Multi-Cone Fuel Burner Apparatus For Multi-Tube Heat Exchanger

a fuel burner and multi-tube technology, applied in lighting and heating apparatus, combustion types, heating types, etc., can solve the problems of unsatisfactory high temperature inside the heating appliance cabinet, unsatisfactory operation noise, and unacceptably large operating nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

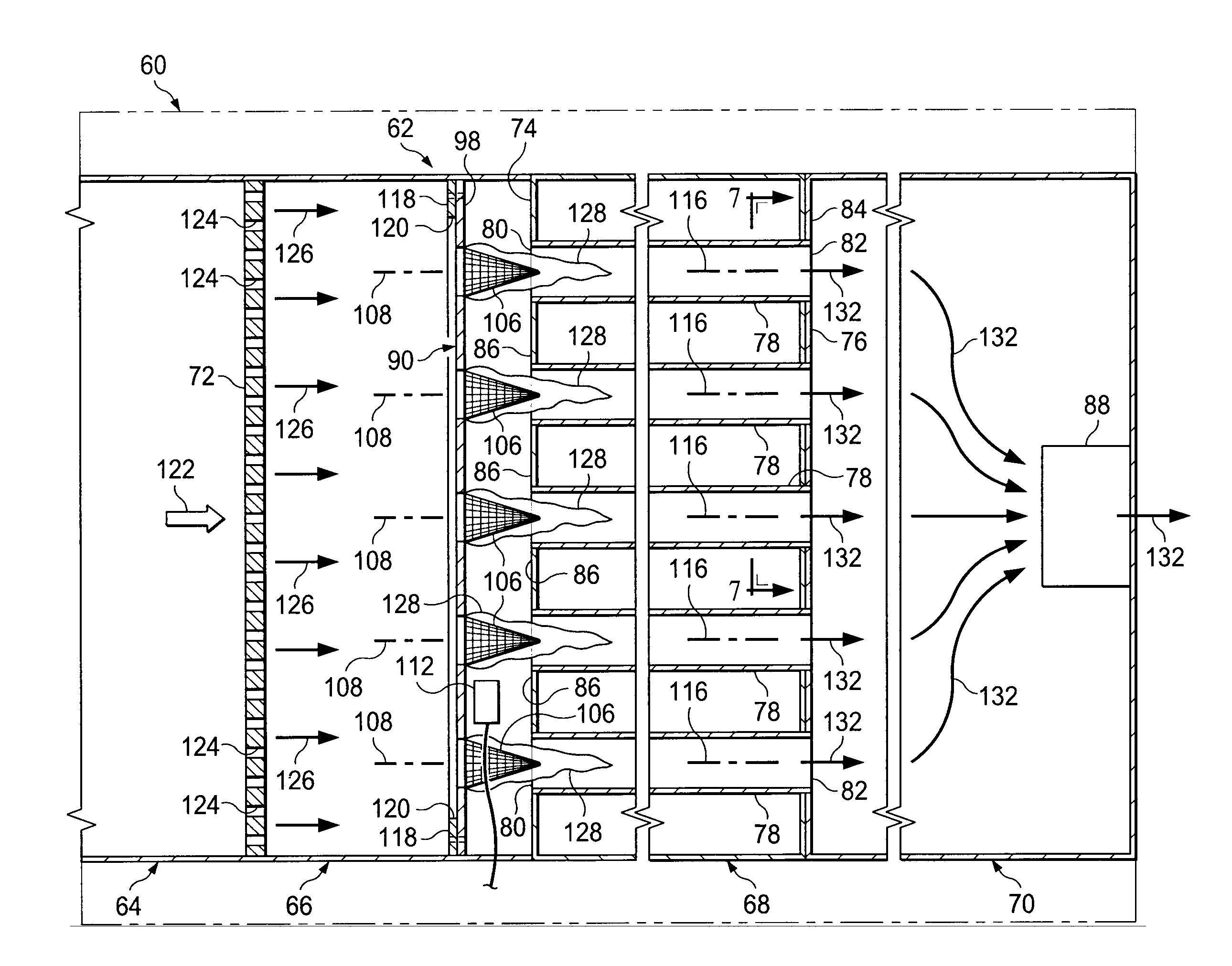

[0019]Cross-sectionally depicted in schematic form in FIG. 3 is a portion of a fuel-fired heating appliance, representatively an air heating furnace 60, that incorporates therein a premixed fuel / air combustion section 62 embodying principles of the present invention. While the heating appliance 60 is representatively an air heating furnace, principles of the present invention are not limited to furnaces, and could be employed to advantage in a variety of other types of fuel-fired heating appliances including, but not limited to, water heaters, boilers and pool heaters.

[0020]The combustion section 62 comprises, from left to right in FIG. 3, a mixing box 64, a burner box or combustion chamber 66, a heat exchange housing 68, and a collector box 70 joined together as indicated. At the juncture of the mixing box 64 and the burner box is a perforated diffuser plate 72 which may be similar in configuration and operation to the perforated diffuser plate 64 illustrated and described in copen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com