Patents

Literature

649results about "Moderator/core" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Premium synthetic lubricants

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

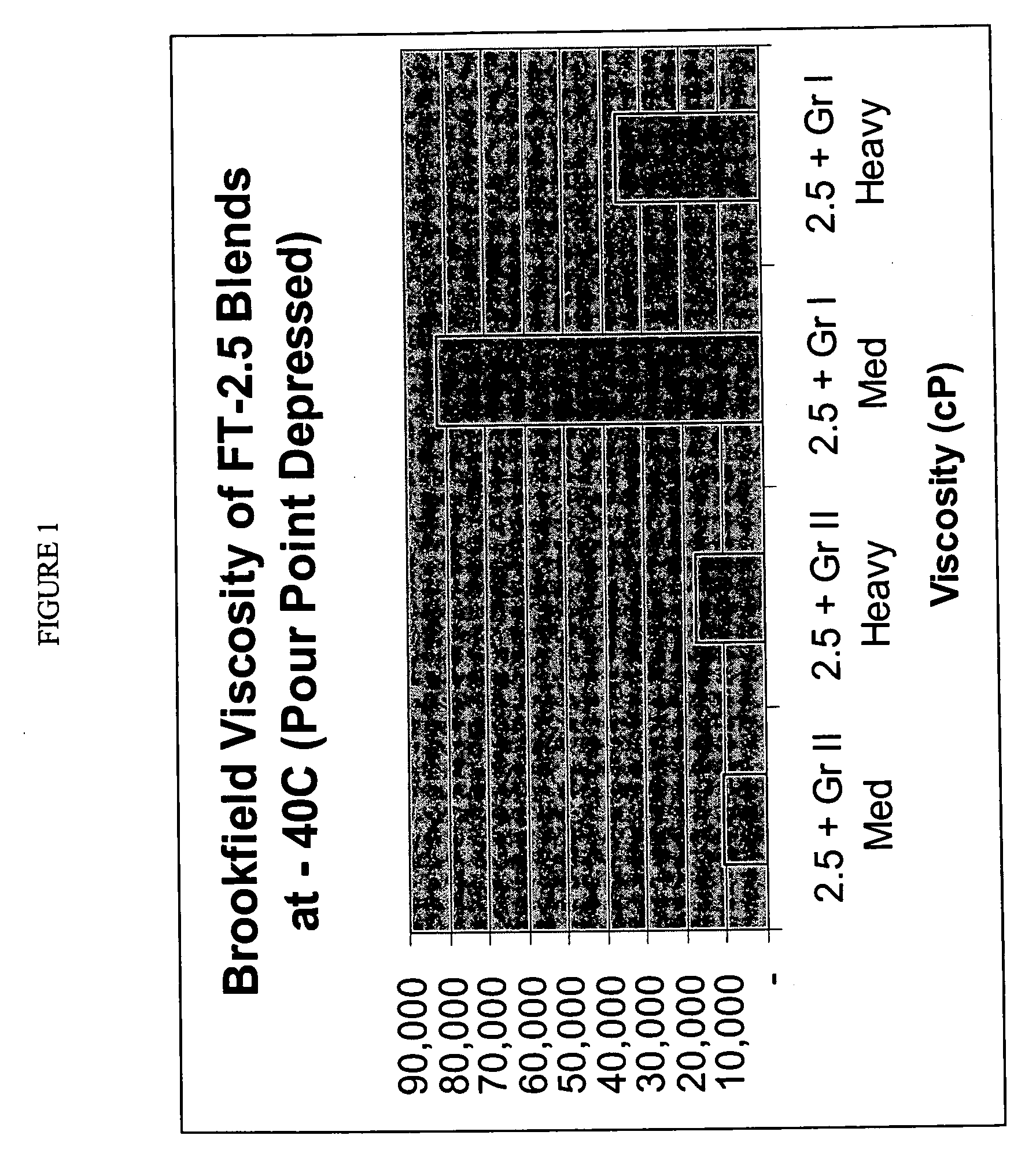

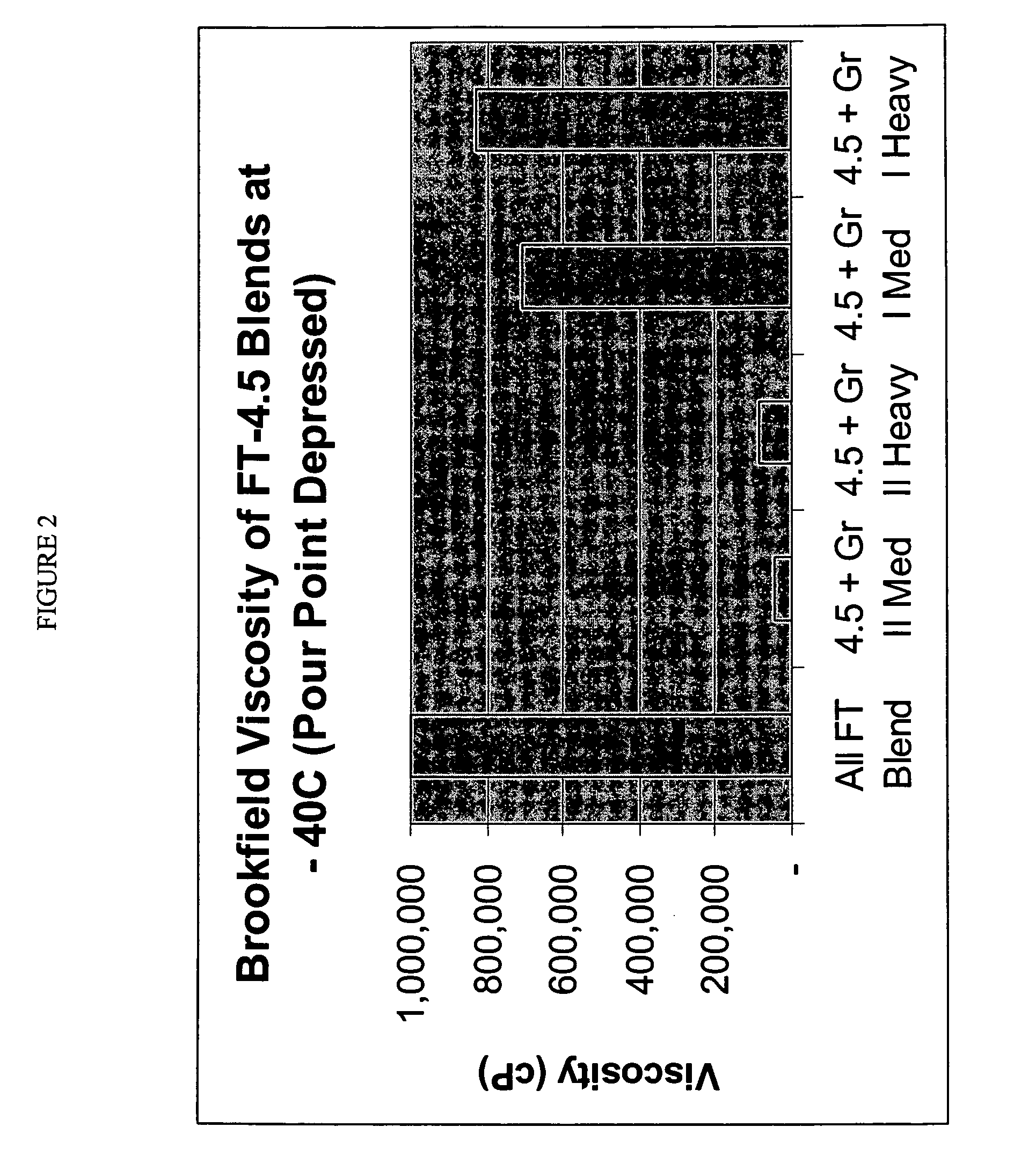

Processes for making lubricant blends with low brookfield viscosities

InactiveUS20050261146A1Improve low temperature performanceLow viscosityRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxSulfur

