Patents

Literature

30results about How to "Control stoichiometric ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

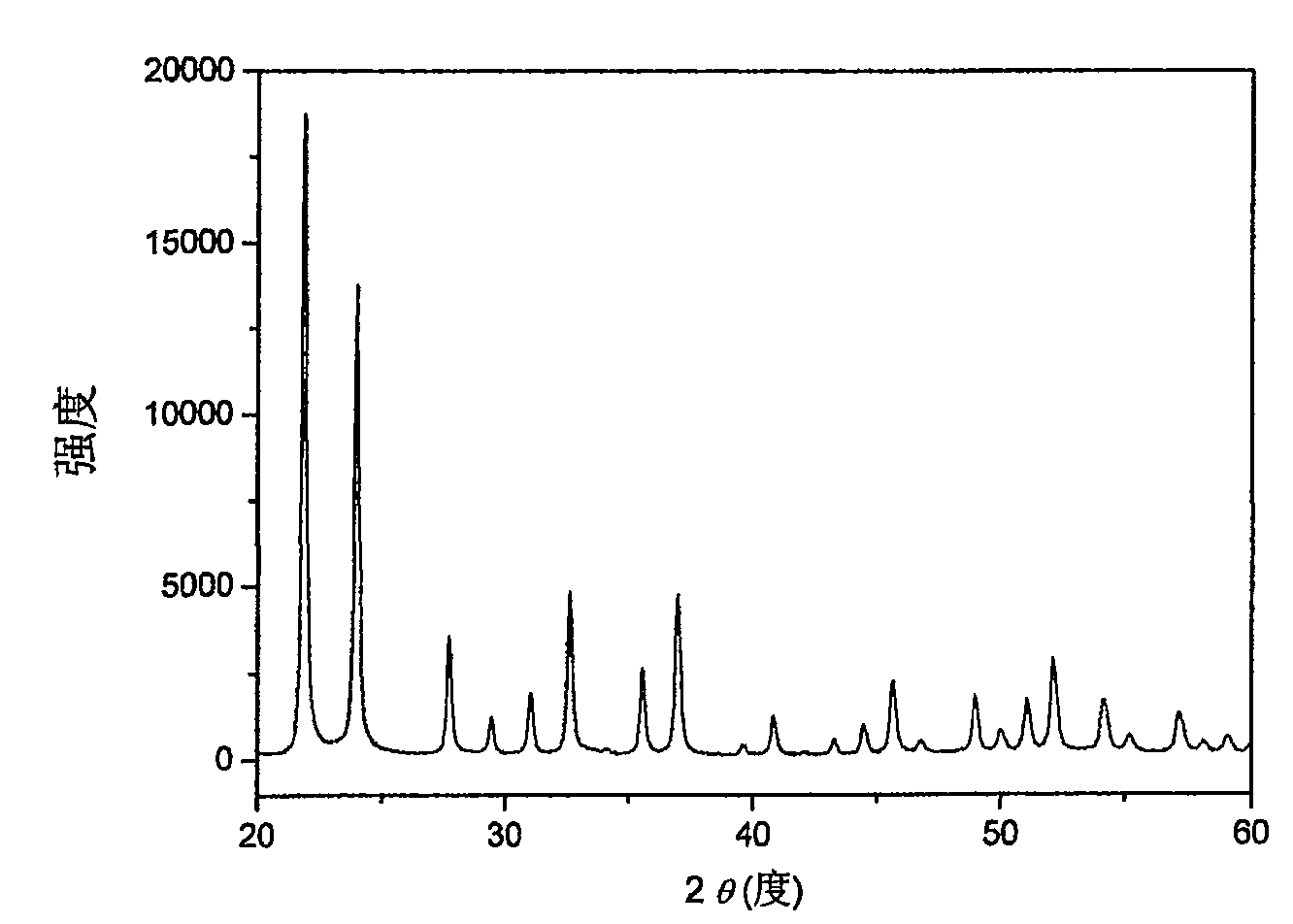

A Trace Cu-doped Bi2S3-Based Thermoelectric Material

InactiveCN102280570AControl stoichiometric ratioPrecise control of stoichiometric ratioThermoelectric device junction materialsMetallurgyElectric properties

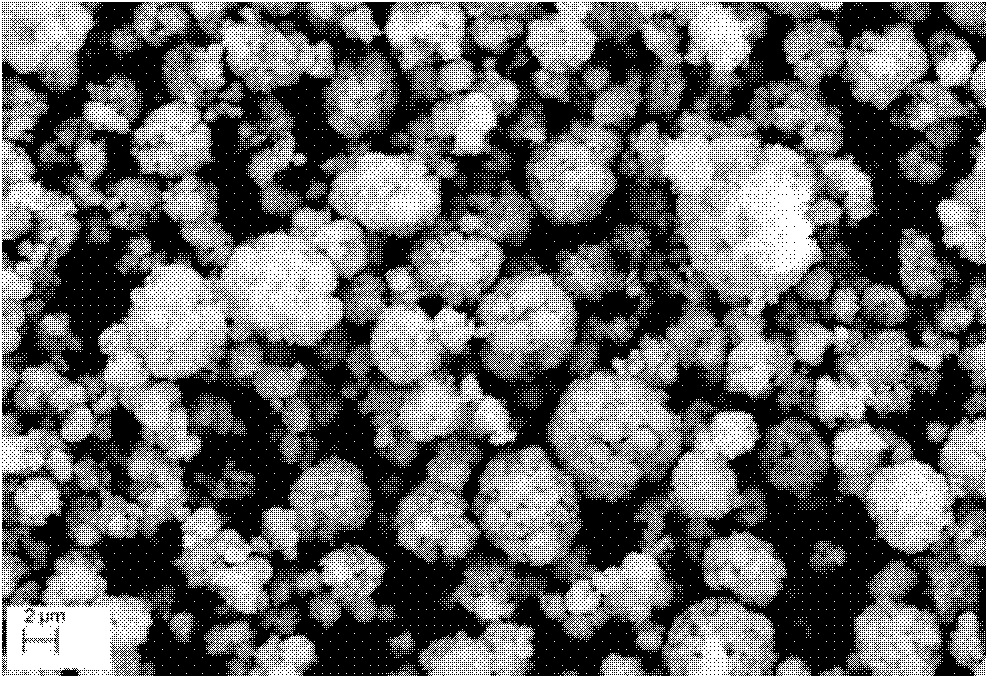

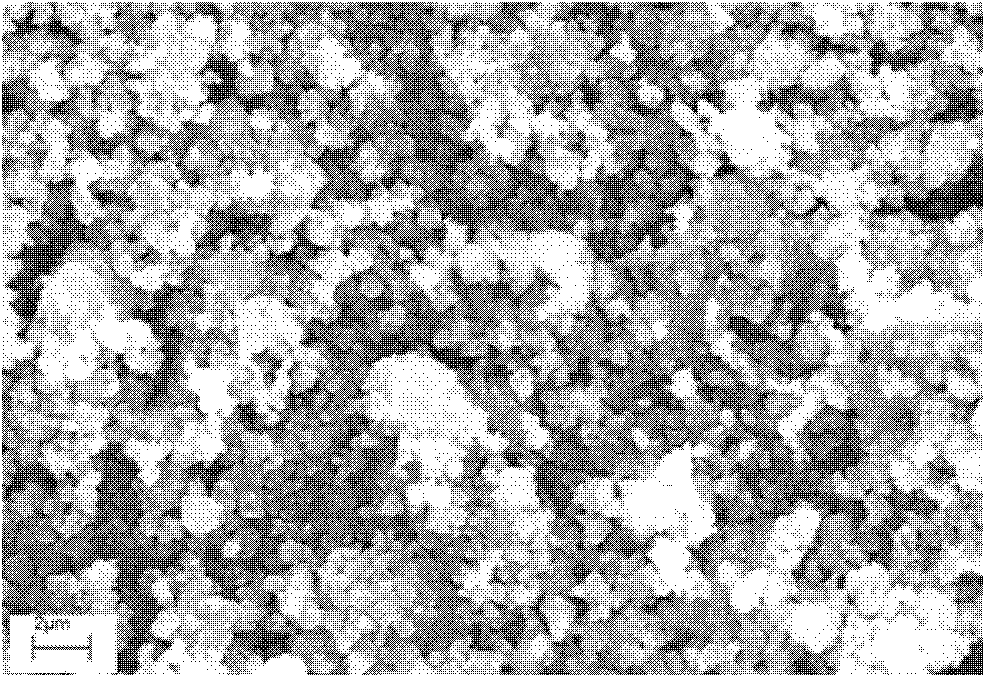

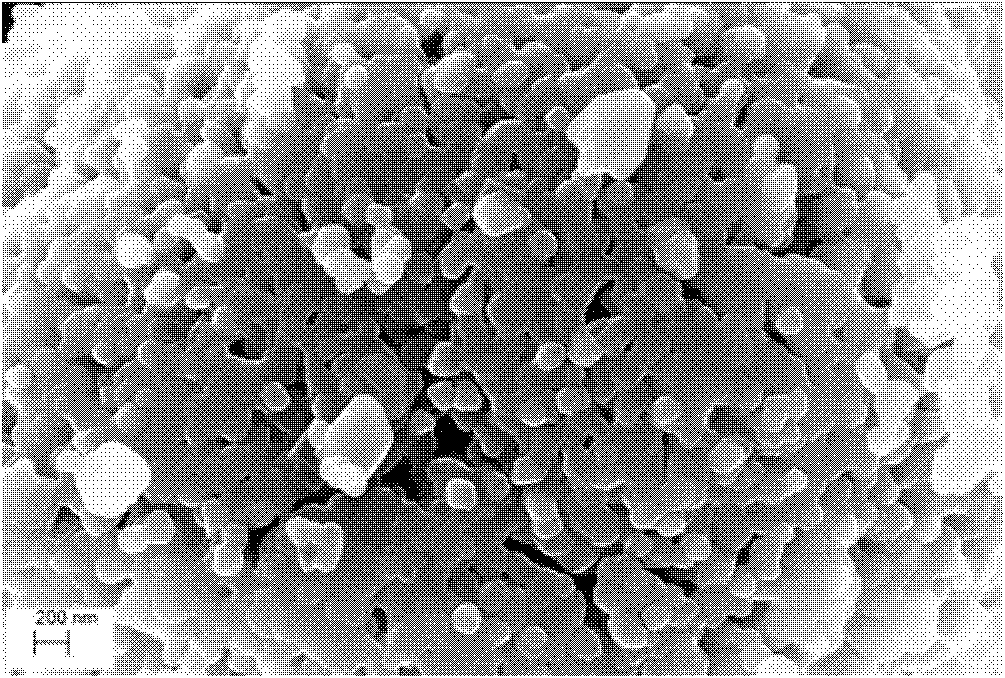

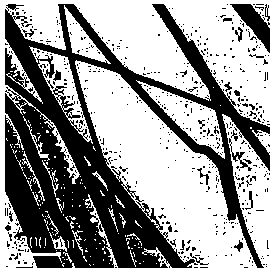

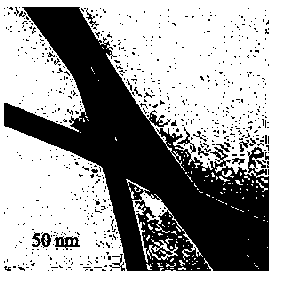

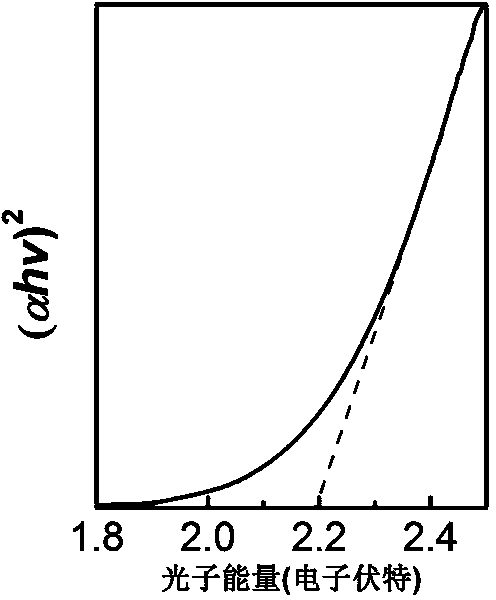

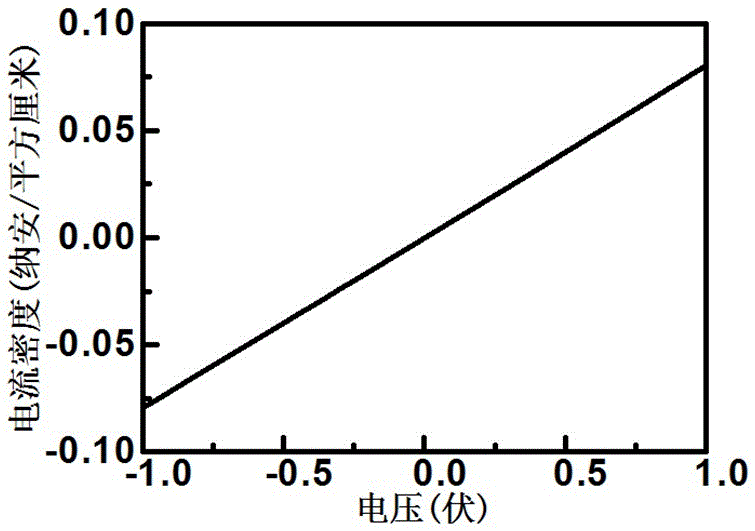

The invention belongs to the technical field of energy materials and in particular relates to a trace Cu-doped Bi2S3-based thermoelectric material. In the thermoelectric material, metal simple substance Bi and Cu powder with the purity of 99.99 percent and simple substance S powder serve as raw materials, the thermoelectric material is prepared according to a chemical general formula of CuxBi2-xS3, wherein x is mole fraction of a Cu component and x is more than or equal to 0.001 and less than or equal to 0.05, and the thermoelectric material is prepared into a block material by combining a discharge plasma sintering technology and a mechanical alloying method. By the method, the trace Cu-doped Bi2S3-based block thermoelectric material can be easy and convenient to prepare, trace Cu is introduced into a Bi2S3 lattice, the carrier concentration of a sample is improved, a power factor is optimized, a Cu-S nano deposition coherent with a substrate structure is formed, and the thermal conductivity is greatly reduced; therefore, the thermoelectric performance of the Bi2S3-based block material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

Gasoline selective hydrodesulfurization catalyst and preparation and application thereof

ActiveCN106268976AReduce usageControl stoichiometric ratioCatalyst activation/preparationRefining to eliminate hetero atomsUltrasonic assistedHydrodesulfurization

