Patents

Literature

388results about How to "Increase heat load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

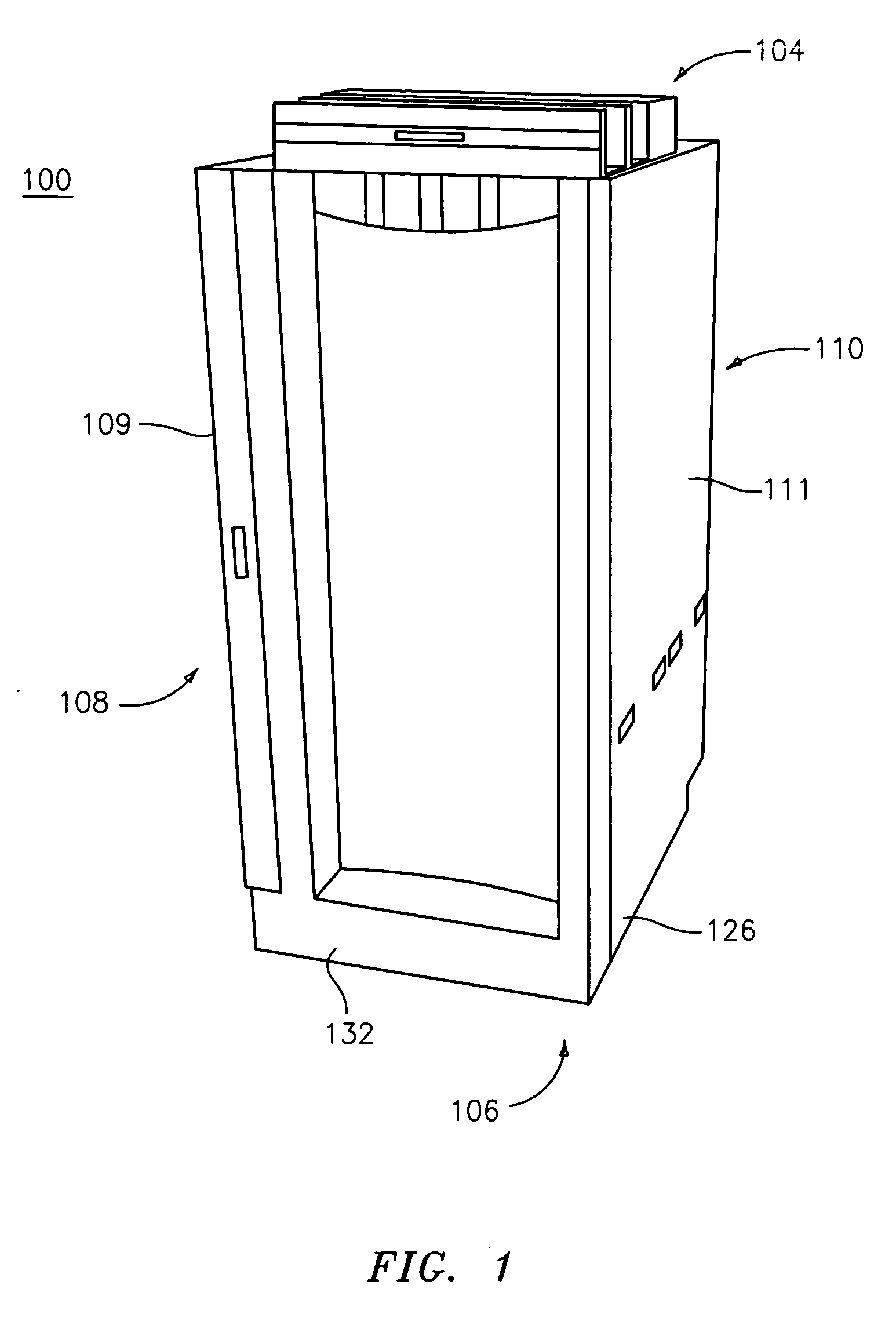

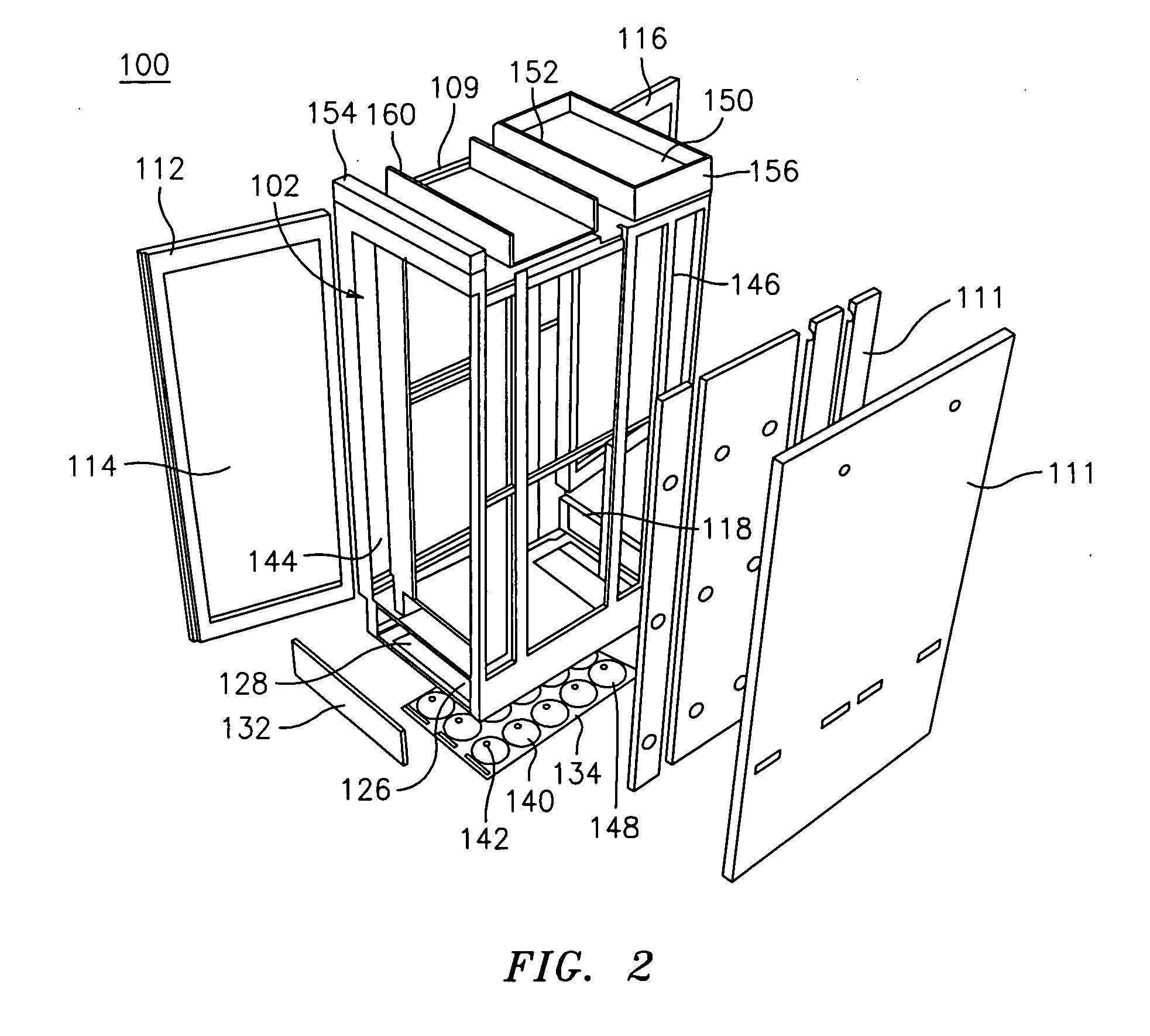

Cabinet for electronic equipment

InactiveUS7643291B2High densityEasy and efficient assemblyMechanical apparatusDigital data processing detailsElectrical and Electronics engineeringElectronic equipment

Owner:ORTRONICS INC

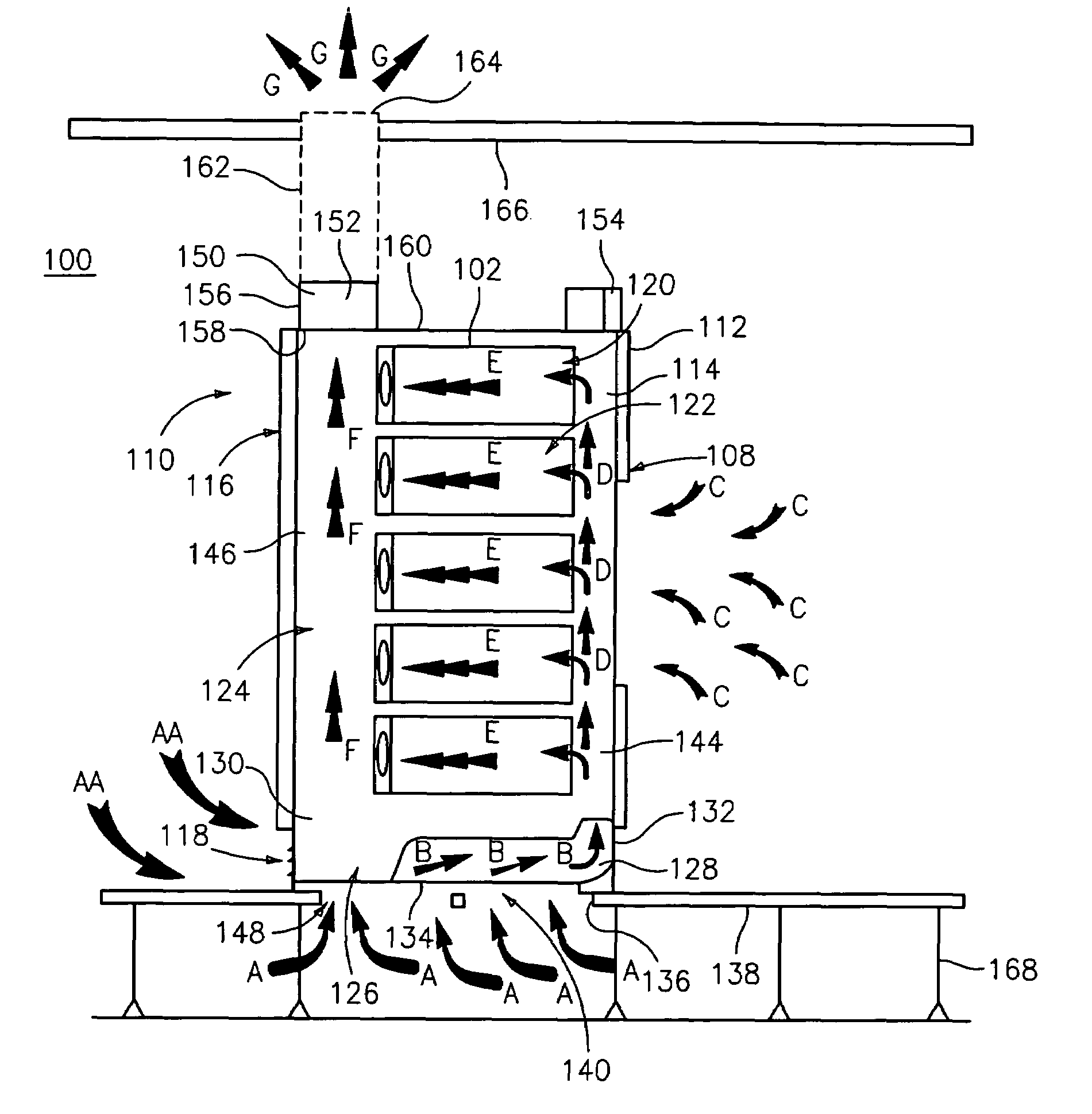

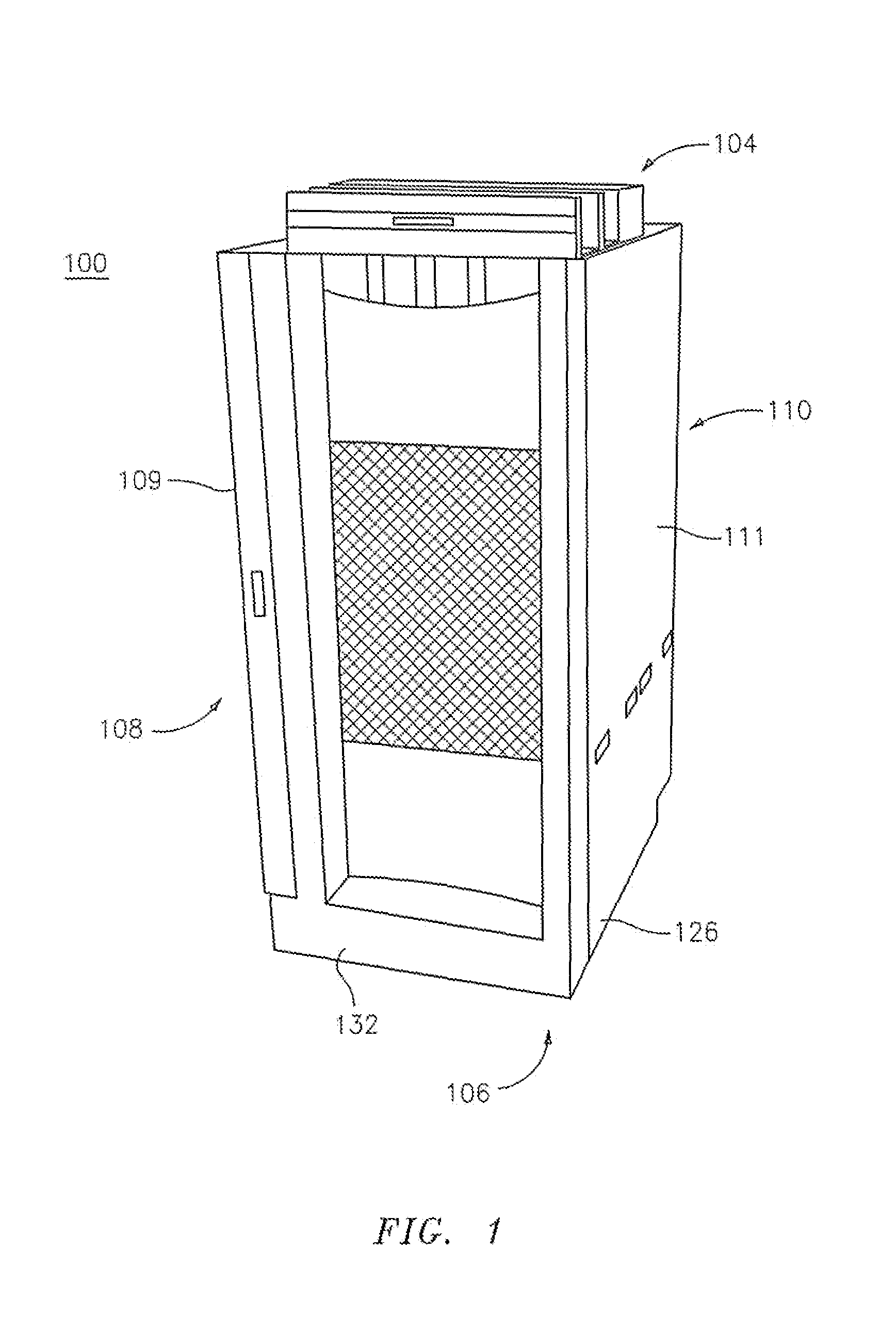

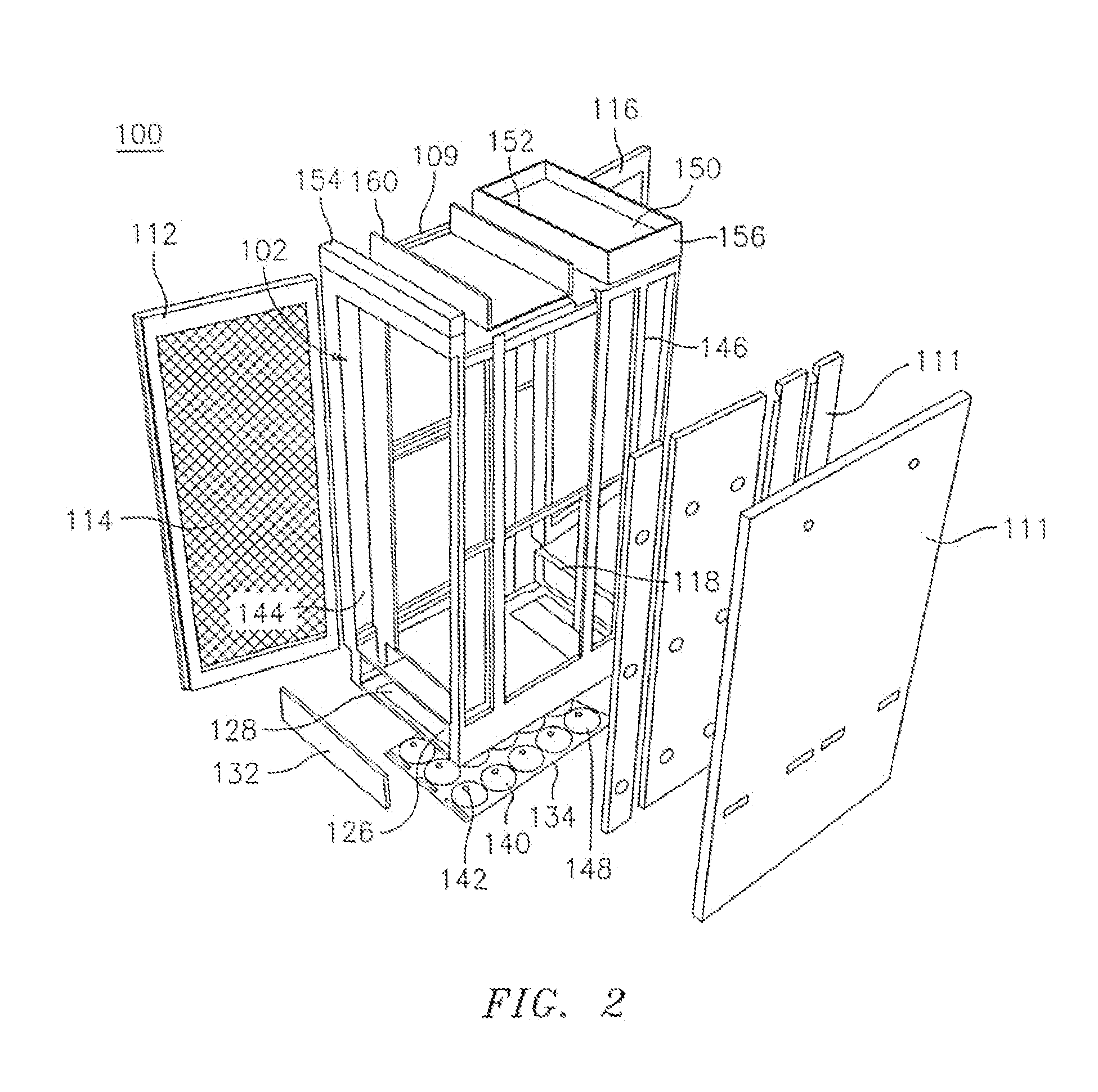

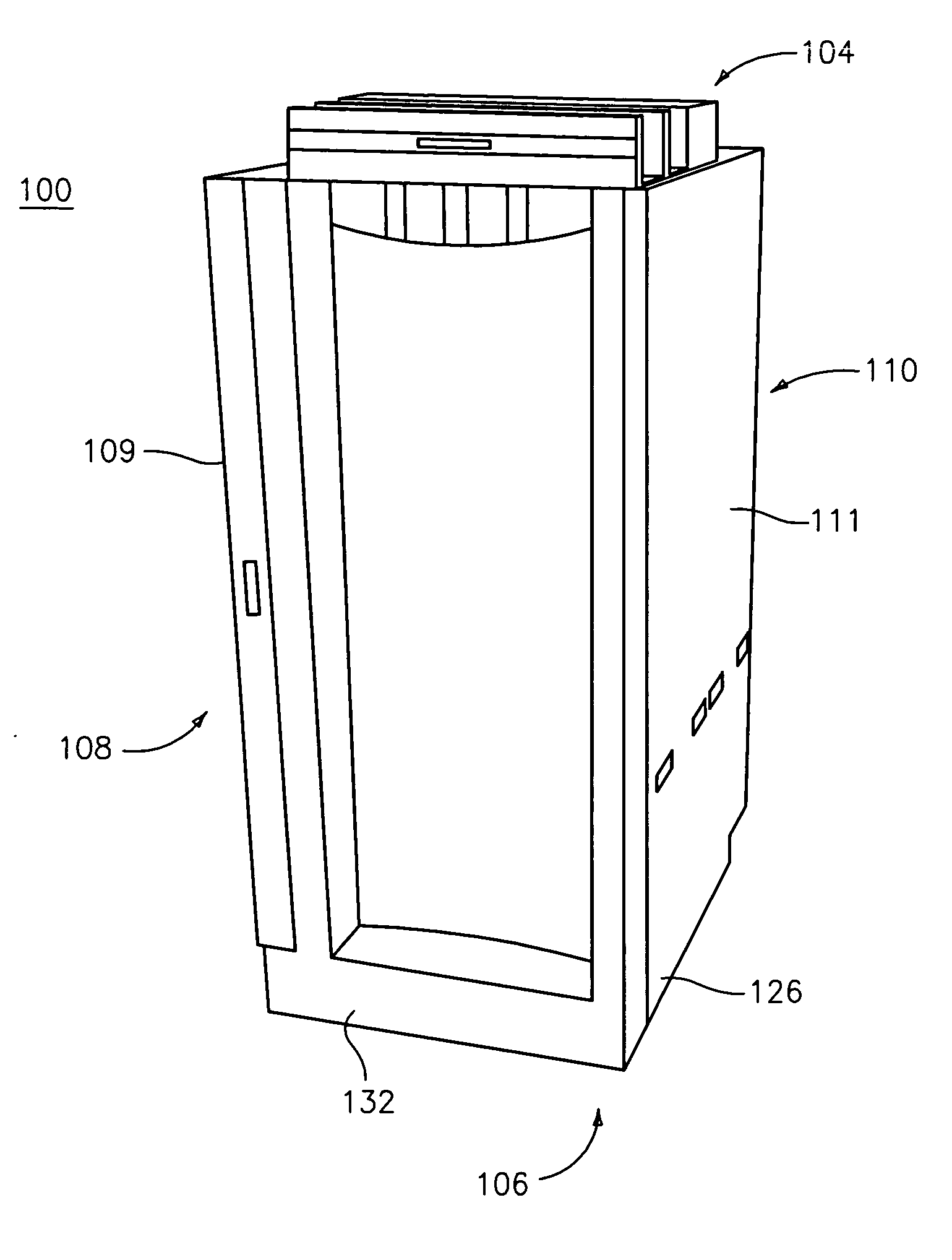

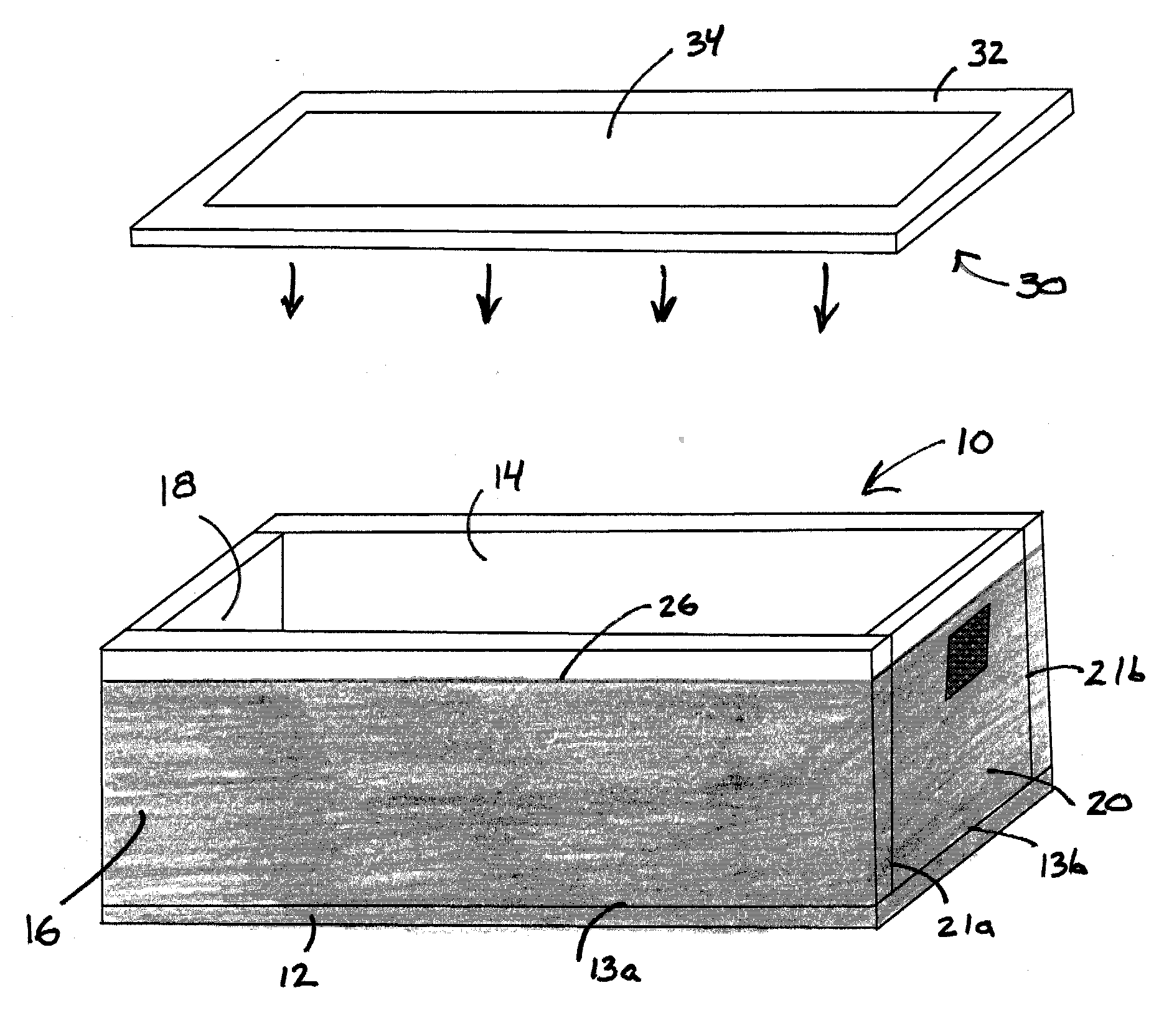

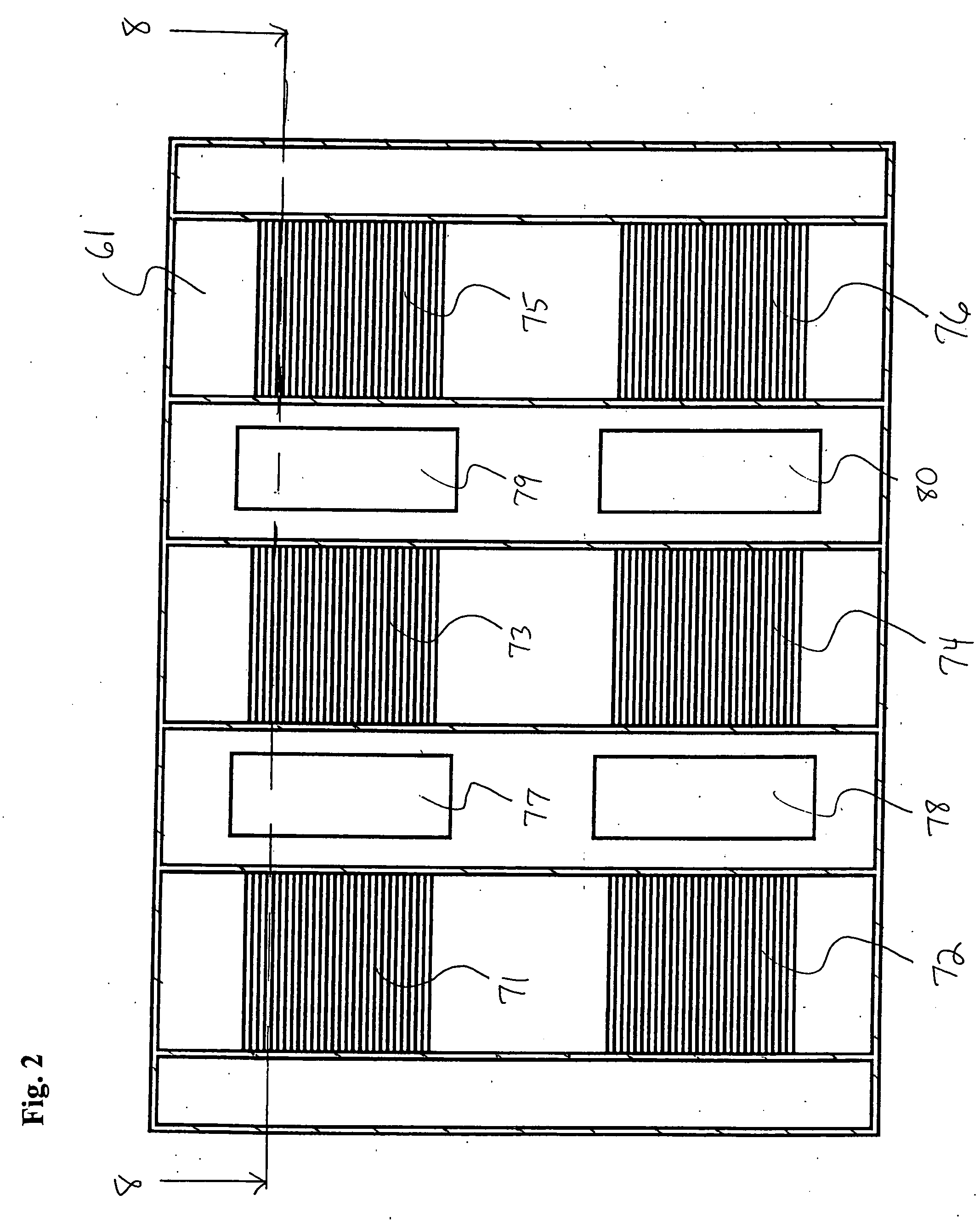

Cabinet for electronic equipment

InactiveUS20090059523A1High densityEasy and efficient assemblyMechanical apparatusDigital data processing detailsEngineeringProduct gas

An electronic equipment cabinet is provided, which includes an upper portion, a lower portion and a support configured to receive electronic equipment. The bottom portion defines a base plenum configured to receive a low temperature gas and communicates with a gas flow distribution pathway, which includes a first plenum communicating with the base plenum and configured to direct the low temperature gas to the support. The gas flow distribution pathway further includes a second plenum configured to receive a high temperature gas flow from the support and direct the high temperature gas flow to the top portion. The top portion includes at least one fan configured to direct the high temperature gas flow from the gas flow distribution pathway. A temperature sensor senses the temperature of the high temperature gas flow and communicates with a control module to control the first plenum and the at least one fan for regulating temperature.

Owner:ORTRONICS INC

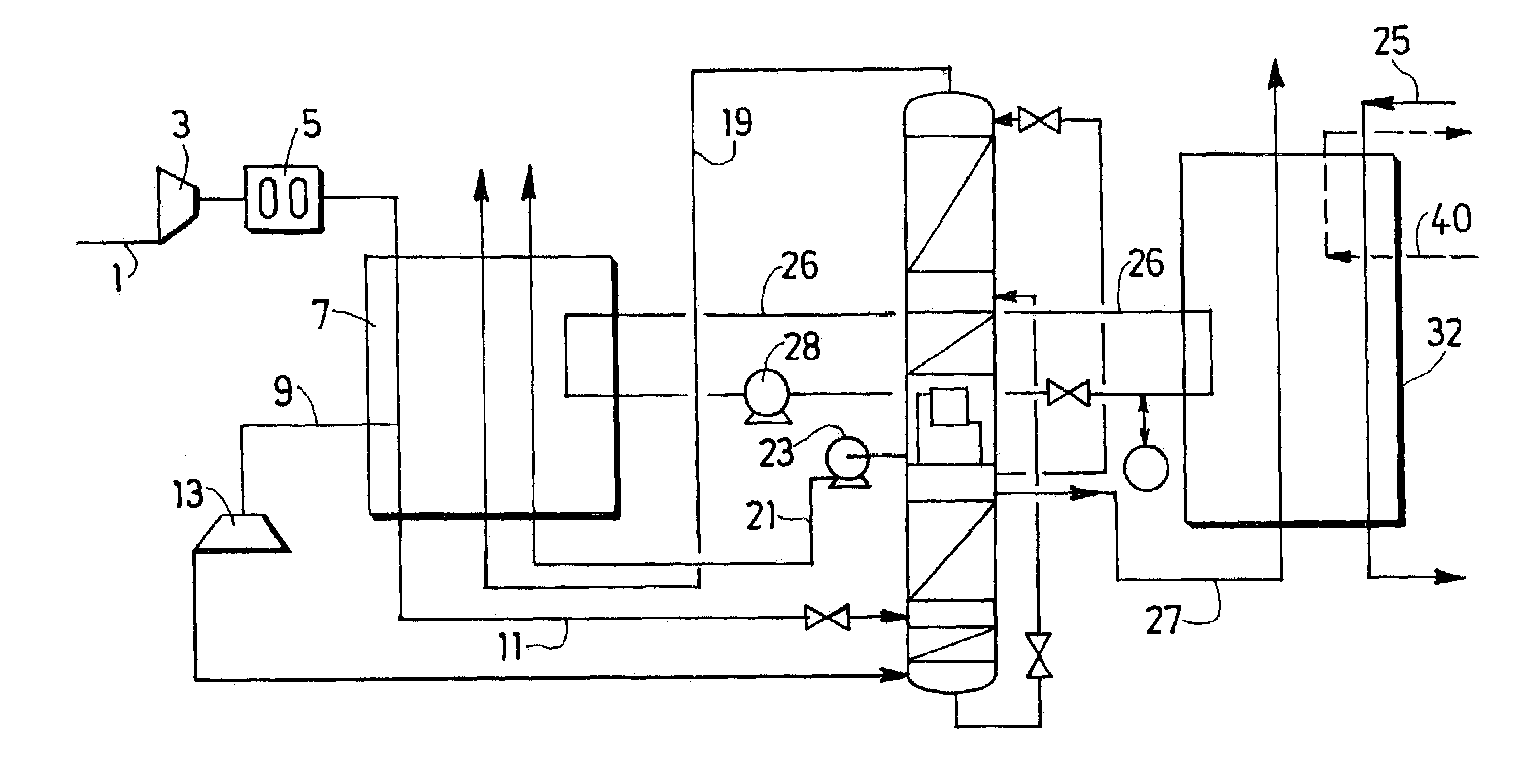

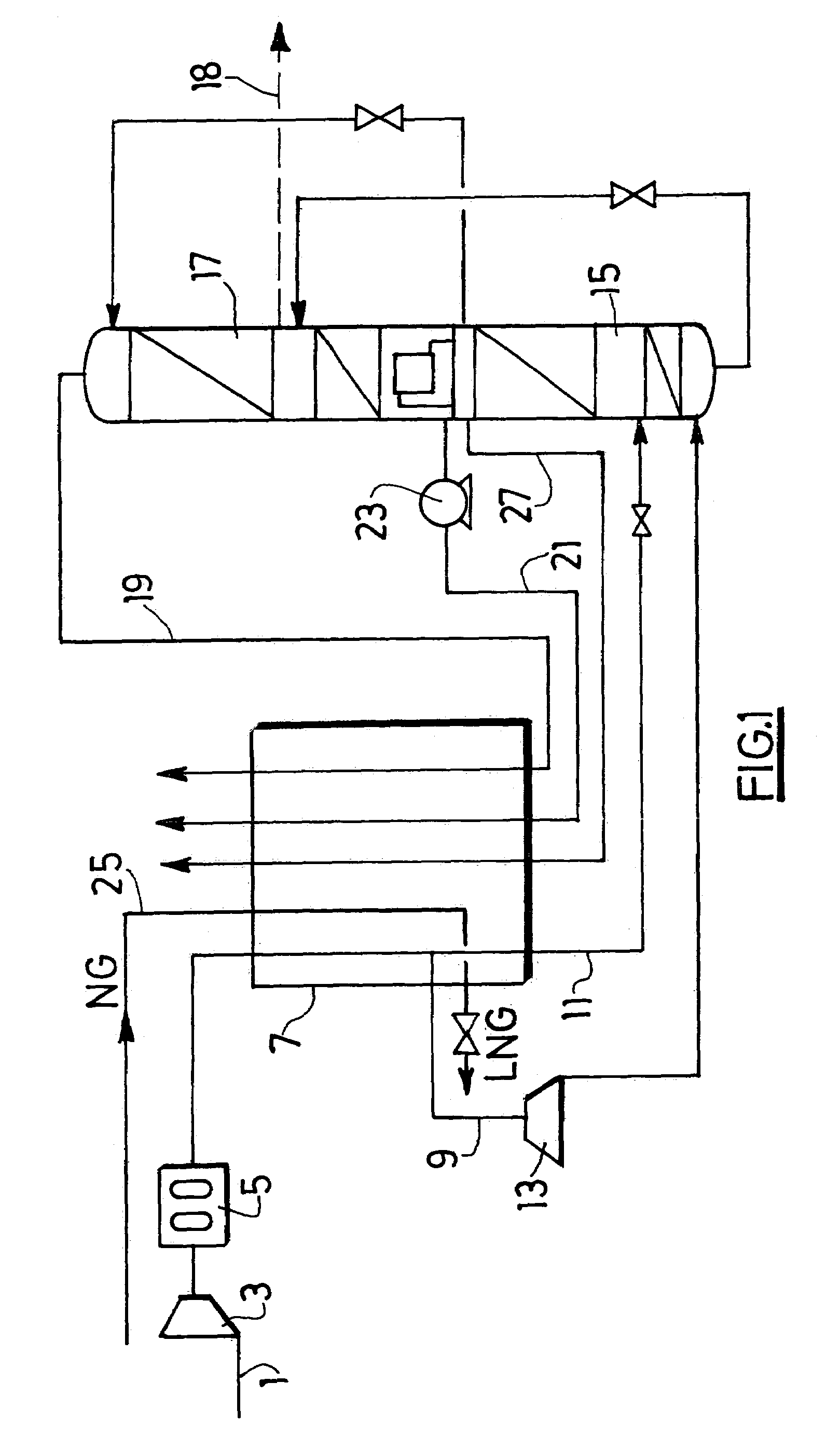

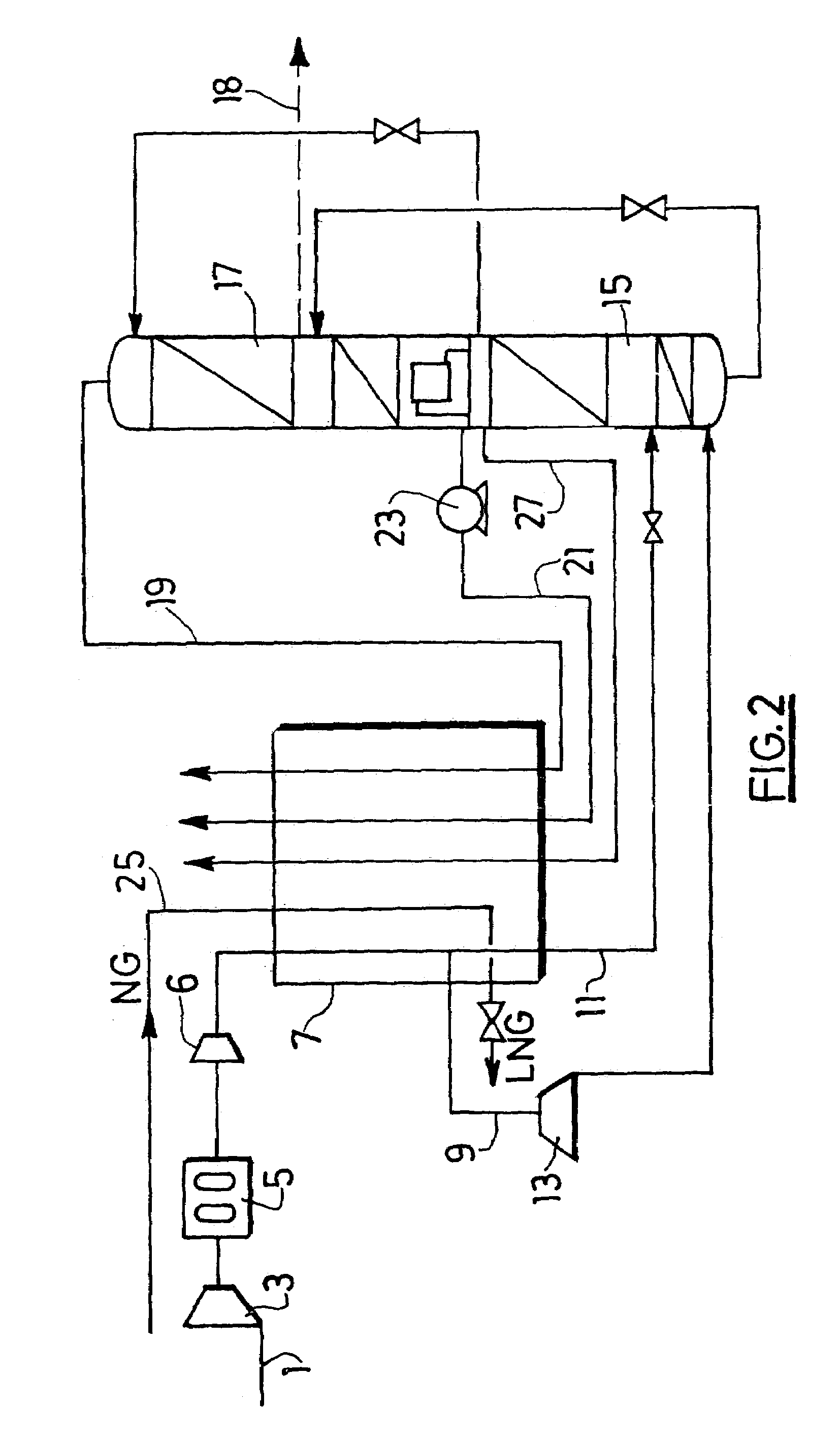

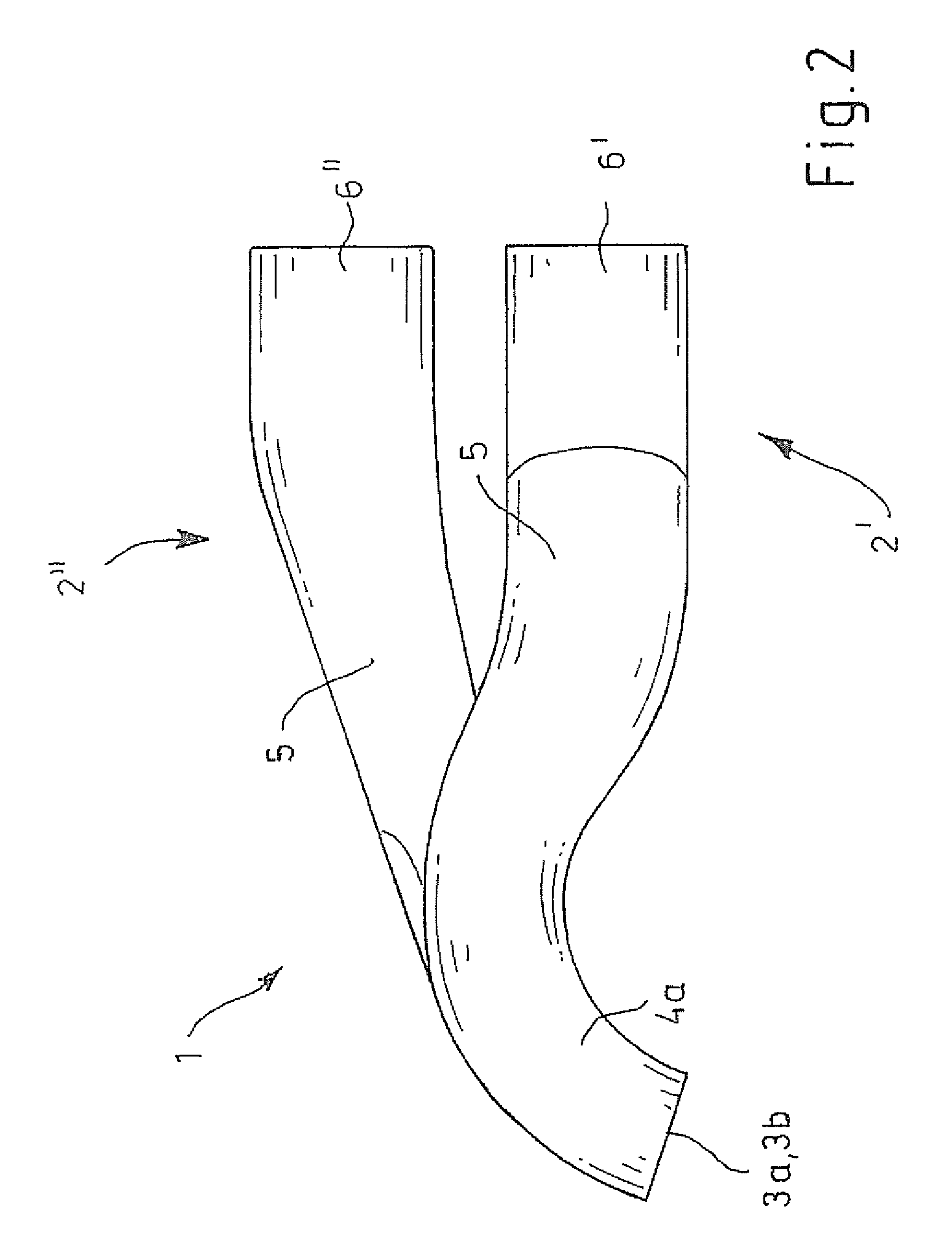

Combined air separation natural gas liquefaction plant

ActiveUS7143606B2Increase power consumptionIncrease the number ofSolidificationLiquefactionFractionating columnProcess engineering