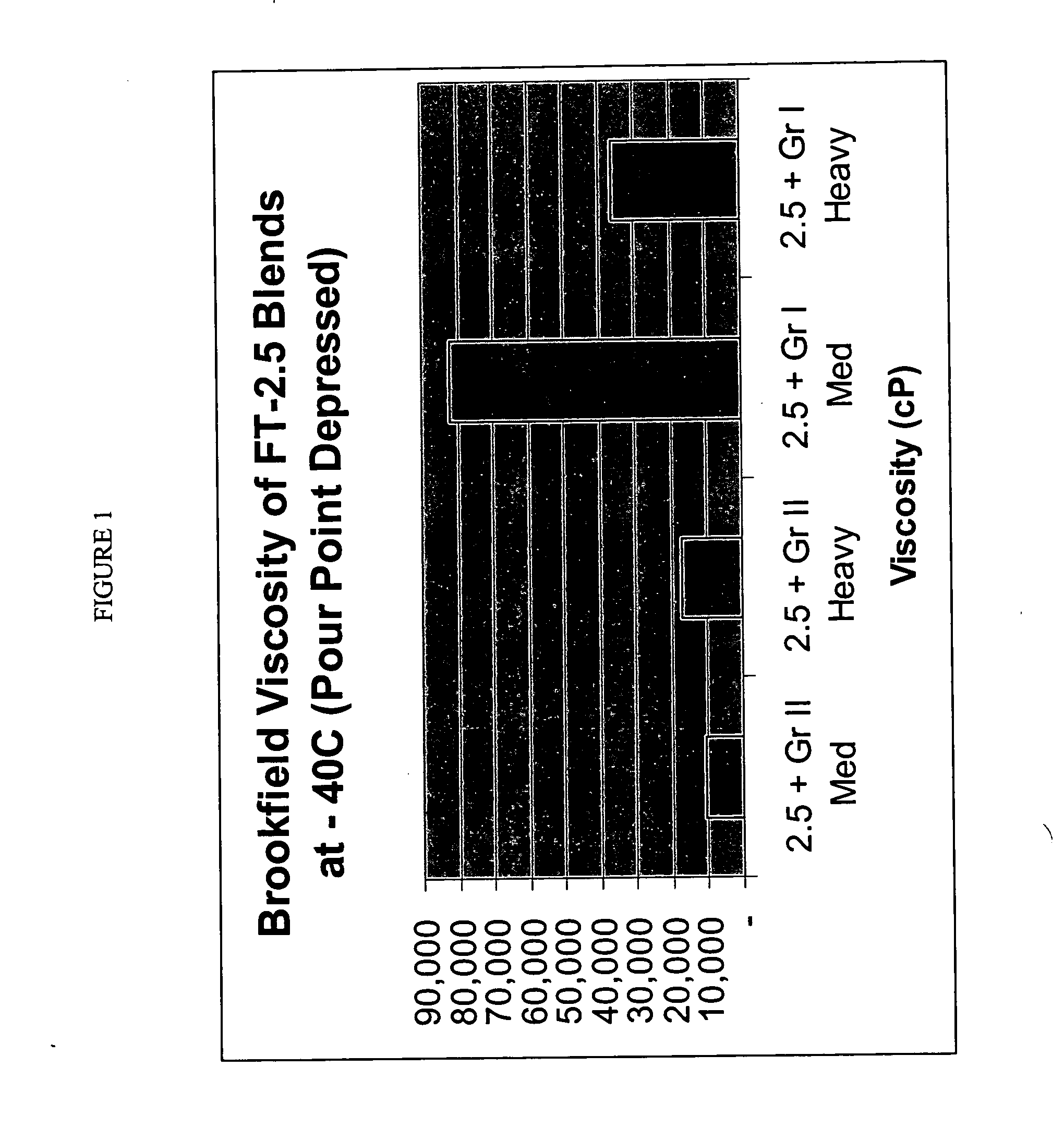

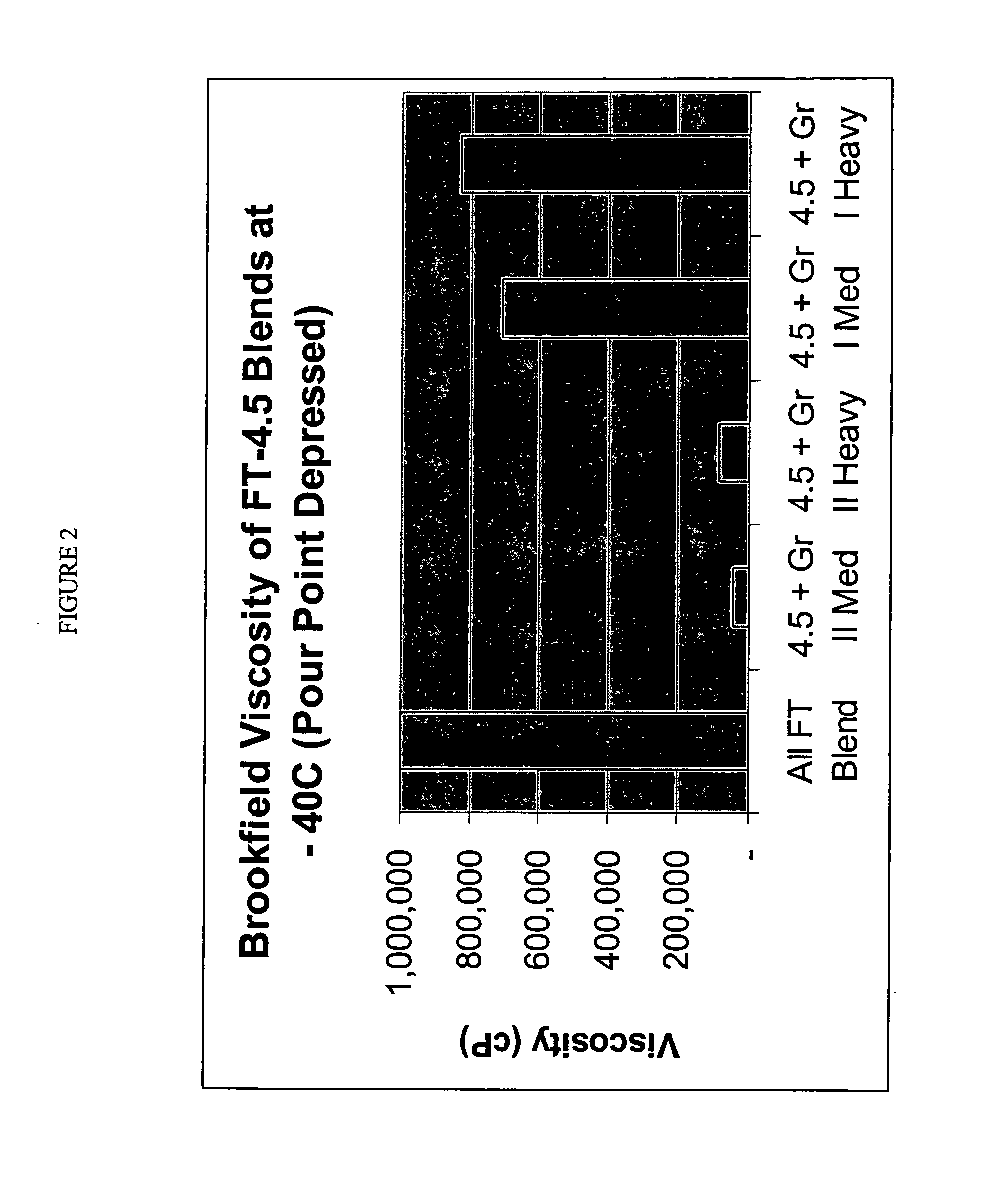

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

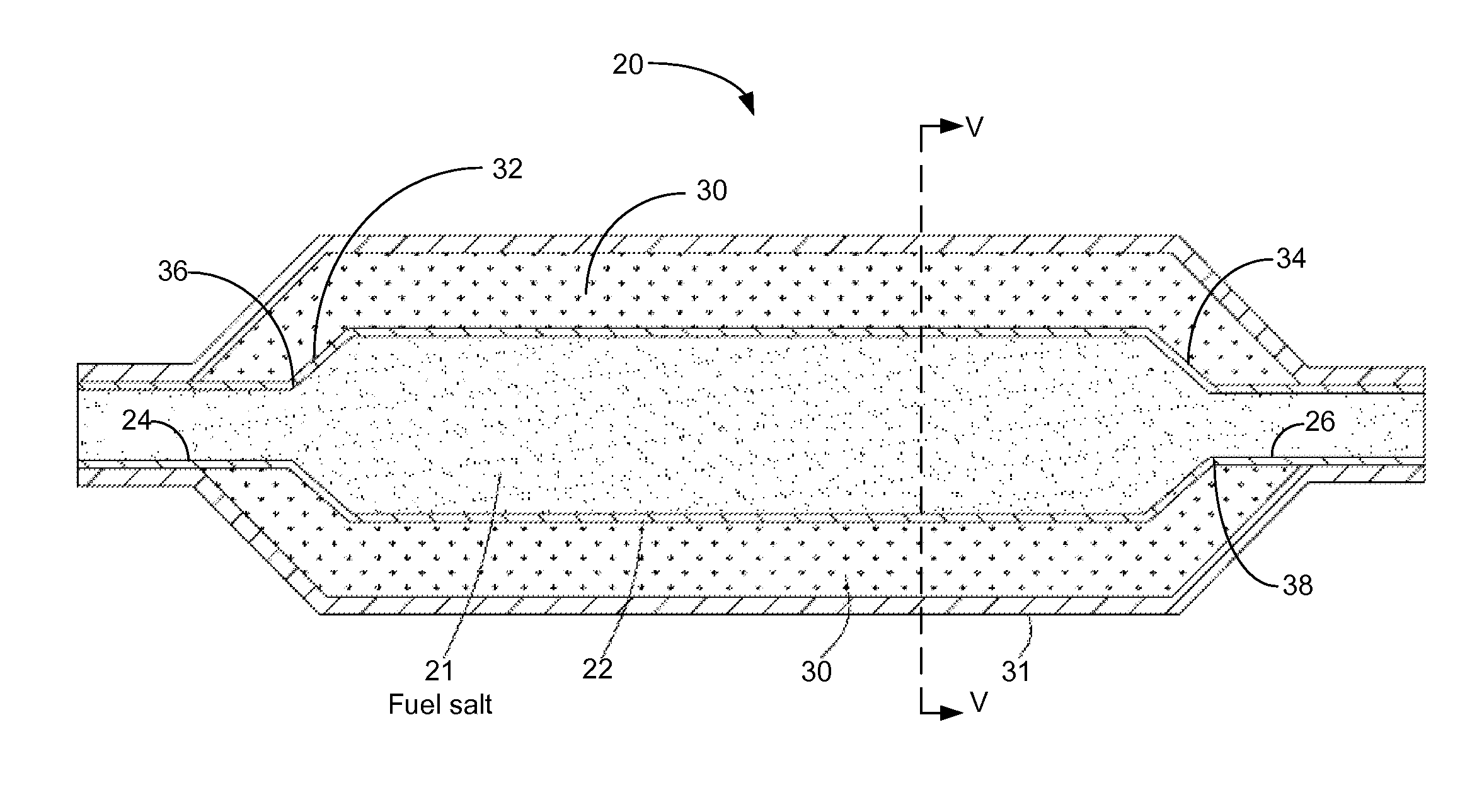

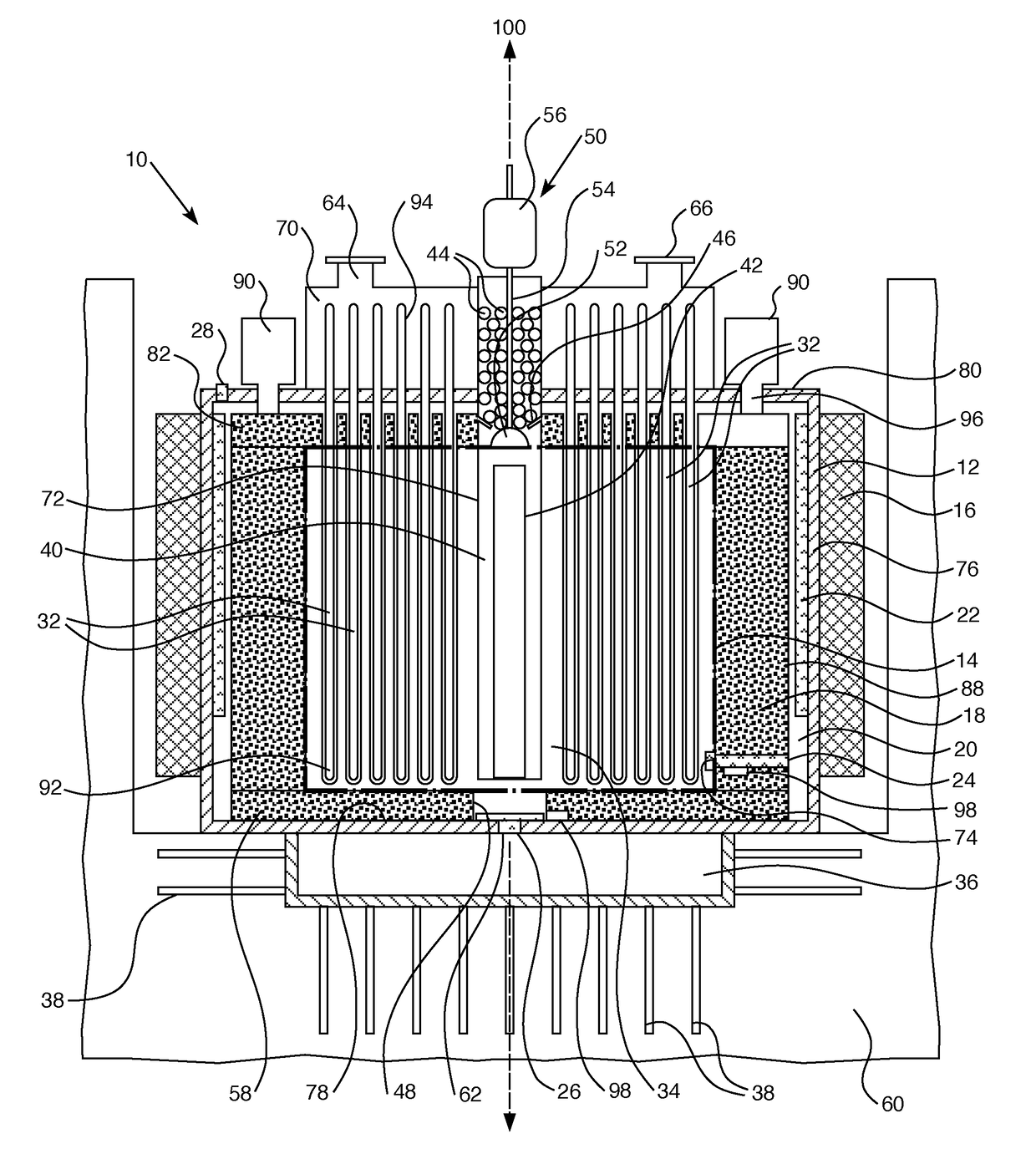

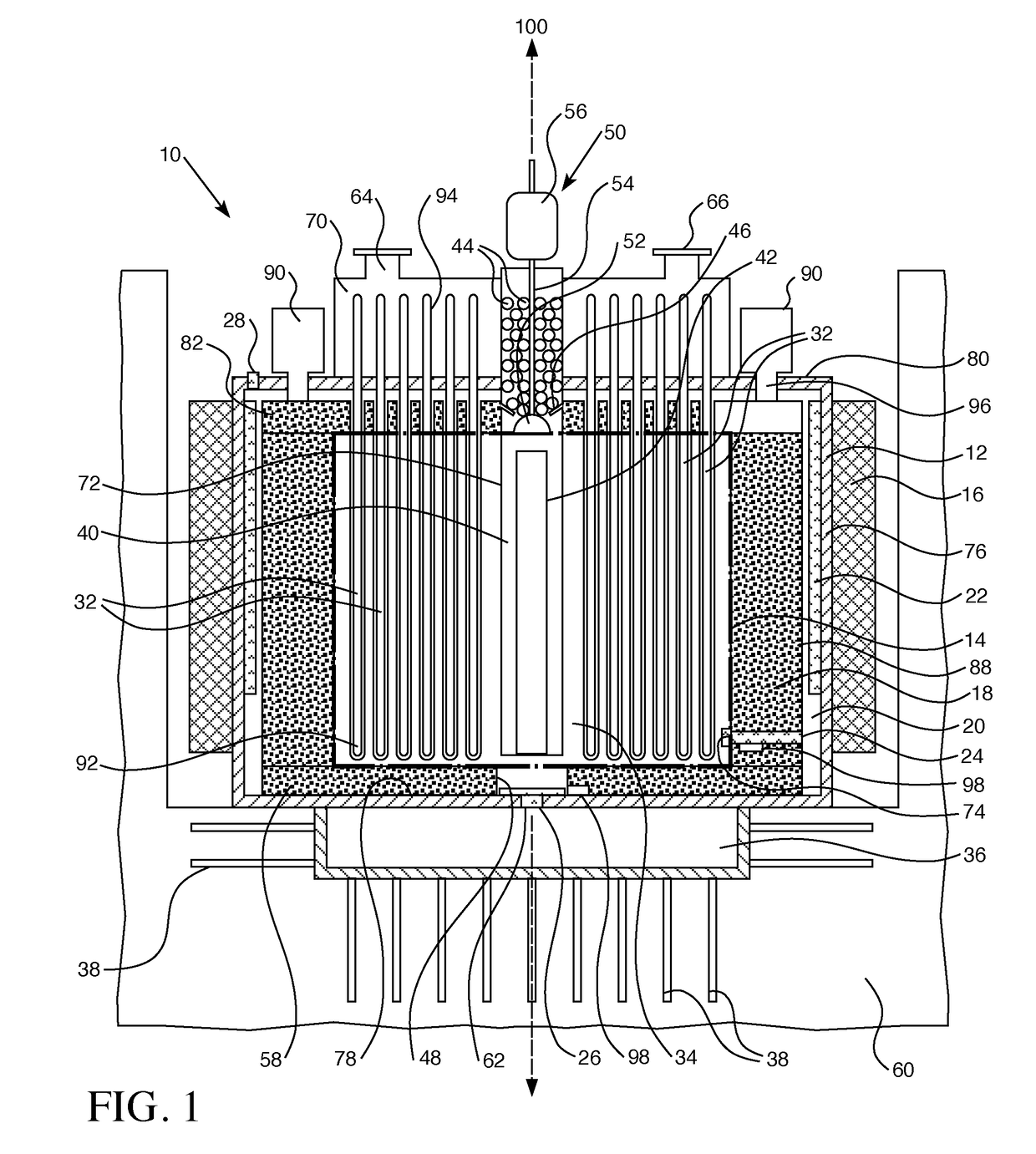

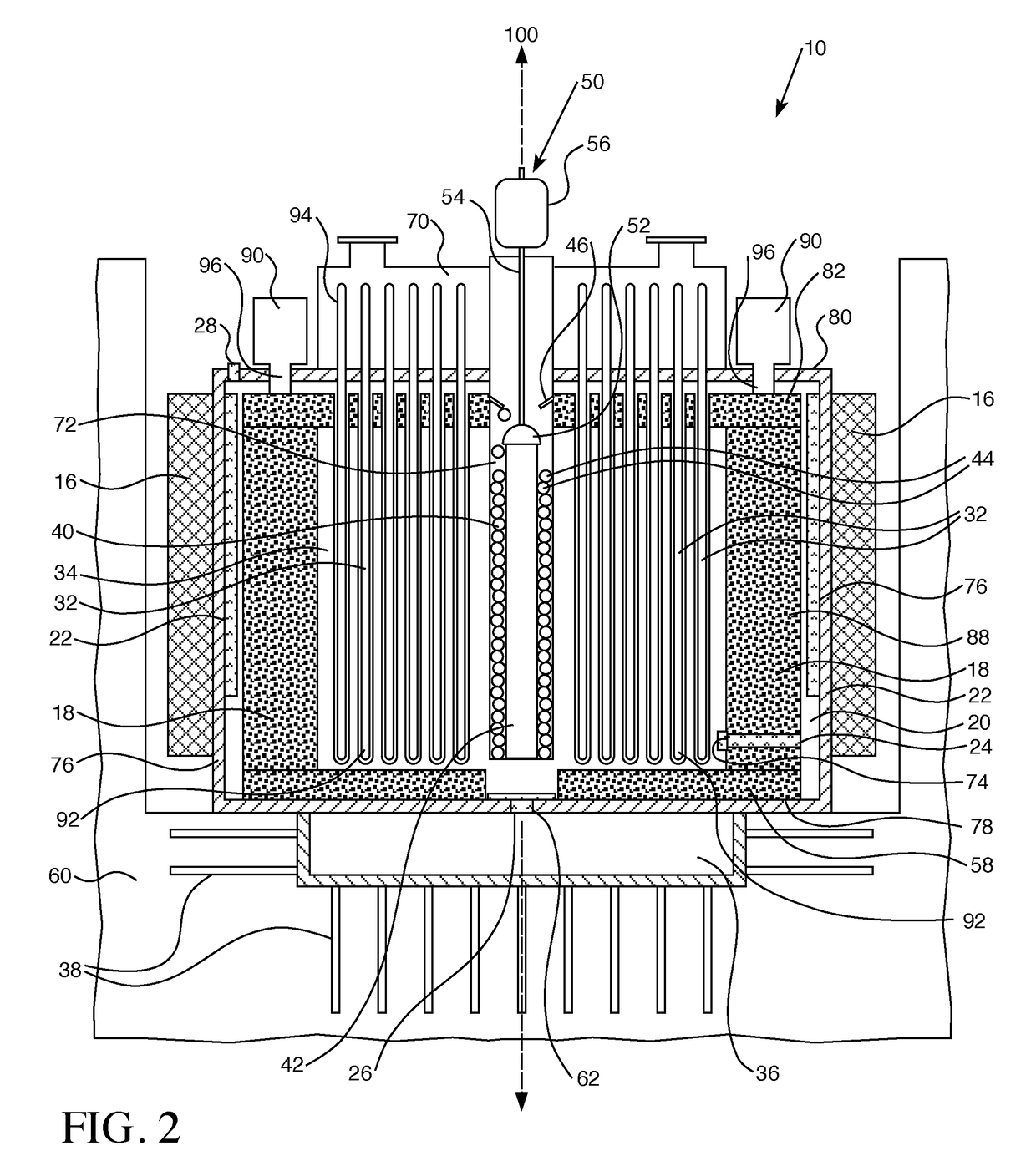

Molten salt nuclear reactor

InactiveUS20090279658A1Maximize probabilityFuel elementsNuclear energy generationBreeder reactorNuclear reactor

A molten salt breeder reactor that has fuel conduit surrounded by a fertile blanket. The fuel salt conduit has an elongated core section that allows for the generation of electrical power on a scale comparable to commercially available nuclear reactors. The geometry of the fuel conduit is such that sub-critical conditions exist near the input and output of the fuel salt conduit and the fertile blanket surrounds the input and output of the fuel salt conduit, thereby minimizing neutron losses.

