Patents

Literature

89results about How to "No need for frequent cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

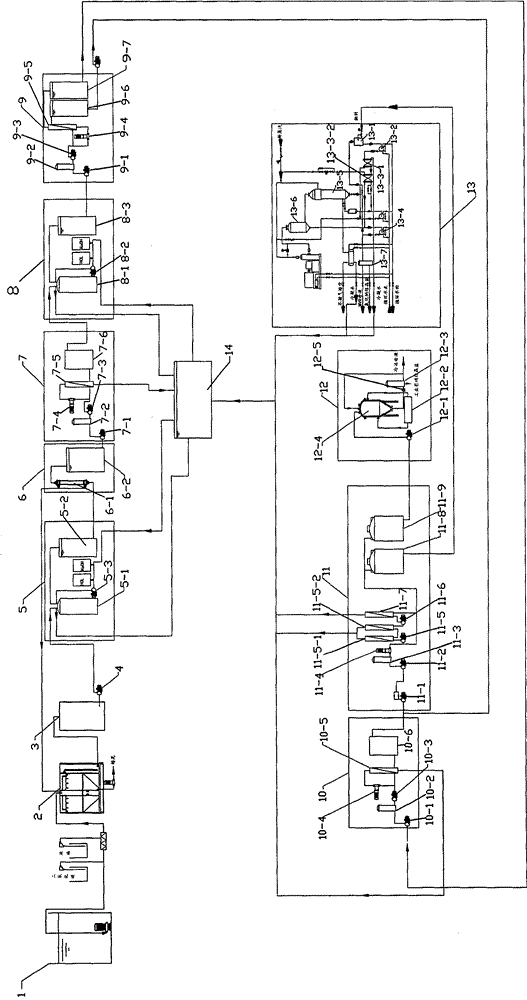

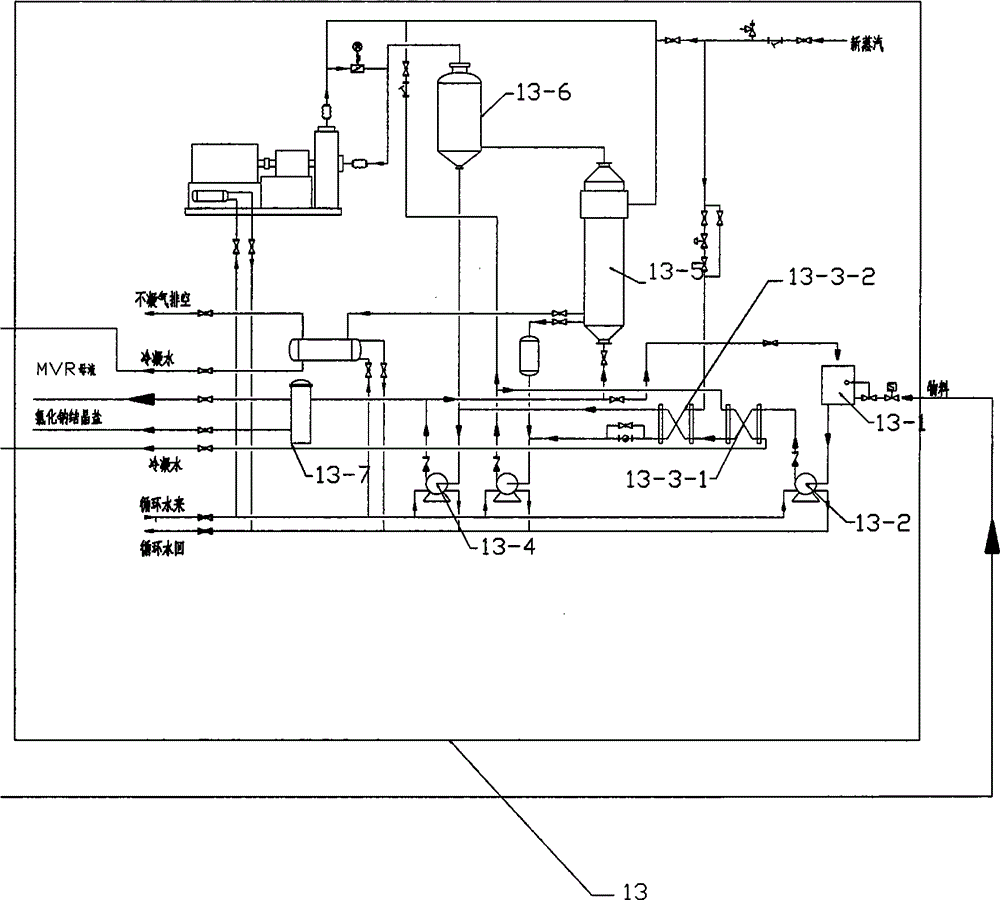

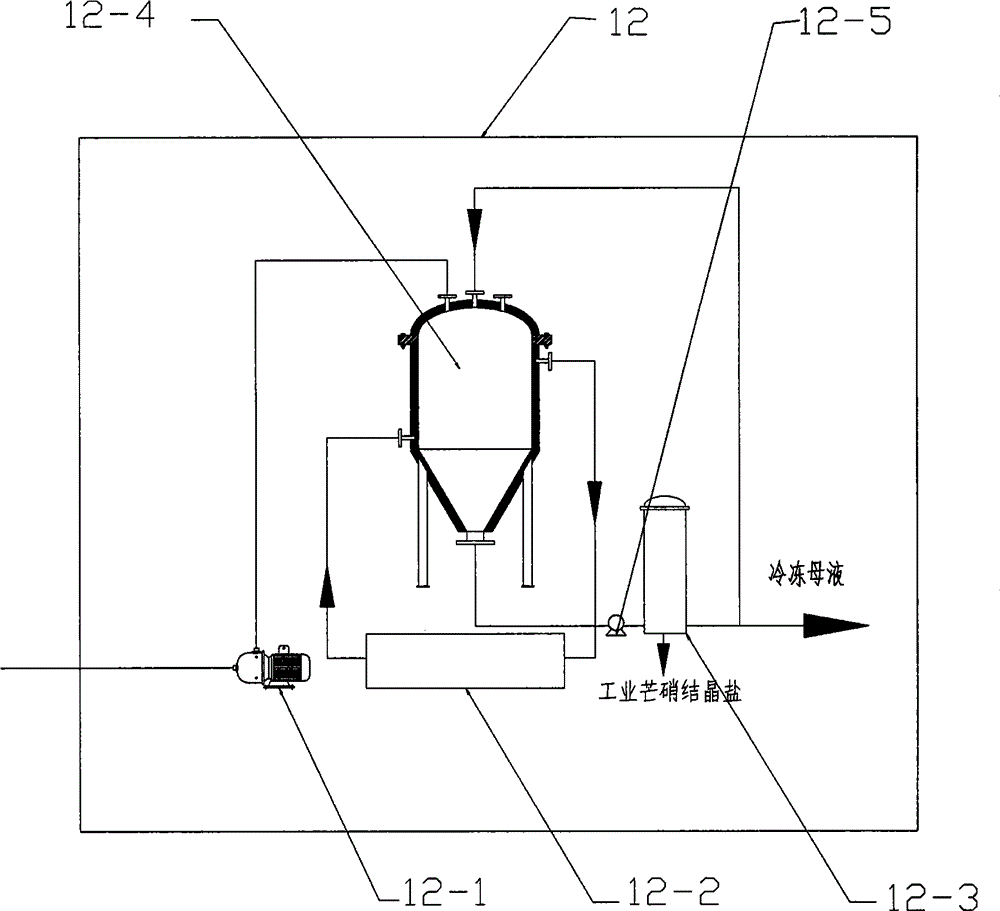

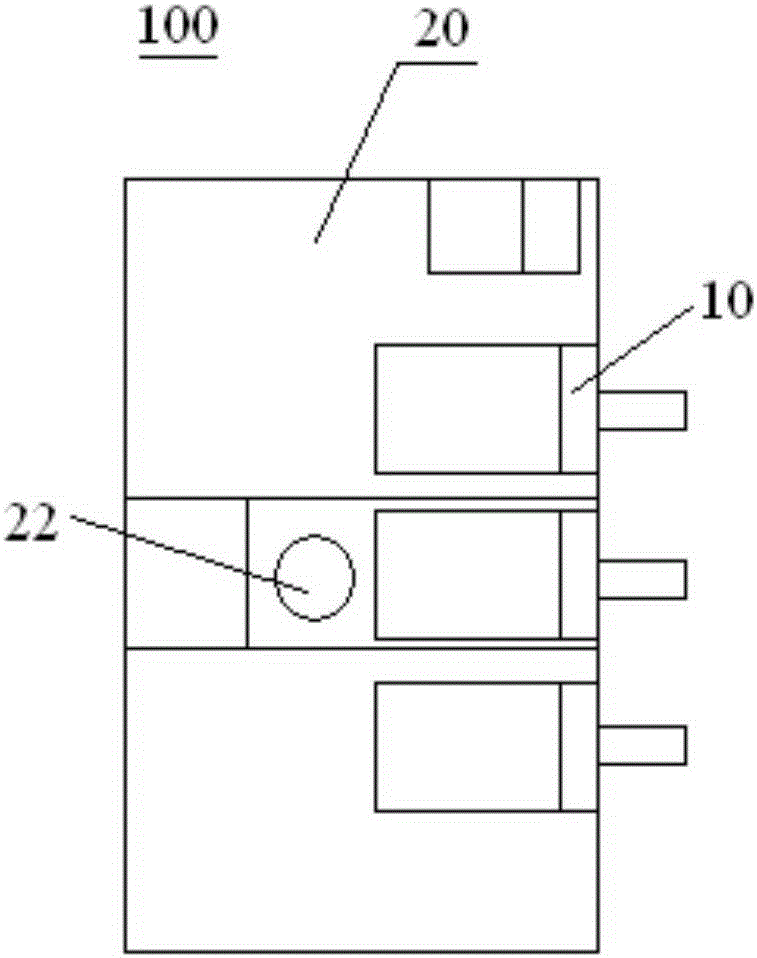

A treatment system for high-salt waste water

InactiveCN104787951ARealize resource utilizationEfficient separationMultistage water/sewage treatmentSalt-wastingSmall footprint

The invention relates to a treatment system for high-salt waste water, and belongs to water treatment techniques. The treatment system comprises an adjusting tank, a high-density sedimentation tank, a V-type filter tank, a first-section ion exchange resin system, an ultrafiltration system, a first-section reverse osmosis system, a second-section ion exchange resin system, a high-pressure nanofiltration system, a second-section reverse osmosis system, a high-pressure flat sheet membrane system and an MVR system in order. The high-pressure nanofiltration system, the high-pressure flat sheet membrane system and a freezing crystallization system are connected in order. The ultrafiltration system is connected to the high-density sedimentation tank. The treatment system reasonably coupling ultrafiltration, nanofiltration, reverse osmosis and a high-pressure flat sheet membrane method and combining MVR crystallization and freezing crystallization techniques is adopted to treatment of the high-salt waste water, and is low in cost, low in running cost, free of secondary pollution, safe, compact in structure, small in occupied space and high in economic value.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Lightweight environment-friendly type pumice for ceramic ware and its production method and usage

InactiveCN1762910AStrong wear resistanceReduce cleanup workloadDry-cleaning apparatus for textilesCeramicwareSewage treatmentMetallurgy

The present invention relates to light environment friendly ceramic pumice and its manufacture and usage. The ceramic pumice is used widely in fading, fluffing, softening, ageing and other processing of clothing, fabric, cloth, etc. The ceramic pumice of the present invention contains no harmful matter, and results in simplified fabric cleaning post-treatment and no environmental pollution. Treating fabric with the ceramic pumice makes fabric soft, good look, personalized, permeable and comfortable.

Owner:何晓洪

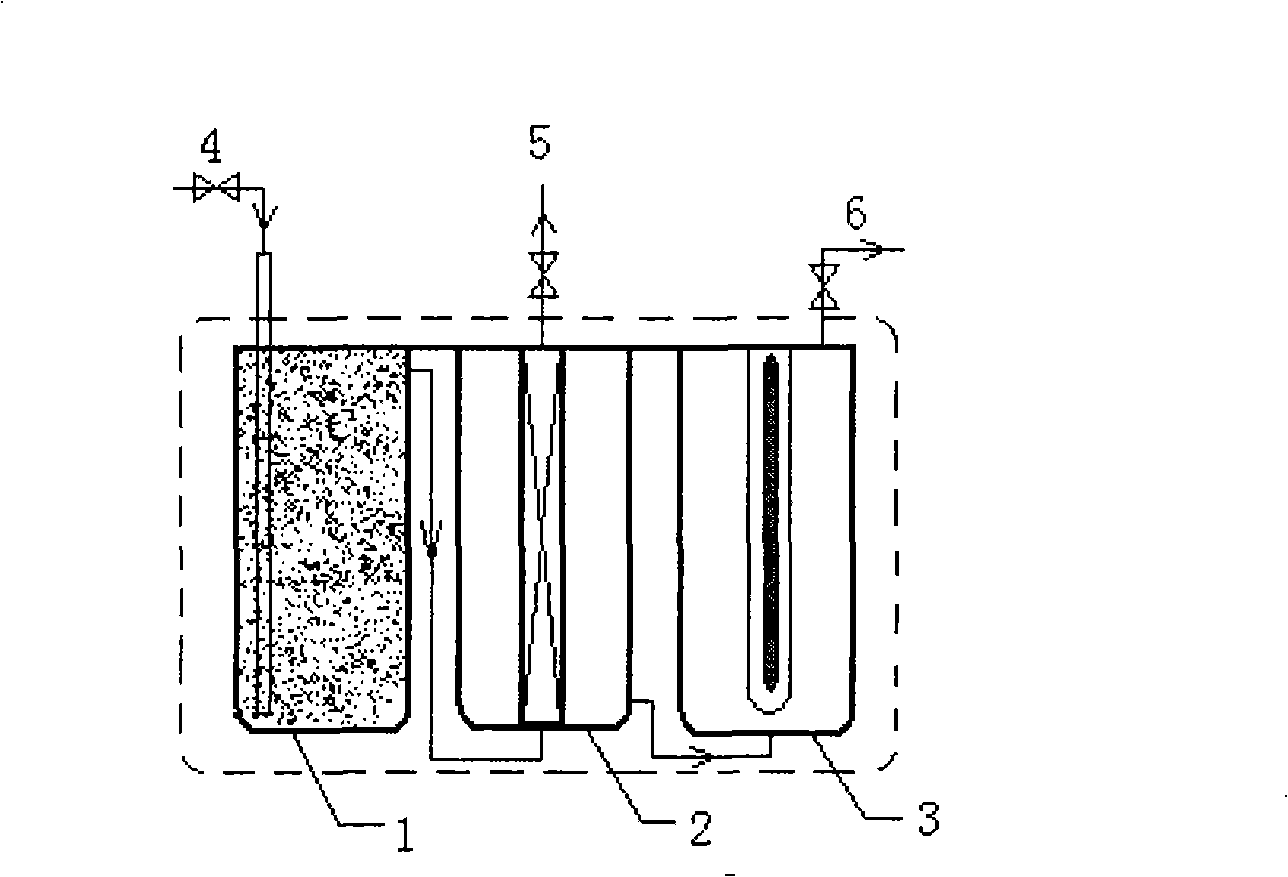

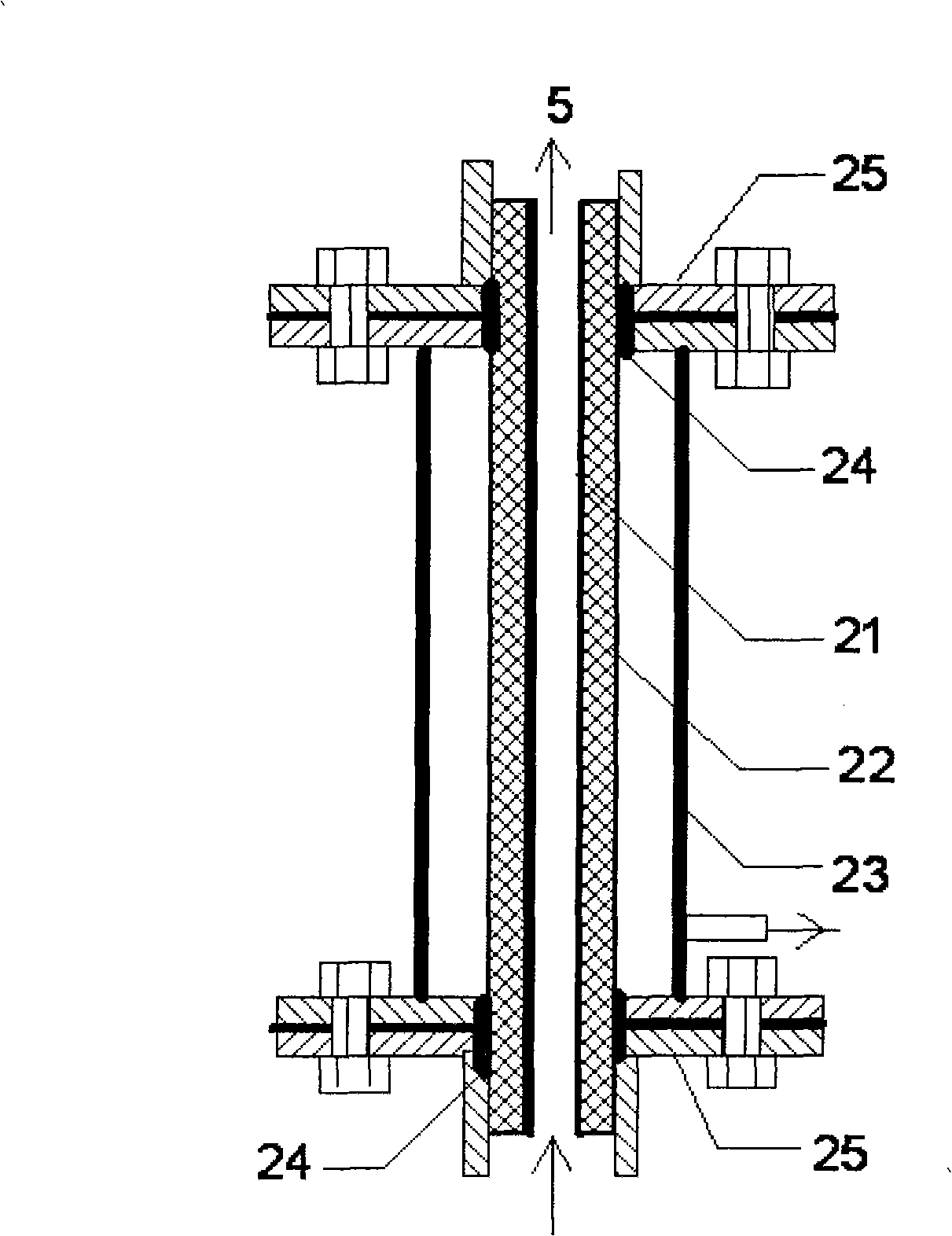

Drinking water purifying device combining photocatalysis and inorganic membrane filtration technology

InactiveCN101538098AAvoid replacementAvoid pollutionWater/sewage treatment by irradiationMultistage water/sewage treatmentActivated carbon filtrationFiltration technique

The invention relates to a drinking water purifying device combining photocatalysis and inorganic membrane filtration technology, comprising an active carbon filtration assembly, an inorganic membrane filtration assembly and a photocatalysis membrane assembly. Water flows into the active carbon filtration assembly and then passes through the inorganic membrane filtration assembly, and finally, purified drinking water flows out of the photocatalysis membrane assembly. The inorganic membrane filtration assembly and the photocatalysis membrane assembly are both mounted vertically to prevent sediment from polluting membranes and avoiding dead flow areas; the active carbon can be soaked in edible alcohol for being utilized repeatedly; the inorganic membrane of the inorganic membrane filtration assembly has high mechanical strength and can resist corrosion; and all assemblies of the device have long service lives and have no needs of frequent cleaning and replacement. The invention adopts the photocatalysis membrane action for sterilization, has good effect, can purify water in depth, loads phtocatalyst on stainless steel or the inner wall of a glass tube and adopts an ultraviolet source to inspire the photocatalysis membrane to react so as to achieve the purpose of sterilization and trace organic matter degradation, have no problems of catalyst separation, and can not cause second water pollution.

Owner:HAINAN NORMAL UNIV

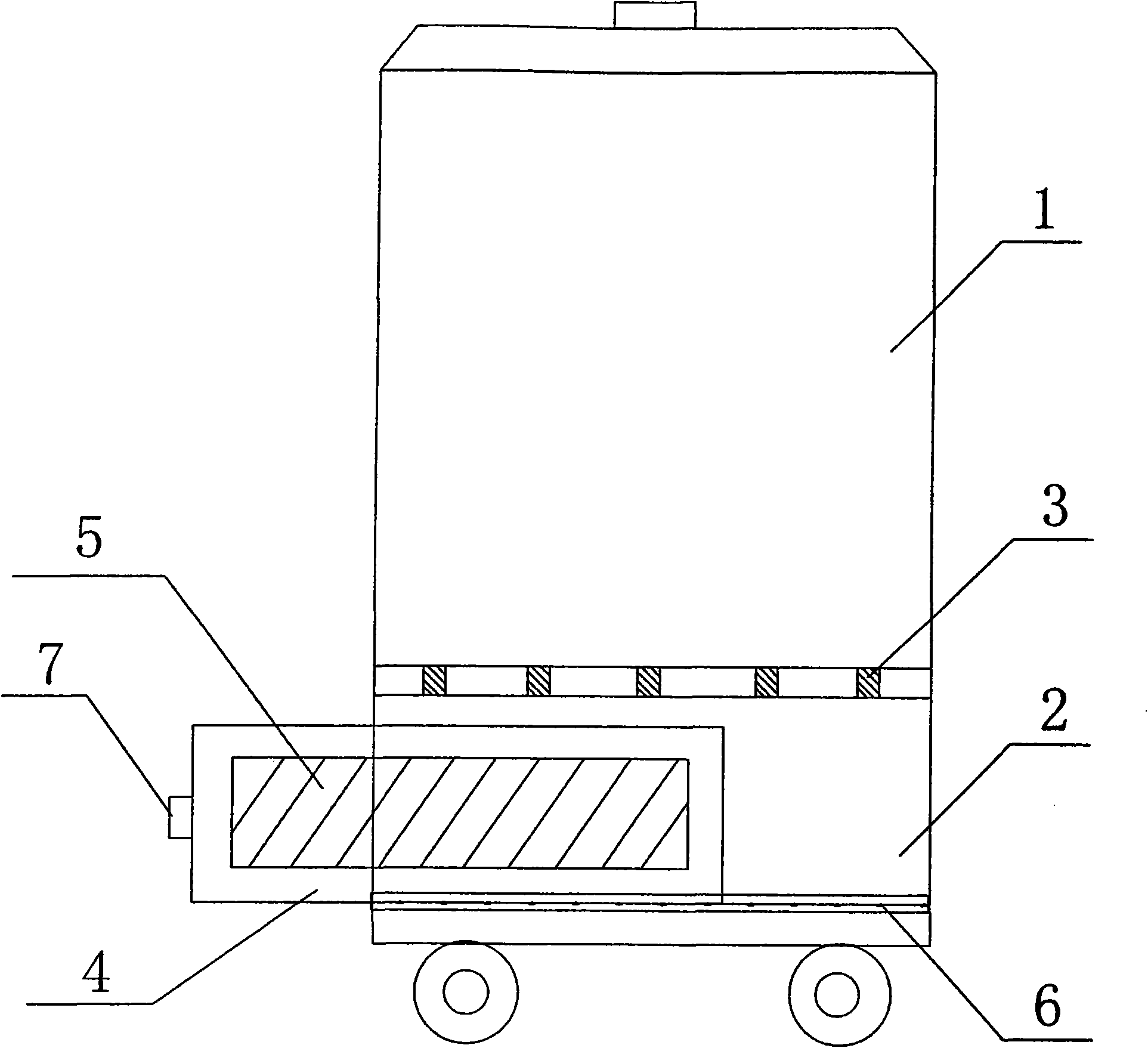

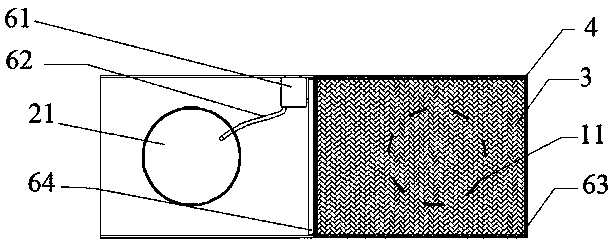

Novel environment-friendly garbage bin with sewage collecting box

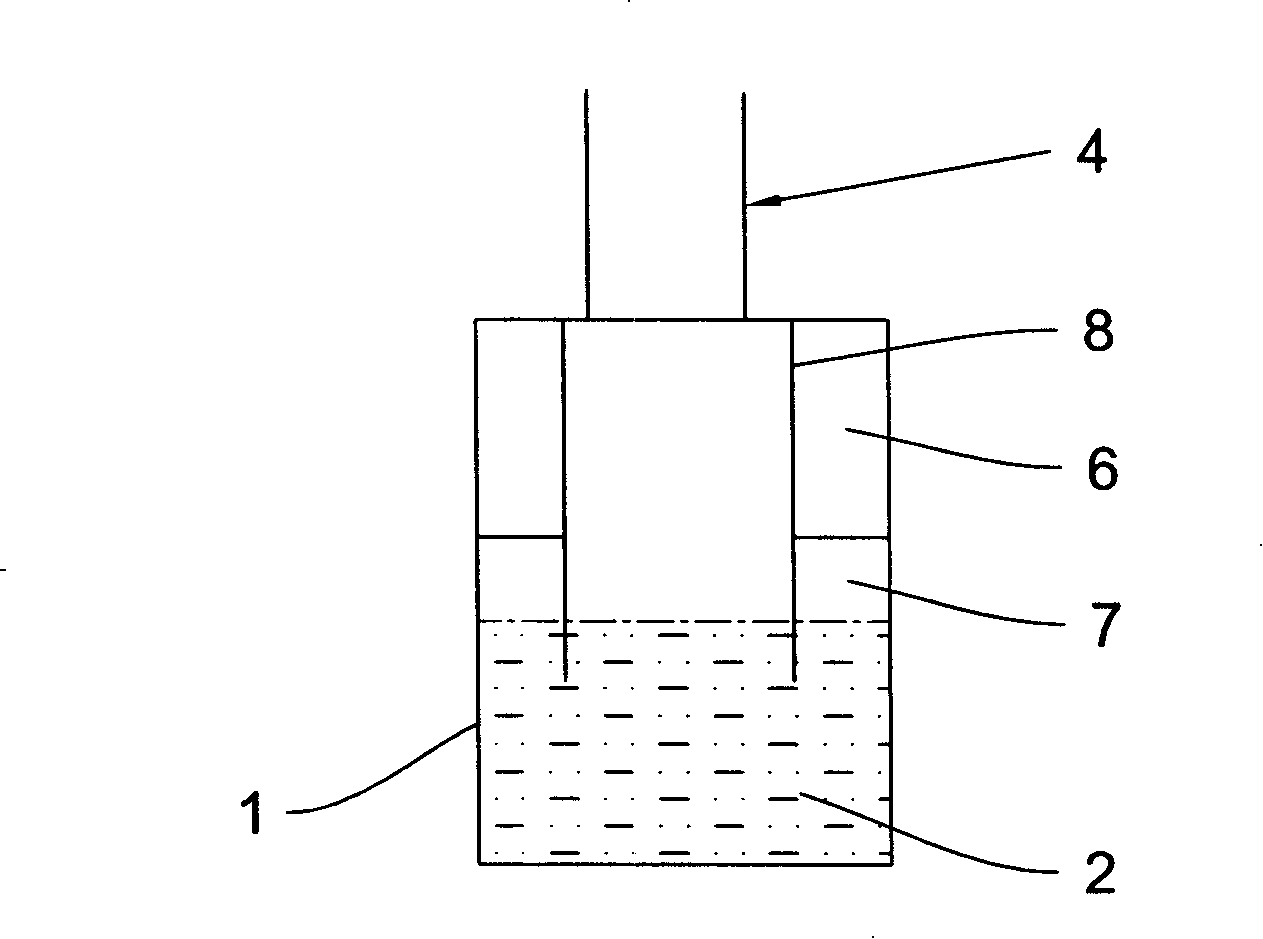

The invention relates to a novel environment-friendly garbage bin with a sewage collecting box, which comprises a bin body, and is characterized in that the bin body is divided into an upper part and a lower part, the upper part is a garbage storing bin (1), and the lower part is the sewage collecting box (2); the bottom of the garbage storing bin is provided with a plurality of pores (3), so that sewage in the garbage storing bin (1) can flow into the sewage collecting box (2) through the pores (3); a storage case (4) is arranged in the sewage collecting box (2); and the storage case (4) is withdrawn from an opening of the sewage collecting box (2), and a sewage absorption bag (5) which is filled with powdery or fine granular absorbing substances is arranged in the storage case (4). The garbage can collect the sewage in the garbage bin, so that the sewage cannot flow out of the garbage bin; the garbage bin not only can protect the environment, but also is convenient to clean; and the garbage bin has the advantages of simple structure, convenient modification, and easy implementation and popularization.

