Titanium tube welding gas protection cover of fixed welding gun

A technology of welding gas and protective cover, applied in welding equipment, supporting device for protection, characteristics of welding rod, etc., to achieve the effect of convenient operation, obvious gas protection effect and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

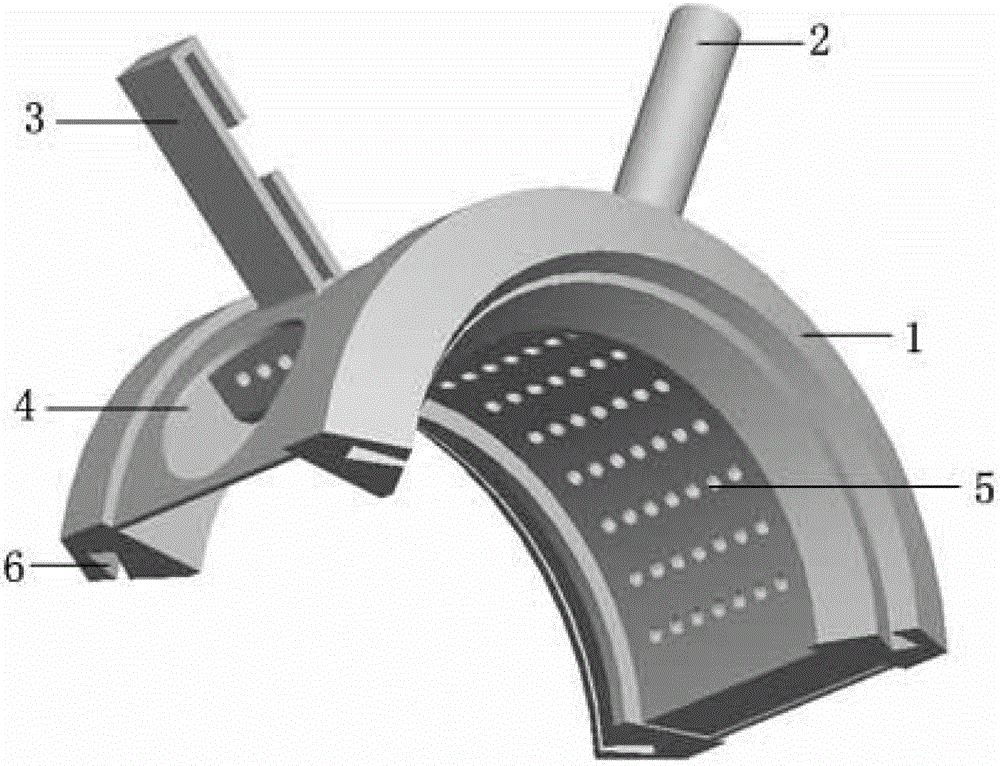

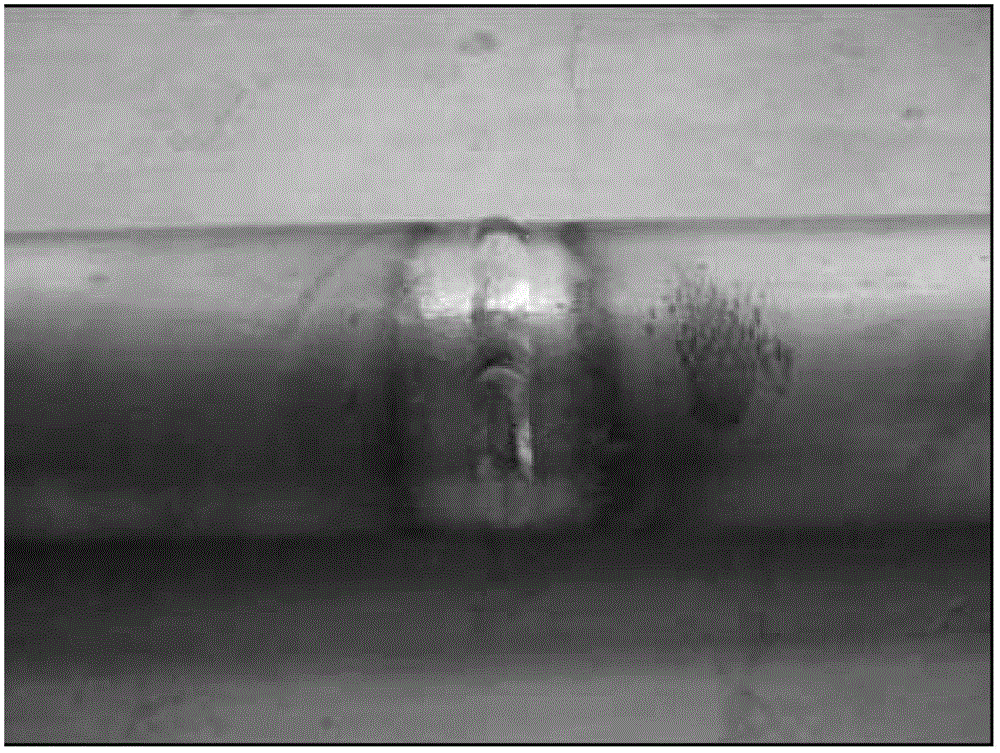

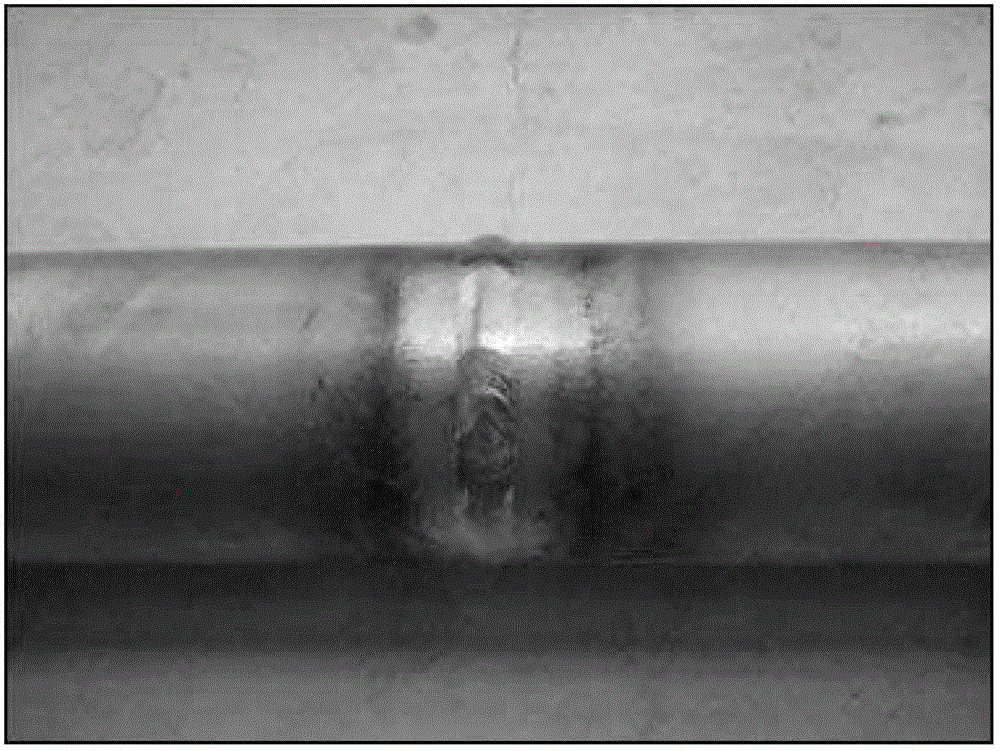

[0013] as attached figure 1 As shown, a titanium tube welding gas shield for fixing a welding torch is composed of an arc-shaped shell 1, a gas introduction pipe 2, a welding operation hole 4, a welding torch fixing device 3, an internal air screen layer 5 and a side groove 6, wherein The gas inlet pipe, welding operation hole and welding torch fixing device are fixed on the upper surface of the arc-shaped shell. The arc-shaped shell and the internal air screen layer are connected into one body by welding, and the two sides of the arc-shaped shell are provided with side grooves. When welding, the device covers the part to be welded, and the welding torch is bound to the welding torch fixing device with a metal hoop, and then the inert gas is introduced into the protective cover through the gas inlet tube, and the argon flow is evenly distributed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com