Flat-panel display of rectangular three-dimensional double straight grid control oblique arc surface cathode structure and manufacturing process thereof

A flat panel display and cathode structure technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of non-simplification of device manufacturing structure, reduction of device operating voltage, and high gate operating voltage. Achieve the effect of reducing production difficulty, reducing damage, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the embodiments.

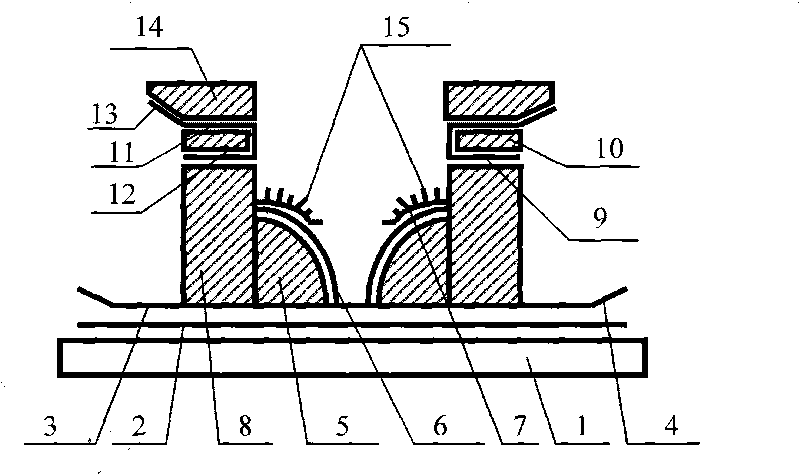

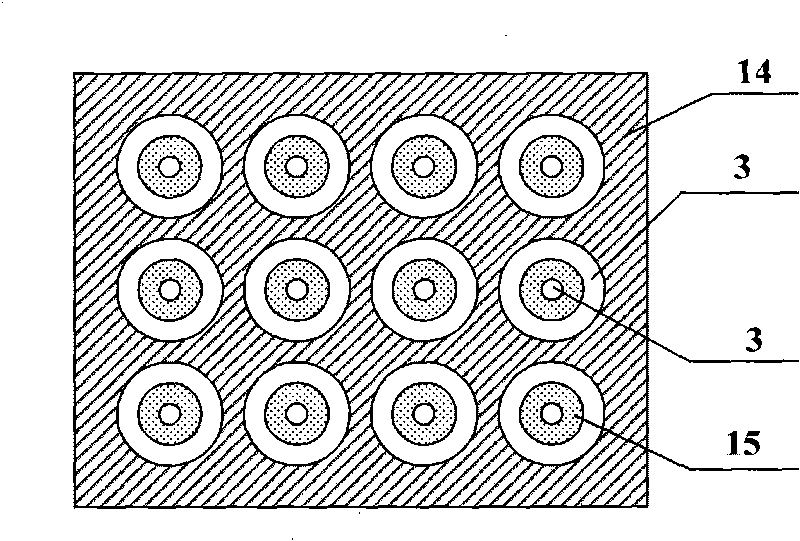

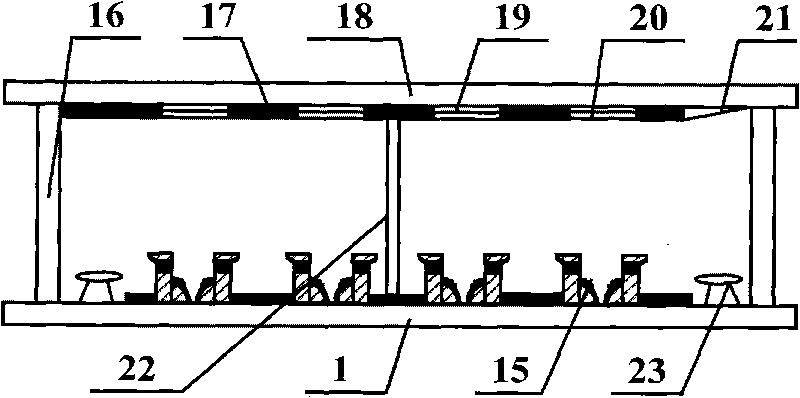

[0043] Such as figure 1 , 2 Shown in , 3, a kind of flat panel display of right-angle three-dimensional dual straight grid-controlled oblique arc cathode structure, comprises the airtight vacuum chamber that is made of anode glass panel 18, cathode glass panel 1 and glass frame 16; Located between anode glass panel 18 and Separation supporter 22 and getter 23 between cathode glass panels 1; anode conductive layer 19, anode lead layer 21, anode insulating layer 17 and phosphor layer prepared on anode conductive layer 19 arranged on anode glass panel 18 20; characterized in that:

[0044] The base material of the right-angle three-dimensional double straight gate-controlled inclined arc surface cathode structure is a cathode glass panel; the insulating paste printed and sintered on the cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com