Patents

Literature

88results about How to "Flexible thickness adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

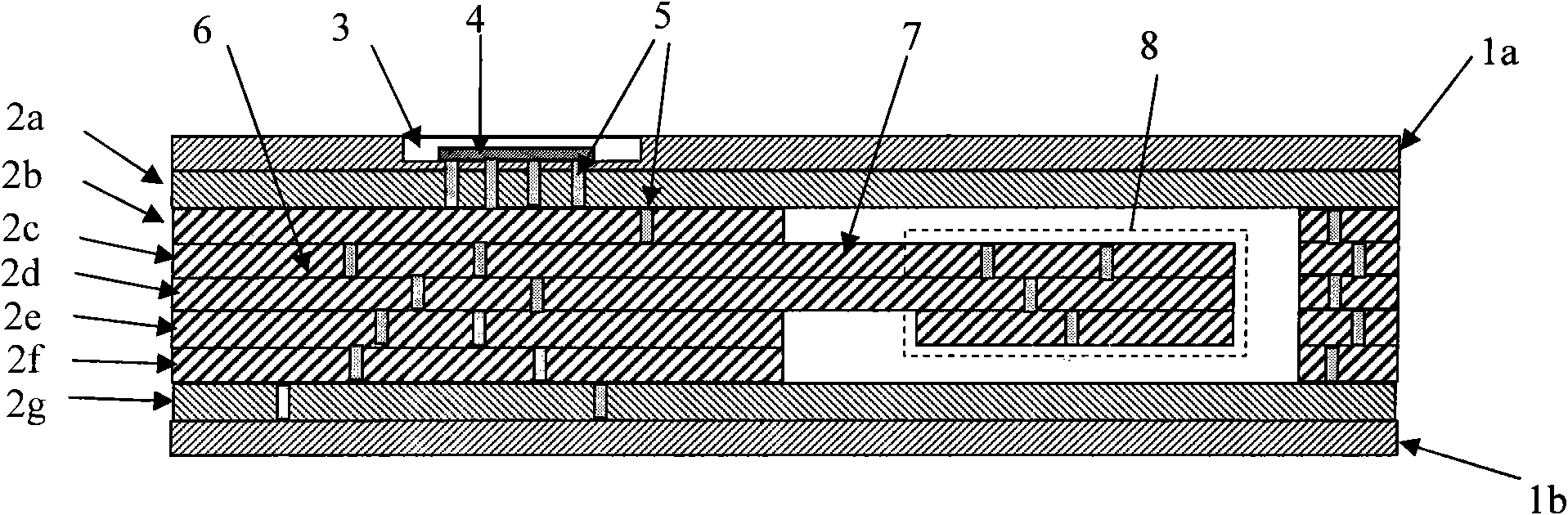

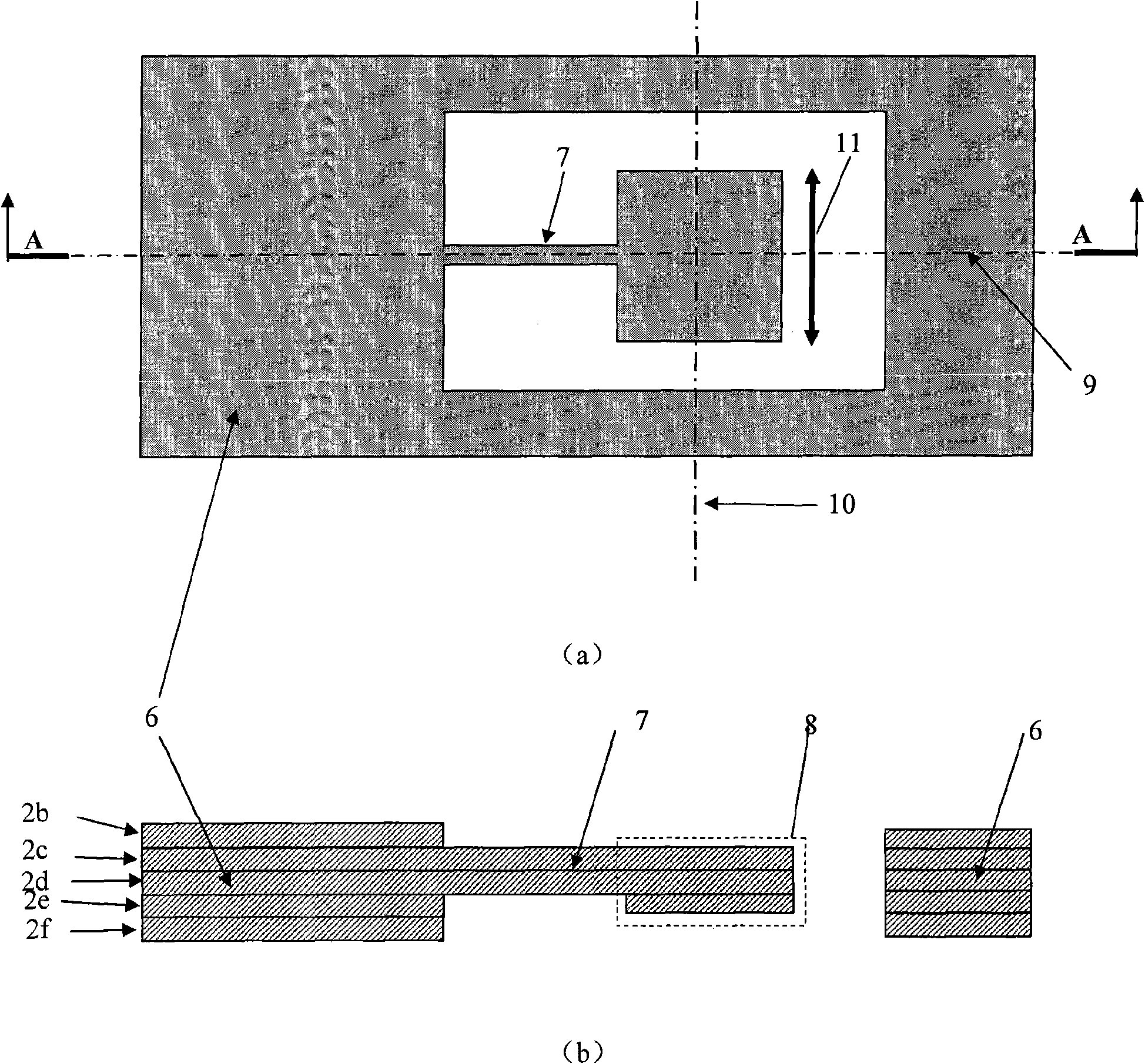

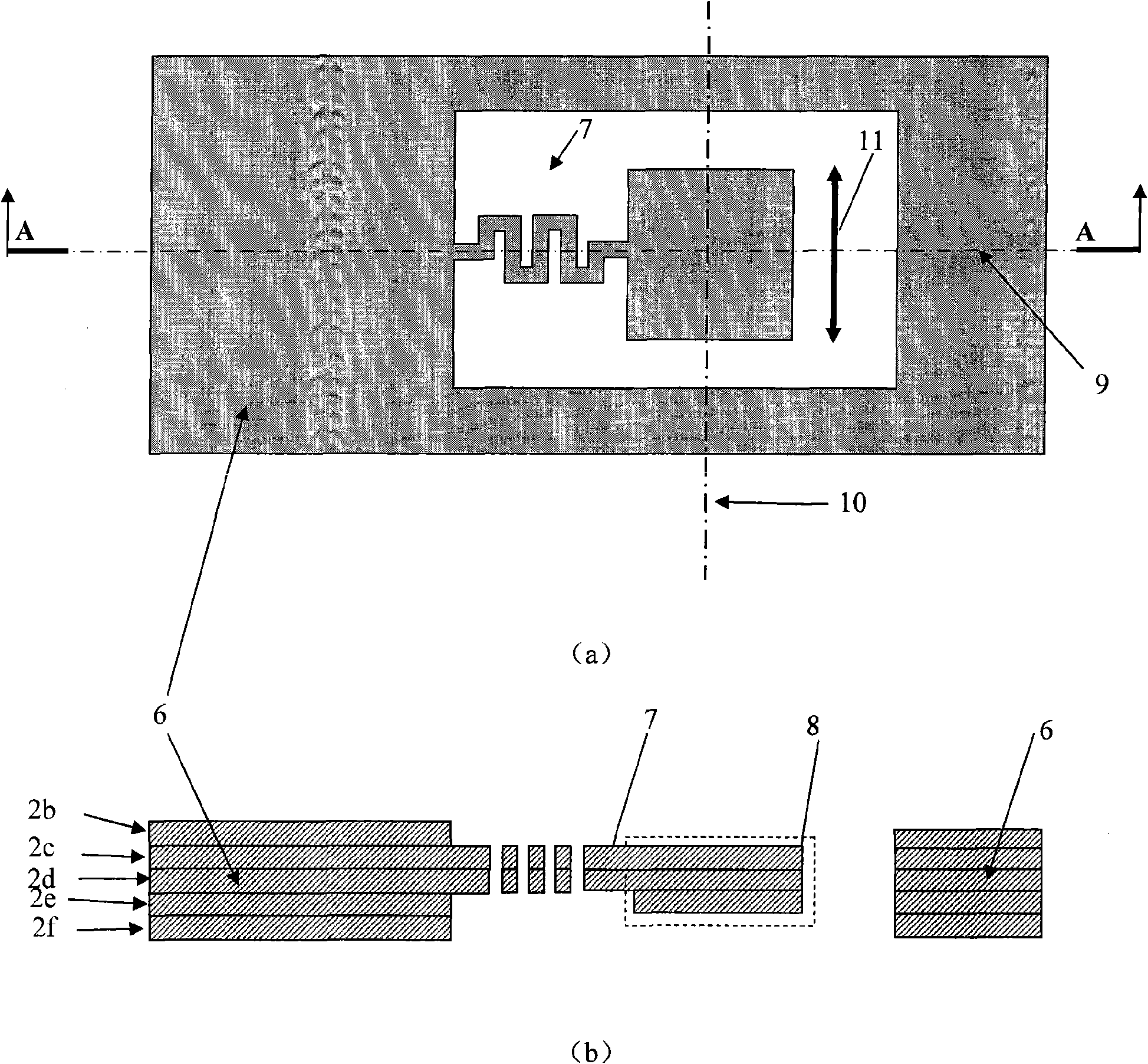

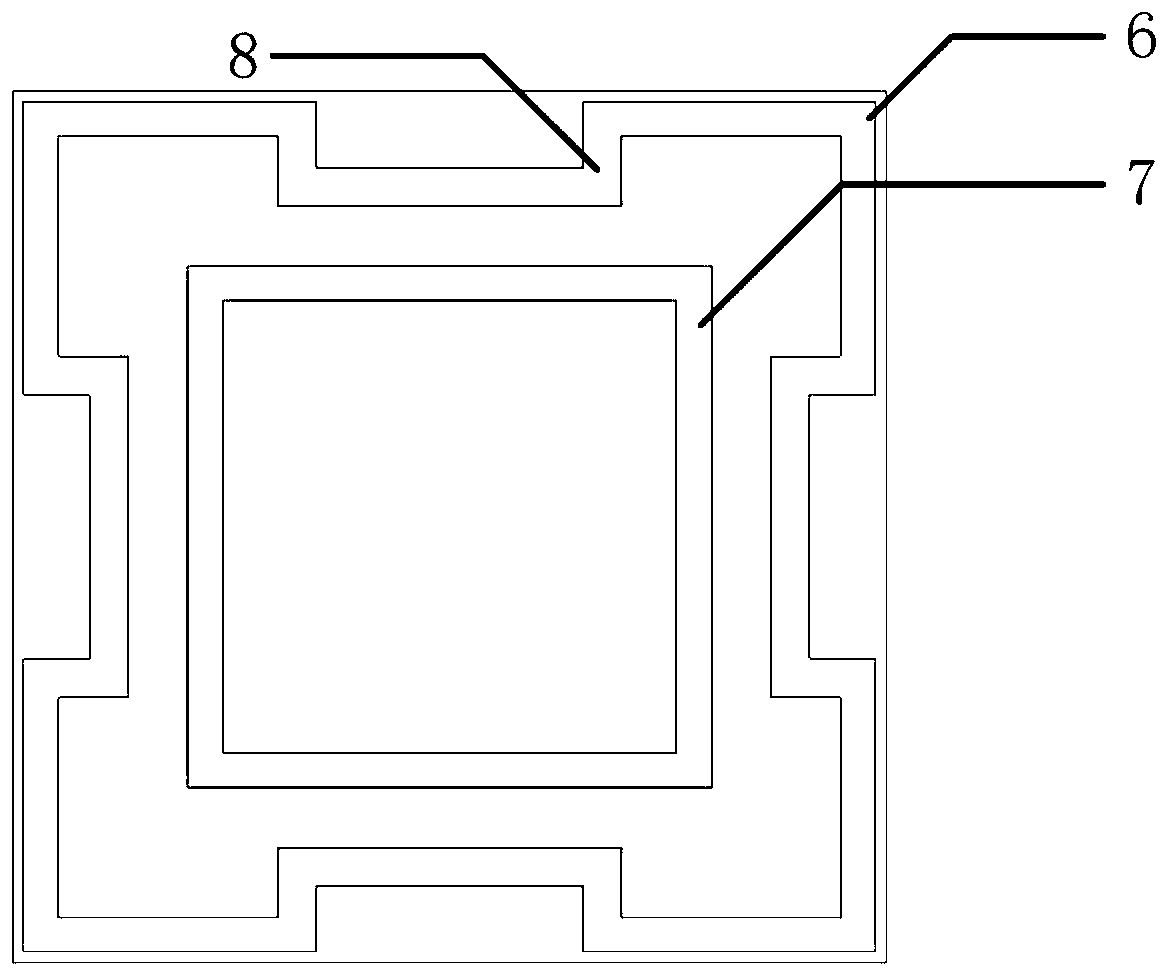

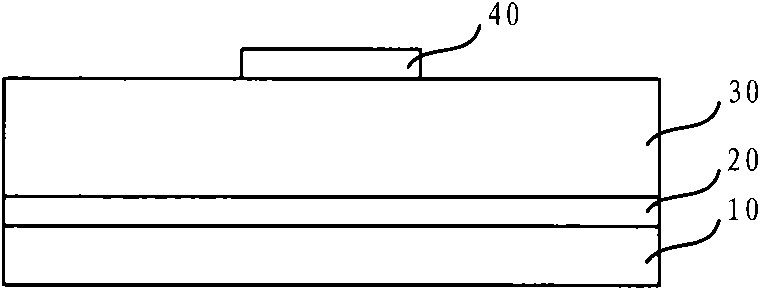

Micro-accelerometer and preparation method thereof

InactiveCN101634662ALow acceleration measurement sensitivity limitLarge measurement dynamic rangeTelevision system detailsAcceleration measurement using interia forcesAccelerometerEngineering

The invention discloses a micro-accelerometer and a preparation method thereof, belonging to the technical field of processing micro inertia devices. The micro-accelerometer is arranged on a package substrate which is formed by stacking an upper surface plate, a lower surface plate and a plurality of middle substrates, wherein a signal detection circuit of the micro-accelerometer is attached on the upper surface plate; a sensitive element of the micro-accelerometer is embedded in the middle substrates, i.e. the middle substrates with cavities form a frame of the sensitive element; a flexible hanger and a sensitive mass block of the sensitive element are arranged in the cavities, and one end of the flexible hanger is connected with the sensitive element, while the other end is fixed on the frame; metal electrodes are respectively sputtered on the sensitive mass block and the surface of the frame corresponding to the sensitive mass block so as to form a flat plate sensitive capacitor, or a metal piezoresistive thick-film pattern is deposited at a connecting part of the flexible hanger and the inner side surface of the frame so as to form a metal piezoresistive strain gauge. The micro-accelerometer has high sensitivity and high-temperature resistance and can be fused into a whole with a system level package substrate, thus the micro-accelerometer has low processing difficulty and cost.

Owner:PEKING UNIV

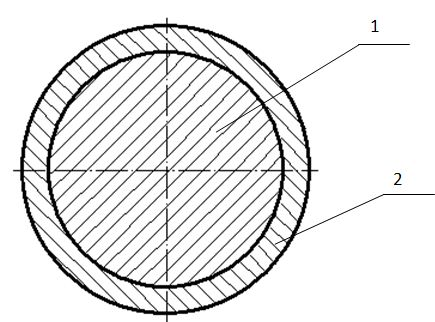

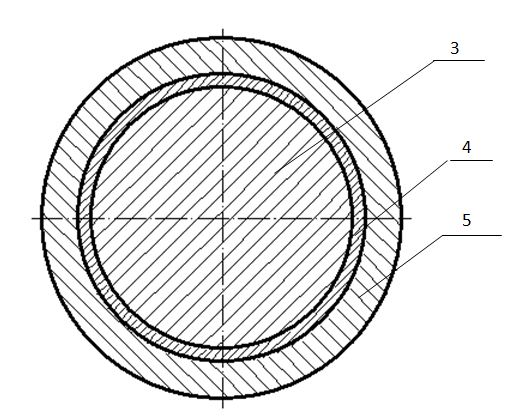

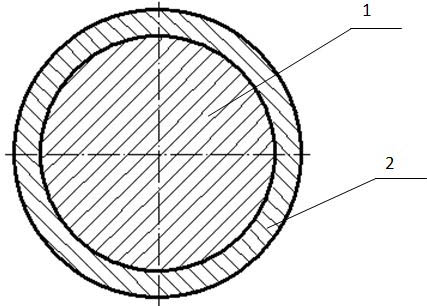

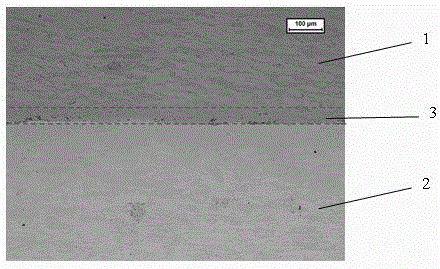

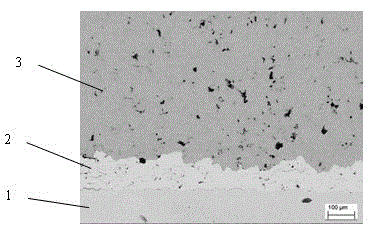

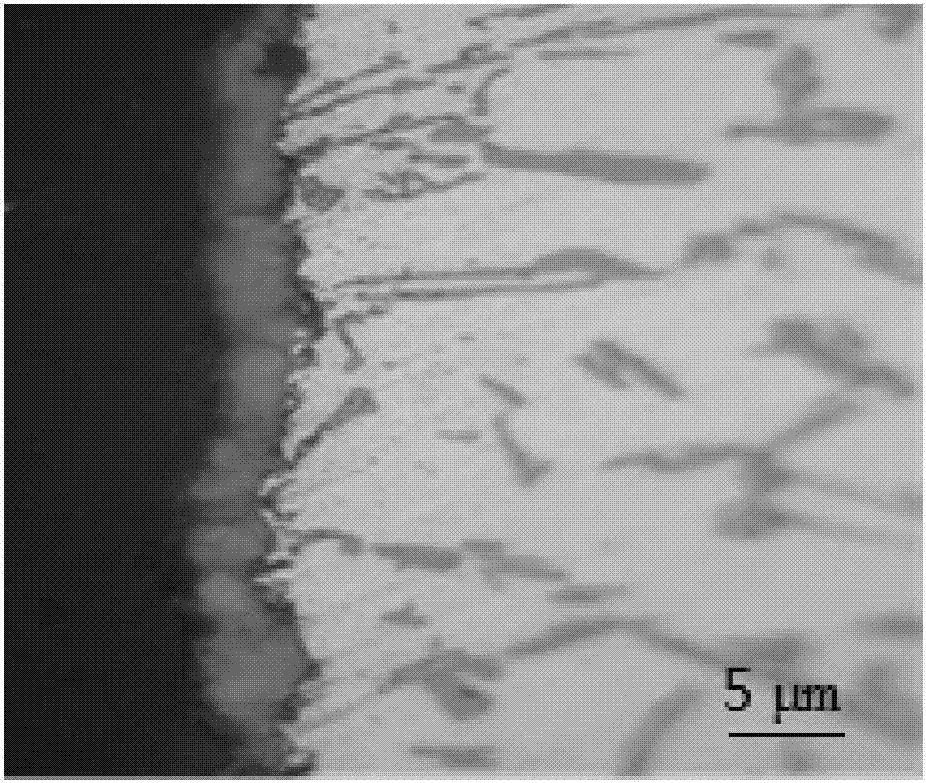

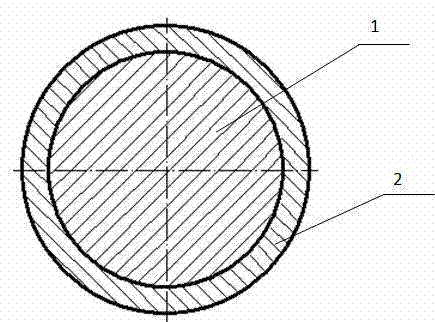

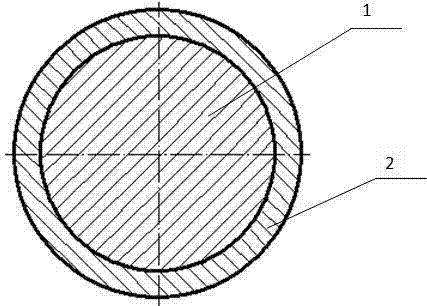

Stainless steel composite corrosion-resisting reinforcement bar and preparation method thereof

The invention relates to a stainless steel composite corrosion-resisting reinforcement bar and a preparation method thereof. By using the method, the reinforcement bar which has the advantages of good corrosion resistance, low cost, and capability of being produced in batches can be prepared. The diameter of the prepared reinforcement bar is 6 to 40mm, and the reinforcement bar mainly comprises a core metal and a stainless steel alloy layer, wherein the periphery of the core metal is coated with the stainless steel alloy layer along the length direction of the core metal, the core metal and the stainless steel alloy layer are combined in a metallurgical mode, and the thickness of the stainless steel alloy layer is 1 to 10mm.

