Large span complex channel concrete casting machine

A comprehensive, concrete technology, applied in the field of machinery and equipment, can solve the problems of unfavorable protection of anti-seepage geomembrane and insulation board, inability to operate continuously in a large area, and many personnel involved in the operation surface, achieving high promotion and utilization value and compact structure , to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

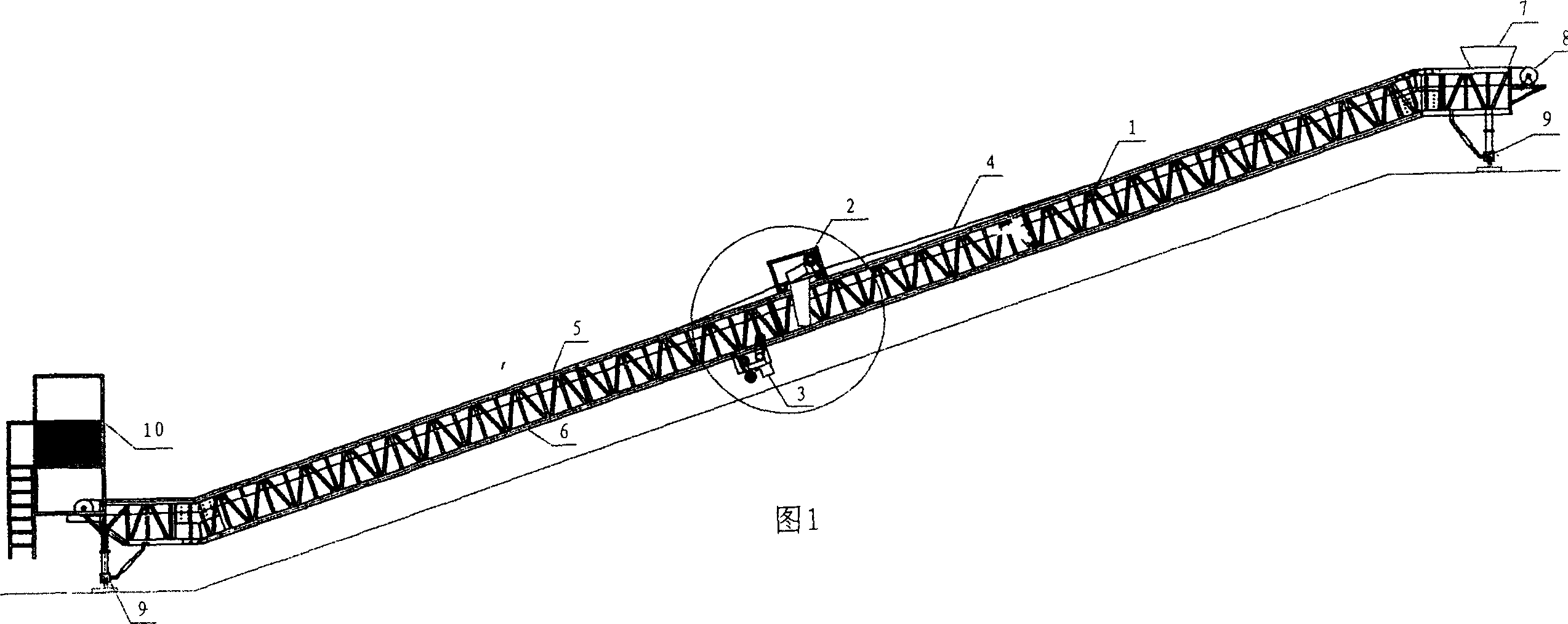

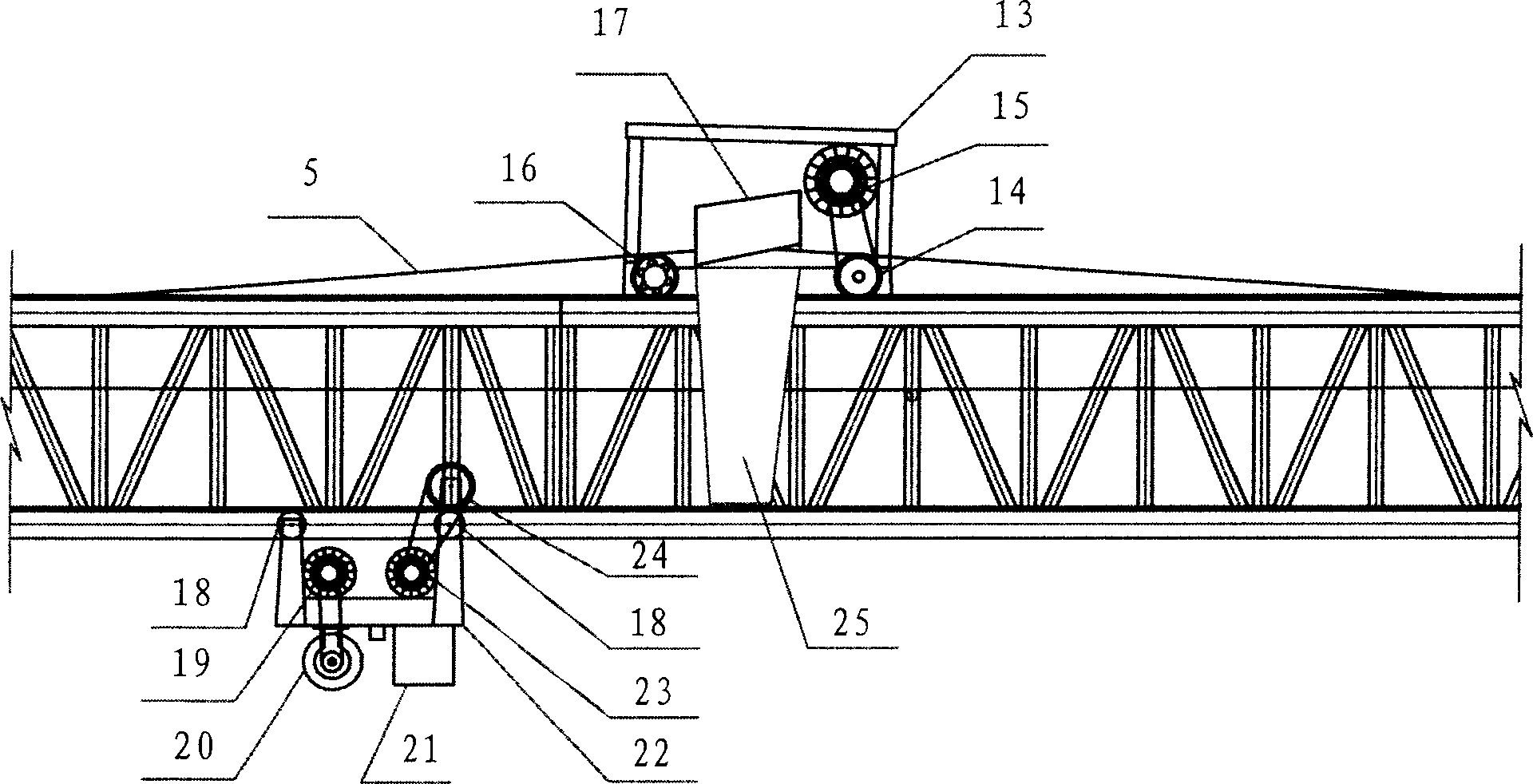

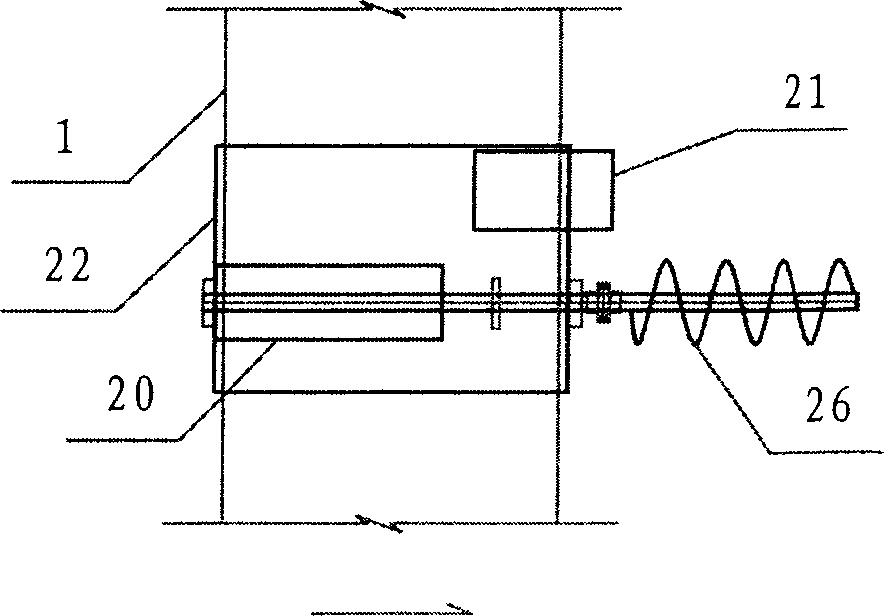

[0020] The present invention comprises a main truss 1, a truss traveling device 9 arranged at both ends of the main truss 1, a driving device operating room 10 of the truss traveling device 9, an upper trolley track 5 and a lower trolley track 6 arranged on the main truss 1, and a trolley track 6 arranged on the upper The cloth trolley 2 on the trolley track 5 that can walk on the upper trolley track 5, the lining trolley 3 that is hung on the lower trolley track 6 and can walk on the lower trolley track 6, and the fabric trolley 2 is provided with a transmission motor driven by the upper trolley. 15. The walking device composed of the main traveling wheel 13 of the upper trolley and the traveling wheel 14 of the upper trolley, the lining trolley 3 is provided with a traveling device consisting of the traveling transmission motor 22 of the lower trolley, the main traveling wheel 19 of the lower trolley and the traveling wheel 20 of the lower trolley, The main truss 1 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com