Patents

Literature

66results about How to "The production process is stable and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

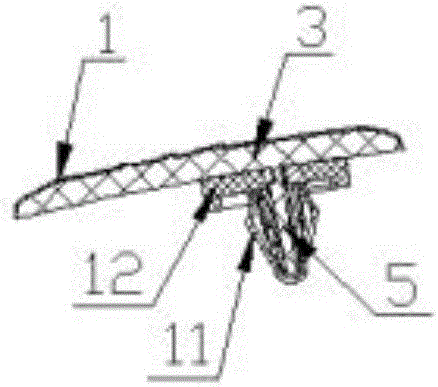

Method for producing bamboo fiber

InactiveCN101538744AEfficient productionThe production process is stable and reliableCane mechanical workingWood working apparatusChemistryEmulsion

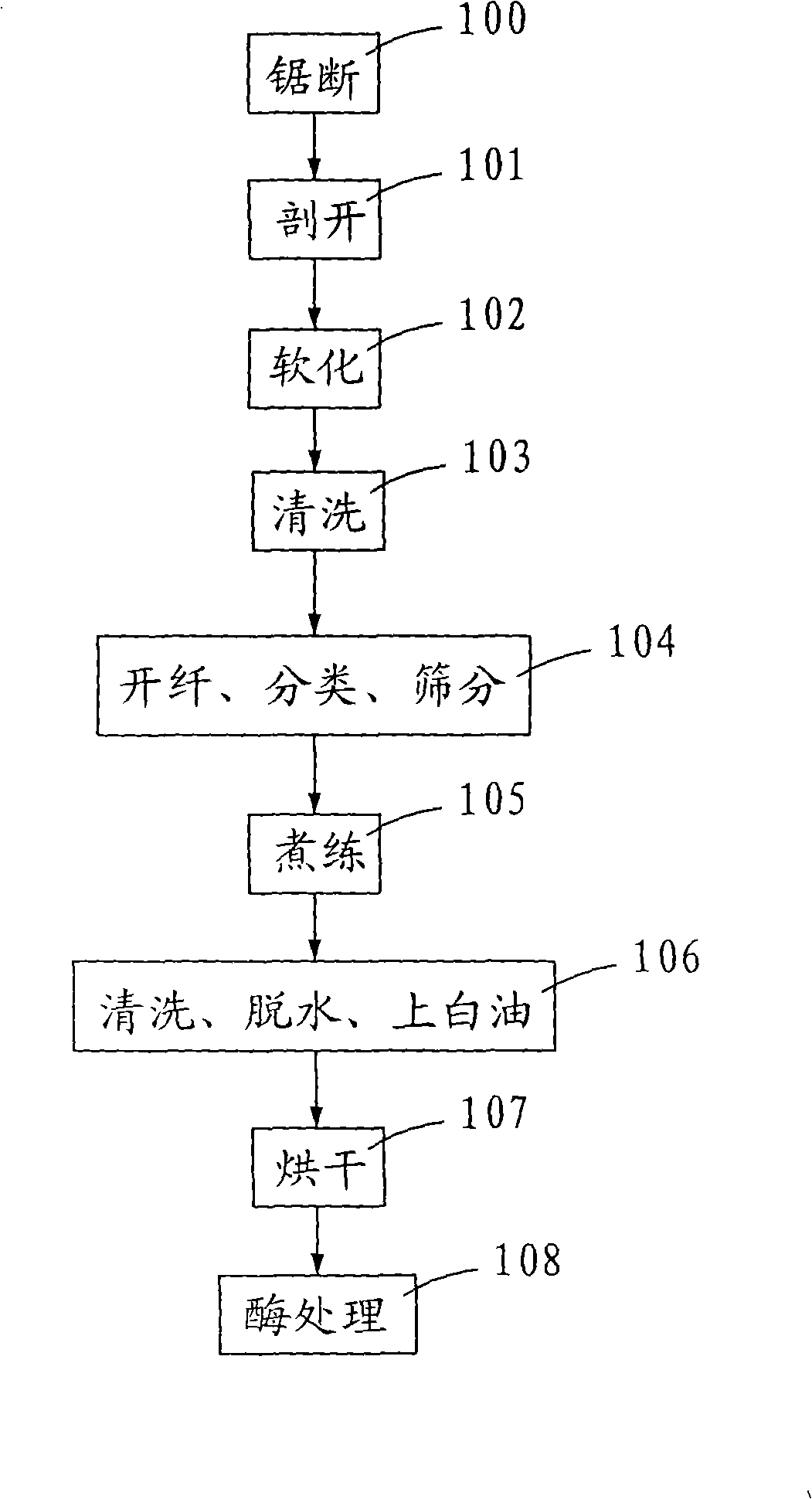

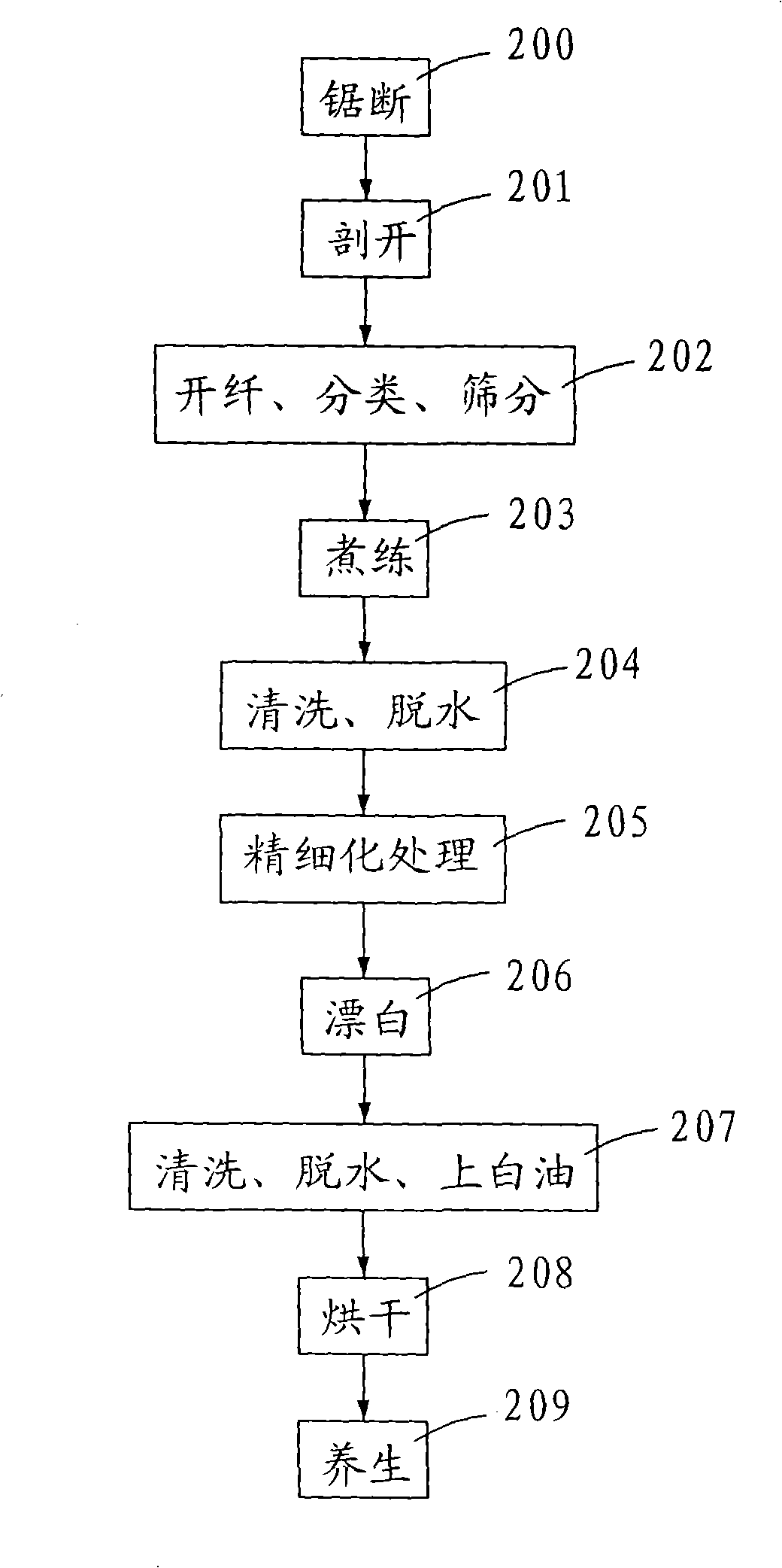

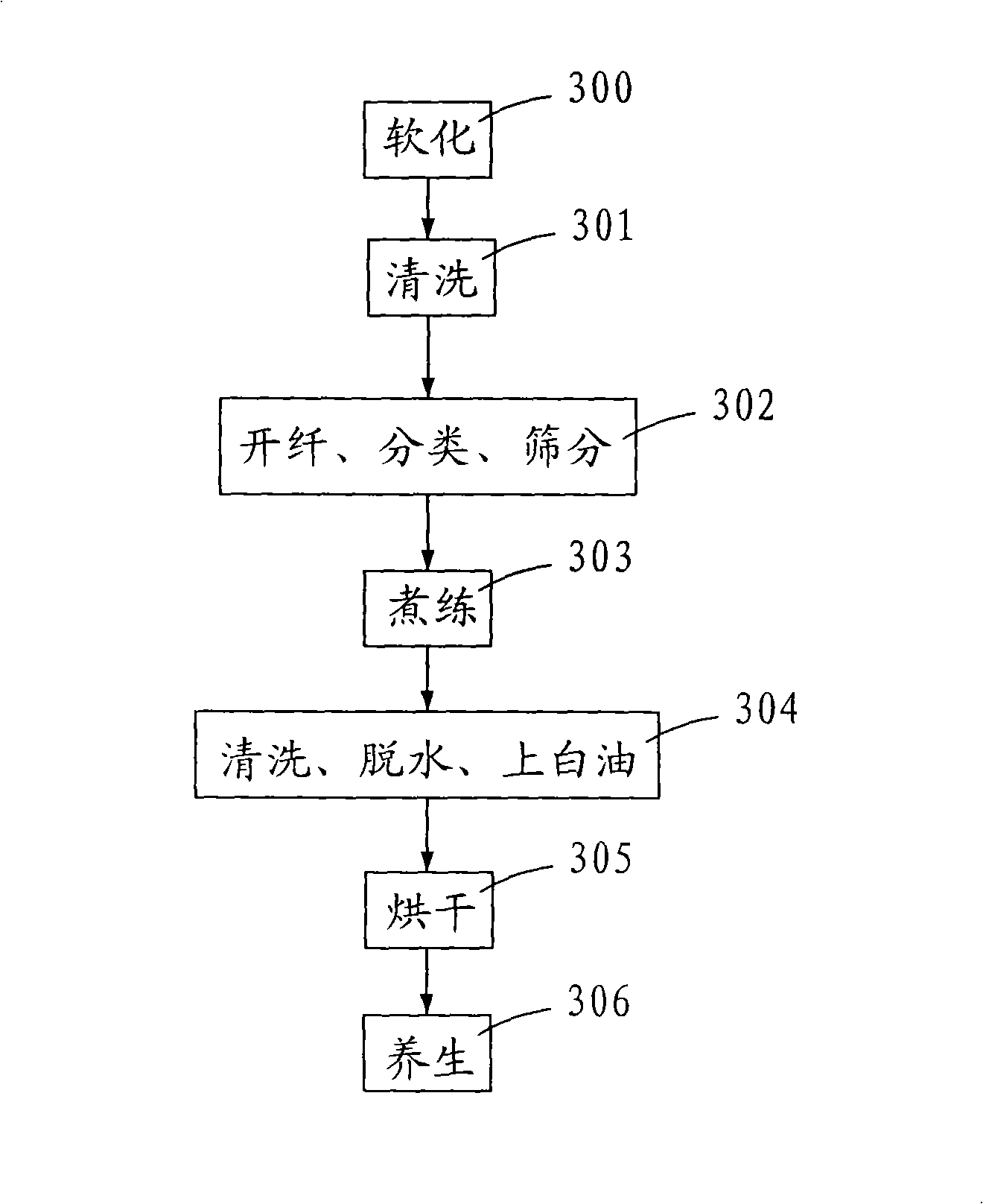

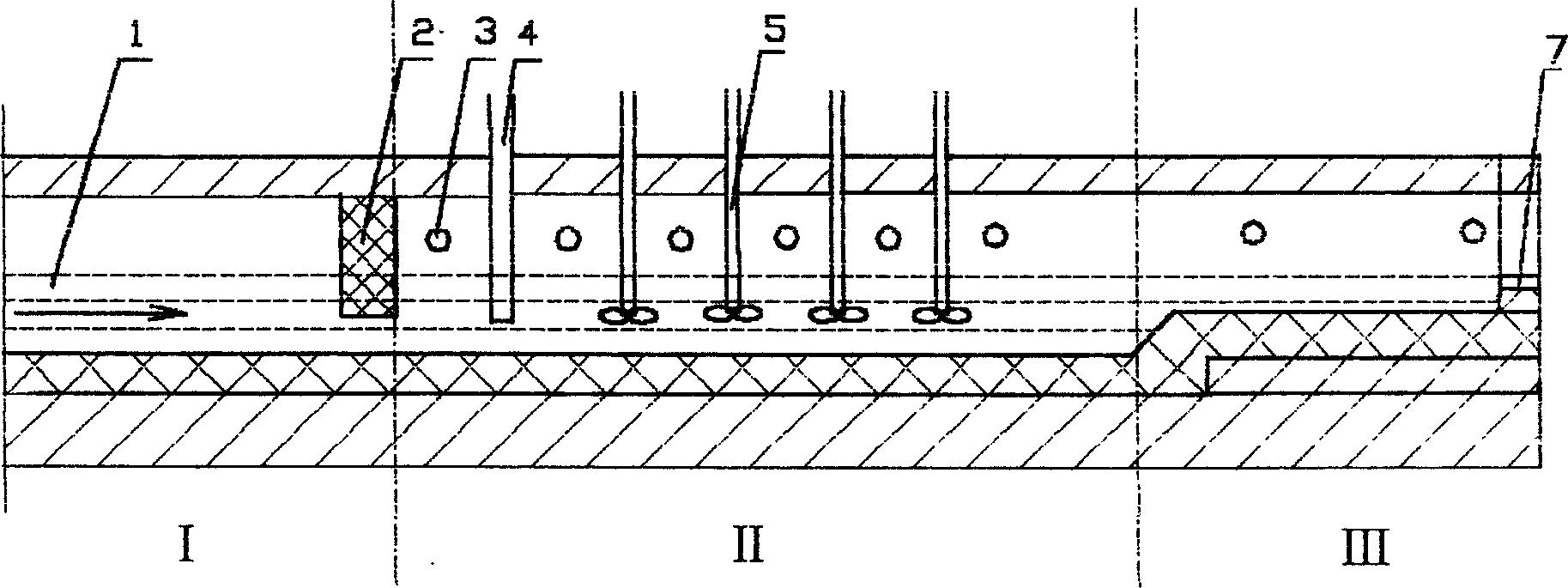

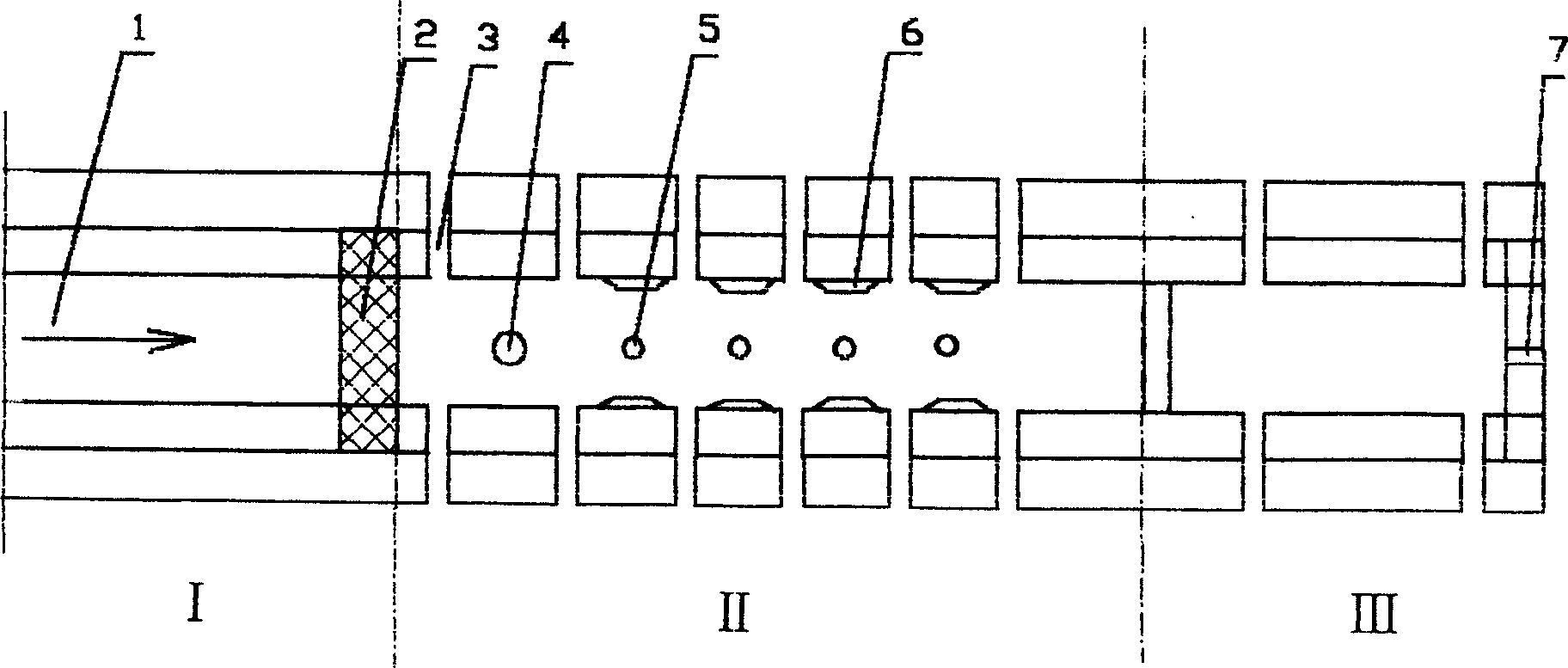

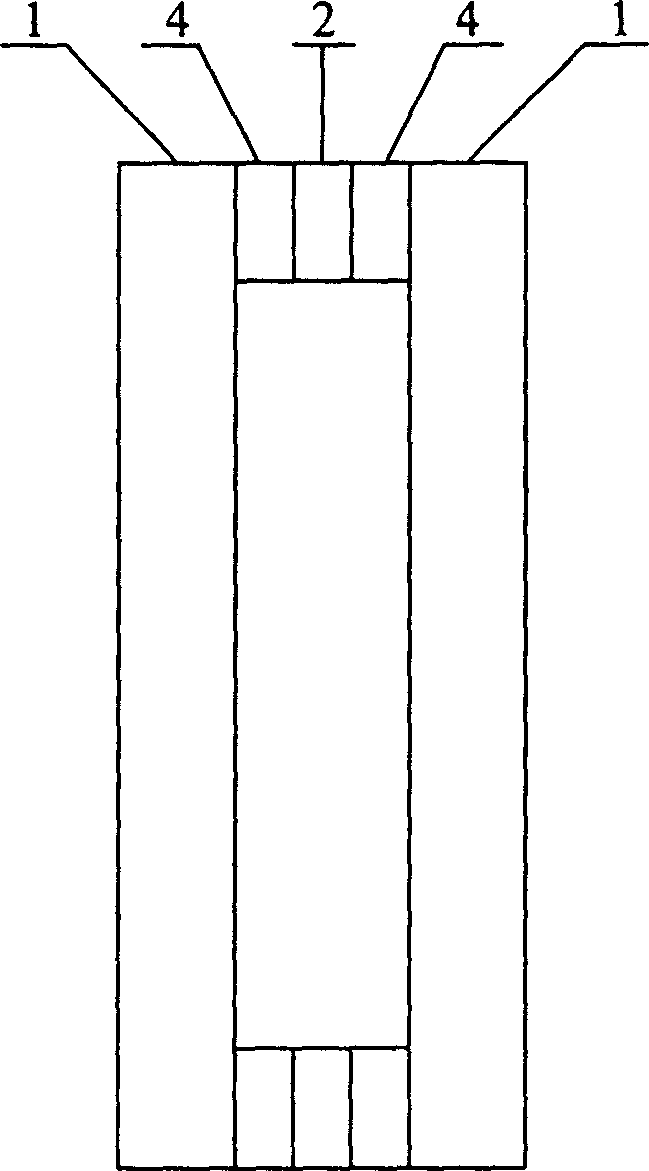

The invention provides a method for producing a bamboo fiber, comprising the following steps of sawing off, splitting and softening the bamboo, sending the bamboo material to a bamboo splitting separator to realize combing, splitting separation and airflow classification, thus obtaining the bamboo filament fiber; cooking and drying the bamboo filament fiber, cleaning, dehydrating, oiling and drying the bamboo filament fiber subsequently; and carrying out the enzyme treatment, thus obtaining the coarse bamboo fiber; subsequently carrying out fine treatment, cleaning and dehydrating, bleaching, cleaning, dehydrating, oiling, drying and curing by emulsion, thus obtaining the fine bamboo fiber. The method has high production efficiency, low processing cost and can prepare the bamboo fiber with the diameter within 0.03-0.15mm and the length within 30-300mm.

Owner:FUJIAN DANHAI MATTRESS

Decorative color microcrystalline glass formula and its production process

InactiveCN1654390AStable and reliable production technology and manufacturing processLow coloring temperatureColoring agentsPower consumption

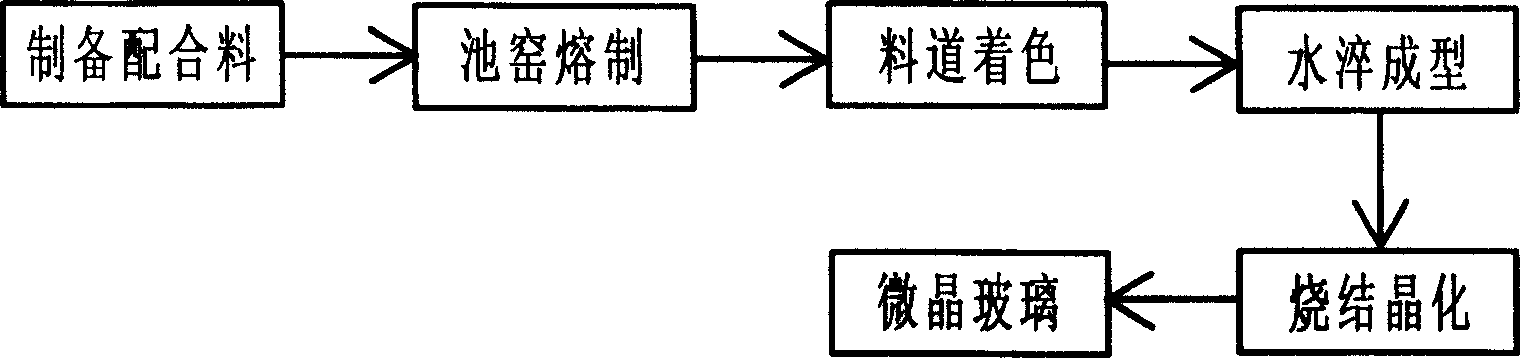

The present invention discloses the material formulation and production process of decorating color microcrystalline glass. The glass consists of: SiO2 55-62 wt%, Al2O3 5-9 wt%, CaO 12-20 wt%, MgO 0-4 wt%, R2O 3-8 wt%, BaO 1-5 wt%, ZnO 3-9 wt%, B2O3 0-2 wt%, Sb2O3 0-4 wt%, Li2O 0-4 wt% and coloring agent in proper amount, with R2O being Na2O or K2O. The present invention solves the problem of matching the base components and coloring agents to make the production process of the color microcrystalline glass stable and reliable. The present invention has relatively low continuous coloring temperature, and makes it possible to produce color microcrystalline glass in different colors through simple process and in low power consumption, high yield and low cost.

