Patents

Literature

97results about How to "High surface brightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

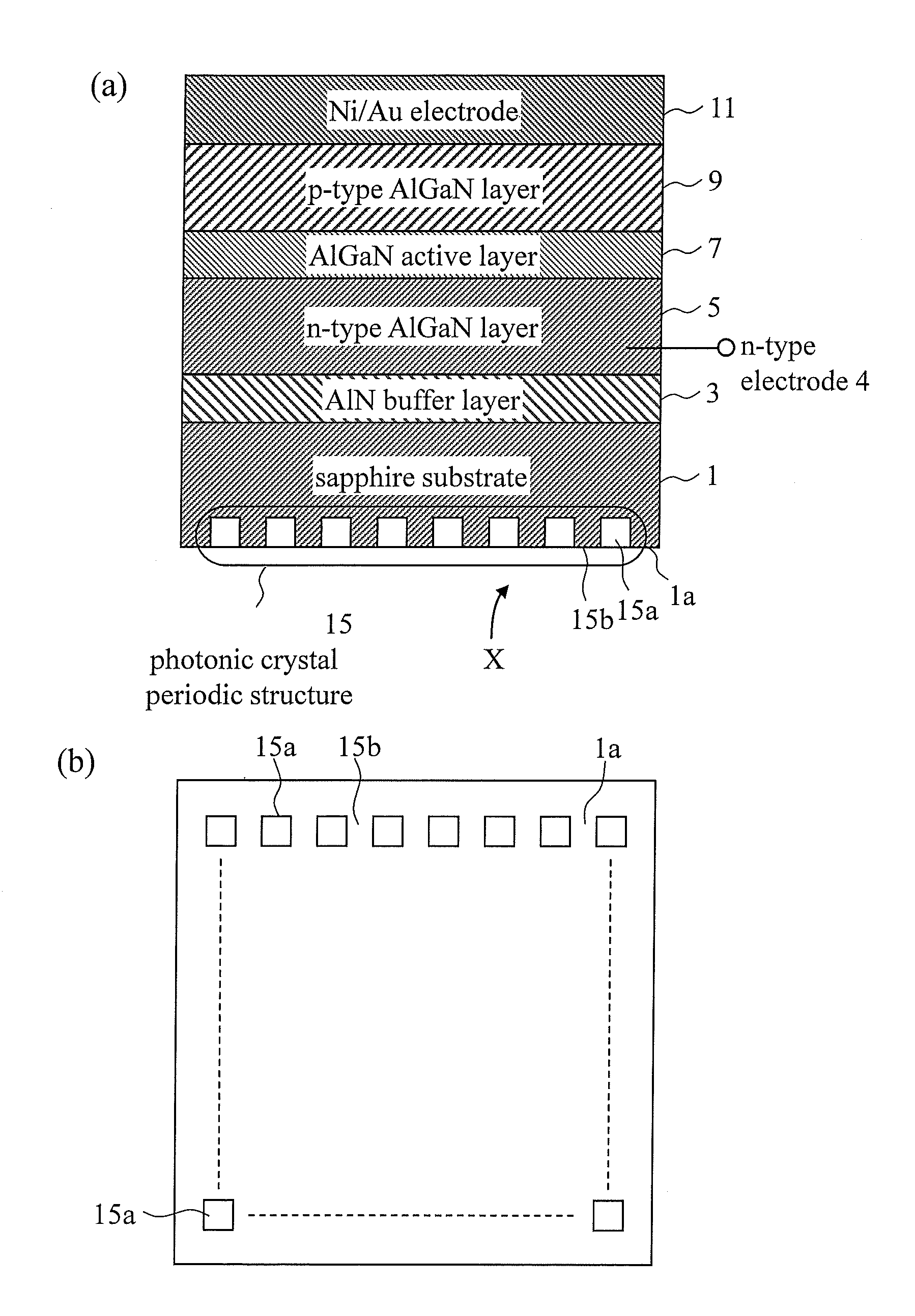

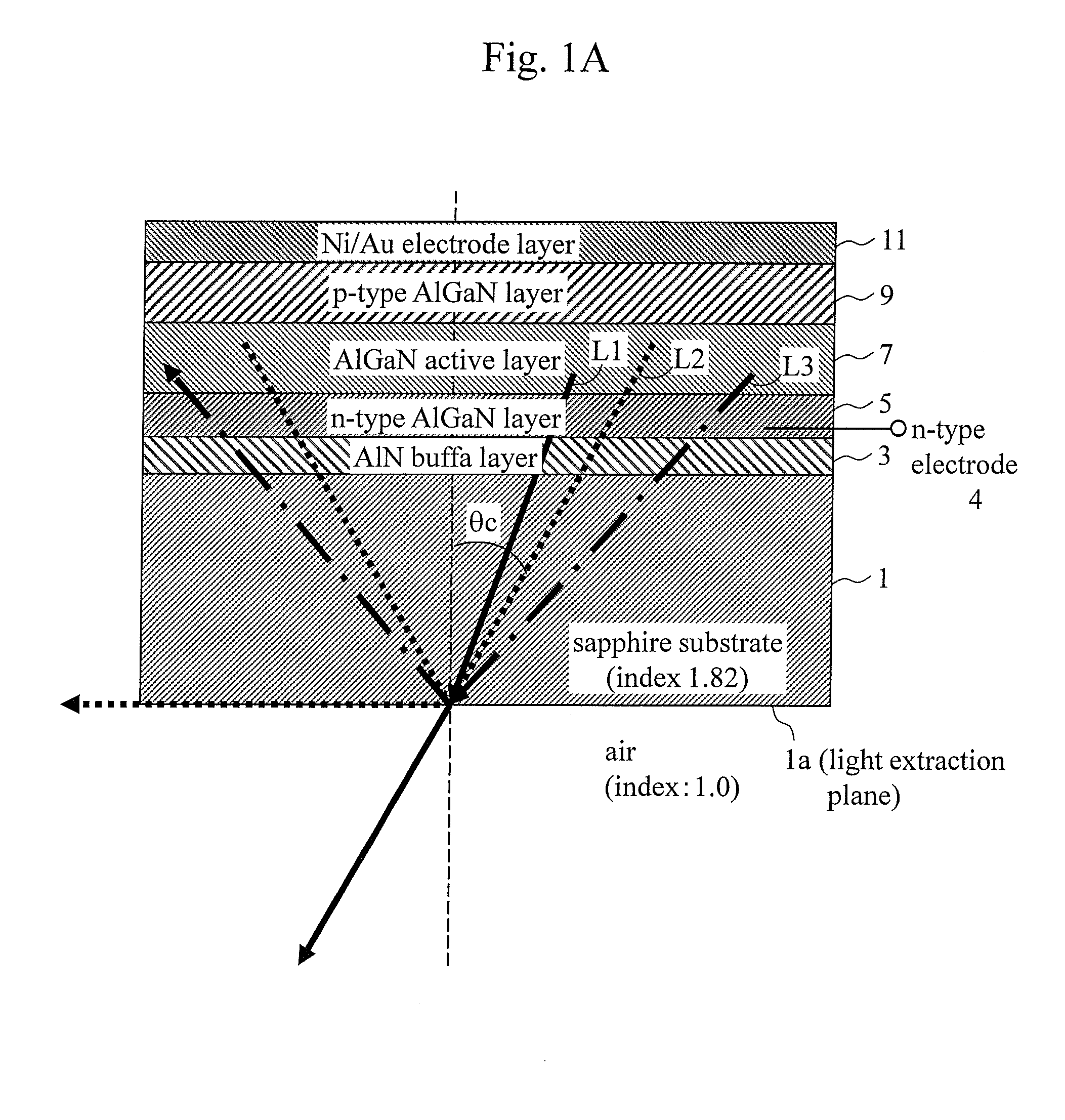

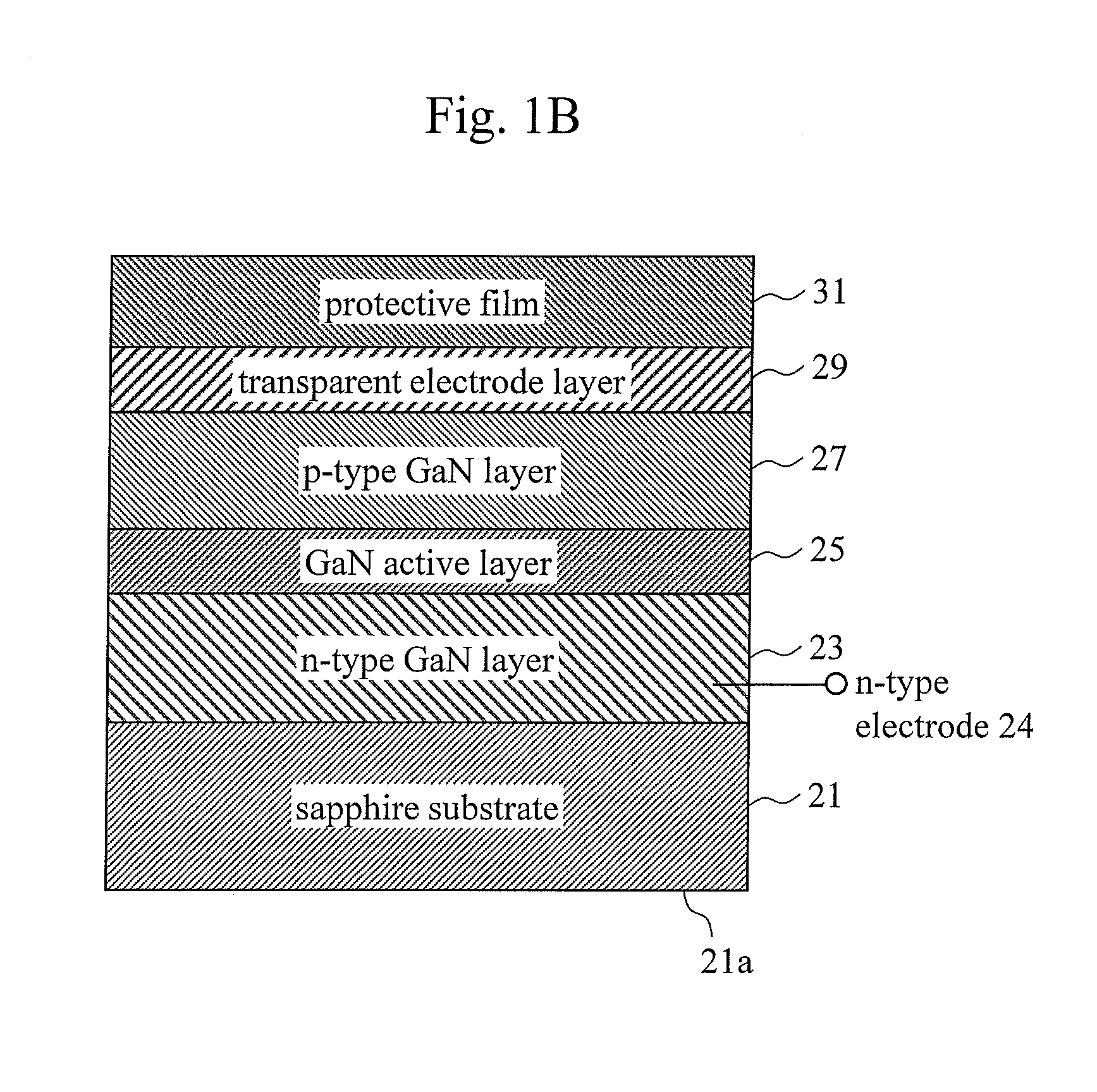

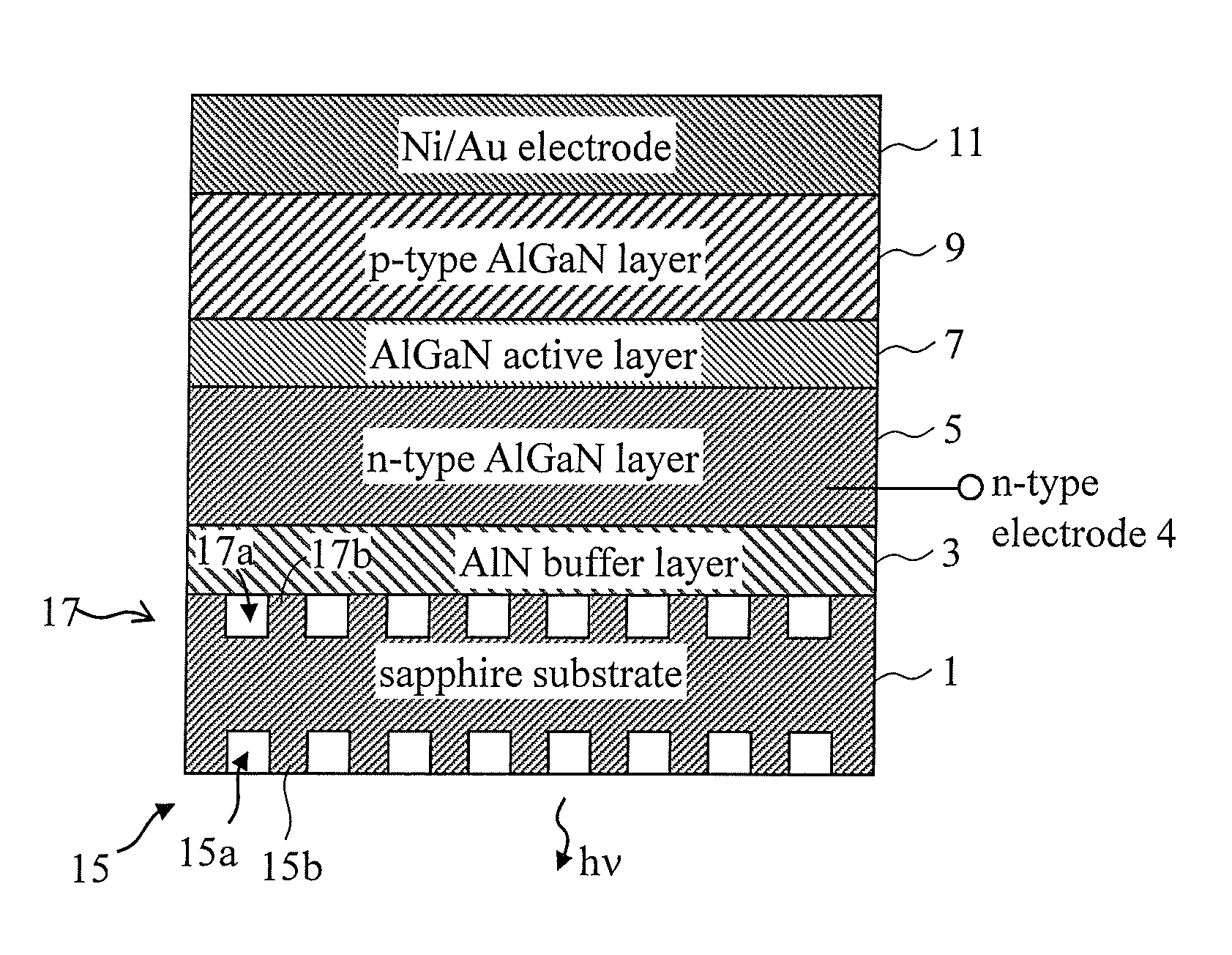

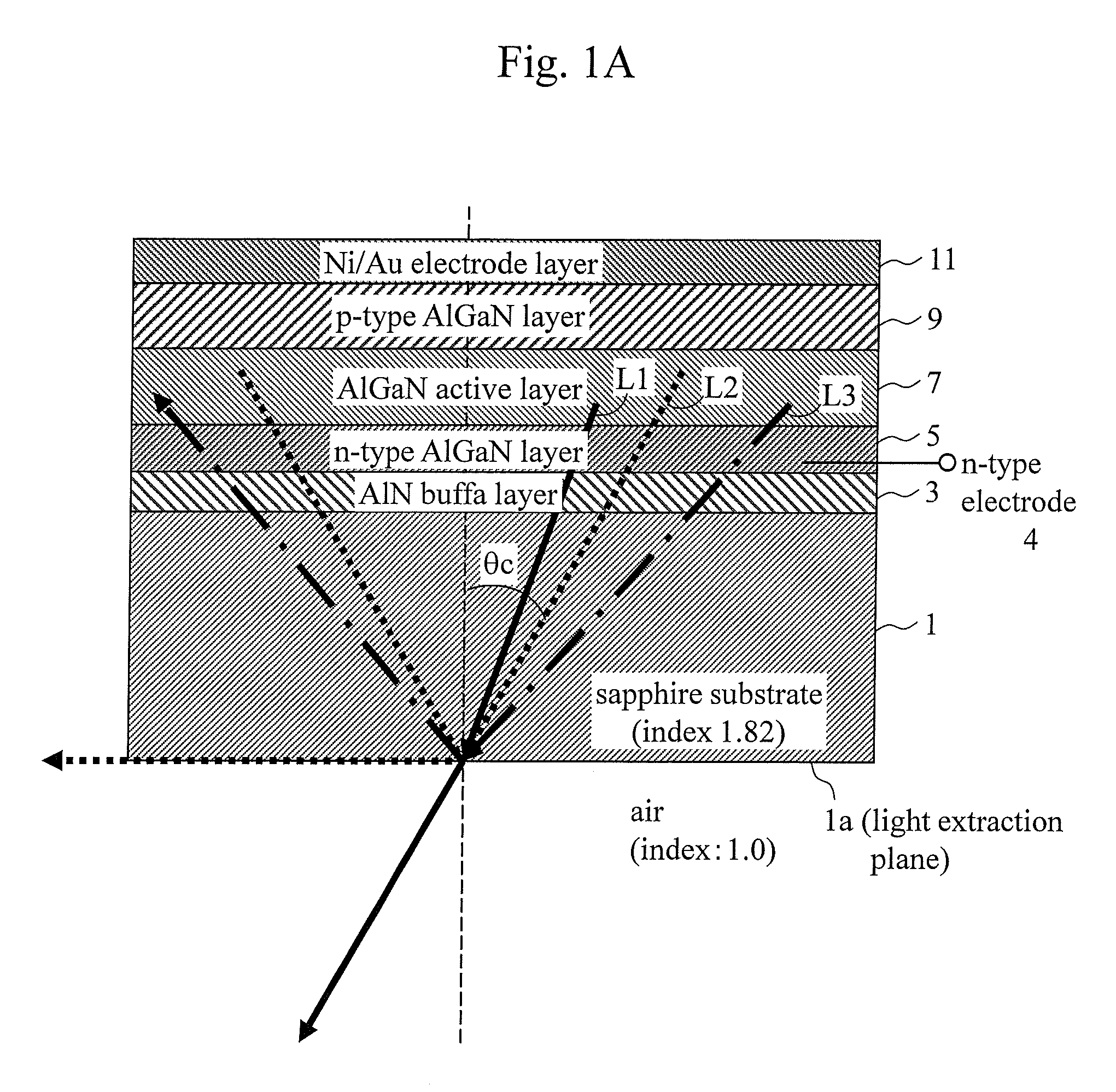

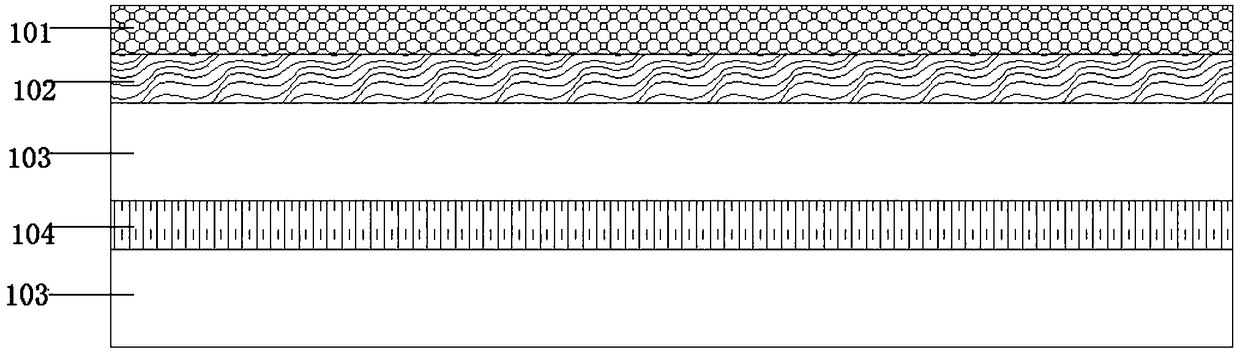

Light emitting element and method for manufacturing same

ActiveUS20140167066A1Low efficiencyHigh light transmittanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPhotonic bandgapRefractive index

A semiconductor light emitting element including, in a light extraction layer thereof, a photonic crystal periodic structure including two systems (structures) with different refractive indices. An interface between the two systems (structures) satisfies Bragg scattering conditions, and the photonic crystal periodic structure has a photonic band gap.

Owner:MARUBUN +3

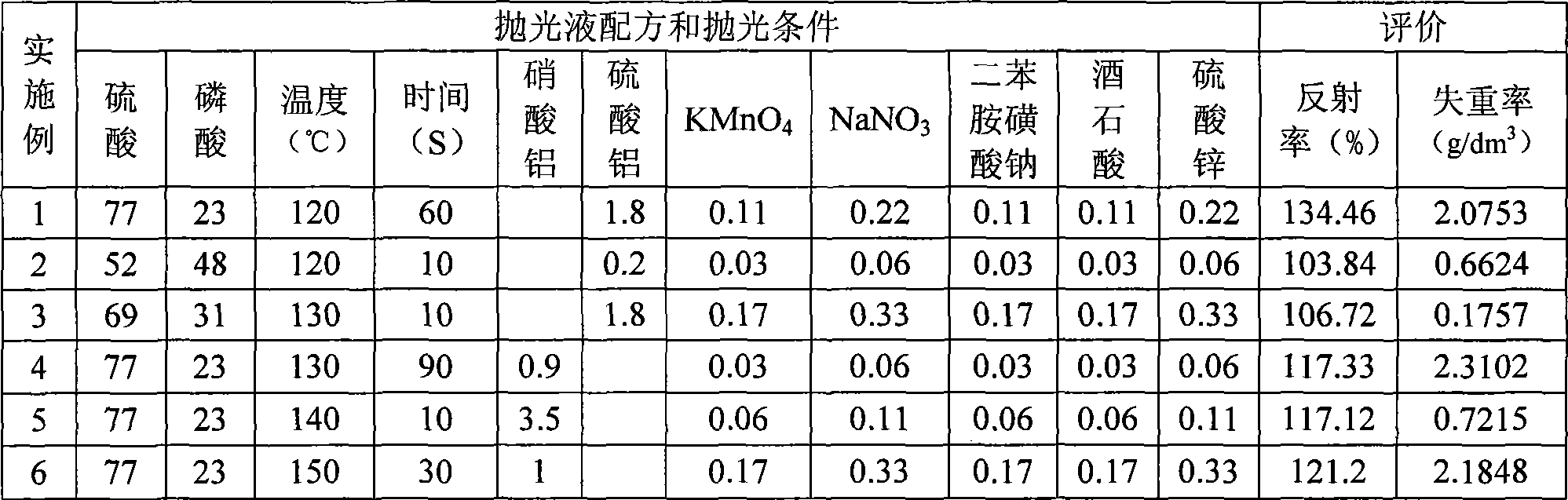

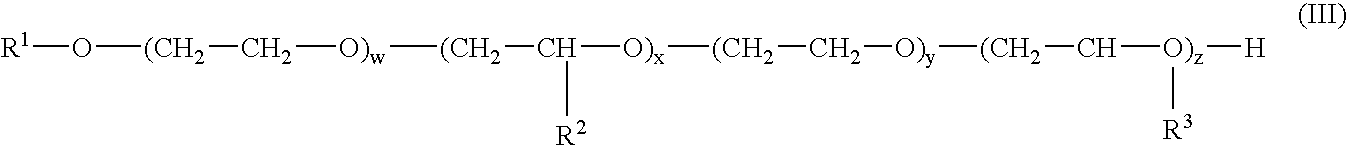

Aluminum product chemical polishing solution and polishing method thereof

InactiveCN101476126AEasy to cleanReduce corrosion pointsPhosphoric acidSodium diphenylamine sulfonate

The invention discloses an aluminium product chemical polishing solution composition with nitric acid free. The composition uses sulfuric acid and phosphoric acid as a basic solution, an additive is composed of aluminium sulphate (or aluminium nitrate), potassium permanganate, sodium nitrate, diphenylamine sulfonic acid sodium salt, tartaric acid and zinc sulfate. Polishing temperature is 110-150 DEG C, polishing time is 10s-120s when the polishing solution is used for polishing. The composition can ensure no nitrogen oxide yellow smoke harm, at the same time ensure the aluminium product having better polishing blare effect for reaching mirror surface brightness, and having little rate of weight loss.

Owner:SHANXI UNIV

Metallic coin stamped with holographic anti-counterfeiting pattern and manufacturing method thereof

InactiveCN103054284ATo achieve the purpose of printingWear-resistantDuplicating/marking methodsOther printing apparatusStampingEngineering

