Patents

Literature

600results about How to "Increase oxygen concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

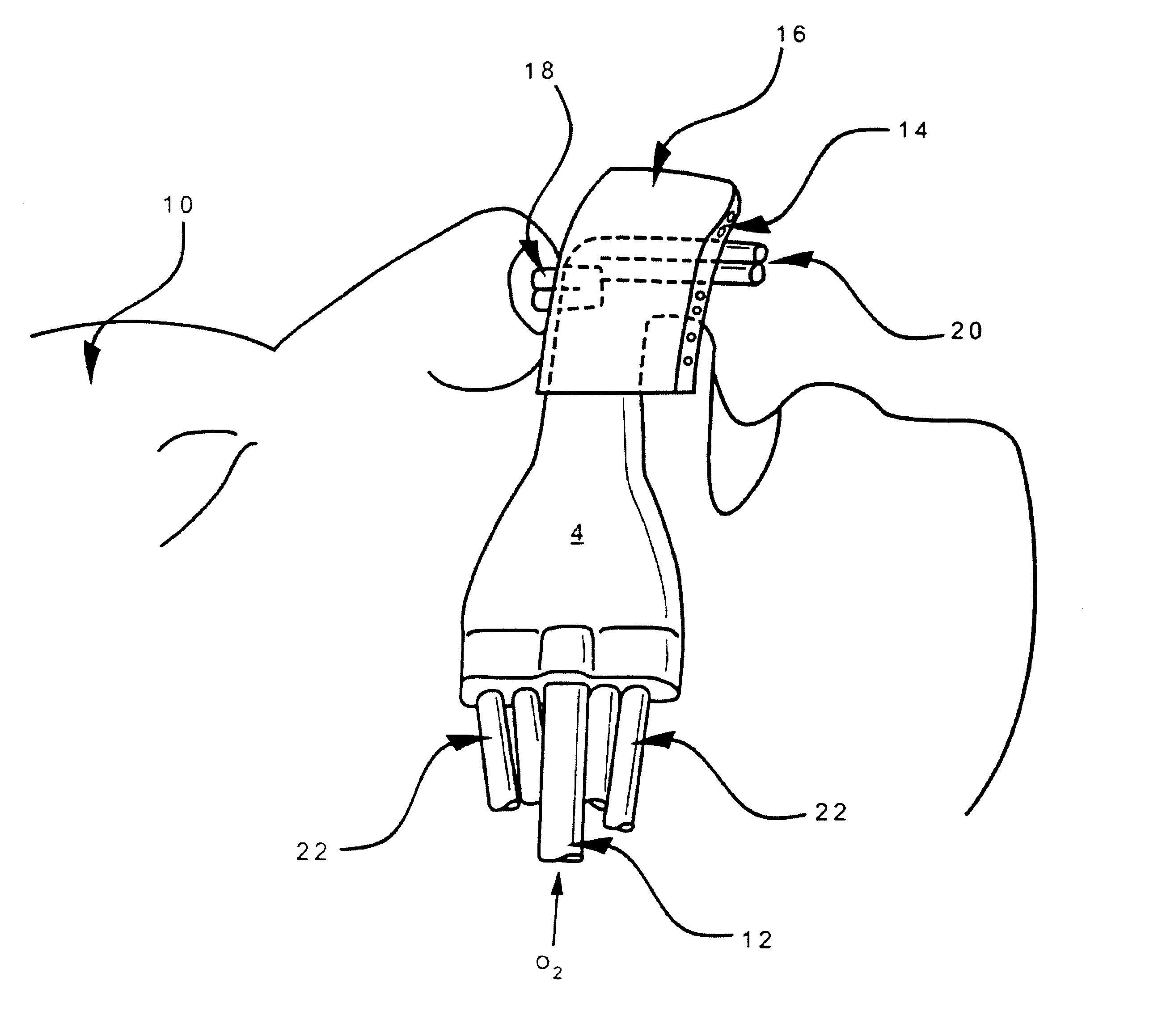

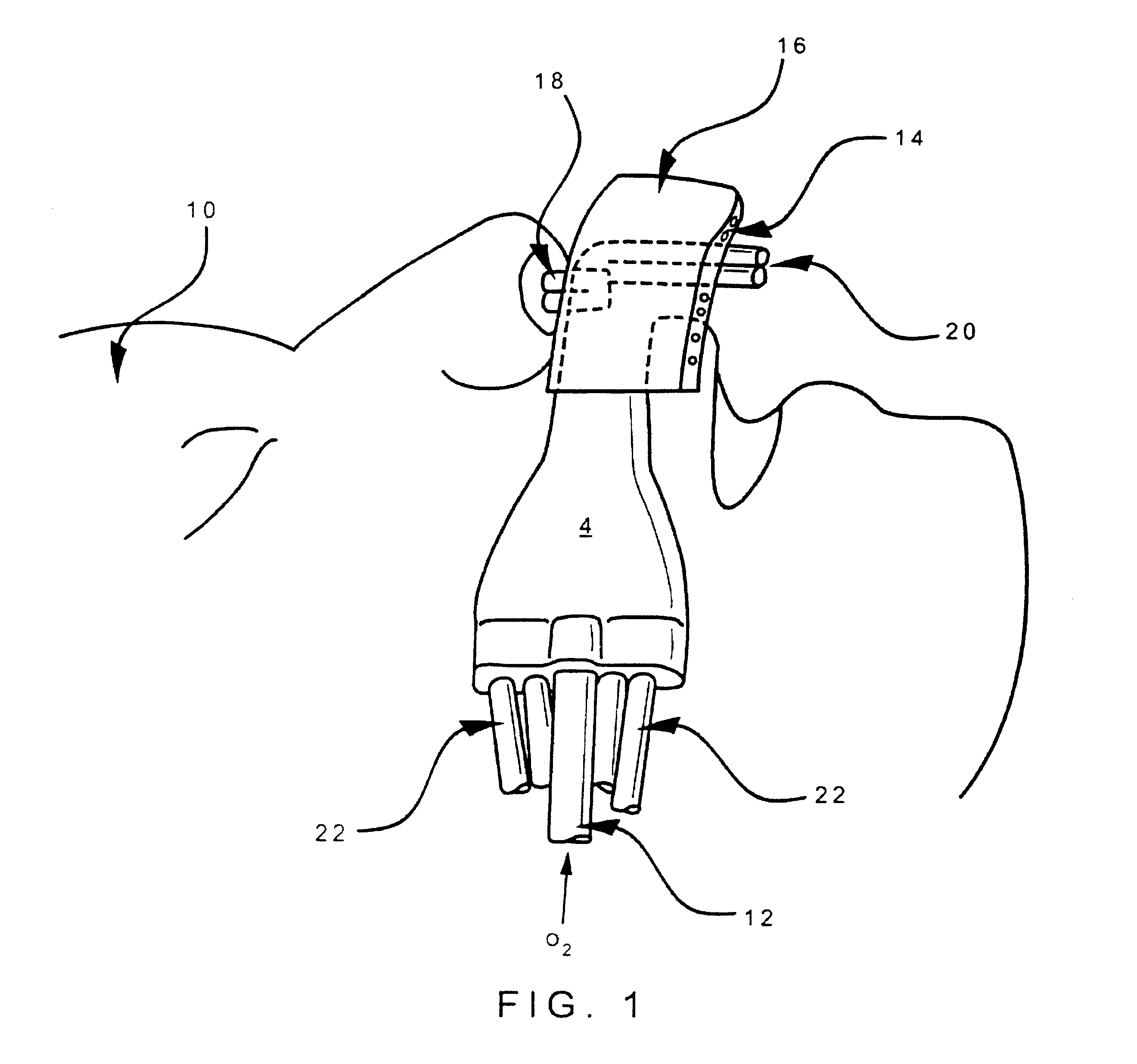

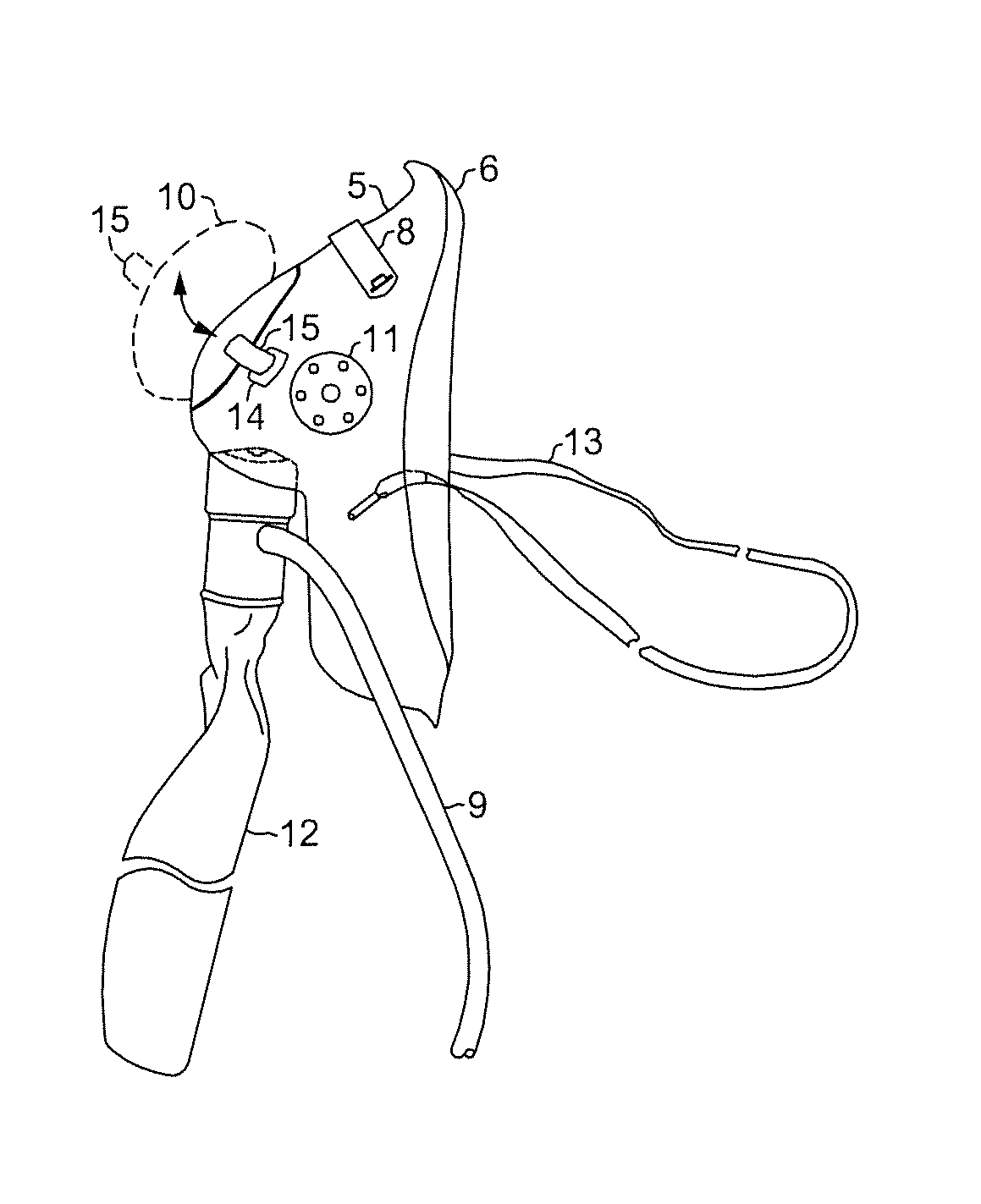

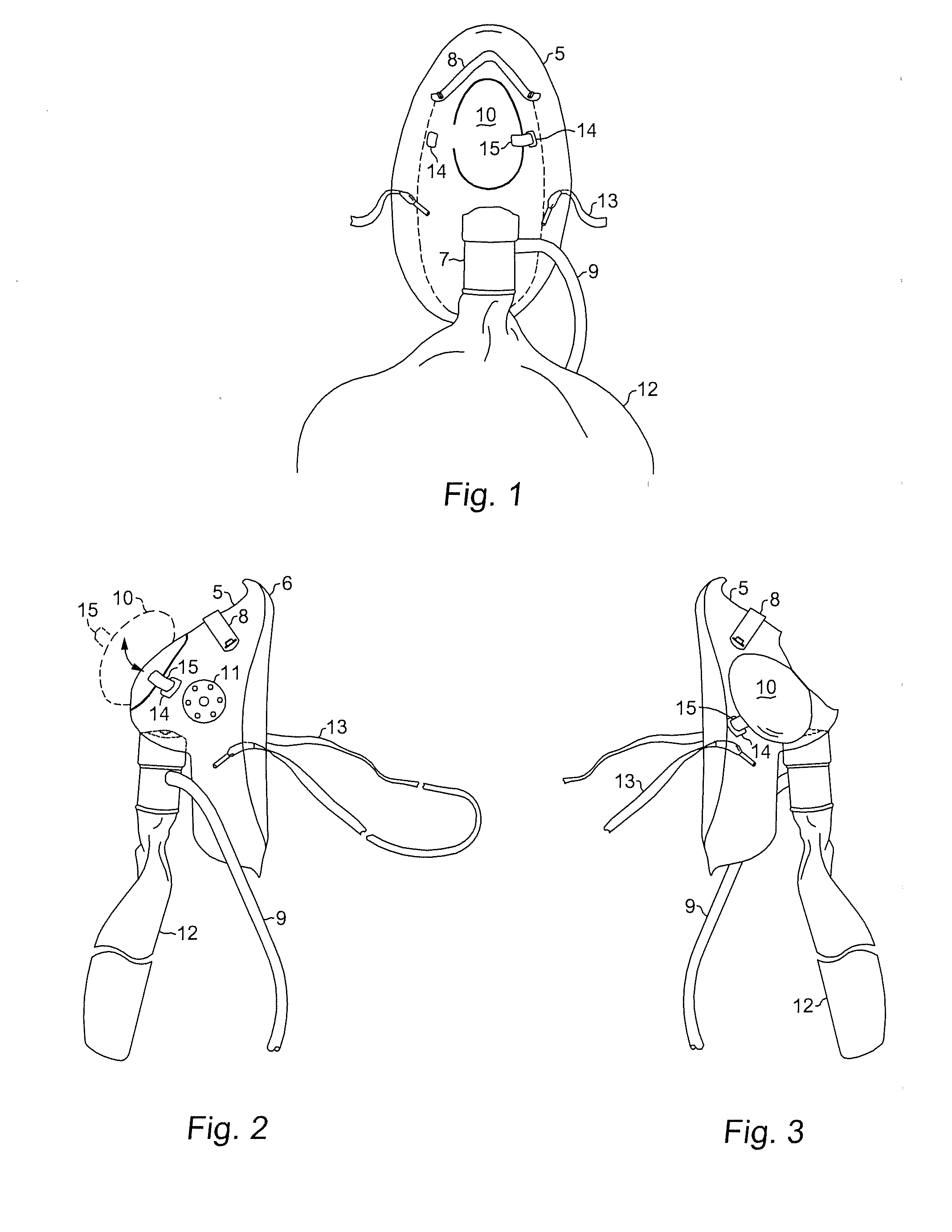

Mask free delivery of oxygen and ventilatory monitoring

InactiveUS6938619B1Increase oxygen concentrationFast sensingOperating means/releasing devices for valvesRespiratory masksOxygen deliveryAirway devices

Disclosed is an apparatus and method for the delivery of supplemental oxygen gas to a person combined with the monitoring of the ventilation of the person with both being accomplished without the use of a sealed face mask. Preferred embodiments of the present invention combine an oxygen delivery device, a nasal airway pressure sampling device, an oral airway pressure sampling device, and a pressure analyzer connected to the sampling devices to determine the phase of the person's respiration cycle and the person's primary airway. The oxygen delivery device is connected to a controller such that it delivers a higher flow of oxygen to the person during the inhalation phase of the person's respiratory cycle. The invention thus increases end tidal oxygen concentrations with improved efficiency comparative to known open airway devices. Embodiments of the invention can include carbon dioxide sampling tubes that continuously sample air from the nose and mouth to determine carbon dioxide concentration during exhalation.

Owner:SCOTT LAB

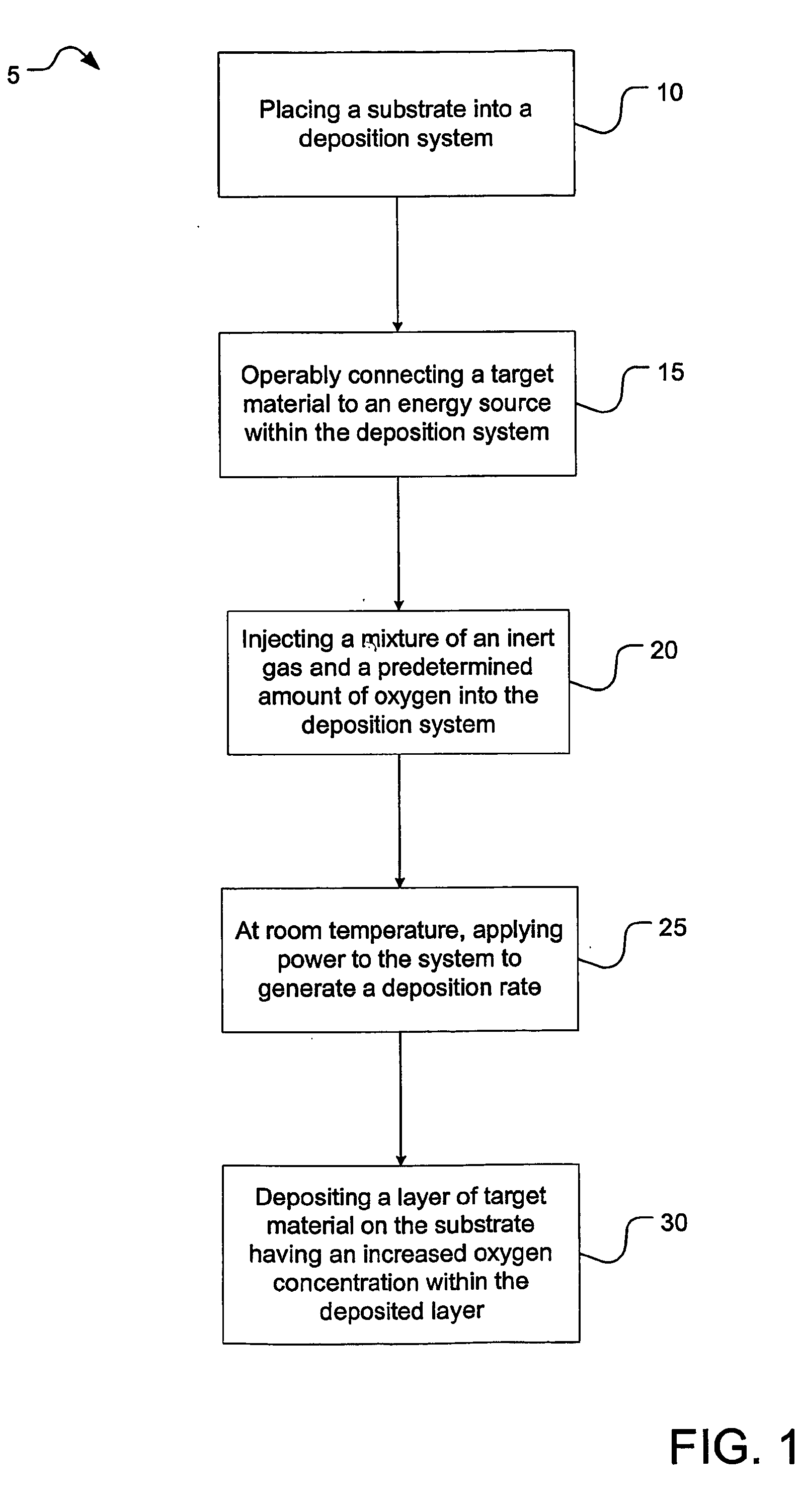

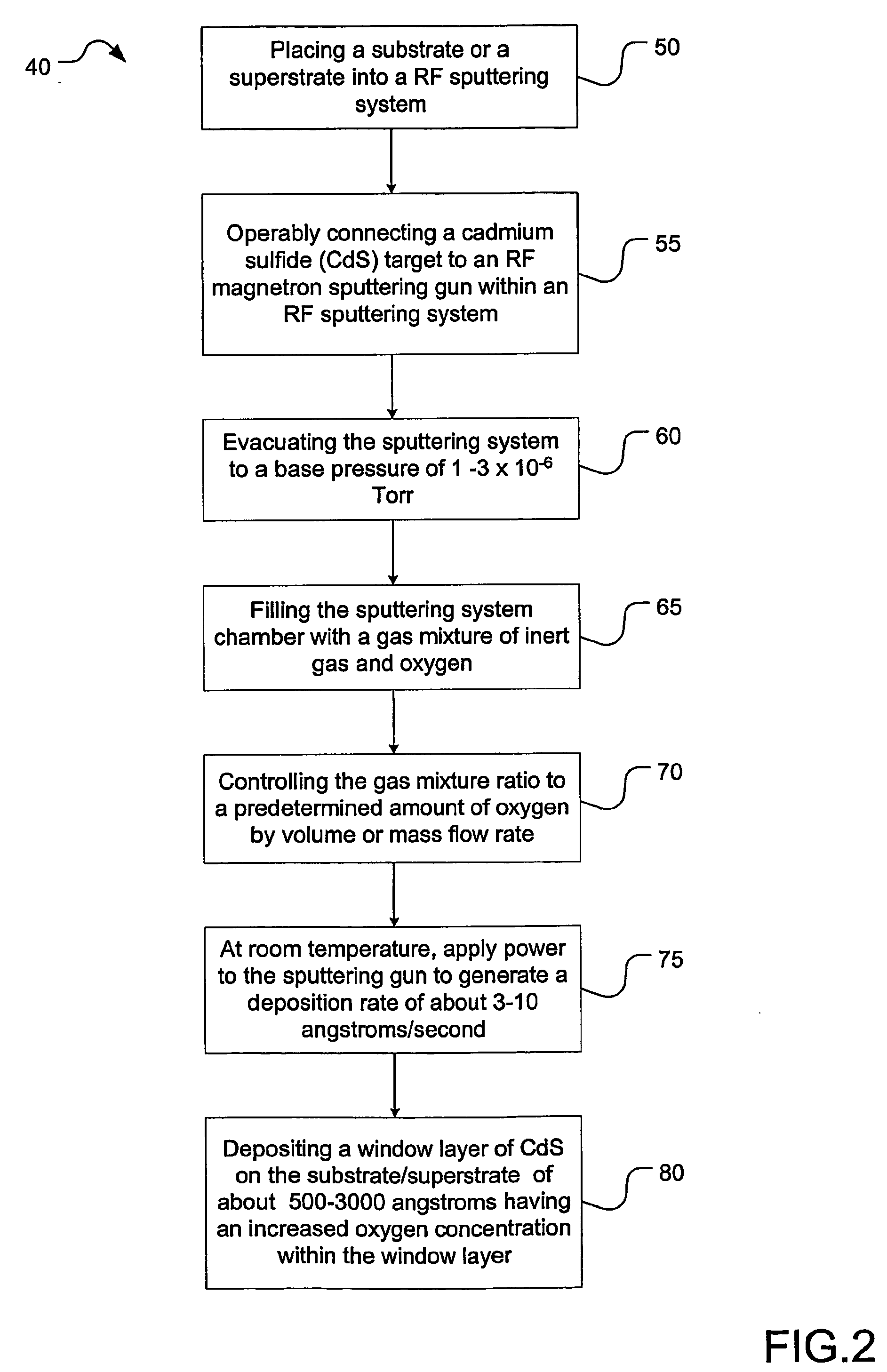

Semiconductor device with higher oxygen (02) concentration within window layers and method for making

InactiveUS20050009228A1Improve efficiencyIncrease oxygen concentrationVacuum evaporation coatingSemiconductor/solid-state device manufacturingHeterojunctionDevice material

A method for making a heterojunction photovoltaic device (200) is provided for converting solar radiation to photocurrent and photovoltage with improved efficiency. The method and apparatus include an improved window layer (230) having an increased oxygen (140) concentration with higher optical bandgap and photo to dark conductivity ratio. The improved photovoltaic device (200) is made using a deposition method which incorporates the use of a gas mixture of an inert gas (115) and a predetermined amount of oxygen (140), deposited at or near room temperature. Window layers contemplated by the present invention include, but are not limited to, cadmium sulfide (CdS) and various alloys of zinc cadmium sulfide (ZnxCd1-xS). To further increase the efficiency of the resultant photovoltaic device (200), deposition parameters are controlled and monitored to improve the deposited window layer (230).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