Owner:陆洪兴

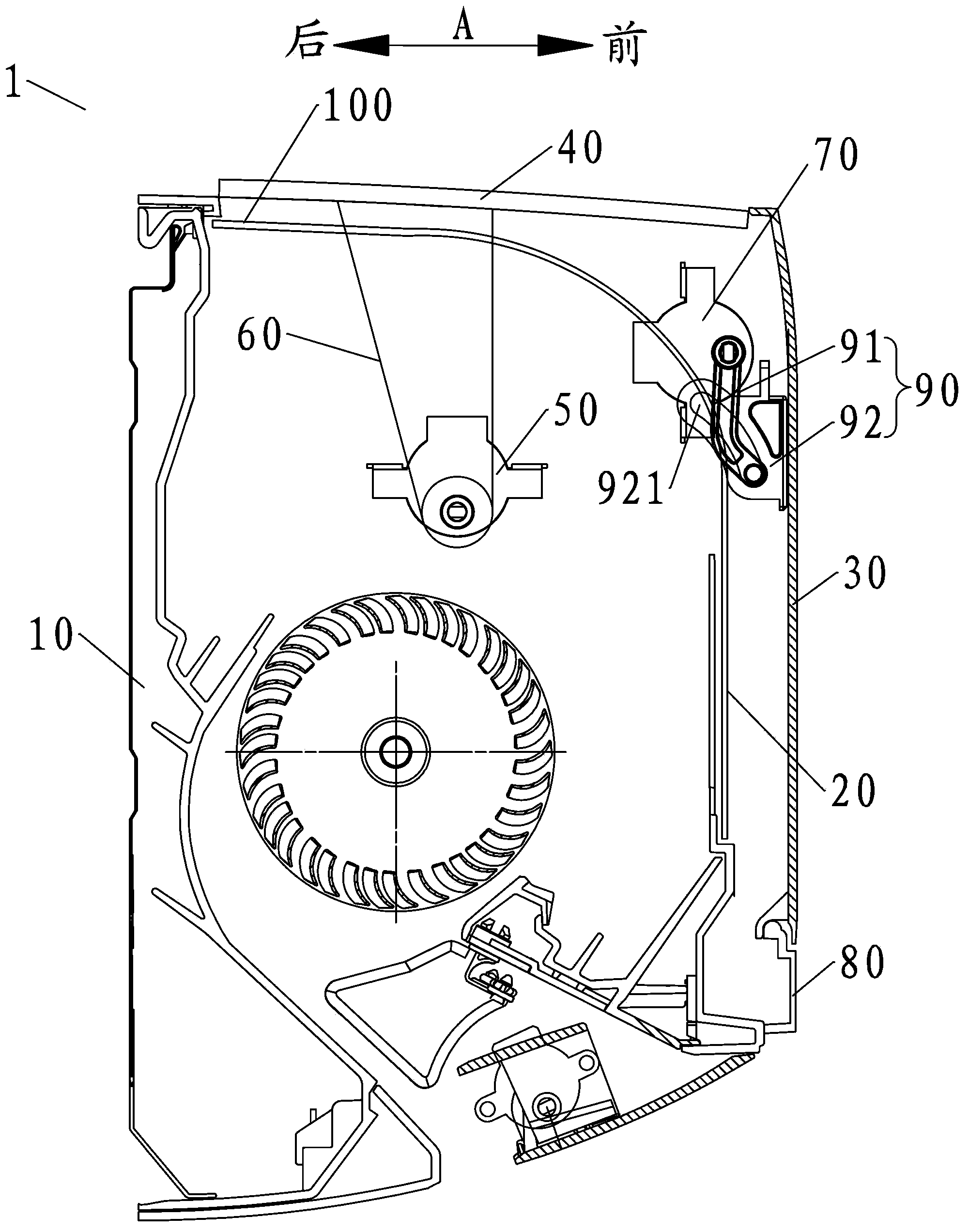

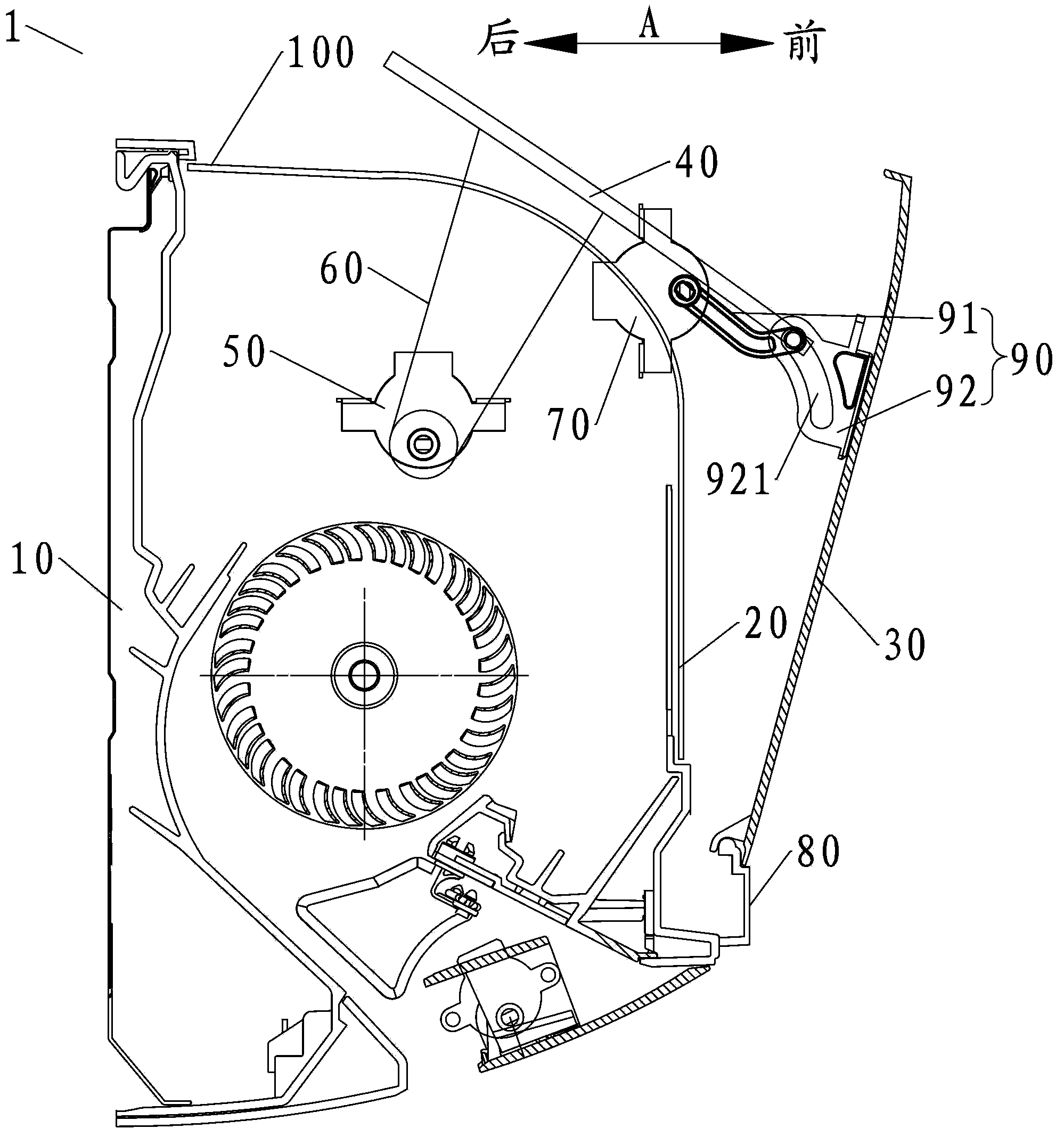

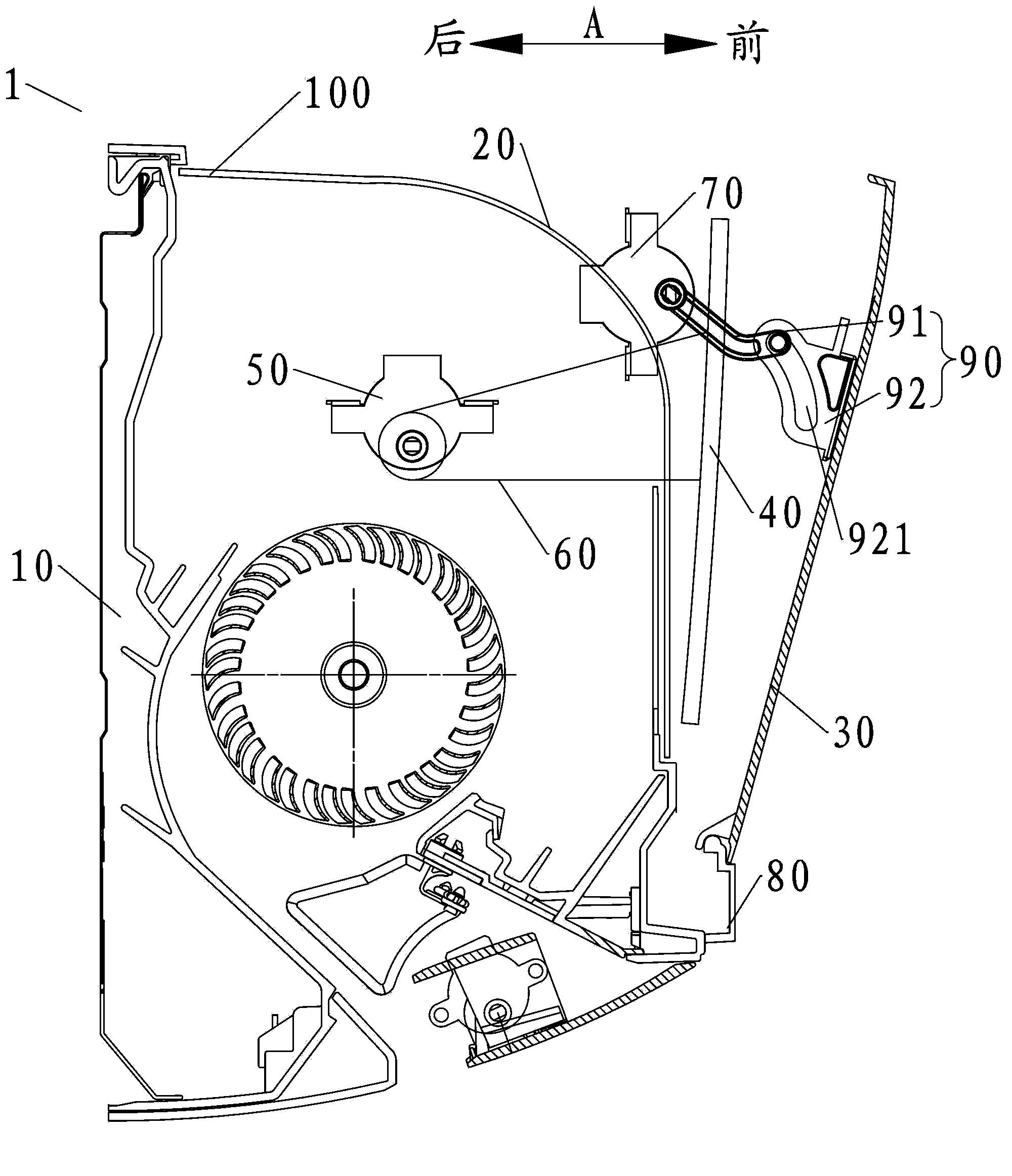

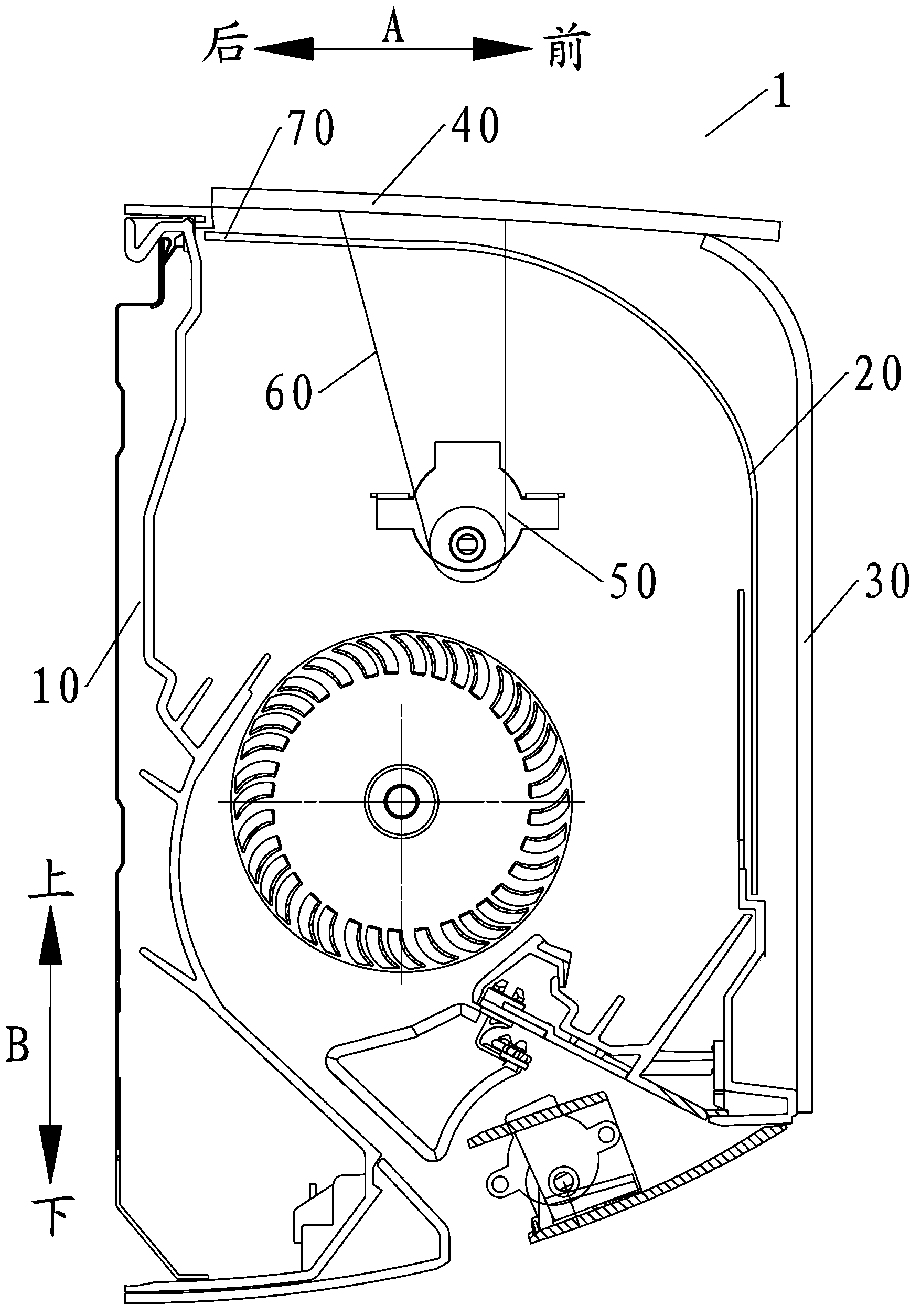

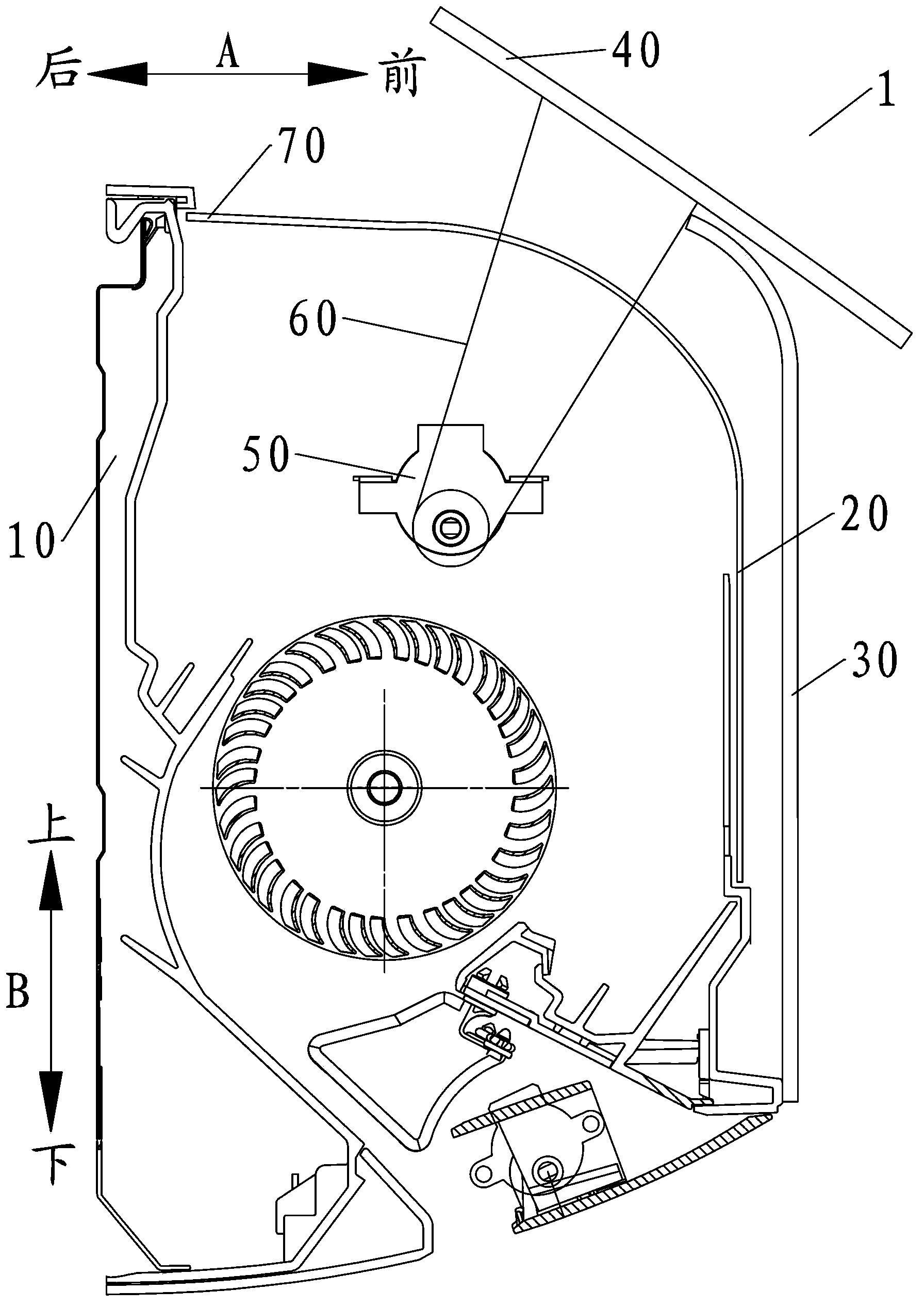

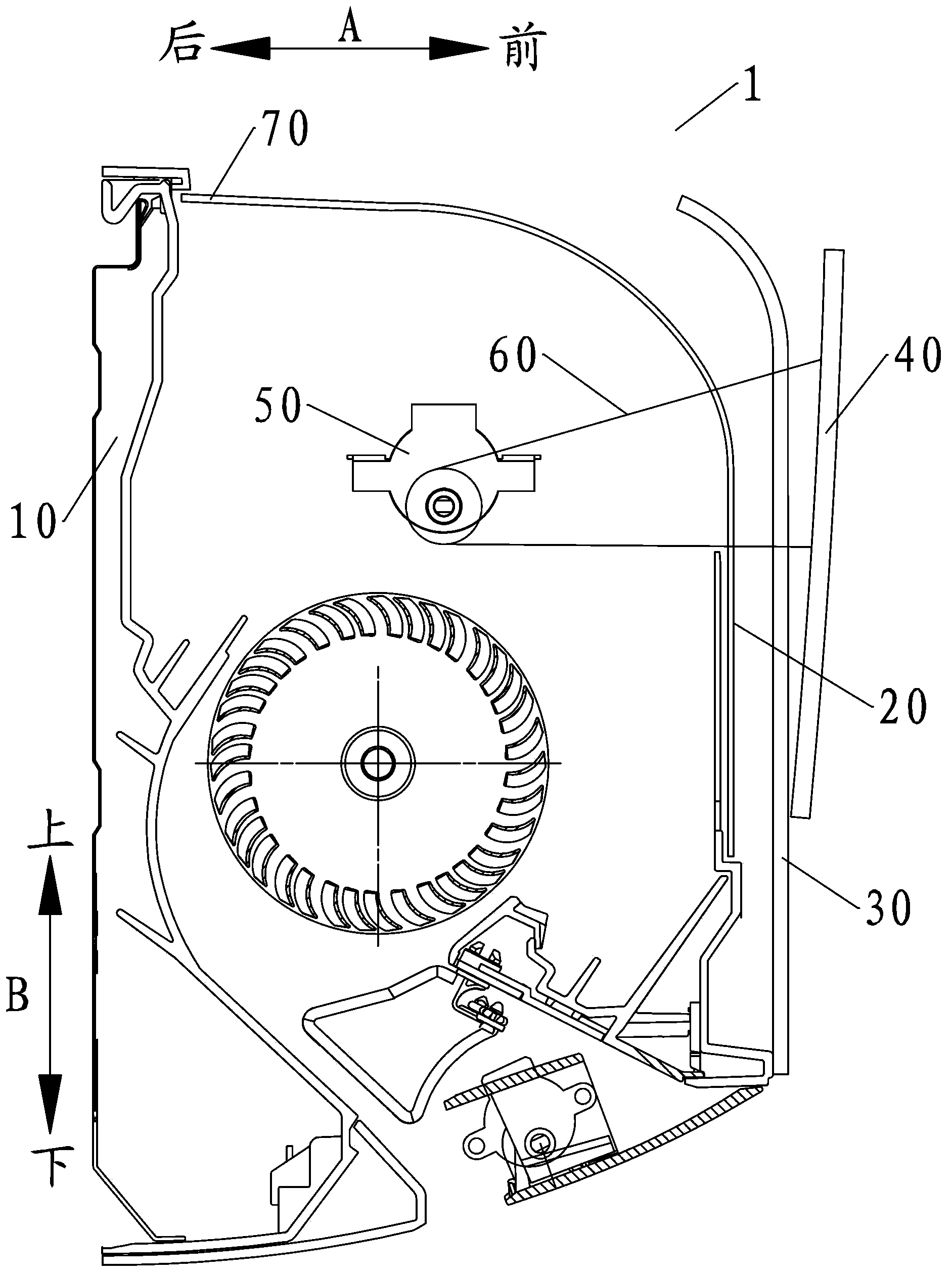

Air conditioner

ActiveCN103900236AStable performanceEasy to useHeating and ventilation casings/coversComputer engineeringEngineering

Owner:MIDEA GRP CO LTD

Filtering dust collector for environmental protection

InactiveCN109011871AImprove filtering effectNo need for frequent cleaningDispersed particle filtrationTransportation and packagingSpiral bladeEngineering

The invention discloses a filtering dust collector for environmental protection. The filtering dust collector comprises a body, the middle of the rear side of the body is fixedly provided with a second motor by a support, a base is arranged at the bottom of the body, a collection bin is fixed on the left side of the base, a first motor is fixed on the right side of the base, a conveying tube is mounted above the middle of the base, a rotating tube is fixed to the conveying tube by a bearing, a spiral blade is mounted on the rotating shaft in a welding manner, the right end of the rotating shaft is connected with the output end of the first motor, a dust bin is arranged above the middle of the body, and a support shaft is mounted between the front side and the rear side of the middle of thedust bin. A stopper block fixed by a spring at an angle of 70 DEG with the horizontal plane is arranged, so dust filter plate collides with the stopper block in every ring of the filter plates rotate, and dusts on the dust filters drop down and are collected, so the dust filter plates keep a good filtering effect in every filtering process, and have no need to be frequently cleaned, thereby the filtering dust collector is convenient to use.

