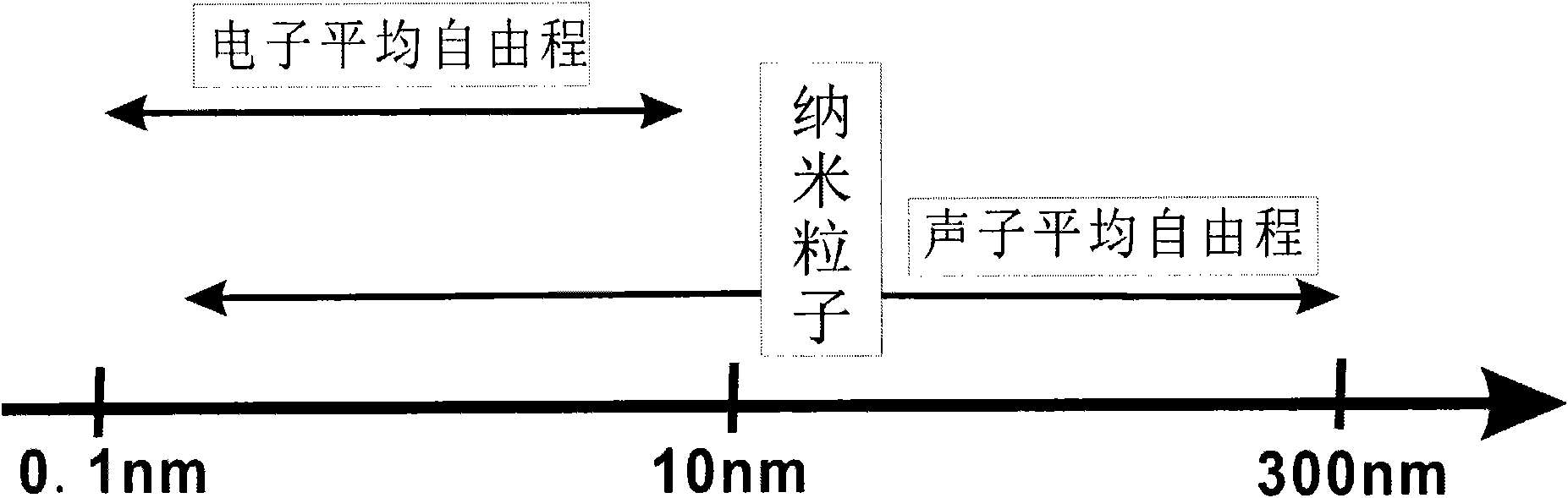

Thermoelectric converter and method thereof

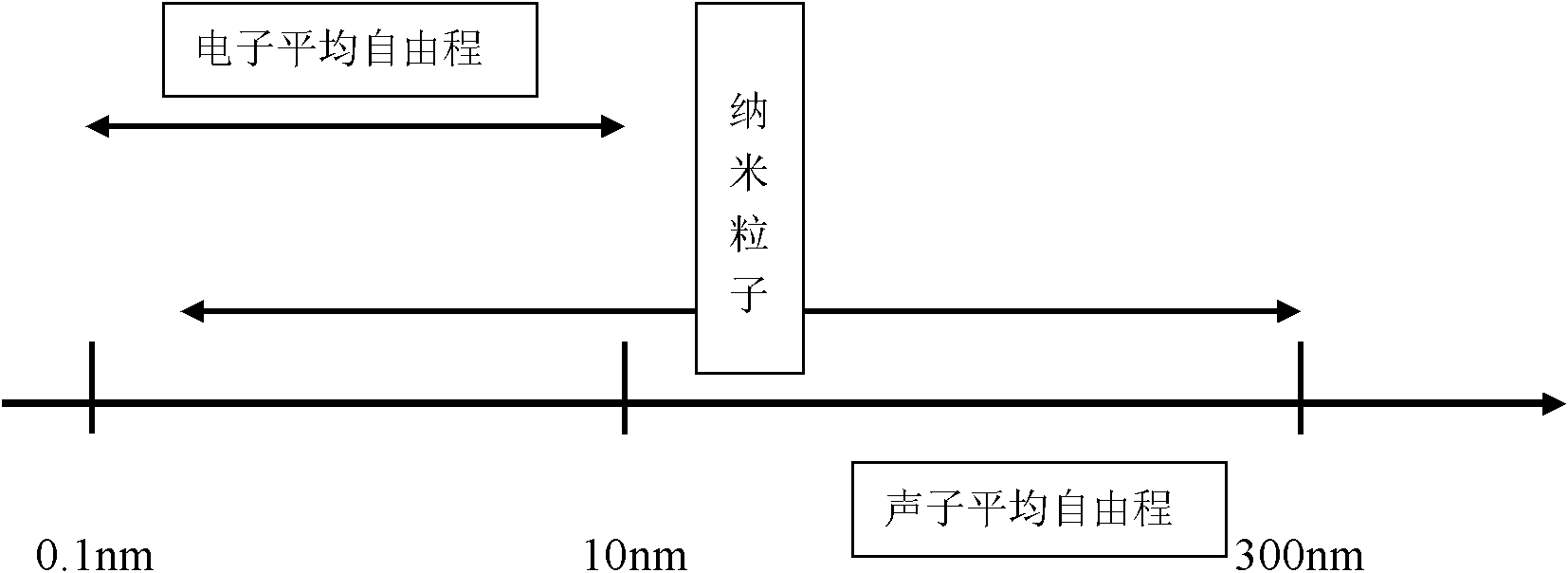

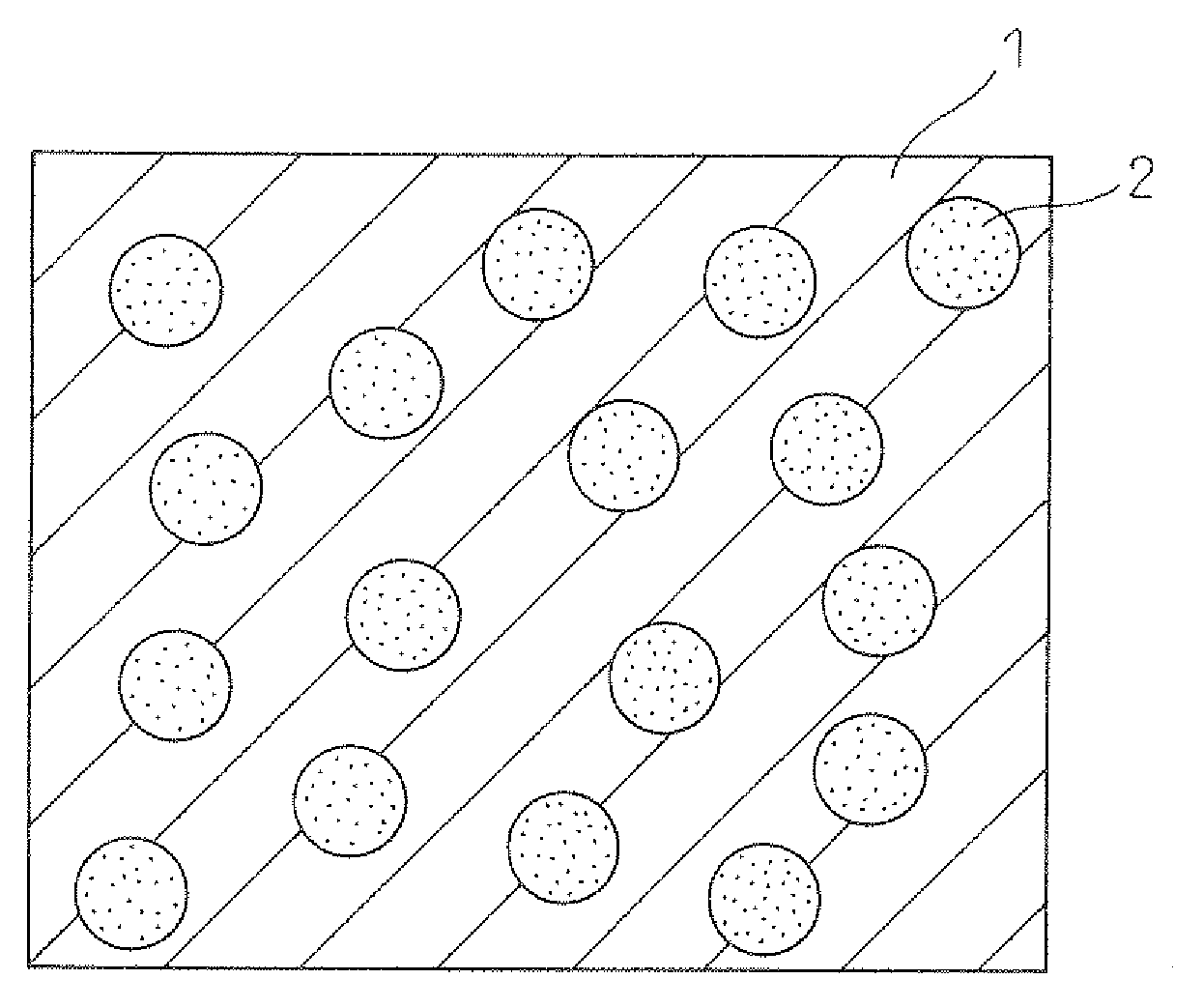

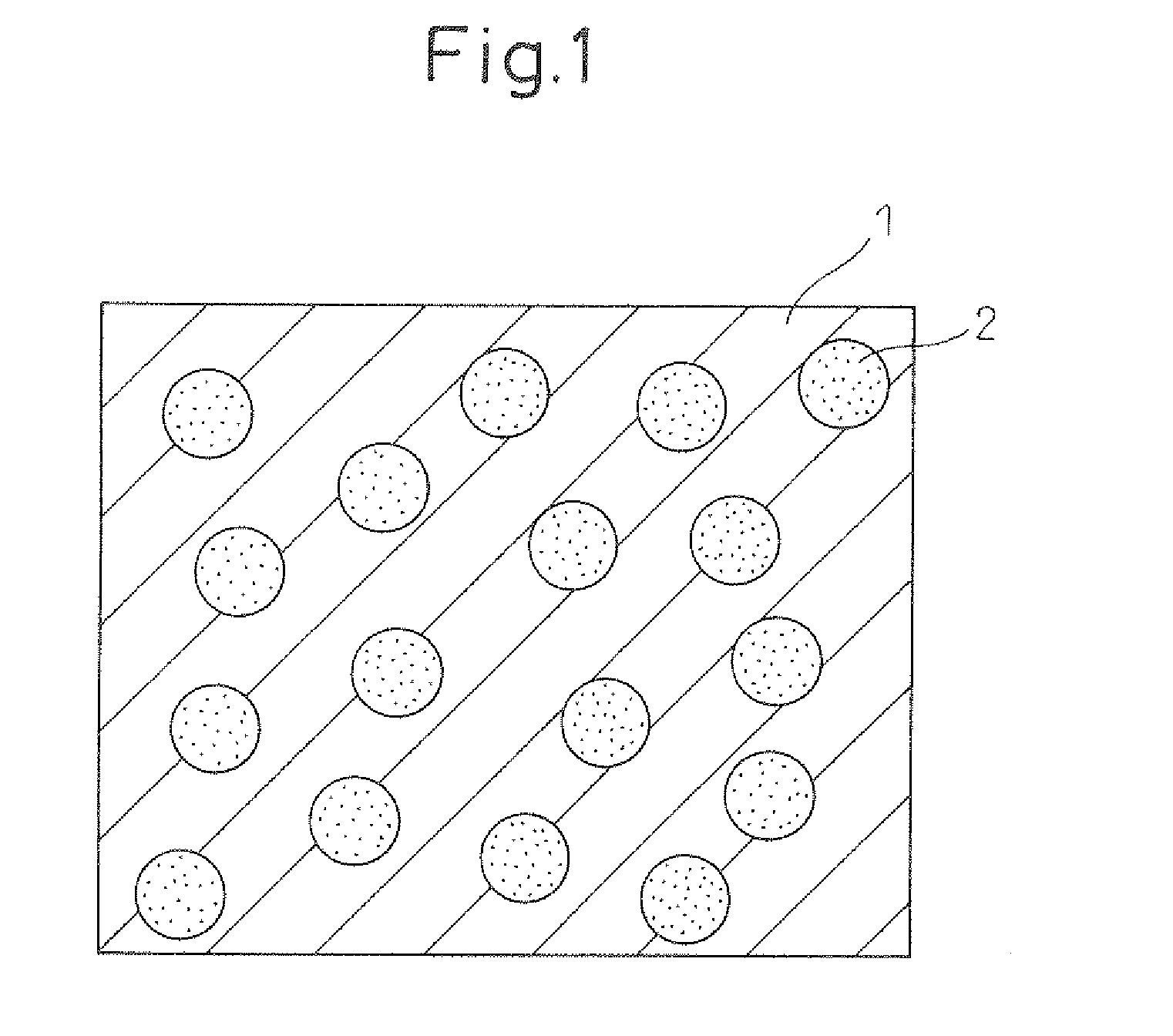

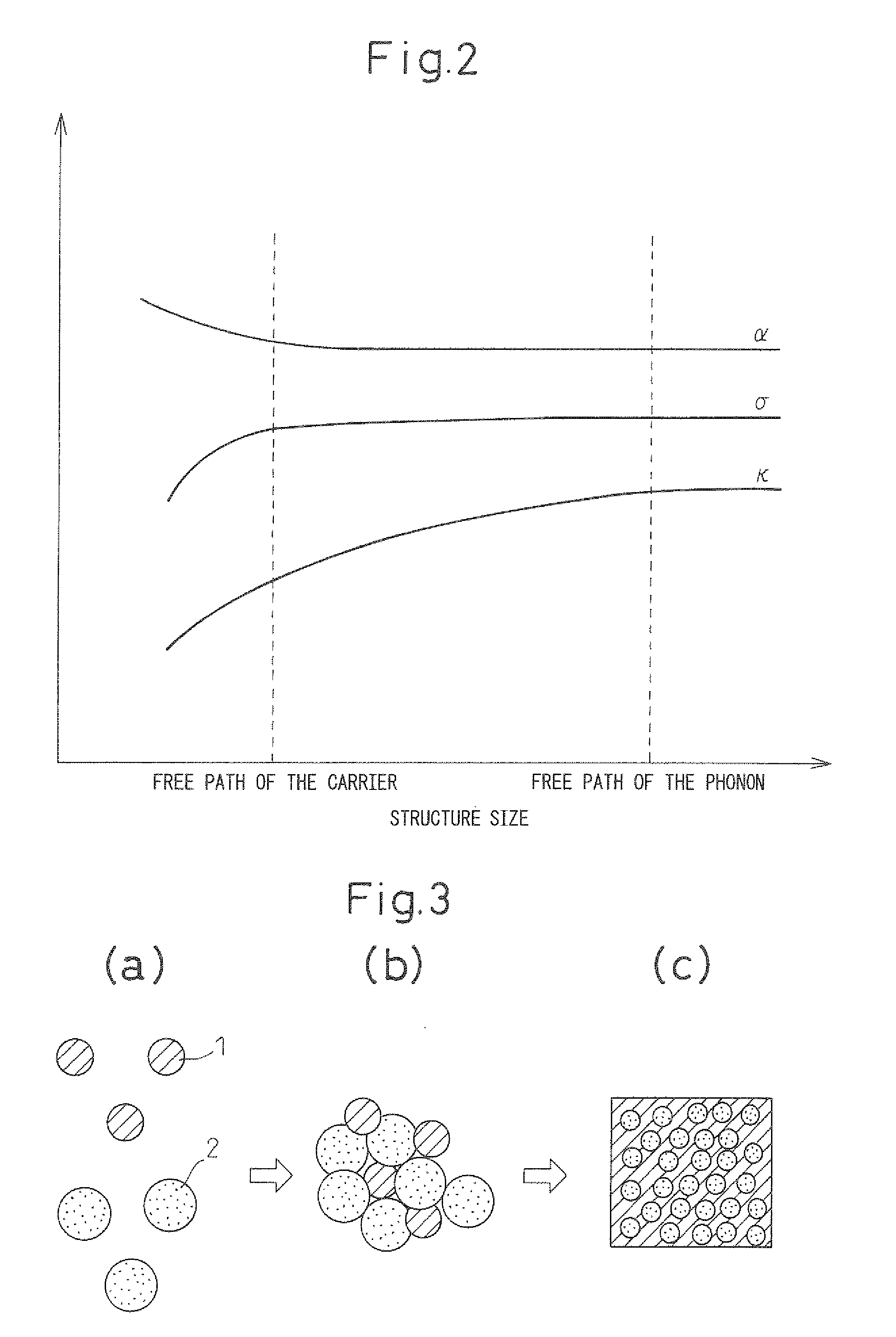

InactiveUS20100170552A1Lower lattice thermal conductivityImprove performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentMean free pathMetallurgy

A thermoelectric converter is made of a first thermoelectric conversion material in which at least one type of second thermoelectric conversion material particles having an average size of 1 to 100 nm is dispersed. At least a part of the second thermoelectric conversion material particles is dispersed at a distance not more than the mean free path of the phonons of the first thermoelectric conversion material.

Owner:TOYOTA JIDOSHA KK

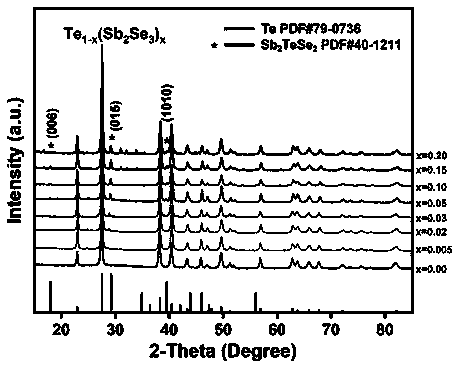

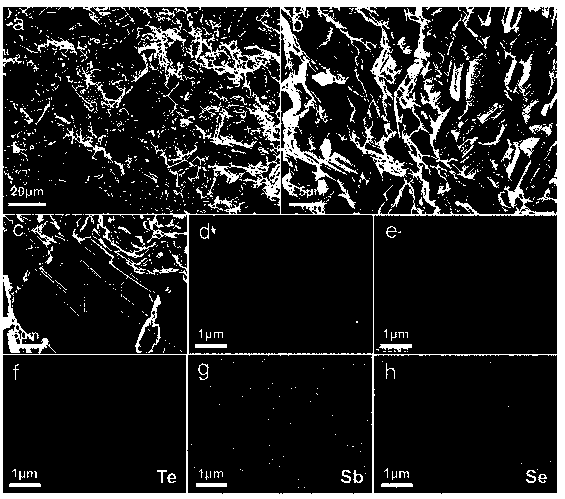

Method for preparing elemental tellurium based composite pyroelectric material

InactiveCN110698203AGood heat transfer performanceOptimize spaceThermoelectric device manufacture/treatmentThermoelectric device junction materialsVertical tubeElectric properties

The invention relates to a method for preparing an elemental tellurium based composite pyroelectric material and belongs to the field of pyroelectric materials. The pyroelectric material is characterized by having a chemical formula of Te1-x(Sb2Se3)x, wherein x is not smaller than 0 and not greater than 0.2. The preparation method disclosed by the invention comprises the following steps: weighingvarious raw material ingredients according to a mole fraction proportioning ratio of the chemical formula, and encapsulating Te cakes, Sb powder and Se powder into a carbon-plated quartz tube throughvacuum encapsulation; then, smelting the quartz tube in a vertical tube type furnace; then, carrying out annealing treatment; and finally, grinding an obtained cast ingot into fine powder, then, carrying out spark plasma sintering, so as to obtain dense mass which has very low thermal conductivity and relatively high pyroelectric properties, wherein the pyroelectric Q-value reaches 0.95. Accordingto the method, the pyroelectric properties of the elemental tellurium based composite pyroelectric material are improved through a smelting process, an annealing process and a spark plasma sinteringprocess. Compared with the prior art, the method has the advantages that through introducing an antimony selenide component, the cooperated optimization of carrier concentration and lattice thermal conductivity is achieved, and the process flow is simple and controllable and is low in cost.

Owner:TAIYUAN UNIV OF TECH

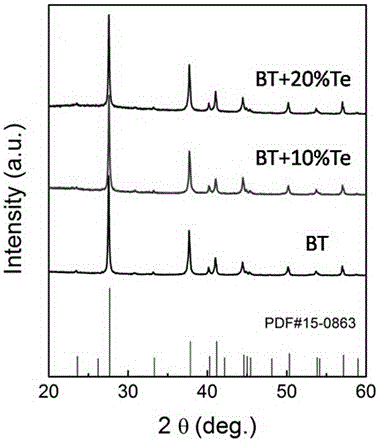

Method for reducing thermal conductivity of bismuth telluride polycrystal lattice

InactiveCN106283173ASimple methodEasy to operatePolycrystalline material growthFrom solid stateBismuth tellurideLattice thermal conductivity

The invention relates to a method for reducing thermal conductivity of a bismuth telluride polycrystal lattice and belongs to the technical field of energy materials. According to the method, bismuth telluride powder is prepared in a mechanical alloying method and is mixed with Te with an additional mass ratio of 5-30% and then undergoes secondary ball milling, and powder with bismuth telluride and simple substance tellurium evenly mixed with each other is obtained. The mixed powder is placed in a graphite die, and a spark plasma sintering process is adopted to perform sintering for 0-30 min at 450-580 DEG C to prepare bismuth telluride polycrystalline blocks. In the spark plasma process, since Te has a low melting point and is liquified completely and since Te is extruded out of the graphite die under the pressure effect, plenty of dislocations are reserved in bismuth telluride blocks, and the lattice thermal conductivity of a material is reduced through introduction of plenty of dislocations. The method is simple in process and easy to operate, and the thermal conductivity is reduced vey obviously.