The invention relates to a laser holographic anti-counterfeiting stamping technology and particularly relates to a metallic coin stamped with a holographic anti-counterfeiting pattern and a manufacturing method thereof and provides the metallic coin which has a laser holographic anti-counterfeiting function and exquisite pattern and is stamped with the holographic anti-counterfeiting pattern and the manufacturing method of the metallic coin. The manufacturing method comprises the following steps of: duplicating a laser holographic image on a metallic nickel plate to form a metal nickel plate for die pressing; coating a release layer, an imaging layer, a die pressing layer, an aluminum plating layer and a dual-layer adhesive layer on a film belt of a base film; positioning, transferring and stamping a laser electrochemical aluminum stamping foil on the metallic coin; heating a stamping head to 80-90DEG C; meanwhile, preheating and improving the temperature of the original metallic coin to 90-100DEG C; and removing the film belt of the base film by the release layer to form the metallic coin with laser holographic pattern. The metallic coin generates a new visual color in the overlapped laser effect and is a novel metal coin anti-counterfeiting type; and in addition, the metallic coin has the advantages of accuracy in positioning, strong three-dimensional sense, abundant layers, simple and quick process, one-time transfer stamping, favorable reproducibility and no pollution.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

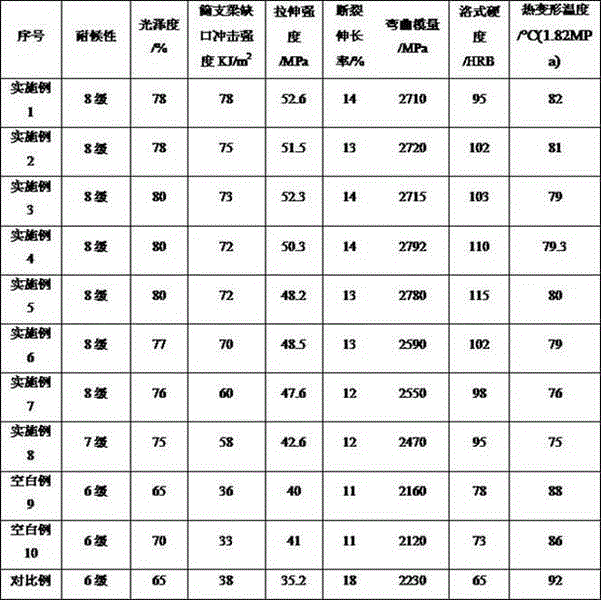

Low-smell high-gloss free-spraying polyamide composition and preparation method thereof

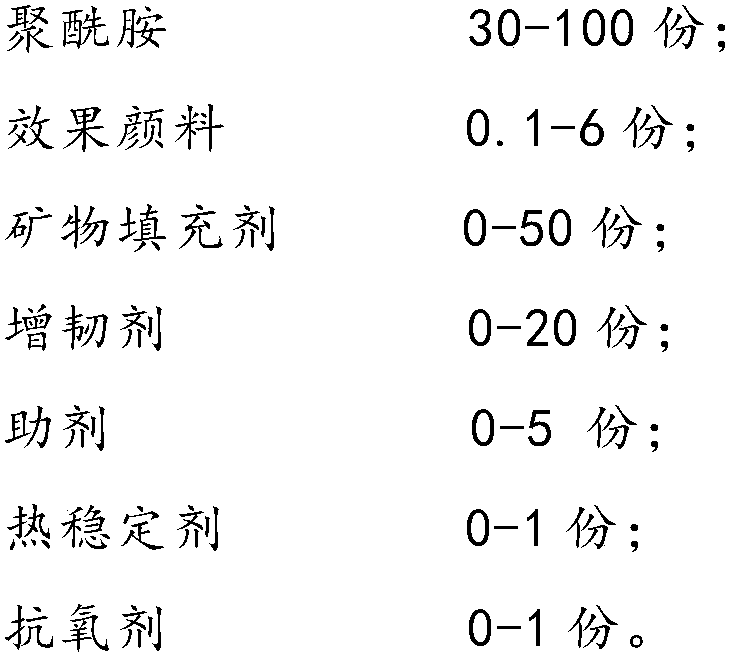

The invention discloses a low-smell high-gloss free-spraying polyamide composition which comprises, by weight, 30-100 parts of polyamide, 0.1-6 parts of effect pigments, 0-50 parts of mineral fillers,0-20 parts of flexibilizers, 0-5 parts of auxiliaries, 0-1 part of heat stabilizers and 0-1 part of antioxidants. Monomers and low-polymer components remaining in the production process of polyamideare eliminated by reaction in the preparation process, and the smell of a low-smell nylon composition is improved. Besides, surface defects of free-spraying workpieces are decreased, brightness is improved, the free-spraying workpieces are closer to appearance effects of painted parts, the smell of the nylon composition is further removed by a smell removal process, and glossiness and tensile strength are further improved by introducing the mineral fillers and the flexibilizers.

