Patents

Literature

32results about How to "Reduce the amount of water vapor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

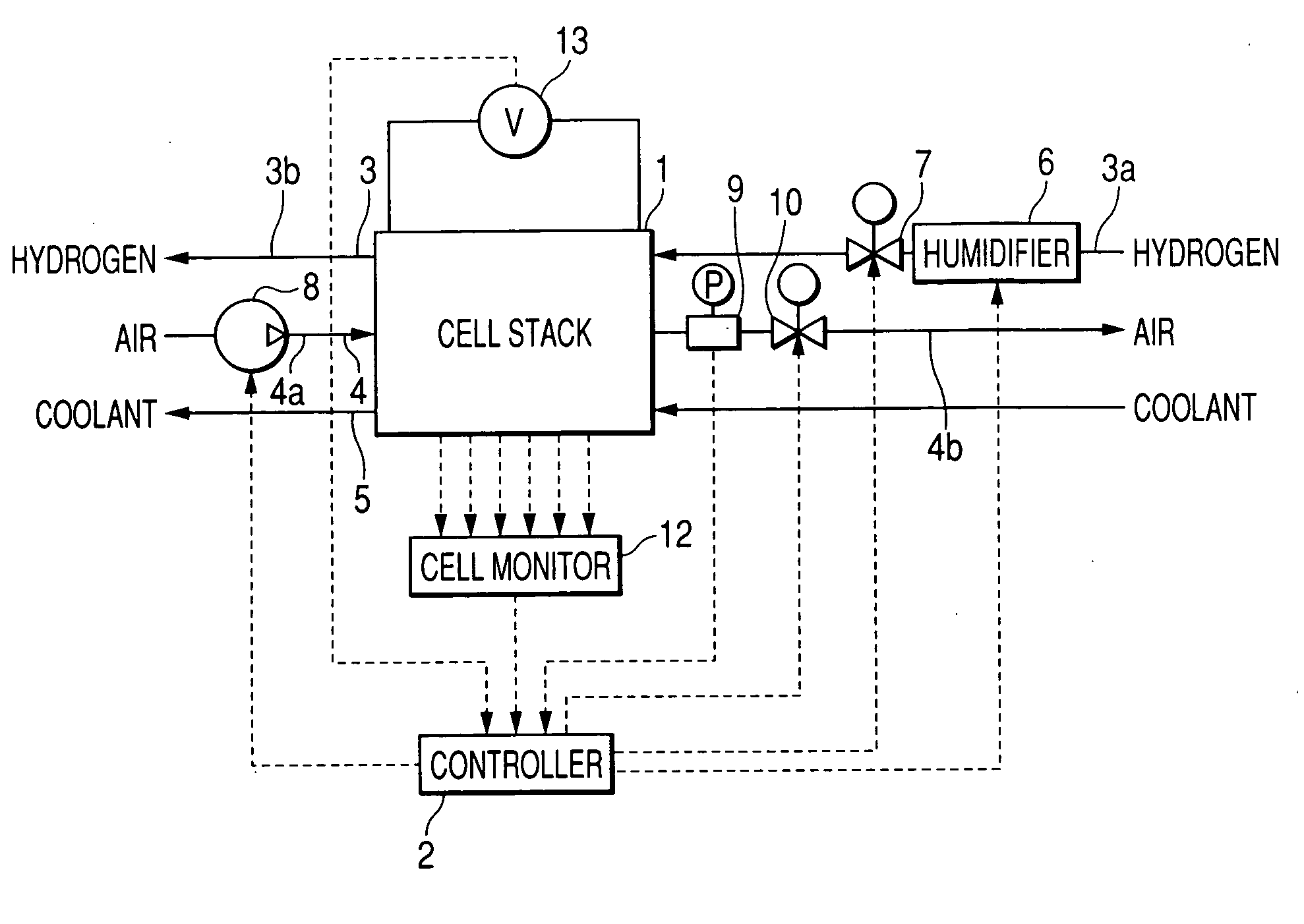

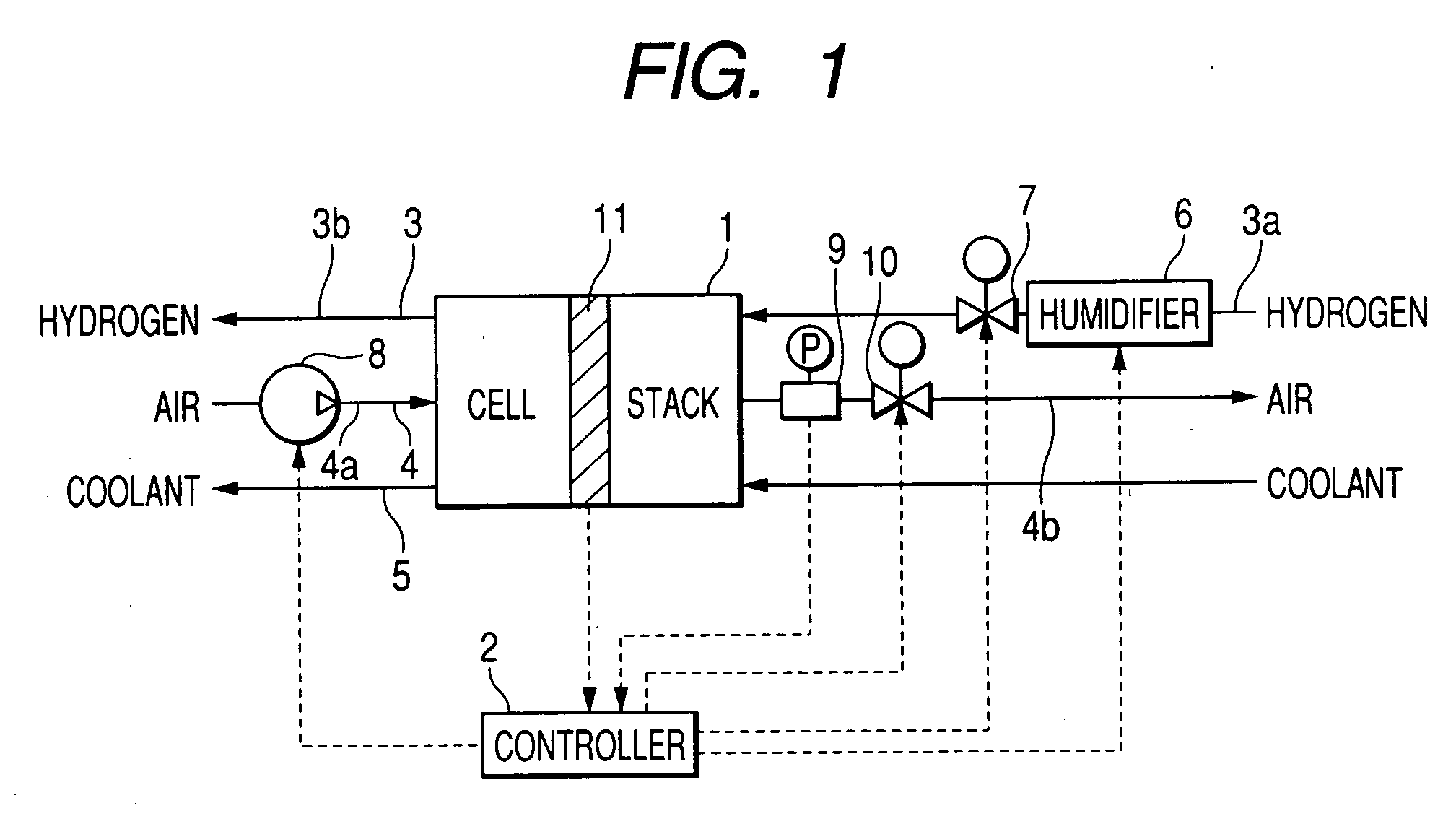

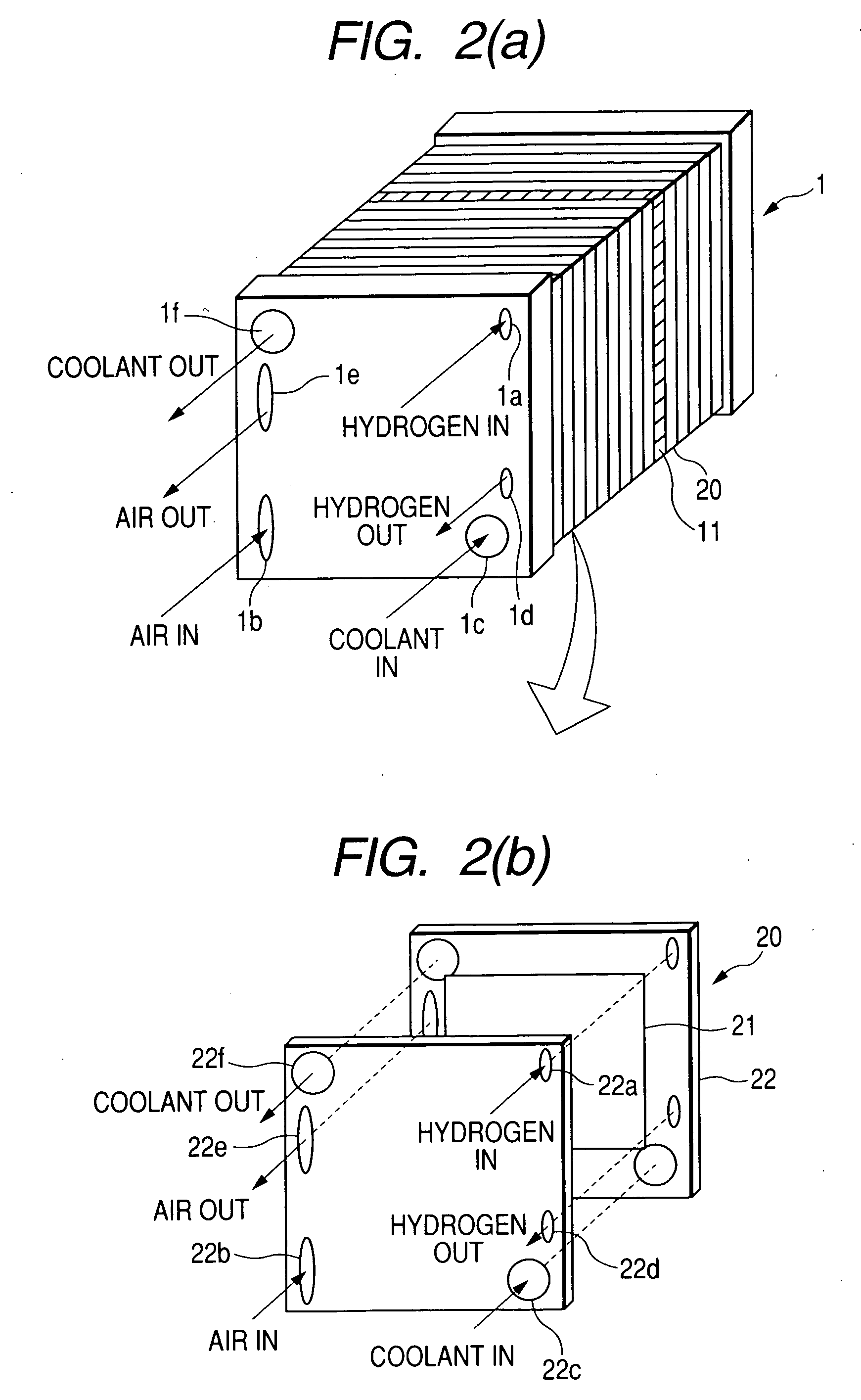

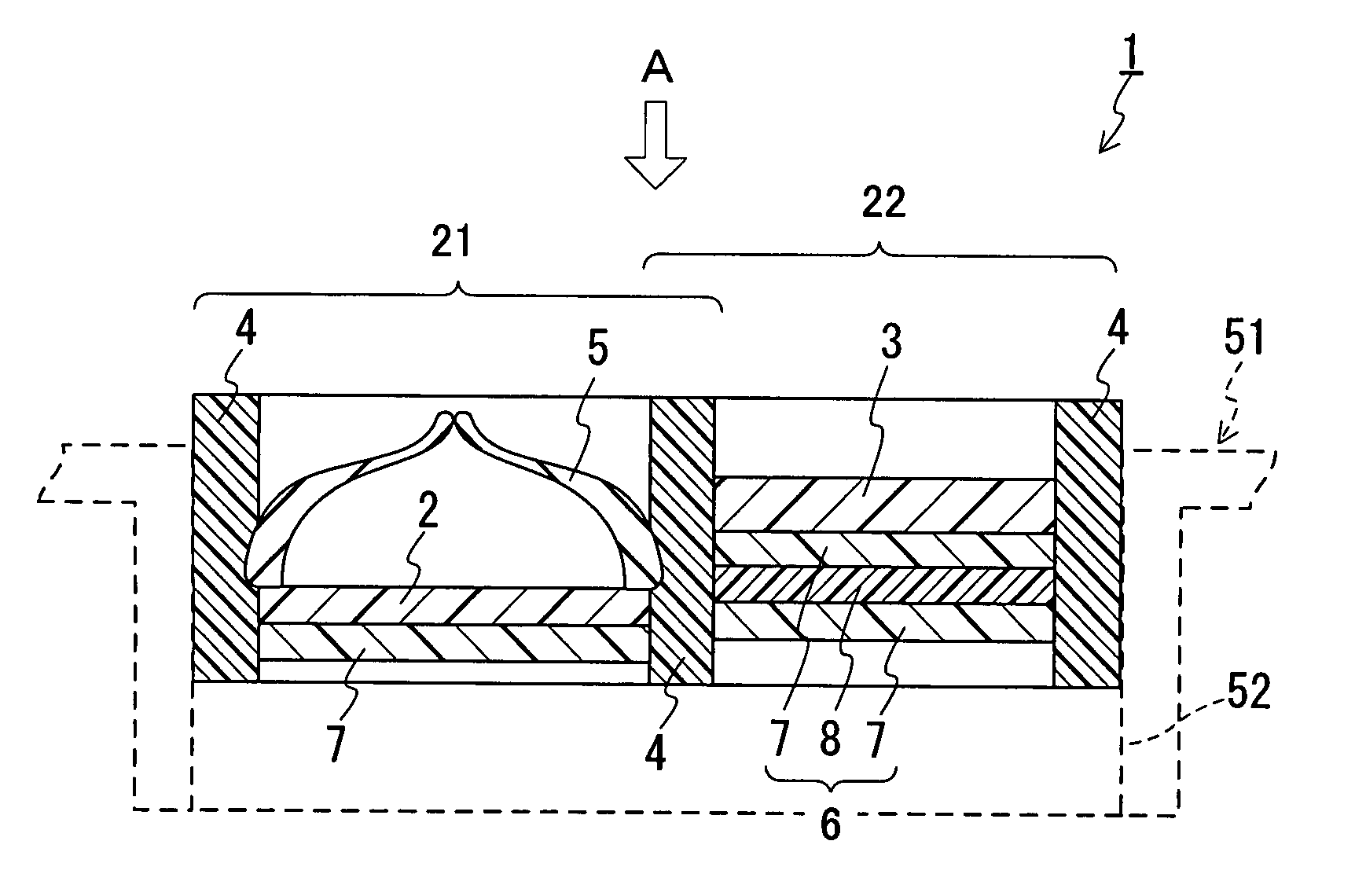

Fuel cell system ensuring stability of operation

InactiveUS20060166058A1Increase oxygen concentrationReduce the amount of water vaporFuel cells groupingFinal product manufactureFuel cellsSystems design

A fuel cell system designed to supply non- or low-humidified air to a fuel cell stack and ensure the stability of operation thereof. The system works to monitor operating conditions of the fuel cell stack and determine whether electrolyte films of fuel cells are getting dried or not or whether an undesirable quantity of water has been produced on the side of air electrodes of the cells or not. When either condition is true, the system works to elevate the pressure of air in an air drain line of the fuel cell stack to enhance the production of water in the cells to keep the electrolyte films or-to transfer the water from the air electrodes to the fuel electrodes of the cells to keep the electrolyte films in a desired wet condition, thereby ensuring the stability of operation of the fuel cell stack.