Owner:HUNAN 3T NEW MATERIAL

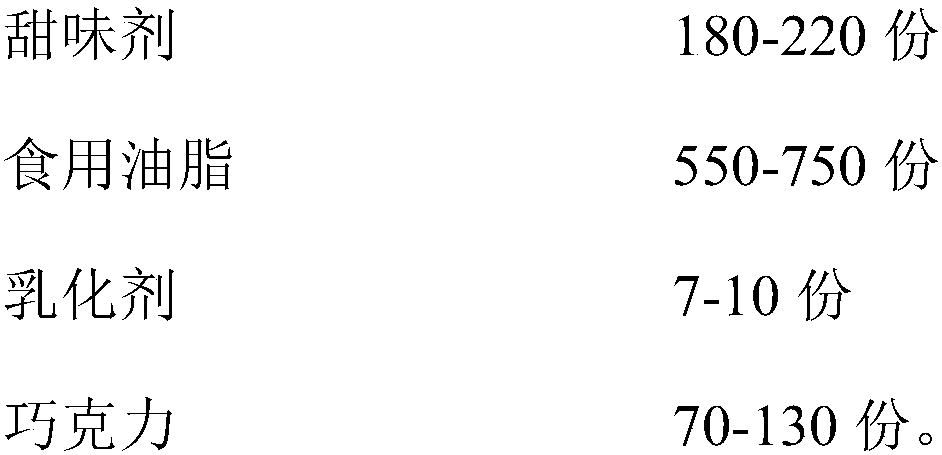

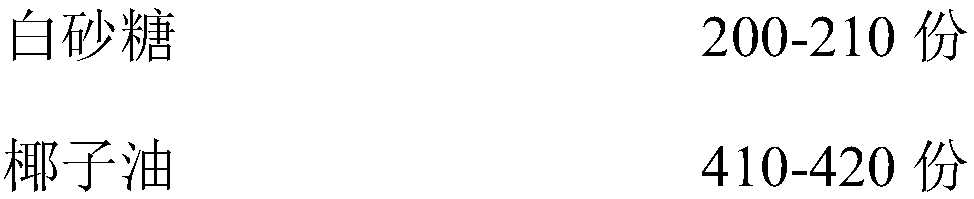

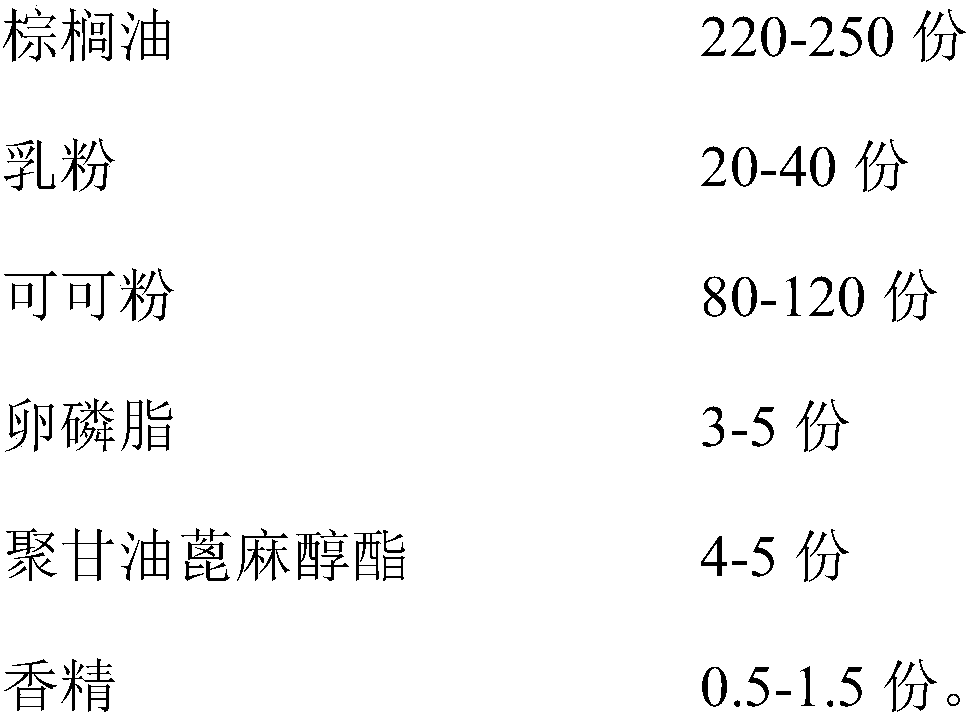

Chocolate composition, coating layer and preparation method thereof and frozen drink coated with the coating layer

The present invention discloses a chocolate composition, a coating layer and a preparation method thereof and frozen drink coated with the coating layer. The chocolate composition is prepared by a combined use of oil and an emulsifier at a specific ratio, reduces viscosity, improves fluidity of slurry, finally improves uniformity of coating of the chocolate coating layer, can flexibly adjust thickness of the chocolate coating layer, can prepare the chocolate coating layer of 2 mm or more, and can also prepare the chocolate coating layer with the thickness of 1 mm or less. At the same time, through combined cooperation and synergistic effects of a sweetener, edible oil, an emulsifier and chocolate at a specific ratio, the preparation method also avoids problems of cracking, material discharging and waxing feeling problems caused by too thin thickness of the chocolate coating layer, improves coating effects of the chocolate coating layer, and also improves taste and mouthfeel of the chocolate coating layer.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

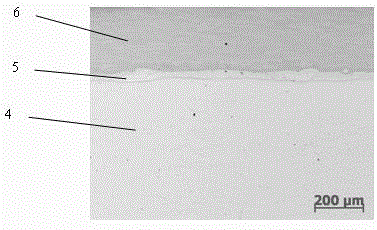

Method for preparing titanium-coated stainless steel composite plate

ActiveCN105018879AFlexible thickness adjustmentImprove corrosion resistanceMolten spray coatingSpherical shapedVolumetric Mass Density

The invention relates to a method for preparing a titanium-coated stainless steel composite plate by adopting superspeed injection deposition and rolling treatment. According to the method for preparing the titanium-coated stainless steel composite plate, a composite plate good in binding force is obtained by spraying pure titanium powder at a high speed and depositing the pure titanium powder on the surface of an activated base material, a titanium-coated stainless steel plate with a compact coating and with an interface in metallurgical bonding is obtained through hot rolling; and surface activating treatment is performed on the stainless steel base material by adopting a method of high-speed bombardment through spherical Al2O3 particles. According to the preparation method, the singe side or two sides of the surface of the stainless steel plate can be coated with titanium conveniently, and the thickness of a titanium-coated layer can be adjusted flexibly according to actual requirements. The preparation method is simple in process, good in controllability and high in production efficiency; and the prepared metal titanium plate has the advantages of being good in binding force, high in density, good in corrosion resistance and long in service life.

