Ultrasonic oscillation electrostatic spinning nozzle and method

An electrospinning and ultrasonic technology, which is used in spinneret assemblies, textile and papermaking, filament/thread forming, etc., can solve problems such as difficult maintenance, clogging of spinneret holes, surface stickiness, etc., to improve production efficiency , the effect of improving stability and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

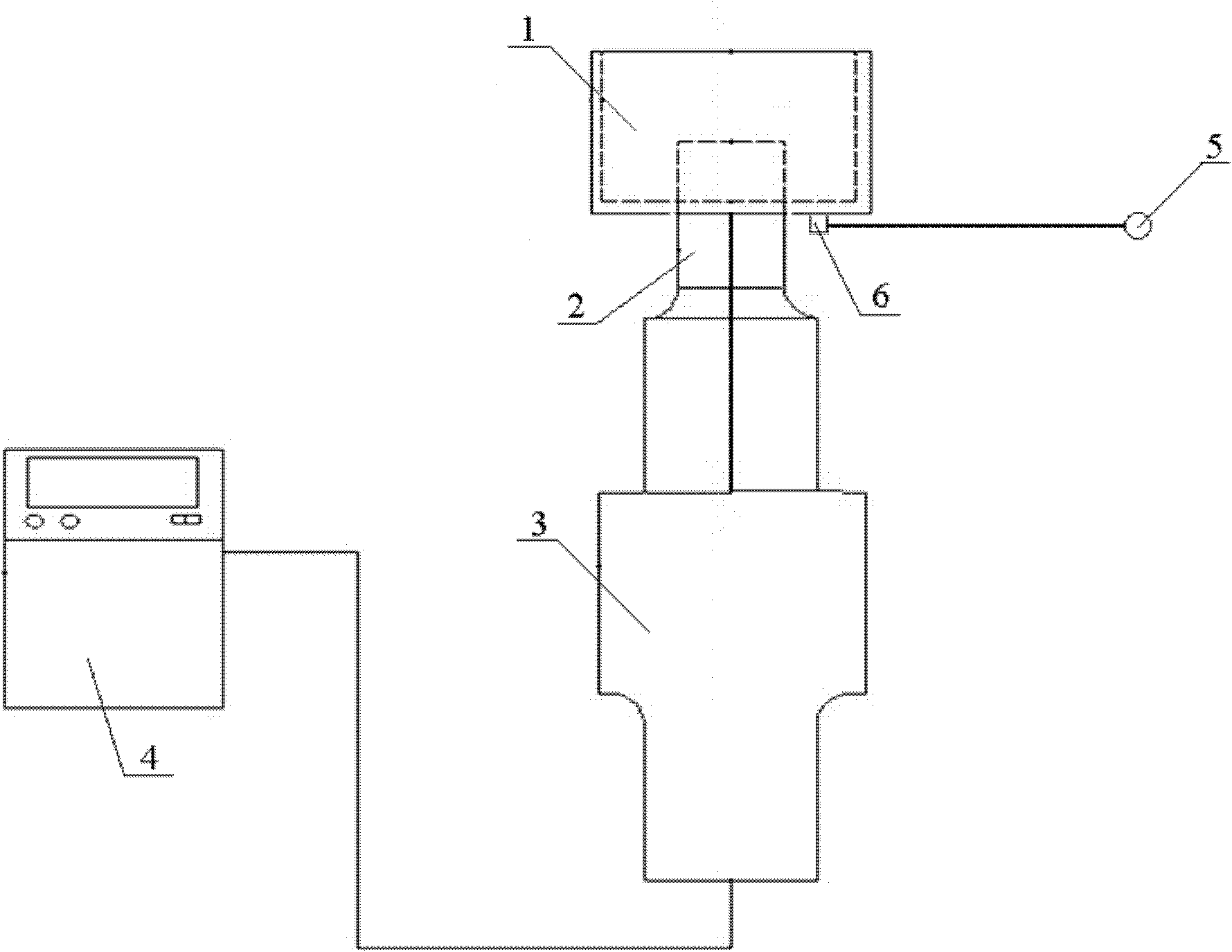

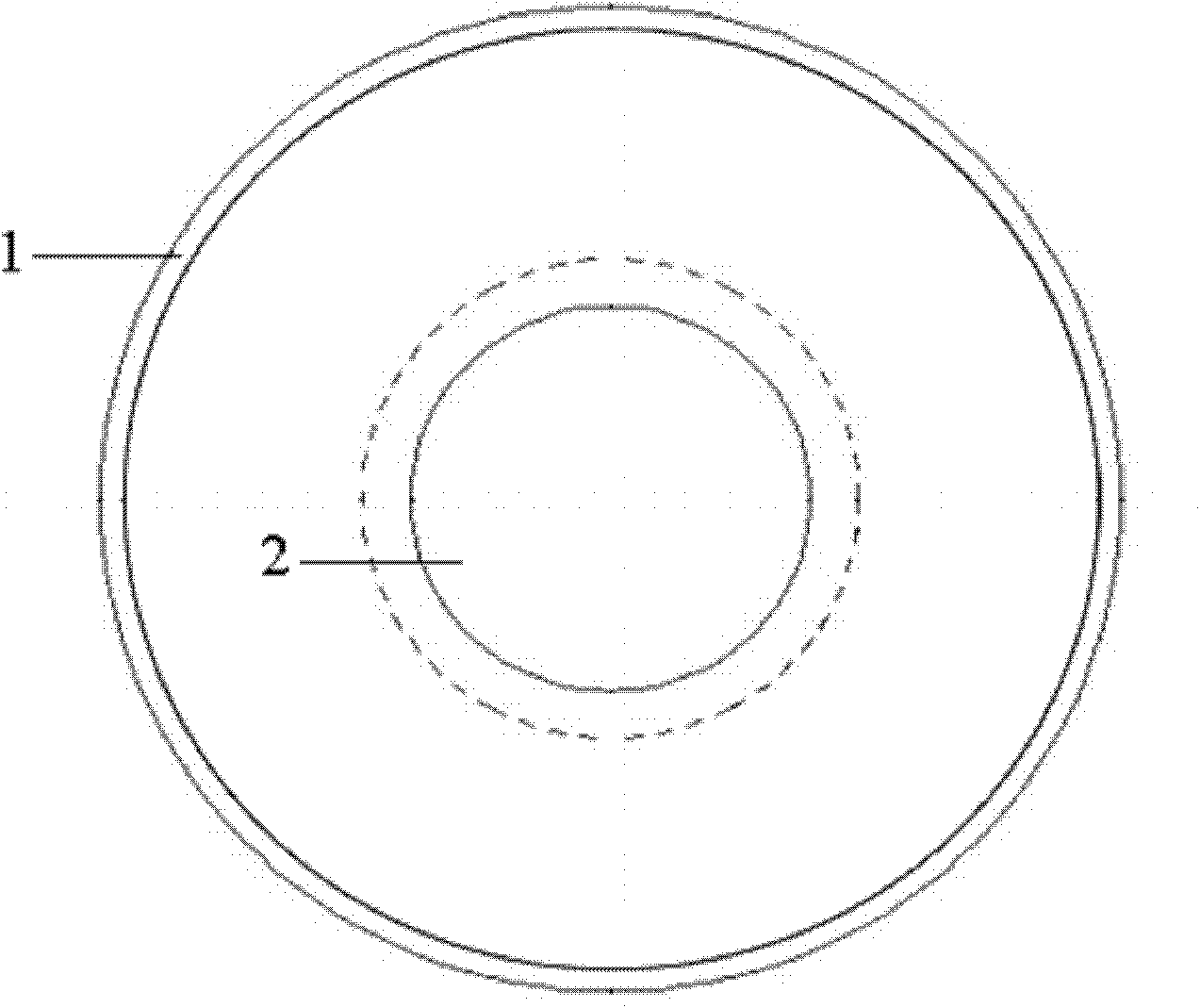

[0025] Embodiment 1: This embodiment relates to an ultrasonic vibration electrospinning nozzle, such as figure 1 As shown, it includes a spinneret 1 and an ultrasonic processor, wherein the ultrasonic processor includes a horn 2 , a transducer 3 and a controller 4 . The top end of the horn 2 is inserted into the spinneret 1 through the bottom surface of the spinneret 1 , and the bottom end of the horn 2 is connected with the transducer 3 . The transducer 3 is connected to the controller 4, and the spinneret 1 is provided with a terminal 6 connected to the high-voltage positive electrode 5, and the spinneret 1 can be directly connected to the high-voltage positive electrode 5 through the terminal 6 to provide spinning solution or The melt is uniformly charged to provide the conditions. The controller 4 controls the ultrasonic pulse state and ultrasonic time, so that the spinning solution or melt injected into the spinneret 1 oscillates, makes the solution or melt in a dynamic ...

