Method and apparatus to promote non-stationary flame

a non-stationary flame and flame retardant technology, applied in lighting and heating apparatus, combustion types, combustion using lumps and pulverulent fuels, etc., can solve problems such as damage to enclosures, excessive oxidation of materials, and inability to achieve optimal arrangement, etc., to achieve uniform temperature of material surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

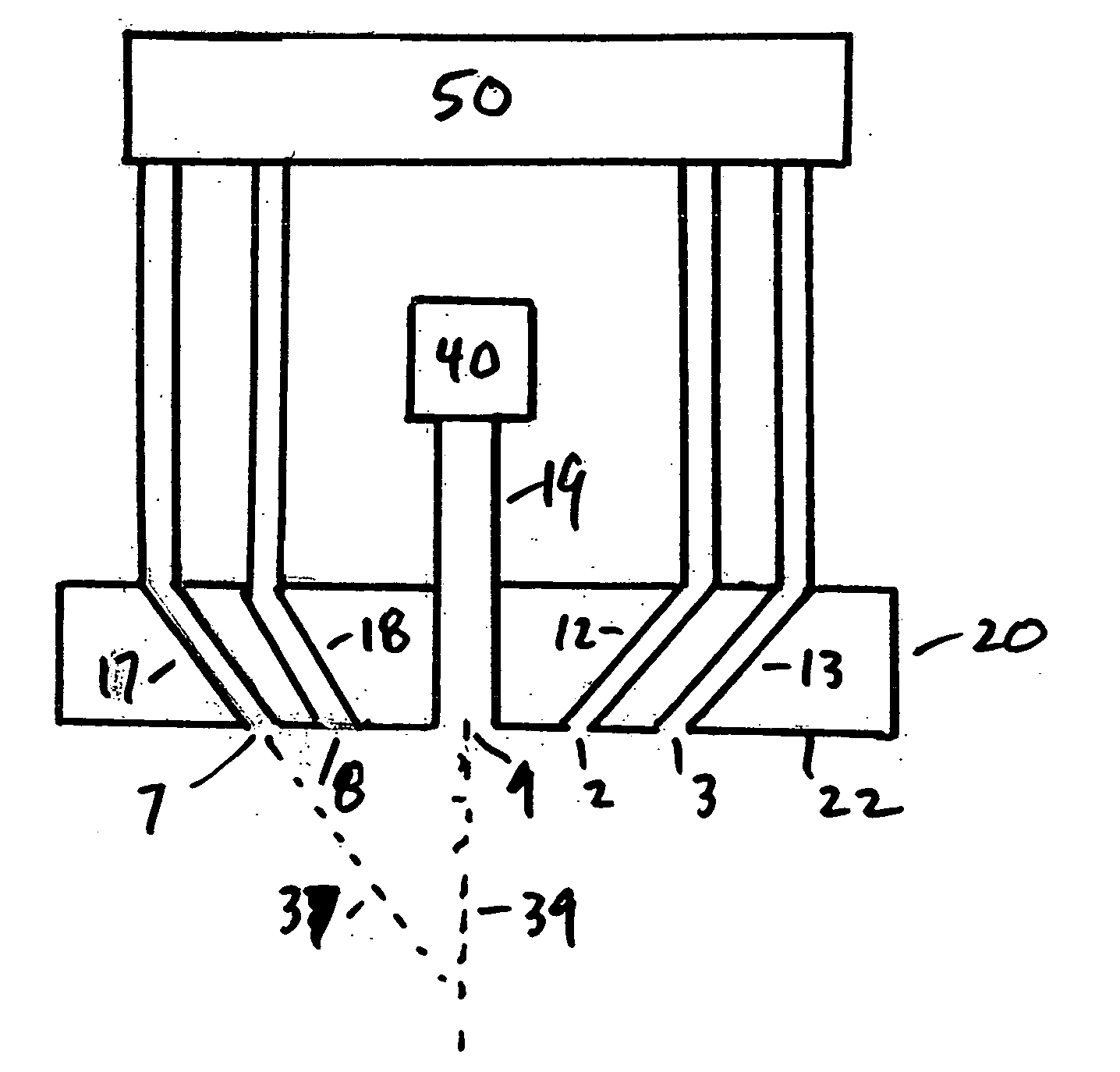

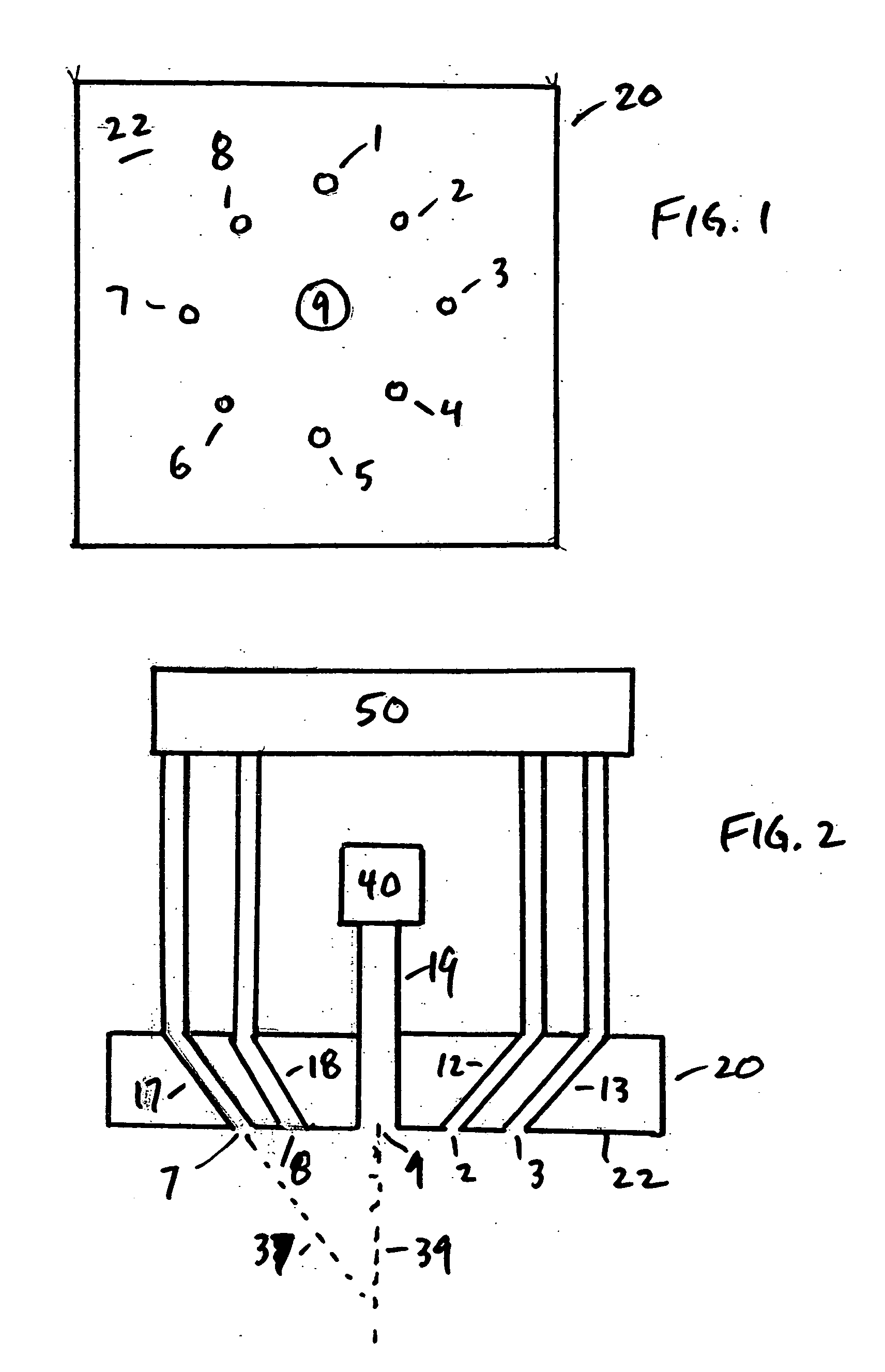