Owner:安庆市荣光玻璃集团有限公司

Semiconductor device having two distinct sioch layers

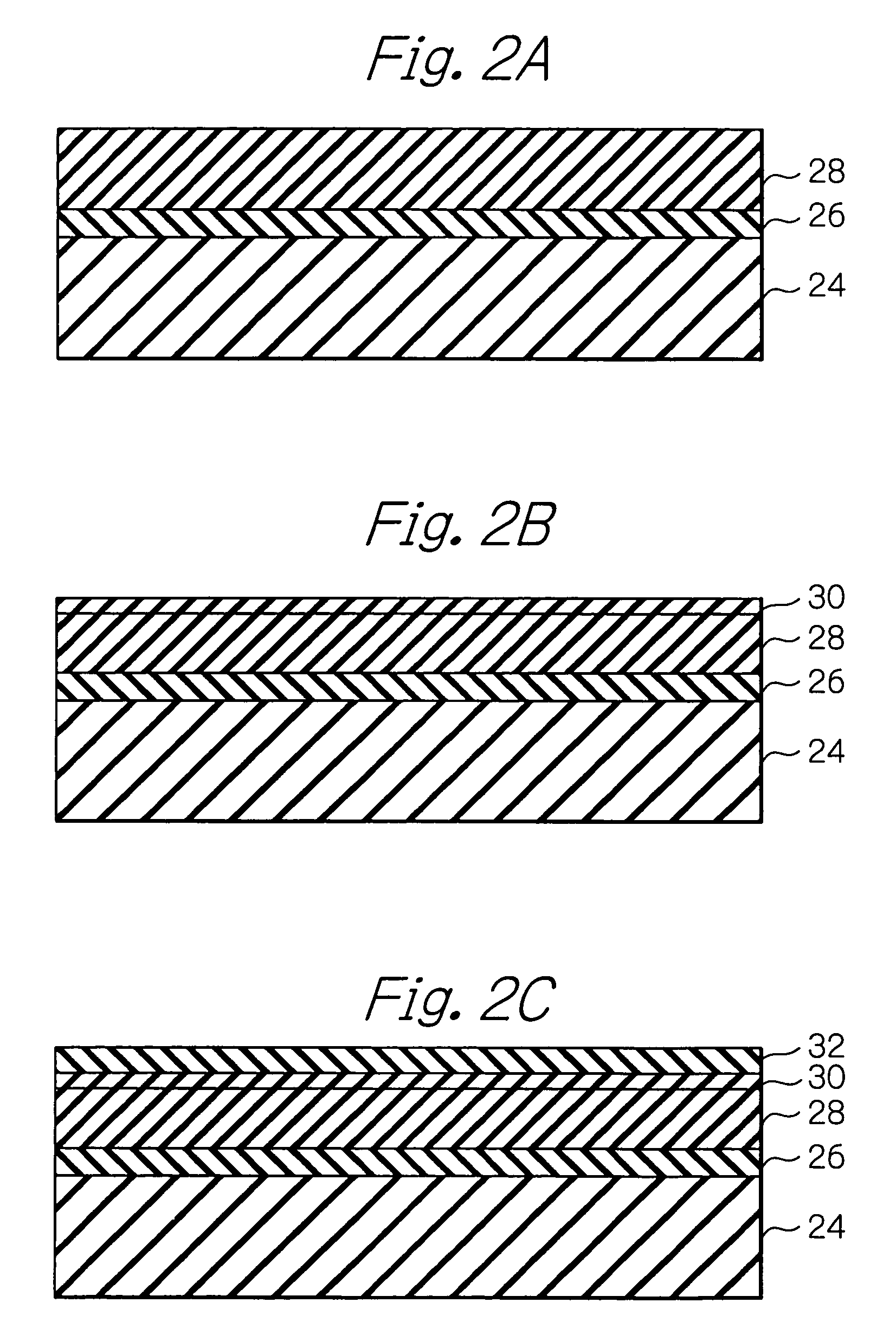

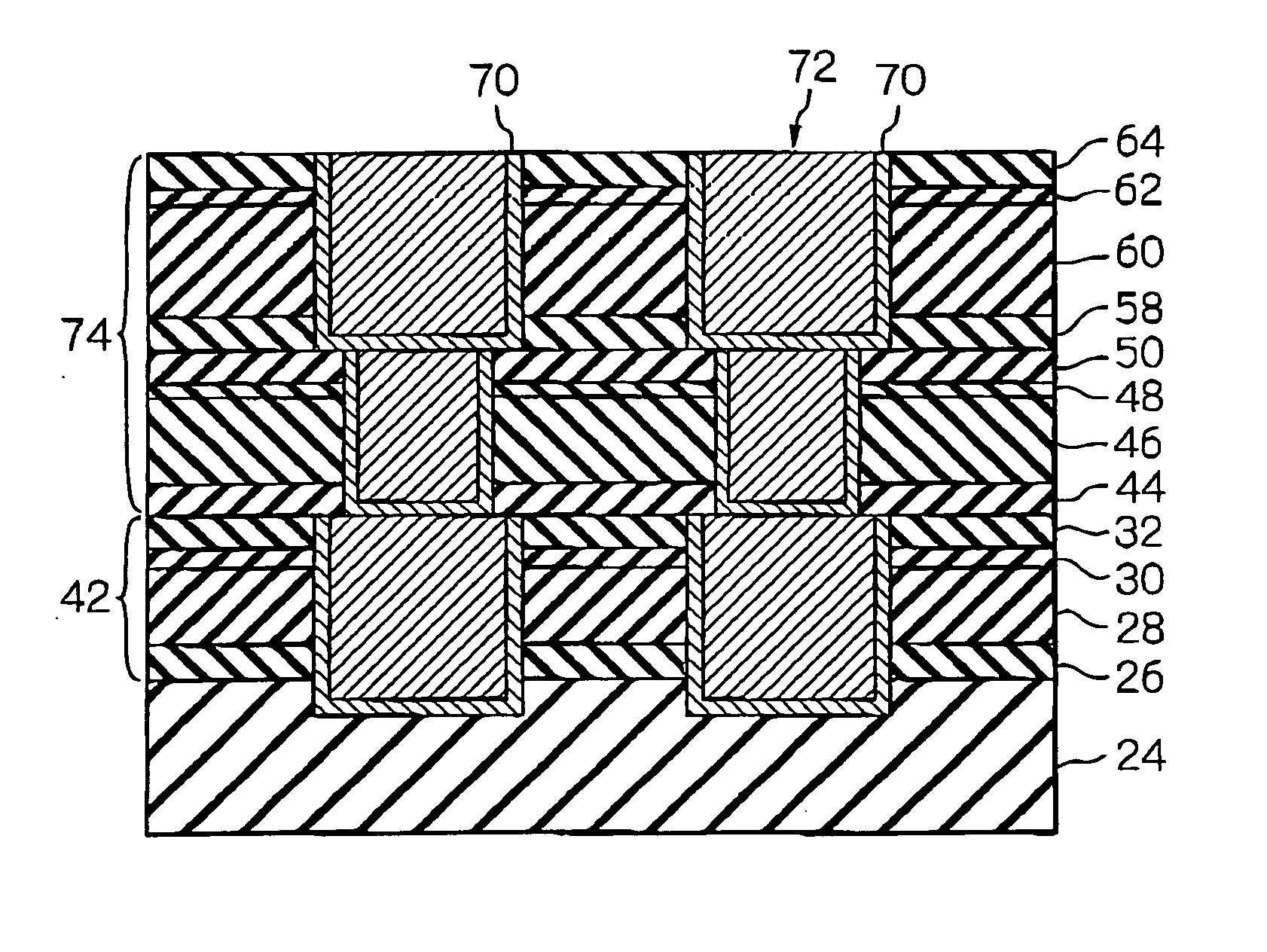

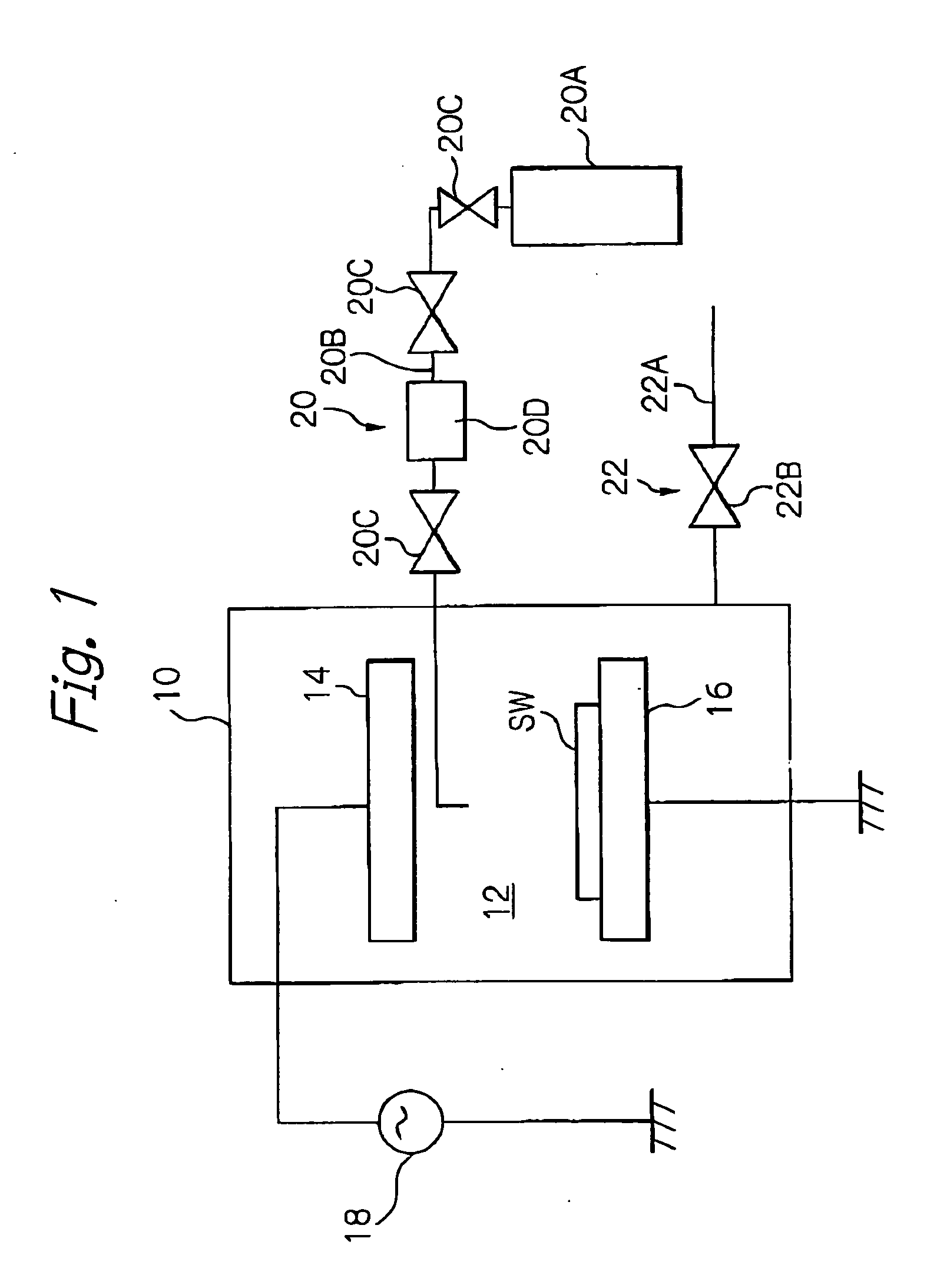

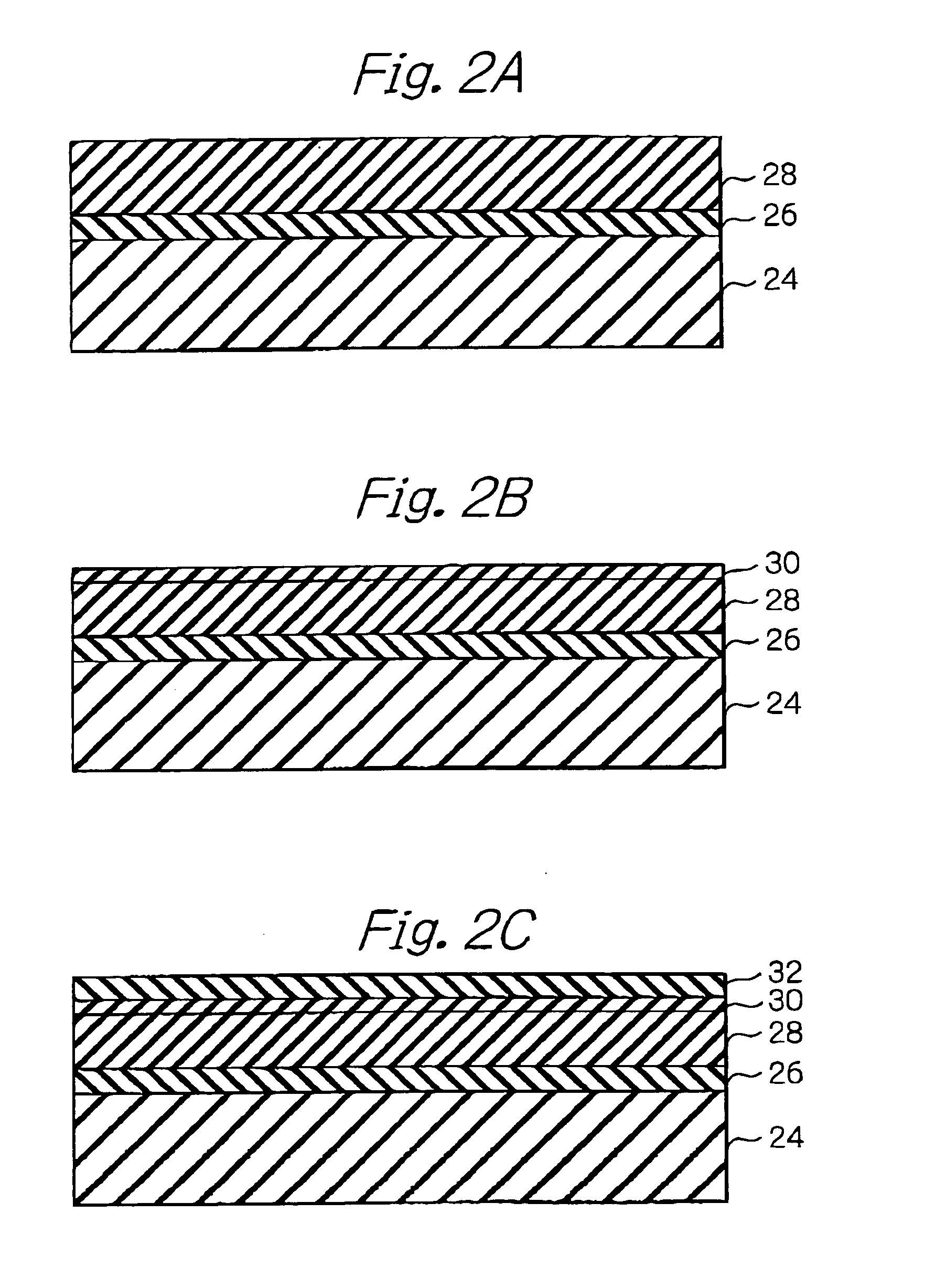

InactiveUS7132732B2High bonding strengthThe production process is stable and reliableSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering physics

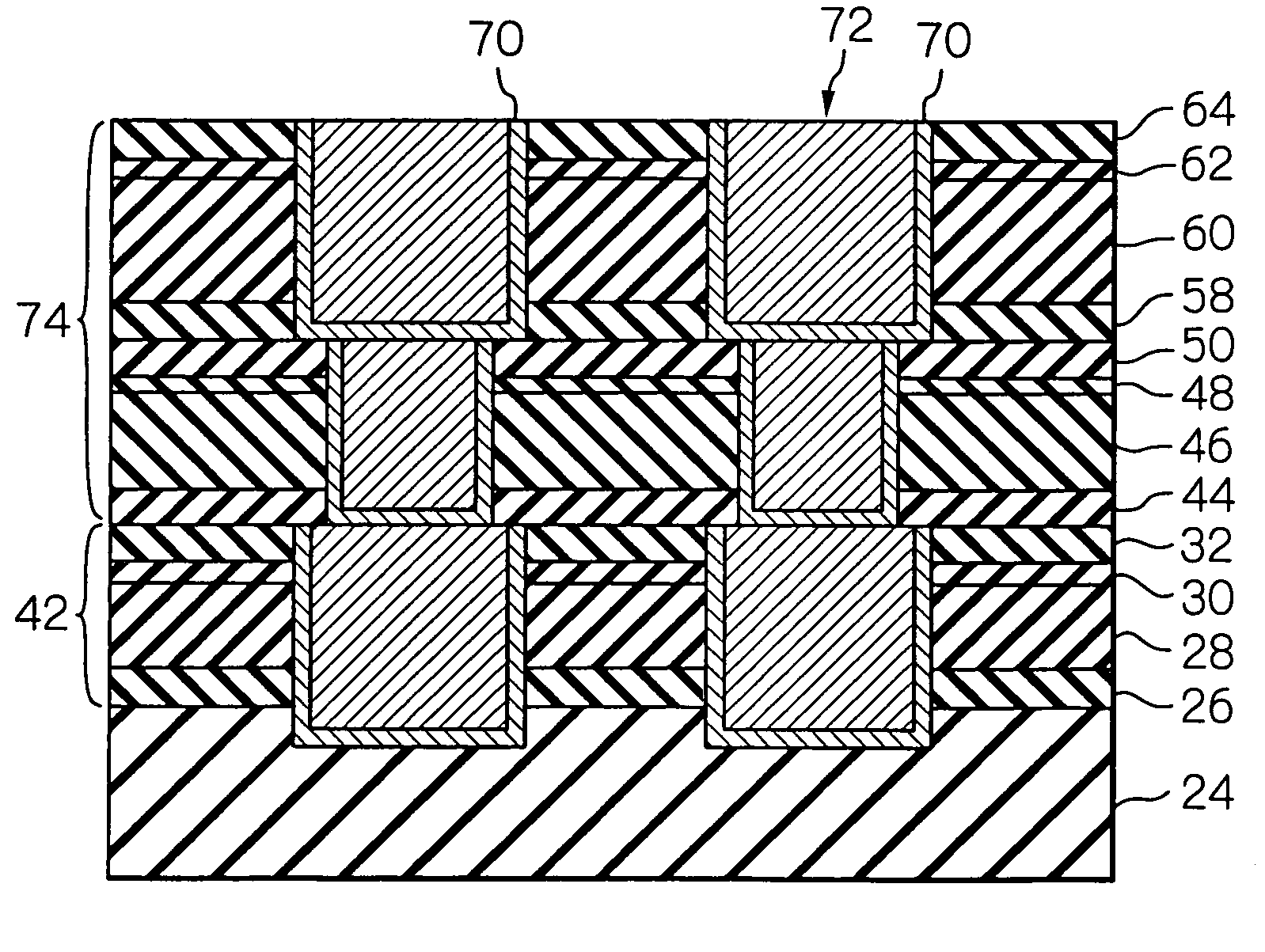

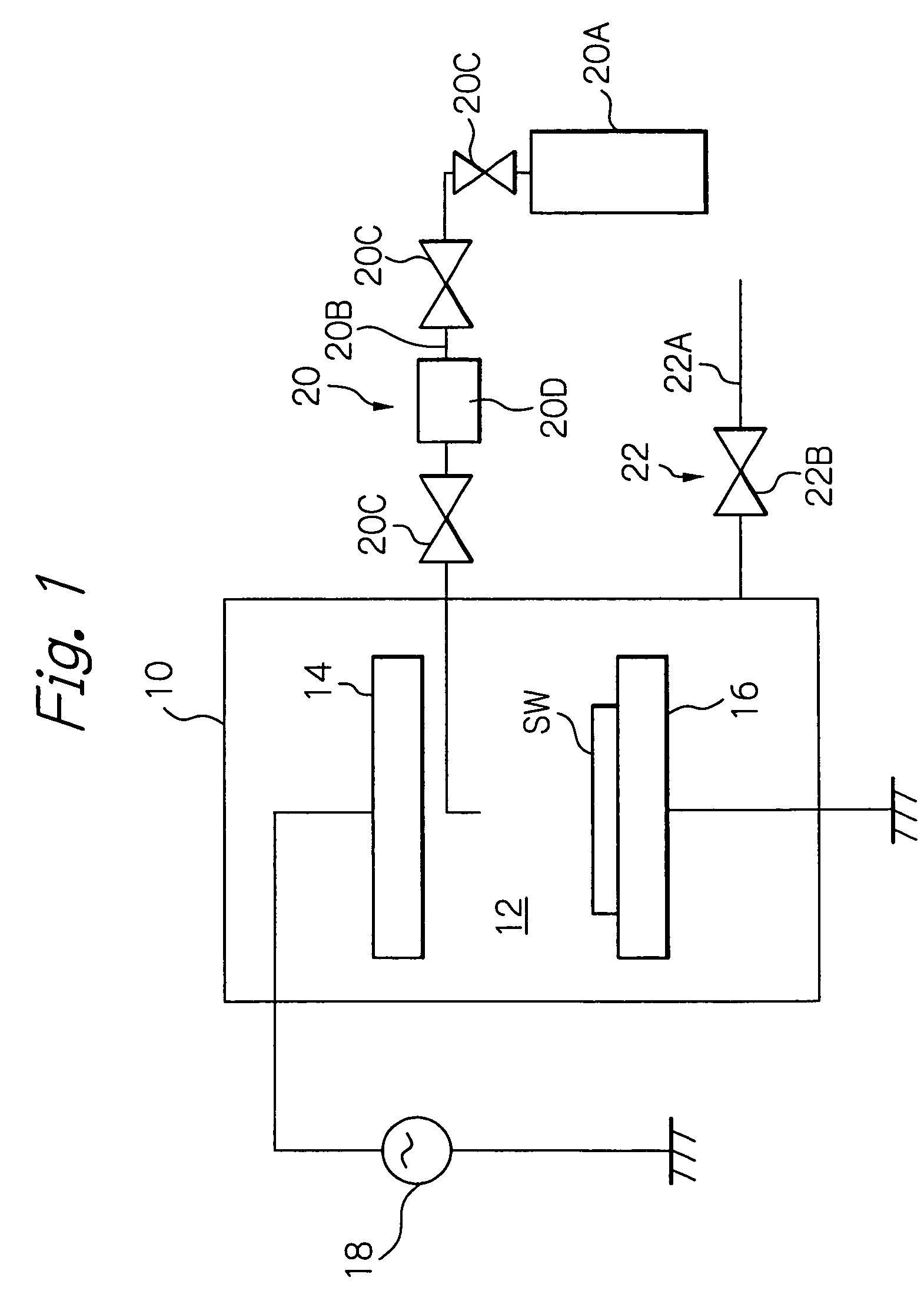

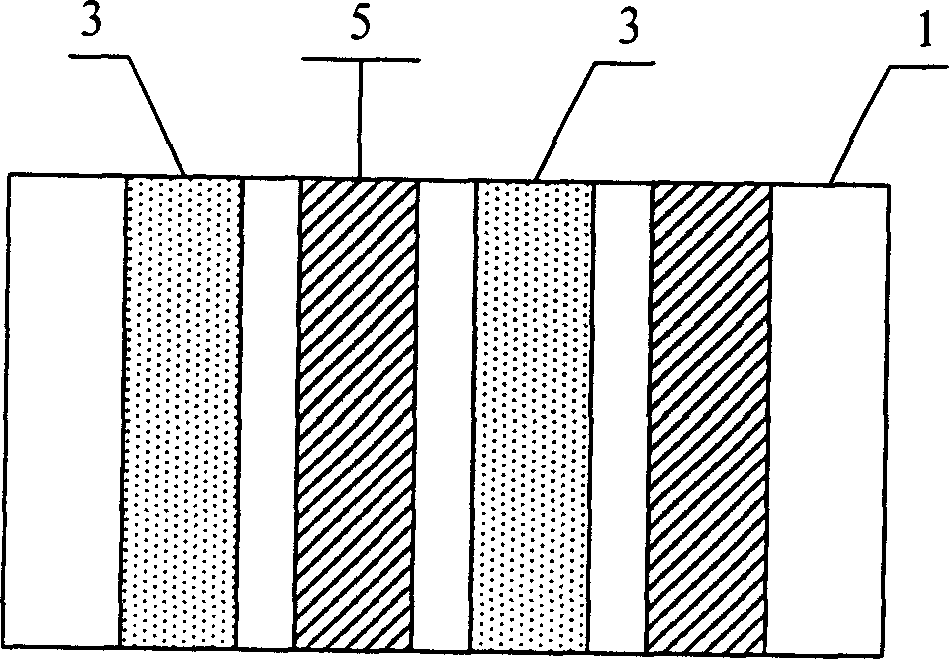

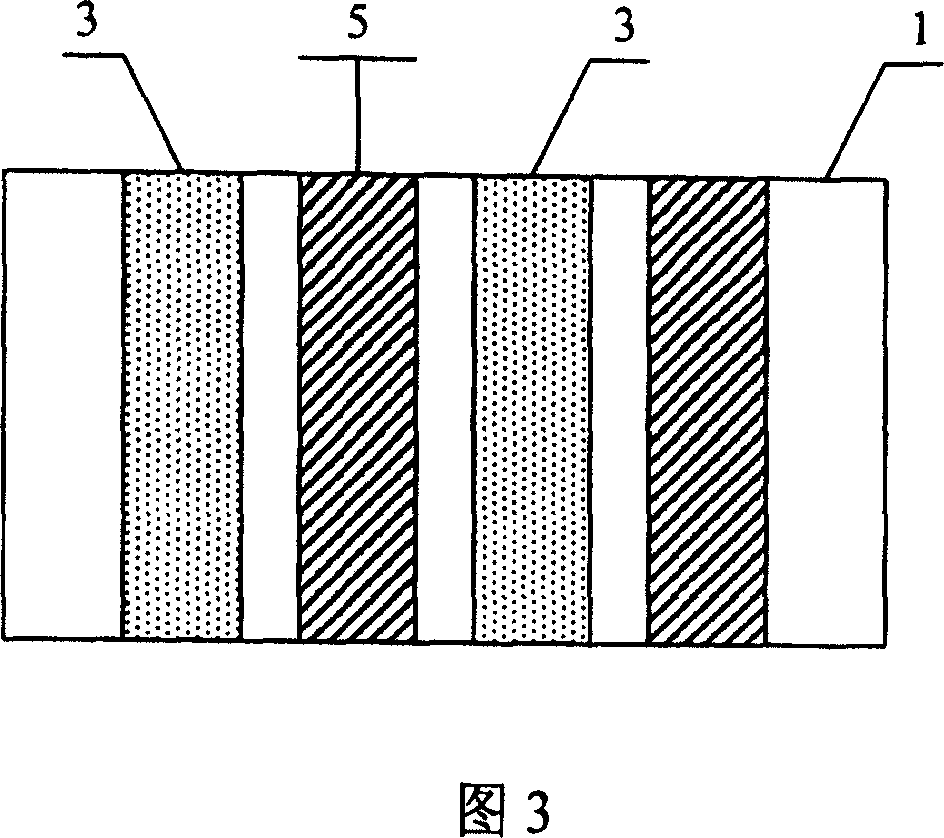

A semiconductor device has a semiconductor substrate, and a multi-layered wiring arrangement provided thereon. The multi-layered wring arrangement includes at least one insulating layer structure having a metal wiring pattern formed therein. The insulating layer structure includes a first SiOCH layer, a second SiOCH layer formed on the first SiOCH layer, and a silicon dioxide (SiO2) layer formed on the second SiOCH layer. The second SiOCH layer features a carbon (C) density lower than that of the first SiOCH layer, a hydrogen (H) density lower than that of the first SiOCH layer, and an oxygen (O) density higher than that of the first SiOCH layer.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device, and production method for manufacturing such semiconductor device

InactiveUS20070045861A1High bonding strengthThe production process is stable and reliableSemiconductor/solid-state device detailsSolid-state devicesHydrogenDevice material

A semiconductor device has a semiconductor substrate, and a multi-layered wiring arrangement provided thereon. The multi-layered wring arrangement includes at least one insulating layer structure having a metal wiring pattern formed therein. The insulating layer structure includes a first SiOCH layer, a second SiOCH layer formed on the first SiOCH layer, and a silicon dioxide (SiO2) layer formed on the second SiOCH layer. The second SiOCH layer features a carbon (C) density lower than that of the first SiOCH layer, a hydrogen (H) density lower than that of the first SiOCH layer, and an oxygen (O) density higher than that of the first SiOCH layer.

