Container insert incorporating thermally insulative panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

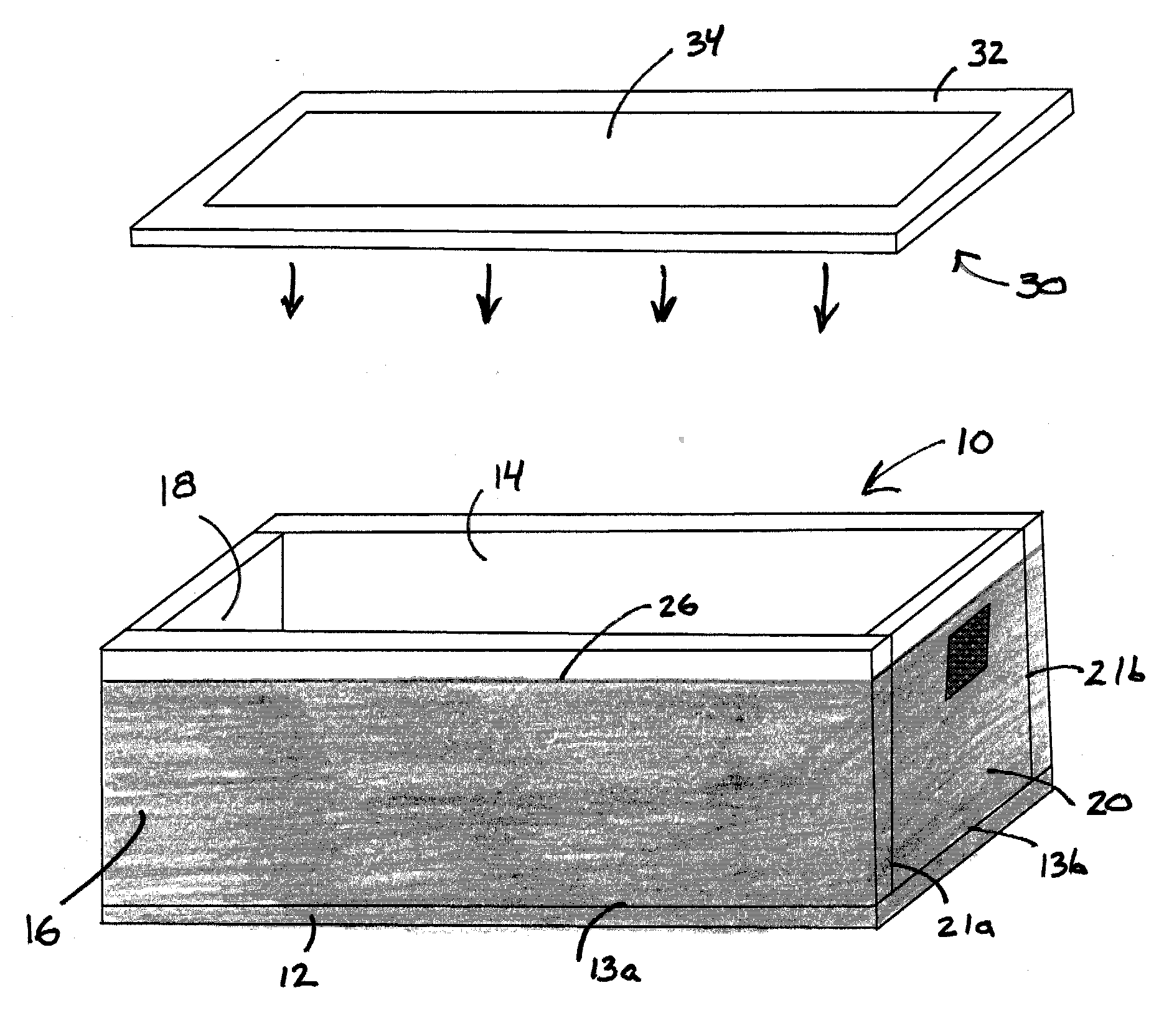

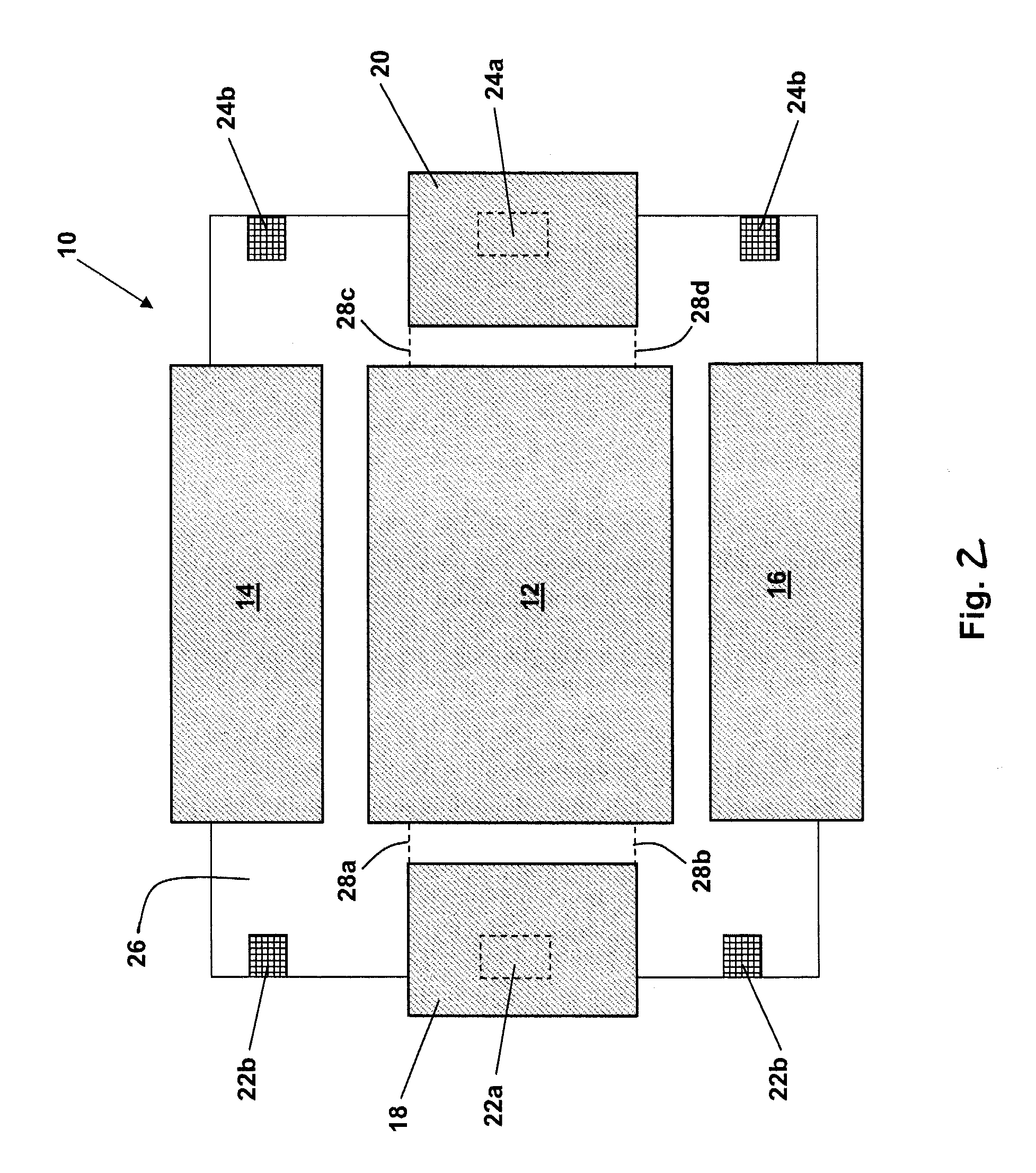

[0026]The present invention is directed to a container insert and a method for using the container insert to thermally insulate products contained therein. In this regard, the container insert includes thermally insulative panels that form the walls of the container insert.