In an integrated process and apparatus for the separation of air by cryogenic distillation and liquefaction of natural gas in which at least part of the refrigeration required to liquefy the natural gas is derived from at least one cryogenic air distillation plant comprising a main heat exchanger (7) and distillation columns (15, 17), wherein the natural gas (25) liquefies by indirect heat exchange in a heat exchanger (7, 32, 34) with a cold fluid (21, 26), the cold fluid being sent to the heat exchanger at least partially in liquid form and undergoing at least a partial vaporisation in the heat exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

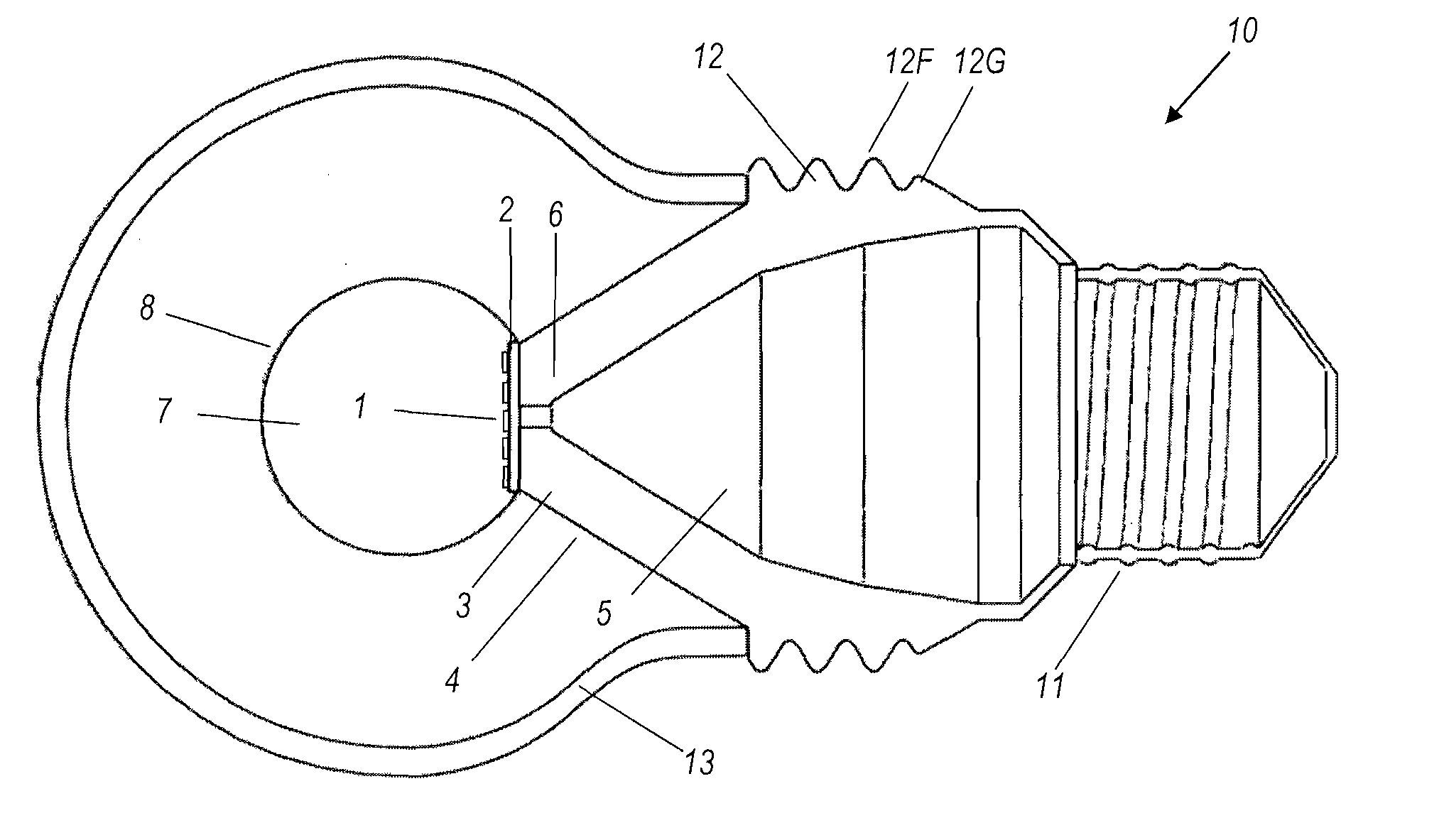

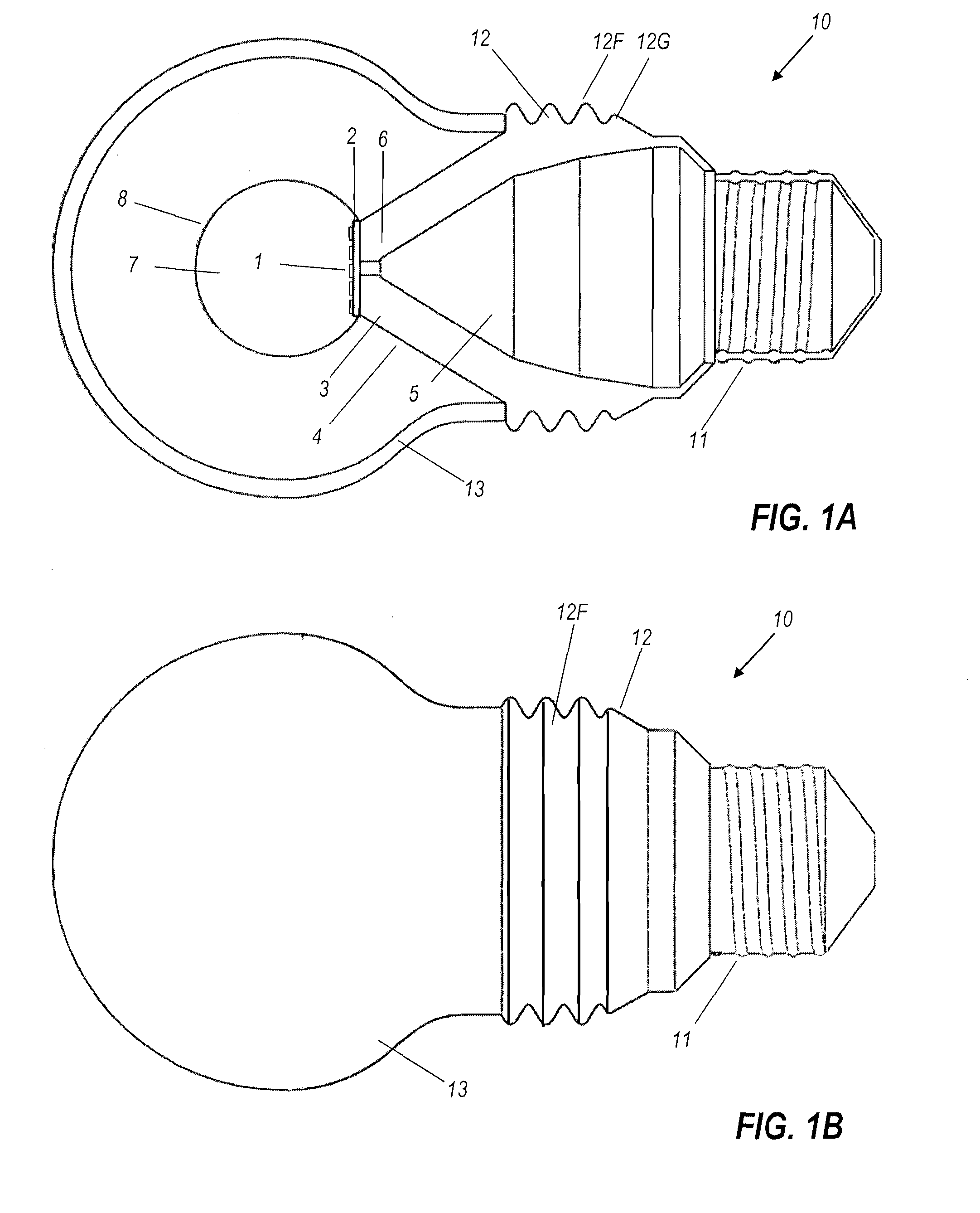

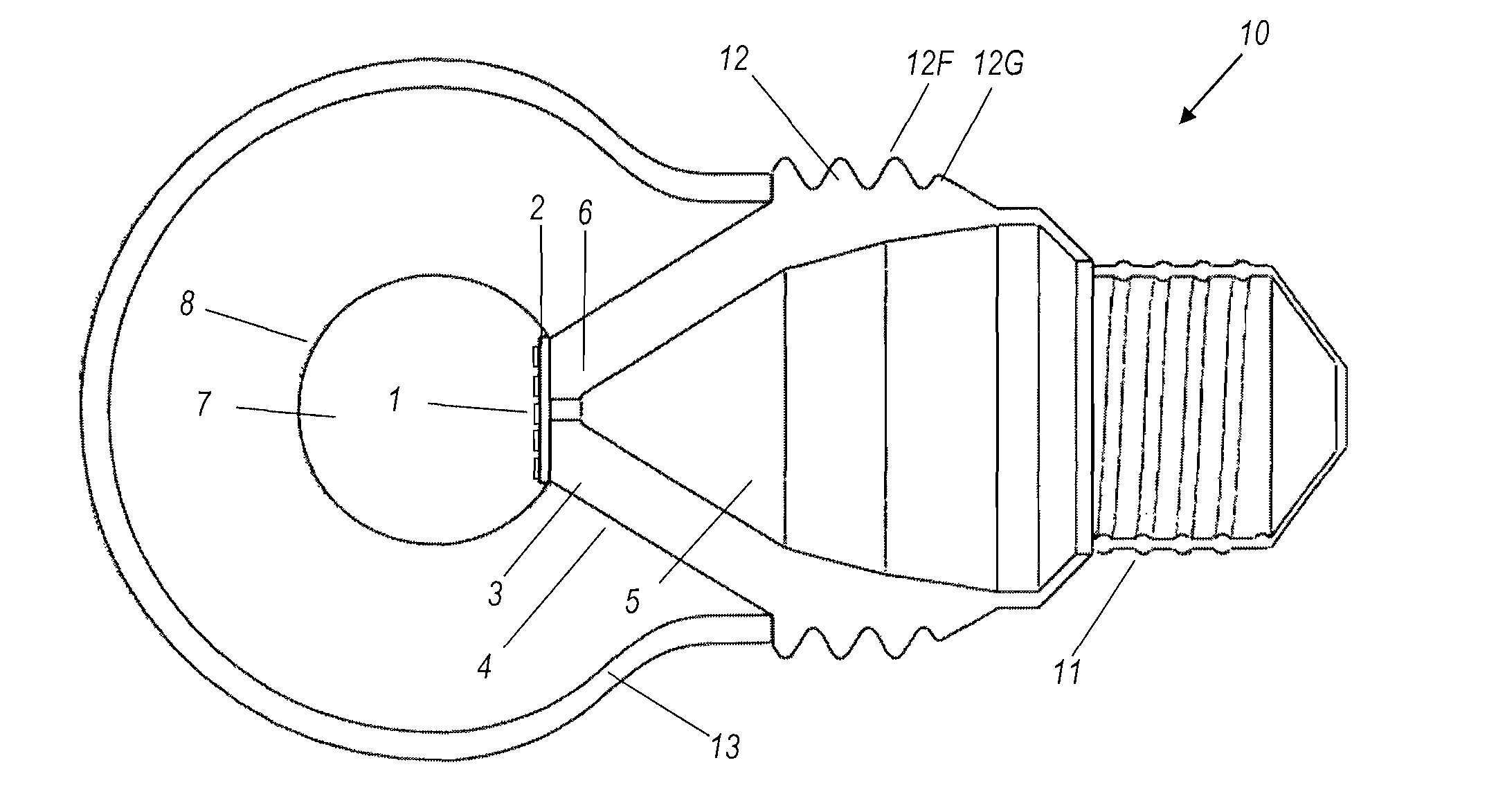

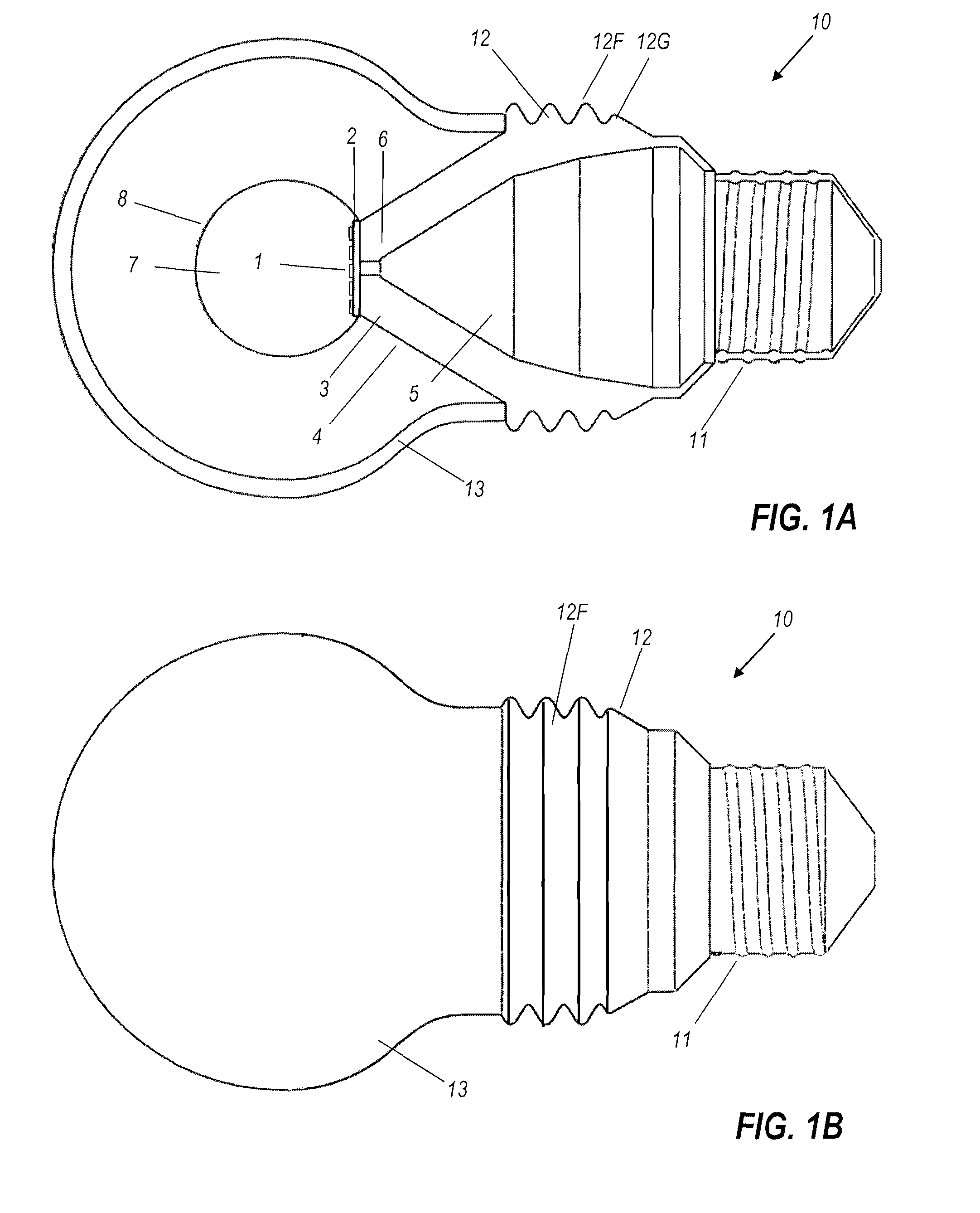

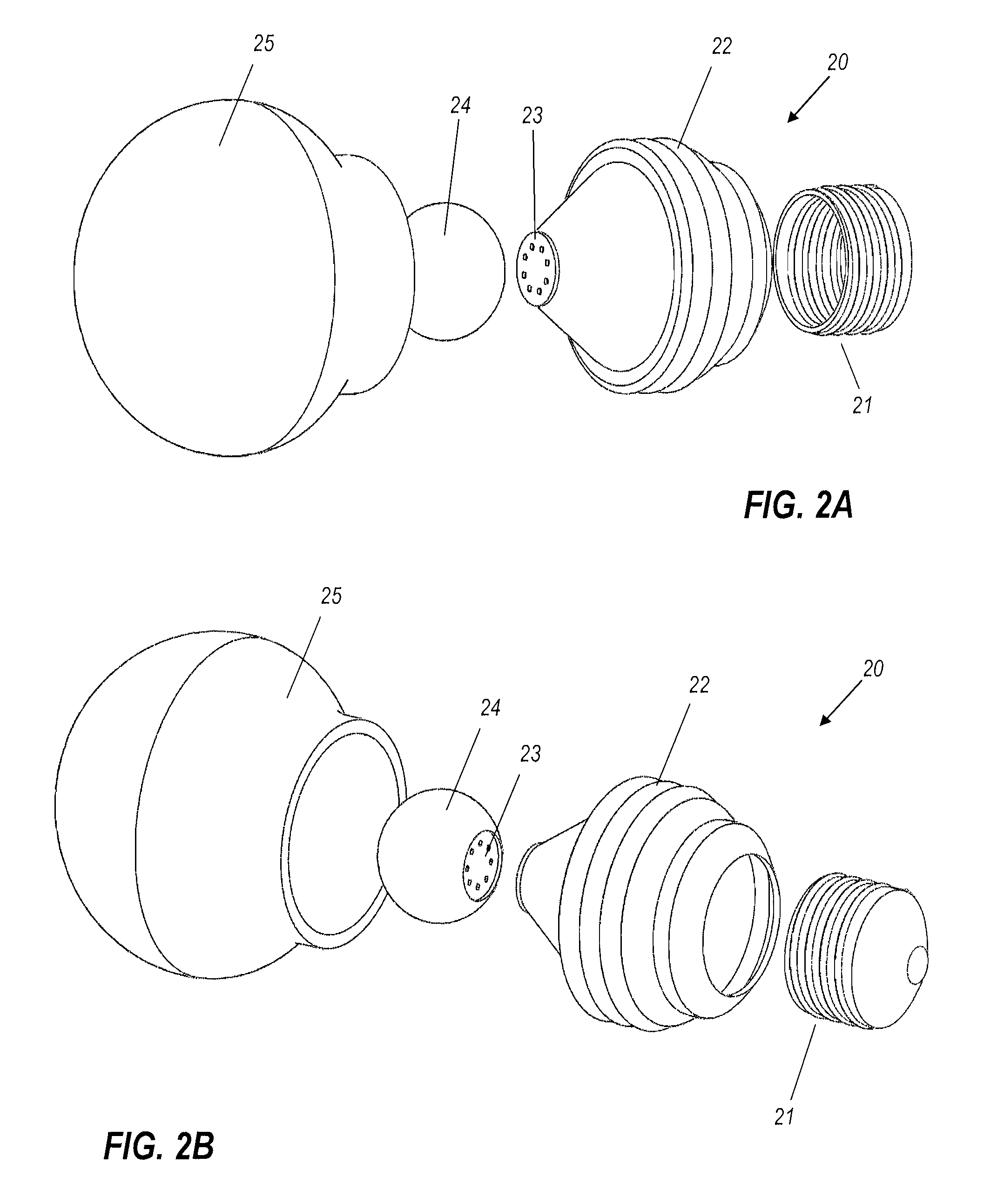

Solid-state light bulb

InactiveUS20110095686A1Reduce decreaseAvoid problemsLight source combinationsLighting support devicesHeat conductingLed array

An example of this light bulb has a light emitting element (which may be an LED array) mounted on a circuit board. The circuit board is mounted on one end of a heat-conducting frame. An Edison screw or other suitable connector, for attaching the light bulb electrically and mechanically to a receptacle, is mounted on the other end of the frame. A transparent phosphor-coated ball has a flat chord face optically bonded to said array. A light-permeable globular enclosure is mounted on the frame, surrounding the ball and both homogenizing the white light output of the bulb but also concealing the yellowing unlit appearance of the remote phosphor ball centrally located within it.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

Solid-state light bulb

InactiveUS8322896B2Reduce heat loadAccelerated dissipationLight source combinationsLighting support devicesPhosphorLed array

An example of this light bulb has a light emitting element (which may be an LED array) mounted on a circuit board. The circuit board is mounted on one end of a heat-conducting frame. An Edison screw or other suitable connector, for attaching the light bulb electrically and mechanically to a receptacle, is mounted on the other end of the frame. A transparent phosphor-coated ball has a flat chord face optically bonded to said array. A light-permeable globular enclosure is mounted on the frame, surrounding the ball and both homogenizing the white light output of the bulb but also concealing the yellowing unlit appearance of the remote phosphor ball centrally located within it.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

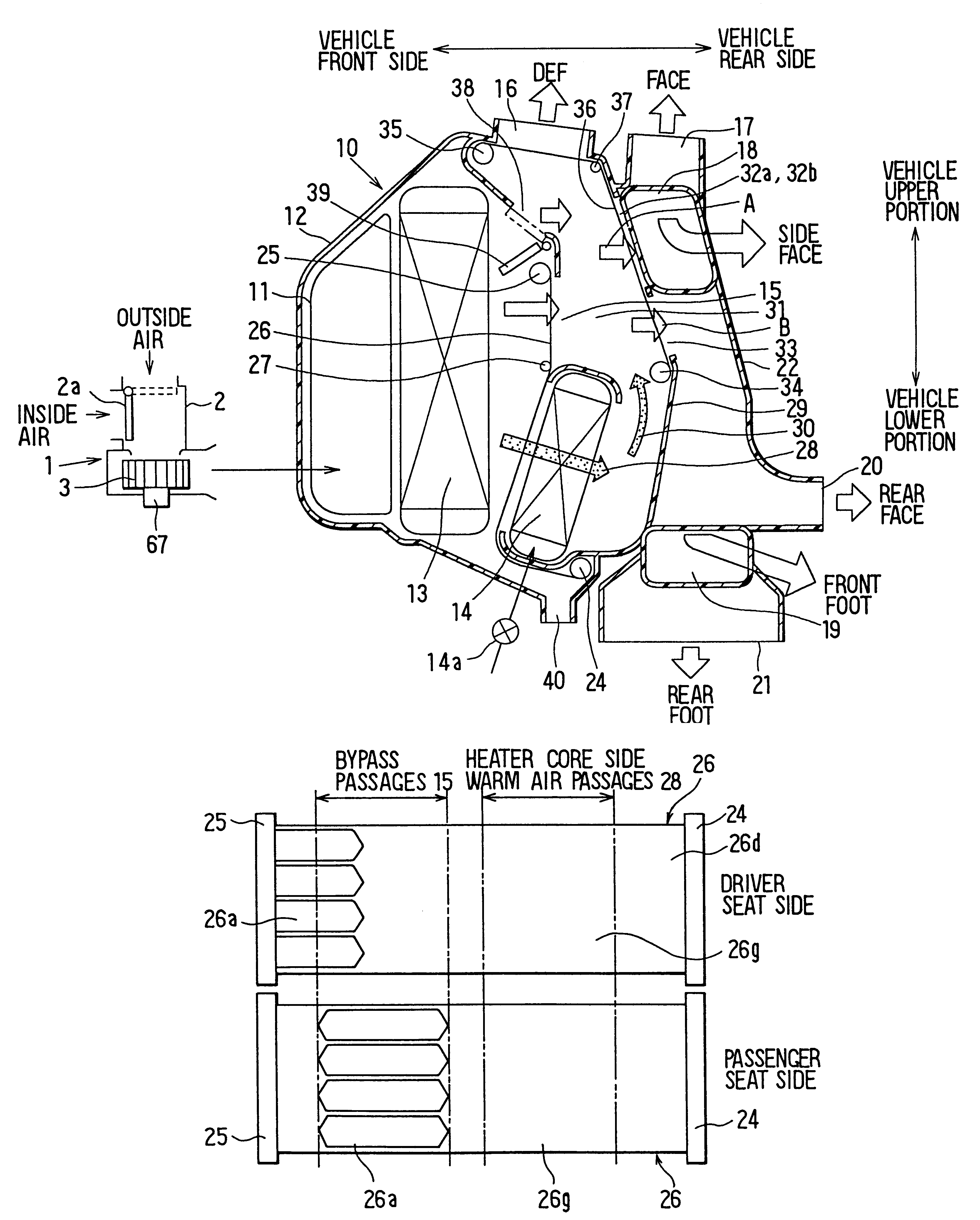

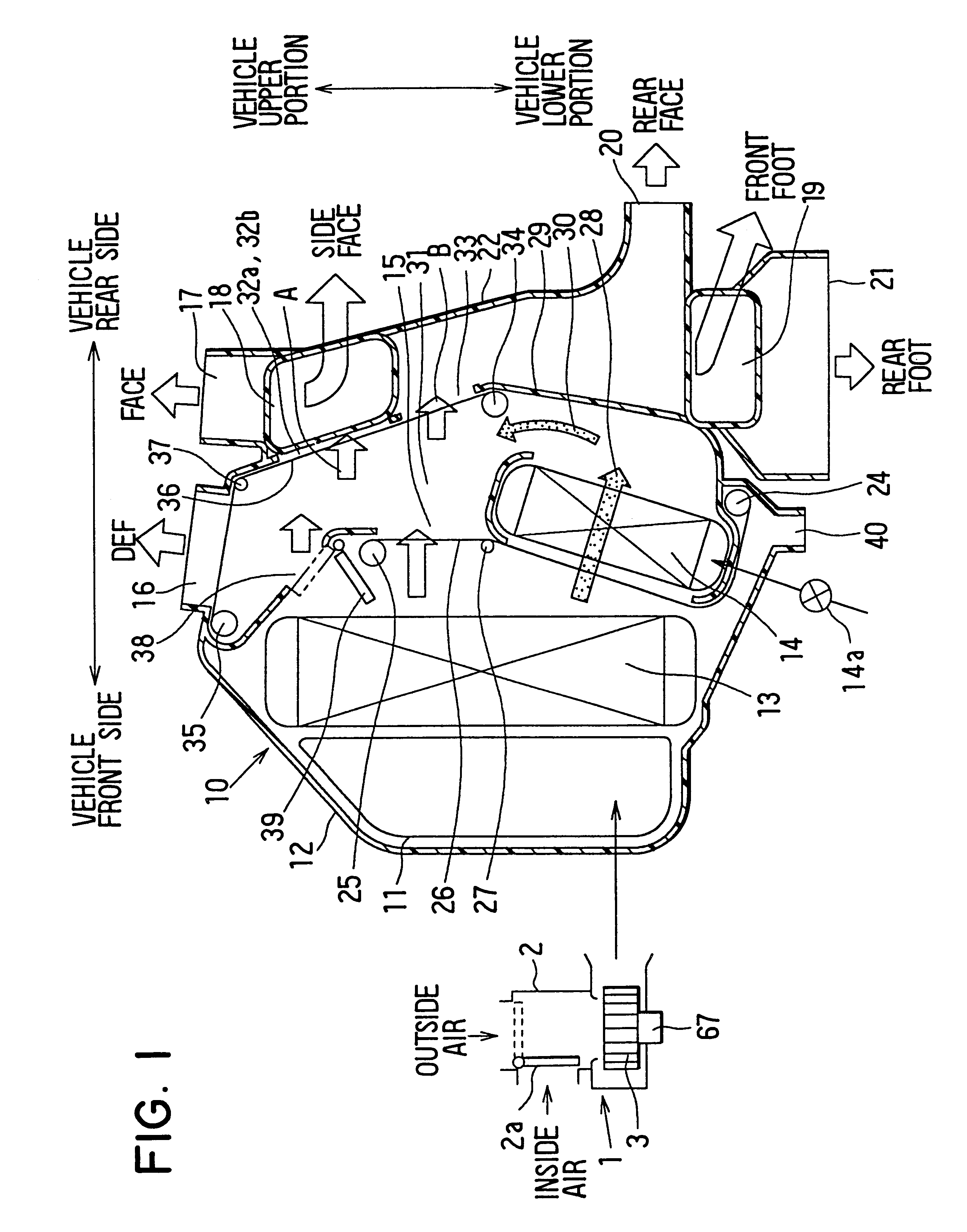

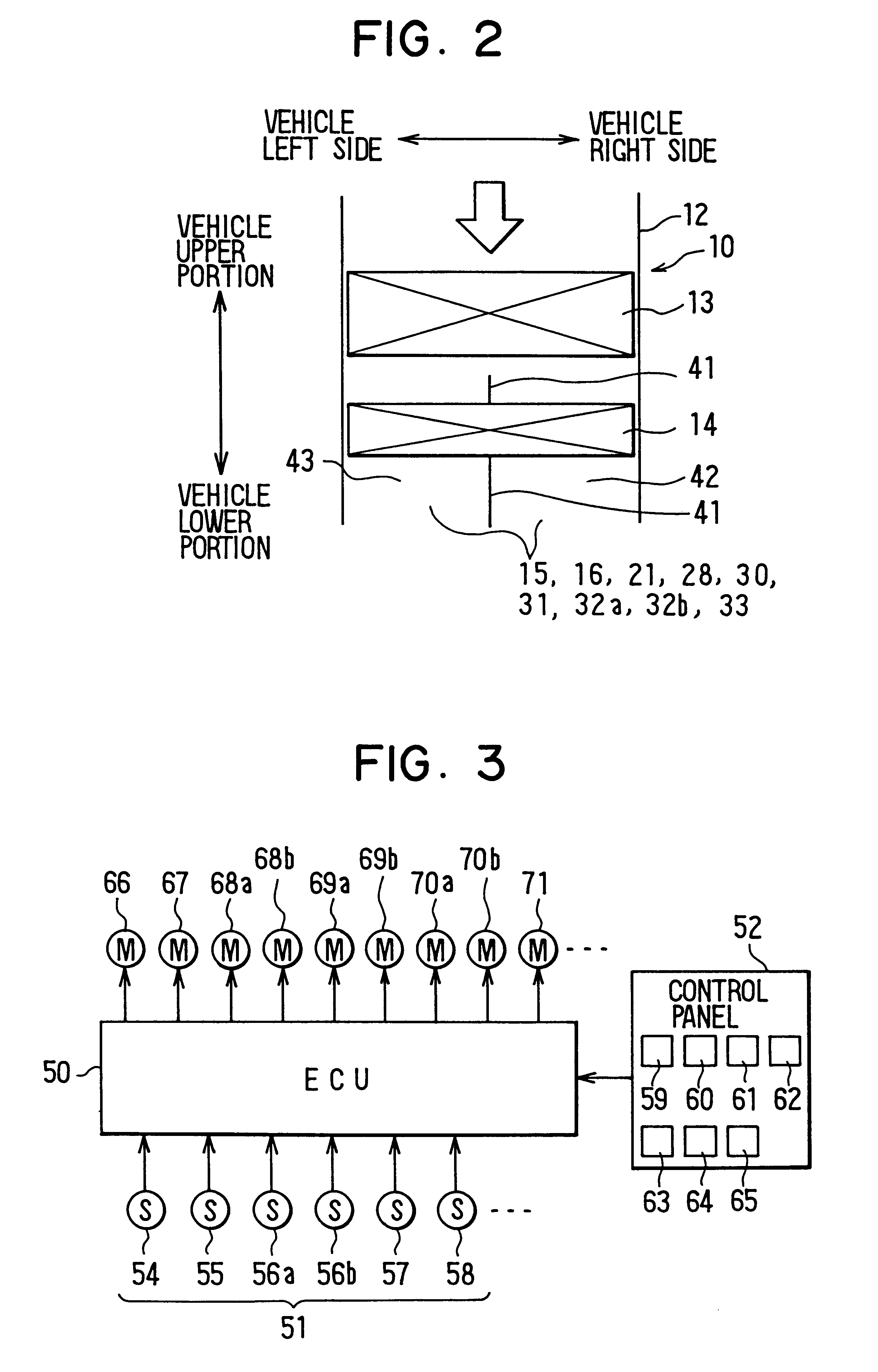

Vehicle air-conditioning system with independent left/right temperature control during maximum cooling

InactiveUS6293339B1Speed up the flowIncrease heat loadValve arrangementsAir-treating devicesDriver/operatorTraffic volume

A vehicle air-conditioning system that independently controls left-right air flow distribution in correspondence with left and right heat loads during a maximum cooling mode. In the system, blowout air flow is increased when driver seat side and passenger seat side air-mixing film members are both positioned in a maximum cooling position, and the heat load has risen in only one of a driver seat side space and a passenger seat side space in a passenger compartment. Further, each respective film member is operated to fully open a cool air bypass passage on the side on which the heat load has risen and the respective film member corresponding to the side on which the heat load has not risen significantly is operated to reduce the open area of the cool air bypass passage. At the same time, fan speed is increased to increase the air blow amount.