Owner:RENESAS ELECTRONICS CORP

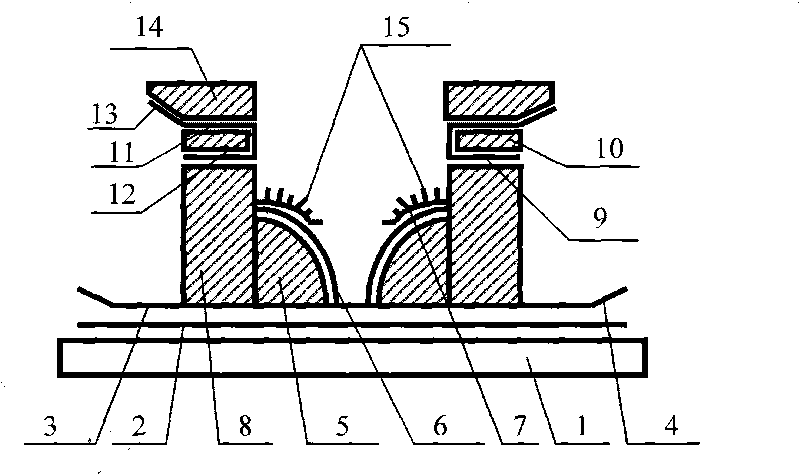

Production method for bamboo fiber

InactiveCN102433594AThe production process is stable and reliableImprove resource utilizationVegetable materialMechanical fibre separationChemistryFineness

The invention relates to a production method for bamboo fiber, which comprises steps of cutting, softening, fiber splitting, scouring, bleaching, cleaning, dewatering, drying, enzyme treatment and the like. An optimal fiber splitting point after bamboo is softened can be fully developed by a fiber splitting separator, machining parameters can be adjusted according to requirement, and different slenderness rates of the fiber are obtained to make the processed bamboo fiber finer and more uniform than original fiber. The production process is reliable, the resource utilization rate is high, the processing cost is low, environmental pollution is low, and the product quality is stable. The fine bamboo pure fiber produced by the invention has the characteristics of uniform length and fineness, high intensity, good flexibility, high moisture absorbing and releasing performance, high air permeability and particularly remarkable bacteria resistance and deodorization, is a new generation natural functional fiber which is cheap and has high quality and superior cost performance, and can be widely applied to fields of textile, building, automobiles and the like.

Owner:常熟市佳懿针纺织品有限公司

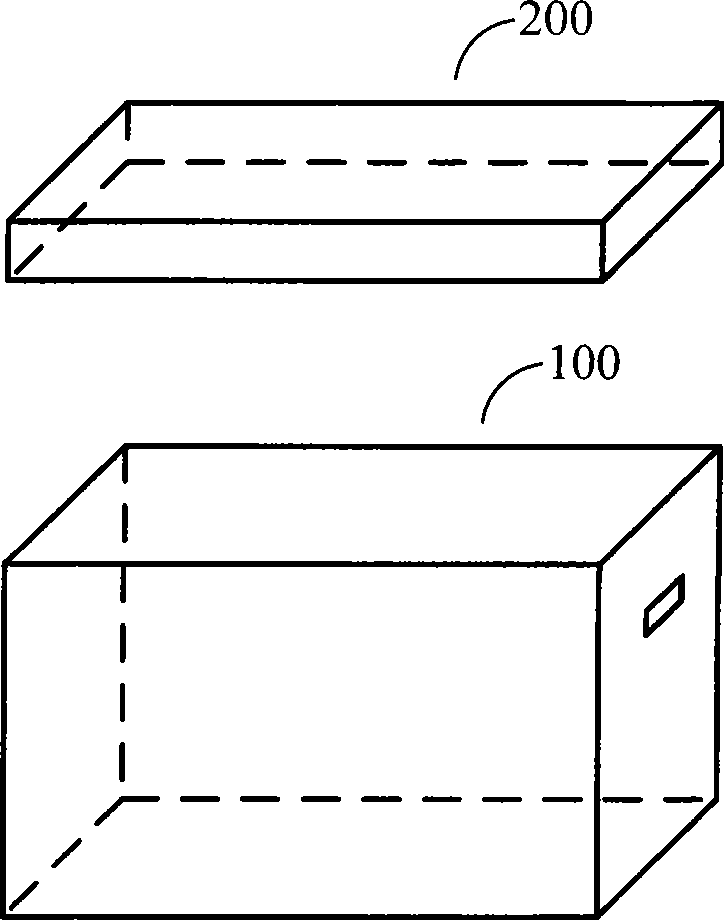

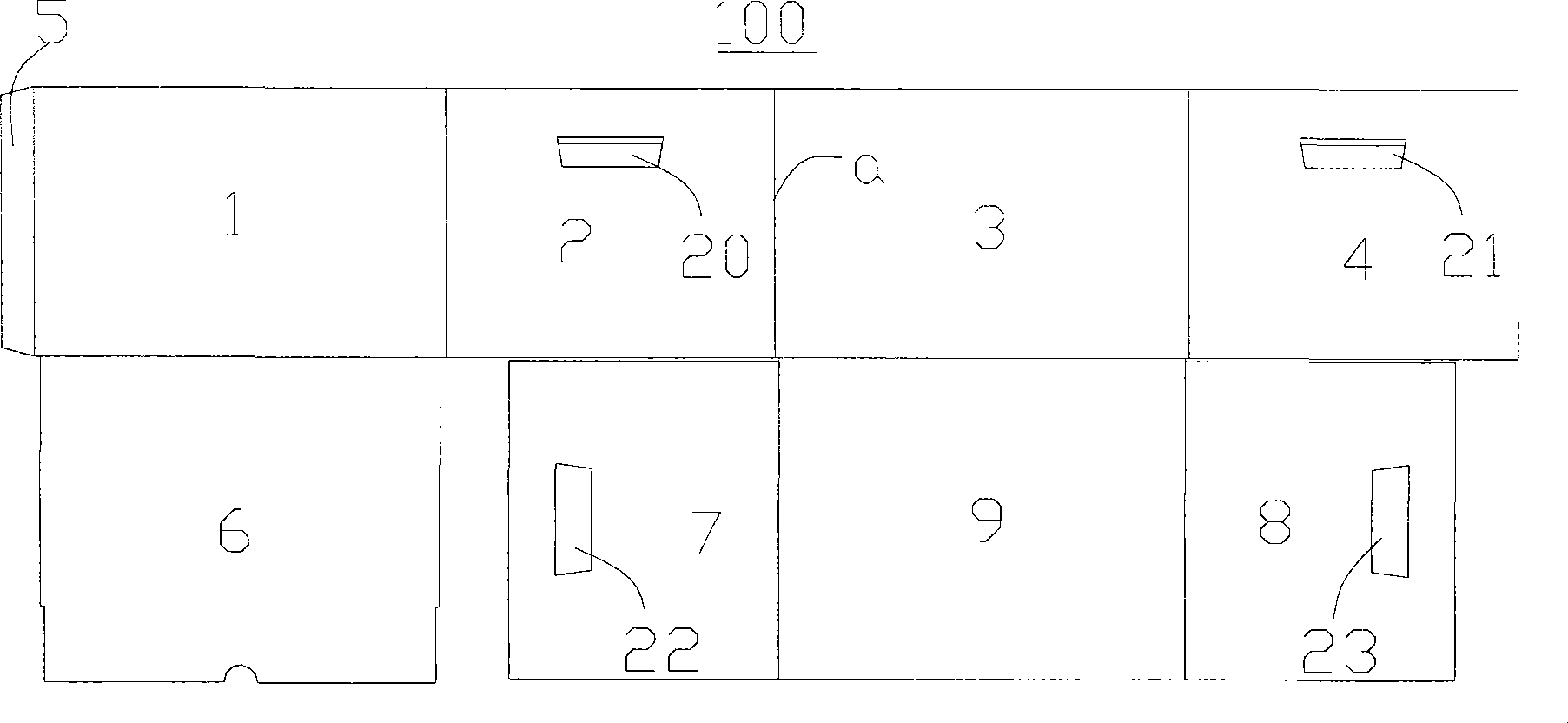

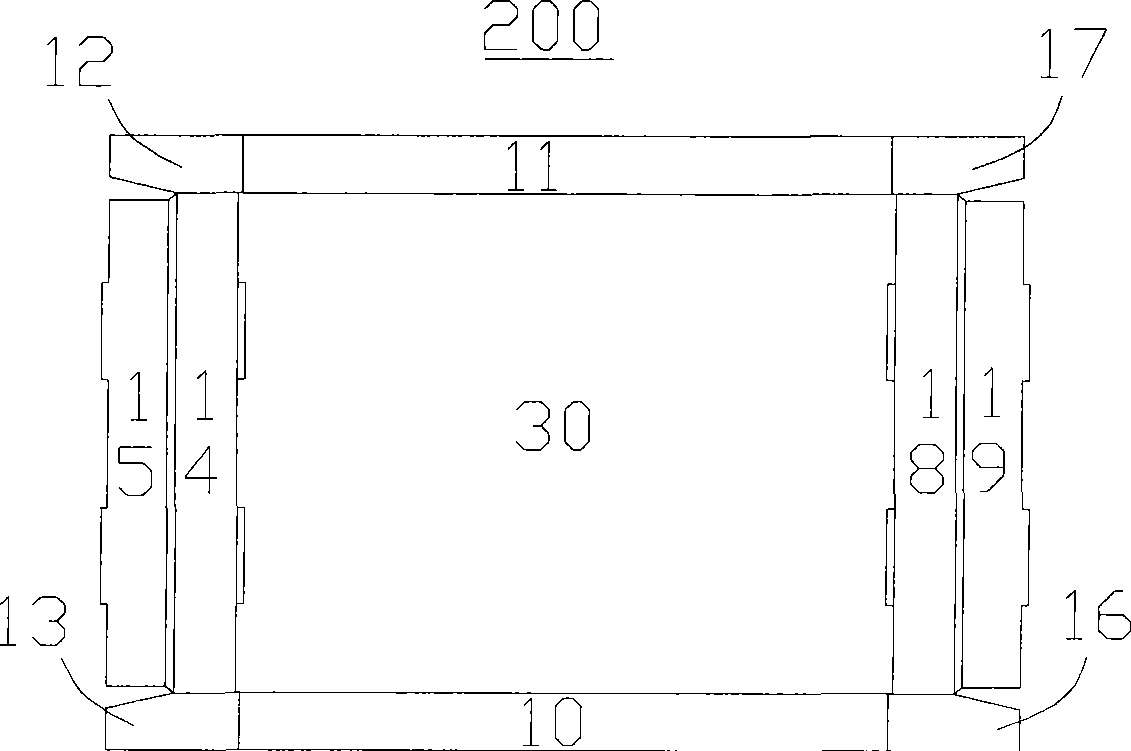

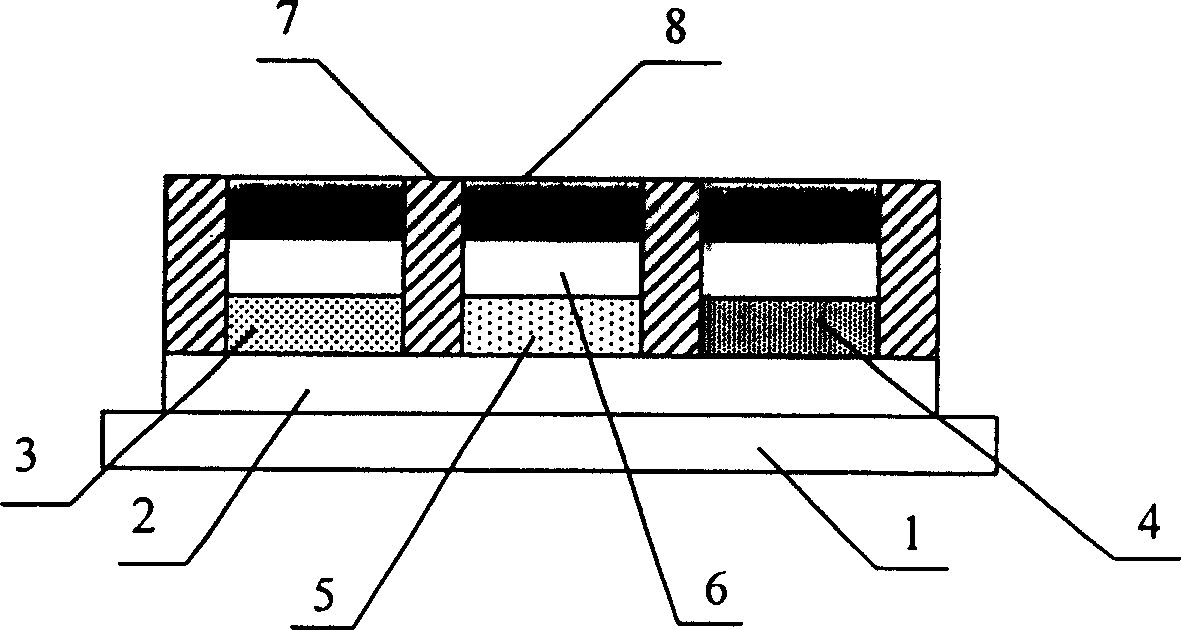

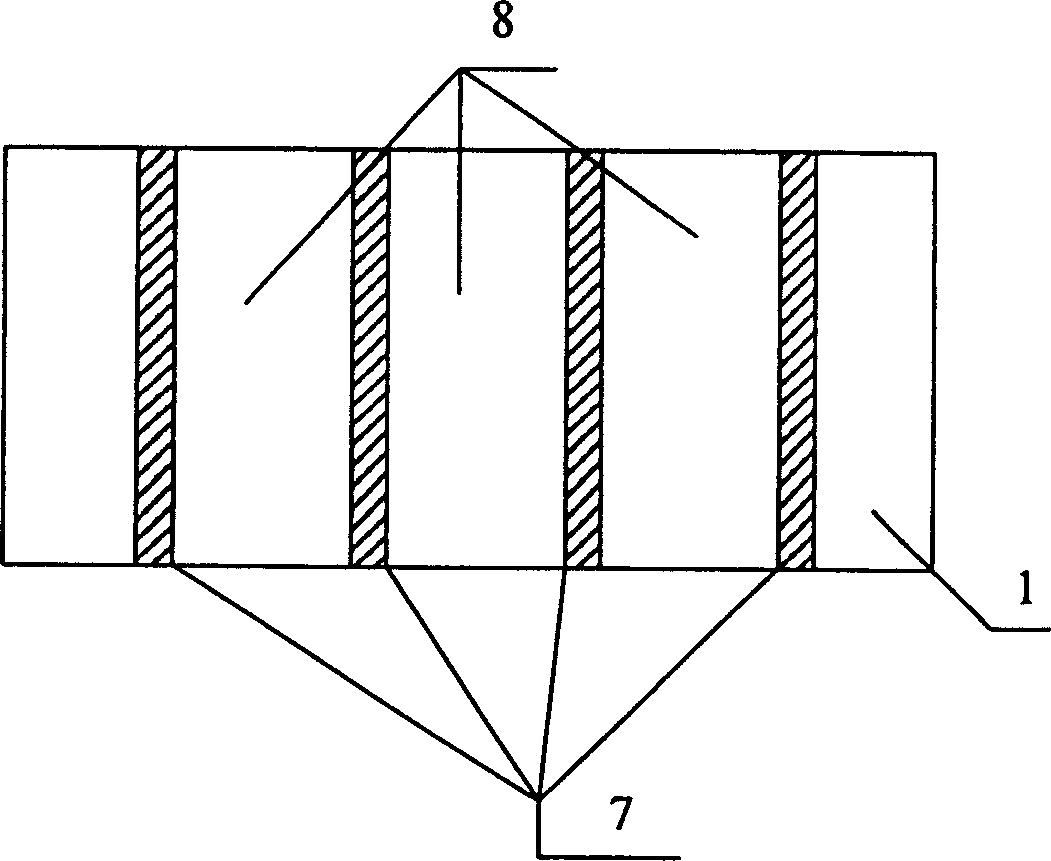

Carton and method for producing the same

ActiveCN101475068AAvoid wastingAvoid damageBoxes/cartons making machineryRigid containersCardboardCarton

The invention discloses a paper box, which comprises a square box body and a square cover body which are formed by folding a paper board. The square box body comprises a first external wall plate, a second external wall plate, a third external wall plate and a fourth external wall plate which are connected through fold marks. The bottom edge of the first external wall plate is connected with an inner bottom plate. The bottom edge of the third external wall plate is connected with an outer bottom plate. Two side edges of the outer bottom plate are connected with a second internal wall plate and a fourth internal wall plate respectively. The first external wall plate, the second external wall plate, the third external wall plate, the fourth external wall plate and the outer bottom plate folded and enclose together to form a square body structure with an open top of a square box body. A second internal wall plate is folded and attached to the inner surface of the second external wall plate. The fourth internal wall plate is folded and attached to the inner surface of the fourth external wall plate. The inner bottom plate is folded and attached to the inner surface of the outer bottom plate. The invention correspondingly discloses a method for making the paper box. The paper box has the advantages of low cost, simple manufacture, firmness, beautiful appearance, environment protection, better object protection and the like.

Owner:深圳华生创新包装有限责任公司

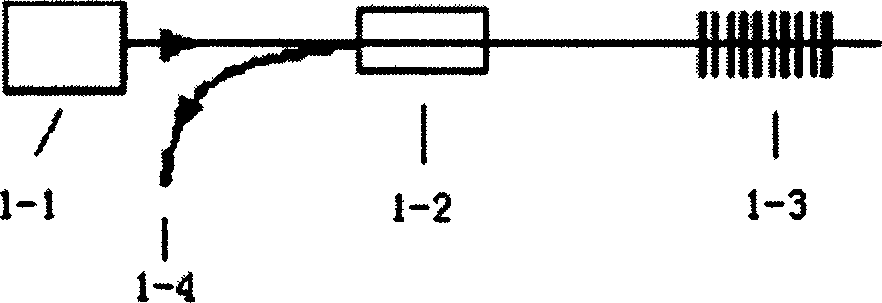

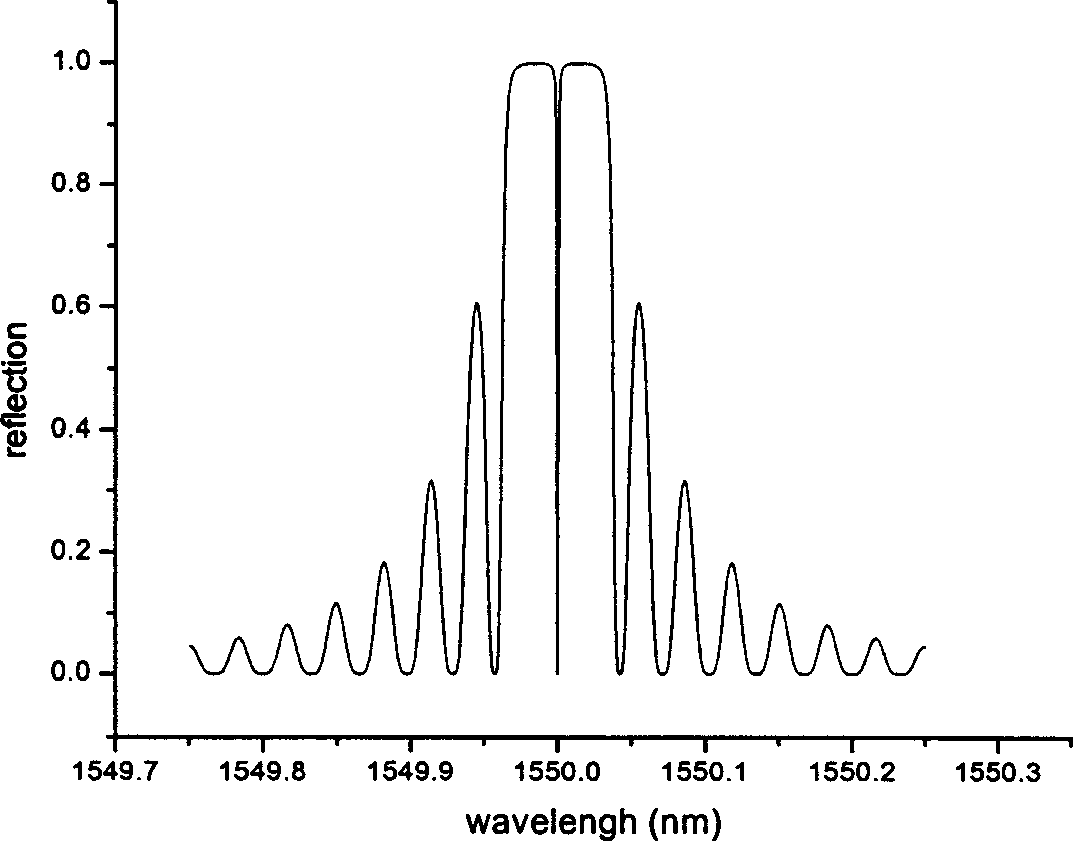

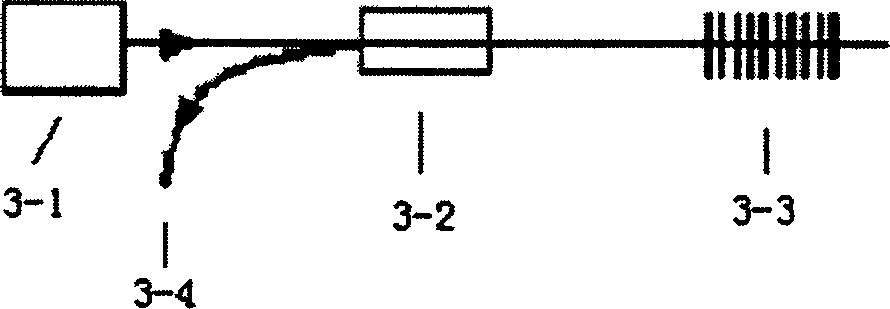

Distributed feedback light waveguide laser

InactiveCN1585213AEasy to makeThe production process is stable and reliableOptical resonator shape and constructionActive medium materialGratingWaveguide lasers

In this invention, in the minus or plus 15%area from the center of the sampling Prague grating which is etched on the light waveguide, on of the sampling period is jumping, while other sampling period is keeping unchanged. The jumped period is 1.4-1.6 or 0.4-0.6 times of the original. The sampling Prague grating makes the respective reflecting peak generate similar slit of the normal grating. The period of this grating possesses the property of linear chirp. When the period jumped to 1.5 or 0.5 times of the original, the -1 level chirp reflecting peak is about to zero.

