Electrowetting-based dampening water applying method and system and application

A technology of dampening water and electrowetting, which is applied to lithographic rotary printing machines, printing, rotary printing machines, etc., can solve the problems of dampening water that have not been reported yet, and achieve the goals of shortening water supply time, high-quality printing, and reducing consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for applying dampening water based on electrowetting, comprising the following steps:

[0048] 1) Add dampening water into the bucket; said dampening water is tap water;

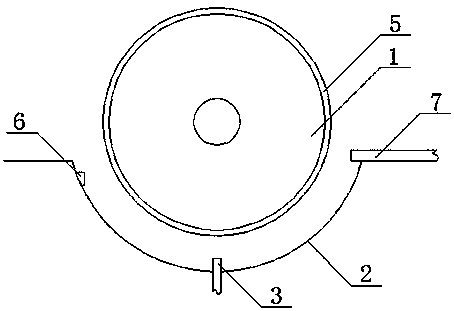

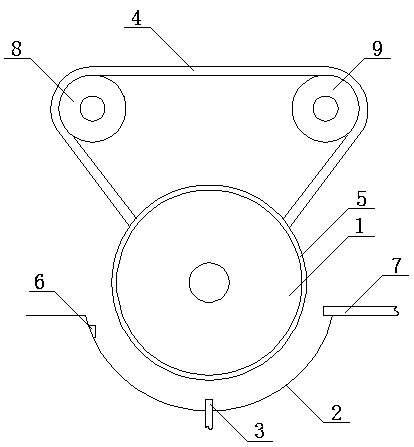

[0049] 2) Start the water roller. The water roller includes a metal roller and a dielectric layer covering the outer surface of the metal roller. The dielectric layer of the water roller is in contact with the dampening water, that is, the metal roller part does not contact the dampening water. contact; the dielectric layer is a ceramic layer; the thickness of the dielectric layer is 1 μm.

[0050] 3) Simultaneously energize the dampening water in the water bucket and the metal roller, so that the dampening water is transferred from the water roller to the printing plate in the form of a continuous and uniform water film. The potential difference between the dampening water and the metal roller is 1V. The thickness of the water film on the water roller is 5 μm, and the contact angle is abou...

Embodiment 2

[0057] A method for applying dampening water based on electrowetting, comprising the following steps:

[0058] 1) Add dampening water into the bucket; the dampening water is deionized water;

[0059] 2) Start the water roller. The water roller includes a metal roller and a dielectric layer covering the outer surface of the metal roller. The dielectric layer of the water roller is in contact with the dampening water, that is, the metal roller part does not contact the dampening water. contact; the dielectric layer is a glass layer; the thickness of the dielectric layer is 10mm.

[0060] 3) The dampening water and the metal roller in the water bucket are energized at the same time, so that the dampening water is transferred from the water roller to the printing plate in the form of a continuous and uniform water film; The potential difference between them is 1000V. The thickness of the water film on the water roller is 3 μm, and the contact angle is about 30°.

[0061] An app...

Embodiment 3

[0067] A method for applying dampening water based on electrowetting, comprising the following steps:

[0068] 1) Add dampening water into the bucket; the dampening water is distilled water;

[0069] 2) Start the water roller. The water roller includes a metal roller and a dielectric layer covering the outer surface of the metal roller, and the dielectric layer of the water roller is in contact with dampening water; the dielectric layer is quartz glass layer; the thickness of the dielectric layer is 10 μm.

[0070] 3) The dampening water and the metal roller in the water bucket are energized at the same time, so that the dampening water is transferred from the water roller to the printing plate in the form of a continuous and uniform water film; The potential difference between them is 500V. The thickness of the water film on the water roller is 0.1 μm, and the contact angle is about 10°.

[0071] An application of a dampening water application method based on electrowettin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com