Patents

Literature

412results about How to "Guaranteed mix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

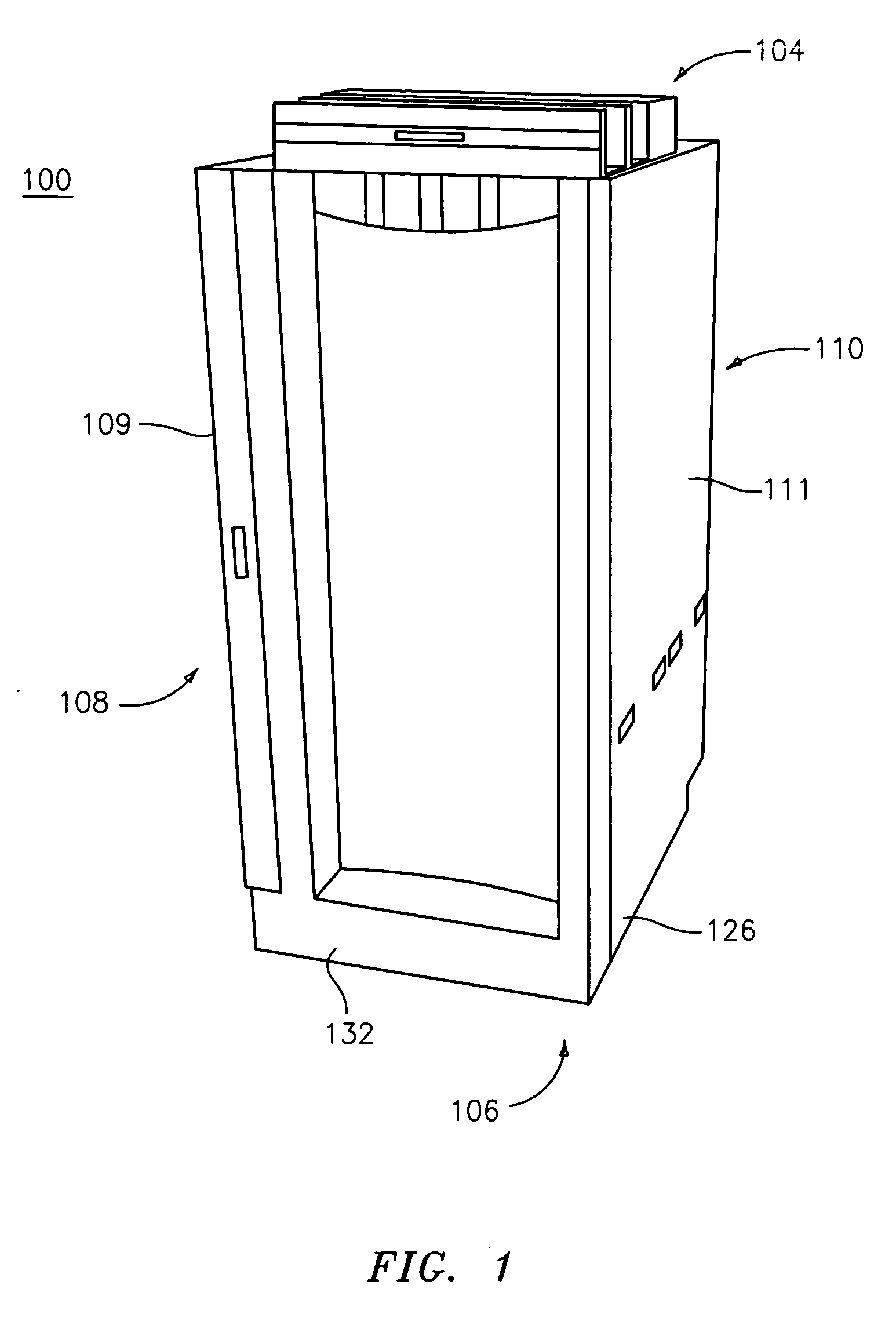

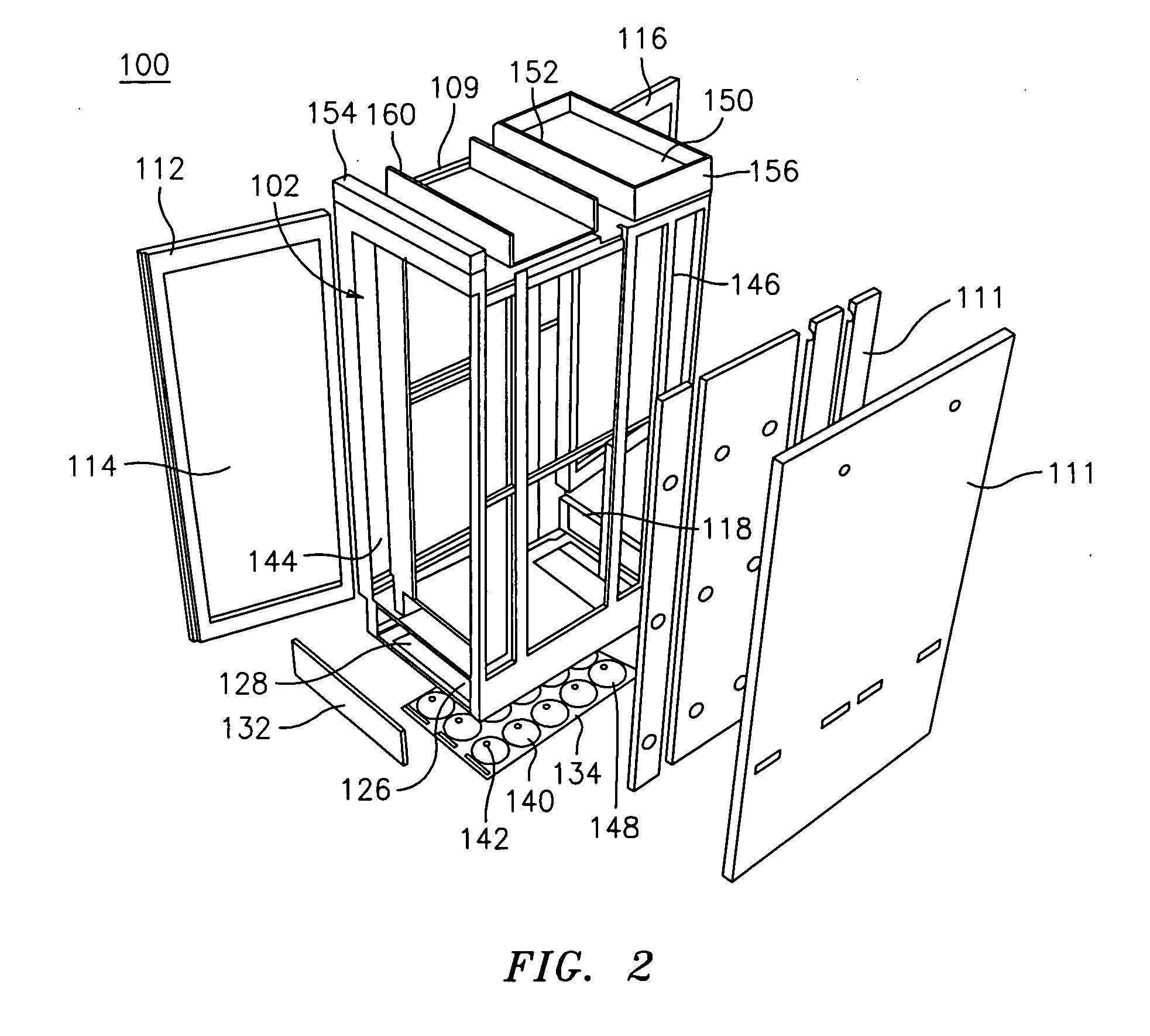

Cabinet for electronic equipment

InactiveUS7643291B2High densityEasy and efficient assemblyMechanical apparatusDigital data processing detailsElectrical and Electronics engineeringElectronic equipment

Owner:ORTRONICS INC

Cabinet for electronic equipment

InactiveUS20090059523A1High densityEasy and efficient assemblyMechanical apparatusDigital data processing detailsEngineeringProduct gas

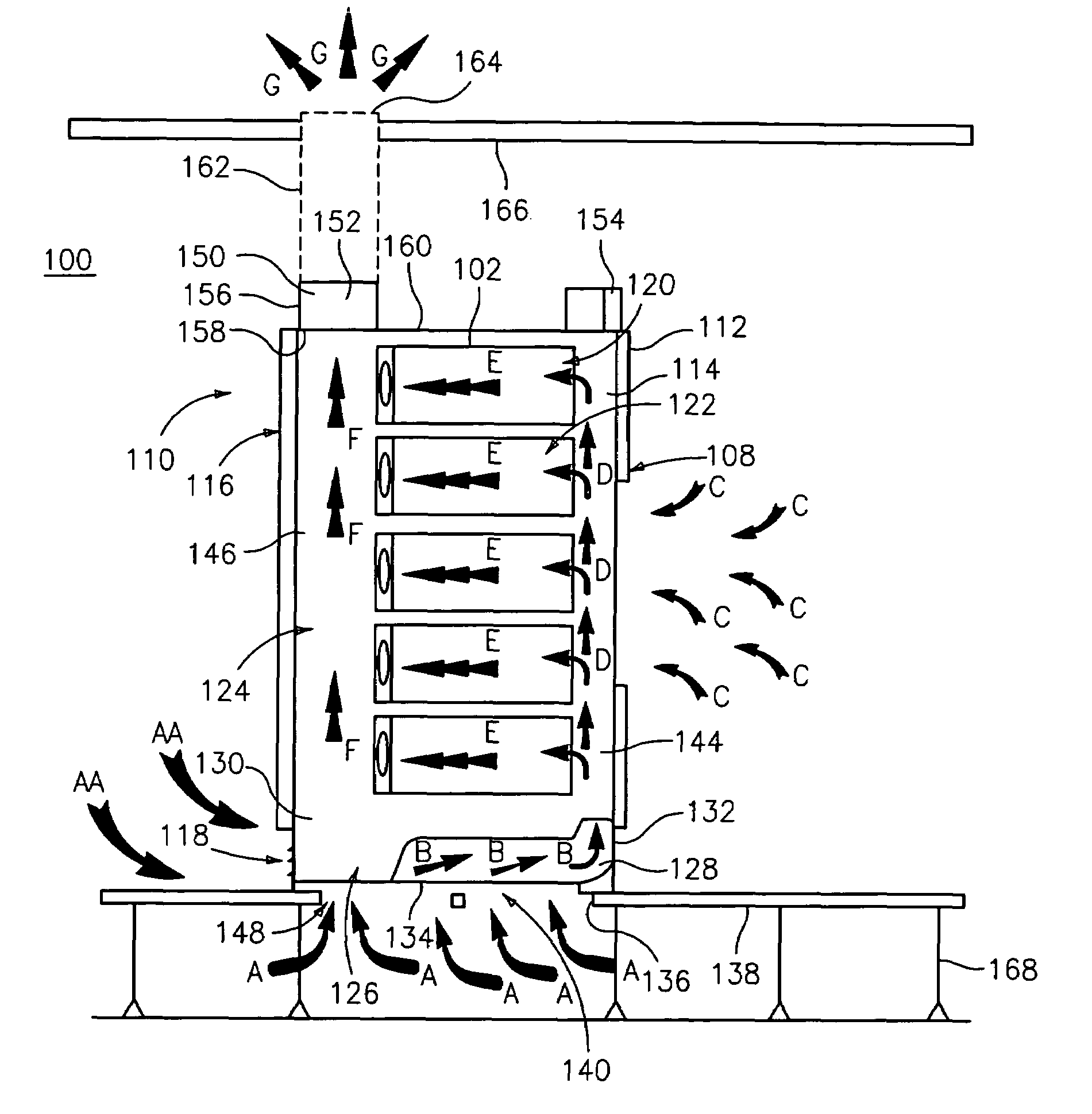

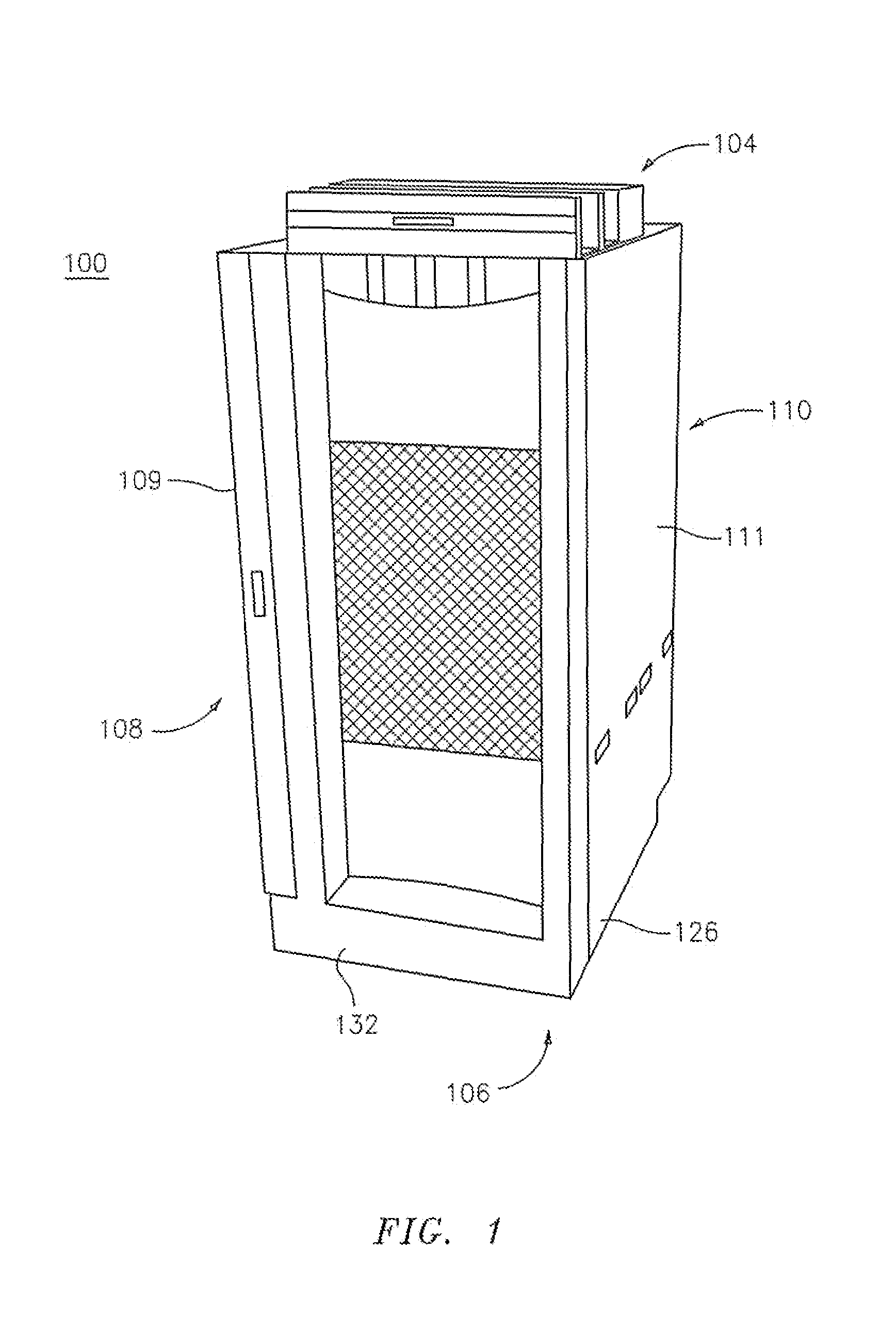

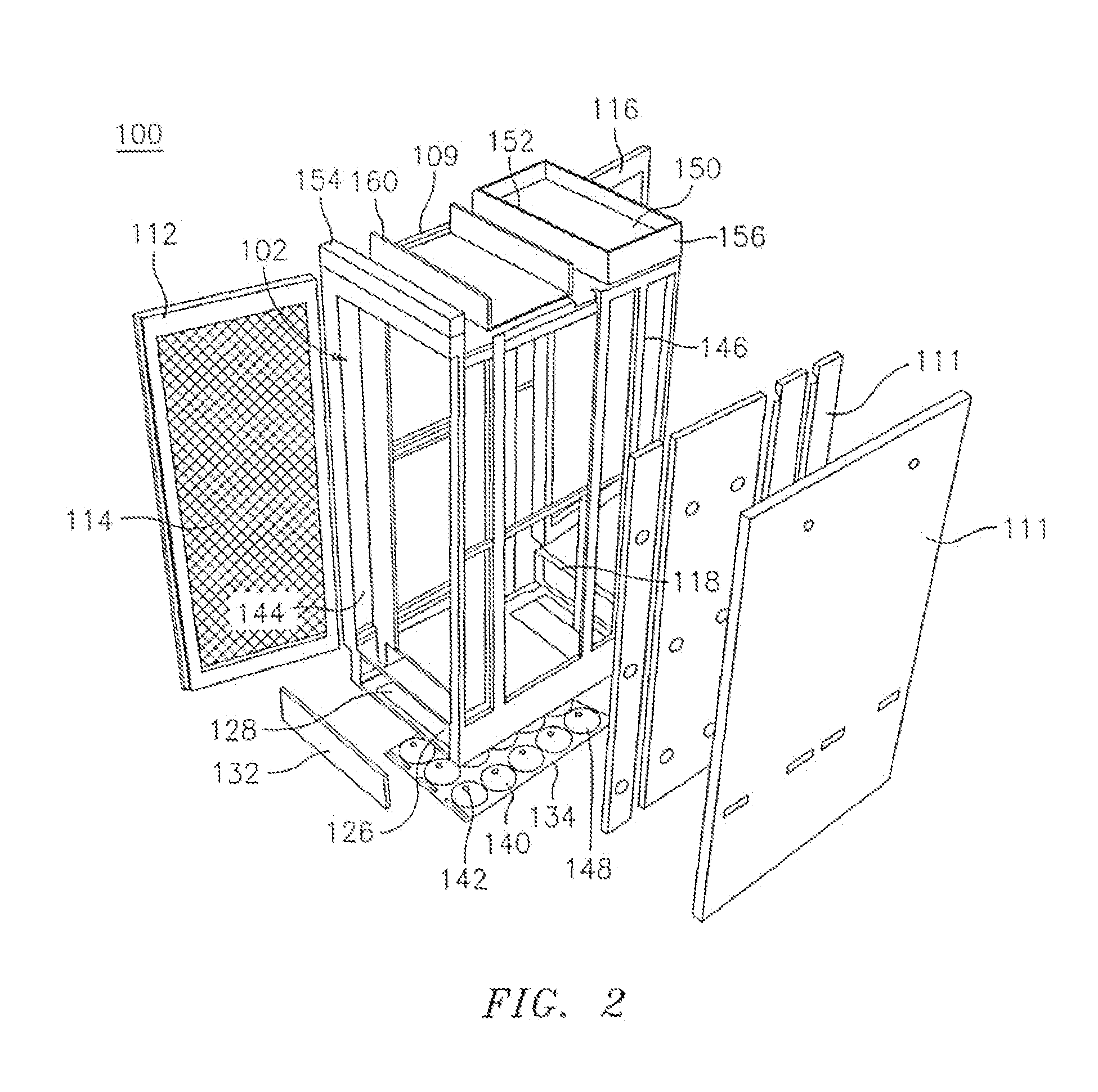

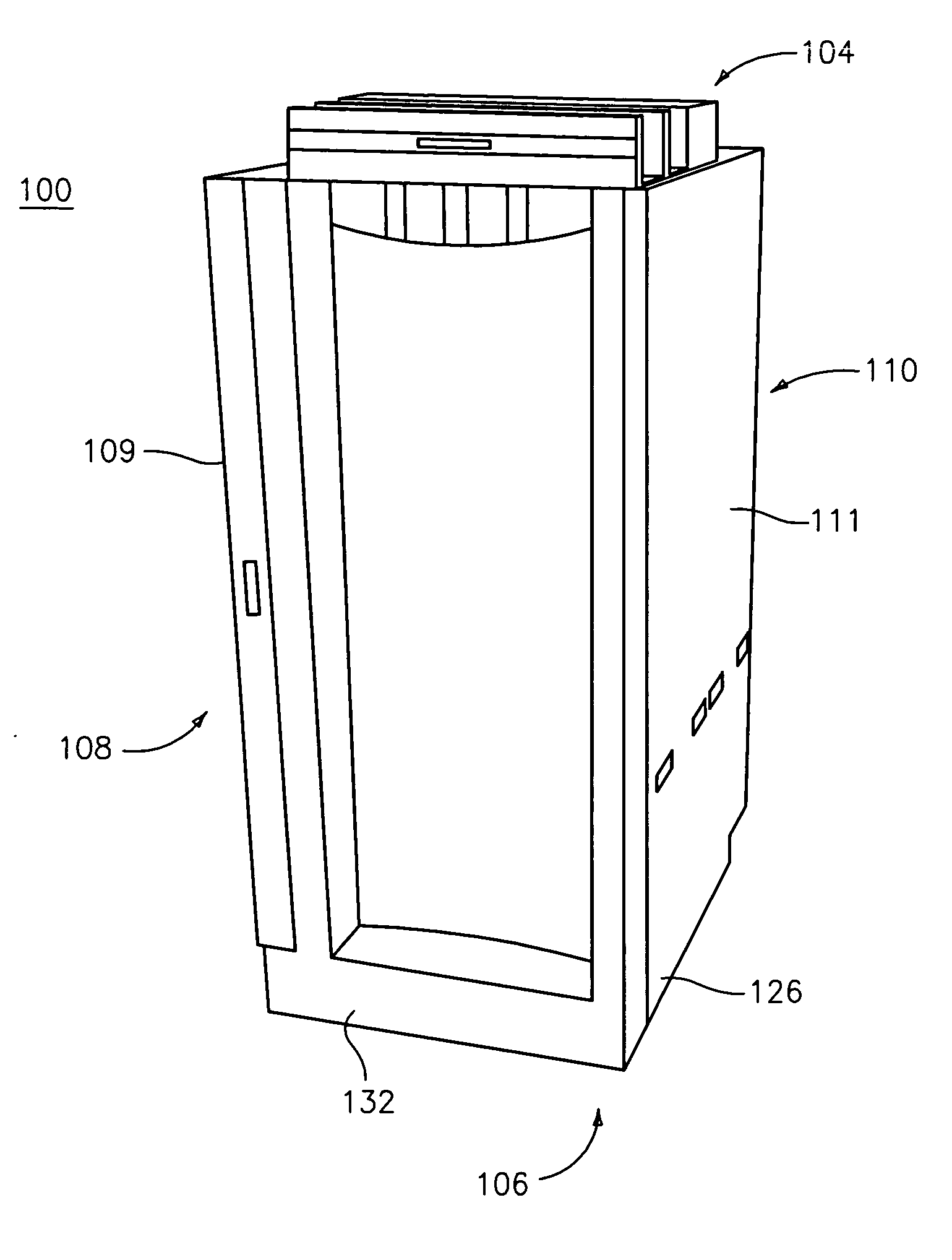

An electronic equipment cabinet is provided, which includes an upper portion, a lower portion and a support configured to receive electronic equipment. The bottom portion defines a base plenum configured to receive a low temperature gas and communicates with a gas flow distribution pathway, which includes a first plenum communicating with the base plenum and configured to direct the low temperature gas to the support. The gas flow distribution pathway further includes a second plenum configured to receive a high temperature gas flow from the support and direct the high temperature gas flow to the top portion. The top portion includes at least one fan configured to direct the high temperature gas flow from the gas flow distribution pathway. A temperature sensor senses the temperature of the high temperature gas flow and communicates with a control module to control the first plenum and the at least one fan for regulating temperature.

Owner:ORTRONICS INC

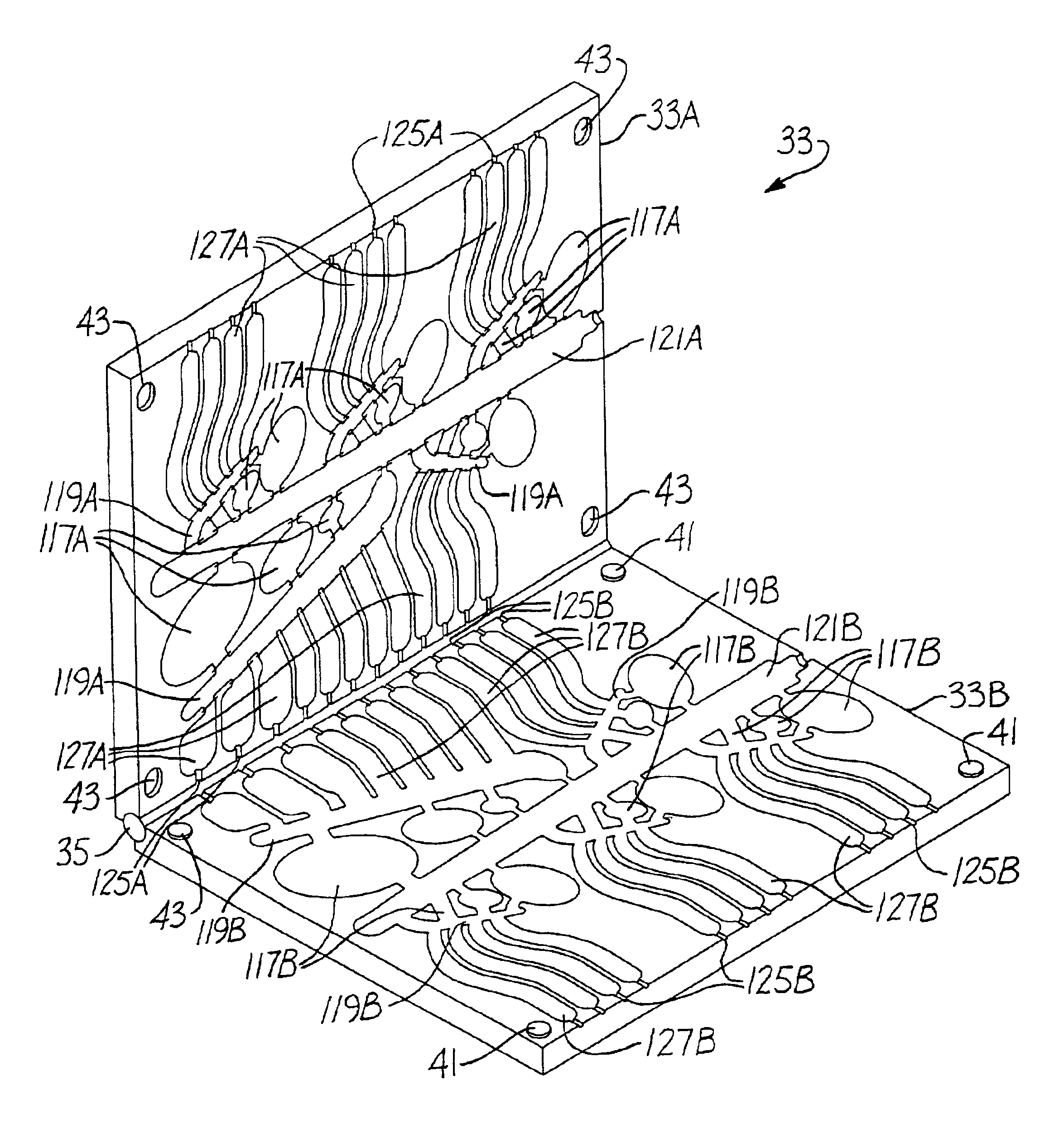

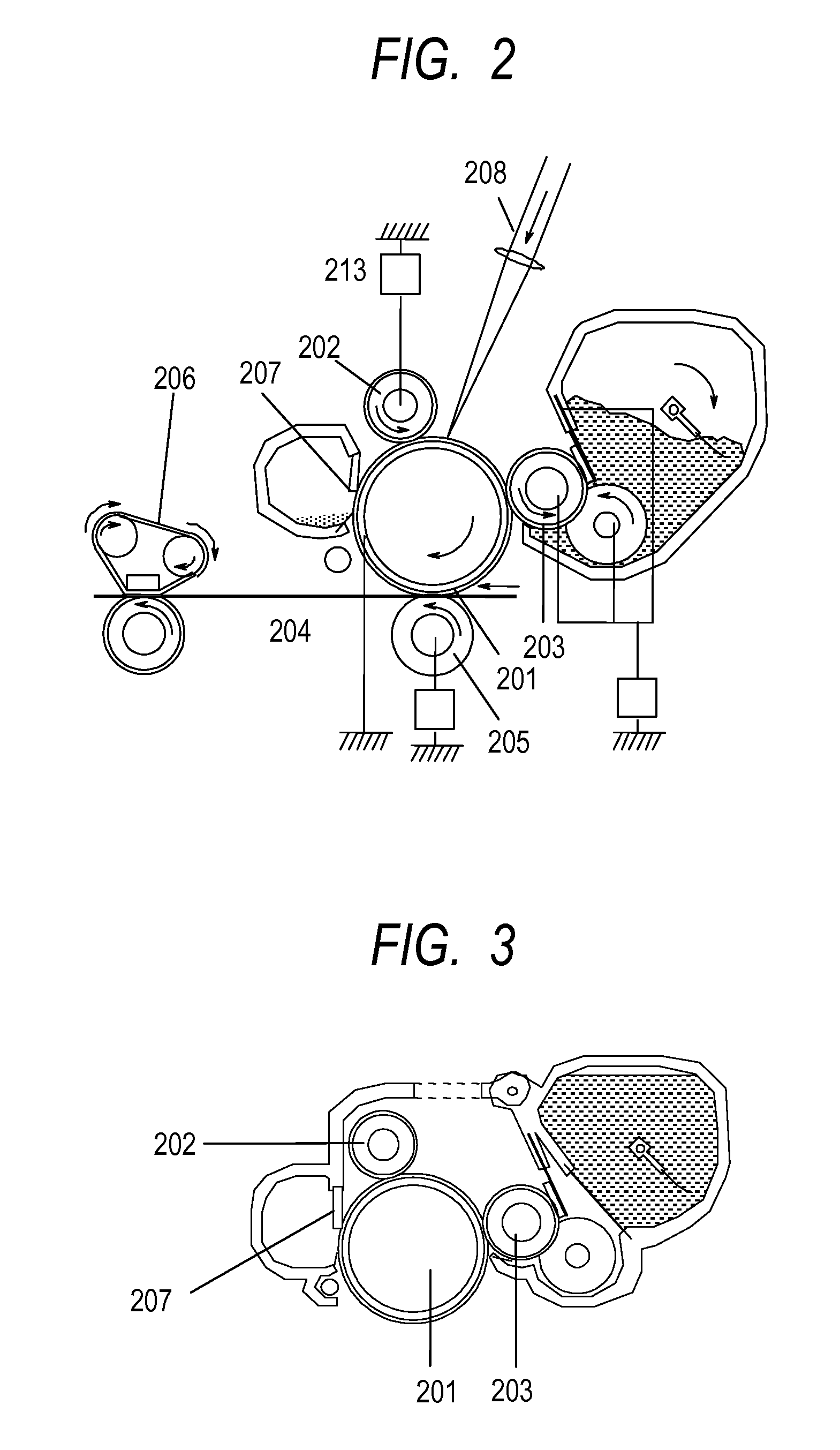

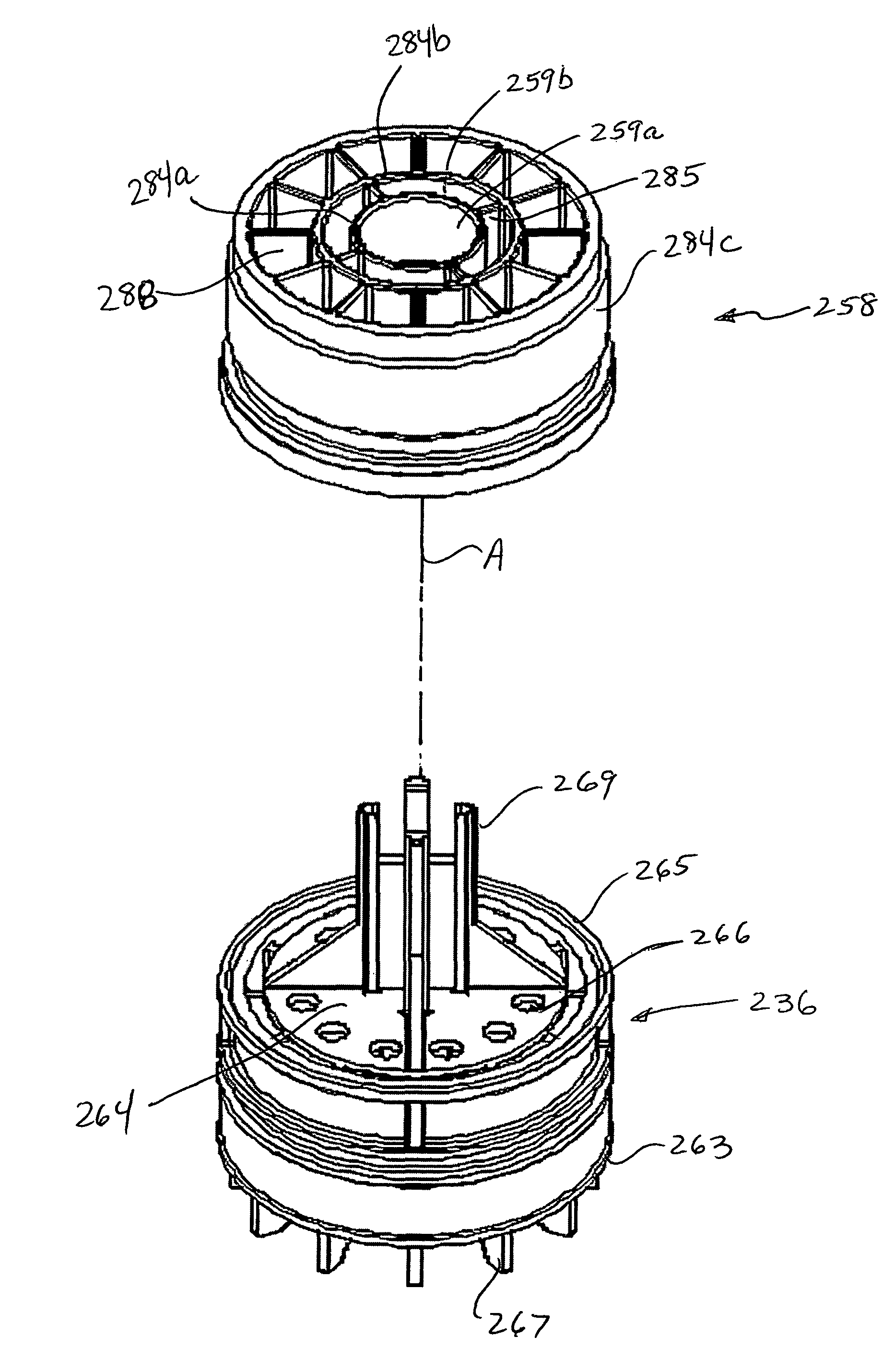

Pump having flexible liner and compounding apparatus having such a pump

InactiveUS6905314B2Facilitates maintenance of sanitary conditionMinimal effortFlexible member pumpsLiquid transferring devicesEngineeringFluid pressure

A pump has a flexible liner which is expanded and contracted by application of positive and negative fluid pressure for receiving and discharging fluent material. The liner is received in a rigid shell which defines the maximum volume received. In discharging fluent material, a vacuum is applied to one side of the liner, while applying pressure to the other side so the liner is collapsed against the rigid shell. The liner is arranged so as to be the only part of the pump which contacts the fluent material, and is replaceable to effect rapid and easy cleaning of the pump. The liner has multiple pump cells which can expand and contract for moving fluent material through the pump cell. The pump cells can be sized and arranged so that by selection of particular pump cells which receive the fluent material, precise volumes can be metered by the pump.