Owner:湖南钜晟环保科技股份有限公司

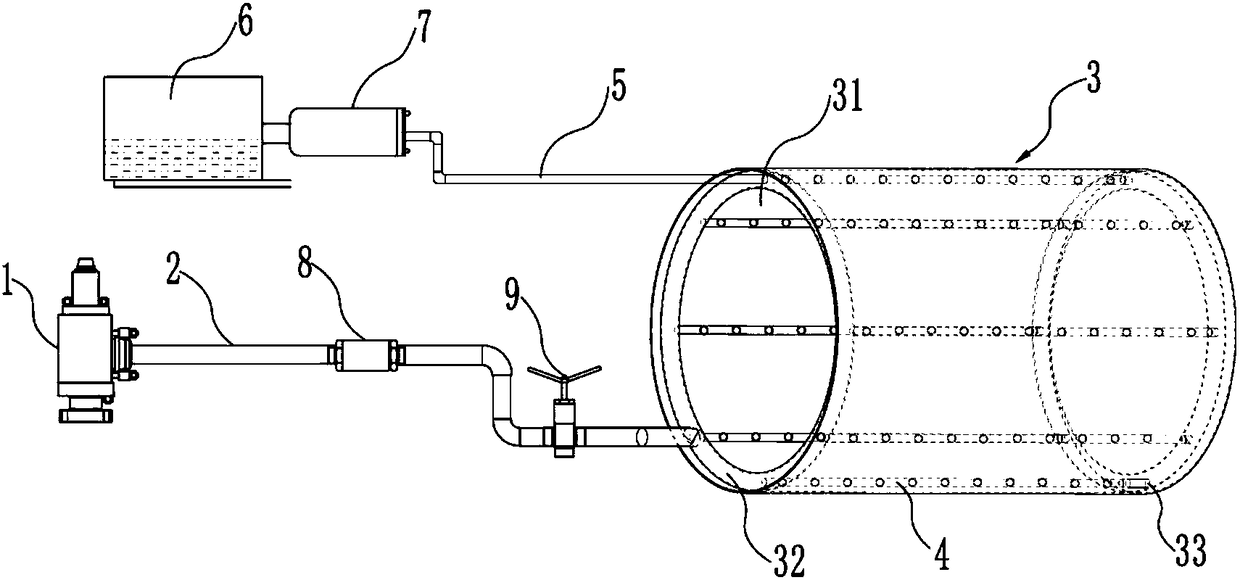

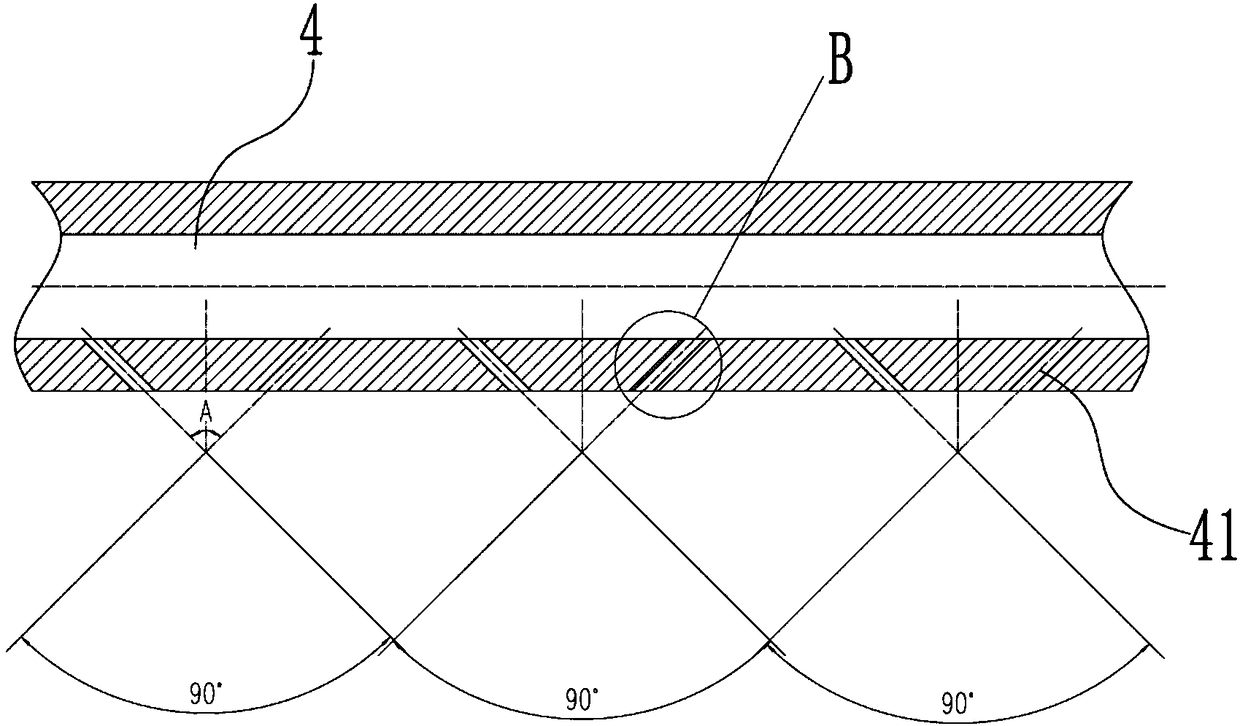

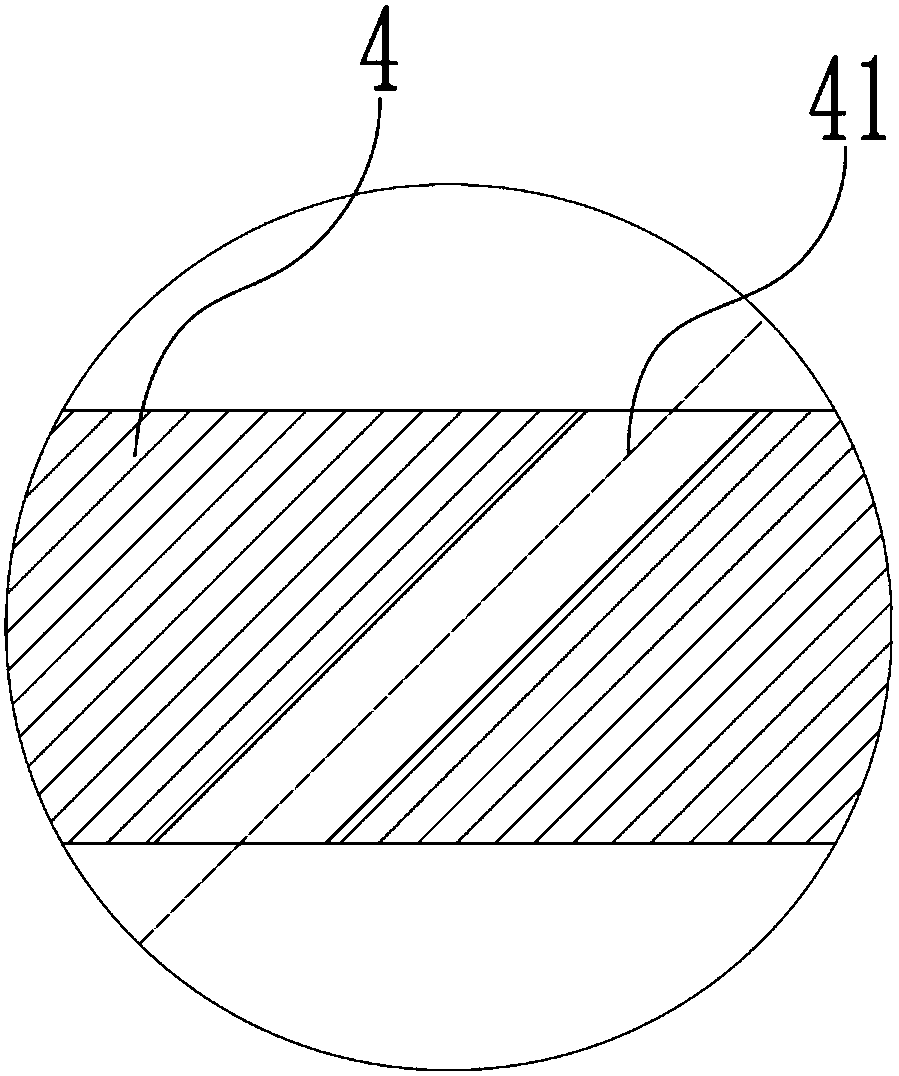

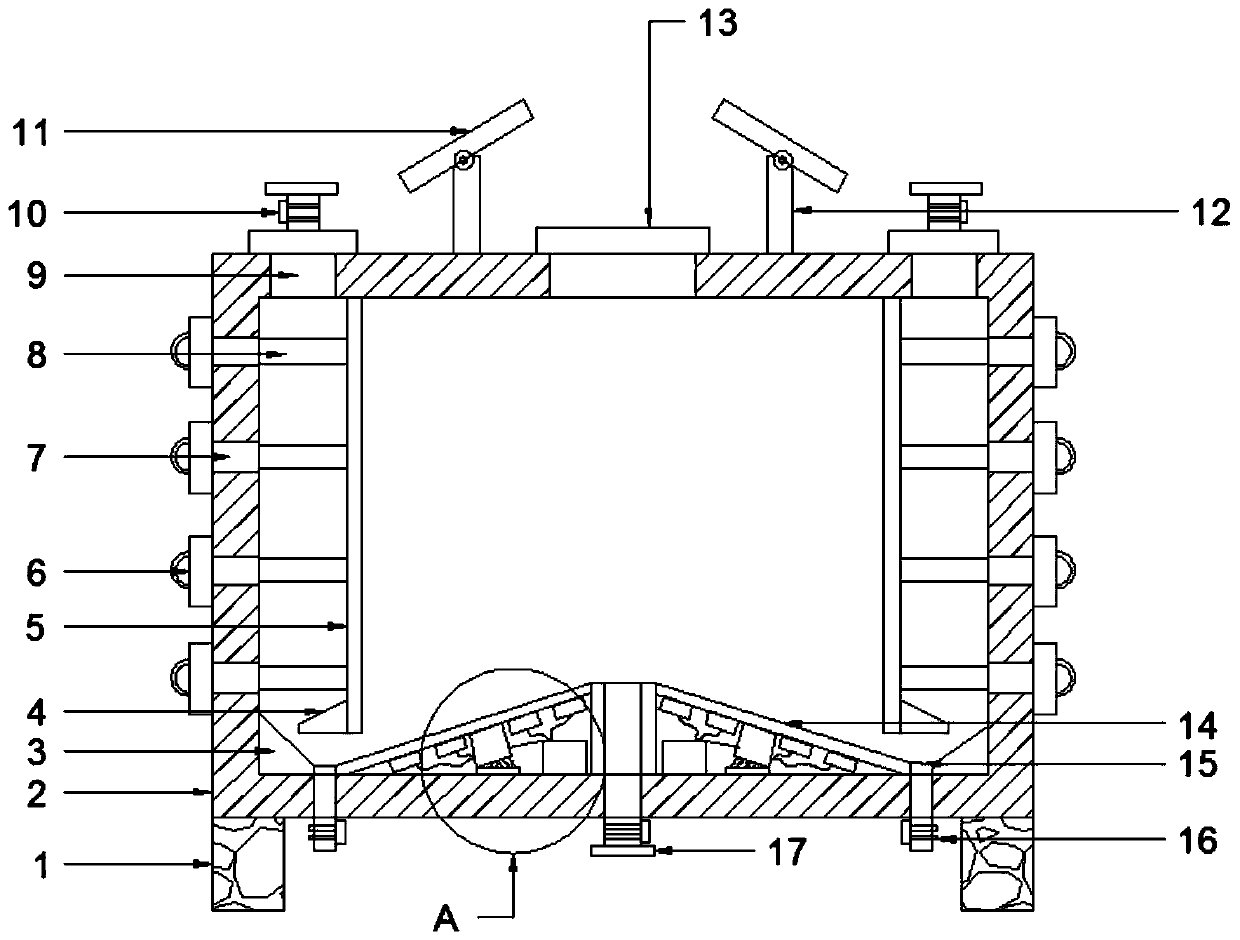

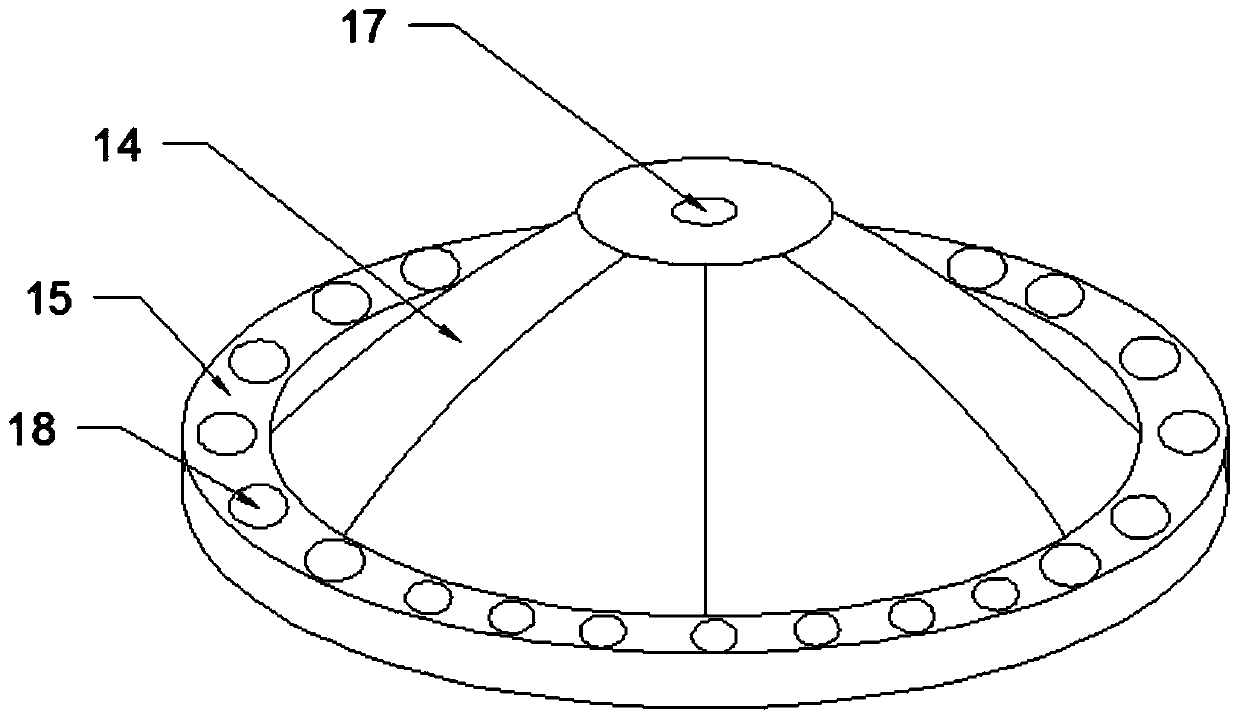

Array self-impact type water-mist cooling device

ActiveCN108518290AWill not deformEliminate injection blind spotsRocket engine plantsEngineeringStructural engineering

The invention belongs to the technical field of ground experiments for liquid propellant rocket engines and discloses an array self-impact type water-mist cooling device with the aim of resolving theproblem in the prior art of incomplete cooling of a cooling device. The device comprises a fire hydrant, a main liquid supply pipeline and a drainage drum. The drainage drum comprises a drum body andannular liquid collection cavities arranged at two ends of the drum body. One end of the main liquid supply pipeline communicates with the fire hydrant and the other end thereof communicates with oneof the annular liquid collection cavities. At least four injection pipes are arranged between the two annular liquid collection cavities and fixed on the inner wall of the drum body along the axial direction and extend from one end of the drum body to the other end thereof. Lines of main injection holes are arranged along the length directions of the injection pipes. The main injection holes are slant hole passages communicating with the injection pipes. The center lines of two adjacent slant hole passages intersect at one point. After the point of intersection departs from the inner wall of the drum body, two main injection holes firstly intersecting with each other become a pair. Center lines of the main injection holes intersect to form an included angle A. The angular bisector of the included angle A is vertical to pipe walls of the injection pipes.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

Air conditioner

InactiveCN103900149ANo need for frequent cleaningImprove performanceLighting and heating apparatusAir conditioning systemsComputer engineering

Owner:MIDEA GRP CO LTD

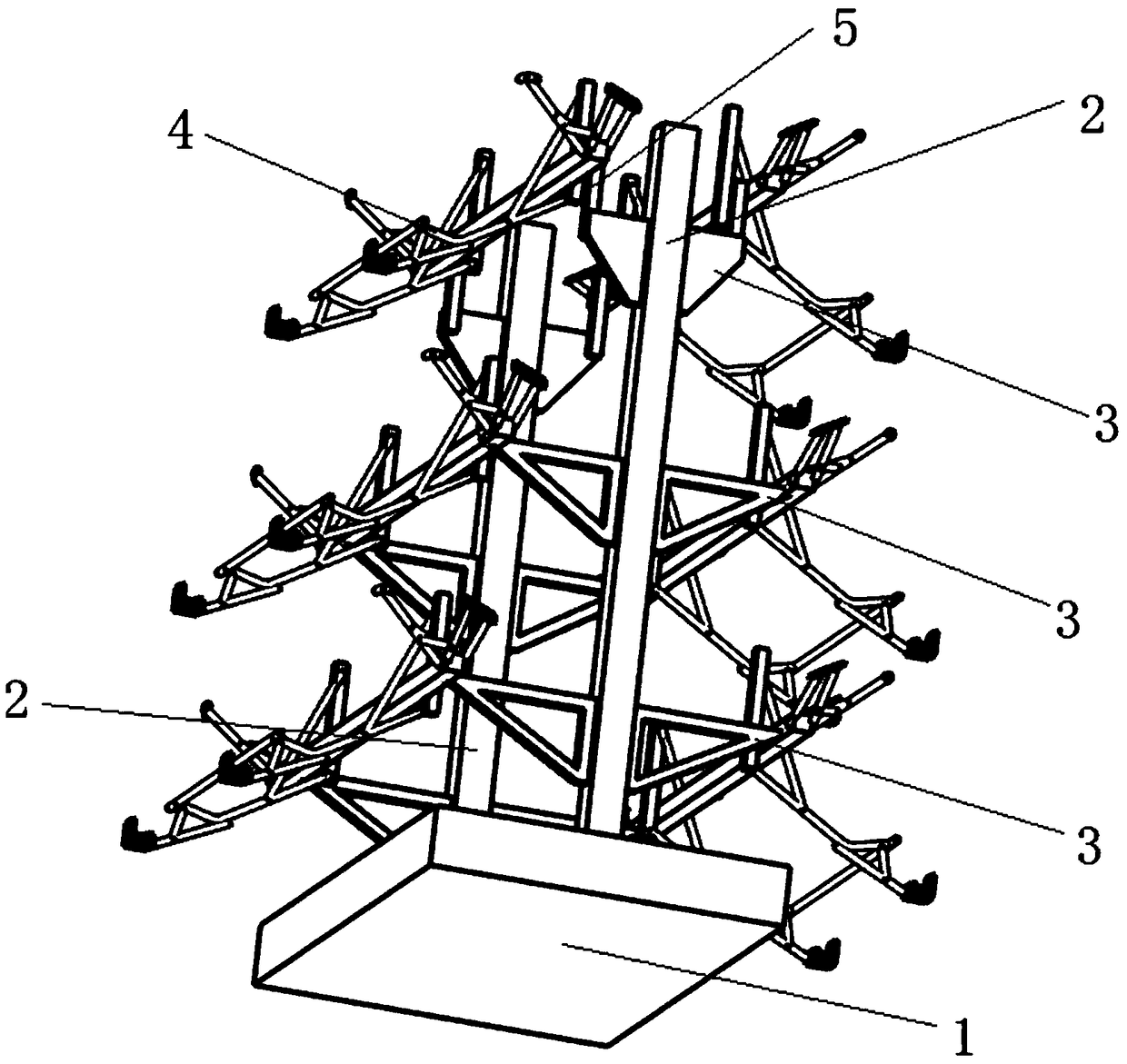

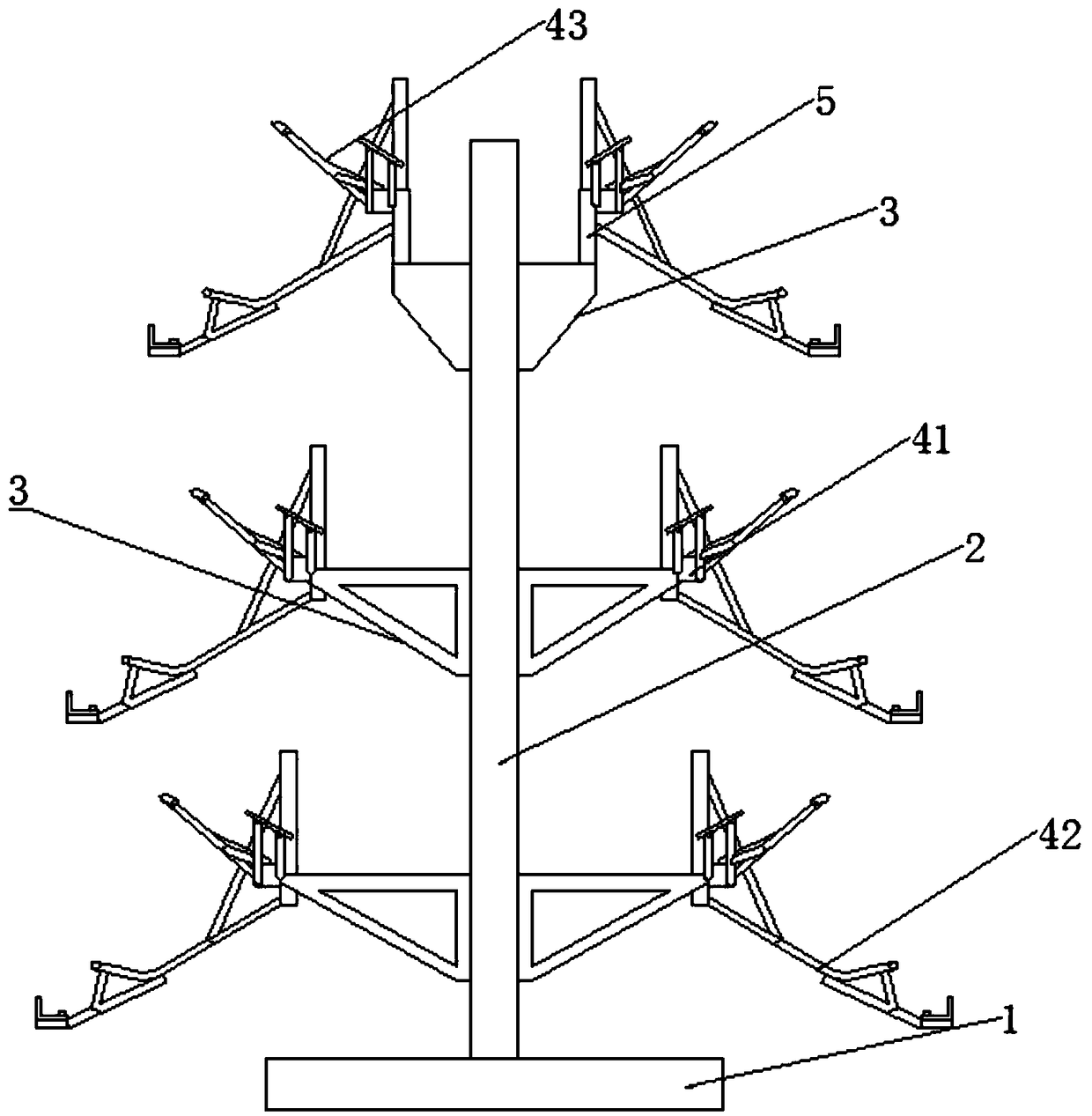

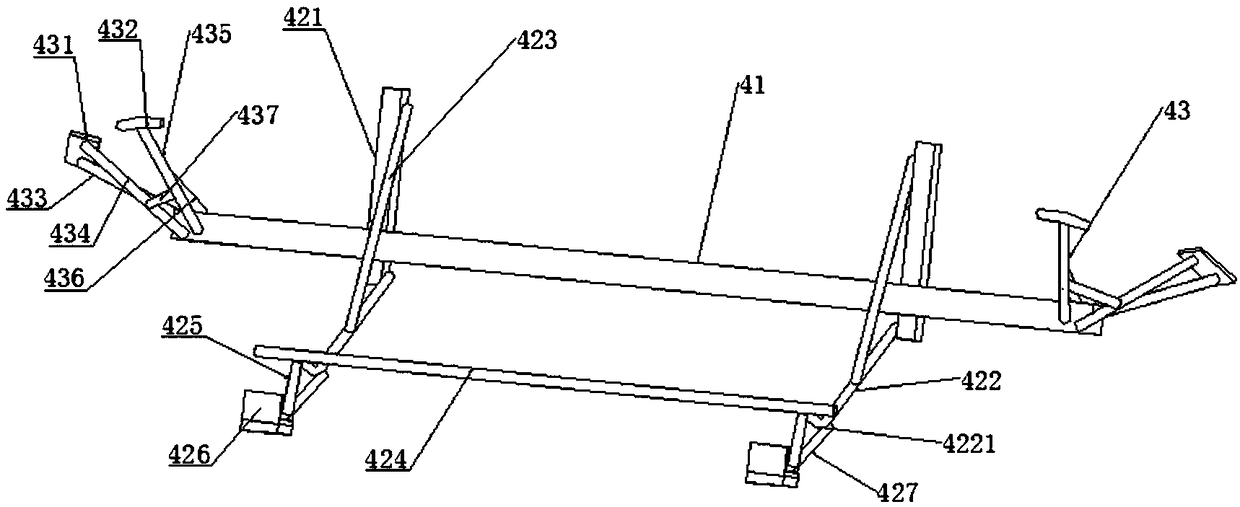

Automobile front bumper spraying hanging tool

PendingCN109395929AAvoid occlusionNot easy to blockSpraying apparatusEngineeringMechanical engineering

The invention discloses an automobile front bumper spraying hanging tool. A base, a basis stand column installed on the base and a plurality of handing frame assemblies fixed to the basis stand columnfrom top to bottom are included; each hanging frame assembly comprises a fixed beam, a front side support and a side face support; the fixed beams are horizontally and fixedly installed on the basisstand column; each front side support comprises a front side stand column, a first stress rod, a reinforcing rod, a front side profile modeling beam and a second stress rod; and each side face supportis symmetrically arranged on the two edges of the corresponding front side support, and comprises a first supporting frame and a second supporting frame. According to the automobile front bumper spraying hanging tool, the plurality of hanging assemblies are arranged on the basis stand column from top to bottom to achieve that spraying is performed on three or more automobile front bumpers at thesame time, and the production efficiency of spraying is greatly improved.

Owner:WUHU ECHOM SCI & TECH

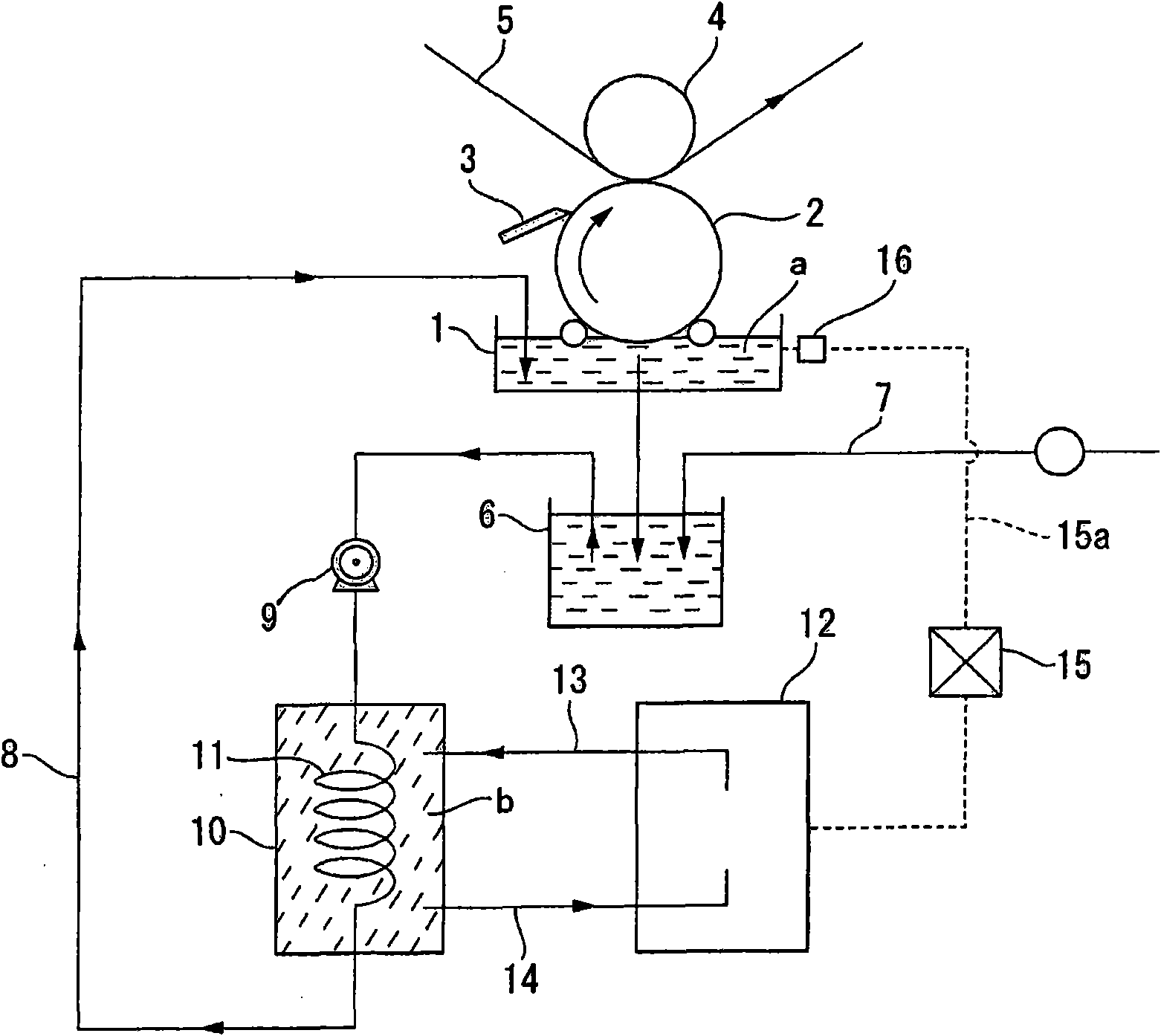

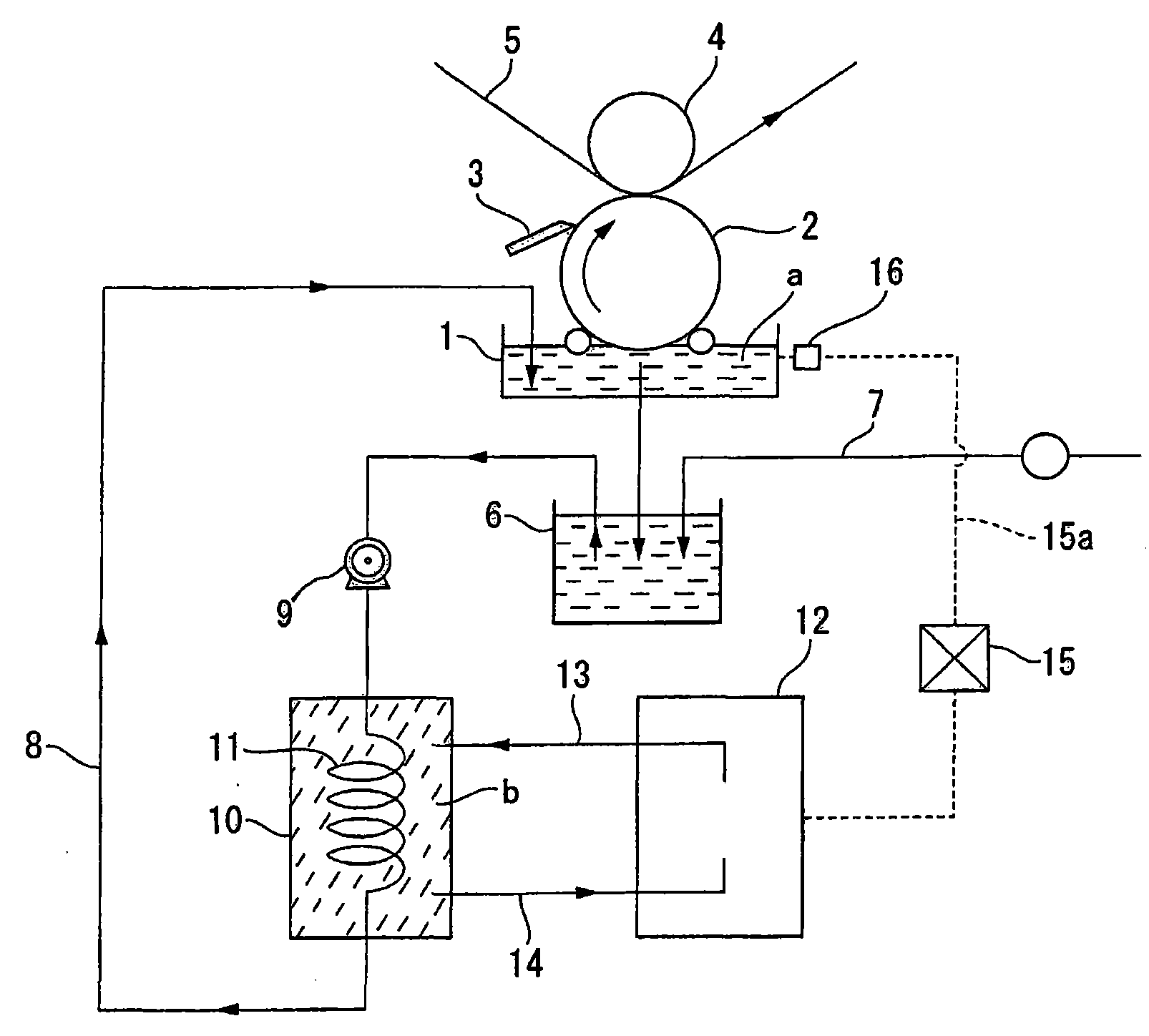

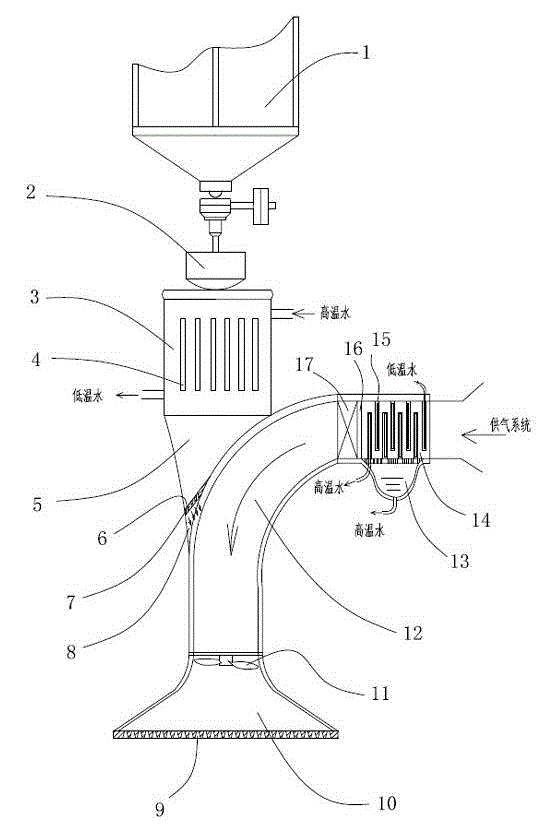

Aquatic ink temperature controller in gravure printing machine using aquatic ink

ActiveCN101850653AUniform temperatureNo need for frequent cleaningRotary intaglio printing pressOther printing apparatusPrinting inkEngineering

The invention provides an aquatic ink temperature controller in a gravure printing machine using the aquatic ink which can prevent photographic fog phenomenon owing to season. A heat exchanger (10) is installed in a temperature adjustment printing ink circulation loop (8) for maintaining the temperature of the aquatic ink in an ink tank (1) between 15-28 DEG C at which photographic fog is avoided. A control circuit (15) performs a feedback control for the driving of a heat source machine (12) according to signals from a sensor (16), so that the heat exchanger (10) makes the temperature of the aquatic ink in the oil tank (1) be 15-28 DEG C.

