Patents

Literature

368results about "Support devices with shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

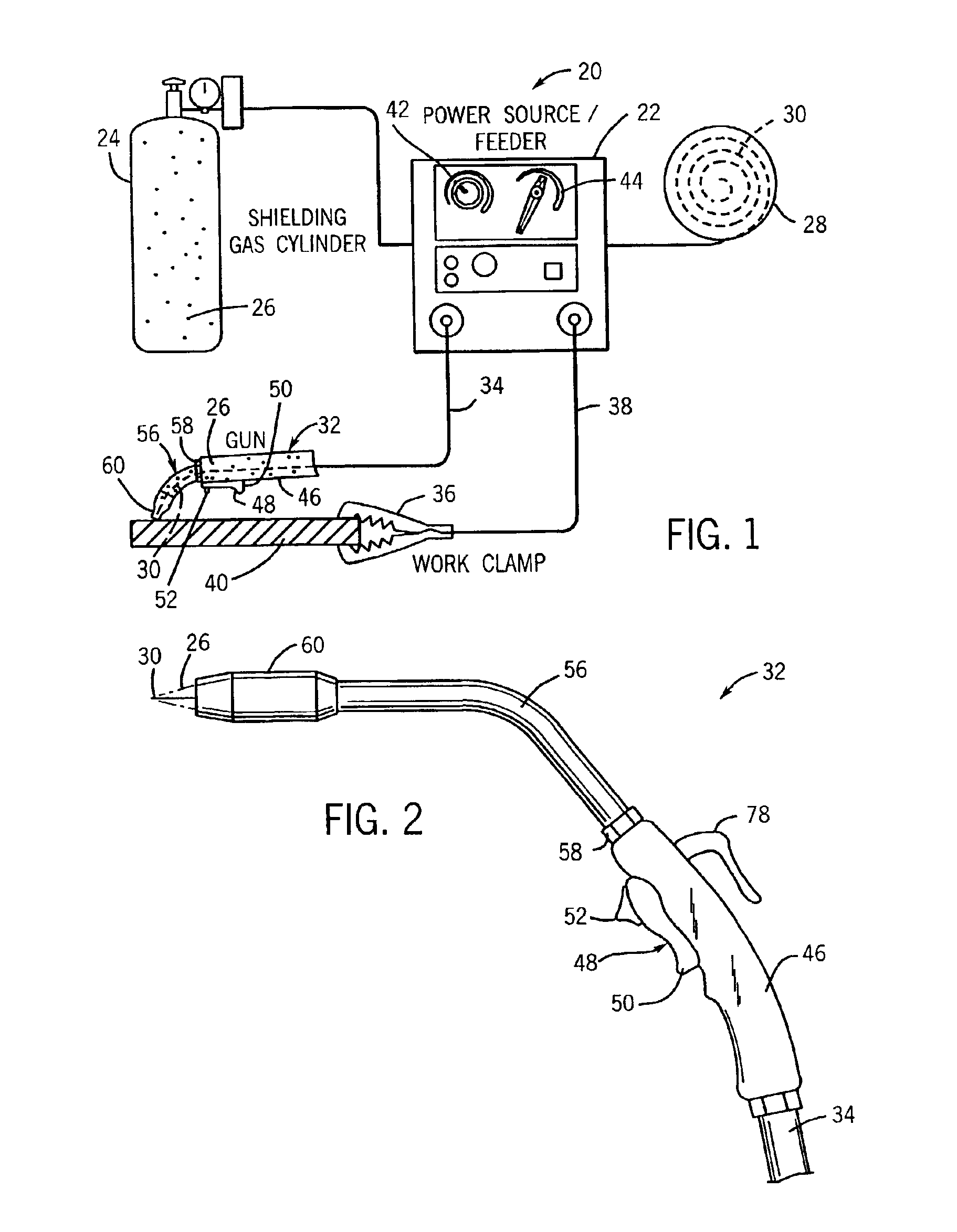

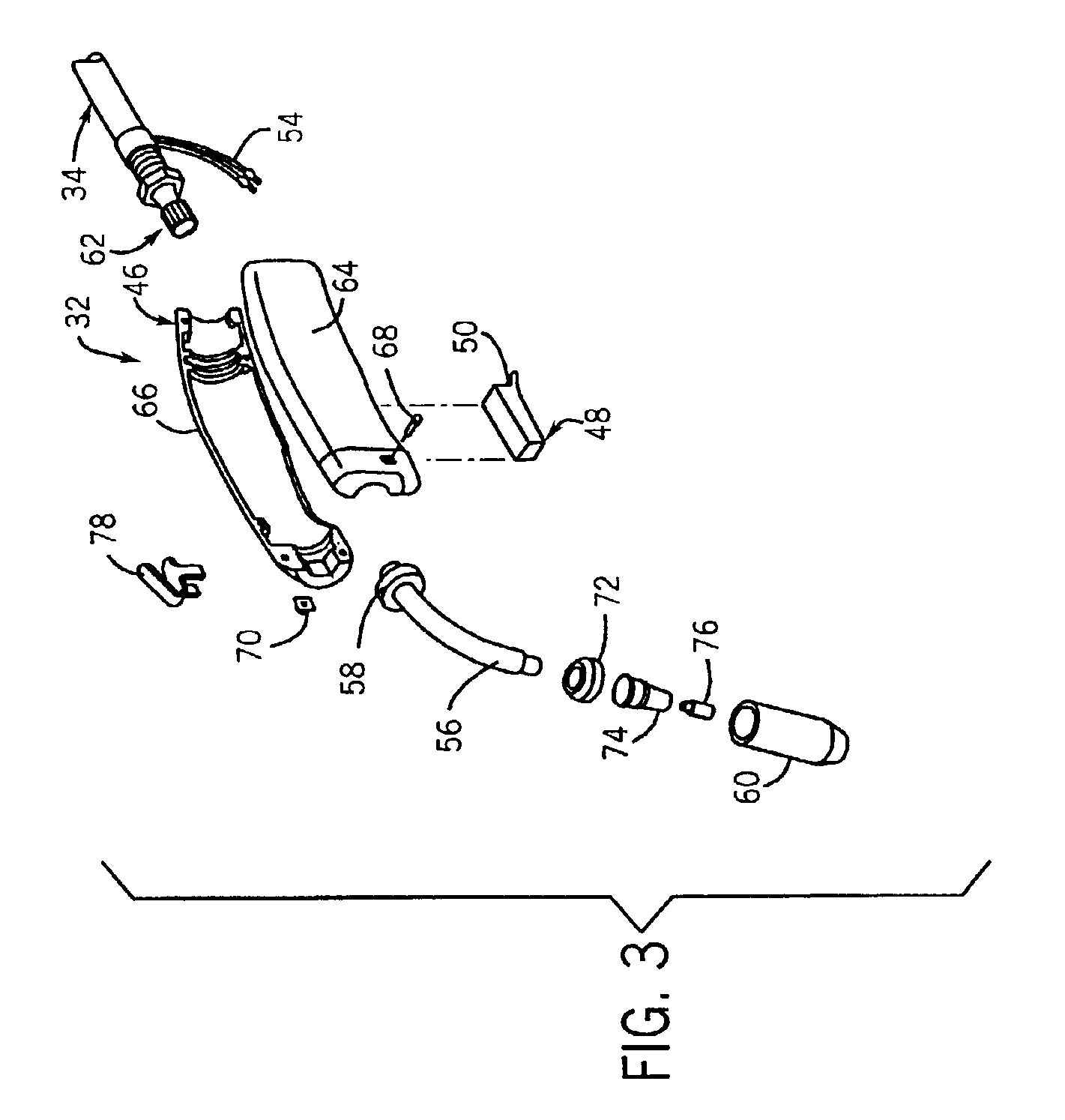

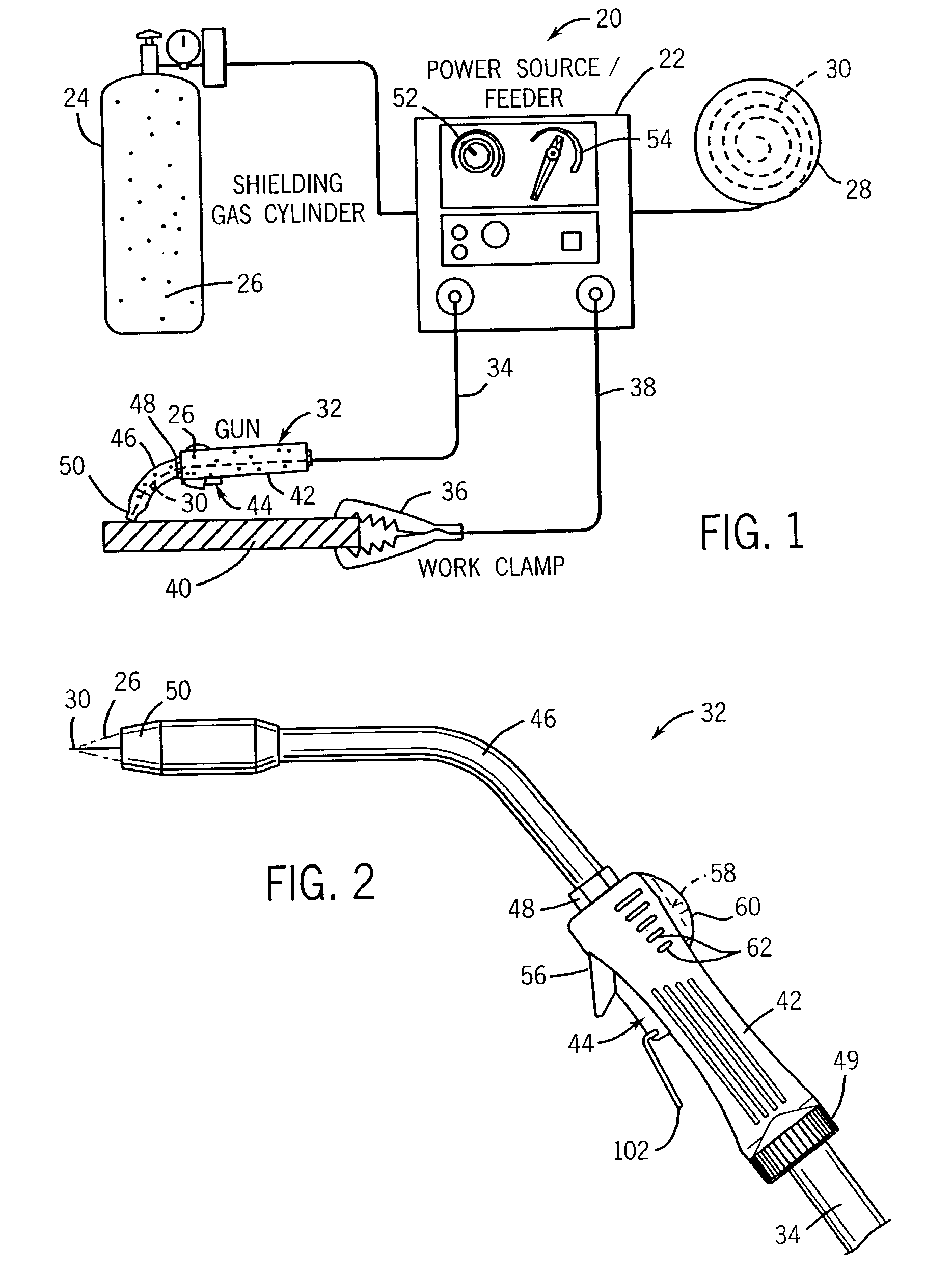

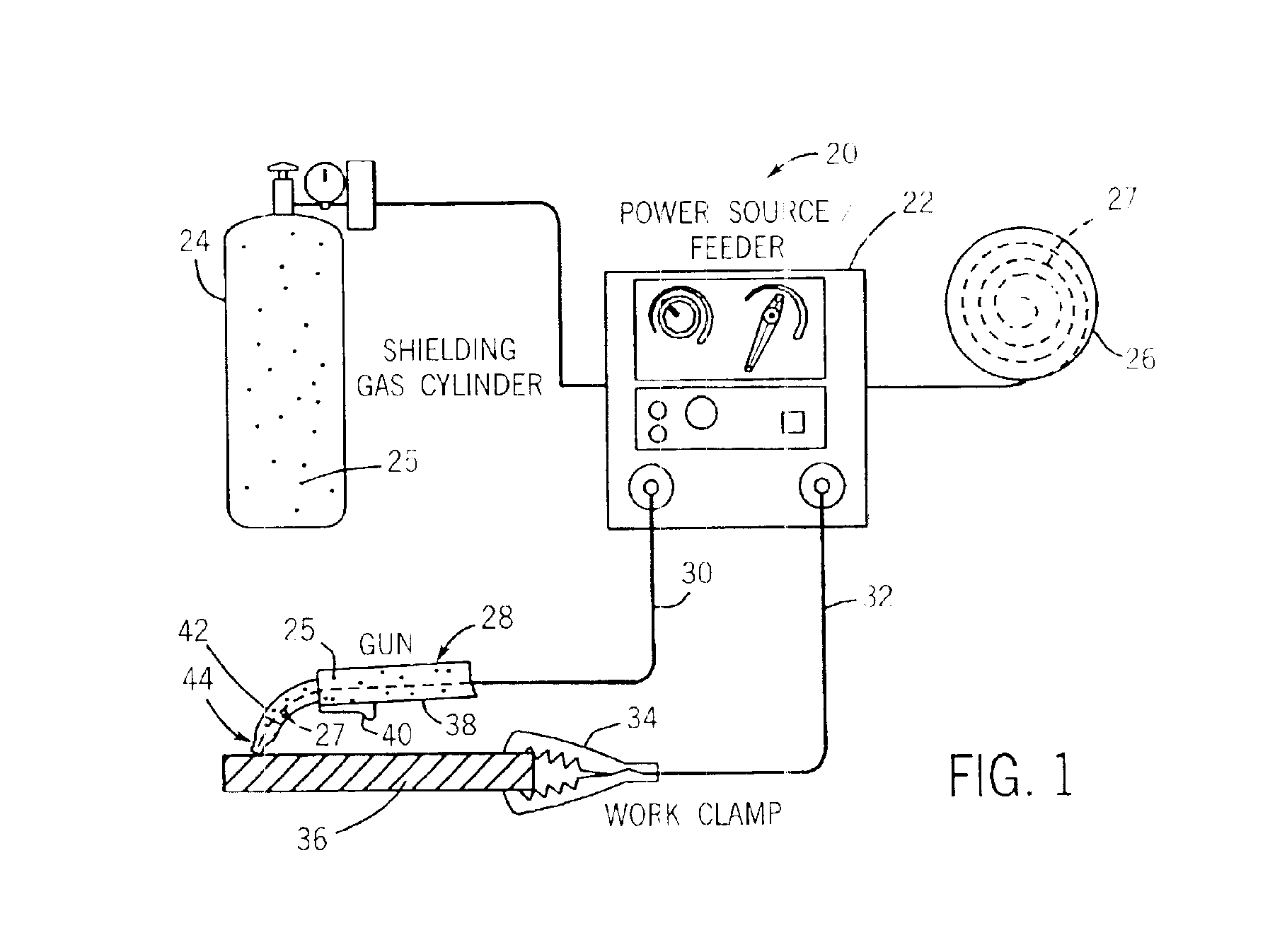

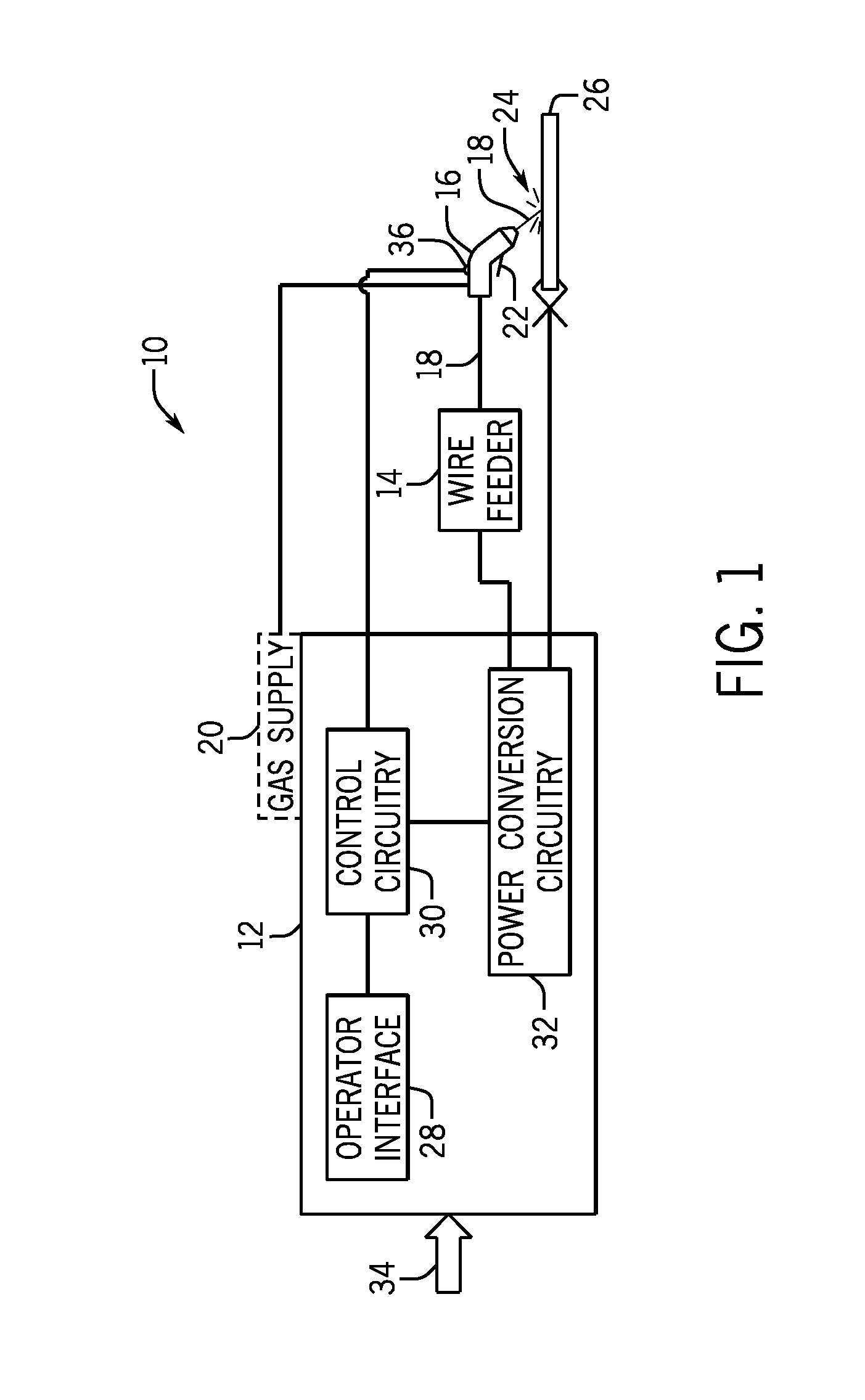

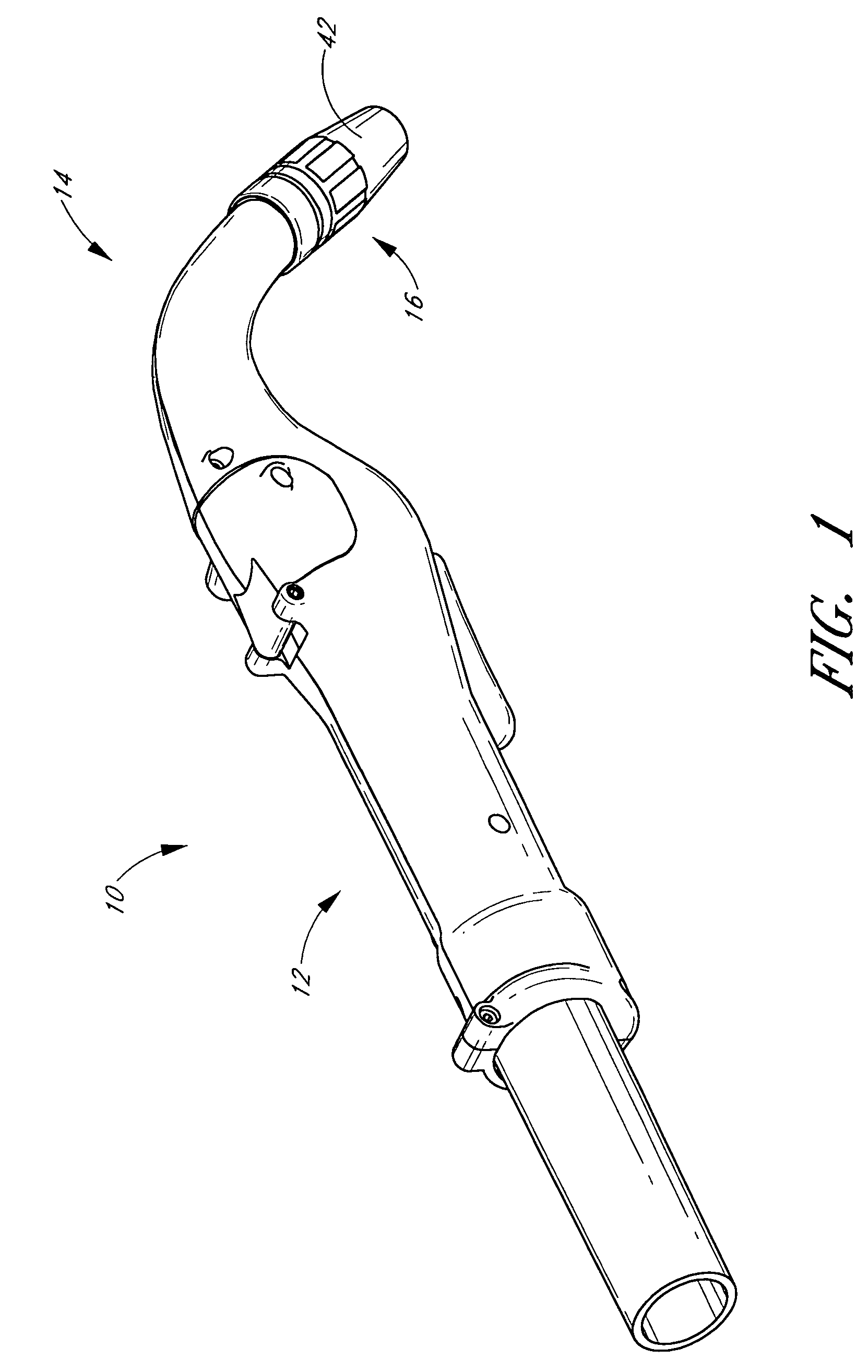

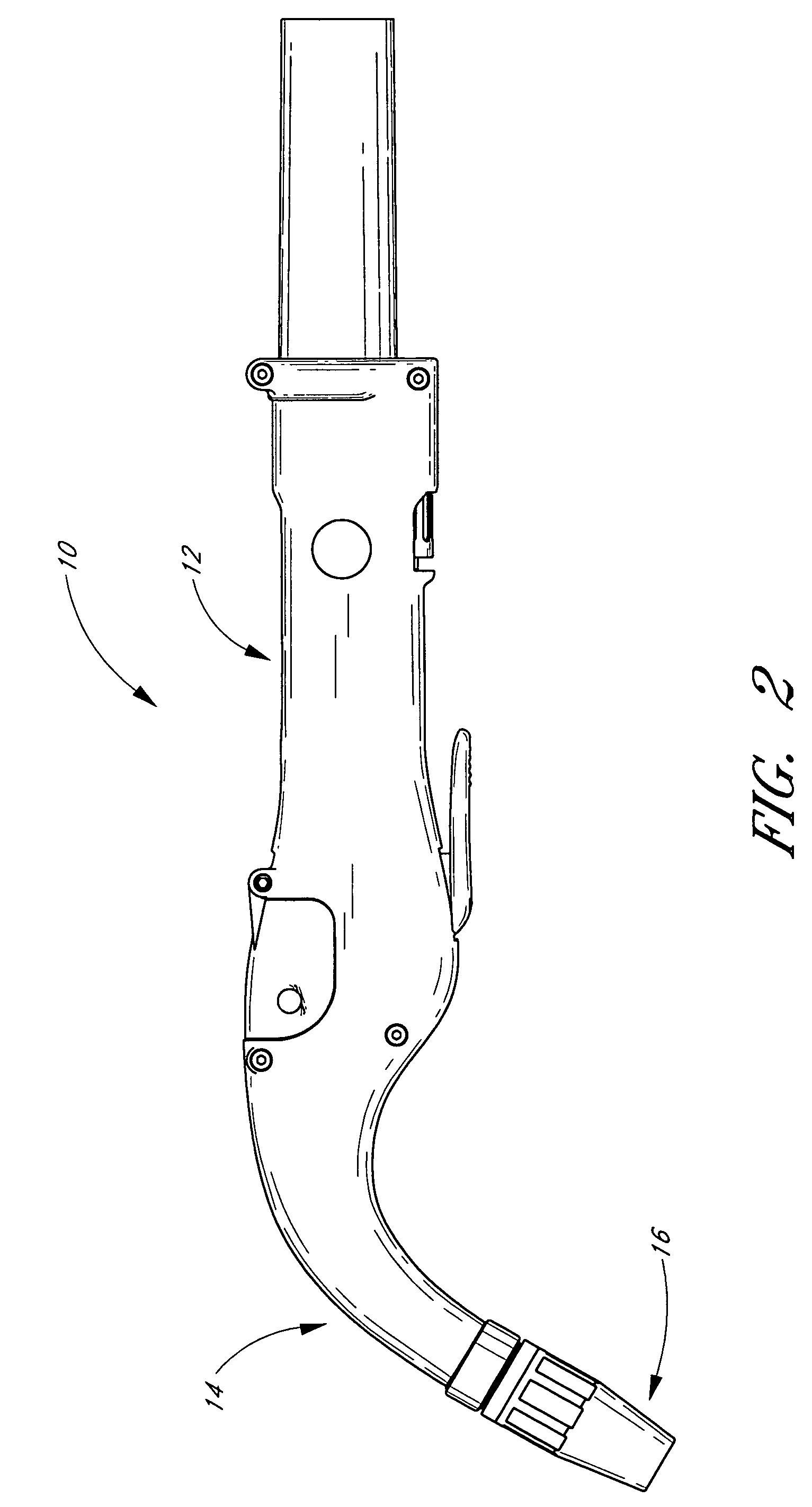

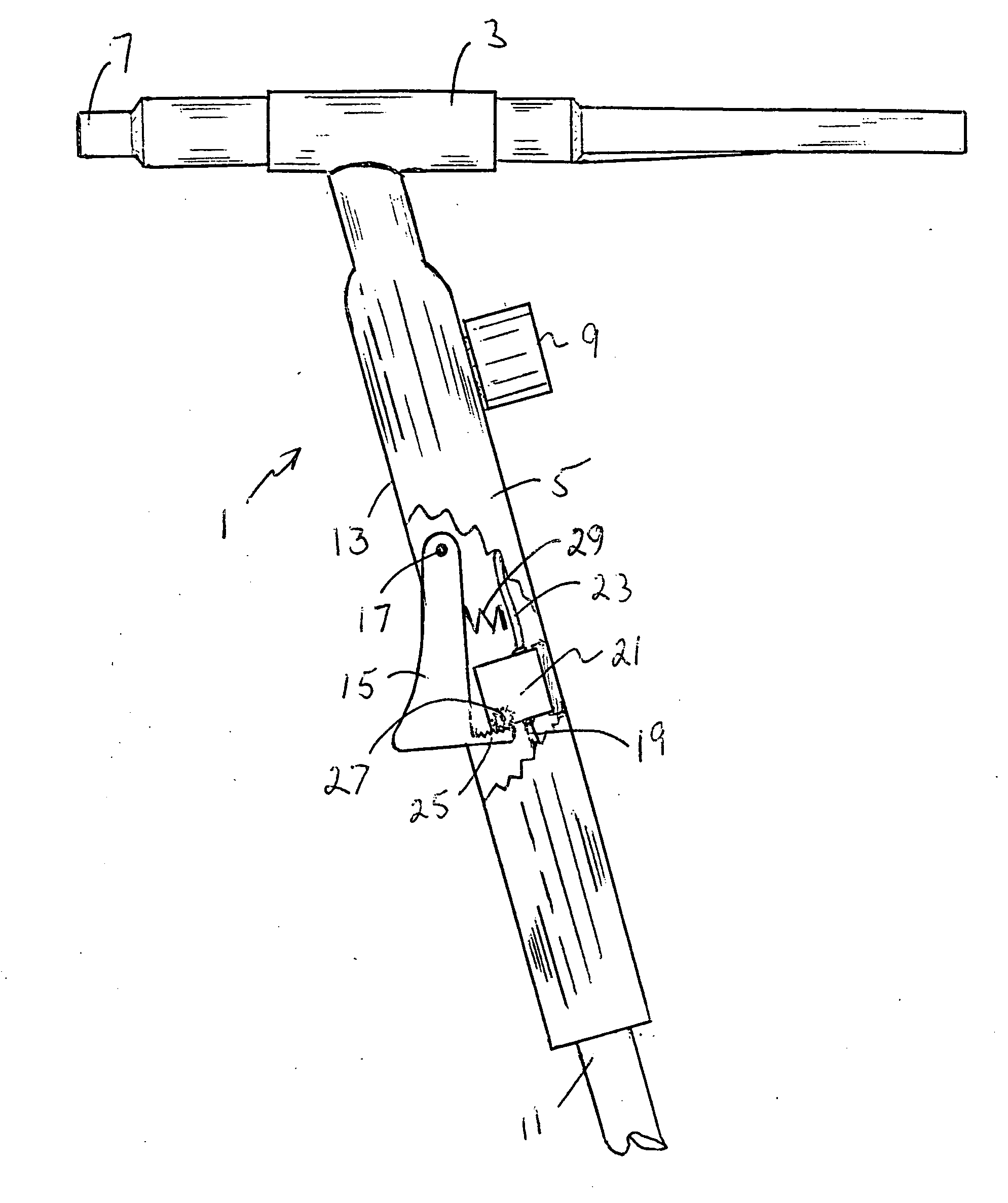

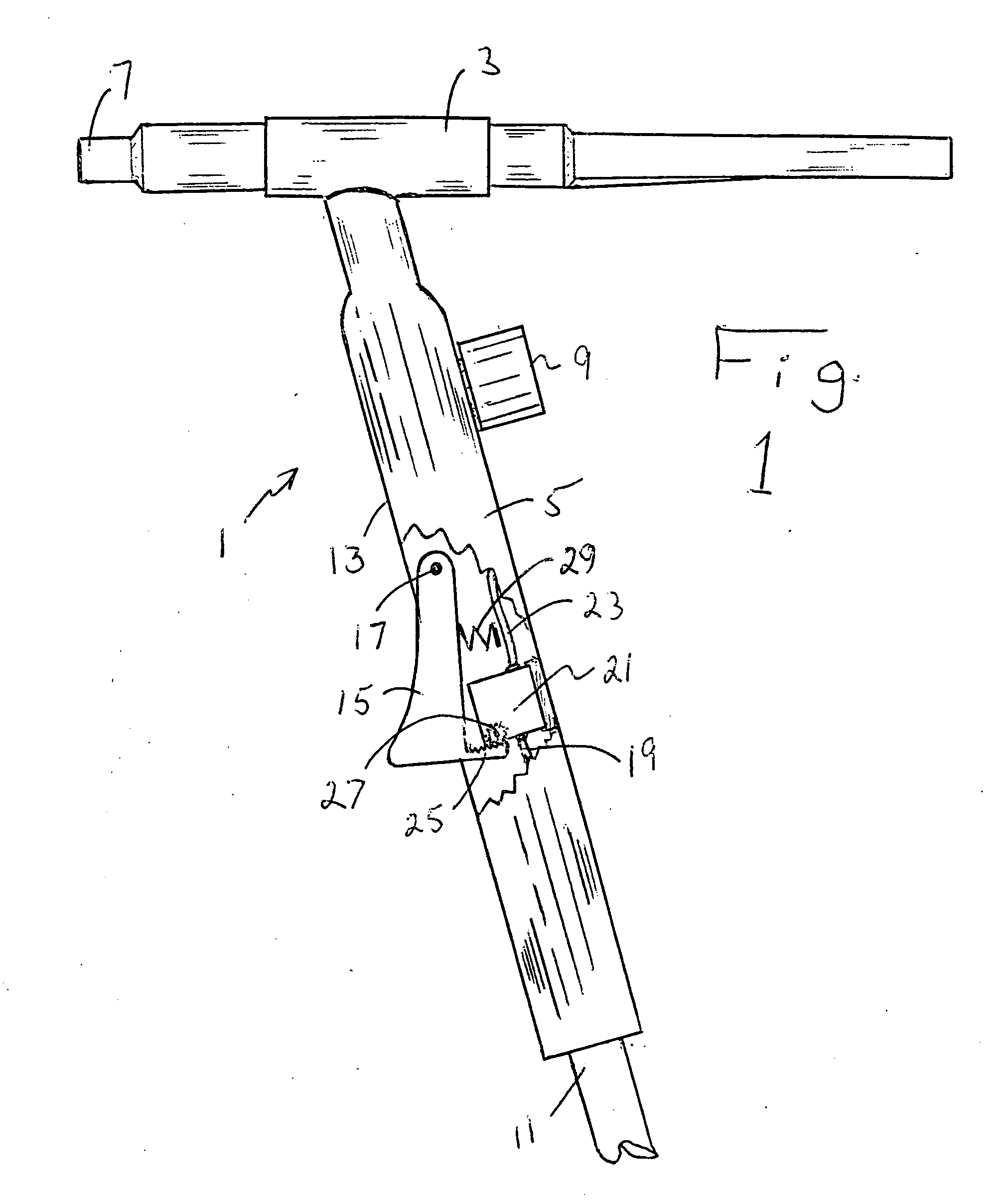

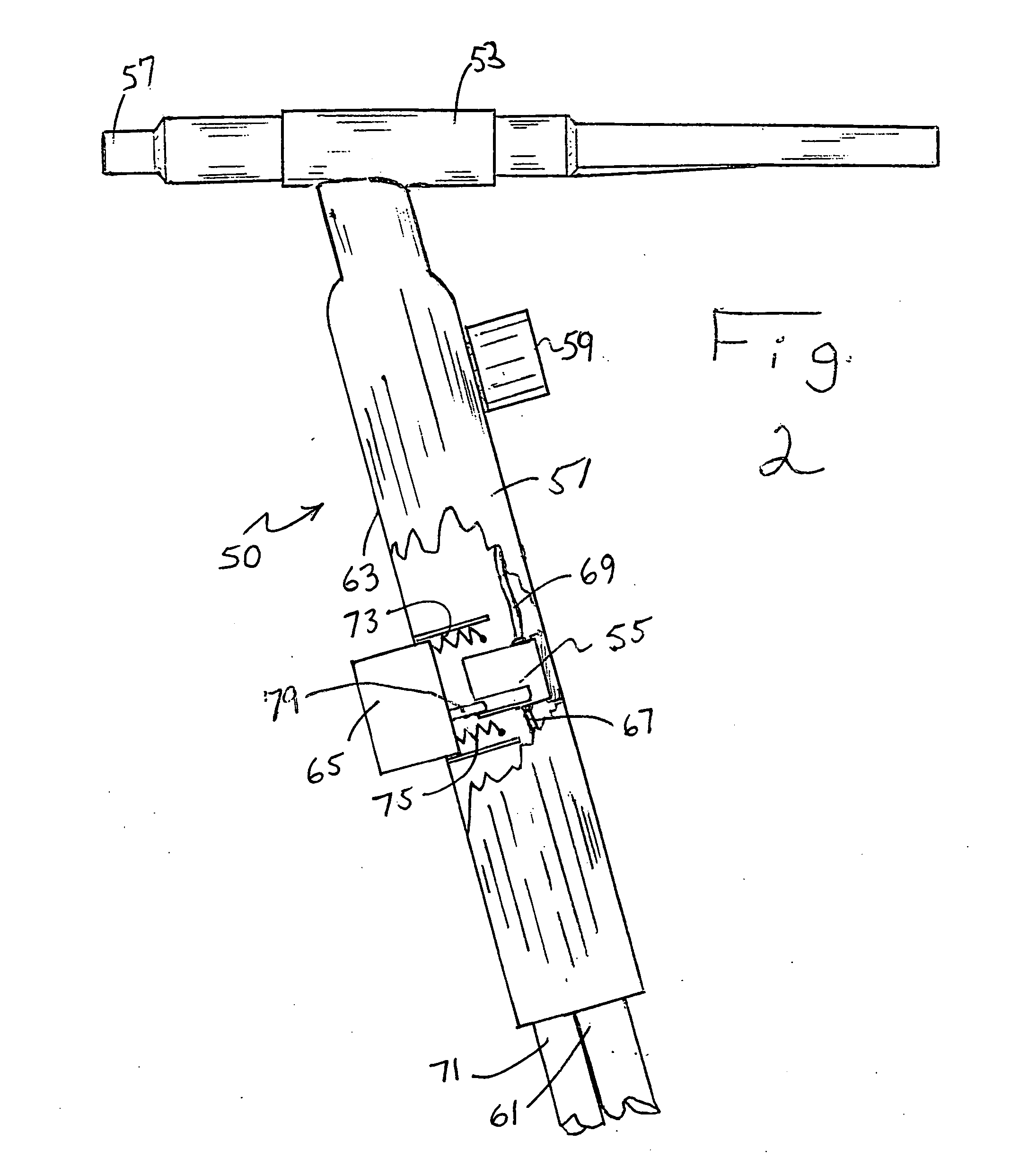

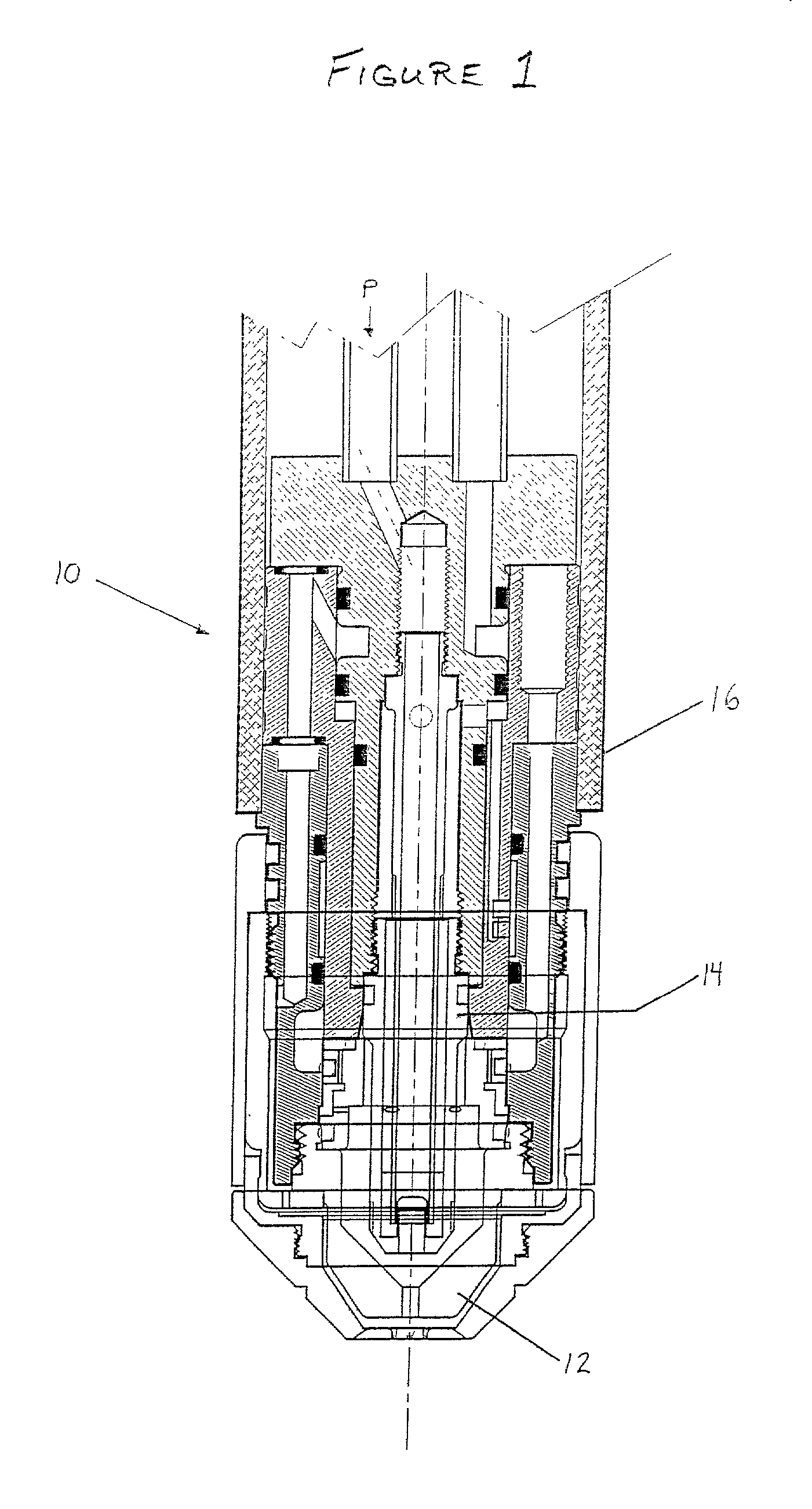

Self-contained locking trigger assembly and systems which incorporate the assembly