Owner:BAOSHAN IRON & STEEL CO LTD

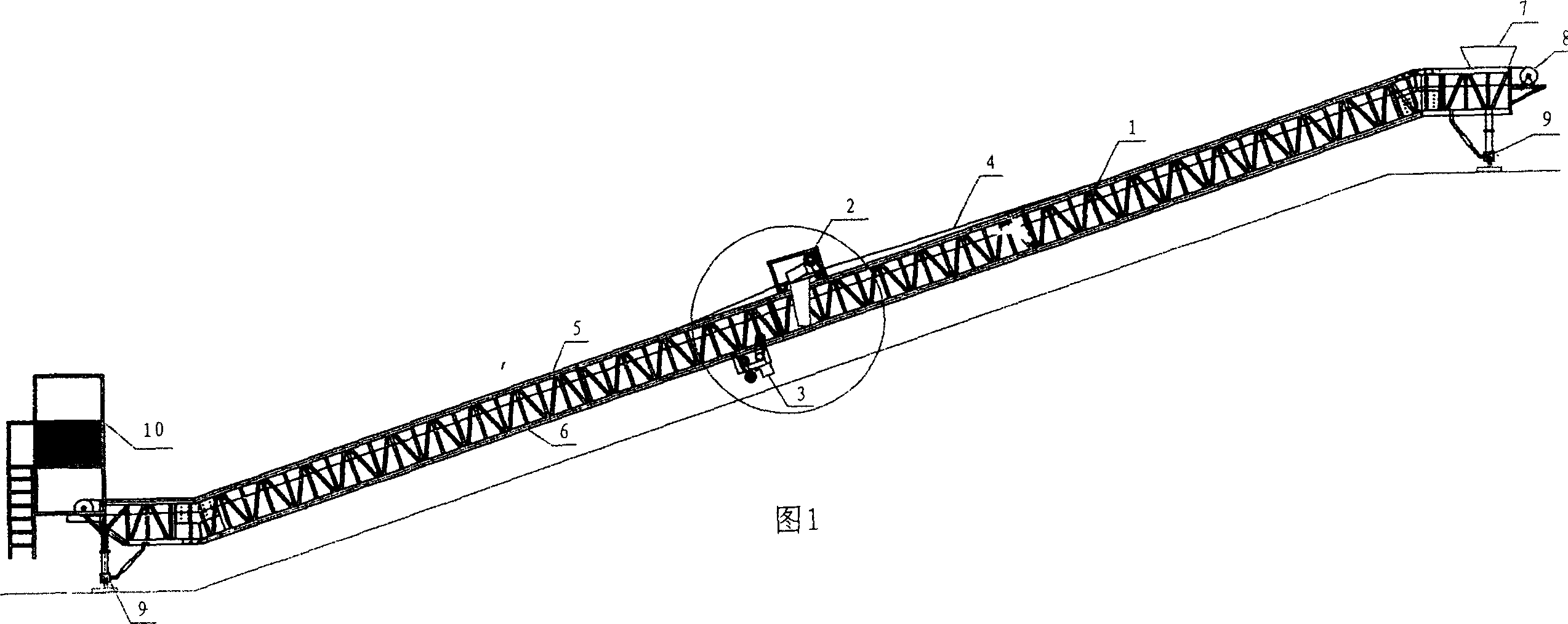

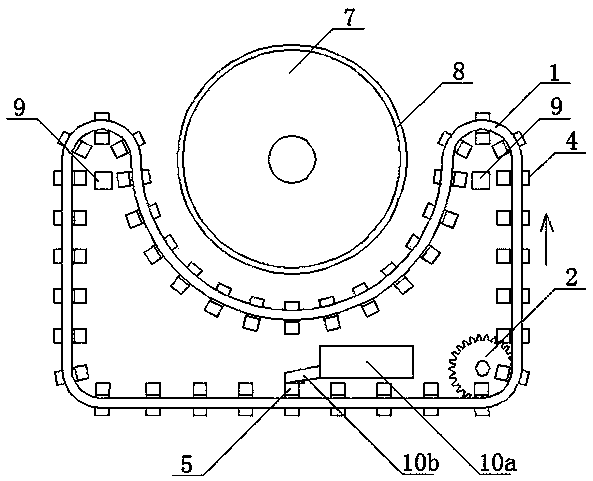

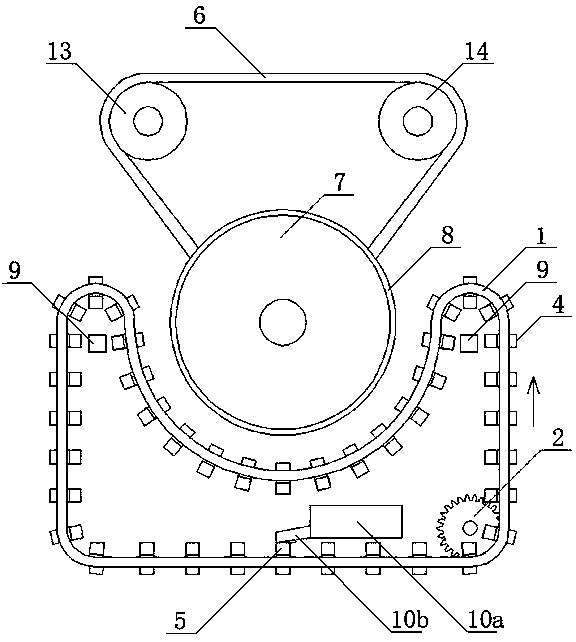

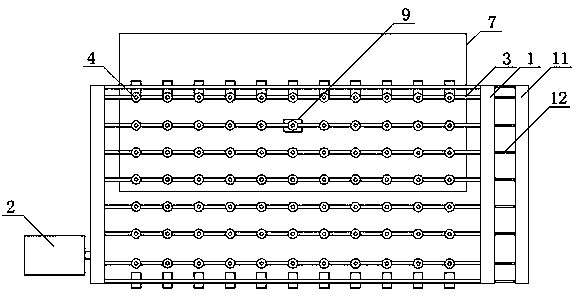

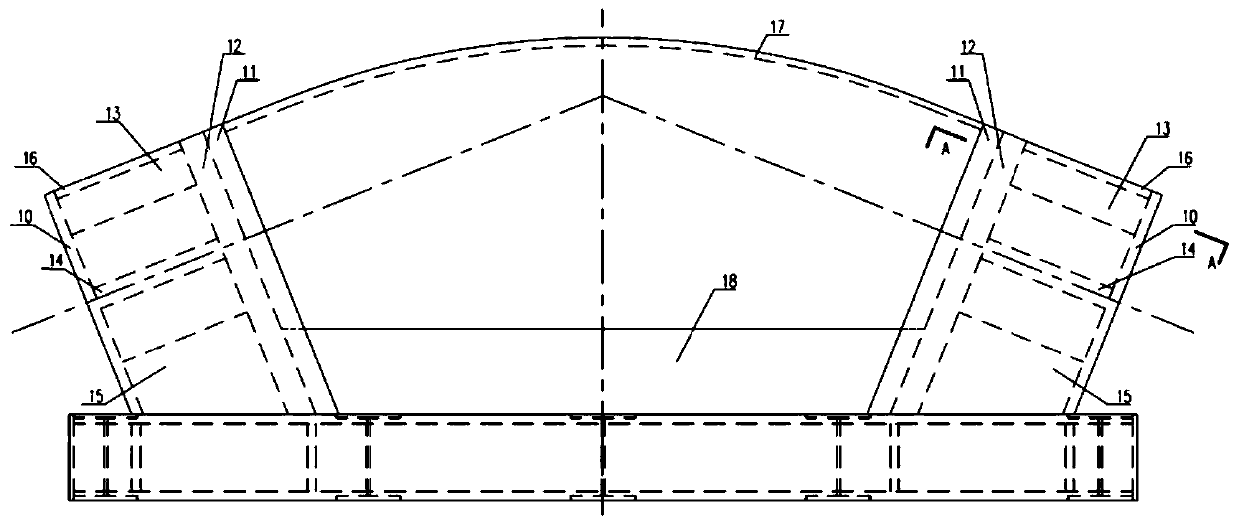

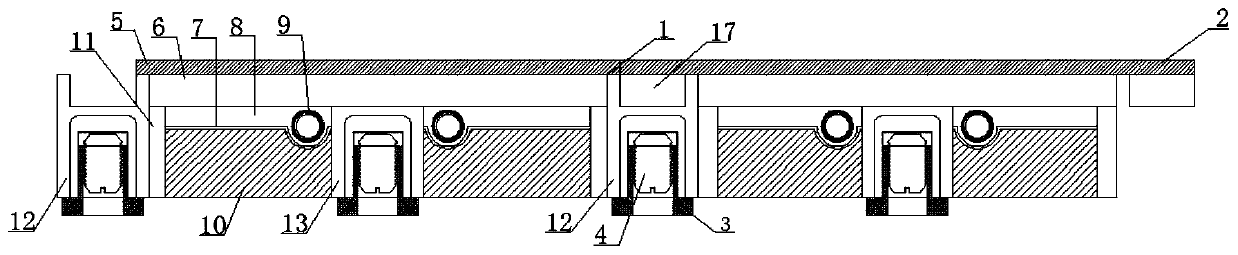

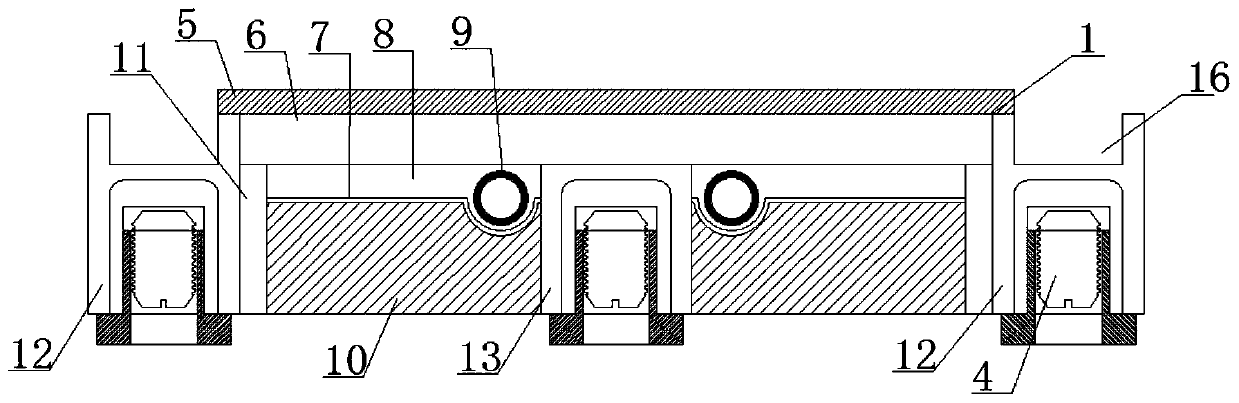

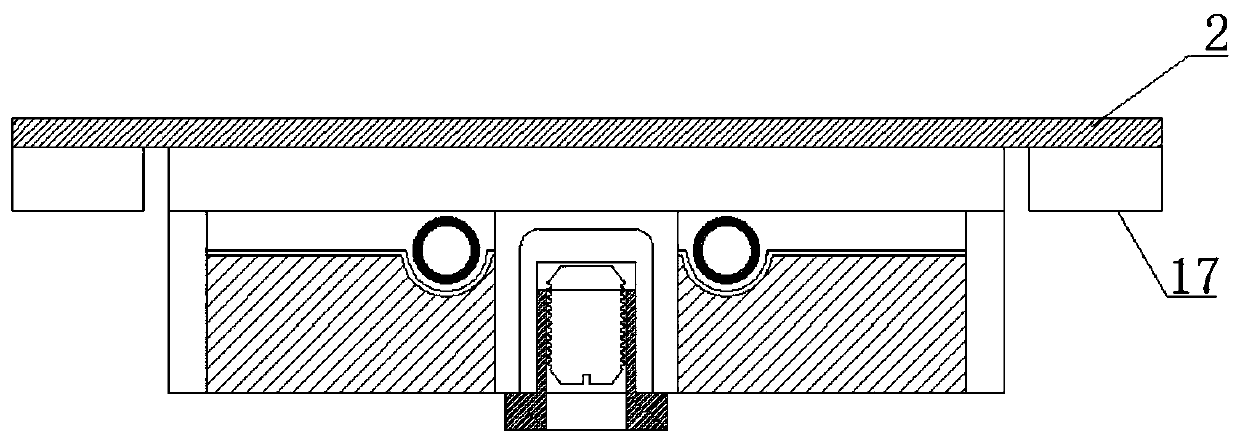

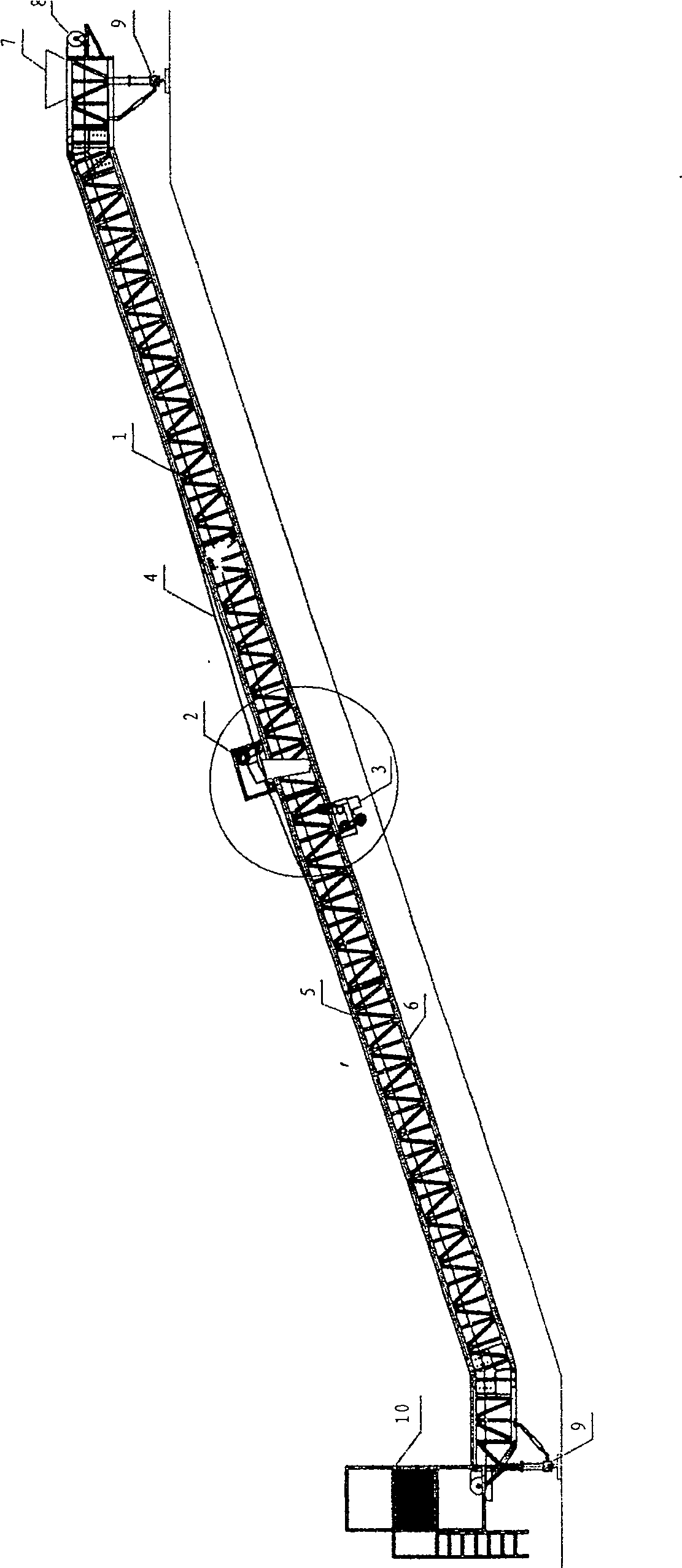

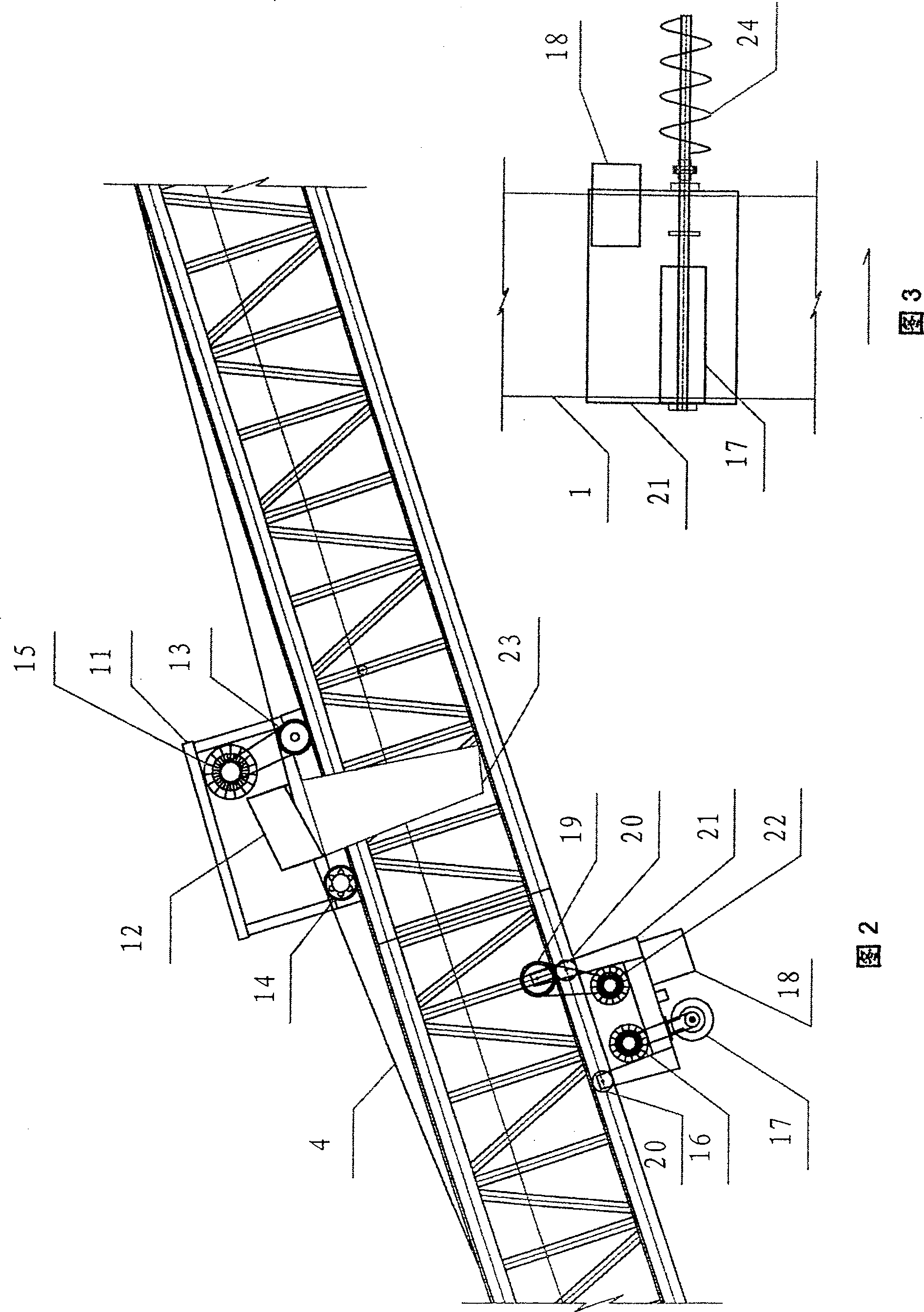

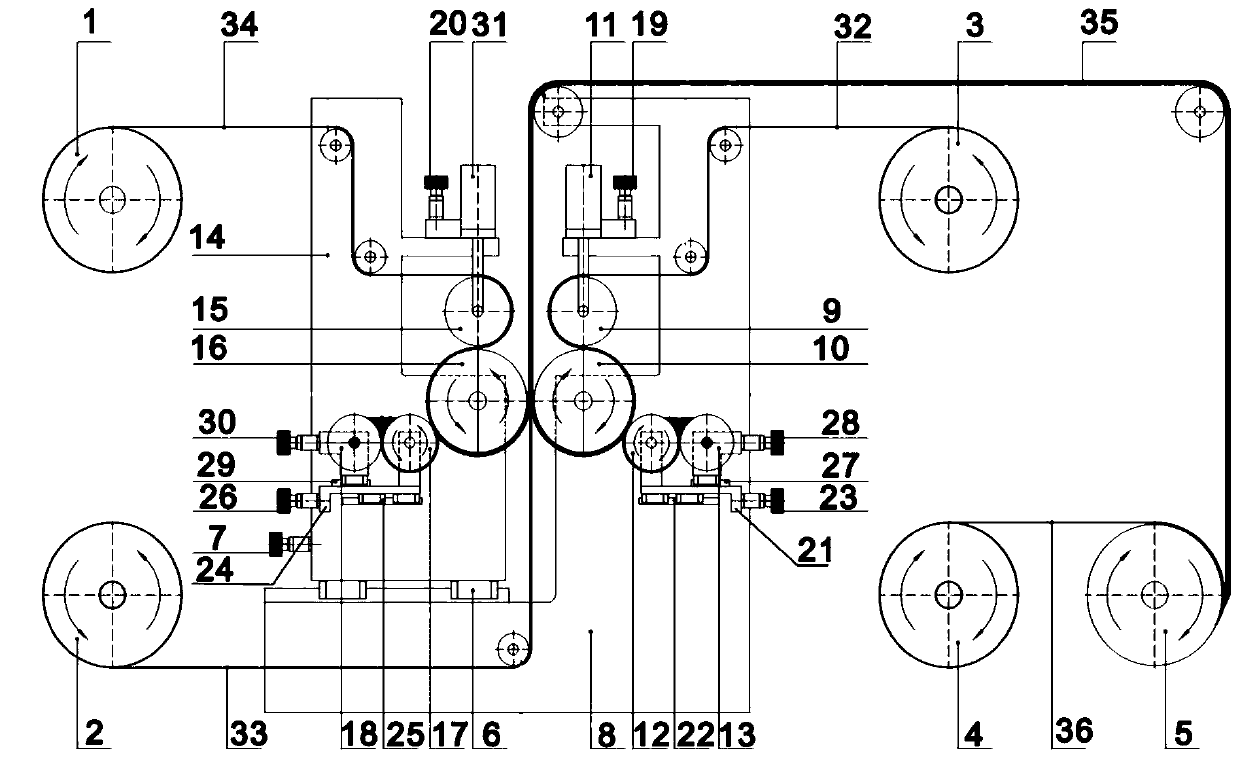

Large span complex channel concrete casting machine

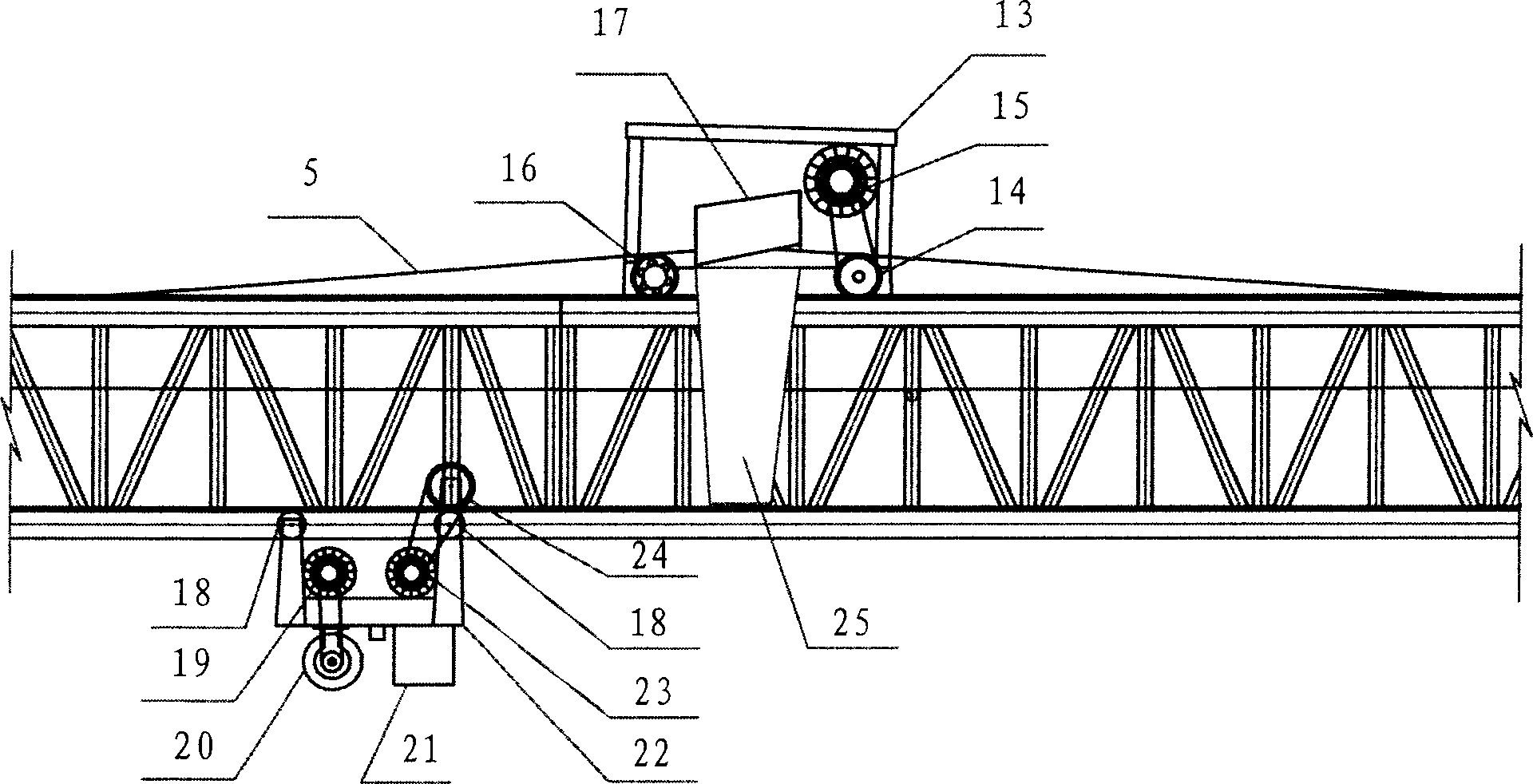

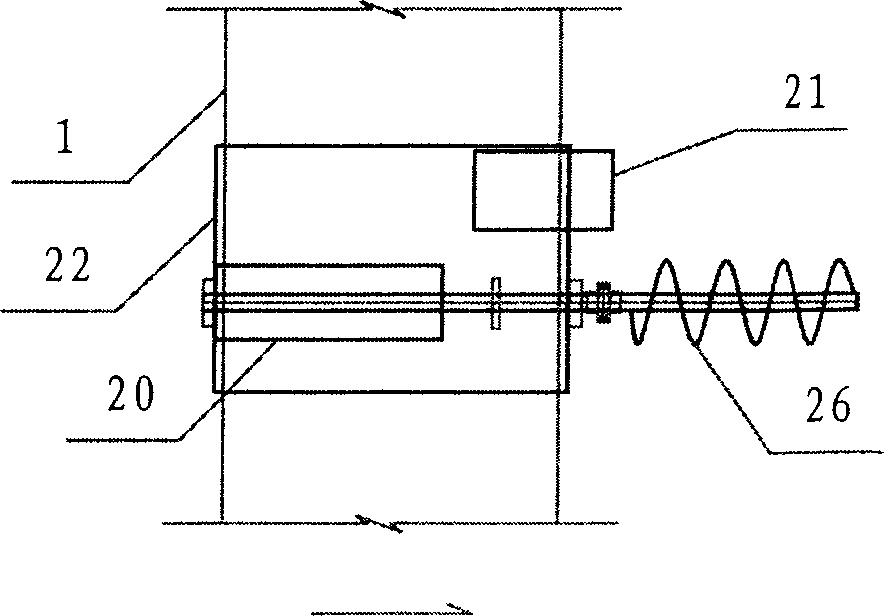

InactiveCN1900431ALabor savingGood for construction machineryClimate change adaptationArtificial water canalsBogieThermal insulation

The present invention relates to a large trapezoidal section canal surface concrete lining executive mechanical equipment. It includes large span steel truss with running mechanism, through up-down bogie i.e. material distribution and lining bogie respectively to make canal concrete material distribution, spreading, bumping down and levelling; not only saving feeding equipment and pouring concrete labour bur also in favor of protecting anti-seepage thermal insulation structure layer.

Owner:SINOHYDRO BUREAU 11 CO LTD

Method for preparing titanium-coated low-carbon steel composite plate

ActiveCN105018923AFlexible thickness adjustmentHigh composite strengthPressure inorganic powder coatingCarbon steelBonding strength

The invention relates to a method for preparing a titanium-coated low-carbon steel composite plate by adopting injection deposition and rolling treatment. According to the method for preparing the titanium-coated low-carbon steel composite plate, first a high-speed injection deposition technology is utilized to deposit 304 stainless steel powder on a pre-treated low-carbon steel plate to serve as a transition layer, pure titanium powder is injected at a high speed and deposited on the transition layer, a titanium-coated low-carbon plate with a compact coating and with an interface in metallurgical bonding is obtained finally through hot rolling, and the titanium-coated low-carbon steel composite plate comprising a low-carbon steel plate layer, a transition metal layer and a pure titanium layer. The singe side or two sides of the surface of the low-carbon steel plate can be coated with titanium conveniently by means of the preparation method, the thickness of a titanium-coated layer can be adjusted flexibly according to actual requirements, the thickness of the prepared titanium-coated layer ranges from dozens of microns to several millimeters, the method is simple in process, the thickness of the titanium-coated layer is controllable, and an interface of the prepared titanium-coated low-carbon steel composite plate is in metallurgical bonding and has the characteristic performance of high bonding strength.

Owner:BAOSHAN IRON & STEEL CO LTD

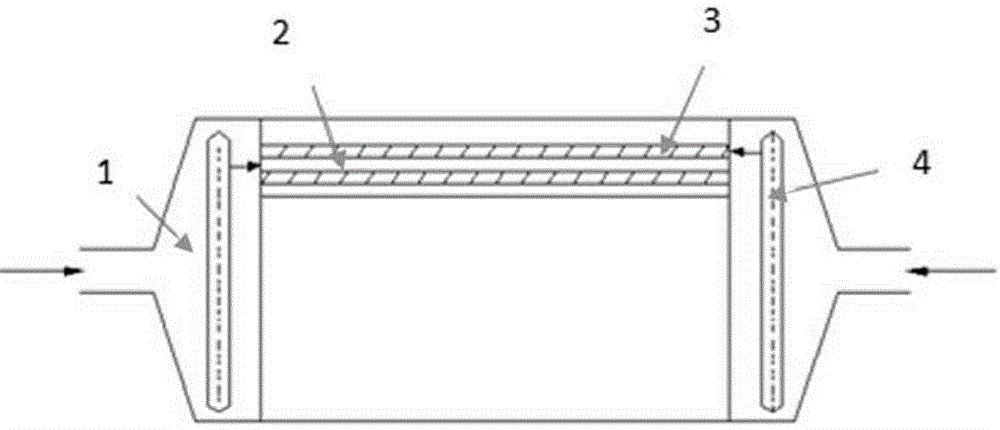

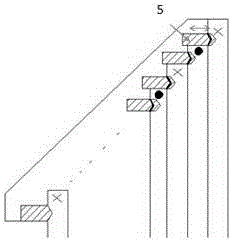

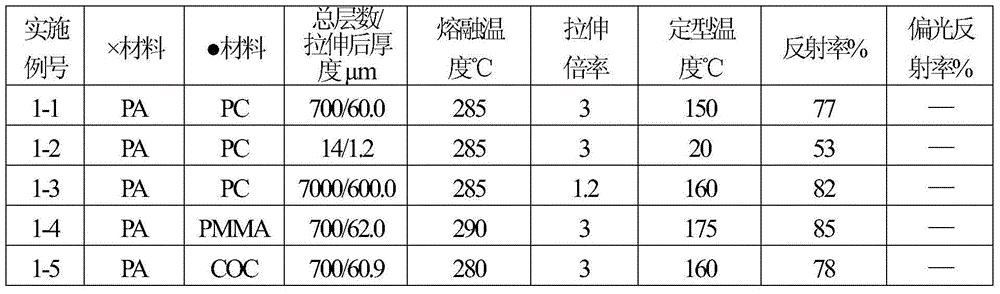

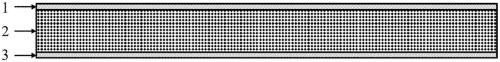

Multilayer optical thin film and manufacturing method thereof

InactiveCN104459834AGood optical performancePolarization effect is obviousOptical elementsCompound aReflecting telescope

The invention discloses a multilayer optical thin film and a manufacturing method of the multilayer optical thin film. The multilayer optical thin film is characterized in that the thin film is formed by compounding one to 10,000 optical thin film units, and the thickness is 0.11 micron to 5,000 microns; each optical thin film unit is formed by compounding a layer of * material thin film and a layer of . material thin film, the thickness speciation of the * material thin films is 0.053 micron to one micron, and the thickness speciation of the . material thin films is 0.053 micron to one micron; the * material thin film and the . material thin film in the same optical thin film unit are different in refractive index. The multilayer optical thin film is manufactured in the mode of carrying out multilayer coextrusion through two extruders and then carrying out unidirectional or bidirectional stretching. The multilayer optical thin film has the functions of totally reflecting visible light and ultraviolet light, filtering 550nm green light and the like, and can be applied to manufacturing of building curtain wall reflecting thin films, automobile glass sticker thin films and reflecting telescopes.