Owner:DENSO CORP

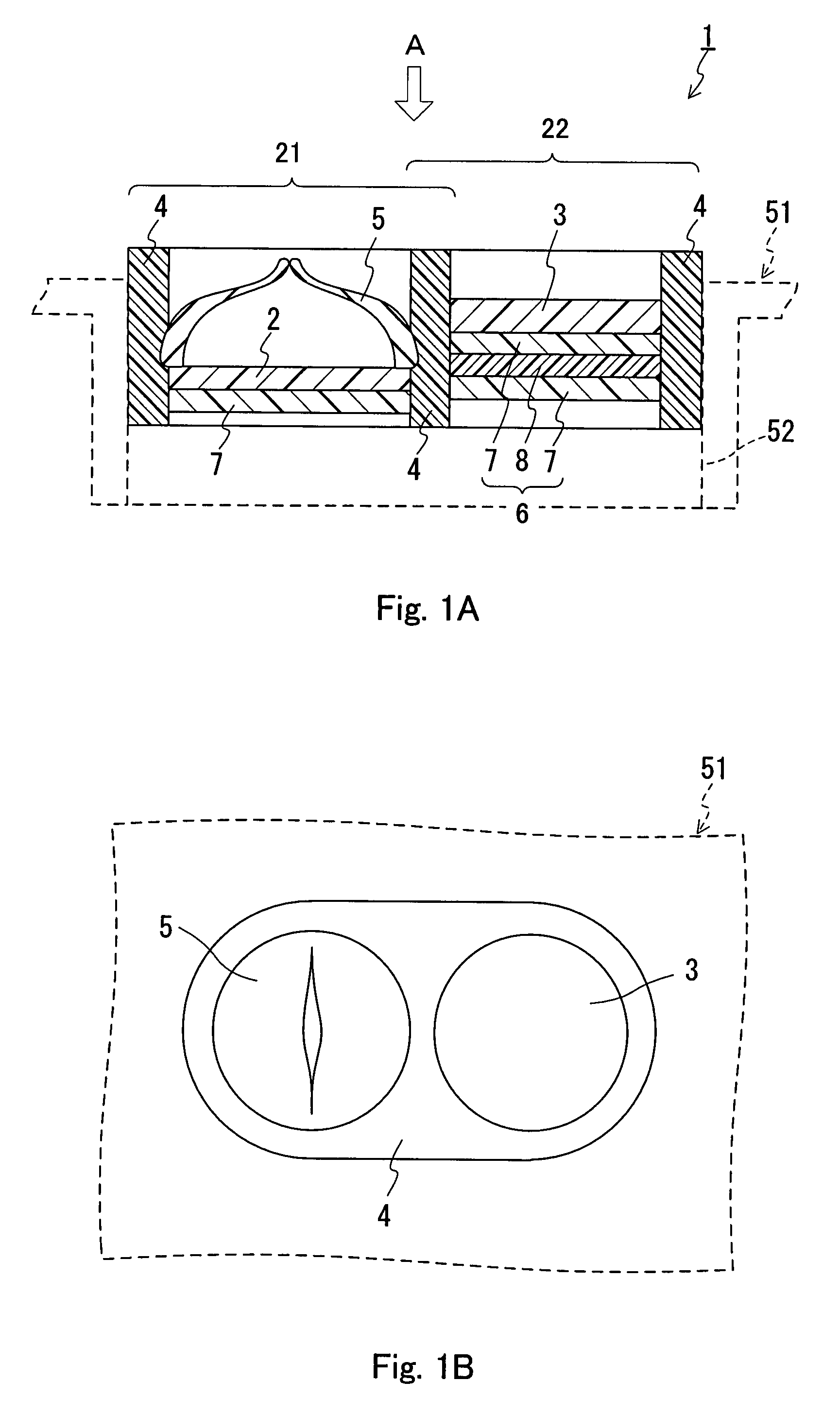

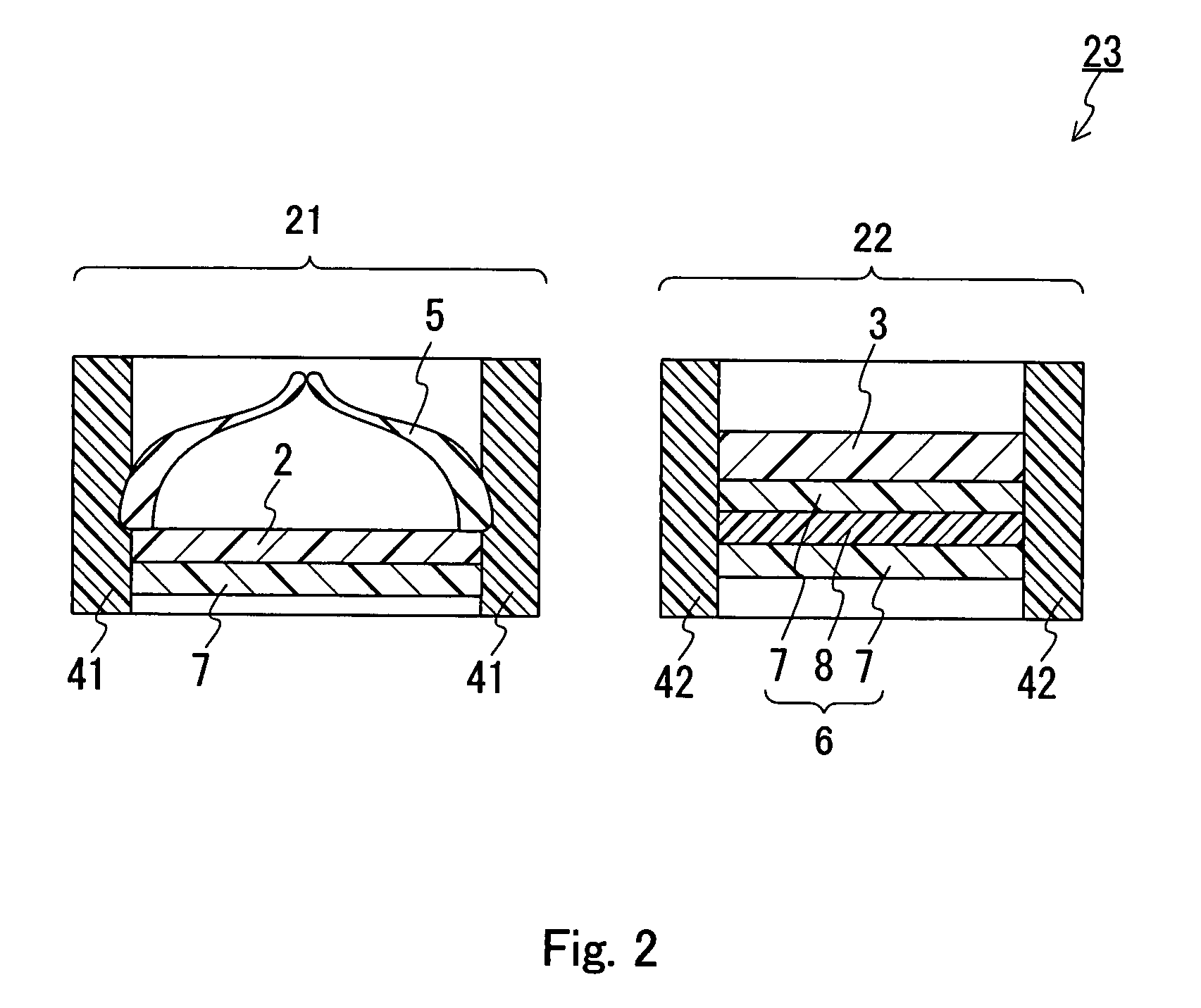

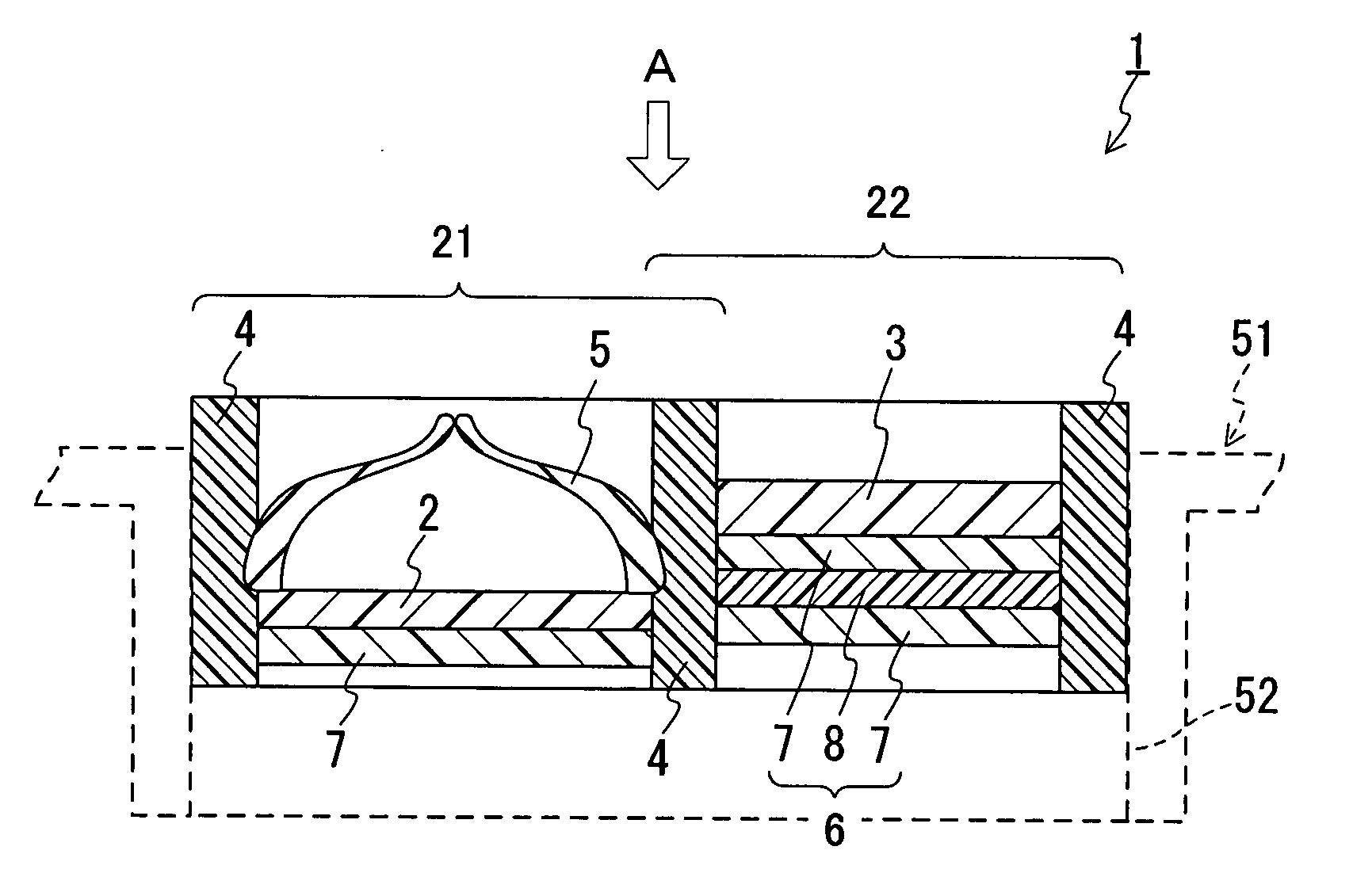

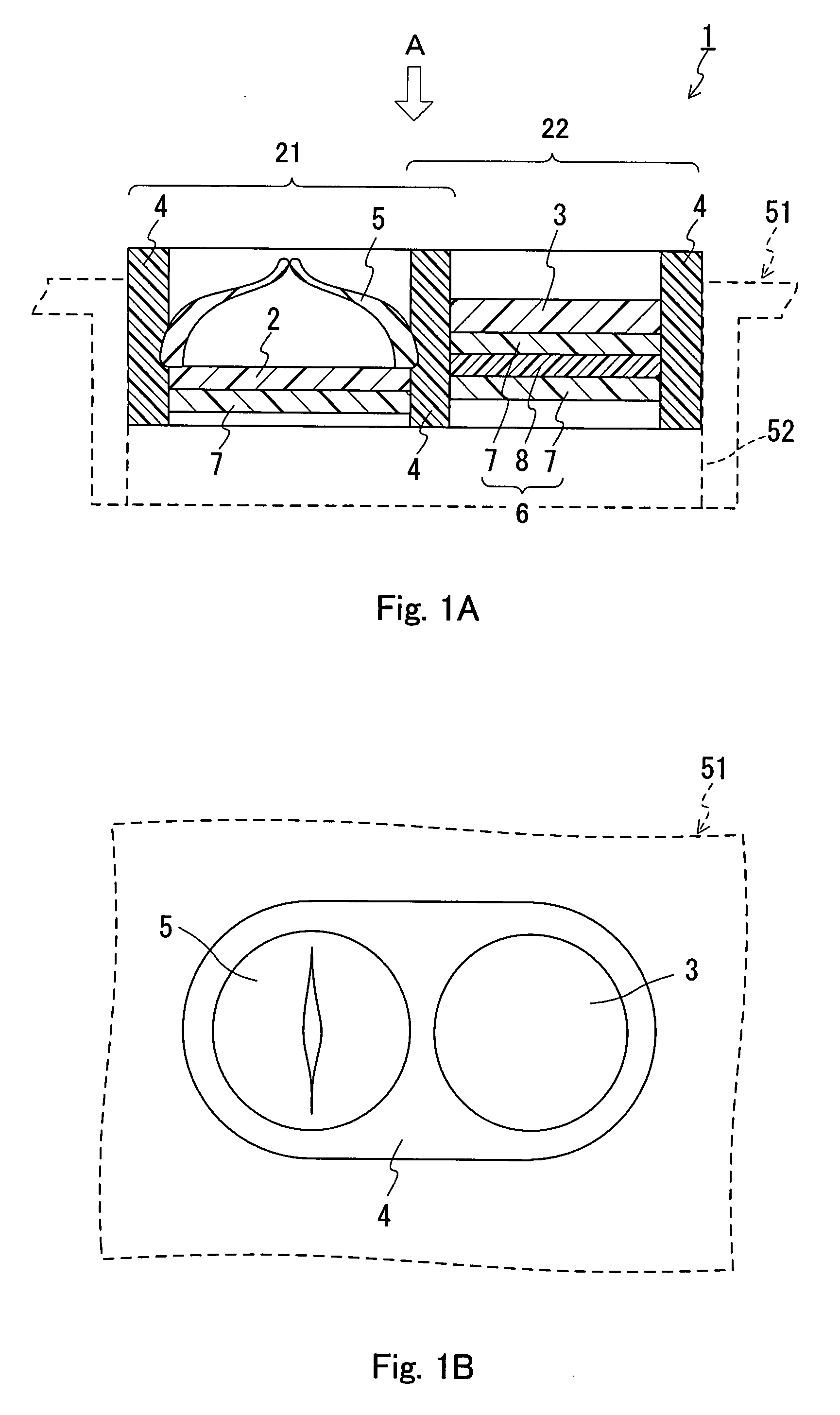

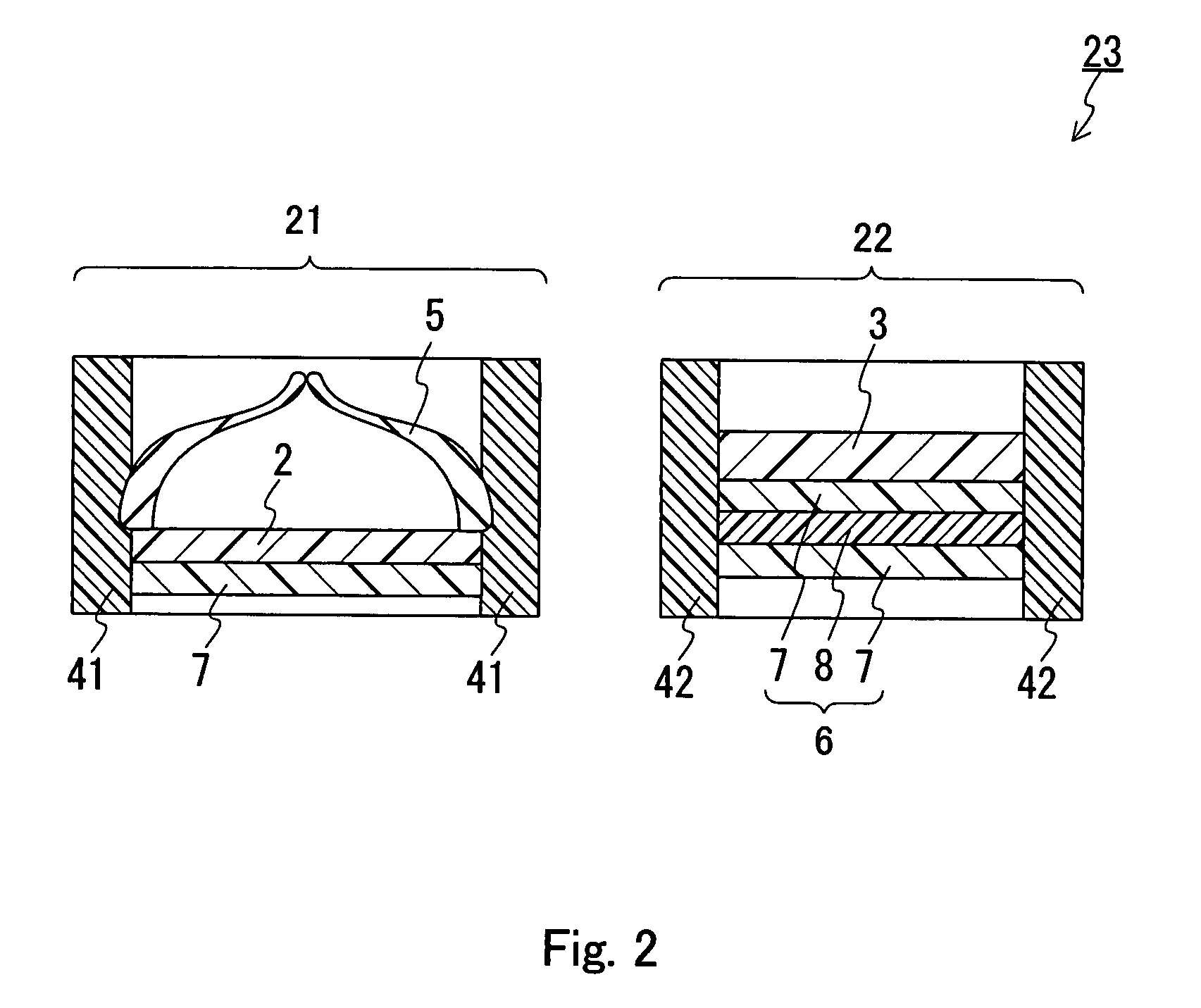

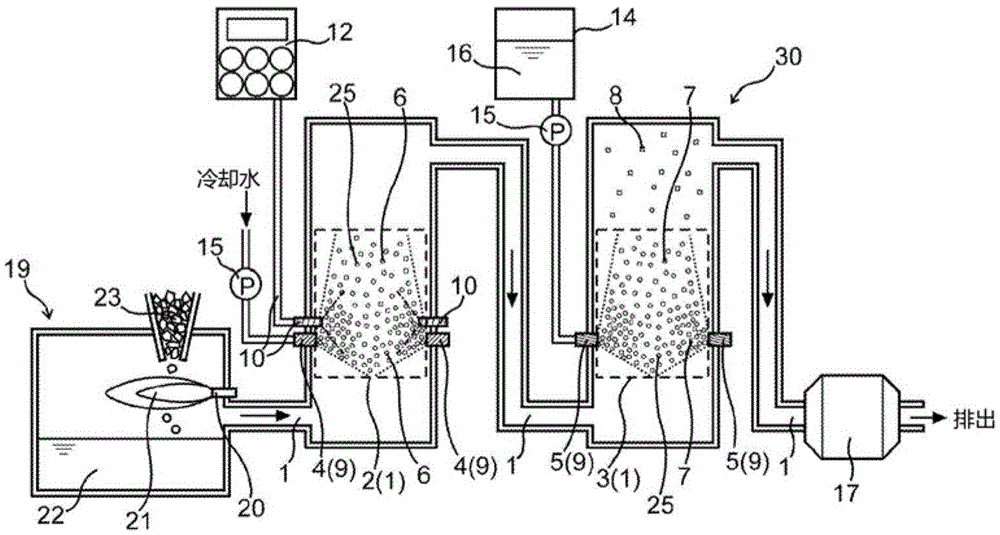

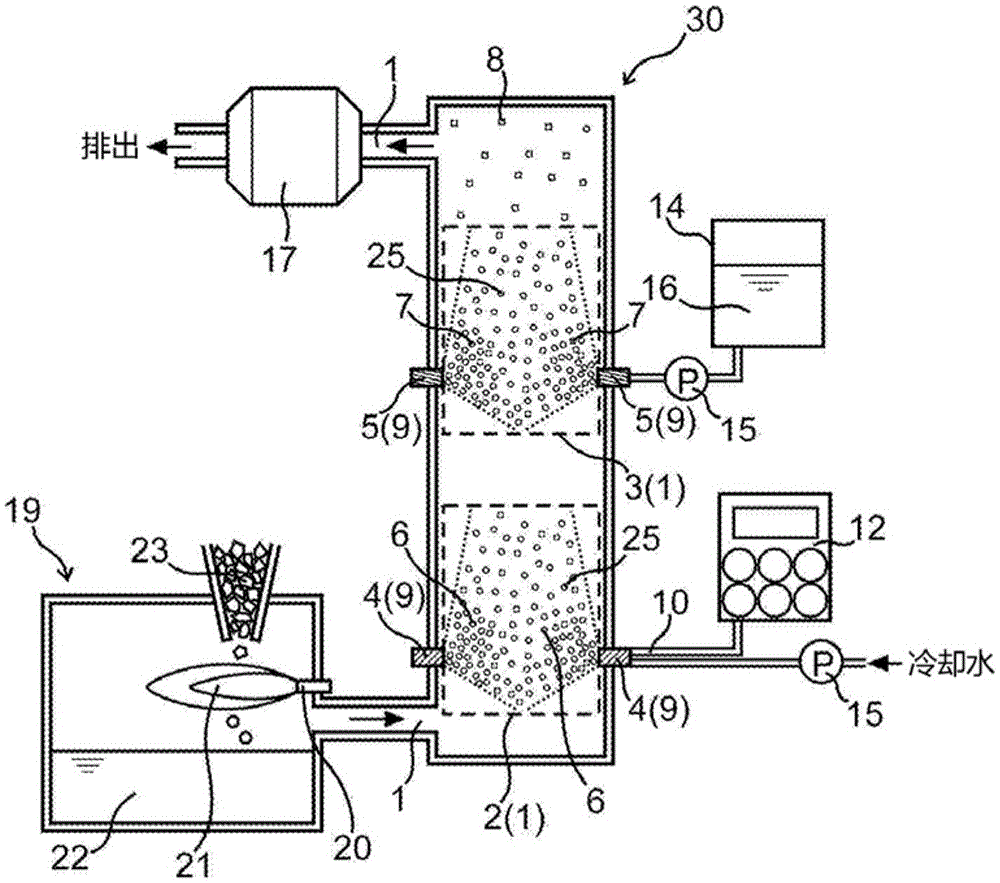

Ventilation member, ventilation member kit, and vented housing and vented tank using them

ActiveUS8069875B2Good effectAvoid enteringDispersed particle separationCheck valvesGas passingProduct gas

A ventilation member and a ventilation member kit are provided that can extend the time until fogging will be produced in a housing and also can shorten the time until the produced fogging will be cleared up even when the interior of the housing has been fogged. A vented housing and a vented tank using them are also provided. A ventilation member includes: a first gas permeable membrane, a second gas permeable membrane, and an absorbing layer allowing a gas passing through an opening of a housing or a tank to permeate therethrough, with the ventilation member being fixed to the opening; a support body for supporting the first gas permeable membrane, the second gas permeable membrane, and the absorbing layer; and a first one-way valve disposed so as to cover the first gas permeable membrane. The first gas permeable membrane and the second gas permeable membrane are disposed in such a manner that the gas permeates through the gas permeable membranes independently of each other. The second gas permeable membrane and the absorbing layer are disposed in such a manner that the gas permeates through the second gas permeable membrane and the absorbing layer successively. The absorbing layer contains a water absorbent.

Owner:NITTO DENKO CORP

Ventilation Member, Ventilation Member Kit, and Vented Housing and Vented Tank Using Them

ActiveUS20090120949A1Good effectAvoid enteringCheck valvesLarge containersGas passingMembrane configuration

A ventilation member and a ventilation member kit are provided that can extend the time until fogging will be produced in a housing and also can shorten the time until the produced fogging will be cleared up even when the interior of the housing has been fogged. A vented housing and a vented tank using them are also provided. A ventilation member includes: a first gas permeable membrane, a second gas permeable membrane, and an absorbing layer allowing a gas passing through an opening of a housing or a tank to permeate therethrough, with the ventilation member being fixed to the opening; a support body for supporting the first gas permeable membrane, the second gas permeable membrane, and the absorbing layer; and a first one-way valve disposed so as to cover the first gas permeable membrane. The first gas permeable membrane and the second gas permeable membrane are disposed in such a manner that the gas permeates through the gas permeable membranes independently of each other. The second gas permeable membrane and the absorbing layer are disposed in such a manner that the gas permeates through the second gas permeable membrane and the absorbing layer successively. The absorbing layer contains a water absorbent.

Owner:NITTO DENKO CORP

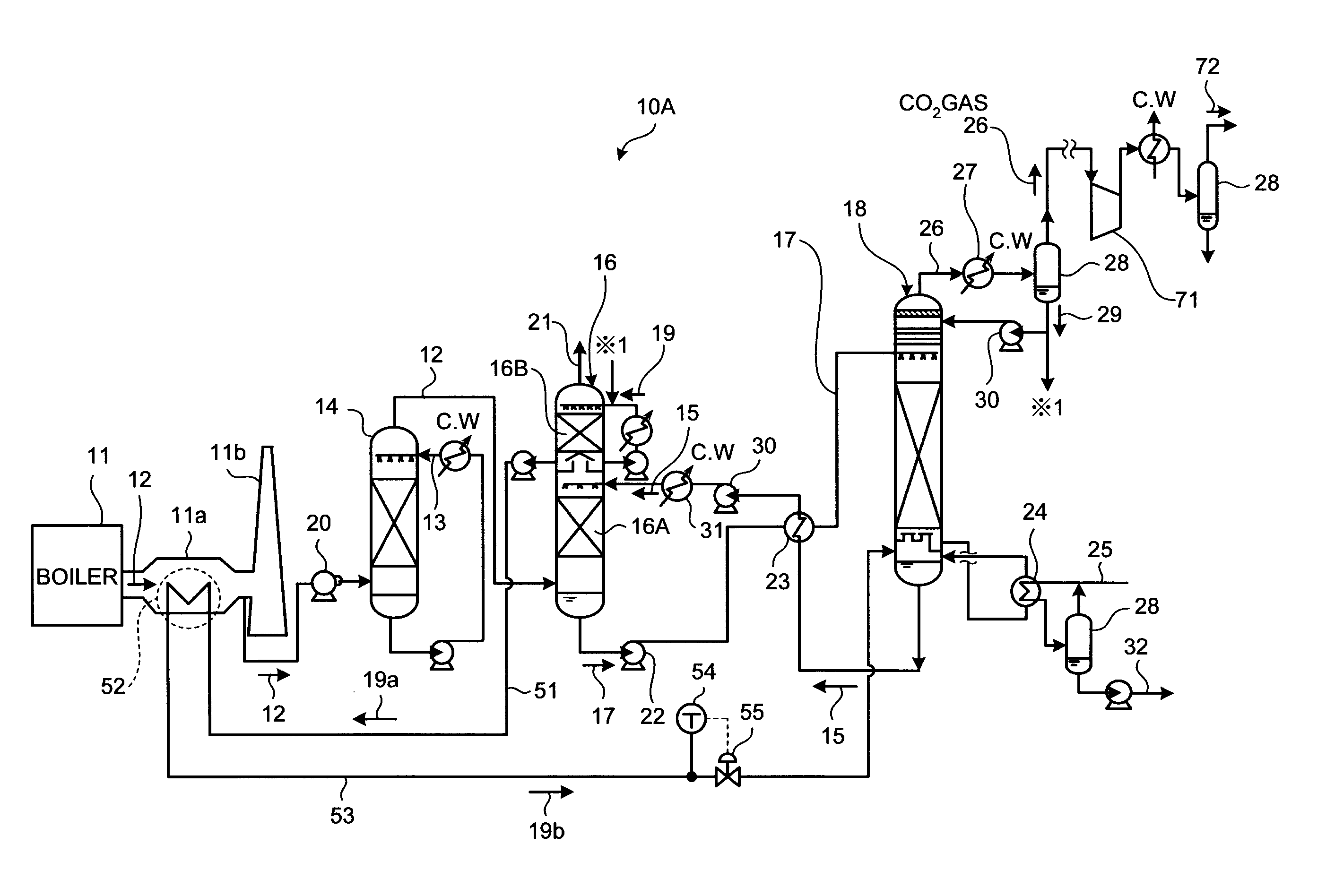

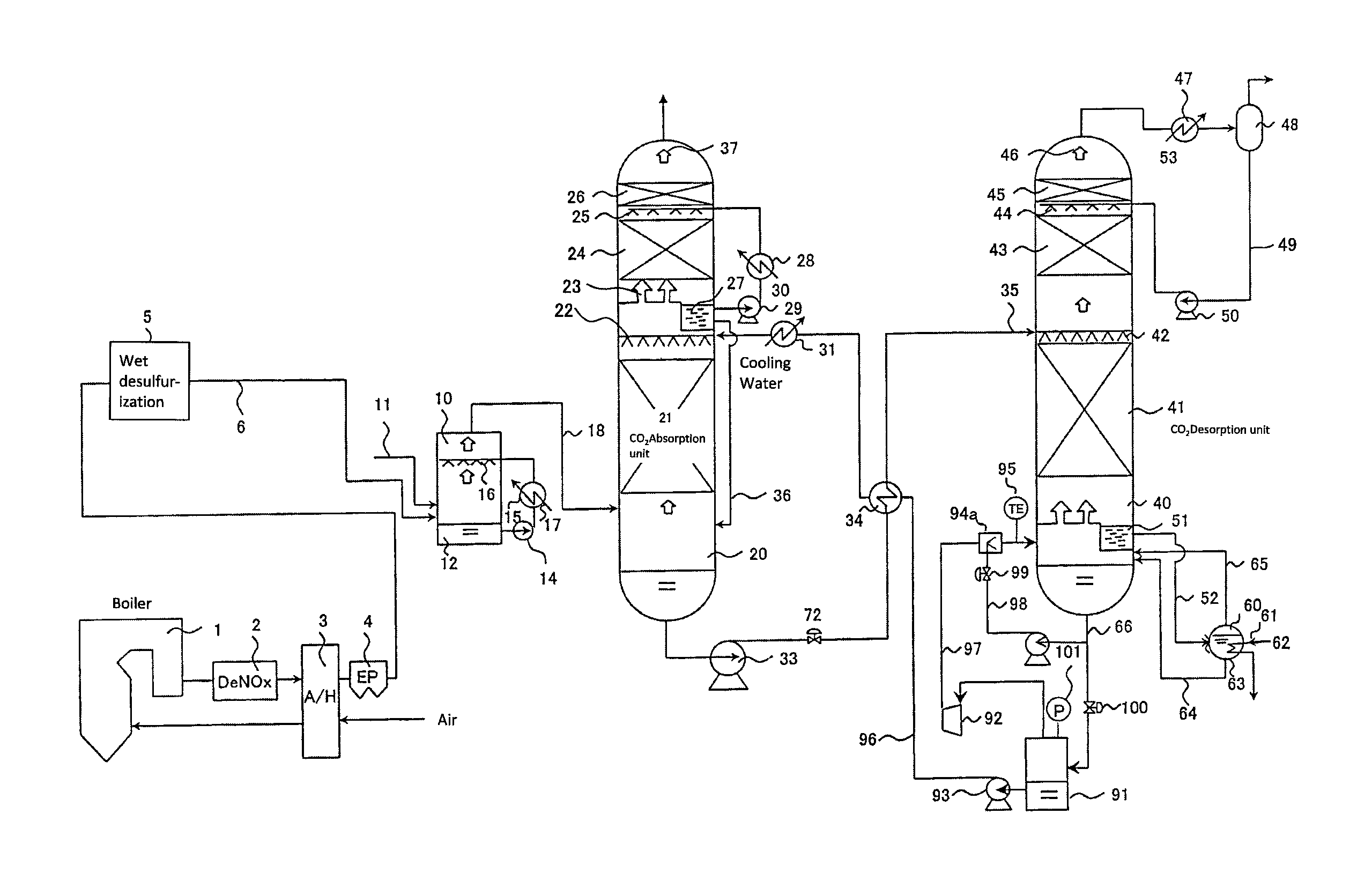

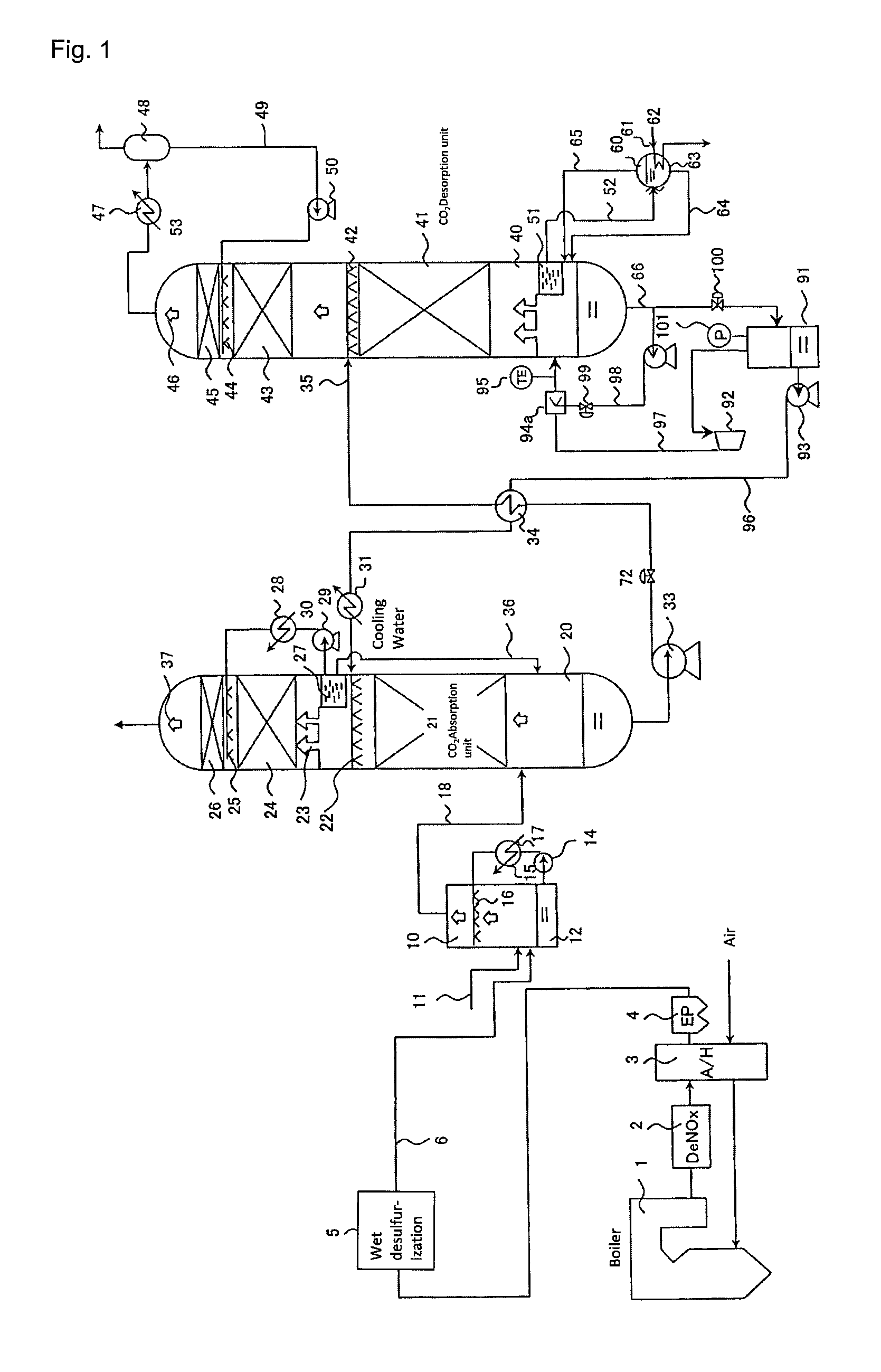

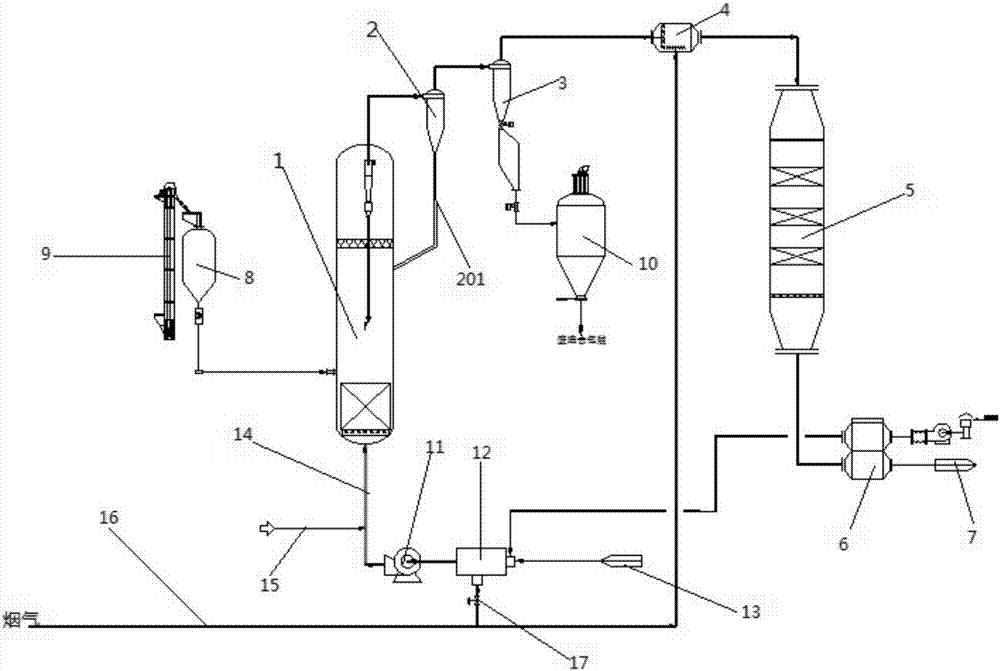

Co2 recovery apparatus

ActiveUS20120234177A1Reduce the amount of water vaporReduce the amount requiredGas treatmentCarbon compoundsCombustionFlue gas

[Problem to be solved] A CO2 recovery apparatus which can significantly reduce the amount of steam and provide further improved energy efficiency is provided.[Solution] The apparatus includes: a flue gas cooling apparatus 14 for allowing cooling water 13 to cool a CO2 and O2 containing flue gas 12 that is emitted from an industrial combustion facility 11 such as a boiler or gas turbine; a CO2 absorber 16 having a CO2 recovery section 16A for bringing the cooled CO2 containing flue gas 12 and a CO2 absorbing CO2 absorbent 15 into contact with each other to remove CO2 from the flue gas 12; and an absorbent regenerator 18 for releasing CO2 from a CO2 absorbed CO2 absorbent 17 to regenerate the CO2 absorbent. The apparatus further includes: a cleansing water divert line 51 for diverting partial cleansing water 19a of circulating cleansing water 19 that has been condensed in a cleansing section 16B in the CO2 absorber 16; a first heat exchanger 52 disposed in the divert line 51 and in a boiler flue gas duct 11a; and a superheated cleansing solution supply line 53 for directing, into the bottom portion of the absorbent regenerator 18, a superheated cleansing solution 19b having heat exchanged with a first heat exchanger 52.