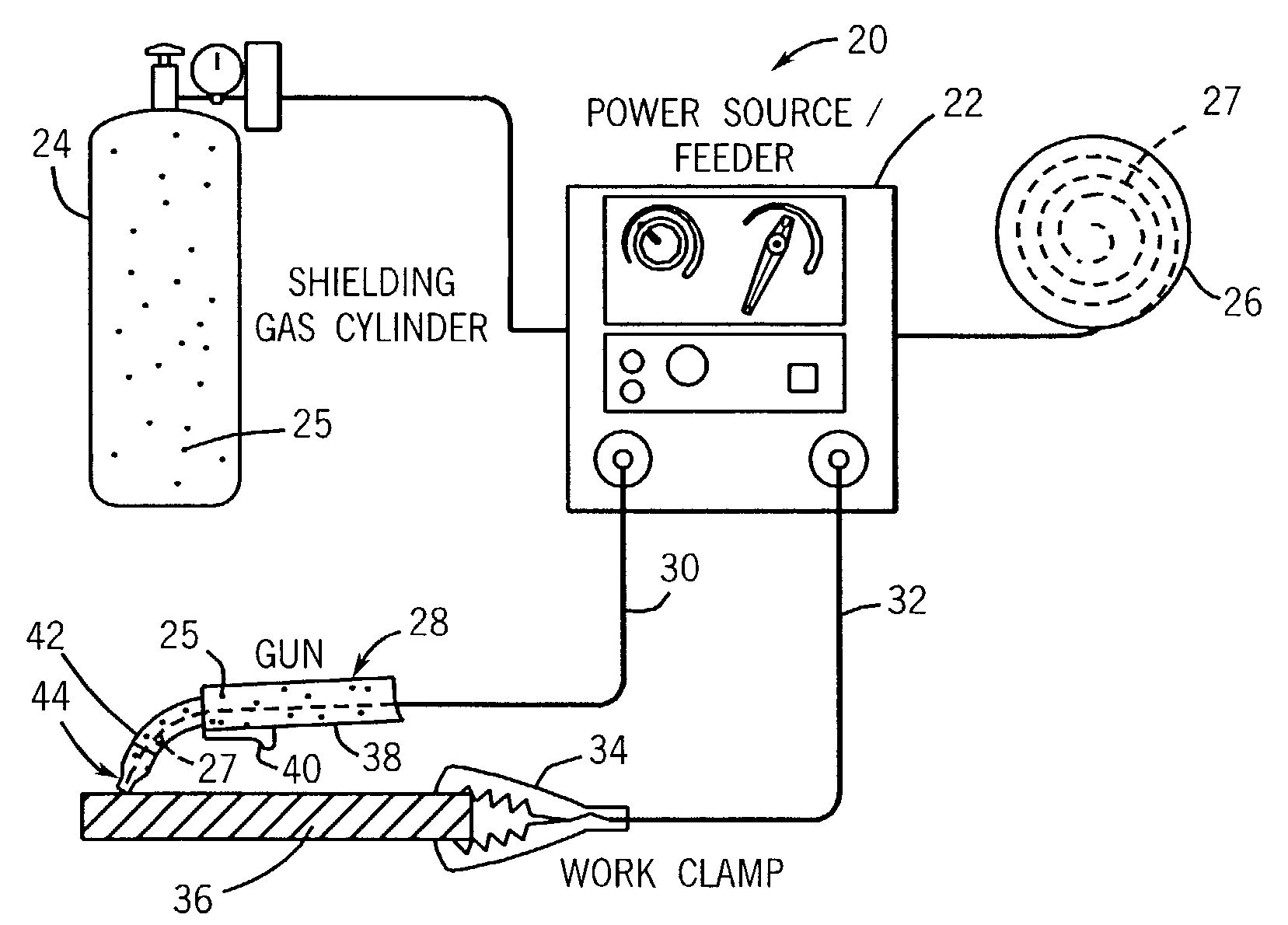

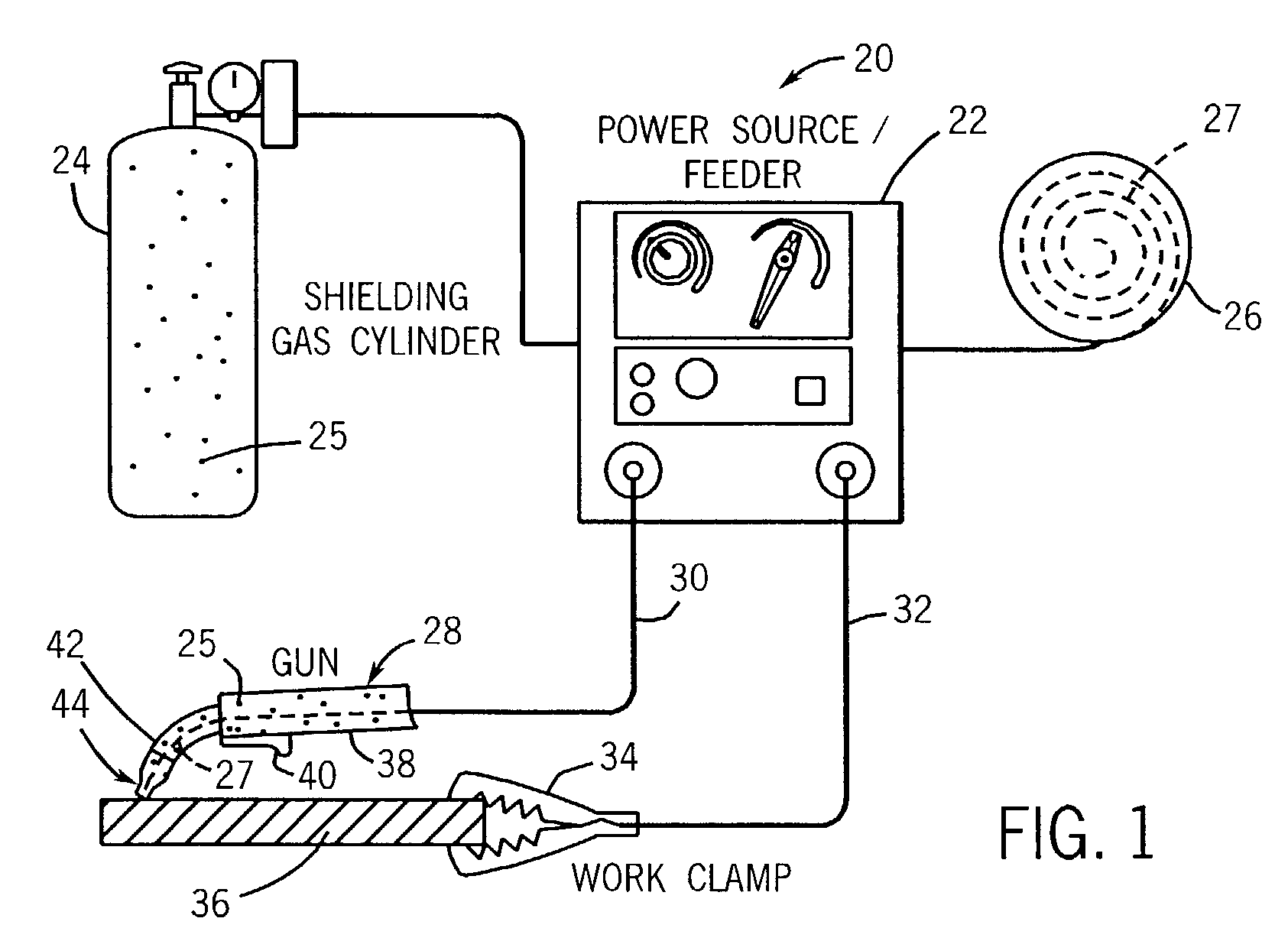

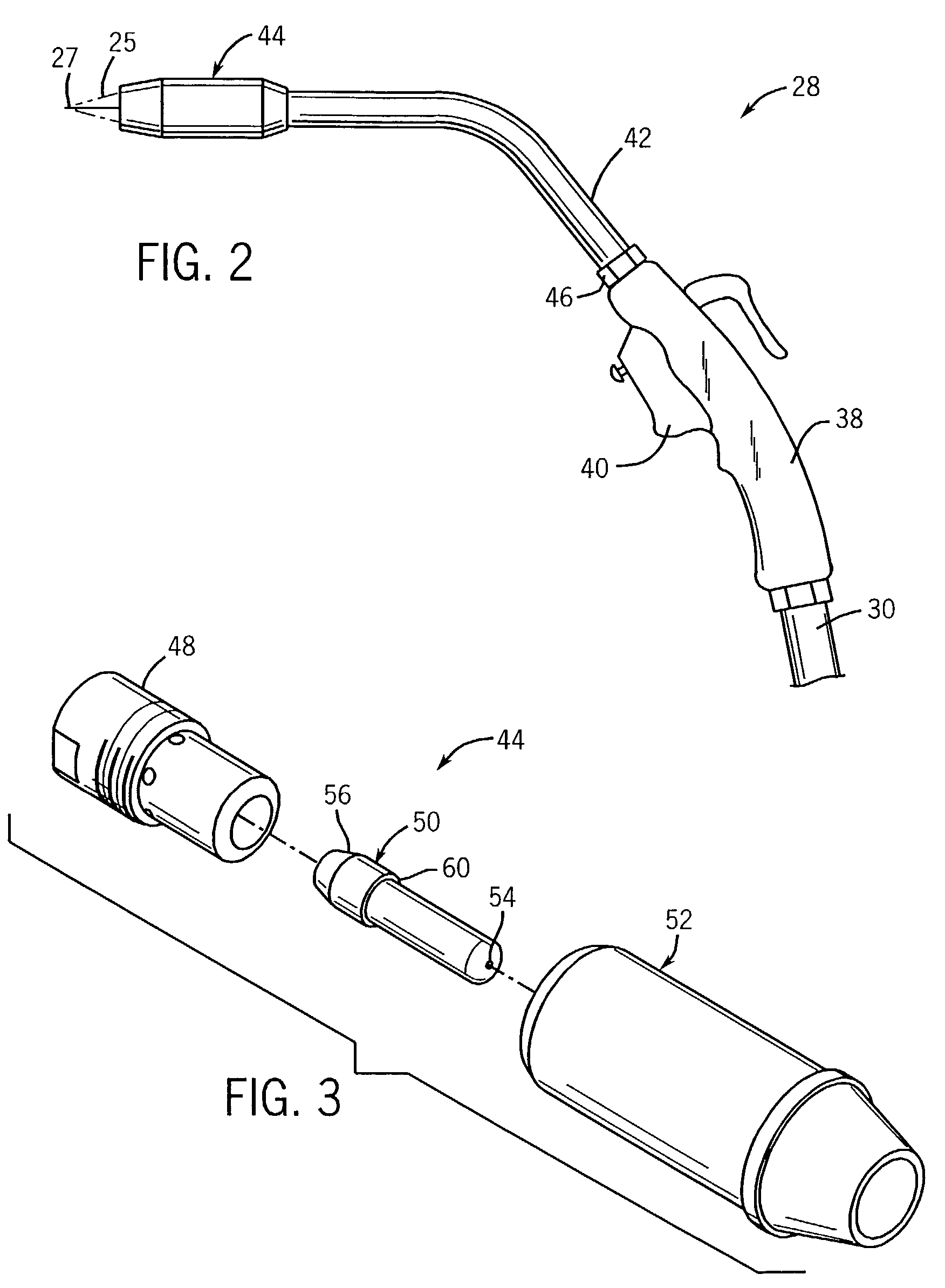

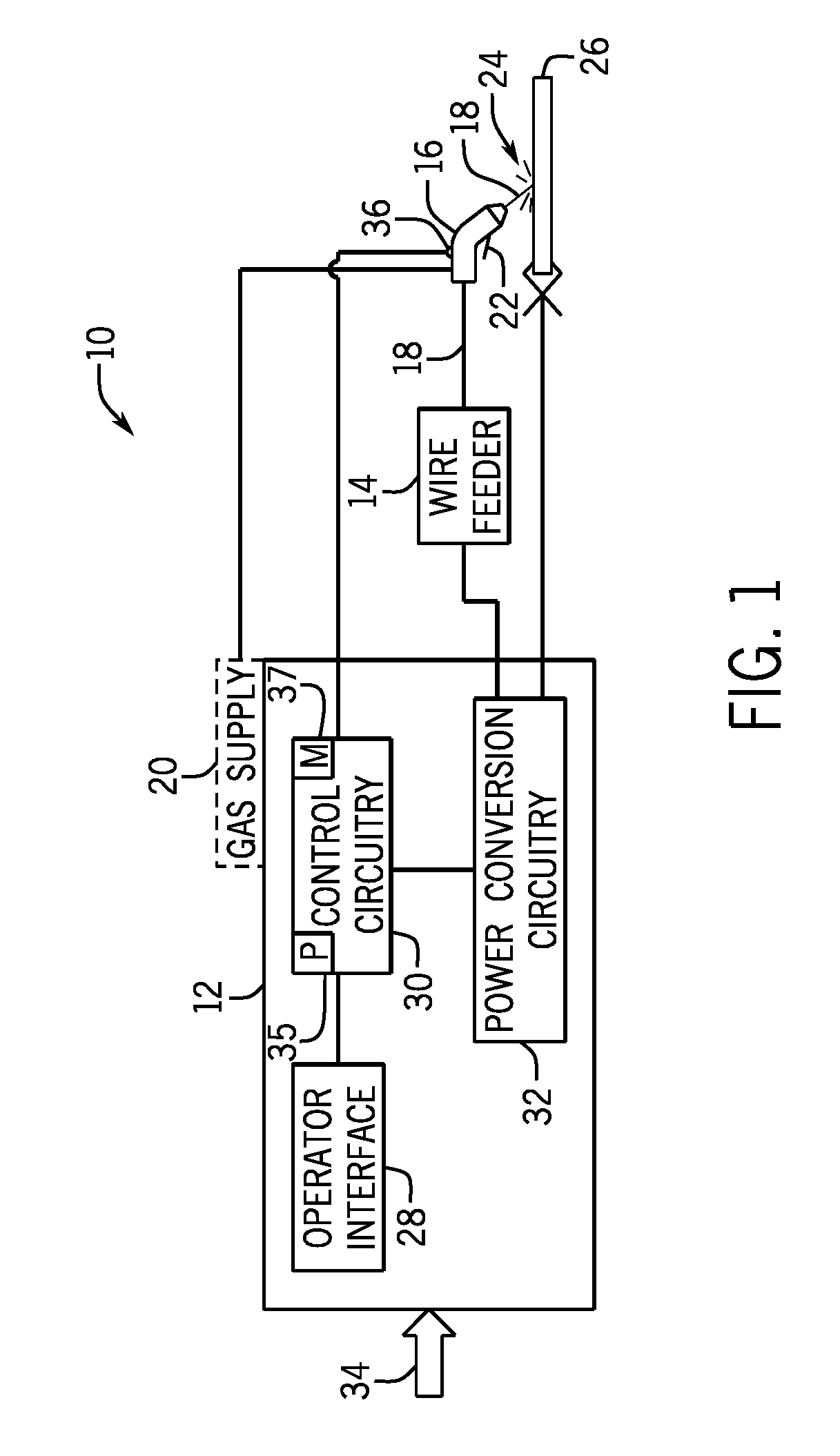

A welding system having a welding implement with a self-contained trigger and trigger locking assembly. The self-contained trigger and trigger locking assembly has a trigger which, when operated, regulates the flow of current from a power source. The trigger lock of the assembly has a movable portion which includes a groove which can engage a complementary structure on the trigger to maintain the trigger in an operating position, thereby allowing continued flow of current from the power source.