Owner:TSINGHUA UNIV

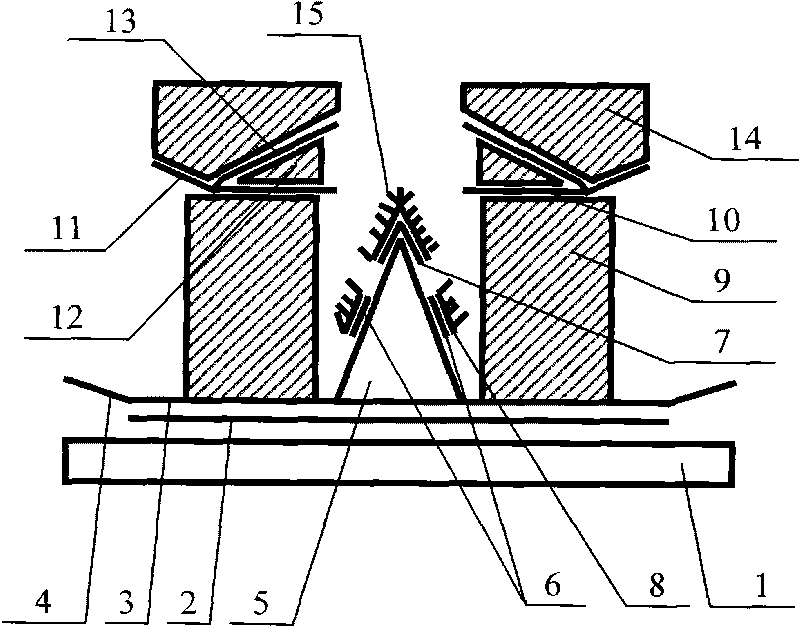

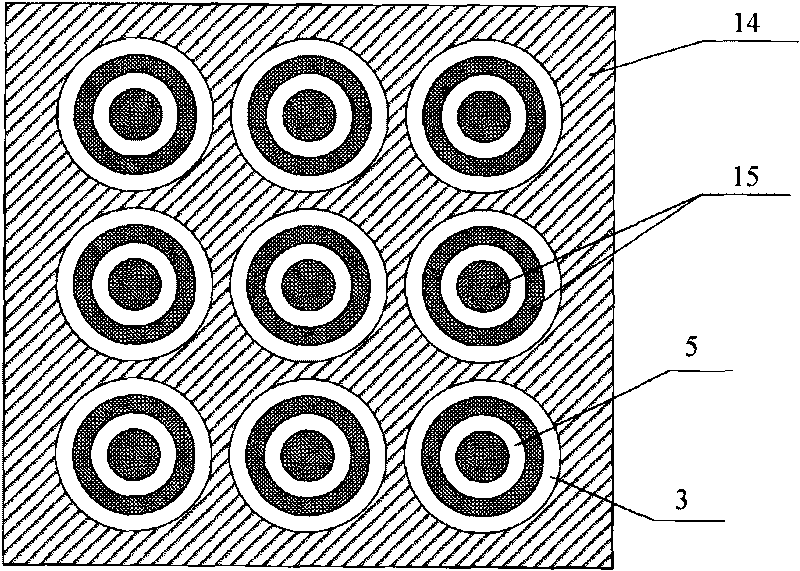

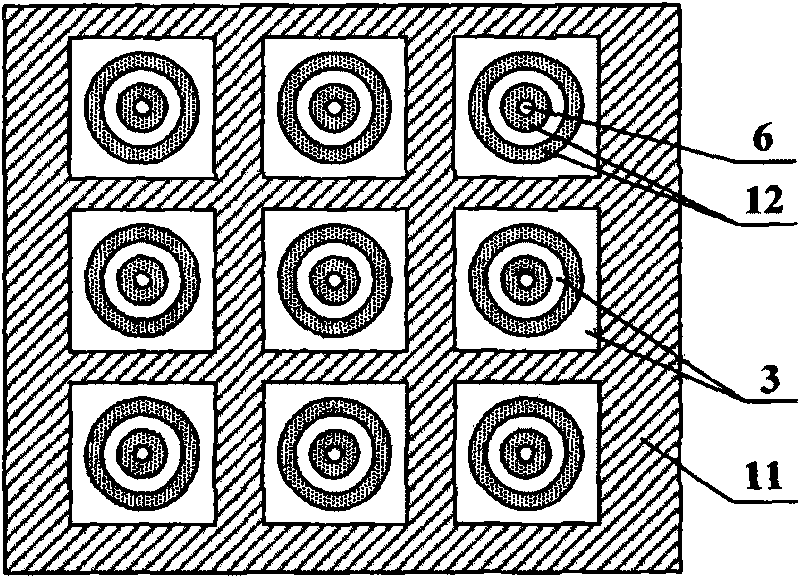

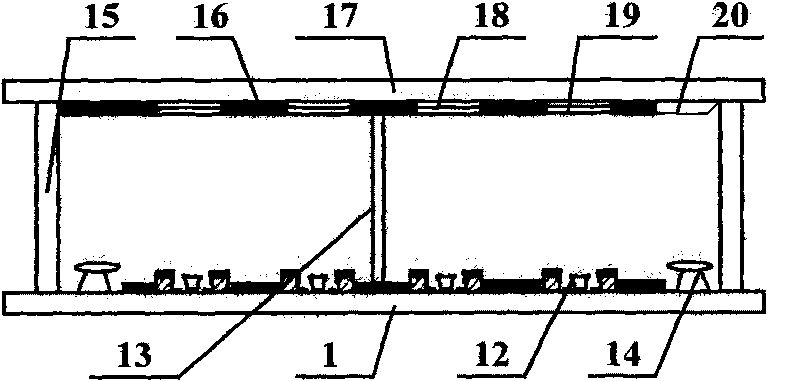

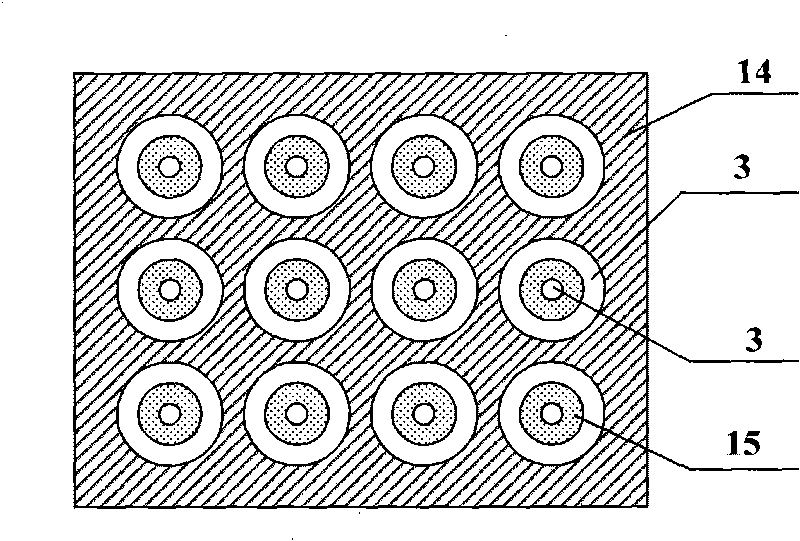

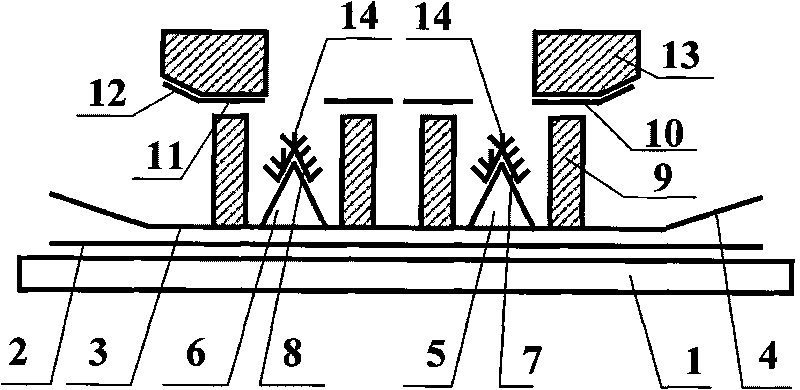

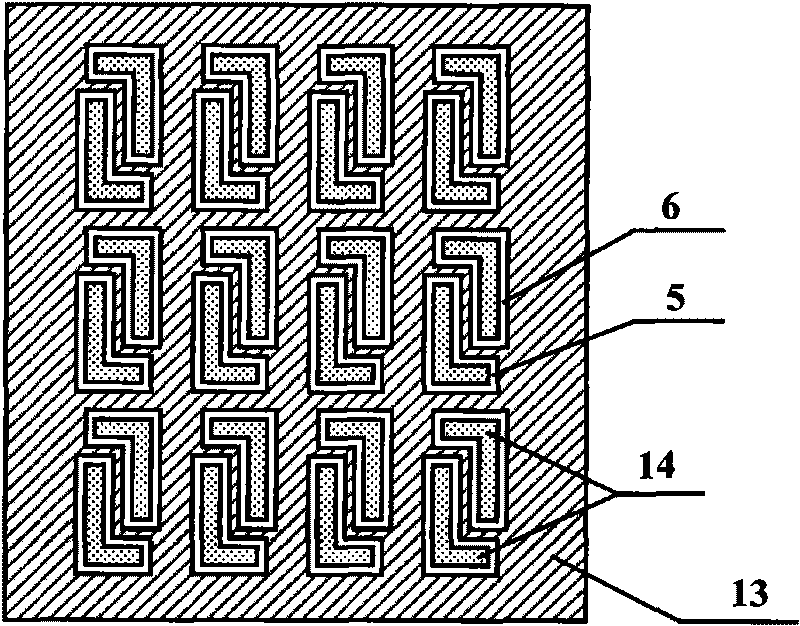

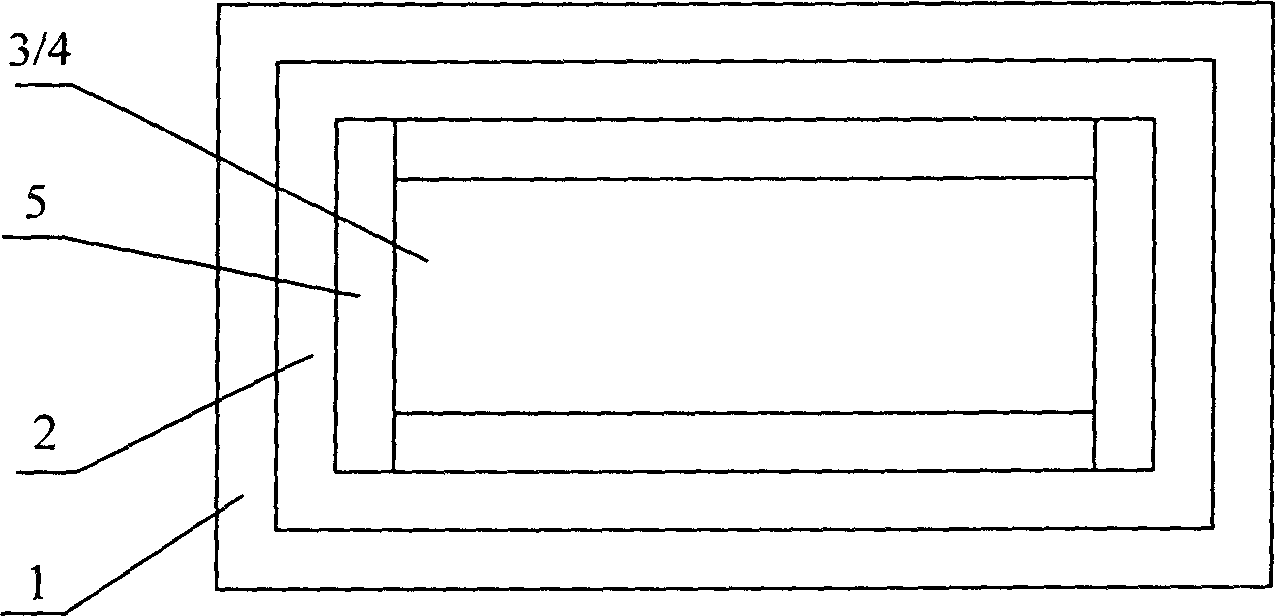

Flat-panel display with inverted Y-shaped inclined high-grating single-point cathodic control structure and manufacture process thereof

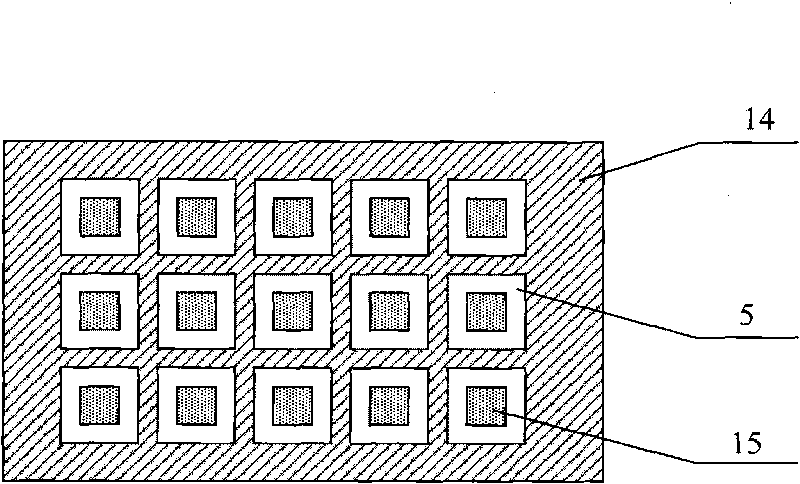

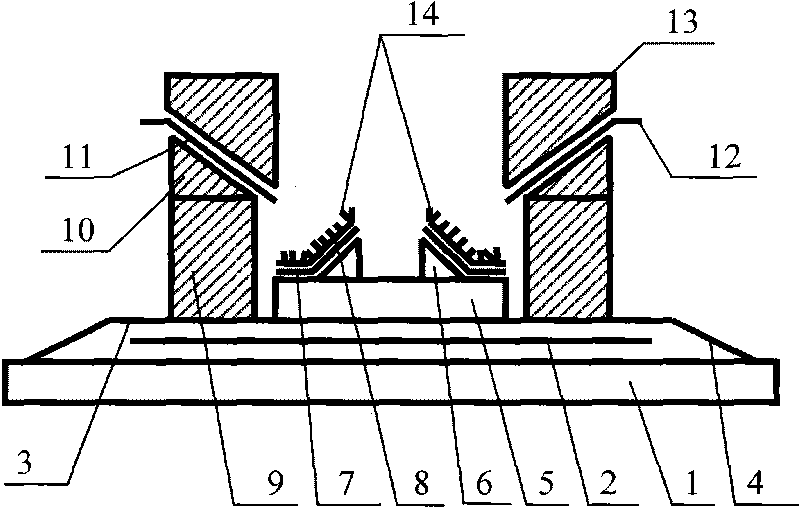

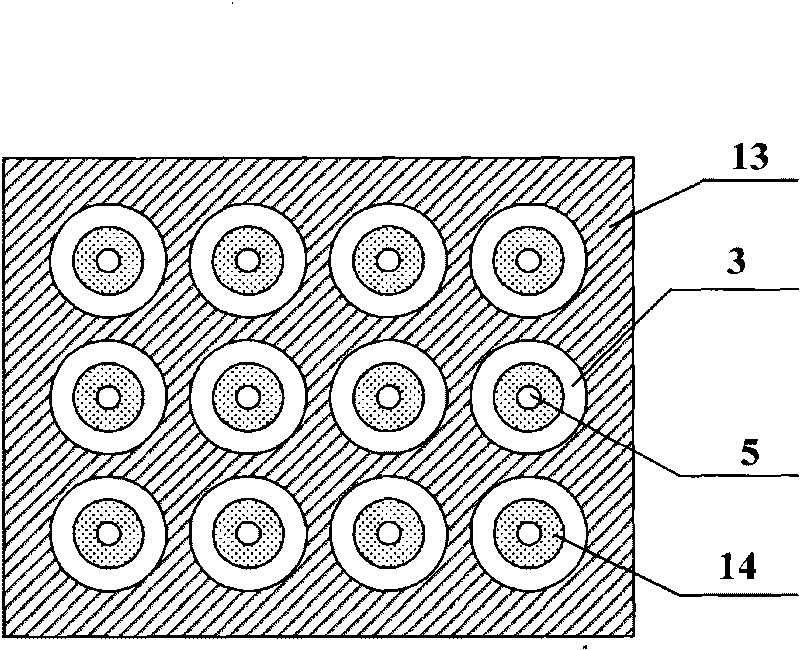

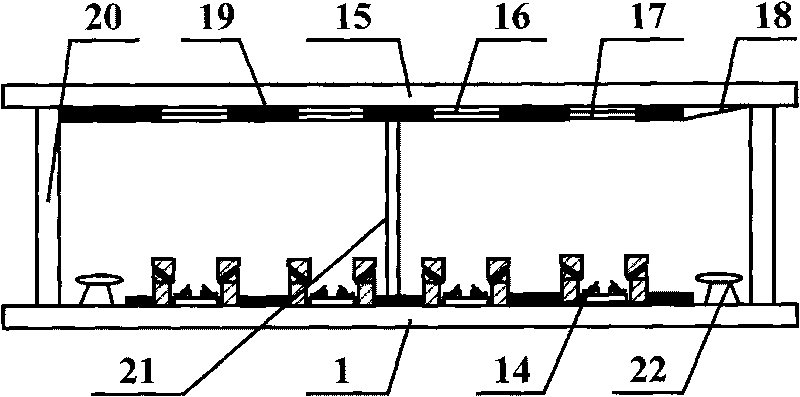

InactiveCN101728192AImprove emission efficiencyIncrease surface areaImage/pattern display tubesCold cathode manufactureGratingInsulation layer

The invention in particular relates to a flat-panel display with an inverted Y-shaped inclined high-grating single-point cathode control structure and a manufacture process thereof. The flat-panel display comprises a sealing vacuum chamber, an anode conduction layer, an anode wiring layer, an anode insulation layer, a fluorescent powder layer prepared on the anode conduction layer, an isolation supporter and a degasifier, wherein the sealing vacuum chamber comprises an anode glass panel, a cathode glass panel and a glass frame; the anode conduction layer, the anode wiring layer, the anode insulation layer and the fluorescent powder layer are arranged on the anode glass panel; and the isolation supporter and the degasifier are arranged between the anode glass panel and the cathode glass panel. The inverted Y-shaped inclined high-grating single-point cathode control structure comprises a cathode glass panel, a barrier and isolation layer, a cathode conducting layer, a cathode wiring layer, a cathode lifting layer, a first cathode transition layer, a second cathode transition layer, a cathode sacrificial layer, a first grating and cathode spacing layer, a first gate electrode layer, a gate electrode wiring layer, a second grating and cathode spacing layer, a second gate electrode layer, a third grating and cathode spacing layer and a carbon nano tube part. The invention has the advantages of low cost, simple manufacture process and stable and reliable manufacture process.

Owner:ZHONGYUAN ENGINEERING COLLEGE

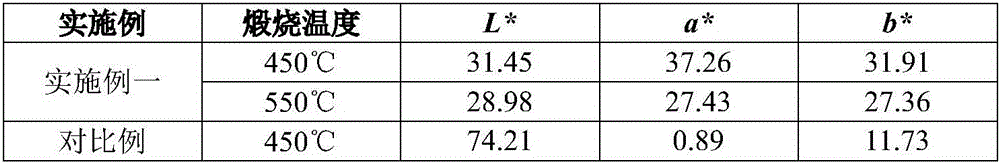

Preparation method of compound coated type cerium sulfide red pigment and product prepared through preparation method

ActiveCN106280551AHigh densityReaction is easy to controlPigment treatment with non-polymer organic compoundsCeriumSilicon oxide

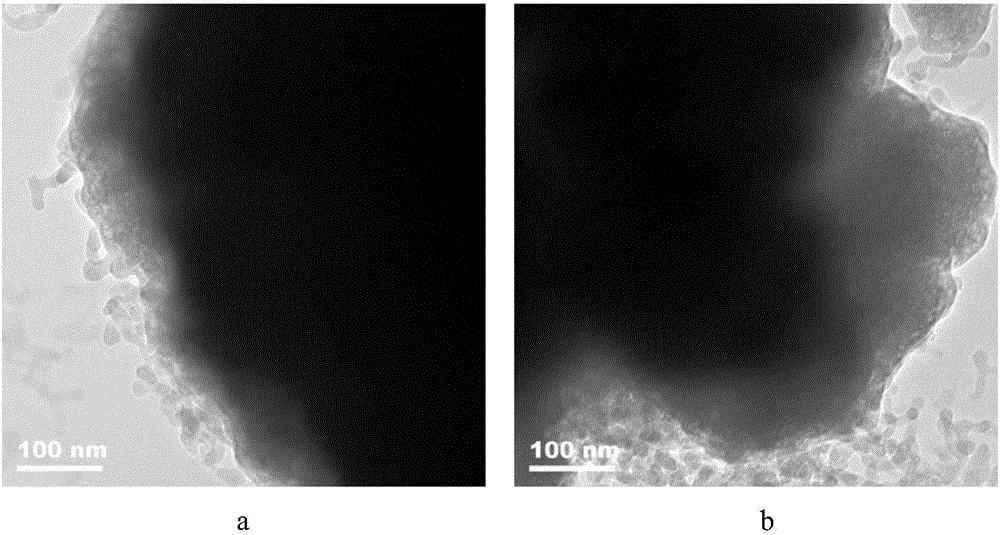

The invention discloses a preparation method of a composite coated cerium sulfide red pigment. The preparation method comprises the steps that firstly, colorant suspension liquid containing gamma-Ce2S3 toner is hydrolyzed by a solution containing Zr<4+>, and after a hydrolysis product is dried, first-time coated precursor powder is prepared; secondly, first-time coated precursor powder suspension liquid is hydrolyzed by a solution containing Si<4+>, and after a hydrolysis product is dried, second-time coated precursor powder is prepared; finally, the second-time coated precursor powder is subjected to calcining treatment in a non-oxidation atmosphere, and then the composite coated cerium sulfide red pigment which has a zirconium oxide-silicon oxide composite coating layer and is densely coated is prepared. The invention further discloses a product prepared through the preparation method. According to the preparation method, by means of stepped hydrolysis-composite coating, reacting is easy to control, effective coating of the surface of cerium sulfide is improved, the preparation process is stable and reliable, and obtaining of the cerium sulfide red pigment with the dense and compact coating layer is promoted. The preparation technology is simple and easy to operate, and the prepared product is high in stability and suitable for industrial popularization.

Owner:JINGDEZHEN CERAMIC INSTITUTE

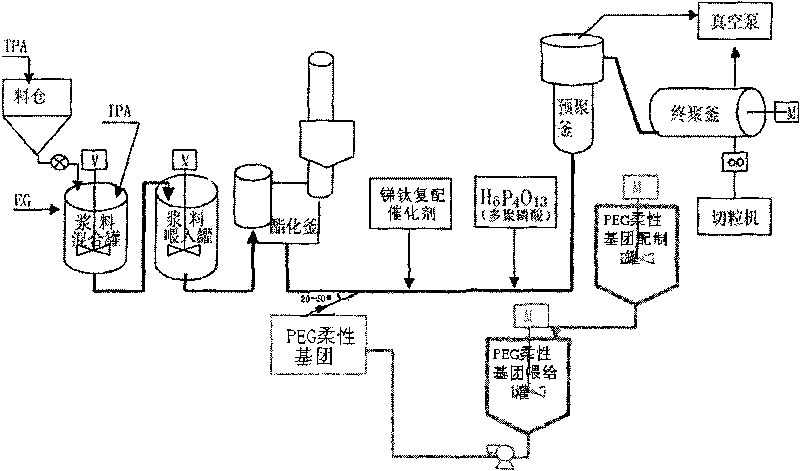

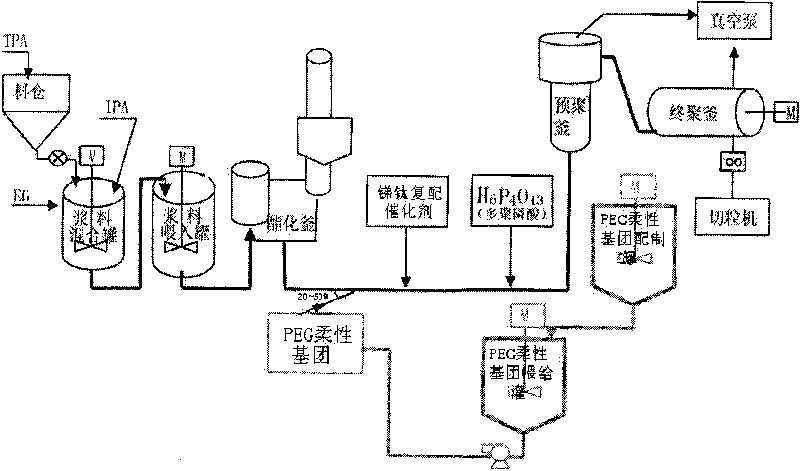

Method for preparing high-flexibility PET copolymer used in spun-lace non-woven fabrics

InactiveCN101704941AEvenly dispersedTightly boundMonocomponent copolyesters artificial filamentWoven fabricAntimony

The invention relates to a method for preparing a high-flexibility PET copolymer used in spun-lace non-woven fabrics, which comprises the following technological processes: (1) stirring p-phthalic acid, m-phthalic acid and glycol in a sizing agent mixing tank in a set mol ratio, pumping the mixture into a sizing agent feeding tank, feeding the mixture into an esterifying kettle through a sizing agent injection nozzle from the sizing agent feeding tank, and evenly mixing and reacting the sizing agent according to a cycle theory of a thermosiphon or under the action of a stirrer; and (2) injecting an oligomer after the esterification and each additive on a pipeline into a pre-polymerization kettle by a gear pump, introducing the materials into a final-polymerization kettle when the materials reach the upper part of the pre-polymerization kettle, filtering a product after the final polymerization by a melt filter, and towing the product to a dicing cutter to prepare polyester slices. The additives in a condensation polymerization process comprise a compound catalyst of antimony and titanium, a flexible radical PEG and a stabilizing agent polyphosphoric acid. The preparation method generates a PEG-PET block copolymer by connecting the flexible radical PEG to a PET trunk chain and adopting a copolymerization method. The fiber produced by using the copolymer has excellent flexibility.