Owner:KUNMING UNIV OF SCI & TECH

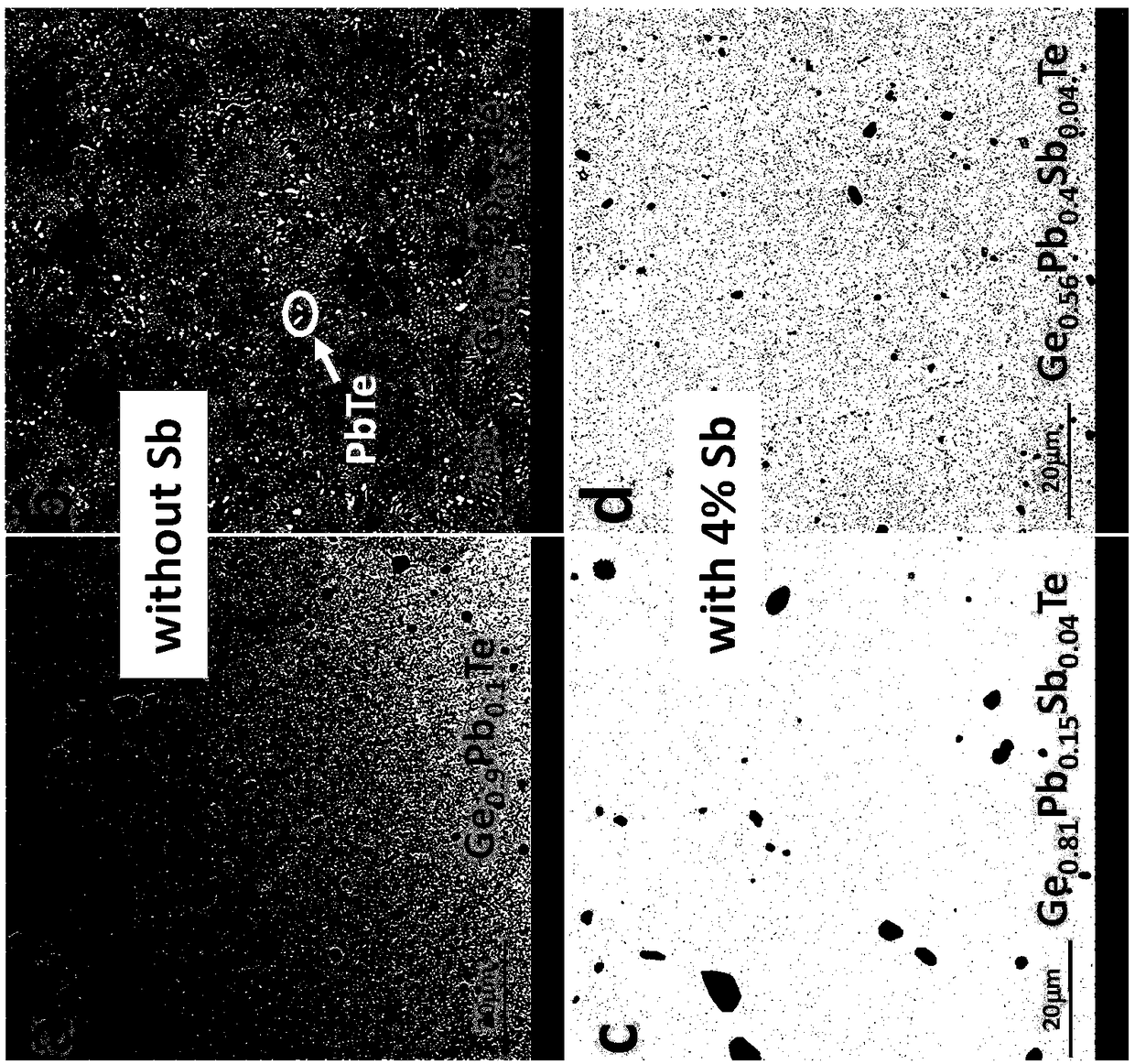

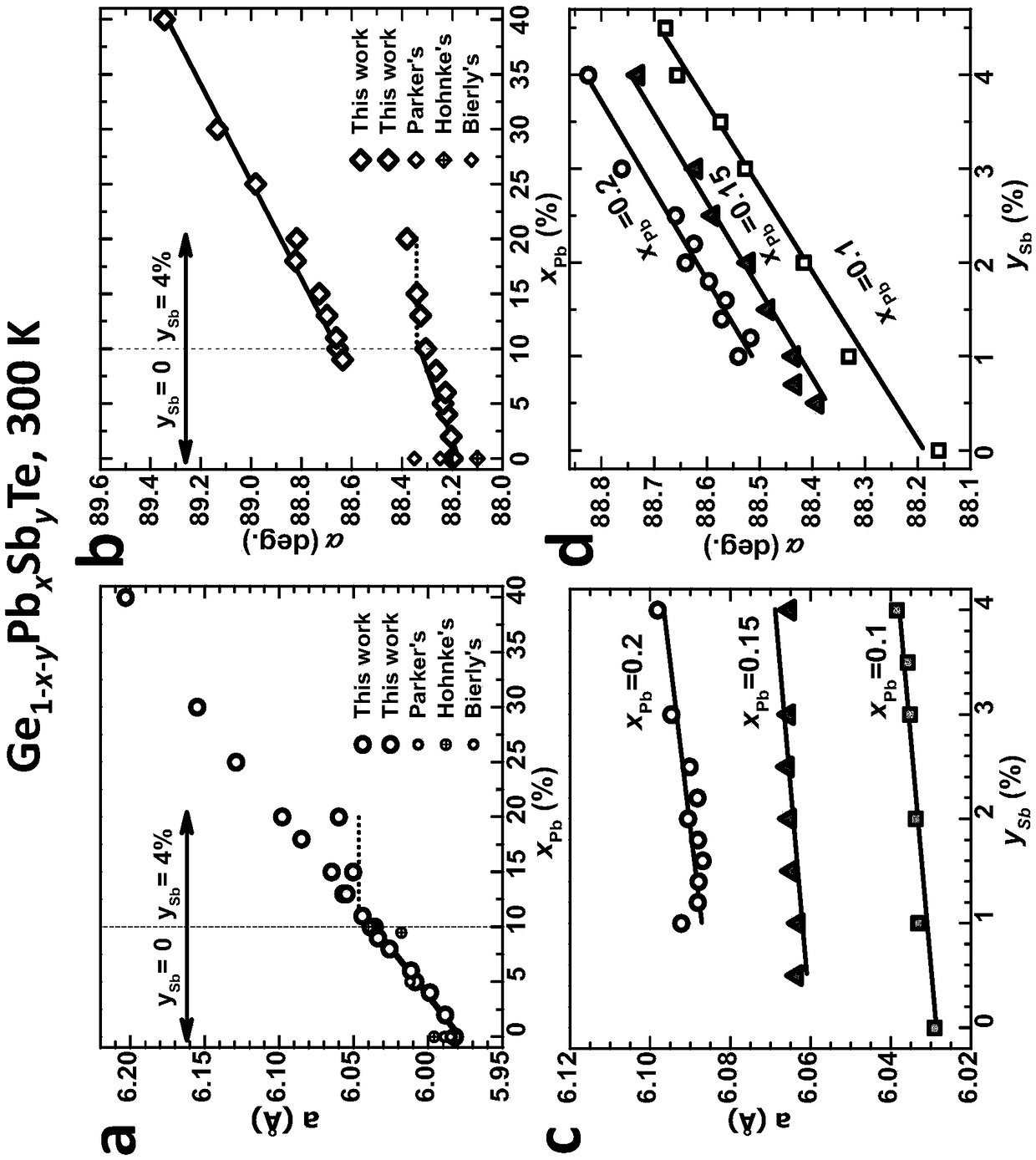

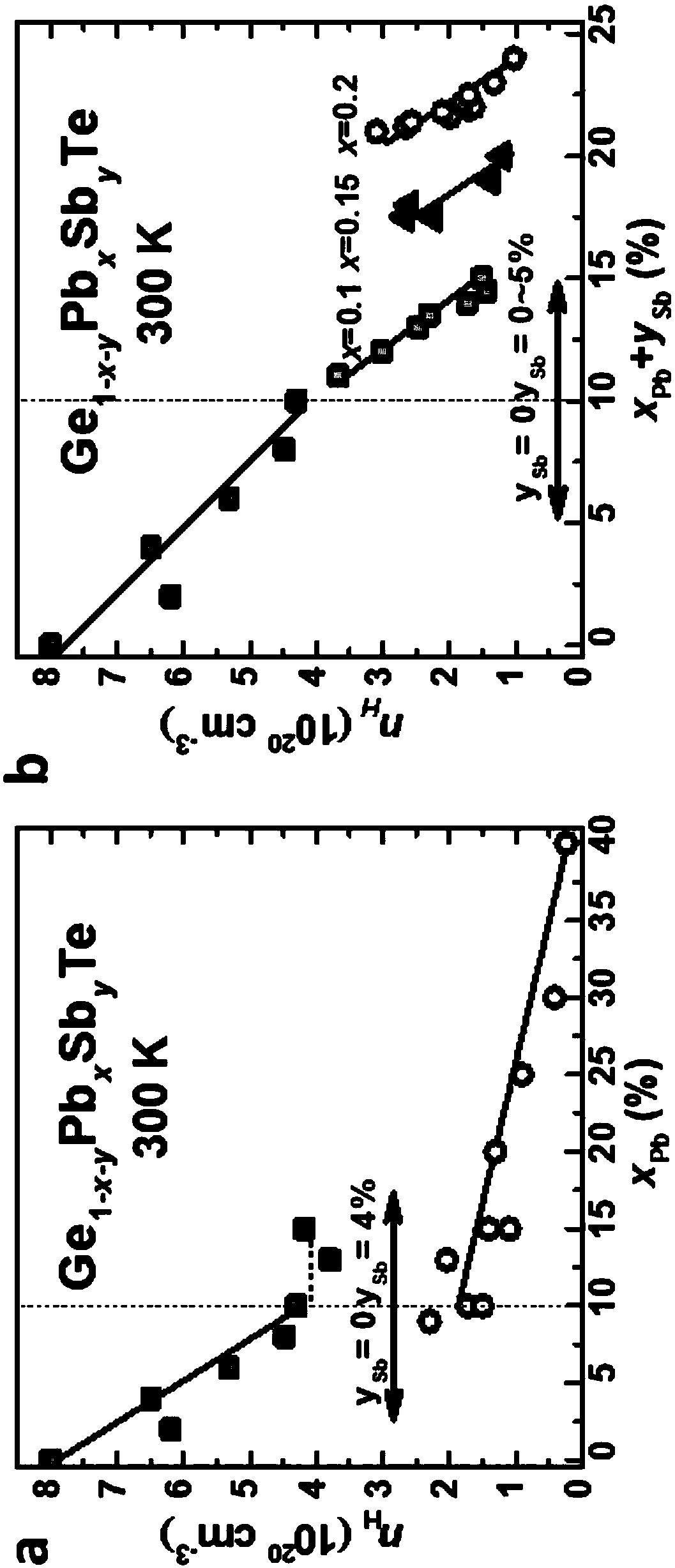

Antimony-doped high-performance GeTe-PbTe solid solution thermoelectric material and preparation method thereof

ActiveCN108735887AAchieve high thermoelectric performanceImprove solubilityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsSolubility

The invention relates to an antimony-doped high-performance GeTe-PbTe solid solution thermoelectric material and a preparation method thereof, wherein the chemical formula is Ge(1-x-y) PbxSbyTe, wherein x is equal to 0-0.4, and y is equal to 0-0.07. The preparation method of the thermoelectric material comprises the following steps: according to the stoichiometric ratio in the above chemical formula, carrying out vacuum package, high-temperature melting and annealing thermal treatment on the single substance elements of Ge, Sb, Pb and Te having high purity (99.99%); grinding into powder; then,carrying out vacuum hot-pressed sintering and fast cooling. Compared with the prior art, the thermoelectrical material prepared by the method in the invention is doped with Sb, so the solubility of PbTe in the GeTe-PbTe solid solution is greatly improved, so that PbTe can obtain high figure of merit in a large solid solution range.

Owner:TONGJI UNIV

Preparation method of SrTiO3/TiO2 composite thermoelectric ceramic material

The invention relates to a preparation method of a SrTiO3 / TiO2 composite thermoelectric ceramic material and belongs to the field of thermoelectric ceramics. The preparation method is used for solving the problems that the thermoelectric performance of the existing SrTiO3 oxide is not high and the sintering temperature is high. The preparation method comprises the steps: firstly, preparing hydrated titanium dioxide fiber; secondly, adding the hydrated titanium dioxide fiber obtained in the step 1 into an Sr(NO3)2 solution, carrying out uniform ultrasonic dispersing, adjusting the pH value of the system to be 8-12 and then carrying out hydrothermal reaction and drying to obtain a composite fiber; and thirdly, carrying out compression molding on the composite fiber and carrying out anaerobic sintering at a temperature of 1100 DEG C-1300 DEG C to obtain the SrTiO3 / TiO2 composite thermoelectric ceramic material. According the preparation method disclosed by the invention, by virtue of doping rare earth elements, the conductivity of the composite thermoelectric ceramic material can be improved. By virtue of preparing the SrTiO3 / TiO2 composite fiber, the ZT value of the SrTiO3-based material is improved to 0.1-0.35 and the sintering temperature is effectively reduced.

Owner:HARBIN INST OF TECH

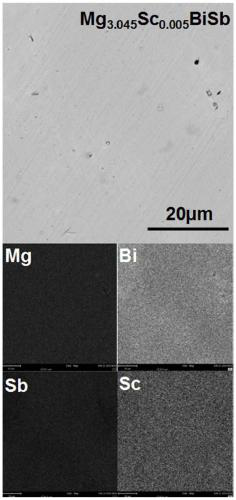

N-type antimonous trimagnetite scandium-doped alloy thermoelectric material and preparation method thereof

InactiveCN111057884AAvoid missingReduced enrichmentThermoelectric device junction materialsLattice thermal conductivityAlloy

The invention relates to an N-type antimonous trimagnetite scandium-doped alloy thermoelectric material and a preparation method thereof. The chemical formula of the thermoelectric material is Mg<3.05-x>Sc<x>Sb<2-y>Bi<y>, wherein y is greater than 0 and less than or equal to 1, and x is greater than 0 and less than or equal to 0.03. Compared with the prior art, cationic electrons are introduced byimproving scandium doping through the solid solution of bismuth trimagnetite, so that carrier concentration and lattice thermal conductivity are regulated and controlled at the same time; the contentof magnesium oxide in the grain boundary of N-type Mg3Sb<2> alloy is reduced through tantalum packaging smelting, so that high mobility is shown. The simple and controllable technology can be widelyapplied to various thermoelectric materials, especially materials with a large number of intrinsic defects, and therefore, a new method is provided for improving thermoelectric performance.

