Patents

Literature

613 results about "Heat of combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The heating value (or energy value or calorific value) of a substance, usually a fuel or food (see food energy), is the amount of heat released during the combustion of a specified amount of it. The calorific value is the total energy released as heat when a substance undergoes complete combustion with oxygen under standard conditions. The chemical reaction is typically a hydrocarbon or other organic molecule reacting with oxygen to form carbon dioxide and water and release heat.

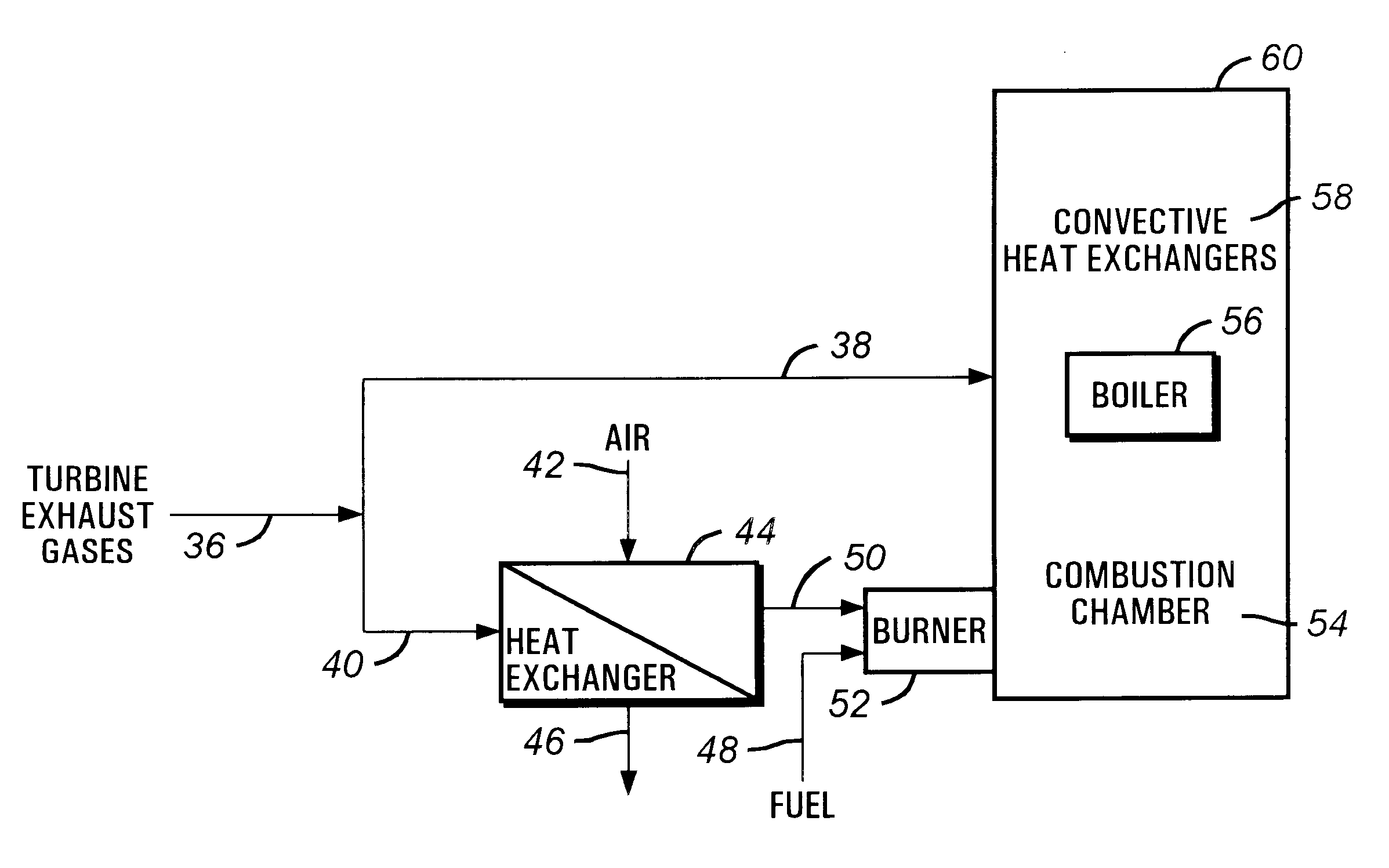

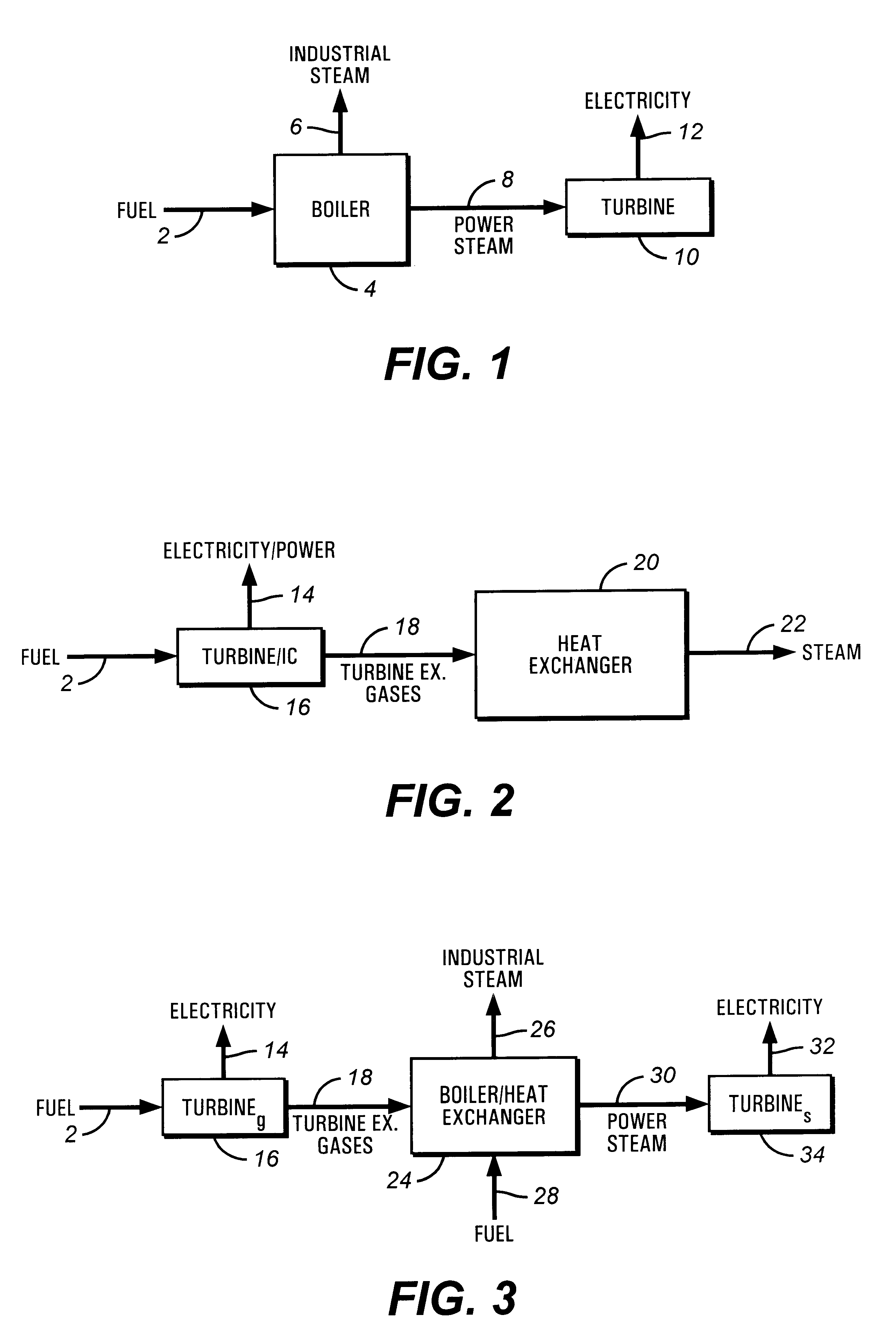

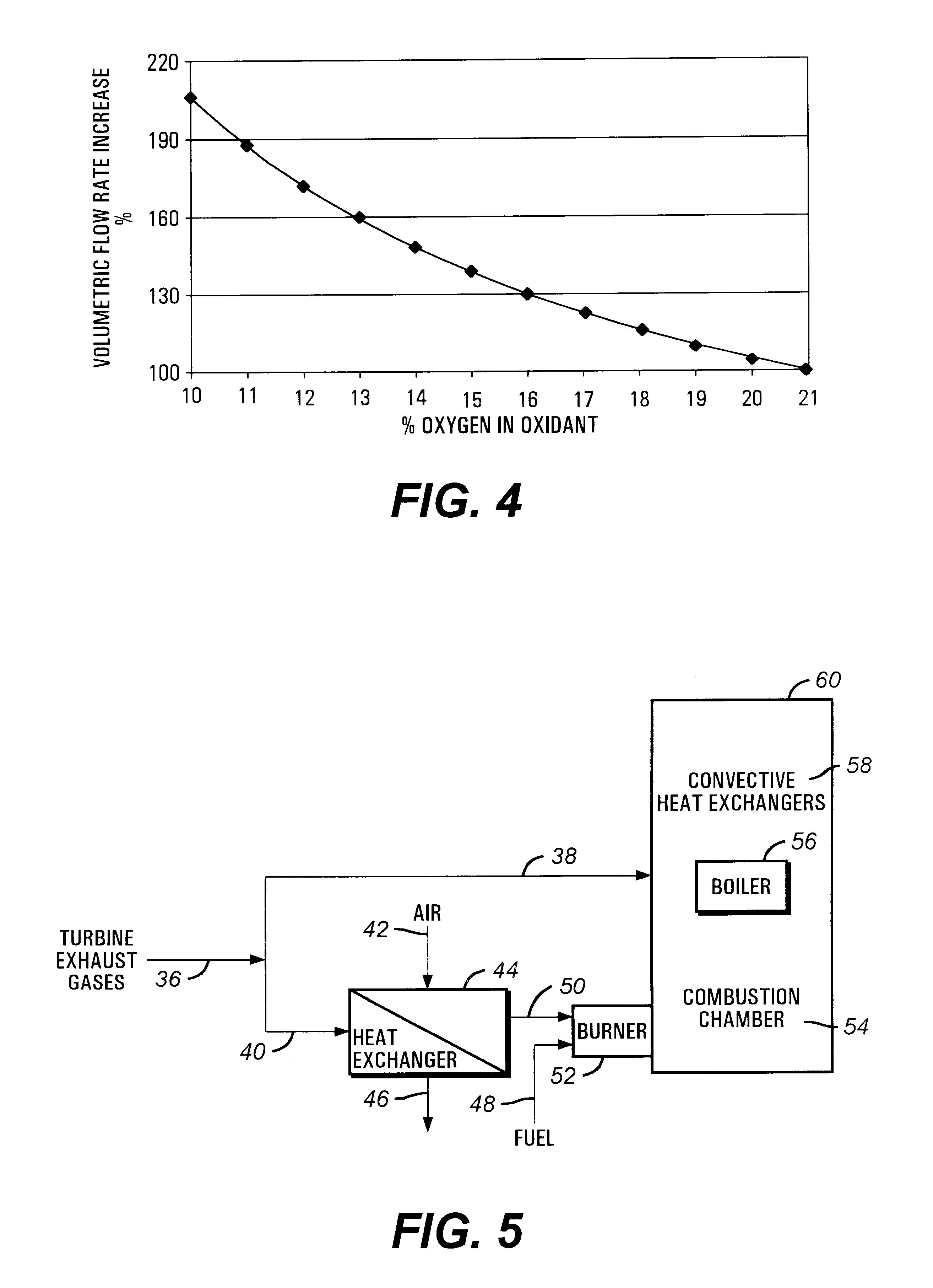

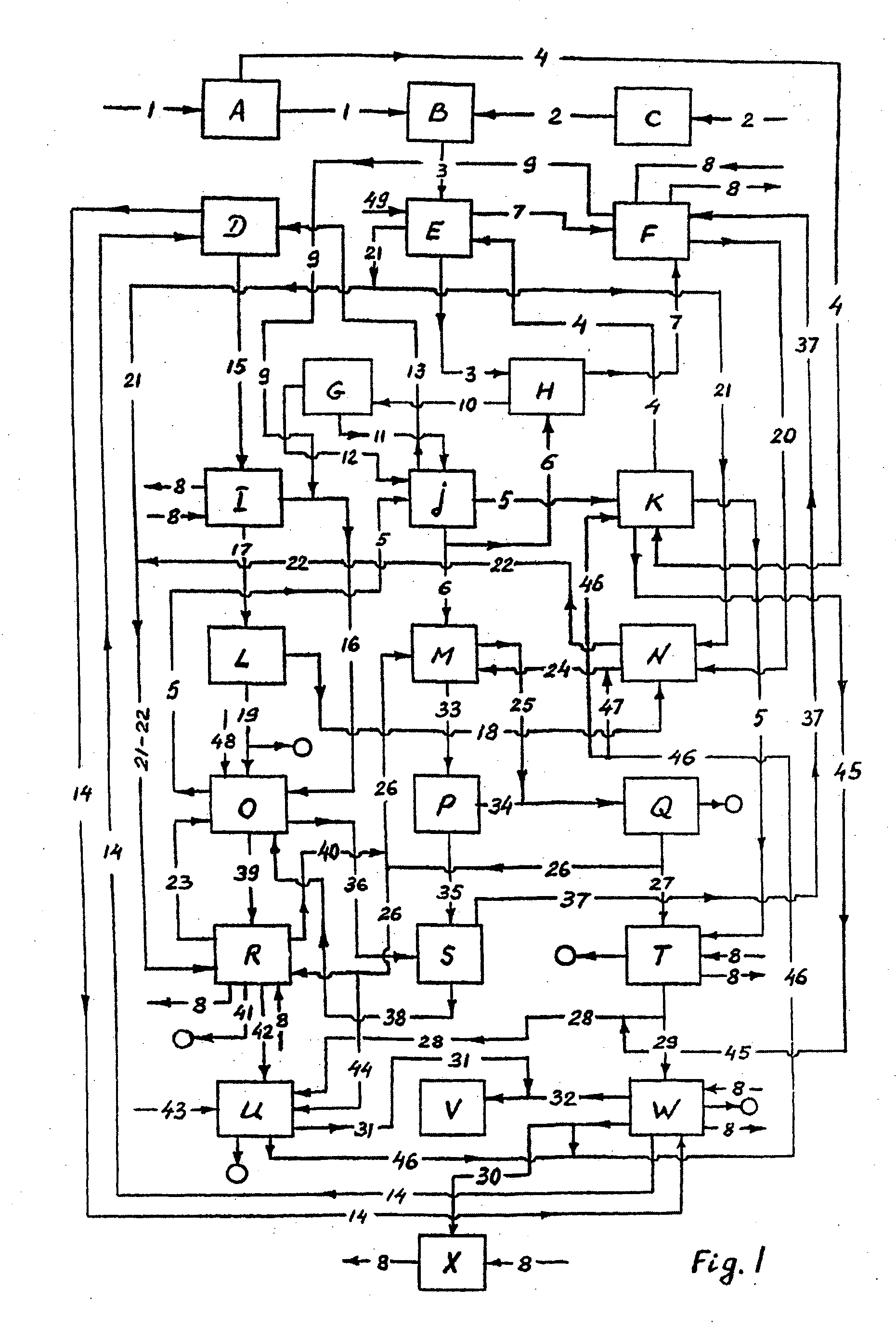

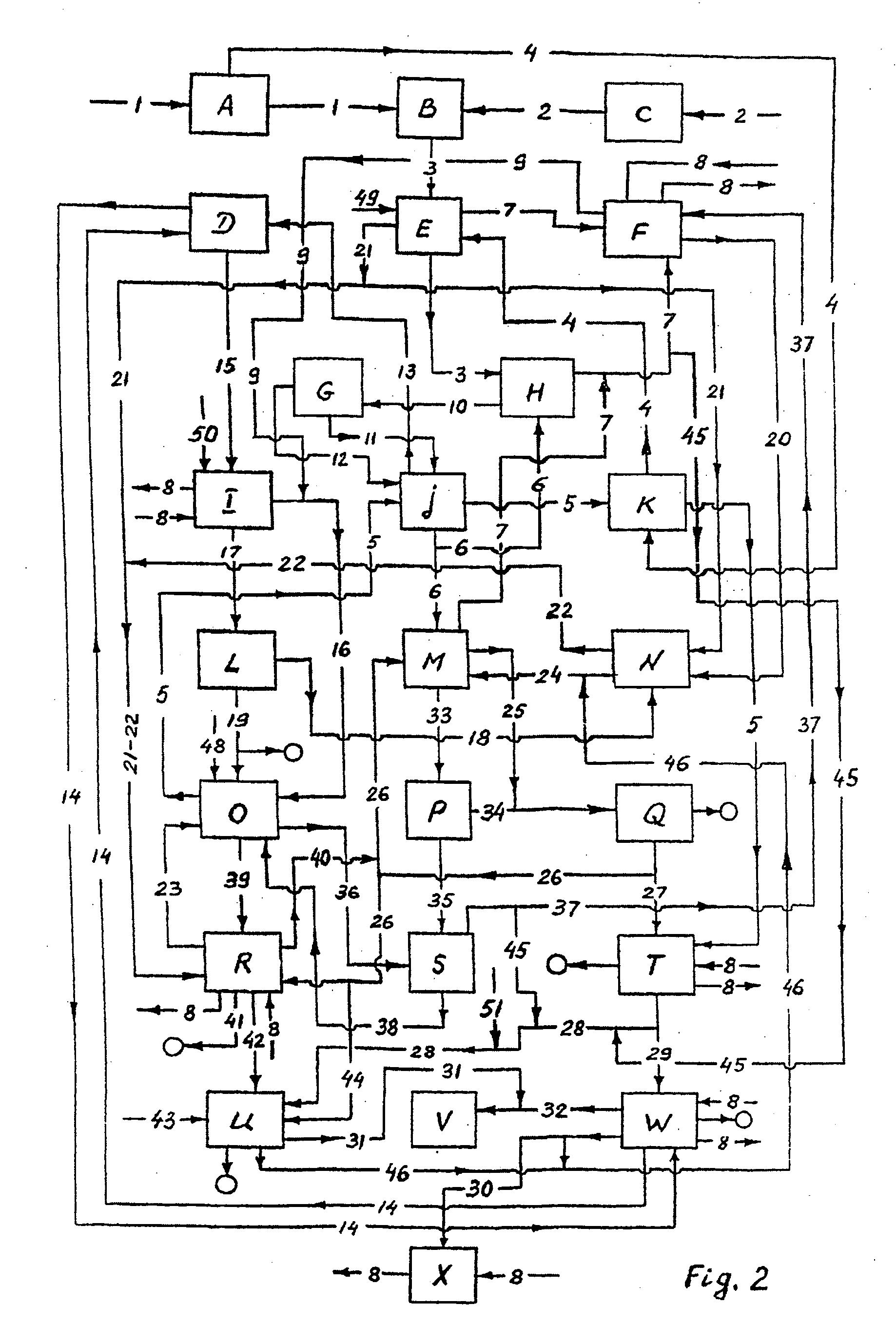

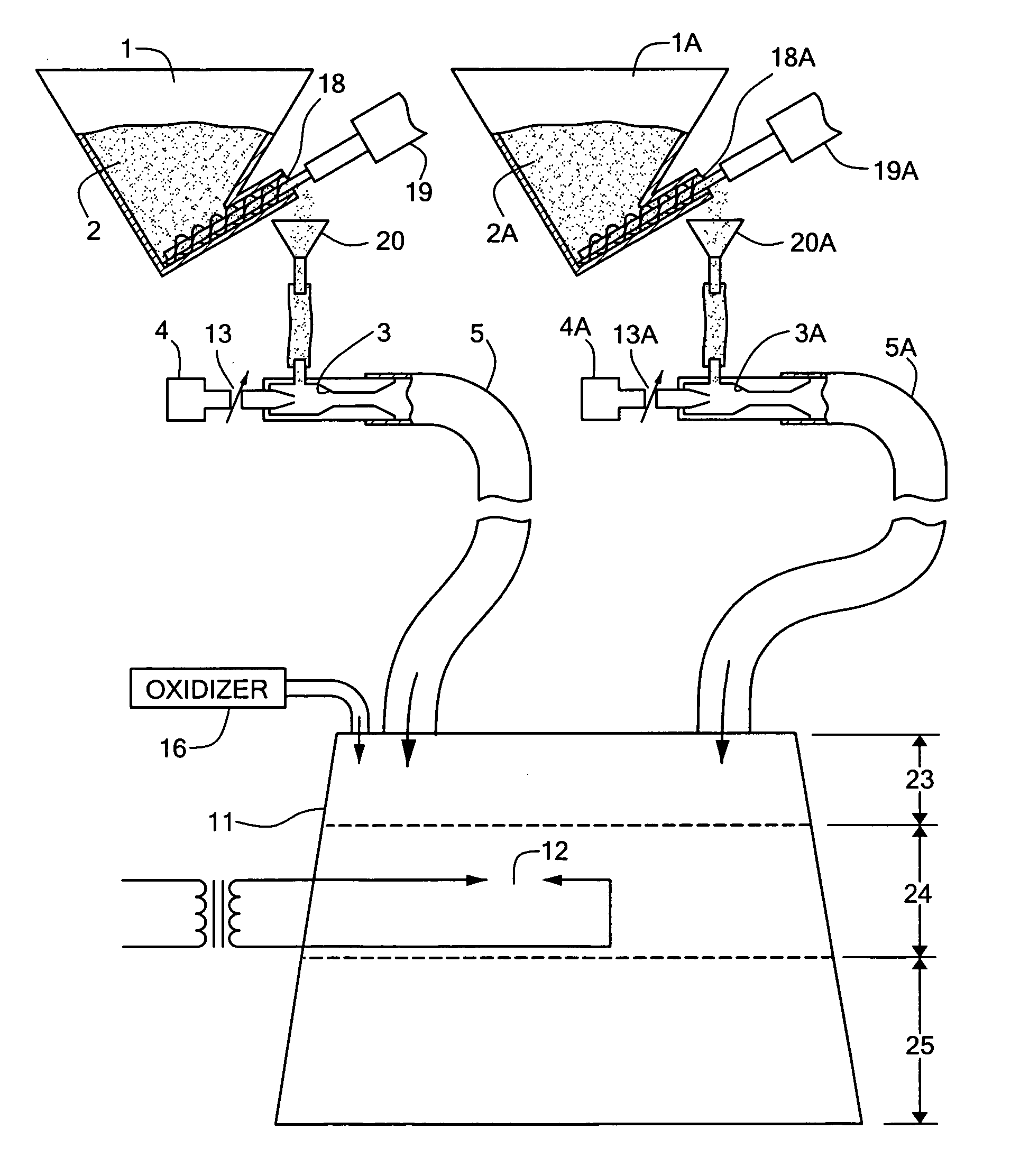

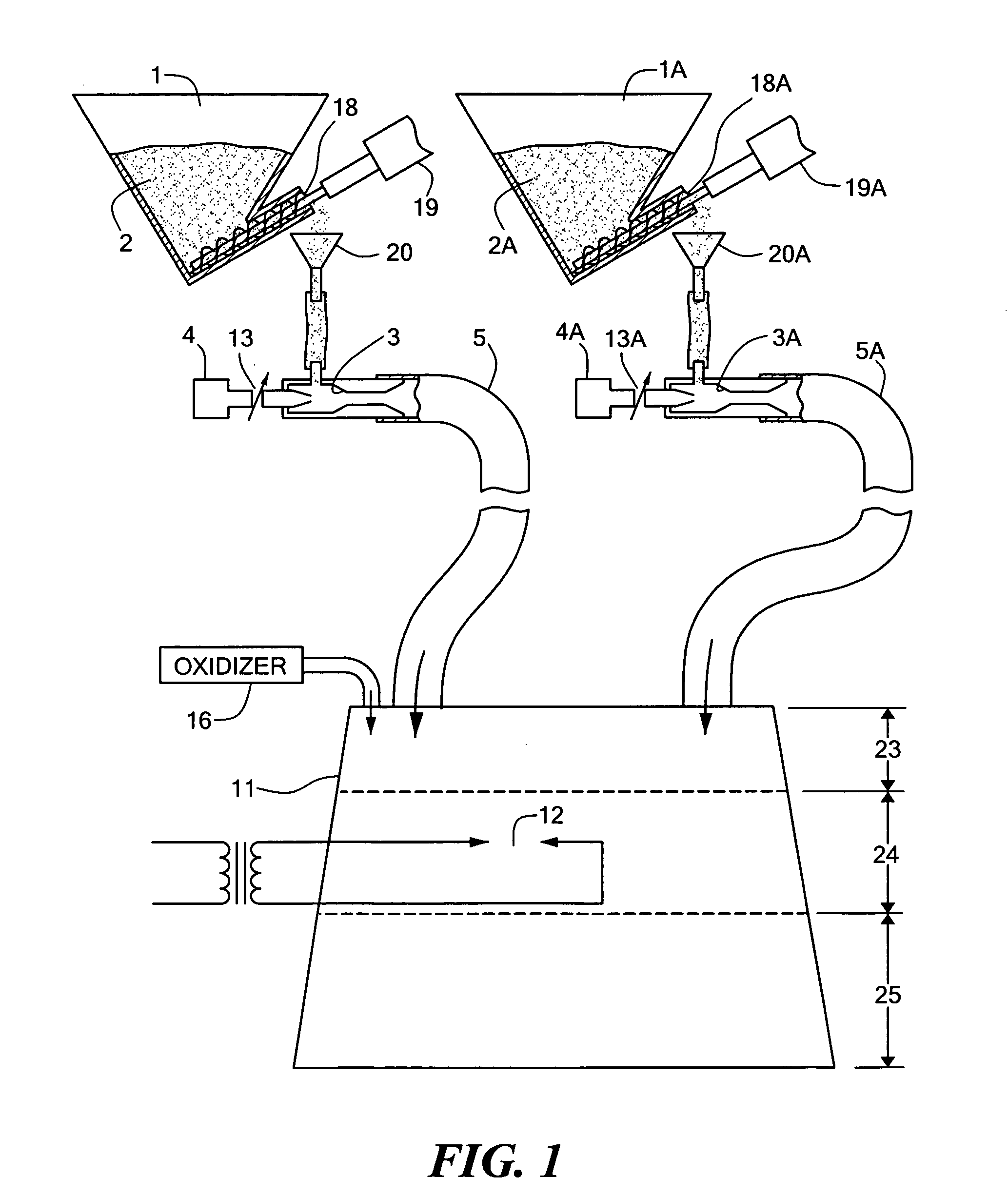

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

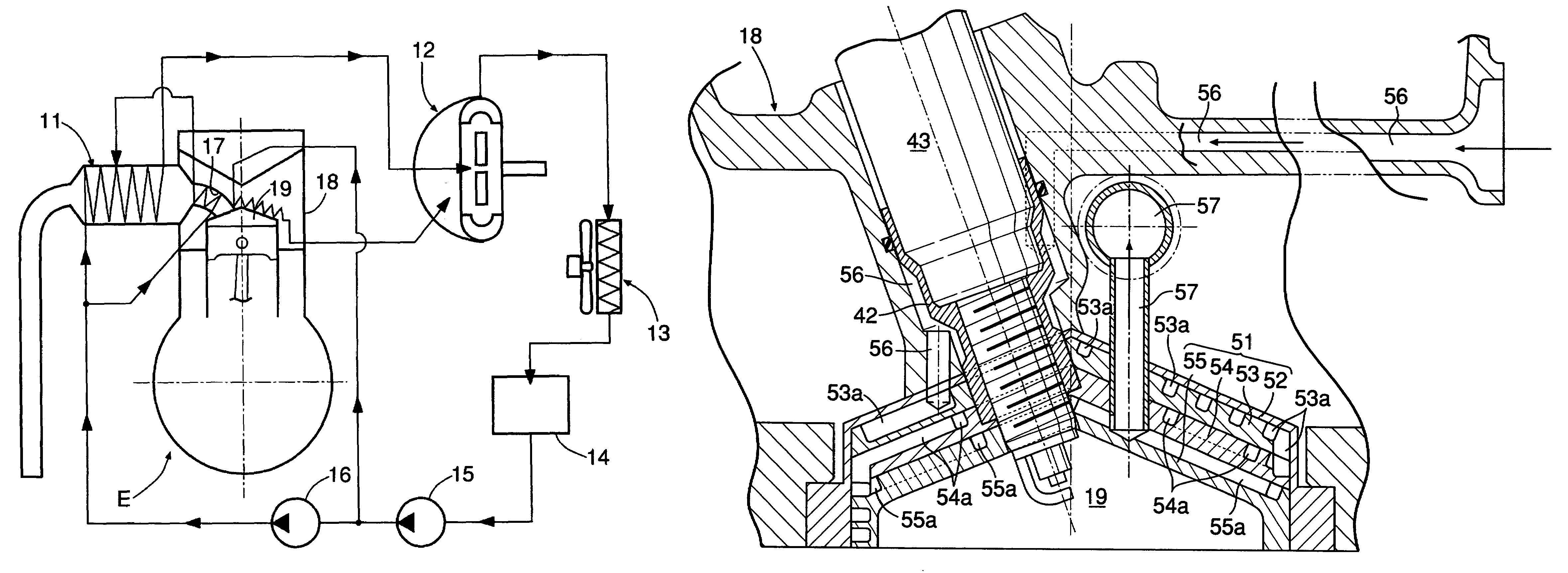

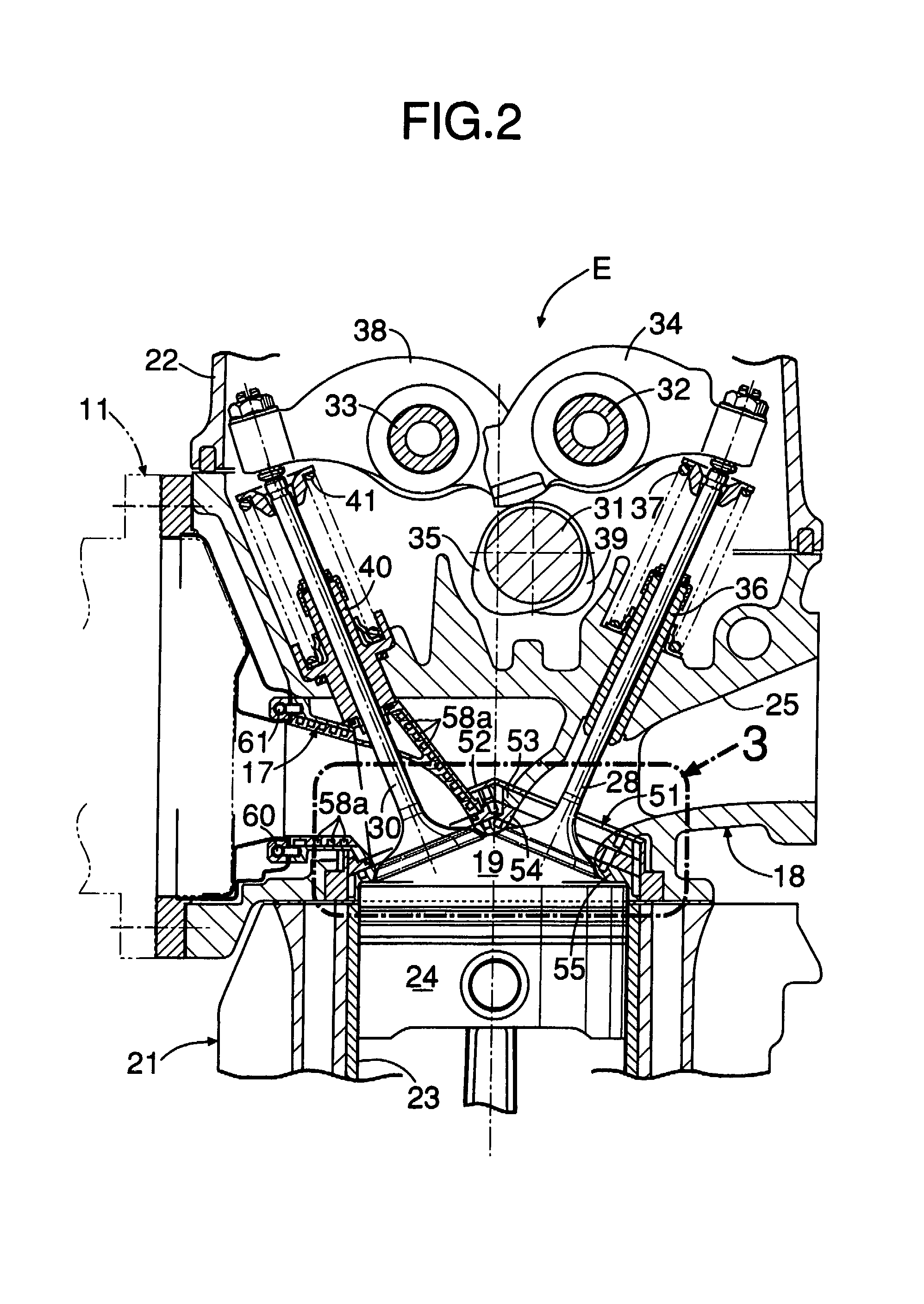

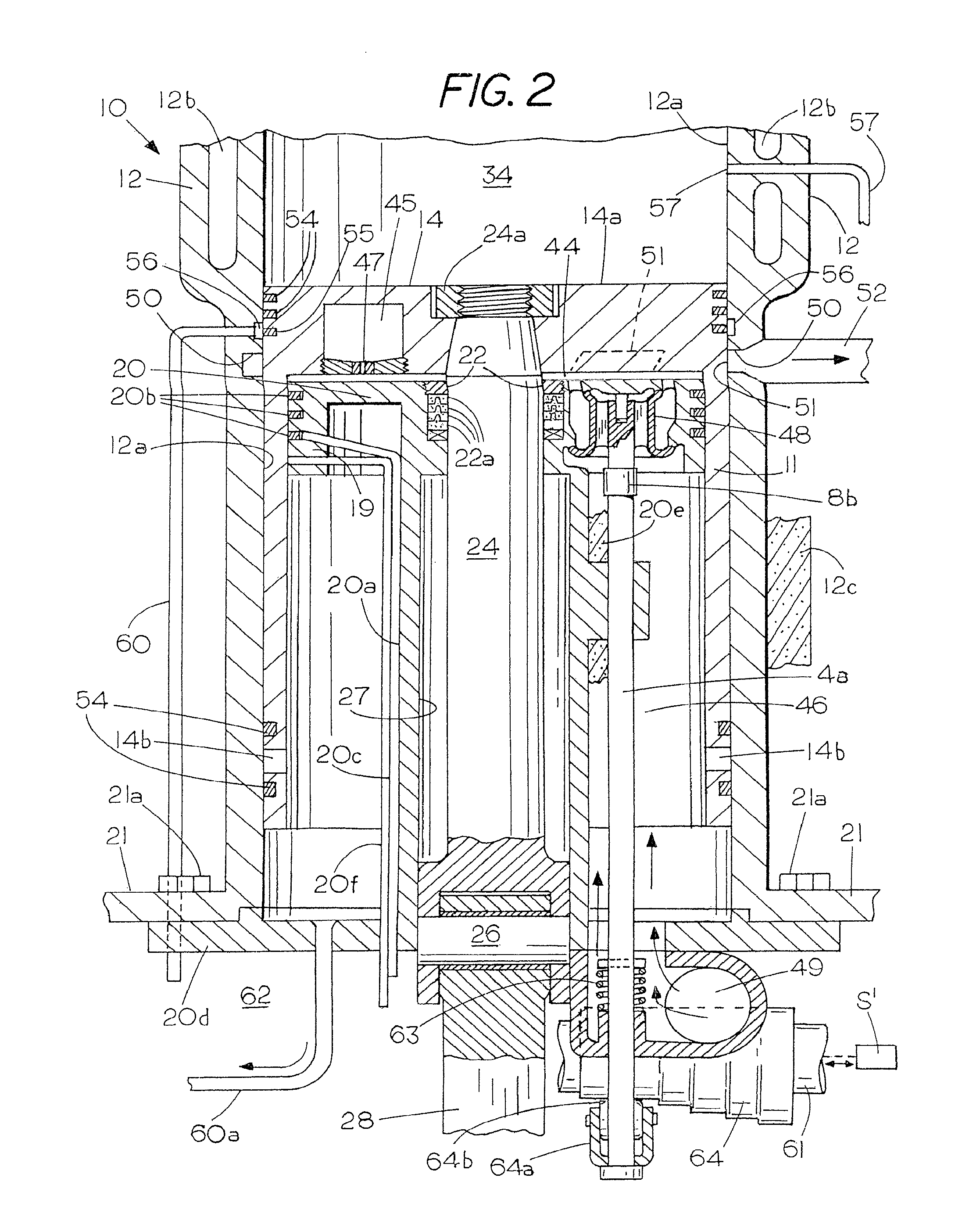

Internal combustion engine

InactiveUS7191740B2Good effectIncrease temperatureLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

A cooling block forming a top wall of a combustion chamber of an internal combustion engine is formed by layering, from the outside to the inside, a casing, an upper layer block, a middle layer block, and a lower layer block. Labyrinth-shaped cooling water passages are formed on upper side faces of the three layers of blocks, and cooling water supplied from a cooling water supply passage flows from the cooling water passage on the side far from the combustion chamber to the cooling water passage on the side close to the combustion chamber, and is discharged from a cooling water discharge passage. Since the cooling water flows in a direction opposite to the direction of emission of heat of combustion from the combustion chamber, it is possible to ensure that there is sufficient difference in temperature between a cylinder head and the cooling water throughout the cooling water passages.

Owner:HONDA MOTOR CO LTD

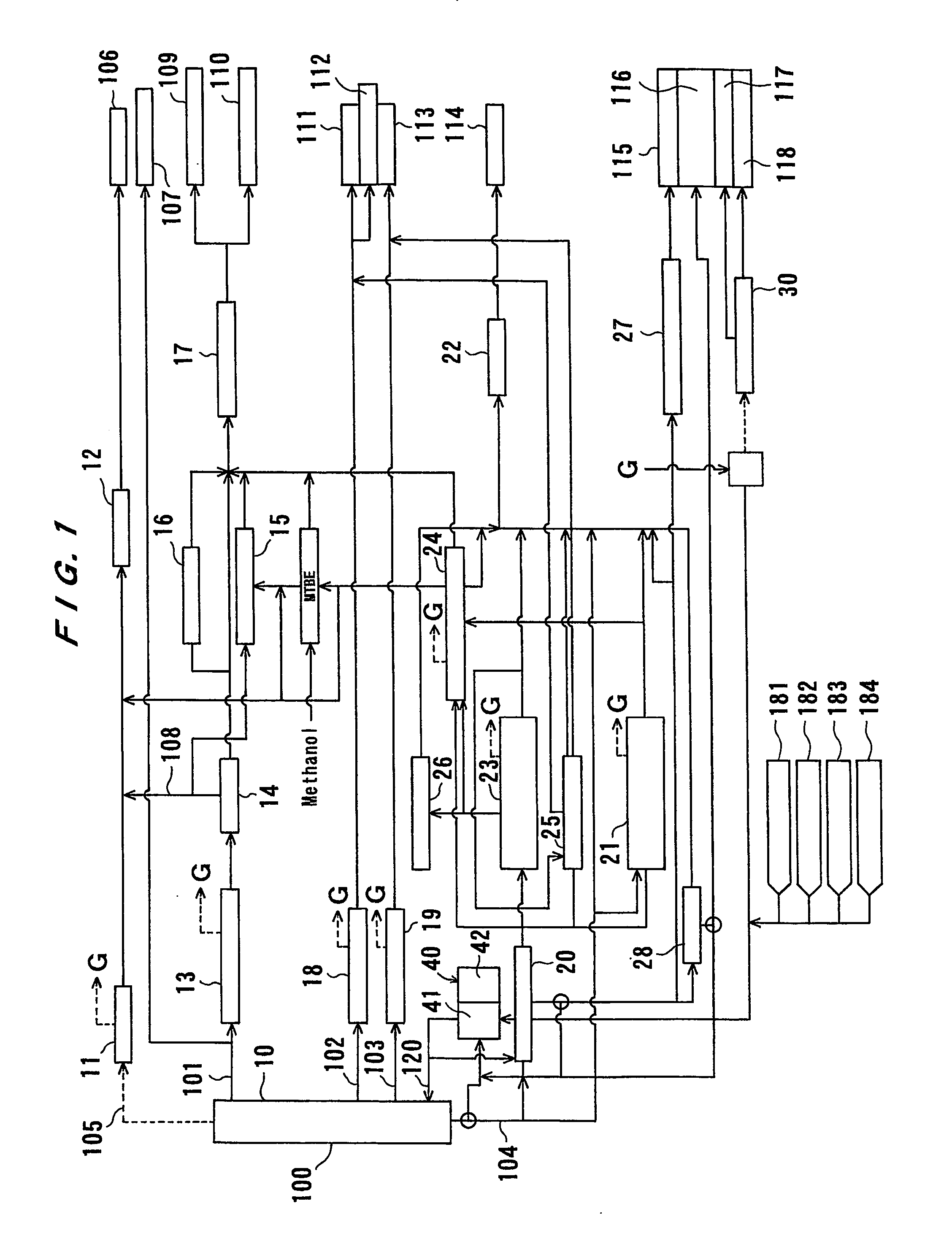

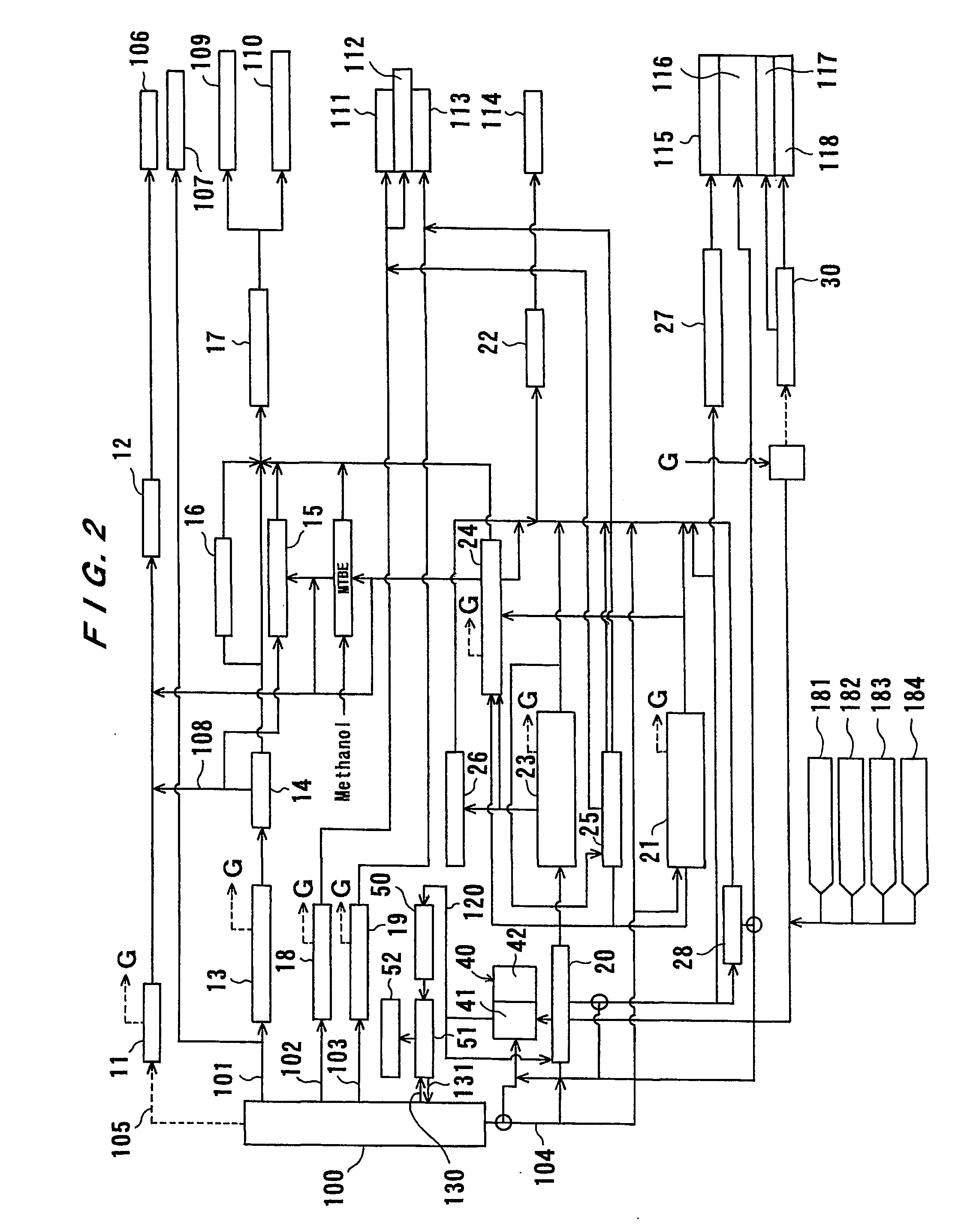

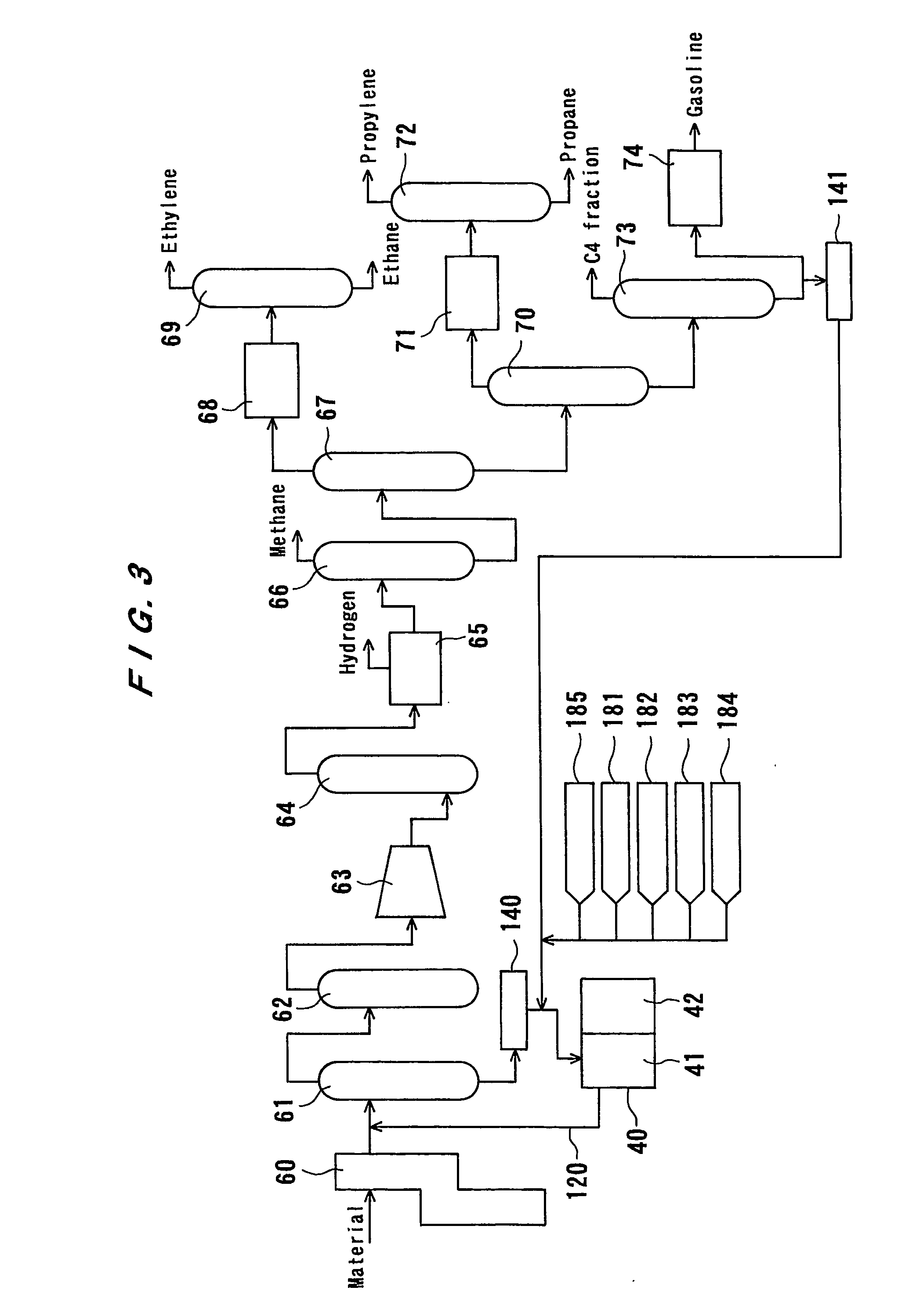

Recycling method and system

InactiveUS20060194990A1Low costThermal non-catalytic crackingTreatment with plural parallel cracking stages onlyDecompositionPetrochemical

A recycling system has a pyrolysis apparatus (40) having a combustion section (42) for selectively combusting a carbon component in materials, and a gasification section (41) for pyrolyzing and gasifying the materials by using heat of combustion in the combustion section (42). The materials include residual oil from an atmospheric distillation unit (10), a vacuum distillation unit (20), and a decomposition unit (28), various wastes including waste plastics (181), wastes (182), and shredder dust (183), and organic matter such as biomass (184). The recycling system has a passage for supplying pyrolysates (120) produced in the gasification section (41) to an oil refinery system or a petrochemical system.

