Method and apparatus to adaptively cool a welding-type system

a cooling system and welding type technology, applied in the field of welding type systems, can solve the problems of increasing the heat of the welding torch, manual operation of the cooling system, and generating a considerable amount of hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

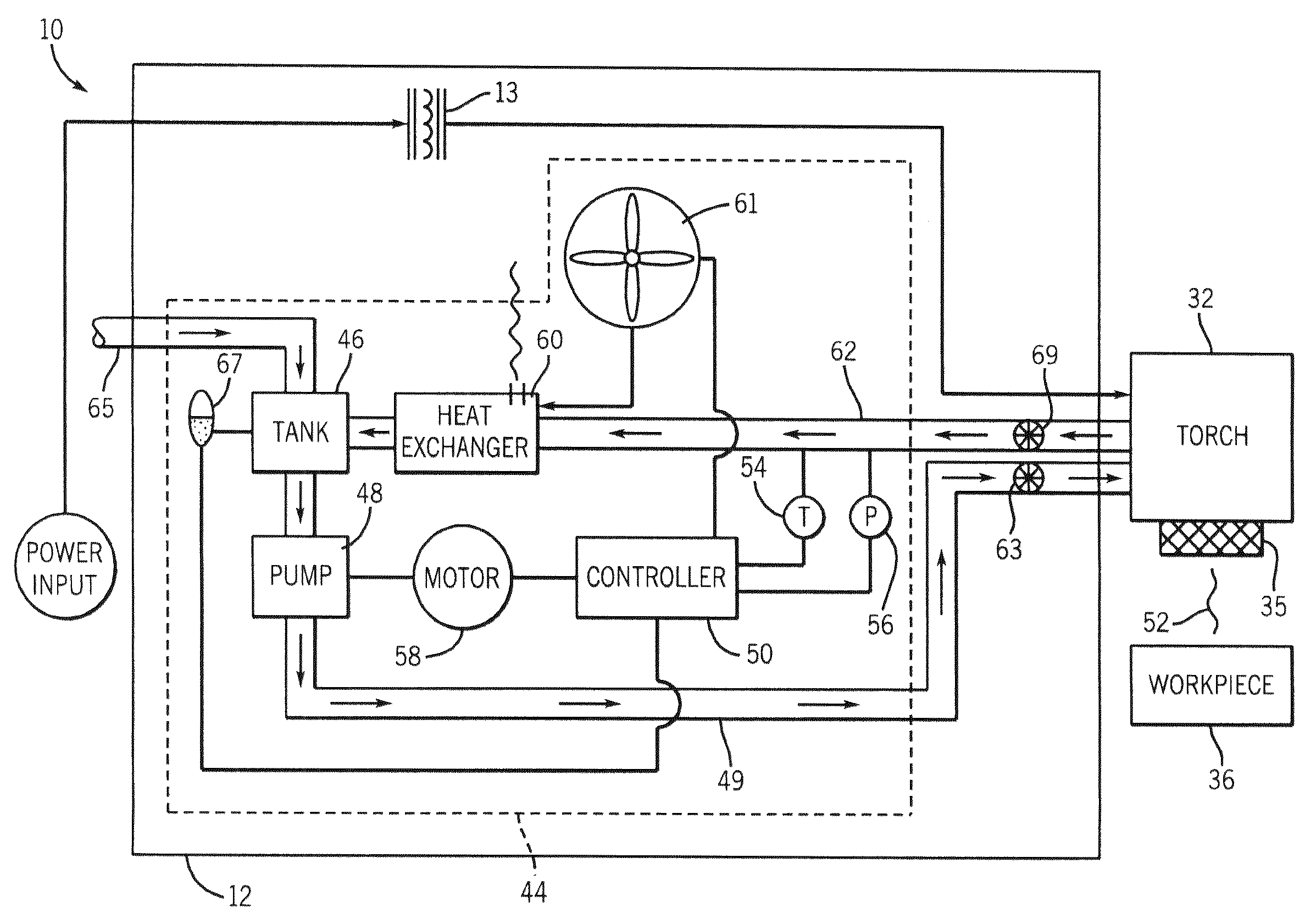

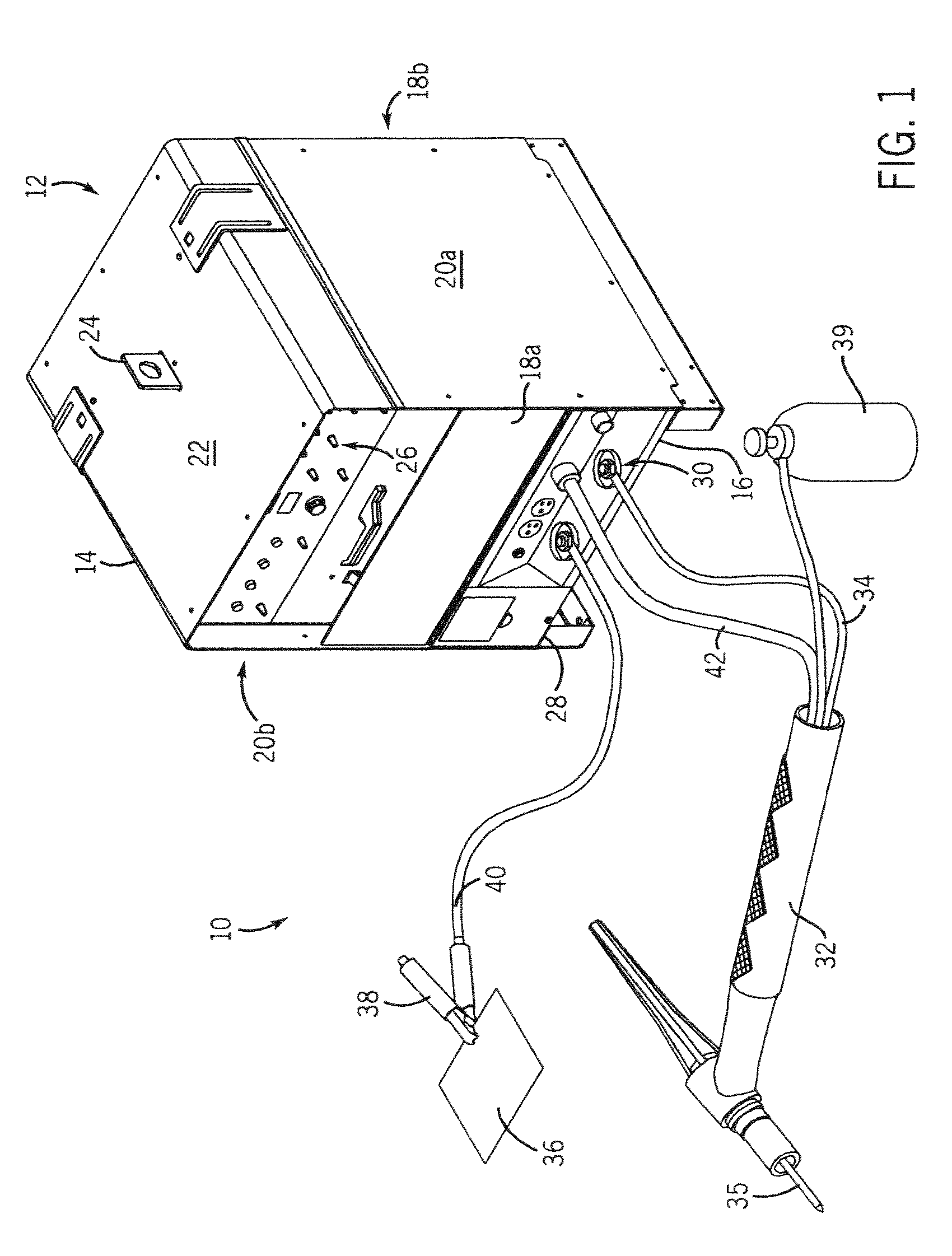

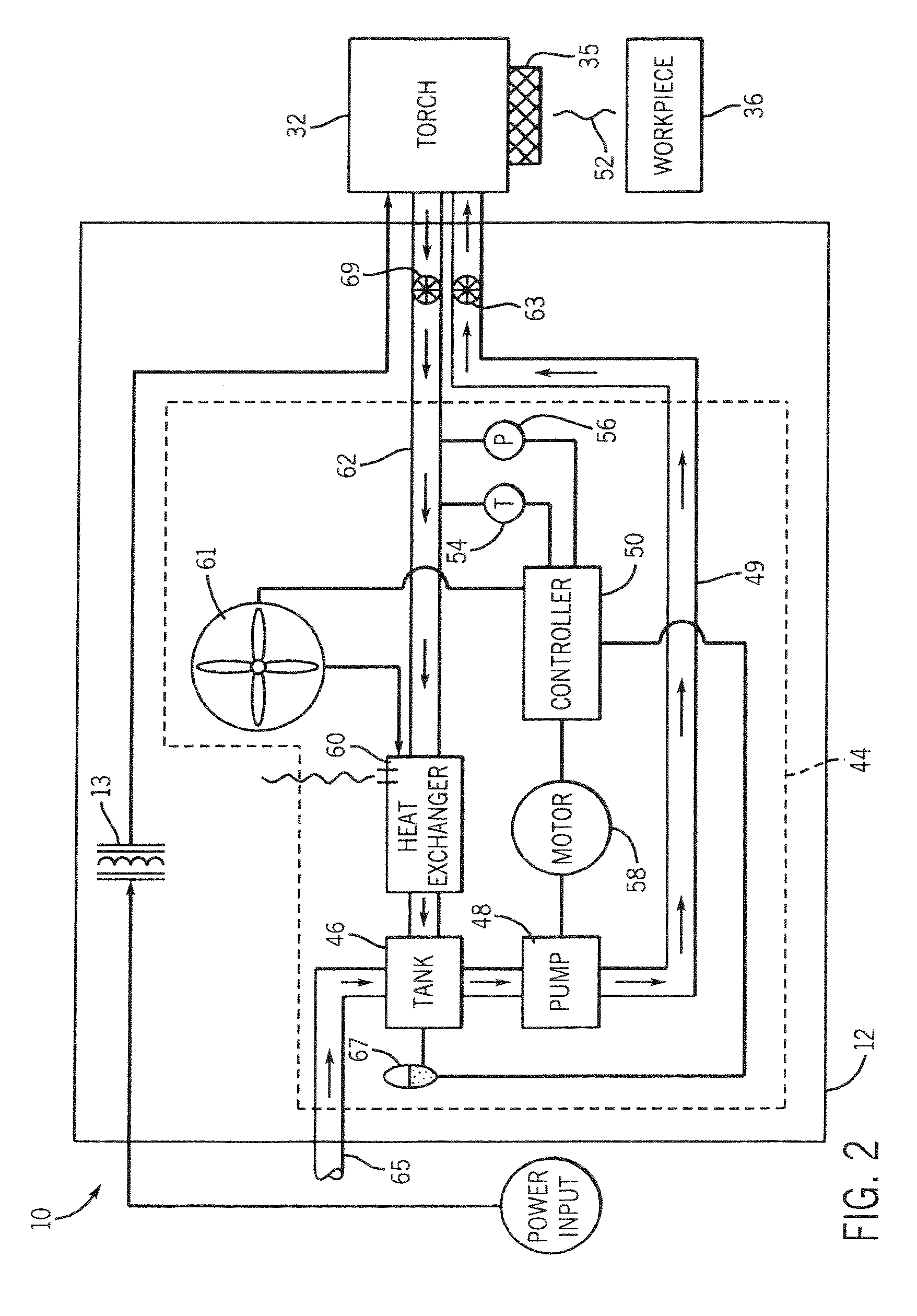

[0018]FIG. 1 is a perspective view of a welding-type system 10 suitable for a number of welding processes including tungsten inert gas (TIG) welding and stick welding. The welding-type system 10 includes a power source 12 disposed within an enclosure 14. Enclosure 14 is defined by a base 16, front and back panels 18a, 18b, and a pair of side panels 20a, 20b attached to the base 12. A top cover 22 having a handle 24 is secured to the pair of side panels 20a, 20b to form enclosure 14. The front panel includes control knobs 26 and outlets and receptacles 28 to facilitate connection of welding accessories to the enclosure. For example, an electrode weld output terminal 30 is used to connect a torch or other welding-type component 32 to the power source via cable 34. The torch is designed to hold a tungsten electrode 35. To complete a welding circuit, a workpiece 36 is introduced to a weld by a clamp 38 that is also connected to the power source by cable 40. A gas cylinder 39 is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com