Owner:TONGJI UNIV

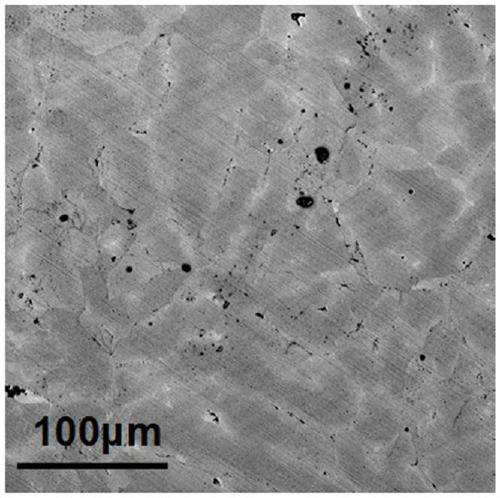

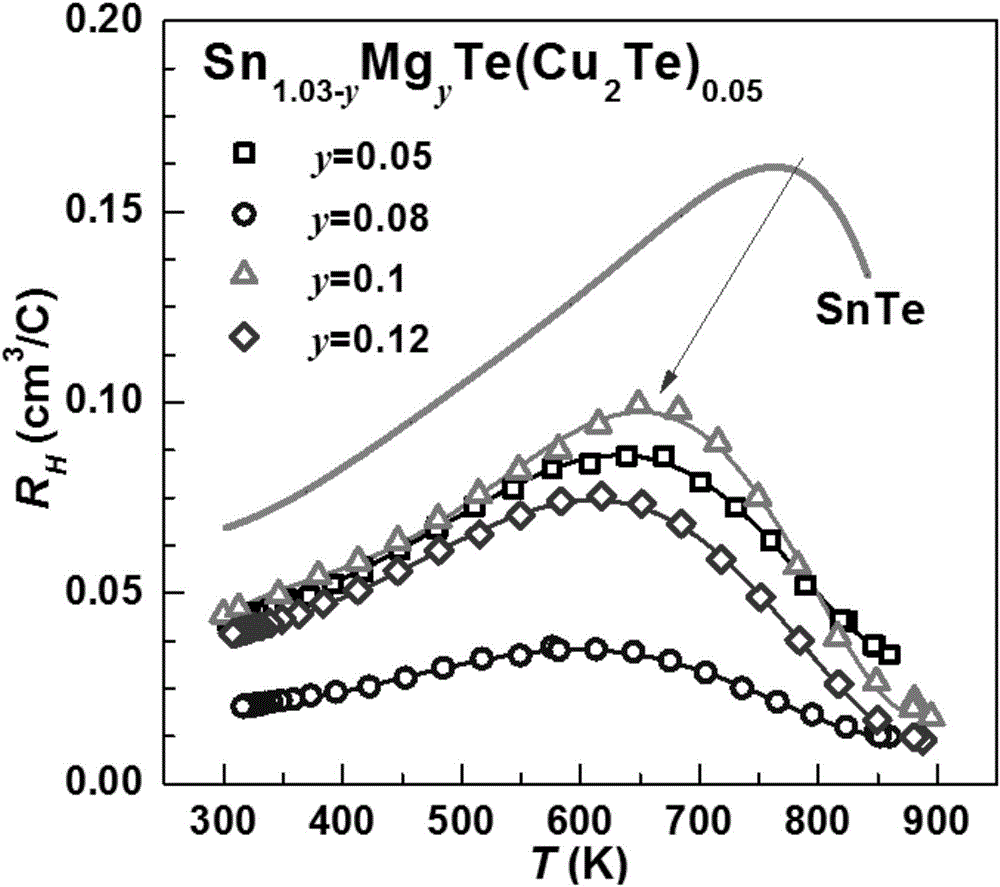

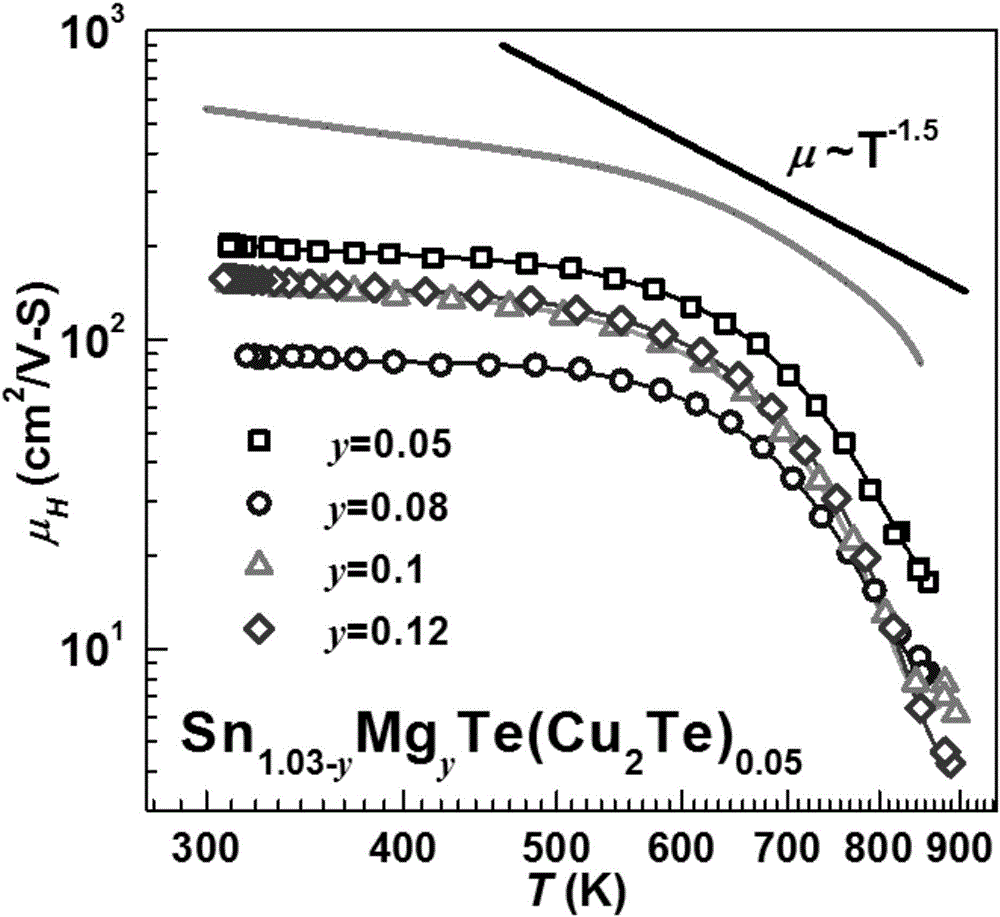

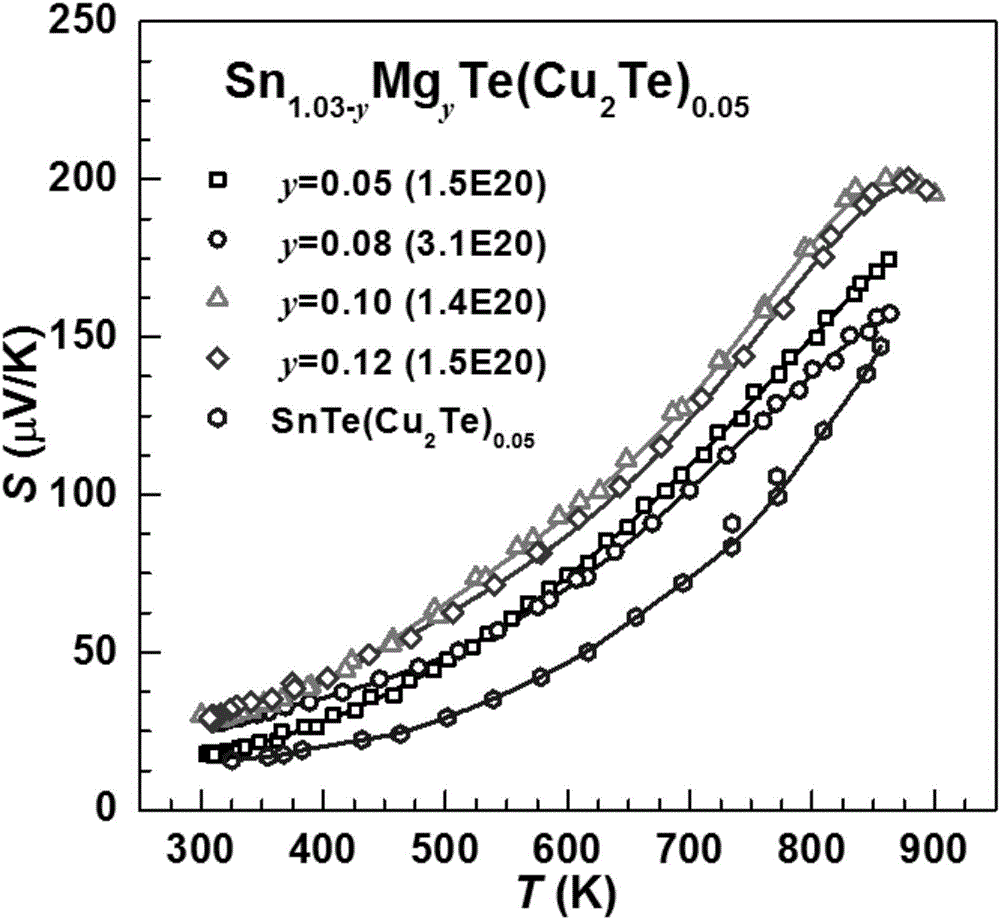

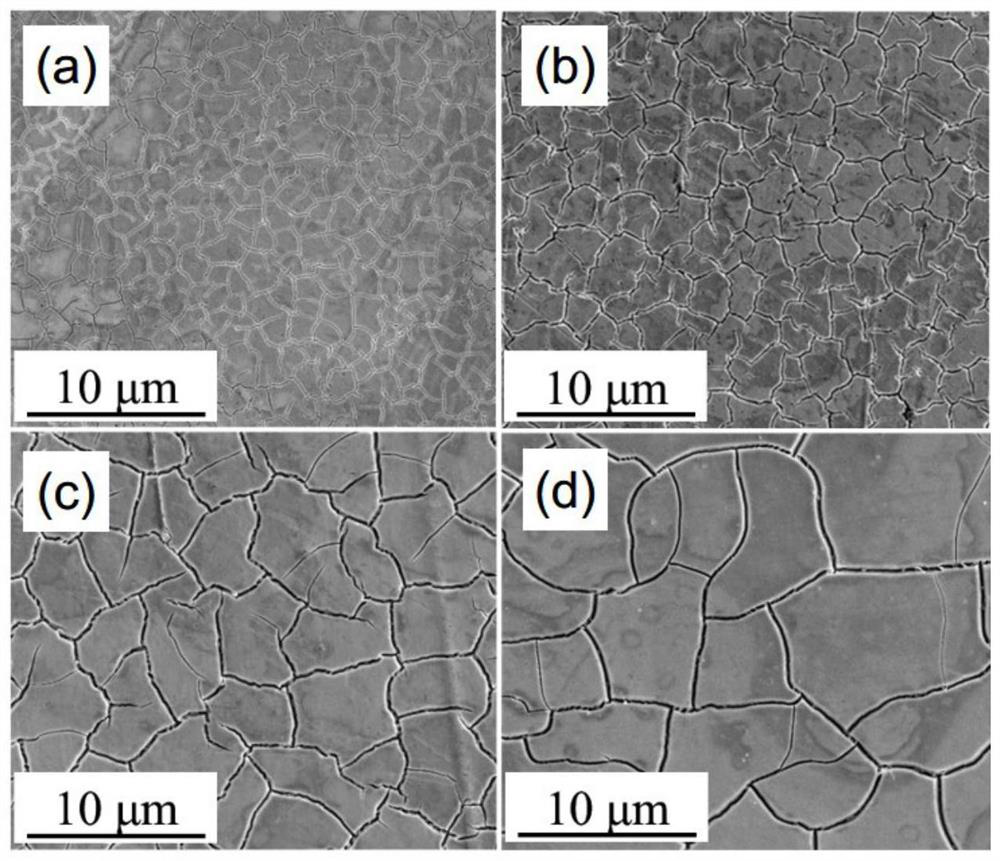

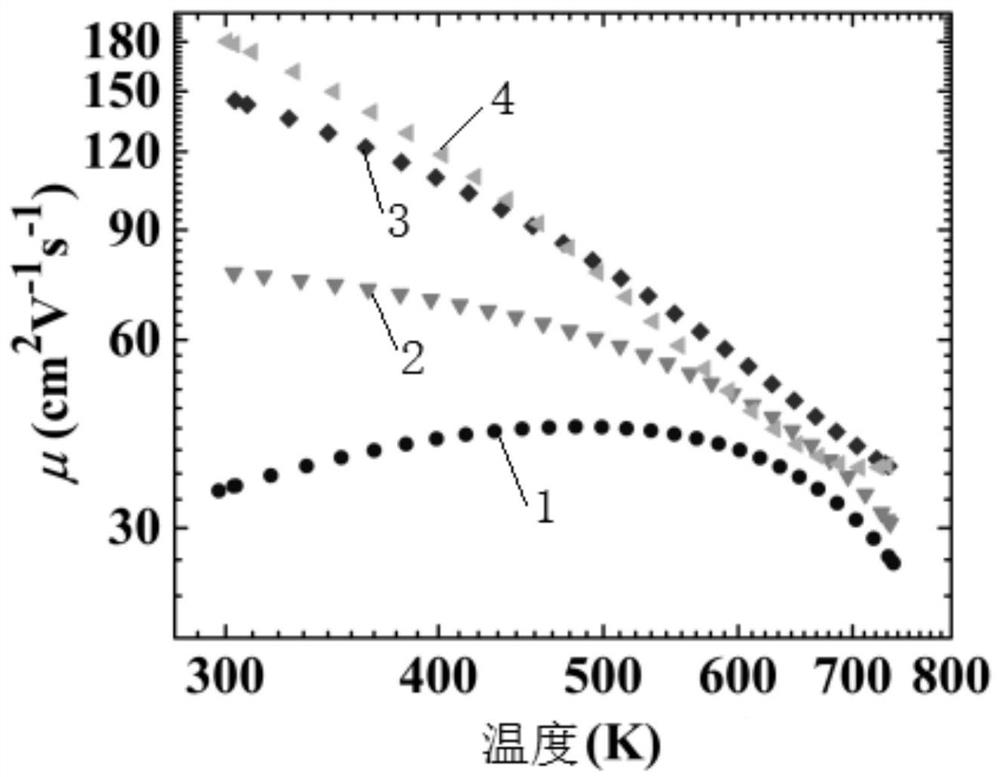

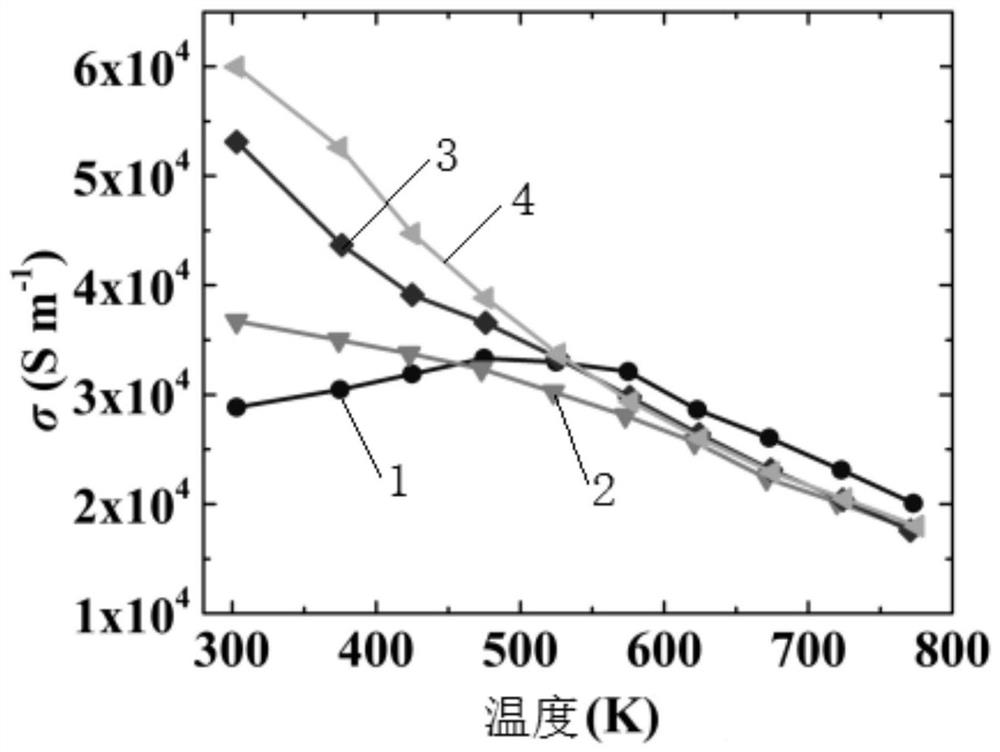

Environment-friendly sulfur group stannide thermoelectric material and preparing method thereof

InactiveCN106676322AImprove thermoelectric performanceImprove thermoelectric conversion efficiencyElectricityLead telluride

The invention relates to a high-performance environment-friendly sulfur group stannide thermoelectric material and a preparing method thereof. The chemical general formula of the thermoelectric material is Sn1.03-yMgyTe(Cu2Te)x(0<x<=0.05, 0<y<=0.12). According to the preparing method, a metal elementary substance with purity larger than 99% is used as a raw material, material matching is carried out according to the stoichiometric ratio of Sn1.03-yMgyTe(Cu2Te)x, after vacuum packaging, high-temperature melting and annealing heat treatment are carried out, the material is ground into powder, and after vacuum hot-press sintering and slow cooling are carried out, a sheet material is obtained and is the novel sulfur group stannide thermoelectric material of the target component. According to the design, in the SnTe material, collaborative optimization of an electrical transport property and a hot transport property is achieved to improve thermoelectric performance of the material. Compared with the prior art, the invention develops a novel high-performance environment-friendly Sn1.03-yMgyTe(Cu2Te)x thermoelectric material, the zT value reaches 1.4 at 900 K, and the material is an environment-friendly high-performance thermoelectric material with potentials for replacing a traditional p-type lead telluride material.

Owner:TONGJI UNIV

Full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material and preparation method thereof

ActiveCN112038473AHigh thermal conductivityImprove thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMetallurgy

The invention discloses a full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material and a preparation method thereof, and relates to an n-type thermoelectric material and a preparation method thereof. The full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material aims to solve the problems that an existing n-type Mg3Sb2-based thermoelectric materialcannot simultaneously obtain high performance at room temperature and high temperature and is poor in mechanical property. The chemical general formula of thefull-temperature-range high-performance n-type Mg-Sb-based thermoelectric material is B<x>Mg<3.2-x>Sb<1.99y>Bi<y>Te<0.01>. The preparation method comprises the following steps of: 1, weighing; 2, ball milling; and 3, sintering. The preparation method is used for preparing the full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material.