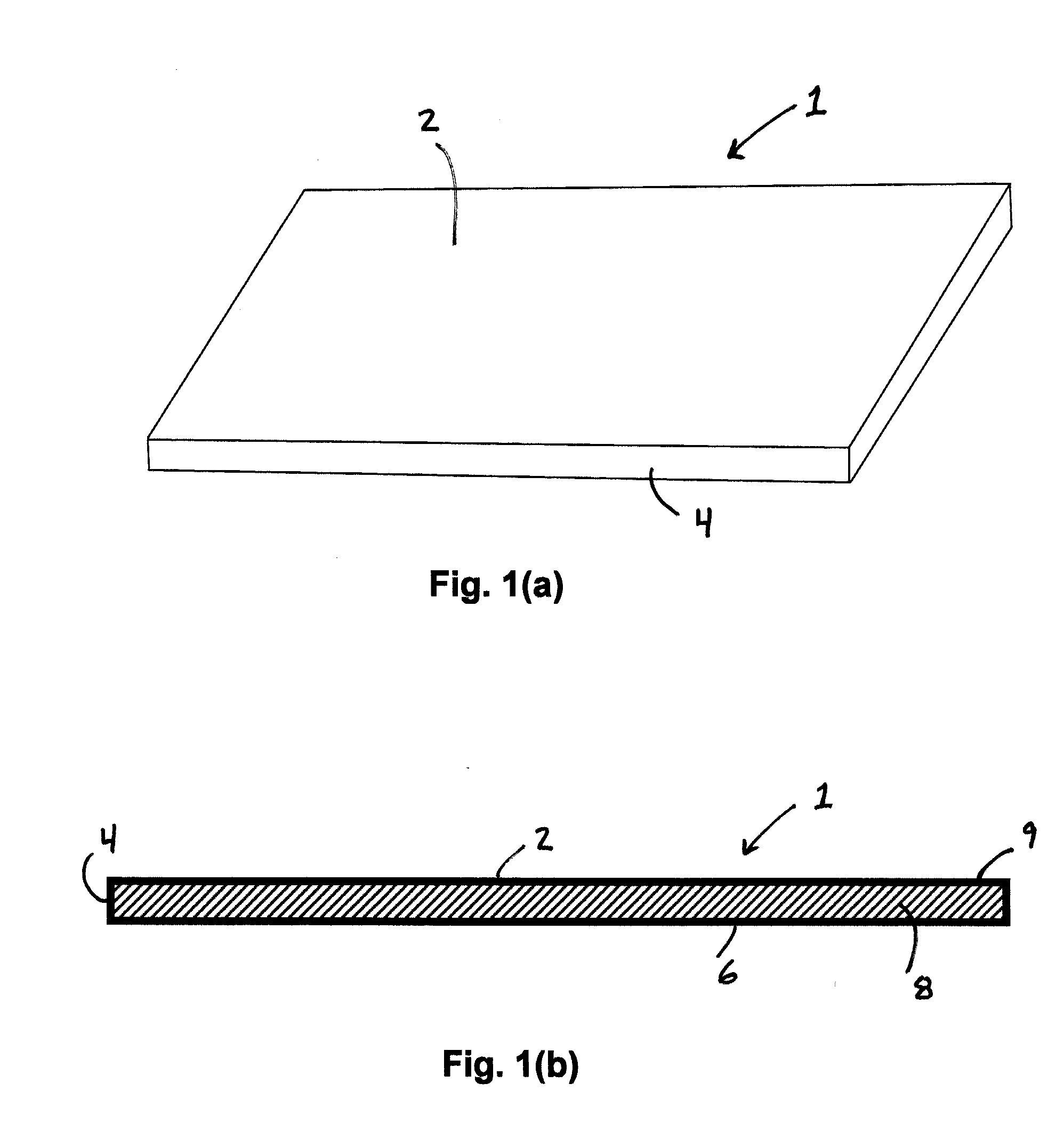

[0027]FIGS. 1(a) and 1(b) illustrate a thermally insulative panel that can be utilized in the container insert. The thermally insulative panel 1 is preferably rigid such that the panel can form a rigid wall of the container insert. The panel 1 includes a top surface 2 and a mutually opposed bottom surface 6. The thermal insulation panel also includes a peripheral edge surface 4 extending along the perimeter of the insulation panel 1. In one embodiment, the peripheral edge surface 4 can have a thickness of from about ¼ inch to about 2 inches.

[0028]In one particularly preferred embodiment, the insulative panel 1 is a vacuum insulation panel (VIP). In this regard, the insulative panel 1 includes a thermally insulativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com