Heat sink

a technology of heat sink and heat sink, which is applied in the direction of indirect heat exchangers, heat exhanger fins, lighting and heating apparatus, etc., can solve the problems of insufficient forced convection to remove heat, affecting the efficiency of heat removal, and increasing heat, so as to achieve enhanced heat dissipation efficiency and return-flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

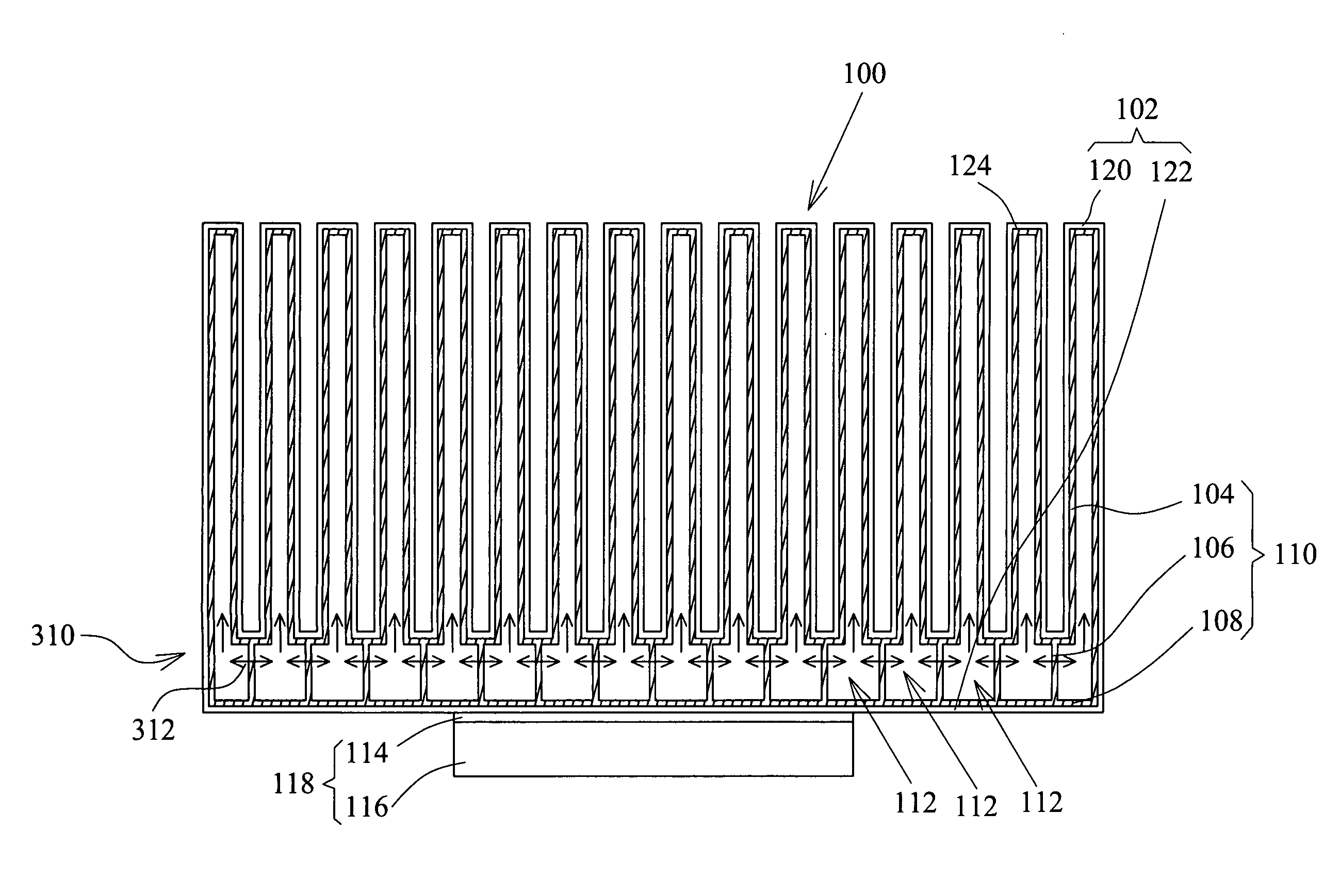

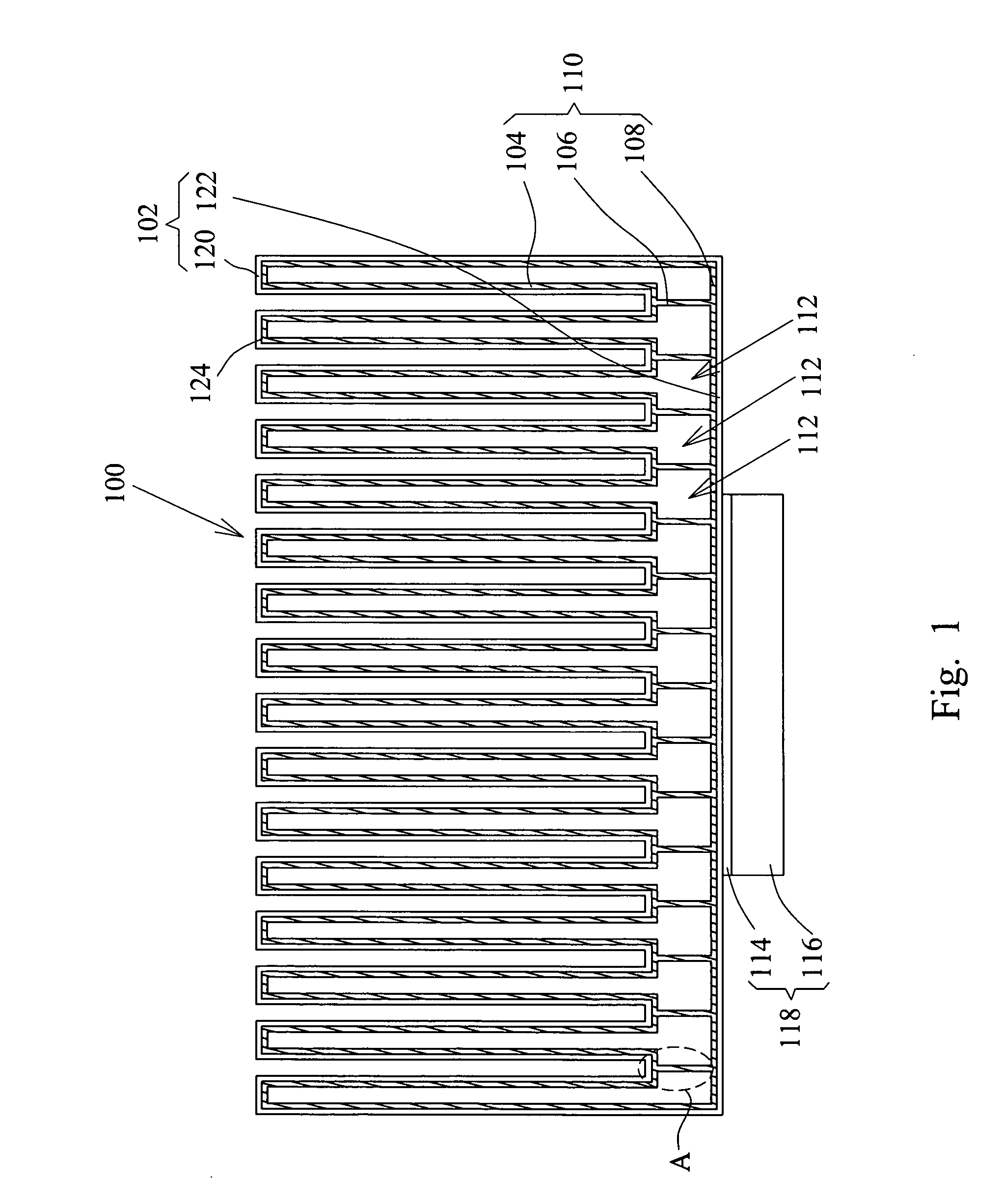

[0028] Referring to FIG. 1, a heat sink 100 includes a main body 102 and a plurality of porous structures 110 inside the main body 102, wherein the main body 102 has a closed room 124 formed therein.

