Micro Hybrid Oxygen Combustion Gas Turbine Generator

A gas turbine generator and oxygen-enriched combustion technology, which is applied to gas turbine devices, engine components, machines/engines, etc., can solve problems such as air pollution, environmental pollution, and ecological damage, so as to improve energy conversion efficiency and reduce air pollution. , The effect of increasing the grade of heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

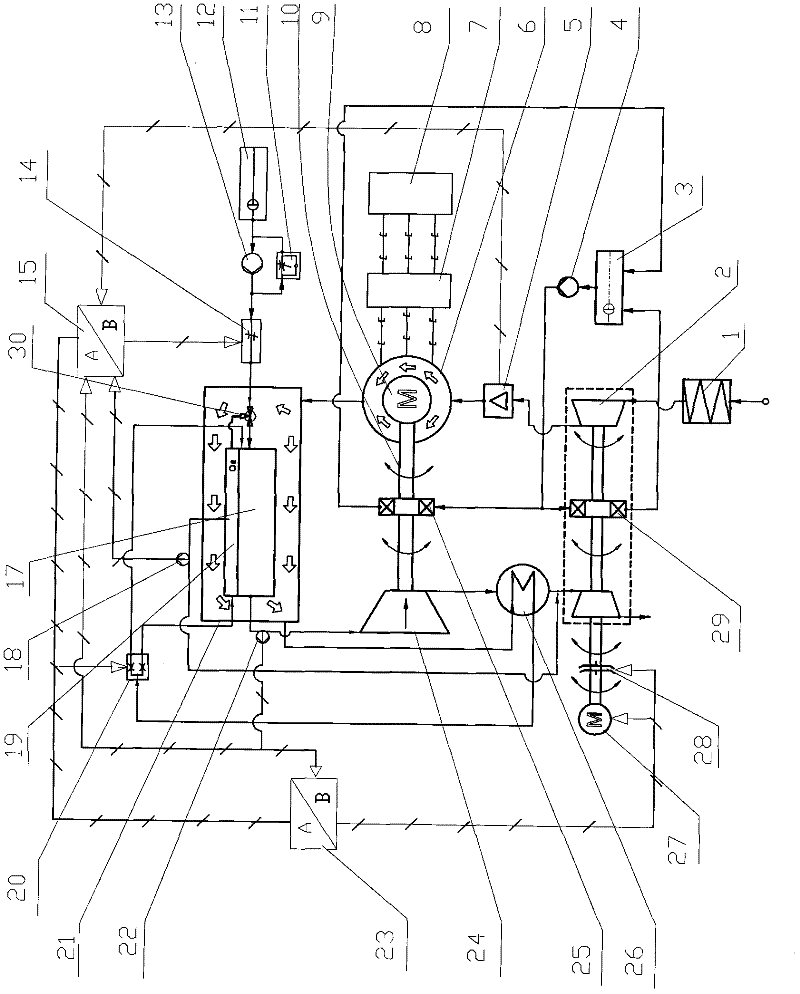

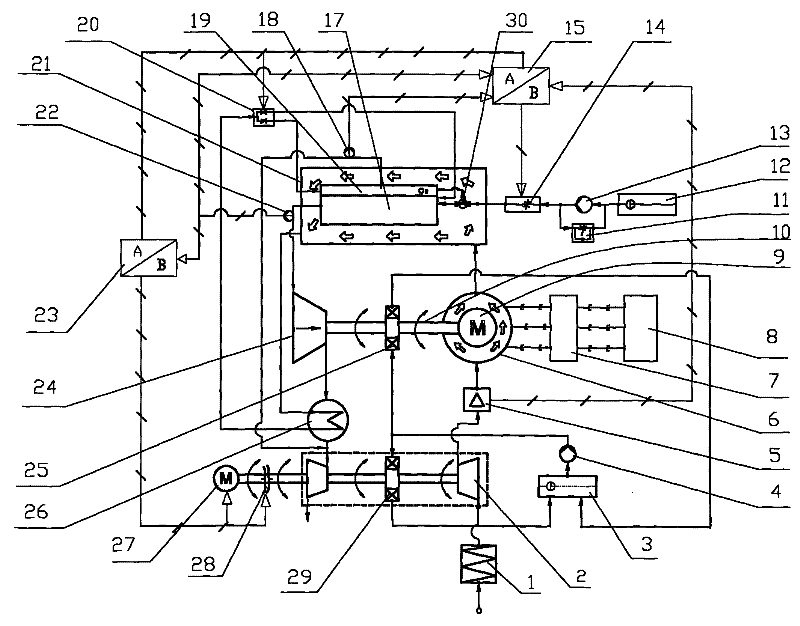

[0023] Embodiment 1: as figure 1 As shown, the micro hybrid oxy-combustion gas turbine generator described in this embodiment is composed of seven systems, including fuel supply system, oxygen-enriched air supply system, combustion work system, control system, power generation system, and energy recovery system and lubricant system.