Owner:HARBIN INST OF TECH

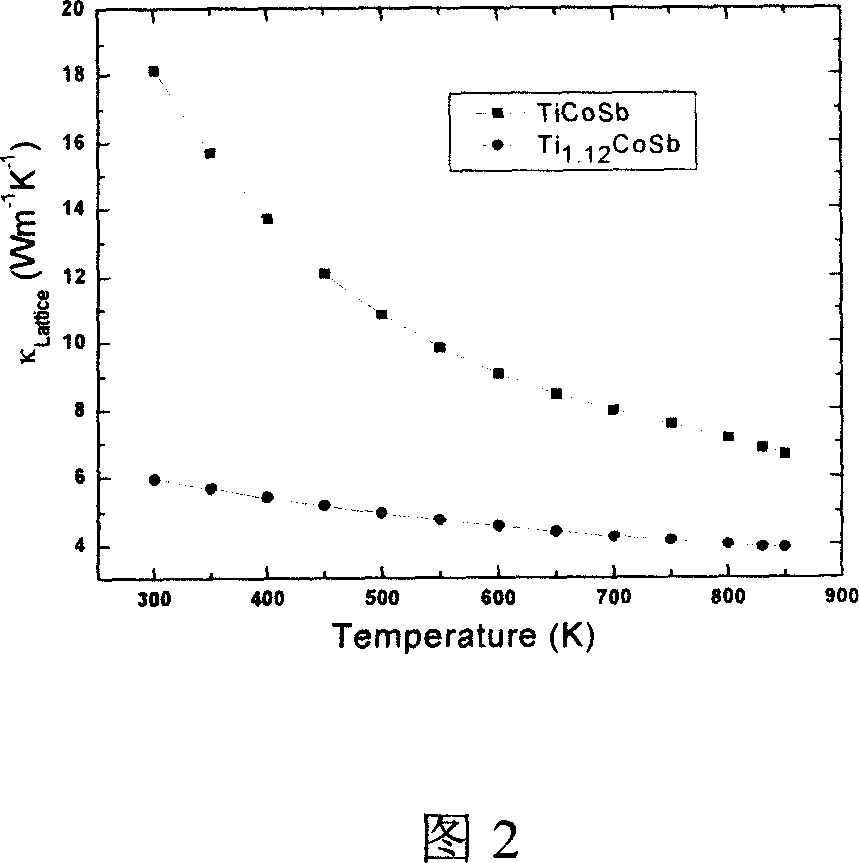

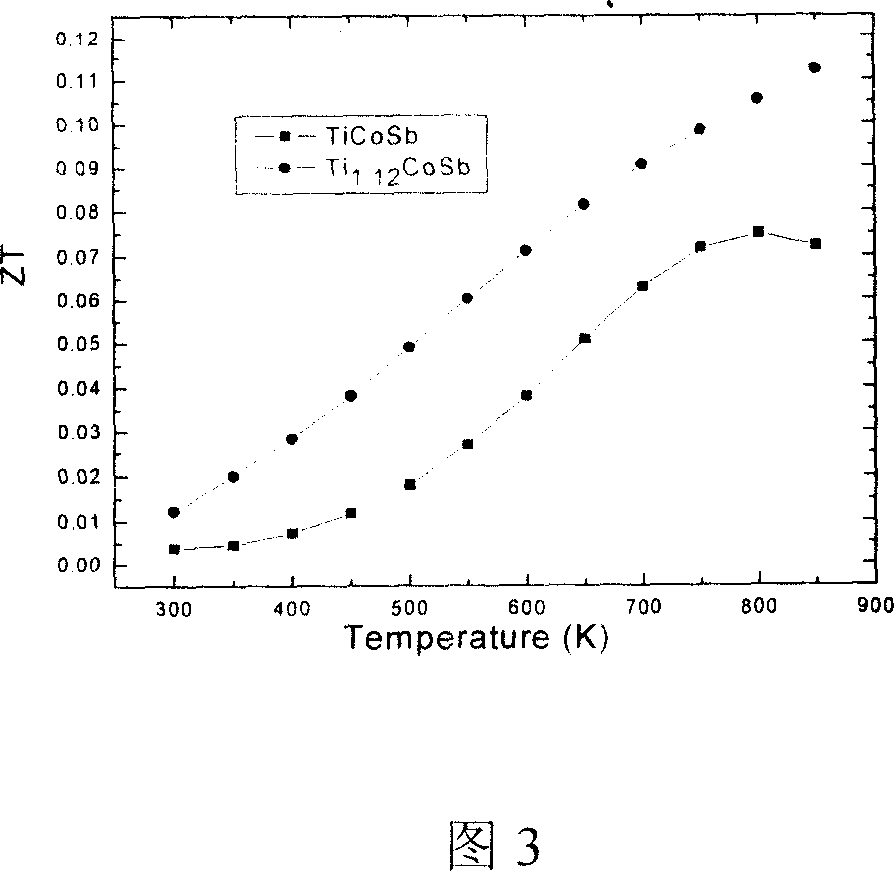

Adulterated titanium-cobalt-stibium based thermoelectric composite material, and preparation method

InactiveCN1958820ALower lattice thermal conductivitySimple processTitaniumLattice thermal conductivity

This invention relates to a method for preparing doped Ti-Co-Sb thermoelectric composites. The general chemical formula of doped Ti-Co-Sb thermoelectric composites is Ti1+xCoy(Me)1-ySbz(Me')1-z, where, x is 0.05-0.20; y is 0.80-1.0; z is 0.85-1.0; Me is one of Ni, Fe, Pd and Pt; Me' is one of Sn, Te and Ge. The method comprises: mixing the raw materials according to the formula, pressing into lamellae, and smelting to obtain TiO2 nanoparticles. The doped Ti-Co-Sb thermoelectric composites have high electrical conductivity, low lattice heat conductivity, and high thermoelectric performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

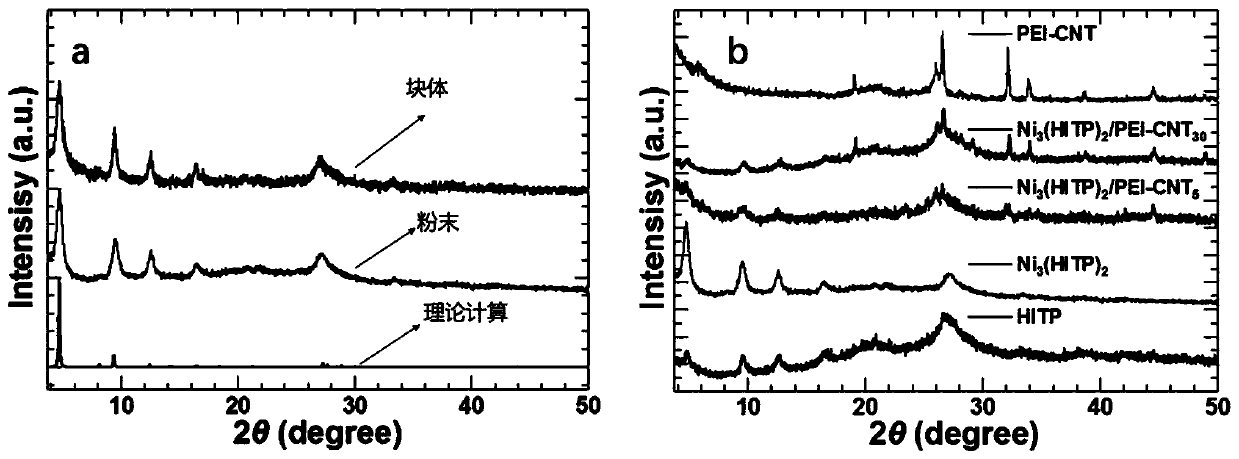

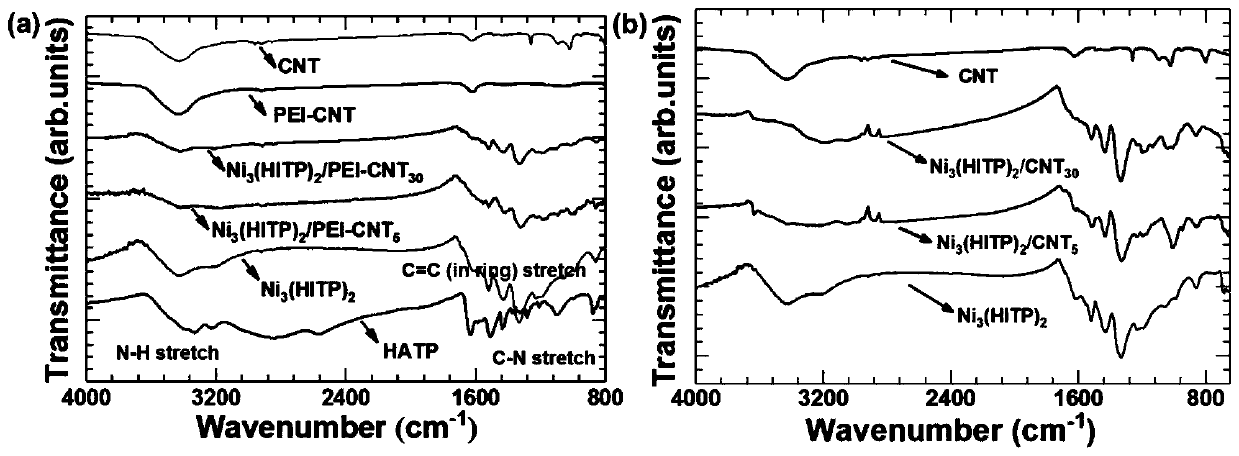

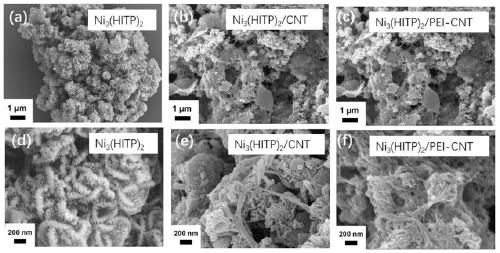

Preparation method of composite material based on metal organic framework and carbon nanotubes, and preparation method of device

ActiveCN111253759ALower lattice thermal conductivityDoping effect weakenedThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsThermal insulation

The invention discloses a preparation method of a composite material based on a metal organic framework and carbon nanotubes, and a preparation method of a device. The preparation method comprises thefollowing steps: firstly, preparing a P-type Ni<3>(HITP)<2> / CNT composite material and an N-type Ni<3>(HITP)<2> / CNT composite material; then respectively tabletting the P-type Ni<3>(HITP)<2> / CNT composite material and the Ni<3>(HITP)<2> / CNT composite material by using a square tabletting mold at a pressure of 10-30 MPa for 5-30 minutes so as to obtain a P-type composite block material and an N-type composite block material, then assembling the P-type composite block material and the N-type composite block material; and connecting connecting parts by using a conductive silver adhesive or a copper wire so as to obtain the device. The N-type stable MOF / CNT composite material with the highest performance is successfully prepared and applied to device circuits, and the porous composite material with high conductivity and low thermal conductivity has potential application value in the fields of catalytic materials, gas adsorption materials, thermal insulation materials and high-performancethermoelectric materials.

Owner:XI AN JIAOTONG UNIV

Shockwave fabrication of thermoelectric materials

InactiveUS20090155117A1Reduce mean free pathExtensive meltingUltra-high pressure processesThermoelectric device manufacture/treatmentThermoelectric materialsMetallurgy

The explosive consolidation of semiconductor powders results in thermoelectric materials having reduced thermal conductivity without a concurrent reduction in electrical conductivity and thereby allows the construction of thermoelectric generators having improved conversion efficiencies of heat energy to electrical energy.

