Cabo pressing machine lubricating system and method

A technology of stem pressing machine and rolling roller, which is applied in the field of tobacco processing, can solve the problems of photoelectric device interference, the atomization area cannot completely cover the entire roller, and the atomization effect is deteriorated, and the effect of stable and reliable production process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

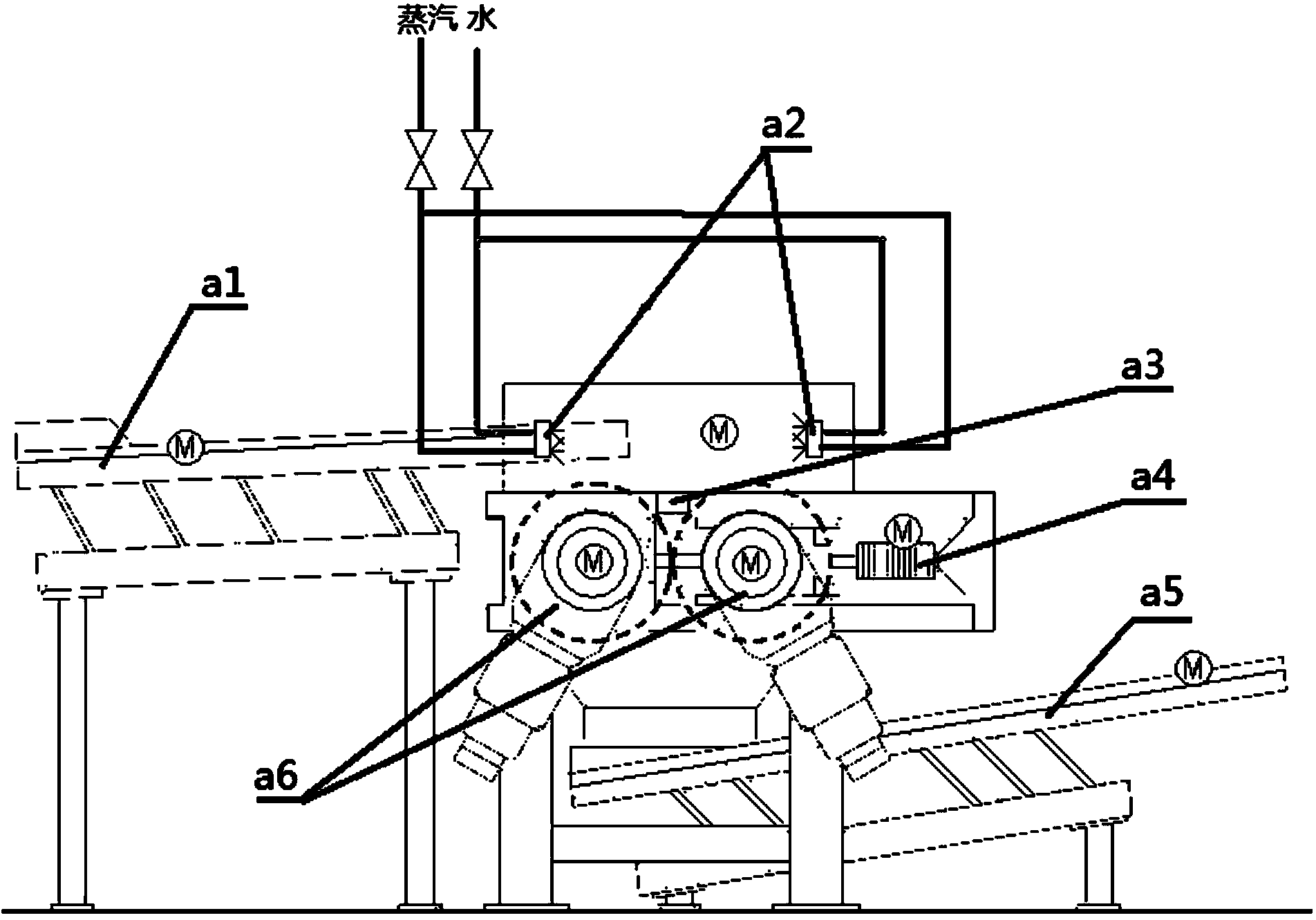