Owner:MITSUBISHI HEAVY IND ENG LTD

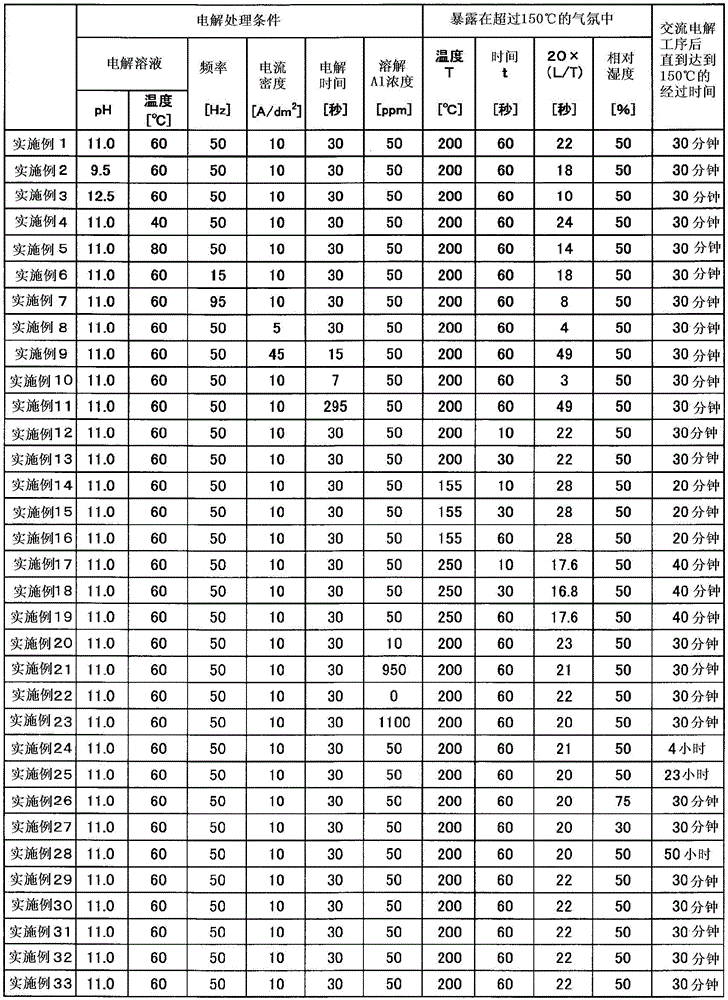

Treated surface aluminum material and manufacturing method therefor as well as said treated surface aluminum material/resin layer bonded material

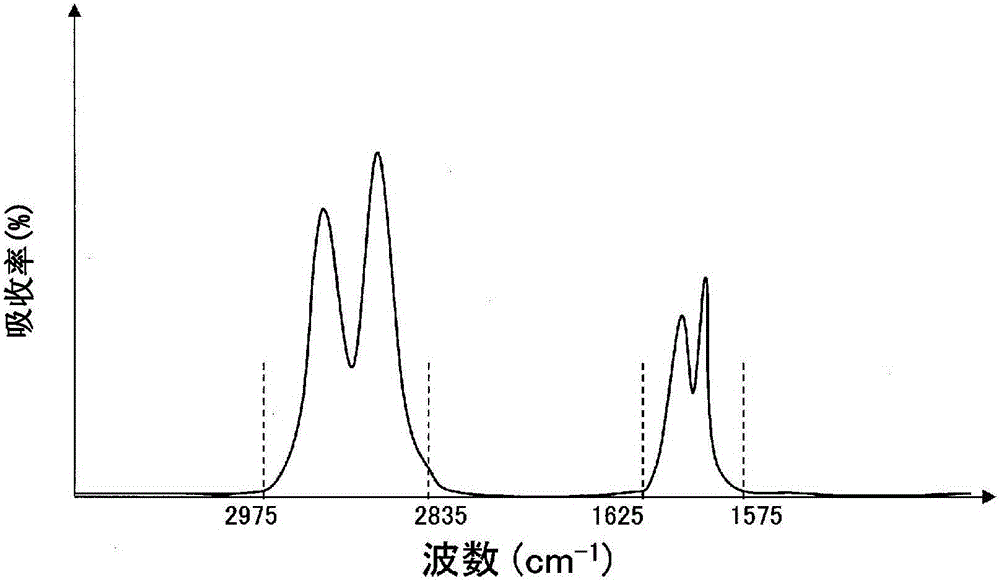

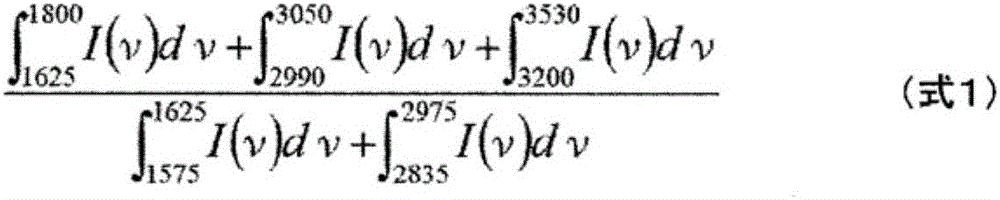

ActiveCN106460221AExcellent adhesionGood adhesionAnodisationMetal layered productsMoistureAluminium oxide

[Problem] To provide a treated surface aluminum material with excellent long term resin adhesiveness over the entire surface of the aluminum material and a stable manufacturing method for such a treated surface aluminum material. [Solution] Provided are a treated surface aluminum material and a manufacturing method therefor, wherein the treated surface aluminum material comprises an aluminum material and an oxide film formed on at least one surface thereof and is characterized in that the oxide film is obtained from a 20-500 nm thick porous aluminum oxide film layer formed on the front surface side and a 3-30 nm thick barrier aluminum oxide film layer formed on the base surface side, 5-30 nm diameter pores are formed in the porous aluminum oxide film layer, and the moisture content contained in the oxide film is not more than 10 [mu]g / cm2.

Owner:FURUKAWA SKY ALUMINUM CORP

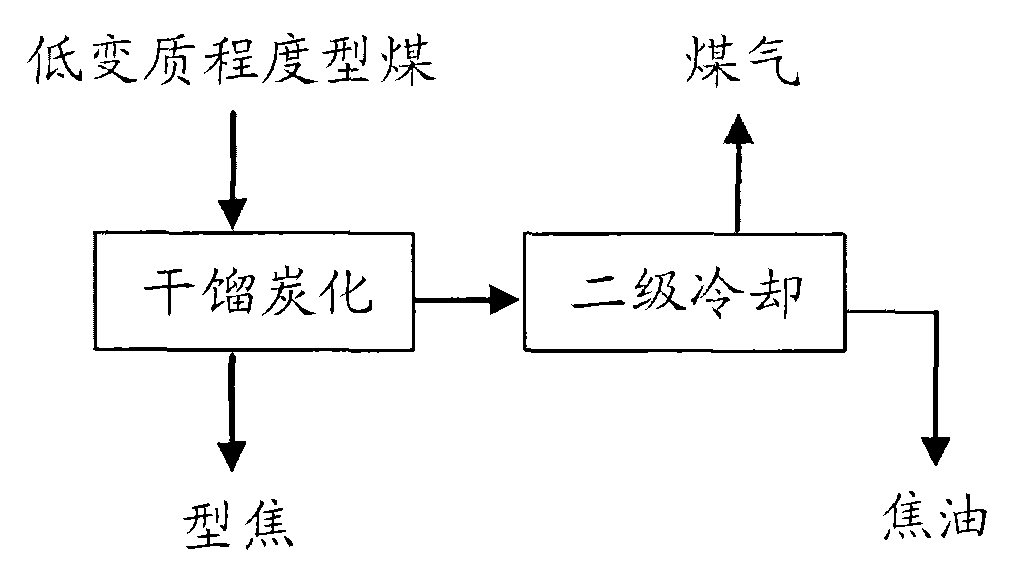

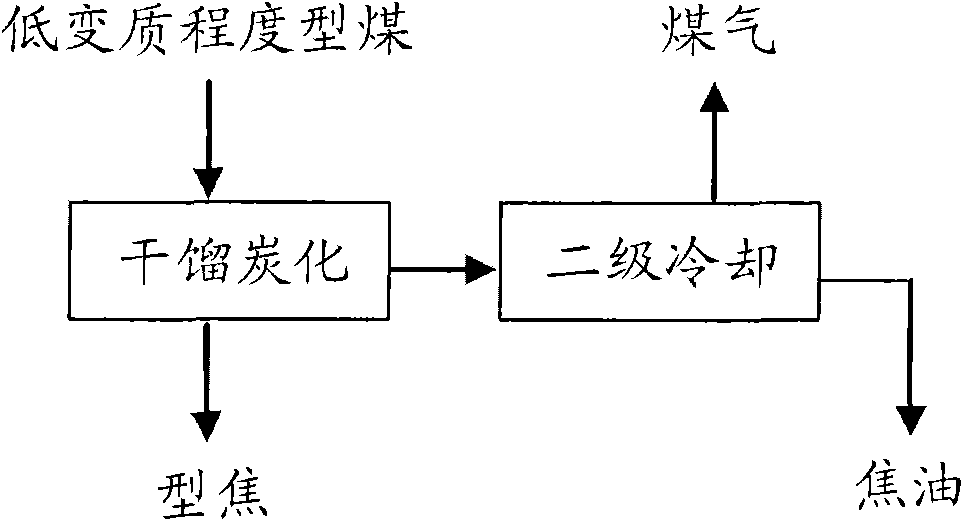

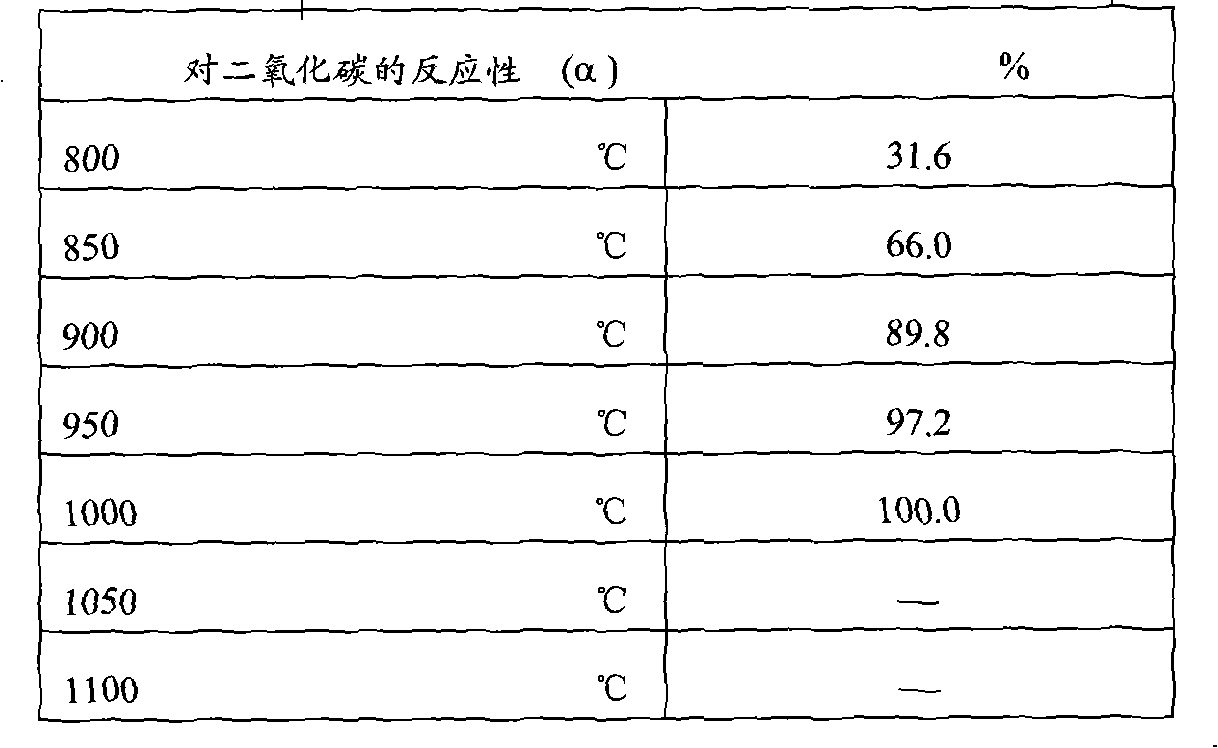

Formed coke and production method of formed coke, coal gas and tar

ActiveCN101775321AHigh calorific valueHigh strengthSolid fuelsIndirect heating destructive distillationTarThermal stability

The invention relates to formed coke and a production method of formed coke, coal gas and tar. The mass percent of dry base volatile components of the formed coke is lower than 10 percent, the mass percent of the dry base fixed carbon content is more than 70 percent, the cold pressure intensity is higher than 400 N / ball, the thermal stability is higher than 90 percent, and the dry base high-position heat generation quantity is more than 6000 cal / g. The production method comprises the following steps: using binderless hot pressing moulded coal of low-deterioration dgree coal as raw materials to carry out dry distillation in an external heating type dry distillation device at the temperature between 550 and 1000 DEG C for obtaining the formed coke; and then, obtaining the coal gas and the tar through indirectly cooling and separating obtained gaseous products. The formed coke produced by the method of the invention has low production cost and good reactive activity, and the production process is simple and effective.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

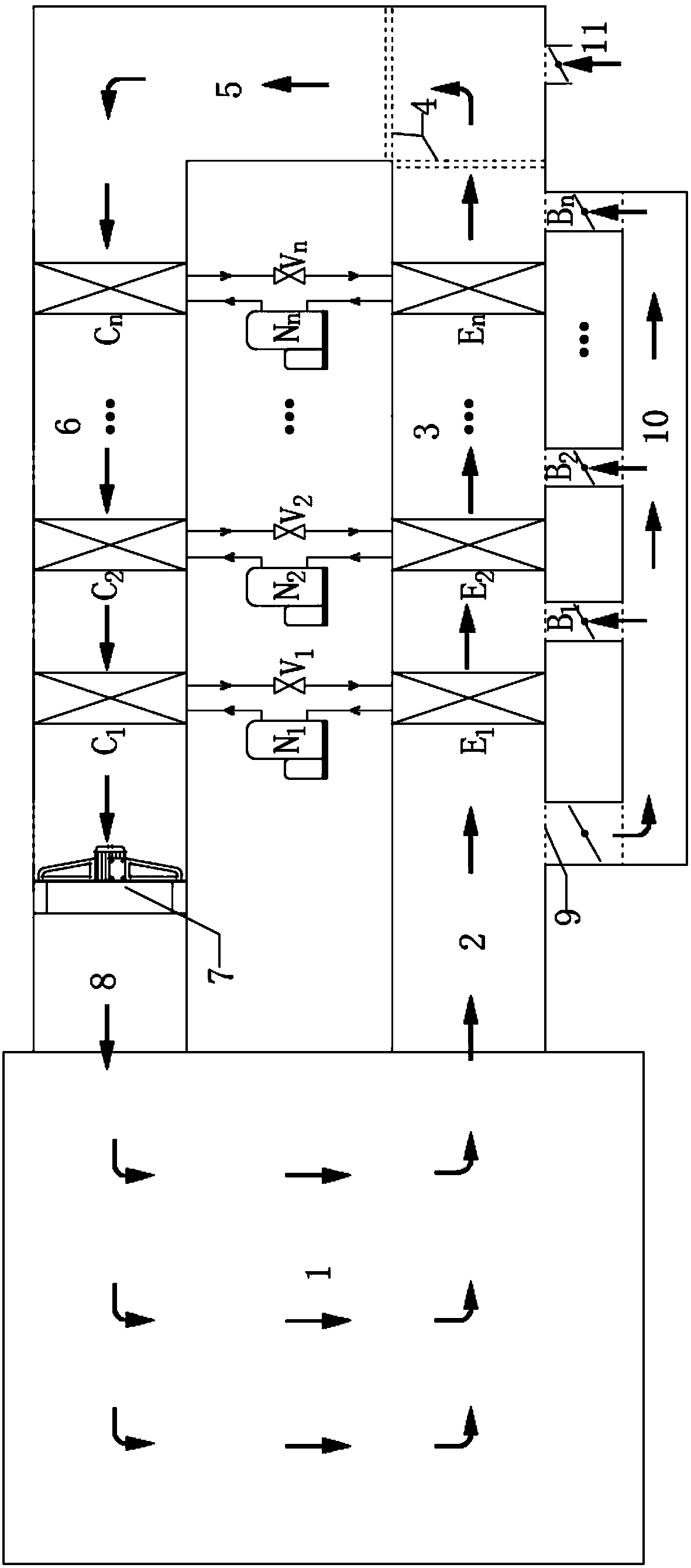

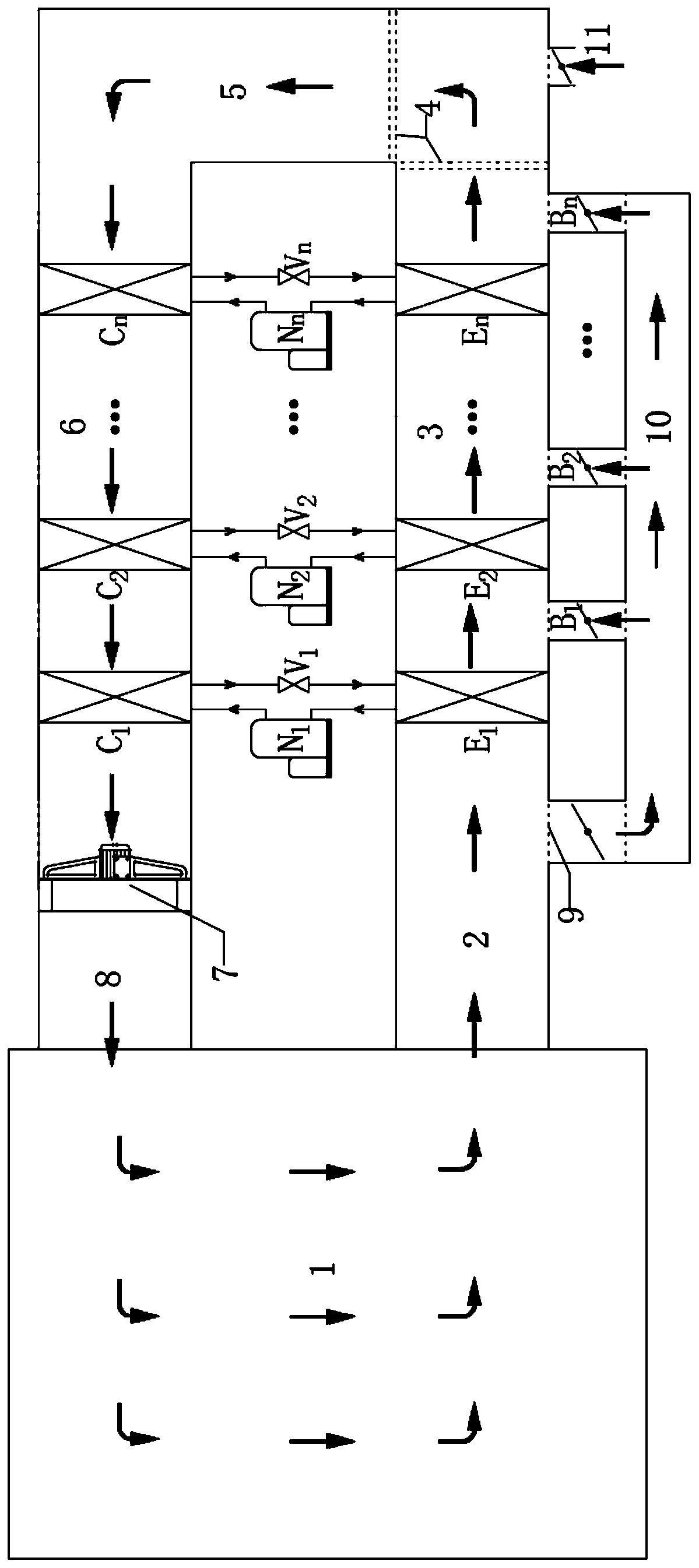

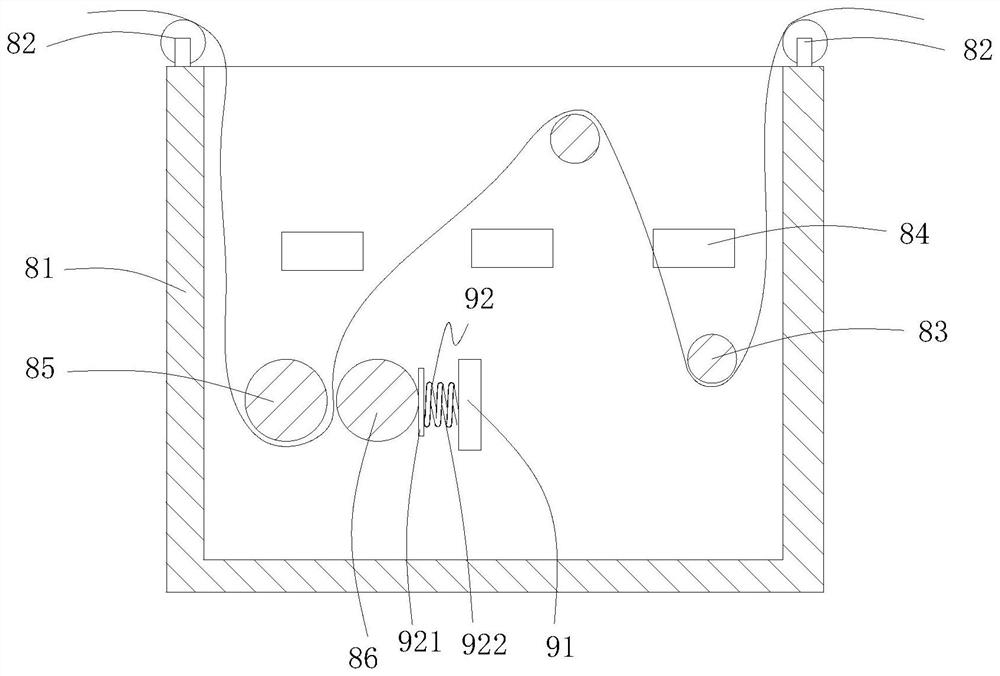

Multi-stage heat pump drying and dehumidifying system with bypass pipeline

ActiveCN107642925AGood dehumidification performanceLower pressure ratioDrying gas arrangementsEfficient regulation technologiesAir volumeEngineering

The invention belongs to the technical field of hot air drying of agricultural and sideline products, and discloses a multi-stage heat pump drying and dehumidifying system with a bypass pipeline. Thesystem comprises a control unit, a main air channel and a drying chamber which is used for containing to-be-dried materials; an air supply inlet for introducing air and an air exhaust outlet for discharging the air are formed in the drying chamber; the two ends of the main air channel are communicated with the air supply inlet and the air exhaust outlet respectively, and the main air channel is internally provided with a main blower, a dehumidifying chamber, a water baffler and a heating chamber, wherein the dehumidifying chamber, the water baffler and the heating chamber are sequentially arranged in the air flow direction; the multi-stage heat pump drying and dehumidifying system further comprises a multi-stage heat pump unit and the bypass pipeline which is communicated with the dehumidifying chamber, and multi-stage heating and multi-stage humidifying are achieved. Compared with a single-stage heat pump drying system, the pressure ratio of a compressor is reduced, the efficiency ofthe compressor is improved, and the air volume control based on the bypass pipeline effectively adjusts the humidifying performance of the system, so that the system has a wider adjusting range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A multi-stage heat pump drying and dehumidification system with bypass pipeline

ActiveCN107642925BGuaranteed uptimeMeet drying requirementsMechanical apparatusDrying gas arrangementsAgricultural scienceAir volume

The invention belongs to the technical field of hot air drying of agricultural and sideline products, and discloses a multi-stage heat pump drying and dehumidification system with a bypass pipeline, comprising: a control unit, a main air duct and a drying room for placing materials to be dried, the drying room An air supply port for introducing gas and an air exhaust port for exhausting gas are provided; the two ends of the main air duct are respectively connected with the air supply port and the air exhaust port, and the main air duct is provided with a main fan and an air exhaust port. A dehumidification chamber, a water baffle, and a heating chamber are arranged in sequence along the airflow direction; it also includes a multi-stage heat pump unit and a bypass pipeline connected with the dehumidification chamber to realize multi-stage heating and multi-stage dehumidification. Compared with the single-stage heat pump drying system, the pressure ratio of the compressor is reduced, and the efficiency of the compressor is improved, and the air volume control based on the bypass pipeline can effectively adjust the dehumidification performance of the system, so that the system has a larger adjustment range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

