Patents

Literature

191 results about "Taylor cone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Taylor cone refers to the cone observed in electrospinning, electrospraying and hydrodynamic spray processes from which a jet of charged particles emanates above a threshold voltage. Aside from electrospray ionization in mass spectrometry, the Taylor cone is important in field-emission electric propulsion (FEEP) and colloid thrusters used in fine control and high efficiency (low power) thrust of spacecraft.

Electrohydrodynamic printing and manufacturing

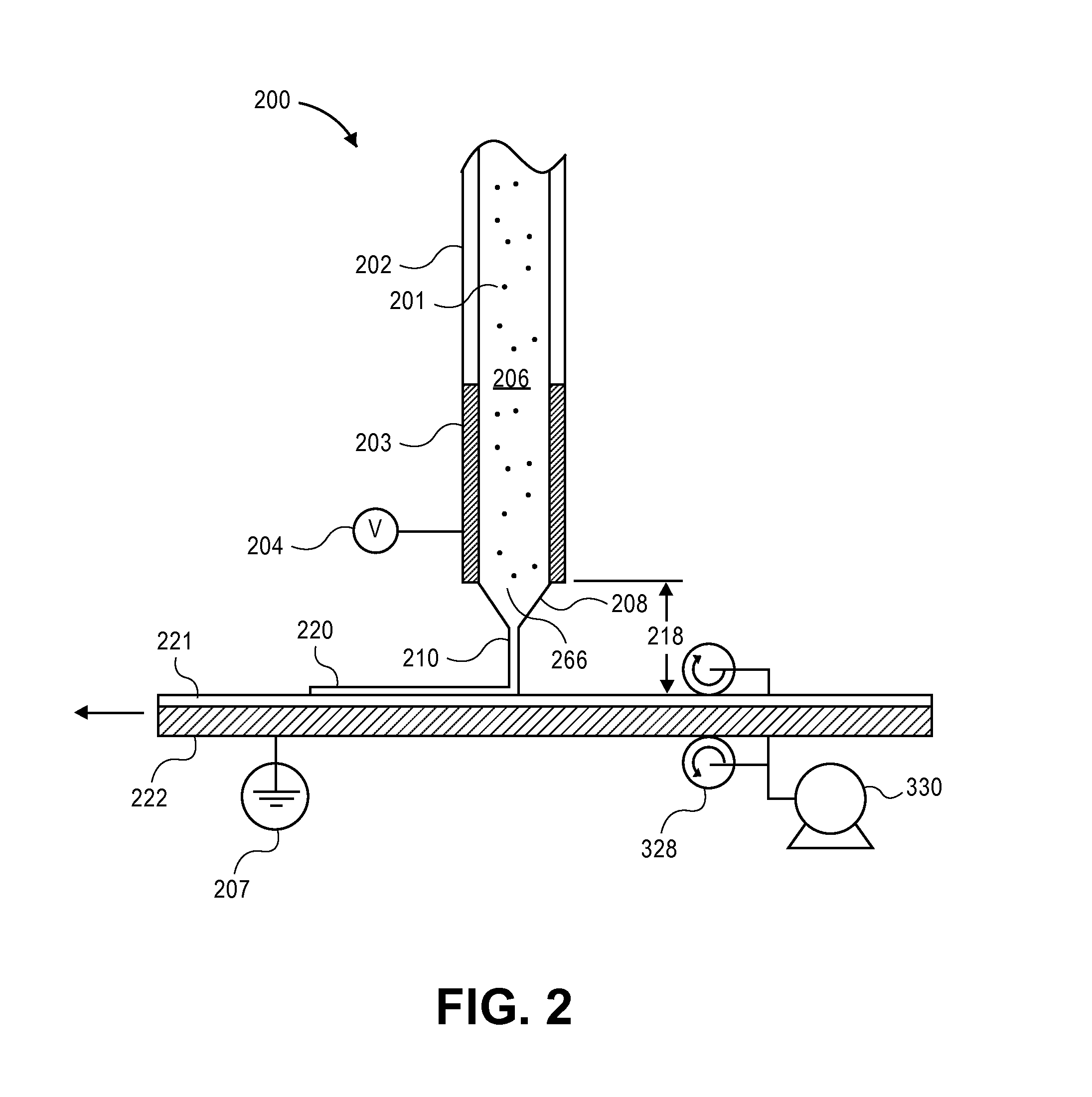

ActiveUS20090233057A1Liquid surface applicatorsElectric discharge heatingFiberManufacturing technology

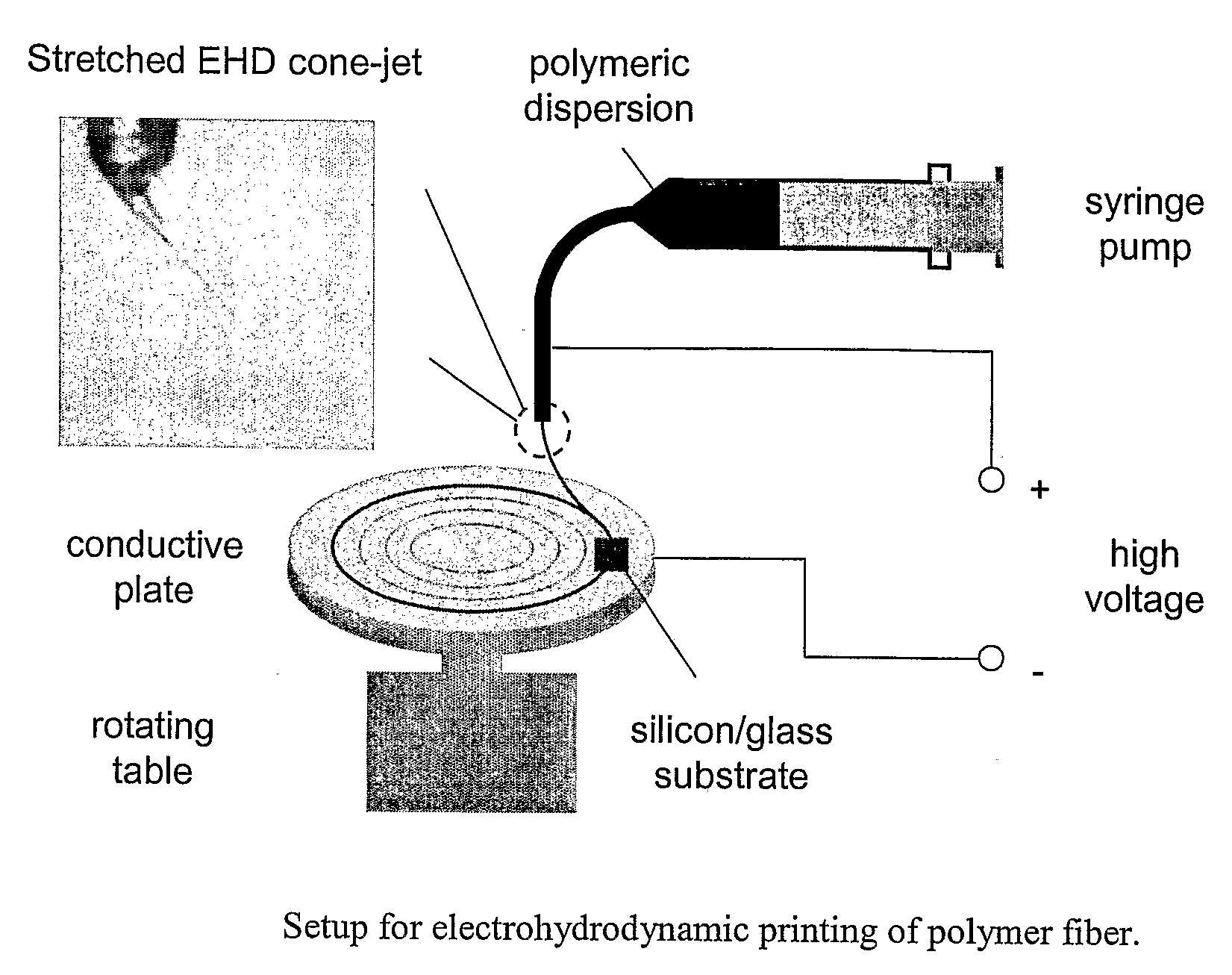

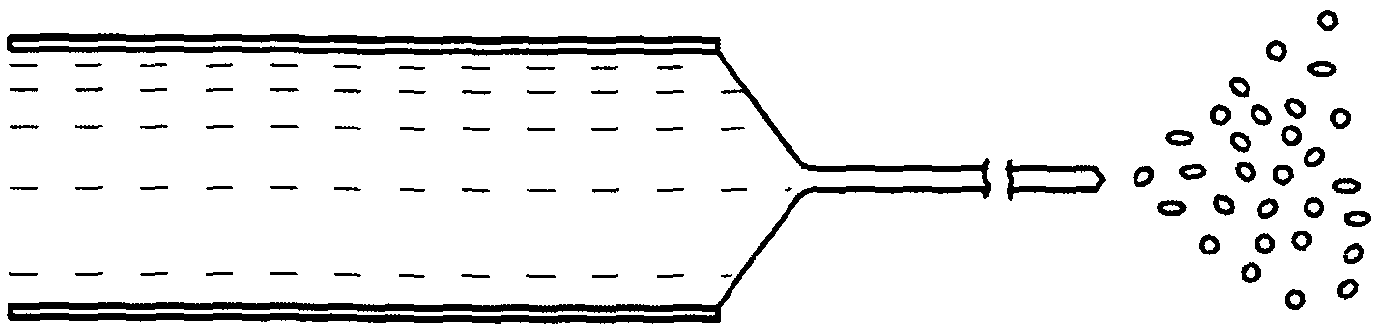

An stable electrohydrodynamic filament is obtained by causing a straight electrohydrodynamic filament formed from a liquid to emerge from a Taylor cone, the filament having a diameter of from 10 nm to 100 μm. Such filaments are useful in electrohydrodynamic printing and manufacturing techniques and their application in liquid drop / particle and fiber production, colloidal deployment and assembly, and composite materials processing.

Owner:THE TRUSTEES FOR PRINCETON UNIV

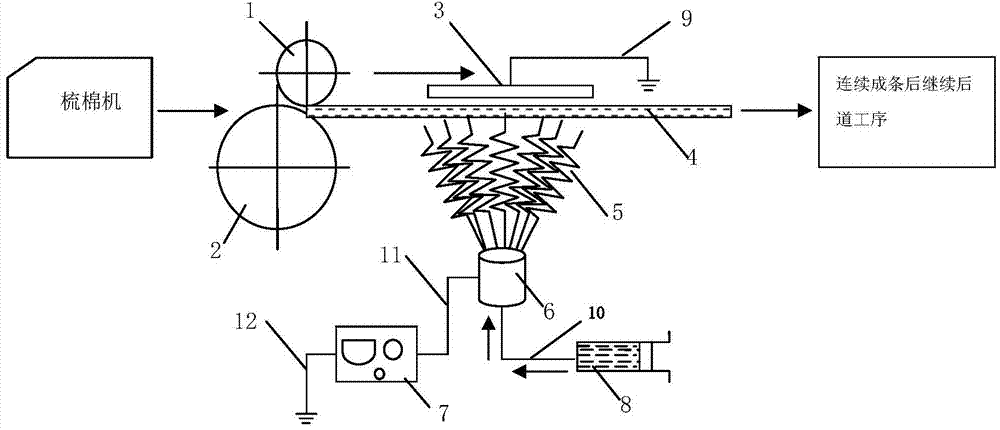

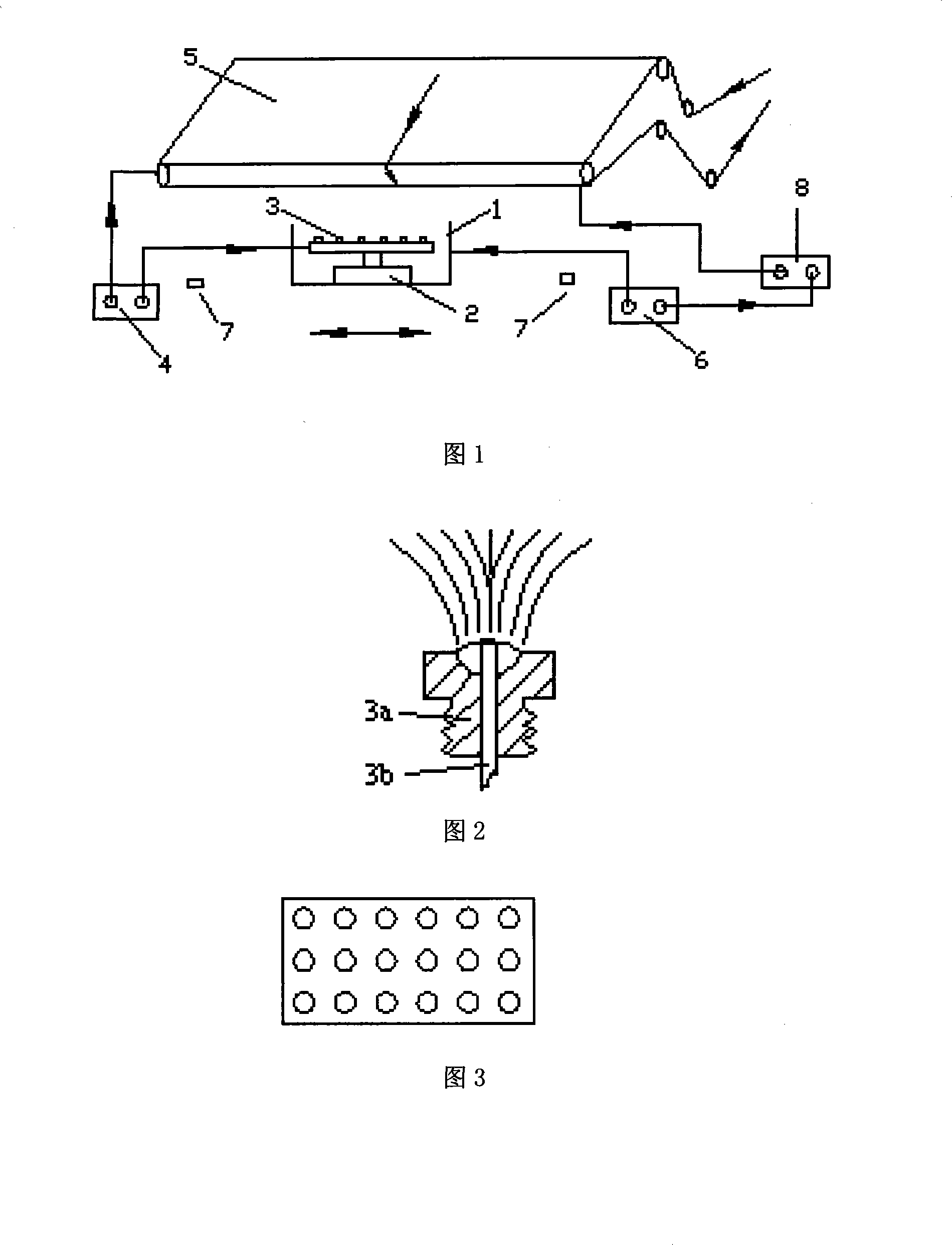

Method for preparing nano-fiber blending composite yarn

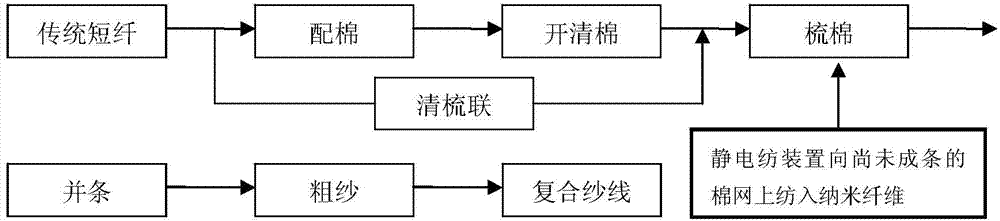

The invention relates to a method for preparing nano-fiber blending composite yarn. The method comprises the steps that (1) a functional high-molecular polymer is dissolved in a corresponding solvent to obtain an even electrostatic spinning solution; (2) traditional spinning, including cotton carding, is carried out on short fibers; (3) electrostatic spinning is carried out on the electrostatic spinning solution by means of a TAYLOR cone multi-spray-head electrostatic spinning machine, wherein spinning jet flows are directly sprayed upwards onto fleece which is about to become sliver and formed in the cotton carding process, then fleece containing nano-fibers is obtained, the fleece containing the nano-fibers enters the next yarn forming process directly after becoming the sliver, and finally the nano-fiber blending composite yarn is obtained. The preparing method is simple. The nano-fiber blending composite yarn prepared through the combination of the electrostatic spinning technique and the traditional spinning technique is functional to a certain degree, belongs to nano-textile in the true sense, and is capable of improving the additional value of a product.

Owner:DONGHUA UNIV

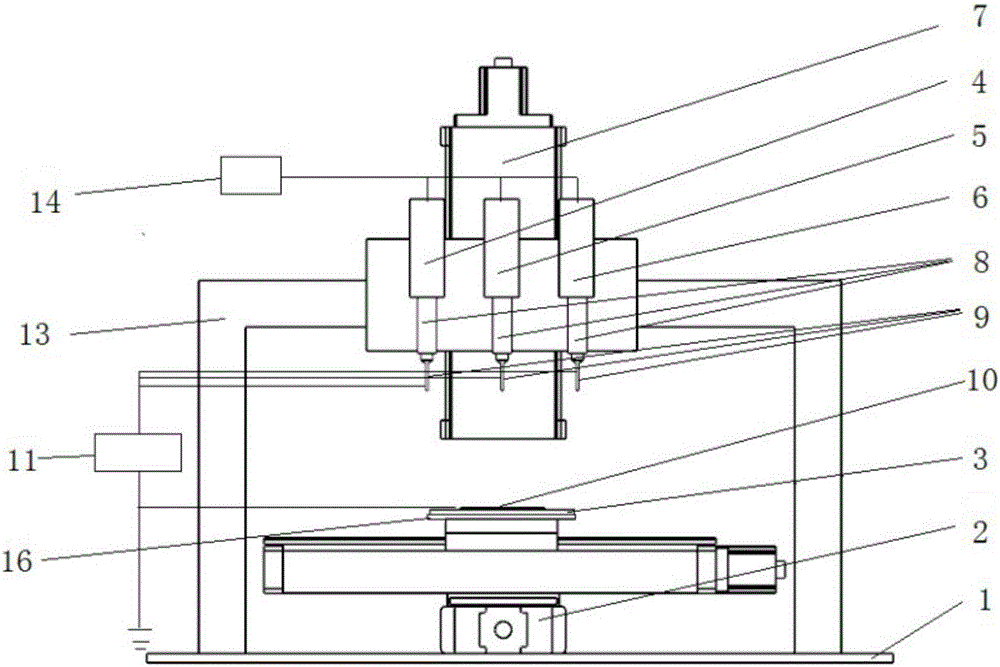

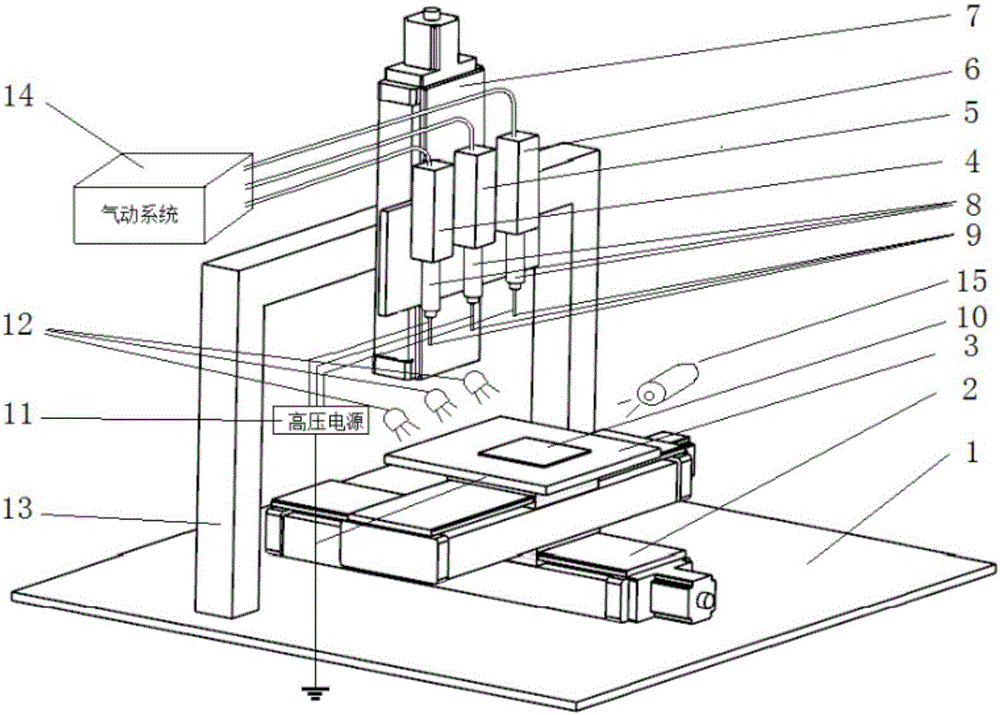

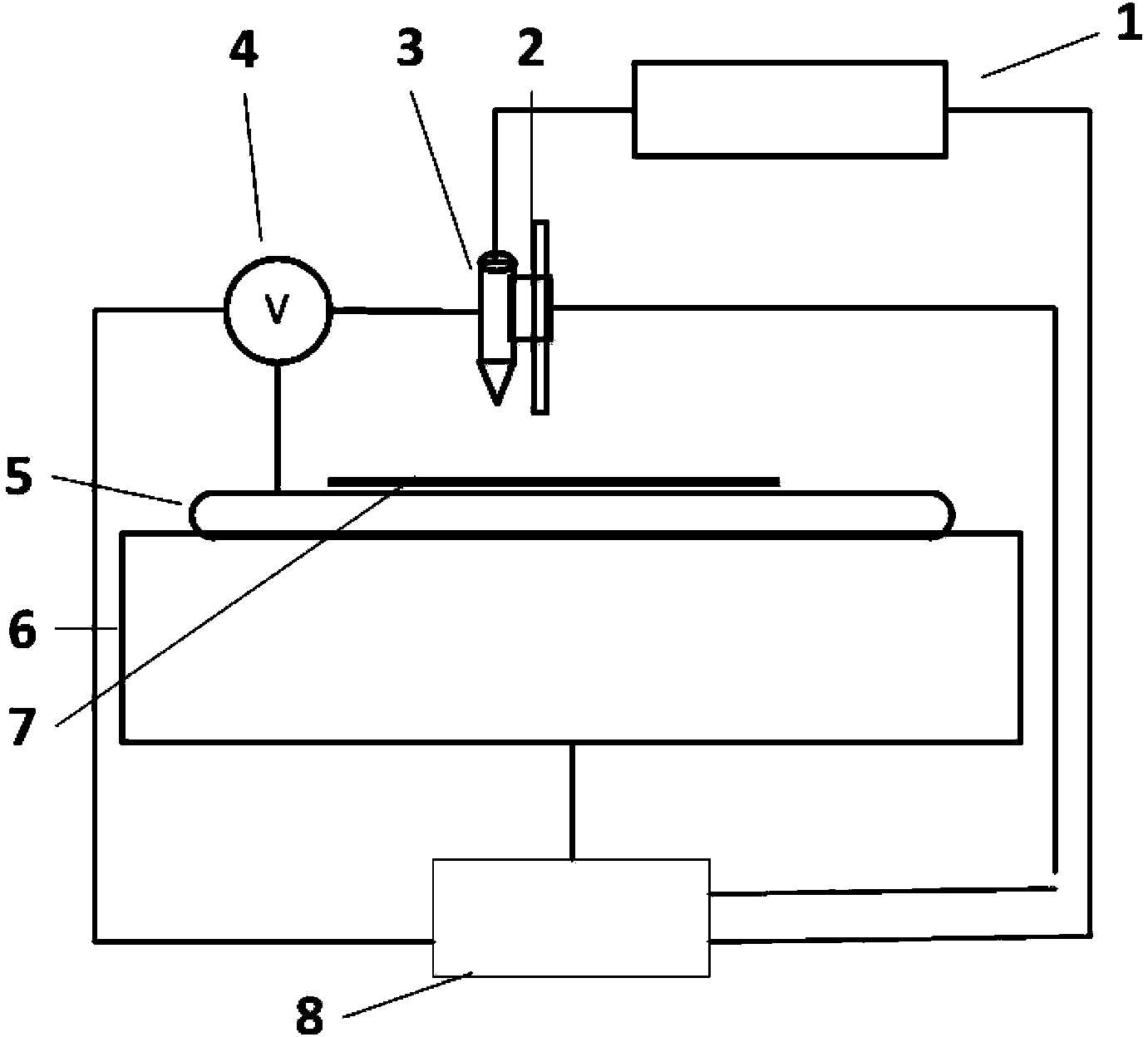

Micro-nano scale 3D printer and method

InactiveCN106738896AHigh resolutionLow costManufacturing driving means3D object support structuresMicro nanoSpray nozzle

The invention discloses a micro-nano scale 3D printer and a method. The 3D printer comprises a spraying head set, a printing tool, a controller and a three-dimensional movement mechanism. The spraying head comprises a plurality of spraying heads, and each spraying head applies a high-voltage pulse power supply between a corresponding electric conductive nozzle and an electric conductive base plate. Fluids are pulled from the nozzles by utilizing strong electric field force formed between the nozzles and the base plate to form Taylor Cones and stable conic jet flows. The controller controls the three-dimensional movement mechanism to drive the spraying head set and the printing tool to move relatively and meanwhile controls the movement of all the spraying heads to conduct micro-droplet spray printing on preset positions of the base material on the printing tool, and a model material, a release material and a supporting material are printed sequentially. Based on electrofluid power spraying printing (namely electric spraying printing), the micro-nano scale 3D printer solves the difficult problems that for micro-nano 3D printing, macro / micro cross-scale manufacturing cannot be achieved, the types of printable materials are few, and support is difficult to remove, and especially overcomes the deficiencies and the limitation, in the aspects of the cost, materials, resolution ratio, macro / micro cross-scale manufacturing, support removing and the like, of the of the current micro-nano scale 3D printing technology.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

