Patents

Literature

165results about How to "Improve combustion thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

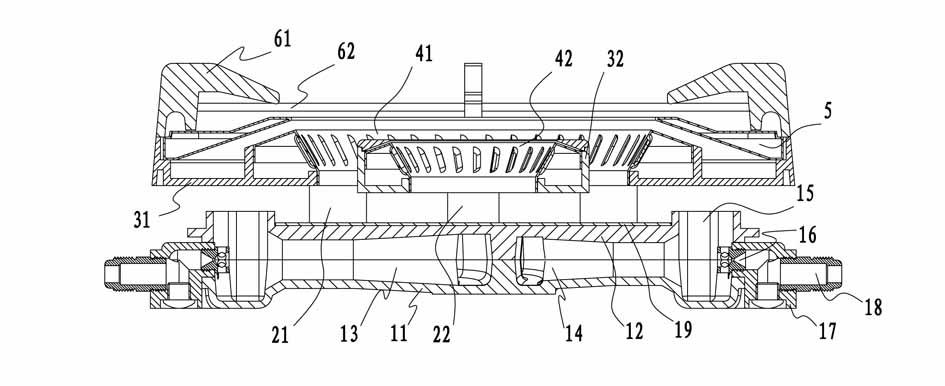

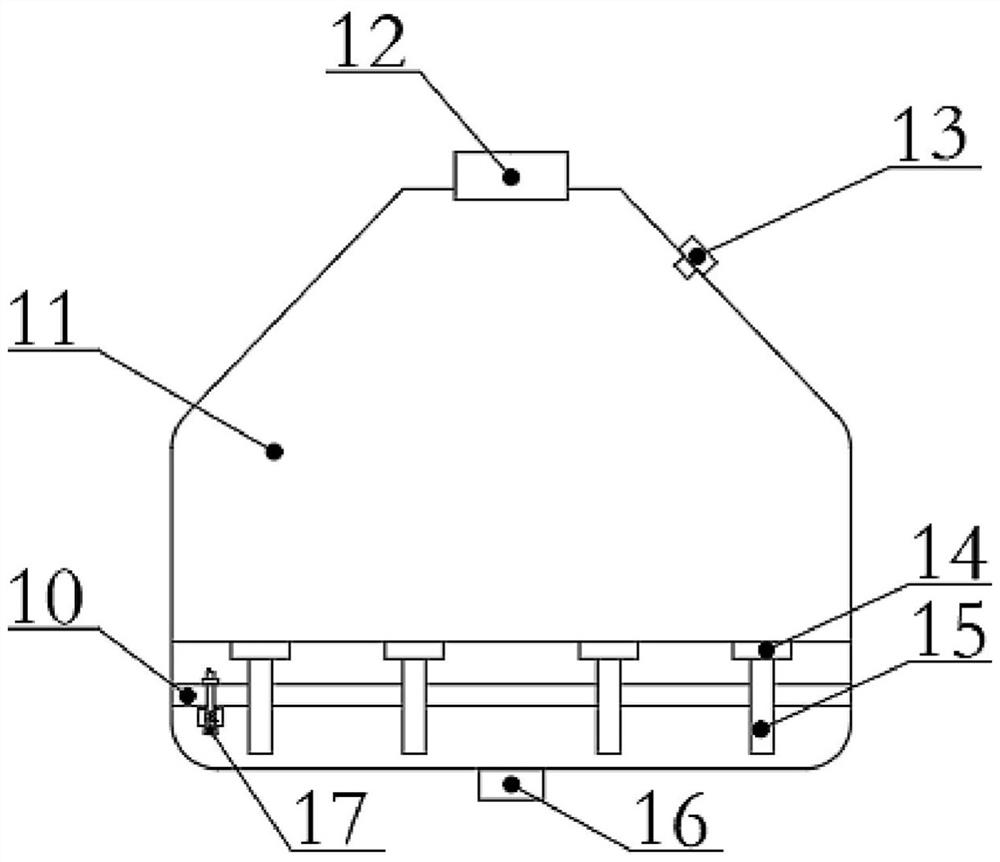

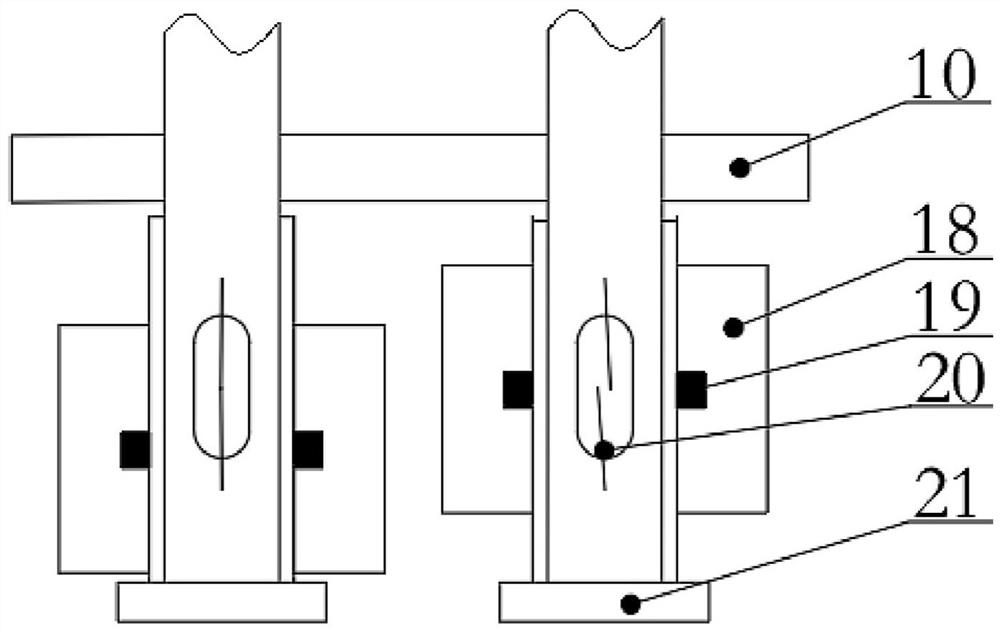

Top-intake burner of gas cooker

InactiveCN102661606AImprove combustion performanceImprove combustion thermal efficiencyDomestic stoves or rangesStoves/ranges topsFuel gasGas stoves