Owner:BAXTER INT INC

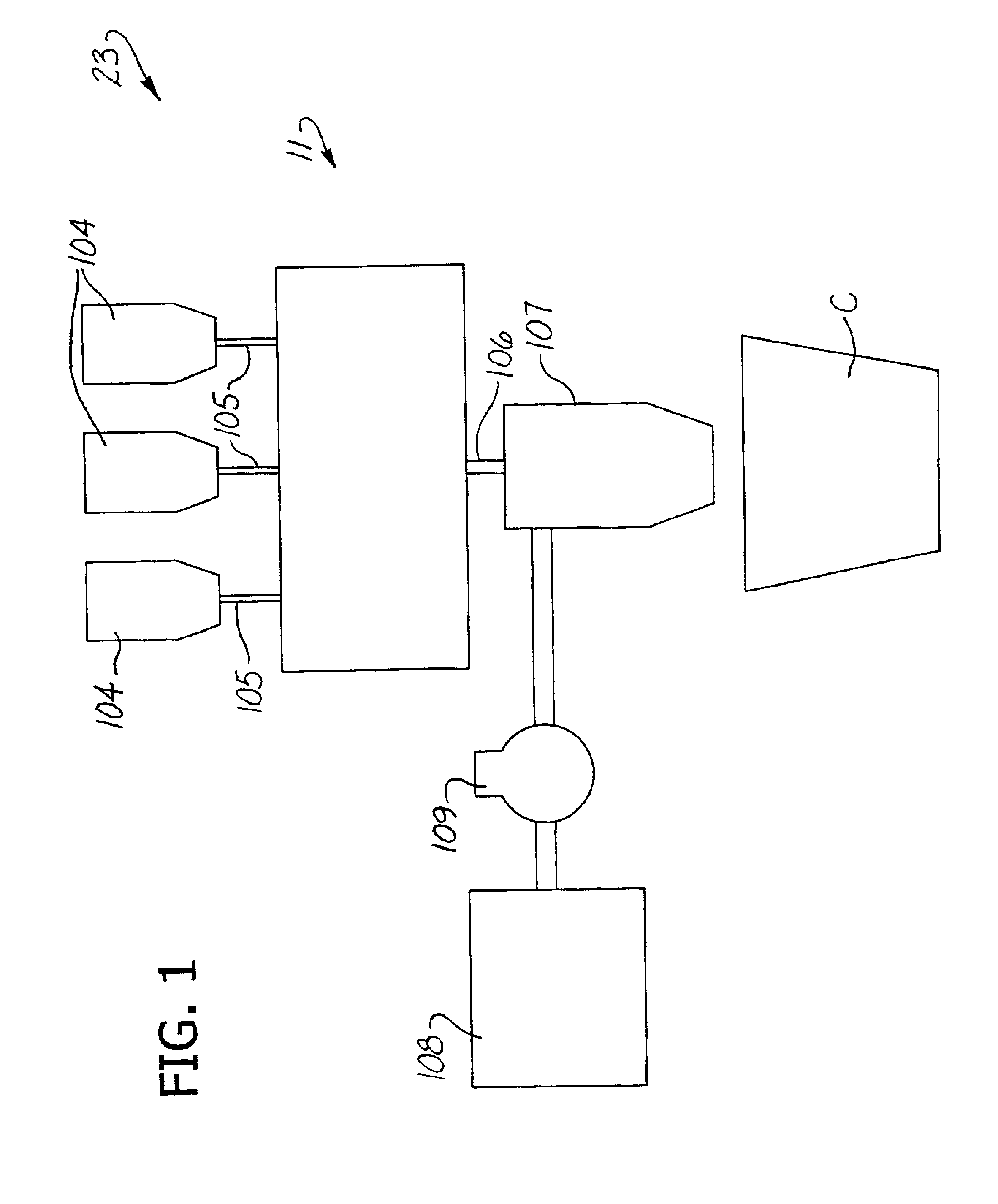

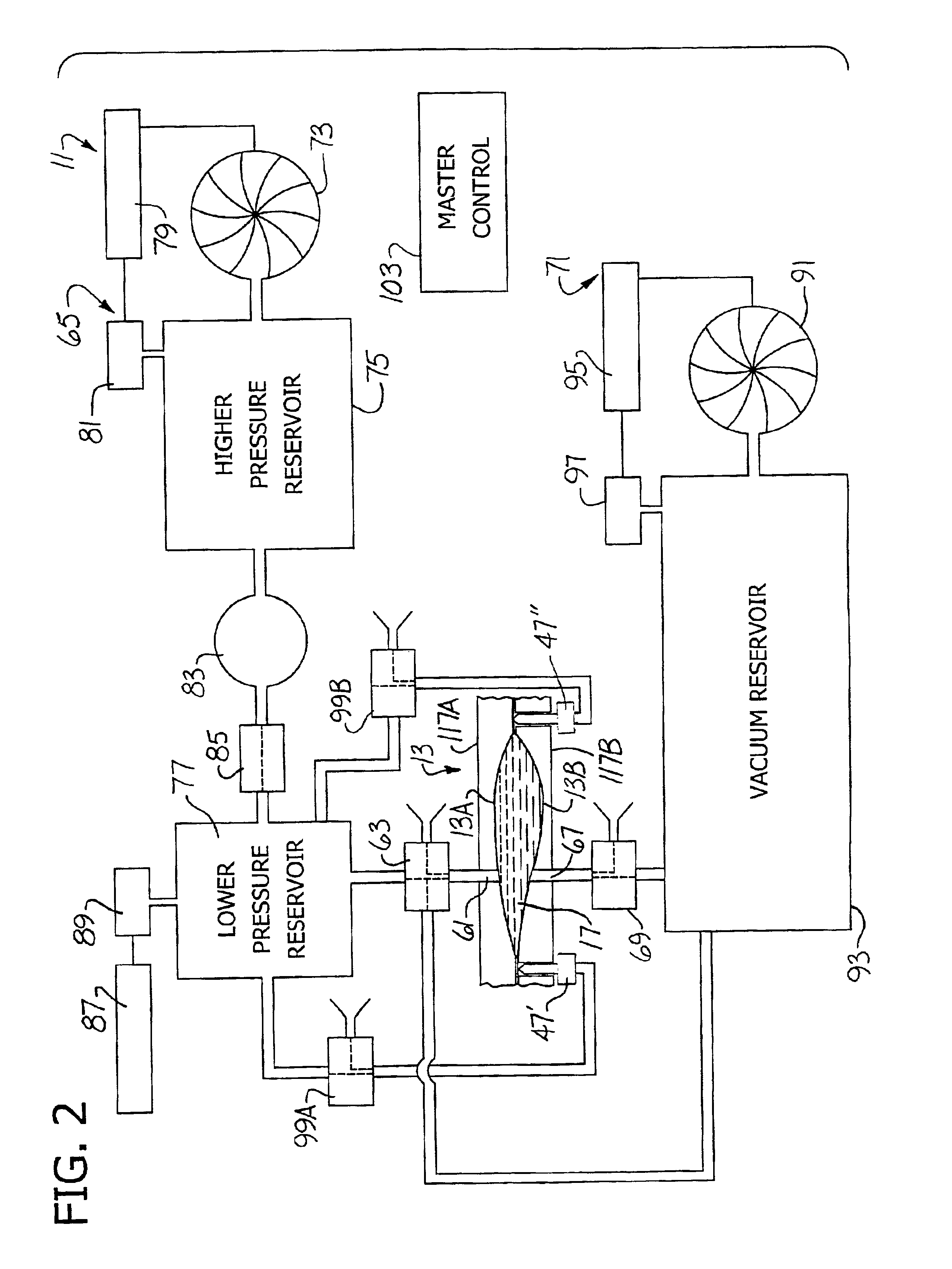

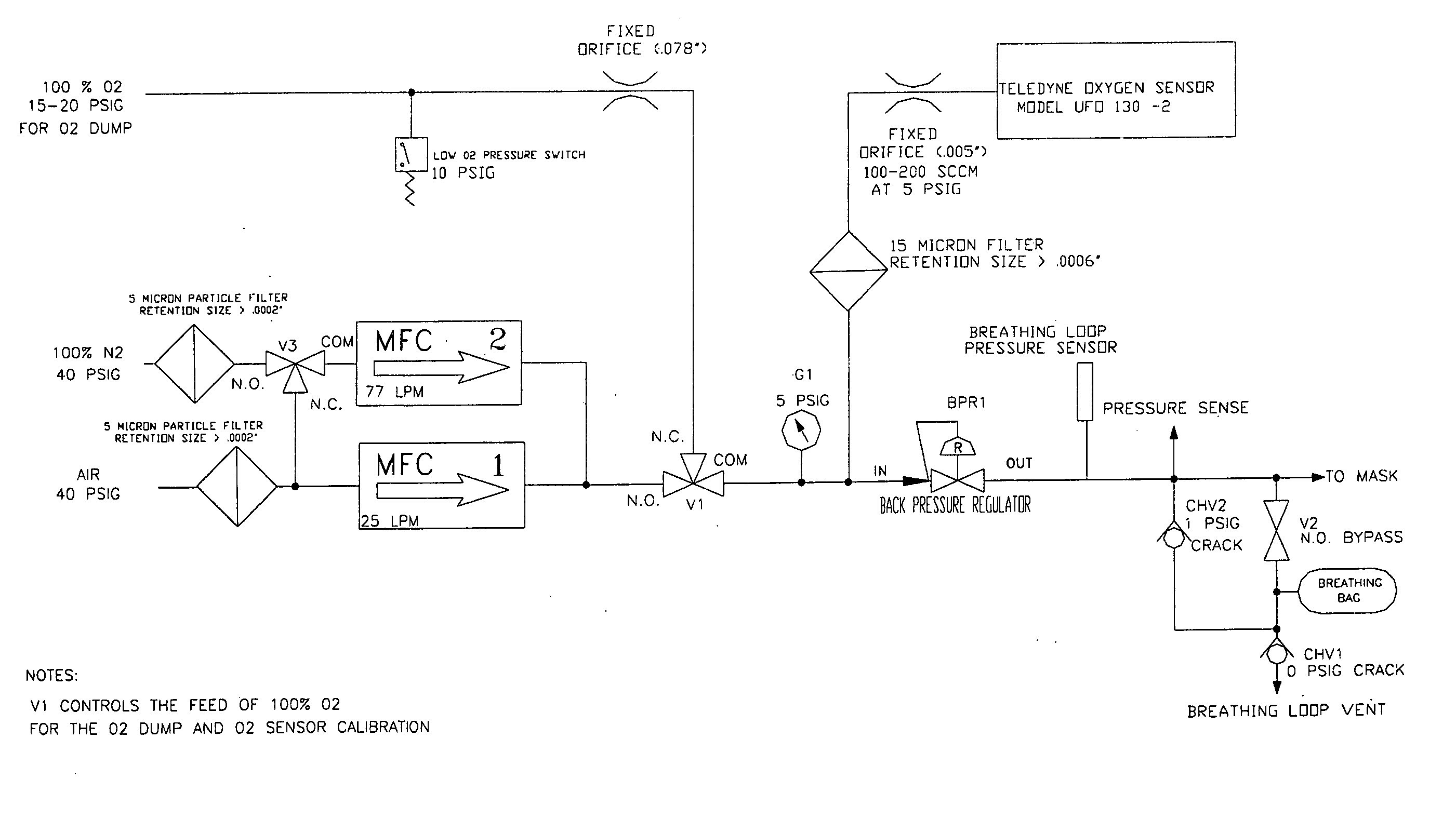

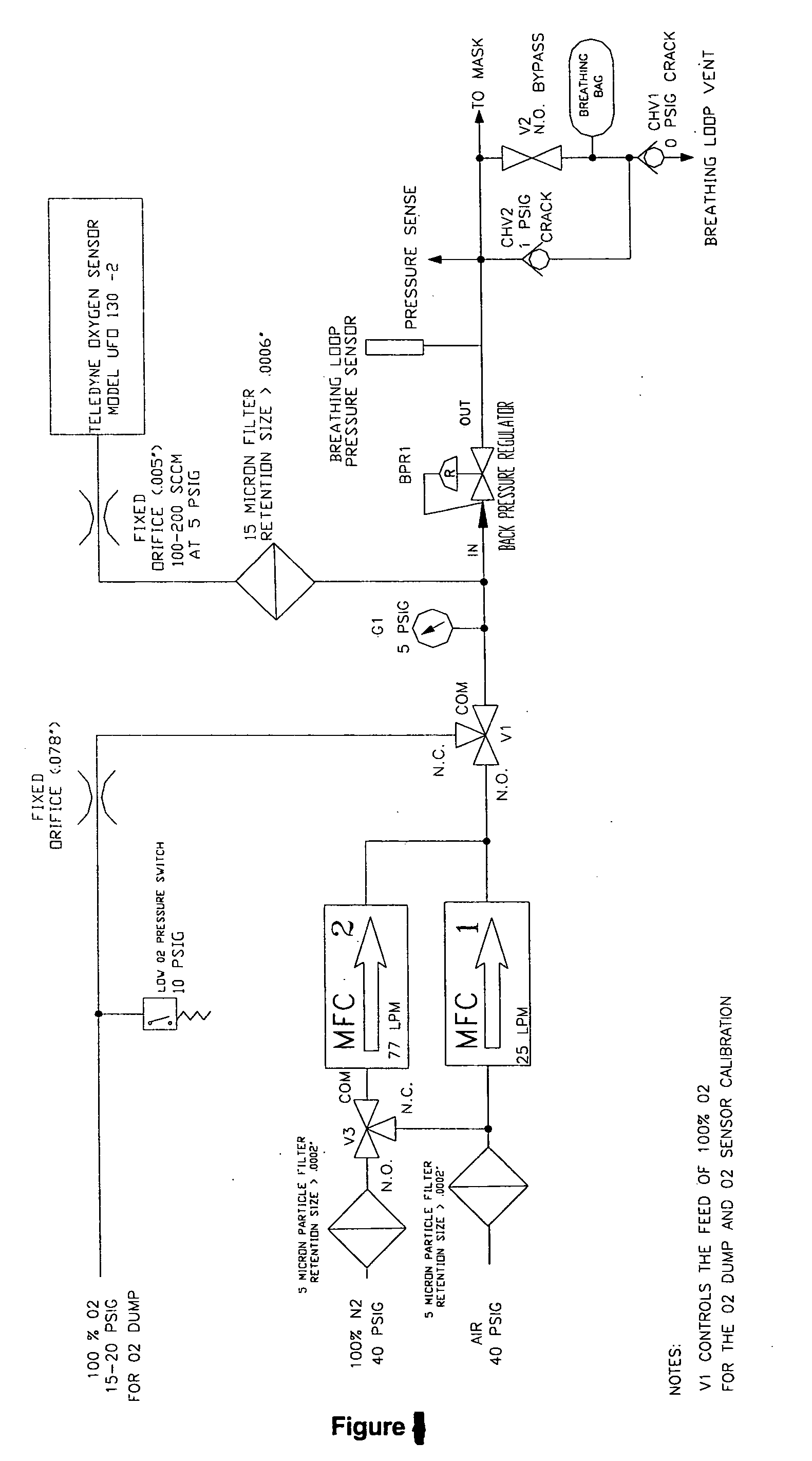

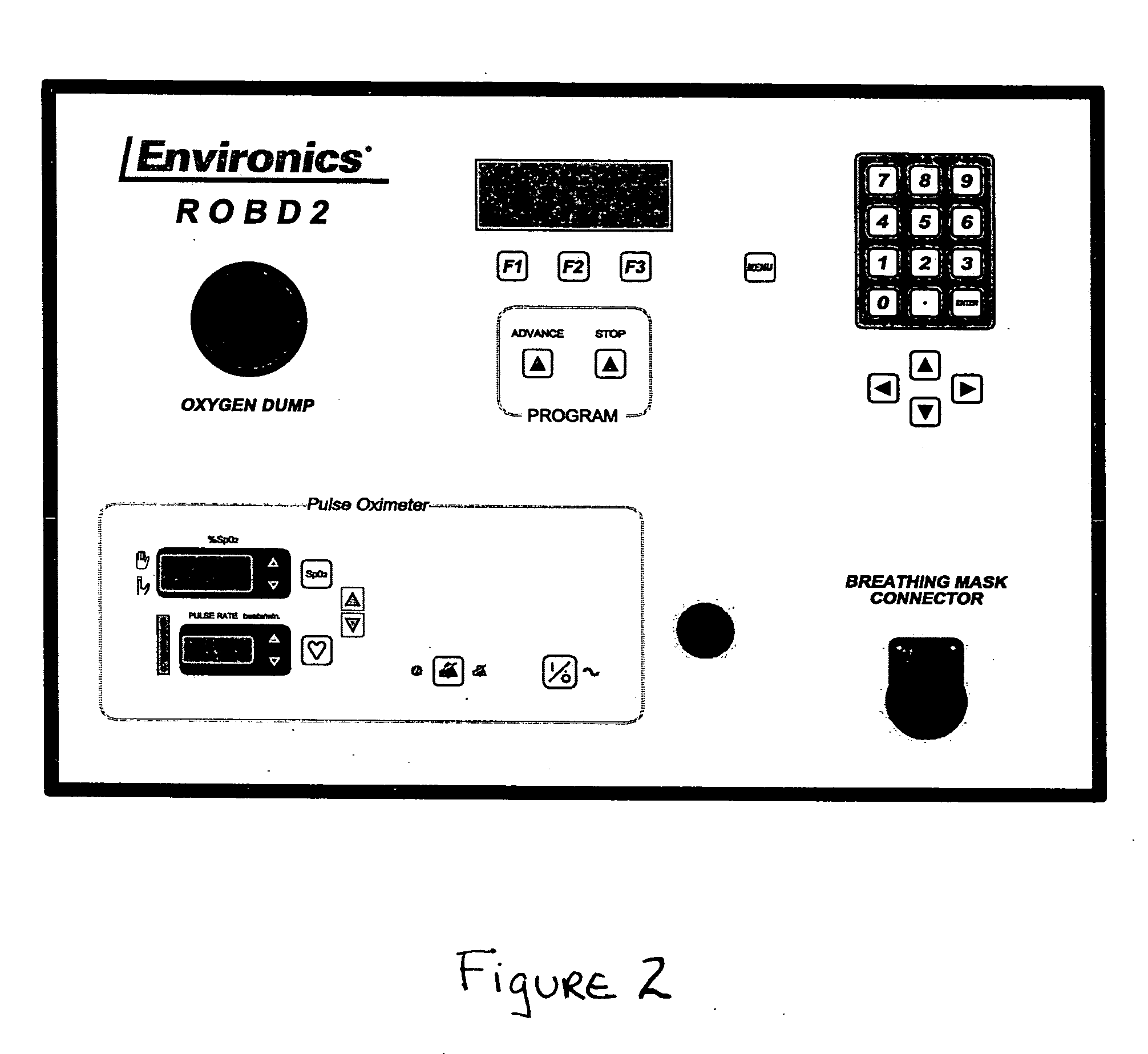

Reduced-oxygen breathing device

The Reduced Oxygen Breathing Device (ROBD2) is an apparatus that dilutes the oxygen present in air to concentrations below 21% by mixing the air with nitrogen. The purpose of this dilution is to simulate the reduced oxygen concentration available as one ascends in altitude. The ROBD2 is unique and different from previous devices that reduce the concentration of oxygen in room air via dilution with nitrogen gas in that it uses sophisticated gas regulating devices known as mass flow controllers. The ROBD also employs a gas extraction device as an independent component of the system that can separate nitrogen gas from air for use in the device.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