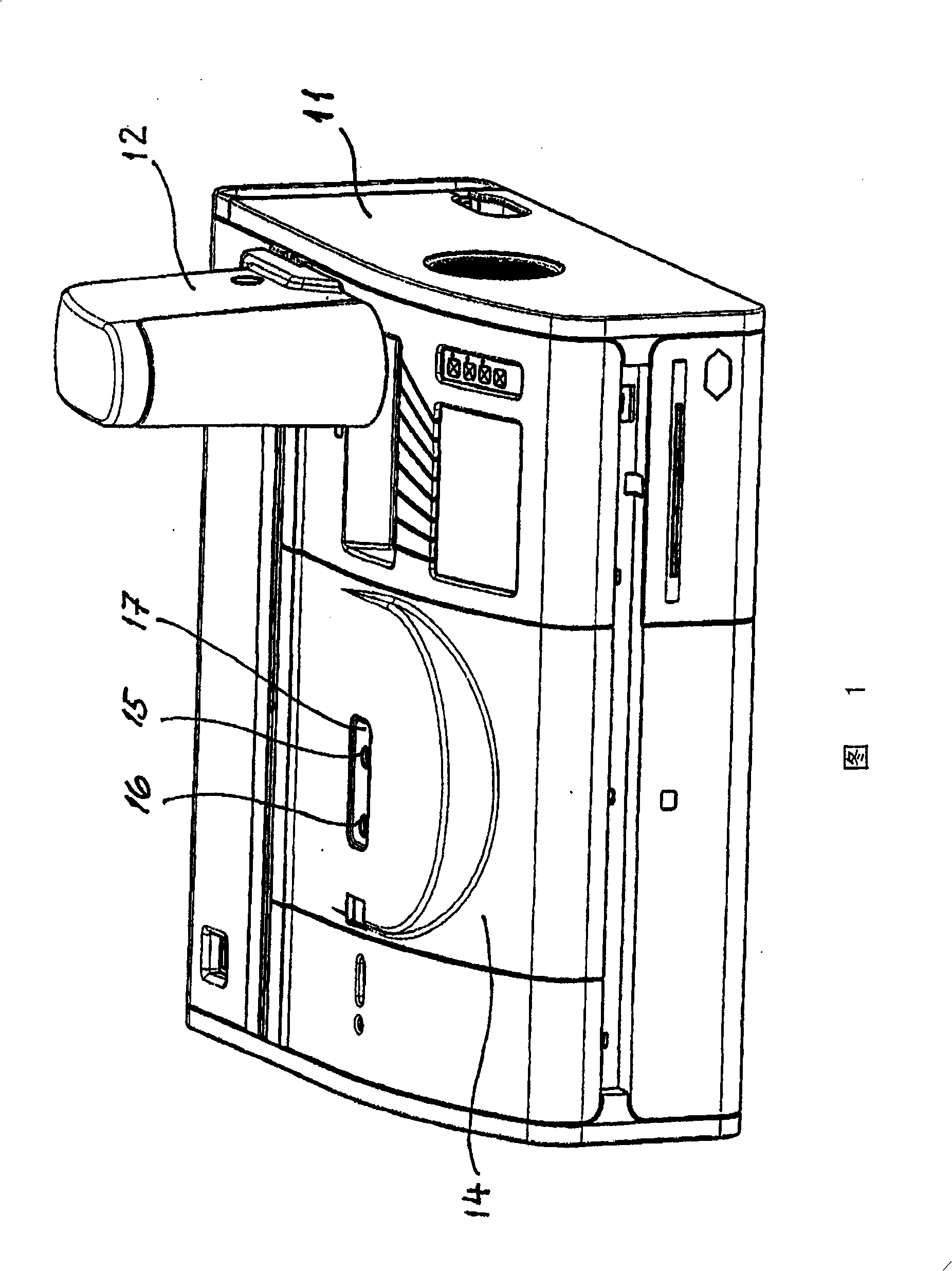

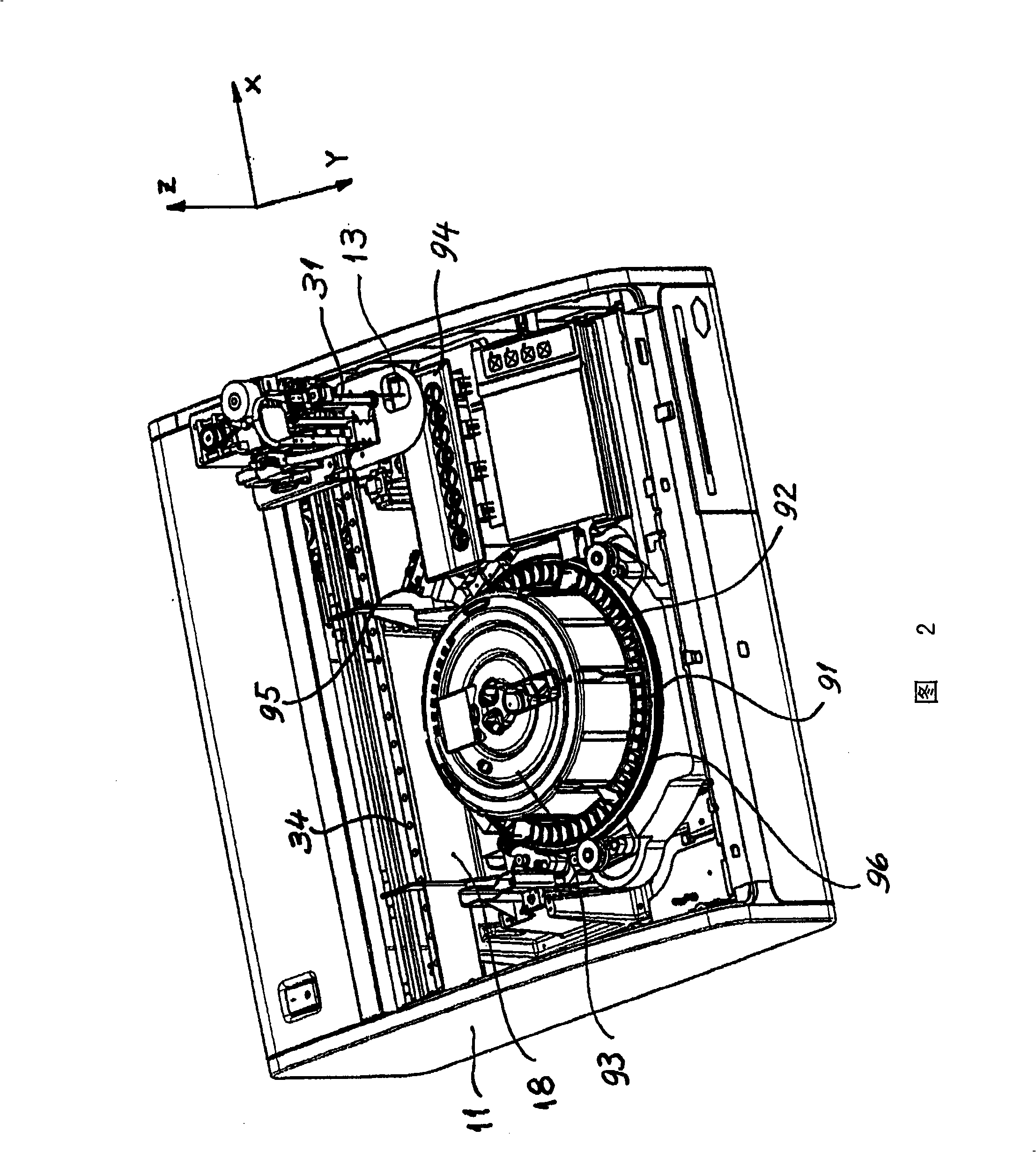

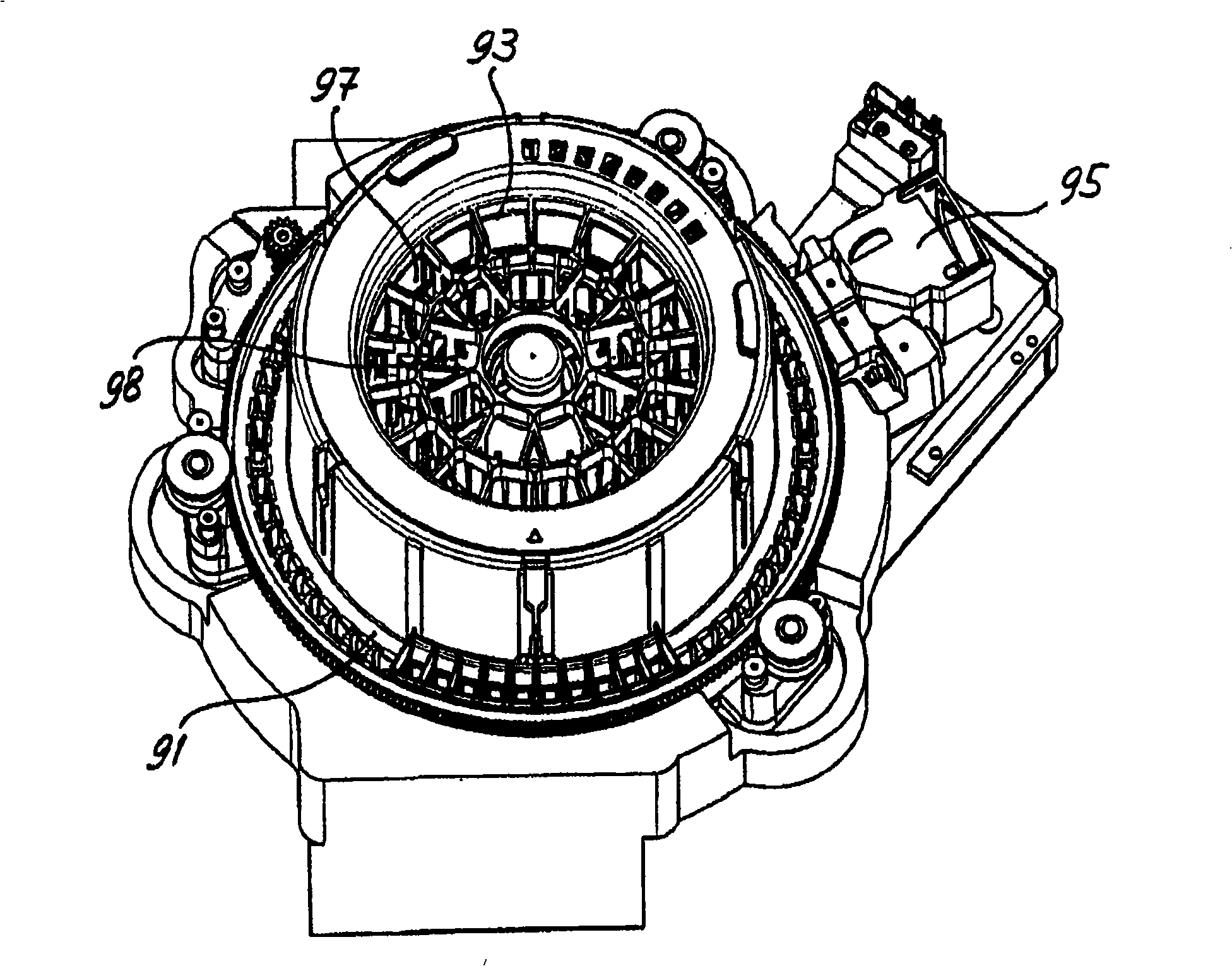

Analyzer with automatically actuated movable closure of pipetting openings

InactiveCN101256192AIncrease manufacturing costEliminate or at least substantially reduce the amount of water vaporLaboratory glasswaresMaterial analysisClinical chemistryEngineering

A clinical chemistry analytical apparatus for automatically analyzing a plurality of biological fluids samples is disclosed. The apparatus provides a movable cover having a pipetting opening which allows insertion of a pipetting needle therethrough, a closure mechanism which in a first state closes the pipetting opening and in a second state leaves it open, a conveyor automatically transporting a reagent container to a pipetting position, at which an opening of the reagent container is aligned with the pipetting opening, and an actuation mechanism which automatically brings the closure mechanism into the second state before introducing the pipetting needle through the pipetting opening and which brings the closure mechanism into the first state after withdrawal of the pipetting needle from the pipetting opening. The actuation mechanism is adapted to actuate the closure mechanism by a displacement of a transport device that moves the pipetting needle to and from at least one pipetting position.