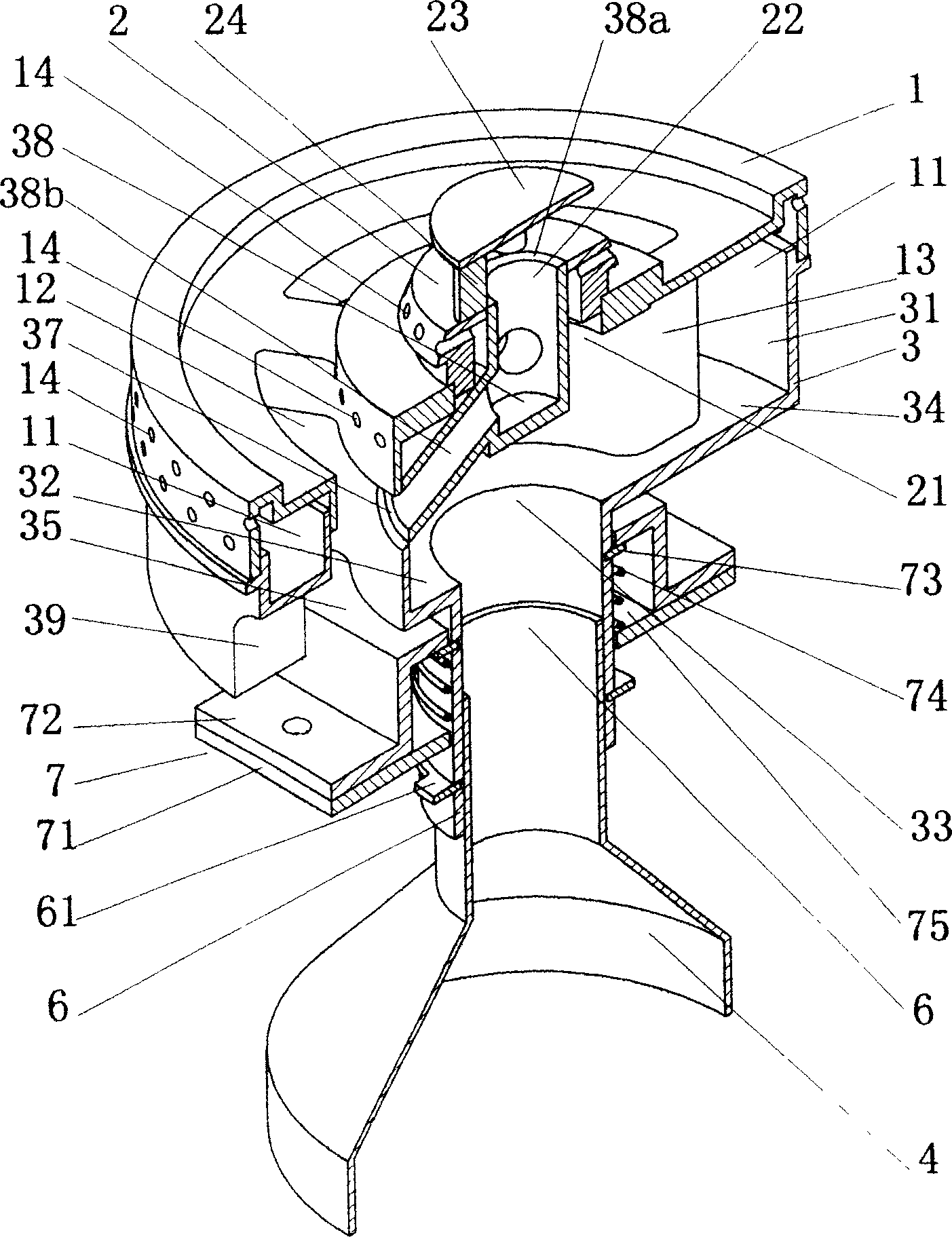

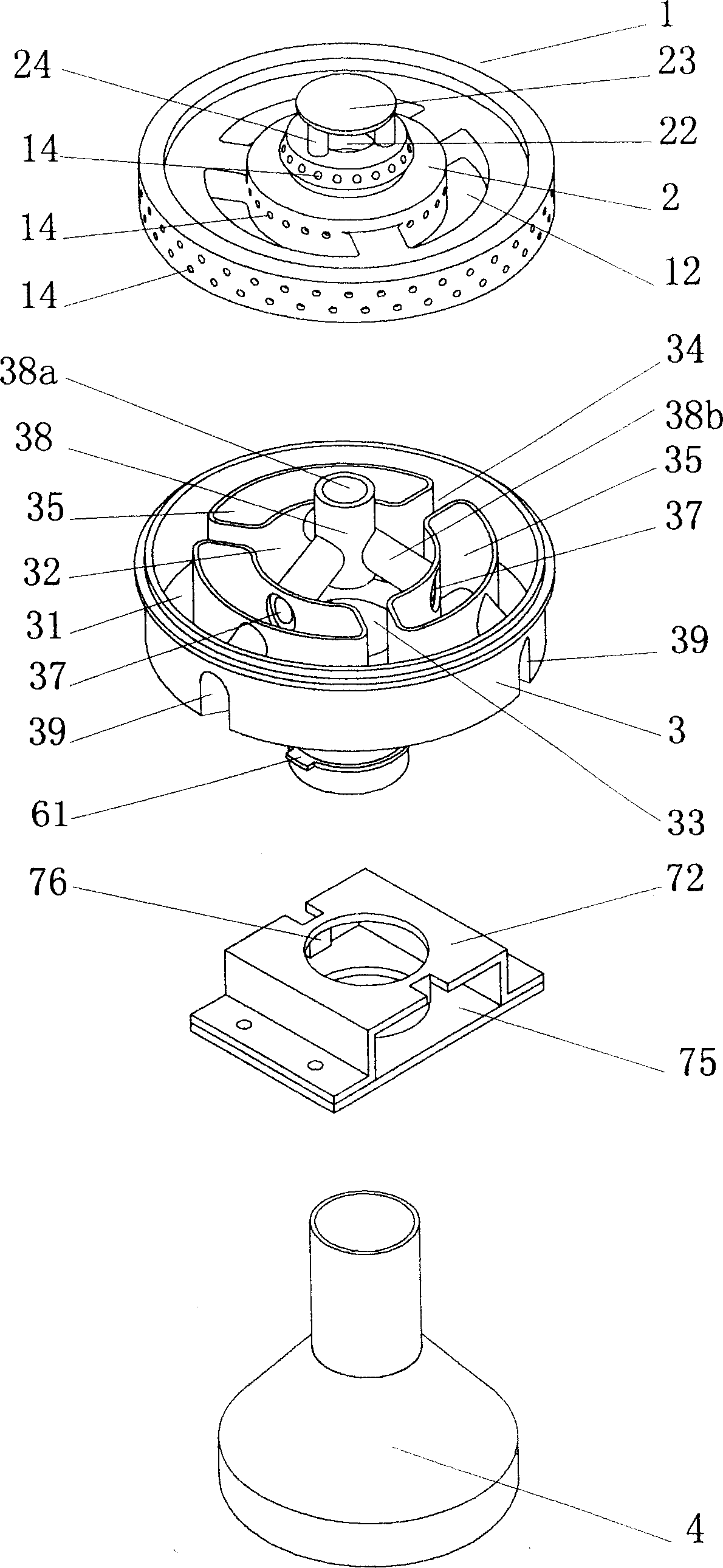

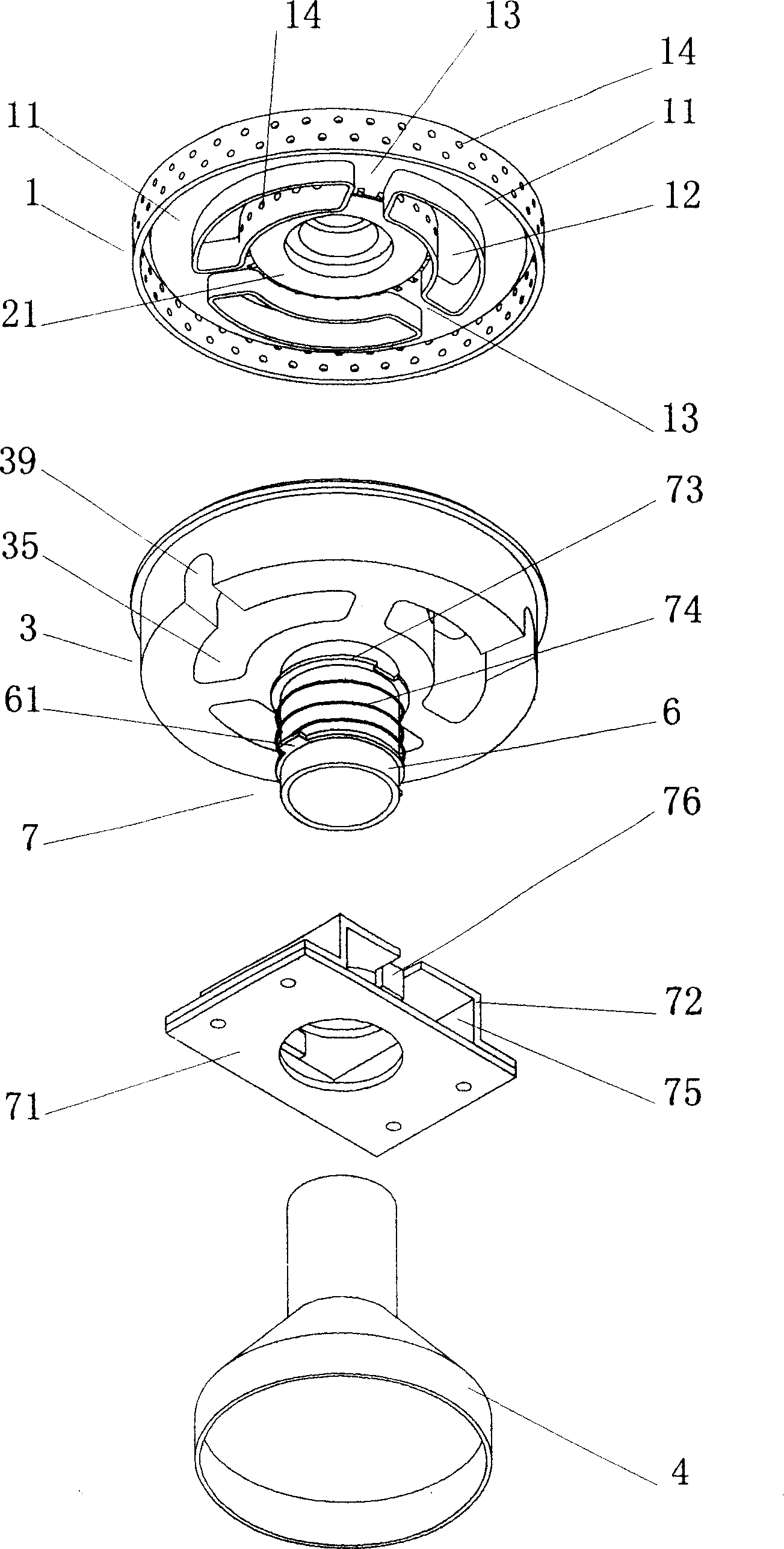

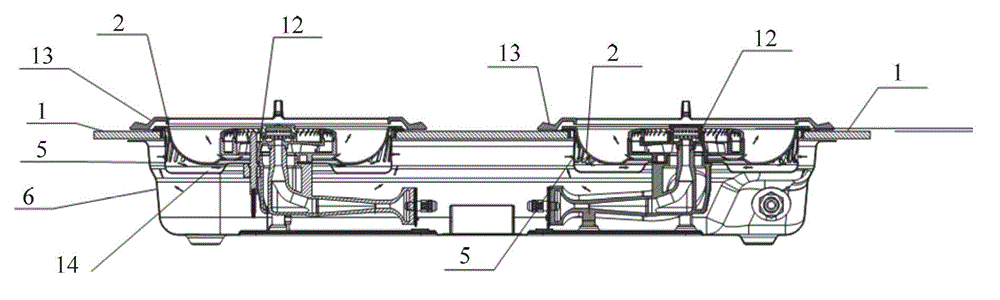

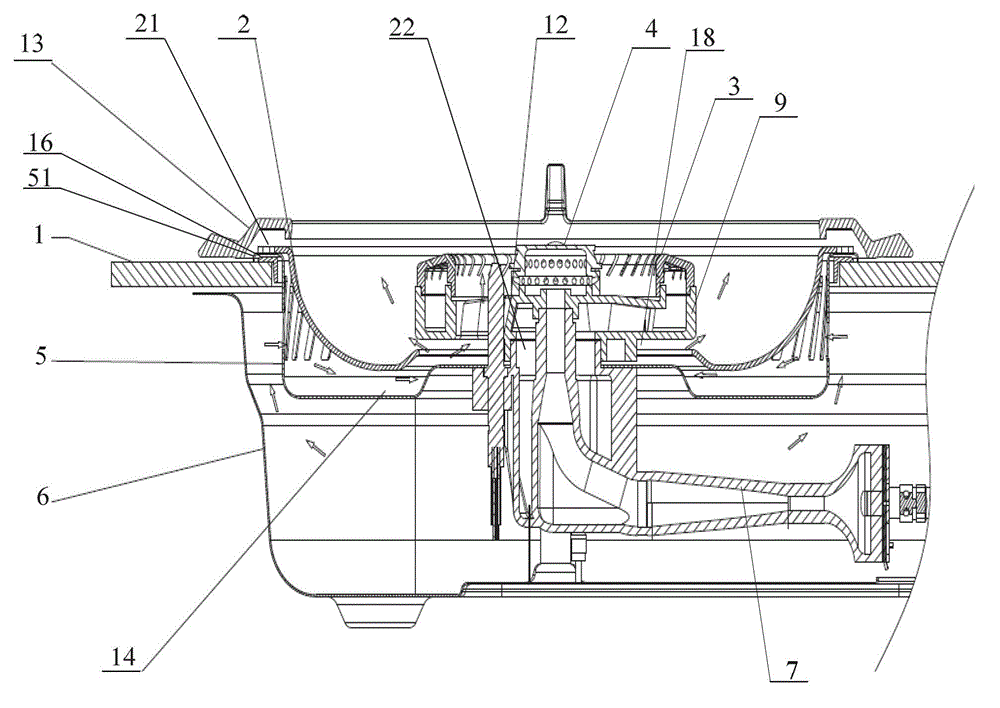

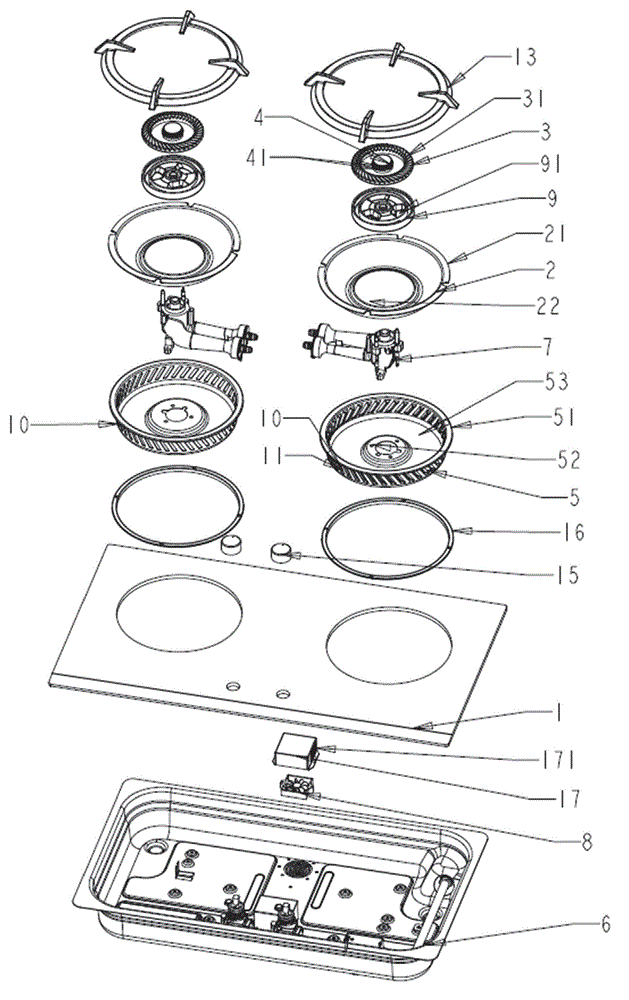

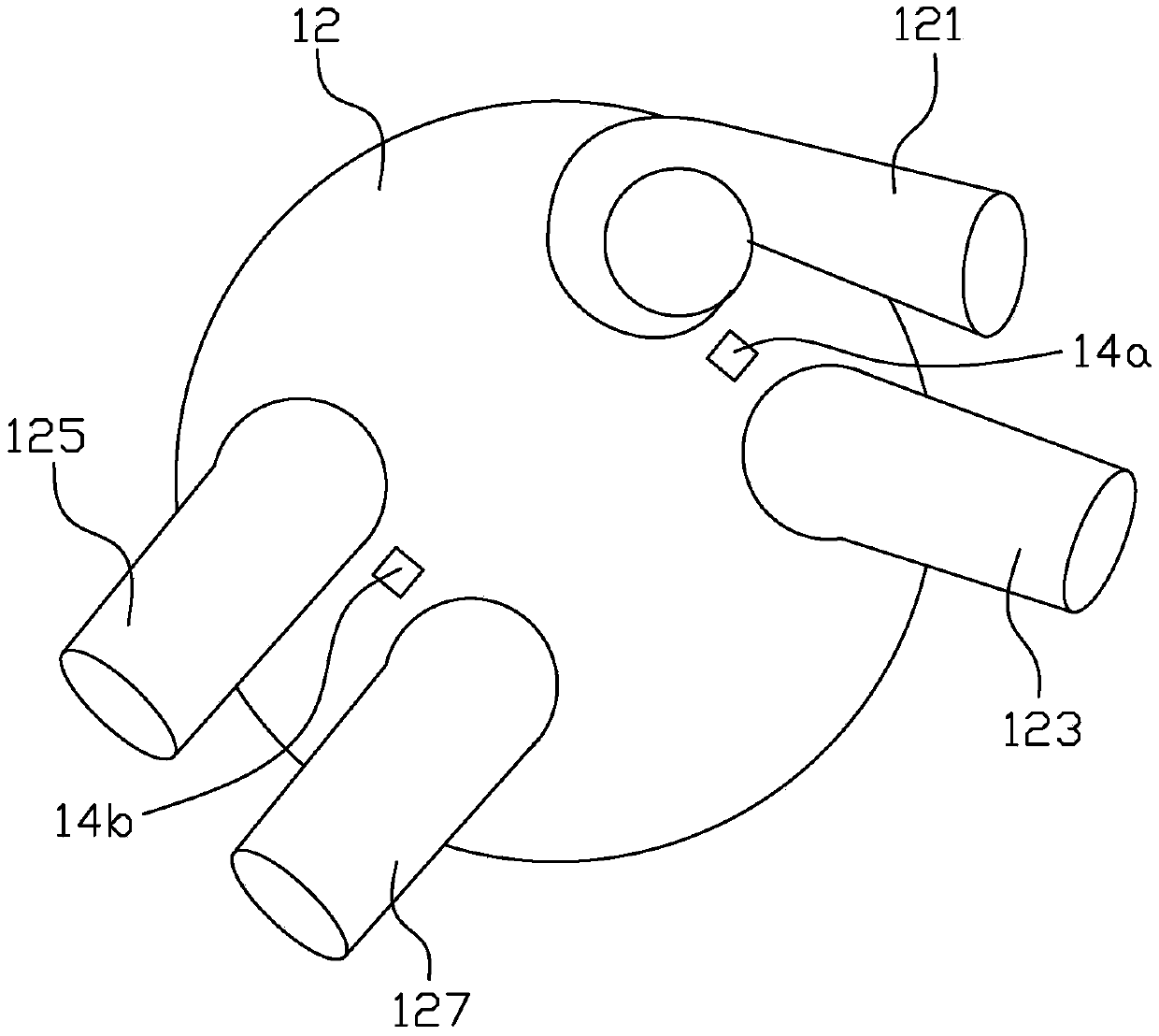

The invention relates to a top-intake burner of a gas cooker. The top-intake burner comprises a burner support, a fire distribution seat and fire caps. The top-intake burner is characterized in that the burner support is combined by an lower support and an upper cover, at least two Venturi ejector pipes are formed, the openings of the Venturi ejector pipes are correspondingly communicated with primary air inlets with an upward opening, a single gas nozzle is mounted in the primary air correspondingly and is disposed right against the center of one of the the Venturi ejector pipes, the other end of the gas nozzle is communicated with a gas inlet pipe, one Venturi ejector pipe is communicated with a fire distribution chamber of the fire distribution seat through one gas guide pipe or multiple gas guide pipes, and an air passage is reserved between the upper cover of the burner support and the fire distribution seat. The top-intake burner is reasonable in structural design, efficient and energy saving, is capable of realizing precision supply of primary and secondary air and complete and stable burning of the gas, and is especially suitable for embedded household gas stoves.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI +1

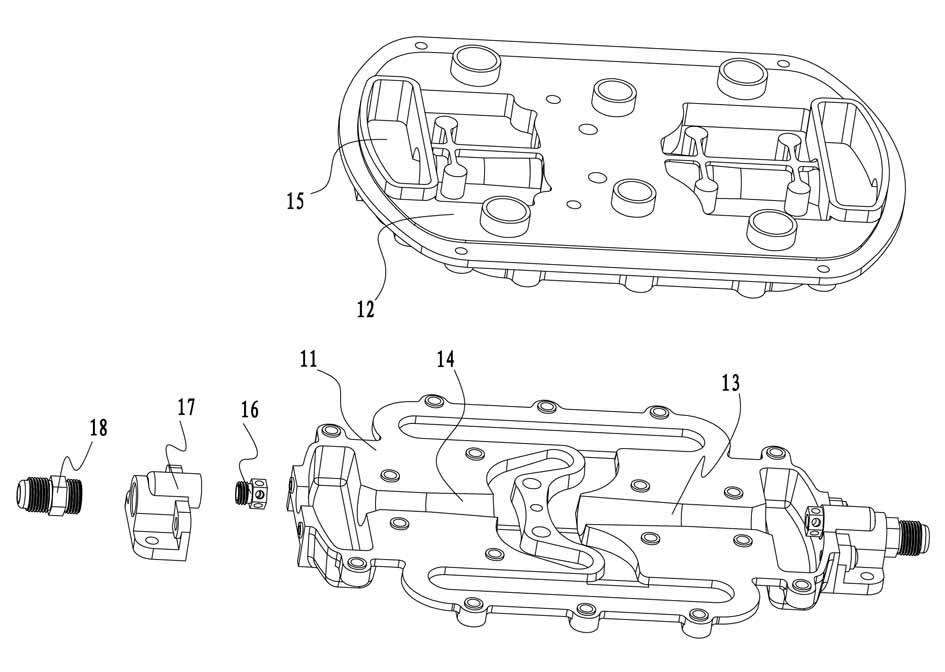

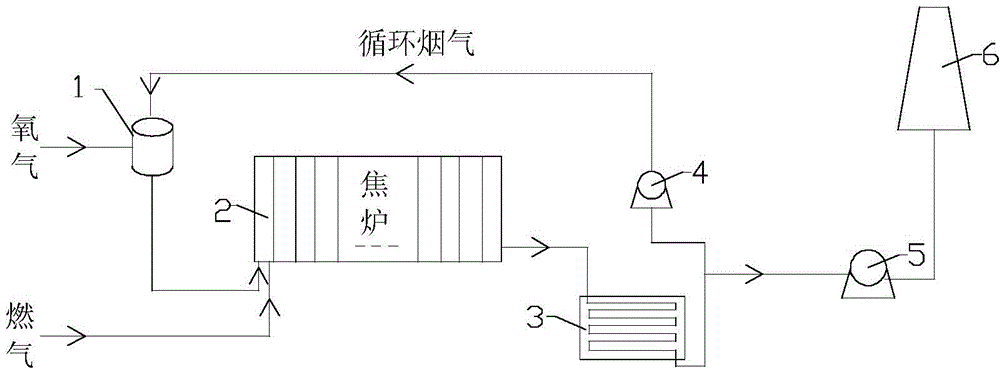

Method and device for reducing emission of NOx in waste flue gas of coke oven

InactiveCN105295962AAvoid introducingEmission reductionCombustible gas coke oven heatingCombustion chamberHeat exchanger

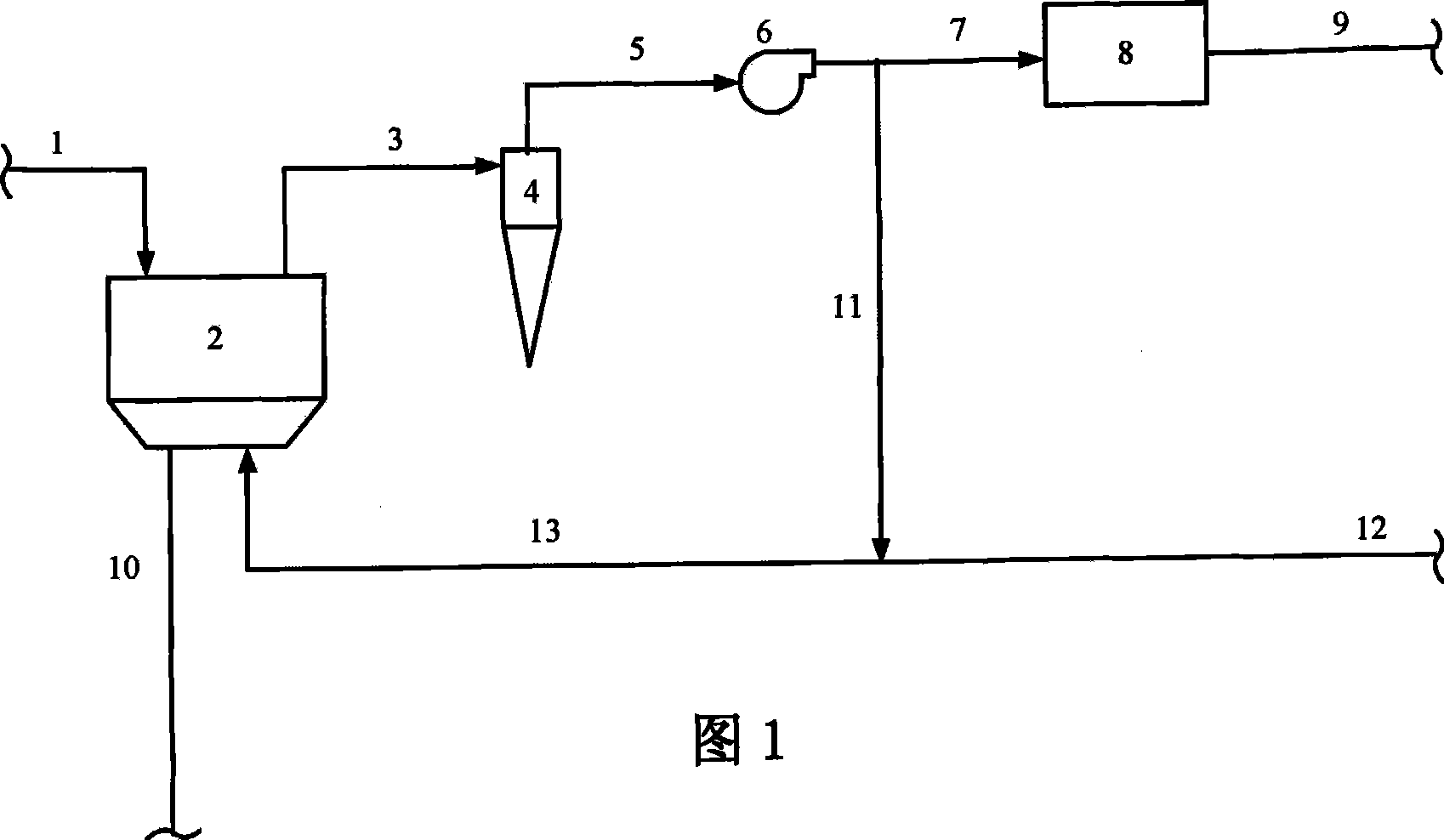

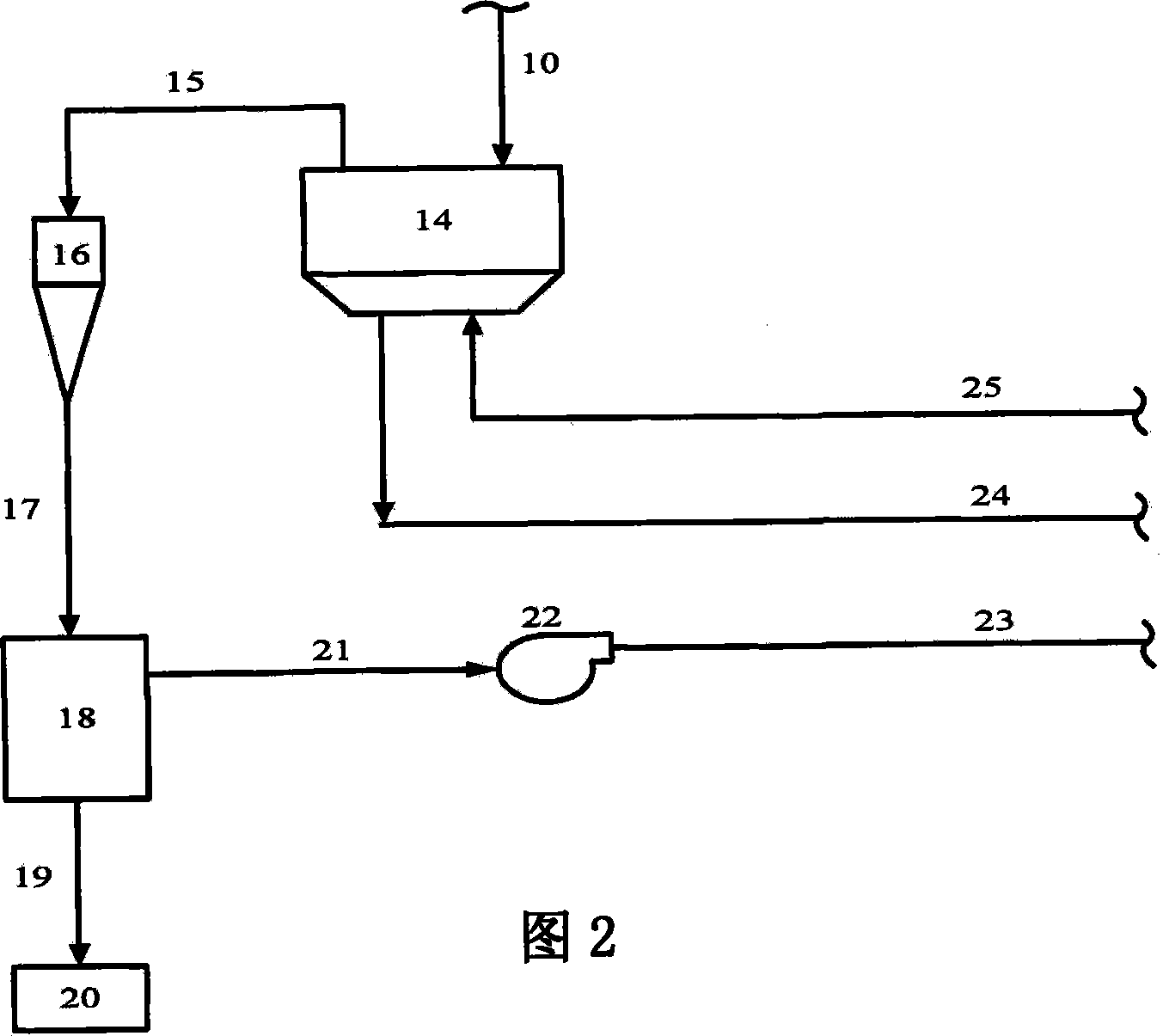

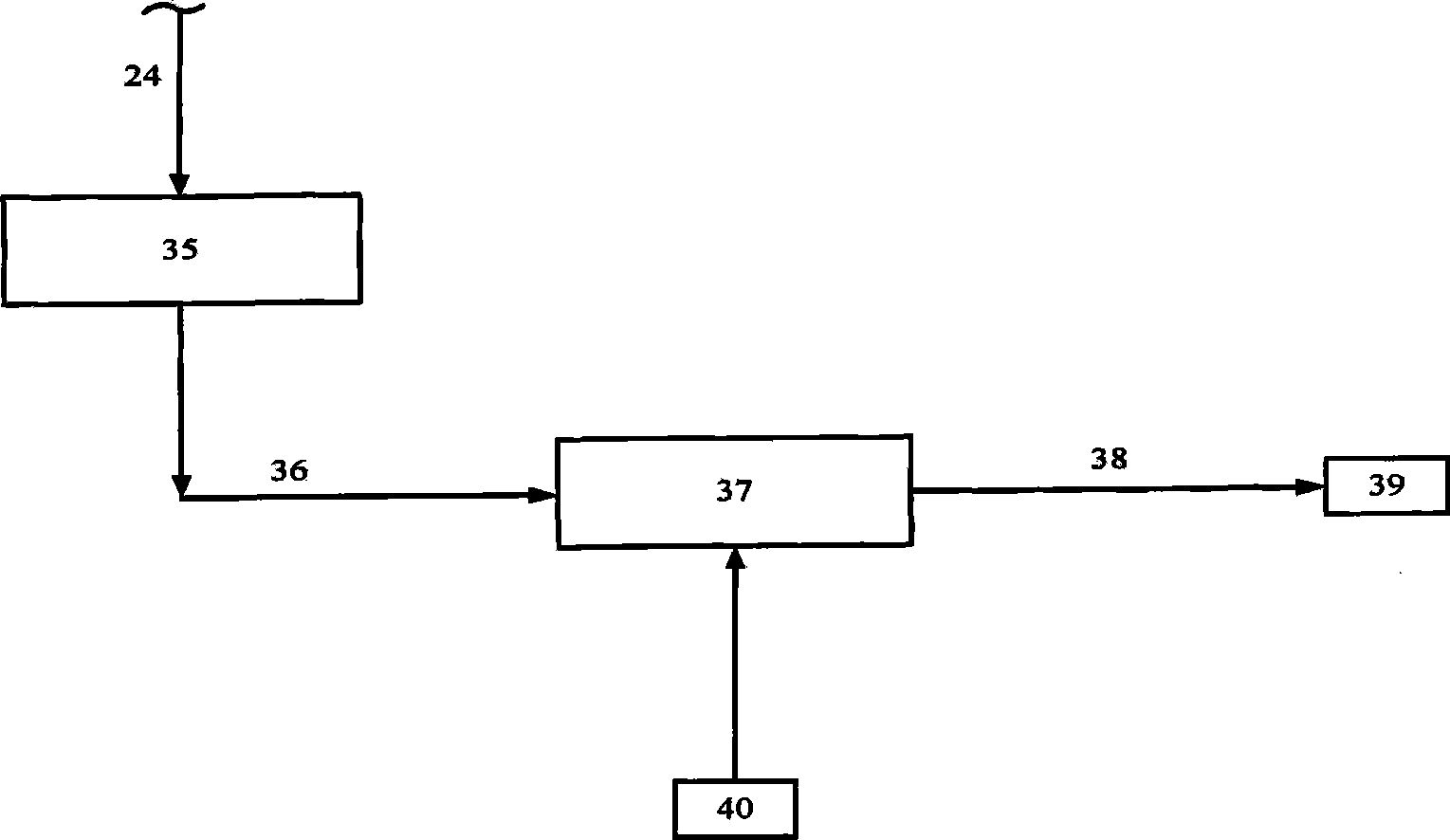

The invention provides a method for reducing emission of NOx in waste flue gas of a coke oven. The method comprises the following steps: (1) introducing oxygen and circulating flue gas of the coke oven into gas mixing equipment to be mixed to obtain a mixed combustion-supporting gas in which the content of O2 is 0-100 percent; (2) introducing gas of the coke oven and the mixed combustion-supporting gas into the combustion chamber of the coke oven to be burnt to produce waste flue gas of the coke oven; (3) after the waste flue gas of the coke oven, produced in the step (2), is cooled down by a heat exchanger, ensuring that part of the waste flue gas of the coke oven enters the gas mixing equipment via a flue gas recirculation blower to be mixed with pure oxygen to produce mixed combustion-supporting gas to participate in combustion and the other part of waste flue gas of the coke oven passes through a smoke removal blower and then enters a smoke discharge chimney to be directly discharged. The method controls production of nitrogen oxides by the waste flue gas of the coke oven from the source, adopts mixing of pure oxygen and circulating flue gas to avoid introduction of N2, and enables emission of nitrogen oxides in the waste flue gas of the coke oven to meet the national standards.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for processing coal with low degree of metamorphism

InactiveCN101429463AGood environmental protectionEmission reductionSolid fuelsEngineeringAtmospheric pollution

The invention provides a technique for processing coal with low metamorphism degree, which comprises the steps of crushing and sieving pretreatment. The technique is as follows: raw coal particles are sent into a drier, and subjected to anoxybiotic hot gas drying under normal pressure, wherein the drying condition is controlled to 10 to 50 cubic meters of hot gas required for each 1 kilogram of the coal, and the temperature of the raw coal particles is controlled to between 210 and 250 DEG C; the raw coal particles are sent into a pyrolysis apparatus, and high-temperature oxygen-poor hot gas is injected according to the flow ratio of 5 to 50 cubic meters per kilogram of coal, wherein the temperature of the oxygen-poor hot gas entering into a pyrolyzing furnace is controlled to between 400 and 950 DEG C, and the oxygen content is controlled to less than 6 percent of the volume; and the coal is fully mixed with the hot gas and heated to a temperature of between 530 and 580 DEG C. The technique has the advantages that the sulfur content is reduced compared with that in the raw coal, so that atmospheric pollution is reduced; solid products produced by the technique have high environment-friendly characteristic; the discharge amount of nitrogen oxide is obviously reduced; and atmospheric pollution is reduced.