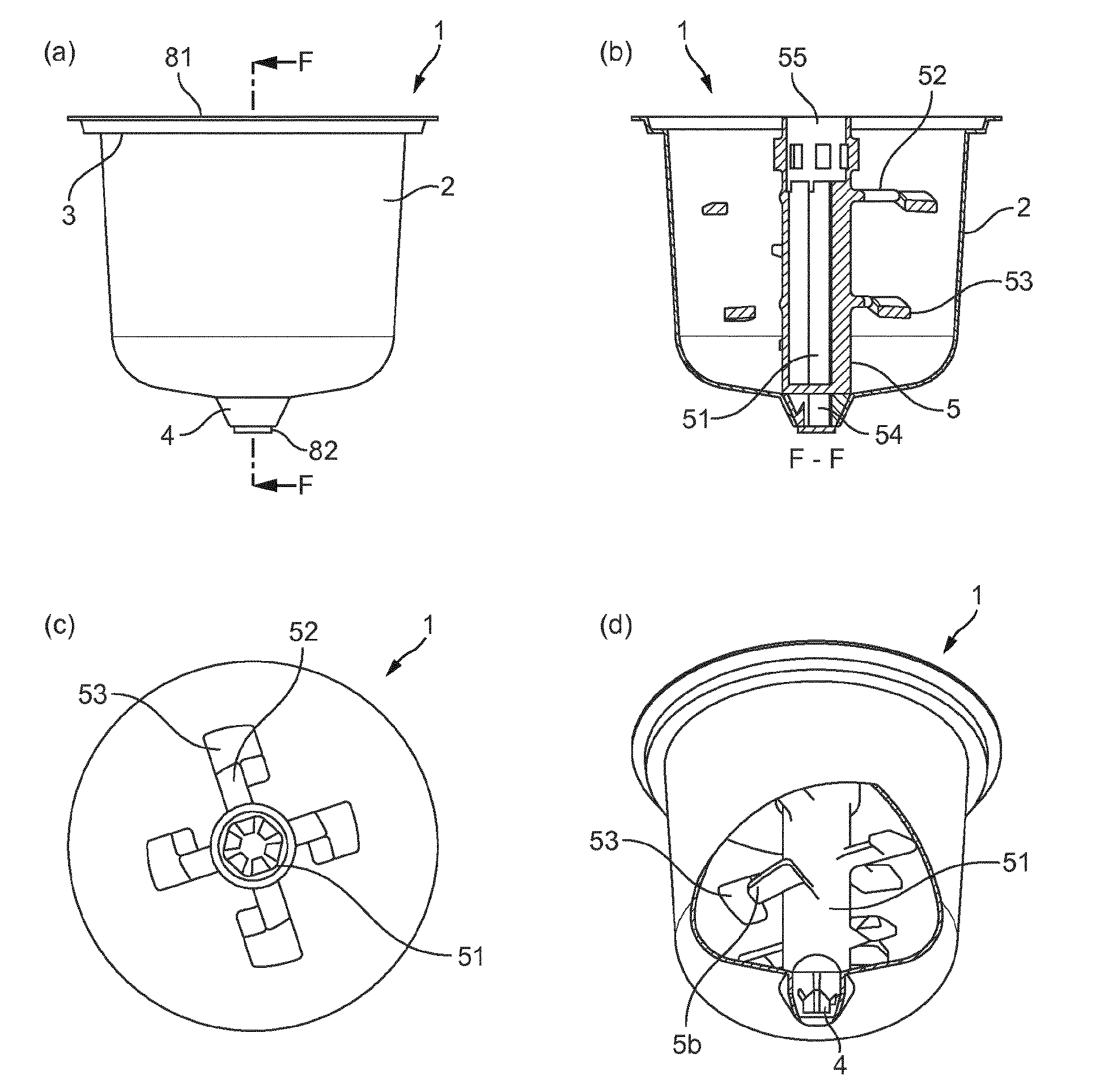

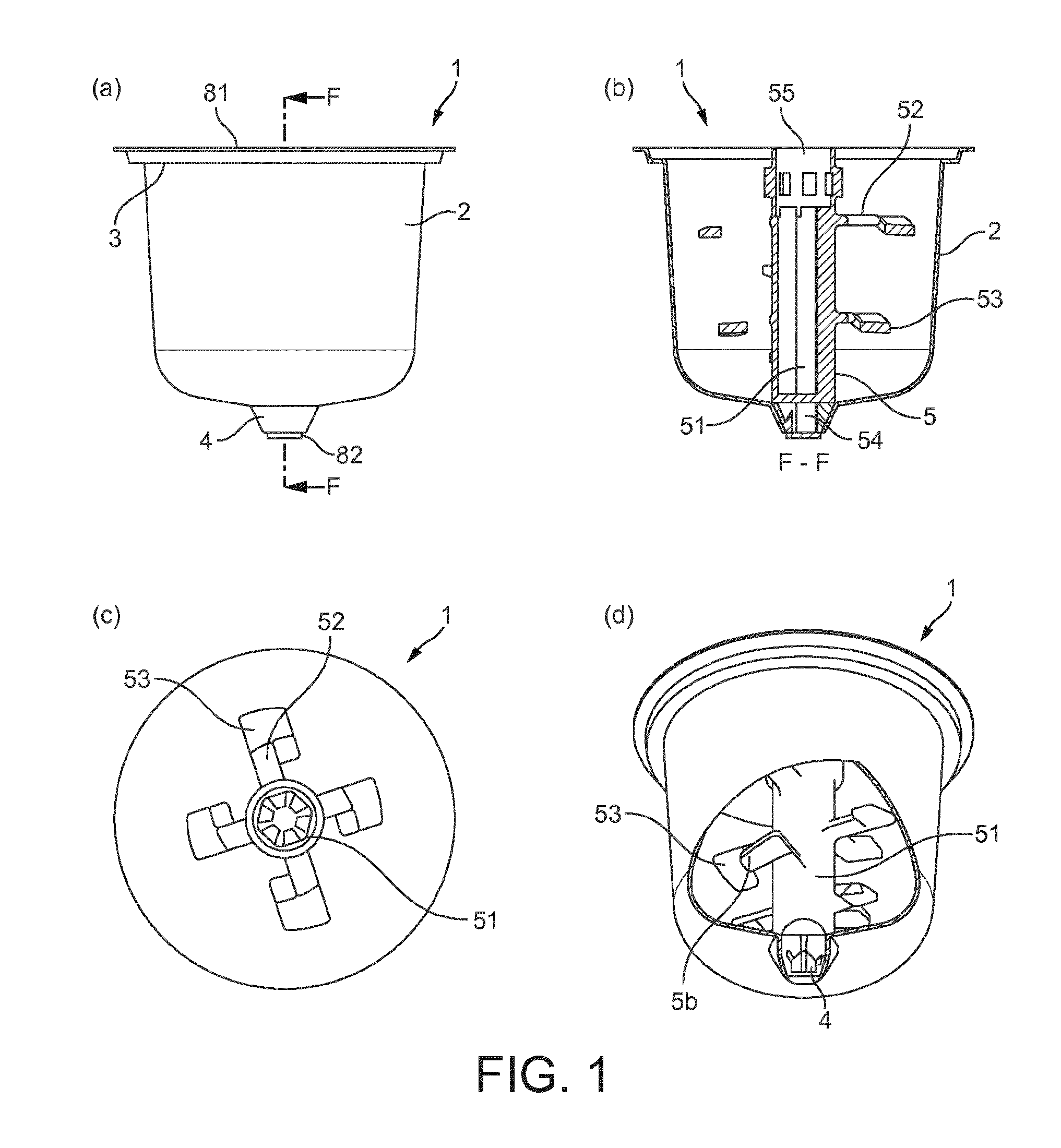

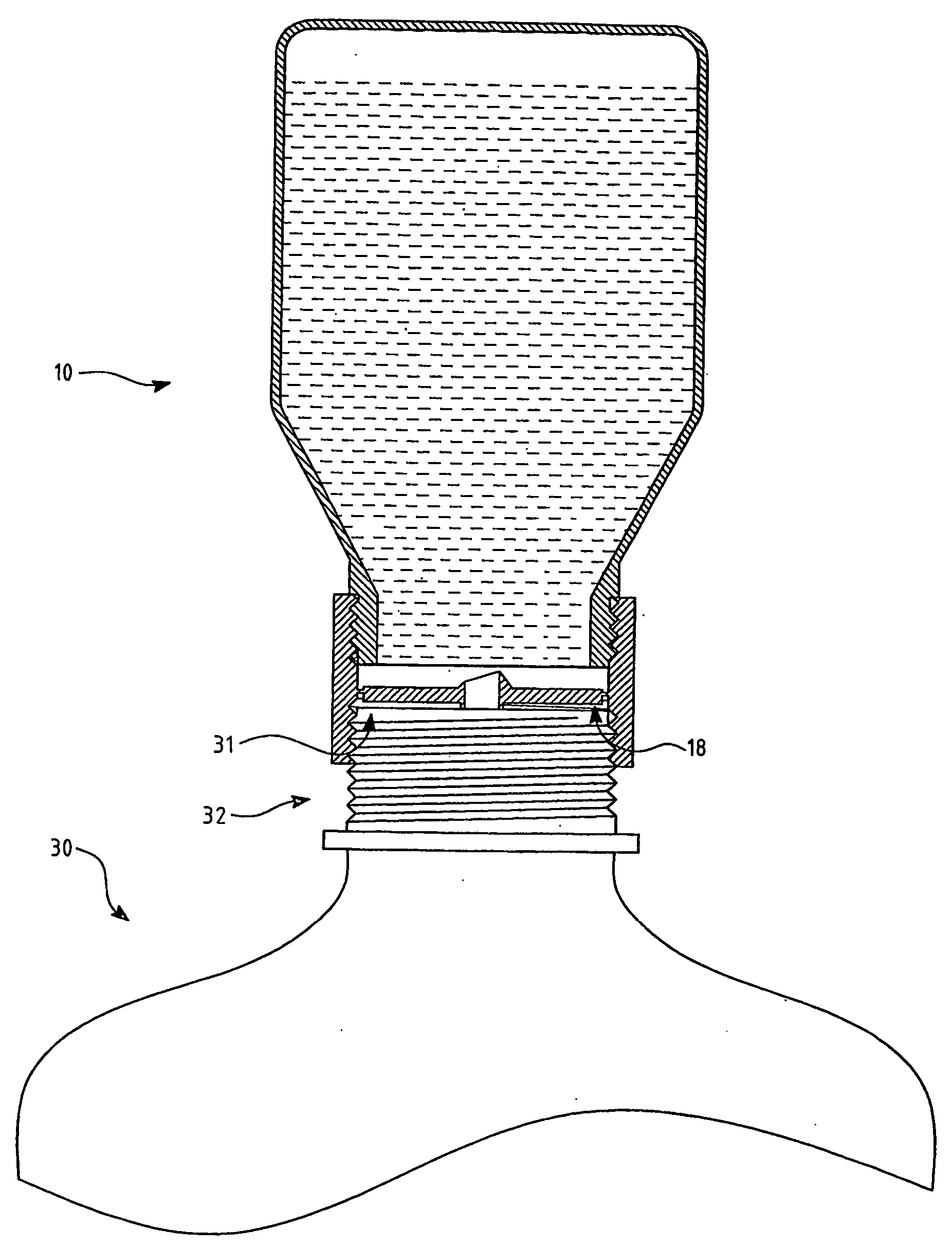

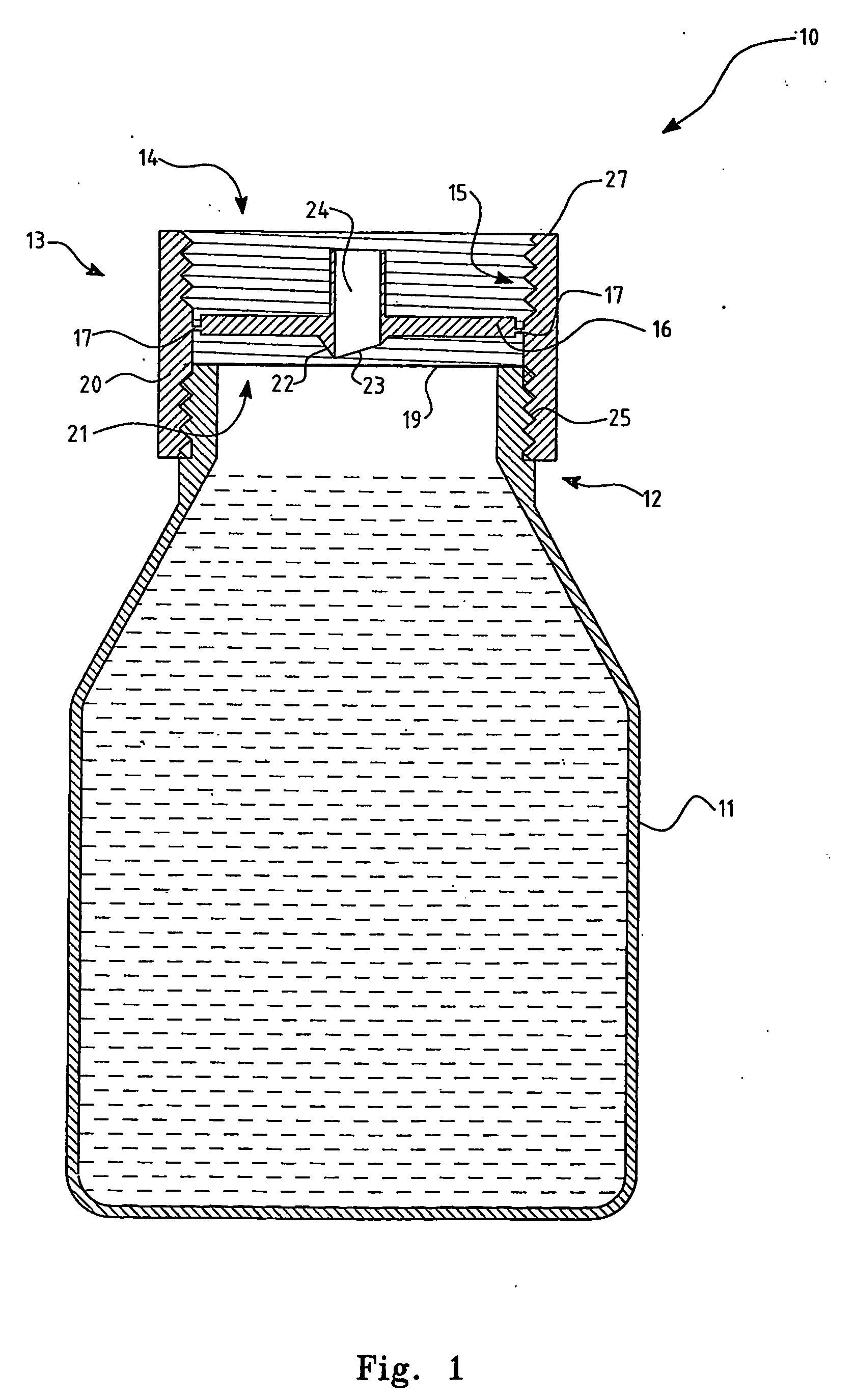

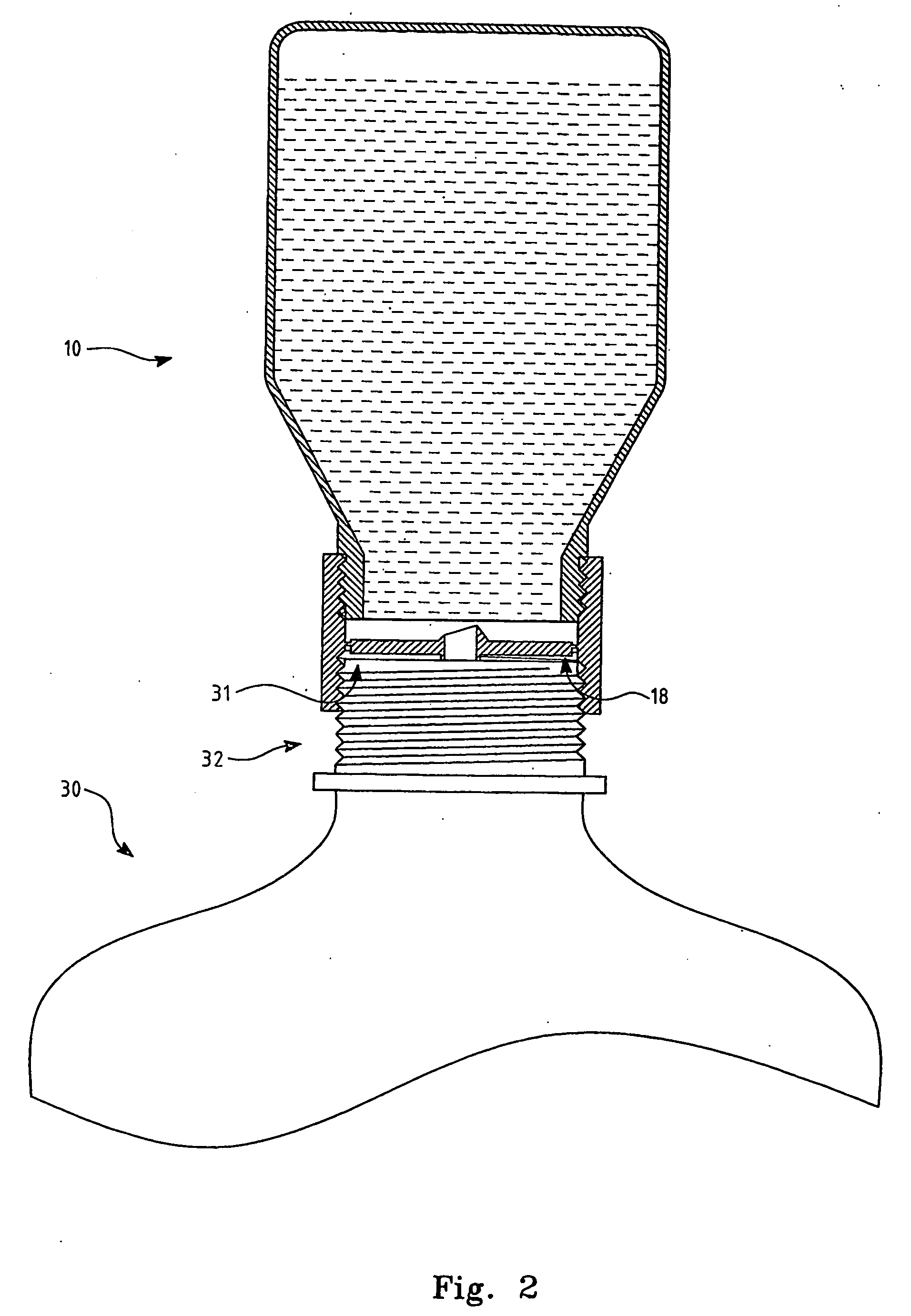

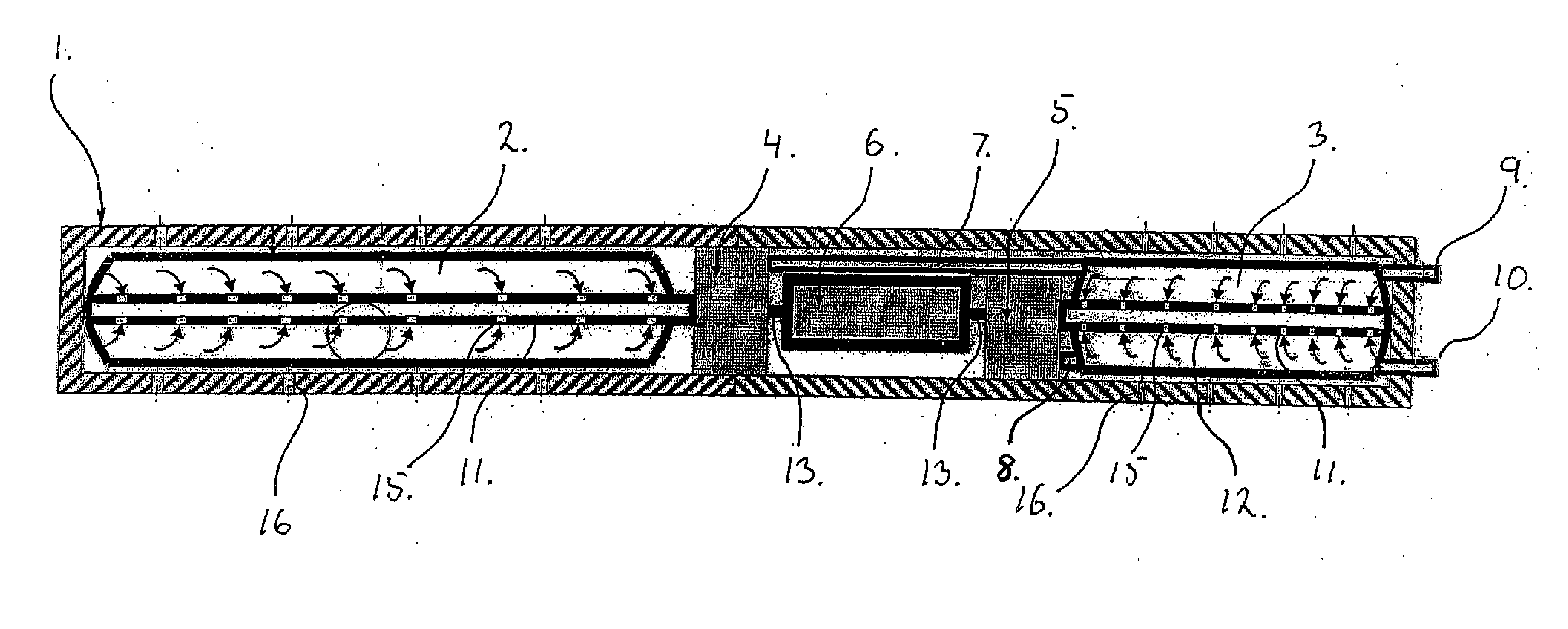

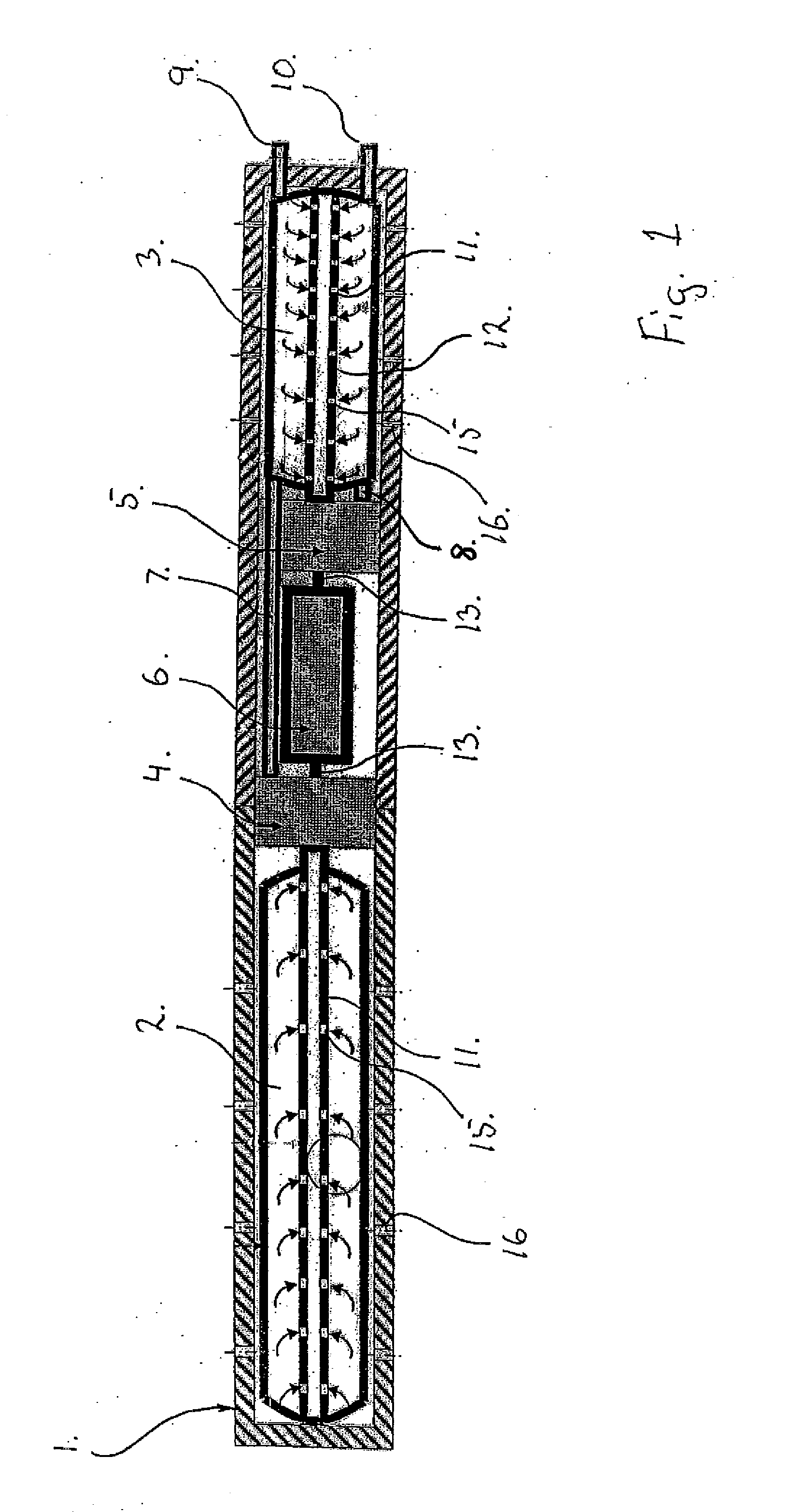

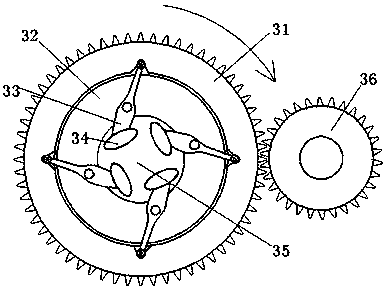

Capsule, method and system for preparing a viscous beverage or food product

InactiveUS20160214787A1Easy and efficientGuaranteed mixRotary stirring mixersBeverage vesselsEngineeringIngested food

The present invention describes a capsule 1 and a system of food or beverage production machine 10, wherein the capsule 1 has an integrated mixing unit 5, which can be moved and / or rotated in respect to a capsule body 2. By rotating the mixing unit 5, beverage or food product ingredients inside the capsule 1 are mixed with a liquid introduced into the capsule 1. The rotation of the mixing unit further generates a pressure, which pushes the produced beverage or food product through a capsule outlet 4. The rotation of the mixing unit can also move the mixing unit 5 between a first position and a second position, in order to selectively open or close the outlet 4 of the capsule 1.

Owner:NESTEC SA

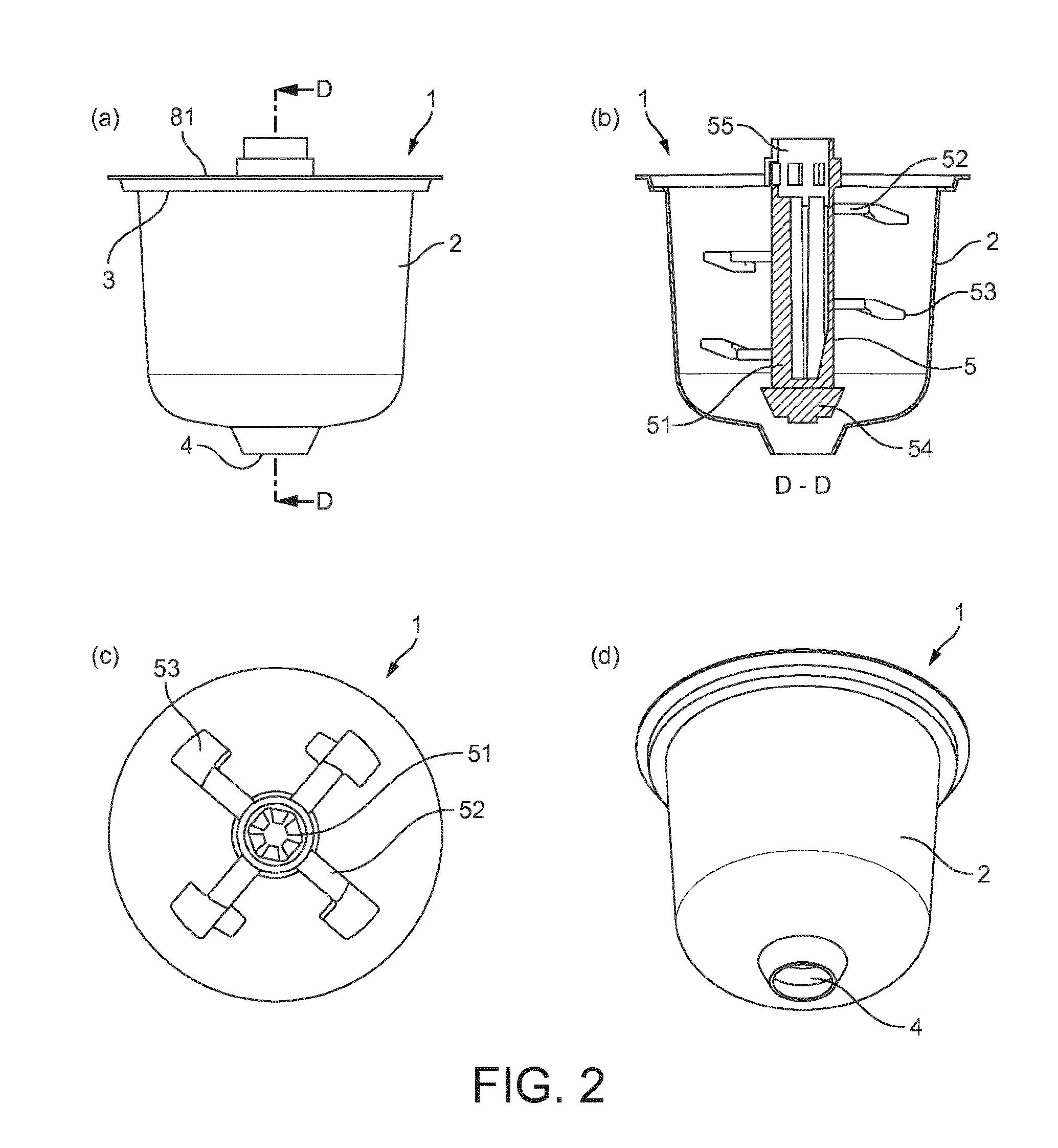

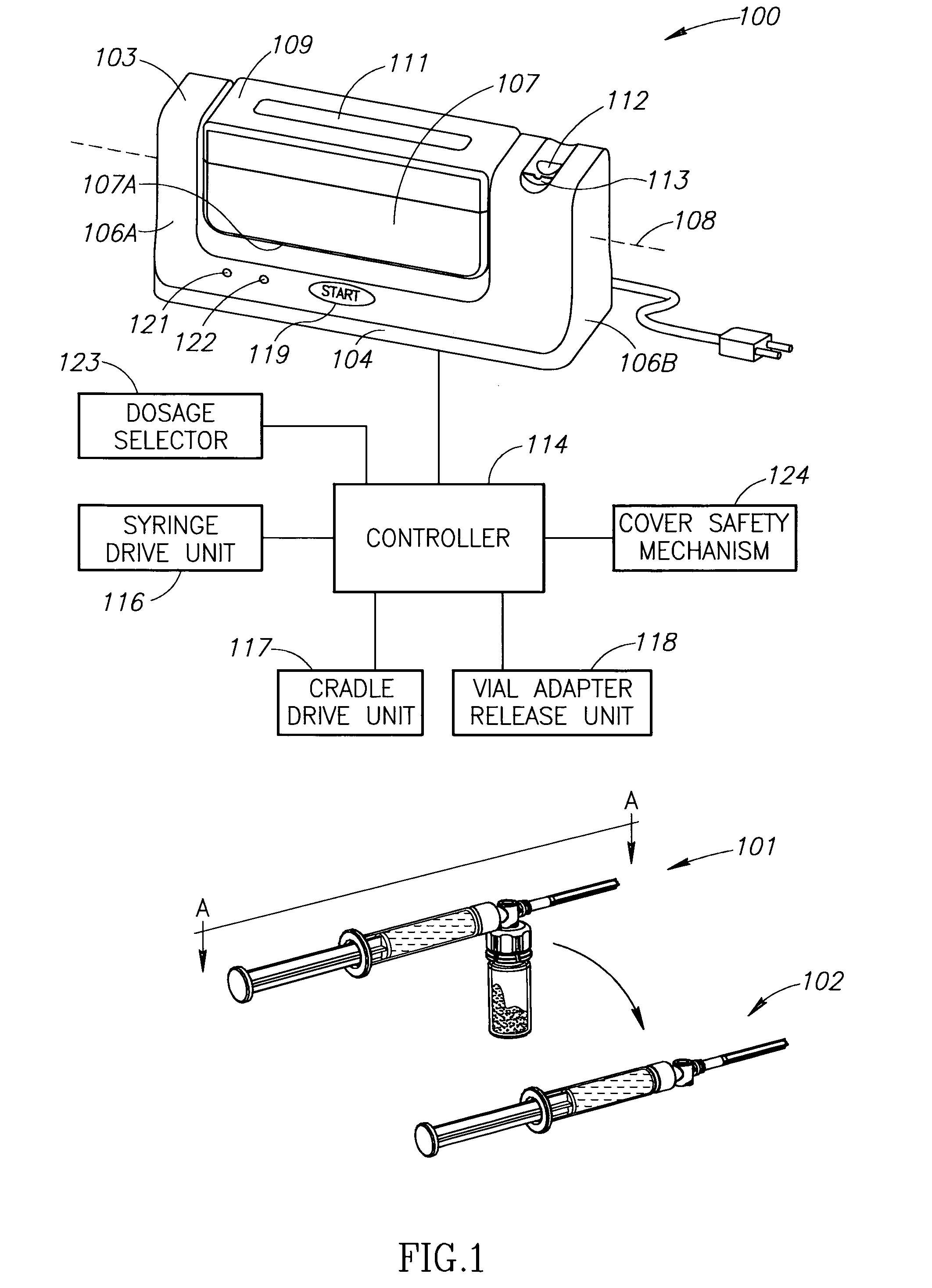

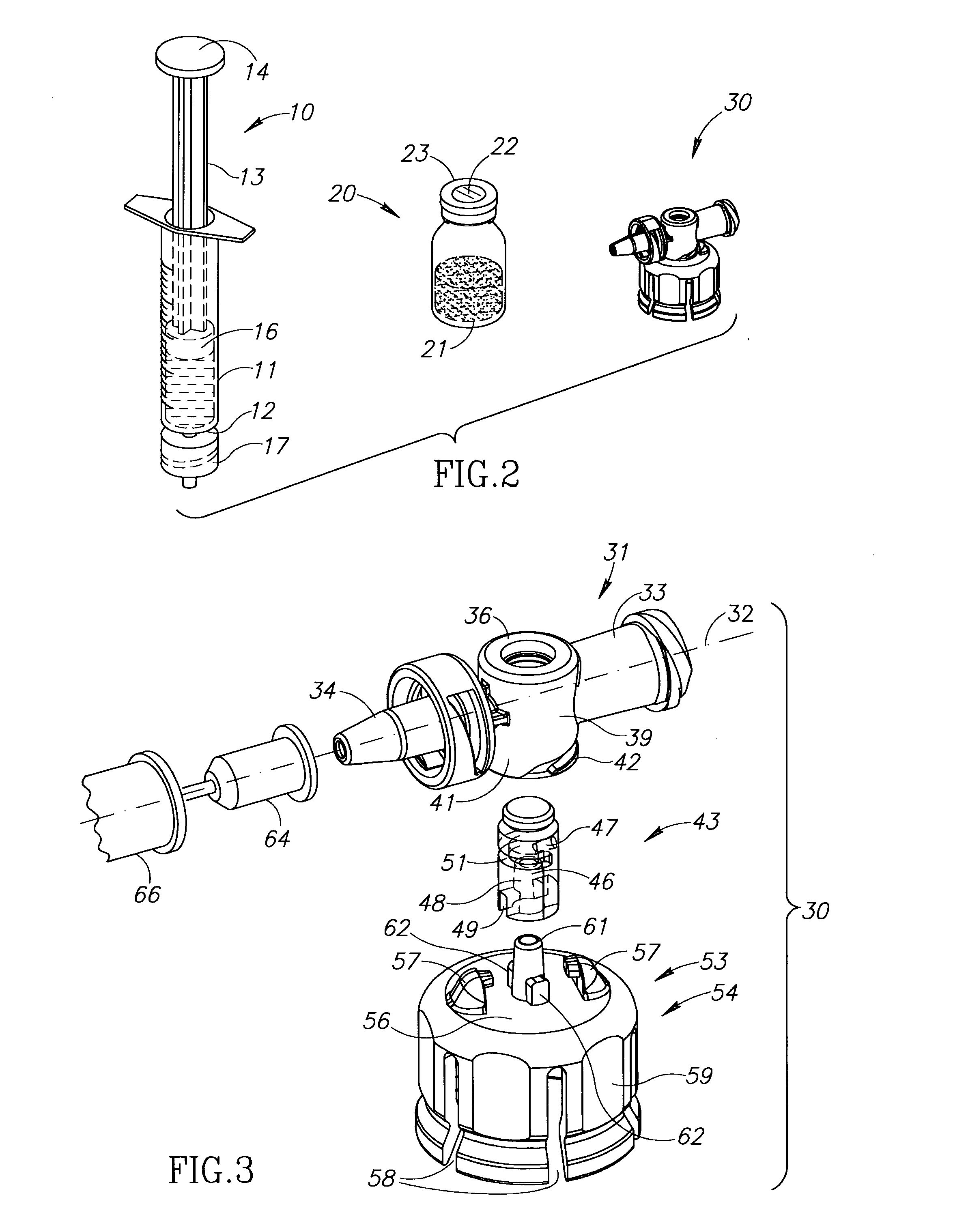

Automatic Liquid Drug Preparation Apparatus for the Preparation of a Predetermined Dosage of Liquid Drug

Automatic liquid drug preparation apparatus for preparing a liquid drug assemblage with a predetermined dosage of liquid drug. The liquid drug assemblage is prepared from a preparatory assemblage including a fluid control device having a body member with a syringe port, a vial adapter, and an administration port, a vial pre-filled with powder or liquid medicament, and a syringe pre-filled with diluent for mixing with the medicament. The automatic liquid drug preparation apparatus includes a housing, a cradle for receiving the preparatory assemblage, and a controller for controlling a motorized syringe drive unit for selectively transferring liquid contents between the syringe and the vial, a motorized cradle drive unit for selectively rotating the cradle relative to the housing, and a motorized vial adapter release unit for selectively detaching the vial adapter with its attached spent vial from the body member to form the liquid drug assemblage.

Owner:MEDIMOP MEDICAL PROJECTS

Fluid and hair-dye dispensers

ActiveUS7121430B2Easy to operateLight weightOpening closed containersBottle/container closureHair dyesEngineering

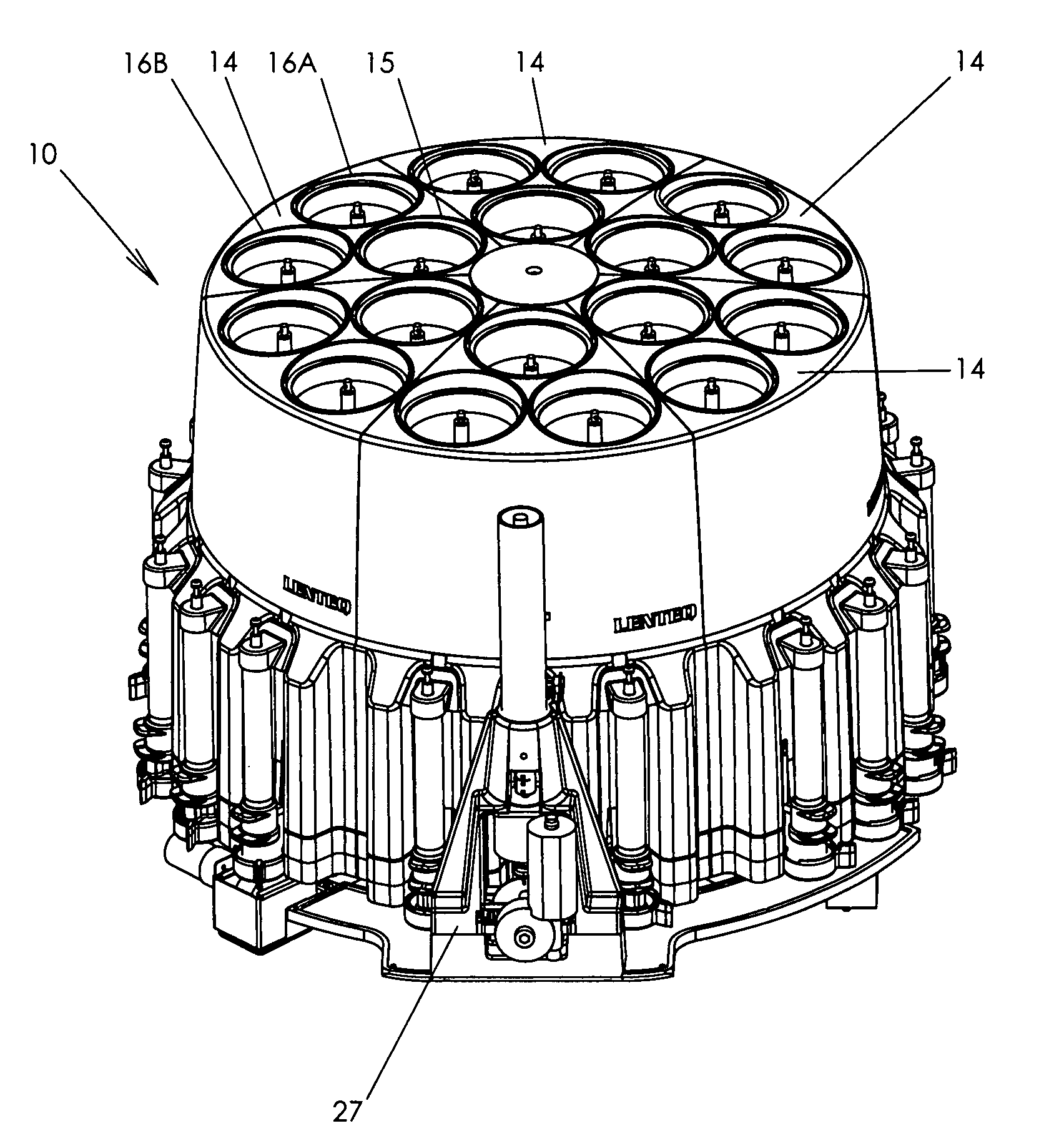

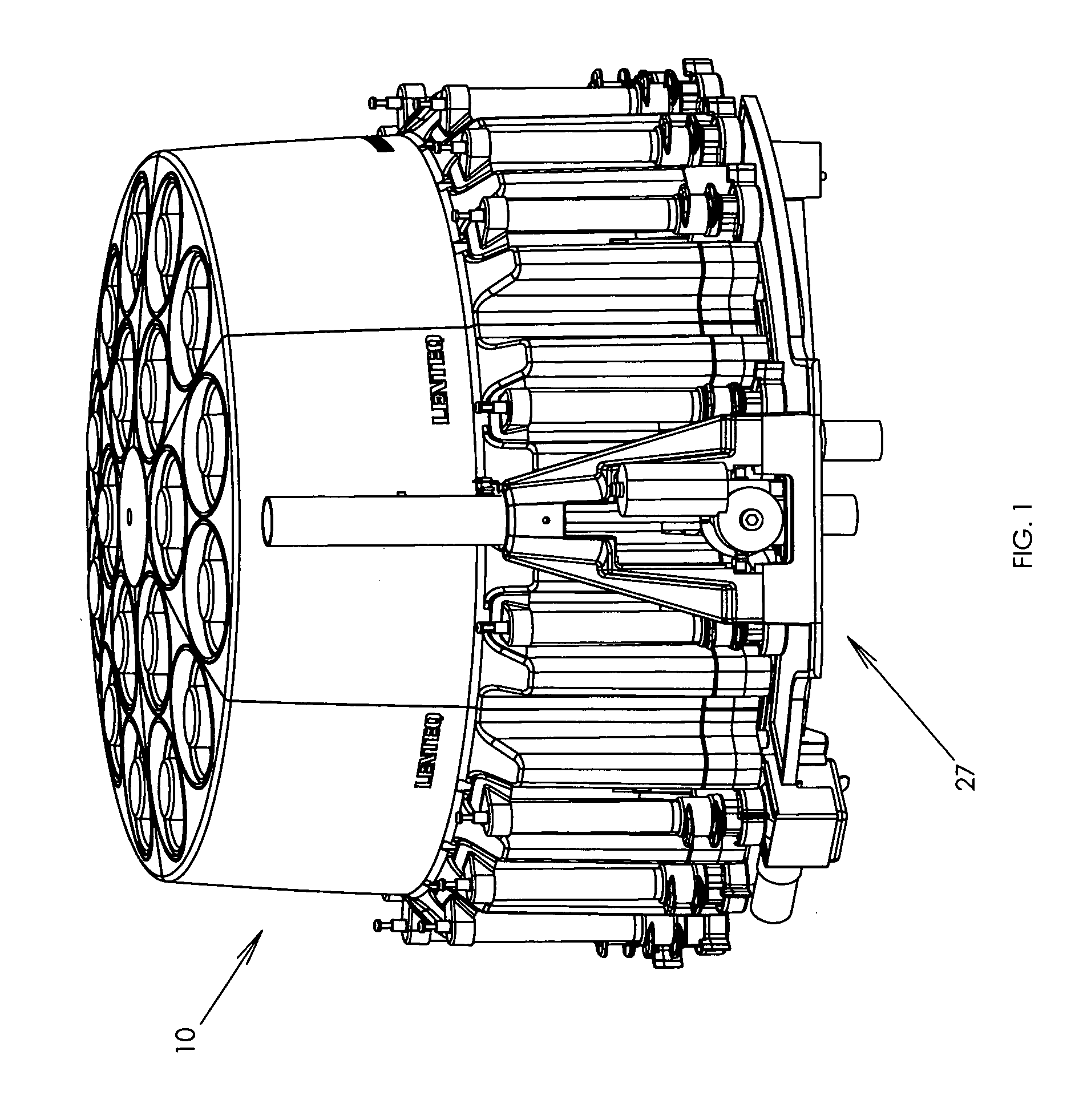

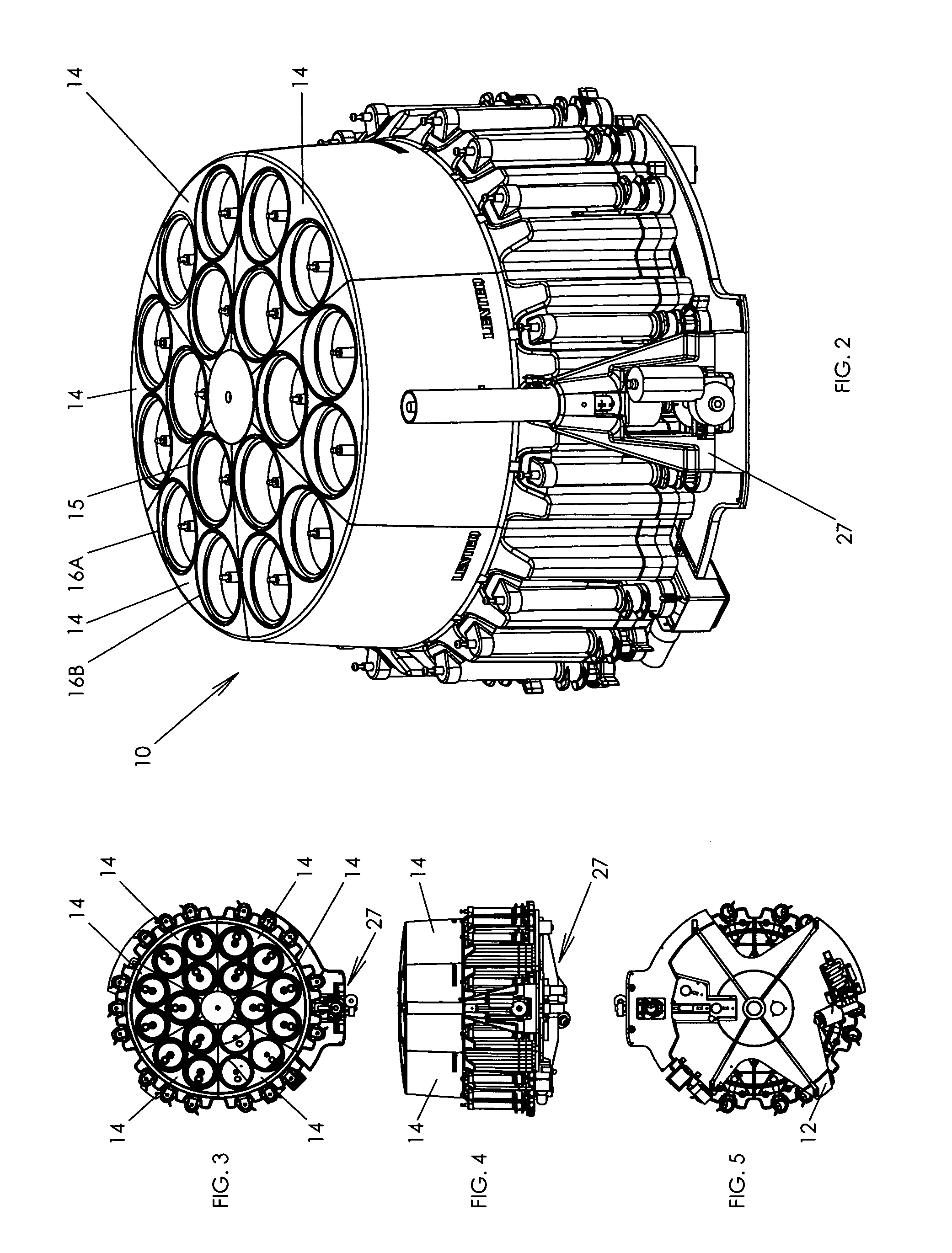

In accordance with the present invention there is provided novel and unique automatic and manual colorant and hair dye dispensers that are easy to operate and provides precision mixing of a large number of colorants and hair dye to make an almost infinite number of colors. The machines are relatively light in weight, easy to operate and maintain and the various components can be readily and easily replaced. In the colorant dispenser this is principally due to the fact that the colorant canisters are supported by a central column and the conventional use of a massive turntable supporting the canisters have been eliminated. In both the automatic and manual illustrated embodiments there is shown six (6) pie-shaped triangular canister units (dispensing units) each including three (3) separate colorant receptacles. There can be more or less dispensing units as desired.