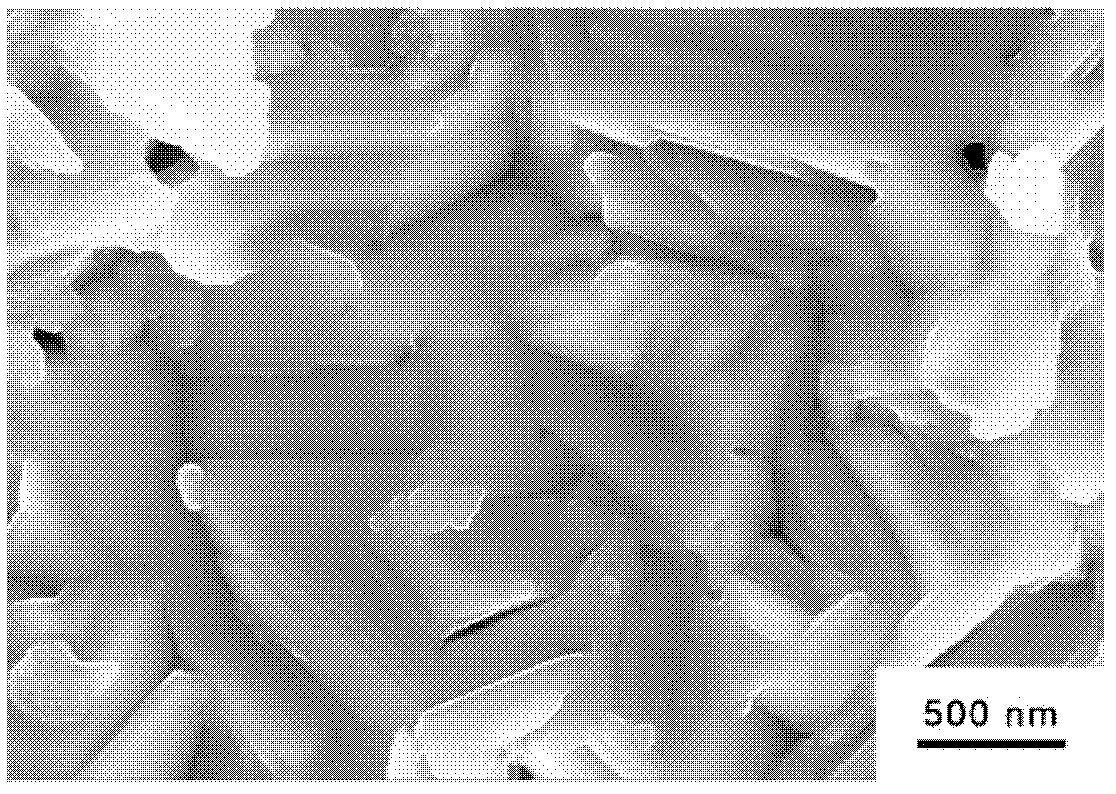

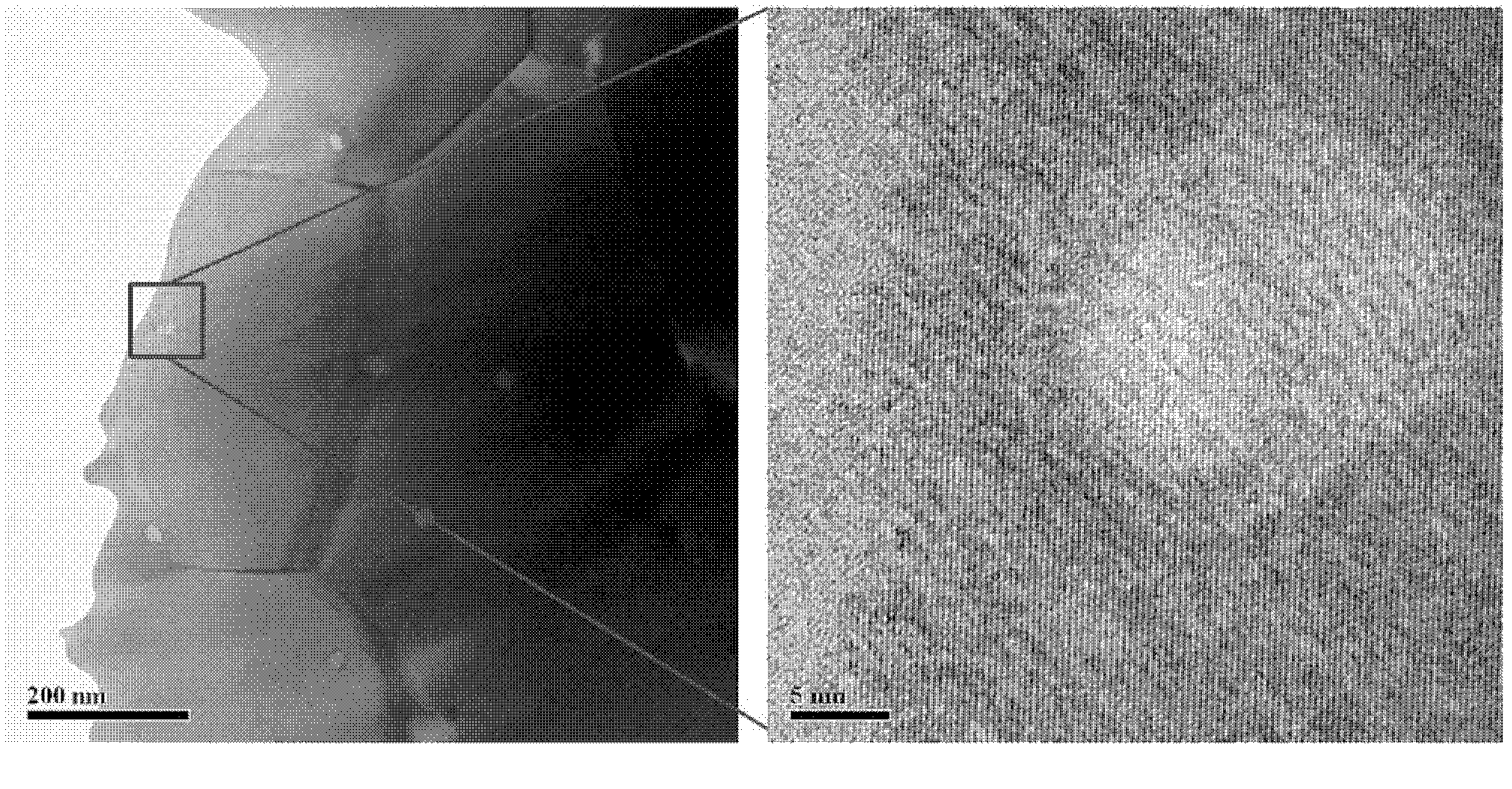

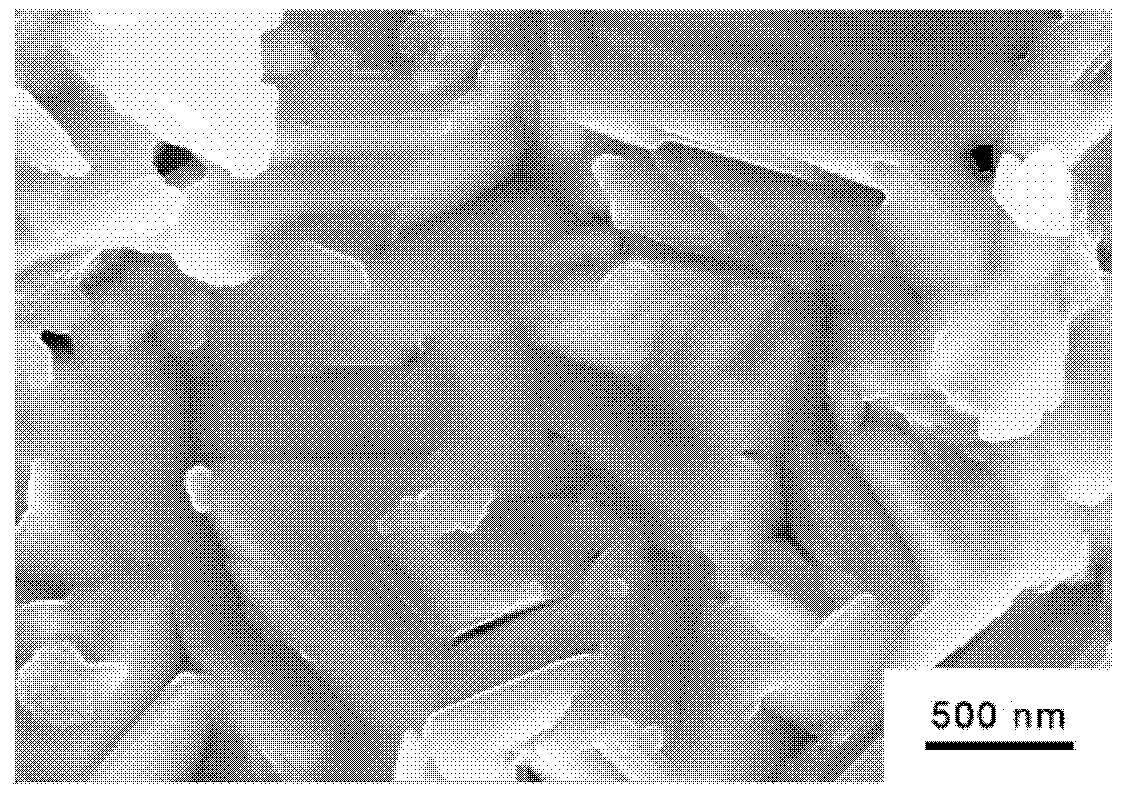

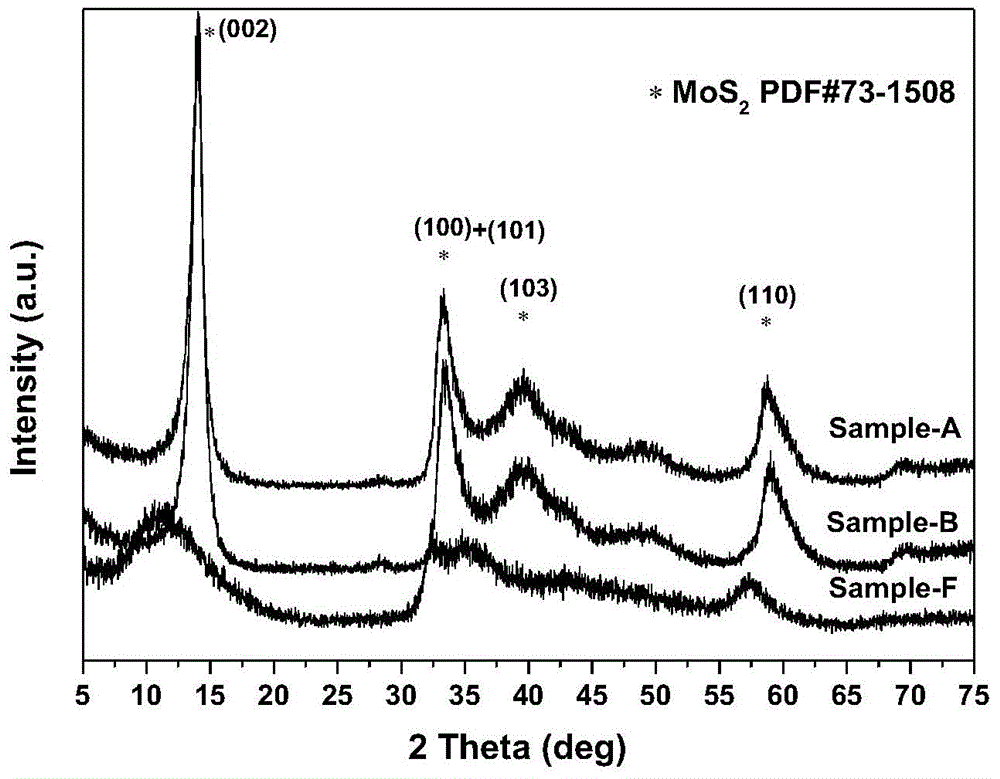

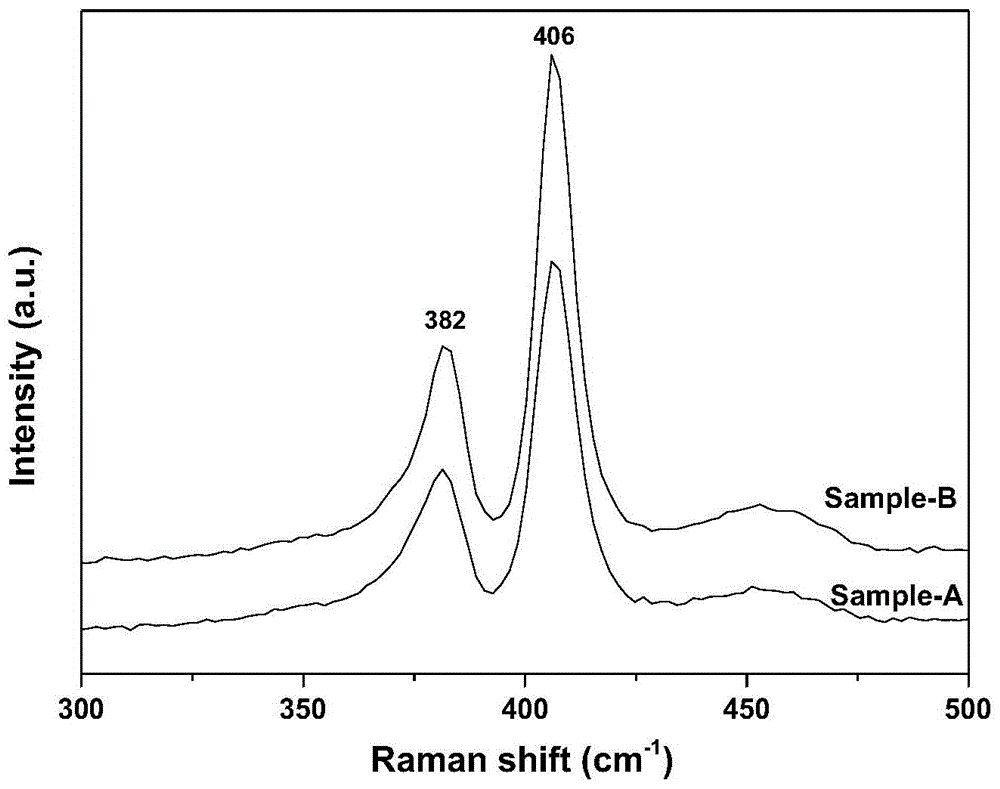

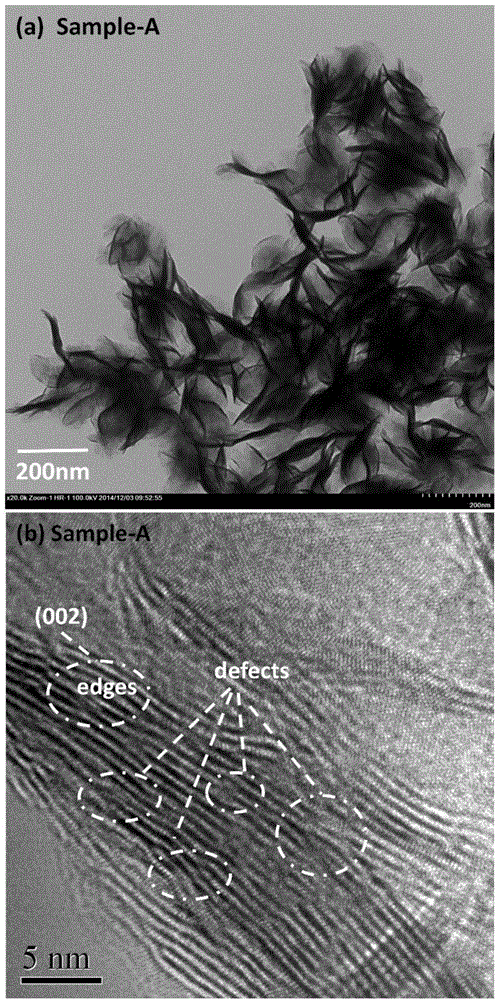

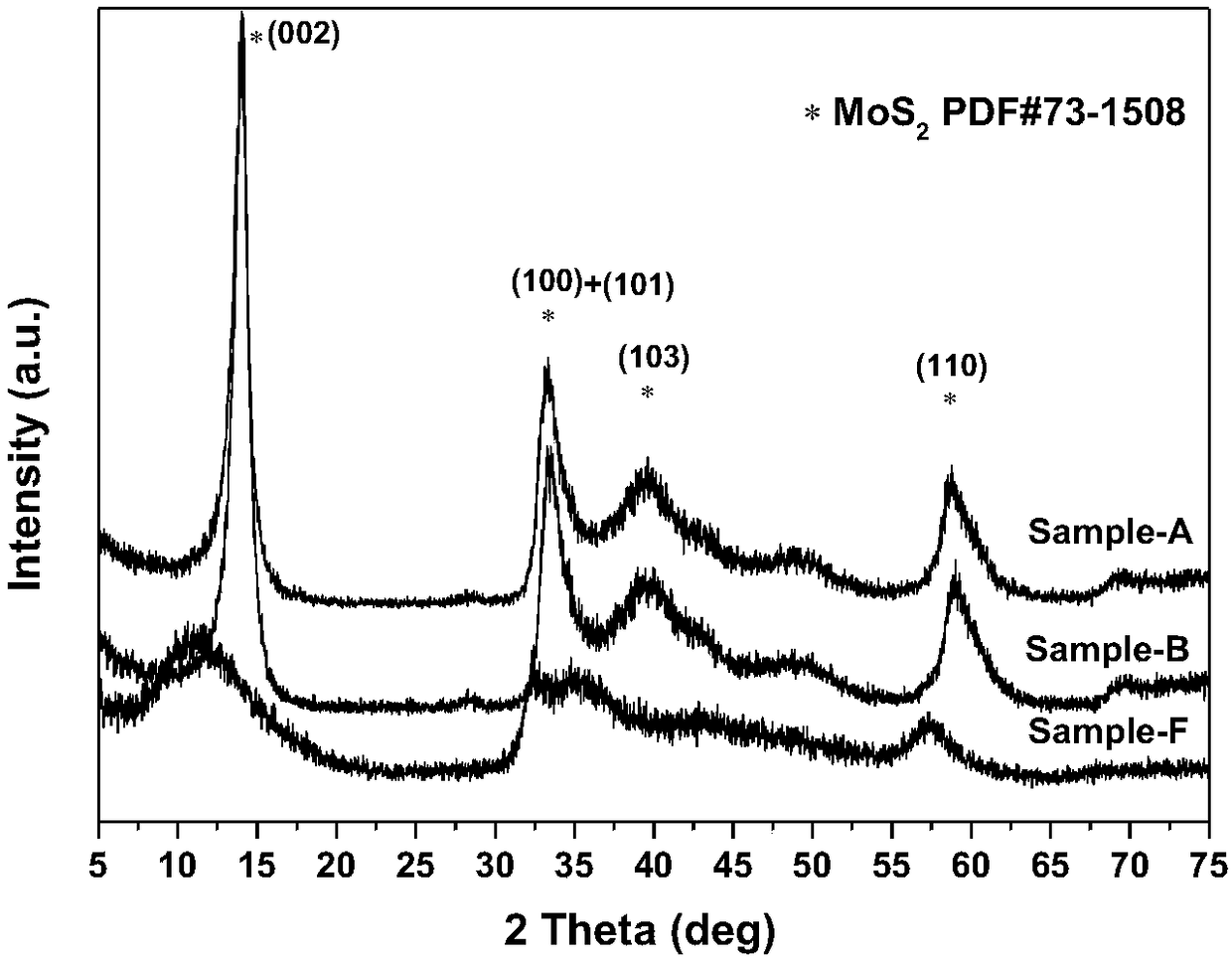

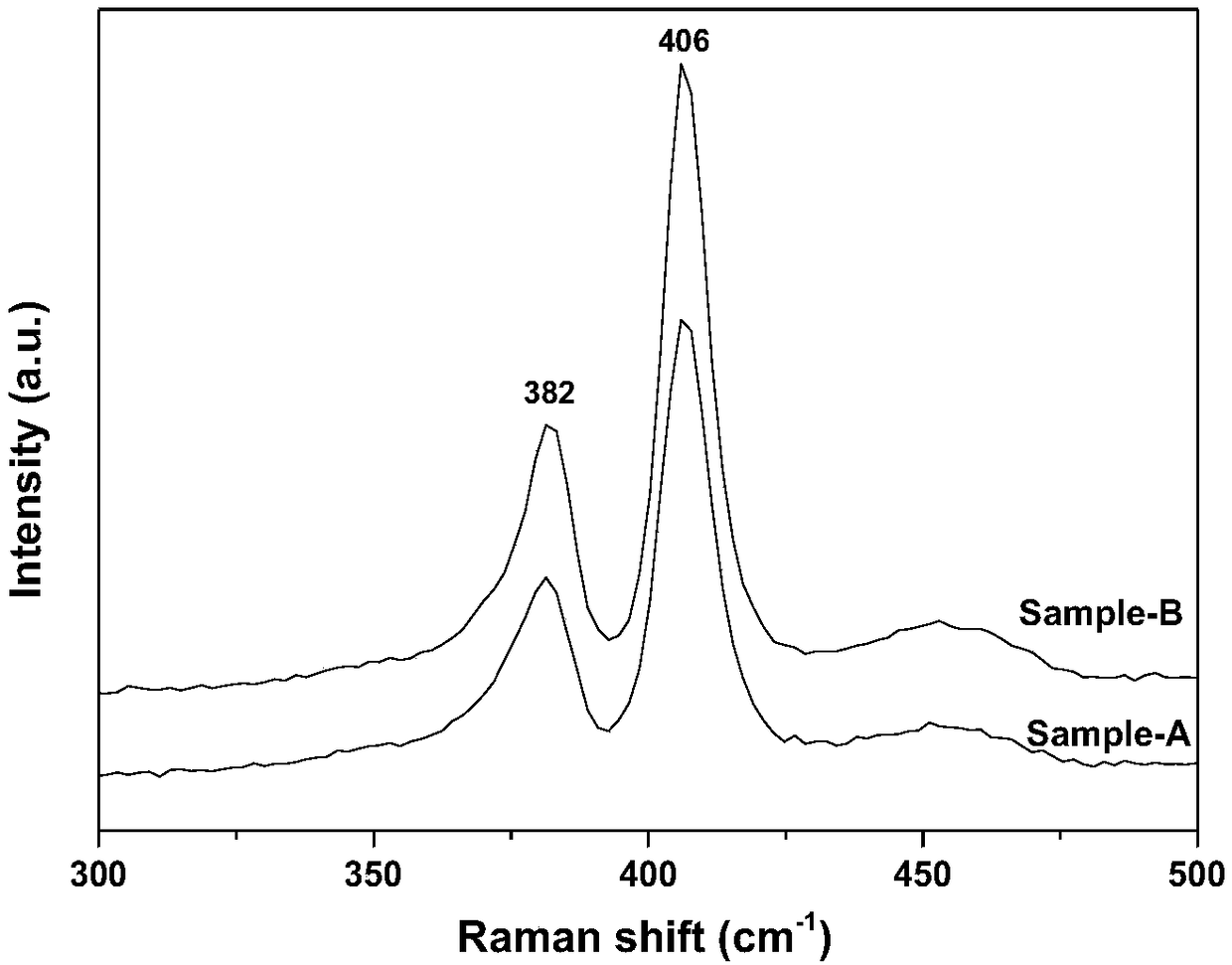

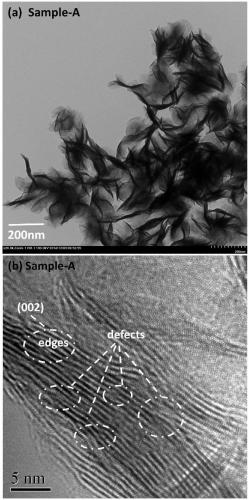

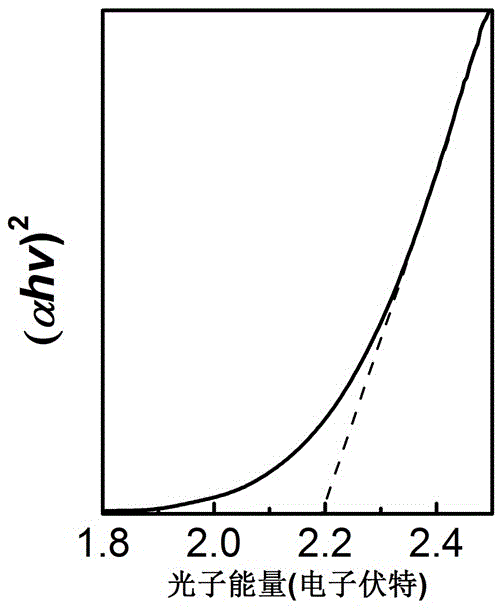

The invention relates to a gasoline selective hydrodesulfurization catalyst and preparation and application thereof. According to the total mass of the catalyst being 100%, the catalyst is prepared from 3-15 wt% of VIII group metal, 45-58 wt% of Mo and 35-40 wt% of S. A preparation method of the catalyst comprises the following steps that 1, a defect-rich molybdenum disulfide nanosheet precursor with a non-stoichiometric ratio is prepared; 2, one kind of VIII group metal is added into the molybdenum disulfide nanosheet precursor through an ultrasonic assisting dipping method, the molar ratio of the VIII group metal to Mo is (0.1-0.5):1, the specific surface area of the molybdenum disulfide nanosheet precursor ranges from 40 m<2> / g to 90 m<2> / g, the pore volume ranges from 0.1 ml / g to 0.25 ml / g, and the molar ratio of sulfur to molybdenum is (1.92-2.10):1. Defect-rich molybdenum disulfide is prepared by controlling the stoichiometric ratio of molybdenum disulfide, and meanwhile more active loci are exposed. Compared with an existing catalyst, the catalyst is applied to a gasoline selective hydrodesulfurization reaction, the hydrogenation saturation factor of olefin is low, and the hydrodesulfurization rate of a sulfur-containing compound is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

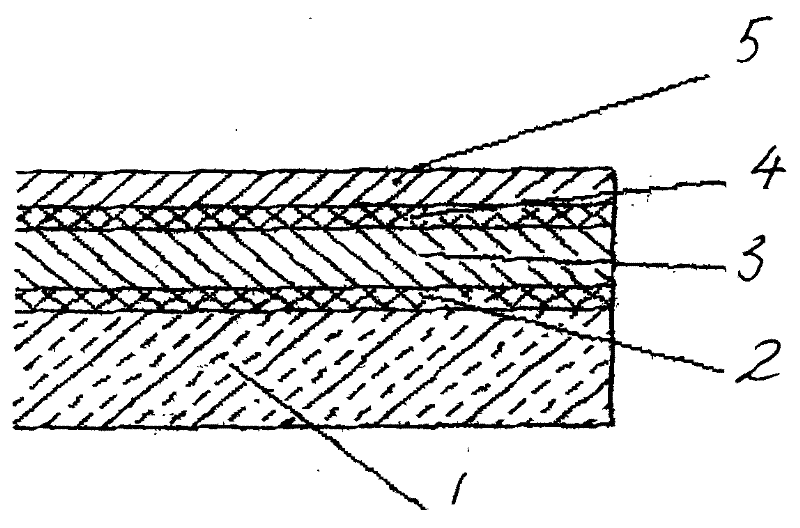

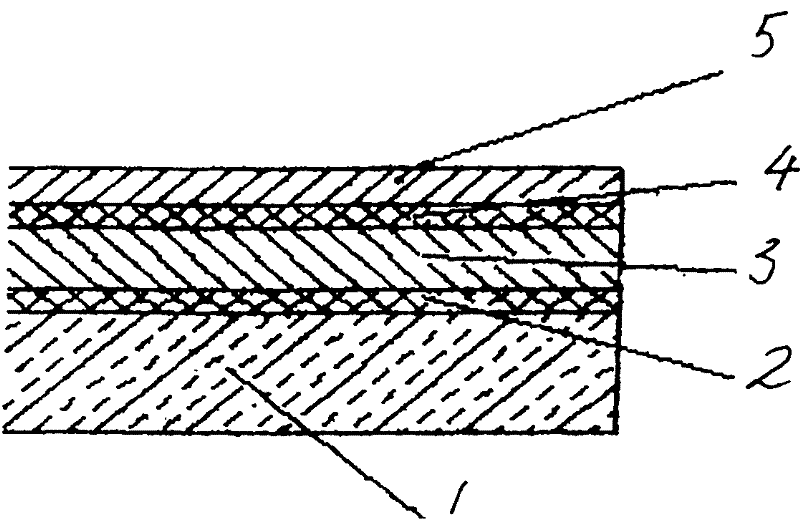

Weather-resistant silver mirror and preparation method thereof

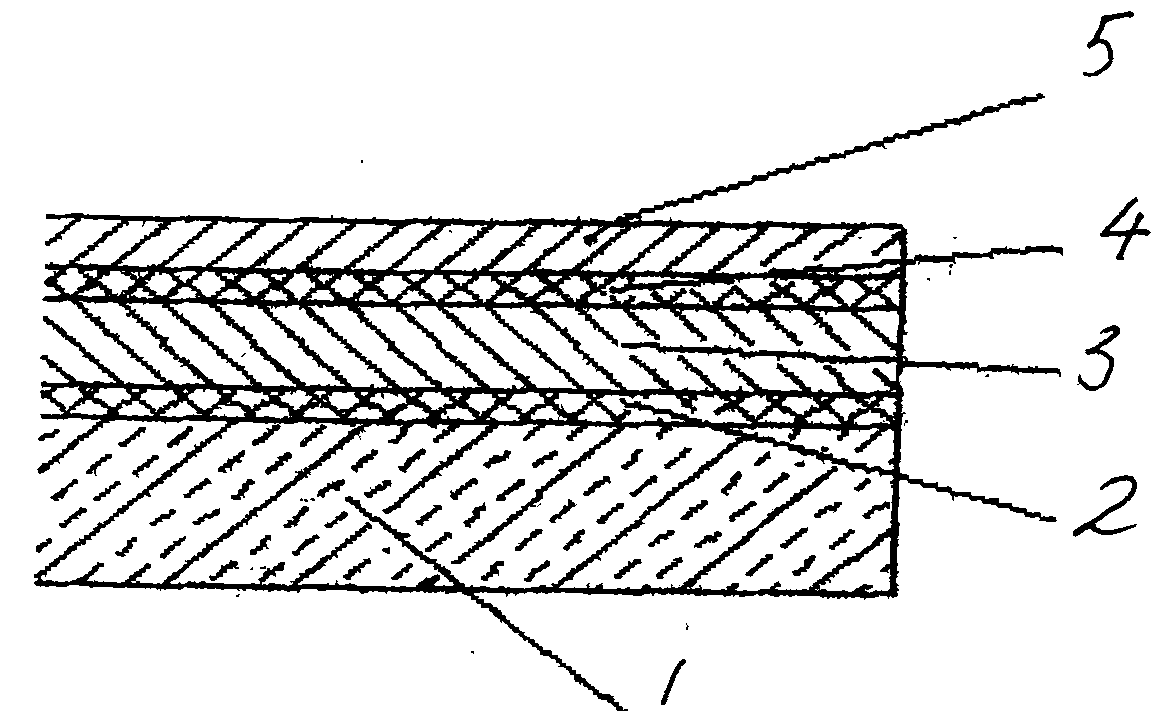

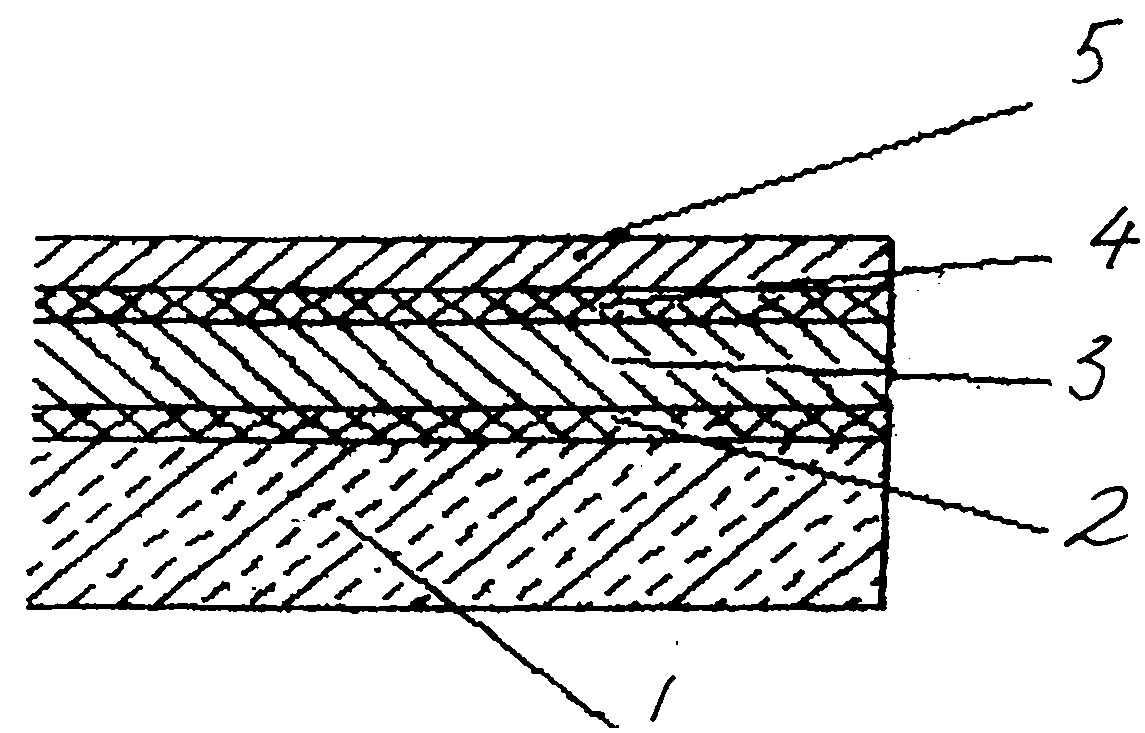

ActiveCN101776778AImprove reliabilityExtended service lifeMirrorsIntermediate frequencyReflective layer

The invention discloses a weather-resistant silver mirror which is particularly suitable for trough solar thermal power generation and a preparation method thereof. The silver mirror orderly consists of a transparent substrate, a first Al2O3 adhesive layer, an Ag reflective layer, a second Al2O3 adhesive protective layer and a SiOx protective layer. The preparation method thereof comprises the step of orderly and respectively plating the first Al2O3 adhesive layer, the Ag reflective layer, the second Al2O3 adhesive protective layer and the SiOx protective layer by adopting a multi-target intermediate frequency response vertical magnetic control sputter to prepare the weather-resistant silver mirror of the invention. The finished product of the weather-resistant silver mirror of the invention has the characteristics of high reflectivity, reliable work, long service life and the like. The preparation method of the invention has the characteristics of advance, reasonability, low cost, low energy consumption, good quality of the finished product and the like.