Owner:EBARA CORP

Reactor and process for making synthesis gas

ActiveUS20060143980A1Improve economyImprove performanceTreatment with plural serial cracking stages onlyCoke ovensSyngasPartial oxidation

The invention relates to reactor systems and processes for producing synthesis gas. In one embodiment, a reactor comprises a first reaction zone comprising a combustion catalyst, wherein the first reaction zone is operated at conditions sufficient to produce a combustion zone product comprising heat generated by the combustion of a fuel. The reactor further comprises a second reaction zone comprising a partial oxidation catalyst, wherein the second reaction zone is adapted to receive the combustion zone product and a reaction feed comprising a hydrocarbon gas. The second reaction zone is operated at conditions sufficient for partially oxidizing the hydrocarbon gas to a product stream comprising synthesis gas. The heat of combustion is transferred directly to the reaction feed by mixing it in a feed mix region located in the reactor between the first and second reaction zones, in such a manner that the reaction feed does not need preheating prior to entering the partial oxidation zone.

Owner:PHILLIPS 66 CO

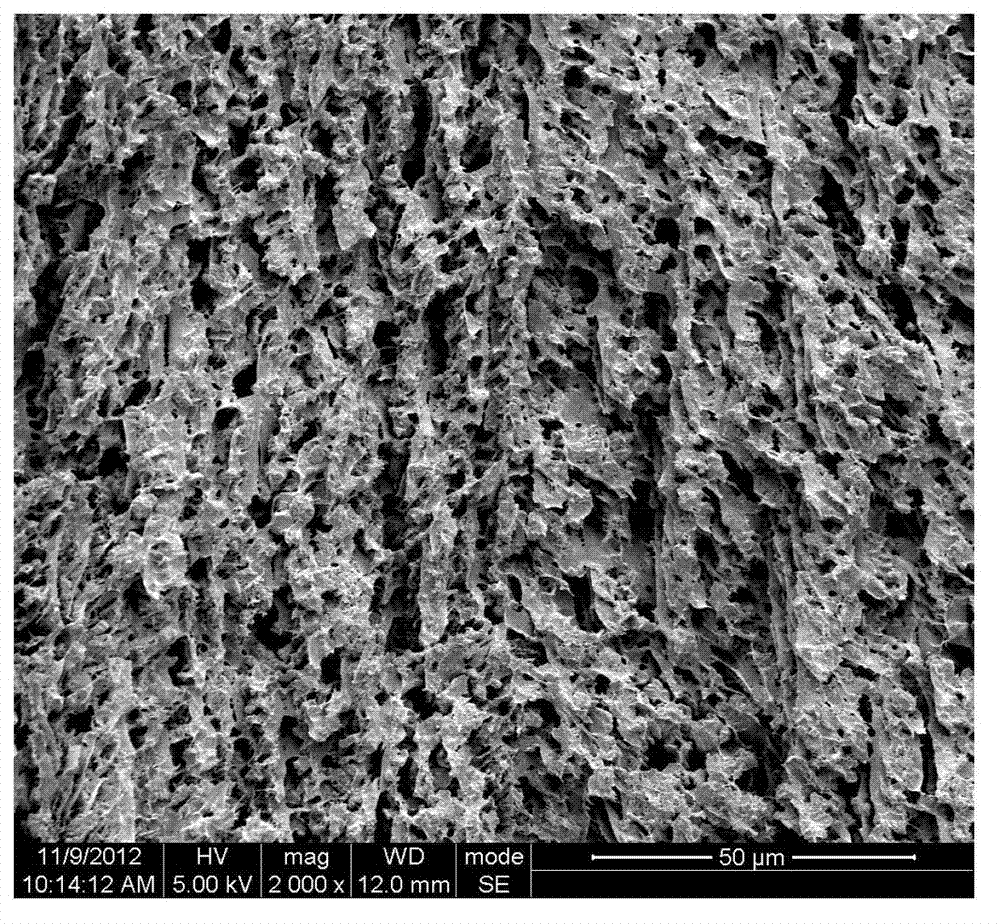

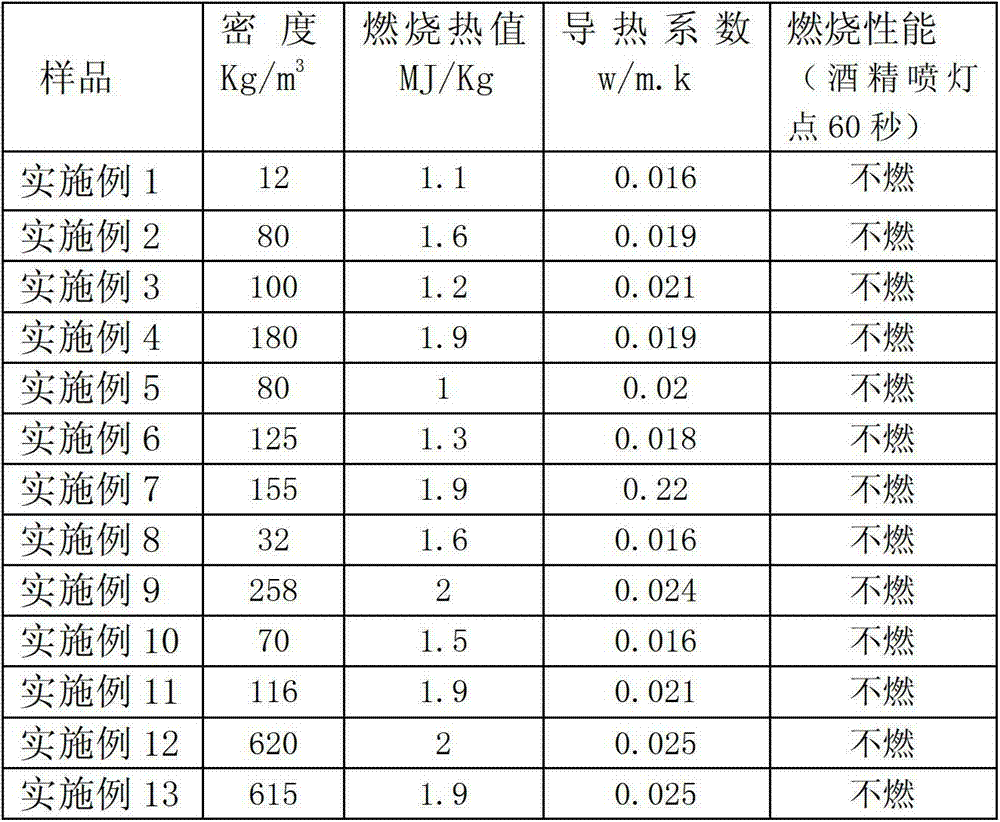

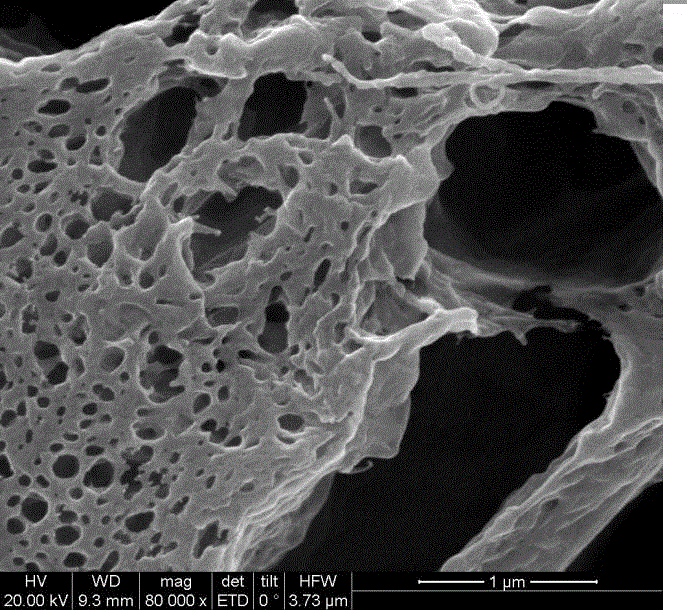

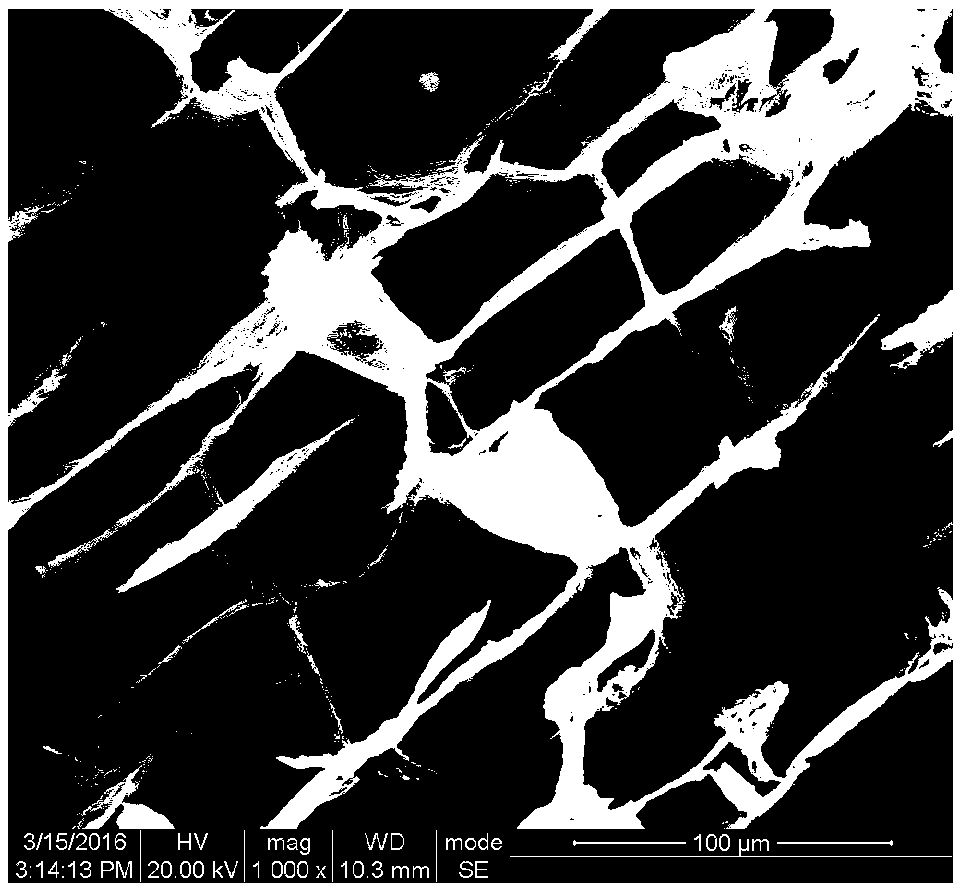

Inorganic micro/nanoparticle/polymer composite building thermal-insulation aerogel material and preparation method thereof

The invention discloses an inorganic micro / nanoparticle / polymer composite building thermal-insulation aerogel material which is compounded from the following components in parts by weight: 0.5-50 parts of inorganic micro / nanoparticle, 0.1-5 parts of polymer, 0-10 parts of crosslinkable polymer, 0.5-20 parts of reinforcing fiber, 0.1-5 parts of defoaming agent and 100 parts of water. The density of the material is 12-620 Kg / m<3>, the heat conductivity coefficient is 0.016-0.025 w / m.k, and the combustion heat value is 1.1-2.0 MJ / Kg. The invention also provides a preparation method of the aerogel material. The aerogel material disclosed by the invention has the advantages of low density, light weight, favorable mechanical strength and low heat conductivity coefficient, and is beneficial to energy saving and consumption reduction. The combustion heat value is lower than 2.0 MJ / Kg, and thus, the aerogel material satisfies the flame-retardant requirements for Grade-A building thermal-insulation materials. The aerogel material is an ideal building flame-retardant thermal-insulation material, and can be widely used in external-wall thermal-insulation occasions.