Owner:STIBBE MANAGEMENT BV

System for combining liquids

InactiveUS20070039975A1Guaranteed mixClosure with auxillary devicesTable equipmentsEngineeringMechanical engineering

Owner:BOCHTLER MARTIN

Method of preparing alpha-sulphonic acid fatty acid ester

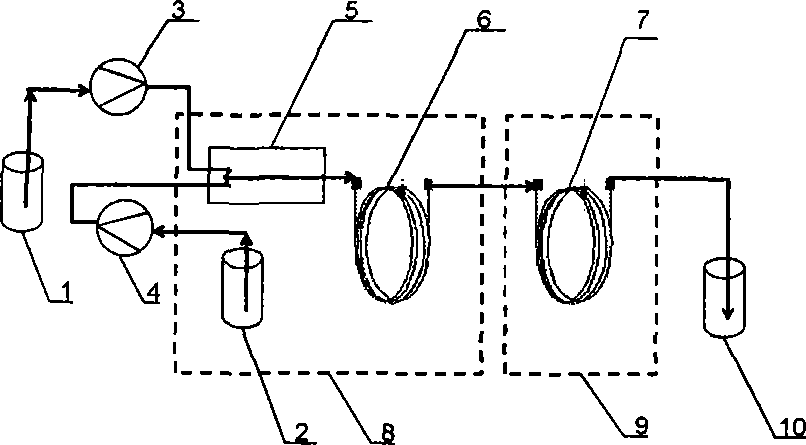

InactiveCN101508660AImprove securityRelaxed reaction conditionsSulfonic acid preparationState of artReaction temperature

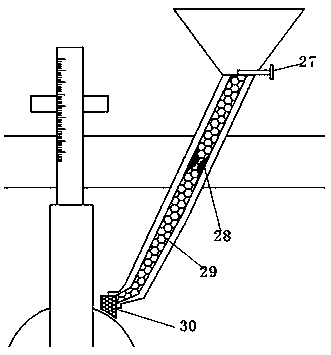

The invention relates to a method for preparing alpha-sulfonic fatty acid ester by sulfonating fatty acid ester, comprising the following steps: injecting the fatty acid ester and a sulfonating agent into a micro-structural reactor (5) and a reactor (6) inside diameter of which is a micro passage respectively, mixing and sulfonating the fatty acid ester and the sulfonating agent, controlling the reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 1ms to 1s in the micro-structural reactor (5) and stay for 0.5 to 30 minutes in the micro-passage reactor (6); and then injecting the reaction materials into a micro-passage reactor (7), aging the reaction materials at a reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 0.5 to 30 minutes in the micro-passage reactor to obtain the alpha-sulfonic fatty acid ester. In the method, the novel micro-structural reactor is adopted, the defect of difficult control due to strong reaction heat release in the prior art is overcome, the materials can be mixed evenly, the released reaction heat can be removed in time, the reaction time can be controlled accurately, and the method has the advantages of good sulfonating efficiency, simple and safe operation and good product quality.

Owner:NANJING UNIV OF TECH

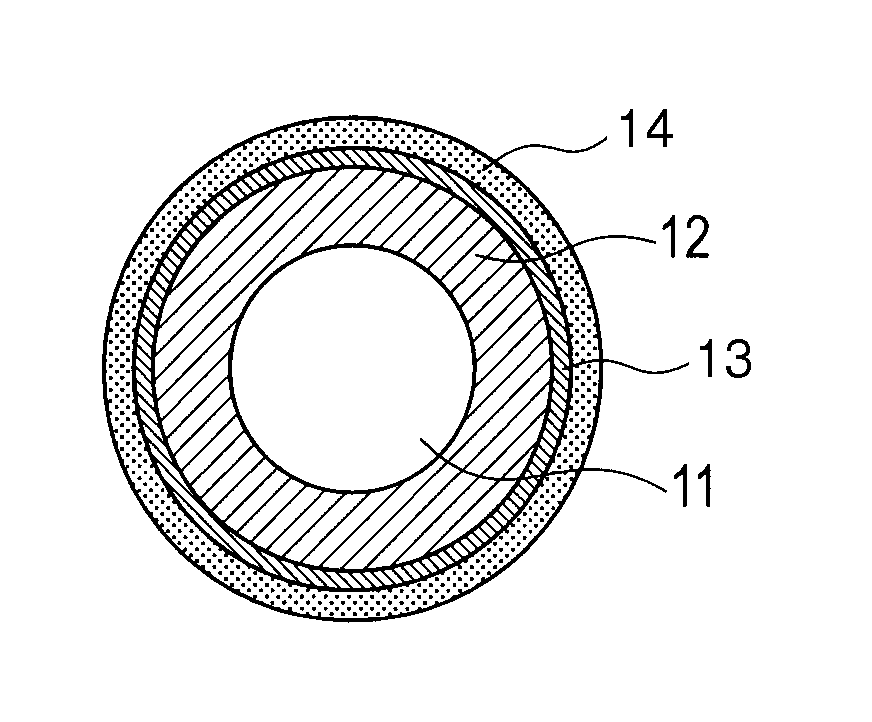

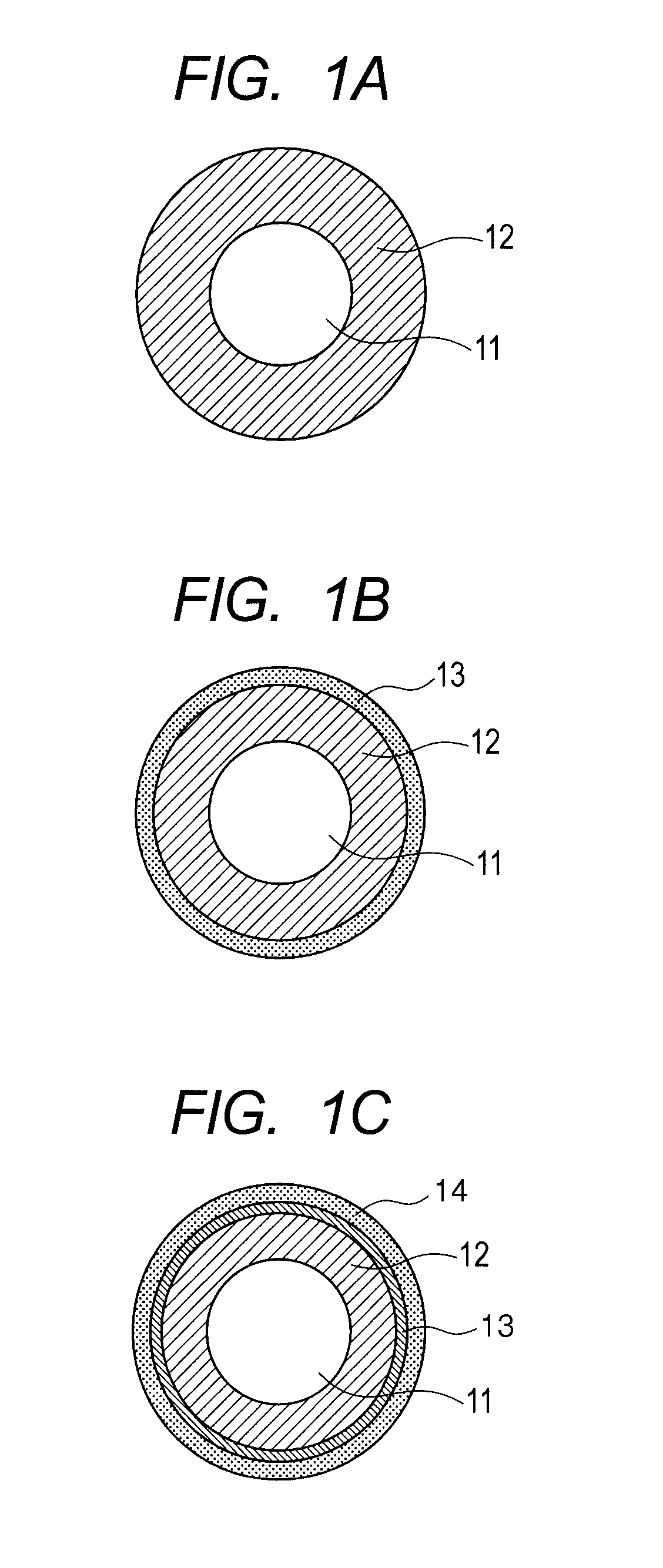

Ionic electro-conductive resin and electro-conductive member for electrophotography

InactiveUS9086643B2Guaranteed mixConductive materialOrganic conductorsConductive polymerOrganic group

Owner:CANON KK

Method and an apparatus for downhole injecting one or more treatment fluids

ActiveUS20120085540A1Guaranteed mixPrecise positioningDrilling rodsFluid removalEngineeringMechanical engineering

Method and apparatus for downhole injecting one or more treatment fluids, and especially for providing one or more seals in an annular space between a well tubular and the surrounding formation or between pipes of a wellbore system, said method comprising the steps of loading the or each treatment fluid separately into one or more fluid containers (2,3) arranged in a injection tool (1), each container comprising container walls surrounding the fluid in the fluid container, and an outlet opening, lowering the injection tool body into the wellbore or the well tubular to a predetermined position, pumping the fluids from each fluid container into the wellbore or the well tubular.

Owner:TOTAL E&P DANMARK AS

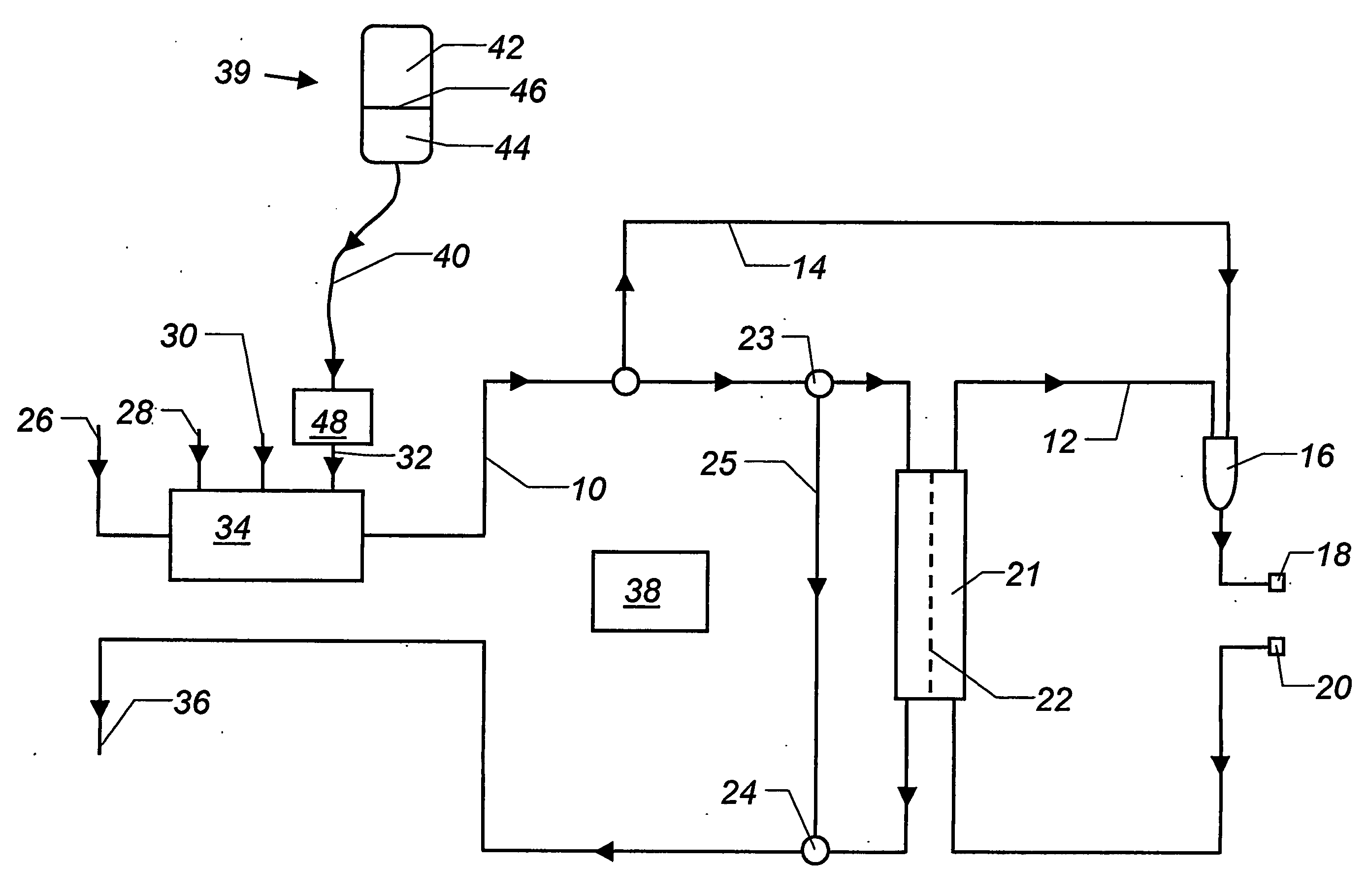

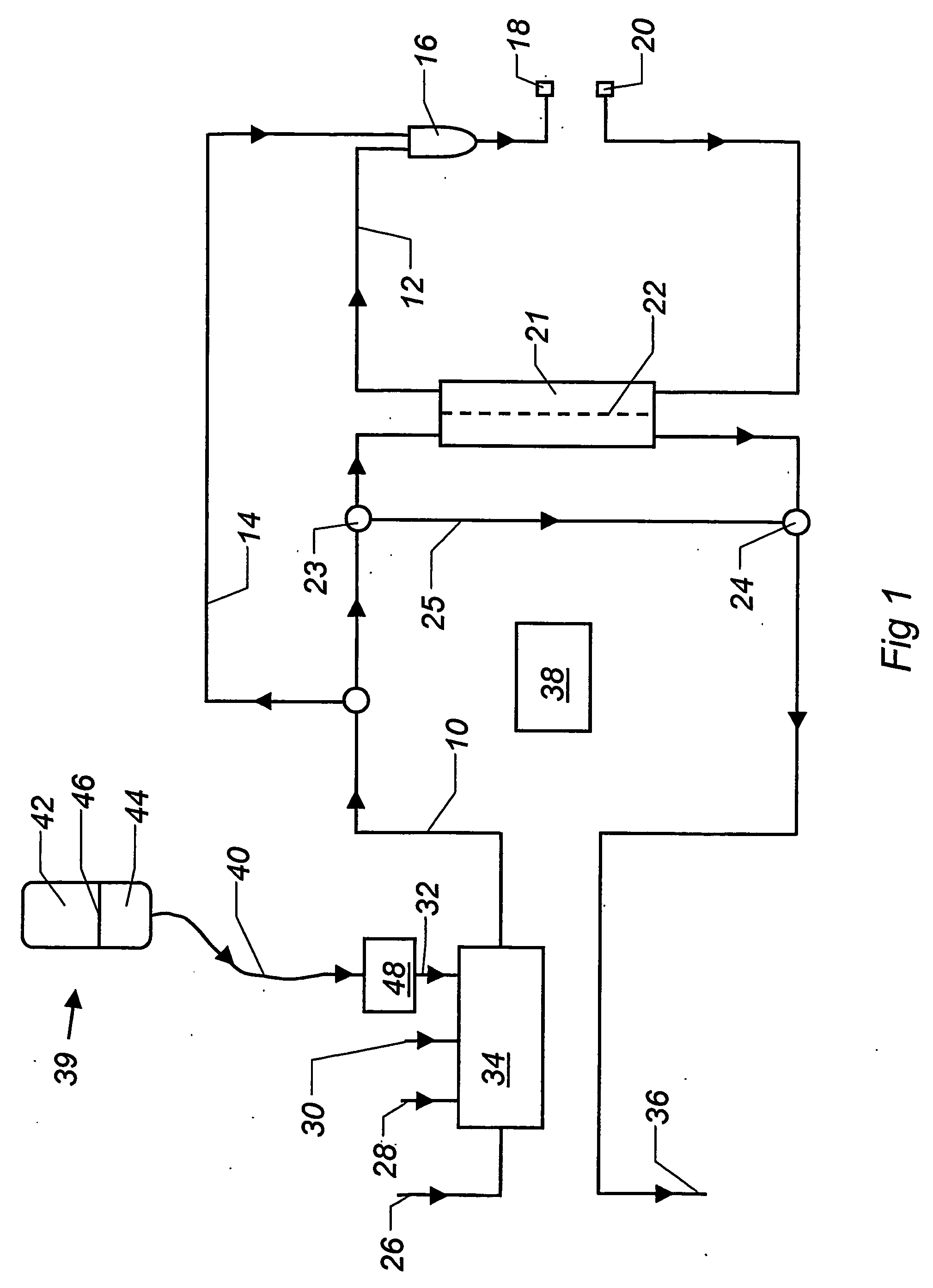

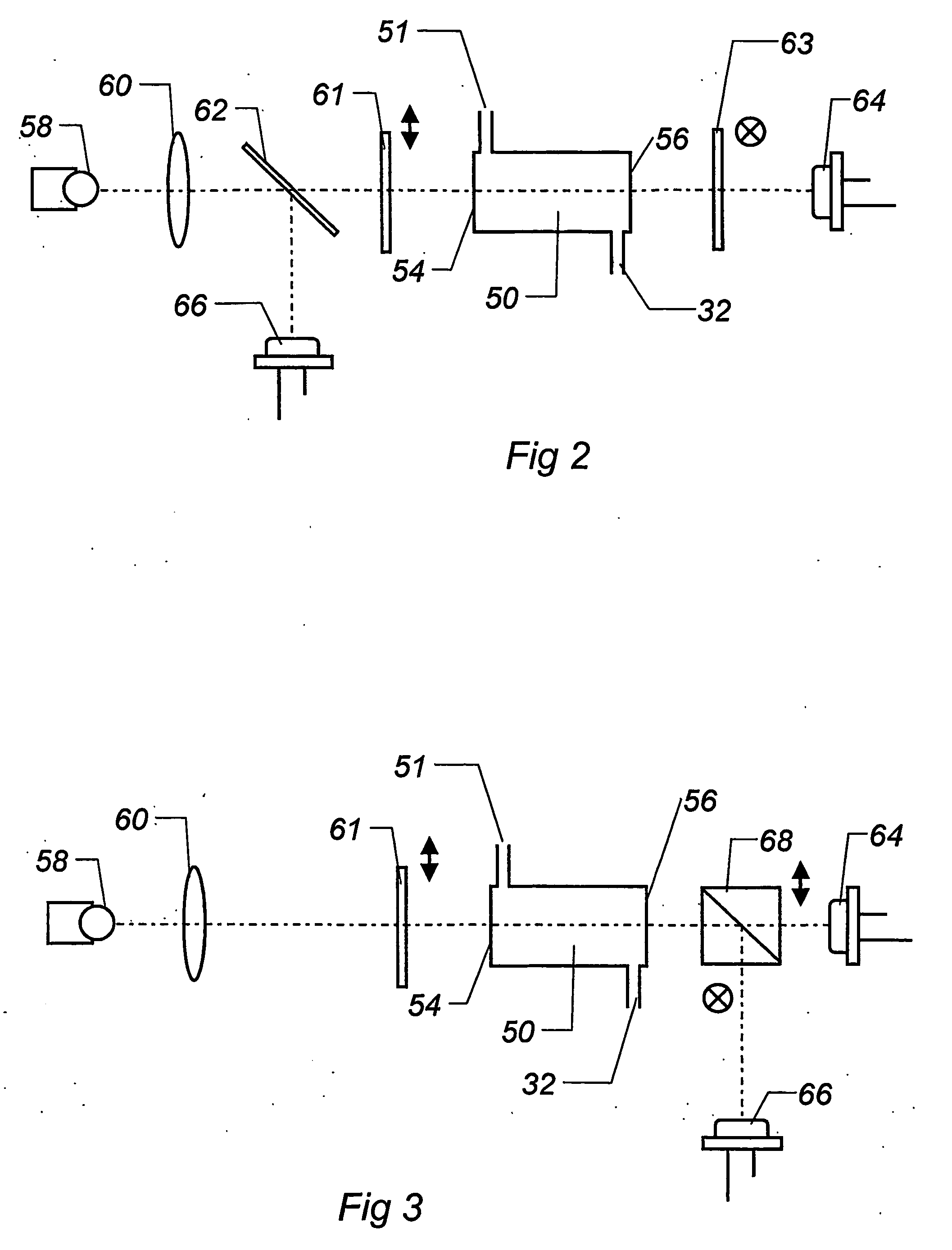

Apparatus, a system and a method relating to hemodialysis, hemodiafiltration, hemofiltration or peritoneal dialysis

InactiveUS20070023334A1Simple and inexpensive implementationAvoid mistakesSolvent extractionPolarisation-affecting propertiesHaemodialysis machineDialysis fluid

The invention relates to an apparatus for hemodialysis, hemodiafiltration, hemofiltration or peritoneal dialysis. The apparatus comprises at least one conduit (10, 14) in which a dialysis and / or infusion fluid is intended to flow. The apparatus has a measurement unit (48) for measuring at least one optically active substance in the fluid. The measurement unit (48) is arranged to measure the concentration of the substance in said fluid by measuring the influence said substance in the fluid has on a polarized beam of light which is transmitted through said fluid. The invention also concerns a system including such an apparatus as well as a method of carrying out a measurement of the concentration of an optically active substance in a dialysis and / or infusion fluid.

Owner:GAMBRO LUNDIA AB

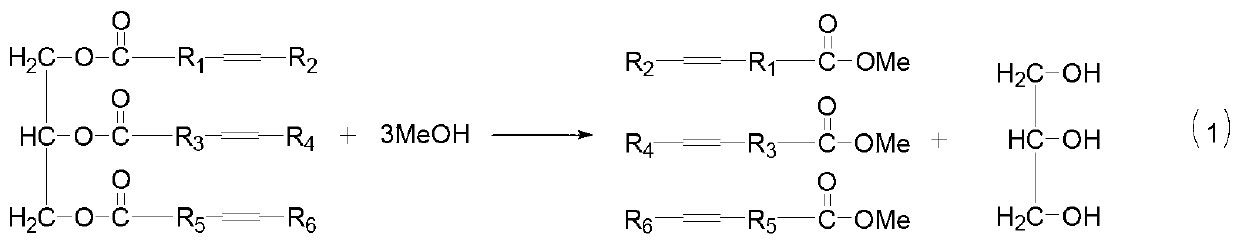

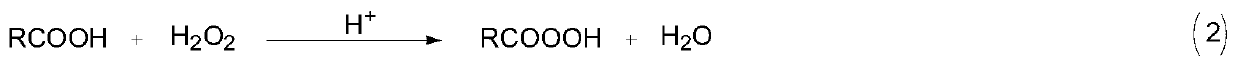

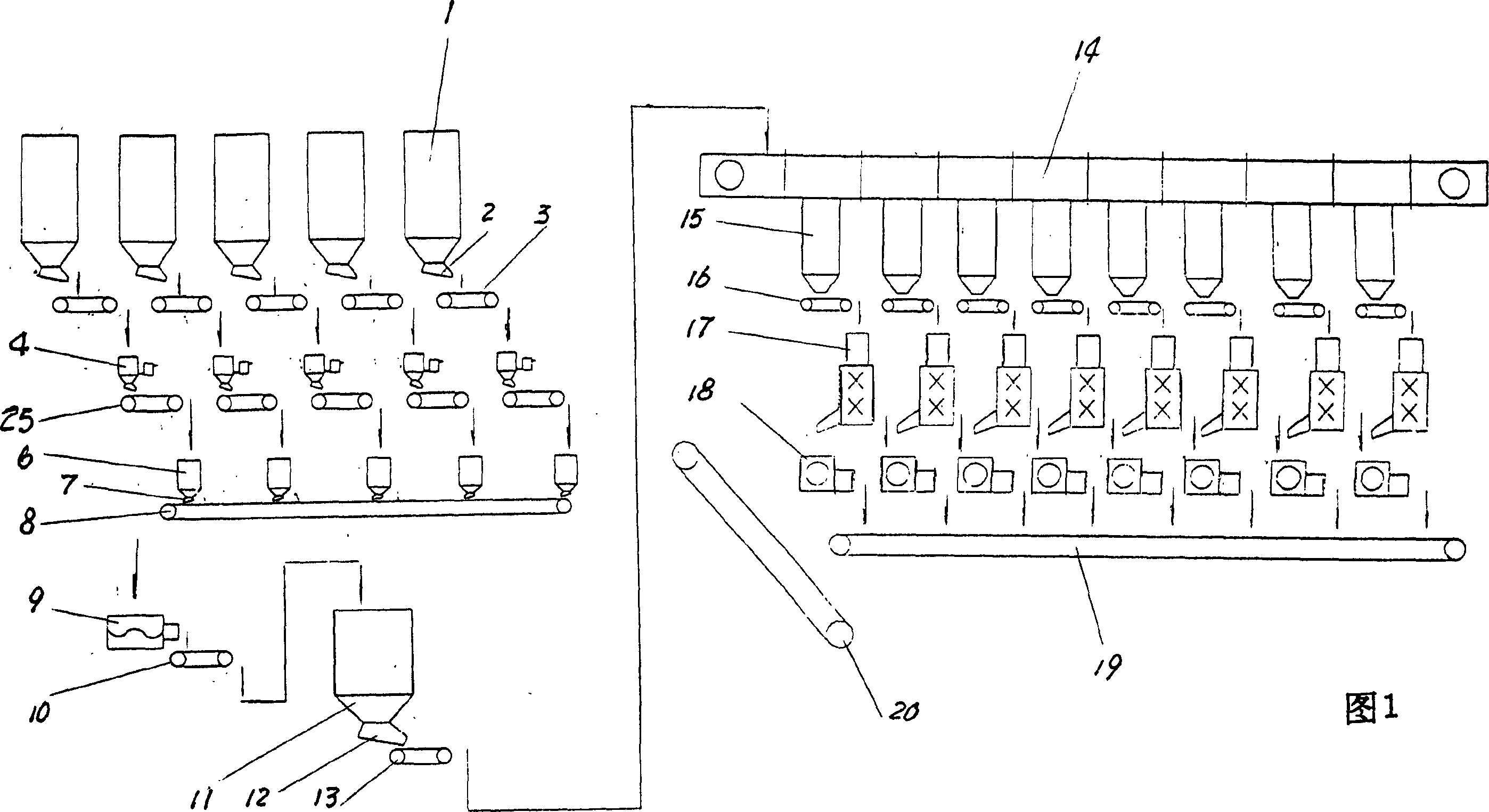

Method for preparing epoxidized fatty acid methyl ester with microreactor one-step method

ActiveCN102993133AImprove product qualityHigh epoxidation yieldOrganic chemistryDouble bondFatty acid methyl ester

The invention discloses a method for preparing epoxidized fatty acid methyl ester with microreactor one-step method, comprising the following steps: injecting oil and fat, low-carbon alcohol and basic catalyst in a first microstructure reactor of a microchannel modularized reaction device, wherein the mole ratio of oil and fat to low-carbon alcohol is 1:11-17, and remaining for 3-10 min at the temperature of 65-85 DEG C; mixing outlet material of the first microstructure reactor with hydrogen peroxide, organic acid, acidic catalyst and stabilizing agent in a second microstructure reactor of the microchannel modularized reaction device, wherein the mole ratio of number of double bonds in organic acid to number of double bonds in oil and fat is 11-17:1, and remaining 1-5 min at the temperature of 65-95 DEG C; guiding the outlet material of the first microstructure reactor in a separator, standing for demixing to remove aqueous solution at lower layer; washing an organic phase at the upper layer with water till the pH is 6.5-7.5; and drying to obtain epoxidized fatty acid methyl ester.

Owner:NANJING UNIV OF TECH

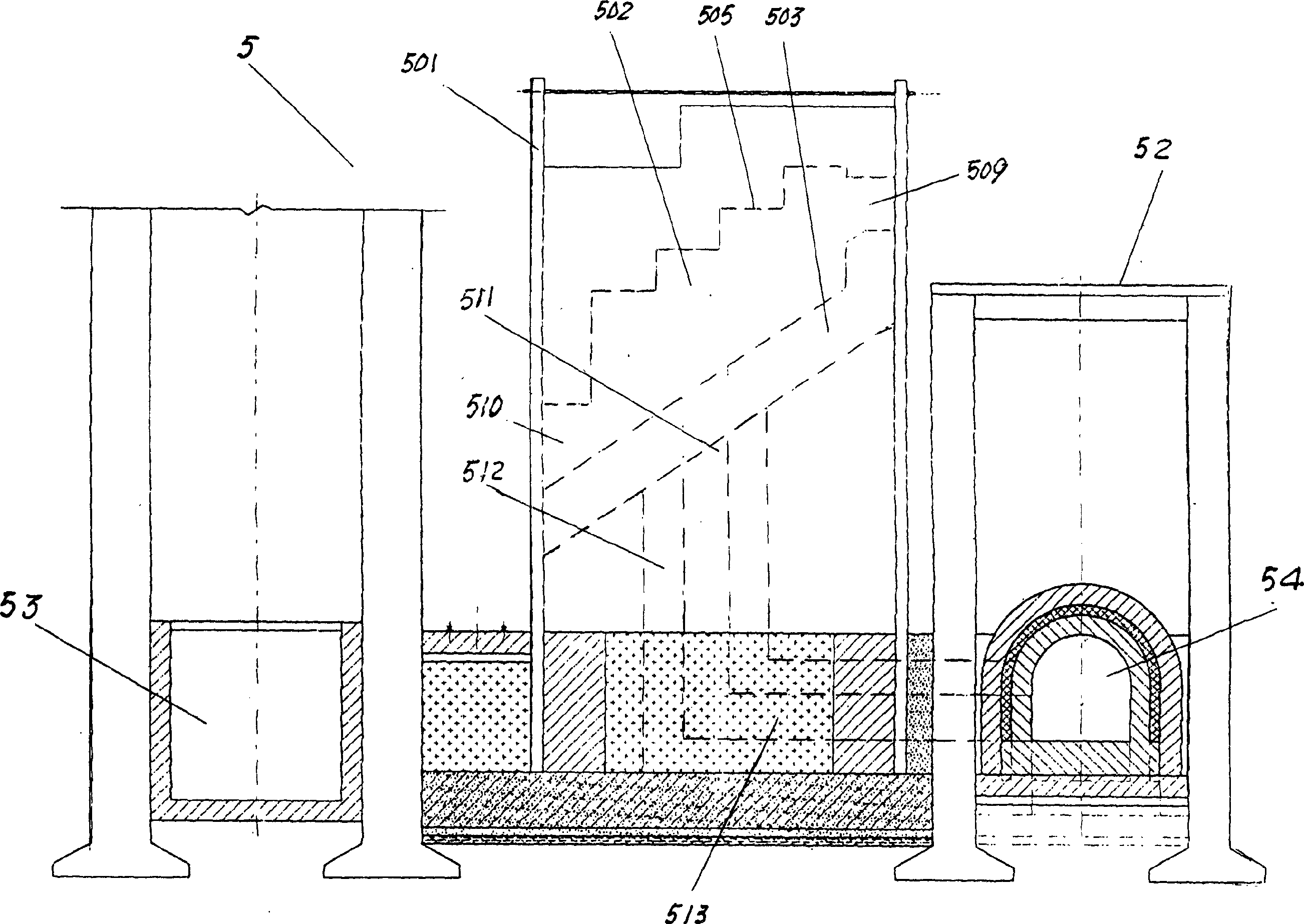

Casting type coke production method and apparatus system used thereof

The present invention relates to a production method of foundry shaped coke and its equipment system for producing said foundry shaped coke. Said method includes the procedures of preparing material,pulverizing, cold stirring, hot stirring, forming and carbonization and coking, and its equipment system includes material-preparing chamber, pulverizing machine, cold stirring machine, hot stirring machine, forming machine and carbonizing furnace, etc.