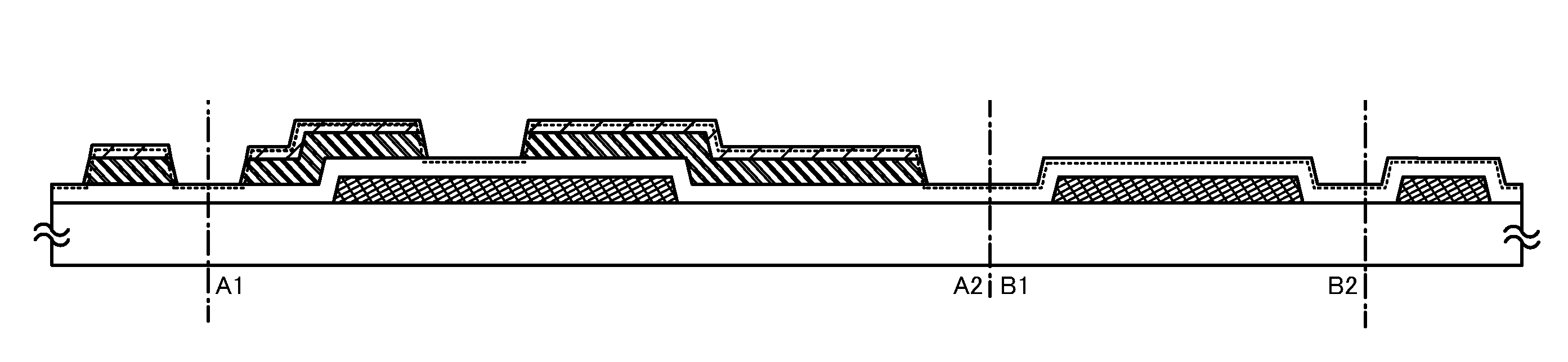

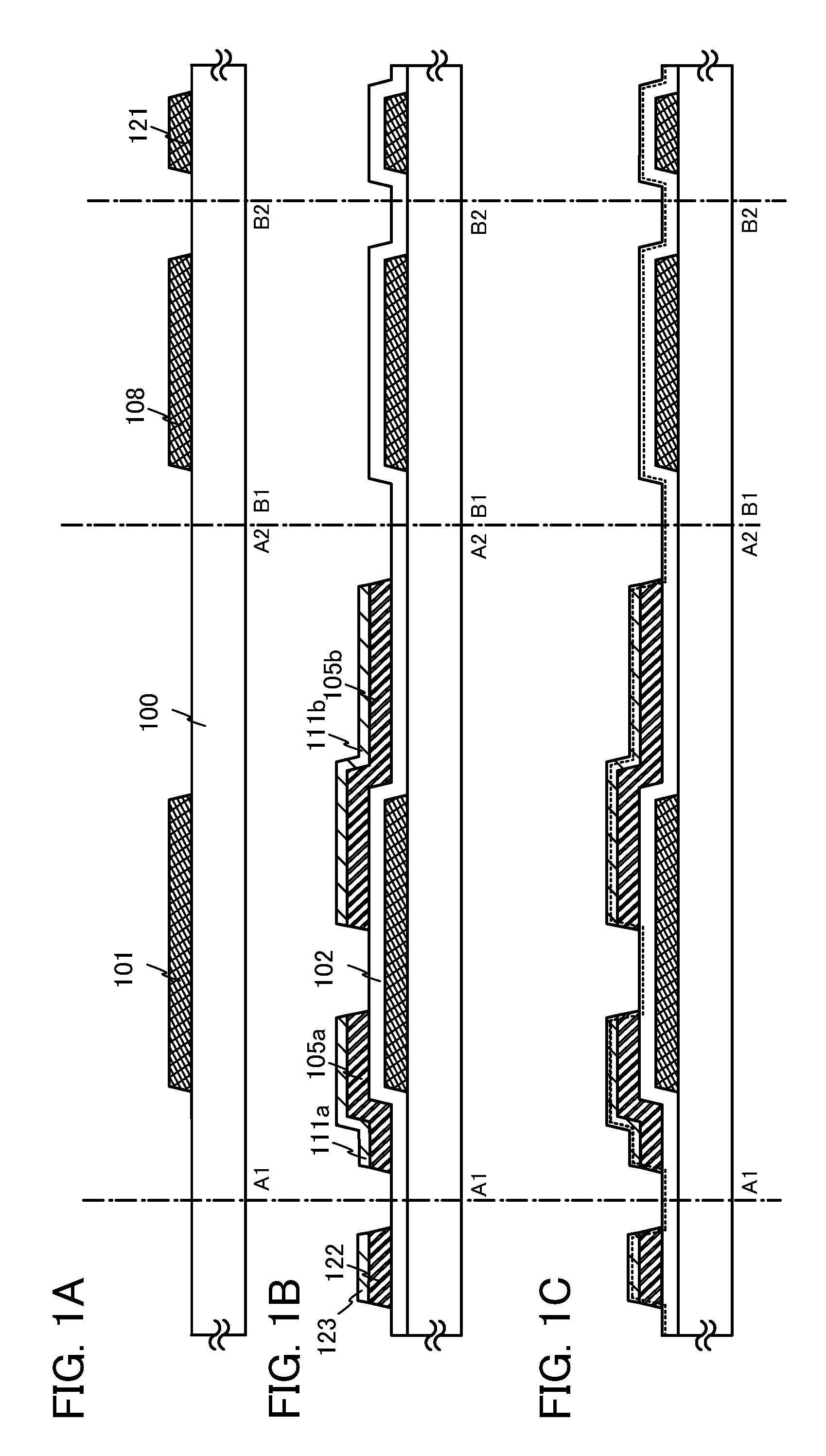

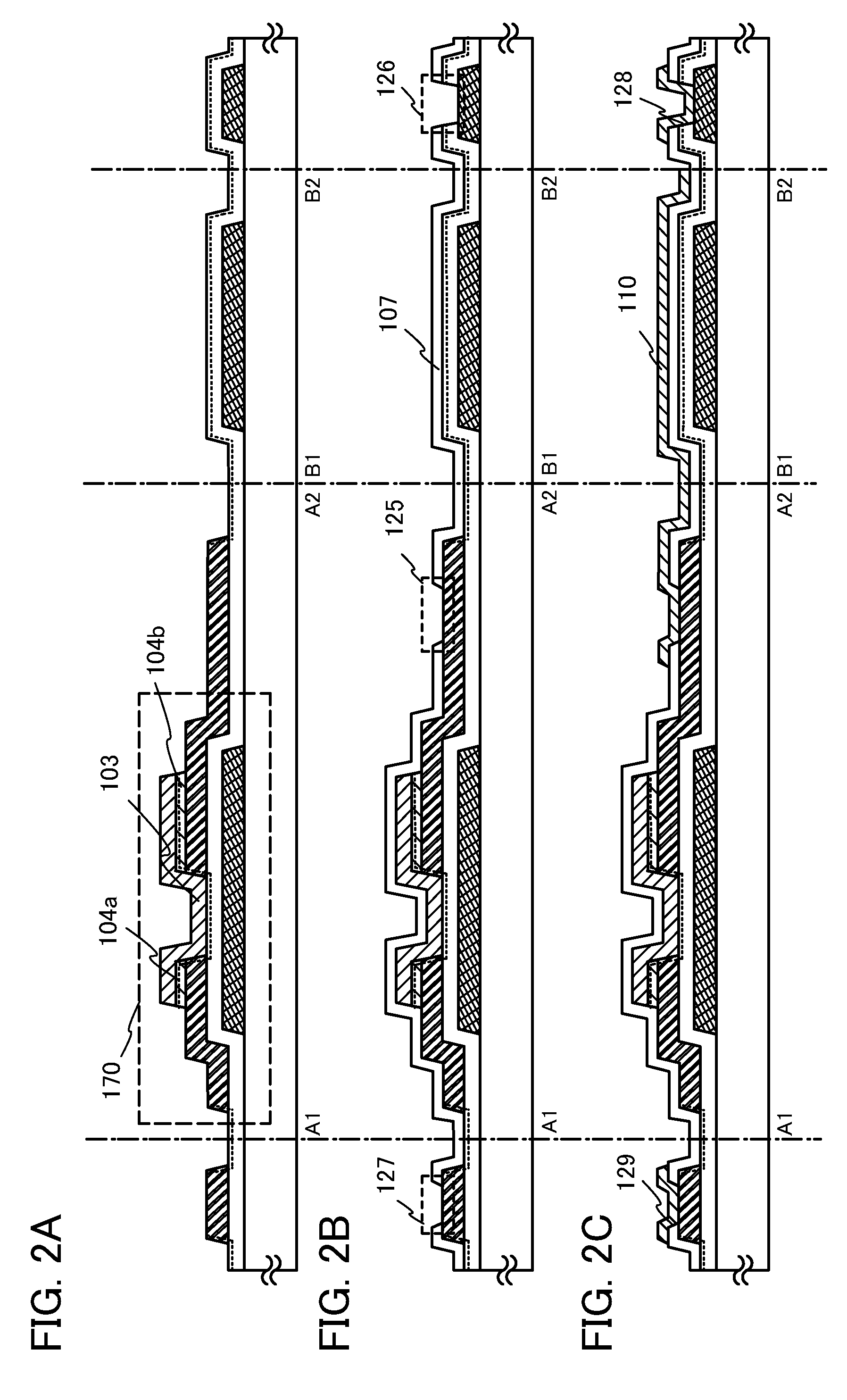

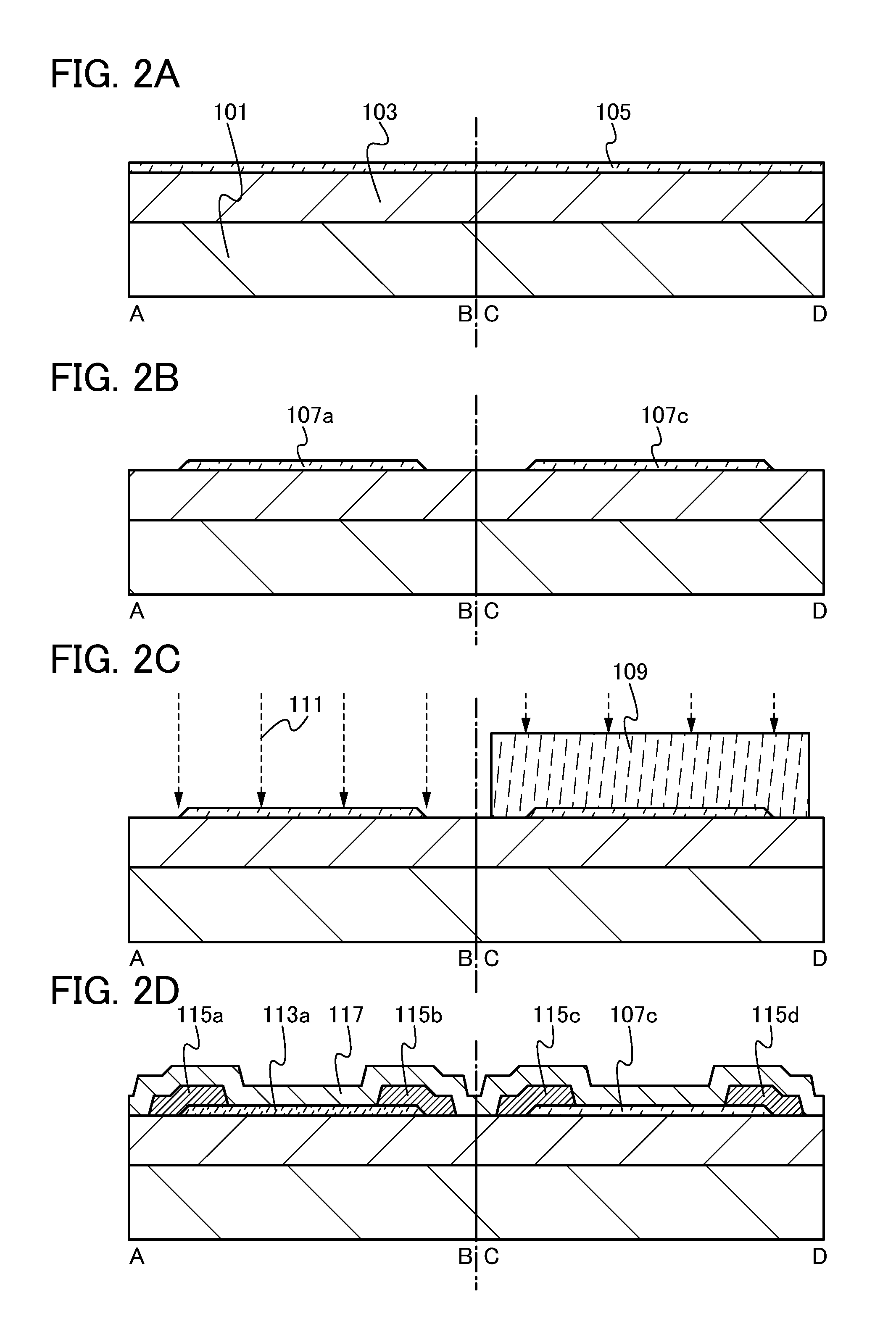

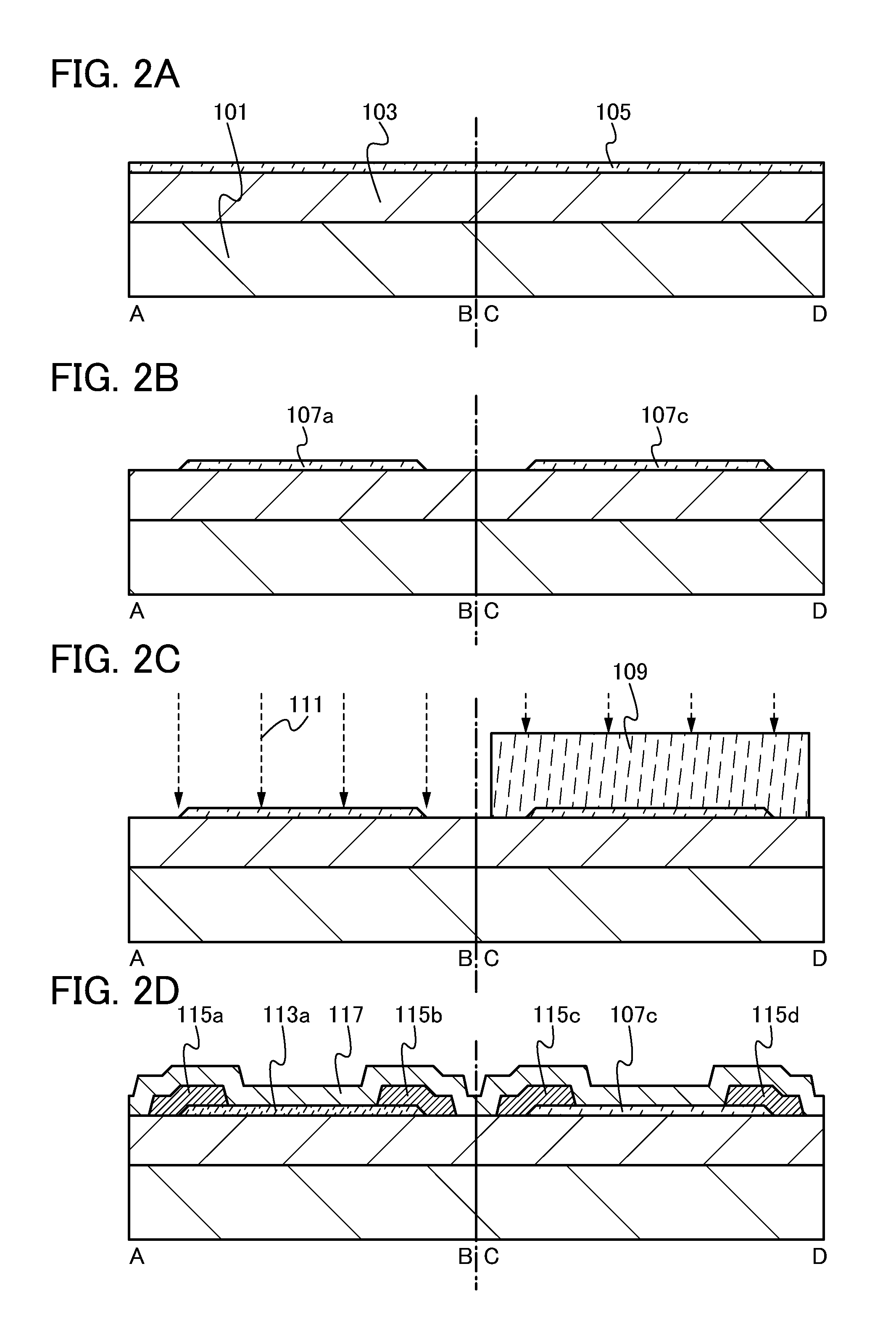

Semiconductor device and method for manufacturing the same

ActiveUS20100065838A1Small currentHigh on-off ratioTransistorSolid-state devicesProduction rateSemiconductor package

An object is to provide a semiconductor device including a thin film transistor with excellent electrical characteristics and high reliability and a method for manufacturing the semiconductor device with high mass productivity. A main point is to form a low-resistance oxide semiconductor layer as a source or drain region after forming a drain or source electrode layer over a gate insulating layer and to form an oxide semiconductor film thereover as a semiconductor layer. It is preferable that an oxygen-excess oxide semiconductor layer be used as a semiconductor layer and an oxygen-deficient oxide semiconductor layer be used as a source region and a drain region.

Owner:SEMICON ENERGY LAB CO LTD

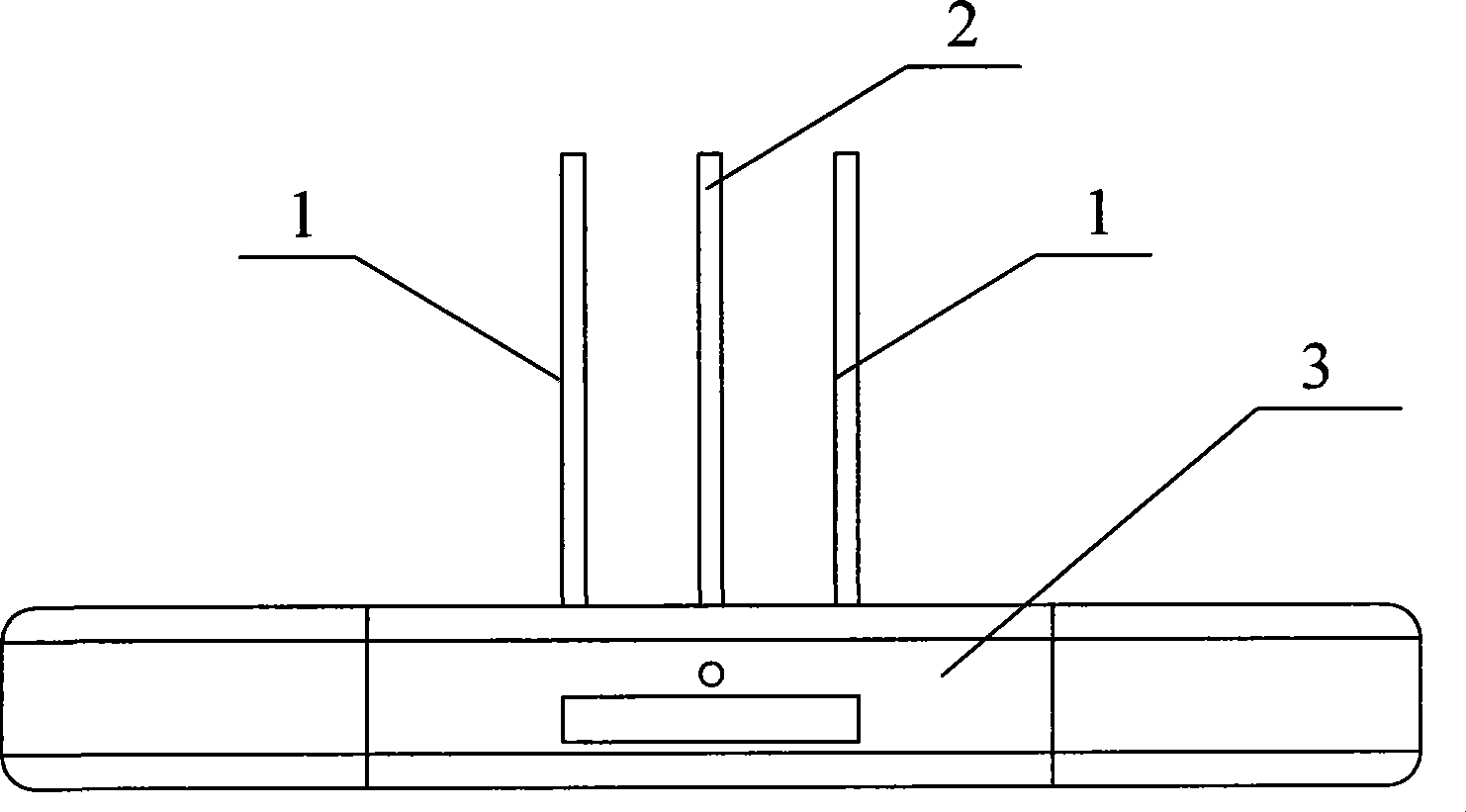

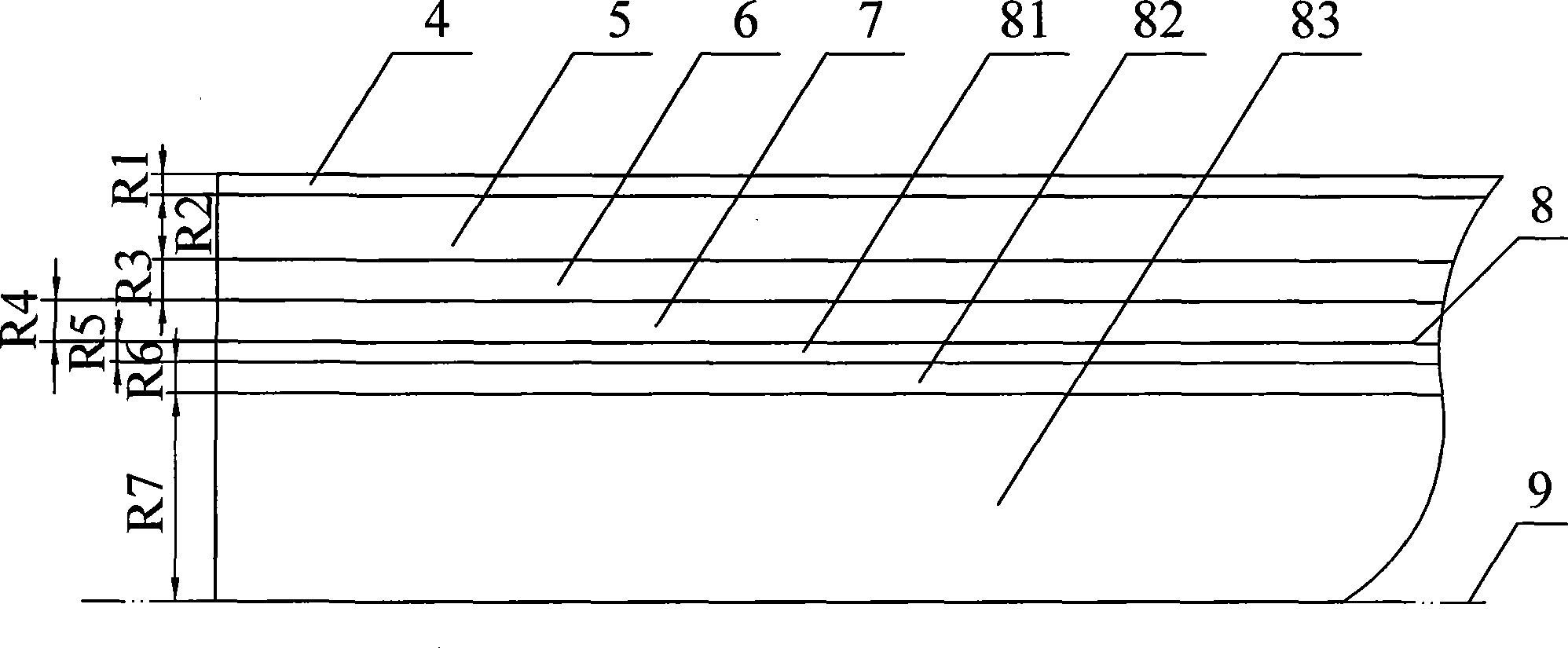

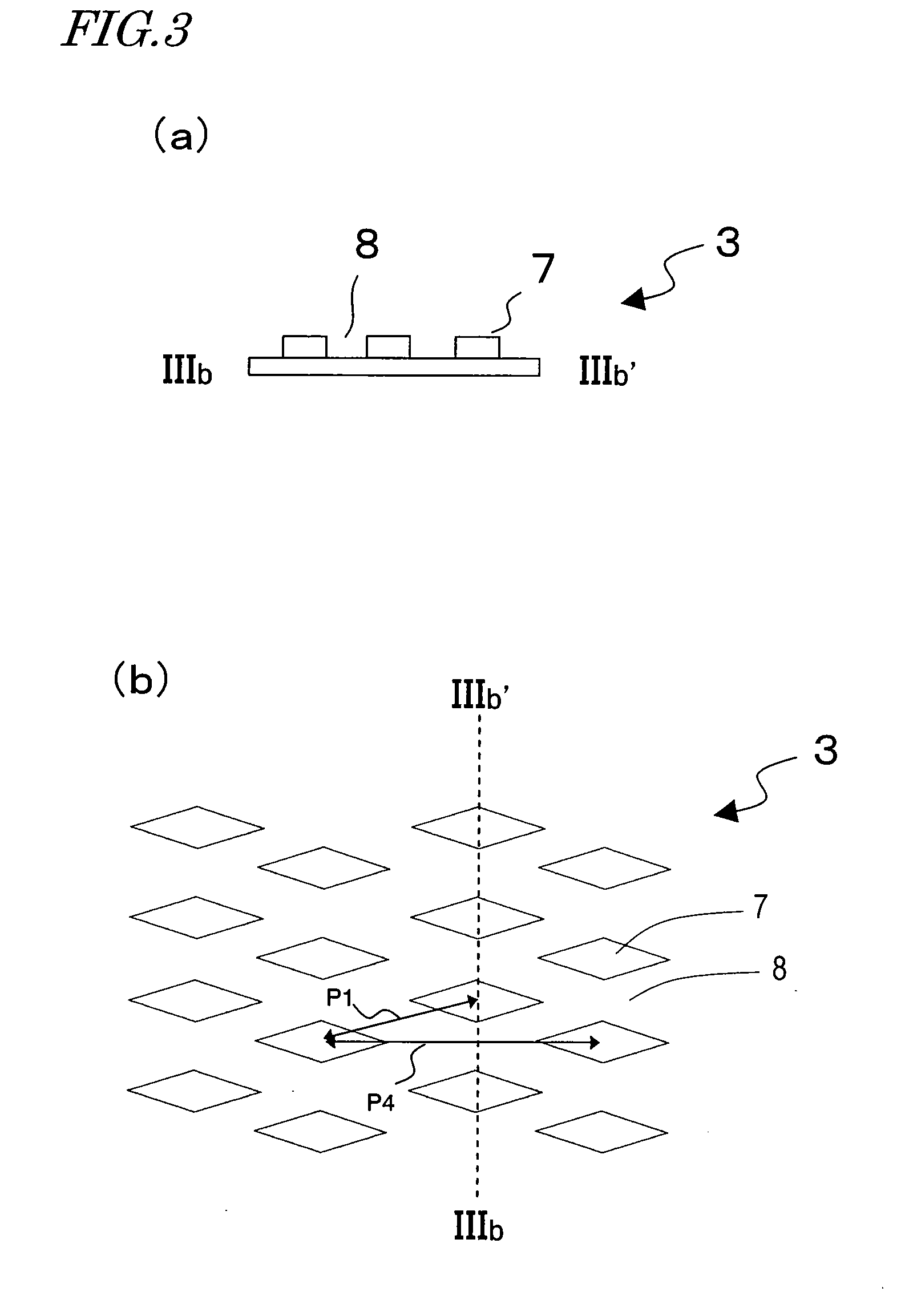

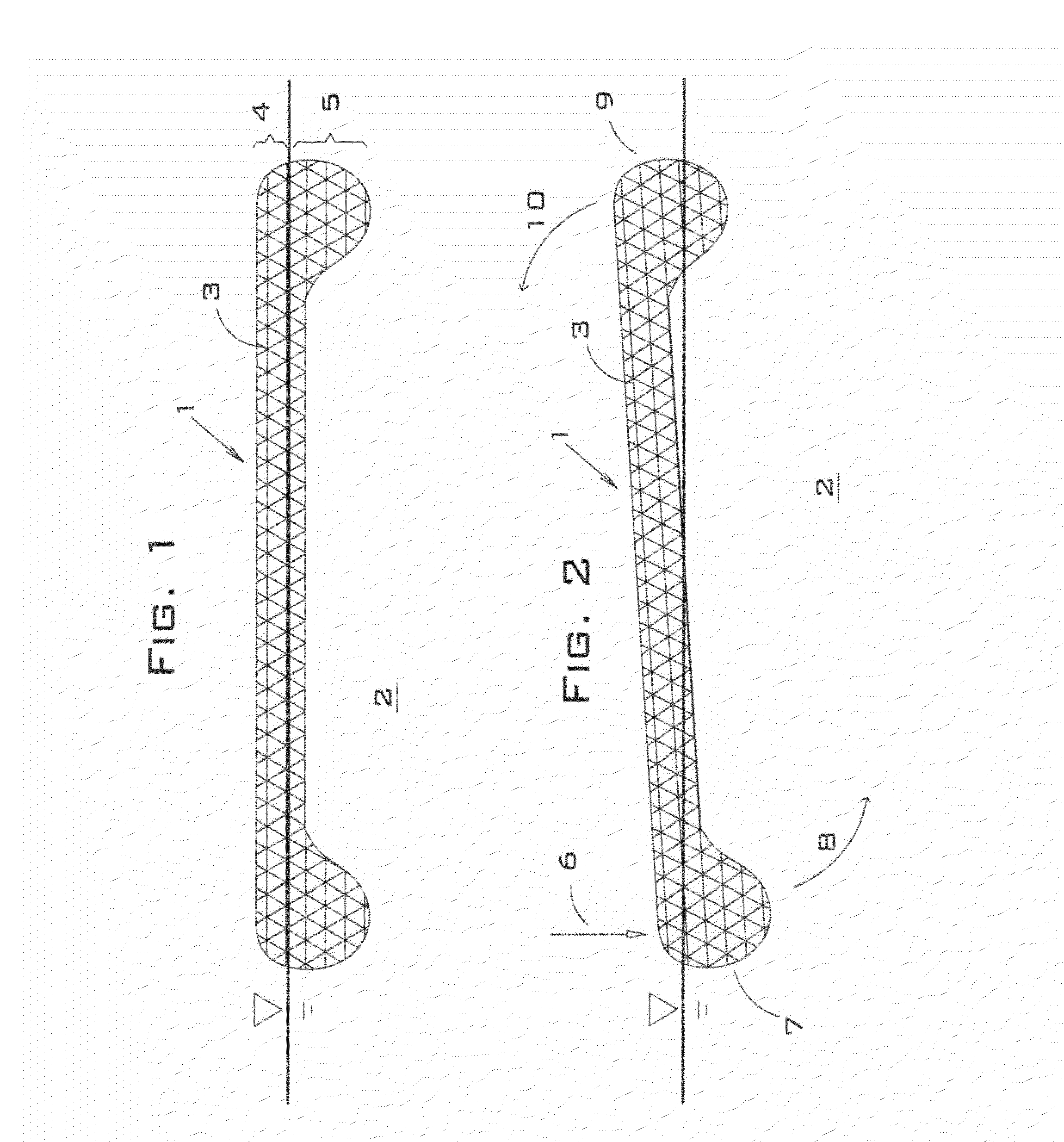

Needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof

ActiveCN101530327AShort response timeStable jobDiagnostic recording/measuringSensorsGlucose sensorsConcentrations glucose

The invention discloses a needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof. The sensor comprises a needle reference electrode (2) and at least one needle working electrode (1) including a conducting layer (8) and an enzyme membrane layer (6), and is characterized in that the working electrode (1) further comprises a polymer material inner membrane layer (7) and a polymer material control diffusion layer (5), and the conducting layer (8), the polymer material inner membrane layer (7), the enzyme membrane layer (6) and the polymer material control diffusion layer (5) are coated in turn from inner to outside. According to the manufacturing method in the invention, the glucose sensor has good stability, high flexibility, wide linear range of output current and glucose concentration, short response time, continuous real-time monitoring, good fastness and stability of enzyme bonding, high flexibility, selectivity and repeatability.

Owner:HUZHOU MEIQI MEDICAL EQUIP CO LTD

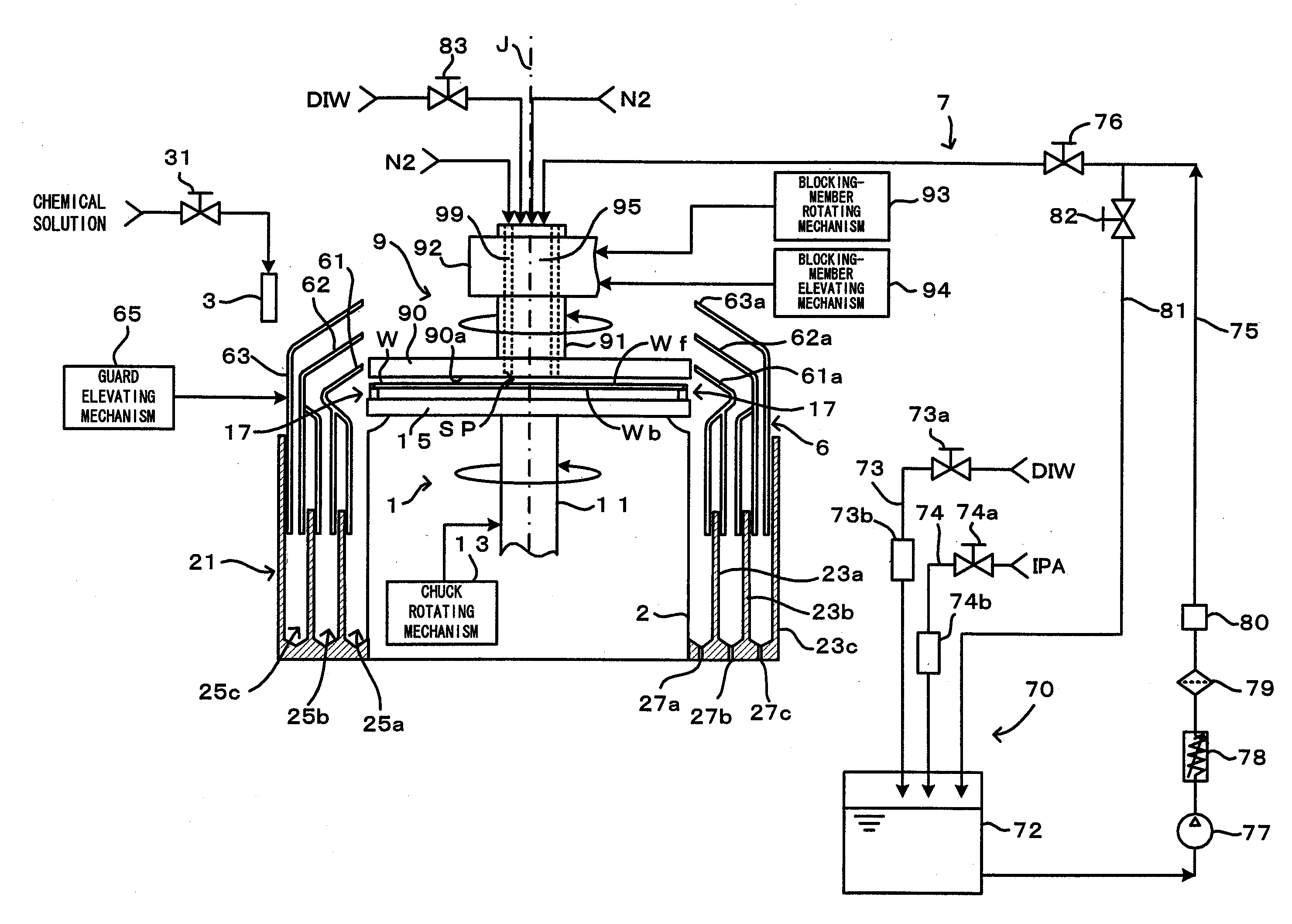

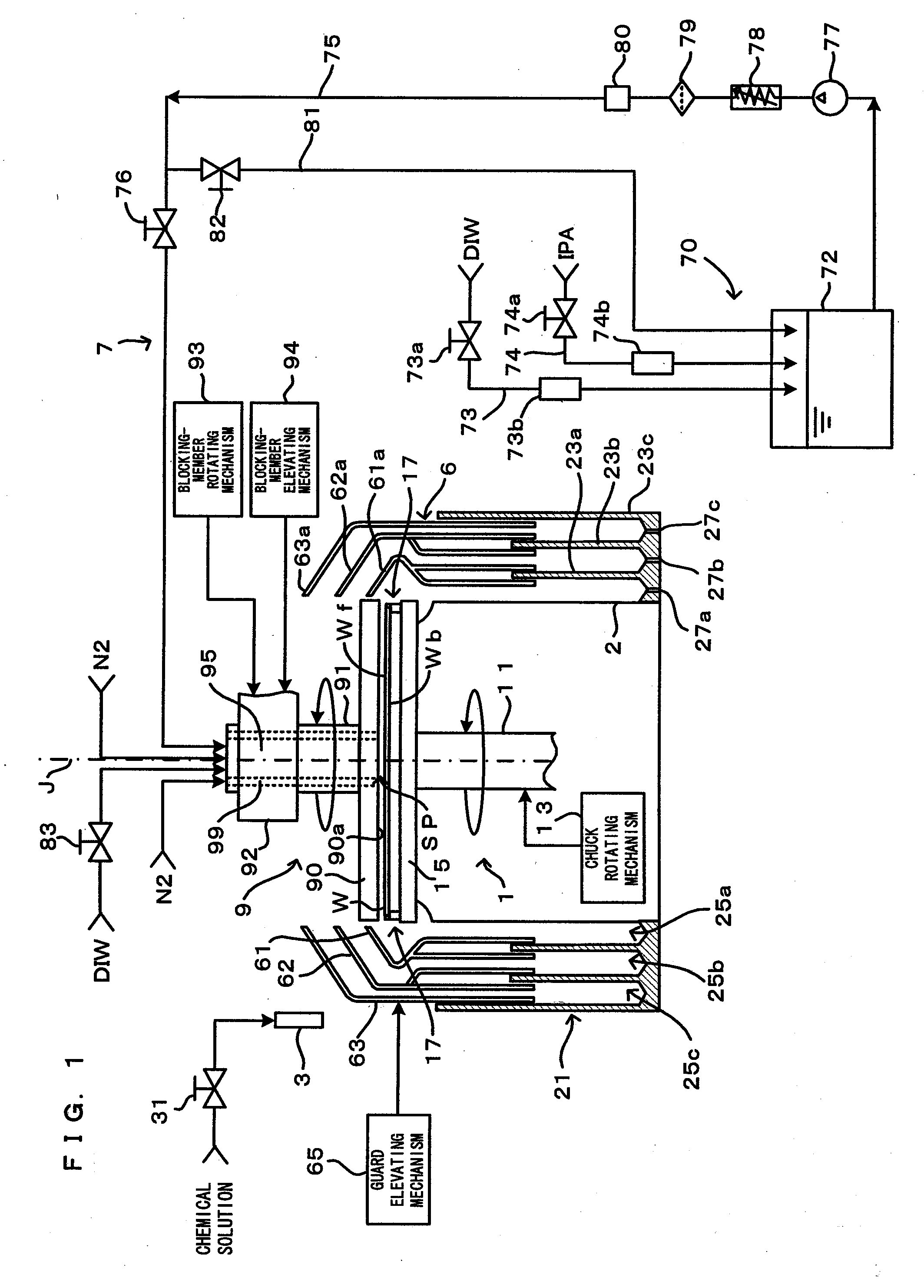

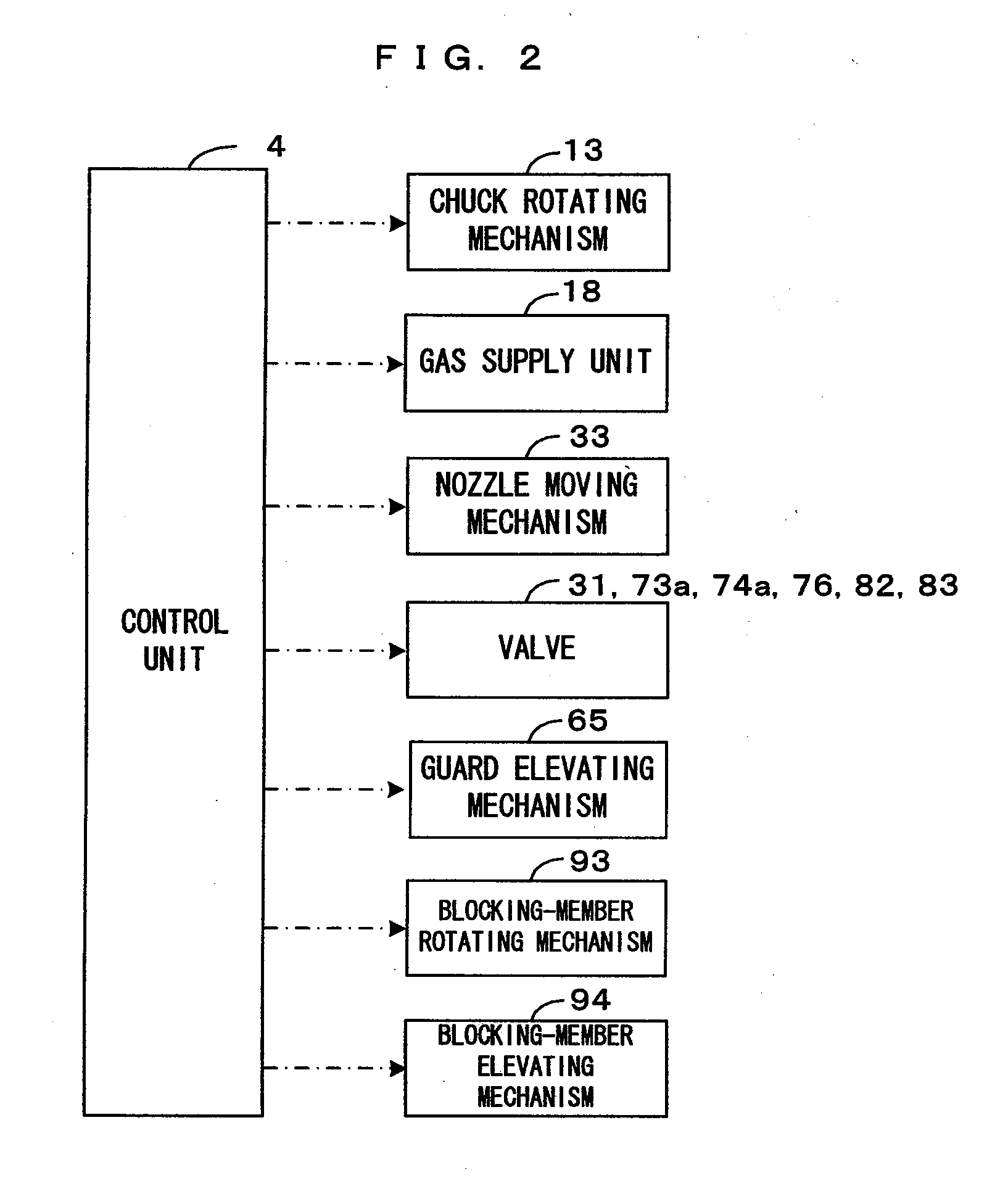

Substrate processing apparatus and substrate processing method

ActiveUS20080078426A1Facilitate agitationReduce surface tensionSemiconductor/solid-state device manufacturingCleaning using liquidsNitrogen gasOxygen

A rinsing liquid (DIW) is discharged from a rinsing liquid discharge port formed in a blocking member to perform rinsing processing to a substrate surface while a nitrogen gas is supplied into a clearance space, and a liquid mixture (IPA+DIW) is discharged from a liquid mixture discharge port formed in the blocking member to replace the rinsing liquid adhering to the substrate surface with the liquid mixture while the nitrogen gas is supplied into the clearance space. Thus, an increase of the dissolved oxygen concentration of the liquid mixture can be suppressed upon replacing the rinsing liquid adhering to the substrate surface with the liquid mixture, which makes it possible to securely prevent from forming an oxide film or generating watermarks on the substrate surface.