Owner:JIANGYIN BOLUN CHEM FIBER

Hydrogenation method for thermoplastic elastomer in series of styrene

InactiveCN101050246AGood compatibilityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsSolventPolymer chemistry

This invention relates to a method for hydrogenating styrene-series thermoplastic elastomer with N2H4.H2O / H2O2 / catalyst system. The method comprises: (1) preparing styrene-series thermoplastic elastomer latex; (2) hydrogenating styrene-series thermoplastic elastomer latex with N2H4.H2O / H2O2 / catalyst system. The method does not need high-pressure apparatus, compressed H2, noble metal catalyst or a large amount of solvent. The product has hydrogenation degree of 85% and gel content lower than 2%. The method has such advantages as simple process, high stability, high reliability, no pollution and wide applications.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

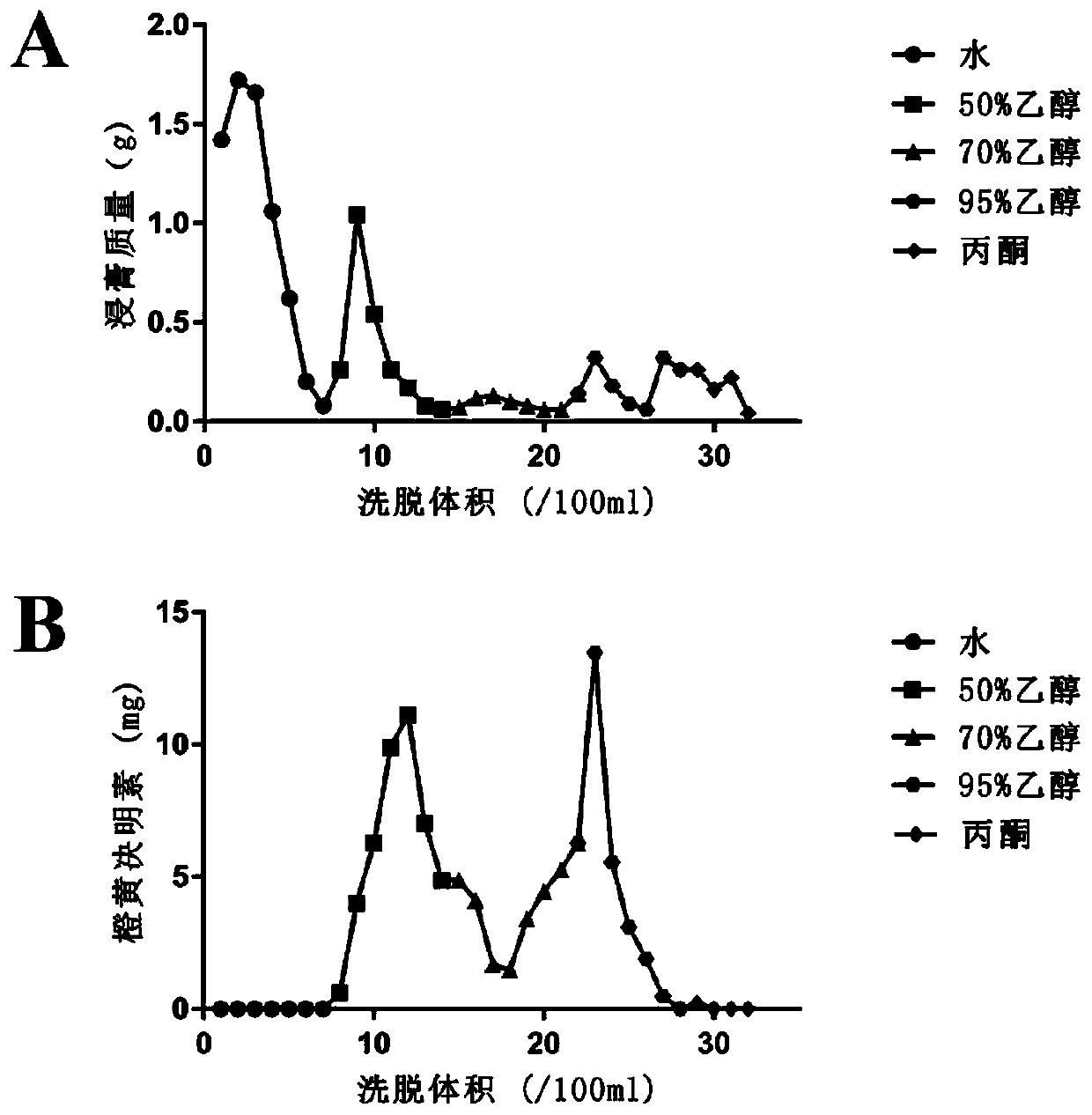

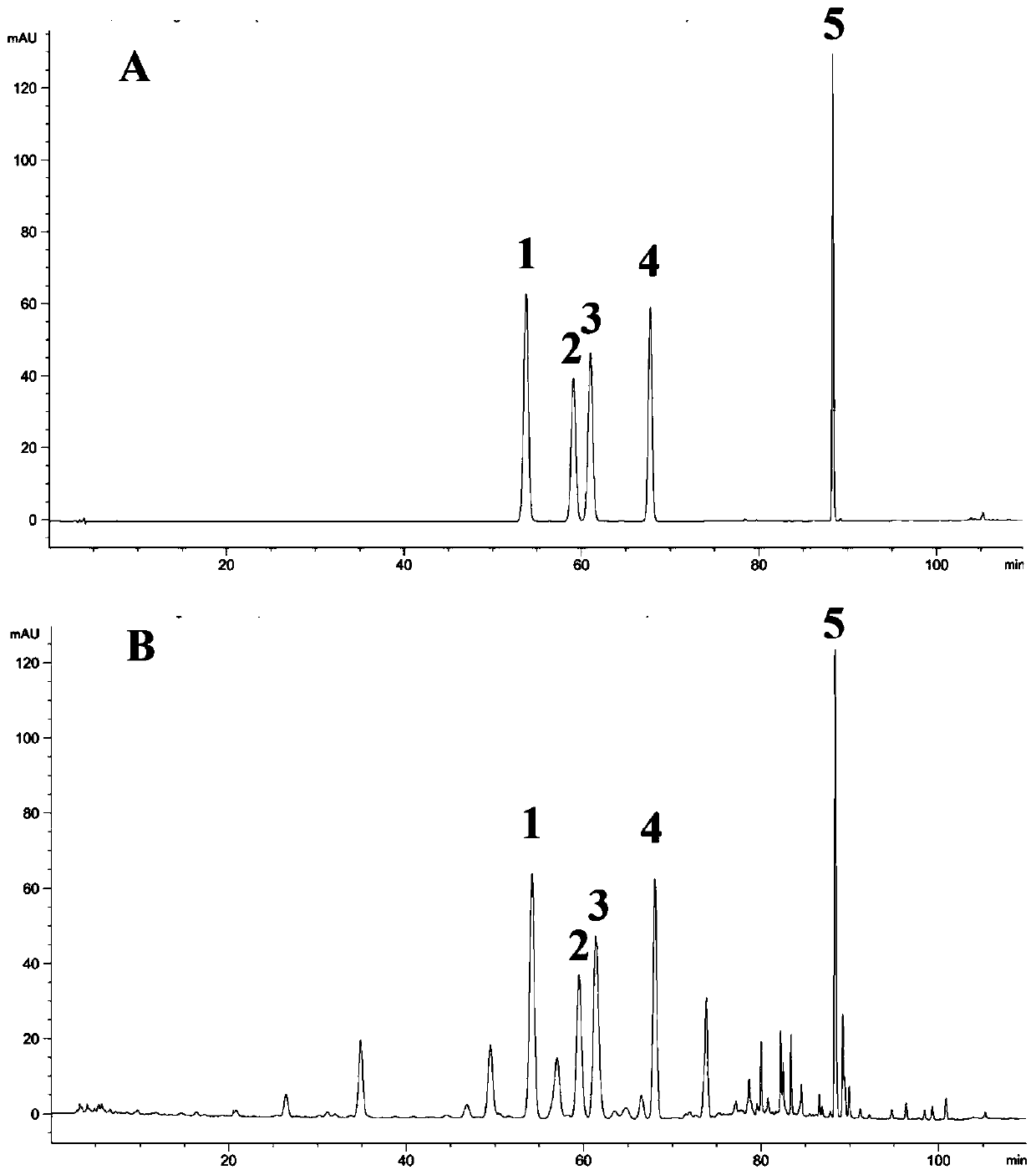

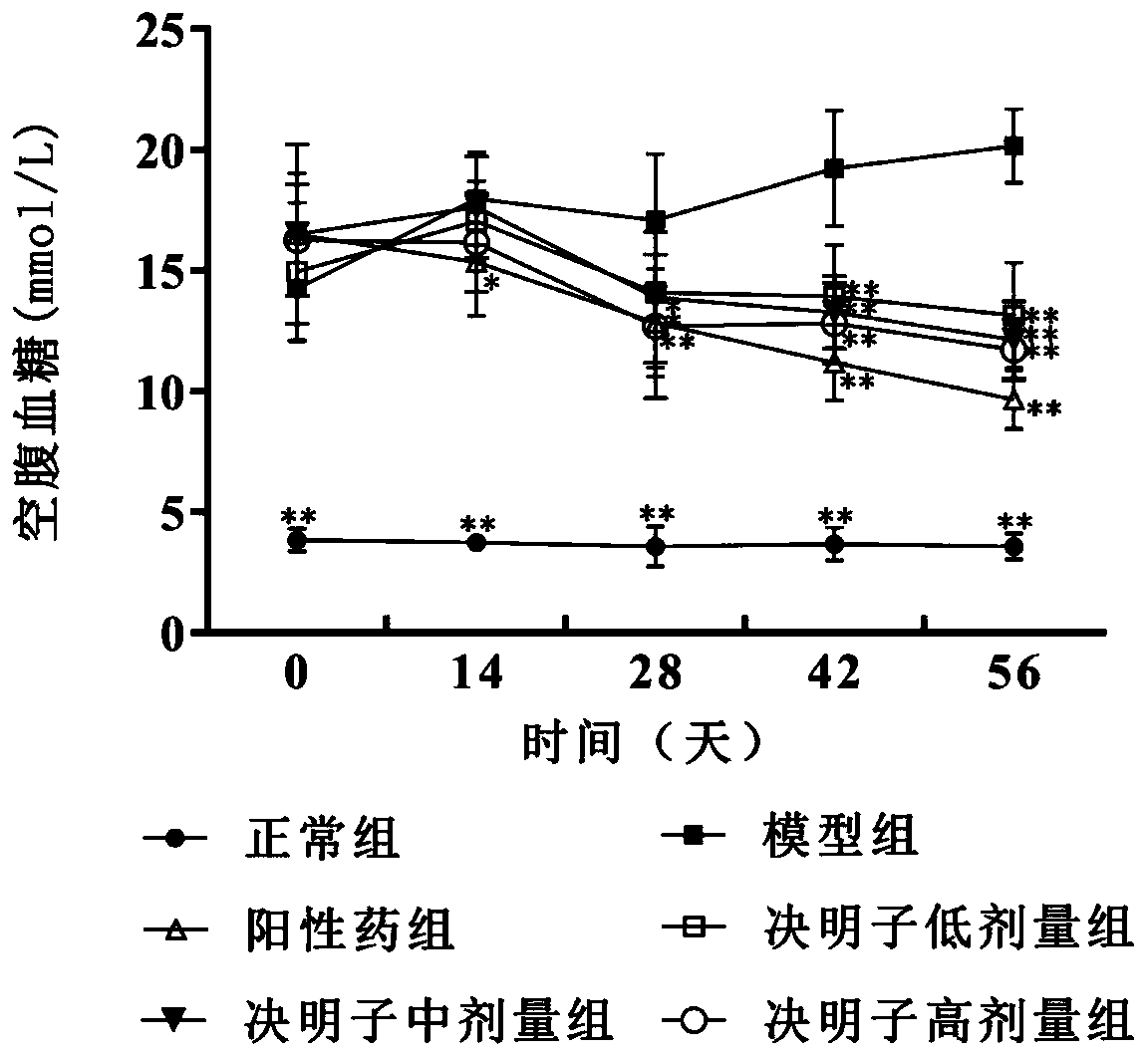

Semen cassiae extract for reducing glucose and lipid and preparing and quality testing method thereof

InactiveCN110101736AGood hypoglycemic and lipid-lowering effectPromote resultsMetabolism disorderComponent separationSemenAqueous solution

The invention belongs to the field of medicines, and discloses a semen cassiae extract for reducing glucose and lipid and a preparing and quality testing method thereof. The extract is a product prepared through ethanol water extraction and large-pore resin purification with semen cassiae as the raw medicine material. The quality testing method of the extract includes the step of finitely detecting the property and content. In the step of finitely detecting the content, the contents of two anthraquinone components and three naphthopyranone components in the semen cassiae extract are measured at the same time through an efficient liquid chromatography method, and the methodological inspection result is good. It is provided through a pharmacological experiment that the semen cassiae extracthas a good glucose and lipid reducing function and can be used for preparing medicines and healthcare products for reducing glucose and lipid. The preparing method is stable and reliable, the qualitycan be controlled, the medicine effect is remarkable, and the semen cassiae extract has good development and application prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

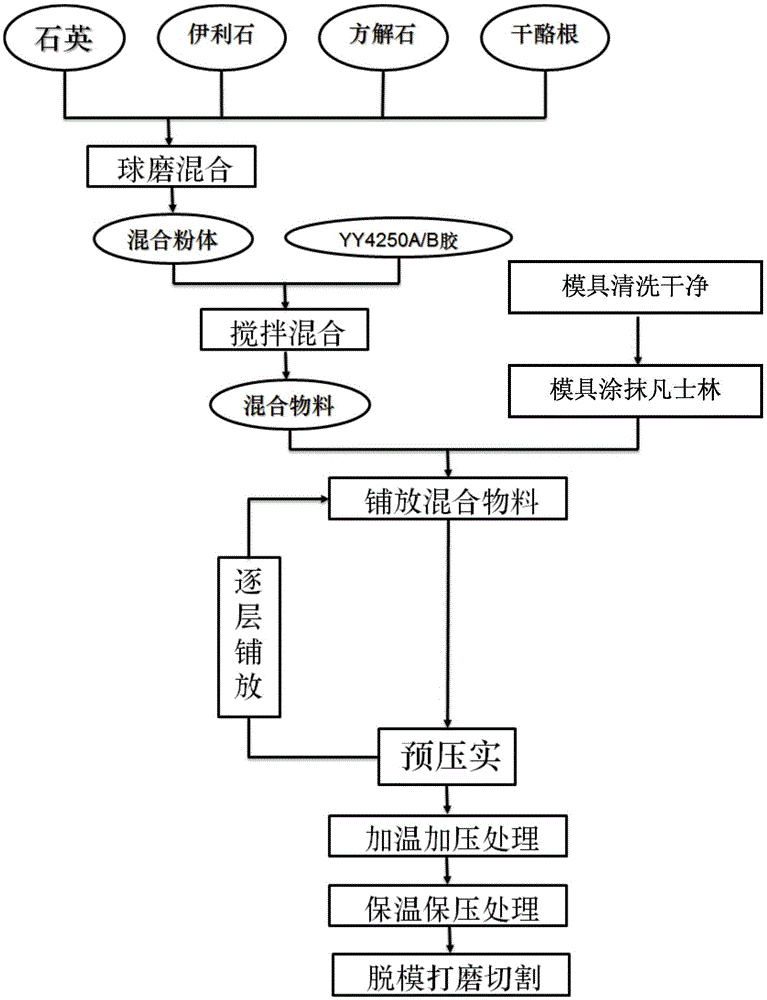

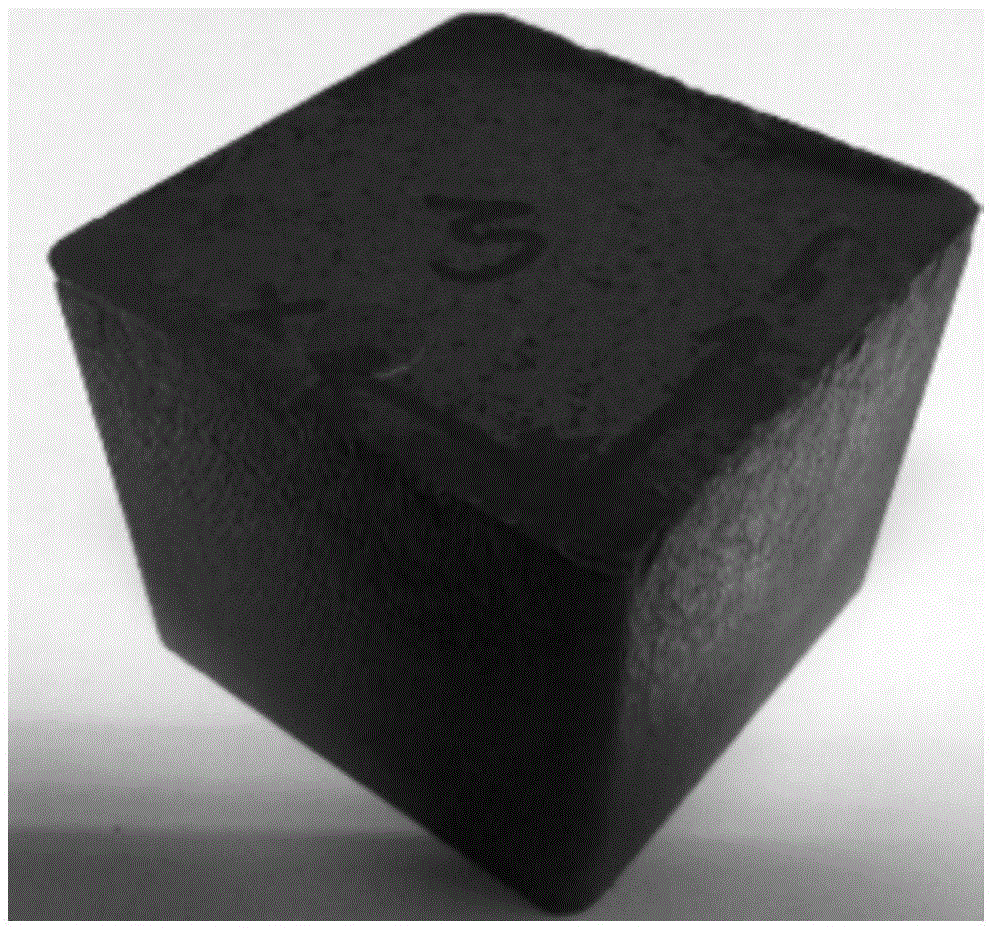

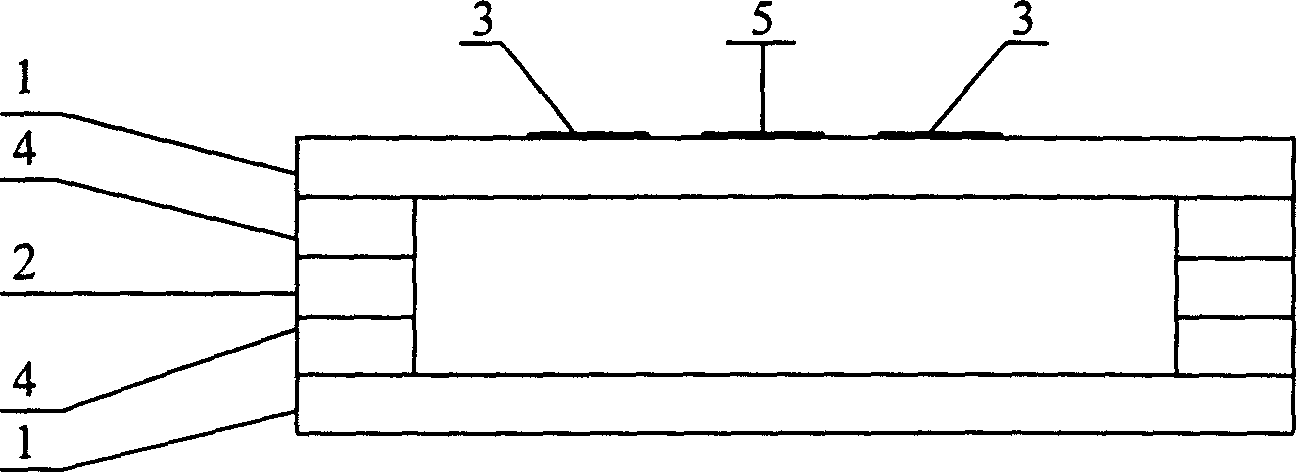

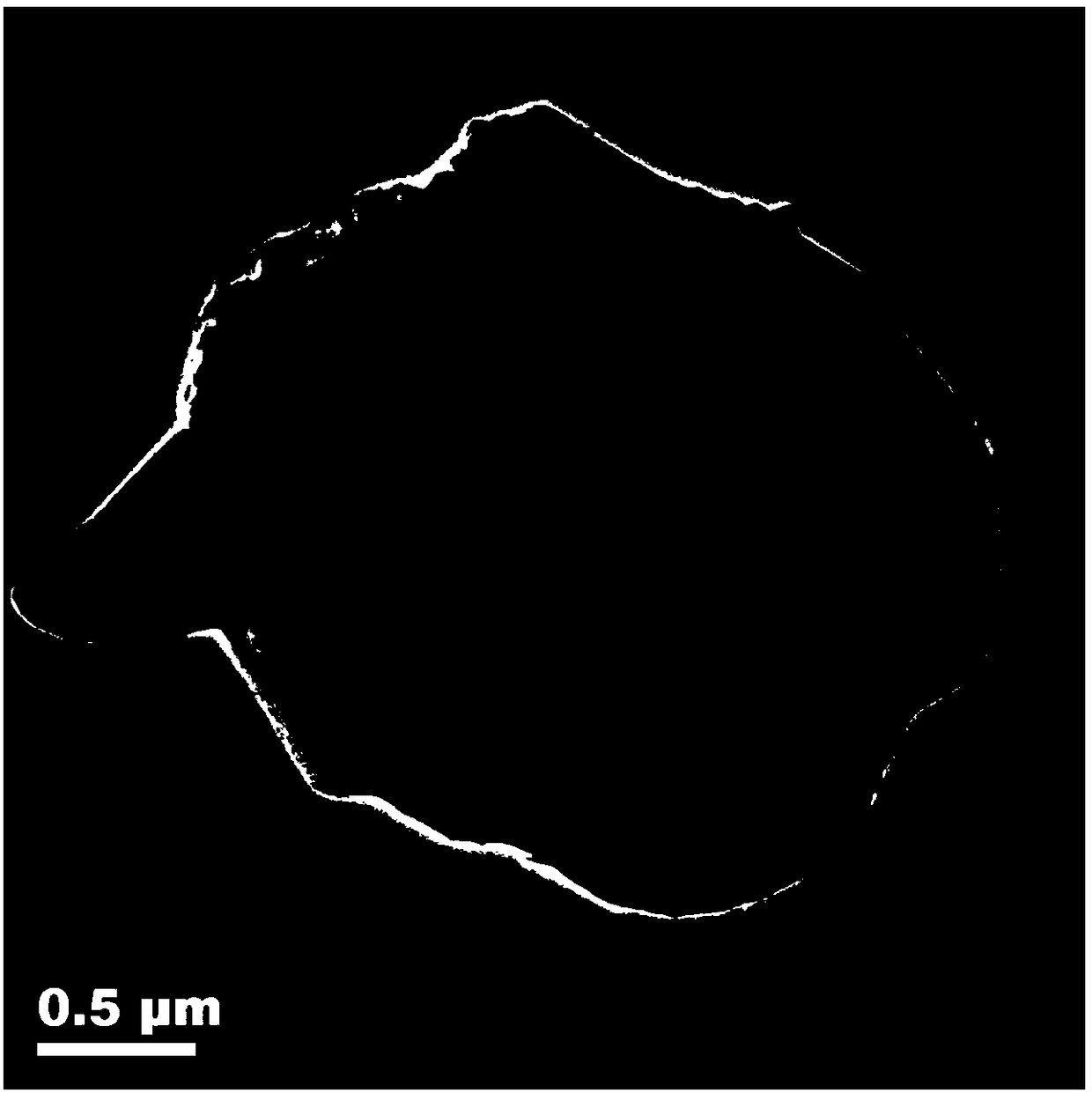

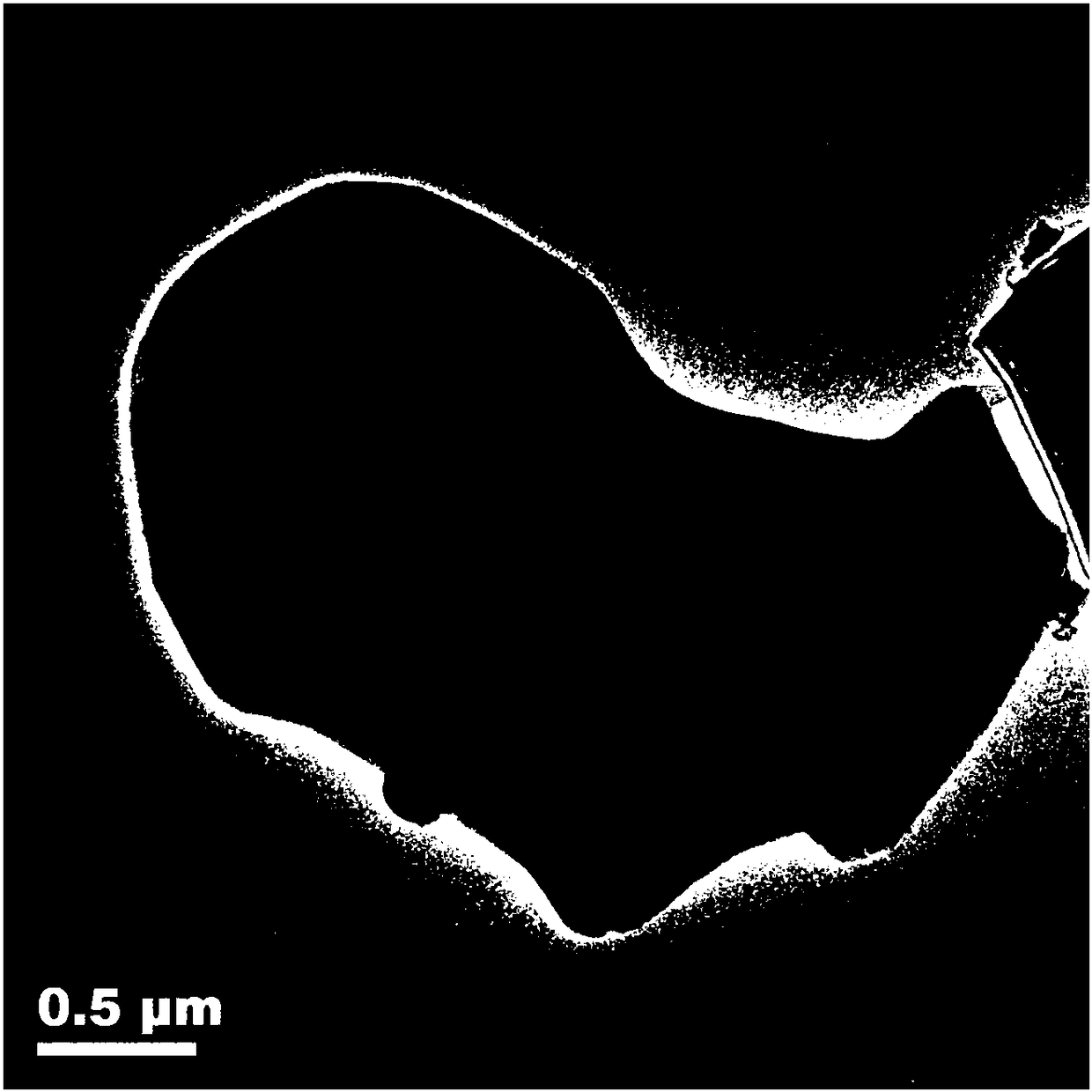

Production method of hot-pressing-based kerogen-containing shale physical model and shale model