Owner:HUNAN HUAYIN ENERGY TECH

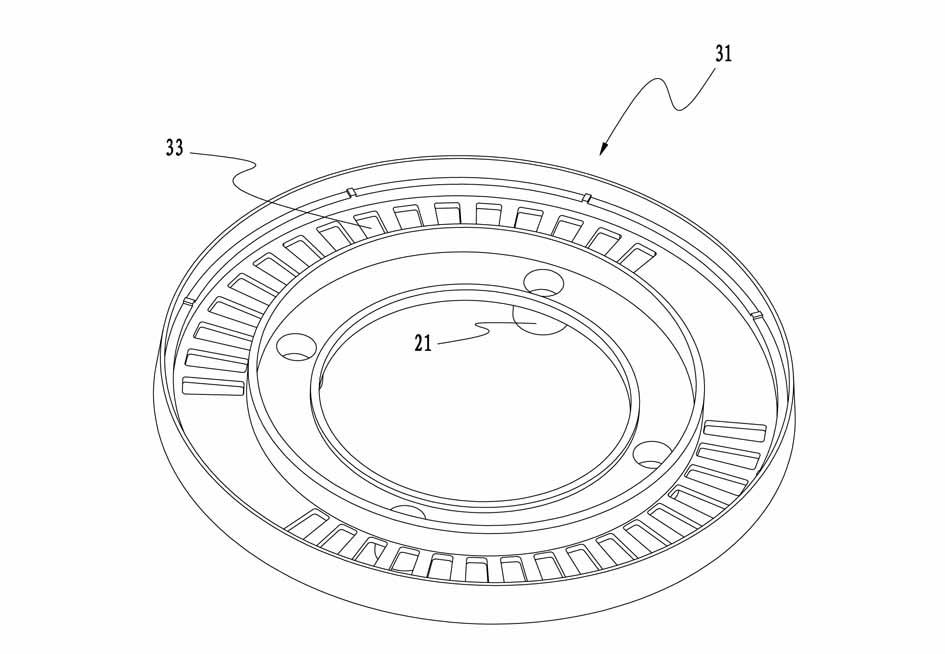

Burner with air balancing device

InactiveCN1900593AOvercoming Insufficient CombustionImprove combustion thermal efficiencyDomestic stoves or rangesGaseous fuel burnerCombustorMixing ratio

Burner with balanced air distribution includes fuel gas seat with pipe of mixing wind being installed on base, and inner fire cover and outer fire cover setup above the fuel gas seat. Outer and inner annular air grooves are setup in seat cavity of the fuel gas seat. Fuel gas channel is setup between outer and inner annular air grooves. There are outer air mixing channels between two adjacent fuel channels, and isolated from fuel gas channels. Inner air mixing channels are setup between outer air mixing channel and inner fire cover. Inner air mixing channels make air possible to enter to central area of the inner fire cover from outer air mixing channels. Thus, the invention overcomes disadvantages of deficient burning caused by not even mixing ratio between fuel gas and air in inner fire cover of traditional burner. Interconnected structure designed for structure of inner and outer air mixing channels is more in favor of balanced matching so as to raise thermal efficiency.

Owner:佛山市顺德区澳羚究星电子科技有限公司

Efficient sulfur-fixing agent and its usage

InactiveCN101074402ASolve the problem of efficient sulfur fixationImprove combustion thermal efficiencySolid fuelsFuel additivesSlagCoal

An efficient sulfur-curing agent and its use are disclosed. It relates to circulation fluidized bed boiler combustion, solid sulfur and ash slag modification. The process is carried out by combusting for efficient sulfur-curing agent and coal to generate hydraulic gel material. The sulfur-curing agent consists of chalky clay, which comprises calcium oxide 35-44%, mineral agent with cand powder and / or calcium chloride fag end, the can powder contains calcium fluoride 40-60%, the calcium chloride fag end contains calcium chloride 30-40%. It's simple, efficient and convenient and has no environmental pollution. It has higher combustion heat utilization rate.

Owner:陈钧

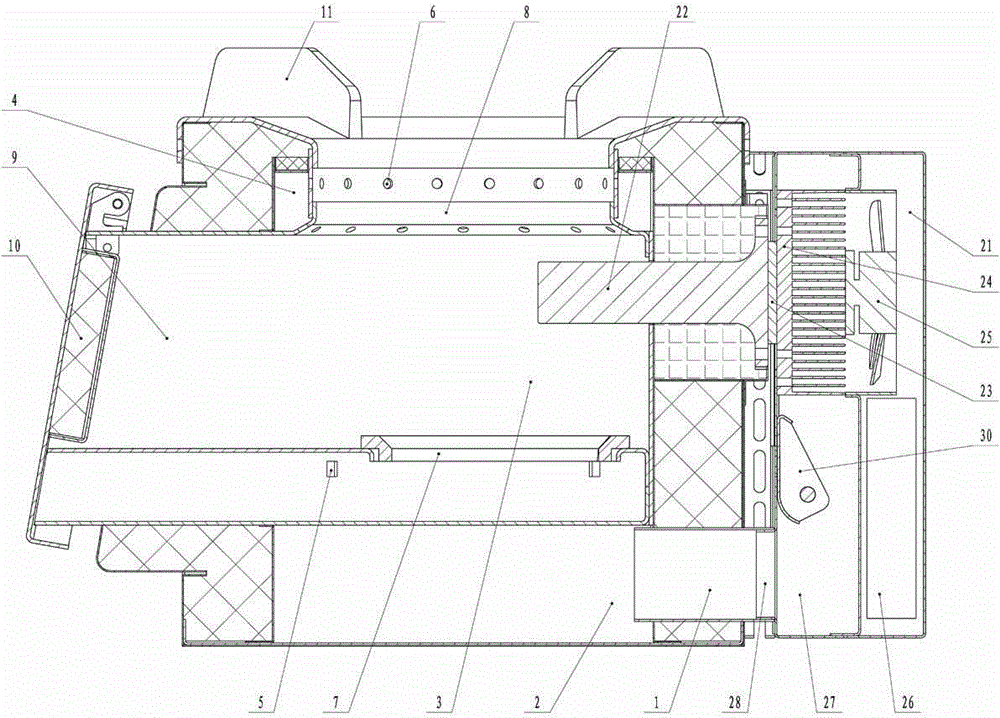

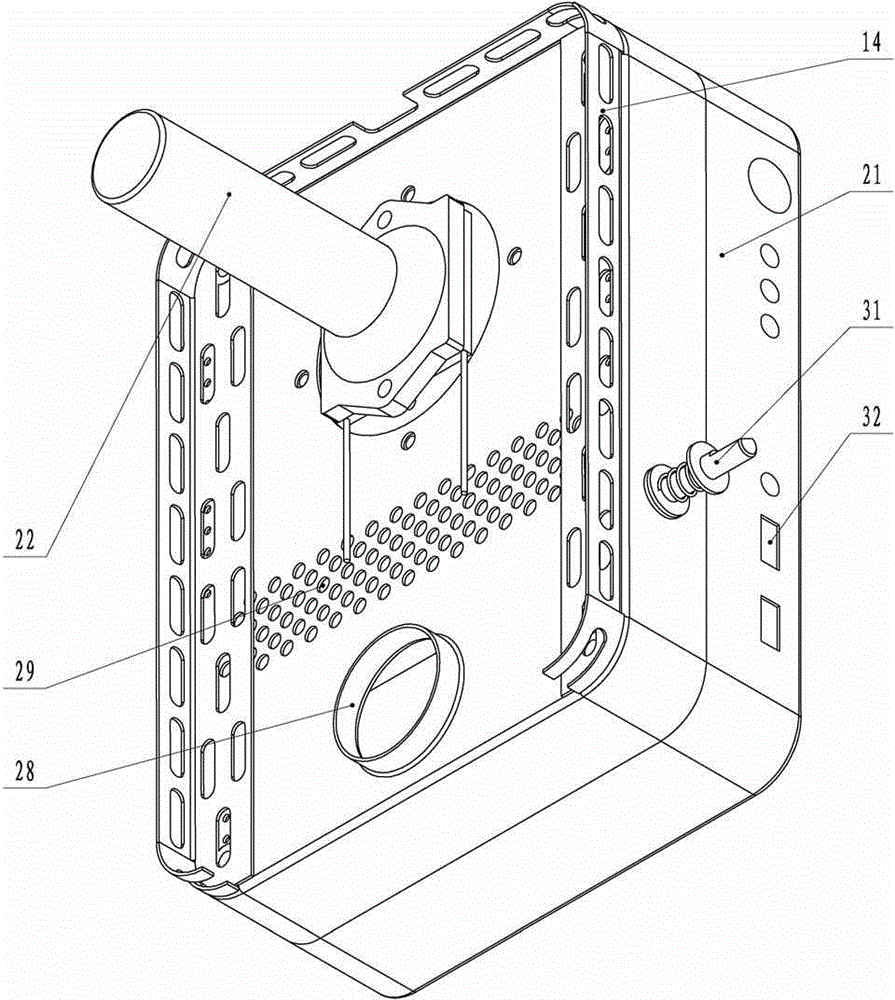

Horizontal continuous feeding and preheating device and strengthened preheating method thereof

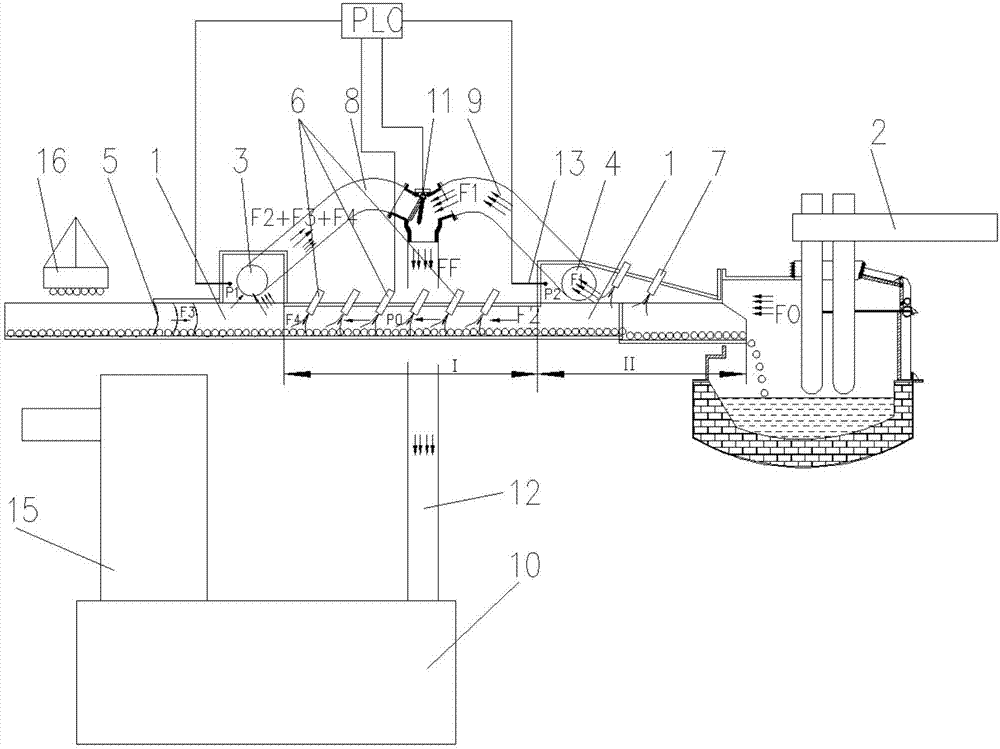

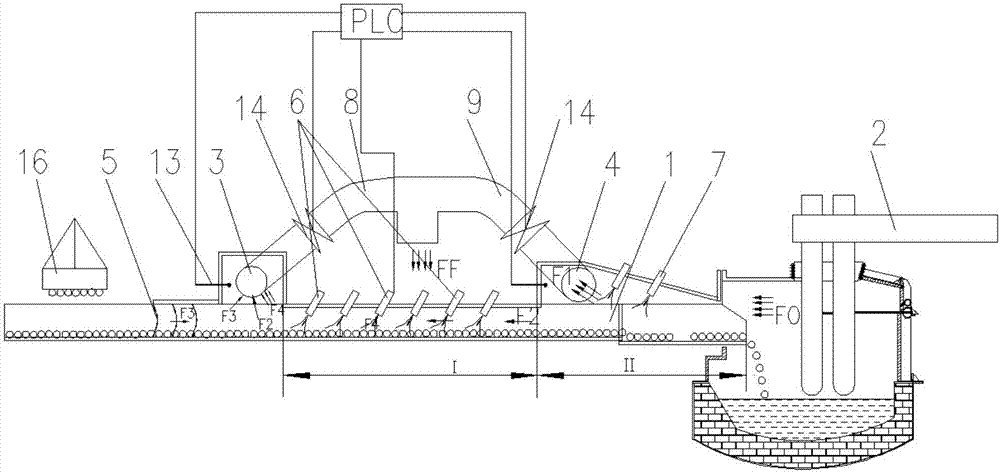

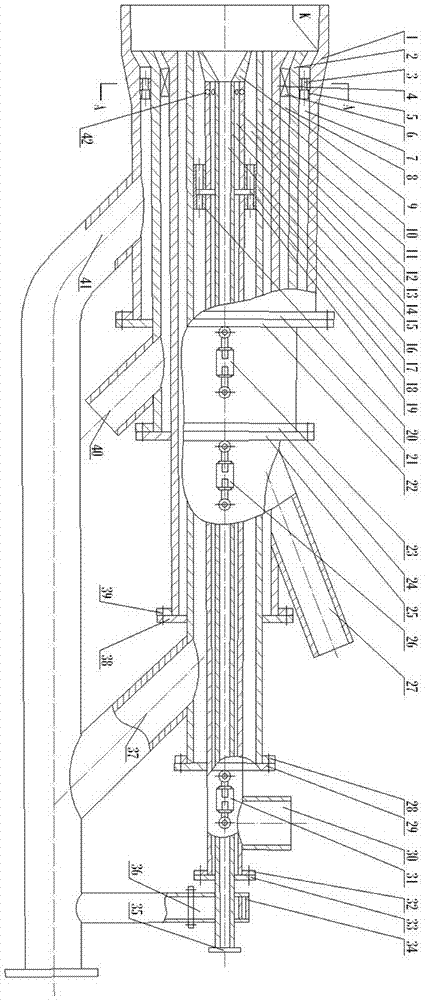

ActiveCN107460274AImprove combustion thermal efficiencyImprove heat transfer effectCharge manipulationPreheating chargesCold airElectric arc furnace

The invention belongs to the field of metallurgical technologies and discloses a horizontal continuous feeding and preheating device and a strengthened preheating method of the horizontal continuous feeding and preheating device. According to the scheme, two dust removal openings are correspondingly formed in the front portion and the rear portion of a horizontal continuous feeding and preheating duct, and the horizontal continuous feeding and preheating duct is divided into a strengthened preheating region and a smoke preheating region by the front dust removal opening and the rear dust removal opening; burners are mounted in the strengthened preheating region, and the two dust removal openings are correspondingly connected with smoke adjustment distributors through smoke pipelines; the dust removal negative pressure of the second dust removal opening is balanced by the jet flow dynamic pressure of the multiple rows of bruners in the strengthened preheating region; and the micro-negative pressure requirement of the first dust removal opening is controlled through a pressure sensor, so that the mixing amount of cold air of the first dust removal opening is reduced, the preheating efficiency of the burners and smoke of an electric arc furnace on steel scrap is improved, and the production is more environmentally-friendly.

Owner:CISDI ENG CO LTD +1

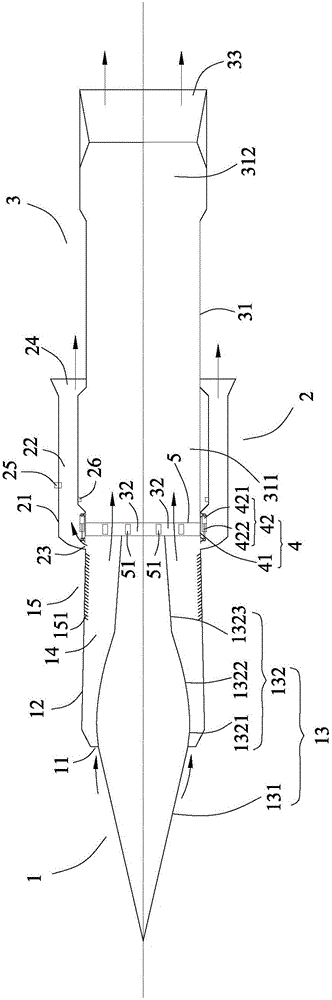

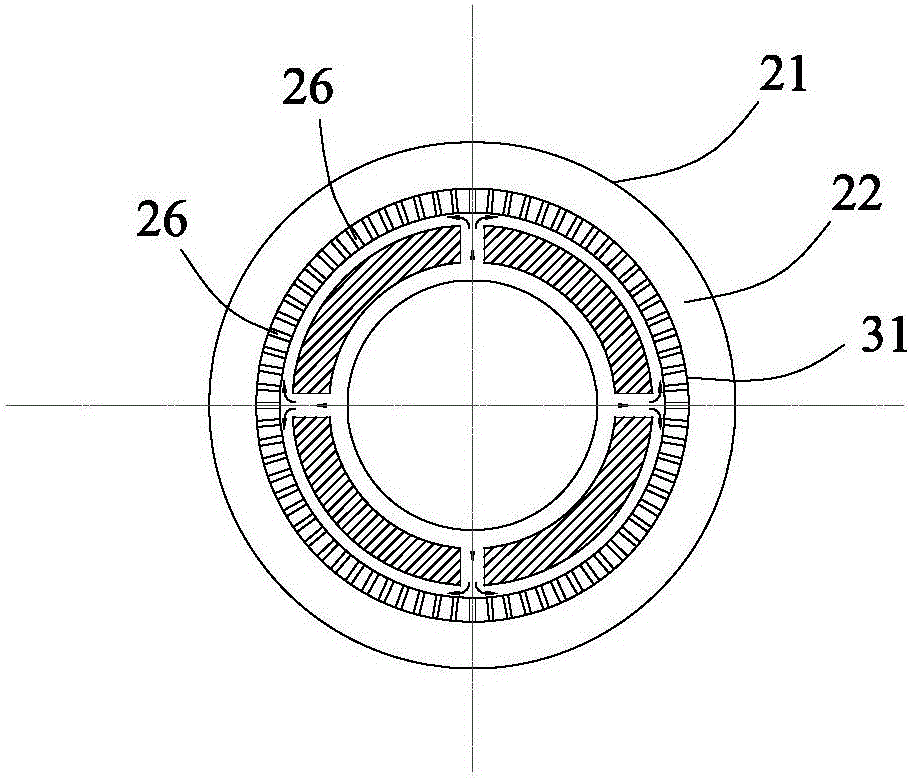

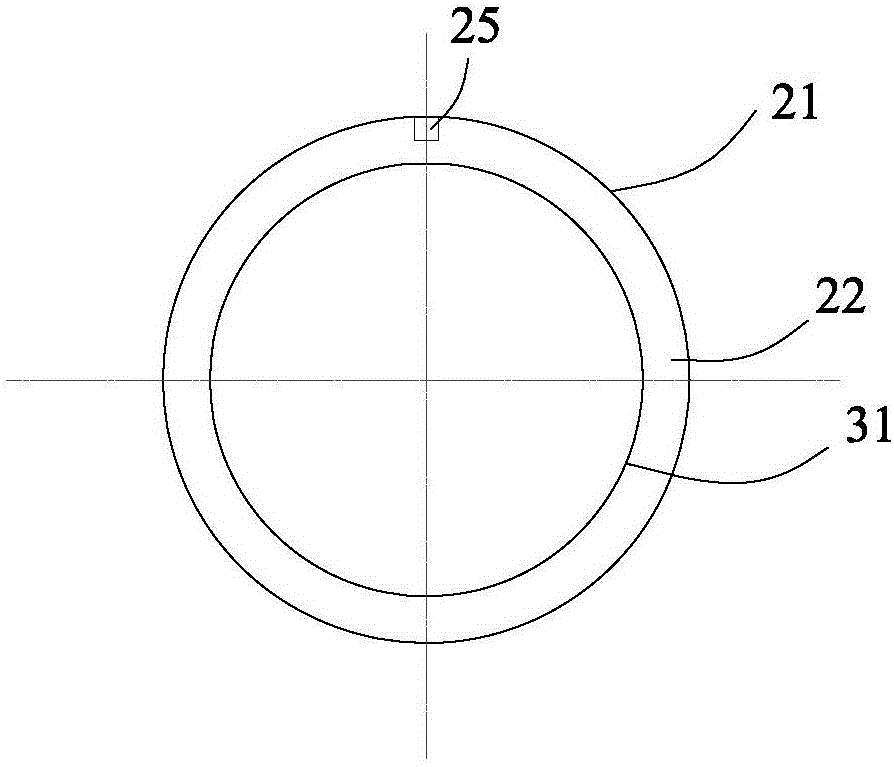

Combined cycle engine

ActiveCN105736178AImprove specific impulseImprove economyGas turbine plantsTurbine/propulsion air intakesDetonationTurbojet engine

The invention provides a combined cycle engine. The combined cycle engine comprises a supersonic air inlet mechanism, a continuous rotation detonation engine body and a turbojet engine body, wherein the supersonic air inlet mechanism is provided with a first gas inlet which communicates with the outside and is opened in the axial direction, and the continuous rotation detonation engine body and the turbojet engine body are fixedly connected to the lower portion of the supersonic air inlet mechanism. The continuous rotation detonation engine body and the turbojet engine body both communicate with the supersonic air inlet mechanism in a controlled mode in order to work in the mode that external gas is introduced into the continuous rotation detonation engine body and the turbojet engine body through the first gas inlet in the controlled mode. According to the combined cycle engine, mode transition can be completed within an operating envelope range, the stable thrust is provided for an aircraft, and then the aircraft hypersonically flies at 5.0 Mach or above in the atmosphere and can land and take off horizontally; in addition, the specific impulse of the engine is improved on the basis of adopting the continuous rotation detonation technique, the combustion heat efficiency is improved, and the economy and the reliability of the engine are improved.