Owner:F HOFFMANN LA ROCHE & CO AG

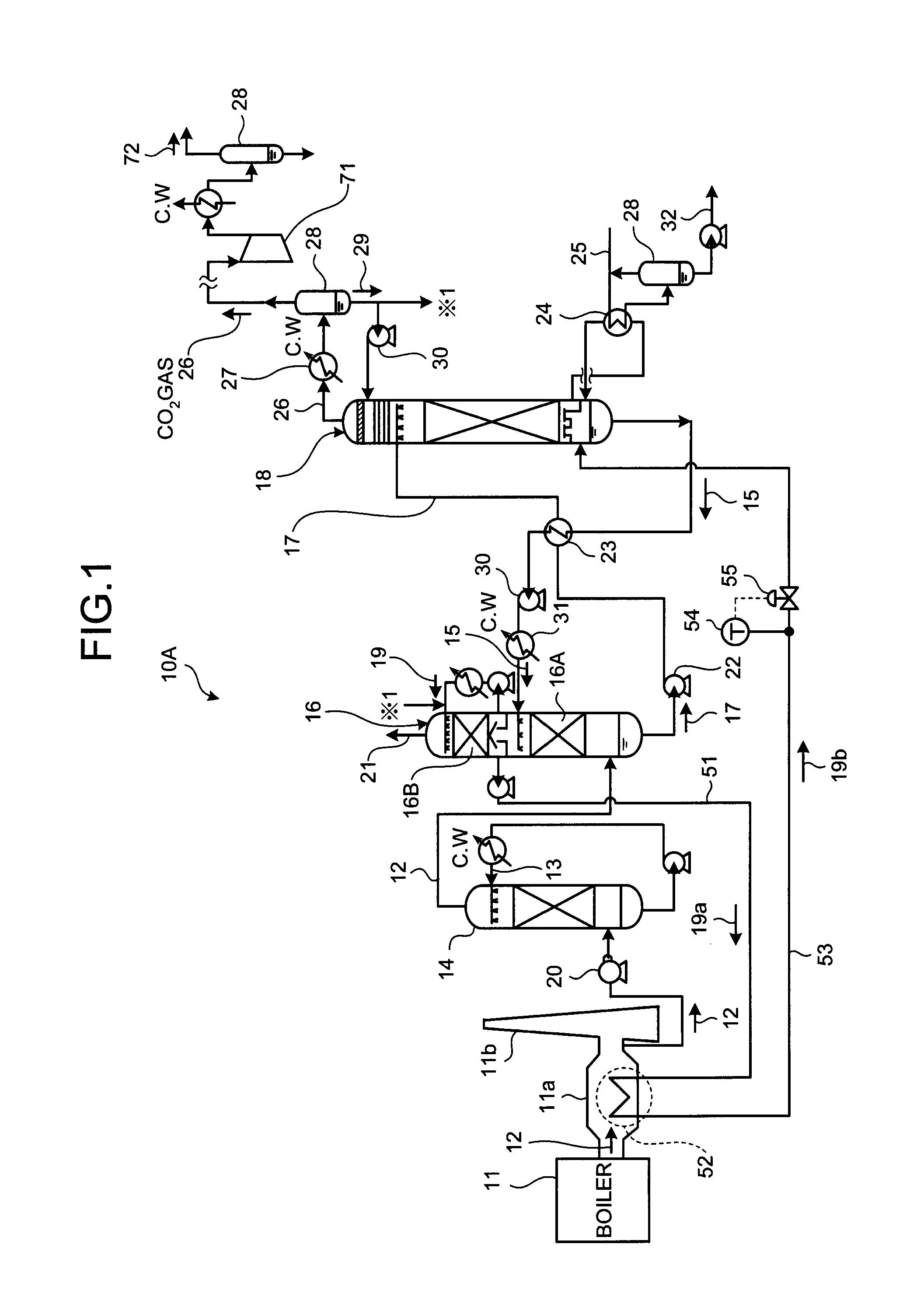

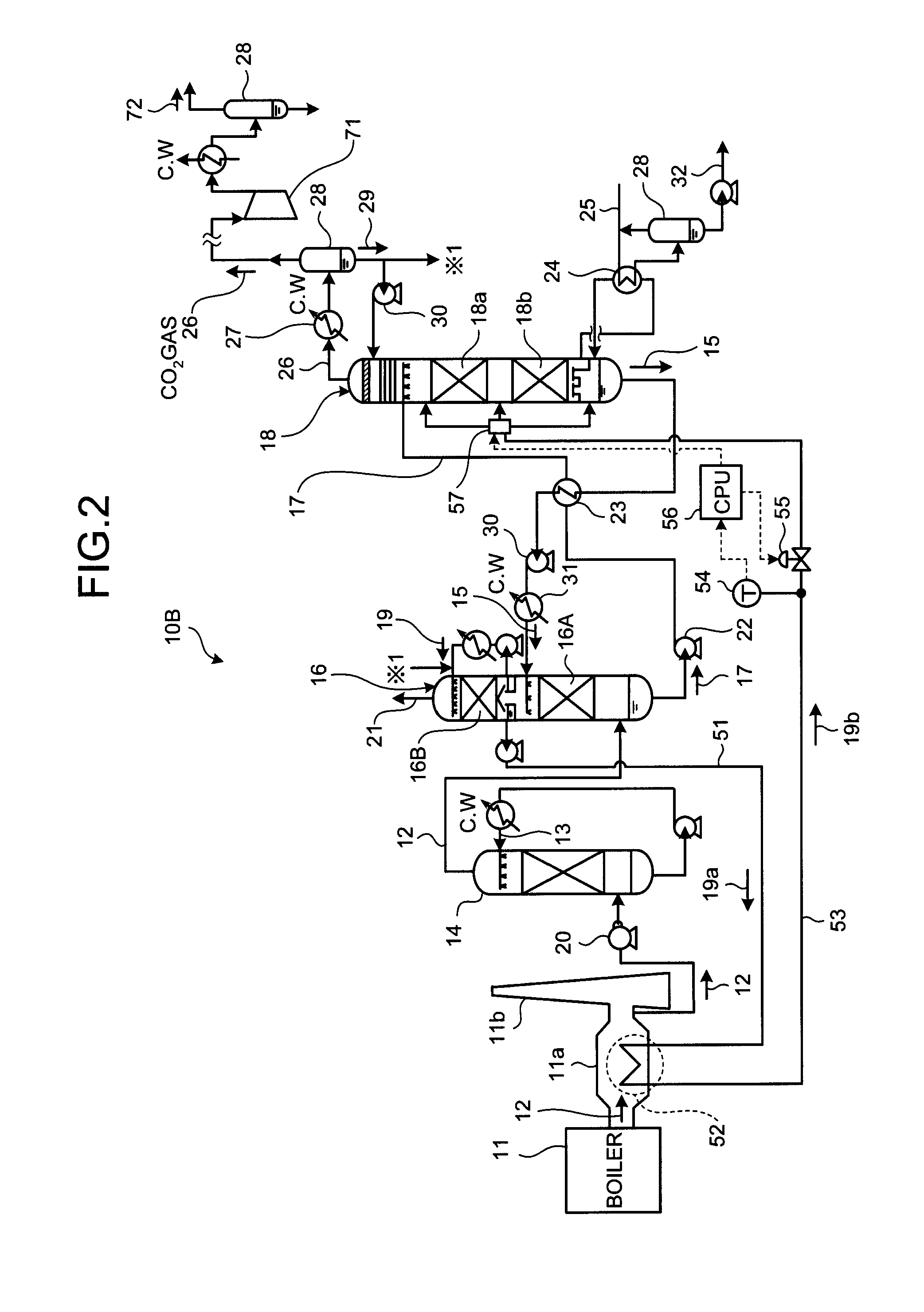

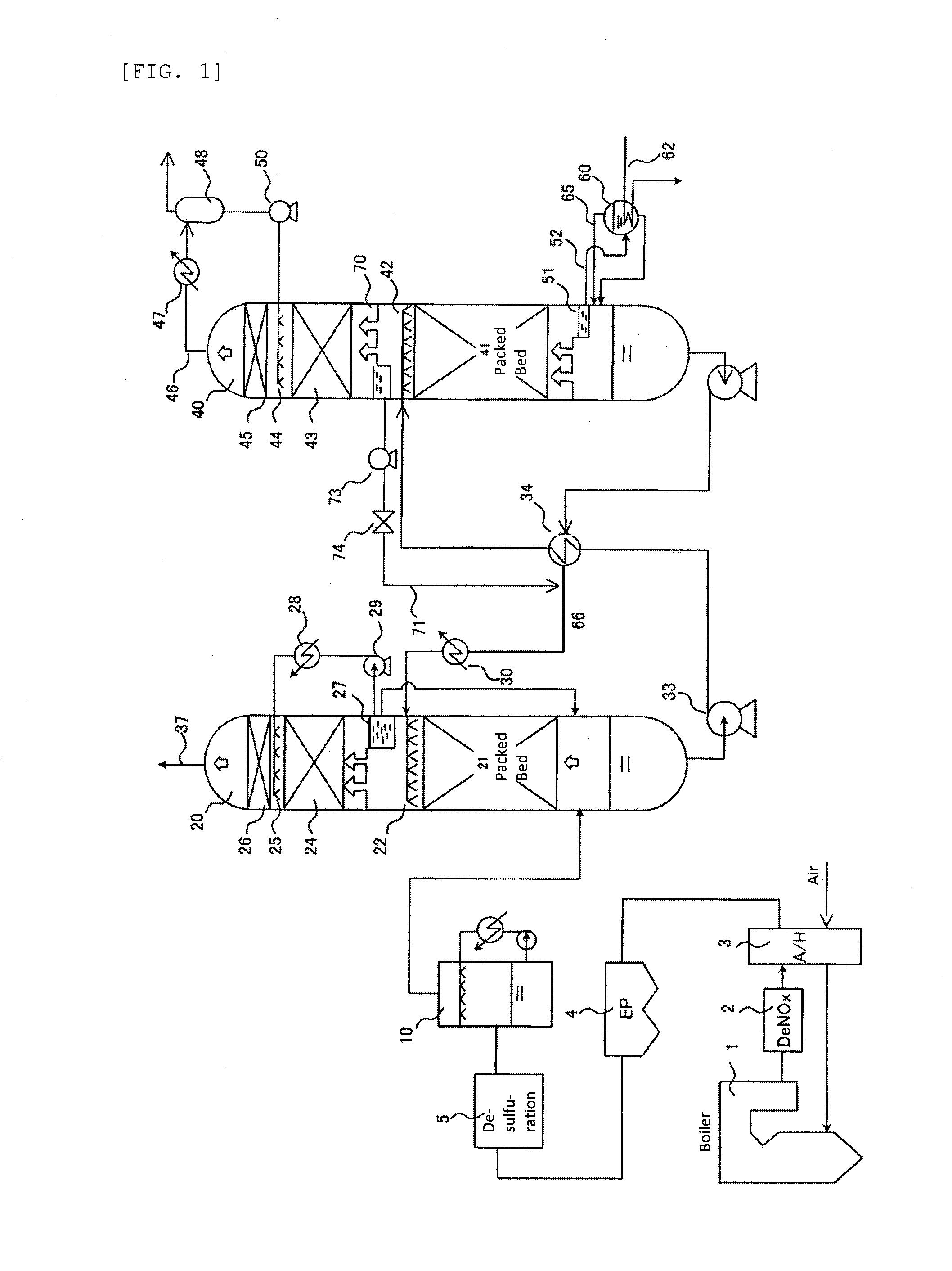

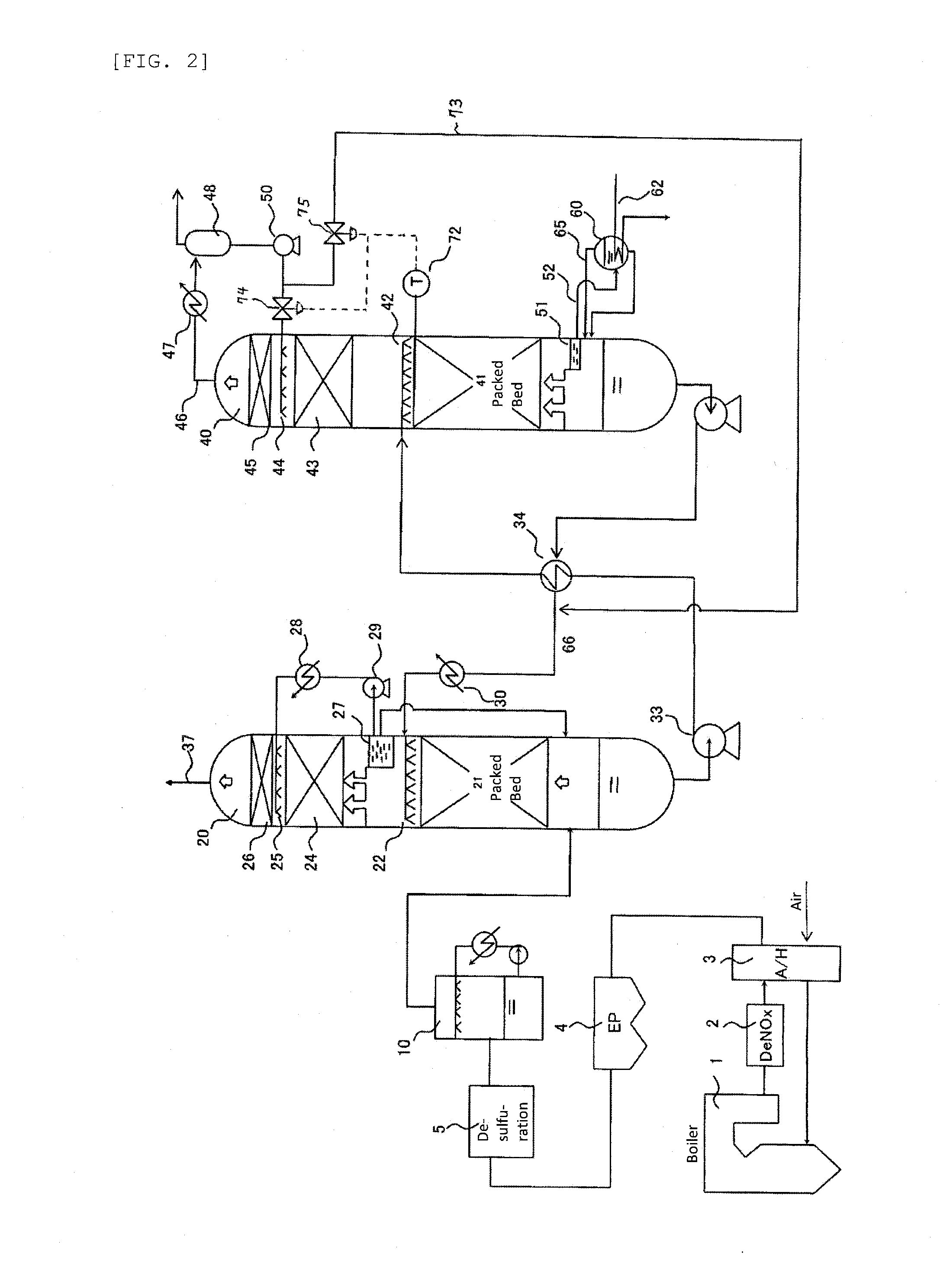

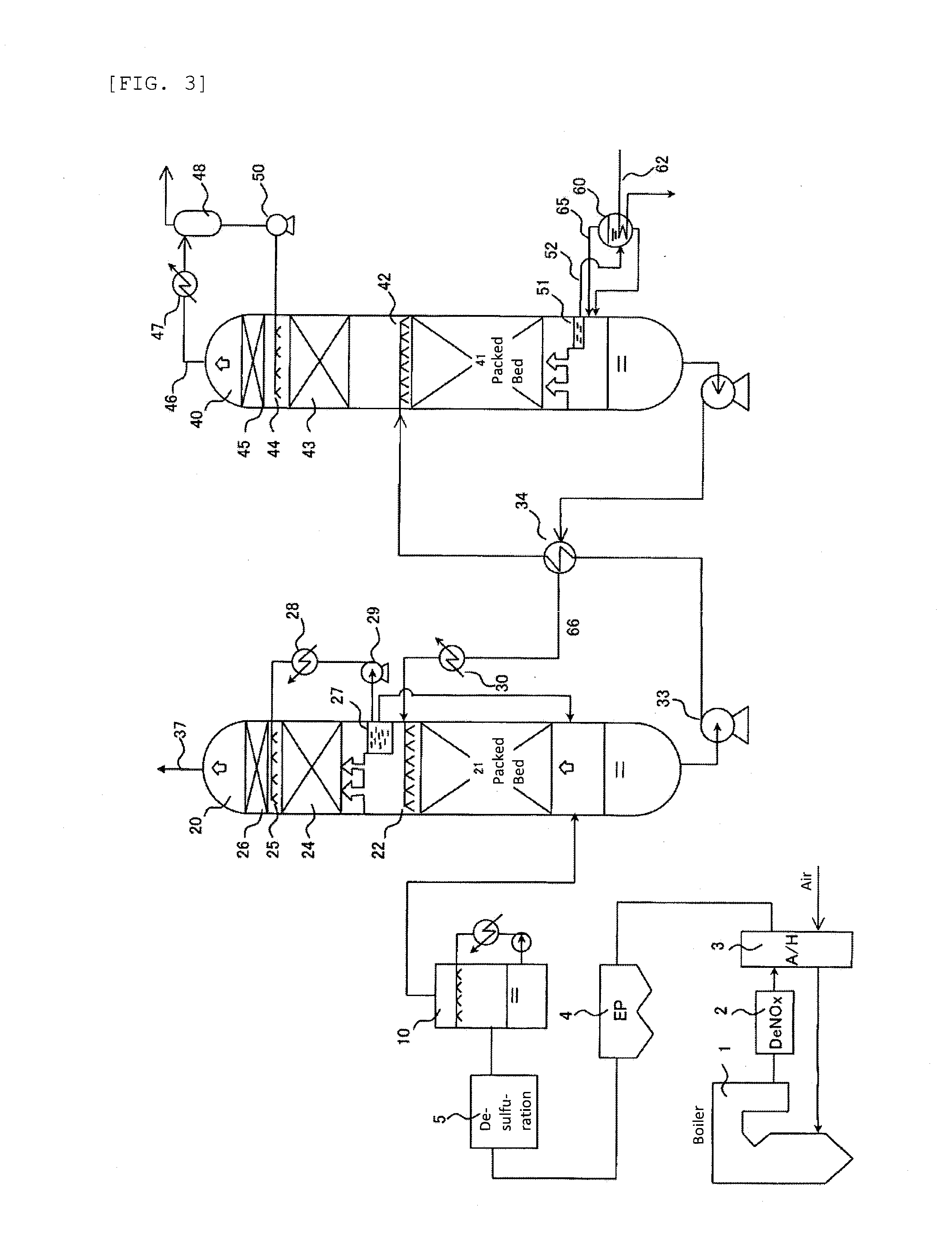

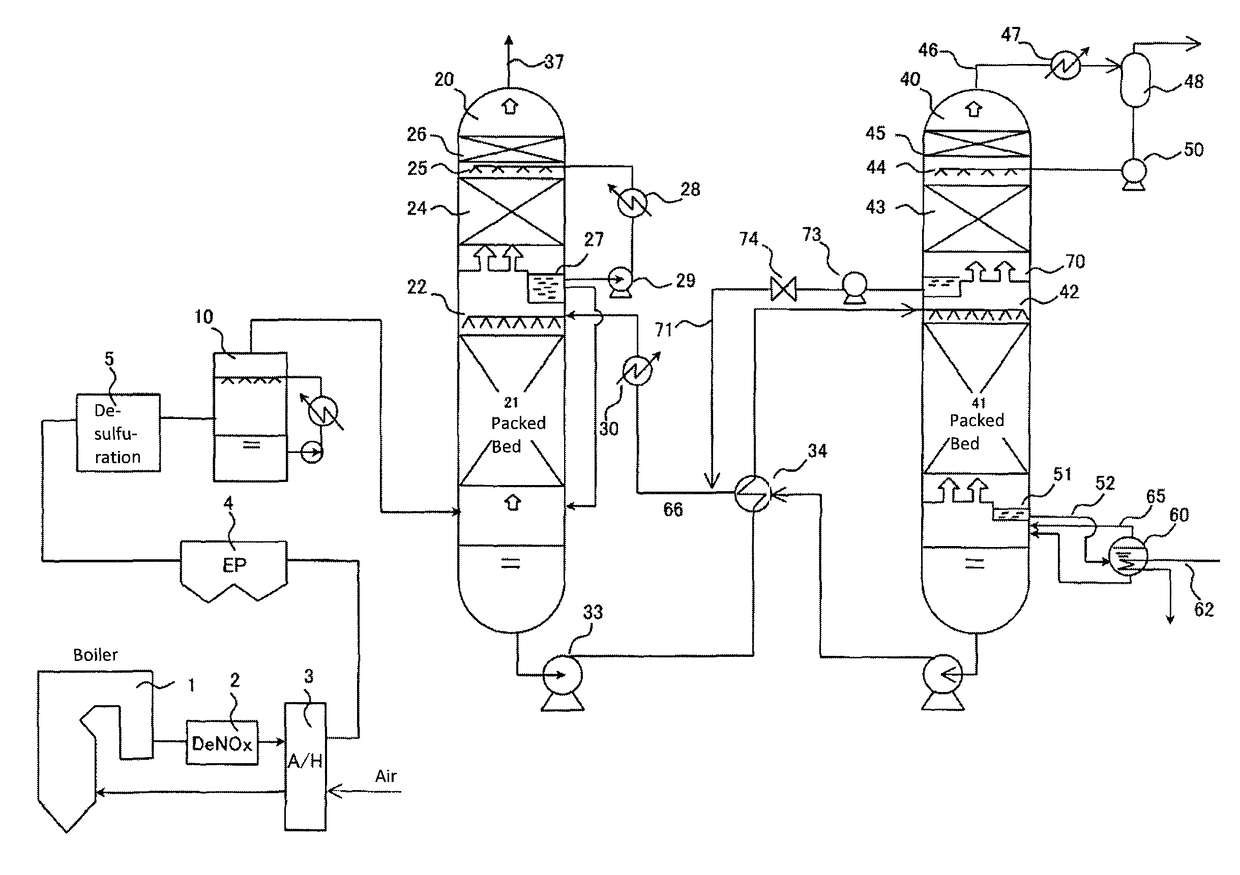

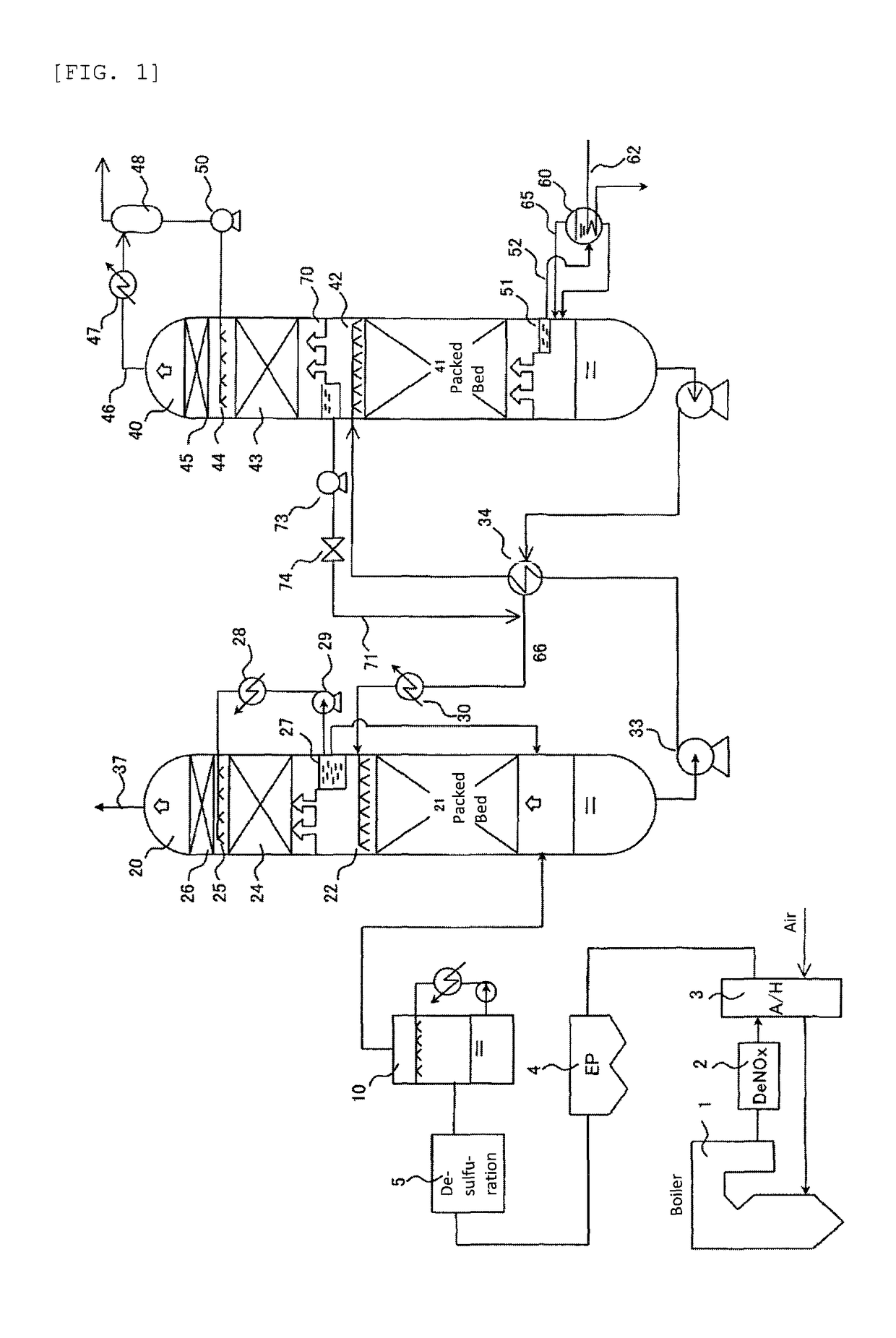

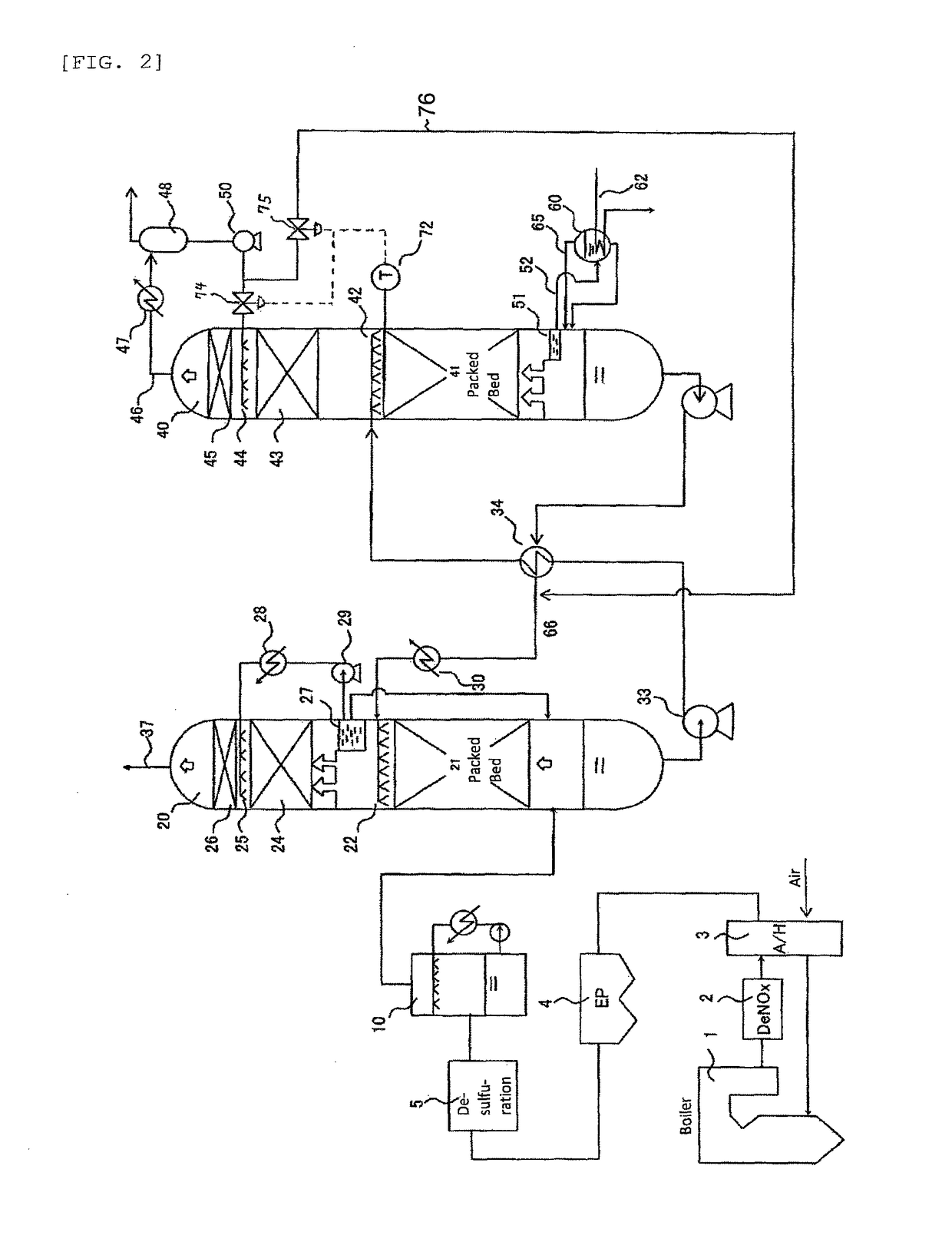

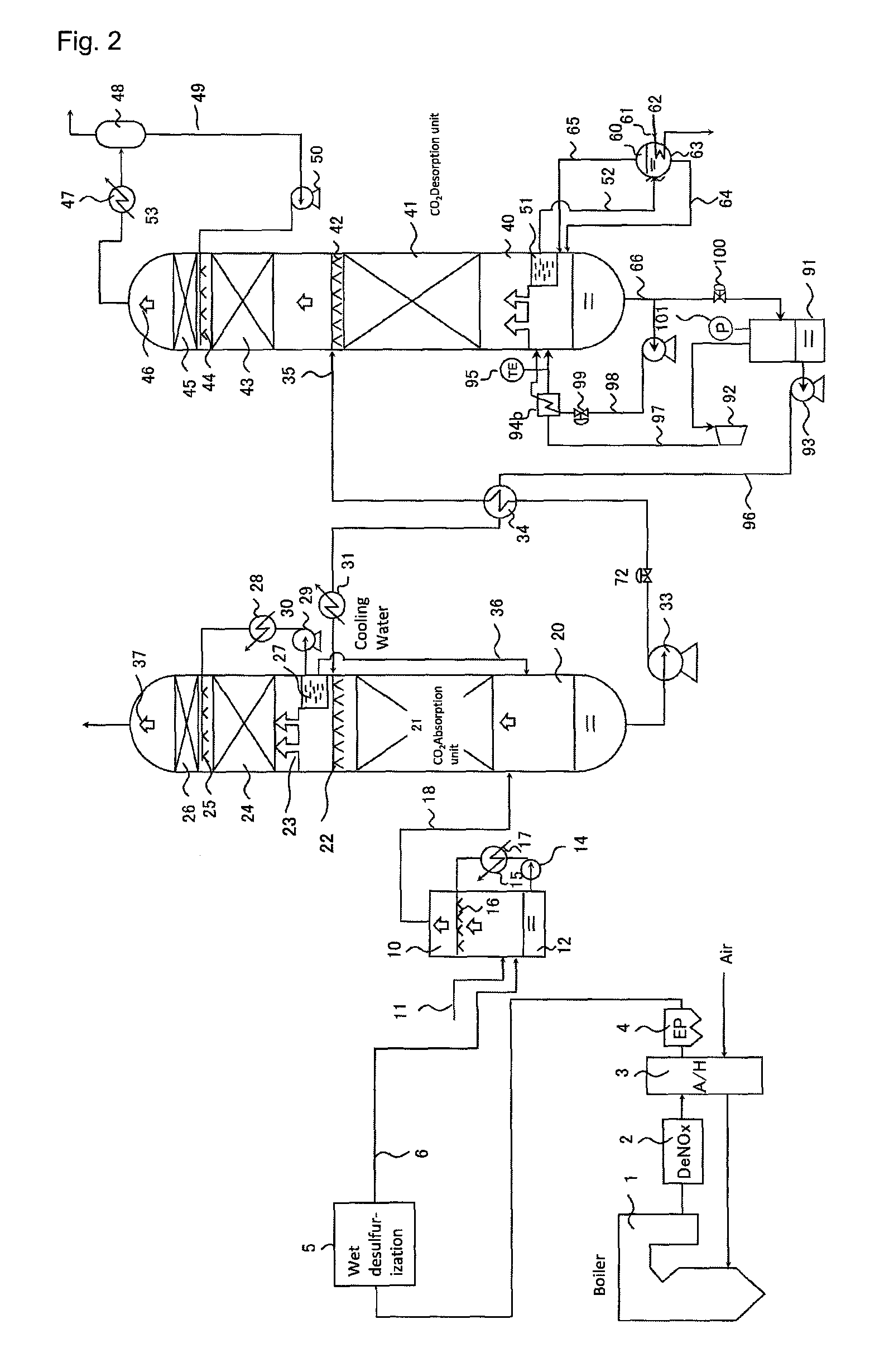

System for chemically absorbing carbon dioxide in combustion exhaust gas

ActiveUS20150030516A1Reduce energy lossReduce amount of water vaporCombination devicesGas treatmentExhaust gasChemistry

A carbon dioxide (CO2) chemical absorption system comprising: a CO2 absorption column for separating CO2 from combustion exhaust gas by absorbing the CO2 in the combustion exhaust gas with a CO2 absorbing liquid mainly composed of an aqueous alkanolamine solution; a regeneration column for regenerating the CO2 absorbing liquid by desorbing CO2 gas from the CO2 absorbing liquid that has absorbed CO2; a condenser for condensing water vapor entrained in the desorbed CO2 gas discharged from the top of the regeneration column, thereby obtaining reflux water; a pipe for returning all or part of the reflux water obtained by the condenser to the top of the regeneration column, and dispersing the reflux water in the regeneration column; a collection plate for collecting the reflux water dispersed in an upper portion of a packed bed in the regeneration column; a pipe for sending the regenerated CO2 absorbing liquid from the bottom of the regeneration column to the top of the absorption column; and a pipe for joining the reflux water collected by the collection plate into the pipe for sending the regenerated CO2 absorbing liquid.

Owner:MITSUBISHI POWER LTD

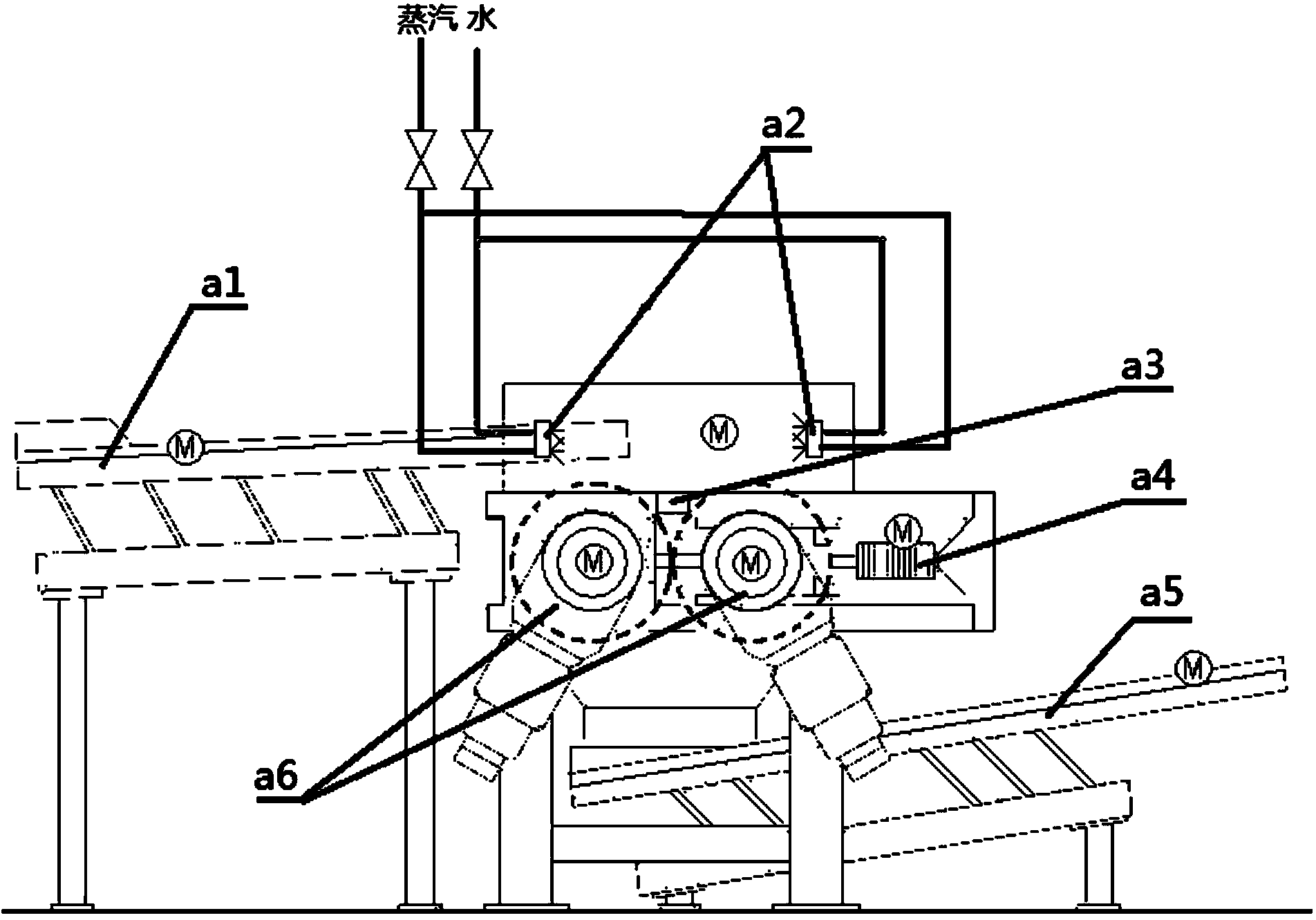

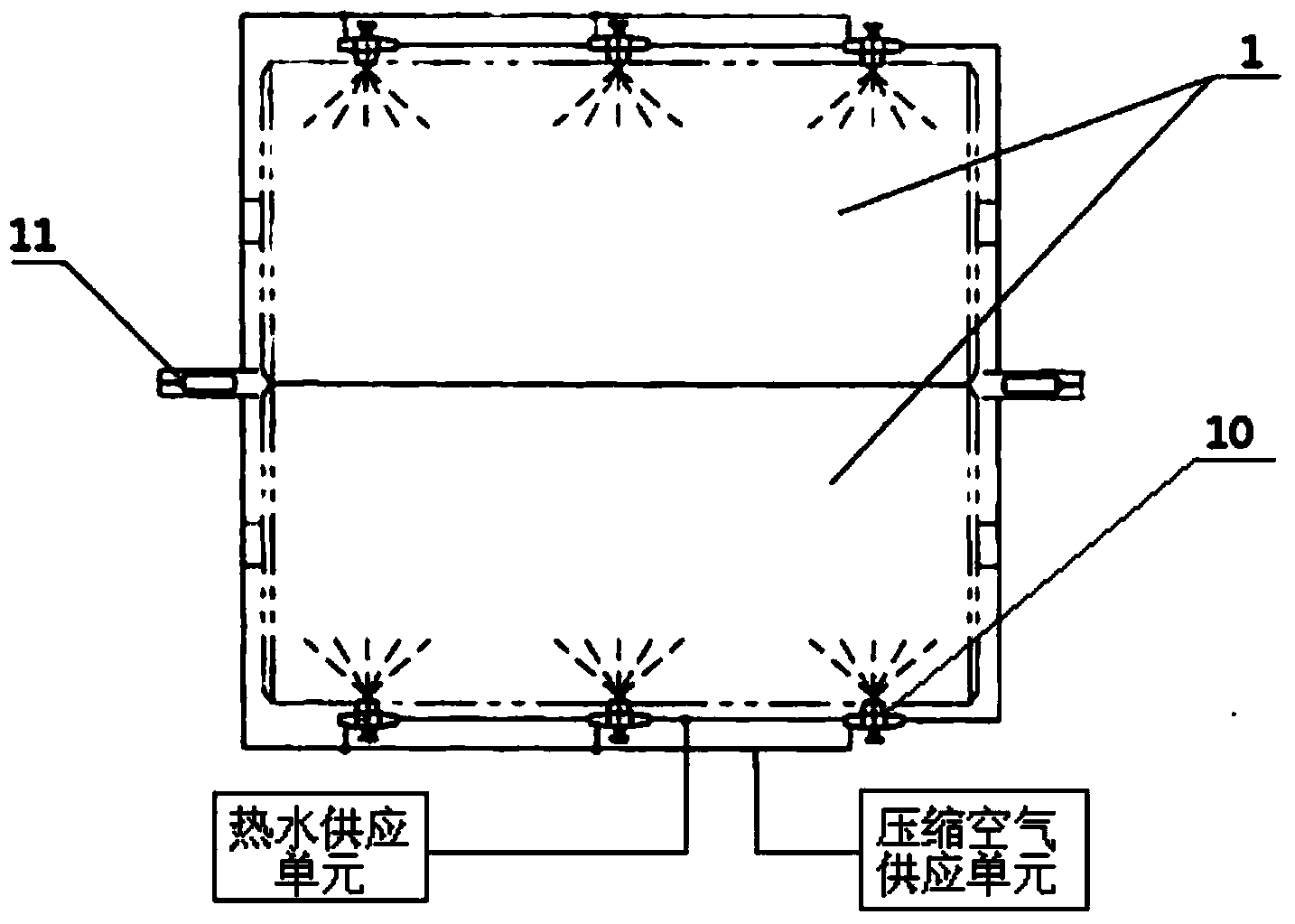

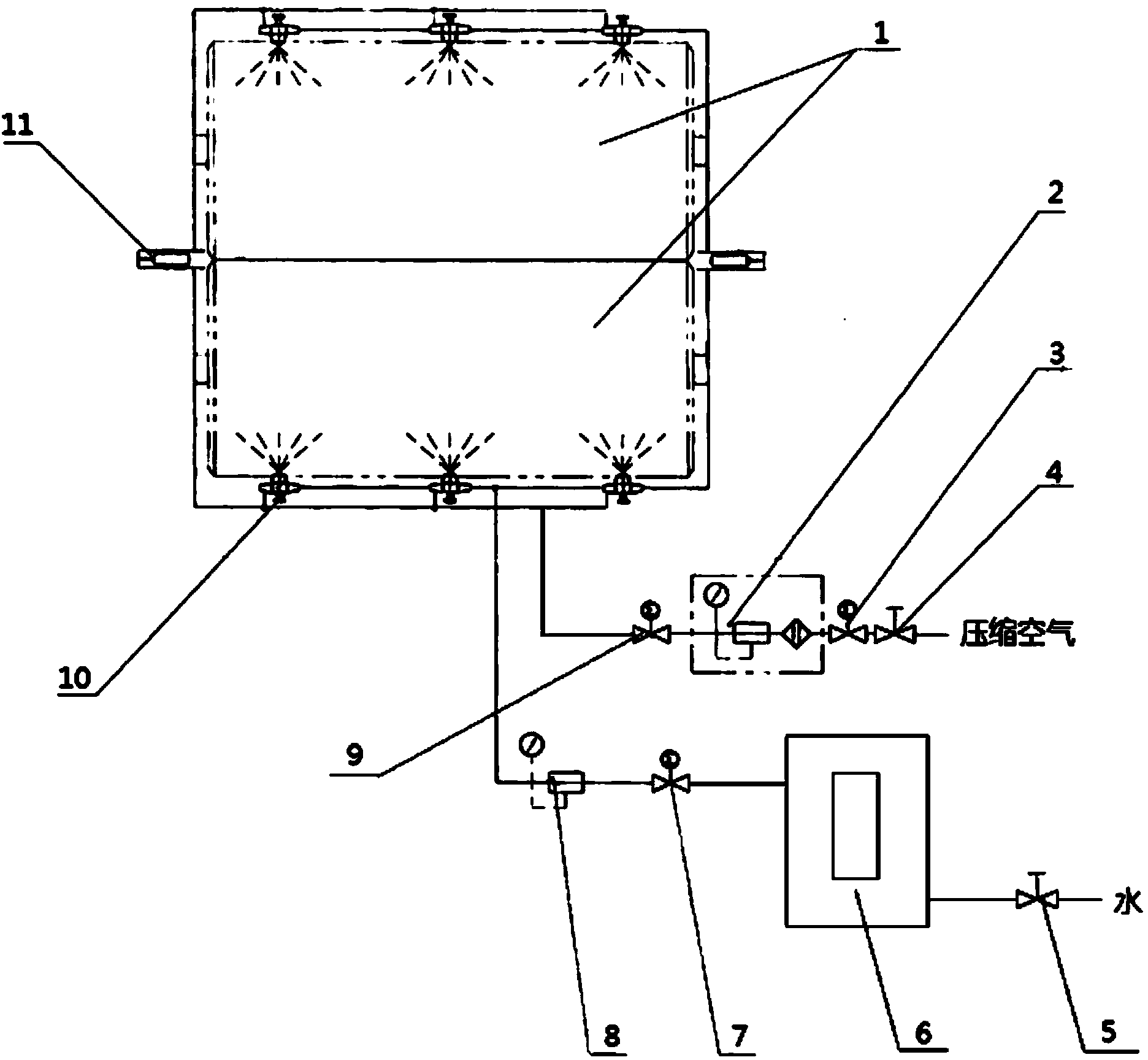

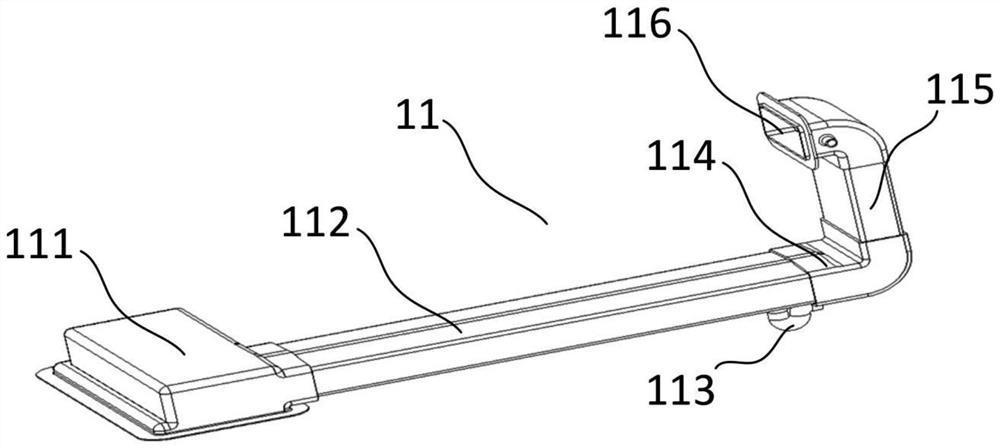

Cabo pressing machine lubricating system and method

InactiveCN104026726AThe production process is stable and reliableStable and reliable productionTobacco treatmentEngineeringThermal water

The invention relates to a cabo pressing machine lubricating system and method. The cabo pressing machine lubricating system can lubricate a roller of a cabo pressing machine. The system comprises a hot water supplying system, a compression air supplying unit and a plurality of double-media nozzles. The hot water supplying unit and the compression air supplying unit are communicated with the double-media nozzles through a pipeline respectively, and the double-media nozzles atomize the hot water supplied by the hot water supplying unit through the compression air supplied by the compression air supplying unit and eject atomized water to the roller. Compared with an existing method for performing atomizing and increasing the temperature of the water through high-temperature steam, the cabo pressing machine lubricating method has the advantages that atomized steam is not used, and therefore the vapor amount is reduced in the cabo pressing machine, and the problem that the lubricating effect is poor or a detecting device is interfered due to inappropriate adjustment on the atomized steam pressure is avoided; the effect of the hot water atomization on the detecting device is small while the hot water atomization achieved through the compression air can meet the roller lubricating requirement, and therefore the production process of the cabo pressing machine is more stable and reliable.

Owner:LONGYAN CIGARETTE FACTORY

System for chemically absorbing carbon dioxide in combustion exhaust gas

ActiveUS9901871B2Reduce heatReduce the amount of water vaporGas treatmentDispersed particle separationCombustionAbsorption column

A carbon dioxide (CO2) chemical absorption system comprising: a CO2 absorption column for separating CO2 from combustion exhaust gas by absorbing the CO2 in the combustion exhaust gas with a CO2 absorbing liquid mainly composed of an aqueous alkanolamine solution; a regeneration column for regenerating the CO2 absorbing liquid by desorbing CO2 gas from the CO2 absorbing liquid that has absorbed CO2; a condenser for condensing water vapor entrained in the desorbed CO2 gas discharged from the top of the regeneration column, thereby obtaining reflux water; a pipe for returning all or part of the reflux water obtained by the condenser to the top of the regeneration column, and dispersing the reflux water in the regeneration column; a collection plate for collecting the reflux water dispersed in an upper portion of a packed bed in the regeneration column; a pipe for sending the regenerated CO2 absorbing liquid from the bottom of the regeneration column to the top of the absorption column; and a pipe for joining the reflux water collected by the collection plate into the pipe for sending the regenerated CO2 absorbing liquid.