Owner:DENSO CORP

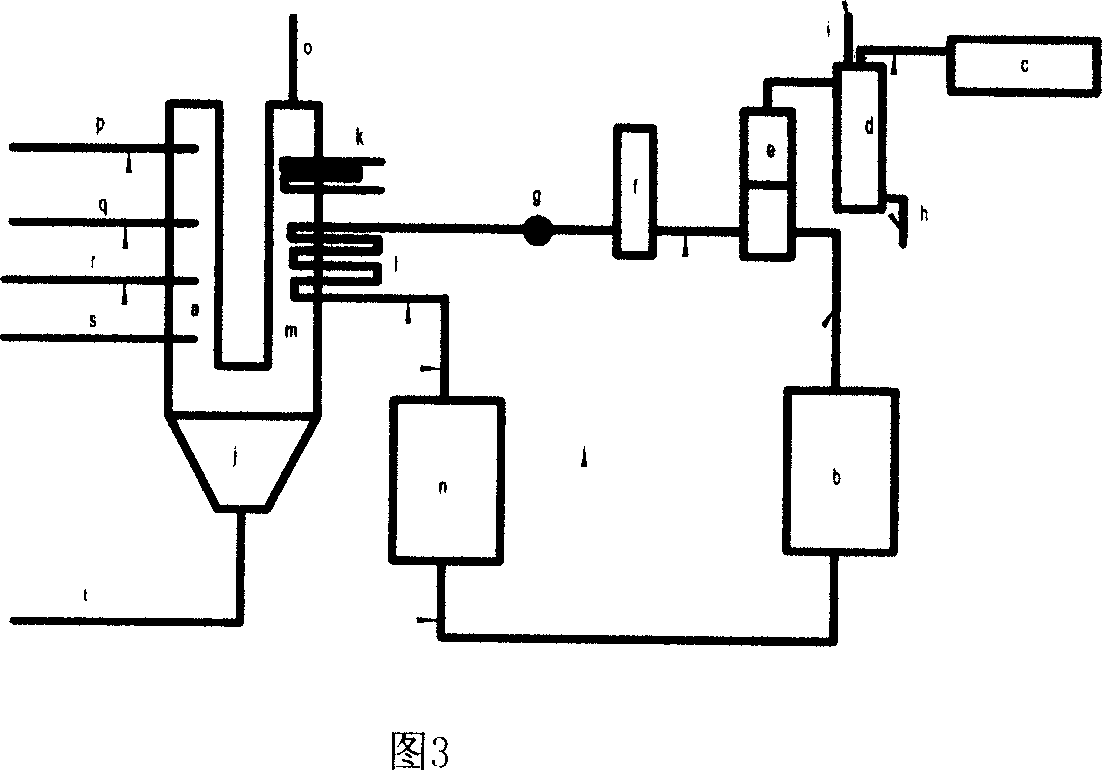

Sludge drying and incinerating treatment process

InactiveCN1931753AAvoid pollutionAvoid harmSludge treatment by oxidationByproduct vaporizationChemical compositionSludge

The present invention relates to environmental protection engineering technology, and is especially sludge drying and incinerating treatment process. The present invention has effective utilization of heat energy, no exhaust of harmful gas and bad smell, no exhaust of dangerous clinker, simple structure and high burning efficiency of the sludge incinerating system, no need of auxiliary fuel and other advantages.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

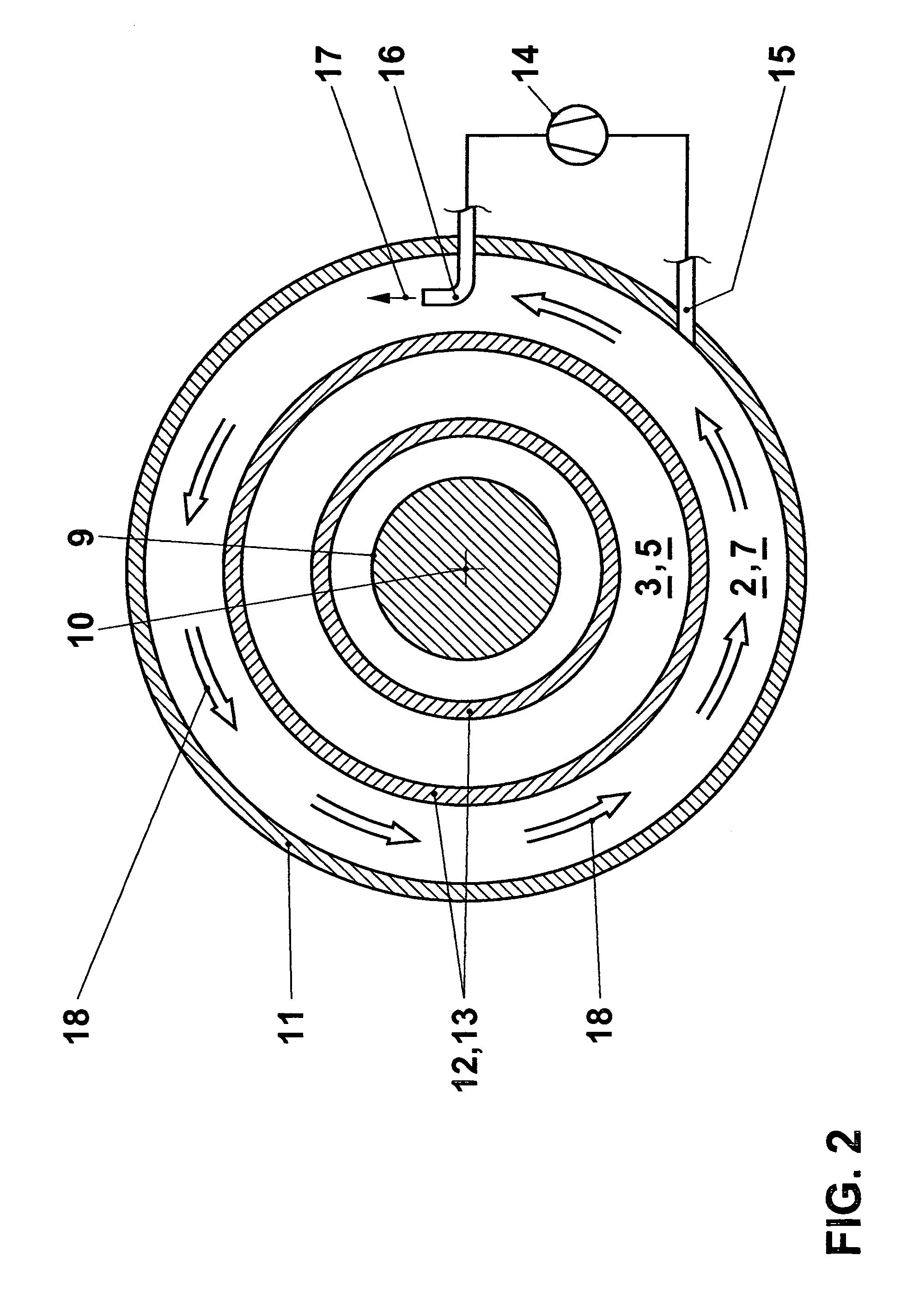

Cooling system of ring segment and gas turbine

ActiveUS20110044805A1Reduce the amount requiredImprove gas efficiencyPump componentsEngine fuctionsCombustionGas turbines

A cooling system of ring segment is provided with: a collision plate that has a plurality of small holes; a cooling space that is enclosed by the collision plate and a main body of the segment body; a first cavity that arranged is the upstream end portion of the segment body in the flow direction of the combustion gas so as to be perpendicular to the axial direction of a rotating shaft; a first cooling passage that communicates from the cooling space to the first cavity; and a second cooling passage that communicates from the first cavity to a fire combustion gas d gas space in the downstream end portion of the segment body in the flow direction of the combustion gas.

Owner:MITSUBISHI HEAVY IND LTD

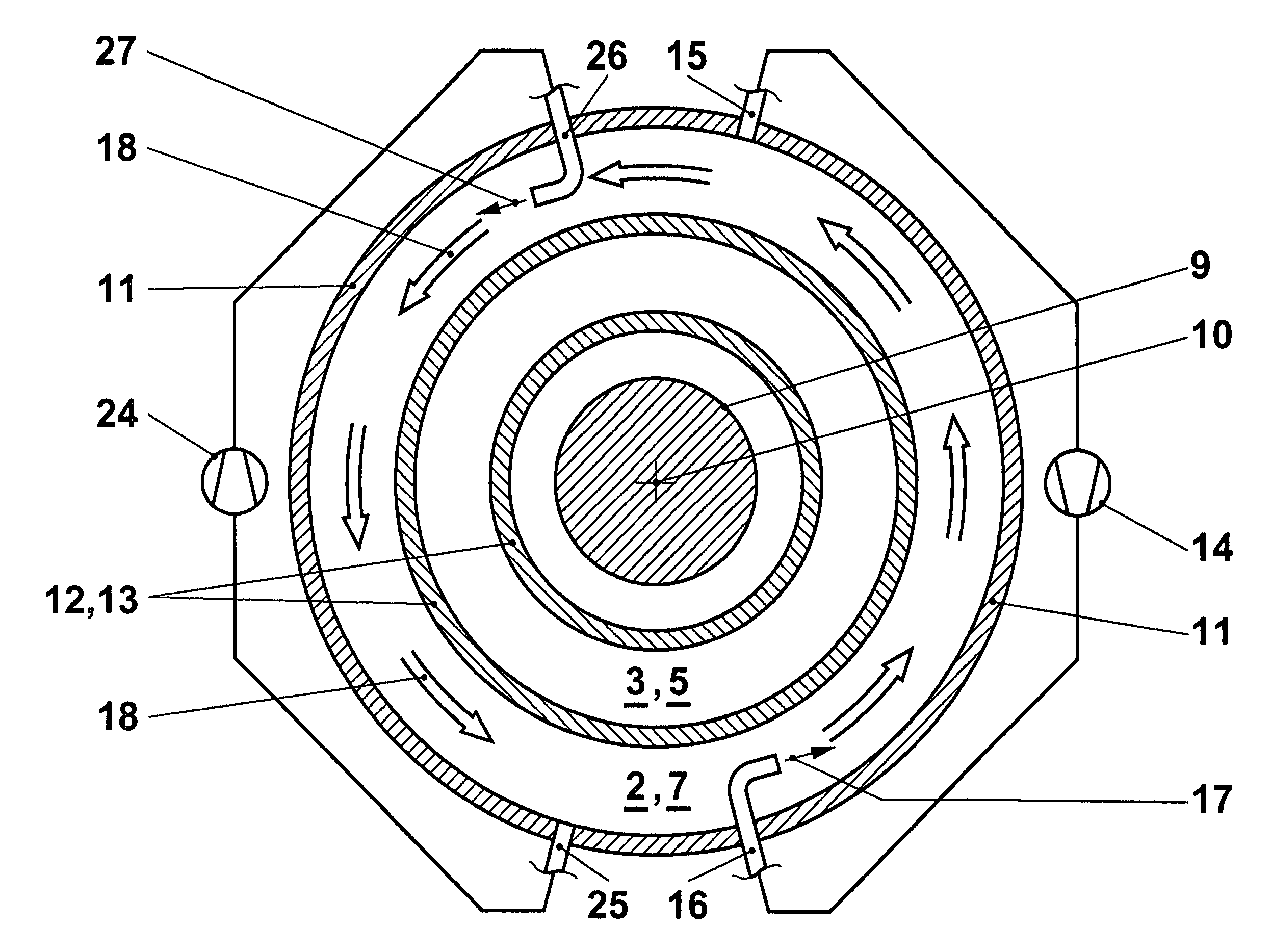

Cabinet cooling

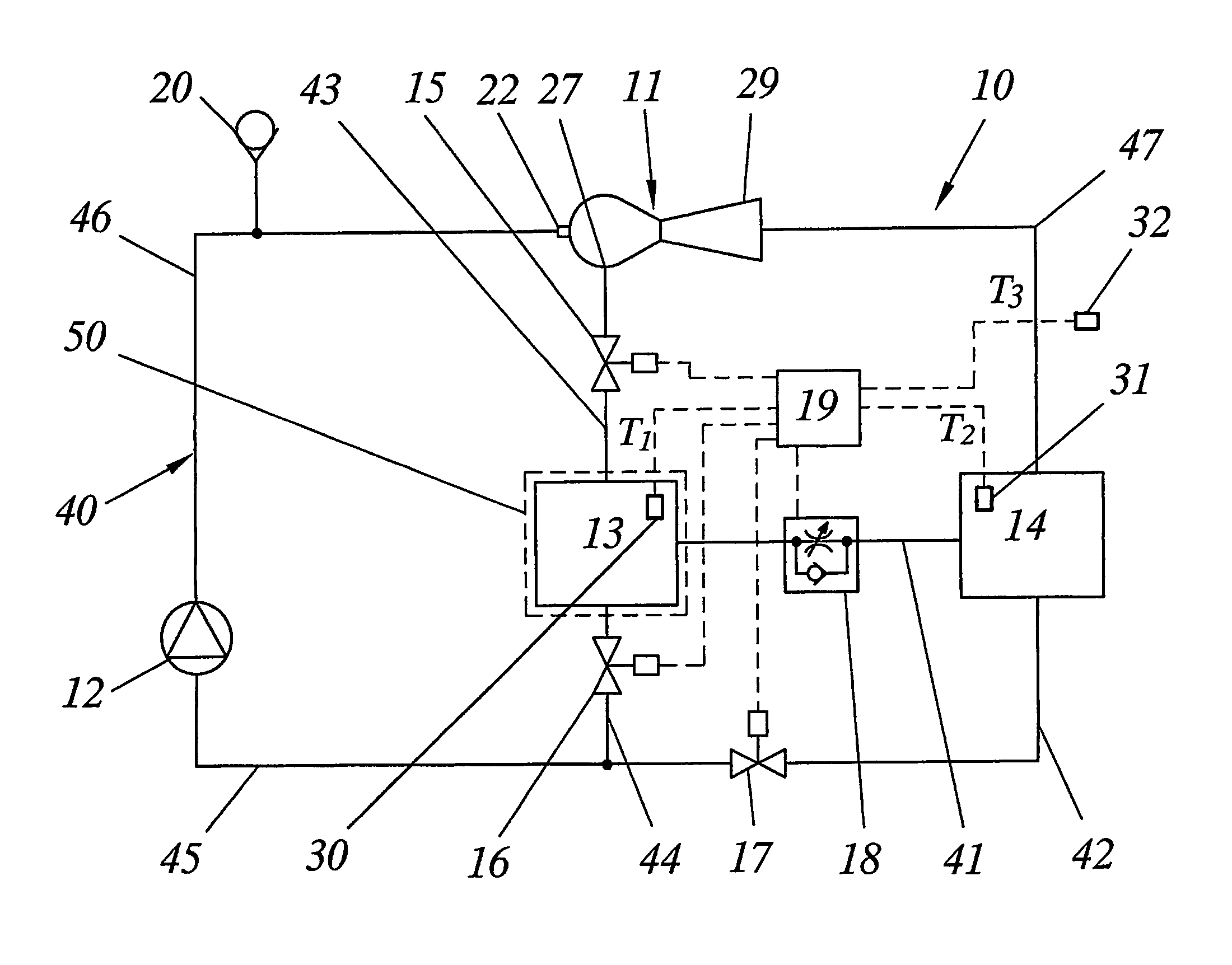

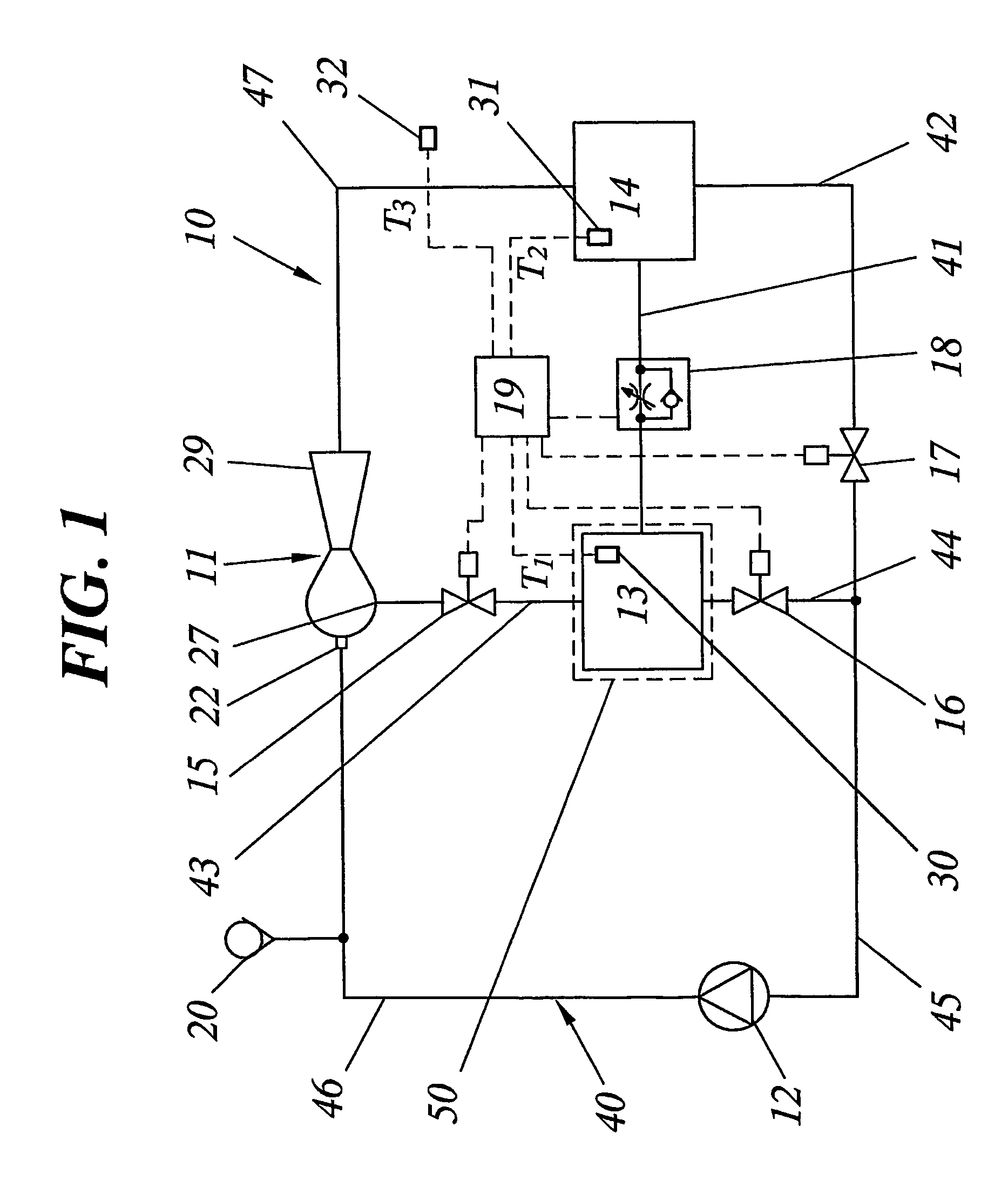

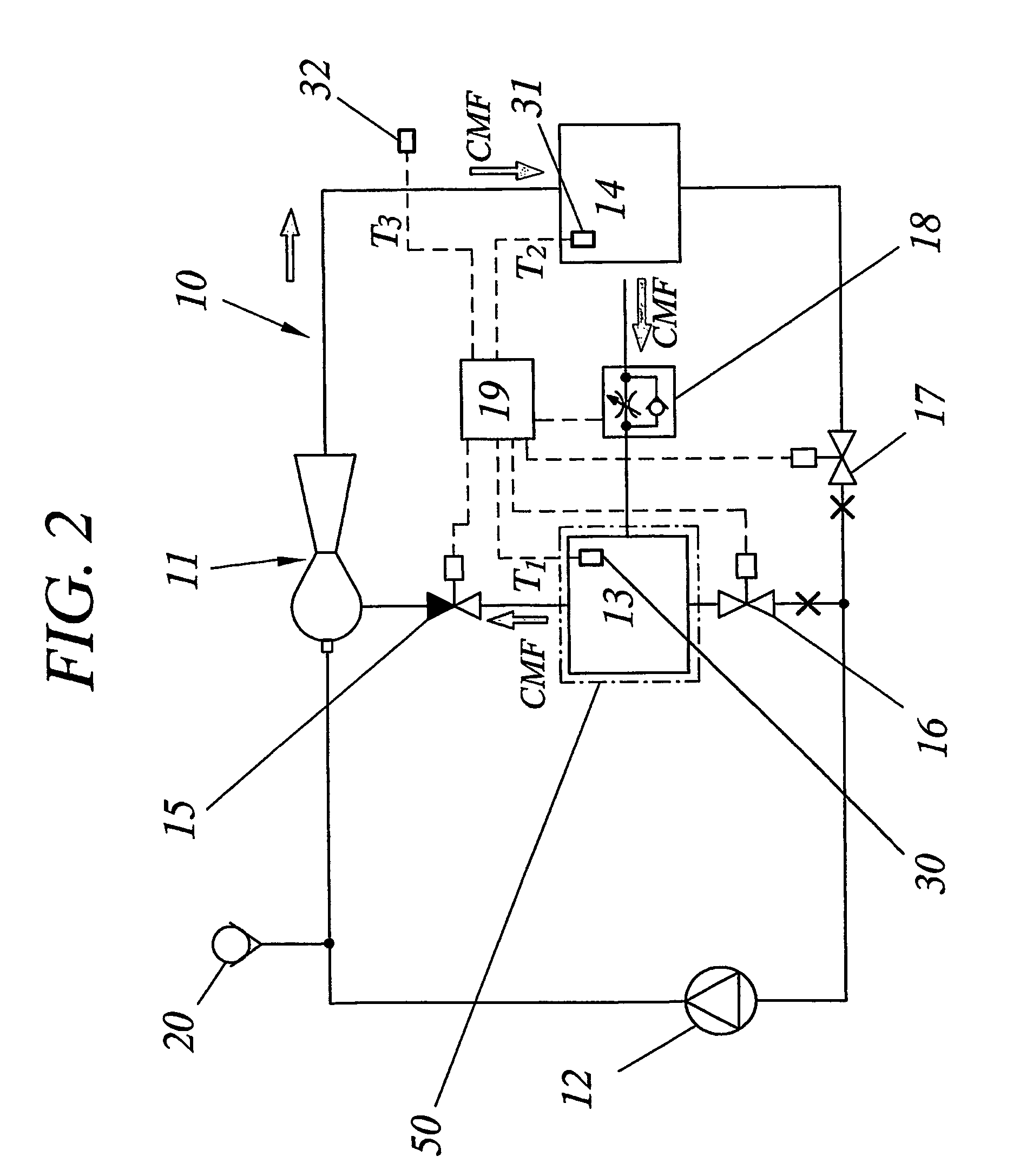

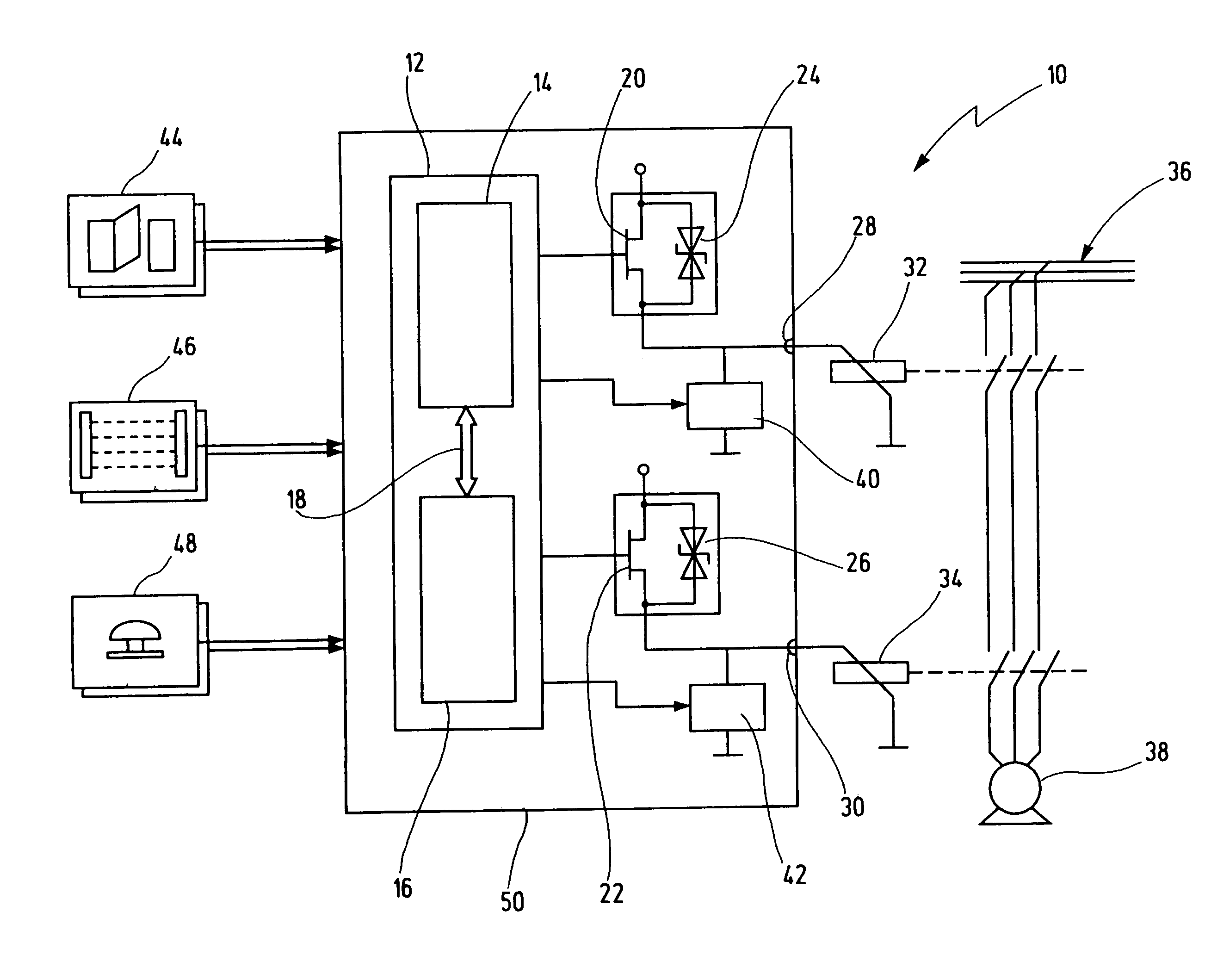

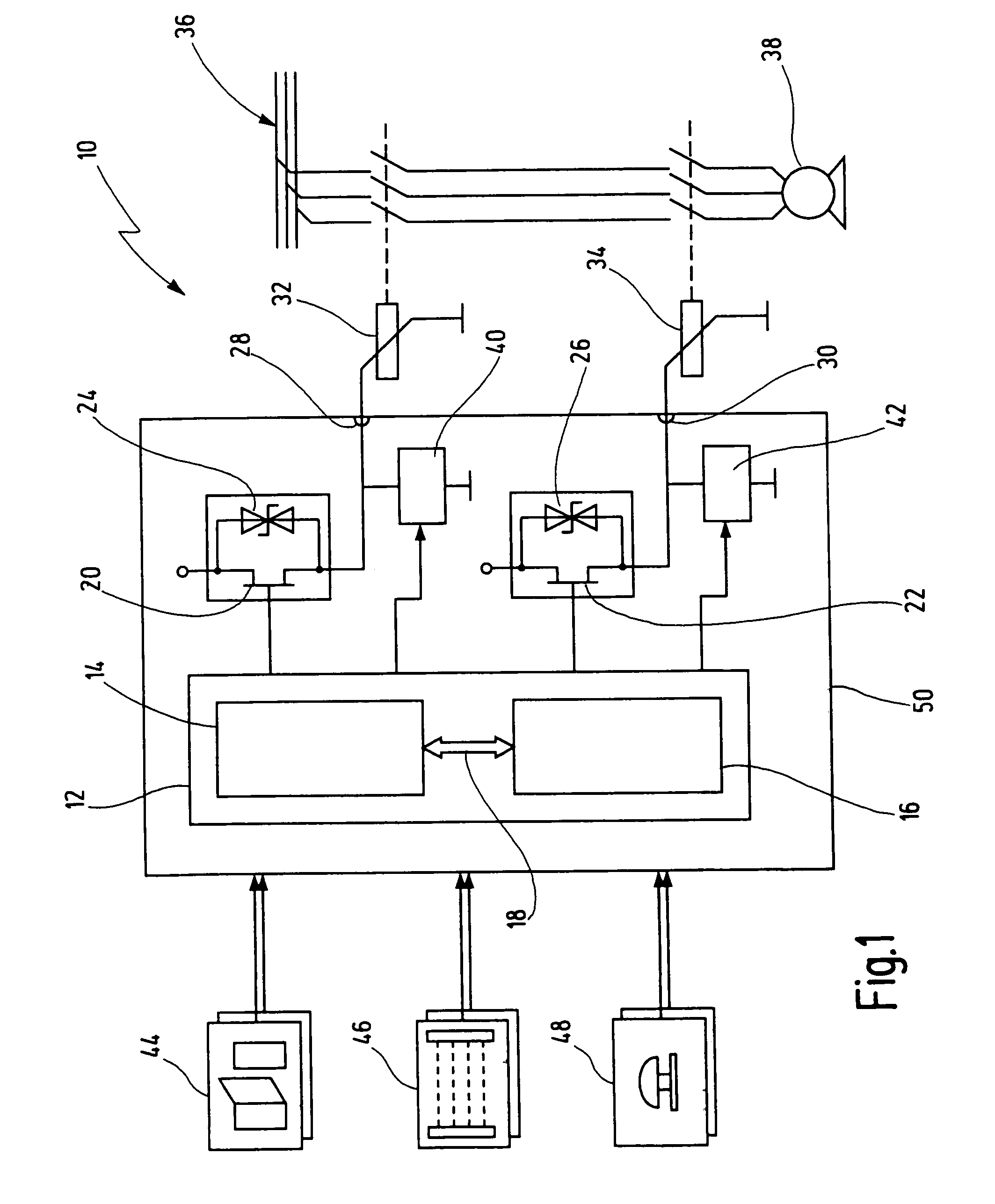

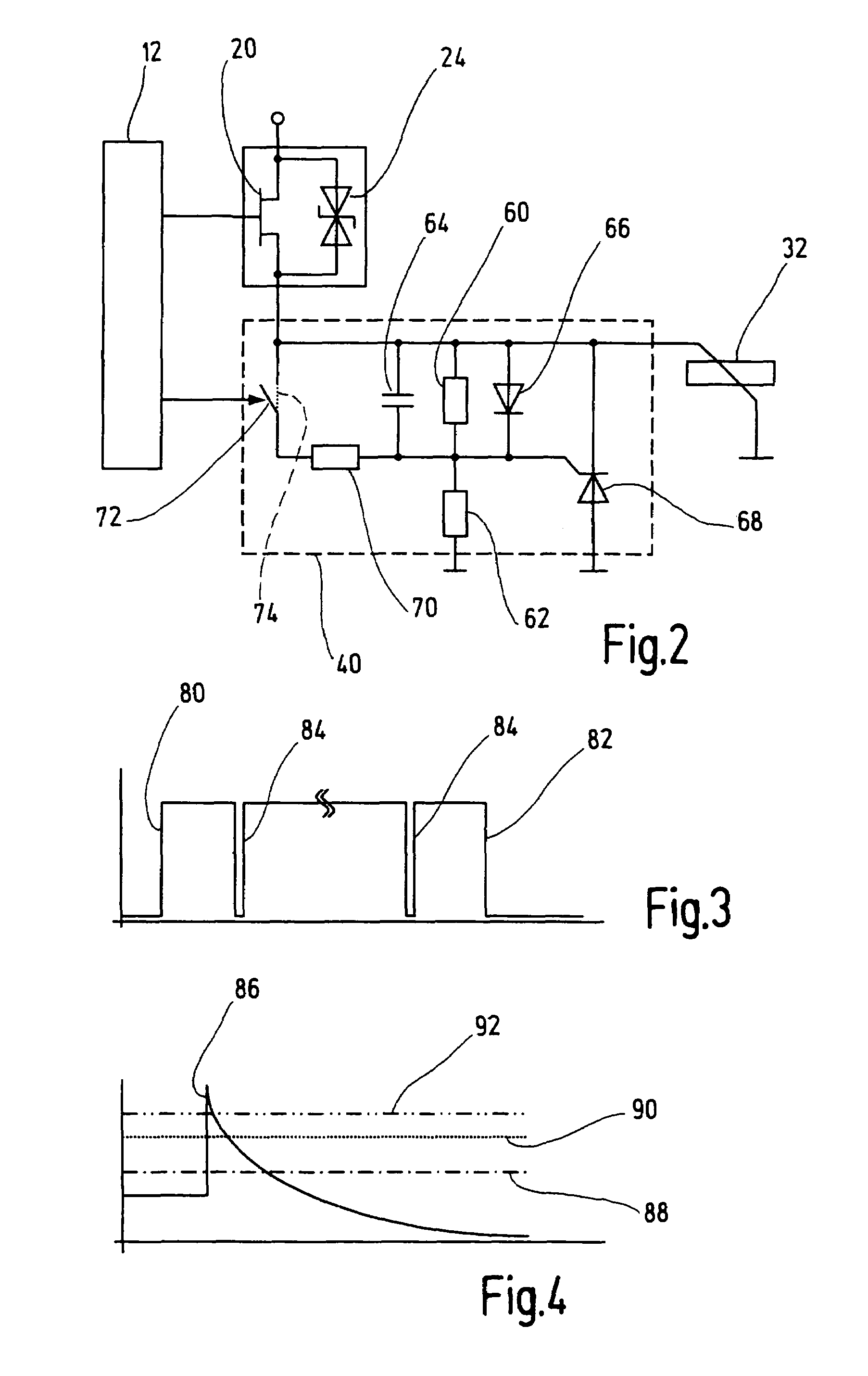

InactiveUS7061763B2Dissipating electronic componentsIncrease heat loadMechanical oscillations controlDomestic cooling apparatusElectronics coolingControl system

A novel electronics cooling method and system is disclosed. A very flexible and efficient operation of an electronics cooling system (10) is achieved by controlling circulation of a cooling medium in a closed system (40) containing an evaporator (13), a condenser (14), an ejector (11) and control valves (15–18). Specifically, the system is continuously allowed to operate in the most appropriate mode by controlling the valves (15–18) of the system (10) based on detected heat load and / or detected heat transfer conditions. By automatically adapting the mode of operation of the system based on the actual prevailing conditions, a unique flexibility is obtained with regard to the cooling mode in which the system will be operated. This means that the cooling capacity will be constantly optimized and that the investment cost as well as the cost for operating the system will be reduced compared to known systems having equal maximum cooling capacity.

Owner:TELEFON AB LM ERICSSON (PUBL)

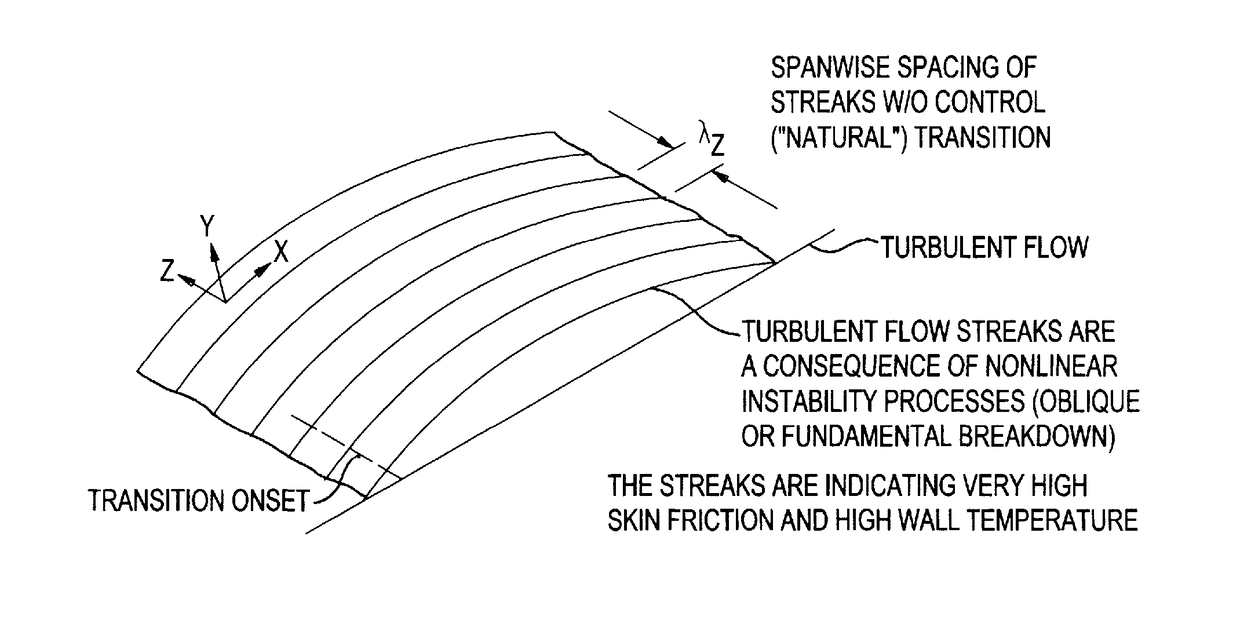

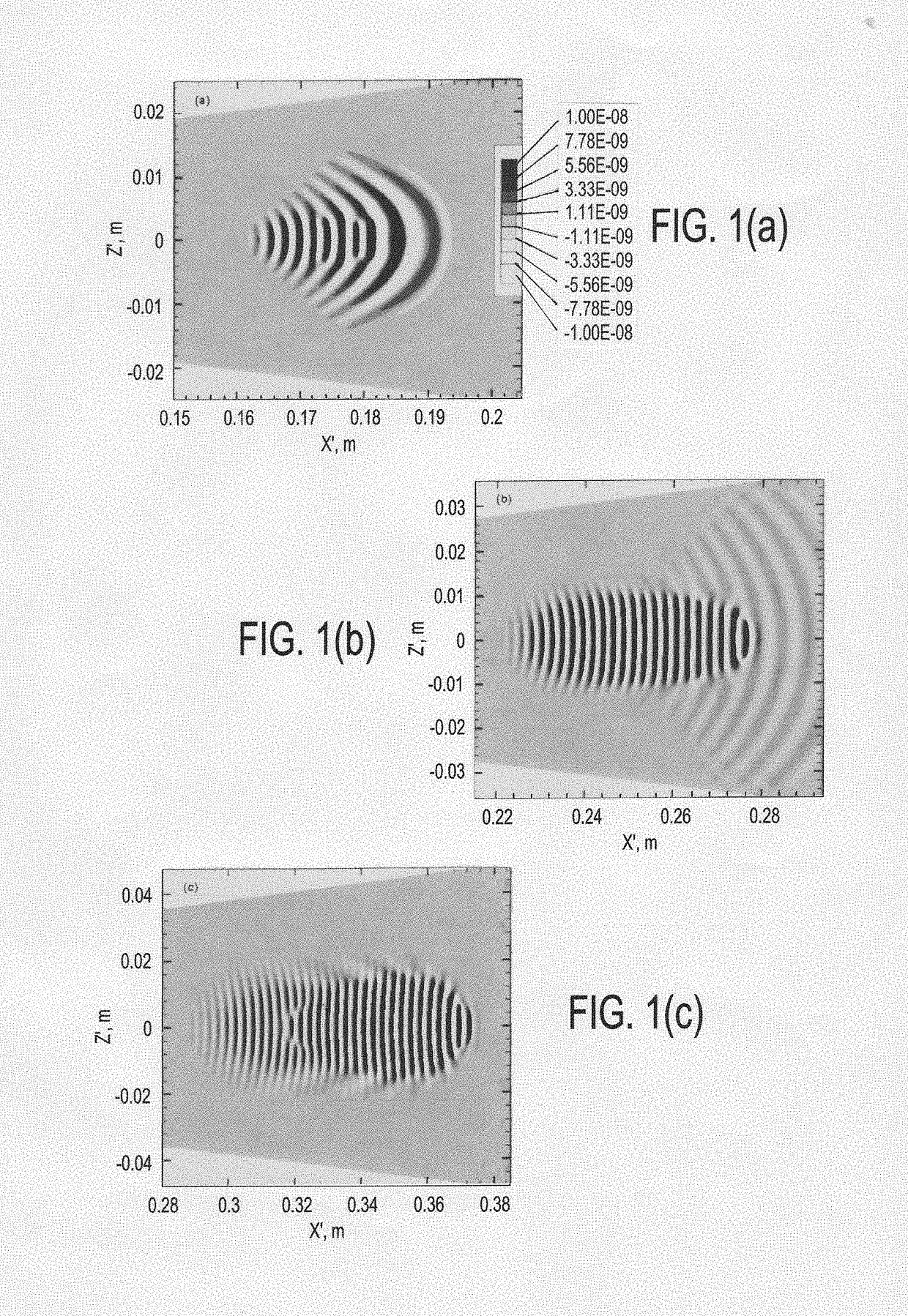

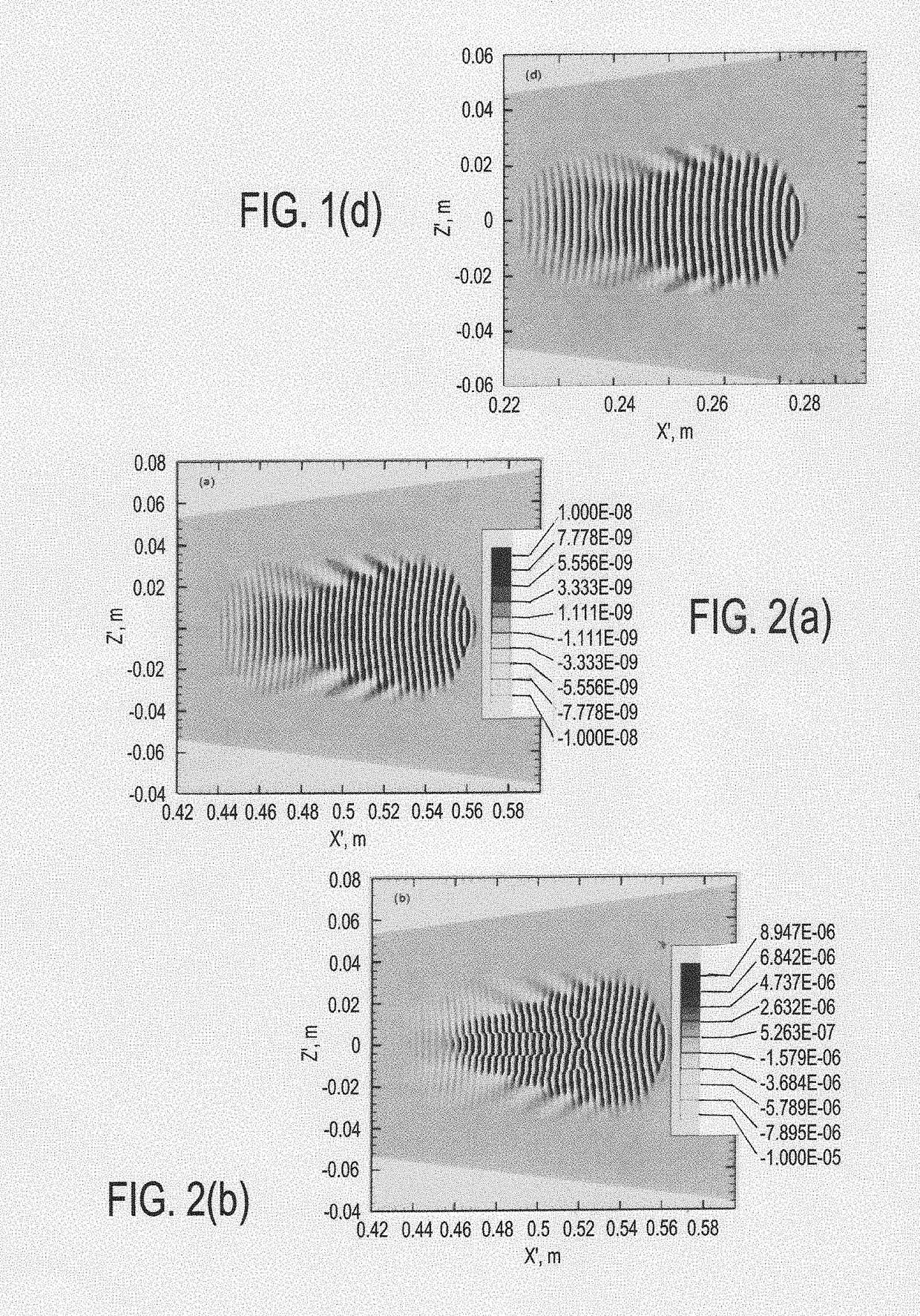

Control of hypersonic boundary layer transition

ActiveUS20170240271A1Increase frictionAffect performanceInfluencers by generating vorticesBoundary layer controlsSpeed of soundThermal protection