Owner:ILLINOIS TOOL WORKS INC

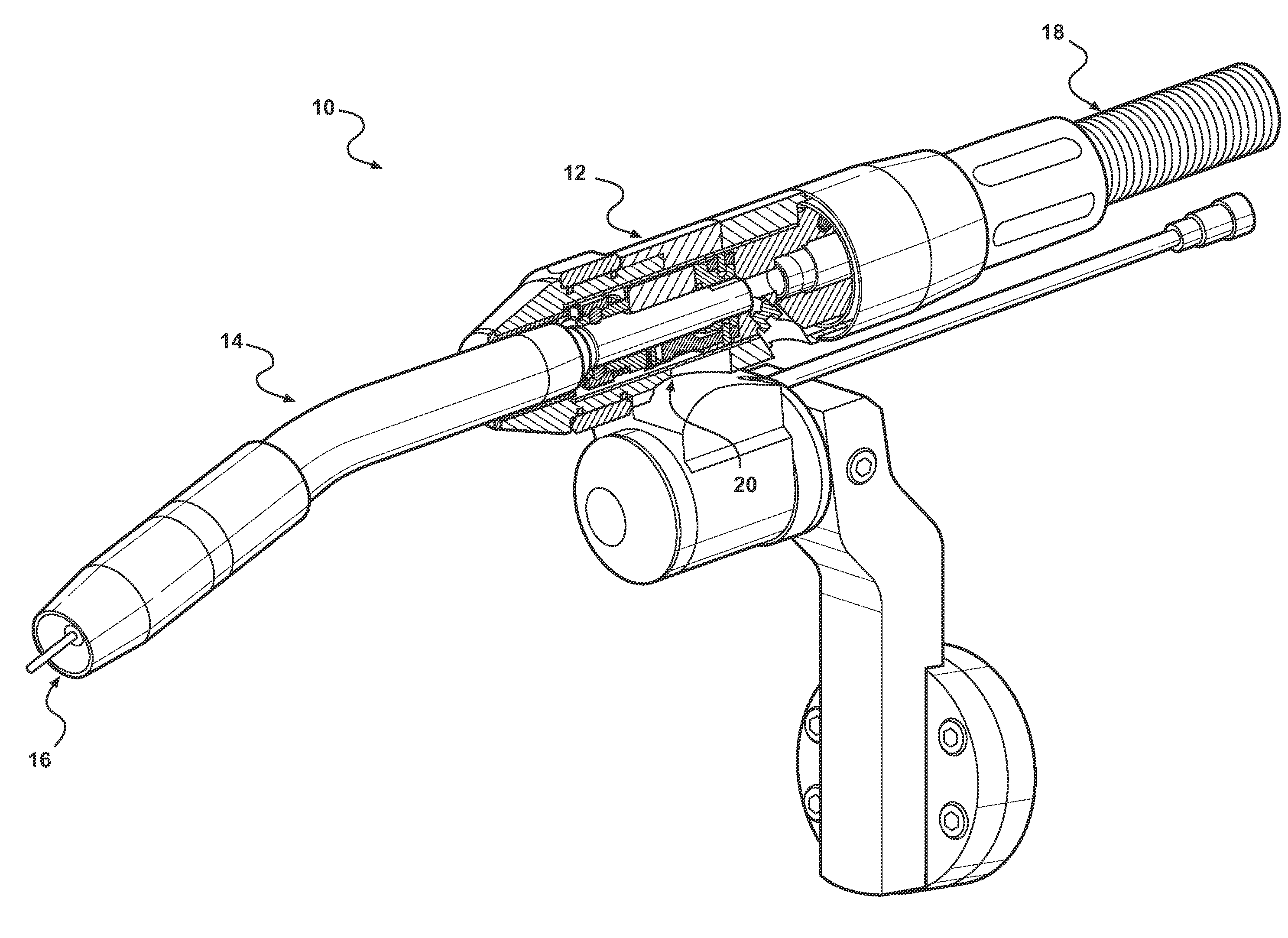

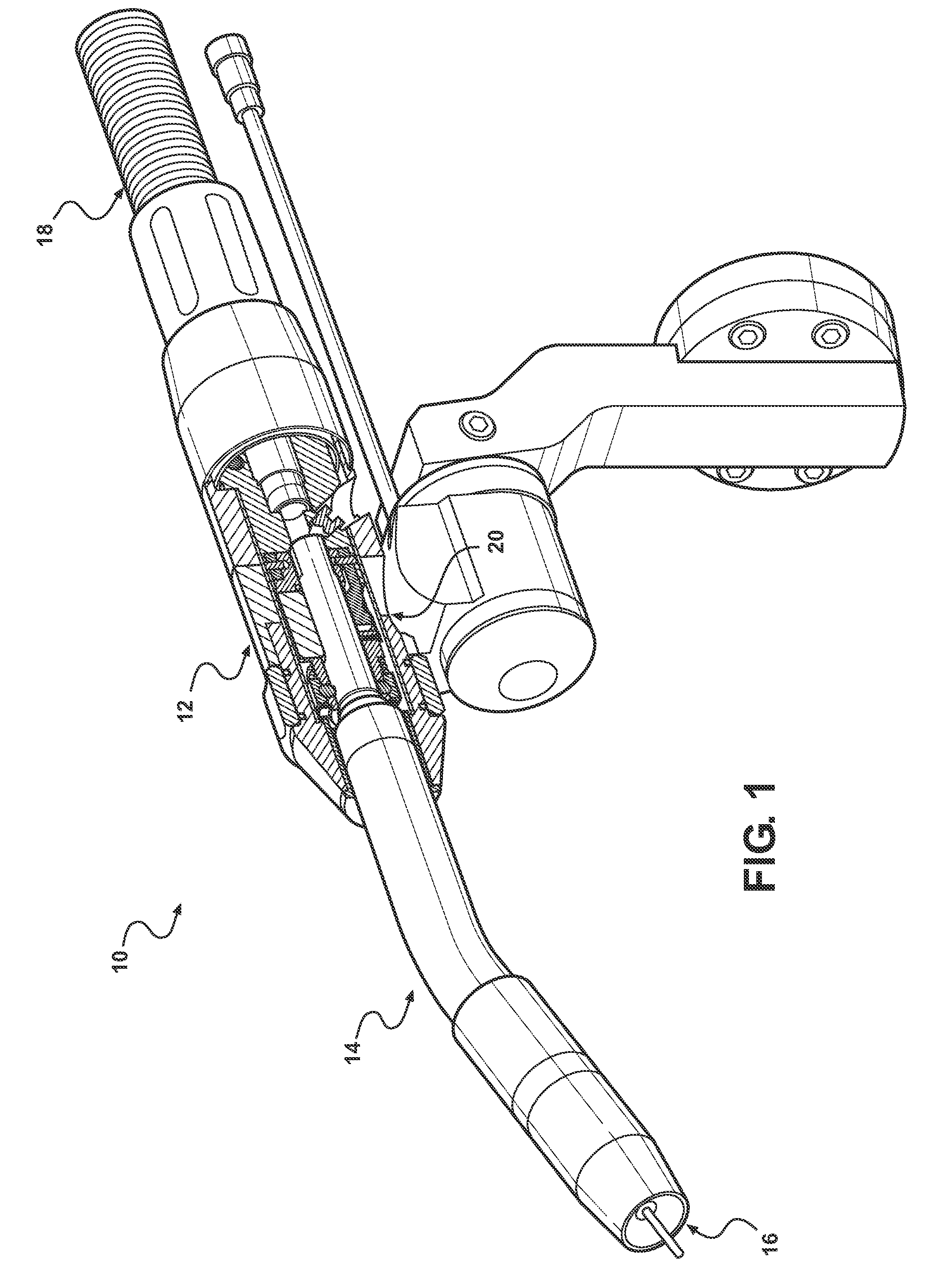

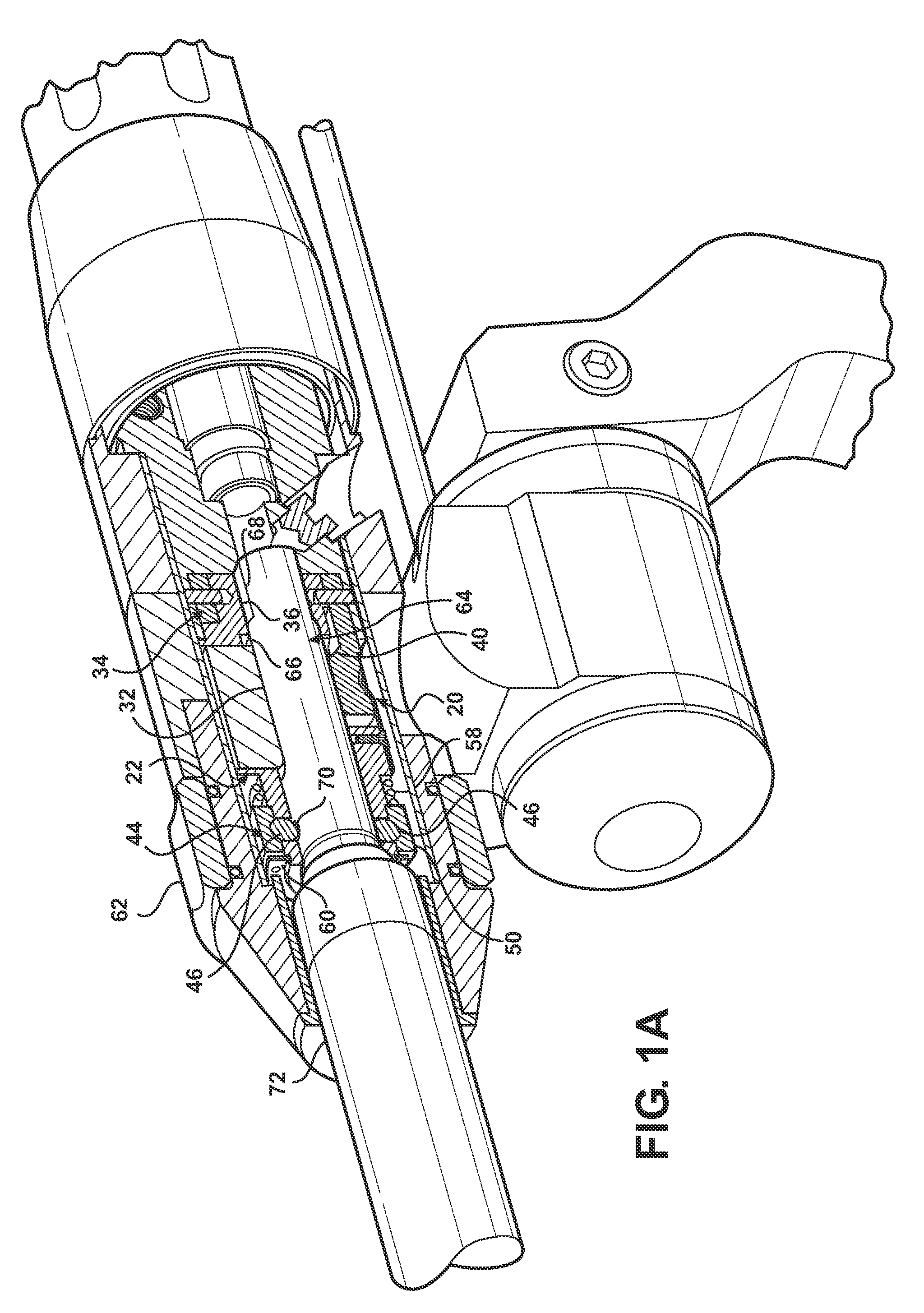

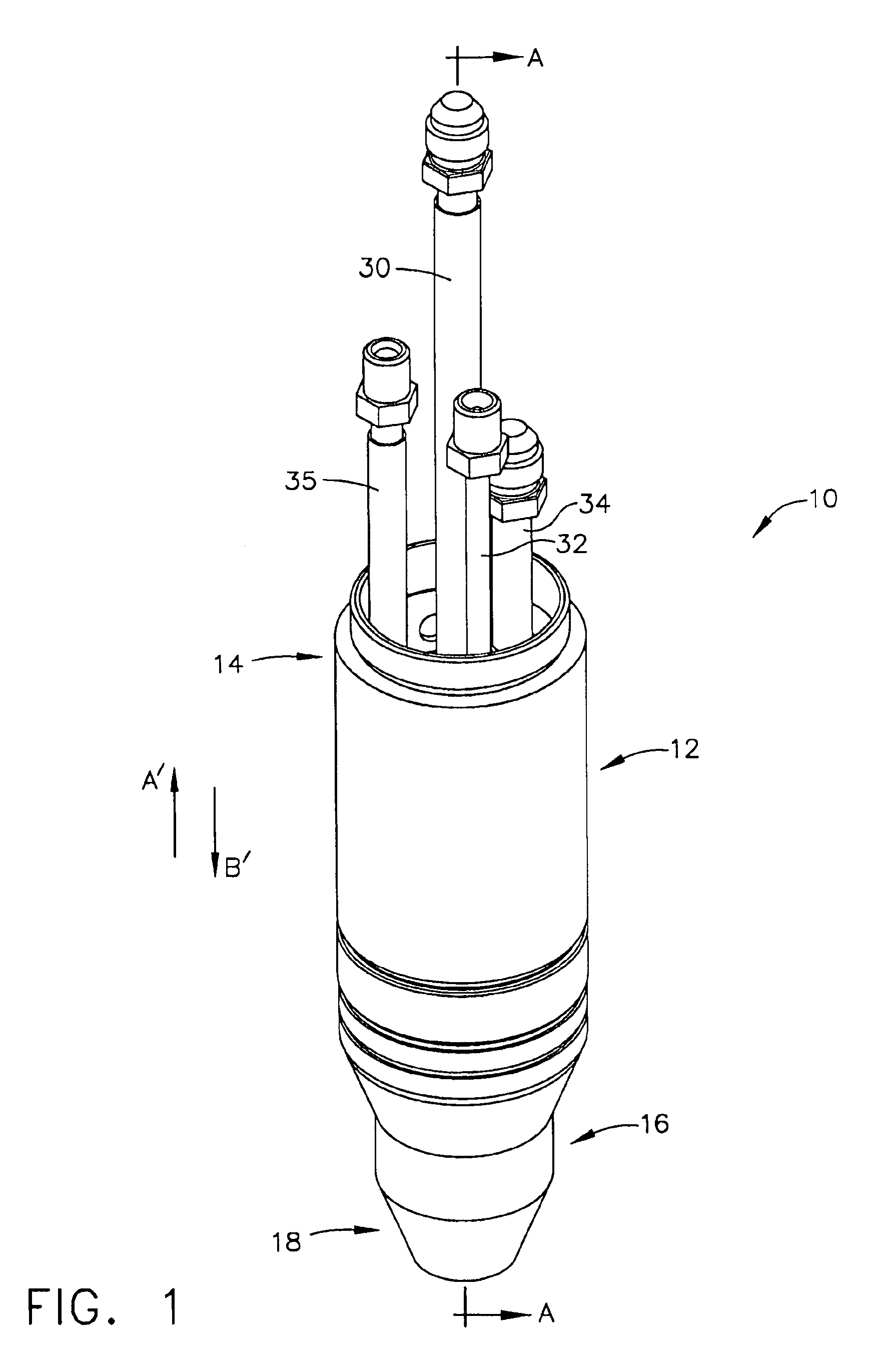

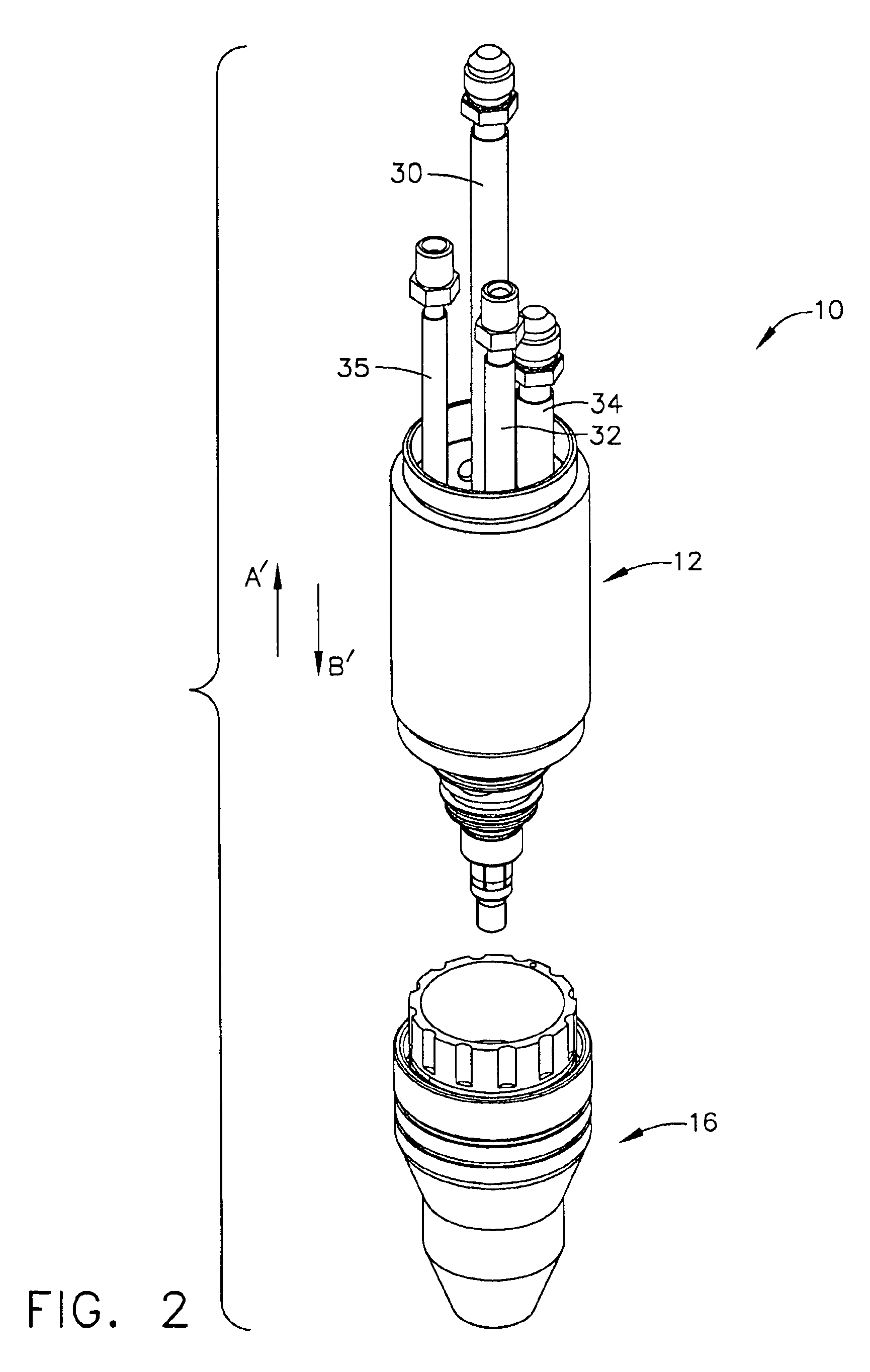

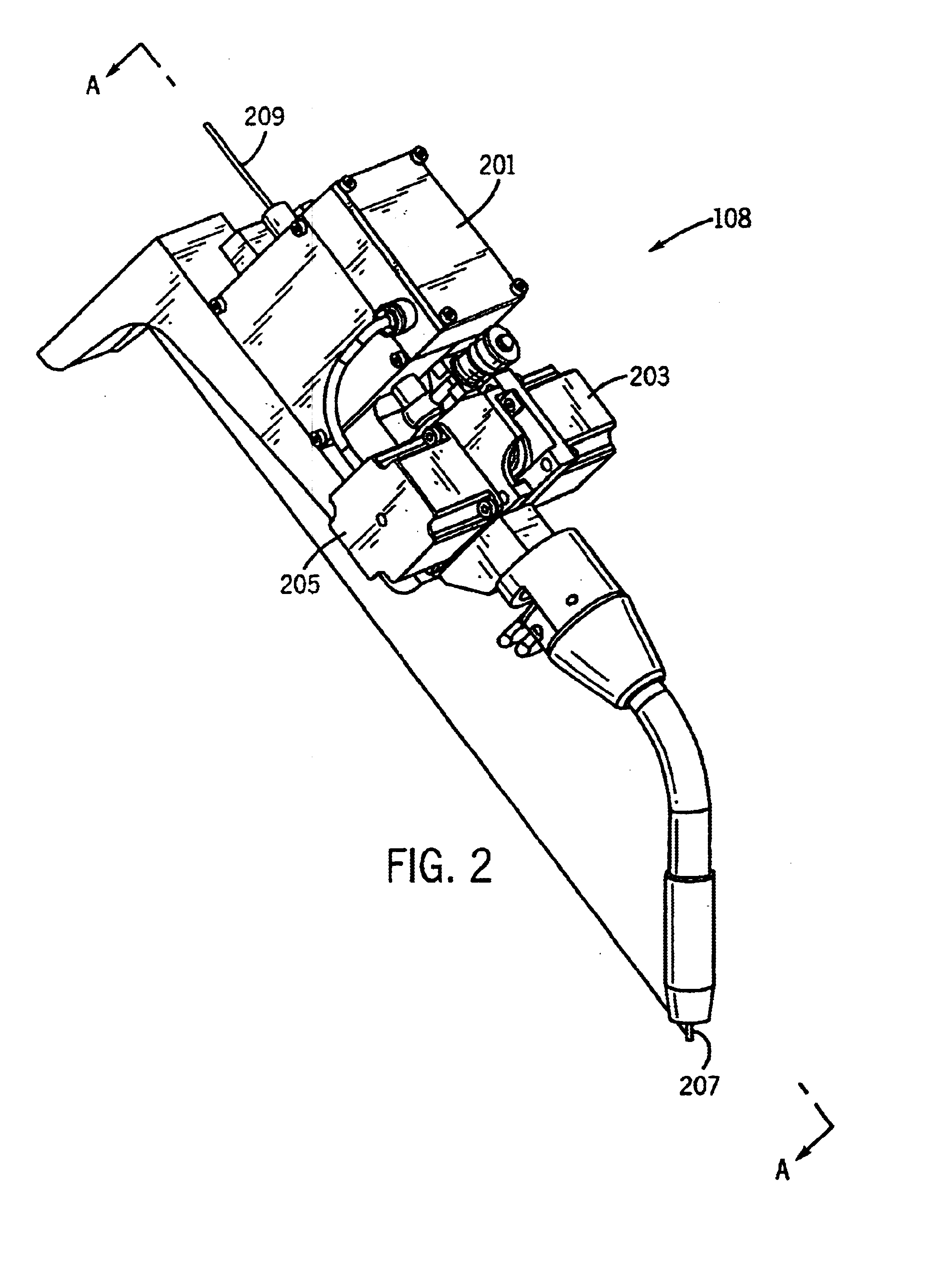

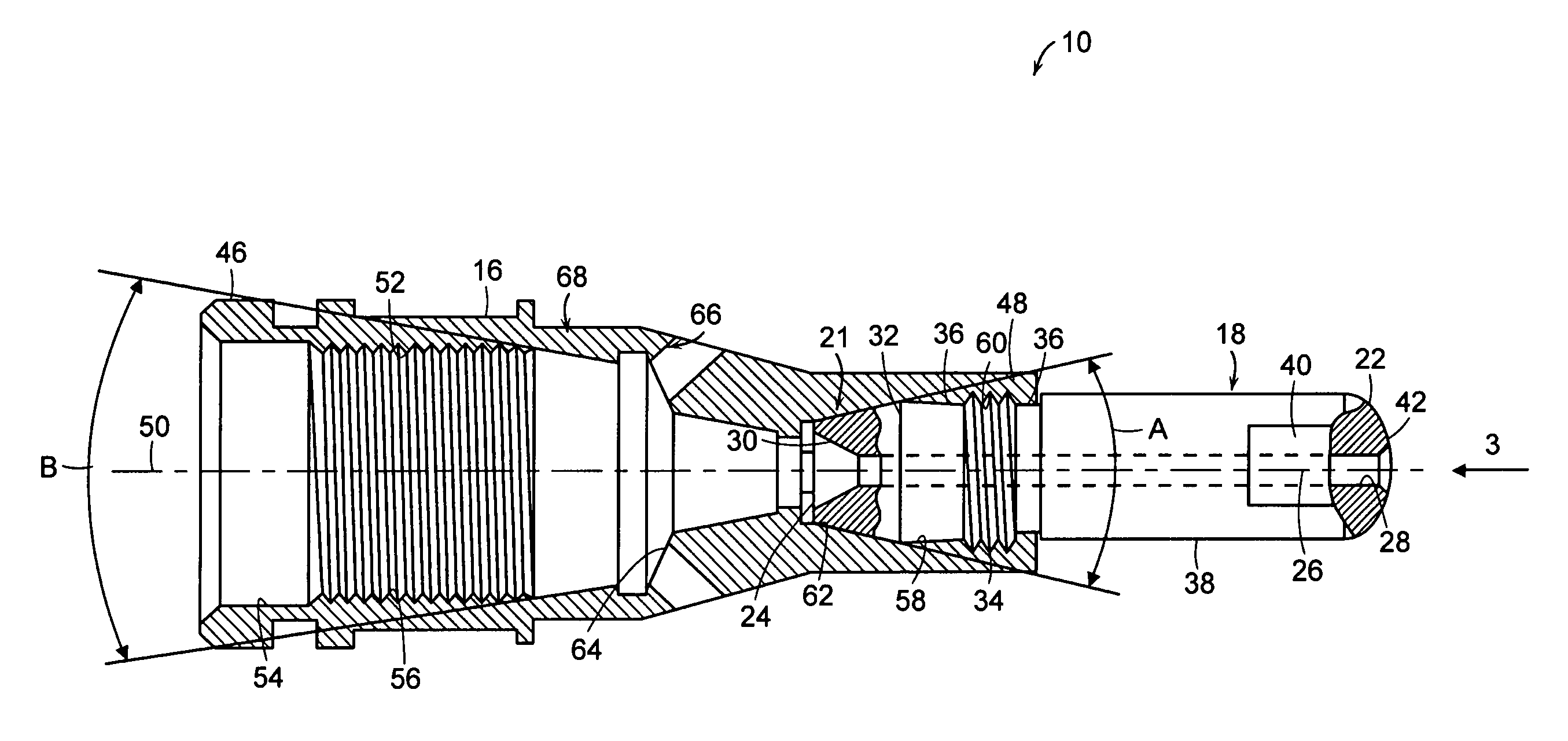

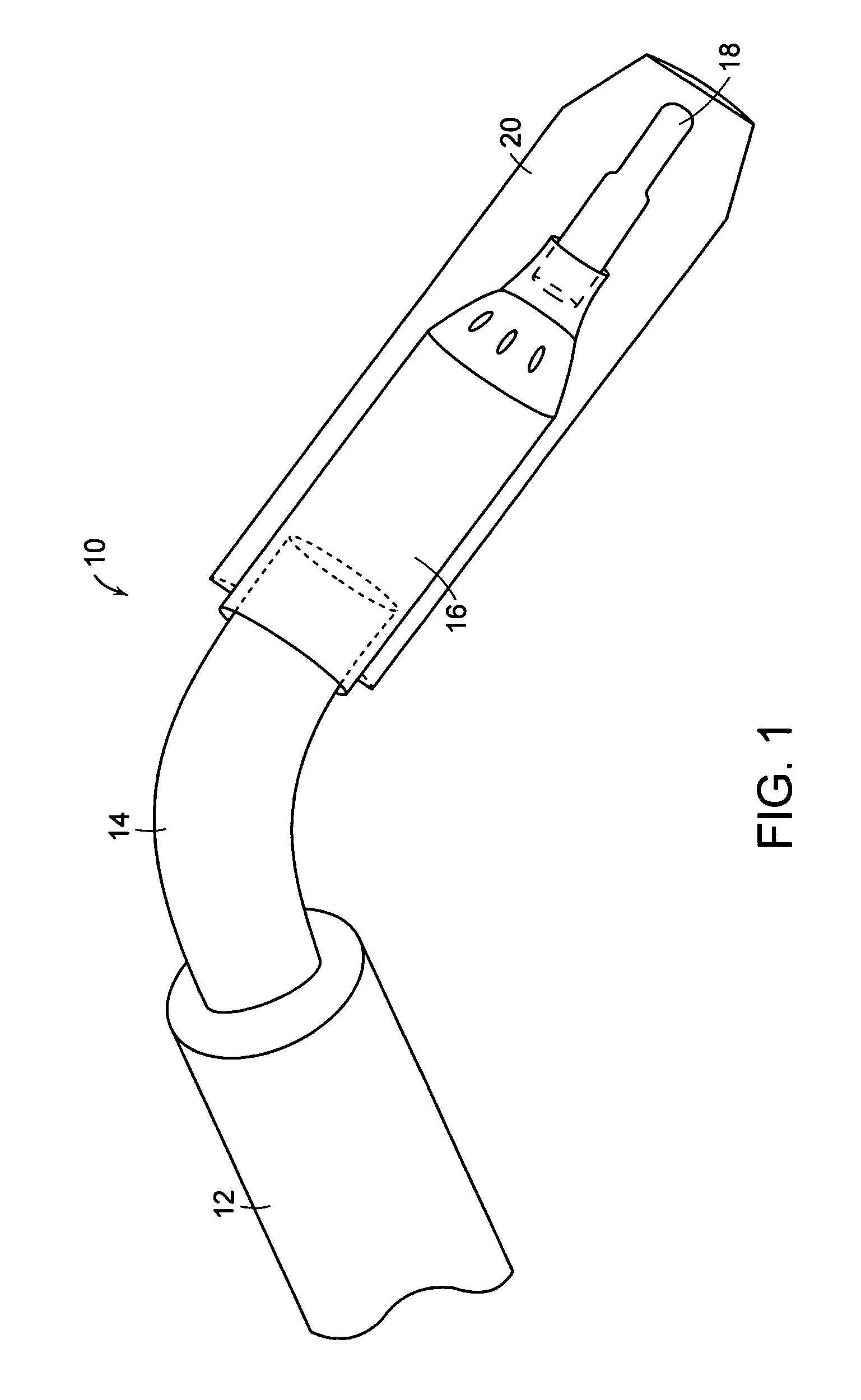

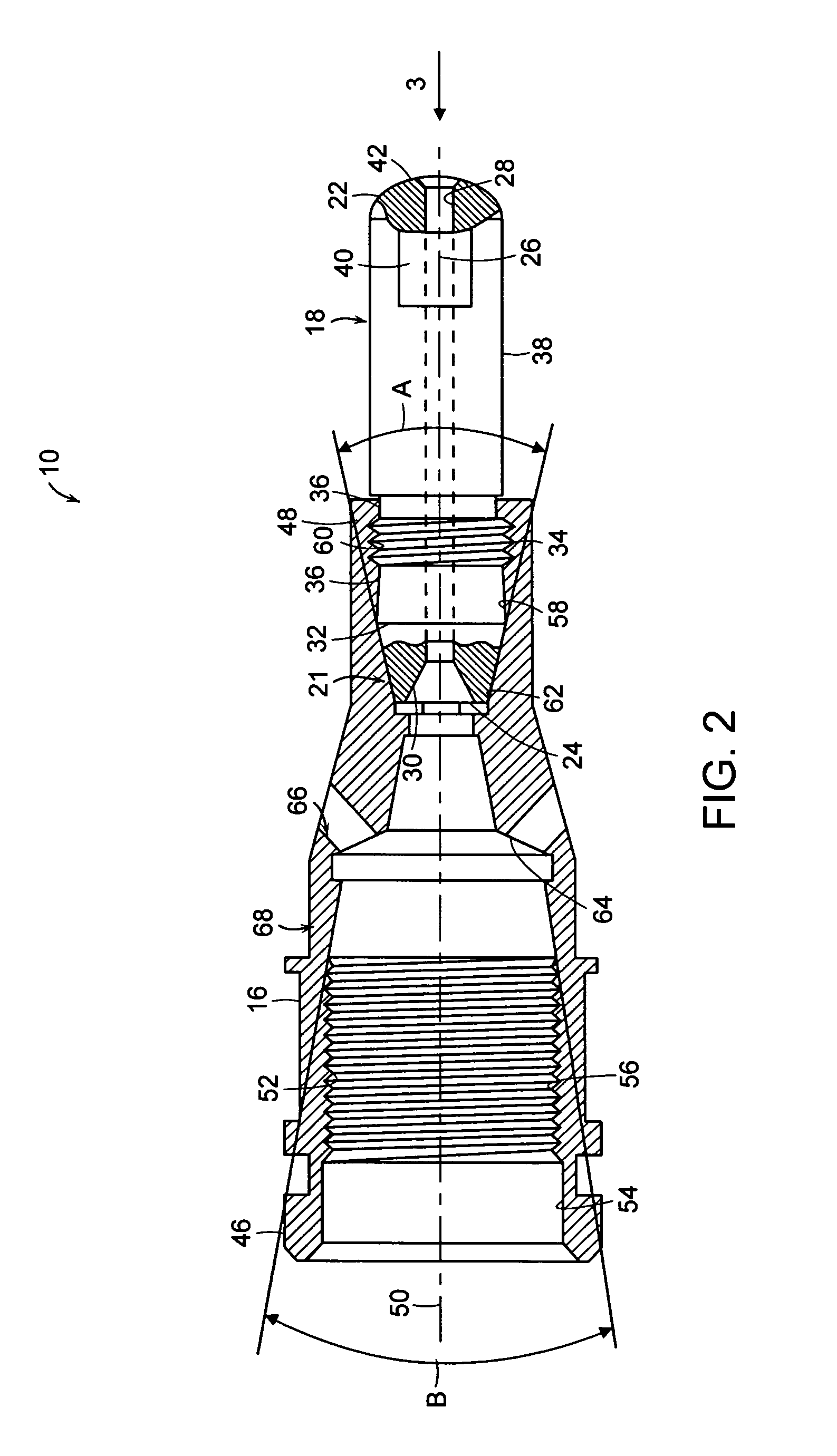

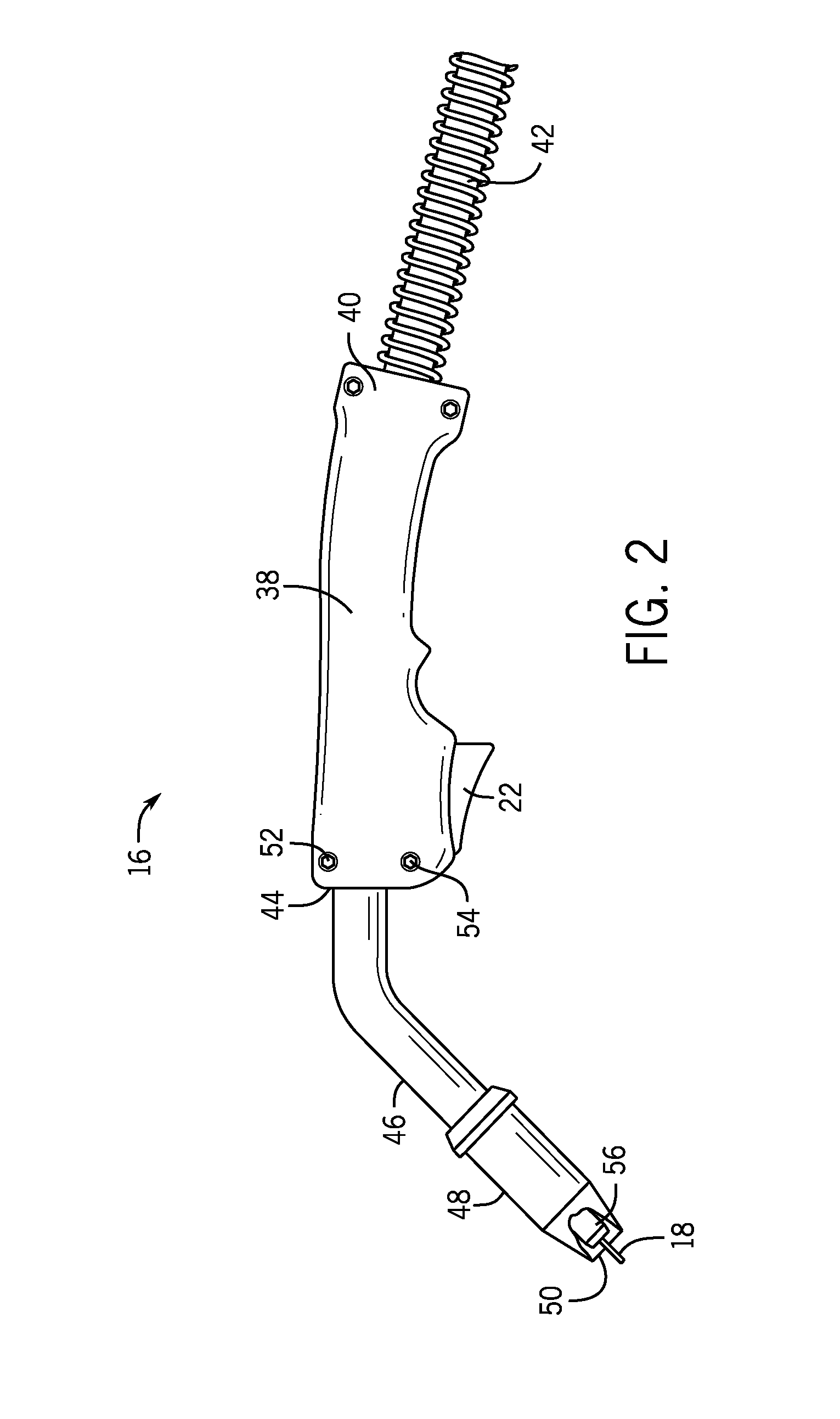

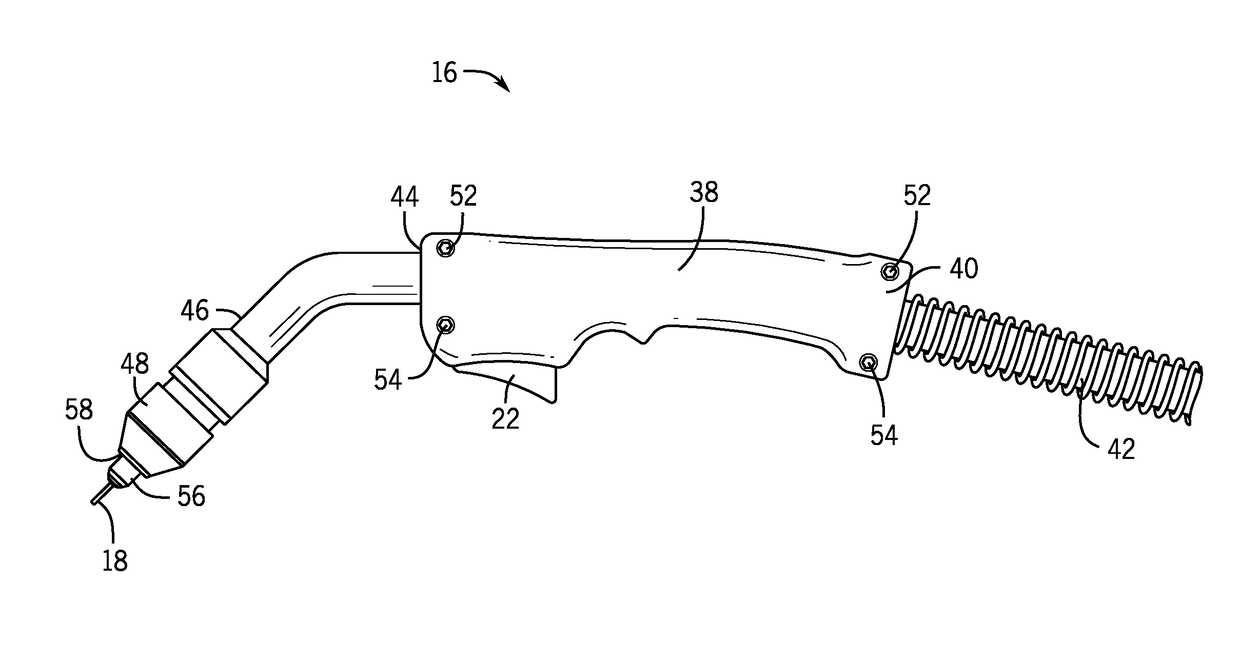

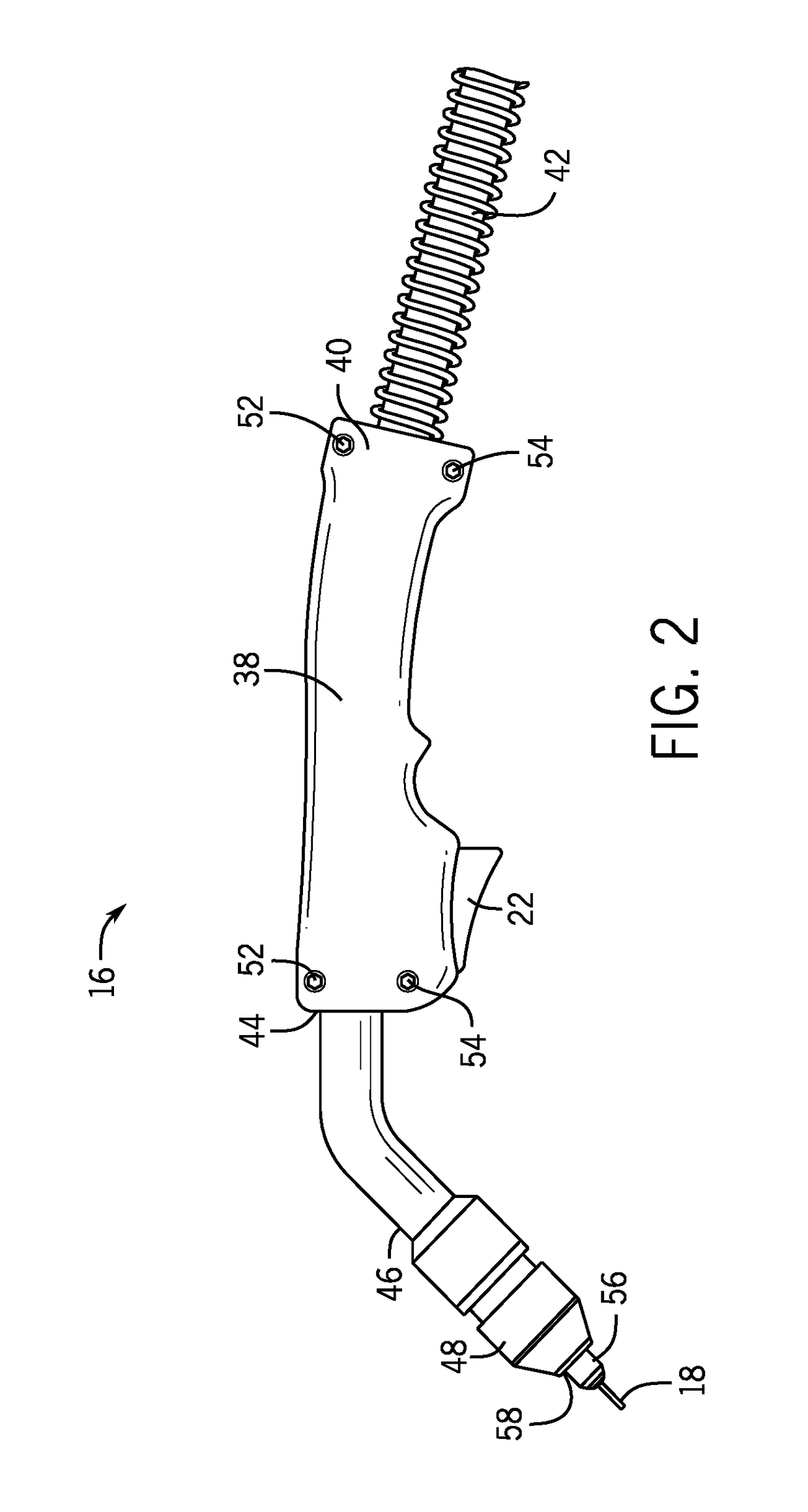

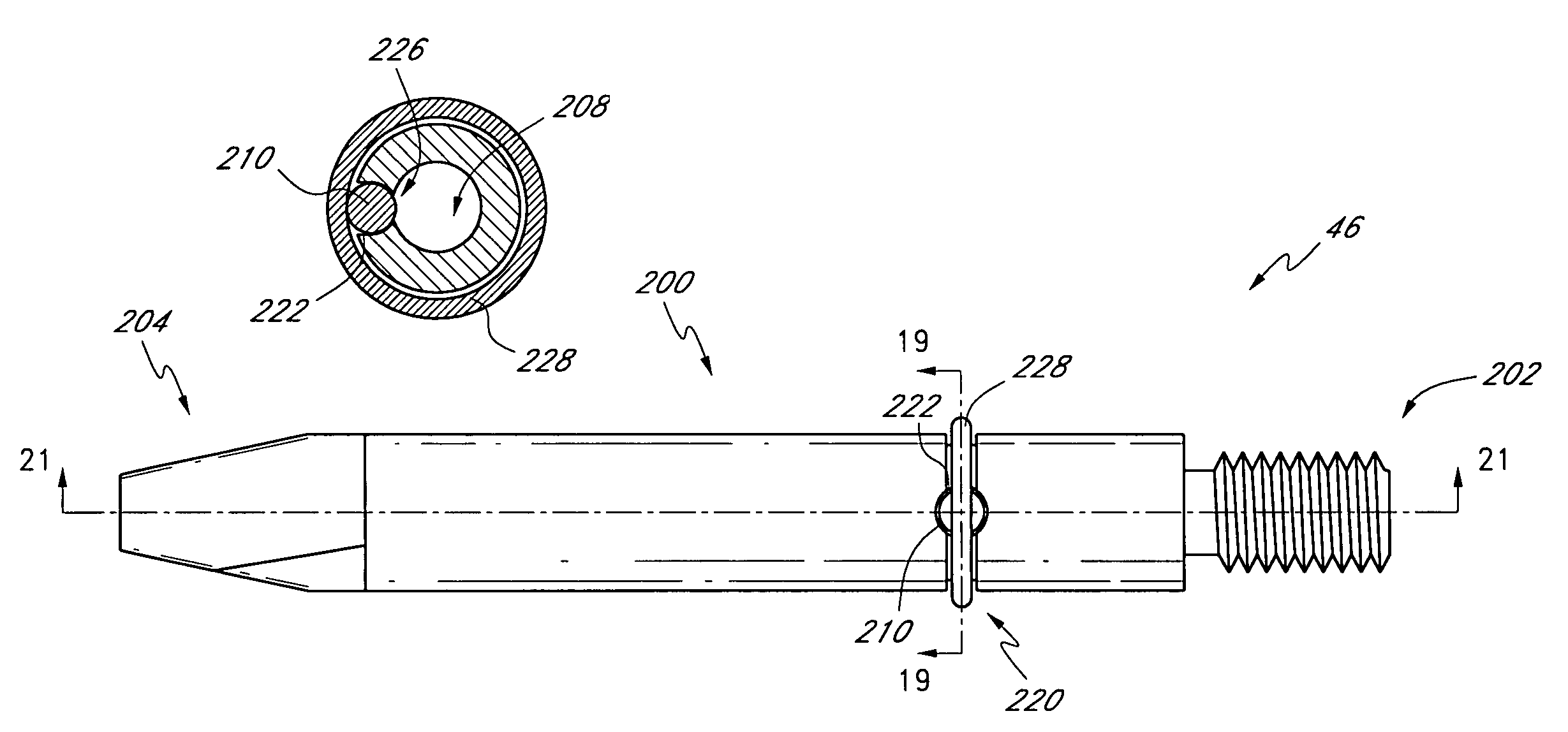

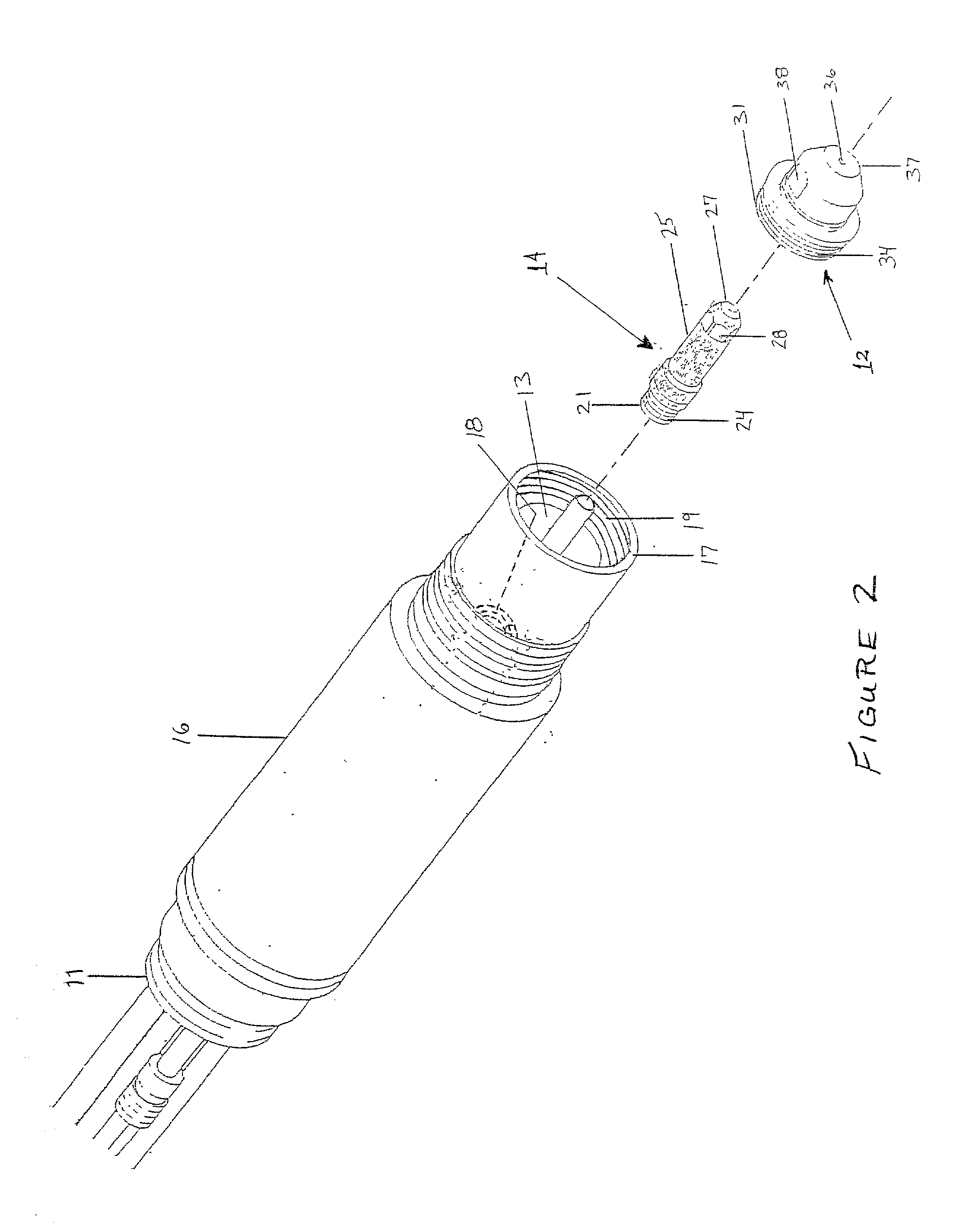

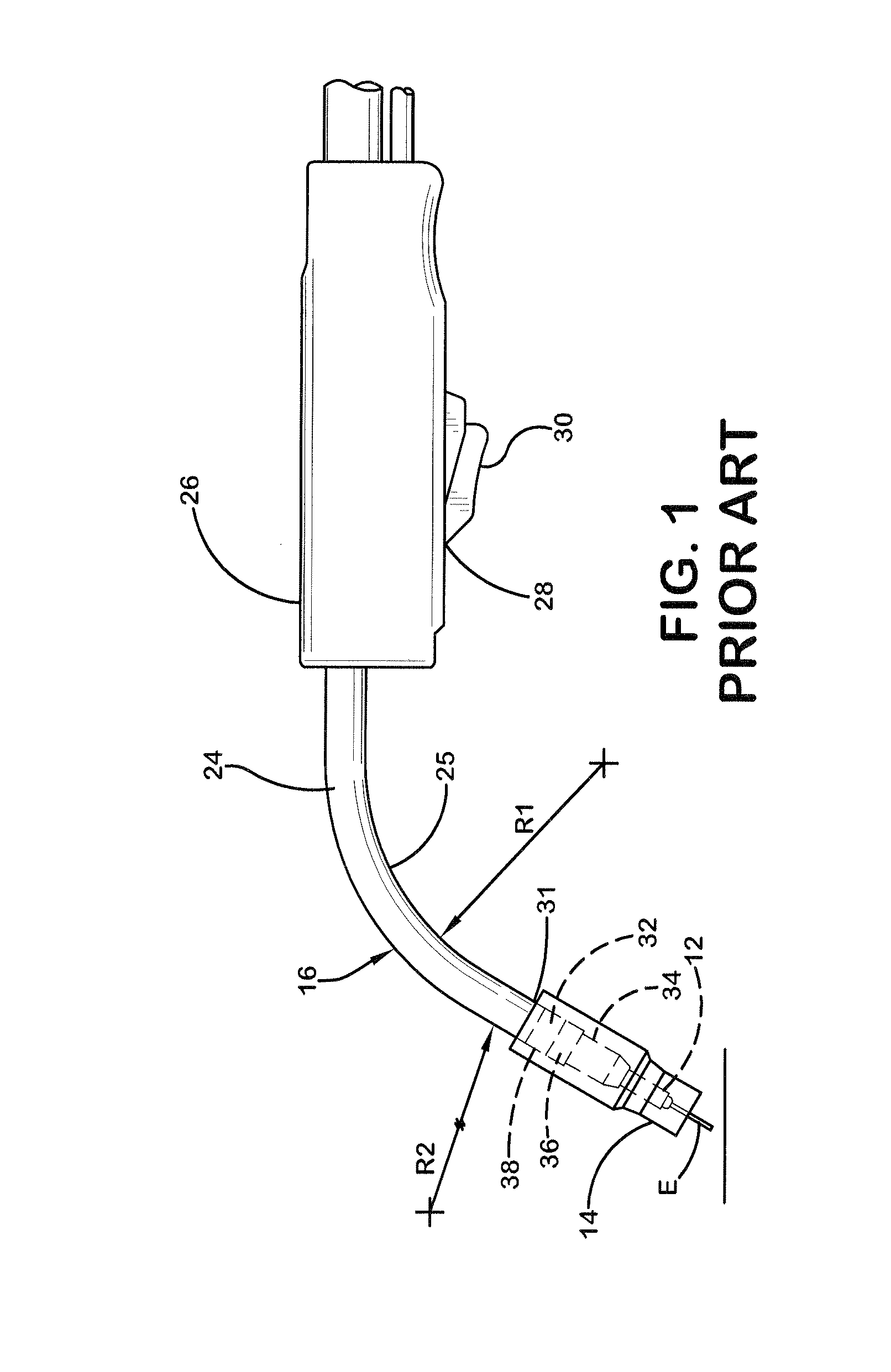

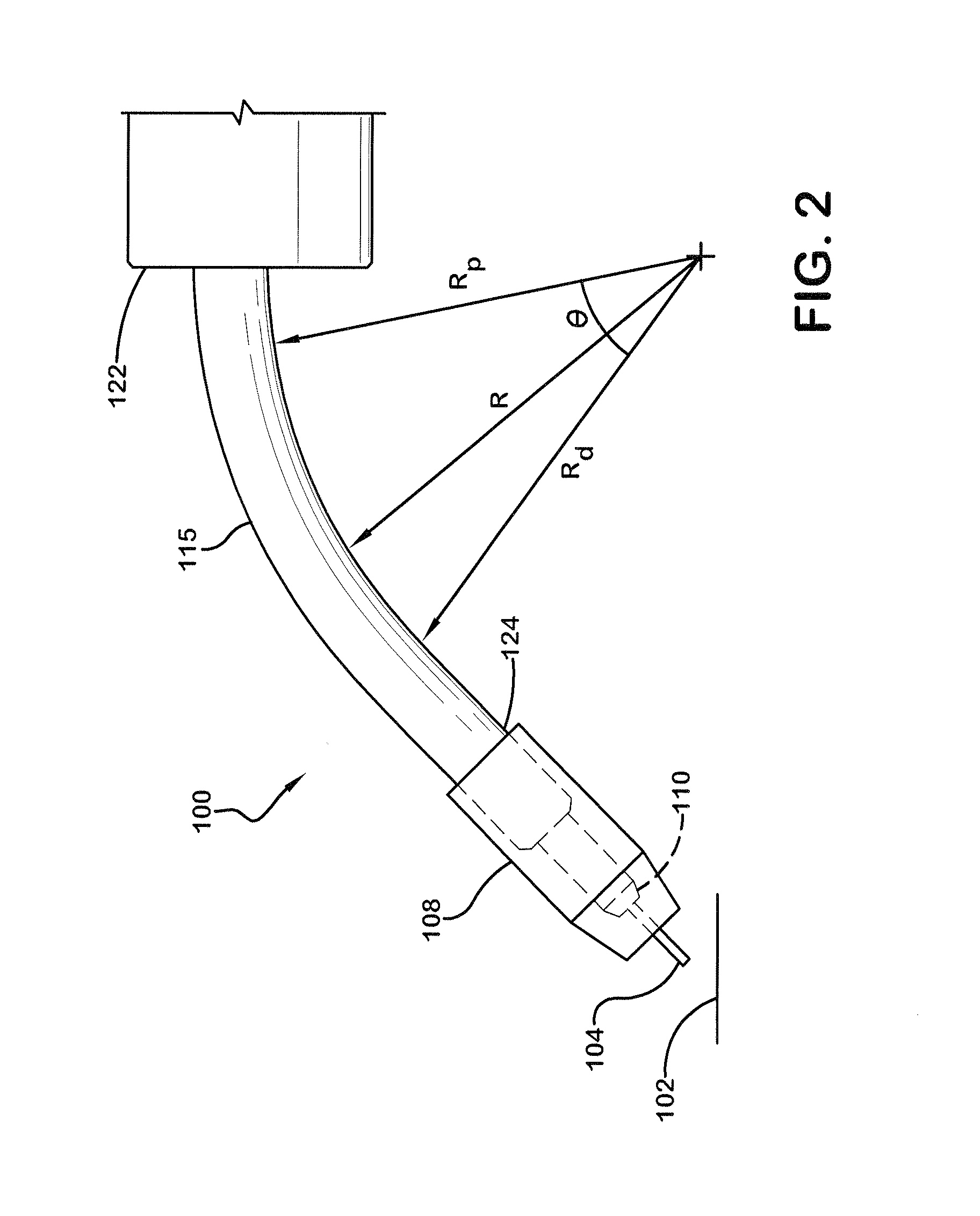

Robotic gmaw torch with quick release gooseneck locking mechanism, dual alignment features, and multiple electrical contacts

InactiveUS20100012637A1Increased durabilityImprove consistencyShielding gas supply/evacuation devicesSupport devices with shieldingLocking mechanismDetent

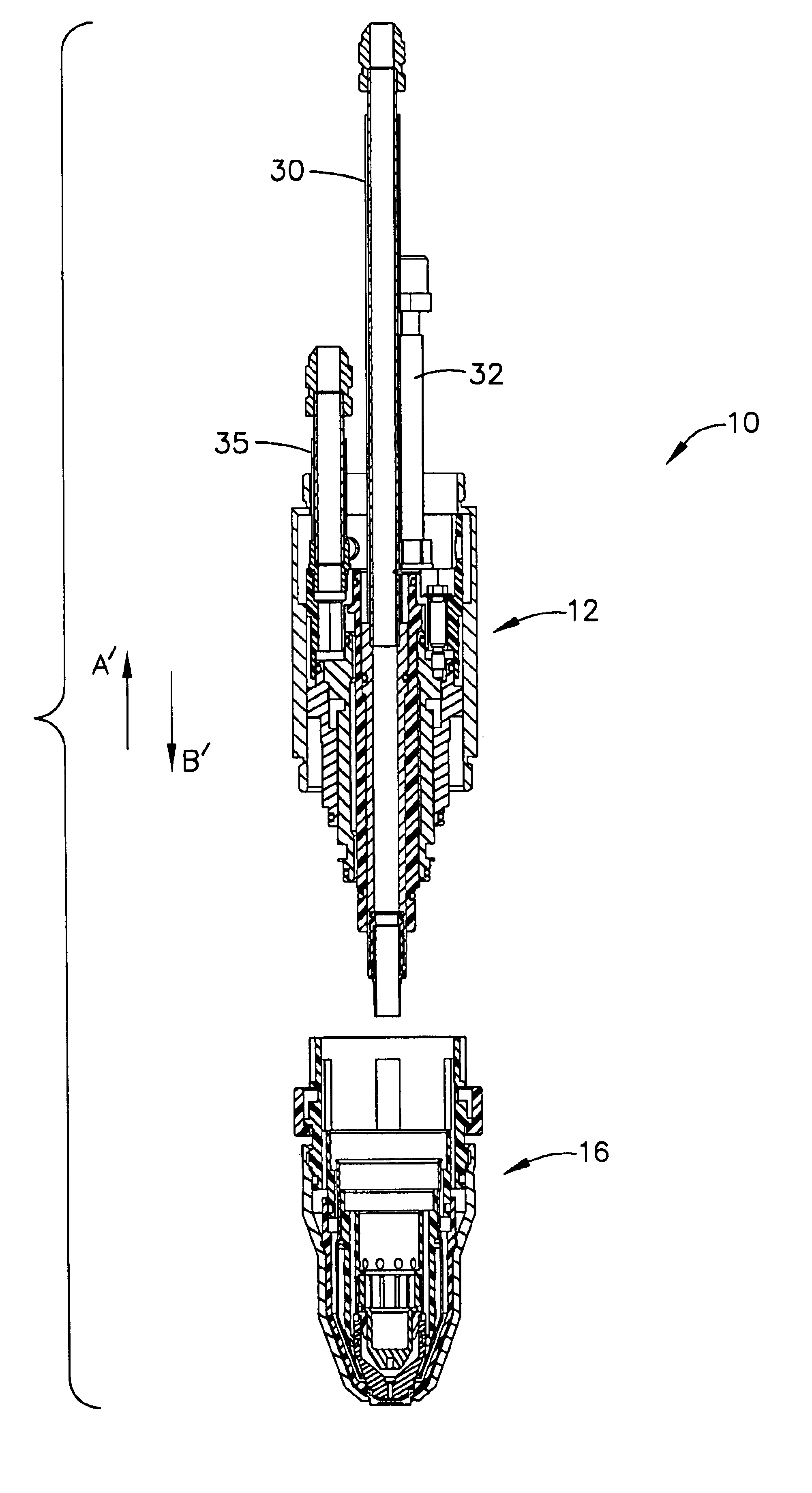

A gooseneck locking mechanism for a robotic GMAW torch having a torch body and a gooseneck includes a connector receiver disposed in the torch body. The connector receiver includes longitudinal ends and a passageway extending between the longitudinal ends. An indexing feature is disposed in the passageway. An elongated connector is mountable on a proximal end of the gooseneck. The connector includes a cooperable indexing feature. The locking mechanism further includes a detent for joining the connector receiver and the elongated connector. The indexing features align the gooseneck relative to the torch body, and the detent secures the connector in the connector receiver for quick release. The locking mechanism may include a plurality of electrical contacts in the connector receiver that are engageable with the connector to provide flow of electrical current through the connector receiver to the gooseneck.