Owner:OTTAWA VALLEY RES ASSOCS

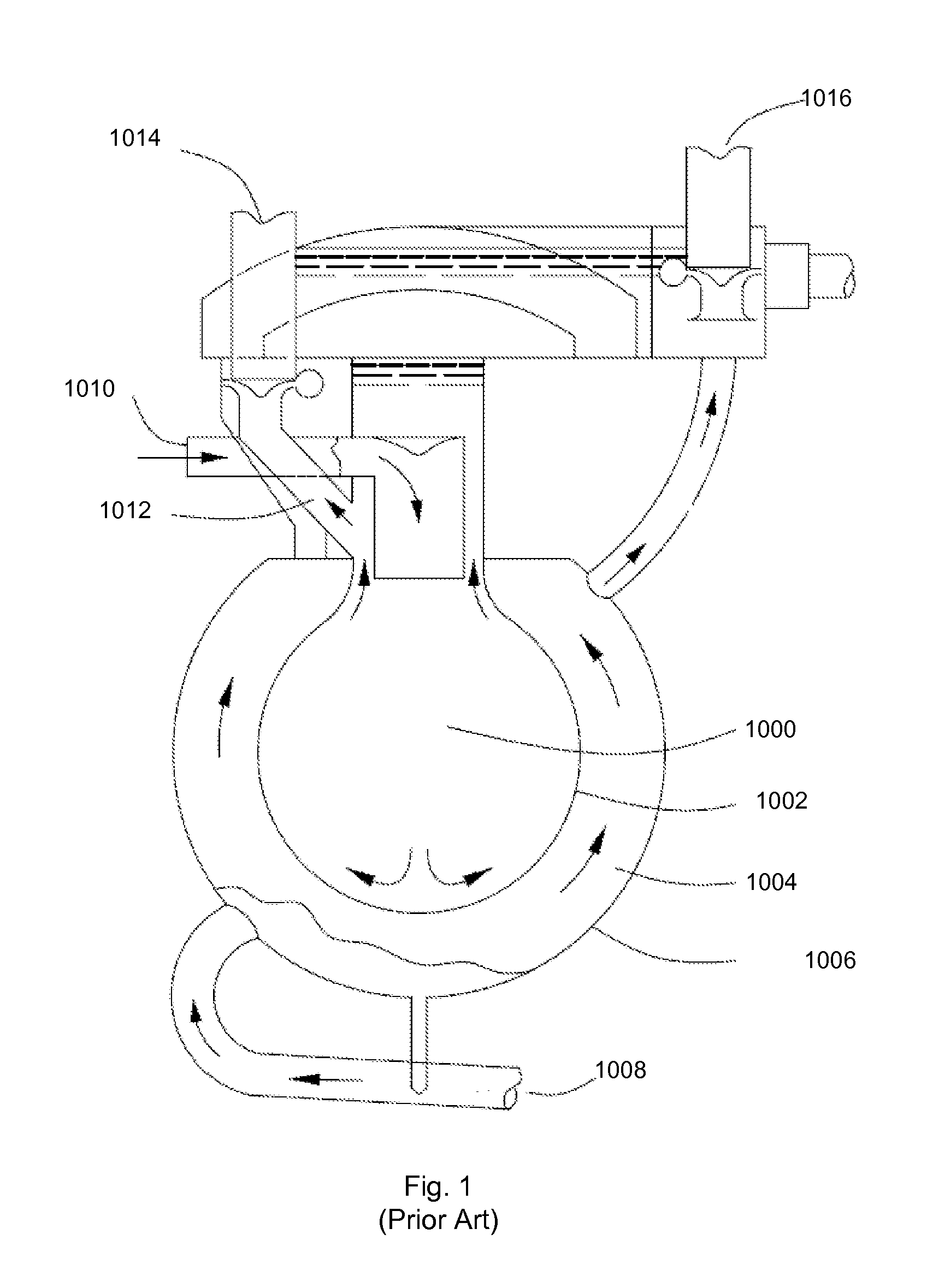

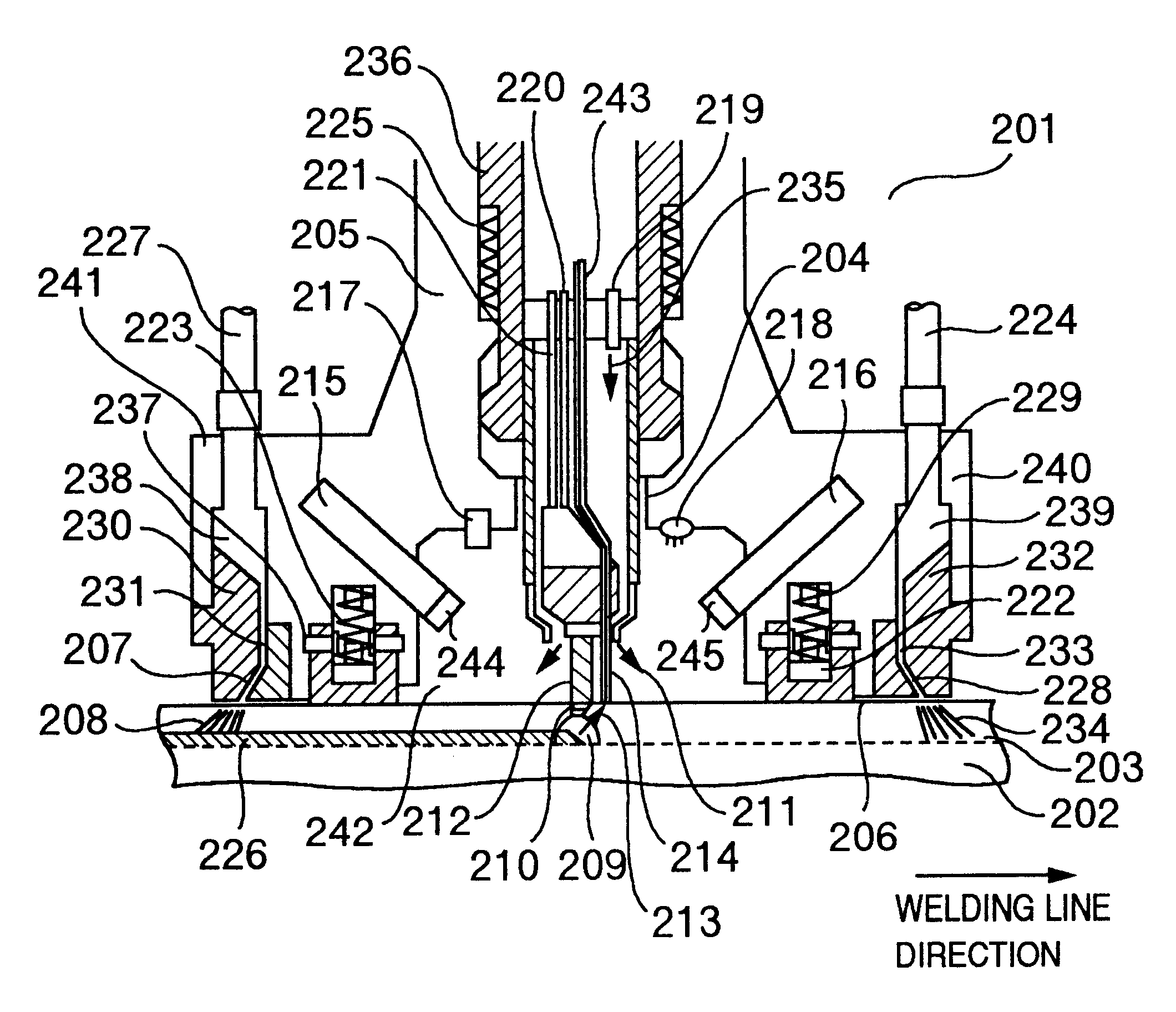

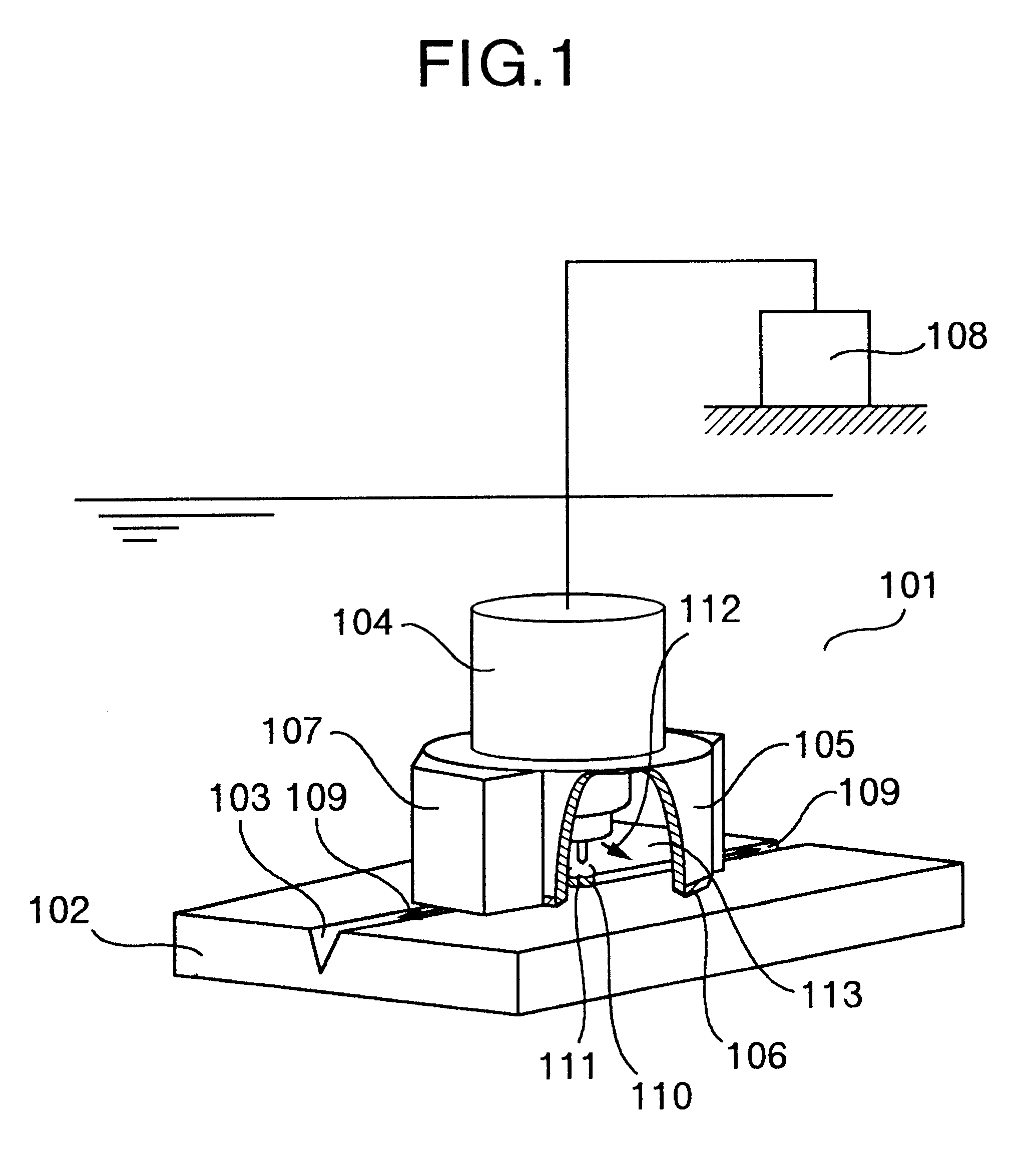

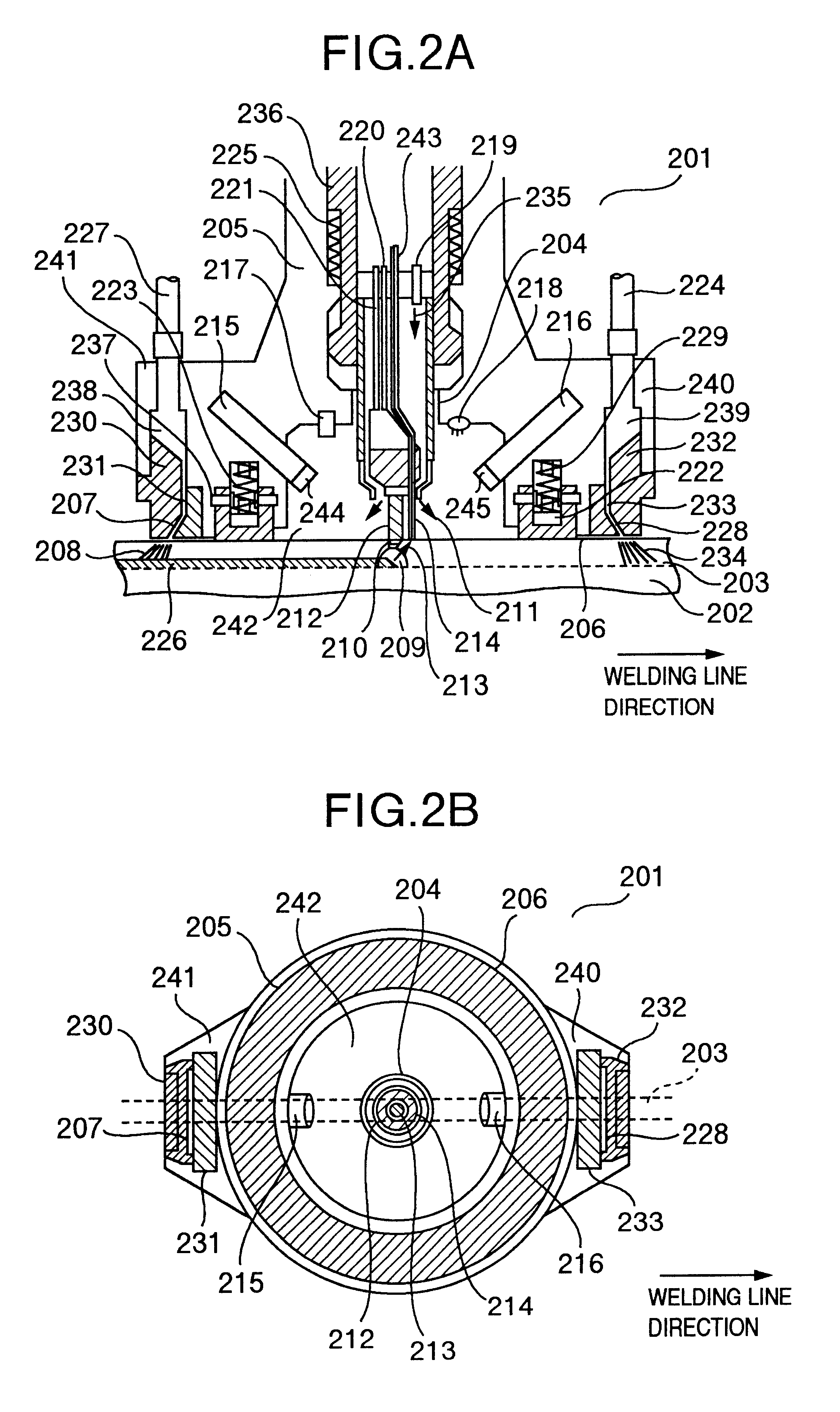

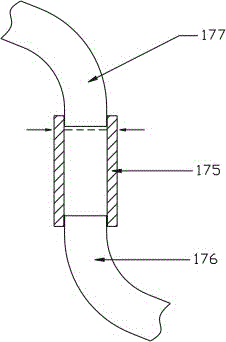

Underwater processing device and underwater processing method

InactiveUS6555779B1Reduce supplyReduce variationSupport devices with shieldingNuclear energy generationNuclear reactorEngineering

Provided are an underwater processing apparatus which can effectively prevent water from entering a shield for a workpiece having a surface ruggedness, and in which variation in a gas flow for a processing part is reduced, a processing method and an application thereof to a nuclear reactor, and the under water processing device is composed of a shield means which locally cover the processing part with the gas in order to prevent water from entering the shield member, the shield means having a solid wall formed of a member which is slidable in a part where it make contact with the workpiece, and adapted to make contact with the workpiece and to be moved up and down by a pressing force, and a water jetting means for forming a water curtain around the outer periphery of the solid wall.

Owner:HITACHI LTD

Blending of low viscosity Fischer-Tropsch base oils with conventional base oils to produce high quality lubricating base oils

ActiveUS7144497B2Liquid organic insulatorsHydrocarbon purification/separationCombustionInternal combustion engine

A process for producing a lubricating base oil blend which comprises (a) recovering a Fischer-Tropsch derived distillate fraction characterized by a kinematic viscosity of about 2 cSt or greater but less than 3 cSt at 100 degrees C.; and (b) blending the Fischer-Tropsch derived distillate fraction with a petroleum derived base oil selected from the group consisting of a Group I base oil, a Group II base oil, a Group III base oil, and a mixture of two or more of any of the foregoing conventional base oils in the proper proportion to produce a lubricating base oil blend characterized as having a viscosity of about 3 or greater; also the base oil blends, finished lubricants, and their use in internal combustion engines.