Owner:商丘市普天工贸有限公司煤化工研究所

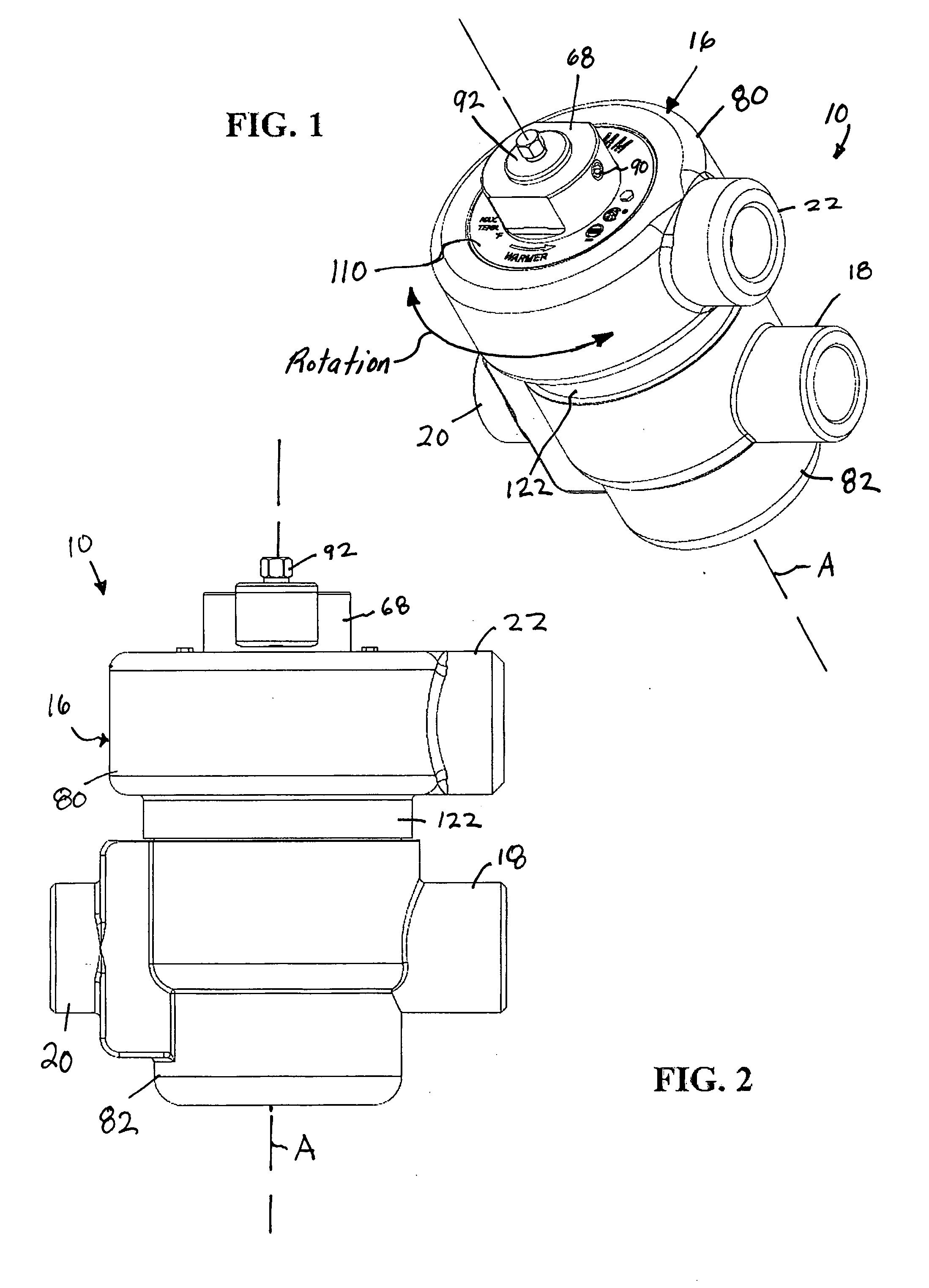

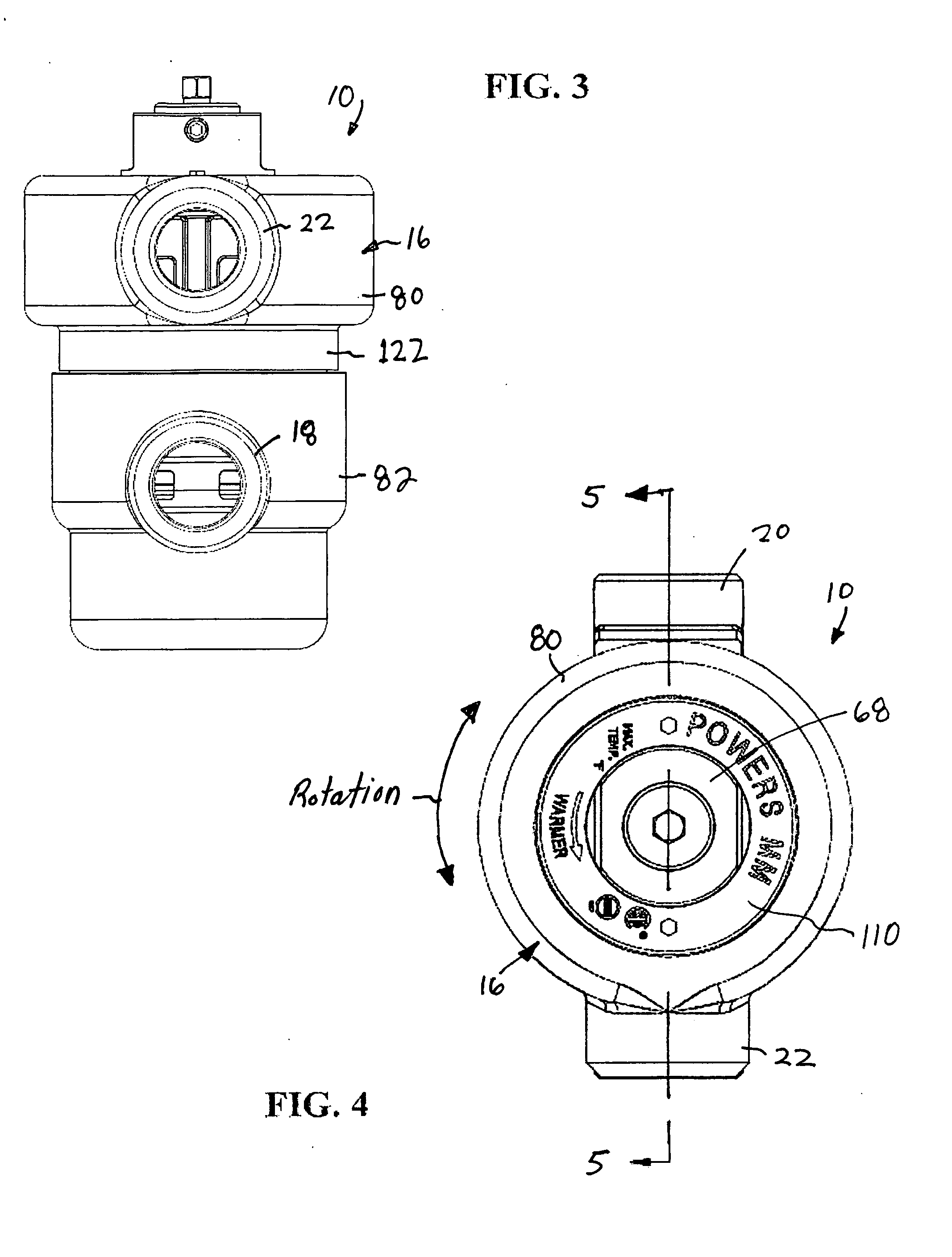

Thermostatic mixing valve

ActiveUS7913926B2Guaranteed mixEasy to disassembleTemperature control without auxillary powerTemperature control with auxillary non-electric powerMixed flowHeat flow

Owner:WATTS REGULATOR

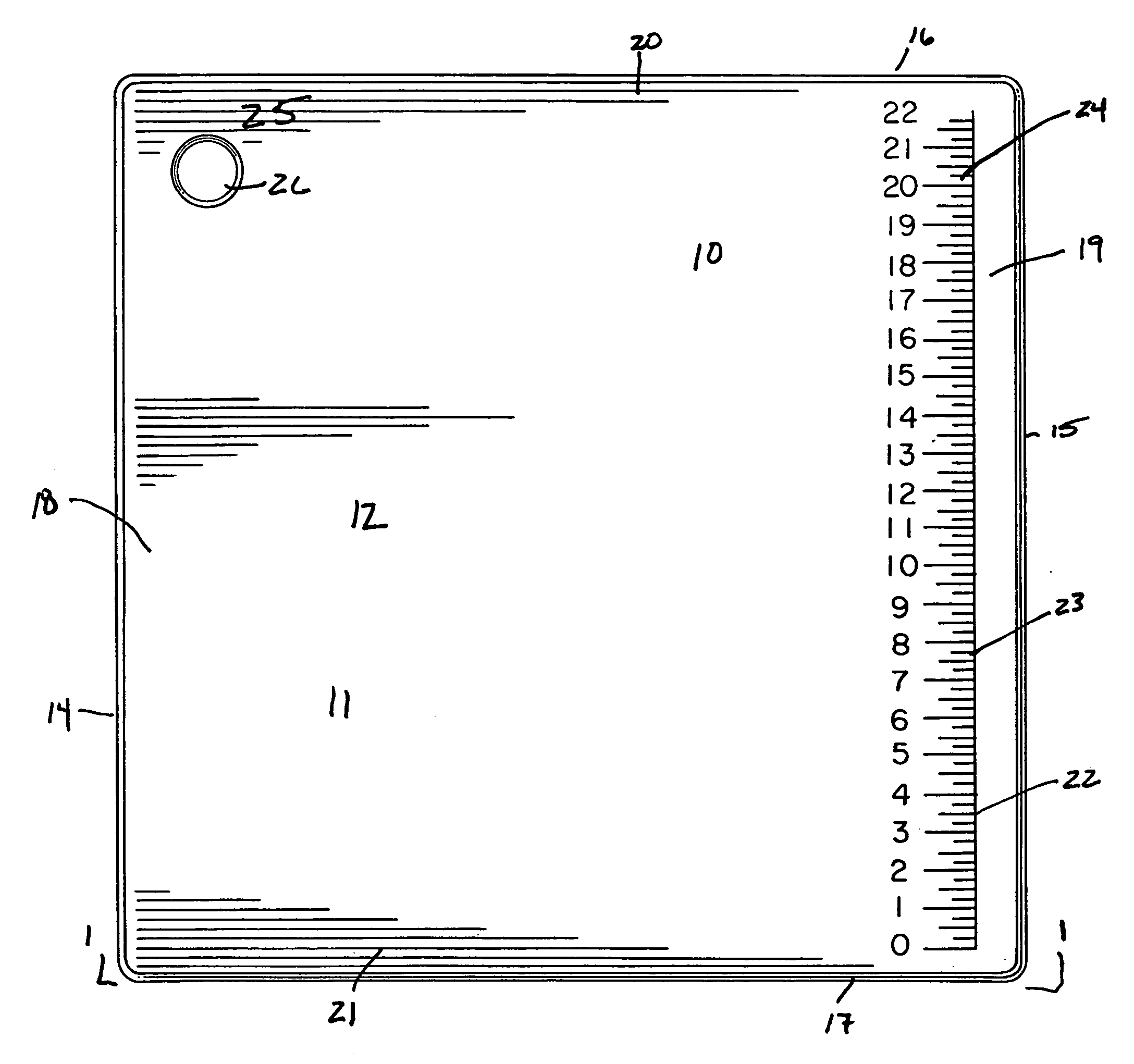

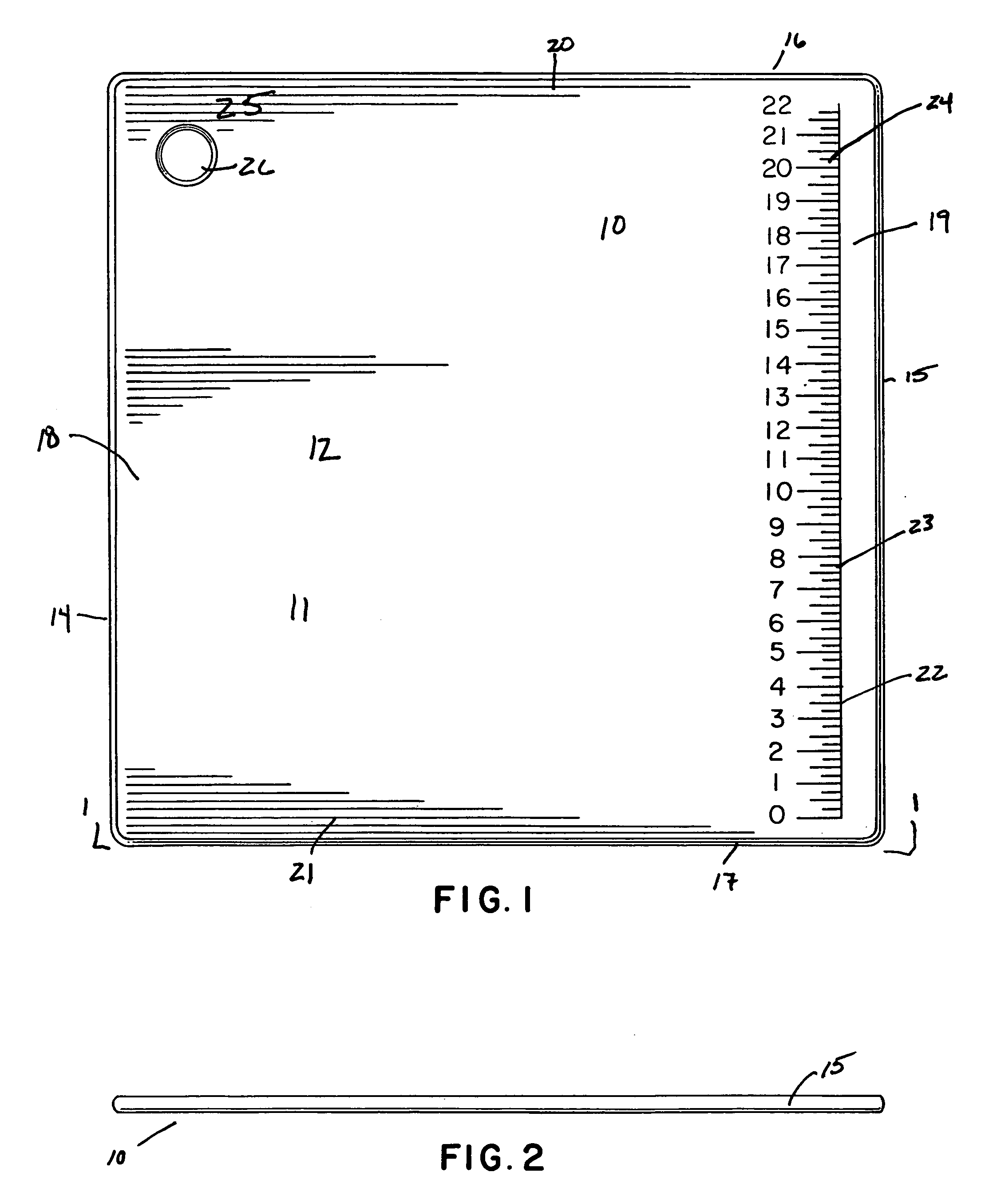

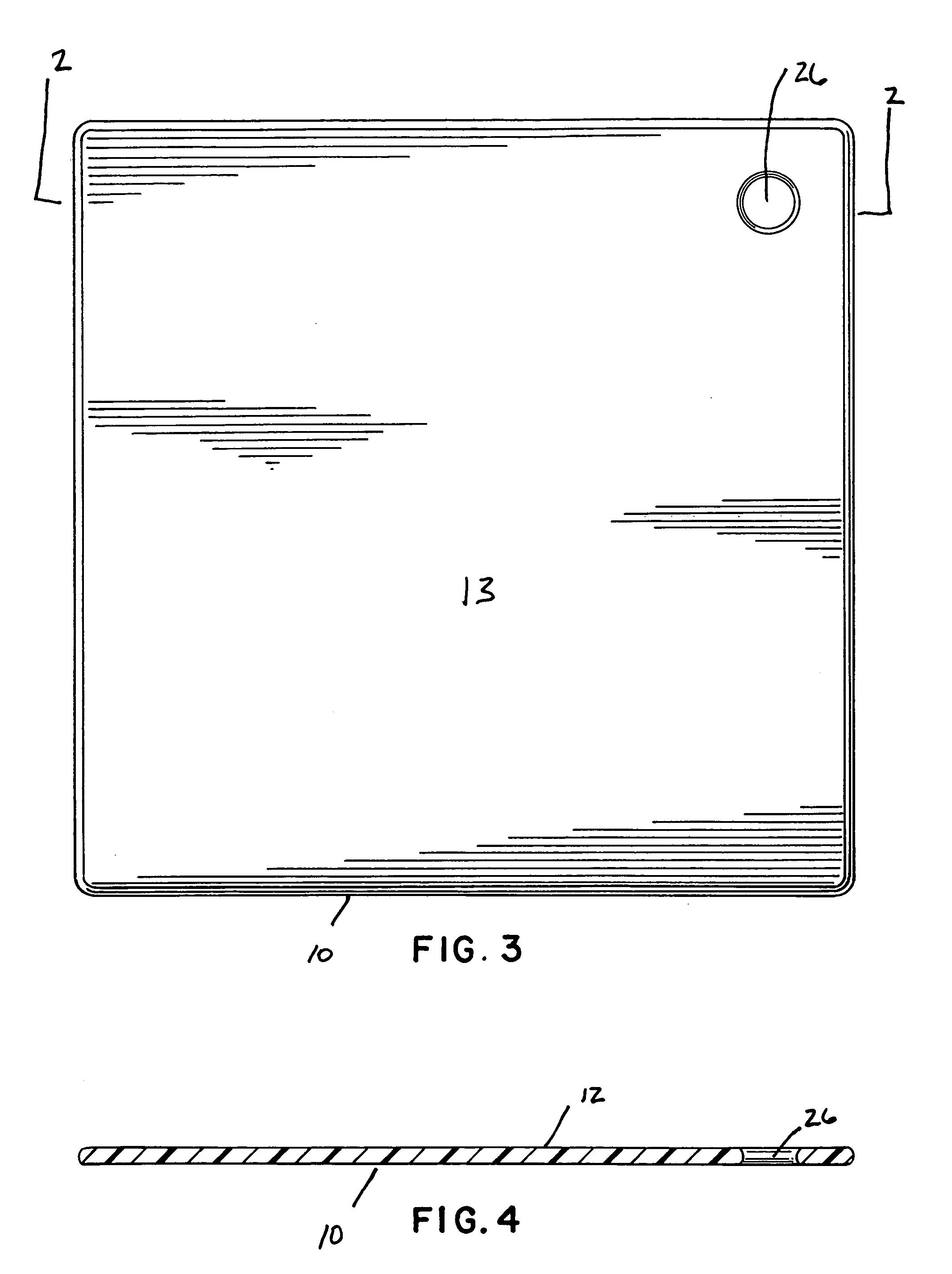

Construction board

InactiveUS6932336B1Effective distributionThe right amountBuilding material handlingPositioning apparatusBrickMaterials science

A mixing and measuring tool formed of high molecular high density polyethylene enables a mason to precisely mix and provide an accurate amount of mortar to each brick saving wasted mortar. The tool presents a frictionless, hard cutting surface for cutting brick or stone. Due to the durable characteristics of the high molecular high density polyethylene, the tool surface will not absorb fluids during mixing yet withstand intense cutting or scraping without damage.

Owner:NUDO PRODS

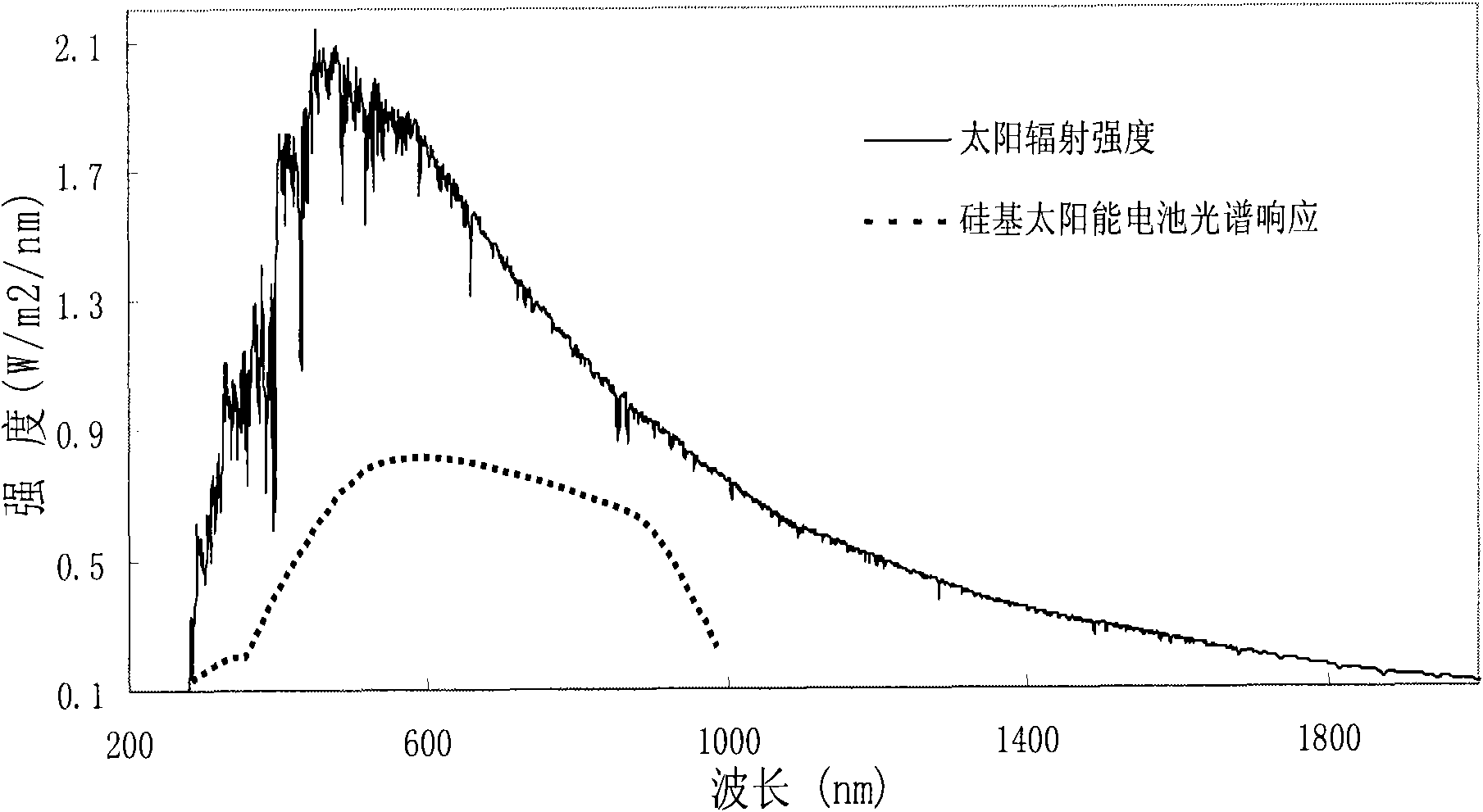

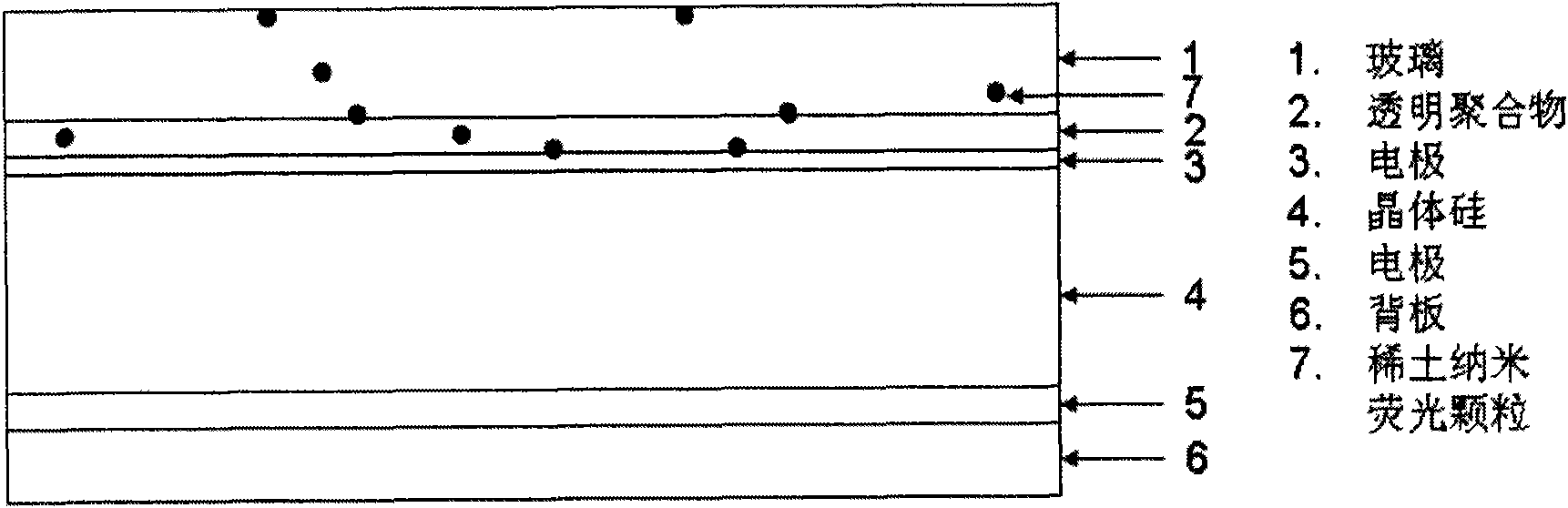

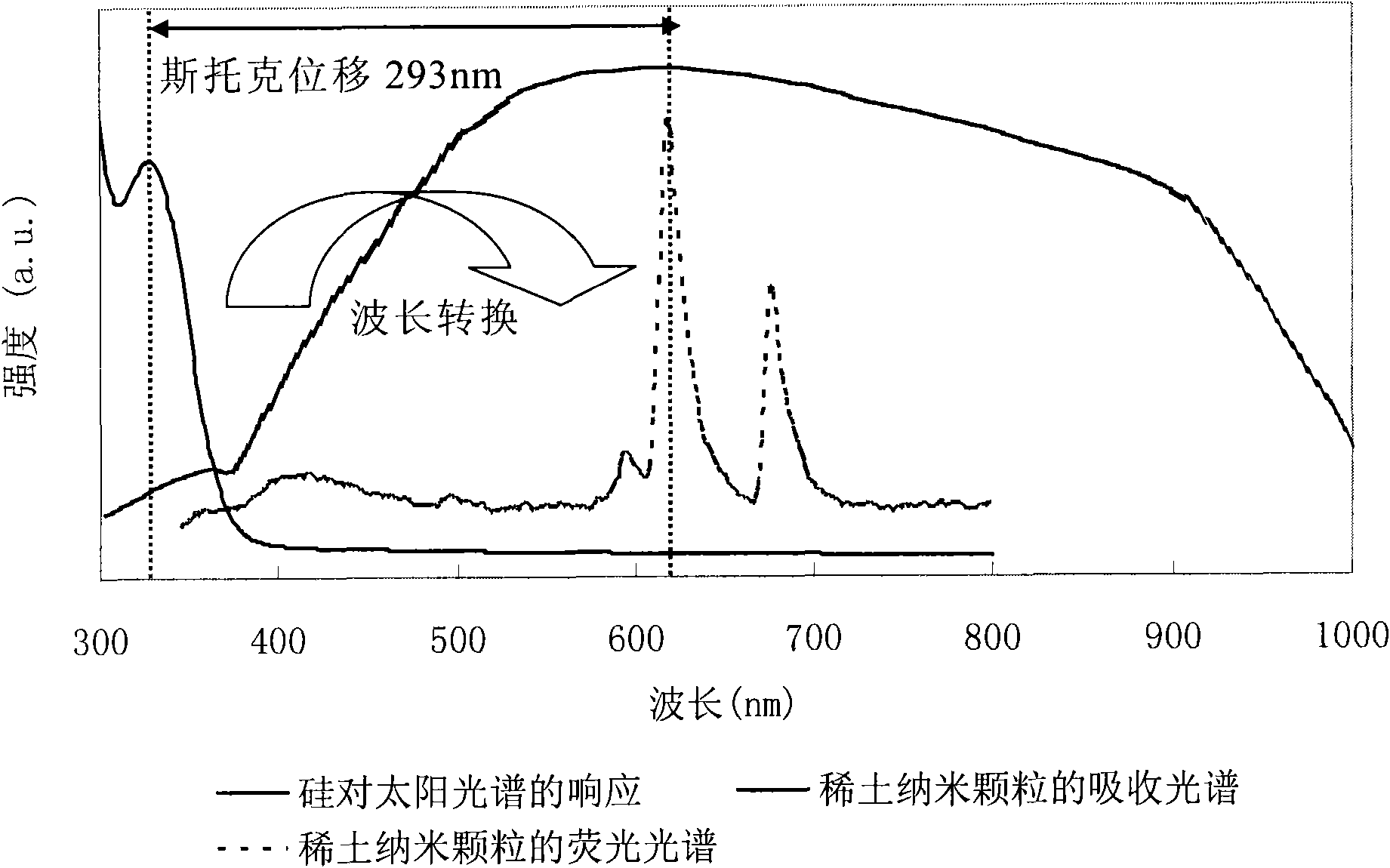

Nano fluorescent particles doping with rare-earth ions and relevant application thereof

InactiveCN101787272AHigh fluorescence efficiencyEffective absorptionTenebresent compositionsPhotovoltaic energy generationMischmetalRare earth ions

The invention provides nano fluorescent particles doping with rare-earth ions. The grain size of the nano particles is 1-200nm, and the nano particles comprise a nano particle matrix and rare-earth ions. The invention also provides a solar battery containing the nano particles.