Owner:TXL GROUP

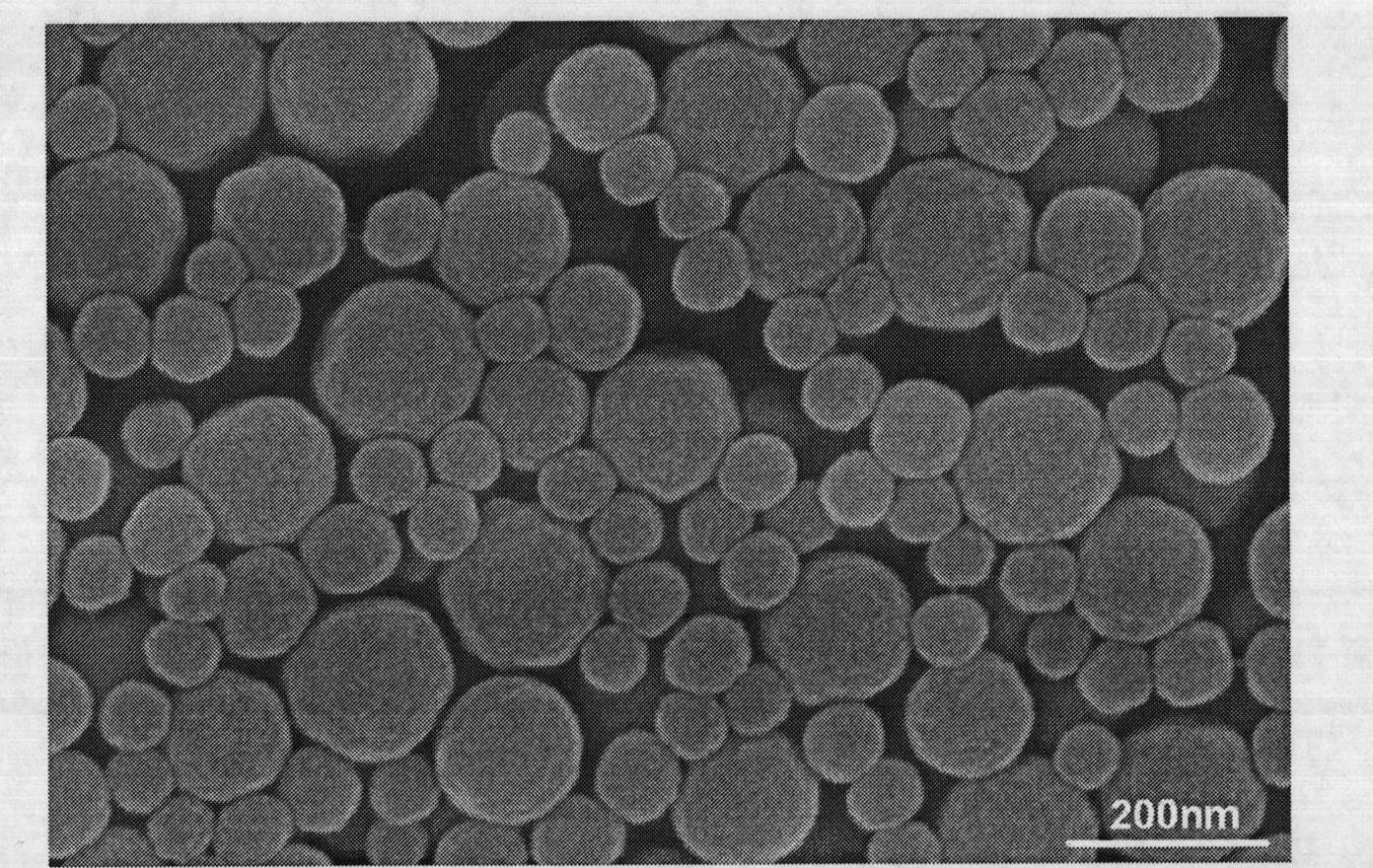

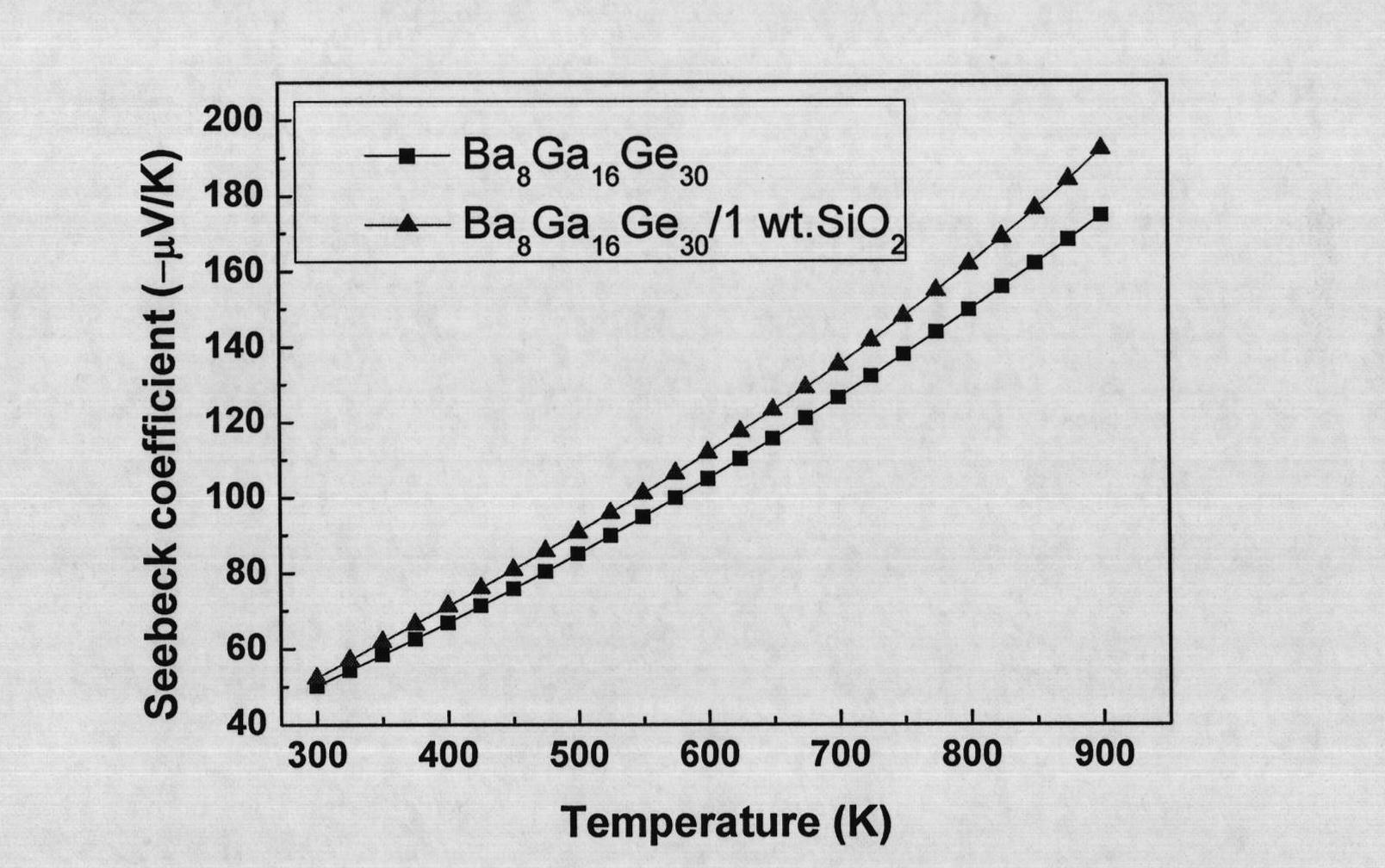

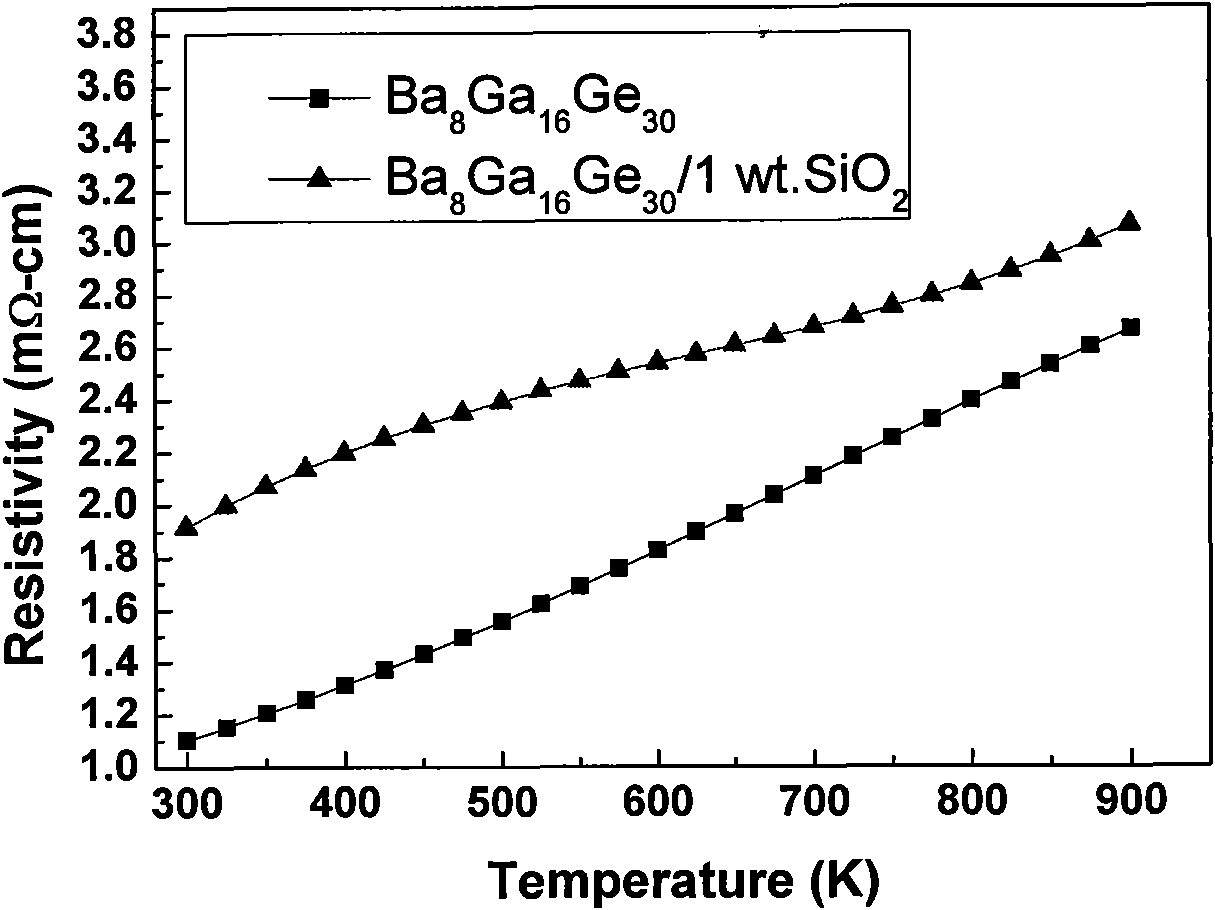

SiO2 nanoparticle composite cage compound thermoelectric material and preparation method thereof

ActiveCN101979688AEnabling regulated electrical transport propertiesRegulating electrical transport propertiesThermoelectric device manufacture/treatmentThermoelectric device junction materialsNano sio2Lattice thermal conductivity

The invention relates to the technical field of thermoelectric materials and discloses a SiO2 nanoparticle composite cage compound thermoelectric material and a preparation method thereof. In the invention, 50 to 300 nanometer SiO2 nanoparticles are mixed with a cage compound, the regulation of the electron transport performance of the cage compound thermoelectric material and the considerable reduction of lattice thermal conductivity