ActiveCN105601169AThe production process is stable and reliableStrong repeatabilityCalcitePhysical model

The present invention provides a production method of a hot-pressing-based kerogen-containing shale physical model and the shale model. The production method comprises the following steps: mixed powder is obtained by ball milling of silica power, calcite, illite and kerogen; a binder is added into the mixed powder for uniformly mixing to obtain a mixed material; the mixed material is layer by layer spread in a hot-pressing die, after each layer of the mixed material is spread, pre-compacting treatment is performed, and a mold filled with the mixed material is obtained; and the kerogen-containing shale physical model can be obtained by final room temperature pre-compacting treatment and heating, pressing and heat and pressure preservation treatment. The production method is a physical model production method which is closest to the natural shale diagenesis environment and diagenetic mechanism. Various petrophysical parameters, mechanical characteristics, seismic properties, microstructure and diagenetic conditions of the kerogen-containing shale physical model are closer to that of natural shale.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

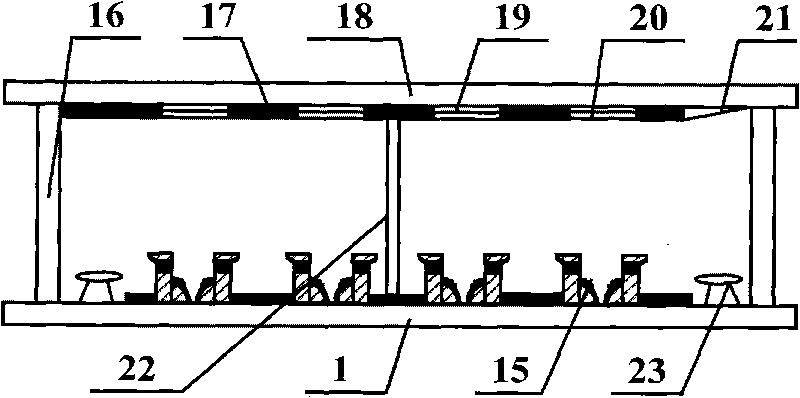

Three-electrode field transmitting displaying device with glass strip array as separated pole and production thereof

InactiveCN1645547AImprove insulation performanceImprove the insulation levelCathode-ray/electron-beam tube vessels/containersImage/pattern display tubesFluorescenceDisplay device

The invention is related to a triple pole field emission display that adopts glass bar as the isolation column between the control grid and positive plate, and adopts sheet mica as insulator between the glass bars, and the glass array through agglomeration as isolation column. It consists of a control grid used to control carbon nanotubes to emit electrons. On the display, there are the positive plates that are photo- etched on the ITO film, the negative plate that is printed carbon nanotubes cathode, and the fluorescent powder layer that is coated on the ITO film.

Owner:ZHONGYUAN ENGINEERING COLLEGE

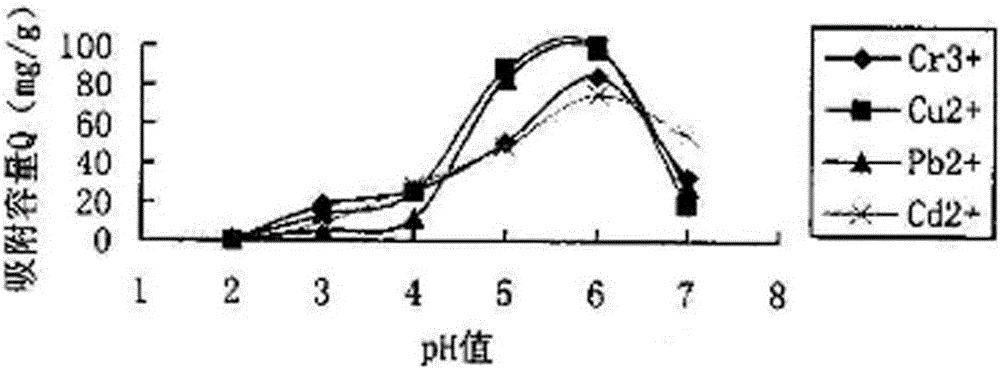

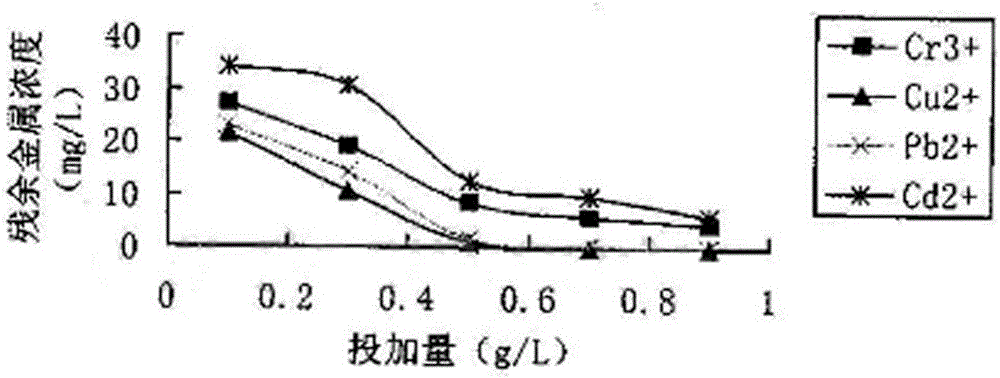

Stabilizing agent for repairing heavy metal pollution and preparation method thereof

The invention provides a preparation method of a stabilizing agent for repairing heavy metal pollution. The method comprises the steps of: providing corn starch, and adding the corn starch into an alkaline solution to form a corn starch paste, conducting first heating treatment on the corn starch paste, at the same time adding the alkaline solution containing epichlorohydrin into the corn starch paste dropwise, carrying out first reaction at 20-40DEG C, and performing first purification treatment to obtain crosslinked starch; infiltrating the crosslinked starch with water, then employing an alkaline compound to adjust the PH to 9.0-12.0, carrying out second heating treatment, adding a cationic etherifying agent dropwise under a constant temperature condition to carry out etherification reaction, and performing second purification treatment so as to obtain a heavy metal stabilizing agent.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

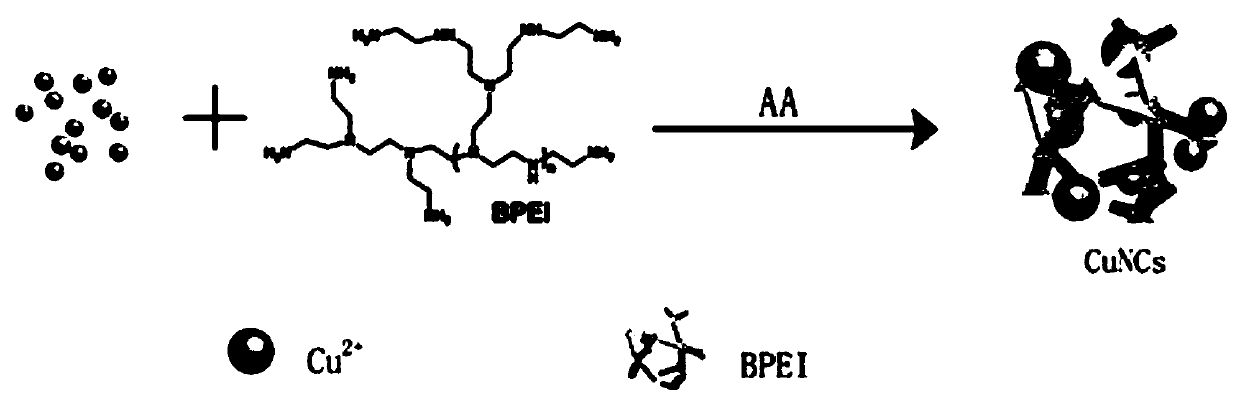

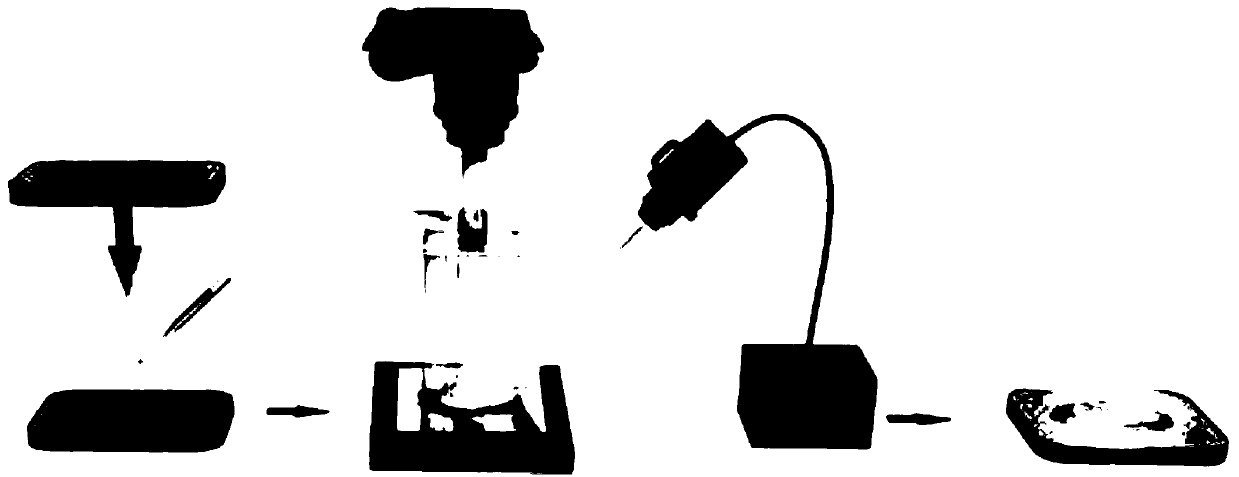

Copper nano-cluster sweat latent fingerprint developing reagent preparation method and sweat latent fingerprint developing method

ActiveCN109557066AReduced particle size is smallGood fluorescence stabilityFluorescence/phosphorescenceFluorescenceLatent fingerprint

The invention provides a copper nano-cluster sweat latent fingerprint developing reagent preparation method and a sweat latent fingerprint developing method. Branched polyethyleneimine is taken as a template, ascorbic acid is taken as a reducing agent, copper sulfide is taken as a raw material to reduce a copper nano-cluster with smaller particle size and variable fluorescence through controllingthe heating condition during the reaction. A solution drop developing method is adopted to develop sweat latent fingerprints and an autonomously built latent fingerprint developing observation systemis used for observing, shooting and fixing the fingerprints. The prepared nanoparticles have the advantages of being small in size, good in stability and strong in fluorescence. The drop developed fingerprints are clear in streak line and obvious detail features under stimulation of natural light and multiband light sources. The drop developed fingerprints can emit different fluorescent lights under the multiband light sources, so as to eliminate the interferences of background colors. Compared with the traditional method, the method provided by the invention is capable of solving the defect that the traditional reagent is low in fingerprint developing sensitivity, weak in binding capacity and difficult to remove the interferences of background colors; and the fingerprint developing methodis high in sensitivity, strong in fluorescence, non-toxic and economic.

Owner:SOUTHWEST UNIVERSITY OF POLITICAL SCIENCE AND LAW

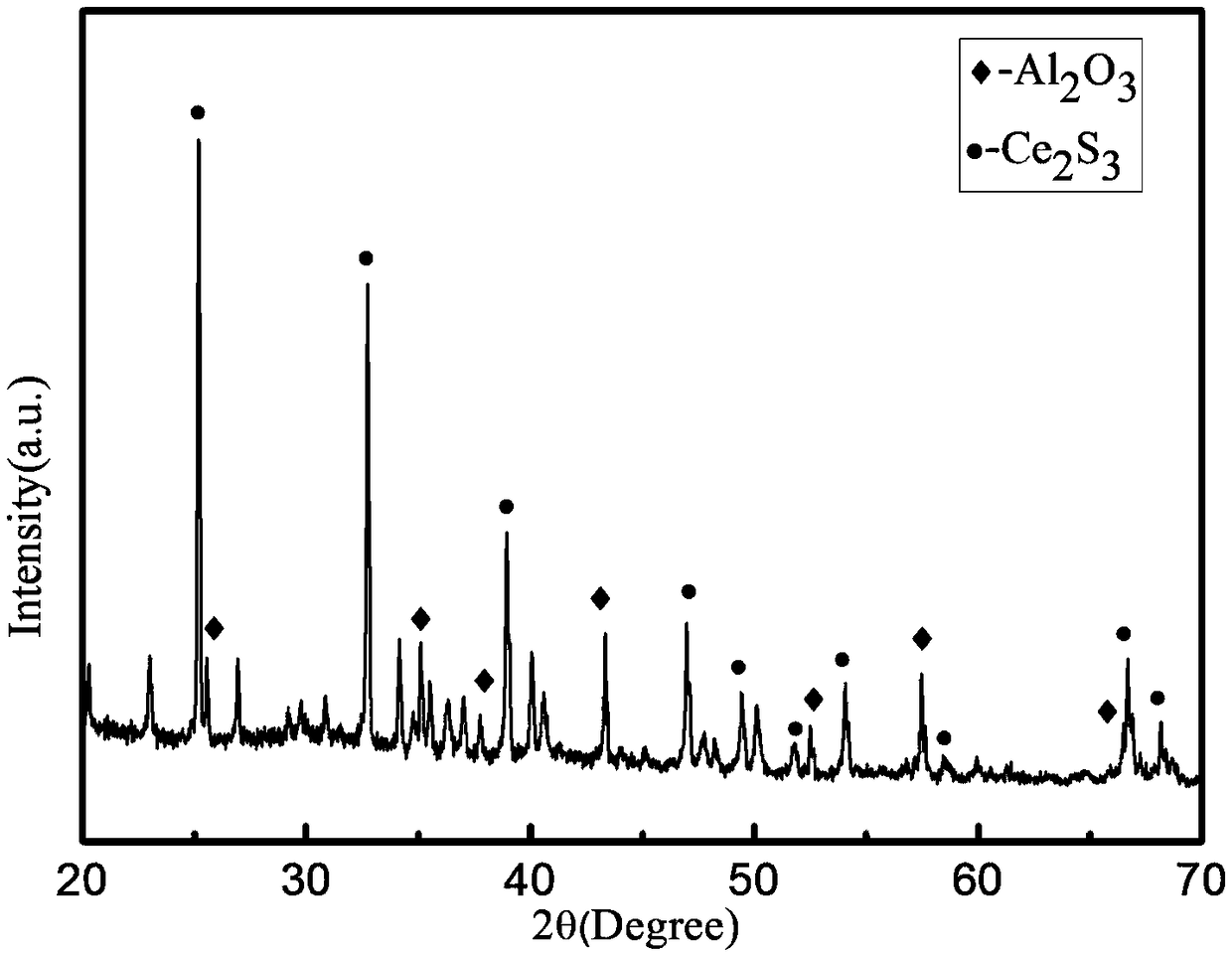

Preparation method of aluminum oxide coated gamma-Ce2S3 red pigment and product prepared by preparation method

ActiveCN108219536AImprove high temperature stabilityGuaranteed decentralizationRare earth metal sulfidesInorganic pigment treatmentVulcanizationHeat treated

The invention discloses a preparation method of an aluminum oxide coated gamma-Ce2S3 red pigment. The preparation method comprises the following steps: firstly, preparing an aluminum hydroxide coatedCeO2 precursor through a liquid-phase method; then carrying out vulcanization atmosphere and inert atmosphere high-temperature vulcanization heat treatment to obtain the aluminum oxide coated gamma-Ce2S3 red pigment. Furthermore, the invention further discloses a product prepared by the preparation method. According to the preparation method disclosed by the invention, gamma-Ce2S3 is effectively stabilized through coating aluminum oxide, so that the high-temperature stability of the coated modified pigment is greatly improved and an application field of the pigment is extremely expanded; the preparation method disclosed by the invention has the advantages that a technology is simple, reaction is easy to control, and a preparation process and product performance are more stable and reliable, so that industrialized popularization and application is facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

