Double-layer hybrid sandwich weft knitting fabric

A mixed knitting, double-layer technology, applied in the direction of weft knitting, textiles, papermaking, knitting, etc., can solve the problems of increased processing costs, insignificant pattern or logo effect, etc., to save costs, achieve air permeability, and shorten the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

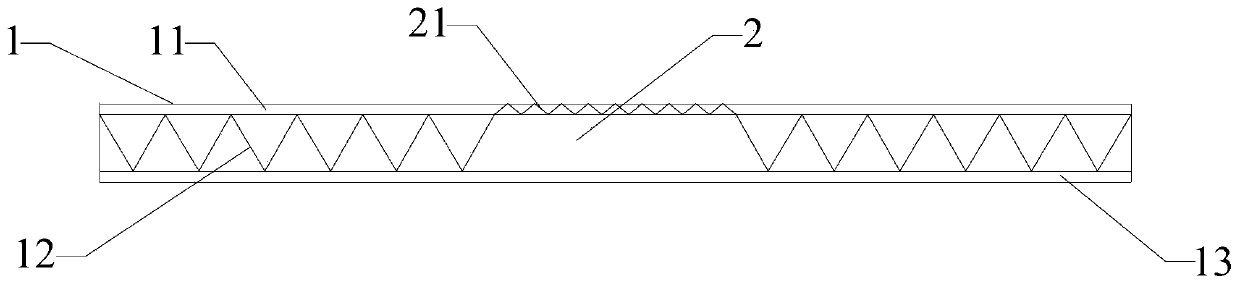

[0033] A double-layer mixed-knitted sandwich weft-knitted fabric, comprising a sandwich weft-knitted fabric body 1 and a jacquard part 2 arranged on the sandwich weft-knitted fabric body 1, and the sandwich weft-knitted fabric body 1 includes surfaces arranged in sequence from outside to inside Weft yarn layer 11, middle weft yarn layer 12 and inside weft yarn layer 13, described middle weft yarn layer 12 is the upright weaving form, and described jacquard part 2 comprises the mixed weaving layer 21 of middle weft yarn layer 12 and surface weft yarn layer 11 mixed knitting, so The thickness of the blended layer 21 is smaller than the stacked thickness of the surface weft layer 11 and the middle weft layer 12 .

[0034] The inner weft yarn layer 13 covers the inner surface of the jacquard part 2 .

[0035] The linear density of the surface weft yarn layer 11 is 75D.

[0036] The linear density of the middle weft yarn layer 12 is 40D.

[0037] The linear density of the inner w...

Embodiment 2

[0042] A double-layer mixed-knitted sandwich weft-knitted fabric, comprising a sandwich weft-knitted fabric body 1 and a jacquard part 2 arranged on the sandwich weft-knitted fabric body 1, and the sandwich weft-knitted fabric body 1 includes surfaces arranged in sequence from outside to inside Weft yarn layer 11, middle weft yarn layer 12 and inside weft yarn layer 13, described middle weft yarn layer 12 is the upright weaving form, and described jacquard part 2 comprises the mixed weaving layer 21 of middle weft yarn layer 12 and surface weft yarn layer 11 mixed knitting, so The thickness of the blended layer 21 is smaller than the stacked thickness of the surface weft layer 11 and the middle weft layer 12 .

[0043] The inner weft yarn layer 13 covers the inner surface of the jacquard part 2 .

[0044] The linear density of the surface weft yarn layer 11 is 30D.

[0045] The linear density of the middle weft yarn layer 12 is 30D.

[0046] The linear density of the inner w...

Embodiment 3

[0051]A double-layer mixed-knitted sandwich weft-knitted fabric, comprising a sandwich weft-knitted fabric body 1 and a jacquard part 2 arranged on the sandwich weft-knitted fabric body 1, and the sandwich weft-knitted fabric body 1 includes surfaces arranged in sequence from outside to inside Weft yarn layer 11, middle weft yarn layer 12 and inside weft yarn layer 13, described middle weft yarn layer 12 is the upright weaving form, and described jacquard part 2 comprises the mixed weaving layer 21 of middle weft yarn layer 12 and surface weft yarn layer 11 mixed knitting, so The thickness of the blended layer 21 is smaller than the stacked thickness of the surface weft layer 11 and the middle weft layer 12 .

[0052] The inner weft yarn layer 13 covers the inner surface of the jacquard part 2 .

[0053] The linear density of the surface weft yarn layer 11 is 150D.

[0054] The linear density of the middle weft yarn layer 12 is 150D.

[0055] The linear density of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com