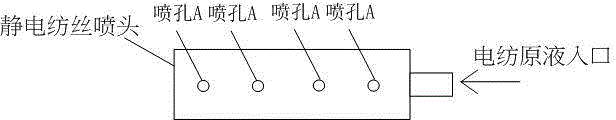

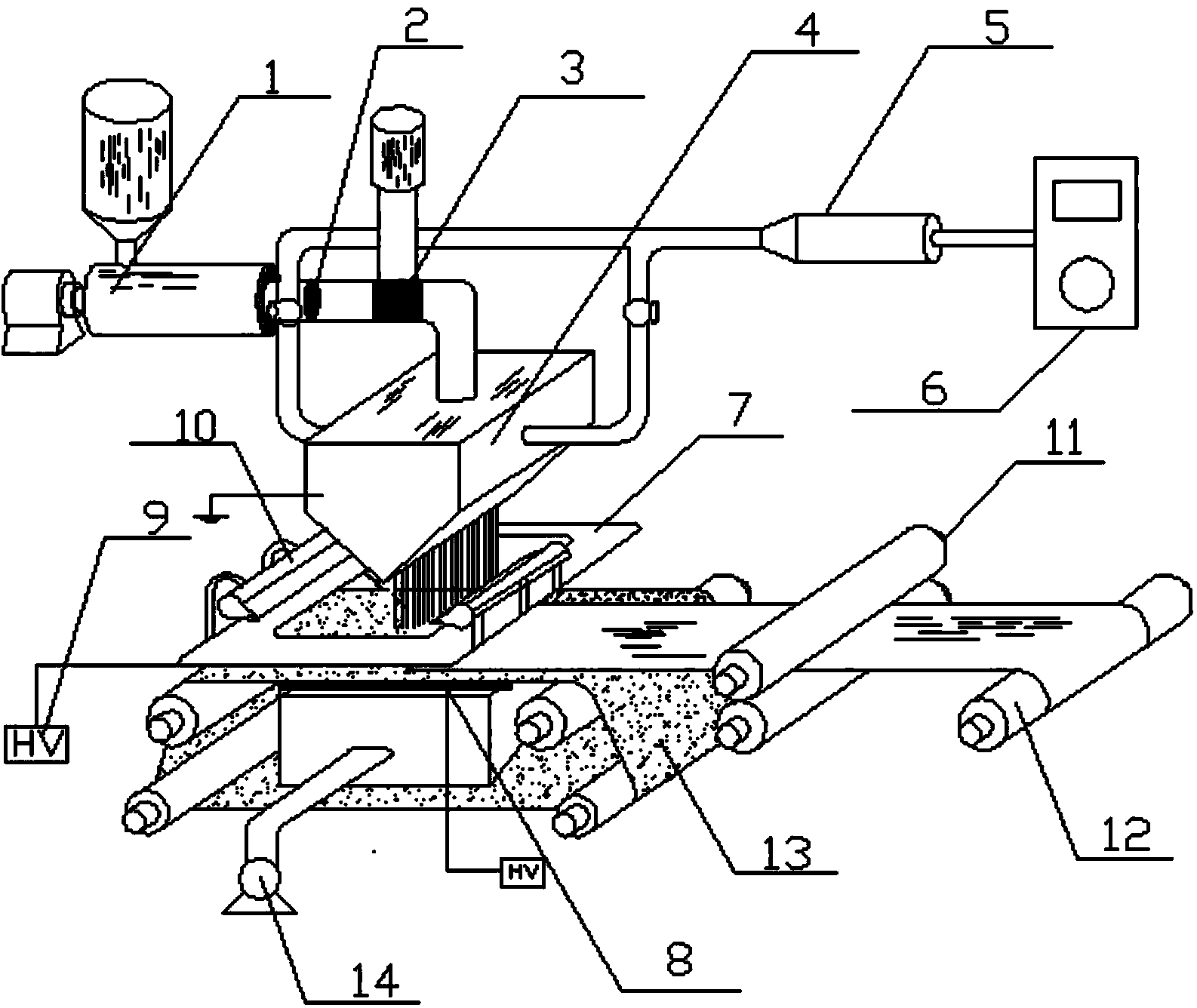

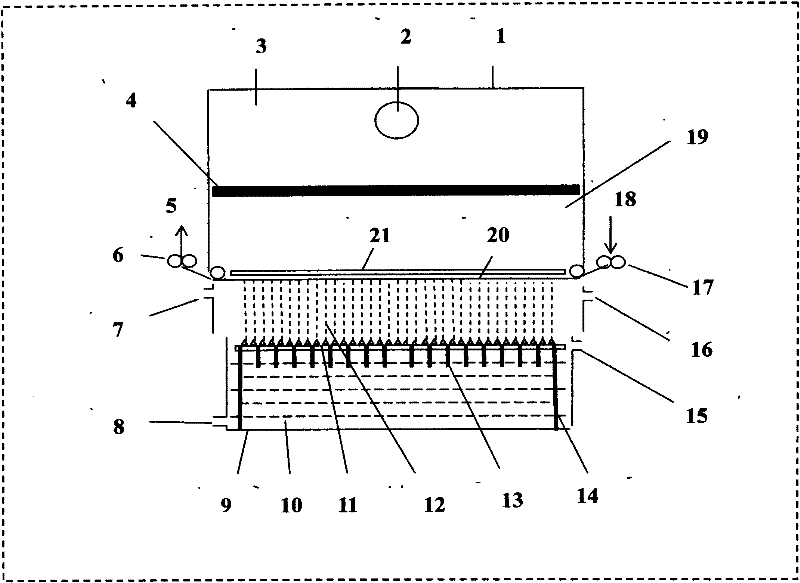

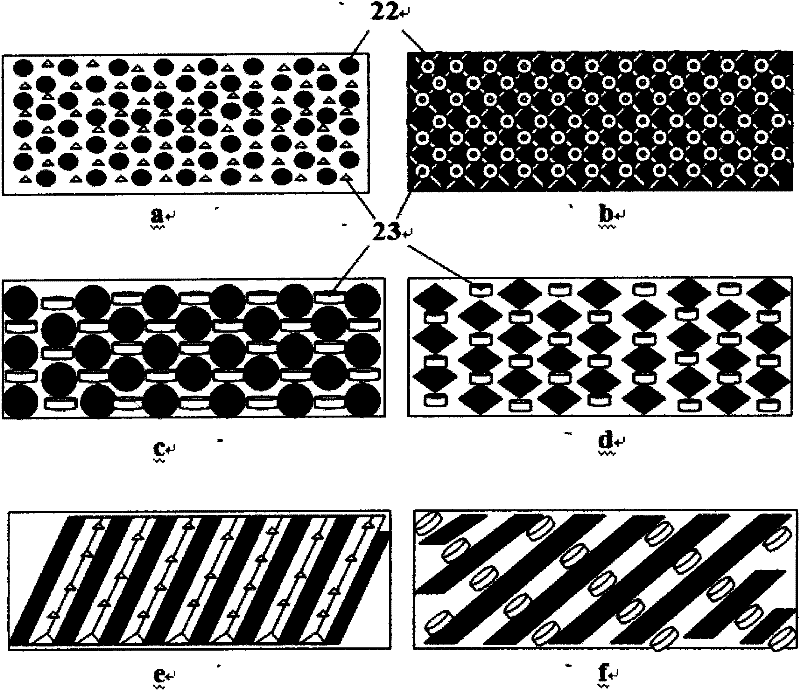

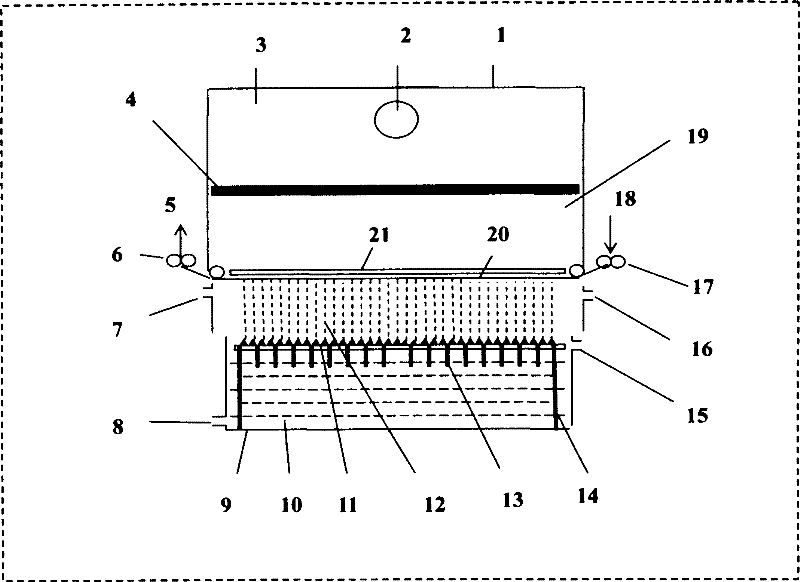

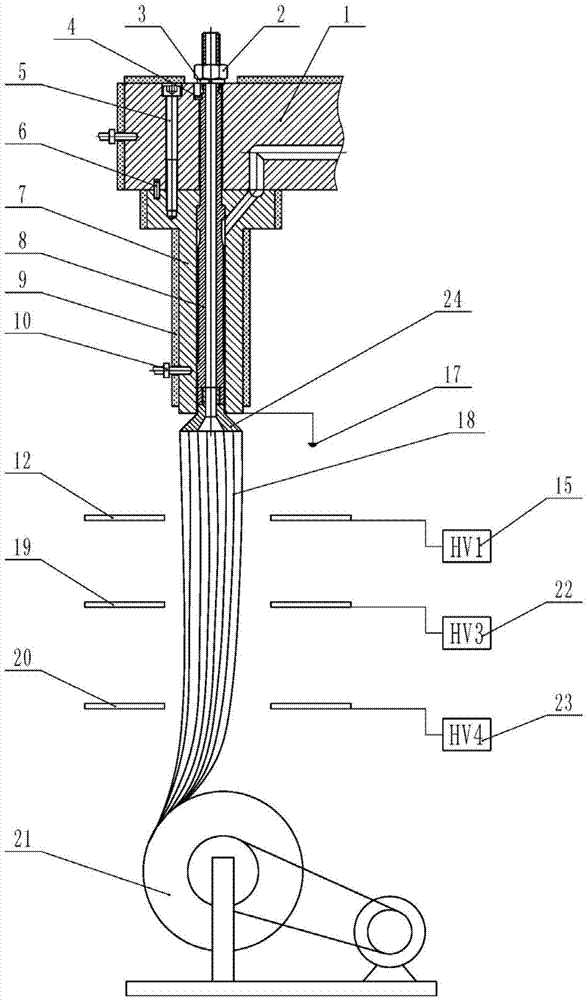

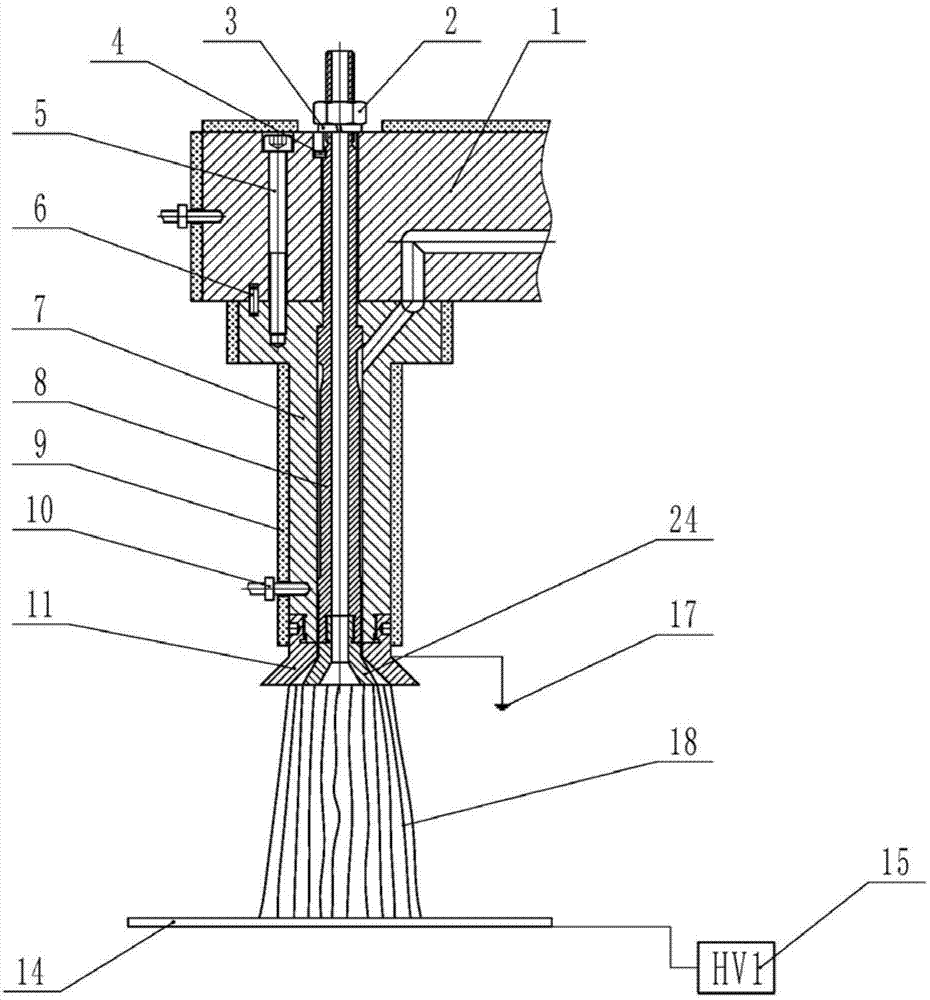

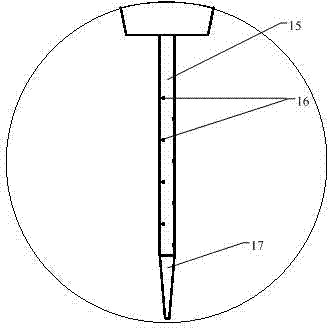

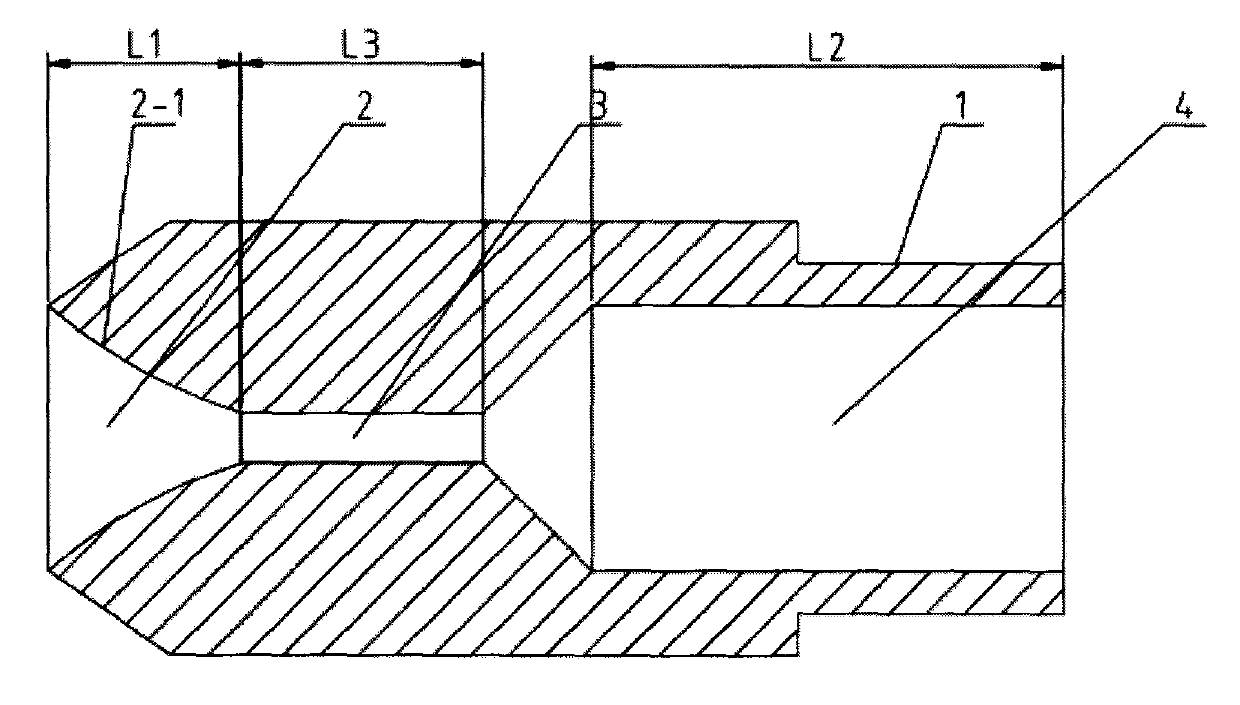

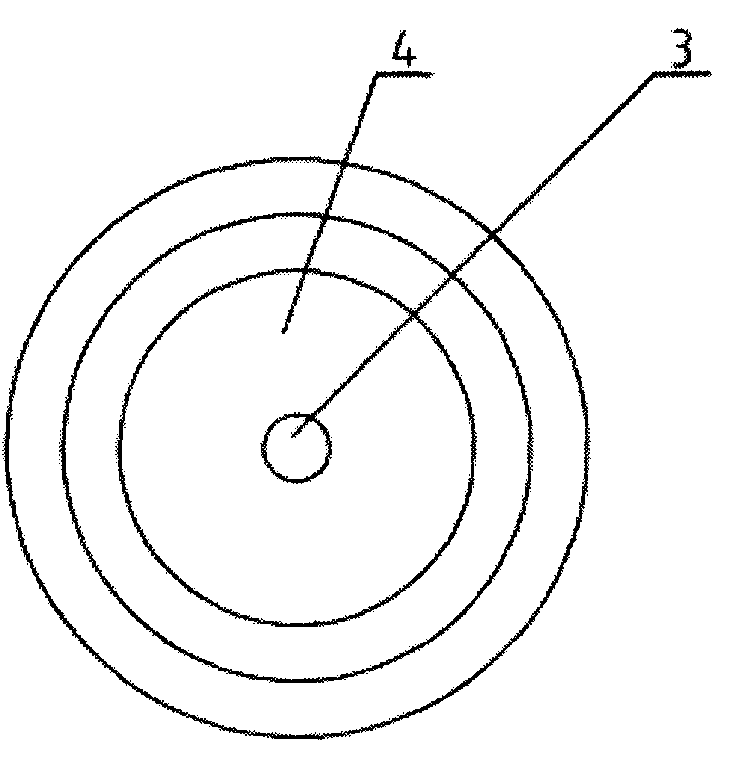

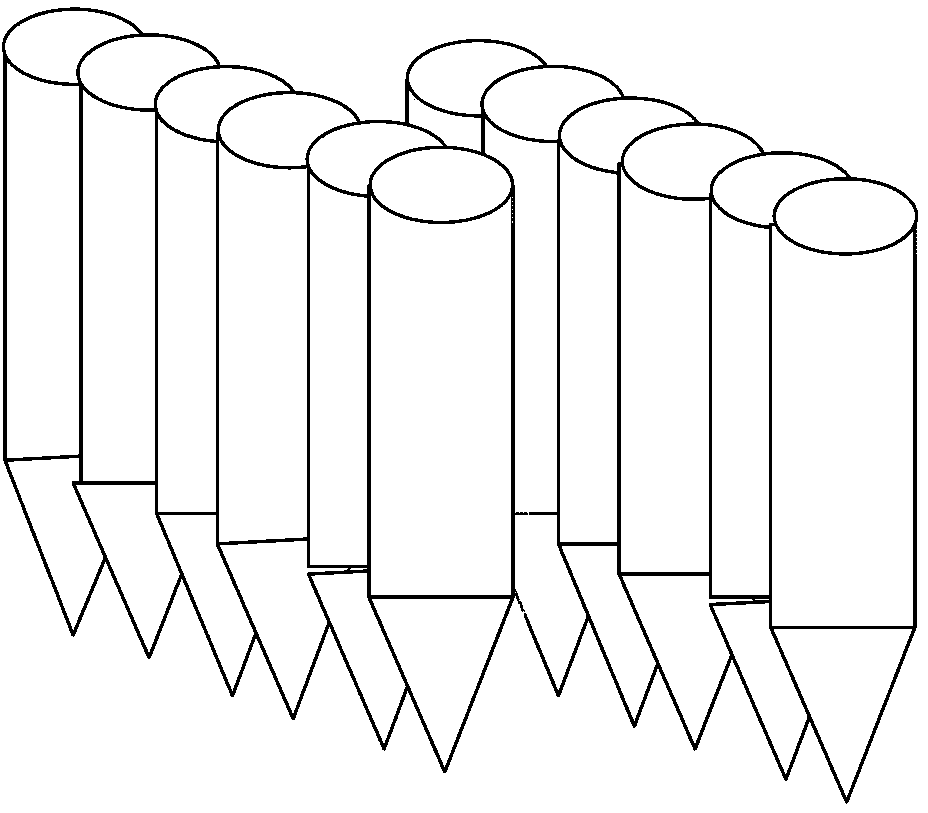

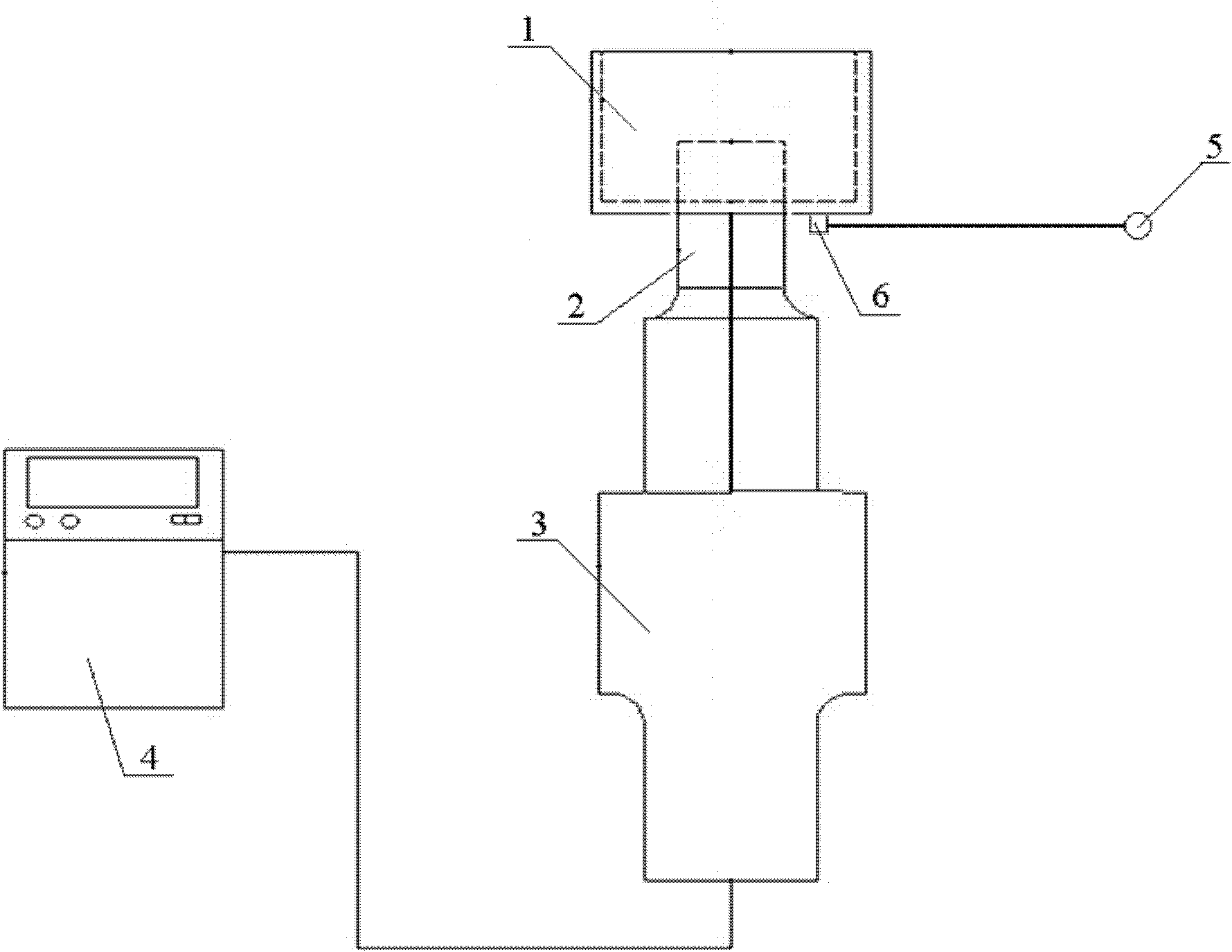

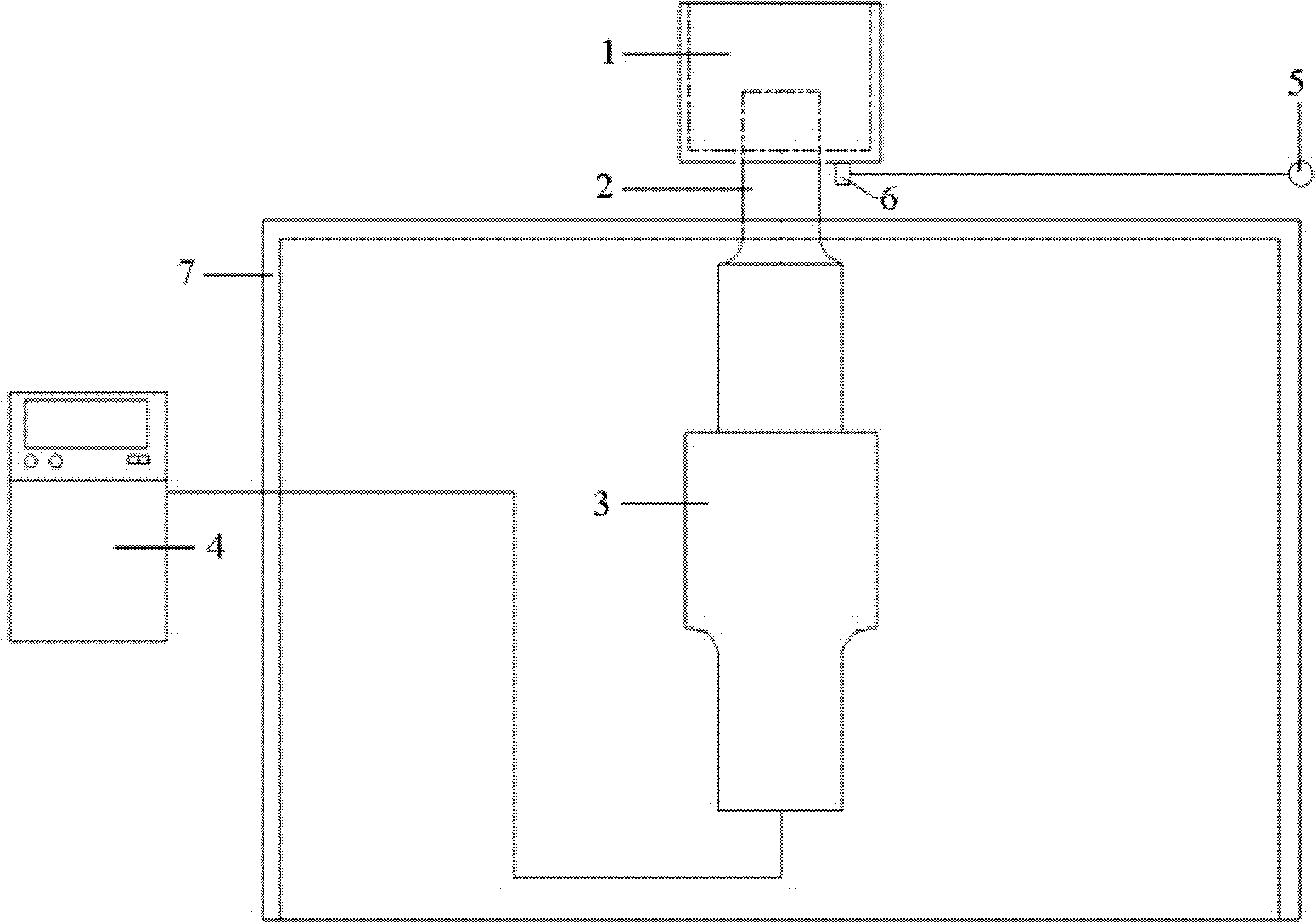

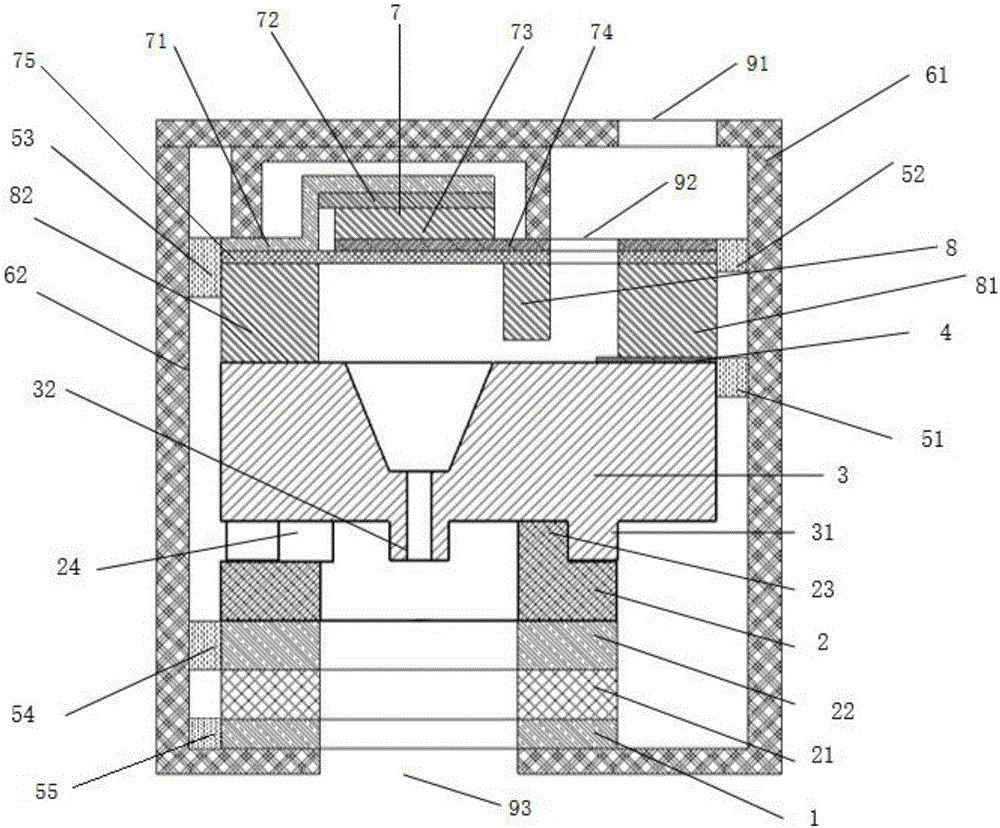

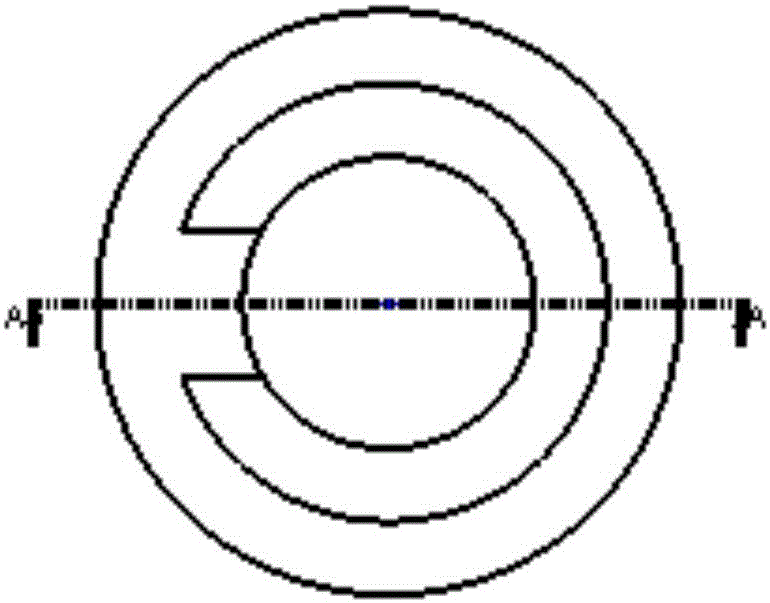

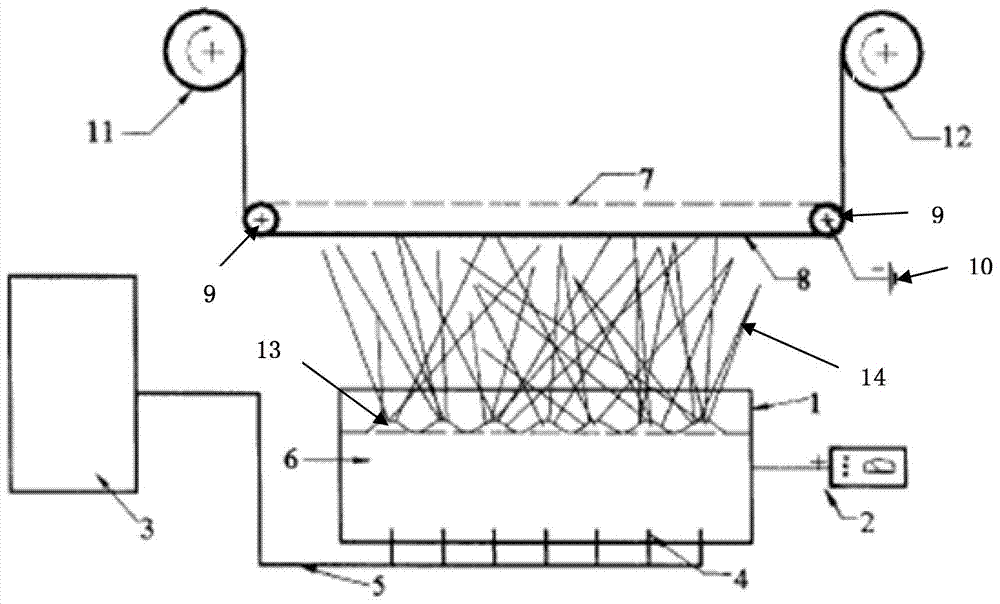

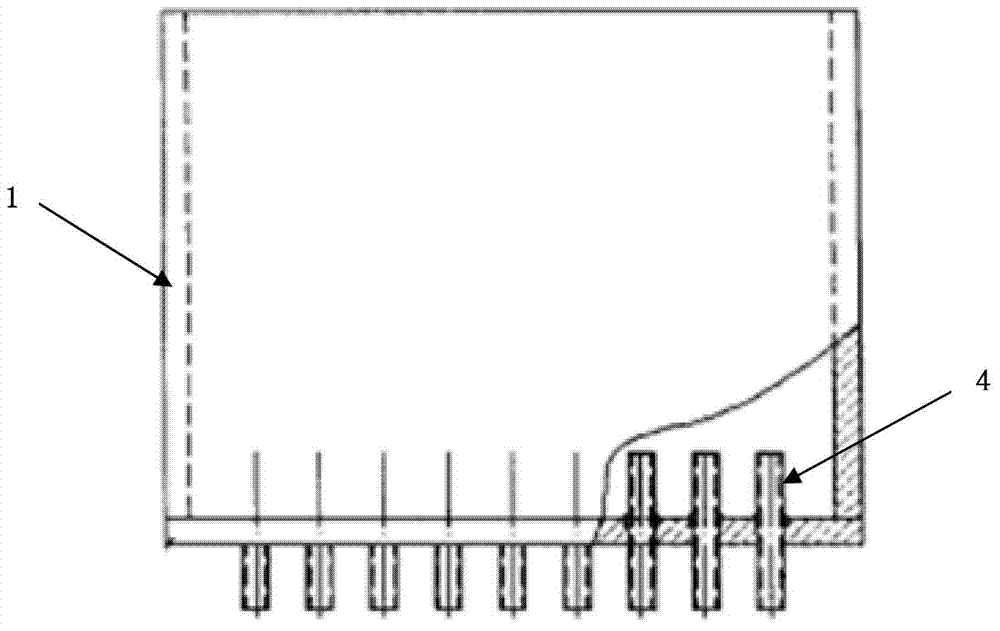

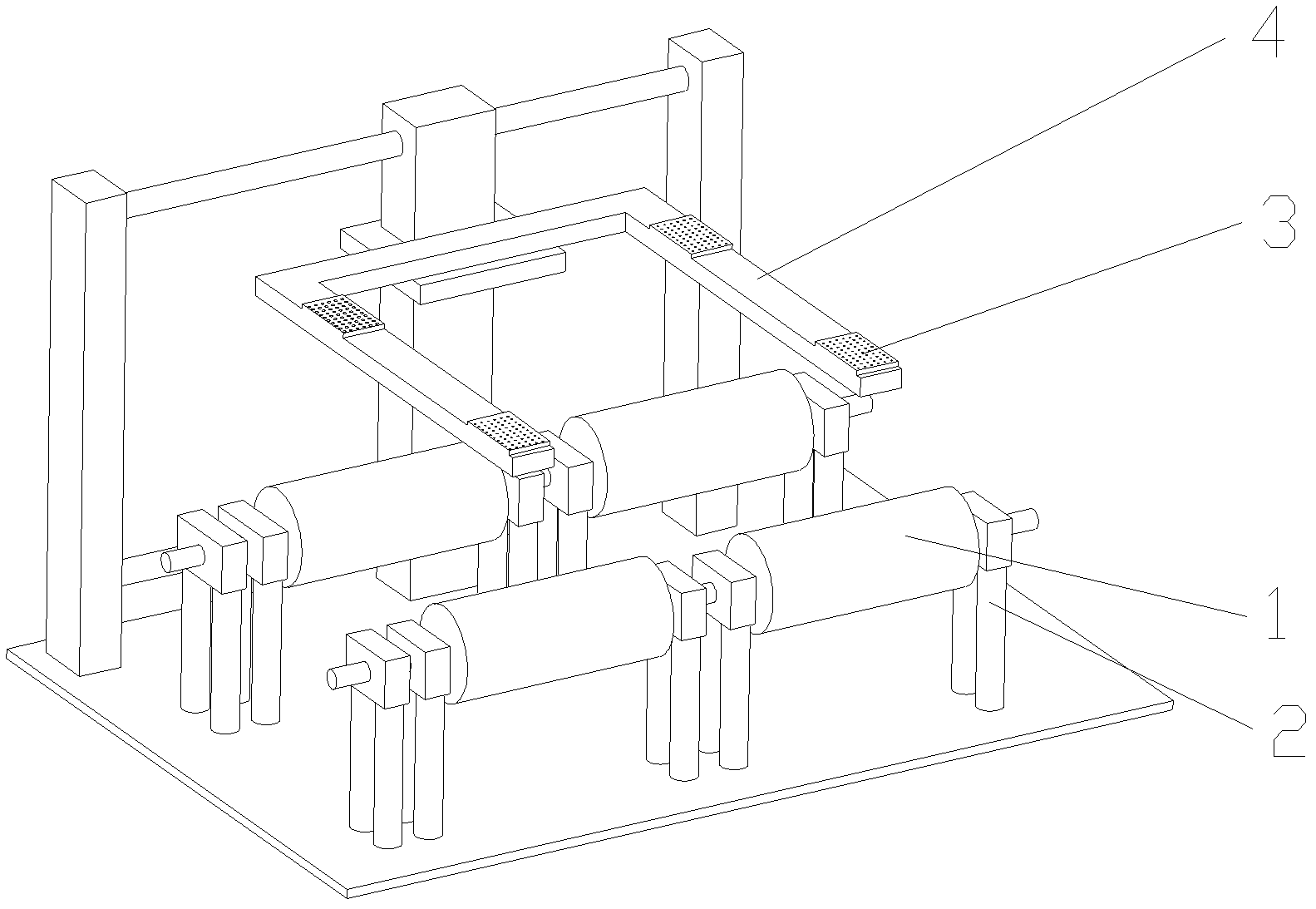

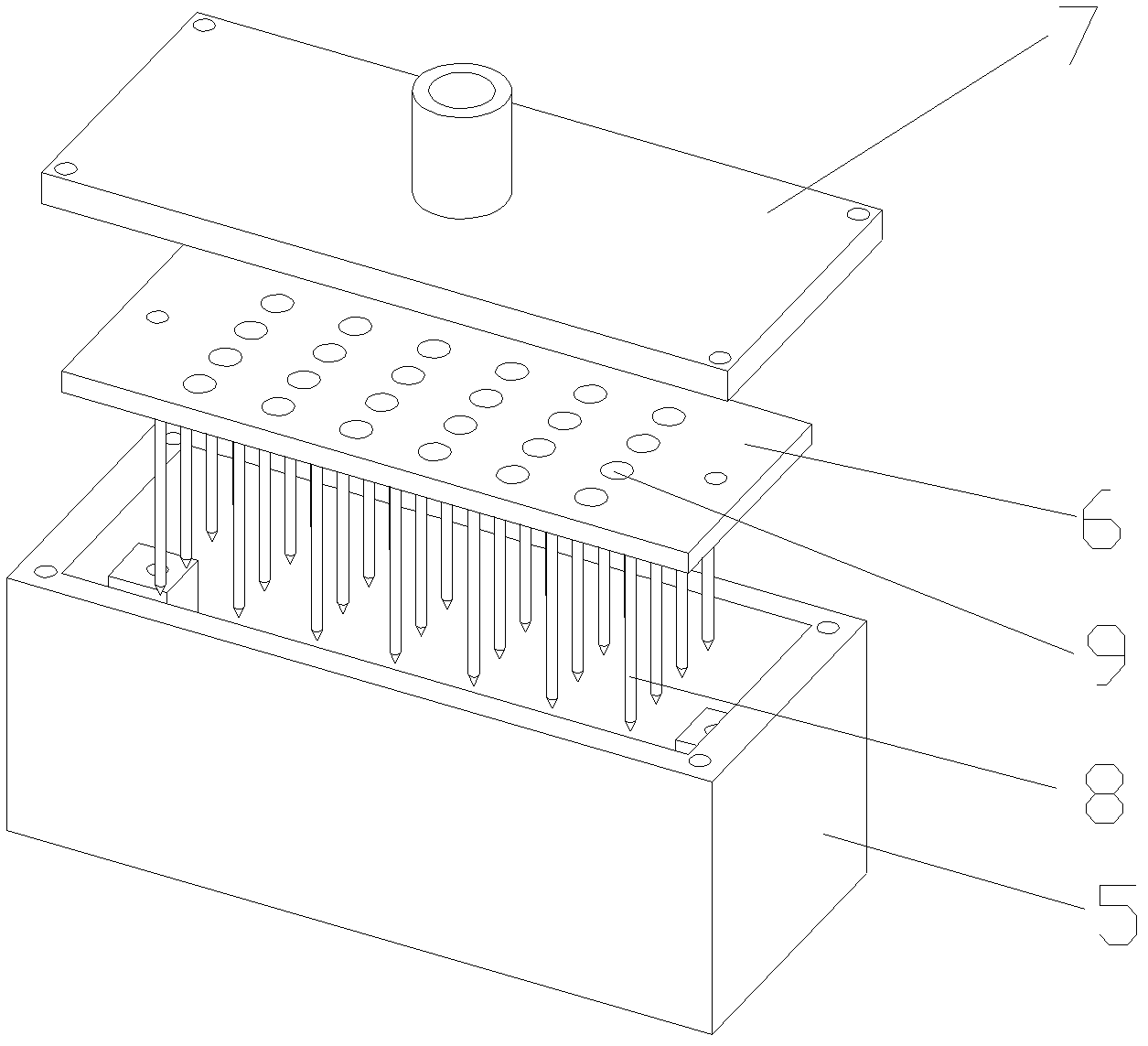

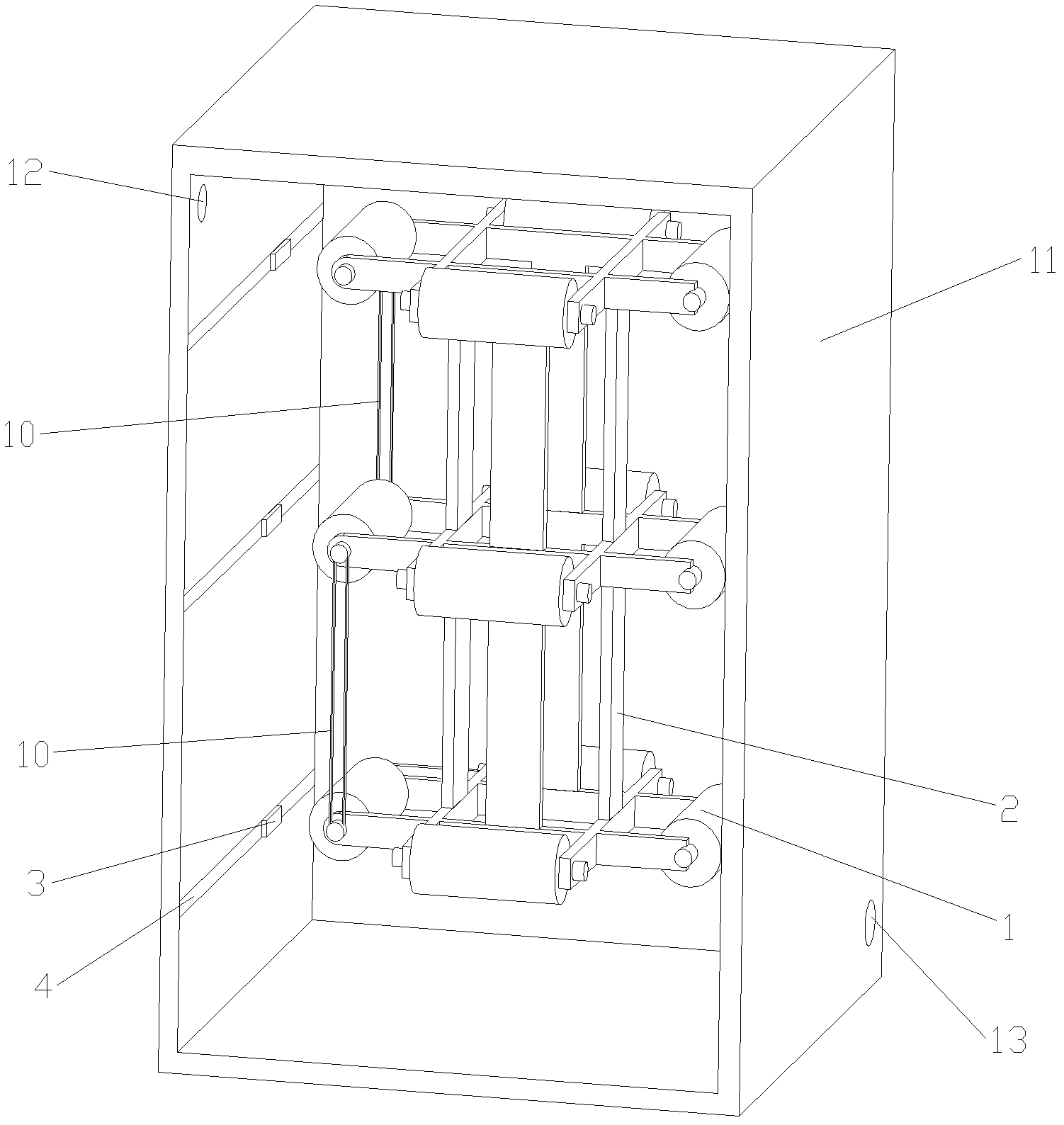

Taylor awl multiple spray head static spinning machine

InactiveCN101210352AIncrease productionElectric field stabilizationSpinnerette packsFilament/thread formingTaylor coneYarn

The invention relates to a Taylor cone multi-nozzle electrostatic spinning machine, which comprises a nozzle box (1), an automatic liquid feeding device (2), a spinneret group, a high-voltage electrostatic generator (4) and a rolling mechanism, wherein the spinneret group is arranged in the nozzle box and is fed with liquid by the automatic liquid feeding device (2), yarns emitted by the electrostatic field generated by the high-voltage electrostatic generator (4) are collected by the rolling mechanism, and the spinneret group consists of a plurality of spinnerets arranged. The invention can improve the quality and the output of felt, and has stable operation and uniform product. Under the same process conditions, the thinness of the spun nanofiber is half the thinness of fiber spun by conventional electrostatic spinning machine.