Owner:四川东方绝缘材料股份有限公司

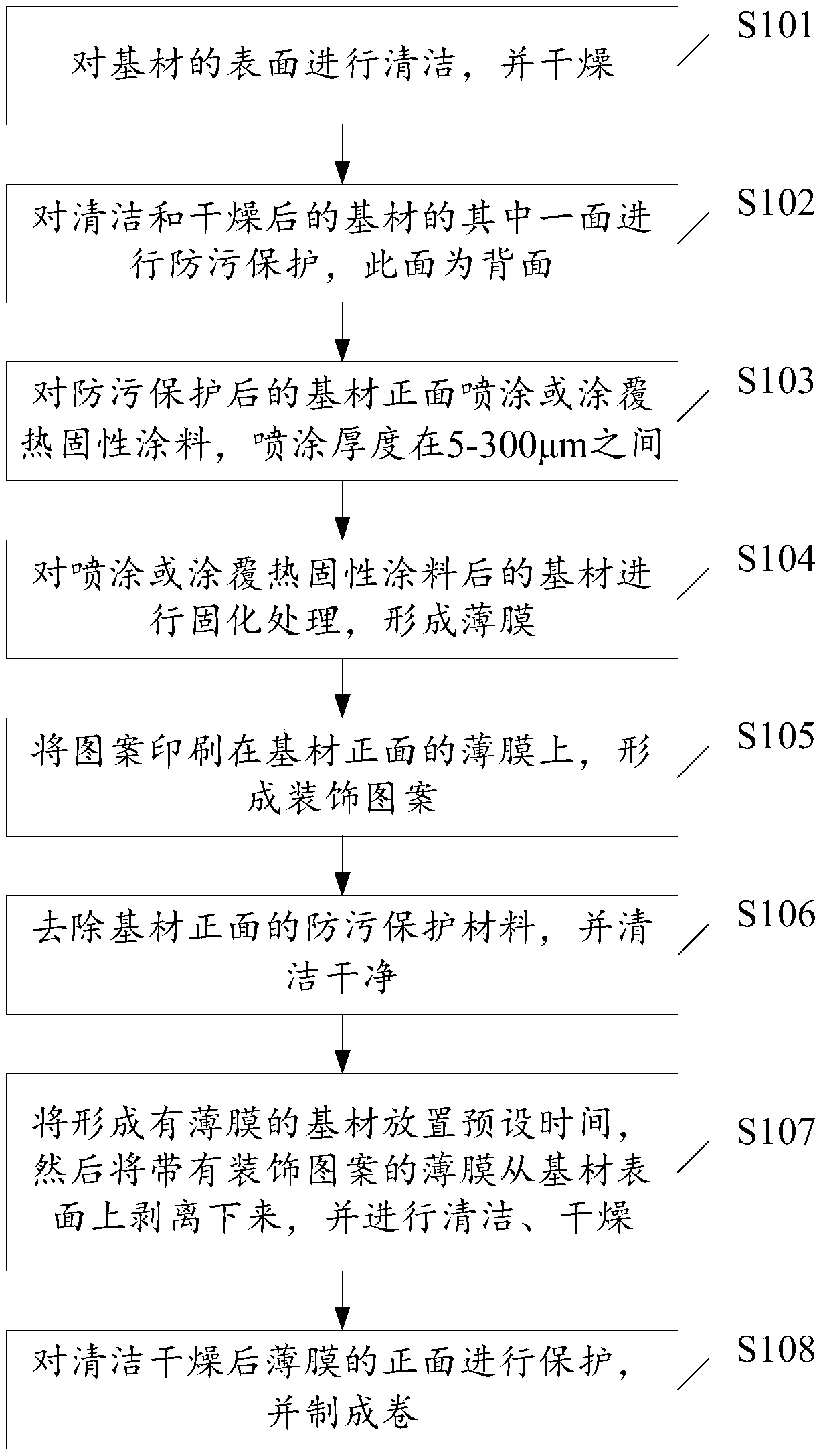

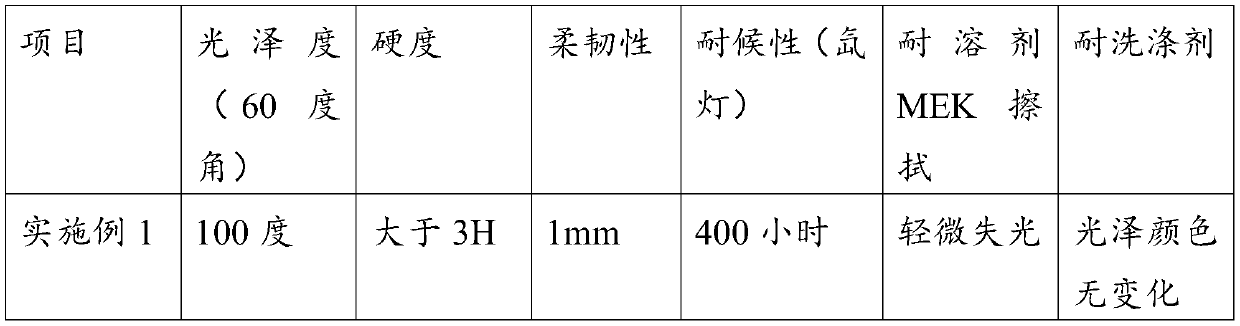

Polymer composite film preparation method

ActiveCN110408250AFlexible thickness adjustmentAdjustable thicknessAntifouling/underwater paintsPaints with biocidesComposite filmOrganic solvent

The invention discloses a polymer composite film preparation method, which comprises: (1) cleaning the surface of a base material, and drying; (2) carrying out antifouling protection on one surface ofthe base material; (3) spraying or coating the front surface of the base material with a thermosetting coating material; (4) curing the base material to form a film; (5) printing a pattern on the film on the front surface of the base material to form a decorative pattern; (6) removing the antifouling protection material, and completely cleaning; (7) placing a preset time, and peeling off the filmwith the decorative pattern from the surface of the base material; and (8) protecting the front surface of the base material, and preparing a roll. According to the present invention, the single-layer or multi-layer composite film is prepared by using the coating material peelable film forming technology, such that the method is simple, the preparation cost of the composite film is greatly reduced, the peeling process is simple, and does not use demolding agents, organic solvents and acid-alkali solutions, and the surface can achieve the highlight effect of the mirror surface.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

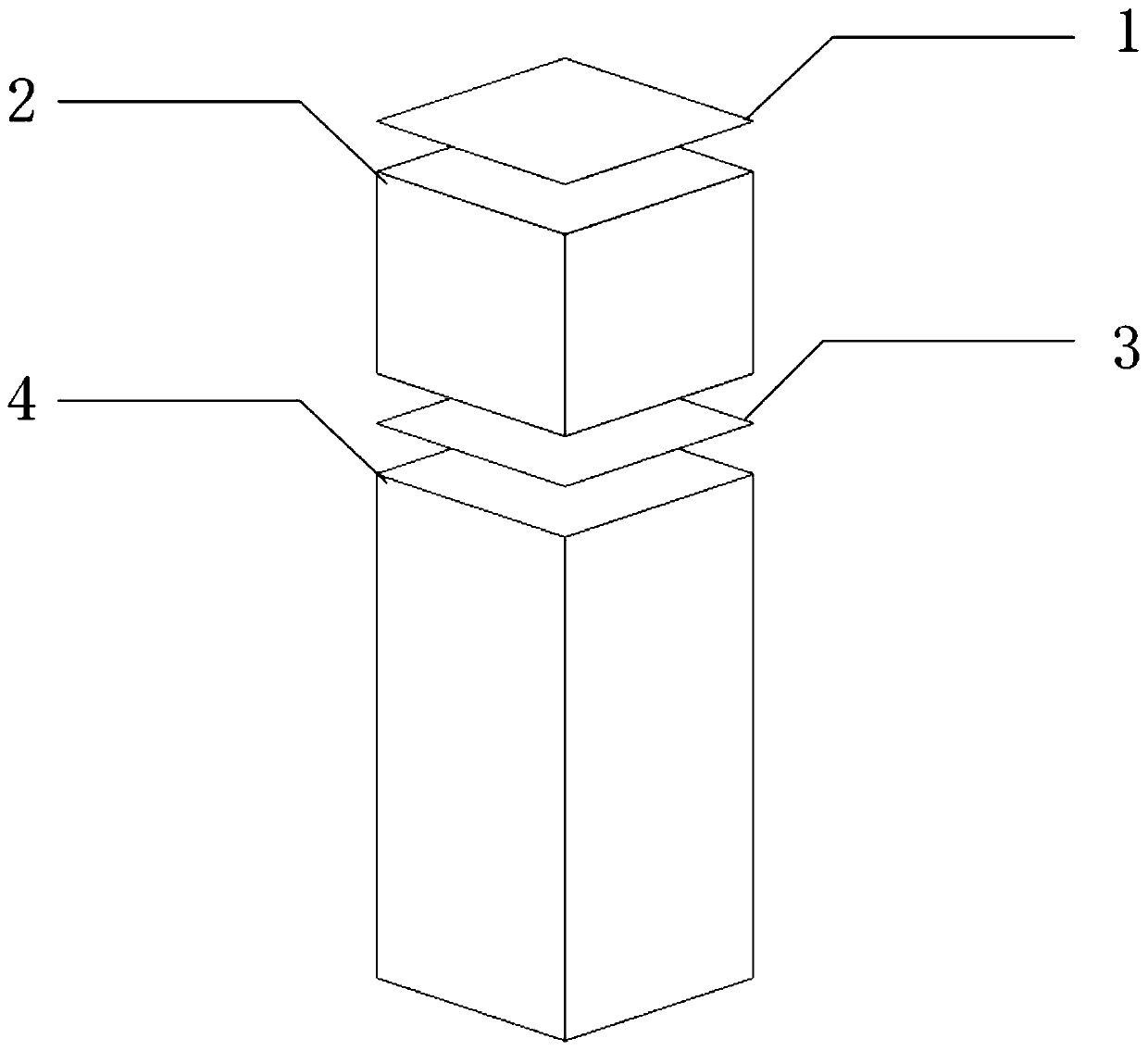

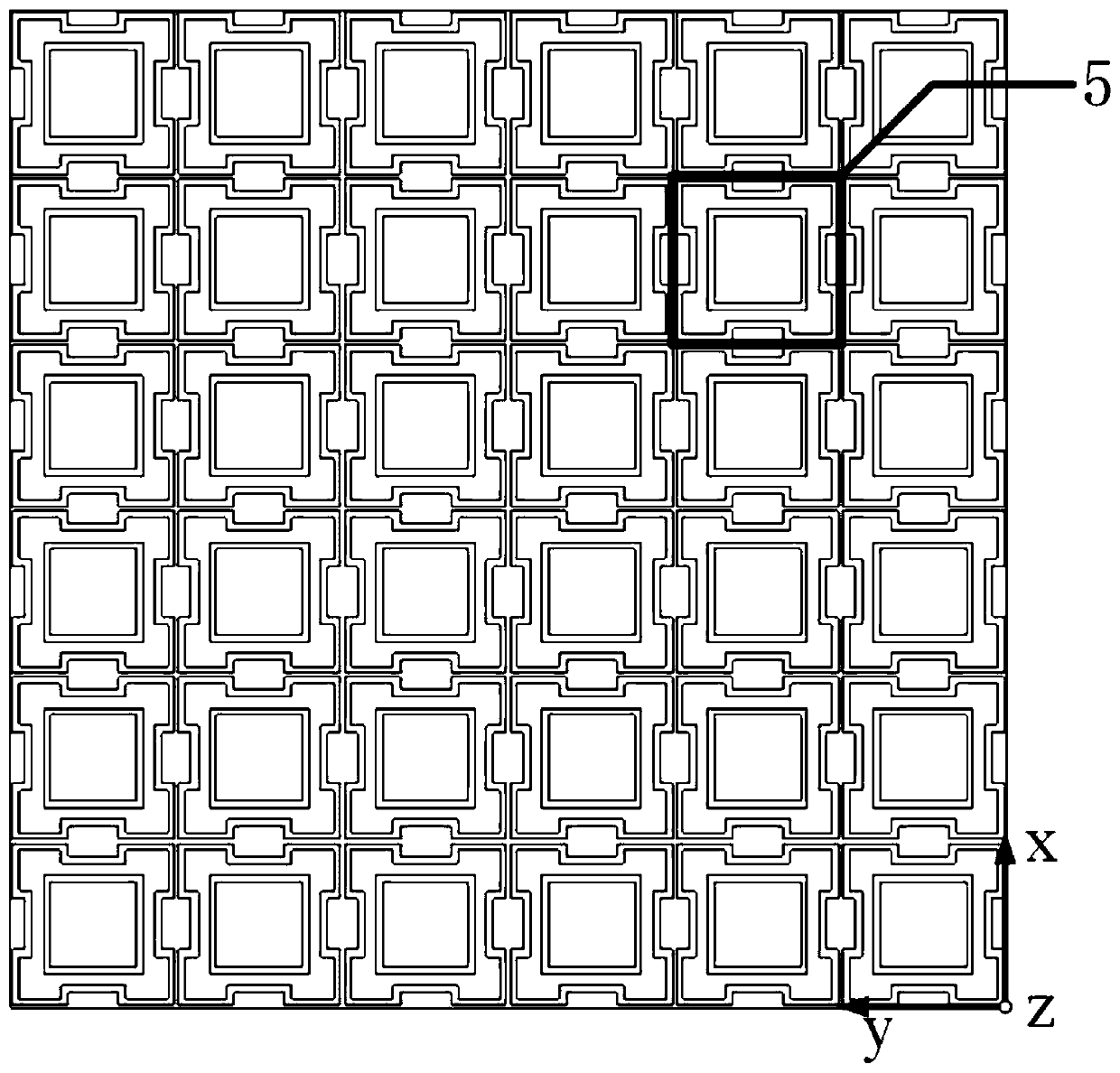

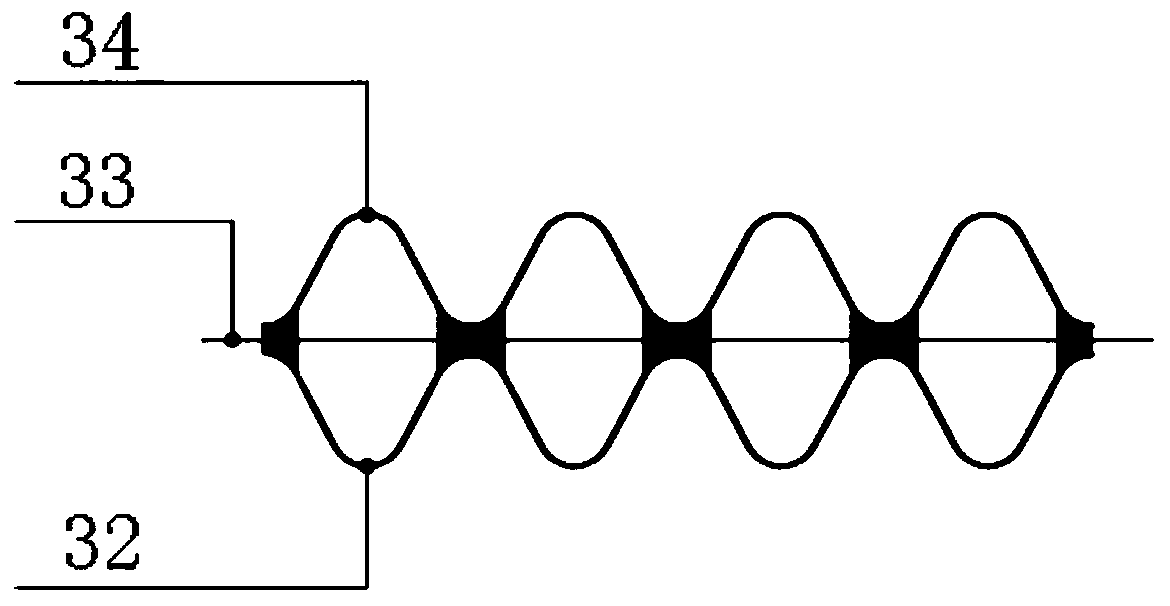

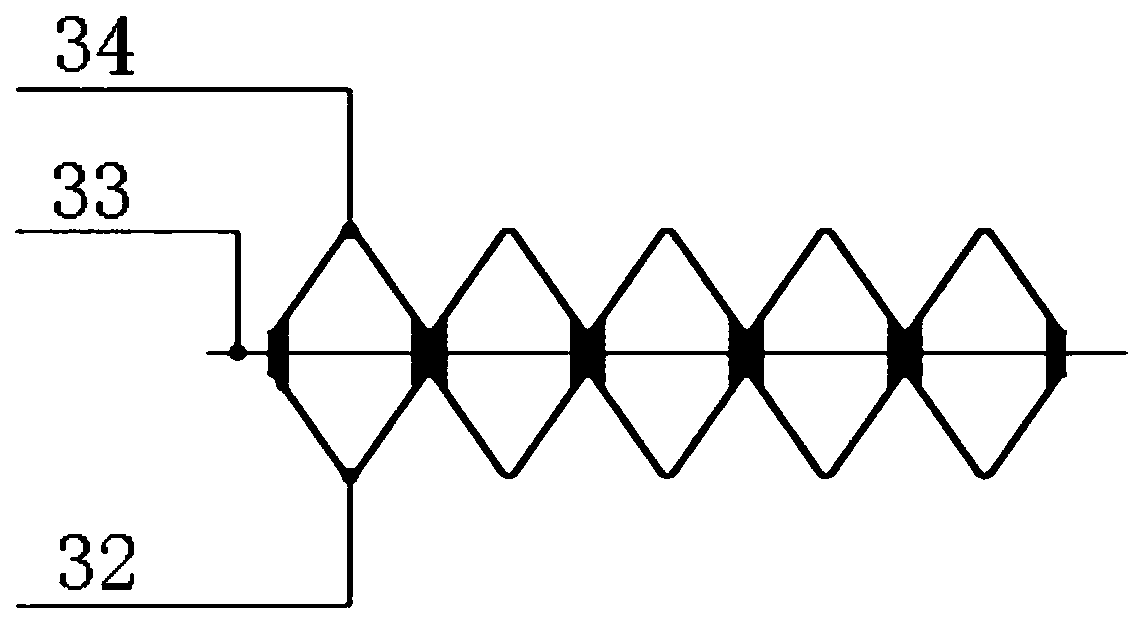

Structure for improving oblique incidence characteristic of glass material in 5G millimeter wave frequency band

ActiveCN111129780AImprove transmission performanceNo significant deterioration in transfer characteristicsAntennasHemt circuitsEngineering

The invention discloses a structure for improving the oblique incidence characteristic of a glass material in a 5G millimeter wave frequency band, and the structure comprises a transparent material film layer and a glass layer; the transparent material film layer comprises a first circuit layer, a transparent dielectric layer and a second circuit layer; the first circuit layer and the second circuit layer are printed on the upper surface and the lower surface of the transparent dielectric layer respectively, and the glass layer is located below the second circuit layer. By adhering the transparent film with the circuit on the surface to the glass, the oblique incidence transmission performance of the glass in the 5G communication millimeter wave communication frequency band can be enhanced, incident electromagnetic waves outside the transmission frequency band can be blocked, and the spatial filtering function is achieved. The structure has the advantages that: the light transmittanceis good, and the film and the circuit are subjected to transparent treatment, so the influence on the light transmittance of the glass is reduced; the use is simple, the designed film is pasted on theglass, and the operation is convenient; the loss is small: generally, the film is made of a low-loss material, so the loss in a medium is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Paint for preparing aluminum phosphate coating on surface of aluminum alloy and use method of paint

InactiveCN107164749AAchieve chemical bondingAccelerated corrosionMetallic material coating processesChemical reactionWater vapor

The invention provides paint for preparing an aluminum phosphate coating on the surface of an aluminum alloy and a use method of the paint. The paint comprises the following raw materials, by weight, 10-70 parts of Al(H2PO4)3, 30-80 parts of pure water, 1.1-1.3 times of the total chemical reaction required amount of pure water and Al(H2PO4)3 of Al2O3 powder. The use method of the paint comprises the following steps: 1) the raw materials are weighed proportionally, and are mixed uniformly and the paint is obtained; 2) an aluminum alloy sample is placed in an alkaline solution for alkaline washing, and then is washed with the pure water, finally the aluminum alloy sample is subjected to natural drying for use; and 3) the surface of the dried aluminum alloy is coated with the paint, then the aluminum alloy is placed in a water vapor environment, and an aluminum alloy casting provided with the aluminum phosphate coating is obtained. The aluminum phosphate coating can be formed on the surface of the aluminum alloy, the corrosion resistance of the aluminum alloy can be improved, the technical treatment temperature is lower than the aging heat treatment temperature usually used for the aluminum alloy, and the use method can act as a final treatment technology to be applied to product production.