Owner:DAINIPPON SCREEN MTG CO LTD

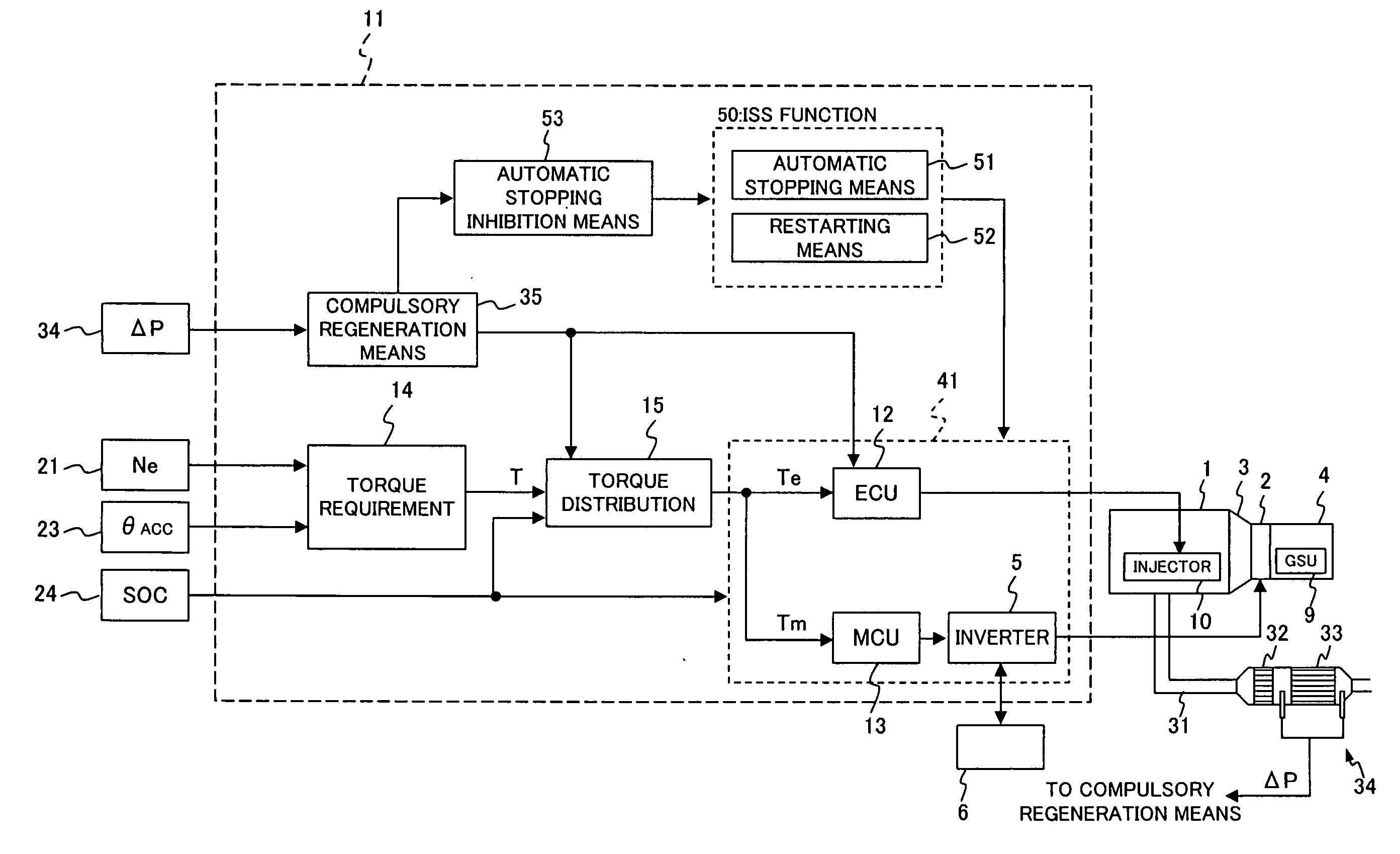

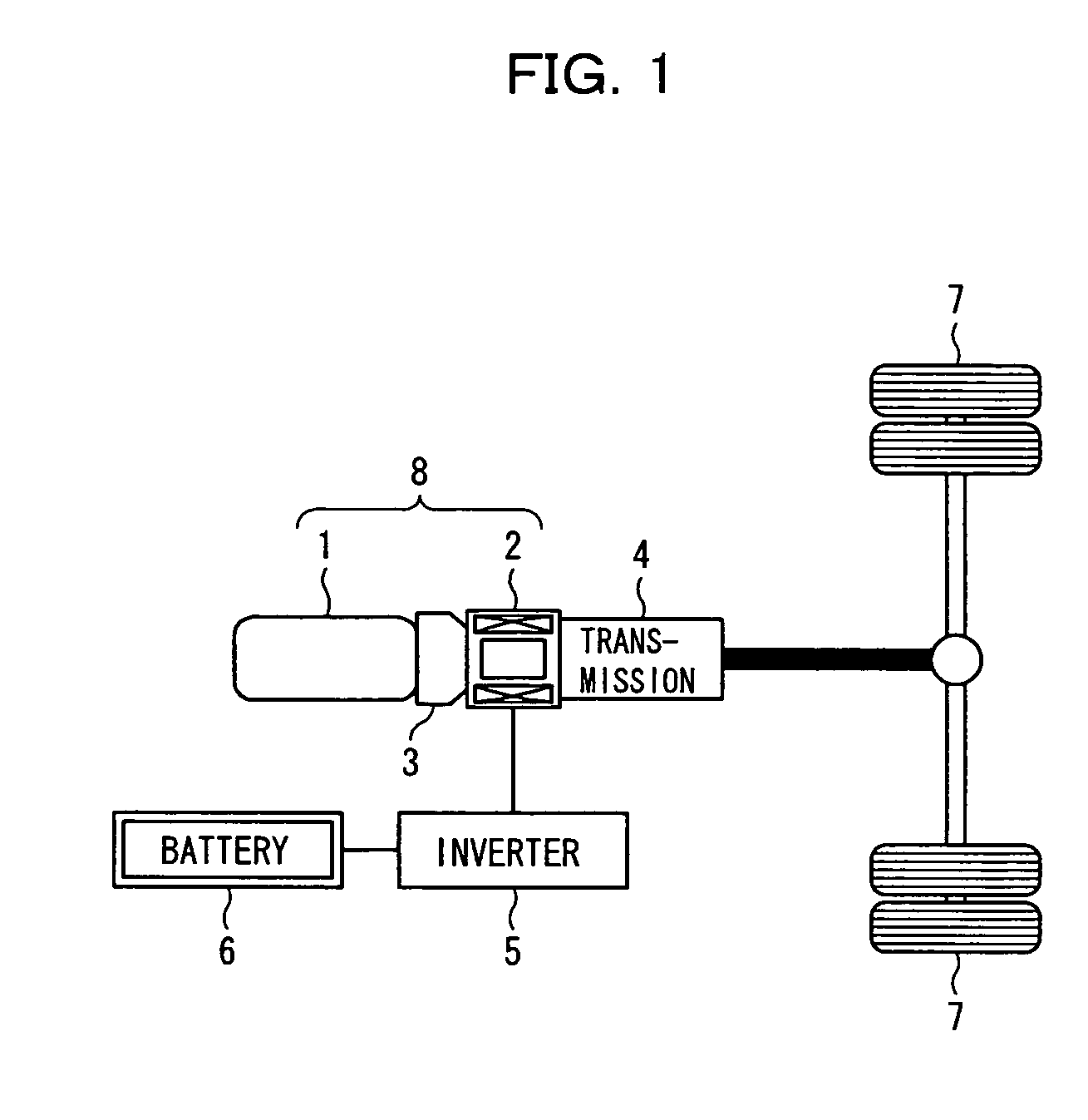

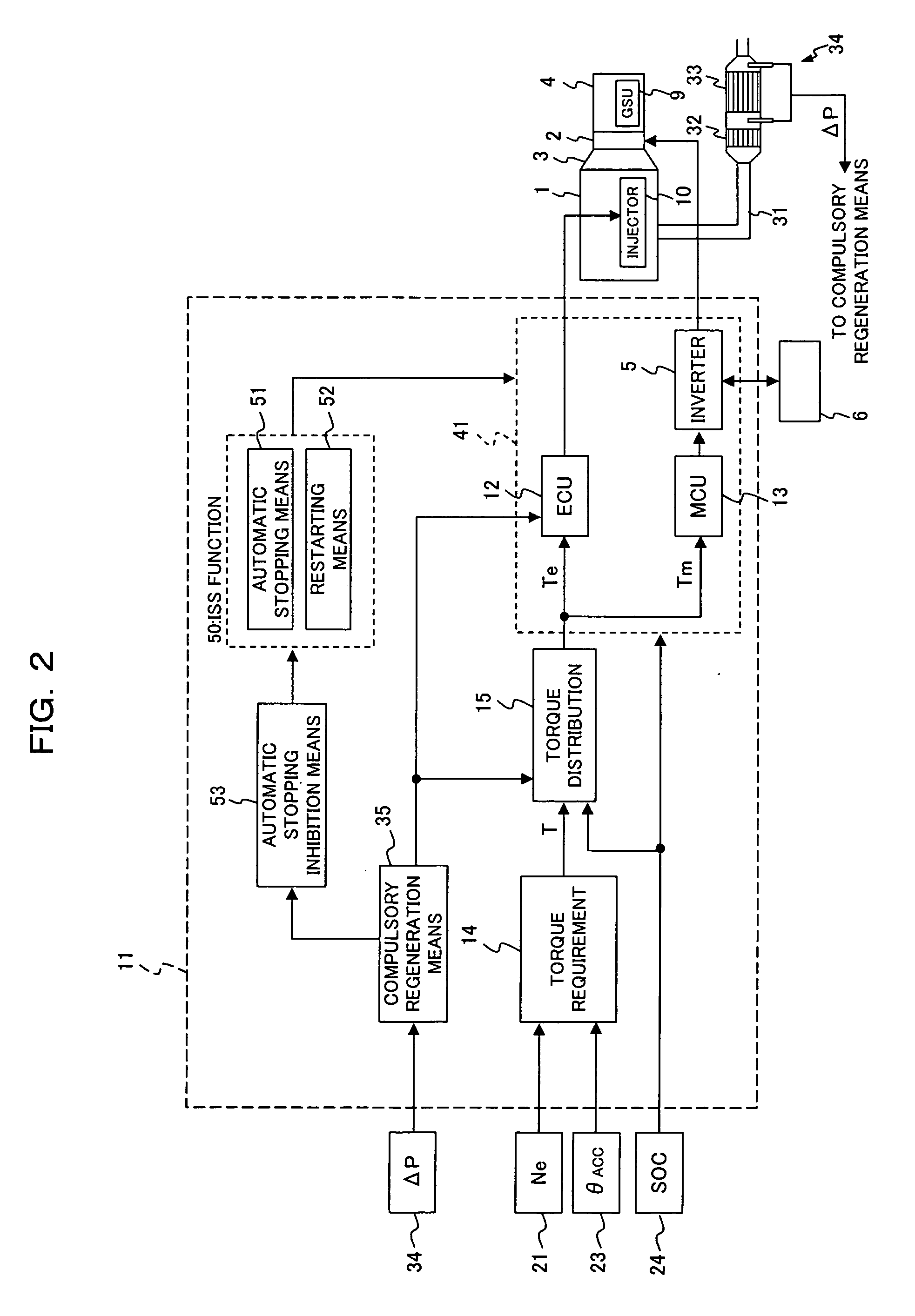

Motor control apparatus for a hybrid vehicle

InactiveUS20060218903A1Increased fuel costShorten the time periodElectrical controlInternal combustion piston enginesParticulatesElectrical battery

A motor control apparatus for a hybrid vehicle in which a diesel engine is used is disclosed by which the compulsory regeneration time period of the hybrid vehicle is reduced to achieve enhancement of the fuel cost. The motor control apparatus for a hybrid vehicle includes a filter for collecting particulate matter in exhaust gas of the diesel engine, compulsory regeneration means for compulsorily regenerating the filter, and battery charging means for converting the output power of the diesel engine into electric power based on a charged state of the battery and charging the battery with the electric power. When the compulsory regeneration is executed, the supply of electric power to the battery by the engine is inhibited.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

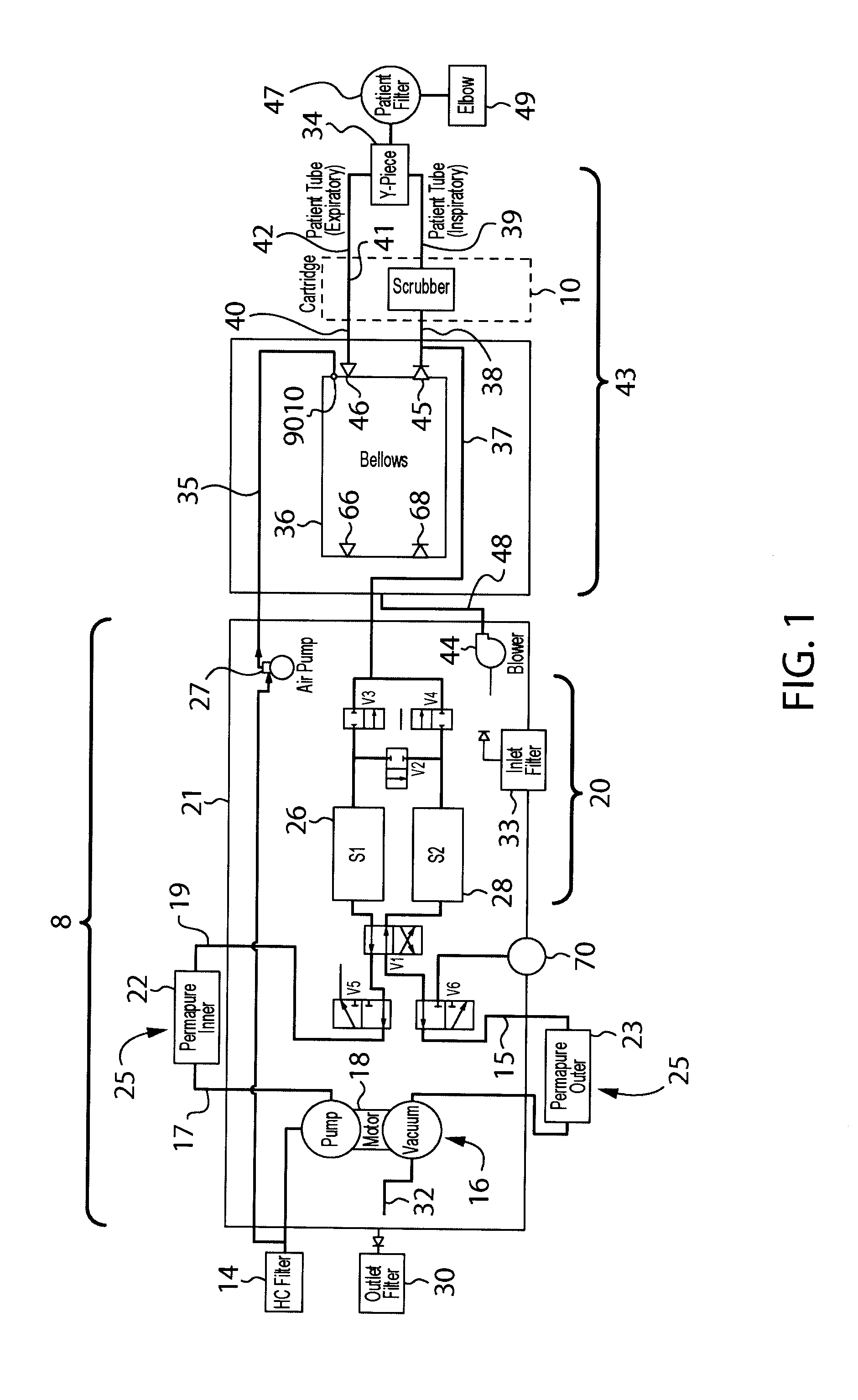

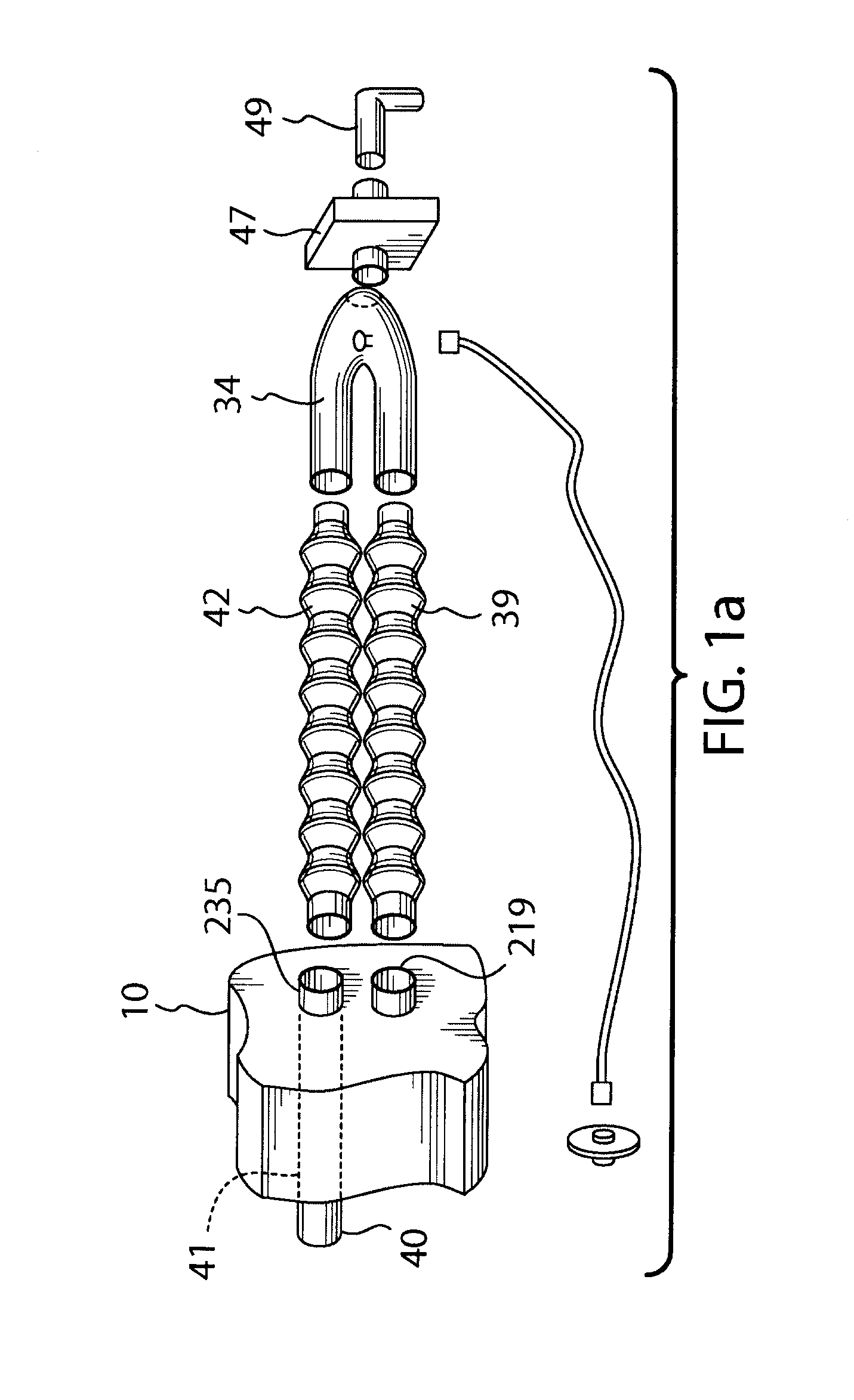

Portable life support apparatus

InactiveUS20150083121A1Great volumeControlling oxygen levels supplied to the patientRespiratory device testingStretcherOxygen concentratorLife support

A portable life support apparatus (1102) and particularly a respiratory support apparatus adapted to be easily mounted to a stretcher is disclosed. Prior devices that attach onto a stretcher are heavy and cumbersome and obstruct access to the patient. Accordingly, there is a great need for a portable emergency support device that overcomes the weight, size, positioning, and other portability disadvantages. One aspect relates to a portable life support device including at least one ambient gas inlet (14); a conditioned gas outlet (30); an oxygen concentrator (26,28) fluidly connected between the at least one gas inlet and the gas outlet, and a ventilator (44) fluidly connected downstream from the oxygen concentrator. A further aspect is directed to a portable life support apparatus in the form of a portable respiratory support apparatus (1102) capable of exploiting both ambient air and expired gas as oxygen sources, wherein the oxygen generator (20) and ventilator (10) are arranged end to end to provide a longitudinal profile that can thus be compactly secured to a stretcher or other similar emergency transport vehicle.

Owner:THORNHILL RES

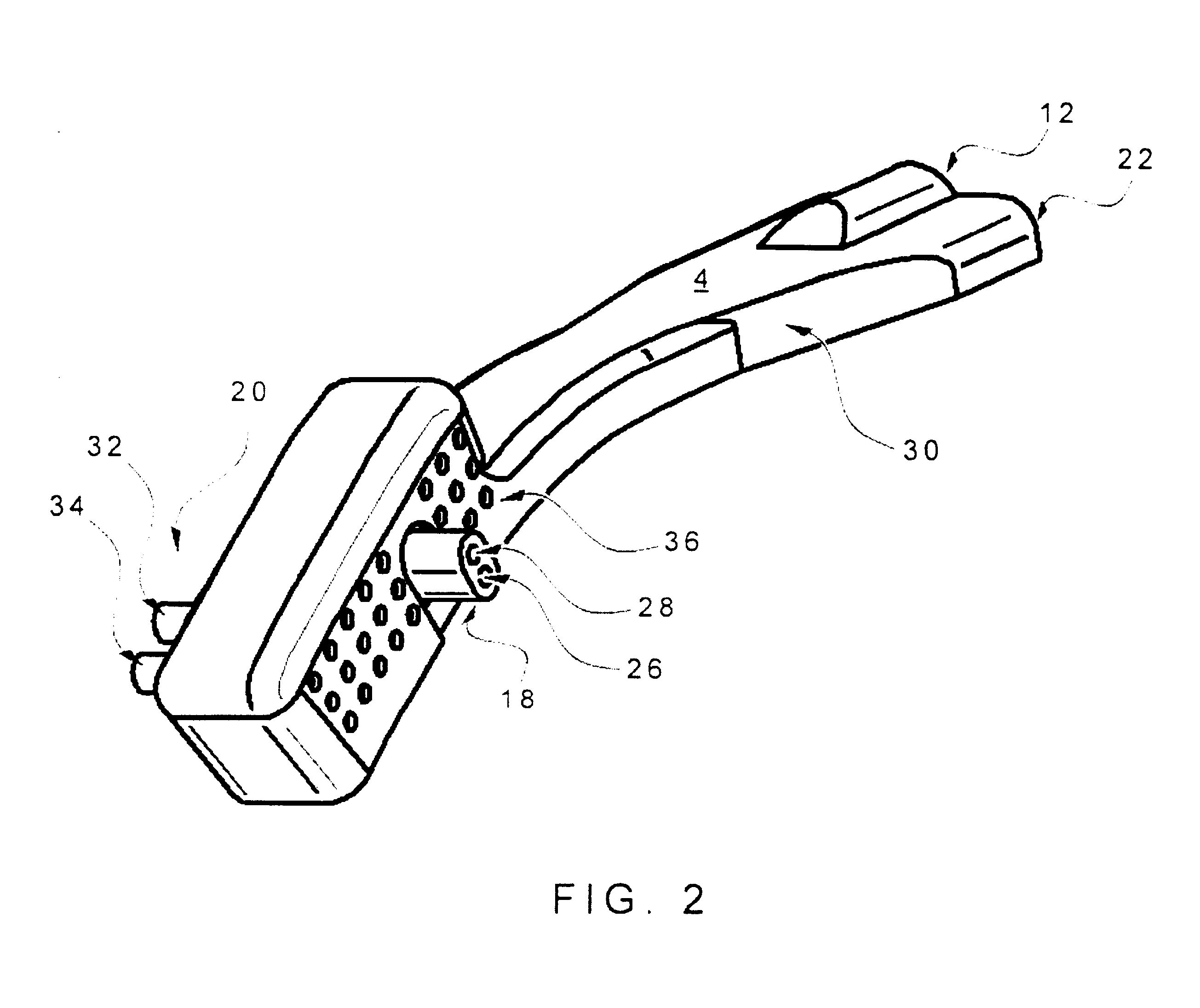

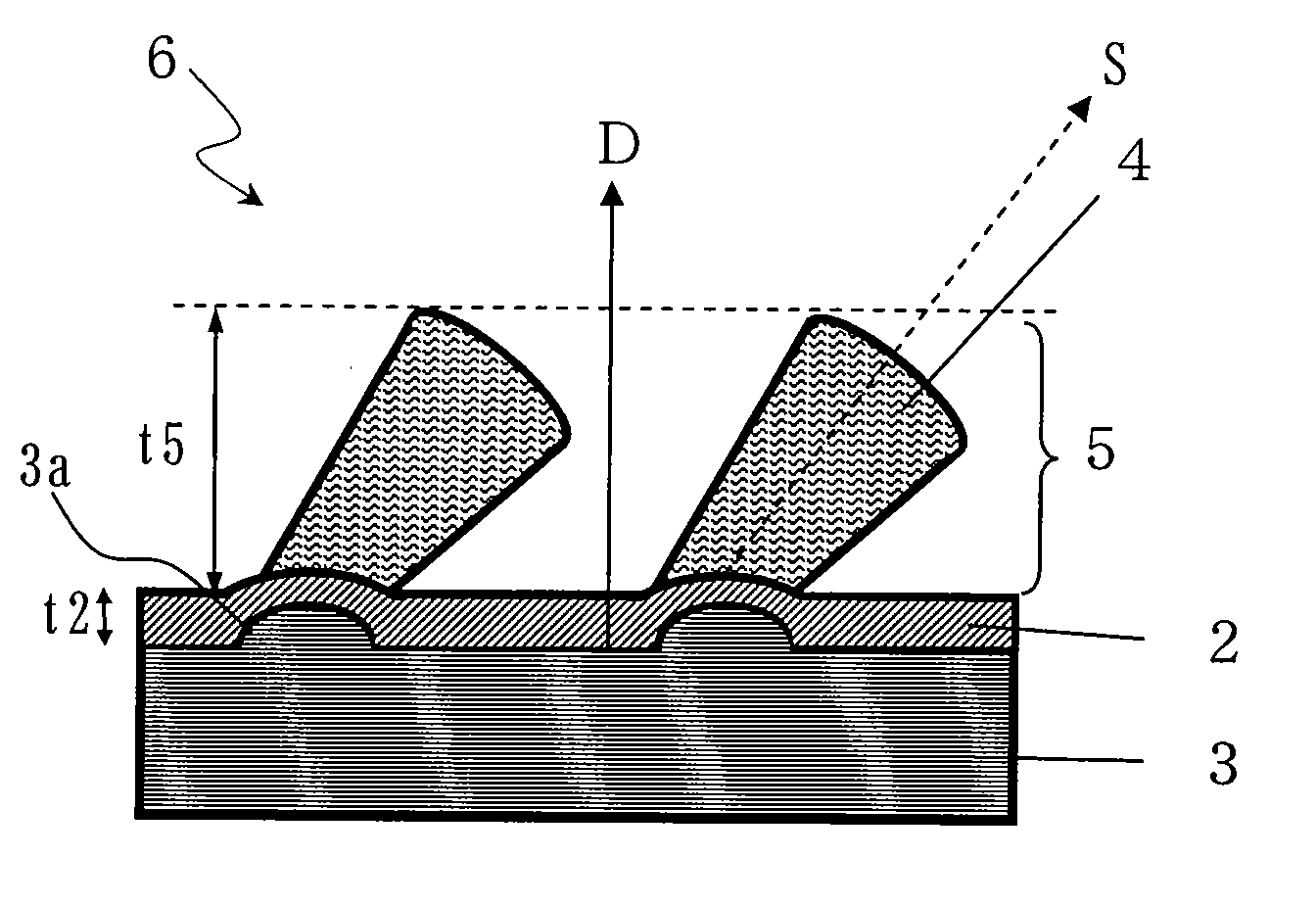

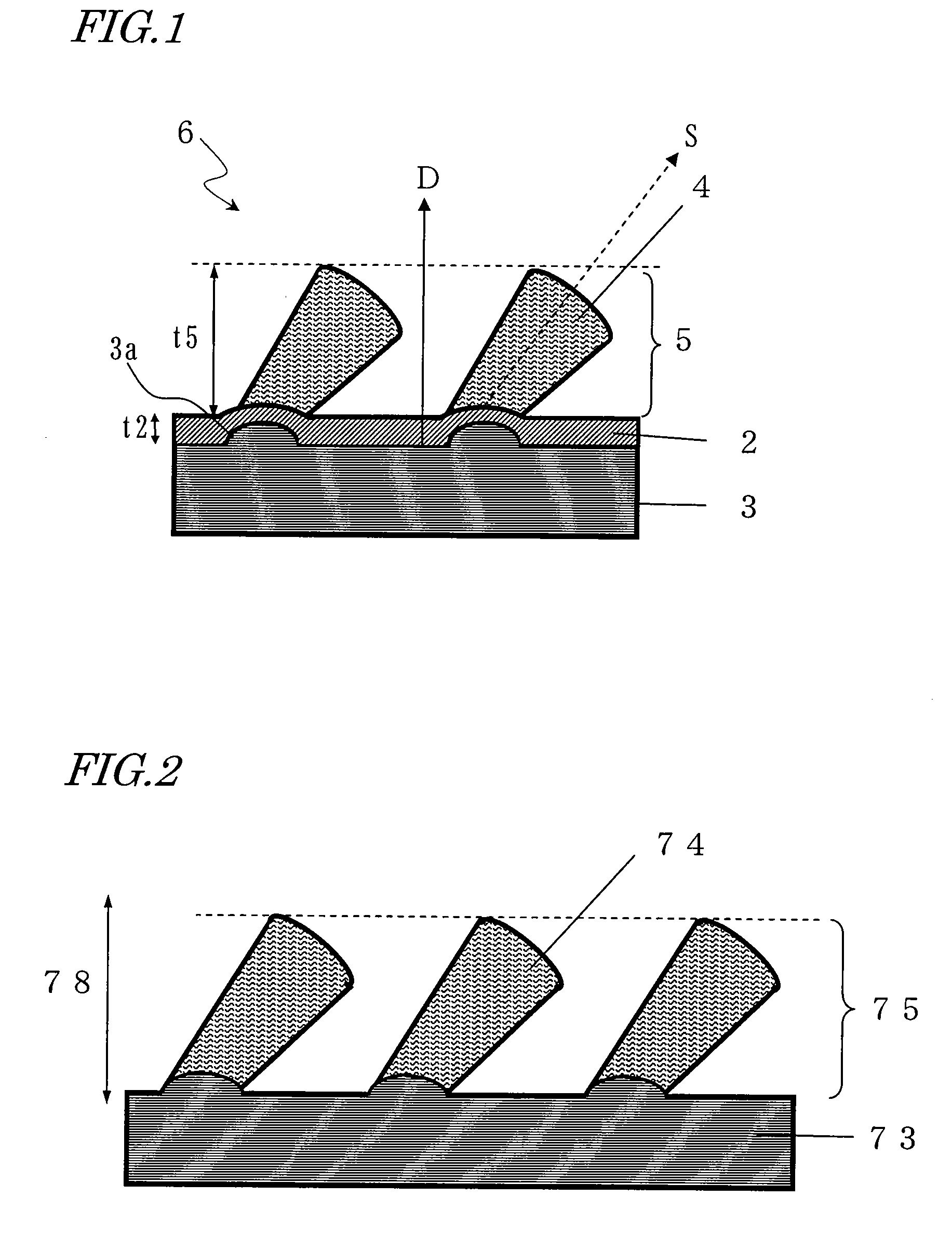

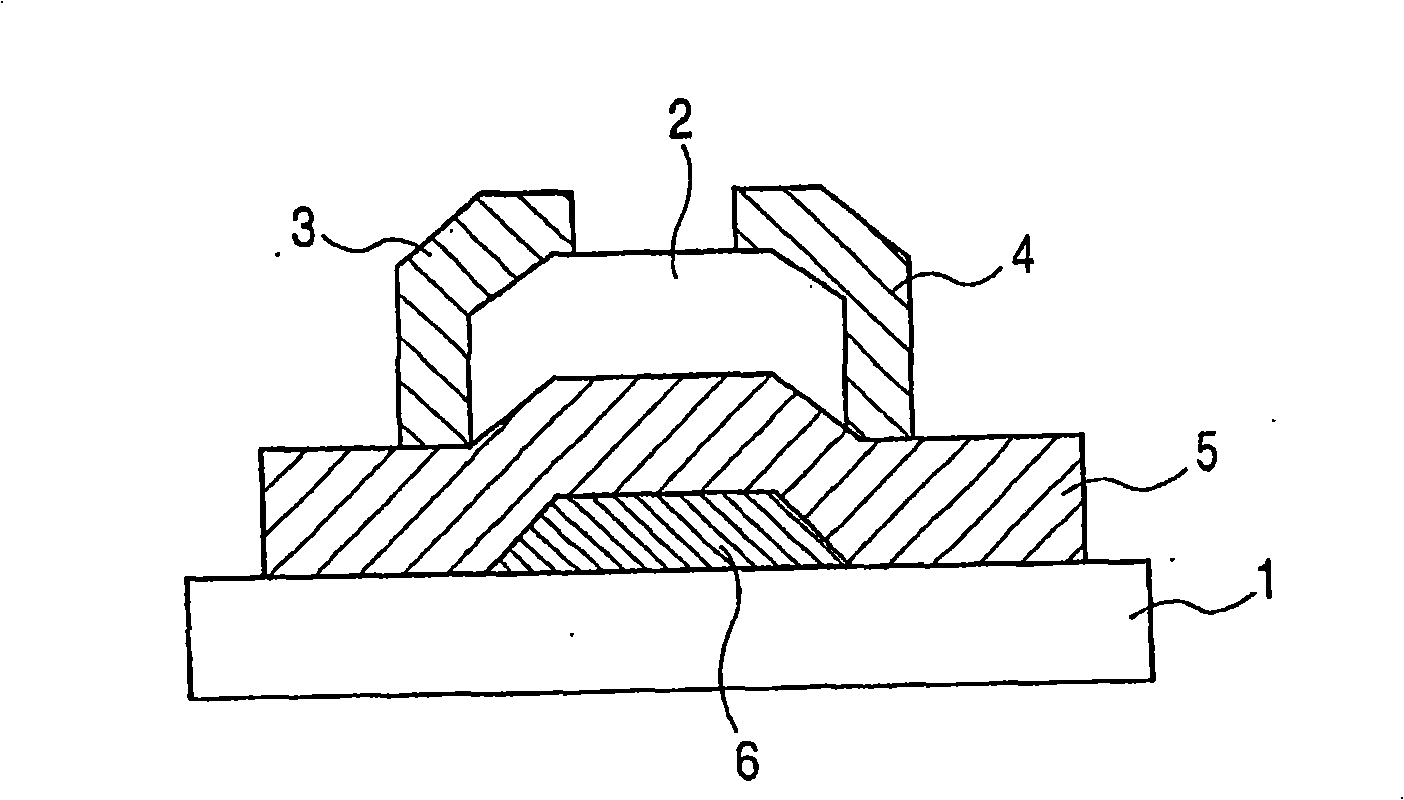

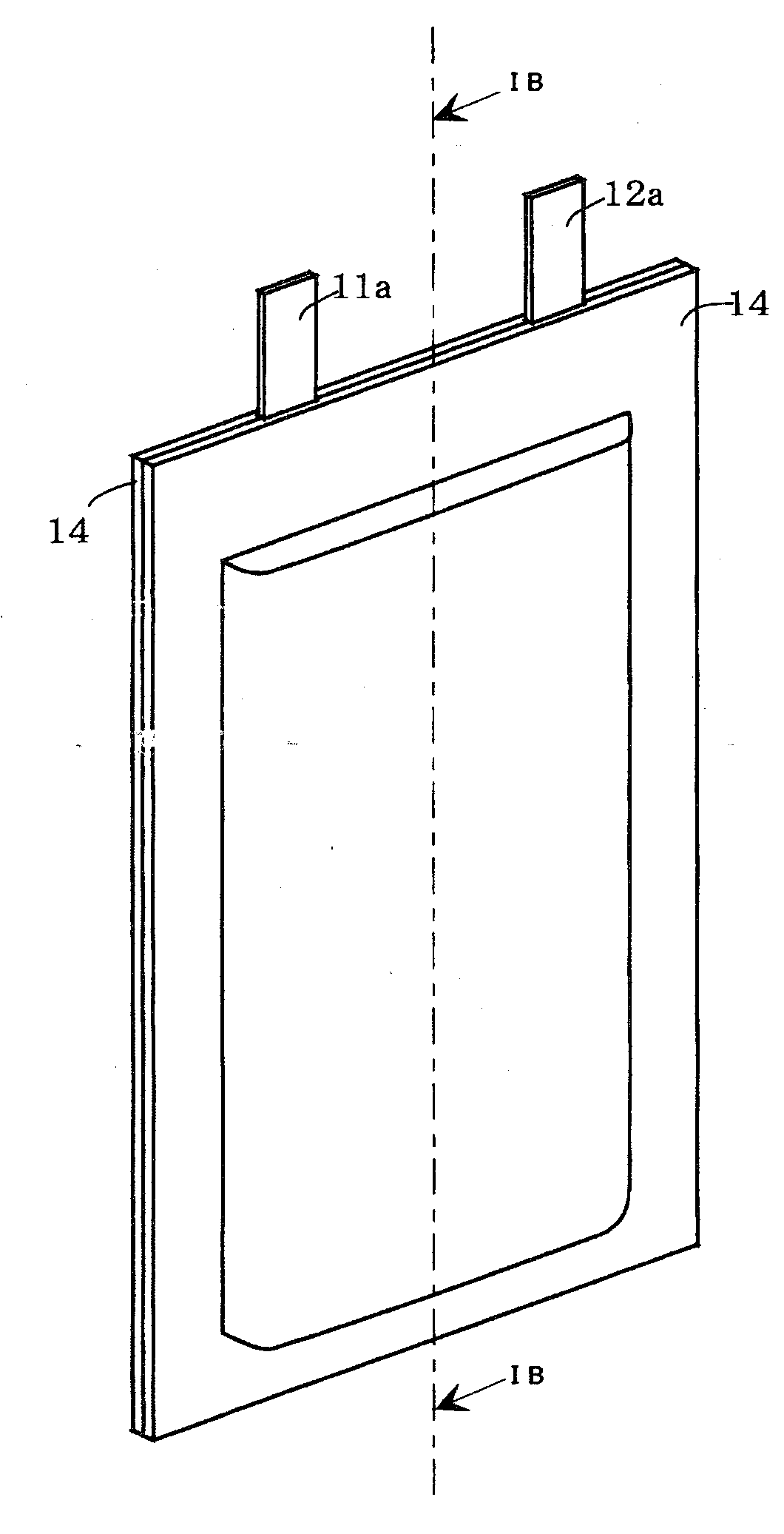

Electrode for nonaqueous electrolyte secondary battery, method for producing same, and nonaqueous electrolyte secondary battery comprising such electrode for nonaqueous electrolyte secondary battery

ActiveUS20090117462A1Reduce stressImproved characteristicElectrode manufacturing processesElectrode carriers/collectorsCurrent collectorEngineering

An electrode for a non-aqueous electrolyte secondary battery 6 according to the present invention includes: a current collector 3; a first active material layer 2 formed on the current collector 3; and a second active material layer 5 provided on the first active material layer 2, the second active material layer 5 including a plurality of active material particles 4. The plurality of active material particles 4 is mainly of a chemical composition represented as SiOx(0≦x<1.2). The first active material layer 2 is mainly of a chemical composition represented as SiOy(1.0≦y<2.0, y>x). The area in which the first active material layer 2 is in contact with the plurality of active material particles 4 is smaller than the area in which the current collector 3 is in contact with the first active material layer 2.

