A two-wire welding gun and a two-wire welding device using the same

A technology of double welding wire and welding wire, which is applied in the direction of protective supporting devices, welding equipment, electrode supporting devices, etc., and can solve the problems of WB deviation of filling welding wire and insufficient melting of filling welding wire WB

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the drawings.

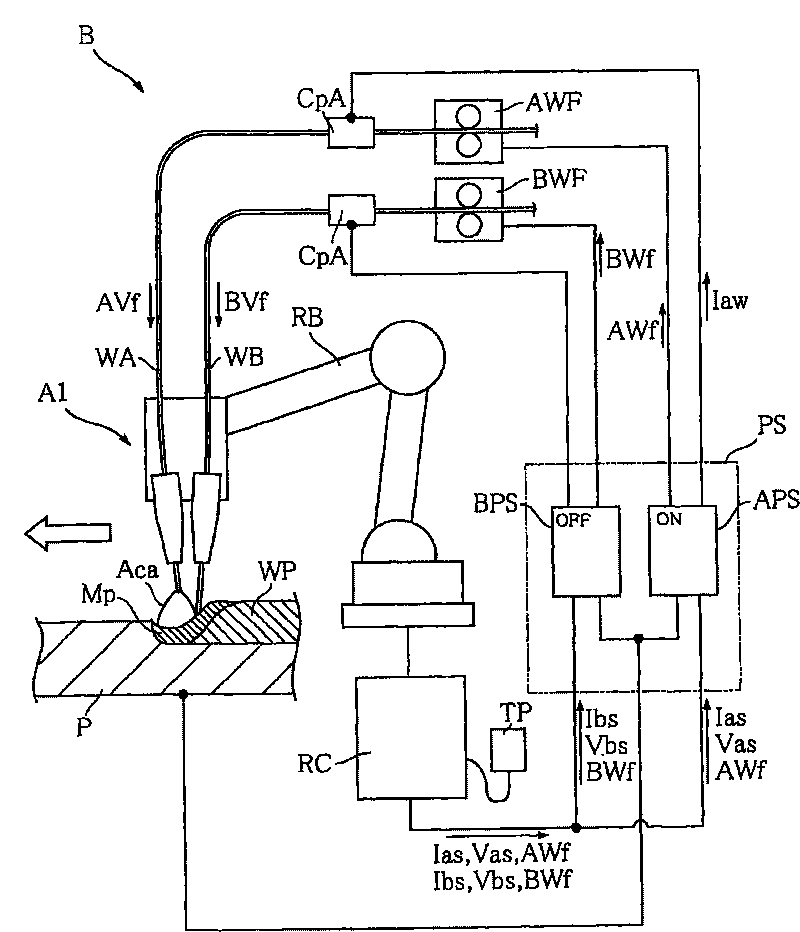

[0043] figure 1 An example of a twin wire welding device according to the first embodiment of the present invention is shown. The twin wire welding apparatus B of the present embodiment includes a twin wire torch A1, a wire feeder AWF, a wire feeder BWF, a welding power source PS, a robot RB, and a robot controller RC. The twin wire welding device B performs twin wire welding using the welding wires WA and WB.