Owner:清航空天(浙江)科技有限公司

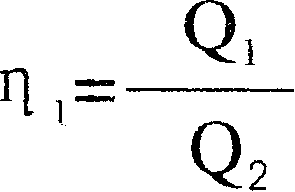

Gas turbine circulated generation process for combining high (mediate) calorific value gas and low calorific value gas

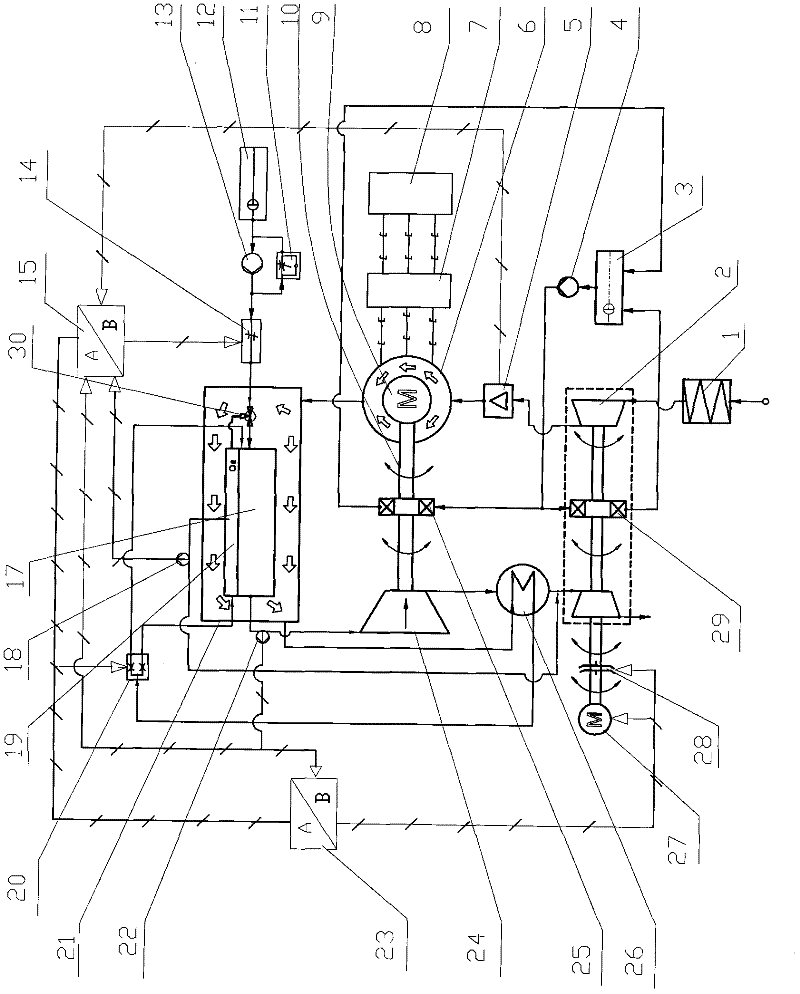

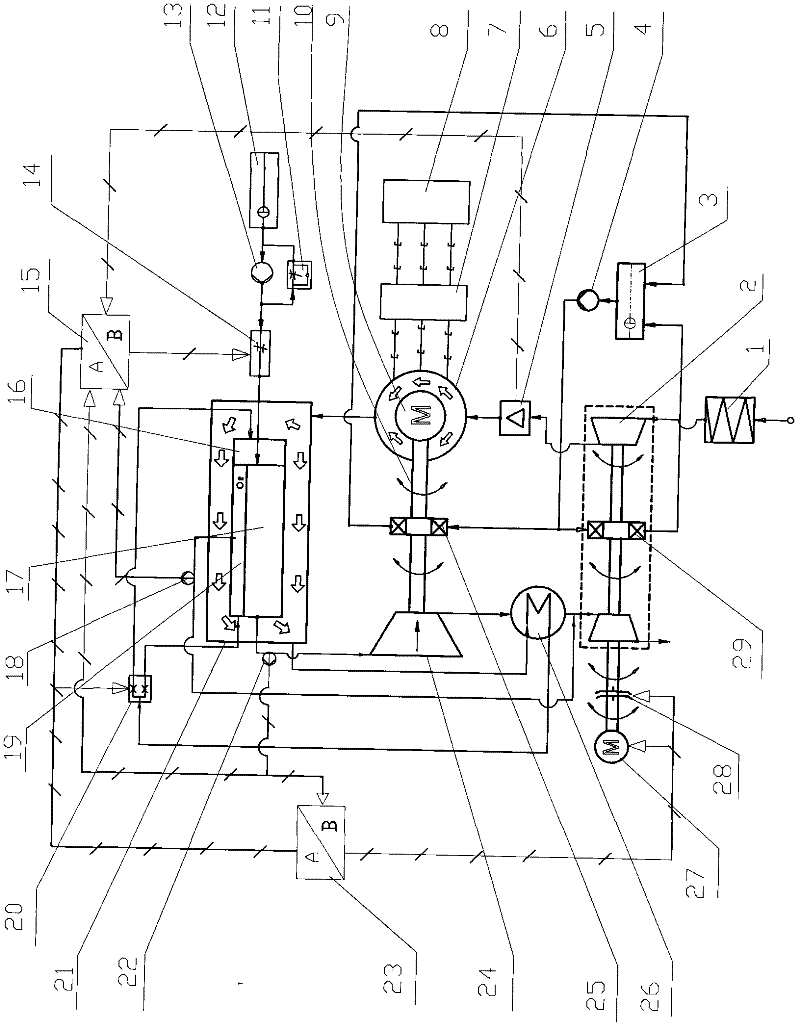

InactiveCN101169071AImprove combustion thermal efficiencyHigh combustion noiseGas turbine plantsCombined combustion mitigationForced inductionThermal efficiency

The invention relates to a combustion engine combination cycle power plant with low heat value, a co-production of the combustion engine combination cycle thermal power plant, an integrated coal gasification cycle combination (IGCC) power plant, and the like. The invention adopts the new technique of gas turbine combined cycle power generating that the high and intermediate heat value gas cooperate with the low heat value gas, and the invention is a technology with high efficiency and low pollution. A low NOx burner provided with a gas turbine and an afterburner boiler adopt a self-cycle preheating heat-storing volution type low NOx gas burning system, therefore the power consumption of the gas supercharger can be reduced by 10-20 percent and the thermal efficiency of the electricity generating of the combined cycle unit can be increased for 5-15 percent. The invention can also solve the problems of the technology difficulty for reconstructing the system and the project cost. The invention can also provide stable combustion for burning the low heat value gas (blast furnace gas), can enable steam cycle system to have larger installed capacity and higher efficiency, and can lower the kilowatt cost. The invention ensures that the combined cycle thermal efficiency can reach about 60 percent, the electricity generating efficiency of the power plant can reach about 55 percent, and the energy can be saved for above 80 percent. The invention can break through a bottleneck that the investment and the electricity generating cost of the intermediate low heat value gas electricity plant are much higher than that of high heat value combined cycle power plant, namely the economic problem, and then the investment cost of the intermediate low heat value gas power plant (or the IGCC) can be lowered greatly.

Owner:邢一崧

Solid fuel furnace with thermoelectric power generation device

InactiveCN104633713ABurn fullyImprove combustion thermal efficiencyBatteries circuit arrangementsDomestic stoves or rangesAir volumeFuel wood

The invention relates to a solid fuel furnace with a thermoelectric power generation device. The solid fuel furnace comprises a solid fuel furnace and a thermoelectric power generation device; the lower end of a blower box of the thermoelectric power generation device is provided with an exhaust room, and the exhaust room is provided with an air pipe for connecting an exhaust hole with the solid fuel furnace; the air exhaust room is further provided with an air volume balance hole, and an air flap and an adjusting handle are installed in the exhaust room; the air flap is adjusted to close the air exhaust hole or the air volume balance hole, and make that the total air volume is unchanged while the air exhaust volumes of the air exhaust hole and the air volume balance hole are in an inversely proportional relationship. The solid fuel furnace can externally provide stable and enough power source without externally connecting the power source; through reasonable distribution of primary and secondary air, the fuel is fully burned; the solid fuel furnace is featured by simple operation, high burning heat efficiency, and few smoke gas emission; the fuel adaption is wide, and it is especially applicable to various fuel wood and other biomass solid fuels; besides, the solid fuel furnace is simple, small and light in structure, and applicable to indoor cooking and outdoor cooking.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

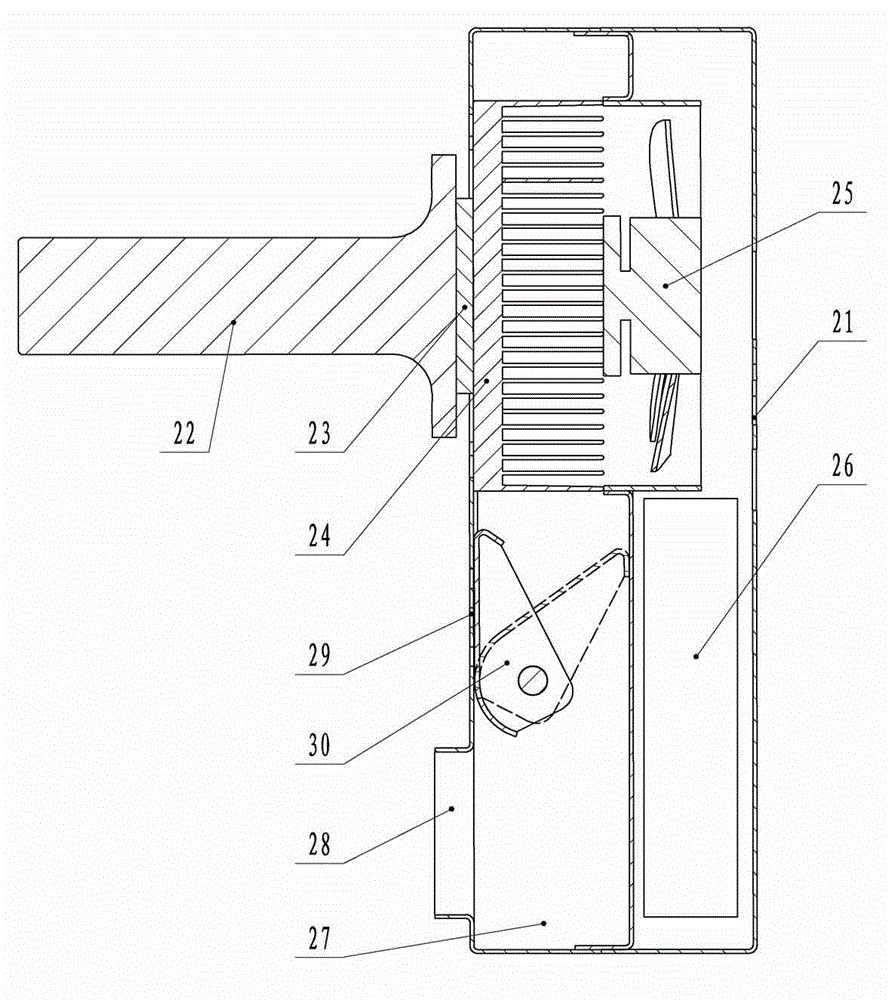

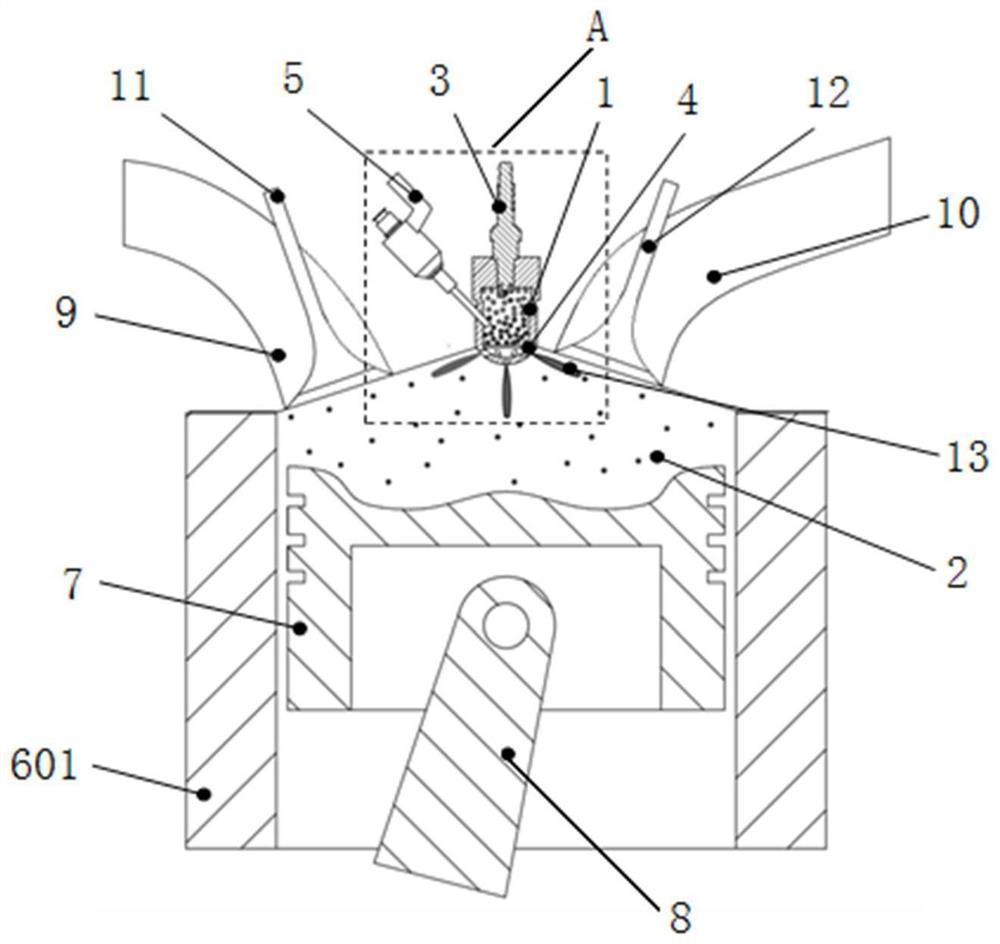

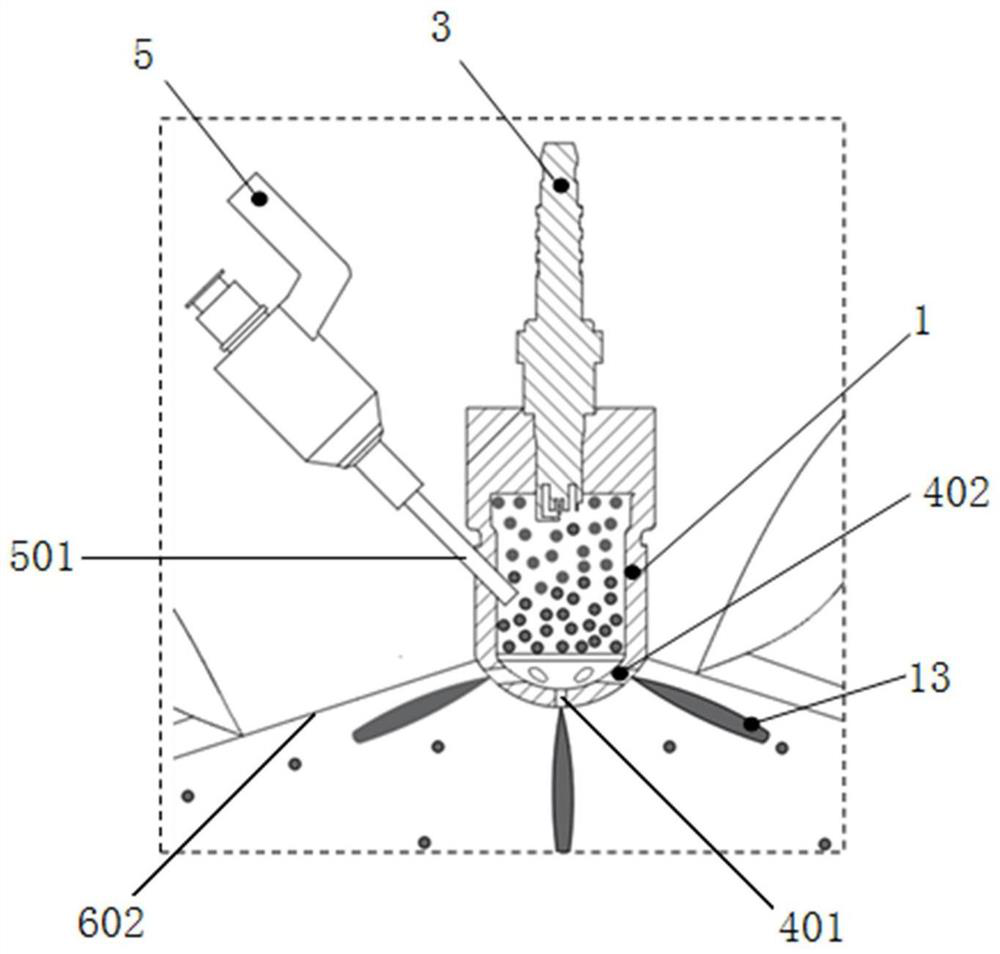

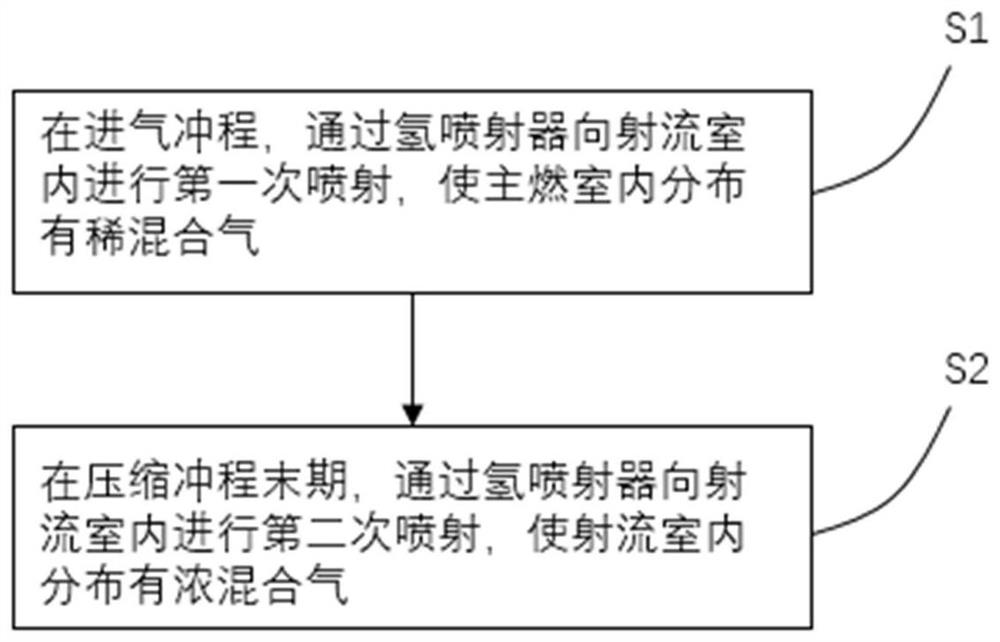

Hydrogen internal combustion engine combustion system and combustion control method

PendingCN113202622AImprove ignition energy and combustion thermal efficiencyInhibit NOx productionInternal combustion piston enginesFuel supply apparatusInjectorCombustion chamber

The invention relates to the technical field of internal combustion engines, and provides a hydrogen internal combustion engine combustion system and a combustion control method. The hydrogen internal combustion engine combustion system comprises a jet flow chamber and a main combustion chamber. A spark plug is arranged in the jet flow chamber, a jet flow hole is formed in the bottom of the jet flow chamber, and the main combustion chamber communicates with the jet flow chamber through the jet flow hole. The system further comprises a hydrogen ejector, and a nozzle of the hydrogen ejector is arranged in the jet flow chamber. The nozzle is used for spraying hydrogen into the jet flow chamber at the tail phase of the air intake stroke and the compression stroke, and in the air inlet stroke, thin mixed gas is distributed in the main combustion chamber. And at the later phase of the compression stroke, concentrated mixed gas is distributed in the jet flow chamber. Based on the active jet flow ignition technology of the jet flow chamber, the heat efficiency of an internal combustion engine can be improved; and meanwhile, the hydrogen two-time ejection technology is adopted, the thin mixed gas and the thick mixed gas are formed in the main combustion chamber and the jet flow chamber respectively, NOx generation can be effectively restrained in the whole combustion chamber, and NOx emission is greatly reduced.