Owner:SICHUAN UNIV

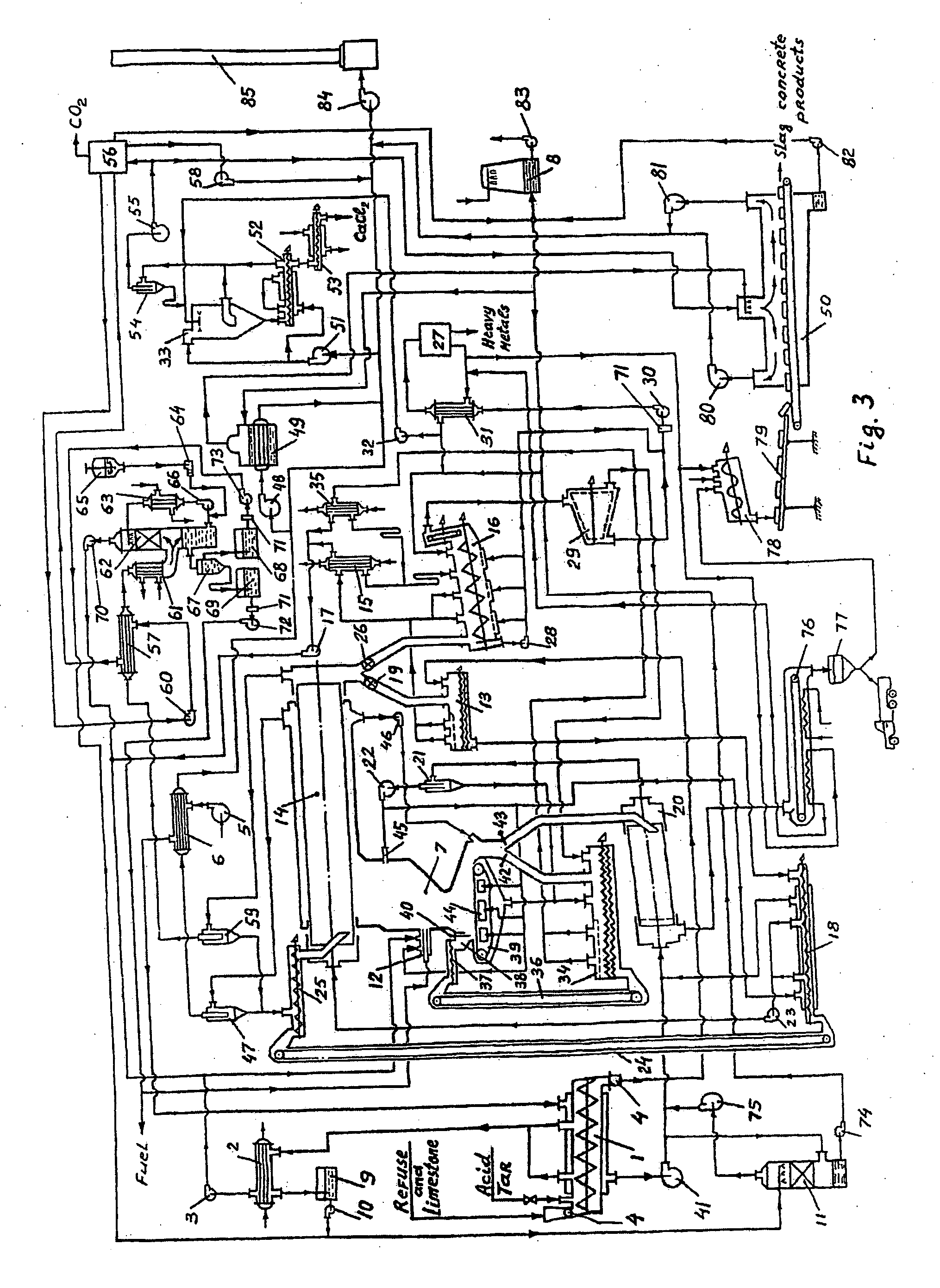

Method and plant for processing waste

ActiveUS20070251433A1Reduce water consumptionReduce the amount requiredSolid waste disposalEnergy inputCombustion chamberSlag

A municipal or like refuse is crushing, mixing with crushed limestone, dry up in two stages—by hot air and by part of solid products of pyrolysis which other part goes on washing out and filtration. Pyrolysis is carried out in two stages—due to heat of the specified part of solid products of pyrolysis and simultaneous neutralization of allocated hydrogen chloride by limestone with reception of calcium chloride, and then due to heat of final chimney gases of the combustion chamber, where in three stages the washed solid products of pyrolysis preliminary drained by a part of combustion chamber slag are burnt together with liquid and gaseous products of pyrolysis. Gas allocated at pyrolysis condense and divide on organic, which is liquid fuel and water phases. Air after a dryer moves to blowing away of light organic substances from the specified water phase, is heated up due to heat of slag and moves in combustion chamber. Washing water goes on allocation of salts of heavy metals and calcium chloride, and slag after molding of a concrete mixture goes to the chamber of thermohumid processing of the slag concrete by a part of damp chimney gases after drying calcium chloride, other part of gases moves to manufacture of liquid carbon dioxide.

Owner:RABINER YURIY

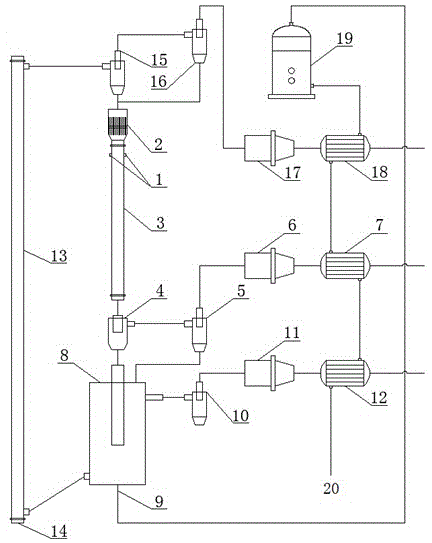

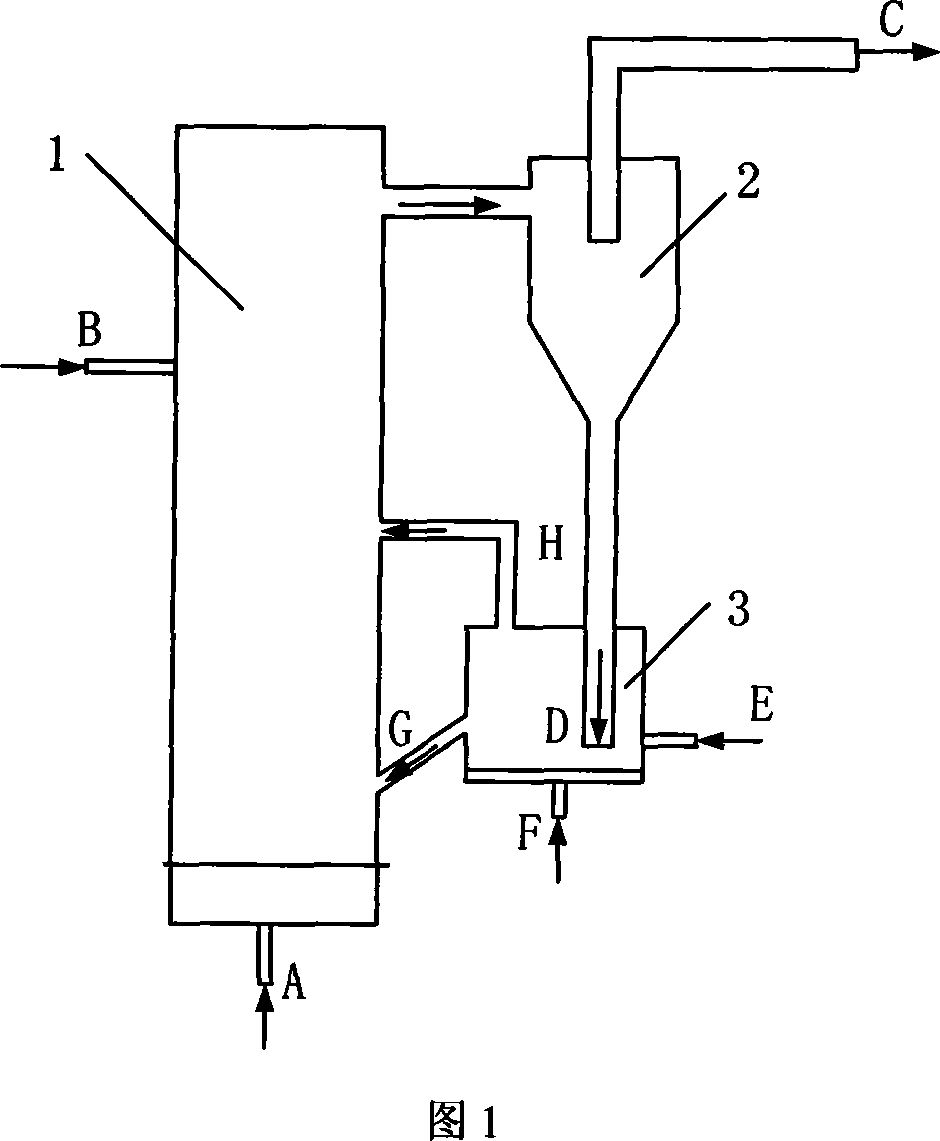

Pyrolysis and gasification device and technology

ActiveCN104789245AImprove qualityImprove oil yieldDirect heating destructive distillationBiofuelsCatalytic pyrolysisSocial benefits

The invention discloses a pyrolysis and gasification device and technology. The device comprises three main reactors, namely, an uplink bed oxidation combustor, a downlink bed rapid pyrolyzer and a bubbling bed gasifier. Feed coal or a mixture of coal and biomass is added from the upper part of the pyrolyzer, is rapidly heated by high-temperature circulating semicoke from the combustor and has a catalytic pyrolysis reaction, and semicoke, tar and gas are produced; through rapid separation, fresh semicoke produced in the pyrolyzer and the high-temperature circulating semicoke are sent into the gasifier to have a gasification reaction with a gasification agent; the semicoke which is not gasified is continuously sent into the combustor to be partially oxidized and combusted under the action of oxygen, so that a large quantity of high-temperature circulating semicoke is obtained. The device and the technology have the advantages that a combustion-pyrolysis-gasification process in graded utilization of raw materials is coupled, co-production of high-quality tar, gas and synthesis gas is realized by the aid of the catalytic activity and the heat-carrying capability of the semicoke, and the economic benefit and the social benefit are high.

Owner:TAIYUAN UNIV OF TECH

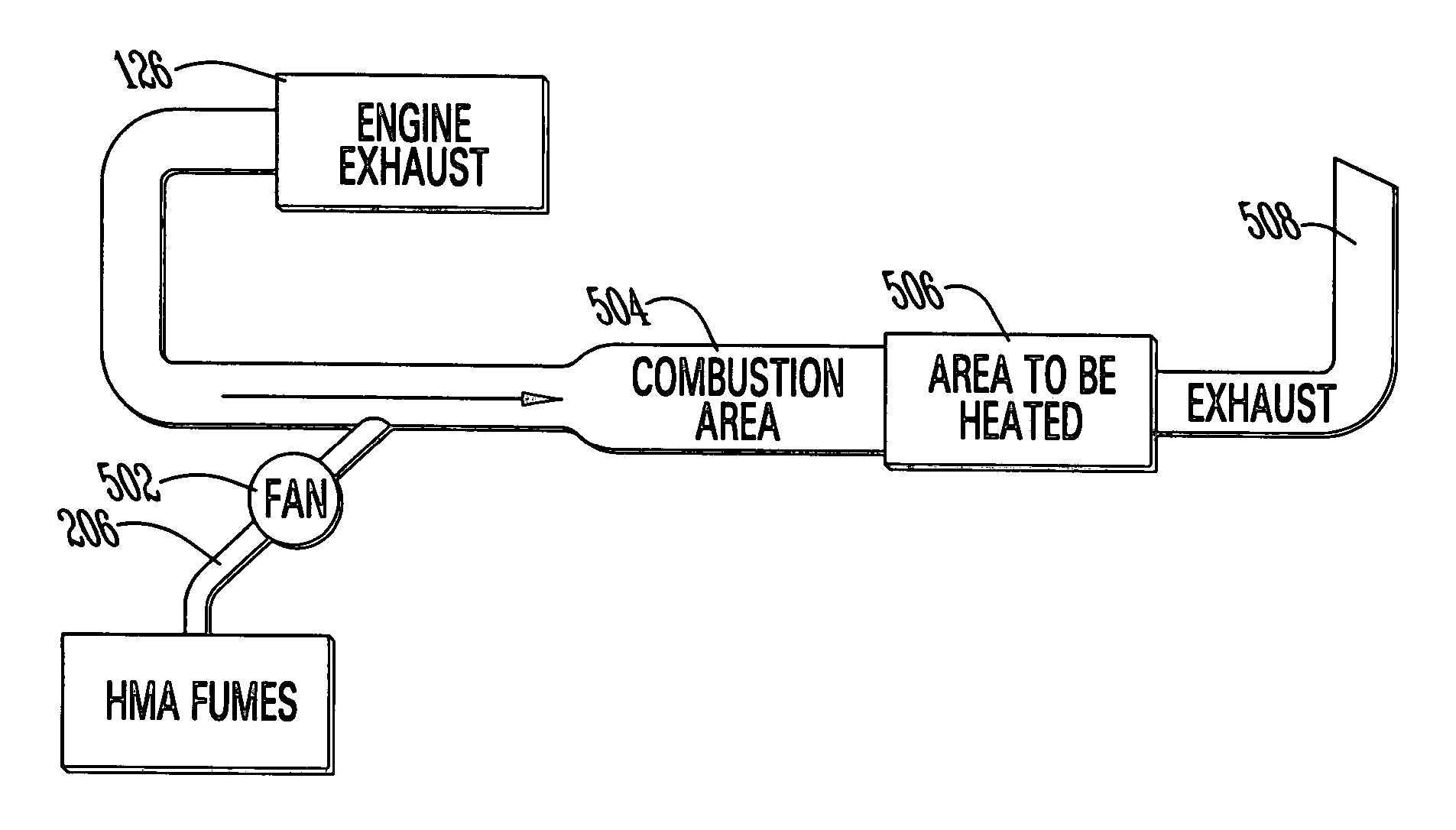

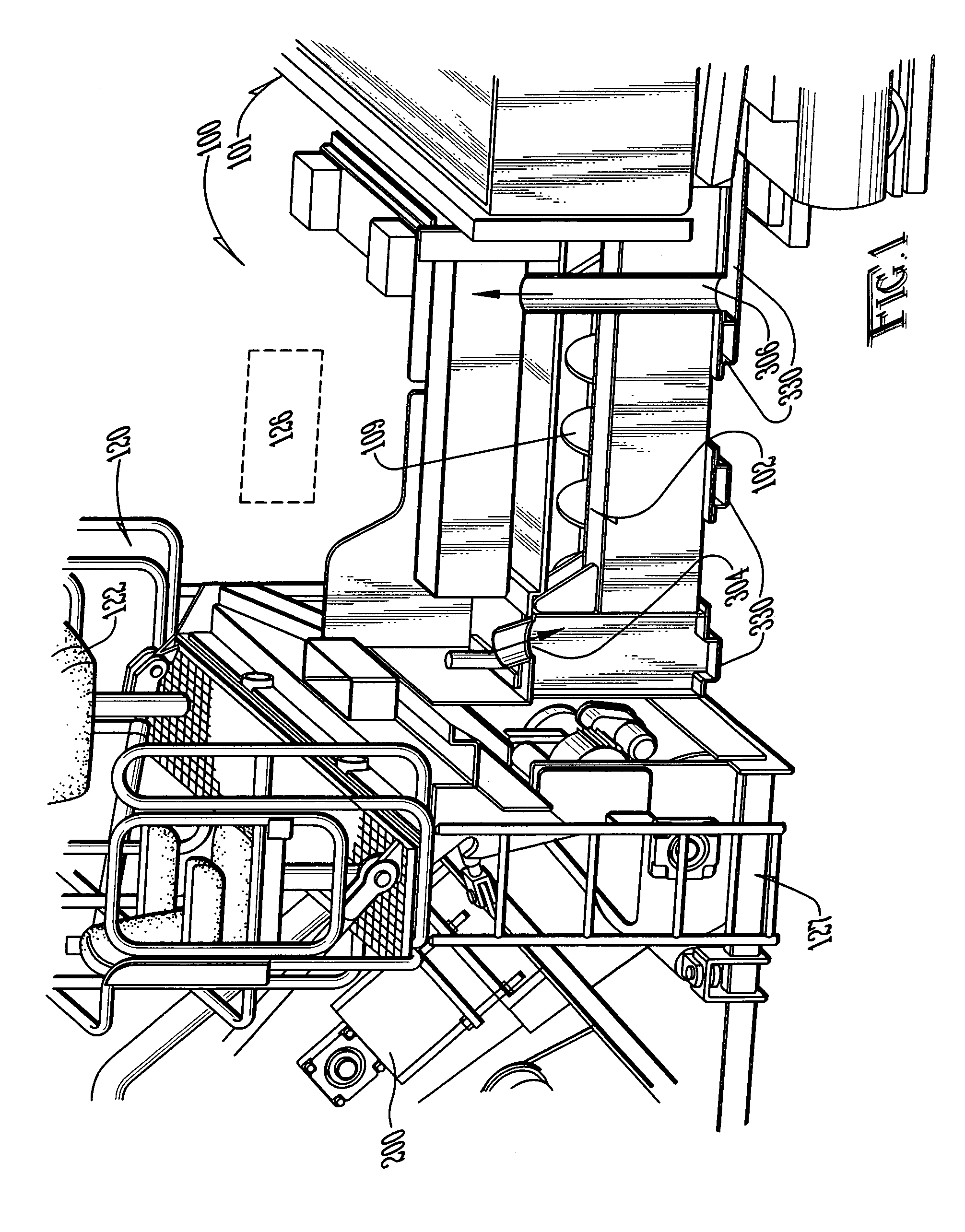

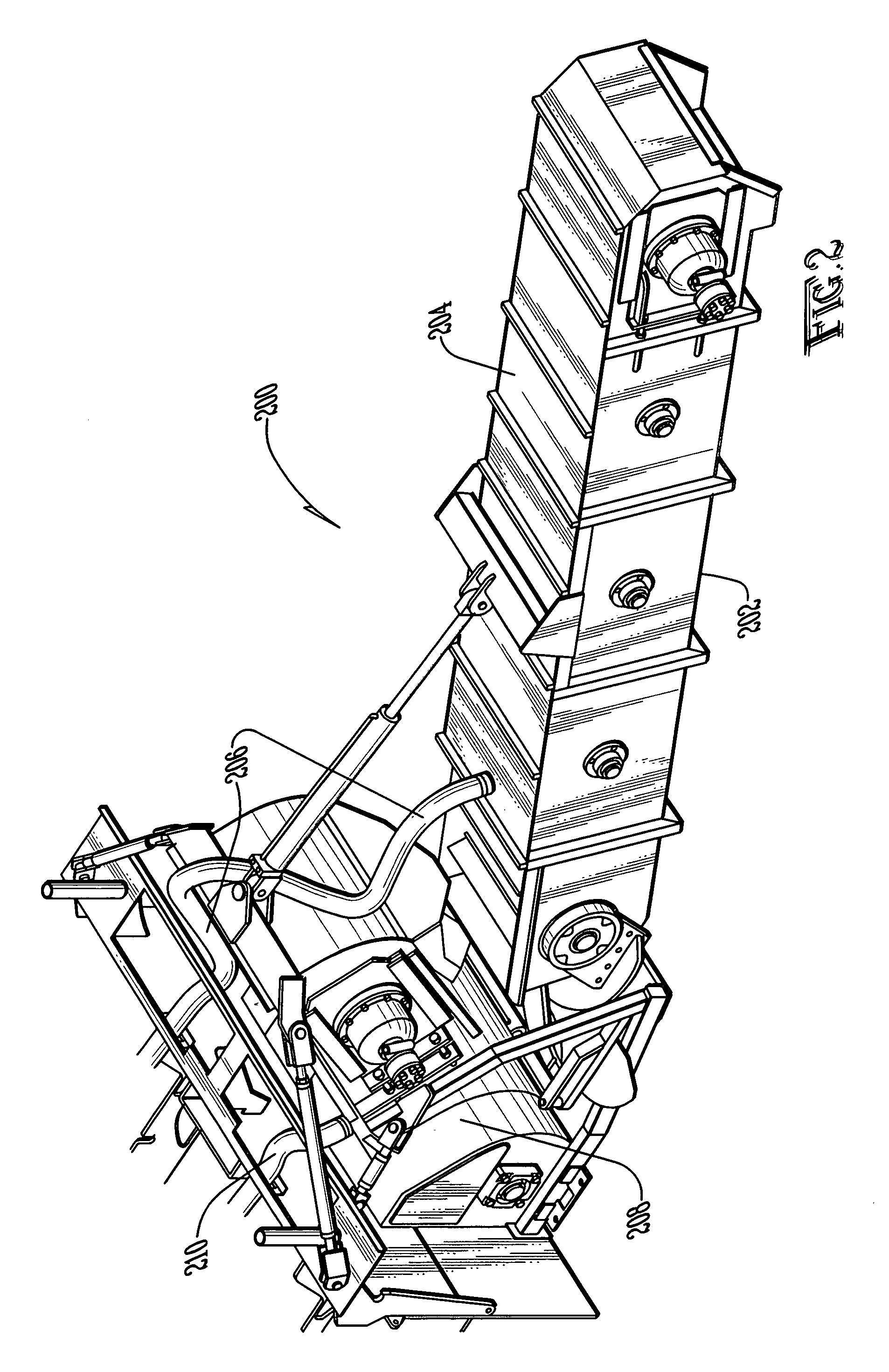

Apparatus and method for heating road building equipment

Owner:CMI TEREX CORP

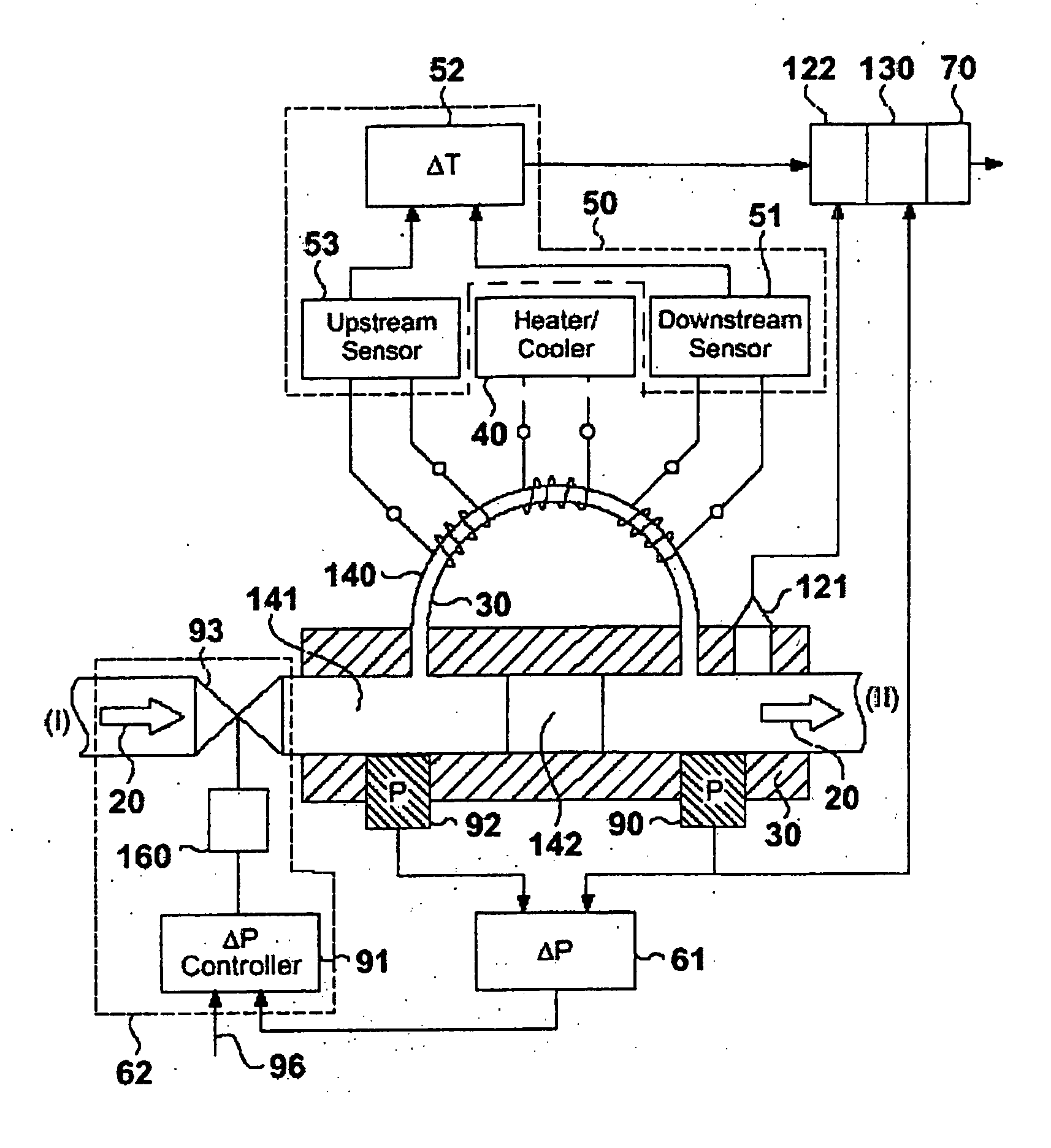

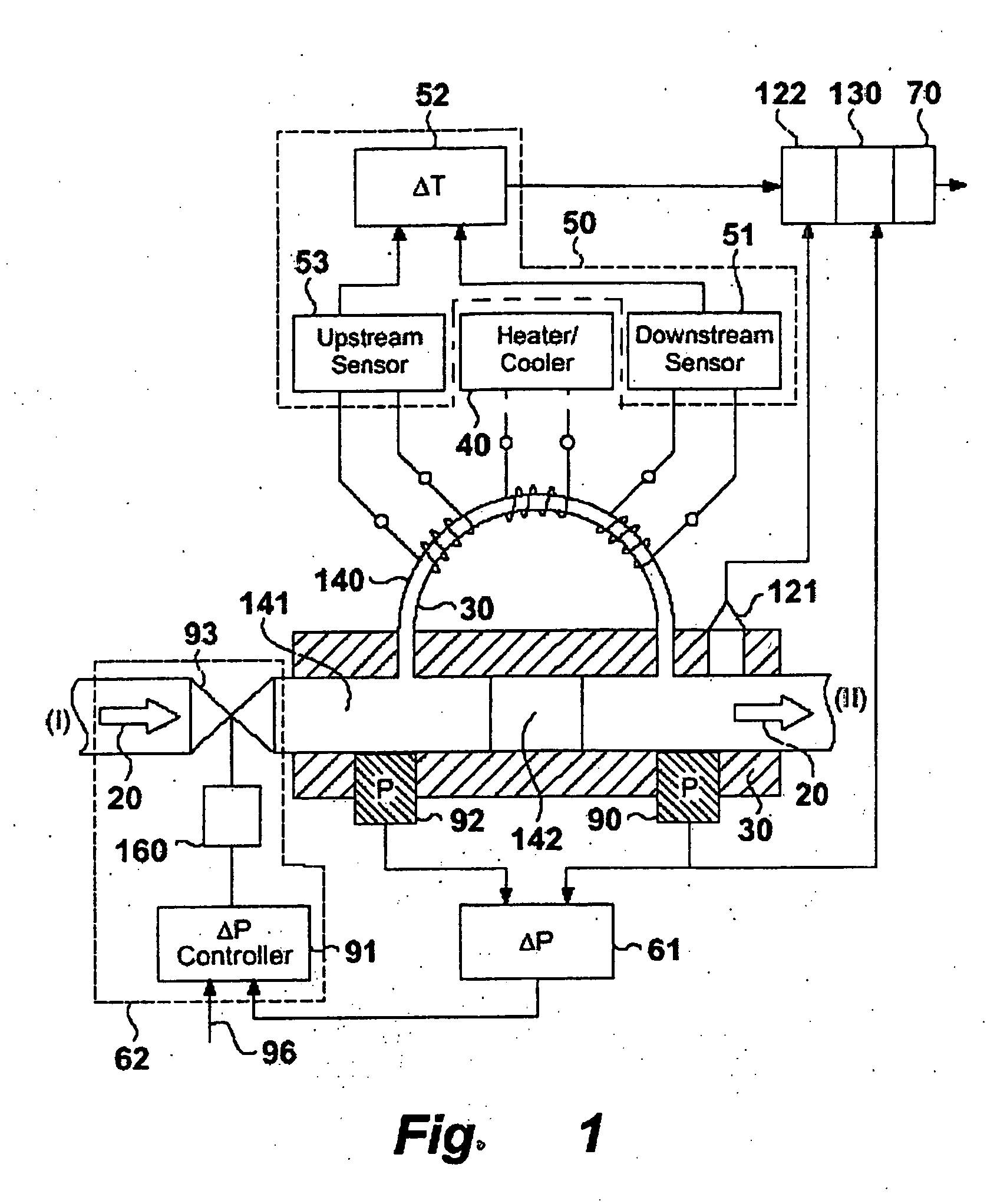

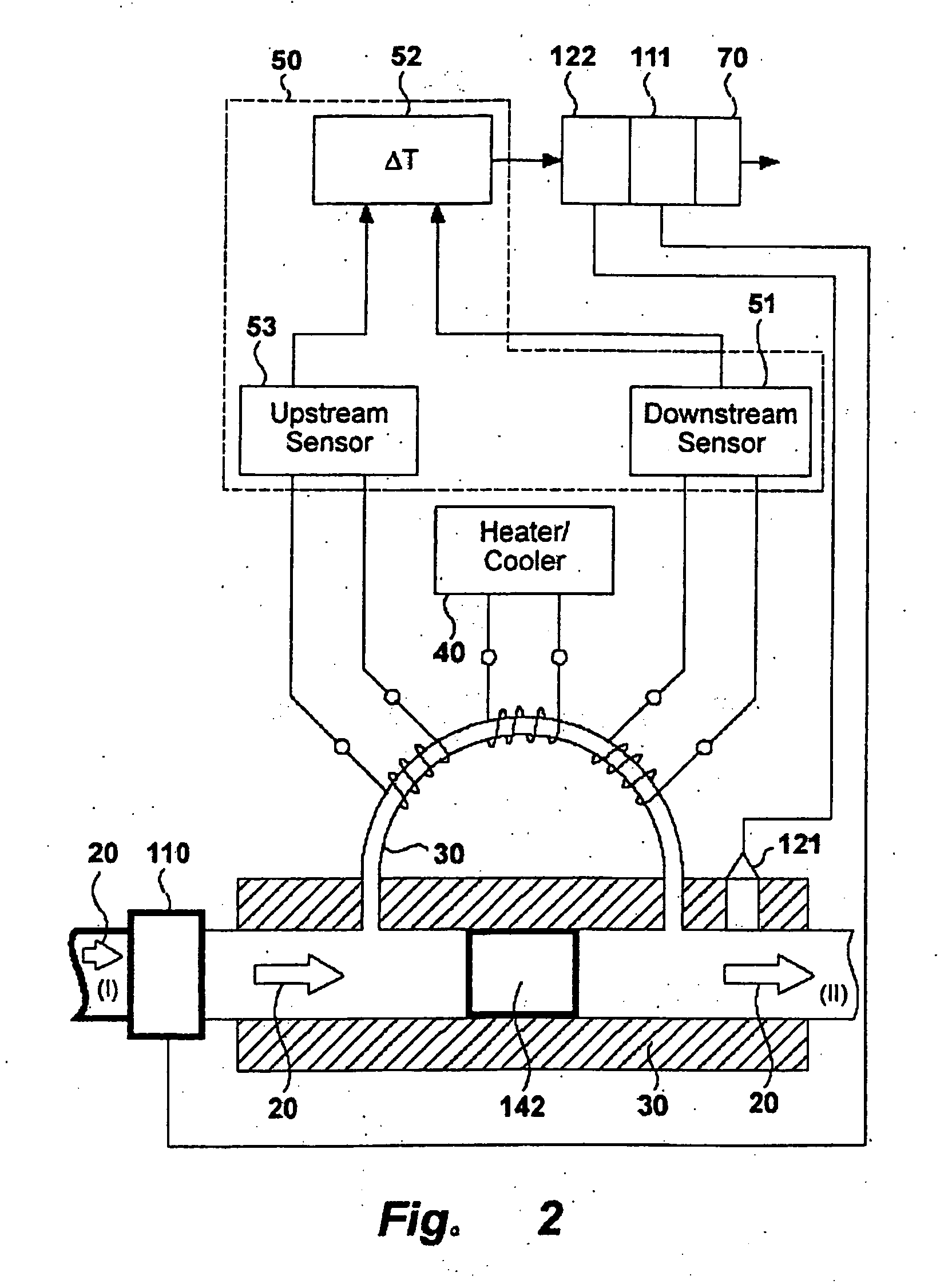

Method and device for determining a charcteristic value that is representative of the condition of a gas

InactiveUS20060123892A1Accurate and reproducible temperature difference measurementReliable characterisationAnalysing fluids using sonic/ultrasonic/infrasonic wavesTesting/calibration apparatusEngineeringTemperature difference

The invention relates to a device and methods for the characterisation of a flowing substance, liquid or gas. Particular embodiments of the invention relates to the use of the device for the identification of a flowing substance for controlling the flow of a fuel or combustion gas to deliver a controlled heat of combustion and for measuring the heat capacity of a gas. Further embodiments of the invention relate to a flow control device for controlling the flow rate of a flowing substance and a method for the combustion of a fuel or combustion gas. The device for the characterisation of a flowing substance comprises: a transport duct on which is mounted a heating or a cooling element; a temperature difference sensor comprising a first temperature measurement cell downstream of the heating or cooling element and means to determine a temperature difference in the flowing substance upstream and downstream of the heating or cooling element; flow control means comprising flow measurement means for measuring a mass flow characteristic and flow correction means for correcting for measured mass flow variations; and evaluation means for evaluating a characterising feature of the flowing substance comprising a function relating temperature differences measured on one or more calibration substances to one or more characterising features of the flowing substance. The device is relatively simple and cheap and gives a quick but accurate and reliable characterisation of a flowing substance, gas or liquid, that can be used in a flow control device to control the flow rate of unknown substances.