Owner:DONGHUA UNIV

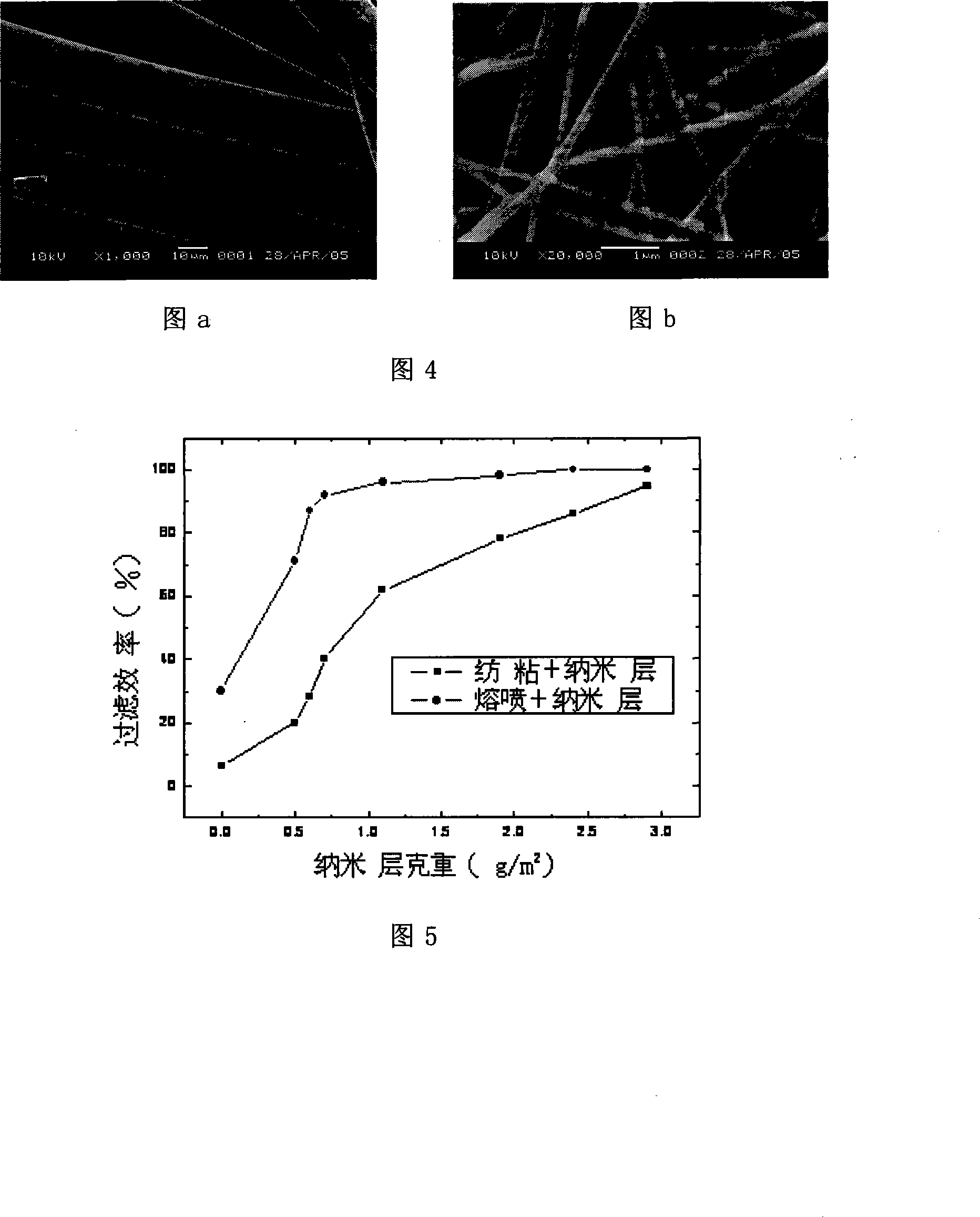

Preparing device and method for forming micro-nanofiber

InactiveCN104451912AHigh yieldImprove diameter preparation issueFilament/thread formingMonocomponent synthetic polymer artificial filamentYarnMicro nano

The invention provides a preparing device and method for forming micro-nanofiber, and belongs to the field of biological materials and tissue engineering. An electrostatic spinning sprayer is provided with different holes arranged side by side, an appropriate amount of original electricity texture liquid is injected into the electrostatic spinning sprayer through a micro-injection pump, a plurality of taylor cones are formed by the parallel spraying holes in the electrostatic spinning sprayer at the same time through externally added high voltage, and therefore the different sizes of original electricity texture yarns can be obtained through the single step, the yield of the original electricity texture yarns is effectively increased, and the micro-nanofiber is prepared. By means of the method for electrostatic spinning, and the electrostatic spinning yield can be increased and is obviously higher than that of single-needle electrostatic spinning; the effective means for adjusting the diameter of the spinning fiber is provided, the uniform micro-nanofiber or micro-nanofiber with different sizes can be prepared, the range of the diameter of the fiber can be controlled to range from 50 nm to 1 mm, and the problem of the productivity and size adjusting in the related fields of the electrostatic spinning micro-nanofiber is effectively solved.

