Metallic coin stamped with holographic anti-counterfeiting pattern and manufacturing method thereof

A technology of holographic pattern and manufacturing method, which is applied in the direction of copying/marking method, printing, coins, etc., can solve the problems of poor adhesion of surface film layer, low definition of metal coin pattern, insufficient brightness, etc., and achieve high surface brightness, Rich layers and strong three-dimensional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

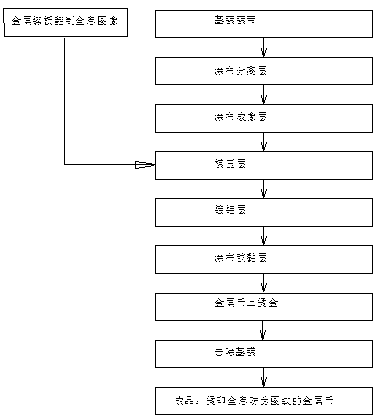

[0030] Embodiment 1: as figure 1 Shown is a flow chart of a method for manufacturing a metal coin hot stamped with an anti-counterfeit holographic pattern, showing a method for manufacturing a metal coin hot stamped with an anti-counterfeit holographic pattern, including the following steps:

[0031] Step 1), the holographic image is reproduced on the metal nickel plate to make a metal nickel plate for molding;

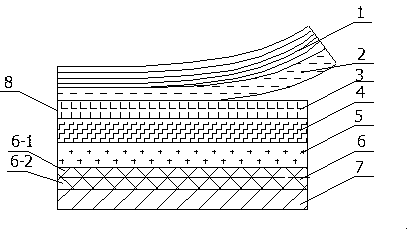

[0032] Step 2) as in figure 2 As shown, it is a structural schematic diagram of a metal coin with an anti-counterfeiting holographic pattern hot stamped in the present invention. figure 2Coating the release layer 2 on the base film film belt 1: prepare the cellulose resin release layer coating according to the composition of the release layer: in parts by mass, 50 parts by mass of toluene, 25 parts by mass of methyl ethyl ketone, fiber 10 parts by mass of plain resin; first mix 50 parts by mass of toluene and 25 parts by mass of butanone with a high-speed mixer a...

Embodiment 2

[0040] This embodiment can also have the following differences, and the rest are the same as in Example 1, and the similarities will not be repeated. In step 2 of the present invention, the following differences can also be found: step 2) in the base film Coating release layer 2 on belt 1: prepare cellulose resin release layer coating according to the composition of the release layer: in parts by mass, 70 parts by mass of toluene, 35 parts by mass of butanone, and 20 parts by mass of cellulose resin ; First mix 70 parts by mass of toluene and 35 parts by mass of butanone with a high-speed mixer and stir evenly, then add 20 parts by mass of cellulose resin and stir for 20 minutes with a high-speed mixer to make a release layer coating and coat it on the base film by a coating machine A release layer 2 is formed on the film tape;

[0041] Molding in step 4): the holographic anti-counterfeiting pattern on the metal nickel plate is molded and transferred to the imaging layer 3 by ...

Embodiment 3

[0045] This embodiment can also have the following differences, and the rest are the same as in Example 1, and the similarities will not be repeated. In step 2 of the present invention, the following differences can also be found: step 2) in the base film Coating release layer 2 on belt 1: Prepare cellulose resin release layer coating according to the composition of the release layer: in parts by mass, 60 parts by mass of toluene, 30 parts by mass of methyl ethyl ketone, and 15 parts by mass of cellulose resin ; first mix 60 parts by mass of toluene and 30 parts by mass of butanone with a high-speed mixer and stir evenly, then add 15 parts by mass of cellulose resin and stir for 20 minutes with a high-speed mixer to make a release layer coating and coat it on the base film by a coating machine The release layer is formed on the film tape;

[0046] In the step 7) of the present invention, the laser anodized aluminum hot stamping foil 8 is positioned, transferred and hot stamped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com