Owner:SHANGHAI KINGFA SCI & TECH +2

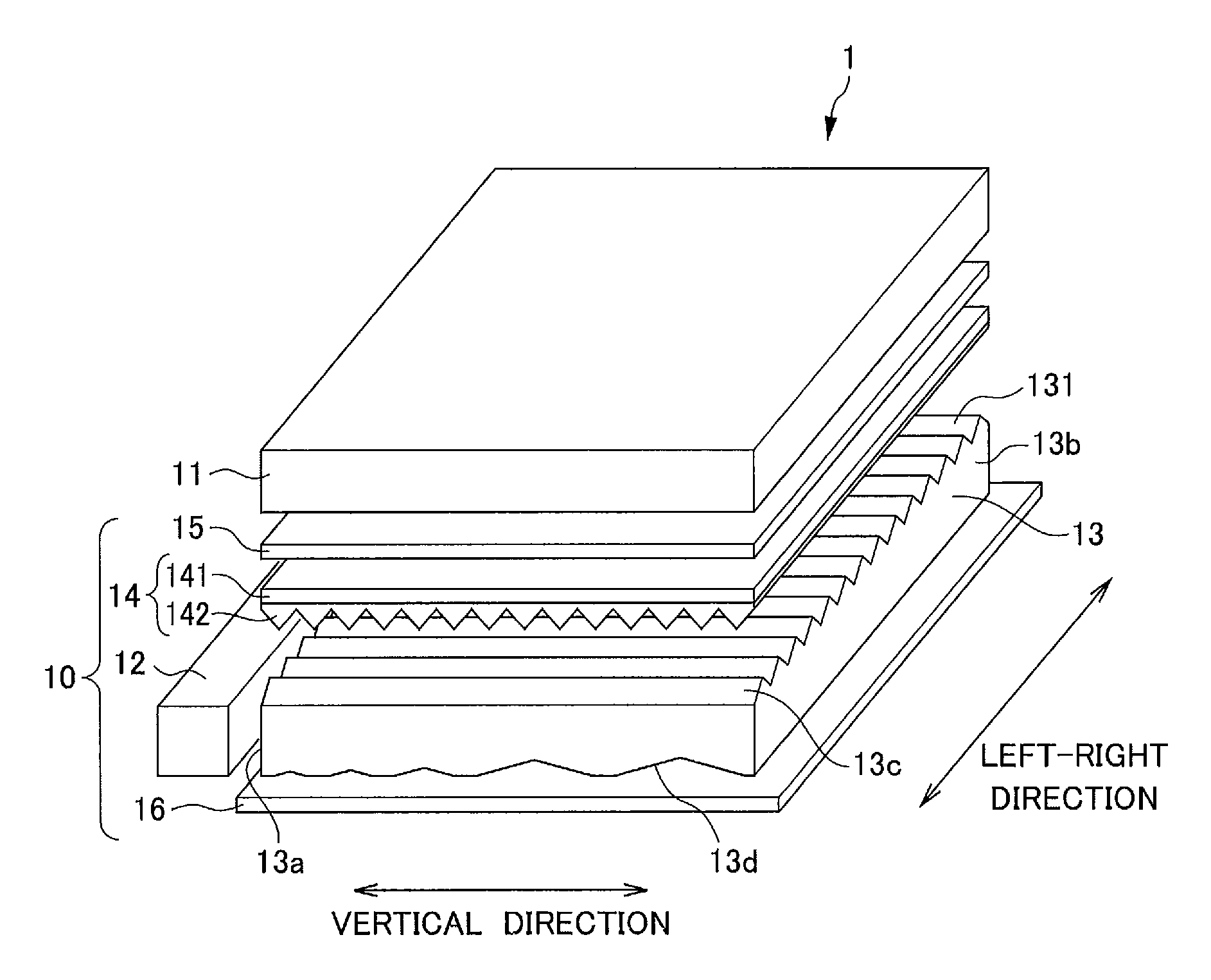

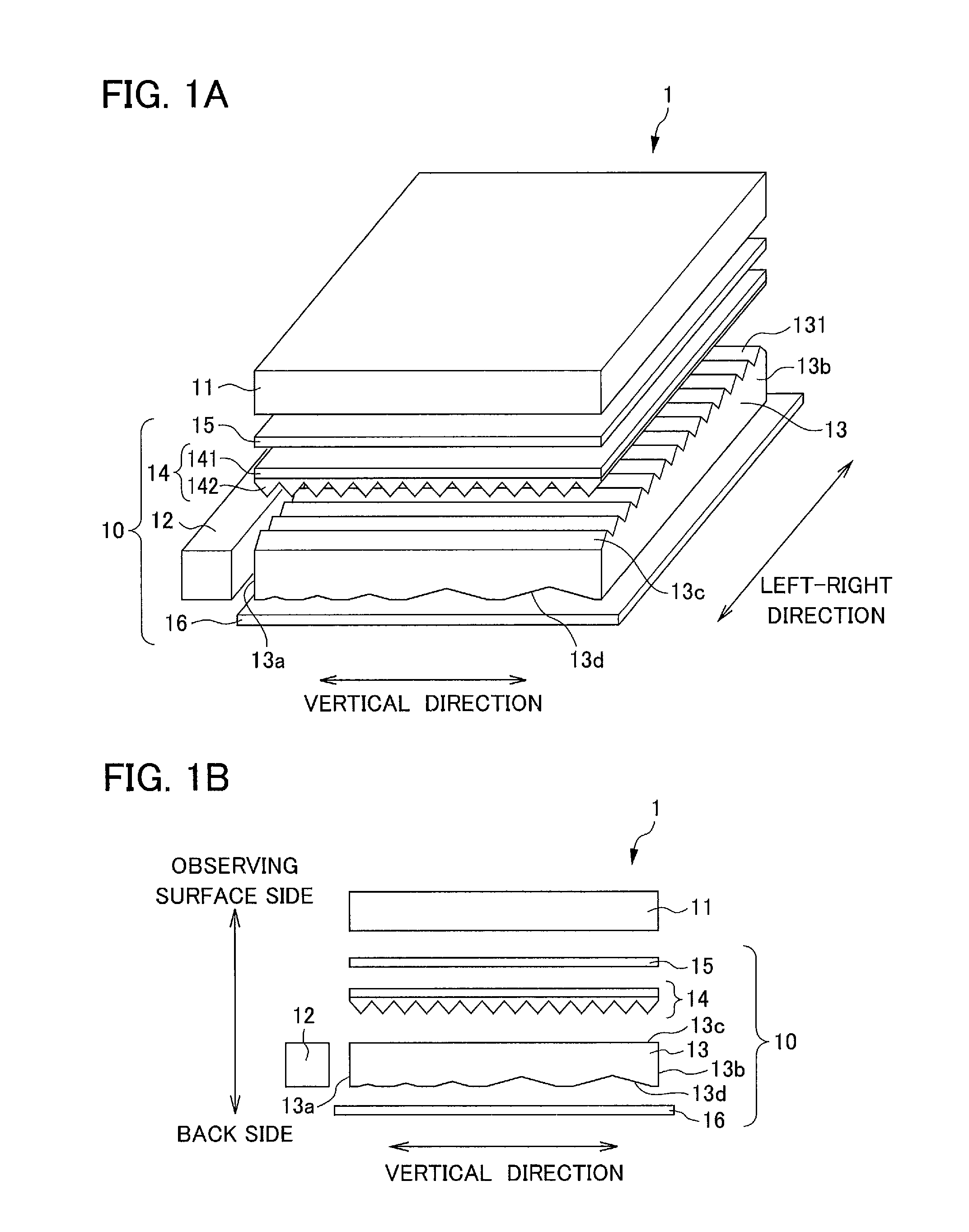

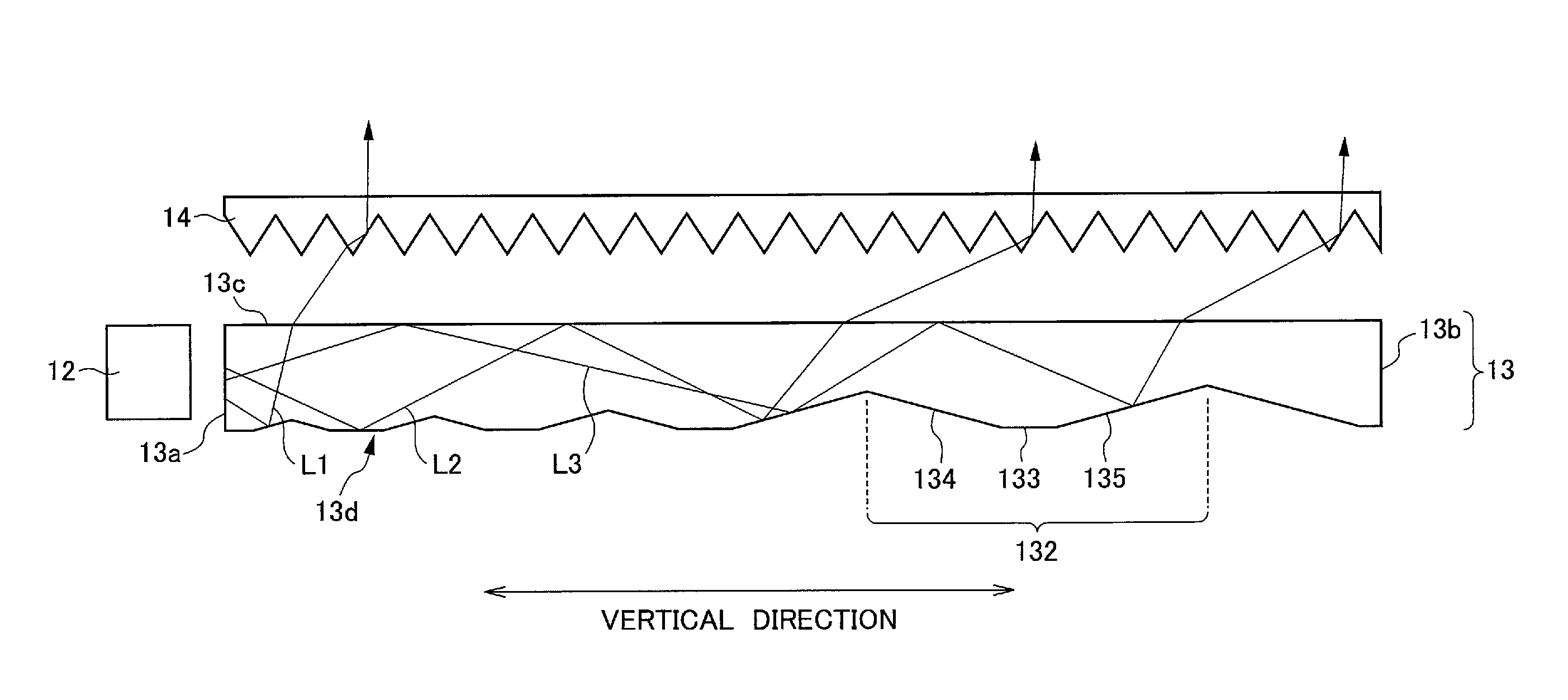

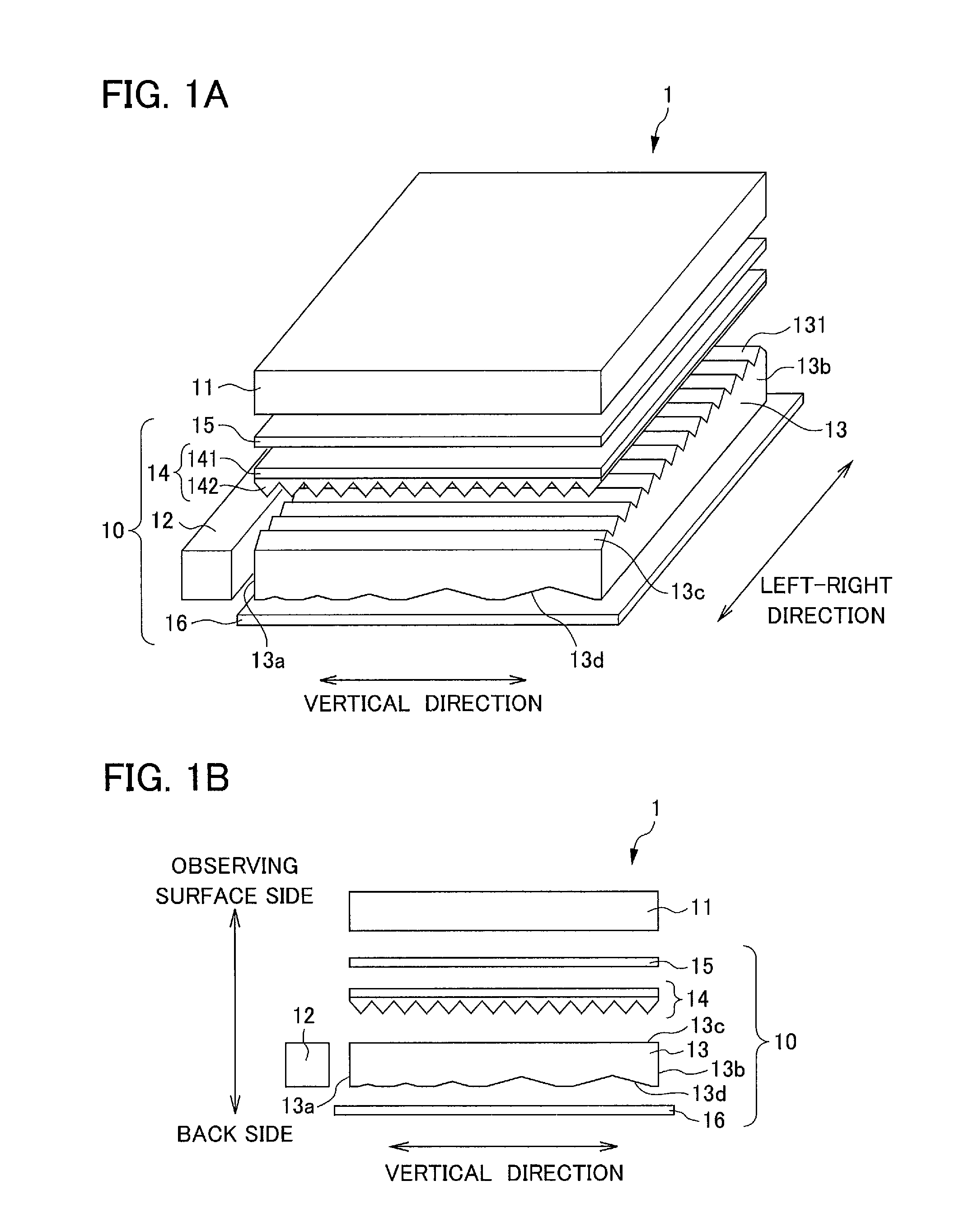

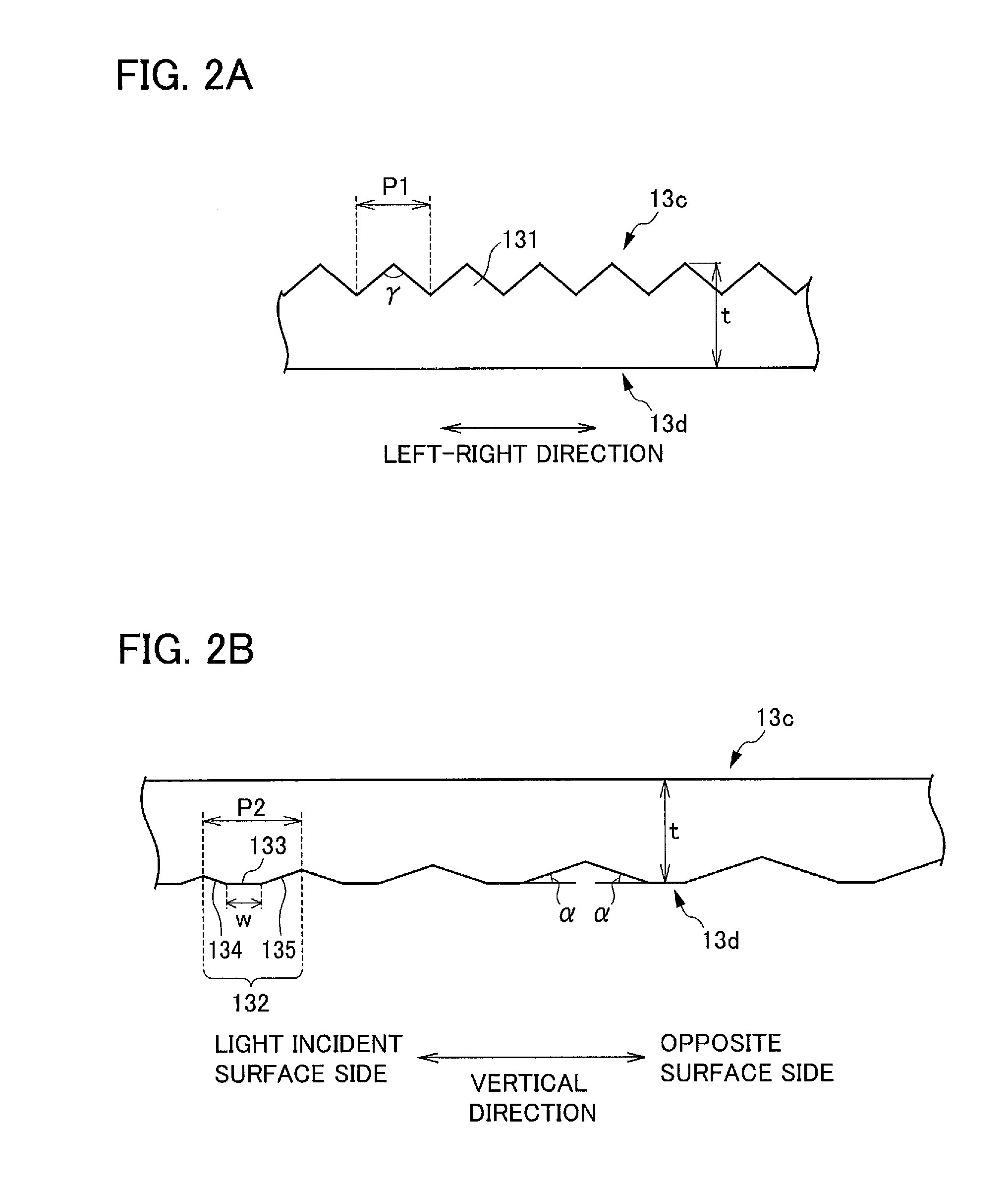

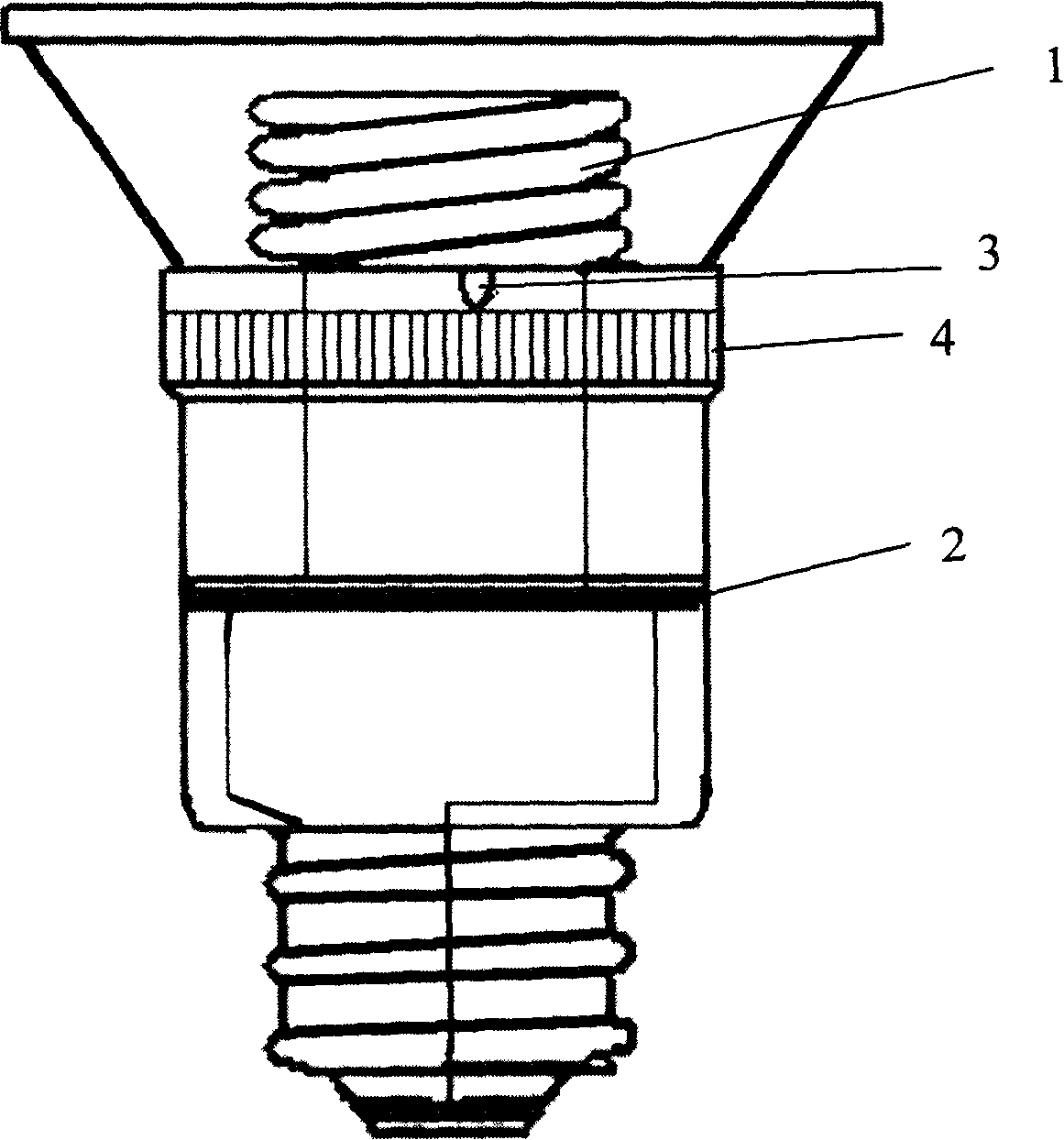

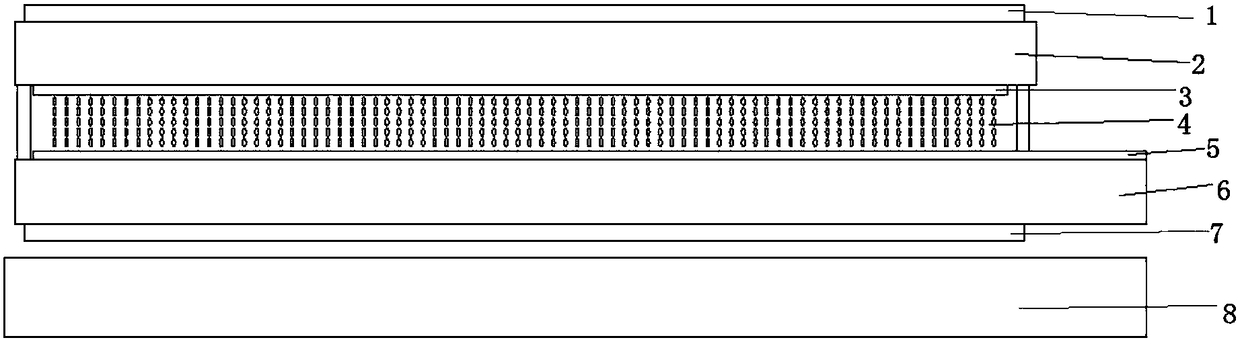

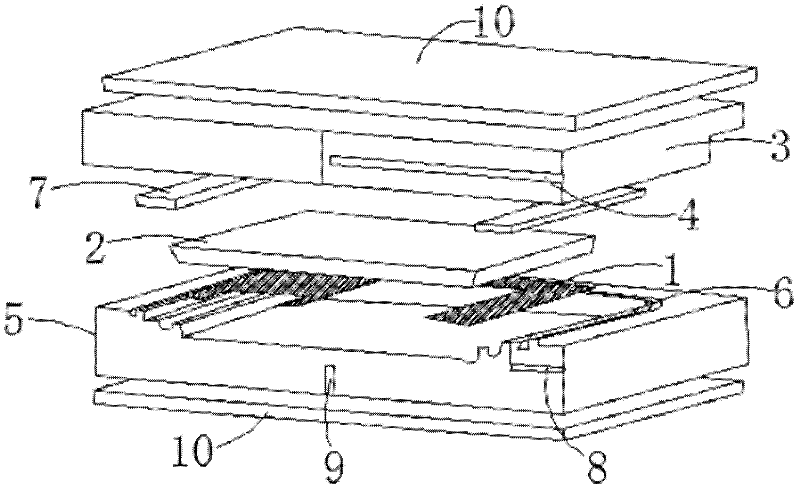

Light guide plate, surface light source device and transmissive display apparatus

ActiveUS20120201045A1Promote lowerImprove brightness uniformityMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

A light guide plate shaped substantially like a plate includes a light incident surface, a light exit surface and a reflective surface, which is opposite to the light exit surface, configured to reflect light toward the light exit surface. A plurality of optical units is arranged along the reflective surface in a direction orthogonal to the light incident surface. Each optical unit is shaped substantially like a quadratic prism that is convex toward the reflective surface and has a top surface and two slopes being formed opposite to each other with respect to the top surface. A dimension of the top surface is constant in a direction of arrangement of the optical units and an interval between adjacent optical units becomes greater as the adjacent optical units lie further away from the light incident surface in the direction of arrangement of the optical units.

Owner:DAI NIPPON PRINTING CO LTD

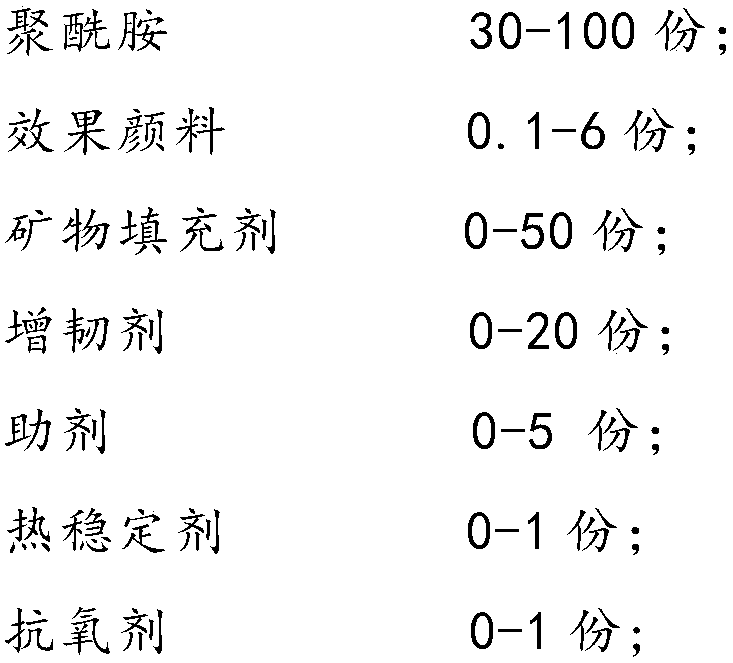

Environment-friendly low-smell and spraying-free polyamide composition and preparation method thereof

The invention discloses an environment-friendly low-smell and spraying-free polyamide composition. The environment-friendly low-smell and spraying-free polyamide composition comprises the following components in parts by weight: 95-100 parts of polyamide, 0.01-5 parts of metal compound, and 0.1-6 parts of effect pigment. According to the environment-friendly low-smell and spraying-free polyamide composition, smell produced in the production process and / or formation process of nylon materials can be extremely reduced; the appearance defects, caused by smell, on spraying-free products, in particular the products emphasizing on appearance and surface aesthetic effects, can be extremely reduced. According to the abovementioned technical scheme, the metal compound is introduced, and the post-processing technology is carried out, so that the surface brightness of the spraying-free polyamide composition is greatly improved.

Owner:SHANGHAI KINGFA SCI & TECH +2

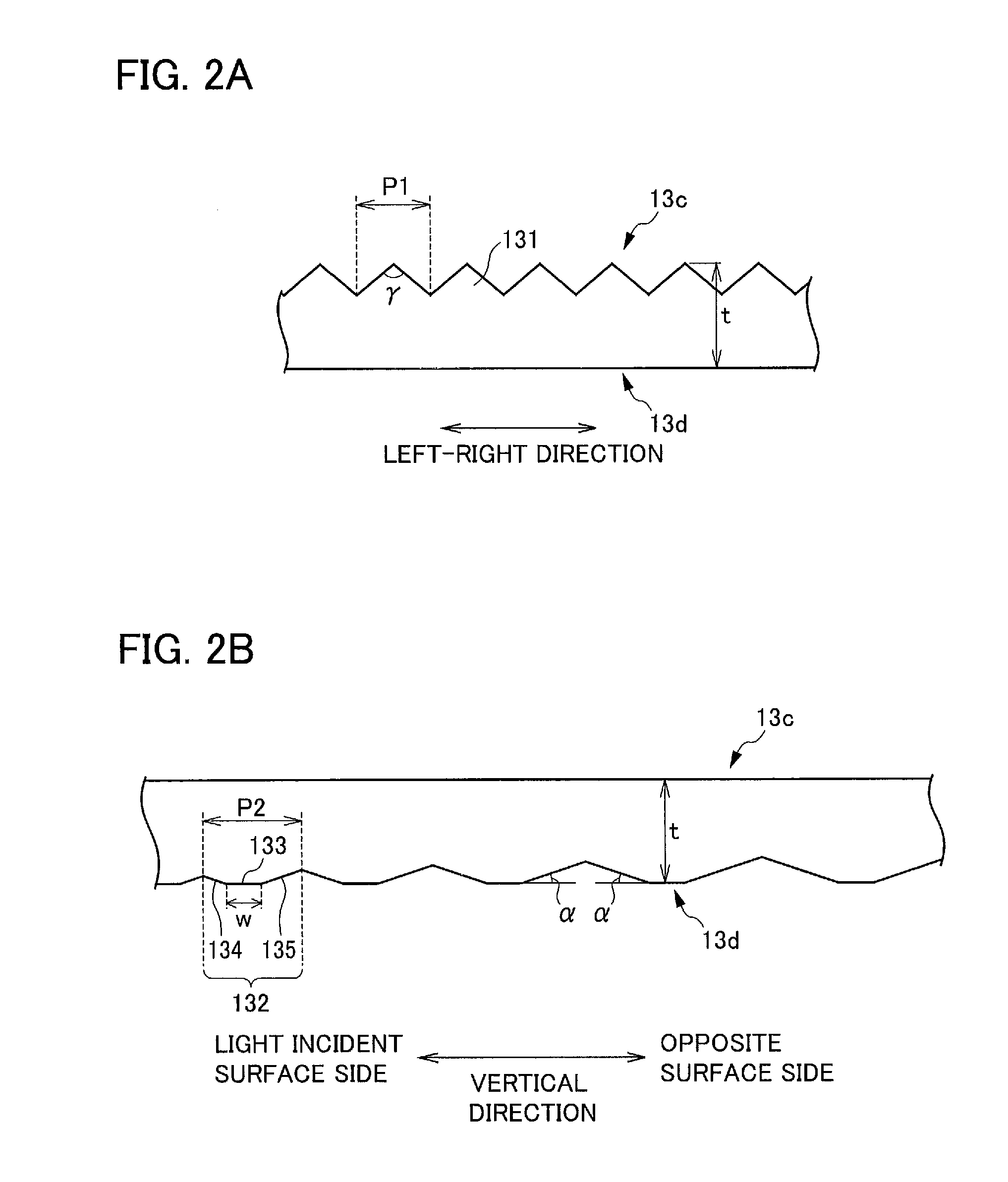

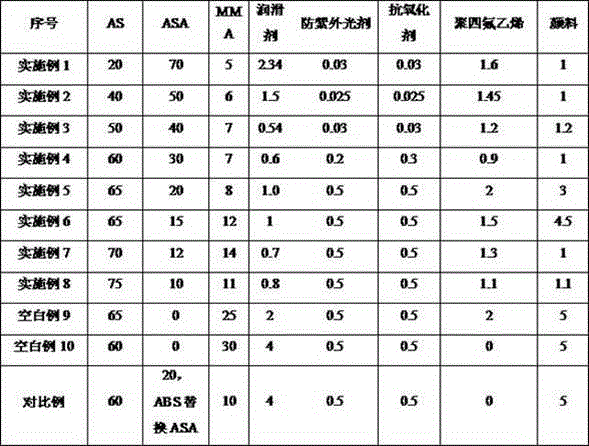

Weather-resistance ASA-based composite material, co-extruded plastic product and plastic product