Owner:PANASONIC CORP

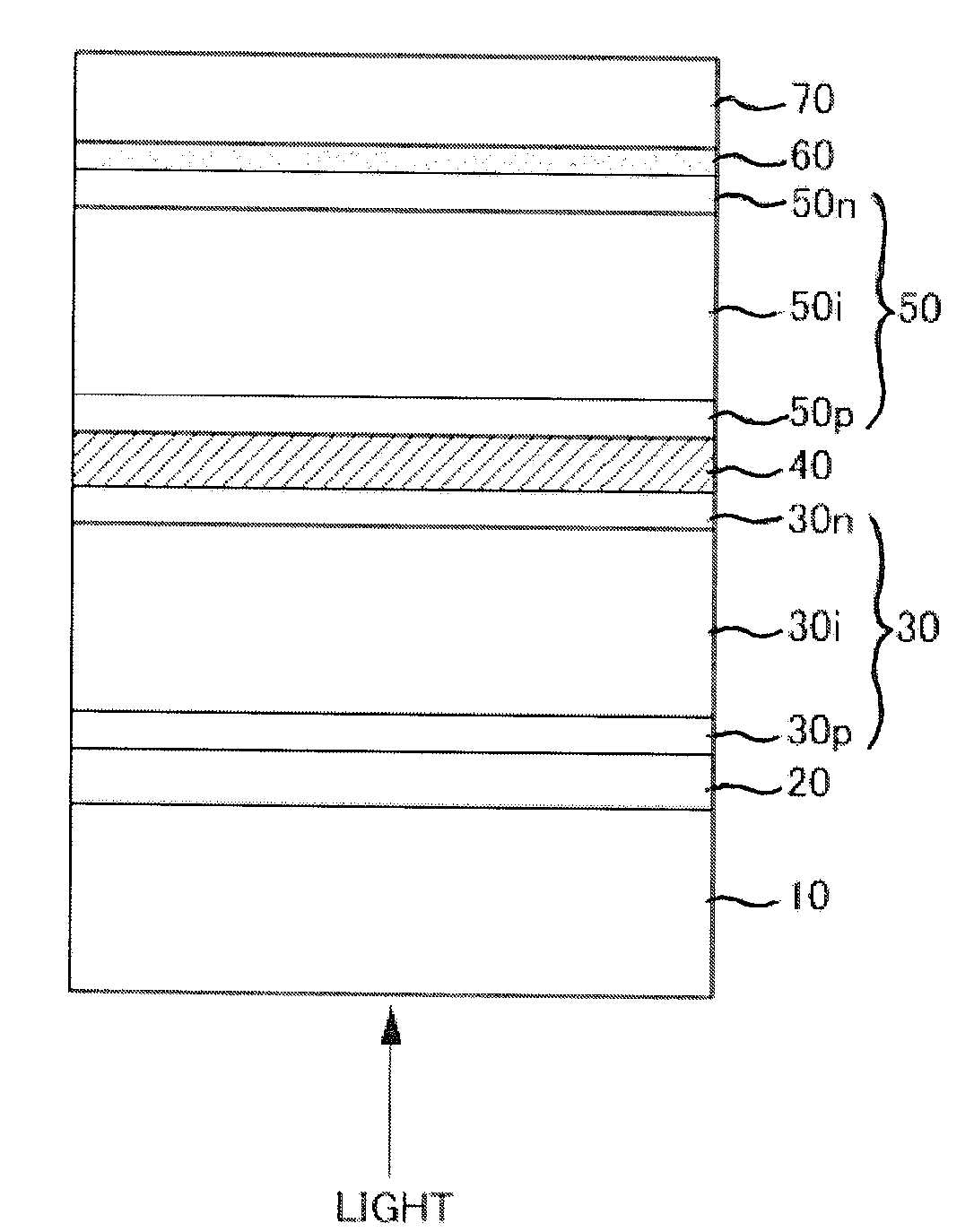

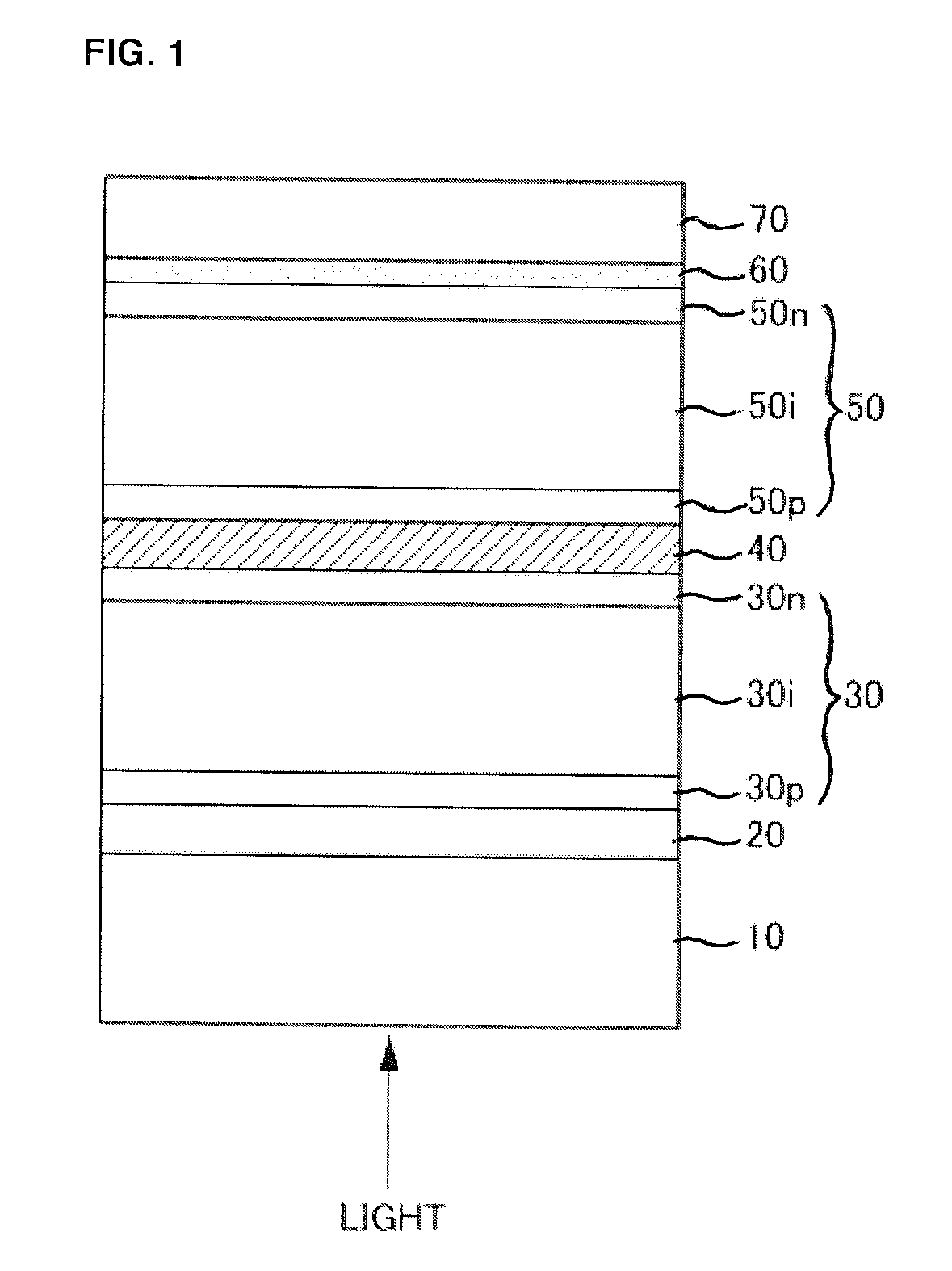

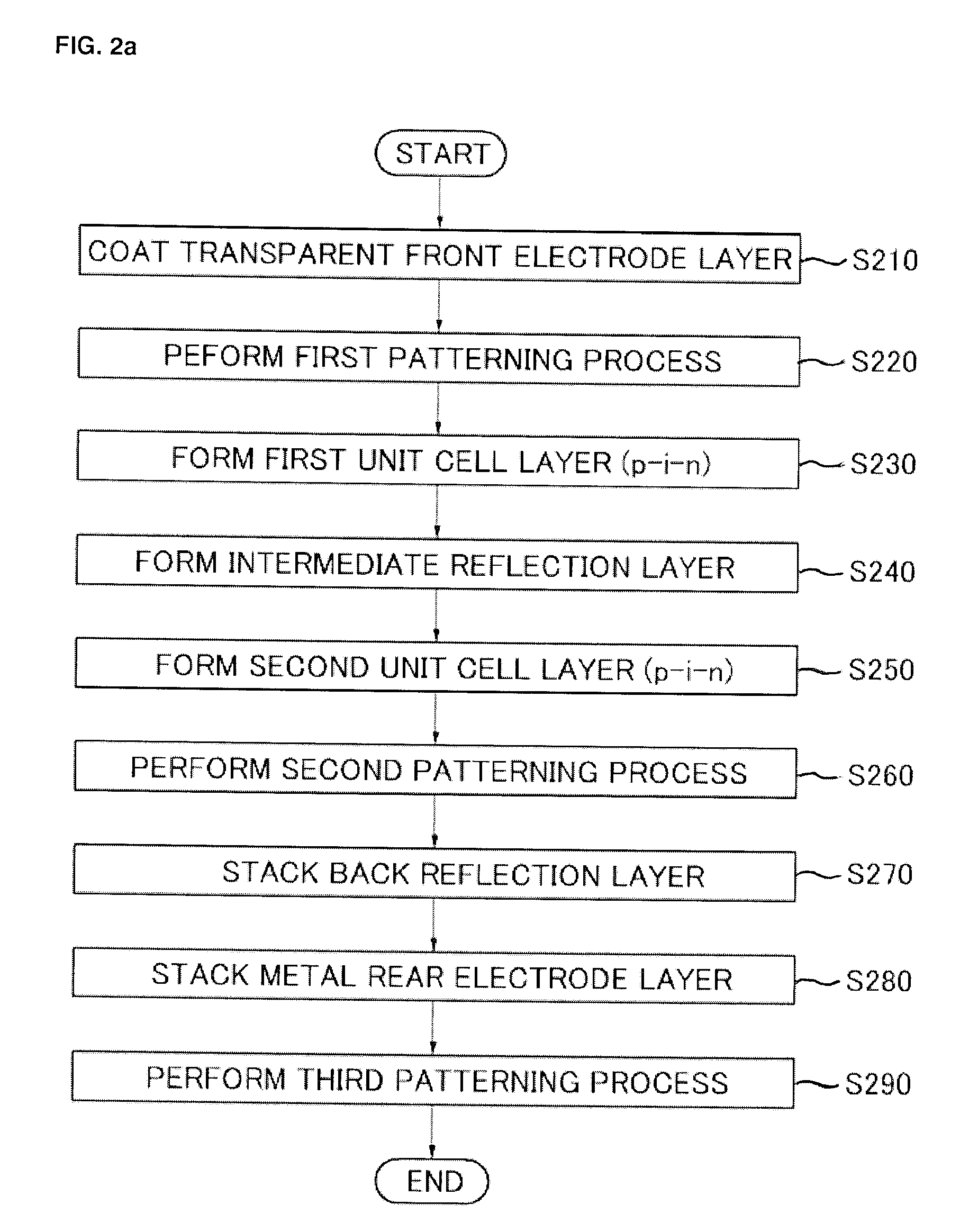

Tandem thin-film silicon solar cell and method for manufacturing the same

InactiveUS20090293936A1Increase oxygen concentrationFinal product manufacturePV power plantsSilicon solar cellOxygen

A tandem thin-film silicon solar cell comprises a transparent substrate, a first unit cell positioned on the transparent substrate, the first unit cell comprising a p-type window layer, an i-type absorber layer and an n-type layer, an intermediate reflection layer positioned on the first unit cell, the intermediate reflection layer including a hydrogenated n-type microcrystalline silicon oxide of which the oxygen concentration is profiled to be gradually increased and a second unit cell positioned on the intermediate reflection layer, the second unit cell comprising a p-type window layer, an i-type absorber layer and an n-type layer.

Owner:INTELLECTUAL DISCOVERY CO LTD

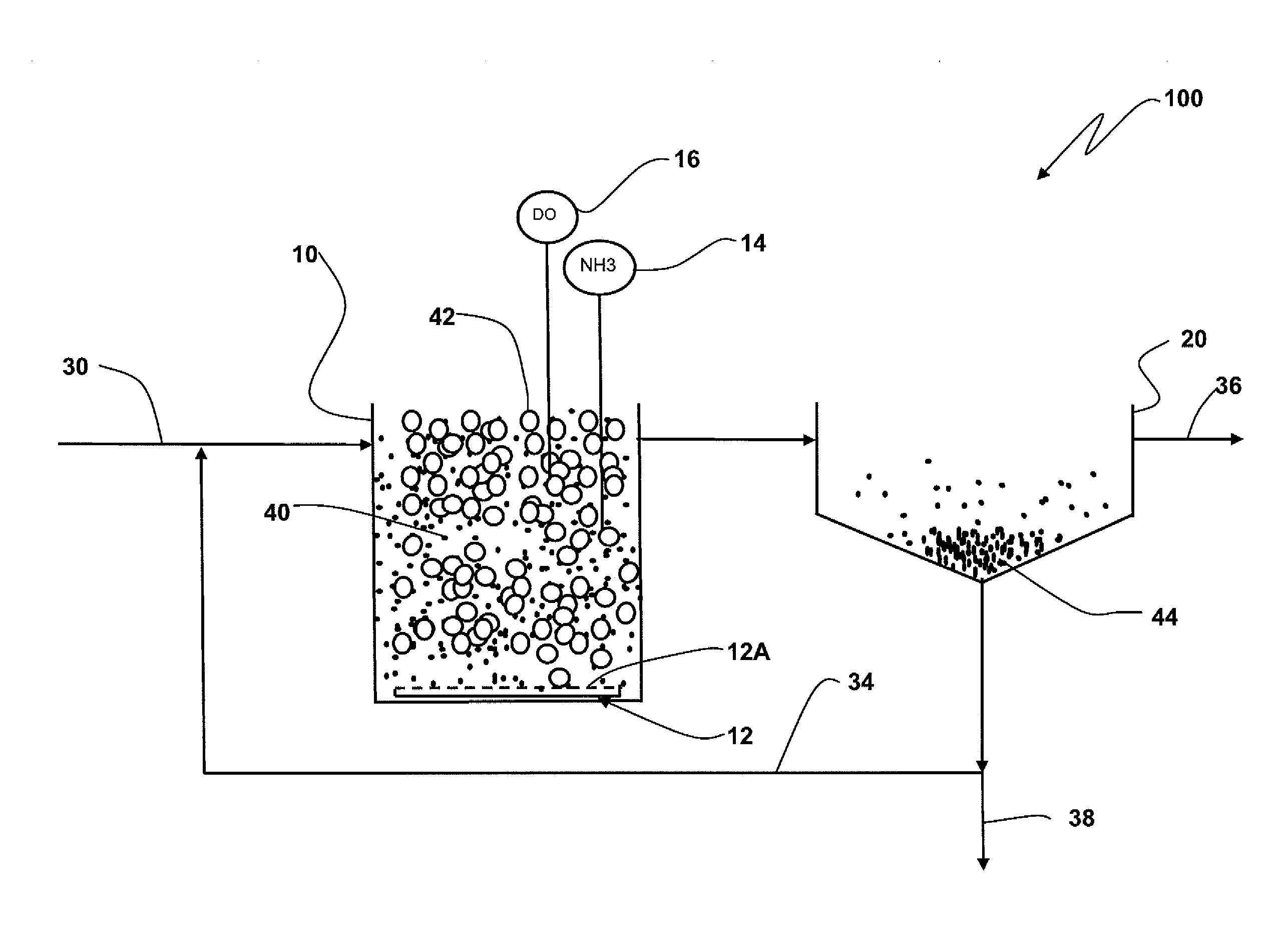

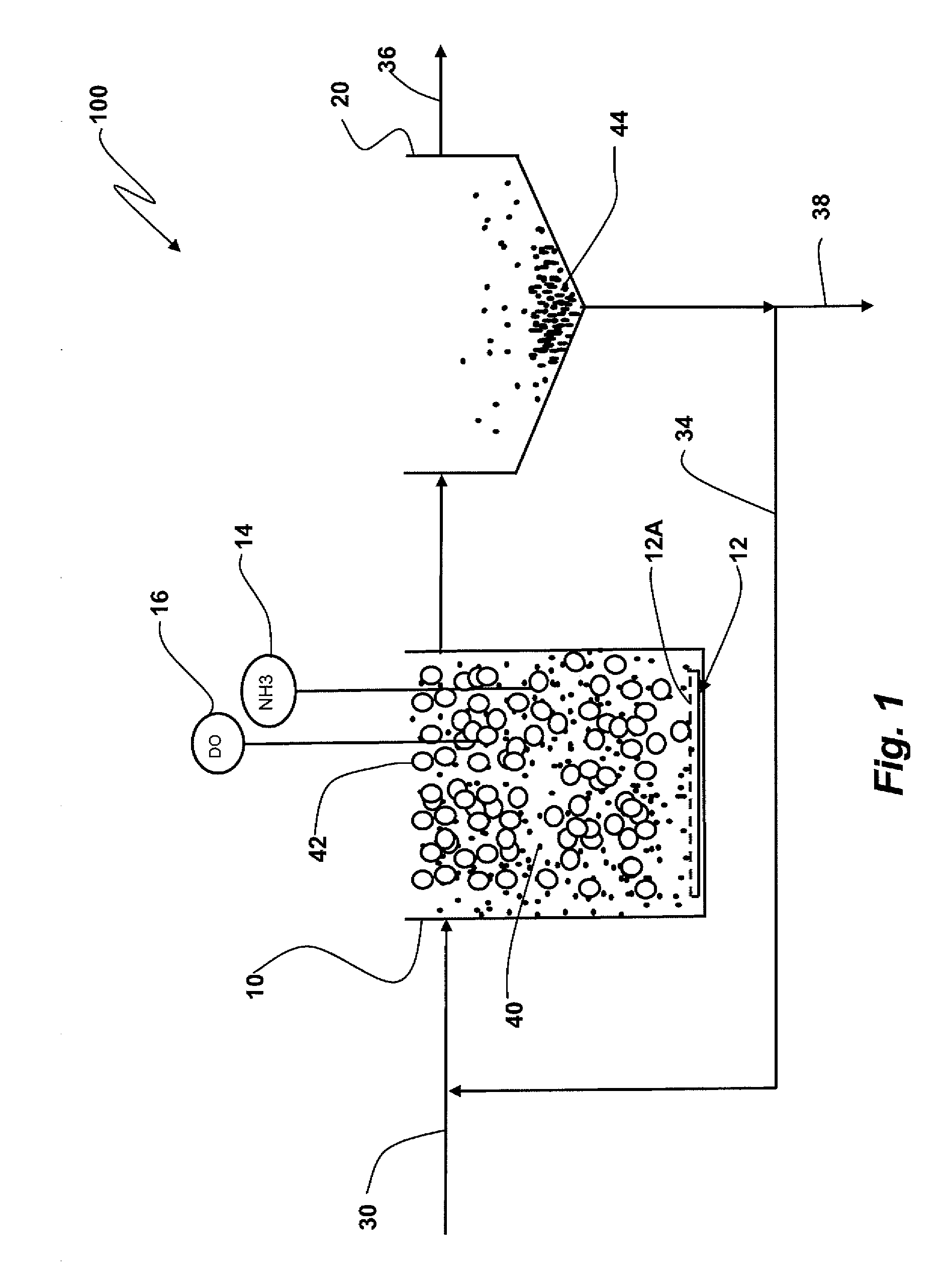

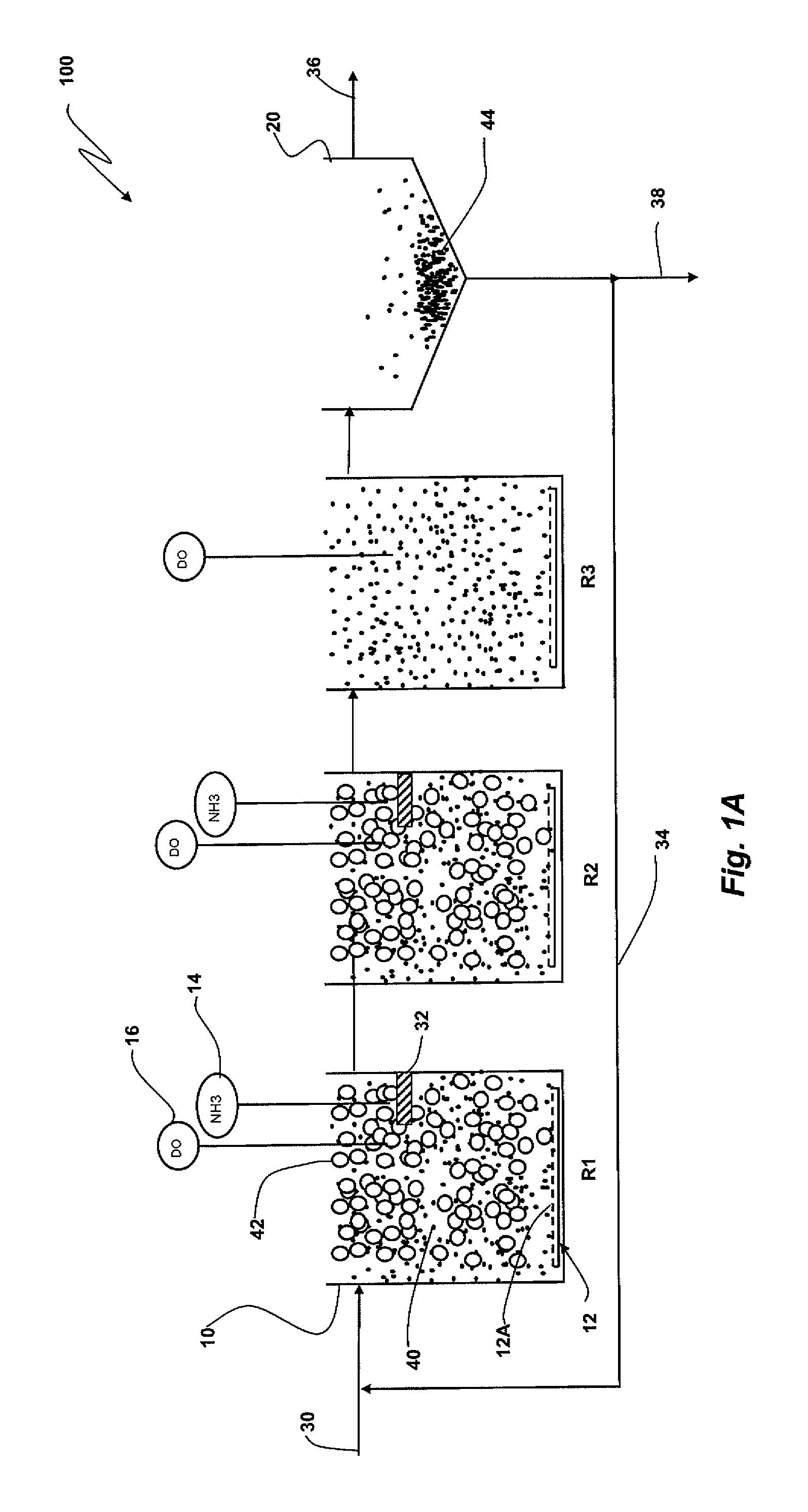

Controlled Aeration of Integrated Fixed-Film Activated Sludge Bioreactor Systems for the Treatment of Wastewater

ActiveUS20110284461A1Efficiently aerate and supply dissolved oxygenIncrease oxygen concentrationWater treatment parameter controlTreatment using aerobic processesActivated sludgeBioreactor

A method of biologically treating wastewater with an integrated fixed film activated sludge process. The integrated fixed film activated sludge process includes biomass suspended in mixed liquor and biomass disposed on carriers. Under certain conditions the dissolved oxygen concentration in a reactor that includes the mixed liquor, biomass suspended in the mixed liquor, and the biomass on the carriers, biological treatment is performed primarily by the biomass in the mixed liquor. This is achieved by controlling or maintaining the dissolved oxygen concentration in the reactor at a relatively low concentration. When the biomass suspended in the mixed liquor is unable to adequately biologically treat the mixed liquor, the dissolved oxygen concentration in the reactor is controlled or maintained at a relatively high concentration. This enables biomass on the carriers to contribute more to the biological treatment of the mixed liquor than when the dissolved oxygen concentration was maintained relatively low.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

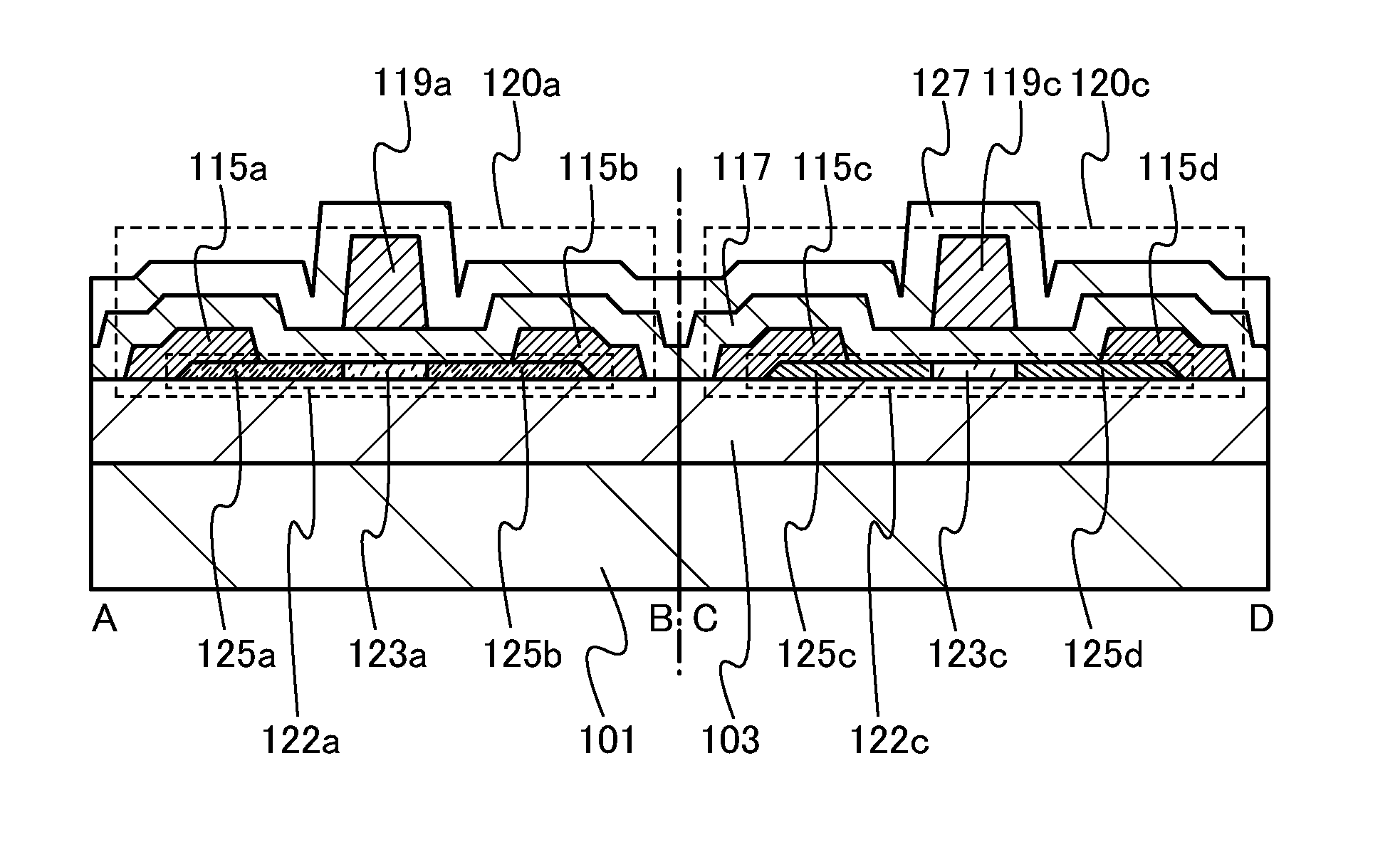

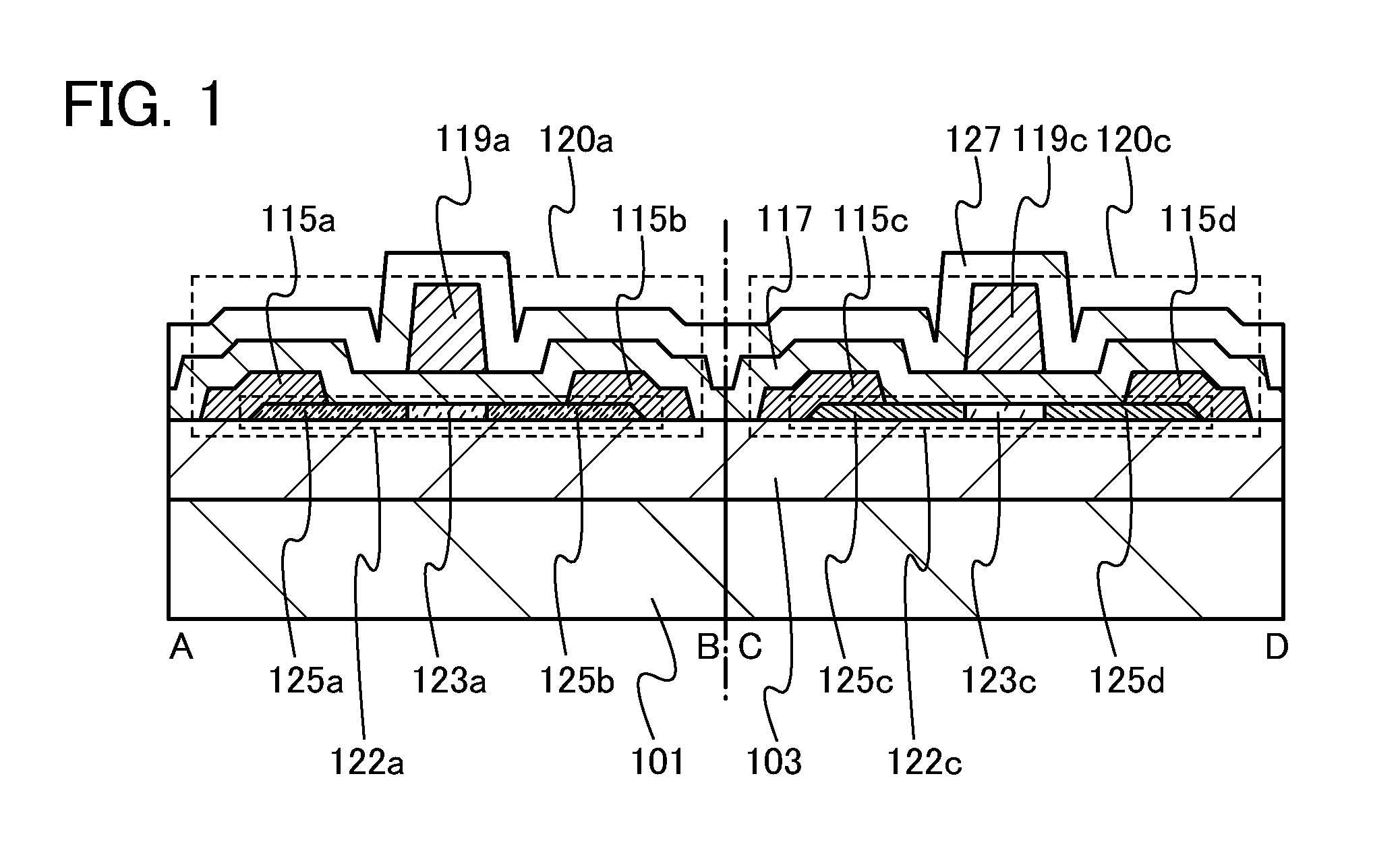

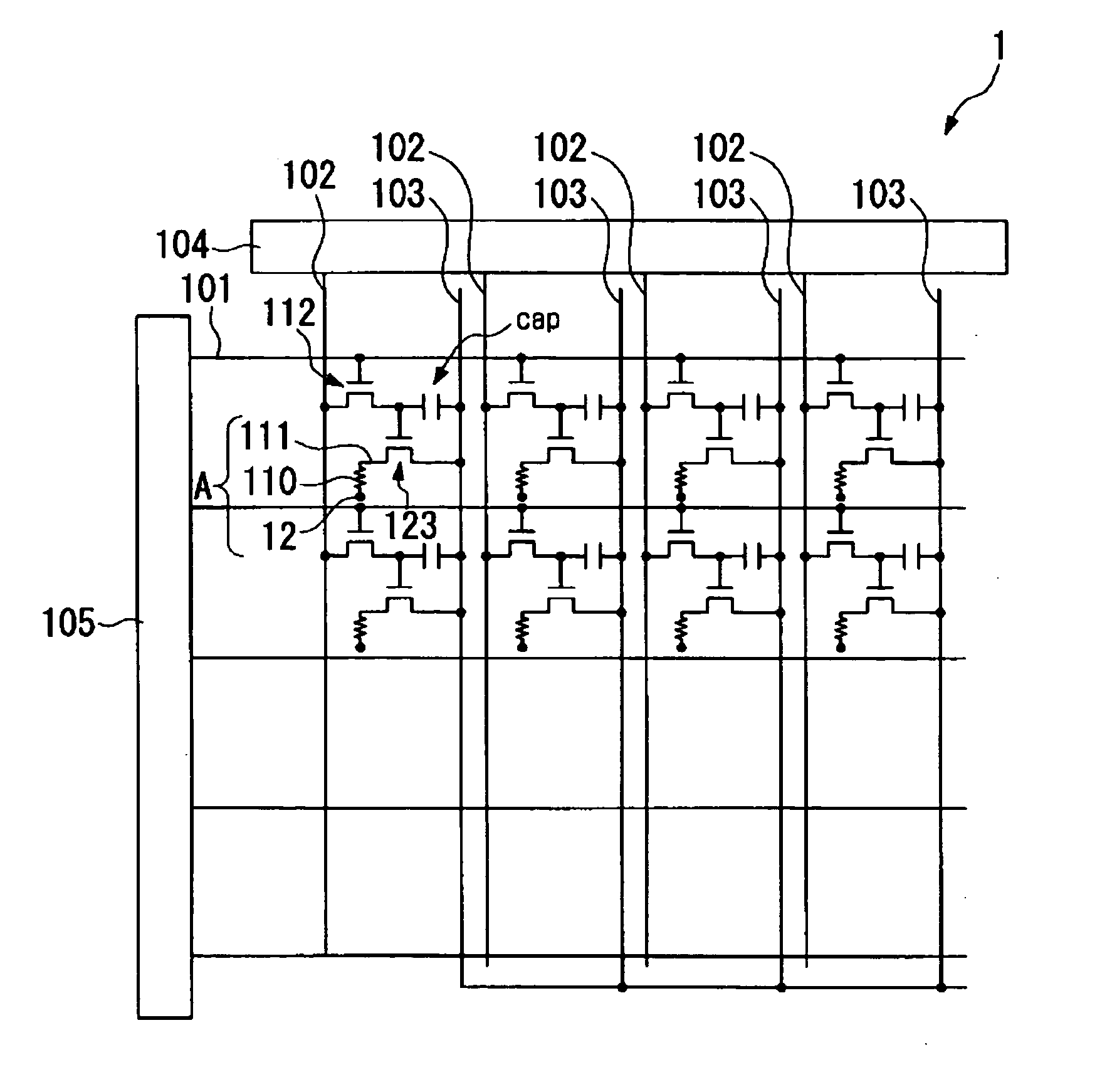

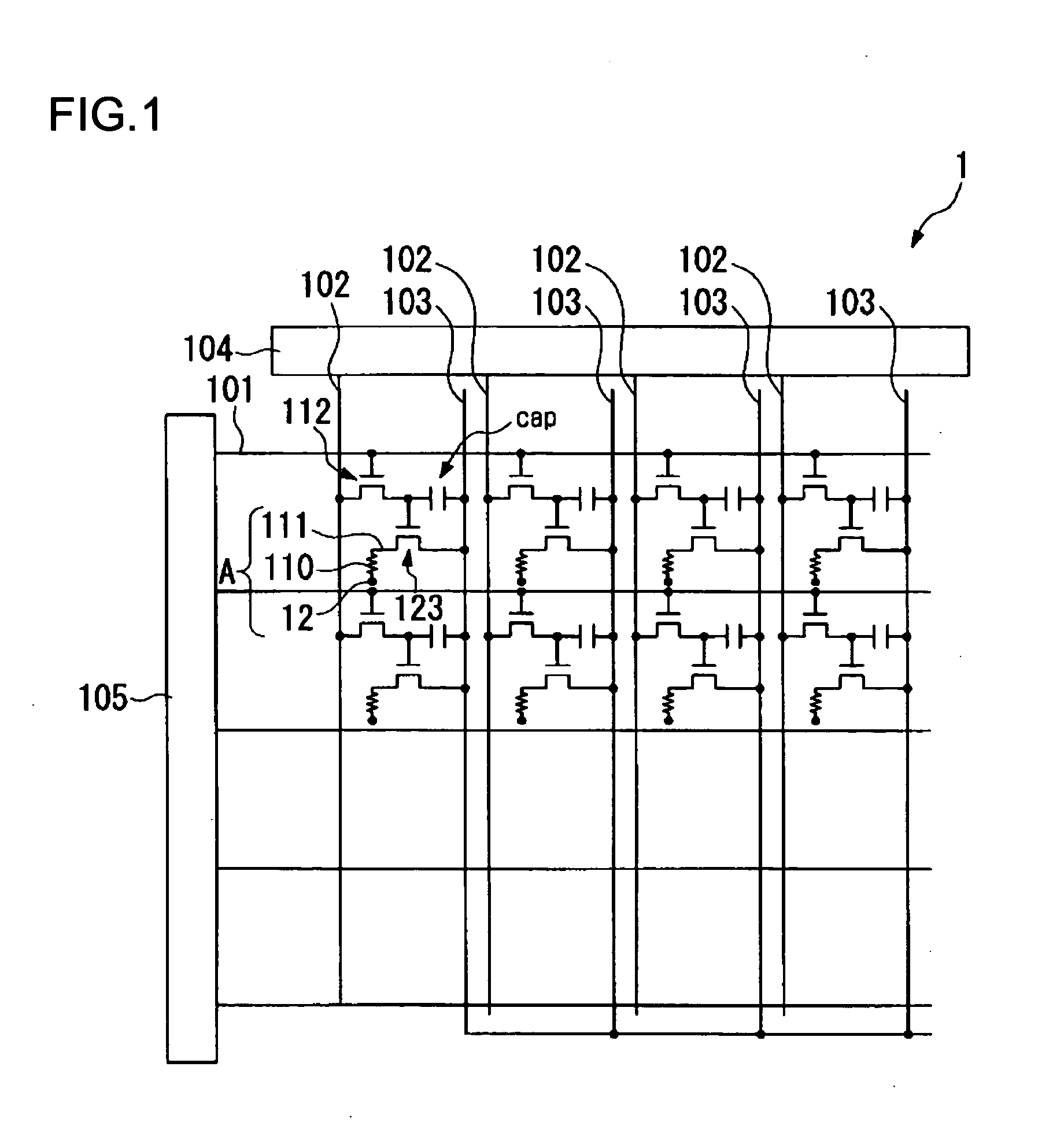

Semiconductor device

ActiveUS20130020569A1Solve the large consumptionIncrease speedSolid-state devicesSemiconductor devicesPower semiconductor devicePower flow