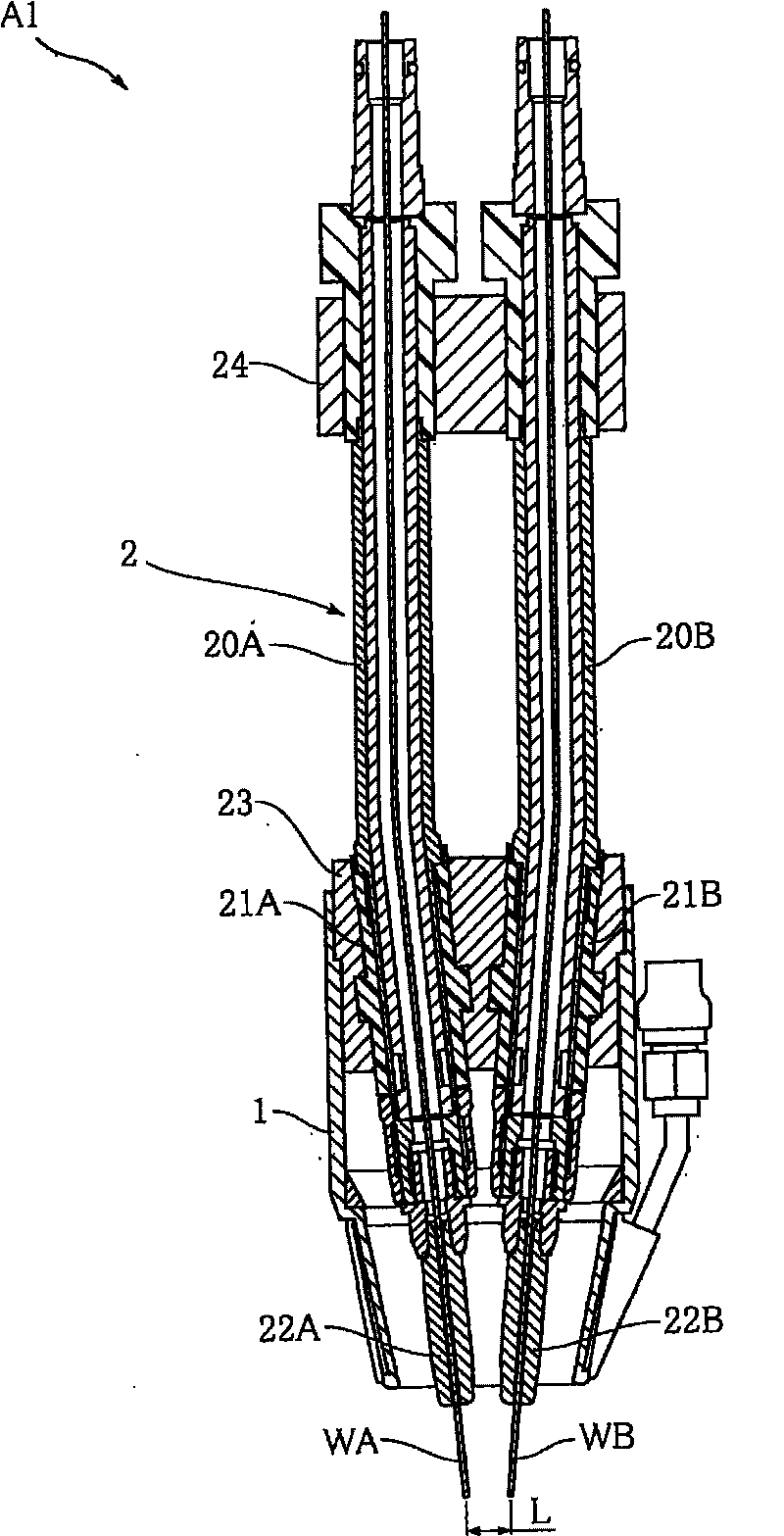

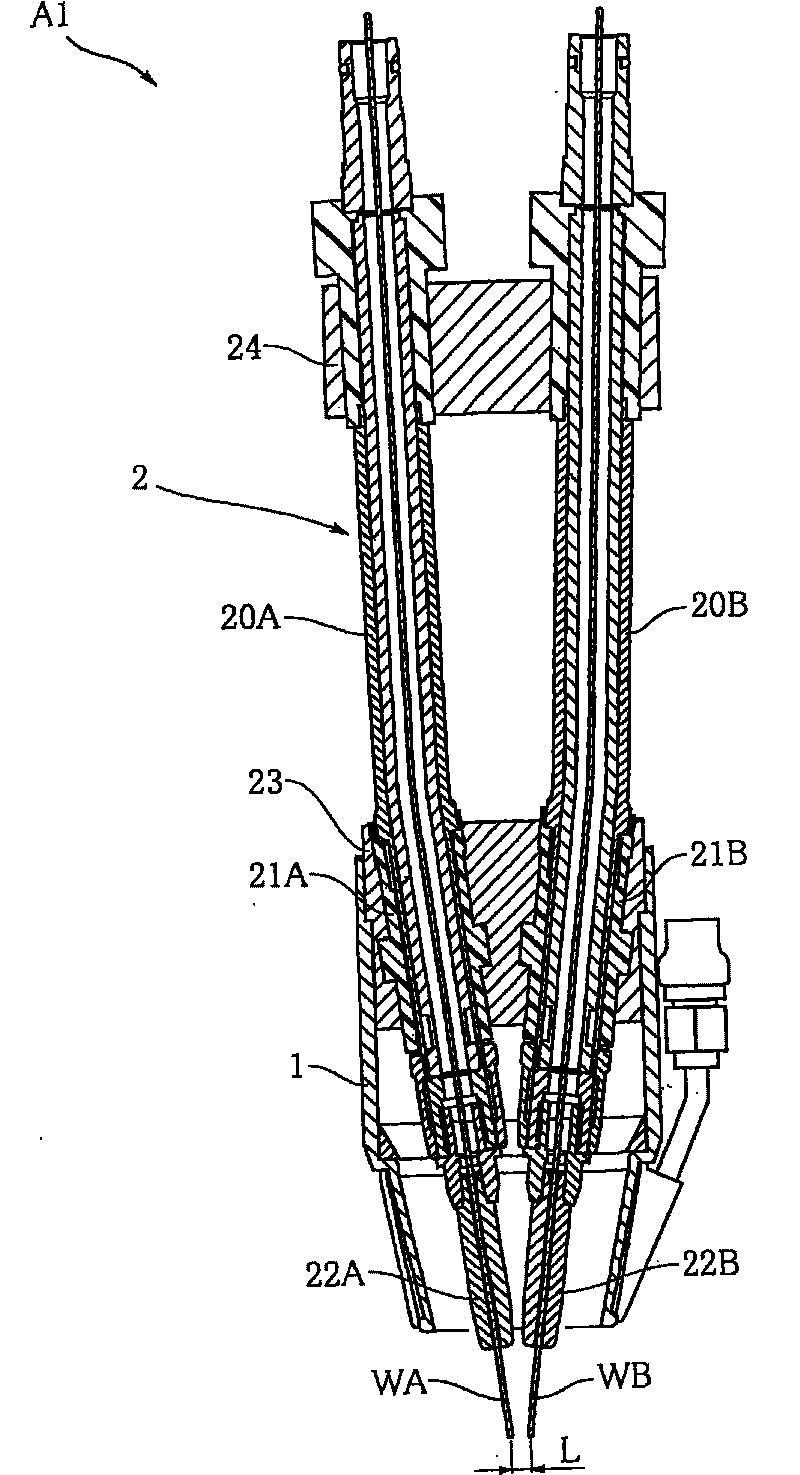

[0044] The twin wire welding torch A1 is installed on the robot RB, and is used to guide the welding wires WA, WB to the welding base material P. Such as figure 2 As shown, the twin wire welding torch A1 is configured to include a hood 1 and a wire support mechanism 2 . The cover 1 is, for example, a cylindrical shape made of Cu, and surrounds a part of the wire support mechanism 2 .

[0045] The welding wire support mechanism 2 hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com