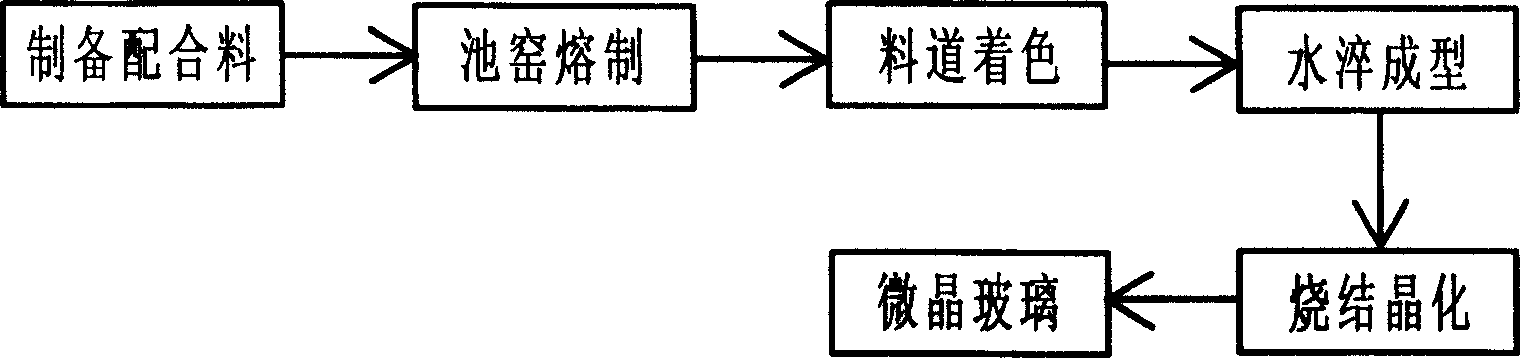

Decorative color microcrystalline glass formula and its production process

A technology for glass-ceramic and color, applied in the field of decorative color glass-ceramic formulation and production technology, can solve the problems of high quality requirements of inorganic high-temperature pigments, long period of changing varieties, and many preparation processes, and achieve the production technology and manufacturing process. Stable and reliable, the production process is simple and effective, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