Owner:CHEVROU USA INC

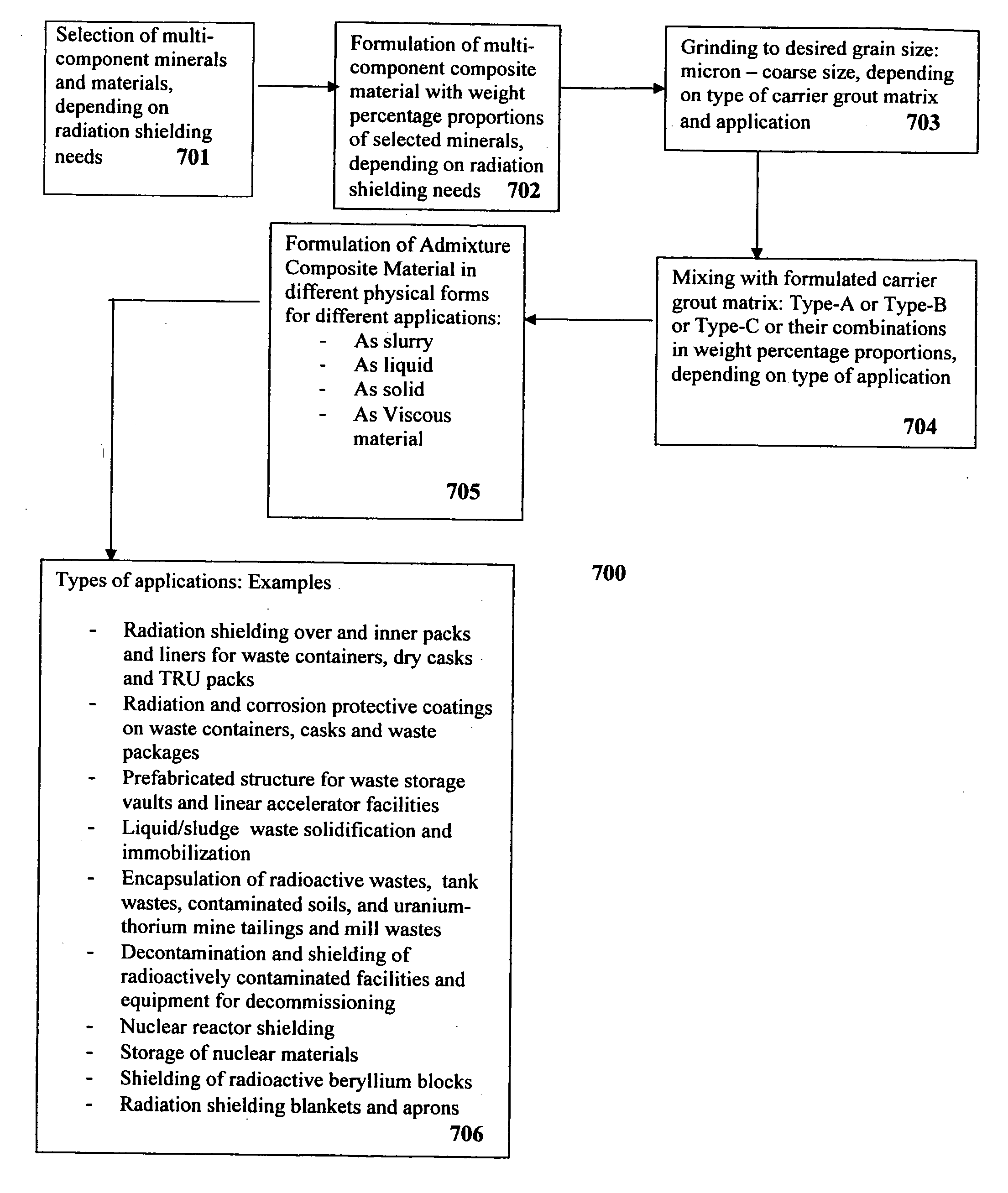

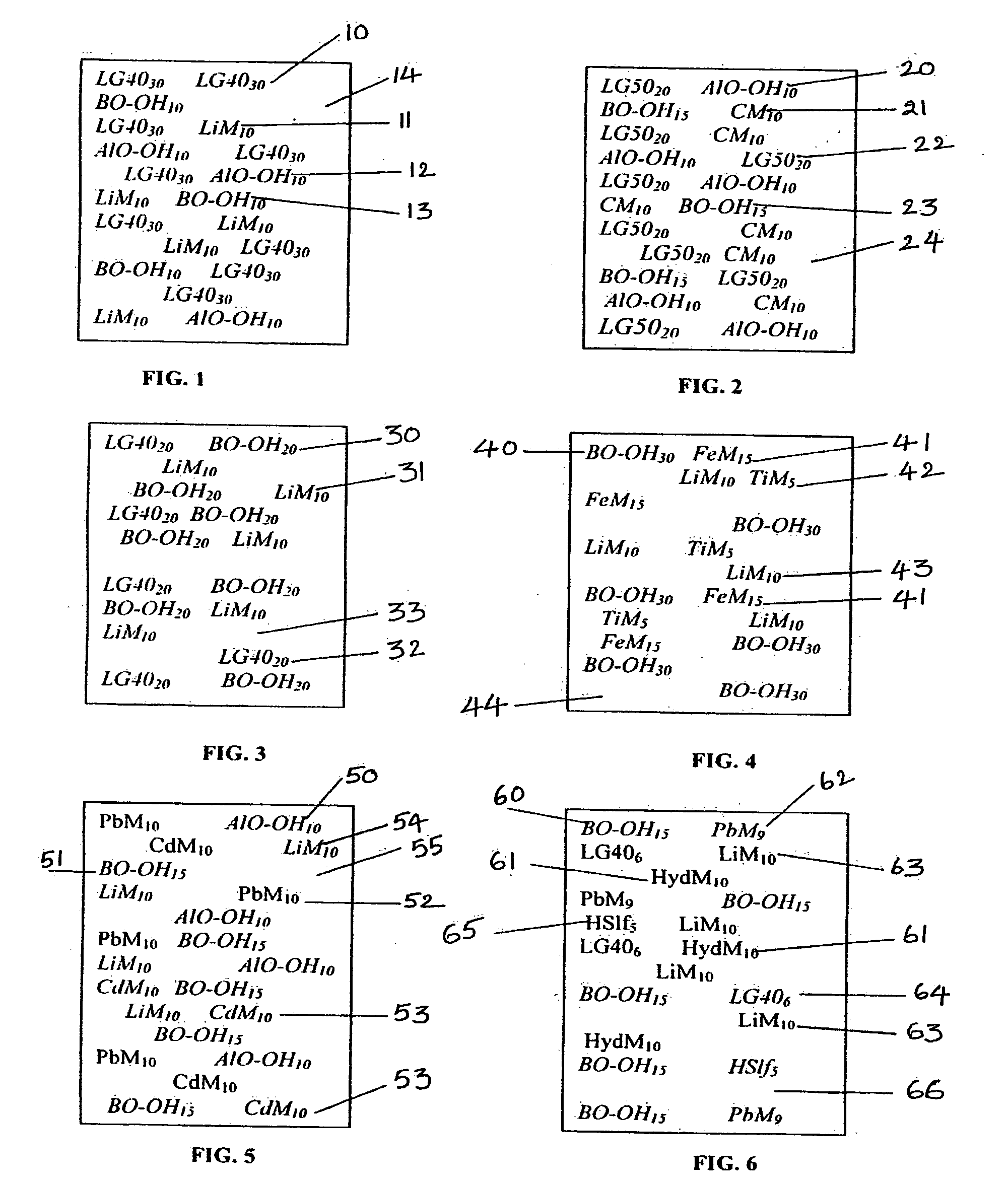

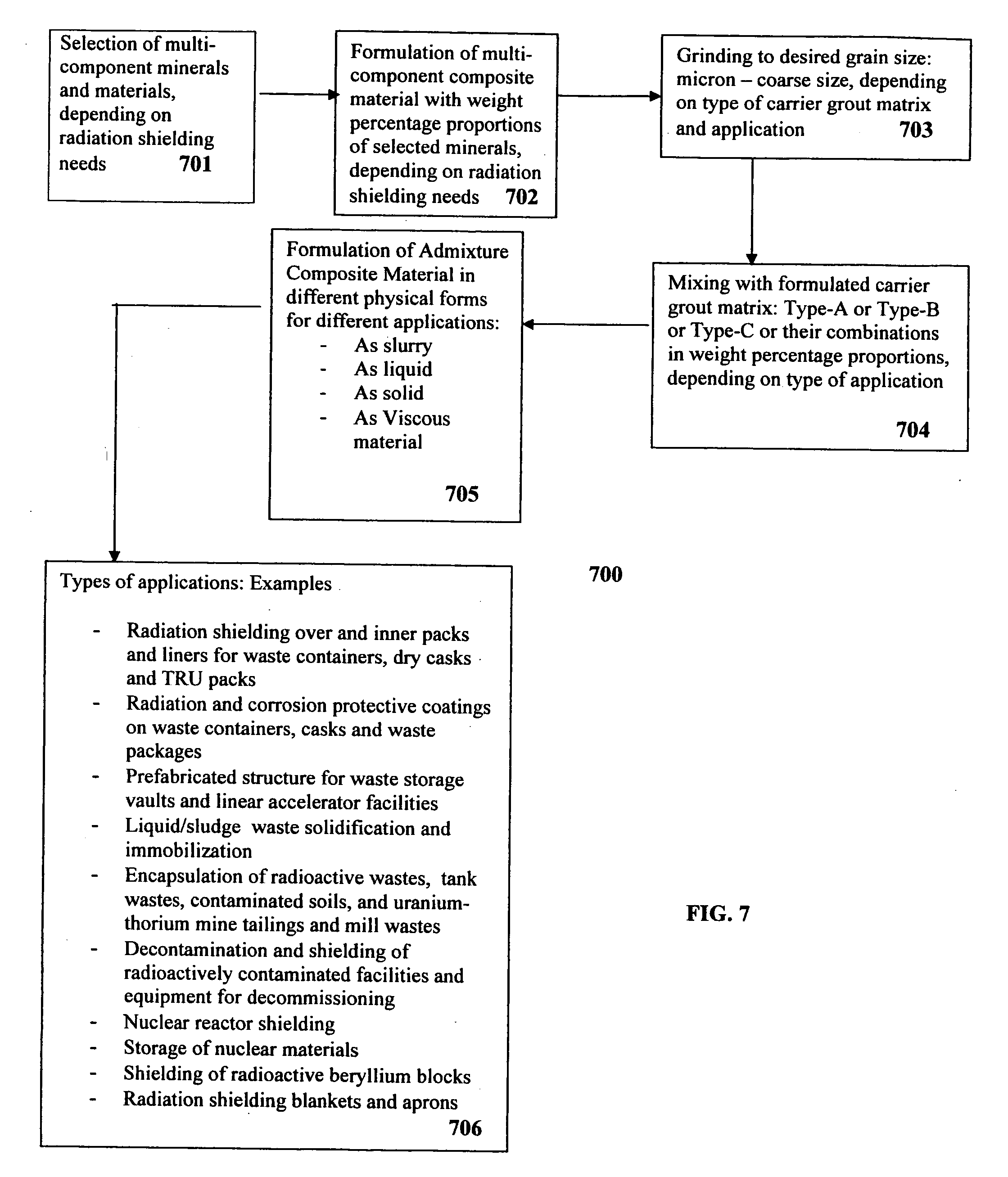

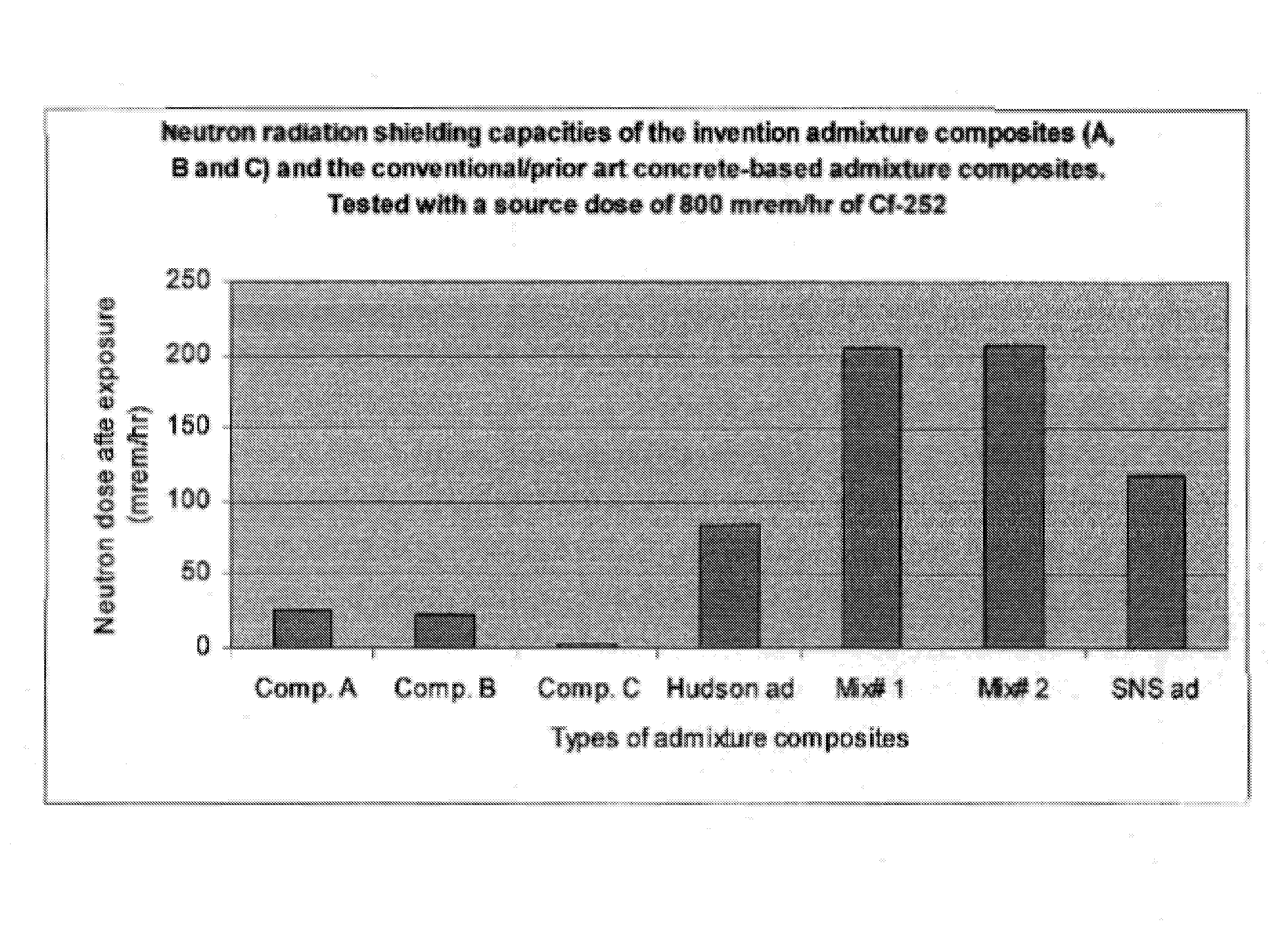

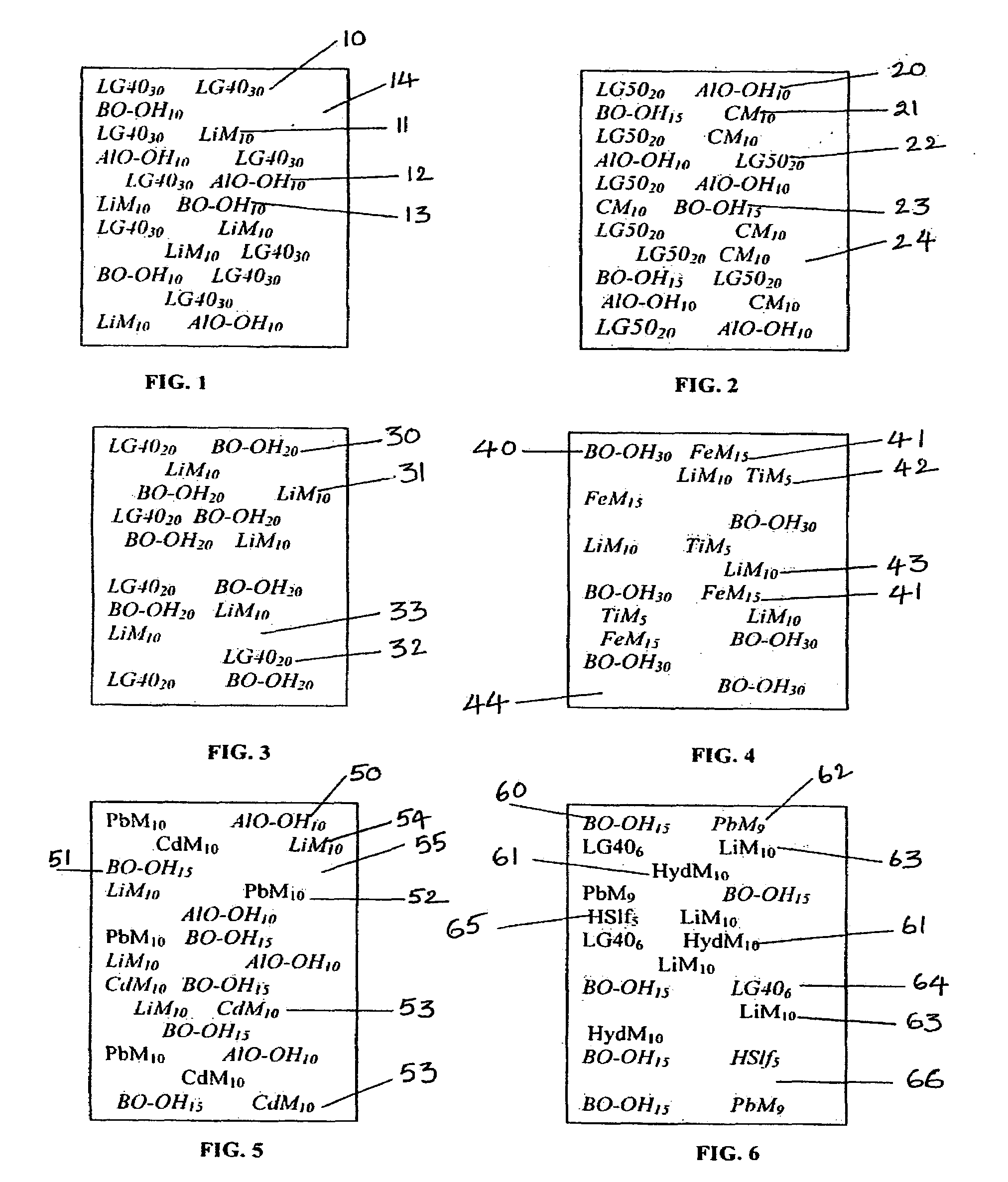

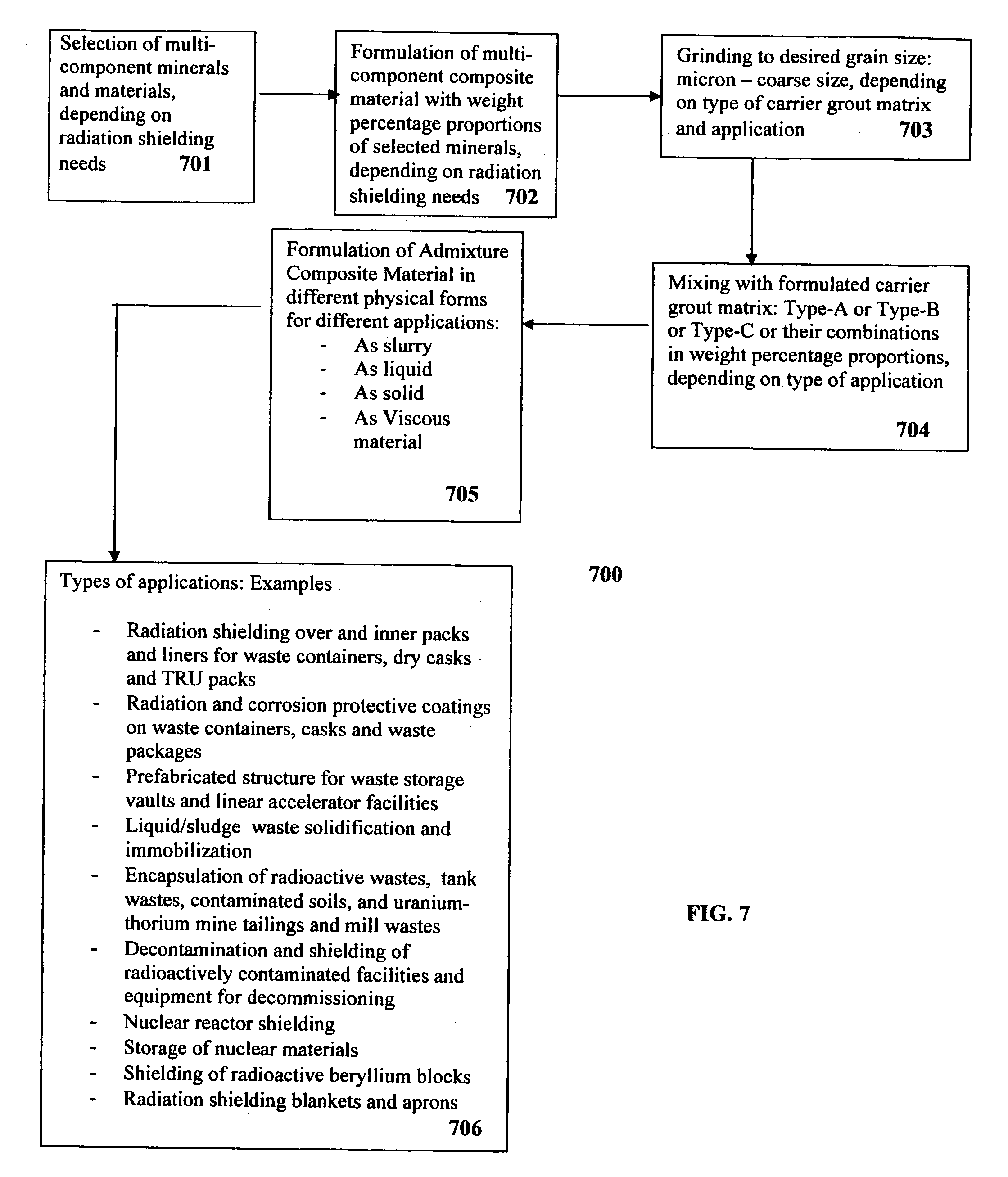

Composite materials and techniques for neutron and gamma radiation shielding

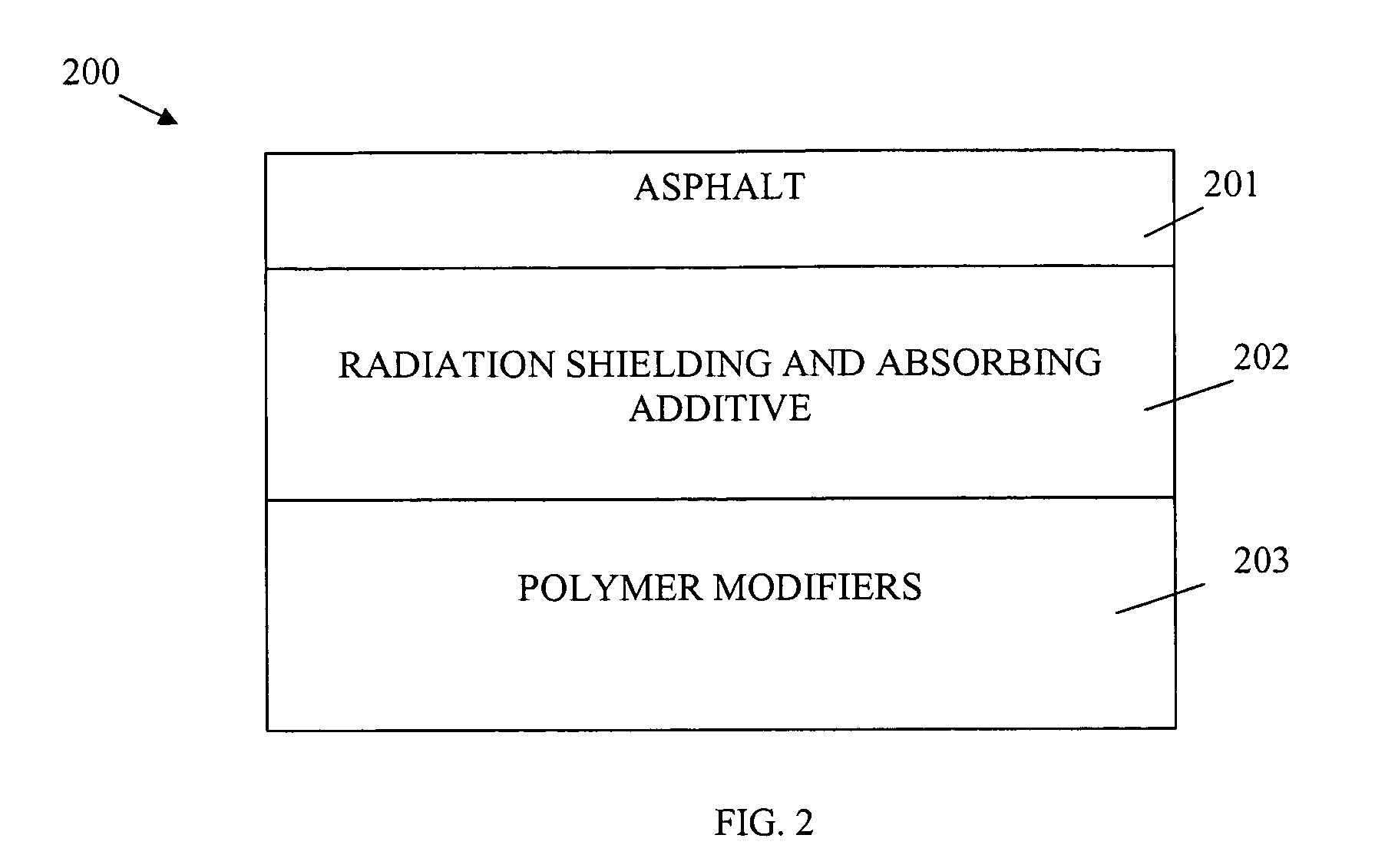

ActiveUS20050258405A1Safe and cost-effective managementIncrease volumeDiffusing elementsNuclear engineering solutionsPolymer modifiedRadioactive waste

This invention deals with multi-component composite materials and techniques for improved shielding of neutron and gamma radiation emitting from transuranic, high-level and low-level radioactive wastes. Selective naturally occurring mineral materials are utilized to formulate, in various proportions, multi-component composite materials. Such materials are enriched with atoms that provide a substantial cumulative absorptive capacity to absorb or shield neutron and gamma radiation of variable fluxes and energies. The