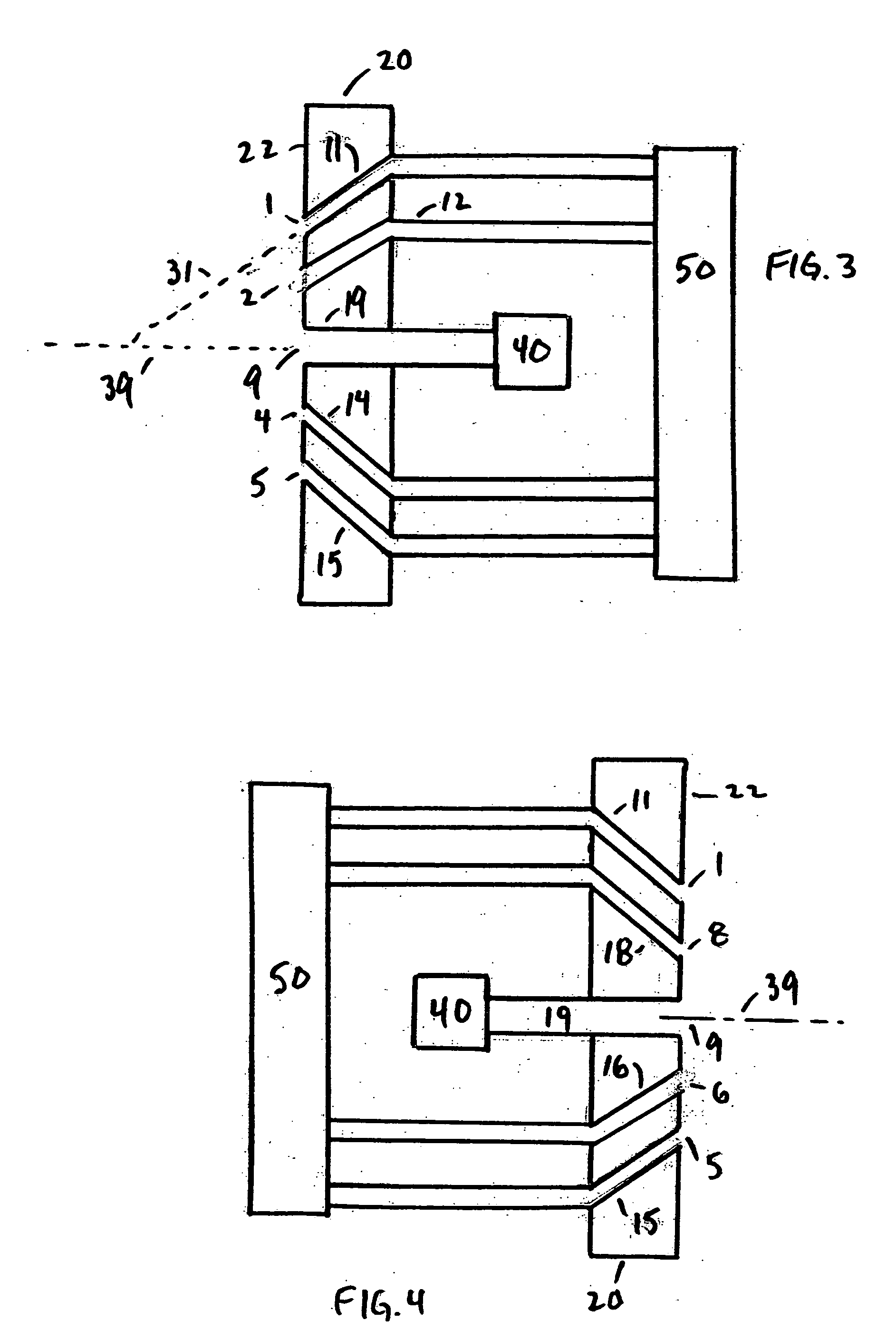

[0041] The burner according to the present invention is generally referred to as 20 in FIGS. 1-4. Burner 20 is preferably formed of refractory material that is capable of retaining its shape and composition when exposed to the temperatures of 1000° F. to 3000° F. to which the burner may be exposed. Examples of such materials include alumina, silica, AZS (alumina-zirconia-silica), mullite, zirconia, and zirconite. Burner 20 can be part of a roof, side wall or bottom of an enclosure such as a furnace in which the desired combustion is carried out.

[0042] Central feed port 9 and outer ports 1 through 8 open in the front 22 of burner 20. Central feed port 9 and the outer ports may be, but are not required to be, in the same plane, so long as the other characteristics described herein are observed. Central feed port 9 can comprise one opening as shown in FIG. 1, or can comprise two or more openings (preferably 1 to 8, more preferably 1 to 3) openings which should be located close to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com