A semiconductor device which can operate at high speed and consumes a smaller amount of power is provided. In a semiconductor device including transistors each including an oxide semiconductor, the oxygen concentration of the oxide semiconductor film of the transistor having small current at negative gate voltage is different from that of the oxide semiconductor film of the transistor having high field-effect mobility and large on-state current. Typically, the oxygen concentration of the oxide semiconductor film of the transistor having high field-effect mobility and large on-state current is lower than that of the oxide semiconductor film of the transistor having small current at negative gate voltage.

Owner:SEMICON ENERGY LAB CO LTD

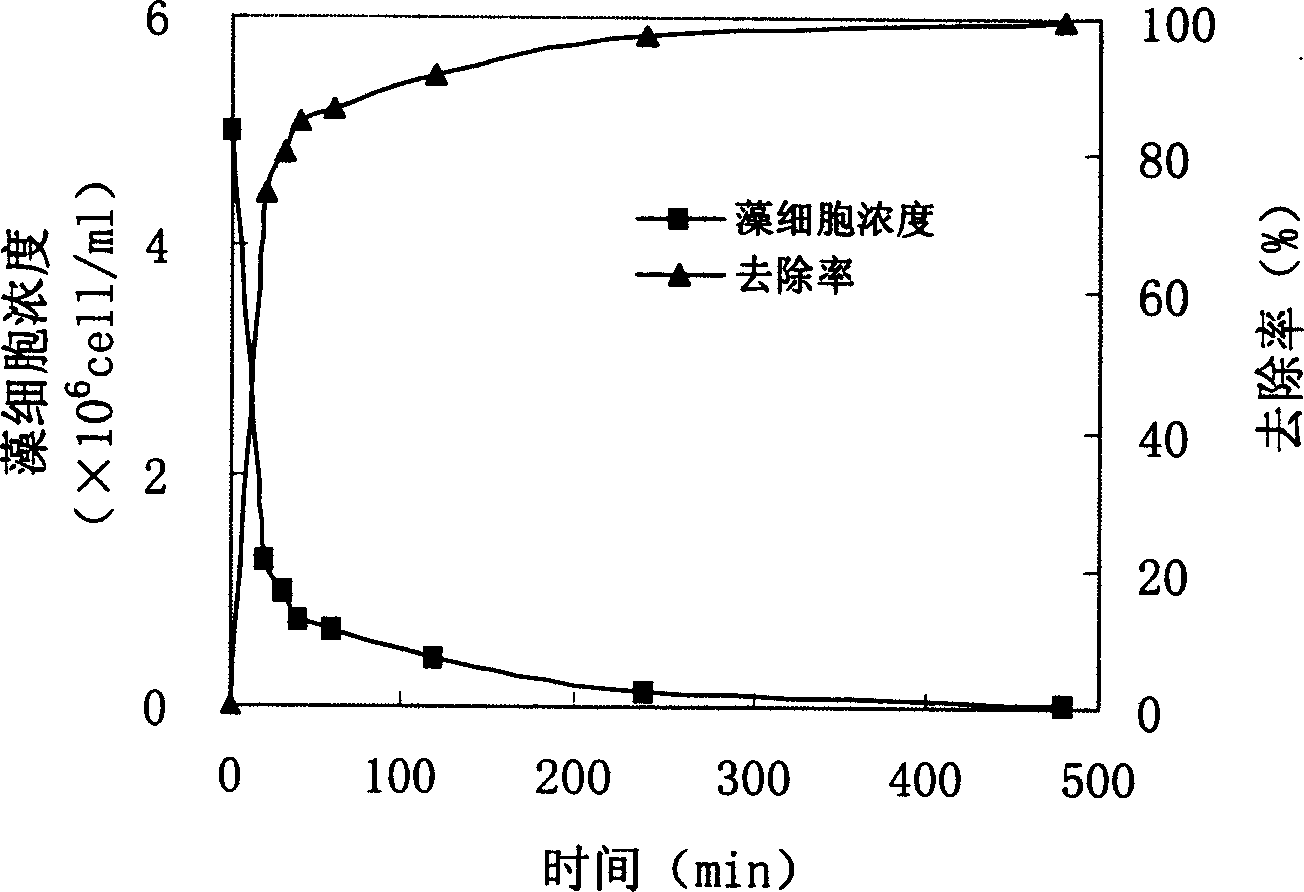

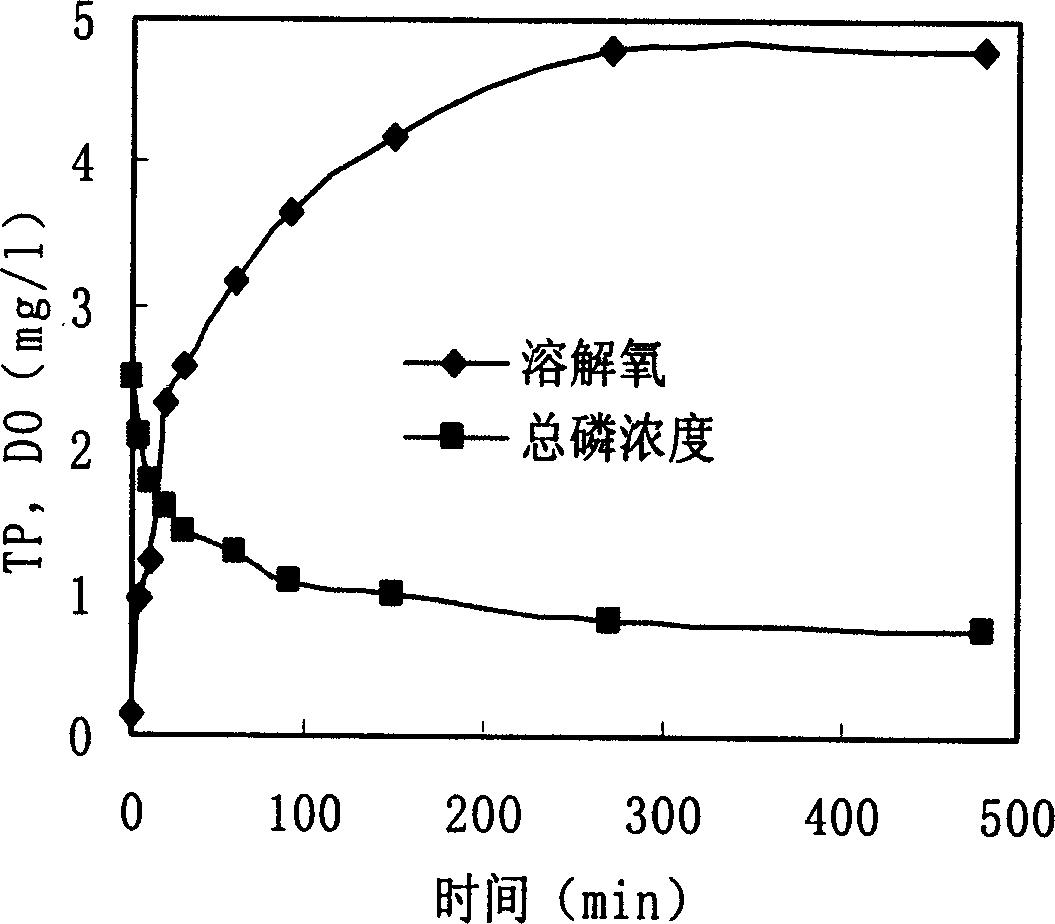

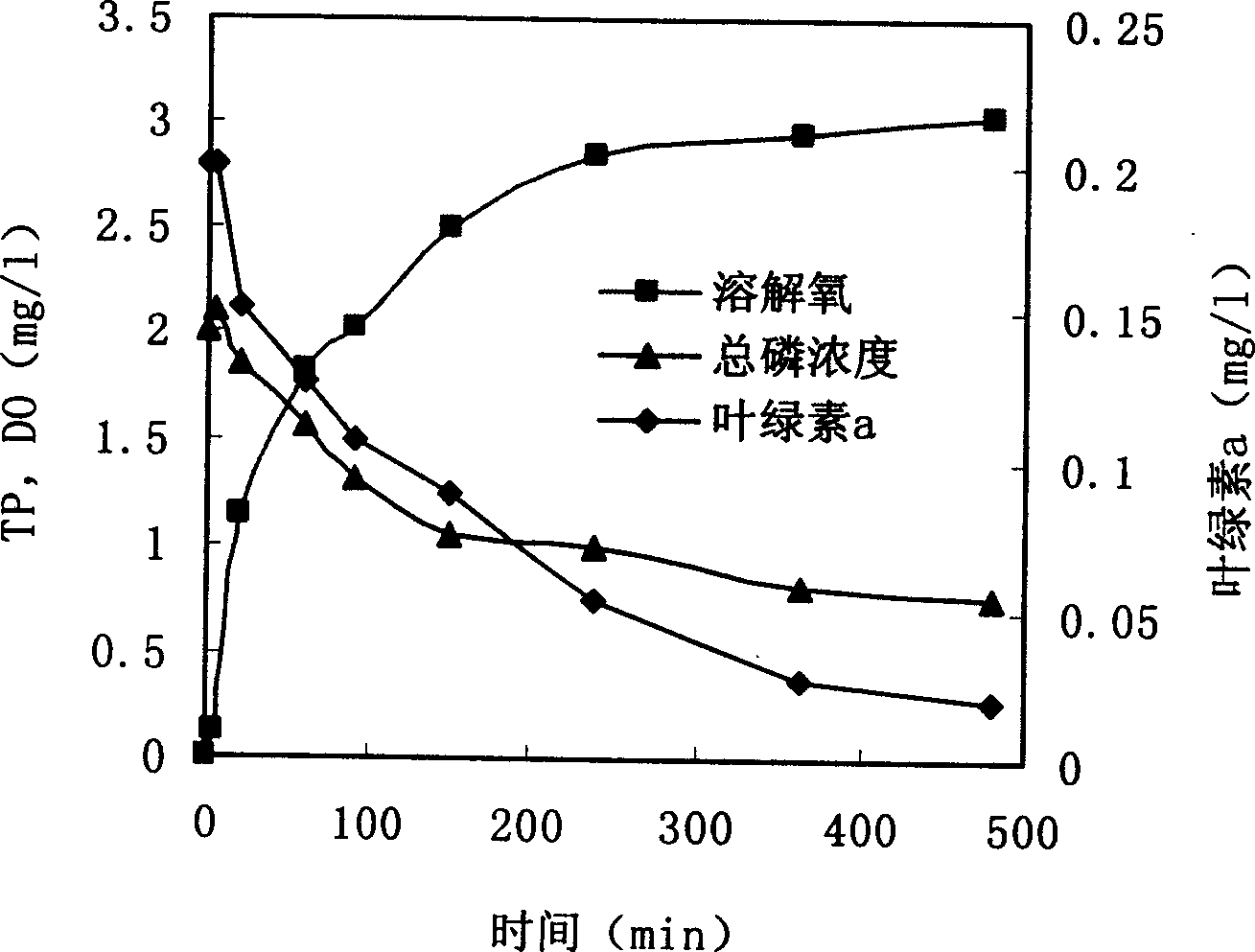

Technique for harnessing water bloom and bed mud secondary pollution using lake sediment

InactiveCN1541952AReduce concentrationIncrease oxygen concentrationWater/sewage treatment by flocculation/precipitationCalcium in biologyEutrophication

The present invention provides one comprehensive technology of utilizing eutrophic and algalbloom polluted precipitant in in-situ algae killing, ventilation and phosphate fixing. By means of the said technology, bed mud or bankside clay is used in treating algalbloom in low cost. The said technology can eliminate algae effectively, increase dissolved oxygen concentration in water, reduce H2S and NH3-N produced, improve water quality, speed the degradation of organic in water, increase calcium in water, make bottom matter loose and ventilating, minimize and fix water body, bed mud and deposited phosphor in algae cell for no further utilization by living things. The present invention may be used in comprehensive treatment of red tide in sea, water bloom in fresh water, etc.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

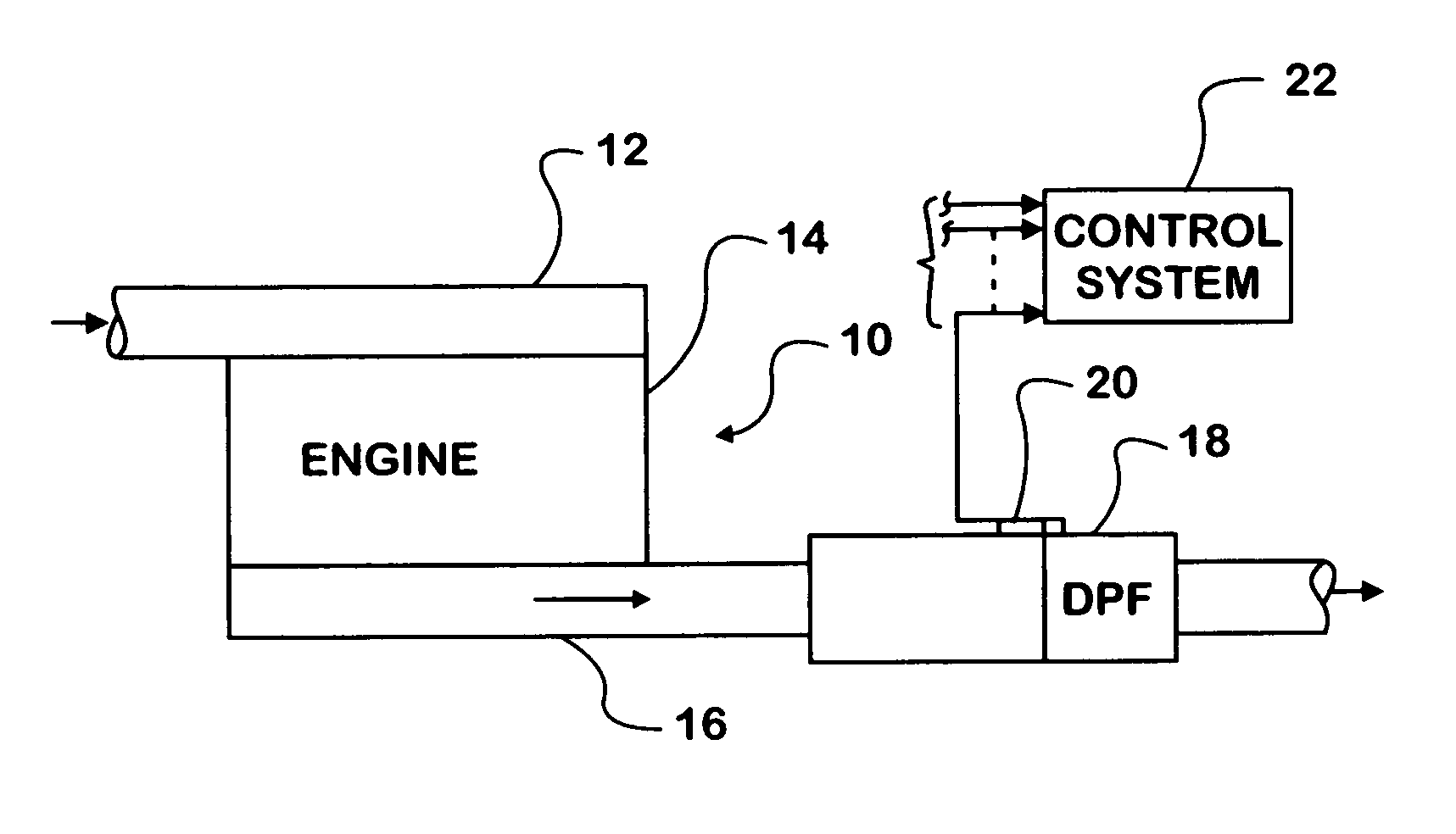

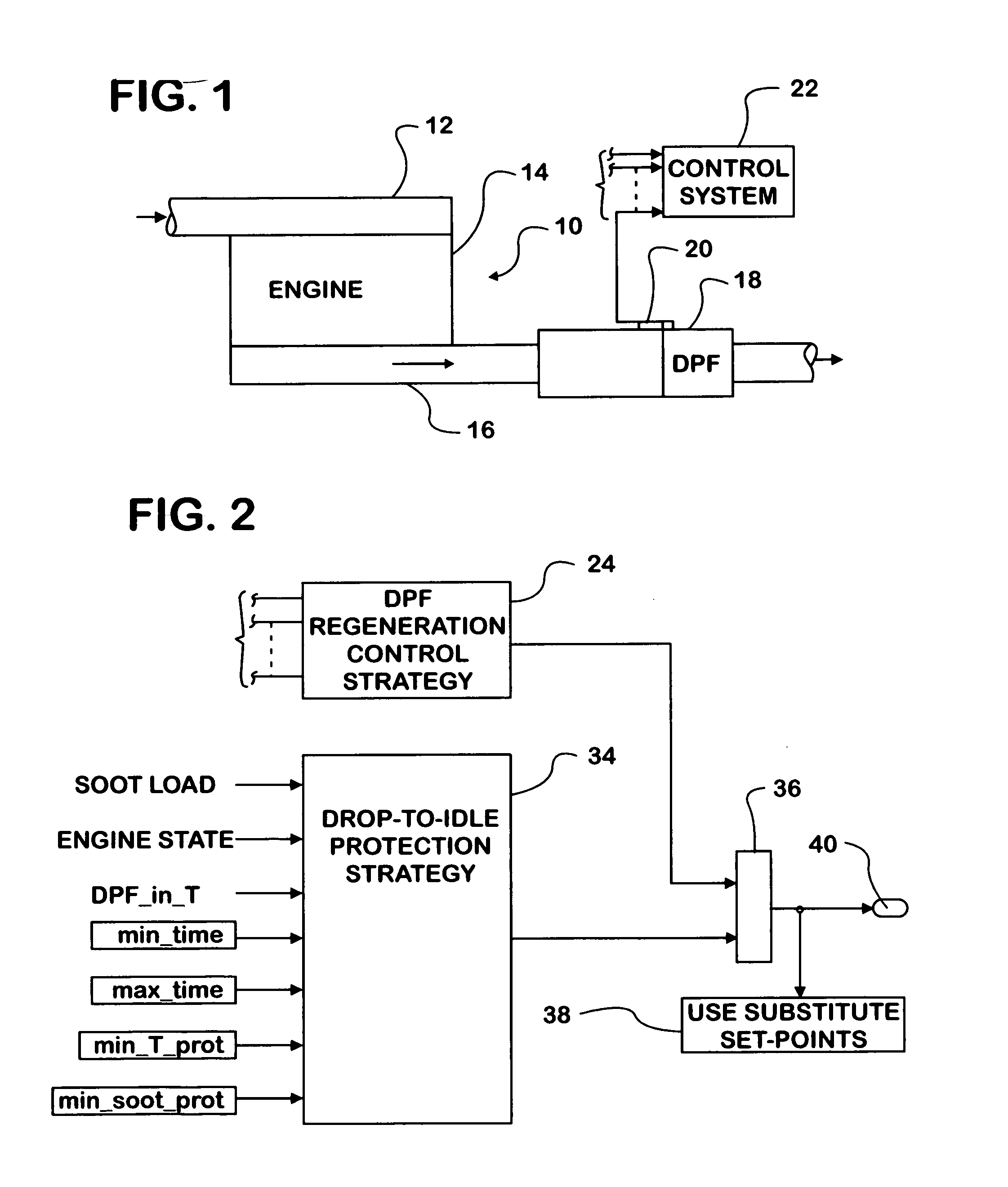

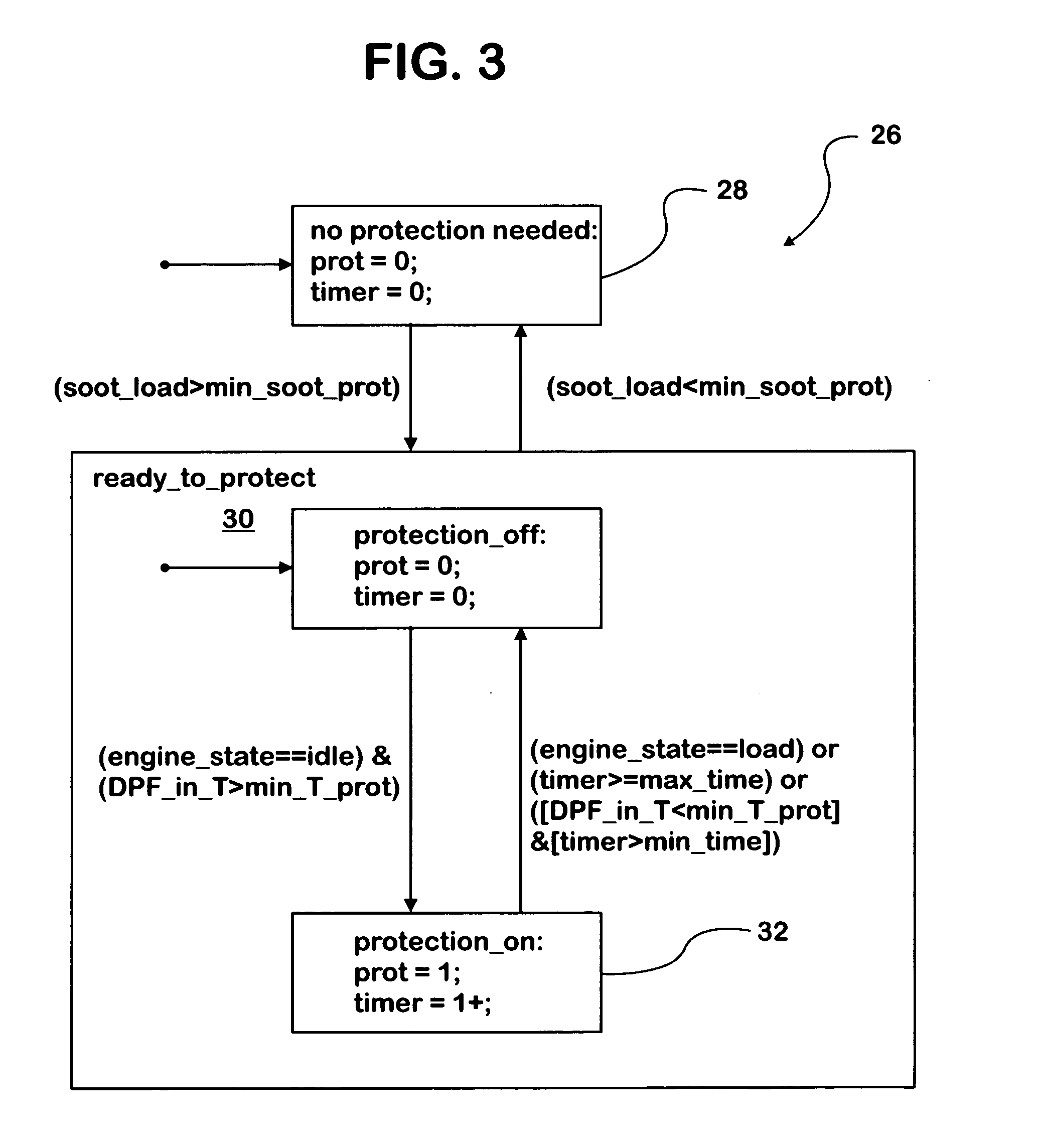

Controlling engine operation during diesel particulate filter regeneration to avoid runaway

InactiveUS20070193258A1Increase oxygen concentrationIncrease temperatureInternal combustion piston enginesExhaust apparatusControl systemIdle speed

A motor vehicle diesel engine (10) has an exhaust system (16) having a diesel particulate filter (18) that traps particulate matter in engine exhaust gases passing through the exhaust system. A control system (22) processes certain data to control engine and diesel particulate filter operation. In response to driver release of the accelerator, the engine decelerates toward idling at a lower low idle speed that has been predetermined appropriate for low idling when the diesel particulate filter is not being regenerated but inappropriate when the diesel particulate filter is being regenerated because of the potential for causing on-going regeneration to become uncontrolled. When the diesel particulate filter is being regenerated, a higher low idle speed sufficiently higher than the lower low idle speed is substituted as the low idle speed set-point essentially eliminating the potential for continuation of on-going diesel particulate filter regeneration becoming uncontrolled as the engine idles.