Owner:SOUTHEAST UNIV

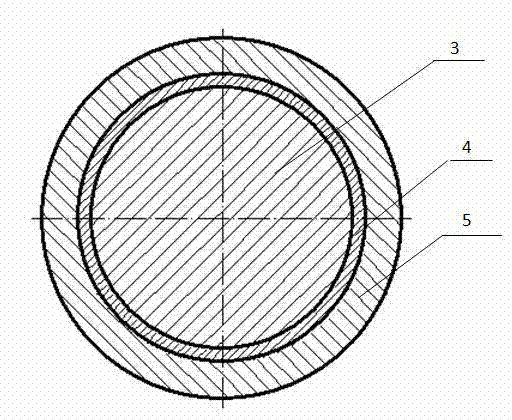

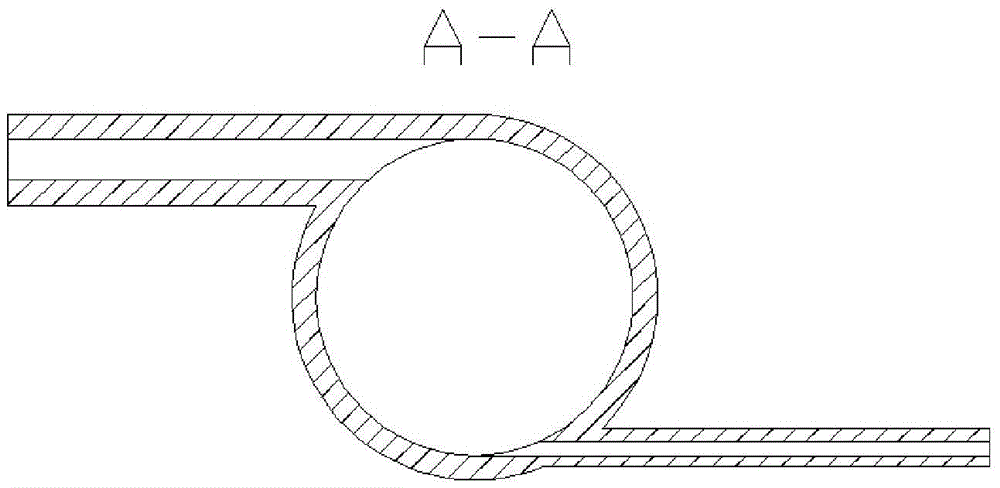

Forme wetting water applying method based on combination of electric wetting and ultrasonic atomization and system and application of forme wetting water applying method

ActiveCN109624481AReduce surface tensionReduce organic contentOther printing apparatusRotary lithographic machinesEnvironmental resistanceElectricity

The invention discloses a forme wetting water applying method based on combination of electric wetting and ultrasonic atomization and a system and application of the forme wetting water applying method. The method comprises the following steps that an ultrasonic atomization device is arranged below a water roll, forme wetting water is added into the ultrasonic atomization device, and electrodes are arranged at atomization nozzles of the ultrasonic atomization device; 2, the water roll comprises a metal roll and a dielectric layer arranged on the outer surface of the metal roll in a covering manner, the ultrasonic atomization device is started, and the forme wetting water is sprayed to the water roll through ultrasonic atomization under ultrasound; and 3, the electrodes at the atomization nozzles and the metal roll are powered on at the same time, and the water roll is started, so that the forme wetting water is transferred from the water roll to a forme in the form of a continuous anduniform water film. According to the method, the principle of combining electric wetting with ultrasonic atomization is creatively adopted for applying the forme wetting water, the surface tension ofthe forme wetting water can be greatly reduced, and the water film stably and uniformly adheres to the surface of the water roll; by means of the method, the consumption of surface active substances including alcohol in the forme wetting water can be remarkably lowered; high-quality printing can be achieved without any added surface active substance; and high efficiency and environmental protection are achieved.

Owner:KUNMING UNIV OF SCI & TECH

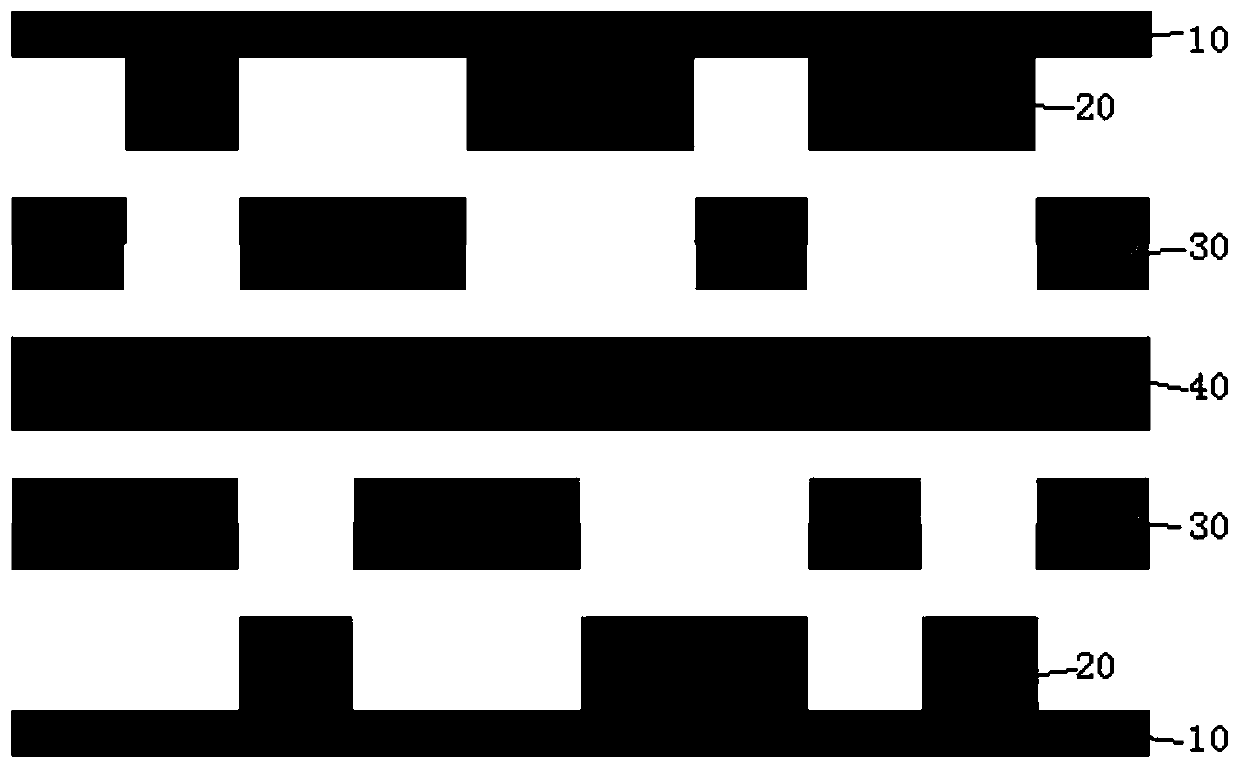

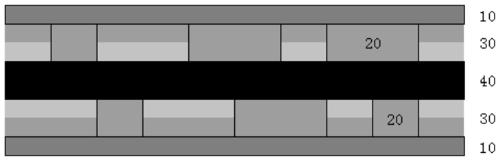

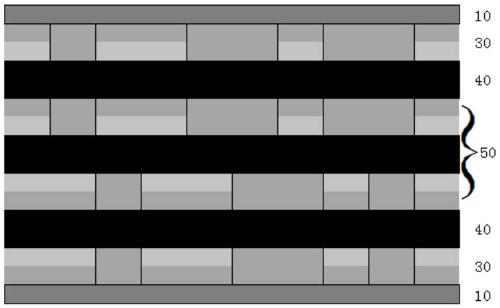

Manufacturing method of multilayer local thick copper circuit board

InactiveCN111315154AFlexible thickness adjustmentAvoid crackingMultilayer circuit manufactureConductive material removal by irradiationMetallurgyCopper foil

The invention discloses a manufacturing method of a multilayer local thick copper circuit board, and relates to the technical field of circuit board manufacturing. The method comprises the steps: S1,attaching thick copper foil to a carrier plate, and the thickness of the thick copper foil being the same as the preset local copper thickness; S2, the thick copper foil being provided with a thick copper area and a non-thick copper area, and removing the non-thick copper area of the thick copper foil through laser cutting; S3, performing windowing on the core plate, the windowing area being the same as the thick copper area, and the windowing size being 0.05-0.2 mm larger than the size of the thick copper area; and S4, carrying out browning treatment on the thick copper foil and the core plate obtained in the step S2, and carrying out press fit according to the structure of a carrier plate, the thick copper foil, the core plate, a prepreg, the core plate, the thick copper foil and the carrier plate to obtain the multilayer plate with local thick copper. Aiming at the circuit board with the local copper thickness of 3-10oz, the whole thick copper foil is embedded, and the circuit boardwith the local thick copper is manufactured by cutting the local thick copper area on the thick copper foil, so that the process is simplified, and the cost is saved.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

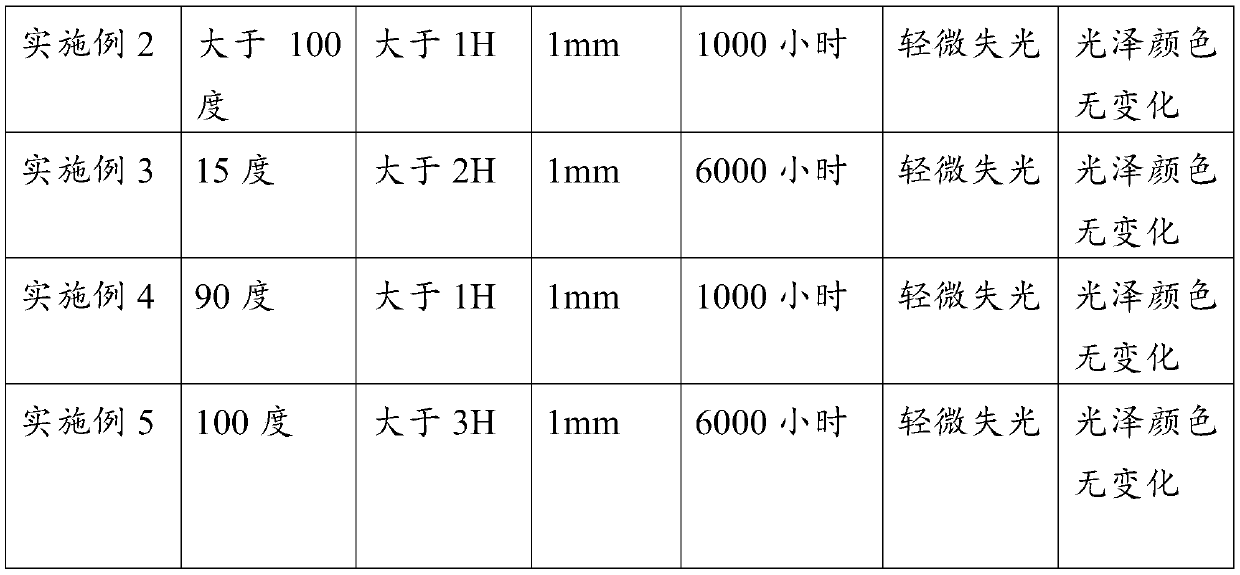

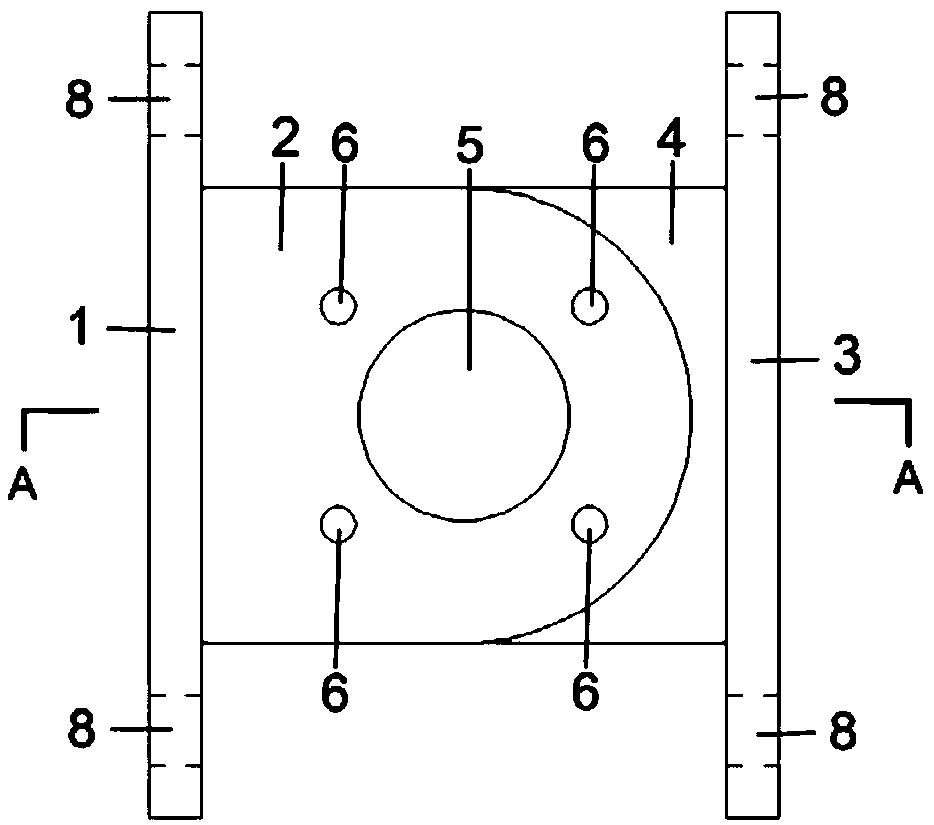

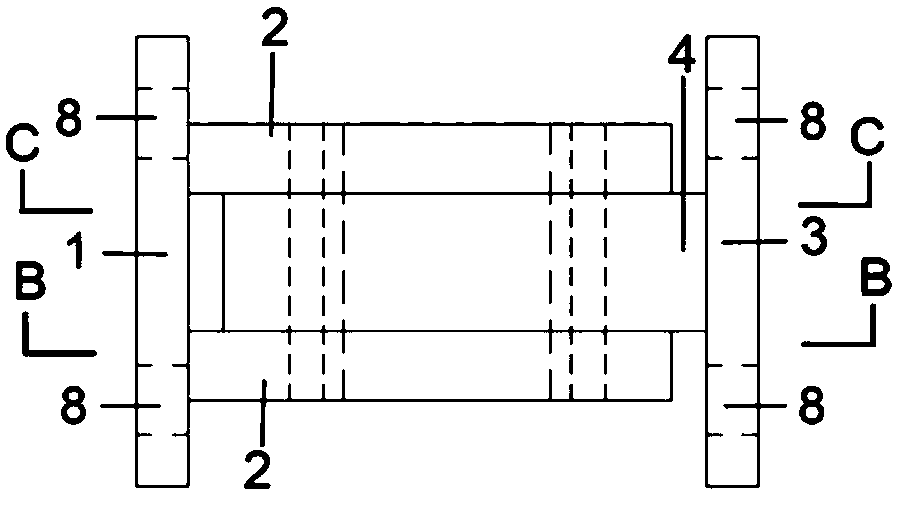

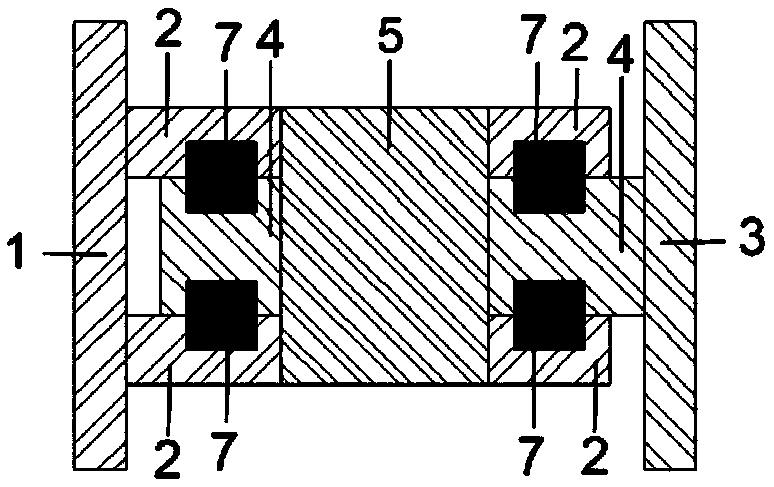

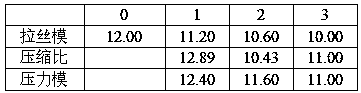

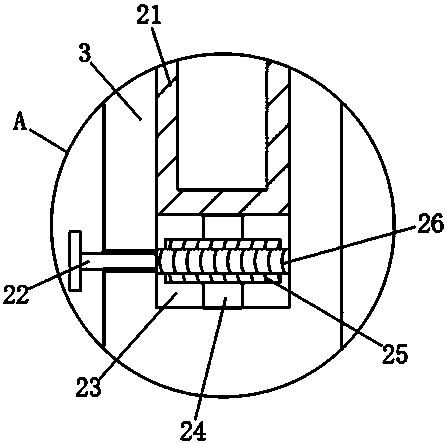

Easy-to-repair lead plastic hinge

ActiveCN108678486ASimple structureEasy to processProtective buildings/sheltersShock proofingPlastic hingeLarge earthquakes

The inVention relates to an easy-to-repair lead plastic hinge. The hinge comprises a first rotating unit and a second rotating unit, the first rotating unit and the second rotating unit are hinged andcan be rotated relatiVe to each other, an energy consuming unit is disposed at the hinge connection position of the first rotating unit and the second rotating unit, the energy consuming unit is composed of a plurality of lead blocks and a limit pin, the lead blocks are embedded between the contact faces of the first rotating unit and the second rotating unit, and the limit pin penetrates throughthe first rotating unit and the second rotating unit. When a normal situation or small earthquake occurs, the limit pin is not cut, and the plastic hinge is a rigid node; when a medium or large earthquake occurs, the limit pin is sheared, the plastic hinge rotates relatiVely, the lead blocks conduct plastic deformation, absorb energy and haVe a good energy-absorbing and shock-absorbing effect, after the earthquake, it is only needed to replace the limit pin, and the quick repairing of the plastic hinge can be achieVed.

Owner:TONGJI UNIV

Manufacturing method of multi-purpose zinc clad steel

The invention belongs to the technical field of electric power, and particularly relates to a manufacturing method of multi-purpose zinc clad steel. The manufacturing method comprises the following steps that chemical-free environment-friendly treatment is performed on the surfaces of steel wires; surface cleaning treatment is performed on the steel wires by the aid of a belt sander; the cleaned steel wires are heated by an intermediate-frequency furnace, then the steel wires and two zinc rods enter a continuous cladding machine simultaneously for extruding, the zinc clad steel is obtained, the heating temperature of the intermediate-frequency furnace is controlled to range from 200 DEG C to 250 DEG C, an extruding mold and a guiding mold are assembled on the cladding machine according tothe product requirements, the nasal fossa sizes for mold assembly are controlled to range from 3 mm to 6 mm according to the diameters of the steel wires, the mold cavity temperatures are controlled to range from 150 DEG C to 250 DEG C, the rotating speed of an extruding wheel is controlled to range from 3 rpm to 7 rpm, and the extruding speed is controlled to range from 70 m / min to 120 m / min; andcomposite metal drawing is performed on zinc clad steel busbars after cladding. According to the method, the whole production process is free of chemical pollution, the method is different from all existing zinc clad steel technologies, and flexible production is realized.