Owner:常州龙腾光热科技股份有限公司

Improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction

ActiveCN102219262APromote growthSimple processCell electrodesManganese oxides/hydroxidesMANGANESE ACETATEOXALIC ACID DIHYDRATE

The invention provides an improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction. The method comprises the following steps: weighing lithium hydroxide monohydrate, nickel acetate and manganese acetate, and oxalic acid dihydrate according to the stoichiometry as follows: Li1+xMnyNi1-x-yO2, x being more than 0 and less than or equal to 1 / 3, y being more than 0 and less than 1, and x+y being more than 0 and less than 1 (wherein the mole ratio of LiOH.H2O to C2H2O4.2H2O is 1:1-1.2), and adding into a ball milling tank together for balling milling for 0.5-2h; obtaining slurry, adding deionized water in the slurry to adjust concentration, spraying and drying the slurry, and roasting the dried powder to obtain the final product -Li1+xMnyNil-x-yO2. The improved method has the following advantages: the process flow is short, the component of the material can be accurately controlled, the problems of material loss and inaccurate stoichiometry caused by repeatedly washing the product in a liquid phase method are overcome, the generation of a large quantity of waste water is avoided; simultaneously, the shape and particle size of a synthesized material can be controlled, the engineering index requirement can be achieved, the impurity pollution caused by dependence of a synthetic material by a solid phase method on crushing process can be overcome, the enriched lithium-manganese-nickel oxide has typical layered structure property, the particle size is 3-12mum, the specific capacity is high, and the cyclic performance is stable.

Owner:湖南金富力新能源股份有限公司

Preparation method of lithium titanate

ActiveCN103290426AControl stoichiometric ratioParticle size is easy to controlElectrolysis componentsElectrolysisElectrical battery

The invention discloses a preparation method of lithium titanate. The preparation method is characterized by comprising the following steps of: combining TiO2 powder which is wrapped by using a carbon source or is mixed by using a carbon material or a tabletting with a metal current collector so as to be used as a cathode; by taking graphite as an anode and taking a molten alkali halide as an electrolyte, electrolyzing for 1-5 hours in an argon atmosphere at an electrolysis temperature of 400-700 DEG C under an electrolysis voltage of 2.0-3.2V, cooling down to be the normal temperature and taking out, subsequently washing in distilled water or an organic solvent, and drying in vacuum so as to obtain LiTiO2 which is wrapped by using the carbon source or is mixed by using the carbon material; washing an electrolysis product, drying the electrolysis product in vacuum, and subsequently firing for 1-3 hours at 600-900 DEG C in air so as to obtain Li4Ti5O12. By utilizing the method, product grain size controllability is realized, and the problems of product batch stability and consistence caused by in-scale production are solved. The lithium titanate prepared by using the method can be used as an energy material to be directly applied to lithium ion secondary batteries and super-capacitors.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

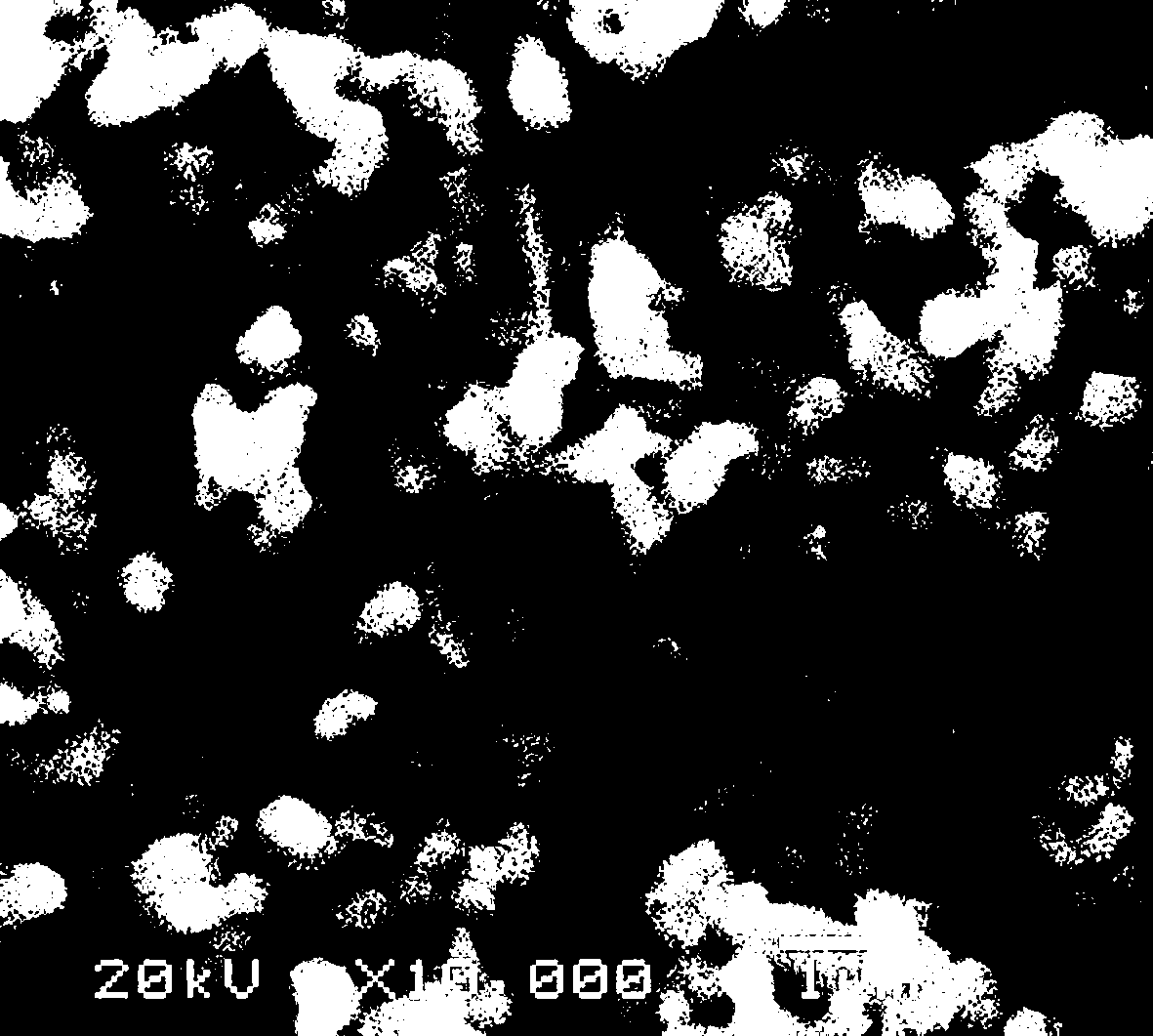

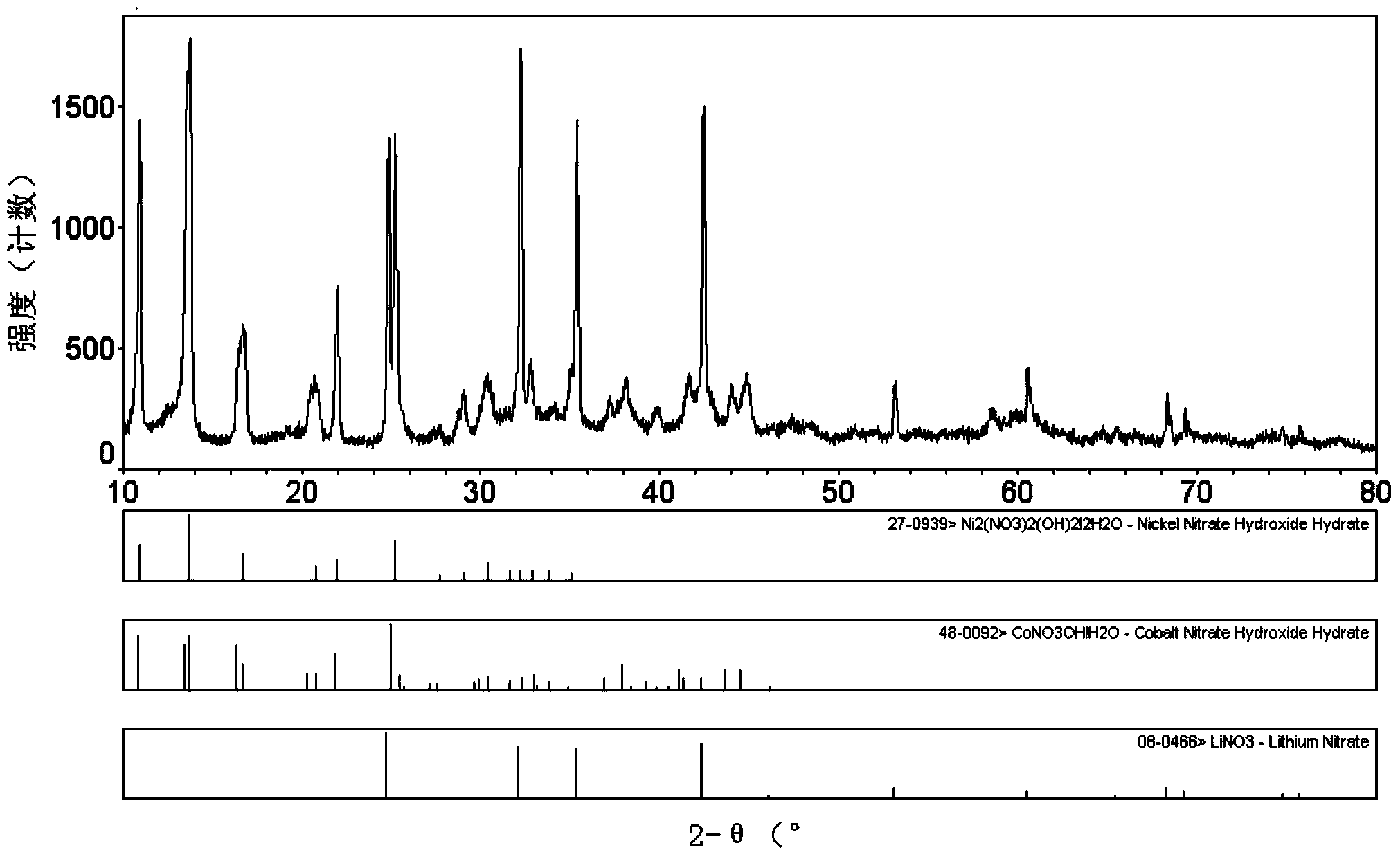

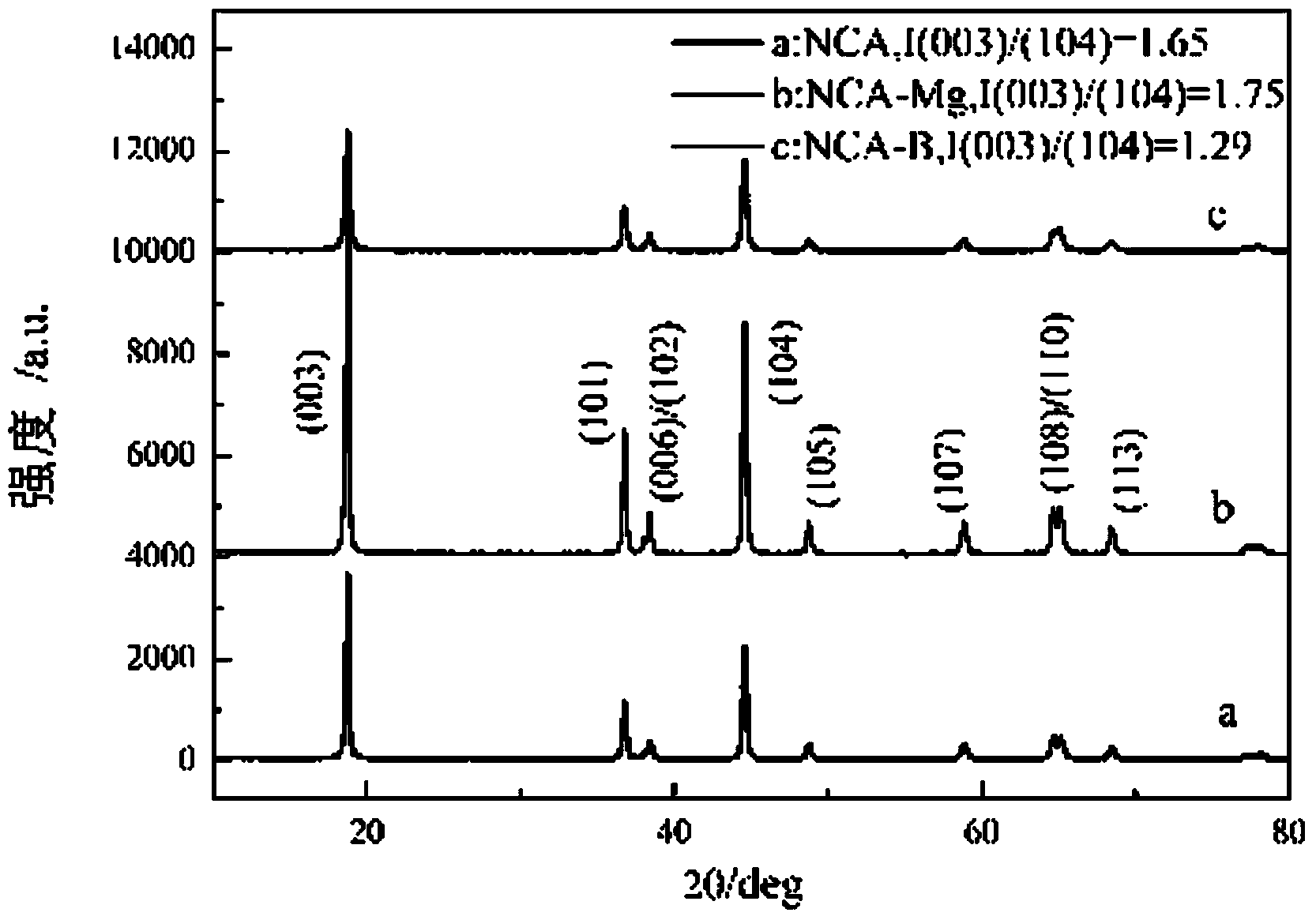

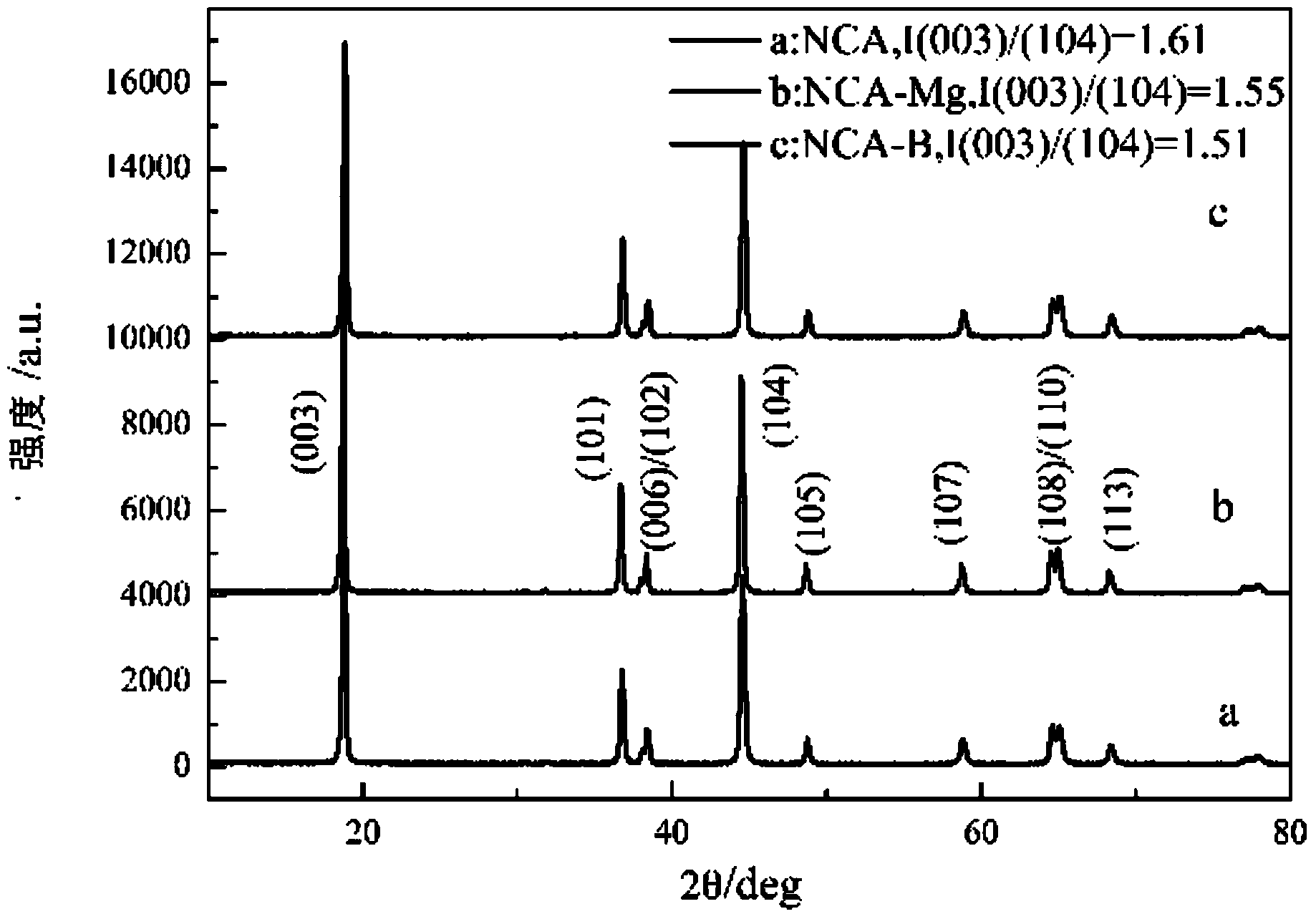

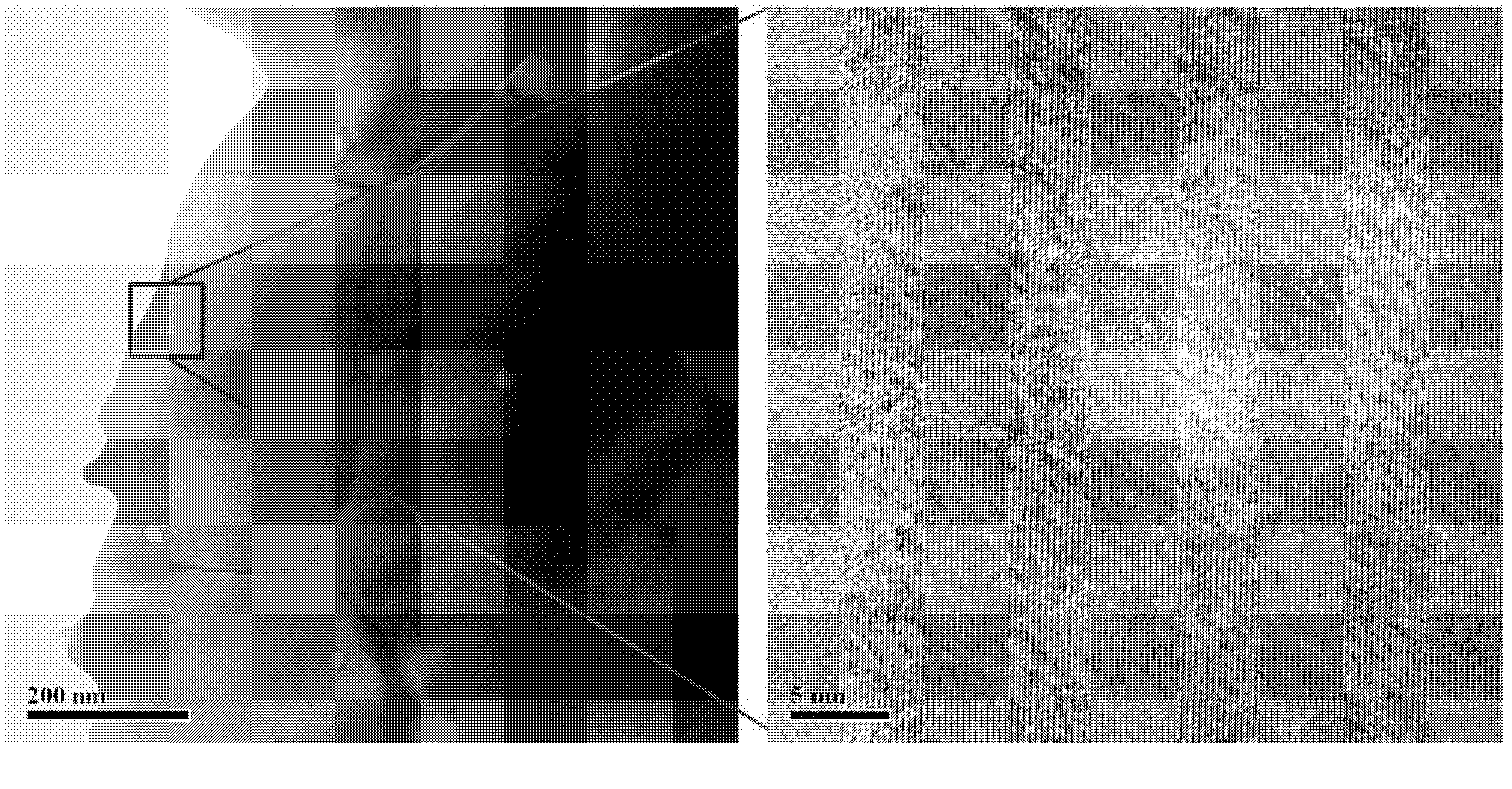

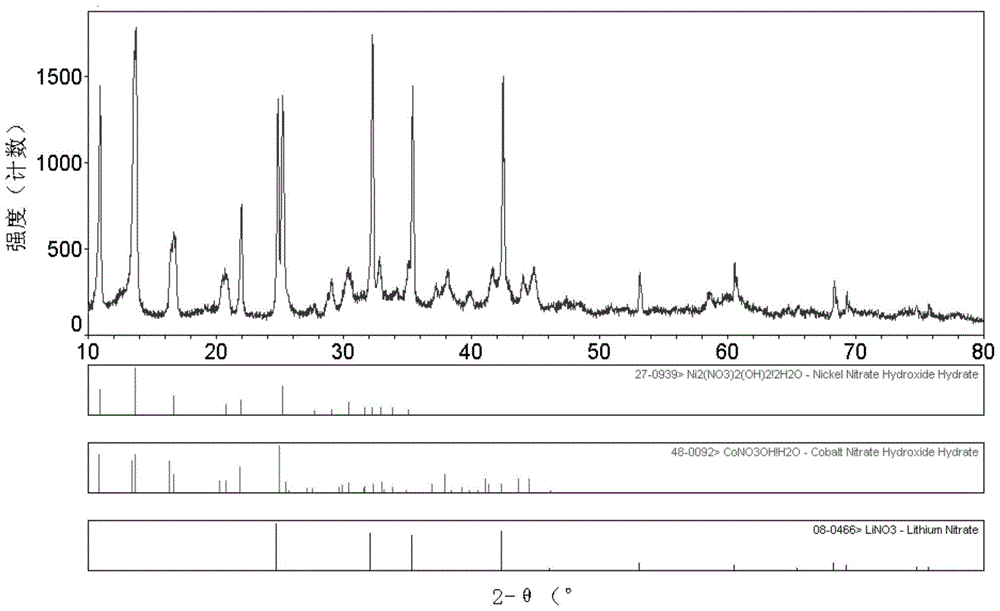

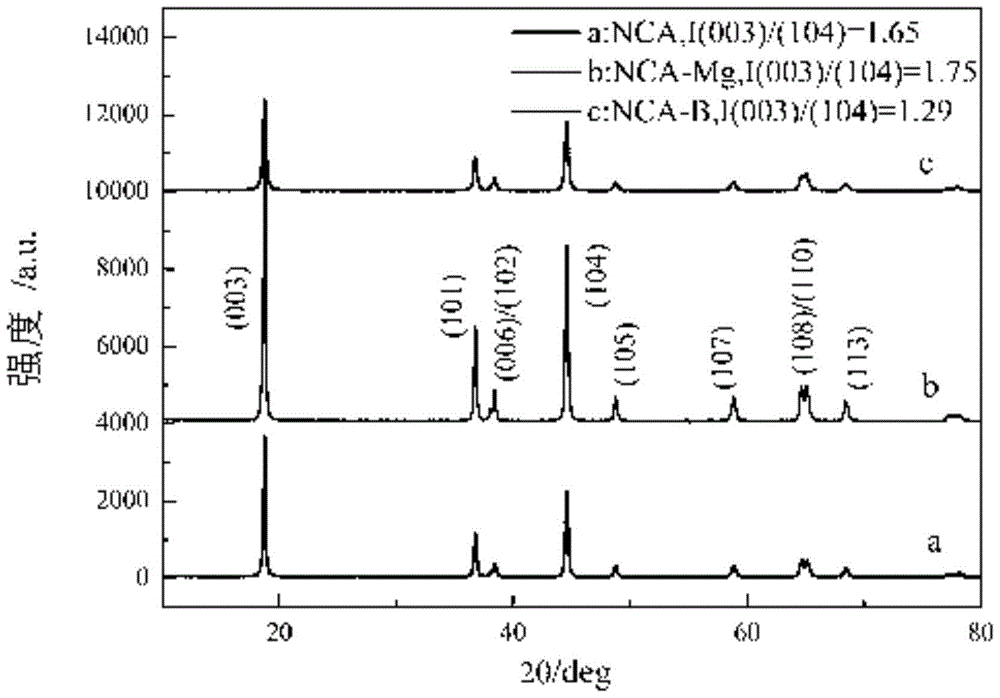

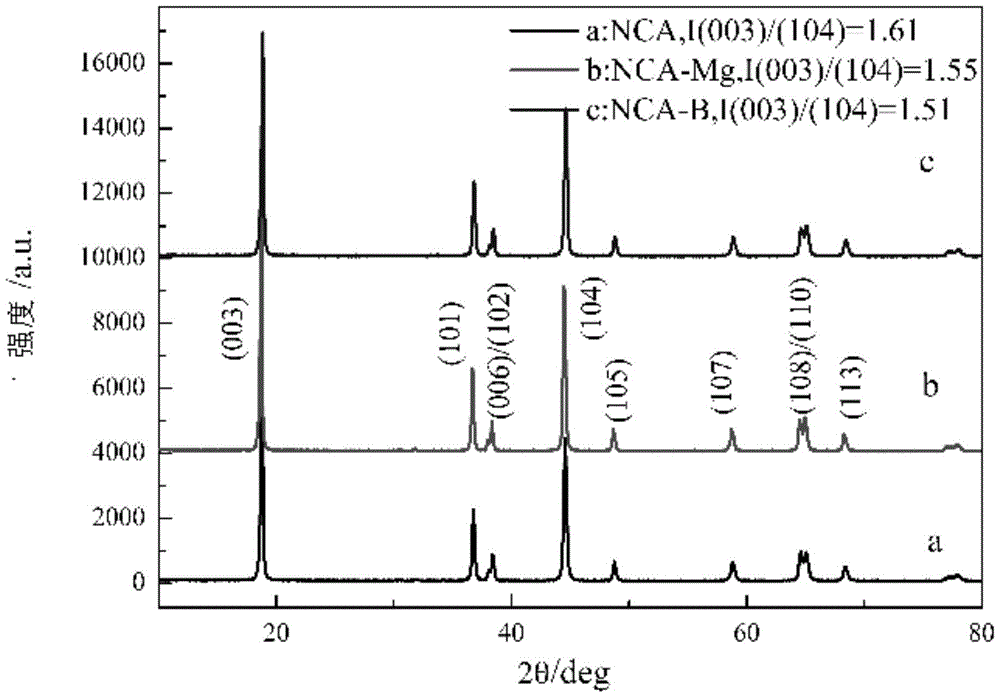

Method for preparing lithium-nickel-cobalt-aluminium oxide material by adopting low-heat solid-phase reaction

