Gasoline selective hydrodesulfurization catalyst and preparation and application thereof

A hydrodesulfurization and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increased carbon deposition process, decreased gasoline octane number, high hydrogenation activity, etc., to achieve The effect of low production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

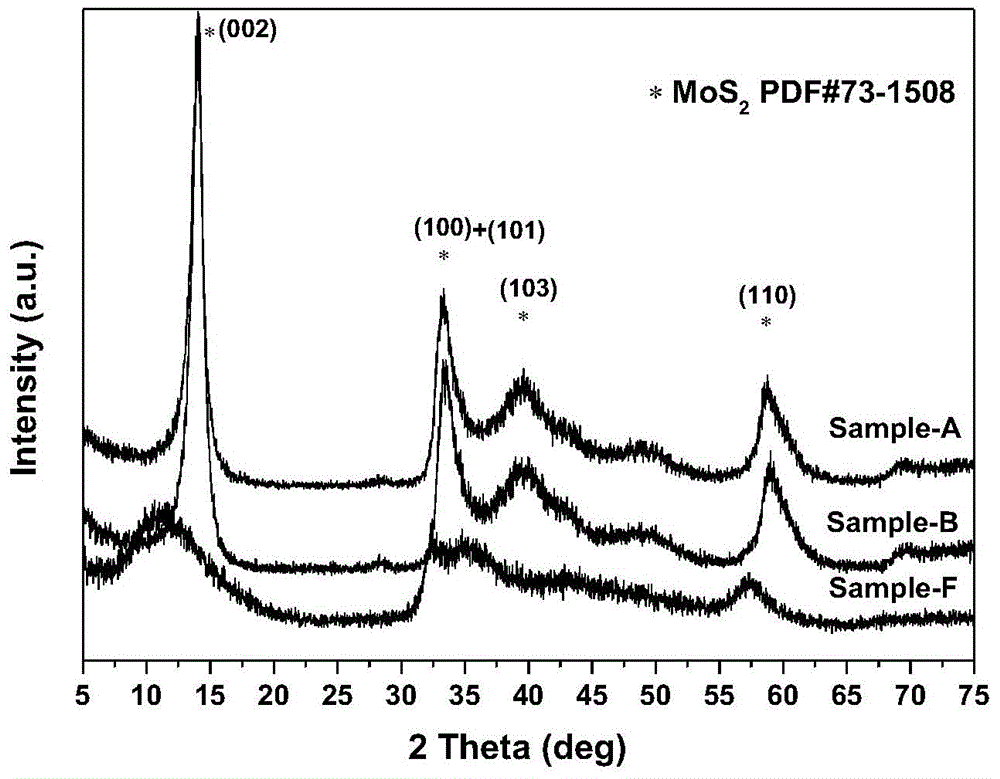

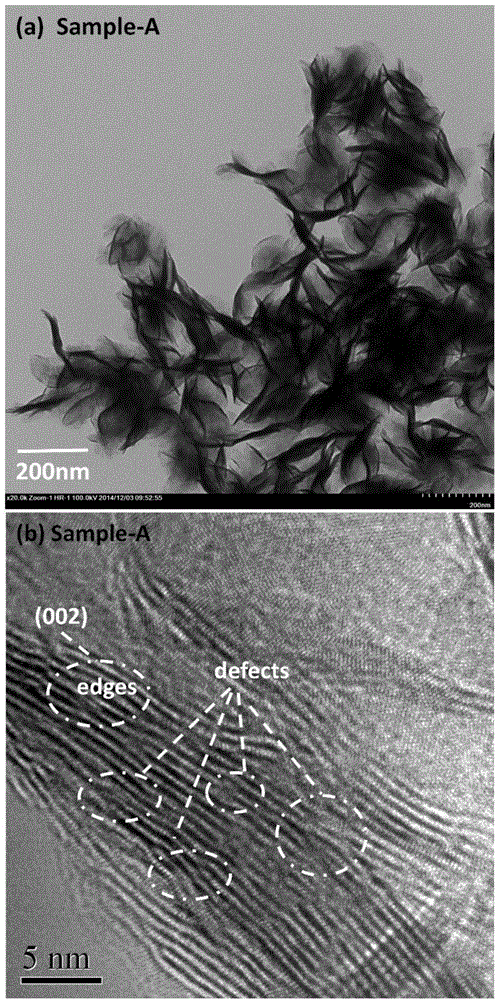

[0049] Mix 4.94g of ammonium heptamolybdate and 9.13g of thiourea and add 140ml of deionized water to dissolve it, transfer to a 200ml hydrothermal kettle, put it in an oven, conduct hydrothermal at 220°C for 18h, and then cool naturally. Suction filtration, ultrasonic washing with a mixed solvent of 1 volume ratio of water and absolute ethanol for 2-4 times, vacuum drying to obtain the precursor of molybdenum disulfide nanosheets; 0.428g cobalt acetate was dissolved in 6ml water, and 2.5g molybdenum disulfide nanosheets The tablet precursor was added to the previously prepared cobalt-containing solution, sonicated and stirred until it became viscous, and then transferred to a vacuum drying oven at 50°C for 24 hours to obtain a catalyst. The catalyst synthesized in this example is represented by Cat-A. The ICP element analysis of the molybdenum disulfide nanosheet precursor in this example showed that the molar ratio of sulfur to molybdenum was 2.03, and the specific surface ar...