[0023] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

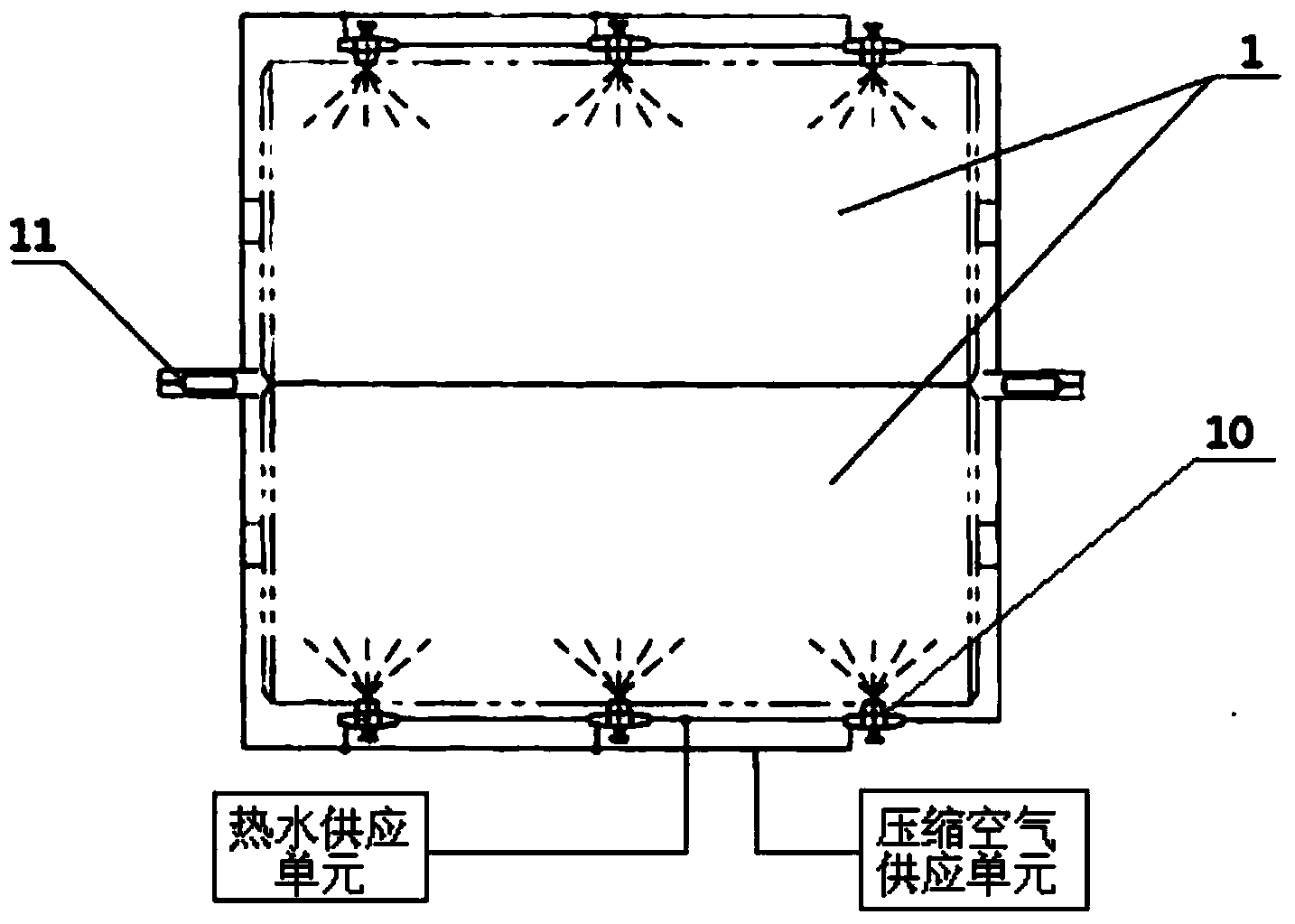

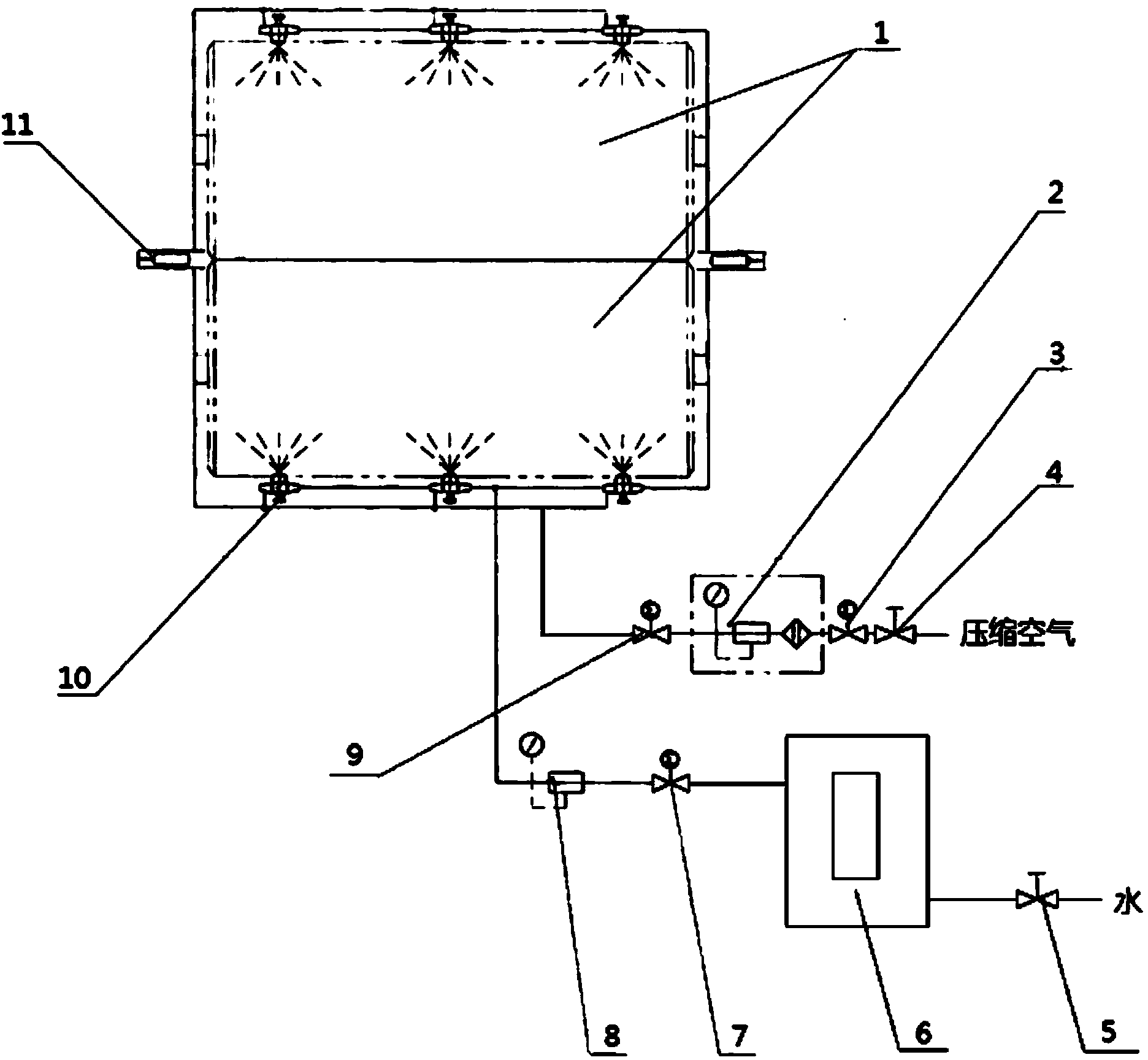

[0024] Such as figure 2 As shown, it is a structural schematic diagram of an embodiment of the moistening system of the stem press machine of the present invention. In this embodiment, the moistening system of the stalk pressing machine can carry out the wetting operation on the rolls of the stalk pressing machine, wherein a pair of pressing rollers 1 of the pressing machine move towards each other, and can process the tobacco stem material entering the stalk pressing machine. system. A photoelectric detector 11 is also provided at the position corresponding to the nip above the pressure roller 1 to detect the occurrence of material blocking. For the pressing machine moistening roller system, it can be independently configured relative to the pressing machine, and can also exist as a part of the pressing machine sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com