ActiveCN103943850AControl stoichiometric ratioWell mixedCell electrodesSecondary cellsAir atmosphereChemical measurement

The invention discloses a method for preparing a lithium-nickel-cobalt-aluminium oxide material by adopting low-heat solid-phase reaction. The method comprises the following steps: a. preparing a precursor, namely weighing lithium hydroxide monohydrate, nickel nitrate hexahydrate, cobalt nitrate hexahydrate, lithium nitrate nonahydrate and a doping element M according to stoichiometry of LiNi(0.8)Co(0.15)Al(0.05+ / -x)M(y)O(2), wherein x is greater than or equal to 0 and is less than or equal to 0.05, y is greater than or equal to 0 and is less than or equal to 0.05, x+y is equal to 0.05, M is B, Zr, Ti or AlPO4, mixing in a high-speed mixer at the rotating speed of 2000r / m for 15 minutes according to a stoichiometric ratio so as to obtain a synthesized material, and drying the synthesized material at the temperature of 120-150 DEG C in vacuum so as to prepare the precursor; and b. roasting the precursor prepared in the step a at the temperature of 600-800 DEG C in an oxygen atmosphere or an air atmosphere so as to obtain the final product-lithium-nickel-cobalt-aluminium oxide material. The method has the following advantages that the stoichiometric ratio of the components is relatively easy to control, the components are uniformly mixed, the synthesis temperature can also be reduced, and the energy consumption and the production cost are reduced.

Owner:山东天骄新能源有限公司

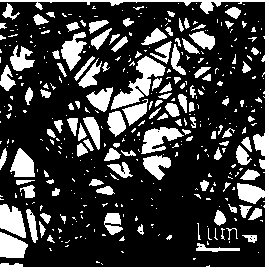

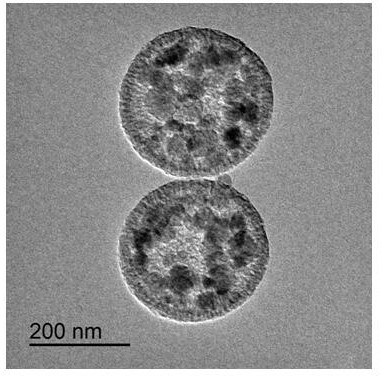

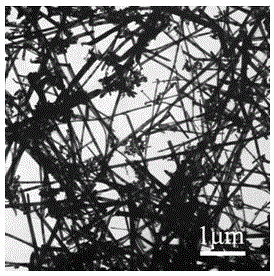

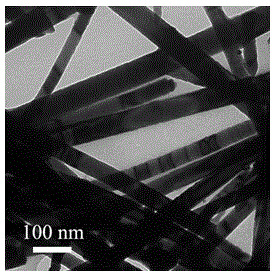

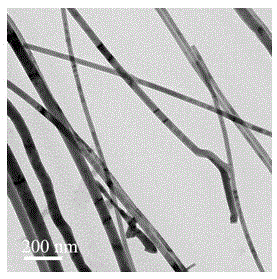

Preparation method of CIST nano wire

ActiveCN104064628AReductivePrevent oxidationMaterial nanotechnologyFinal product manufactureIndiumTrioctylphosphine

A preparation method of a CIST nano wire belongs to the technical field of new-generation thin-film solar cell materials. A toluene solution of Bi nanoparticles and a precursor solution of Se and Te are prepared separately. Then under the protection of nitrogen, trioctylphosphine is heated and added into the toluene solution of the Bi nanoparticles, and then the precursor solution containing indium acetate, copper acetate and Se is added into the mixture. After reactions, the precursor solution containing indium acetate, copper acetate and Se is added drop by drop. After reactions are completed, the mixture is cooled and toluene is added. Then the mixture is subjected to centrifugation. The solid phase is taken, is washed with toluene, and is subjected to centrifugation and vacuum drying. Then the CIST nano wire is obtained. The method uses the metal Bi nanoparticles as a catalyst. The toluene solution of the Bi nanoparticles is used, so that the concentration of the Bi nanoparticles can be effectively controlled, and the liquid form facilitates taking the catalyst. The method is simple in technique, can effectively control the stoichiometric ratio of multi-component materials, and obtains a large batch of high-purity CIST nano wires.

Owner:YANGZHOU UNIV

Film formation method of n-type In2S3 buffer layer and application of film formation method of n-type In2S3 buffer layer

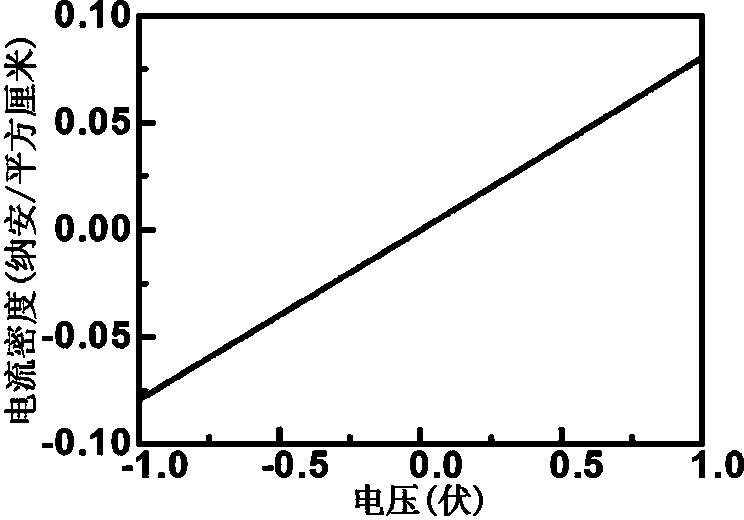

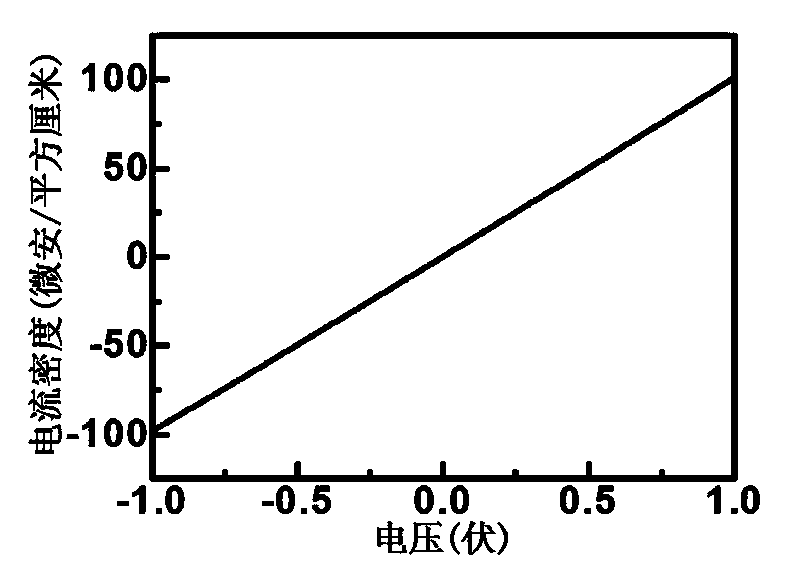

ActiveCN104269461AGood electrical conductivityControl stoichiometric ratioFinal product manufactureVacuum evaporation coatingElectrical batterySolar cell

The invention relates to a new film formation method of an n-type In2S3 buffer layer and application. According to the film formation method and the application, the shortcomings in the prior art for manufacturing the In2S3 buffer layer are overcome. The film formation method includes the steps of manufacturing an In2S3 cake, manufacturing an In2S3 target material block, manufacturing In2S3 thin film, conducting annealing, and obtaining the n-type indium sulfide buffer layer with the electrical resistivity smaller than or equal to 5*10<-3>Ohm cm. By means of a solar cell obtained by a product of the new film formation method, the open-circuit voltage is 0.29 V, and the short-circuit current is 7.7 nA. The new film formation method has the advantages that the film formation method and the product are good in thin film uniformity coincidence, good in conductivity, stable in chemical constitution, free of environmental pollution and the like.

Owner:黄山市开发投资集团有限公司

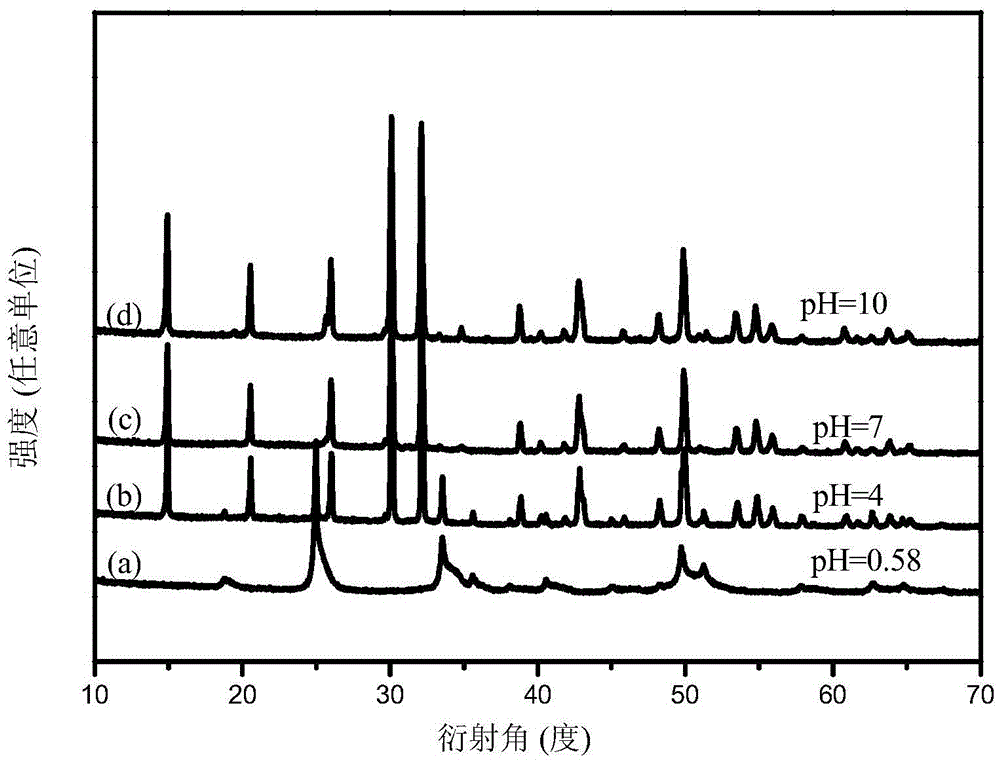

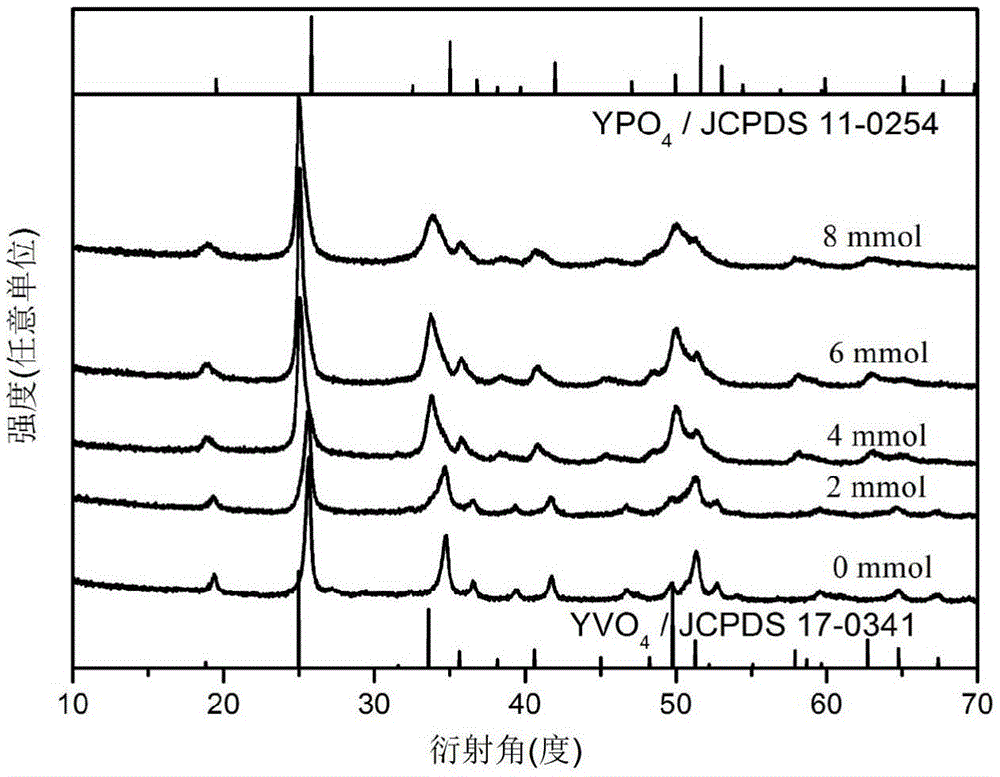

Preparation method of yttrium phosphate vanadate europium-doped or samarium-doped luminescent microspheres

InactiveCN105419800ASignificant technological progressLow reaction temperatureLuminescent compositionsYttriumPhosphate

The invention provides a preparation method of yttrium phosphate vanadate europium-doped or samarium-doped luminescent microspheres. The method comprises the steps of firstly, compounding yttrium oxide and europium oxide or samarium oxide into nitric acid solutions; mixing the yttrium nitrate solution with the europium nitrate solution (or the samarium nitrate solution); adding a complexing agent to an obtained mixed solution, and conducting stirring at the normal temperature of 25 + / - 1 DEG C; stirring NH<4>VO<3>, nitric acid, NH<4>H<2>PO<4> and water, obtaining a clear light-yellow solution, adding the obtained mixed turbid solution to the light-yellow solution, adjusting pH with nitric acid and ammonia water, conducting stirring and mixing, obtaining a yellow turbid solution, transferring the yellow turbid solution into a hydro-thermal reaction kettle for a hydro-thermal reaction, conducting cooling, centrifugation and washing after the hydro-thermal reaction is ended, and obtaining the yttrium phosphate vanadate europium-doped or samarium-doped luminescent microspheres. The preparation method has the advantages of being low in reaction temperature, low in equipment requirement and simple in operation, and the obtained yttrium phosphate vanadate europium-doped or samarium-doped luminescent microspheres are controllable in morphology and good in luminescence property.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

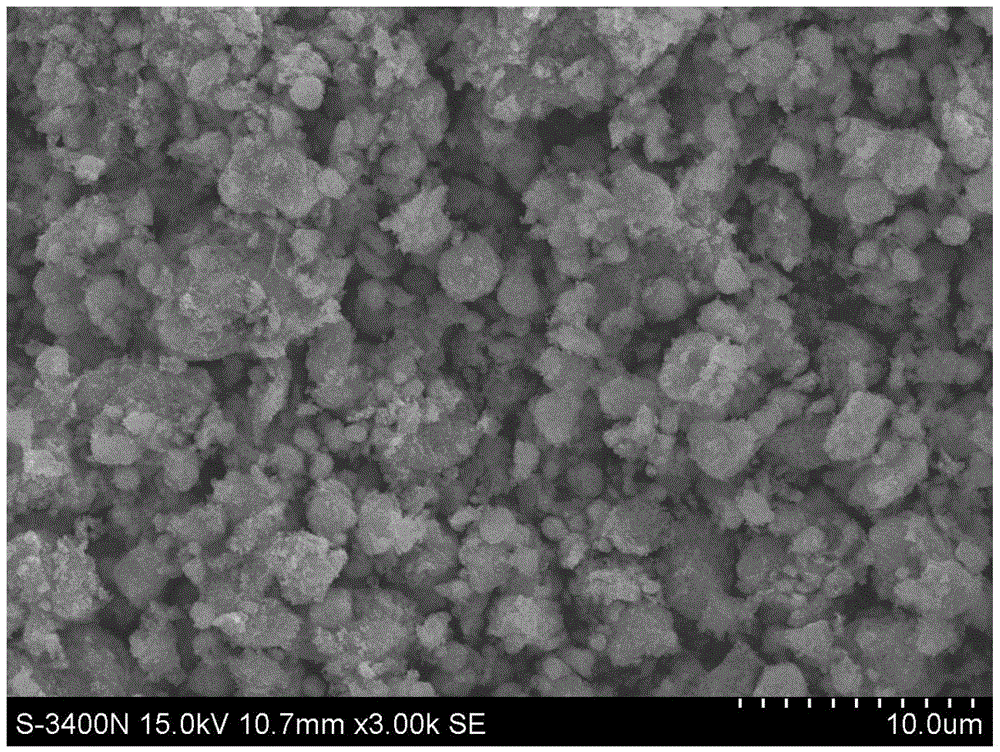

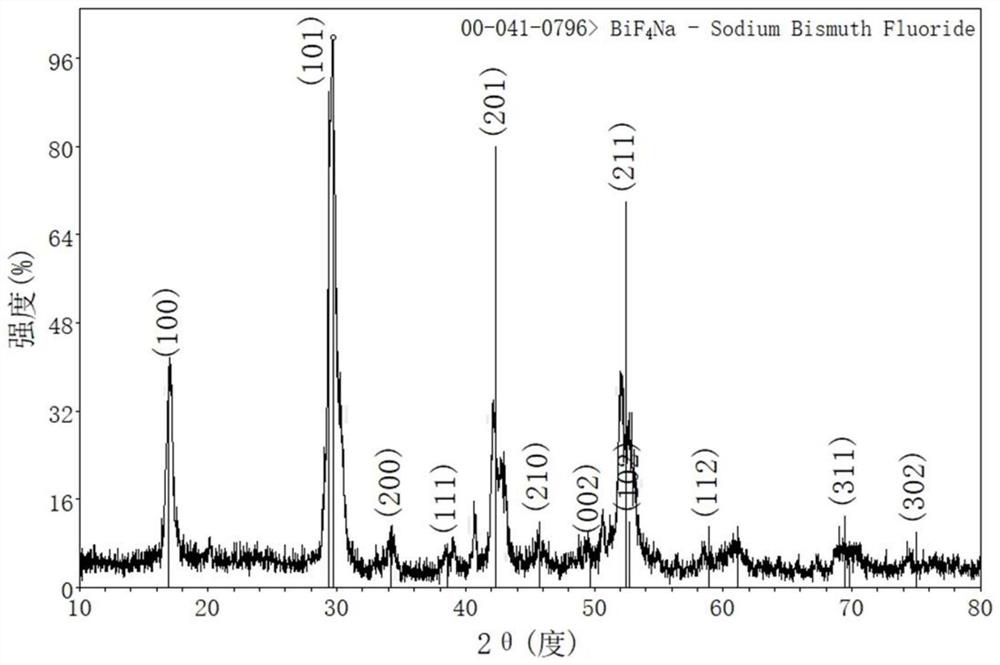

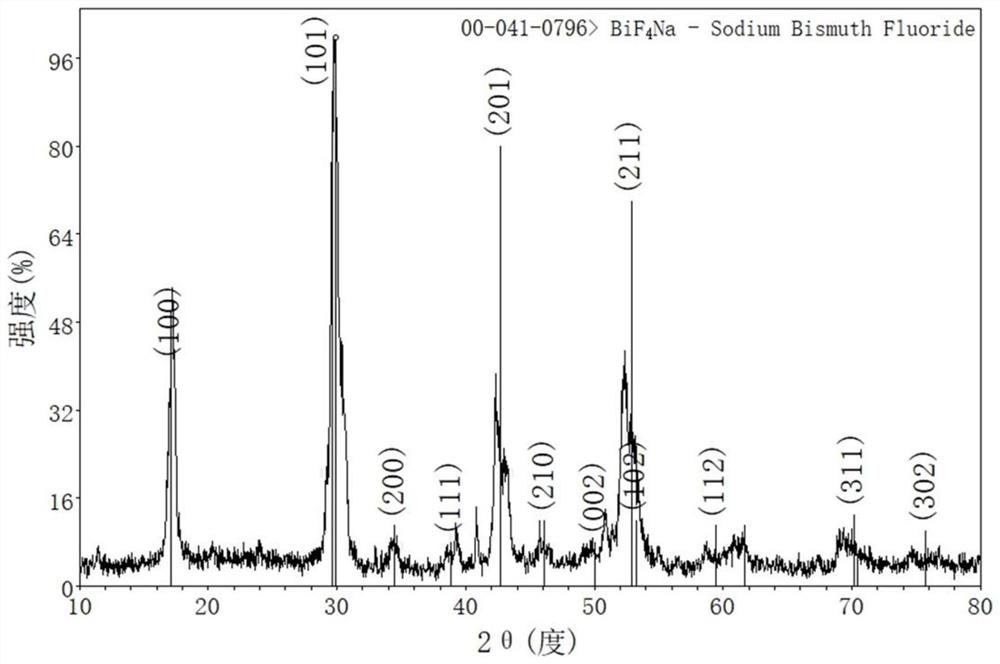

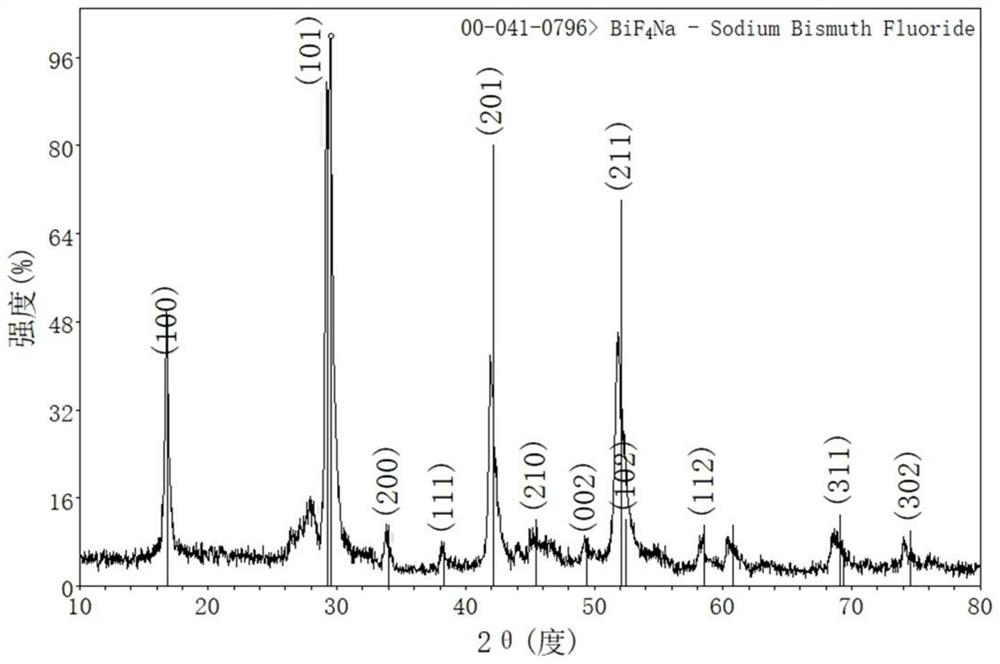

Method for preparing rare earth doped NaBiF4 nanoparticles by ultrasonic solution method and application thereof

PendingCN112408475ASolve hidden dangers of biological safety and environmental pollutionThe synthesis process is fastLuminescent compositionsBismuth compoundsSolventInorganic salts

The invention discloses a method for preparing rare earth doped NaBiF4 nanoparticles by an ultrasonic solution method and application thereof. The method comprises the following steps: dissolving a bismuth source and a sodium source in a solvent to prepare a solution A; adding nitrate containing rare earth into the solution A, and then dispersing inorganic salt of fluoride into a solvent to prepare a solution B; and mixing the solution B and the solution A to prepare a mixed solution, mixing the solution B and the solution A to form a milk white mixed solution under the action of ultrasonic phonation, and completing the growth of the nanocrystals through rapid nucleation and subsequent kinetic competition process of the nanocrystals; then carrying out solid-liquid separation to obtain white powder C, and drying the powder C to obtain NaBiF4-based nano powder with a hexagonal phase structure. The method is simple and feasible in process and good in repeatability, the whole reaction system does not pollute the environment, and the provided process route not only has good application prospects and economic benefits, but also has important practical value.