A system and method for controlling hypersonic boundary layer transition for a hypersonic flight vehicle are disclosed. The reduction or elimination of hot streaks that naturally occurs in the boundary layer transition process during hypersonic flight is achieved by utilizing various techniques. One such technique utilizes roughness elements to counteract streak development. The techniques for reducing or eliminating the streaks are tailored such that the nonlinear stages of transition are profoundly altered. This results in significant drag reduction, and consequently an increase in range of the vehicle, and also a reduction of the weight penalty due to the Thermal Protection Systems (TPS) as less protective material would be required, thus allowing for an increased payload and / or range of the vehicle.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

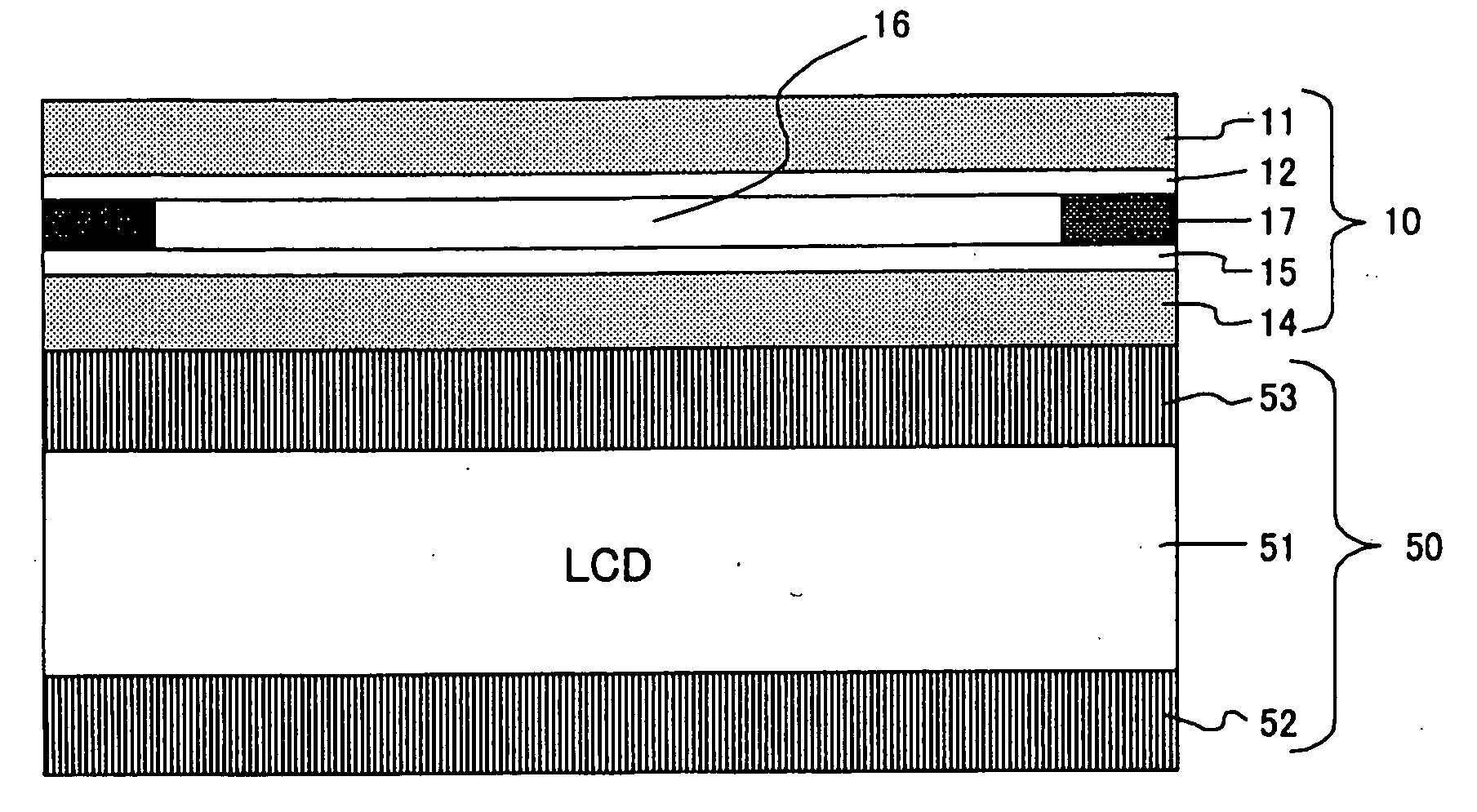

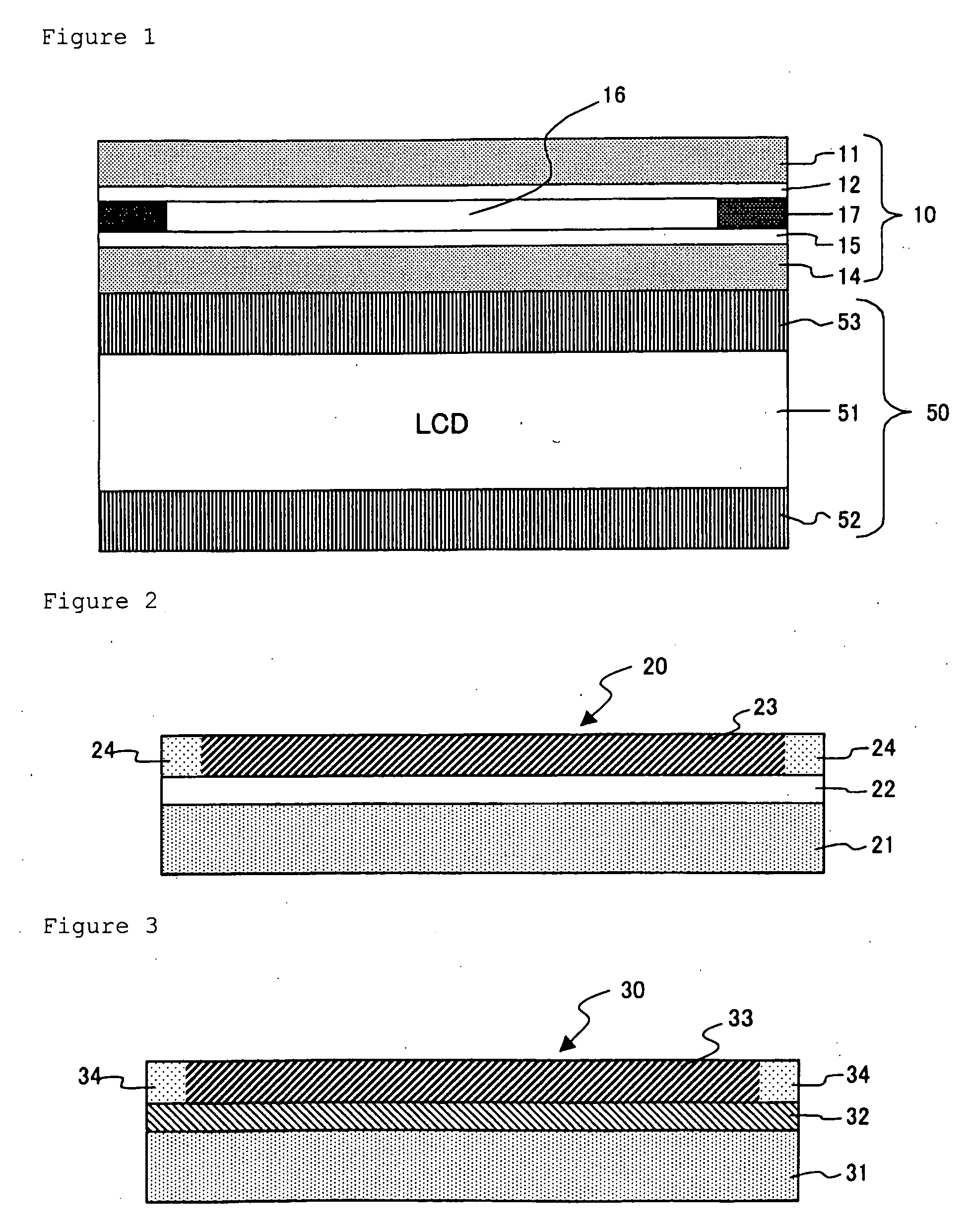

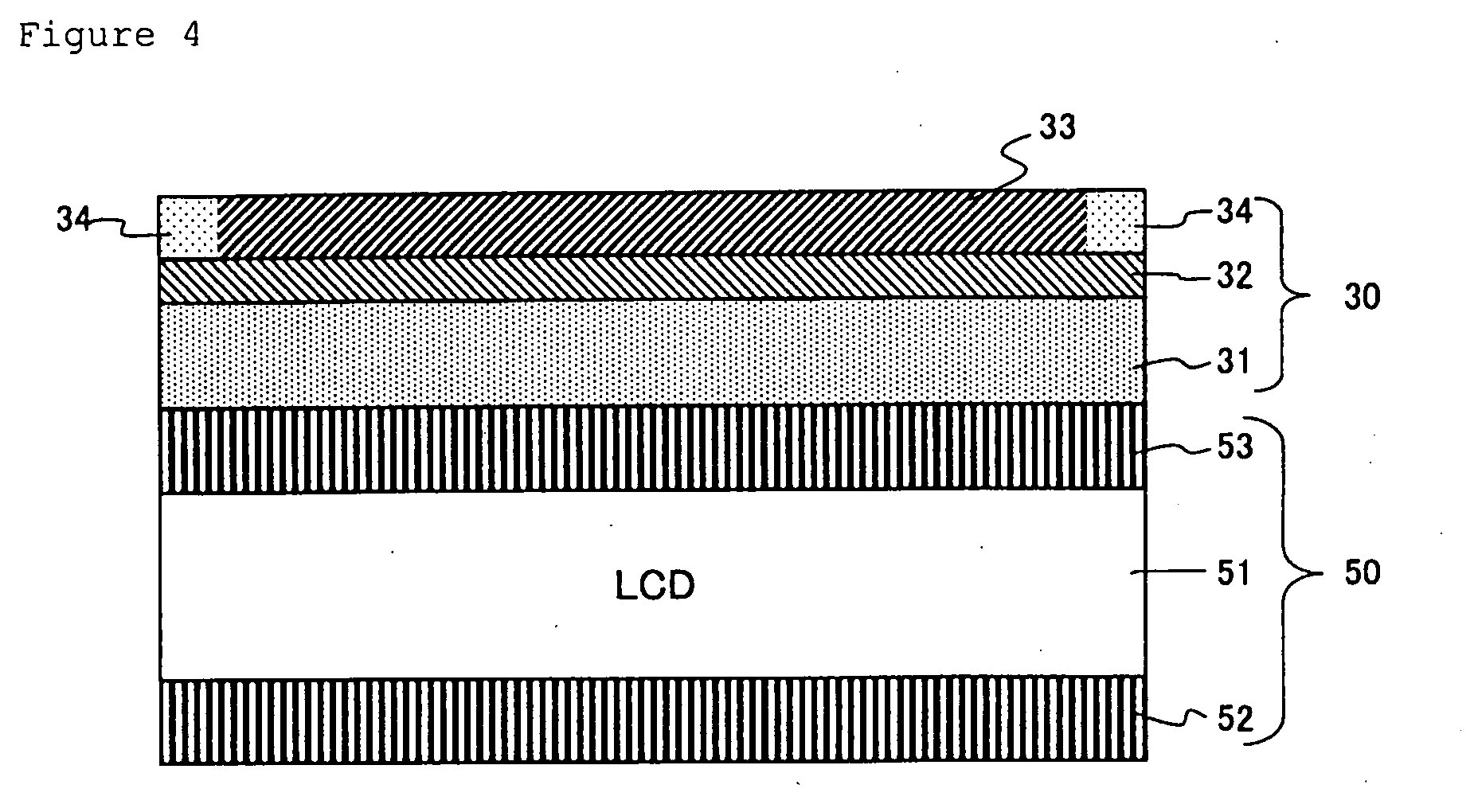

Capacitive touch panel, manufacturing method therefor and liquid crystal display apparatus provided with the touch panel

InactiveUS20100164896A1Low costImprove performanceLaminationLamination apparatusIndiumLiquid-crystal display

A capacitive touch panel, which is capable of providing high quality display, without a problem of position detection, even in the case where a production process with lower cost and higher heat load is adopted, by application of a transparent conductive film with high heat resistance; a manufacturing method therefor, and a liquid crystal display apparatus.A capacitive touch panel having a structure where at least a transparent conductive film and a dielectric layer are laminated onto a transparent substrate, and a member for position detection comprising at least a wiring portion for position detection along with a electrodes for position detection is arranged at said substrate frame portion, characterized in that the transparent conductive film is composed of an oxide having indium oxide as a main component and containing gallium and tin; and this is provided by a method for producing a capacitive touch panel, characterized in that after forming an amorphous transparent conductive film composed of an oxide having indium oxide as a main component and containing gallium and tin onto the transparent substrate or the like.

Owner:SUMITOMO METAL MINING CO LTD

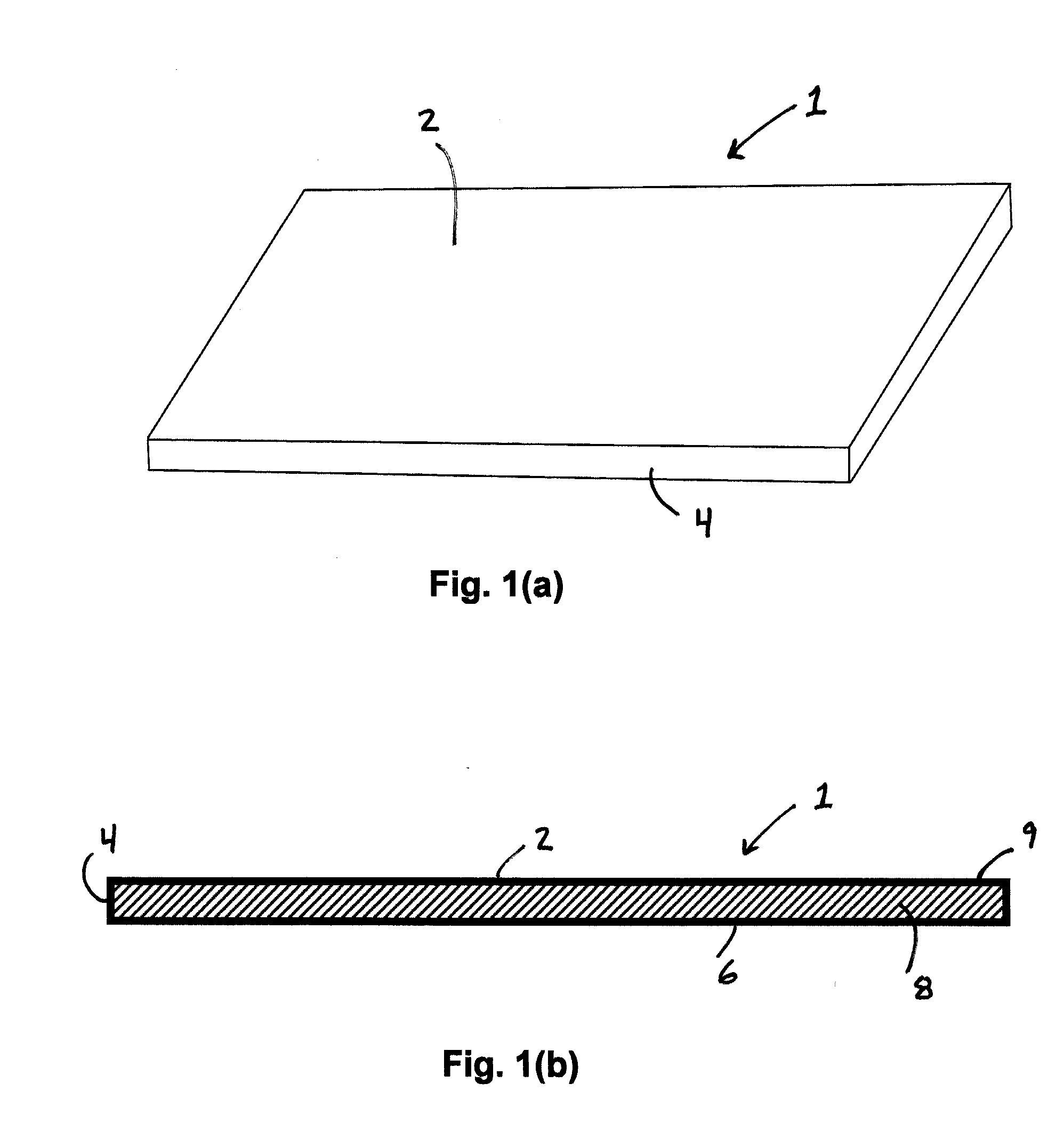

Container insert incorporating thermally insulative panels

InactiveUS20090001086A1Improve thermal performanceReduce the amount requiredDomestic cooling apparatusLighting and heating apparatusBackplaneEngineering

A container insert for providing a thermally insulated enclosure. The container insert includes a bottom panel, side panels and end panels that are interconnected by a plastic backing sheet. The side panels and end panels can be pivoted upwardly to form side walls and end walls. The plastic backing sheet covers the seams between adjacent insulation panels to provide a moisture barrier. The plastic backing sheet can also urge adjacent panels together to reduce the gap between adjacent panels and improve thermal performance.

Owner:NANOPORE INC

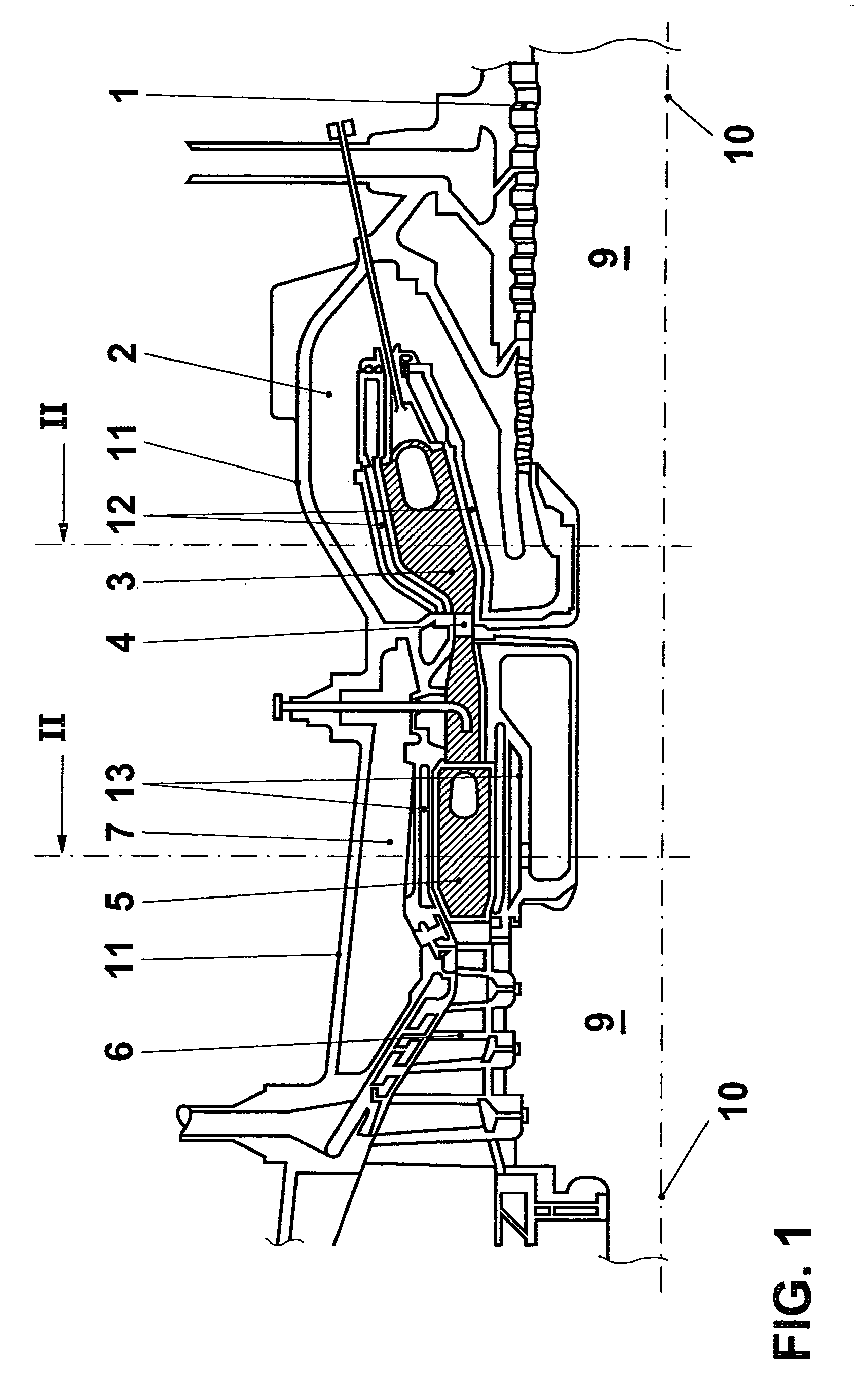

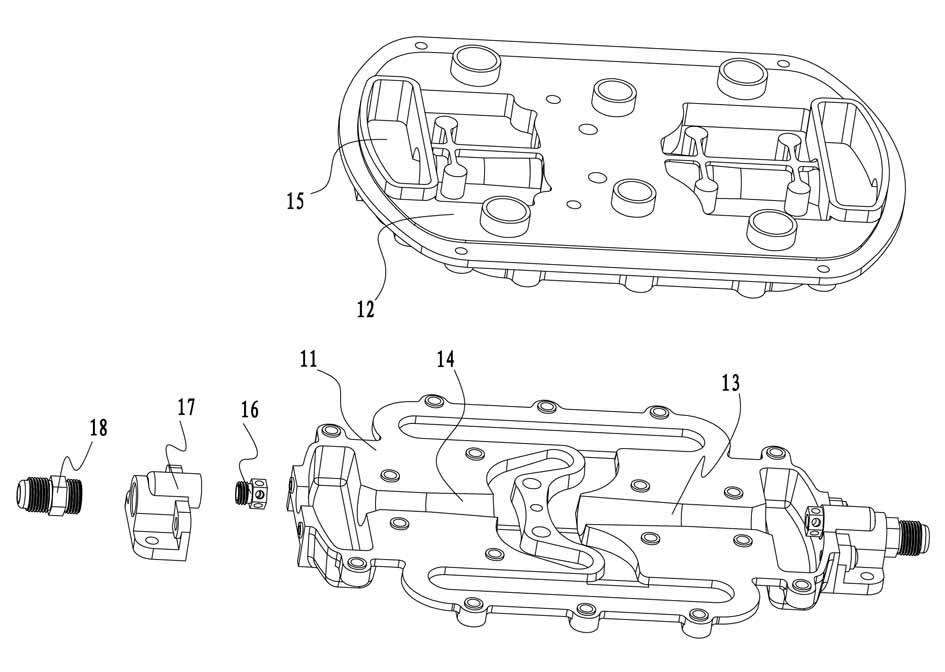

Cylinder head for an internal combustion engine

ActiveUS20100083920A1High strengthCompact structureCylinder headsSilencing apparatusCylinder headEngineering

A cylinder head adapted to be mounted to a cylinder block of an internal combustion engine has a cooling jacket at least partially integrated in the cylinder head. The engine has two groups of cylinders: inside cylinders and outside cylinders. Each cylinder has at least one exhaust port, each leading to an individual duct. Individual ducts of outside cylinders converge to form an outside combined duct. In a four-cylinder, individual ducts of inside cylinders converge to form an inside combined duct with the inside combined duct remaining separated from the outside combined duct by the cooling jacket. The inside combined duct is farther away from the mounting surface of the cylinder head to the cylinder block than the outside combined duct. The cooling jacket includes: upper, middle, and lower cooling jackets and connectors between the upper and lower cooling jackets.