Owner:EMERSON ELECTRIC CO

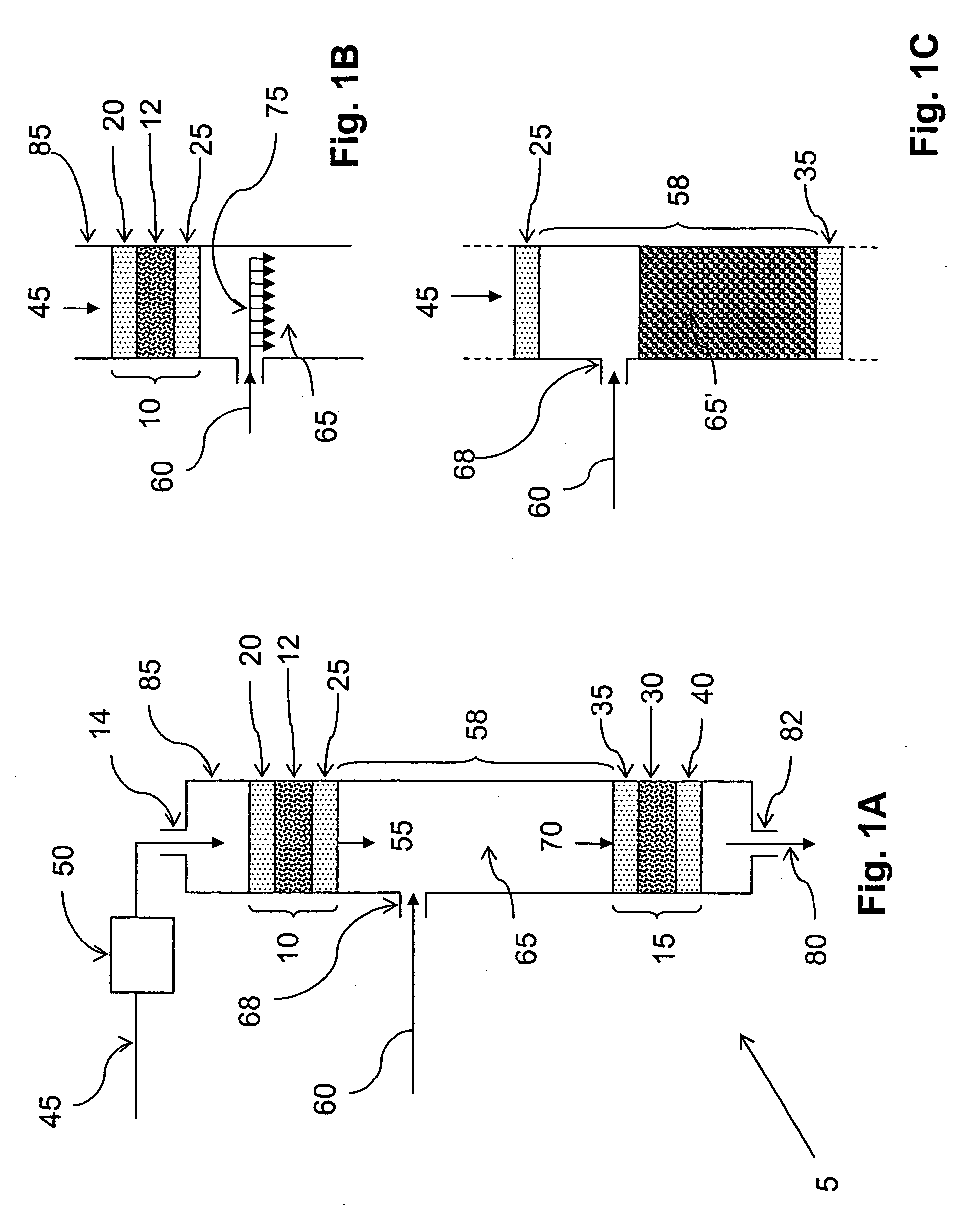

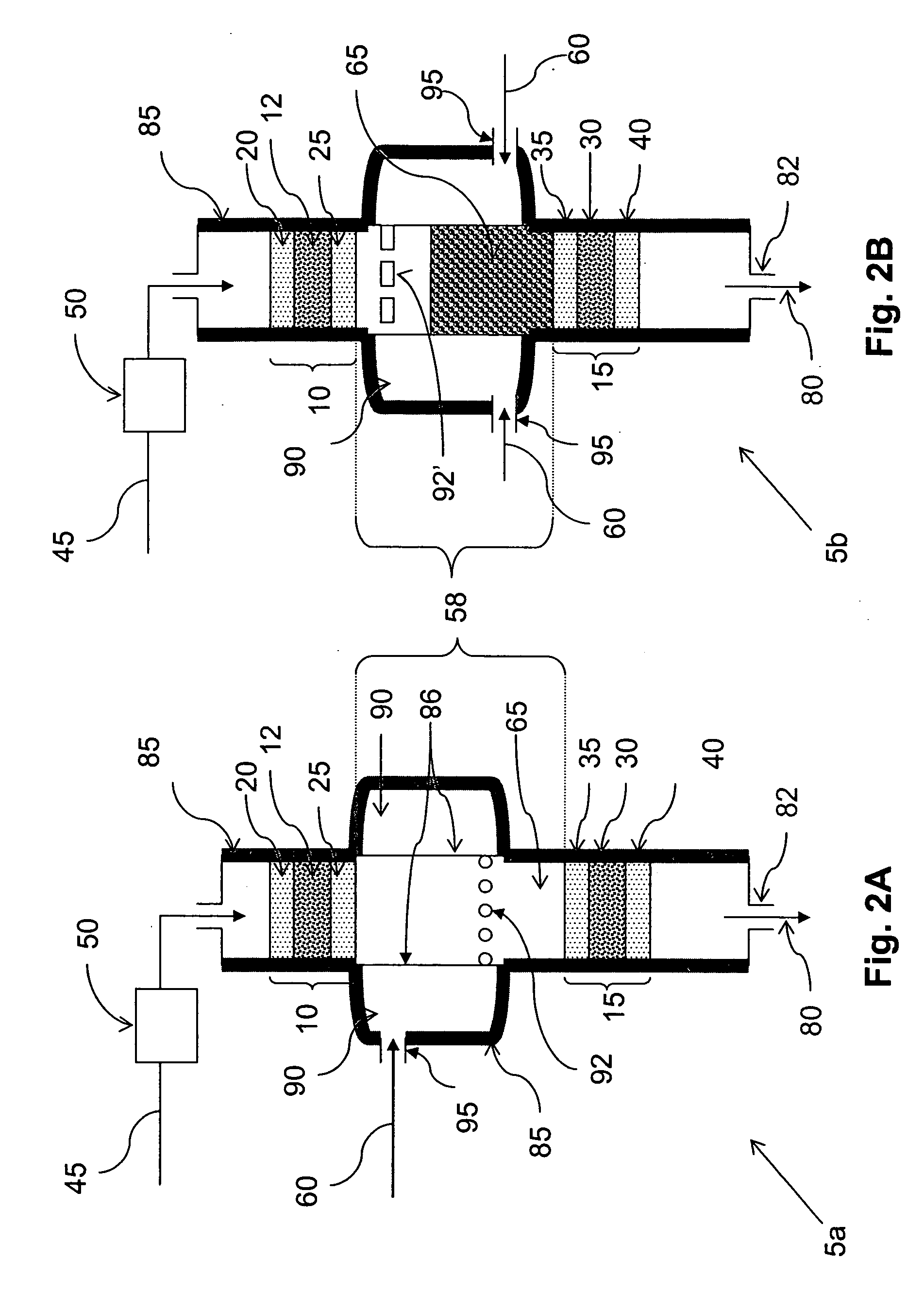

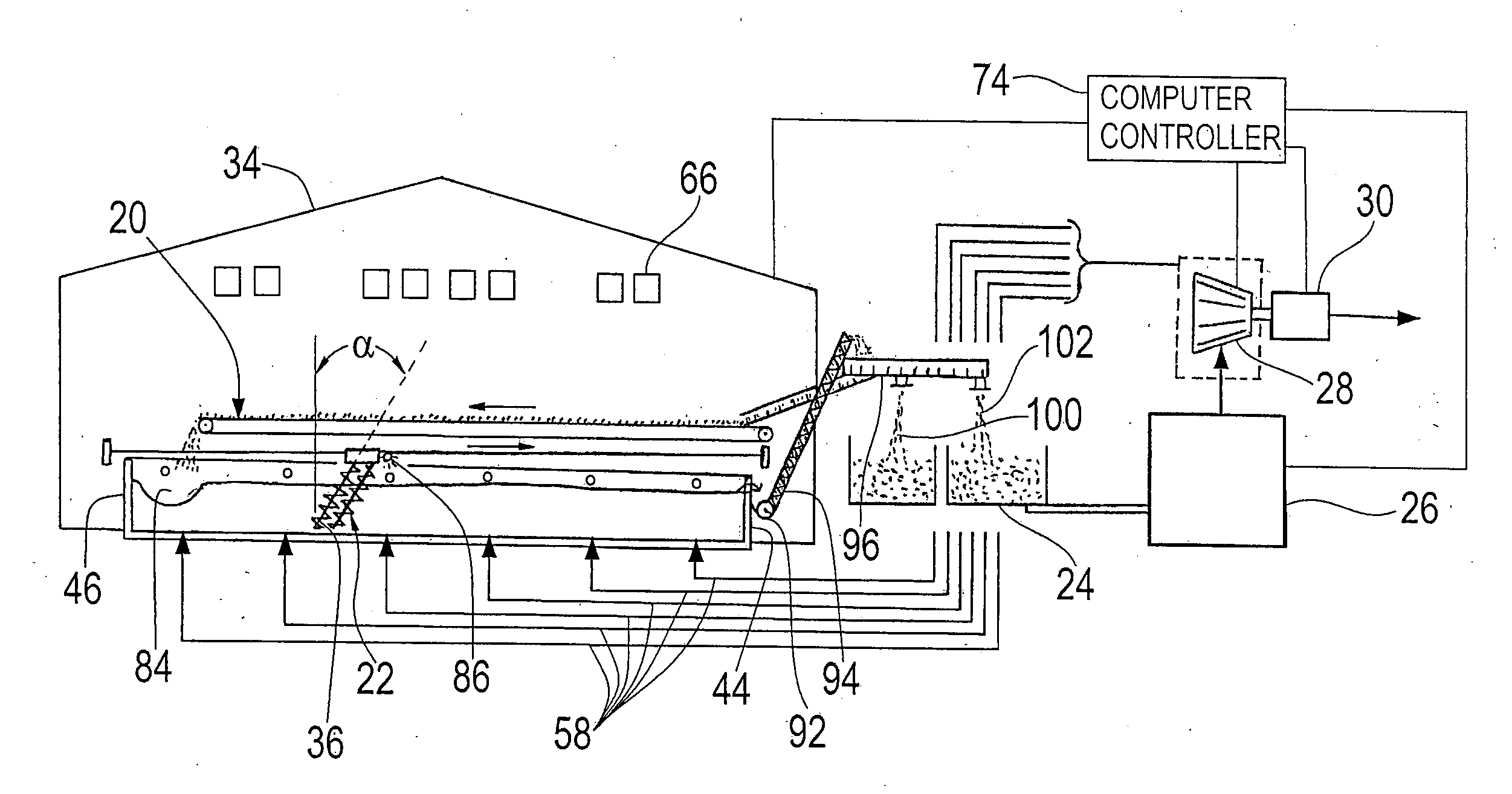

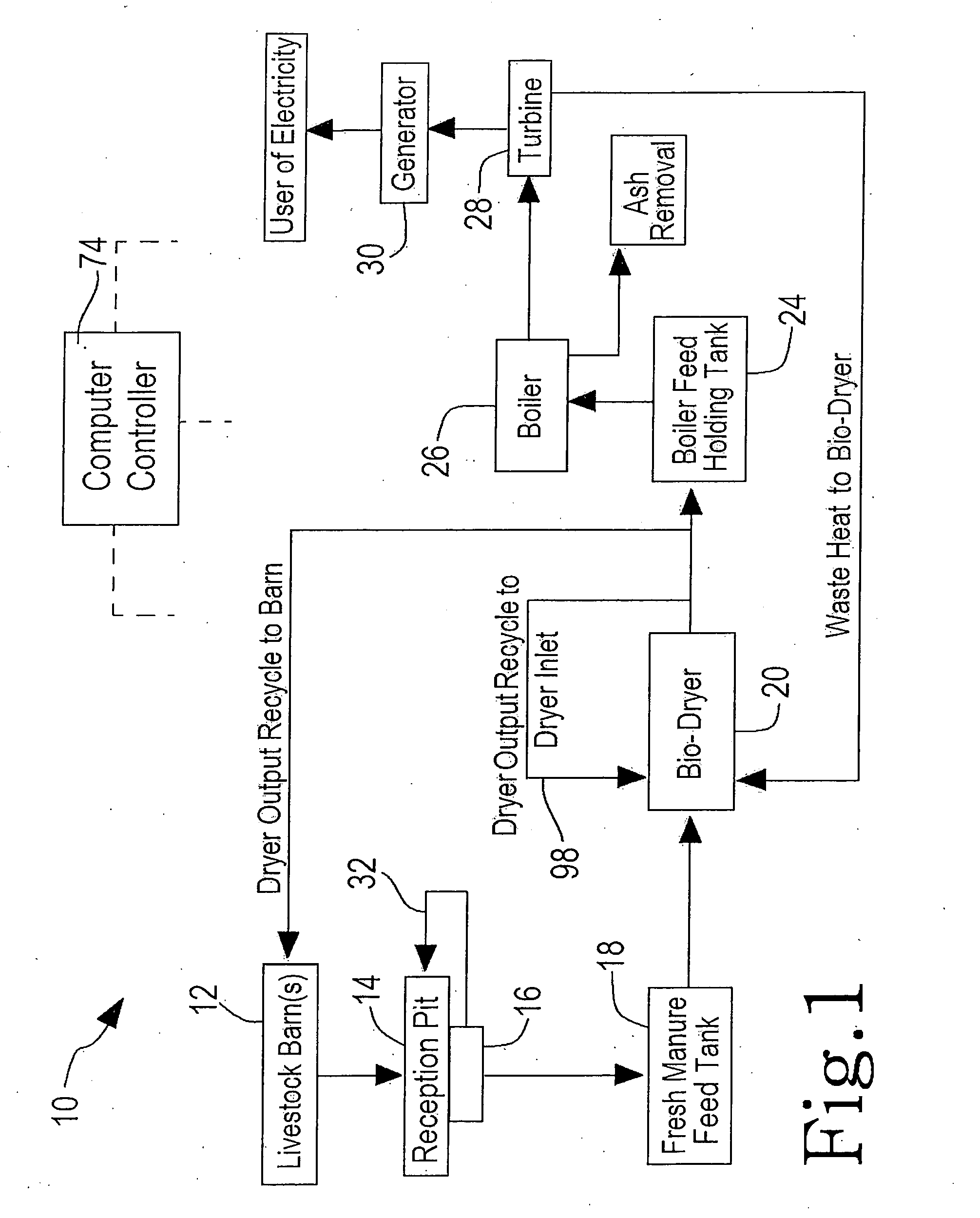

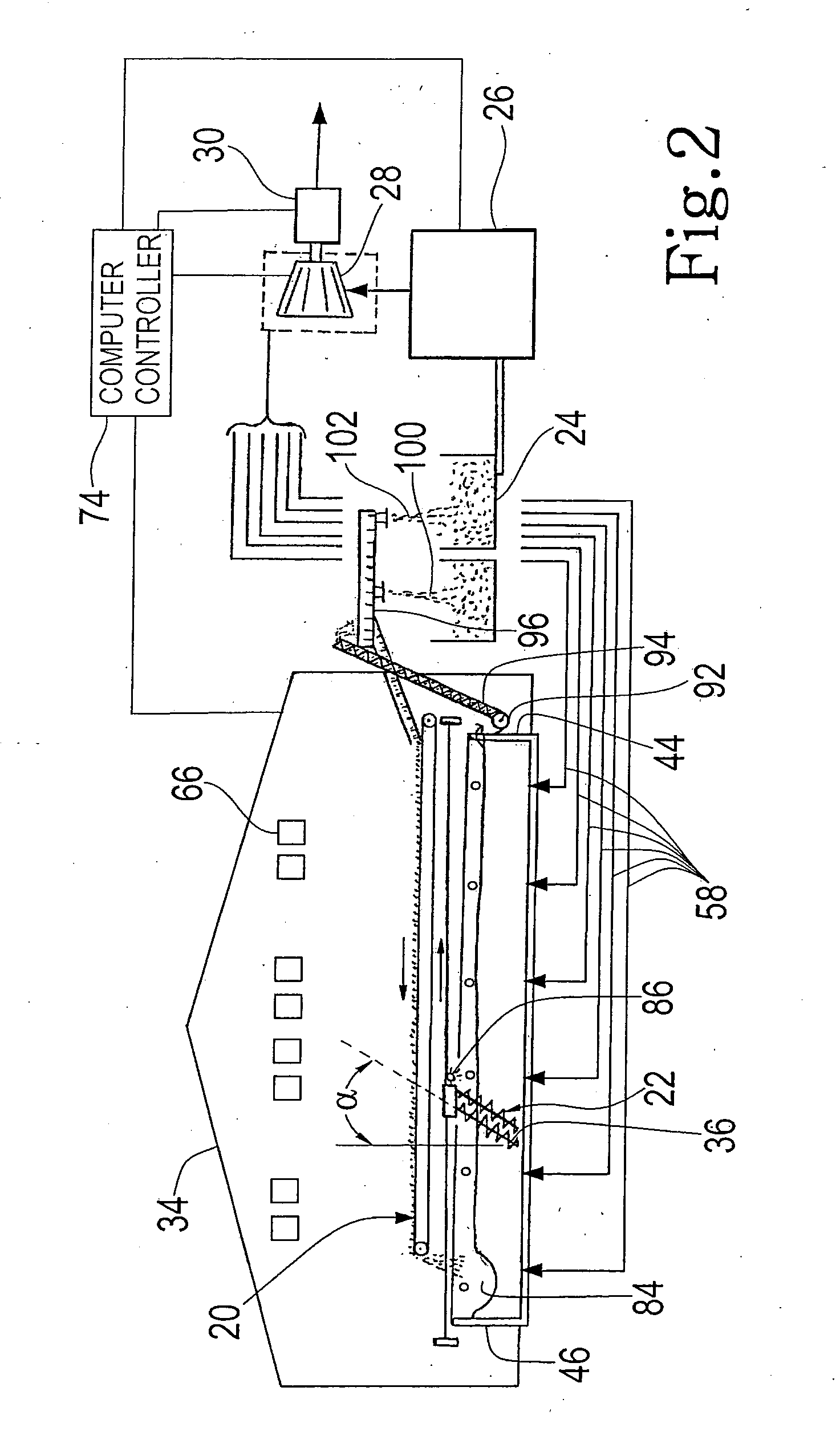

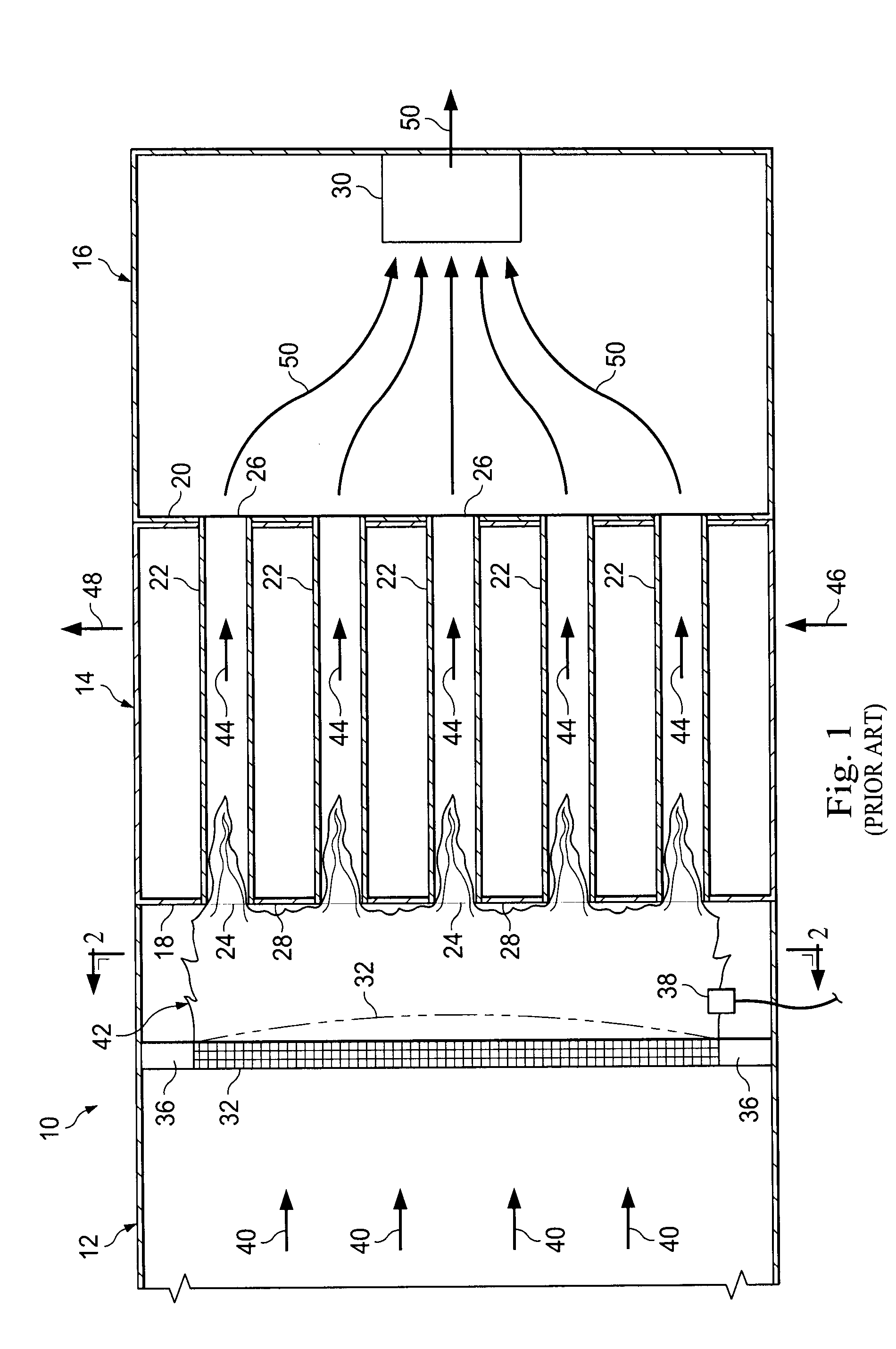

Biomass converters and processes

InactiveUS20080134540A1Reduce decreaseQuick limitBio-organic fraction processingExcrement fertilisersProcess engineeringDefining length

This invention pertains to a bio-mass processing system, and method of processing waste bio-mass, wherein one or more mixers mixes a bed of bio-mass material such as manure at substantially any and all locations in a defined length and width portion of the bed, in a dryer. Heated air percolates upwardly through the bed. Separation apparatus separates a relatively dryer fraction of the bio-mass material from the dryer. The separated finished product from the dryer is optionally fed to a boiler where the dried bio-mass material is burned. Heat of combustion from the boiler is used as dryer heat for drying the bio-mass feed material in the dryer. Excess heat is optionally used to produce steam, which powers a turbine, which powers an electrical generator. Residual ash from the combustion process comprises about 2% by weight of the solids content of e.g. a feed stream coming into the dryer.