Owner:SHAANXI UNIV OF SCI & TECH

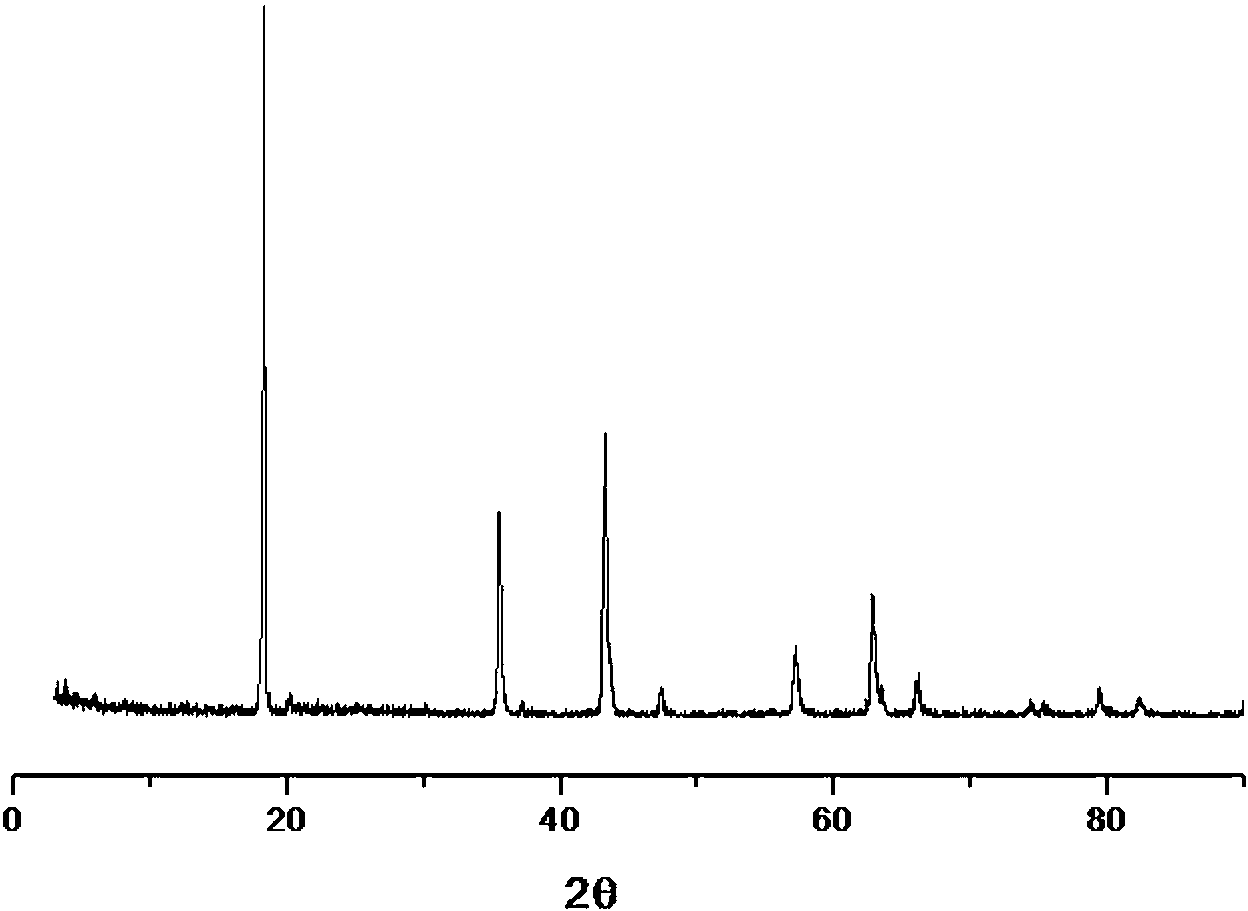

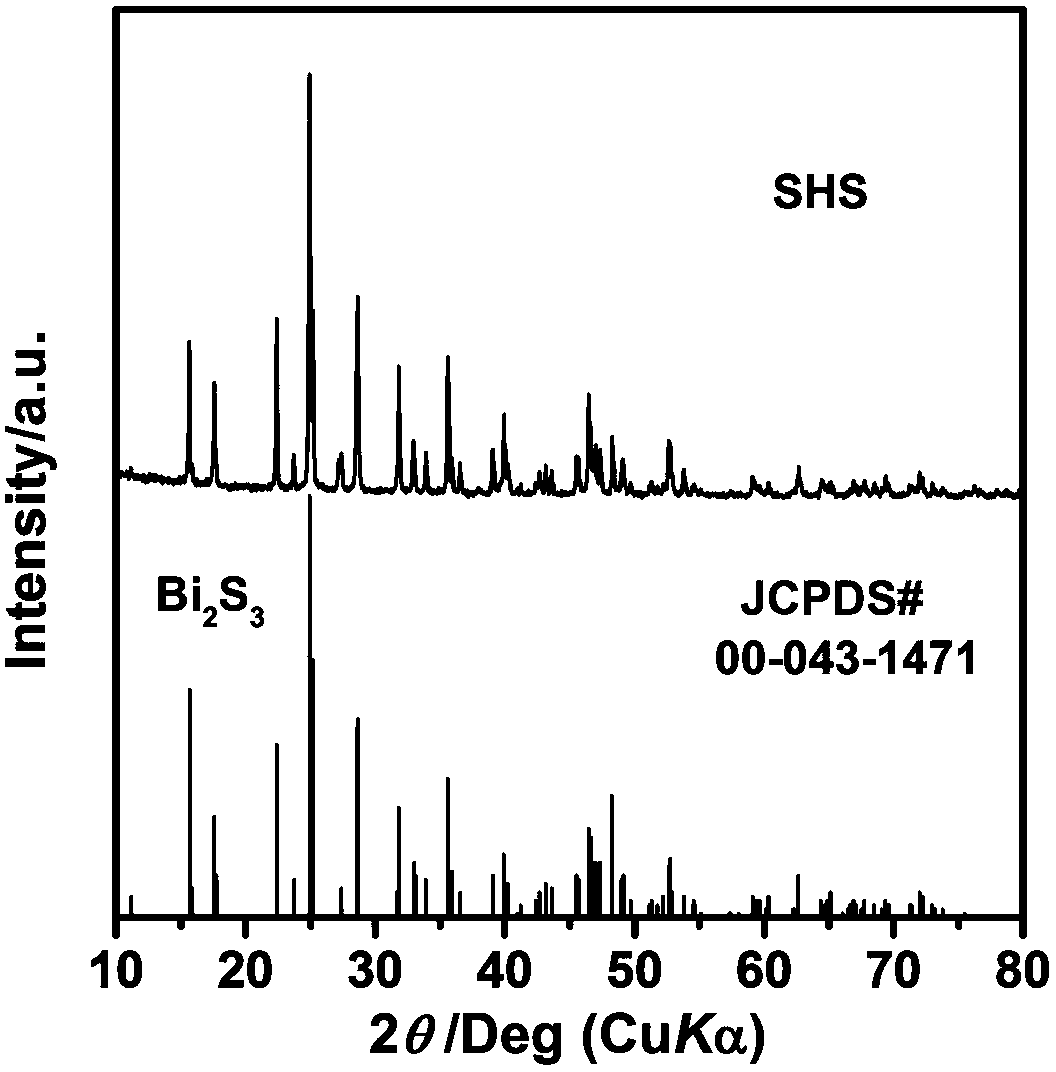

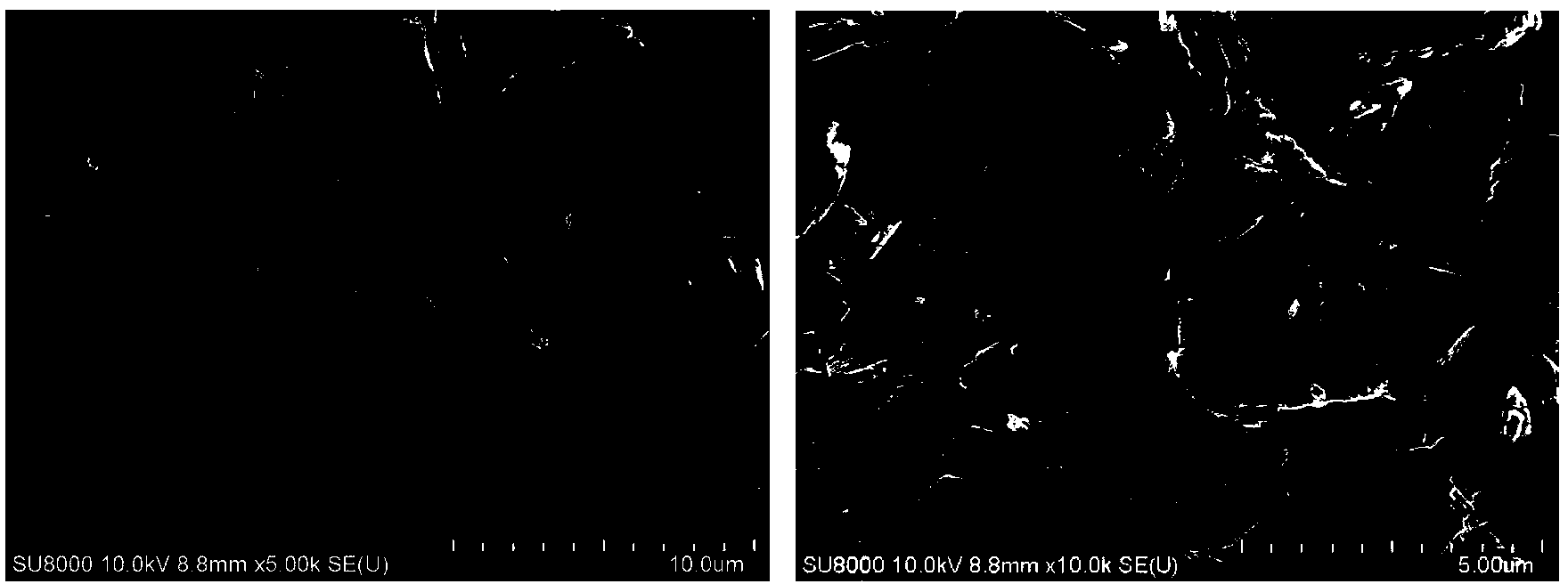

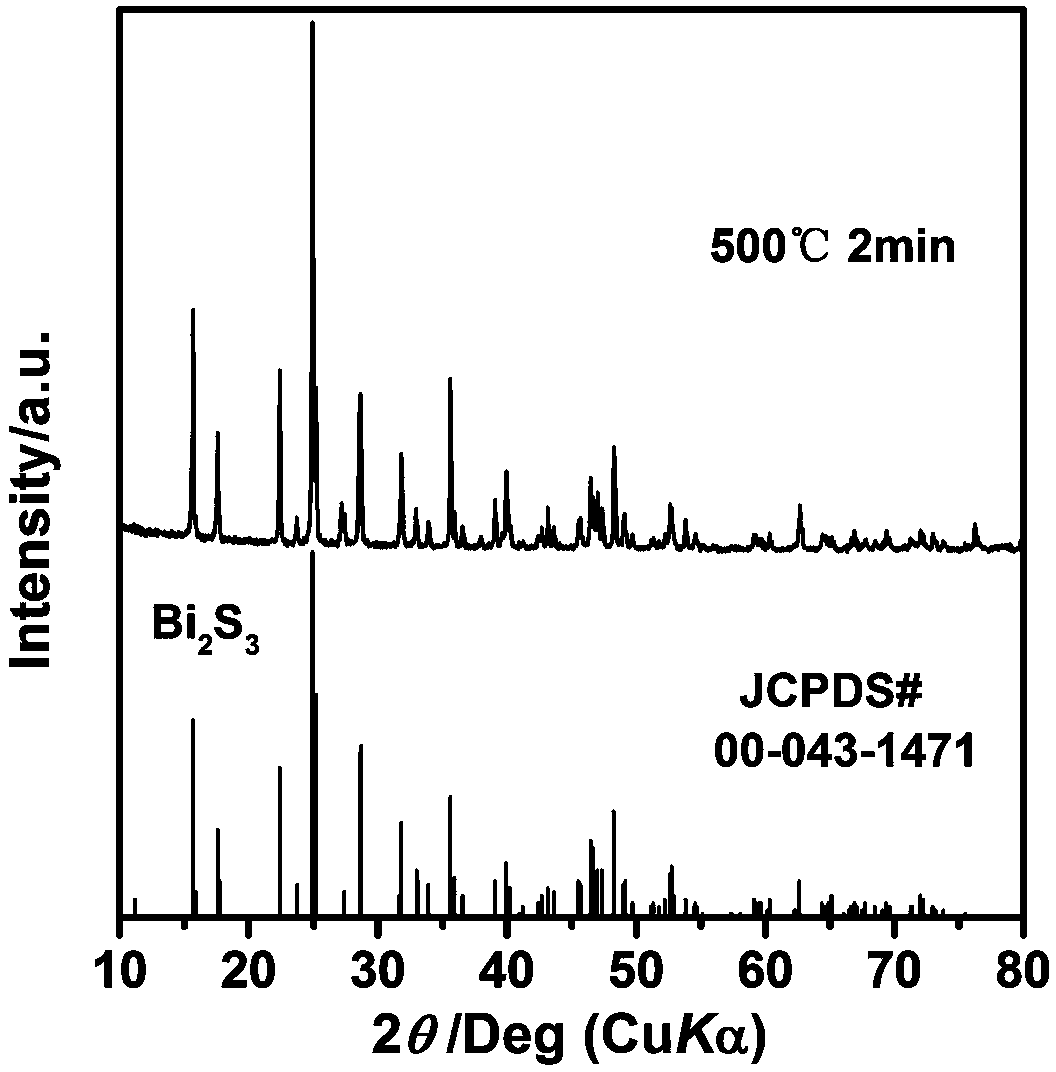

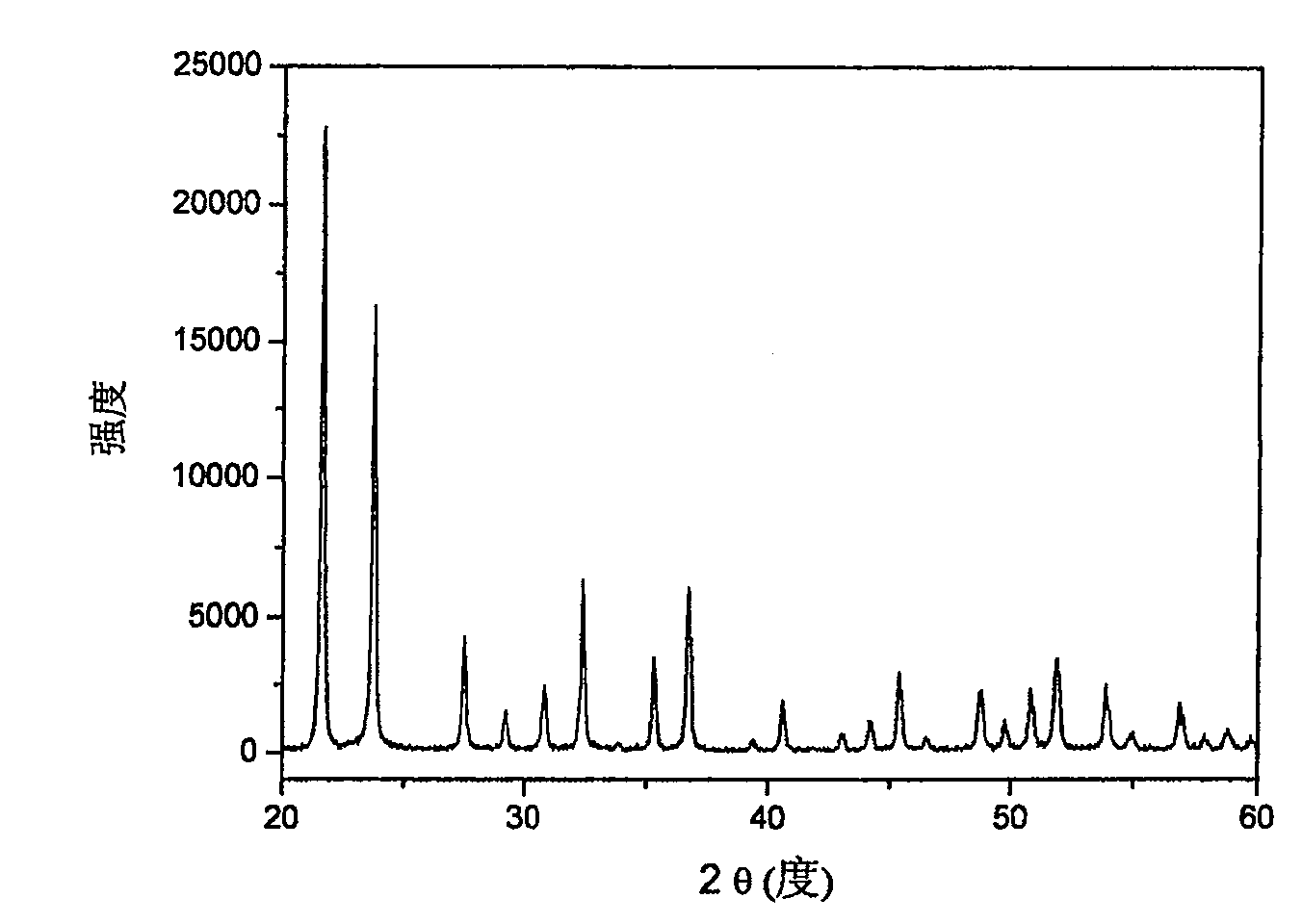

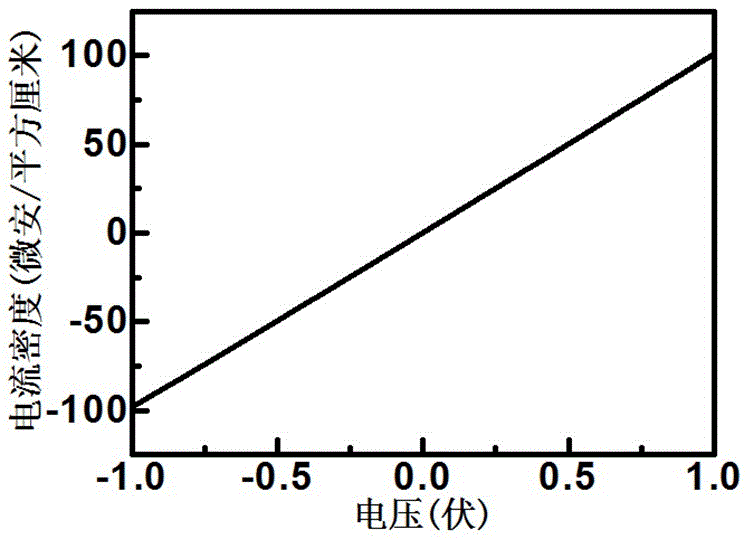

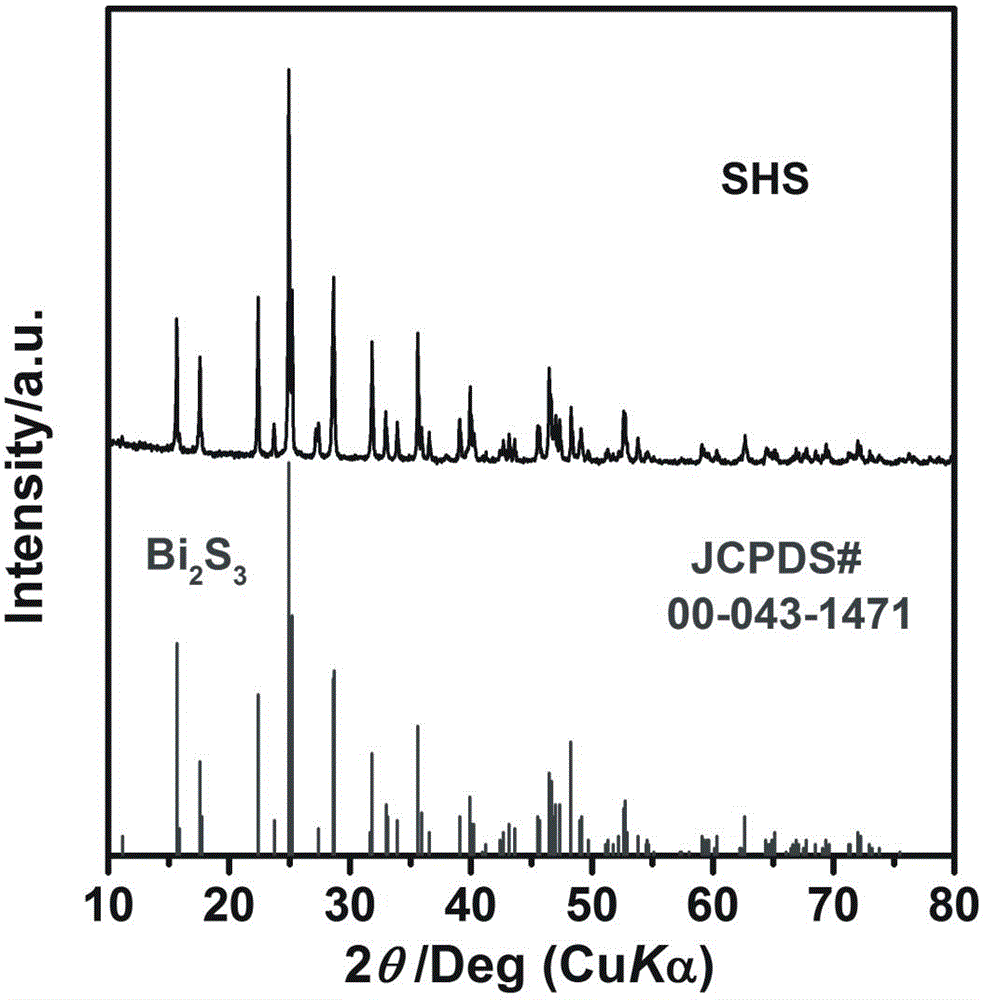

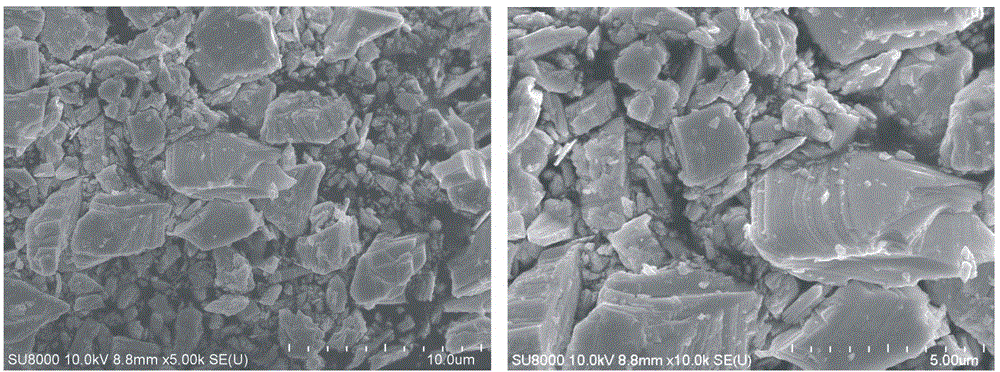

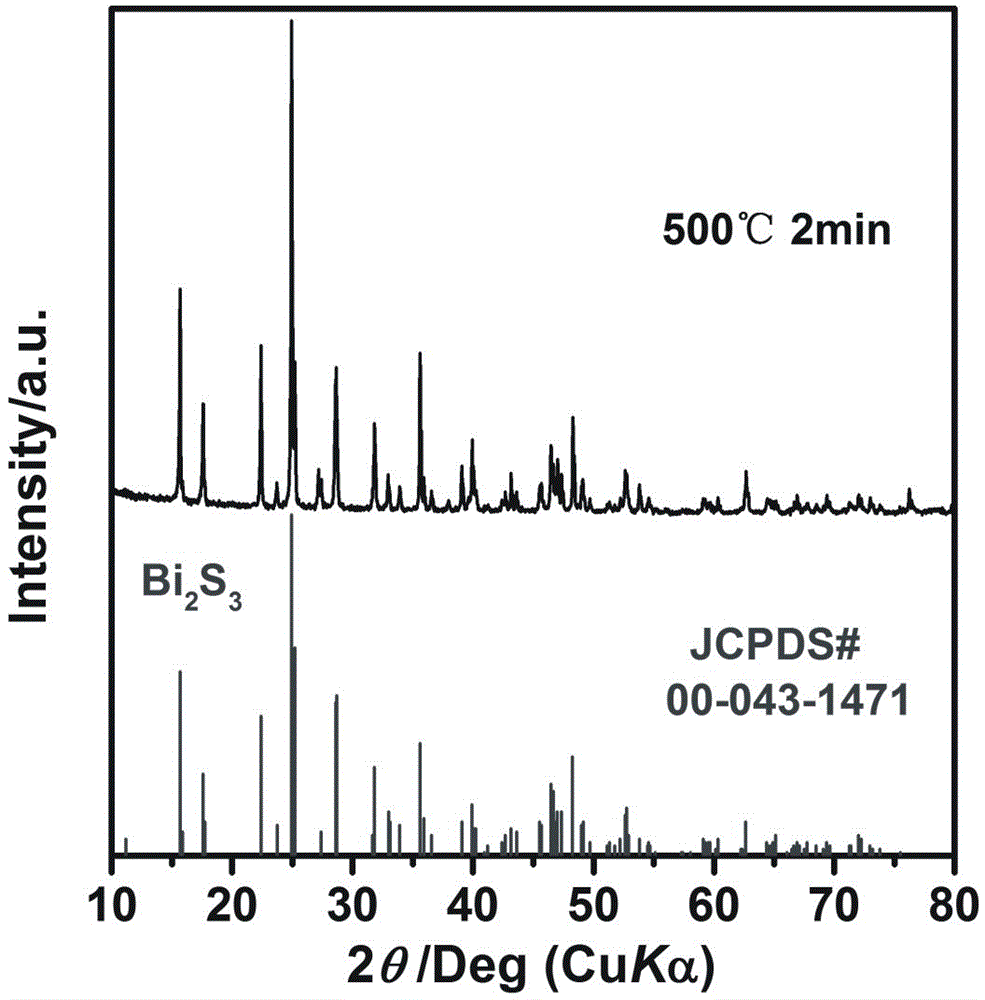

Method for rapidly preparing single-phase Bi2S3 thermoelectric compound

ActiveCN103435099AControl stoichiometric ratioQuick responseBismuth compoundsThermoelectric device junction materialsMetallurgyReagent

The invention relates to a method for rapidly preparing a single-phase Bi2S3 thermoelectric compound. The method comprises the following steps: (1), preparing Bi powder and S powder as raw materials at a stoichiometric ratio Si:S = 2:3.06, the sulfur powder material being excessive by 2% relative to the stoichiometric ratio of compound Bi2S3, and then grinding and thoroughly mixing them to obtain reactants; (2), initiating the reactants obtained in step (1) to take place a self-propagating reaction or thermal explosion reaction, and after the reaction is completed, naturally cooling to obtain a single-phase Bi2S3 thermoelectric compound. The method provided by the invention has the advantages of high reaction speed, simple equipment, good repeatability, high efficiency, energy conservation and the like.

Owner:WUHAN UNIV OF TECH

Preparation method of weather-resistant silver mirror

The invention discloses a method for preparing a weather-resistant silver mirror which is suitable for trough solar thermal power generation. The silver mirror orderly consists of a transparent low-iron super white float glass substrate, a first Al2O3 adhesive layer, an Ag reflective layer, a second Al2O3 adhesive protective layer, a SiOx protective layer and at least two waterproof protective macromolecule paint layers. The preparation method thereof comprises the step of: adopting a multi-target intermediate frequency response vertical magnetic control sputtering coater, respectively and orderly plating the first Al2O3 adhesive layer, the Ag reflective layer, the second Al2O3 adhesive protective layer, the SiOx protective layer and the at least two waterproof protective macromolecule paint layers and preparing the weather-resistant silver mirror of the invention. The inventive preparation method has the characteristics of advanced and reasonable preparation method, low preparation cost, low energy consumption, high reflectivity of the prepared weather-resistant silver mirror, reliable work, long service life and the like.

Owner:常州龙腾光热科技股份有限公司

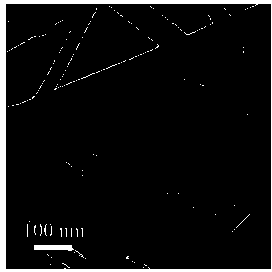

Method of catalytic preparation of copper-indium-tellurium nanowires

The invention discloses a method of catalytic preparation of copper-indium-tellurium nanowires, and belongs to the field of production technologies of a new generation of film solar cell materials. The method comprises the following steps: respectively preparing methylbenzene solution of bismuth nanoparticles and precursor solution containing indium acetate, copper acetate and tellurium, heating trioctylphosphine under the protection of nitrogen, adding the methylbenzene solution of the bismuth nanoparticles, dropping the precursor solution containing the indium acetate, the copper acetate and the tellurium, after the reaction is completed, cooling and injecting methylbenzene, centrifuging, taking a solid phase and drying in vacuum after centrifugal washing through methylbenzene so as to obtain the copper-indium-tellurium nanowires. According to the method, the metal bismuth nanoparticles can be taken as a catalyst, the adopted instrument and equipment are cheap, the operation process is simple, a stoichiometric ratio of multi-component materials is effectively controlled to obtain the high-purity copper-indium-tellurium nanowires, and a large batch of high-quality nanowires can be produced. In addition, the length of the nanowires can be controlled through adjusting the concentration of the bismuth nanoparticles or the concentration of the precursor.