Owner:TSINGHUA UNIV

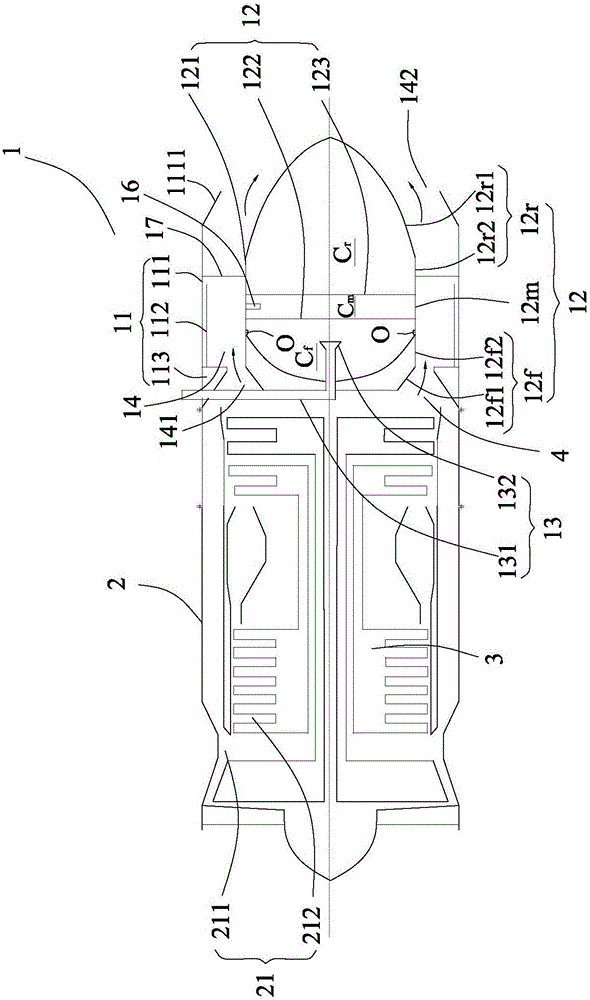

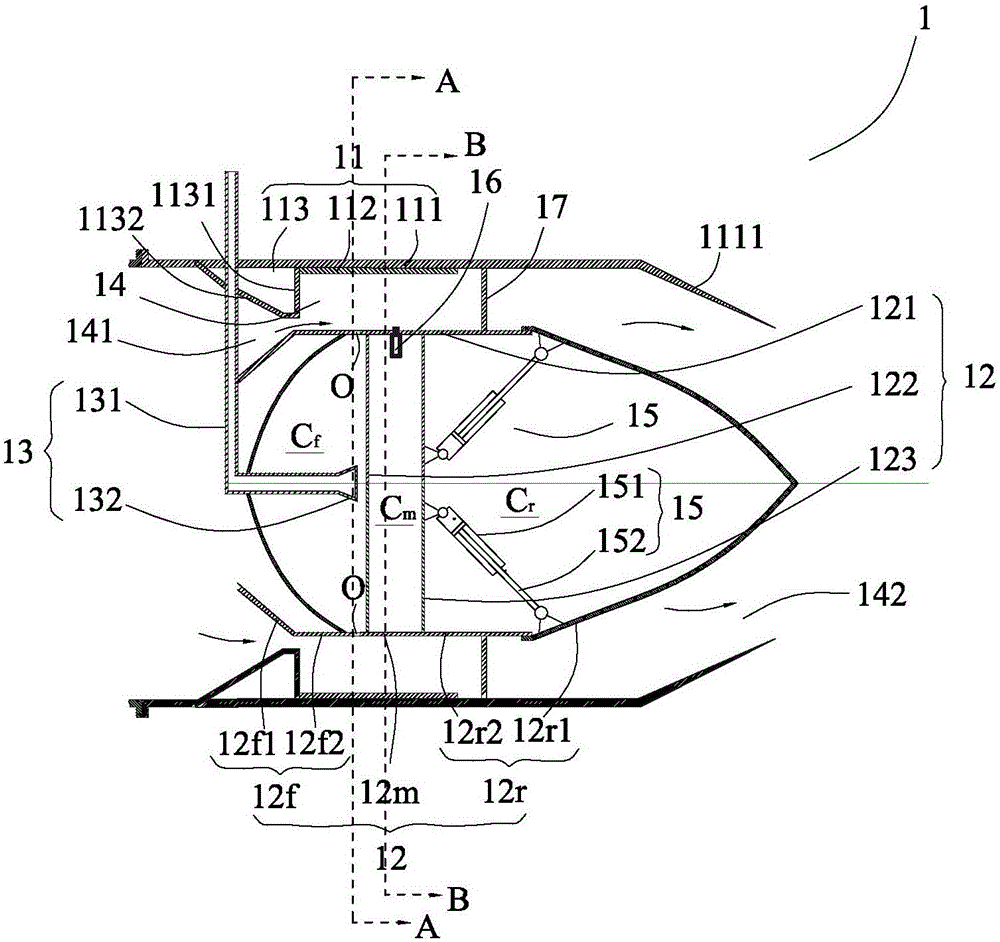

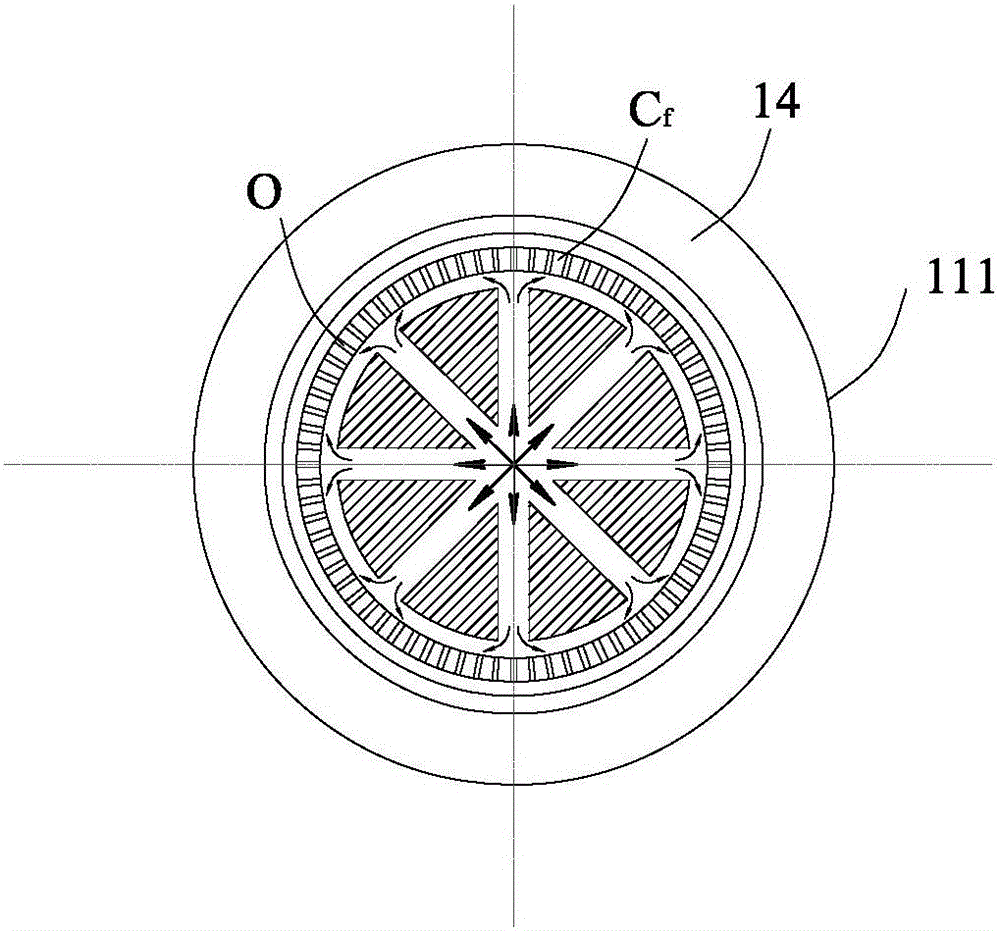

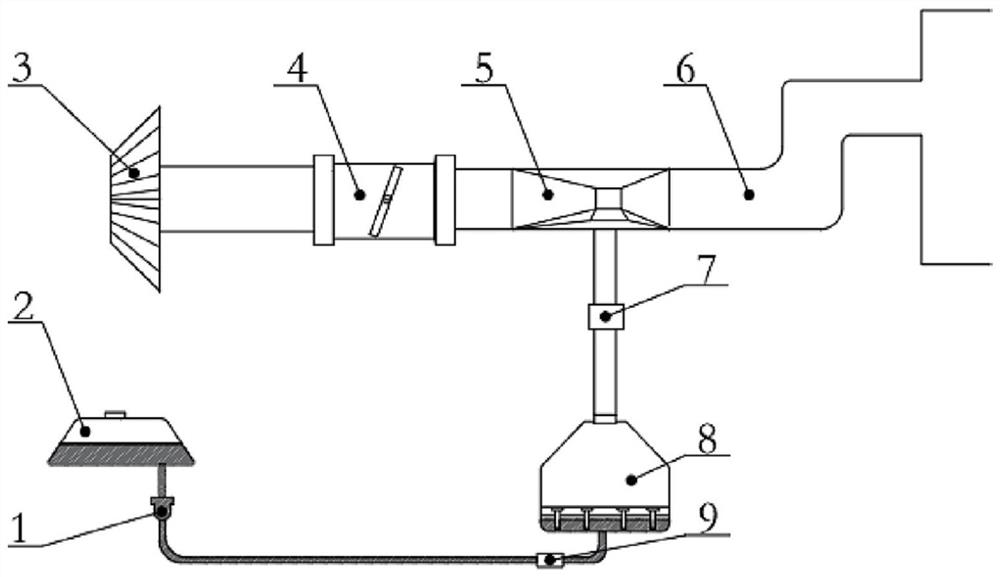

Afterburner and turbine engine

ActiveCN105698219ASolve combustion instabilityImprove efficiencyGas turbine plantsExplosive combustion chamberAutomotive engineeringCombustion chamber

The invention provides an afterburner and a turbine engine. The afterburner comprises an outer cylinder assembly, a center body assembly, an oil way assembly, an annular combustion chamber and an igniter; the center body assembly comprises a front body, a middle body and a rear body, wherein the front body is located at the axial front end of the afterburner and forms a gas inlet, accepting entry of oxygen-containing gas, of the annular combustion chamber with the outer cylinder assembly, the middle body is located behind the front body along the axis and is connected to the front body and integrated with the front body, and the rear body is located behind the middle body in the axial direction, is arranged in the middle body in a slid and sleeved mode and forms a gas outlet of the annular combustion chamber with the outer cylinder assembly; the igniter is arranged at the corresponding part, forming the annular combustion chamber with the outer cylinder assembly, of the center body assembly and is used for igniting fuel gas formed by fuel and the oxygen-containing gas entering the annular combustion chamber, then rotation and knocking combustion of the fuel gas are realized, and therefore the problem that combustion of the afterburner is instable is solved, the heat efficiency of combustion is improved, and the power capability of working media is improved.

Owner:清航空天(浙江)科技有限公司

Ultrasonic atomization fuel auxiliary supply system

InactiveCN111828208ASmall change in intake resistanceAchieve premixCombustion-air/fuel-air treatmentMachines/enginesElectronic throttleUltrasonic atomization

The invention discloses an ultrasonic atomization fuel auxiliary supply system. The system is characterized in that an ultrasonic atomization generator is matched with a Venturi mixer for use, so thatpremixed fuel gas with a certain proportion of fresh charge entering an engine is realized, the combustion heat efficiency of the engine is effectively improved, the emission of harmful gas of the engine is reduced. The system mainly aims at a fuel supply system of methanol which is a clean fuel, utilizes the ultrasonic atomization unit to atomize methanol into methanol mist, is matched with thenegative pressure adsorption principle of the Venturi tube, and realizes premixing of air and methanol mist through the adjusting function of an electronic throttle valve on the air inlet flow; and the heat efficiency of the engine is improved in an auxiliary fuel gas supply mode of the premixing part, and emission of the engine is improved.

Owner:唐山阳光动力科技有限公司

Preparation method of rare-earth oxide material containing tourmaline

InactiveCN103623832ALow ignition temperatureHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationRare earth

The invention provides a preparation method of a rare-earth oxide material containing tourmaline. According to the method, tourmaline micro powder is added during a hydrothermal preparation process, and a micro electric field generated by spontaneous polarization of the tourmaline micro powder is utilized to control the increase of particle sizes of rare-earth oxide particles in hydrothermal reaction, so that more reaction active sites are exposed while the specific surface area of the rare-earth oxide material is increased, the catalytic oxidation reactivity of high perovskite type rare-earth oxides is promoted, and defects in the preparation process and application of the conventional perovskite type rare-earth oxides are overcome. The method can be widely used for pretreatment of catalytic materials, brings favorable economic benefits and social benefits to China in the fields of catalytic oxidation, industrial organic waste gas treatment, automobile emission purification and the like, and is of important positive significance in energy conservation, emission reduction and reasonable use of energy sources.

Owner:HEBEI UNIV OF TECH

Gas stove

ActiveCN102913956AImprove combustion thermal efficiencyImprove replenishment abilityDomestic stoves or rangesLighting and heating apparatusEngineeringHeating efficiency

The invention discloses a gas stove. The gas stove comprises a panel provided with an opening, a bottom case which is used for supporting the panel, a burner and an energy-collecting disk which is arranged at a position of the opening of the panel, wherein the burner is located in the energy-collecting disk, a pressurization disk is arranged on the lower portion of the energy-collecting disk, and a secondary air supplementing hole is arranged on the side wall of the pressurization disk. The energy-collecting disk is arranged on the surrounding of the burner and is used for conducting energy-collecting reflection for energy generated by the burner, the heat emission and the heat convection are greatly reduced, the gas burning heat efficiency is improved, the pressurization disk is arranged on the lower portion of the energy-collecting disk, the secondary air supplementing hole is arranged on the side wall of the pressurization disk, the air outside the pressurization disk enters from the secondary air supplementing hole and is used for supplementing the burner with the secondary air through the channel between the energy-collecting disk and the pressurization disk, a pressurization fan is arranged on the bottom case of the gas stove, an air duct structure is arranged on the surrounding of the pressurization fan, the burning is complete, the gas burning heat efficiency is improved further and the effect of the inner temperature increment of the gas stove is reduced.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

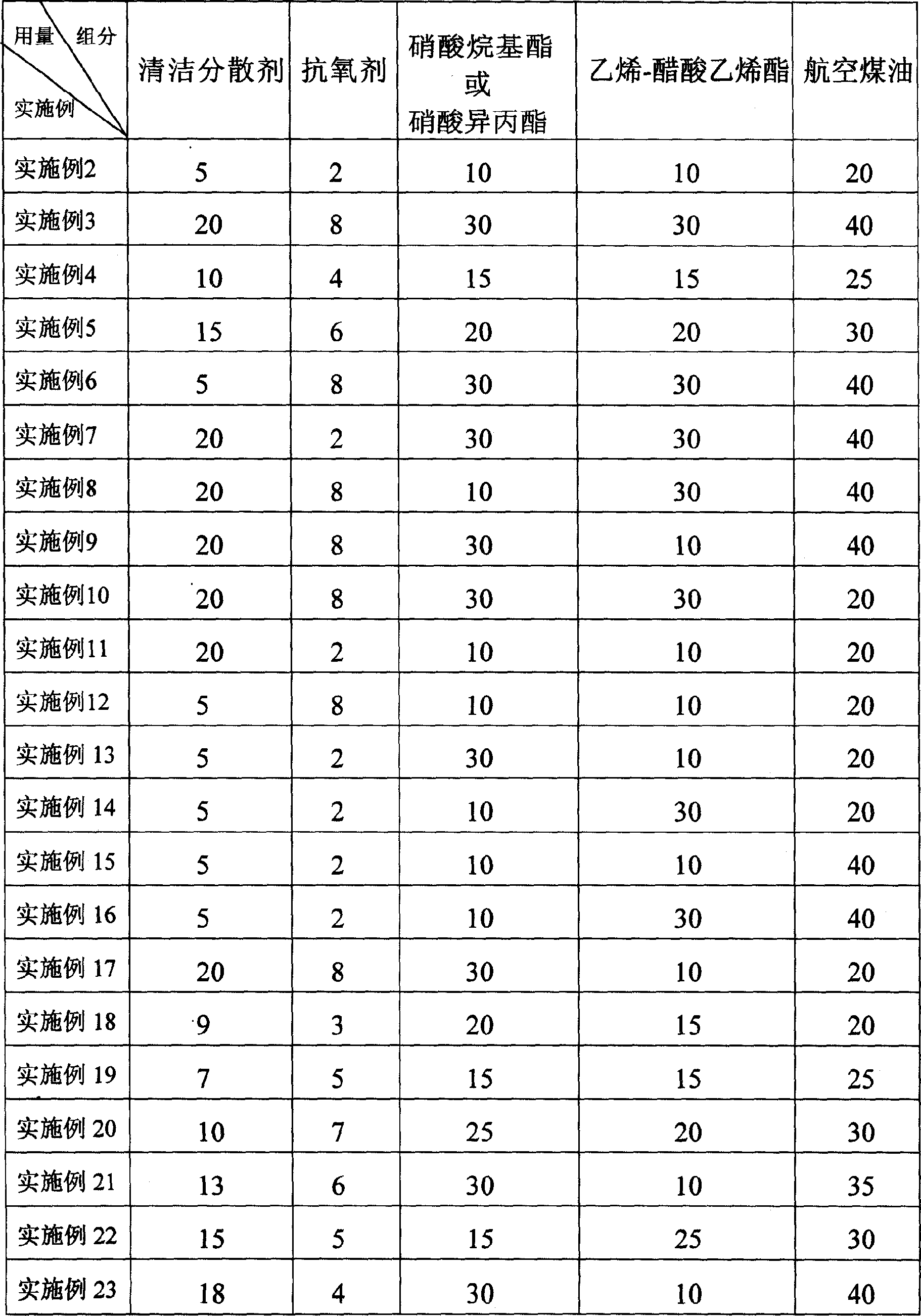

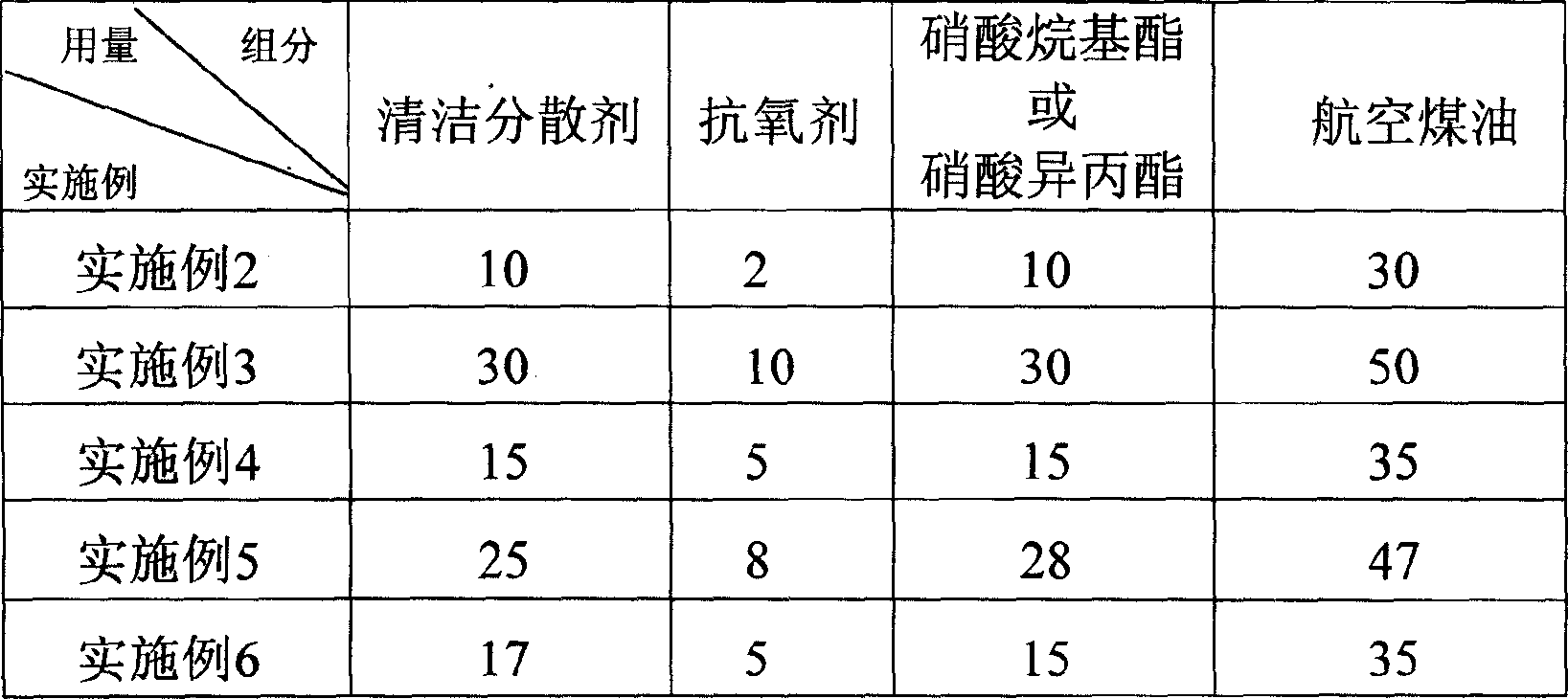

Smoke abatement anti-freeze agent for diesel fuel

The invention provides an environment-friendly type diesel smoke abatement and anti-freeze agent for purifying emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate or ethylene / vinyl acetate and high grade plane kerosene through high-shearing mixing and emulsion process. The invention can realize good intensified smoke abatement property and fluidity for diesel under low-temperature.

Owner:牛云龙

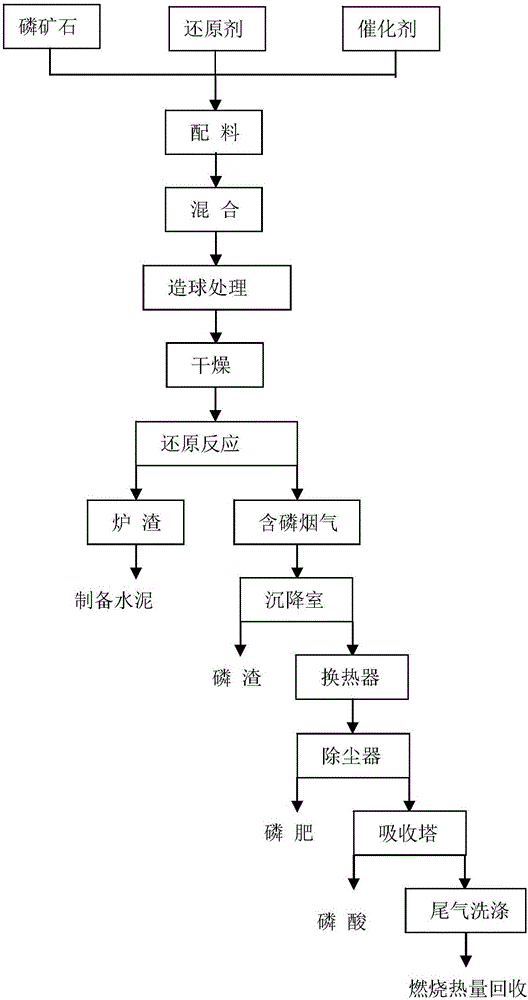

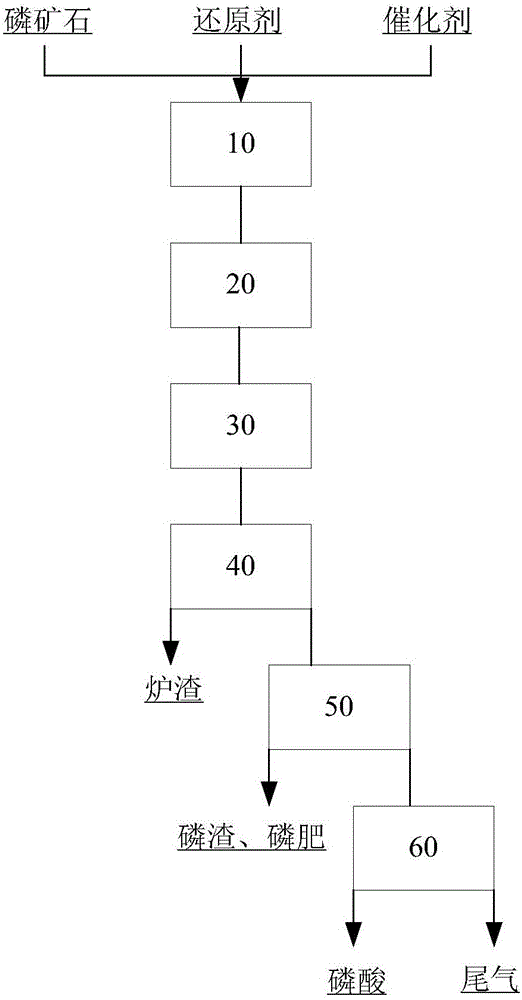

Method and system for preparing phosphoric acid

InactiveCN105752956AImprove efficiencyImprove the efficiency of phosphoric acid productionPhosphoric acidSlagPhosphate

The invention provides a method and system for preparing phosphoric acid.The method for preparing phosphoric acid includes the steps that phosphate ore, a reducing agent and a catalyst are mixed to obtain a mixed material; the mixed material is subjected to pelletizing treatment to obtain a globular material; the globular material is dried to obtain a dried globular material; the globular material is subjected to a reduction reaction inside a heat storage type rotary hearth furnace to obtain phosphorus-containing smoke and furnace slag; the phosphorus-containing smoke is subjected to an oxidation reaction to obtain phosphorus pentoxide steam; the phosphorus pentoxide steam reacts with water to obtain phosphoric acid.By the utilization of the method, the preparation efficiency and quality of phosphoric acid can be effectively improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Ultralow-concentration gas machine combustion system and control method thereof

PendingCN111237092AIncrease intake pressureImprove inflation efficiencyElectrical controlInternal combustion piston enginesCombustion systemCommon rail

The invention provides an ultralow-concentration gas machine combustion system and a control method thereof. The ultralow-concentration gas machine combustion system comprises an air exhaust turbocharging device, an ultralow-concentration gas pressurizing inlet device, a diesel common-rail micro-jet ignition device, a diesel injector cooling circulation device, an EMS control unit and a pluralityof cylinders, wherein the air exhaust turbocharging device can improve the air inlet pressure and efficiency, the ultralow-concentration gas pressurizing inlet device can improve the gas inlet densityto meet the requirements of different loads for a high-pressure gas flow rate, and the diesel injector cooling circulation device decreases the combustion temperature of an injector under a high loadand greatly lowers the probability that the ejector burns down or gets stuck. Under the combined action of all the devices, normal ignition and normal combustion based on the ultralow-concentration gas machine combustion system are realized, and normal starting and operating of a gas machine are ensured.

