Aquatic ink temperature controller in gravure printing machine using aquatic ink

A gravure printing machine, using water-based technology, used in gravure rotary printing machines, general parts of printing machinery, printing machines, etc., can solve problems such as poor printing

Active Publication Date: 2010-10-06

FUJI TOKUSHU SHIGYO

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] As a means to solve the above-mentioned poor printing problem, in the above-mentioned patent document 1, a heat exchanger is directly installed at the bottom of the ink pool, the heat medium generated by the heat source machine is circulated in the heat exchanger, and the temperature of the water-based ink in the ink pool is controlled. adjust

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

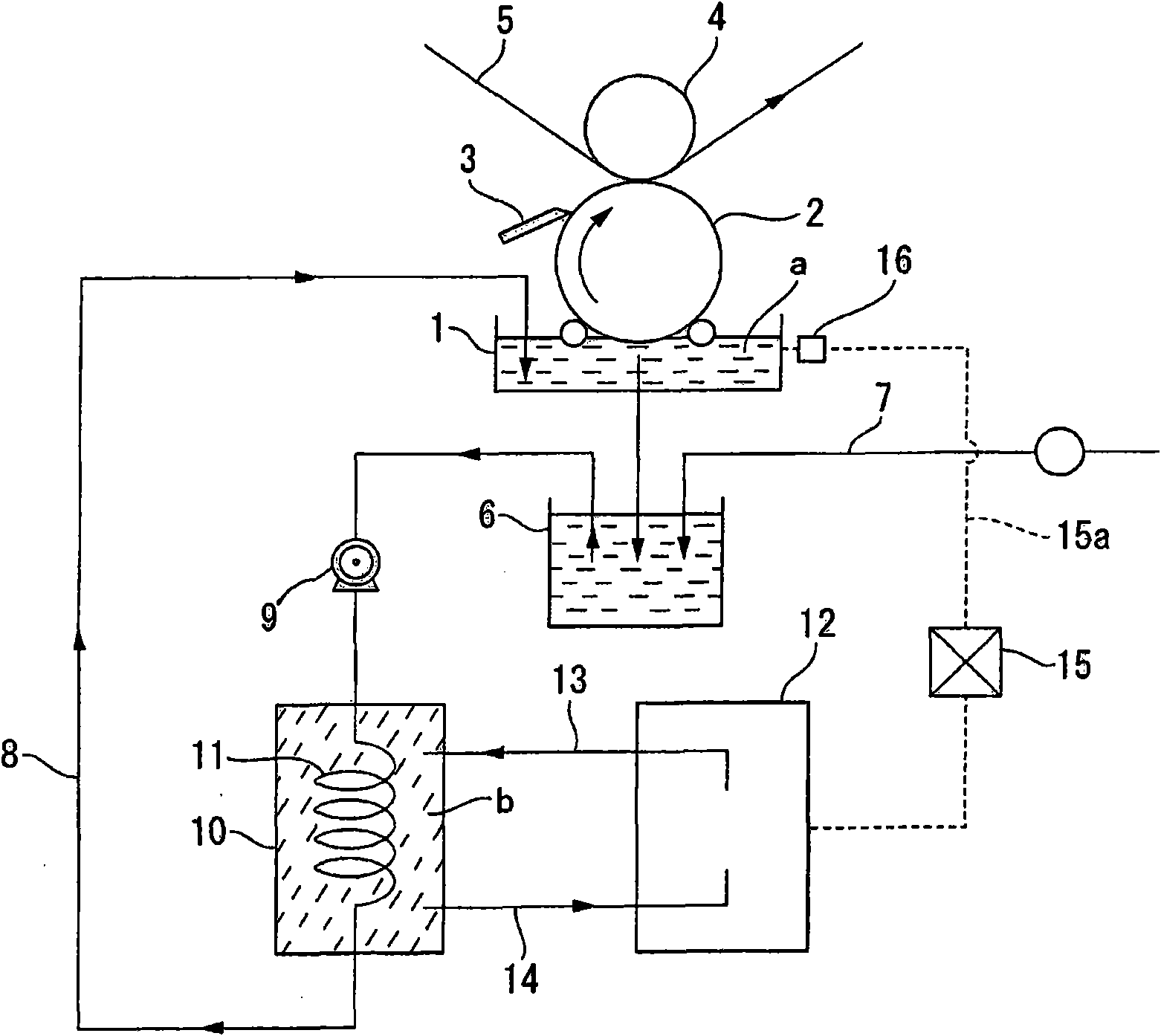

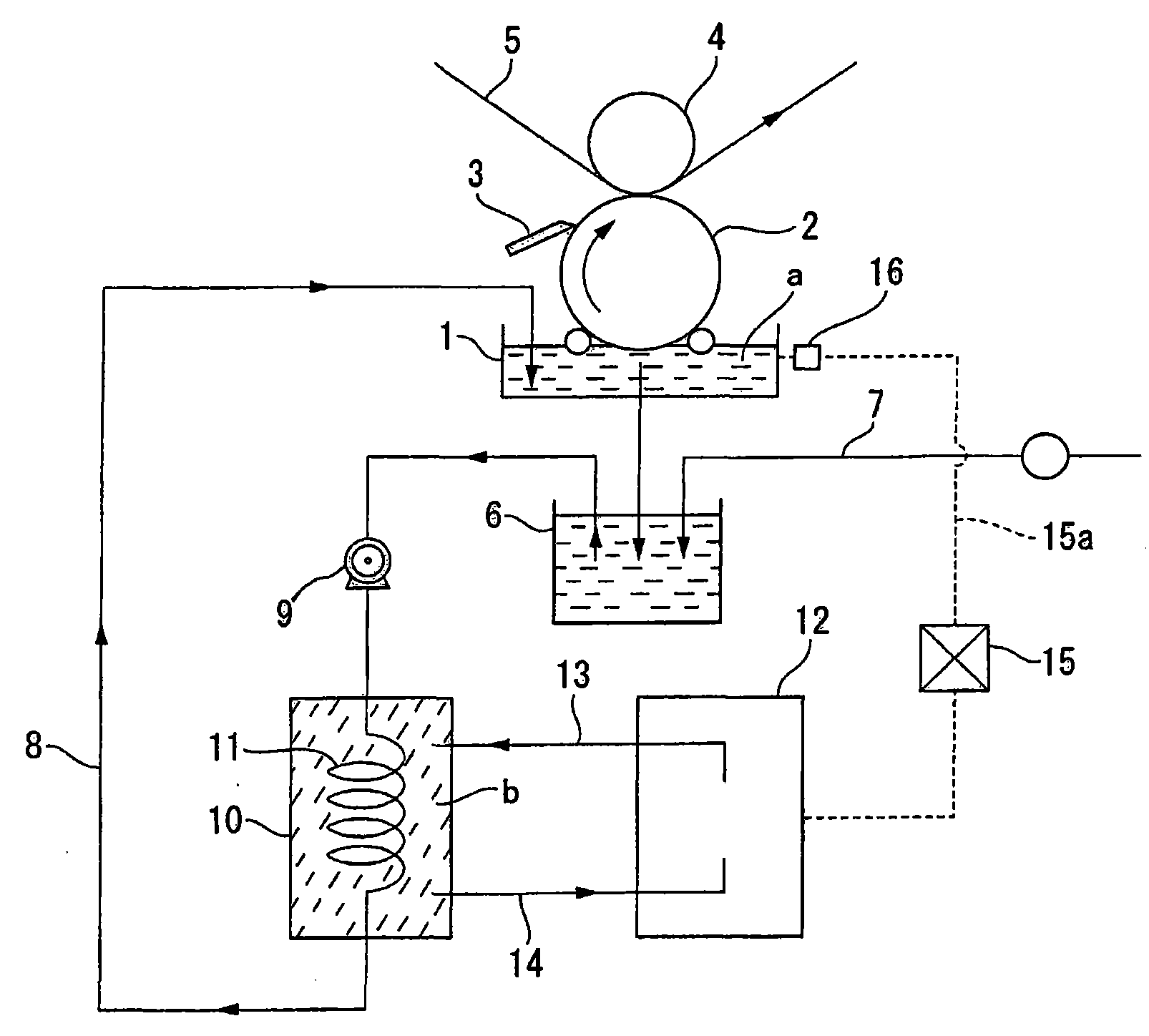

[0033] according to figure 1 The present invention described in the first aspect of the present invention will be described in detail.

[0034] figure 1 Among them, reference numeral 1 is an ink pool, 2 is a cylinder, 3 is a doctor blade, 4 is a cylinder, and 5 is a film to be printed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides an aquatic ink temperature controller in a gravure printing machine using the aquatic ink which can prevent photographic fog phenomenon owing to season. A heat exchanger (10) is installed in a temperature adjustment printing ink circulation loop (8) for maintaining the temperature of the aquatic ink in an