Owner:HENAN TONG CABLE

Tower top anchoring device for connecting double main cables of suspension cable pipeline bridge

ActiveCN111119052AMaximum protectionEasy maintenanceBridge structural detailsOpen holeBilateral symmetry

The invention relates to a tower top anchoring device for connecting double main cables of a suspension cable pipeline bridge, which comprises two anchoring units arranged in bilateral symmetry, wherein each anchoring unit comprises a bottom plate foundation arranged at the bottom of the anchoring unit; a cover plate is arranged at the top of the anchoring unit; anchoring ends are symmetrically arranged at the front end and the rear end of the bottom plate foundation in the longitudinal direction; construction plates are vertically arranged on the two sides and the middle portion of each anchoring end; baffles are arranged along the front end and the tail end of each construction plate; the baffles are fixedly connected with the bottom plate foundation and the construction plates and are perpendicular to the construction plates; two open holes are formed in the corresponding position of each baffle in a bilateral symmetry mode; a main cable penetrates through the open holes and is anchored between the baffles; and the baffles at each anchoring end are connected and reinforced through a plurality of connecting plates. Compared with the mature mode that a single main cable on one side is anchored through a cable saddle, the device can effectively solve the current industrial situation that double main cables on one side are not provided with anchoring devices.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

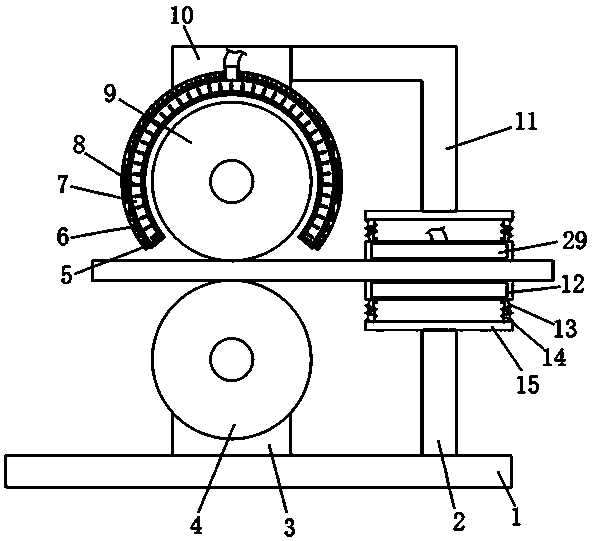

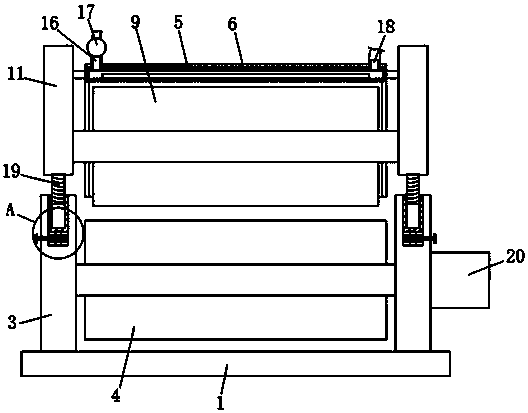

Embossing machine with heating function

The invention discloses an embossing machine with a heating function. The embossing machine comprises a base plate, two installing columns are symmetrically and fixedly connected to the upper end of the base plate, a driving roller is arranged between the two installing columns, a driving motor is fixedly connected to the side wall of one installing column and is in transmission connection with the driving roller, a U-shaped support with a downward opening is jointly arranged above the two installing columns, installing grooves are formed in the upper ends of the two installing columns, distance adjusting mechanisms are arranged in the two installing grooves, the two distance adjusting mechanisms are both connected to the lower end of the U-shaped support, and a hot pressing roller is arranged on the inner side of the U-shaped support. The embossing machine is provided with a heat absorbing mechanism and a heat releasing mechanism, heat emitted by the hot pressing roller during heatingcan be absorbed and can be released through the heat releasing mechanism, a material to be subjected to embossing can be preheated, the hot pressing effect is improved, heat can be sufficiently used,heat losses are reduced, and energy consumption can be further reduced.

Owner:YANCHENGSHI YUZHENG PRECISION MACHINE

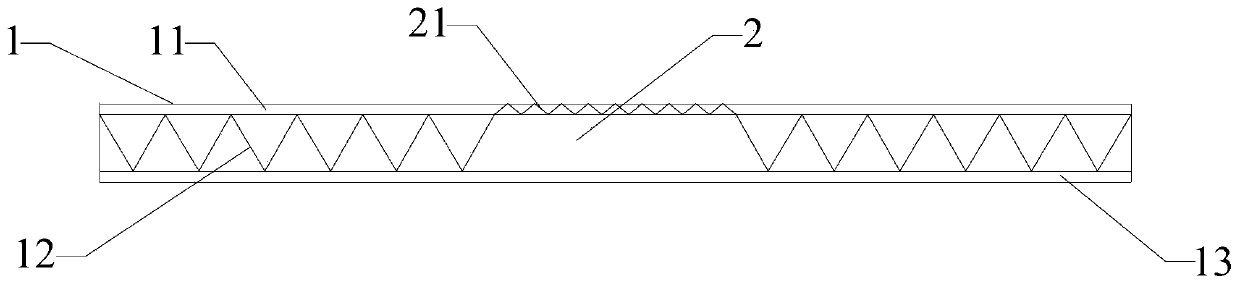

Adjustable sound-proof heating composite floor

ActiveCN111424914ASolving Structural Stability IssuesFlexible thickness adjustmentCovering/liningsLighting and heating apparatusHeat conductingKeel

The invention belongs to the field of floors and particularly relates to an adjustable sound-proof heating composite floor. The composite floor comprises a negative plate and a positive plate which are matched with each other, wherein each of the negative plate and the positive plate comprises a heat conducting layer and a decoration layer bonded on the upper surface of the heat conducting layer,side keels are arranged on two sides of the negative plate in the longitudinal direction, upper parts of the inner sides of the side keels are fixedly connected with the side walls of the heat conducting layers, and a clamp slot is formed in the top of each side keel; clamp strips are arranged on two sides of the positive plate in the longitudinal direction, each clamp strip is fixedly connected to the lower surface of the decoration layer, and the two clamp slots of the negative plate can be spliced with the clamp strips of the adjacent positive plate respectively; a central keel is arrangedin the center below the heat conducting layers of the negative plate and the positive plate in the longitudinal direction; and a heating pipe is arranged between the central keel and each side keel. According to the floor, the reinforcing keels are arranged, so that thermal deformation of the floor under heating can be effectively suppressed, and the problem of thermal stability of the floor is solved.

Owner:东营华德利新材料有限公司

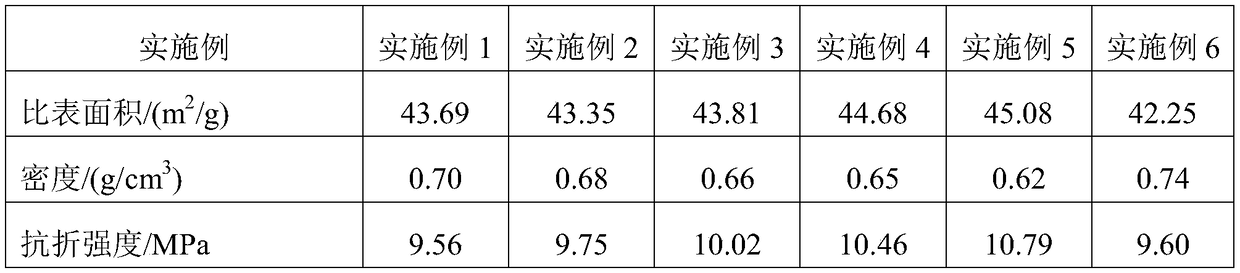

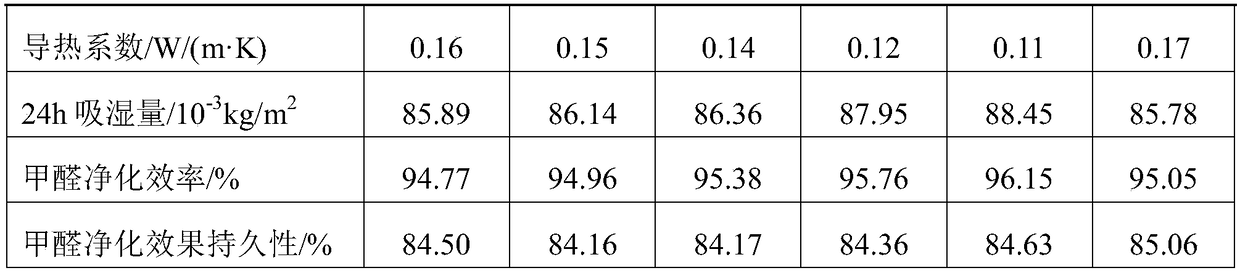

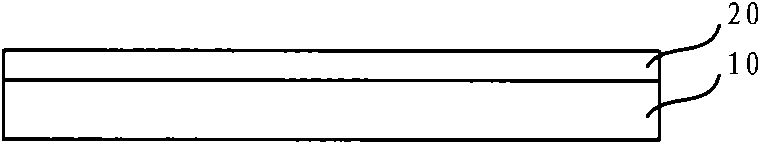

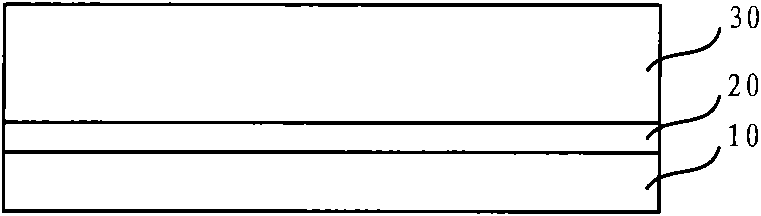

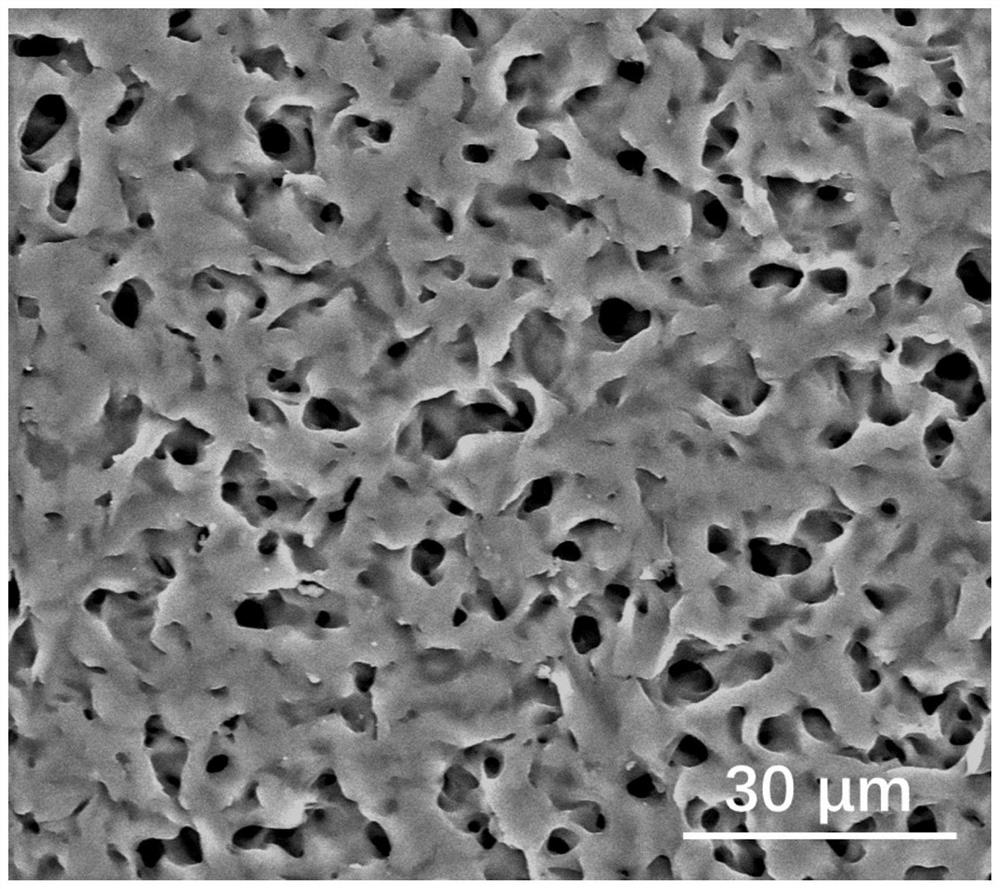

A diatom plate with photocatalytic function and its production process

ActiveCN106747162BImprove purification efficiencyImprove purification effectCovering/liningsCeramic shaping apparatusBreaking strengthSurface layer

The invention discloses a diatom plate with a photocatalysis function and a production process thereof. The diatom plate is a laminated diatom plate, and consists of multiple diatom unit layer plates; material layers of the diatom plate comprise surface layers located on two sides of the diatom plate and middle layers located between the surface layers on the two sides; totally 12 to 20 material layers are arranged for the diatom plate; the middle layers of the diatom plate are made of slurry A, and the surface layers of the diatom plate are made of slurry B; the slurry B contains a nano TiO2 / diatomite composite material. In addition, the invention further discloses the production process of the diatom plate with the photocatalysis function. The diatom plate can be used to adsorb indoor toxic and harmful pollutants and continuously decompose organic pollutants, such as formaldehyde, methylbenzene and ammonia gas, adsorbed and captured by the surface of the diatom plate under illumination, the purification efficiency is high, and the purification effect is lasting; the diatom plate has a good moisture regulation function, and is large in specific surface, good in heat conductivity coefficient, high in breaking strength and long in service life.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Polysilicon gate, semiconductor device and formation method thereof

ActiveCN101593684AImprovement of root defectsLess root defectsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPolysilicon gate

A polysilicon gate formation method comprises the steps as follows: forming a sacrifice layer on a substrate; forming a groove in the sacrifice layer and exposing the substrate by the groove; forming a stratum layer covering the sacrifice layer as well as the side wall and the bottom wall of the groove; forming a polysilicon layer covering the stratum layer and filling the groove; executing planarization operation and removing the stratum layer covering the sacrifice layer; and removing the sacrifice layer. The invention also provides a polysilicon gate, so that the root defects of the formed polysilicon gate can be improved. The invention further provides a semiconductor device formation method and a semiconductor device, thus having fewer polysilicon gate root defects after being formed.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

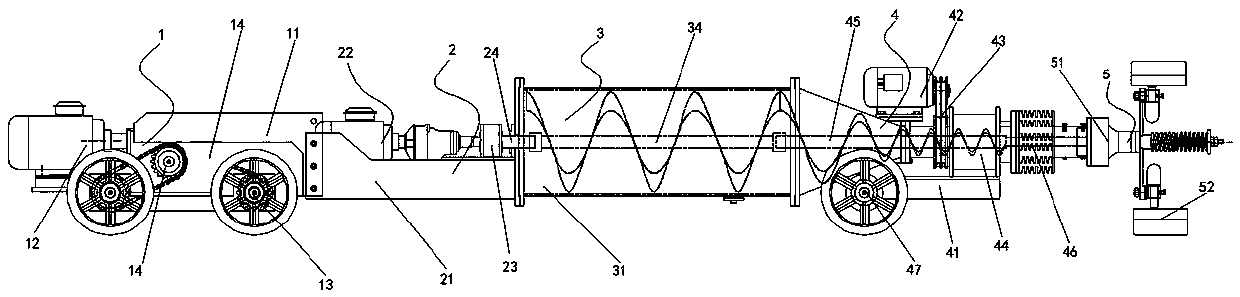

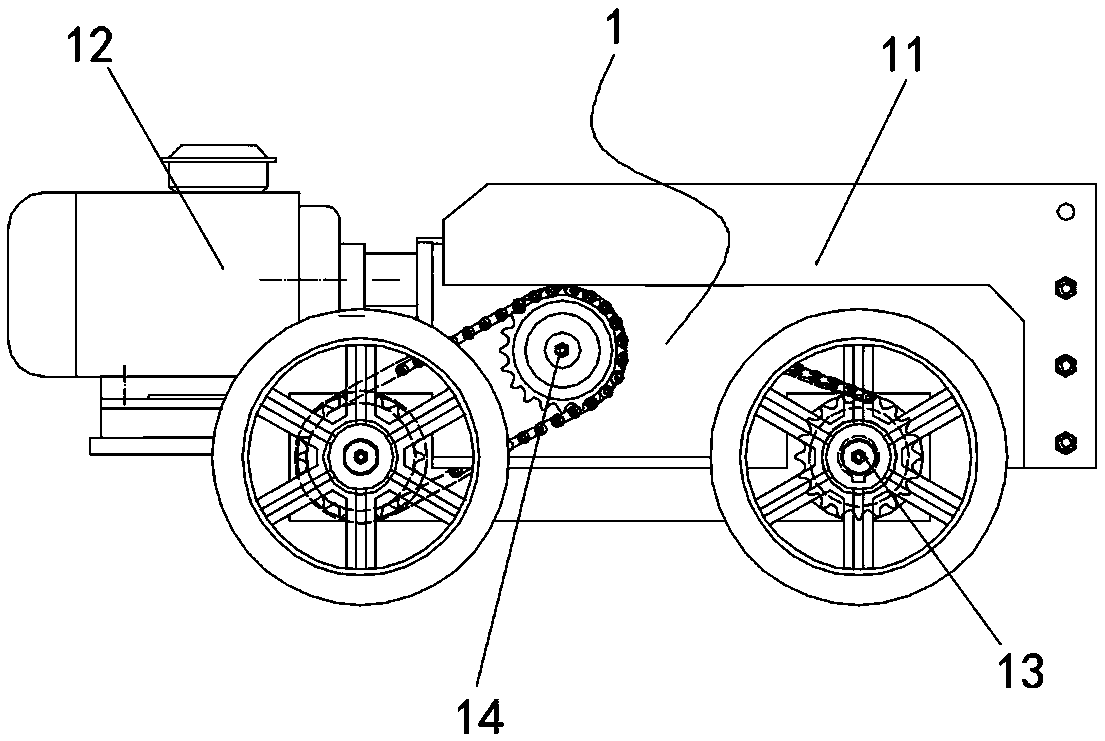

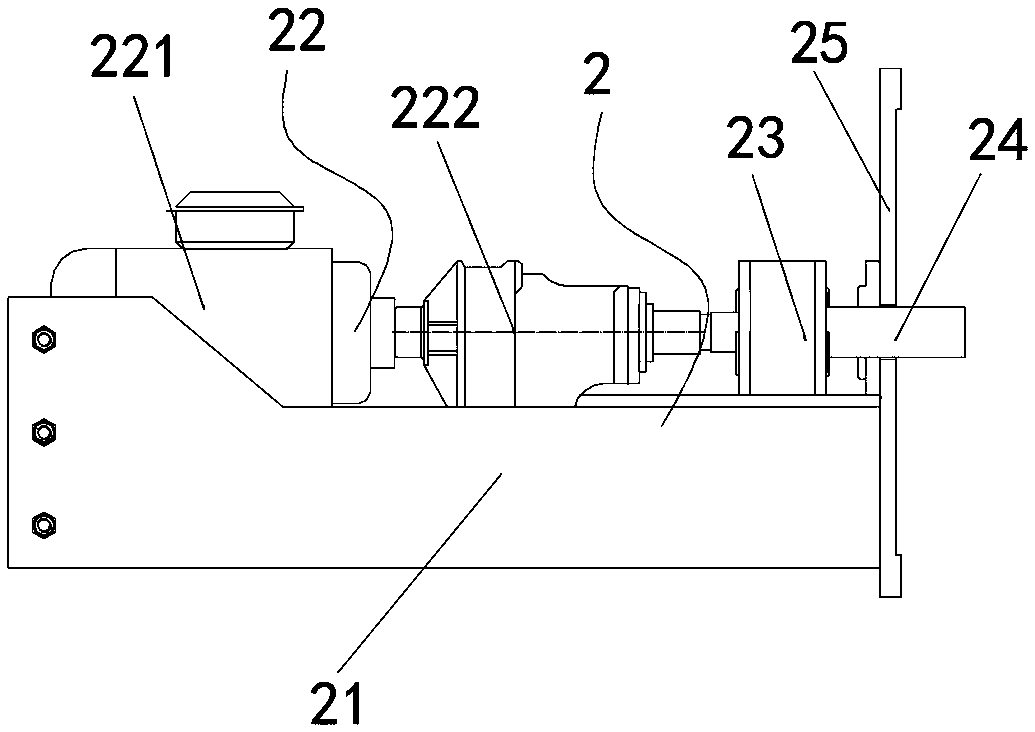

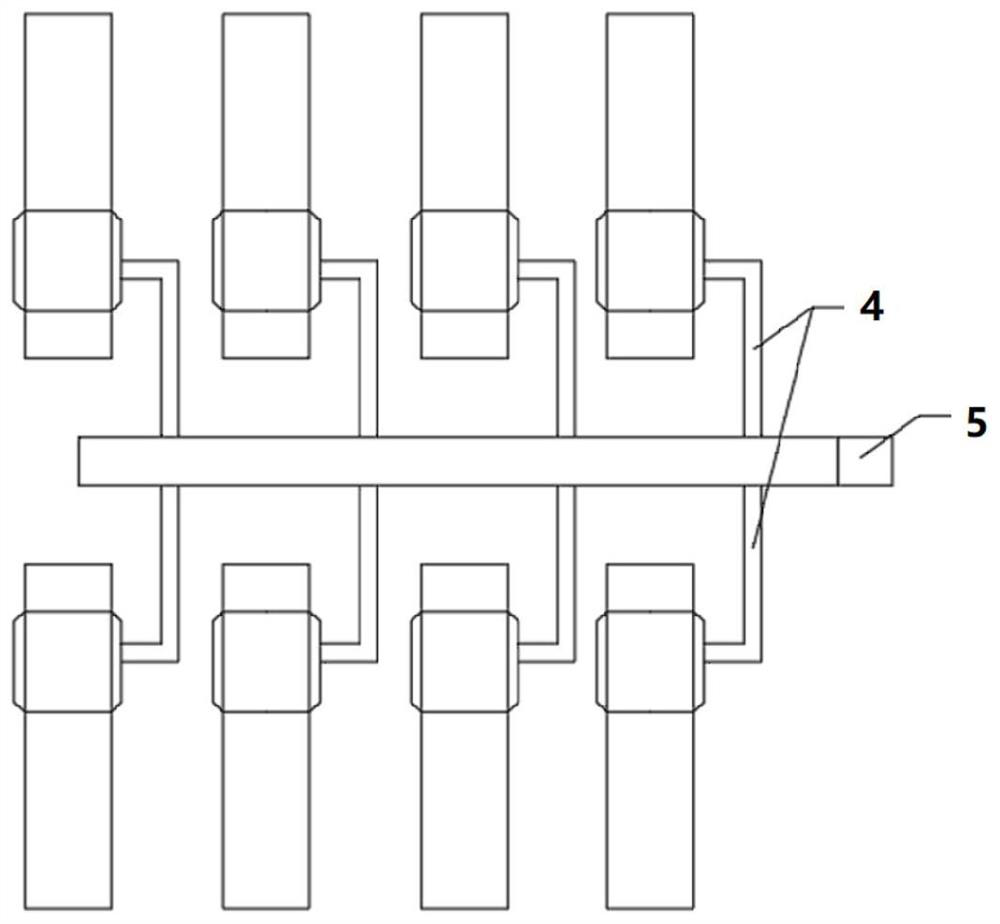

Sewage pipeline repair and structure reinforcement equipment and use method thereof

