Ultrasonic chemical coloring method for stainless steel

A chemical coloring and ultrasonic technology, applied in the direction of chromate treatment, can solve the problem of unsatisfactory stainless steel coloring effect, and achieve the effect of improving coloring production efficiency, short coloring time and reducing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

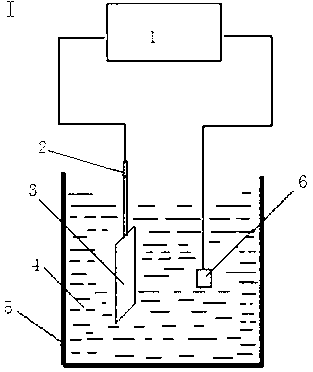

Method used

Image

Examples

Embodiment 1

[0034] First, the polished stainless steel workpiece is pretreated, after degreasing, washing and activation, it is ready for use, and the frequency of the ultrasonic generator is adjusted to 300kHz, and the sound intensity is 3.0kW / m 2 , the coloring temperature is 65°C, pour the chemical coloring liquid into the corrosion-resistant container and then place it in the liquid medium (water) of the ultrasonic generator, and start coloring when the temperature of the coloring liquid reaches the set temperature. Among them, the ultrasonic transducer is at the bottom of the container and acts in parallel with the stainless steel workpiece. The coloring potential of chemical coloring is 0.1894V, the terminal potential is 0.1784V, and the coloring potential difference △Φ=11mV. After hardening and sealing treatment, uniform color, edge and overall Blue stainless steel with no color difference. After magnifying 100 times with a polarizing microscope, it can be seen that compared with the...

Embodiment 2

[0036] The polished stainless steel workpiece is pretreated first, after degreasing, washing and activation, it is ready for use, and the frequency of the ultrasonic generator is adjusted to 135kHz, and the sound intensity is 8.0kW / m 2 , the coloring temperature is 50°C, pour the chemical coloring liquid into the corrosion-resistant container and then place it in the liquid medium (water) of the ultrasonic generator, and start coloring when the temperature of the coloring liquid reaches the set temperature. Among them, the ultrasonic transducer is at the bottom of the container and acts perpendicular to the stainless steel workpiece. The coloring potential of chemical coloring is 0.1895V, the terminal potential is 0.1695V, and the coloring potential difference △Φ=20mV. After hardening and sealing treatment, uniform color, edge and overall Gold-yellow stainless steel with no color difference. After magnifying 100 times with a polarizing microscope, it can be seen that compared ...

Embodiment 3

[0038] The polished stainless steel workpiece is pretreated first, after degreasing, washing and activation, it is ready for use, and the frequency of the ultrasonic generator is adjusted to 50kHz, and the sound intensity is 5.0kW / m 2 , the coloring temperature is 50°C, the chemical coloring liquid is directly added to the ultrasonic generator whose inner wall is coated with a corrosion-resistant coating, and the coloring is carried out when the temperature of the coloring liquid reaches the set temperature. Among them, the ultrasonic transducer is at the bottom of the container and acts in parallel with the stainless steel workpiece. The coloring potential of chemical coloring is 0.1891V, the terminal potential is 0.1651V, and the coloring potential difference △Φ=24mV. After hardening and sealing treatment, uniform color, edge and overall Fuchsia stainless steel with no color difference. After magnifying 100 times with a polarizing microscope, it can be seen that compared wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com