Owner:FUJI TOKUSHU SHIGYO

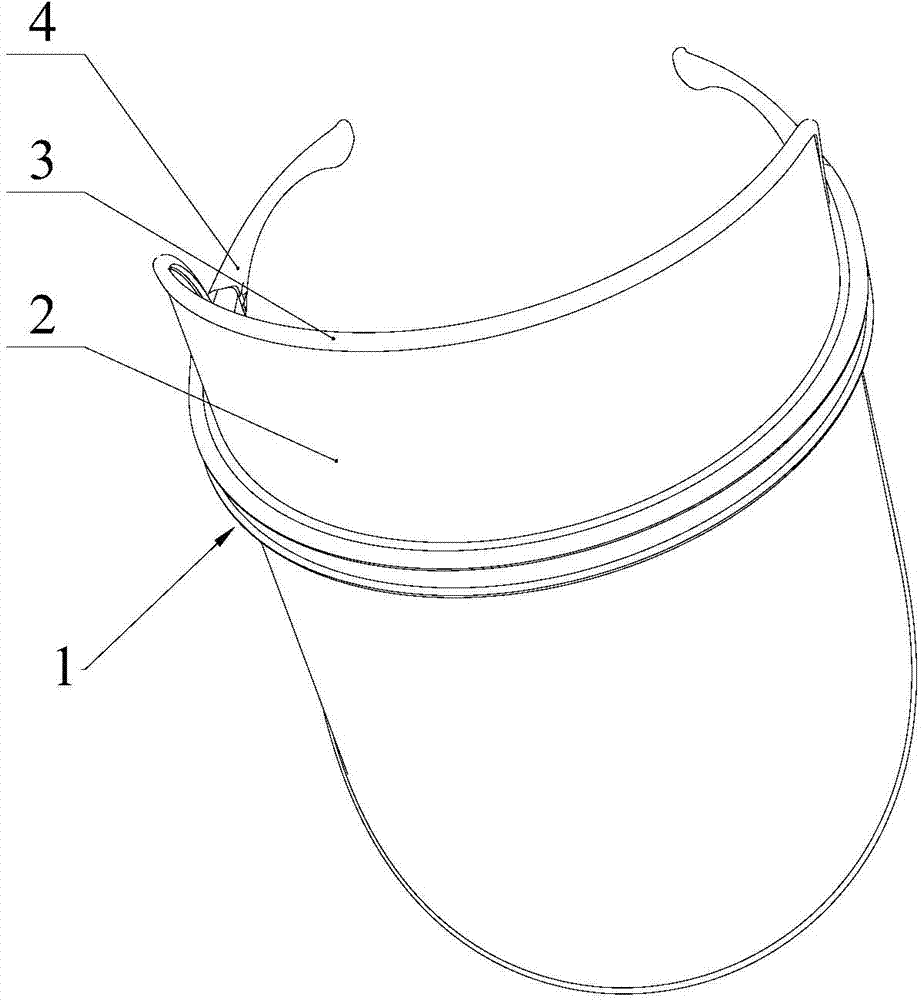

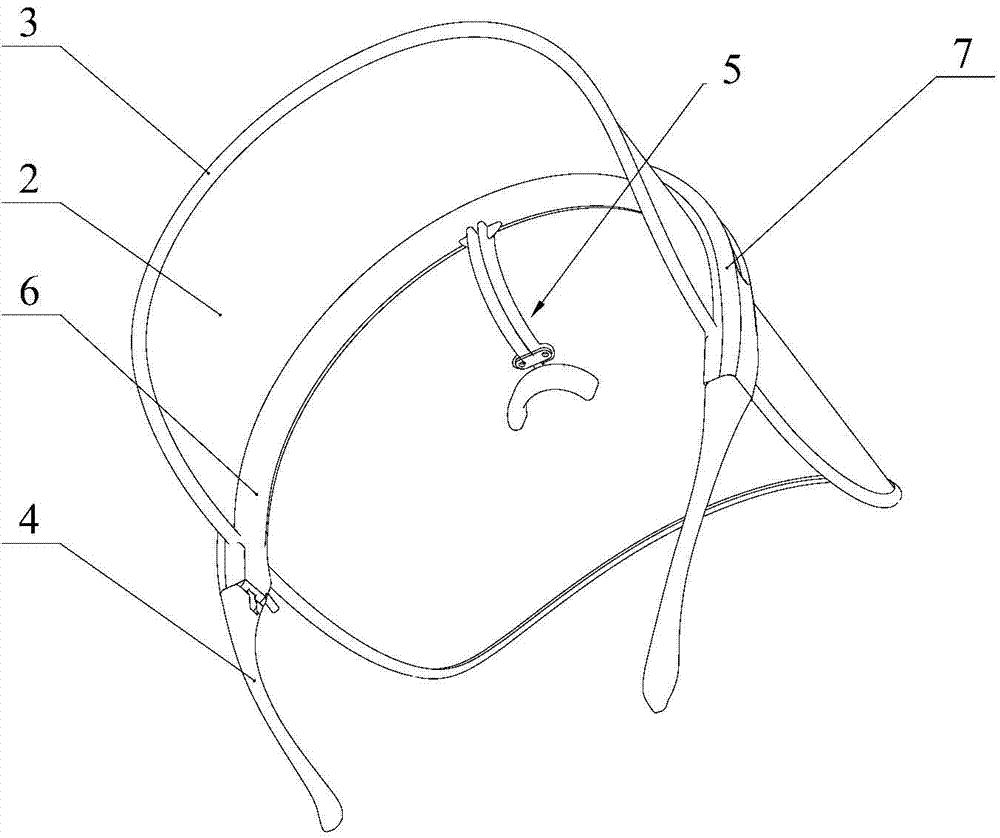

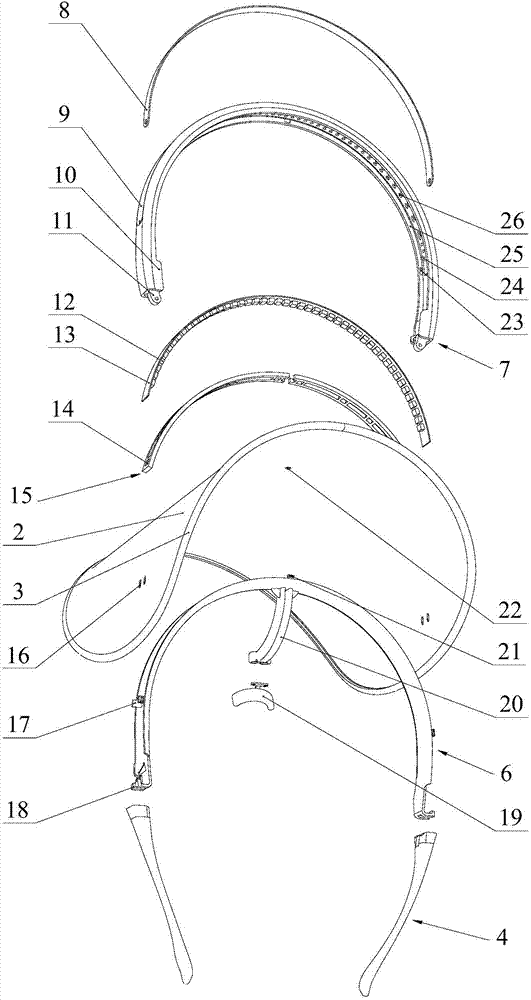

Light-emitting mask

The invention discloses a light-emitting mask comprising a light-emitting component and a mask body and further comprising a framework and ear hooks installed on the framework, wherein the mask body is a light guide board fixed to the framework; the light-emitting component is installed on the framework; the light-emitting component corresponds to the light guide point on the light guide board; the framework comprises an inner frame and an outer frame which are buckled with each other; the light guide board is fixed between the inner frame and the outer frame. The light guide board can cover the whole face, only a strip-shaped framework part of the whole light guide board is shielded, the shielded part of the light guide board is the eye part of the user, and the user experience is good; the light guide board does not make direct contact with the face, frequent cleaning is not required, use is convenient and rapid, and sanitation is achieved; heat is diffused out through cooling holes and cooling fins; the whole outer frame and the light guide board can be better attached to each other through a pressing strip, the sealing performance is better, gaps are avoided, light is not leaked easily, and water or dust does not enter the light-emitting mask easily.

Owner:SHANGHAI HONGYE PHOTOELECTRIC TRADING

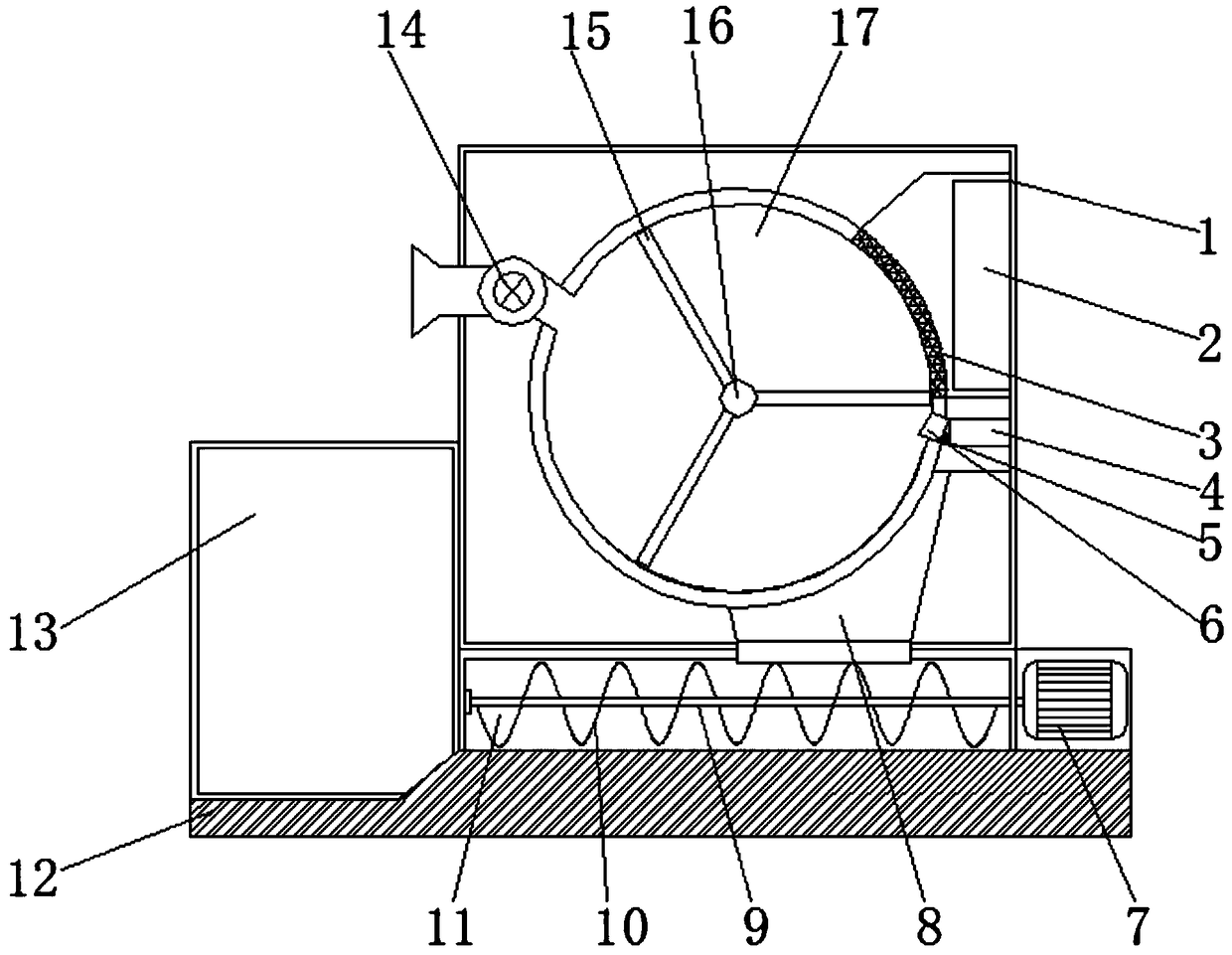

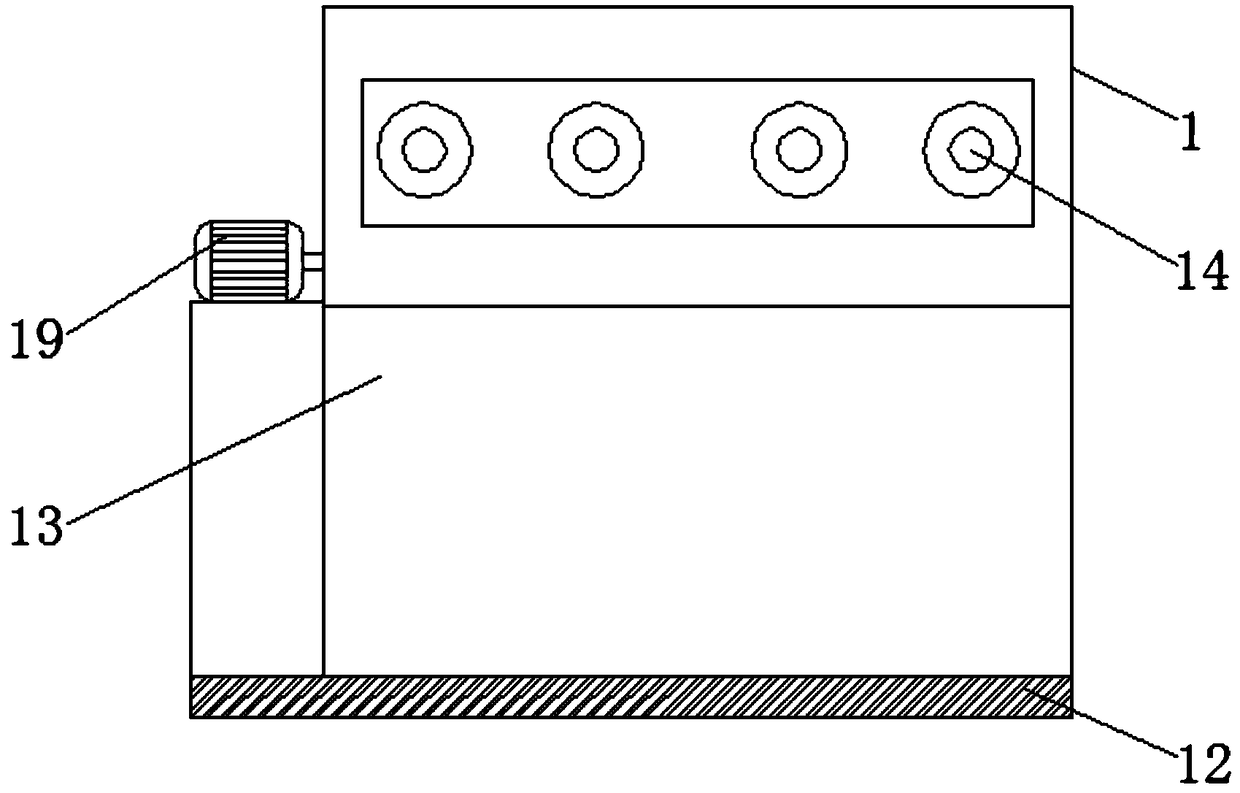

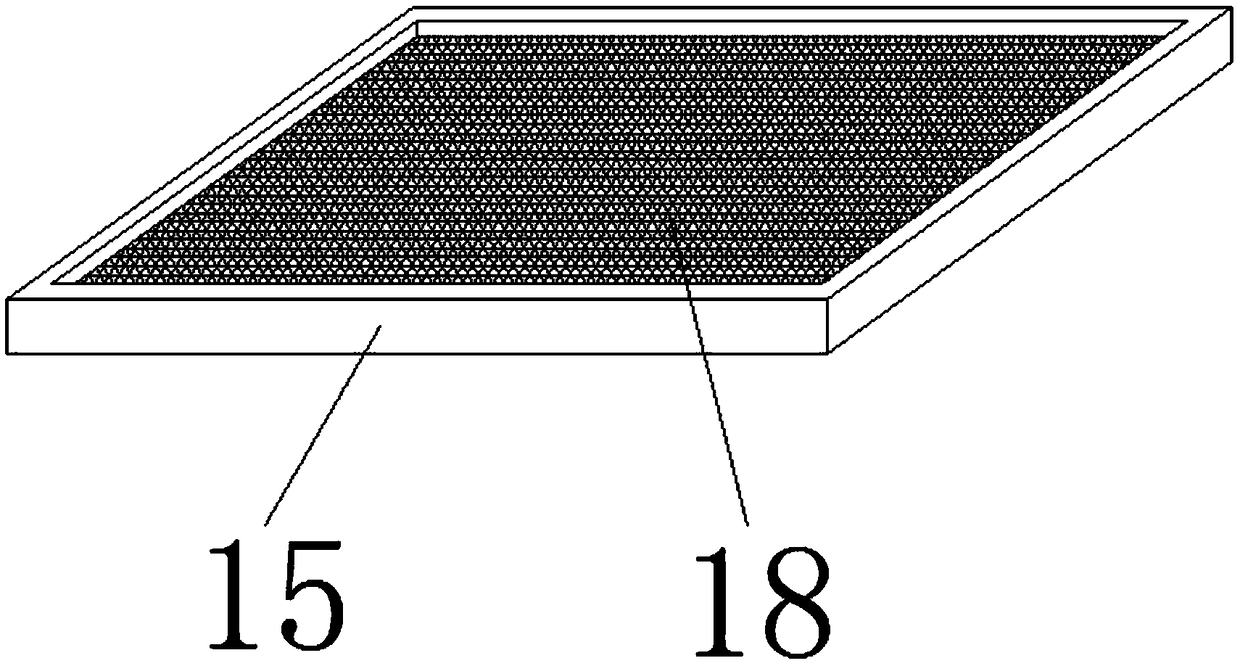

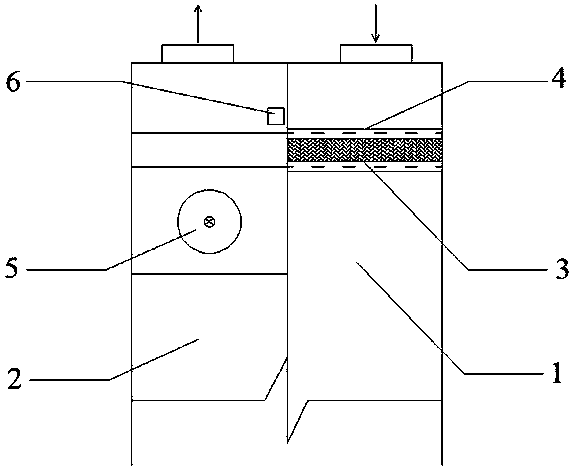

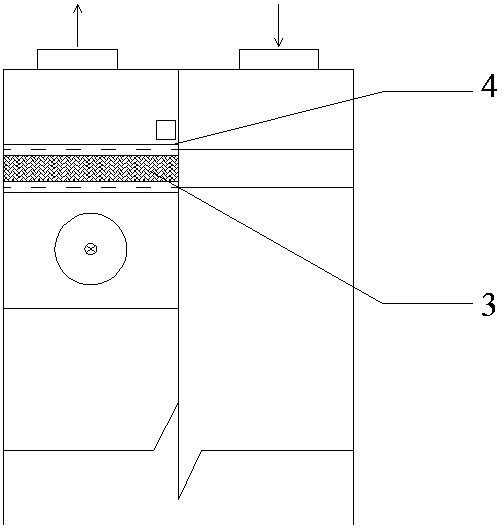

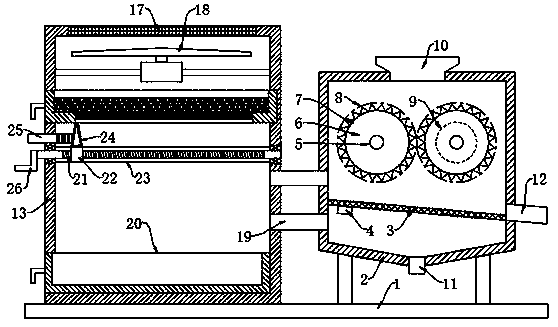

Self-cleaning device of dust filtering part and fresh air system

PendingCN108548266ANo need for frequent cleaningNo frequent replacementMechanical apparatusDispersed particle filtrationReciprocating motionFresh air

The invention relates to a self-cleaning device of a dust filtering part. The self-cleaning device comprises a fresh air channel, an air exhausting channel, the dust filtering part and further comprises a driving device, wherein the fresh air channel and the air exhausting channel are adjacently arranged side by side, and a mutual communicating through groove is formed between the fresh air channel and the air exhausting channel; and the driving device can drive the dust filtering part to penetrate through the through groove in the radial direction of the fresh air channel and the air exhausting channel to do reciprocating motion. According to the device, the dust filtering part carried by a moving part can be driven by the driving part to do reciprocating motion in the adjacent channel, so that the fresh air system can filter dust while the fresh air is circulated, and the dust filtering part does not need to be cleaned and replaced frequently, so that the use cost of the fresh air system is reduced, and the convenience and the cleanliness are improved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

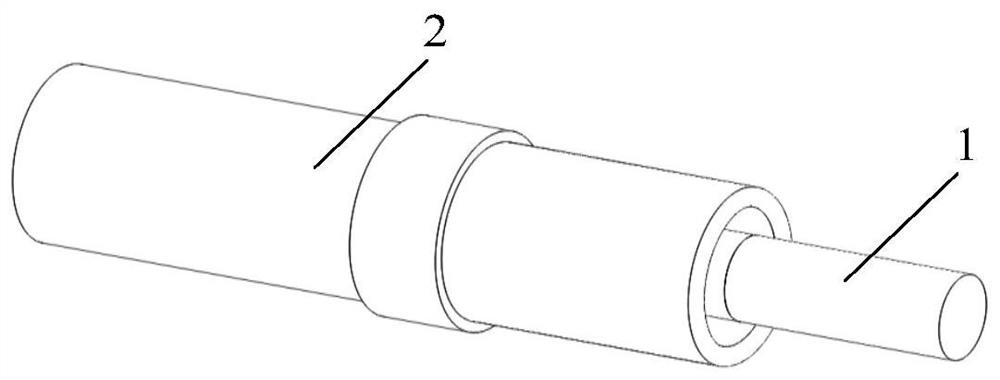

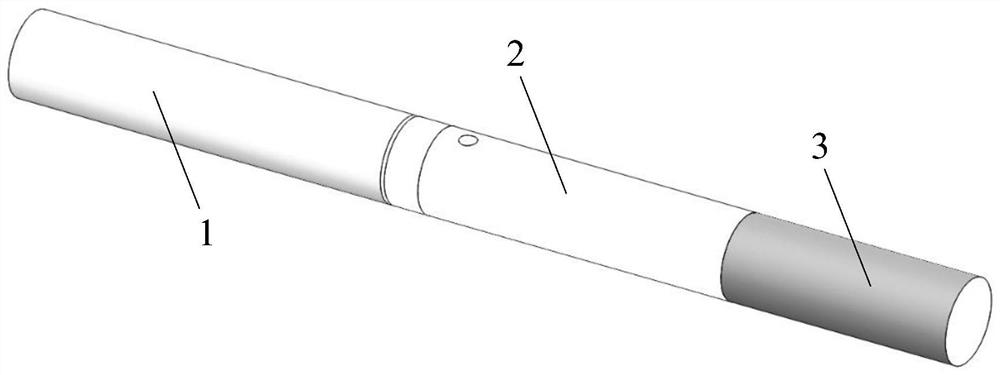

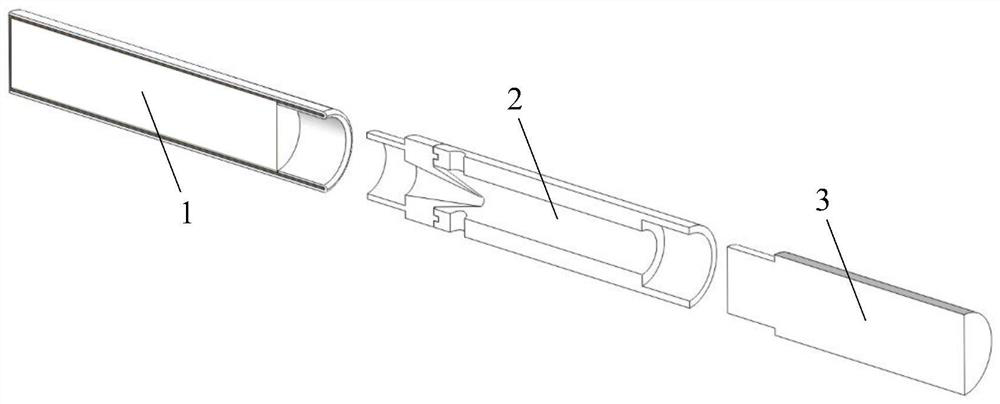

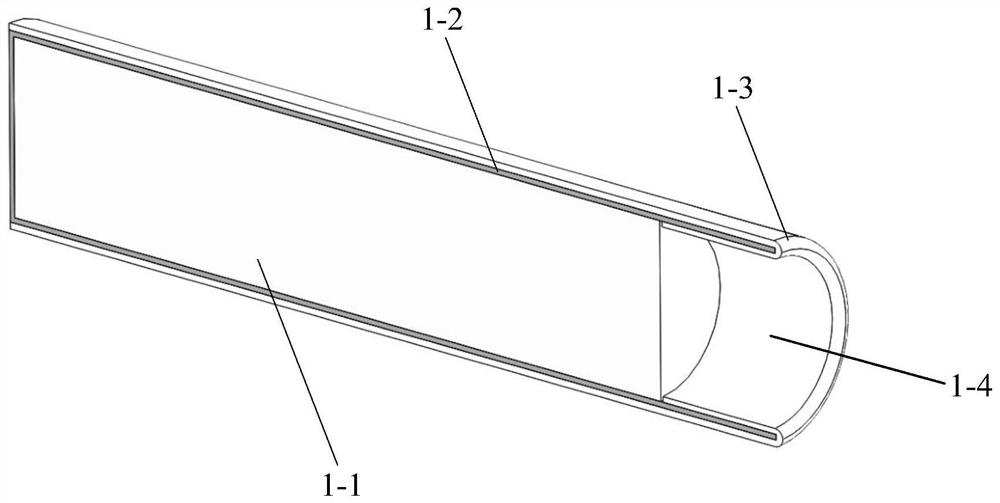

Closed heating non-combustible cigarette and assembly

ActiveCN112704262ALower oxygen levelsWon't fallCigar manufactureTobacco smoke filtersPhysicsMouthfeel