Owner:中科环能(天津)动力科技有限公司

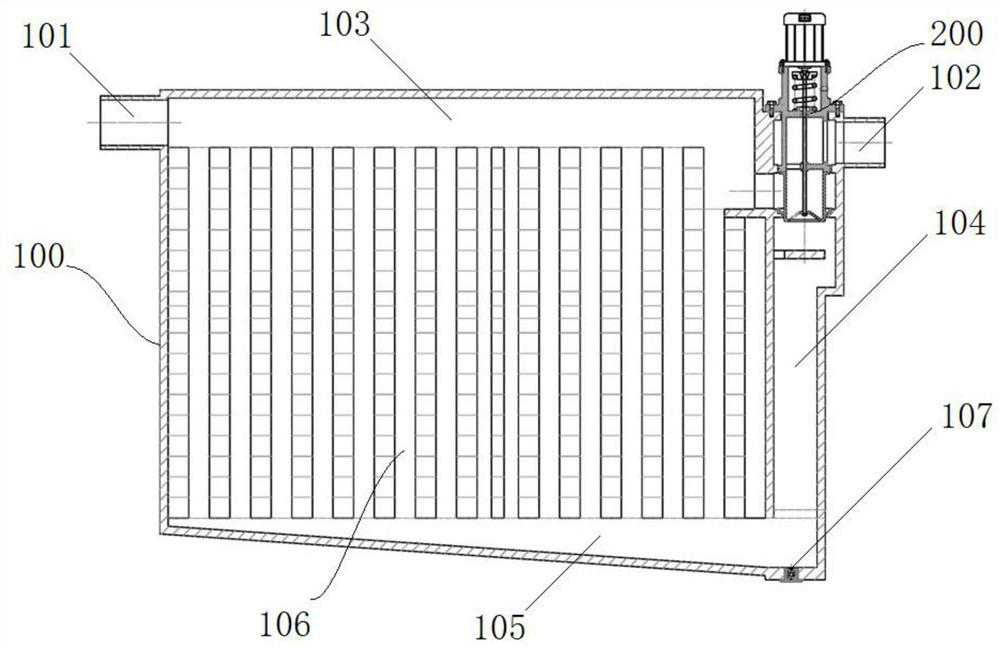

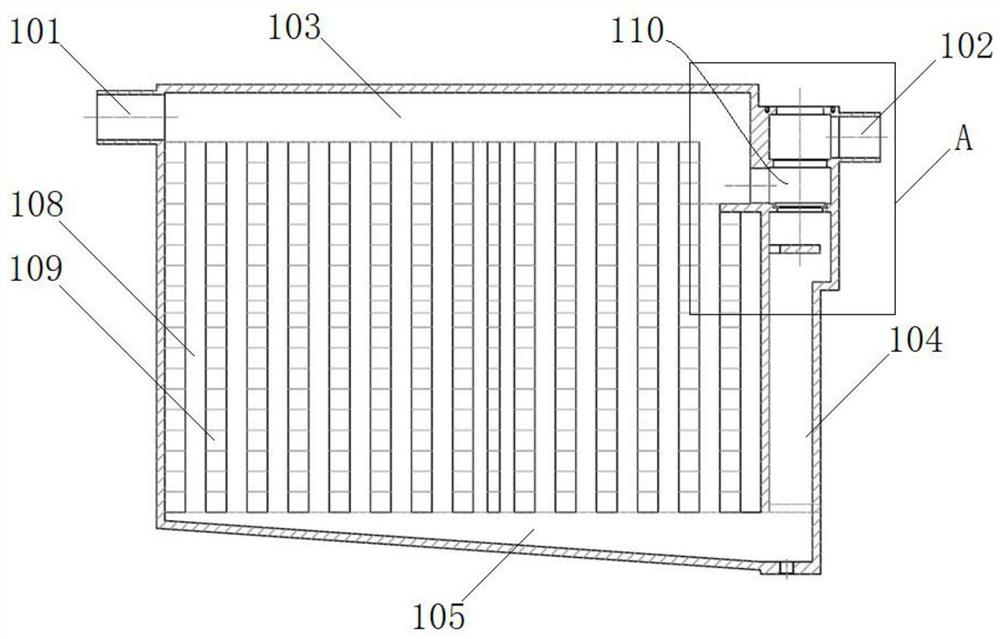

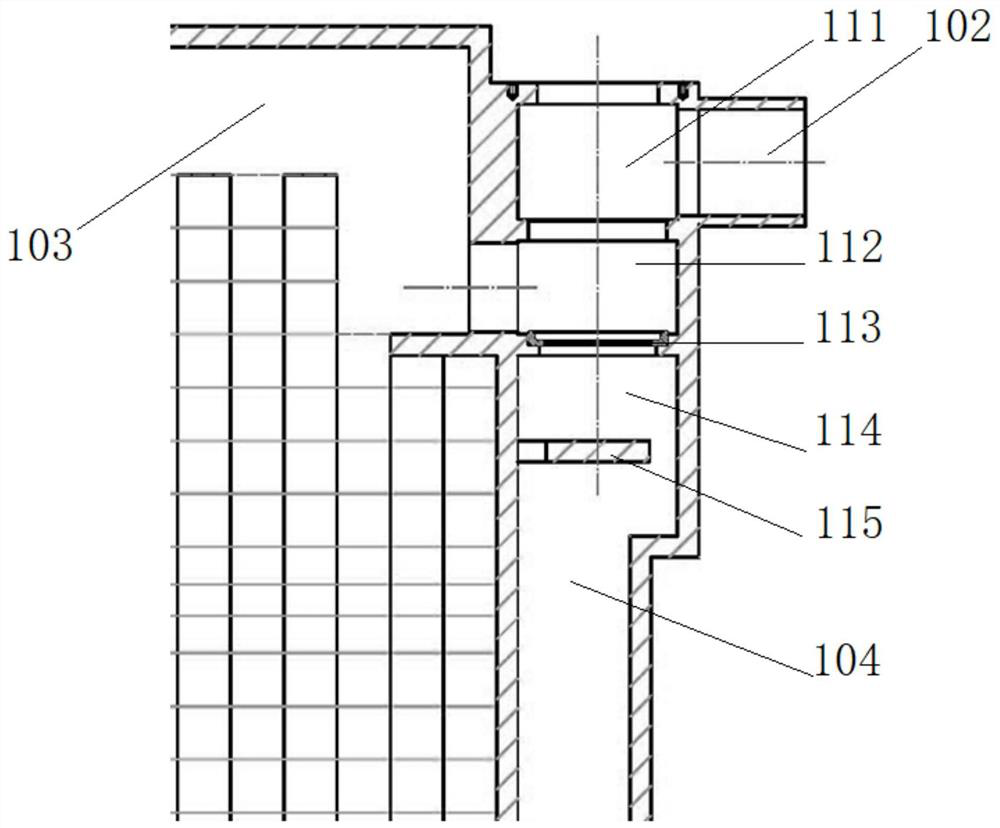

Cooling-temperature-controllable-type engine intercooler assembly

ActiveCN111810288AAdjustable temperatureImprove combustion thermal efficiencyInternal combustion piston enginesThermodynamicsGas passing

The invention relates to a cooling-temperature-controllable-type engine intercooler assembly, and belongs to the technical field of supercharged engine intercoolers. The cooling-temperature-controllable-type engine intercooler assembly comprises an intercooler, a front gas channel, a rear gas channel and a temperature adjusting valve; the intercooler is provided with a gas inlet hole and a gas outlet hole; the front gas channel is connected between the gas inlet hole and the gas outlet hole and used for circulating gas not passing through the interior of a cooling device; the rear gas channelis connected between the gas inlet hole and the gas outlet hole and used for circulating gas passing through the interior of the cooling device; and the temperature adjusting valve adjusts the gas temperature in the gas outlet hole by adjusting the opening degree of a gas outlet of the front gas channel and / or the rear gas channel. The interior of the intercooler is arranged into a cooling and non-cooling double-gas-channel form, and the temperature adjusting valve is arranged at the common outlet of the front gas channel and the rear gas channel; the temperature adjusting valve can control the mixing ratio of the gas in the front gas channel to the gas in the rear gas channel to meet the control requirement of the gas inlet temperature of an engine, and the gas inlet temperature of the engine is automatically controlled; and the temperature adjusting valve can adjust the temperature after intercool to enable gas inlet temperatures of all operating points of the engine to be controlledin the optimal state.

Owner:DONGFENG COMML VEHICLE CO LTD

Coal combustion catalyst

ActiveCN104371791AReduce manufacturing costImprove combustion thermal efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsRare-earth elementCombustion

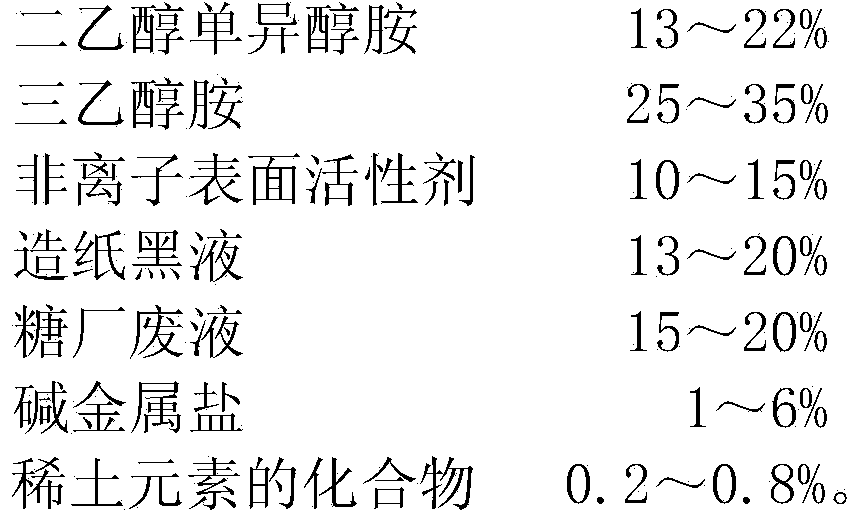

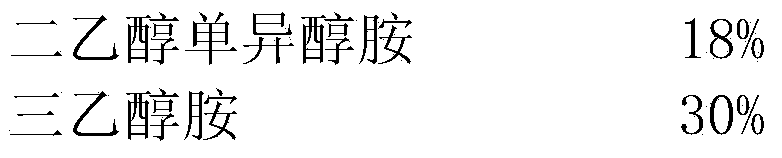

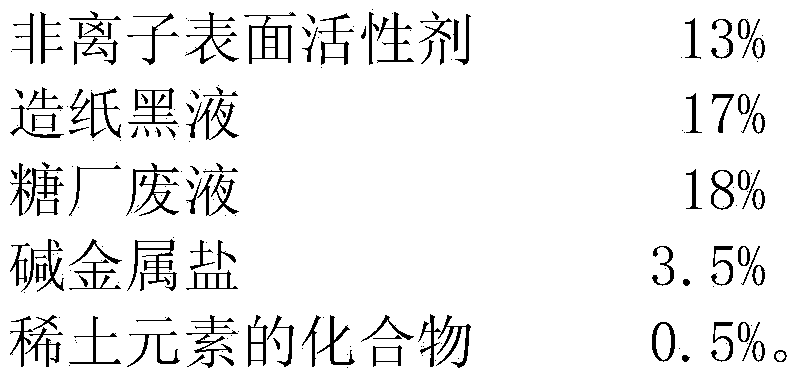

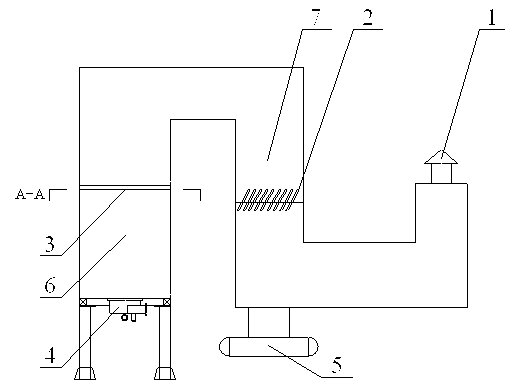

The invention relates to the technical field of coal energy, and discloses a coal combustion catalyst, which is prepared by the following raw materials in percentage by weight: 13-22% of diethanol monoisopropanol amine, 25-35% of triethanolamine, 10-15% of non-ionic surfactant, 13-20% of papermaking black liquid, 15-20% of sugar refinery waste liquid, 1-6 parts of alkaline metal salt, and 0.2-0.8% of rare earth element compounds. The performances of the coal catalyst can be mainly optimized, the cost is lowered, the firing point and after-combustion temperature of the coal can be reduced by the coal combustion catalyst, the combustion speed of the coal can be increased, and coal is thoroughly combusted, so that not only the coal consumption and cost be reduced, but also the emission of SO2, NOx and other harmful gases can be reduced, and the coal combustion catalyst can provide favorable conditions for combusting inferior coal instead of high-quality coal.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

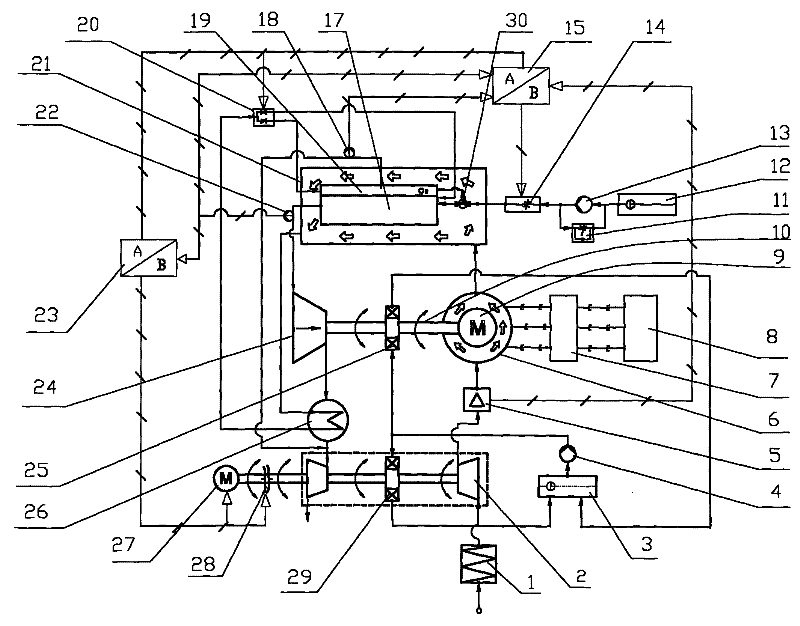

Chemical waste gas boiler furnace for combustion

The invention discloses a chemical waste gas boiler furnace for combustion. The boiler furnace comprises a chimney, an inclined louver, a crossed air distributing pipe, a combustion device, a drain device, a combustion chamber, a fume passage, a first fan and a second fan, wherein the boiler furnace body forms an N shape, the combustion device is positioned at the lower end part of one end of the N-shaped boiler furnace body, the combustion chamber is arranged above one end of the N-shaped boiler furnace body, the upper end of the combustion chamber is connected with the fume passage, the middle part of the boiler combustion chamber is provided with the crossed air distributing pipe, the crossed air distributing pipe is uniformly provided with a plurality of air distributing holes from top to bottom, the end part of the crossed air distributing pipe is respectively connected with the first fan and the second fan, the part of the fume passage on a second curved passage of the N-shaped boiler furnace body, corresponding to the combustion chamber, is provided with the inclined louver, the outer side of the bottom of the lower part of the inclined louver is provided with the drain device, and the upper end part of the other end of the N-shaped boiler furnace body is provided with the chimney. The boiler furnace has the advantage that the boiler body structure is vertically arranged, so the occurrence of aggregating and detonation of residual hydrogen and backfire is avoided, and the safe and reliable running of the device is ensured.

Owner:ZHEJIANG TUFF BOILER

Multichannel rotational flow flame stabilization stepless regulation multifuel combustion combustor

The utility model relates to a multi-channel swirling flow stabilizing flame stepless adjustable mixed combustion burner, which relates to a burner, in particular to a mixed combustion burner using pulverized coal and gas as fuel or a single combustion burner of pulverized coal and gas. It is equipped with a conical ring flame stabilizer in the center of the burner shell, the small head of the flame stabilizer is connected to the central air pipe and the gas pipe, and the outer wall of the gas pipe is connected to a gas mixer. A volute swirler and an adjustment pull rod are arranged on the outer wall of the gas ring joint and the gas pipe at the other end. The outer layer of the gas pipe is equipped with a fire channel, a primary air channel, a secondary air channel and a clean air channel. The secondary air duct and the clean air duct are equipped with swirlers and conical air nozzles respectively. The outer wall of the outlet of the clean air inner pipe and the secondary air inner pipe is made with a cone angle of 15-20° that expands outwards, and the cross-sectional area of the outlet can be changed arbitrarily in the axial direction, and the airflow velocity can be changed. The flame stabilizer can move axially to change the outlet angle of the central air. In this way, the heat load flame shape can be adjusted steplessly, and the combustion temperature can be organically combined with the process conditions. The invention is a pulverized coal and gas burning device with high efficiency, energy saving and low emission of NOx.