Owner:ZHEJIANG UNIV

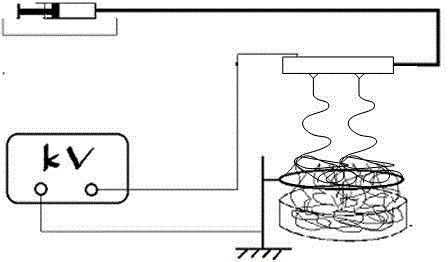

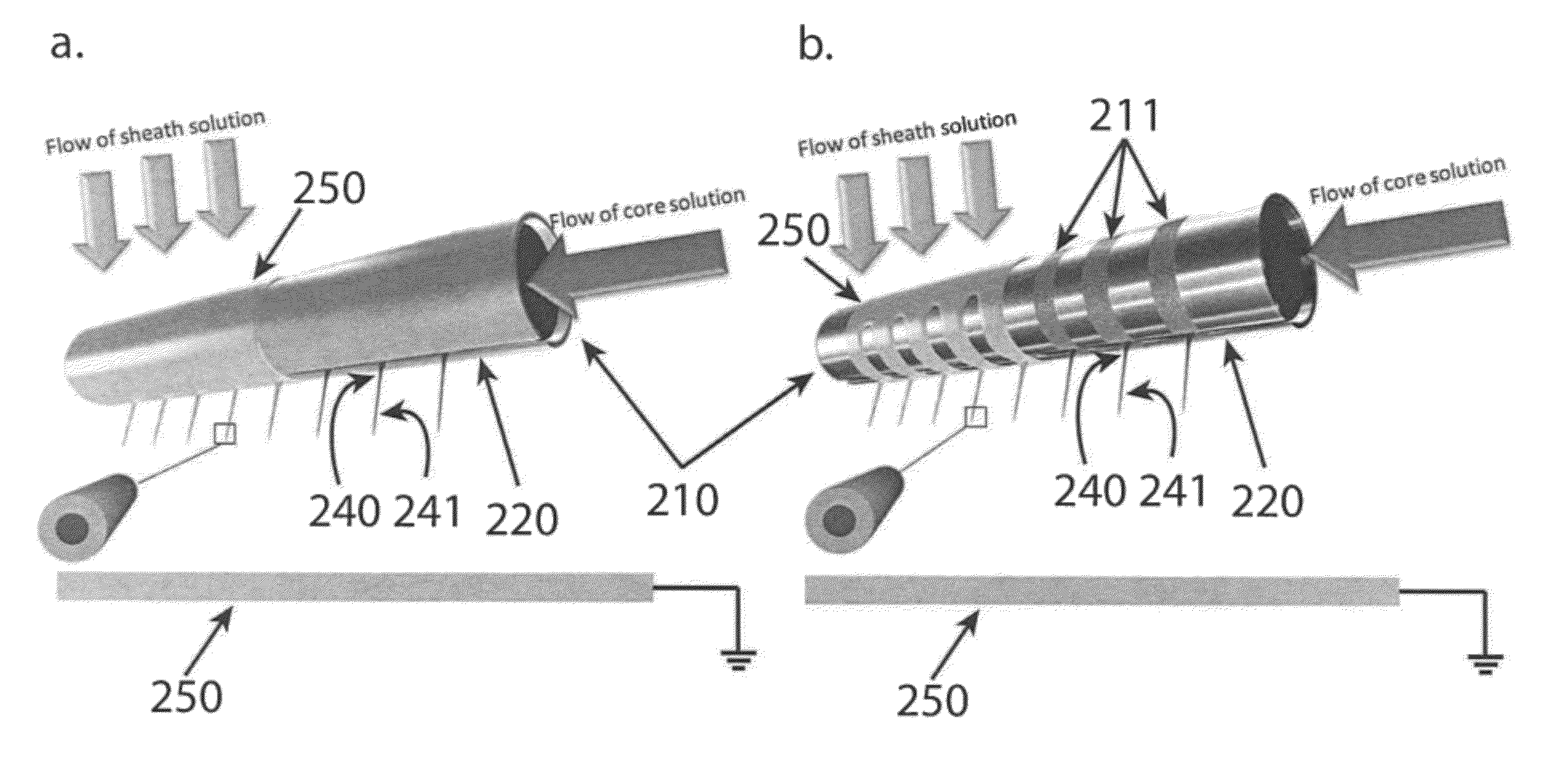

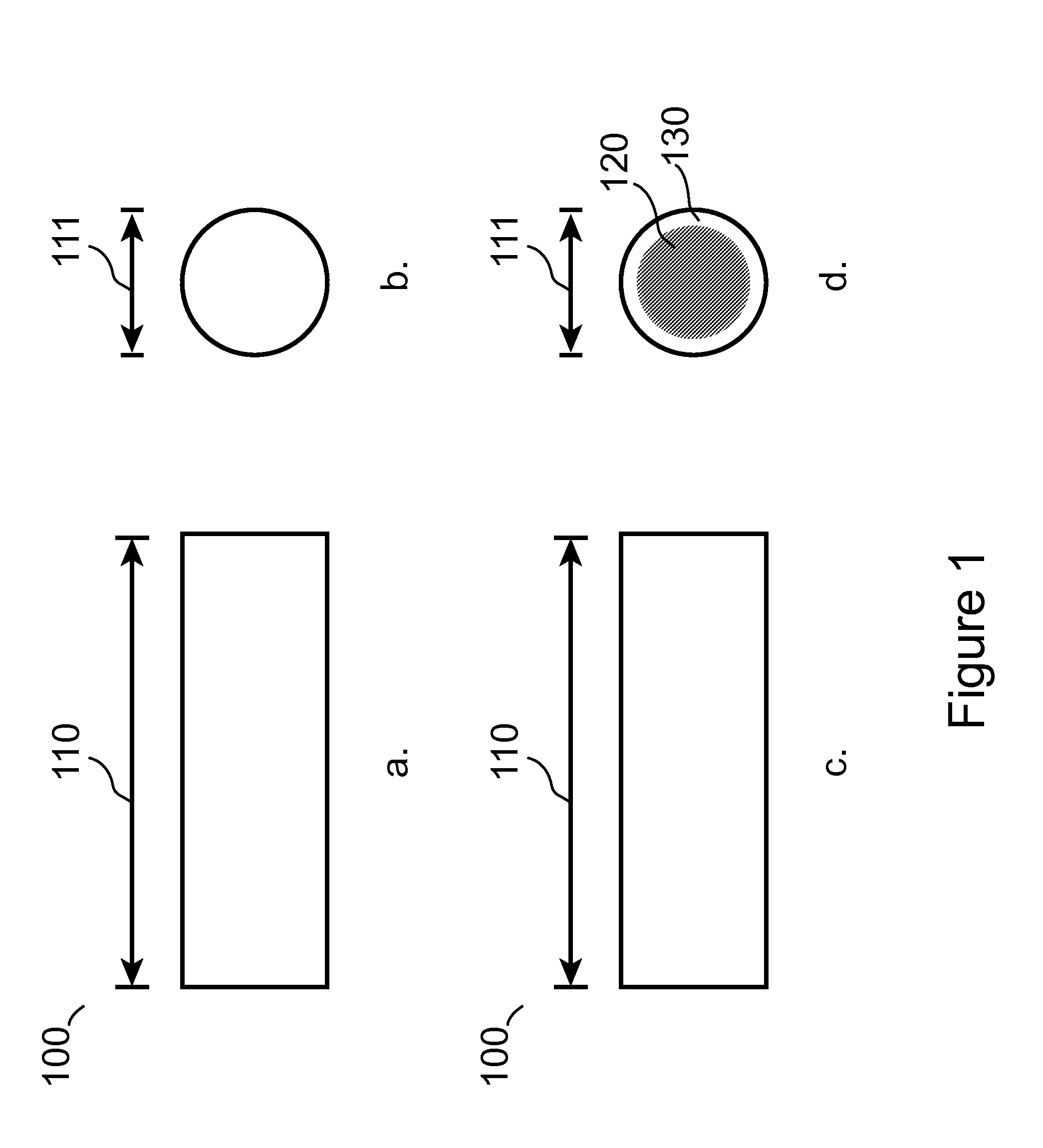

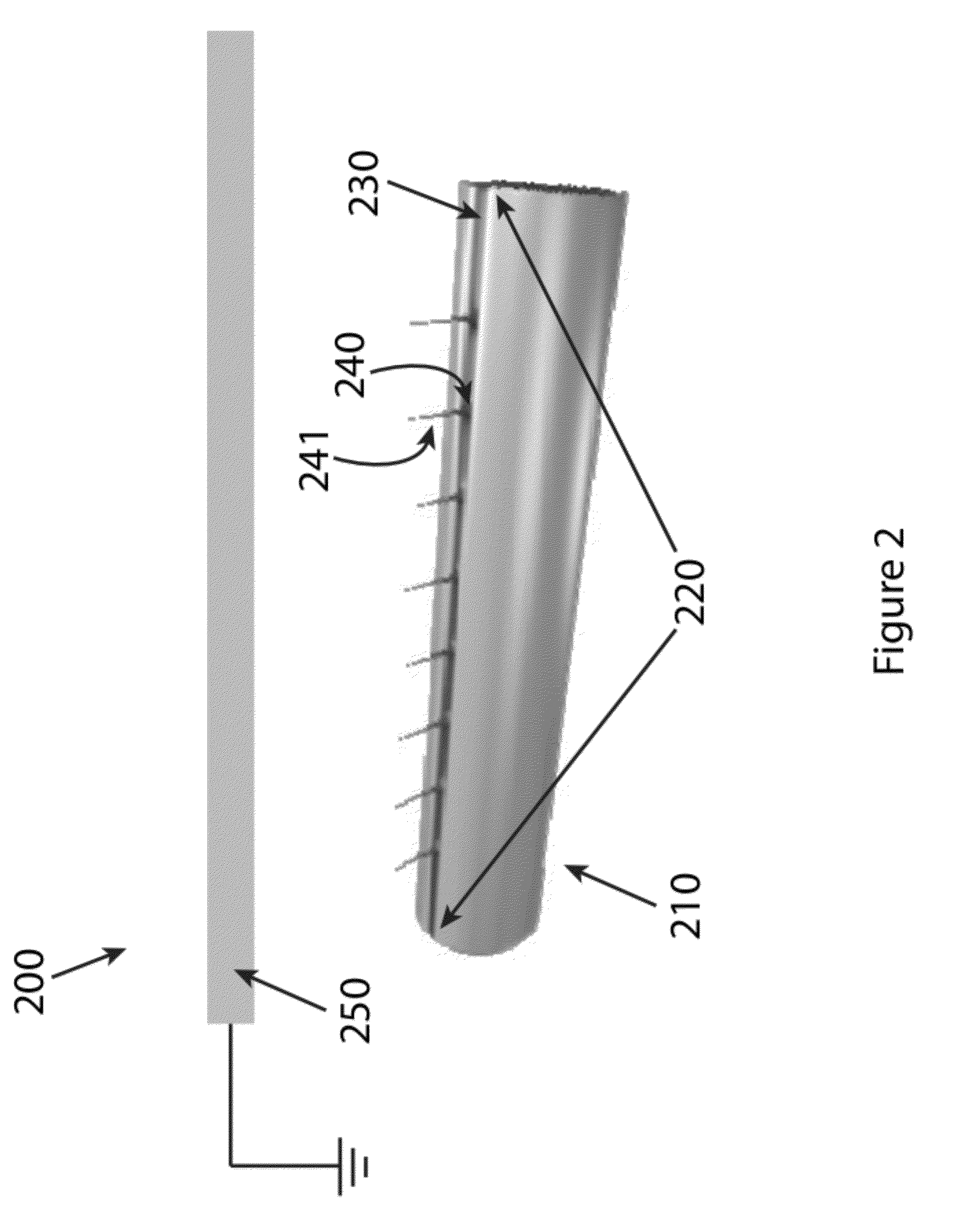

Electrospinning Process for Manufacture of Multi-Layered Structures

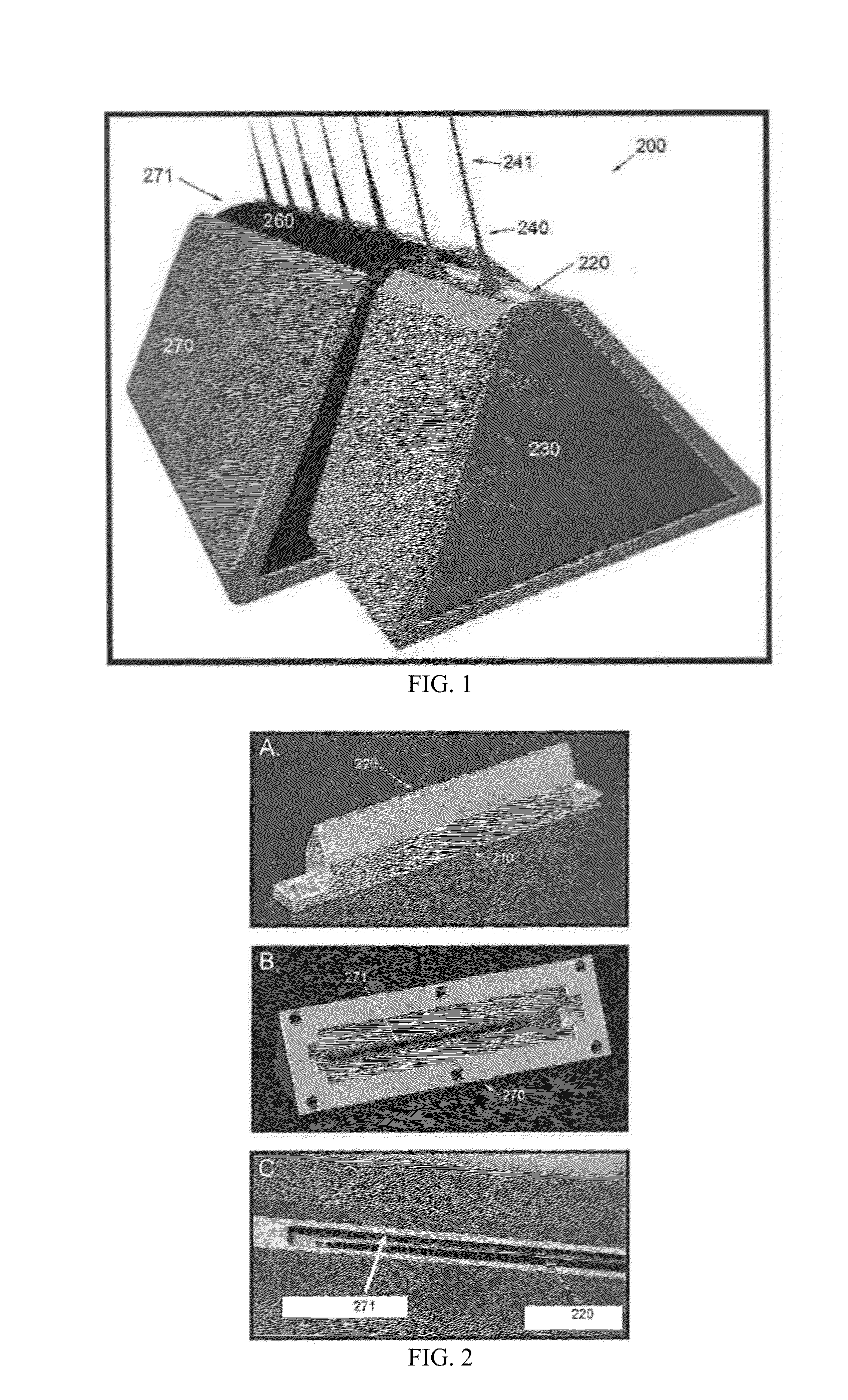

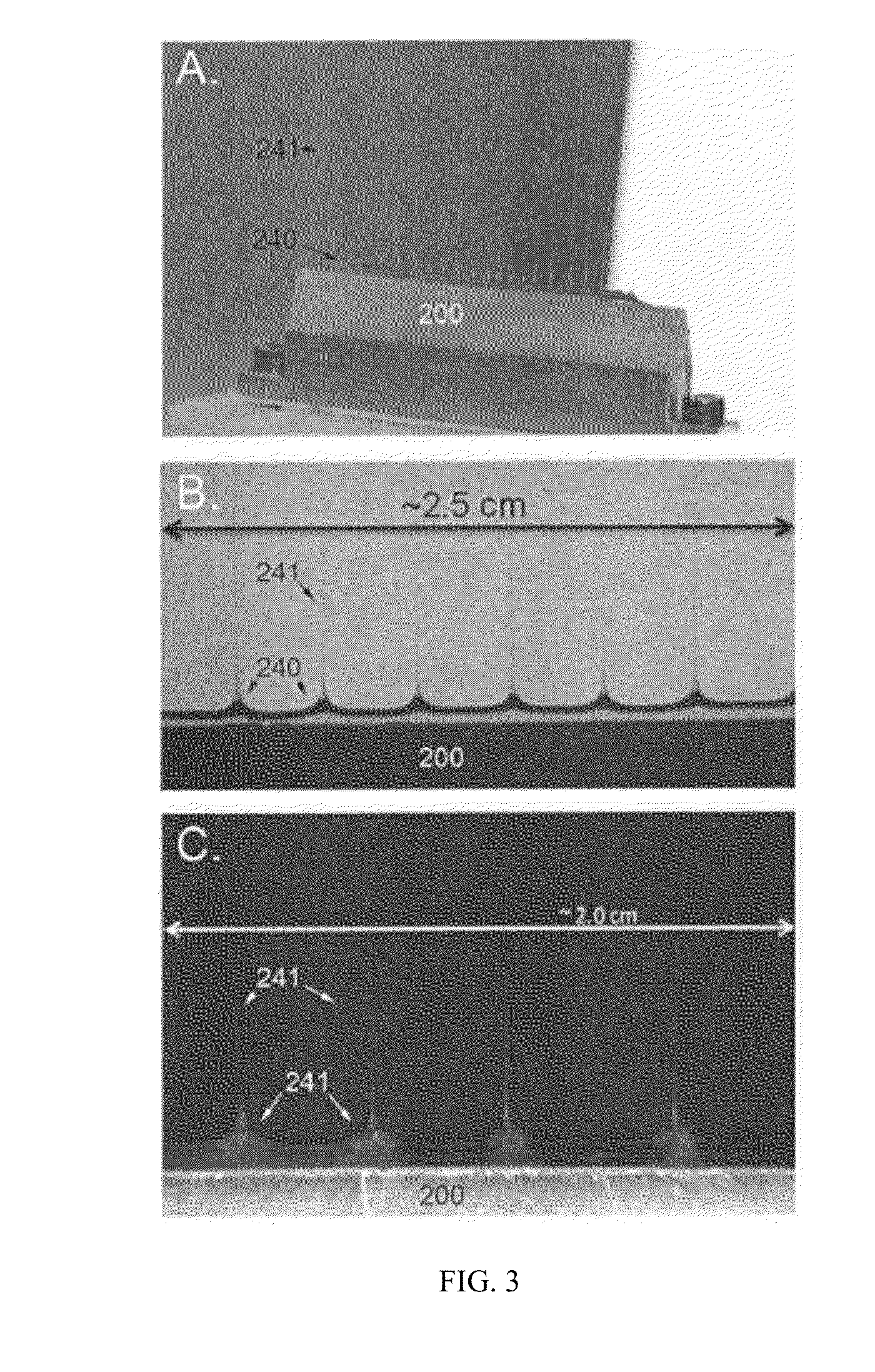

Devices and methods for high-throughput manufacture of concentrically layered nanoscale and microscale fibers by electrospinning are disclosed. The devices include a hollow tube having a lengthwise slit through which a core material can flow, and can be configured to permit introduction of sheath material at multiple sites of Taylor cone formation.

Owner:ARSENAL MEDICAL

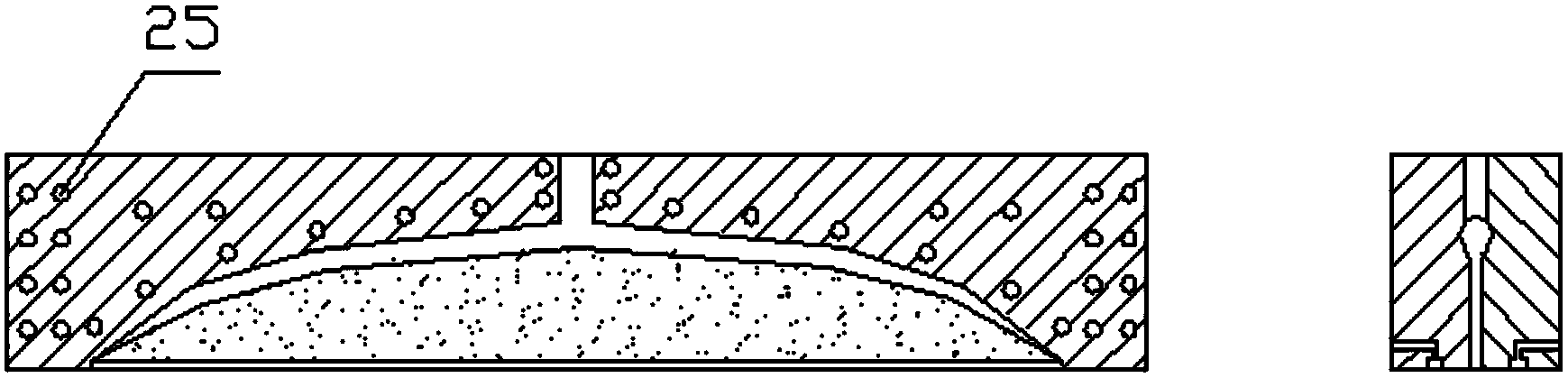

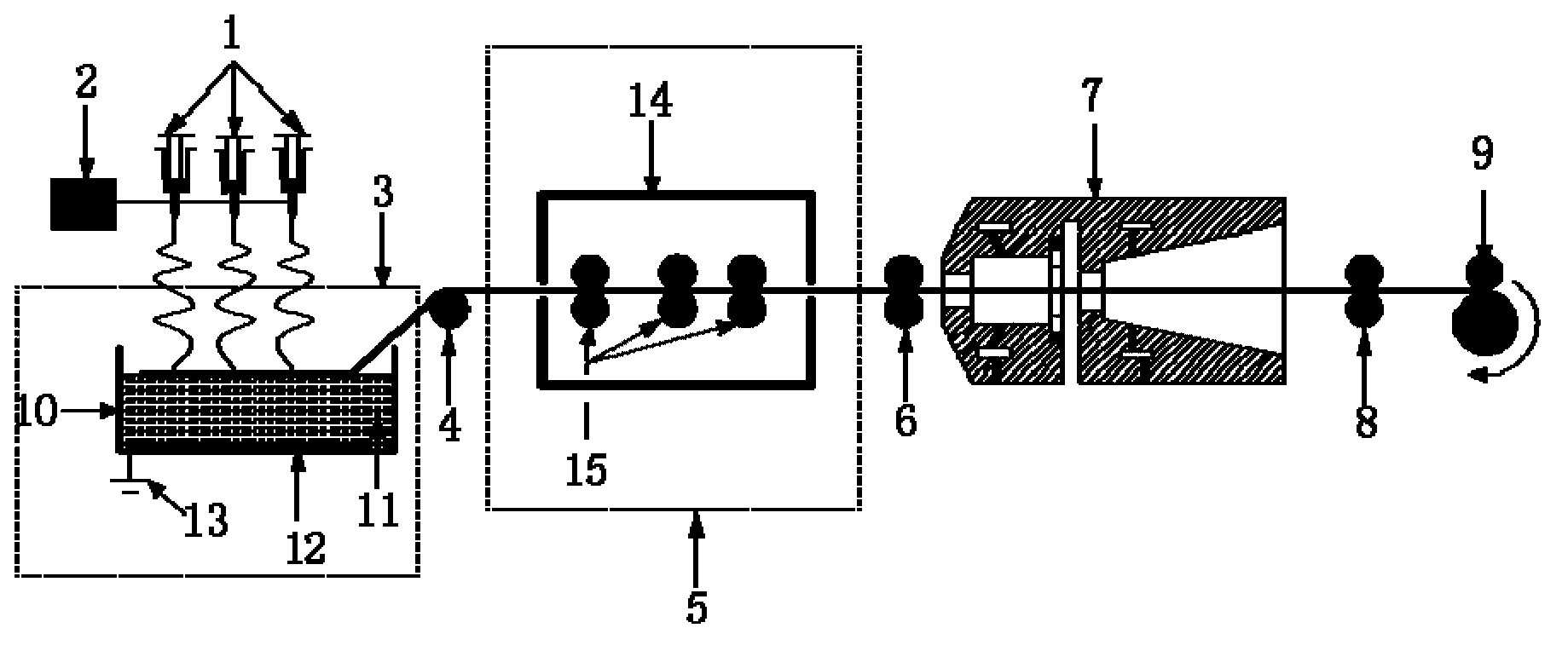

Differential melt electro-blowing spinning device and technology for preparing nanofibers in batches

ActiveCN103451754ARealize industrial productionRealize batch preparationFilament/thread formingNon-woven fabricsFiberSpinning

The invention discloses a differential melt electro-blowing spinning device and technology for preparing nanofibers in batches, and belongs to the field of electrostatic spinning. The device mainly comprises an extruder, a filter screen, a melt metering pump, a spinning manifold, an airflow heating device, an air compressor, an upper plate electrode, a lower plate electrode, a high-voltage electrostatic generator, a guide air knife, a hot rolling device, a receiving device, a screen spreading belt and an air draft system. An outlet of the extruder is connected with the filter screen, and the melt metering pump is connected between the filter screen and the spinning manifold through a flange. Airflow is divided into two portions through a flow divider to be connected to the spinning manifold; after melt is divided and guided in flow through the spinning manifold, a thin uniform-flowing melt layer is obtained at the lower end of a wavy flow guide plate; under the high-voltage electrostatic action, the melt layer forms a plurality of Taylor cones in a self-organization manner, the Taylor cones are stretched and split continuously under the conditions of high-speed airflow and high-voltage electrostatics, and superfine fibers are formed at the receiving end of the screen spreading belt by means of curing. By the aid of the device and technology, difficulties of high viscosity of polymers, low yield, complicated devices and the like are overcome, and industrial production of differential melt electro-blowing spinning can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

Electrospinning Process for Manufacture of Multi-Layered Structures

Devices and methods for high-throughput manufacture of concentrically layered nanoscale and microscale fibers by electrospinning are disclosed. The devices include a hollow tube having a lengthwise slit through which a core material can flow, and can be configured to permit introduction of sheath material at multiple sites of Taylor cone formation formation.

Owner:ARSENAL MEDICAL

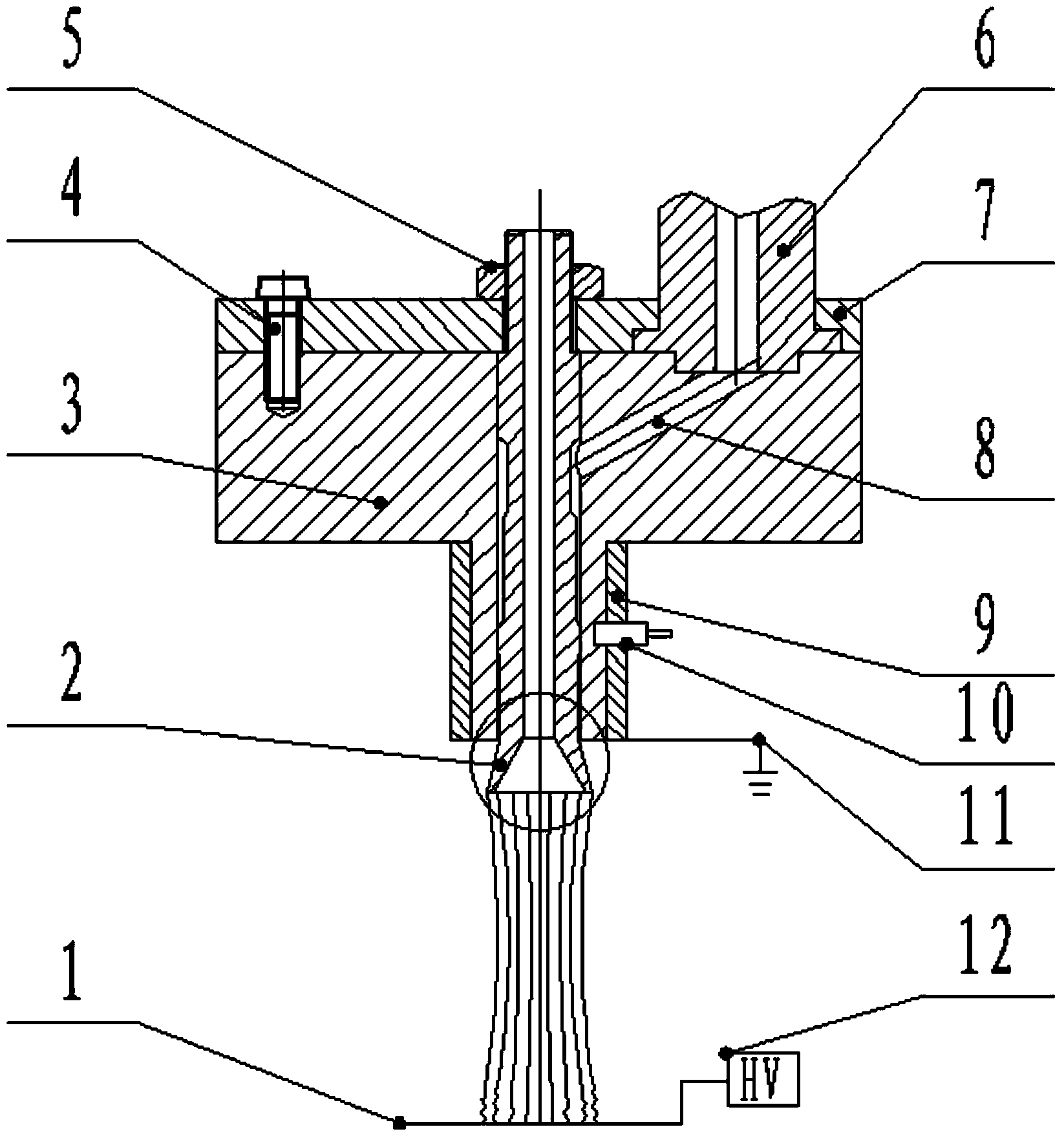

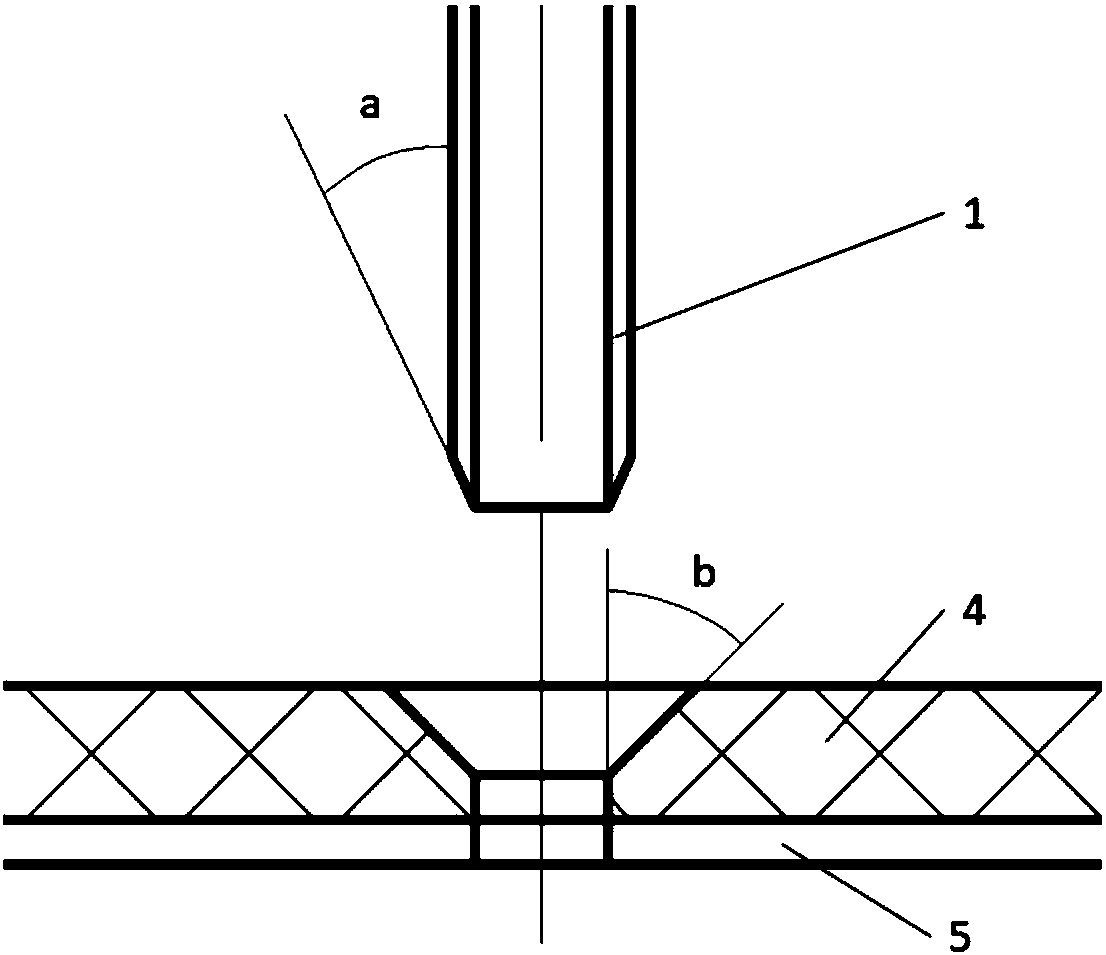

Outer conical surface type electrostatic spinning sprayer assisted by airflow

ActiveCN103668486ASmall diameterAvoid disturbing influenceFilament/thread formingHigh pressureGuide tube

The invention discloses an outer conical surface type electrostatic spinning sprayer assisted by airflow, and belongs to thee field of electrostatic spinning. The device comprises a fiber receiving plate, an outer conical surface airflow guide tube, a machine head, a screw, a positioning nut, a material barrel, a material barrel fixing block, a heating ring, a temperature sensor, a grounding electrode, a high-voltage electrostatic generator and the like, flux is evenly distributed to the conical surface sprayer through a flow channel on the outer wall of the airflow guide tube, a flux film naturally thins in the forming process under the action of gravity and adhesive power, the flux forms a Taylor cone at the tip end of the outer conical surface under the action of high-voltage static, and therefore jet flow spinning is formed. Due to the fact that the flux film thins, the diameters of fibers can be effectively reduced, the fibers are further stretched under the action of high-speed airflow, fiber bundles are made to converge inwards due to internal and external pressure difference formed by the high-speed airflow, the density distribution of the fibers is effectively improved, the device can also be used for eliminating interference of the high-speed airflow on the flux film, and the diameters of the fibers can be more uniform.