Owner:ILLINOIS TOOL WORKS INC

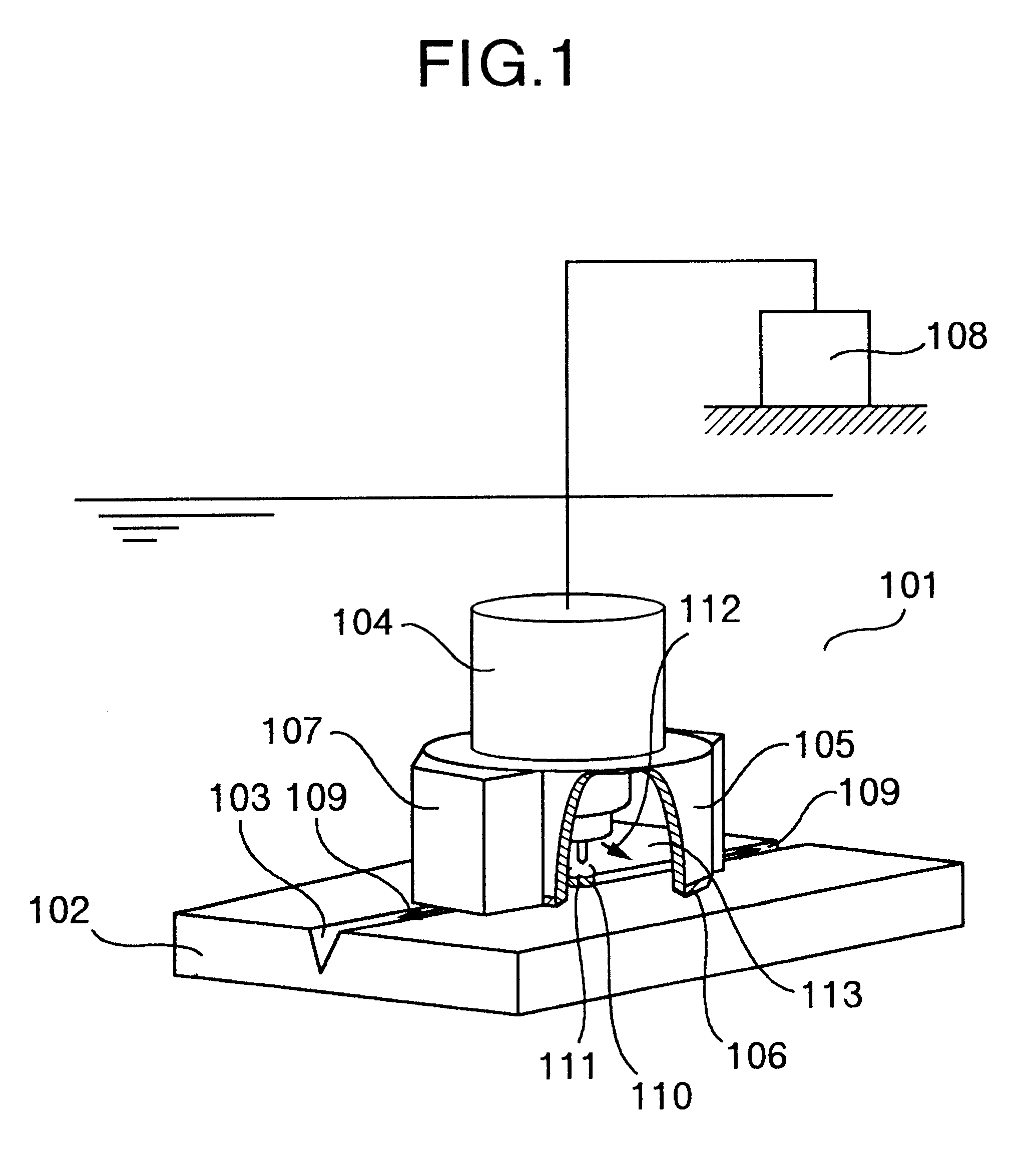

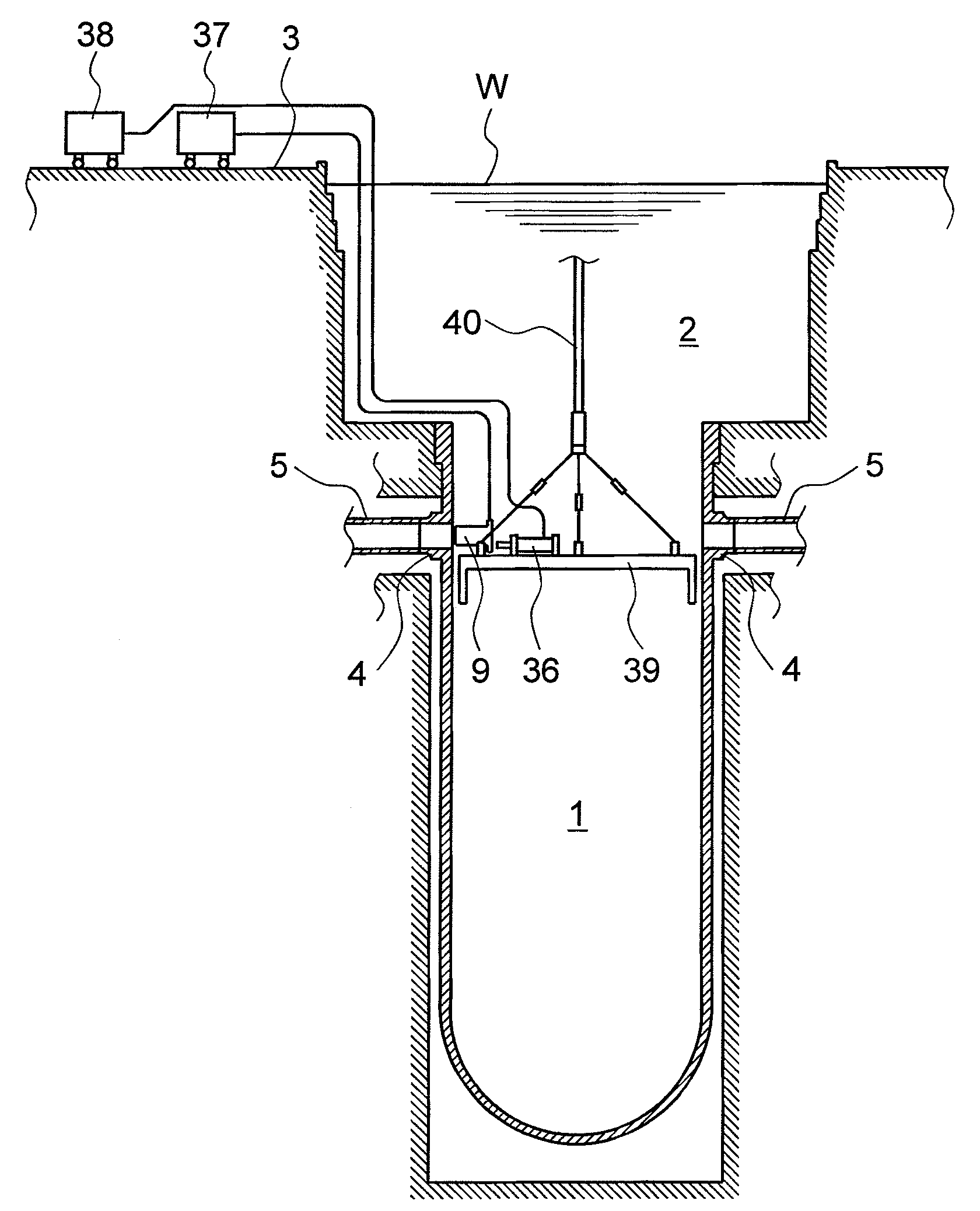

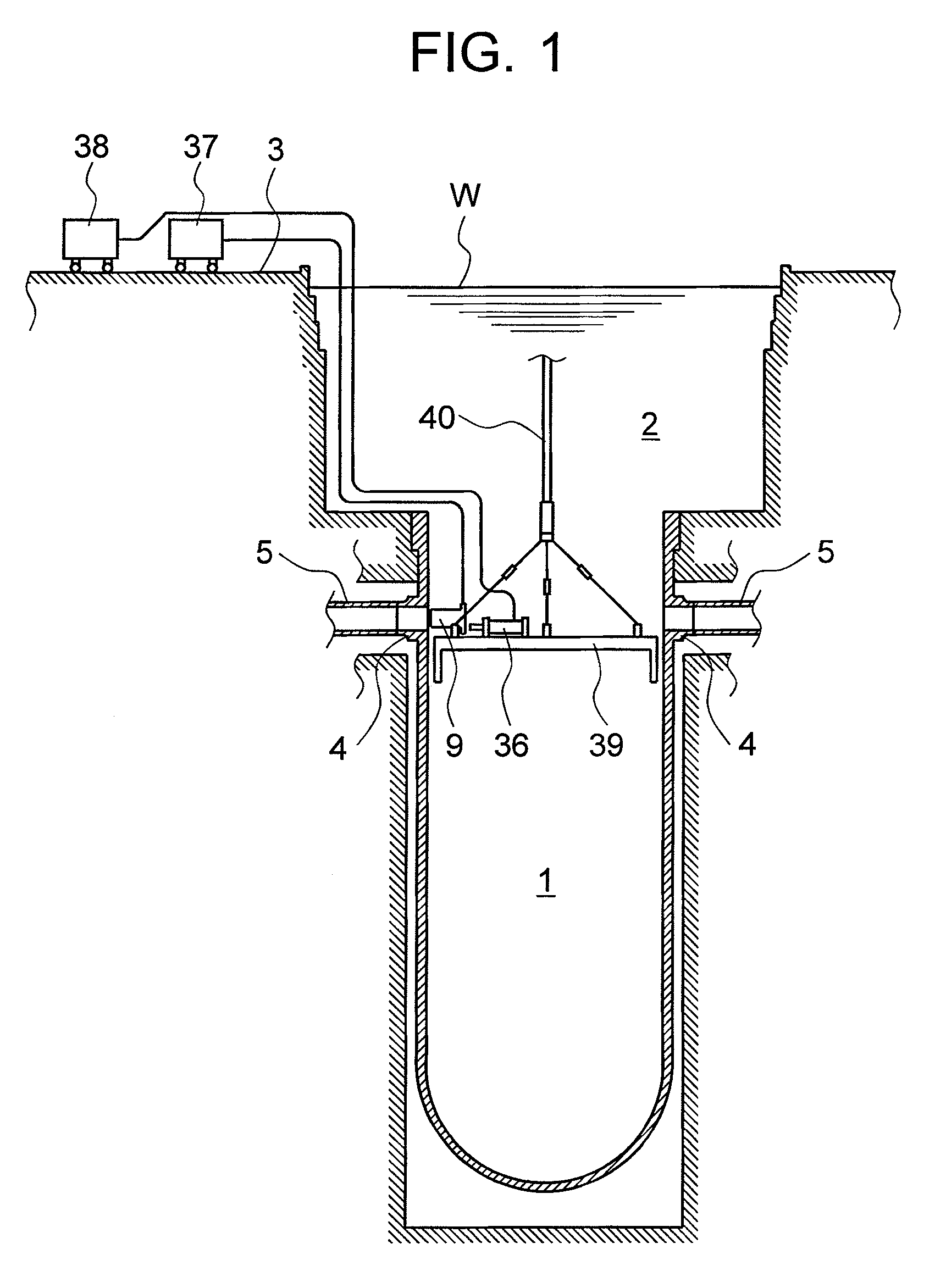

Underwater processing device and underwater processing method

InactiveUS6555779B1Reduce supplyReduce variationSupport devices with shieldingNuclear energy generationNuclear reactorEngineering

Provided are an underwater processing apparatus which can effectively prevent water from entering a shield for a workpiece having a surface ruggedness, and in which variation in a gas flow for a processing part is reduced, a processing method and an application thereof to a nuclear reactor, and the under water processing device is composed of a shield means which locally cover the processing part with the gas in order to prevent water from entering the shield member, the shield means having a solid wall formed of a member which is slidable in a part where it make contact with the workpiece, and adapted to make contact with the workpiece and to be moved up and down by a pressing force, and a water jetting means for forming a water curtain around the outer periphery of the solid wall.

Owner:HITACHI LTD

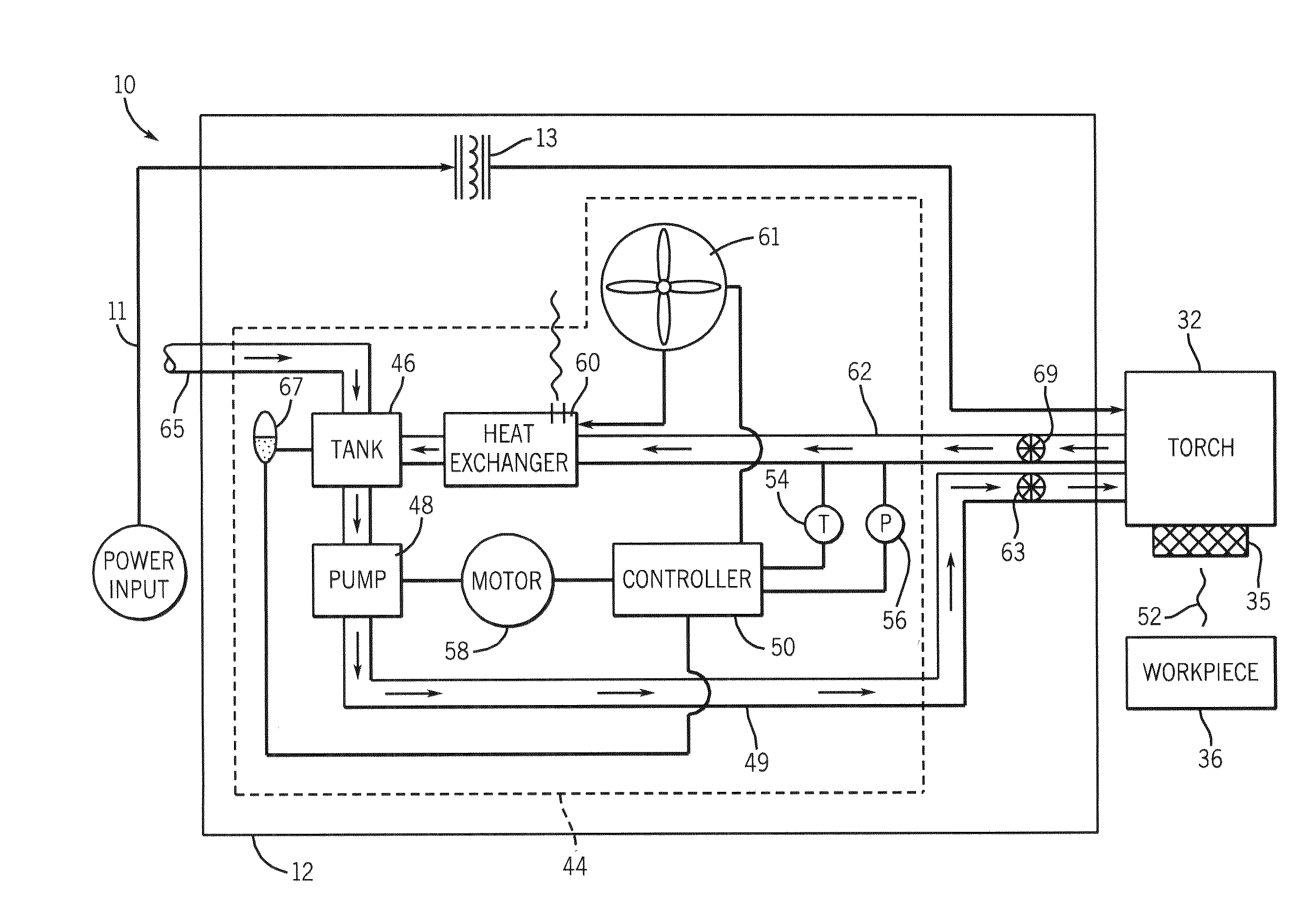

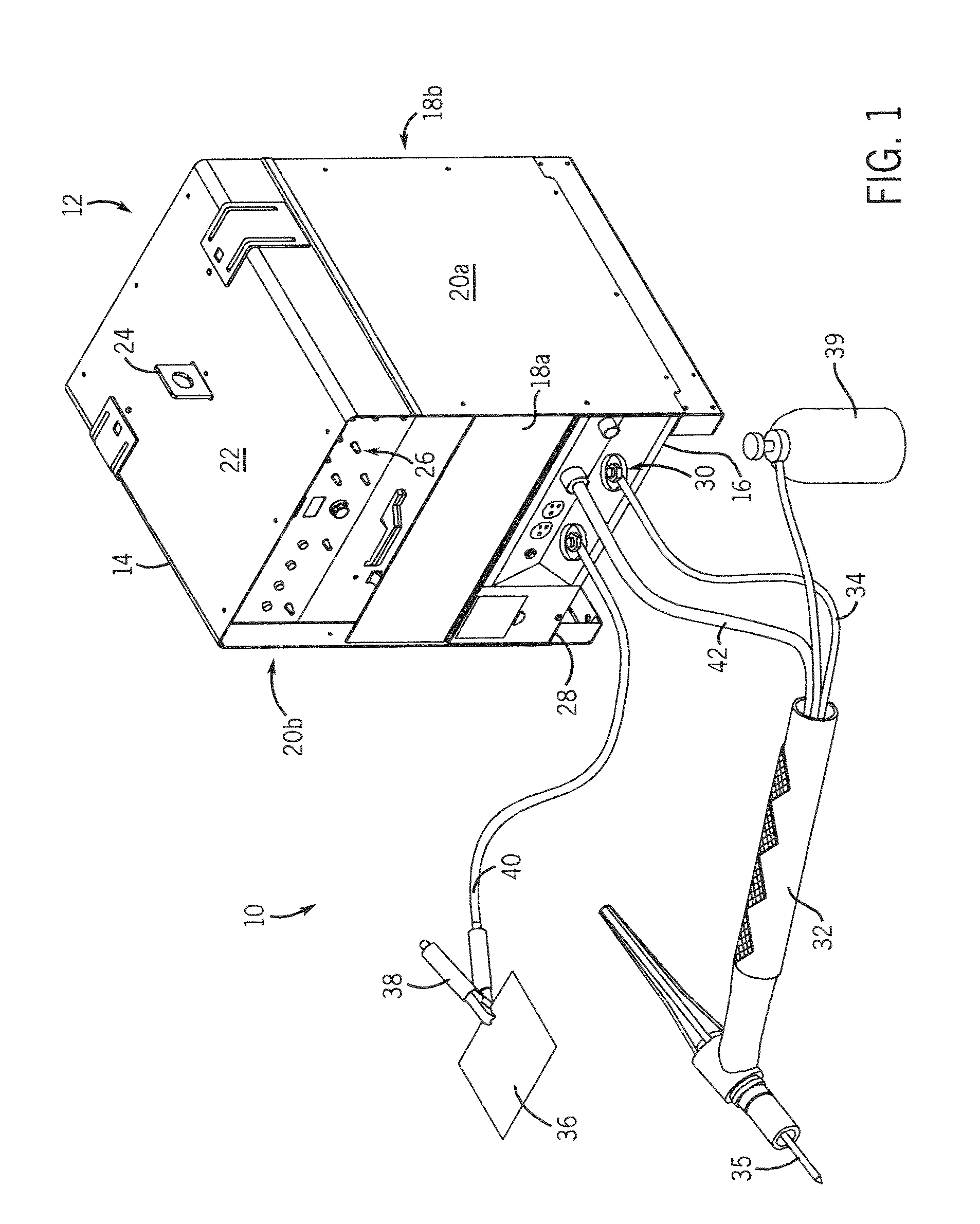

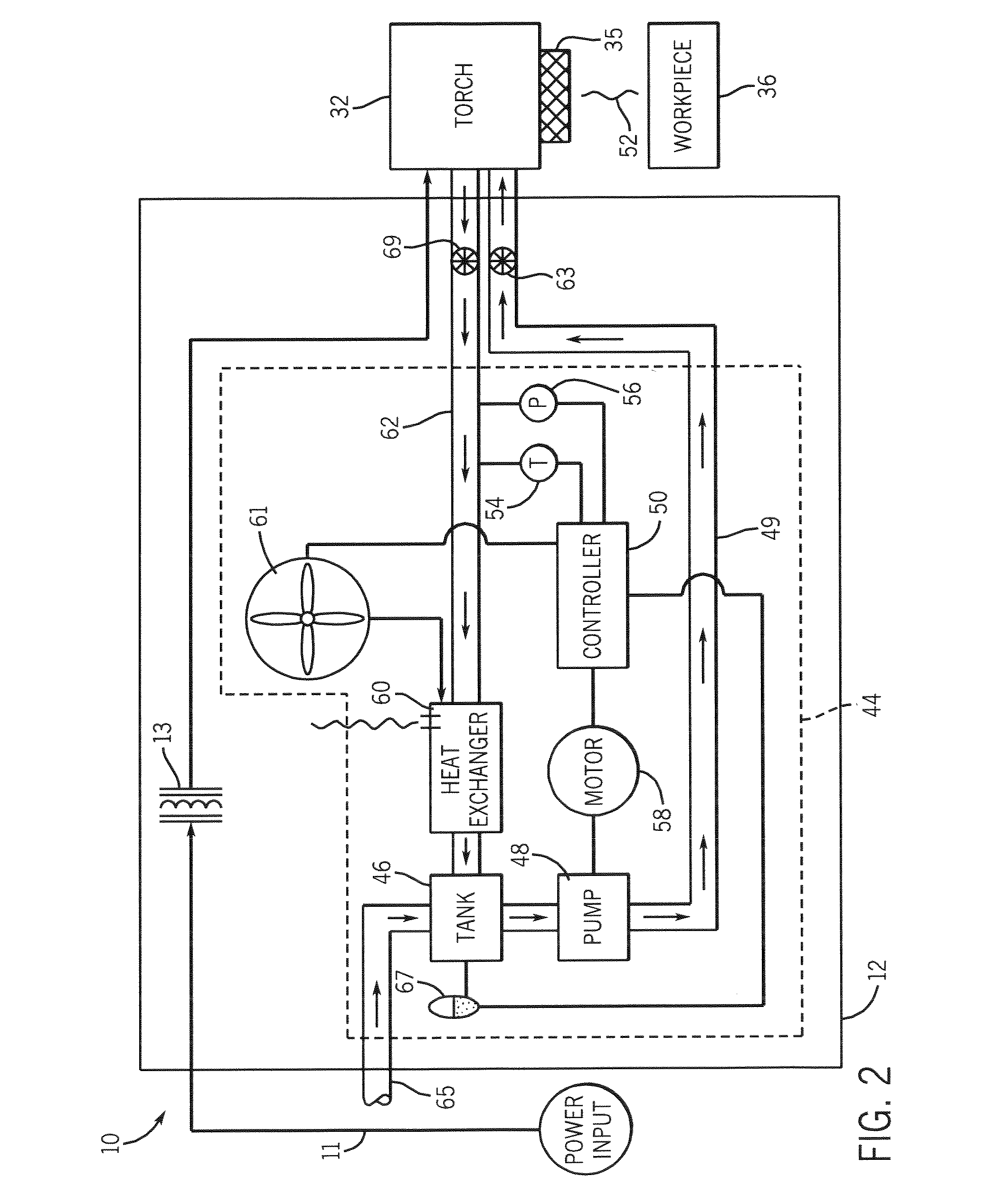

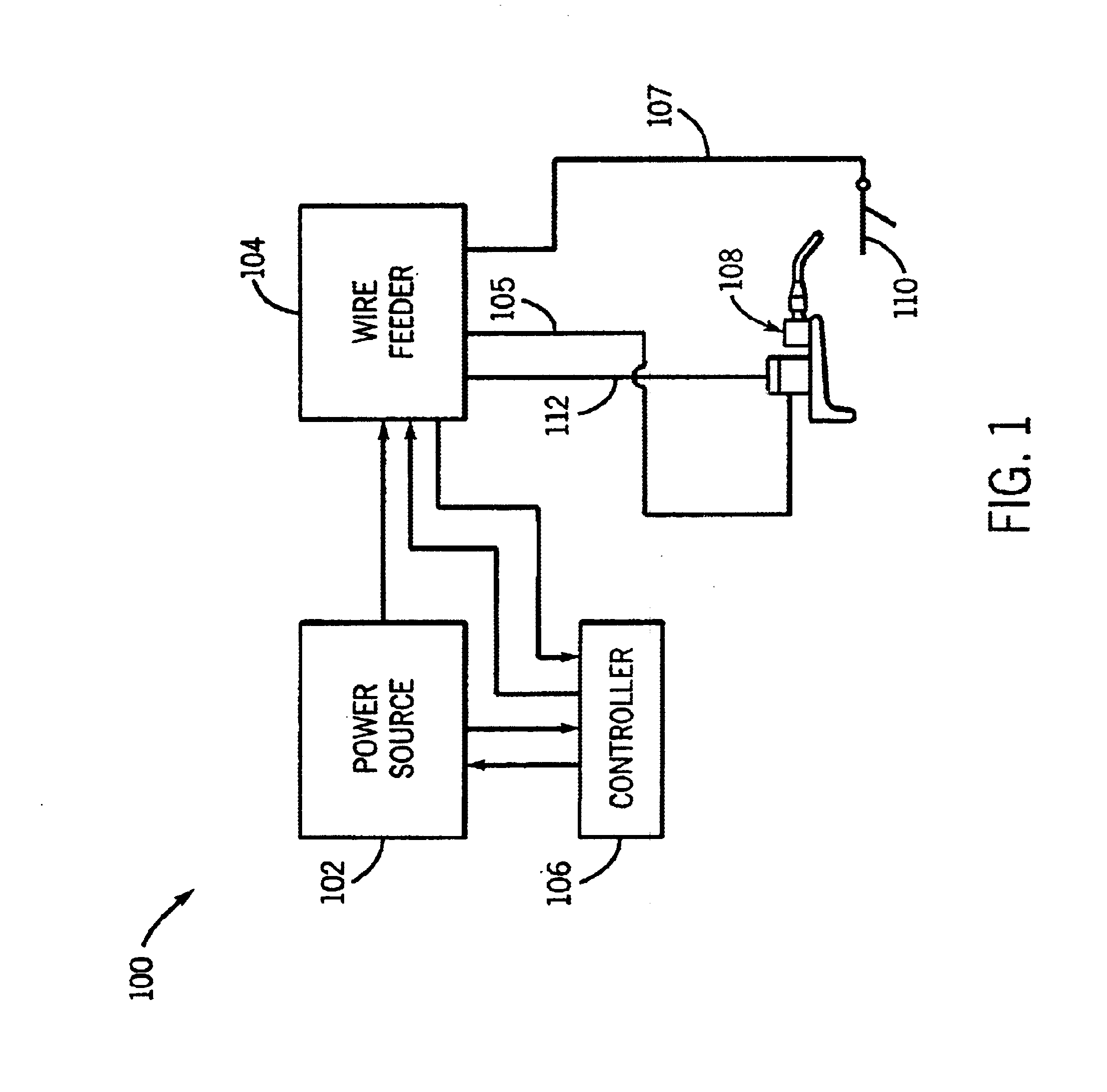

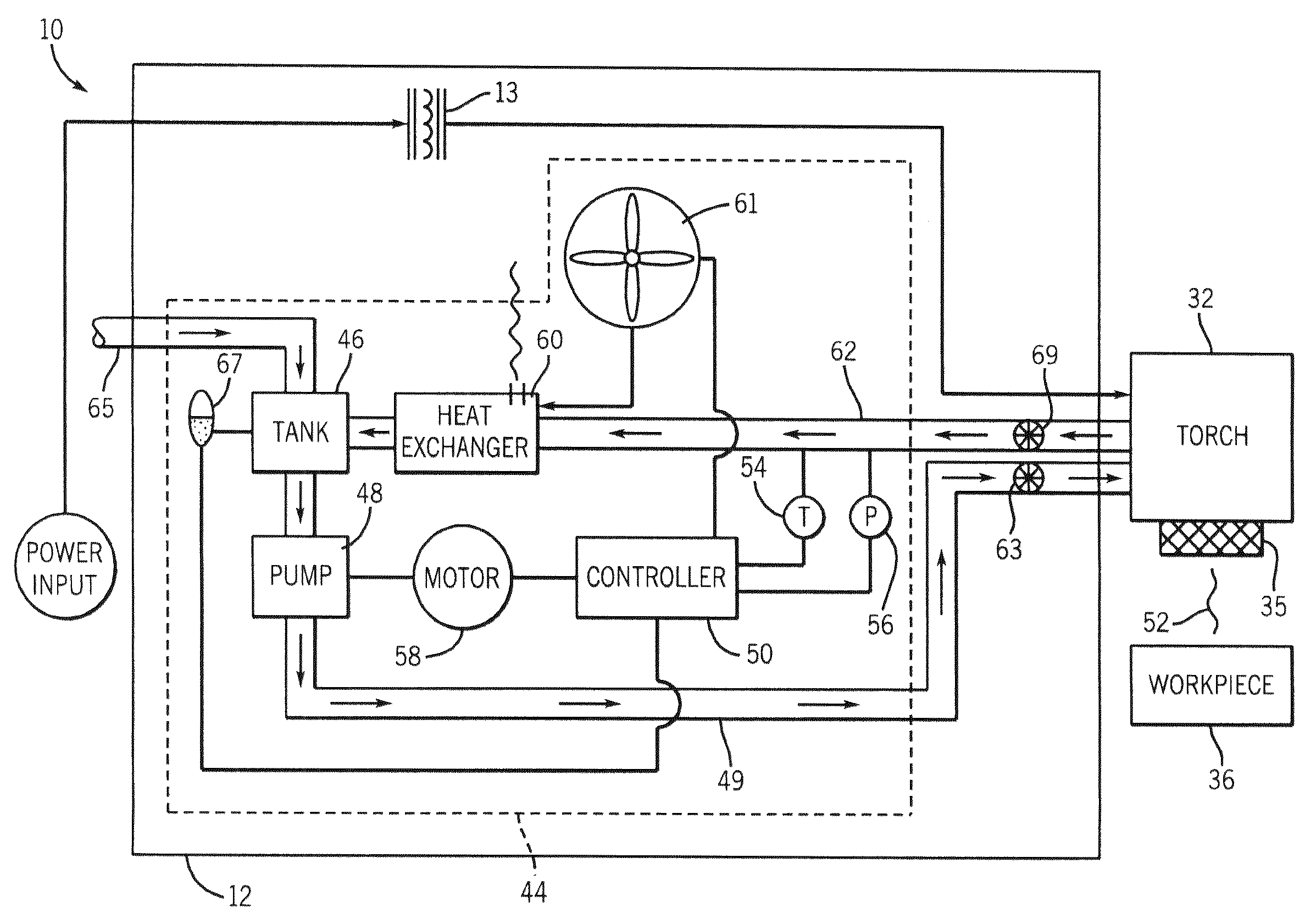

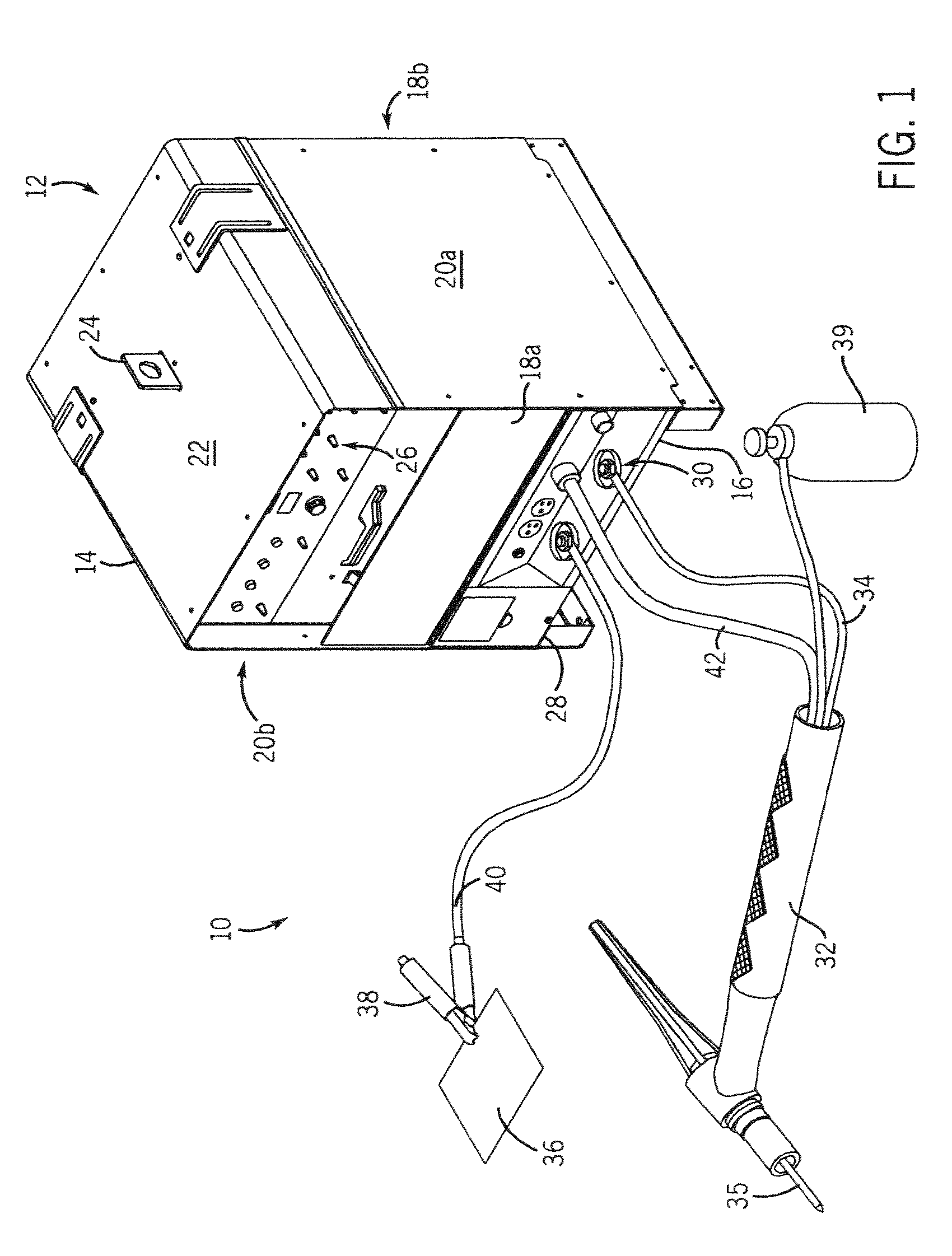

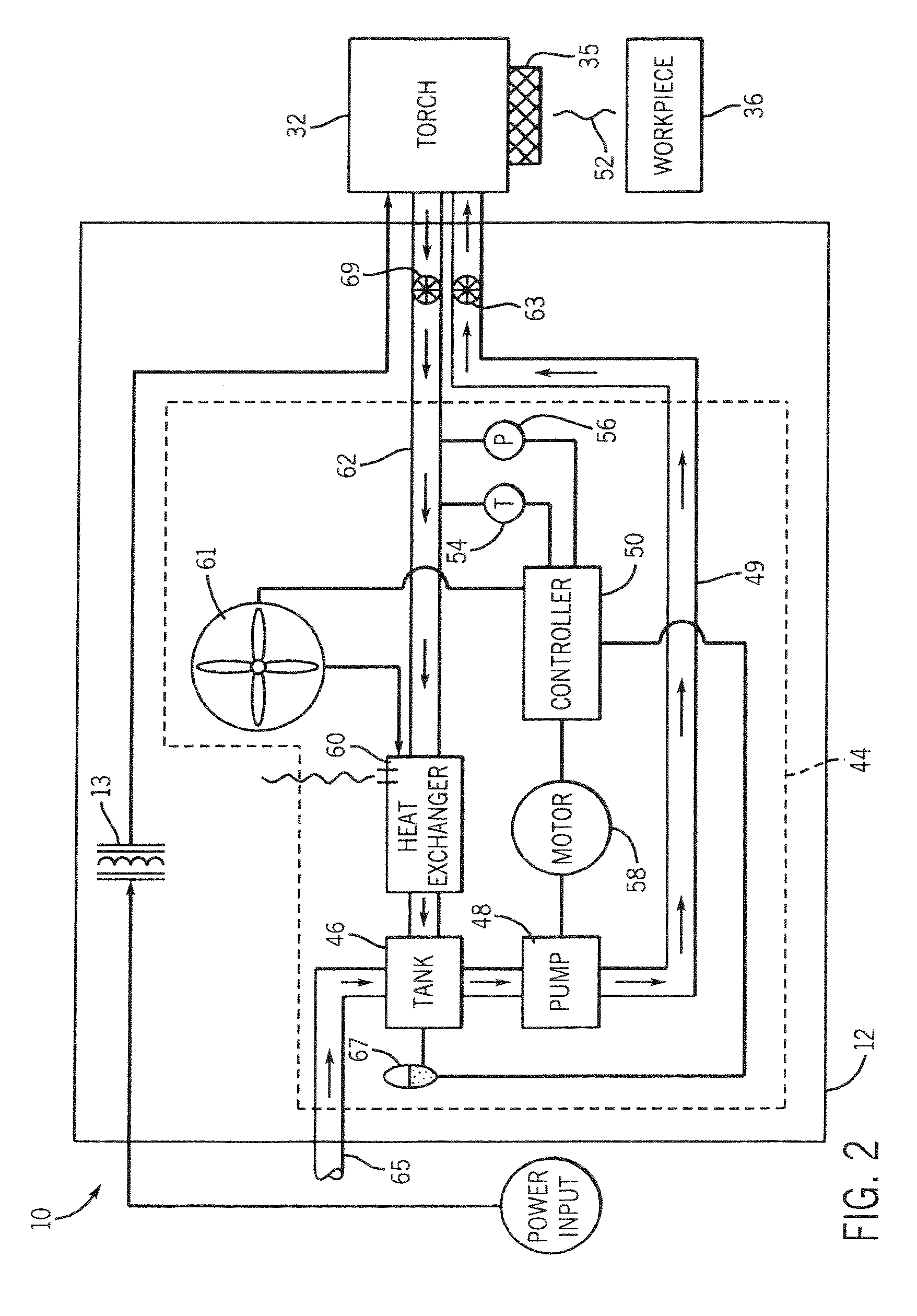

Method and apparatus to adaptively cool a welding-type system

ActiveUS20050016979A1Support devices with shieldingCooled electrode holdersEngineeringBiological activation

A cooling system connected to provide coolant to a welding-type component automatically circulates coolant through the welding component upon activation of the welding component. A controller is configured to regulate the cooling system such that upon activation of the welding-type component coolant is caused to at least flow through the welding-type component and circulate after deactivation of the welding torch until a temperature of the coolant falls below a certain value or a specified time period has expired.

Owner:ILLINOIS TOOL WORKS INC

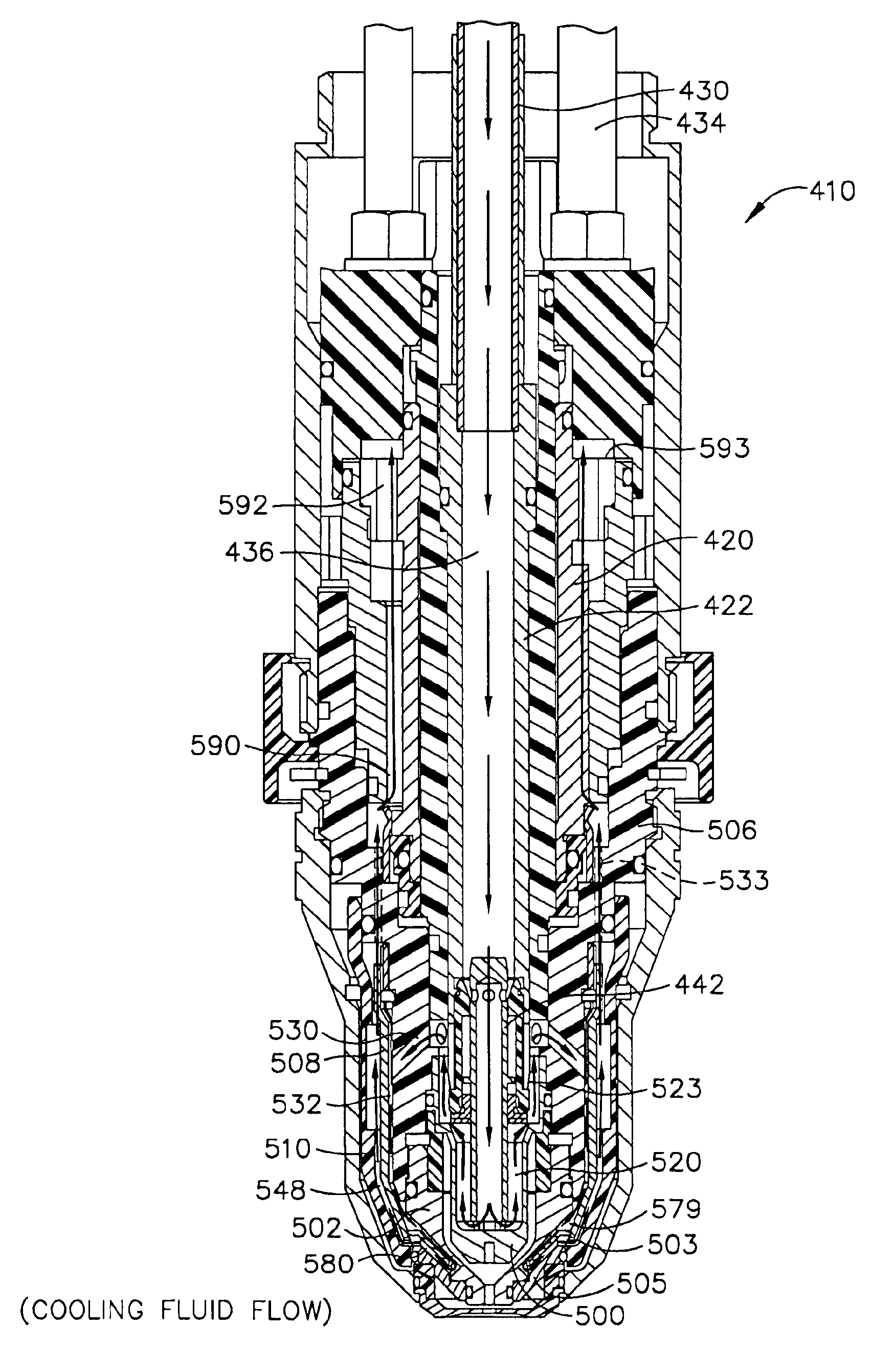

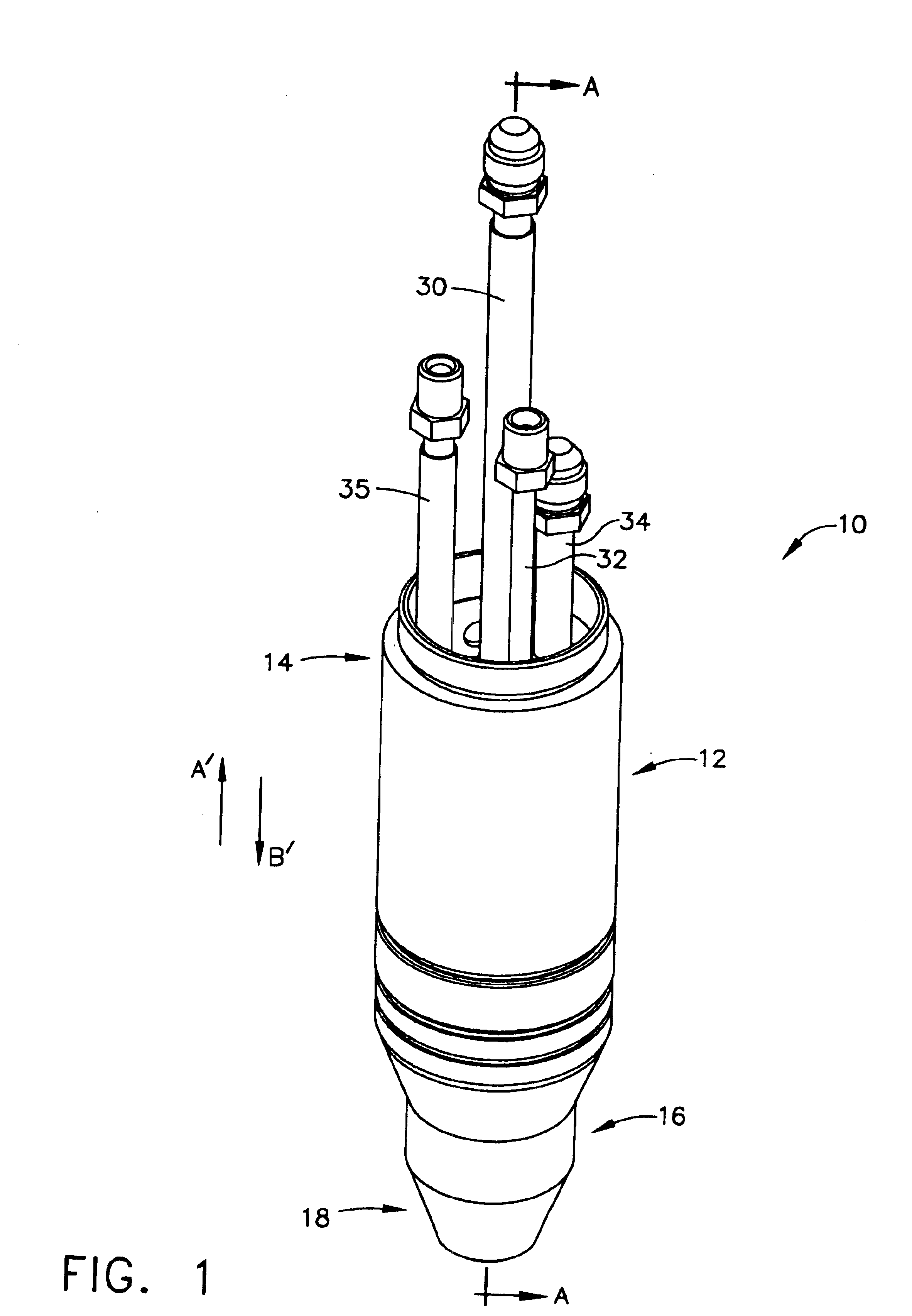

Plasma arc torch cooling system

InactiveUS6946616B2Precision coolingHigh trafficSupport devices with shieldingPlasma welding apparatusRadial positionEngineering

Owner:VICTOR EQUIP

Arc welder and torch for same

InactiveUS6259059B1Increase currentStable welding processSupport devices with shieldingElectrode accessoriesElectric arcEngineering