The invention relates to a closed heating non-combustible cigarette and assembly, which comprises a closed heating non-combustible cigarette and a heating smoking set, the closed heating non-combustible cigarette is inserted into the heating smoking set to be heated and smoked when in use, and the closed heating non-combustible cigarette is characterized by comprising a tobacco rod, a hollow smoke extraction cone, a smoke transmission pipe and a filter tip, wherein all the parts sequentially abut against one another and are wrapped by an external rolling material, at least one through hole is formed in the side wall of the flue gas conveying pipe, and the through hole penetrates through the external rolling material; the heating smoking set comprises a heating section, a cover cap and a sealing ring, a cigarette containing cavity and a heating element are arranged in the heating section, and an inner cavity of the cover cap is of a divergent structure. The product has the advantages that air does not flow through the tobacco section, the oxygen content of the tobacco section can be reduced, and the heating temperature is greatly increased; a closed structure is adopted, tobacco residues cannot fall off, and smoking sets do not need to be cleaned frequently; the aroma components in the tobaccos are released more sufficiently and are easy to release continuously, the taste is closer to that of traditional tobaccos, and the tobaccos are easier to accept by traditional smokers.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

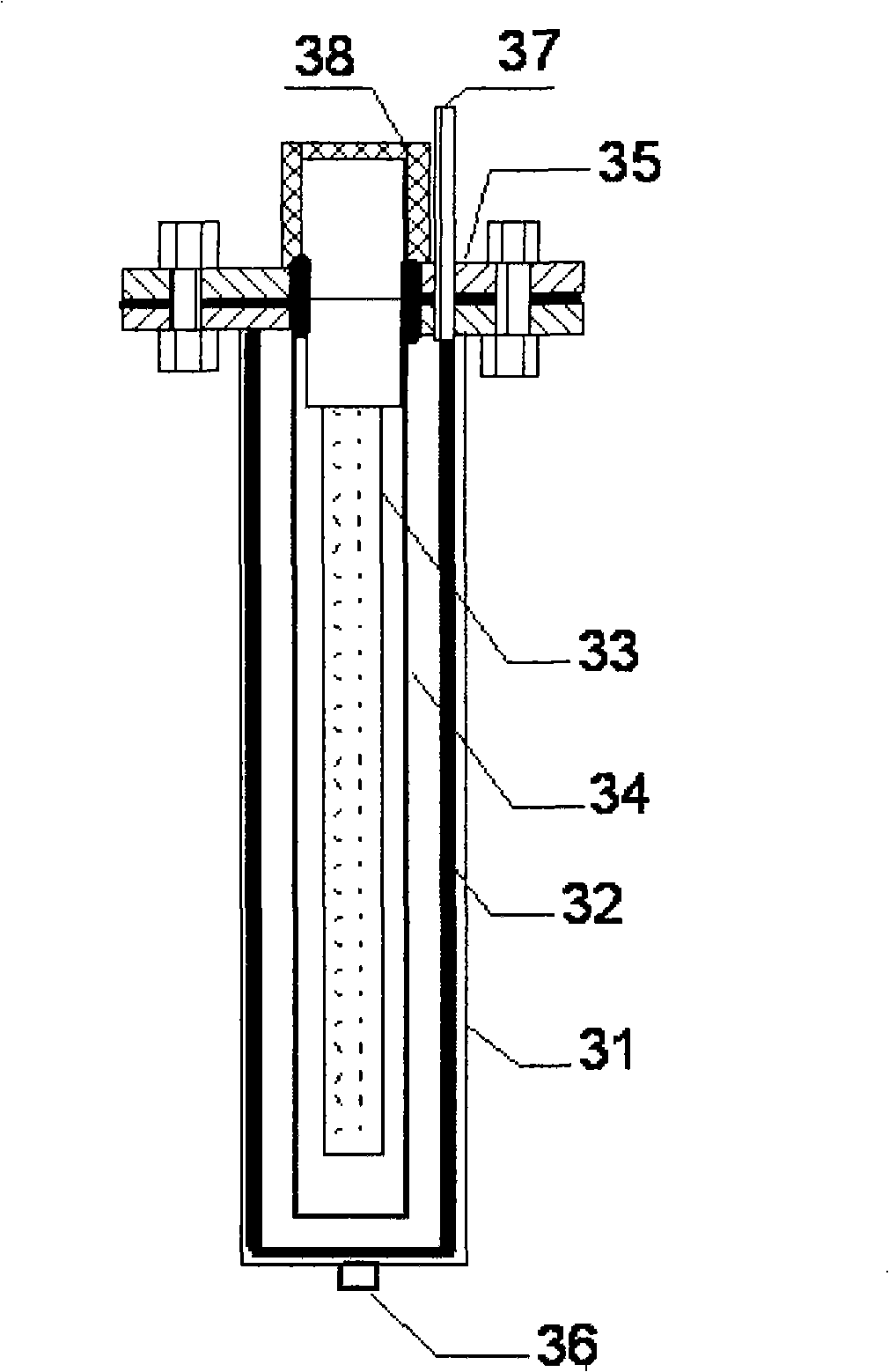

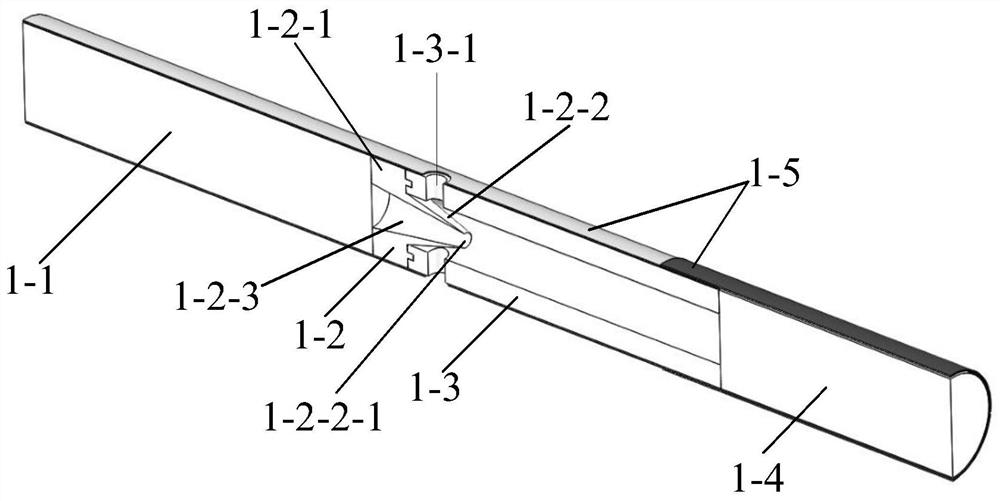

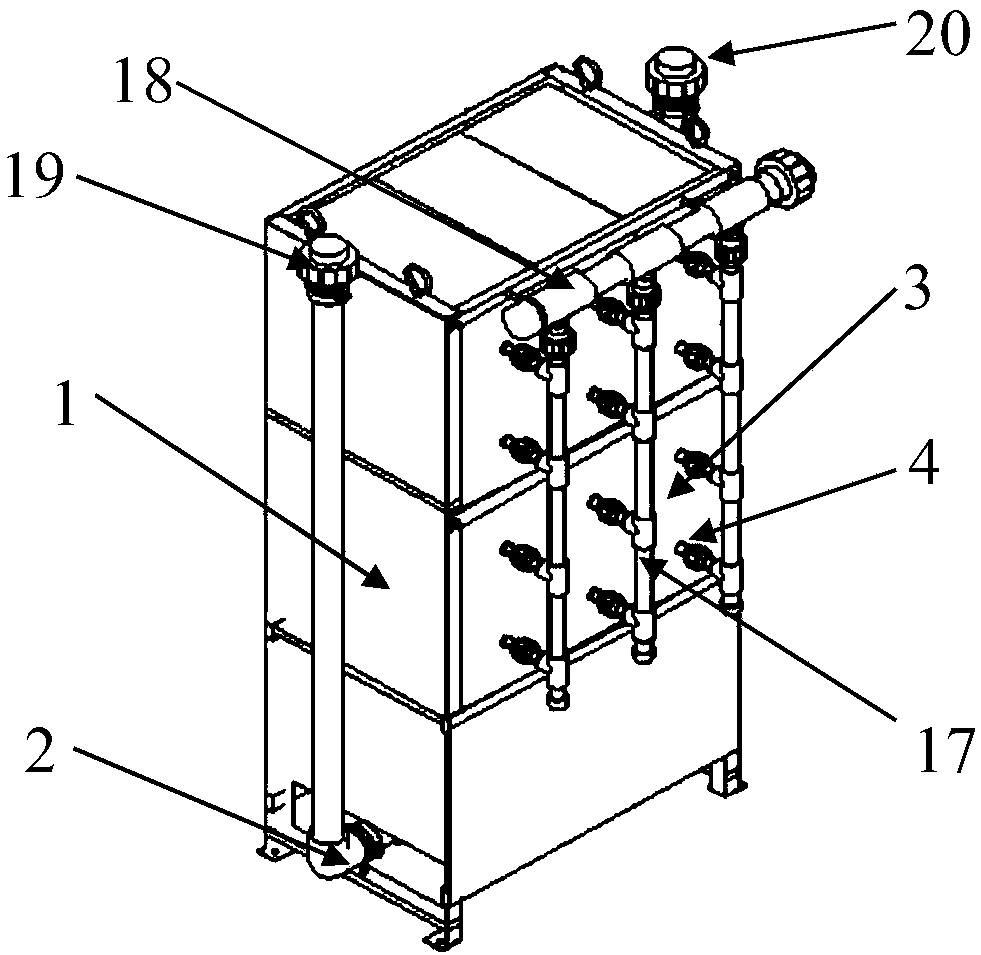

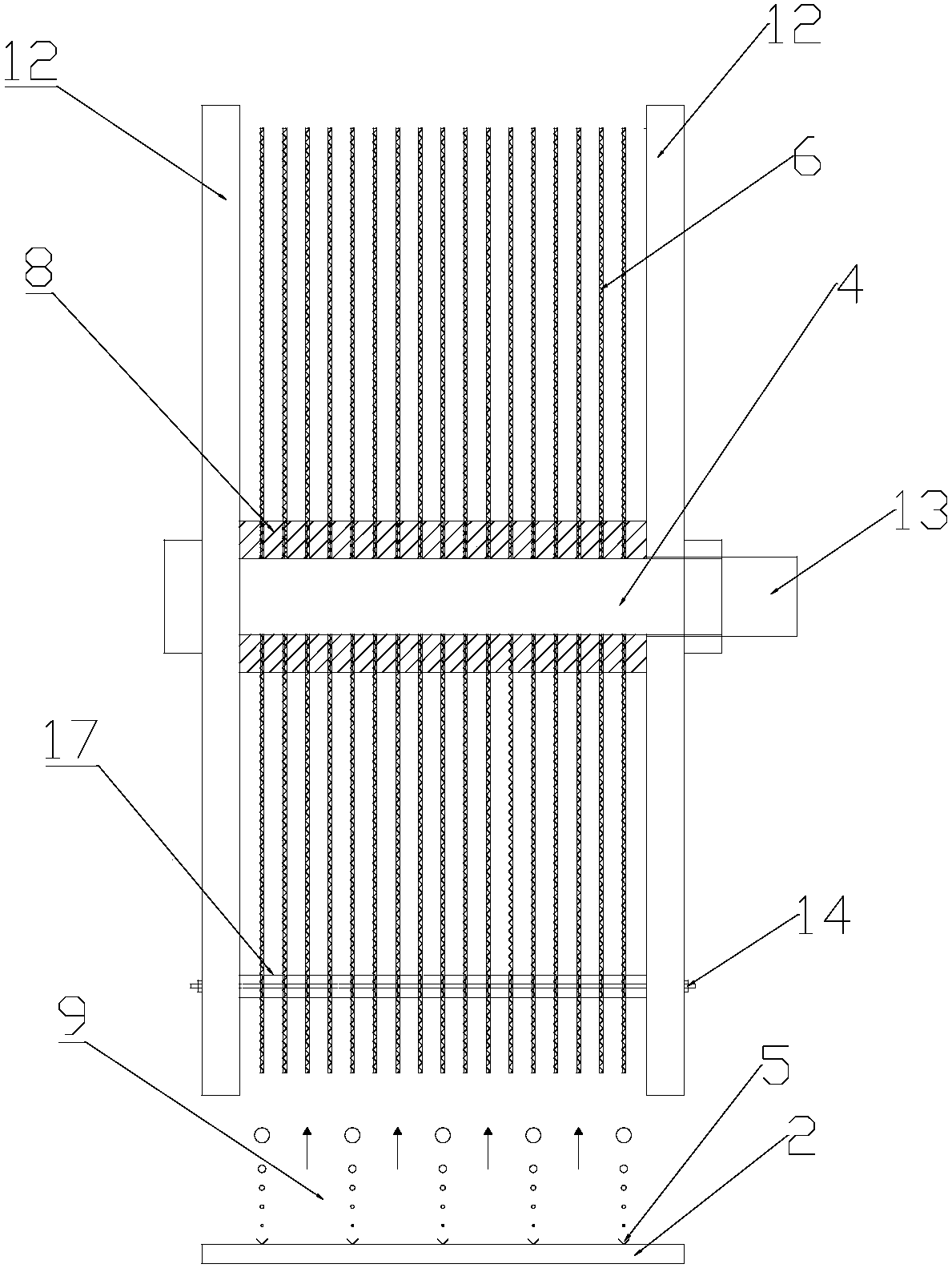

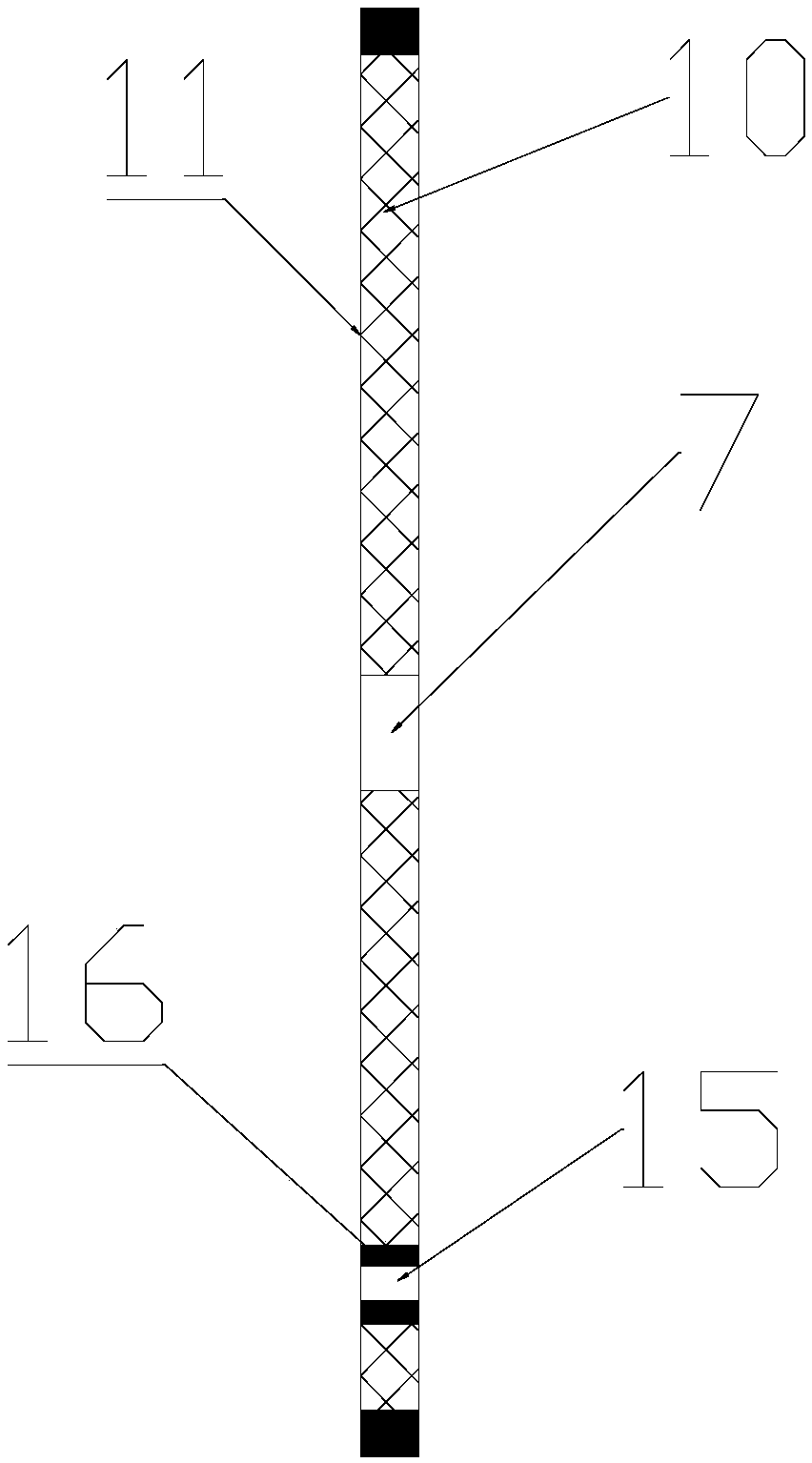

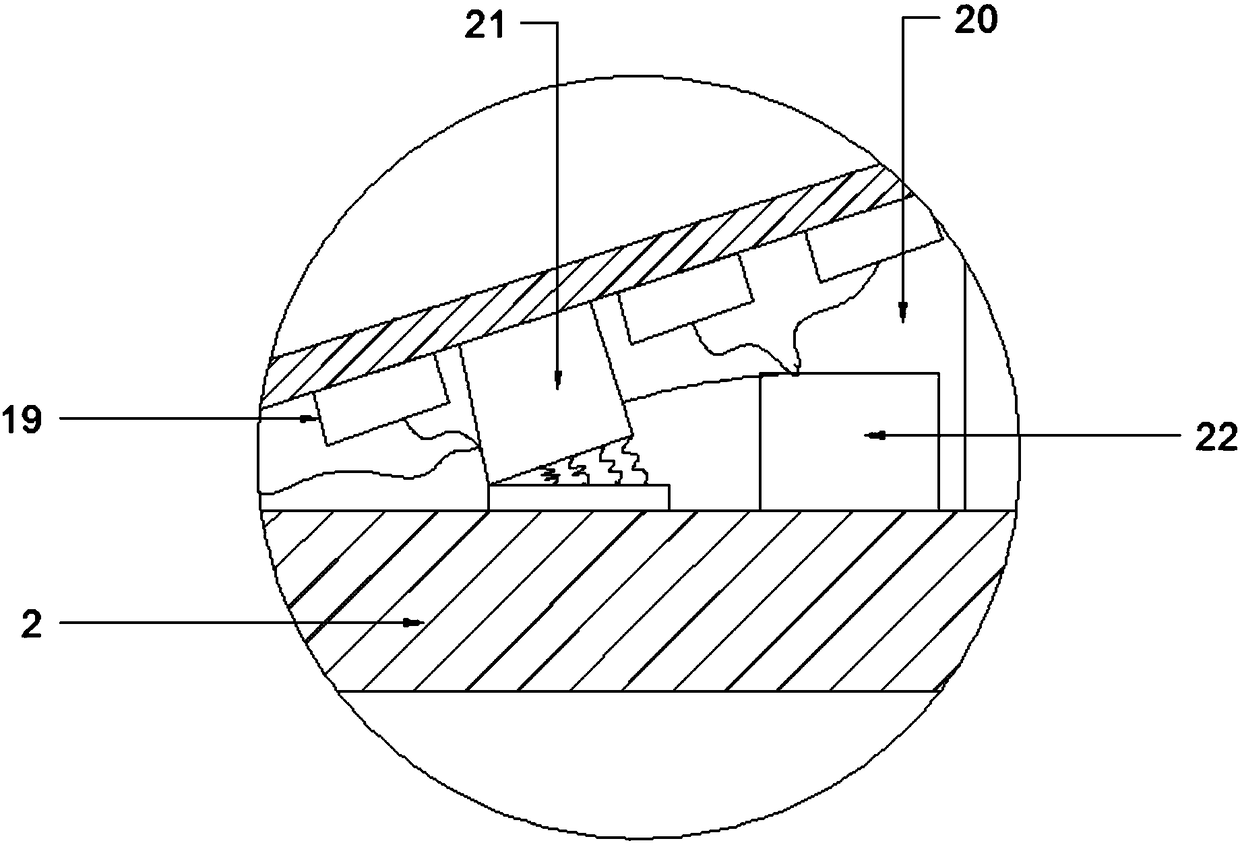

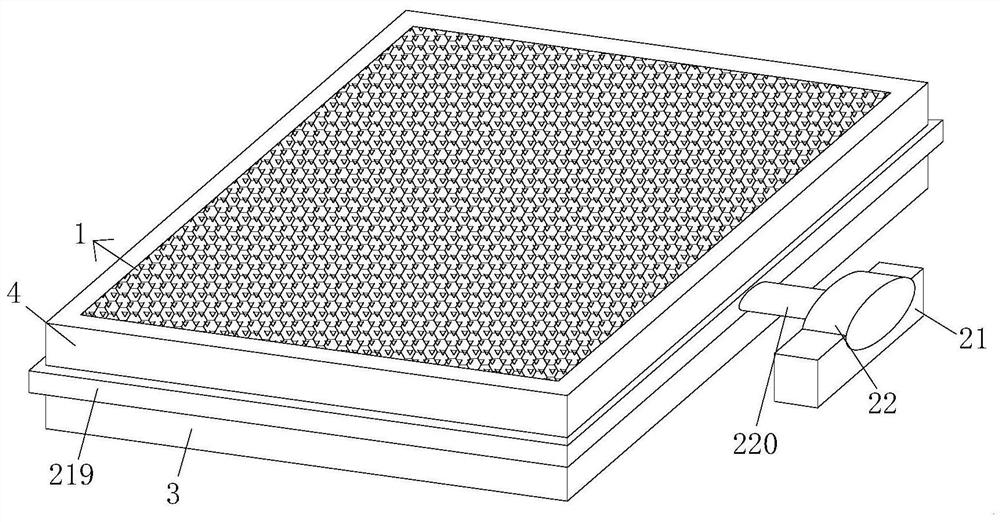

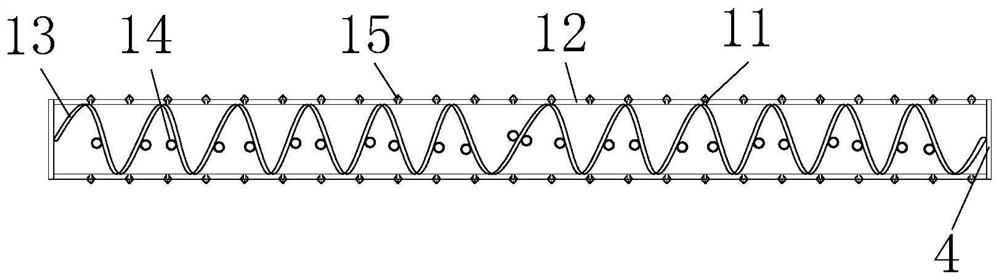

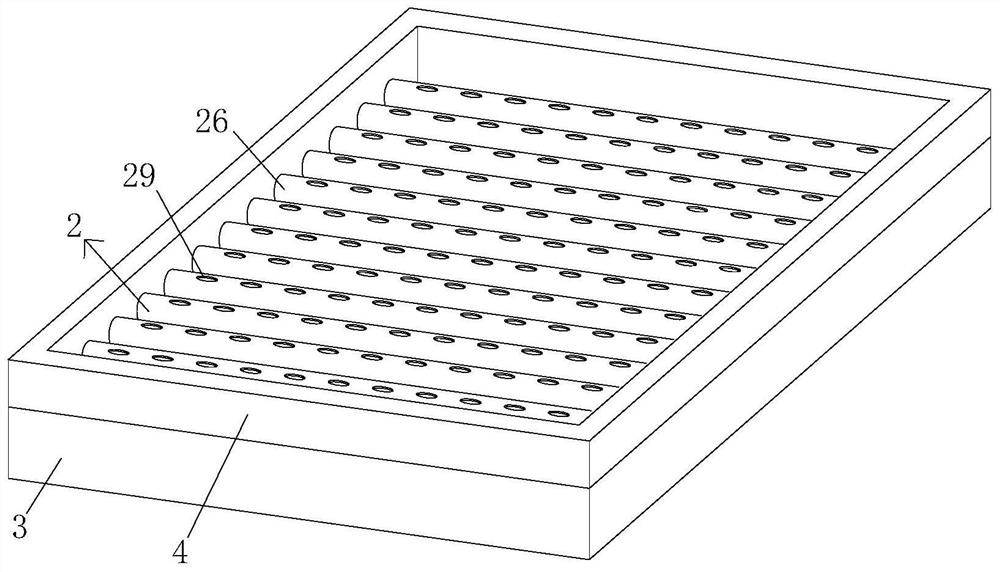

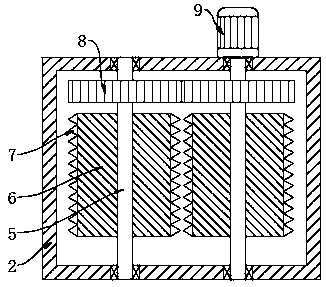

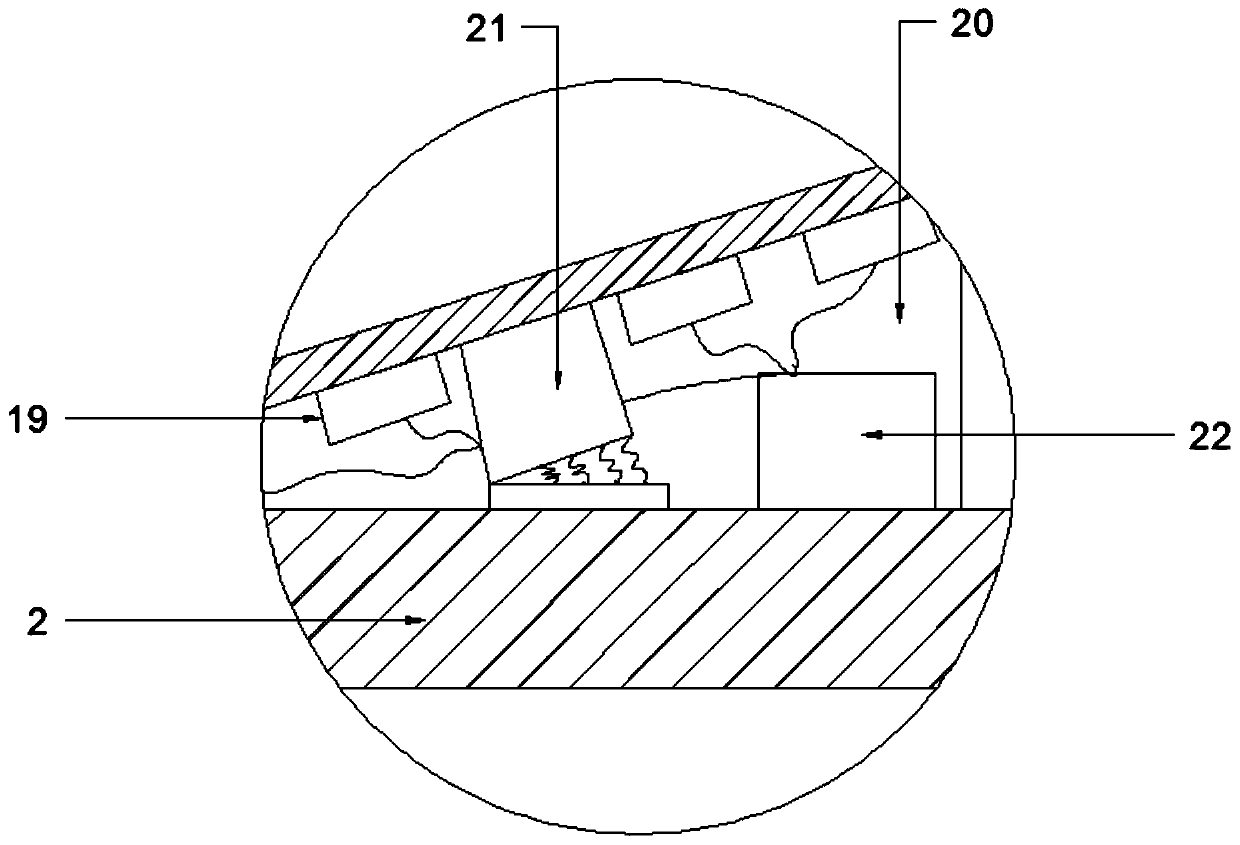

Flat plate membrane filtering assembly

PendingCN108043229AAvoid depositionFiltration water quality is stableUltrafiltrationWater/sewage treatment bu osmosis/dialysisSludgeMembrane surface

The invention discloses a flat plate membrane filtering assembly, which comprises a membrane box, wherein an aeration pipe is arranged at the lower part of the membrane box; a plurality of membrane piles fixed on the membrane box are arranged above the aeration pipe; a plurality of aeration holes right aligned with the membrane piles are formed in the aeration pipe; each membrane pile comprises awater collecting pipe; a plurality of flexible flat plate membrane sheets are arranged on the water collecting pipe in a sleeving way; a through hole through which the water collecting pipe passes isformed in each flexible flat plate membrane sheet; liquid discharging holes communicating with the inside of the flat plate membrane sheets are formed in positions, provided with the flexible flat plate membrane sheets, on the water collecting pipes; an upper sealing separation ring is arranged between the two adjacent flexible flat plate membrane sheets. The flat plate membrane filtering assemblyhas the advantages that the shaking state can be maintained by the flexible flat plate membrane sheets under the aeration state; the deposition of sludge on the surface of the membrane sheets can beeffectively prevented; the quality of the filtered water is more stable; the filtering membrane cannot be easily blocked; the frequency cleaning of the filtering membrane surface is not needed; the service life of the filtering membrane is long; the operation cost of the filtering membrane assembly can be effectively reduced, and the like.