Owner:ECOCOMBUSTION ENERGY SYST CORP

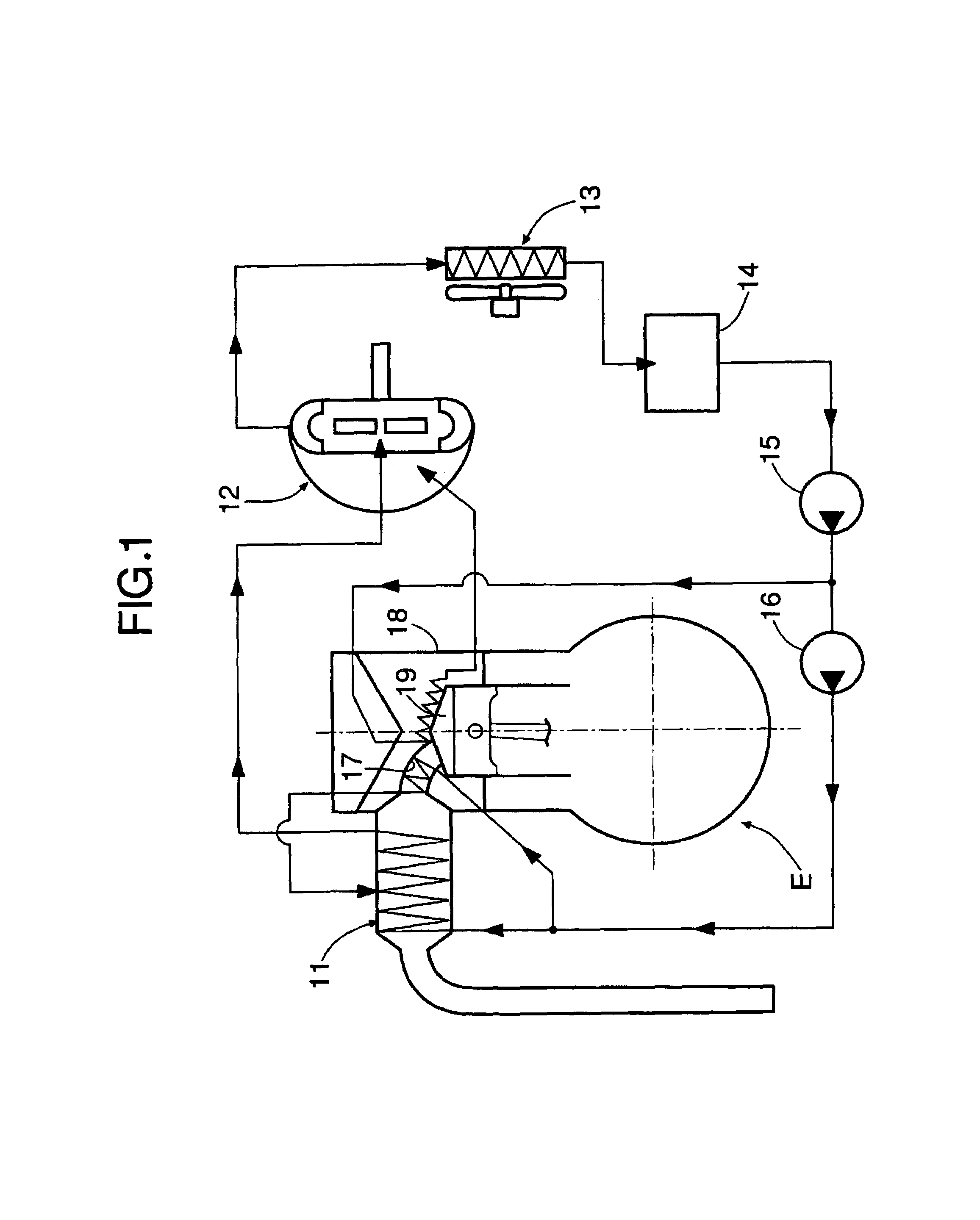

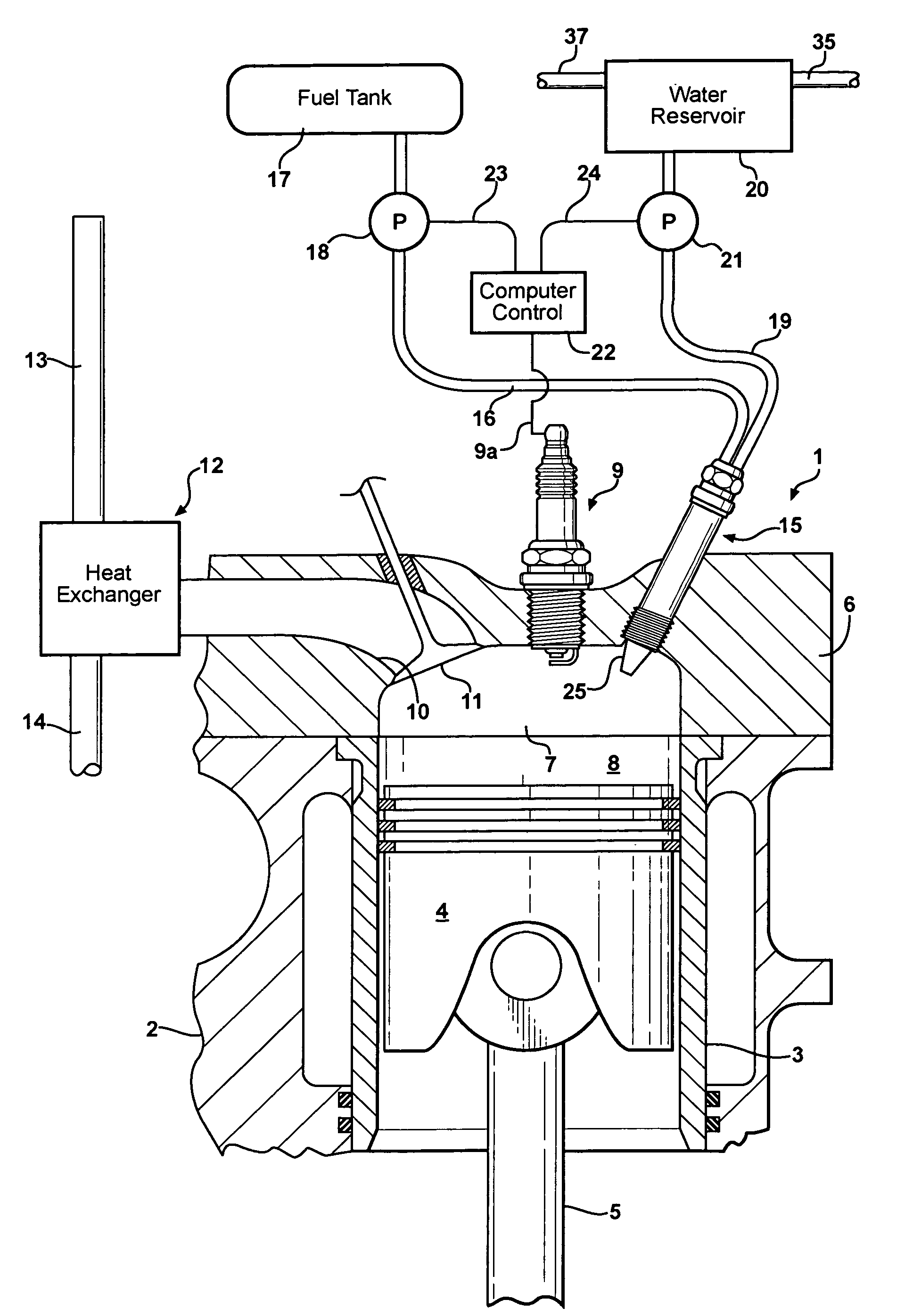

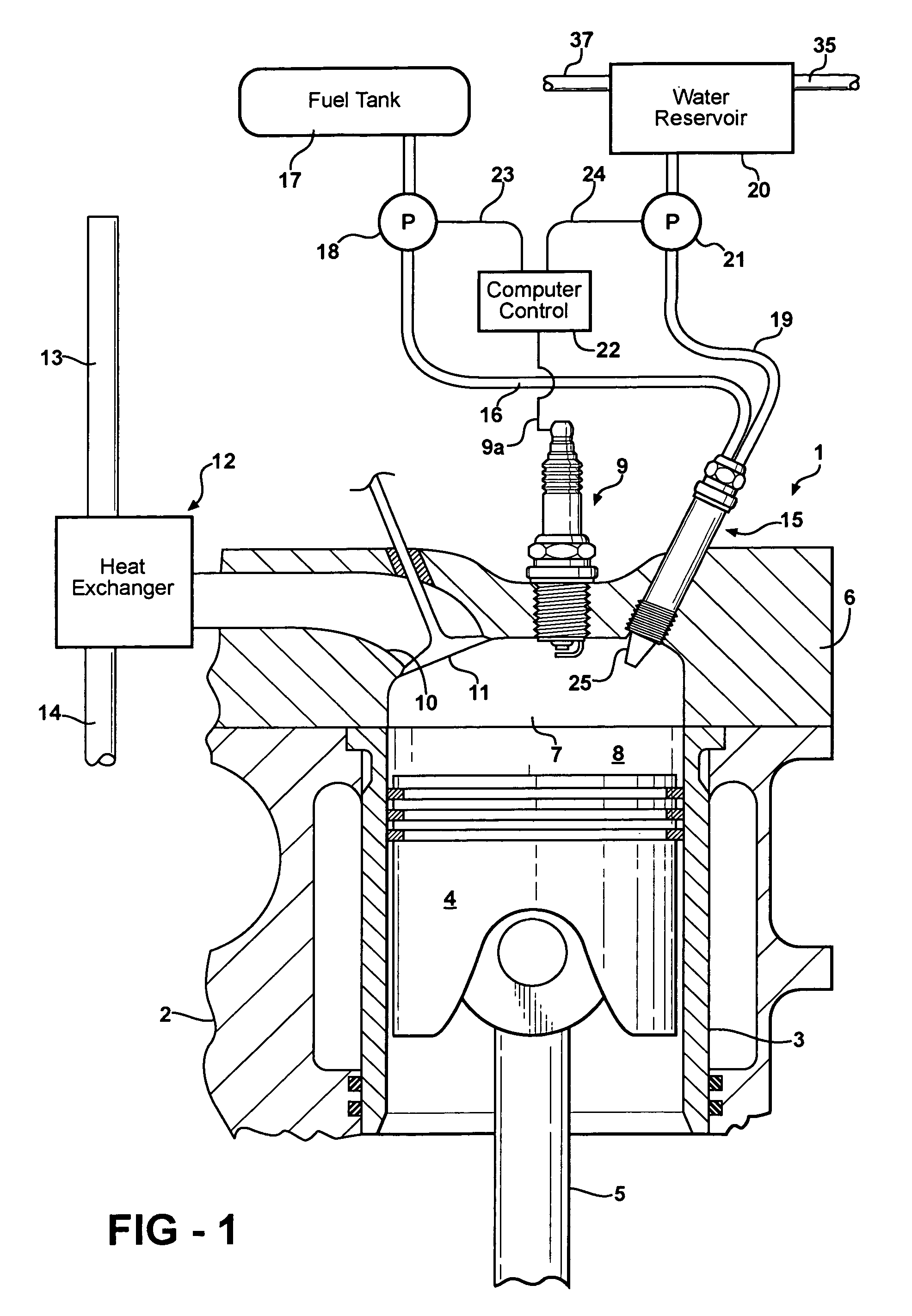

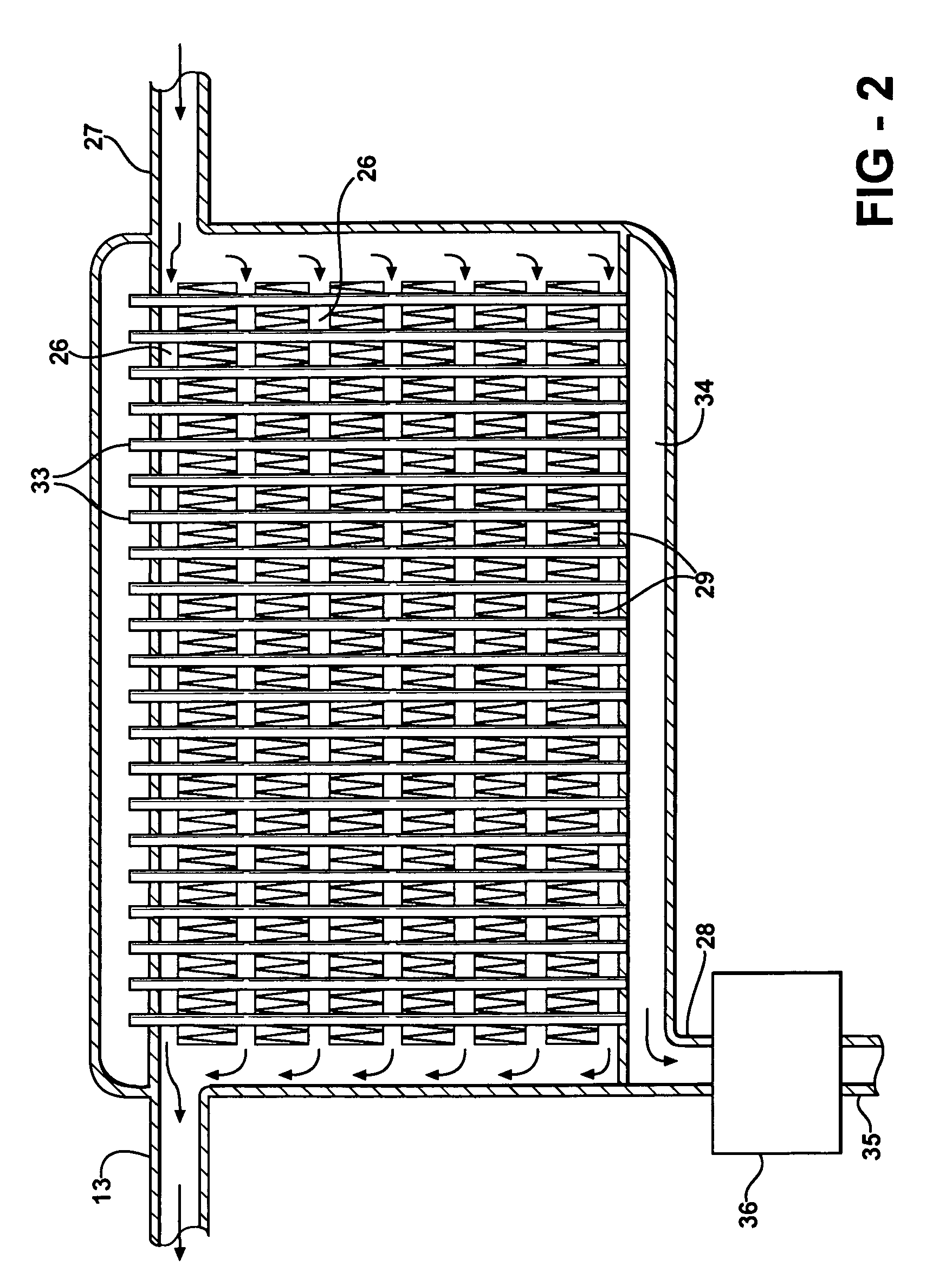

Internal combustion engine and method of operating

InactiveUS7367306B1Quantity minimizationInternal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineInternal combustion engine

An internal combustion engine having at least one cylinder within which is a reciprocable piston movable in a compression stroke followed by movement in a power stroke and wherein a combustible fuel mixture is injected into the combustion chamber, compressed, ignited, and burned to produce the power stroke of the piston. After the fuel has been ignited and during the compression of such mixture a quantity of water from a reservoir is injected into the combustion chamber and converted by the heat of combustion into superheated steam, thereby generating within the combustion chamber a force which assists in driving the piston through its power stroke. The products of combustion and steam are discharged from the cylinder following the power stroke and cooled in a heat exchanger in which the steam is condensed, following which the gases are exhausted and the condensate returned to the water reservoir.

Owner:HOLDEN RANDALL W

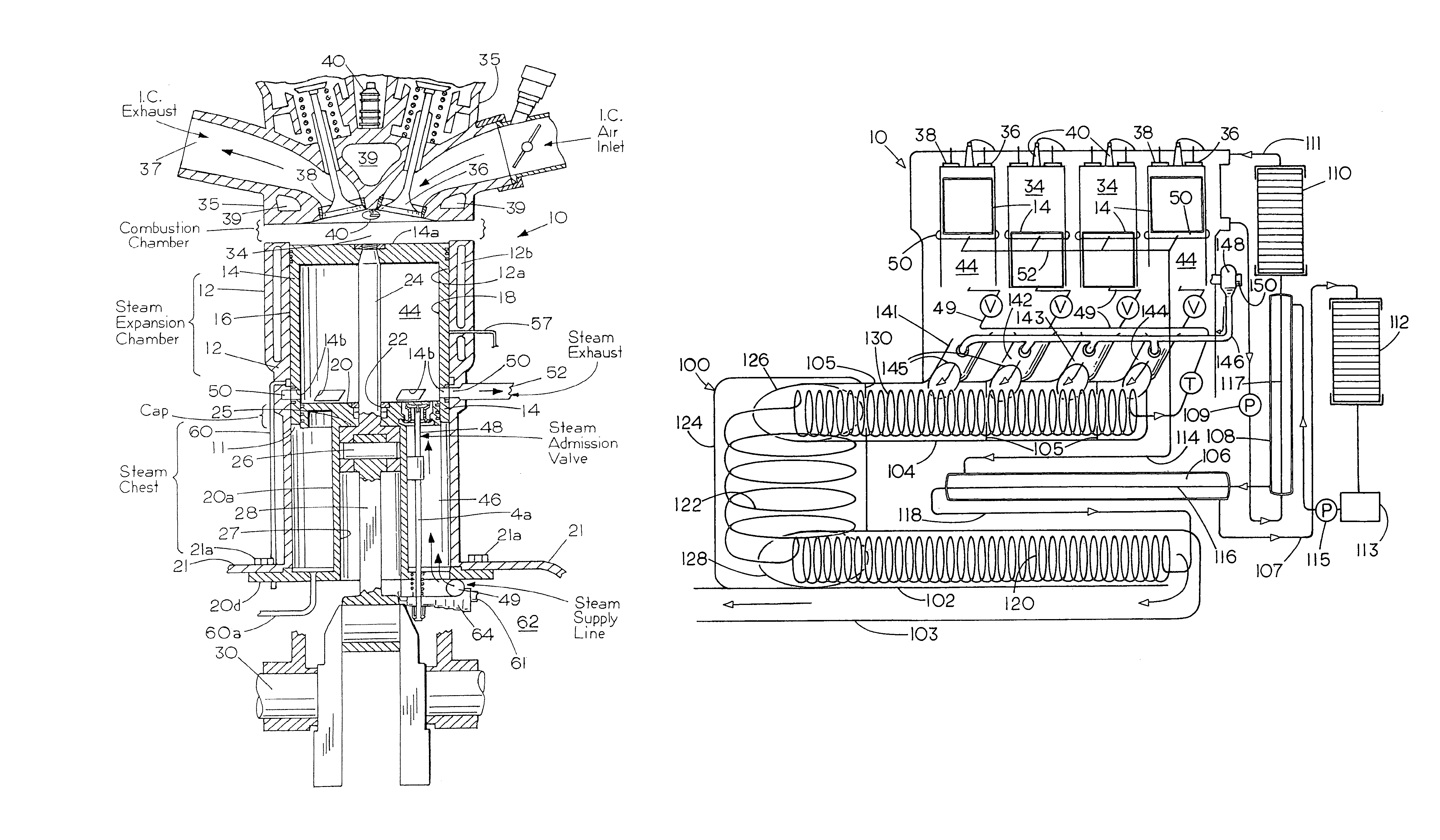

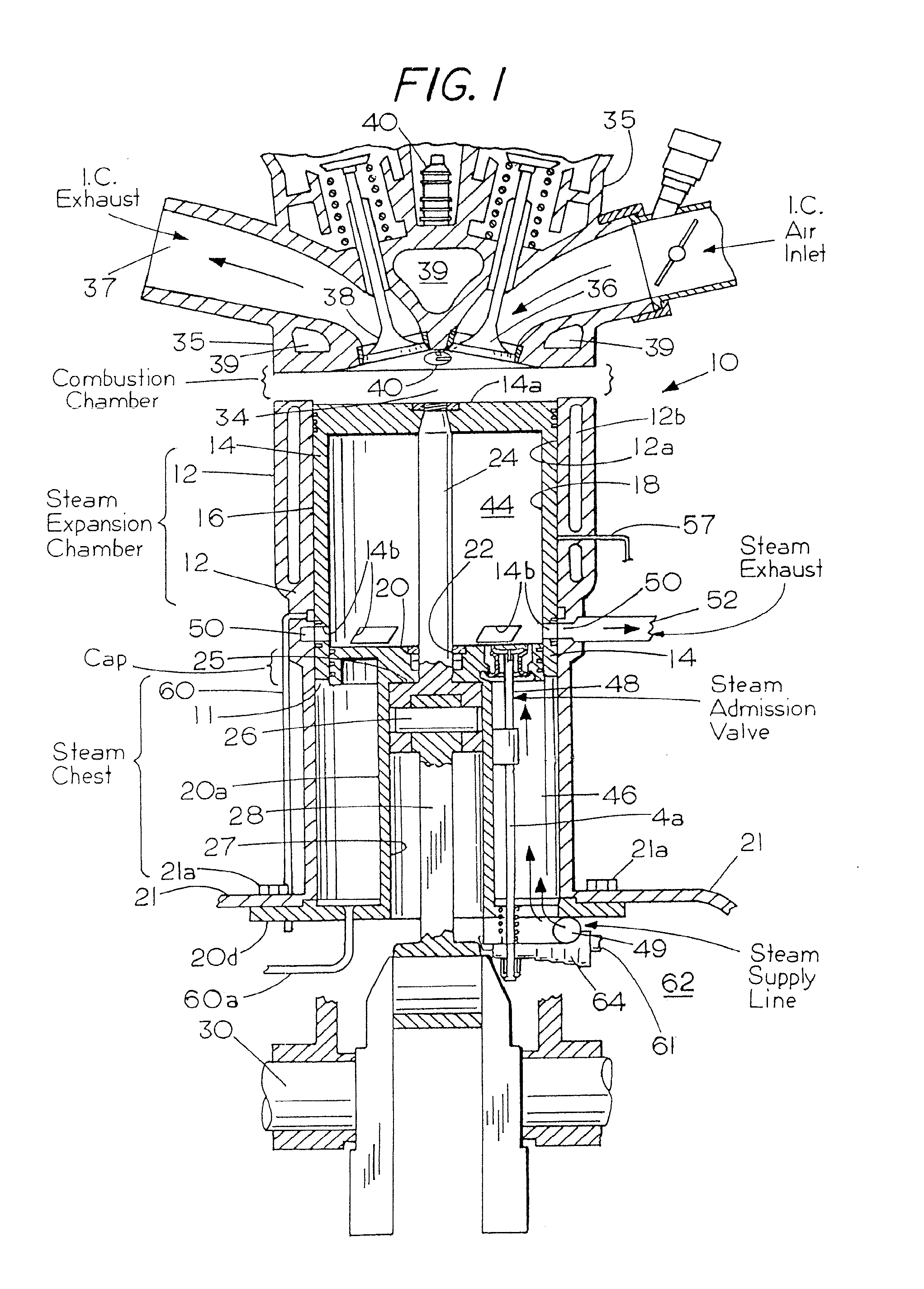

Internal combustion engine with auxiliary steam power recovered from waste heat

ActiveUS7997080B2Effectively economizeImprove efficiencyInternal combustion piston enginesSteam regenerationExternal combustion engineEngineering

Owner:THERMAL POWER RECOVERY

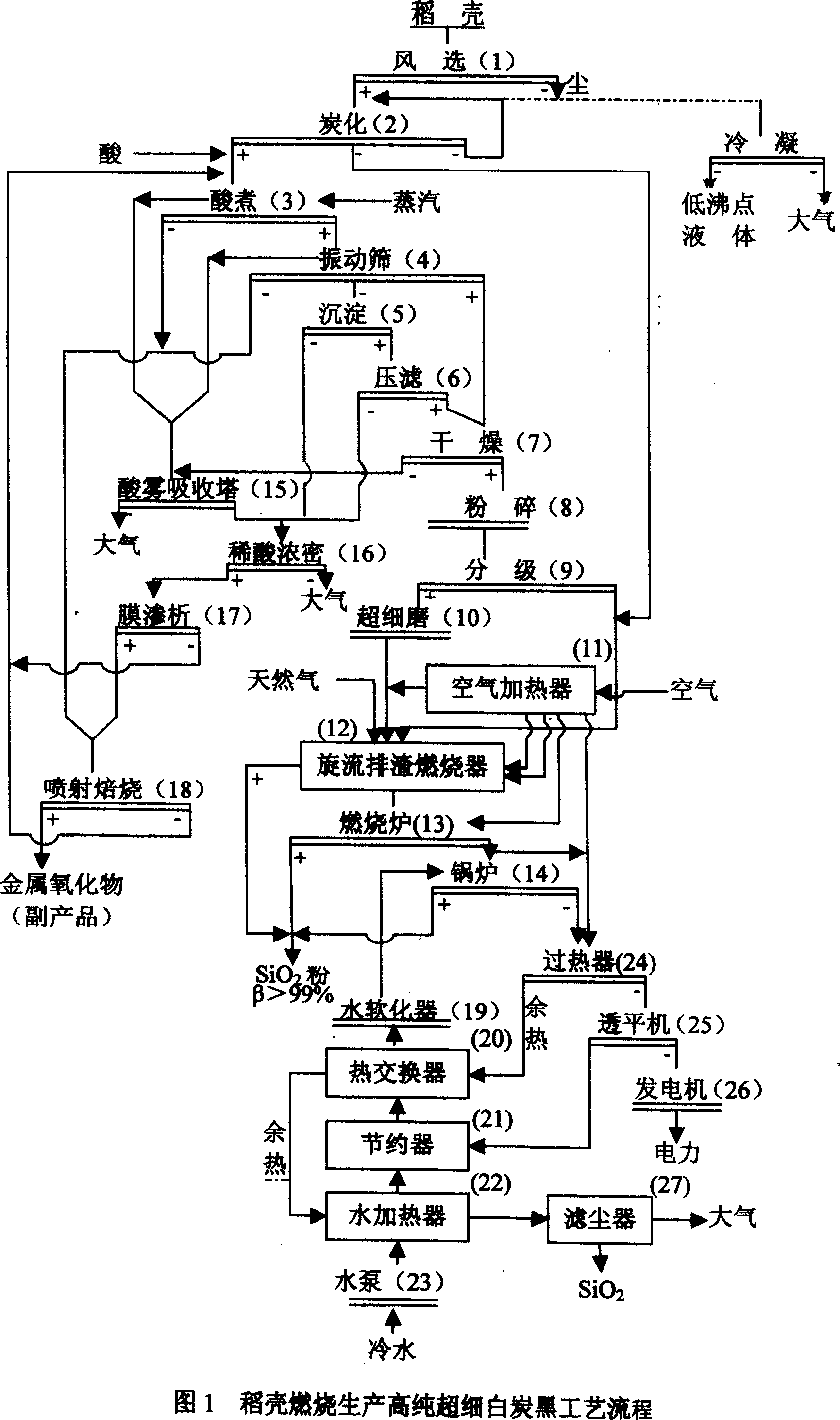

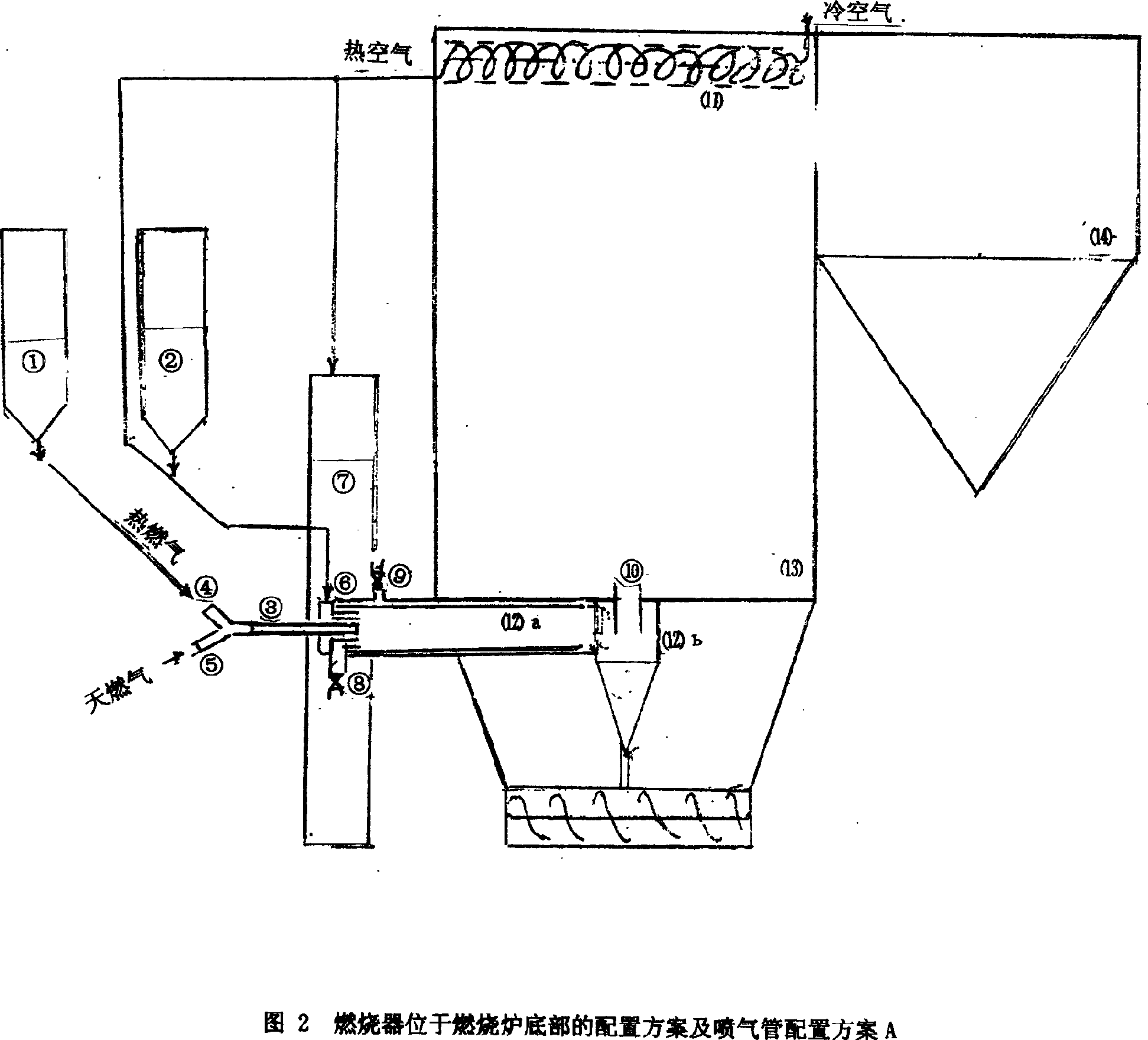

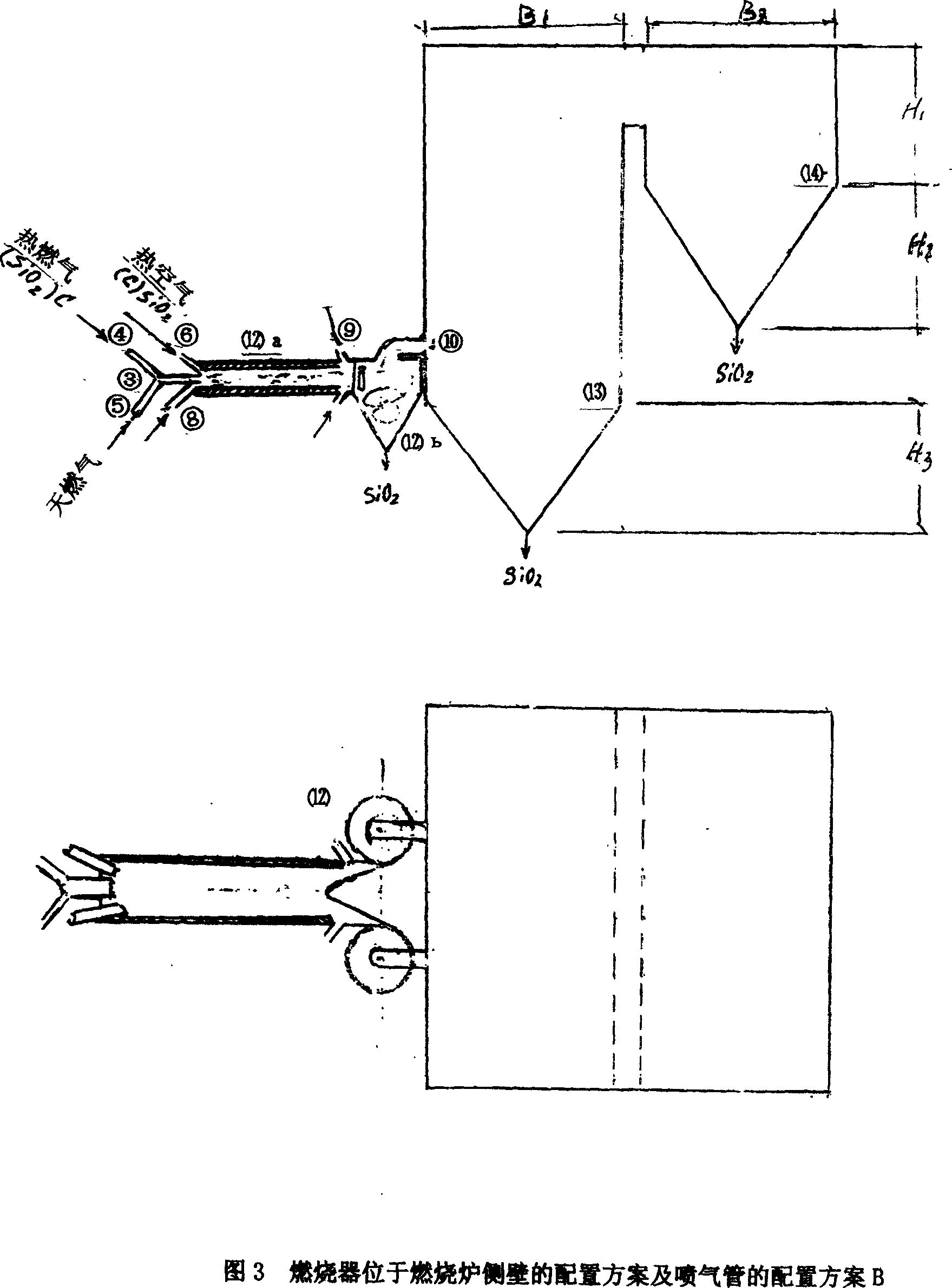

Process for producing super-fine high-purity white carbon from rice hull and burning heat

InactiveCN101028926AIncrease dissociationImprove product qualitySilicaCombustion systemProcess engineering

A process for preparing high-purity superfine white carbon black from rice husk by the heat generated by burning the rice husk includes such steps as charring, acid treating, pulverizing, sieving, burning in a serial combustion system to obtain white carbon black and waste acid, and treating the waste acid for reuse.