Owner:LINCOLN GLOBAL INC

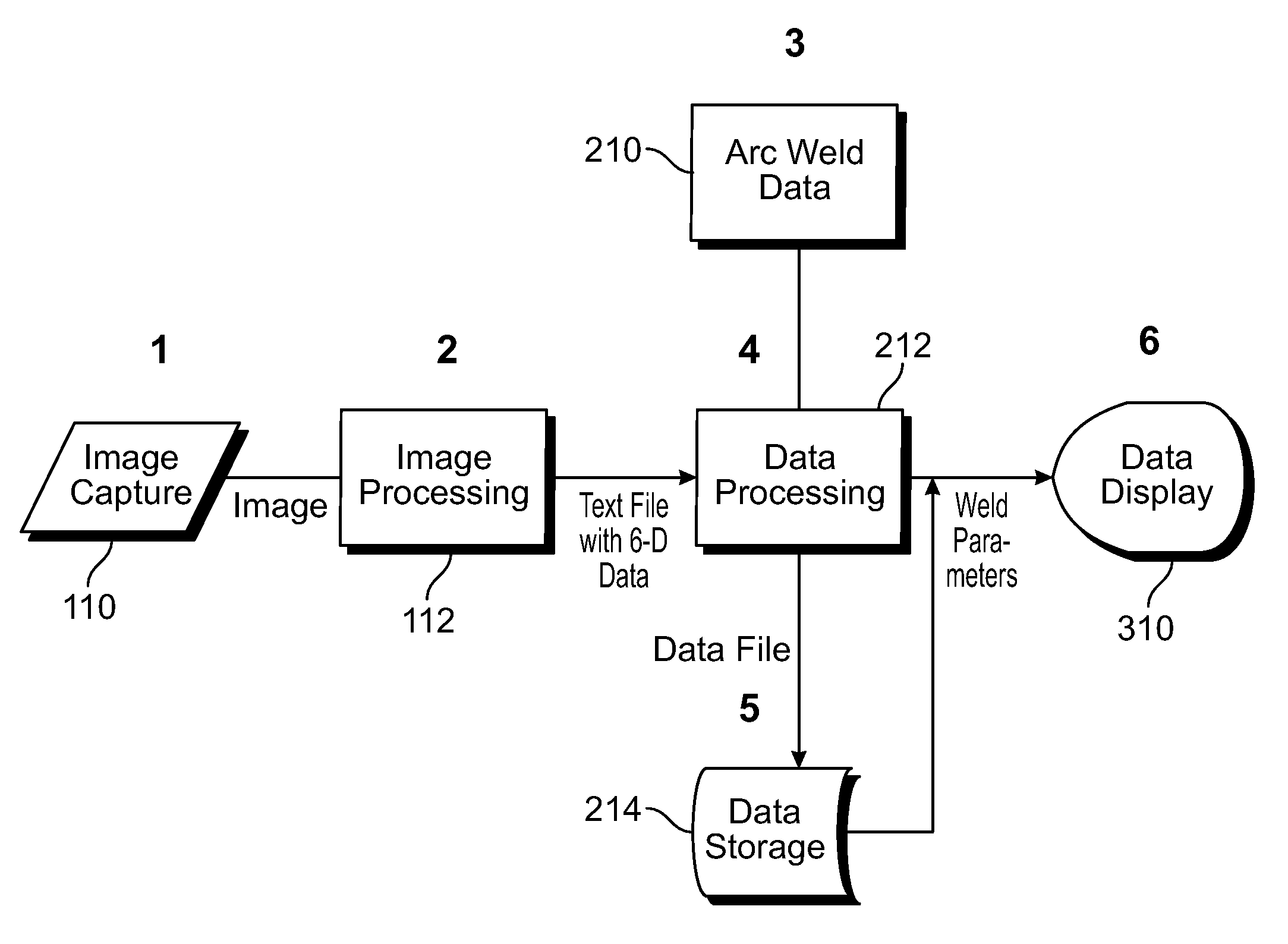

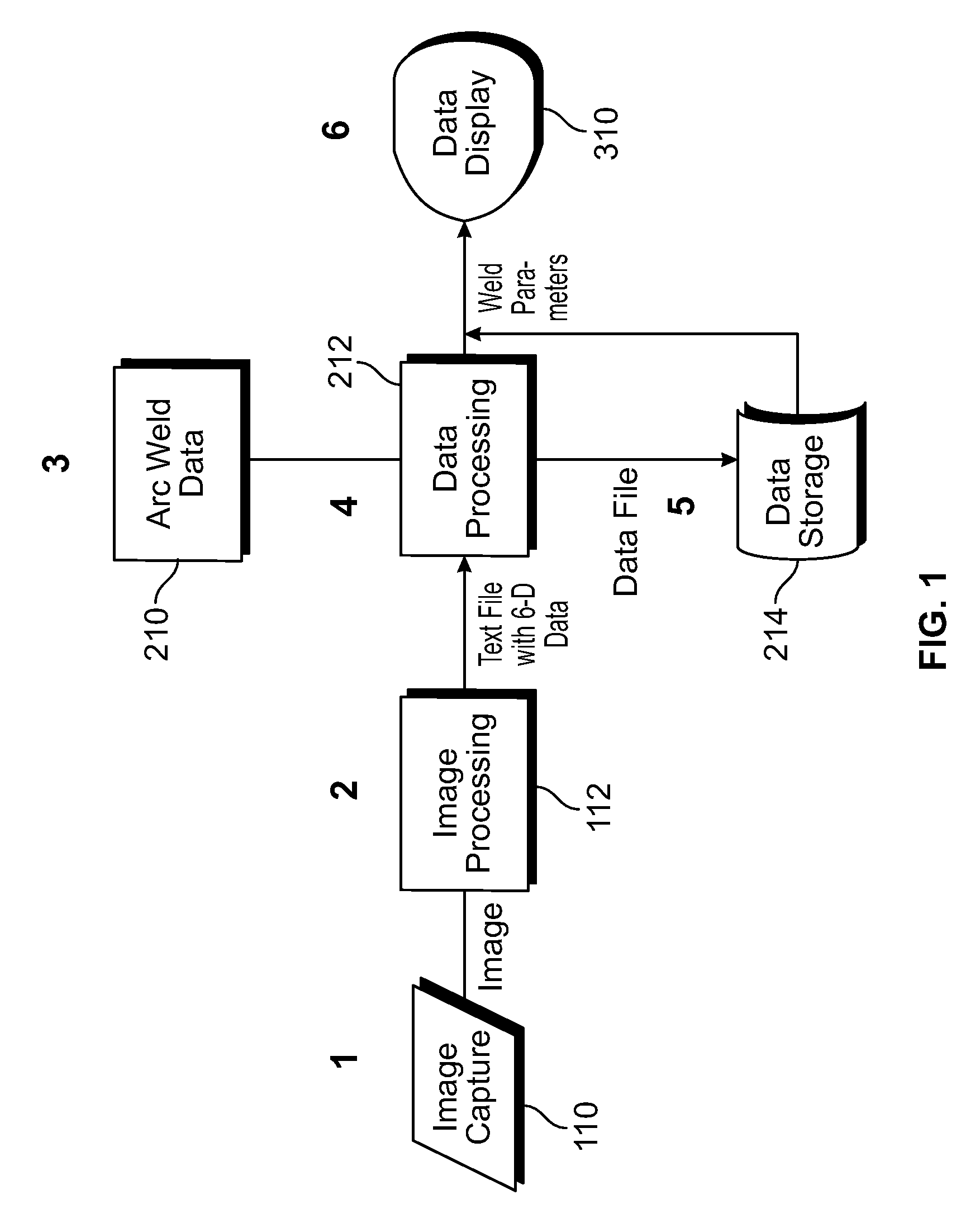

System for characterizing manual welding operations

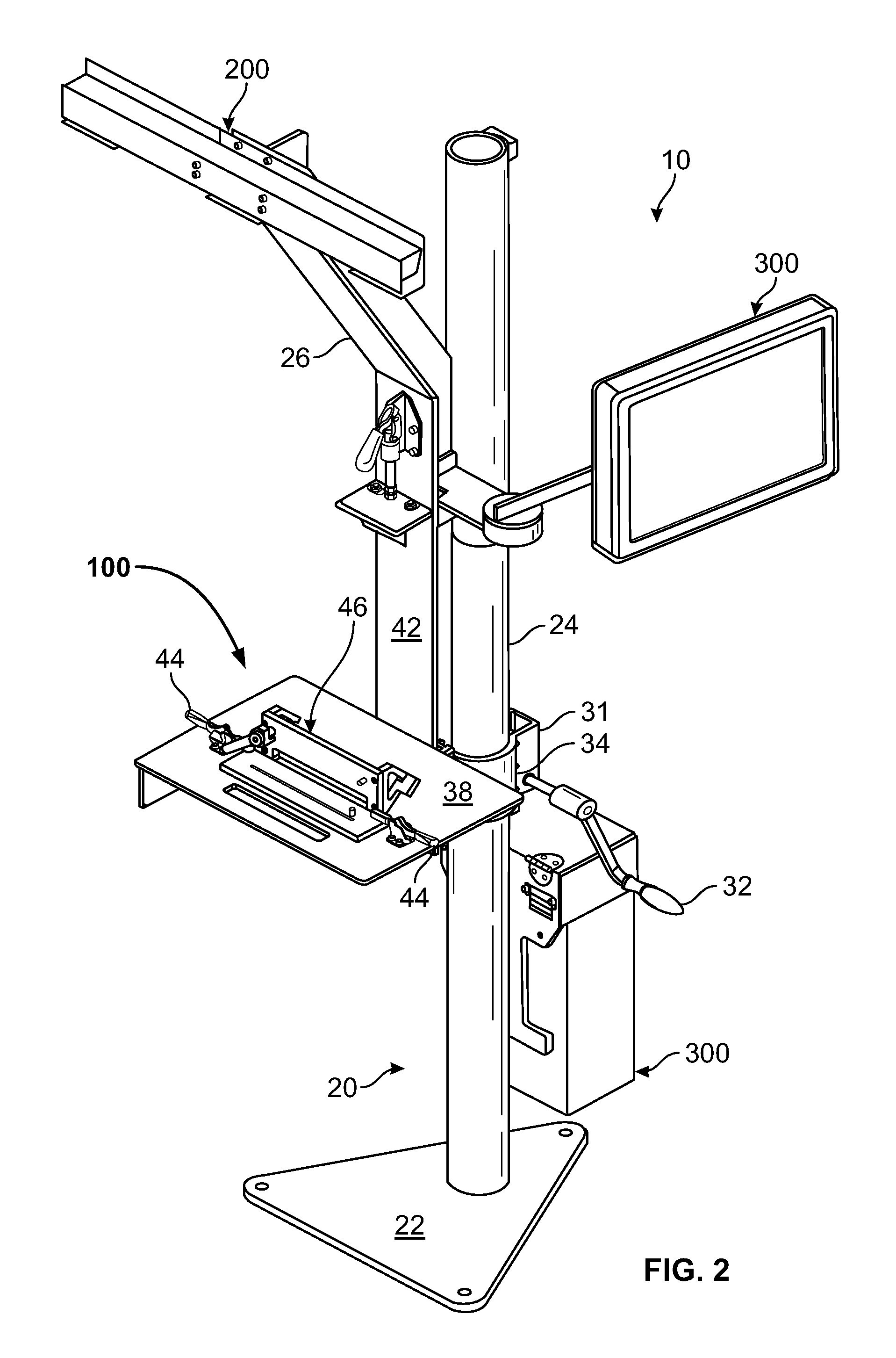

ActiveUS9221117B2Improve signal-to-noise ratioSupport devices with shieldingWelding/cutting auxillary devicesImage systemWelding

A system for characterizing manual welding exercises and providing valuable training to welders that includes components for generating, capturing, and processing data. The data generating component further includes a fixture, workpiece, at least one calibration devices each having at least two point markers integral therewith, and a welding tool. The data capturing component further includes an imaging system for capturing images of the point markers and the data processing component is operative to receive information from the data capturing component and perform various position and orientation calculations.

Owner:LINCOLN GLOBAL INC

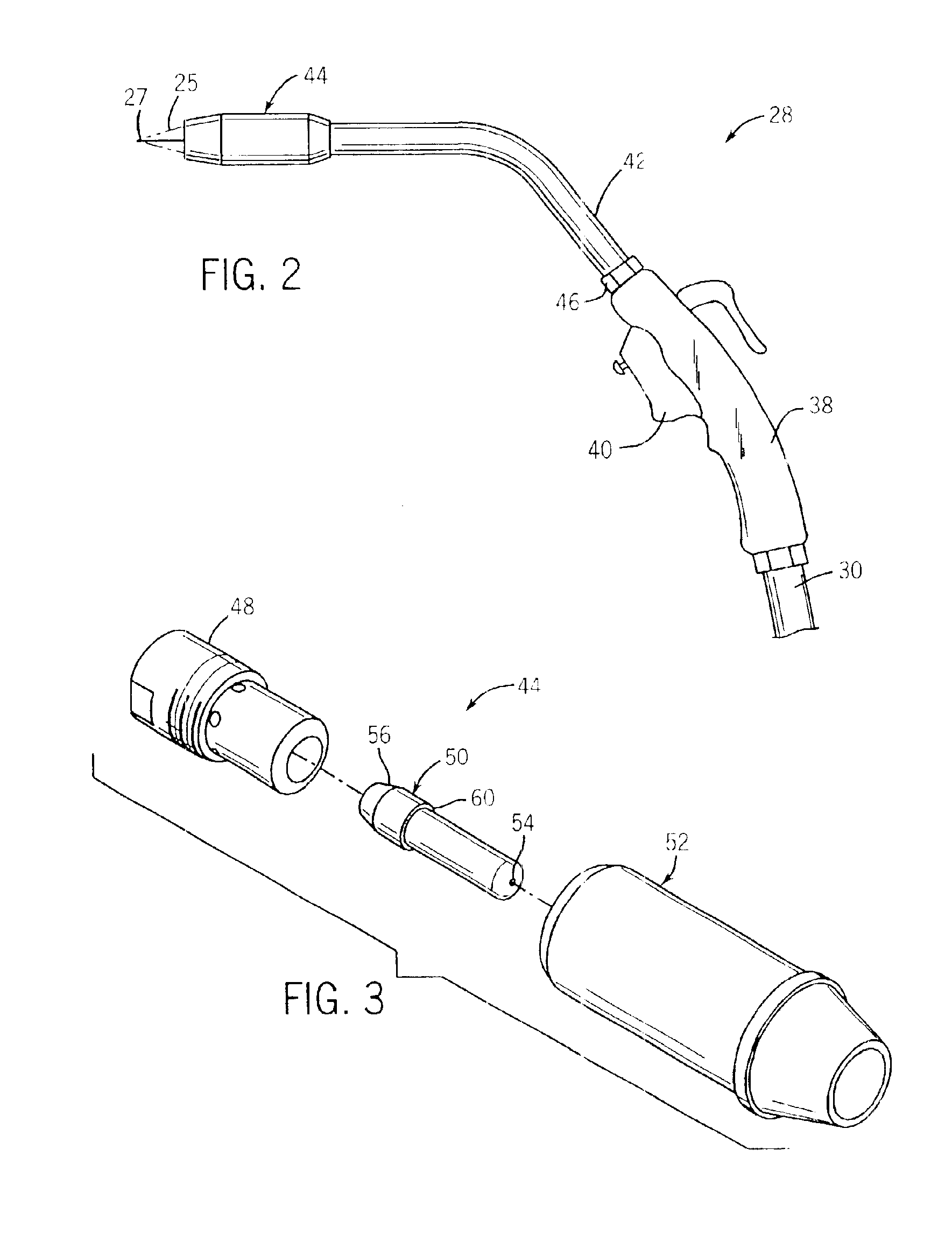

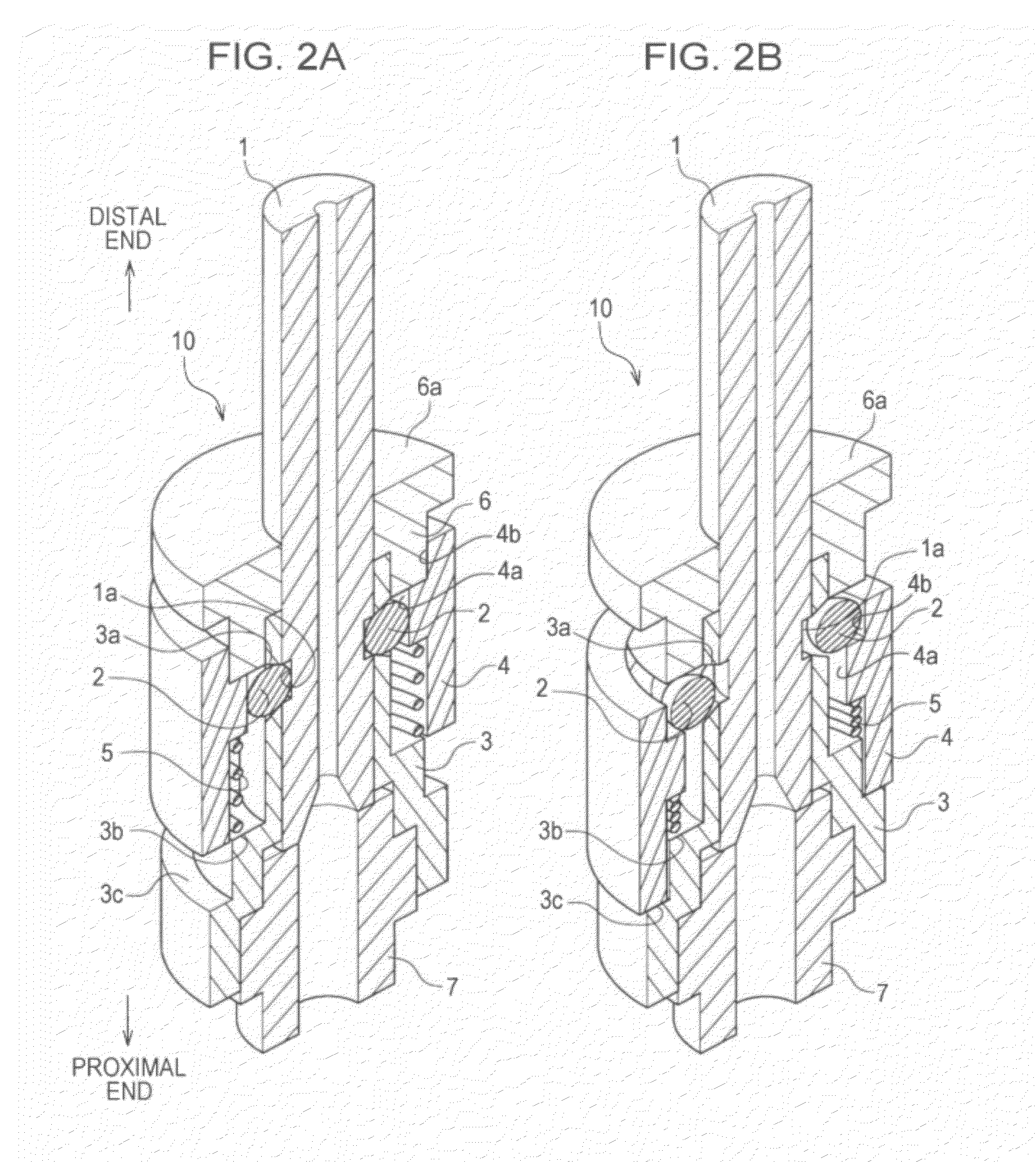

Welding contact tip and diffuser

InactiveUS6847009B2Reduce heatExtended component lifeSupport devices with shieldingElectrode accessoriesAxial forceEngineering

A welding contact tip and diffuser assembly for use in a welding apparatus. The assembly includes an electrically conductive contact tip having a tapered exterior surface, a diffuser having a cavity with a tapered interior surface, and a releasable connection for holding the contact tip in the diffuser. The connection includes at least one detent element in either the diffuser or the contact tip, at least one recess forming a ramp in the other of the diffuser or contact tip, and at least one spring. The spring biases the detent element into the recess and against the ramp to generate an axial force against the ramp. The axial force tends to urge the tapered surfaces of the contact tip and diffuser into contact with one another.

Owner:VICTOR EQUIP

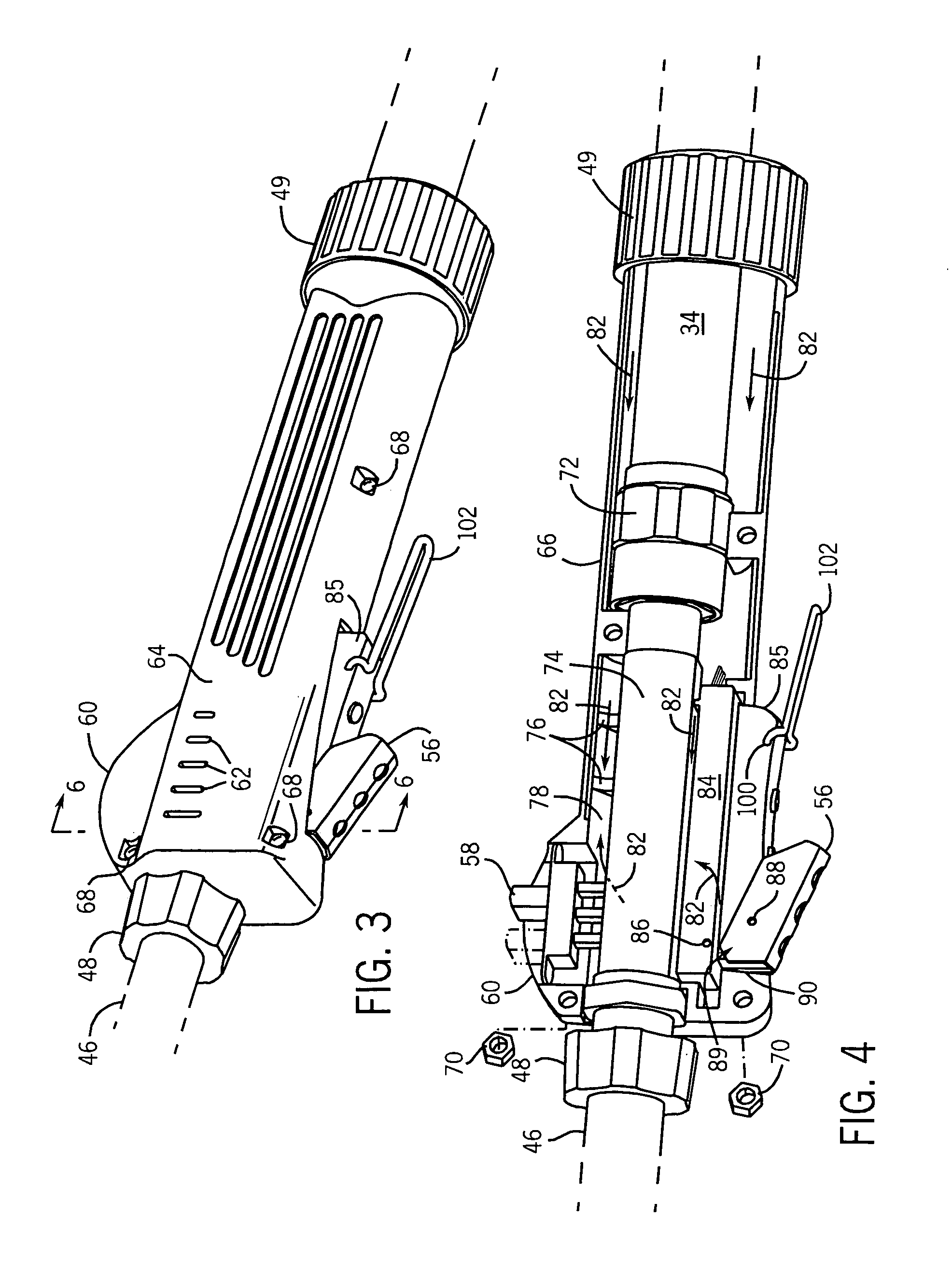

Welding gun having contact tip and method of operating same

InactiveUS7105775B2Support devices with shieldingNon-shielding electrode holdersAbutmentBiomedical engineering

A welding gun adapted to secure a contact tip within the welding gun without threading the contact tip and without the use of tools. The contact tip may be adapted to abut a surface of a first member disposed within the welding gun. The surface may be a surface of a gas diffuser. The surface may be adapted to abut the contact tip. The contact tip also may be adapted for abutment with a second member to urge the contact tip toward the first member. The second member may be a portion of a nozzle adapted to abut the contact tip to urge the contact tip toward the surface of the first member. A method of assembling a welding gun also is provided. The method may comprise disposing a contact tip between a first and a second member and capturing the contact tip between the first and second members.

Owner:ILLINOIS TOOL WORKS INC

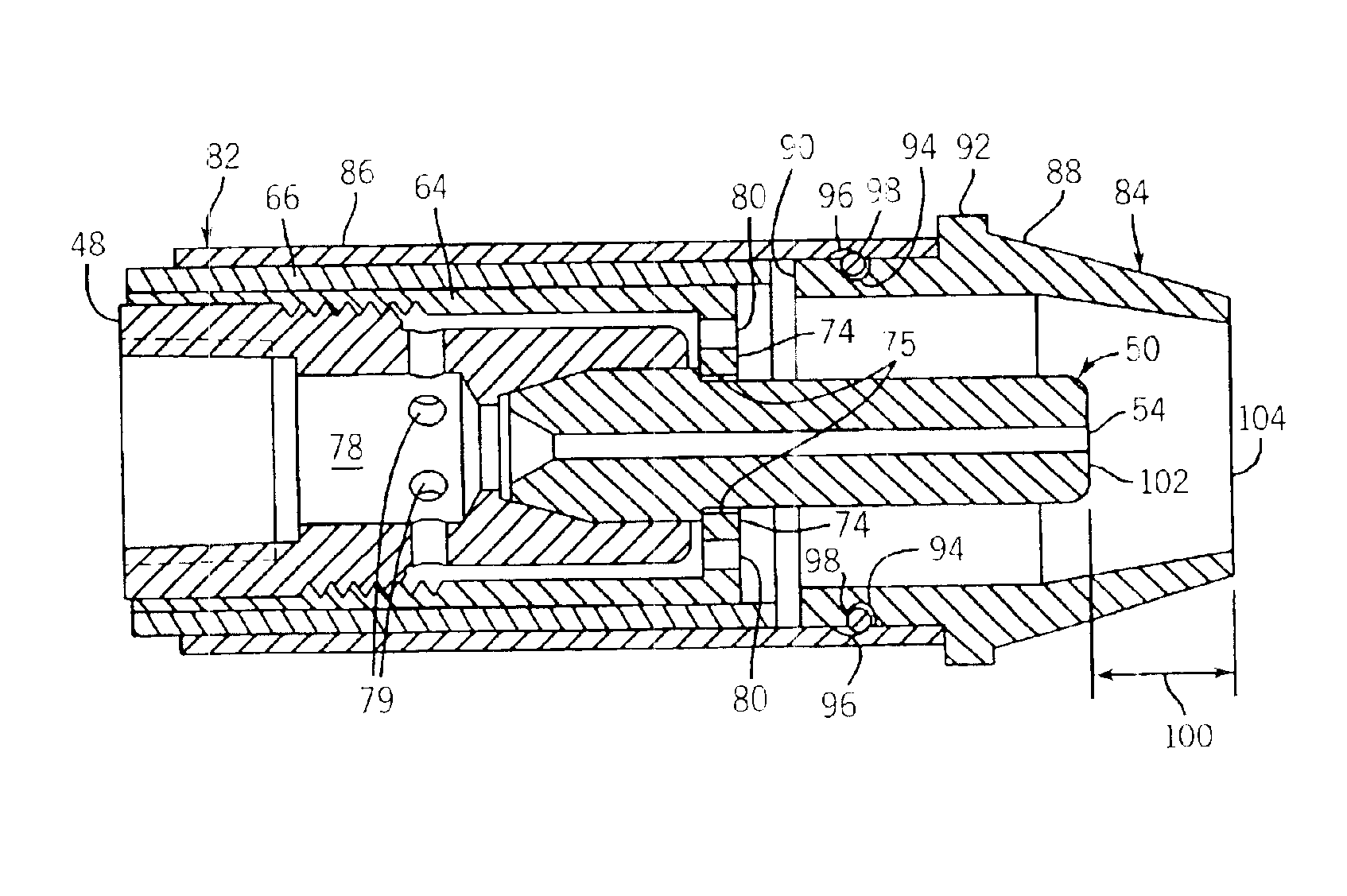

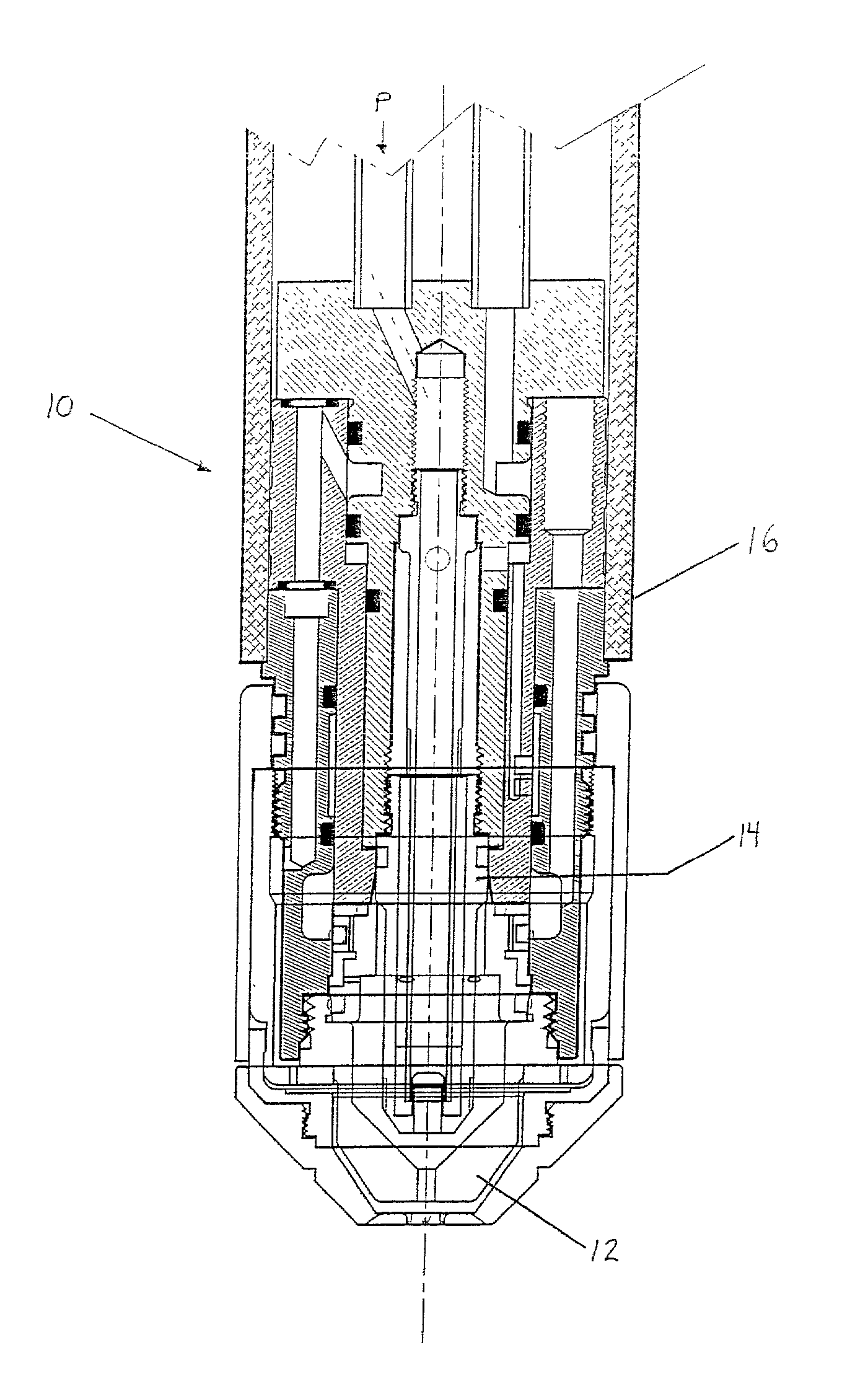

Plasma arc torch head connections

InactiveUS6919526B2Precision coolingHigh trafficSupport devices with shieldingPlasma welding apparatusElectrical connectionTorch

A plasma arc torch is provided that comprises torch head connections that are made between consumable components and a torch head independent of rotational alignment of the consumable components. Accordingly, connections for the flow of a cooling fluid, plasma gas, and / or a secondary gas are made independent of rotational alignment. Additionally, electrical connections are also provided that are independent of rotational alignment of the various plasma arc torch components.