Owner:湖北满天星节能环保科技有限公司

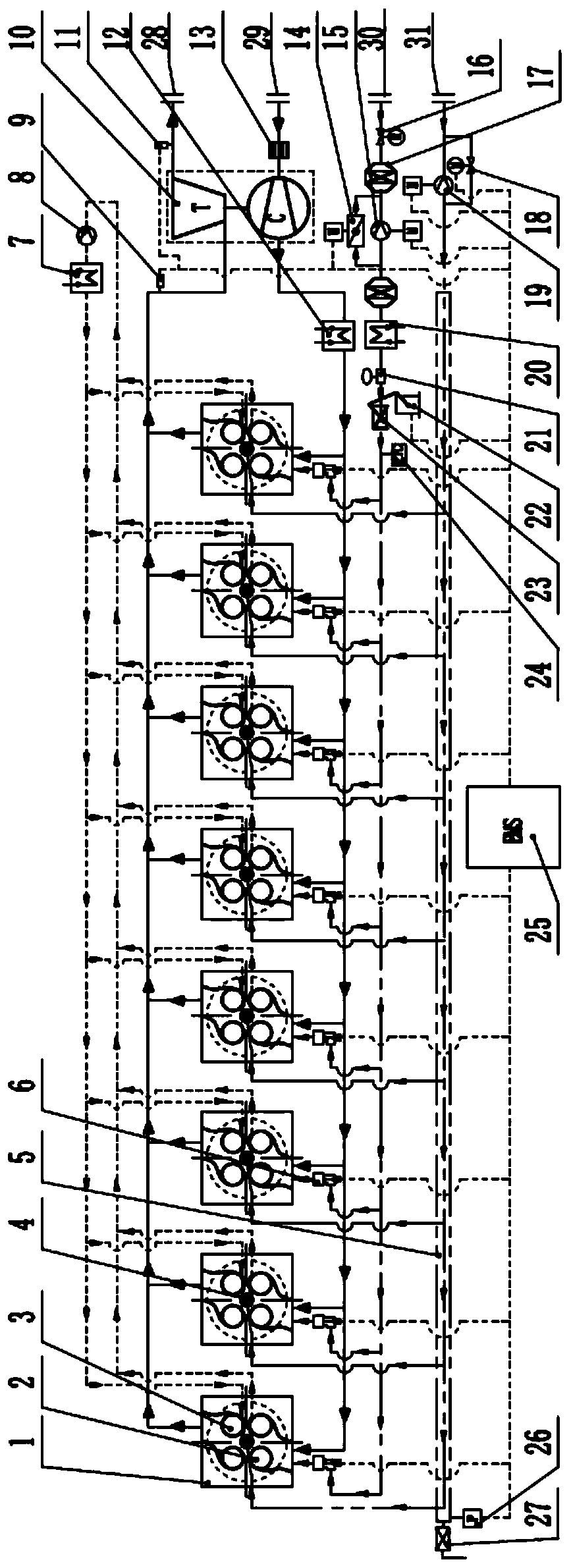

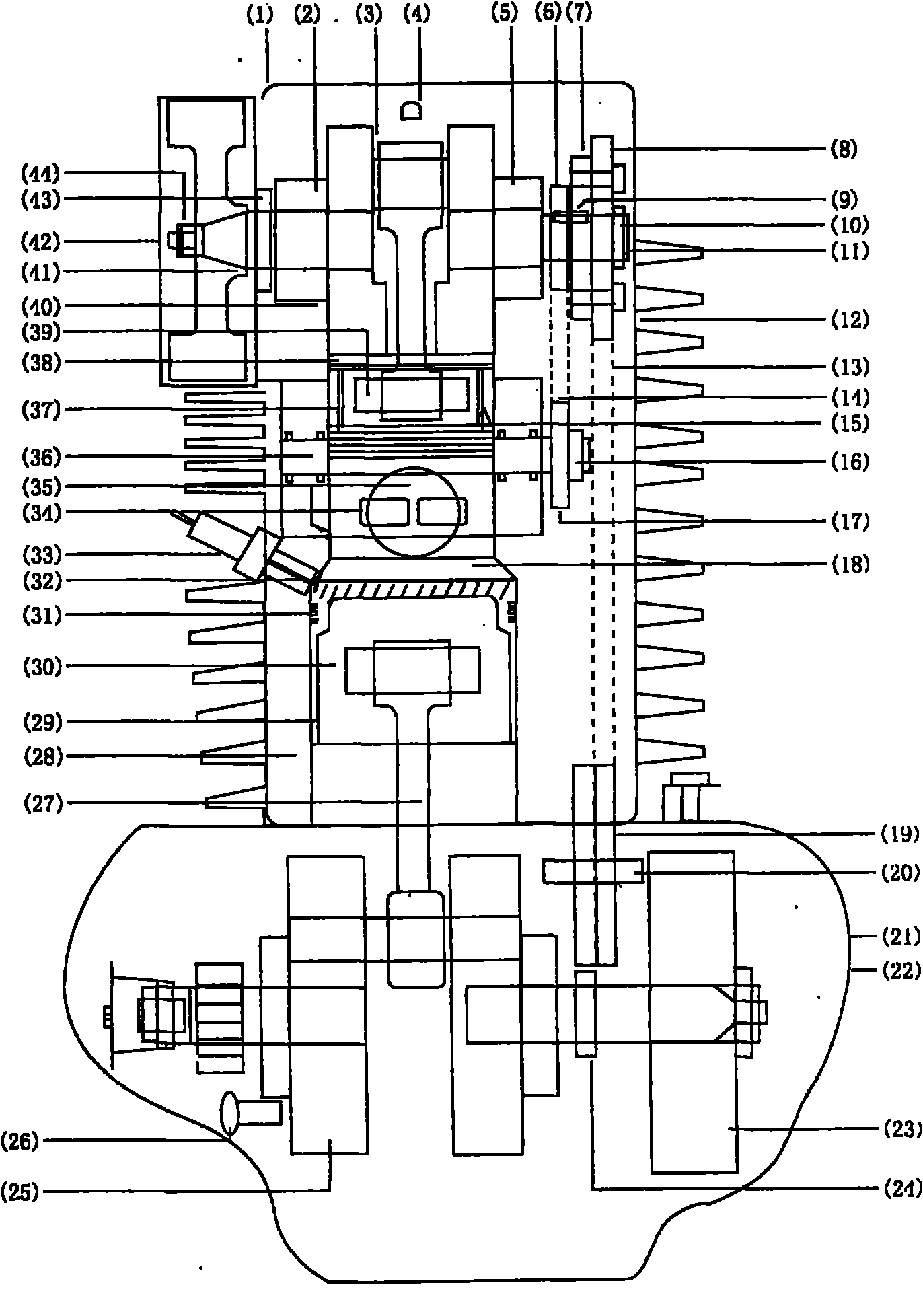

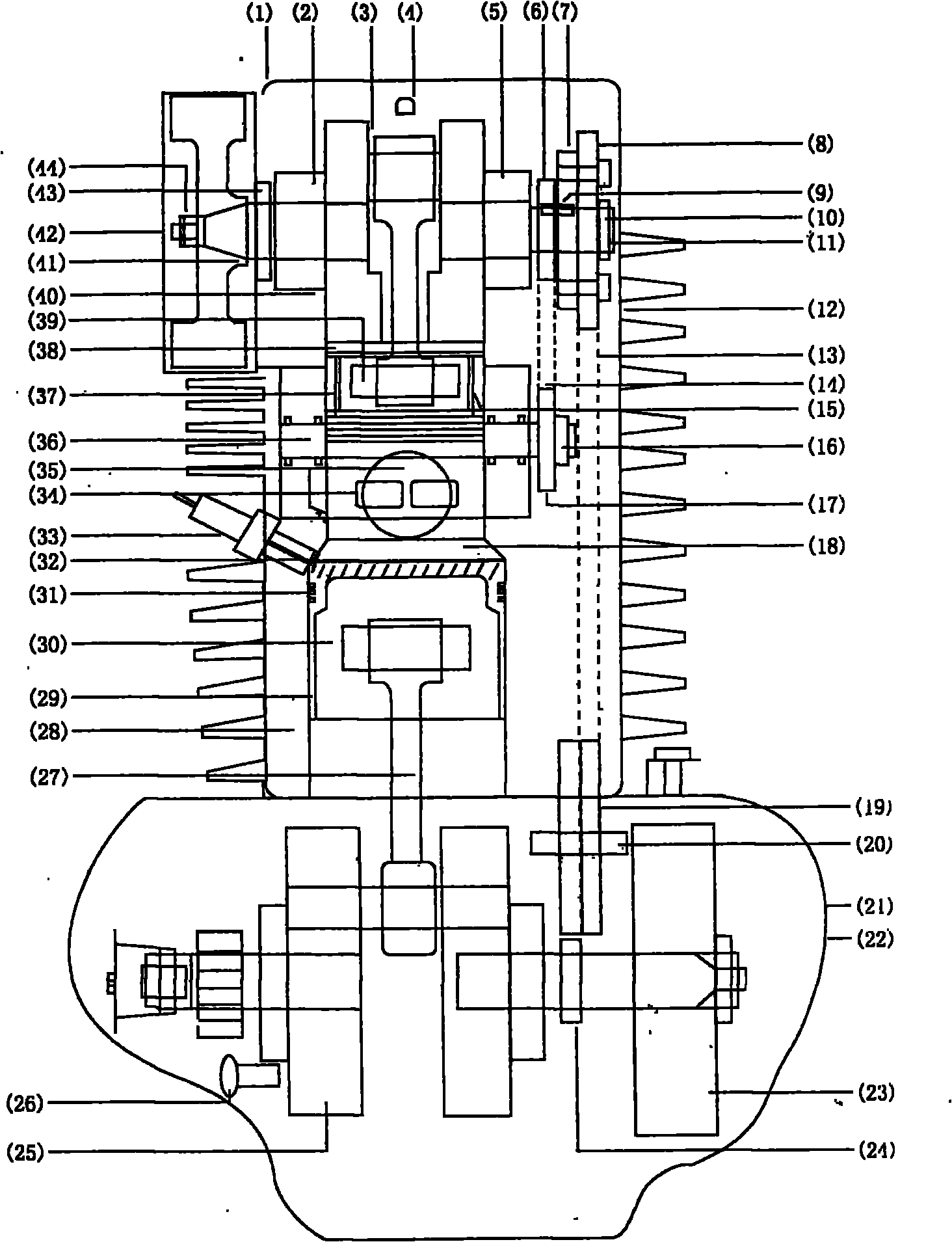

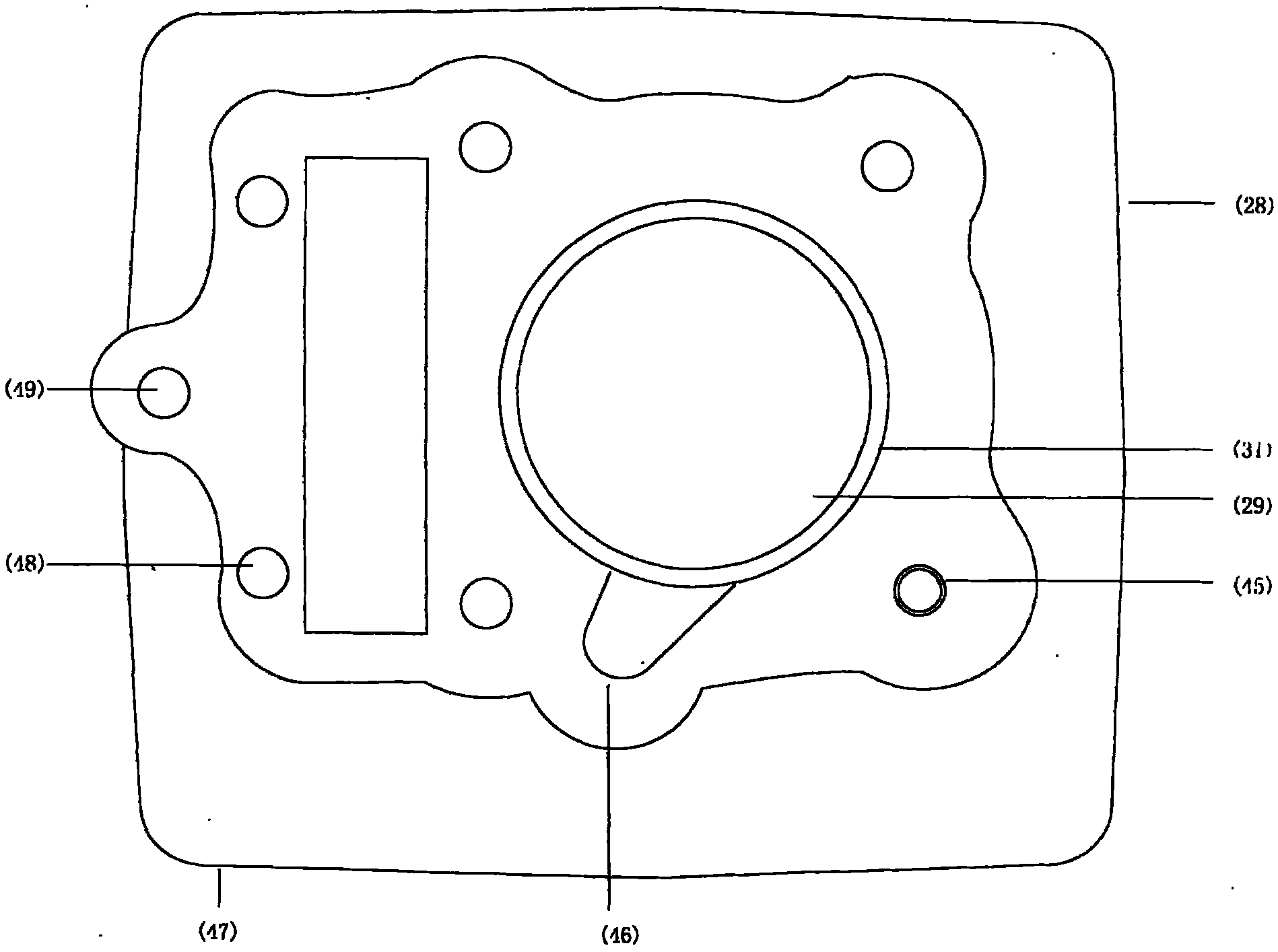

Novel four-stroke layered double-swirling combustion energy-saving internal-combustion engine with new air distribution mechanism

ActiveCN102094702AStable jobImprove qualityInternal combustion piston enginesElectric ignition installationPistonFuel oil

The invention relates to a four-stroke layered double-swirling combustion energy-saving internal-combustion engine with a new air distribution mechanism, and is particularly suitable for various internal-combustion engines for seas, land and space. A cylinder (28) and a cylinder oil nozzle gasket (32) are arranged on a crankcase (85) of a conventional four-stroke single-cylinder gasoline rod ejector, the new air distribution mechanism is arranged in a small cylinder head (12), and a small cylinder (40) is arranged inversely. The front of the wall of the small cylinder (40) is provided with two ports (34), and a small piston (38) slides up and down to suck air and exhaust air. The sucked air rotationally enters along the walls of the big cylinder (28) and the small cylinder (40), the inlet fuel oil rotationally enters, the big and the small pistons apply work at the same time, and the exhausted air pushes a suction-exhaust turbine (51) to apply first work. The internal-combustion engine has the advantages of simple structure, good lubricating condition, long service life, stable work, high revolution rate and no noise; and the engine realizes layered double-swirling combustion of the fuel oil swirled in the middle of an hot air interlayer, and realizes three-time work application in one-time combustion, so that the engine has higher high-power output, saves the fuel oil by about 50 percent and reduces the emission by 85 percent.

Owner:杨成元

Coal-burning energy releasing powder and its prepn

The present invention discloses one kind of coal-burning energy releasing powder and its preparation process. The coal-burning energy releasing powder consists of saltpeter 0.5-1.5 weight portions, ferric dicyclopentadiene or allyl cyanurate 1-2 weight portions, potassium permanganate or potassium bromide 0.3-0.7 weight portions, sodium nitrate or calcium nitrate 0.3-0.7 weight portions, potassium permanganate or potassium persulfate 1.5 -2.5 weight portions, strontium nitrate or sodium bichromate 0.5-1.5 weight portions, calcium fluoride 1.5-2.5 weight portions, coal slag or char slag 1.5-2.5 weight portions, loess or lime 1.5-2.5 weight portions, potassium chlorate or potassium persulfate 0.5-1.5 weight portions, potassium nitrate 0.5-1.5 weight portions, and sodium chloride 80-90 weight portions. It can promote combustion of coal to convert the latent energy of coal into heat completely.

Owner:张学义

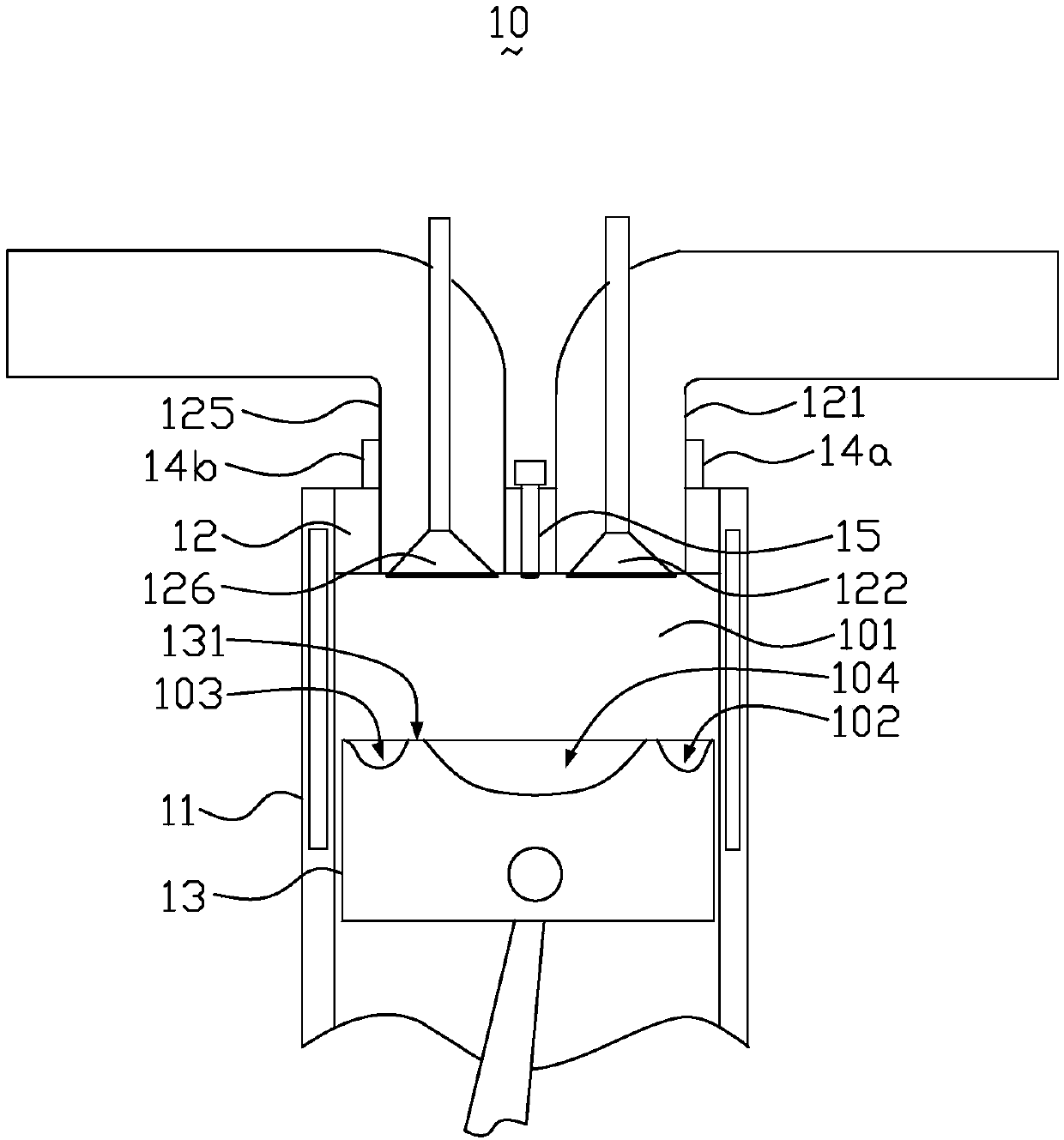

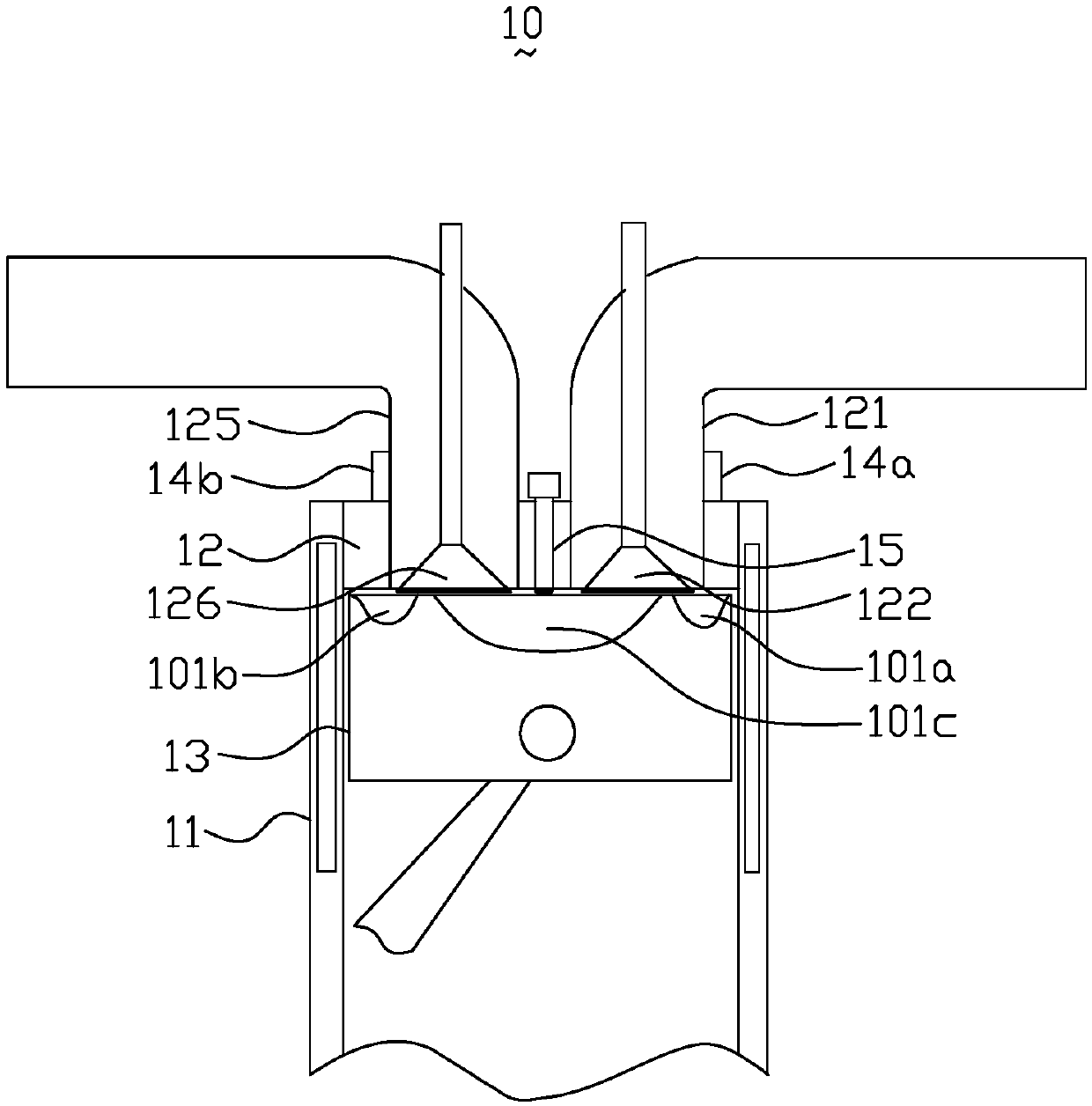

Engine and double-jet combustion method thereof

PendingCN110953067AStable and reliable fireImprove combustion thermal efficiencyInternal combustion piston enginesCylinder headsJet flowThermal efficiency

The invention relates to an engine. The engine comprises an air cylinder, a cylinder cover, a piston, a first spark plug, a second spark plug and a fuel injector which is used for injecting fuel intothe air cylinder; the cylinder cover is arranged on the air cylinder; the piston is movably arranged in the air cylinder; a spiral air incoming channel and a tangential air incoming channel are formedin the cylinder cover; the spiral air incoming channel is used for inputting vortex air into the air cylinder; the tangential air incoming channel is used for inputting air into the air cylinder; a first combustion groove, a second combustion groove and a third combustion groove are formed in the end surface, close to the cylinder cover, of the piston; the first combustion groove is communicatedwith the third combustion groove through a first jet flow channel; the second combustion groove is communicated with the third combustion groove through a second jet flow channel; the first spark plug, the second spark plug and the oil injector are arranged on the cylinder cover; the first spark plug corresponds to the first combustion groove; and the second spark plug corresponds to the second combustion groove. The reliable and stable ignition of the engine of the invention in an overall lean-burn mode can be achieved, and combustion heat efficiency is effectively improved. The invention further relates to a double-jet combustion method of the engine.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

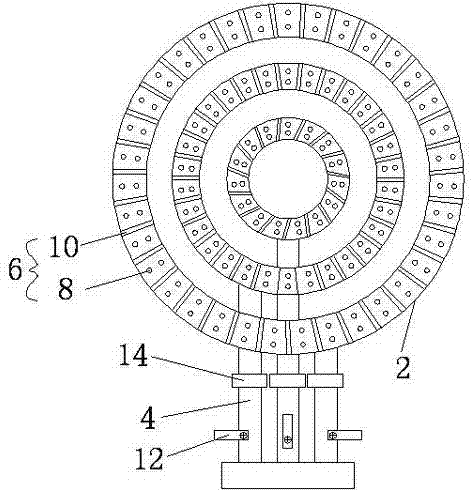

Collar-shaped efficient energy-saving gas cooking range

The invention provides a collar-shaped efficient energy-saving gas cooking range which comprises a plurality of annular fire distributors and gas pipes. Gas can be delivered into the fire distributors by the gas pipes, and a plurality of fire holes are formed in each fire distributor and are integrally annularly and uniformly distributed on the fire distributor. The collar-shaped efficient energy-saving gas cooking range is characterized in that the fire holes include circular holes and linear holes which are alternately formed. The collar-shaped efficient energy-saving gas cooking range has the advantages that the fire holes include the circular holes and the linear holes which are alternately formed in an arrayed manner, intensive flame of spots, lines and surfaces can be formed by the aid of the fire holes during combustion fire generation, accordingly, a spot heating mode is replaced by line and surface heating modes, heat loss can be reduced, and the collar-shaped efficient energy-saving gas cooking range is high in heat efficiency; a basin gathering fire circle can be formed during combustion fire generation by the fire distributors which sequentially sleeve one another from the outside to the inside, the integral flame forms heat collecting sunken ring regions and can be gathered at the bottoms of pots, accordingly, heat loss can be prevented, and the combustion heat efficiency further can be improved.

Owner:WUJIANG GERUIFU HARDWARE

Micro Hybrid Oxygen Combustion Gas Turbine Generator

InactiveCN102297025AReduce pollutionIncrease oxygen concentrationTurbine/propulsion fuel valvesGas turbine plantsControl systemMicro gas turbine

The invention relates to a micro gas turbine generator employing mixed oxygen-enriched combustion, and the technical problem of the invention is to provide a micro gas turbine generator employing mixed oxygen-enriched combustion and having the characteristics of reducing pollution, improving the thermal power recovery grade of exhaust gas and possessing thermal efficiency higher than that of traditional gas turbines. A technical scheme for solving the problem is the micro gas turbine generator employing mixed oxygen-enriched combustion. The generator is characterized by comprising a fuel supply system, an oxygen-enriched air supply system, a combustion working system, a control system, a power generation system and an energy recovery system. The generator provided in the invention is mainly suitable for micro gas turbine generators.

Owner:江西惟思特科技发展有限公司

Catalytic detersive of diesel fuel

The invention provides an environment-friendly type diesel catalysis detersive for cleaning emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate and high grade plane kerosene through high-shearing mixing and emulsion process. The agent can improve combustion efficiency according to the combustion conditions.

