Device for realizing nitrogen increment on surface of steel through nitrogen arc and nitride in-situ metallurgy

An in-situ metallurgy and nitride technology, applied in metal material coating process, coating, etc., can solve the problems of drying time, ineffective effect, hydrogen-induced cracks, etc., and achieve simple operation, high bonding strength, good The effect of high strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

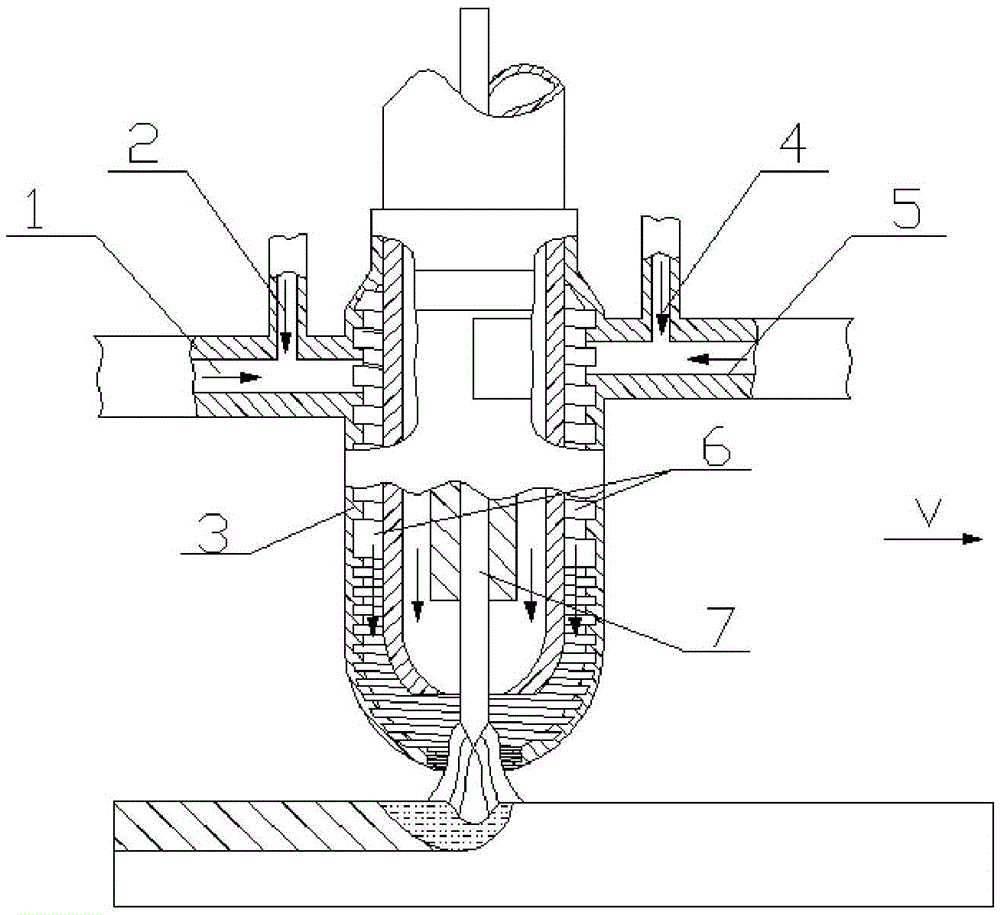

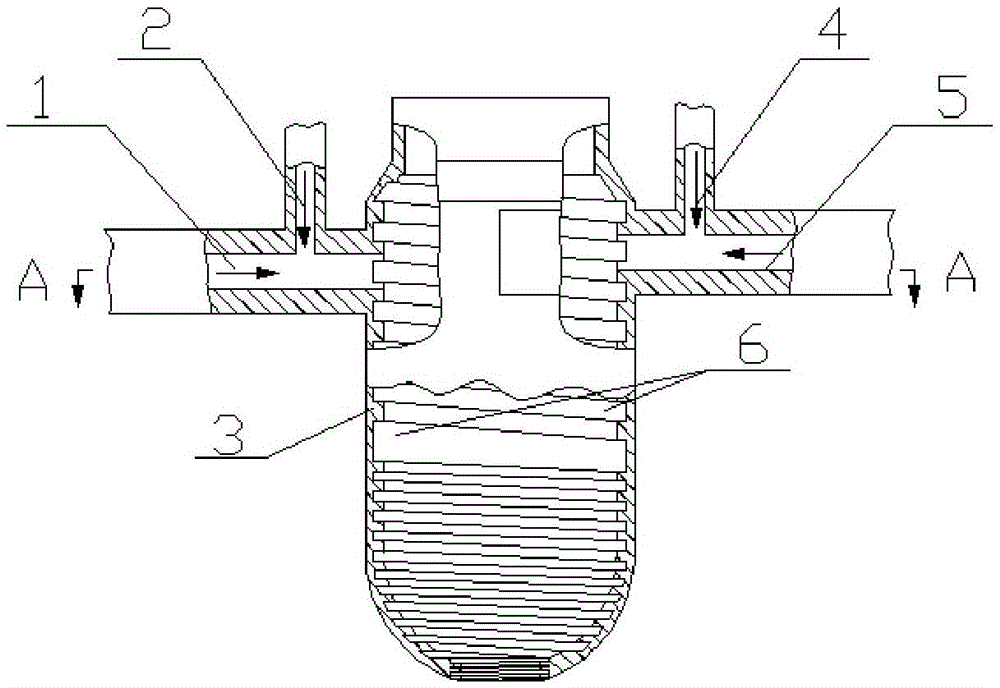

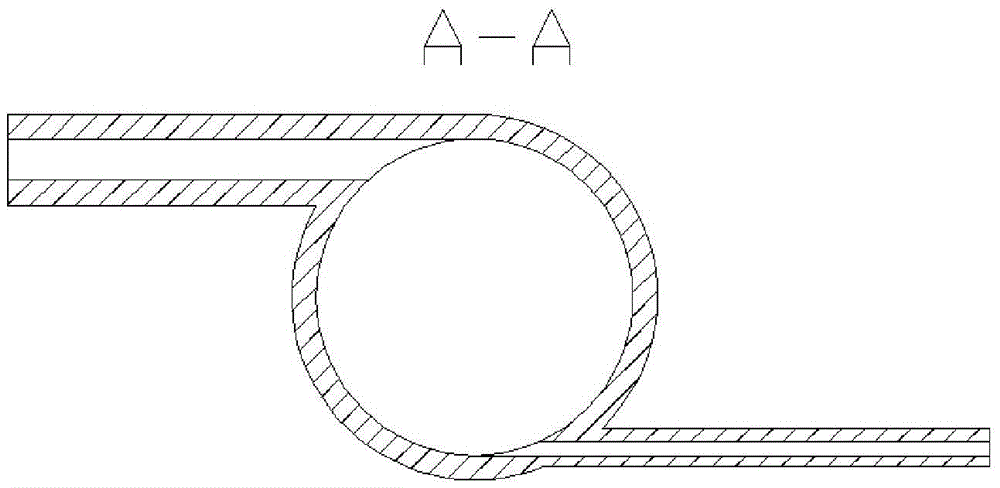

[0059] Use such as figure 1 In the device shown, nitrogen arc and nitride in-situ metallurgy are used to realize nitrogen addition on the steel surface, and a high nitrogen steel layer with a thickness of 2 mm is obtained on the surface of Q235B steel. The target composition of the high nitrogen steel layer is shown in Table 1.

[0060] Table 1 Chemical composition requirements (%) of the target high nitrogen steel layer

[0061] chemical composition

N

Mn

Cr

Mo

Si

C

Fe

Standard specification

0.8-2.4

12-18

18-23

1.0-2.5

≤1

≤0.1

margin

[0062] Adopt the method of the present invention to adopt nitrogen arc and nitride in-situ metallurgy to realize nitrogen increase on steel surface, and its specific steps are:

[0063] Step 1: Determine the iron content W through the target alloy composition of the target high nitrogen steel layer Fe %; determine the iron powder as the powder feeding raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com