Owner:BEIJING UNIV OF CHEM TECH

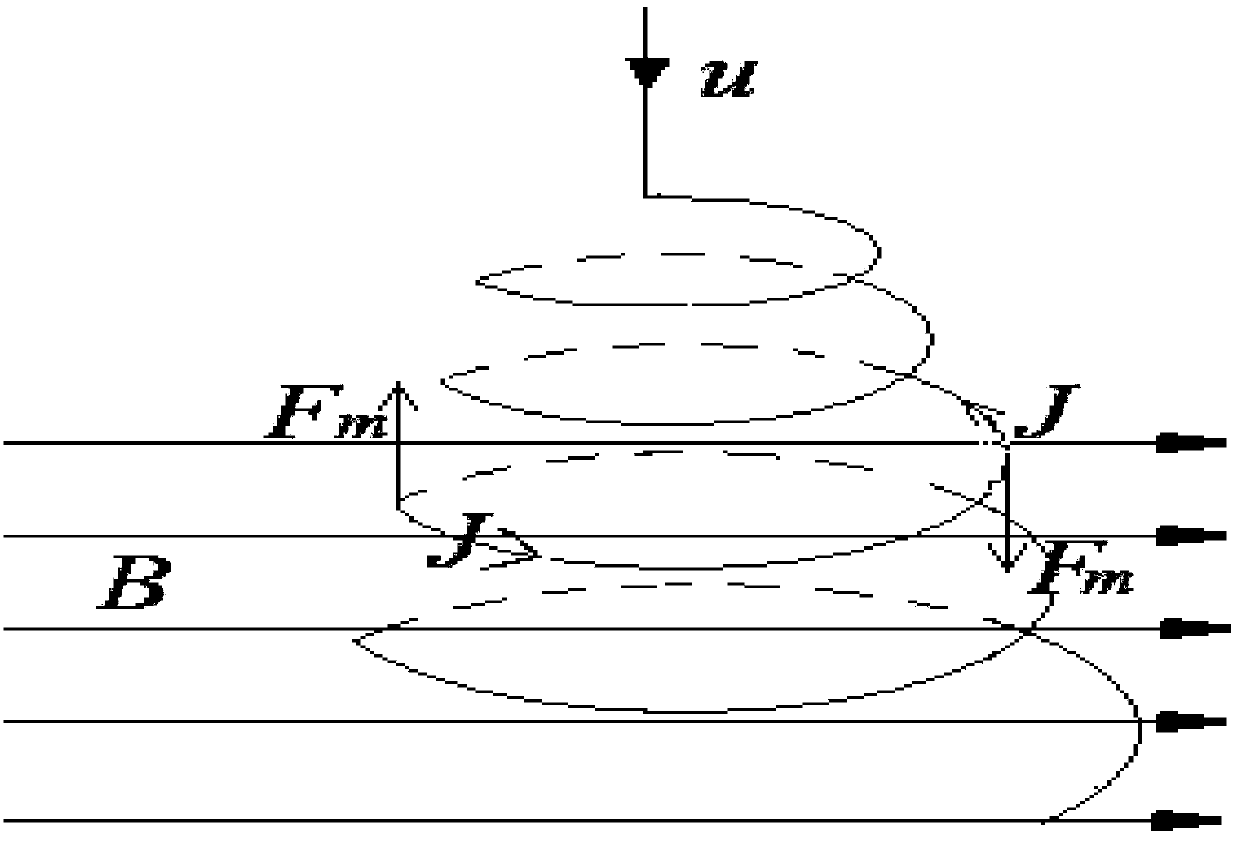

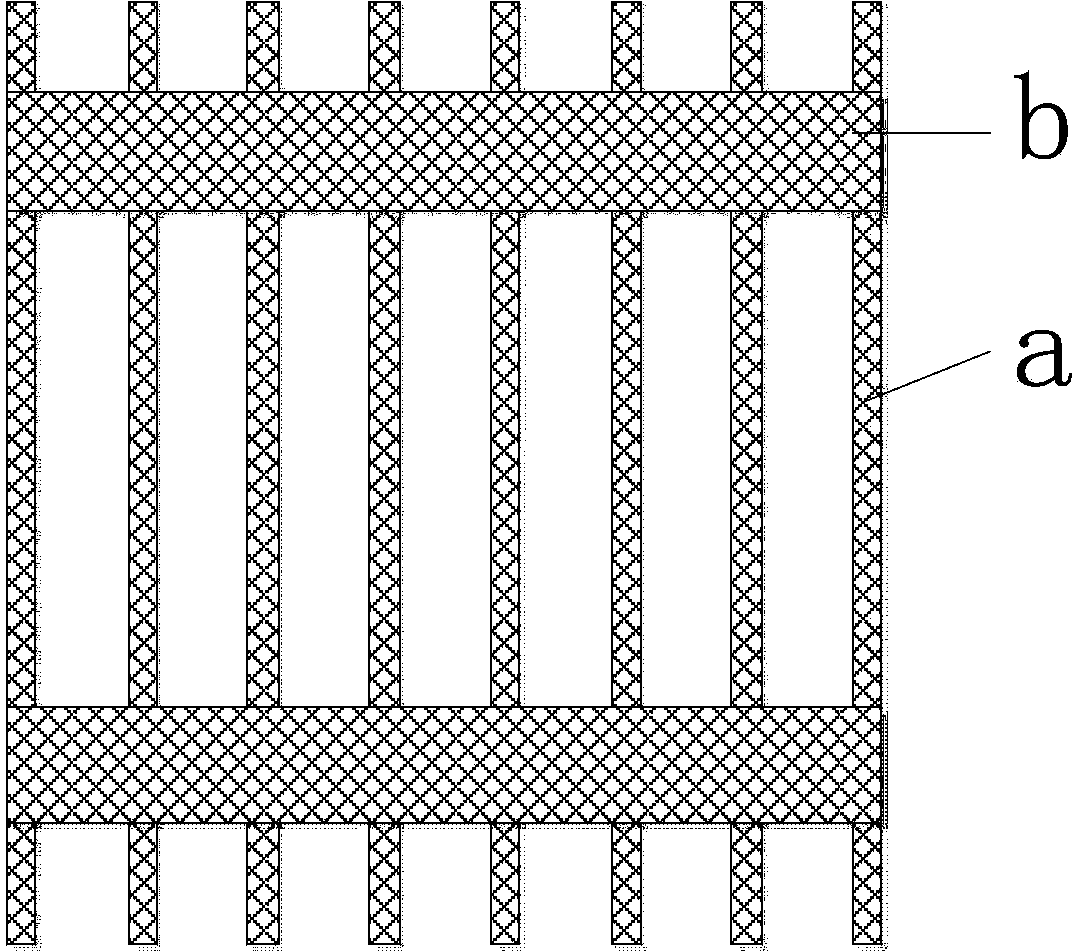

Continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes

InactiveCN102650095AImprove driftOvercoming electrostatic repulsionFilament/thread formingNon-woven fabricsElectrospun nanofiberNanofiber

The invention relates to a continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes. The method comprises the following steps: (1), electrified electrodes are kept in a vibrating state to drive polymer liquor to a plurality of protrusions on the upper surfaces of the electrified electrodes, so as to form a Taylor cone, and ensure that the whole upper surfaces become spinning surfaces, which obtains high spinning production capacity; (2), air in the space between two electrodes is sucked to the back side of a counter electrode to generate an air flow, so that stressed drift of nanofiber is accelerated, and the nanofiber is sucked to be laid on a continuous receiving screen to form a membrane; and (3) the air flow is heated dry hot air. The equipment comprises a polymer container, the vibrating electrified electrodes, the continuous receiving screen, the counter electrode and a negative pressure chamber, wherein the upper surfaces of the vibrating electrified electrodes are approximately in accordance with the liquid level; the counter electrode is made of a metal mesh or a porous metal plate; the negative pressure chamber comprises a hood, a rear air chamber, a balancing plate and an air suction pump; each vibrating electrified electrode is a metal mesh-shaped plane or a porous metal flat plate; innumerous holes and innumerous small protrusions are formed on the plane; and the small protrusions are regularly arranged and higher than the plane. The invention facilitates mass production of the electrospun nanofiber membranes.

Owner:谢维

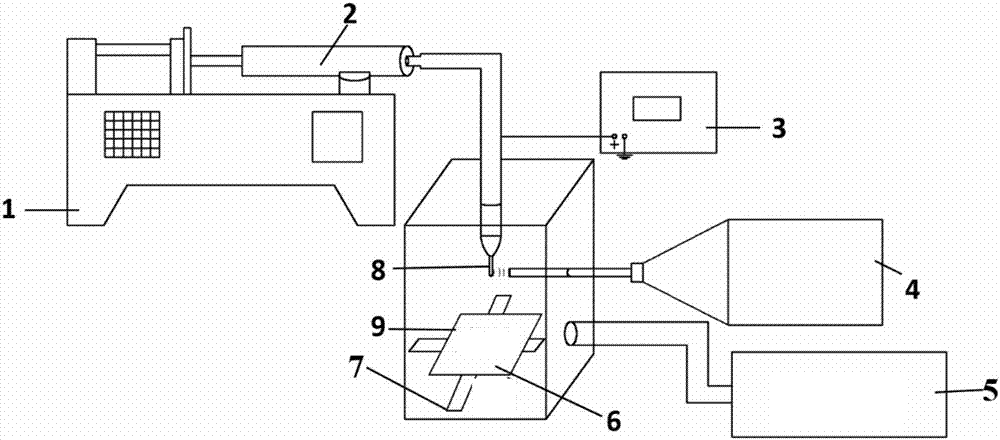

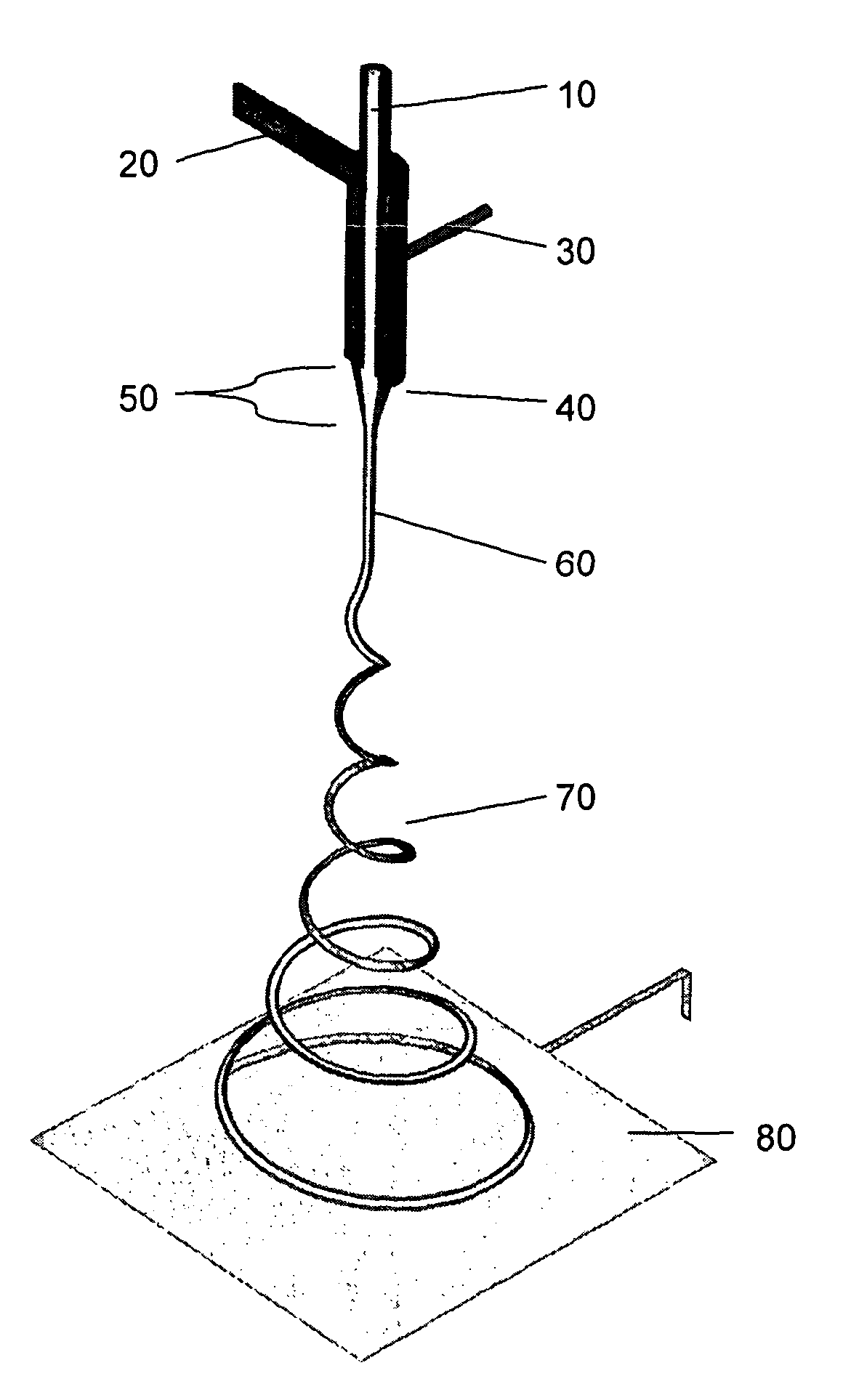

Device and method for twisting electrostatic spinning nanofiber into yarn in jetting mode

InactiveCN103266365AEasy alignmentIncrease productionFilament/thread formingContinuous wound-up machinesYarnFiber

The invention relates to a device and a method for twisting electrostatic spinning nanofiber into yarn in a jetting mode. A spinning solution is injected in an injector of a fiber jetting device, a needle of the injector is connected with a high voltage static electricity generating device, the spinning solution is subjected to the effect of electric field force to form a Taylor cone to jet flow, the spinning solution is deposited on the surface of a solvent in a water tank to form a felt-shaped material, nanofiber bundles are formed by the felt-shaped material through mobility of the solvent and traction of a roller and subsequent devices, a drafting device is heated to remove the solvent contained in the nanofiber bundles to achieve effective drafting, the nanofiber bundles are sent in a Laura jaw, an air compressor is started, the nanofiber bundles enter a double-nozzle twisting device and are twisted into the yarn through mutual effect of a first nozzle and a second nozzle, and the yarn is led out through an output roller and wound into a cylinder through a winding device. The device and the method for twisting the electrostatic spinning nanofiber into the yarn in the jetting mode integrate fiber jetting, condensation, bundle concentration, drafting, twisting and winding and are simple in device and process, suitable for various polymer spinning solutions and capable of achieving continuous and large-scale production of the nanofiber yarn.

Owner:DONGHUA UNIV

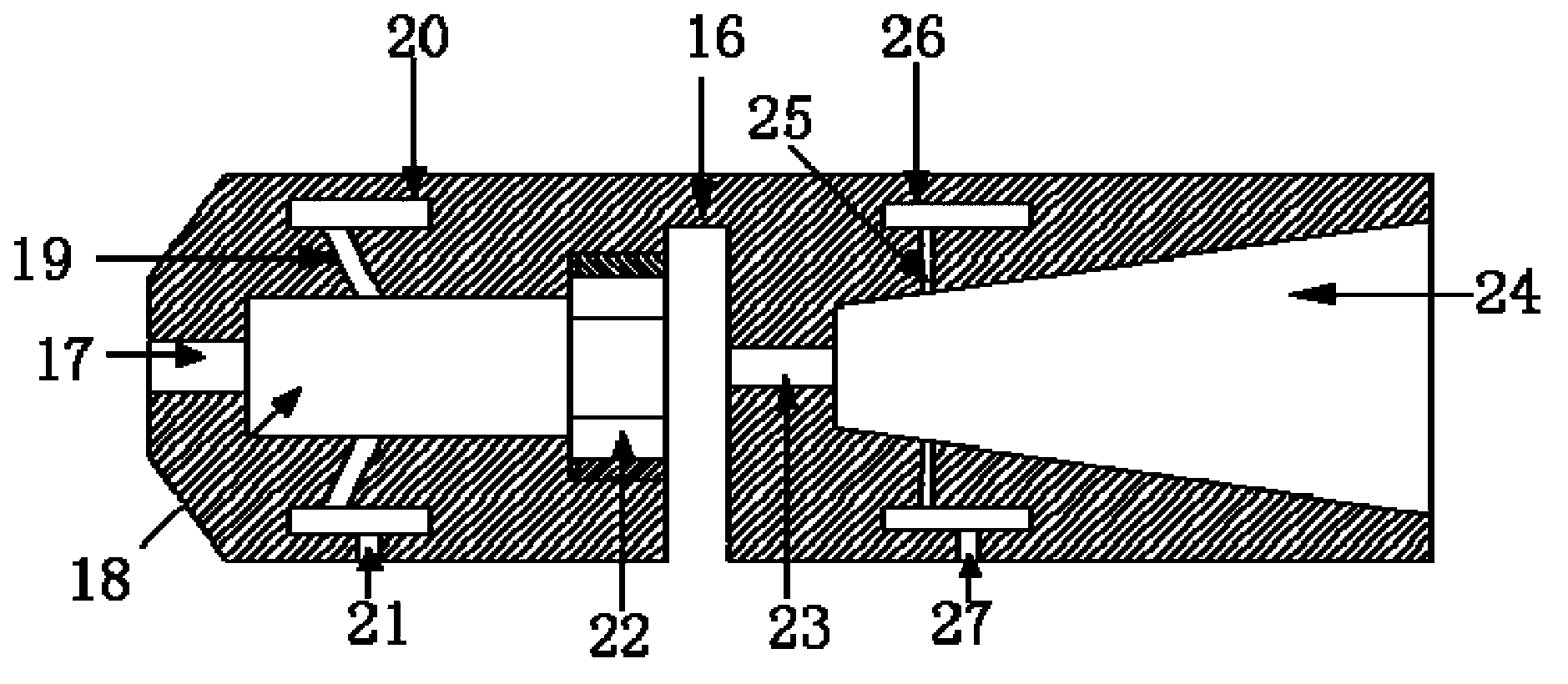

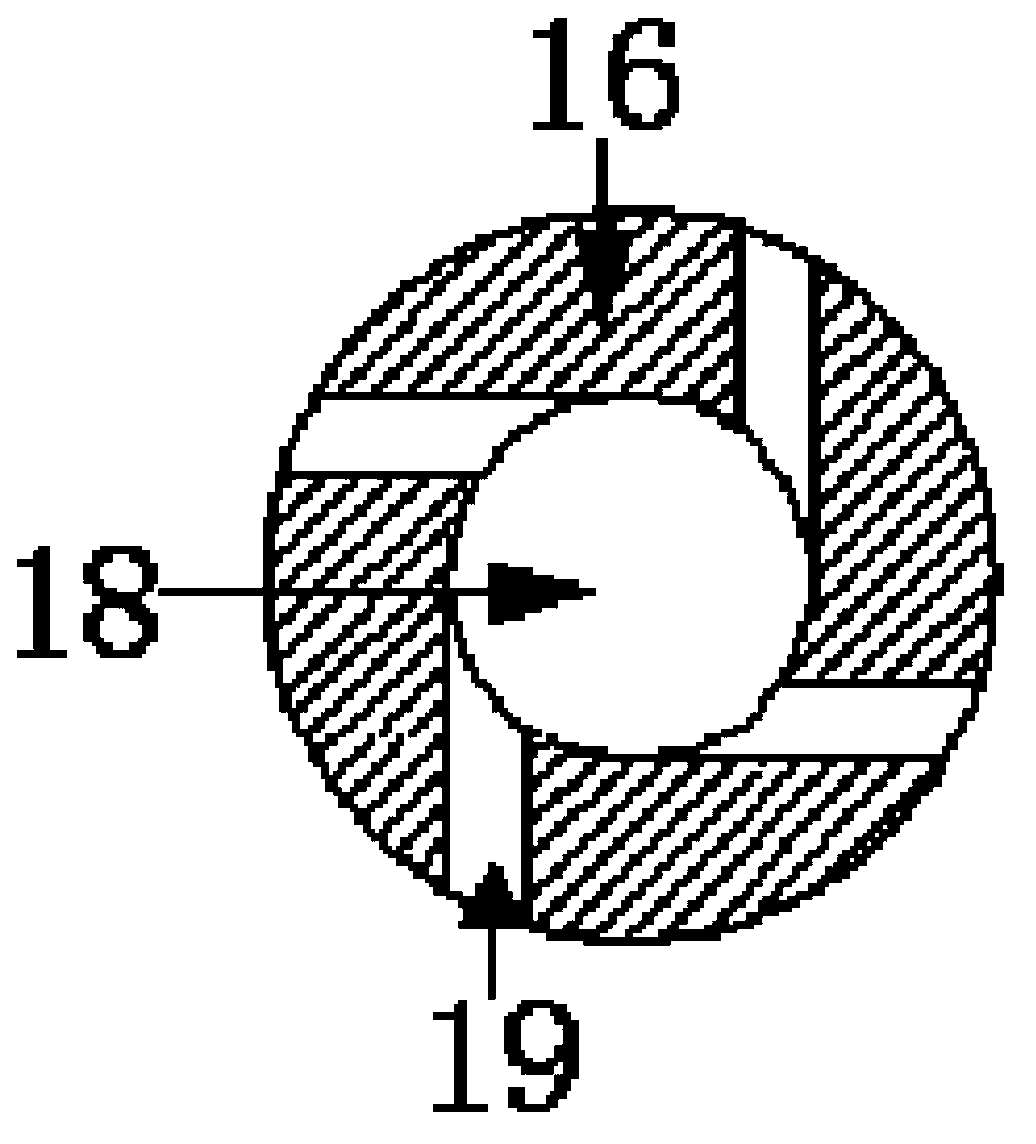

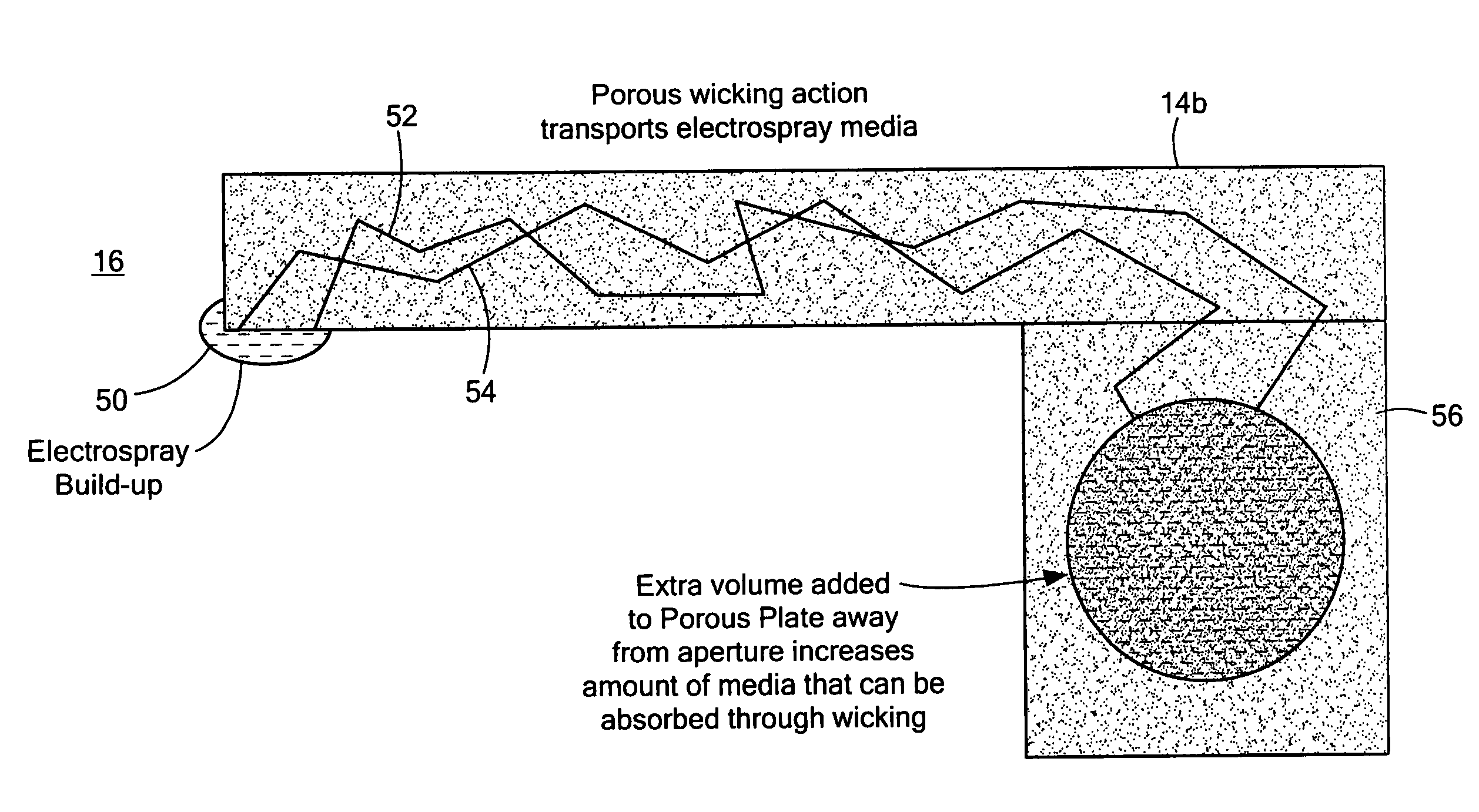

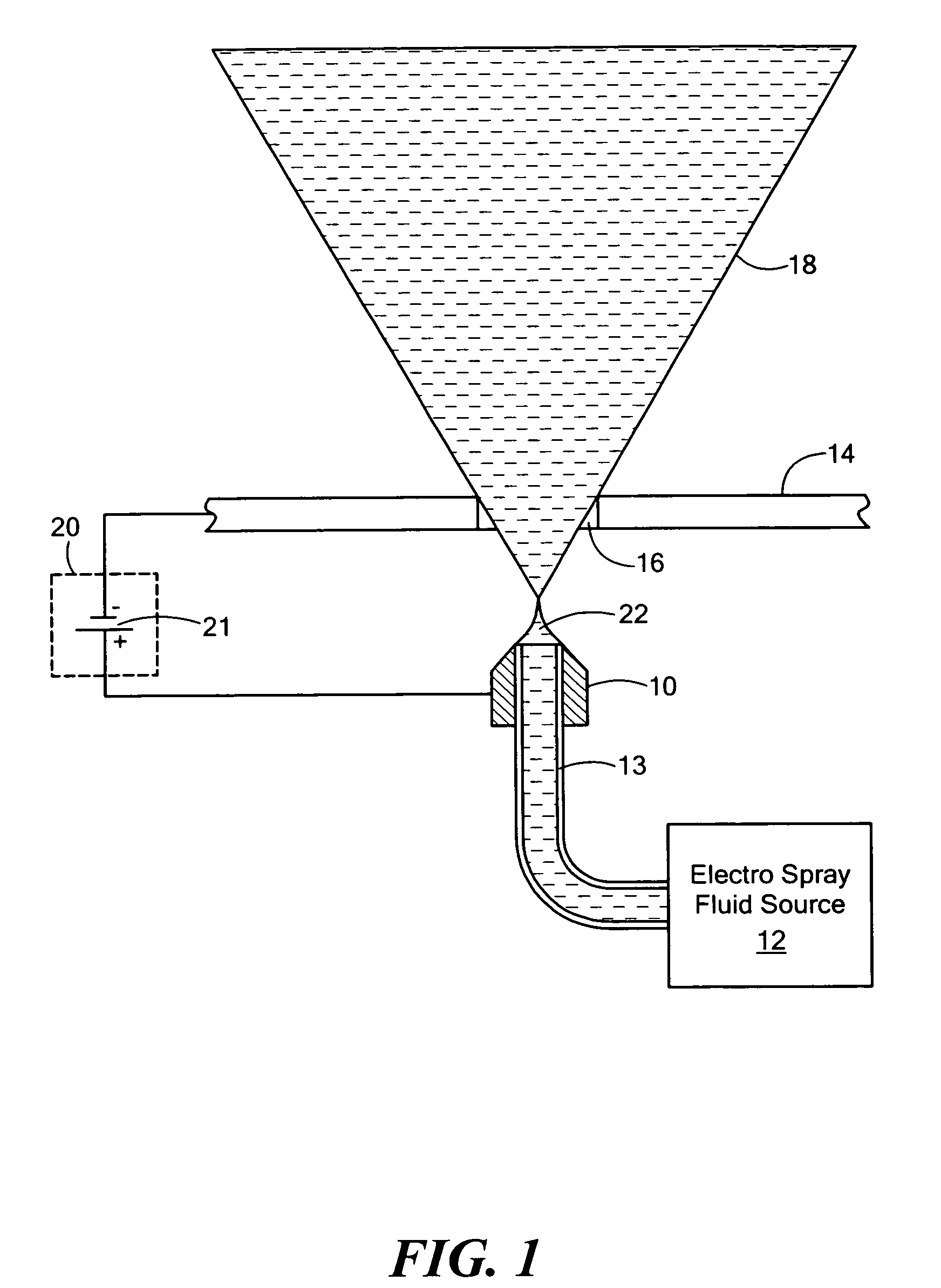

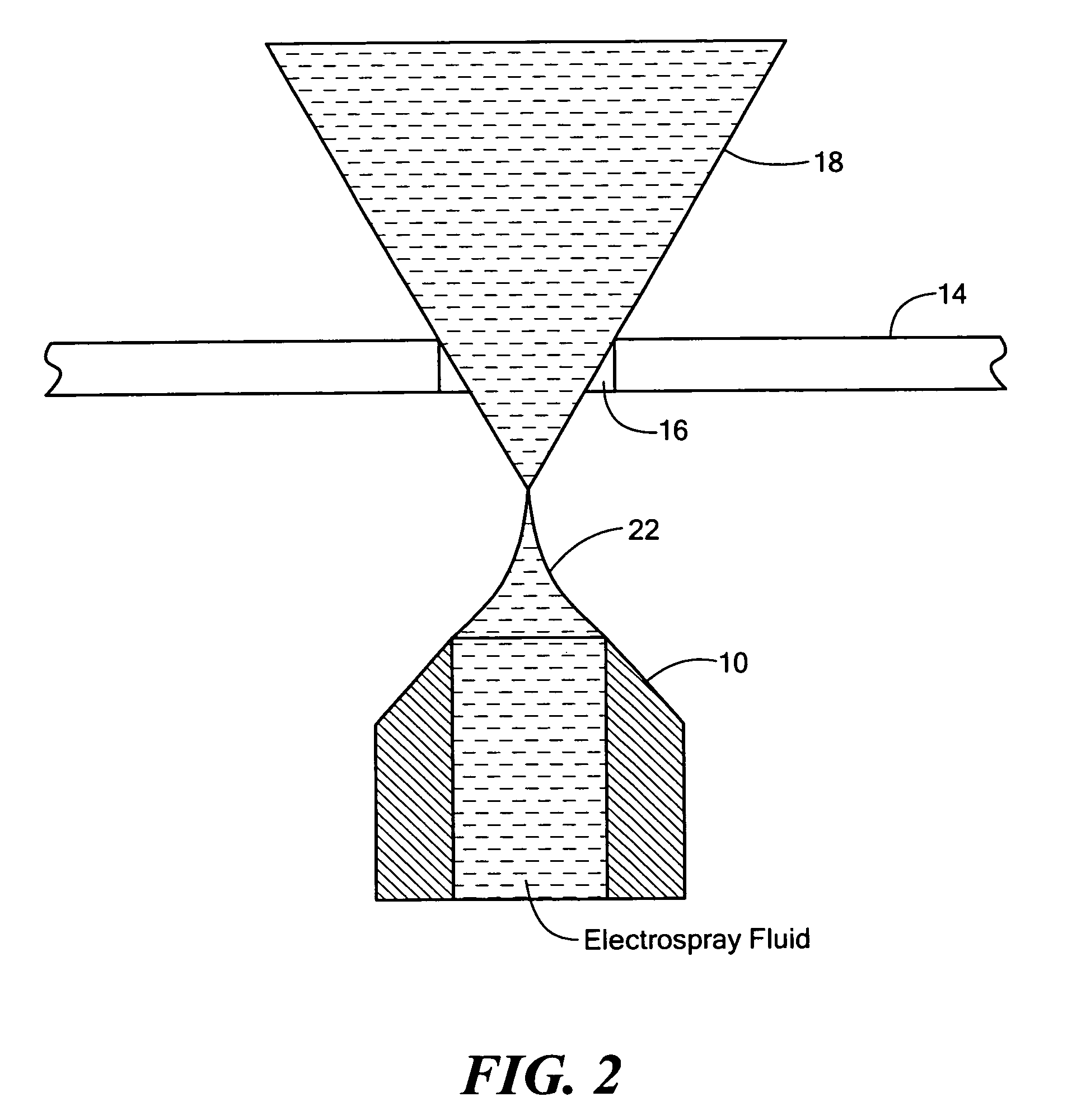

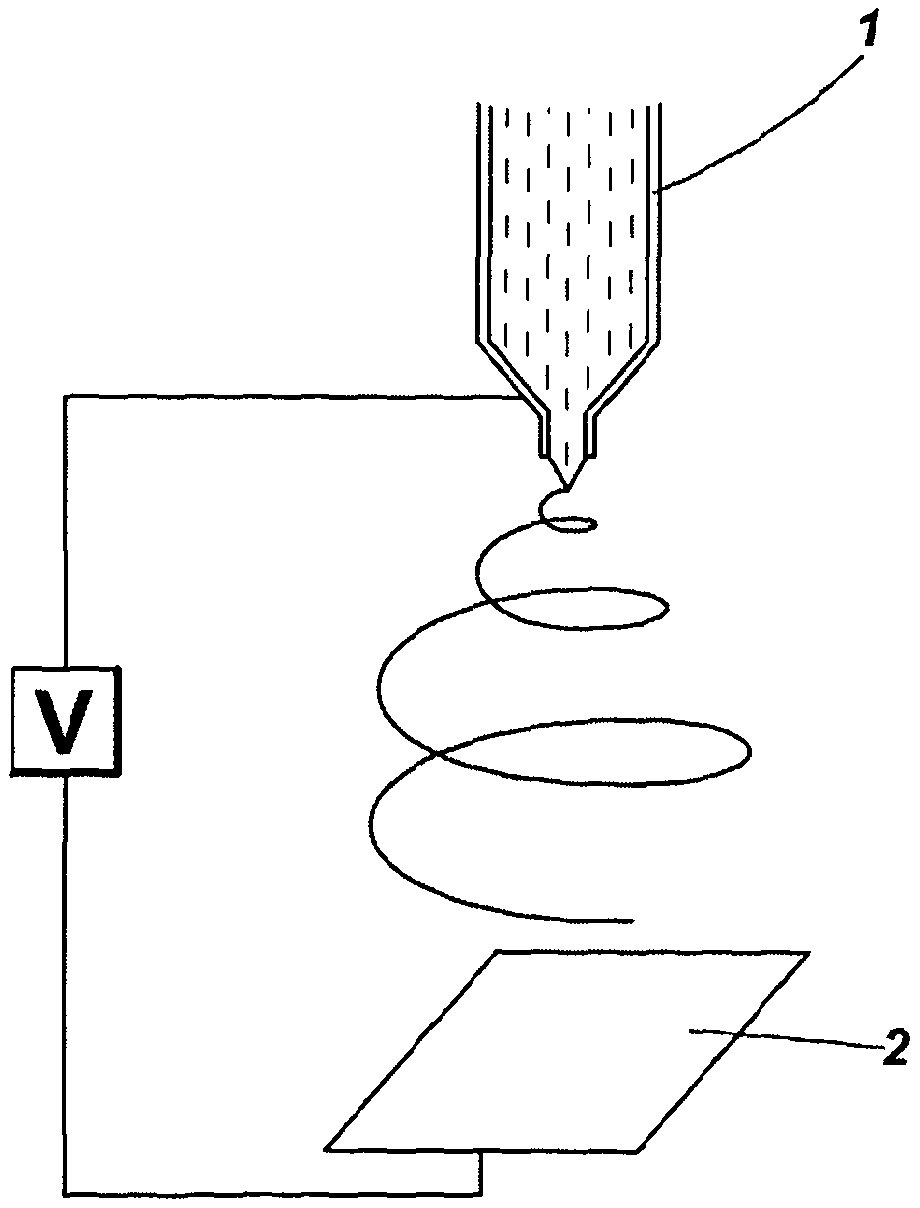

Electrospray device

ActiveUS7932492B2Prevent buildupPrevents back spray and shortingIon sources/gunsIsotope separationEngineeringTaylor cone

An electrospray device includes an electrospray emitter adapted to receive electrospray fluid; an extractor plate spaced from the electrospray emitter and having at least one aperature; and a power supply for applying a first voltage between the extractor plate and emitter for generating at least one Taylor cone emission through the aperature to create an electrospray plume from the electrospray fluid, the extractor plate as well as accelerator and shaping plates may include a porous, conductive medium for transporting and storing excess, accumulated electrospray fluid away from the aperature.

