A method of nitrogen arc in-situ metallurgy pre-laying nitride to realize nitrogen increase on steel surface

An in-situ metallurgy and nitride technology, applied in arc welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of hydrogen-induced cracks, insignificant effect, and drying time, etc., and achieve good high-strength corrosion resistance, High bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

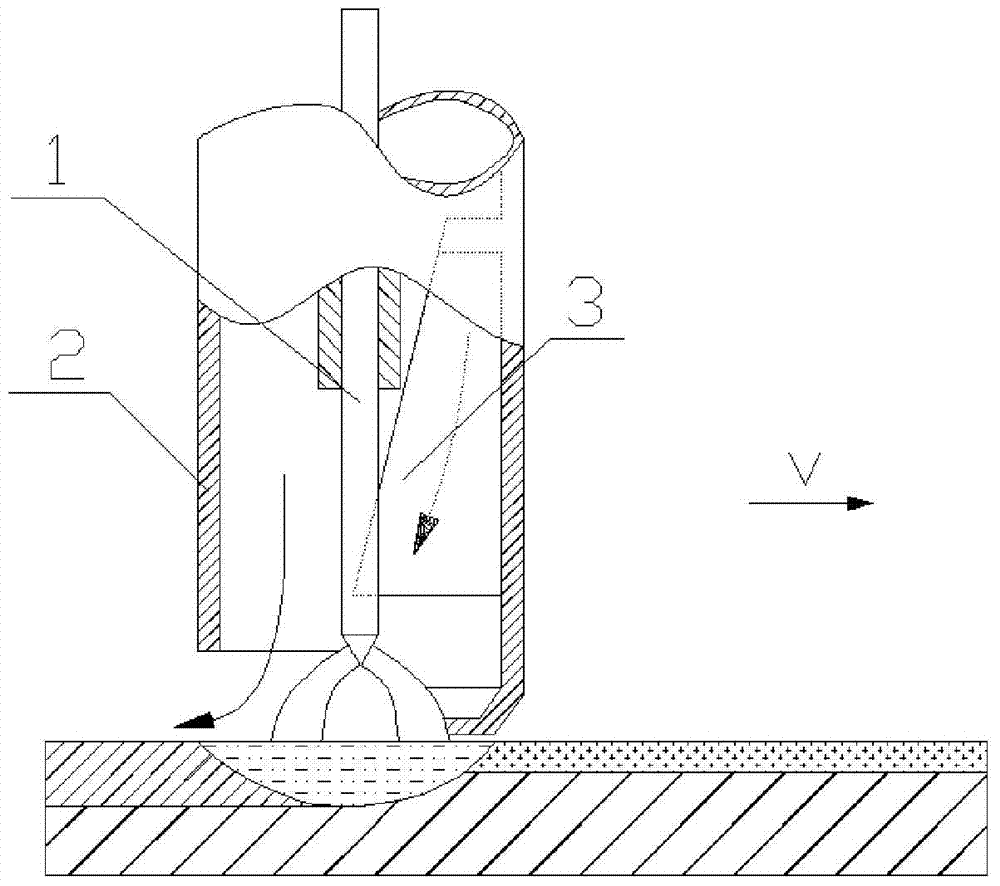

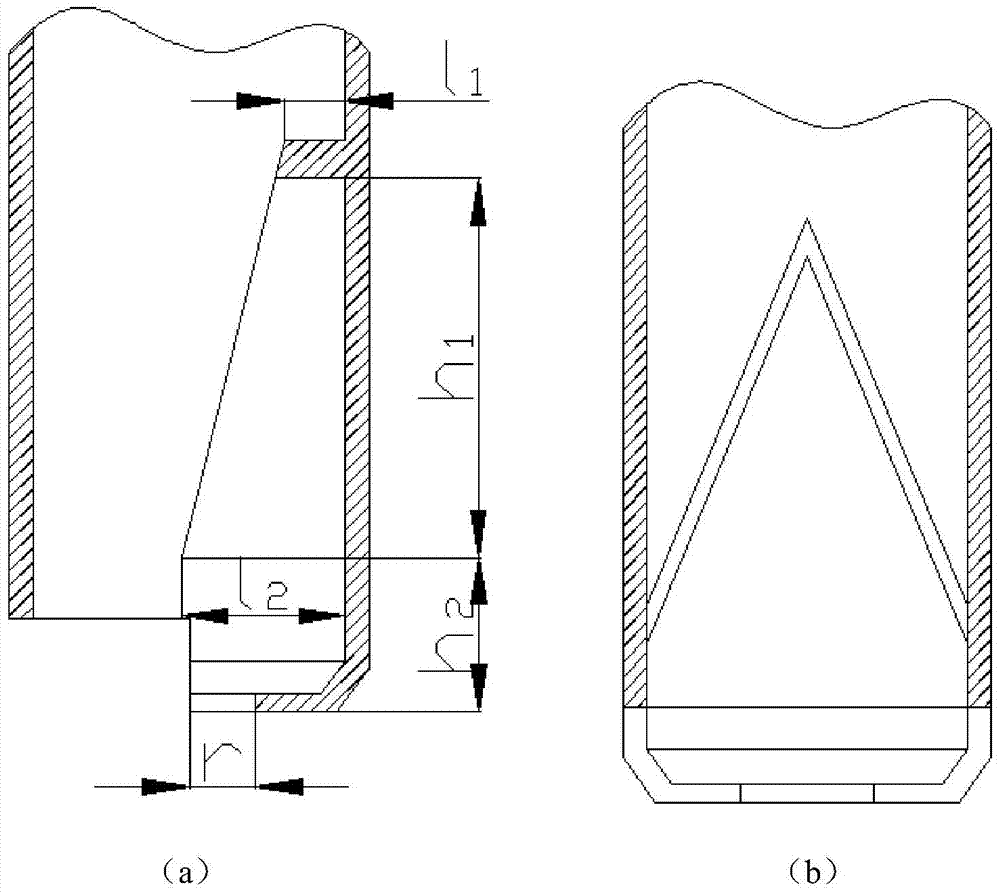

[0041] A method for increasing nitrogen on the steel surface by using nitrogen arc and nitride composite in-situ metallurgy according to the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

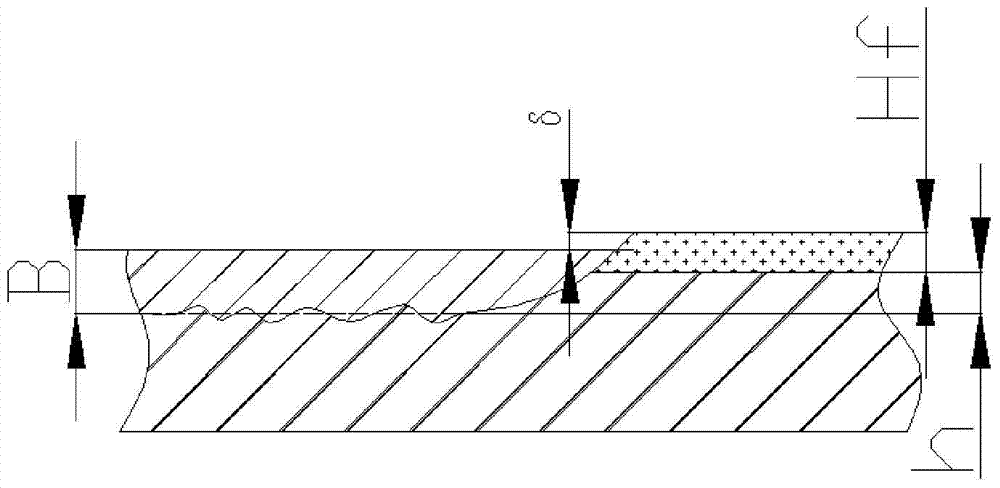

[0042] use as figure 1 The device shown uses nitrogen arc and nitride in-situ metallurgy to increase nitrogen on the steel surface, and obtains a high-nitrogen steel layer with a thickness of 2 mm on the surface of Q235B steel. The target composition of the high nitrogen steel layer is shown in Table 1.

[0043] Table 1 The chemical composition requirements of the target high nitrogen steel layer (%)

[0044] chemical composition

N

mn

Cr

Mo

Si

C

Fe

standard specification

0.8-2.4

12-18

18-23

1.0-2.5

≤1

≤0.1

margin

[0045]The present invention adopts nitrogen arc as a nitrogen atmosphere electric arc, including electric arc and plasma arc; first, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com