The invention relates to a weather-resistance ASA-based composite material, a co-extruded plastic product and a plastic product. The composite material comprises the following components in percentage by mass: 20%-84% of an acrylonitrile-styrene copolymer, 10%-70% of an acrylonitrile-acrylic-styrene copolymer, 5%-30% of acrylic resin, and 1%-10% of an aid. The composite material comprises the acrylonitrile-styrene copolymer, the core-shell-structured acrylonitrile-acrylic-styrene copolymer, and acrylic resin; by virtue of the core-shell-structured acrylonitrile-acrylic-styrene copolymer, the composite material is endowed with excellent weather resistance; the acrylonitrile-styrene copolymer has high temperature resistance, excellent glossiness and chemical medium resistance and excellent hardness, rigidity and dimensional stability; by virtue of acrylic resin, good intermiscibility between the core-shell-structured acrylonitrile-acrylic-styrene copolymer and the acrylonitrile-styrene copolymer is achieved, thereby being beneficial to the machining, manufacturing and forming of the composite material.

Owner:SHENZHEN YICAIHONGXIANG NEW MATERIALS TECH CO LTD

Coating method of bathroom furniture materials and bathroom furniture material

ActiveCN103056080AHigh surface brightnessGuaranteed fullnessSynthetic resin layered productsPretreated surfacesHuman healthSurface finishing

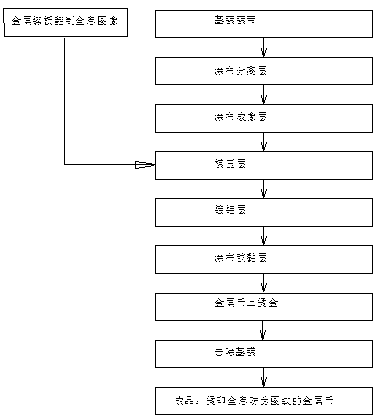

The invention discloses a coating method of bathroom furniture materials and a bathroom furniture material. The coating method is applicable to base materials of wood, metal or plastics and the like and specifically includes the following steps that (1) the base materials are subjected to surface treatment, and surfaces of the base materials are subjected to sanding; (2) water-based transparent putty is coated on the surfaces of the base materials, microwave drying is performed, and photosensitive paint film curing is performed; (3) putty layers on the surfaces of the base materials are subjected to sanding; (4) one or two layers of water-based primer is / are applied to the surfaces of the base materials, microwave drying is performed, and then photosensitive paint film curing is performed; (5) water-based primer layers on the surfaces of the base materials are subjected to sanding; and (6) one or two layers of water-based finish paint is / are applied to the surfaces of the base materials, microwave drying is performed, and then photosensitive paint film curing is performed. Water-based paint is used as the coating material, the water-based paint uses water as diluents of the paint, and heavy metal is not contained or scarcely contained in the paint, so that harm to human health is absent.