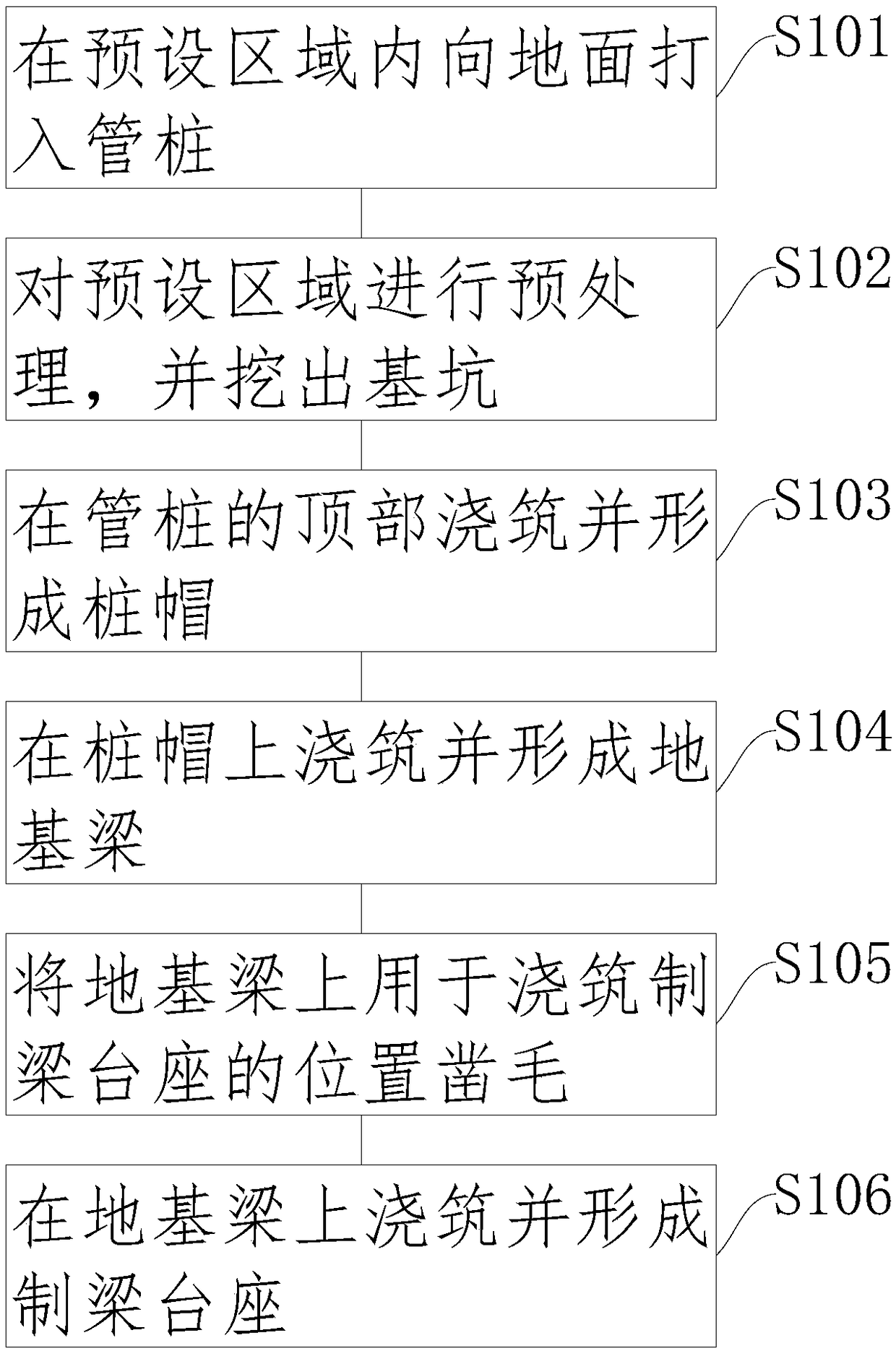

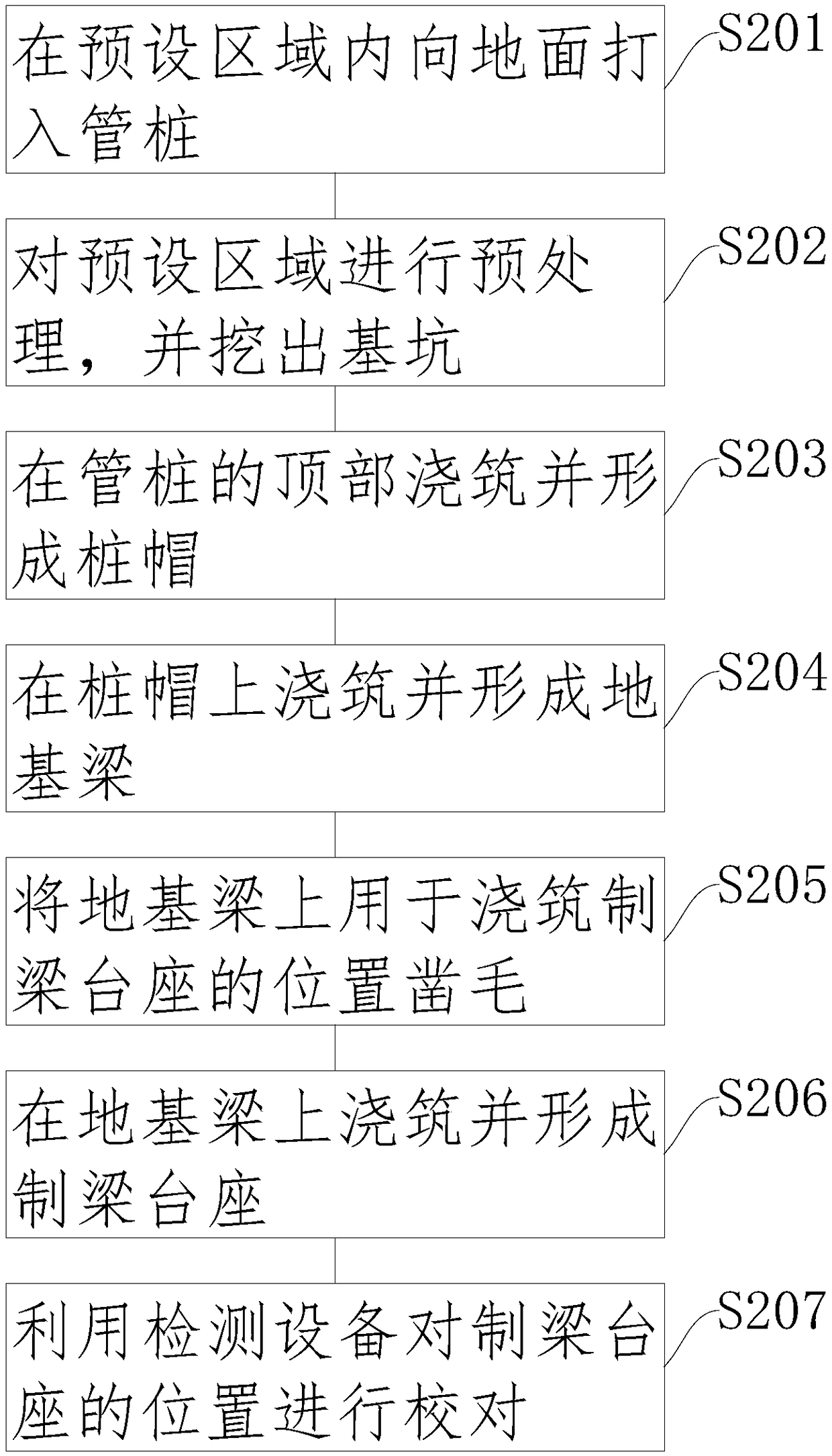

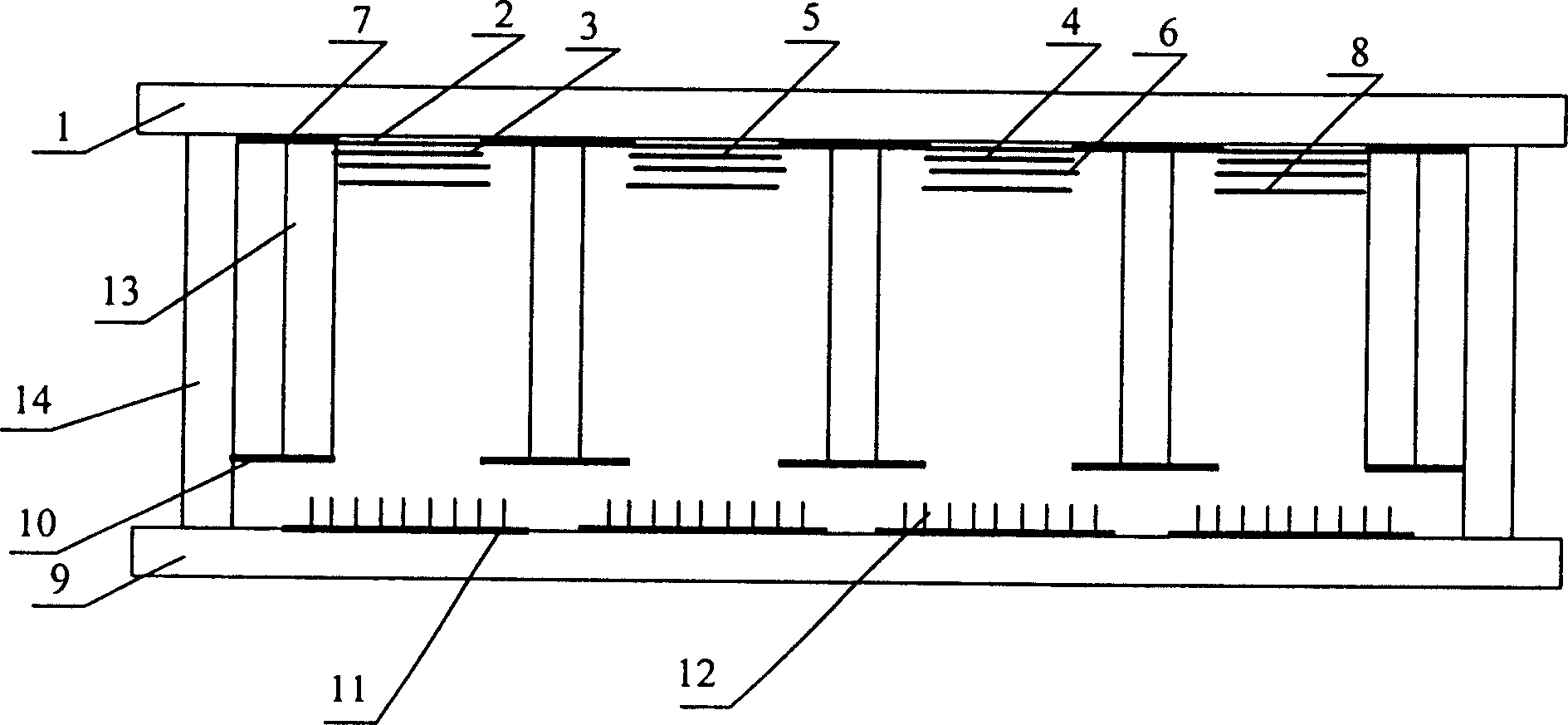

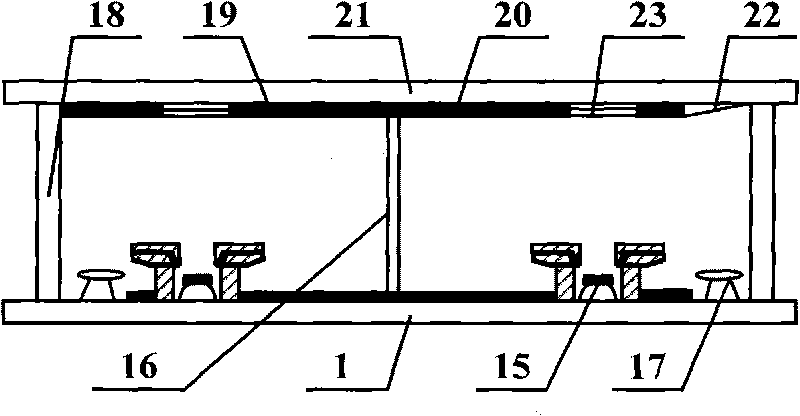

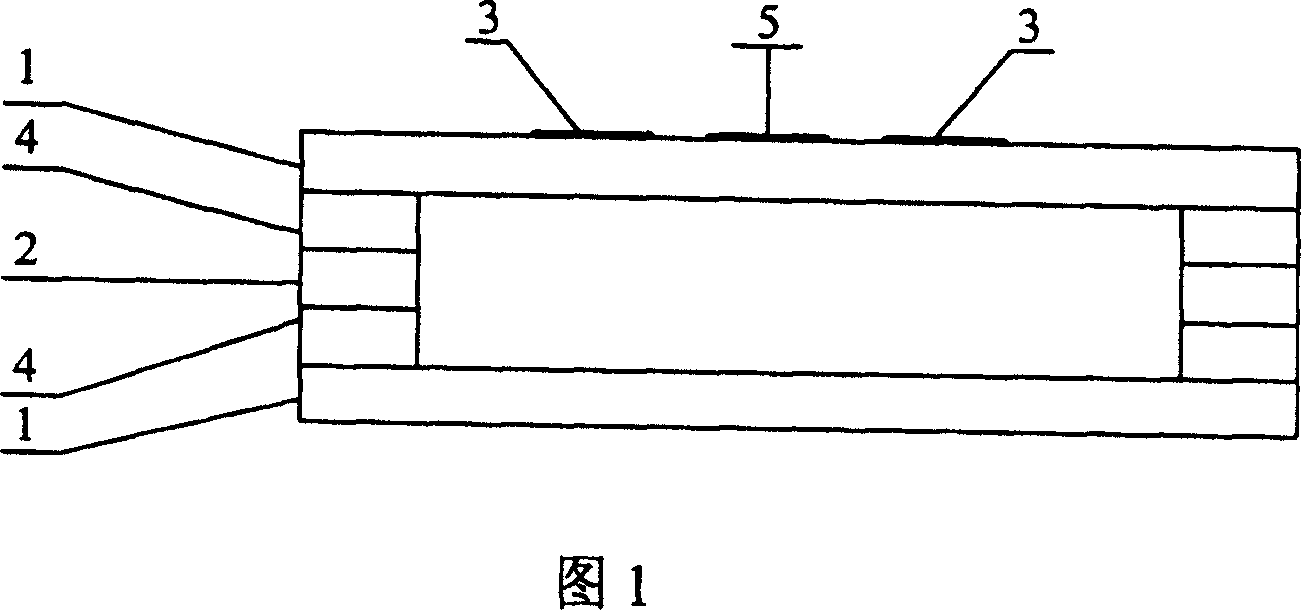

Construction method for beam-making platform and construction method for box beam prefabricated factory

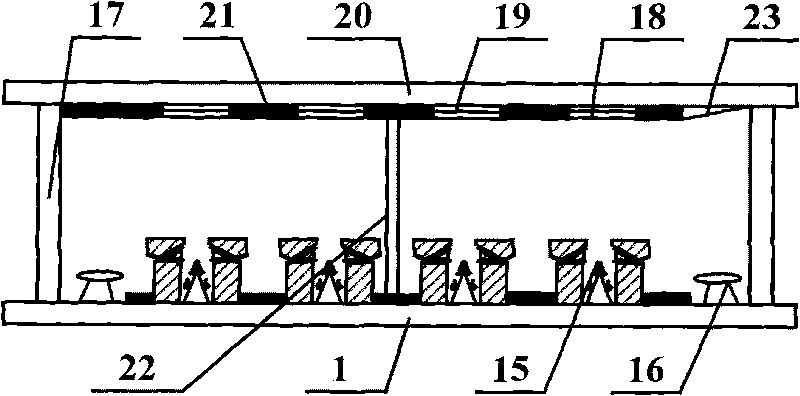

InactiveCN108943368AThe production process is stable and reliableGuarantee beam qualityAuxillary shaping apparatusState of artPile cap

The invention discloses a construction method for a beam-making platform and a construction method for a box beam prefabricated factory and relates to the technical field of beam factory construction.The construction method comprises the following steps: throwing tubular piles into the ground in a preset area; pouring the tops of the tubular piles and forming pile caps; pouring the pile caps andforming foundation beams; and pouring the foundation beams and forming the beam-making platform. Compared with the prior art, according to the construction method for the beam-making platform providedby the invention, by adopting the steps of pouring the pile caps and forming foundation beams and pouring the foundation beams and forming the beam-making platform, the beam-making platform which isstable and reliable and avoids non-uniform differential settlement can be manufactured, so that the beam-making quality is guaranteed, and the construction method is high in practicality and safe andefficient.

Owner:NO 2 ENG CO LTD OF CHINA RAILWAY CONSTR 11 BUREAU GRP +1

Tripolar carbon nanotube display with filtering structure and process for preparing same

InactiveCN1667788AQuality improvementReduce distractionsImage/pattern display tubesCold cathode manufactureFlat glassManufacturing technology

This invention relates to a three-pole two-dimensional display of an anode panel structure applying the method of combining a Sn In oxide film, a color filter layer and a blocking layer and its manufacturing technology including a vacuum cavity made up of flat glasses, an anode panel produced by the method of combining Sn In oxide film the color filter layer and the blocking layer and a cathode panel printed with carbon nm tubes and insulation separating post elements.

Owner:ZHONGYUAN ENGINEERING COLLEGE

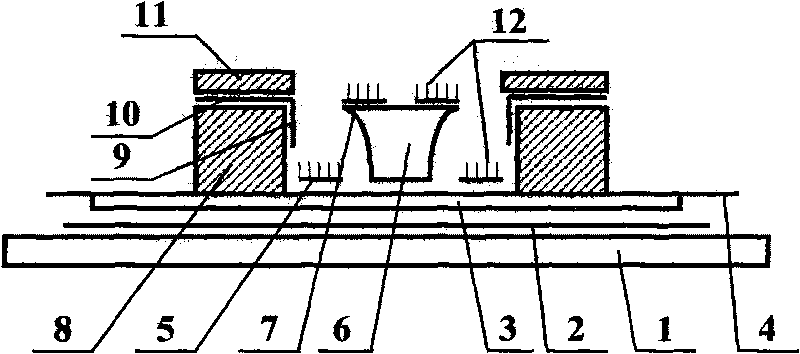

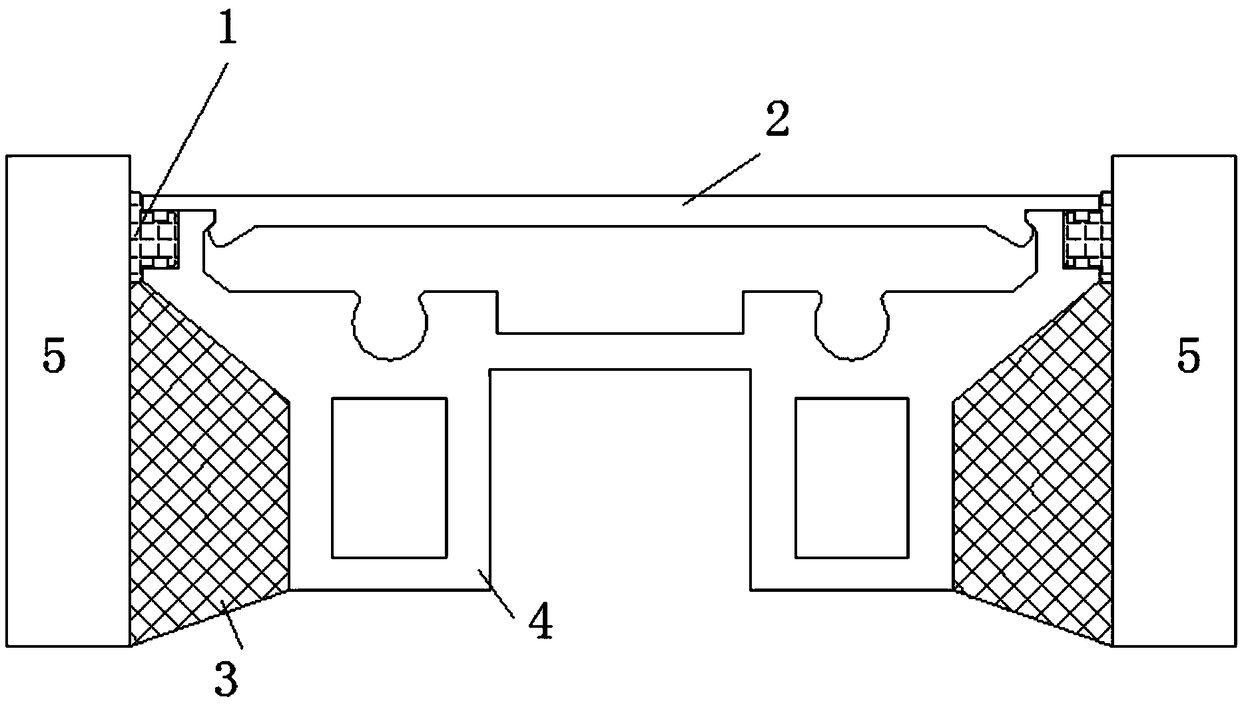

Flat-panel display with side-elevation square grid-controlled inverted round table type cathode structure and manufacturing process thereof

InactiveCN101764024AIncrease the launch areaImprove emission efficiencyImage/pattern display tubesCold cathode manufactureRound tableDisplay device

The invention relates to a flat-panel display with side-elevation square grid-controlled inverted round table type cathode structure and a manufacturing process thereof, wherein the flat-panel display comprises a sealed vacuum chamber, a side-elevation square grid-controlled inverted round table type cathode structure, an isolated wall, a getter, an anode conducting layer, an anode lead layer, an anode isolated layer and a fluorescent powder layer, wherein the sealed vacuum chamber comprises a cathode panel, an anode panel and a glass frame; the side-elevation square grid-controlled inverted round table type cathode structure is arranged on the cathode panel; the isolated wall and the getter are positioned between the anode panel and the cathode panel; the anode conducting layer, the anode lead layer and the anode isolated layer are arranged on the anode panel, and the fluorescent powder layer is prepared on the upper surface of the anode conducting layer. The flat-panel display has the advantages of low cost, simple manufacturing process and stable and reliable manufacturing process.

Owner:ZHONGYUAN ENGINEERING COLLEGE

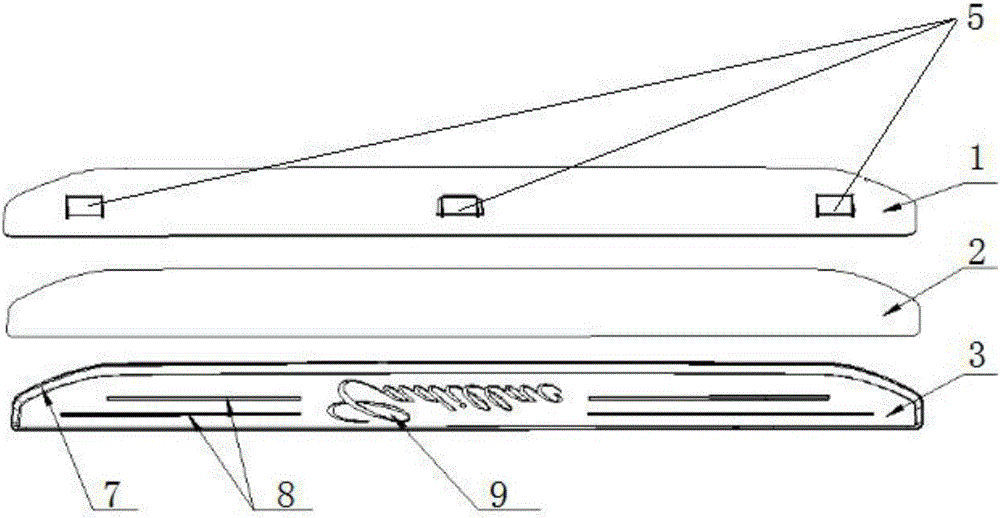

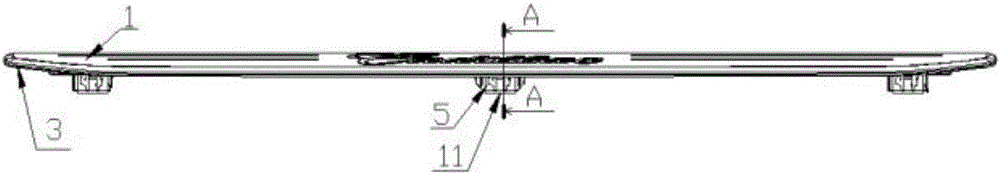

Method for manufacturing automobile welcome pedal

ActiveCN106256608AReduced risk of crackingStable structurePretreated surfacesSteps arrangementAdhesiveEngineering

The invention discloses a method for manufacturing an automobile welcome pedal. The method includes the four procedures of stamping, spraying, insert injection molding and accessory adding. An aluminum substrate and a plastic substrate are welded into a firm overall insert injection molding body through a polymer thermosensitive adhesive, and the structure is stable, firm and durable. The risk that a traditional automobile welcome pedal is prone to cracking is greatly reduced. The production process is rapid and convenient, and the production efficiency of the product can be greatly improved. The product is high in precision, the relative positions of the edges of the aluminum substrate and the plastic substrate are very tidy, and the appearance is attractive and fashionable. Binding force of the contact faces of the aluminum substrate and the plastic substrate can be uniform and firm; the polymer thermosensitive adhesive cannot overflow to the outer surface of the product through the edge of the product; spraying efficiency is high, and the manufacturing process is stable and reliable. The problems of internal stress and product structure deformation caused by different shrinkage degrees between the plastic substrate and the aluminum substrate can be effectively eliminated.

Owner:SHANGHAI YINGHUI TECH DEV

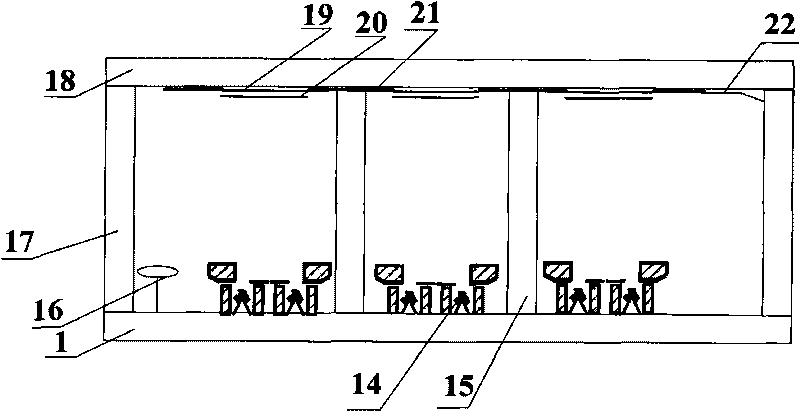

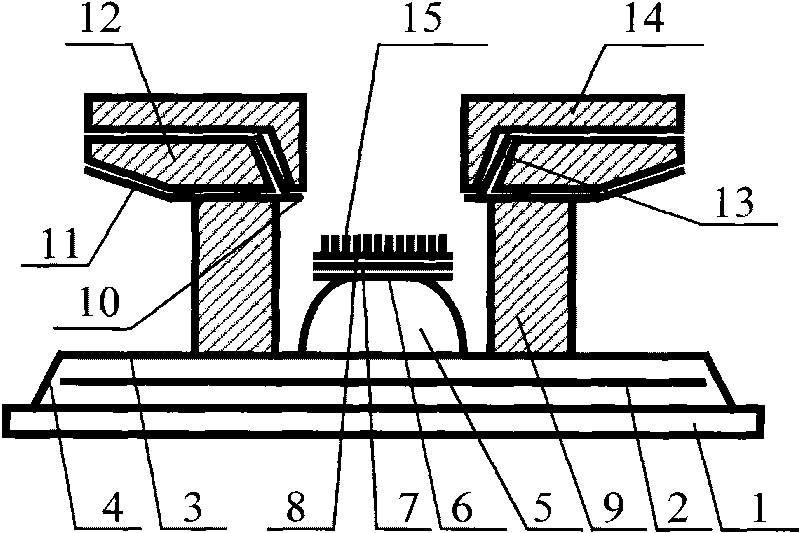

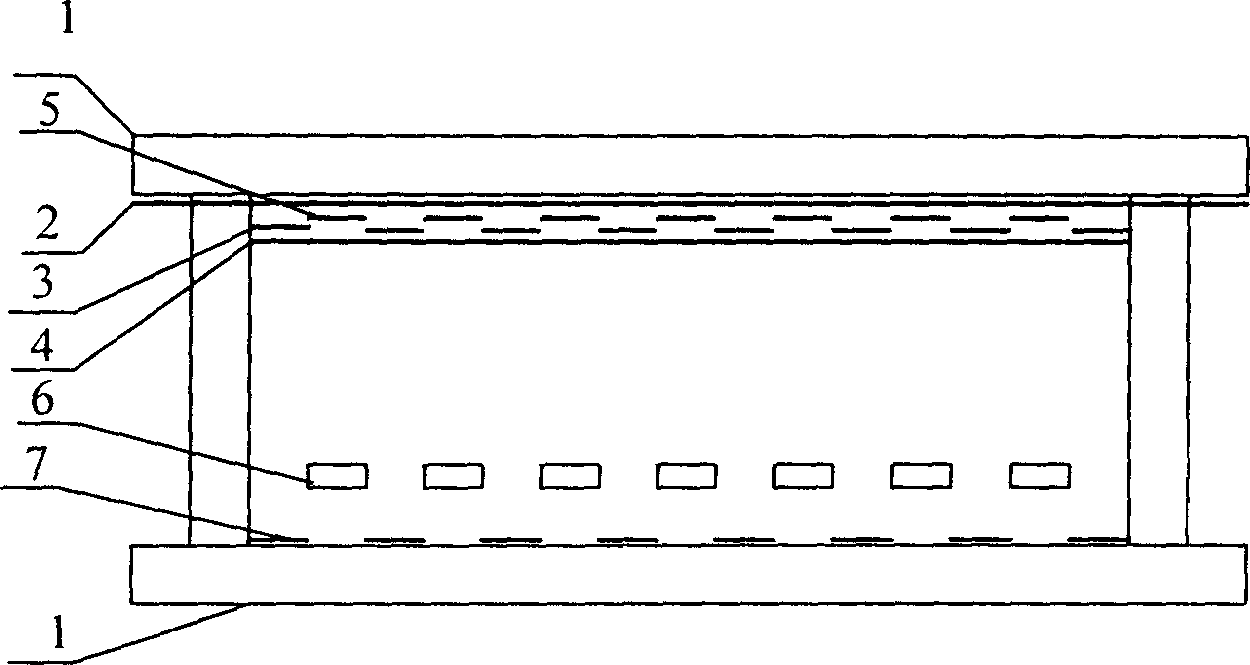

Flat-panel display of rectangular three-dimensional double straight grid control oblique arc surface cathode structure and manufacturing process thereof

InactiveCN101728190AIncrease surface areaImprove emission efficiencyImage/pattern display tubesCold cathode manufactureCarbon nanotubeDisplay device

The invention especially relates to a flat-panel display of a rectangular three-dimensional double straight grid control oblique arc surface cathode structure and a manufacturing process thereof. The flat-panel display comprises a sealed vacuum chamber, a separating and supporting device, a getter, an anode conducting layer, an anode lead layer, an anode insulating layer and a fluorescent powder layer, wherein the sealed vacuum chamber comprises an anode glass panel, a cathode glass panel and a glass frame; the separating and supporting device and the getter are positioned between the anode glass panel and the cathode glass panel; the anode conducting layer, the anode lead layer and the anode insulating layer are arranged on the anode glass panel; and the fluorescent powder layer is prepared on the anode conducting layer. The rectangular three-dimensional double straight grid control oblique arc surface cathode structure comprises a cathode panel, an isolating layer, a cathode conducting layer, a cathode connecting line layer, a cathode bottom layer, a cathode transition layer, a cathode sacrifice layer, a first insulating and isolating layer, a first grid conducting layer, a second insulating and isolating layer, a second grid conducting layer, a third grid conducting layer, a grid connecting line layer, a third insulating and isolating layer and a carbon nano tube part. The invention has the advantages of low cost, simple manufacturing process and stable and reliable manufacturing procedures.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat panel display of right-angle bending pair-group grid controlled cathode structure and manufacturing process thereof

InactiveCN101764026AImprove performanceSimple manufacturing processImage/pattern display tubesCold cathode manufactureDisplay deviceEngineering

The invention relates to a flat panel display of a right-angle bending pair-group grid controlled cathode structure and a manufacturing process thereof. The flat panel display comprises a sealed vacuum chamber, the right-angle bending pair-group grid controlled cathode structure, an anode conducting layer, a cathode lead wire layer, an anode shielding layer, a fluorescent powder layer, a partition wall and a getter, wherein the sealed vacuum chamber is composed of a cathode panel, an anode panel and a glass enclosure frame; the right-angle bending pair-group grid controlled cathode structure is arranged on the cathode panel; the anode conducting layer, the anode lead wire layer and the anode shielding layer are arranged on the anode panel; the fluorescent powder layer which is manufactured on the anode conducting layer; the partition wall and the getter are arranged between the anode panel and the cathode panel,. The flat panel display has the advantages of low cost, simple manufacturing process, and stable and reliable manufacturing operation.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat plate display of suspension square cathode type high angle grid control structure and manufacturing process thereof

InactiveCN101728187AImprove emission efficiencyIncrease the launch areaImage/pattern display tubesCold cathode manufactureCarbon nanotubeDisplay device

The invention particularly relates to a flat plate display of a suspension square cathode type high angle grid control structure and a manufacturing process thereof. The flat plate display comprises the following components: a sealed vacuum chamber consisting of a cathode glass panel, an anode glass panel and a glass frame; an anode drainage layer, an anode connection layer and an anode covering layer which are arranged on the anode glass panel, and a luminescent layer which is prepared on the anode drainage layer; and an isolator and a getter which are positioned between the anode glass panel and the cathode glass panel. The suspension square cathode type high angle grid control structure comprises a cathode glass panel, a cathode barrier layer, a cathode bottom layer, a cathode connection layer polar enhancement layer, a cathode translation layer, a cathode transition layer, a cathode sacrificial layer, a first blocking layer, a first grid drainage layer, a grid connection layer, a second blocking layer, a second grid drainage layer, a third blocking layer and a carbon nanotube. The flat plate display has the advantages of low cost, simple manufacturing process and stable and reliable manufacturing course.