Embodiment 2

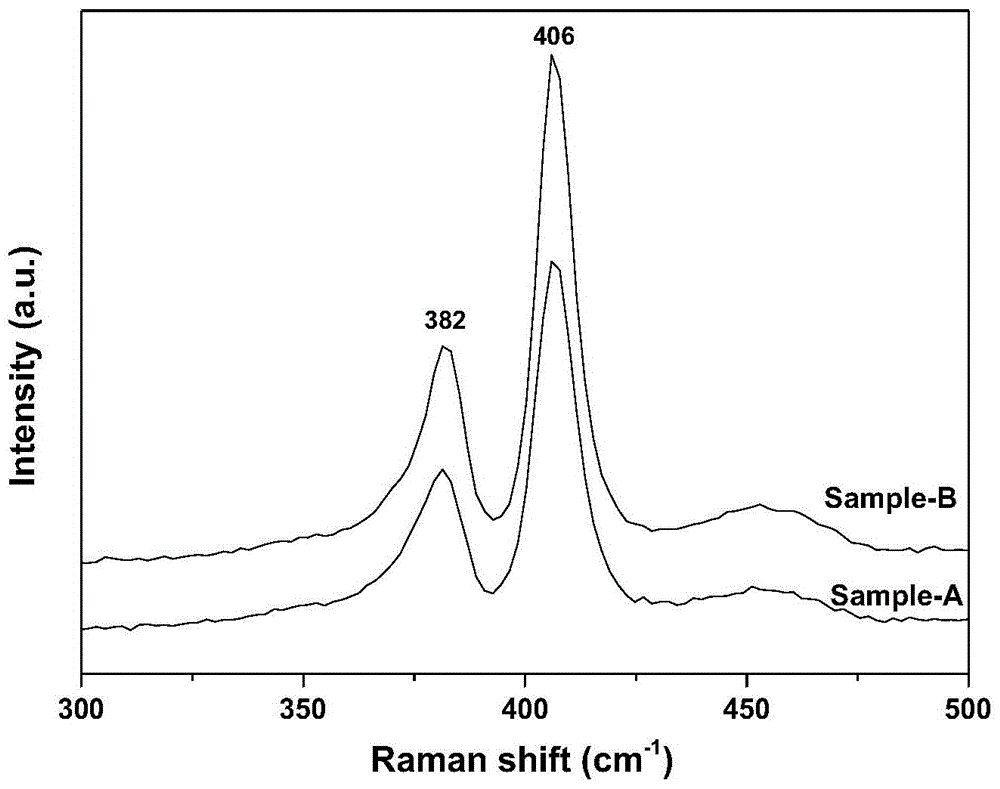

[0051] A catalyst was prepared in the same manner as described in Example 1, except that 6.39 g of thiourea was used instead of the thiourea used in Example 1. The catalyst synthesized in this example is represented by Cat-B. The ICP element analysis of the molybdenum disulfide nanosheet precursor in this example showed that the molar ratio of sulfur to molybdenum was 1.98, and the specific surface area determined by nitrogen adsorption was 60m. 2 / g, its XRD characterization is as figure 1 As shown, the Raman spectrum is as figure 2 Shown.

Embodiment 3

[0053] A catalyst was prepared in the same manner as described in Example 1, except that 4.26 g of thiourea was used instead of the thiourea used in Example 1. The catalyst synthesized in this example is represented by Cat-C. The ICP element analysis of the molybdenum disulfide nanosheet precursor in this example showed that the molar ratio of sulfur to molybdenum was 1.94, and the specific surface area determined by nitrogen adsorption was 41 m. 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com