Owner:佛山市国人智能科技有限公司

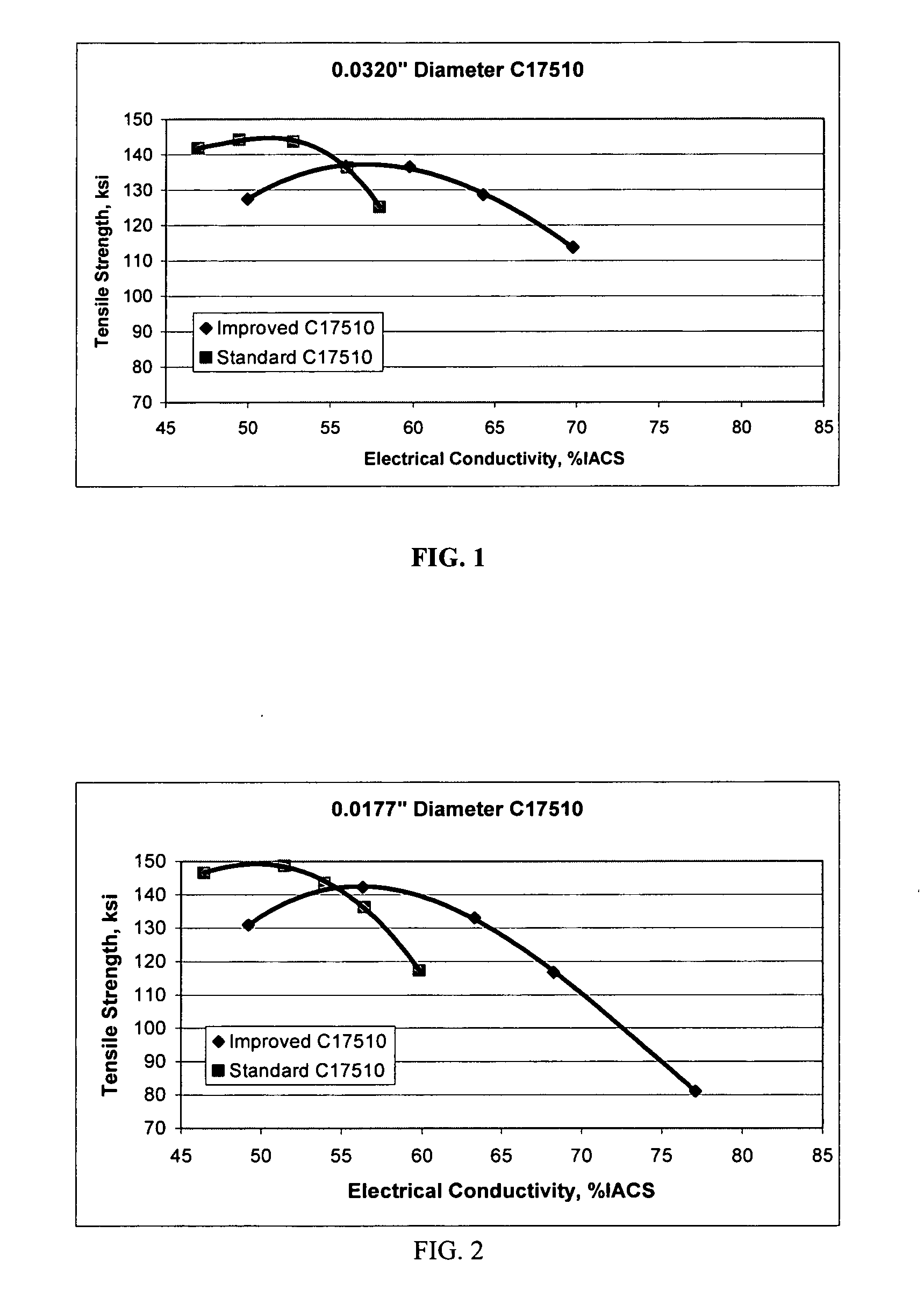

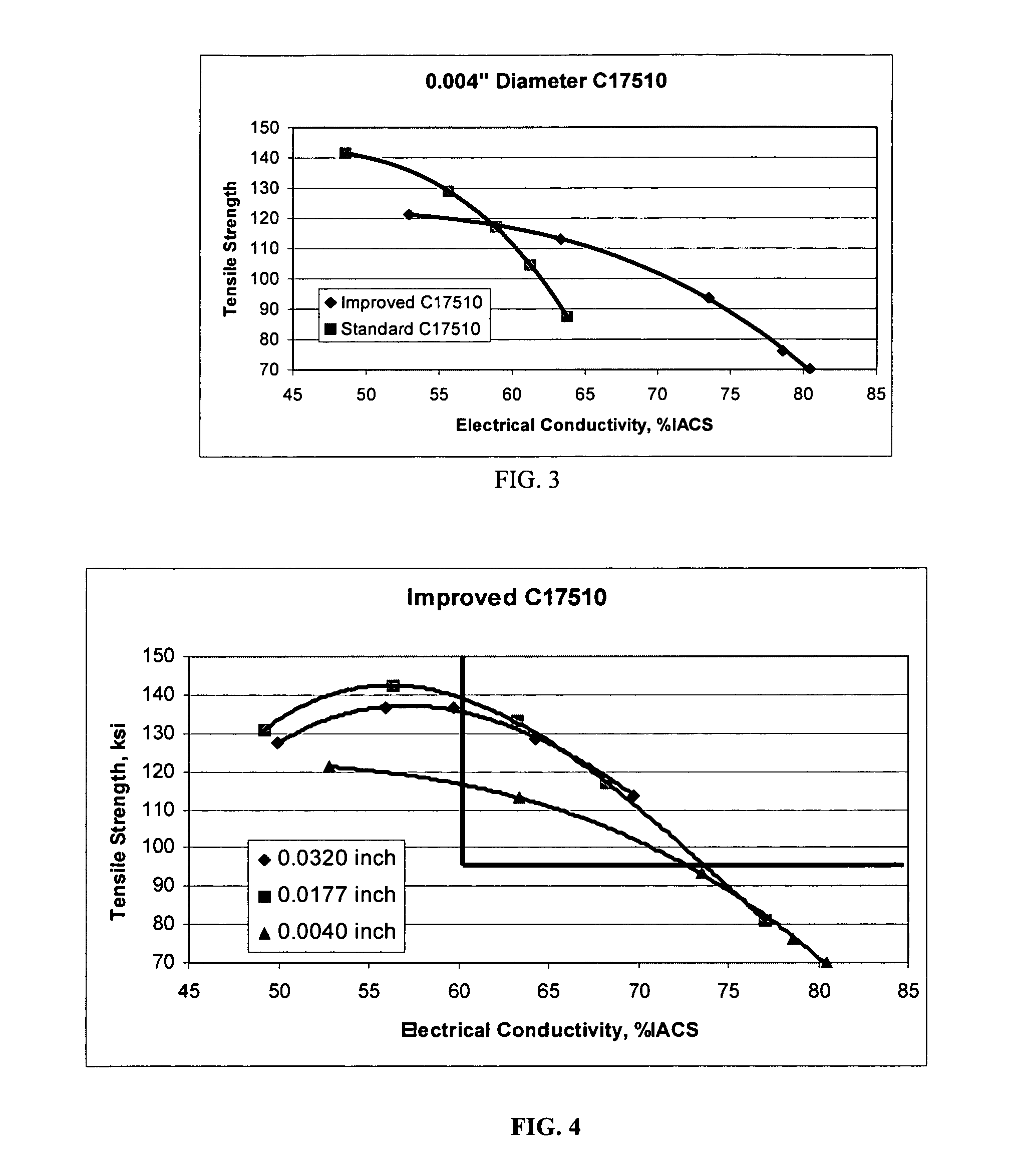

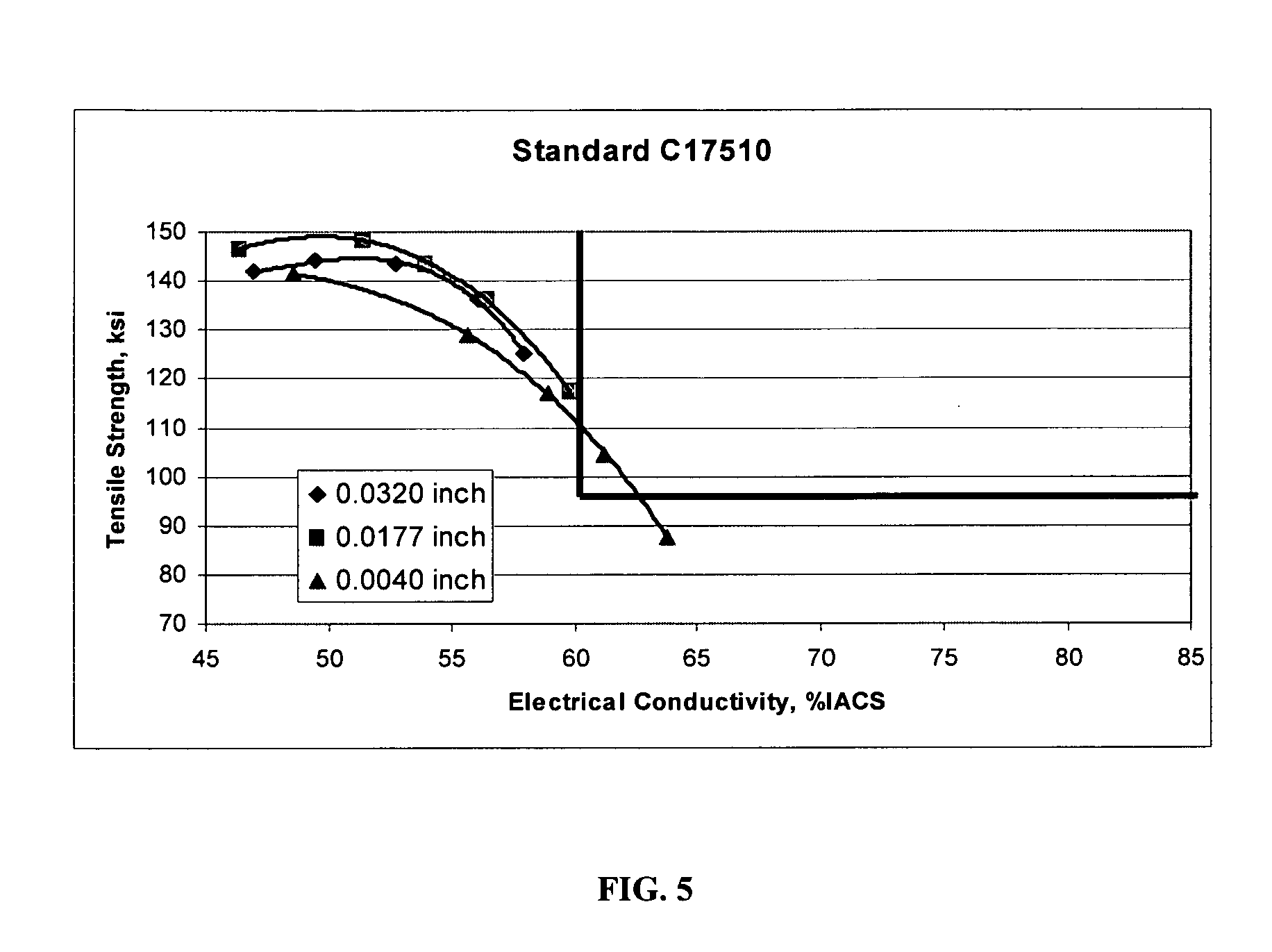

Beryllium-copper conductor

InactiveUS20080202643A1Improve conductivityHigh surface brightnessConductive materialElectrical conductorAlloy

A process is provided for forming an age hardened wire for use as an electrical conductor, which wire is formed from a copper base alloy consisting of from 1.25 to 3.6 wt % nickel, from 0.25 to 0.45 beryllium, and the balance copper and impurities which do not affect the properties of said alloy, with the nickel and beryllium being present in the copper base alloy in a ratio of nickel to beryllium from 5.0 to 8.0. The process comprises the steps of providing a copper base alloy material consisting of from 1.25 to 3.6 wt % nickel, from 0.25 to 0.45 beryllium, and the balance copper and impurities which do not affect the properties of said alloy, which nickel and beryllium are present in the copper base alloy in a ratio of nickel to beryllium from 5.0 to 8.0, cold working the material in a single step; and age hardening the cold worked material in a single step to form a wire in a cold worked and aged hardened condition having an electrical conductivity of at least about 60% IACS.

Owner:FISK ALLOY WIRE

Light guide plate, surface light source device and transmissive display apparatus

ActiveUS8550687B2Promote lowerImprove brightness uniformityMechanical apparatusCoupling light guidesLight guideOptoelectronics

A light guide plate shaped substantially like a plate includes a light incident surface, a light exit surface and a reflective surface, which is opposite to the light exit surface, configured to reflect light toward the light exit surface. A plurality of optical units is arranged along the reflective surface in a direction orthogonal to the light incident surface. Each optical unit is shaped substantially like a quadratic prism that is convex toward the reflective surface and has a top surface and two slopes being formed opposite to each other with respect to the top surface. A dimension of the top surface is constant in a direction of arrangement of the optical units and an interval between adjacent optical units becomes greater as the adjacent optical units lie further away from the light incident surface in the direction of arrangement of the optical units.

Owner:DAI NIPPON PRINTING CO LTD

Light emitting element and method for manufacturing same

ActiveUS9349918B2Low efficiencyHigh light transmittanceSemiconductor/solid-state device testing/measurementSemiconductor devicesPhotonic bandgapRefractive index

A semiconductor light emitting element including, in a light extraction layer thereof, a photonic crystal periodic structure including two systems (structures) with different refractive indices. An interface between the two systems (structures) satisfies Bragg scattering conditions, and the photonic crystal periodic structure has a photonic band gap.

Owner:MARUBUN +3

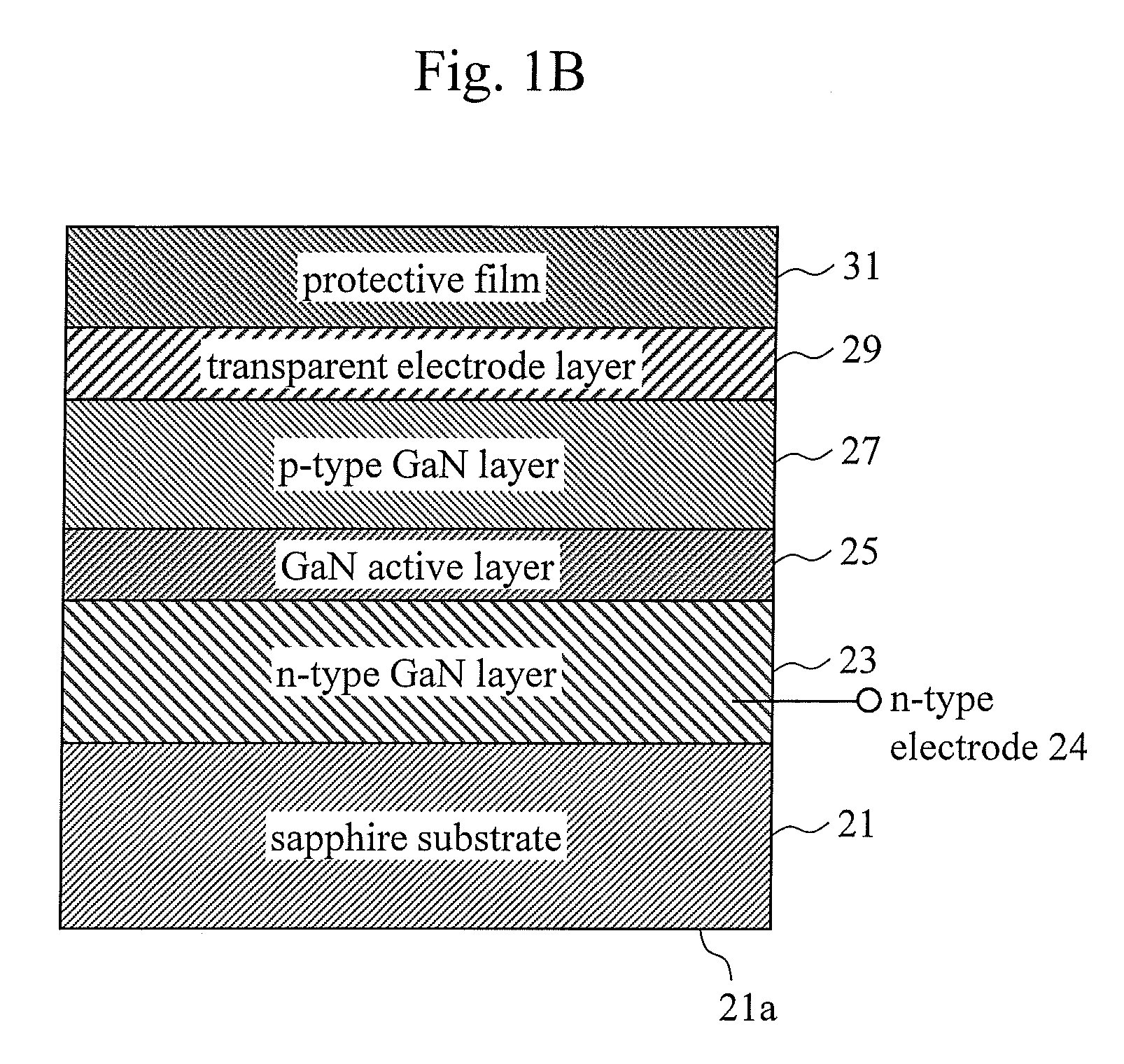

New type non-filament florescent lamp working in brightness arc transition zone

InactiveCN101202198AImprove reliabilityExtend your lifeElectric lighting sourcesVacuum evaporation coatingSurface brightnessInsulation layer

The invention relates to a novel wireless fluorescent lamp which works in a bright arc transition zone, comprising a lamp tube, an electrode, a drive, a lamp casing and a lamp cup or lampshade. The electrode consists of tungsten, or molybdenum or iron. More than one layers of anti cathode sputtering films are arranged on the surface of the electrode. Super-pure argon air is filled into the lamp tube with an air-filling pressure ranging from 800 Pa to 6665Pa. The work current of the lamp tube is between 7MA and 60MA. A cold end is arranged in the lamp tube and a titanium mercury zirconium aluminum 16 alloy amalgam or an indium mercury zirconium aluminum 16 alloy amalgam is arranged in the cold end. An insulation layer is arranged between the lamp cup or lampshade and the lamp casing. The cold end extends from the lamp cup or lampshade to the insulation layer. The invention enhances light effect and surface brightness, and has small volume, high flux, enhanced reliability and long service life. The manufacture of the drive is easy, the manufacturing cost is low and the cost performance is high, furthermore, the proposal of the EMC is easy, the cost for restraining electromagnetic interference wires is low and the effect for restraining electromagnetic interference is good.