Owner:MITSUBISHI POWER LTD

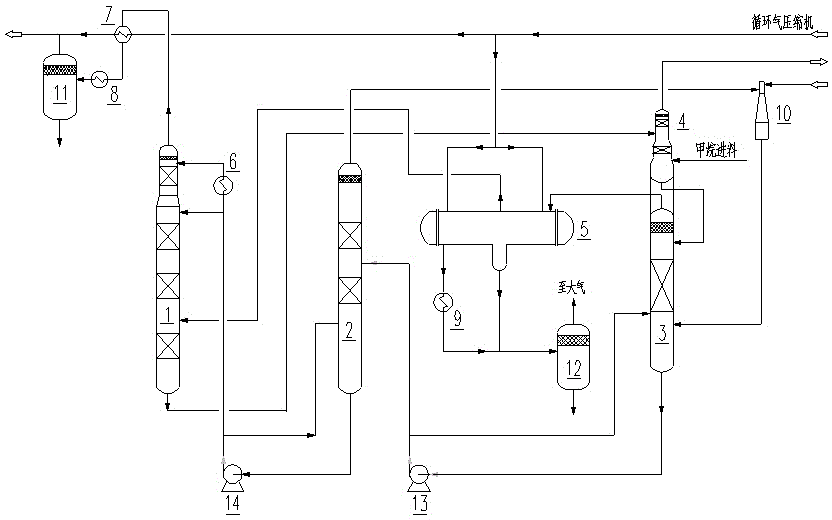

Method for removing carbon dioxide in recycle gas for synthesizing ethylene oxide/glycol

ActiveCN102675248BReduced regeneration heat consumptionReduce heat consumptionOrganic chemistryBulk chemical productionTemperature controlPtru catalyst

The invention belongs to the technical field of gas purification and provides a decarbonization solution and a decarbonization method due to the fact that CO2 content in recycle gas needs to be lowered when a novel high selective catalyst is adopted for synthesizing ethylene oxide / glycol. The solution is composed of potassium carbonate and an inorganic activating agent. Two-section absorption process of appropriate flow distribution and temperature control is adopted. Desorbing of the solution adopts novel transformation regeneration energy-saving technology, differential pressure is formed between two towers of a pressurization regeneration tower and a normal pressure regeneration tower by using a desorbing effect of an adjustable supersonic speed steam ejector on the normal pressure regeneration tower, mixed gas containing a large amount of water vapour is desorbed for gas stripping and regeneration for the pressurized regeneration tower. By means of the method, residue CO2 in the recycle gas after decarbonization is greatly reduced, and simultaneously solution reclaimed heat consumption is reduced by more than 30% compared with conventional potassium carbonate decarbonization process.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

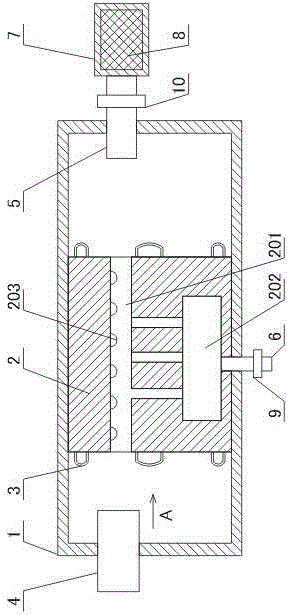

Drum type natural gas drying device

InactiveCN104117269BReduce the amount of water vaporExtended service lifeGaseous fuelsDispersed particle separationSorbentWater vapor

The invention discloses a cylindrical natural gas drying device. The device comprises a drying cavity, a condensation column, a condensation pipe, a gas inlet pipe, a gas outlet pipe, a liquid outlet pipe, a drying pipe and adsorbents, wherein the condensation column is arranged in the drying cavity; the condensation pipe penetrates through the condensation column back and forth in the peripheral direction of the condensation column; a plurality of horizontal runners are formed in the condensation column; a liquid collecting cavity is formed in the lower part of the condensation column, is arranged below the horizontal runners and is communicated with each horizontal runner; the gas inlet pipe is arranged on the left of the drying cavity; the gas outlet pipe is arranged on the right of the drying cavity; the liquid outlet pipe is communicated with the liquid collecting cavity; perforated plates are arranged at the two ends of the drying pipe; the adsorbents are arranged in the drying pipe; the drying pipe is communicated with the gas outlet pipe. The device is suitable for natural gases with high water vapor contents and can prevent the adsorbents from losing effects in a short time and improve the natural gas drying effects.

Owner:随州中燃城市燃气发展有限公司

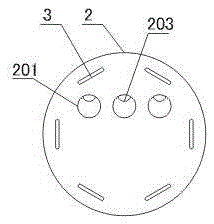

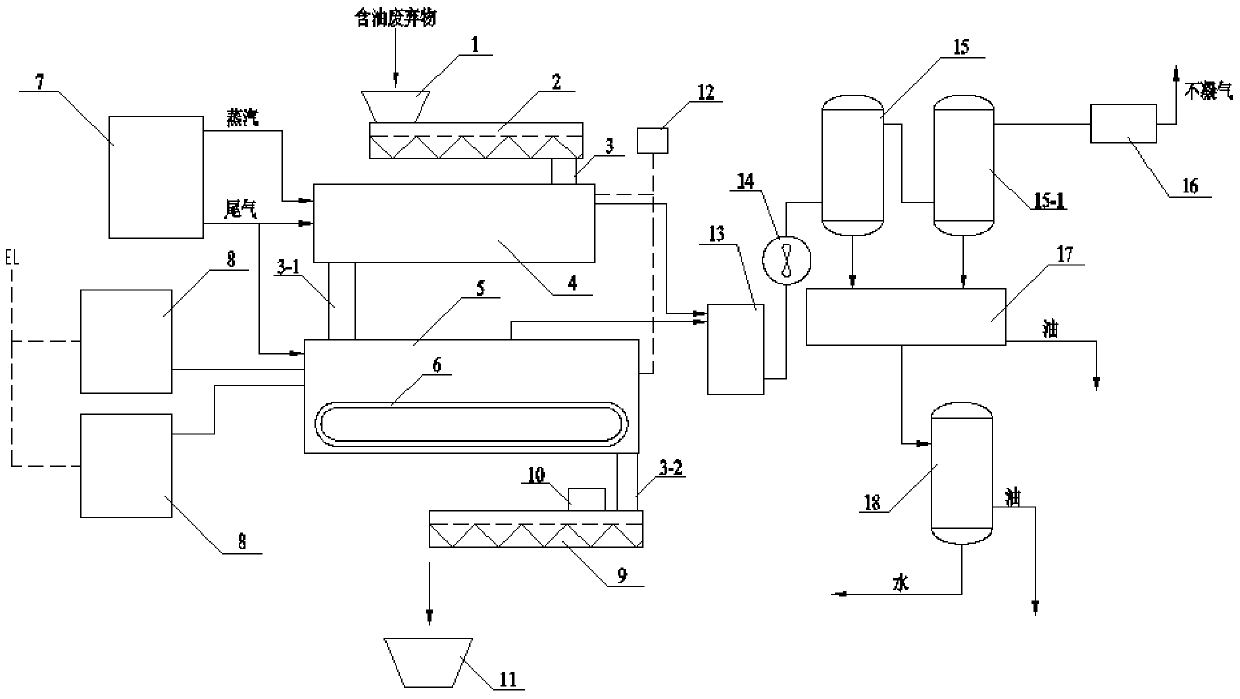

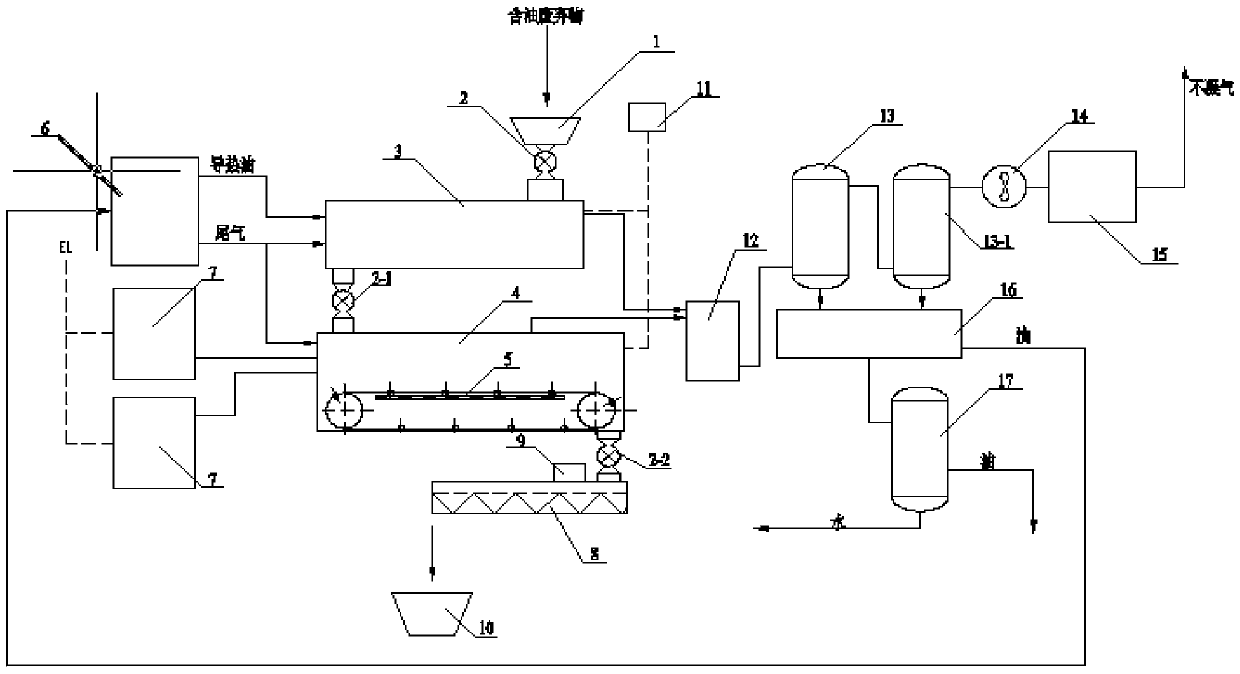

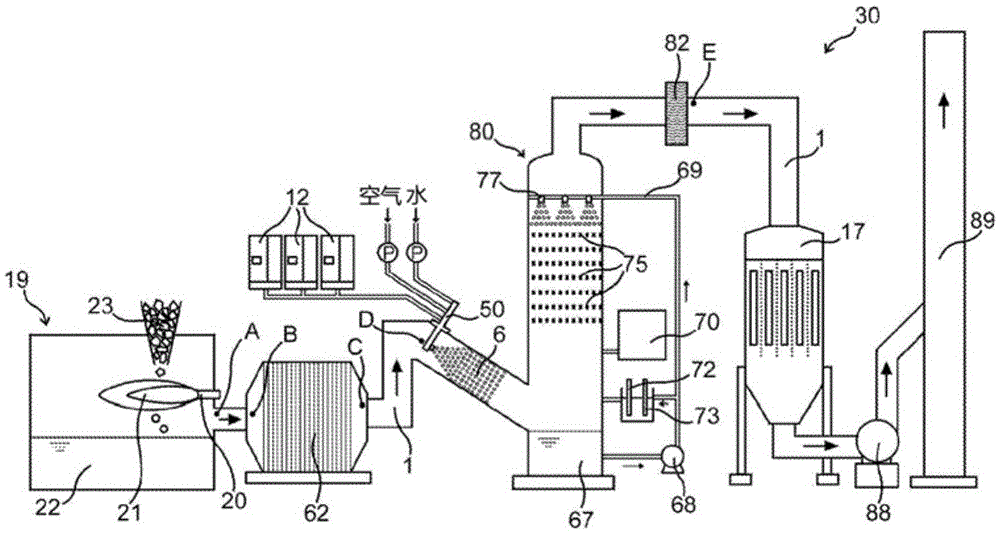

Industrial treatment method and device for oil field waste

ActiveCN103923670BLow boiling pointIncrease gasification rateElectrical coke oven heatingLiquid hydrocarbon mixture productionOil processingMicrowave pyrolysis

An industrial treatment method for oil field wastes comprises: performing sampling analysis on oil field wastes, and preheating to 80°C to 300°C using high-temperature steam or thermal conduction oil; then performing microwave pyrolysis treatment, controlling pressure at -5000 to -100 Pa, and obtaining treated solid substances and gas; condensing, separating and purifying the gas and recycling the gas so as to obtain water, oil and non-condensable gas. An industrial treatment device for oil field wastes comprises a feed hopper, a dryer, a microwave heating cavity, a microwave generator, a heating device, and a condensation, separation and purification device. The feed hopper is connected to the dryer. The dryer is connected to the microwave heating cavity. A steam or thermal conduction oil outlet of the heating device is connected to a steam or thermal conduction oil inlet of the dryer. Gas outlets of the dryer and the microwave heating cavity are both connected to the condensation, separation and purification device. The microwave generator is connected to the microwave heating cavity. The treatment method and device have good treatment effects, high energy utilization rate and high economic efficiency.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Exhaust gas treatment method, and exhaust gas treatment device

ActiveCN105451862AInhibit thermal decompositionReduce the amount of water vaporGas treatmentDispersed particle separationExhaust gasExhaust fumes

This exhaust gas treatment method is characterized by involving a step for supplying ozone and a first liquid, which is water or an aqueous solution, into an exhaust gas that contains NOx and that is 150 DEG C or higher, and for generating a first mist, in which the water droplets of the first liquid are suspended, in the exhaust gas containing ozone gas. This exhaust gas treatment method may also involve a step for generating, in the exhaust gas that passed through the first mist, a second mist by spraying a second liquid which is a reducing agent aqueous solution.

Owner:OSAKA PREFECTURE UNIV PUBLIC CORP +1

Network tube type natural gas drying device

ActiveCN104117268BKeep dryExtended service lifeGaseous fuelsDispersed particle separationSorbentWater vapor

The invention discloses a network tube type natural gas drying device, which comprises a drying chamber, a horizontal condensation pipe, a vertical condensation pipe, an air inlet pipe, an air outlet pipe, a liquid collection box, a liquid outlet pipe, a drying pipe and an adsorbent; the bottom of the drying chamber is provided with Tapered opening, the liquid collection box communicates with the tapered opening, the horizontal condensation pipe and the vertical condensation pipe are arranged crosswise; the air inlet pipe is arranged on the left side of the drying chamber, the air outlet pipe is arranged on the right side of the drying chamber, and the liquid outlet pipe is arranged on the liquid collection The bottom of the box; the two ends of the drying pipe are provided with porous plates, the adsorbent is arranged in the drying pipe, and the drying pipe is connected with the air outlet pipe. The invention is suitable for the natural gas with high water vapor content, can prevent the adsorbent from failing in a short time, and improve the drying effect of the natural gas.

Owner:天津市金万航石油物资装备有限公司

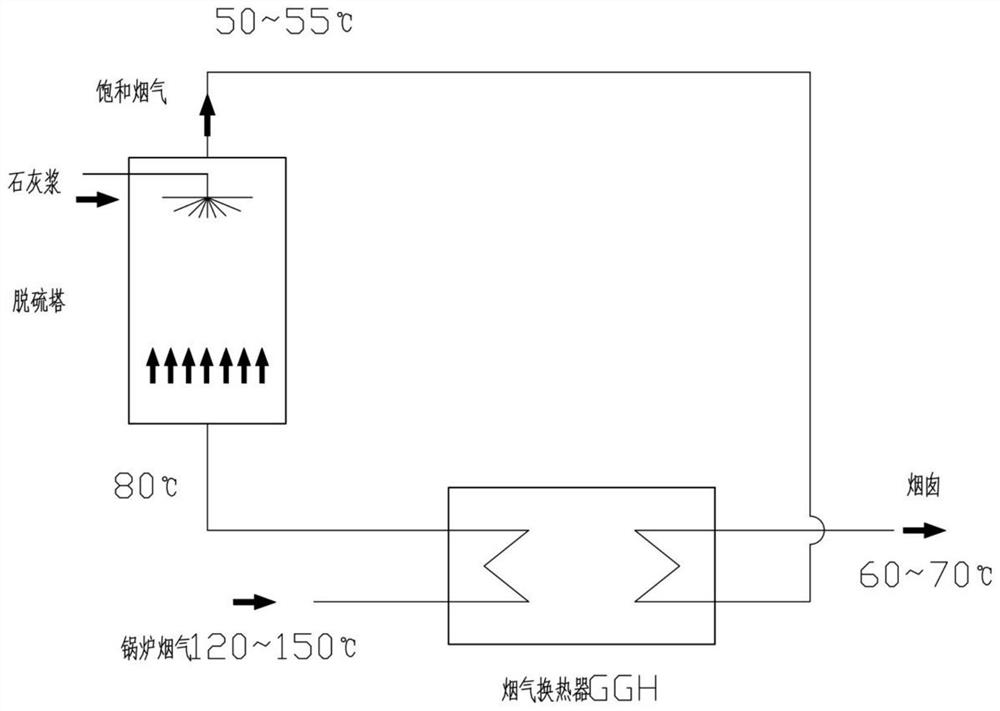

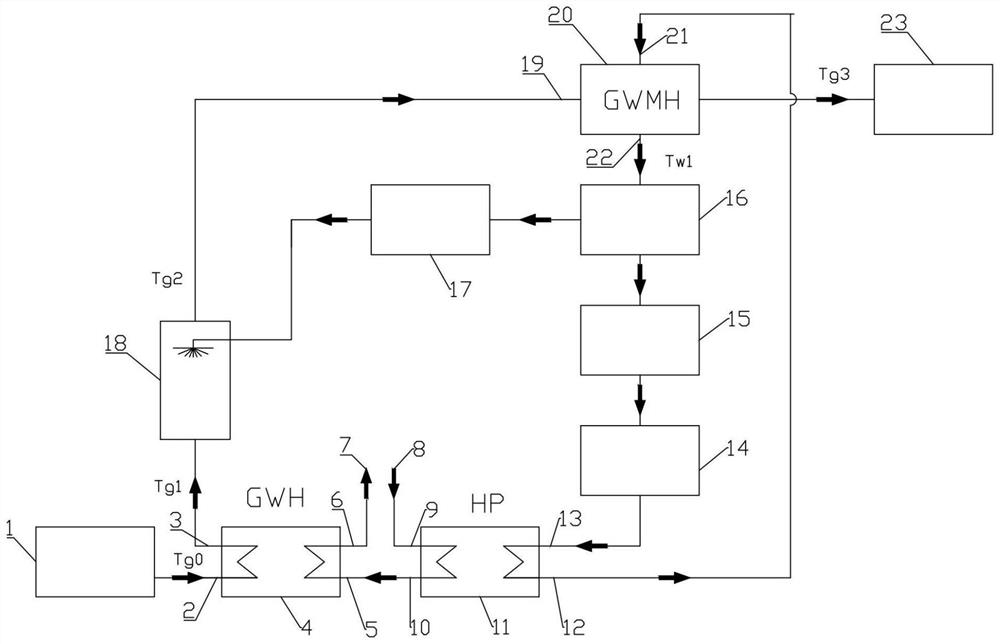

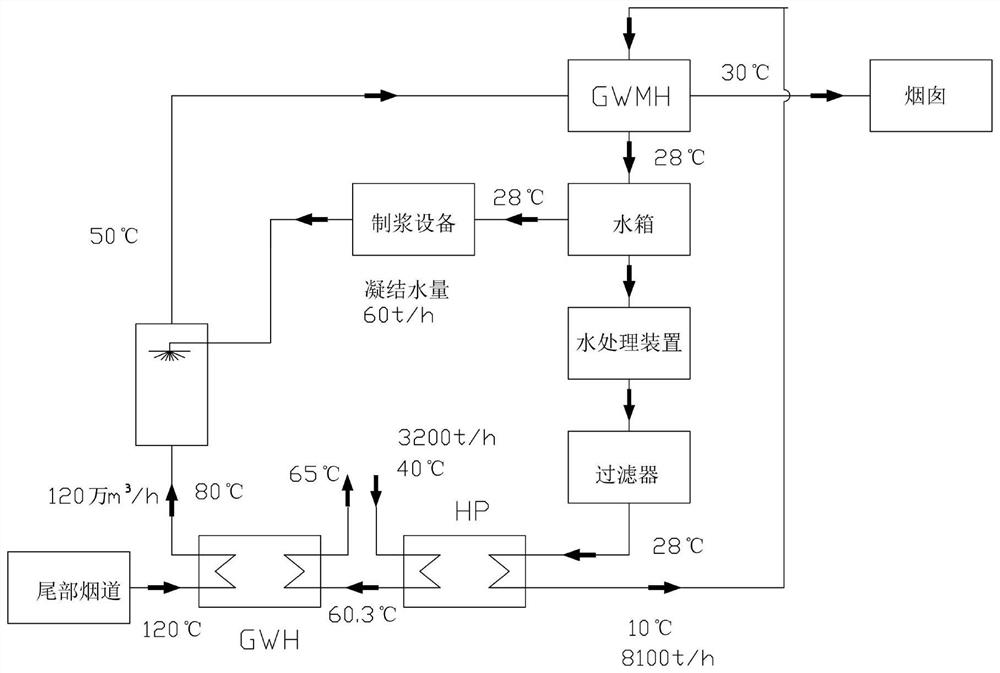

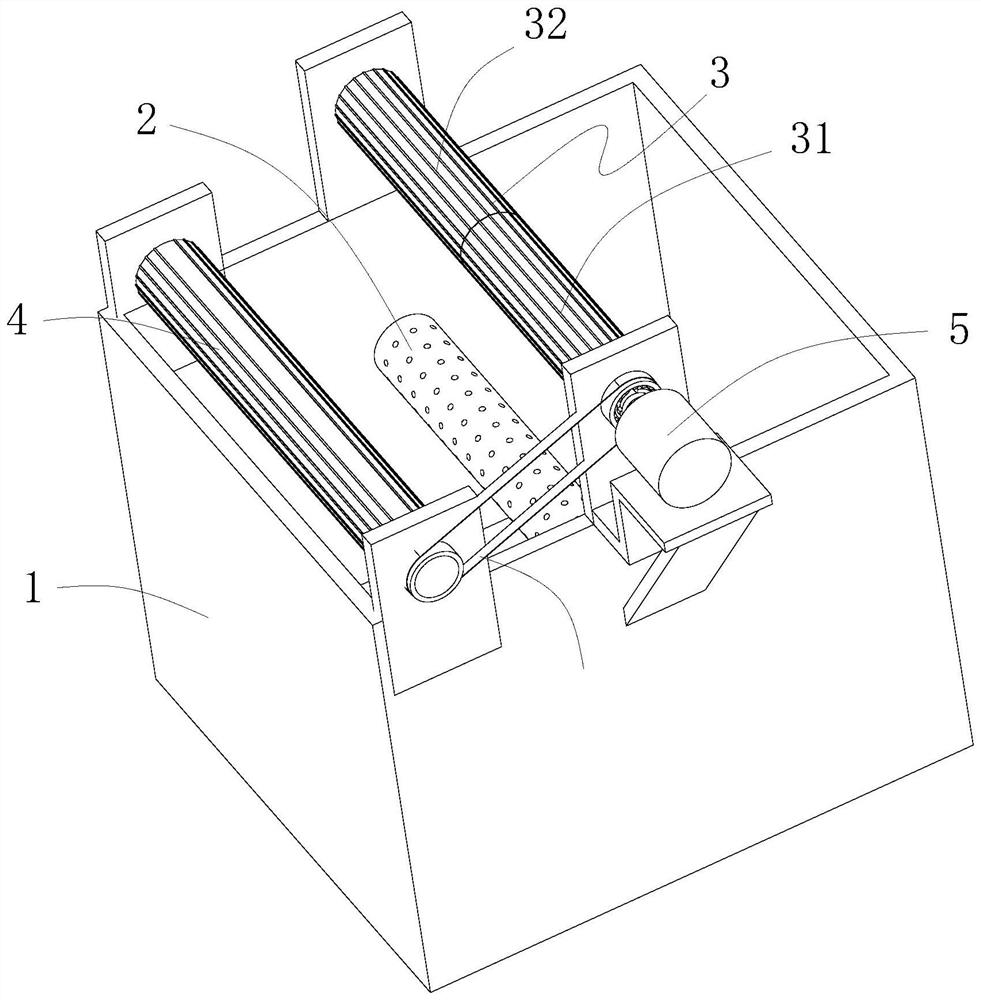

Flue gas waste heat recovery system with heat pump and gas-water surface type heat exchanger coupled

PendingCN114811630AReduce the temperatureReduce effluxHeat pumpsEmission preventionFlue gasWater circulation

The invention discloses a flue gas waste heat recovery system with a heat pump and a gas-water surface type heat exchanger coupled. The flue gas waste heat recovery system comprises a boiler waste heat recovery system and a heat consumer heat supply system. The boiler waste heat recovery system further comprises a tail flue connected with the boiler, a gas-water surface type heat exchanger connected to the tail flue, a desulfurizing tower connected with the gas-water surface type heat exchanger, a gas-water mixing heat exchanger connected with the desulfurizing tower and a water circulation system connected with the gas-water mixing heat exchanger. The heat consumer heat supply system is connected with the gas-water surface type heat exchanger and the water circulation system at the same time. According to the flue gas waste heat recovery system with the heat pump and the gas-water surface type heat exchanger coupled, the flue gas temperature is reduced, meanwhile, waste heat of flue gas can be recovered and utilized, meanwhile, flue gas sensible heat and water vapor latent heat after desulfurization are recovered, and the energy-saving efficiency of the whole system is improved by 10% or above.

Owner:TSINGHUA UNIV +2

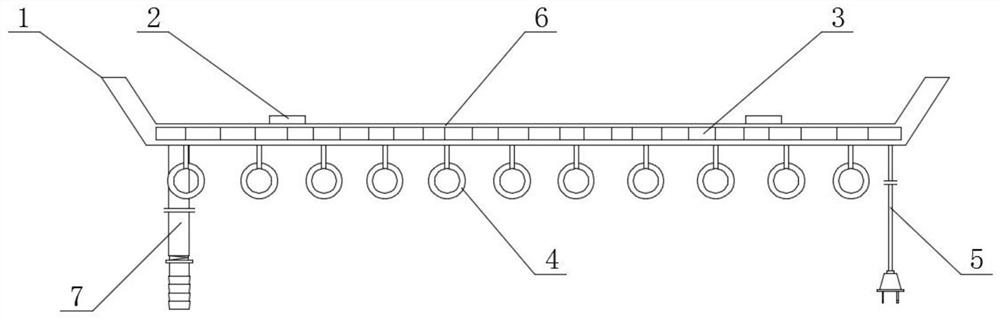

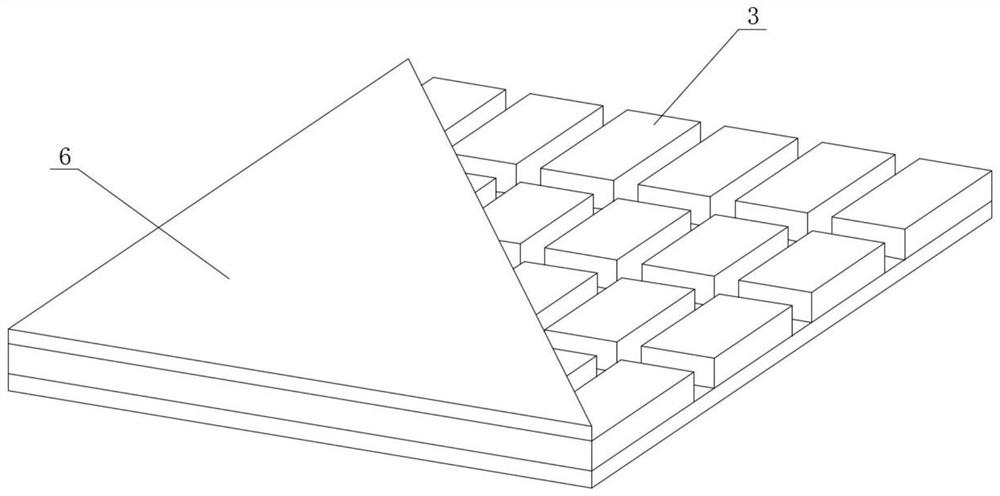

A Dyeing System Applicable to Gradient Dyeing of Cloth

ActiveCN109594252BKeep dryImprove drying efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsMechanical engineeringCotton material

The invention discloses a dyeing system suitable for gradual dyeing of cloth, which comprises a dyeing mechanism, a drying mechanism and a winding mechanism arranged at the rear side of the dyeing mechanism; The cloth guide roller for conveying; the driving part is used to drive the cloth guide roller to rotate, and the driving part works intermittently; the reset structure is used to drive the cloth guide roller to keep pace with the cloth guide roller after the driving part stops working. The cloth is rotated in the opposite direction of the conveying direction; the drying mechanism includes a drying box, two rolling shafts arranged on the upper part of the box, a cloth guide roller arranged in the box, a water squeezing device and a device arranged in the center of the box. The hot air drying parts in the box. After the dyeing of the present invention, the drying process is carried out directly through the drying device, and then it can be directly wound up, and the work efficiency is high; and the water squeezing device is arranged at the middle and lower part of the box body, so that the water squeezed out during water squeezing will not flow along the fabric It flows, and the efficiency of the cloth drying is high.