use of naturally occurring minerals in synergistic combination with formulated modified cement grout matrix, polymer modified asphaltene and maltene grout matrix, and polymer modified polyurethane foam grout matrix provide the radiation shielding product. These grout matrices are used as carriers for the radiation shielding composite materials and offer desired engineering and thermal attributes for various radiation management applications.

Owner:SAYALA DASHARATHAM

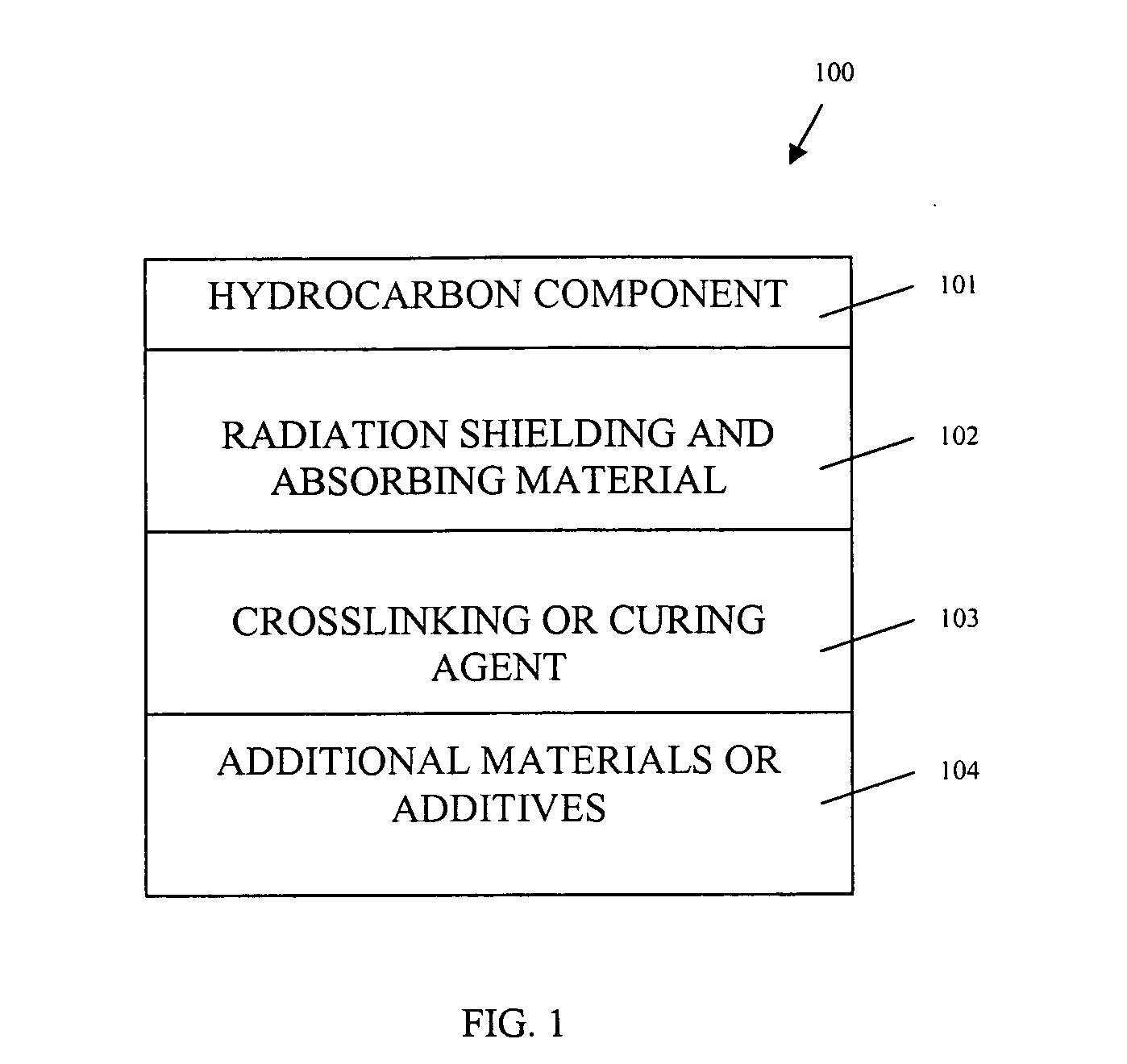

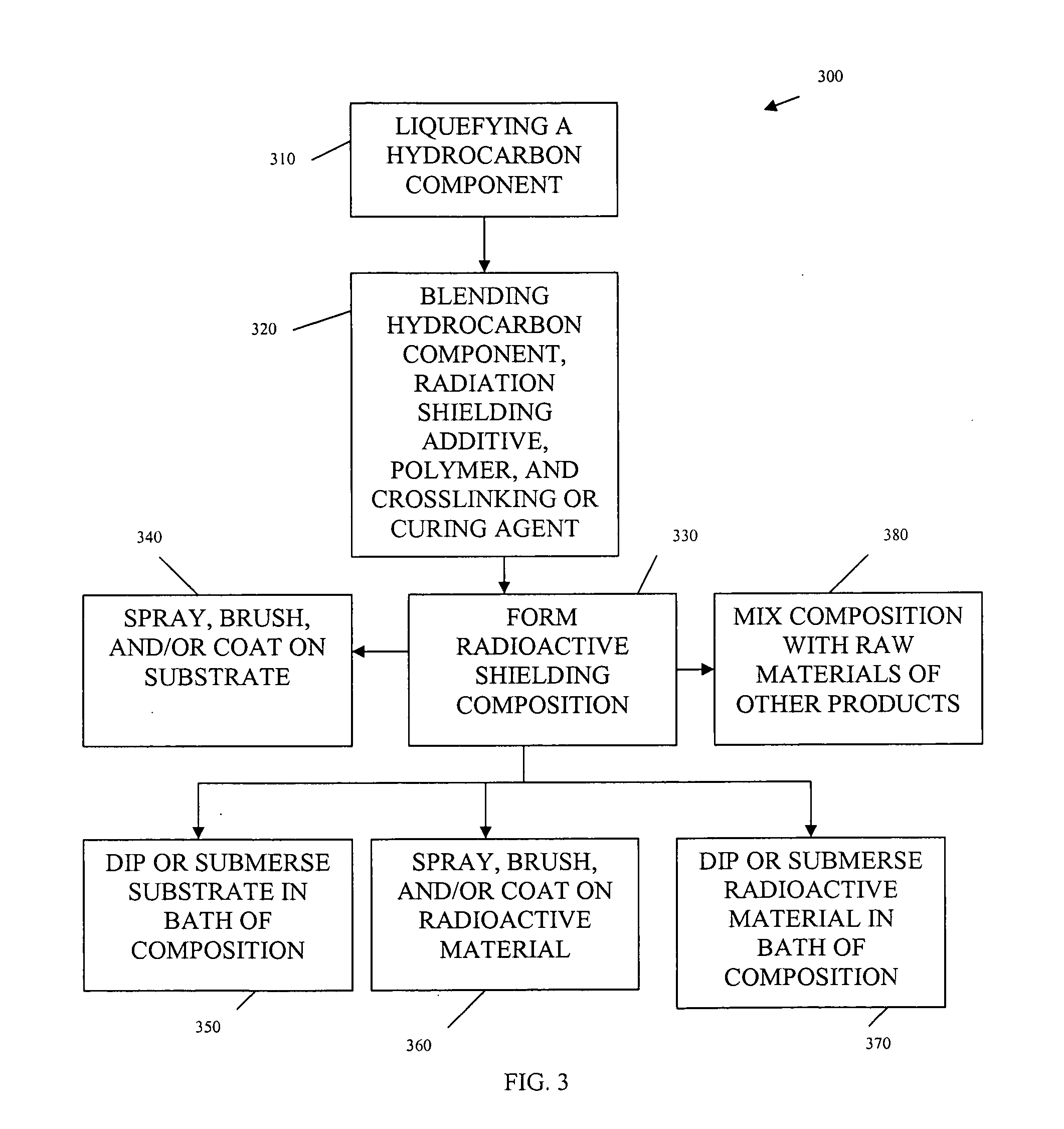

Techniques and compositions for shielding radioactive energy

InactiveUS20060074141A1Other chemical processesNuclear engineering problemsRadiation shieldNuclear chemistry

Techniques and compositions are provided for shielding radioactive energy. The composition includes a hydrocarbon component and a radiation shielding and absorbing material or additive. The composition may be applied to substrates or to radioactive materials. Moreover, the composition may be mixed with raw materials of products.