Owner:陈宗烈

Fireproof polyurethane floor coating

InactiveCN106189775AAvoid human health hazardsAchieving complete environmental protectionFireproof paintsWax coatingsSolventParaffin wax

The invention discloses fireproof polyurethane floor coating. The floor coating comprises the following components in parts by weight: 78 to 86 parts of waterborne polyurethane resin, 20 to 24 parts of melamine formaldehyde resin, 15 to 25 parts of polyvinyl acetate emulsion, 16 to 18 parts of paraffin emulsion, 3 to 7 parts of alkylbenzene sulfonate, 6 to 8 parts of vinyl trimethoxysilane, 11 to 14 parts of hydroxyethyl cellulose, 3 to 7 parts of dinonylnaphthalene sulfonic acid, 1 to 4 parts of butyl titanate, 4 to 7 parts of citric acid, 3 to 7 parts of zinc naphthenate, 2 to 4 parts of sodium borate, 5 to 12 parts of a polyurethane curing agent and 10 to 15 parts of a polyurethane dispersant. The fireproof polyurethane floor coating disclosed by the invention is free of solvents, non-toxic and harmless, and environment-friendly to avoid harm of the organic solvents on health of a human body, and can realize completely environment-friendly construction and application. Furthermore, the fireproof polyurethane floor coating has the characteristics of better water resistance and fire resistance, high tinting strength and yellowing resistance, and further is higher in layer surface brightness, brighter in color and luster and more excellent in physical properties.

Owner:张海棠

PCD cutter with high performance

InactiveCN104551154AHighly corrosiveStrong oxidation abilityMilling cuttersWorkpiecesPolycrystalline diamondCobalt

The invention discloses a PCD cutter with high performance. A manufacturing method comprises the following steps: (1) providing the PCD cutter including a cutter base body and a PCD blade which is welded on the cutter base body and consists of a blade base body and a polycrystalline diamond layer; (2) spraying Teflon on a part of outer surface, except the polycrystalline diamond layer, of the PCD cutter to form a protective layer; (3) preparing cobalt-etching solutions, putting the PCD cutter into the cobalt-etching solutions and uniformly stirring the cobalt-etching solutions for 0.5-3 hours at the temperature of 50-90 DEG C; taking out the PCD cutter; cleaning to be neutral; finally removing the Teflon sprayed on the outer surface of the PCD cutter. According to the PCD cutter, metal cobalt in the polycrystalline diamond layer at the edge opening of the PCD cutter is removed, so that the phenomenon that blade breaking or breakage caused by the edge opening of the PCD cutter because of the metal cobalt can be avoided, the service life of the PCD cutter is prolonged, and the surface luminance of processing pieces is improved.

Owner:深圳章源精密工具技术有限公司

Holographic dot printing method

InactiveCN102501664AHigh surface brightnessGood lookingPattern printingOther printing apparatusSurface brightnessAdhesive

The invention relates to the holographic anti-counterfeiting printing industry, in particular to a holographic dot printing method. The invention provides a printing method which can realize laser effect patterns on accurate positions and also contain delicate patterns printed by the printing machine with superimposed printing, large range, high accuracy and high printing quality. The holographic dot printing method comprises the following steps of: adopting paper as a base material and adopting the printing machine as printing equipment; manufacturing a printing and color-brightening screen; printing common printing colors; printing UV (Ultraviolet) adhesive by a color class of the printing machine; gluing a laser film and the paper printed with the UV adhesive; adopting a method with irradiation of a UV lamp for UV curing, removing a thin-film layer, coating a holographic laser layer on a UV adhesive layer of dots in a sticky manner, and obtaining common printing colors at the dot positions without the UV adhesive; and manufacturing holographic laser printing paper. According to the method provided by the invention, the superimposition of color and brightness is carried out microcosmically, the surface brightness is improved, the surface appearance is excellent, the positioning is accurate, the printing accuracy is high, and the printing and laser effects are superimposed in persistence of vision to generate a new visual color.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

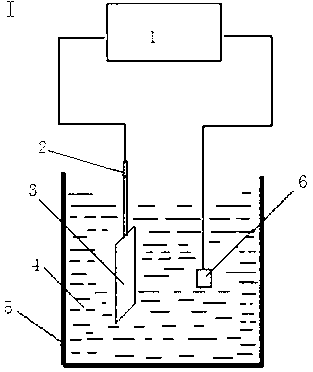

Ultrasonic chemical coloring method for stainless steel

InactiveCN102703956ALow coloring temperatureReduce coloring energy consumptionChromatisationPotential differencePre treatment

The invention discloses an ultrasonic chemical coloring method for stainless steel. The method comprises the following steps of: pre-treating the polished stainless steel, performing chemical coloring under ultrasonic irradiation conditions of certain temperature, frequency and sound intensity, and implementing coloring of different colors by controlling potential difference. The method is low in coloring temperature, short in coloring time and wide in color range; and comprehensive performance such as brightness, abrasion resistance and corrosion resistance of the colored stainless steel is remarkably improved.

Owner:TAIYUAN UNIV OF TECH

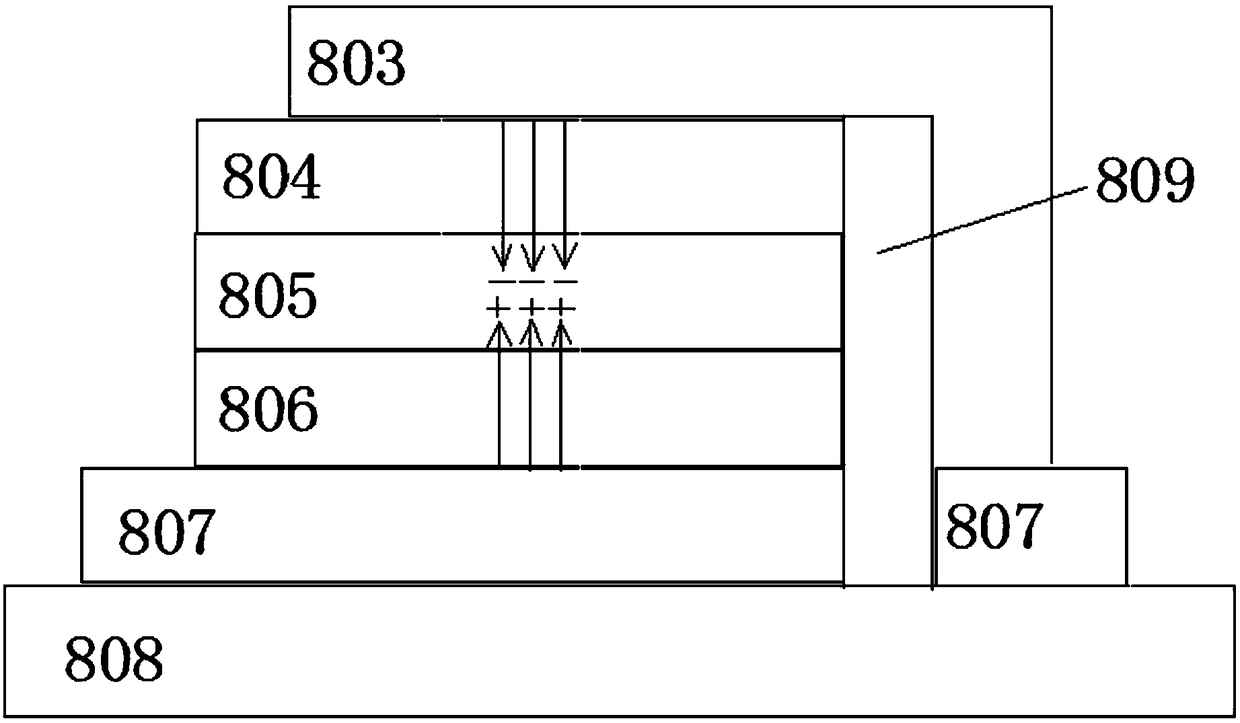

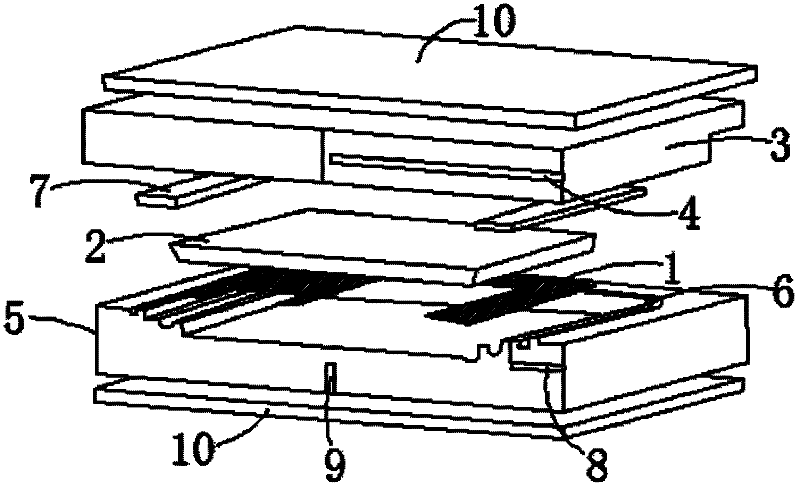

Liquid crystal display screen for emitting light through quantum dots

InactiveCN108459435AExtended service lifeHigh surface brightnessSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionLiquid-crystal display

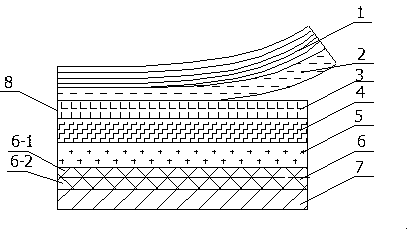

A liquid crystal display screen for emitting light through quantum dots comprises a planar polaroid, a liquid crystal box, a bottom polaroid and a quantum dot light-emitting board. The planar polaroidis arranged on the upper side of the liquid crystal box. The quantum dot light-emitting board is arranged below the liquid crystal box. The bottom polaroid is arranged between the quantum dot light-emitting board and the liquid crystal box. The quantum dot light-emitting board comprises a sealed frame, a brightening membrane and a quantum dot material layer. The quantum dot material layer is arranged in the sealed frame. The brightening membrane is arranged on the upper side of the sealed frame. The quantum dot material layer comprises an AI electrode, an electronic transmission layer, a quantum dot light-emitting layer, a hole transport layer, ITO electrodes and a PET substrate. The ITO electrodes are arranged on the left side and the right side of an isolation plate respectively. The AIelectrode, the electronic transmission layer, the quantum dot light-emitting layer and the hole transport layer are sequentially overlapped on the ITO electrode on the left side of the isolation plate from top to bottom. One end of the AI electrode extends to be connected with the ITO electrode on the right side of the isolation plate. Electroluminescence is conducted through the quantum dot material layer, and the short-circuit phenomenon is reduced.

Owner:VARITRONIX HEYUAN DISPLAY TECH

Aluminium alloy polishing solution and preparation method thereof

ActiveCN104109482ANarrow particle size rangeGood roughness controlPolishing compositions with abrasivesActive agentCeramic membrane

The invention provides an aluminium alloy polishing solution. The aluminium alloy polishing solution is prepared from the following raw materials by weight: 92.5-97 parts of a silica sol, 1-2.5 parts of a stabilizer, 1-2.5 parts of an active agent and 1-2.5 parts of a synergist. A preparation method of the aluminium alloy polishing solution comprises the following steps of removing metal ions and other impurities from a silica sol raw material by adopting a 100 nano-scale ceramic membrane filtration system; adding the filtrated silica sol into a sealed reaction tank under a vacuum negative pressure state; adding the stabilizer, the active agent and the synergist into the sealed reaction tank under the vacuum negative pressure state; stirring thoroughly; and mixing uniformly to prepare a finished product of the aluminium alloy polishing solution. The prepared aluminium alloy polishing solution has the advantages of no corrosion, small usage amount, low cost, few scratches and high polishing rate. Besides, compared with a conventional acid polishing solution, the aluminium alloy polishing solution has no pollution and can be recycled easily.

Owner:HEBEI YUTIAN HAOYUAN NANO MATERIAL

Air pressure shaping technology of carbon fiber product and glass fiber product and used die

The invention discloses an air pressure shaping technology of a carbon fiber product and a glass fiber product and a used die. The technology employs a briquetting in the shaping process, the briquetting can improve the precision of the product, and Using a booster pump and air pressure shaping enable uniform pressure in a mold cavity, resin on the carbon fiber pre-dip cloth or the glass fiber pre-dip cloth can flow stably under the high temperature and high pressure situation. Thereby a carbon fiber semi-finished product or a glass fiber semi-finished product with smooth surface which does not possess cavity and pin hole can be obtained, the difficulty for subsequent surface treatment can be reduced and the subsequent operation and time can be saved, the surface brightness and qualitative sense of the carbon fiber product and the glass fiber product can be enhanced. A die structure of the invention provides equipment support for the technology, so that the technology of the invention can be enforced.

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

Homographic dot printing color and preparation method thereof

InactiveCN102490421AHigh surface brightnessGood lookingSynthetic resin layered productsPattern printingLaser patterningEngineering

The invention relates to a printing method of the homographic anti-counterfeiting printing industry, and provides a homographic dot printing color and a preparation method thereof, which are capable of printing laser pattern colors onto paper by the aid of a printing machine and realize an anti-counterfeiting reflection effect. The homographic dot printing color is provided with a homographic bright color, the homographic bright color is arranged at an optional position of a printing dot so as to form the homographic dot printing color, the bright color is generated by an information reflecting layer of a homographic film, and the information reflecting layer of the homographic film is a composite layer which is processed by a laser homographic method and formed in the homographic film. Colors and brightness are overlaid microcosmically, patterns with a laser effect and exquisite patterns printed by a printing machine can be arranged at precise positions and are added with printing colors, large-breadth, high-precision and high-quality printing is realized, paper with novel surfaces and high brightness is manufactured, the appearance is excellent, positioning is accurate, a printing effect and the laser effect are visually detained and stacked to generate novel visual colors, and the homographic dot printing color is a novel anti-counterfeiting type of printing color.

Owner:JIU GUOCHUN WUHAN PACKAGING TECH CO LTD

Multifunction horniness metal screen capable of erase and write-in, nondust, projection of extinction facula distinctly and manufacturing method thereof

InactiveCN1963660ASolve the phenomenon of mirror reflectionEliminate specular reflectionsPolishing machinesProjectorsHard metalExtinction

This invention relates to one multi-function hard metal screen to erase words without dust, which is characterized by the following: the erase words without dust projects multi-function hard metal screen by use of cracker board as materials with positive surface with dark delustring surface with its back surface coated with high bright metal powder glue layer and protective layer to process multi-function hard metal screen through hard metal screen positive surface process and back surface process.