Owner:YANGZHOU UNIV

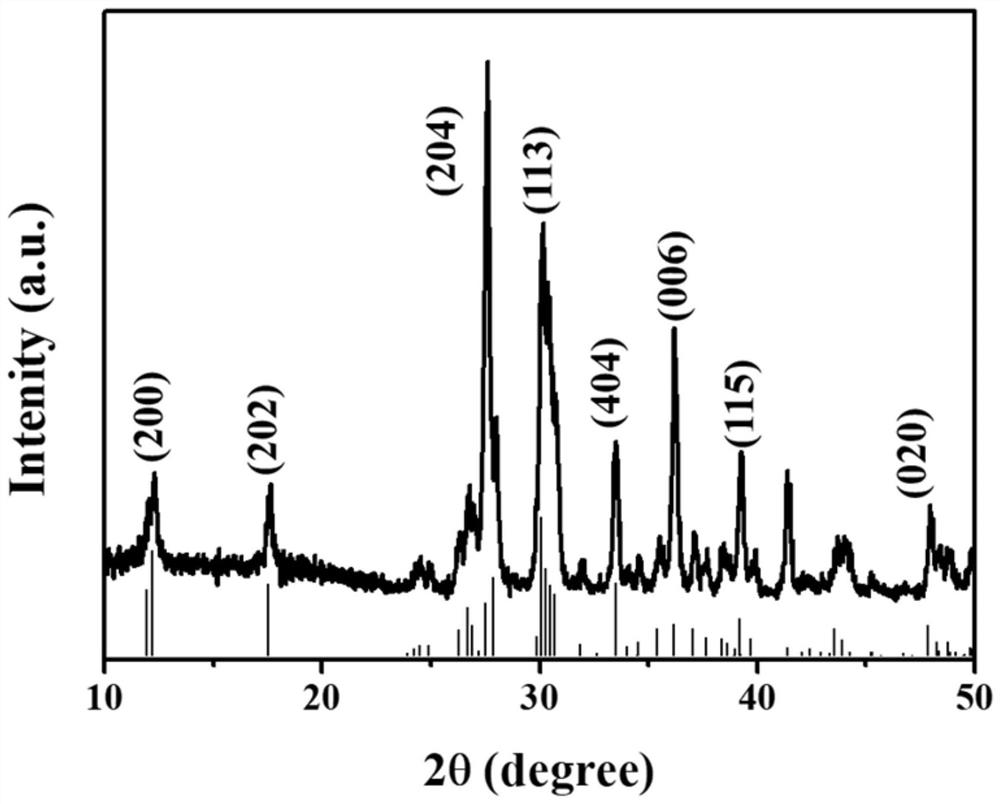

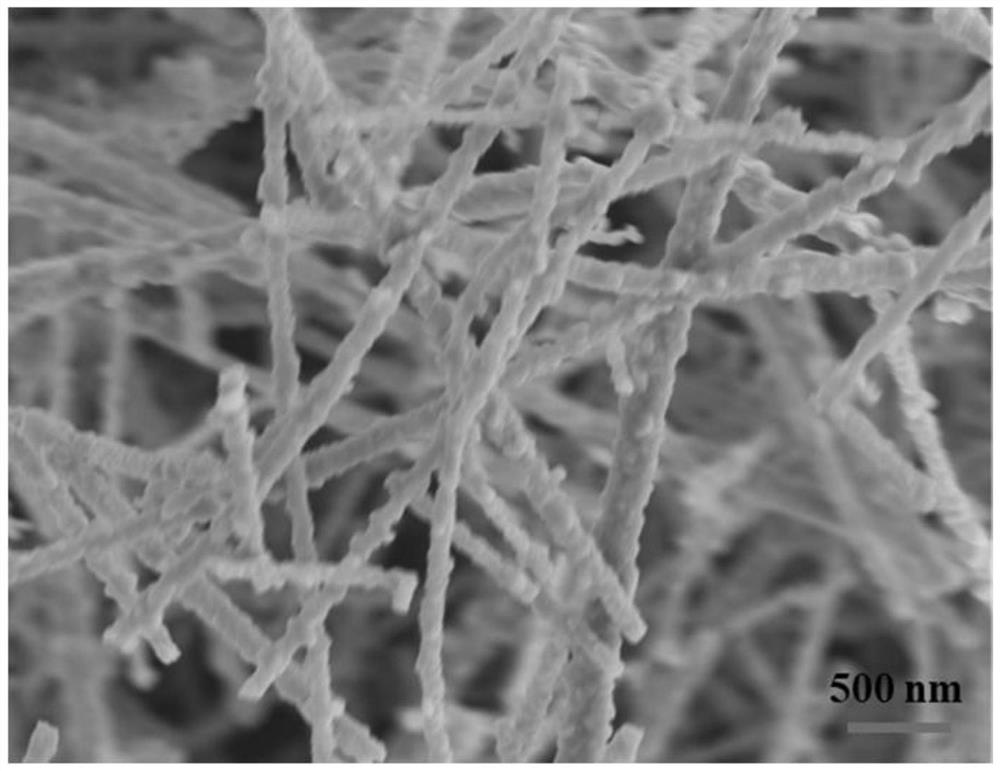

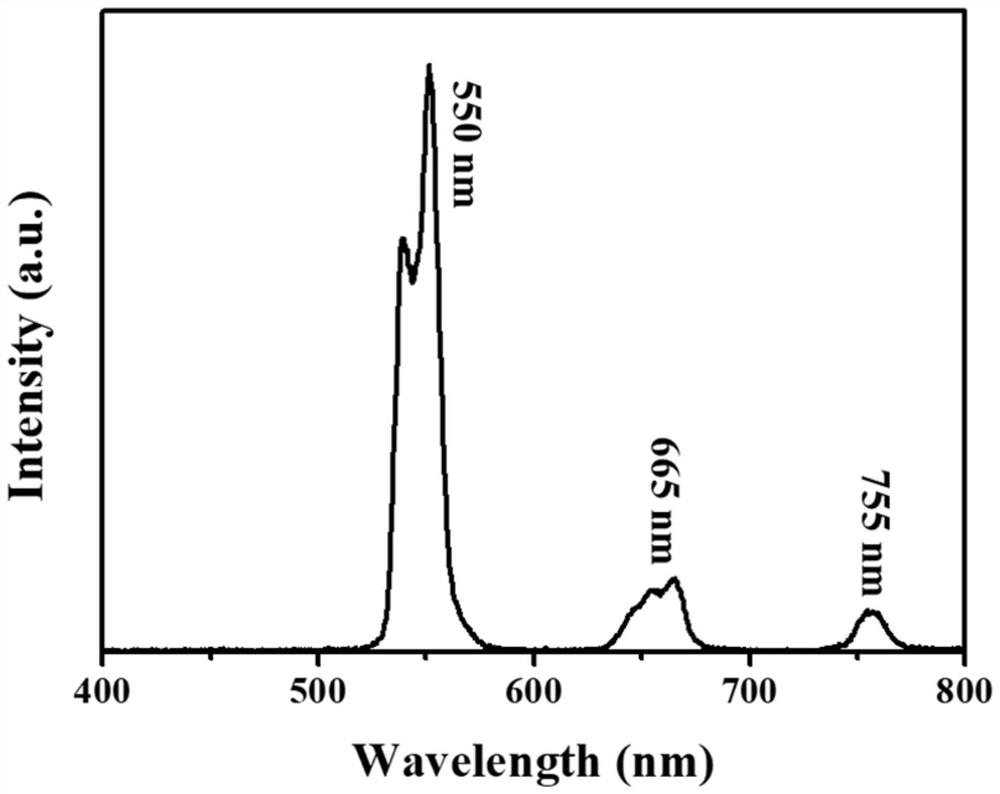

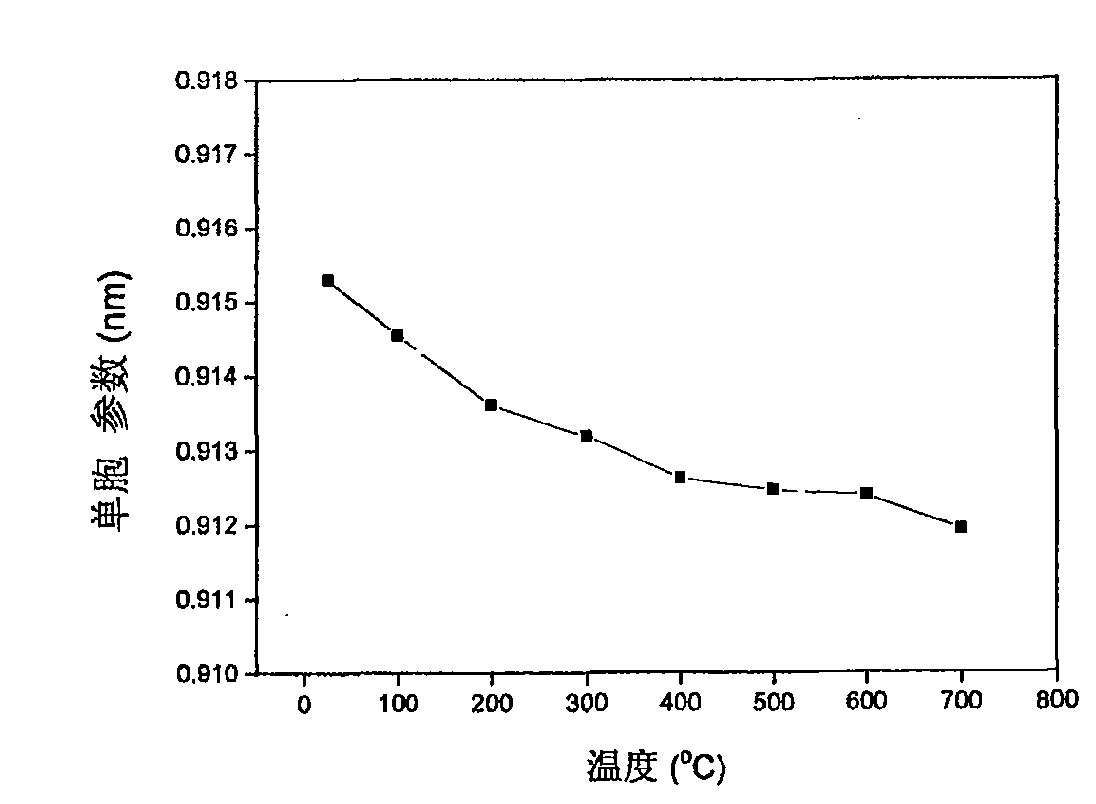

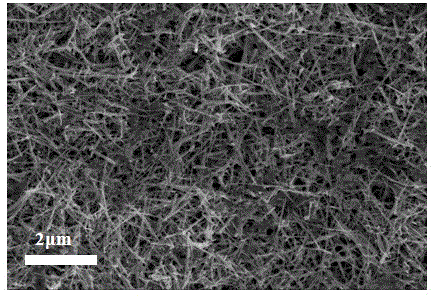

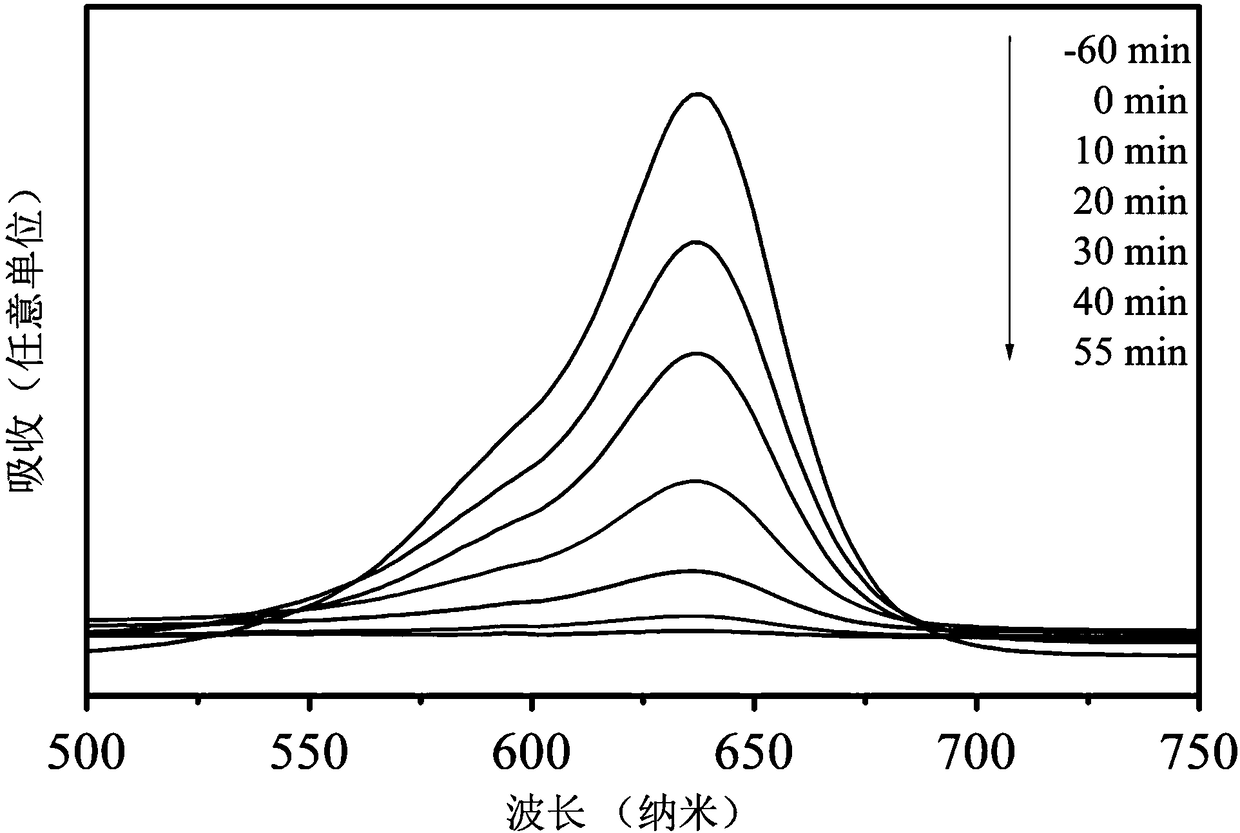

Rare earth doped Bi2Ti4O11 high-purity green nanofiber and preparation method and application thereof

InactiveCN112176456ANot hydrolyzedImprove luminosityElectroconductive/antistatic filament manufactureInorganic material artificial filamentsSpinningPyrrolidinones

The invention discloses a rare earth doped Bi2Ti4O11 high-purity green nanofiber and a preparation method and application thereof. Glacial acetic acid and N,N-dimethylformamide are used as solvents, tetrabutyl titanate, bismuth nitrate, ytterbium nitrate and holmium nitrate are used as experimental raw materials, a proper amount of polyvinylpyrrolidone is added to improve the viscosity and conductivity of a solution, and after an electrostatic spinning precursor solution is prepared, the electrostatic spinning precursor solution is moved into an electrostatic spinning device; high pressure isapplied, the precursor solution forms a Taylor cone at a needle tip under the combined action of electric field force and surface tension, and filaments are sprayed to a collecting plate; then materials on the collecting plate are moved into a muffle furnace, heat treatment is carried out, and pure one-dimensional Bi2Ti4O11:Yb3+, Ho3+ nano materials can be obtained; and finally, under excitation of a 980nm laser device, a sample shows the excellent green up-conversion luminescence property, the luminescence intensity is decreased along with increase of the temperature, and the excellent temperature sensing property is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

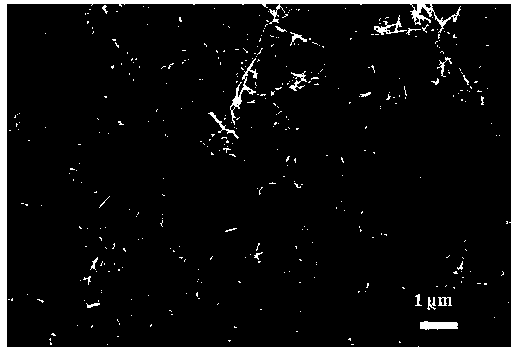

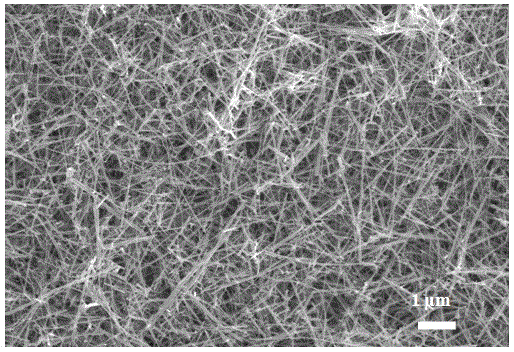

Preparation method of egg yolk‑eggshell structure nitrogen-doped carbon-coated ferric oxide@tin dioxide magnetic nanobox

ActiveCN105914358BControl stoichiometric ratioSimple equipmentMaterial nanotechnologyCell electrodesCarbon layerTin dioxide

The preparation method of egg yolk-eggshell structure nitrogen-doped carbon-coated ferric oxide@tin dioxide magnetic nano box belongs to the field of nanomaterial production technology. A layer of silicon dioxide is coated on the surface of ferric oxide cubic nano cubes, and then Under the action of potassium stannate trihydrate and urea, an egg yolk-eggshell structure ferric oxide@tin dioxide nanobox is formed, and finally dopamine is coated, carbon and nitrogen sources are introduced, and calcined in an inert atmosphere to form a conductive carbon layer, while converting ferric oxide to ferric oxide. The equipment adopted in the present invention is simple, the preparation cost is low, the operation process is simple and convenient, the materials required in the reaction process are low-toxic and harmless, and the stoichiometric ratio of multi-component materials can be effectively controlled to obtain uniform size, uniform distribution and good shape. Well-controlled, it can be used for industrial mass production of high-quality egg yolk-eggshell structured magnetic nanomaterials.