Owner:THERMAL DYNAMICS

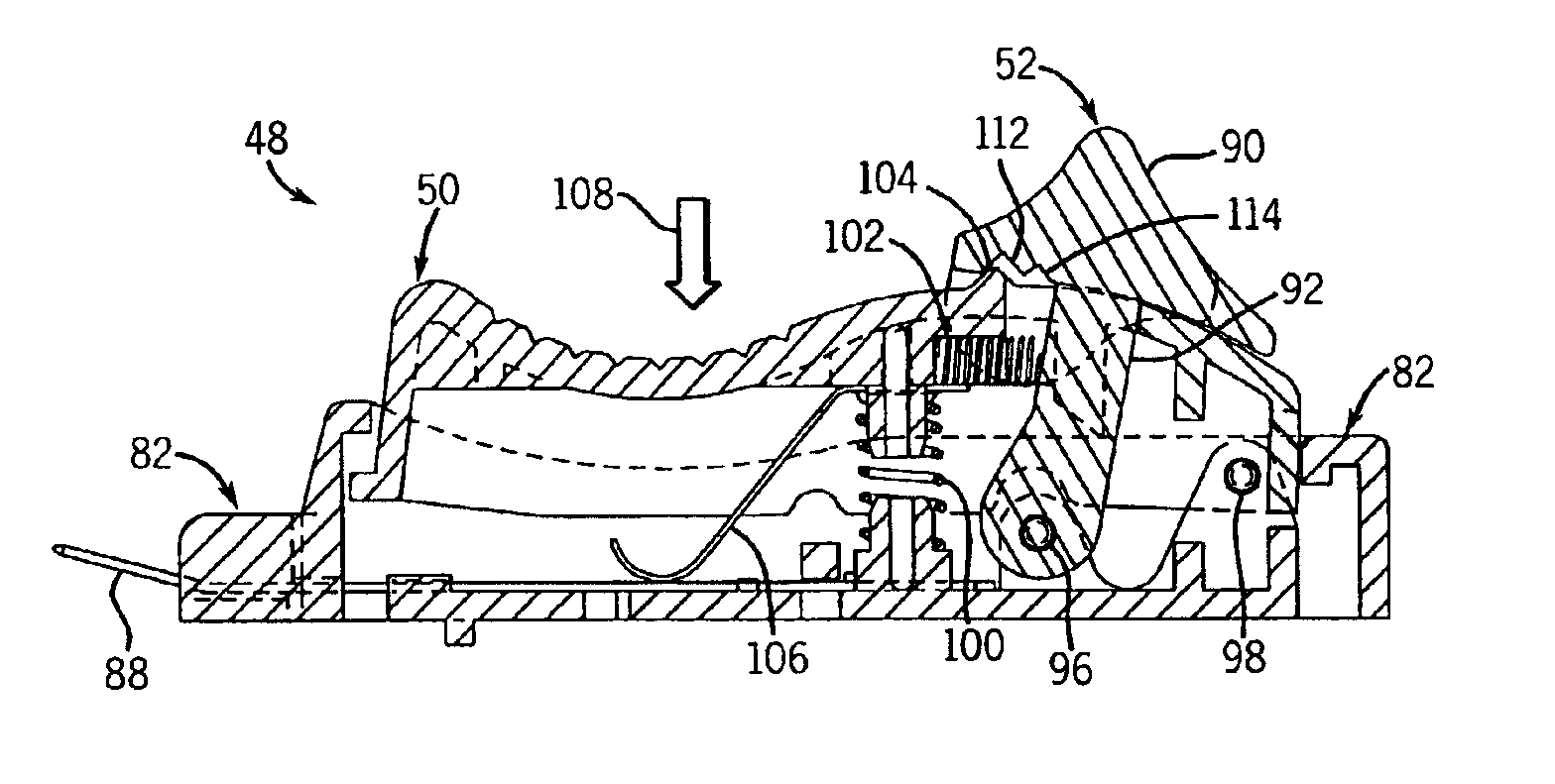

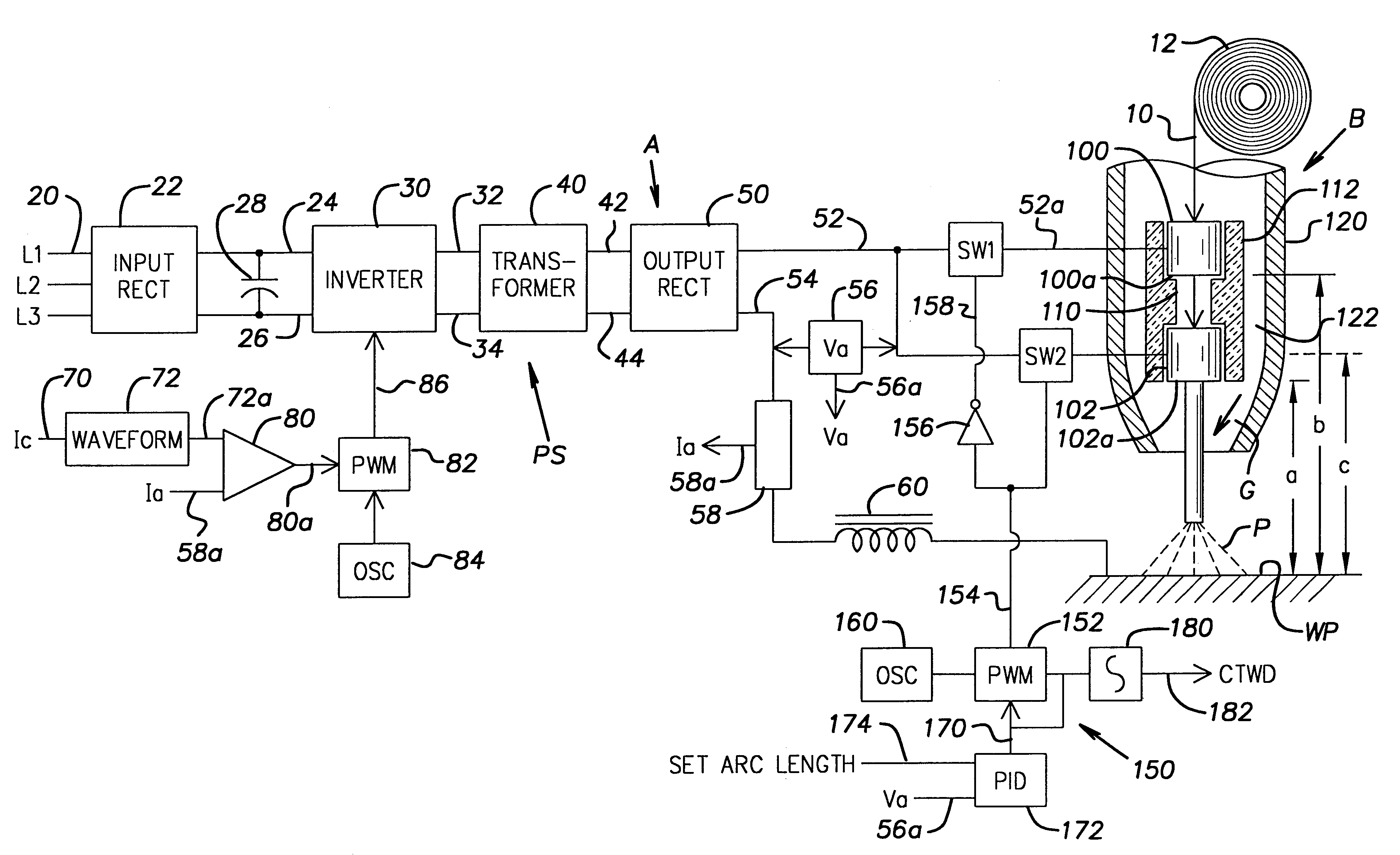

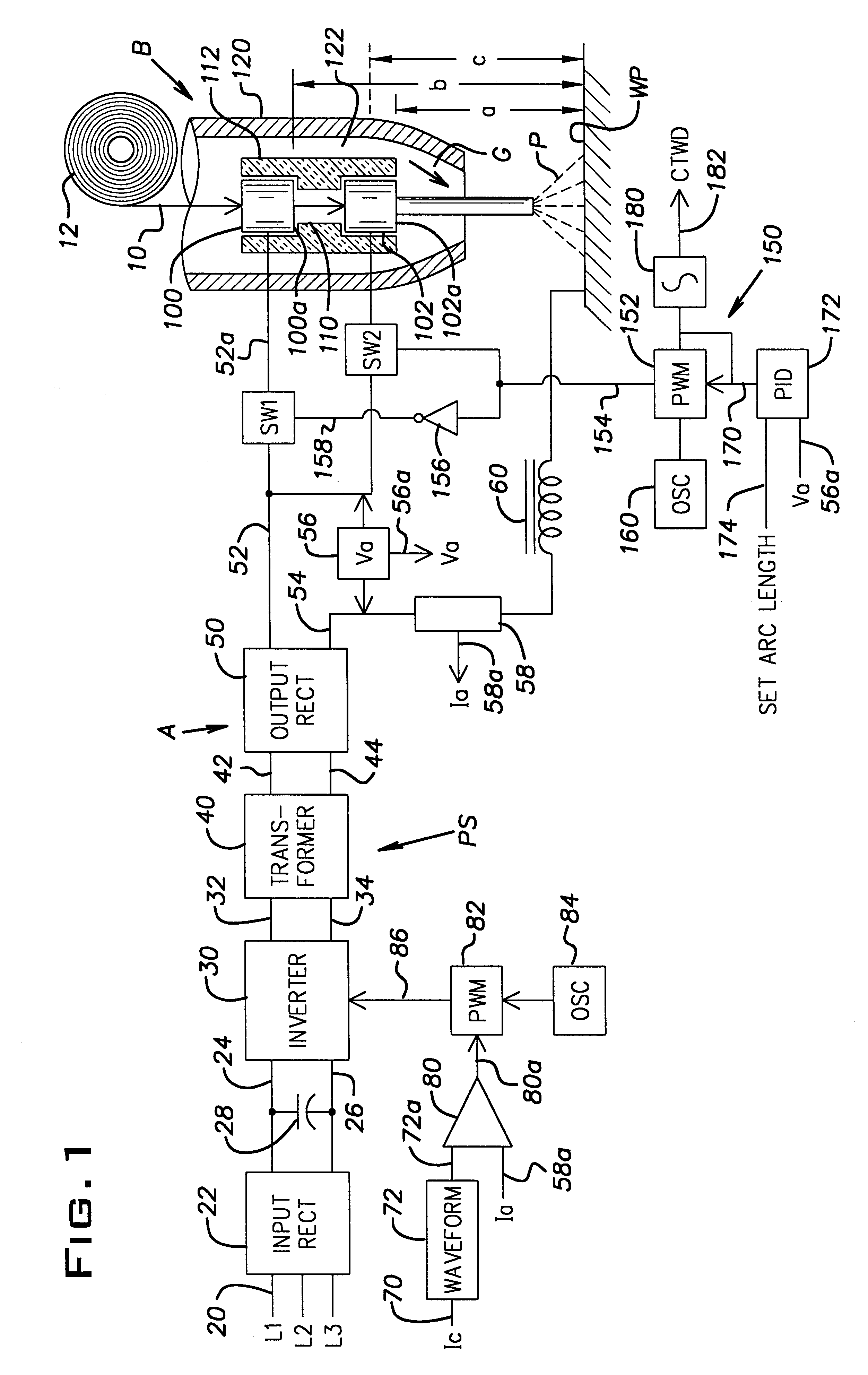

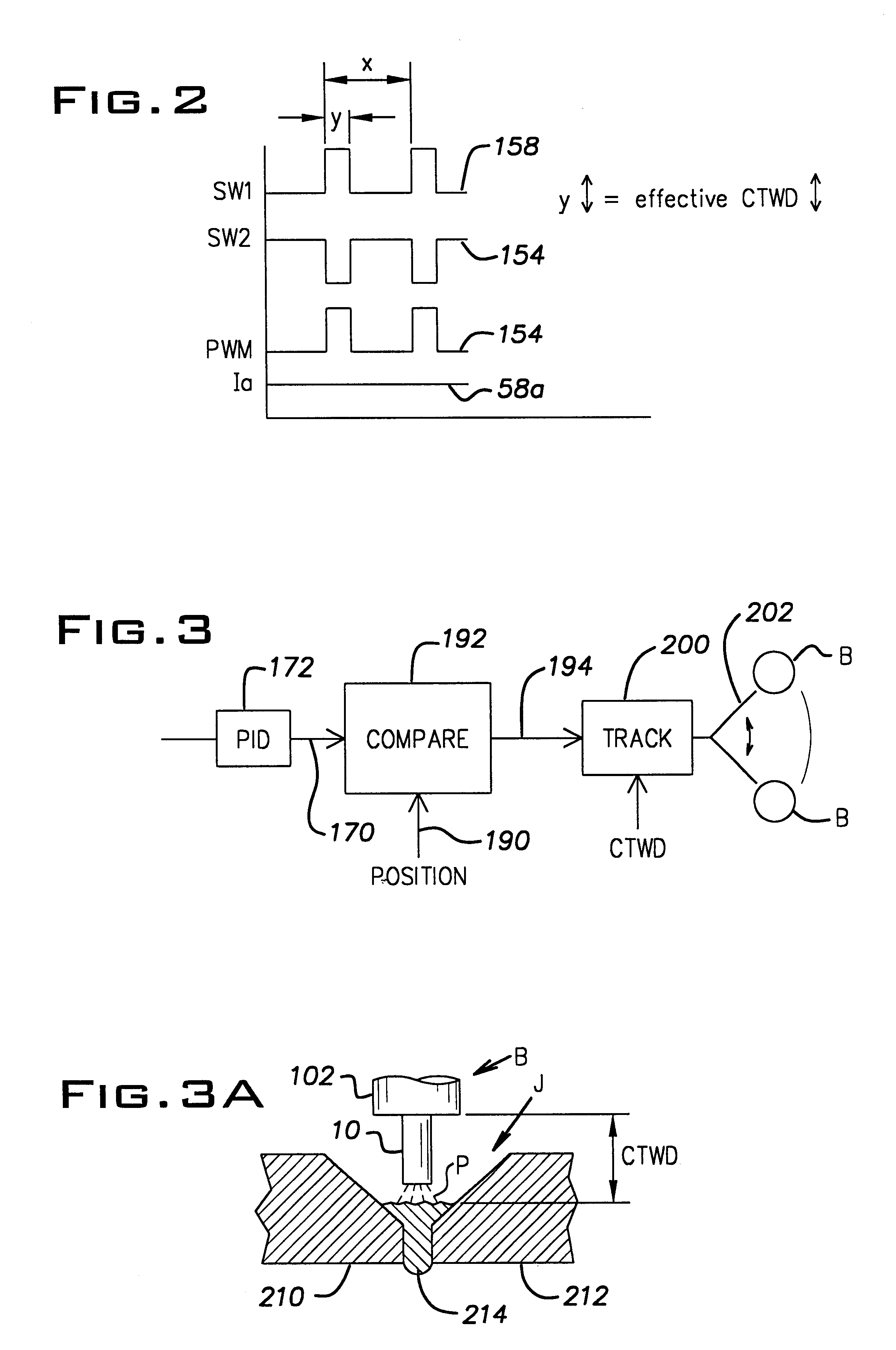

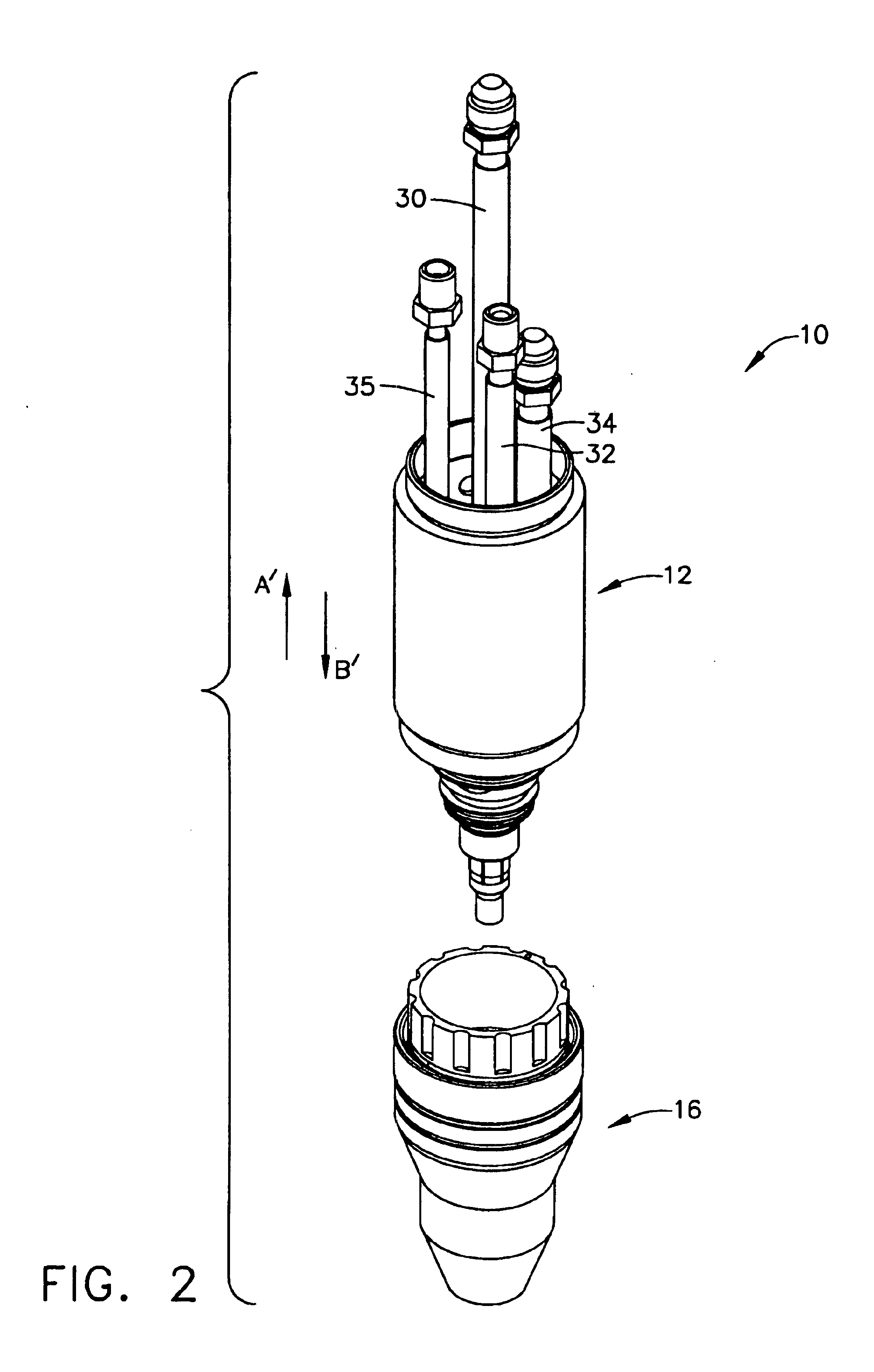

Method and apparatus for welding with mechanical arc control

InactiveUS6963048B2Support devices with shieldingWelding/cutting media/materialsPath lengthWire tension

A method and apparatus for feeding wire from a source of wire to a weld includes one or more motors disposed adjacent the wire to drive the wire to the weld. A buffer is disposed between the source and an arc end of the torch. Another motor may be disposed near the wire source.A wire tension controller may be provided. The one or more motors advance and retract the wire, and wire is stored, or the path length altered, when the wire is retracted.

Owner:ILLINOIS TOOL WORKS INC

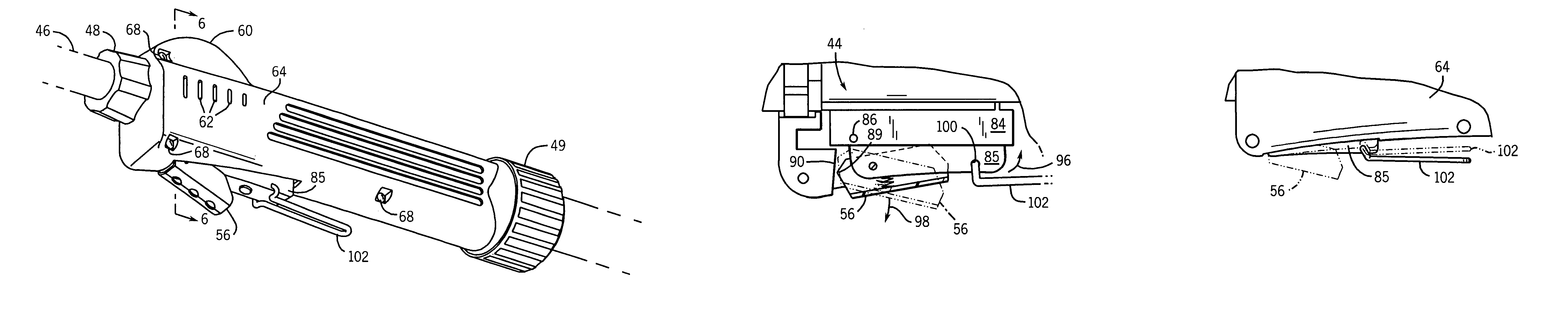

System and method for operating and locking a trigger of a welding gun

InactiveUS6979799B2Support devices with shieldingContact operating partsEngineeringMechanical engineering

A welding system having a welding gun. The welding gun is adapted with a trigger. The welding gun may have a lever to lock the trigger in a desired pivoted position. The lever may pivot the trigger as the lever is pivoted. The welding gun may have a trigger extension to enable a user to pivot the trigger by depressing the trigger extension. The trigger extension may be plastically deformed. The trigger extension may be removable. The trigger extension may be rotatable.

Owner:ILLINOIS TOOL WORKS INC

Taper locking features between components of a welding device

ActiveUS7176412B2Improve and extend useful life of componentReduce chanceSupport devices with shieldingWelding/cutting auxillary devicesEngineeringScrew thread

Locking engagement connections between various components of a welding device can include tapered features having varied thread patterns and / or varied angles to ensure that the components remain tight during service. For example, locking engagement connections can be incorporated between a nozzle and a retaining head, a retaining head and a gooseneck, and / or a contact tip and a retaining head.

Owner:ILLINOIS TOOL WORKS INC

Welding gun having a removable nozzle end portion and method for operating same

A welding gun having a removable end portion. The end portion may be adapted to direct gas from the welding gun. The end portion may be conical-shaped. The end portion may be removed without tools. The end portion also may be adapted to be secured to and / or removed from the welding gun in a linear movement. A method of assembling a welding gun. The method may comprise urging a nozzle end member and a nozzle body into engagement to secure the nozzle end member to the nozzle body.

Owner:ILLINOIS TOOL WORKS INC

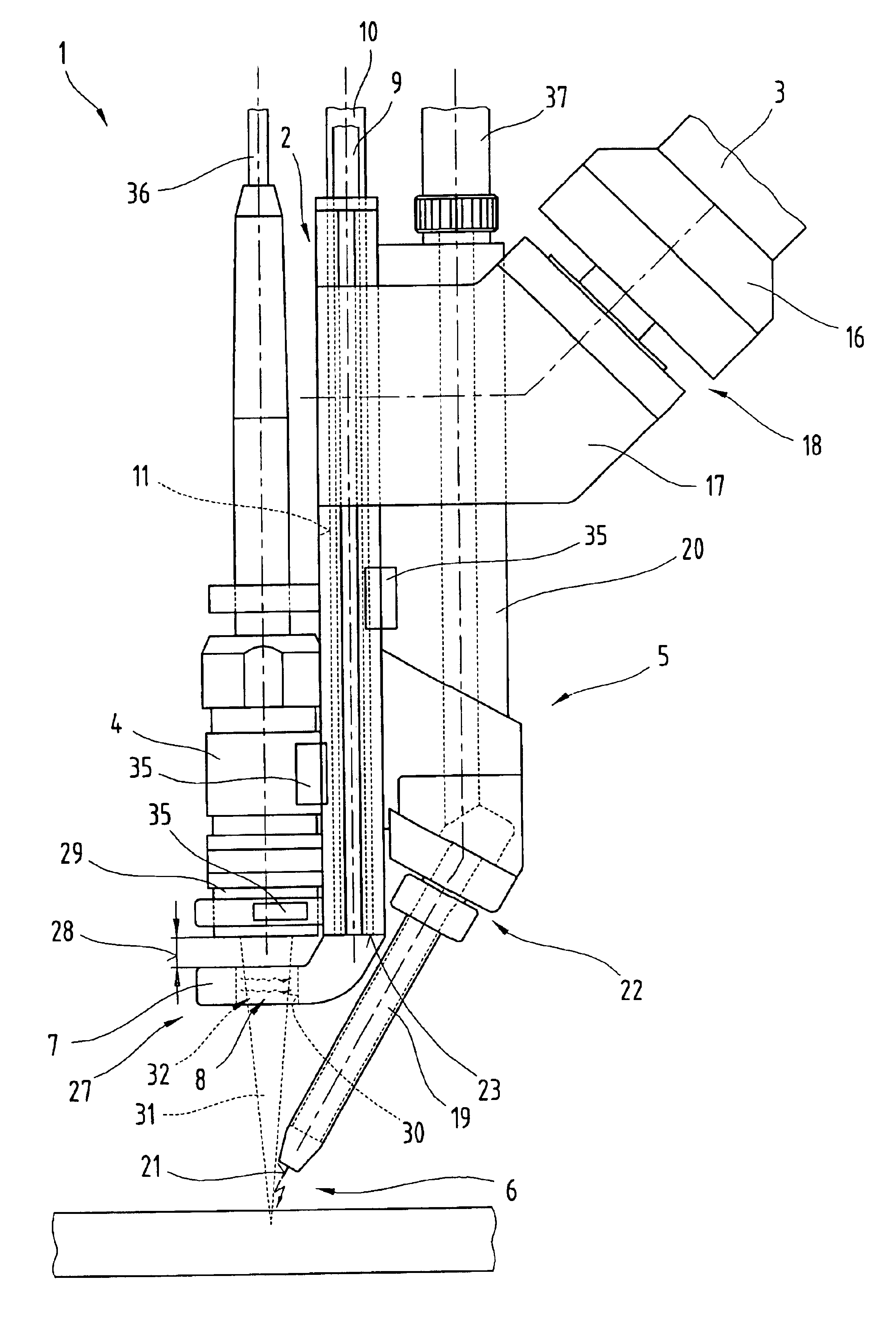

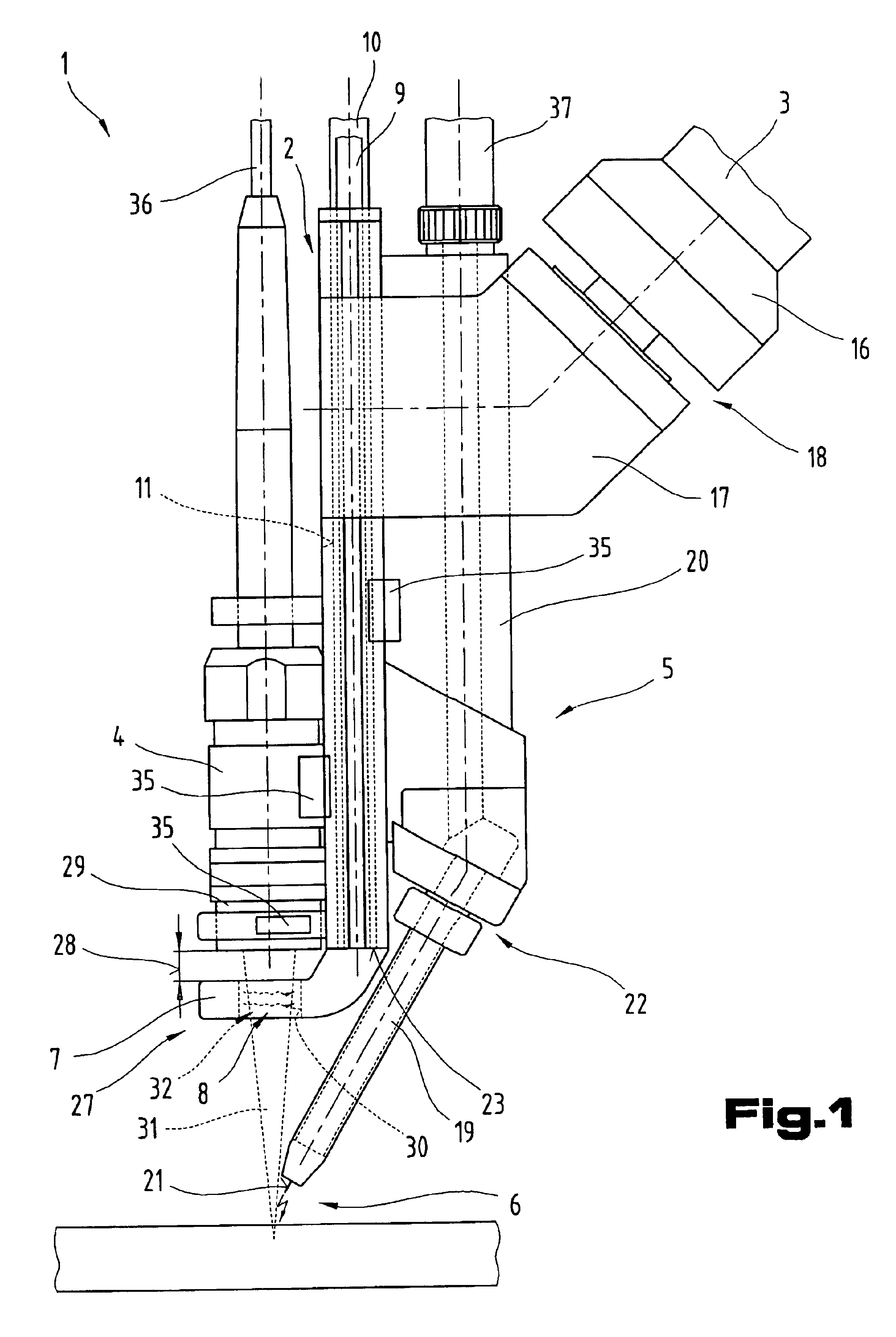

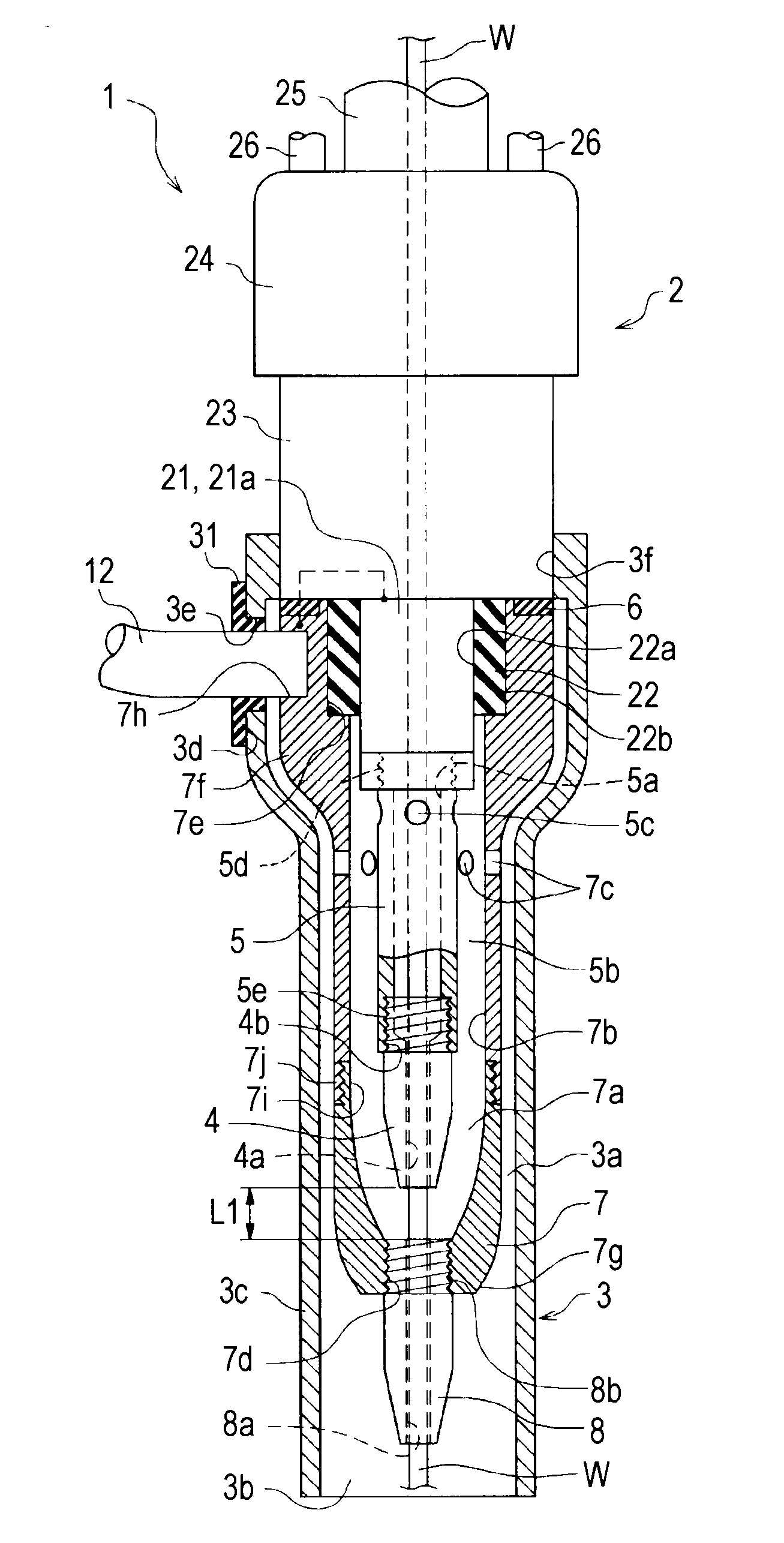

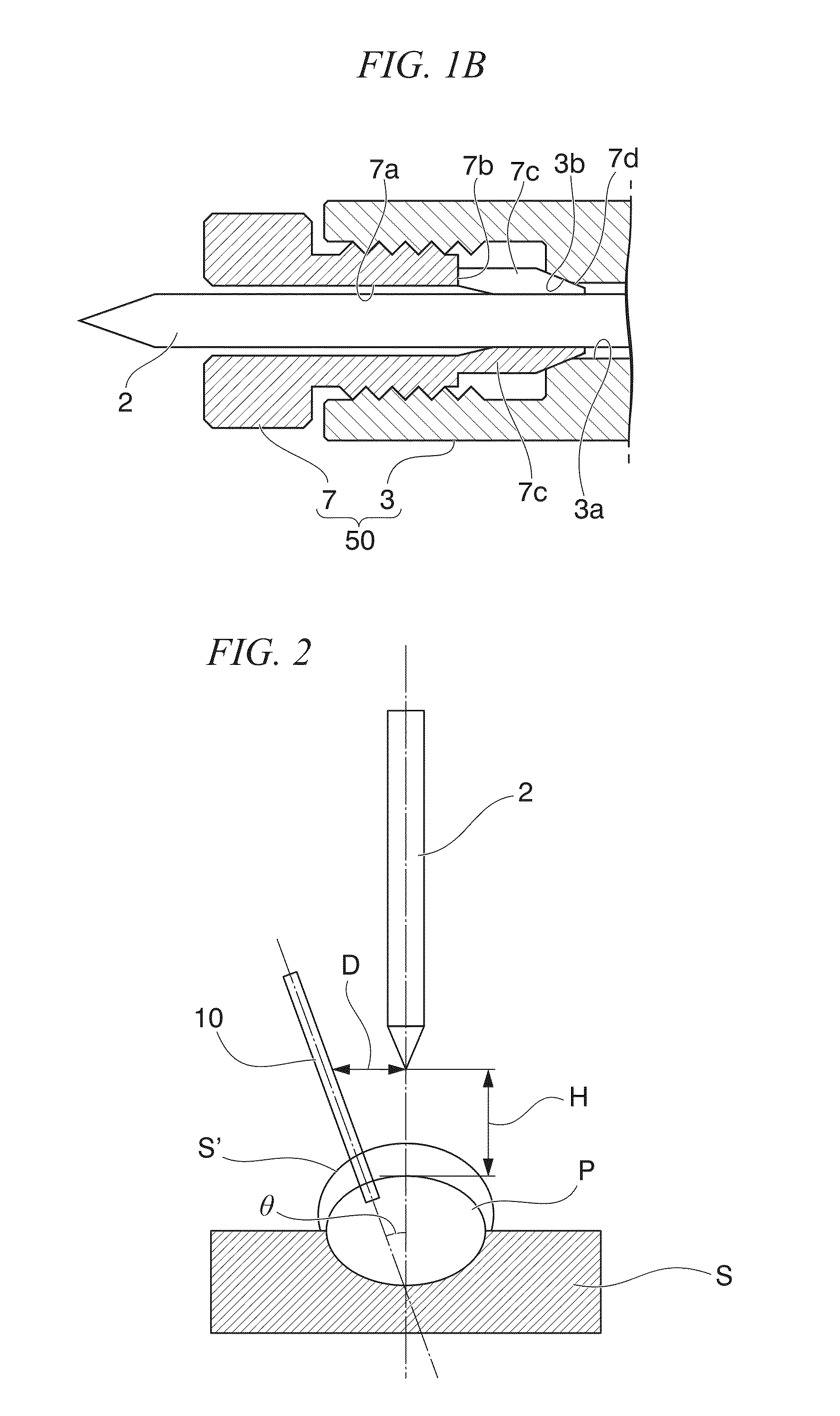

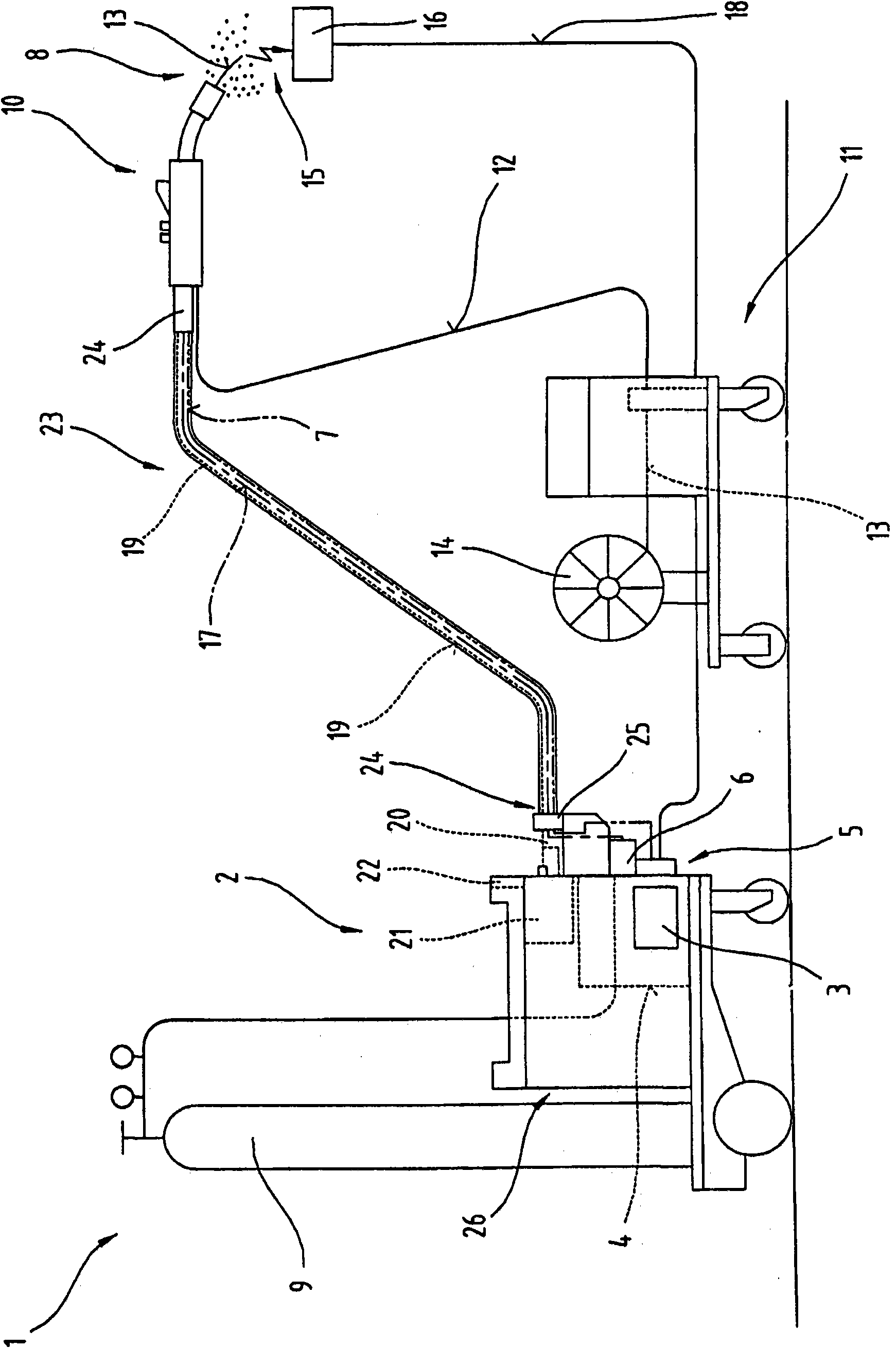

Device for a laser-hybrid welding process

InactiveUS6844521B2Small component sizeSimple structureSupport devices with shieldingWelding/cutting media/materialsLaser-hybrid weldingEngineering

The invention describes an apparatus, in particular a laser hybrid welding head (1) for a laser hybrid welding process, in which a laser (4) or laser optics or an optical focussing unit and elements of a welding torch (5) for an arc welding process and / or a feed device for a welding wire as well as a device for generating a cross jet (8) connected by at least an incoming line (9) and an outgoing line (10) to a compressed air supply system, are mounted on at least one mounting element (2). The incoming line (9) and the outgoing line (10) carrying compressed air for the cross jet (8) are disposed between the two components, in particular the laser (4) and laser optics or the optical focussing unit and the elements of the welding torch (5) or feed device for the welding wire (21).

Owner:FRONIUS INTERNATIONAL GMBH

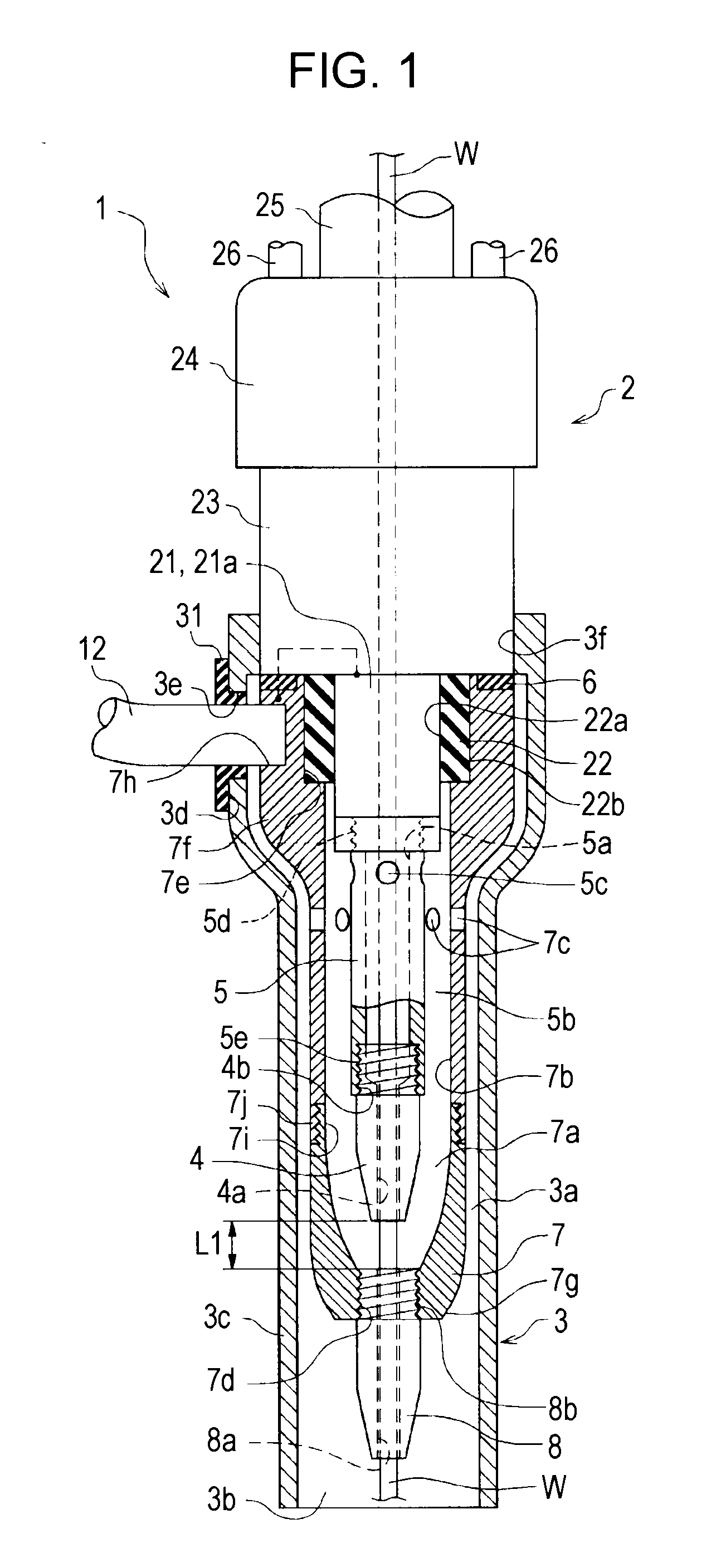

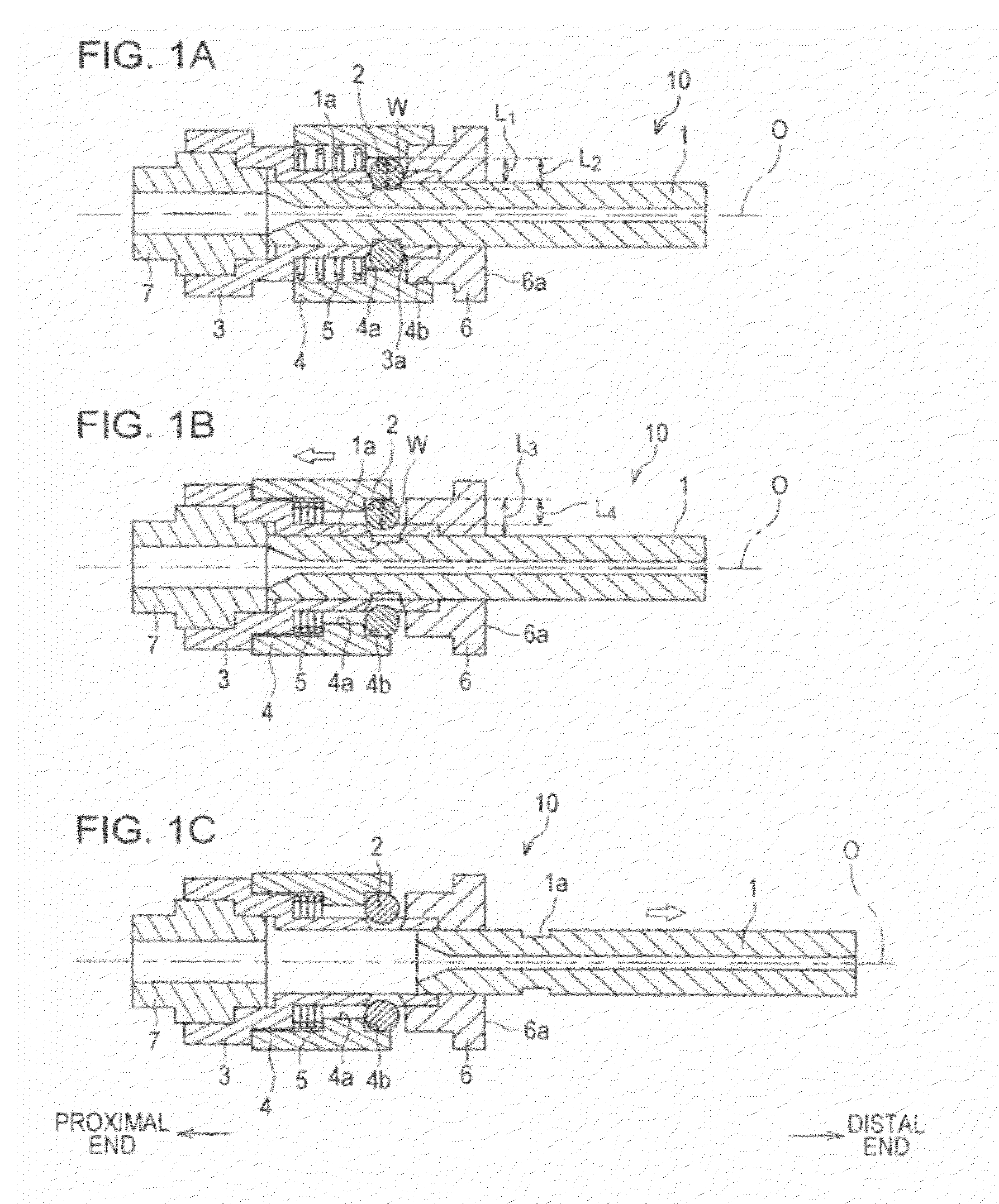

Welding torch

InactiveUS20120285932A1Reduce wearReduce frequencySupport devices with shieldingElectrode accessoriesPower flowWelding torch

A welding torch includes: a first tip body to which a welding wire, gas, and current having passed through a torch body is supplied; a first tip provided at a distal end of the first tip body to supply electric current having passed through the first tip body to the welding wire; an insulating bushing provided inside the nozzle, on the outer periphery of the first tip body; a second tip body to which electric current from a power source is supplied; and a second tip provided at the distal end of the second tip body to supply the current having passed through the second tip body to the welding wire. The first tip and the second tip are axially arranged at a predetermined distance and supply electric current to the welding wire.