Owner:郭梦雄

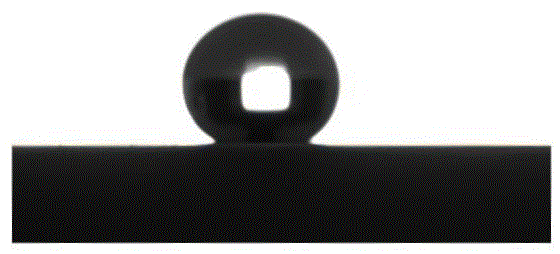

Hydrophobic natural macromolecule/attapulgite composite aerogel and preparation method thereof

PendingCN106732214ALow priceWide variety of sourcesAerogel preparationColloidal chemistry detailsFreeze-dryingPetrochemical

The invention discloses a preparation method of a hydrophobic natural macromolecule / attapulgite composite aerogel. The preparation method includes the steps: firstly, dissolving natural macromolecules into water to obtain transparent solution; secondly, adding attapulgite and organic silicon modifying agents into the solution, uniformly stirring mixture, and freezing the mixture; finally, performing vacuum freeze drying for the mixture to obtain corresponding hydrophobic natural macromolecule / attapulgite composite aerogel. The hole diameter of the composite aerogel is 2-700nm, the BET specific surface area of the composite aerogel highly reaches 30-800m<2>*g<-1>, the apparent density of the composite aerogel is 0.02-0.35g*cm<-3>, the heat conductivity of the composite aerogel is 0.01-0.05W*m<-1>*k<-1>, the compression modulus of the composite aerogel is 0.05-10MPa, the contact angle of the composite aerogel is 90 DEG C to 179.9 DEG C, and combustion heat value of the composite aerogel is 0.6-1.9MJ-kg<-1>. The natural macromolecule / attapulgite composite aerogel prepared by the method is good in blocking performance and hydrophobicity, low in density and heat conductivity and high in strength, the combustion heat value is lower than 1.9MJ-kg<-1>, A-grade flame-retardant requirements are met, the preparation method is simple in process, short in period and free from pollution, and the prepared hydrophobic natural macromolecule / attapulgite composite aerogel is applied to the field such as building energy conservation, petrochemical industry and sewage treatment.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

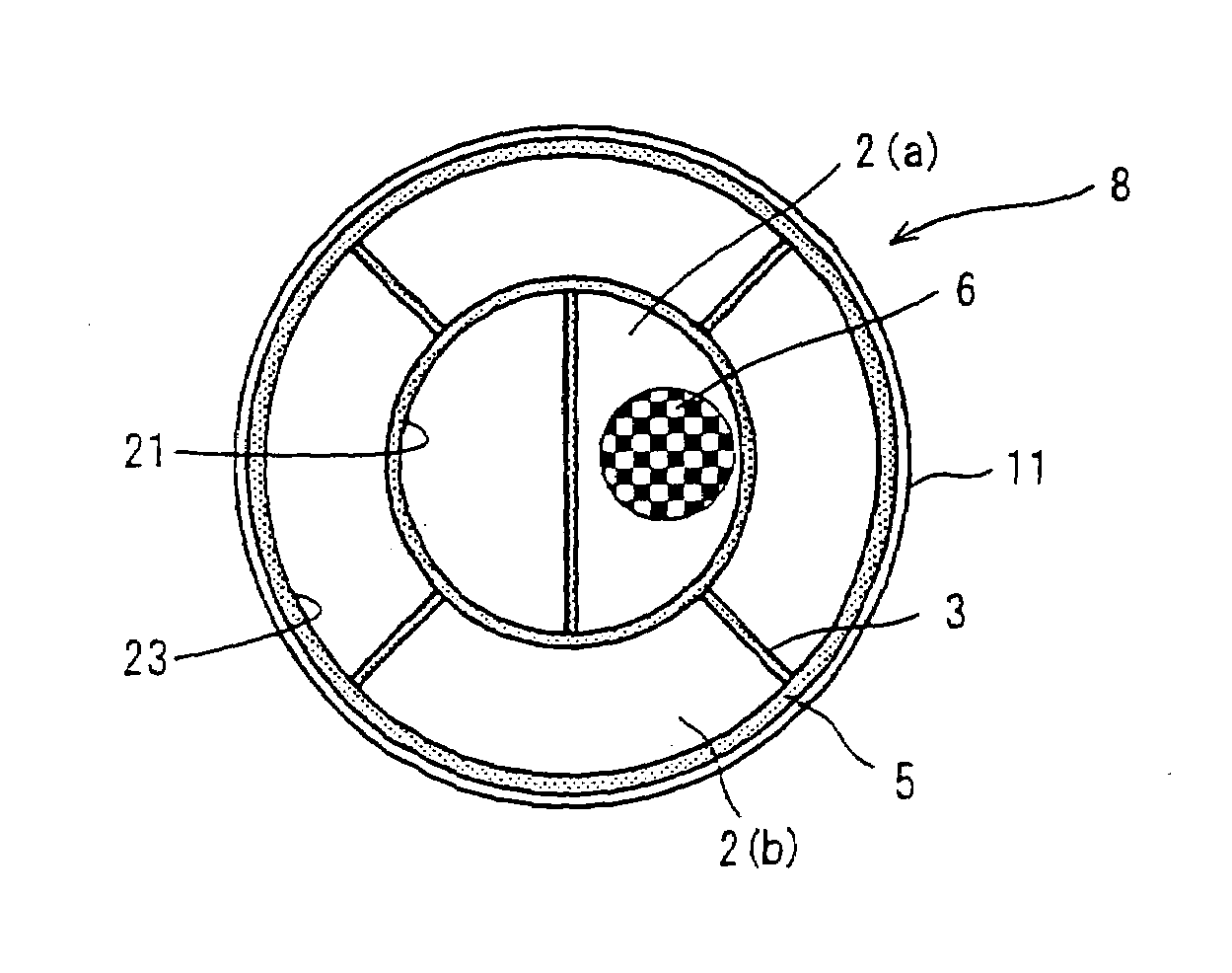

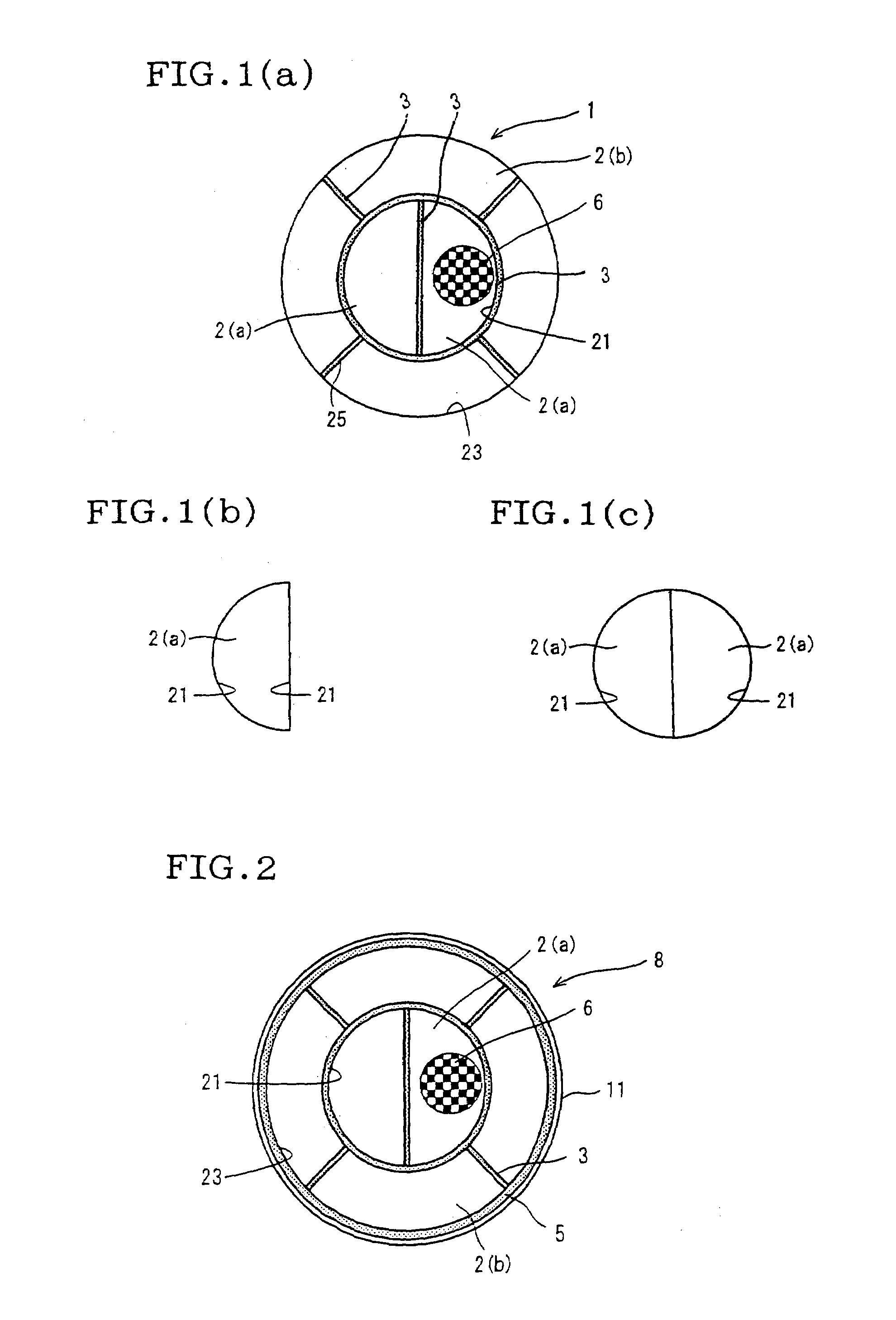

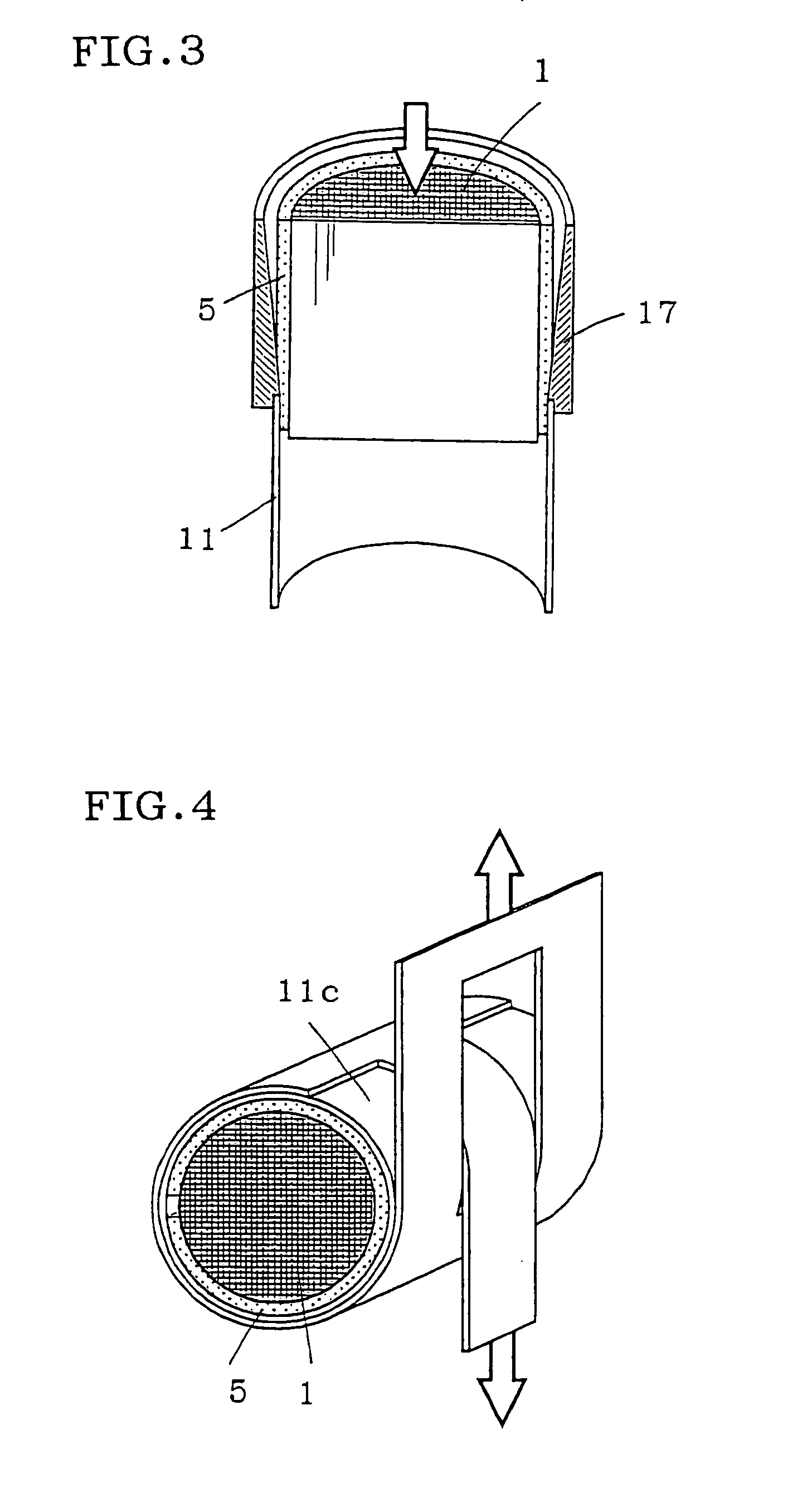

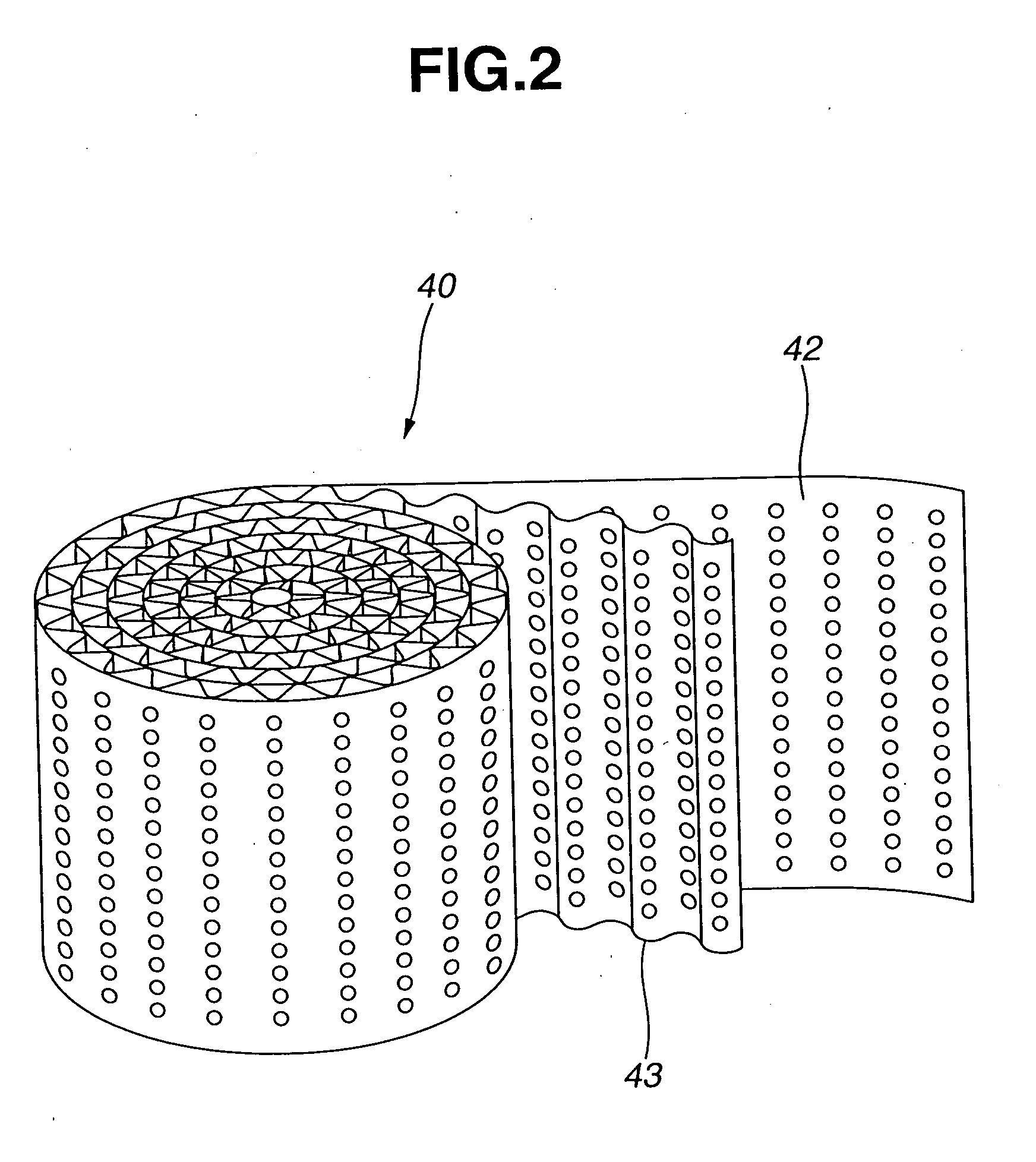

Honeycomb structure and assembly thereof

A honeycomb structure obtained by bonding, into one piece, a plurality of honeycomb segments (2) each having a plurality of passages (6) surrounded by cell walls and extending in the axial direction of the segment. In the honeycomb structure, a material A (3) having compressive elasticity is provided between a side surface (21) of at least one honeycomb segment [2(a)] not constituting the outermost peripheral surface (23) of the honeycomb structure (1) and a side surface of the honeycomb segment [(2(b)) adjacent thereto. A honeycomb structure assembly (8) obtained by providing a material B (5) having compressive elasticity on the outermost peripheral surface (23) of the honeycomb structure (1) in a compressed state and thereby compression-holding the resulting honeycomb structure in a metallic container (11). A honeycomb structure using materials having compressive elasticity (B) is resistant to breakage, and has superior durability and reliability, by reducing the thermal stress generated therein during use by a sharp temperature change of inflow gas, a local heat of reaction and a local heat of combustion.

Owner:NGK INSULATORS LTD

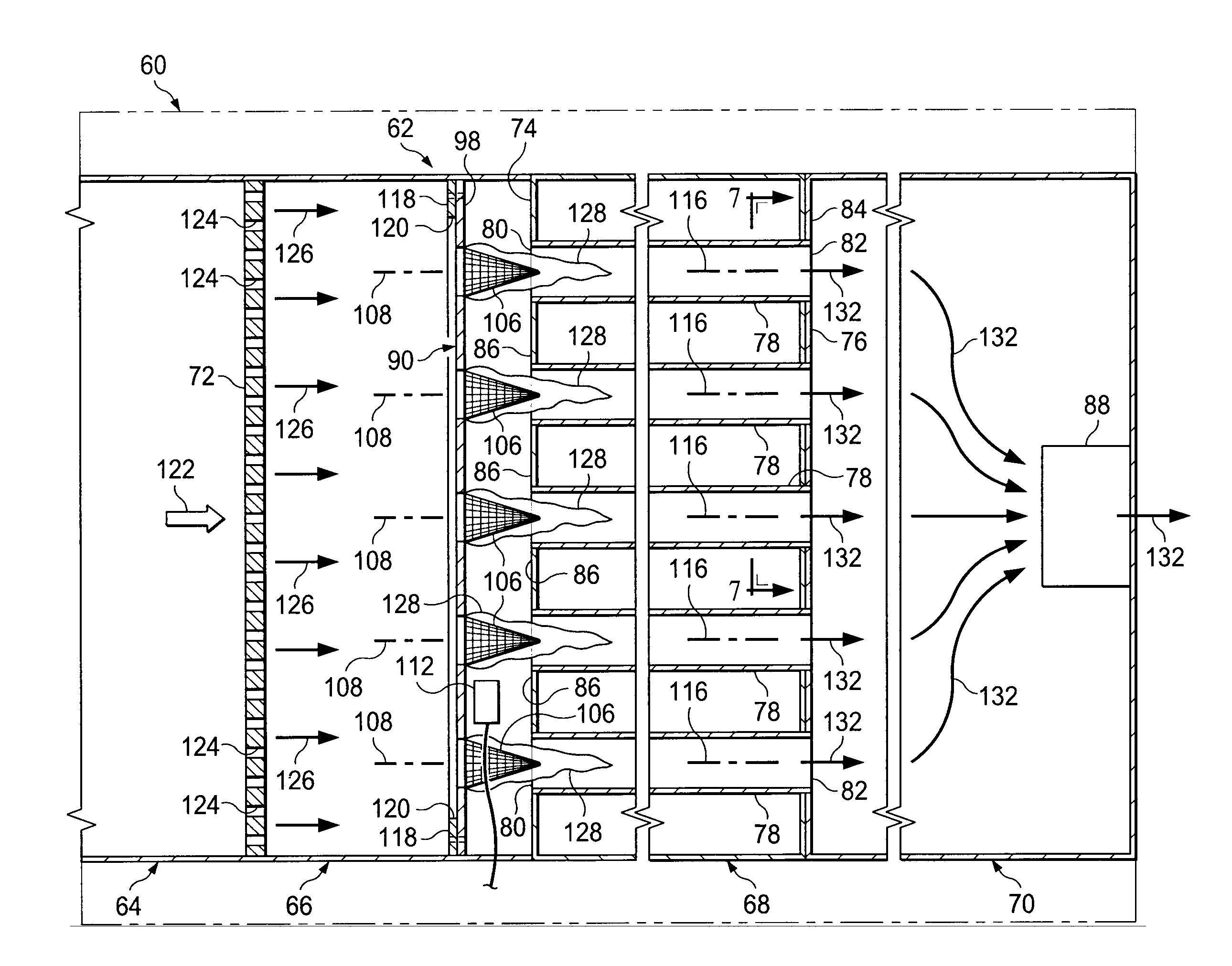

Multi-Cone Fuel Burner Apparatus For Multi-Tube Heat Exchanger

InactiveUS20150192291A1Hot-air central heatingAir-treatment apparatus arrangementsMixed flowCombustor

Installed in a fuel-fired heating appliance is a specially designed burner assembly operative to receive and combust a pre-mixed flow of fuel and air to create therefrom a spaced apart plurality of flames which are aligned with and flow directly into the inlets of a corresponding spaced plurality of heat exchanger tubes. The flames create within the tubes hot combustion gases that transfer combustion heat to a supply fluid flowed externally across the tubes. The burners are of a hollow perforate metal construction, are mounted on and forwardly project from a support structure toward the tube inlets, and have rearwardly facing open inlet ends that receive the pre-mixed flow of fuel and air. In one illustrated embodiment thereof, the burners have conical configurations, and in another illustrated embodiment have generally dome-shaped configurations. Via a flame carryover structure, a single igniter is utilized to ignite all of the burners.

Owner:RHEEM MFG CO

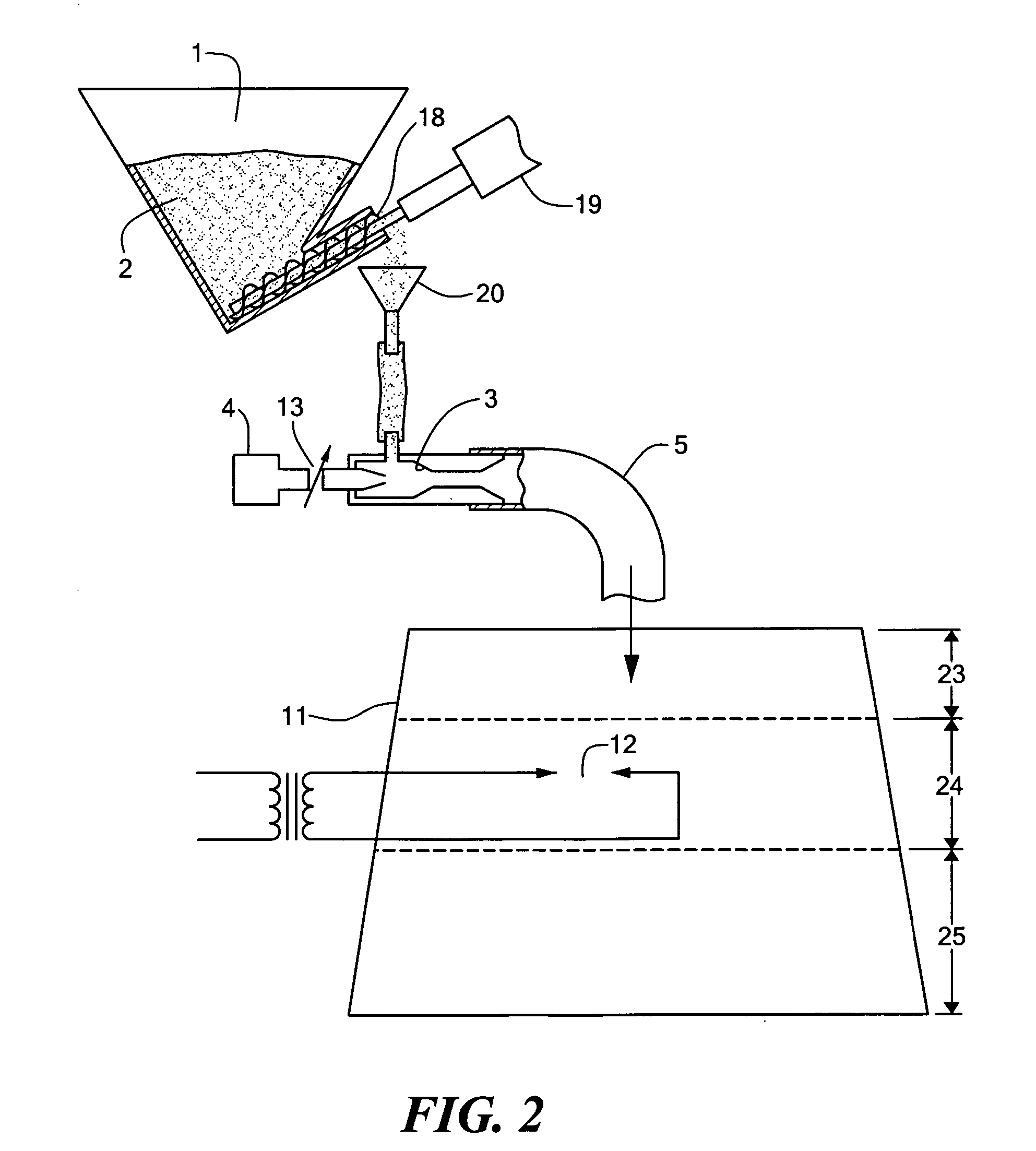

Flame spraying process and apparatus

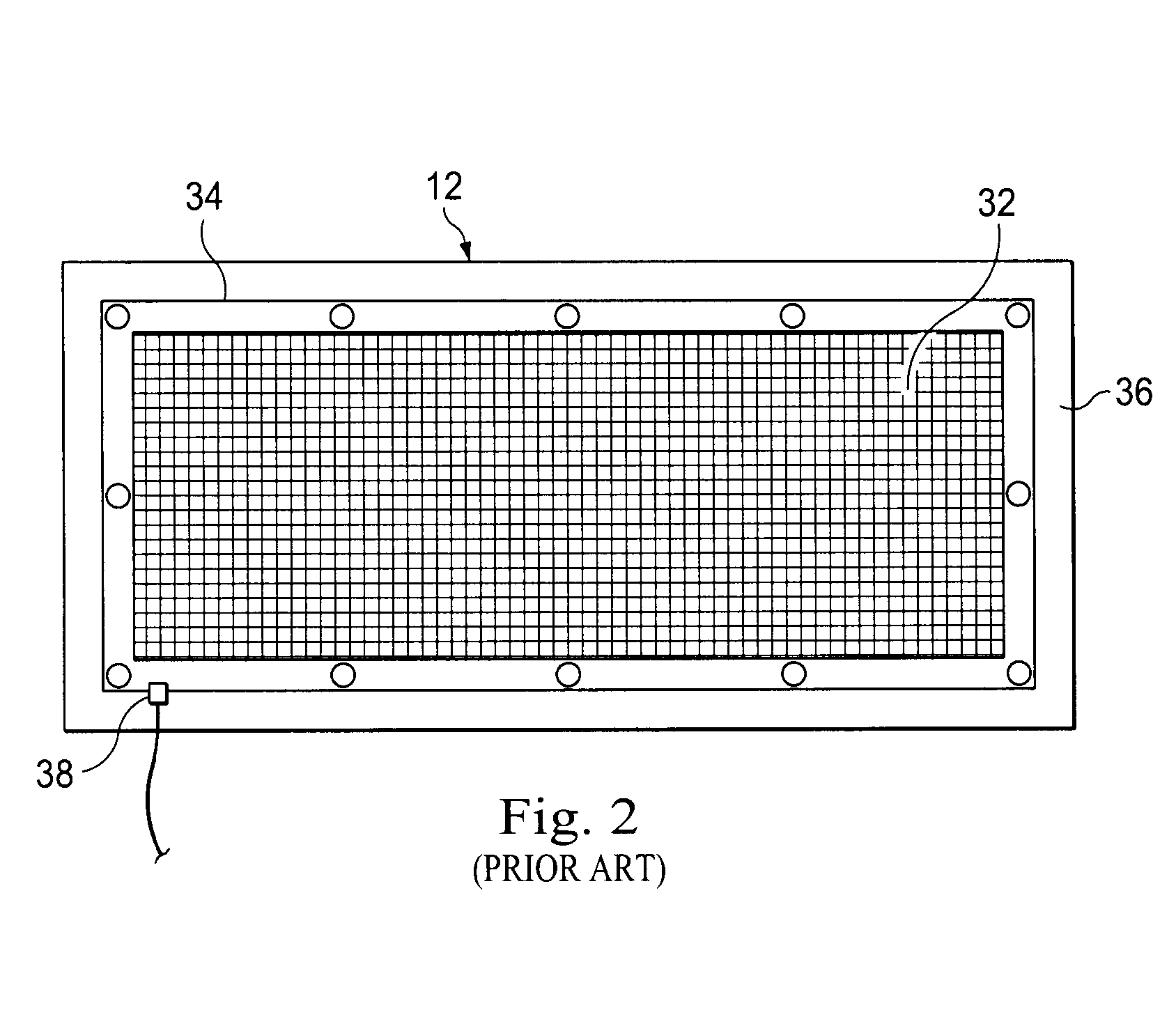

InactiveUS20060062928A1Avoid insufficient heatingLiquid surface applicatorsMolten spray coatingCombustion chamberRefractory

A process, apparatus and material composition for forming a coherent refractory mass on a surface wherein one or more non-combustible materials are mixed with one or more metallic combustible powders and an oxidizer, igniting the mixture in a combustion chamber so that the combustible metallic particles react in an exothermic manner with the oxidizer and release sufficient heat to form a coherent mass of material under the action of the heat of combustion, and projecting this mass against the surface so that the mass adheres durably to the surface.

Owner:GJL PATENTS

Resource utilization method of kitchen waste

InactiveCN102371266AReduce processing costsAchieving a circular economySolid waste disposalOil and greaseBiodiesel

The invention provides a resource utilization method of kitchen waste. The resource utilization method comprises the following steps: a. carrying out high-temperature instantaneous sterilization on the collected kitchen waste and then storing the sterilized kitchen waste; b. removing free water and oil out of the kitchen waste; c. carrying out oil-water separation and exchange reaction on a liquid phase so as to prepare biodiesel, and then carrying out waste water treatment; d. carrying out magnetic separation and further dewatering; e. processing with a catalyst; f. transforming combustion heat energy; and g. removing colloid out of the liquid phase through oil-water separation so that the colloid can be taken as fuel oil, and then carrying out waste water treatment on an aqueous phase. The resource utilization method has the beneficial effects that the kitchen waste is fully recycled so as to solve the problems of waste water, waste gas and the like; the effects of high efficiency, energy conservation, low consumption and environmental protection are realized; wastes are changed into valuables; and the treatment cost is low, thus achieving the purpose of circular economy.

Owner:青岛福瑞斯生物能源科技开发有限公司

Biomass fluid bed combustion device and combustion method

InactiveCN101059243AExtended stayReduce sulfur contentIncinerator apparatusFluidized bedCarbonization

The present invention discloses a biomass fluidized-bed device and the method, the device includes a burning reactor equipped with at least one air inlet and a smoke gas outlet and a pyrolytic gasifying reactor which is connected with the burning reactor through pyrolytic gas connecting pipes and refeed connecting pipes, the pyrolytic gas connecting pipes are inserted into the upper or the middle of burning reactor, refeed connecting pipes are inserted into the lower of burning reactor, the pyrolytic gasifying reactor is also equipped with a gas inlet and a feeding mouth; the method is: first transmitting the biomass and addition agent into pyrolytic gasifying reactor to pyrolytic gasifying and generating carbonization pyrolytic gas; second transmitting the reacted pyrolytic gas into the dilute phase burning zone of burning reactor, transmitting the carbonization biomass into the dense phase burning zone of burning reactor to burn, the reacting temperature in pyrolytic gasifying reactor is 400-800deg.C and the reacting temperature in burning reactor is 600 -950deg.C, the method in the invention has characteristics of highly effective burning and effective preventing of base metal corrosion during the burning process.

Owner:SOUTHEAST UNIV

Hydrogen combustion heater

InactiveUS20050142507A1Easy constructionImprove the heating effectCapillary burnersIndirect carbon-dioxide mitigationPtru catalystEngineering

The invention relates to a hydrogen combustion heater. This heater includes (a) a passage for allowing hydrogen gas and air to flow therethrough; (b) a first catalyst provided in the passage, the first catalyst being heated, when electricity is applied thereto, thereby starting a first combustion of a first mixture of the hydrogen gas and the air in the first catalyst; and (c) a heat exchanger provided downstream of the first catalyst in the passage, the heat exchanger being adapted to transfer heat generated by the first combustion to a heating medium of the heat exchanger.