Owner:INT ENGINE INTPROP CO LLC

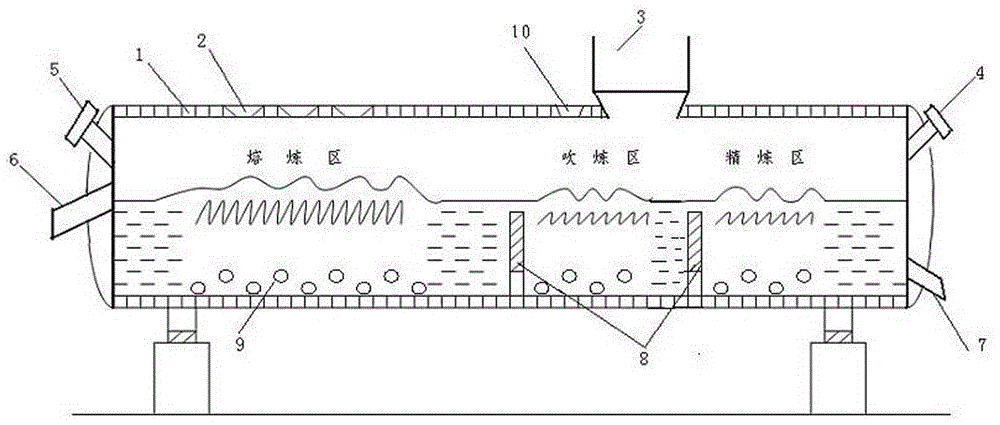

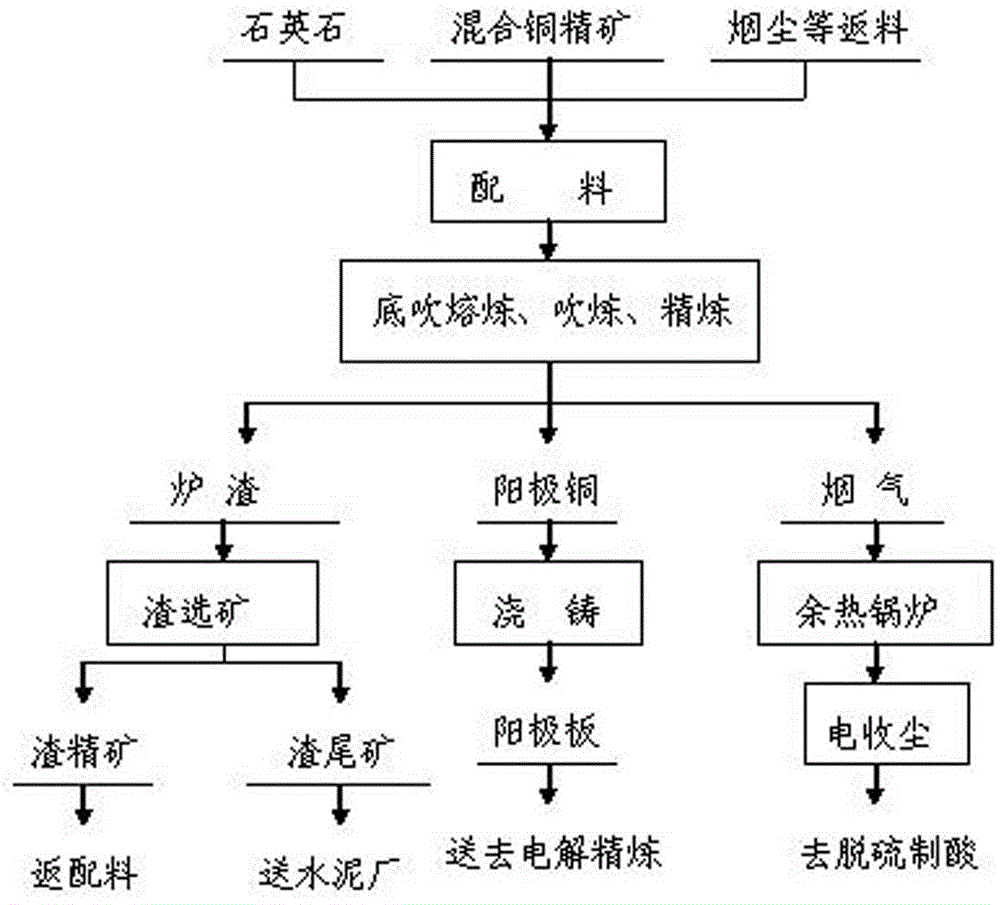

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

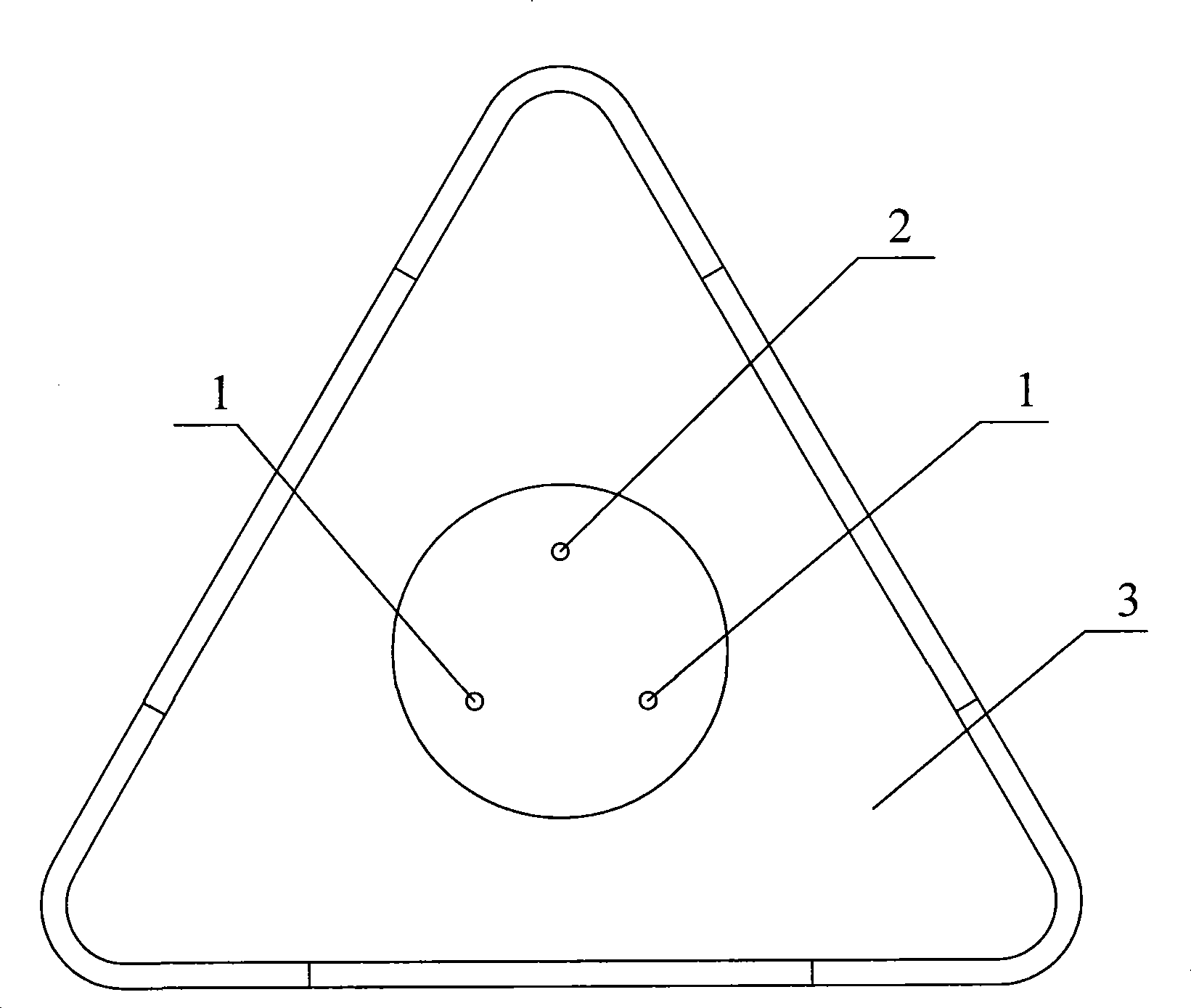

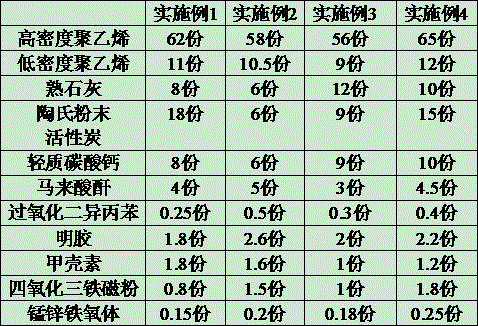

Hydrophilic carrier for microbial biofilm formation

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

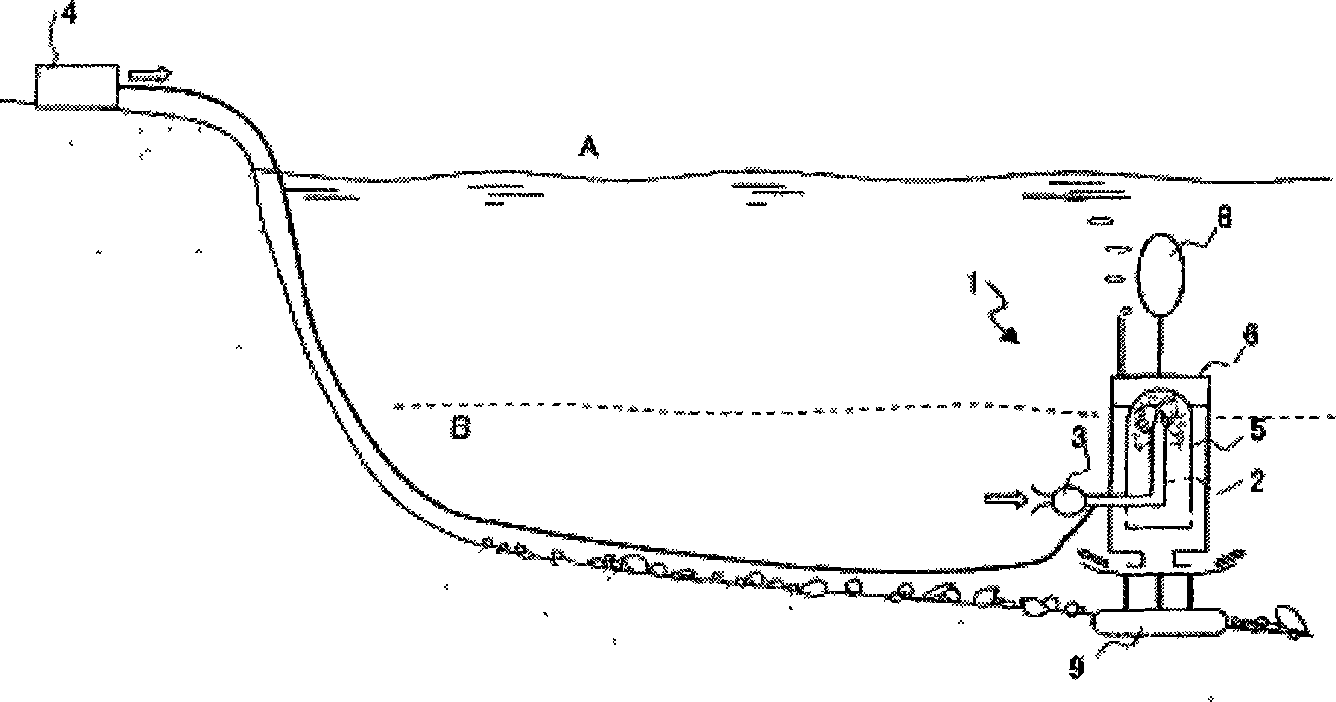

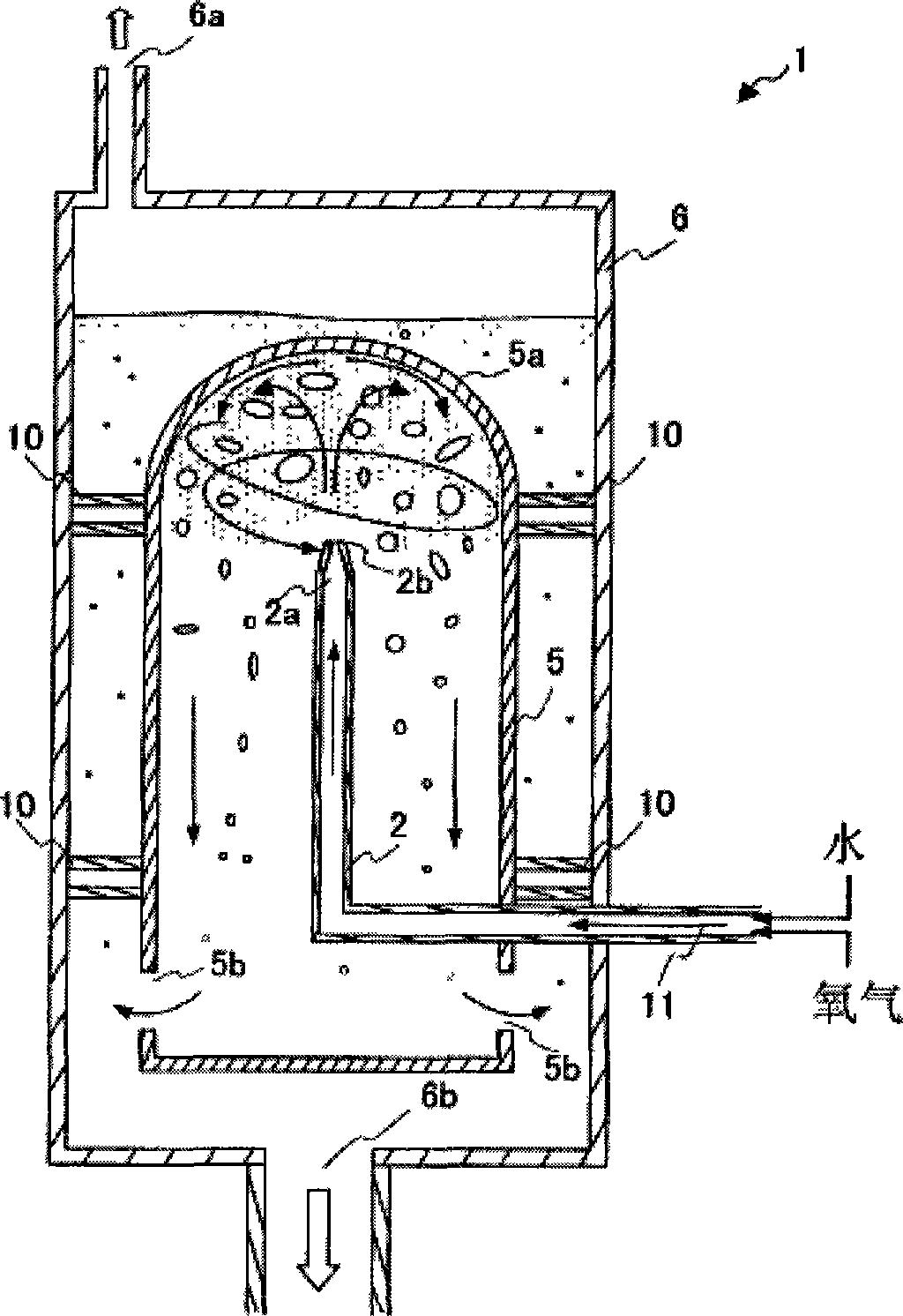

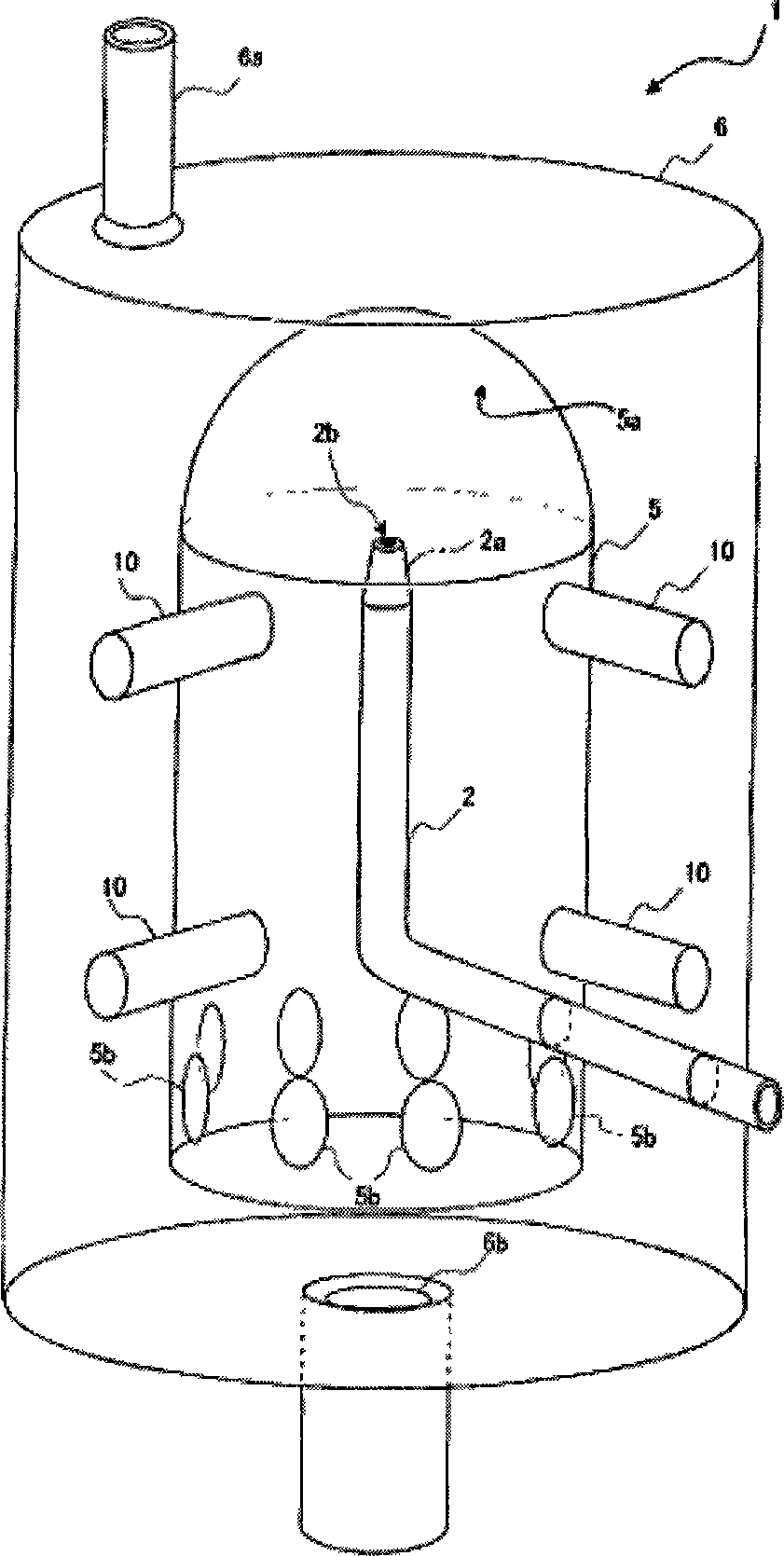

Gas-liquid dissolution apparatus

ActiveCN1914123ASimple structureIncrease contact areaTreatment using aerobic processesFlow mixersMomentumProduct gas

The invention relates to a gas-liquid dissolution apparatus that is capable of dissolving an oxygenic gas in water introduced from an oxygen-poor water zone to thereby increase the concentration of dissolved oxygen and feeding back the resultant water to the water zone. There is provided a gas-liquid dissolution apparatus including pump (3) for introducing water from an oxygen-poor water zone; oxygen supply unit (4) for supplying an oxygenic gas; gas-liquid dissolution chamber (5) of tubular form longer than is wide, the chamber (5) furnished at its lower part with at least one hole (5b) and furnished at its upper part with dome-shaped top board (5a); nozzle (2) with its distal end internal part tapered, which nozzle jets the gas from the oxygen supply unit (4) and the water from the pump (3) upward so as to collide with the internal wall of the top board (5a) of the gas-liquid dissolution chamber (5), thereby attaining vigorous agitation of gas and water by the momentum of the jet; gas-liquid separation chamber (6) which communicates through the hole (5b) with the gas-liquid dissolution chamber (5) so that the bubbles and water outflowing through the hole (5b) from the gas-liquid dissolution chamber (5) are stocked and separated from each other; and water delivery port (6b) for feeding back the water separated from bubbles toward the oxygen-poor water zone.

Owner:MATSUE DOKEN +1

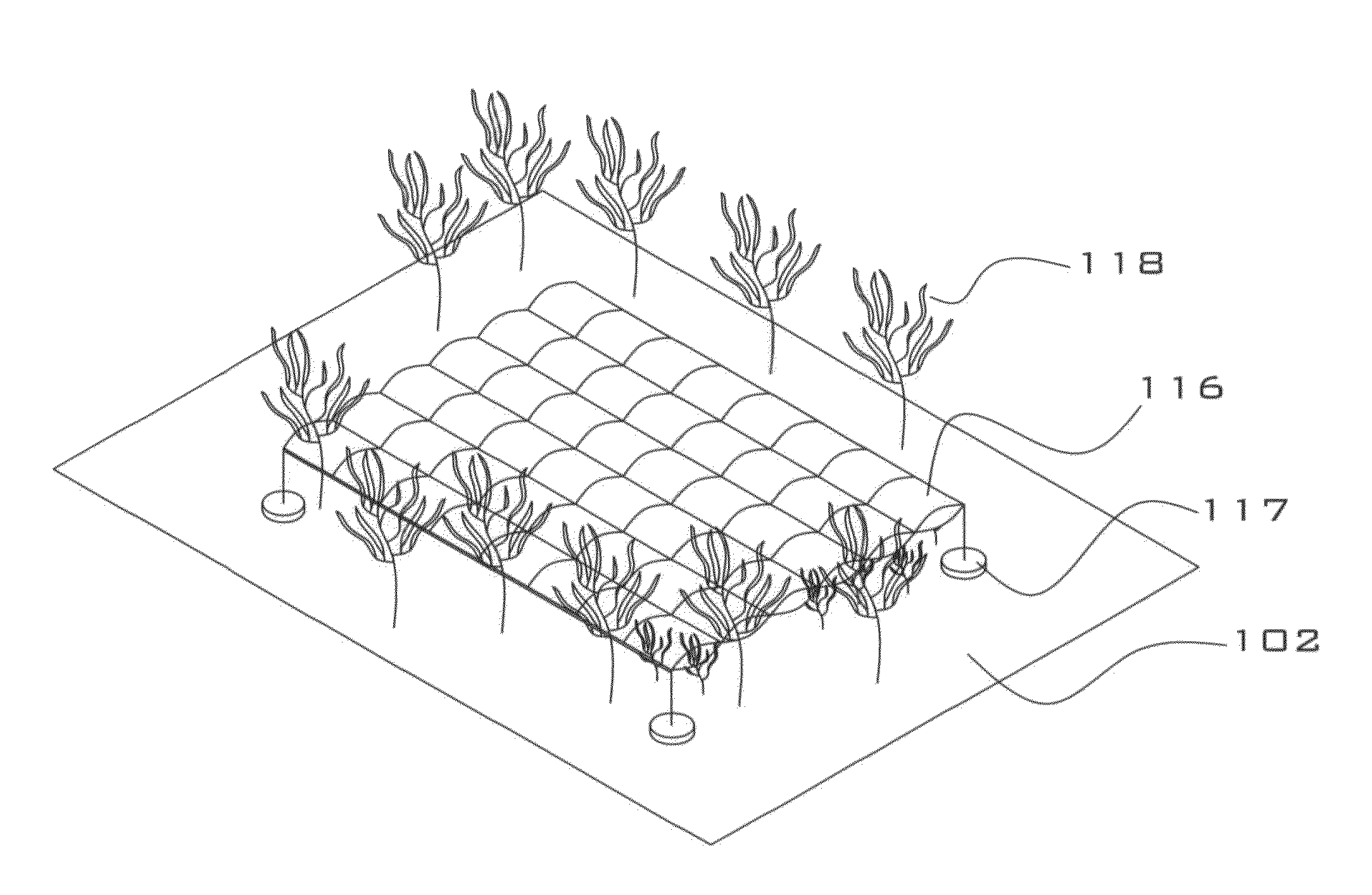

Low-cost microbial habitat for water quality enhancement and wave mitigation

InactiveUS20130125825A1Improve stabilityAvoid excessive massClimate change adaptationPisciculture and aquariaFiberWater quality

A simulated coral reef comprising a polymer matrix body comprised of sheets of permeable and porous nonwoven polymer fiber matting, outwardly extending deployment connectors, and anchor connectors that connect the matrix body to an anchor assembly. A simulated coral reef comprising pieces of polymer matrix and / or permeable bag units strung together vertically by a connecting rod attached to an anchor assembly. A simulated coral reef comprising pieces of polymer matrix, permeable bag units, and surface attachment structures in which the pieces of polymer matrix and permeable bag units are attached to the surface attachment structures by a connecting cable. A simulated coral reef comprising a weed blanket fully submerged in a water body and suspended over the bottom of the water body. A simulated coral reef comprising hanging curtains suspended from asurface attachment structure. A simulated coral reef comprising sheets of permeable polymer matrix attached to a rigid metal frame.

Owner:FOUNTAINHEAD

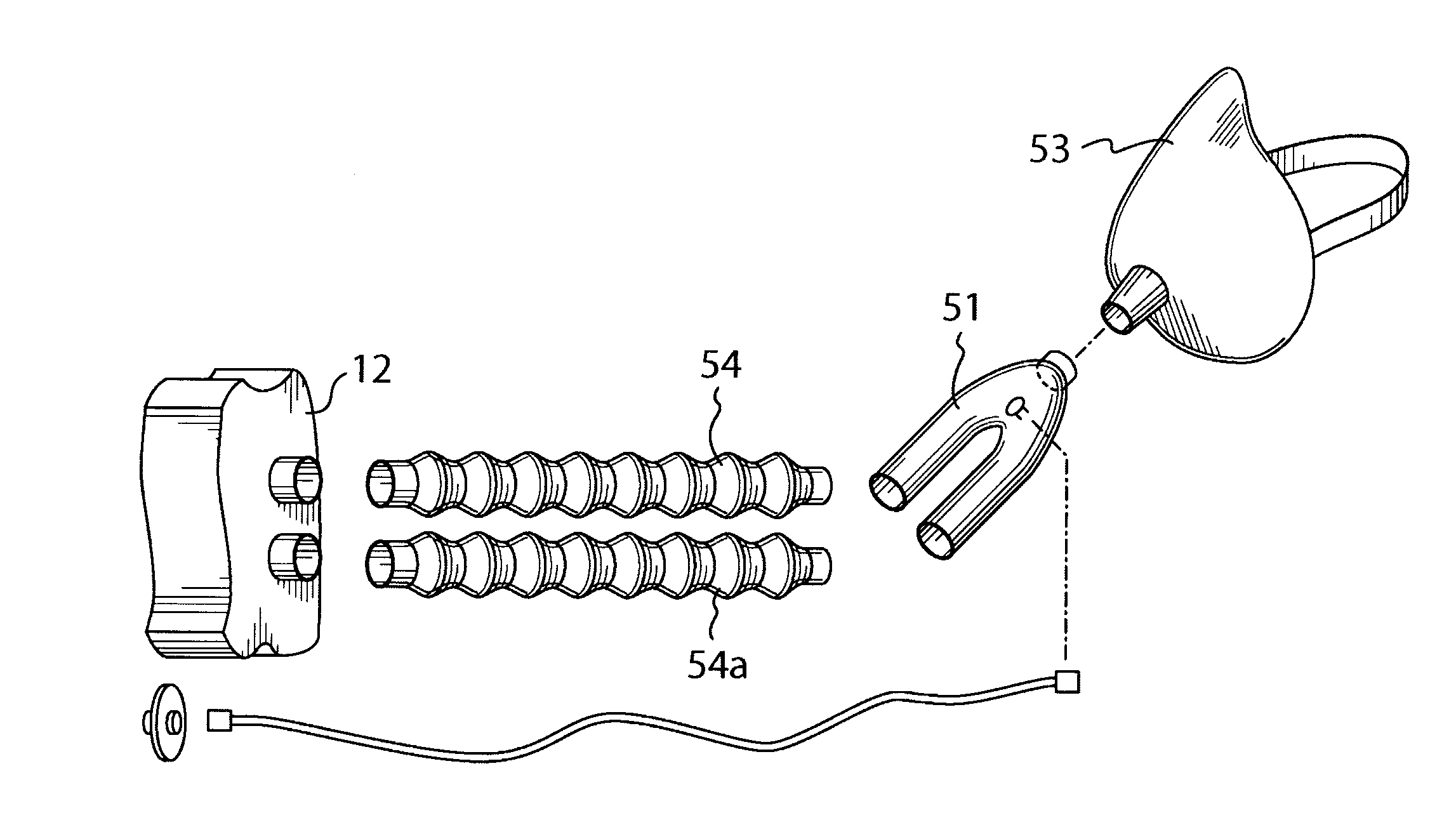

Oxygen mask adaptable for upper gastrointestinal (UGI) endoscopy procedures providing enhanced oxygen concentration to maintain patient oxygenation

InactiveUS20140243600A1Increase oxygen concentrationMaintain oxygenationGastroscopesOesophagoscopesUpper gastrointestinalOxygen mask

An oxygen mask adaptable for upper gastrointestinal (UGI) endoscopy procedures providing enhanced oxygen concentration to maintain patient oxygenation. An oxygen mask in accordance with the present invention provides an aperture of sufficient dimensions to enable substantially unimpeded placement and manipulation of an endoscope during an endoscopic procedure while an overlying closure is in an open position and yet may also be closed to cover the aperture when the procedure is not being performed.

Owner:EISENBERGER MICHELLE

Combination of disinfectors and its applications used in aquiculture

InactiveCN1430896AInhibits and hinders synthesisStunted growthBiocideAnimal repellantsDisinfectantAdhesive

A composite disinfectant for culturing aquatic products contains potassium (or sodium) perferrite, excipient, and / or pH regulator, stabilizer, adhesive, talc powder and magnesium stearate. Its advantages are high effect on disinfecting, enriching oxygen in water, and removing heavy metals, organic substances and harmful suspended substances, and no poison.

Owner:王永东

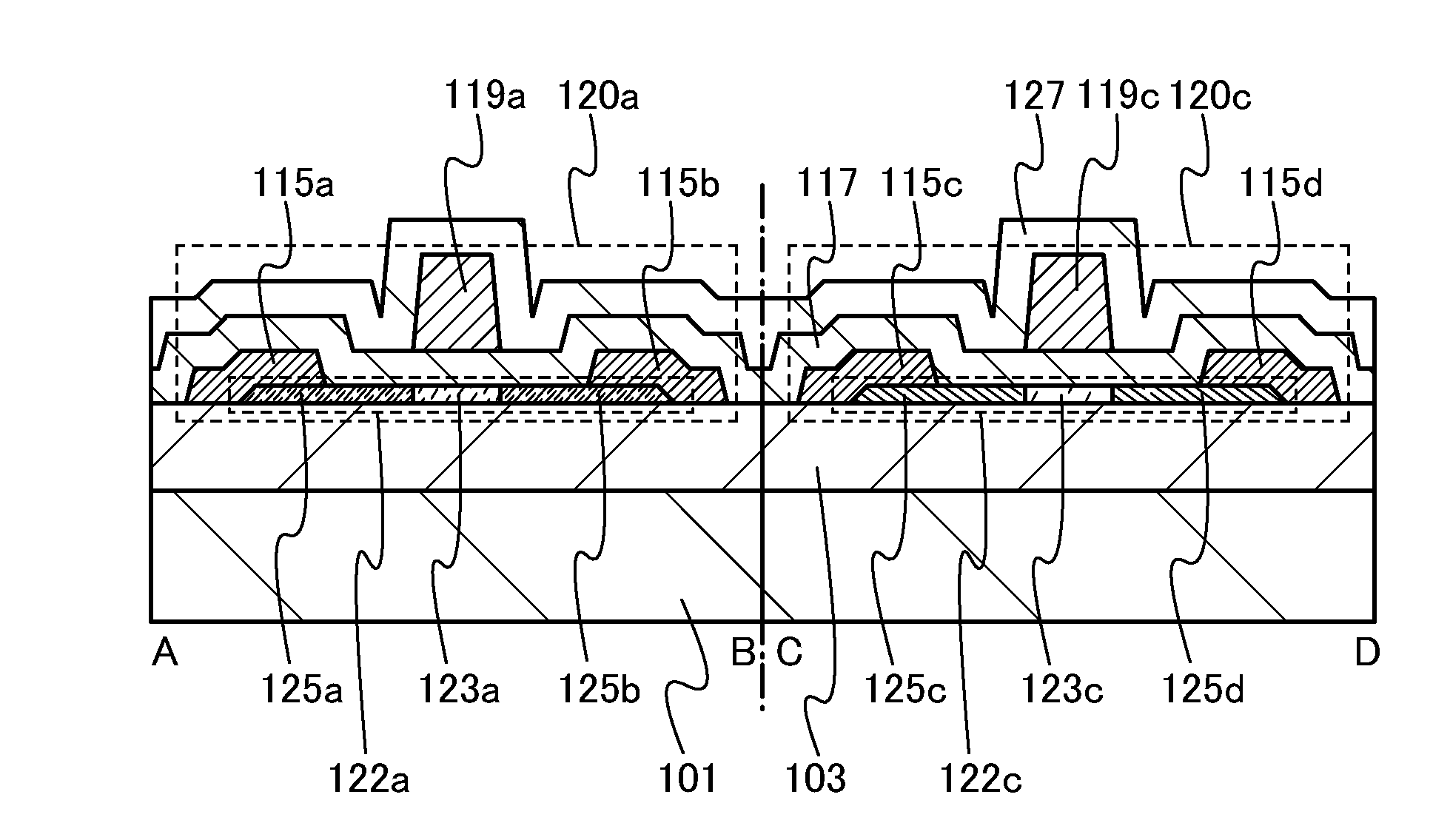

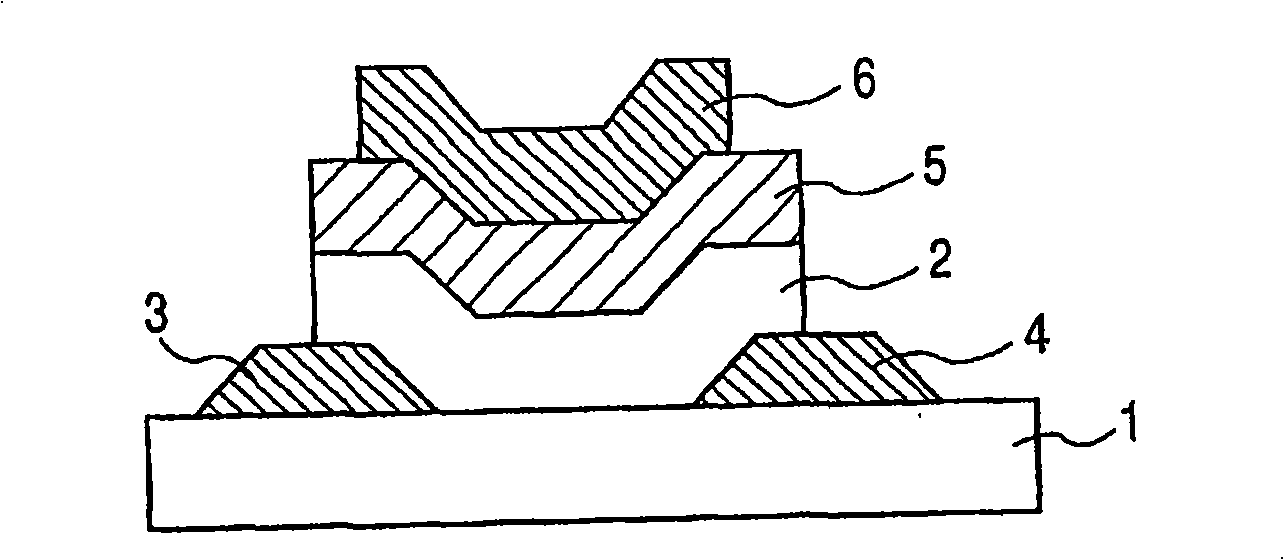

Thin-film transistor and display device oxide semiconductor and gate dielectric having an oxygen concentration gradient

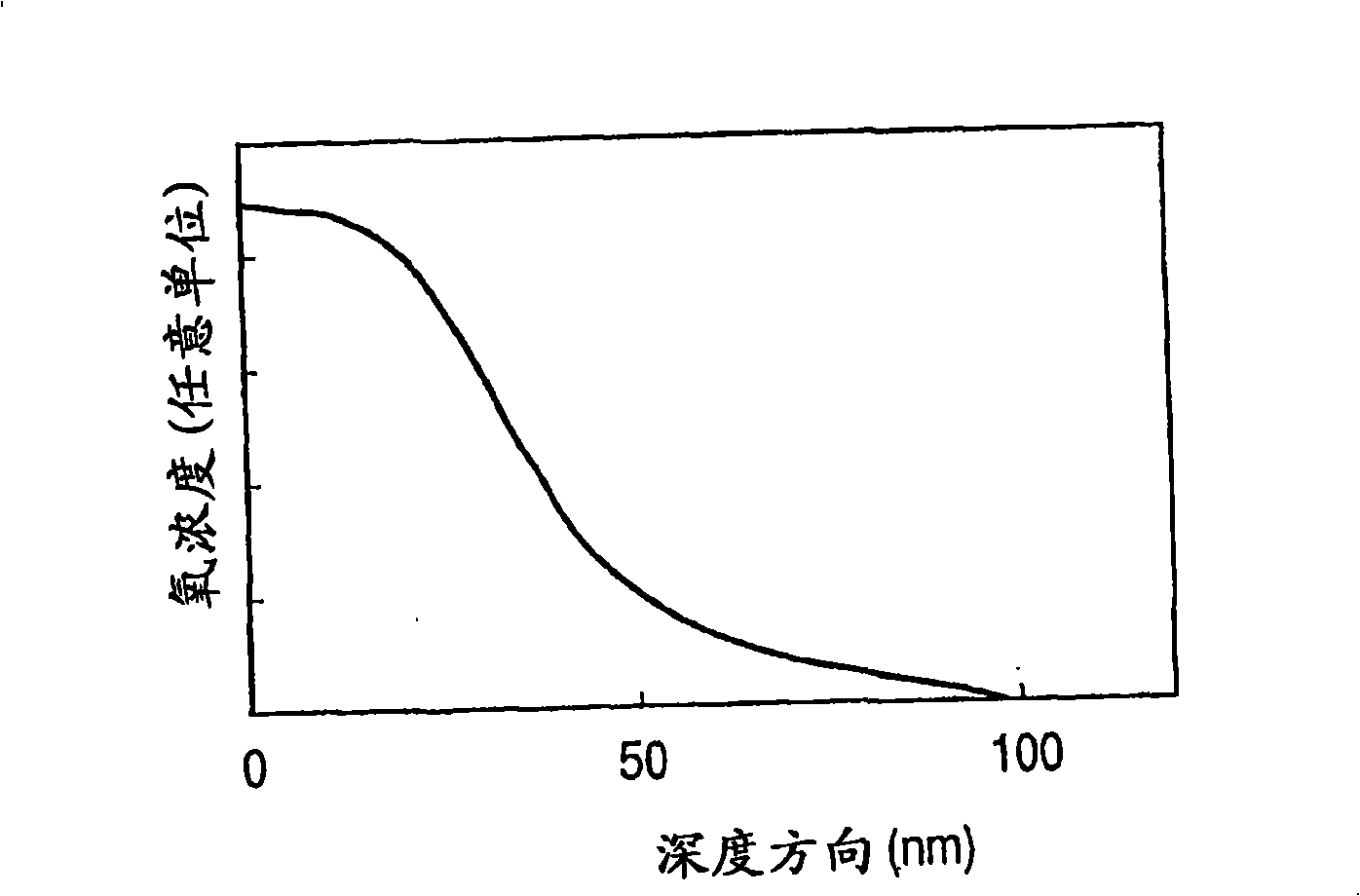

InactiveCN101405869AIncrease oxygen concentrationReduce oxygen concentrationTransistorSemiconductor/solid-state device manufacturingDielectricGate dielectric

The thin-film transistor of the present invention has at least a semiconductor layer including: on a substrate, a source electrode, a drain electrode, and a channel region; a gate insulating film; and a gate electrode, wherein the semiconductor layer is an oxide semiconductor layer, and wherein the gate insulating film is amorphous silicon including at least O and N, and the gate insulating film has a distribution of an oxygen concentration in a thickness direction so that the oxygen concentration is high in the side of an interface with an oxide semiconductor layer and the oxygen concentration decreases toward the side of the gate electrode.