Owner:KOBE STEEL LTD

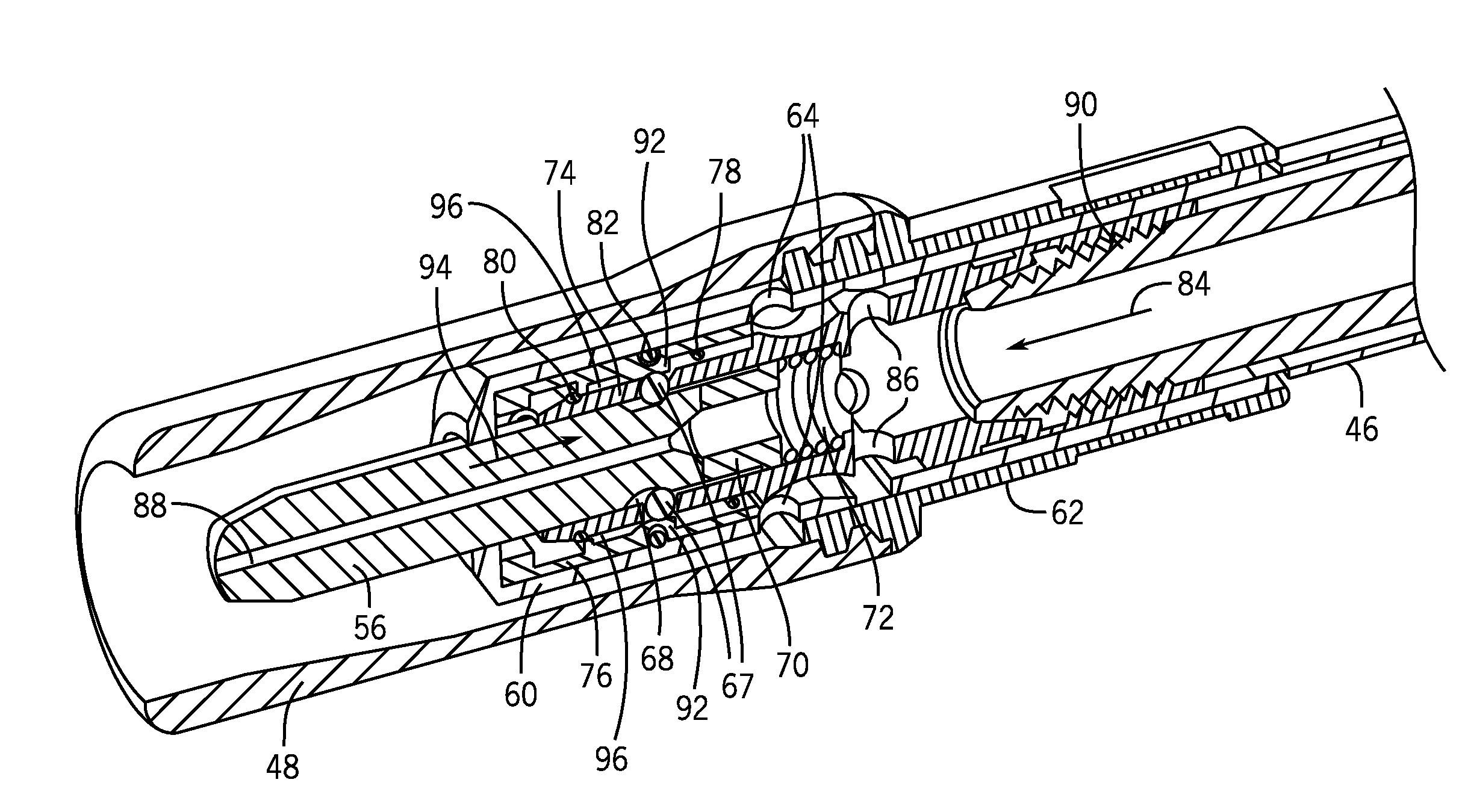

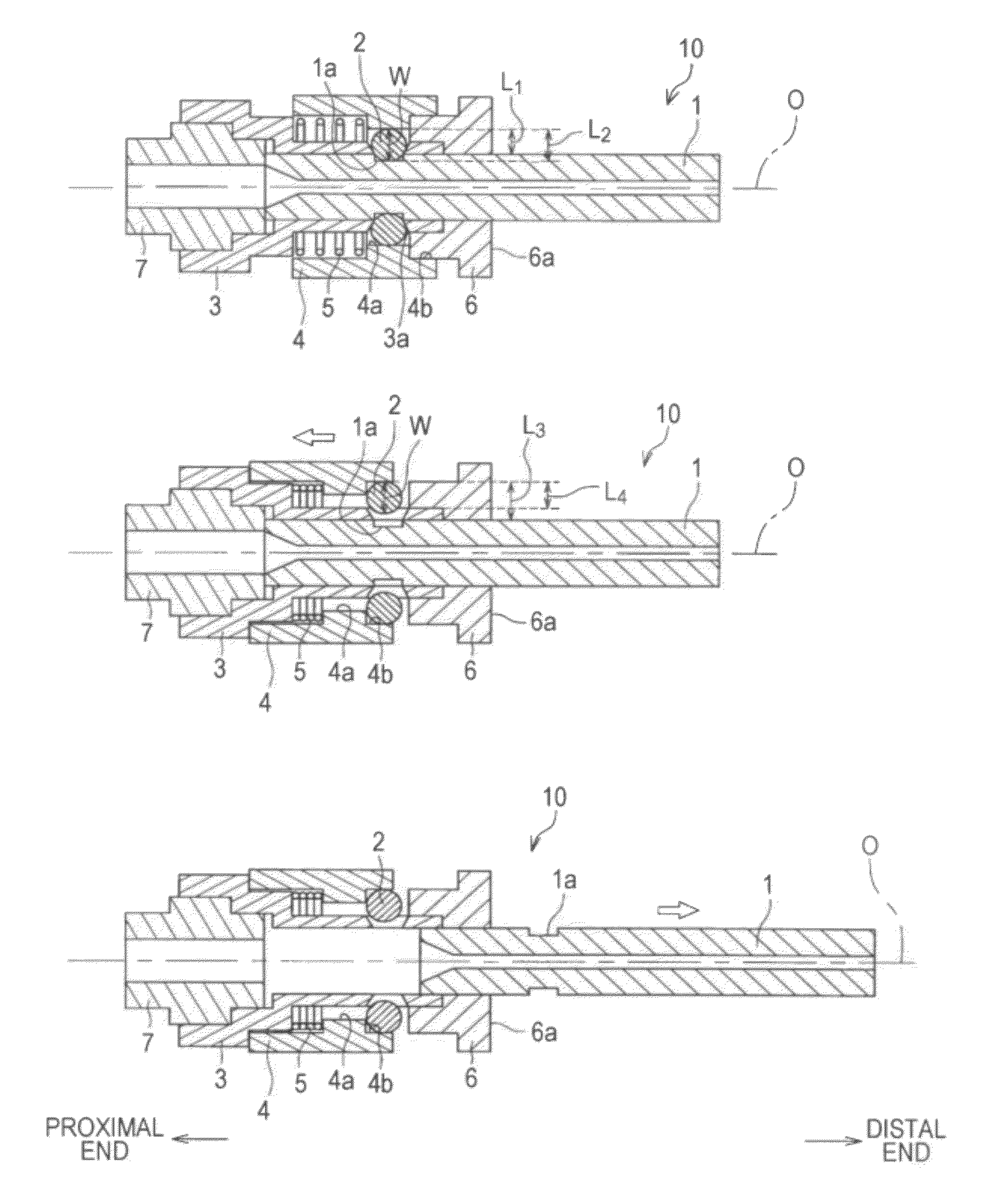

Contact tip and receiving assembly of a welding torch

InactiveUS20160144446A1Support devices with shieldingElectrode accessoriesMechanical engineeringWelding torch

A method to replace a contact tip in a welding system includes applying a first force toward a neck of a welding torch to remove the contact tip via a quick release mechanism. Additionally, the method includes inserting a new contact tip into the quick release mechanism and applying a second force on the new contact tip toward the neck of the welding torch until the new contact tip is locked in place within the quick release mechanism.

Owner:ILLINOIS TOOL WORKS INC

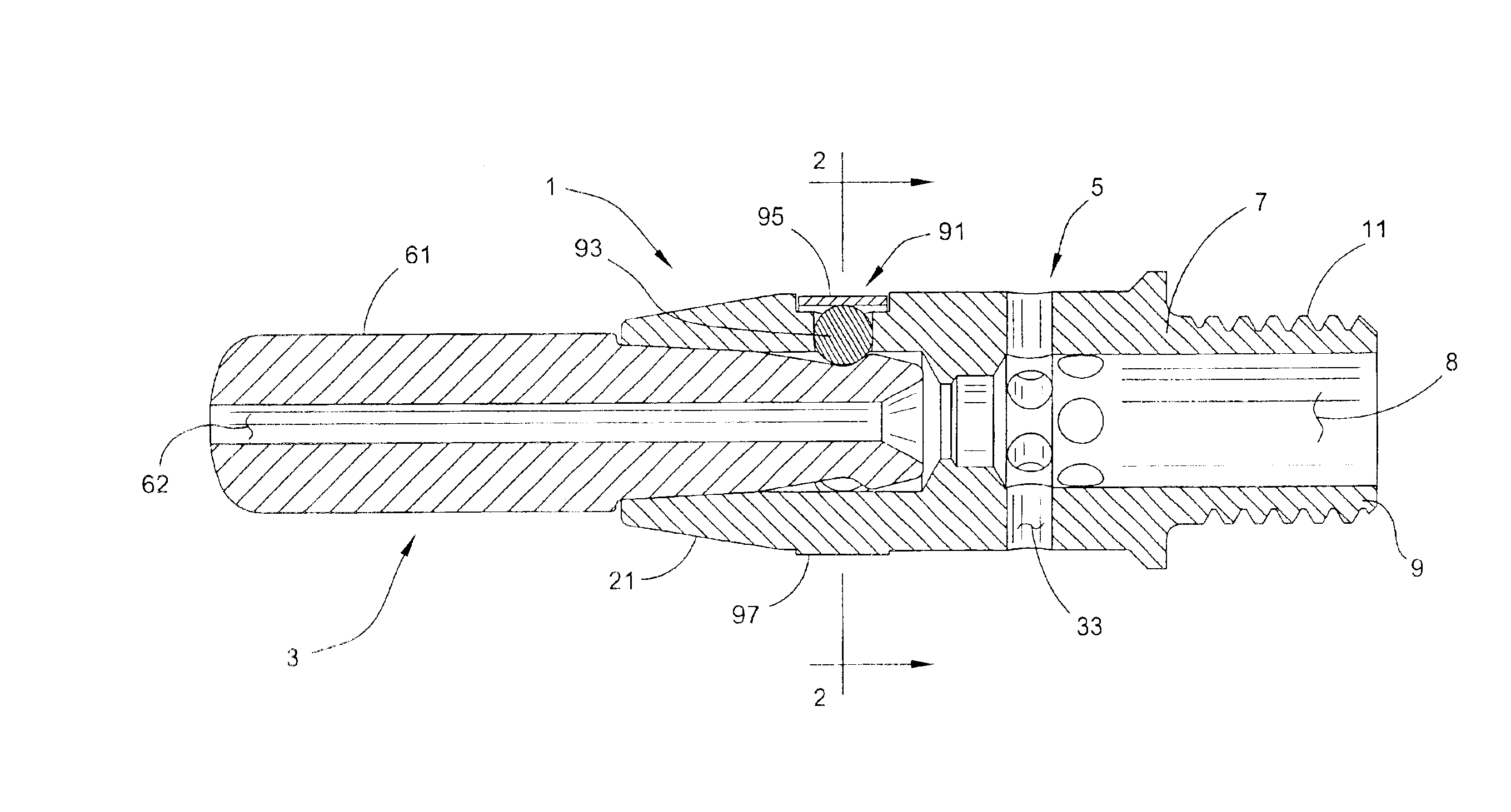

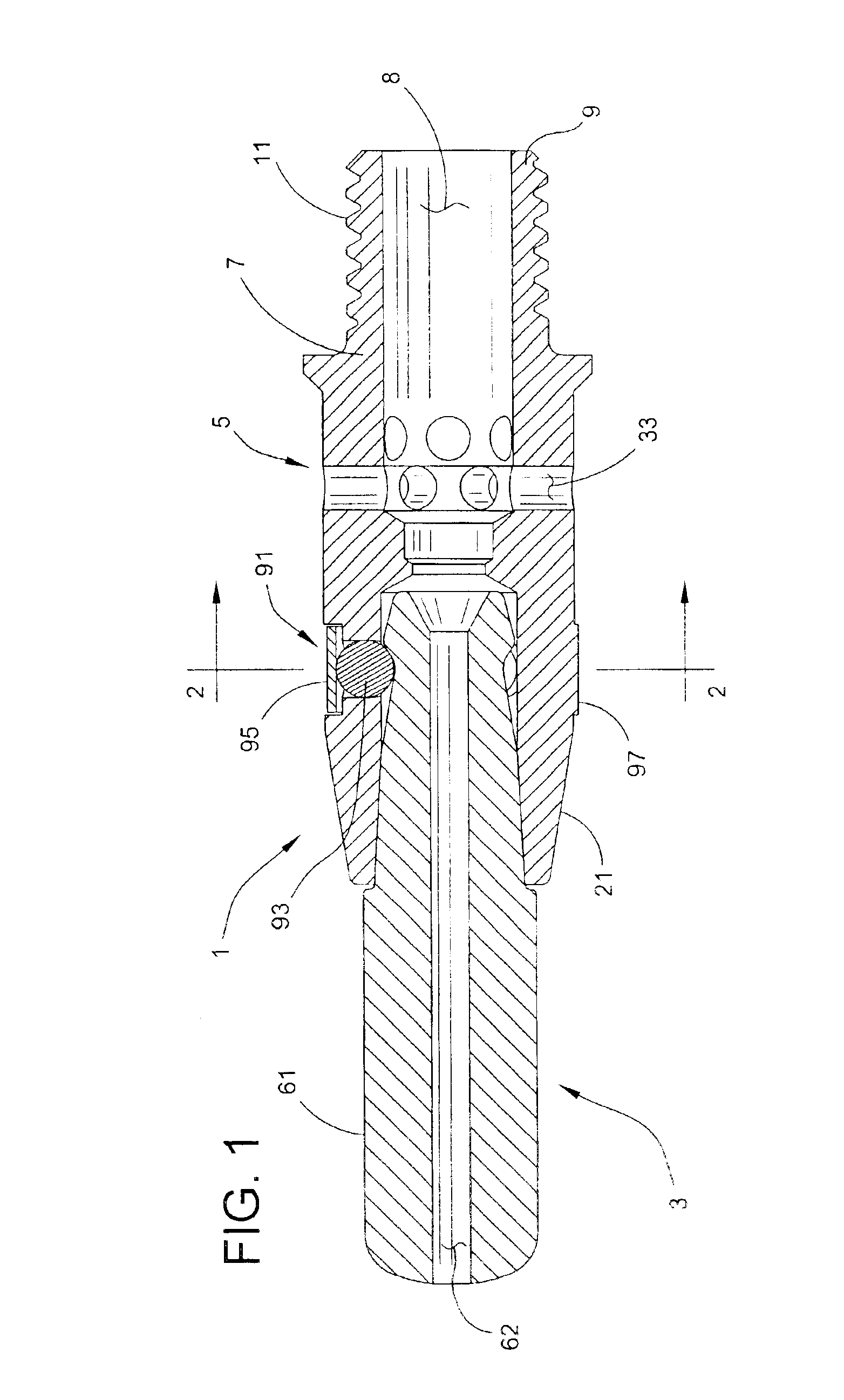

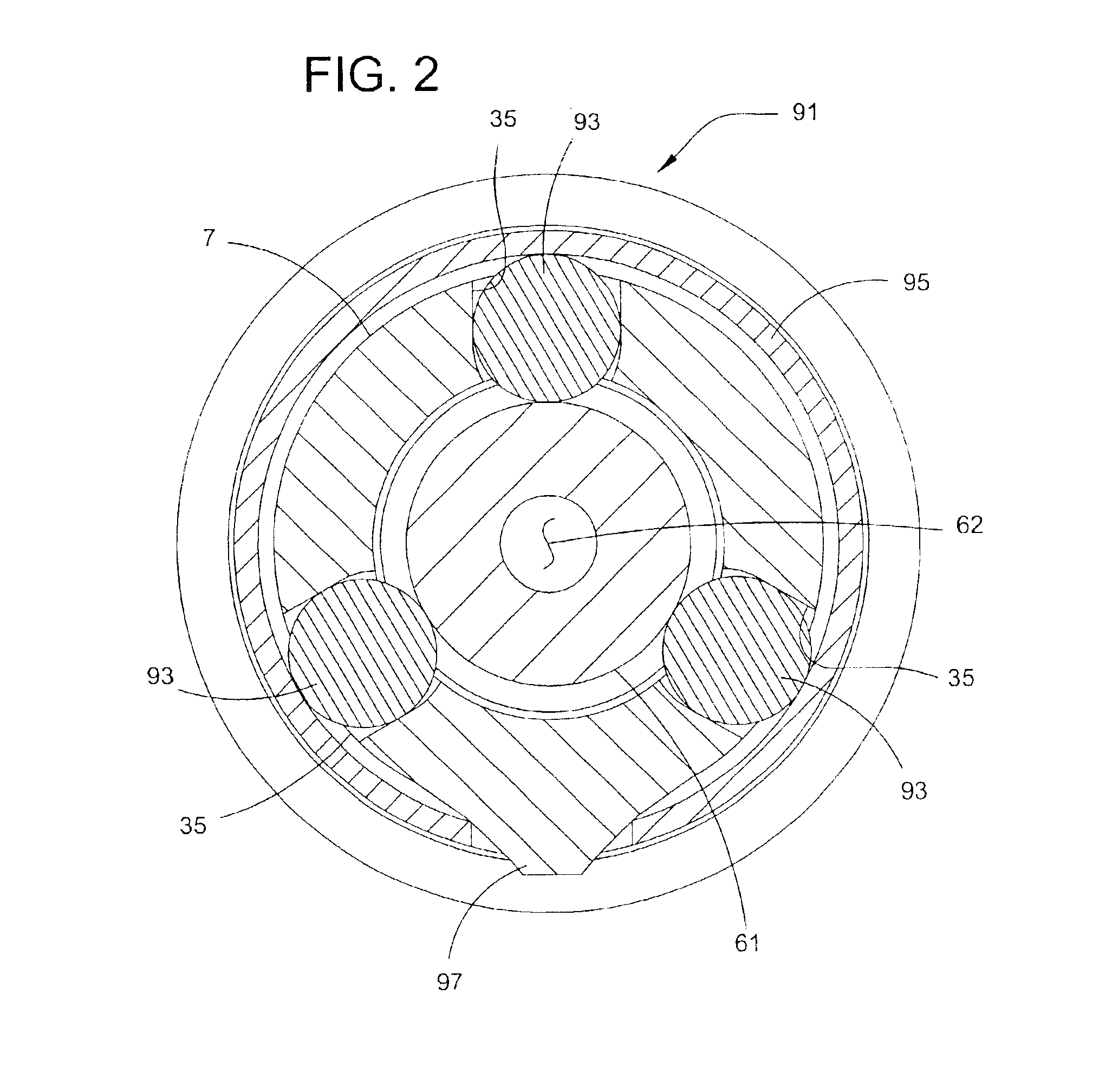

Contact tip rotary lock of a welding torch

ActiveUS20170080511A1Solve the complicated replacementSimplifies securementSupport devices with shieldingMetal working apparatusLocking mechanismEngineering

A welding torch system includes a diffuser assembly that includes a locking mechanism to receive a contact tip. Additionally, the welding torch system includes the contact tip, which includes locking elements configured to interact with the locking mechanism of the diffuser assembly to secure the contact tip within the diffuser assembly. Further, the contact tip is rotated within the diffuser assembly to securely align the locking elements with the locking mechanism.

Owner:ILLINOIS TOOL WORKS INC

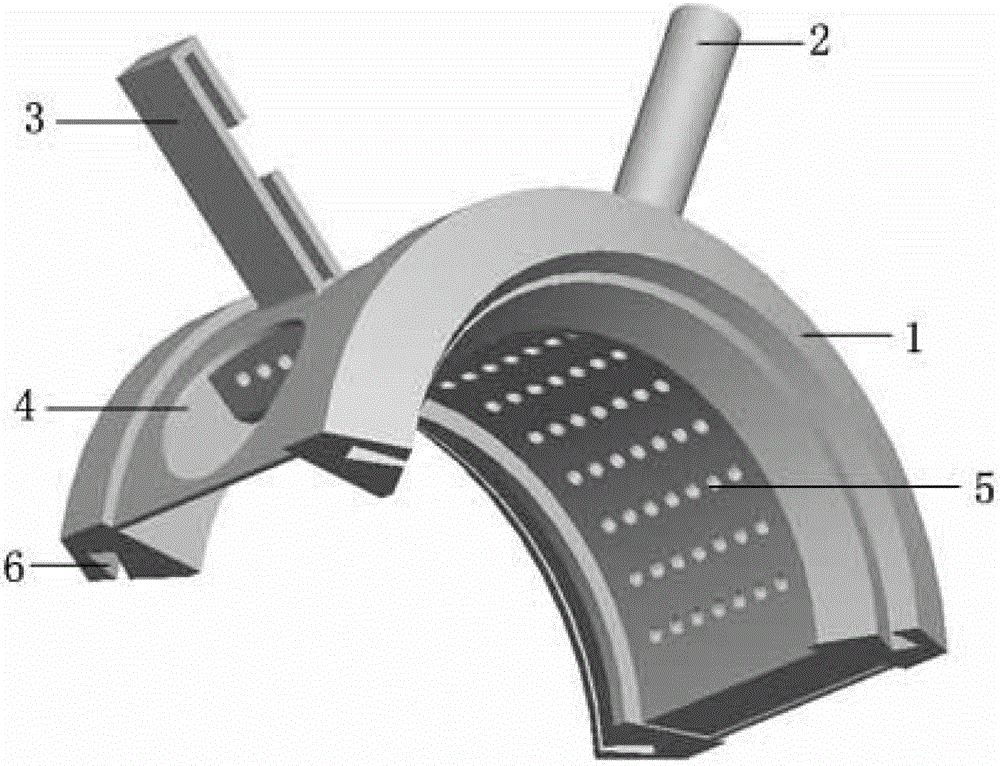

Titanium tube welding gas protection cover of fixed welding gun

InactiveCN102909465AImprove protectionSimple structureSupport devices with shieldingTitaniumWelding process

The invention discloses a titanium tube welding gas protection cover of a fixed welding gun. The titanium tube welding gas protection cover comprises an arc-shaped aluminum housing, an argon lead-in tube, an internal gas sifter, a welding gun fixing device and a side surface rubber groove. During the welding process, the protection cover covers a part needed to be welded, and the welding gun is bound to the welding gun fixing device by using a ferrule, then gas is led into the protection cover through the argon lead-in tube, and then argon flow is uniformly distributed to the surface of a welding part through the gas sifter, and finally the side surface rubber groove is filled with rubber so as to enhance argon shield. As the welding gun is fixed to the gas protection cover through the ferrule, a welder fills a welding wire into a welding operation hole by one hand and rotates the gas protection cover by another hand so as to finish the welding operation. The titanium tube welding gas protection cover of the fixed welding gun is simple in structure and convenient to operate, and has a remarkable gas protection effect.

Owner:TIANJIN UNIV

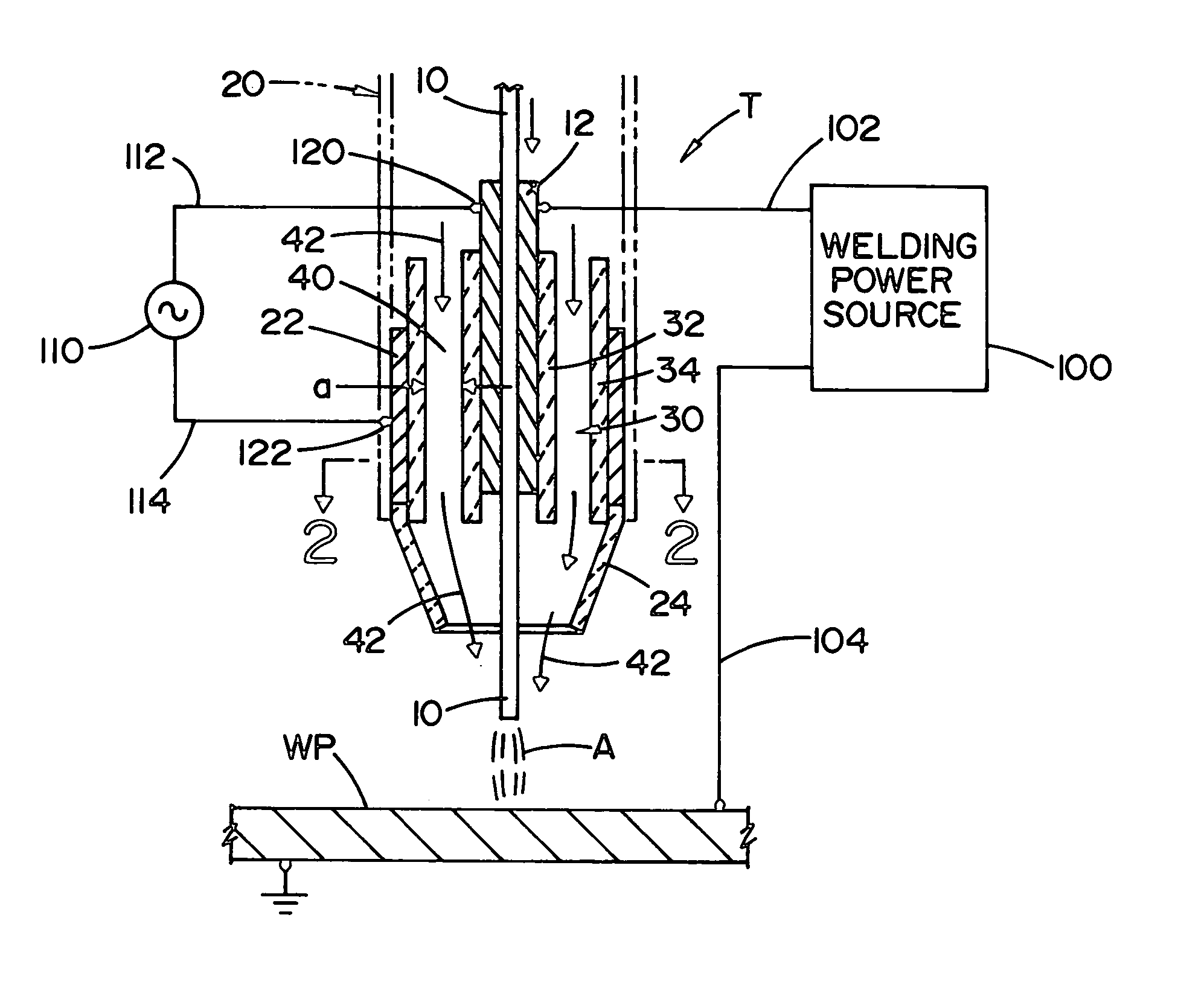

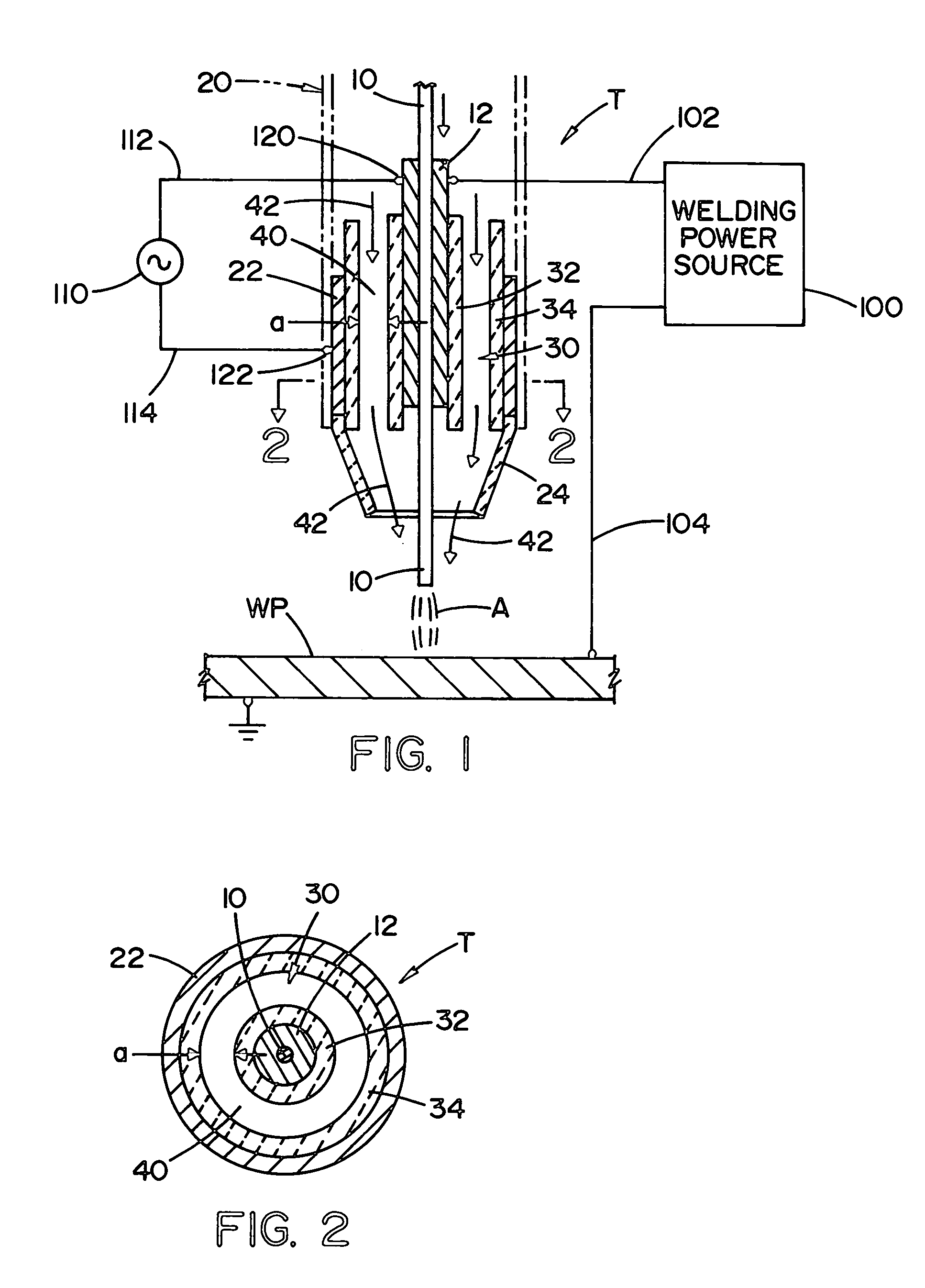

Welding torch with plasma assist

ActiveUS20050211685A1Quality improvementSupport devices with shieldingWelding/cutting media/materialsHigh frequency powerCarbon Dioxide / Helium

An electric arc welding torch having a central conductive contact tube for electrical contact between a power source and a welding wire moving through the contact tube toward a workpiece, a conductive sleeve concentric with the tube to define an annular chamber between the tube and the sleeve, a first dielectric barrier sleeve fixed on the conductive sleeve and a second dielectric sleeve on the tube where the dielectric sleeves are spaced from each other to define an annular gas passage extending around the moving wire and terminals to connect a high frequency power source between the tube and the conductive sleeve to create a dielectric barrier discharge plasma issuing from the gas passage. This torch is used in a novel welding method where the shielding gas envelope around the arc is a plasma.

Owner:LINCOLN GLOBAL INC

Welding torch, welding tip, and welding robot

InactiveUS20120125903A1Good adhesionEasy to removeSupport devices with shieldingElectrode accessoriesEngineeringWelding torch

A welding torch includes a tip connection body, a holding member, a fixing member, and a welding tip. The holding member is displaceable in the axial direction of the tip connection. The fixing member fixes the welding tip in place in the axial direction of the welding tip when the fixing member is in contact with a smaller diameter portion, and the fixing member releases the welding tip when the fixing member is in contact with a larger diameter portion.

Owner:KOBE STEEL LTD

Welding gun contact tip

InactiveUS7271366B2Increase exposureConsistent flowSupport devices with shieldingEngineeringContact element

A contact tip for a welding gun includes an elongate body having a first end, a second end, and a first opening extending longitudinally between the first end and the second end. The elongate body has an outer surface and an inner surface. The elongate body has a second opening extending radially through a side portion of the elongate body between the outer surface and the inner surface. At least a portion of the second opening is configured to support a contact element. A contact element is configured to be supported within at least a portion of the second opening of the elongate body and extend at least partially into the first opening of the elongate body. A retention member is configured to couple the contact element with the elongate body.

Owner:M K PRODS

Method and apparatus to adaptively cool a welding-type system

InactiveUS20050016978A1Support devices with shieldingCooled electrode holdersNuclear engineeringBiological activation

A cooling system connected to provide coolant to a welding-type component automatically circulates coolant through the welding component upon activation of the welding component. A controller is configured to regulate the cooling system such that upon activation of the welding-type component coolant is caused to at least flow through the welding-type component and circulate after deactivation of the welding torch until a temperature of the coolant falls below a certain value or a specified time period has expired. The cooling system is constructed to be integrally disposed within a power source housing.

Owner:ILLINOIS TOOL WORKS INC

Welding torch with variable power trigger

InactiveUS20050023263A1Support devices with shieldingElectric discharge heatingRange of motionEngineering

The present invention welding torch includes a holdable torch gun having a first connection for hook up to a gas or water supply, and a second connection for hook up to a power supply. The gun has a discharge barrel with an outlet end, and a handle extending downwardly from the discharge barrel. The discharge barrel has a front facing in a same direction as the outlet end of the discharge barrel. The handle has a variable power trigger located thereon such that the trigger is spring loaded away from the handle and may be moved by pressure toward the handle, the trigger having an unsqueezed position and a fully squeezed position and a range of motion area between the unsqueezed position and the fully squeezed position. The handle also has an amperage control mechanism located therein and connected to the second connection. The trigger is moveably connected to the amperage control mechanism such that the unsqueezed position prevents any current to flow to the discharge barrel, the fully squeezed position permits maximum current to flow to the discharge barrel and any squeezed portion therebetween permits a proportionate amount of current to flow to the discharge barrel in proportion to distance between the unsqueezed position and the fully squeezed position. The welding torch amperage control mechanism may be a linear potentiometer or the trigger may include a rack gear functionally connected to a geared rotary potentiometer.

Owner:BLIDE DANIEL J

Electrodes and nozzles having improved connection and quick release

InactiveUS20030209525A1Reduced service lifeSimple designSupport devices with shieldingPlasma welding apparatusElectrical resistance and conductanceFast release

Electrode and nozzle that seat within a retaining member and in two different seating locations relative to retaining member. The electrode and nozzle each include an interwoven-double-start thread having two thread cuts, which start 180 degrees from one another as measured around the circumference of the electrode or nozzle. Additionally, the retaining member includes an interwoven-double-start thread having two thread cuts, which start 180 degrees from one another as measured around the circumference of the electrode or nozzle. Because of the configuration of the interwoven-double-start threads, the two seating locations of the electrode and nozzle are 180 degrees apart thereby enabling the electrode and nozzle to be used twice as long as conventional electrodes and nozzles which include a single cut thread. Further, the electrode, nozzle, and retaining member include mating frustum surfaces, which are configured and dimensioned so that the electrode and nozzle seat within the retaining member with less than one turn of the electrode and nozzle relative to the retaining member. Therefore, the electrode and nozzle may be quickly inserted in, and removed from, the retaining member. Moreover, the mating frustum surfaces, and interwoven-double-start threads provide a large area of contact between the electrode and nozzle and retaining member hence providing a strong connection, as well as reducing resistance heating, therebetween.

Owner:AMERICAN FLASHLIGHT TIP

Preserving apparatus for welded joint portion and preserving method therefor

InactiveUS20090166338A1Improve welding qualityShielding gas supply/evacuation devicesSupport devices with shieldingEngineeringAtmosphere

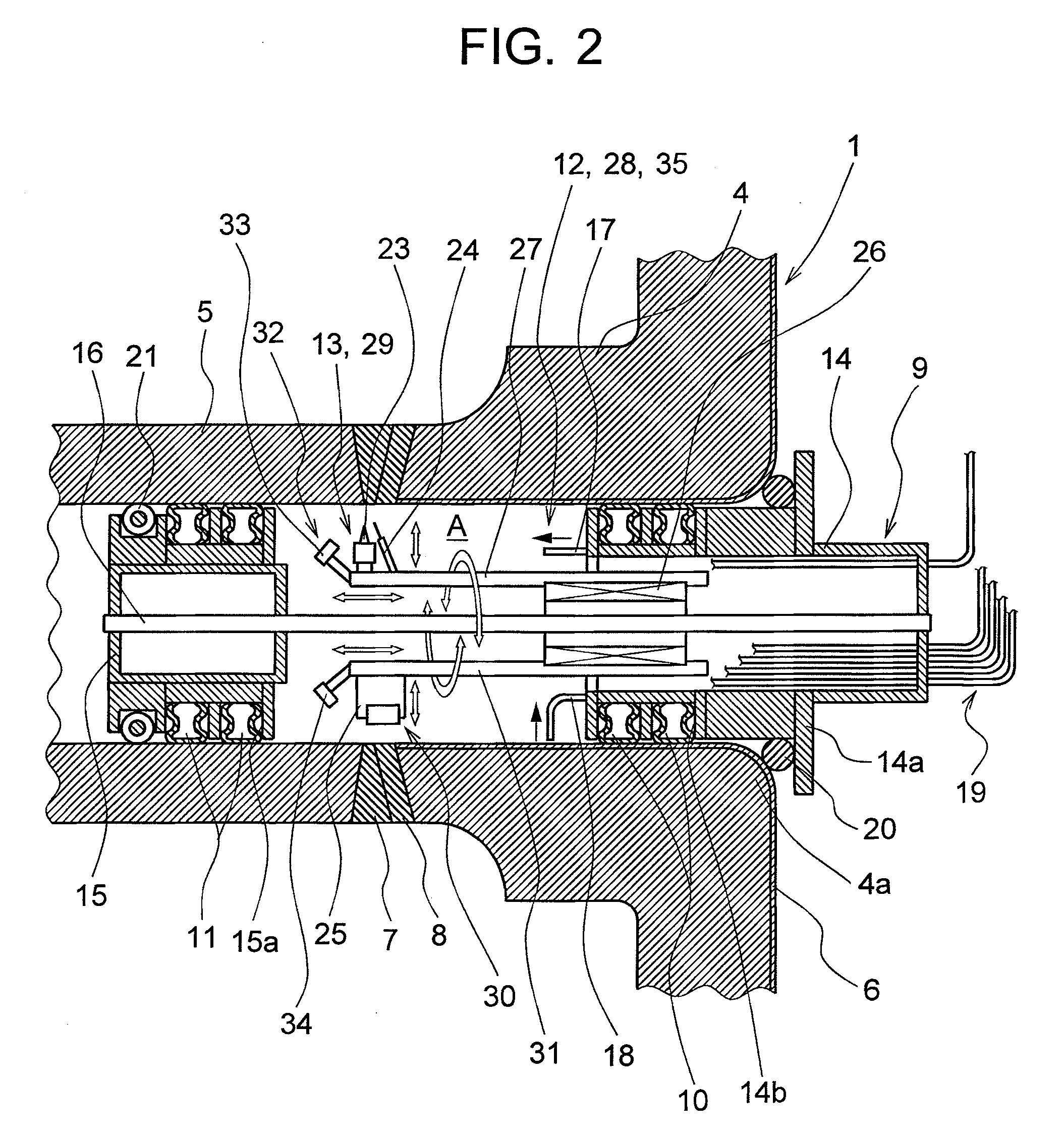

A preserving apparatus for preserving welded joint portions 7, 8 by deposit welding on the inner surface of the welded joint portions 7, 8, in which a nozzle 4 and a pipe 5 supported under water are joined, the apparatus having: a seal member 9 that is disposed in front and behind the welded joint portions 7, 8 to be deposit welded within the nozzle 4 and pipe 5, and serves to demarcate and form a closed operation area A within the nozzle 4 and pipe 5; water drainage means 12 for draining the inside of the operation area A demarcated and formed by the seal member 9 and obtaining a gas atmosphere therein; and welding means 13 for deposit welding on the inner surface of the welded joint portions 7, 8 within the operation area A in which the gas atmosphere has been created.