Embodiment 2

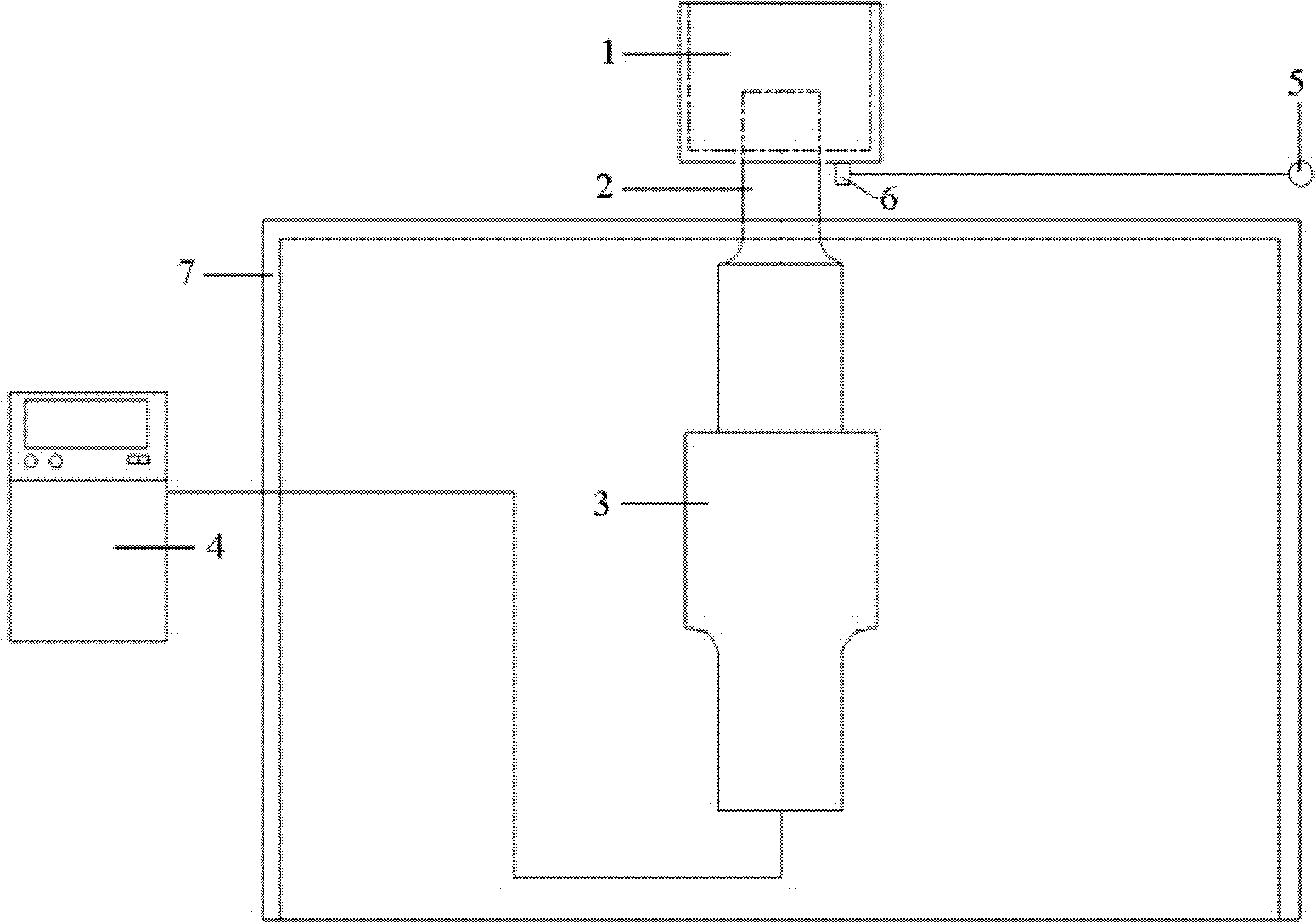

[0028] Embodiment 2: This embodiment also relates to an ultrasonic oscillating electrospinning nozzle. This embodiment is roughly the same as Embodiment 1, the difference being that the electrospinning nozzle involved in this embodiment also includes a shielding cover 7 . The horn 2 is divided into an upper half and a lower half, the spinneret 1 and the upper half of the horn 2 are arranged above the shield 7, and the lower half of the horn 2 and the transducer 3 are arranged on Below the shield. Wherein, the upper half of the horn 2 is made of insulating resin (such as PVC resin, EVA resin, etc.), and the lower half of the horn 2 is made of metal materials (such as copper, silver, etc.). In this embodiment, by installing a shielding cover outside the horn 2 and the transducer 3, the interference of the electric field on the electrospinning can be shielded, thereby ensuring the quality of the electrospinning.

Embodiment 3

[0029]Embodiment 3: This embodiment relates to a method of ultrasonic vibration electrospinning, comprising the following steps: (1) adding spinning solution to the spinneret through an automatic infusion device, and keeping the liquid volume of the injected spinning solution higher than The top of the horn is slightly horizontal. Wherein, the spinning solution is an aqueous solution of polyvinyl alcohol (PVA) with a mass concentration of 10%. (2) Place the receiving base cloth on the upper end of the spinneret with a distance of 20 cm. (3) Turn on the controller, turn on the time start / stop button, and set the ultrasonic time to 30 minutes, and select the continuous ultrasonic state. Under the mechanical effect of ultrasonic waves and cavitation, the horn oscillates the spinning solution to make it flow dynamically. (4) Connect the terminal on the spinneret to the high-voltage positive electrode, and adjust the voltage of the high-voltage positive electrode to 60kV. (5) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com