Owner:李树权

Filled depression tablets and method for their production II

InactiveUS20050238711A1Large displacementImprove solubilityDetergent materialsPill deliveryPsychiatry

Owner:HENKEL KGAA

Treatment process applied before aluminum plating on threaded stainless steel parts by virtue of multi-arc ion plating and application of treatment process

InactiveCN104630700AHigh surface brightnessMeet lubricityVacuum evaporation coatingSputtering coatingSurface brightnessElectrolysis

The invention discloses a treatment process applied before aluminum plating on threaded stainless steel parts by virtue of multi-arc ion plating, and belongs to the technical field of stainless steel process treatment. The process comprises the following steps: carrying out drying and cleaning treatment before sand blasting on stainless steel screws; carrying out manual sand blasting treatment on the processed screws; washing the screws with hot water through ultrasonic wave and blow-drying the surfaces of the parts; implementing electrolytic polishing under constant voltage for 30-120s and controlling current density at 5-7A / dm<2>; implementing passivating treatment; and cleaning the parts in hot water at 38-42 DEG C for 2min and blow-drying the parts. By virtue of manual sand blasting and electrolytic polishing, the treatment process disclosed by the invention can be used for not only improving the surface brightness of the aluminum-plated screws, but also significantly reducing the dark-point defect, so as to remarkably improve the product rate and meet the requirements of the aluminum-plated screws on lubricating and conducting properties during using.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

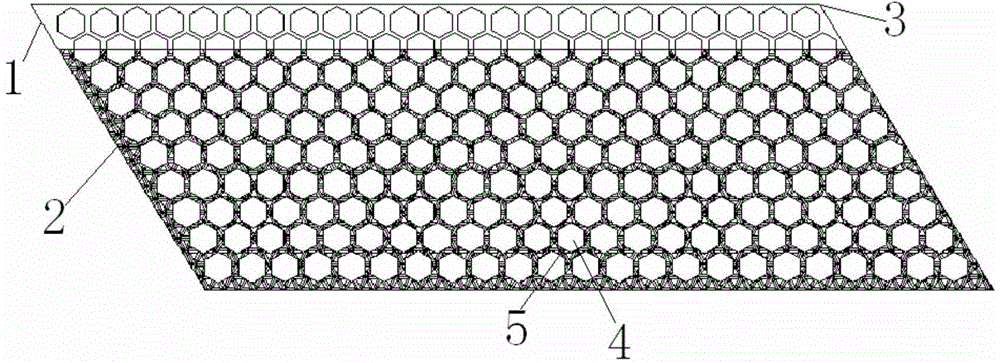

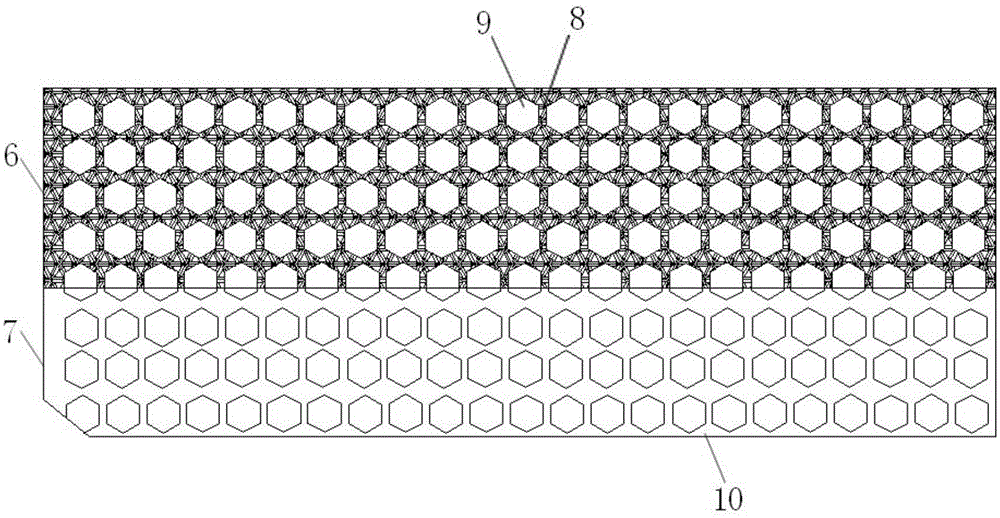

Fluorescent photocatalytic water-permeable brick and preparation method thereof

ActiveCN112537935AImprove light reflection effectGood light transmissionSingle unit pavingsSidewalk pavingsBrickCarbon nitride

The invention belongs to the technical field of engineering construction materials, and particularly relates to a fluorescent photocatalytic water-permeable brick and a preparation method thereof. Thefluorescent photocatalytic water-permeable brick is of a double-layer structure, wherein the lower layer of the water-permeable brick is a recycled aggregate water-permeable layer, and the upper layer of the water-permeable brick is a fluorescent photocatalytic composite concrete layer. According to the invention, the water-permeable brick is used as a matrix and is divided into a double-layer structure by adopting a layered forming method, so the strength of the water-permeable brick is guaranteed, and the utilization rate of a fluorescent material and a carbon nitride nanosheet is increased; the wear resistance and the waterproof performance of the water-permeable brick are enhanced by adding quartz sand and a PTB emulsion; and due to the addition of the carbon nitride nanosheet and fluorescent powder, the water-permeable brick has the functions of self-sustained luminescence, visible-light catalytic gas purification and self-cleaning. The water-permeable brick is suitable for parkaisles or sidewalks, meets the permeable requirements of pavements, has the fluorescent property to play a role in identification at night, continuously degrades pollutants through photocatalysis, keeps clean and tidy, and is beneficial to popularization and application.

Owner:FUZHOU UNIV

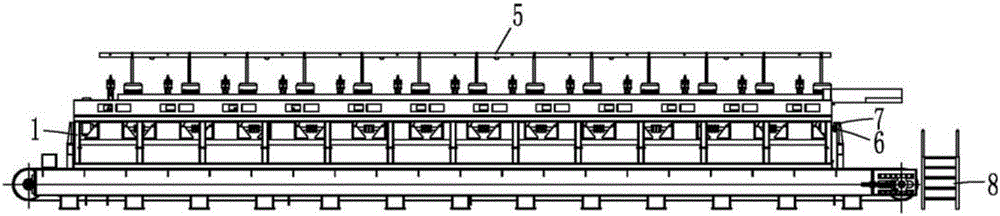

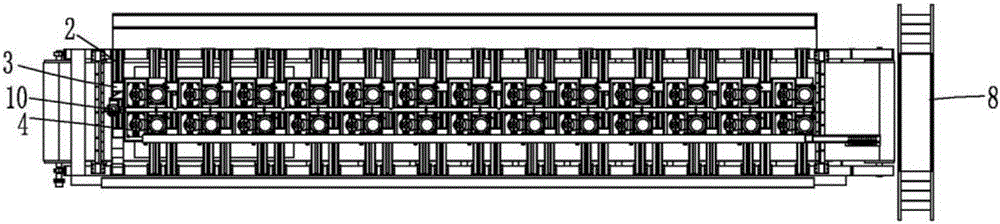

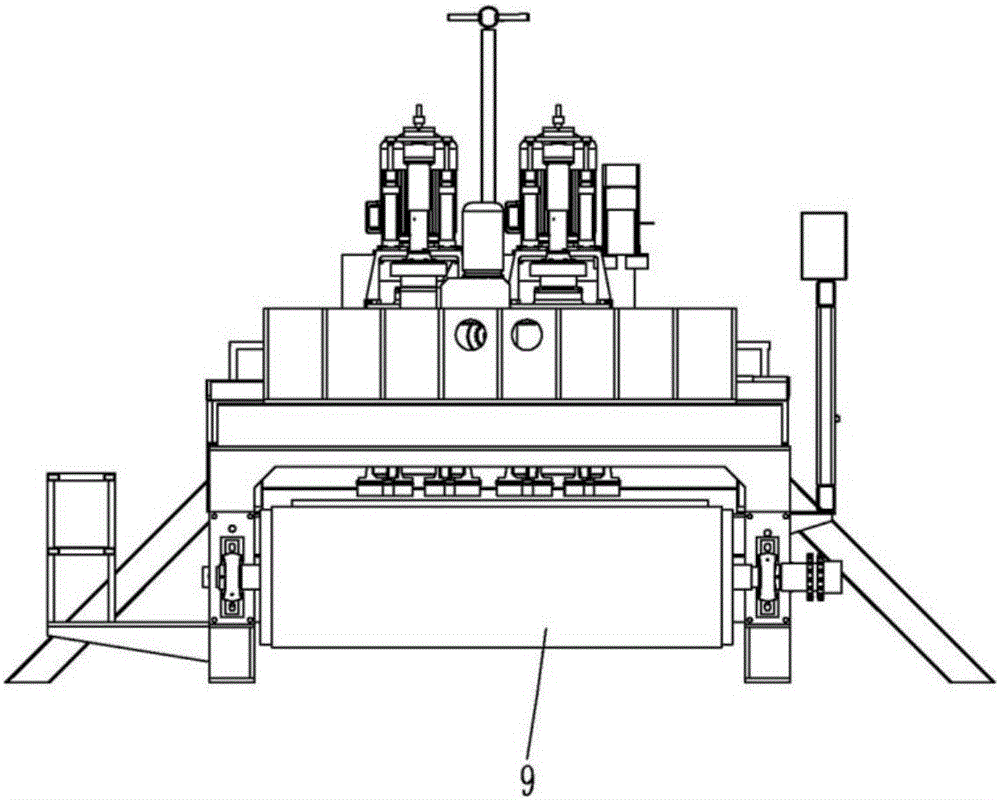

Polishing equipment applied to surface of stone

InactiveCN106064330AReduce walking distanceHigh surface brightnessGrinding carriagesGrinding feedersEngineeringWater cooling

The invention provides polishing equipment applied to the surface of a stone. The polishing equipment comprises a rack, and is characterized by further comprising a pair of polishing head groups which is arranged on the upper end surface of the rack side by side along the length direction of the rack and is used for polishing the stone, a sliding mechanism arranged between the pair of polishing head groups and the width direction of the rack, a driving mechanism for driving the pair of polishing head groups to do reciprocating movement along the width direction of the rack, and a belt conveying mechanism which is arranged at the bottom end of the rack and is used for conveying the stone and polishing the stone, wherein a water cooling system for supplying cooling water is arranged above the pair of polishing head group. According to the polishing equipment applied to the surface of the stone, on the one hand, the surface of the stone can be polished repeatedly to improve the brightness of the surface of the stone; on the other hand, the walking stroke of the whole row of polishing heads can be reduced, so that the feeding speed of the polished stone can be increased, and the production efficiency of a stone polishing plate can be improved.

Owner:佛山市金博特机械有限公司

Metal surface grinding and polishing agent and preparation method thereof

InactiveCN108192506AIncrease flow rateConsistent surface temperaturePolishing compositions with abrasivesFoaming agentAnticoagulant

The invention relates to the technical field of metal surface treatment, in particular to a metal surface grinding and polishing agent and a preparation method thereof. The metal surface grinding andpolishing agent is prepared from the following ingredients in parts by weight: 16 to 33 parts of grinding agents, 1 to 2 parts of anti-foaming agents, 0.5 to 2 parts of sodium carbonate, 0.5 to 2 parts of surfactants, 0.5 to 2 parts of fatty alcohol ammonium sulfate, 0.5 to 1.5 parts of surface dimming agents, 0.5 to 1.5 parts of corrosion inhibitors, 0.2 to 0.5 part of suspending agents, 0.2 to 0.6 part of anticoagulants and 60 to 70 parts of water. By using the metal surface grinding and polishing agent provided by the invention, during the grinding and polishing on the metal surface, the multi-time coarse grinding and medium grinding links in the middle can be reduced; the production efficiency is improved.

Owner:东莞华拓研磨材料有限公司

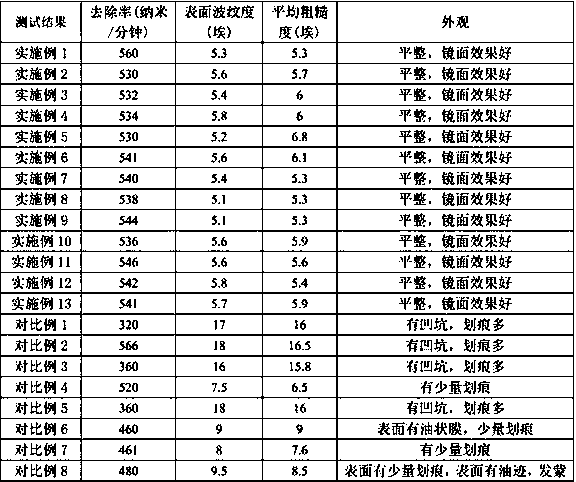

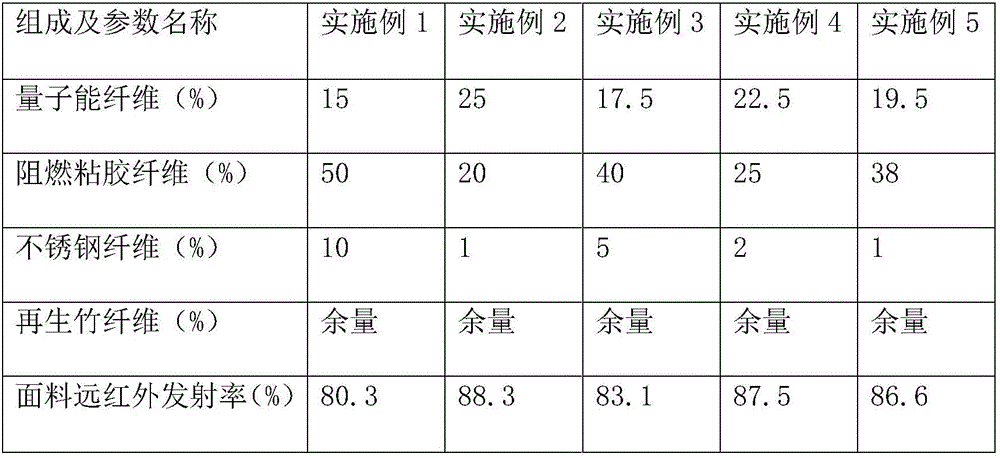

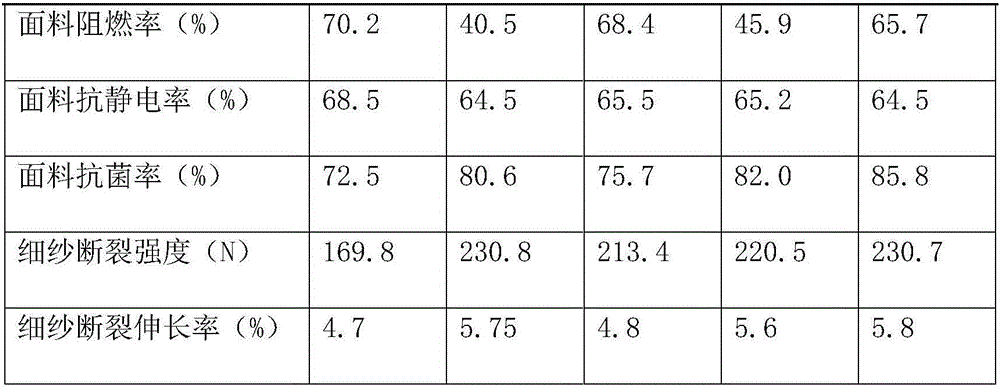

Fabric containing quantum energy fiber and preparation method of fabric

InactiveCN106757602AWell mixedSignificant flame retardancyTwo or more solvent application treatmentWoven fabricsViscoseFar infrared

The invention discloses fabric containing quantum energy fiber. The fabric comprises, by weight, 15-25% of the quantum energy fiber, 20-50% of flame-retardant viscose fiber, 1-10% of stainless steel fiber and the balance of regenerated bamboo fiber. The fabric has the advantages that the quantum energy fiber has excellent physiochemical performance and has a far infrared medical care function, the flame-retardant viscose fiber has good flame-retardant performance, and the stainless steel fiber and the flame-retardant viscose fiber are small in friction factor and are close in static and dynamic friction factor, so that the fabric is enabled to be soft in hand feel. The fabric has all functions that the quantum energy fiber has and has flame-retardant, antistatic and antibacterial effects; the stainless steel fiber can improve activity of quantum energy in the quantum energy fiber, so that the fabric is enabled to have better far infrared medical care effect.