Owner:CALSONIC KANSEI CORP

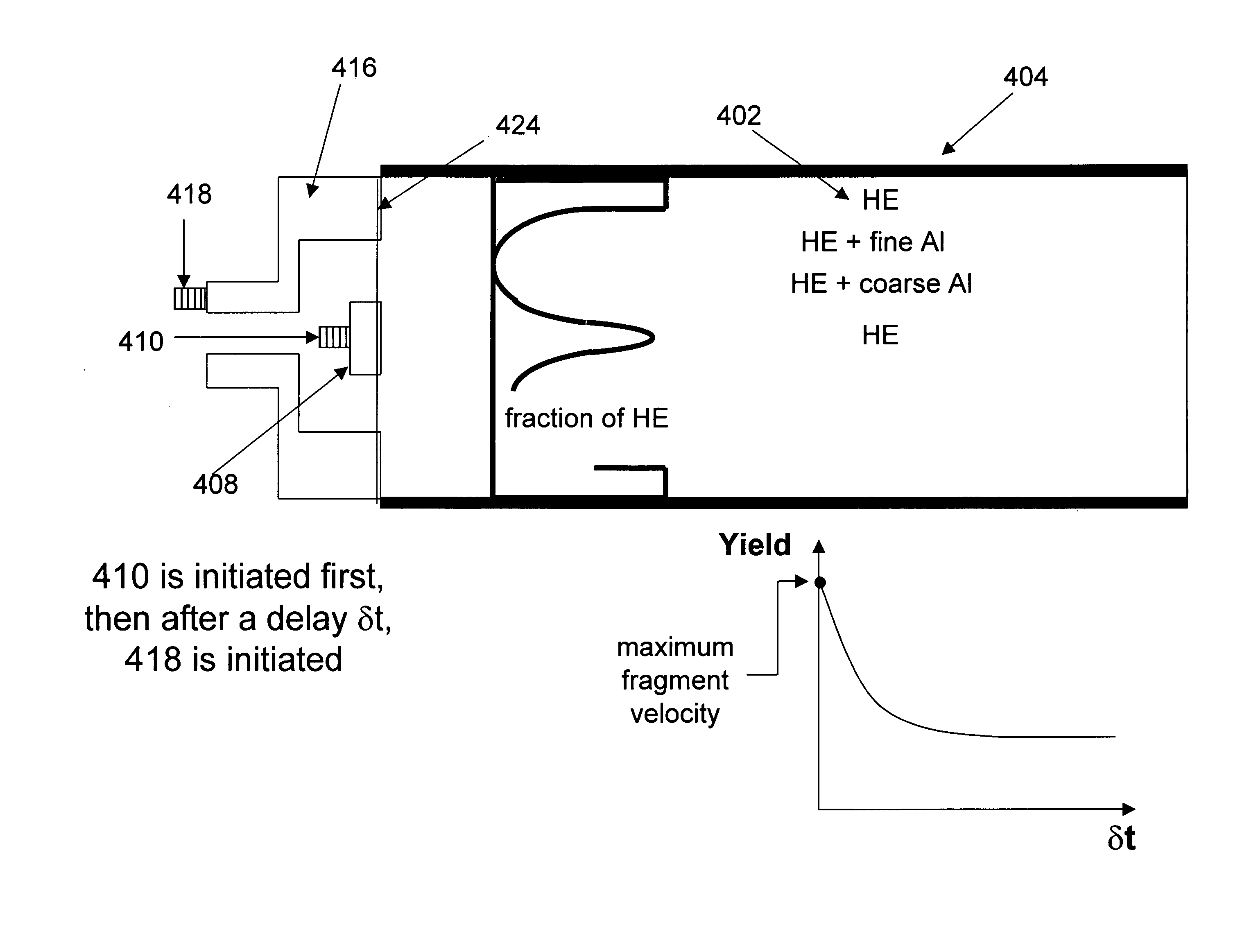

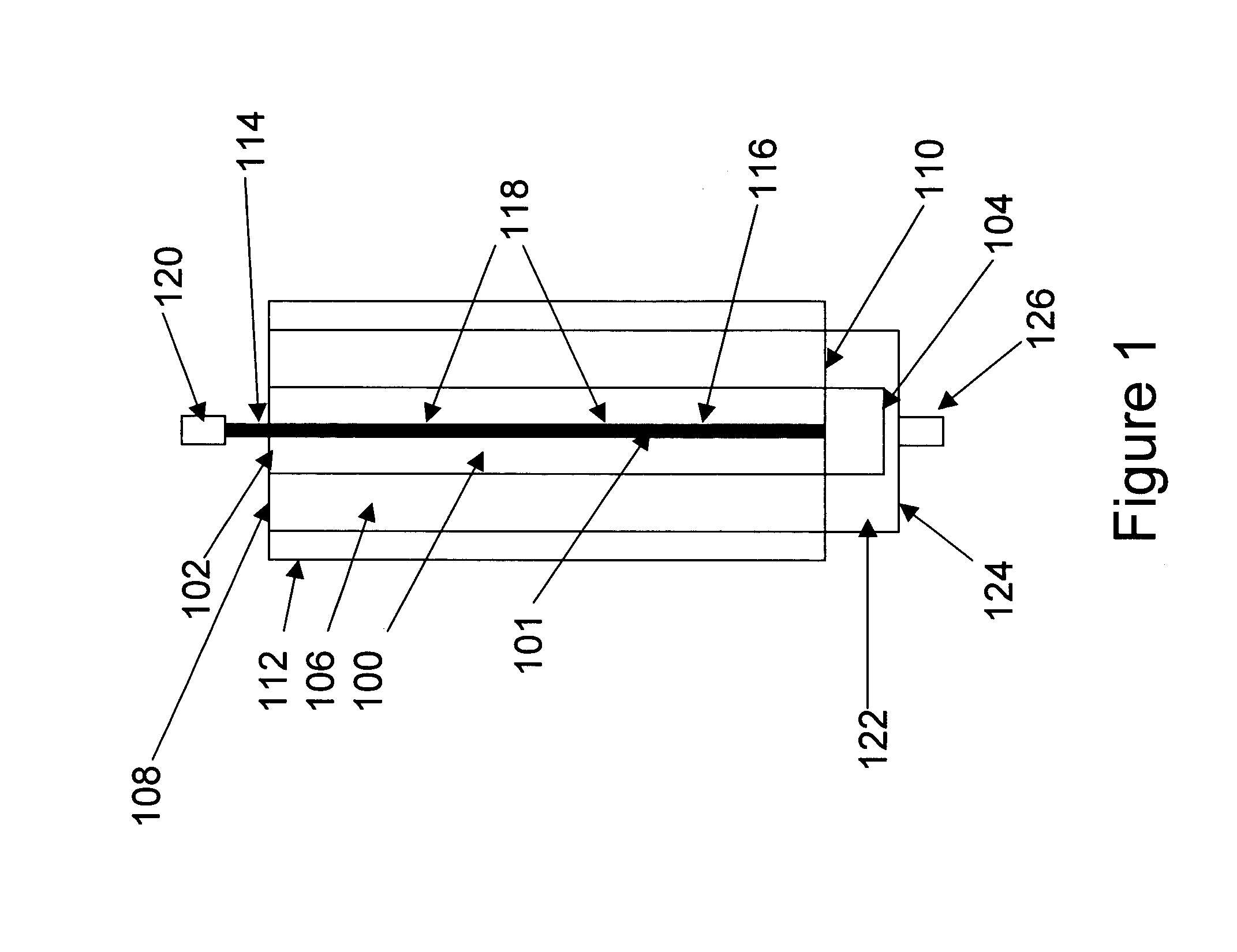

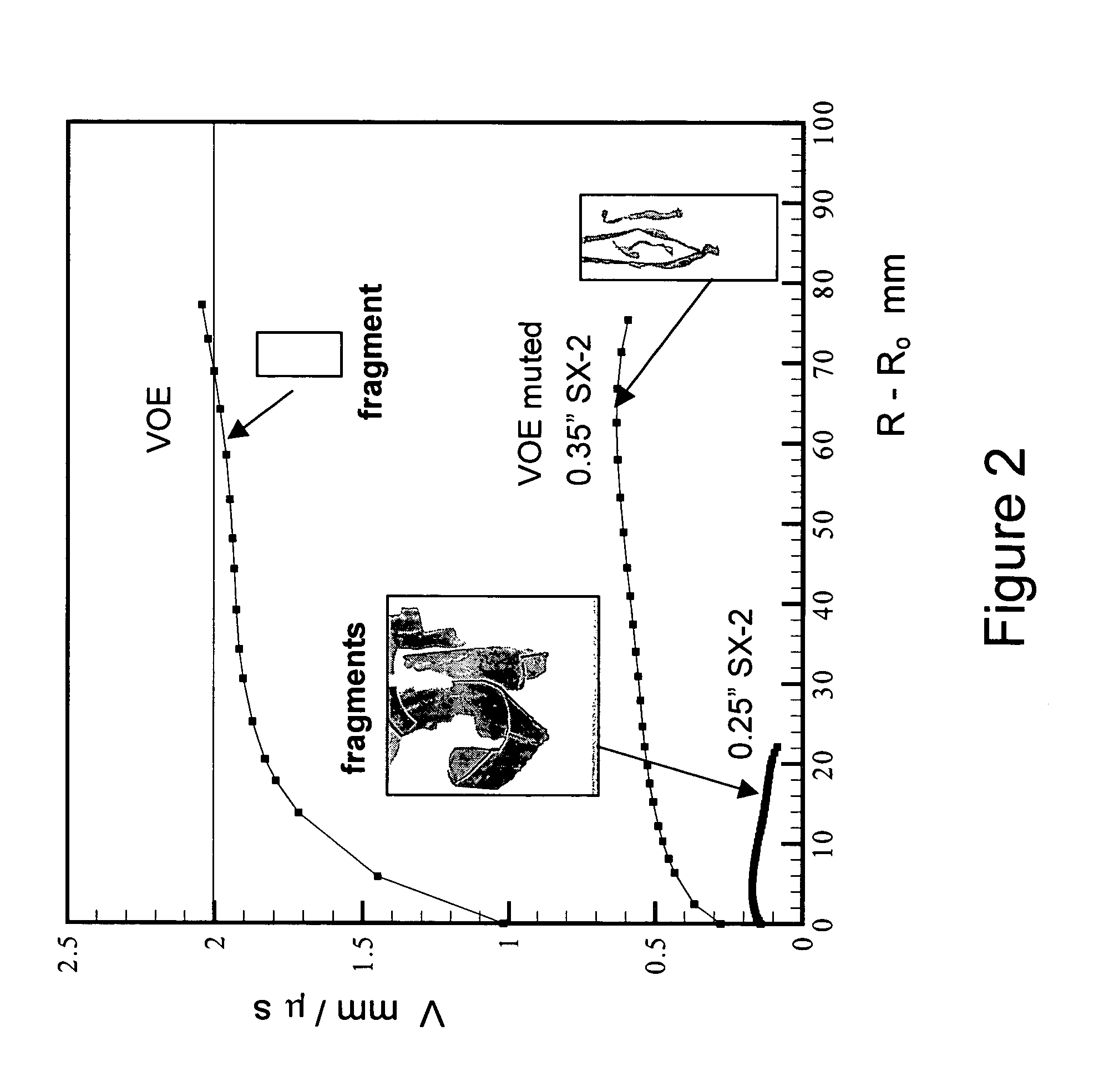

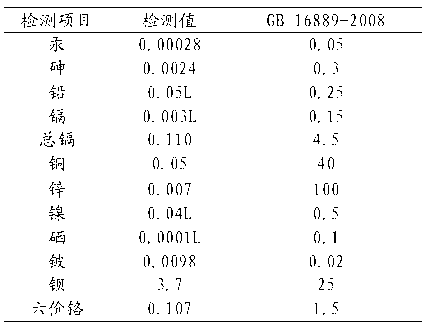

Variable output and dial-a-yield explosive charges

The invention, as embodied herein, comprises a variable yield warhead comprising an inner core of cylindrically-shaped, explosive material surrounded by an outer annulus of a different explosive material. The inner core explosive material has a heat of combustion comprising about 16 kcal / cc or higher and the outer annulus of explosive material has a heat of detonation comprising about 2.1 kcal / cc or higher. A warhead casing surrounds the outer annulus of material. The warhead has a dual initiation system. The first initiation system comprises a detonation cord that extends substantially through the inner core of explosive material and has an initiator at the tope side. The second initiation system comprises a booster explosive that contacts the bottom side of the outer annulus of explosive material and an initiator proximate to the booster.

Owner:NAVY AS REPRESENTED BY THE SEC OF THE UNITED STATES OF AMERICA THE

Method for treating flying ash through low-temperature molten sintering

InactiveCN103230924ALower melting temperatureImprove curing effectSolid waste disposalProcess engineeringHeat of combustion

The invention discloses a method for treating flying ash through low-temperature molten sintering and belongs to the technical field of hazardous solid waste treatment. The process is finished through the following steps of: mixing the flying ash and a fluxing agent subjected to crushing treatment, adding water into the mixed components, prefabricating into blocks, throwing the blocks into a solid waste incinerator, and performing low-temperature molten sintering on the blocks containing the flying ash by utilizing combustion heat in the furnace in a process of combusting the solid wastes. According to the method for treating flying ash through low-temperature molten sintering, the melting temperature of the flying ash can be effectively reduced, the physical form of the flying ash can be changed, and the flying ash can be subjected to molten sintering treatment by fully utilizing conventional solid waste incineration equipment, so that the equipment investment cost is saved; the flying ash is treated by utilizing the combustion heat in the process of combusting the solid wastes, so that the energy consumption can be reduced; and moreover, the flying ash subjected to molten sintering is good in curing agent, and heavy metal ions in the flying ash can be effectively prevented from leaching out.

Owner:广东生活环境无害化处理中心有限公司 +1

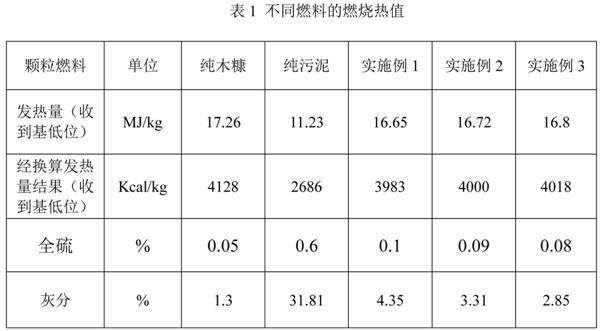

Environment-friendly biomass granular fuel and preparation method thereof

The invention discloses an environment-friendly biomass granular fuel, which comprises the following components in part by weight: 80-85 parts of sawdust, 5-10 parts of sludge and 0.1-1 part of illegally recycled waste cooking oil. A preparation method of the environment-friendly biomass granular fuel comprises the following steps: drying the sawdust and the sludge, adding the illegally recycled waste cooking oil to the sawdust and the sludge, agitating the mixture uniformly, and processing the mixture into cylindrical grains under conditions of a high temperature and a high pressure. By using the biomass granular fuel provided by the invention, the production cost is decreased; the energy consumption is decreased; the combustion heat value is high; the combustion time is long; the wear of a machine is reduced; the environment is protected effectively; the fuel problem is solved; simultaneously, the health is also protected; the biomass granular fuel is environment-friendly; the cost is decreased; after the biomass granular fuel is combusted, waste residues can be returned to the nature to be used as a fertilizer, and also can be used as a raw material of an environment-friendly brick; and the resource utilization and the harmless treatment of waste materials such as the sludge, the illegally recycled waste cooking oil and the like are achieved.

Owner:曹其宽

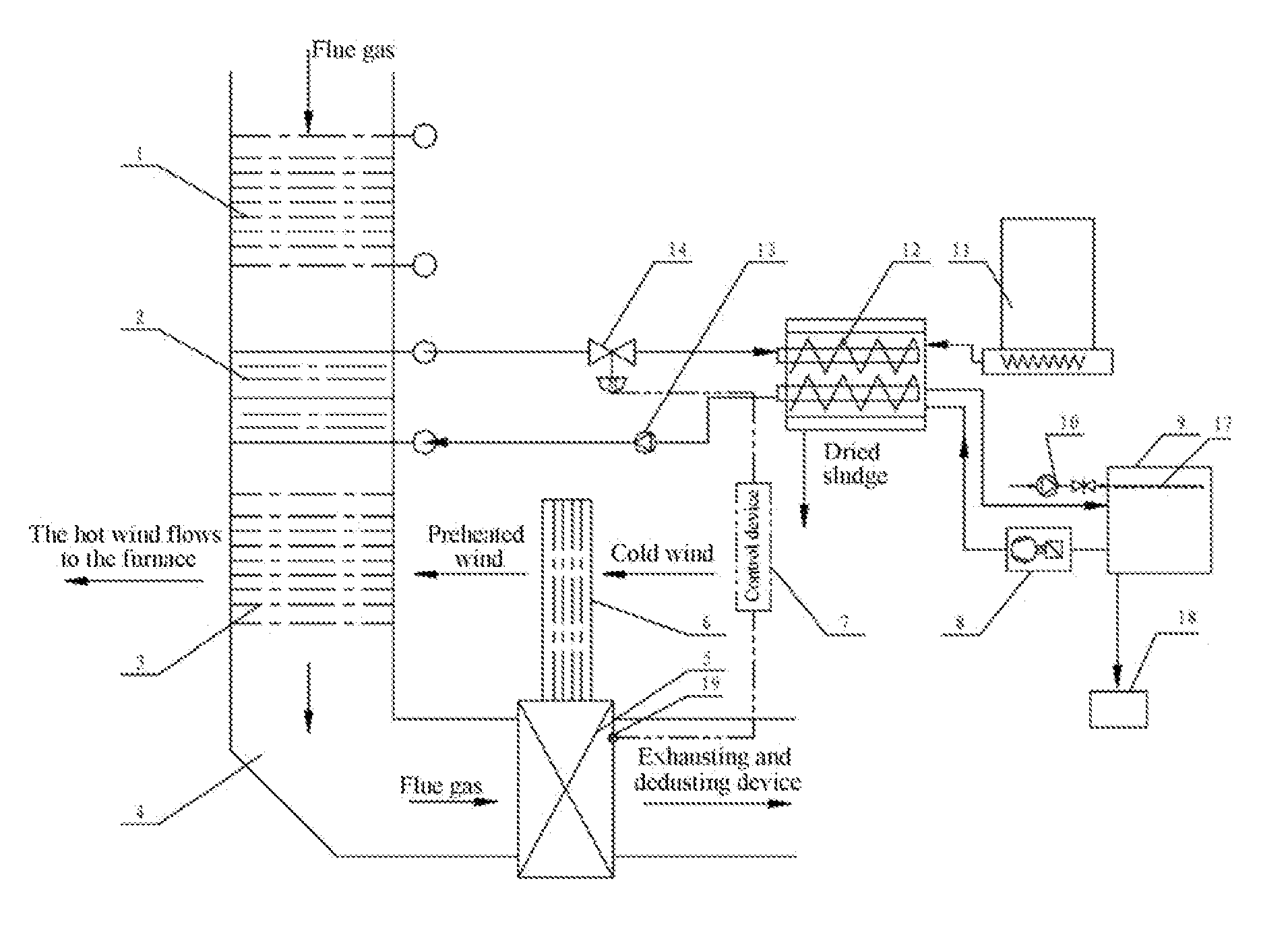

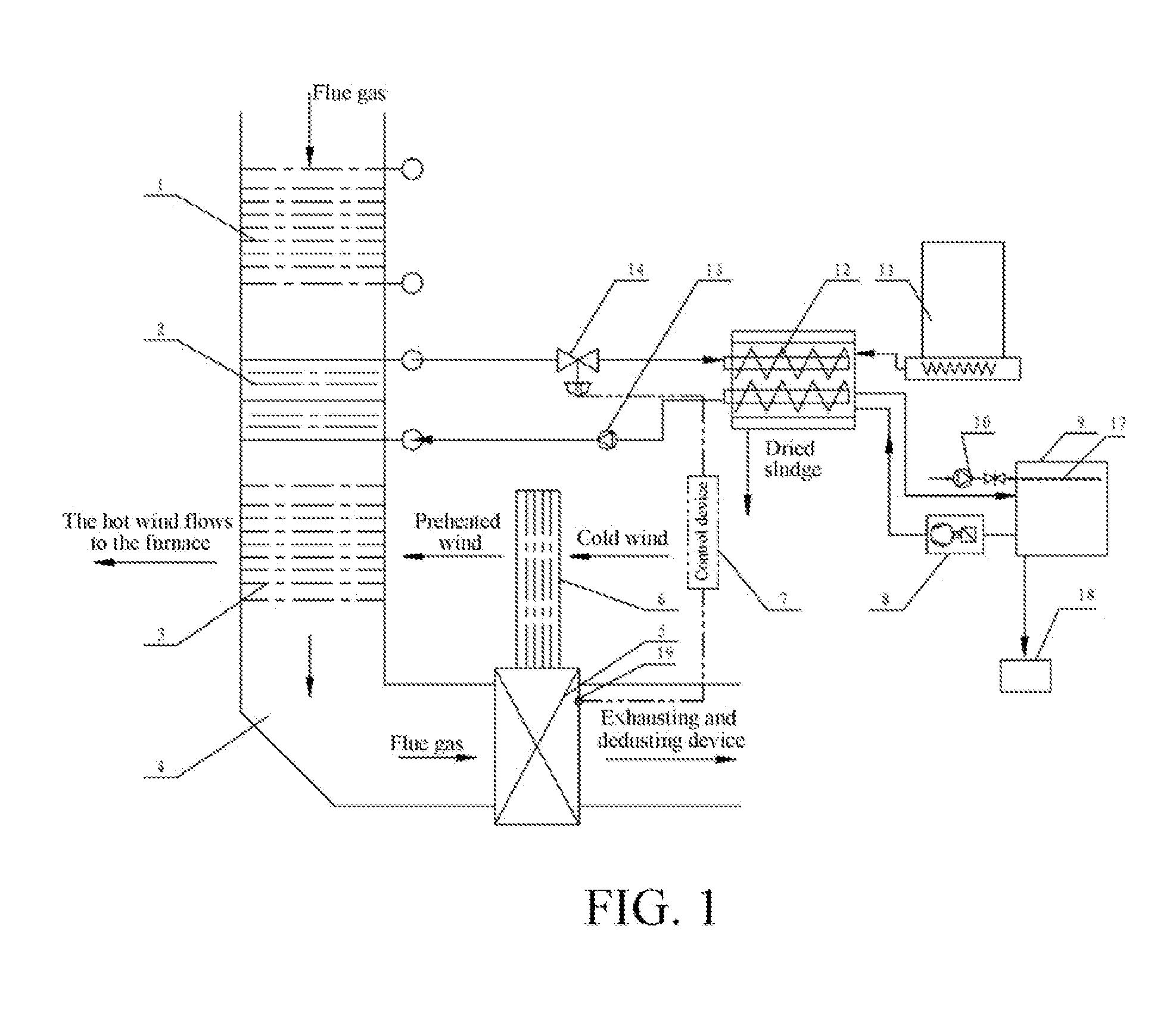

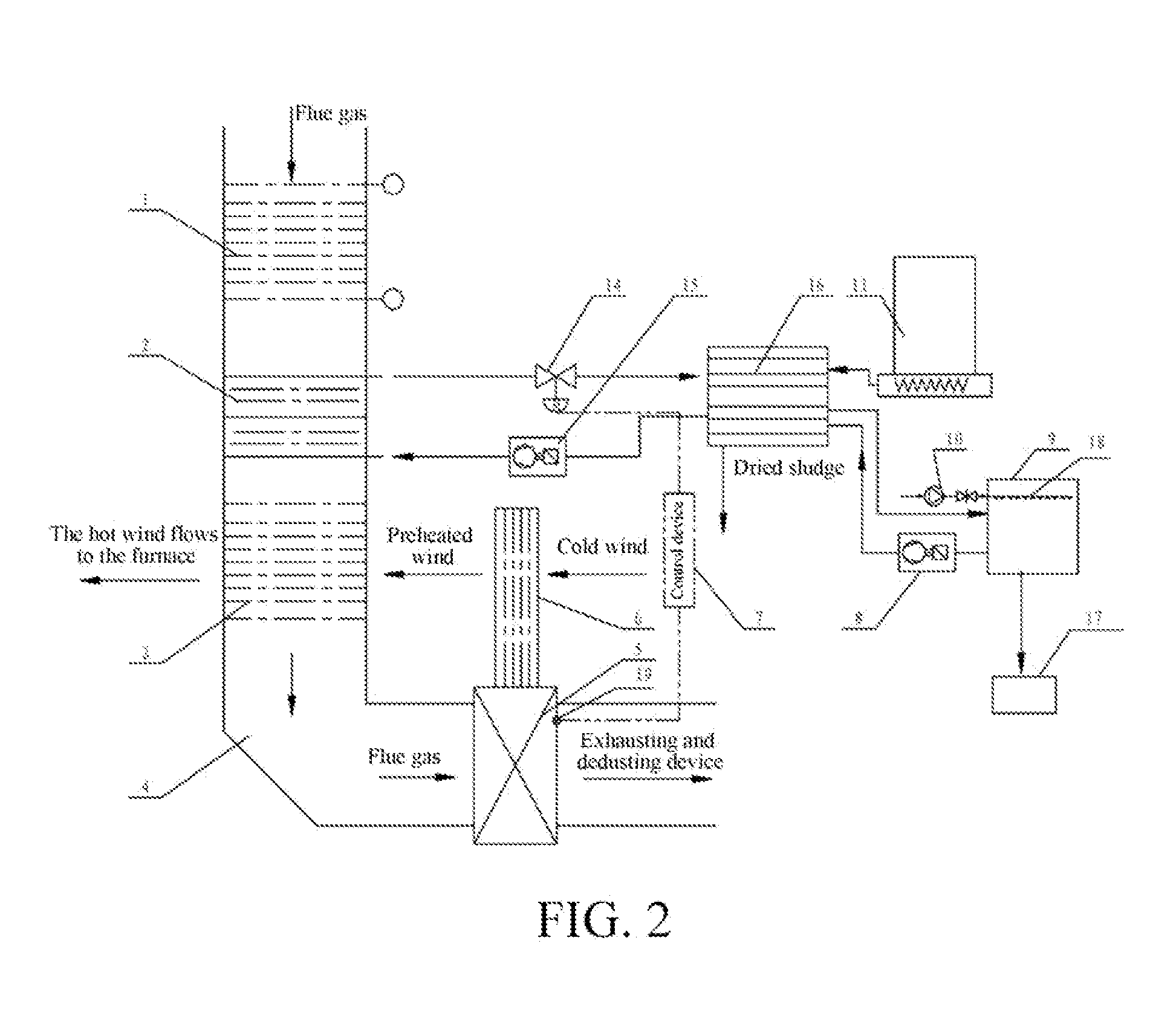

Non-contact Sludge Drying System With Flue Gas Heat

InactiveUS20130305554A1Reduce energy consumptionMaximize useSludge treatment by de-watering/drying/thickeningSludge dryingAir preheaterSludge

A non-contact sludge drying system with flue gas heat according to the present invention includes a dryer, and further includes an economizer, a high-temperature flue gas heat recovery device, and an air preheater that are successively disposed in the flue along a flue gas flowing direction. A heater is disposed in the dryer, the high-temperature flue gas heat recovery device is connected to the heater by a circulation pipe, a heat transfer medium is disposed in the circulation pipe, a heat transfer medium driving device is disposed on the circulation pipe, and the dryer is connected to a sludge vapor recovery system. The non-contact sludge drying system with flue gas heat according to the present invention uses the flue gas heat from a thermal power plant boiler or another industrial boiler as a heat source to further dehydrate and dry the dehydrated sludge of the sewage treatment plant, so that the dried sludge can be used as a fuel with certain heat of combustion or composted for further treatment.