Owner:YANGZHOU UNIV

Preparation method of hollow carbon nanospheres with internal confined growth MOFs

ActiveCN107522867BIncreased chance of collisionControl stoichiometric ratioNanotechnologyNano-carbonResin microsphereSilicic acid

Owner:YANGZHOU UNIV

A method for catalytically preparing copper indium tellurium nanowires

Owner:YANGZHOU UNIV

Cerium doping zirconium tungstate negative heat expansion conductive ceramic powder and preparation method thereof

InactiveCN100567209CPrevent volatilizationHigh purityNon-metal conductorsCe elementMaterials science

Owner:UNIV OF SCI & TECH BEIJING

A kind of preparation method of copper indium selenium tellurium nanowire

ActiveCN104064628BReductiveImprove solubilityMaterial nanotechnologyFinal product manufactureIndiumNanowire

A preparation method of a CIST nano wire belongs to the technical field of new-generation thin-film solar cell materials. A toluene solution of Bi nanoparticles and a precursor solution of Se and Te are prepared separately. Then under the protection of nitrogen, trioctylphosphine is heated and added into the toluene solution of the Bi nanoparticles, and then the precursor solution containing indium acetate, copper acetate and Se is added into the mixture. After reactions, the precursor solution containing indium acetate, copper acetate and Se is added drop by drop. After reactions are completed, the mixture is cooled and toluene is added. Then the mixture is subjected to centrifugation. The solid phase is taken, is washed with toluene, and is subjected to centrifugation and vacuum drying. Then the CIST nano wire is obtained. The method uses the metal Bi nanoparticles as a catalyst. The toluene solution of the Bi nanoparticles is used, so that the concentration of the Bi nanoparticles can be effectively controlled, and the liquid form facilitates taking the catalyst. The method is simple in technique, can effectively control the stoichiometric ratio of multi-component materials, and obtains a large batch of high-purity CIST nano wires.

Owner:YANGZHOU UNIV

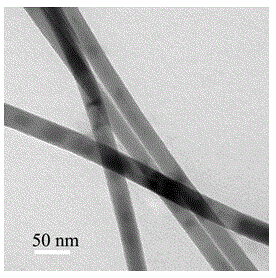

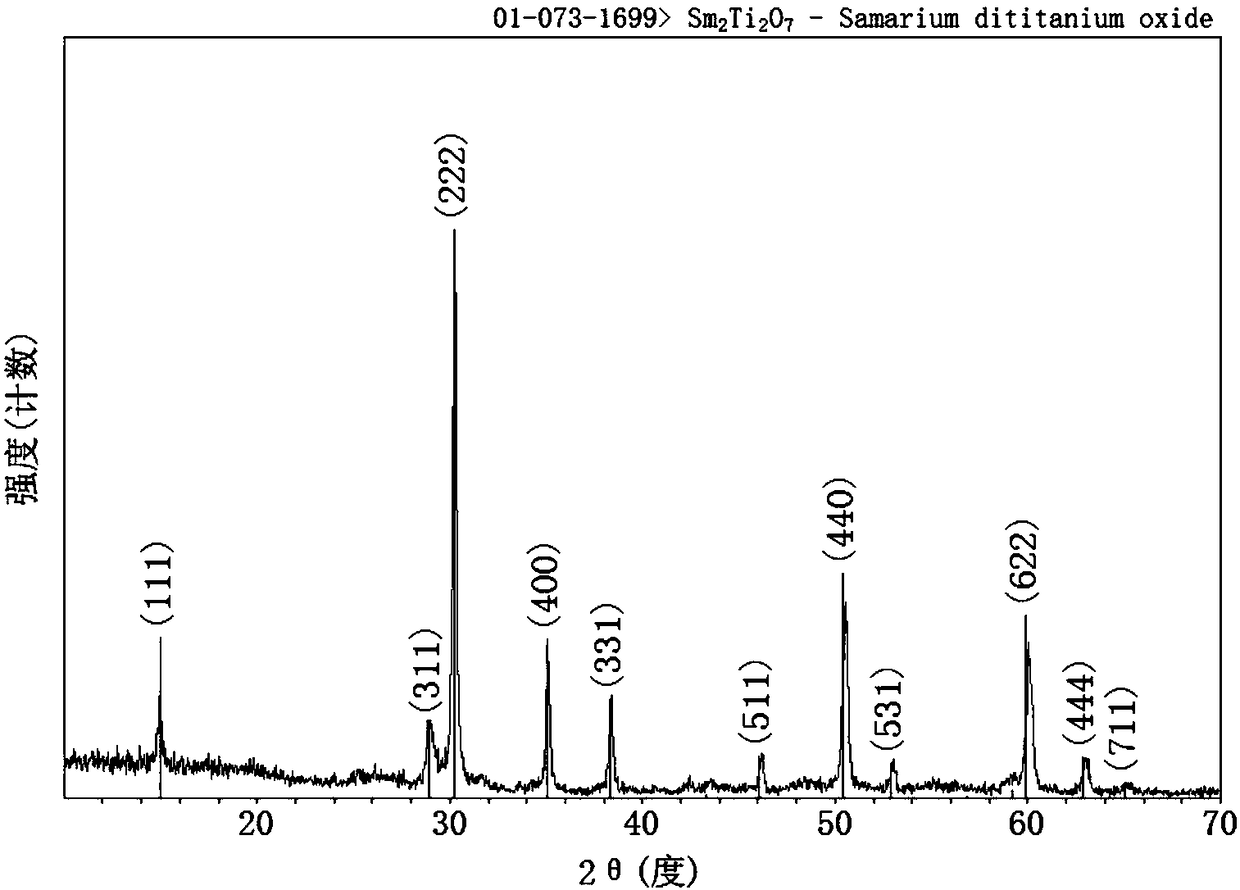

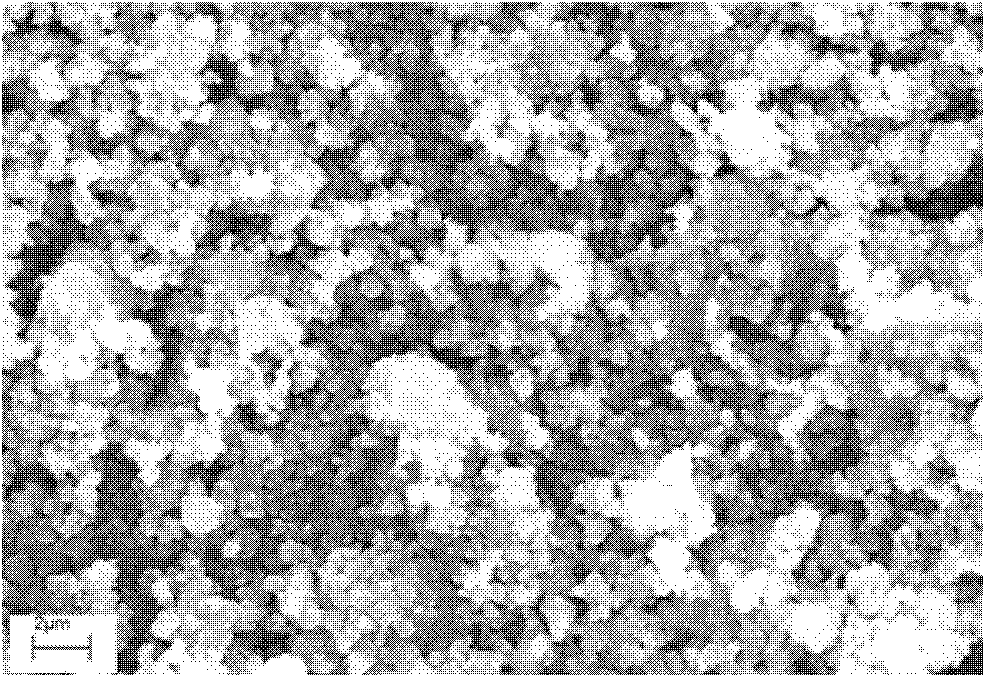

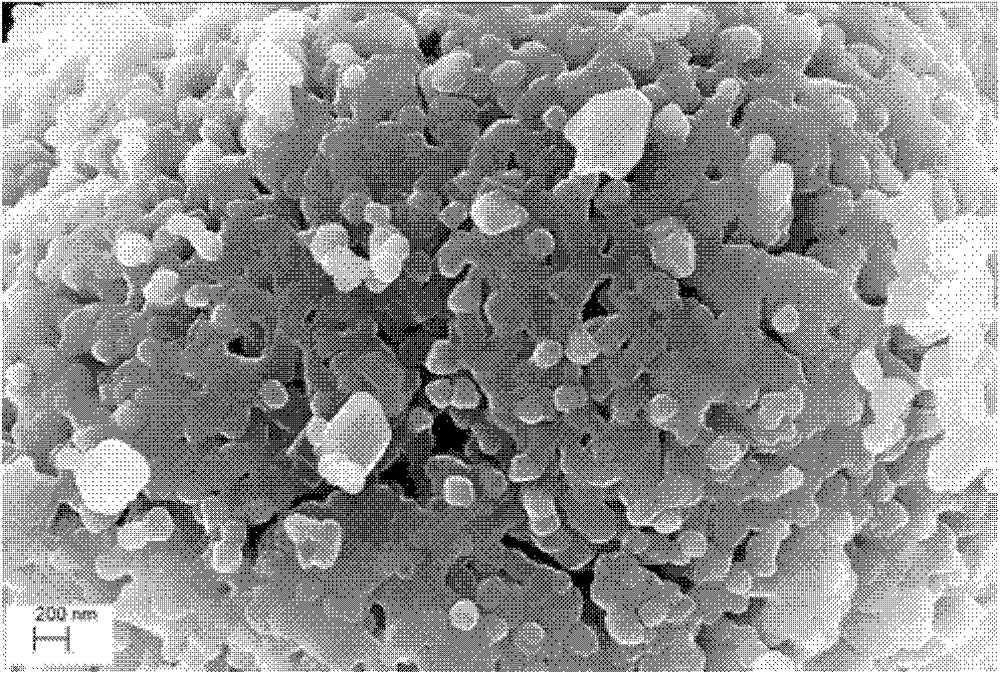

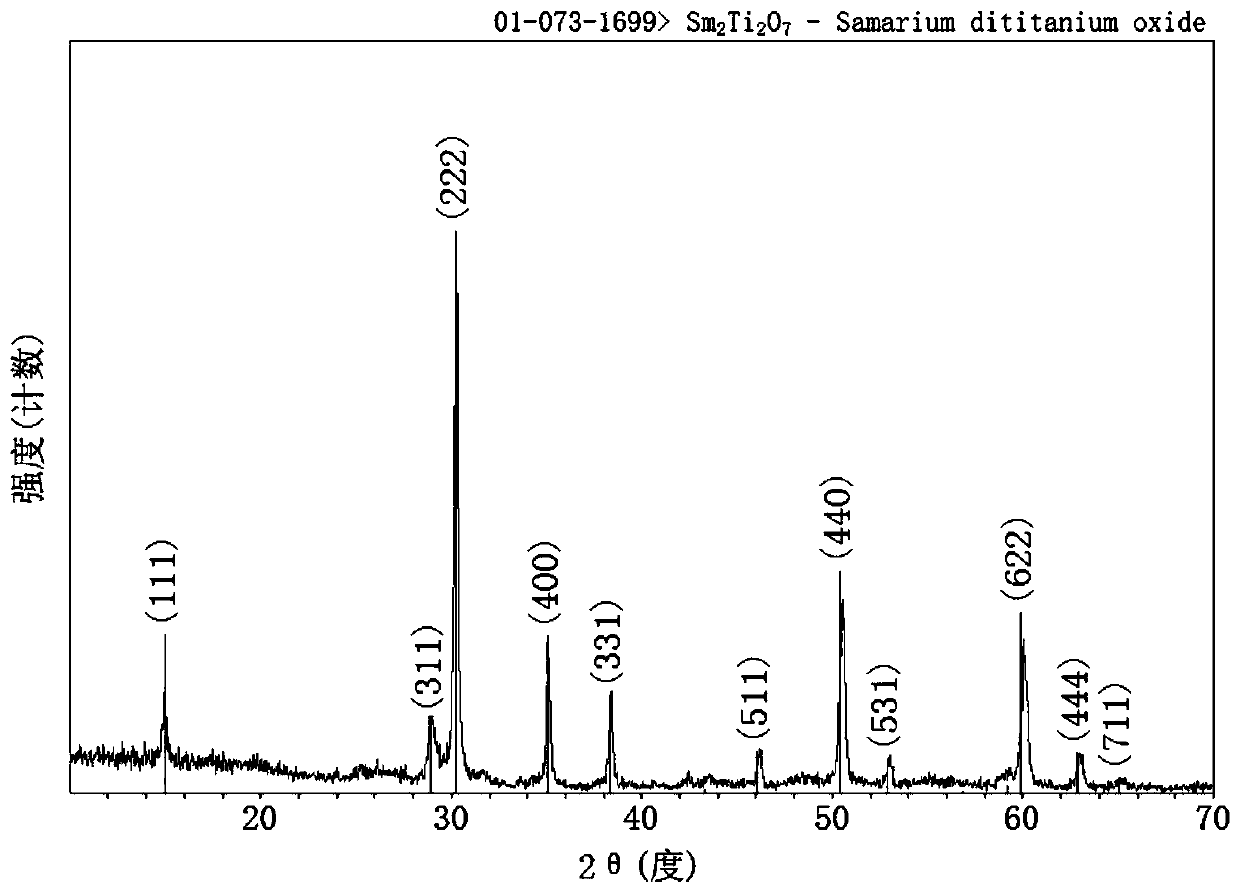

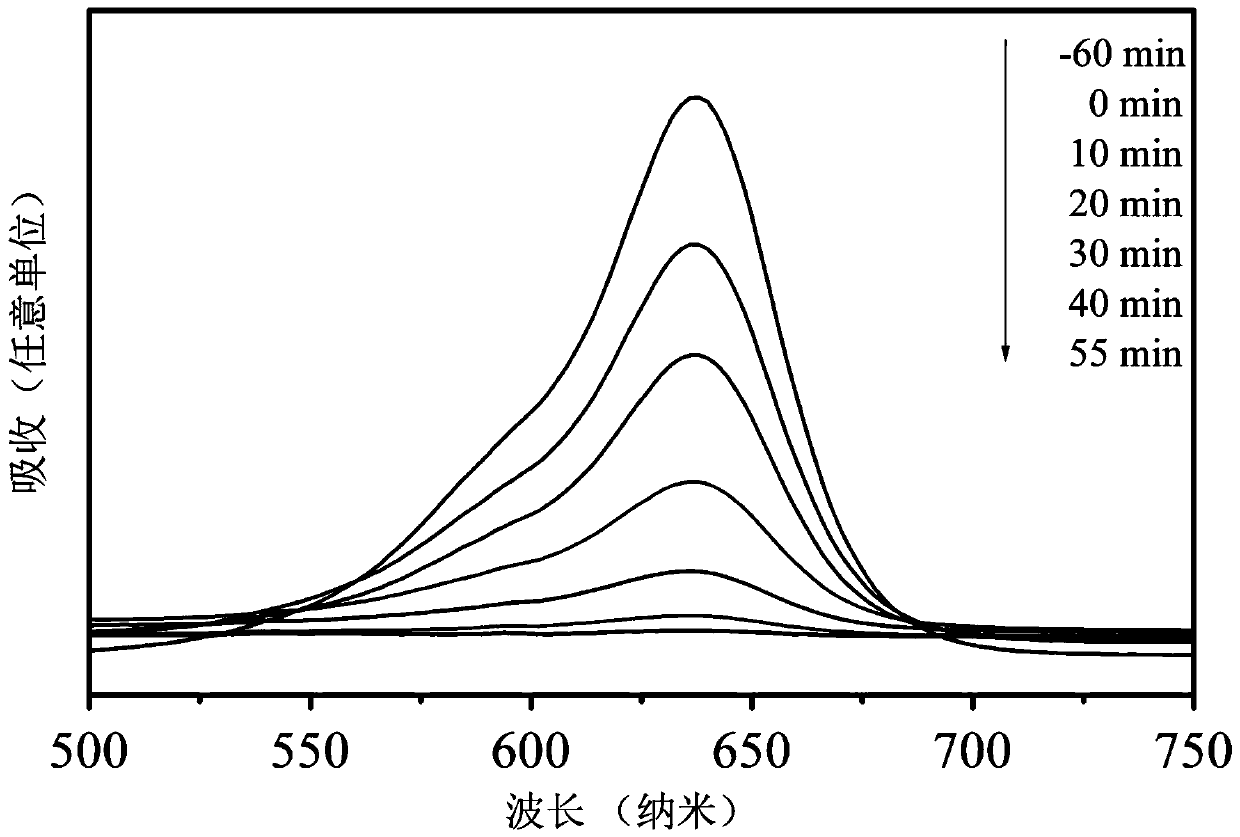

Single-phase samarium titanate nano-powder prepared by using solution method, and method for preparing single-phase samarium titanate nano-powder

ActiveCN108083328AControl stoichiometric ratioNo harmMaterial nanotechnologyTitanium compoundsPhysical chemistryWhite powder

The invention relates to single-phase samarium titanate nano-powder prepared by using a solution method, and a method for preparing the single-phase samarium titanate nano-powder. The method comprisesthe following steps: firstly dispersing a samarium source and a titanium source into a solvent according to a molar ratio of 1 to (1.1-1.3) to obtain a solution A; adjusting the pH value of the solution A to be neutral to obtain a milk-white mixed solution B; separating the milk-white mixed solution B to obtain white powder; drying the powder obtained in the third step, and then calcining to obtain the single-phase samarium titanate nano-powder. According to the method, the aim of accurately controlling the stoichiometric ratio of ternary Sm-Ti-O chemical elements is achieved by fully dissolving and dispersing the samarium source and the titanium source in a solvent medium as well as mixing and reacting the samarium source and the titanium source at an atomic scale, so that other impurities are prevented from appearing, and the aim of preparing the single-phase Sm2Ti2O7 is further realized.