Owner:EI DU PONT DE NEMOURS & CO

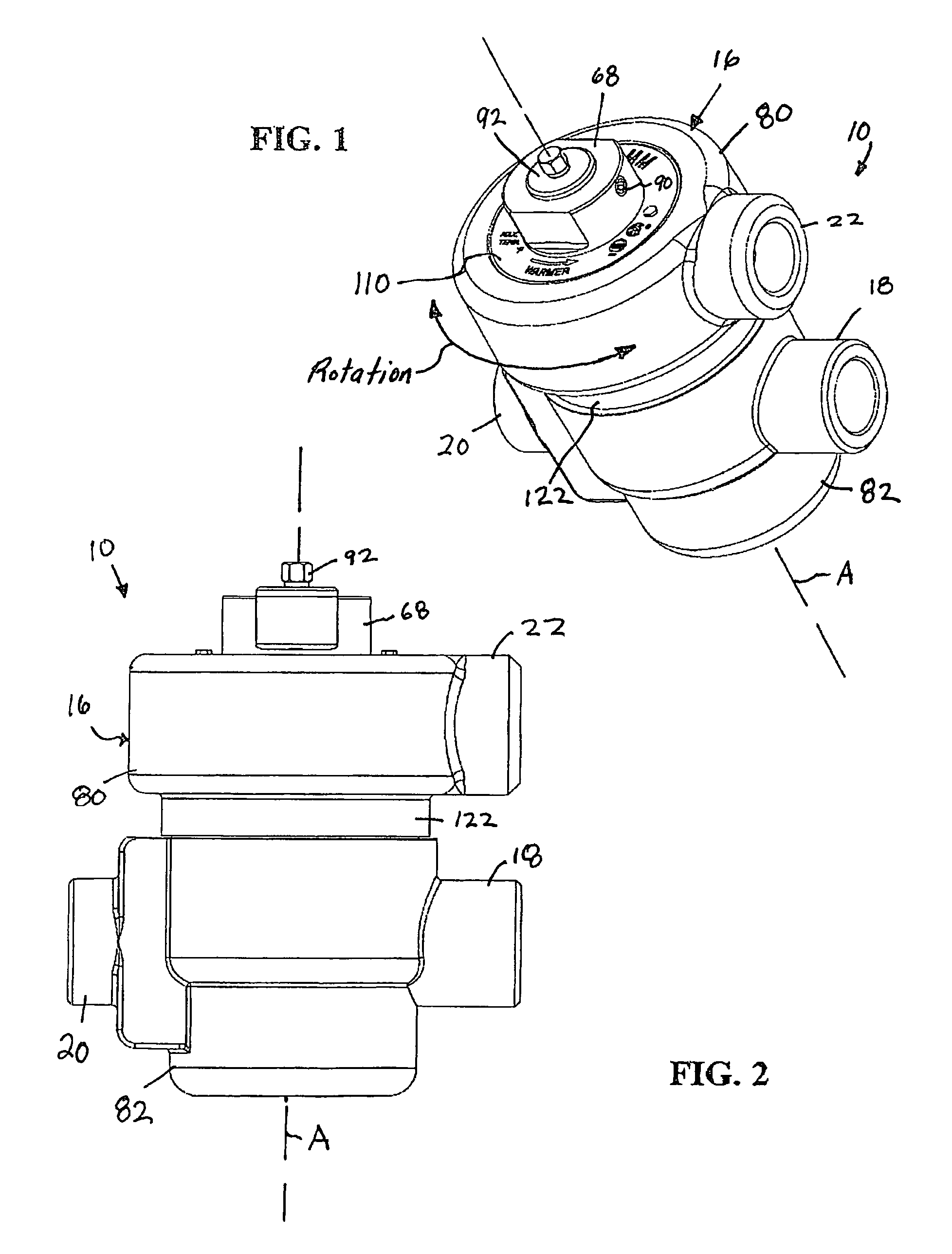

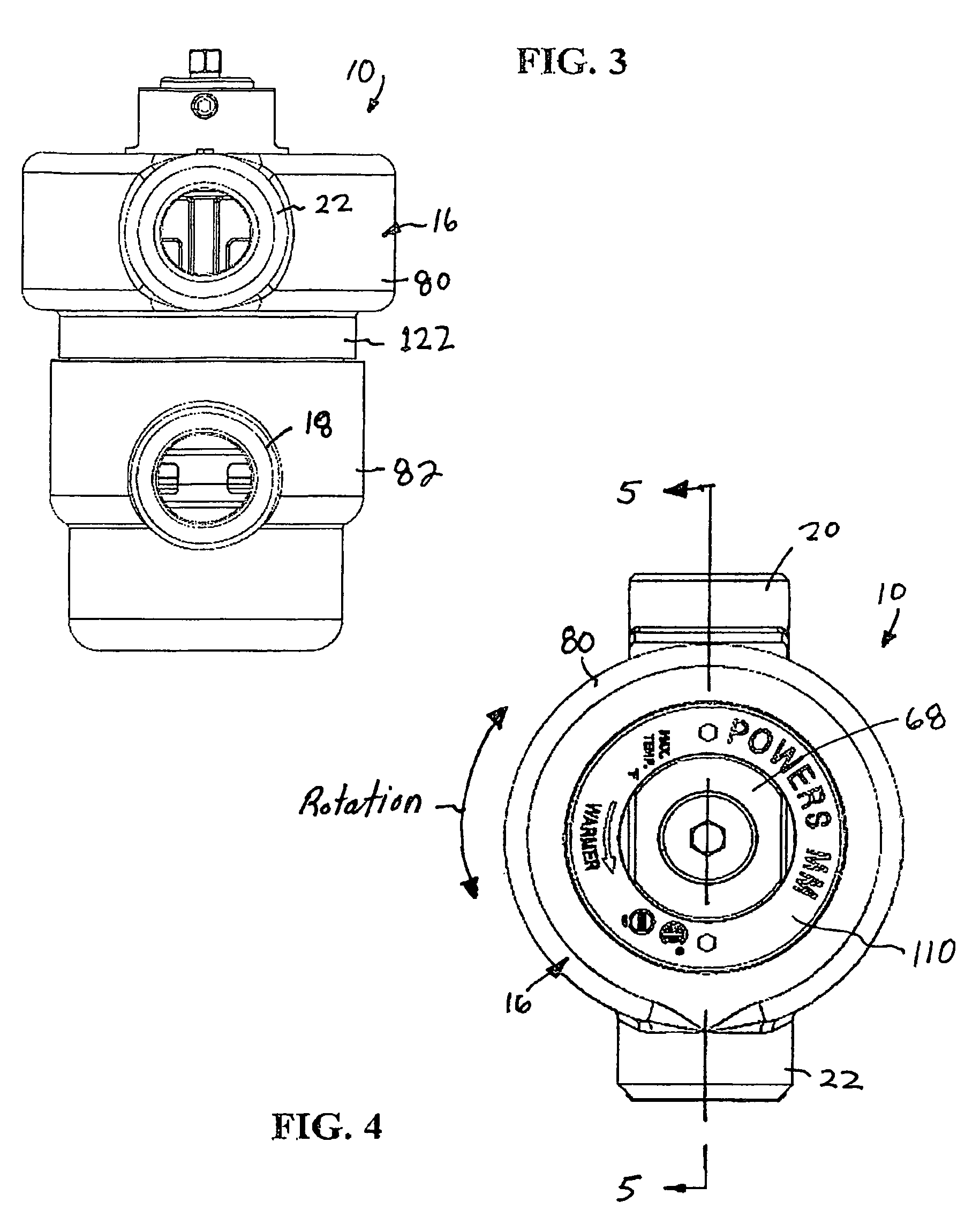

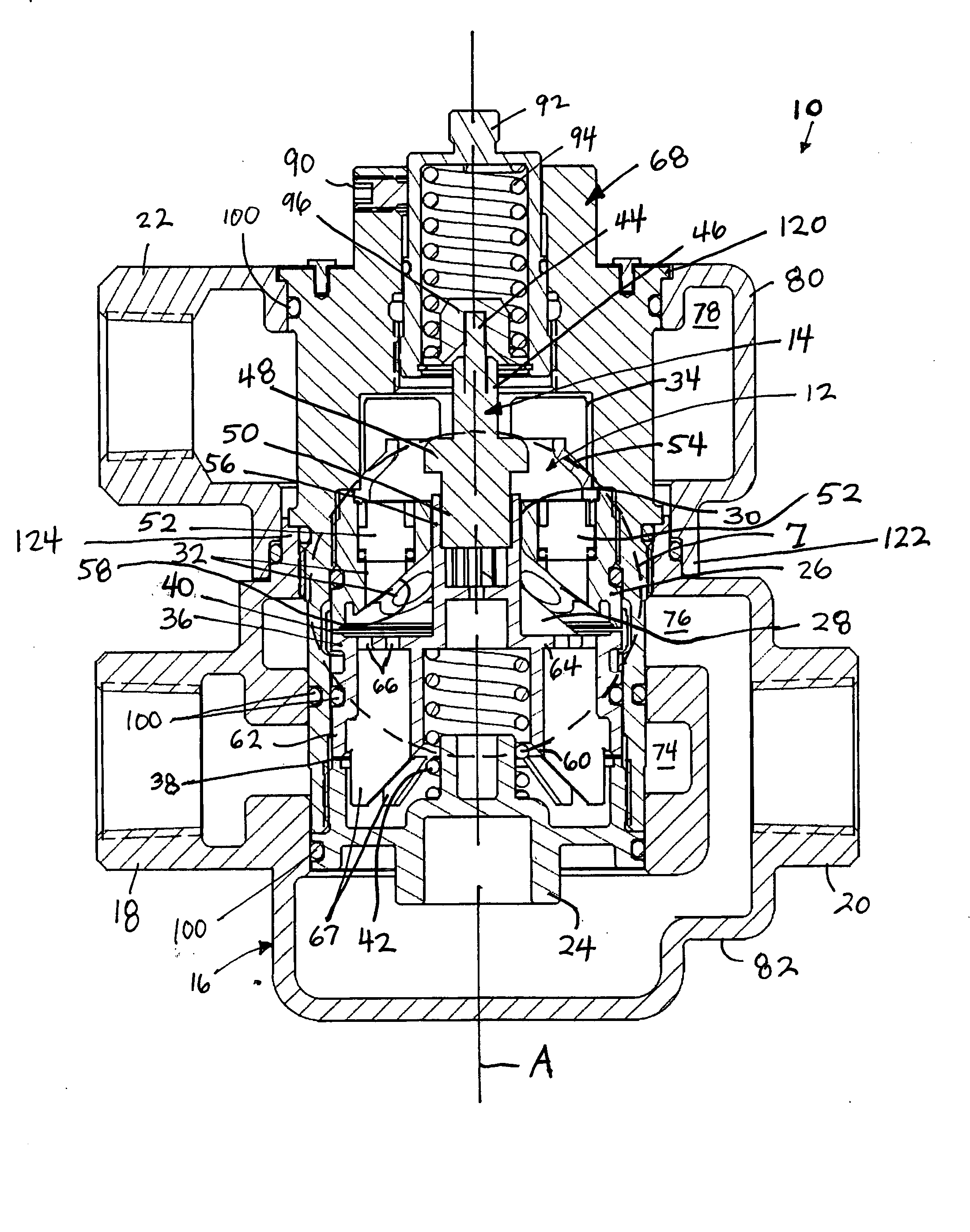

Thermostatic mixing valve

InactiveUS20070194137A1Guaranteed mixEasy to disassembleTemperature control without auxillary powerTemperature control with auxillary non-electric powerThermostatic mixing valveCheck valve

A thermostatic mixing valve (TMV) including a low-flow passageway and a high-flow passageway connecting a mixing chamber and a sensing chamber, and a check valve received in the high-flow passageway adapted to open and allow additional flow from the mixing chamber to the sensing chamber upon fluid flow through the valve rising to at least a predetermined high flow rate. The TMV accommodates a wide range of flows yet does not allow excess flow to bypass the sensing chamber which contains a thermal motor of the valve. Even at high flow rates, therefore, the TMV accurately mixes fluid.

Owner:WATTS WATER TECH

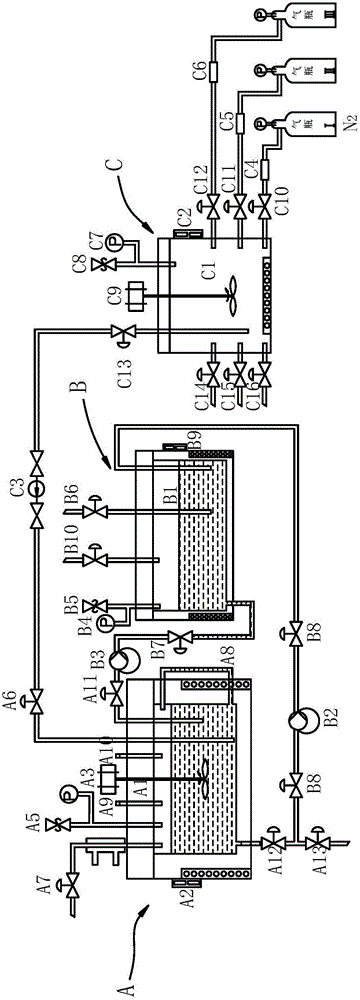

Corrosion testing device capable of simulating complex environment and testing method thereof

ActiveCN105891094AGuaranteed accuracyEnsure scientificWeather/light/corrosion resistanceTemperature controlGas composition

The invention discloses a corrosion testing device capable of simulating the complex environment and a testing method thereof. The device comprises a dynamic high-temperature autoclave system, a medium circulation system and a gas mixing system which can be used for conducting corrosion tests on a sample; the medium circulation system cooperates with the dynamic high-temperature autoclave system so that the medium in the testing environment can be replaced or circulated, and thus the solution medium or flow velocity under the actual working condition is simulated; the gas mixing system is communicated with and cooperate with the dynamic high-temperature autoclave system to simulate the gas composition and pressure environment required by the tests; the dynamic high-temperature autoclave system is internally provided with a medium temperature controller which is used for simulating the temperature under the actual working condition. According to the testing device, multiple types of testing parameters are considered comprehensively, an expansion interface is provided, multiple types of actual working conditions can be effectively simulated, corrosion performance evaluation and research of multiple types of materials, such as stress corrosion, uniform corrosion, erosion corrosion, pitting corrosion, crevice corrosion, electrochemical corrosion, coating corrosion resistance evaluation and corrosion inhibitor efficiency evaluation, in the complex environment are completed, and correctness and scientificity of the test result are guaranteed.

Owner:HEFEI GENERAL MACHINERY RES INST +1

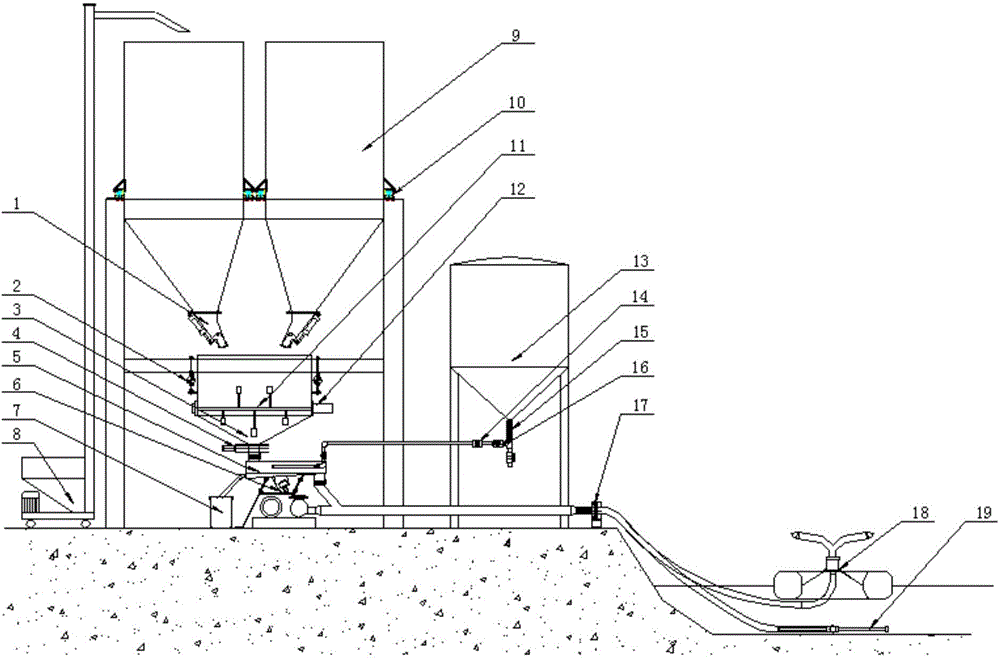

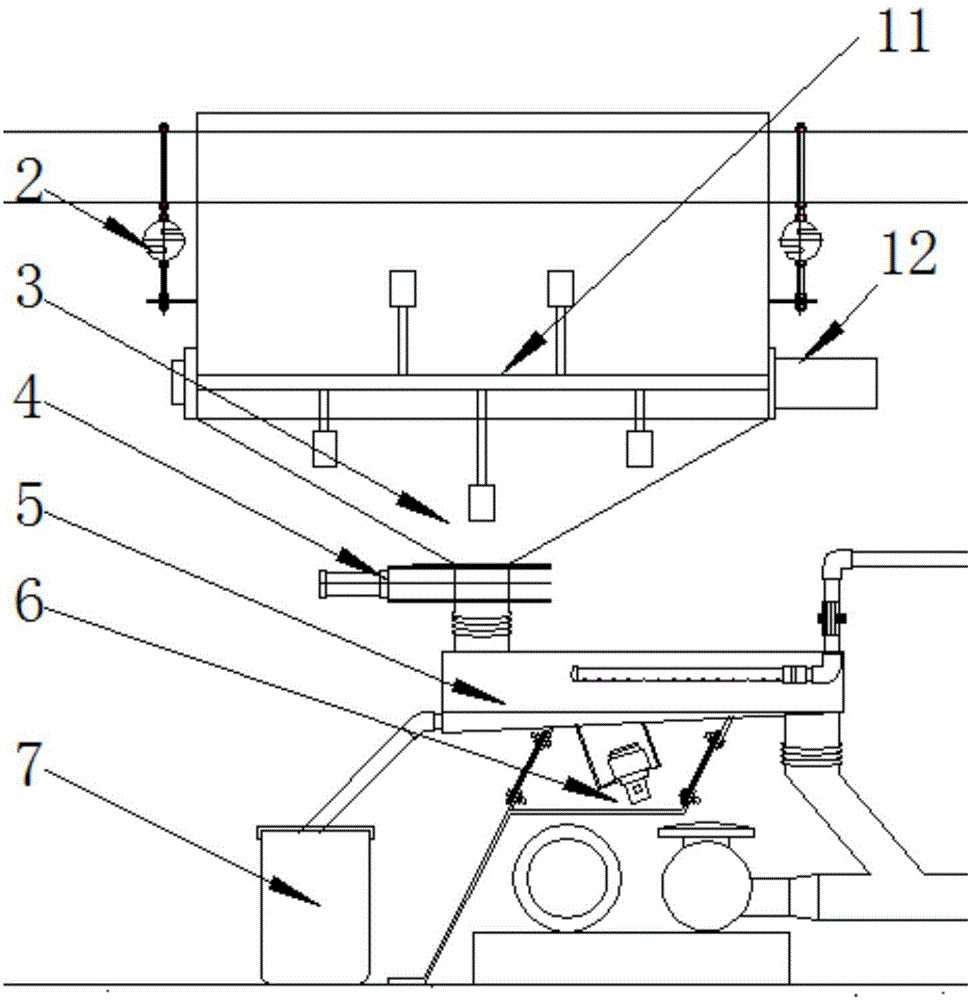

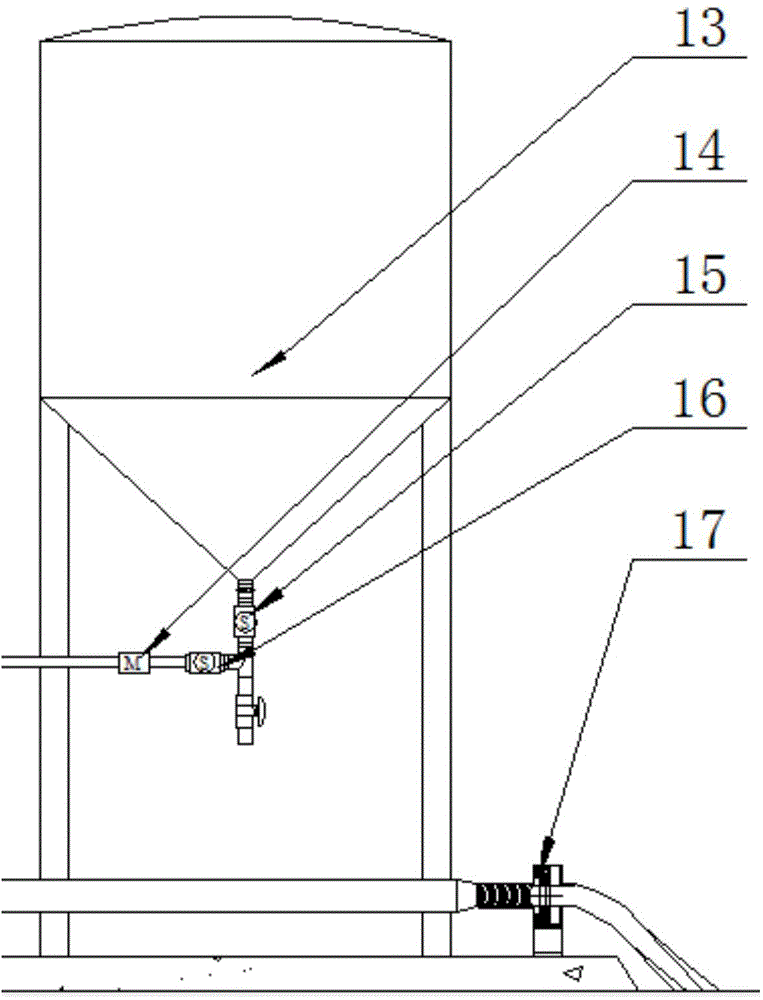

Automatic mixing, adjusting and feeding system for aquaculture feed

InactiveCN104823900APrecise Automatic MixingNot easy to sprayClimate change adaptationPisciculture and aquariaHigh densityMaterial scattering

The present invention relates to an automatic mixing, adjusting and feeding system for an aquaculture feed, wherein a feed bin weighing module which is used for automatically feeding back and controlling loading weight and unloading weight is arranged on a combined feed bin; a pneumatic valve on the bottom of the combined feed bin is aligned to a proportioning bin below; an air brake on the bottom of the proportioning bin is aligned to a feed mixing bin below; a vibrating conveyer is arranged in a mixing bin; and the vibrating conveyer is used for filtering a powdery feed to a powdery material collecting barrel; a bacterial (liquid) barrel is communicated with the mixing bin through a liquid conveying pipeline to add a bacterial liquid or a medicinal liquid into the feed, and to uniformly mix by virtue of the vibrating conveyer; the bottom of the vibrating conveyer is communicated with an air pump conveying pipeline through a pipeline; a fan is divided into two air paths through a pneumatic three-way joint, one path is used for blowing the feed and annularly scattering the feed through a rotary material scattering machine floating on the water surface while the other path is used for aerating and oxygenating a water body in a feed feeding region through an underwater aeration pipe in a material scattering region of the material scattering machine so as to improve dissolved oxygen demand of a high-density feeding fish school in the feed feeding region.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

RH injection refining device and application thereof

The invention provides an RH injection refining device and application thereof. The device comprises an RH ascending pipe and an RH descending pipe; pipe walls of the RH ascending pipe and the RH descending pipe are provided with through holes which are connected with an external air supply or a feeding device by spraying pipes. A method of removing small inclusions by using the device comprises:after deoxidation alloying, blowing inert gas into the descending pipe by using the spraying pipes, wherein the gas flow is 10-500L / min and air pressure is 1.0-15atm; or blowing carbonate power into steel liquid, wherein the particle size of the powder is less than 3mm, the feeding rate is 1-100kg / ton steel, the carrier is Ar, N2 or CO2 inert gas, the gas flow is 10-800L / min, and air pressure is 1.0-20atm. The invention has the characteristics of simple equipment, convenient operation, reasonable process, low cost, and good effect. The invention has the advantages of effectively removing small inclusions from steel, regulating alloying elements, manufacturing dispersion steel of small oxide, and achieving the aims of decarburization, desulfurization, dephosphorization, steel slag modification and the like.

Owner:ANGANG STEEL CO LTD

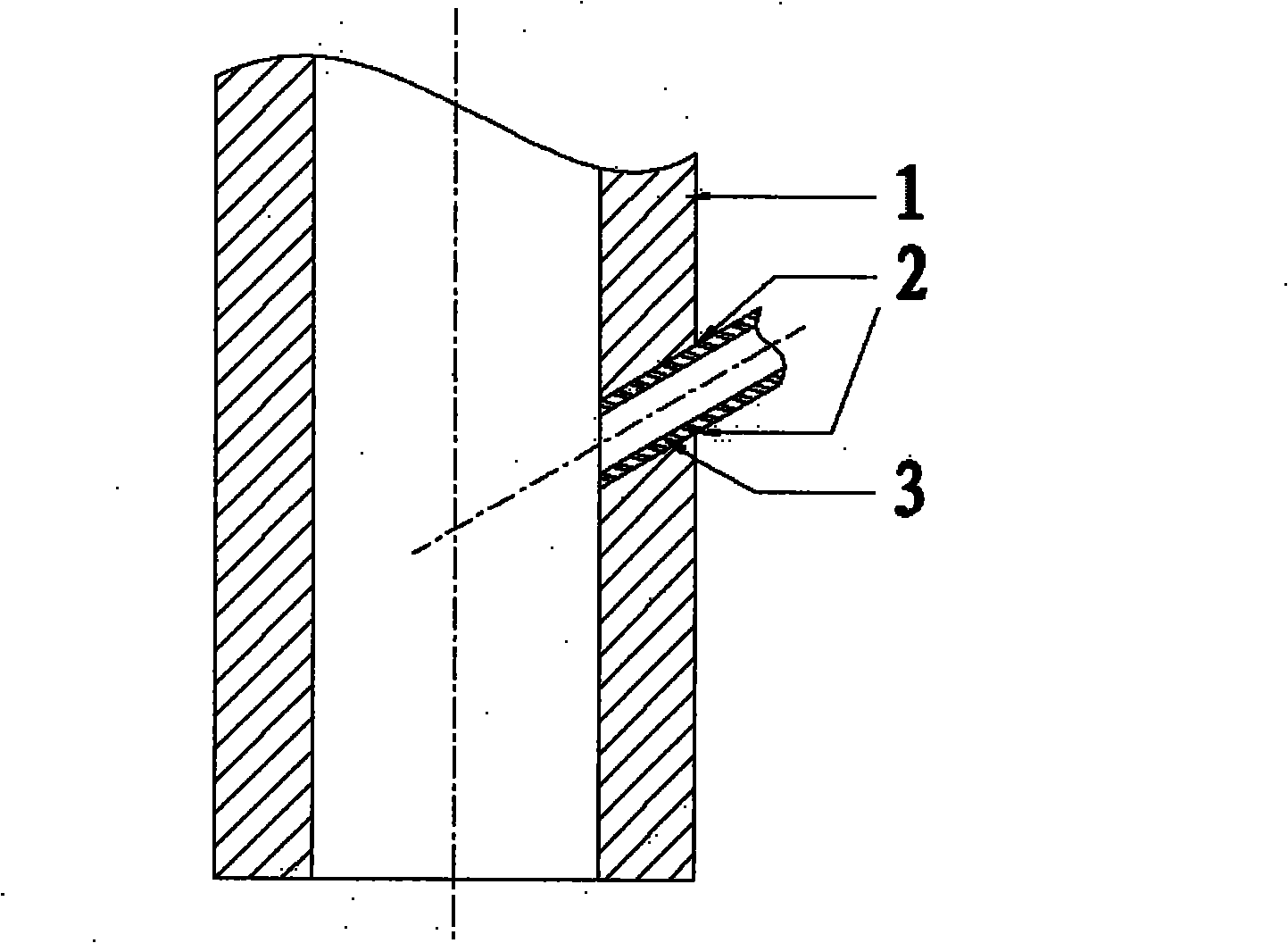

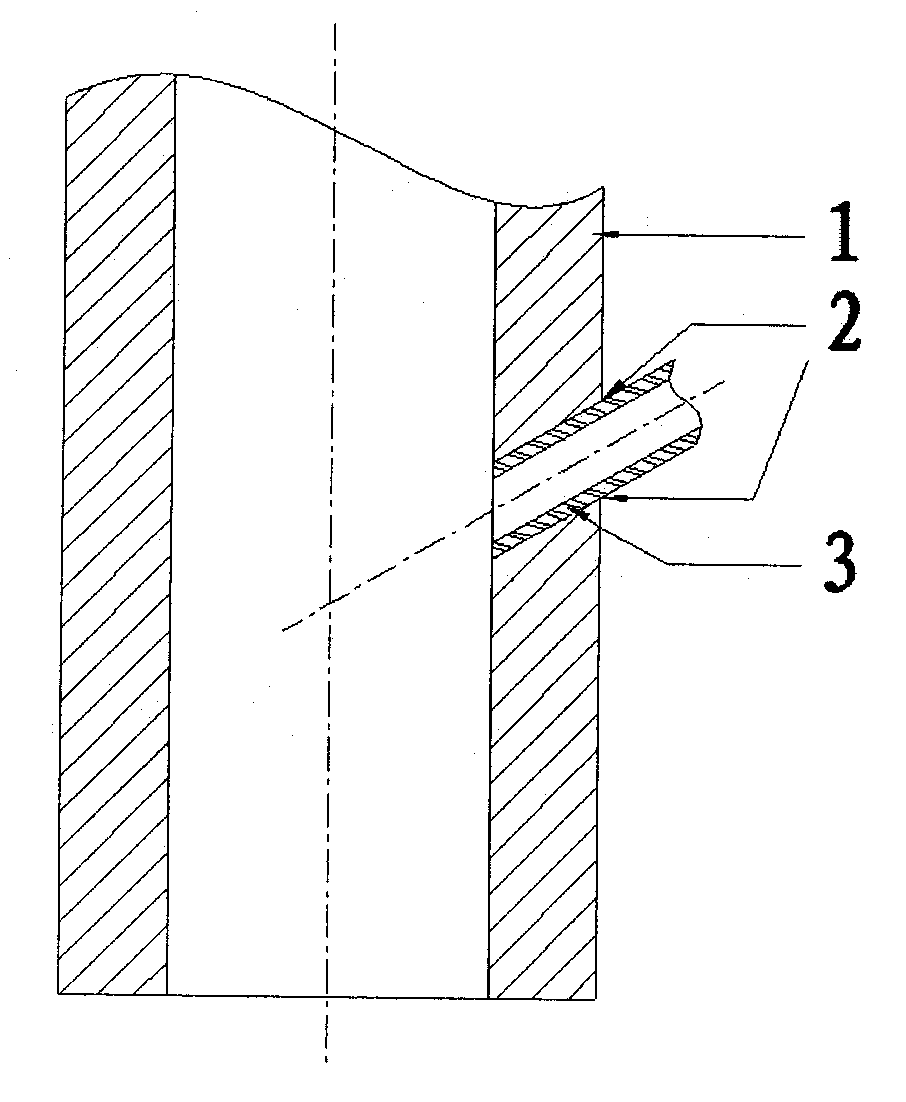

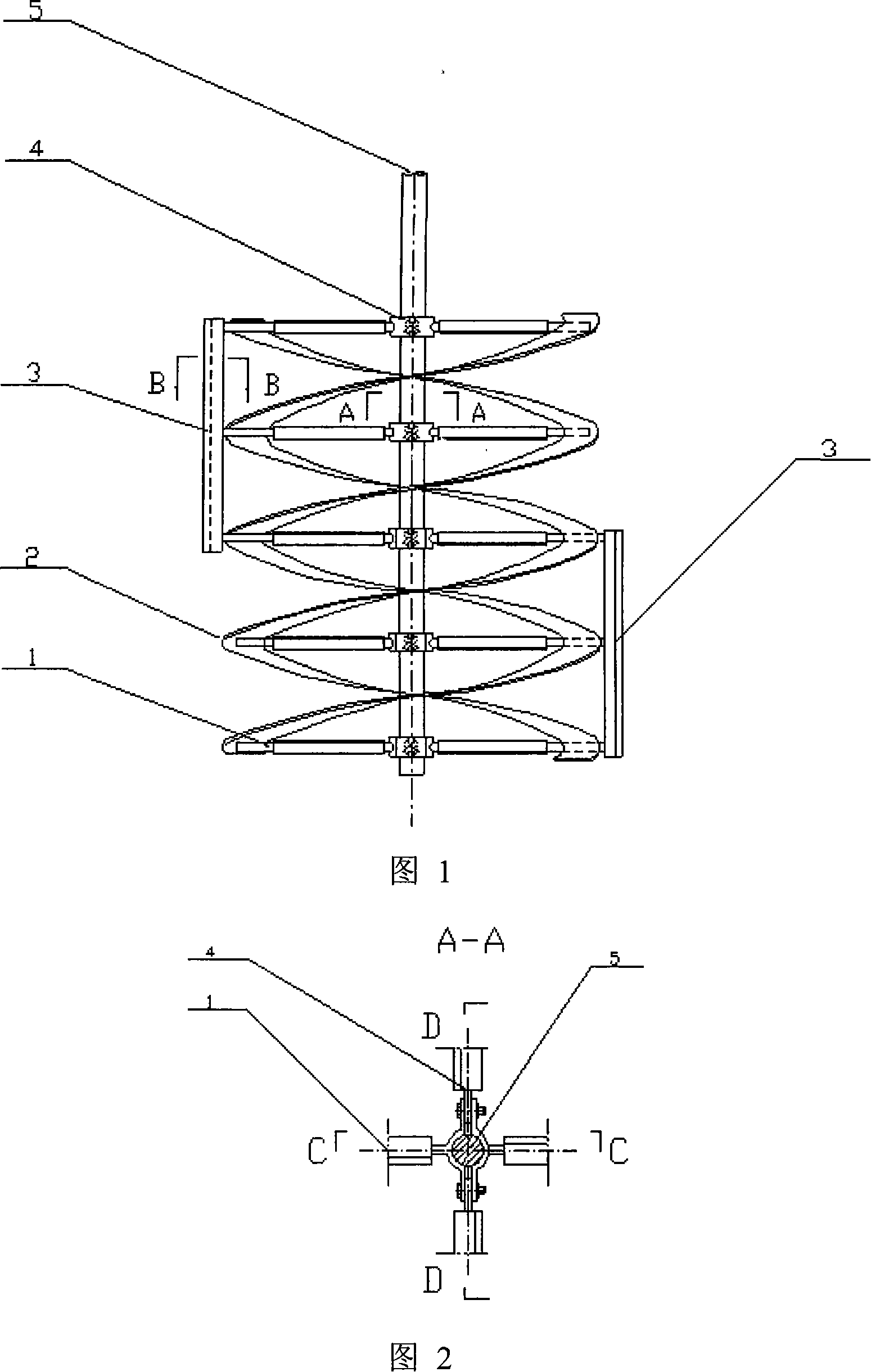

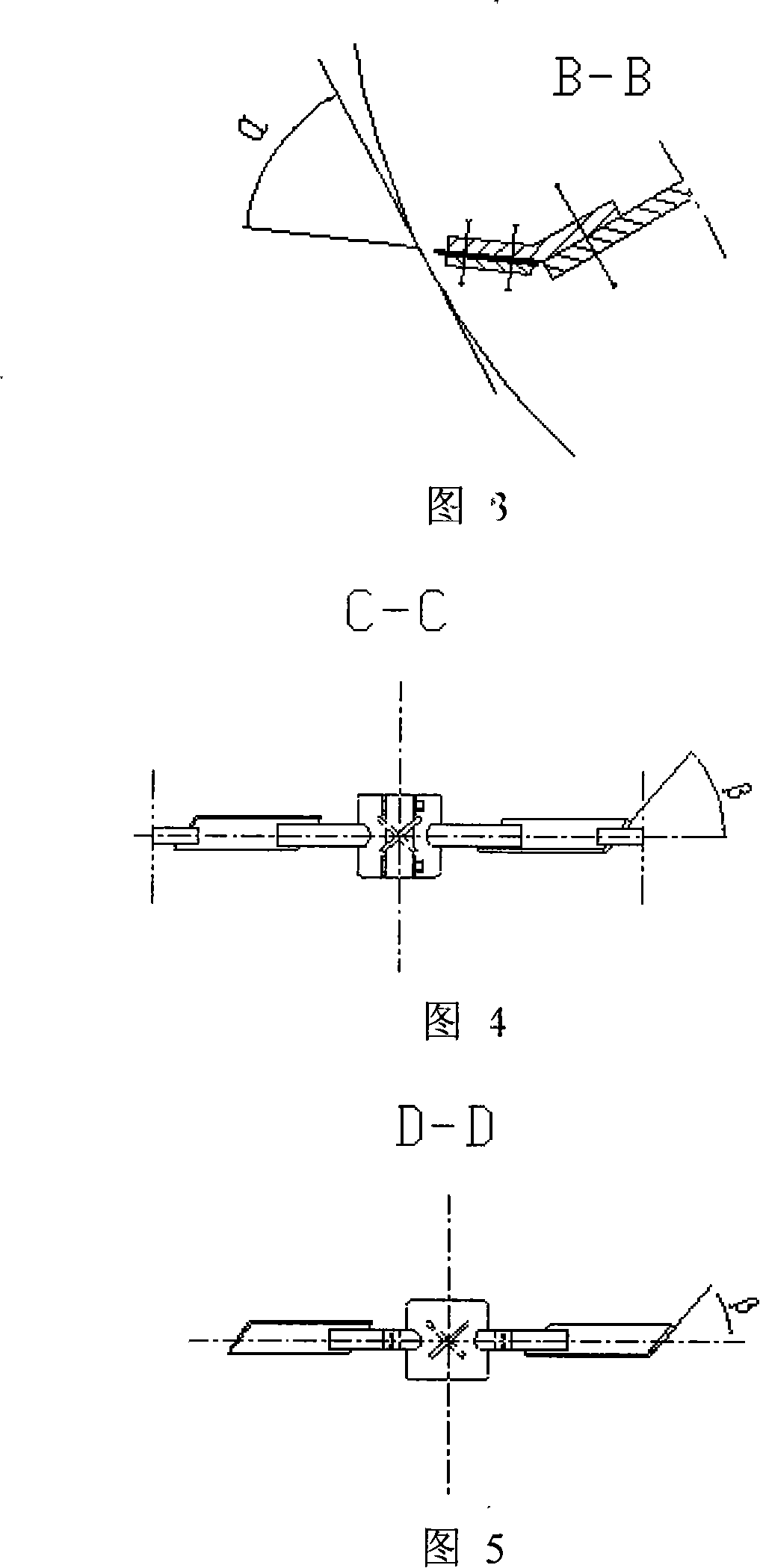

Double helical ribbon multi-layer oar blade scraping cutter type stirrer

InactiveCN101234309AAvoid liquid-liquid separationUniform temperatureRotary stirring mixersTransportation and packagingIncomplete mixingMaterial system