are realized by adding a proper amount of the SiO2 nanoparticles, and finally the hermoelectric property of the cage compound thermoelectric material is improved. In addition, the preparation method of the SiO2 nanoparticle composite cage compound thermoelectric material is simple and easy to implement, overcomes the drawbacks of introducing other impurities easily and preventing the mixed second-phase particles from dispersing and agglomeration easily of the traditional preparation method, and makes the nano SiO2 particles uniformly dispersed and mixed with the cage compound thermoelectric material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

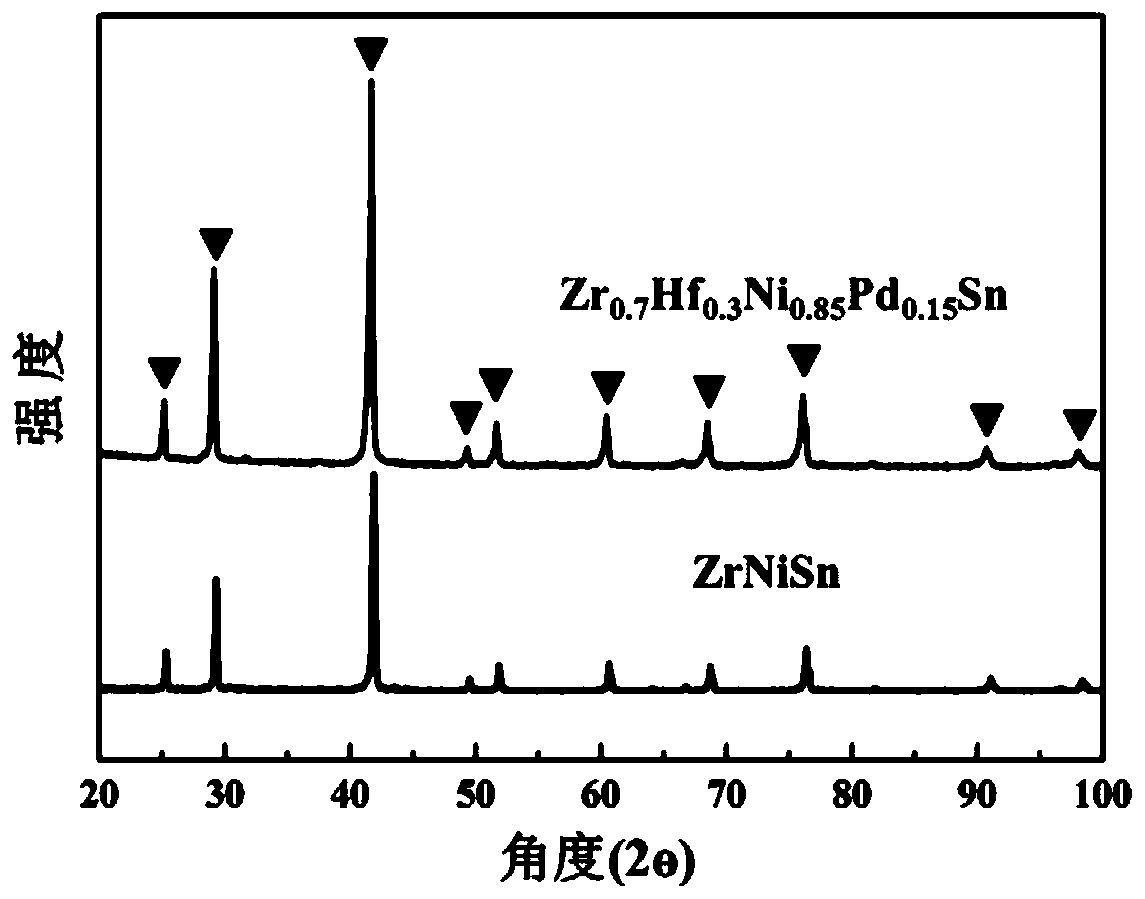

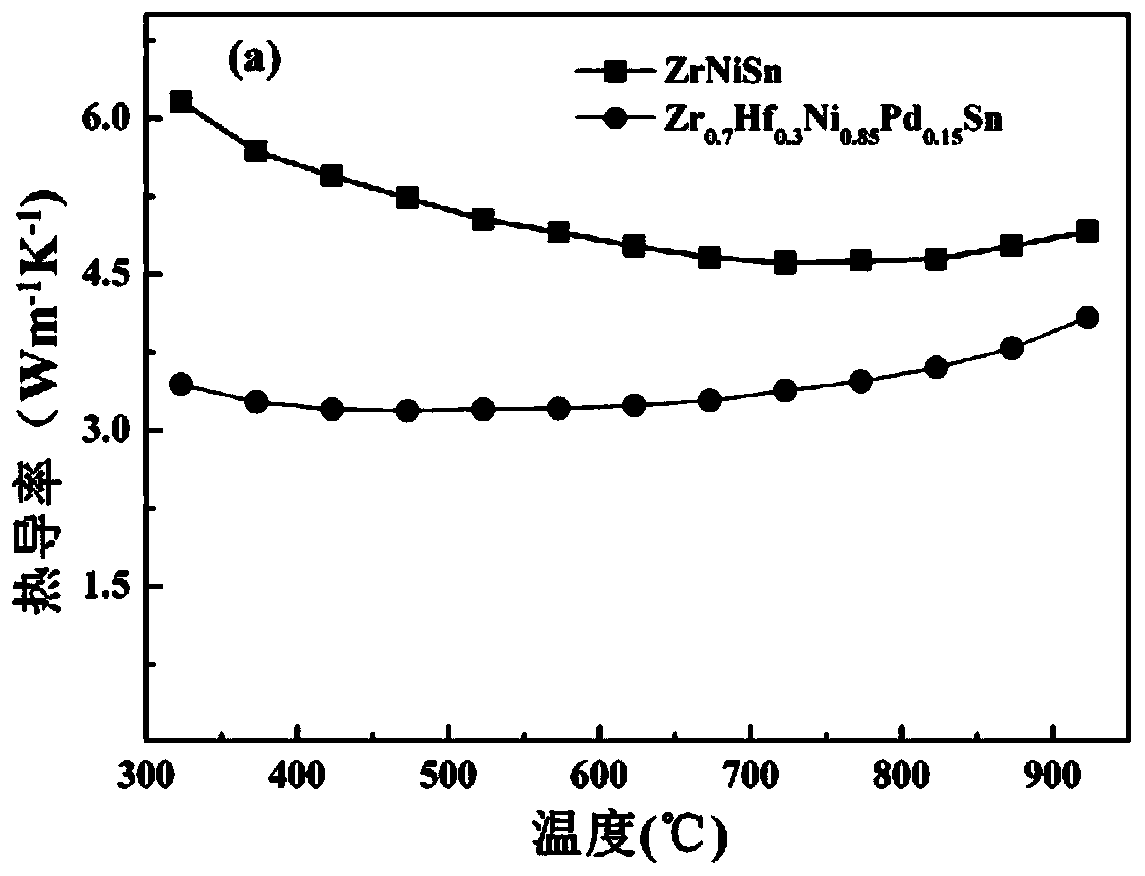

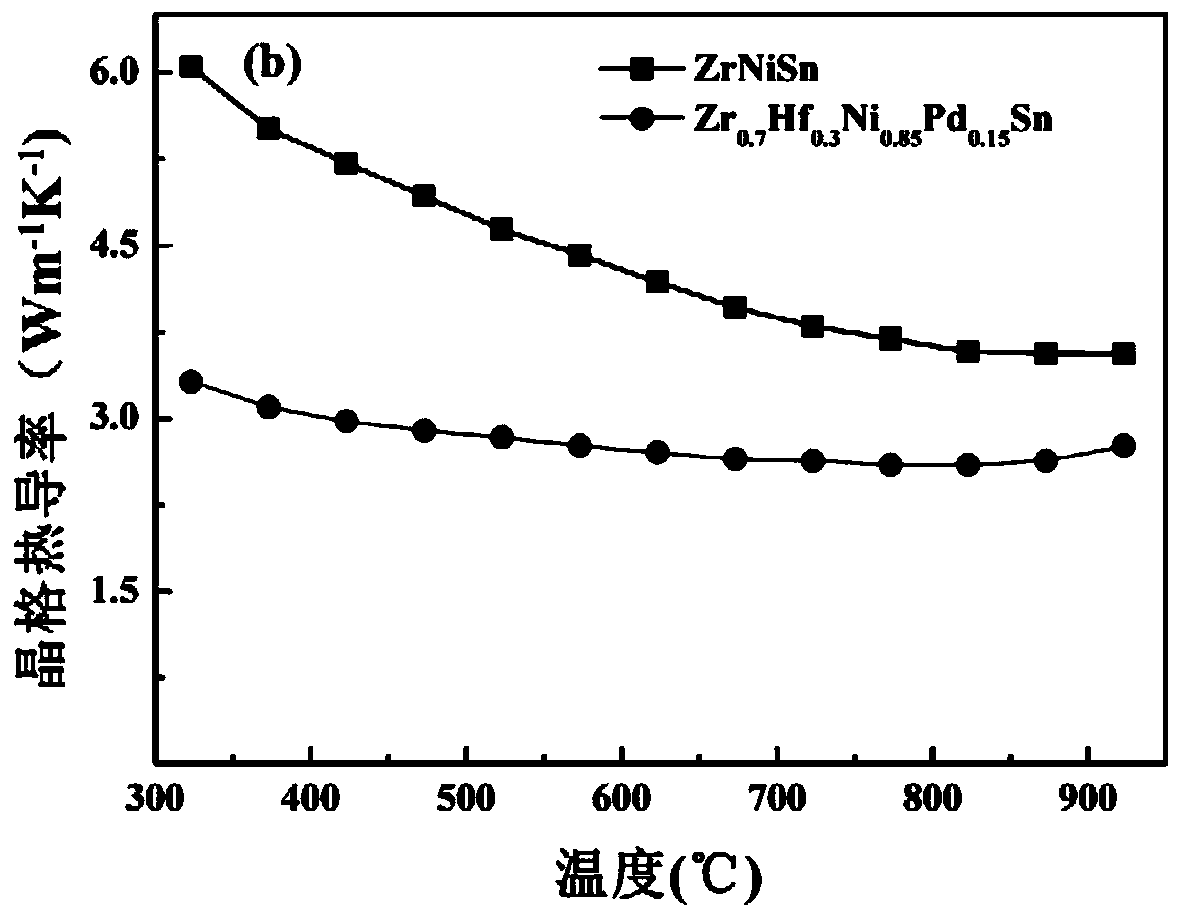

High entropy Half-Heusler thermoelectric material with low lattice thermal conductivity and preparation method thereof