Owner:JIAXING LIREN ENVIRONMENTAL PROTECTION TECHCO LTD

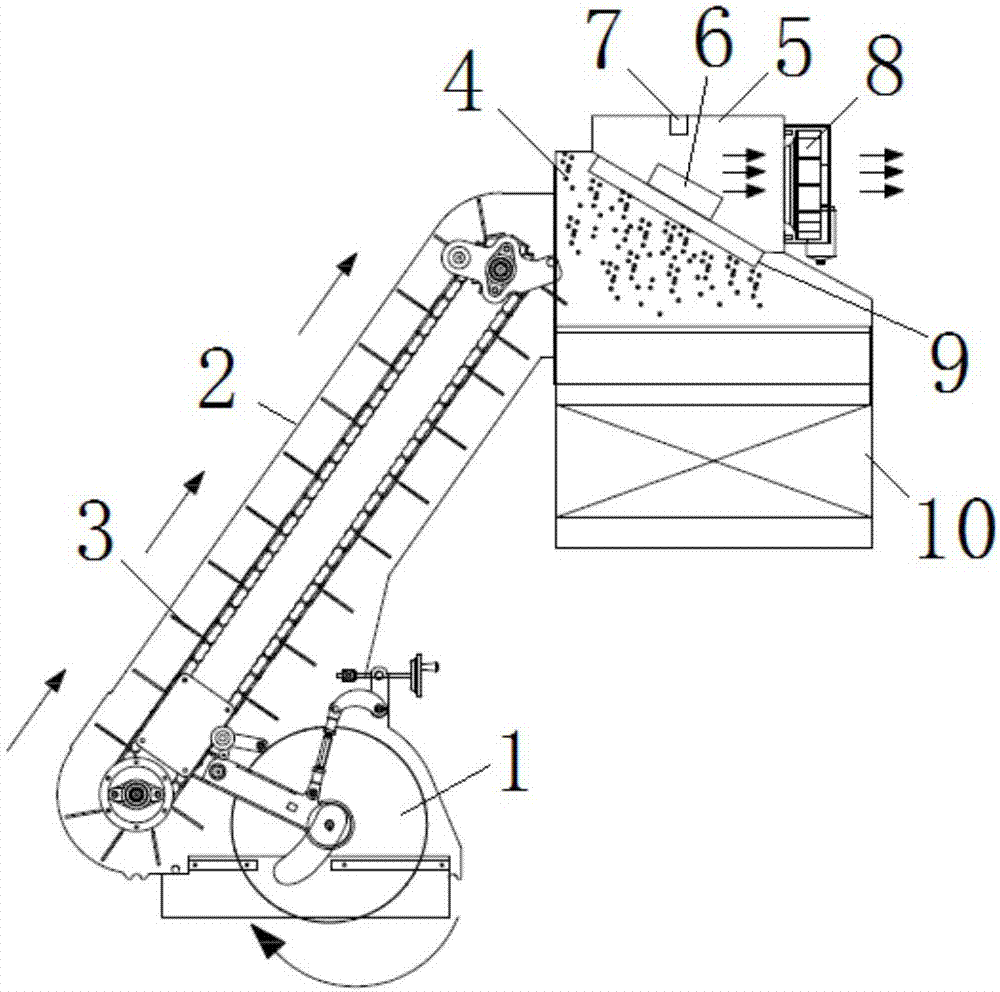

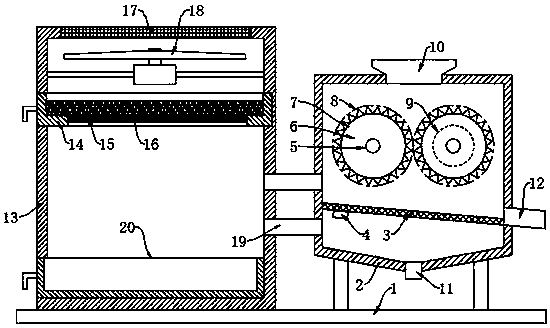

Rubbish collecting mechanism of sweeping vehicle

ActiveCN107313384AReasonable structural designNo need for frequent cleaningRoad cleaningRefuse collectionWaste collection

The invention discloses a rubbish collecting mechanism of a sweeping vehicle. The rubbish collecting mechanism comprises a main brush box body, a main brush, a conveying channel and a dust collecting box, wherein the main brush is arranged in the main brush box body; the lower end of the conveying passage communicates with the main brush box body; the upper end of the conveying passage communicates with the dust collecting box; an opening opposite to a dustbin is formed in the lower part of the dust collecting box; a pulverizing box is arranged at the opening of the lower part of the dust collecting box; and a discharging opening opposite to the dustbin is formed in the lower part of the pulverizing box. The rubbish collecting mechanism disclosed by the invention is reasonable in structural design; after rubbishes collected by the main brush and the conveying channel are pulverized by the pulverizing box, so that storing capacity of the dustbin is increased, frequently cleaning the rubbishes in the dustbin is not needed, and the sweeping efficiency is improved.

Owner:ANHUI NANBO ROBOT CO LTD

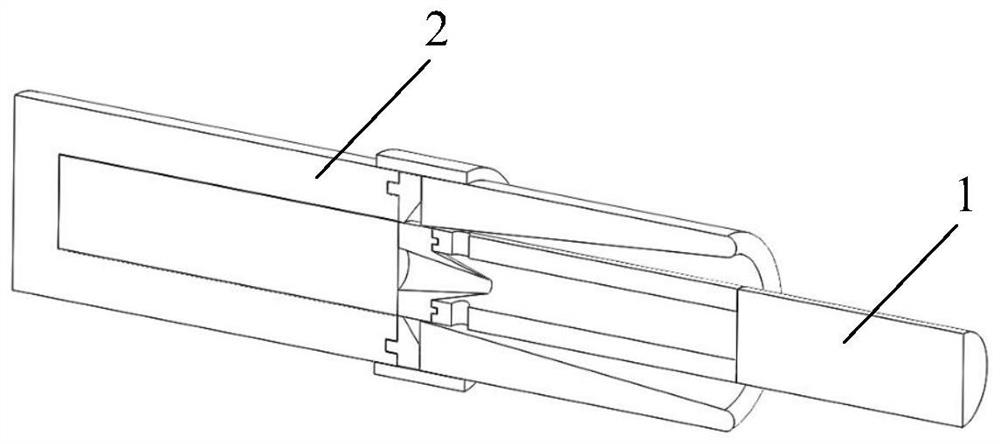

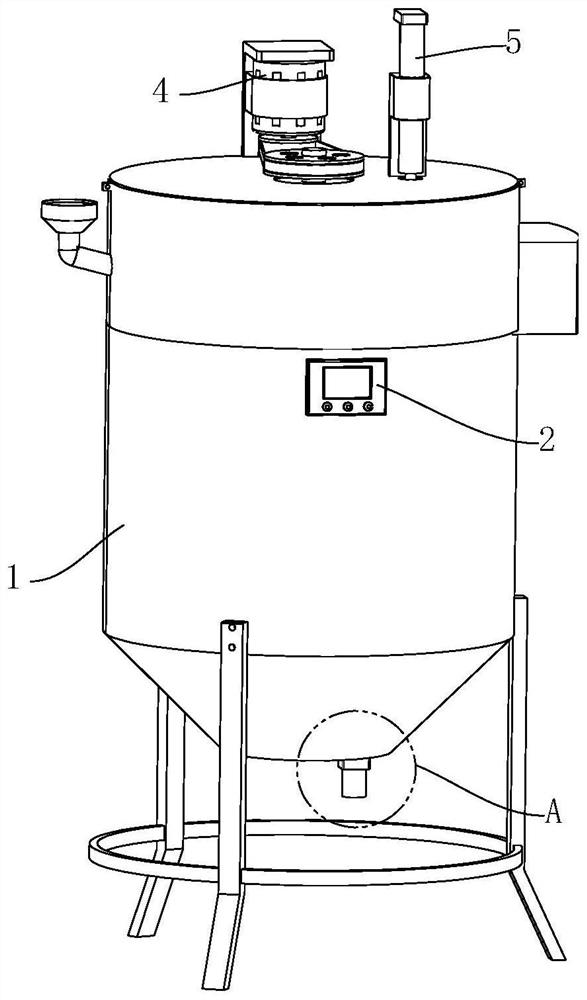

Oxygen-poor heating type cigarette assembly

ActiveCN112704261ARelease fullyLower oxygen levelsCigar manufactureTobacco smoke filtersBiotechnologyMechanical engineering

The invention relates to an oxygen-deficient heating type cigarette assembly. The oxygen-deficient heating type cigarette assembly comprises an oxygen-deficient heating type smoking set, an oxygen-deficient heating type cigarette and an oxygen-deficient heating type smoking method. The oxygen-deficient heating type smoking set comprises a heating section and a smoke extracting piece which can be arranged in a split mode with the heating section, the heating section is provided with a cigarette containing cavity, and the smoke extracting piece comprises a hollow smoke extracting cone and a smoke conveying pipe. The oxygen-deficient heating type cigarette comprises a tobacco section and a filter tip section which are detachably connected with each other, during smoking, the tobacco section and the filter tip section of the oxygen-deficient heating type cigarette are detached and assembled with the smoke extraction part respectively to form a sectional type cigarette; the tobacco section of the sectional type cigarette is inserted into the cigarette containing cavity, a heating element is started, and smoking is conducted. The oxygen-deficient heating type cigarette assembly is designed for the first time, the cigarette structure is greatly simplified through the split type cigarette design, the oxygen-deficient environment of a tobacco section can be kept, the heating temperature is increased, tobacco residues cannot fall off, and smoking sets are kept clean.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Rapid catalysis device for production of petrochemical industry and working method thereof

ActiveCN112934154AWon't breakMaximize efficacyCatalytic crackingChemical/physical/physico-chemical stationary reactorsProcess engineeringPetrochemical

The invention relates to the technical field of petroleum processing, in particular to a rapid catalysis device for production of the petrochemical industry and a working method thereof. The rapid catalysis device comprises a reaction kettle and further comprises a controller, a sealing disc, a stirring mechanism, a catalysis mechanism and a cleaning mechanism, wherein the stirring mechanism comprises a rotating shaft, a driving assembly and three rotating assemblies; the catalysis mechanism comprises a placement frame, a telescopic assembly and a leakage prevention assembly; the cleaning mechanism comprises an arc-shaped collection box, a hammering assembly and a brushing assembly; the arc-shaped collection box is fixedly arranged at the top of the sealing disc; a touch assembly and the brushing assembly are symmetrically arranged on the circumferential outer wall of the rotating shaft; and the driving assembly and the telescopic assembly are electrically connected with the controller. According to the rapid catalysis device for the production of the petrochemical industry and the working method thereof, frequent cleaning is not needed, oil stains are convenient to clean, stirring is more careful, a catalysis process can be accelerated, catalysis efficiency is higher, power consumption is small, and catalysis cost can be reduced.

Owner:SHANGHAI PINGWEI TECH DEV CO LTD

Environment-friendly and water-saving secondary water supply box free of cleaning

ActiveCN108130936APrevent fallingGuaranteed to workHollow article cleaningMagnetic separationEngineeringElectromagnet

The invention discloses a water-saving secondary water supply box free of cleaning. The water-saving secondary water supply box comprises a water supply box body, multiple pulling plate holes are formed in the two side walls of the water supply box body, filtering plates penetrate into the water supply box body through the pulling plate holes, pulling plates are fixed to the outer side ends of thefiltering plates, the tops of clapboards are fixed to the tops inside the water supply box body, buffering plates are arranged below diversion plates, a base platform is arranged in the center of thebottom inside the water supply box body, a water outlet pipe penetrates through the center of the base platform, a water filtering tank is arranged at the junction of the base platform and the buffering plates, the base platform is internally provided with an equipment cavity, an equipment cavity vibrator, electromagnets and an accumulator, wherein the accumulator is electrically connected with solar panels, the solar panels are aslant fixed to the top of the water supply box body, an overhauling opening is formed in the center of the top of the water supply box body, and water inlet pipes are arranged at the outer sides of panel supports, and enter the water supply box body through water inlets. By means of the water-saving secondary water supply box free of cleaning, the filtering plates and the electromagnets are utilized for attraction, the cleanliness of the water supply box is improved, the cost for manual cleaning is reduced, water is saved, and multiple effects of protecting the environment, saving energy and cleaning the water supply box are achieved.

Owner:苏州斯尔斯特新材料科技有限公司

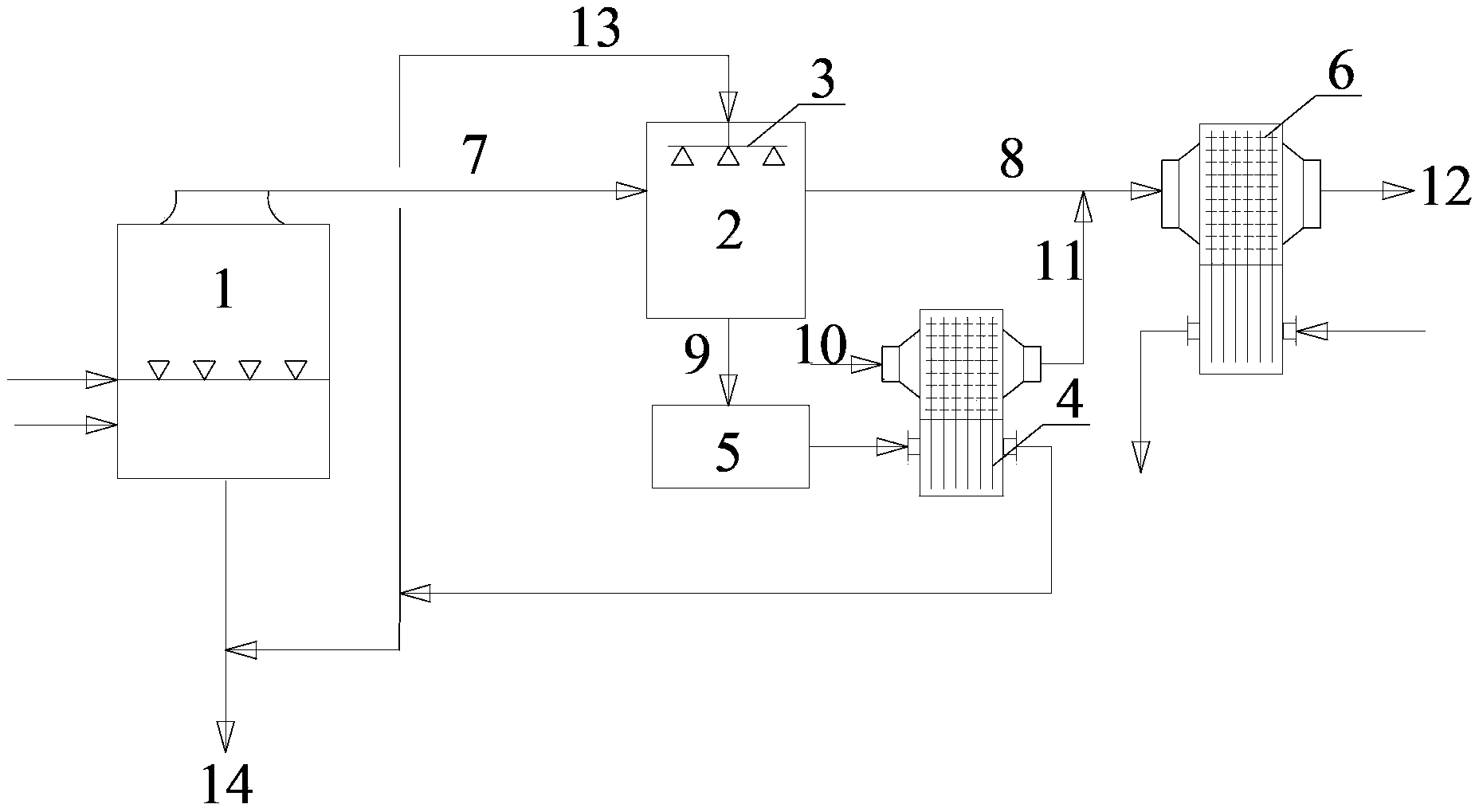

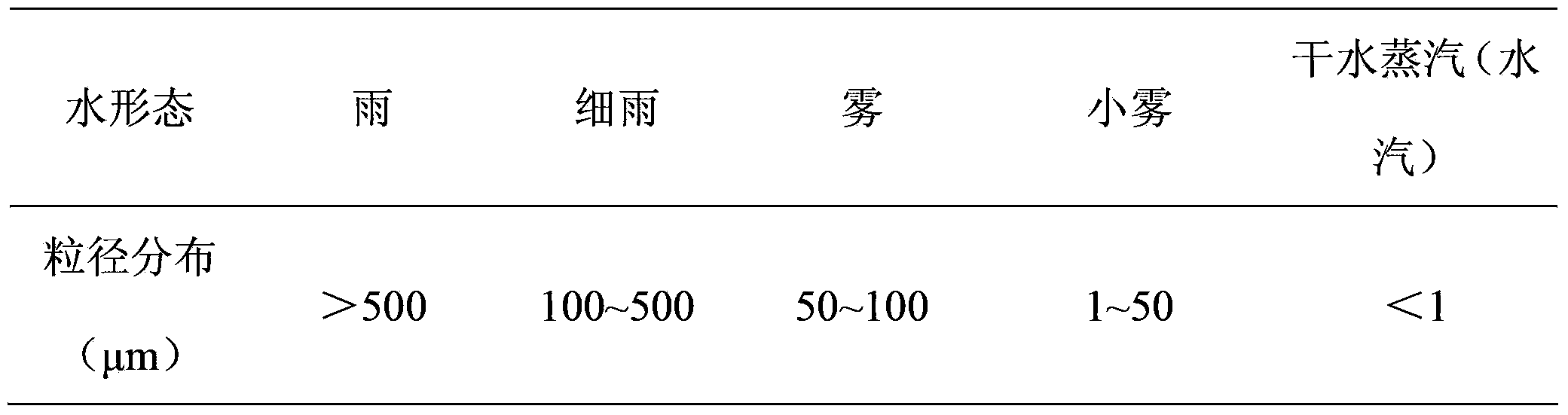

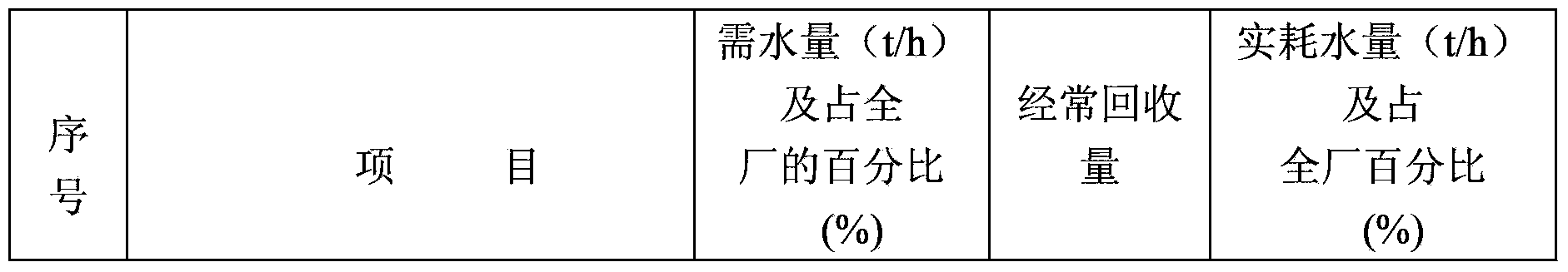

Cooling tower water vapor and heat energy recovery method and system

The invention discloses a cooling tower water vapor and heat energy recovery method and system. The method comprises the steps that water vapor exhausted by a cooling tower is introduced into a condenser; in the condenser, water atomization is carried out on a condensing agent to form fine particles which are sprinkled on the water vapor, and the water vapor is condensed into water by meeting the cold; air in the dry heat state is exhausted from the condenser. The system comprises the cooling tower and the condenser. An outlet of an air cylinder at the top of the cooling tower is connected with a water vapor inlet of the condenser. In the condenser, a condensing agent ejector is arranged above the water vapor inlet. According to the cooling tower water vapor and heat energy recovery method and system, the water evaporation loss of the cooling tower can be effectively reduced, the energy which should be abandoned by the system can also be recovered and cooled, and the zero release of the cooling tower of a circulating water system is basically achieved. By the adoption of the system, only appropriate adjustment is required for an existing cooling tower, the condenser and a heat pipe exchanger are additionally arranged, the most economical cooling water spray is used as the condensing agent, and an efficient heat pipe is used for recycling heat energy.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

Water washing stone for ceramic products and producing method thereof

InactiveCN1583662ASave manpower and material resourcesReduce the number of water passesRougheningCeramicwareCeramicSewage treatment

Stone preparation by ceramics and its producing process. A light, wear-resisting, high capability and environmental protection stone produced by ceramics is used in the washing process of habiliment and drygoods. The washing process of habiliment and drygoods. The low cost, high producing efficiency of ceramics stone flyblow cloth so it decreases the times of washing water. Fare is reduced greatly.

Owner:林柄楠

Self-adaptive negative suction type sole mud scraping grid based on miners

The invention provides a self-adaptive negative suction type sole mud scraping grid based on miners. The sole mud scraping grid comprises a self-adaptive mud scraping mechanism used for rubbing sole mud and cleaning the sole mud, a self-adaptive negative pressure mud removing mechanism used for sucking and scraping the sole mud in a negative pressure mode, a supporting bottom frame used for installing and supporting the self-adaptive negative pressure mud removing mechanism, and a four-side supporting frame used for installing and supporting the self-adaptive mud scraping mechanism. The self-adaptive mud scraping mechanism is arranged in the four-side supporting frame. The invention relates to the field of mine cleaning. According to the self-adaptive negative suction type sole mud scraping grid based on miners, the special sole mud scraping grid which can efficiently remove sole mud ash and is easy to clean is designed in view of the problem of smudginess in an existing mine factory caused by sole mud, and the problem that sole mud scraping equipment used in a common mine factory can hardly automatically scrape mud and contain the mud ash, is low in repeated utilization rate, is required to be cleaned frequently and is difficult to clean is solved.

Owner:汪海

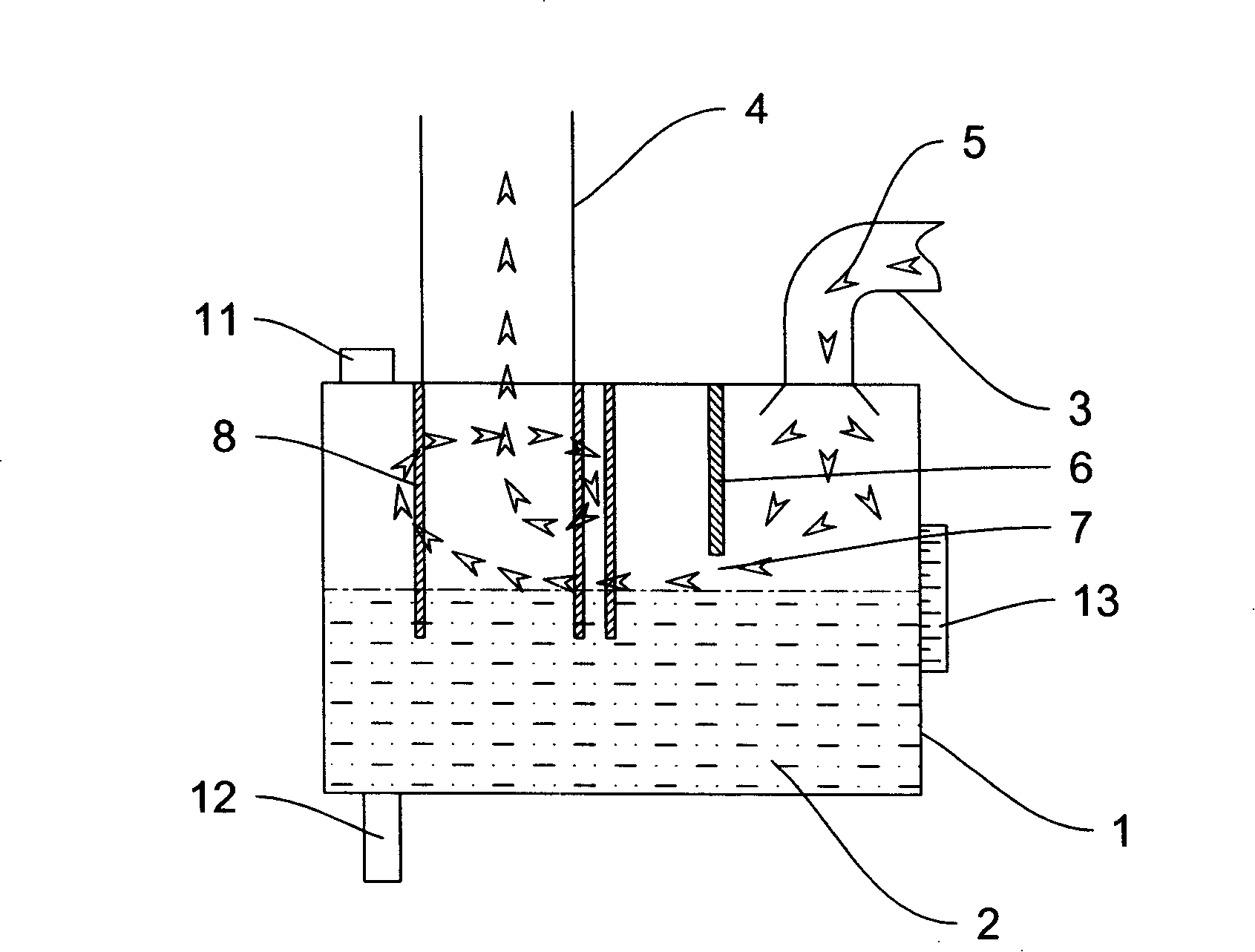

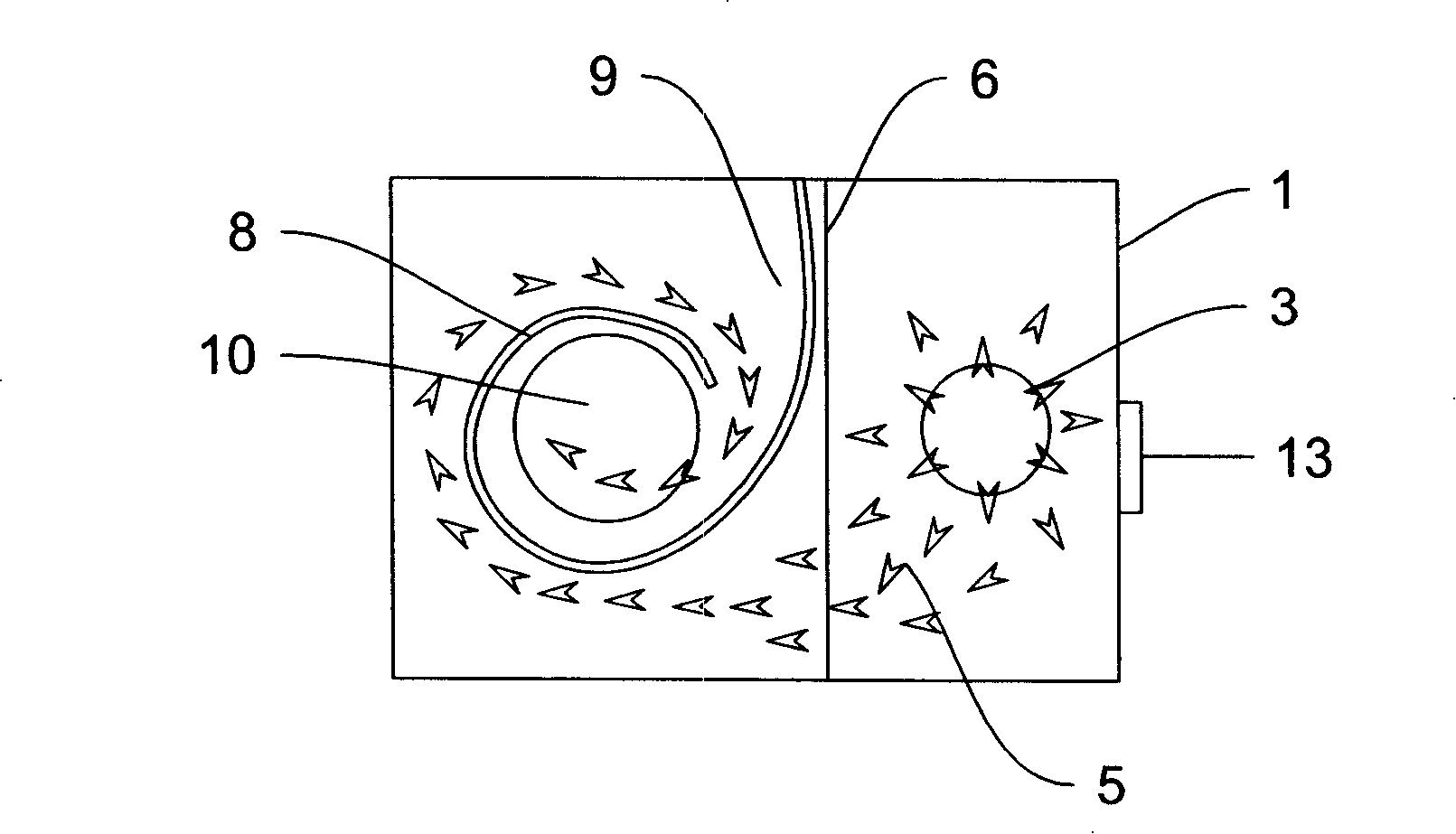

Dust collection method with filtering liquid and device using the method

InactiveCN101219317AReduce flow rateNo need for frequent cleaningUsing liquid separation agentFlue gasLiquid tank

