Sludge drying and incinerating treatment process

A sludge drying and treatment method technology, applied in the direction of oxidation treatment of sludge, by-product vaporization, etc., can solve the problems of multiple harmful substances, polluting the environment, complex processes, etc., and achieve good safety, high heat utilization rate, and system structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

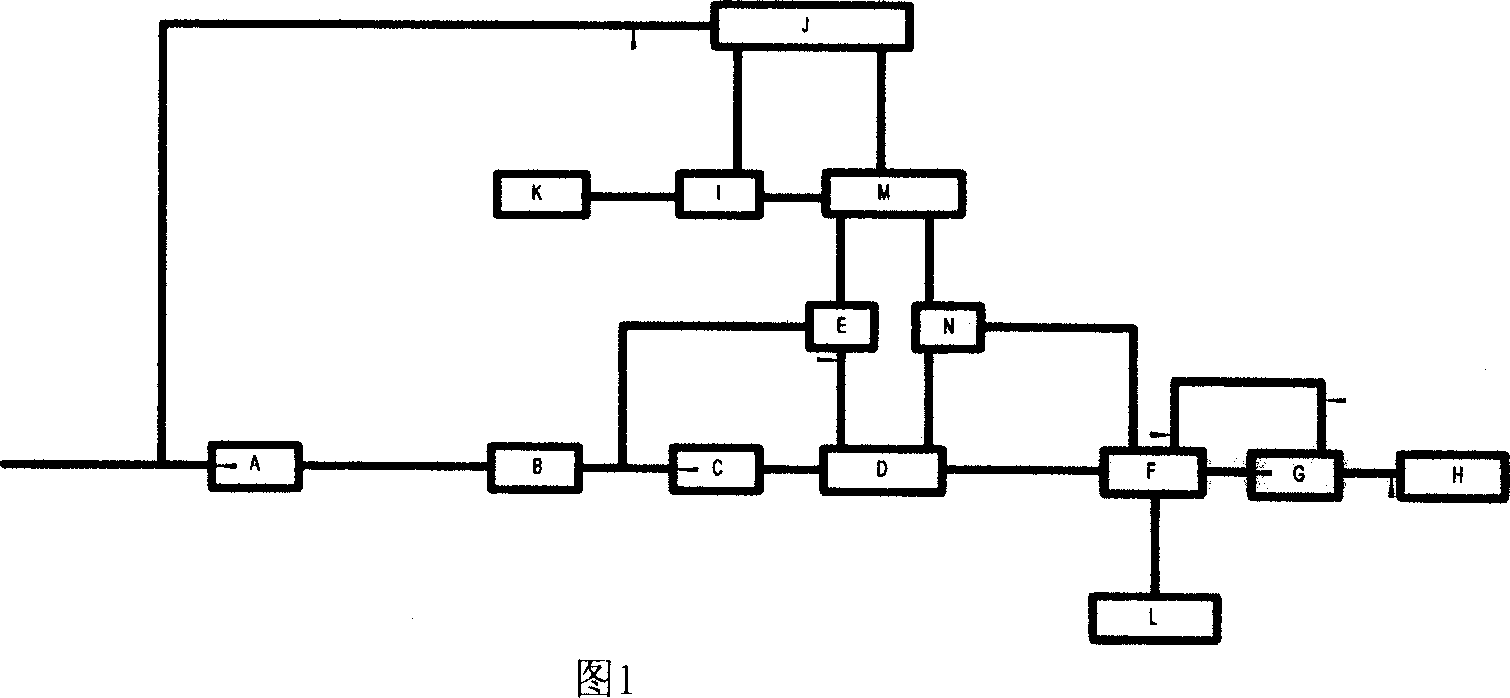

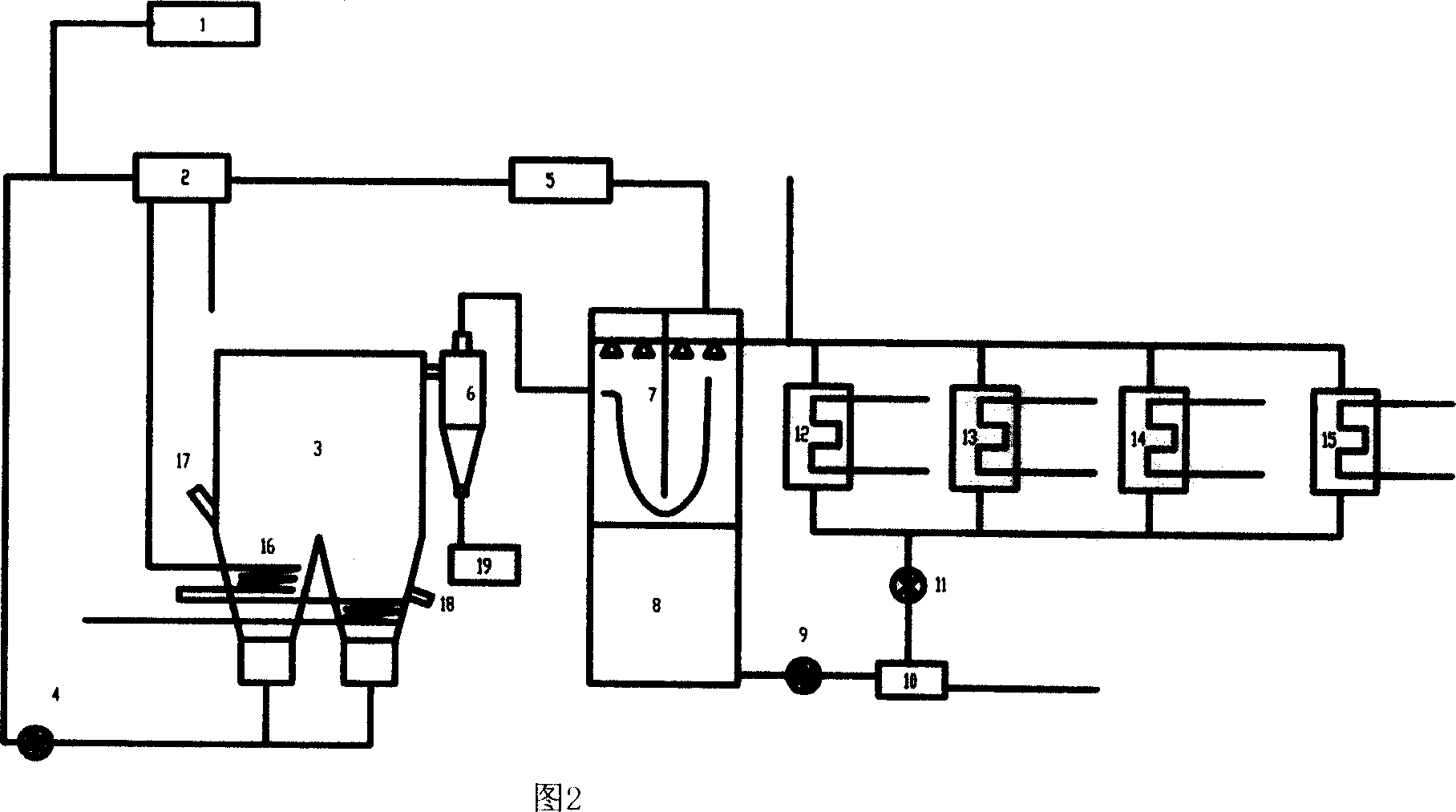

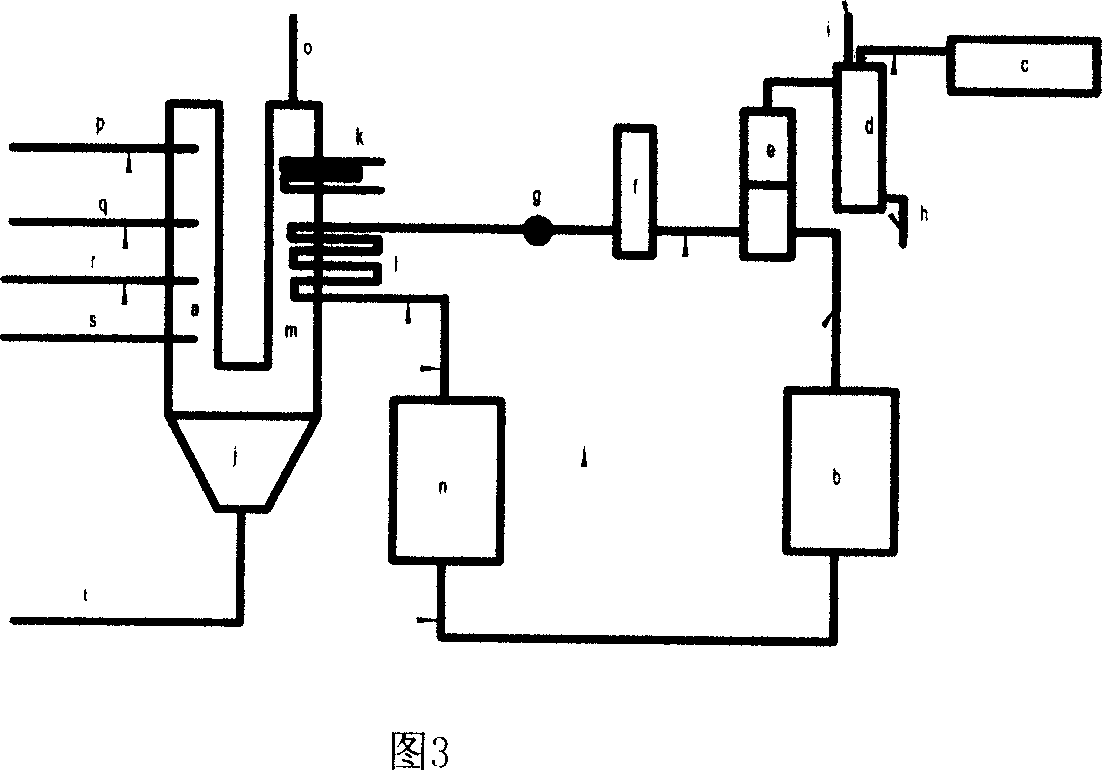

[0050] Fig. 1 is a schematic diagram of the process of the present invention. The sludge with a water content of about 95% from the sewage treatment plant and the sludge slurry sedimentation tank is first heated to 50°C, and then sent to the mechanical dehydration device A for preliminary mechanical dehydration to reduce the water content to 80% to 65%. After preliminary dehydration, the sludge is sent to the mechanical granulation device B for mechanical extrusion granulation to form columnar particles with a diameter and height of about 1-3 cm or spherical particles with a diameter of 1-3 cm. The granulated sludge is mixed with the dried sludge fine powder separated by the gas-solid separator E located at the outlet of the fluidized bed sludge drying device D, and sent to the drum mixer C for mixing and stirring to make the sludge dry The sludge fine powder adheres to the surface of wet sludge particles. The sludge particles coming out of the drum agitator C then enter the...

Embodiment 2

[0055] Wet sludge temperature (step 1)

Embodiment 3

[0057] Wet sludge temperature (step 1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com