The invention discloses sewage pipeline repair and structure reinforcement equipment and a use method thereof. The equipment adopts a sectional type detachable design and comprises a walking section,a slurry conveying section, a slurry barrel section, a slurry spraying section and a finishing section from back to front, and adjacent sections are detachably connected, wherein the walking section takes charge of controlling and adjusting movement of the equipment, the slurry conveying section takes charge of stirring and conveying a repair material, the slurry barrel section takes charge of storing the repair material, the slurry spraying section takes charge of spraying the repair material onto a pipeline wall, and the finishing section takes charge of finishing the sprayed repair materialand guaranteeing uniformity and smoothness of coatings. The sectional type detachable design is adopted, the equipment can be lifted in a to-be-repaired pipeline in a sectional type, and mechanical rapid repair under the condition of non-excavation of the sewage pipeline; the slurry spraying section can be quickly and effectively bonding the repair material on the pipeline wall, and repair coatings are uniform, not prone to bubbling, high in adhesion and not prone to peeling; the coating thickness can be adjusted by controlling the spraying speed and / or walking speed, and the equipment is flexible and convenient.

Owner:BEIJING MUNICIPAL ENG RES INST

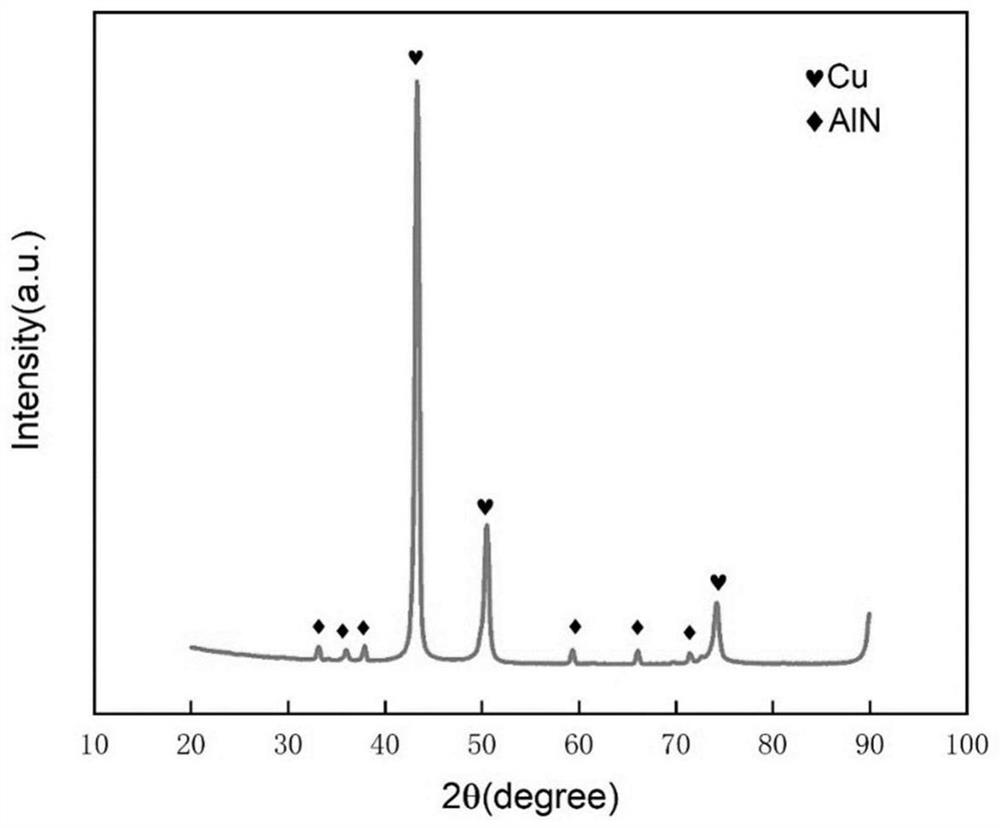

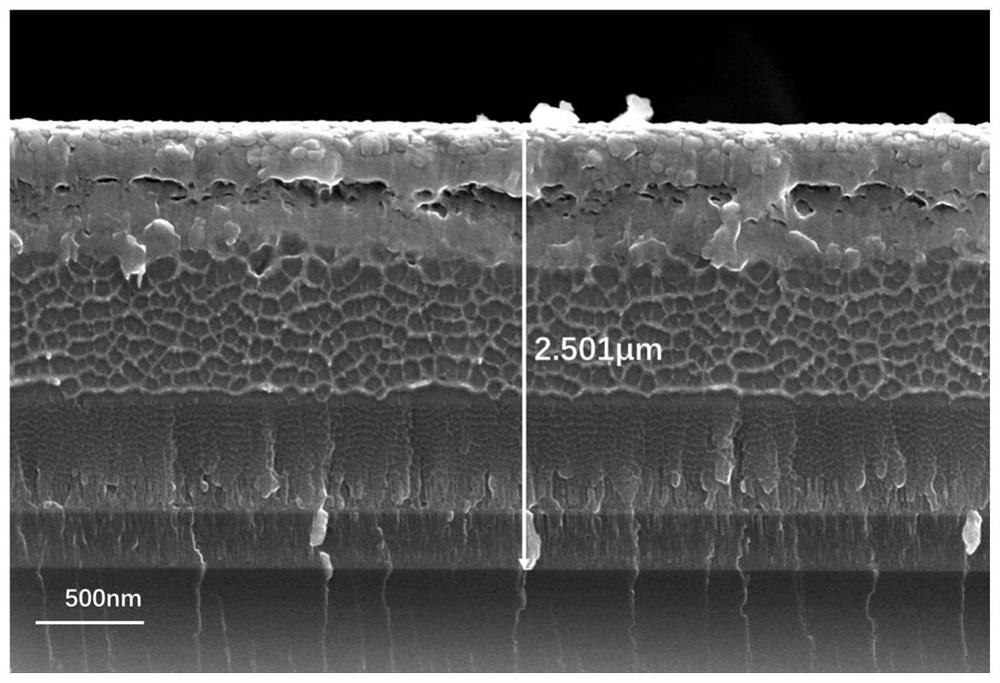

Metallization and heat sink integrated preparation method of AlN ceramic substrate

ActiveCN113174575AImprove package strengthReduce packaging process flowFinal product manufactureSemiconductor/solid-state device detailsDeposition processHeat sink

The invention discloses a metallization and heat sink integrated preparation method of an AlN ceramic substrate. According to the preparation method, a Ti metallization layer, a Ti-Cu gradient transition layer and a Cu heat sink layer are sequentially formed on the AlN ceramic substrate by the aid of a physical vapor deposition technology, and a transition layer Al3Ti+TiN is formed between an AlN layer and a Ti layer in the deposition process. The method specifically comprises the steps that surface polishing treatment is performed on the AlN ceramic substrate; the polished AlN ceramic substrate is soaked, cleaned and then dried; the surface of the cleaned AlN ceramic substrate is sequentially plated with the Ti metallization layer, the Ti-Cu gradient transition layer and the Cu heat sink layer by the aid of a magnetron sputtering deposition method, in the deposition process, the transition layer Al3Ti+TiN is automatically formed between the AlN layer and the Ti layer, and finally, the metallization and heat sink integrated AlN ceramic substrate is formed. According to the method, the metallization and heat sink integrated plating layer is deposited on the AlN ceramic substrate by the aid of the high vacuum magnetron sputtering technology, so that the overall packaging strength is greatly improved, the packaging process flow is shortened, the packaging consumption is reduced, and the production cost is remarkably reduced.

Owner:XI AN JIAOTONG UNIV

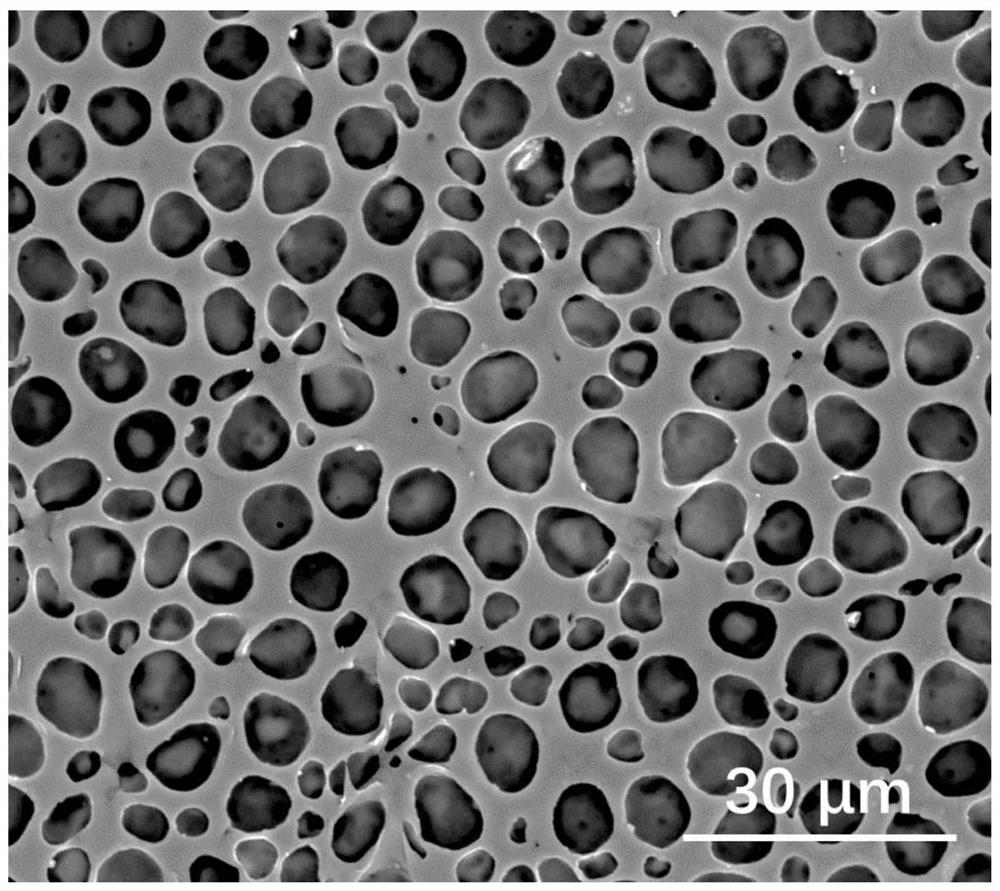

Preparation method of cathode with composite metal layer for rare earth electrolysis

PendingCN113755901AFlexible thickness adjustmentImprove bindingElectrodesIsosceles trapezoidElectrolysis

The invention discloses a preparation method of a cathode with a composite metal layer for rare earth electrolysis. The preparation method comprises the following steps: (1) forming a groove structure of which the cross section is an isosceles trapezoid in a set area by using a tungsten rod matrix; (2) preparing a model layer, and obtaining a tungsten rod matrix containing the model layer, wherein the model layer is made of a high-molecular polymer foam material; (3) coating the surface of the model layer with paint, and obtaining the tungsten rod matrix containing the model layer after being coated with the paint; (4) putting the tungsten rod matrix which is coated with the paint and contains the model layer and obtained in the step (3) in a pouring system, and pouring molten metal liquid; and (5) annealing to obtain the cathode with the composite metal layer for rare earth electrolysis. The cathode prepared by the preparation method is long in service life.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

Stainless steel composite corrosion-resisting reinforcement bar and preparation method thereof

The invention relates to a stainless steel composite corrosion-resisting reinforcement bar and a preparation method thereof. By using the method, the reinforcement bar which has the advantages of good corrosion resistance, low cost, and capability of being produced in batches can be prepared. The diameter of the prepared reinforcement bar is 6 to 40mm, and the reinforcement bar mainly comprises acore metal and a stainless steel alloy layer, wherein the periphery of the core metal is coated with the stainless steel alloy layer along the length direction of the core metal, the core metal and the stainless steel alloy layer are combined in a metallurgical mode, and the thickness of the stainless steel alloy layer is 1 to 10mm.

Owner:HUNAN 3T NEW MATERIAL

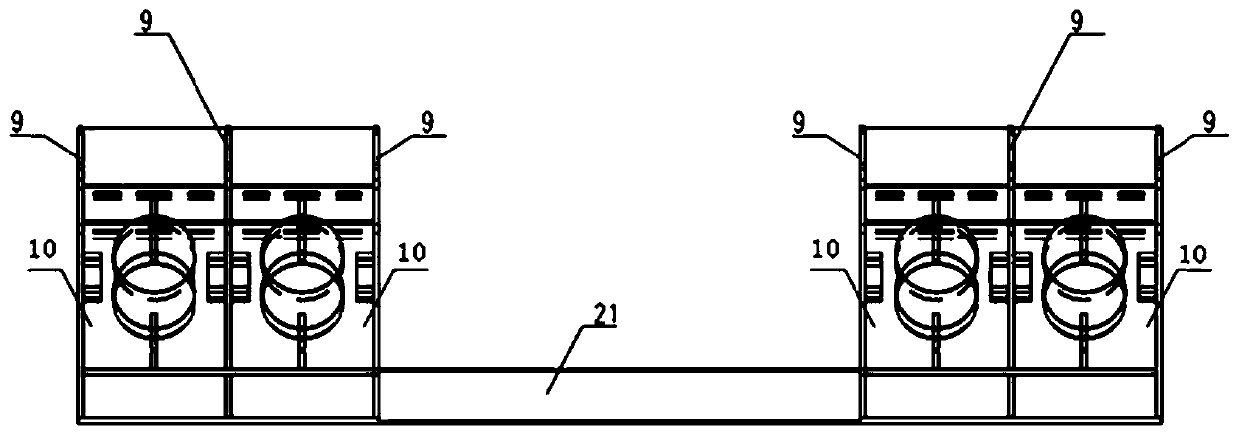

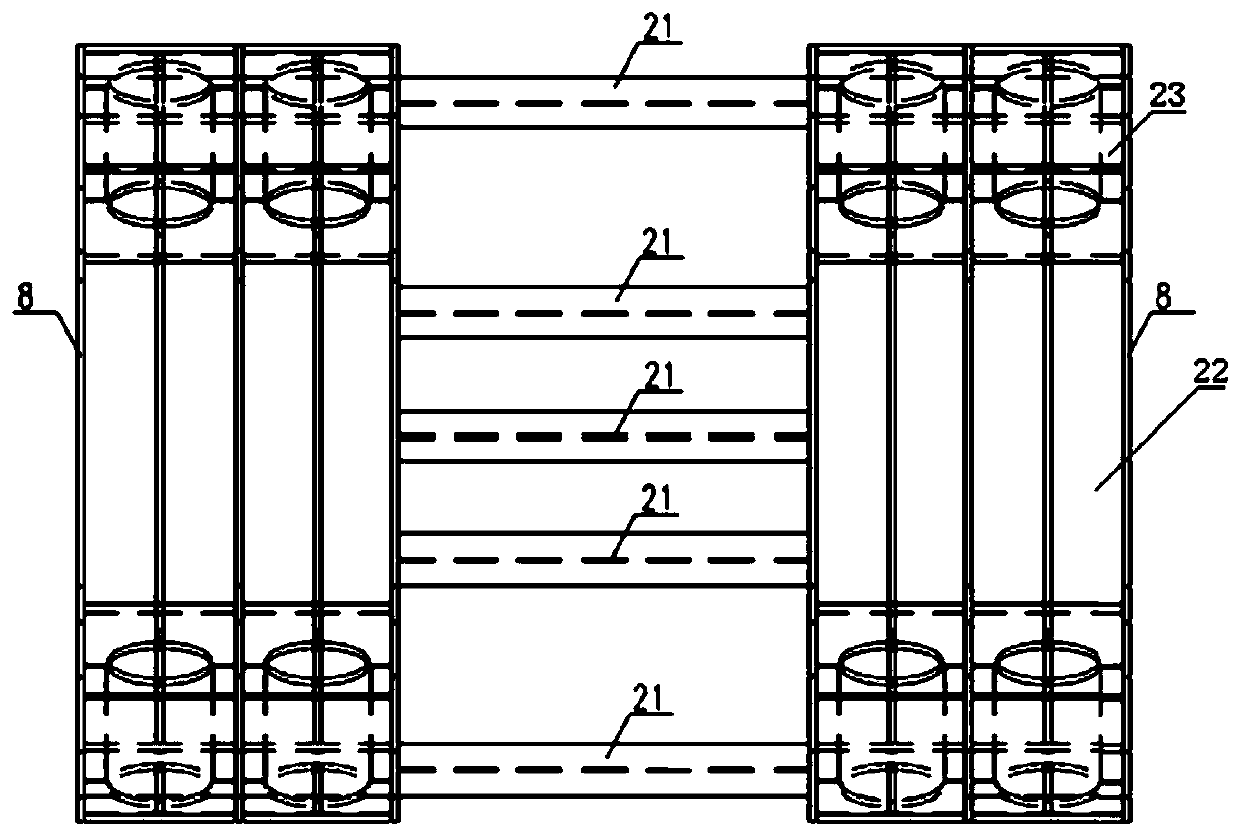

Large span complex channel concrete casting machine

InactiveCN100507162CLabor savingGood for construction machineryClimate change adaptationArtificial water canalsBogieThermal insulation

The present invention relates to a large trapezoidal section canal surface concrete lining executive mechanical equipment. It includes large span steel truss with running mechanism, through up-down bogie i.e. material distribution and lining bogie respectively to make canal concrete material distribution, spreading, bumping down and levelling; not only saving feeding equipment and pouring concrete labour bur also in favor of protecting anti-seepage thermal insulation structure layer.