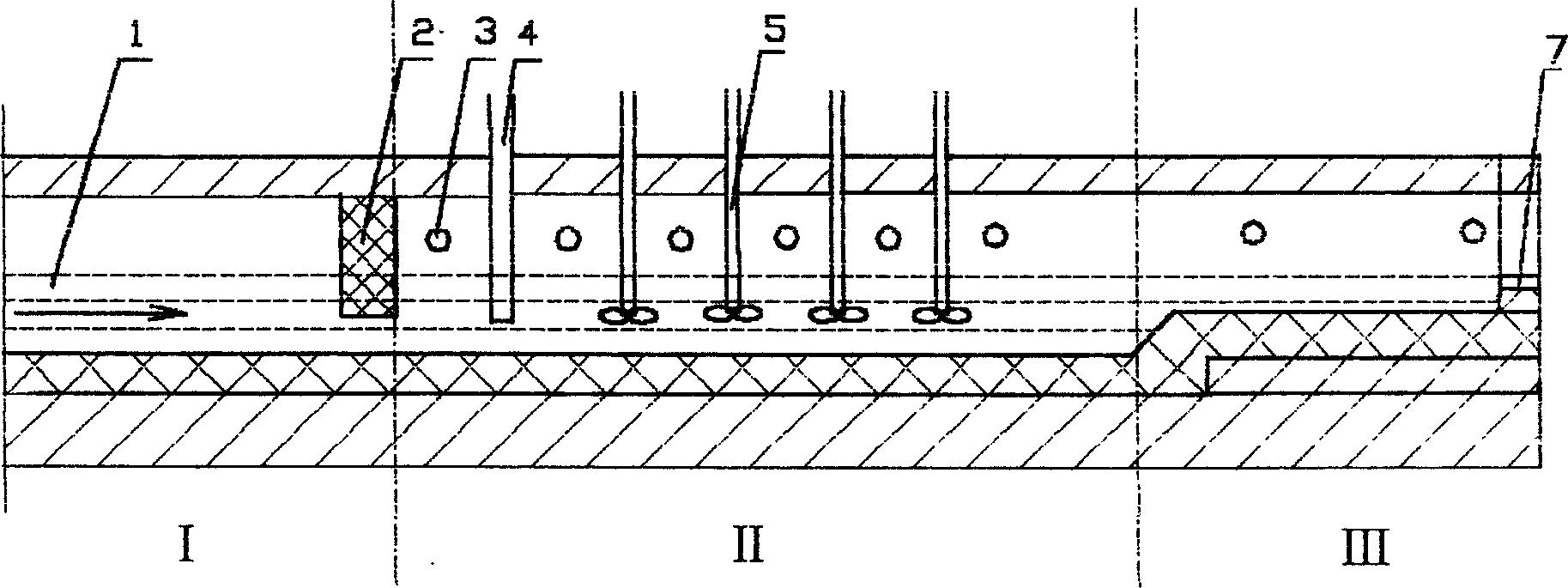

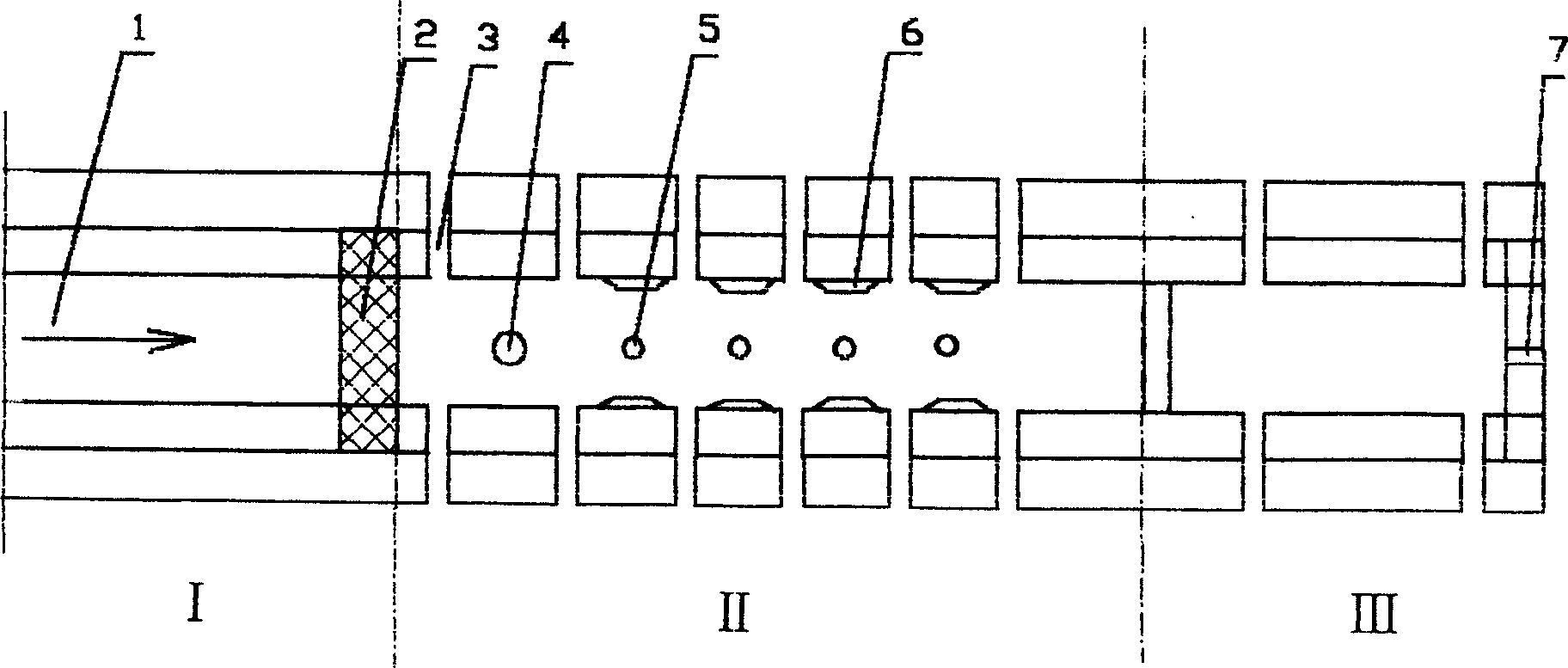

Method used

Image

Examples

Embodiment 1

[0024] A kind of decorative white glass ceramics, containing the following chemical components (weight percent):

[0025] SiO 2 60.3 Al 2 o 3 6.6 CaO 17.0 MgO 0.06

[0026] Na 2 O 4.0 BaO 4.8 ZnO 6.0 B 2 o 3 0.3

[0027] Sb 2 o 3 0.5 Li 2 O 0.5

Embodiment 2

[0029] A beige glass-ceramic for decoration, containing the following chemical components (percentage by weight):

[0030] SiO 2 59 Al 2 o 3 6.0 CaO 16.5 MgO 1.5

[0031] Na 2 O 5.3 K 2 O 2.2 BaO 3.0 ZnO 4.1

[0032] B 2 o 3 0.5 Sb 2 o 3 0.4 Li 2 O 1.5 Colorant NiO 0.05

Embodiment 3

[0034] A gray glass-ceramic for decoration, containing the following chemical components (percentage by weight):

[0035] SiO 2 59.5 Al 2 o 3 5.5 CaO 18 Na 2 O 5.0

[0036] K 2 O 2.1 BaO 3.0 ZnO 4.0 B 2 o 3 0.5

[0037] Sb 2 o 3 0.4 Li 2 O 2.0 Colorant MnO 2 1.1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com