Owner:FORD GLOBAL TECH LLC

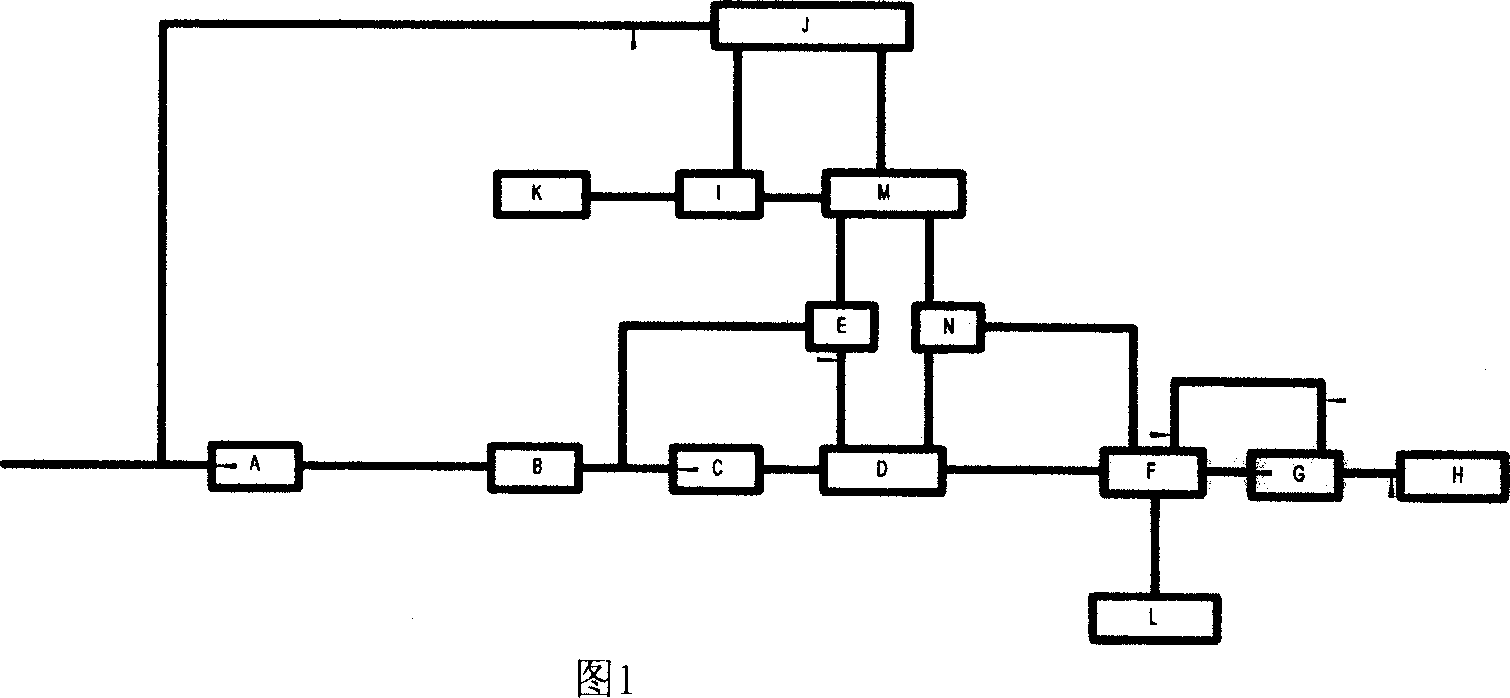

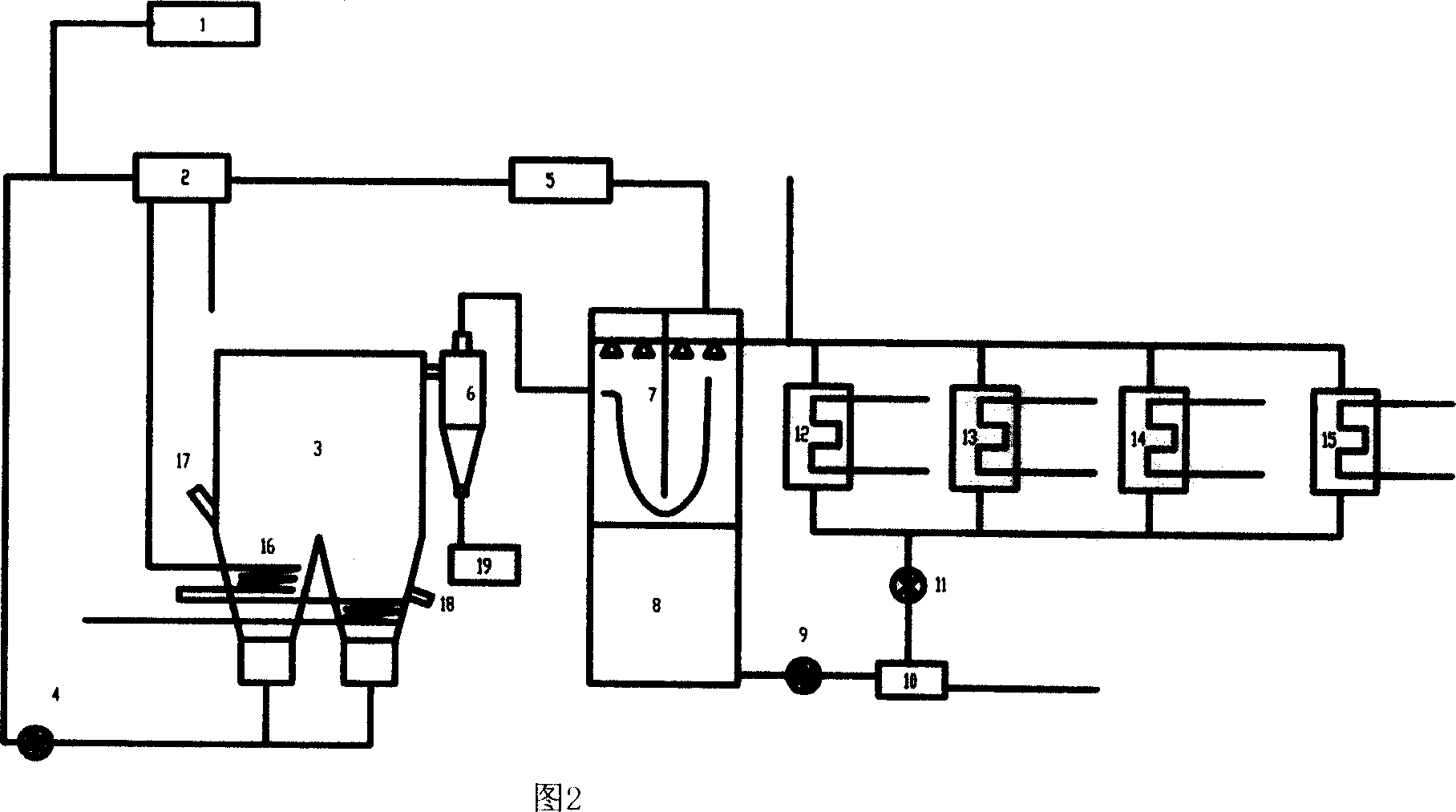

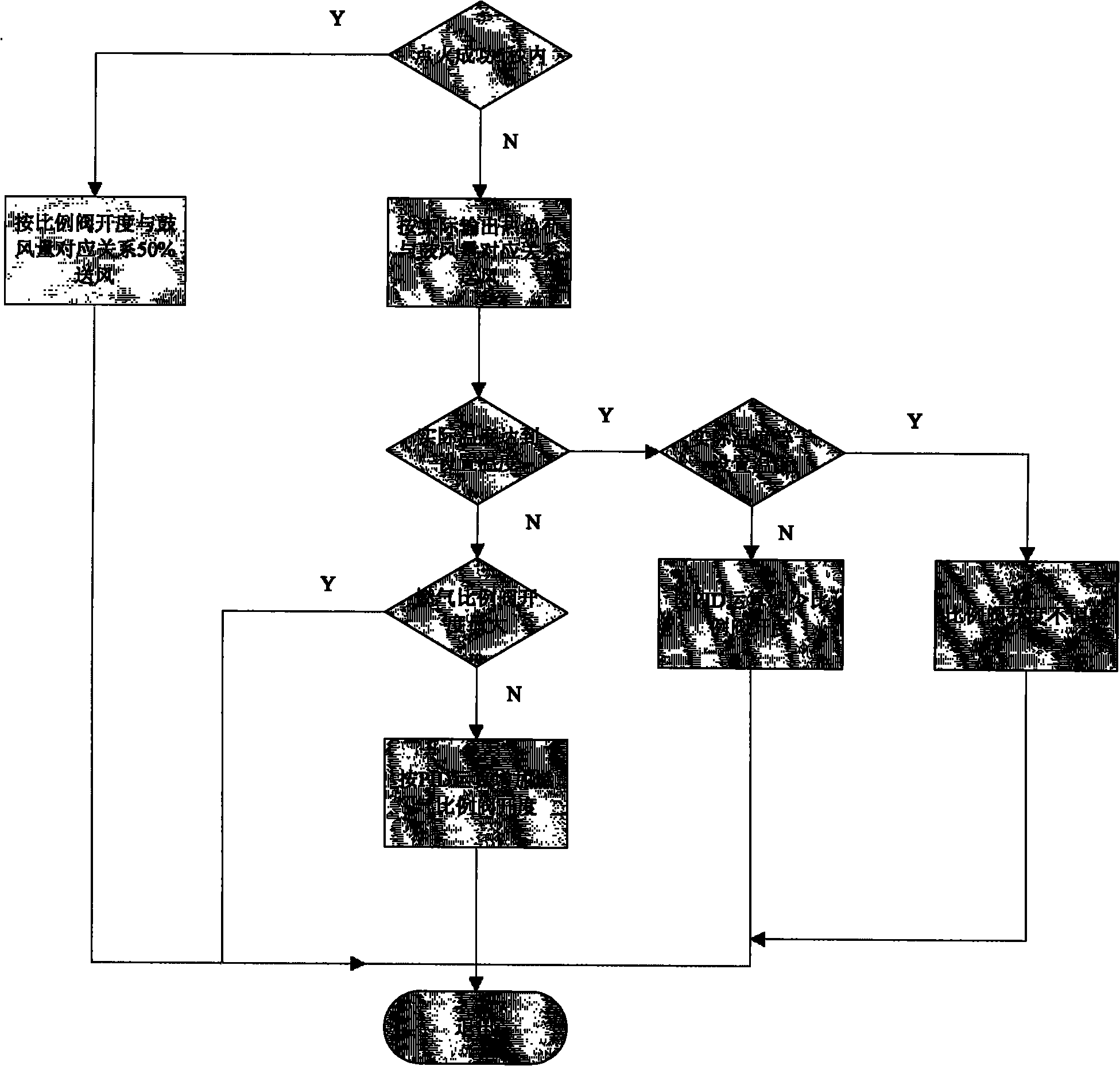

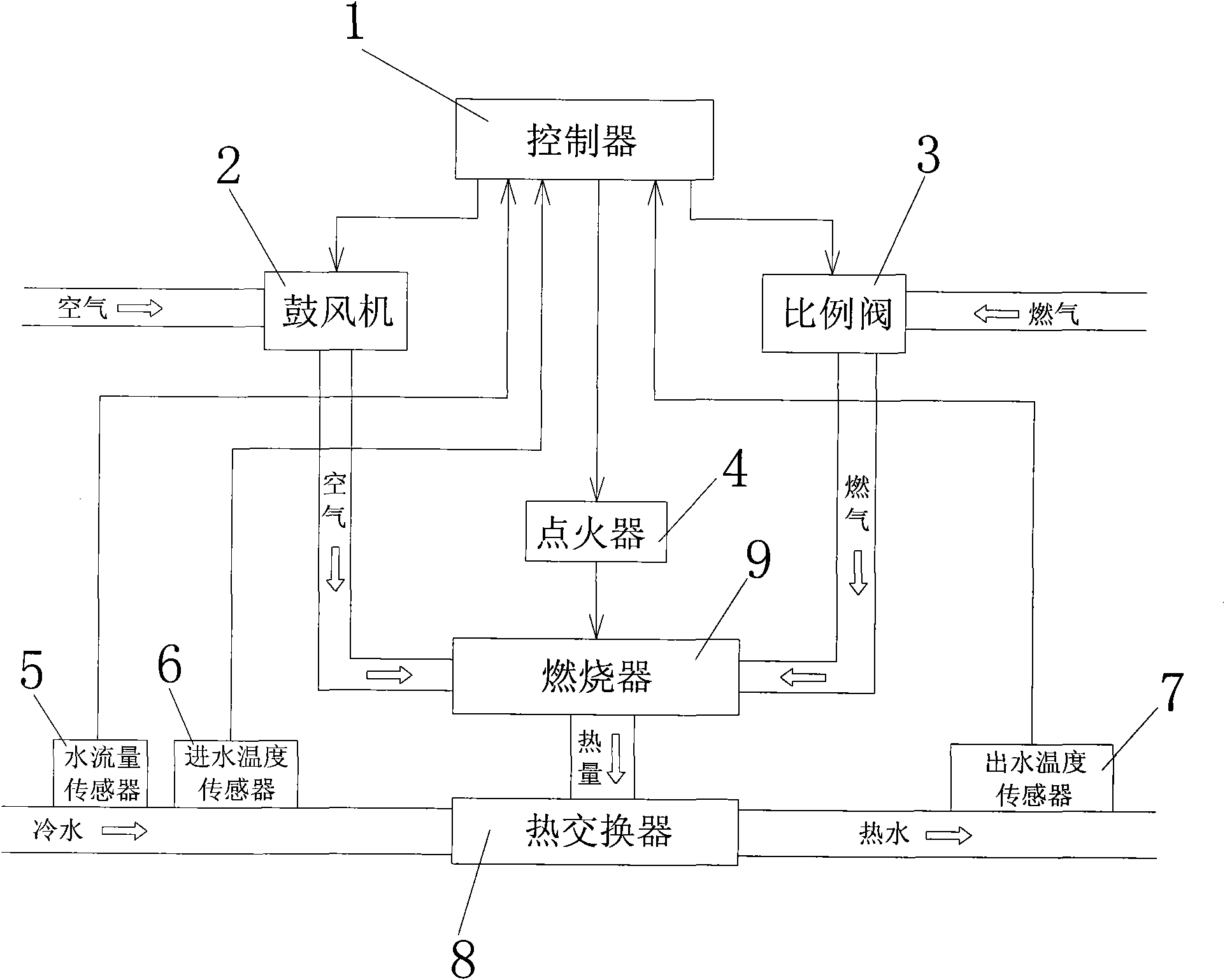

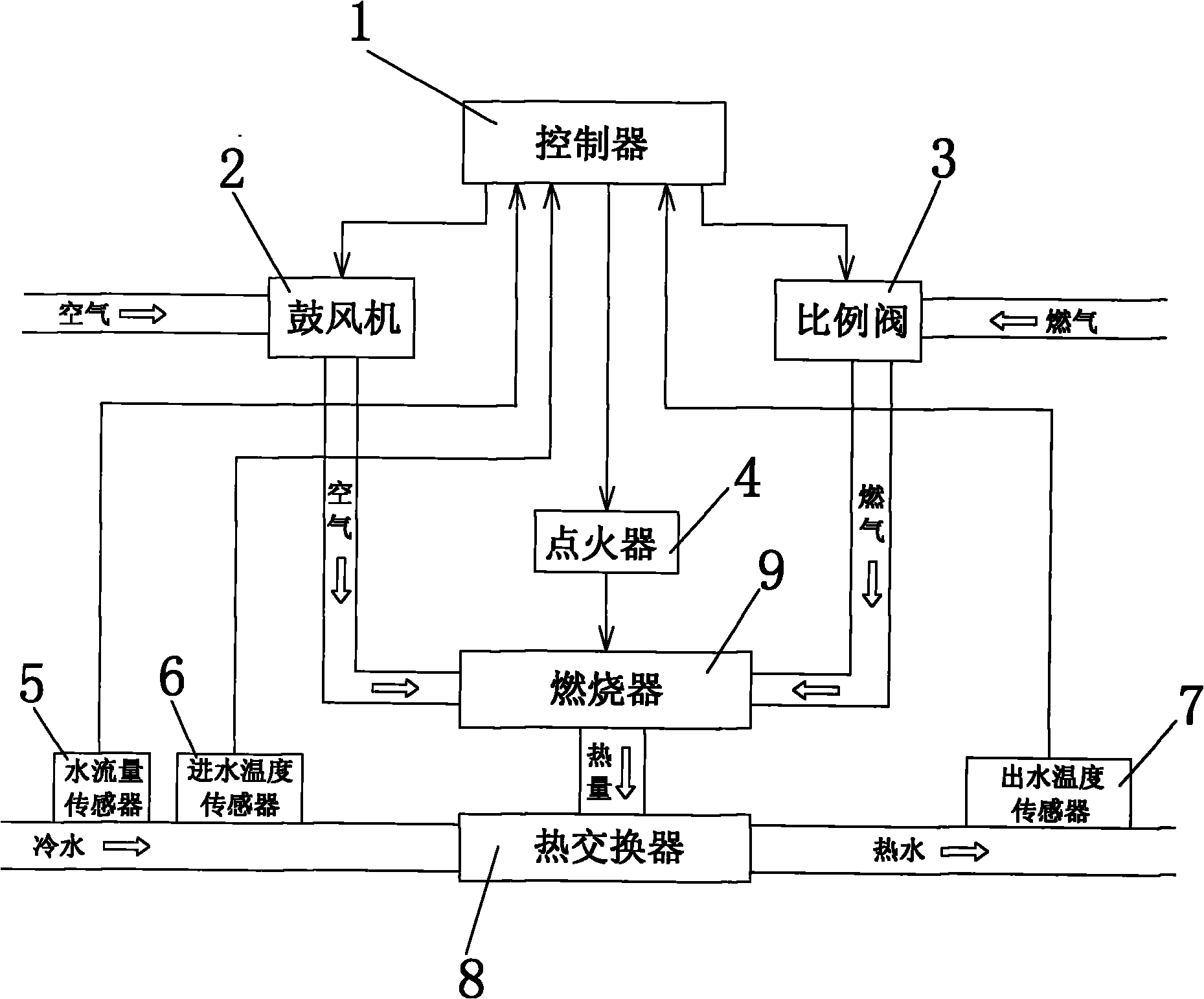

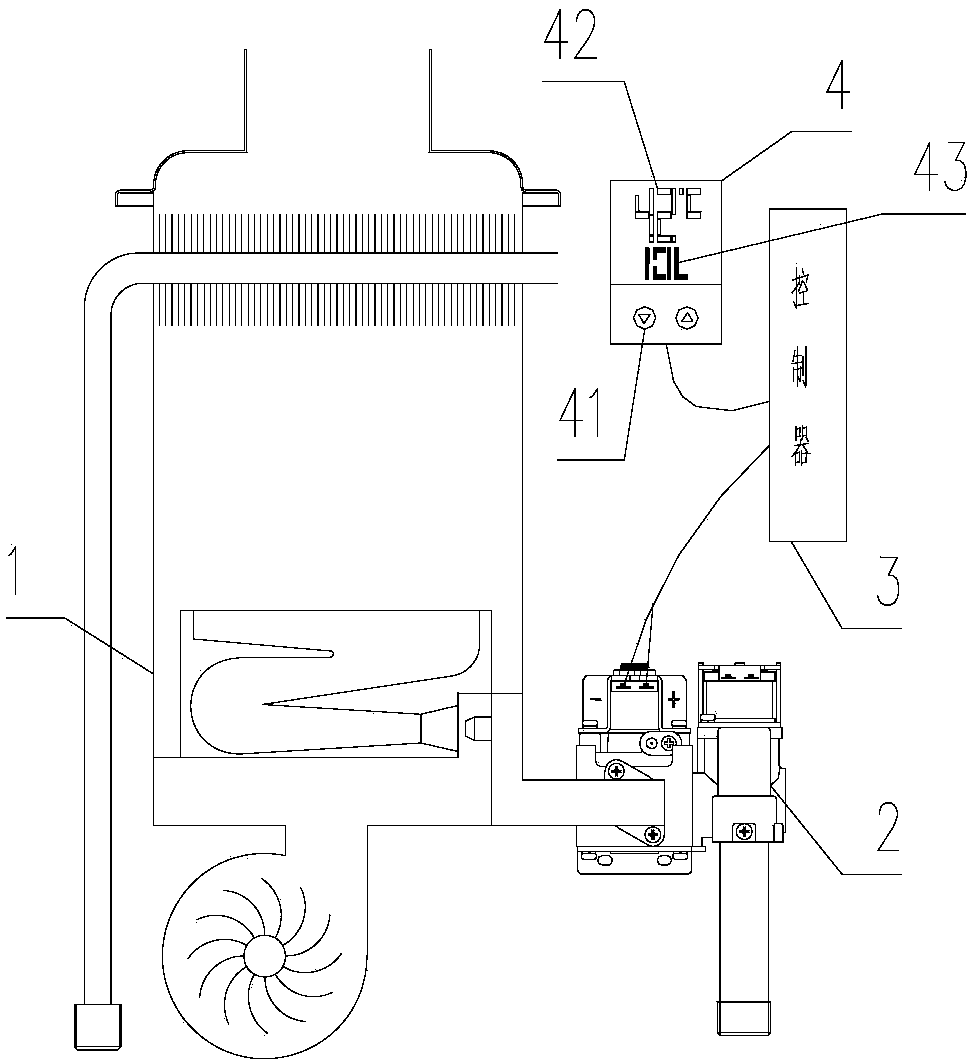

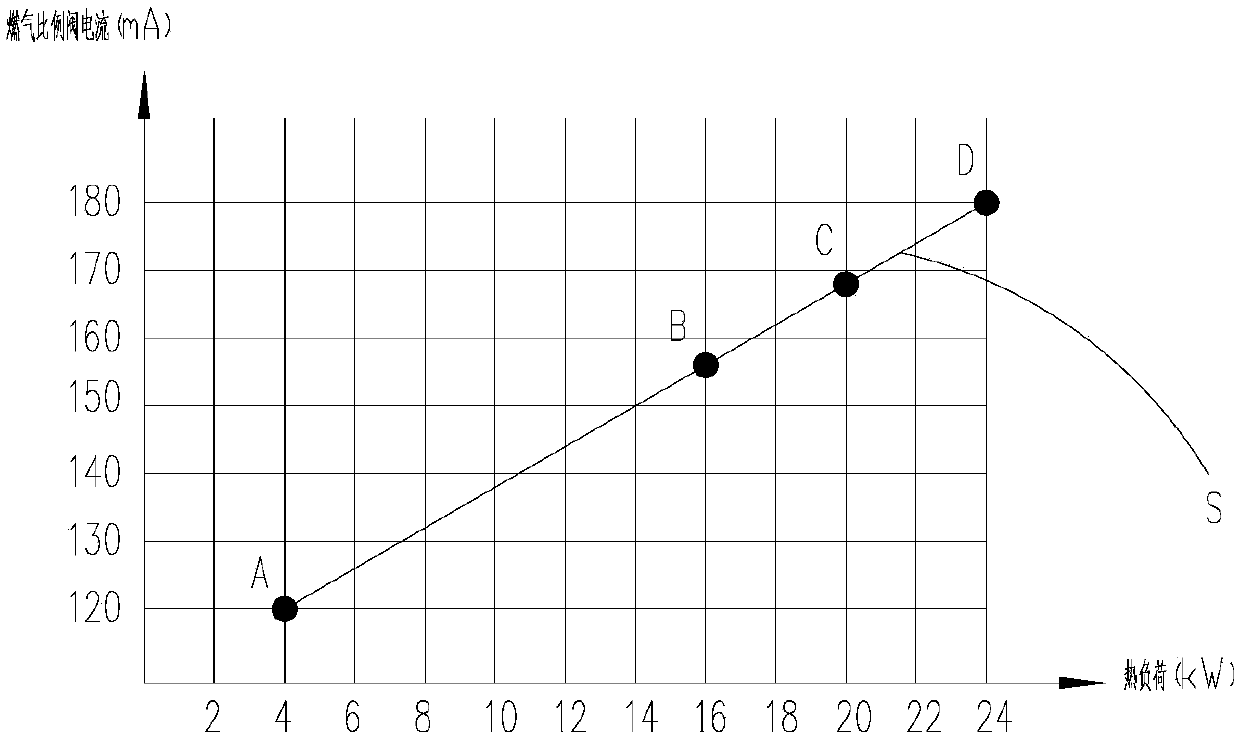

Blowing type gas water heater constant temperature control method and control system thereof

The invention relates to a blowing type gas water heater constant temperature control method, which is characterized in that after the water heater is successfully ignited, a controller calculates the current thermal load Q according to the water flow V, water inflowing temperature T0, water outflowing temperature T1 set by a user, calculates and controls the air quantity S output by an air flower according to the thermal load Q, guarantees the flame not to be blown out, and causes the heater to work when the gas supply is low. The blowing type gas water heater constant temperature control system comprises a central controller, the air blower, a gas proportional valve, an igniter, a water flow sensor, a water inflowing temperature sensor and a water outflowing temperature sensor; after the igniter is successfully ignited, the controller calculates and controls the air quantity S output by the air blower according to the thermal load Q; when the real water outflowing temperature T11 is less than the set water outflowing temperature T1, the controller controls the gas proportional valve to increase the openness of the valve thereof and the air demand of the gas passage so that the real water outflowing temperature T11 reaches the set water outflowing temperature T1. The invention causes that the heater can work when the gas supply quantity is low, can rapidly recover the constant temperature state when the gas supply quantity recovers, thus being convenient for users to use.

Owner:GUANGDONG HUAMEI JUNDA ELECTRIC APPLIANCES

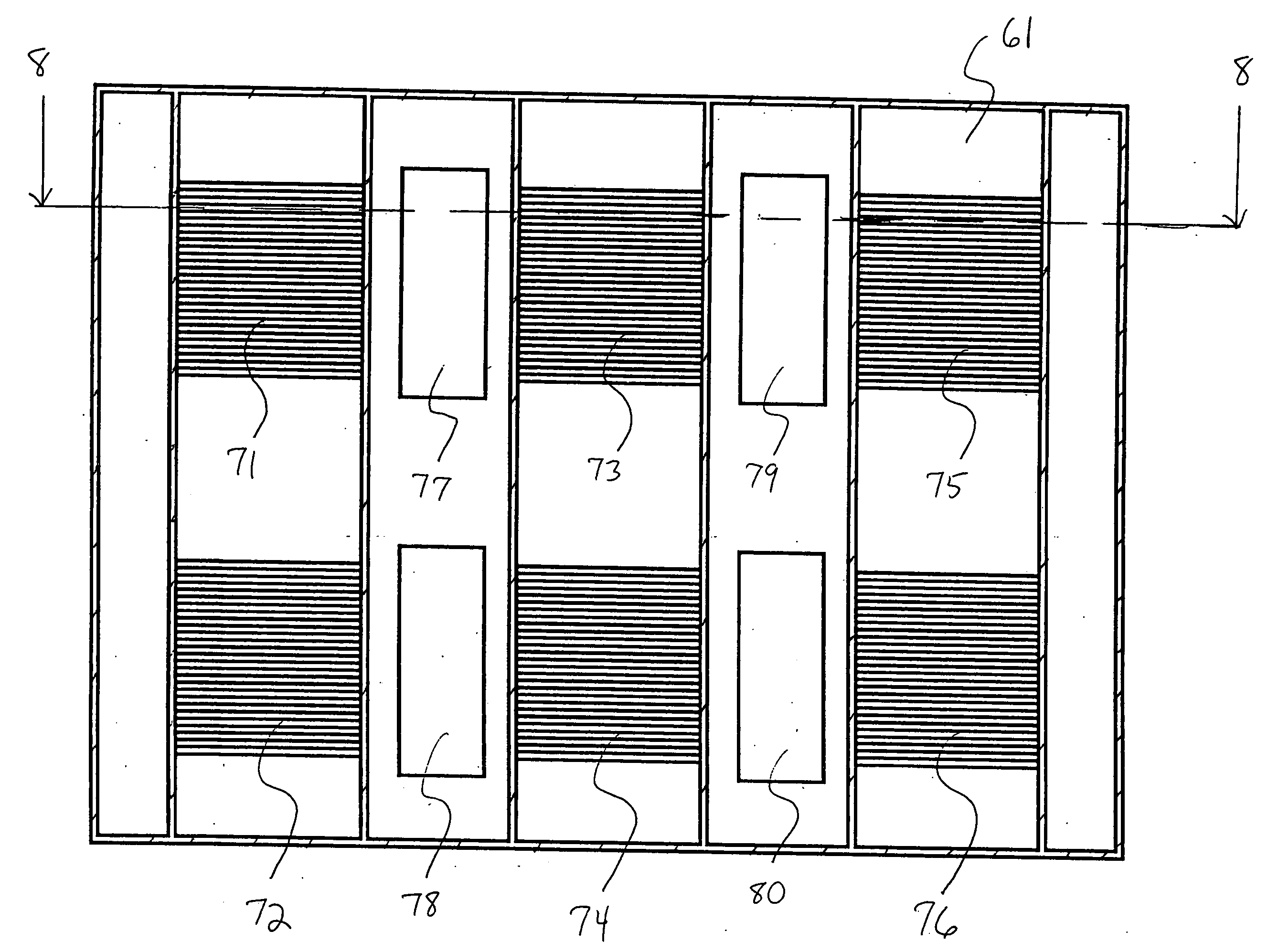

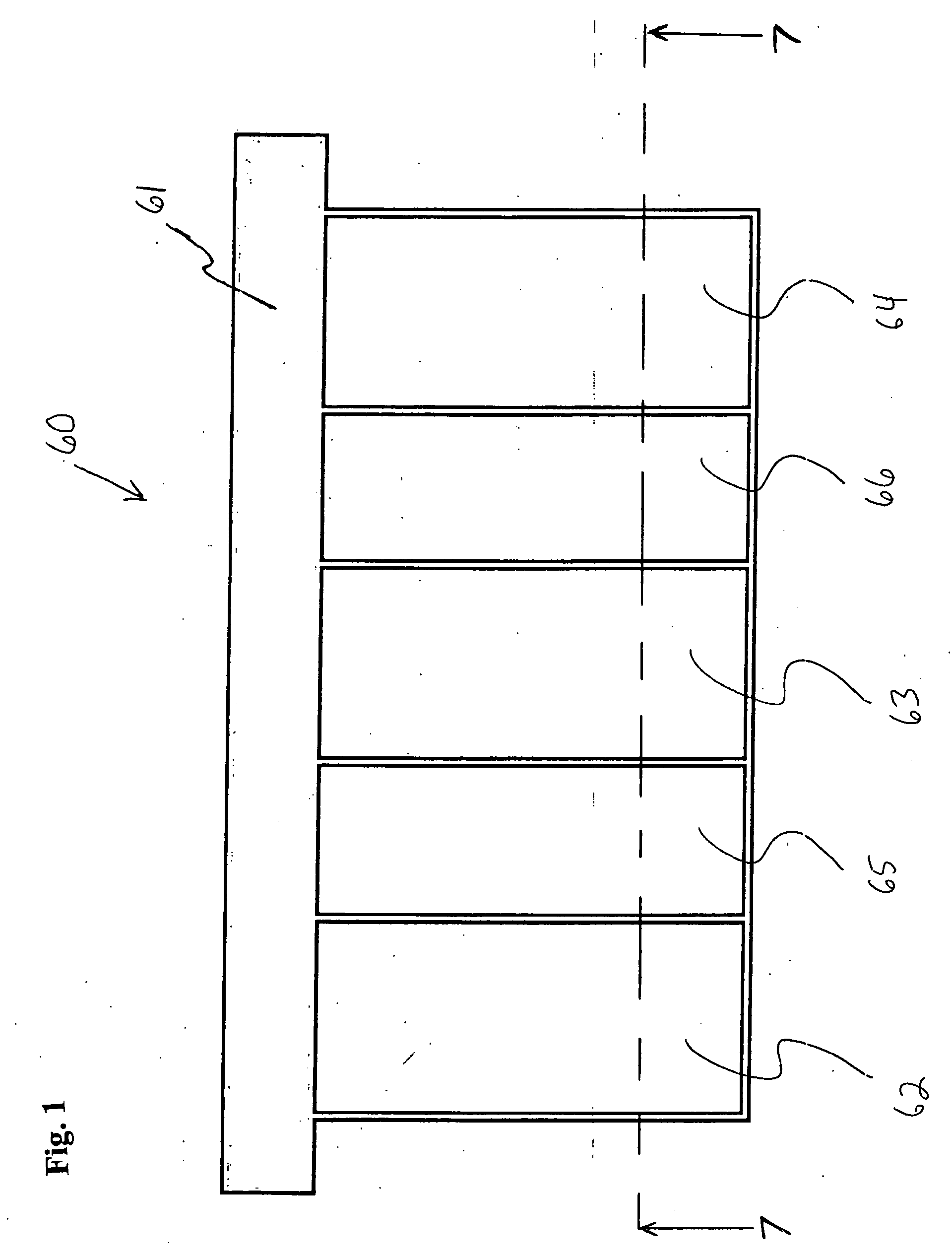

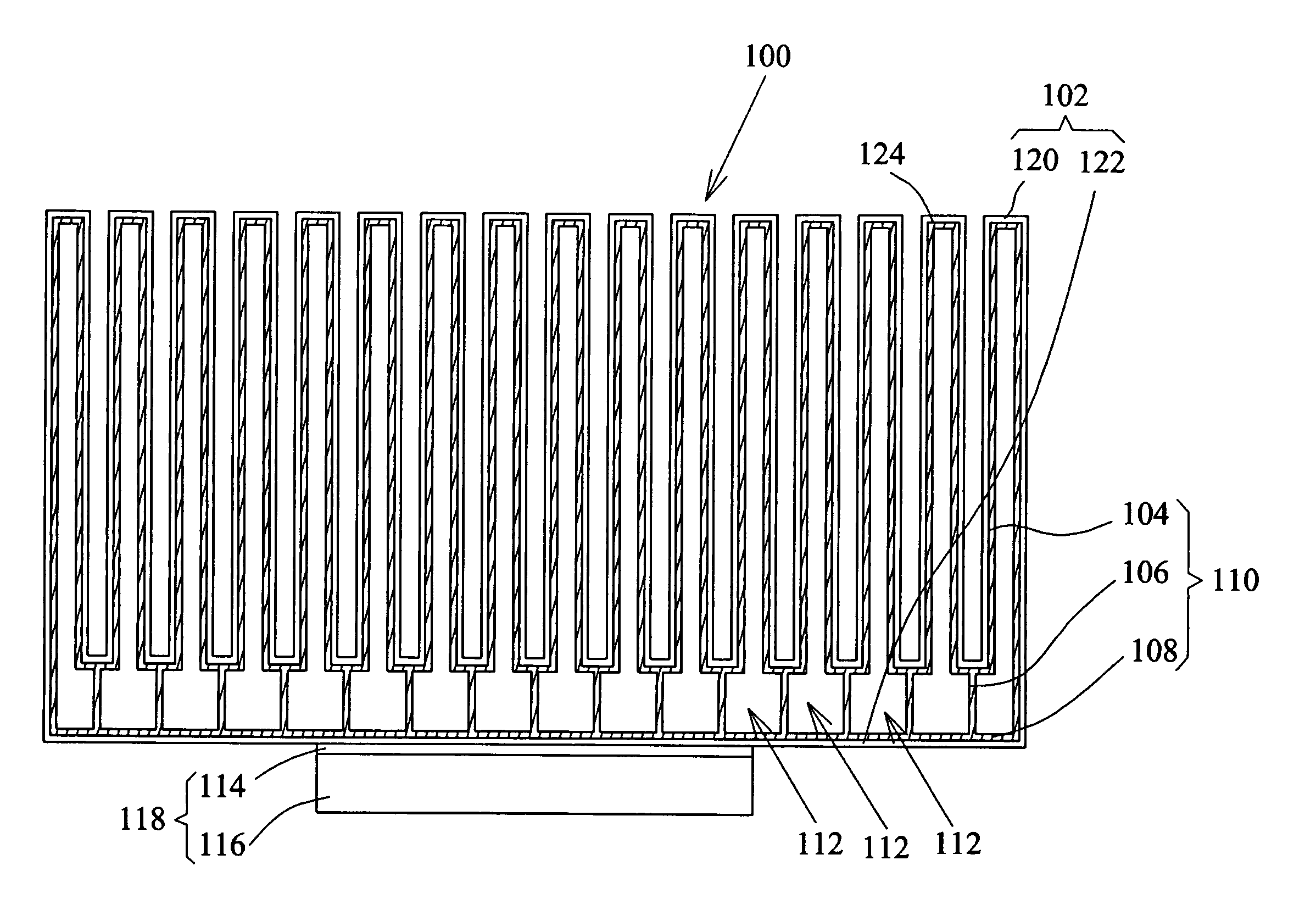

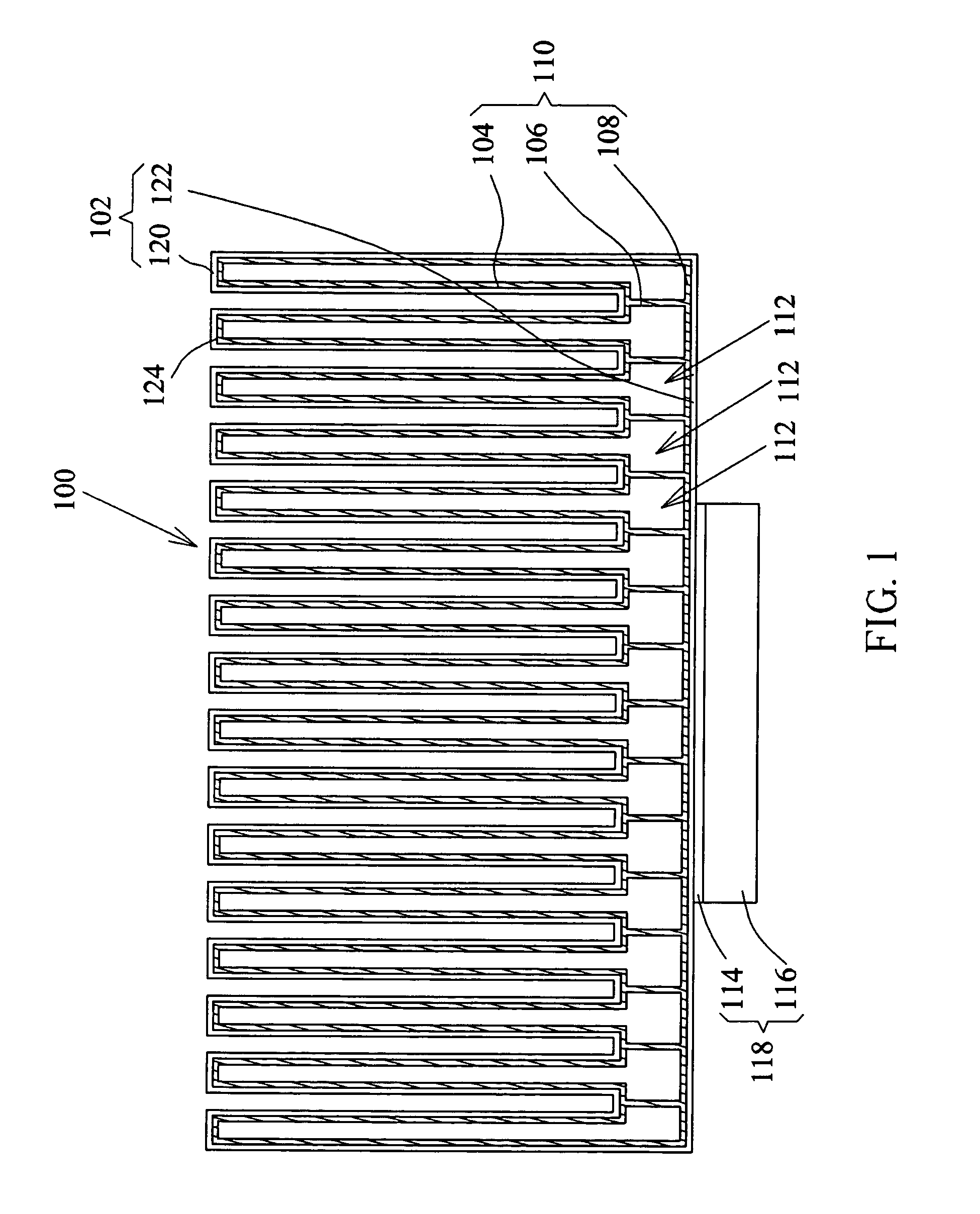

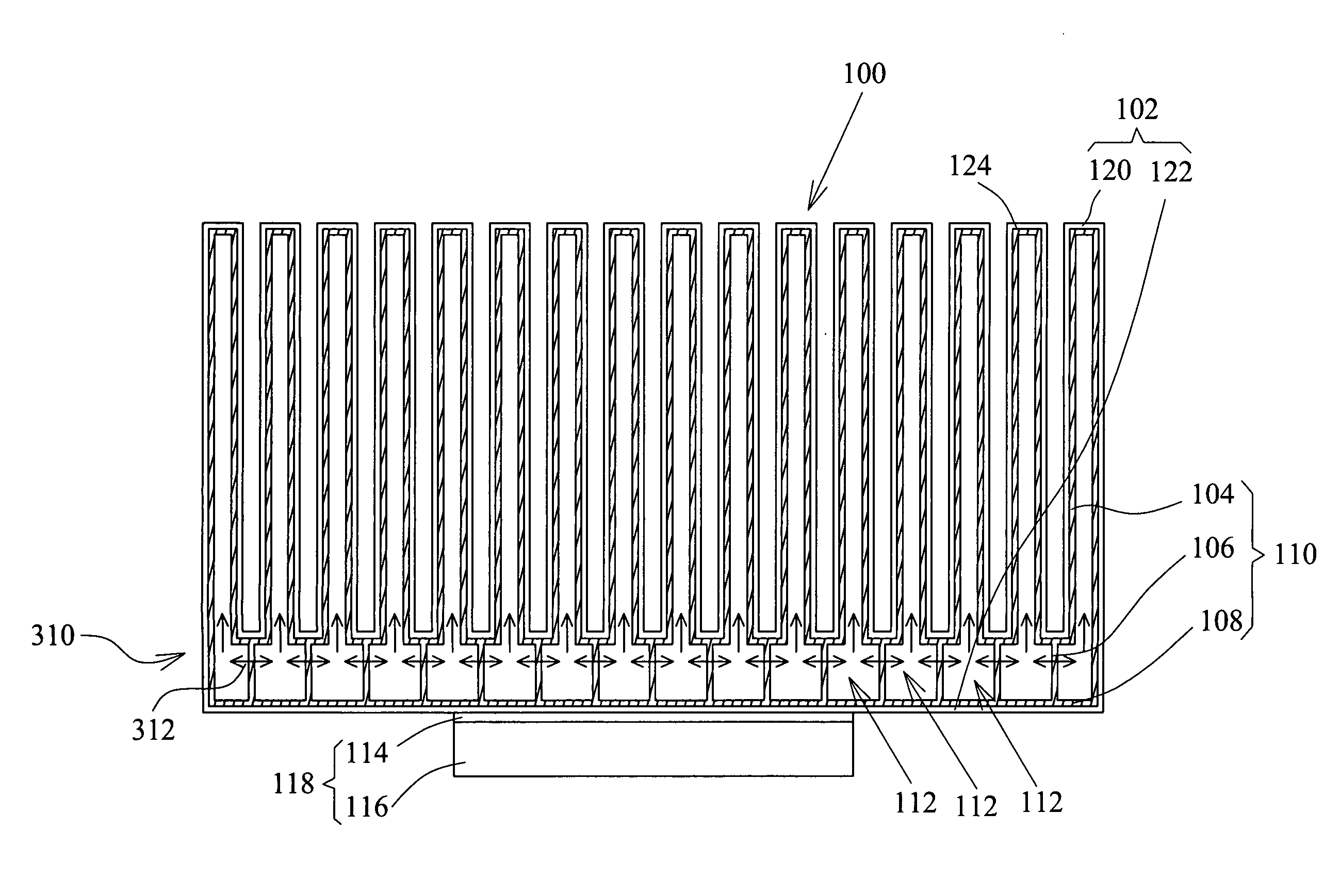

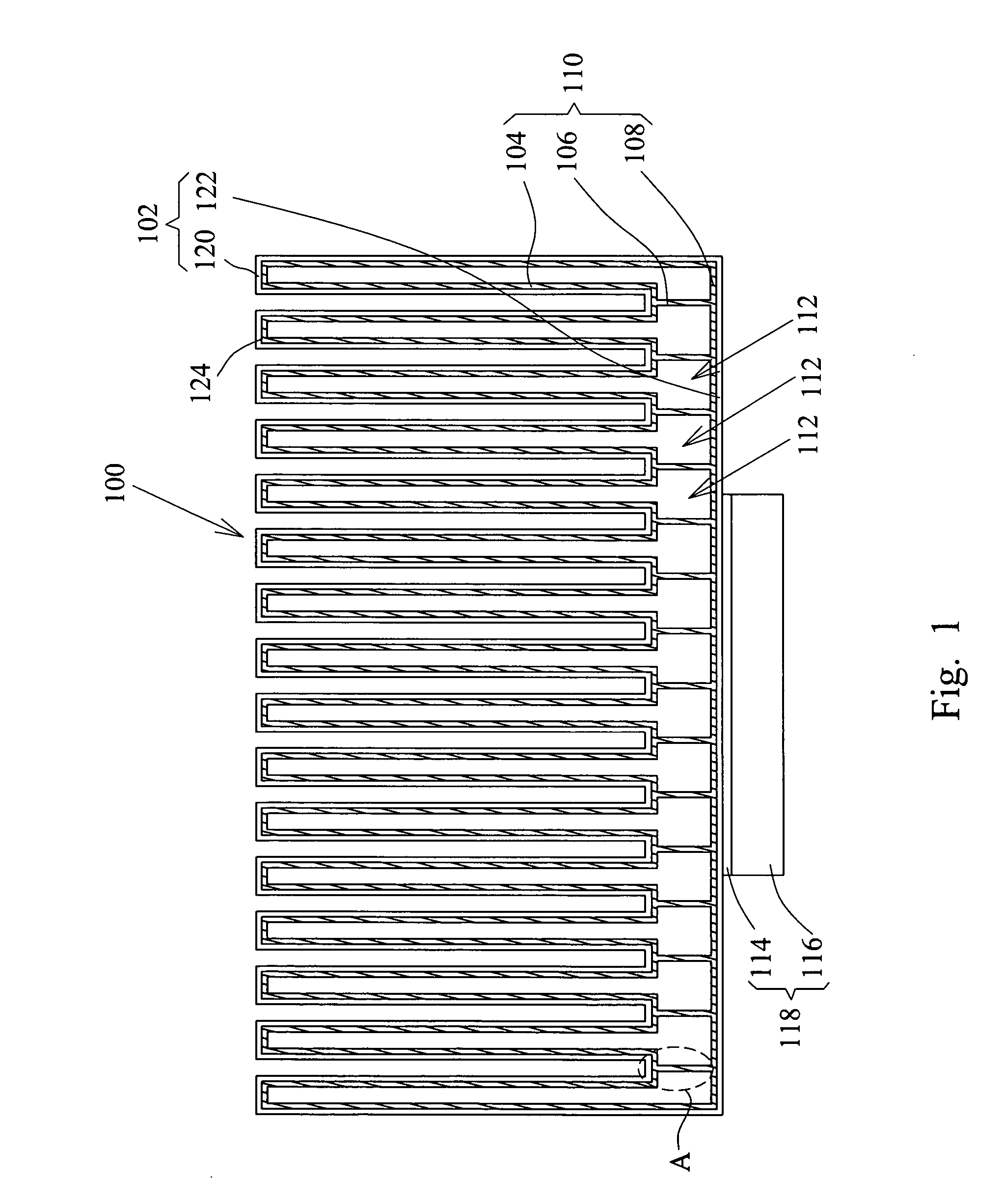

Method and apparatus for dissipating heat, and radar antenna containing heat dissipating apparatus

InactiveUS20060268518A1Minimize powerTemperature controlHeat exchange apparatusCooling/ventilation/heating modificationsRadar antennasEngineering

There is provided a heat dissipation device comprising at least one inlet plenum, at least one outlet plenum and chambers, in which the chambers communicate directly with the inlet plenum and with the outlet plenum. Also provided is a heat dissipation device comprising at least two inlet plenums, at least two outlet plenums and at least two chambers, the first chamber communicating directly with a first inlet plenum and a first outlet plenum, the second chamber communicating directly with a second inlet plenum and a second outlet plenum. Also provided are methods of dissipating heat, comprising passing fluid across and / or through such devices. Also provided are radar antennas comprising radar electronic components mounted on such devices.

Owner:SAAB INC

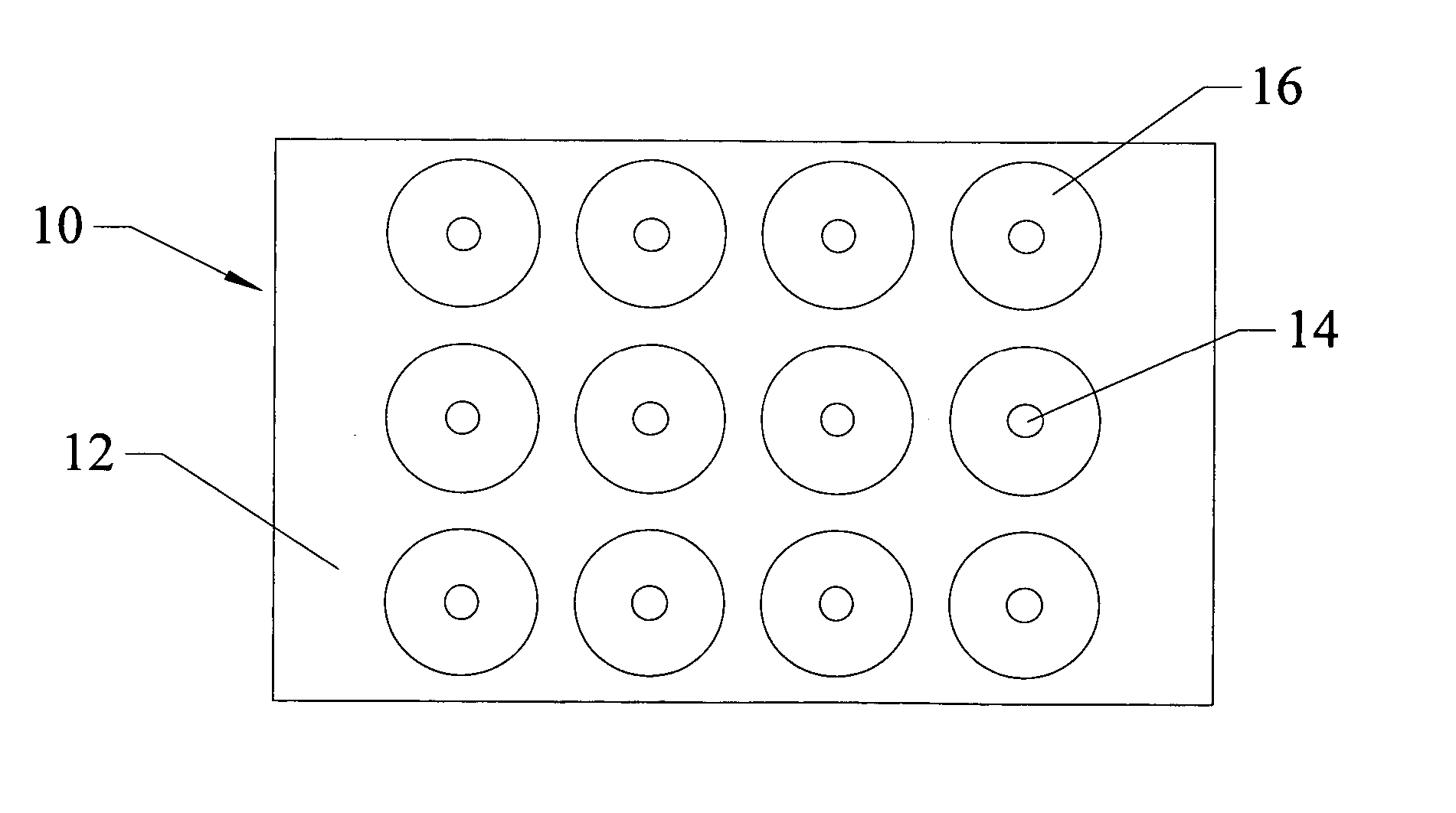

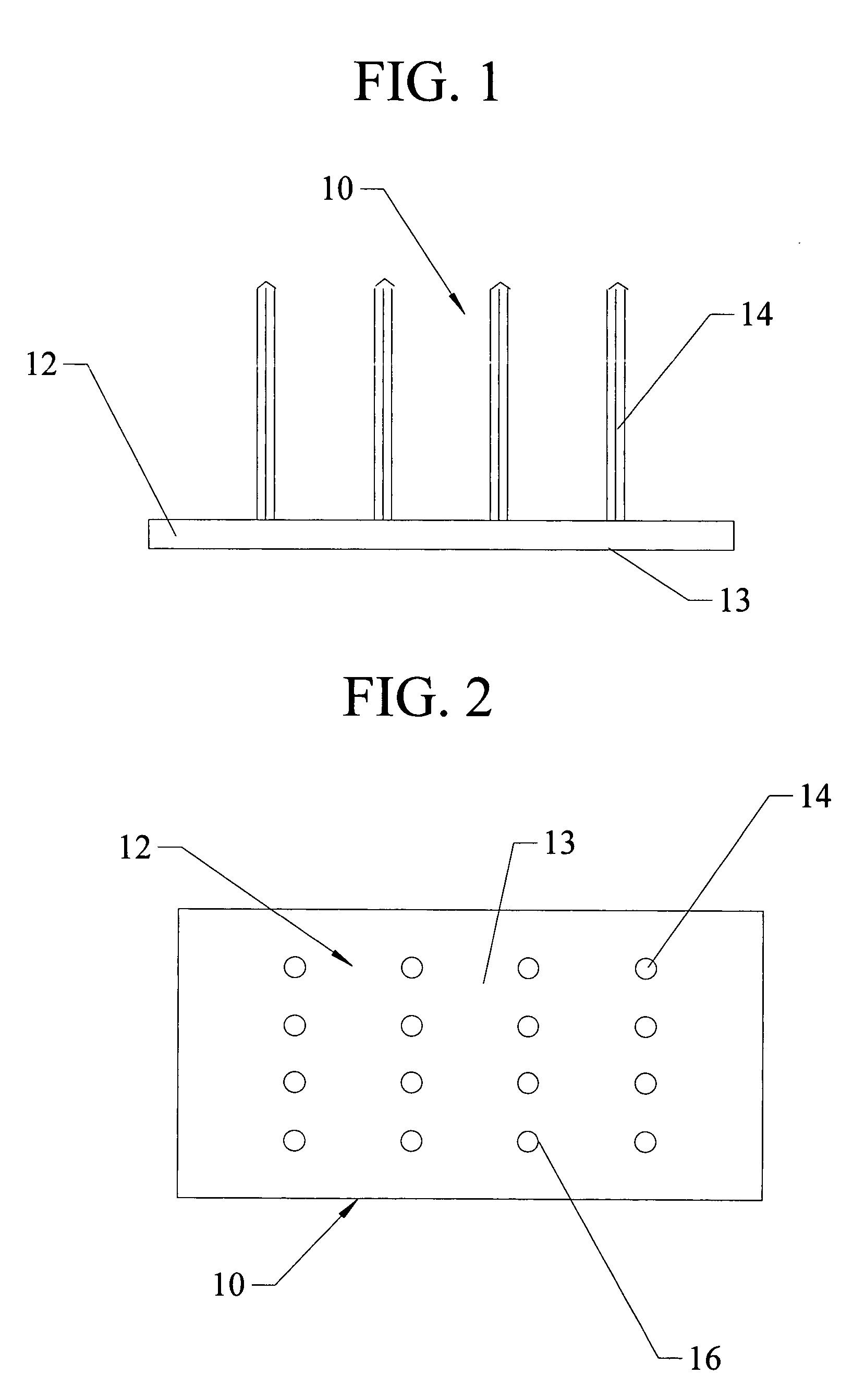

Heat sink

InactiveUS20050199376A1Solve the low heat dissipation efficiencyIncrease heat loadIndirect heat exchangersHeat exhanger finsHeat spreaderEngineering

A heat sink including a main body and a plurality of porous structures is disclosed. The main body has a plurality of hollow fins and a base. The fins and the base form a closed room. The porous structures are set on the interior surfaces of different fins, and are connected to the base. Each porous structure defines a vapor chamber.