[0024] The fuel supply system includes a fuel tank 12, a fuel delivery pump 13 and a controllable flow valve 14 connected in sequence along the fuel delivery direction, wherein the output end of the controllable flow valve 14 is connected to an input end of the jet valve 30, and the jet valve 30 The other input end is connected to the pure oxygen output port of the pure oxygen generator 19 in the oxygen-enriched air supply system, and the output end of the jet valve 30 is connected to the fuel input end of the combustion chamber 17 in the combustion power system. In order to make the controllable flow valve 14 control the actual fuel injection v...

Embodiment 2

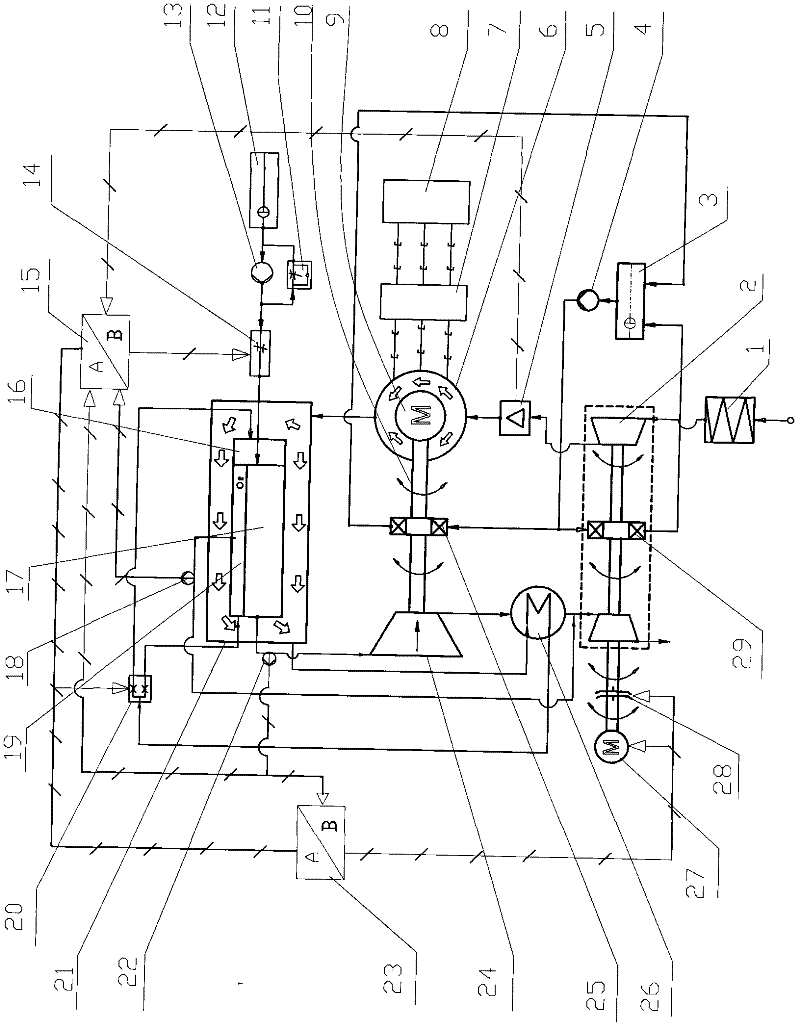

[0037] Embodiment 2: as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1 (using the fuel jet to absorb pure oxygen and then mix and dilute it with air in the combustion chamber). At the entrance, there is a premixing chamber 16 which communicates with the air inlet of the combustion chamber 17 and the pure oxygen output port of the pure oxygen generator 19. At the same time, the corresponding pipeline is adjusted as follows: the output end of the controllable flow valve 14 is directly connected to the combustion chamber 17, an output port of the controllable proportional valve 20 is communicated with the air inlet of the premix chamber 16, and the other output port is still communicated with the pure oxygen generator 19, and the pure oxygen produced by the pure oxygen generator 19 is connected with the The air output by the controllable proportional valve 20 is mixed and diluted in the premix chamber 16 to form oxygen-enriched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com