The invention relates to a filterliquor dedusting method, which comprises the steps that firstly, flue gases are led into an air inlet pipe through a sealed liquid tank; secondly, a wind-delay device arranged inside the liquid tank is employed to cause the flow velocity of the flue gases to be reduced and flow close to liquid level; thirdly, a cyclone device arranged inside the liquid tank causes the flue gases after spinning to be discharged into the air through a discharge pipe. Since the flue gases are led into the sealed liquid tank, the flow velocity of the flue gases is reduced and the flue gases flow close to the liquid level after the flue gases are processed by the wind-delay device; as the liquid inside the liquid tank can absorb the soot of the flue gases, thus directly absorbing the soot of the flue gases into the liquid; the flue gasses spin through the cyclone device, which lengthens the flowing distance of the flue gasses inside the liquid tank, thus leading the flue gasses to fully contact with the liquid level. Therefore, a dedusting device is unnecessarily to be cleaned frequently, and the liquid inside the liquid tank is merely changed according to actual situations, thereby achieving the aim of dedusting at a time and having no secondary pollution. Besides, the invention further relates to a filterliquor dedusting device for the dedusting method.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Mute air exhaust port of a roller type sand making machine

InactiveCN110328010AReduce pollutionBeneficial to human healthDispersed particle filtrationDirt cleaningEngineeringHuman health

The invention discloses a mute air exhaust port of a roller type sand making machine, and relates to the technical field of sand making machines. The mute air exhaust port of the roller type sand making machine comprises a base, the top of the base is fixedly provided with a crushing box through a support, a dust removal box is further fixedly arranged at the top of the base, an upper air suctionpipe and a lower air suction pipe are fixedly connected to the right wall of the dust removal box, and the upper air suction pipe and the lower air suction pipe correspondingly penetrate through the left wall of the crushing box and extend to the upper side and the lower side of a screen; an air outlet is formed in the top wall of the dust removal box, and a grid plate is fixedly clamped at the air outlet, the inner top of the dust removal box is fixedly connected with a fan through a support, the dust removal box is provided with a first drawer, the first drawer is located below the fan, andsliding grooves matched with the first drawer are formed in the front left side wall and the rear left side wall of the dust removal box correspondingly; and a rectangular port is formed in the bottomof the first drawer, and a filter screen is fixedly connected in the rectangular port. According to the mute air exhaust port, dust generated in the sand making process is collected and filtered, sothat the air pollution is reduced, and the human health of workers is facilitated.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

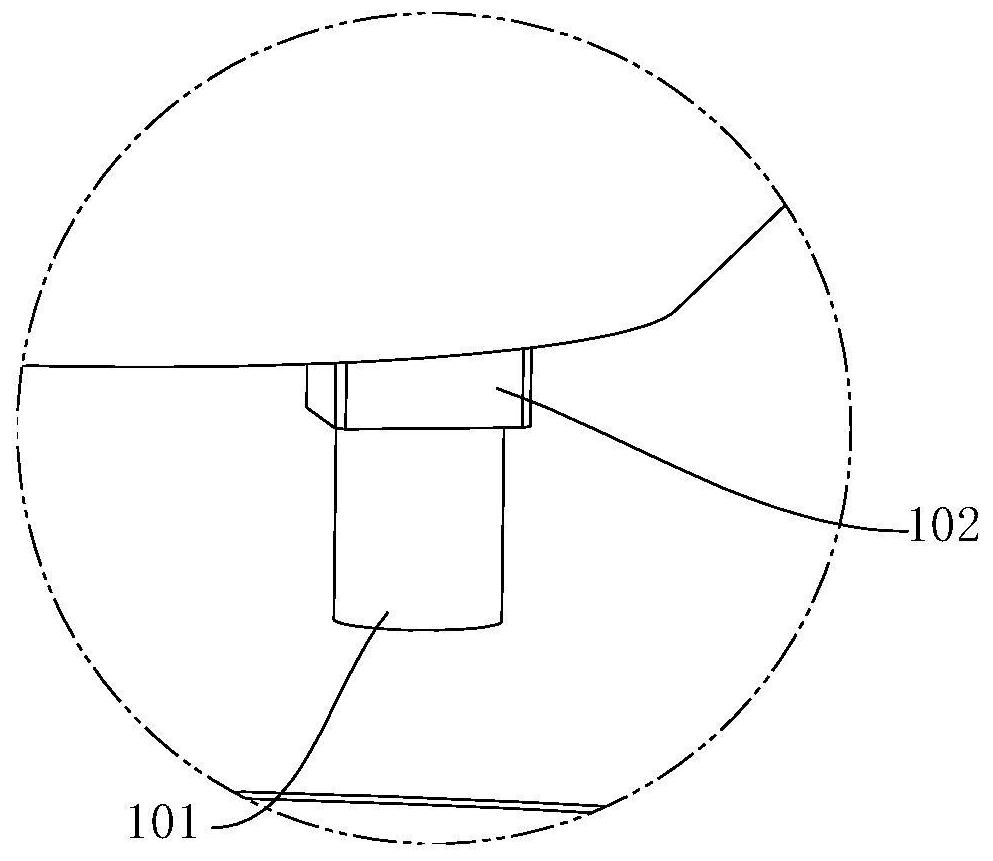

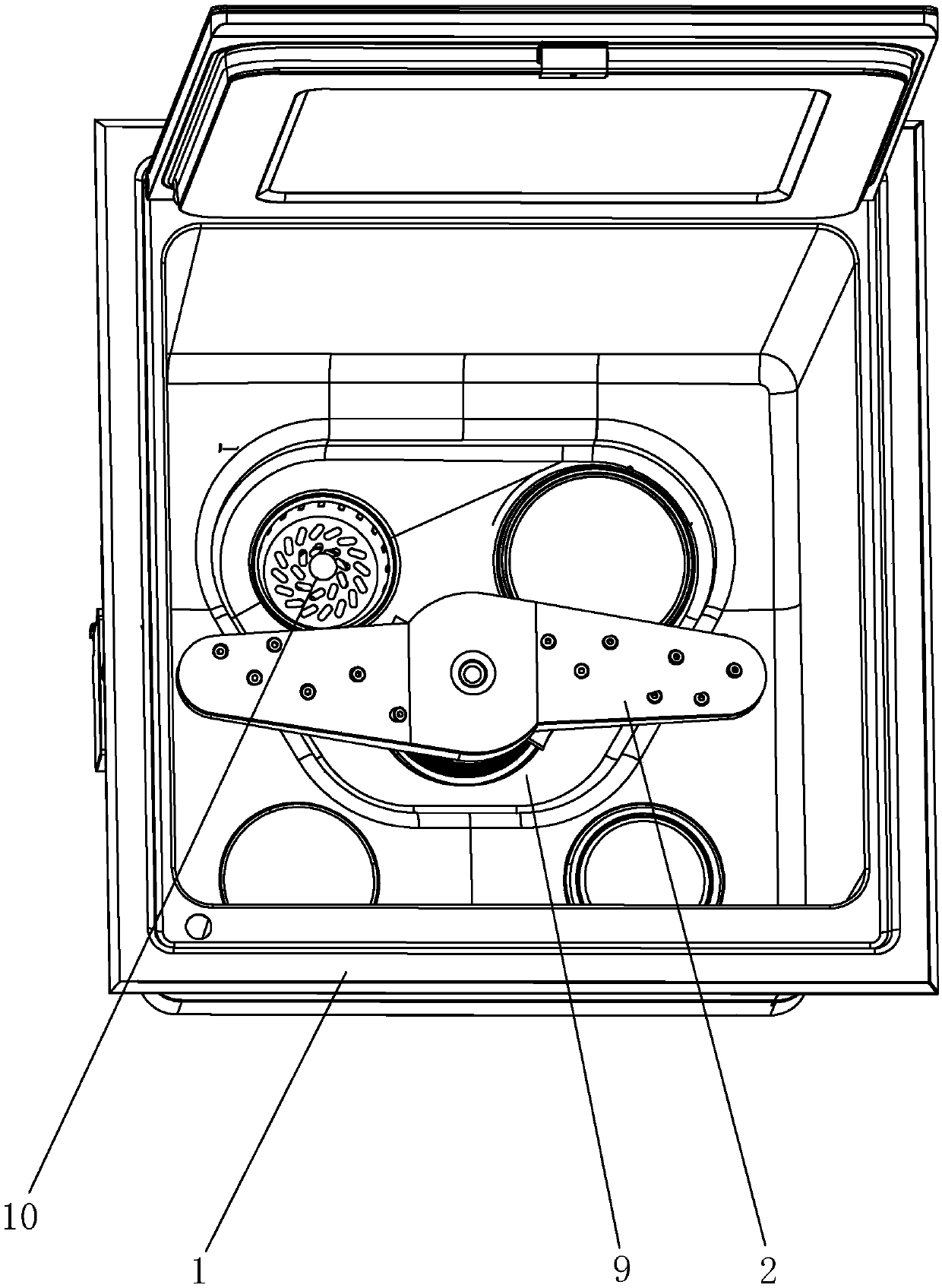

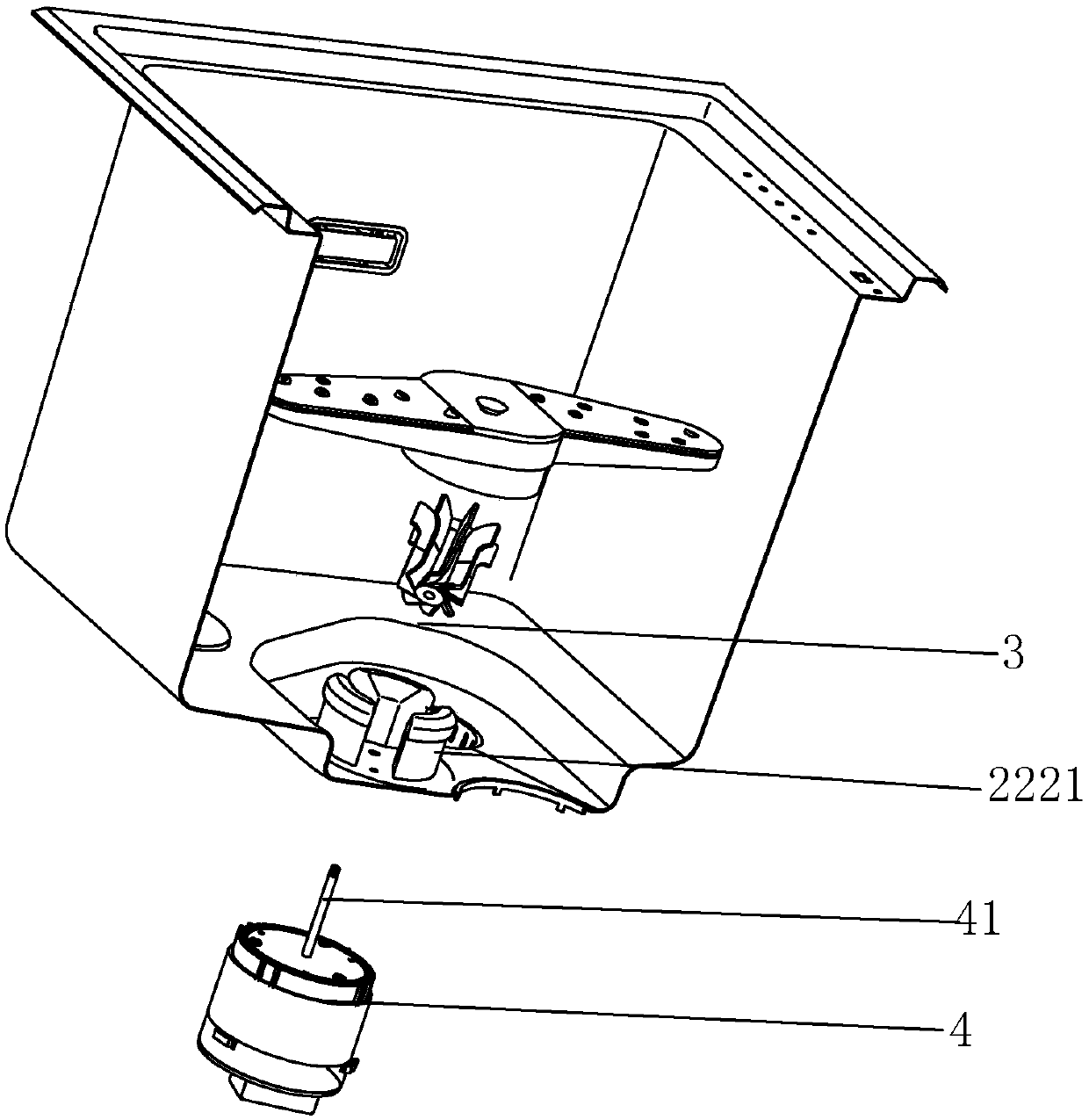

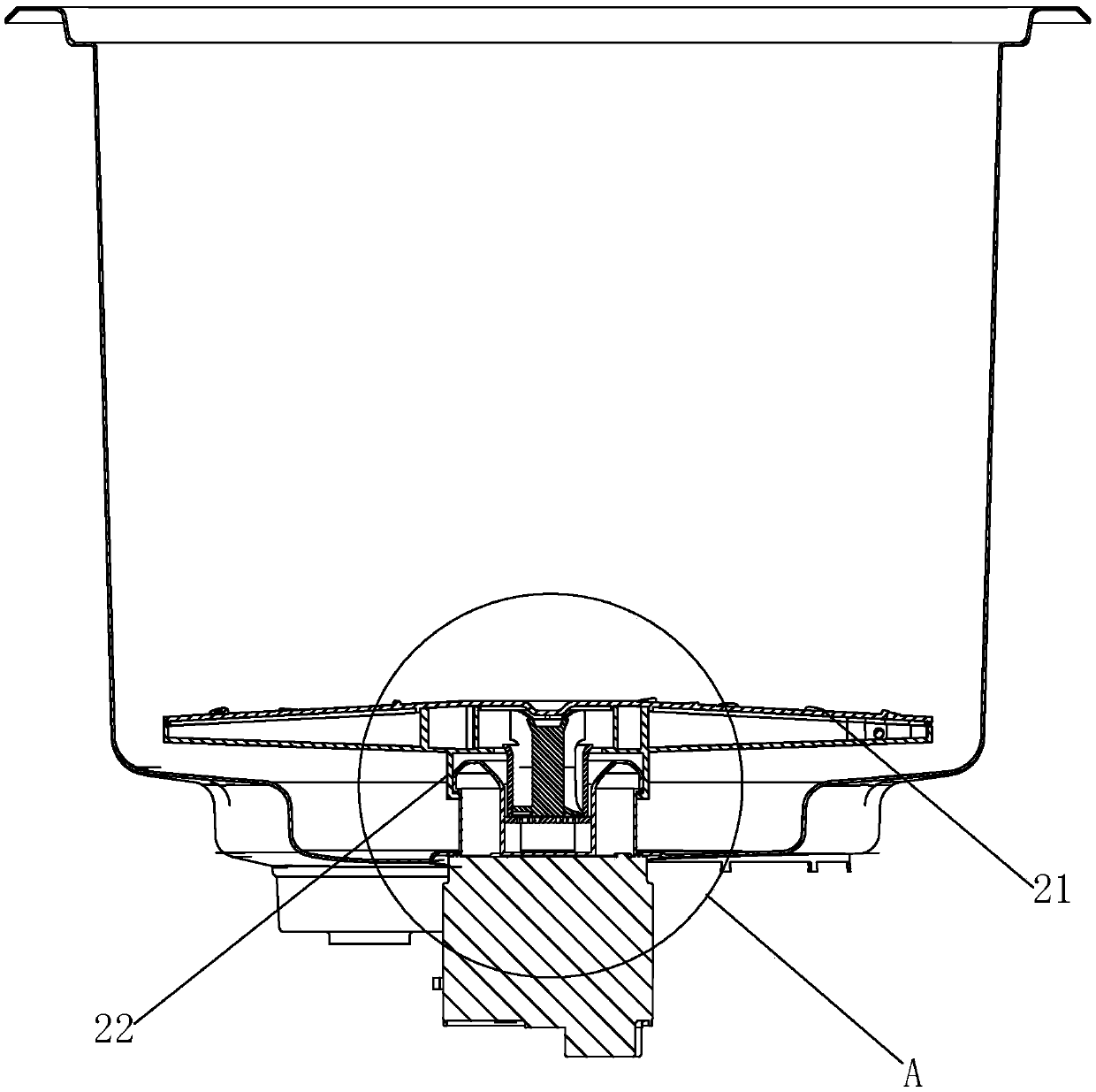

Spraying system and washing machine provided with same

PendingCN109549590AReduce manufacturing costEasy to disassemble and cleanTableware washing/rinsing machine detailsImpellerWater filter

The invention provides a spraying system. The spraying system comprises a spraying arm unit, a pump, and a pump power source for driving the pump to rotate, wherein the spraying arm unit comprises a spraying arm and a spraying arm support assembly supporting the spraying arm to rotate, the spraying arm is provided with water outlets, a mounting hole is formed in the bottom of the spraying arm, theupper section of the pump extends into a water outlet cavity, the pump comprises an impeller and blades, the spraying arm support assembly comprises a hollow sleeve arm downwards extending to the position close to the bottom of the impeller from the periphery of the mounting hole and having the draining effect, the sleeve arm surrounds the outside of the impeller, the spraying arm further comprises a water filtering screen mounted on the spraying arm support assembly, the sleeve arm forms a pump water drawing hole at the position corresponding to the bottom end of the impeller, the sleeve armforms the pump water drawing hole at the position corresponding to the bottom end of the impeller, and the water filtering screen covers the pump water drawing hole so that the water filtering screen, the sleeve arm and the spraying arm define a circular water draining area. For the spraying system, the number of the parts of the washing machine is reduced from the whole, the mounting and dismounting are convenient, and the manufacturing cost of the whole machine is reduced.

Owner:ZHEJIANG ZEPPELIN INTELLIGENT TECH CO LTD

Novel glass duster

ActiveCN105084782AAvoid defects susceptible to dustNo need for frequent cleaningAir compressorDistributor

The invention relates to a novel glass duster which solves the defects that an air compressor of an existing electrostatic jet duster is prone to block a filter and cause an alarm during a dusting process and the filter needs to be frequently cleaned and replaced and is troublesome to use. The lower part of a distributor is connected with a mildewproof isolating powder reserving part which is connected with an archwise bended jet channel, the jet channel is connected with a plant air supply system, the lower end of the reserving part is a dust outlet, and the dust outlet is formed in a bended outer side part of the jet channel; a dust jet opening is formed at the lower end of the jet channel, and a pressure regulating valve and a jet condensing dehumidifying part are arranged at the inlet of the jet channel. By virtue of the plant air supply system, a stable and long-term jet source which is not affected can be obtained so as to avoid the defect that the air compressor is liable to influence of dust, and therefore, the filter is not needed to be frequently cleaned and replaced; high-temperature gas in the jet channel is radiated to the reserving part through a jet channel wall so as to preheat the mildewproof isolating powder in the reserving part, so that the using effect of the mildewproof isolating powder is improved.

Owner:ZHANGZHOU KIBING GLASS +1

3D printing PVD mold and method thereof

InactiveCN110216815AImprove cooling effectIncrease productivityAdditive manufacturingIncreasing energy efficiencyHardnessVolumetric Mass Density

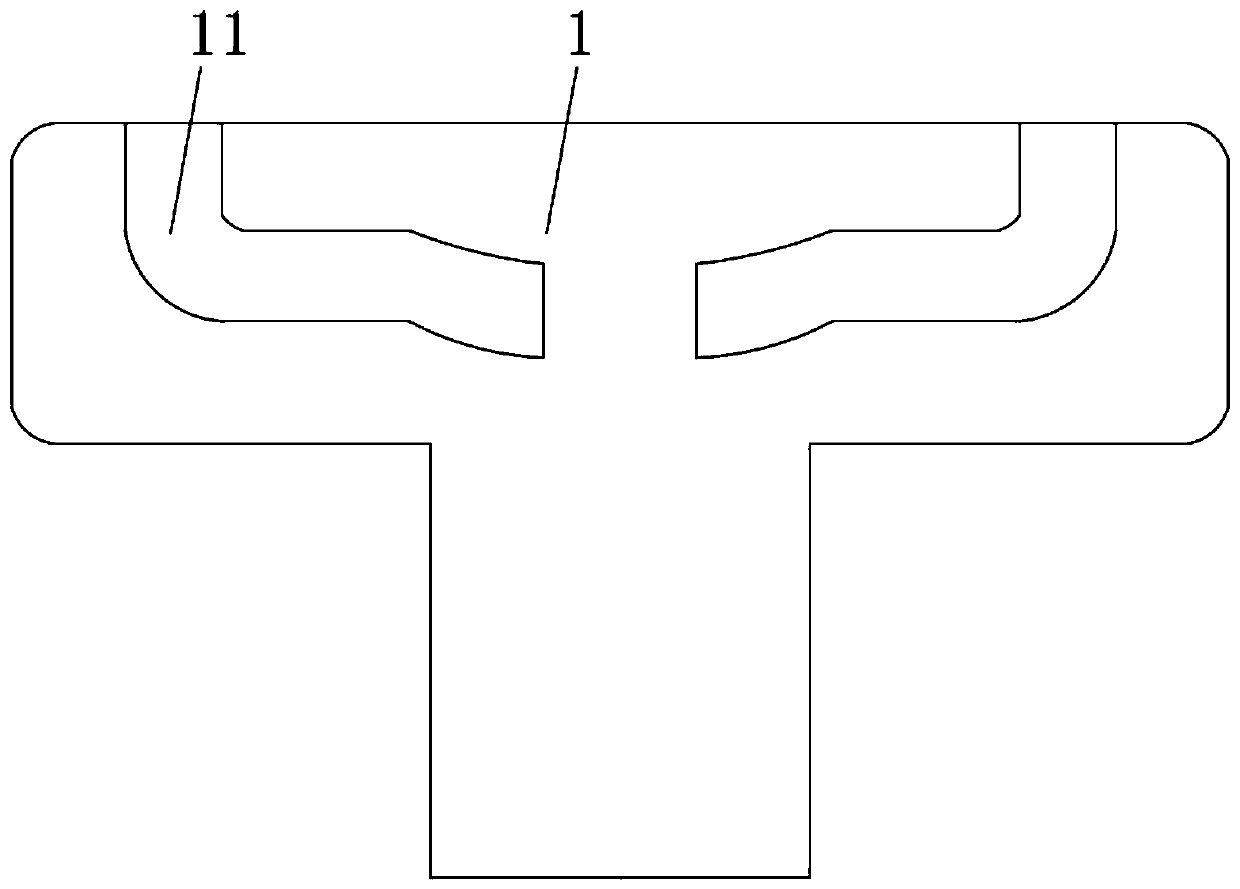

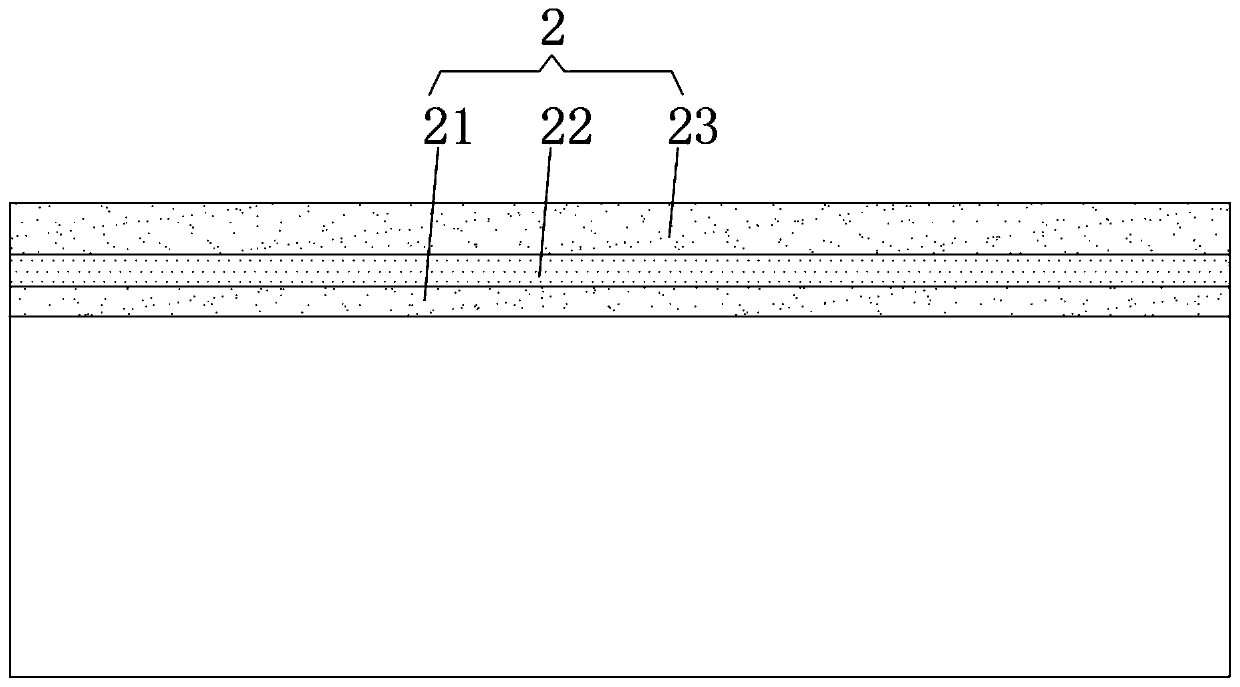

The invention discloses a 3D printing PVD mold, and relates to the technical field of 3D printing. The 3D printing PVD mold comprises a mold body, the mold body is T-shaped, the surfaces of the two sides of the mold body are provided with conformal water paths, and a coating is arranged on the surface of the mold body. The invention further discloses a printing method of the 3D printing PVD mold.The printing method comprises the following steps of A, establishing a model; B, carrying out additive manufacturing; C, polishing; D, carrying out surface treatment; and E, coating. According to the3D printing PVD mold, the changeable water paths can be designed according to the shape of the mold, the newest 3D printing technology is adopted instead of a conventional drilling process, the product can achieve the most effective cooling in a short time, the production efficiency is greatly improved, and the product cost is reduced; and the prepared mold is high in precision, low in roughness,high in density, higher in hardness than a forged piece, and the tensile strength is superior to that of a casting.

Owner:JIMEI UNIV

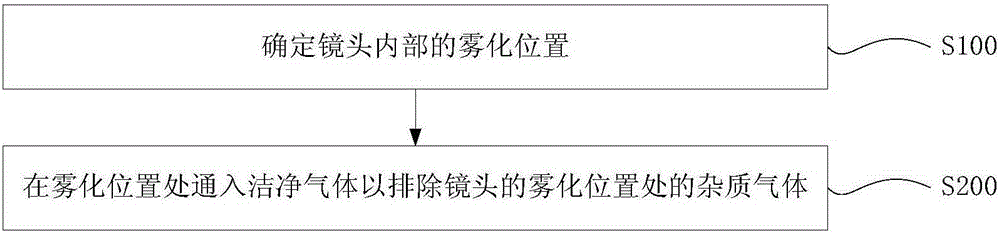

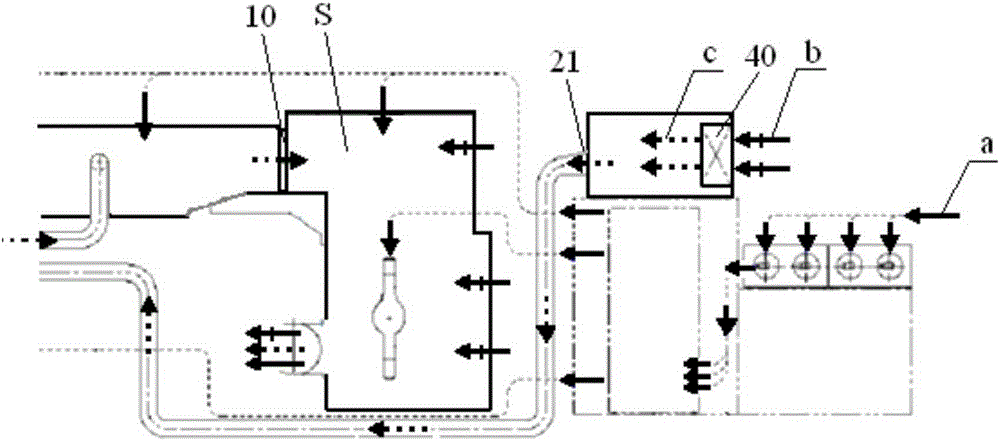

Method and device used for preventing inner part of camera lens from atomization

ActiveCN105223786AHigh transparencyNo frequent replacementPhotomechanical exposure apparatusMicrolithography exposure apparatusCamera lensComputer science

The invention discloses a method and a device used for preventing an inner part of a camera lens from atomization. The method comprises the following steps: determining an atomization position of the inner part of the camera lens; and introducing clean gas into the atomization position to remove impure gas at the atomization position of the camera lens. With the adoption of the method and device used for preventing the inner part of the camera lens from atomization, the transparency of the camera lens is effectively improved so that the camera lens does not need to be usually replaced, cleaned and maintained; and on the one hand, the productivity in a photoetching production process is improved, and on the other hand, the service life of the camera lens can be prolonged and the production cost is greatly reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

An environmentally friendly, water-saving and non-cleaning secondary water supply tank

ActiveCN108130936BPrevent fallingGuaranteed to workHollow article cleaningMagnetic separationWater useWater saving

The invention discloses a water-saving secondary water supply box free of cleaning. The water-saving secondary water supply box comprises a water supply box body, multiple pulling plate holes are formed in the two side walls of the water supply box body, filtering plates penetrate into the water supply box body through the pulling plate holes, pulling plates are fixed to the outer side ends of thefiltering plates, the tops of clapboards are fixed to the tops inside the water supply box body, buffering plates are arranged below diversion plates, a base platform is arranged in the center of thebottom inside the water supply box body, a water outlet pipe penetrates through the center of the base platform, a water filtering tank is arranged at the junction of the base platform and the buffering plates, the base platform is internally provided with an equipment cavity, an equipment cavity vibrator, electromagnets and an accumulator, wherein the accumulator is electrically connected with solar panels, the solar panels are aslant fixed to the top of the water supply box body, an overhauling opening is formed in the center of the top of the water supply box body, and water inlet pipes are arranged at the outer sides of panel supports, and enter the water supply box body through water inlets. By means of the water-saving secondary water supply box free of cleaning, the filtering plates and the electromagnets are utilized for attraction, the cleanliness of the water supply box is improved, the cost for manual cleaning is reduced, water is saved, and multiple effects of protecting the environment, saving energy and cleaning the water supply box are achieved.

