Feedforward control method and system for nanometer operation robot, medium and electronic equipment

A nanometer operation and feedforward control technology, applied in the direction of program control manipulators, instruments, manipulators, etc., can solve problems such as difficult to solve, poor applicability, etc., to achieve good real-time, stable and reliable manufacturing and assembly, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

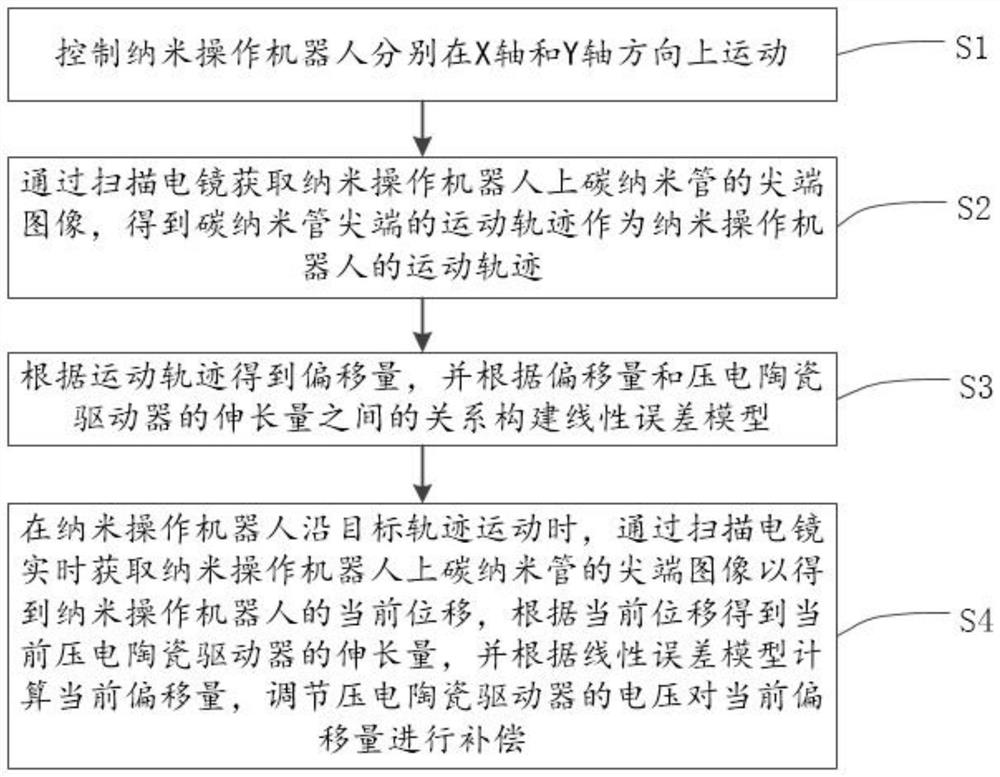

[0058] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

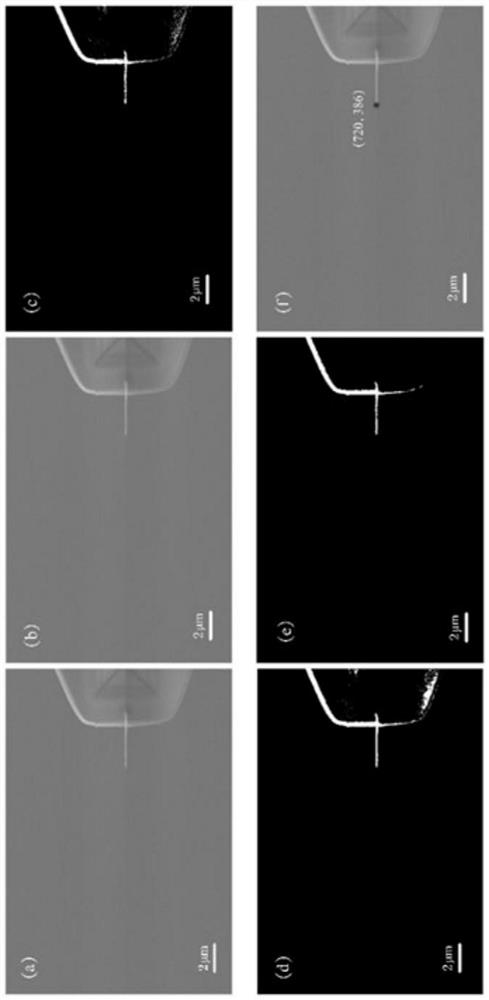

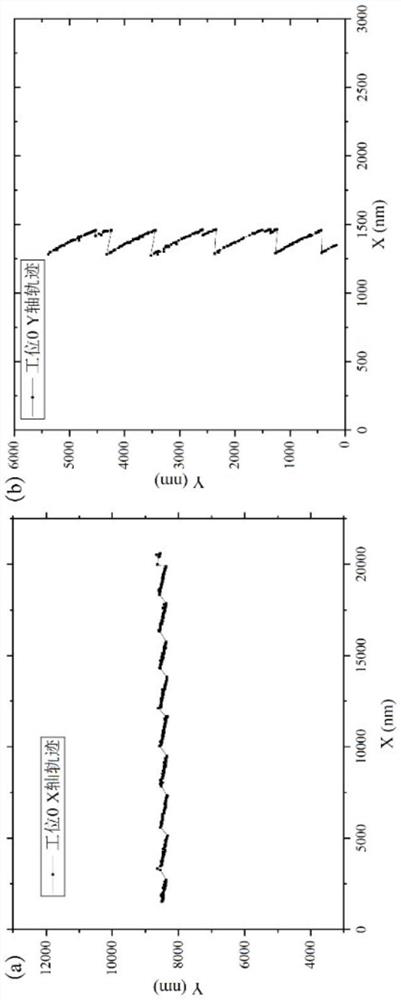

[0059] At present, the mainstream method of fabricating nanodevices is a "top-down" method, that is, removing some specific materials from the substrate to form the desired structure. Nanomanipulation is a "bottom-up" nanodevice fabrication technology, which can fabricate nanodevices by building three-dimensional nanostructures with basic materials. For example, carbon nanotubes (CNTs) can be used to build field effect transistors (FETs) to obtain carbon nanofield effect transistors (CNT-FETs). Due to the excellent electrical properties of carbon nanotubes, CNT-FETs far outperform silicon-based FETs and can be used for Fabrication of high-performance carbon-based chips. Aided by SEM v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com