Owner:CANON KK

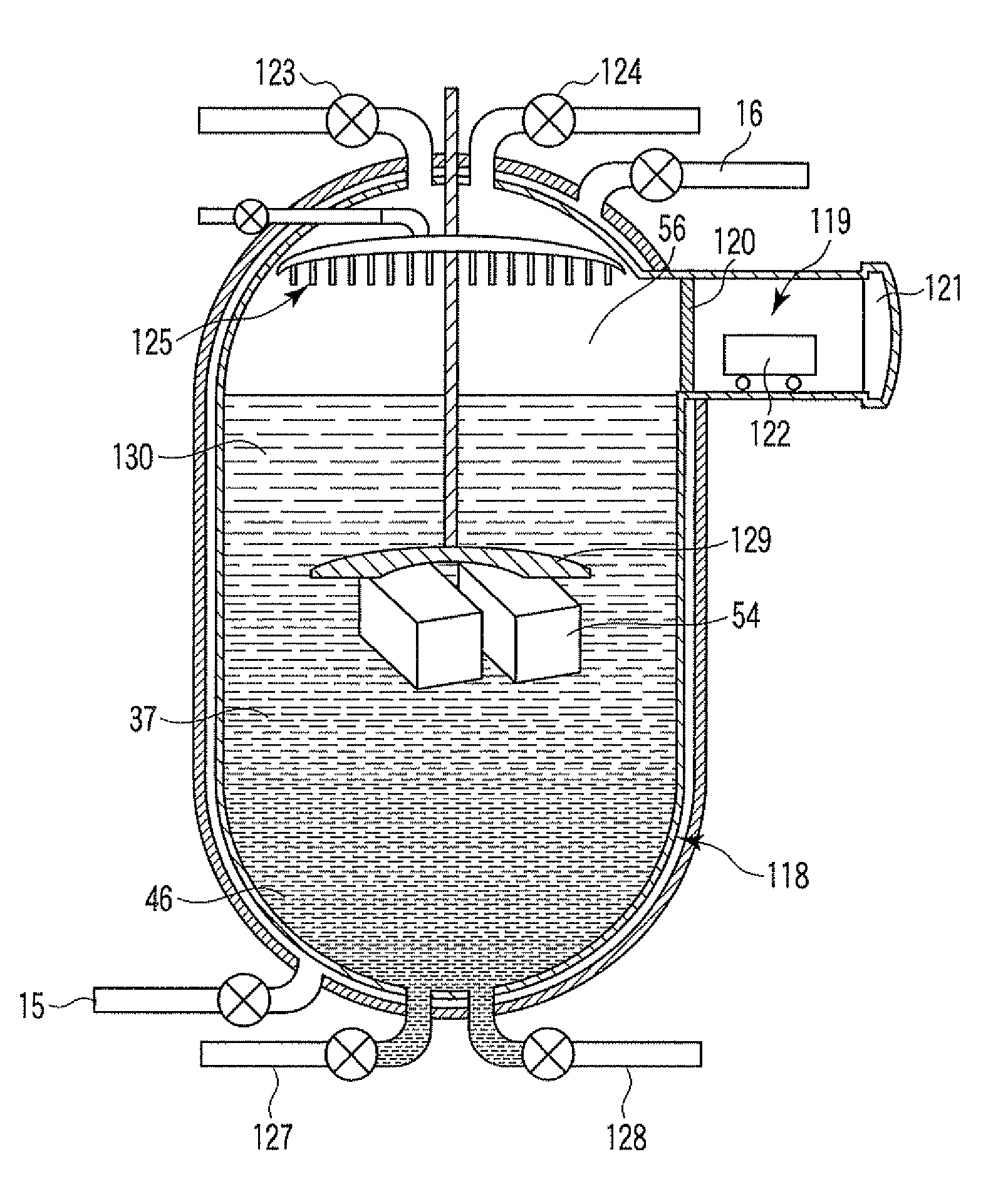

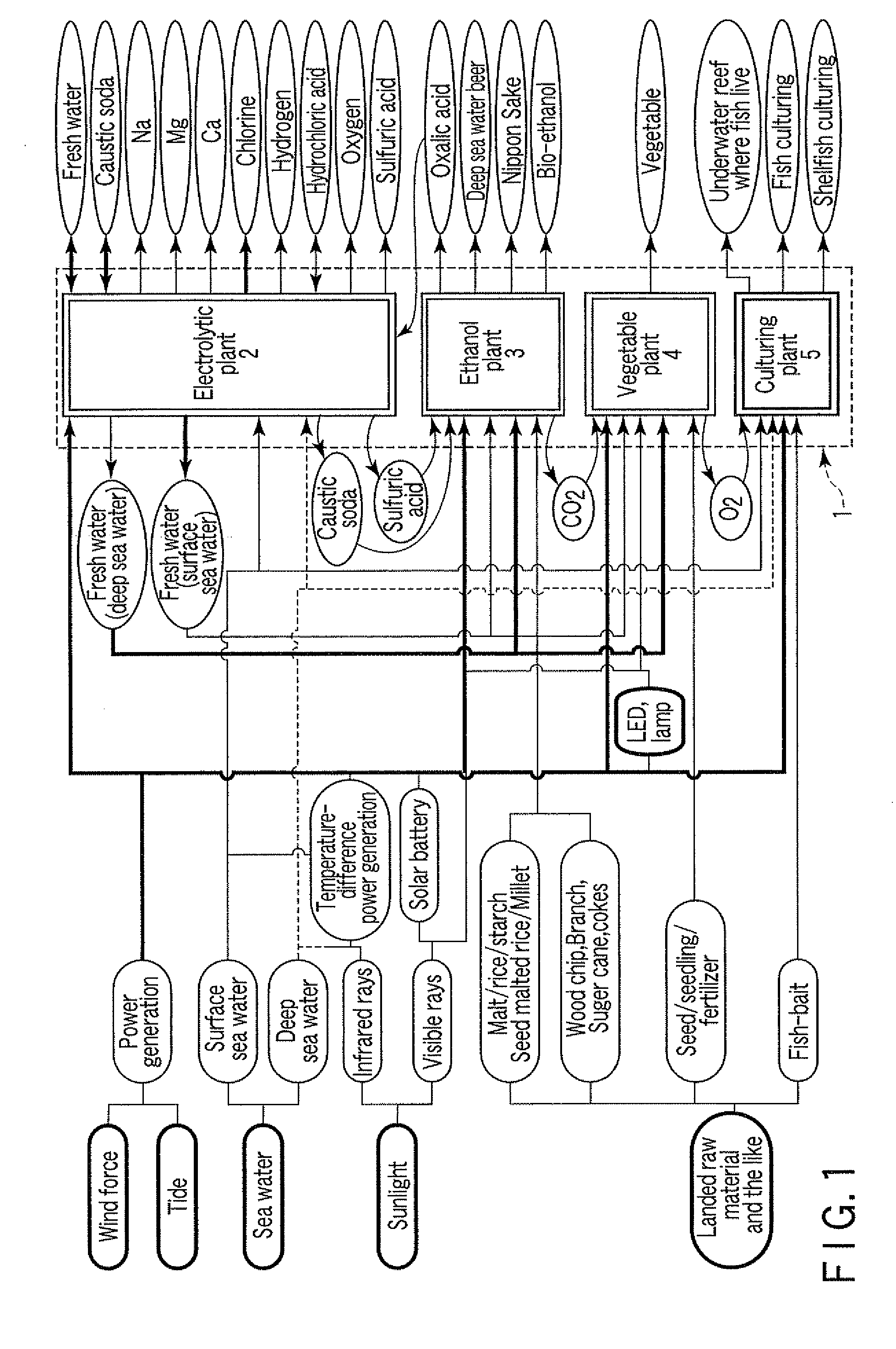

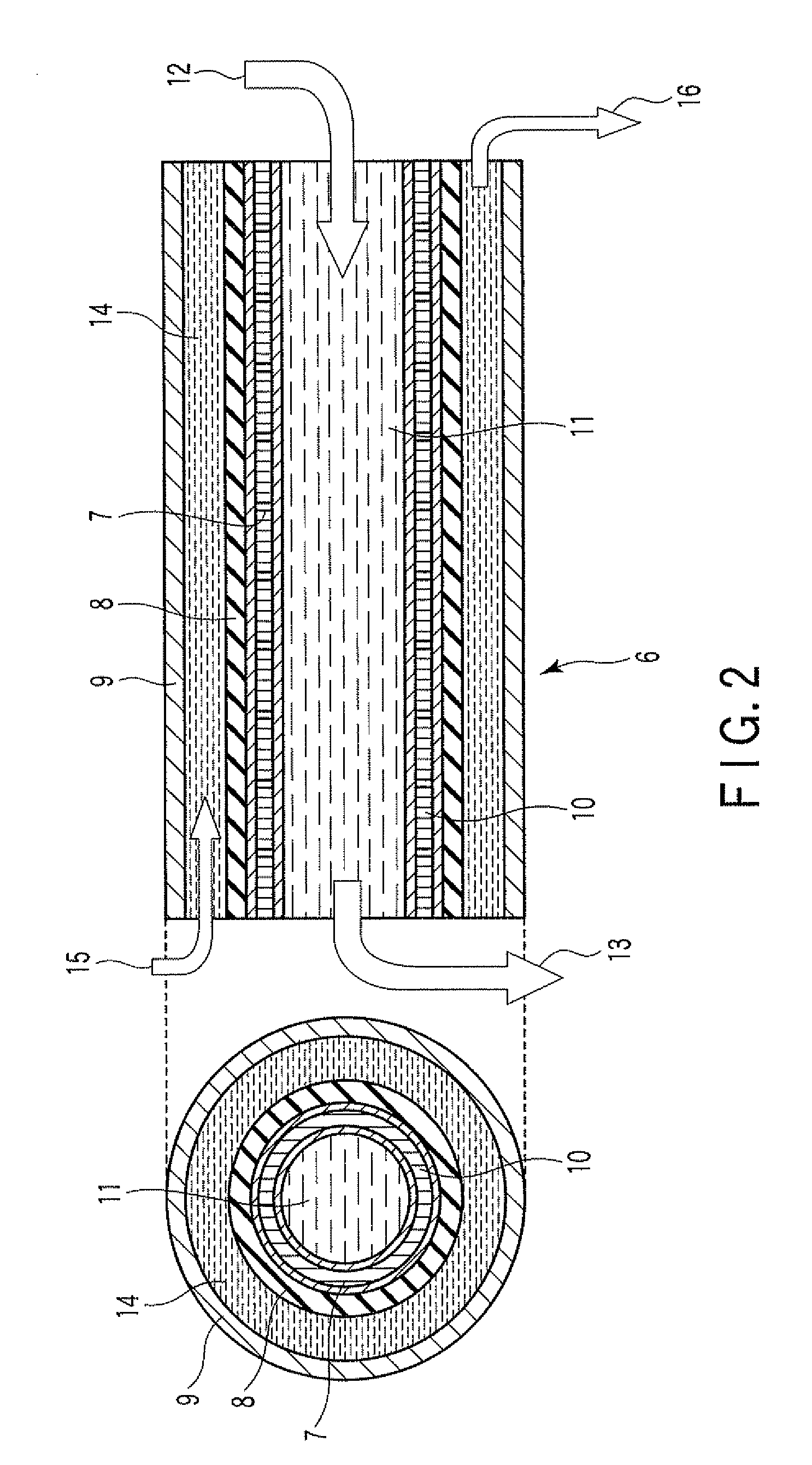

Onsite integrated production factory

ActiveUS20100051450A1Low costDemand is substantialSolar heating energyElectrolysis componentsFresh water organismPotassium

Using electric power obtained by marine wind force and a tide, sea water is electrolyzed to produce fresh water, sodium, magnesium, calcium, potassium, caustic soda, chlorine, hydrochloric acid, sulfuric acid, hydrogen, oxygen or the like, at the same time, unloaded malts, saw dust and the like are fermented to brew ethanol, carbon dioxide generated here is used for photosynthesis to culture vegetables and oxygen generated here is supplied to a fish preserve and an under reef where fish live to culture fishes and also returned to sea water dropped in the concentration of oxygen to suppress the generation of a red tide.

Owner:M HIKARI & ENERGY LAB

Nonaqueous electrolyte secondary battery

ActiveUS20080241702A1Satisfactory performanceSatisfactory retentionOrganic electrolyte cellsNon-conductive material with dispersed conductive materialGlutaric anhydridePhysical chemistry

In a nonaqueous electrolyte secondary battery according to an embodiment of the invention, a nonaqueous electrolyte contains: a tertiary carboxylate ester represented by the following general formula (1) in an amount of a range of 3% by mass or more and 80% by mass or less based on the total mass of the nonaqueous solvent:where R1, R2, R3, R4 represent a (C1 to 4) alkyl group, respectively, and one or more acid anhydride selected from succinic anhydride, glutaric anhydride, and glycolic anhydride in an amount of a range of 0.1% by mass or more and 5% by mass or less based on the total mass of the nonaqueous electrolyte. By containing such a constitution, in other words, by containing a nonaqueous solvent capable of stabilizing the coating film of the negative electrode, a nonaqueous electrolyte secondary battery in which not only can satisfactory cycle performance and retention characteristics be obtained, but also the overcharging performance is largely improved, can be provided.

Owner:PANASONIC ENERGY CO LTD

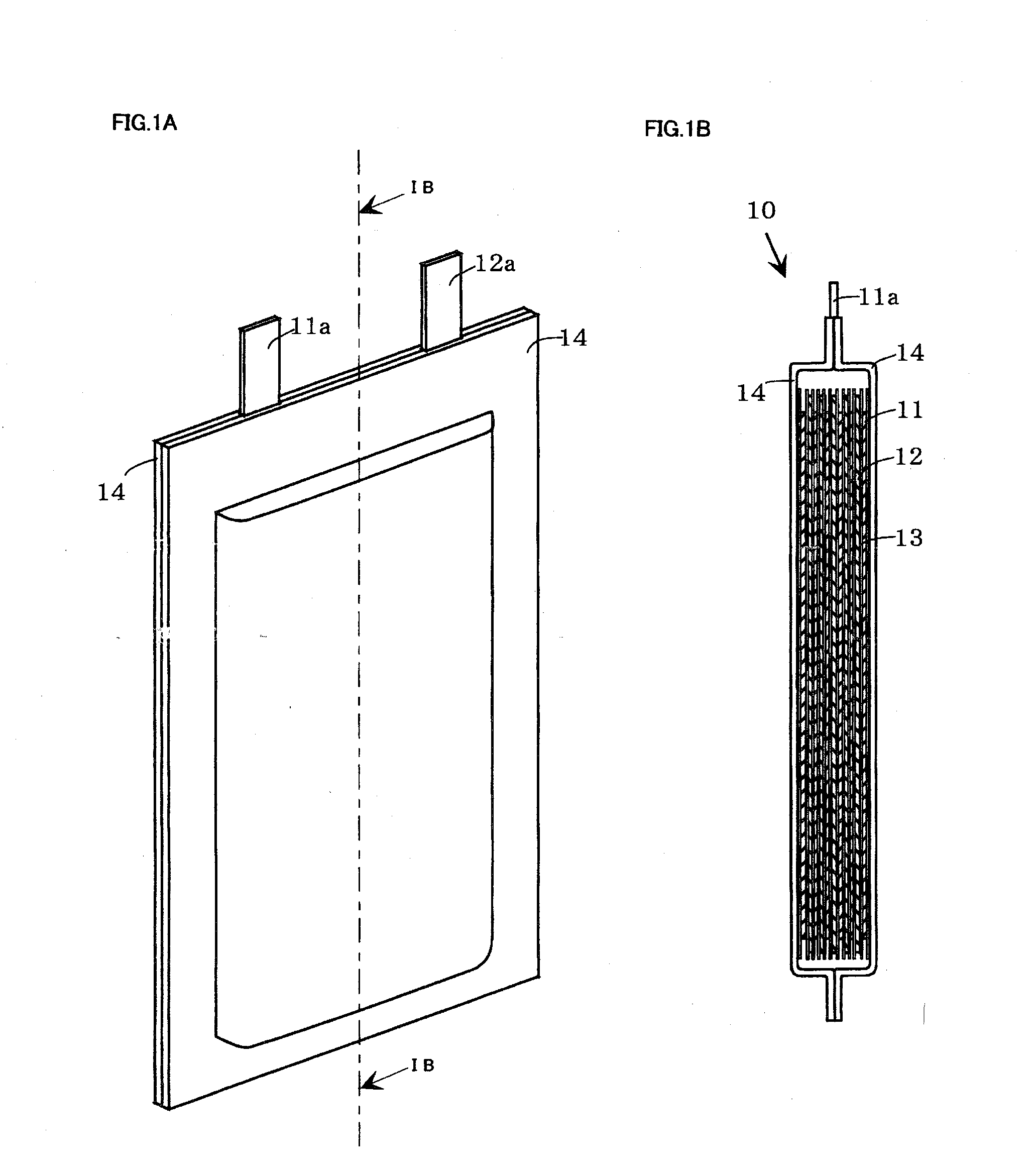

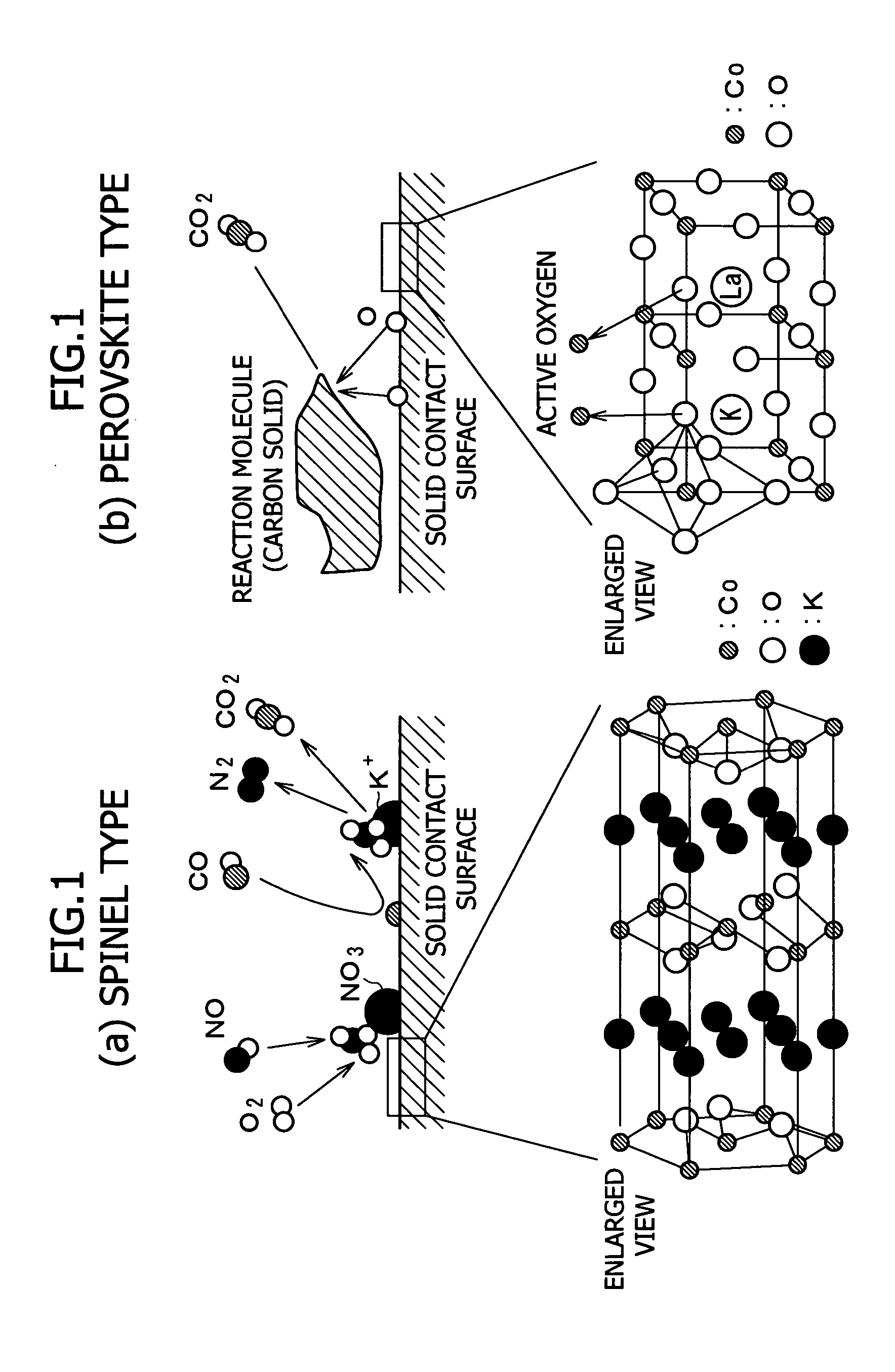

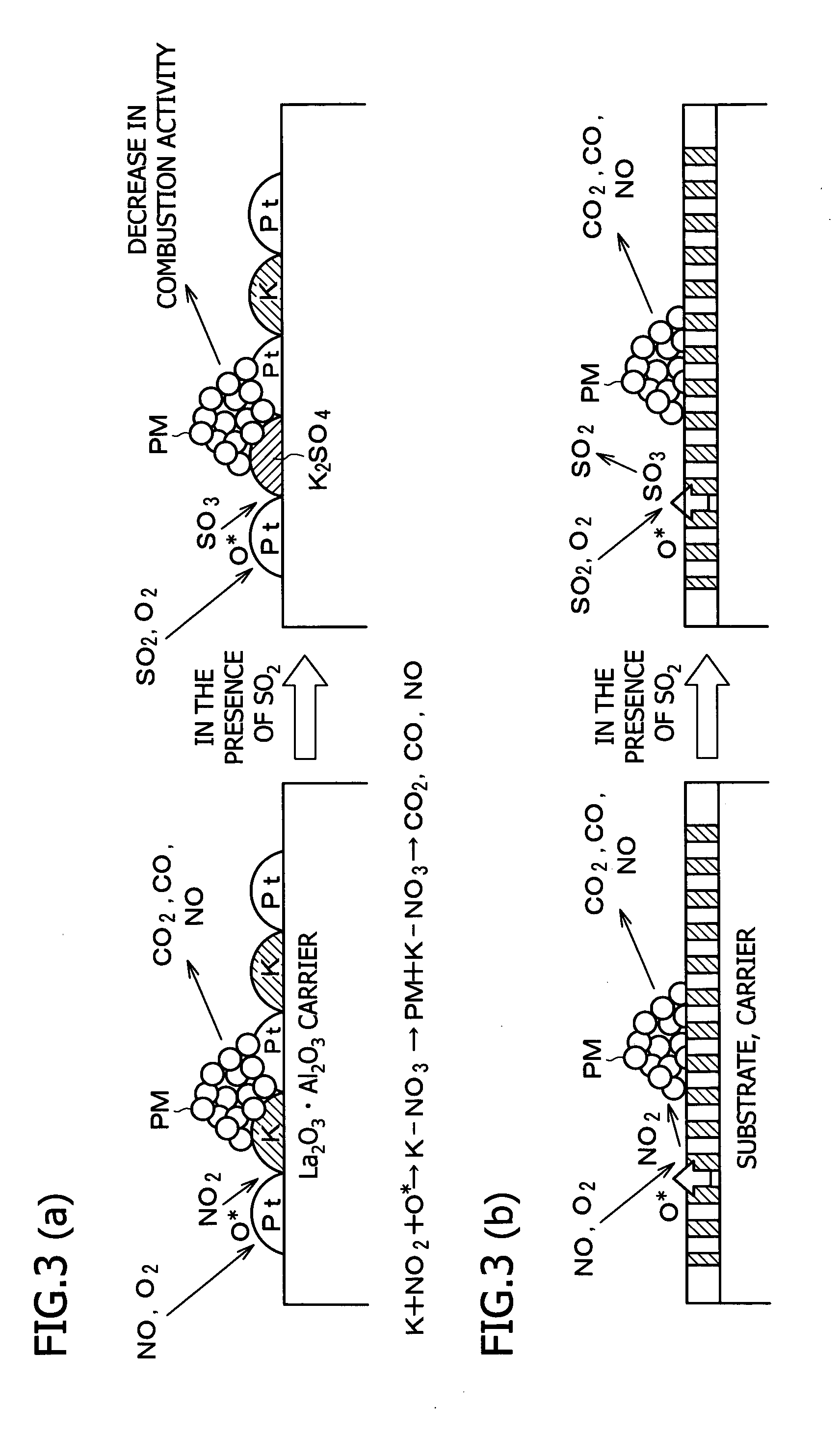

Exhaust gas treatment catalyst and exhaust gas treatment method

ActiveUS20050049143A1Efficient removalImprove anti-sulfur poisoning performanceFluid couplingsExhaust apparatusParticulatesAlkaline earth metal

The present invention provides an exhaust gas treatment catalyst characterized by containing a compound oxide expressed by the following general formula (1),AMxOy (1)(wherein A represents an alkali metal or alkaline earth metal, M represents Cr, Mn, Fe, Co or Ni, O represents oxygen, and 0<x≦4 and 0<y≦8) and an exhaust gas treatment method using the said catalyst. According to the present invention, there can be provided an exhaust gas treatment compound oxide that can effectively remove particulates and NOx contained in exhaust gas with a high oxygen concentration that is discharged from a diesel engine etc., and also has excellent resistance to sulfur poisoning.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

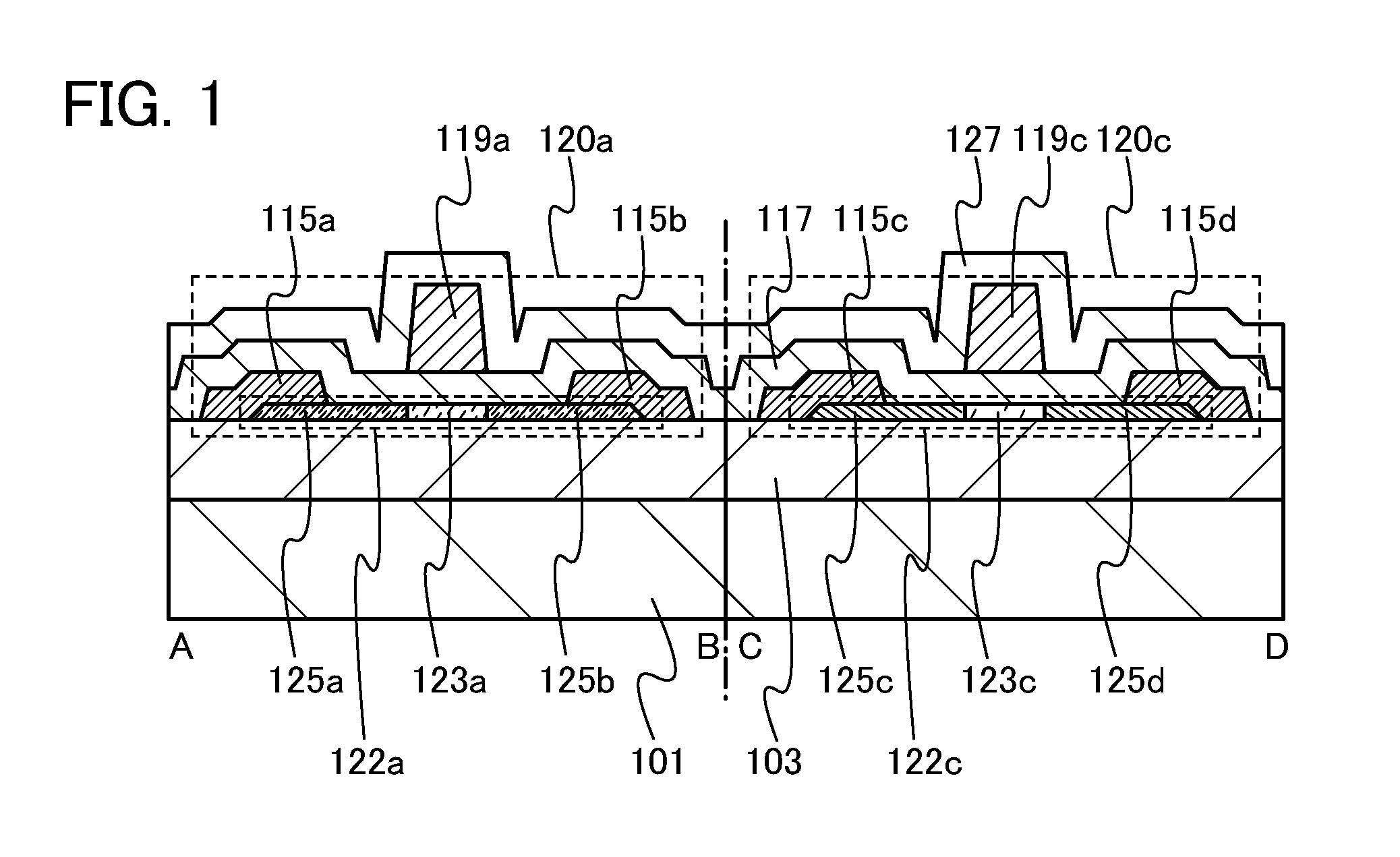

Semiconductor device

ActiveUS8643008B2Solve the large consumptionIncrease speedSolid-state devicesRadiation controlled devicesPower semiconductor devicePower flow

A semiconductor device which can operate at high speed and consumes a smaller amount of power is provided. In a semiconductor device including transistors each including an oxide semiconductor, the oxygen concentration of the oxide semiconductor film of the transistor having small current at negative gate voltage is different from that of the oxide semiconductor film of the transistor having high field-effect mobility and large on-state current. Typically, the oxygen concentration of the oxide semiconductor film of the transistor having high field-effect mobility and large on-state current is lower than that of the oxide semiconductor film of the transistor having small current at negative gate voltage.

Owner:SEMICON ENERGY LAB CO LTD

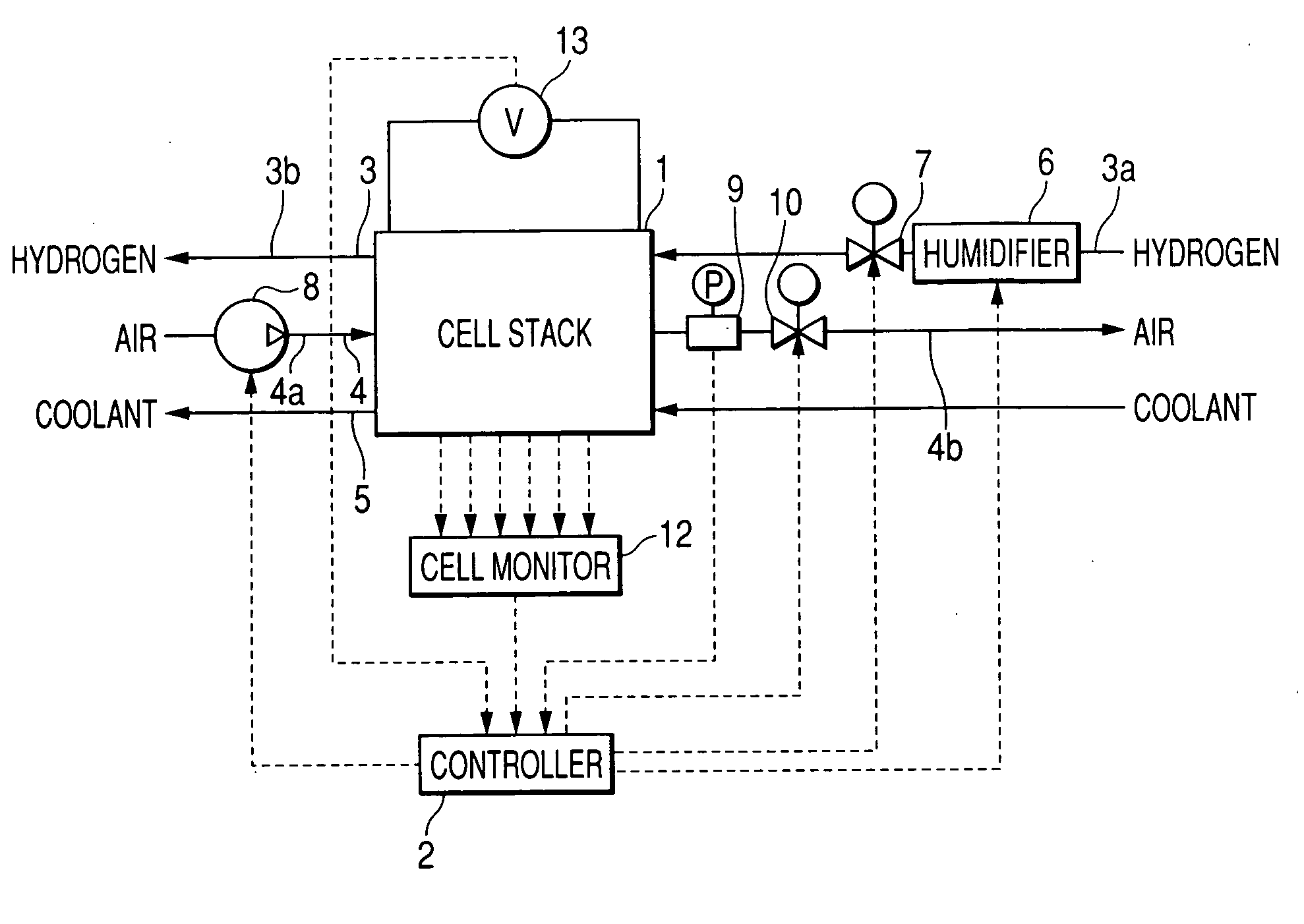

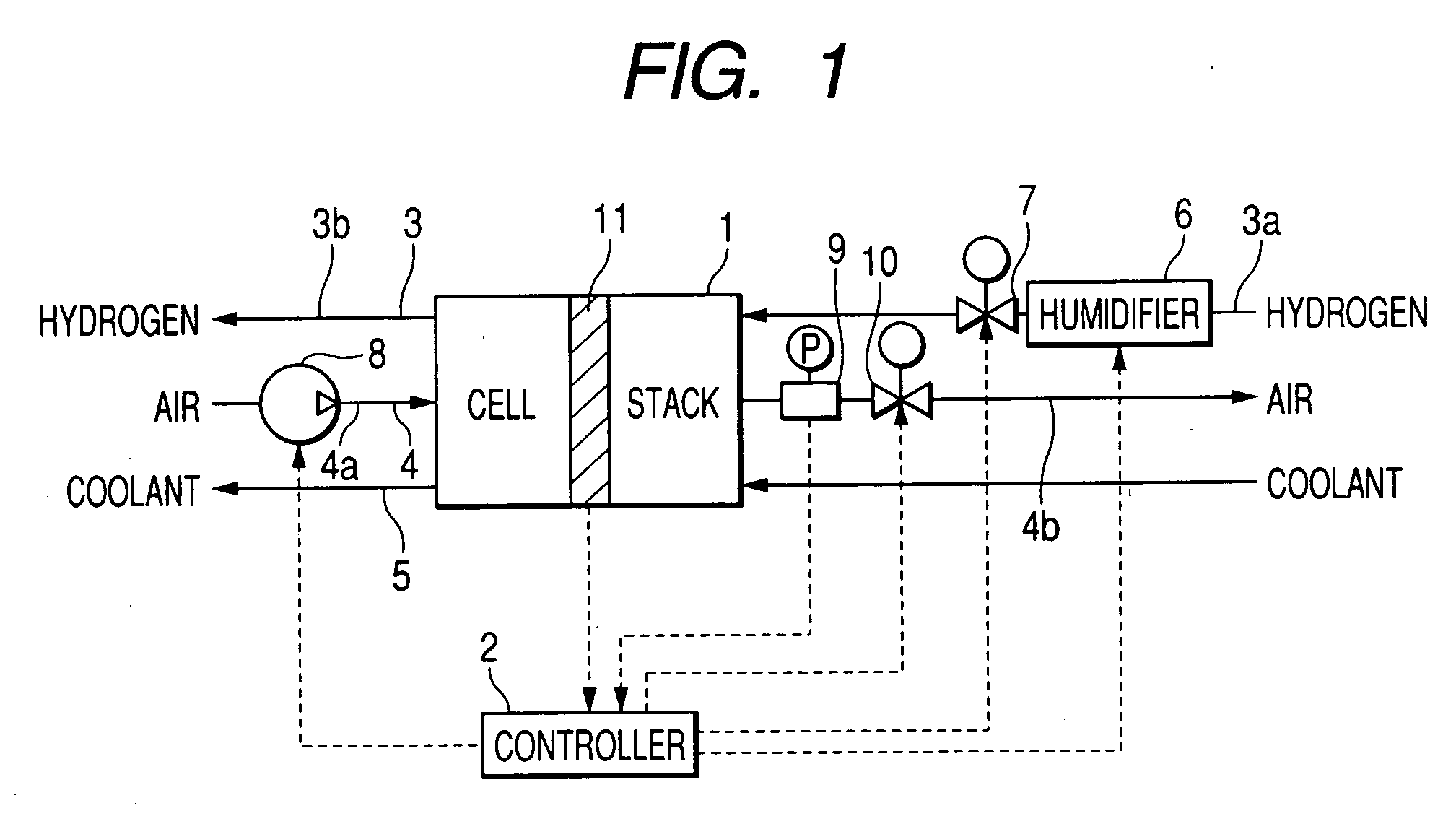

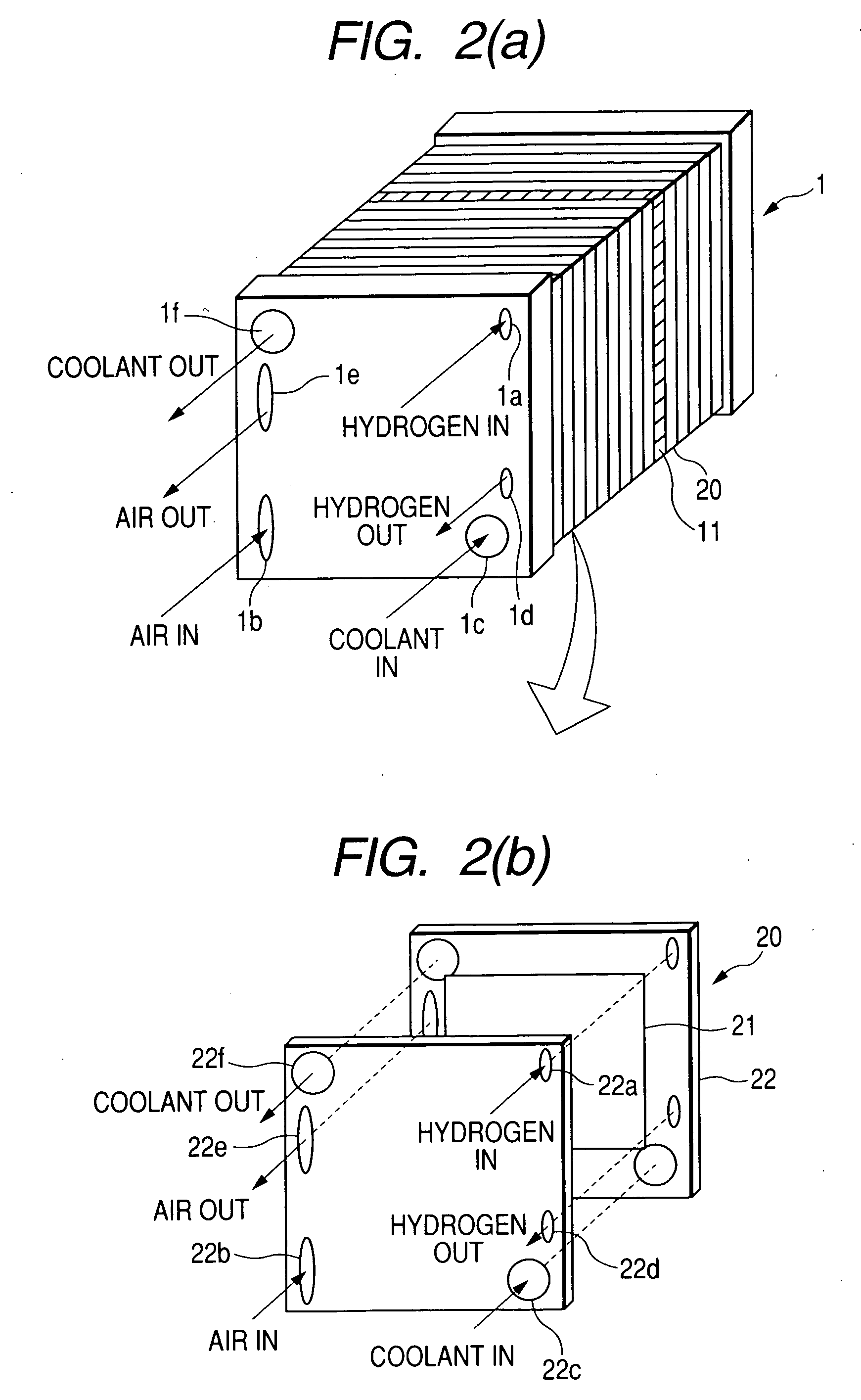

Fuel cell system ensuring stability of operation

InactiveUS20060166058A1Increase oxygen concentrationReduce the amount of water vaporFuel cells groupingFinal product manufactureFuel cellsSystems design

A fuel cell system designed to supply non- or low-humidified air to a fuel cell stack and ensure the stability of operation thereof. The system works to monitor operating conditions of the fuel cell stack and determine whether electrolyte films of fuel cells are getting dried or not or whether an undesirable quantity of water has been produced on the side of air electrodes of the cells or not. When either condition is true, the system works to elevate the pressure of air in an air drain line of the fuel cell stack to enhance the production of water in the cells to keep the electrolyte films or-to transfer the water from the air electrodes to the fuel electrodes of the cells to keep the electrolyte films in a desired wet condition, thereby ensuring the stability of operation of the fuel cell stack.