Owner:成都莒纳新材料科技有限公司

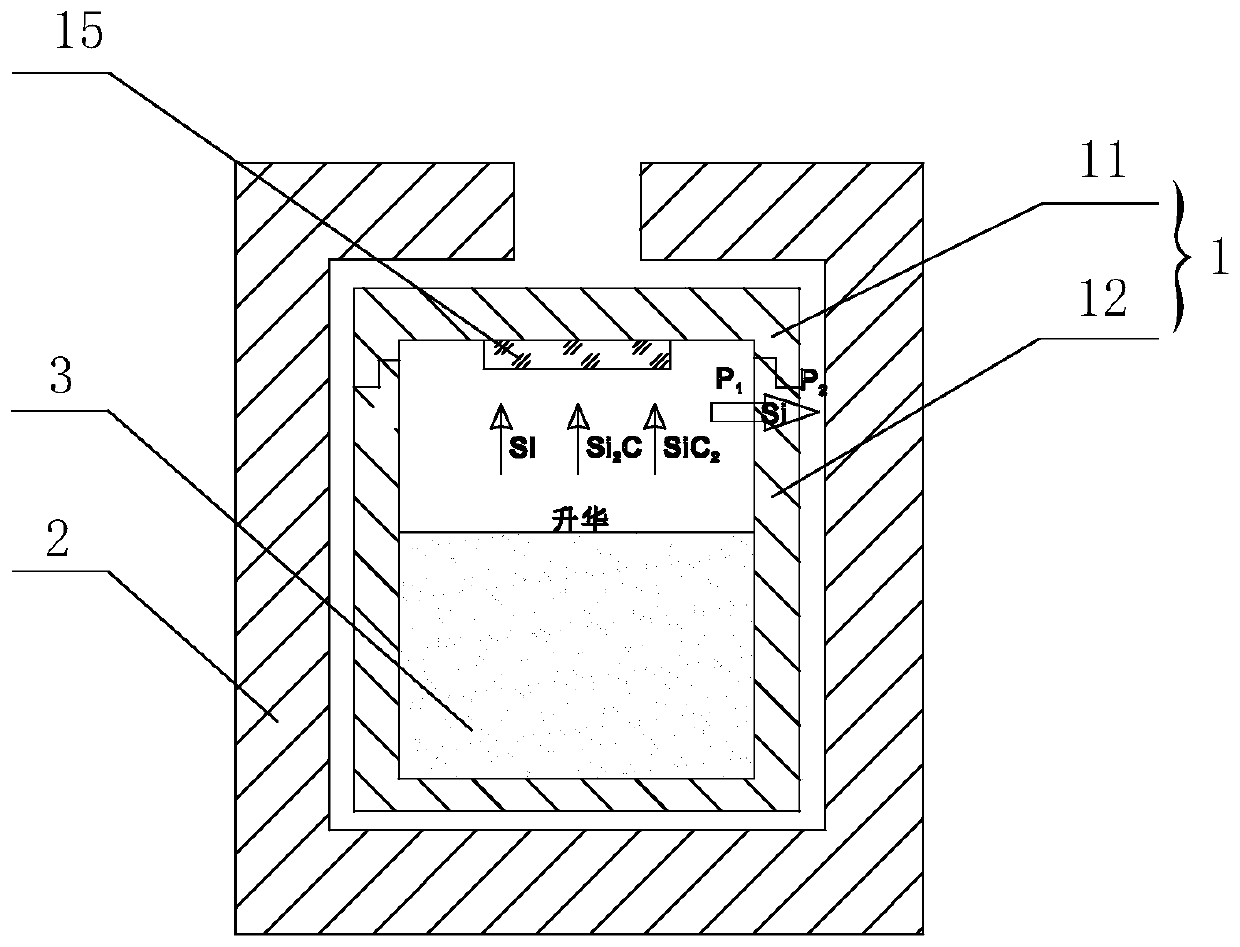

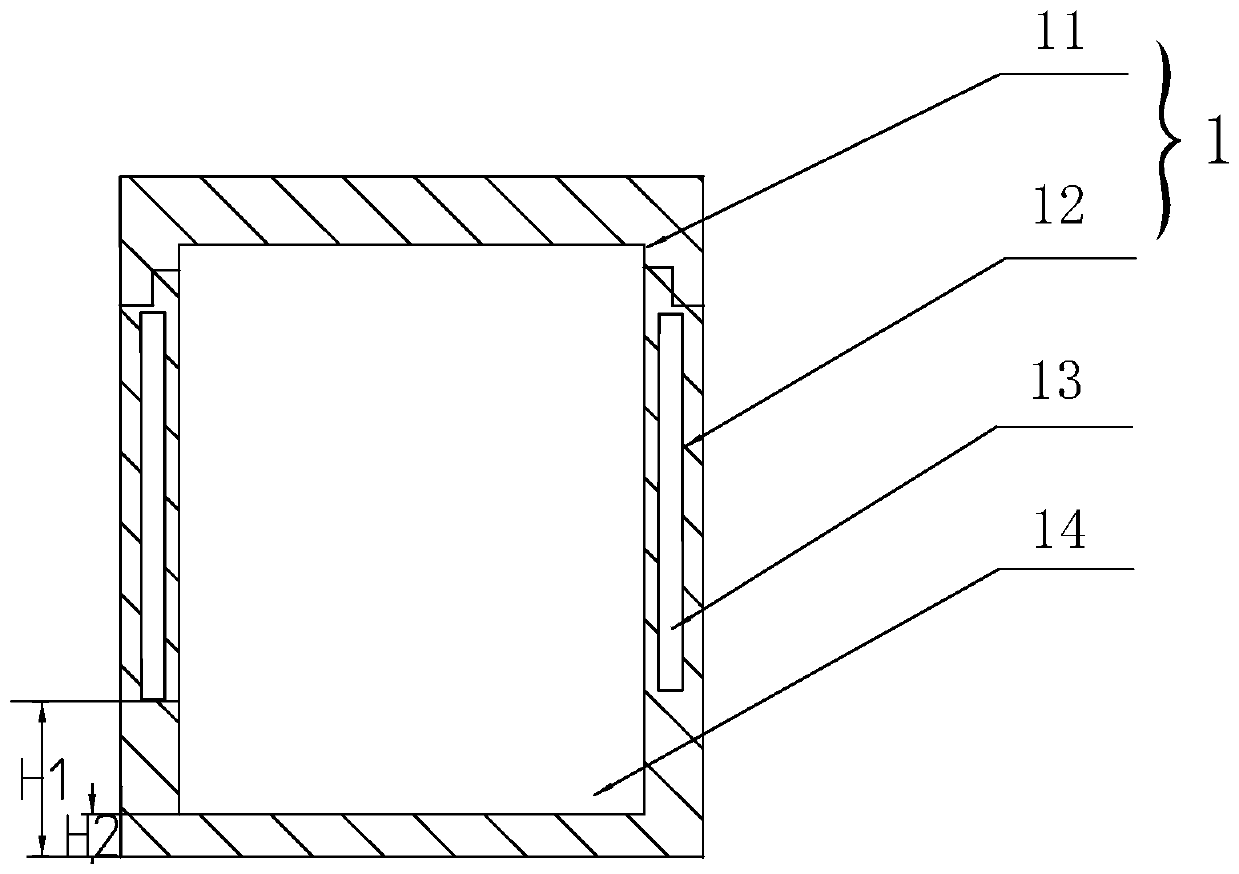

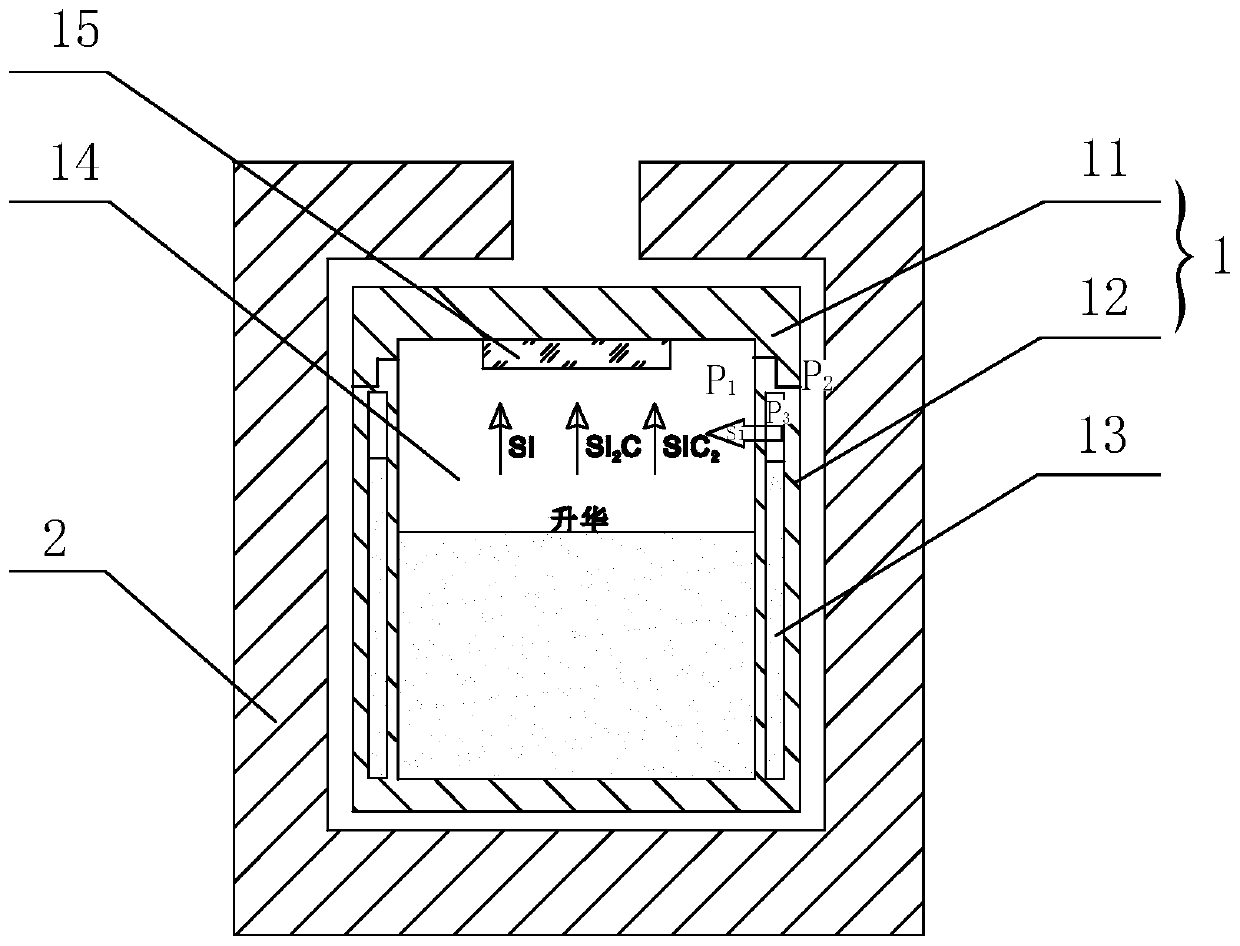

Crucible for growing silicon carbide crystals by physical vapor transport

InactiveCN106894091BPromote growthControl stoichiometric ratioPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention provides a crucible for growing a silicon carbide crystal through a physical vapor transport method. The crucible comprises a crucible body, wherein the crucible body comprises a bottom wall and a sidewall which encircle an inner chamber in which silicon carbide polycrystalline powder is stored; furthermore, an interlayer chamber for storing a silicon source is formed in the sidewall; the silicon source is used for supplying Si vapor pressure in the interlayer chamber, and the Si vapor pressure in the interlayer chamber is not less than that in the inner chamber. According to the crucible, the interlayer chamber is arranged in the sidewall of the crucible body, and the silicon source is positioned in the interlayer chamber and used for supplying proper Si vapor concentration, so that the spreading direction of Si vapor in a SiC monocrystal growing chamber can be controlled under the Si steam concentration gradient effect, and as a result, the stoichiometric ratio in the whole silicon carbide monocrystal growing process can be effectively controlled, and the defect that a carbonaceous inclusion is generated in the silicon carbide crystal can be avoided; moreover, raw materials can be prevented from serious carbonizing, and the high-quality silicon carbide growth can be promoted.

Owner:SHANDONG UNIV +2

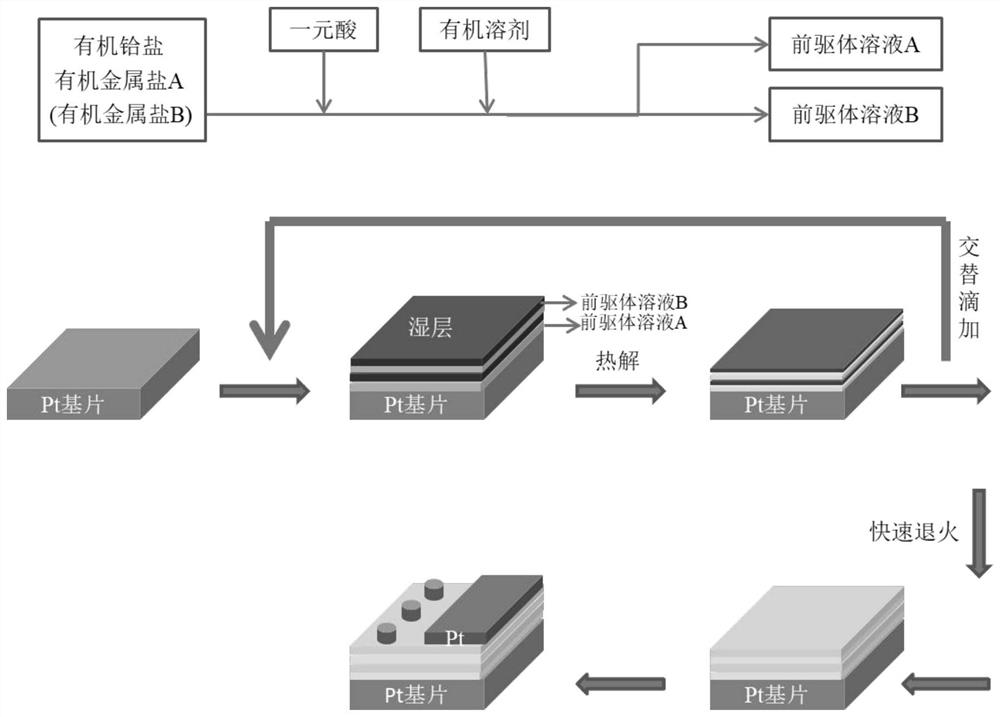

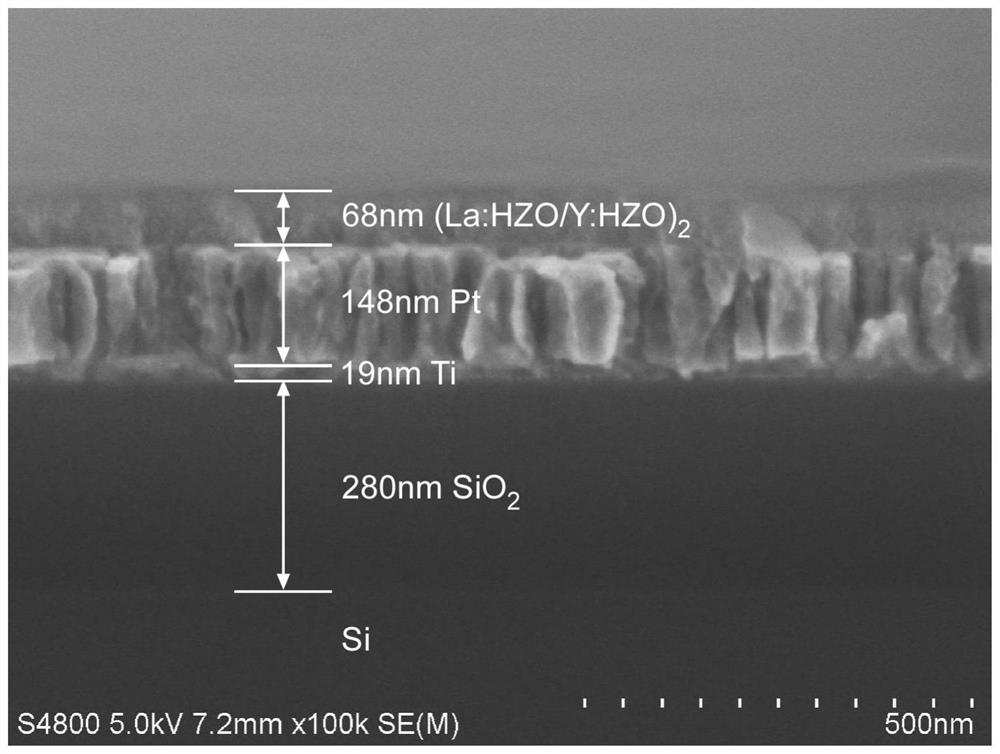

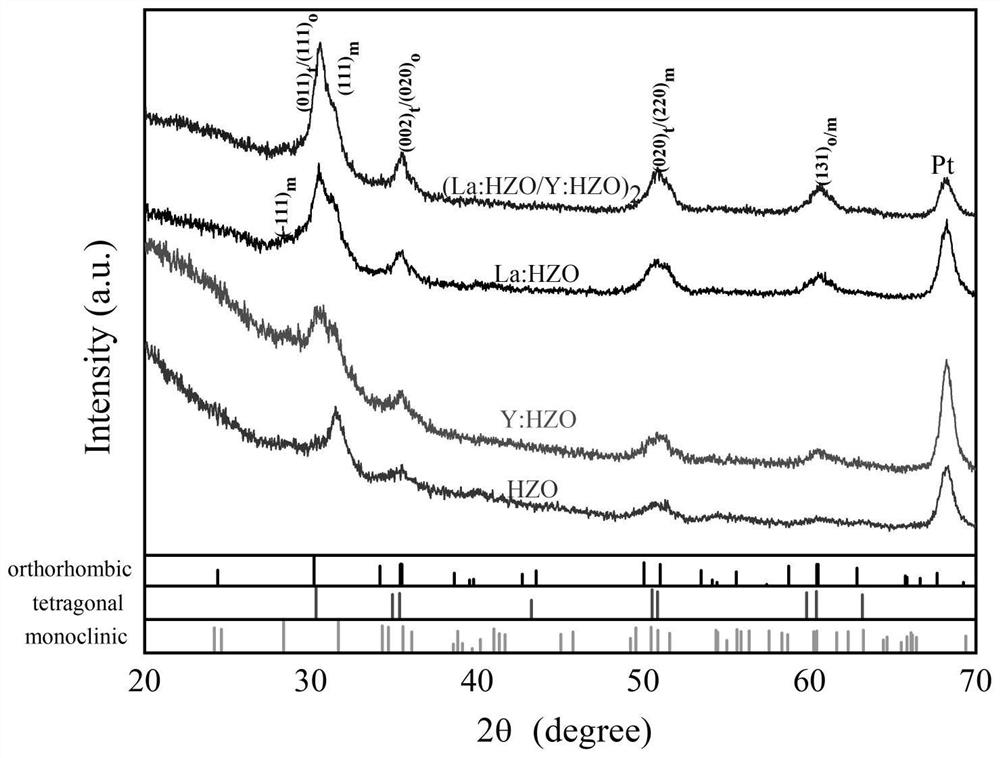

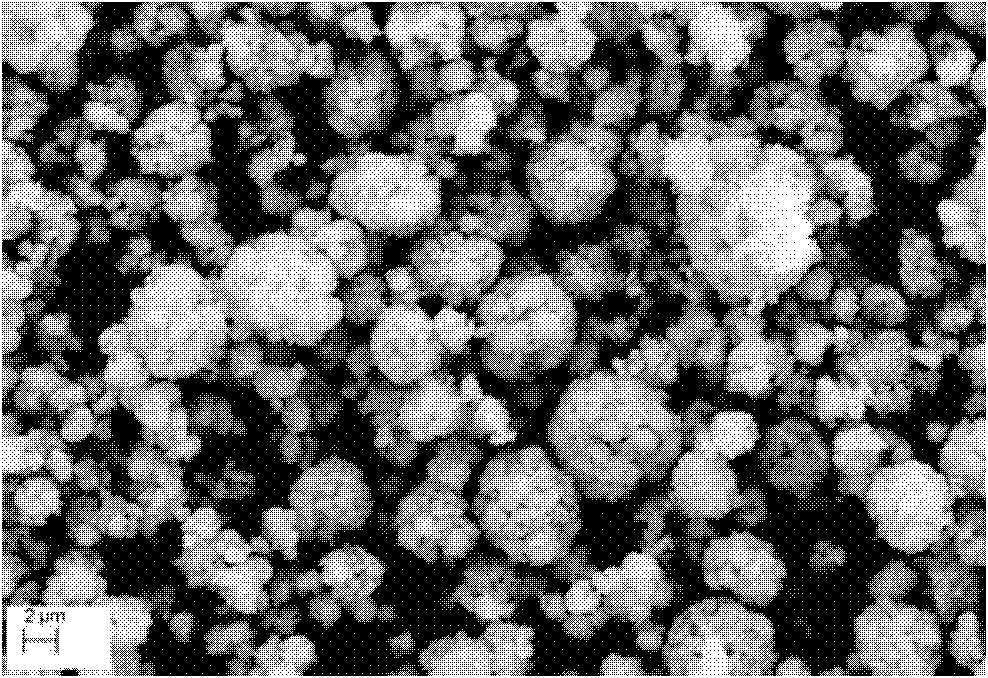

Preparation method of alternately growing ferroelectric film

PendingCN114420544AEasy to dopeAchieve preparationSemiconductor/solid-state device manufacturingPlatinumOrganic solvent

The invention provides a preparation method of alternately growing ferroelectric films, and belongs to the technical field of ferroelectric films. The preparation method comprises the following steps: weighing an organic hafnium salt and an organic metal salt with multiple doped elements according to a preset proportion, putting the weighed organic hafnium salt and organic metal salt into a container, and sequentially adding monobasic acid and an organic solvent; heating and stirring until the solution is clarified, and continuously stirring to room temperature to obtain various precursor solutions with different solution concentrations, different doping elements, different doping amounts and the like; dropwise adding two or more precursor solutions to a platinum substrate in an alternating manner for spin-coating treatment; and performing annealing operation to obtain the multi-element doped Hf < 0.5 > Zr < 0.5 > O < 2 > (HZO) ferroelectric film which grows alternately. By adopting a chemical solution deposition method, the alternately growing multi-element doped HZO ferroelectric film can be prepared under the condition of not using large equipment, the preparation process is simple, the equipment cost is low, and large-scale production is easy.

Owner:XIANGTAN UNIV

Improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction

ActiveCN102219262BPromote growthSimple processCell electrodesManganese oxides/hydroxidesLithium hydroxidePhysical chemistry

The invention provides a method for preparing layered lithium-rich manganese-nickel oxides by an improved low-heat solid-phase method, according to Li1+xMnyNi1-x-yO2,0

Owner:湖南金富力新能源股份有限公司

Single-phase samarium titanate nanopowder prepared by a solution method and method thereof

ActiveCN108083328BControl stoichiometric ratioNo harmMaterial nanotechnologyTitanium compoundsBarium titanateChemical element

The invention relates to a single-phase samarium titanate nanopowder prepared by a solution method and a method thereof. First, the samarium source and the titanium source are dispersed in a solvent according to a molar ratio of 1: (1.1 to 1.3) to obtain solution A; solution A is adjusted to neutral pH value to obtain a milky white mixed solution B; separate the milky white mixed solution B to obtain a white powder; dry the powder obtained in step three and then calcine to obtain single-phase samarium titanate nanopowder . In the present invention, the samarium source and titanium source are fully dissolved and dispersed in the solvent medium, and the samarium source and titanium source are mixed and reacted at the atomic scale to achieve precise control of the chemistry between the ternary Sm-Ti-O chemical elements. The purpose of the stoichiometric ratio is to prevent the appearance of other impurities and achieve the preparation of single-phase Sm 2 Ti 2 O 7 The goal.

Owner:成都莒纳新材料科技有限公司

Preparation method of lithium titanate

ActiveCN103290426BControl stoichiometric ratioParticle size is easy to controlElectrolysis componentsElectrolysisElectrical battery

The invention discloses a preparation method of lithium titanate. The preparation method is characterized by comprising the following steps of: combining TiO2 powder which is wrapped by using a carbon source or is mixed by using a carbon material or a tabletting with a metal current collector so as to be used as a cathode; by taking graphite as an anode and taking a molten alkali halide as an electrolyte, electrolyzing for 1-5 hours in an argon atmosphere at an electrolysis temperature of 400-700 DEG C under an electrolysis voltage of 2.0-3.2V, cooling down to be the normal temperature and taking out, subsequently washing in distilled water or an organic solvent, and drying in vacuum so as to obtain LiTiO2 which is wrapped by using the carbon source or is mixed by using the carbon material; washing an electrolysis product, drying the electrolysis product in vacuum, and subsequently firing for 1-3 hours at 600-900 DEG C in air so as to obtain Li4Ti5O12. By utilizing the method, product grain size controllability is realized, and the problems of product batch stability and consistence caused by in-scale production are solved. The lithium titanate prepared by using the method can be used as an energy material to be directly applied to lithium ion secondary batteries and super-capacitors.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Trace Cu-doped Bi2S3-based thermoelectric material

InactiveCN102280570BControl stoichiometric ratioPrecise control of stoichiometric ratioThermoelectric device junction materialsMetallurgyElectric properties

The invention belongs to the technical field of energy materials and in particular relates to a trace Cu-doped Bi2S3-based thermoelectric material. In the thermoelectric material, metal simple substance Bi and Cu powder with the purity of 99.99 percent and simple substance S powder serve as raw materials, the thermoelectric material is prepared according to a chemical general formula of CuxBi2-xS3, wherein x is mole fraction of a Cu component and x is more than or equal to 0.001 and less than or equal to 0.05, and the thermoelectric material is prepared into a block material by combining a discharge plasma sintering technology and a mechanical alloying method. By the method, the trace Cu-doped Bi2S3-based block thermoelectric material can be easy and convenient to prepare, trace Cu is introduced into a Bi2S3 lattice, the carrier concentration of a sample is improved, a power factor is optimized, a Cu-S nano deposition coherent with a substrate structure is formed, and the thermal conductivity is greatly reduced; therefore, the thermoelectric performance of the Bi2S3-based block material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

A method for preparing lithium nickel cobalt aluminum oxide material by low heat solid state reaction

ActiveCN103943850BControl stoichiometric ratioWell mixedCell electrodesSecondary cellsAir atmosphereChemical measurement

The invention discloses a method for preparing a lithium-nickel-cobalt-aluminium oxide material by adopting low-heat solid-phase reaction. The method comprises the following steps: a. preparing a precursor, namely weighing lithium hydroxide monohydrate, nickel nitrate hexahydrate, cobalt nitrate hexahydrate, lithium nitrate nonahydrate and a doping element M according to stoichiometry of LiNi(0.8)Co(0.15)Al(0.05+ / -x)M(y)O(2), wherein x is greater than or equal to 0 and is less than or equal to 0.05, y is greater than or equal to 0 and is less than or equal to 0.05, x+y is equal to 0.05, M is B, Zr, Ti or AlPO4, mixing in a high-speed mixer at the rotating speed of 2000r / m for 15 minutes according to a stoichiometric ratio so as to obtain a synthesized material, and drying the synthesized material at the temperature of 120-150 DEG C in vacuum so as to prepare the precursor; and b. roasting the precursor prepared in the step a at the temperature of 600-800 DEG C in an oxygen atmosphere or an air atmosphere so as to obtain the final product-lithium-nickel-cobalt-aluminium oxide material. The method has the following advantages that the stoichiometric ratio of the components is relatively easy to control, the components are uniformly mixed, the synthesis temperature can also be reduced, and the energy consumption and the production cost are reduced.

Owner:山东天骄新能源有限公司

A gasoline selective hydrodesulfurization catalyst and its preparation and application

ActiveCN106268976BReduce usageControl stoichiometric ratioCatalyst activation/preparationRefining to eliminate hetero atomsPtru catalystUltrasonic assisted

The invention relates to a gasoline selective hydrodesulfurization catalyst and preparation and application thereof. According to the total mass of the catalyst being 100%, the catalyst is prepared from 3-15 wt% of VIII group metal, 45-58 wt% of Mo and 35-40 wt% of S. A preparation method of the catalyst comprises the following steps that 1, a defect-rich molybdenum disulfide nanosheet precursor with a non-stoichiometric ratio is prepared; 2, one kind of VIII group metal is added into the molybdenum disulfide nanosheet precursor through an ultrasonic assisting dipping method, the molar ratio of the VIII group metal to Mo is (0.1-0.5):1, the specific surface area of the molybdenum disulfide nanosheet precursor ranges from 40 m<2> / g to 90 m<2> / g, the pore volume ranges from 0.1 ml / g to 0.25 ml / g, and the molar ratio of sulfur to molybdenum is (1.92-2.10):1. Defect-rich molybdenum disulfide is prepared by controlling the stoichiometric ratio of molybdenum disulfide, and meanwhile more active loci are exposed. Compared with an existing catalyst, the catalyst is applied to a gasoline selective hydrodesulfurization reaction, the hydrogenation saturation factor of olefin is low, and the hydrodesulfurization rate of a sulfur-containing compound is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Film-forming method and application of n-type in2s3 buffer layer

ActiveCN104269461BGood electrical conductivityControl stoichiometric ratioFinal product manufactureVacuum evaporation coatingIndiumElectrical battery

Aiming at the deficiencies in the preparation of the In2S3 buffer layer in the prior art, the invention provides a new film-forming method and application of the n-type In2S3 buffer layer. The film-forming method of the present invention comprises preparing In2S3 cake, preparing In2S3 target block, preparing In2S3 thin film, annealing and obtaining an n-type indium sulfide buffer layer with a resistivity not greater than 5×10-3 Ω·cm. The solar cell obtained by the product of the present invention has an open circuit voltage of 0.29 V and a short circuit current of 7.7 nA. Beneficial technical effects: The film-forming method and product of the present invention have the advantages of good film uniformity, good electrical conductivity, stable chemical composition, and no environmental pollution.

Owner:黄山市开发投资集团有限公司

A method for rapid preparation of single-phase bi2s3 thermoelectric compounds

ActiveCN103435099BControl stoichiometric ratioQuick responseBismuth compoundsThermoelectric device junction materialsReagentChemical engineering

The present invention relates to a method for rapidly preparing single-phase Bi2S3 thermoelectric compounds, which comprises the following steps: 1) preparing Bi powder and S powder as raw materials according to the stoichiometric ratio Bi:S=2:3.06, relative to the stoichiometric ratio of the compound Bi2S3 For example, the excess of raw sulfur powder is 2%, and then they are ground and mixed uniformly to obtain the reactant; 2) The reactant in step 1) is induced to self-propagating reaction or thermal explosion reaction, and after the reaction is completed, it is naturally cooled to obtain a single-phase Bi2S3 thermoelectric compound. The invention has the advantages of fast response speed, simple equipment, good repeatability, high efficiency and energy saving, and the like.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com