Owner:TERRY INDS

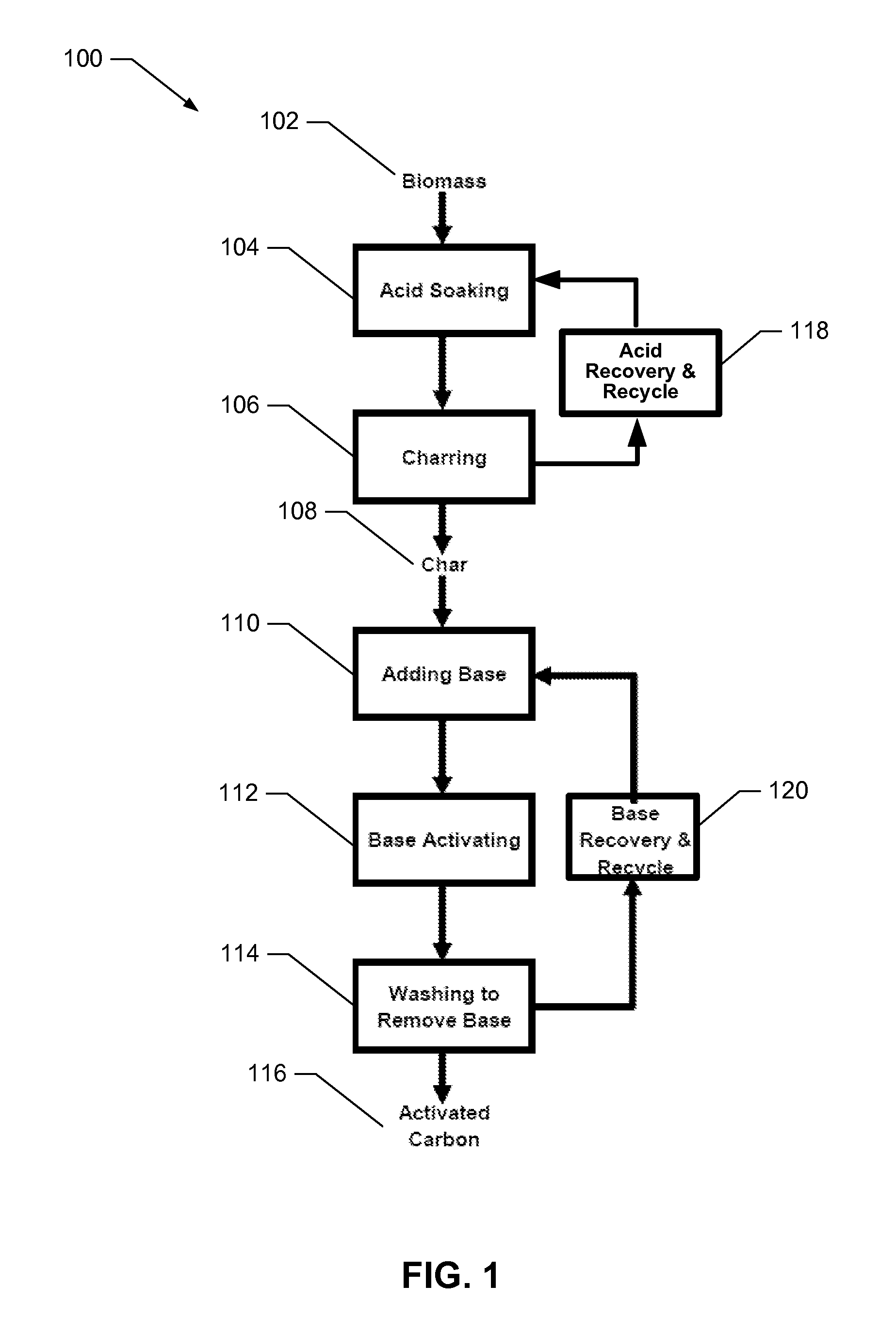

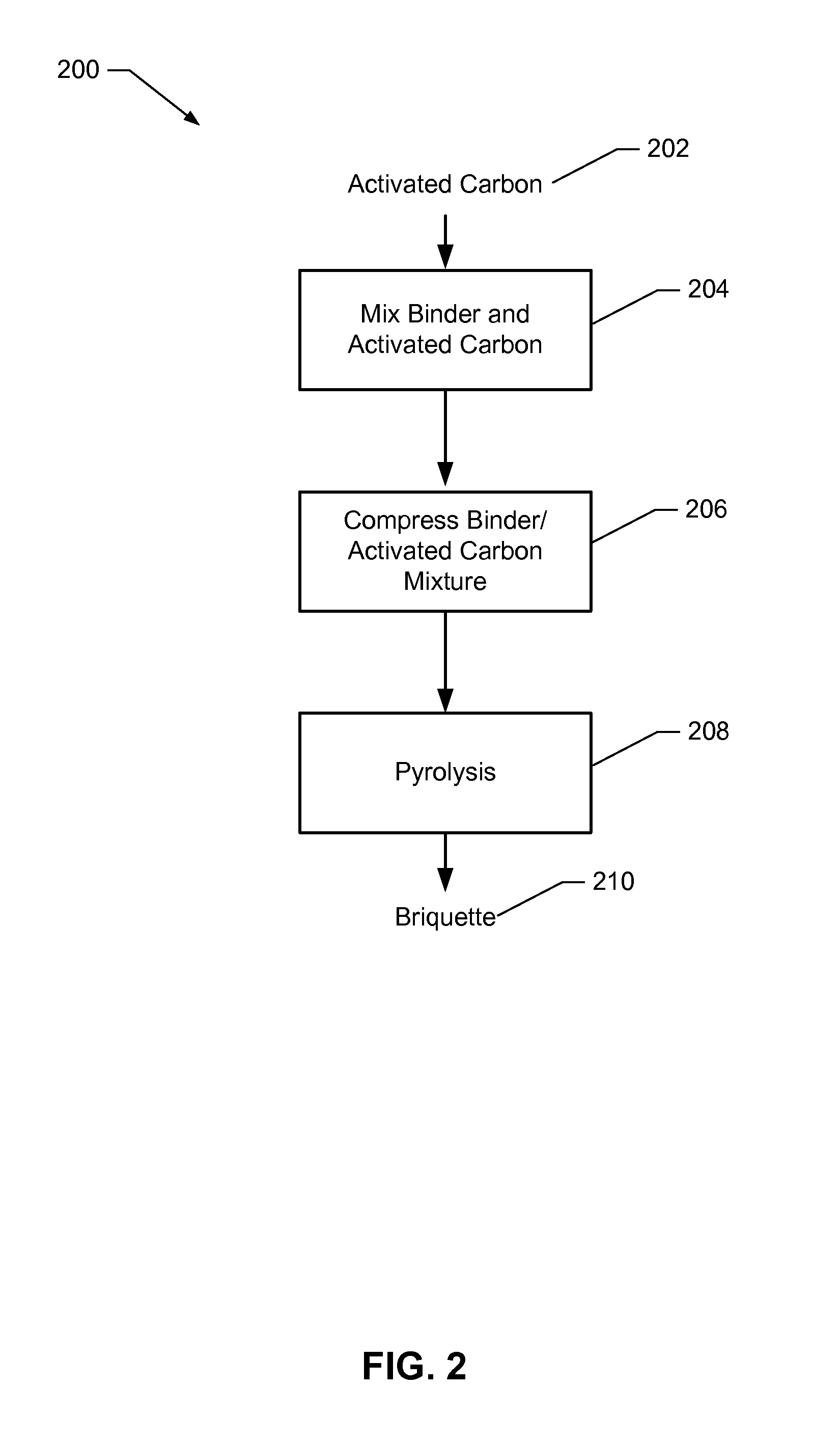

High surface area carbon and process for its production

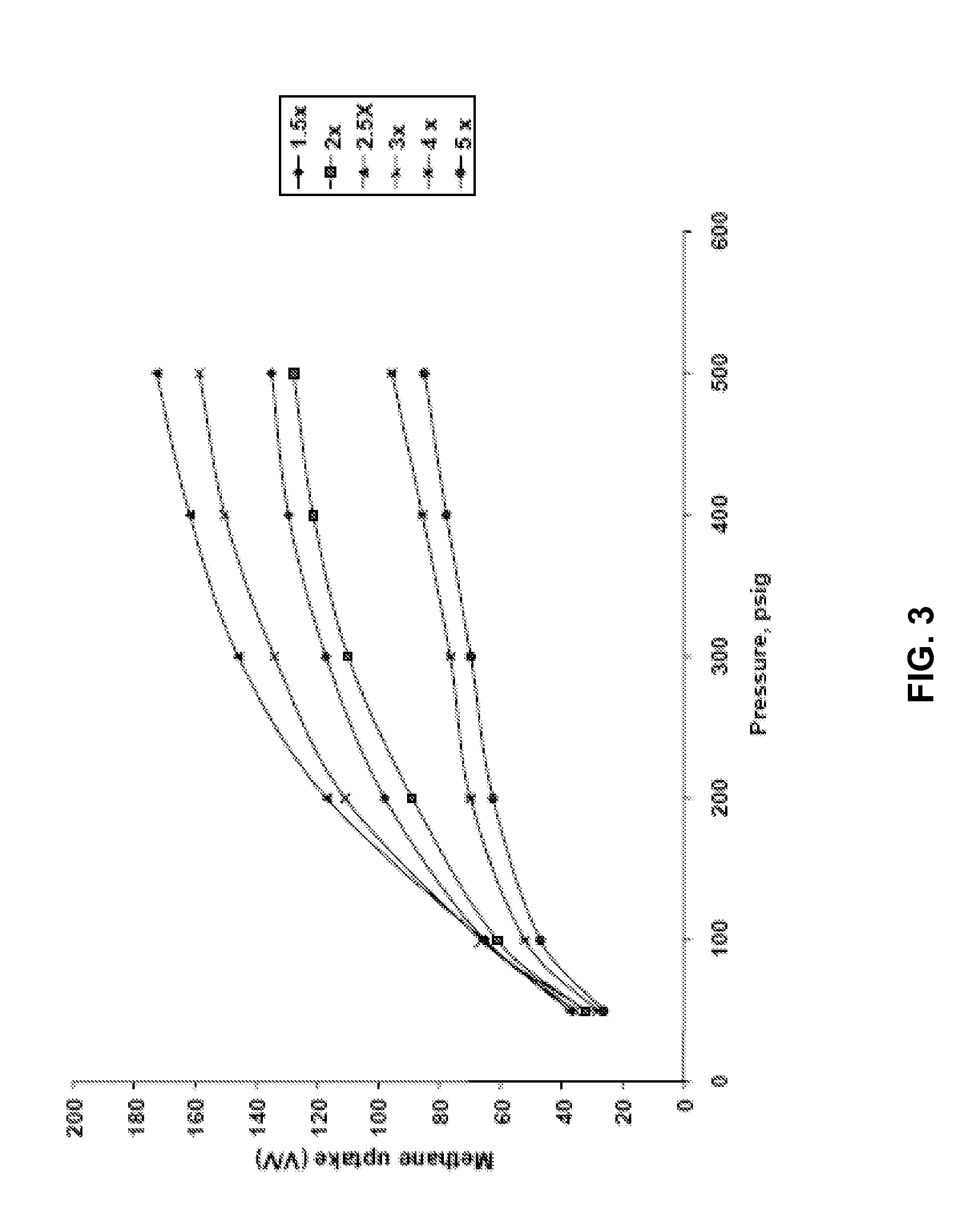

Activated carbon materials and methods of producing and using activated carbon materials are provided. In particular, biomass-derived activated carbon materials and processes of producing the activated carbon materials with prespecified surface areas and pore size distributions are provided. Activated carbon materials with preselected high specific surface areas, porosities, sub-nm (<1 nm) pore volumes, and supra-nm (1-5 nm) pore volumes may be achieved by controlling the degree of carbon consumption and metallic potassium intercalation into the carbon lattice during the activation process.

Owner:UNIVERSITY OF MISSOURI

Method for the preparation of composite silica alcogels, aerogels and xerogels, apparatus for carrying out the method continuously, and novel composite silica alcogels, aerogels and xerogels