Owner:BUSEK

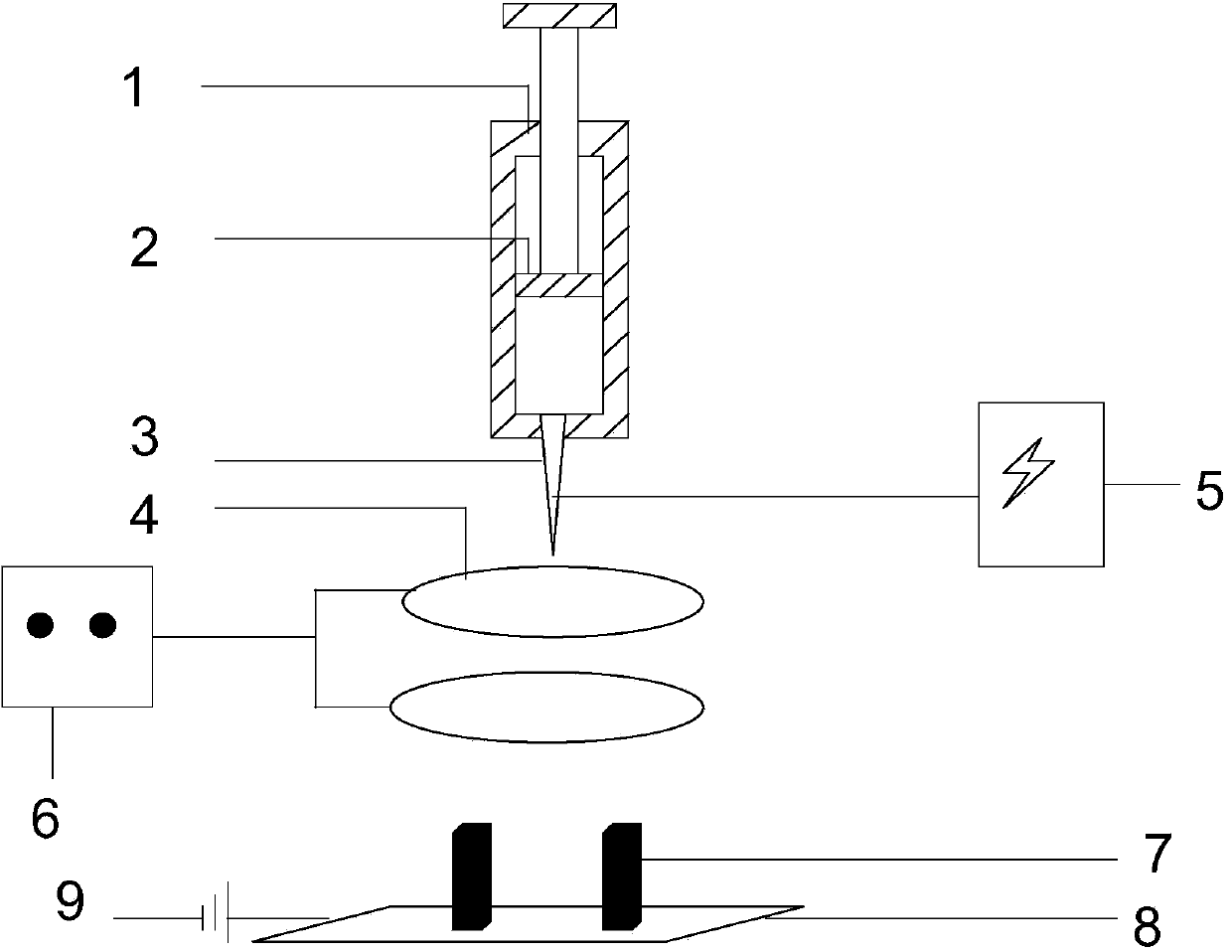

Electrostatic spinning device for manufacturing nano fibers in electromagnetic field with coupling method

InactiveCN103614791AGood orientationHigh degree of orderFilament/thread formingFiberElectromagnetic field coupling

The invention discloses an electrostatic spinning device for manufacturing nano fibers in an electromagnetic field with a coupling method. The electrostatic spinning device comprises a material basket, a piston, a spinning nozzle, a high-voltage power supply device, a receiving plate and a grounding power line. The electrostatic spinning device further comprises an electric conduction coil arranged between the spinning nozzle and the receiving board and right opposite to the spinning nozzle and the receiving board. Two electromagnets are arranged on the receiving board in parallel. The orientation of nano fibers collected by electrified polymer solutions is greatly improved under the action of the electromagnetic field which is large enough. Meanwhile, the positively charged coil is added in the flow jetting process of polymers, jet flow can be stabilized, the range of a Taylor cone is reduced, and the degree of order of the nano fibers is further improved. The electrostatic spinning device for manufacturing the nano fibers in the electromagnetic field with the coupling method is simple in structure, convenient to operate, easy to control and short in technological process.

Owner:SUZHOU UNIV

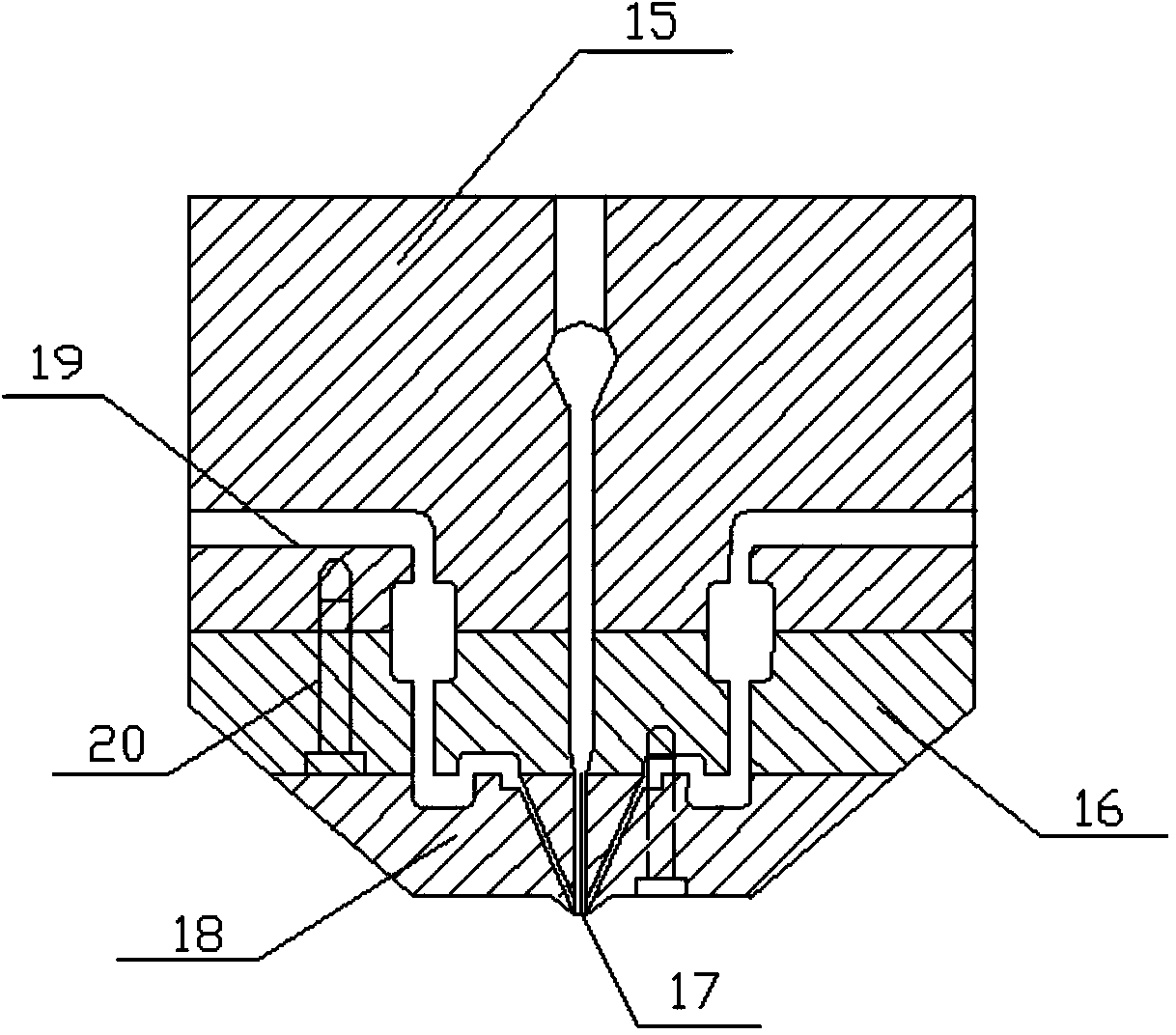

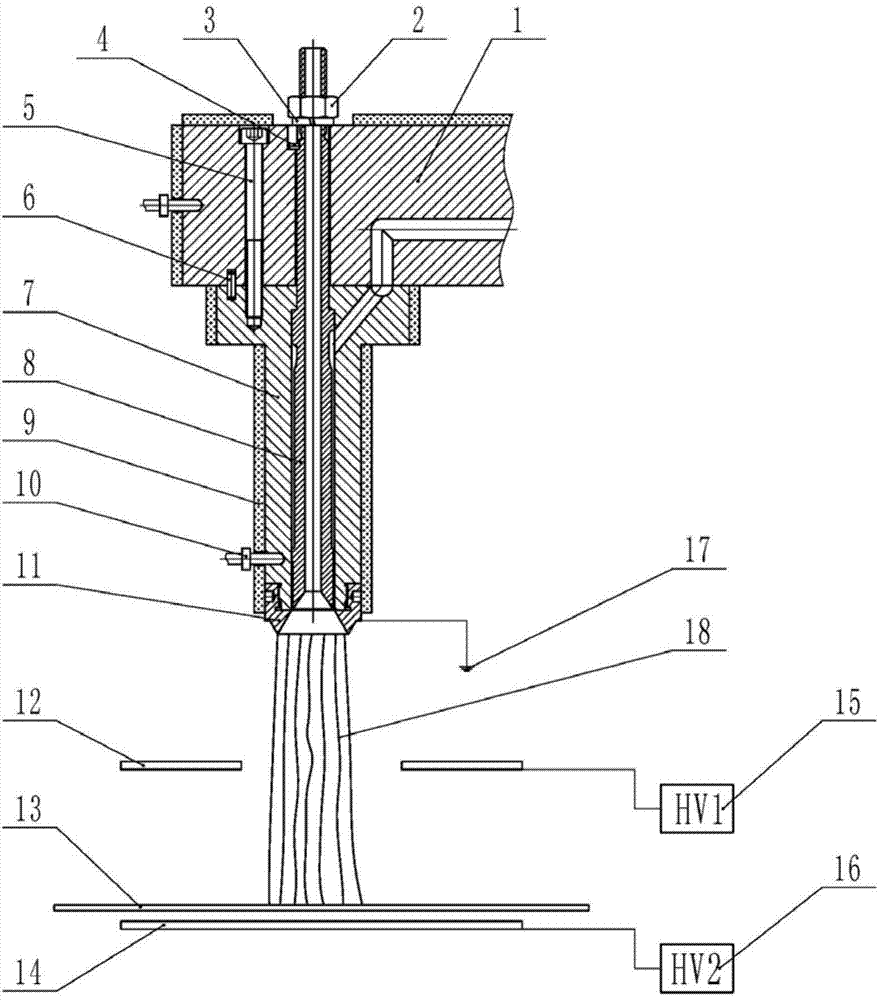

Melt differential electrostatic spinning device and process

InactiveCN103572387AEasy processing and assemblySimple structureFilament/thread formingFiberEngineering

The invention discloses a melt differential electrostatic spinning device and process. The device mainly comprises a melt differential electrostatic spinning nozzle and a multi-electric-field coupling strong drafting device, wherein the melt differential electrostatic spinning nozzle is arranged above the multi-electric-field coupling strong drafting device. The melt differential electrostatic spinning nozzle mainly comprises a spreader plate, a nut, a spring washer, an air duct locating pin, a screw, a nozzle body locating pin, a nozzle body, an air duct, a heating device, a temperature sensor, an inner cone nozzle and a grounding electrode. The multi-electric-field coupling strong drafting device mainly comprises a first plate electrode, a second plate electrode, a first high-voltage electrostatic generator, a second high-voltage electrostatic generator and a fiber receiving plate. Under the action of force of a wind field and an electric field, finally, polymer melt is differentially and evenly distributed to form dozens of Taylor cones of one circle along the edge of the conical face, then dozens of jet flow are formed and refined to be nanometer filaments, a plurality of melt differential electrostatic spinning nozzle bodies are installed below the spreader plate so as to achieve mass production of nanometer fibers, the structure is simple, and parts are easy to machine and assemble.

Owner:BEIJING UNIV OF CHEM TECH

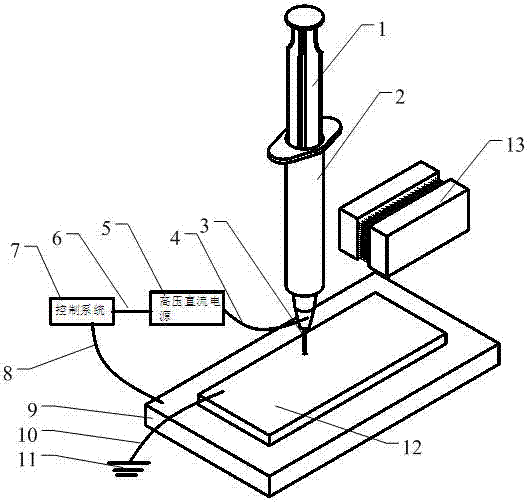

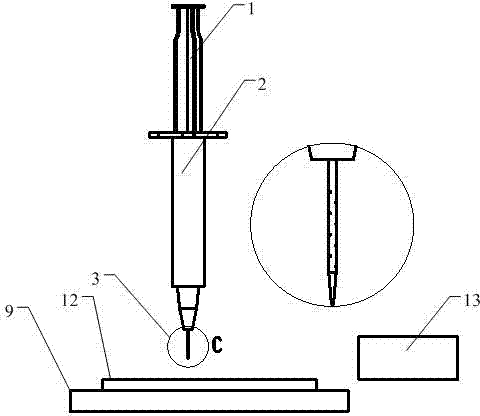

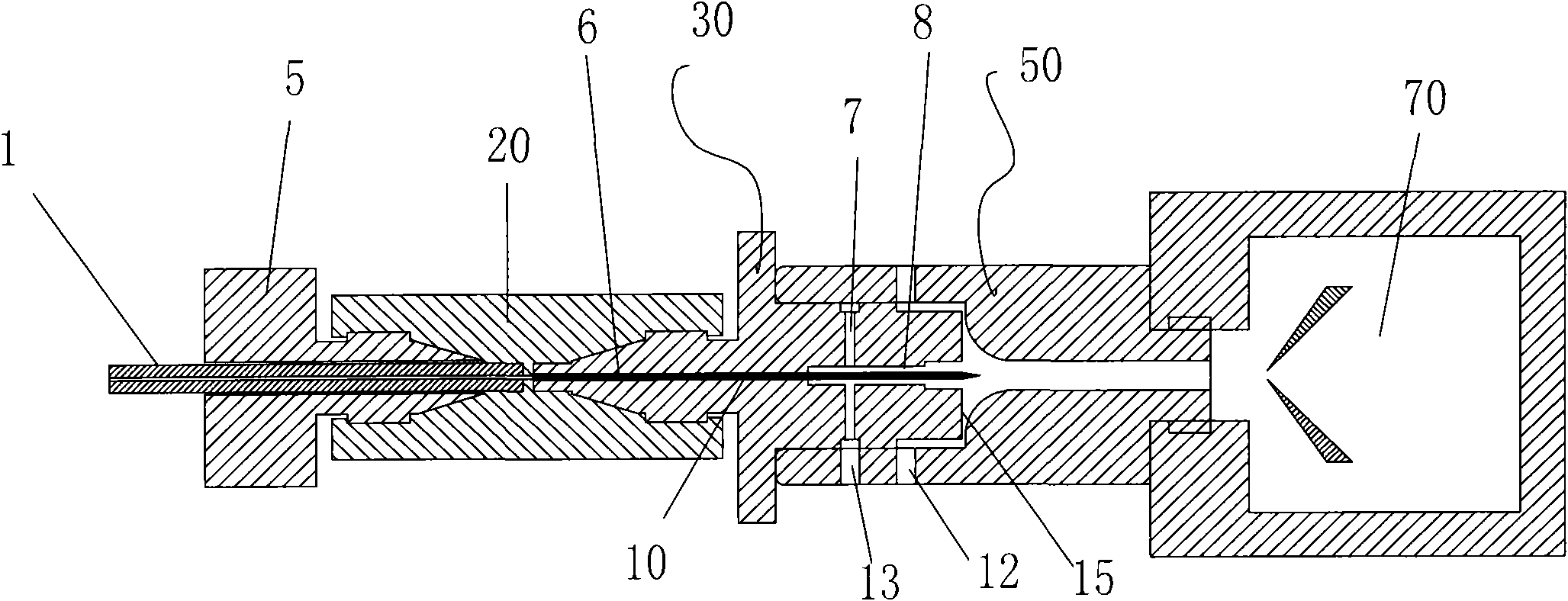

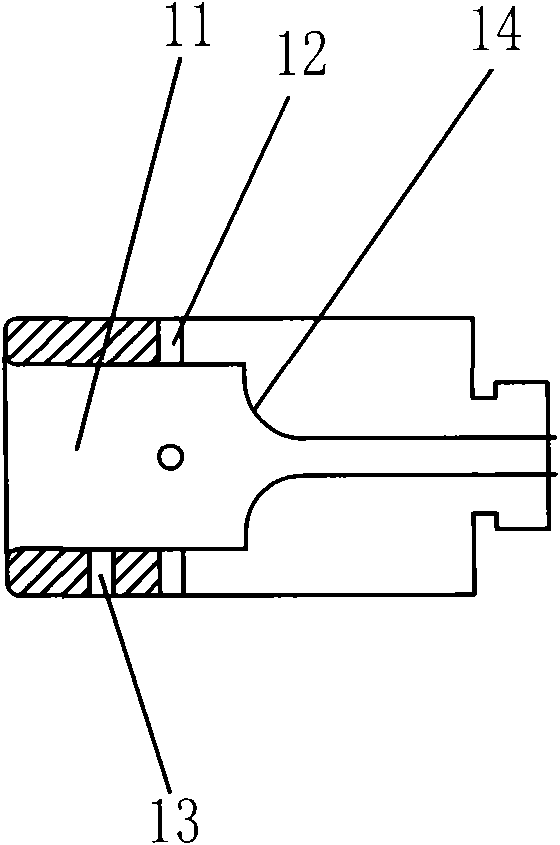

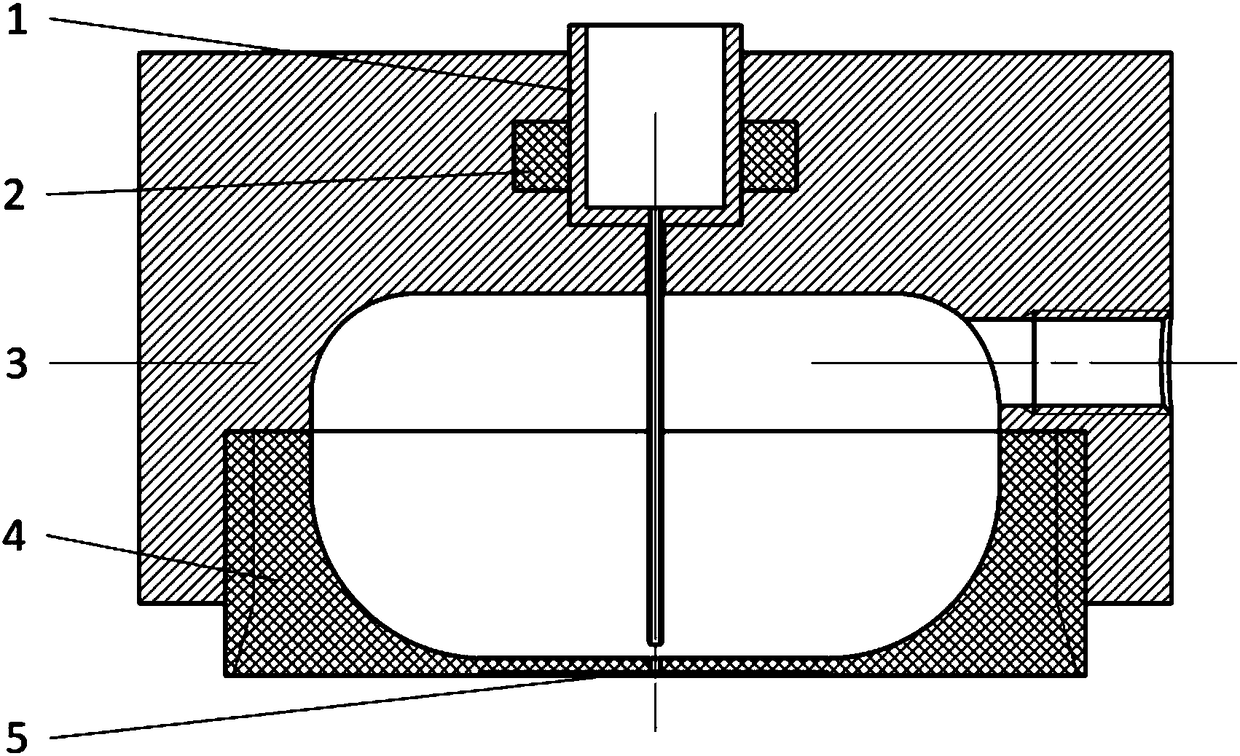

Electrostatic spinning device and cleaning method of electrostatic spinning nozzle of electrostatic spinning device

ActiveCN103898622ASolve the blockageEasy to realize automatic cleaningSpinnerette packsFilament/thread formingFiberJet flow

The invention provides an electrostatic spinning device and a cleaning method of an electrostatic spinning nozzle of the electrostatic spinning device. The electrostatic spinning device comprises an injector pushing mechanism, an injector, the electrostatic spinning nozzle, a control system, a movement platform and a collector, wherein the injector is arranged on the movement platform, the injector pushing mechanism is arranged at one end of the injector, the electrostatic spinning nozzle is arranged at the other end of the injector, a high-voltage direct-current power supply is connected with the electrostatic spinning nozzle, the high-voltage direct-current power supply and the movement platform are connected with the control system, and the collector is arranged on the movement platform; the electrostatic spinning nozzle comprises an upper nozzle portion and a lower nozzle portion which are connected with the injector, the upper nozzle portion is of a hollow structure, the side wall of the upper nozzle portion is provided with a through hole, the lower nozzle portion is in a solid cone shape, solution in the injector oozes out through the through hole, the solution flows to the tail end of the nozzle along the Taylor cone to form a Taylor cone and jet flow, and the jet flow is collected on the collector and deposits to form fibers. The electrostatic spinning device and the cleaning method can resolve the problem of blocking of the nozzle, and thinner fibers can be spun. The cleaning method of the nozzle is easy and convenient to implement.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