ActiveCN110592459ASolid solubility of major elementsLower lattice thermal conductivityThermoelectric device manufacture/treatmentTransportation and packagingLattice thermal conductivityMixed materials

The present invention provides a high entropy Half-Heusler thermoelectric material with a low lattice thermal conductivity and a preparation method thereof. The general formula of the high entropy Half-Heusler thermoelectric material with the low lattice thermal conductivity is ZrxHf1-xNiyPd1-ySn, wherein x=0.6-0.8, and y=0.8-0.9. The preparation method of the high entropy Half-Heusler thermoelectric material with the low lattice thermal conductivity comprises the following steps: proportioning and mixing the materials according to the general formula Zr0.7Hf0.3Ni0.85Pd0.15Sn, placing the mixed materials in a magnetic suspension smelting furnace for smelting, grinding and drying an ingot obtained by smelting to obtain powder, and sintering the powder by adopting a discharge plasma sintering technology to obtain the high entropy Half-Heusler thermoelectric material with the low lattice thermal conductivity. The high entropy Half-Heusler thermoelectric material has the low lattice thermal conductivity and high ZT value.

Owner:DALIAN UNIV OF TECH

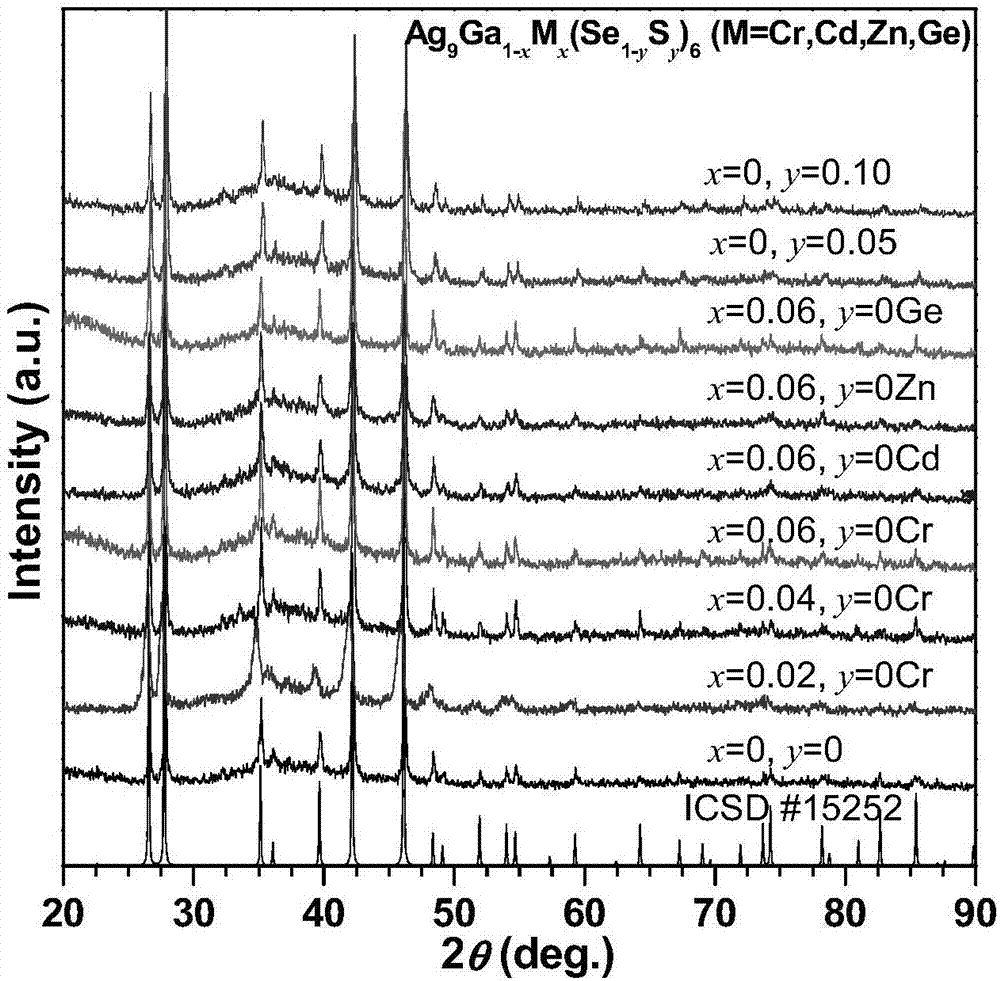

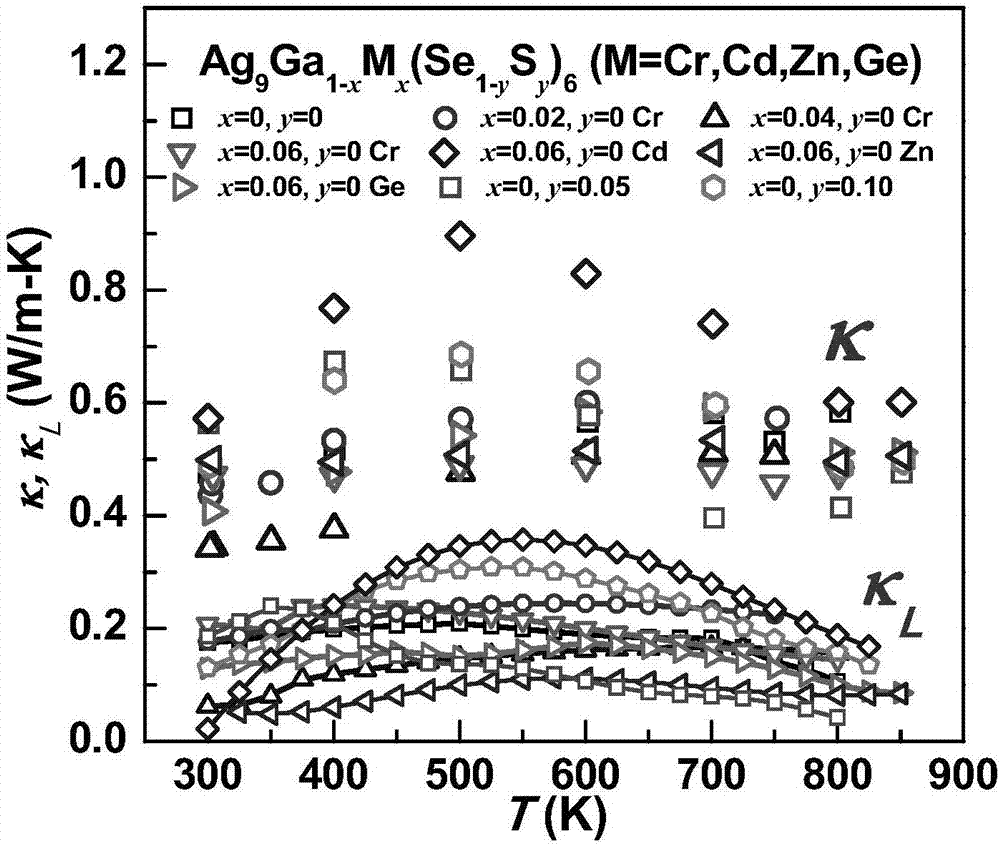

Novel low-thermal-conductivity argyrodite thermoelectric material and preparation method thereof

InactiveCN107359231ALower lattice thermal conductivityHigh purityThermoelectric device manufacture/treatmentThermoelectric device junction materialsAdditive ingredientArgyrodite

The invention relates to a novel low-thermal-conductivity argyrodite thermoelectric material and a preparation method thereof. A chemical formula of the thermoelectric material is Ag9Ga1-XMx(Se1-YSy)6, wherein, M is one selected from Cr, Cd, Zn or Ge, 0< / =x< / =0.06, and 0< / =y< / =0.10; during preparation, a simple substance with the purity of more than 99.99% is used as a raw material, and ingredients are weighed according to the stoichiometric ratio and placed in a sealed quartz tube for vacuum packaging; a muffle furnace is used for heating, so that the high-purity raw material is subjected to a melt reaction at a high temperature and then to rapid quench cooling, to obtain a first ingot; the first ingot is vacuum packaged in the quartz tube, and is subjected to high temperature annealing treatment and then to rapid quench cooling, to obtain a second ingot; the second ingot is grinded into powder which is placed in a graphite mold, hot pressed sintering is carried out throguh induction heating and temperature rise in a vacuum atmosphere, then slow cooling is performed, and completing the preparation. Compared with the prior art, the thermoelectric material of the invention has the advantages of stable mechanical property, very low lattice thermal conductivity (0.2W / m K), and good application prospect.

Owner:TONGJI UNIV

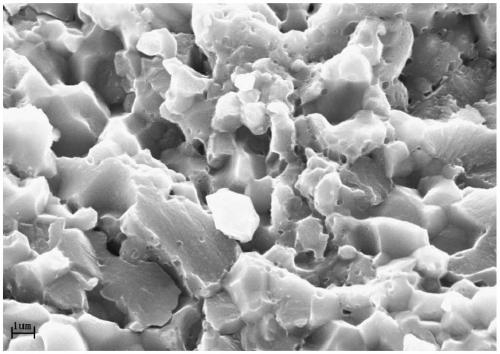

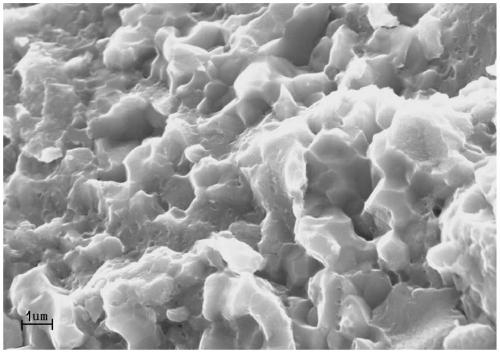

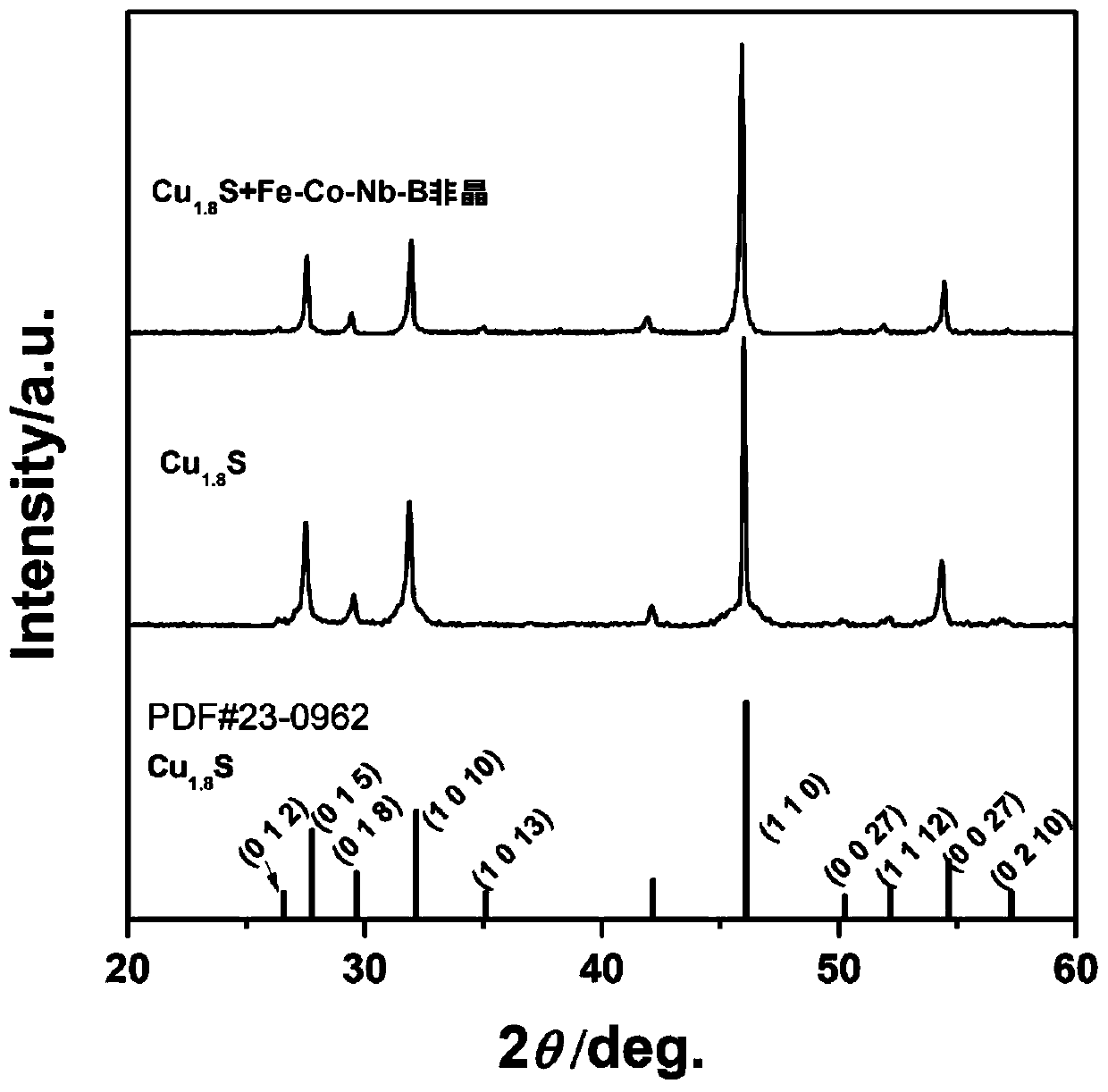

Cu1.8S-based polycrystalline-amorphous metal composite thermoelectric material and preparation method thereof

ActiveCN111244258AHigh thermoelectric figure of meritLower lattice thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBall millAmorphous metal

The invention belongs to the technical field of thermoelectric materials, and discloses a Cu1.8 S-based polycrystalline-amorphous metal composite thermoelectric material. The Cu1.8 S-based polycrystalline-amorphous metal composite thermoelectric material comprises a matrix phase Cu1.8 S and an amorphous second phase M, M is Fe-based amorphous metal, and the amorphous second phase is dispersed anddistributed in the matrix phase Cu1.8 S in the form of a nano precipitate. The preparation method comprises the following steps of carrying out ball milling on the elemental Cu powder and the elemental S powder by using a ball milling tank to obtain the Cu1.8S powder; performing ball milling on the Cu1.8S-based powder and the Fe-based amorphous metal powder to obtain the mixed powder, and sintering the mixed powder to obtain the blocky Cu1.8S-based polycrystalline-amorphous metal composite thermoelectric material. According to the invention, the problem of poor thermoelectric performance of the existing thermoelectric material is solved.