Owner:DELTA ELECTRONICS INC

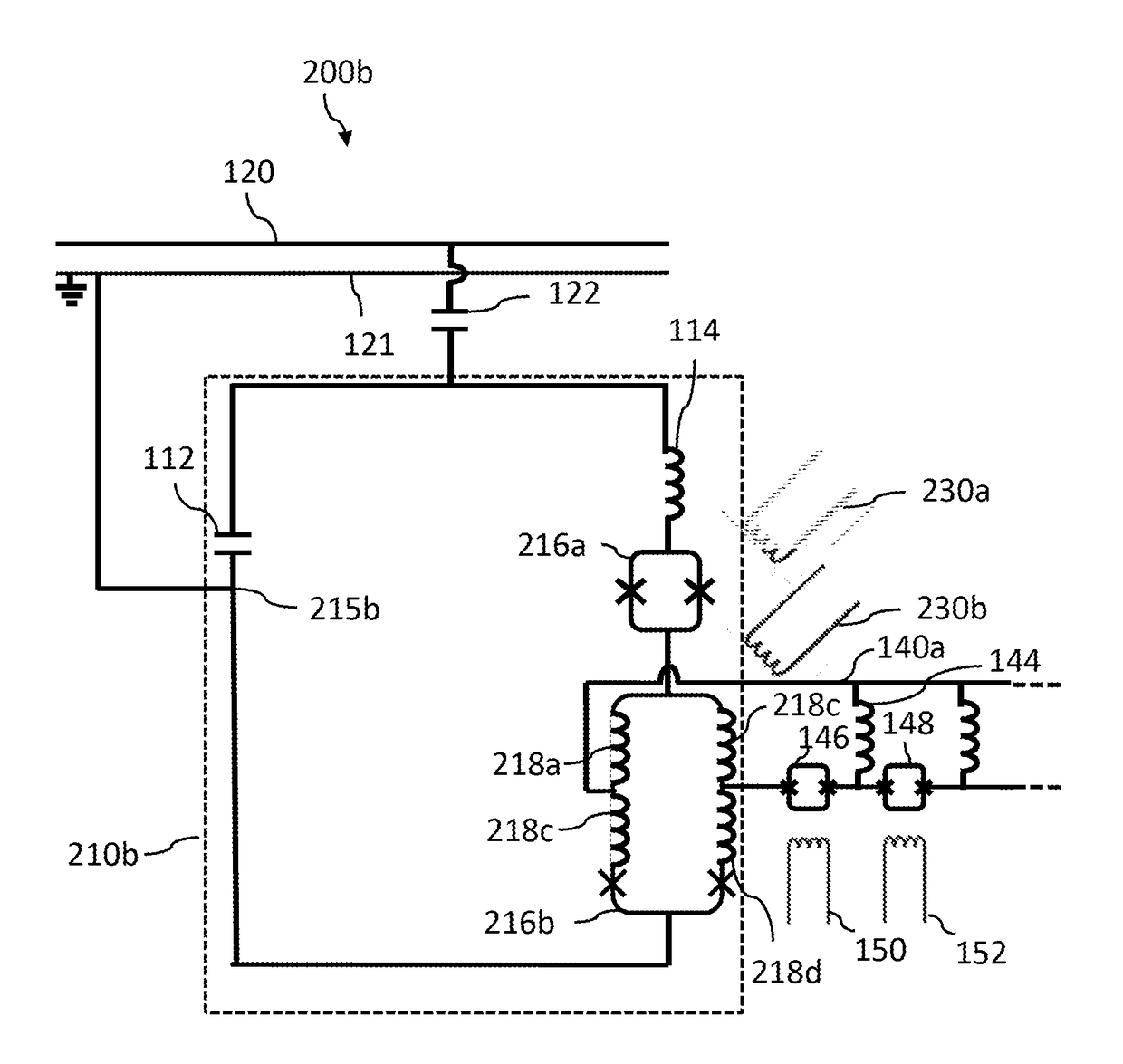

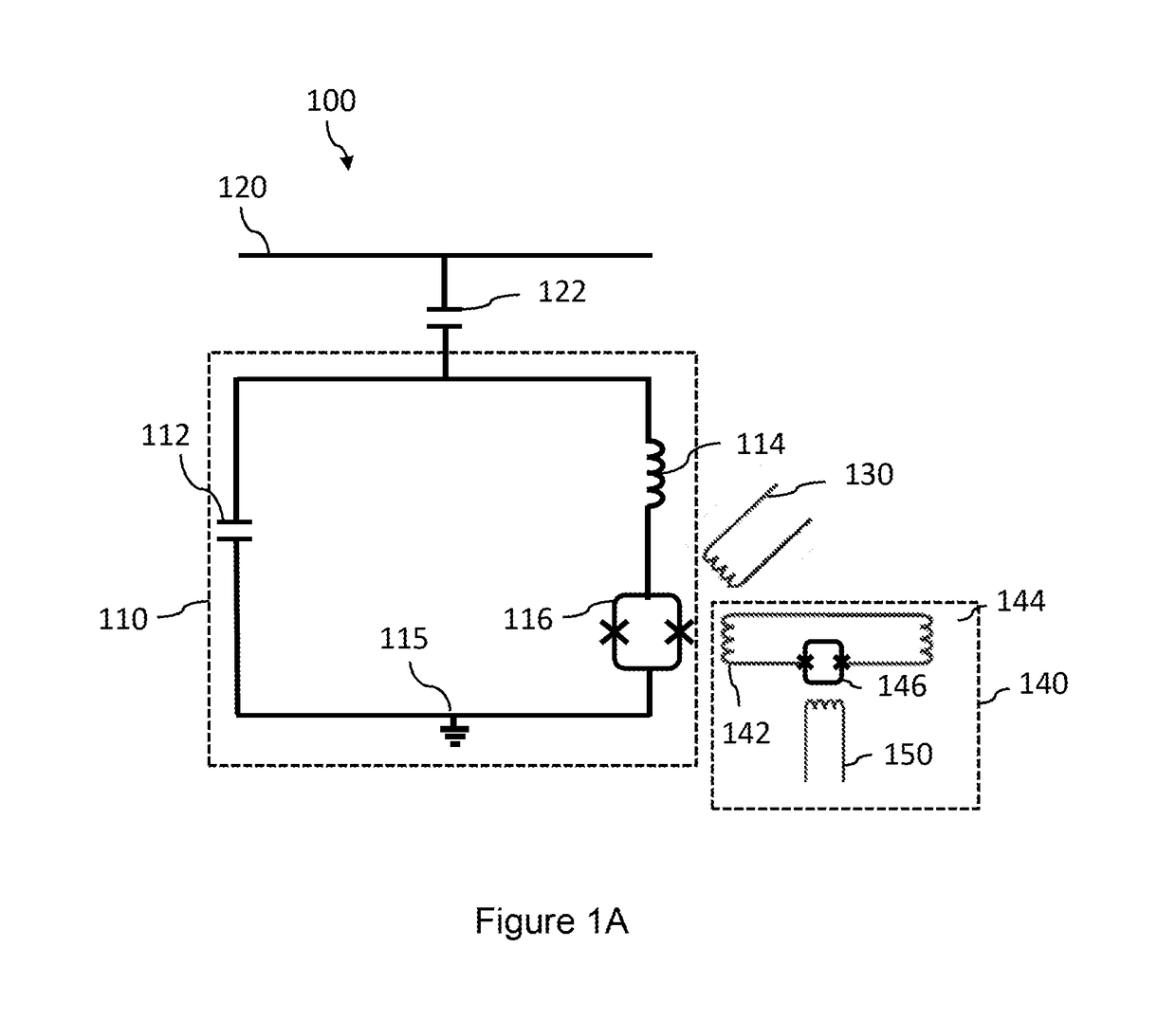

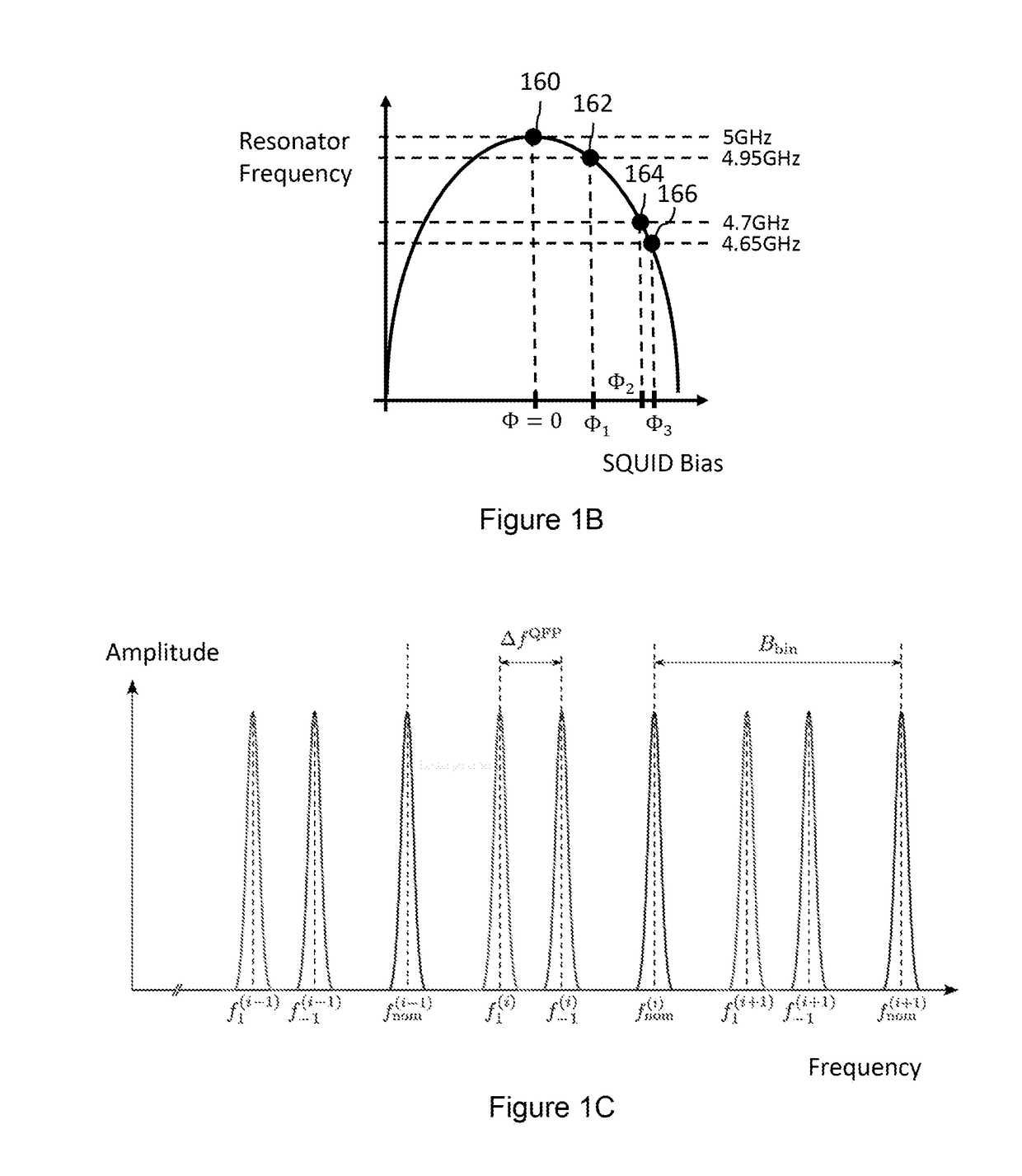

Frequency multiplexed resonator input and/or output for a superconducting device

ActiveUS20180145631A1Increase powerIncrease hardware costQuantum computersMultiple-port networksCapacitanceShift register

A superconducting input and / or output system employs at least one microwave superconducting resonator. The microwave superconducting resonator(s) may be communicatively coupled to a microwave transmission line. Each microwave superconducting resonator may include a first and a second DC SQUID, in series with one another and with an inductance (e.g., inductor), and a capacitance in parallel with the first and second DC SQUIDs and inductance. Respective inductive interfaces are operable to apply flux bias to control the DC SQUIDs. The second DC SQUID may be coupled to a Quantum Flux Parametron (QFP), for example as a final element in a shift register. A superconducting parallel plate capacitor structure and method of fabricating such are also taught.

Owner:D WAVE SYSTEMS INC

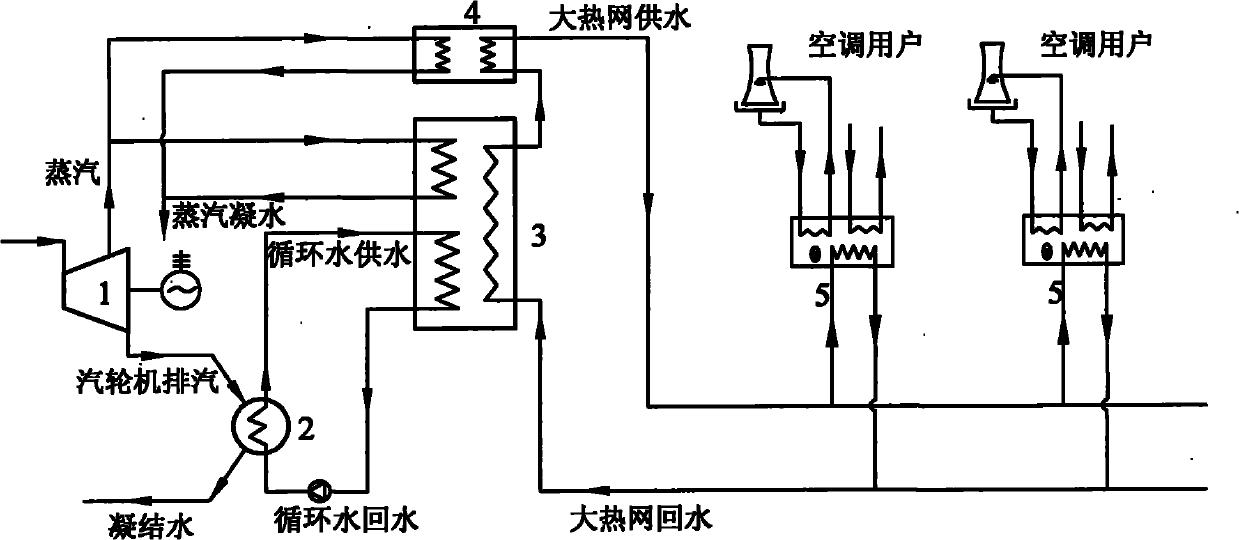

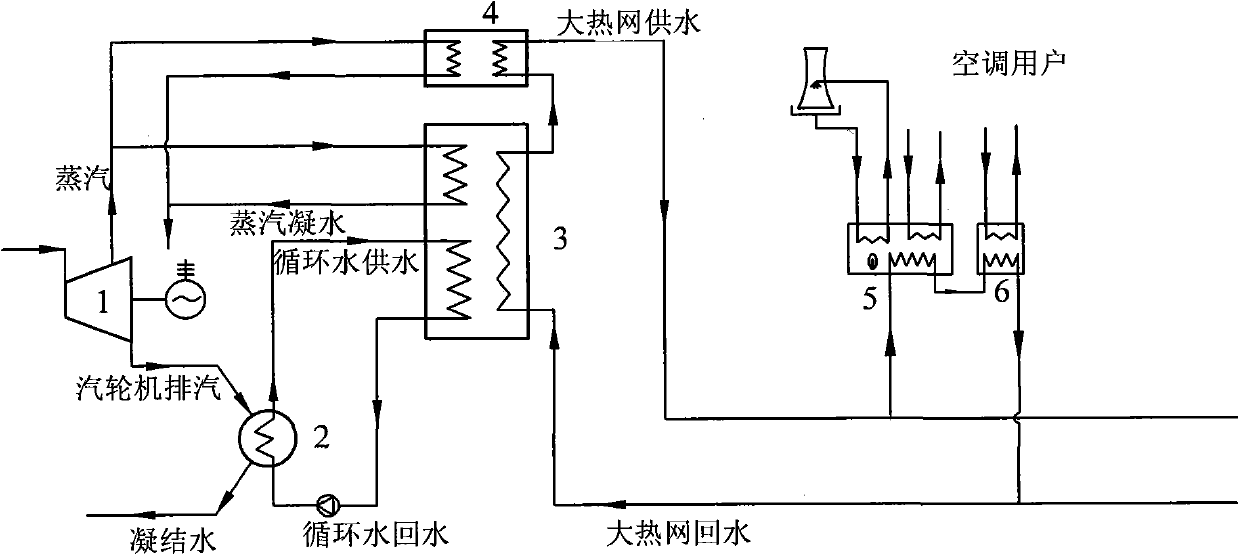

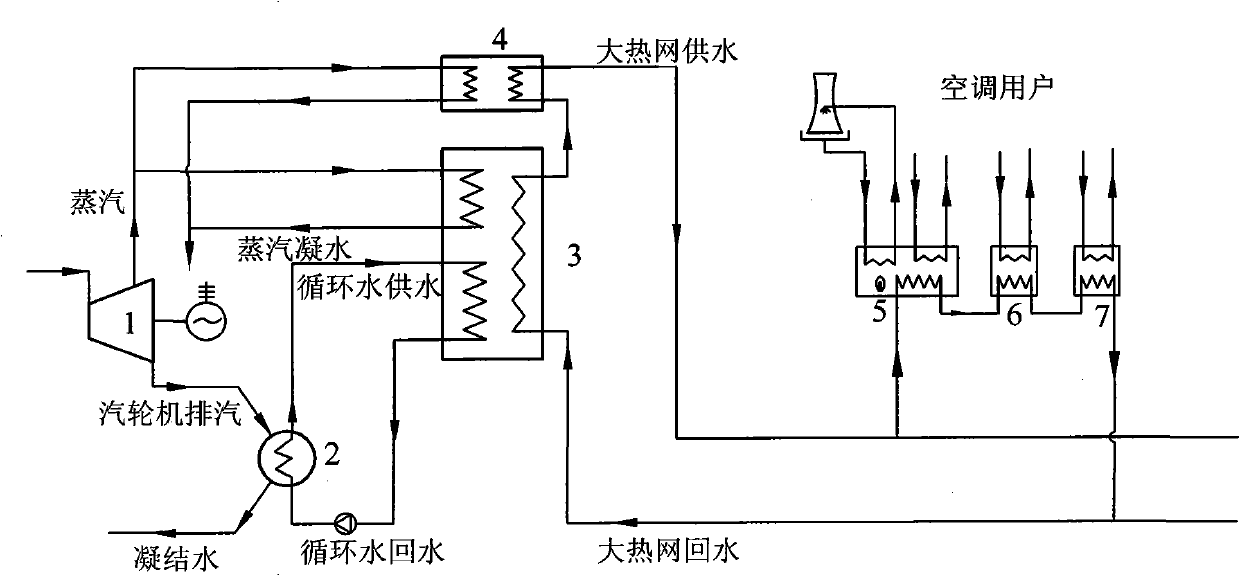

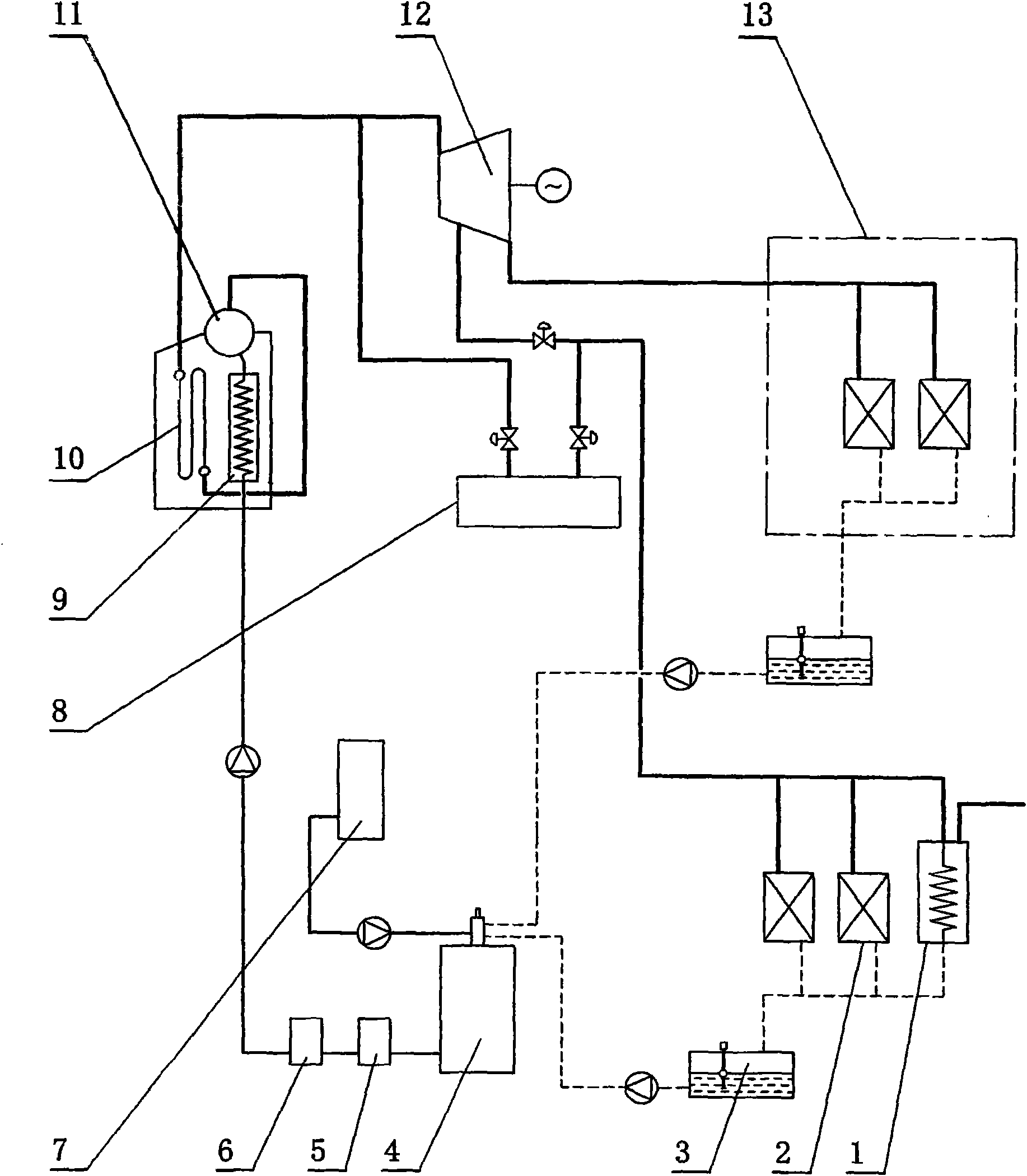

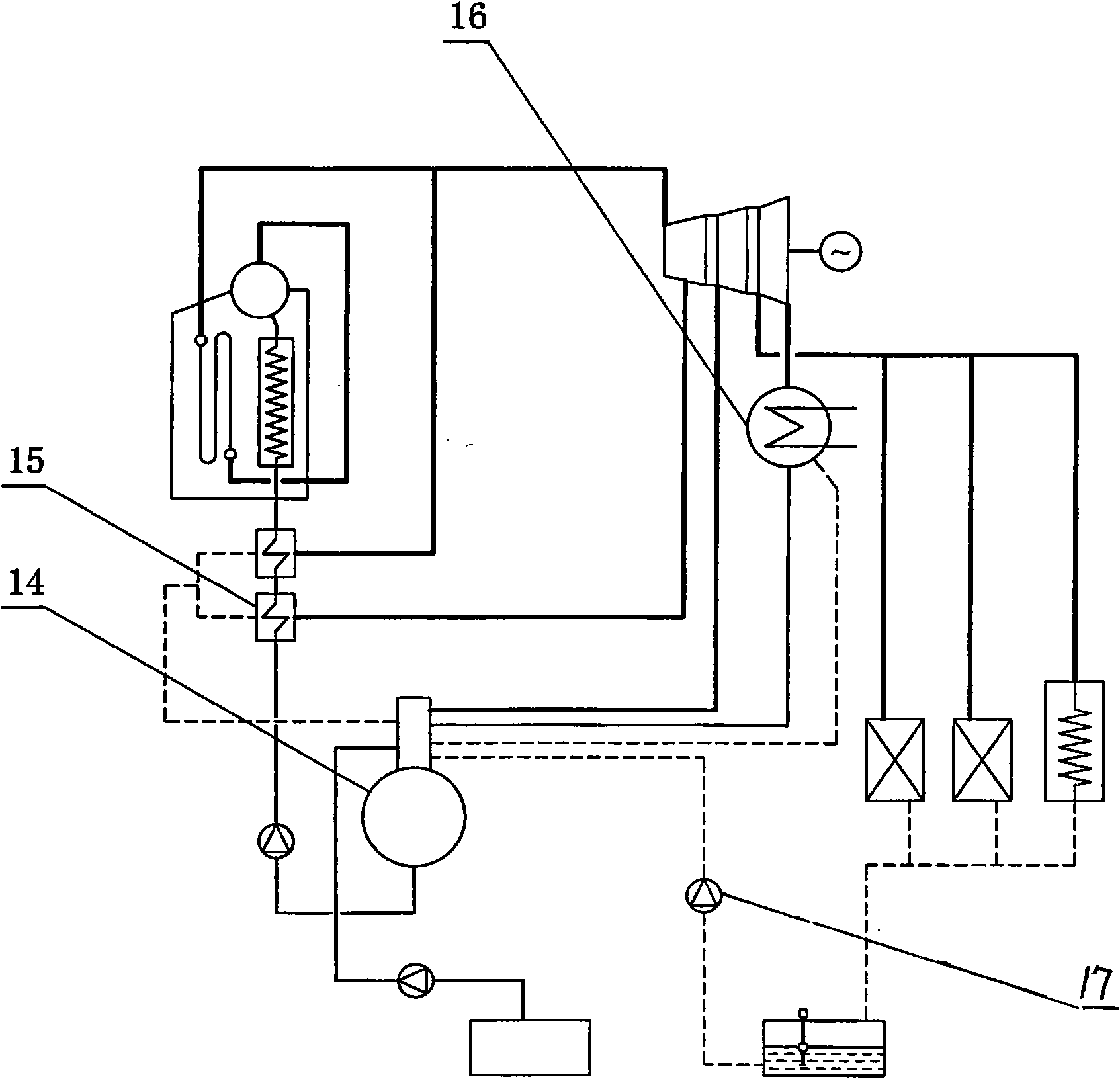

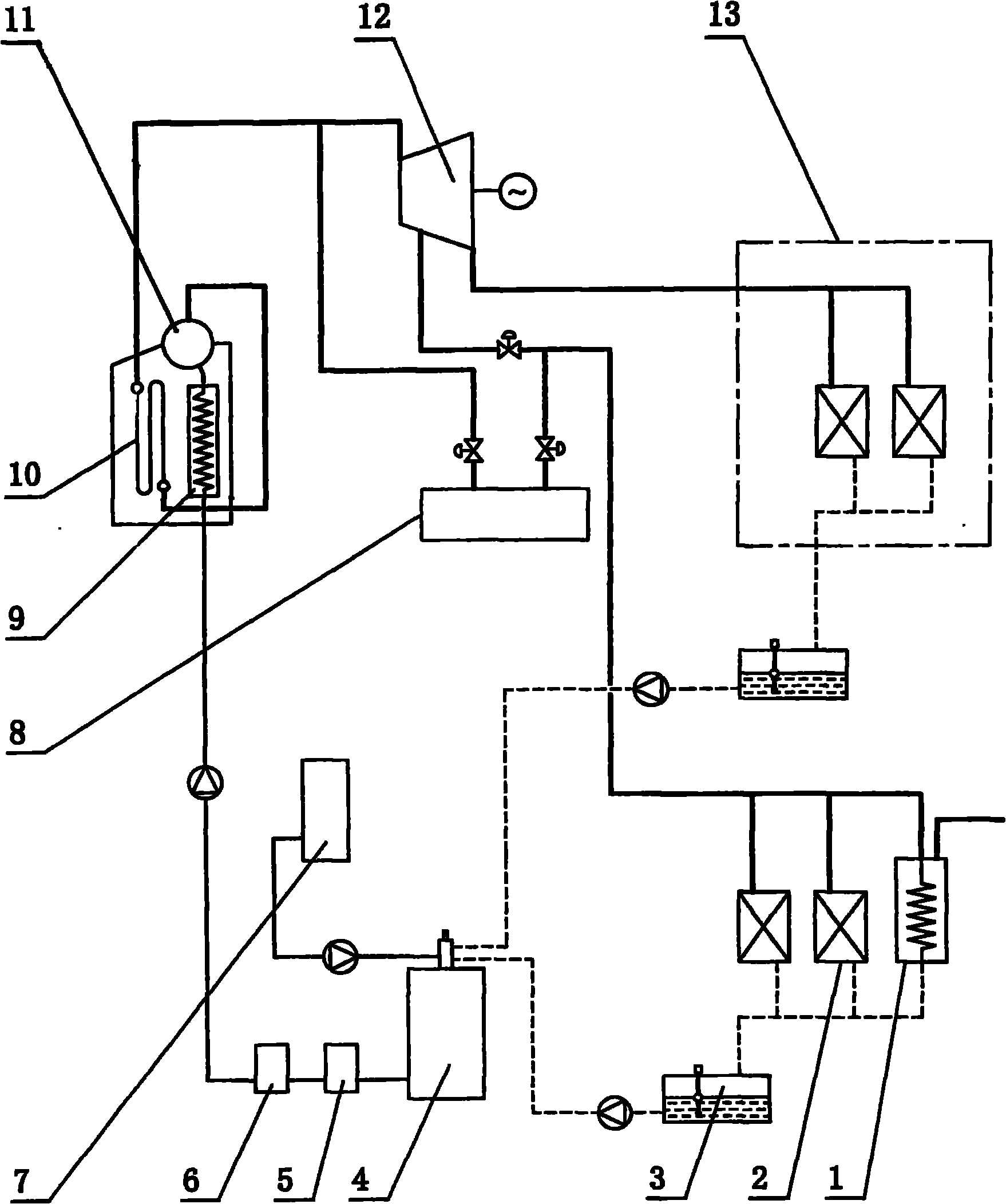

Cooling mode driven by utilizing urban heat supply network

InactiveCN101949612AIncrease heat loadCut power peaksClimate change adaptationSteam useNuclear engineeringWater supply

The invention discloses a cooling mode driven by utilizing an urban heat supply network, which belongs to the technical field of cooling modes. In the mode, hot water of the heat supply network is utilized to drive an absorption refrigerator and a solution dehumidifier to cool and dehumidify the place of a user; meanwhile, the water of the heat supply network after driving the cooling and the dehumidification can be used for preheating domestic hot water and further recharging the heat to the underground through a buried pipe so as to gradually reduce the backwater temperature of the heat supply network, and the heat recharged to the underground can be extracted for heat supply in winter. In a power plant, a mode of the combination heating of a condenser, a steam absorption heat pump and a steam-water heat exchanger is adopted to realize the gradual heating of the backwater of the heat supply network. Compared with the conventional distributed cooling mode and centralized cold water supply mode, the mode can utilize spare urban heat supply network resource in a refrigeration season, increase the heat load of a thermal power plant, recycle the waste heat of the circulating water of the power plant, and facilitate cutting down a power peak due to air conditioning load and even saving power.

Owner:TSINGHUA UNIV +1

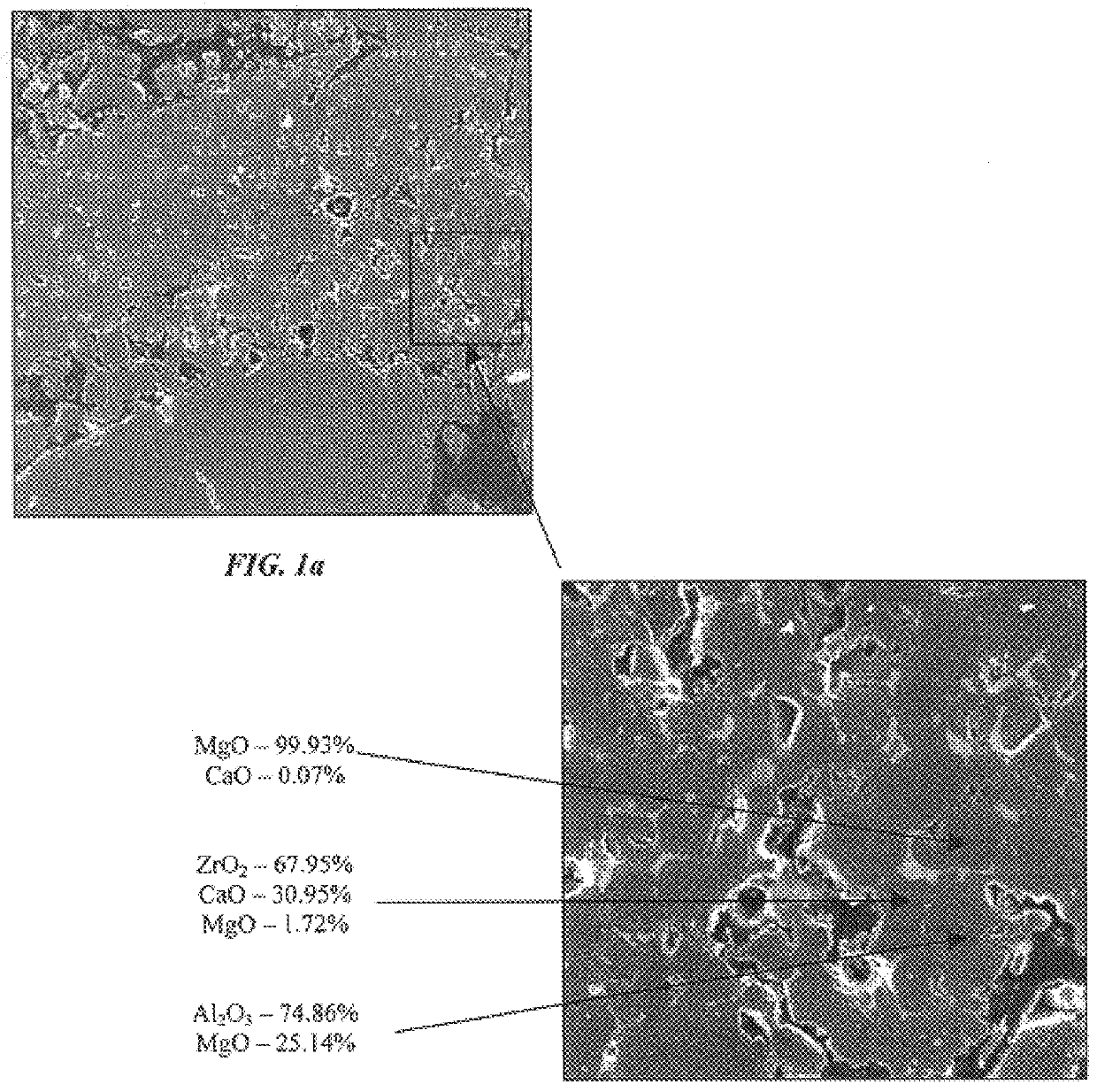

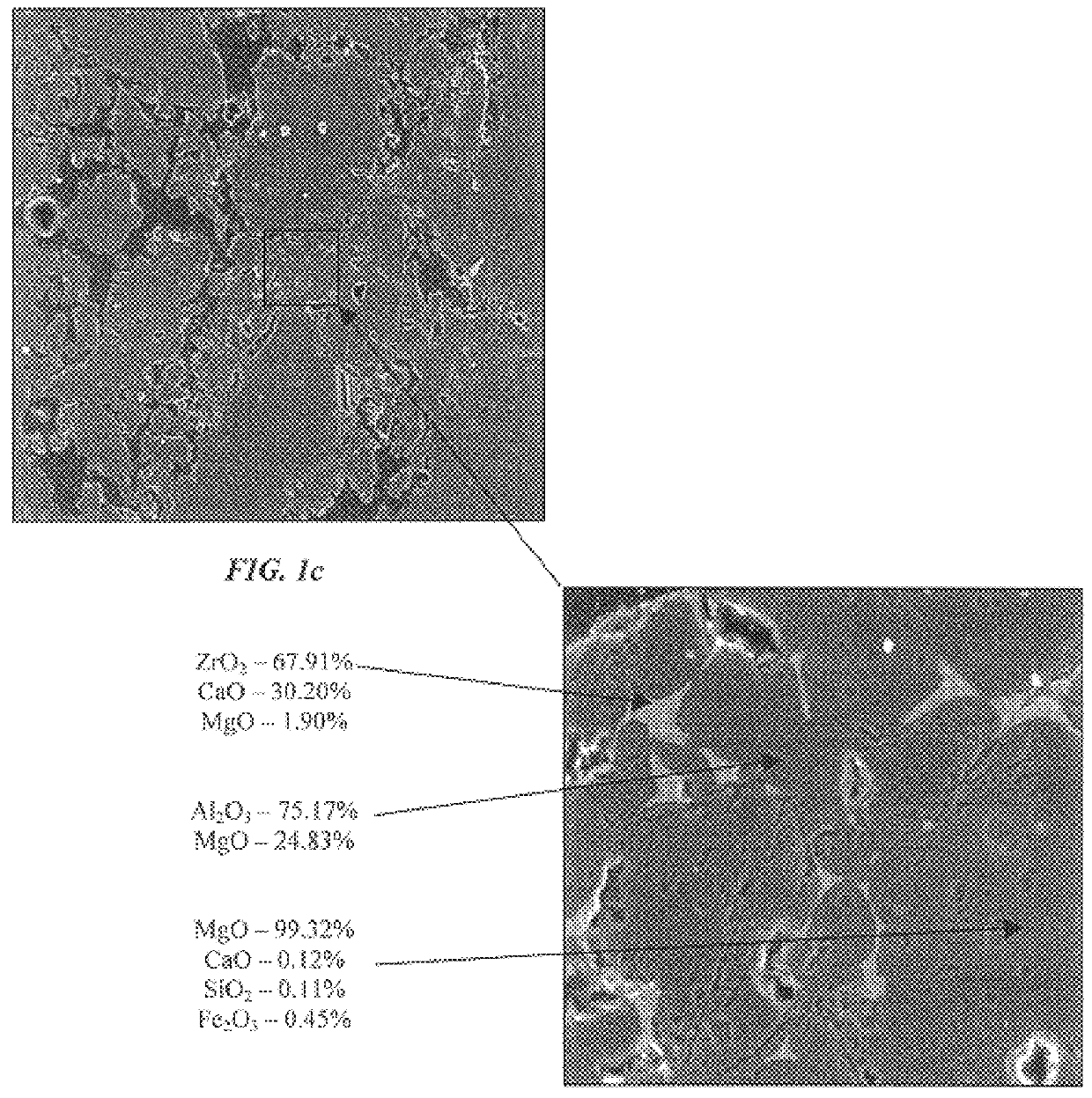

Magnesia spinel refractory brick

The present invention discloses novel magnesia-spinel refractory compositions and bricks formed thereof that exhibit longer lining life, greater hot strength and reduced tendency to spall under high thermal loading conditions. The invention is designed to slow or retard the reaction between spinel and lime through the addition of zirconia in the form of an alumina-zirconia grain to the refractory mix. Zirconia reacts more readily with the lime in the refractory composition and surrounding environment to form calcium zirconate.

Owner:BAKER REFRACTORIE

Cylinder head for an internal combustion engine

ActiveUS8061131B2Thermal inertiaShorten the lengthCylinder headsSilencing apparatusCylinder headCylinder block

A cylinder head adapted to be mounted to a cylinder block of an internal combustion engine has a cooling jacket at least partially integrated in the cylinder head. The engine has two groups of cylinders: inside cylinders and outside cylinders. Each cylinder has at least one exhaust port, each leading to an individual duct. Individual ducts of outside cylinders converge to form an outside combined duct. In a four-cylinder, individual ducts of inside cylinders converge to form an inside combined duct with the inside combined duct remaining separated from the outside combined duct by the cooling jacket. The inside combined duct is farther away from the mounting surface of the cylinder head to the cylinder block than the outside combined duct. The cooling jacket includes: upper, middle, and lower cooling jackets and connectors between the upper and lower cooling jackets.

