Method for preparing titanium-coated low-carbon steel composite plate

A low-carbon steel and low-carbon steel technology, applied in pressure inorganic powder coating and other directions, can solve the problems of low yield of titanium materials, difficulty in obtaining titanium-steel composite plates, etc., achieving good controllability, high composite strength, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

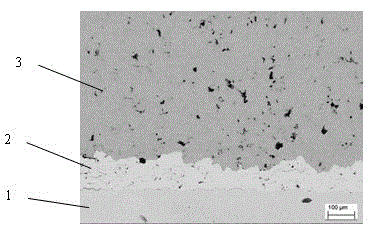

Image

Examples

Embodiment 1

[0027] The preparation method in the present embodiment comprises the following steps:

[0028] (1) Material preparation: use 200mm×100mm×10mm low-carbon steel (IF) steel plate with a thickness of 10mm as the substrate, and low-oxygen and low-hydrogen high-purity titanium powder obtained by hydrogenation dehydrogenation as the titanium coating raw material, using gas The spherical 304 stainless steel powder produced by the atomization method is the raw material for the transition layer. Among them, the particle size distribution range of pure titanium powder is 5-100 um, the average particle size is 32 um, and the particle shape is irregular; the particle size distribution range of 304 stainless steel powder is 10-80 um, the average particle size is 32 um, and the particle shape is spherical ;

[0029] (2) Substrate pre-treatment: The treatment method is to remove the surface oxide layer by sandblasting first, and then use high-pressure gas to blow off the sandblasting residu...

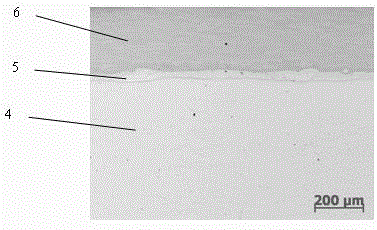

Embodiment 2

[0034] The preparation method in the present embodiment comprises the following steps:

[0035] (1) Preparation of materials Q235 steel plate with a thickness of 200mm×100mm×5mm and a thickness of 5mm is selected as the substrate, and low-oxygen and low-hydrogen high-purity titanium powder obtained by hydrodehydrogenation is used as the raw material for titanium cladding. The particle size distribution range of pure titanium powder is 5-100 um, the average particle size is 32 um, and the particle shape is irregular; the particle size distribution range of 304 stainless steel powder is 10-50 um, the average particle size is 35 um, and the particle shape is spherical;

[0036] (2) Substrate pre-treatment: The treatment method is to remove the surface oxide layer by sandblasting first, and then use high-pressure gas to blow off the sandblasting residue.

[0037] (3) Deposition of the transition layer by high-speed spray deposition method: the above-mentioned 304 stainless steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com