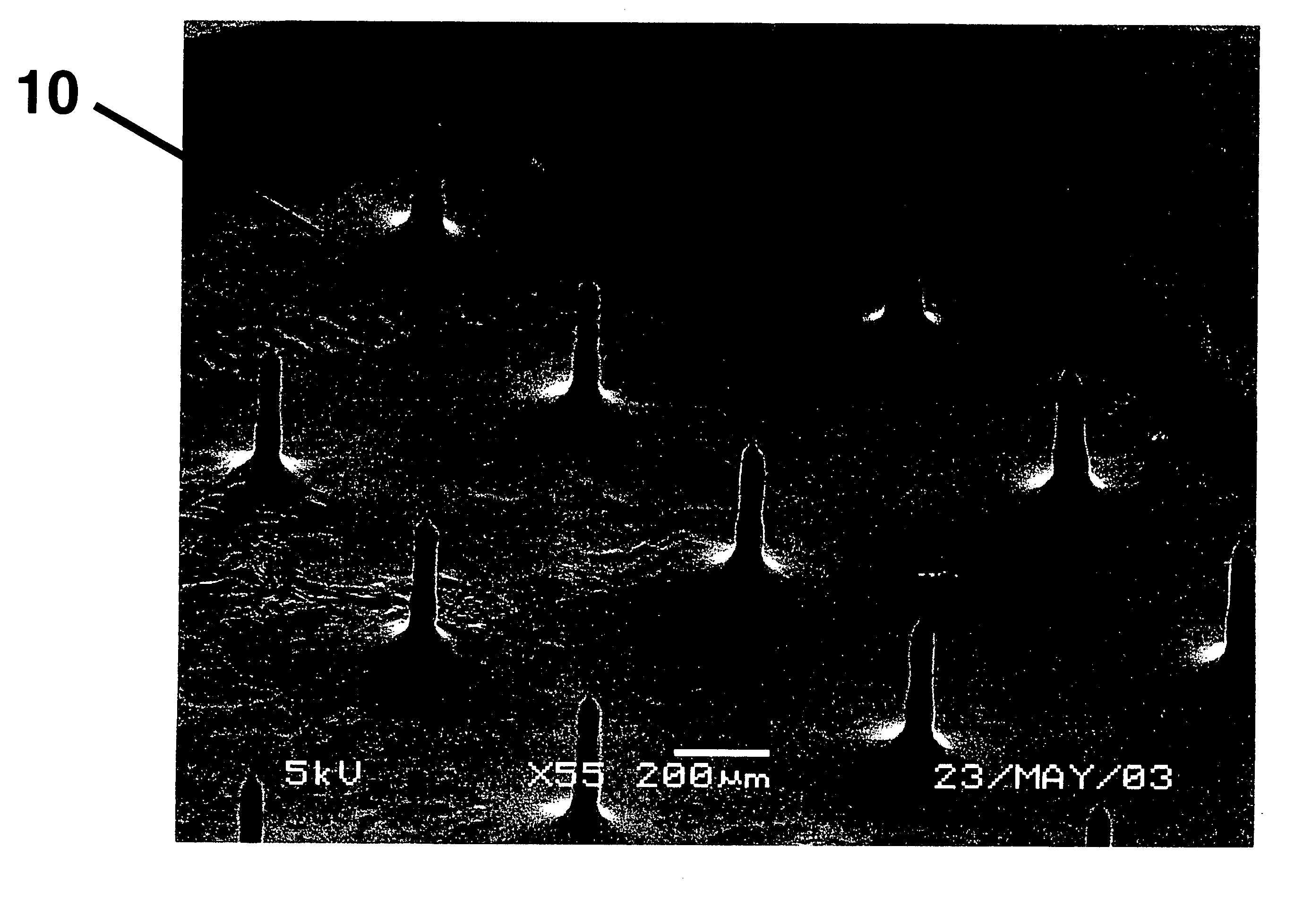

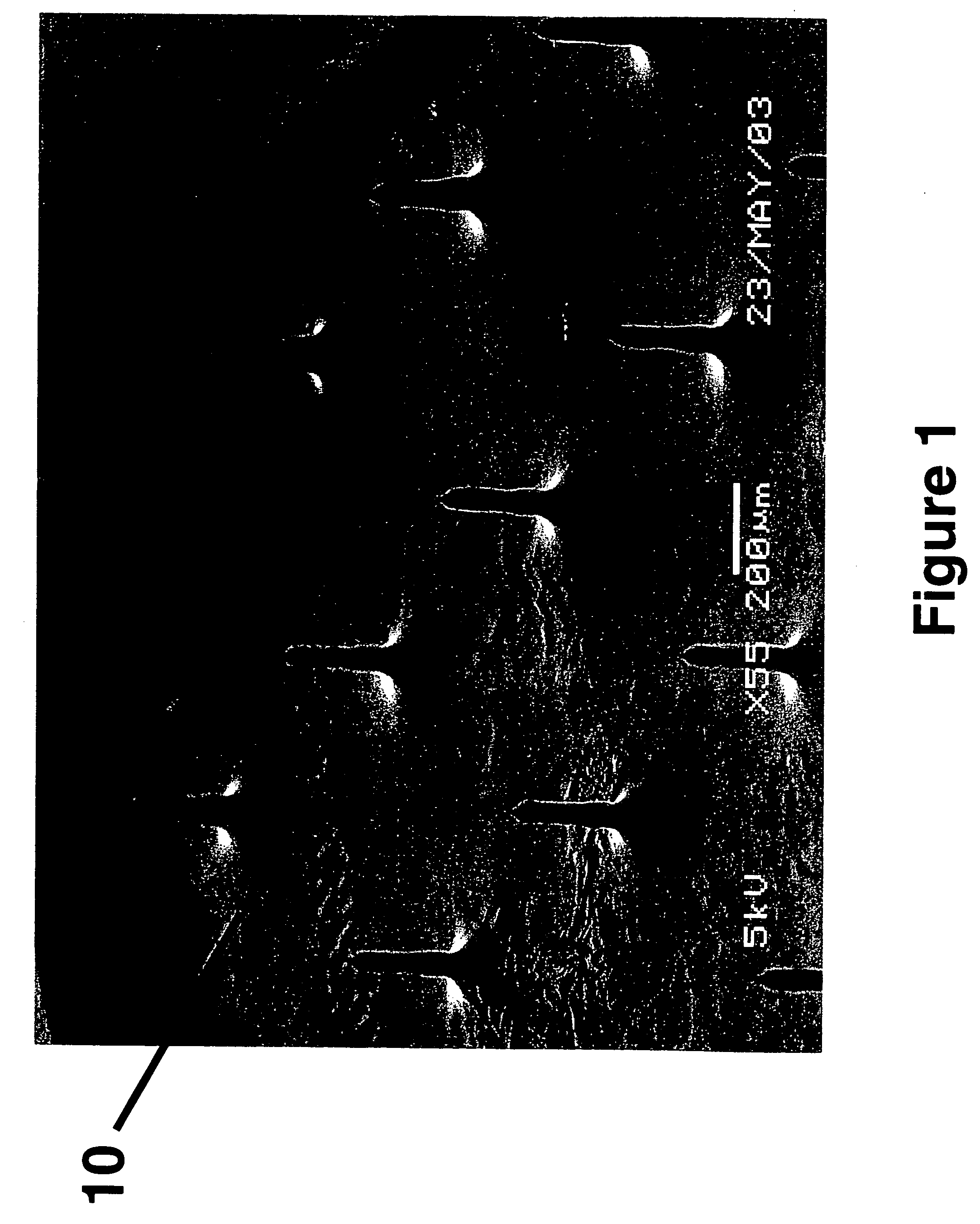

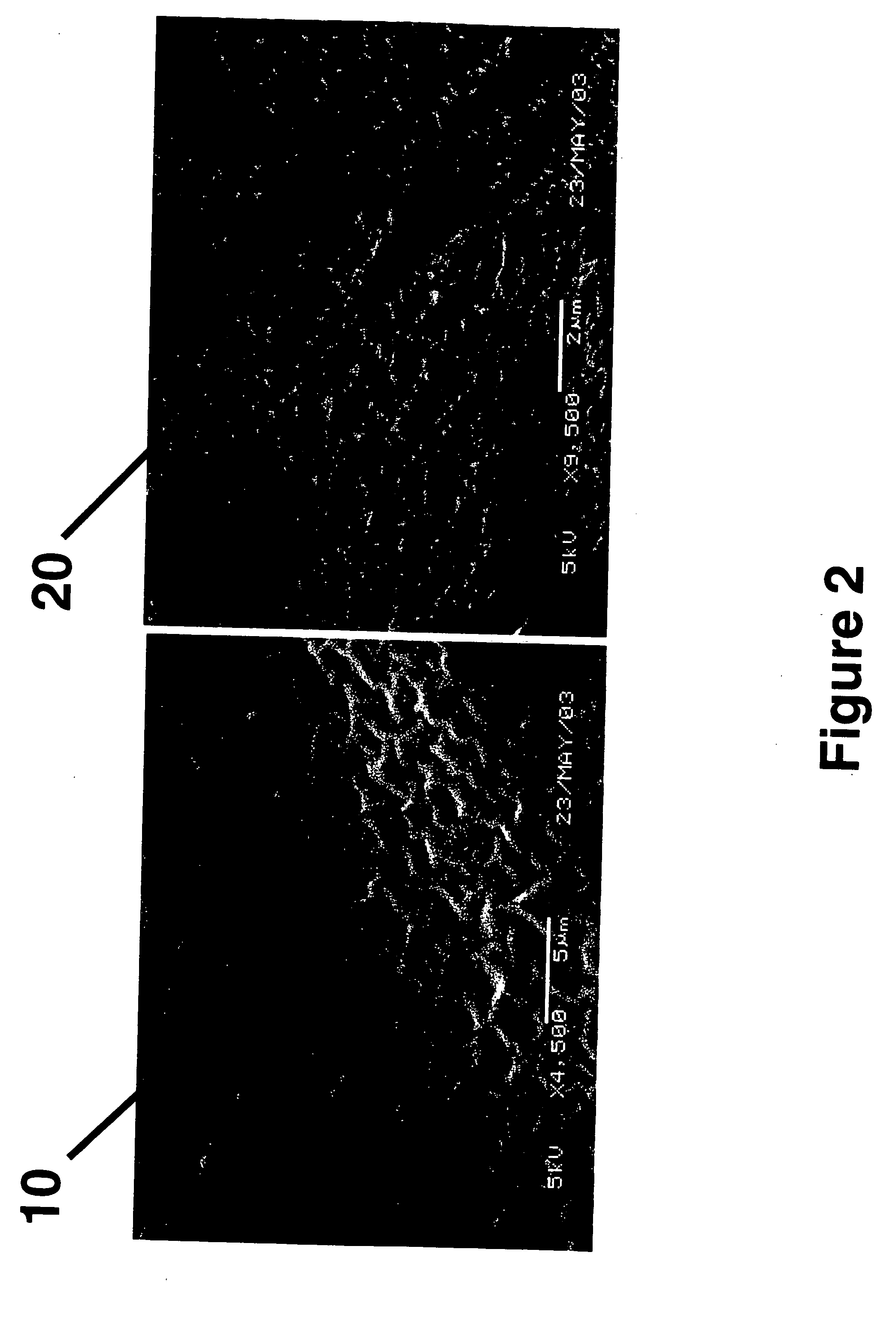

Method of utilizing MEMS based devices to produce electrospun fibers for commercial, industrial and medical use

A method of fiber production relating in general to electrospinning and specifically to MEMS (Micro ElectroMechanical Structures). Utilizing integrated circuit manufacturing processes, a nanoscale, self-contained device has been developed to execute the process of electrospinning large arrays of fibers and fiber arrays. One of the benefits of using the disclosed MEMS device is that the voltage required to produce a “so called” Taylor Cone would is substantially reduced and the requirement of a hydrostatic feed negated through the use of passive capillarity based wick surface treatment.

Owner:CONNECTICUT ANALYTICAL

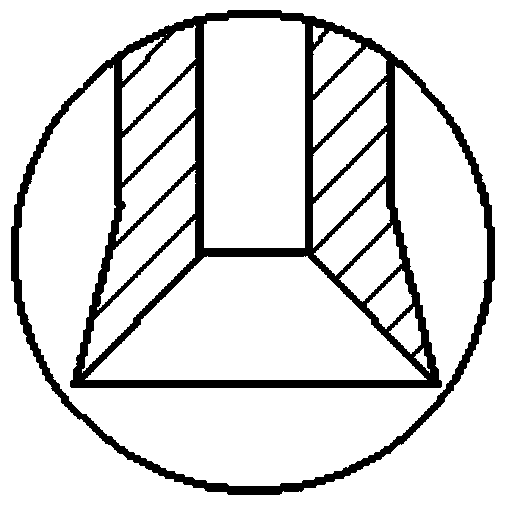

Spray tube electrospinning head

InactiveCN103422180AIncrease speedIncreased polarizationSpinnerette packsFilament/thread formingTaylor coneElectric field

The invention discloses a spray tube electrospinning head, and belongs to the field of electrospinning. The spray tube electrospinning head comprises an electrospinning head body, wherein a solution connecting portion is arranged on the tail portion of the electrospinning head body, a horn-shaped spinning nozzle, a polarization throat port and a solution chamber hole are formed in the electrospinning head body in sequence from top to bottom, and are communicated with one another, the inner wall face of the spinning nozzle is a circular-arc curved surface which gradually expands outwards, the port diameter of the polarization throat port is smaller than the hole diameter of the solution chamber hole, the outer wall of the head portion of the electrospinning head body is of a cone shape, and the diameter of the cone gradually decreases outwards. The spray tube electrospinning head can increase the forming speed of a Taylor cone, improve the velocity of a solution when the solution passes through the spray tube electrospinning head, and is better in electric field directivity.

Owner:常州市亚国新能源科技有限公司

Device for manufacturing patterned graphene through laser-induced deposition

ActiveCN106927452AEnable patterned manufacturingLow costMaterial nanotechnologyGrapheneProtection systemCo2 laser

The invention discloses a device for manufacturing patterned graphene through laser-induced deposition, and relates to the field of graphene. The device comprises an electrospinning direct-write precursor platform, a laser-induced graphene platform and a deposition graphene receiving platform, wherein the electrospinning direct-write precursor platform is provided with an injection pump, an injector and a direct current power supply; the laser-induced graphene platform is provided with a CO2 laser and an inert gas protection system; the deposition graphene receiving platform is provided with a collection plate and a two-dimensional motion platform; the injector is connected with the injection pump, the direct current power supply provides power for the injector, the light beam of the CO2 laser is focused on the Taylor cone outflux of the injector, the collection plate is arranged on the two-dimensional motion platform and positioned below the Taylor cone outflux of the injector, and the inert gas protection system provides inert gas protection for the deposition graphene receiving platform. The device of the laser-induced deposition manufacturing patterned graphene has the advantages of being continuable in manufacturing, low in cost and low in environment requirement and equipment requirement.

Owner:XIAMEN UNIV

Device and method for preparing gate electrodes of solar cell

ActiveCN103456835AIncrease aspect ratioHigh aspect ratioFinal product manufacturePrintingSilver pasteElectricity

The invention provides a device and method for preparing gate electrodes of a solar cell. The device comprises a silver paste supplying device, a nozzle height adjusting module, a nozzle, a programmable-control high-voltage generator, an adsorption platform, a motion platform and a control unit. The method comprises the steps of placing a solar substrate on the adsorption platform, and preparing the first gate electrode and the second gate electrode, wherein the width of the second gate electrode is larger than that of the first gate electrode. The electric spinning direct writing process is utilized for printing the solar electrodes, an electric field is utilized for pulling silver paste in the nozzle to lines with the diameters smaller than the diameter of the nozzle, and the widths and the heights of the printed grid lines can be controlled by controlling the different voltages, the height of the nozzle and the feed speed of a substrate. The voltages affect the stability of a Taylor cone at a certain height, the height affects the heights of the printed grid lines mainly by affecting the degree of cure of the grid lines in the air, the larger the height is, the higher the printed grid lines become, the feed speed of the substrate mainly affects the widths of the printed grid lines, and the higher the speed is, the thinner the grid lines become.

Owner:HUAZHONG UNIV OF SCI & TECH

Analyte separator with electrohydrodynamic taylor cone jet blotter

Devices, systems, and methods are disclosed that analyze a biological or other fluid sample using an electrophoresis or other separation method and then emit the fluid sample with separated constituents using an electrohydrodynamic spray to form a Taylor cone and jet, without dispersion into droplets, onto a substrate that moves with respect to the emitter. Electrodes can be shared between the electrophoresis and electrospray elements, and an adjunct fluid can help draw the separated sample into the Taylor cone. A micro-machined capillary channel on a chip can supply multiple lines to a substrate.

Owner:LI COR

Ultrasonic oscillation electrostatic spinning nozzle and method

InactiveCN102212892AIncrease productionImprove stabilitySpinnerette packsFilament/thread formingFiberTransformer

The invention relates to an ultrasonic oscillation electrostatic spinning nozzle, which comprises a spinning nozzle and an ultrasonic processor, wherein the ultrasonic processor comprises an amplitude transformer, a transducer and a controller; the top of the amplitude transformer passes through the bottom of the spinning nozzle and is placed in the spinning nozzle; the bottom end of the amplitude transformer is connected with the transducer; the transducer is connected with the controller; and the spinning nozzle is of an open disc, and the spinning nozzle is provided with a binding post connected with a high-voltage positive electrode. The invention also relates to an electrostatic spinning method, which comprises the following steps of: adding spinning solution or melt into the spinning nozzle through an automatic transfusion device, keeping the liquid level of the injected spinning solution or melt higher than the horizontal plane of the top of the amplitude transformer, starting the controller and a high voltage, forming a Taylor cone through the spinning solution or melt under the action of ultrasonic oscillation, and upwards extracting the jet. The surface tension of the spinning solution or melt is overcome, multiple pieces of jet are formed, the yield of electrostatic spinning is increased, the spinning stability of the spinning nozzle is improved, and continuous and large-scale production of nano fibers can be realized.

Owner:DONGHUA UNIV

Piezoelectric type integrated spray head used for electrofluid jet printing

The invention relates to the field of electrofluid jet printing equipment, in particular to a piezoelectric type integrated spray head used for electrofluid jet printing. The piezoelectric type integrated spray head comprises an outer bracket, a piezoelectric structure, a spray head, a lower electrode supporting ring and a lower electrode ring, wherein the piezoelectric structure is positioned above the spray head; an upper electrode is arranged on the upper part of the spray head; the lower electrode supporting ring and the lower electrode ring are sequentially arranged below the spray head; after the piezoelectric structure, the upper electrode and a lower electrode are electrified, electric fields are formed between the spray head and the lower electrode ring, so that a solution forms Taylor cones on the spray head. The piezoelectric type integrated spray head overcomes the defect that existing electric jet printing equipment cannot meet high-frequency spraying, can realize high-frequency high-resolution printing; and the lower electrode is integrated to the spray head end, so that the whole jet printing system is more flexible, and a base plate with a complex shape can be used to print. The piezoelectric type integrated spray head further has the advantages of being simple in structure, low in manufacturing cost, suitable for large-scale production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