Owner:SHAOXING UNIVERSITY

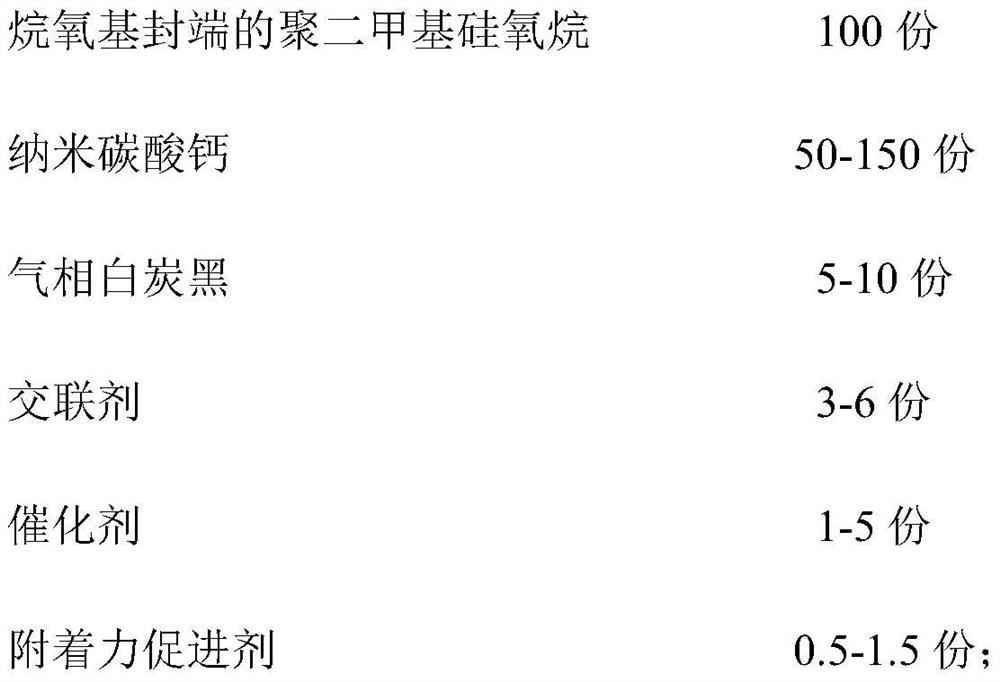

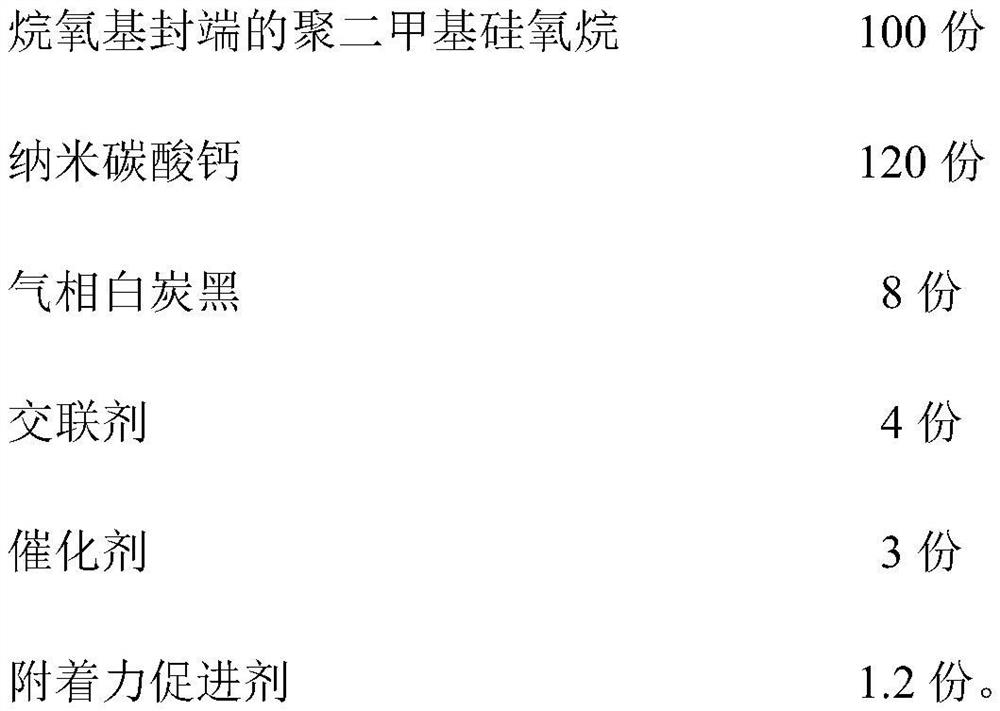

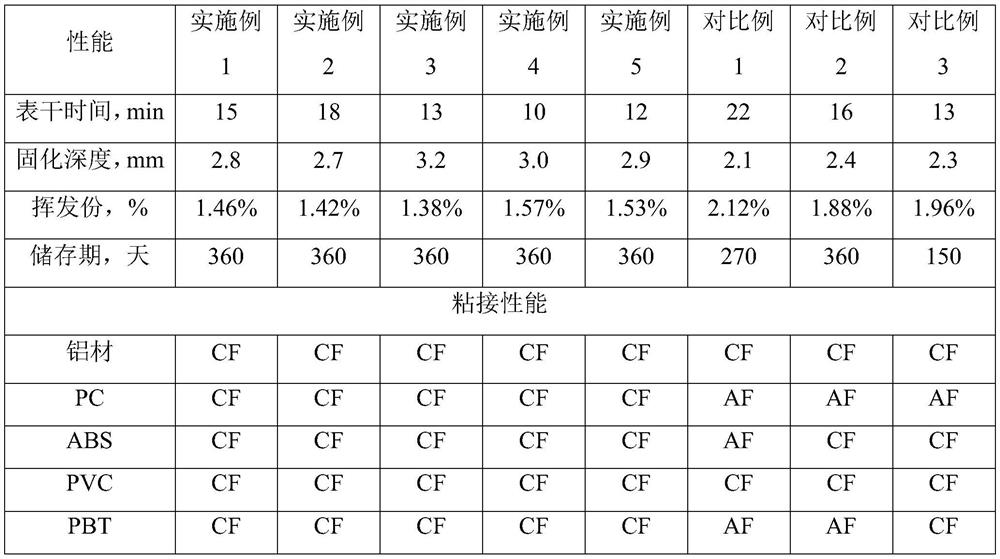

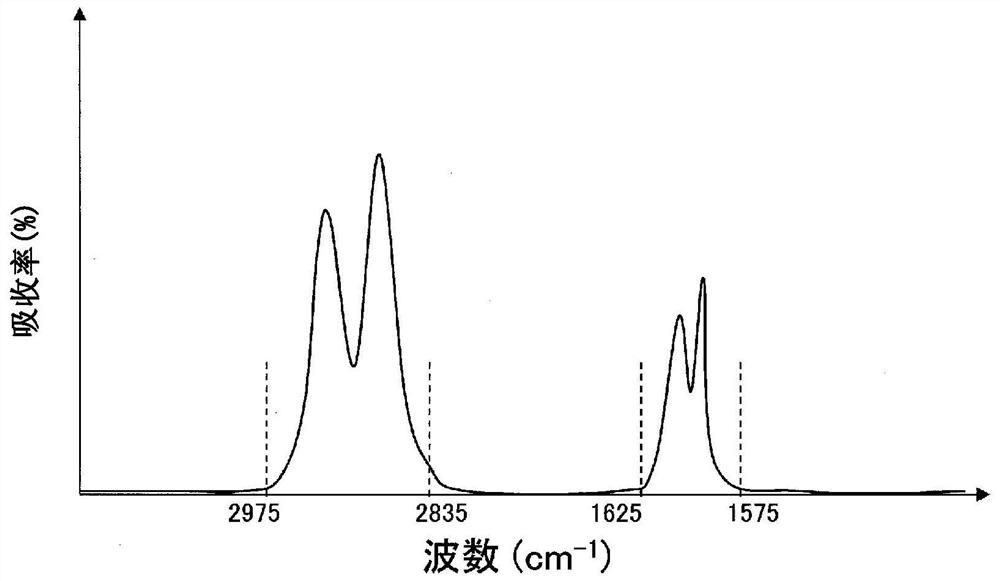

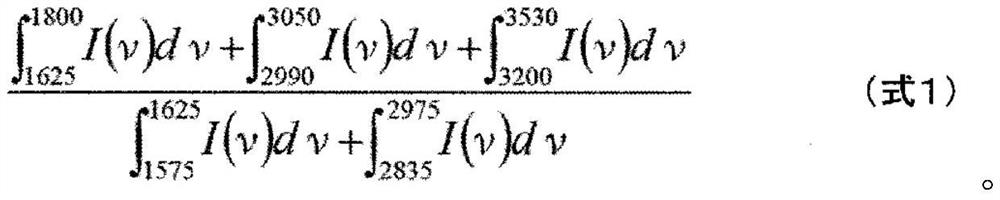

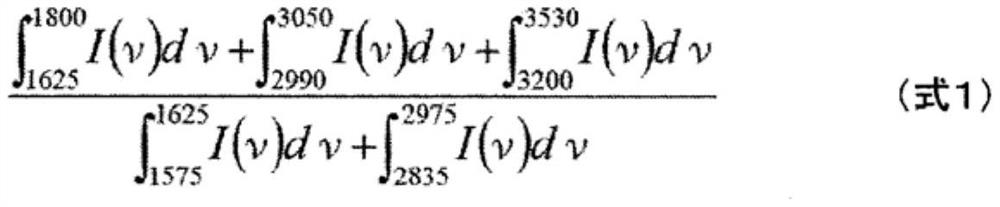

A kind of low voc organosilicon sealant and preparation method thereof

ActiveCN111303829BReduce the amount of water vaporFaster curing and crosslinkingNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention provides a low-VOC silicone sealant, which comprises the following preparation raw materials in parts by weight: 100 parts of alkoxy-terminated polydimethylsiloxane, 50-150 parts of nano-calcium carbonate, and 5 parts of fumed white carbon black. -10 parts, 3-6 parts of crosslinking agent, 1-5 parts of catalyst, 0.5-1.5 parts of adhesion promoter; the alkoxy-terminated polydimethylsiloxane has a structure shown in formula (1) A compound or composition, the adhesion promoter is a compound or composition having the structure shown in formula (2). The invention belongs to the technical field of silicone sealants, and provides a low-VOC silicone sealant with low odor, good adhesive performance, storage stability and weather resistance, and can be widely used in household appliances, electronic equipment, lighting fixtures, indoor Bonding and sealing in decoration and other fields.

Owner:佛山东麓科技有限公司

Surface-treated aluminum material, manufacturing method thereof, and bonded body of the surface-treated aluminum material/resin layer

ActiveCN106460221BExcellent adhesionGood adhesionAnodisationMetal layered productsTERM resinAluminium

An object of the present invention is to provide a surface-treated aluminum material excellent in long-term resin adhesion over the entire surface of the aluminum material, and to provide a stable manufacturing method for such a surface-treated aluminum material. The solution to the problem is to provide a surface-treated aluminum material and a manufacturing method thereof, the surface-treated aluminum material is characterized in that it contains an aluminum material and an oxide film formed on at least one surface thereof, and the above-mentioned oxide film is formed by A porous aluminum oxide film layer with a thickness of 20 to 500 nm on the surface side and a barrier aluminum oxide film layer with a thickness of 3 to 30 nm formed on the substrate side, the porous aluminum oxide film layer is formed with a diameter of 5 Small pores of ~30nm, the moisture contained in the above oxide film is 10μg / cm 2 the following.

Owner:FURUKAWA SKY ALUMINUM CORP

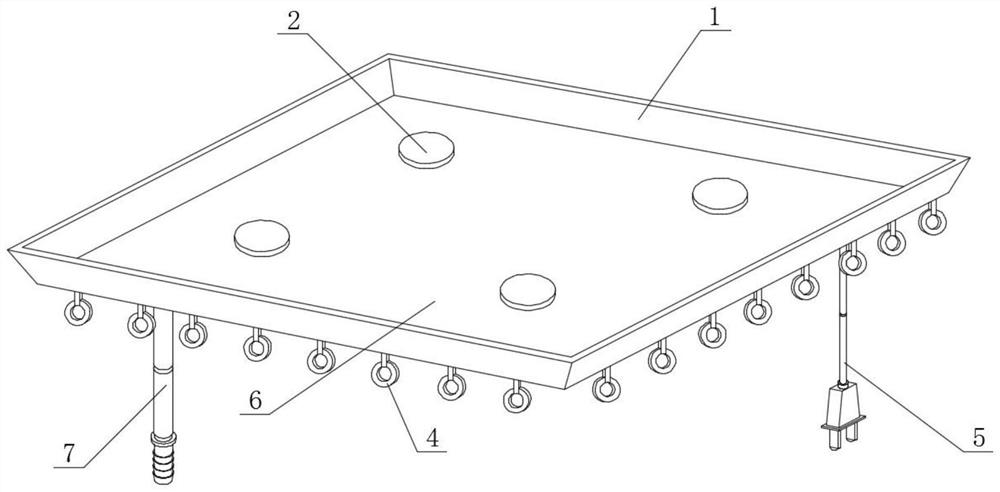

Building rain leakage treatment device

InactiveCN112482829AGood energy saving effectImprove practicalityRoof drainageSpecial buildingStructural engineeringMechanical engineering

The invention provides a building rain leakage treatment device. The device comprises a water-stop sheet body; a waterproof material layer is fixed to the upper end of the water-stop sheet body; a humidity detector is fixed to the upper end of a waterproof material layer; a hook is fixed to the lower end of the water-stop sheet body; a sewer pipeline is fixed to the position, at the lower end of the water-stop sheet body, behind the hook; a charging line is fixed to the right side, located at the lower end of the water-stop sheet body, of the sewer pipeline; and a heating layer is fixed to theinterior of the water-stop sheet body. According to the building rain leakage treatment device, the problem that a device with a water seepage solving function and a home convenience function does not exist at present is solved; the device is novel, good in practicability, high in safety degree; the built-in heating layer is of a small heating plate combined structure, so that modification and installation are convenient; and the building rain leakage treatment device is good in energy-saving effect and high in social benefit.

Owner:HUANGSHAN UNIV

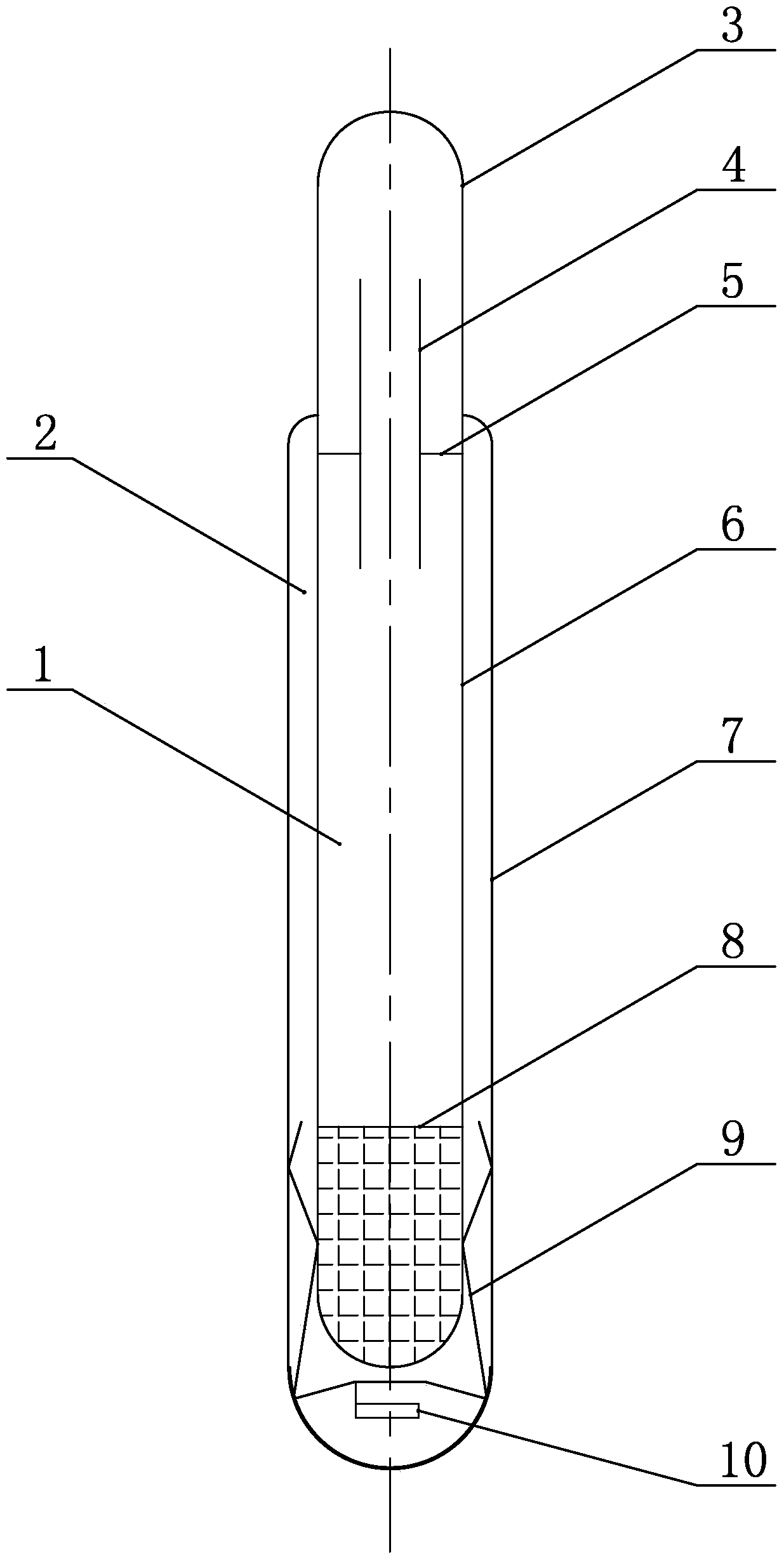

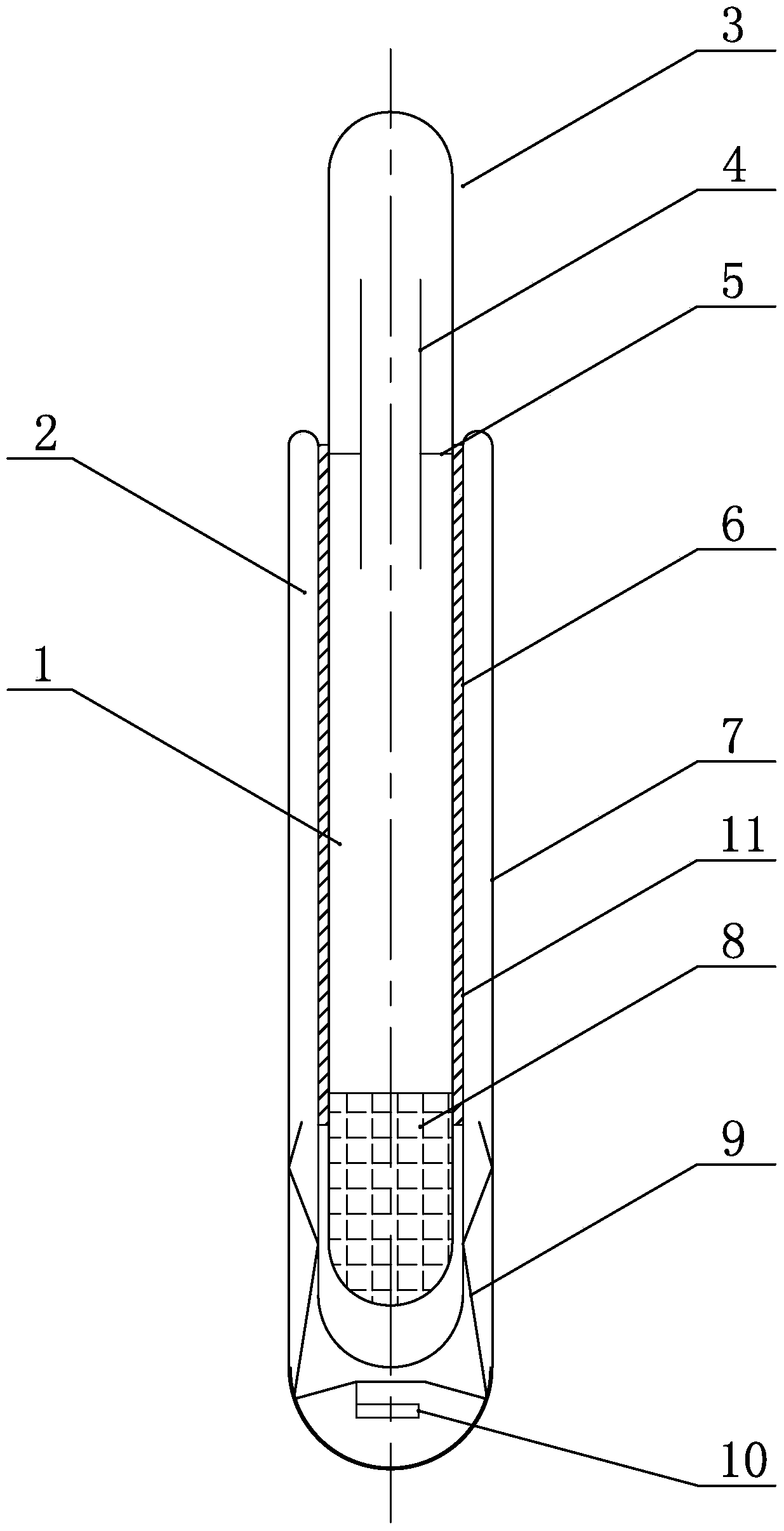

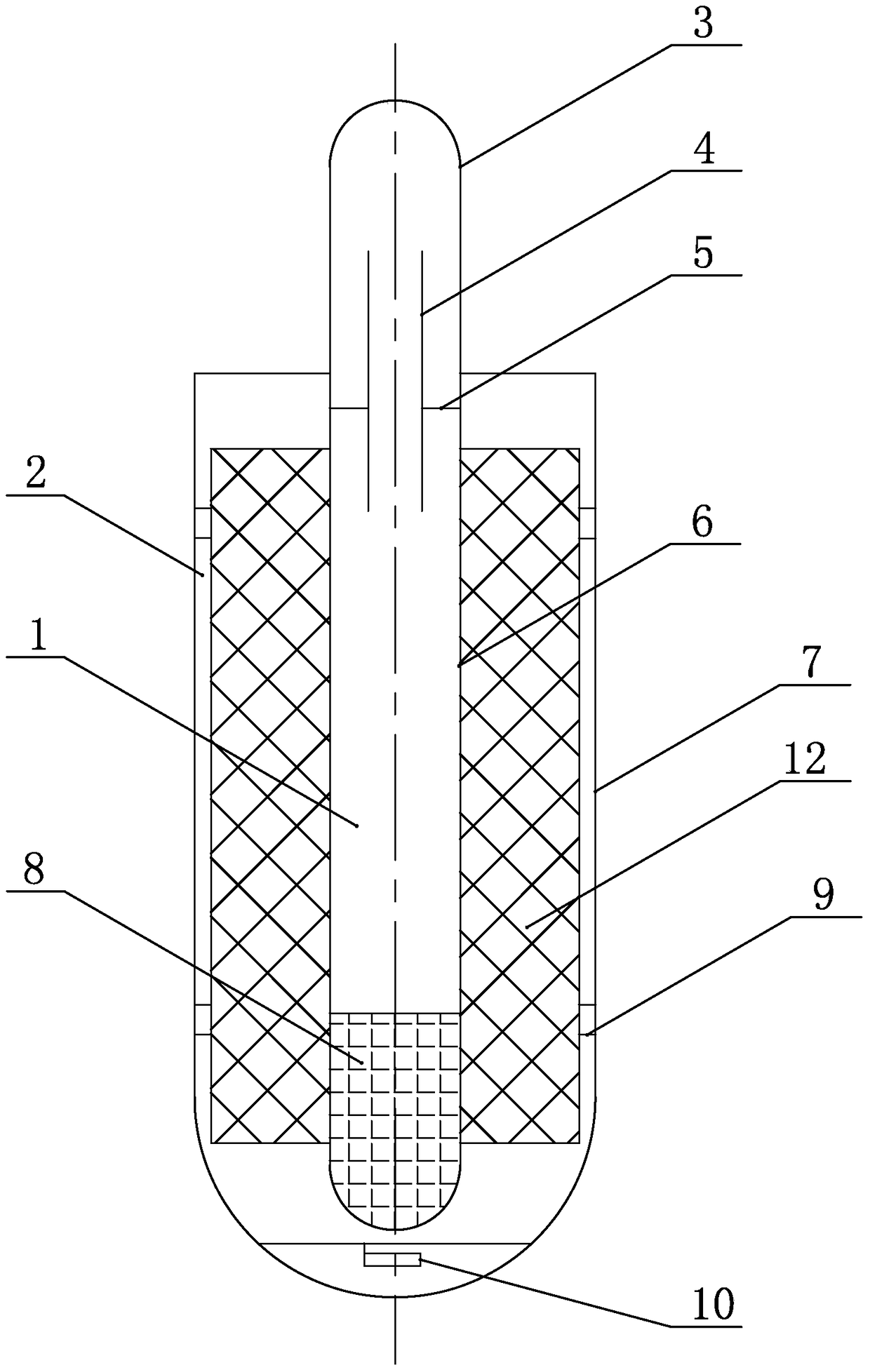

Solar tube and its processing method

InactiveCN105352221BSimple structureEasy to useMachines using solar energyHeating and refrigeration combinationsEngineeringCover glass

The invention relates to a solar tube and a machining method thereof, in particular to the solar tube capable of achieving the functions of heat collecting and refrigerating and the machining method thereof. The solar tube which is simple in structure, safe in use and low in cost and the machining method thereof are provided. The solar tube comprises an inner tube body and a cover glass tube arranged outside the inner tube body in a sleeving mode. A condensing tube is arranged above the inner tube body. The connector position of the condensing tube, the inner tube body and the cover glass tube is sealed to form an annular sealing opening. An inner vacuum cavity body is formed between the condensing tube and the inner tube body, and an outer vacuum cavity body is formed between the inner tube body and the cover glass tube. An annular clapboard arranged horizontally is fixed to the inner wall of the inner vacuum cavity body and is fixed to the upper portion of the inner vacuum cavity body. A flow resisting tube is installed on the annular clapboard. The central axial line of the flow resisting tube is parallel to that of the inner tube body. A working medium is arranged at the bottom of the inner vacuum cavity body. The external surface of the inner tube body is coated with a selective absorbing coating. A bracket is arranged inside the outer vacuum cavity body. A getter is placed on the bracket.