Owner:SHANGHAI FUBO ENVIRONMENTAL PROTECTION EQUIP

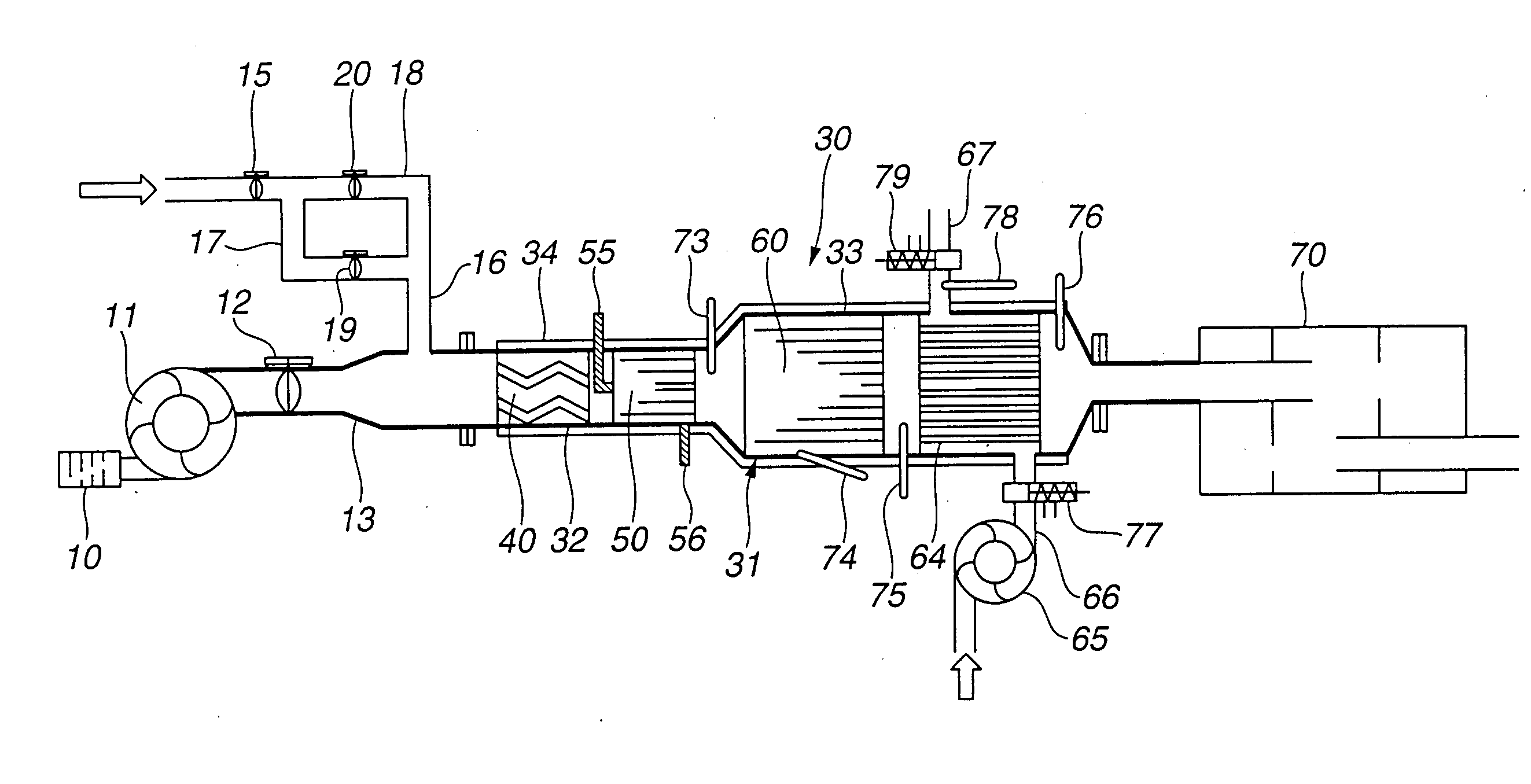

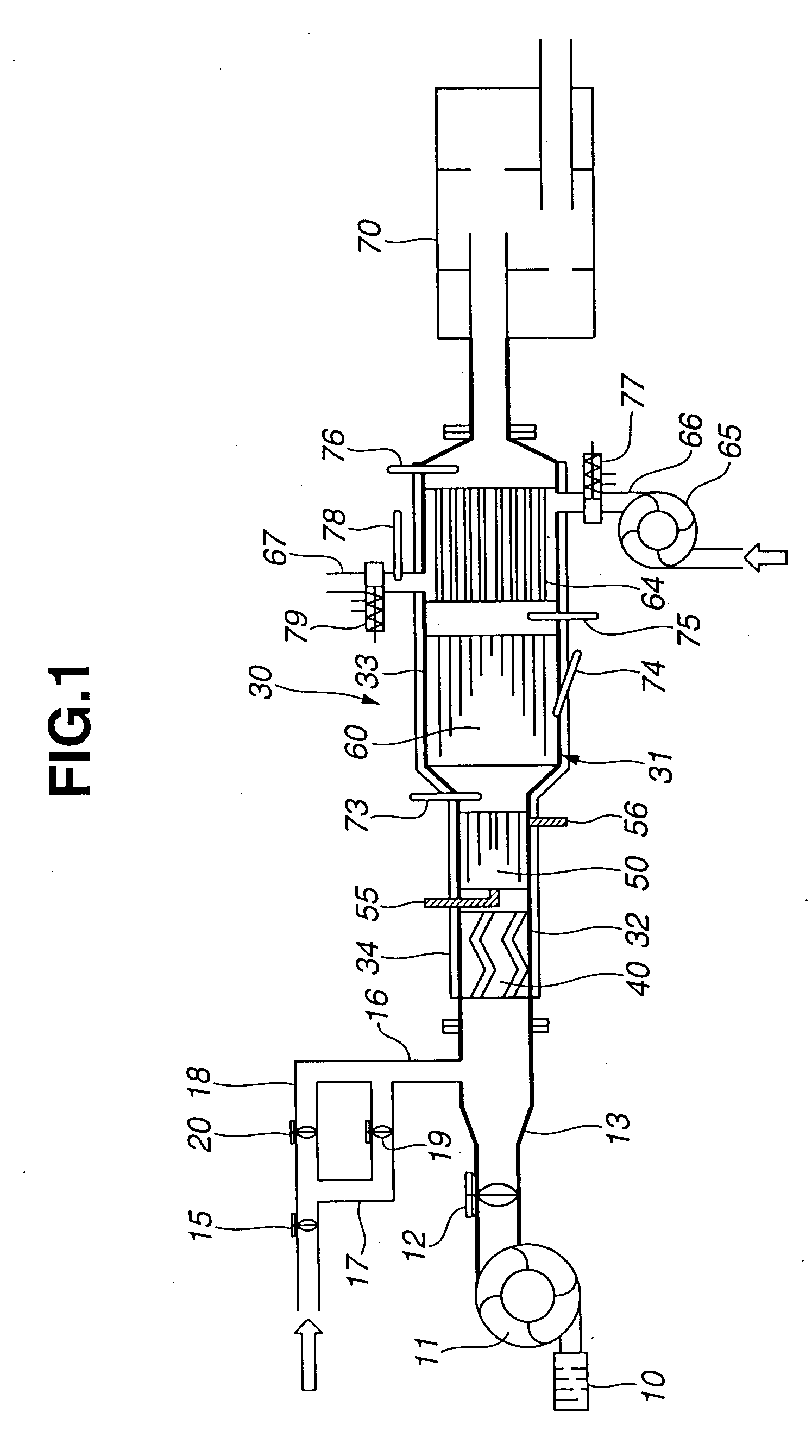

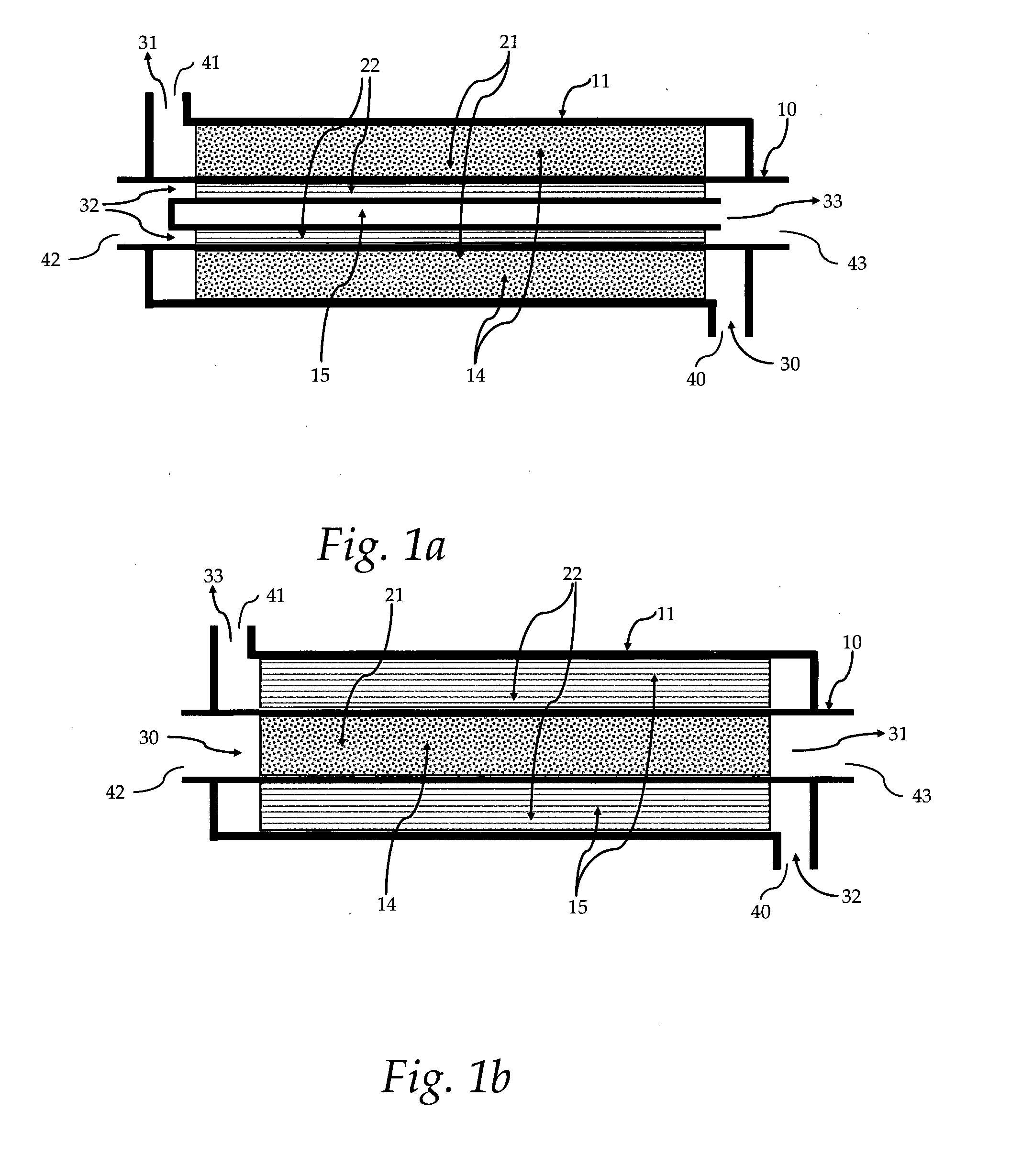

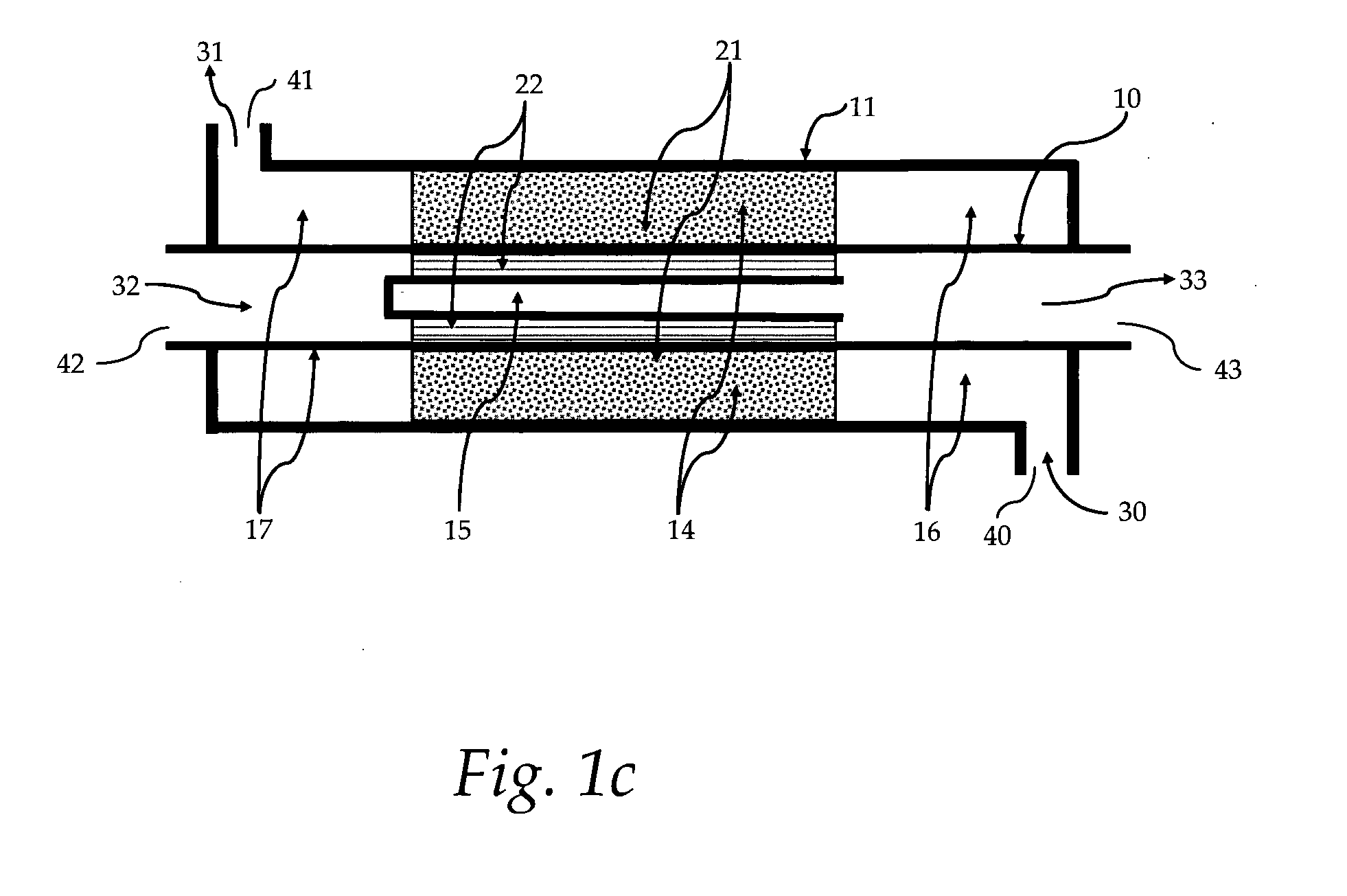

Heat integrated reformer with catalytic combustion for hydrogen production

ActiveUS20140369897A1Promotes reformation reactionImprove distributionHydrogenEnergy inputSteam reformingFuel treatment

A heat integrated steam reformer, which incorporates a catalytic combustor, which can be used in a fuel processor for hydrogen production from a fuel source, is described. The reformer assembly comprises a reforming section and a combustion section, separated by a wall. Catalyst (21) able to induce the reforming reactions is placed in the reforming section, either in the form of pellets or in the form of coating on a suitable structured catalyst substrate such as fecralloy sheets. Catalyst (22) able to induce the combustion reactions is placed in the combustion section in the form of coating on suitable structured catalyst substrate such as fecralloy sheet. A steam and fuel mixture (30) is supplied to the reforming section (14) where it is reformed to produce hydrogen. A fuel and an oxygen (32) containing gas mixture is supplied to the combustion section where it is catalytically combusted to supply the heat for the reformer. The close placement of the combustion and reforming catalysts facilitate efficient heat transfer. Multiple such assemblies can be bundled to form reactors of any size. The reactor made of this closely packed combustion and reforming sections is very compact.

Owner:HELBIO

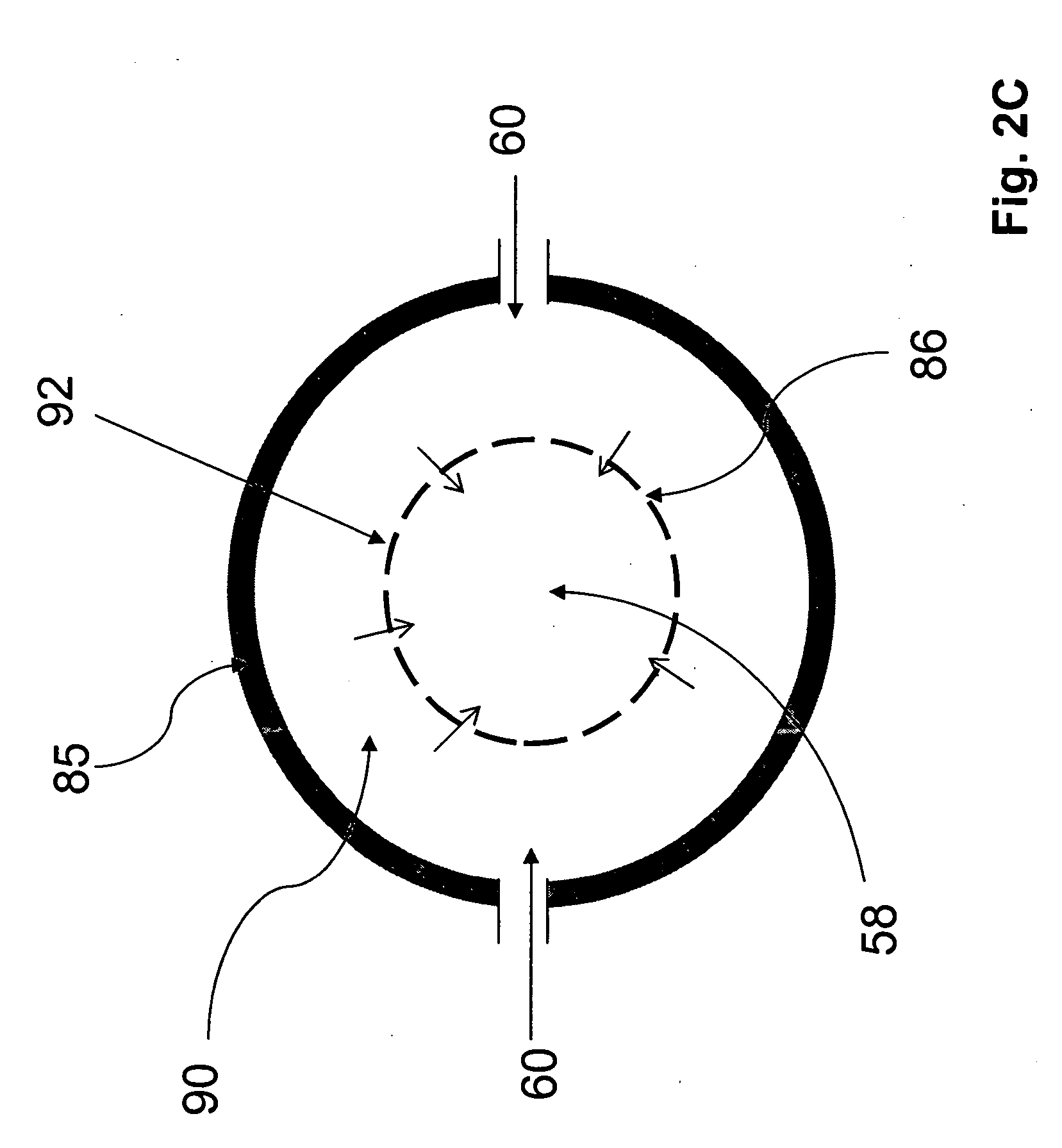

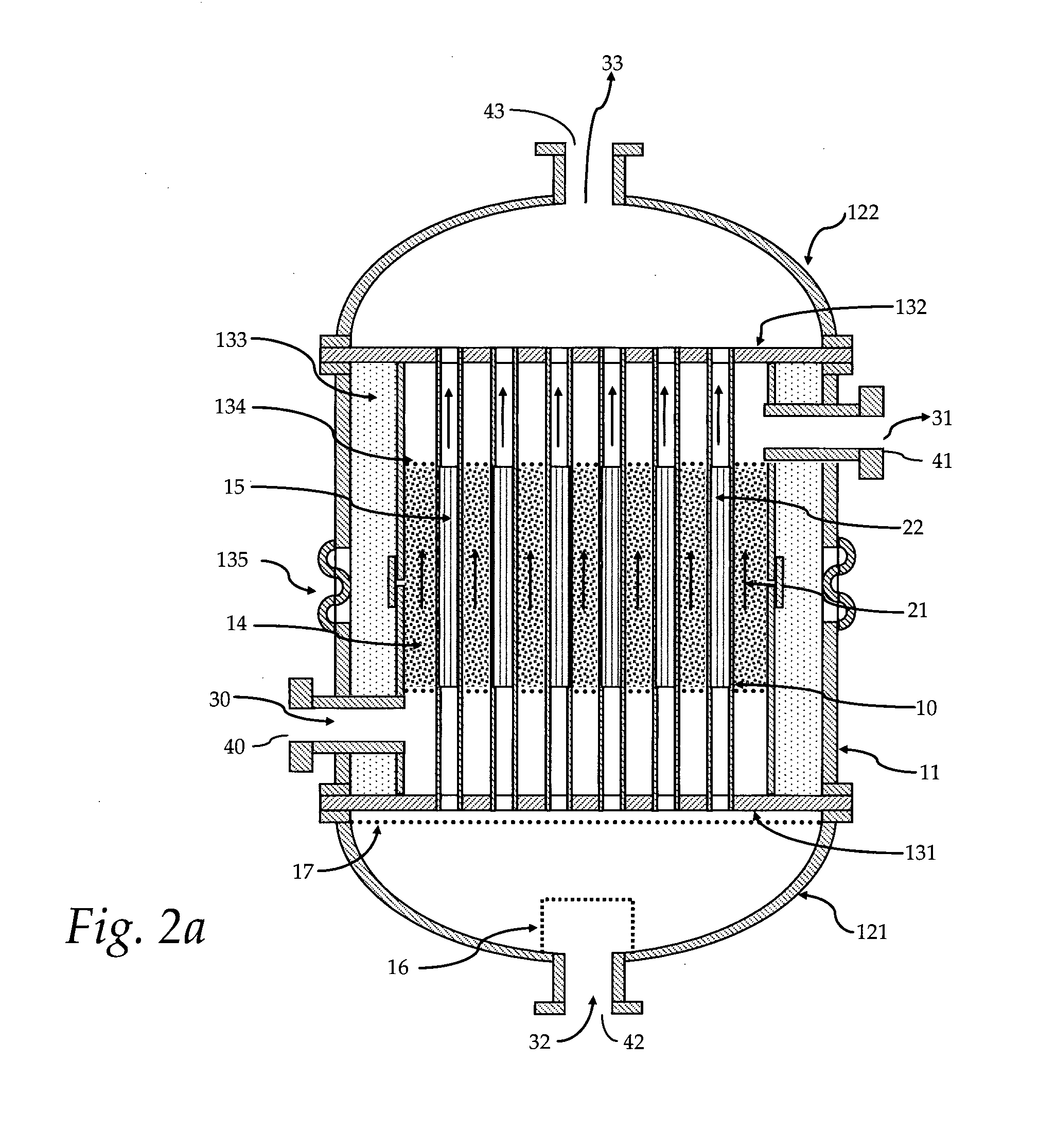

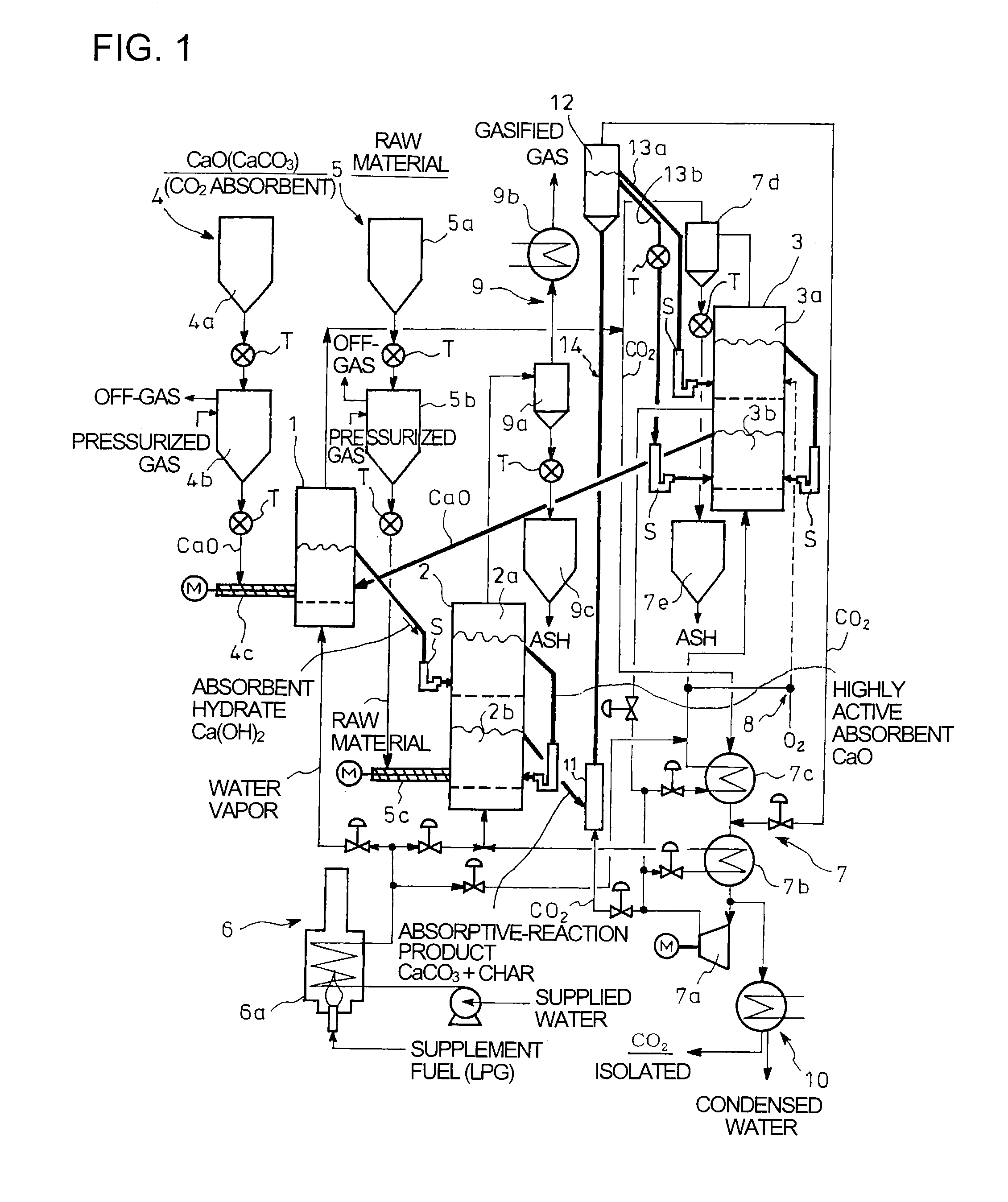

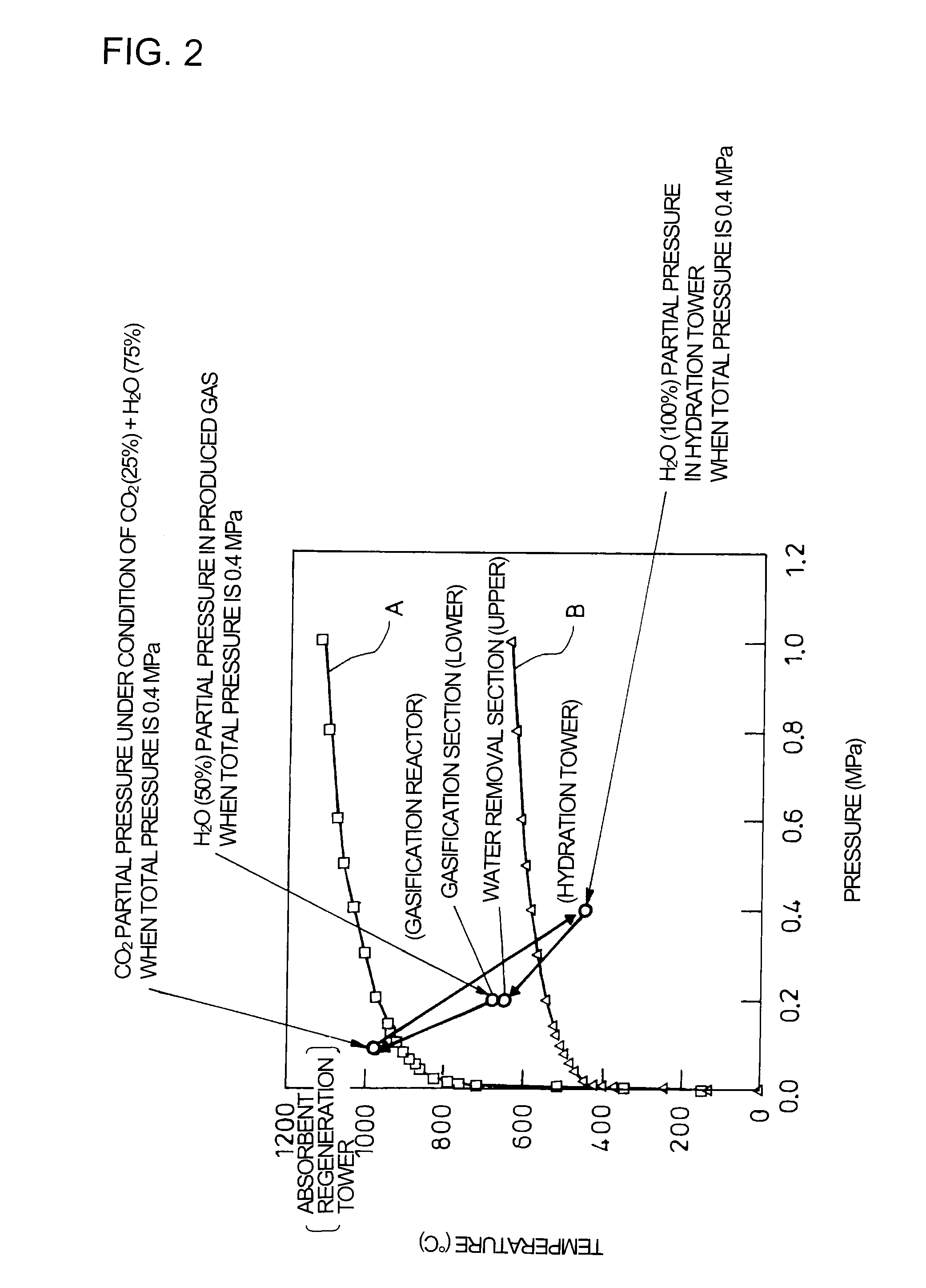

Method and apparatus for gasification with co2 recovery

ActiveUS20100266477A1Good effectSimple structureGas treatmentCarbon compoundsHydration reactionWater vapor

Gasification of carbon-containing raw material into gasified gas and recovery of CO2 are enabled at the same pressure throughout a system.Provided are a hydration tower 1 for performing hydration reaction by contact of CaO with water vapor while keeping at a predetermined pressure and a temperature at or below an upper limit for production of Ca(OH)2; a gasification reactor 2 with a water removal section 2a for dehydration of Ca(OH)2 introduced through heating to obtain highly active CaO and with a gasification section 2b for production of char through reaction of a raw material with water vapor and production of gasified gas through gasification of the char, CO2 being absorbed by CaO from the section 2a to produce CaCO3, heat of reaction at that time being used for the gasification of the raw material, the gasified gas being used as a heat source for the dehydration in the section 2a; and an absorbent regeneration tower 3 in which, in the presence of the char-containing CaCO3 from the section 2b, CO2, water vapor and oxygen, CaCO3 is calcined with heat of combustion of the char to separate it into CO2 and CaO, the resultant CaO being supplied to the hydration tower 1. The pressure in the reactor 2 and in the tower 3 connected to the tower 1 is the same as pressure in the tower 1.

Owner:IHI CORP

Preparation method of high-activity red mud-based concrete admixture

The invention relates to a preparation method of a high-activity red mud-based concrete admixture, belonging to a preparation method of a composite activated mineral admixture. The preparation method comprises the steps of: by taking red mud as main raw materials and industrial waste slag of carbide slag, desulfurization gypsum and the like as auxiliary materials, performing heating power activation through the self combustion heat of unburned coal gangue to obtain the high-activity red mud-based concrete admixture, wherein in the process of blending concrete materials, 20% by weight of the red mud composite replaces PO52.5, or PO42.5, or PC32.5 portland cement, under the condition of keeping other blending materials, the cost of per cubic meter concrete blended can be saved greatly, the strength of the blended concrete in each age is equal to or higher than that of the compared concrete, and the newly blended concrete has the characteristics of being good in peaceability, small in slump loss, low in hydration heat, good in later strength transitivity, sulfate corrosion-resistant, strong in chemical corrosion resistance, and good in durability, having no adverse influence on the property of the concrete, and the like.

Owner:CHINA UNIV OF MINING & TECH

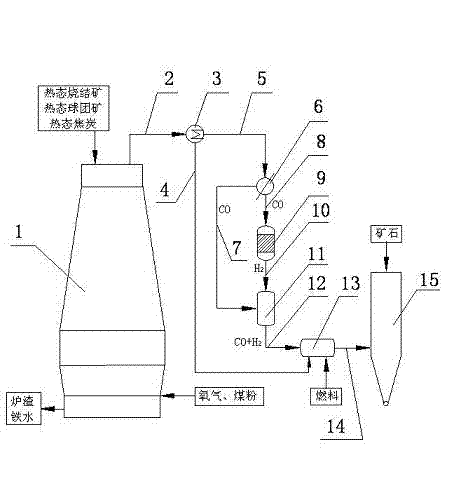

Joint production process of crude fuel hot charging and total heat oxygen blast furnace and vertical furnace

InactiveCN102758048AImprove use valueIncrease profitBlast furnace detailsShaft furnaceCo2 removalShaft furnace

The invention relates to a joint production process of a crude fuel hot charging and total heat oxygen blast furnace and a vertical furnace, and is characterized in that hot charging of a furnace material of a blast furnace adopts total heat oxygen combustion, the heat oxygen temperature is not less than 650 DEG C, after heat exchange and CO2 removal, coal gas at the furnace top of the blast furnace is converted to generate H2 through water gas, a part of blast furnace gas without the CO2 can be mixed according to a volume ratio of H2 / CO of 1-2: 1, the pressure is increased to 0.5-0.7 MPa, the blast furnace gas is heated to 800-900 DEG C, and sponge iron is produced for a gas-based vertical furnace. According to the invention, the problems of less blast furnace bosh gas volume, insufficient heat of a furnace body and poor pre-reduction property of the furnace material of the total oxygen blast furnace can be solved by hot charging of raw materials, through joint production of the total oxygen blast furnace and the gas-based blast furnace, a large amount of blast furnace gas is reasonably utilized, energy is saved, emission is reduced, and ultra-low carbon dioxide emission is realized.

Owner:WISDRI ENG & RES INC LTD

High-strength low-heat-conductivity grade A noninflammable aerogel foam and preparation and application thereof

ActiveCN108264372ALow thermal conductivityGood mechanical propertiesCeramicwareHigh intensityLimiting oxygen index

The invention provides a high-strength low-heat-conductivity superhydrophobic polymer matrix noninflammable aerogel material, comprising, by weight, 0.5-10.0 parts of inorganic particles, 0.03-2.0 parts of a branched polymer binder, 0-2.0 parts of a crosslinkable polymer, 0-1.0 part of a crosslinking agent, and 0-3 parts of a surfactant. The invention also discloses a preparation method of the material; the material has the density of 5-100 kg / m<3>, specific modulus of 10-150 MP cm<3> / g, heat conductivity coefficient of 0.010-0.070 W / (m K), extreme oxygen index of higher than 50%, combustion heat value of 1.0-4.0 MJ / kg, good superhydrophobicity and water contact angle of greater than 150.0 DEG. Before and after combustion, the material has high strength and structural stability, and secondary damage possibly caused by shrinking or collapse after burning is decreased to maximum extent.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com