Method of preparing alpha-sulphonic acid fatty acid ester

A technology of sulfonic acid fatty acid ester and fatty acid ester, which is applied in the fields of sulfonic acid preparation and organic chemistry, can solve problems such as difficulty in removing heat in time, high reaction temperature, and long reaction time, and achieve short reaction residence time and high reaction time. The effect of low temperature and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

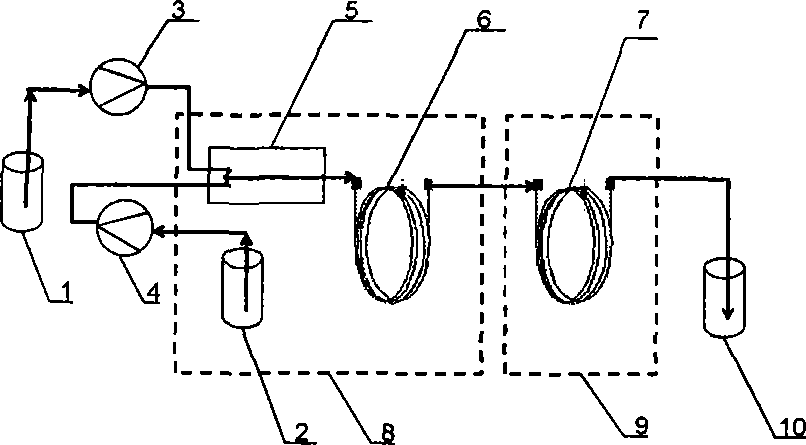

Embodiment 1

[0038] 98% concentrated sulfuric acid (storage tank 1) and preheated palm oil fatty acid methyl ester (storage tank 2) are injected into the temperature control unit with the flow rate of 0.71ml / min and 4.29ml / min by high-pressure pumps 3 and 4 respectively. In a rectangular cross-toed glass microstructure reactor 5 with a channel width of 0.05mm, a depth of 0.15mm, and a length of 40mm at 65°C, the residence time is 3.6ms, and after mixing, it enters a polytetrafluoroethylene microchannel reactor with an inner diameter of 2mm 6. Adjust the residence time of the reactants in the microchannel reactor to 3min, and then enter the polytetrafluoroethylene microchannel reactor 7 with an inner diameter of 2mm at a temperature controlled at 85°C to adjust the residence time of the reactants in the microchannel reactor The time was 2.5 minutes, and the reaction product (storage tank 10) was collected, and the sulfonation rate of the reaction was calculated by extraction method to be 74....

Embodiment 2

[0040] Free SO 3 Content is the oleum (storage tank 1) of 50% and the palm oil fatty acid methyl ester (storage tank 2) that preheated, inject into with the flow rate of 1.53ml / min, 3.47ml / min by high-pressure pump 3,4 respectively The temperature is controlled at 80°C in a rectangular cross-toed glass microstructure reactor 5 with a channel width of 0.05 mm, a depth of 0.15 mm, and a length of 40 mm. The residence time is 3.6 ms. After mixing, it enters a polytetrafluoroethylene microchannel with an inner diameter of 2 mm. Reactor 6, adjust the residence time of the reactant in the microchannel reactor to be 2min, then enter the polytetrafluoroethylene microchannel reactor 7 with an inner diameter of 2mm at 90°C and control the temperature of the reactant in the microchannel reactor The residence time is 5min, and the reaction product (storage tank 10) is collected to obtain a sulfonation rate of 98.8%, and the free fatty acid methyl ester content in the sulfonation product i...

Embodiment 3

[0042] With 99% chlorosulfonic acid (storage tank 1) and the palm oil fatty acid methyl ester (storage tank 2) of preheating, inject to temperature with the flow rate of 1.11ml / min, 1.89ml / min by high-pressure pump 3,4 respectively Controlled at 85°C in a stainless steel slit cross-toed microstructure reactor 5 with a channel width of 0.04mm, a depth of 0.15mm, and a length of 25mm, the residence time is 3.0ms, and after mixing, it enters a stainless steel microchannel reactor with an inner diameter of 1.2mm 6. Adjust the residence time of the reactant in the microchannel reactor to be 0.8min, and then enter the polytetrafluoroethylene microchannel reactor 7 with an inner diameter of 2mm at a temperature of 85°C to adjust the reactant's residence time in the microchannel reactor. The residence time was 1.3 min, and the reaction product was collected (storage tank 10). The sulfonation rate of the reaction was 95.3%, and the free fatty acid methyl ester content in the sulfonation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com