Owner:SINOHYDRO BUREAU 11 CO LTD

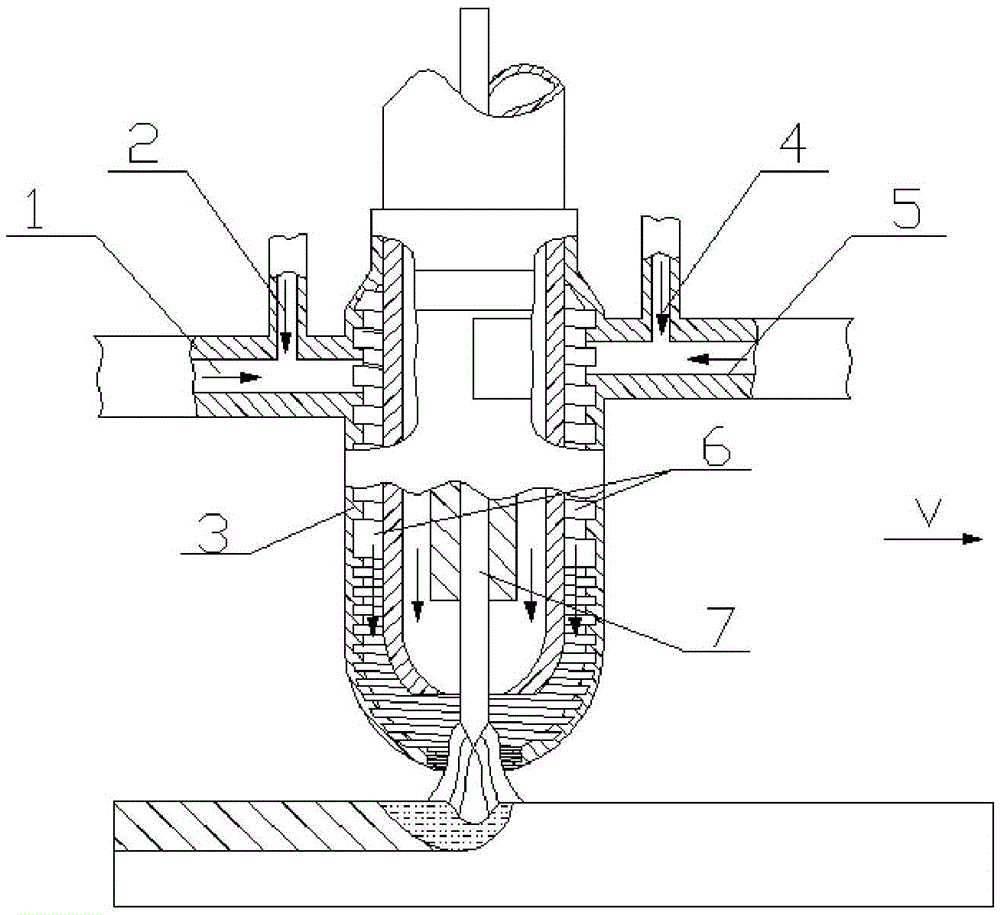

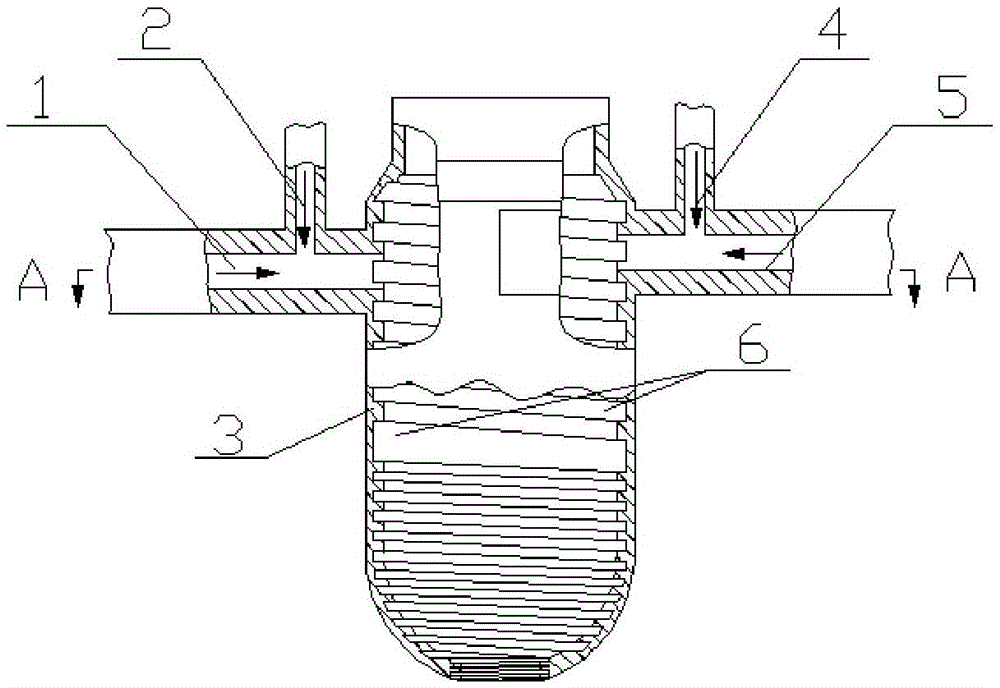

Device for realizing nitrogen increment on surface of steel through nitrogen arc and nitride in-situ metallurgy

ActiveCN105525289ARealize nitrogen increase and high nitrogen temperingAvoid cloggingMetallic material coating processesAfter treatmentIron powder

The invention belongs to the field of surface treatment of materials, and particularly relates to a device and method for realizing nitrogen increment on the surface of steel through nitrogen arc and nitride in-situ metallurgy. Nitride alloy powder and iron powder are mixed evenly through a two-way coaxial spiral air powder cover, heated through a nitrogen arc and then conveyed onto the surface of a steel base material to be treated. Meanwhile, the nitride alloy powder, the iron powder and part of the base material are heated and smelted through the nitrogen arc; a molten pool is stirred through electromagnetic stirring with an electric arc and swinging of a welding gun so that alloy elements in the molten pool and the molten base material are fully smelted and mixed. A high-nitrogen steel layer is formed on the surface of the steel after the molten pool is cooled and solidified. The nitrogen content of the high-nitrogen steel layer obtained after treatment is high and is far lager than the maximum nitrogen content obtained through a common surface nitrogen increment treatment method. Through real-time adjustment of the nitrogen increment process, high-nitrogen steel layers with different components and properties can be obtained.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

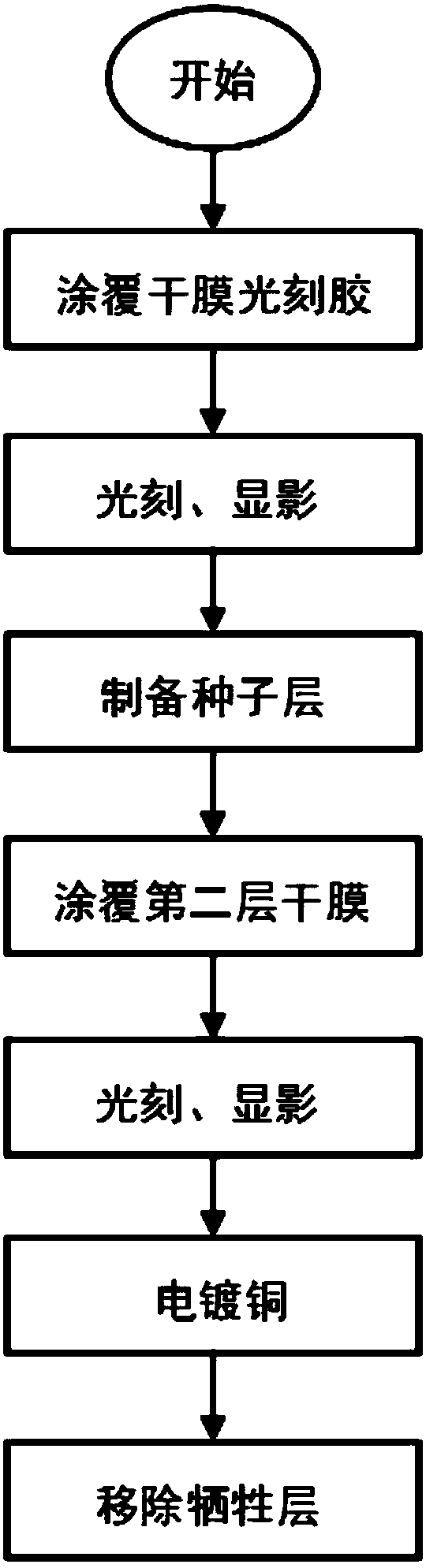

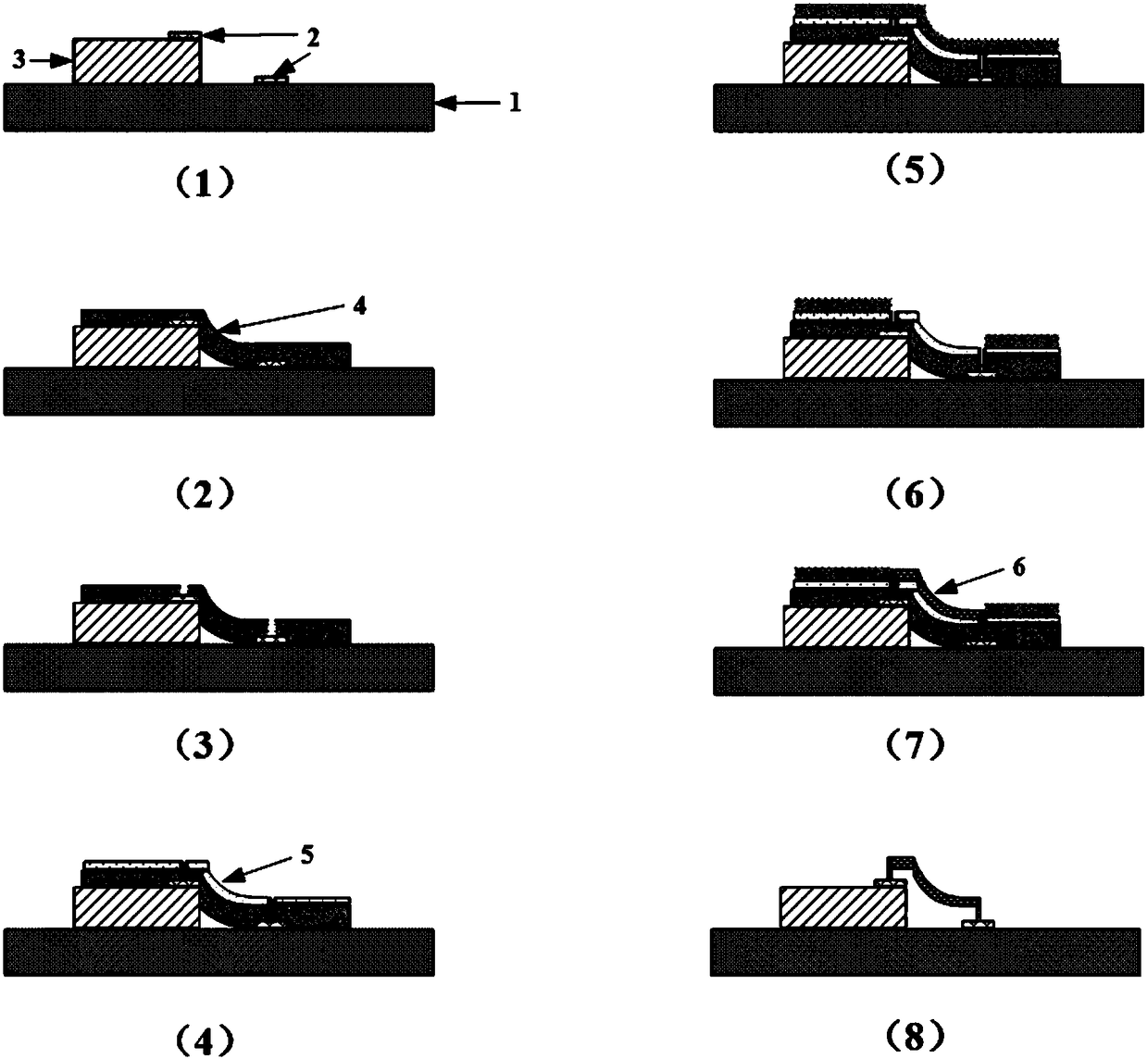

Method for realizing ultra-fine package lead based on photolithography and electroplating

ActiveCN108242433AAchieve connectionSolve Oxidation ProblemsSemiconductor/solid-state device detailsSolid-state devicesUltra fineCopper

The invention discloses a method for realizing ultra-fine package lead based on photolithography and electroplating. The method comprises a step of coating a surface of a substrate with the fixation of a chip and metal pads with a layer of dry film photoresist, a step of carrying out photolithography and development and showing through holes in a dry film on the chip and the metal pads, a step ofpreparing a seed layer on a formed surface, a step of coating the surface of the seed layer with a layer of dry film photoresist, a step of carrying out photolithography and development again such that the through holes on the metal pads and the seed layer under a lead between the through holes are exposed, a step of plating the surface of the exposed seed layer with a layer of copper and forminga lead between the metal pads, and a step of removing the dry film photoresist and the seed layer as sacrificial layers and finally forming a floating lead interconnect structure. According to the method, wire bonding is replaced by the photolithography and electroplating process, the connection between the chip and the substrate pads is achieved, the size of the lead is not restricted by a traditional wire bonding process, and so the feature size of the lead can be further reduced to the precision of photolithography.

Owner:SHANGHAI JIAO TONG UNIV

Double-layer hybrid sandwich weft knitting fabric

The invention relates to the technical field of fabric structures, in particular to a double-layer hybrid sandwich weft knitting fabric. The contrast ratio of a jacquard weaving fabric and other areasof a surface weft layer is achieved by the aid of material differences of yarns of a middle weft layer and the surface weft layer, production processes can be effectively shortened, cost is saved, the thickness of the jacquard weaving fabric can be flexibly adjusted, and breathability, heat retention properties and protective properties of the sandwich weft knitting fabric are achieved. As the hybrid jacquard weaving fabric and the sandwich weft knitting fabric can be woven once, respectively weaving is omitted, any staggered structure of the hybrid jacquard weaving fabric and the sandwich weft knitting fabric can be formed on the same fabric once, and any jacquard weaving shape can be effectively processed.

Owner:FUJIAN HUAFENG NEW MATERIALS

A kind of manufacturing method of multi-purpose zinc-clad steel

The invention belongs to the technical field of electric power, and particularly relates to a manufacturing method of multi-purpose zinc clad steel. The manufacturing method comprises the following steps that chemical-free environment-friendly treatment is performed on the surfaces of steel wires; surface cleaning treatment is performed on the steel wires by the aid of a belt sander; the cleaned steel wires are heated by an intermediate-frequency furnace, then the steel wires and two zinc rods enter a continuous cladding machine simultaneously for extruding, the zinc clad steel is obtained, the heating temperature of the intermediate-frequency furnace is controlled to range from 200 DEG C to 250 DEG C, an extruding mold and a guiding mold are assembled on the cladding machine according tothe product requirements, the nasal fossa sizes for mold assembly are controlled to range from 3 mm to 6 mm according to the diameters of the steel wires, the mold cavity temperatures are controlled to range from 150 DEG C to 250 DEG C, the rotating speed of an extruding wheel is controlled to range from 3 rpm to 7 rpm, and the extruding speed is controlled to range from 70 m / min to 120 m / min; andcomposite metal drawing is performed on zinc clad steel busbars after cladding. According to the method, the whole production process is free of chemical pollution, the method is different from all existing zinc clad steel technologies, and flexible production is realized.

Owner:HENAN TONG CABLE

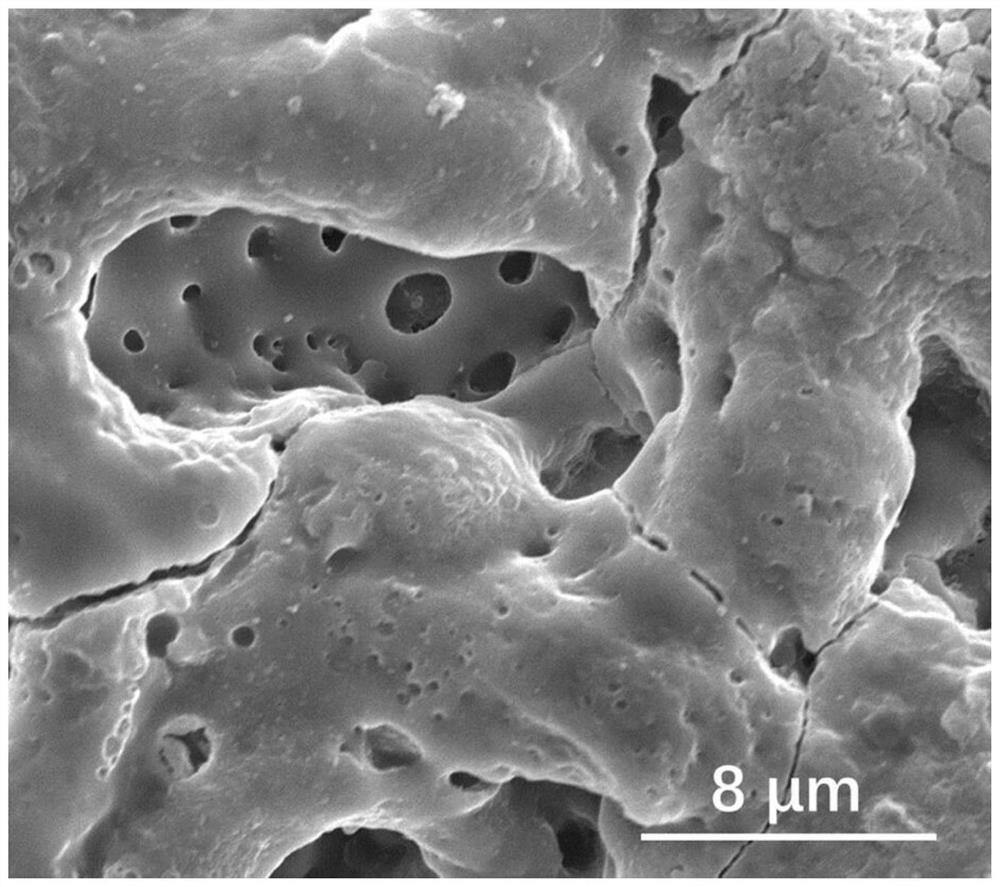

Hole sealing method for micro-arc oxidation film layer

ActiveCN112064091AImprove corrosion resistanceMacro surface smoothingAnodisationProsthesisMicro arc oxidationMetallurgy

The invention discloses a hole sealing method for a micro-arc oxidation film layer. The hole sealing method for the micro-arc oxidation film layer comprises the following steps of 1) cleaning and drying magnesium / magnesium alloy with the micro-arc oxidation film layer; 2) preparing a polycaprolactone solution; 3) dipping the magnesium / magnesium alloy with the micro-arc oxidation film layer in thepolycaprolactone solution; 4) performing vacuum drying on the dipped magnesium / magnesium alloy with the micro-arc oxidation film layer; 5) repeating the steps 3) and 4) for multiple times; and 6) putting the magnesium / magnesium alloy with the micro-arc oxidation film layer treated in the step 5) into a closed container, heating until the temperature in the closed container exceeds a melting pointof polycaprolactone, pressurizing and holding, cooling to the room temperature, and reducing the pressure. According to the hole sealing method for the micro-arc oxidation film layer provided by the invention, the micro-arc oxidation film layer is subjected to hole sealing through a dipping-dip coating-curing method, so that the macroscopic surface of the material can be smooth, and hole sealing is firm; and then micropores are sealed through heating, pressurizing, cooling and pressure reducing operation, so that the corrosion resistance of the magnesium / magnesium alloy is greatly improved onthe basis of the micro-arc oxidation film layer.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

Hollow corrugated plate type film embossing system

InactiveCN109794171AImprove throughputFlexible thickness adjustmentSemi-permeable membranesMechanical engineering

The invention discloses a hollow corrugated plate type film embossing system. The system comprises an unwinding part a, an unwinding part b, an unwinding part c, an unwinding part d, a winding part and a fixed embossing part, wherein the fixed embossing part is connected with a movable embossing part through a rail a. The hollow corrugated plate type film embossing system is used for producing hollow corrugated plate type films and has high production efficiency, and the produced hollow corrugated plate type films have a large flux. By adjusting the gaps between the parts, the embossing depth,the gluing amount, the glue coating thickness and the thickness of finished products of the hollow corrugated plate films can be flexibly adjusted, and a variety of different hollow corrugated platefilms can be produced.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com