ink tank (1) between 15-28 DEG C at which photographic fog is avoided. A control circuit (15) performs a feedback control for the driving of a heat source machine (12) according to signals from a sensor (16), so that the heat exchanger (10) makes the temperature of the aquatic ink in the oil tank (1) be 15-28 DEG C.

Description

technical field [0001] The invention relates to a water-based ink temperature regulating device in a gravure printing machine using water-based ink. Background technique [0002] In a gravure printing machine, the use of water-based ink is extremely effective in terms of environmental measures and improvement of the printing work environment compared with the use of oil-based ink. No. 11-250423, Japanese Patent Application No. 2000-141712, and Japanese Patent Application No. 2000-106154 are inventions for practical application. [0003] In addition, in the case of water-based ink, the temperature of the ink used has a significant impact on the completion of printing, so the applicant of the present invention has proposed to adjust the temperature of the ink to 15°C to 28°C for printing (Japanese Patent Application No. 2002-086886 ). [0004] That is, the temperature of the water-based ink fluctuates greatly due to temperature changes between summer and winter. For example...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B41F31/02B41F9/06

CPCB41F13/187B41F31/002B41F31/02B41F31/06B41M1/10

Inventor 中屋克己金藤茂树

Owner FUJI TOKUSHU SHIGYO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com