Owner:KUNMING UNIV OF SCI & TECH

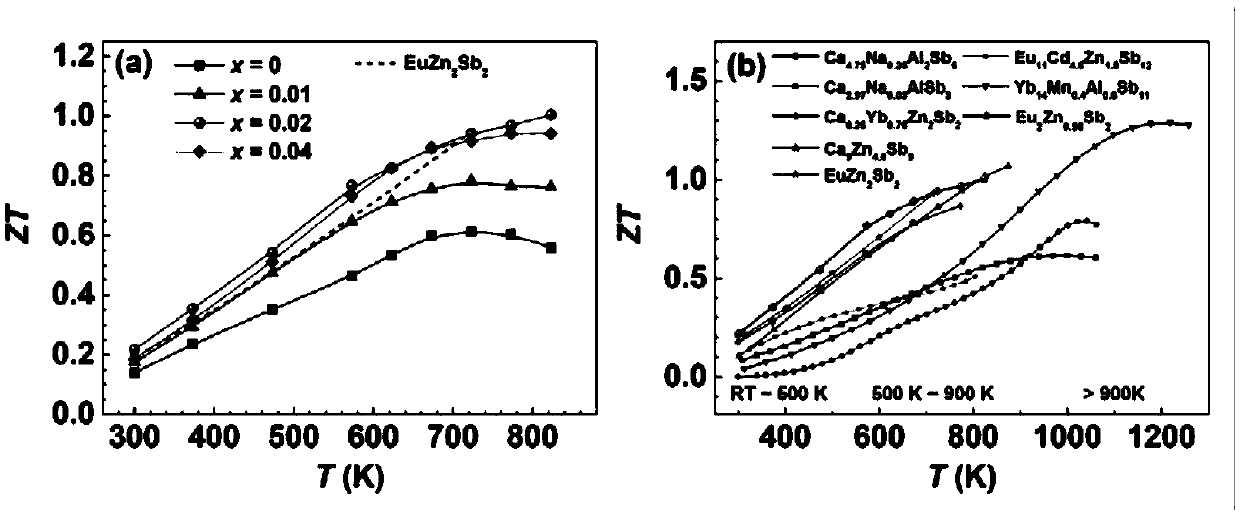

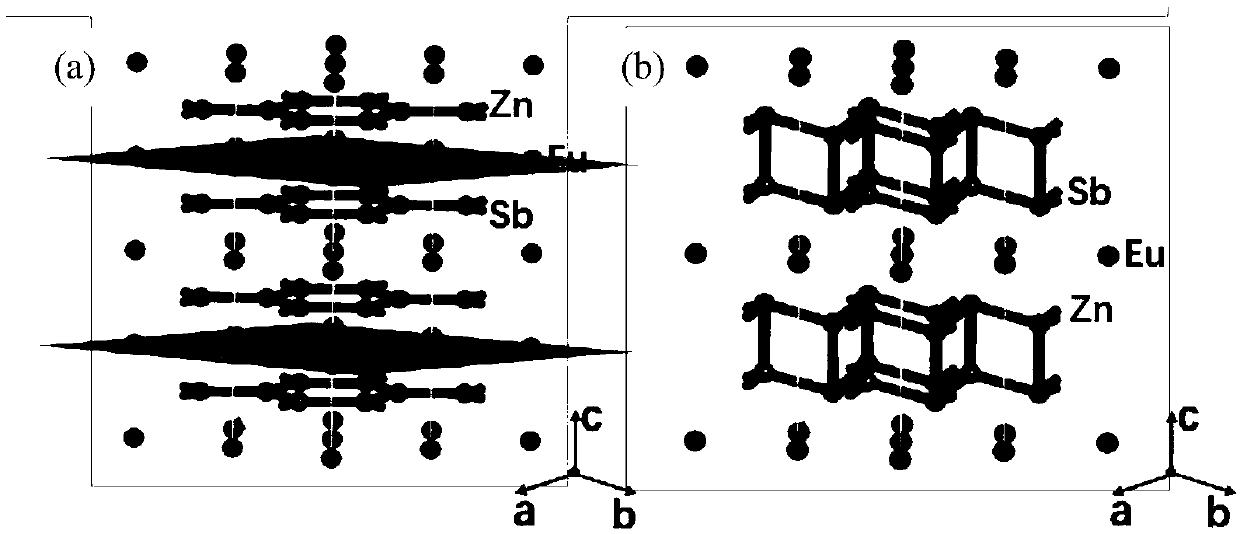

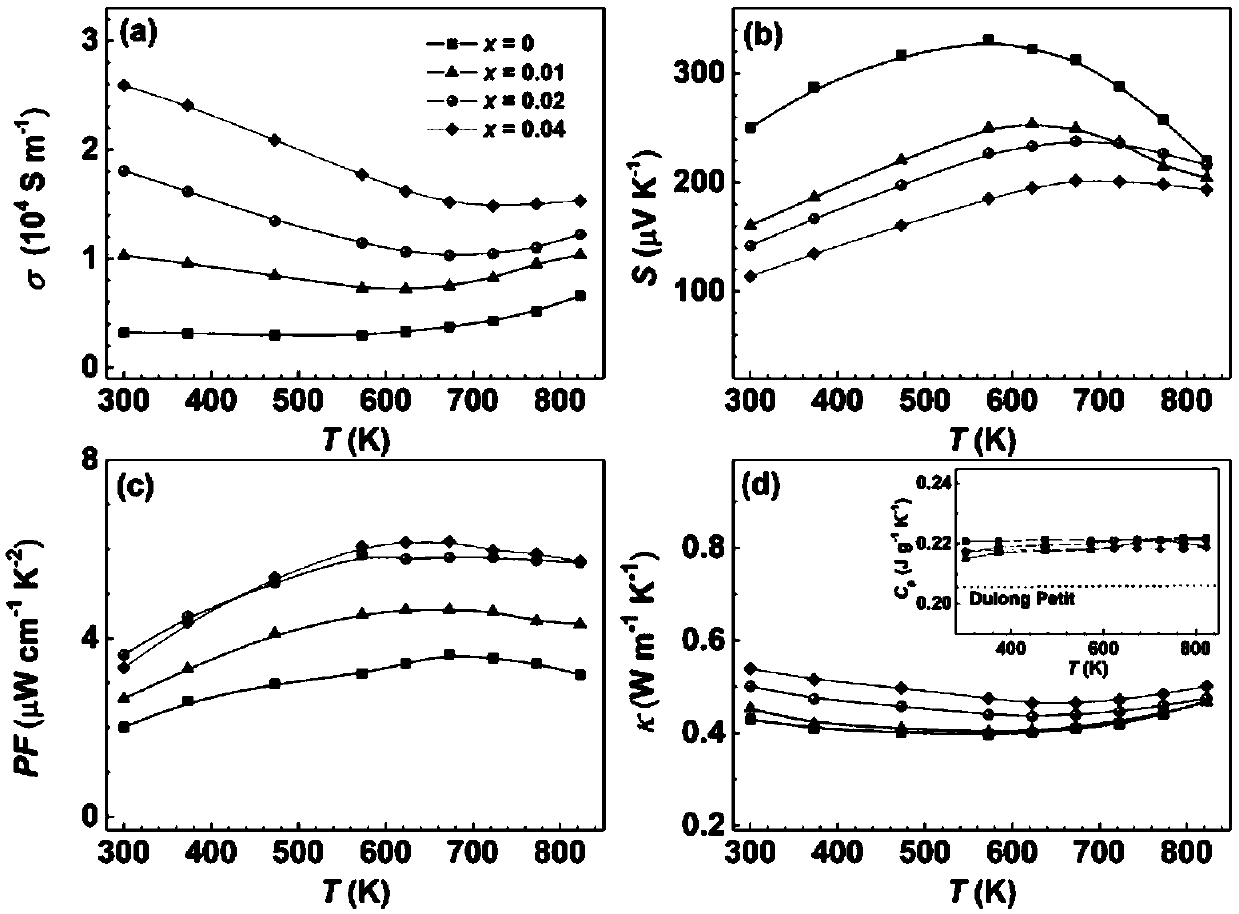

Europium-zinc-antimony-based Zintl phase thermoelectric material and preparation method thereof

ActiveCN109536821ALower lattice thermal conductivityHigh carrier mobilityAntimony compoundsChemical composition

The invention provides a europium-zinc-antimony-based Zintl phase thermoelectric material and a preparation method thereof. The chemical composition of the europium-zinc-antimony-based Zintl phase thermoelectric material is Eu2Zn(1-x)Sb2, wherein x is greater than or equal to 0 and less than or equal to 0.1. Compared with a reported 1-2-2 type europium-zinc-antimony compound, the new Eu, Zn and Sbternary compound thermoelectric material is of a completely-different crystal structure; a compound of the structure is extremely low in crystal lattice heat conductivity and high in carrier mobility; the electrical transport property can be effectively improved by adjusting the vacancy of Zn; double-pole diffusion is inhibited; and the thermoelectric performance of the material is improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

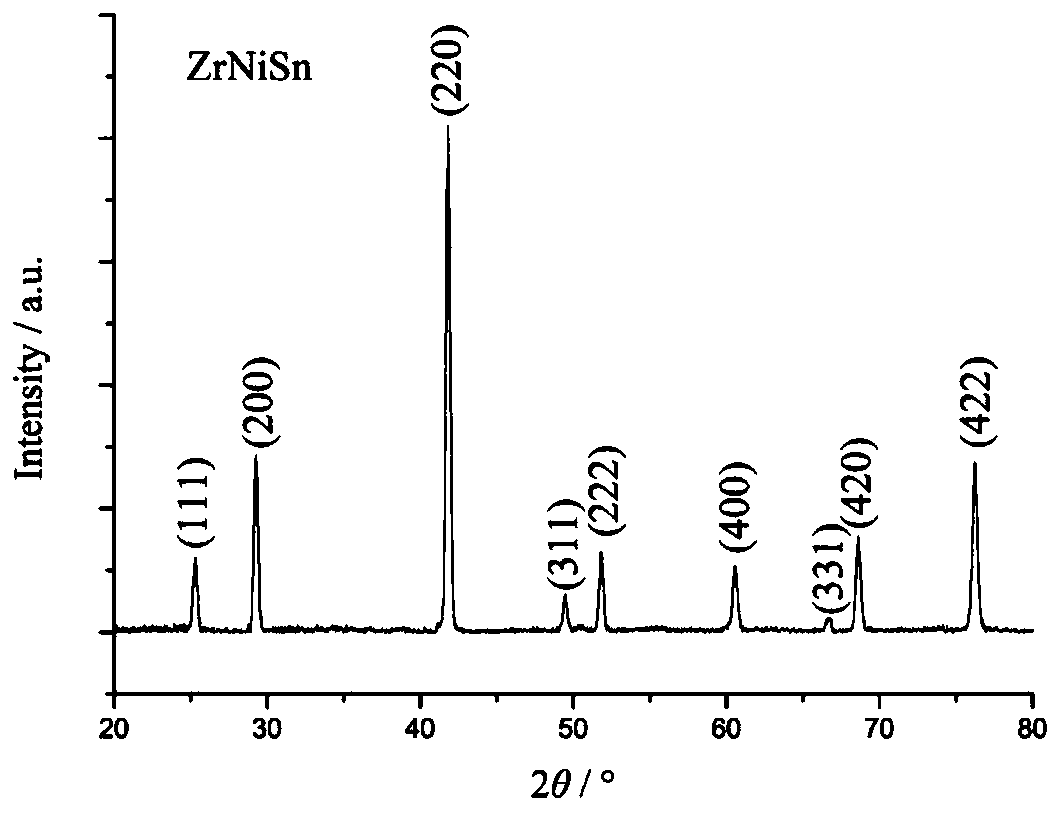

Method for rapidly preparing ZrNiSn thermoelectric material

InactiveCN110042264AShort synthesis cycleReduce energy consumptionThermoelectric device junction materialsCombustionLattice thermal conductivity

The invention provides a method for rapidly preparing ZrNiSn thermoelectric material and belongs to the technical field of thermoelectric material preparation. The method comprises the following steps: pressing mixed powder consisting of Zr powder, Ni powder and Sn powder into a green body; carrying out combustion synthesis reaction on the green body under the supergravity condition; and obtainingZrNiSn thermoelectric material after cooling. According to the method, the thermoelectric material is prepared by utilizing the combustion synthesis reaction under the supergravity condition, the material density is increased while avoiding grain growth, the heat conductivity of the crystal lattice of ZrNiSn thermoelectric material is reduced favorably, and the thermoelectric performance of the material is optimized. The result of the embodiment indicates that the the the thermoelectric figure of merit of the prepared ZrNiSn thermoelectric material can reach 0.65 at 923K. In addition, the preparation method also has the characteristics of being short in synthesis period and low in energy consumption and is suitable for large-scale industrial production.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com