Owner:牛云龙

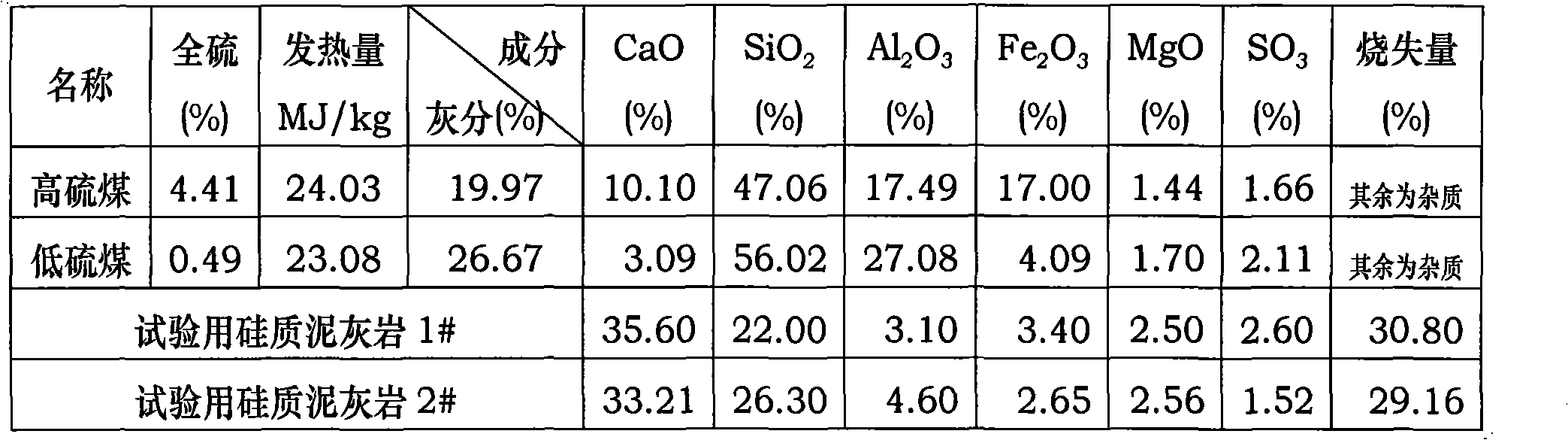

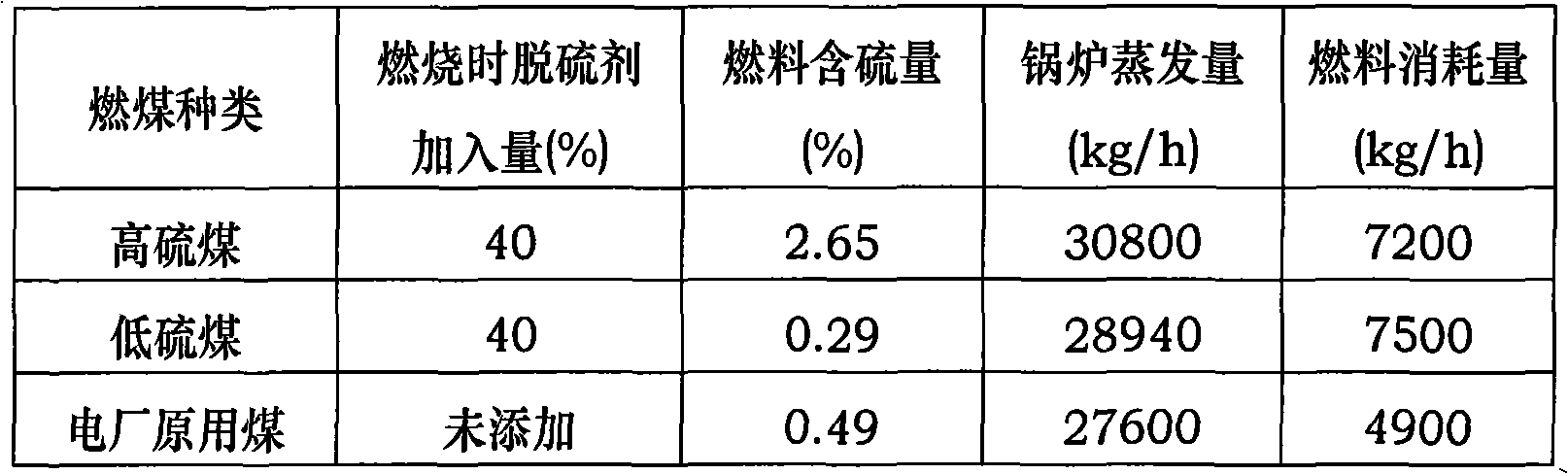

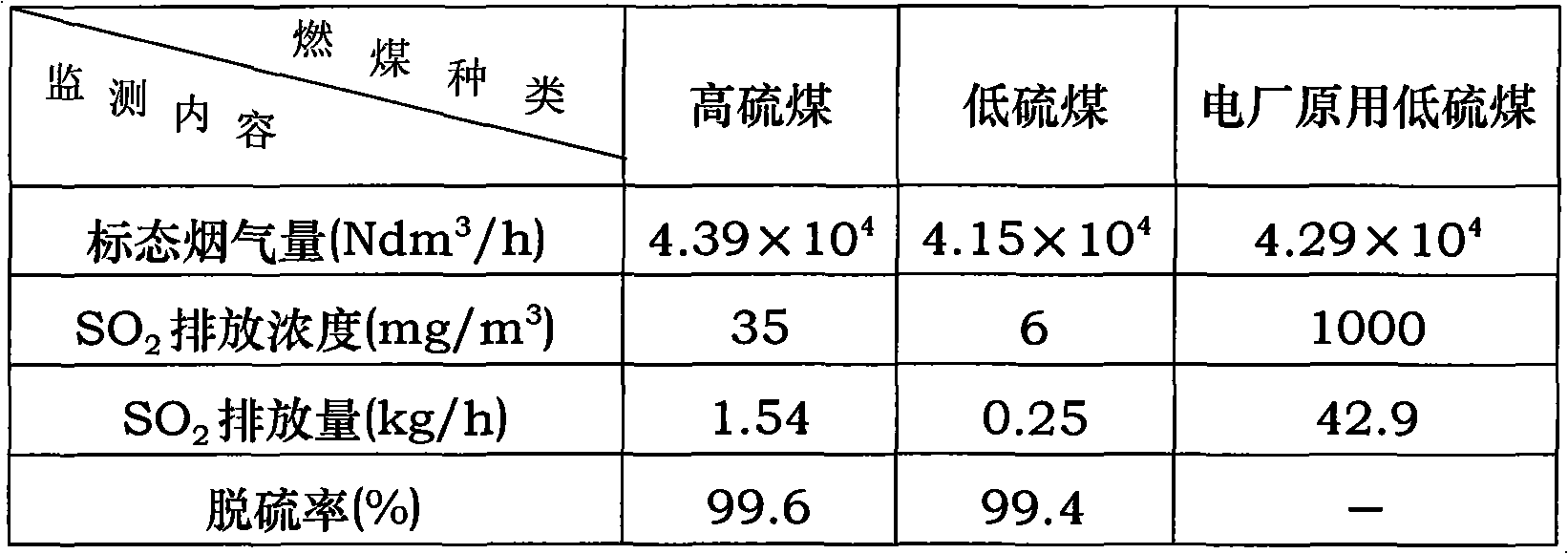

Fire coal or inferior coal desulfurizer for sulfur fixation in circulating fluidized bed boiler

InactiveCN102373105AReduce processing costsReduce desulfurization costSolid fuelsGranularityFluidized bed

The invention discloses a fire coal or inferior coal desulfurizer for sulfur fixation in a circulating fluidized bed boiler. The desulfurizer provided by the invention is made from siliceous marlite with its granularity being less than 4mm and a zeolite powder with its granularity being less than 0.1mm; 100g of the desulfurizer contains 98-99g of siliceous marlite. The desulfurizer is uniformly blended in fire coal or inferior coal and 15-40g of the desulfurizer is added into 100g of fire coal or inferior coal. With the addition of the desulfurizer in fire coal or inferior coal, 80-99.6% of sulfur content can be removed from fire coal or inferior coal.

Owner:郭仕民

Method for heating and adjusting temperature of plant heat collector in winter

InactiveCN103141345ASimple structureLow costClimate change adaptationGreenhouse cultivationCombustion chamberEngineering

The invention belongs to the technical field of warming and temperature adjustment, and relates to a method for heating and adjusting temperature of a plant heat collector in winter. The method comprises the following steps of firstly, constructing a heat collector frame according to the structure of the conventional vegetable heat collector, and spreading a transmitting thin film material on the top side face of the heat collector frame; then selecting a biomass fuel combustion heat collecting device, and fixedly arranging a combustion chamber, a flue, a smoke box and a smoke ventilator in the heat collector; and filling the collected biomass fuel in the combustion heat collecting device, igniting the biomass fuel, switching on the electric smoke ventilator to make the fuel in the combustion heat collecting device completely combusted and dissipate heat to adjust and raise the temperature of the heat collector through the combustion chamber, the flue and the smoke box in the combustion heat collecting device, regularly recycling dust in each dust box, adding clear water, and stacking in a pit for natural fermentation, so as to prepare a biomass organic fertilizer. The design principle is reliable, the heating process is simple, the fuel is easily obtained, the combustion heat efficiency is high, the heating and temperature adjusting effect is good, and the environment friendliness is realized.

Owner:孙吉廷

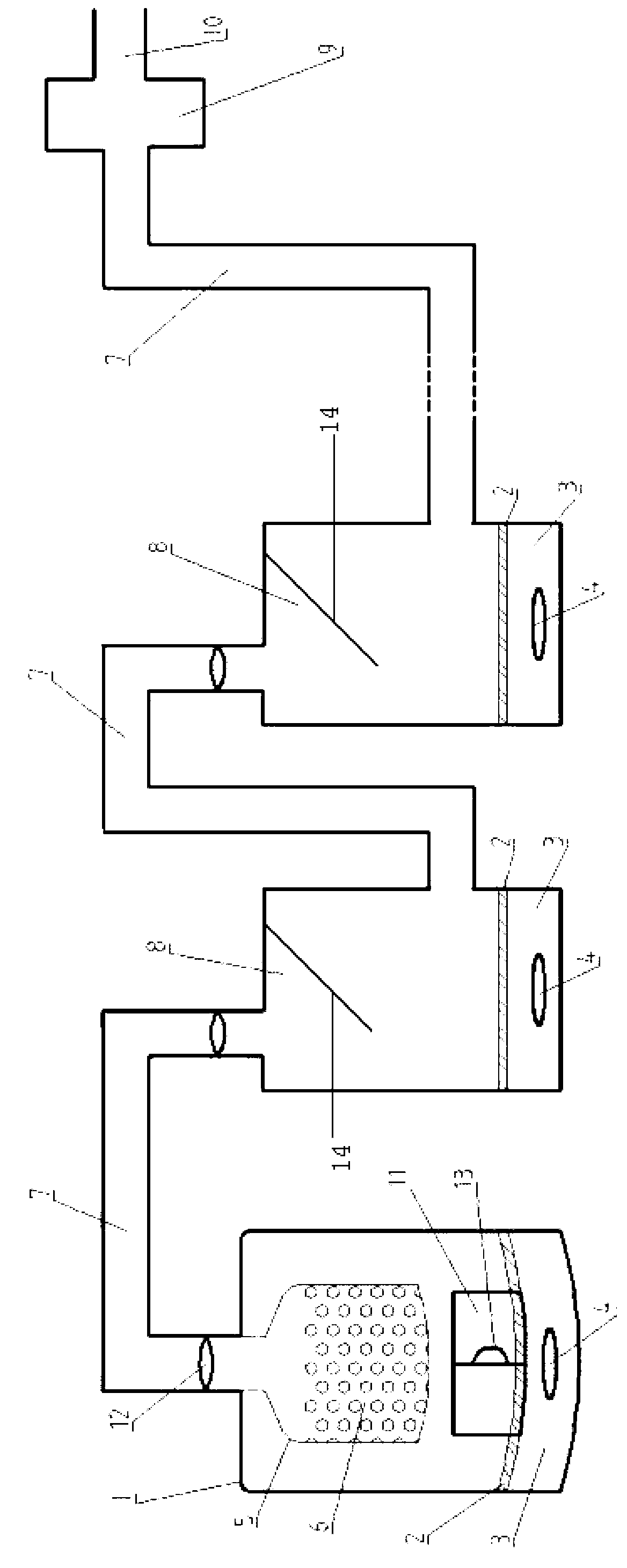

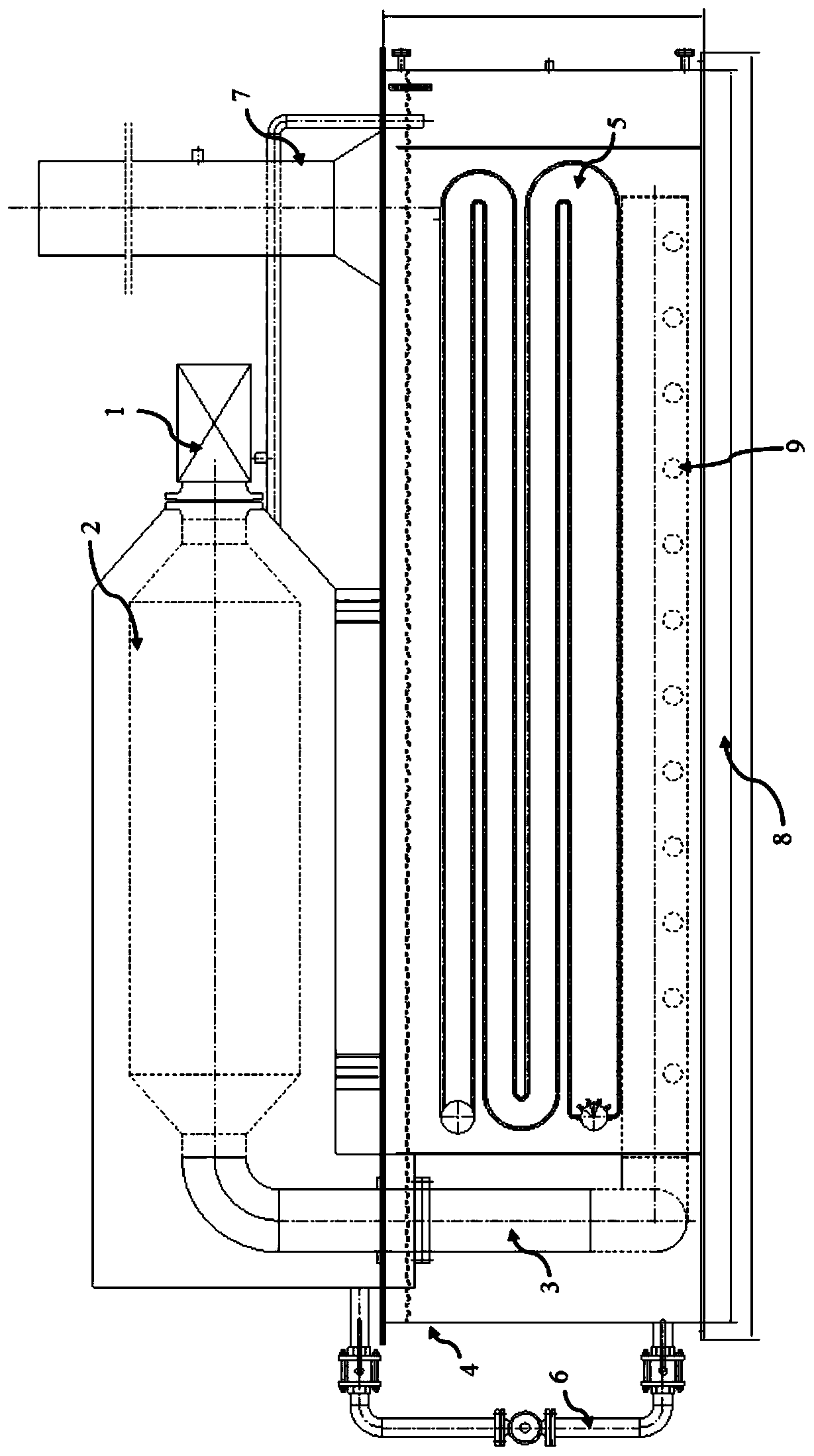

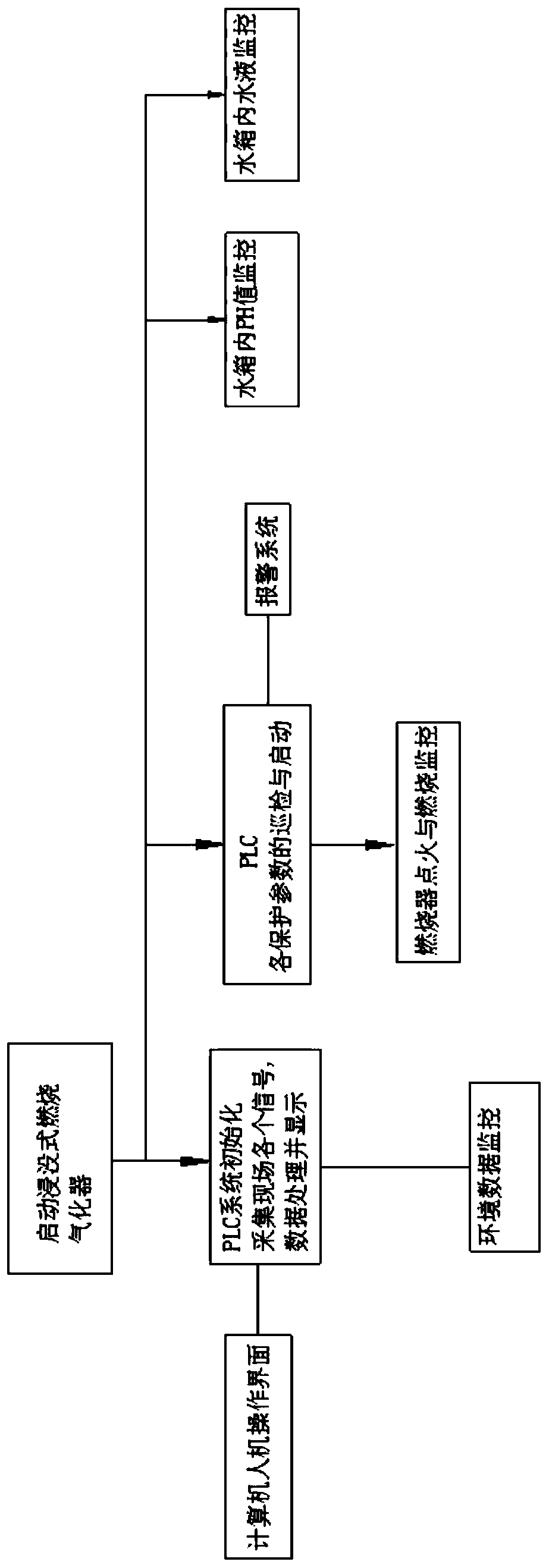

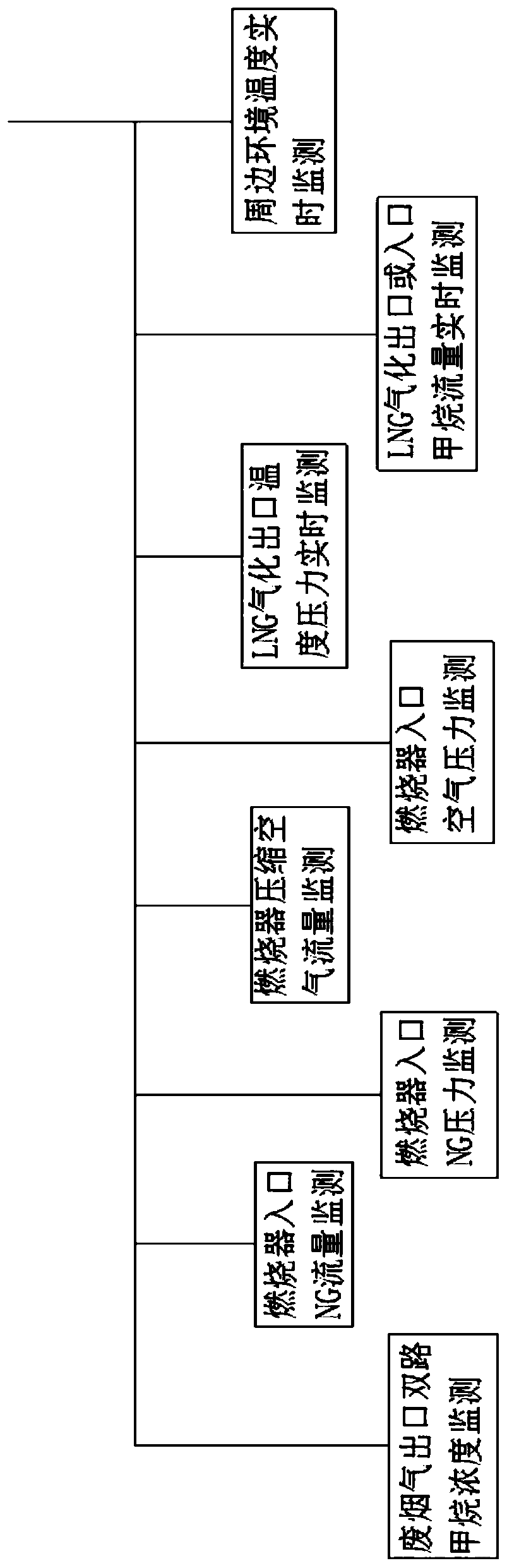

Submerged combustion vaporizer and monitoring system thereof

PendingCN110030492AStable working conditionShorten the lead timePipeline systemsIndustrial gasThermodynamics

The invention discloses a submerged combustion vaporizer and a monitoring system of the submerged combustion vaporizer and relates to the technical field of cryogenic liquid gasification of liquefiednatural gas and industrial gas industries. A combustor, a hearth, a smoke pipeline, a water tank, a gasifying pipeline, a water supplanting pipeline and a chimney all adopt the installation manner offixed skid mounting, so that the submerged combustion vaporizer can achieve precise assembly and complete-machine debugging work in a manufacturing factory, when a client needs the submerged combustion vaporizer, the submerged combustion vaporizer can be transported to the location of the client like a container, and operation of the submerged combustion vaporizer can be achieved just through pipeline connection work; the installation manner enables the work condition of the submerged combustion vaporizer to be more stable, the delivery cycle of the submerged combustion vaporizer is greatly shortened, and the capacity that the product can be used as soon as landing is achieved. Meanwhile, since the hearth and the combustor are horizontally arranged on the upper side of the water tank, theheight of the submerged combustion vaporizer is greatly reduced, the submerged combustion vaporizer is attractive and elegant, and the situation that the submerged combustion vaporizer is prone to suffering lightning stroke due to a remarkable height on an open field is avoided.

Owner:无锡特莱姆气体设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com