Owner:DENSO CORP

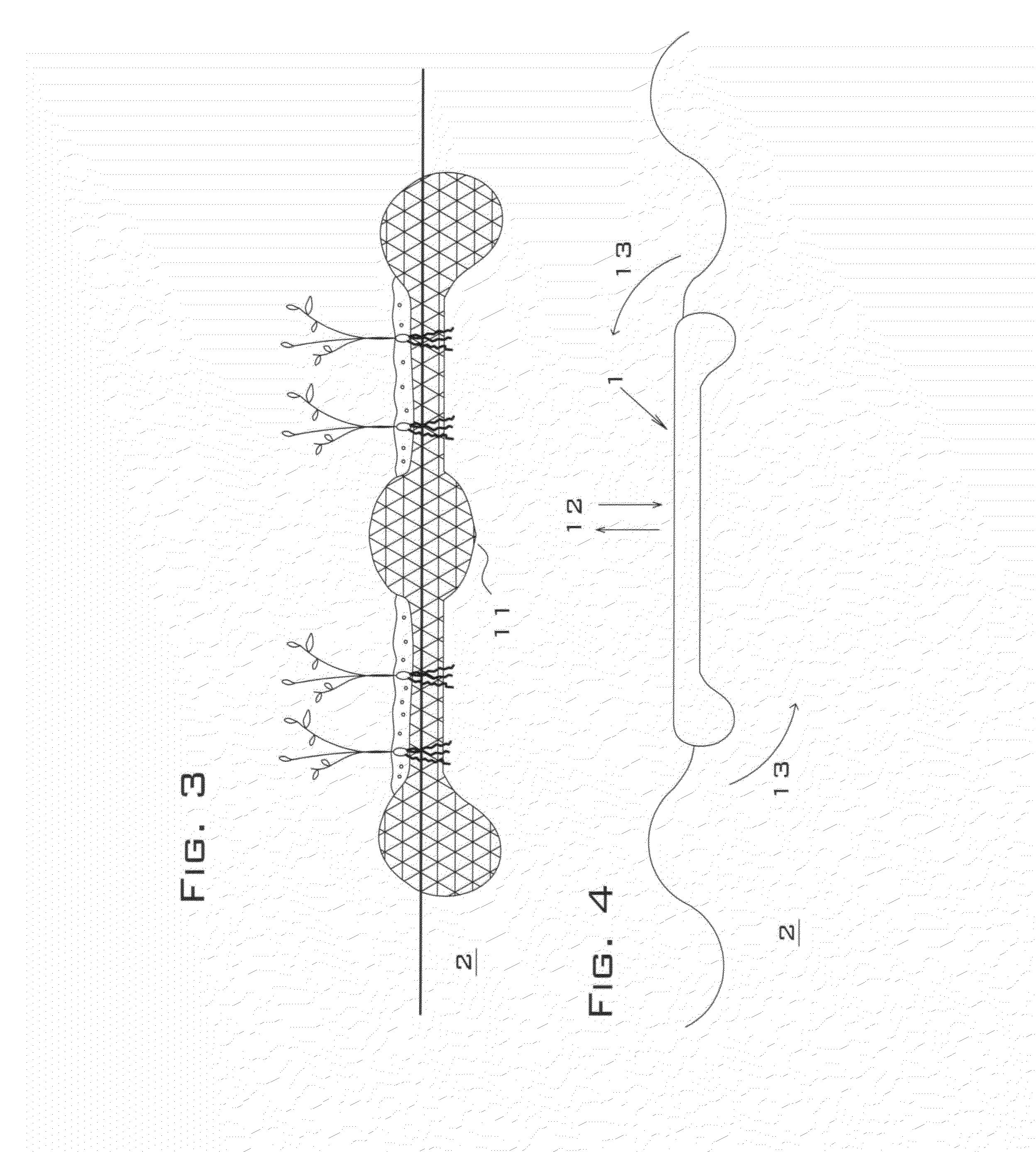

Preparation method and application of porous hydrophilic denitrification biological carrier

ActiveCN102174253AHigh self-acidification rateBiologically activeSustainable biological treatmentBiological water/sewage treatmentSludgeActive agent

The invention discloses a preparation method and application of a porous hydrophilic denitrification biological carrier. The method comprises the following steps of: adding 75 mass parts of polyether polyol, 25 mass parts of polymer polyol, 3 mass parts of blackwash, 2 mass parts of dichloromethane, 0.25 mass part of surfactant, 0.25 mass part of amine catalyst, 0.3 mass part of tin catalyst and 5 mass parts of water into a 23 to 27 DEG C reaction kettle, and stirring; adding 52.5 mass parts of active agent, and uniformly stirring; adding 62.5 mass parts of toluene diisocynate, uniformly stirring, and performing reaction molding; and putting polyurethane foam subjected to reaction molding into a demolding tank, and blasting for demolding to obtain a magnetic biological denitrification carrier. The carrier prepared by the method has adsorption and catalytic oxidation effects and large specific surface area, a highly active biological film can be quickly formed, microbial cells can reproduce and grow on the huge surface of the carrier and absorb and degrade toxic or inhibiting substances, the carrier has a strong nitrification effect and a certain denitrification effect and can remove total nitrogen, and the residual sludge is obviously reduced.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

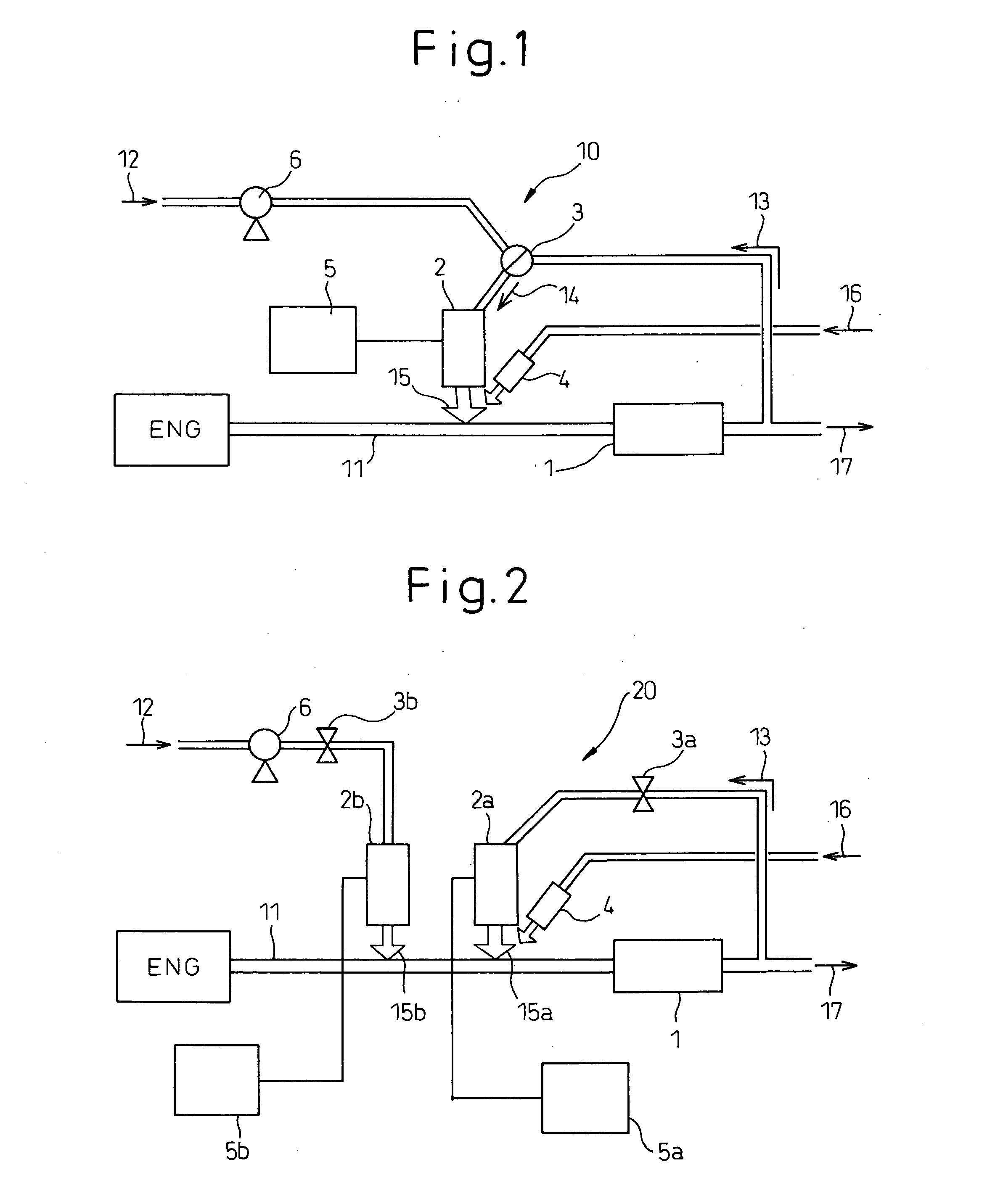

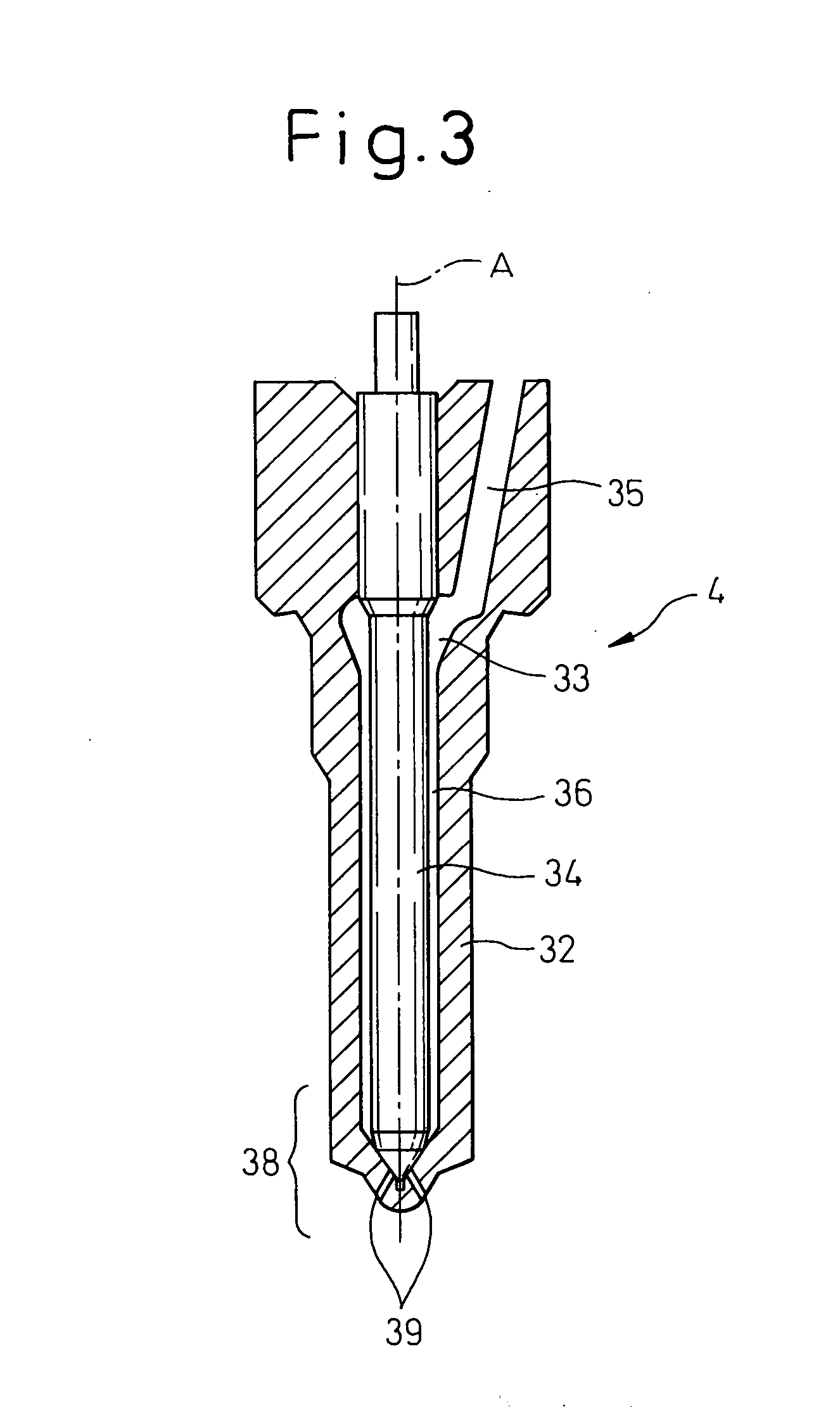

Exhaust gas purifying apparatus and method for controlling it

InactiveUS20060113181A1Easy to crackAccelerates reformingGas treatmentInternal combustion piston enginesPlasma generatorExhaust fumes

The present invention provides an exhaust gas purifying apparatus 10 which can effectively purify an exhaust gas with the use of a plasma. The present exhaust gas purifying apparatus 10 comprises a NOx purifying catalyst 1 disposed in an exhaust gas pipe 11 for an internal combustion engine (ENG); a plasma generator 2 for converting a gas into a plasma and supplying the plasma to the exhaust pipe at the upstream of the NOx purifying catalyst; a switching device 3 for selectively supplying one of a recirculated exhaust gas 13 and air 12 as a gas to be converted into a plasma to the plasma generator 2; and an injector 4 for adding a reducing agent to the gas 14 to be converted into a plasma or a plasma 15 converted from the gas by the plasma generator. The present invention further provides a method for controlling the exhaust gas purifying apparatus.

Owner:CRYOQUIP +1

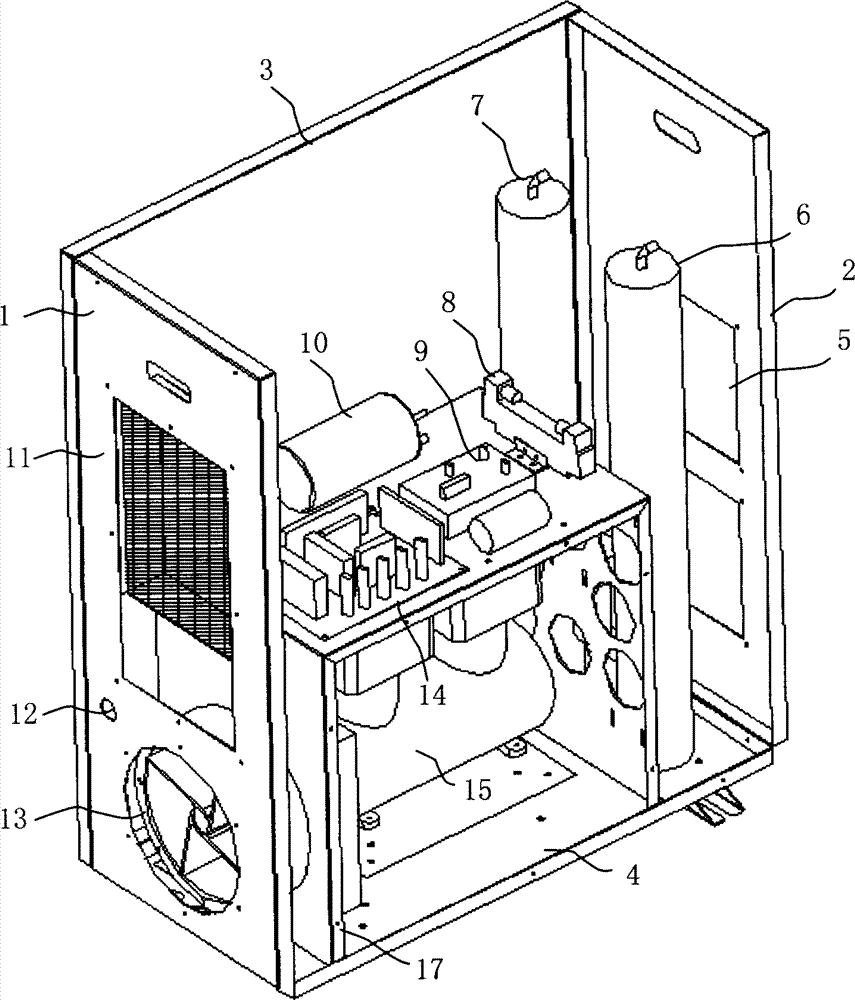

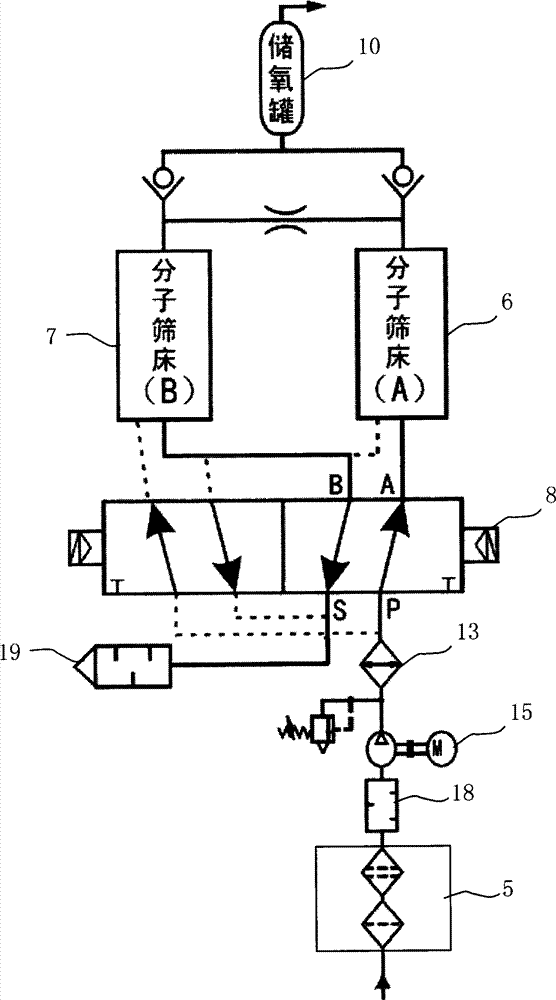

Air purifying and fresh air oxygen supplying oxygenerator

InactiveCN102923667AQuality improvementIncrease oxygen concentrationOxygen preparationOzone generatorMolecular sieve

The invention discloses an air purifying and fresh air oxygen supplying oxygengenerator which comprises a molecular sieve installed in a box body. The molecular sieve comprises a first molecular sieve and a second molecular sieve, wherein air inlets of the first molecular sieve and the second molecular sieve are connected with an air compressor through a solenoid valve, moisture separators are arranged among the first molecular sieve, the second molecular sieve and the solenoid valve, and air outlets of the first molecular sieve and the second molecular sieve are connected with an oxygen storing tank. By enabling the two molecular sieves to be connected with the air compressor and arranging the oxygen storing device and an adjusting device, the air purifying and fresh air oxygen supplying oxygengenerator exchanges the indoor and outdoor air, simultaneously fills oxygen in a room, can improve oxygen concentration in a space, and thoroughly cures the symptoms of dizziness, oppression in chest and the like caused by anoxia. Further, the oxygengenerator can further be provided with an ozone generator or a negative ion generator to perform sterilizing and degerming, remove decoration pollution and peculiar smell and improve indoor air quality.

Owner:上海康盟保健用品有限公司

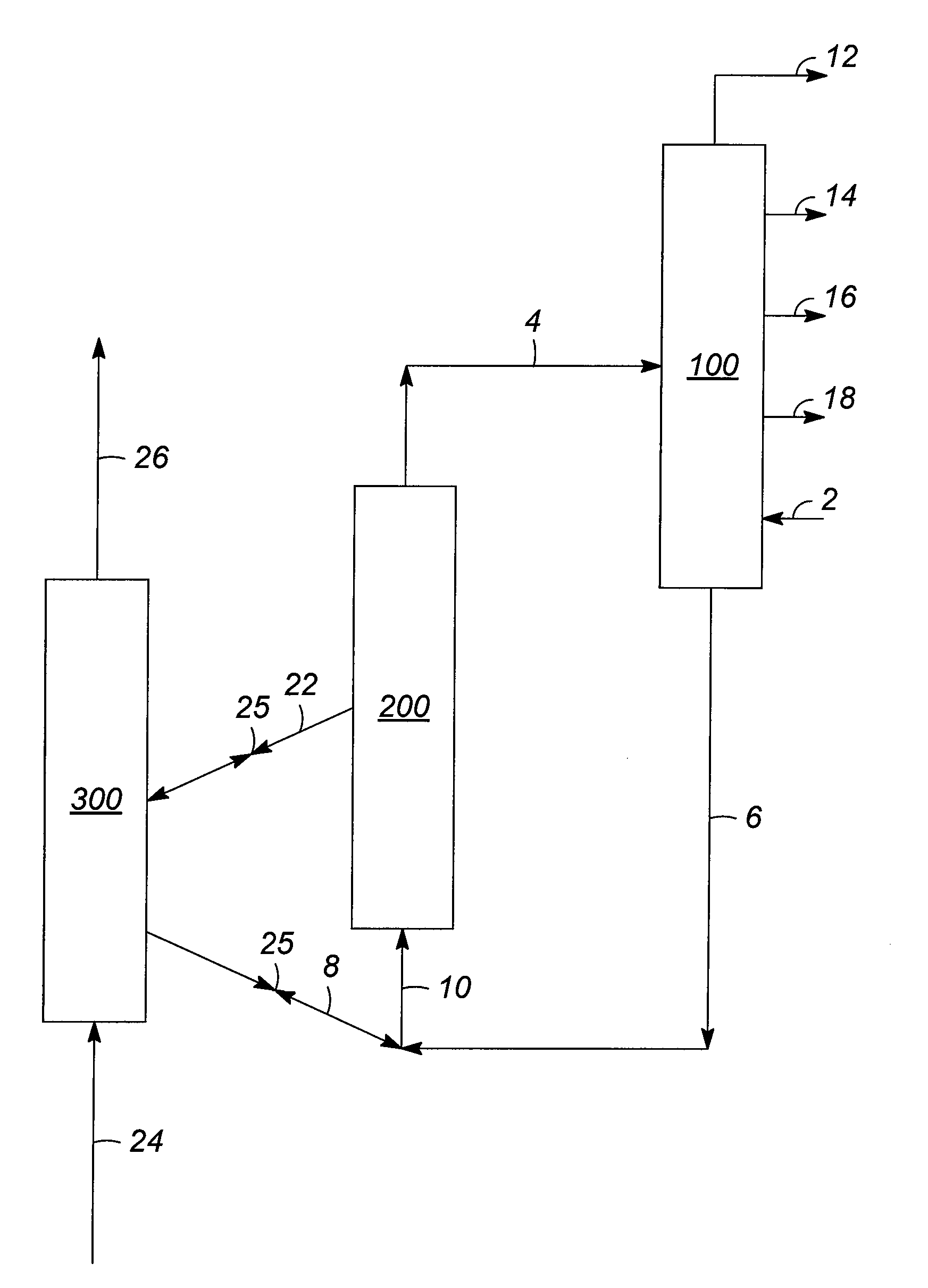

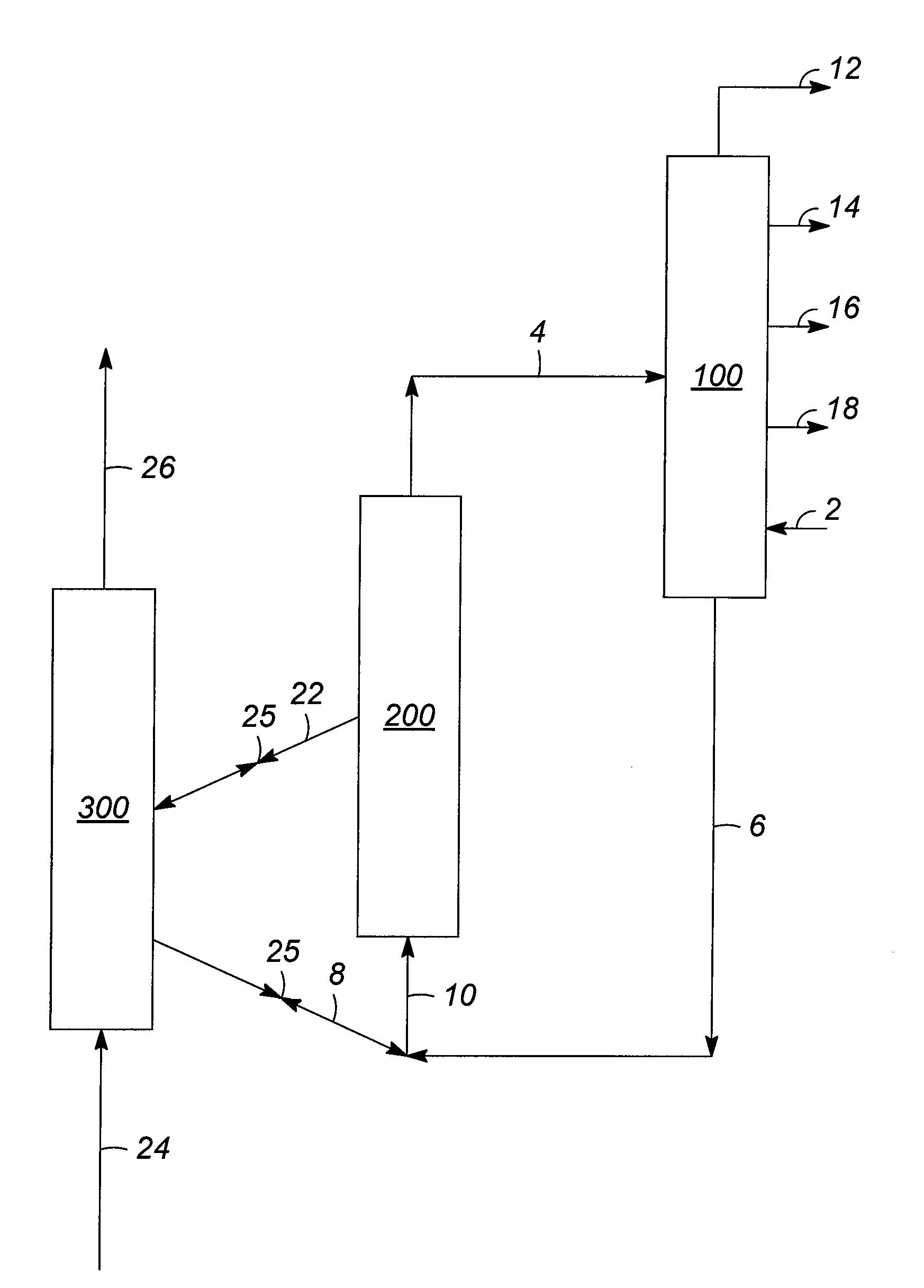

Direct feed/effluent heat exchange in fluid catalytic cracking

ActiveUS8007662B2Reduce the amount requiredIncrease productionCatalytic crackingOther chemical processesDistillationHydrocarbon

Fluid catalytic cracking (FCC) processes are described, in which hydroprocessed hydrocarbon streams or other hydrocarbon feed streams having a low coking tendency are subjected to direct heat exchange with the FCC reactor effluent, for example in the FCC main column. The processes operate with sufficient severity such that little or no net FCC main column bottoms liquid (e.g., with a 343° C. (650° F.) distillation cut point) is generated. Regeneration temperatures with the representative low coking tendency feeds are beneficially increased by using an oxygen-enriched regeneration gas stream.

Owner:UOP LLC

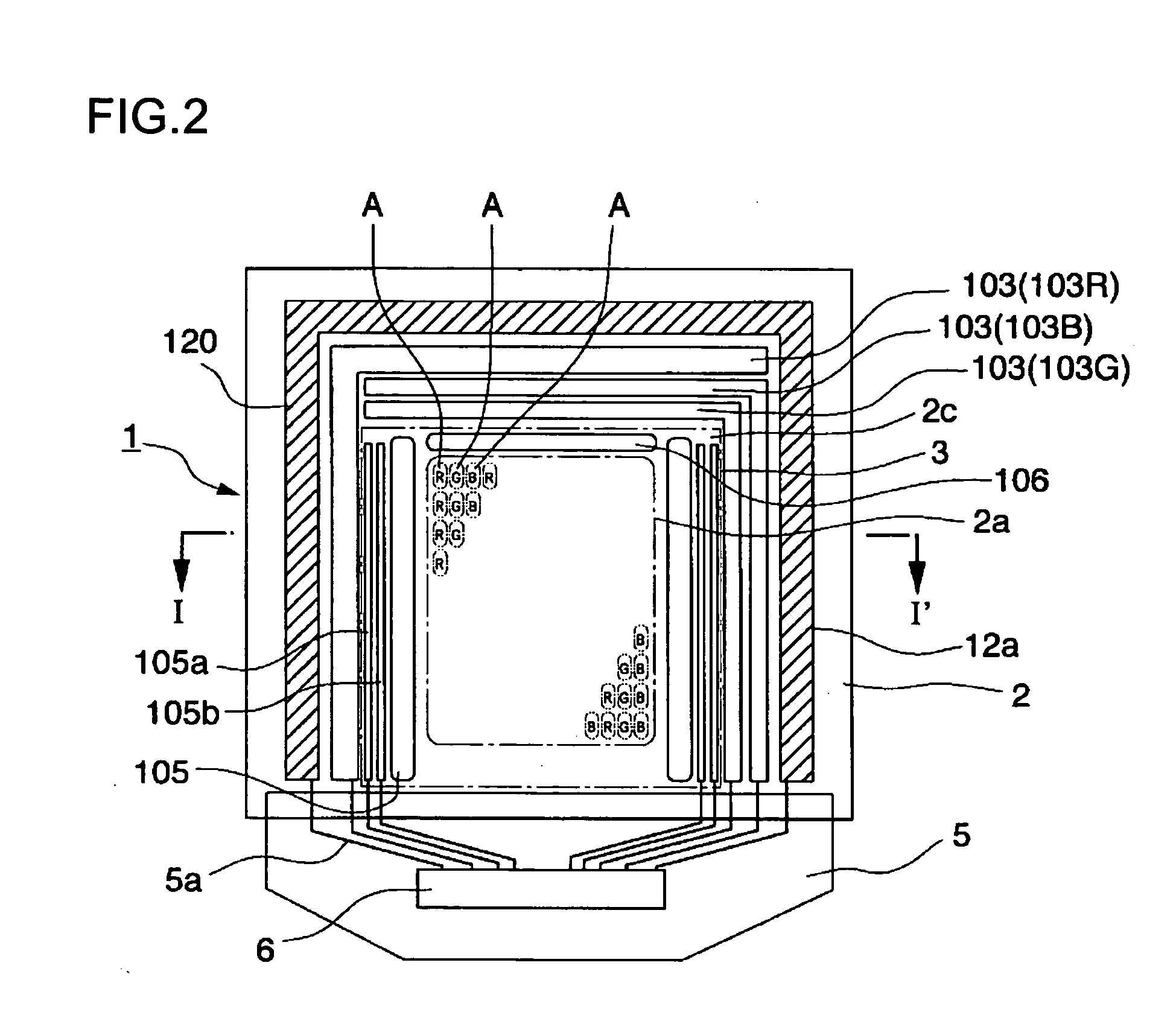

Electroluminescent display device, method for manufacturing the same, and electronic equipment

InactiveUS20050040759A1High light efficiencyReduction in efficacy can be reduced and preventedDischarge tube luminescnet screensElectroluminescent light sourcesOxygenElectron

A transparent cathode electrode technology for an electroluminescent display device having a top emission structure, provides a top emission type electroluminescent display device and a method to manufacture the same. Oxidation of a substrate film can be reduced or prevented during the film formation of a metal oxide. Electronic equipment including this display device is also provided. A first electrode, a function layer including a luminescent layer, and a transparent second electrode made of a metal oxide are laminated on the substrate in that order from the lower surface. At this time, the oxygen concentration in the second electrode is made to vary in the film thickness direction, and the oxygen concentration in the vicinity of the interface between the second electrode and the function layer is made lower than the average oxygen concentration in the second electrode.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com