Owner:苏州斯尔斯特新材料科技有限公司

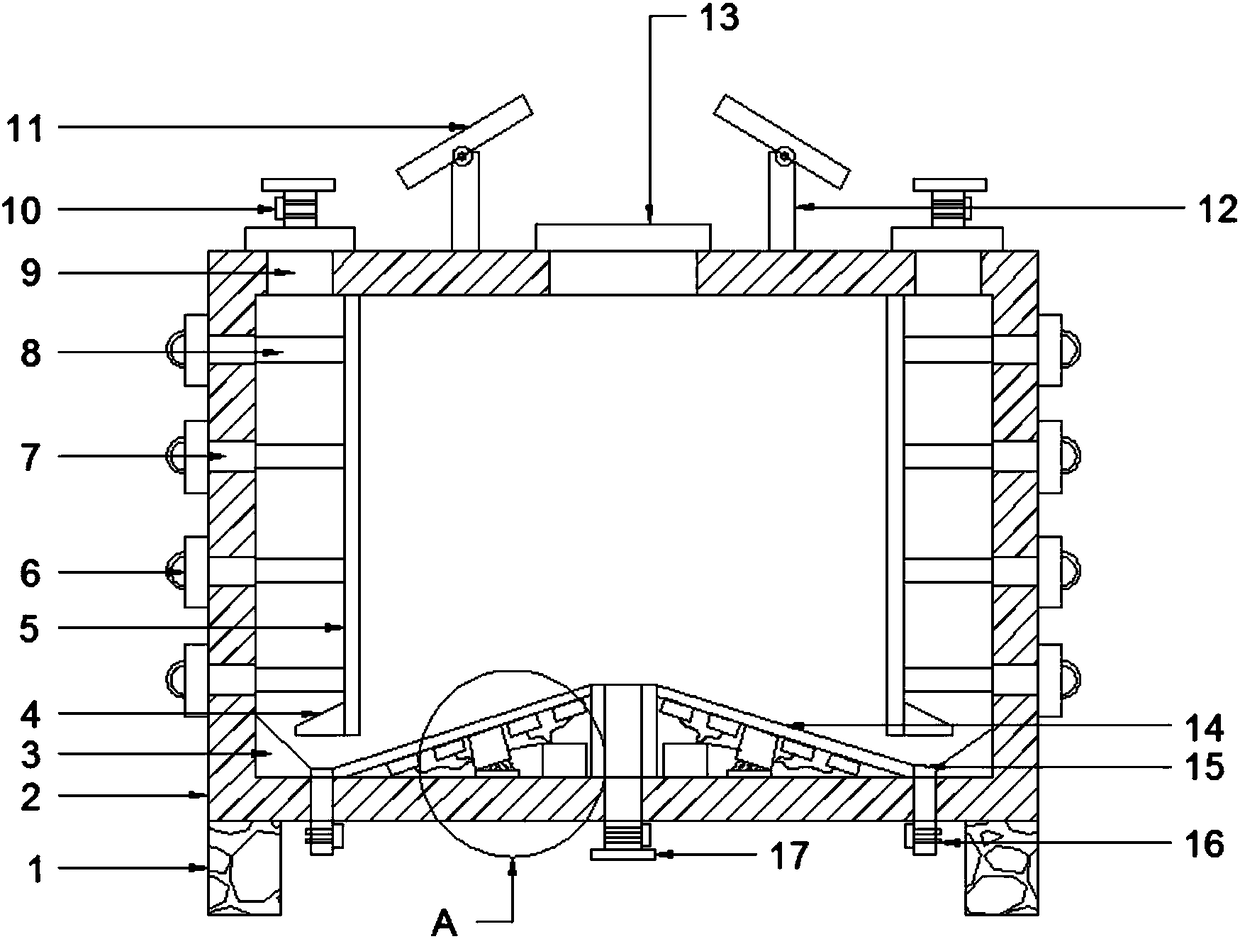

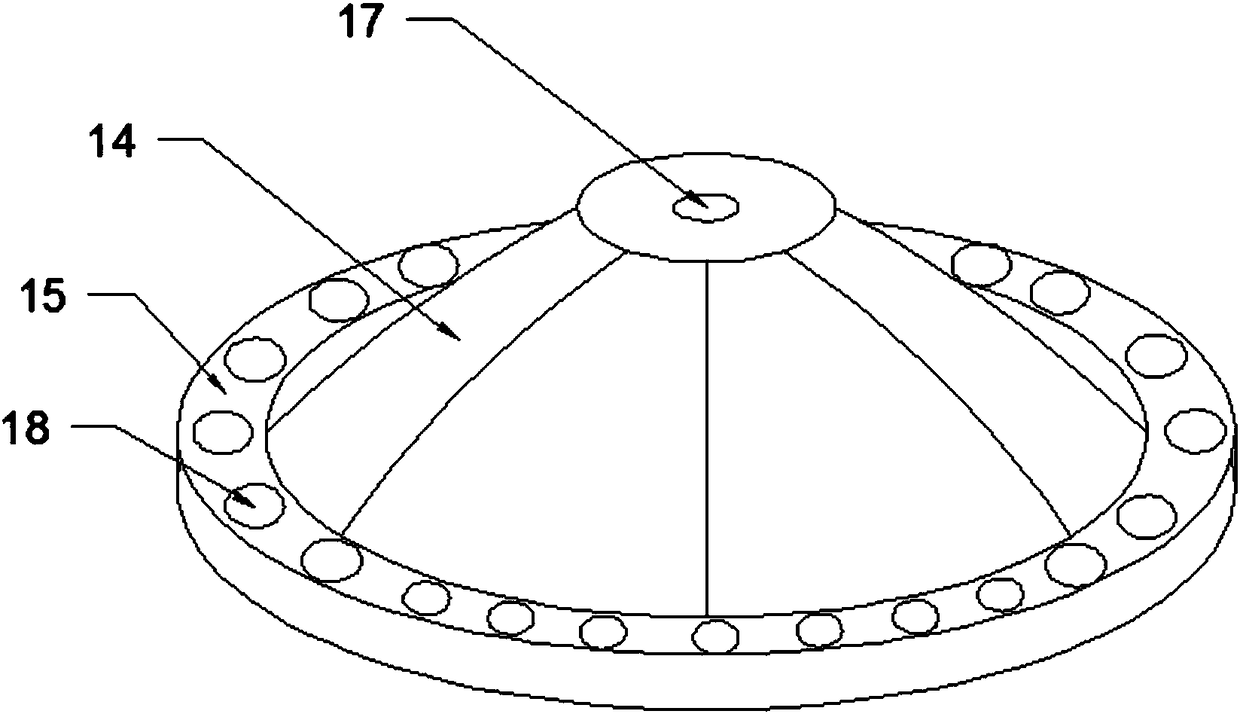

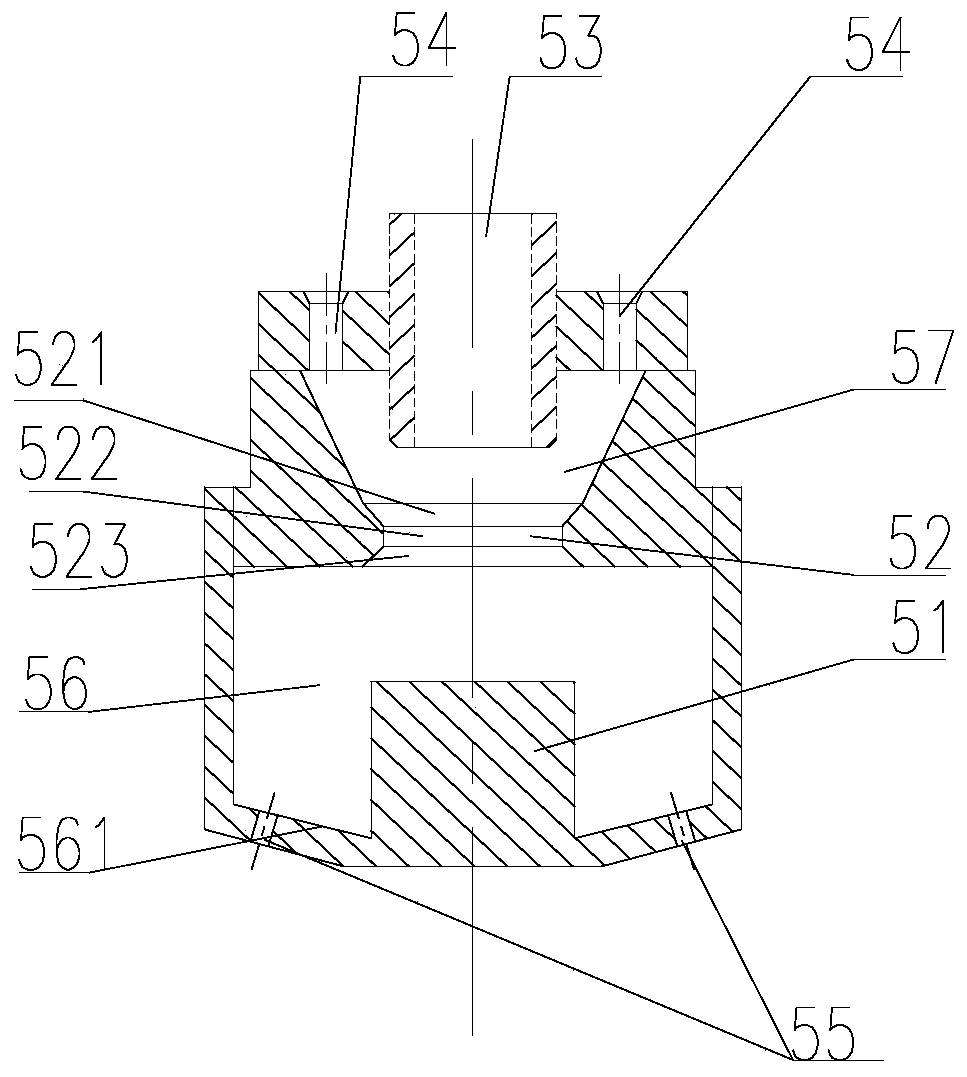

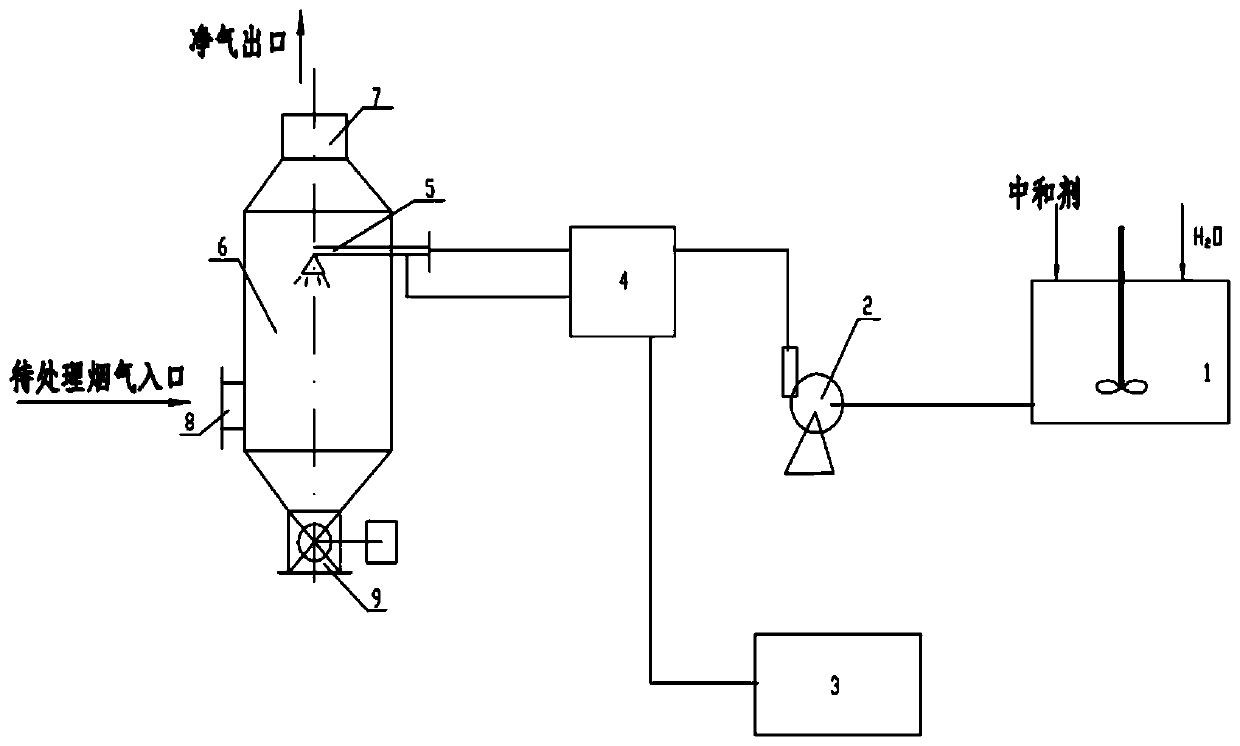

Two-phase flow semi-dry deacidification device for flue gas

InactiveCN110237691ALarge specific surface areaIncreases the chance of a contact reactionGas treatmentDispersed particle separationPollutantFlue gas

The invention provides a two-phase flow semi-dry deacidification device for flue gas. The device comprises a reaction tower, a spray gun unit arranged in the reaction tower, a compressed gas supply unit, a neutralizer supply unit and a control unit; and the interior of the spray gun unit is provided with a multi-stage atomization structure for atomizing and spraying a neutralizing agent entering the spray gun unit and deacidifying the flue gas in the reaction tower. According to the device provided by the invention, through a specific spray gun capable of realizing multi-stage atomization, the liquid neutralizing agent can be subjected to atomization for multiple times to form fine particles with an average particle diameter of 30-100 [mu]m, so that the specific surface area of the neutralizing agent is greatly increased, the chance of a contact reaction of the neutralizing agent and pollutants in the flue gas is greatly increased, and the purpose of removing the acidic pollutants in the flue gas is achieved; at the same time, the liquid neutralizing agent and water are atomized to form the fine particles, so that reduction of a temperature of the flue gas and full dry operation of the reaction tower are facilitated; and the device does not produce wastewater, and does not need to be cleaned frequently, thereby greatly reducing the investment and running costs.

Owner:彭馨

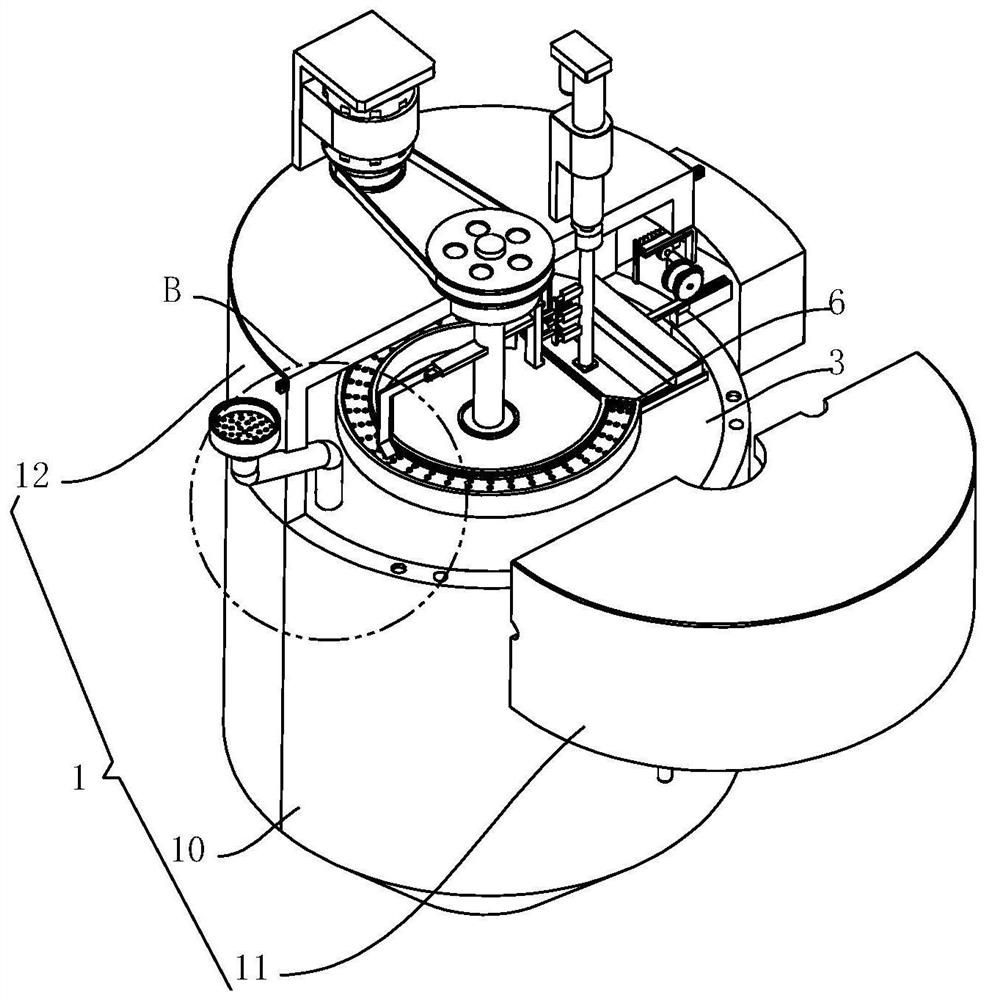

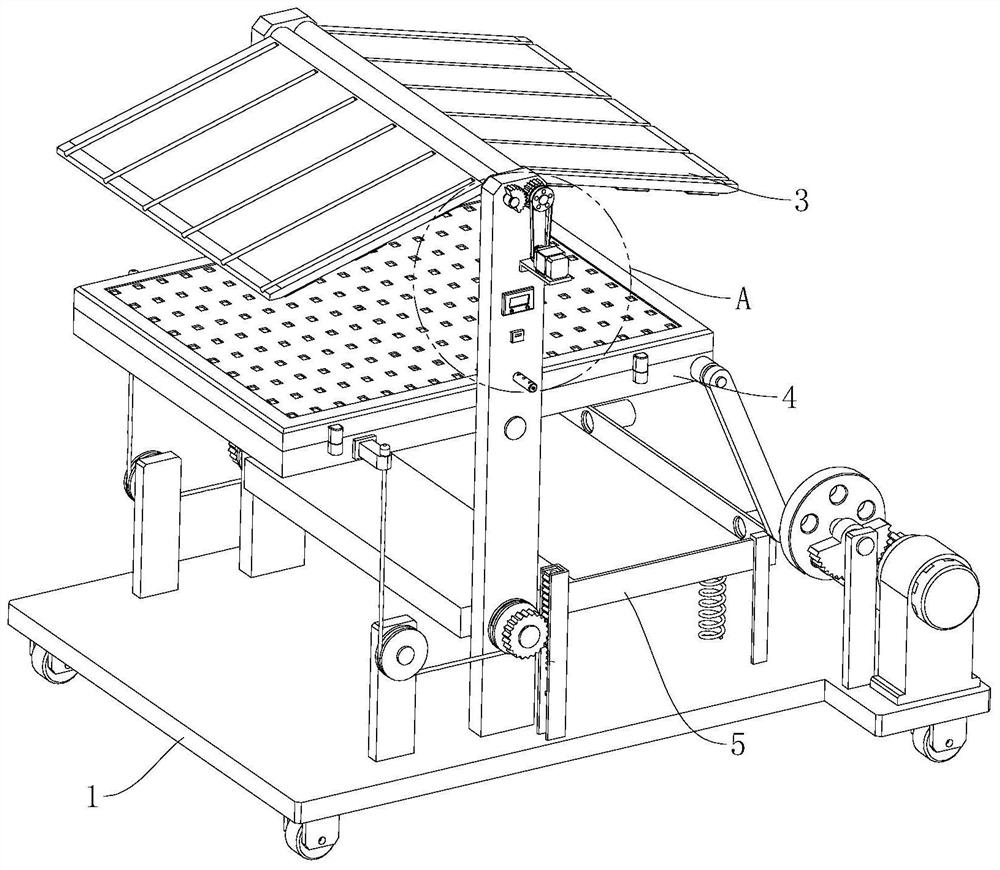

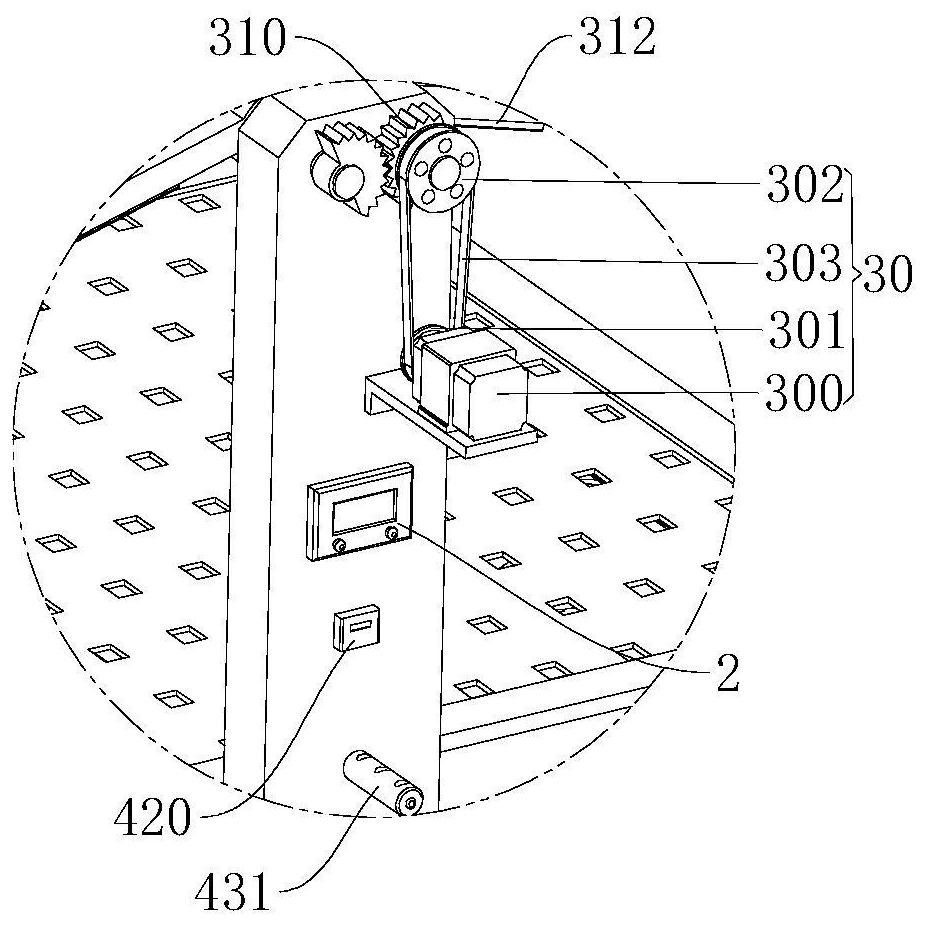

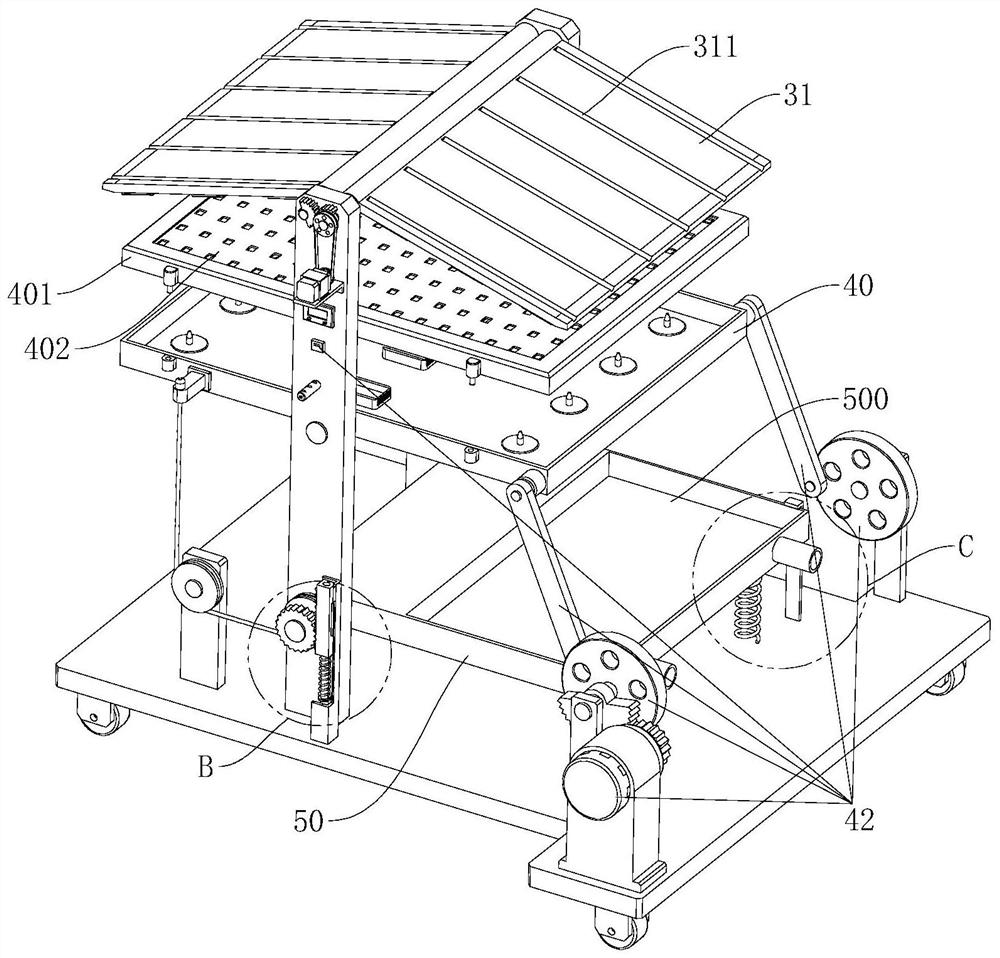

Aquatic product airing equipment

InactiveCN112400971AFully and evenly dryDry evenlyAnimal repellantsCleaning using liquidsAquatic productEnvironmental engineering

The invention relates to the technical field of aquatic product processing, in particular to aquatic product airing equipment. The equipment comprises a base and four universal wheels and further comprises a controller, a rainproof mechanism, an airing mechanism and a drainage mechanism, the airing mechanism comprises an airing disc, a placing assembly, an angle adjusting assembly and two verticalplates, the rainproof mechanism comprises a driving assembly and two baffles, the drainage mechanism comprises an adjusting plate, two traction assemblies and two limiting assemblies, the two limiting assemblies are symmetrically arranged at the end, away from the vertical plates, of the adjusting plate, the airing disc is located between the adjusting plate and the two baffles, and the angle adjusting assembly and the driving assembly are electrically connected with the controller. The aquatic product airing equipment has good drainage effect and better insect expelling effect, and no pollution is caused. Meanwhile, the airing angle can be automatically adjusted according to the illumination intensity, water such as grease generated during airing can be discharged in time, and taking isconvenient after airing.

Owner:李明磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com