A double helical ribbon stirrer with multiple layers of blade scrapers comprises a stirring shaft (5), helical ribbons (2), support blades (1), separate blades (4) and a soft scraper (3). The support blades (1) and the separate blades (4) are layered and arranged on the stirring shaft (5), and the support blade and the separate blade of each layer are arranged on the stirring shaft (5) symmetrically, and the support blade (1) and the separate blade (4) keep a dip beta of 10 degrees to 45 degrees with the radical level section, and smaller dip can reduce the loss of useful work effectively. The helical ribbons (2) are connected with the stirring shaft (5) through the support blades (1) which have the functions of connecting ribs and strengthening ribs, thus causing reasonable structure design of the whole stirrer. The soft scraper (3) is divided into two sections which are fixed on the top of the helical ribbons (2) symmetrically, and an angle alpha between the soft scraper (3) and a still wall is 20 degrees to 60 degrees. The soft scraper (3) can scrape sticky material on the stirring still wall in time, thus solving the problem of incomplete mixing on the surface of the still wall and avoiding the damage to the still wall. The stirrer of the invention provides a material system that can adapt to different viscosities, in particular to the material system which has large viscosity variation range in a short time.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

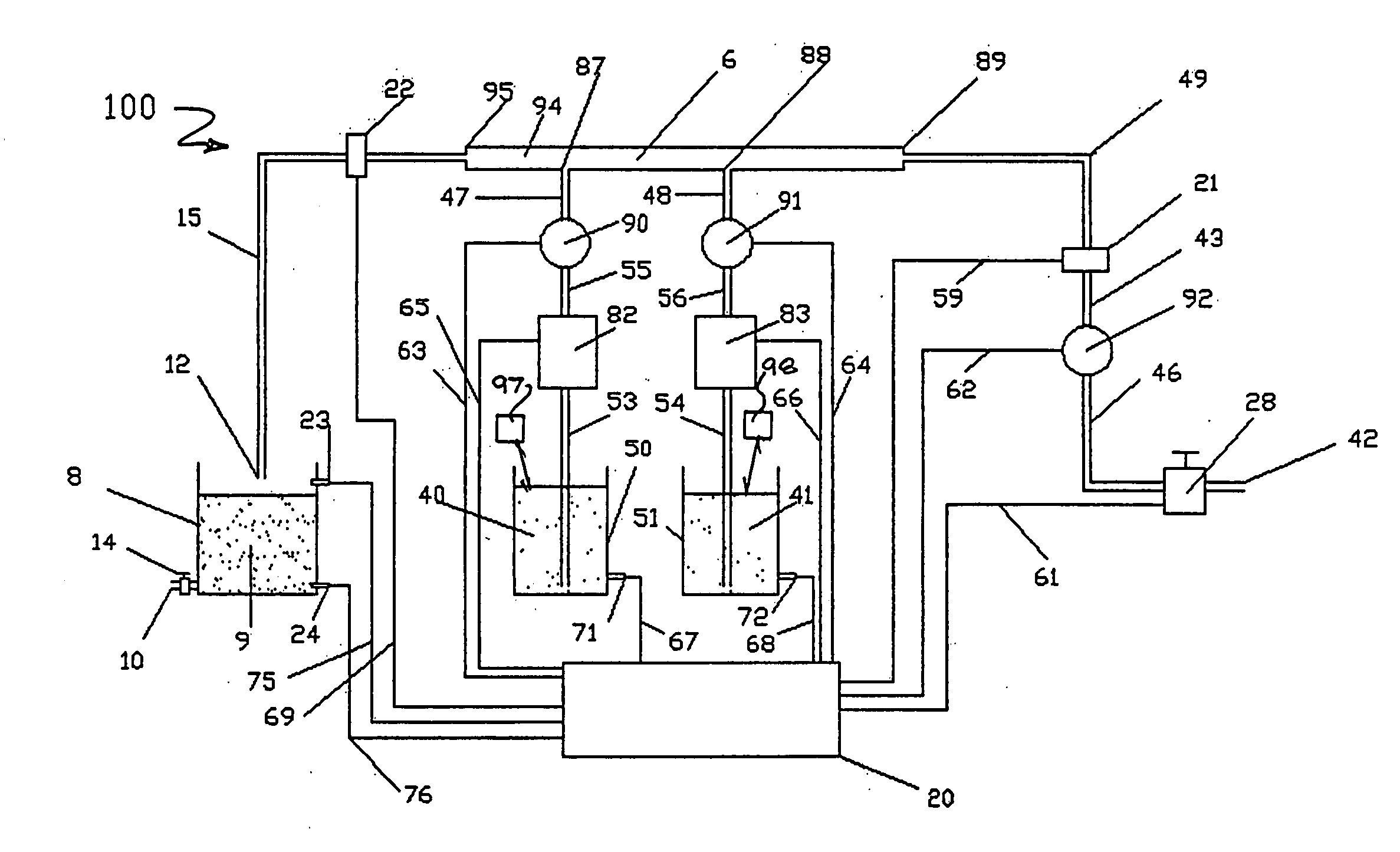

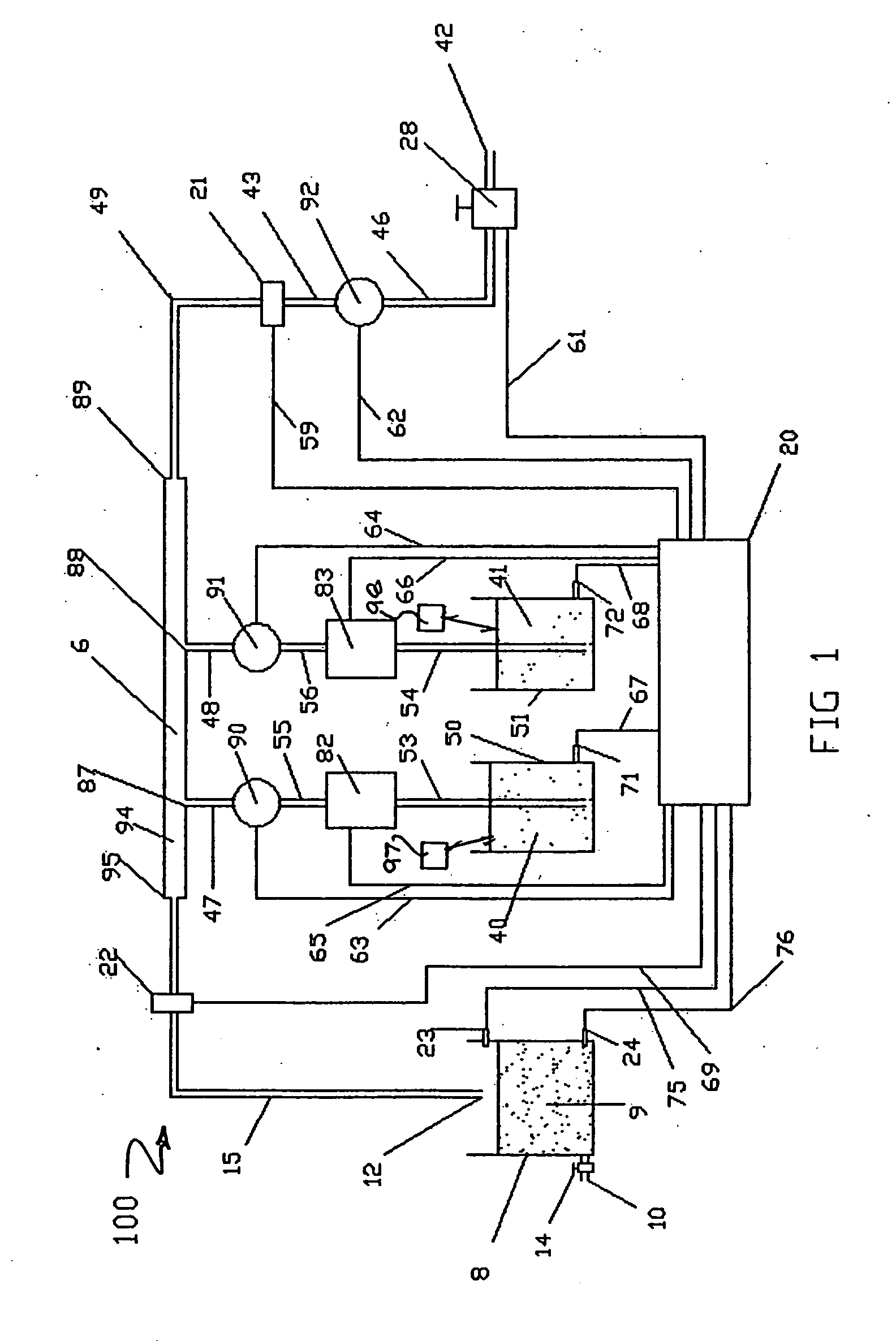

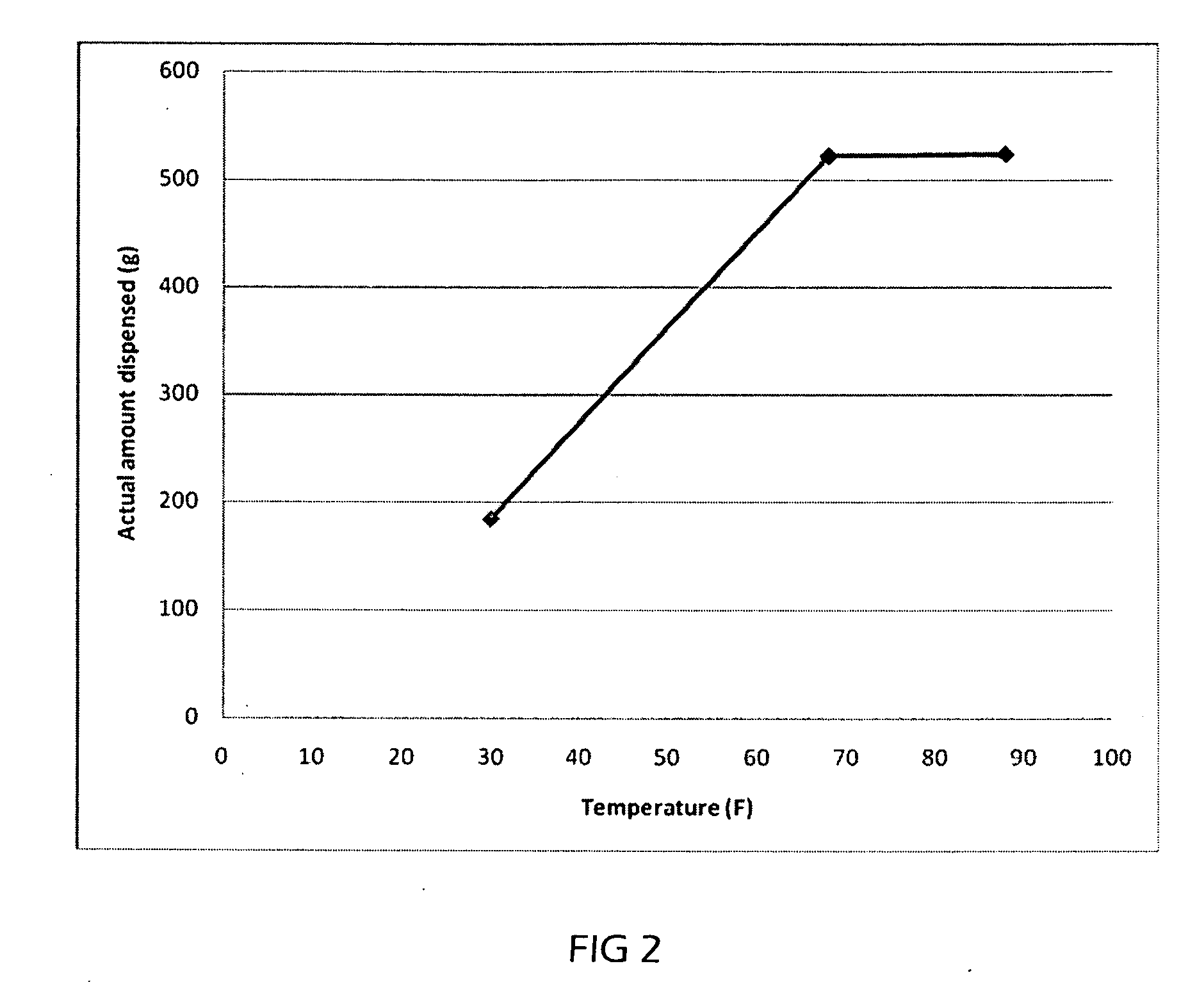

Methods and apparatus for mixing dairy animal treatment chemicals

InactiveUS20110110179A1Eliminate deficienciesEasy to adjustBiocideControlling ratio of multiple fluid flowsControl mannerEngineering

A system for mixing dairy animal teat dip from water and additives. The system includes a mixing manifold into which the water and additives are fed and mixed in a controlled manner. Mixed teat dip is automatically quality tested and monitored to provide data for controlling quantities of water and additives being fed to the manifold.

Owner:GEA FARM TECH

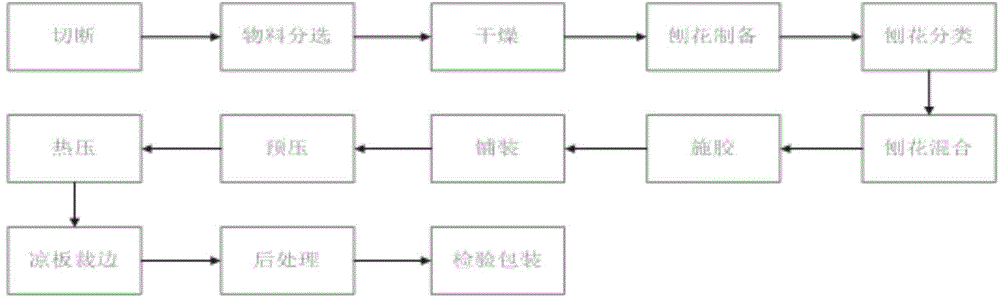

Shaving board manufacturing method

InactiveCN105171890AWidely usedBroaden the field of applicationDomestic articlesFlat articlesControl levelSizing

A shaving board manufacturing method includes the following steps of (1) cutting-off and sorting, (2) shaving preparation and classification, (3) shaving mixing, (4) sizing, (5) laying, (6) hot pressing and (7) after-treatment. Shaving boards are manufactured through puelia production. Compared with the prior art, the method has the advantages that (1) raw materials are widely used, puelia can be used independently for board manufacturing and can be mixed with other raw materials for board manufacturing, the application field of the puelia is widened, the problems of the deficiency and uncertainty of non-wood shaving board raw materials are solved, the design scale of a single production is enlarged, and production cost can be reduced; (2) various raw materials are precisely mixed through independent equipment, and the control level of the production line can be improved; (3) puelia shaving guarantees the uniformity and consistency of fibers by means of a smashing and precise grinding two-stage manufacturing mode, and the product yield is increased and subsequent processing performance is improved; (4) by means of distribution of the overall technology and equipment, the problem caused when puelia is applied to industrialization of board manufacturing is solved.

Owner:HUNAN WANHUA ECOLOGICAL PLATE IND CO LTD

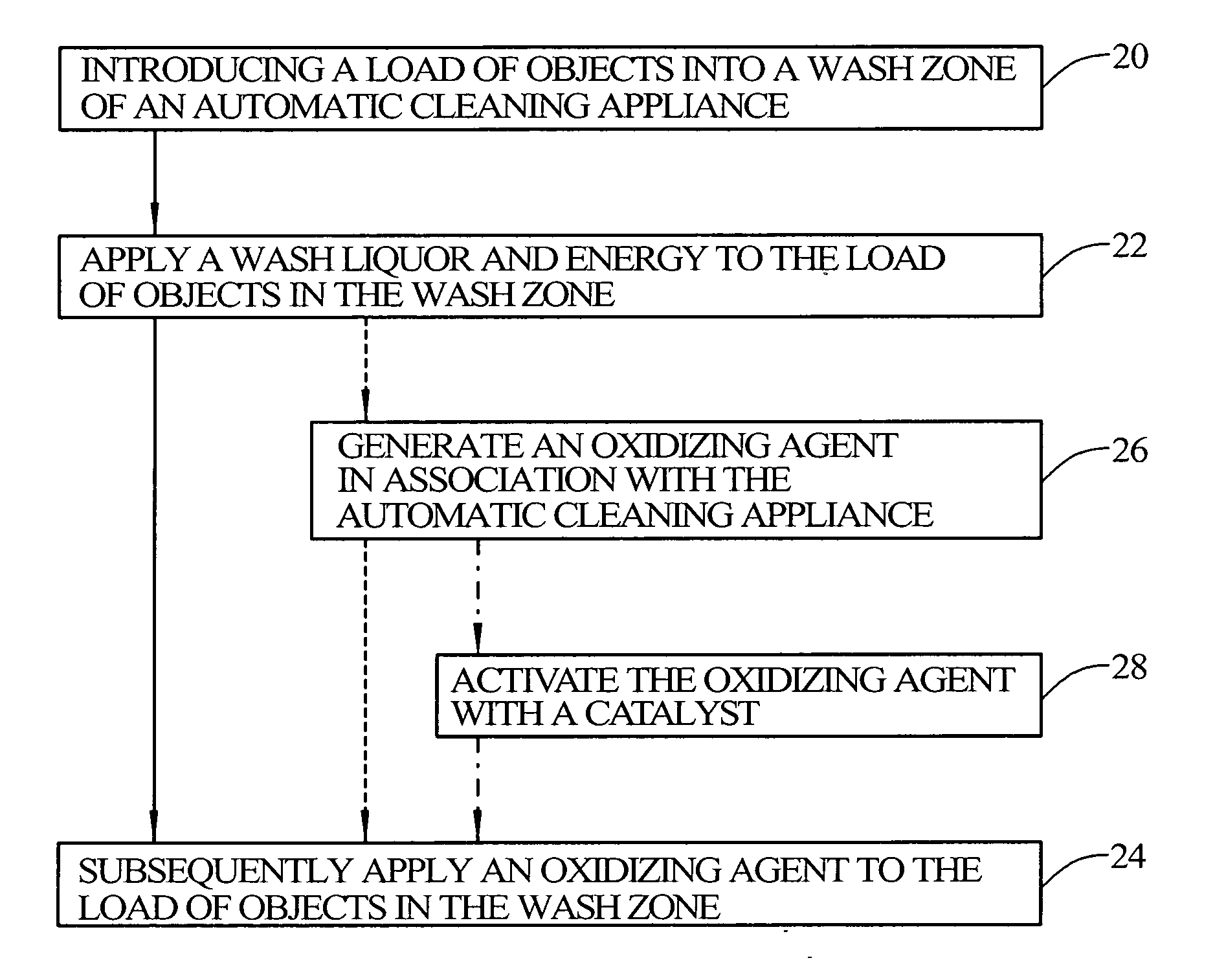

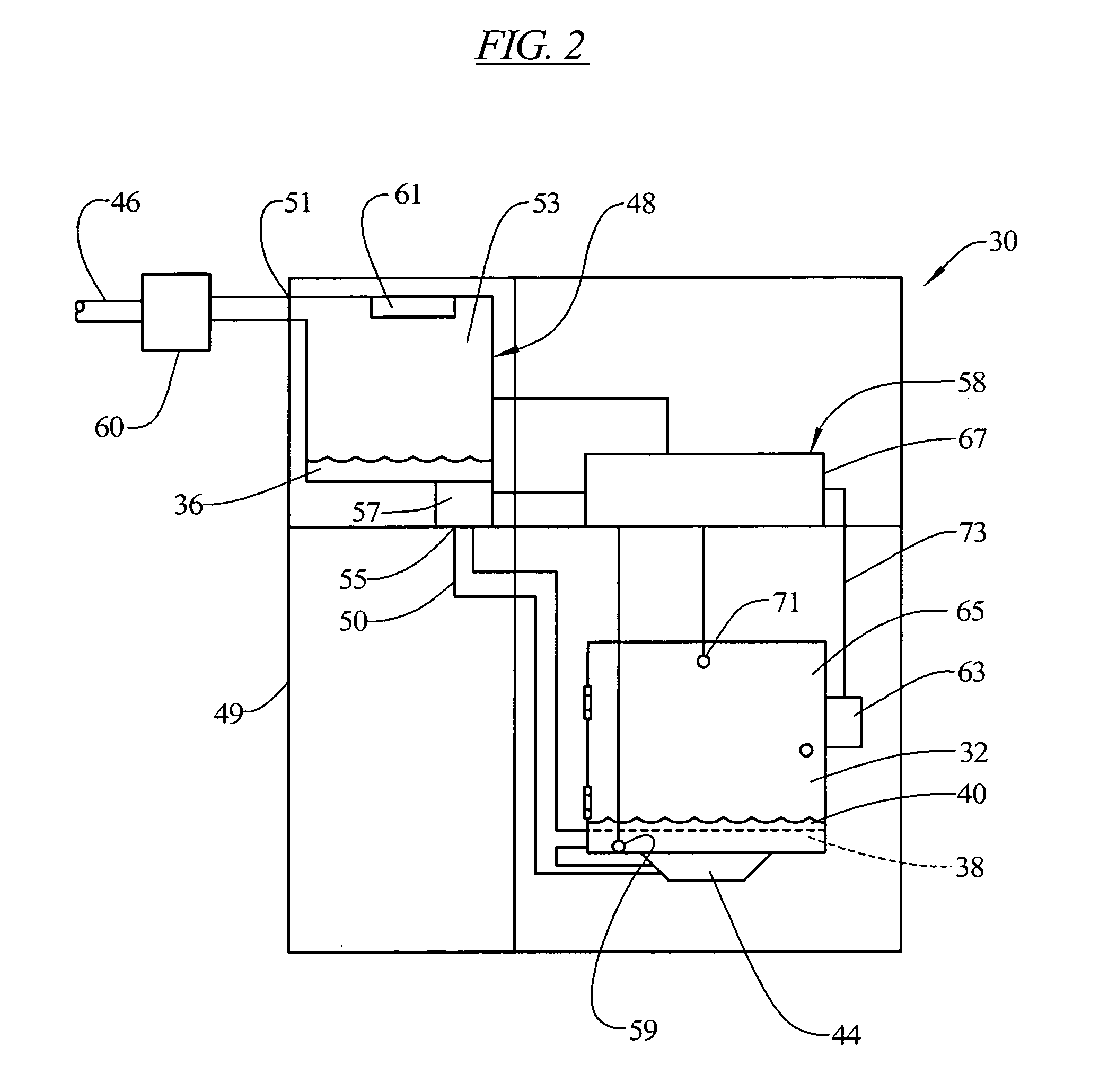

Method and apparatus for cleaning objects in an automatic cleaning appliance using an oxidizing agent

InactiveUS20050224099A1Guaranteed mixOrganic/inorganic per-compounds compounding agentsCleaning and washing methodsEngineeringOxidizing agent

A method and apparatus for cleaning objects in an automatic cleaning appliance is provided that includes the steps of introducing a load of objects into a wash zone of the automatic cleaning appliance, applying a wash liquor and at least one of electromagnetic, chemical and mechanical energy to the load of objects in the wash zone to remove soil from the load of objects, and subsequently applying an oxidizing agent to the load of objects through the medium of a fluid applied to the load of objects. The oxidizing agent may be generated in association with the automatic cleaning appliance.

Owner:WHIRLPOOL CORP

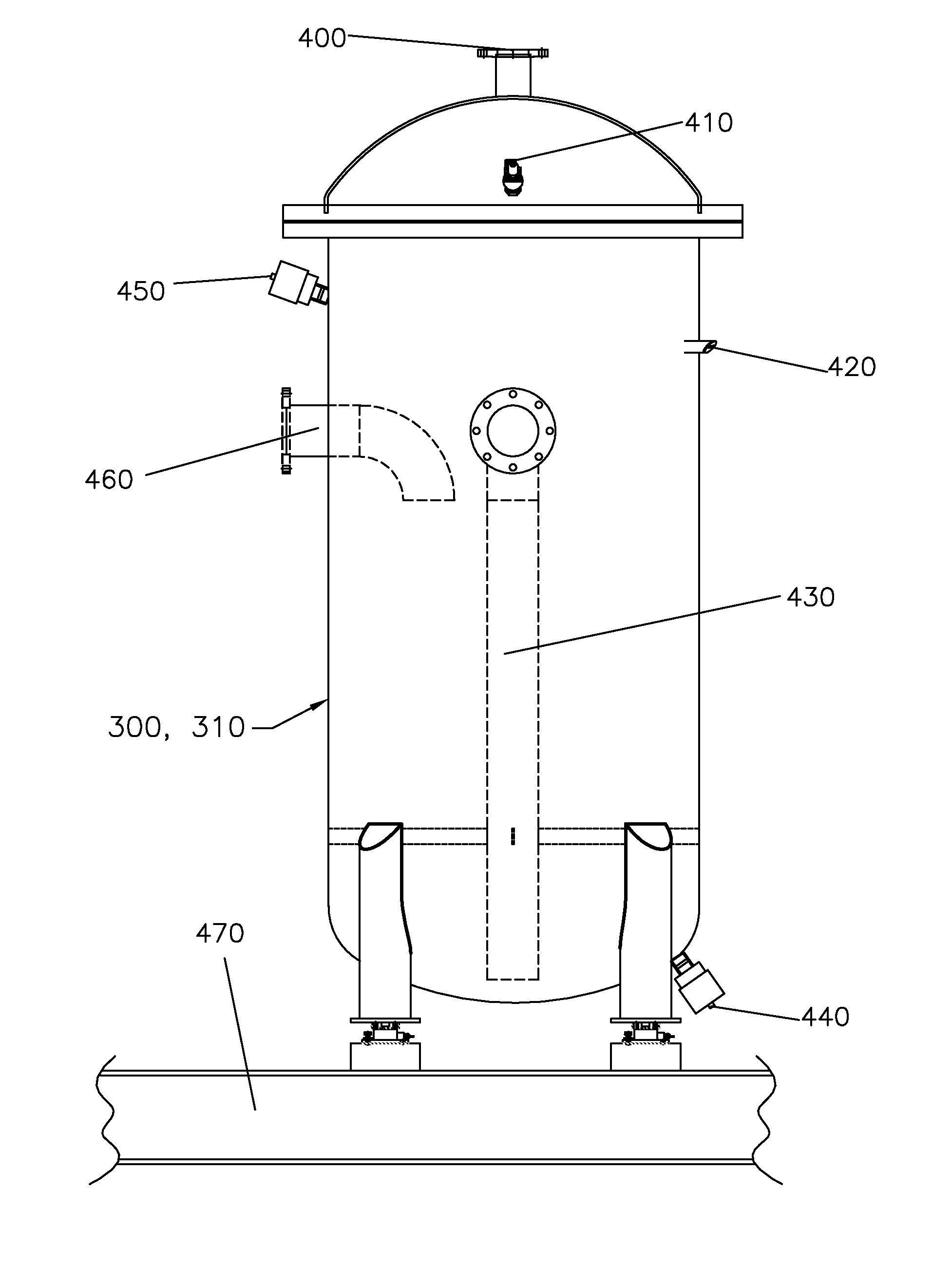

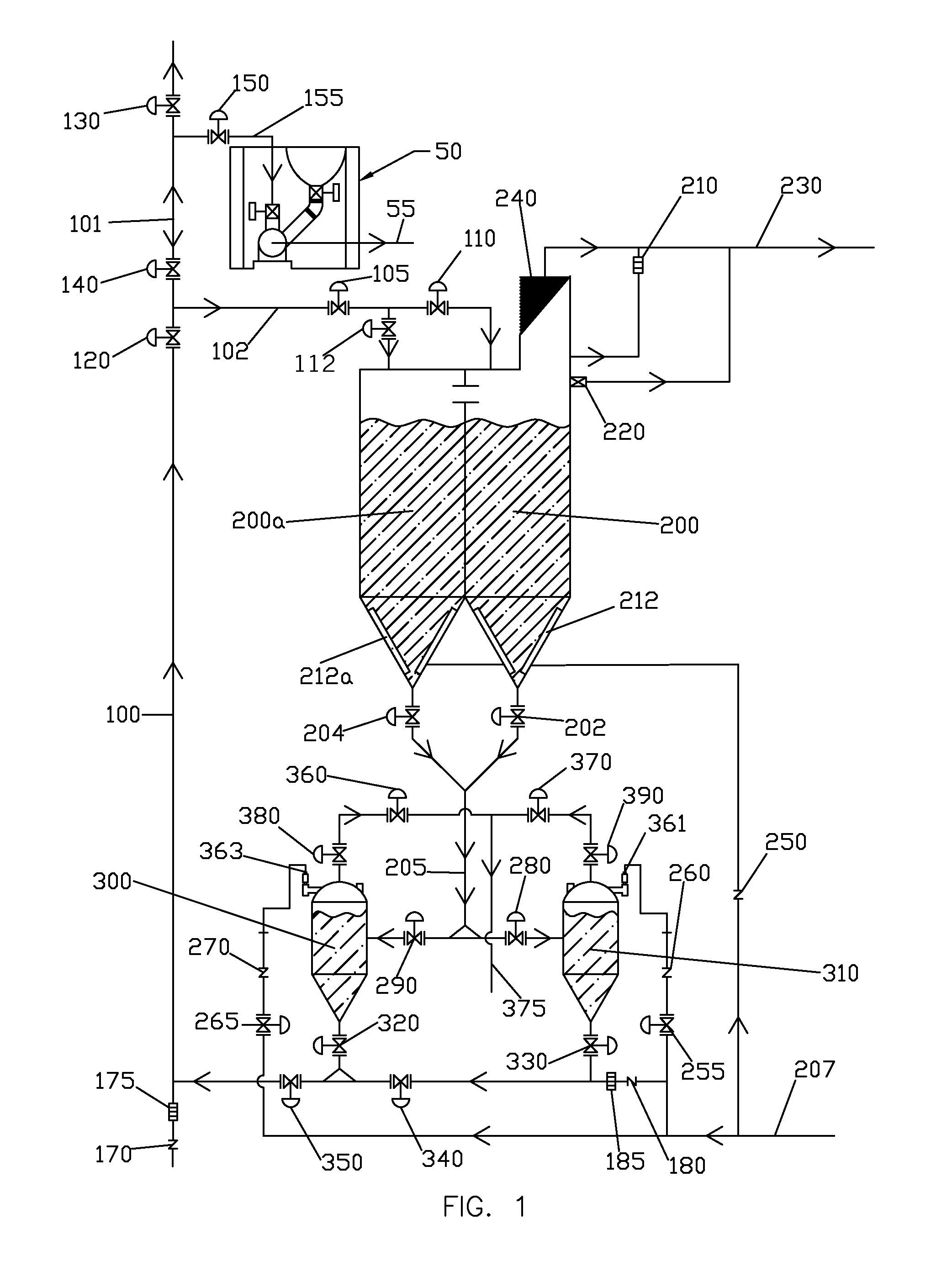

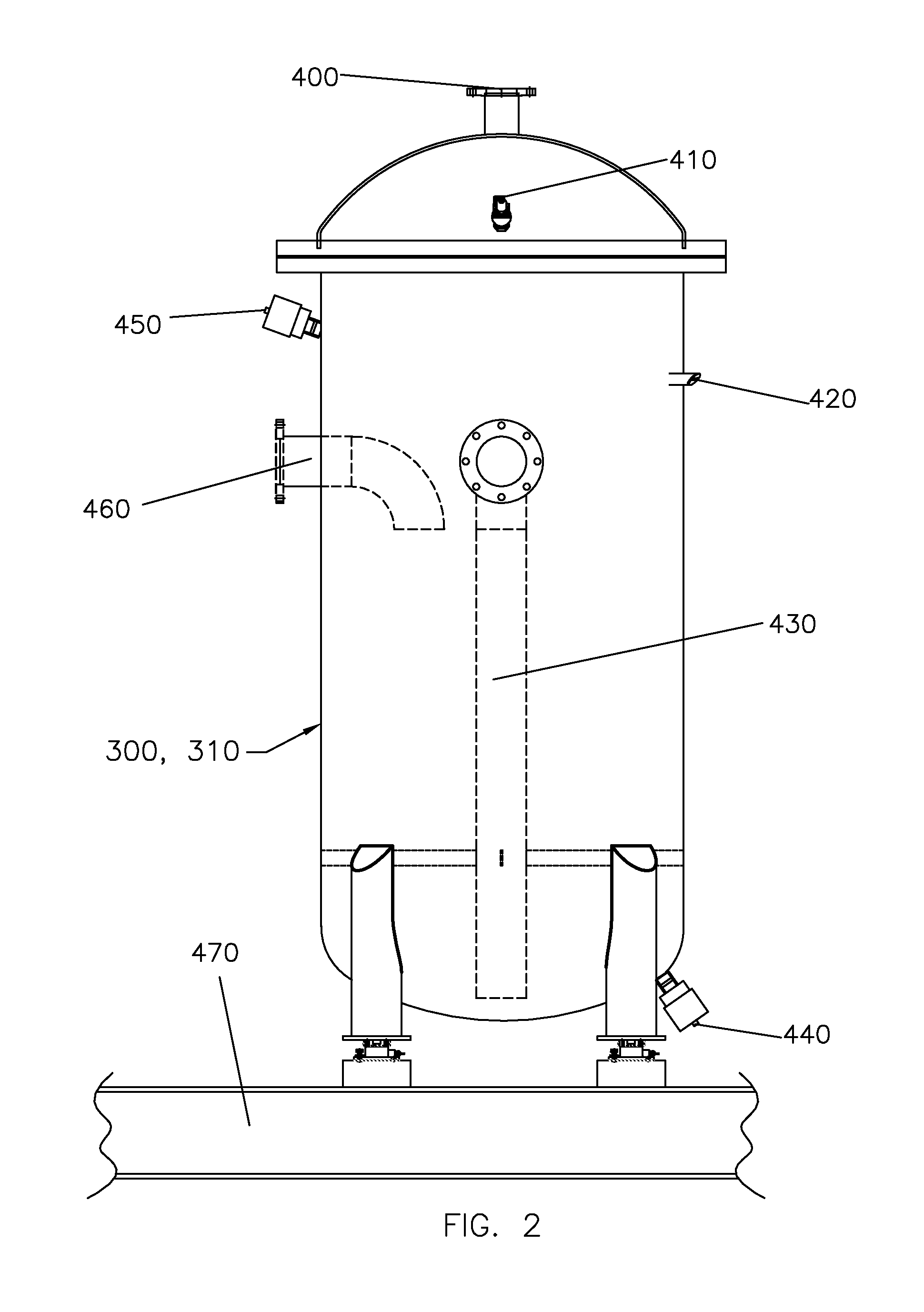

Accurate Dry Bulk Handling System and Method of Use

InactiveUS20140030031A1Minimal of effortMinimal of spaceFlow mixersMixer accessoriesSodium BentoniteFluidized bed

Rapid evacuation and deployment of dry materials is achieved by the dual structure of this device and the method of using it to fill and empty vacuum reloading tanks automatically. This permits materials such a bentonite, barite or cement to be handled easily and without dust on a rig floor and mixed appropriately as needed for well control and completion operations. Dry bulk material is offloaded from an offshore supply vessel into atmospheric tanks, which provide fluidized bed systems to aerate and agitate and move material through piping into the vacuum re-loader tanks. The dual re-loader tank system allows one tank to be emptied while another fills thereby providing sufficient flexibility to expertly manage receiving, storage, transfer, filtration and control of the bulk material on various space-critical platforms, including offshore rigs and service vessels, that require the handling of dry bulk materials in an accurate and dust-free manner.