Owner:ZHUJI SHUANGJIN KNITTING & TEXTILE

Metal polishing agent

The invention discloses a metal polishing agent comprising the following raw materials in parts by weight: 25-40 parts of sodium oleate, 20-30 parts of coco dimethyl amine oxide, 5-15 parts of triethanolamine, 5-10 parts of silica, 3-8 parts of an emulsifier, 1-3 parts of a dispersant, 0.5-2 parts of a defoaming agent, 0.1-1 part of a surfactant, and 0.3-2 parts of a flame retardant. Compared with the prior art, the metal polishing agent has strong stability and good coverage performance, can increase the brightness of the surface of metals, besides, is environmentally friendly and healthy, cannot cause harm to the environment and human body health, has the advantages of simple operation and low cost, and can be widely used for metal polishing treatment.

Owner:昆山瑞昱化工有限公司

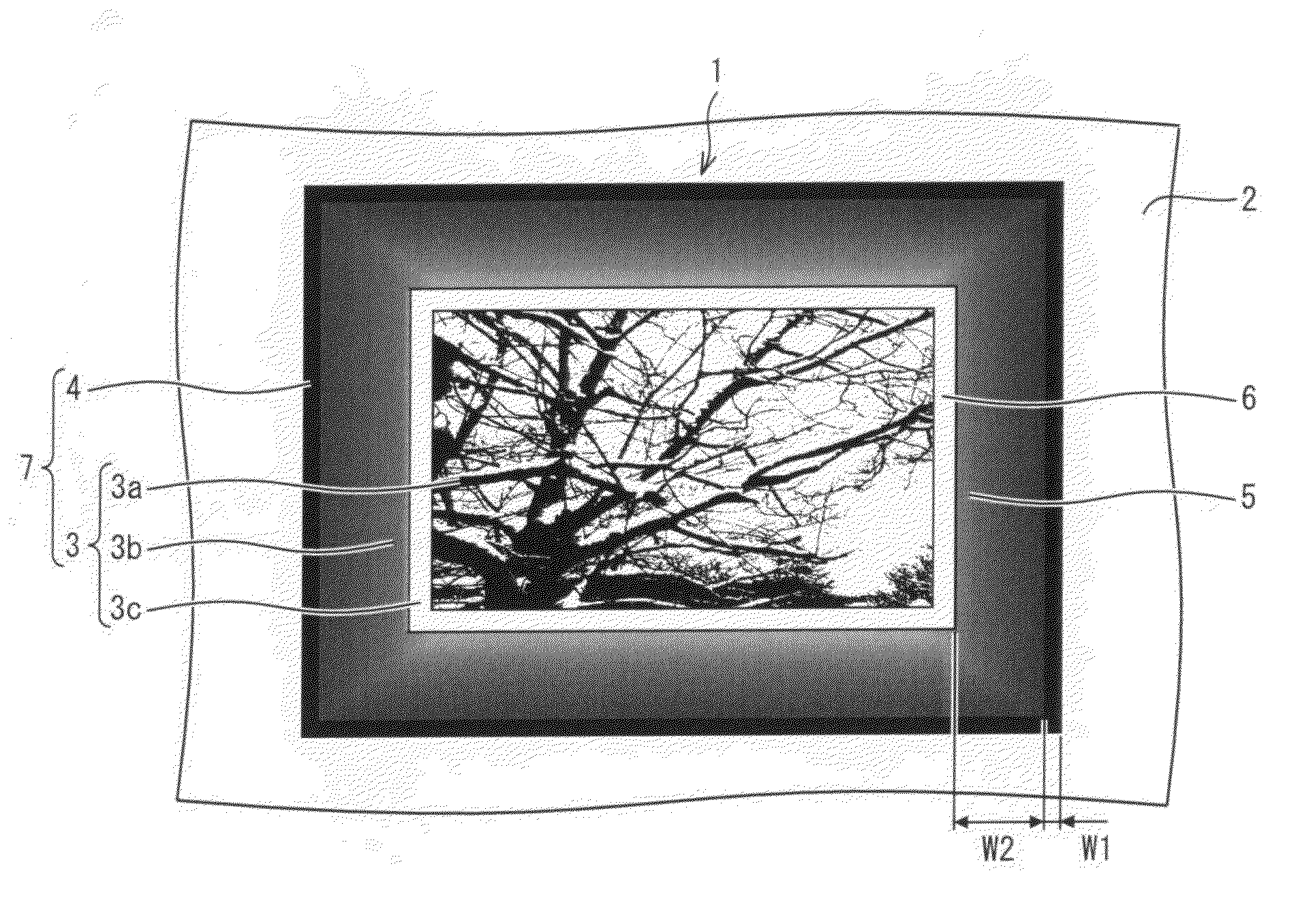

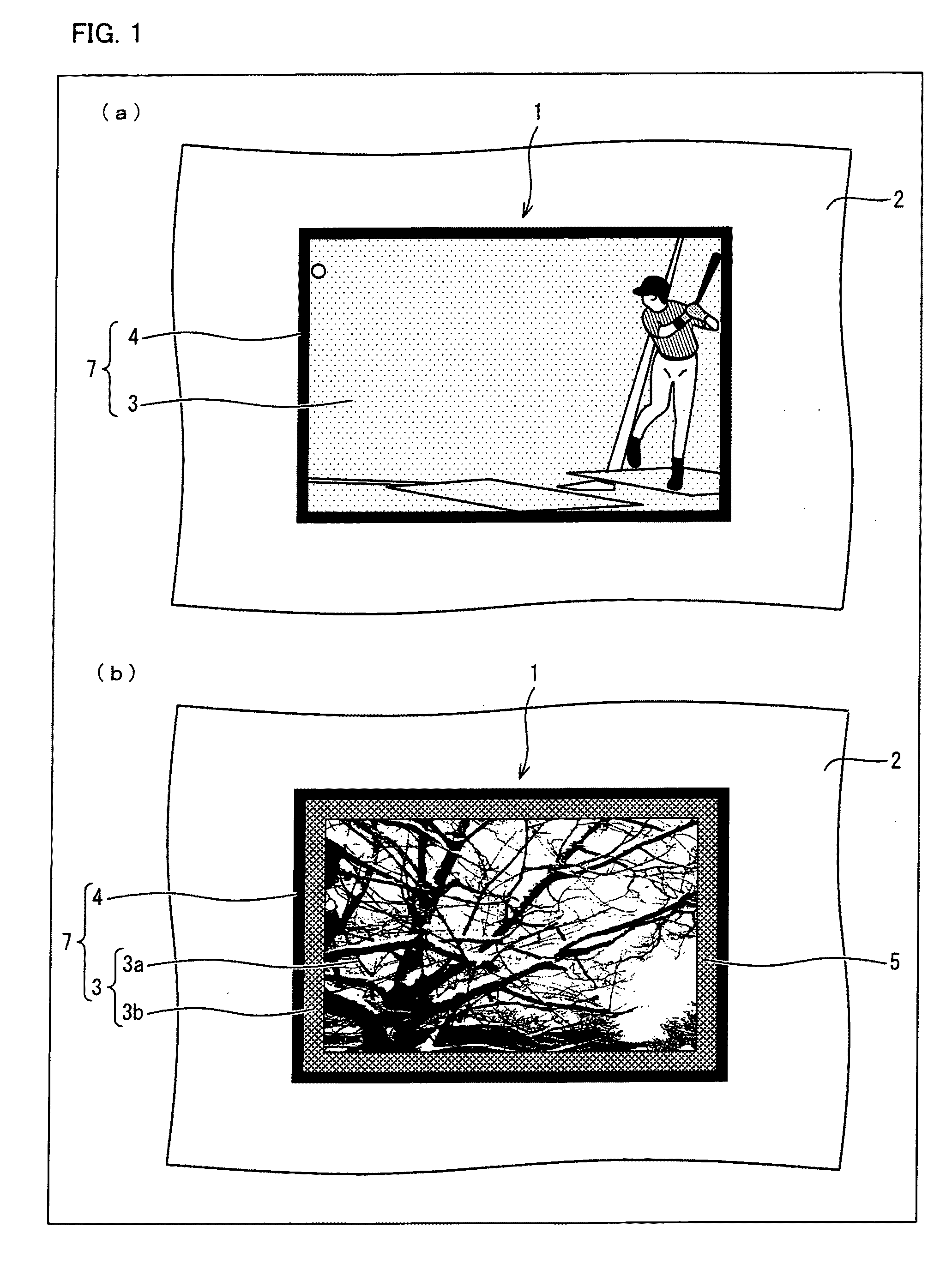

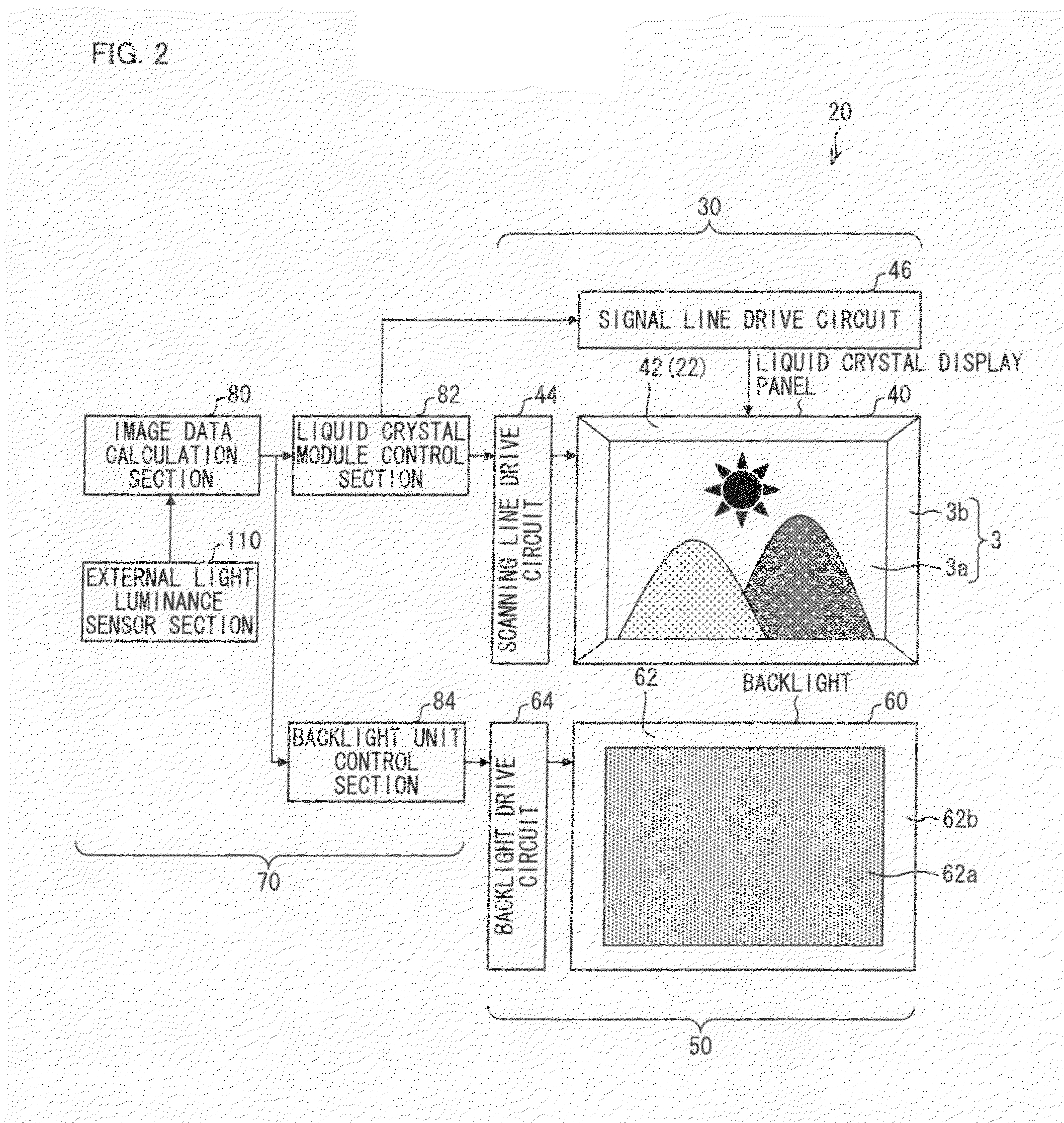

Television receiver and method for driving television receiver

InactiveUS20110134324A1High surface brightnessTelevision system detailsColor television detailsTelevision receiversComputer graphics (images)

A decorative image is displayed in a decorative image display region; in the decorative image, a decorative frame is displayed in a peripheral section of a decorative frame display region, and the decorative frame display region has a surface luminance higher than that of the decorative image display region.

Owner:SHARP KK

Self-leveling clean plastic and preparation method thereof

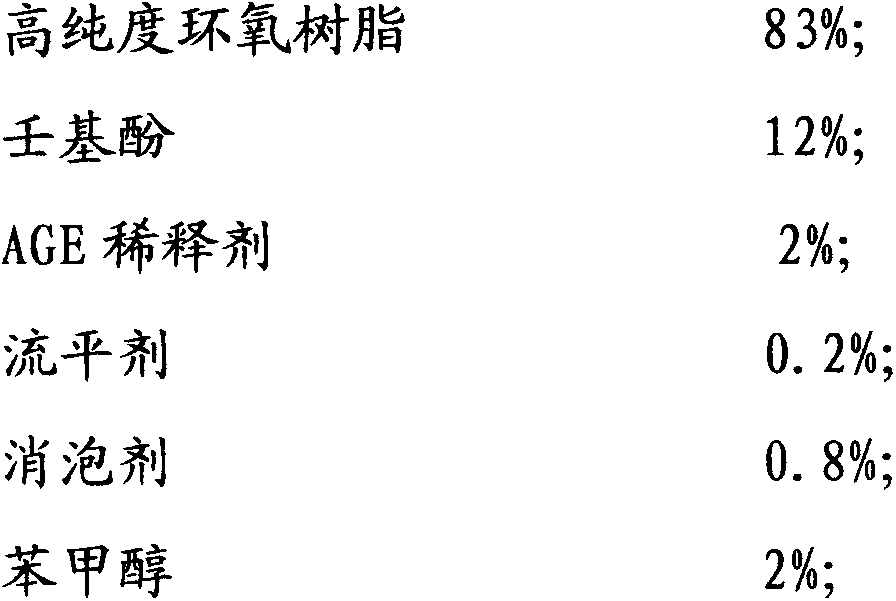

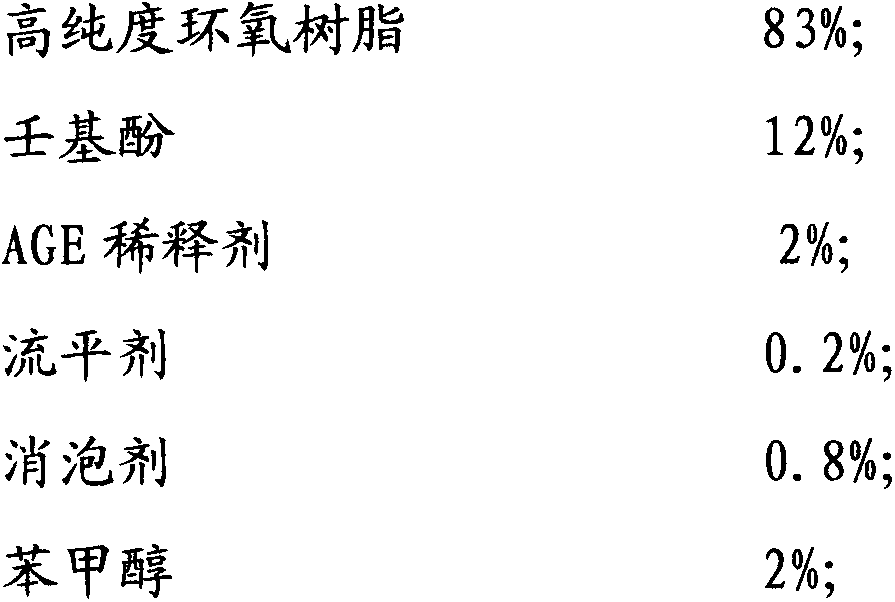

The invention discloses a self-leveling clean plastic. The self-leveling clean plastic comprises a glue A and a glue B in the mixing ratio of 3:1, wherein the glue A consists of the following components in percentage by weight: 83% of high-purity epoxy resin, 12% of nonyl phenol, 2% of AGE diluter, 0.2% of leveling agent, 0.8% of de-foaming agent and 2% of benzyl alcohol, and the glue B consists of the following components in percentage by weight: 75% of polyether amine, 12.5% of T403, and 12.5% of modified IPDA. The self-leveling clean plastic disclosed by the invention is safe, nonflammable and environment-friendly (the emission of substances such as formaldehyde and dimethylbenzene which are harmful to human body is avoided), has good leveling property and high brightness, is convenient to operate and is relatively low in cost.

Owner:刘义贤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com