Owner:ZHONGYUAN ENGINEERING COLLEGE

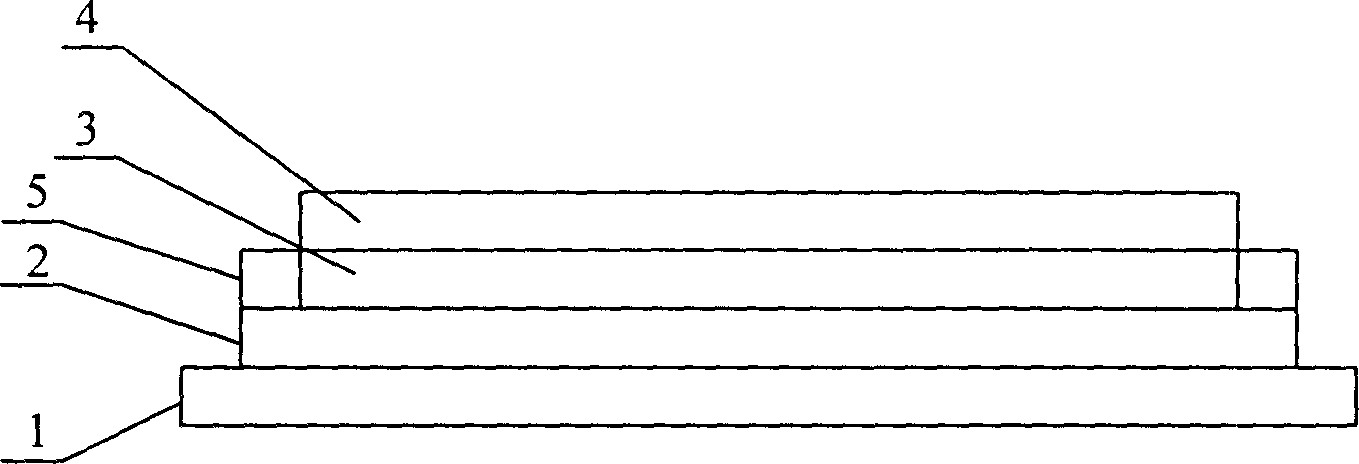

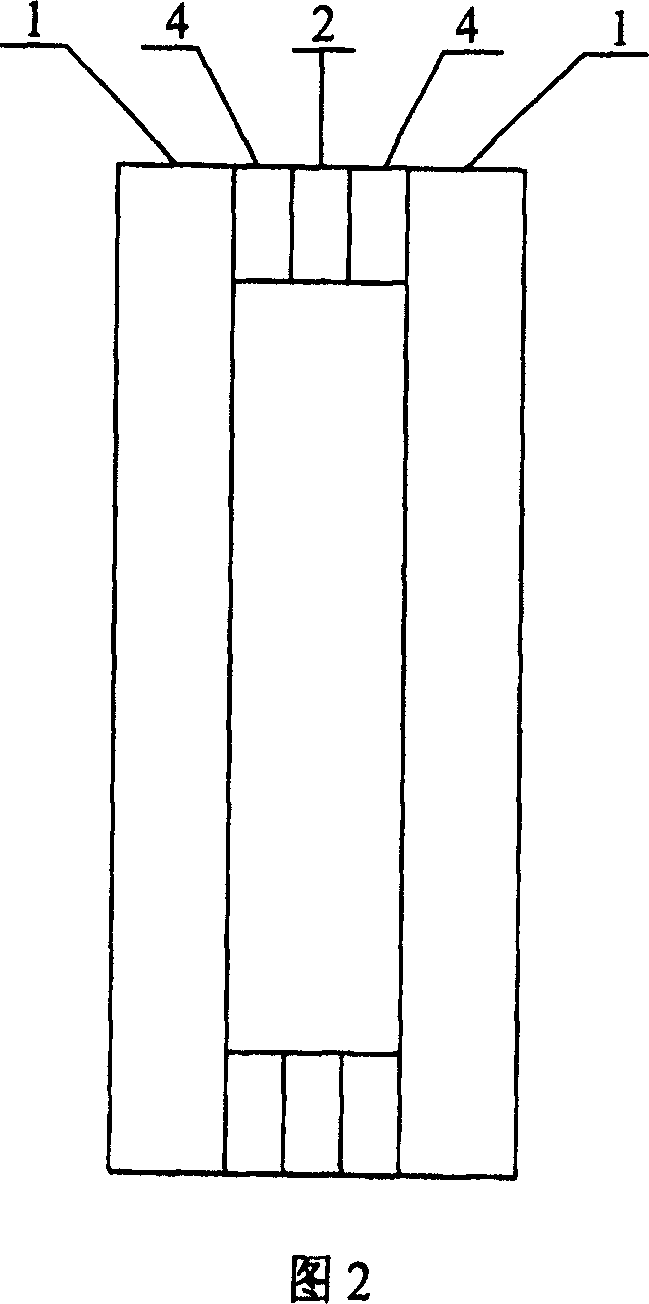

Double-layer glass window and manufacture method thereof

PendingCN109252796AEasy to adjustReduce processing difficultyClimate change adaptationWindows/door improvementEngineeringAir pollution

The invention relates to a double-layer glass window, comprising support structures and a pair of glass plates; the edge of each support structure is provided with a groove; the grooves help limit seal strips; the glass plates are correspondingly compressed to the support structures via the seal strips, and the glass plates are fixed to the support structures via glue; the support structures are provided with vacuumizing holes for vacuumizing a space formed by the support structures and the glass plates; the seal strips are not sticky. The glass plates can be adjusted during aligning so that process difficulty is relieved. A printing retaining edge around the periphery of the window can be omitted, so that material cost is reduced, air pollution is reduced, and attractiveness of the double-layer glass window can be improved; the step of sampling inspection on tightness is omitted; tightness full inspection is completed naturally and ingeniously in the production process.

Owner:SHANGHAI OUJIE CLEANROOM TECH

Three pole flat plate display produced by photoetching and aluminium film plating method and its producing process

InactiveCN1649068AAvoid shortened service lifeIncrease display brightnessTube/lamp screens manufactureImage/pattern display tubesManufacturing technologyCarbon nanotube

This invention relates to a three-pole panel display and its manufacturing technology applying a method of combining the SnIn oxide film photo-etching and Al film evaporation and plating including a vacuum cavity composed of plate glasses, a control grid for controlling carbon nm tube cathode emit electrons, an anode panel prepared by the method of combining SnIn oxide film photo-etching and Al film plating, a cathode plate printed with carbon nm tubes, having the advantages of simple structure, low production cost and stabilized process.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Three-electrode field transmitting displaying device with glass strip array as separated pole and production thereof

InactiveCN100341105CImprove insulation performanceImprove the insulation levelCathode-ray/electron-beam tube vessels/containersImage/pattern display tubesFluorescenceField emission display

The invention is related to a triple pole field emission display that adopts glass bar as the isolation column between the control grid and positive plate, and adopts sheet mica as insulator between the glass bars, and the glass array through agglomeration as isolation column. It consists of a control grid used to control carbon nanotubes to emit electrons. On the display, there are the positive plates that are photo- etched on the ITO film, the negative plate that is printed carbon nanotubes cathode, and the fluorescent powder layer that is coated on the ITO film.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display of slope high-ring grid-control multi-face cathode structure and manufacturing process thereof

InactiveCN101728191AIncrease surface areaImprove emission efficiencyImage/pattern display tubesCold cathode manufactureCarbon nanotubeFlat panel display

The invention in particular relates to a flat-panel display of a slope high-ring grid-control multi-face cathode structure and a manufacturing process thereof. The flat-panel display comprises a sealed vacuum chamber, an isolating support, a degasifier, an anode conducting layer, an anode connecting line layer, an anode barrier layer and a fluorescent powder layer, wherein the sealed vacuum chamber consists of an anode glass panel, a cathode glass panel and a glass frame; the isolating support and the degasifier are arranged between the anode glass panel and the cathode glass panel; the anode conducting layer, the anode connecting line layer and the anode barrier layer are arranged on the anode glass panel; and the fluorescent powder layer is prepared on the anode conducting layer. The slop high-ring grid-control multi-face cathode structure comprises the cathode glass panel, a separating layer, a cathode conducting layer, a cathode connecting line layer, a cathode substrate layer, a cathode heightening layer, a cathode transition layer, a cathode sacrifice layer, a first insulating layer, a second insulating layer, a grid conducting layer, a grid connecting line layer, a third insulating layer and a carbon nano tube part, and has the advantages of low cost, simple manufacturing process and stable and reliable manufacturing operation.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Feedforward control method and system for nanometer operation robot, medium and electronic equipment

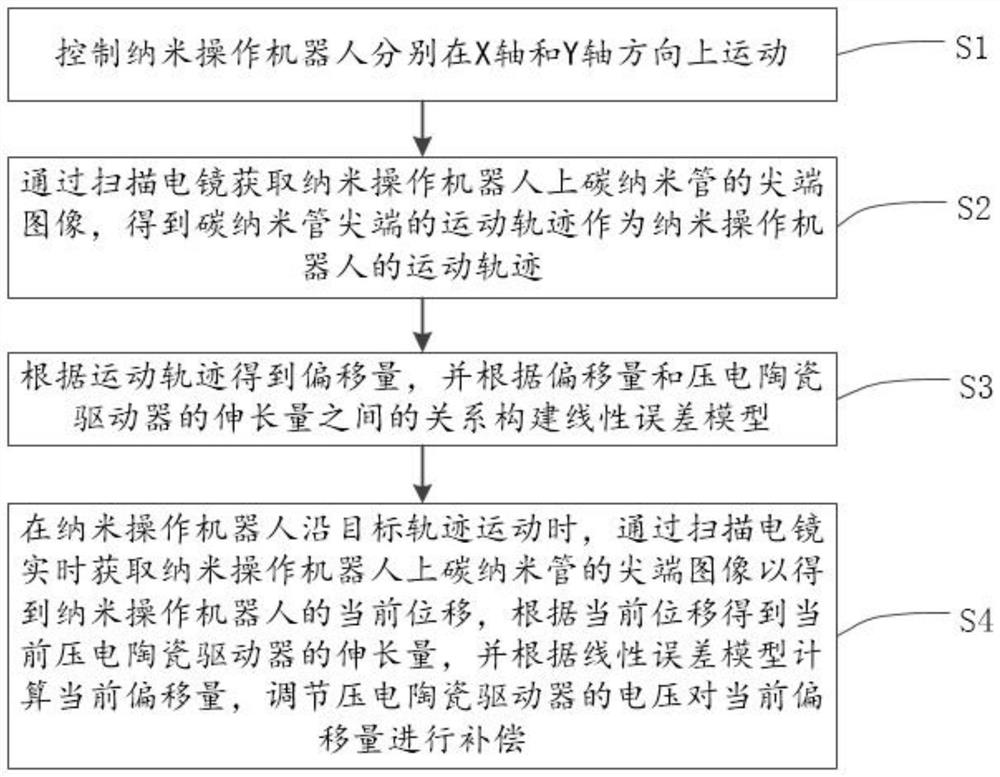

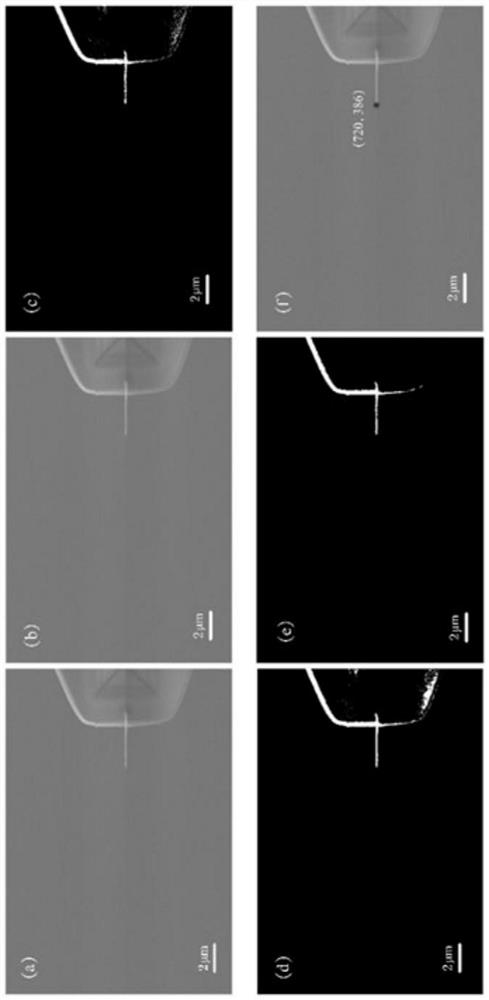

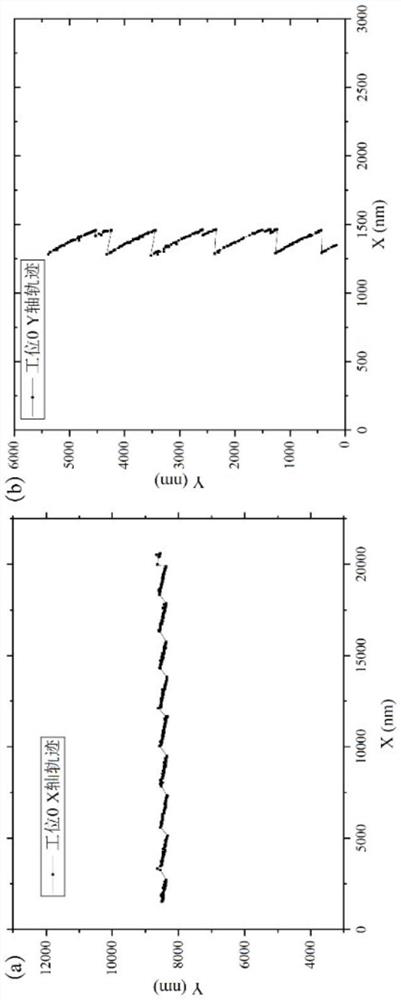

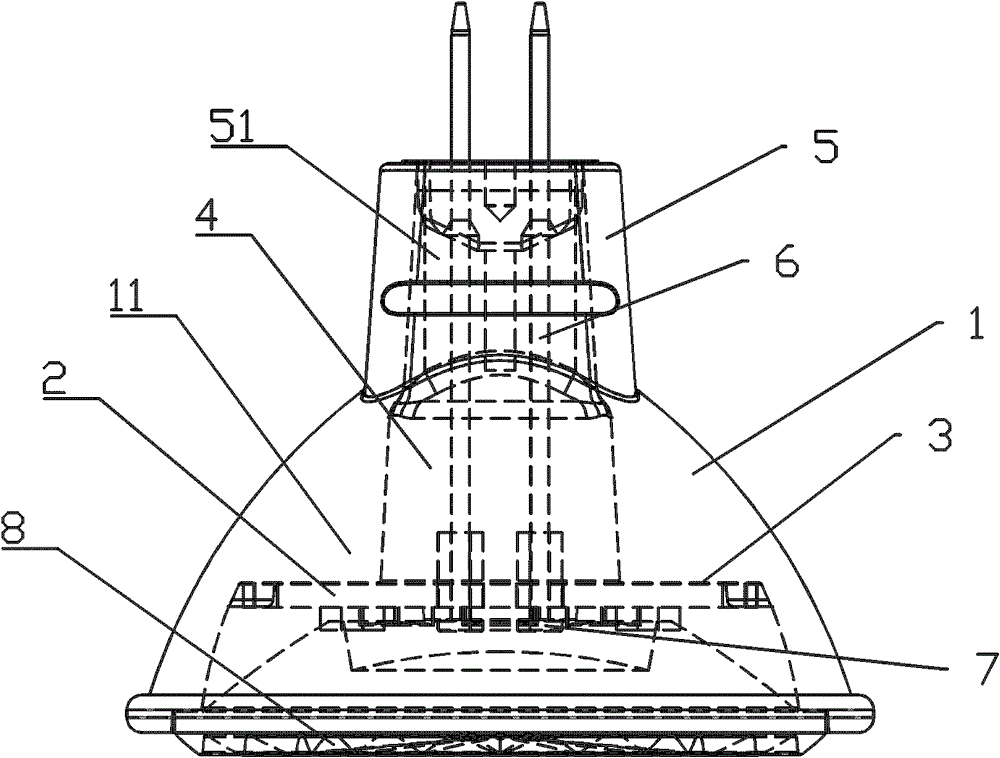

InactiveCN114654460AFeedforward control in real timeHigh resolutionImage enhancementProgramme-controlled manipulatorCarbon nanotubeScanning electron microscope

The invention discloses a feedforward control method for a nanometer operation robot. The feedforward control method comprises the steps that the nanometer operation robot is controlled to move in the X-axis direction and the Y-axis direction respectively; acquiring a tip image of the carbon nano tube on the nano operation robot through a scanning electron microscope, and taking the obtained motion trail of the tip of the carbon nano tube as the motion trail of the nano operation robot; obtaining offset according to the motion trail, and constructing a linear error model according to the relationship between the offset and the elongation of the piezoelectric ceramic driver; when the nano operation robot moves along the target track, acquiring a tip image of a carbon nano tube on the nano operation robot in real time through a scanning electron microscope to obtain the current displacement of the nano operation robot, obtaining the elongation of the current piezoelectric ceramic driver according to the current displacement, and calculating the current offset according to a linear error model; and adjusting the voltage of the piezoelectric ceramic driver to compensate the current offset. According to the invention, real-time and high-precision feedforward control of the nanometer operation robot can be realized.

Owner:SUZHOU UNIV

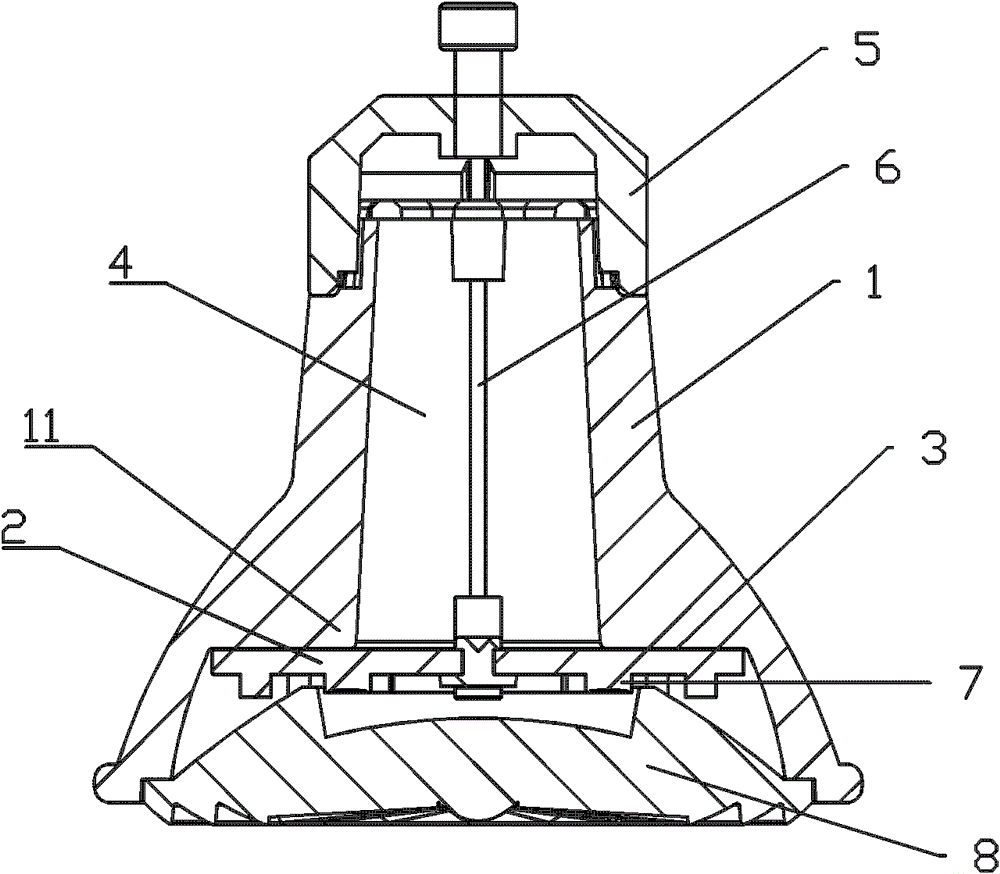

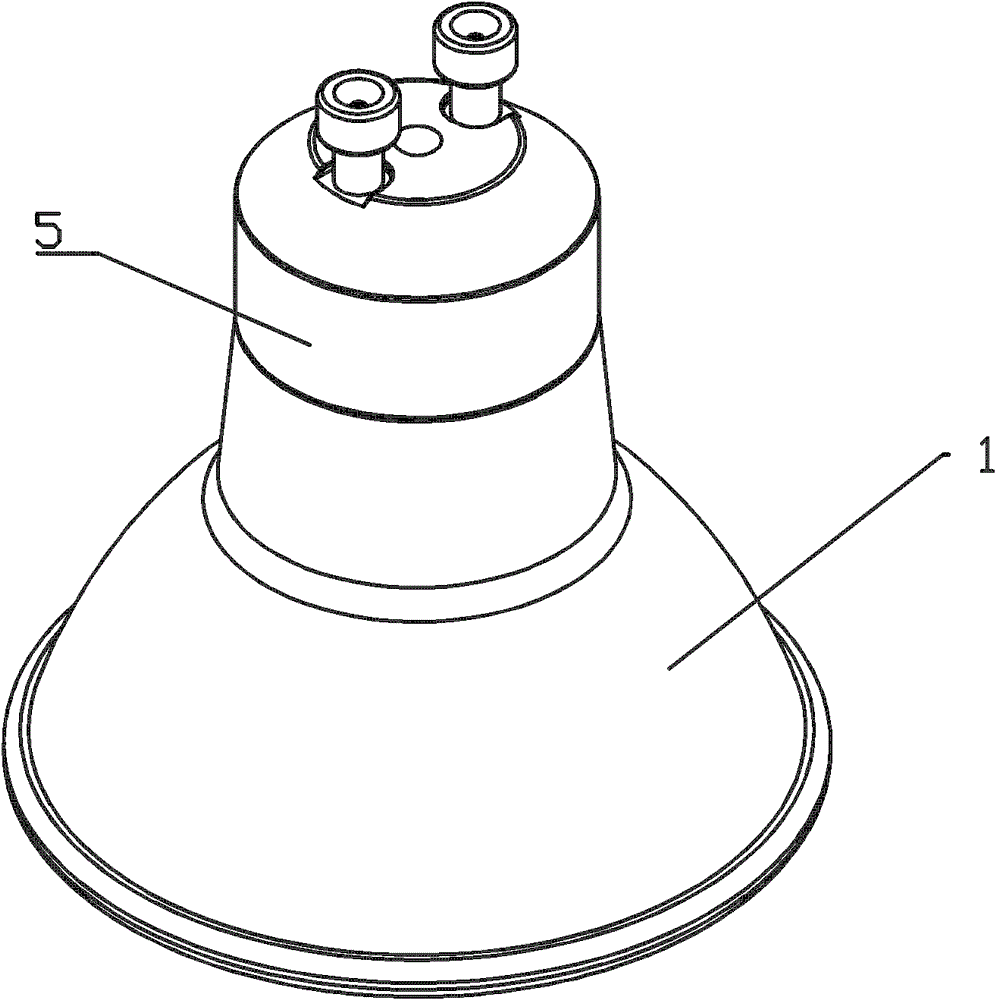

Light-emitting lamp body heat dissipation structure, corresponding lighting device and manufacturing method thereof

InactiveCN102818234BIncrease contact areaIncrease temperaturePlanar light sourcesLighting heating/cooling arrangementsWork performanceDual action

The invention relates to a heat dissipation structure of a light-emitting lamp body, which includes a glass shell and a heating component arranged in the glass shell; wherein the heating component and the glass shell are in close contact, and the area of the closely contacting part is maximized. The present invention also relates to a lighting device with the heat dissipation structure and a method for manufacturing the lighting device. Adopting the heat dissipation structure of the light-emitting lamp body, the corresponding lighting device and its manufacturing method are cheap and economical, and play the dual functions of insulation and heat transfer; ensure that the glass shell and the heat-generating parts have as large a contact area as possible, and become the main heat sink. The load transmission path, heat-conducting silicone potting can ensure high-efficiency heat transfer, and the metal-based circuit board further improves the efficiency of heat transfer, effectively avoiding excessive internal temperature of the luminous lamp body, energy saving, safety and environmental protection, and prolonging the service life. The structure is simple and practical. The manufacture is convenient and fast, the working performance is stable and reliable, and the scope of application is relatively wide, which brings great convenience to people's work and life.

Owner:蔡子丰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com