Owner:PROVEN TECH INC

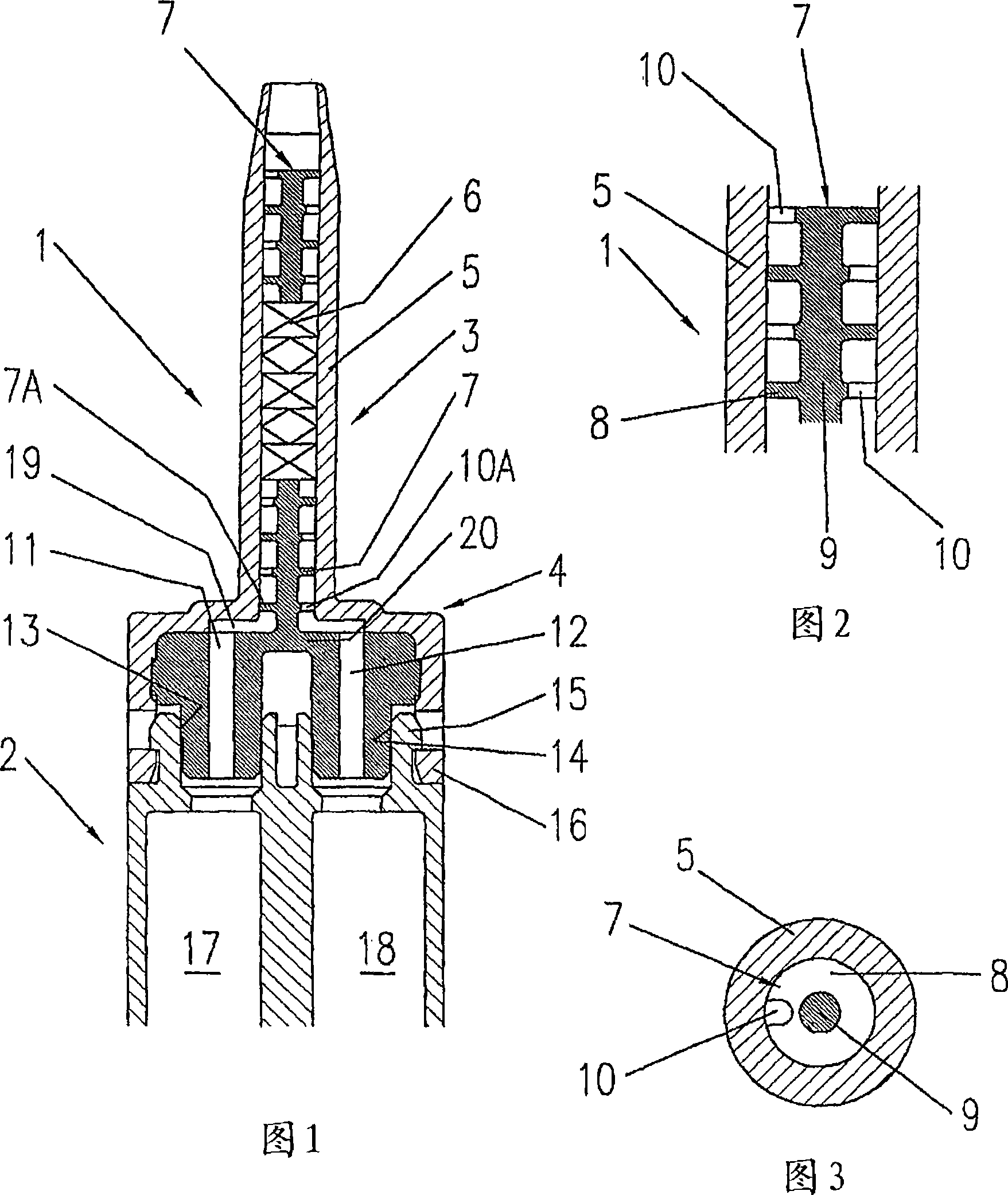

Static mixer

ActiveCN101056697AGuaranteed mixMix to ensure that both substances are thoroughlyRotating receptacle mixersLiquid surface applicatorsEngineeringStatic mixer

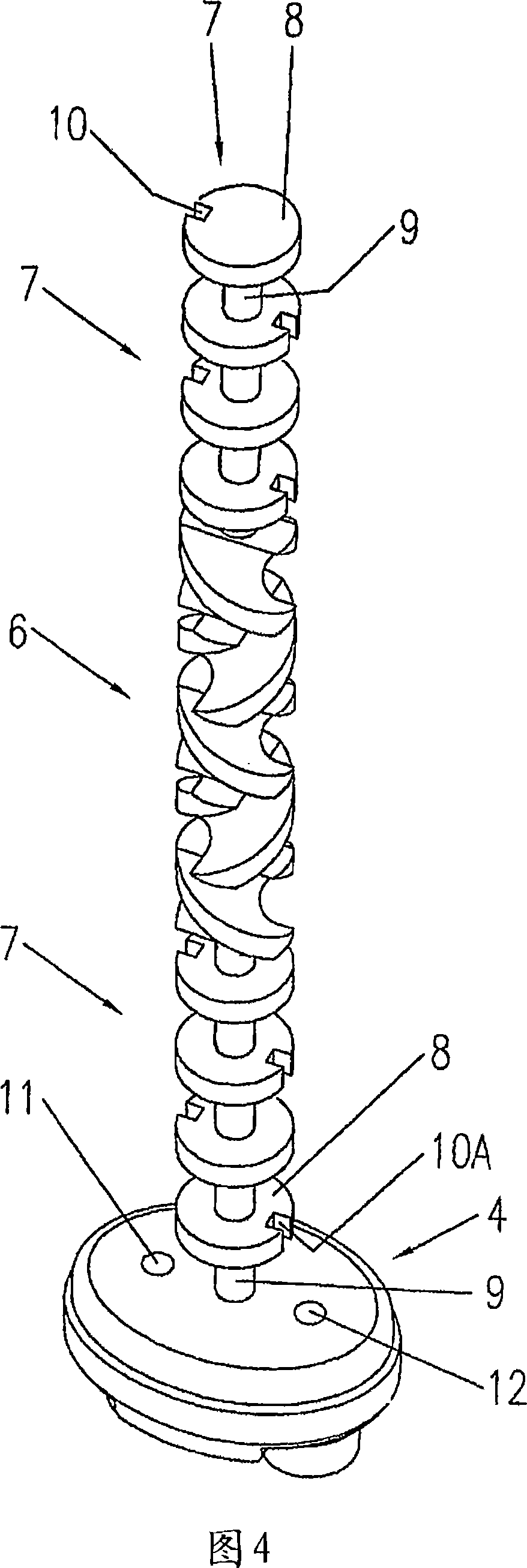

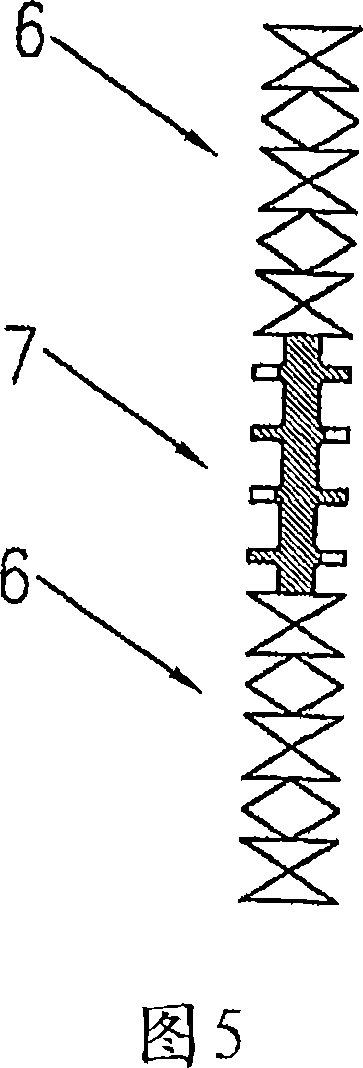

The static mixer for two components comprises a housing (3) having an input part (4) and mixing elements disposed inside the housing. Known mixers use mixer helices as the mixing elements. The inventive mixer is characterized in that at least one mixing element is configured as a discoid shear blade (7, 7A) having a passage (10, 10A) on its disk (8). Such shear elements allow to mix even very small quantities, which are delivered dropwise, since higher shearing rates are produced during discharge at the shear blade passages and vortices are produced at the discharge end, which is particularly advantageous for the use of such mixers in the medical field.

Owner:MEDMIX SWITZERLAND AG

Automatic crisp fried cake forming machine

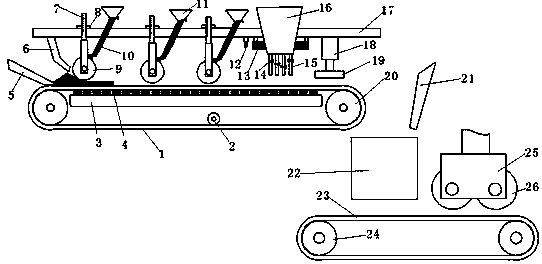

InactiveCN107751281AEasy to shapeFast formingDough-sheeters/rolling-machines/rolling-pinsDough mixing/kneading machinesEngineeringConveyor belt

The invention discloses an automatic crisp fried cake forming machine. A kneading assembly is arranged at the output end of a cake crust forming assembly; a finished crisp fried cake forming assemblyis arranged at the output end of the kneading assembly; an auxiliary material blanking assembly is arranged on the cake crust forming assembly; and the cake crust forming assembly comprises a cake crust forming conveyor belt, multiple groups of forming wheel assemblies and an oiling assembly. The forming machine disclosed by the invention is convenient and rapid to form, and with the adoption of stepped forming, the formed crisp fried cake has high quality. During forming, the cake crust is gradually formed by utilizing the multiple groups of forming wheels, and chopped green onion and other auxiliary materials are spread, and a pressing plate is utilized for pressing downwards once, so that the subsequent auxiliary materials are prevented from dropping. Then, the kneading assembly is utilized for performing repeated kneading, so that the chewy property of the cake is improved, the cake is formed into the finished product again after kneading, and therefore, the taste of the crisp fried cake is greatly improved. In addition, the oiling assembly is arranged on each pressing wheel, so that the cake and the oil can be well mixed, the performance of the crisp fried cake is improved, and the cake can be prevented from being stuck to one another.

Owner:栗永伟

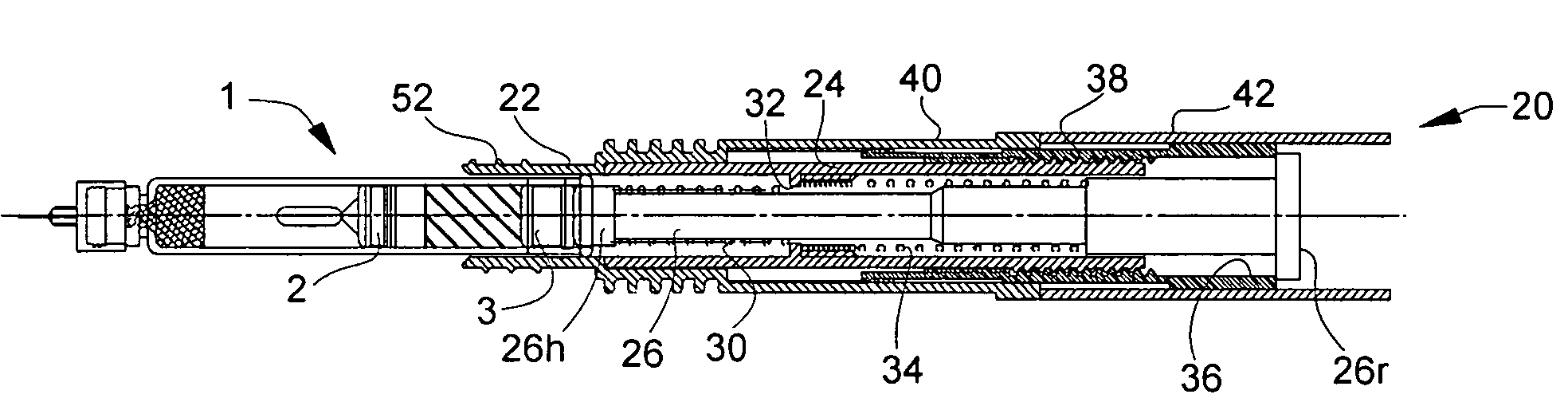

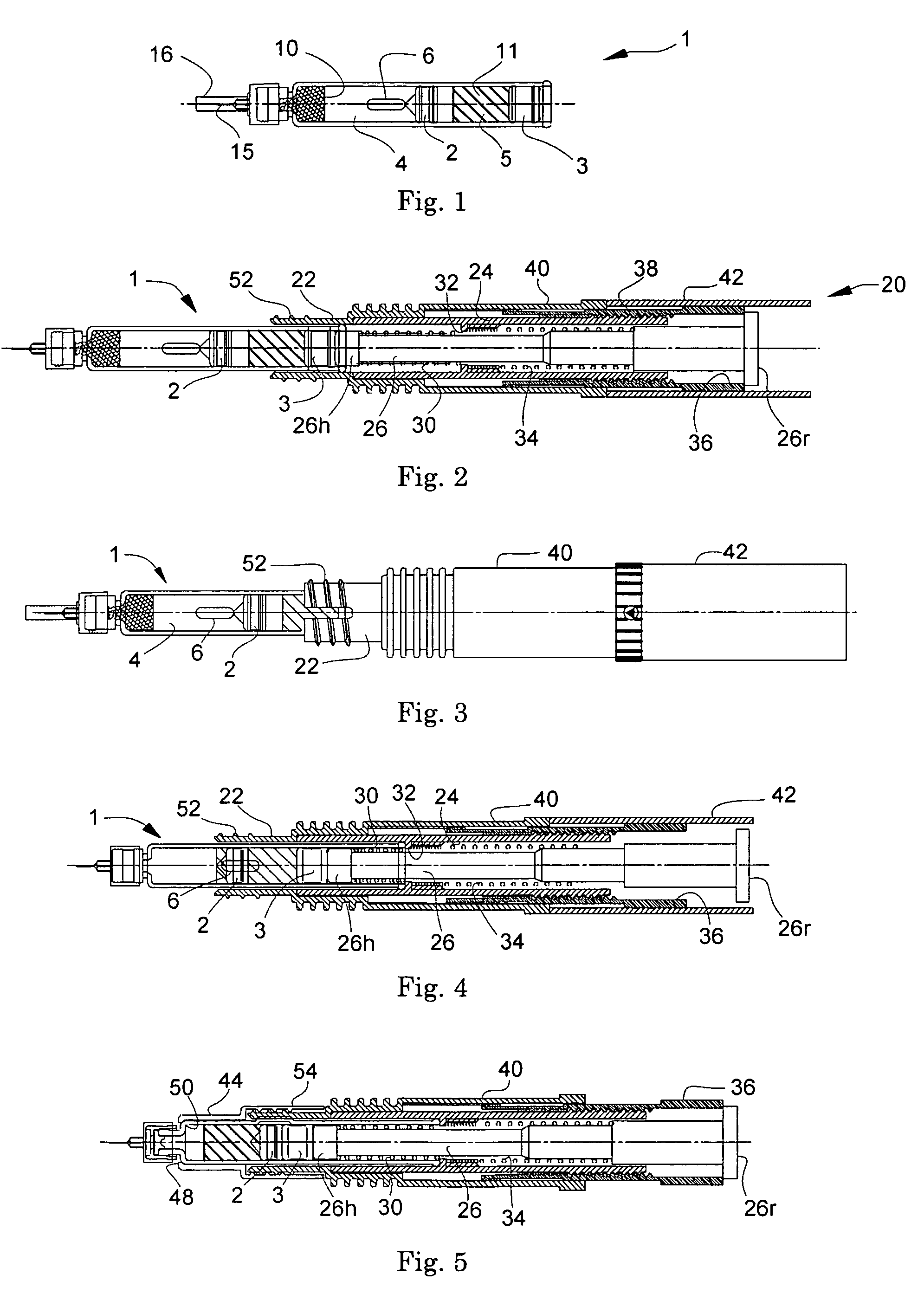

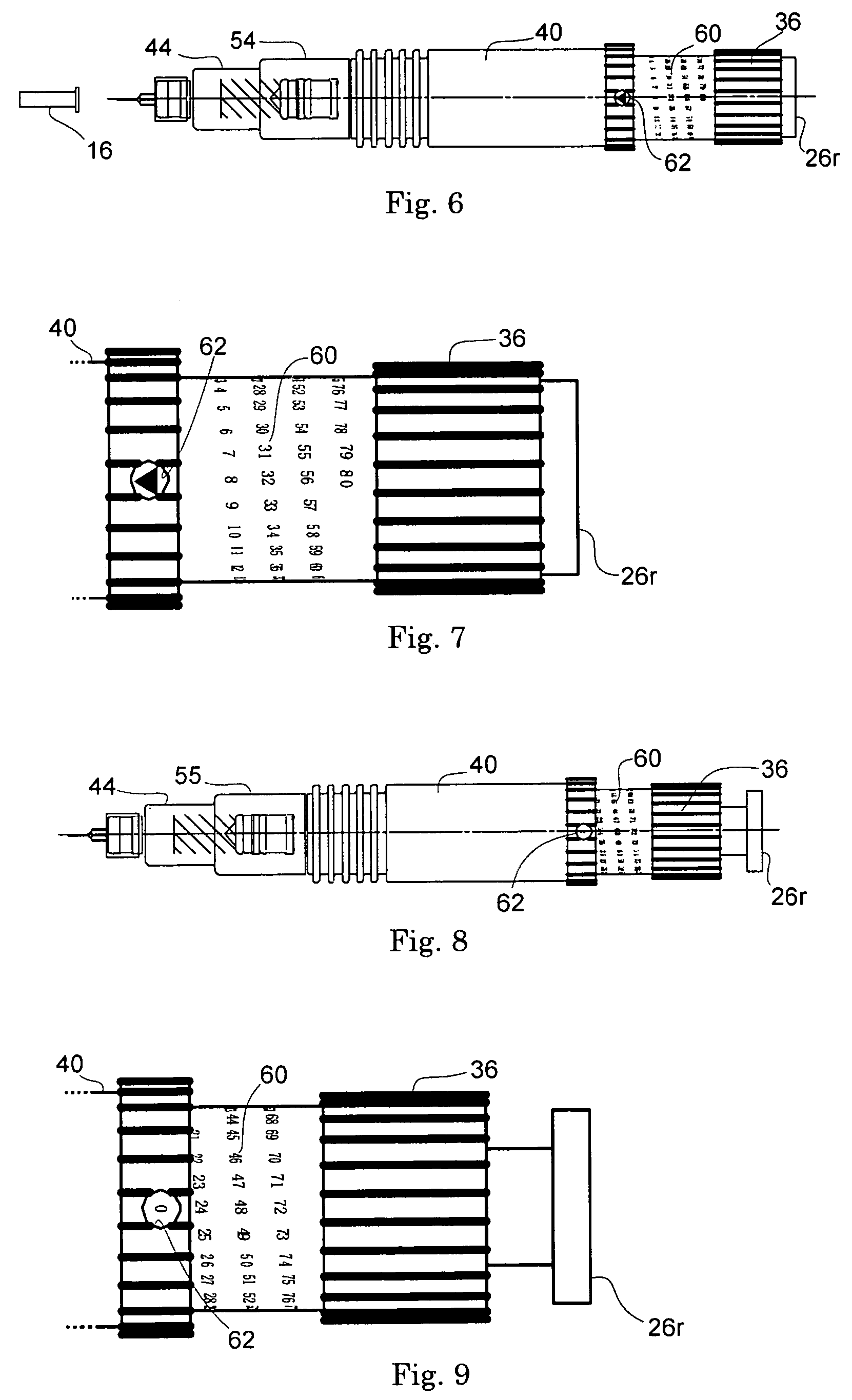

Injection device

InactiveUS7534222B2Guaranteed mixEasy to adjustAutomatic syringesMedical devicesScrew threadInjection device

An injection device is disclosed which is designed to receive therein a two-compartment syringe, and to be used to mix the pharmaceutical agents and then conduct injections. The injection device comprises a cylindrical barrel portion so configured that the two-compartment syringe can be inserted therein in a rear-end first manner, a piston rod for pushing the slidable rear wall to advance, a front spring that is compressed, when the two-compartment syringe is inserted, and then push back the piston rod in the forward direction, and a sleeve which can be shifted back and forth and is provided by screw engagement with the outer surface of the rear part of the barrel portion to block the forward movement of the piston rod.

Owner:JCR PHARMA

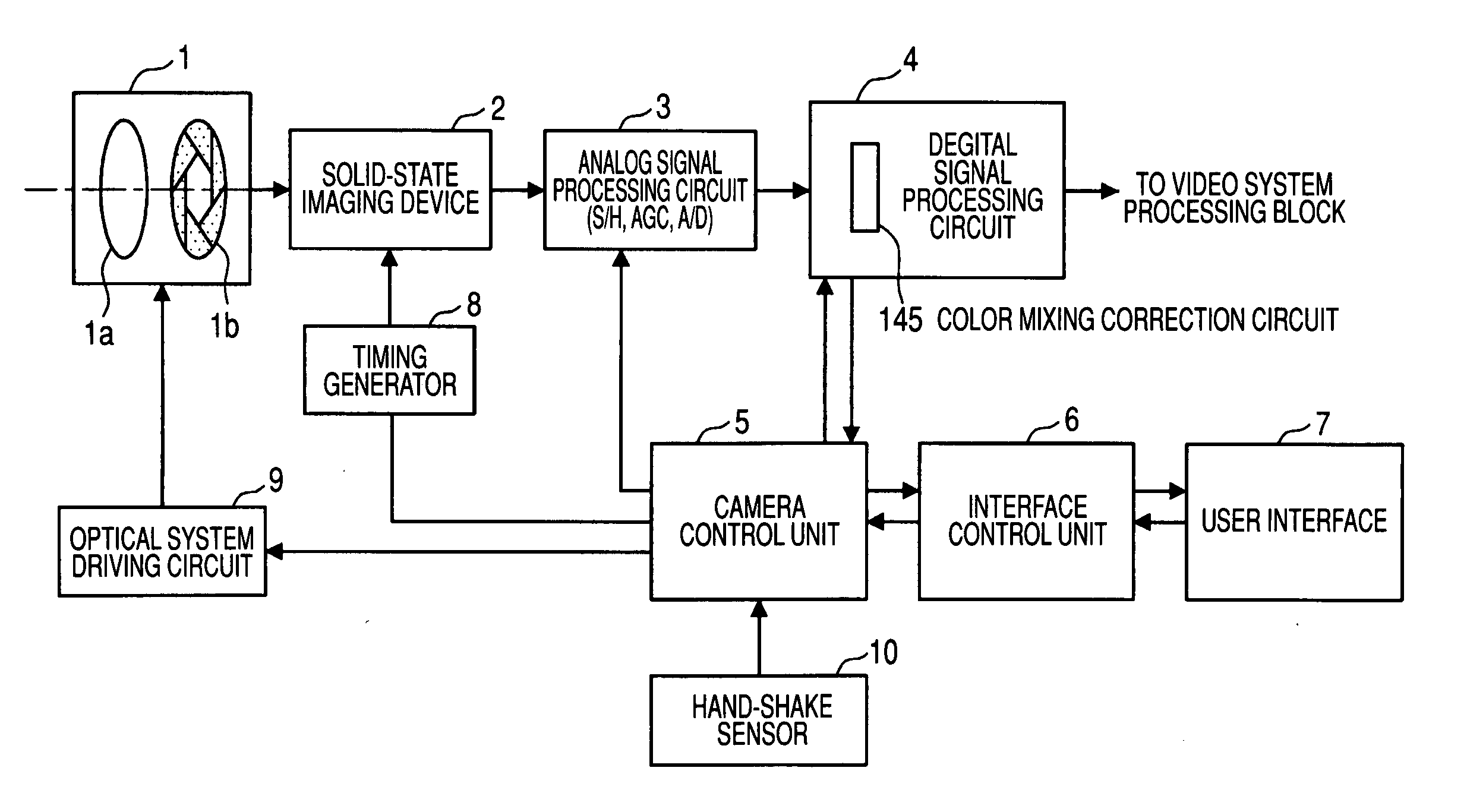

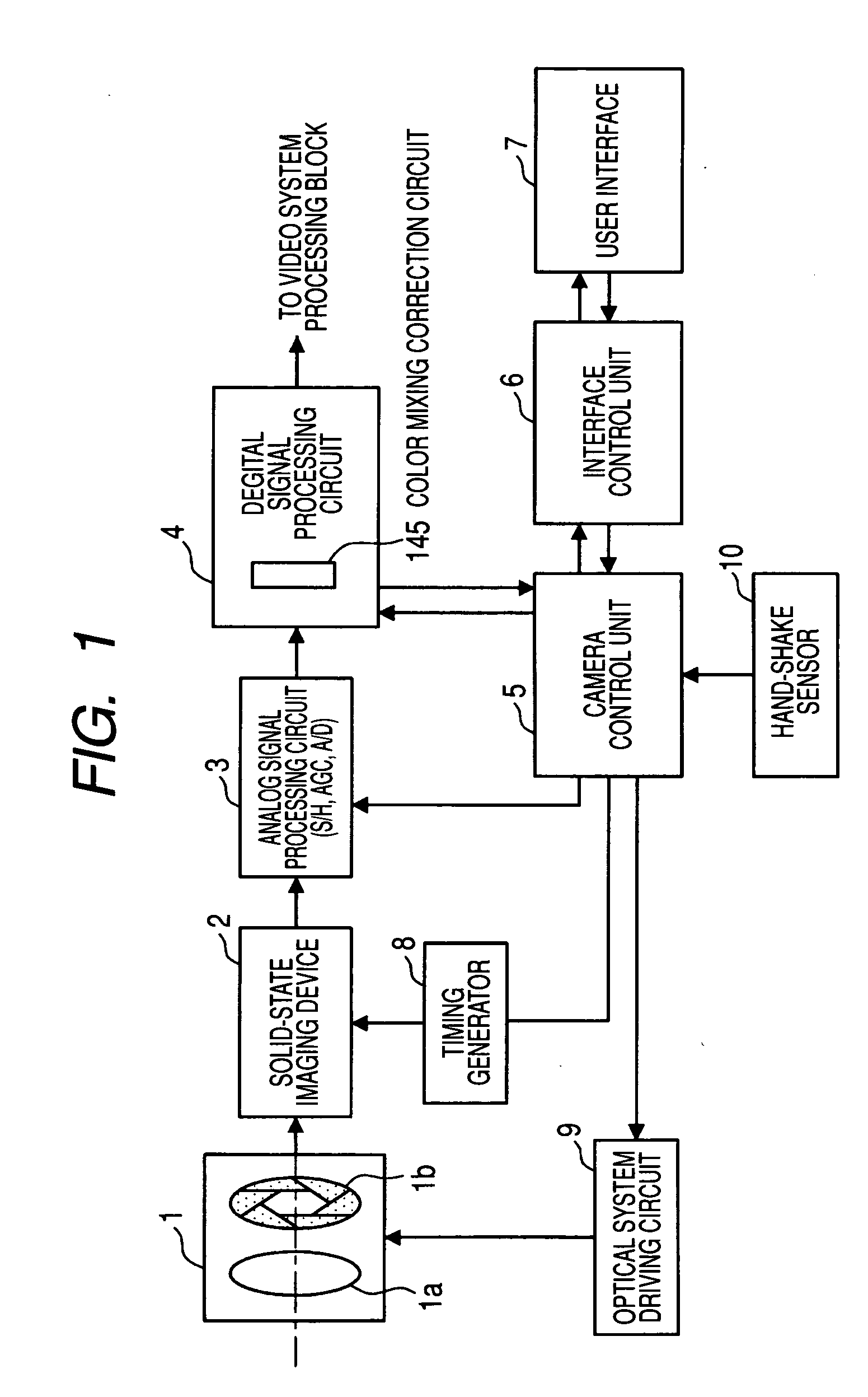

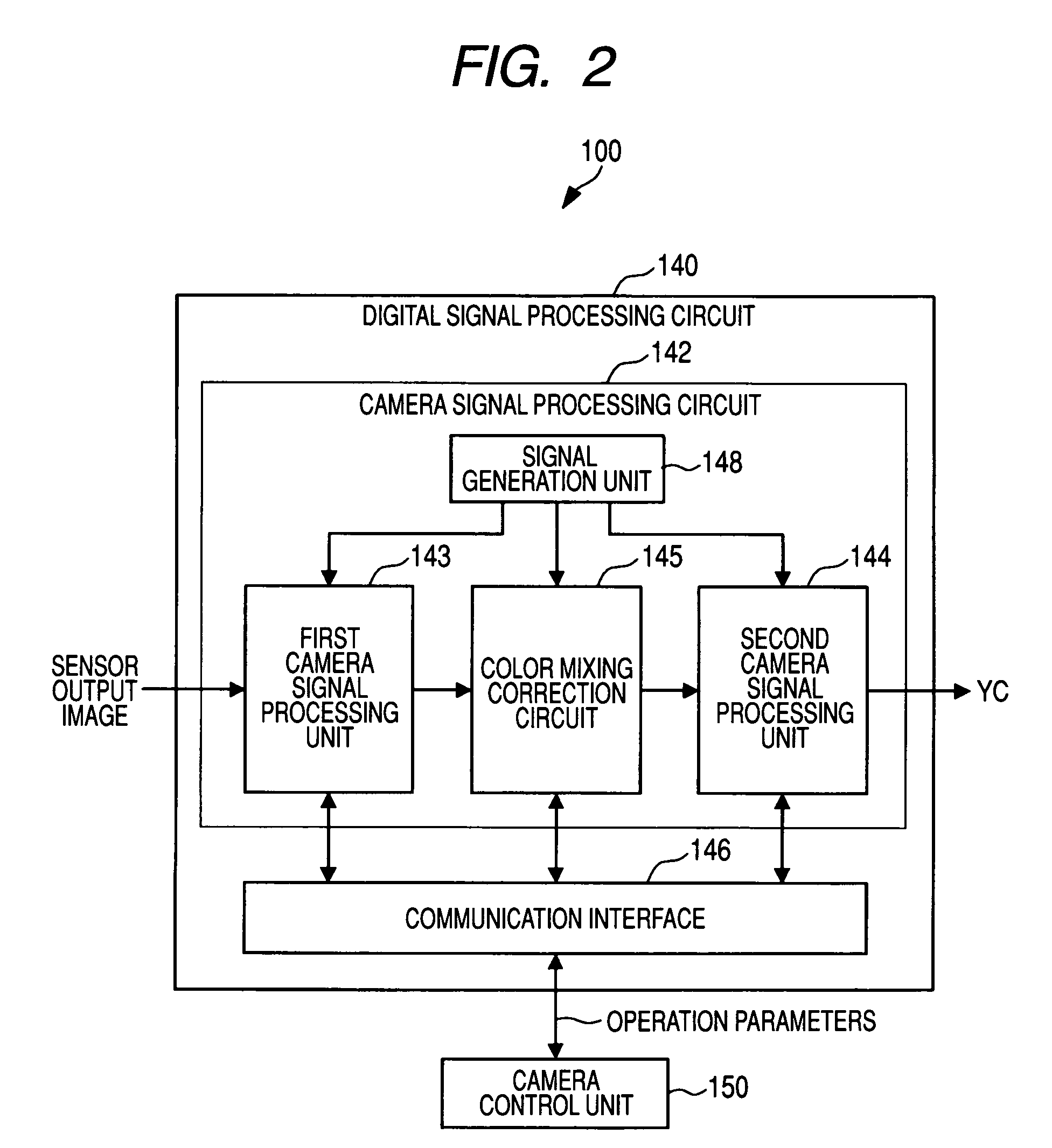

Signal processing device for solid-state imaging device, imaging apparatus having the signal processing device, signal processing method, and program

InactiveUS20090096887A1Guaranteed mixPrecise processingTelevision system detailsTelevision system scanning detailsPhotoelectric conversionParameter distribution

A signal processing device for a solid-state imaging device correcting inter-pixel color mixing in the solid-state imaging device in which color filters having a color component constituting a primary component among luminance components and other color components are disposed on a surface of a two-dimensional array of pixels including a photoelectric conversion element is disclosed. The signal processing device includes a parameter distribution unit two-dimensionally distributing correction parameters in a pixel array surface on which a plurality of pixels are arranged and a signal correcting unit correcting a signal for a pixel of interest using each of signals for a plurality of surrounding pixels adjacent to the pixel of interest in the pixel array surface and using two-dimensionally distributed correction parameters for each of the signals.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com