Owner:IHI CORP

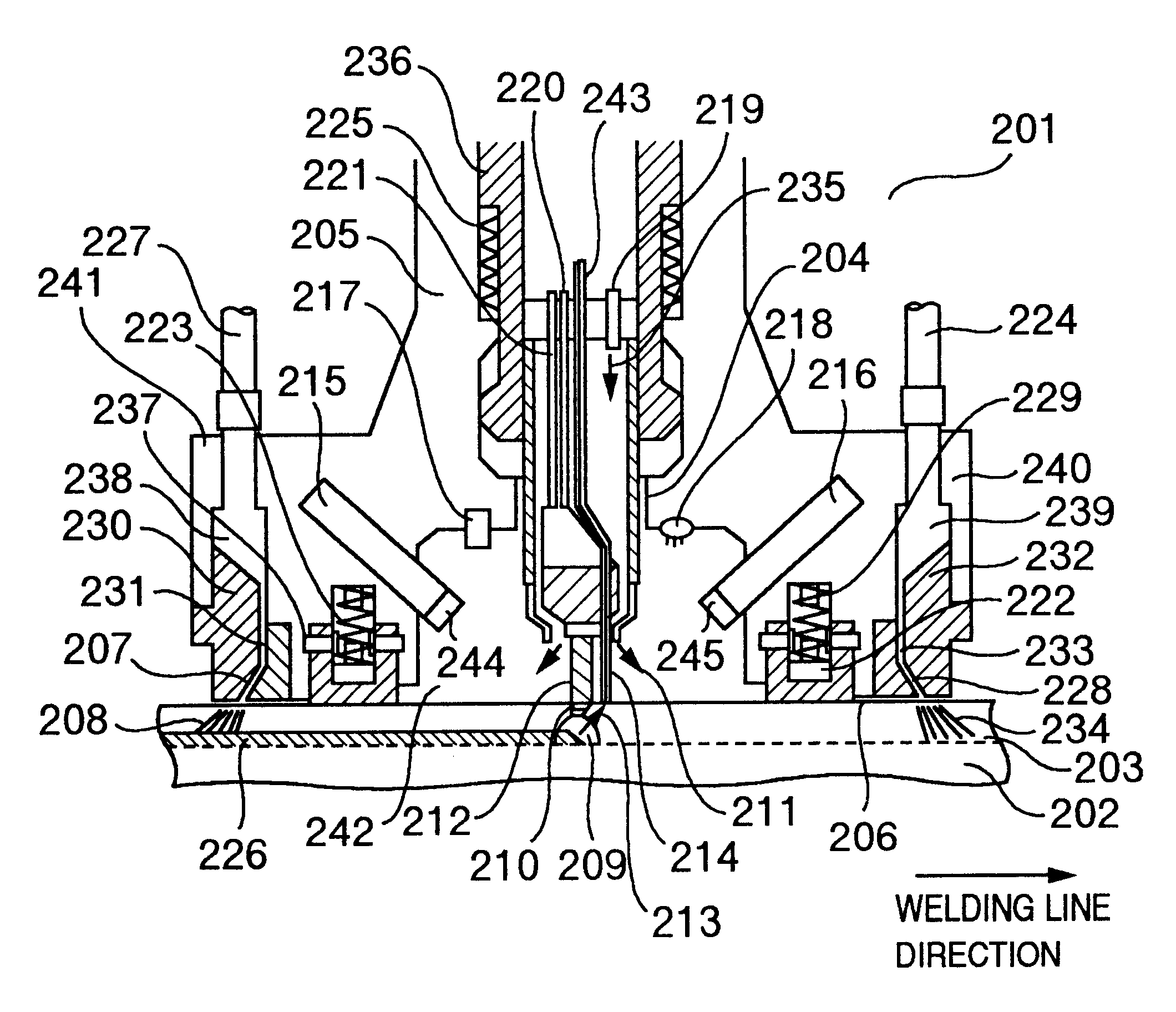

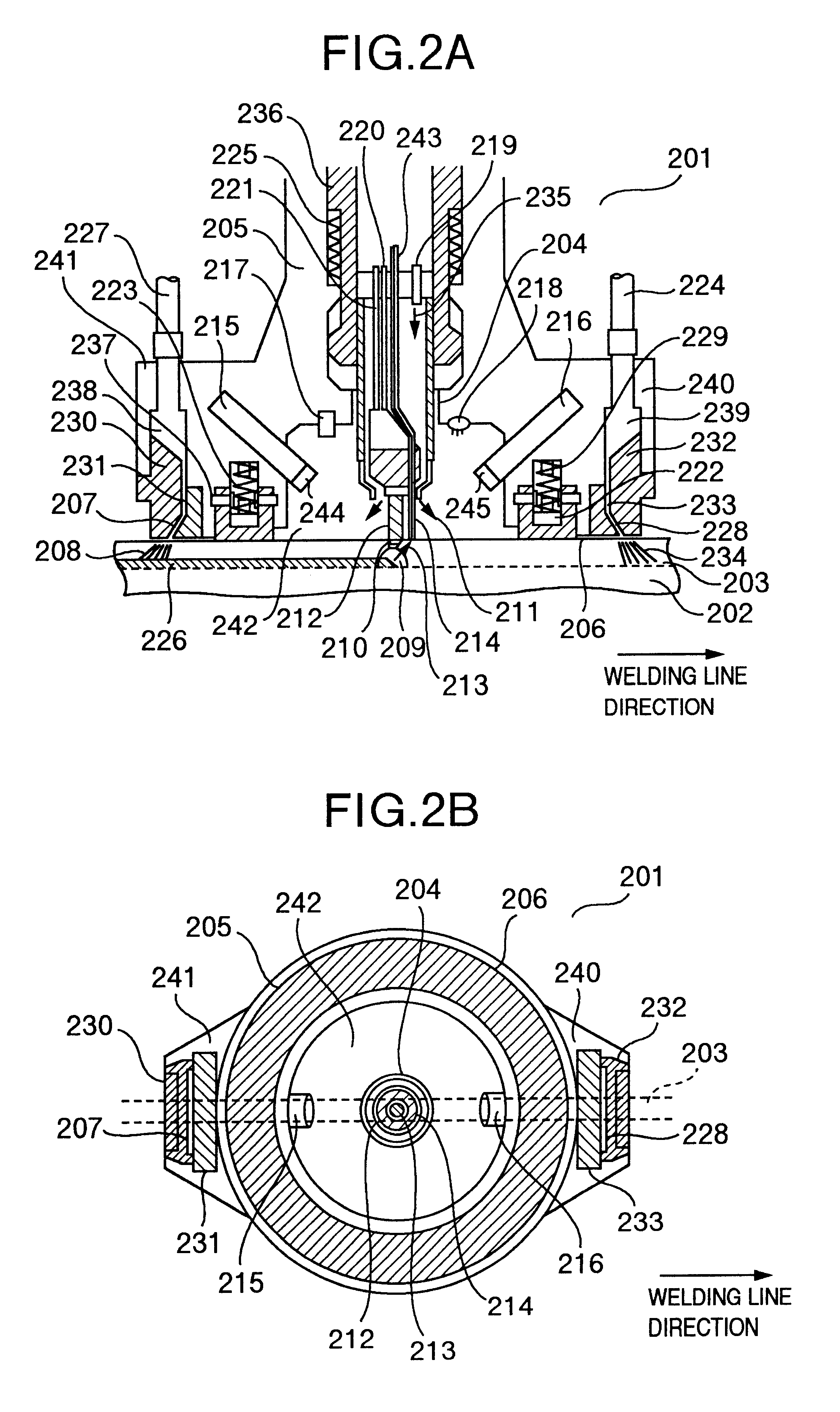

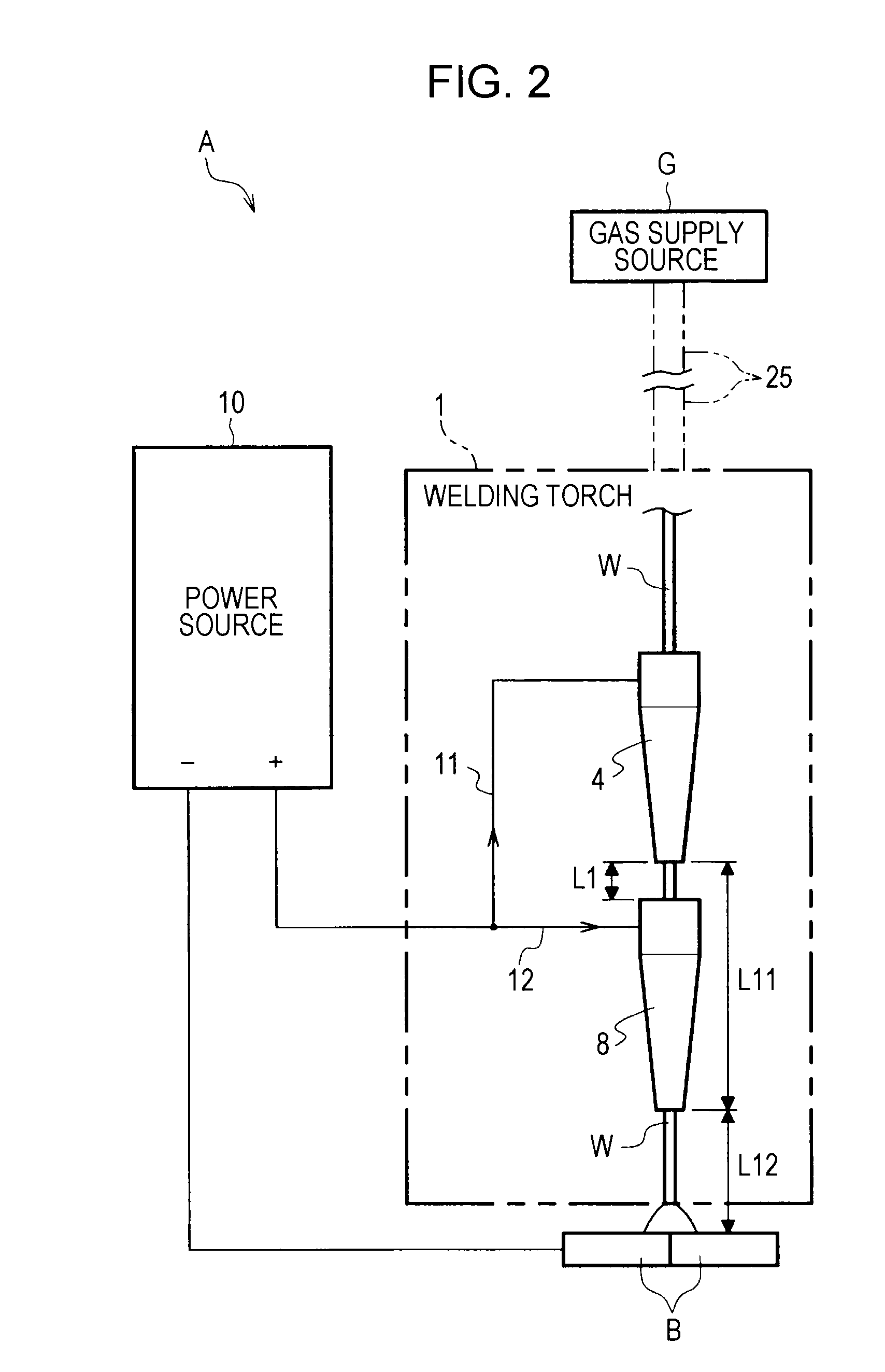

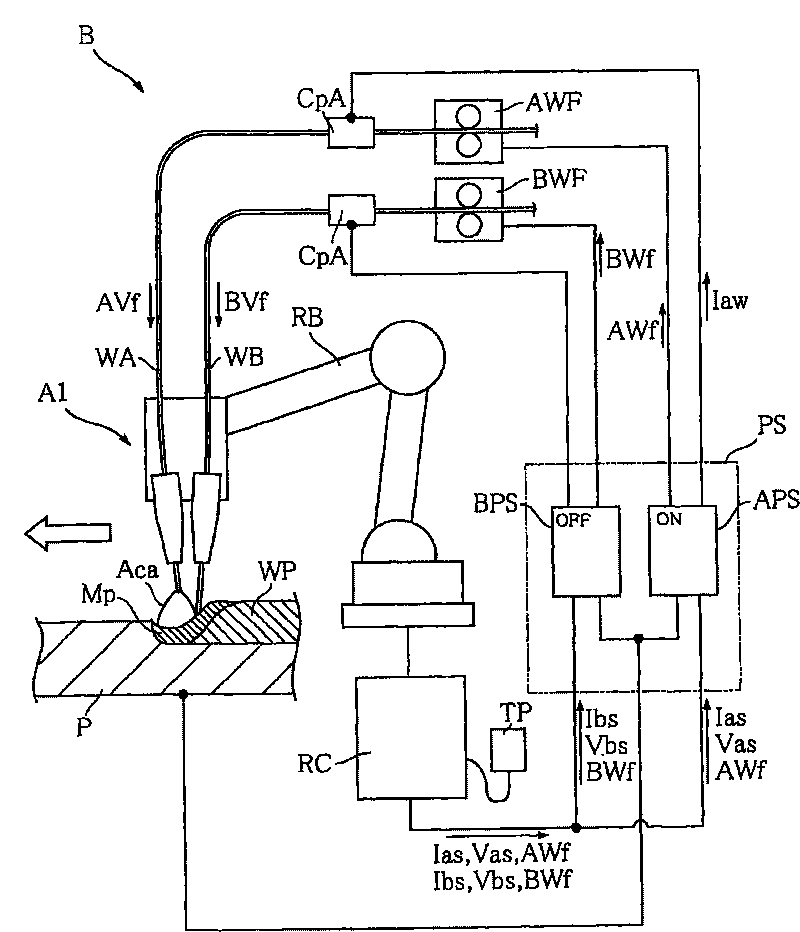

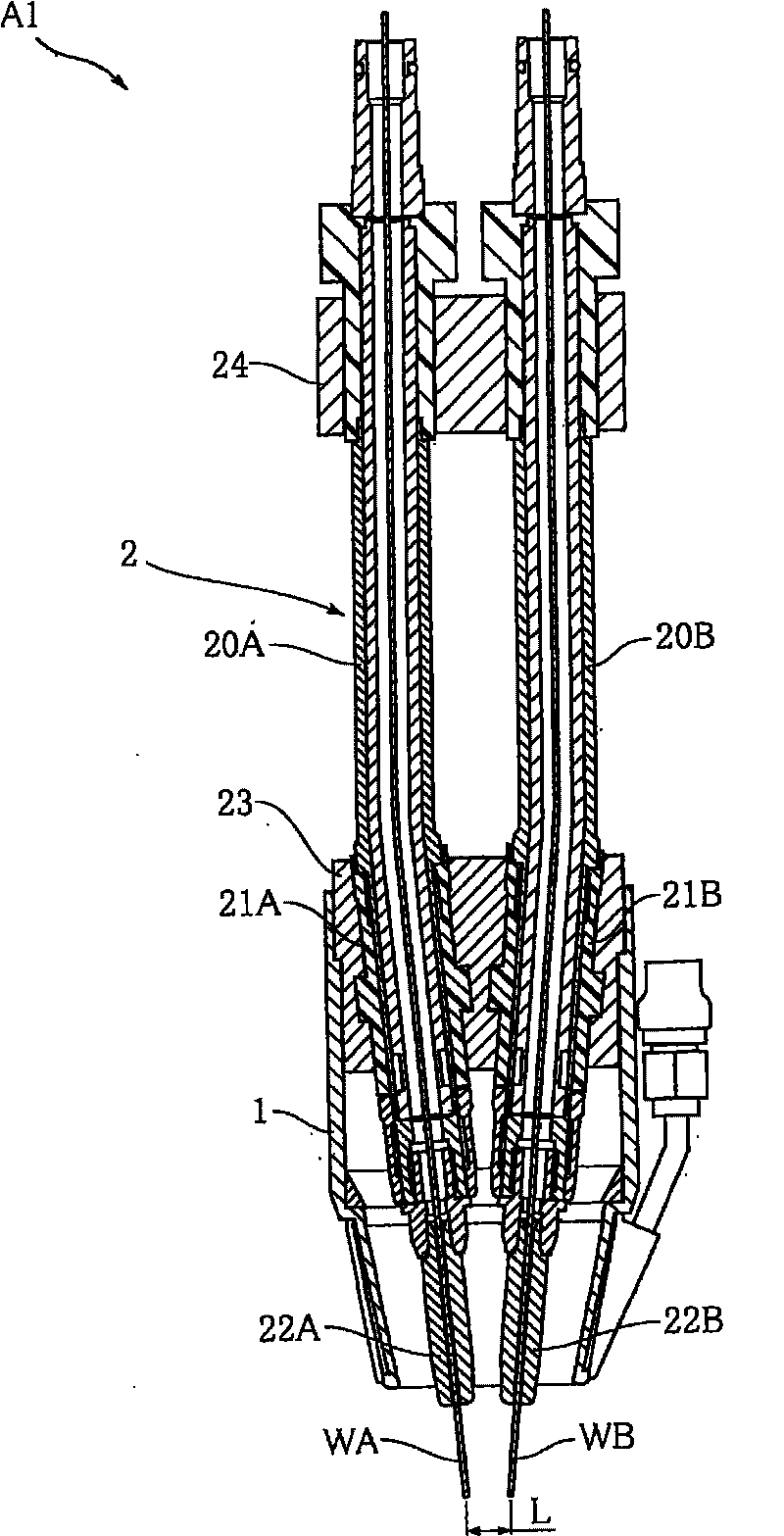

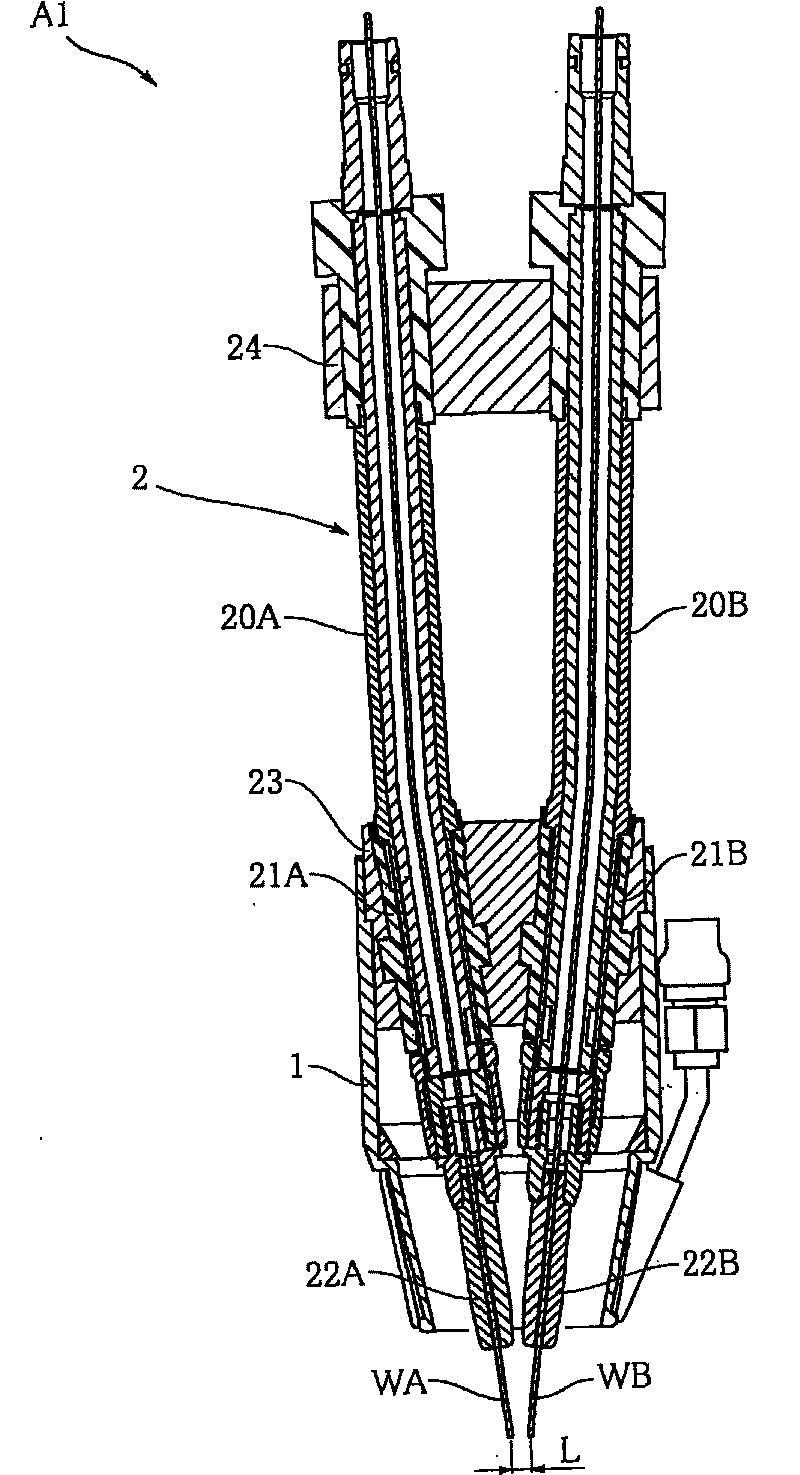

A two-wire welding gun and a two-wire welding device using the same

The invention provides a two-wire welding gun that can perform two-wire welding smoothly, and a two-wire welding device using the same. The two-wire welding gun (A1) is provided with a welding wire holding mechanism (2) that can hold a first welding wire (WA) in front of welding direction and a second welding wire (WB) behind the welding direction; the welding wire holding mechanism (2) makes distance (L) between front ends of the first welding wire (WA) and the second welding wire (WB). With such structure, frontend distance (L) between the welding wires (WA, WB) can be set suitable for board thickness of welding mother plate and welding speed, and is capable of realizing smooth two-wire welding.

Owner:DAIHEN CORP

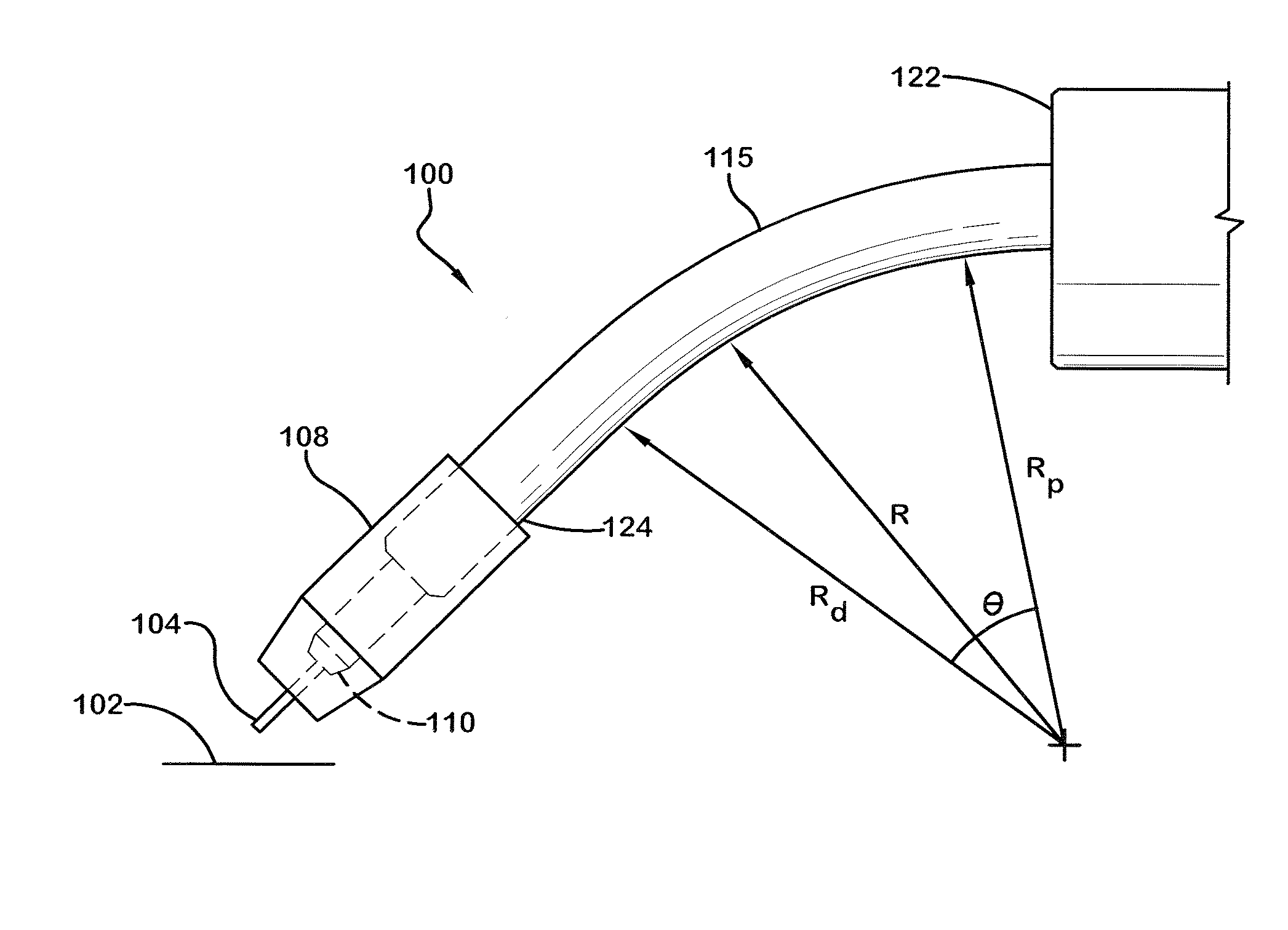

Welding gooseneck with variable radius

InactiveUS20140263254A1Support devices with shieldingElectrode holder supportersEngineeringMechanical engineering

Owner:LINCOLN GLOBAL INC

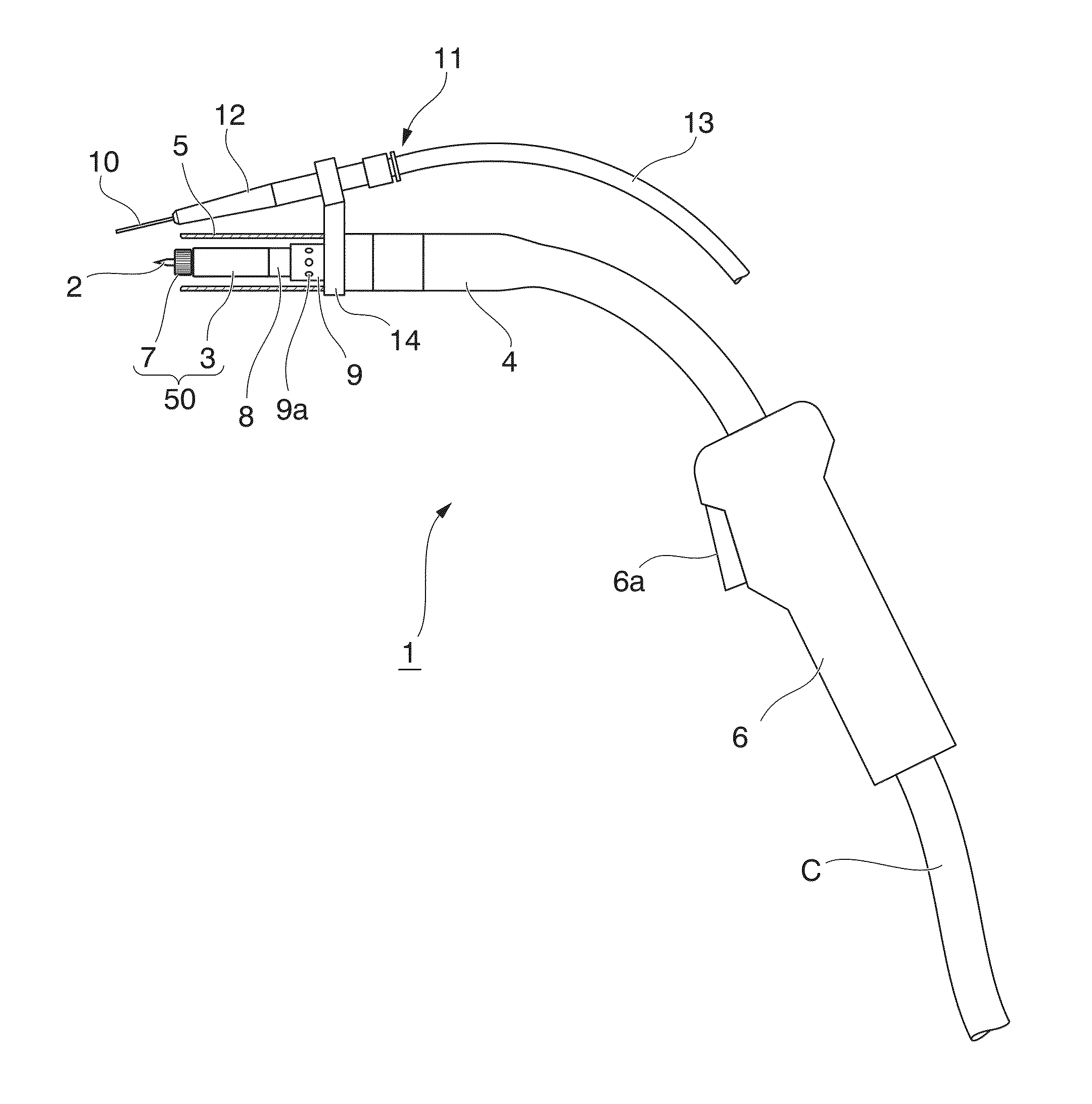

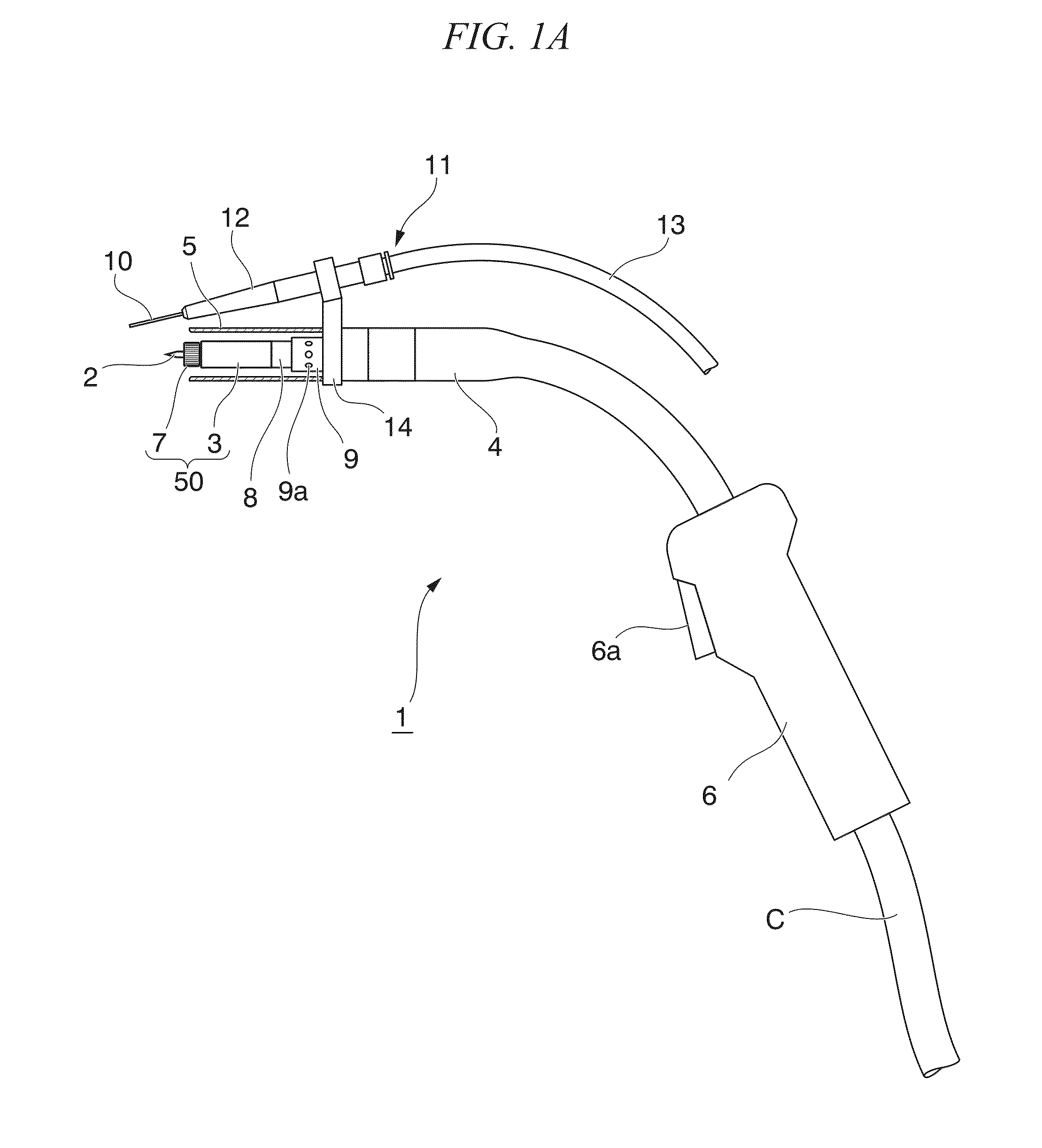

Semi-automatic welding system, conversion adapter kit, and welding torch

InactiveUS20150048057A1Support devices with shieldingElectrode accessoriesSemi automaticWelding power supply

According to the present invention, a non-consumable electrode type semi-automatic welding system which can conduct welding with high weld deposit and high speed is provided. A welding torch (1), in which a non-consumable electrode (1) generating an arc between the non-consumable electrode and an object to be welded and a torch nozzle (5) ejecting a shield gas toward a welding pool of the object to be welded generated by the arc are provided; a wire feeder (502) which delivers a welding wire (10) toward the welding pool of the object to be welded from a tip end of a feeding head, the feeding head being mounted on the welding torch (1) via an attaching jig (14); and a welding power source (501) which supplies electric power and shield gas to the welding torch (1); are provided and one or more among the welding torch (1), the wire feeder (502), and the welding power source (501) are constituted by applying at least one part of a welding torch, wire feeder, and welding power source provided in a consumable electrode type semi-automatic welding system.

Owner:NIPPON SANSO CORP

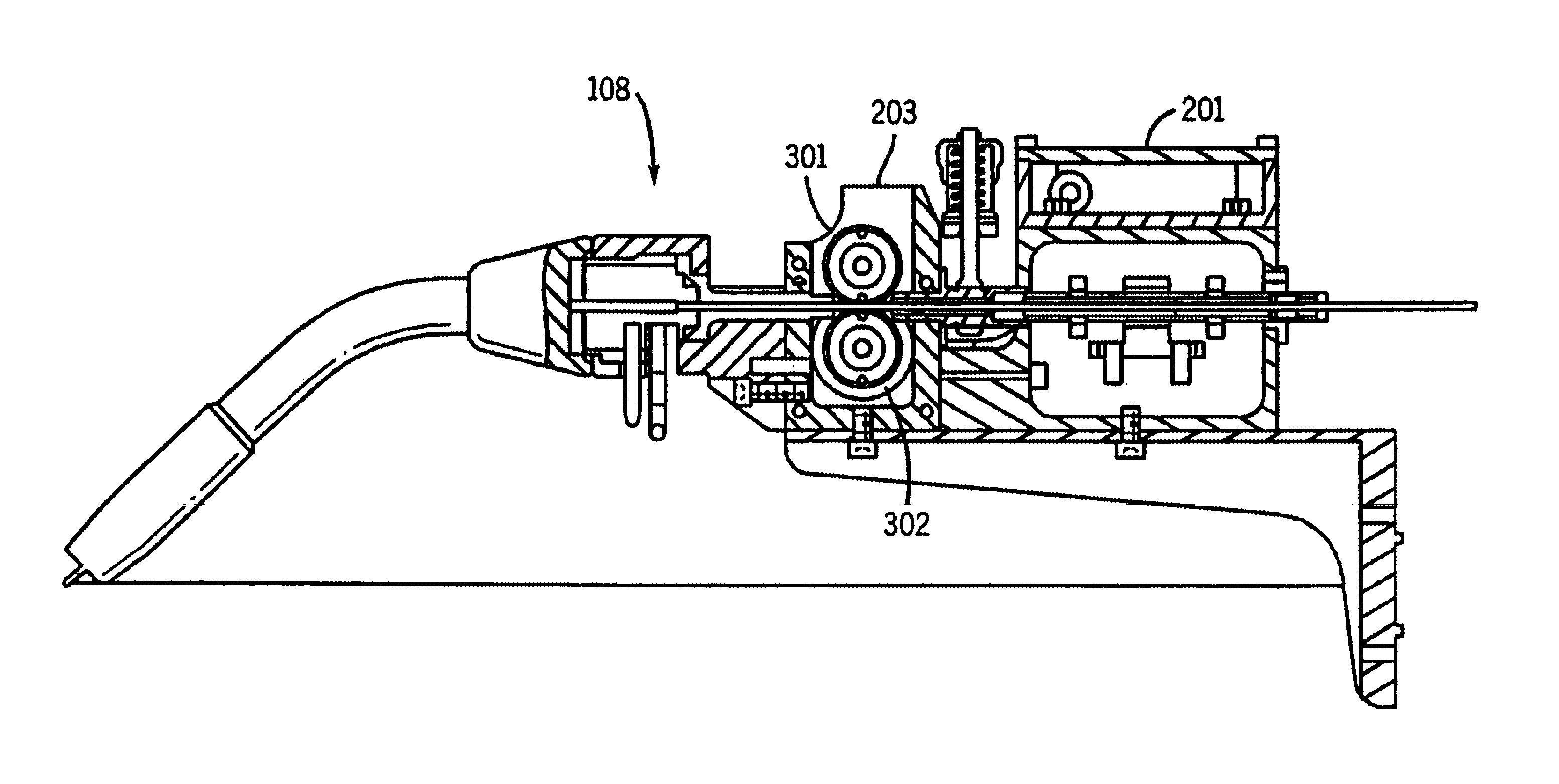

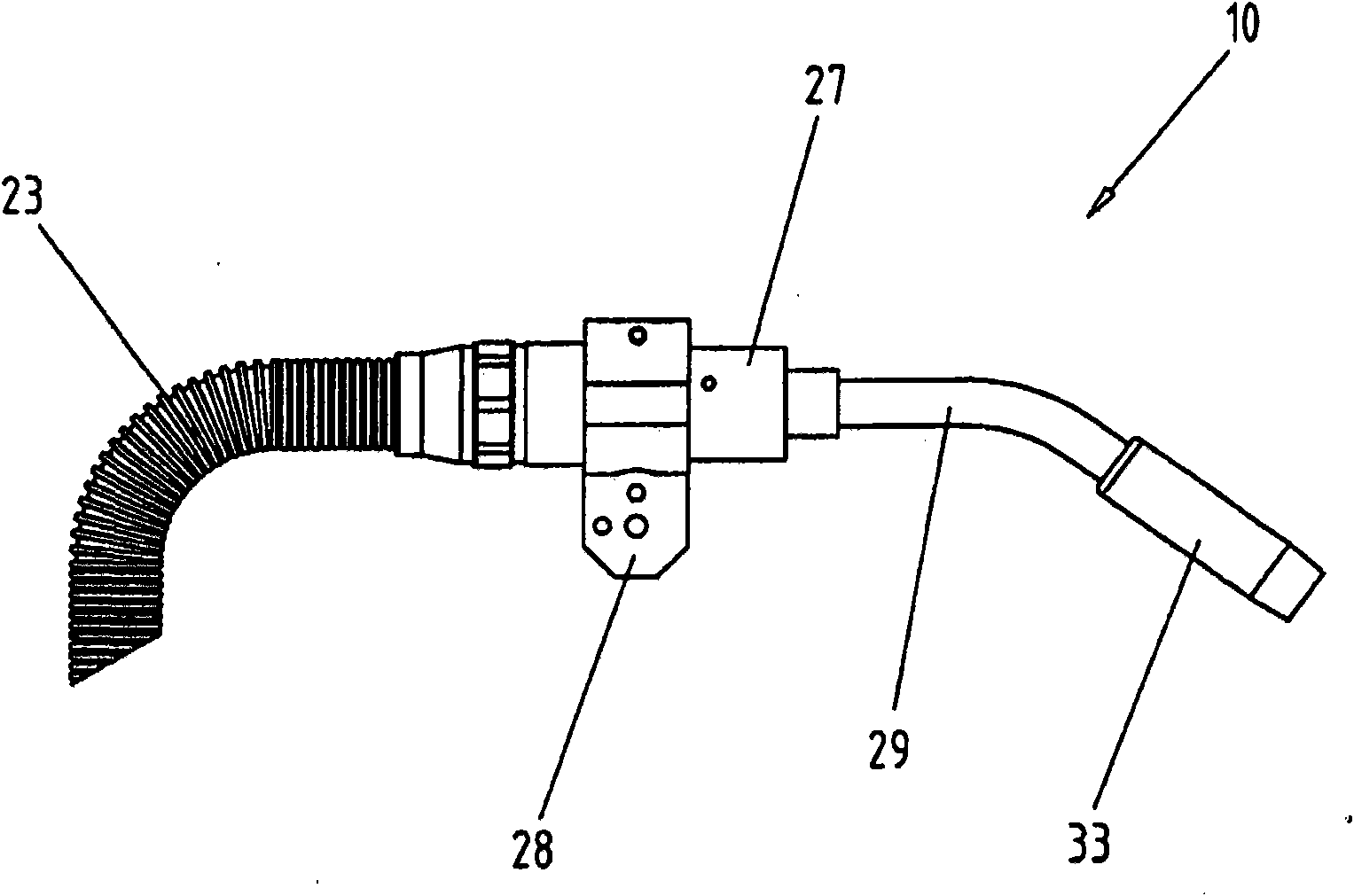

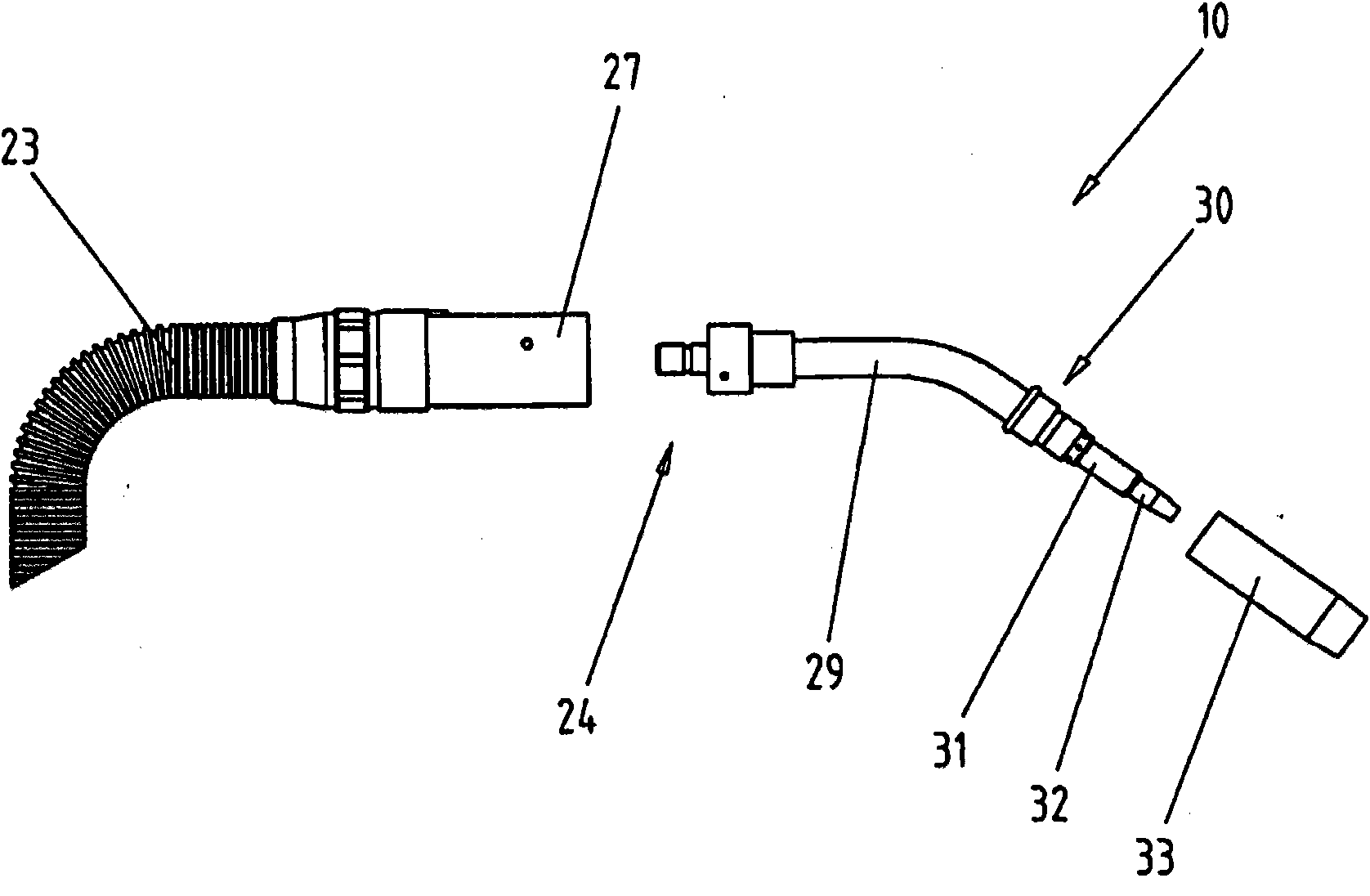

Gas nozzle attachment

ActiveCN101925433AEasy to installEasy to replaceSupport devices with shieldingEngineeringWelding torch

The invention relates to a system for attaching a gas nozzle (33) to a gas nozzle holder (30) disposed on a welding torch (10), said holder being configured for the removable attachment of the gas nozzle (33). One part of the gas nozzle holder (30) is configured eccentrically. In order to create such an attachment, the eccentric part of the gas nozzle holder (30) is configured for receiving a ring fixing element (35) and that another part of the gas nozzle holder (30) together with at least one part of the nozzle fitting (31) of the welding torch (10) forms a guide for the gas nozzle (33) and the gas nozzle (33) can be attached by way of rotary movement. The fixing element (35) is formed by an open ring. Each end of the ring rises in a radial direction relative to the outline of the circular ring part.

Owner:FRONIUS INTERNATIONAL GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com