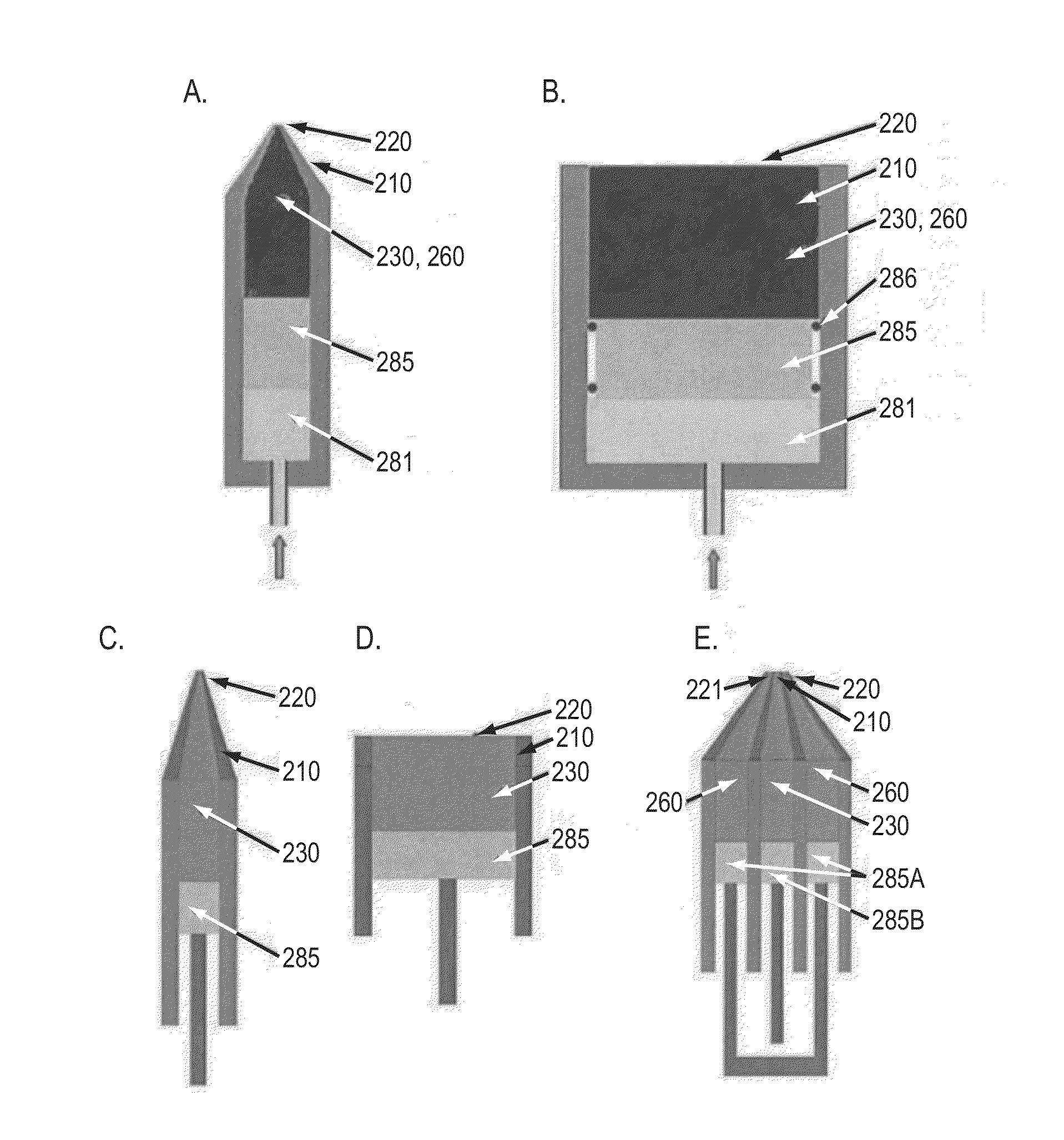

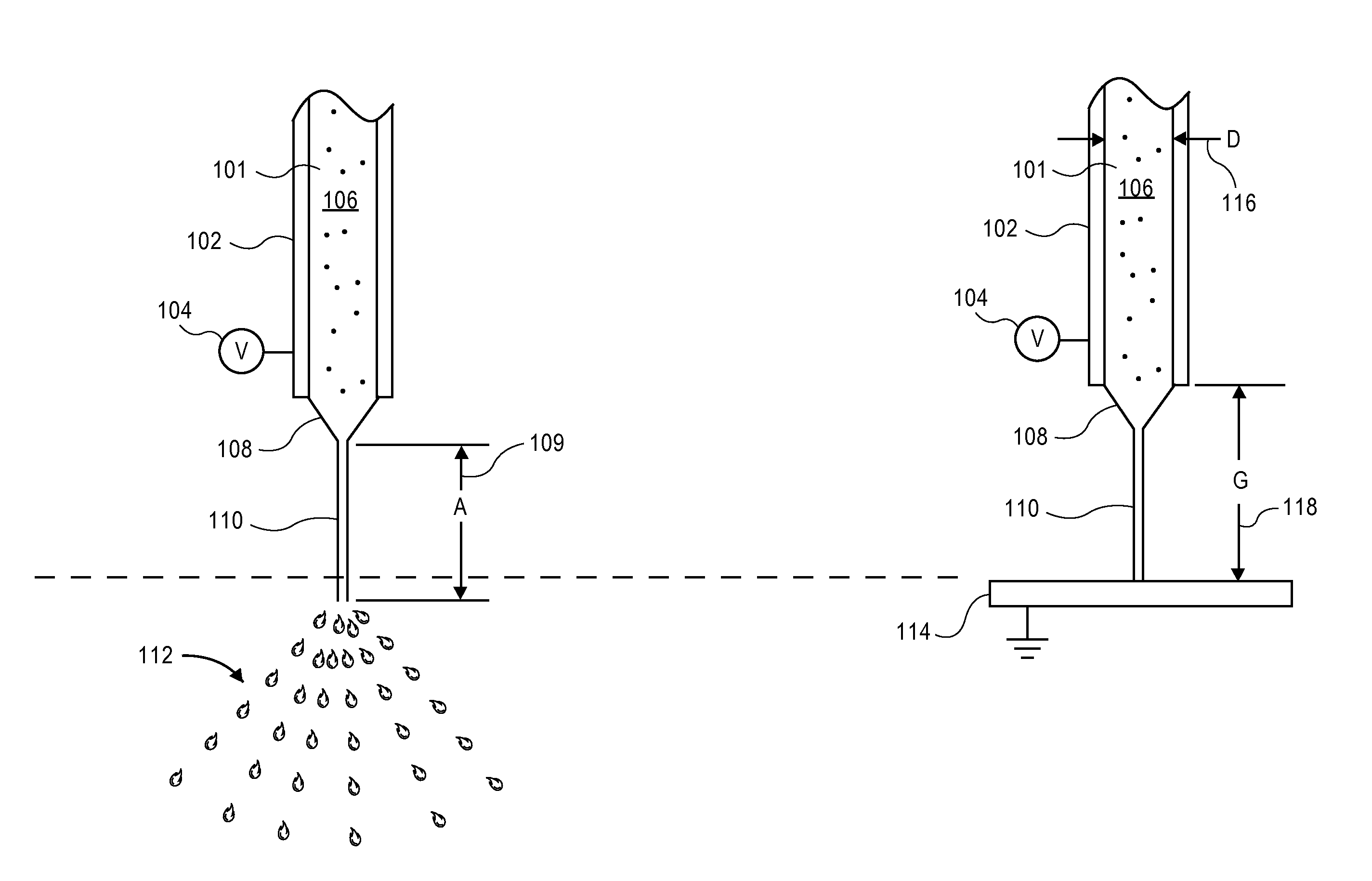

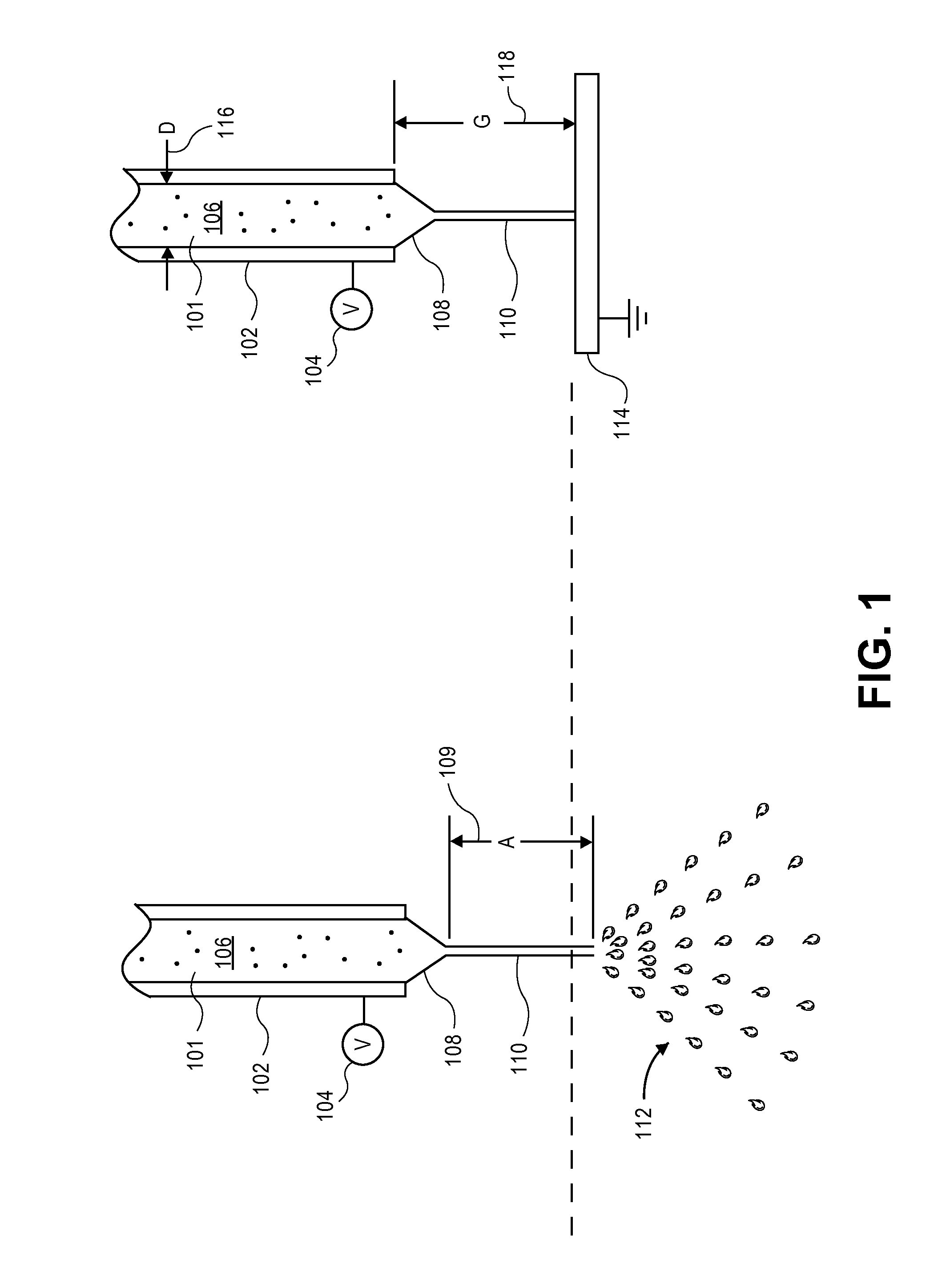

Electrospray source

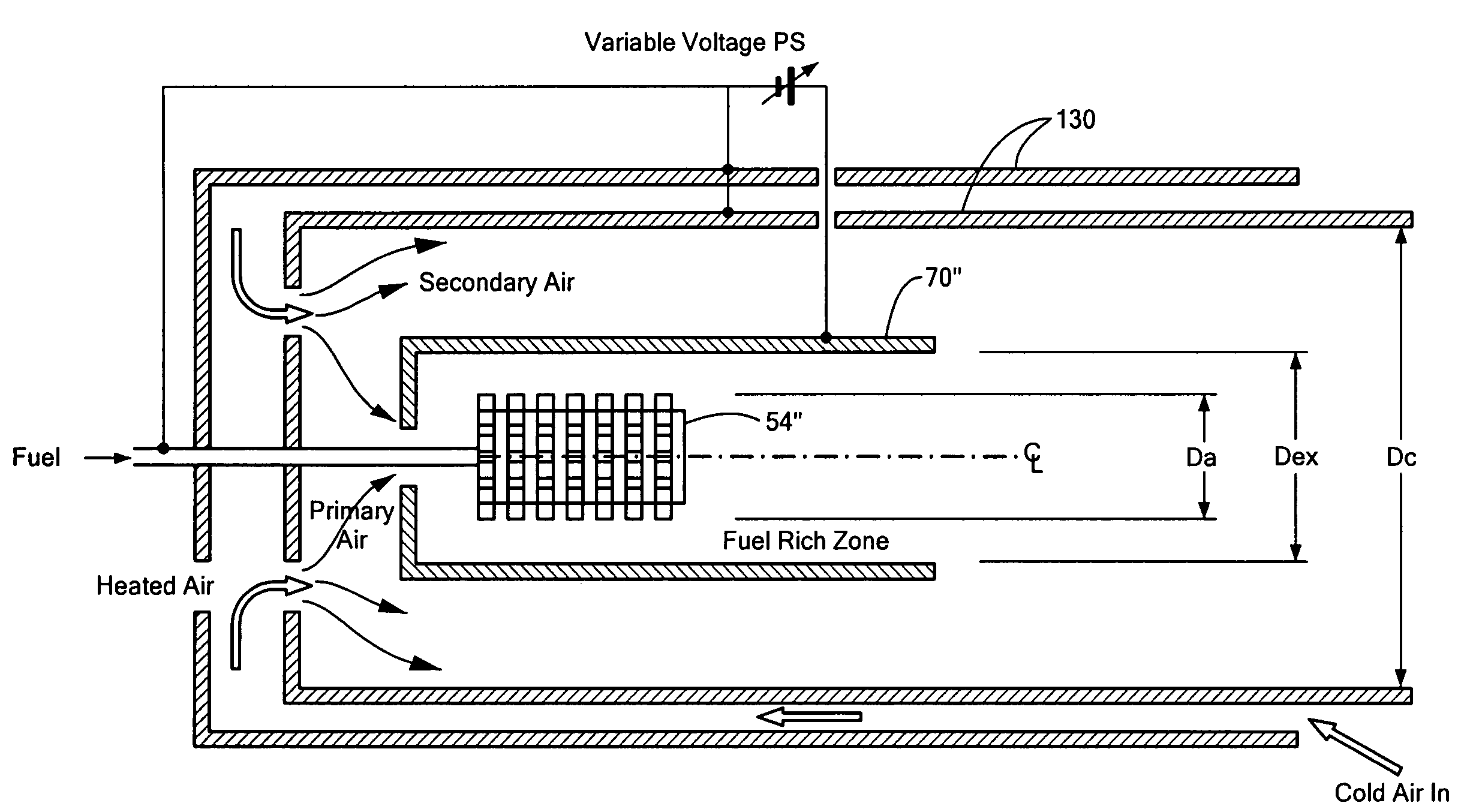

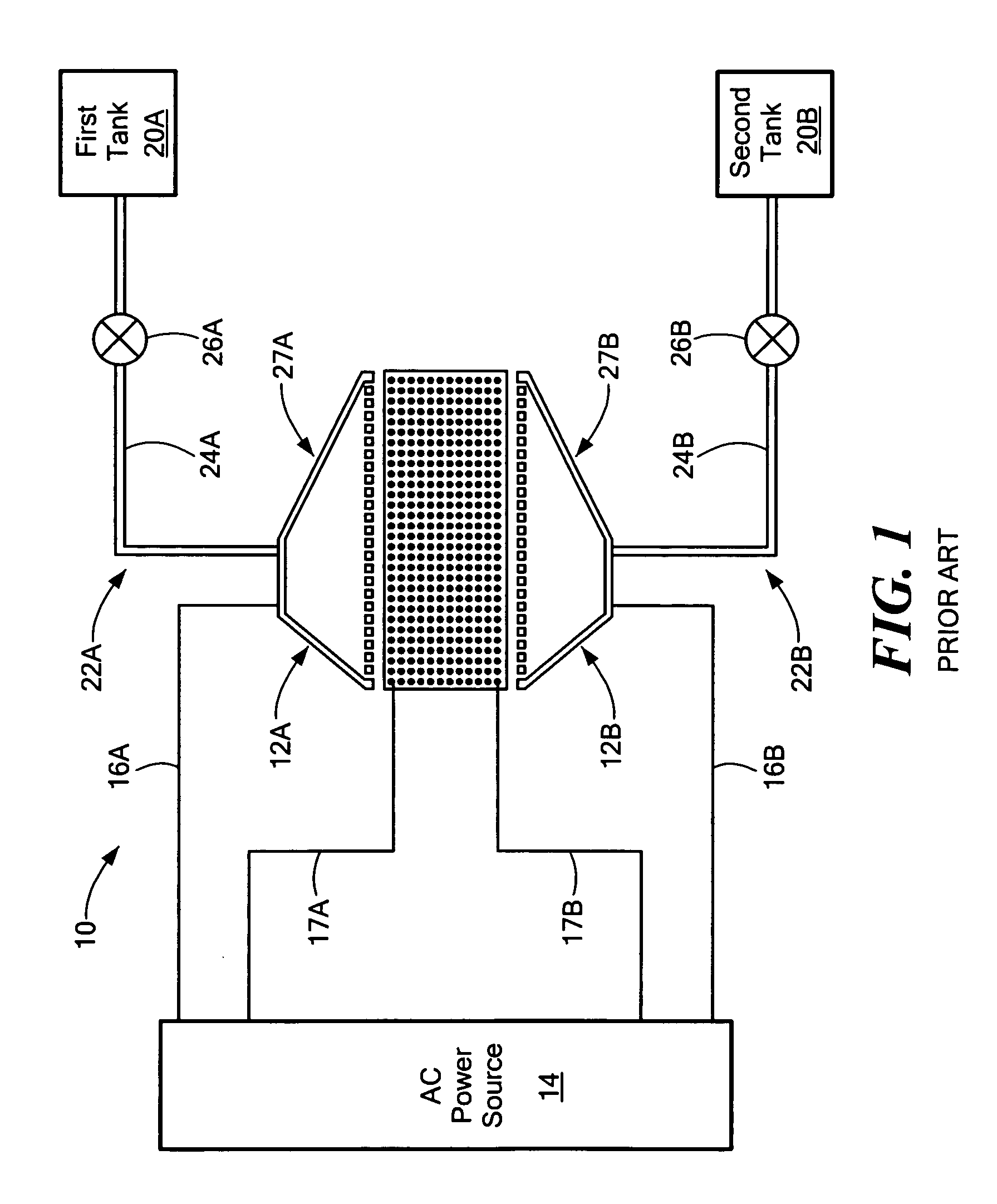

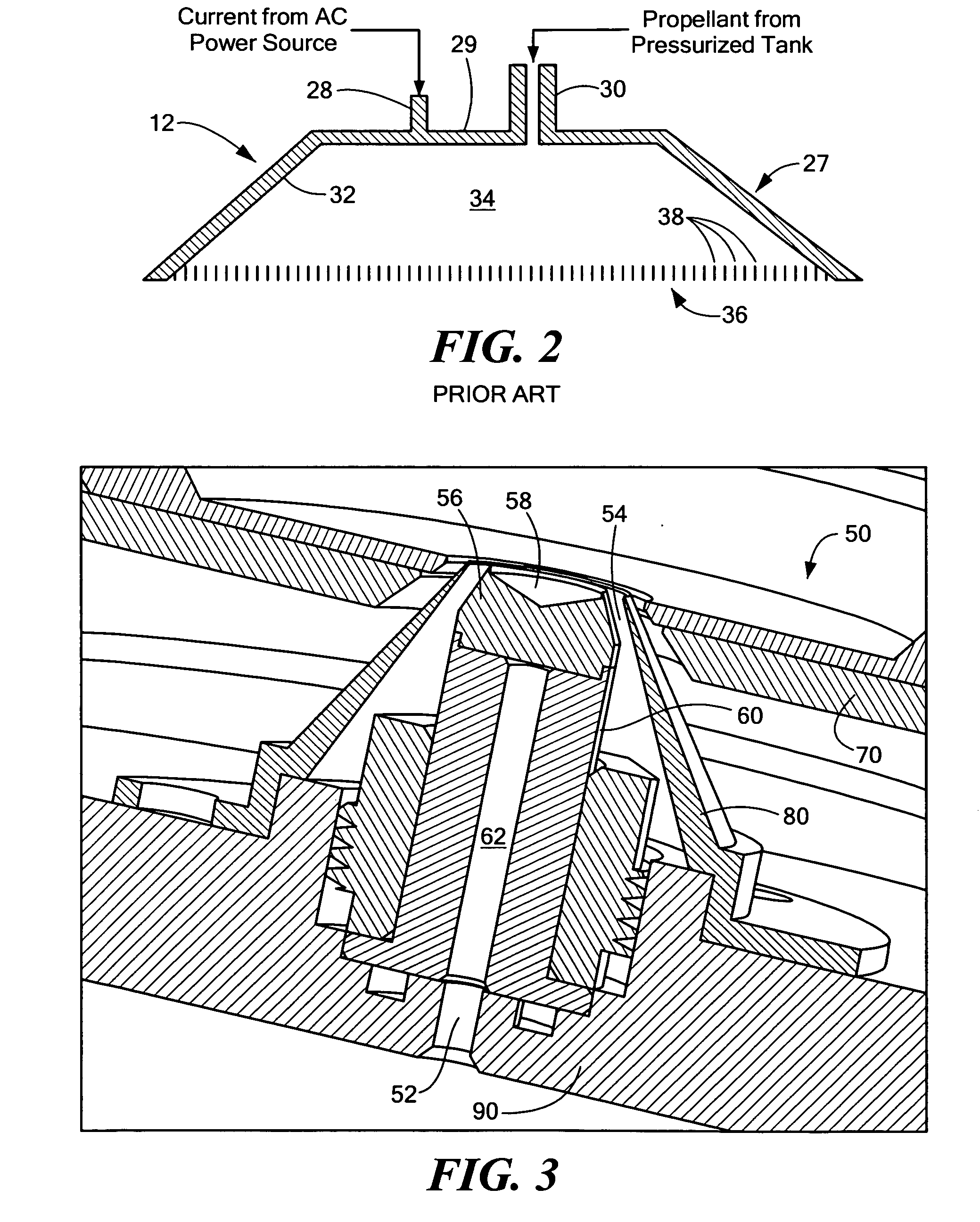

ActiveUS20090113872A1Easy to manufactureReduce manufacturing costCosmonautic vehiclesCosmonautic propulsion system apparatusWorking fluidEngineering

An electrospray source useful for a variety of applications and including an emitter with a porous media flow distributor having a surface forming multiple Taylor cones. A casing about the porous media flow distributor controls the direction of a working fluid through the porous media. An extractor is at a potential different than the emitter for forming the Taylor cones. A guard electrode is disposed between the emitter and the extractor and is at or above the potential of the emitter for shaping the electric field formed between the emitter and the extractor.

Owner:BUSEK

Electrostatic spinning device and method for mass nanometer/micrometer fibers

The invention relates to an electrostatic spinning device and method for mass nanometer / micrometer fibers. The electrostatic spinning device is provided with a liquid storage tank with an opening in the top, a bubble generator, a high-voltage electrostatic generator and a negative electrode collecting device, wherein the bubble generator and the high-voltage electrostatic generator are in coupling connection with polymer fluid in the liquid storage tank, and the negative electrode collecting device is located above the opening of the liquid storage tank. The bubble generator comprises an air pump and an air guide pipe connected with the air pump, a plurality of airflow nozzles are arranged on the air guide pipe, and each airflow nozzle is located in the bottom inside the liquid storage tank or in the polymer fluid in the middle. According to the electrostatic spinning device and method for the mass nanometer / micrometer fibers, a large number of protrusions can be obtained through an air pump jet stream mode, then a large number of Taylor cones are obtained, and finally the mass nanometer / micrometer fibers are obtained. The electrostatic spinning device and method for the mass nanometer / micrometer fibers greatly improves production efficiency of nanometer / micrometer fiber electrostatic spinning, and enables the purpose of mass production or industrialization of the nanometer / micrometer fiber electrostatic spinning to be achieved.

Owner:SUZHOU UNIV

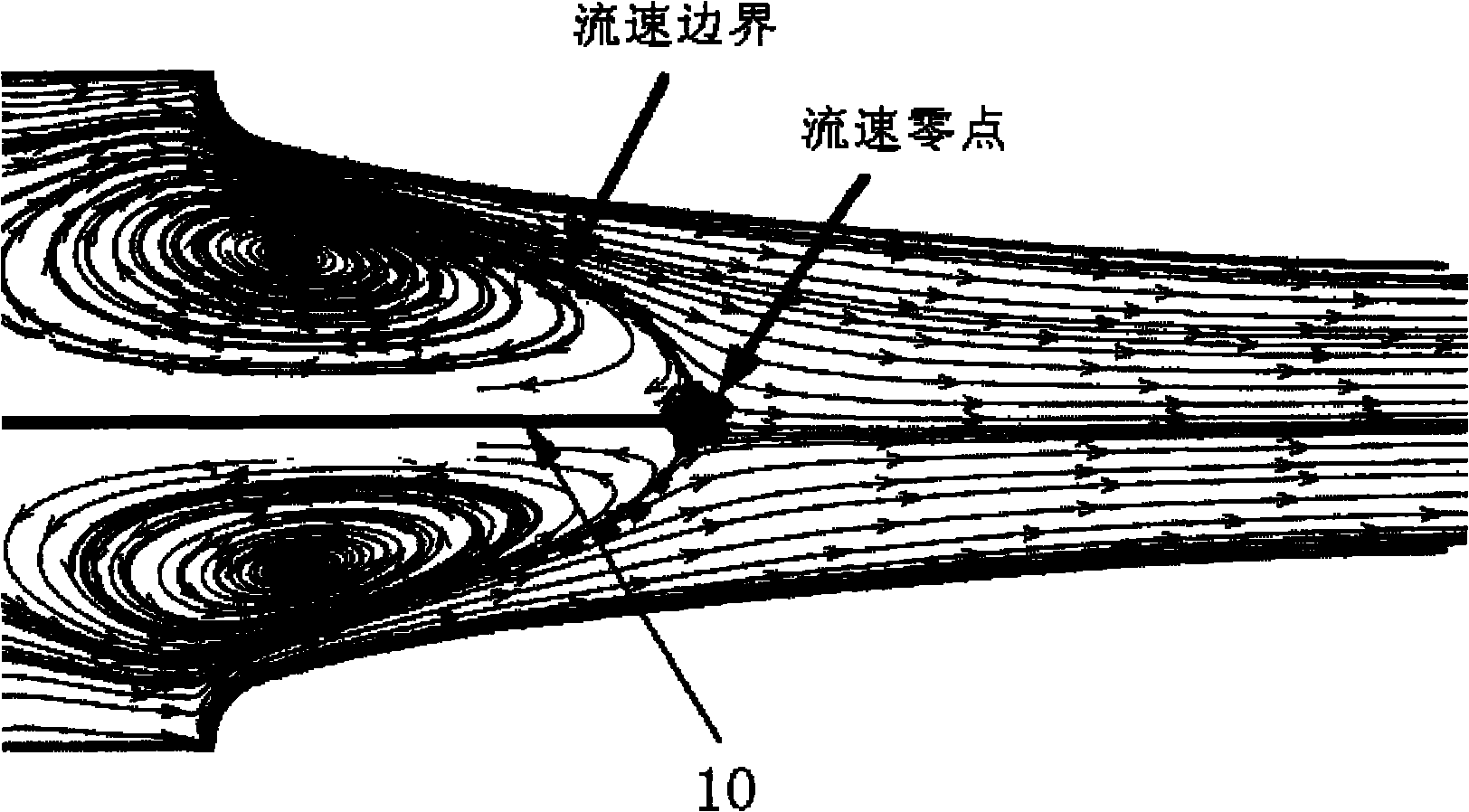

Electro-spray ion generator

ActiveCN102142352AImprove transmission efficiencyStable ion emissionComponent separationIon sources/gunsElectricityElectro spray

The invention discloses the field of an analytical instrument, in particular to an instrument for ion generation of medical micromolecules and biological macromolecules. The instrument is provided with a hollow capillary emission needle and a launch emission support. The emission needle support forms a laminar flow gas flowing forwards around the emission needle to eliminate the capillary reverseflow effect of liquid flowing out from the hollow capillary emission needle outside a capillary, so that the liquid flows forwards. An inlet infused in the capillary in a vacuum mode I specially designed into an arc-shaped mechanism, so the speed of airflow at some position at any direction is zero, the position is just the outlet of the hollow capillary emission needle, therefore the stability of a Taylor cone of the top end of the point of the emission needle is ensured in the large flow range, and finally a stable ion flow is obtained. The instrument has the advantages of stable ion emission, high ion transmission efficiency and the like and can be widely applied to occasions of ion source preparation.

Owner:ZHEJIANG HAOCHUANG BIOTECH

Method of utilizing MEMS based devices to produce electrospun fibers for commercial, industrial and medical use

InactiveUS20050121470A1Electric discharge heatingLiquid flow controllersFiberIntegrated circuit manufacturing

A method of fiber production relating in general to electrospinning and specifically to MEMS (Micro ElectroMechanical Structures). Utilizing integrated circuit manufacturing processes, a nanoscale, self-contained device has been developed to execute the process of electrospinning large arrays of fibers and fiber arrays. One of the benefits of using the disclosed MEMS device is that the voltage required to produce a “so called” Taylor Cone would is substantially reduced and the requirement of a hydrostatic feed negated through the use of passive capillarity based wick surface treatment. CROSS REFERENCE TO RELATED APPLICATIONS Provisional Application No. 60 / 526879 was filed on 4 Dec. 2003

Owner:CONNECTICUT ANALYTICAL

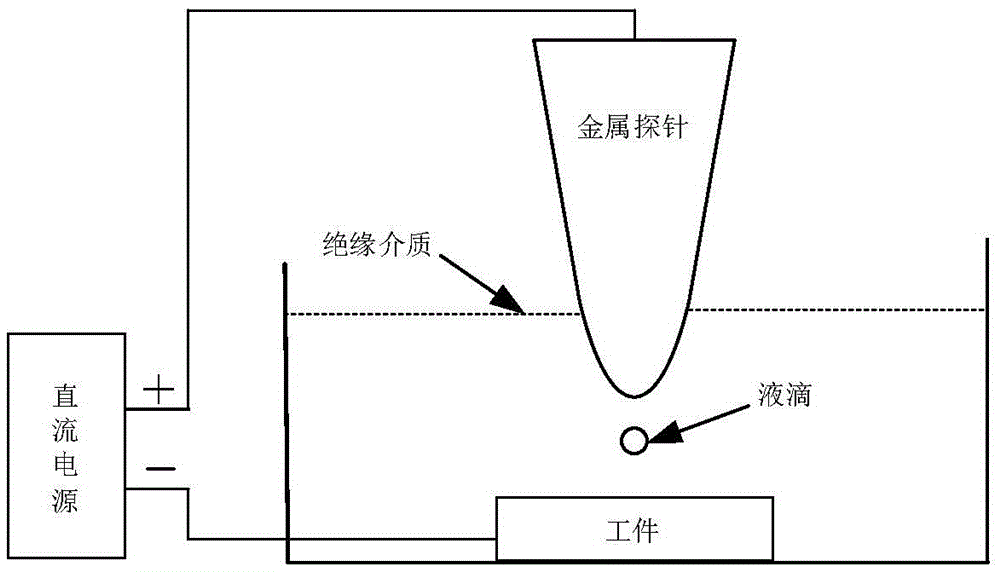

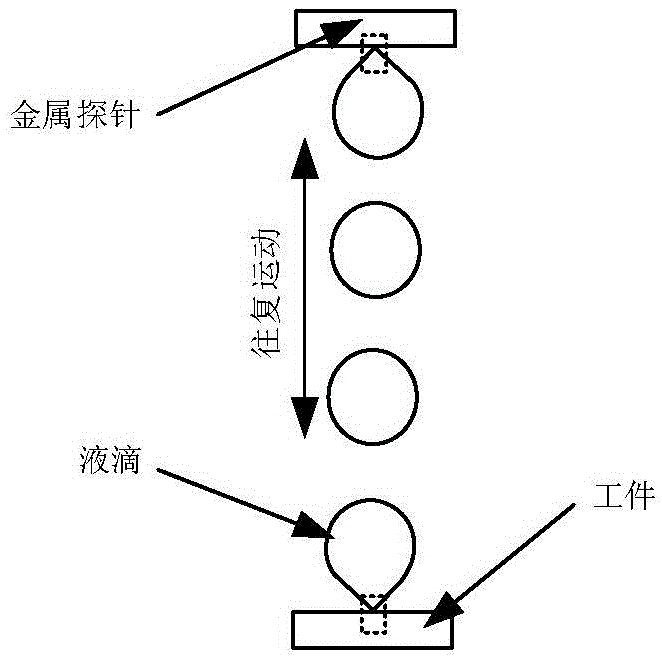

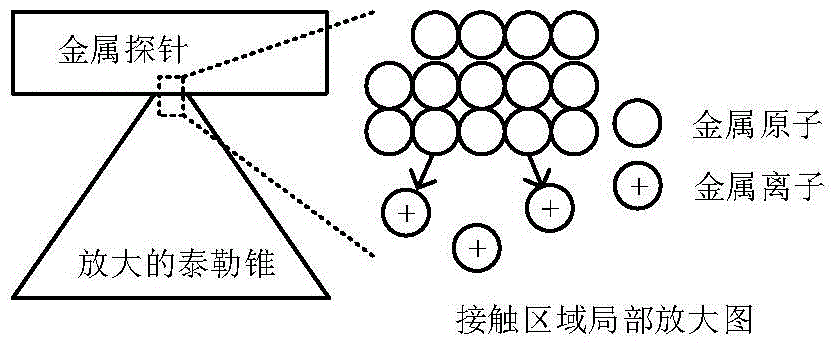

Micro-nano electrochemical deposition machining method based on liquid drop Taylor cone

ActiveCN105420763AAchieving Atomic-Level Deposition ProcessingEnables deposition processingElectroforming nanostructures3D structure electroformingMicro nanoManufacturing technology

The invention relates to a micro-nano electrochemical deposition machining method based on a liquid drop Taylor cone, and belongs to the technical field of micro-nano manufacturing. The method comprises the steps that liquid drops containing deposited metal ions are firstly put between a metal probe and a workpiece, and the materials of the probe are deposited materials; the probe and the workpiece are both immersed in an insulating medium, and the insulating medium and water are not compatible; the probe and the workpiece are connected with the positive pole and the negative pole of a direct-current power source respectively; the liquid drops do reciprocating motion between the probe and the workpiece under the action of an electric field; and when the liquid drops are close to the probe and the workpiece, the Taylor cone is formed on the surfaces of the liquid drops under the action of the electric field, by means of the electrochemical action generated during contact of the liquid drop Taylor cone, the probe and the workpiece, metal atoms of the metal probe are changed into metal cations to enter the liquid drops, then the metal cations are carried by the liquid drops to the surface of the workpiece and conveyed to the surface of the workpiece through the liquid drop Taylor cone, the metal cations obtain electrons on the surface of the workpiece to be changed into atoms to be deposited, and therefore micro-nano electrochemical deposition machining is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Electric spinning machine

The invention relates to an electric spinning machine, comprising a multi-roller receiving device, a spinning spray head and a vacuum box body. The multi-roller receiving device comprises a plurality of rotary planar rollers and a plurality of tridimensional rollers; an electric spinning liquid spinning device comprises a spray head and an electric spinning liquid supply device, the spray head comprises a needle and a liquid storage container with a through hole; the electric spinning liquid flows out from a gap between the needle and the through hole, the electric spinning liquid forms into Taylor cones through the spray head, and filaments are discharged and are conveyed to more than two receiving rollers; each receiving roller corresponds to at least one spray head, and the spray head does reciprocating motion along the axial direction of the corresponding receiving roller; and the electric spinning liquid spinning device and the receiving device are contained in the vacuum box body, the air is processed after leaving the vacuum box through the extract opening, of the vacuum box, and then the air returns to the vacuum box through the air inlet of the vacuum box to perform next circulation. The electric spinning machine has the advantages of simple structure and can effectively improve the production efficiency, so that the electric spinning machine is suitable for application in the static spinning field.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH +1

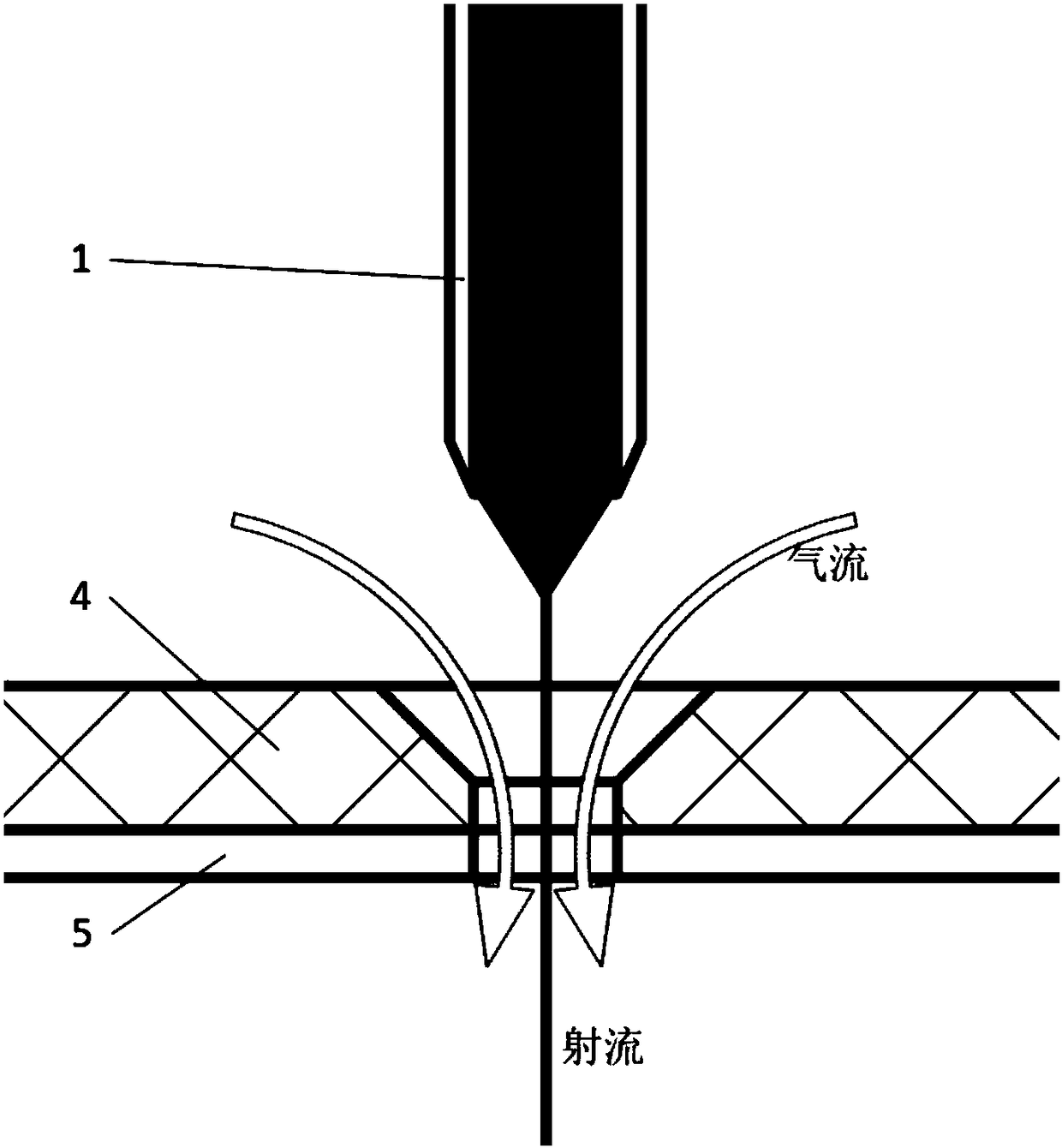

Electric field-flow field mixed controlled electrofluid jet printing method and device

The invention discloses an electric field-flow field mixed controlled electrofluid jet printing method and device and belongs to the technical field of micro / nano fabrication. According to the electric field-flow field mixed controlled electrofluid jet printing method and device, a sprayer outlet pipe is a capillary pipe; a fluid outlet with a chamfering angle is formed in the lower part of the capillary pipe; fluid around the capillary pipe forms a focused stable fluid flow field below a sprayer under the chamfering action of the fluid outlet; a grounding electrode is arranged below the fluidoutlet; a through hole coaxial with the fluid outlet is formed in the grounding electrode; a high voltage static electric field is applied between the sprayer and the grounding electrode; electrofluid flowing out of the capillary pipe forms Taylor Cone and pulls out a jet flow under the combined action of the high voltage static electric field and the fluid flow field; and the jet flow penetratesthrough the fluid outlet and the through hole for printing. According to the electric field-flow field mixed controlled electrofluid jet printing method and device, the electric current jet printingtechnology and the flowing focusing technology are combined to improve the printing precision and resolution ratio and solve the problem that general electrofluid jet printing cannot print on an insulating base plate or the base plate with a free hook face.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of electrospinning fibres

A method of electrospinning fibres is disclosed. The fibres have an inner core surrounded by a porous outer shell. The method comprises co-electrospinning first and second liquids as core and shell respectively, the second liquid surrounding the first liquid in a jet issuing from a Taylor cone, wherein the first and second liquids are miscible or semi-miscible with each other, such that pore generation is driven in the shell of the fibre. The liquids may be solutions or melts. The electrical conductivity, viscosity, miscibility and other parameters of the liquids determine the structure of the produced fibres. As well as producing fibres having a porous shell there are described methods of co-electrospraying porous beads as well as core- shell vesicles having a porous shell. The methods may be used to produce hydrogen storage fibres, vesicles and beads.; The methods may also be used for producing controlled drug- delivery fibres, vesicles and beads.

Owner:科学技术设备委员会

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com