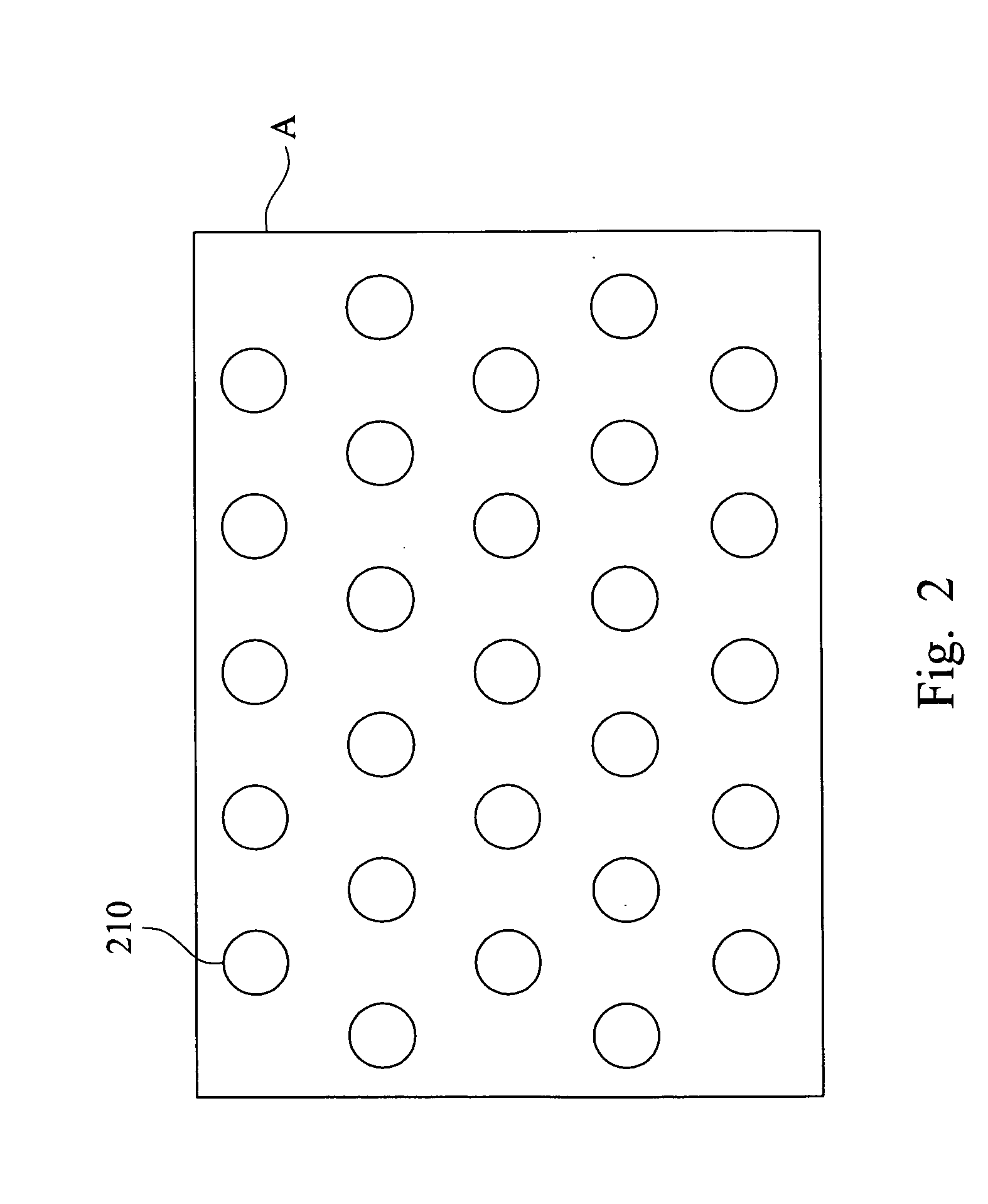

[0029] The main body 102 has a plurality of hollow protrusions 120 and a base 122 connecting to a heat source 118. The shape and / or size of the base 122 varies in accordance with the placement of the protrusions 120 and the shape of the heat source 118. Each protrusion 120 is hollow and has two ends; the end proximate the base 122 has an opening and the other end is closed. The protrusions 120 are in a shape of fin, column, lamella, cone, or lump; and in a form of curve, arch, slant, vertical, or any other form. The protrusions 120 and the base 122 of the main body 102 can be one-piece molded or jointed by soldering, engaging, embedding, adhering, or a combination of any of the methods listed thereof. Moreover, the closed room 124 can be divided into a plurality of vapor chambers 112 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com