Owner:FORD GLOBAL TECH LLC

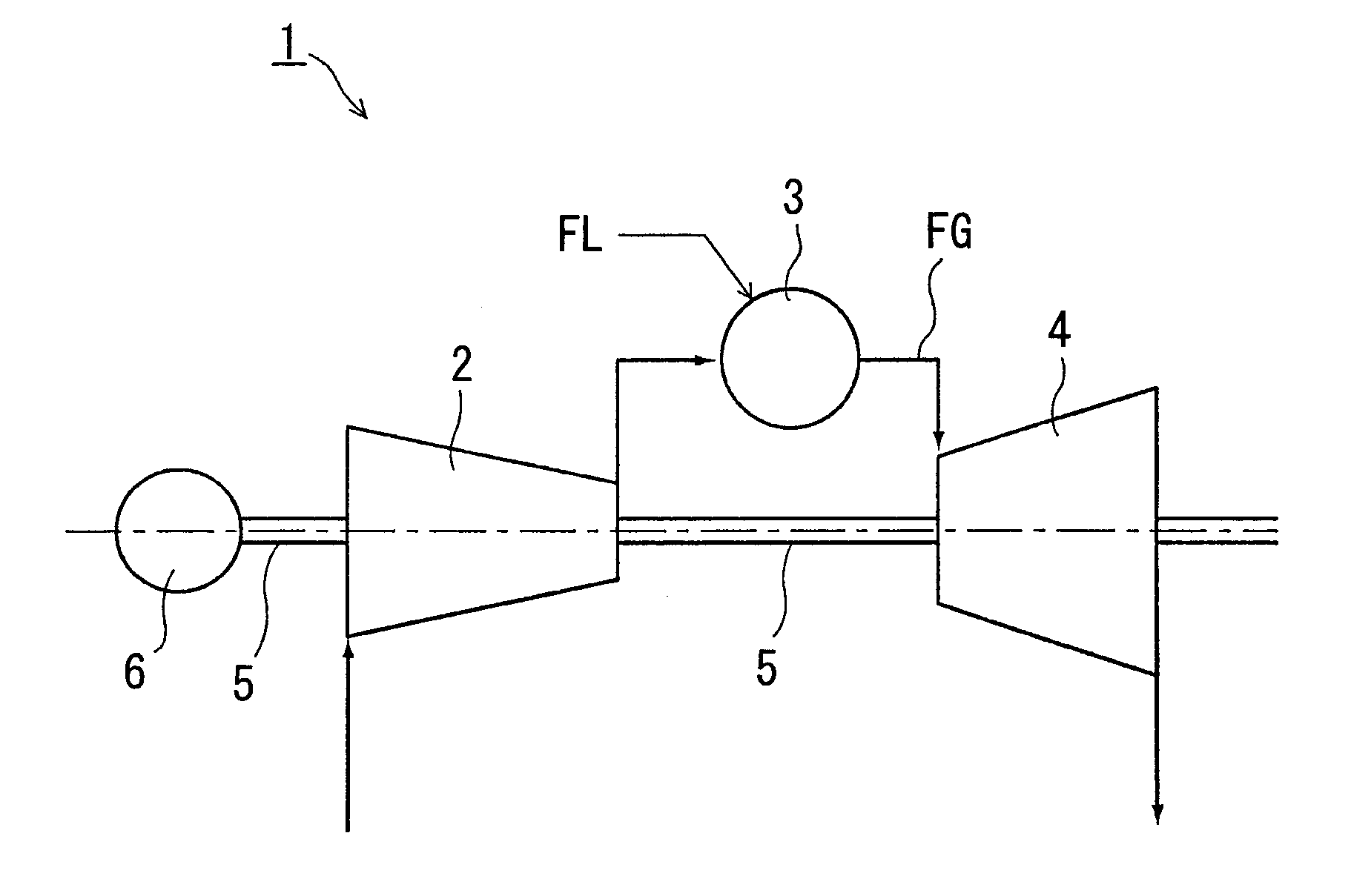

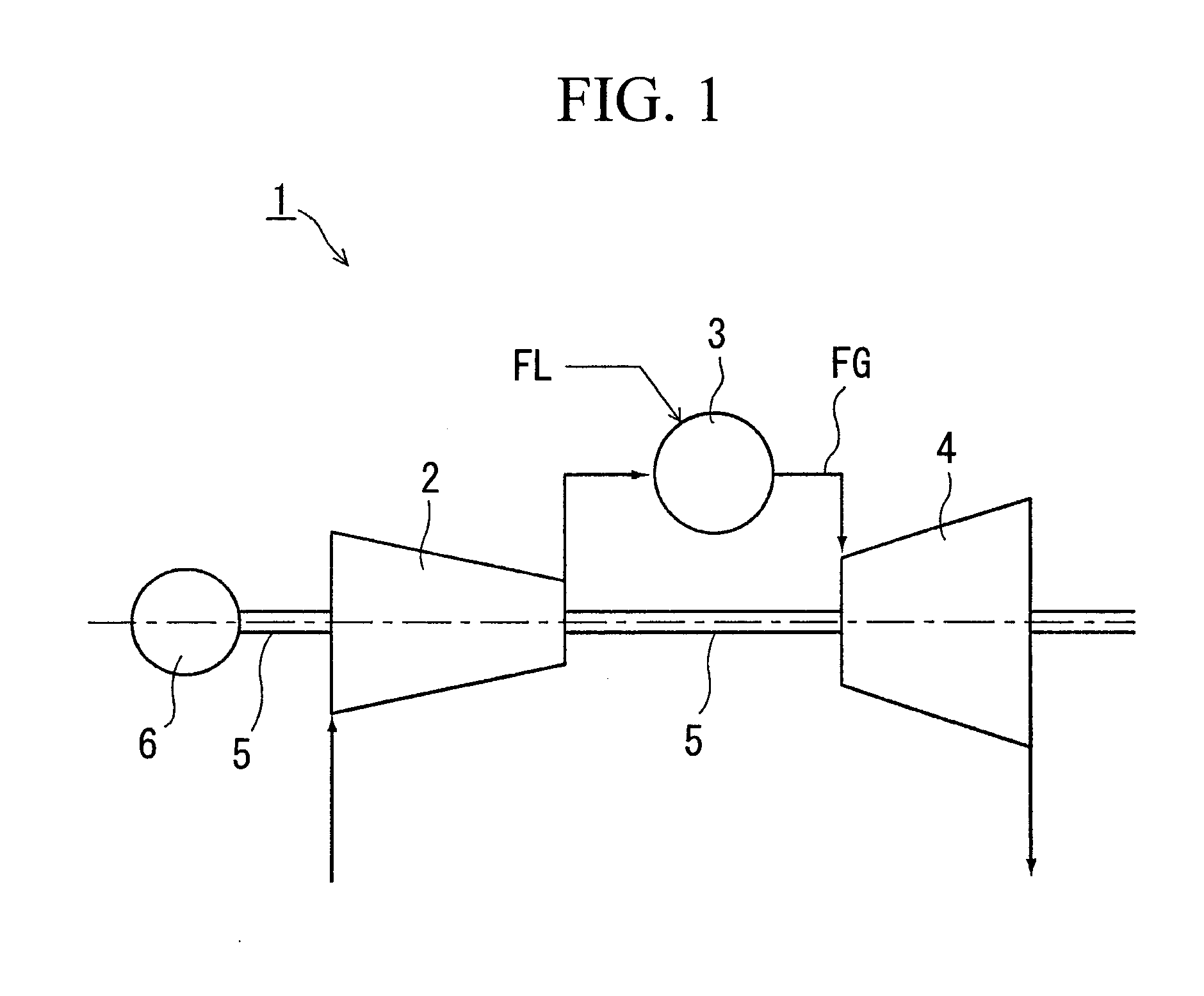

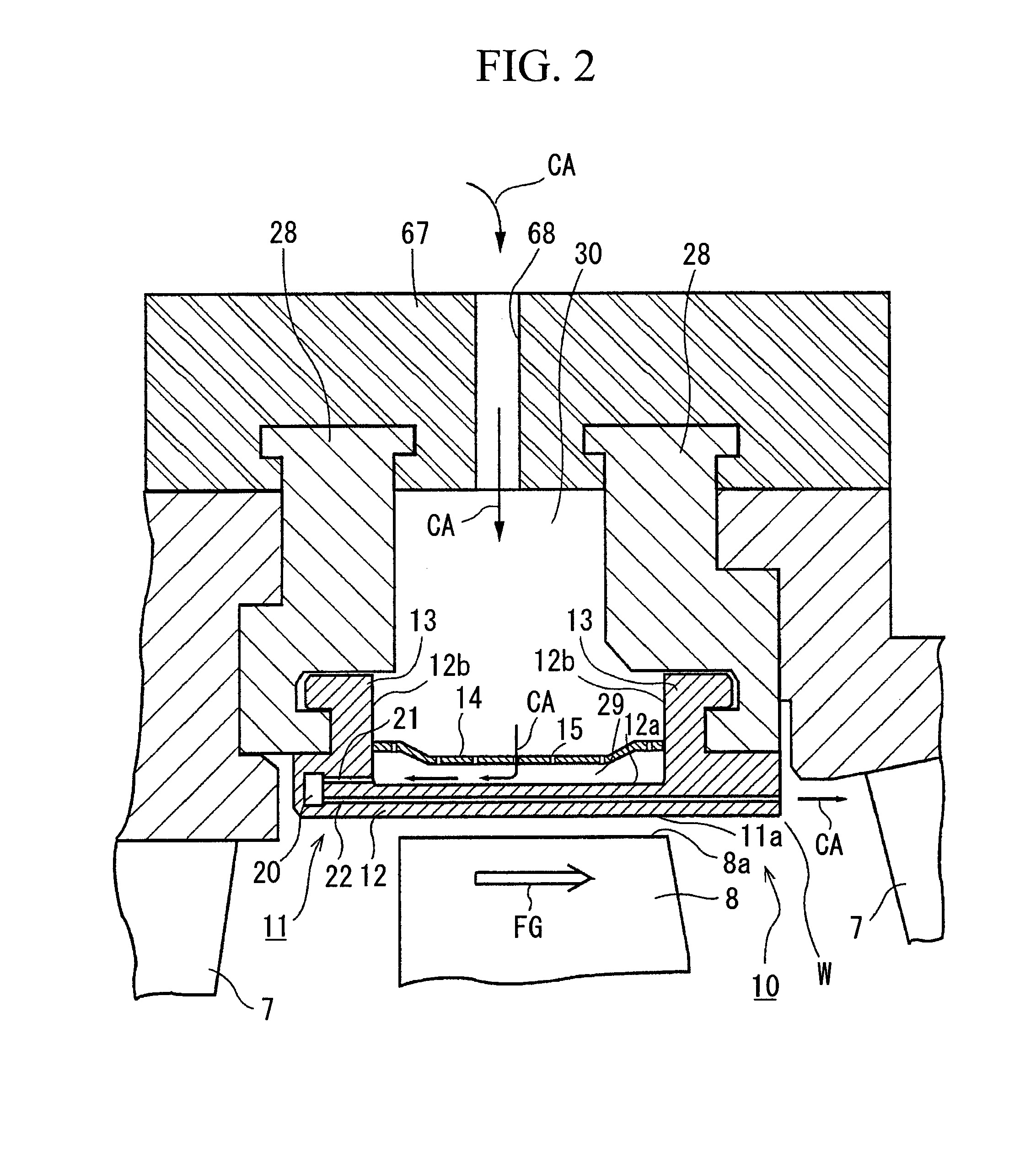

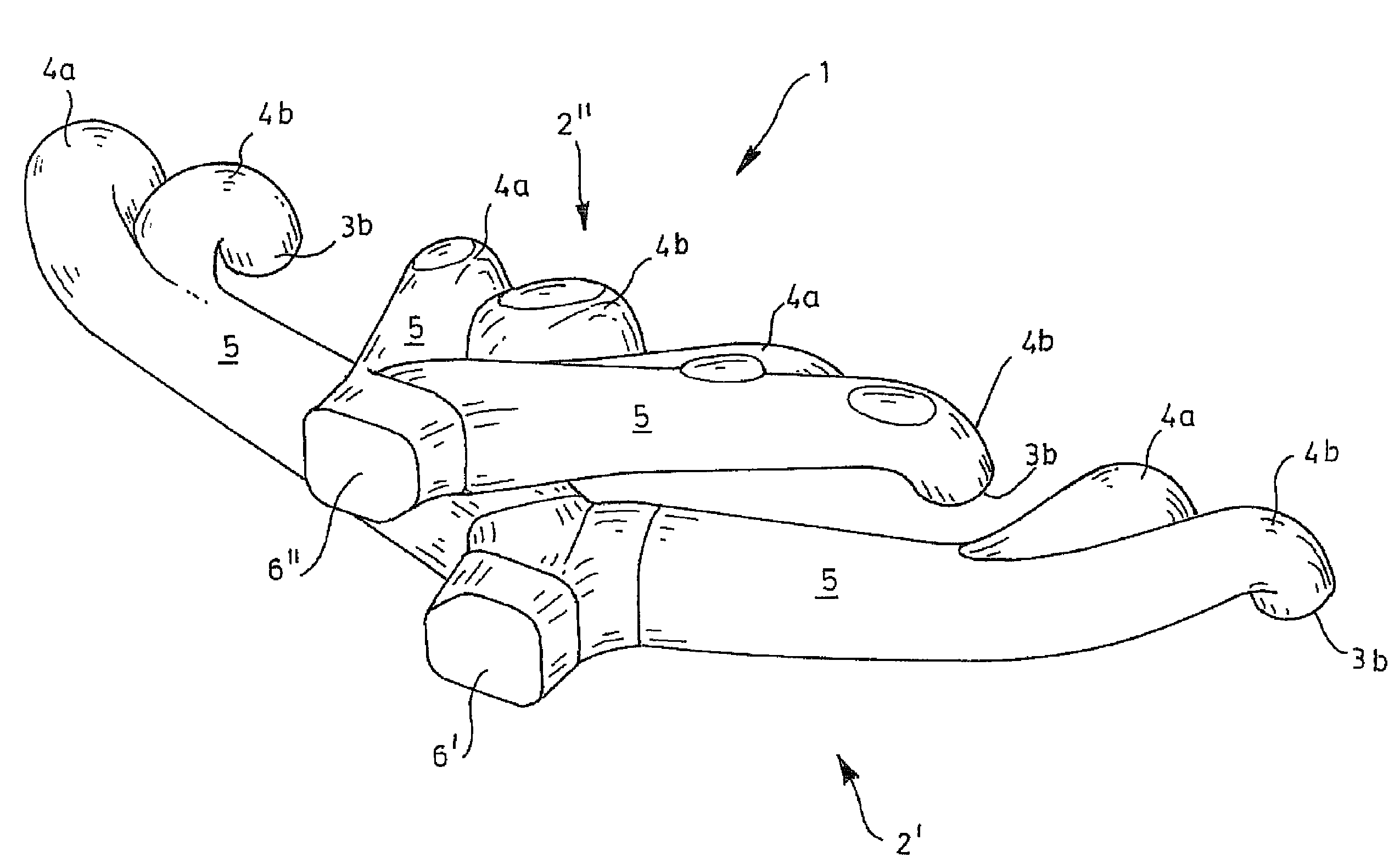

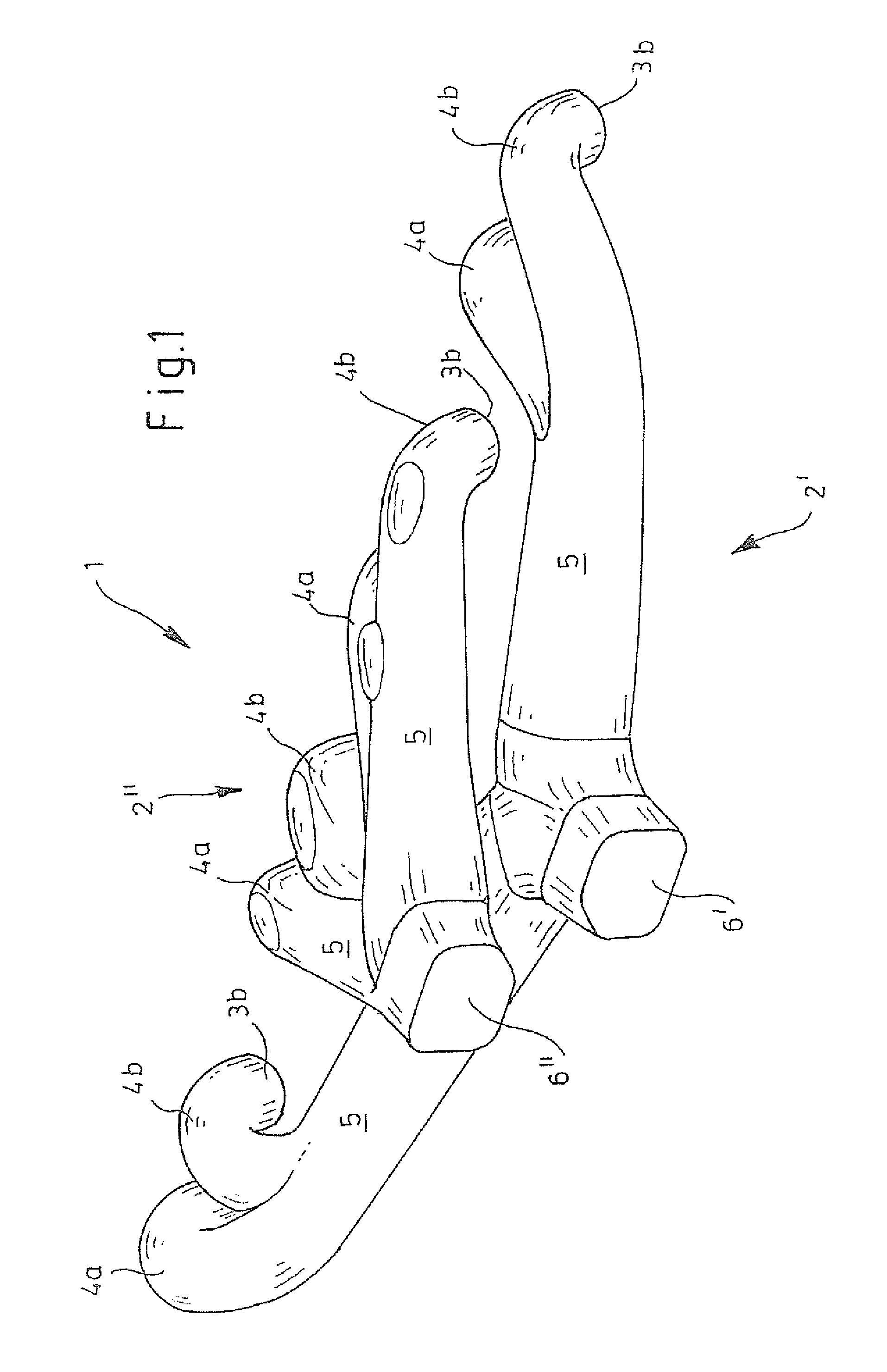

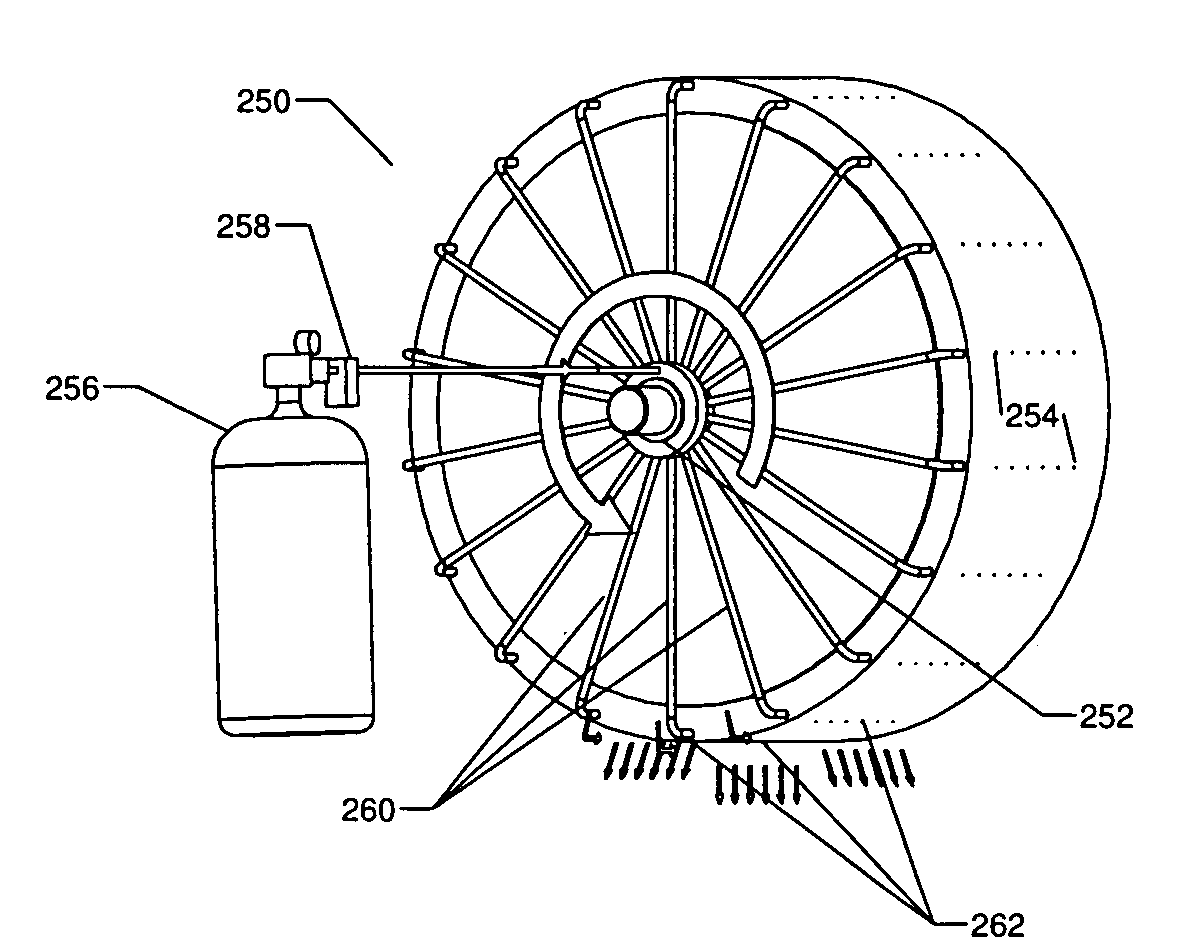

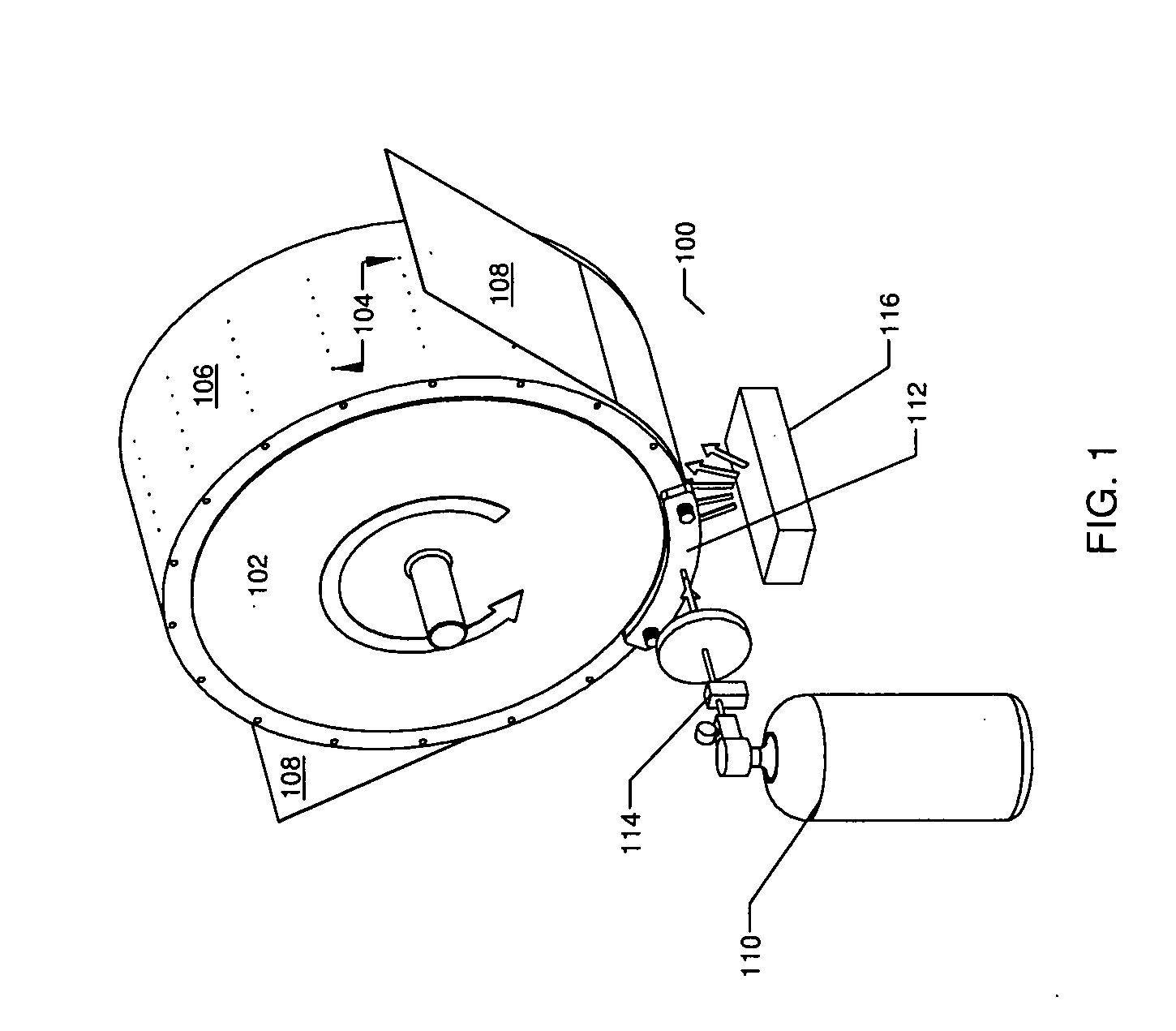

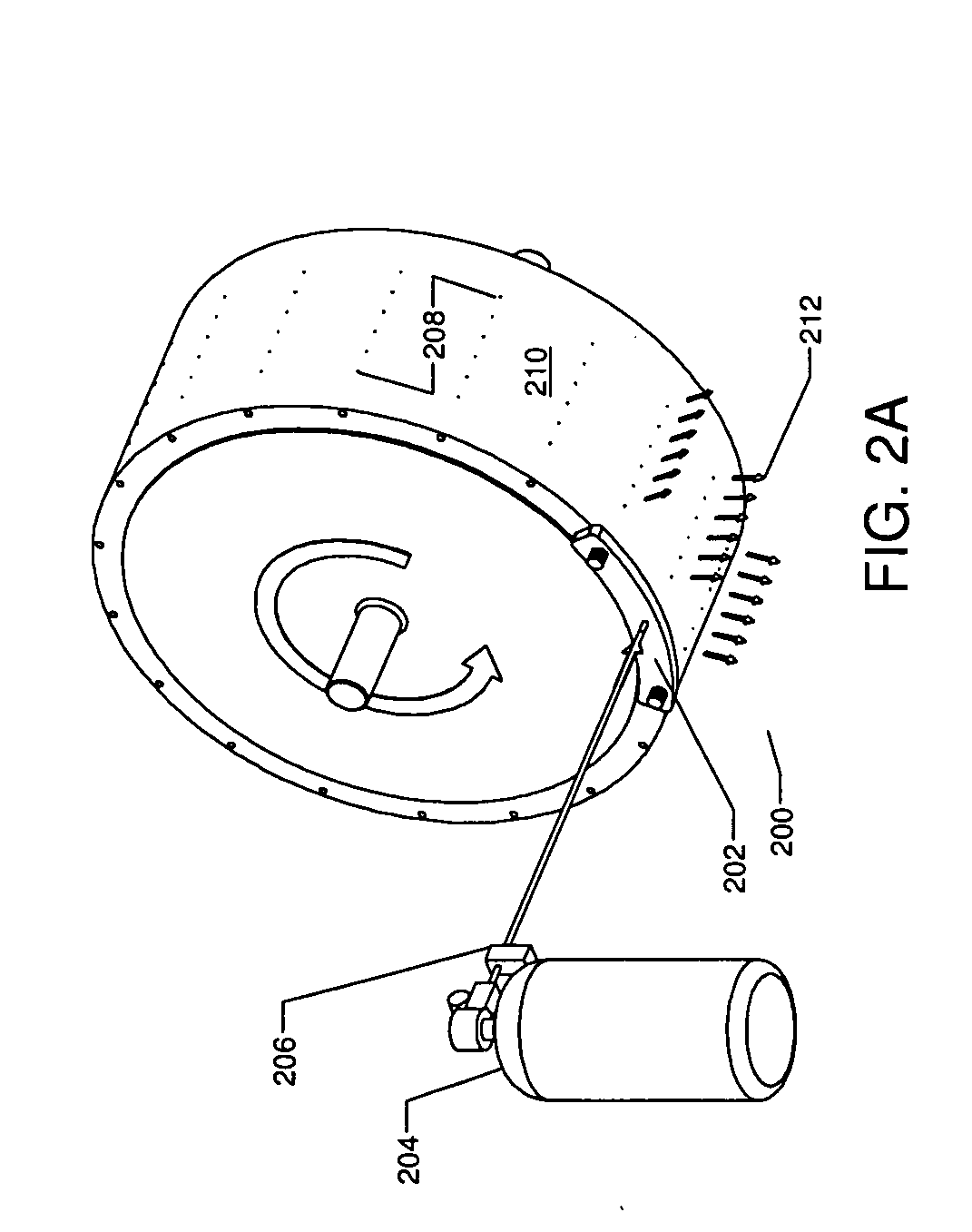

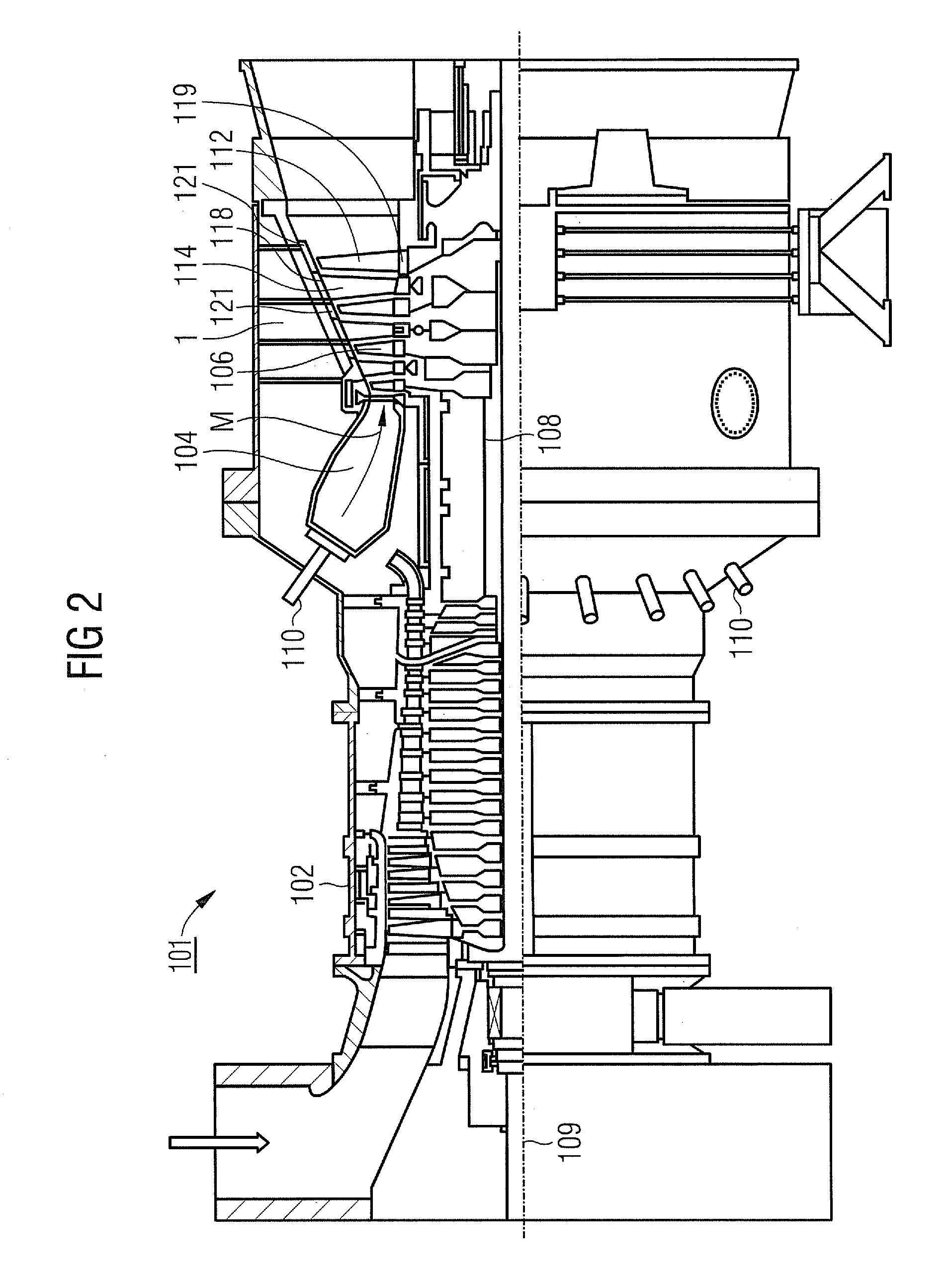

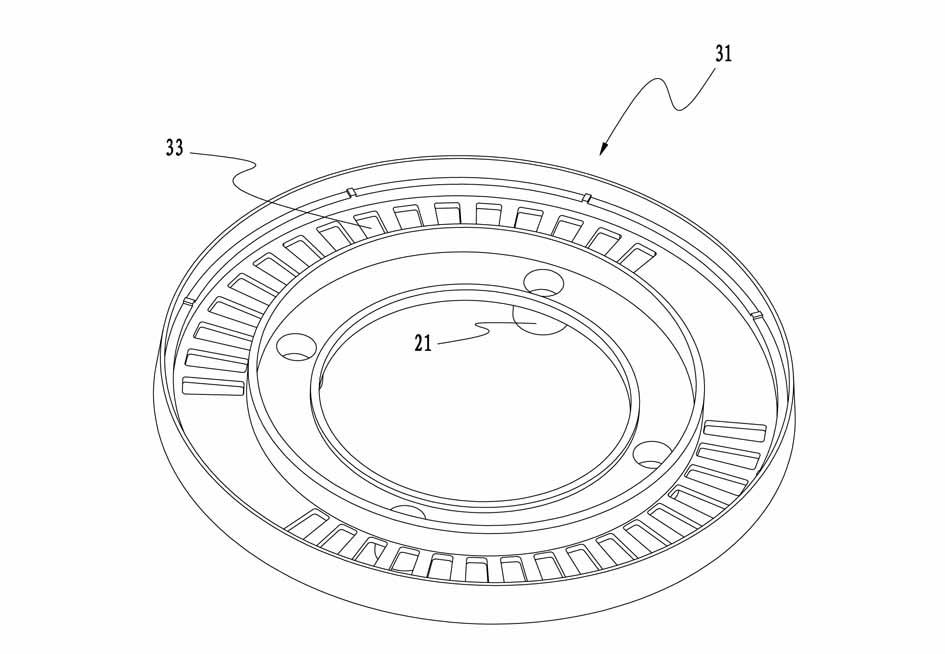

Turbomachine

InactiveUS7329084B2Increase heat loadUse directlyPump componentsEngine fuctionsEngineeringDistortion

Suitable means for driving a flow are arranged in annular or ring-segment-shaped cavities that are formed in particular in multi-shell casings of turbomachines. Arranged inside the cavity are ejectors that are supplied via suitable means with a motive-fluid flow which in turn excites the flow, preferably a circumferential flow or a helical flow. The invention is suitable in particular for avoiding casing distortions when turbomachines are at rest.

Owner:ANSALDO ENERGIA SWITZERLAND AG

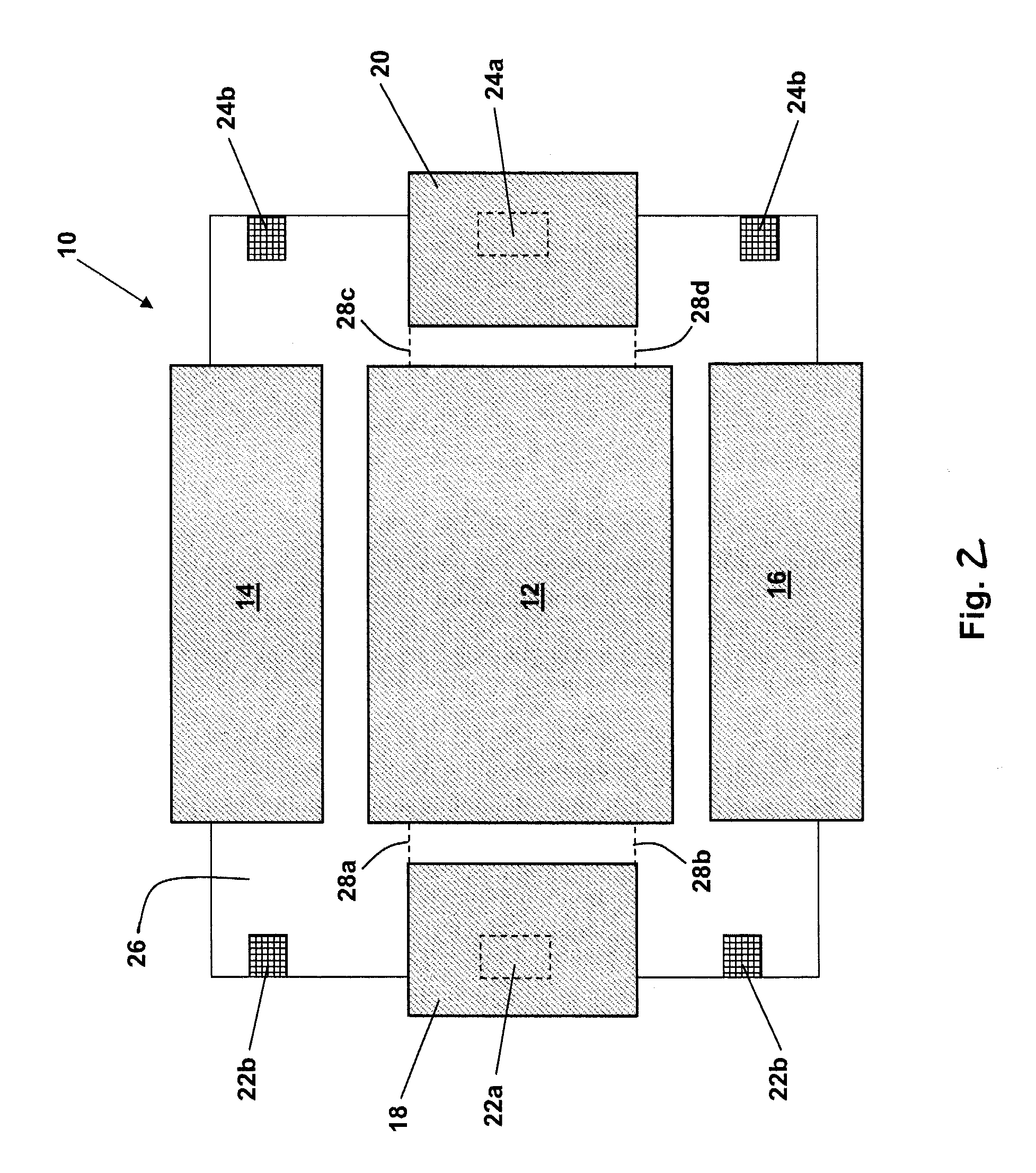

Web Substrate Deposition System

InactiveUS20100291308A1Increase heat loadIncrease speedCellsVacuum evaporation coatingProduct gasProcess engineering

A deposition system includes a drum for supporting a web substrate during deposition that defines a plurality of apertures in an outer surface for passing cooling gas. A gas manifold includes an input that is coupled to an output of a gas source and at least one output that is coupled to the plurality of apertures in the outer surface of the drum. The gas manifold provides gas to the plurality of apertures that flows between the outer surface of the drum and the web substrate, thereby increasing heat transfer from the web substrate to the drum. At least one deposition source is positioned so that material deposits on the web substrate.