Owner:北京越洋高科节能技术有限公司

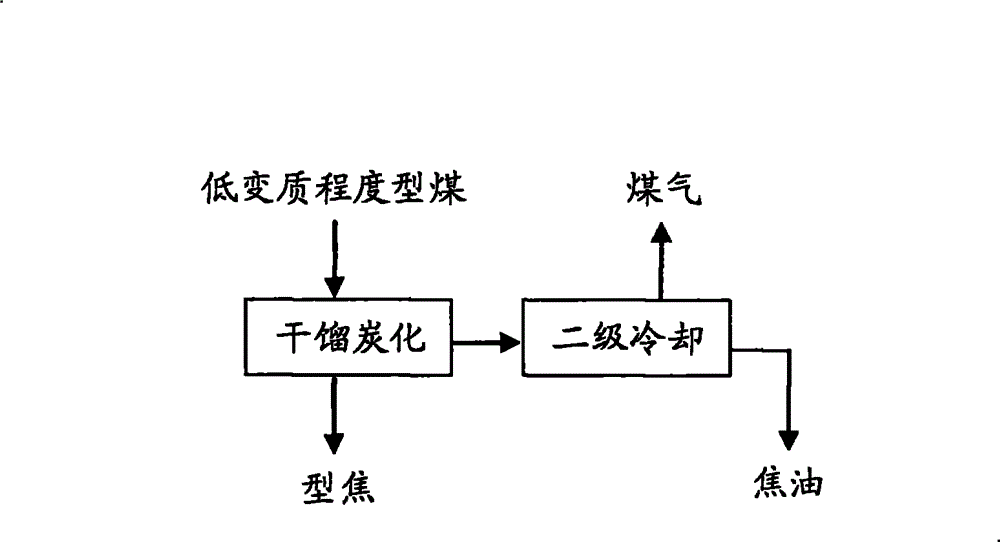

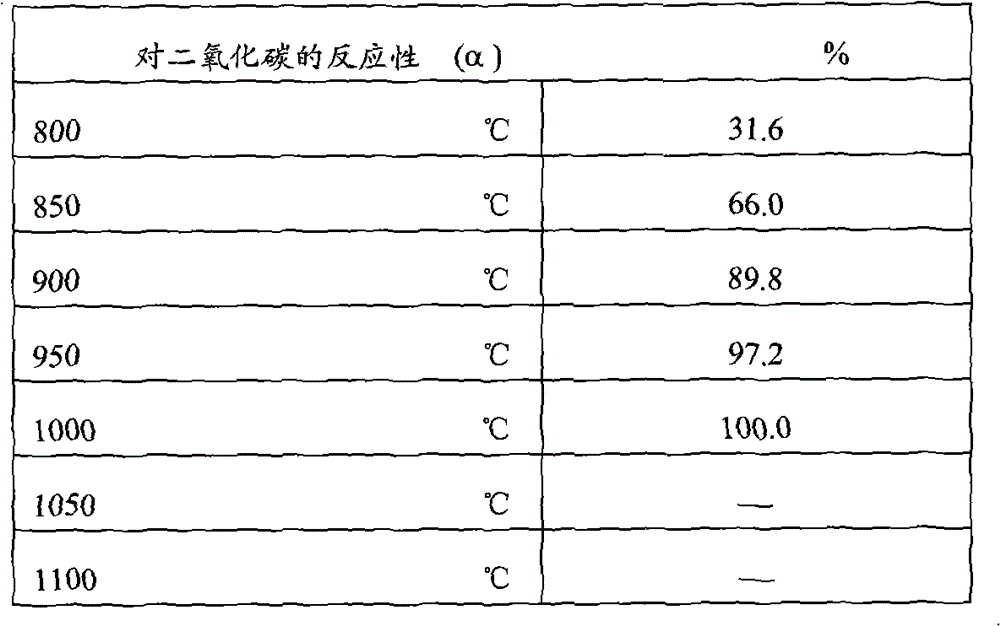

Formed coke and production method of formed coke, coal gas and tar

ActiveCN101775321BHigh calorific valueHigh strengthSolid fuelsIndirect heating destructive distillationTarThermal stability

The invention relates to formed coke and a production method of formed coke, coal gas and tar. The mass percent of dry base volatile components of the formed coke is lower than 10 percent, the mass percent of the dry base fixed carbon content is more than 70 percent, the cold pressure intensity is higher than 400 N / ball, the thermal stability is higher than 90 percent, and the dry base high-position heat generation quantity is more than 6000 cal / g. The production method comprises the following steps: using binderless hot pressing moulded coal of low-deterioration dgree coal as raw materials to carry out dry distillation in an external heating type dry distillation device at the temperature between 550 and 1000 DEG C for obtaining the formed coke; and then, obtaining the coal gas and the tar through indirectly cooling and separating obtained gaseous products. The formed coke produced by the method of the invention has low production cost and good reactive activity, and the production process is simple and effective.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Carbon dioxide chemical absorption system installed with vapor recompression equipment

ActiveUS9463411B2Inhibit deteriorationImprove thermal efficiencyGas treatmentCarbon compoundsTemperature controlCombustion

Owner:MITSUBISHI HITACHIPOWER SYST LTD

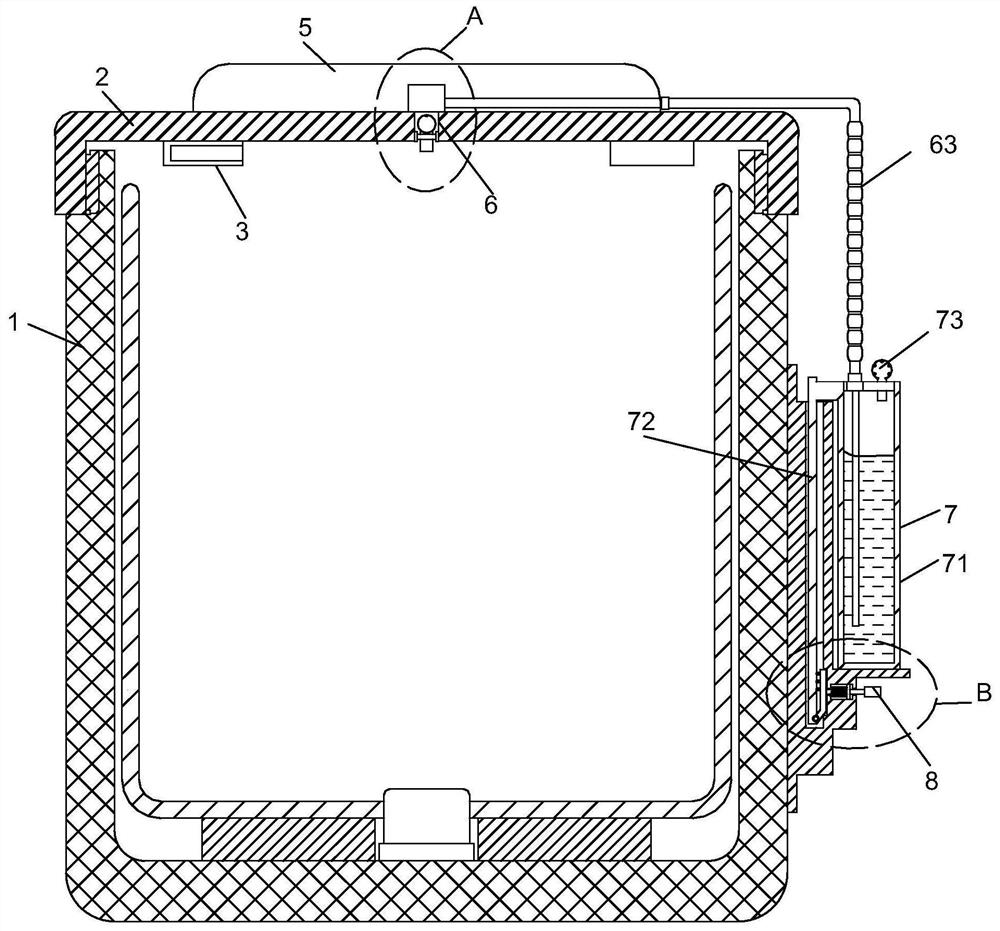

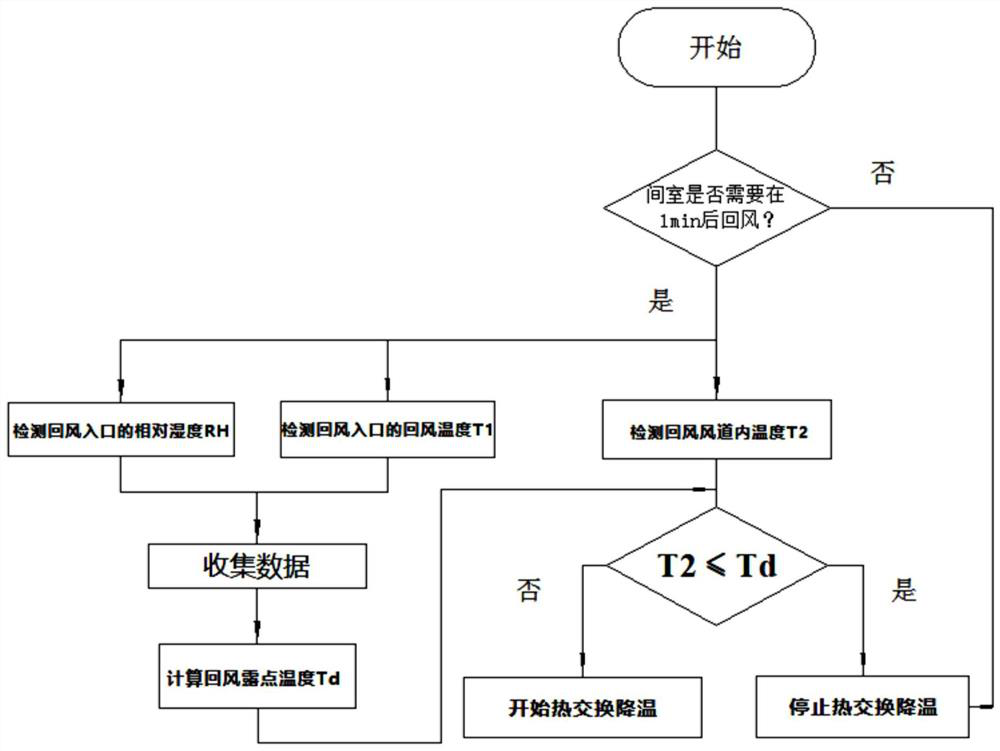

Air-cooled refrigerator

PendingCN113566480AReduce the amount of water vaporReduce frosting rateLighting and heating apparatusDomestic refrigeratorsThermodynamicsHigh humidity

The invention relates to an air-cooled refrigerator. The air-cooled refrigerator comprises a refrigerator body, an evaporator, an air return duct assembly and a cooling air duct assembly, wherein an evaporator chamber and a refrigerating chamber are defined in the refrigerator body; the evaporator is arranged in the evaporator chamber and is configured to cool air flow flowing through the evaporator so as to form cooling air flow; the air return duct assembly is configured to guide the air flow in the refrigerating chamber to the evaporator; and the cooling air duct assembly is configured to cool the air return duct assembly through heat exchange by means of the cooling air flow flowing through the cooling air duct assembly. By arranging the cooling air duct assembly, the cooling air flow discharged by the evaporator flows through the cooling air duct assembly so as to cool the air return duct assembly through heat exchange, so that return air is cooled, the internal temperature of an air return duct is below the dew point temperature, air with high humidity recovered from the refrigerating chamber is condensed in the air return duct, the humidity of the air in the air return duct is reduced, the frosting rate of water vapor on the evaporator is reduced, the defrosting cycle time is prolonged, the defrosting frequency is reduced, the energy consumption of the refrigerator is reduced, and the use cost of a user is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

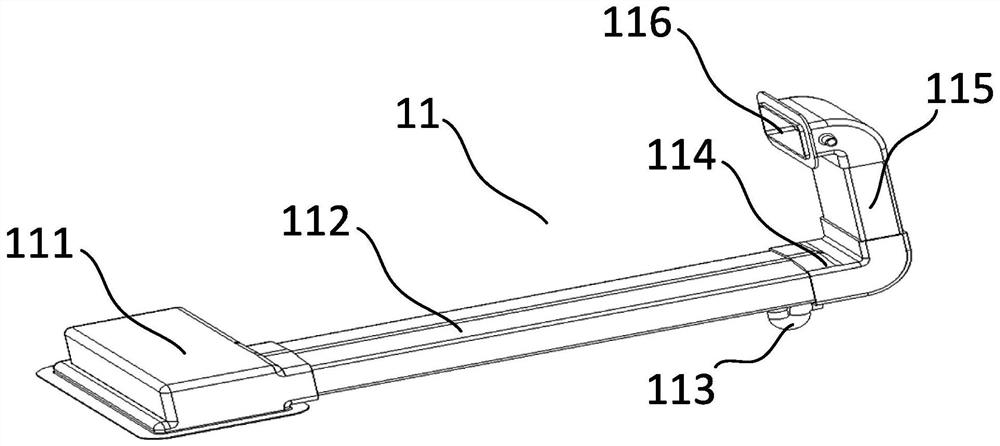

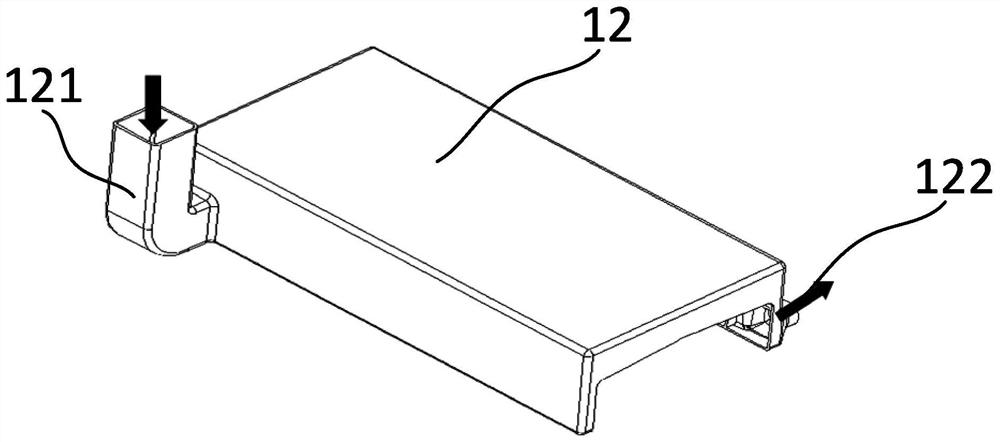

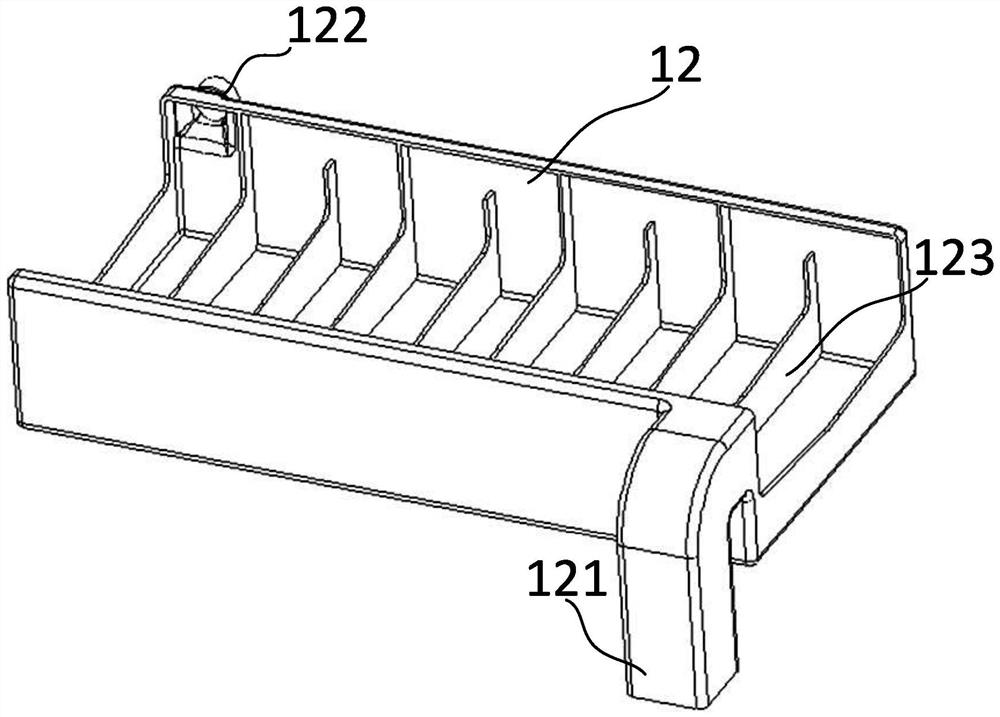

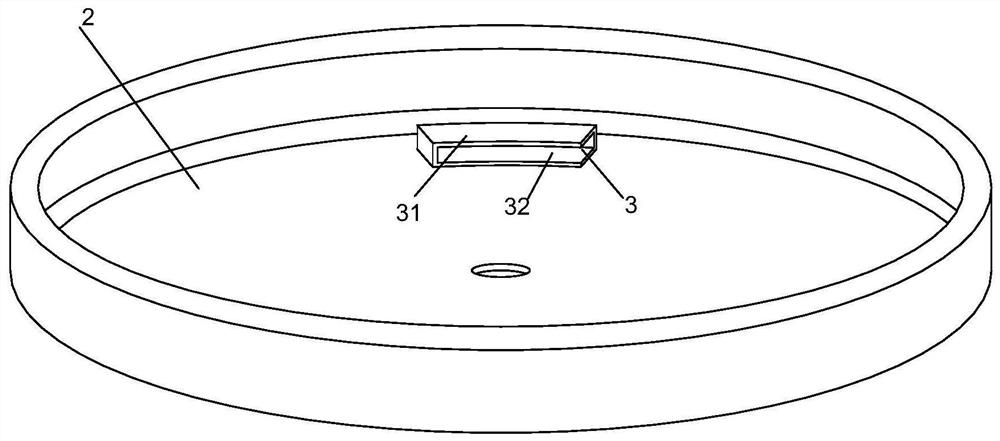

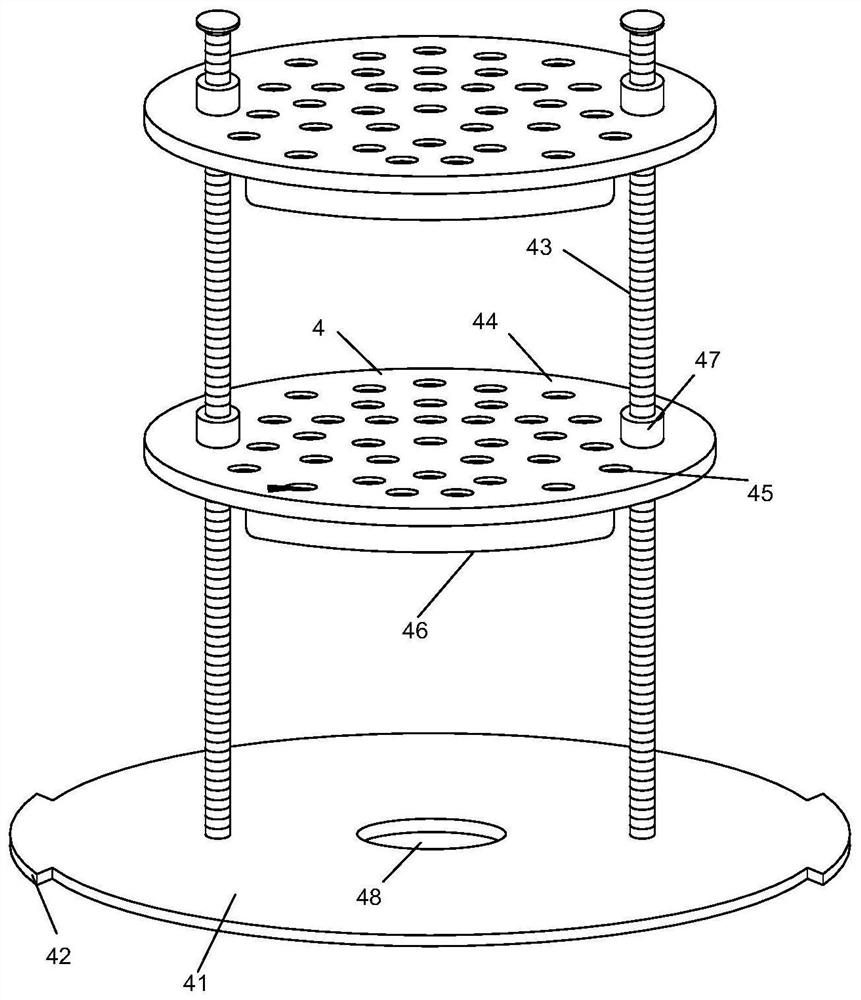

A household rice cooker

ActiveCN110840229BInstalled and disassembledGood cooking effectCooking insertsVessels with intergral heatingAgricultural scienceAgricultural engineering

The invention belongs to the technical field of electric rice cookers, and specifically relates to a household electric rice cooker, which includes a rice cooker body, a clamping mechanism, a storage mechanism, a pressure relief mechanism, a liquid accumulation mechanism and a fixing mechanism. The cover, and the handle shell is fixedly installed on the cover of the rice cooker, and the two clamping mechanisms with the same specifications are installed on the inner wall of the cover of the rice cooker and are symmetrically distributed with each other. The clamping mechanisms include arc-shaped plates and limiting slots , the arc-shaped plate is fixedly installed on the inner wall of the cover of the electric cooker, and a limit slot is opened on the arc-shaped plate, the storage mechanism is connected with the cover of the electric cooker through a snap-fit mechanism, and the pressure relief mechanism is arranged on the cover of the electric cooker On the body and the handle housing, the fixing mechanism is fixedly installed on the outer wall of the rice cooker body. The household electric rice cooker provided by the invention has the advantages of simultaneously cooking multiple dishes and reducing water vapor discharge when the cover is opened.

Owner:谢绍刚

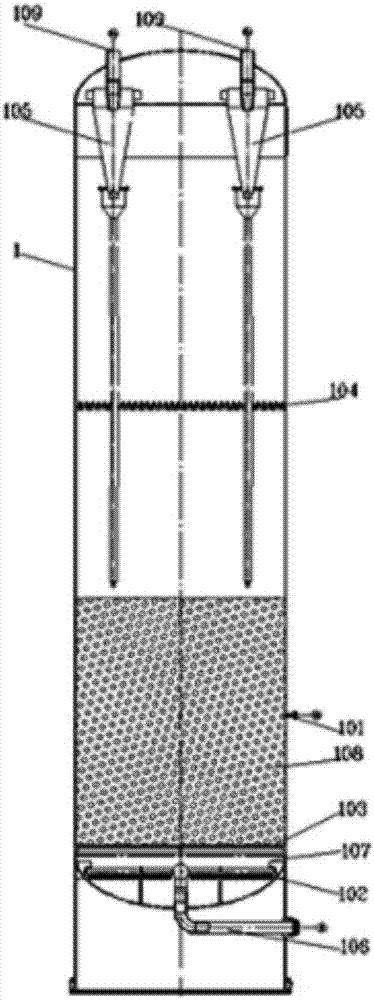

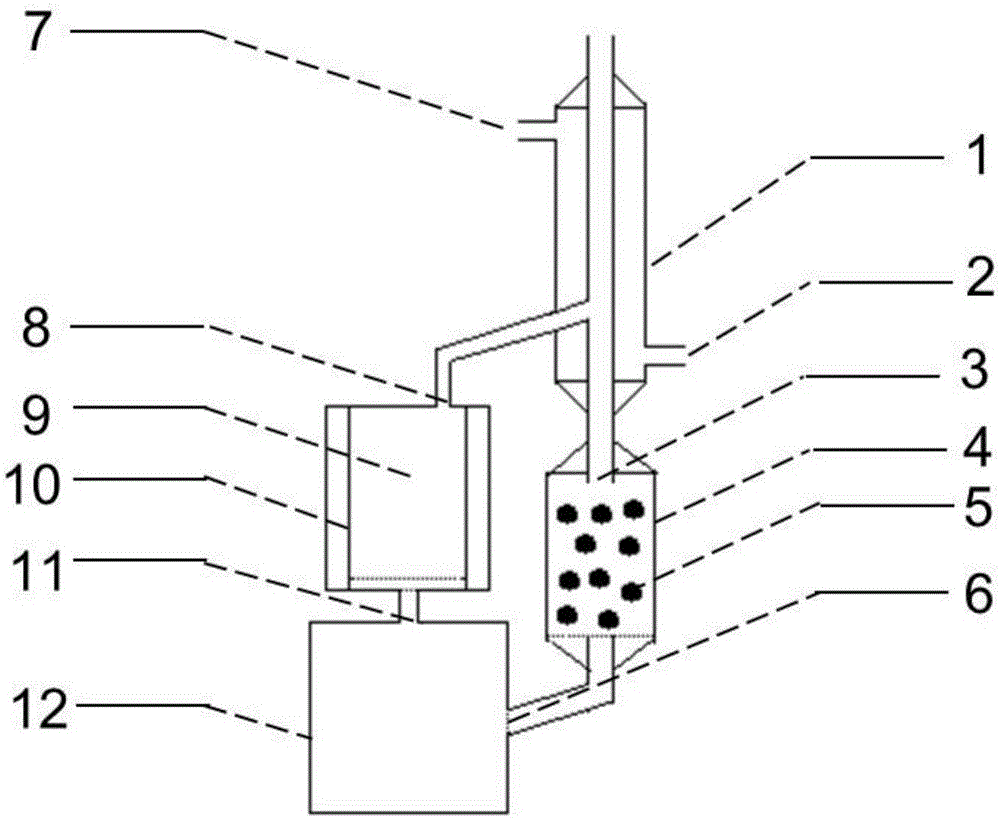

Decomposition and denitration system of fluidized bed type urea and its derivative and process thereof

ActiveCN106890567AImprove decomposition abilityTake advantage ofGas treatmentSolid waste disposalAir preheaterCyclone

The invention provides a decomposition and denitration system of fluidized bed type urea and its derivative and a process thereof, and belongs to the technical field of smoke gas denitration. The system comprises a fluidized bed reactor, a first-grade cyclone separator, a second-grade cyclone separator, a smoke gas and reaction gas mixer, a multi-layered denitration reactor and an air preheater. A fluidized gas distributor, a fluidized plate, a catalyst bed layer, and a gas gear dust collector and an inner cyclone are arranged in the fluidized bed reactor. The invention further relates to a process for decomposition and denitration by using the system. The decomposition and denitration system applies the fluidized bed reactor to decompose the raw materials, and the decomposition rate is up to 95%. The raw materials in the invention are industrial emission; the fluidized bed reactor is used for decomposing urea and its derivative, and NH3 generated from triamine waste product and triamine secondary product so as to perform the denitration on the smoke gas; the smoke gas also provides the fluidized medium for the fluidized bed reactor; meanwhile, the recycle of the urea, the triamine waste product and the smoke gas is realized; the waste treatment and denitration cost are reduced, and the environment pollution is further reduced.

Owner:BEIJING EDGEIN TECH

Method for reducing defrosting rate of air-cooled refrigerator

PendingCN113669986AReduce frosting rateIncrease defrost cycle timeLighting and heating apparatusDomestic refrigeratorsDew pointEvaporator

The invention relates to a method for reducing the defrosting rate of an air-cooled refrigerator. The method comprises the step of carrying out heat exchange cooling on return air in a return air pipeline of a refrigerating chamber so as to realize cooling and dehumidification of the return air before the return air enters an evaporator. The return air in the return air pipeline of the refrigerating chamber is subjected to heat exchange cooling, so that the temperature in the return air pipeline is below the dew point temperature, the return air is cooled before entering the evaporator, air with high humidity recycled from the refrigerating chamber is condensed in the return air pipeline, the water vapor content in the return air is reduced, the amount of the water vapor in contact with the evaporator in unit time is reduced, the frosting rate of the evaporator is reduced, the defrosting cycle time is prolonged, the defrosting frequency is reduced, the defrosting energy consumption is reduced, and the use cost of a user is saved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

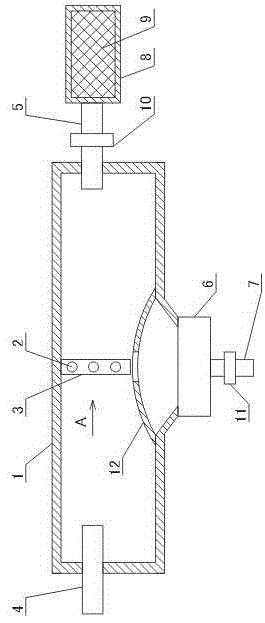

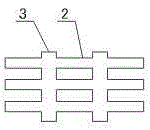

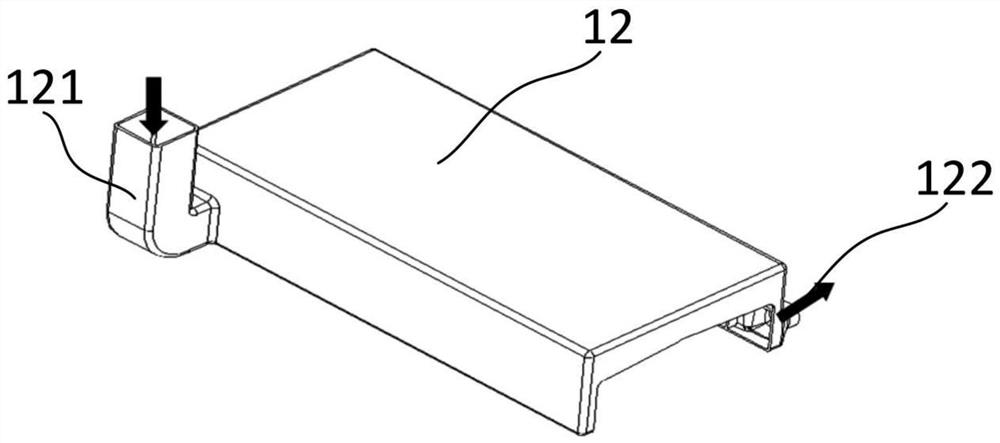

Vapor extracting device with silicagel column separating device and application of vapor extracting device

InactiveCN106730984AReduce the amount of water vaporLow extractabilityIon-exchange process apparatusIon-exchanger regenerationWater vaporEngineering

The invention discloses a vapor extracting device with a silicagel column separating device. The vapor extracting device with the silicagel column separating device comprises an extracting tank (9) and a silicagel column (4), wherein a heating device (10) is arranged on the outer layer of the extracting tank, an upper port of the extracting tank is communicated with the lower part of a condensing tube (1) through a still gas outlet (8), and a lower port of the extracting tank is communicated with an upper port of a vapor generating device (12) through a vapor outlet (11); an upper port of the silicagel column (4) is communicated with a lower port of the condensing tube (1) through a condensate outflow port (3), and a lower port of the silicagel column (4) is communicated with the vapor generating device (12) through a moisture outlet (6). The invention further discloses the application of the vapor extracting device to the extraction of volatile components in tobacco.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com