Gas stove

A gas stove and burner technology, applied in the field of kitchen utensils, can solve the problems of waste, heat loss, and inability to fully utilize the heat of gas combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

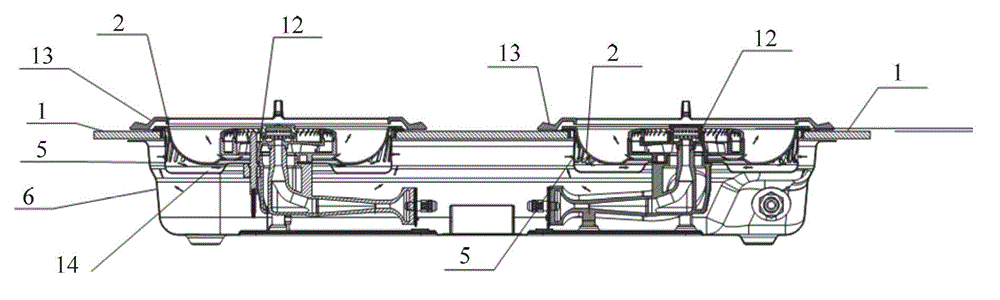

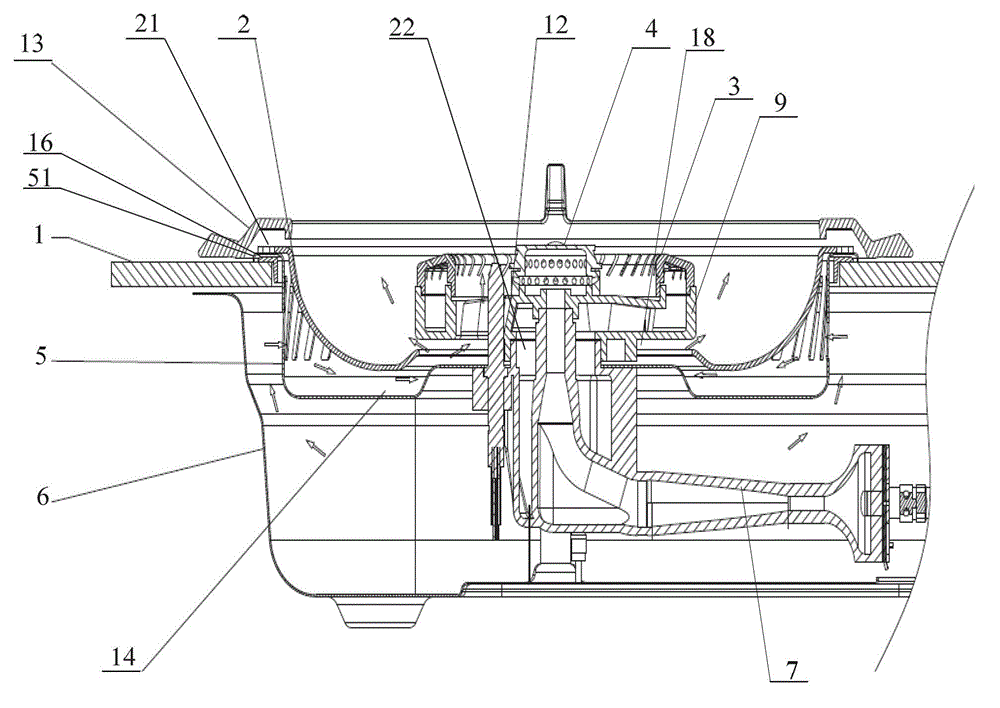

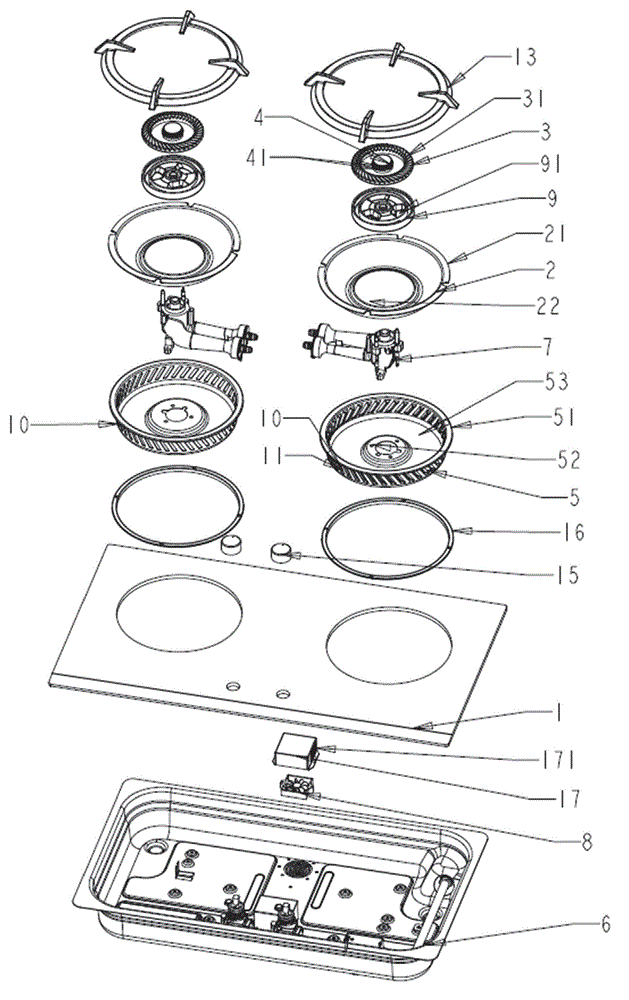

[0032] Such as Figure 1 to Figure 4 As shown, a gas stove proposed in this embodiment includes a panel 1 with an opening, a bottom case 6 supporting the panel 1, a burner assembly 12, and a pot support 13 arranged at the opening of the panel 1. The burner assembly 12 Fire holes 41 and / or fire grooves 31 are arranged on the top, and the gas stove also includes a bowl-shaped energy gathering pan 2 arranged at the opening of the panel 1, and the burner assembly 12 is located on the energy gathering pan 2 Inside, and the fire holes 41 and / or fire grooves 31 of the burner assembly 12 are not higher than the top surface of the energy collecting plate 2 .

[0033] In this embodiment, the burner assembly 12 is embedded in the energy collecting plate 2, and the fire hole 41 and / or the fire groove 31 of the burner assembly 12 are not higher than the top surface of the energy collecting plate 2, so that the fire hole 41 of the burner assembly 12 41 and / fire groove 31 ejection flames ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com