Owner:VEECO INSTR

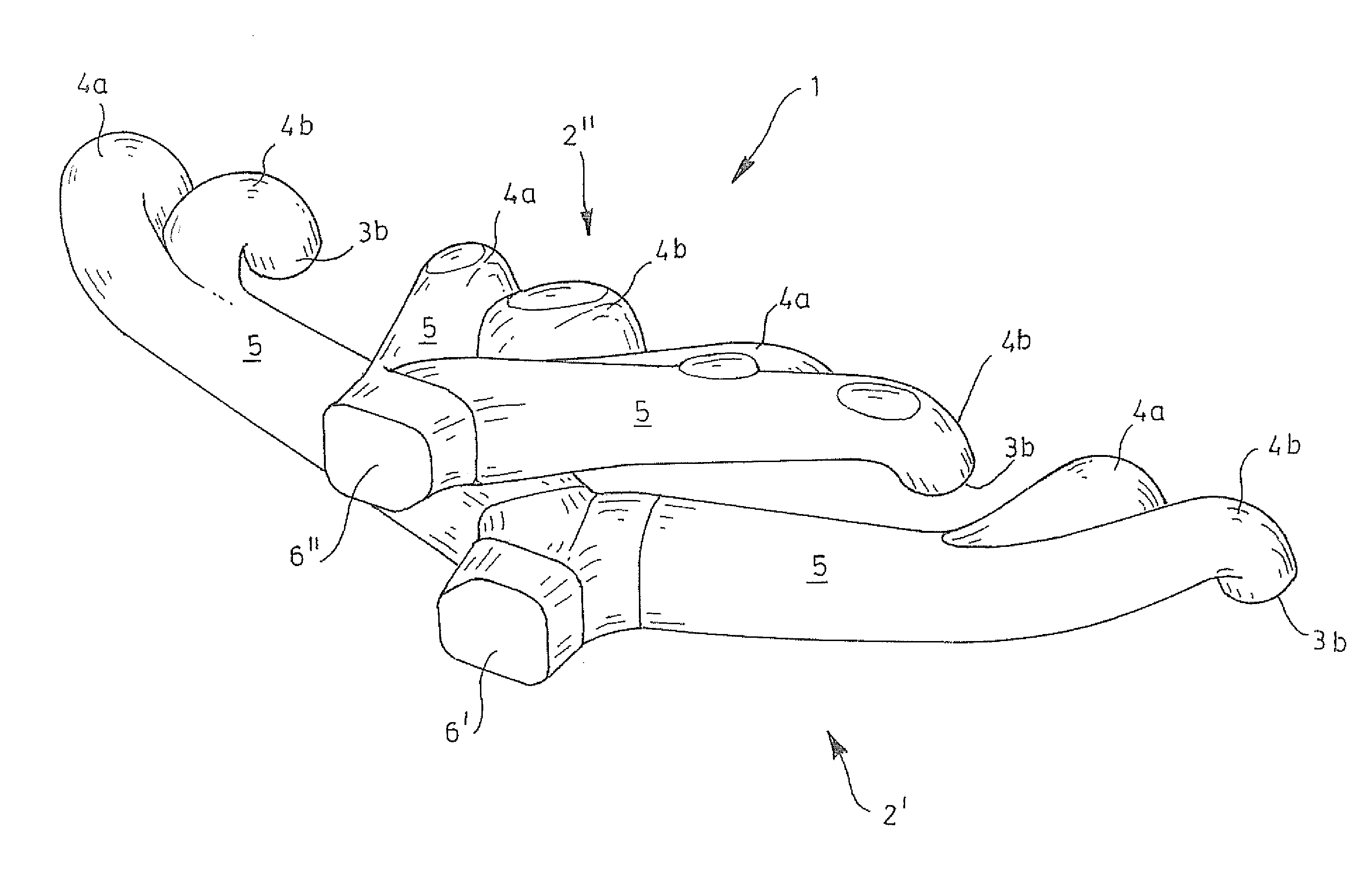

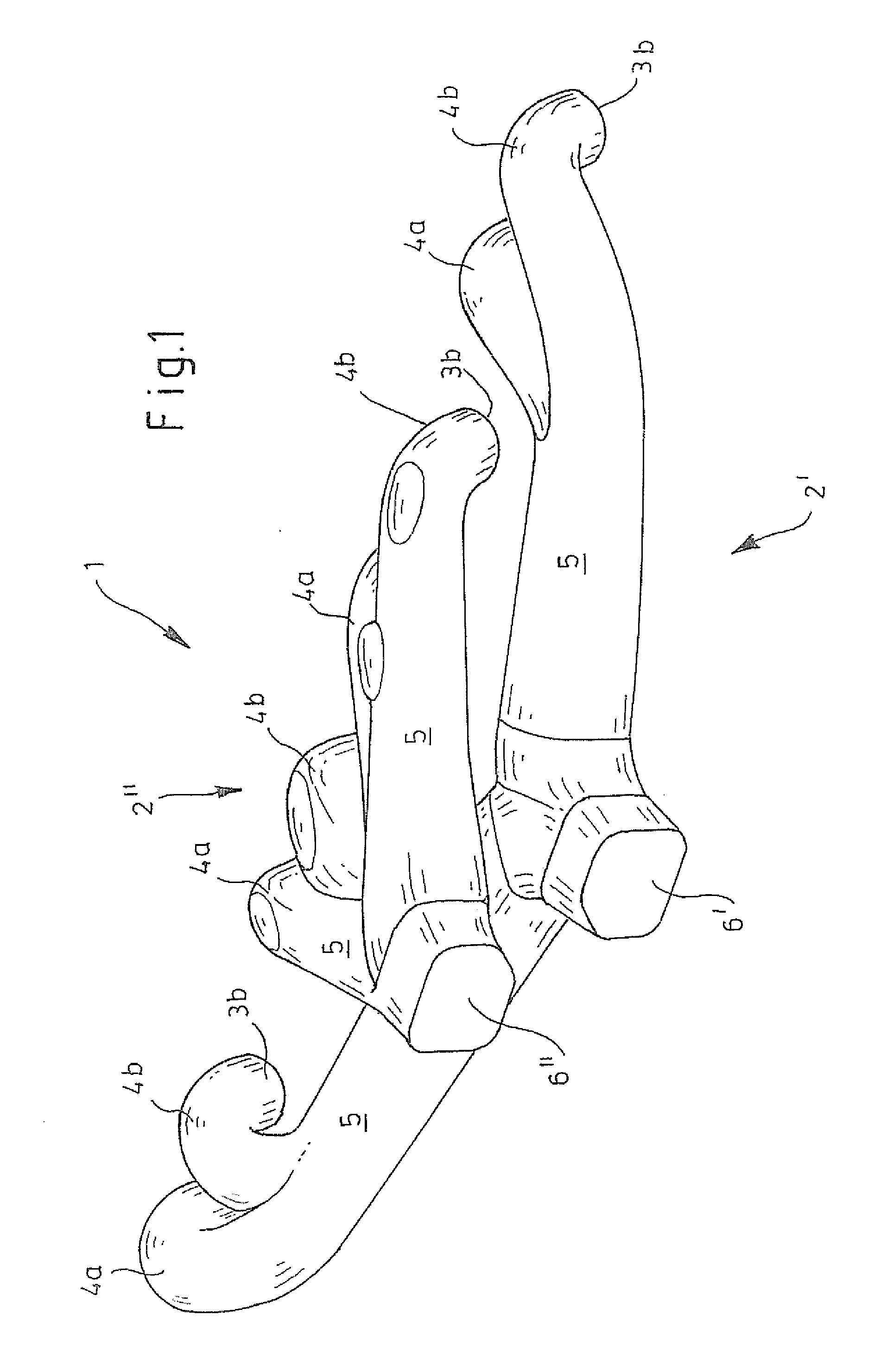

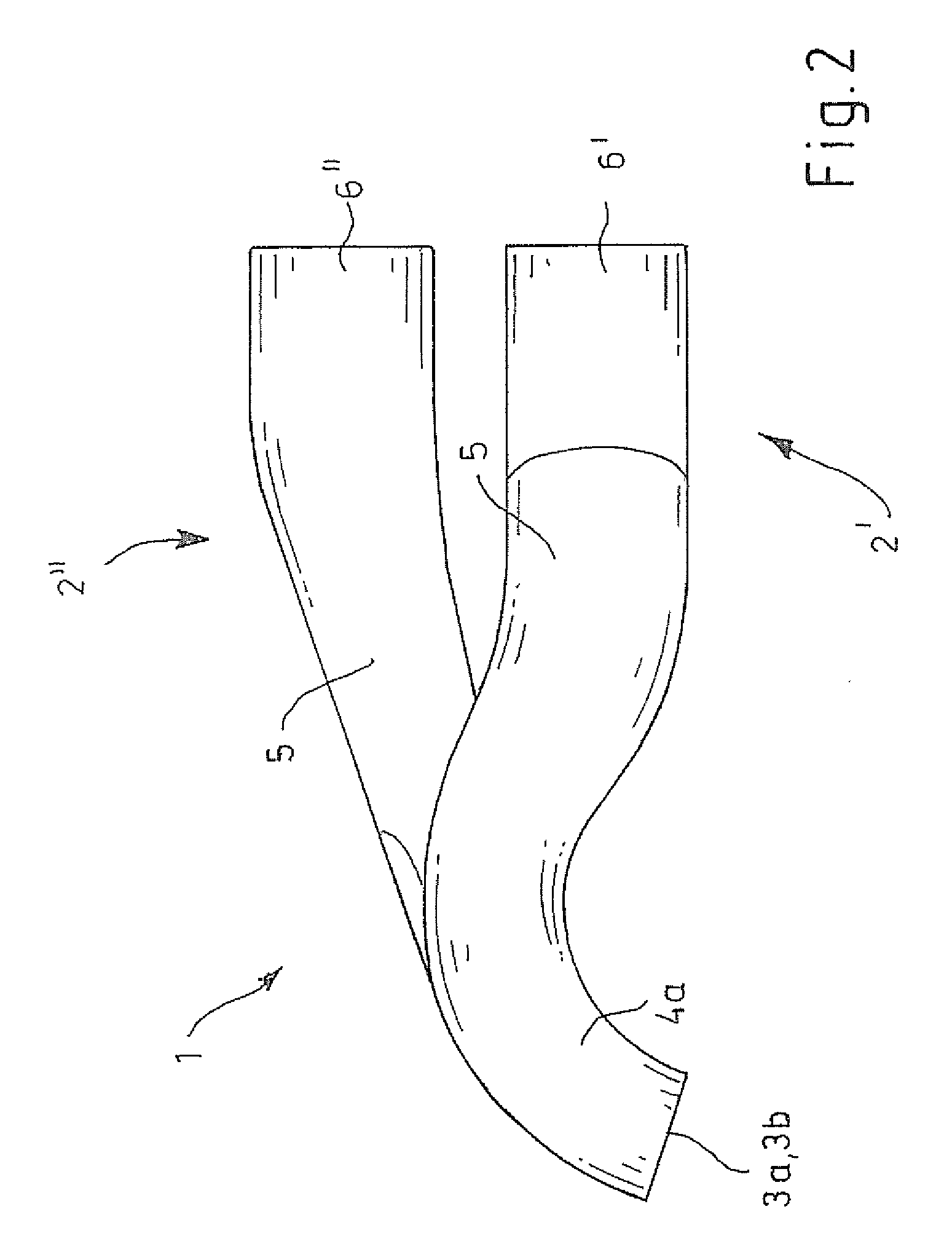

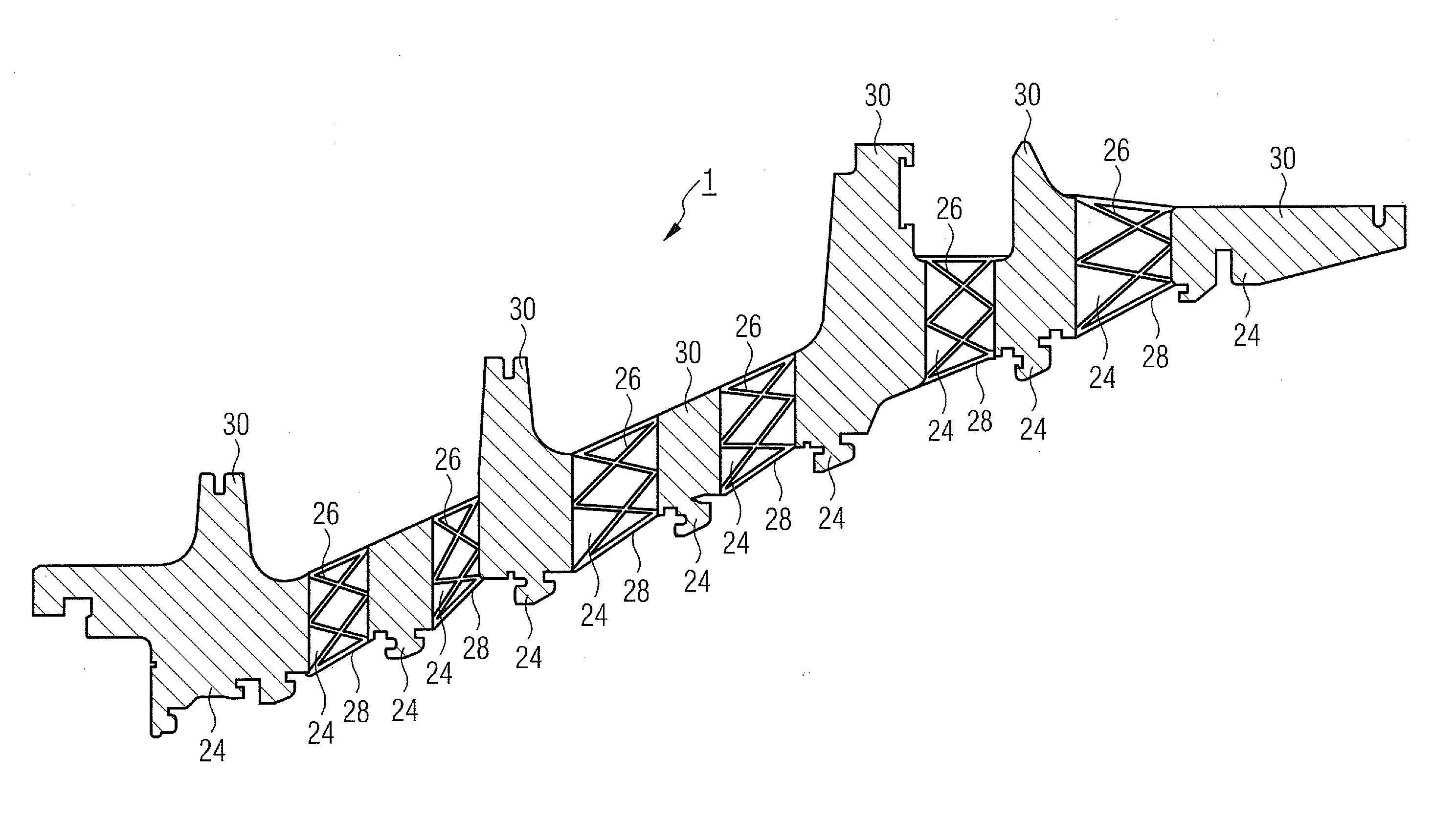

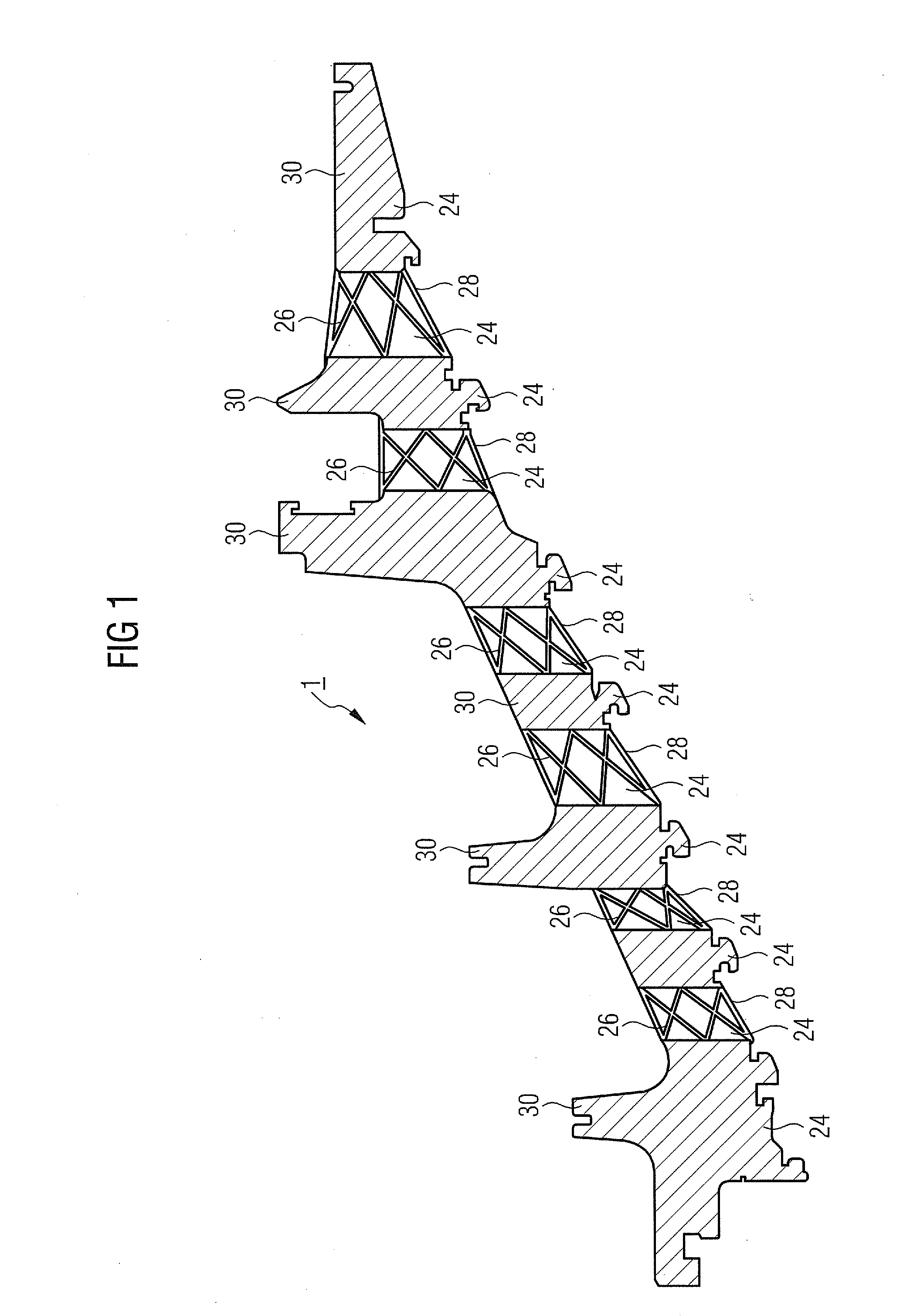

Axially segmented guide vane mount for a gas turbine

InactiveUS20110268580A1Temperature impactEasy constructionPump componentsStatorsEngineeringOperational safety

A stator blade carrier for a gas turbine is provided. The stator blade carrier includes a plurality of axial segments. At least one axial segment is designed as a tubular lattice structure. This allows a simpler design technically and a more flexible adaptation to the temperature profile present on the stator blade carrier to maintain operational safety.

Owner:SIEMENS AG

Top-intake burner of gas cooker

InactiveCN102661606AImprove combustion performanceImprove combustion thermal efficiencyDomestic stoves or rangesStoves/ranges topsFuel gasGas stoves

The invention relates to a top-intake burner of a gas cooker. The top-intake burner comprises a burner support, a fire distribution seat and fire caps. The top-intake burner is characterized in that the burner support is combined by an lower support and an upper cover, at least two Venturi ejector pipes are formed, the openings of the Venturi ejector pipes are correspondingly communicated with primary air inlets with an upward opening, a single gas nozzle is mounted in the primary air correspondingly and is disposed right against the center of one of the the Venturi ejector pipes, the other end of the gas nozzle is communicated with a gas inlet pipe, one Venturi ejector pipe is communicated with a fire distribution chamber of the fire distribution seat through one gas guide pipe or multiple gas guide pipes, and an air passage is reserved between the upper cover of the burner support and the fire distribution seat. The top-intake burner is reasonable in structural design, efficient and energy saving, is capable of realizing precision supply of primary and secondary air and complete and stable burning of the gas, and is especially suitable for embedded household gas stoves.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI +1

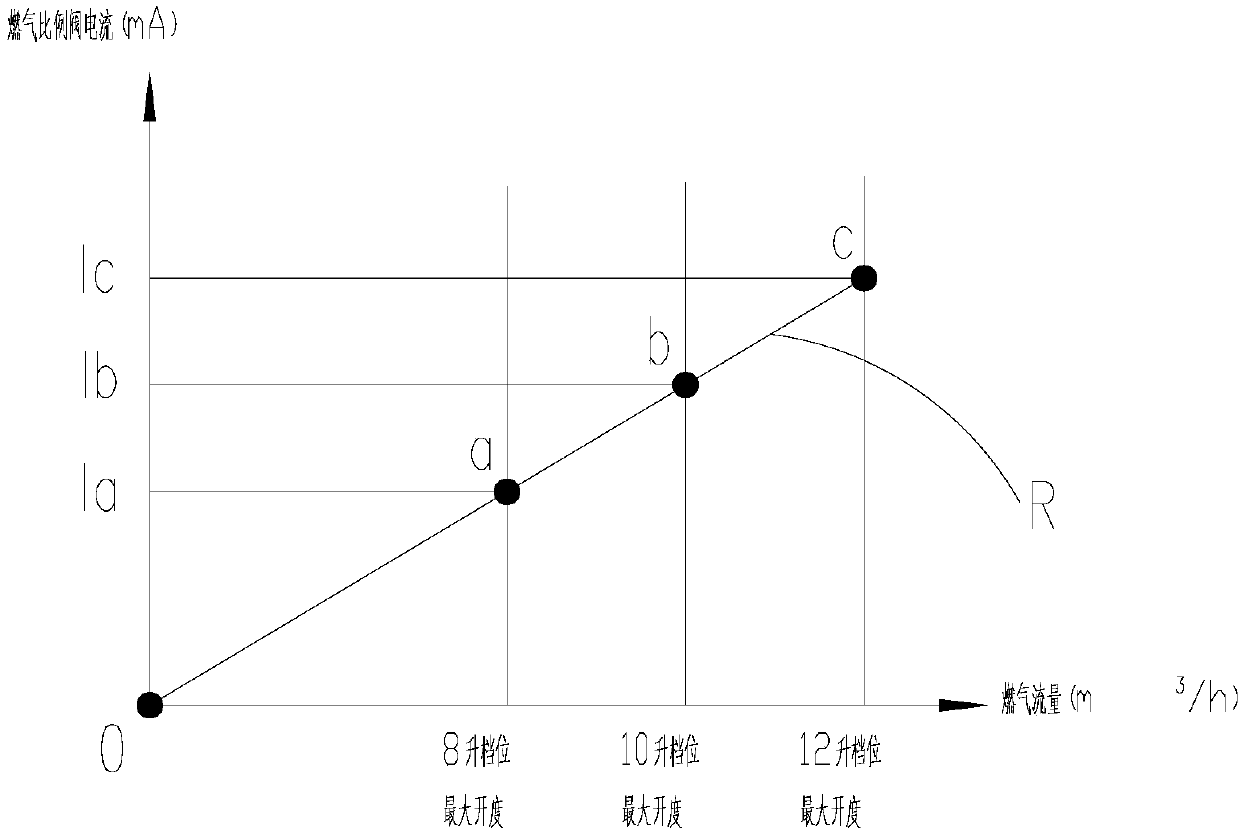

Intelligent gas water heater with lifting function

PendingCN107781978AMeet the water needs of different occasionsMeeting water needsWater heatersWater useThermodynamics

The invention discloses an intelligent gas water heater with a lifting function. The intelligent gas water heater comprises a gas water heater body, a gas proportional valve, a main controller and anoperation display, wherein the gas proportional valve is arranged on a gas supply channel of the gas water heater body, and the main controller is arranged on the gas water heater body. The gas proportional valve and the operation displayer are electrically connected with the main controller, the main controller changes the gas flow opening degree by adjusting the working current of the gas proportional valve so as to control the heat load of the water heater, a temperature setting key is arranged on the operation display, and the main controller automatically sets the maximum opening degree of the gas proportional valve at the preset temperature according to the preset temperature preset by the temperature setting key. The main controller changes the gas flow opening degree by adjusting the working current of the gas proportional valve so as to control the heat load of the water heater, the maximum opening degree of the gas proportional valve is automatically set to be different fromthe preset temperature according to the preset temperature, and the lifting number suitable for users to use can be automatically set according to the preset temperature, so that the water requirements of the users on different occasions can be met.

Owner:VATTI CORP LTD

Heat sink

InactiveUS20060237167A1Solve the low heat dissipation efficiencyIncrease heat loadIndirect heat exchangersHeat exhanger finsEngineeringHeat spreader

Owner:DELTA ELECTRONICS INC

Safety switching device and method for failsafe shutdown of an electric load

InactiveUS7573693B2Easy to installIncrease heat loadEmergency protective arrangement detailsOvervoltage protection resistorsVoltage spikeSwitching signal

Owner:PILZ (COMPANY)

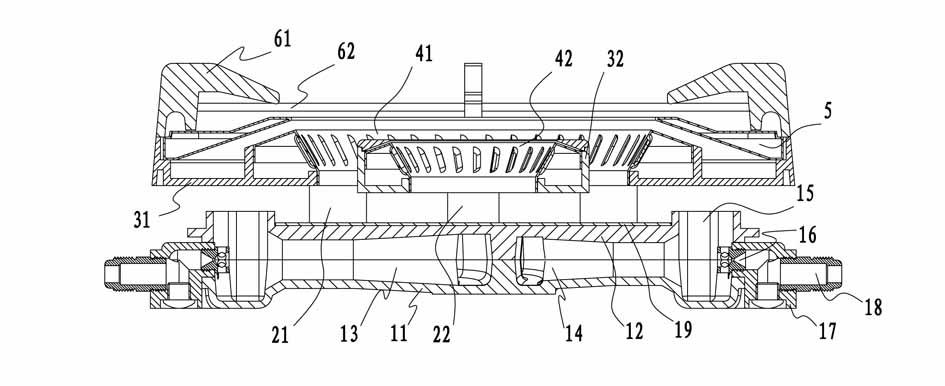

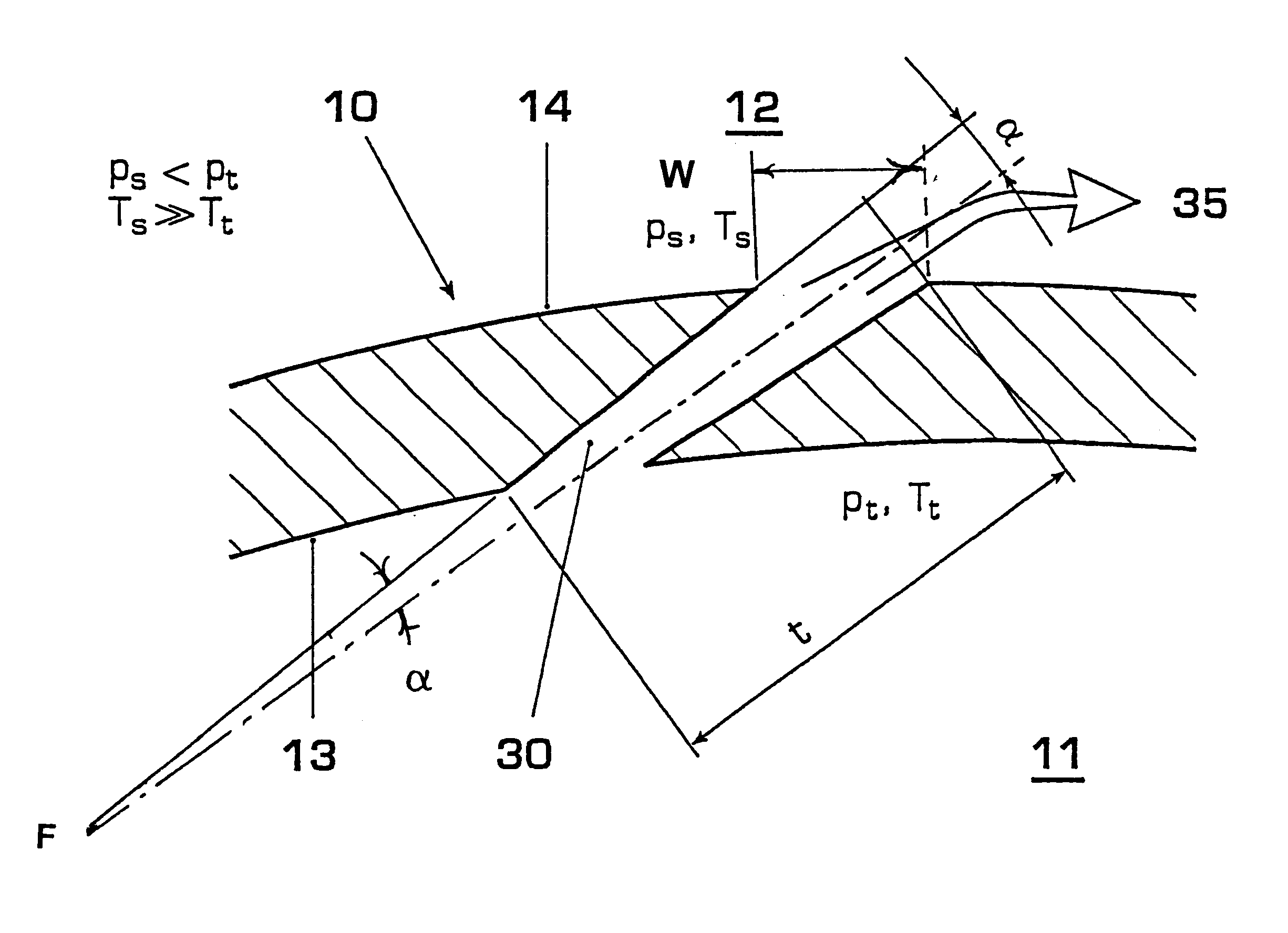

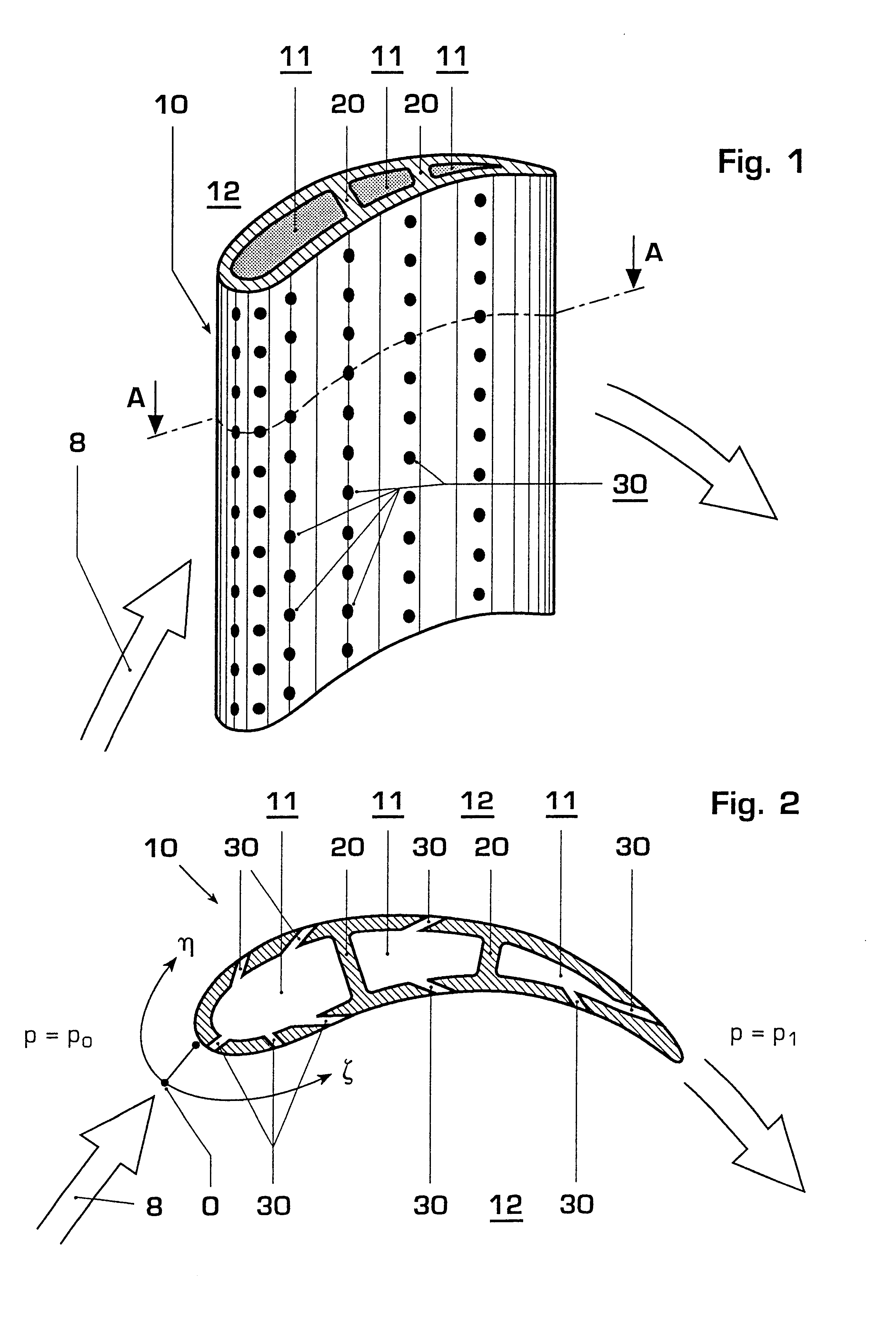

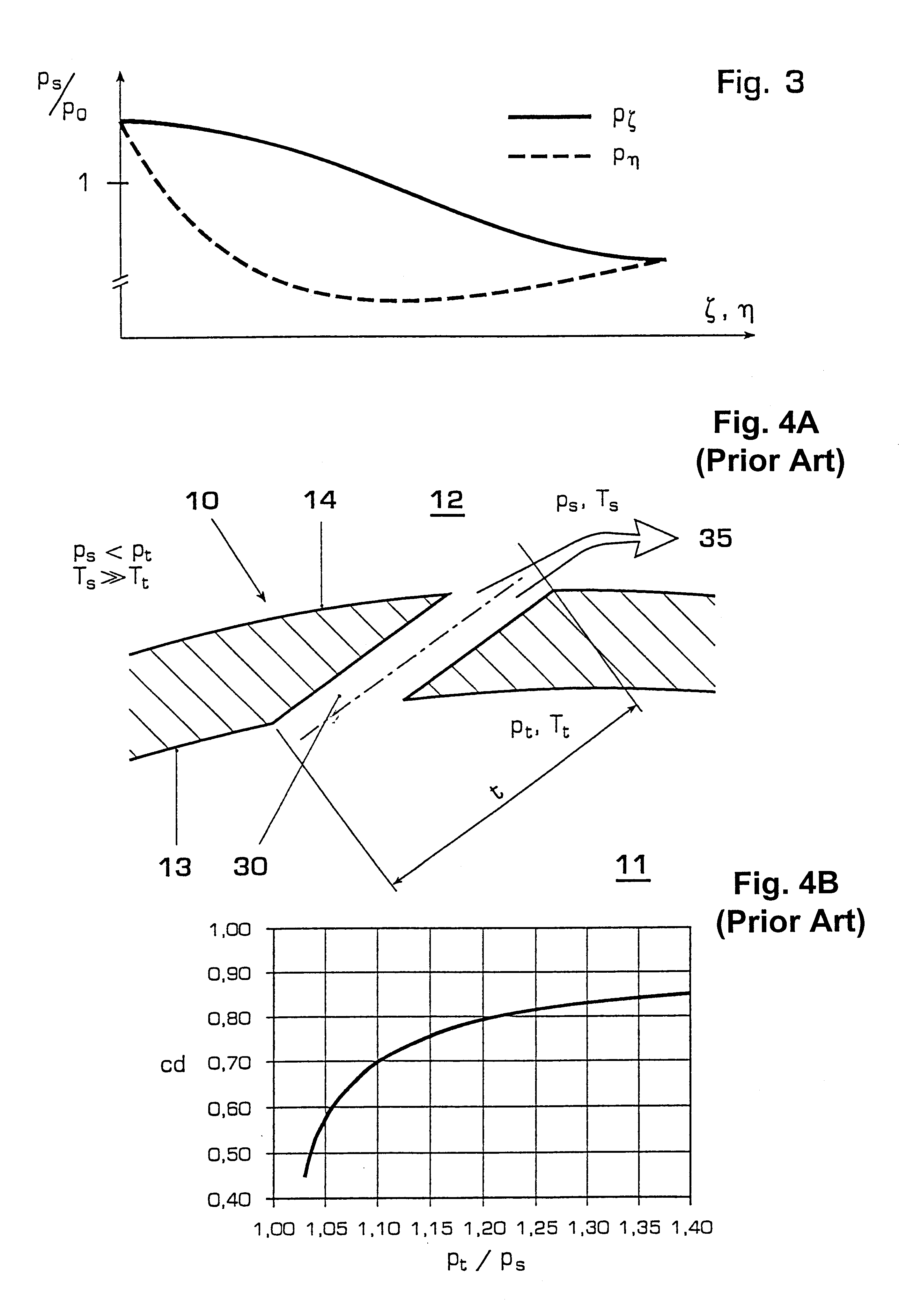

Cooled components with conical cooling passages

InactiveUS6923247B1High product precisionIncrease heat loadPropellersEngine manufactureMachiningCooling channel

A thermally highly loaded machine component (10), which is protected from overheating by film cooling, is provided with conical cooling passages (30) of circular cross section. The cooling passages are designed so as to be divergent from the cold-gas side (13) toward the hot-gas side. The conical cooling passages, as compared with cylindrical passages with regard to the mass flow of cooling medium (35) fed through the cooling passages, are substantially less dependent on the pressure ratio between the cold-gas side (13) and hot-gas side (14) of the component. The straight conical cooling passages of round cross section throughout may be produced in a very simple manner by laser drilling, with a convergent cutting beam being used for the machining.

Owner:ANSALDO ENERGIA IP UK LTD

Closed circulatory phase-change heat supply system for heat and power cogeneration

InactiveCN101994531APrevent penetrationIncrease heat loadSteam useEnergy industryThermal energyWater storage tank

The invention provides a closed circulatory phase-change heat supply system for heat and power cogeneration, comprising a boiler, a turbine generator set, a heat accumulator, a heat device, a drain tank, a water storage tank, an economizer and an assorted connection pipe, a water pump, a control valve and the like. A steam pipe of the boiler for steam supply is connected with a steam inlet of the heat accumulator and a steam inlet of the turbine generator set; a steam supply inlet of the heat accumulator and a steam pumping and exhausting outlet of the turbine generator set are respectively connected with a steam inlet of the heat device to ensure that the heat accumulator adjusts the load of a heat supply system; the condensate water of the heat device is collected in the water storage tank after passing through the drain tank via a condensate water pipe; and a water outlet pipe of the water storage tank is connected to the economizer of the boiler, therefore, an enclosed circulatory heat supply system is formed. During the running of the system, the condensate water is not flashed and lost under the saturated high-temperature state, therefore, the heat utilization rate of the system is improved, both the whole system and the running are simplified, and the project investment and the operation cost are reduced.

Owner:刘绍允

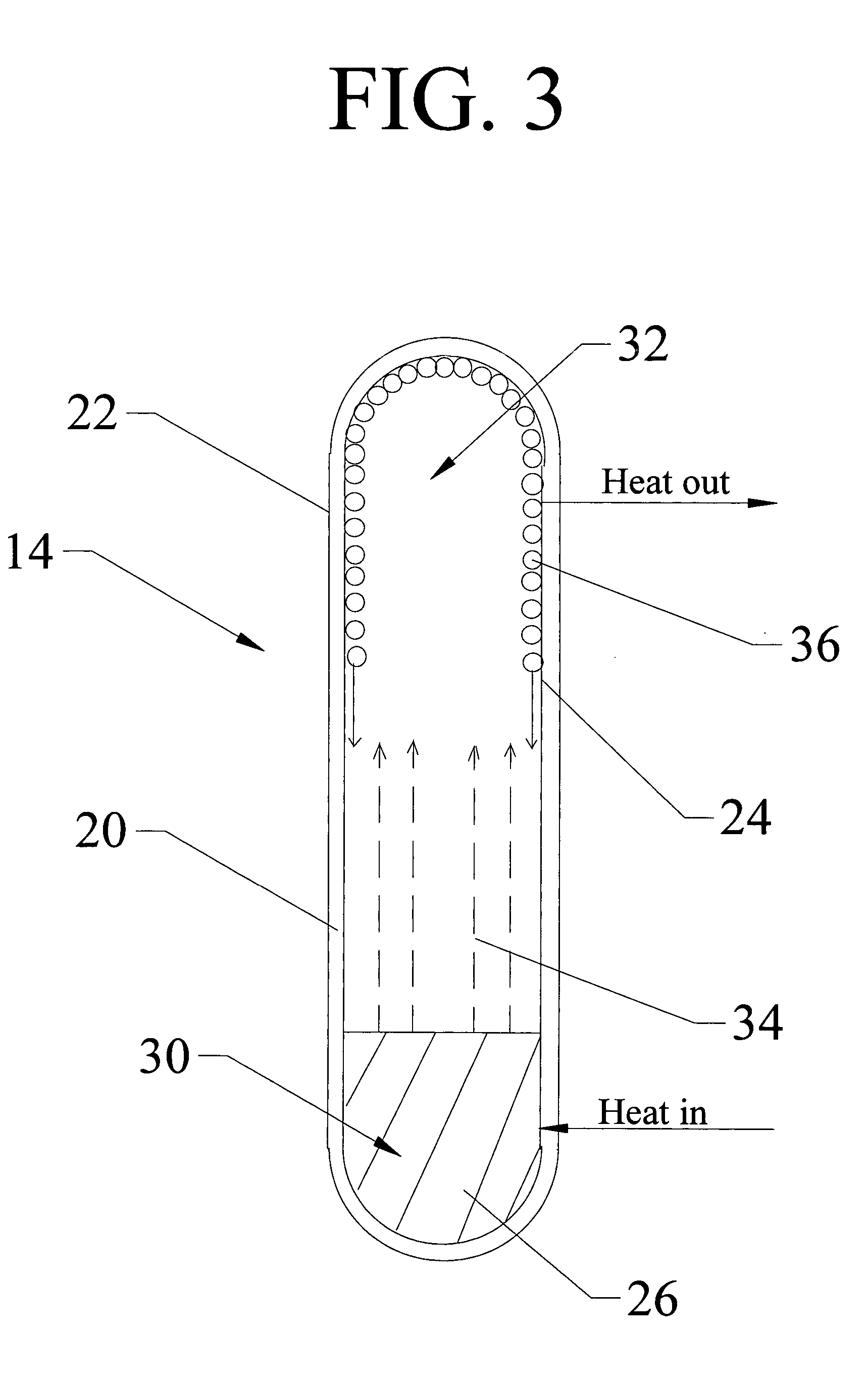

Heat sink, assembly, and method of making

InactiveUS20050135062A1Reduce system sizeLow costSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A heat sink, method of making a heat sink, and a heat sink assembly. The heat sink includes a base and a plurality of heat pipes that extend from the base. The base is dimensioned and shaped to promote good thermal contact with the heat source, and the heat pipes are attached thereto in such a manner as to promote good thermal contact to the working fluid. Each heat pipe includes an outer surface and an inner surface that form a condenser portion from which from heat is transferred during condensation of the working fluid.

Owner:AALL POWER HEATSINKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com