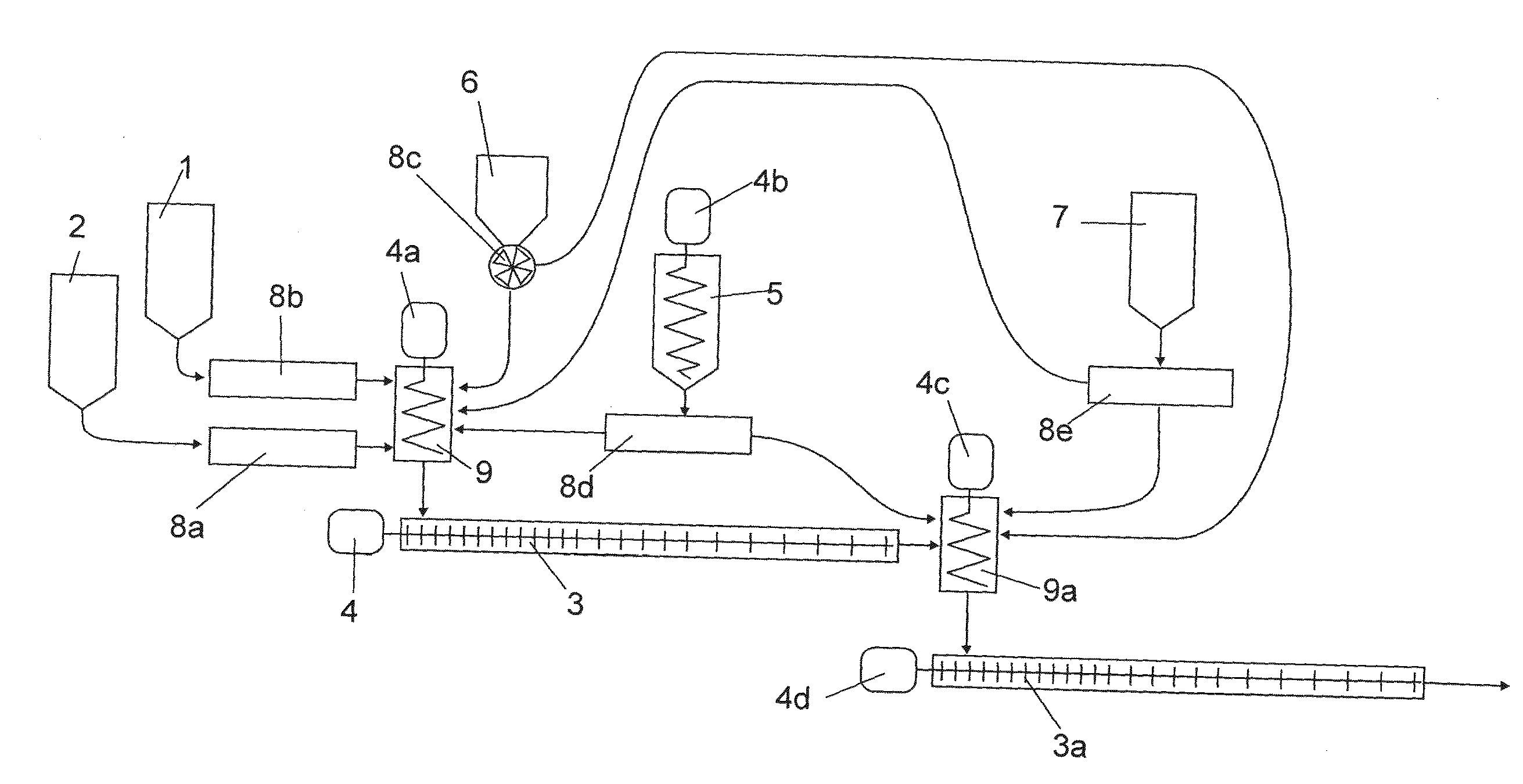

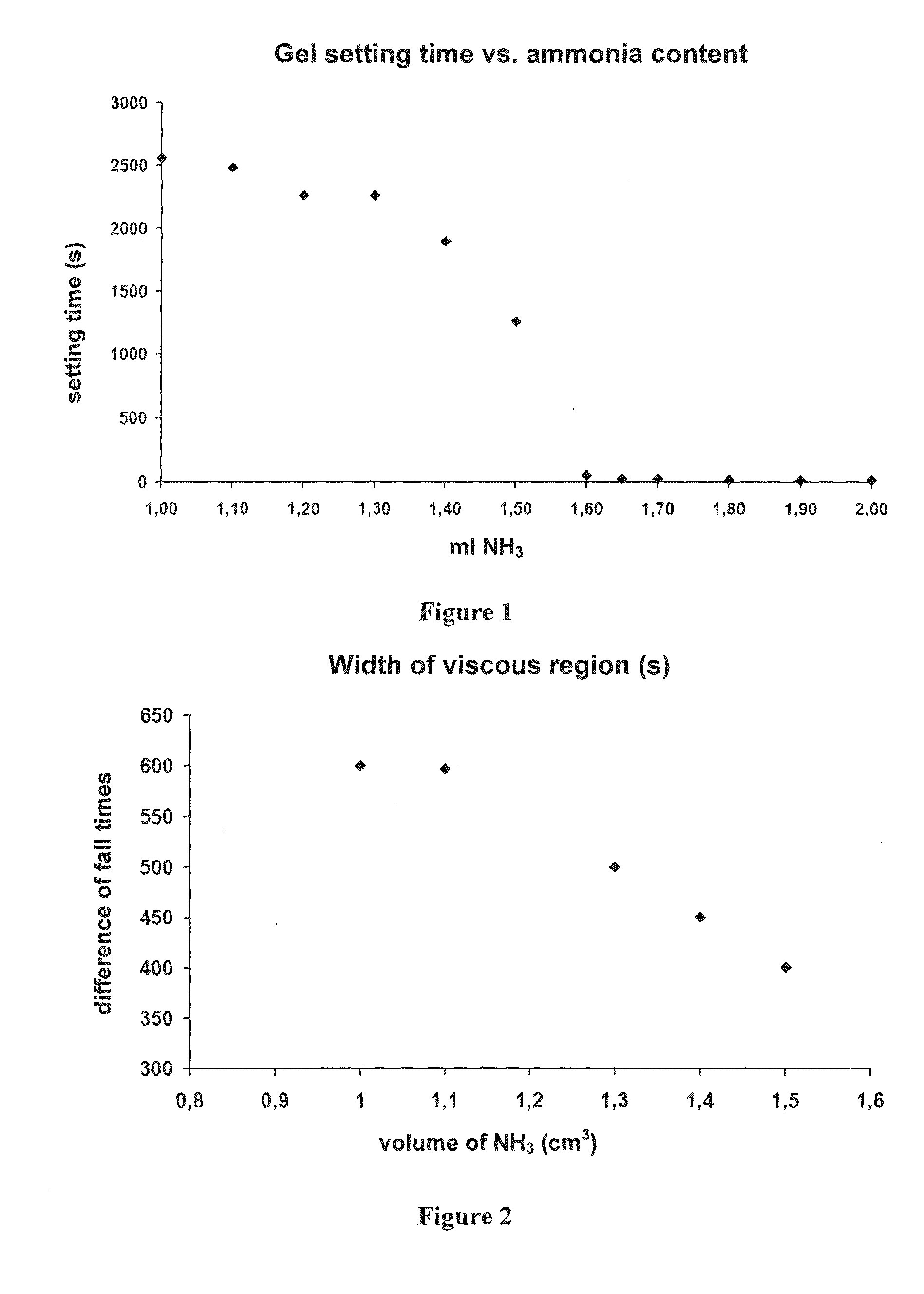

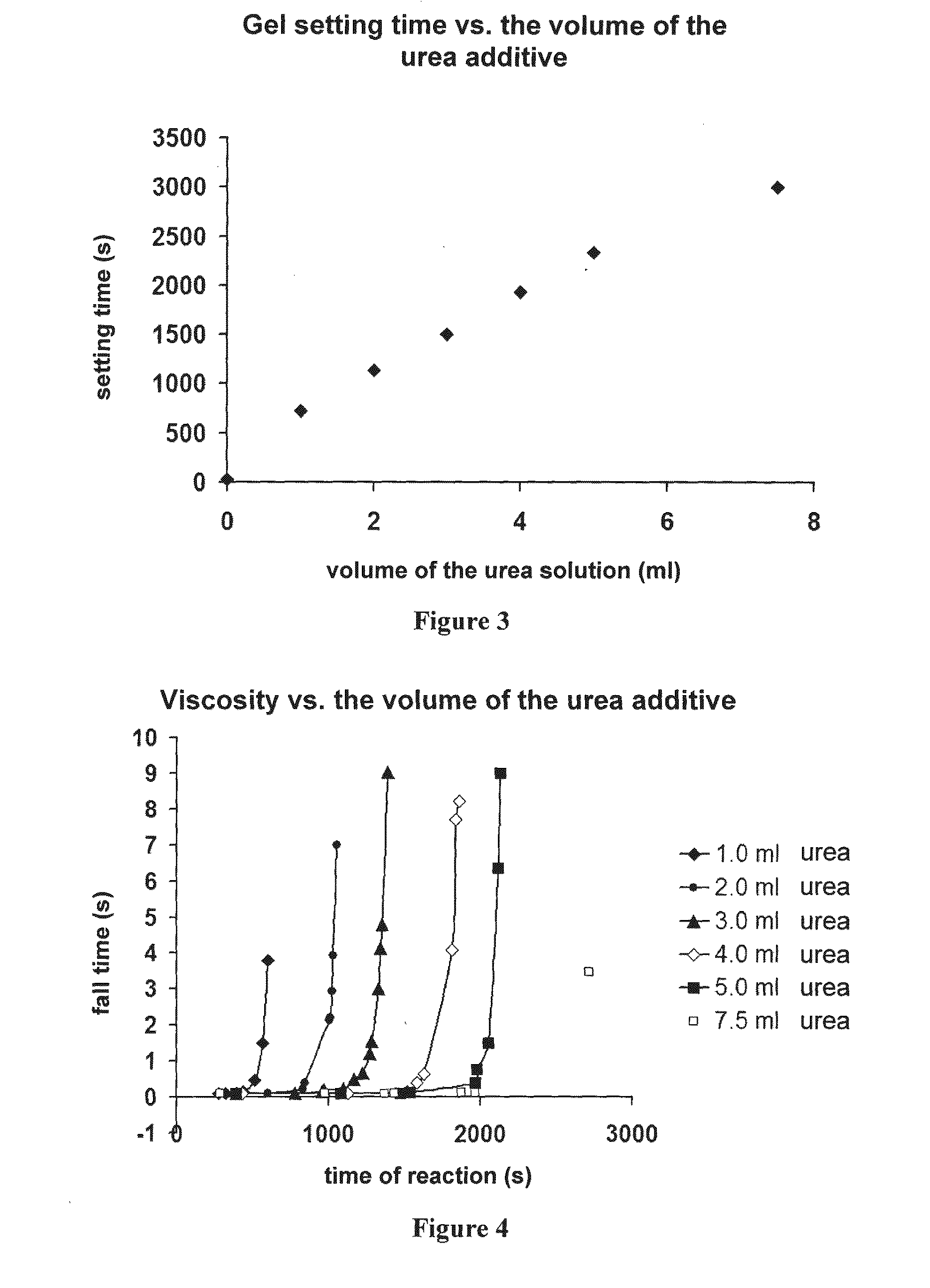

The invention relates to a method for the preparation of composite silica alcogels, aerogels and xerogels, comprisingi) providing a reaction mixture comprising at least the following:silane reagent,base catalyst,gelation retarding additive,aqueous / organic solvent mixture,guest particle,ii) agitating the reaction mixture as necessary and sufficient until achieving the viscosity where the spontaneous movement of the guest particles does not occur anymore; andiii) shaping the material obtained to a desired shape during or after step ii); theniv) drying, if desiredThe method according to the invention is also useful in continuous manufacturing technology, and the invention provides an apparatus for applying the method.The invention further provides novel composite silica alcogels, aerogels or xerogels obtainable by the method according to the invention.

Owner:DEBRECEN UNIV OF

Composition and method for inhibition of formation of gas hydrates

InactiveUS6596911B2Using liquid separation agentDistillation purification/separationSolventOnium compound

A method and a composition used therein are disclosed for inhibiting formation of hydrocarbon hydrates. The composition comprises an onium compound, an amine salt and, optionally, a solvent. The method and composition are particularly useful for oil and gas production

Owner:BAKER HUGHES INC

Metal-carbon composites and methods for their production

InactiveUS20150306570A1Similar and improved propertyHigh activityCarbon compoundsInorganic active ingredientsCarbon compositesCapacitive deionization

A method of forming a metal-carbon composite, the method comprising subjecting a precursor composition to a curing step followed by a carbonization step, the precursor composition comprising: (i) a phenolic component, (ii) a crosslinkable aldehyde component, (iii) a polymerization catalyst, and (iv) metal-containing particles, wherein said carbonization step comprises heating the precursor composition at a carbonizing temperature of at least 300° C. for sufficient time to convert the precursor composition to said metal-carbon composite. The produced metal-carbon composite, devices incorporating them, and methods of their use (e.g., in capacitive deionization and lithium ion batteries) are also described.

Owner:UT BATTELLE LLC

Processes for making lubricant blends with low brookfield viscosities

ActiveUS20050258078A1Improve low temperature performanceExcellent low Brookfield viscosityHydrocarbon purification/separationLiquid hydrocarbon mixture productionSulfurBase oil

Lubricant blends and finished gear oils comprising a Fischer-Tropsch derived lubricant base oil fraction, a petroleum derived base oil, and a pour point depressant are provided. The Fischer-Tropsch derived lubricant base oil fraction comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

In-cycle shuffle

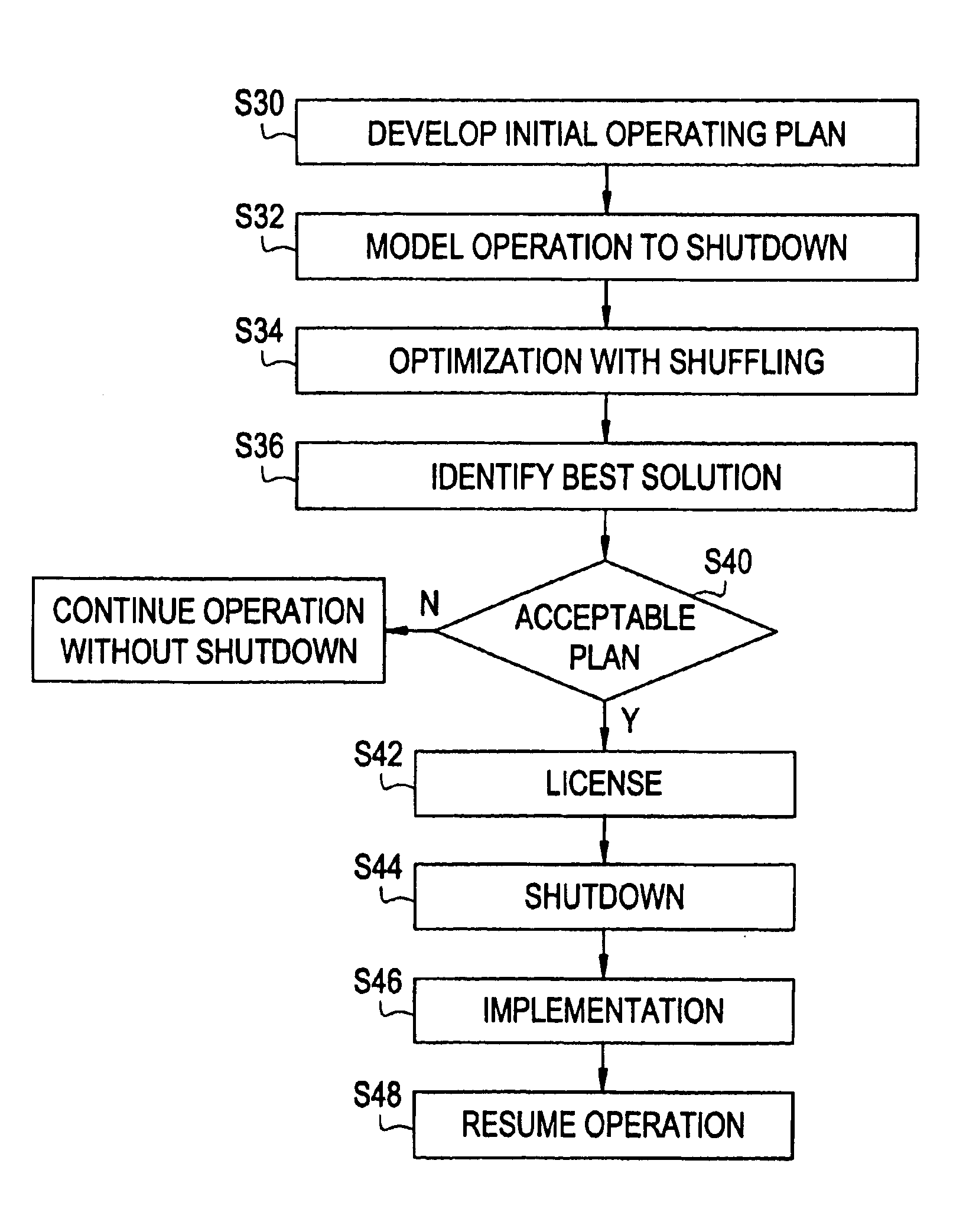

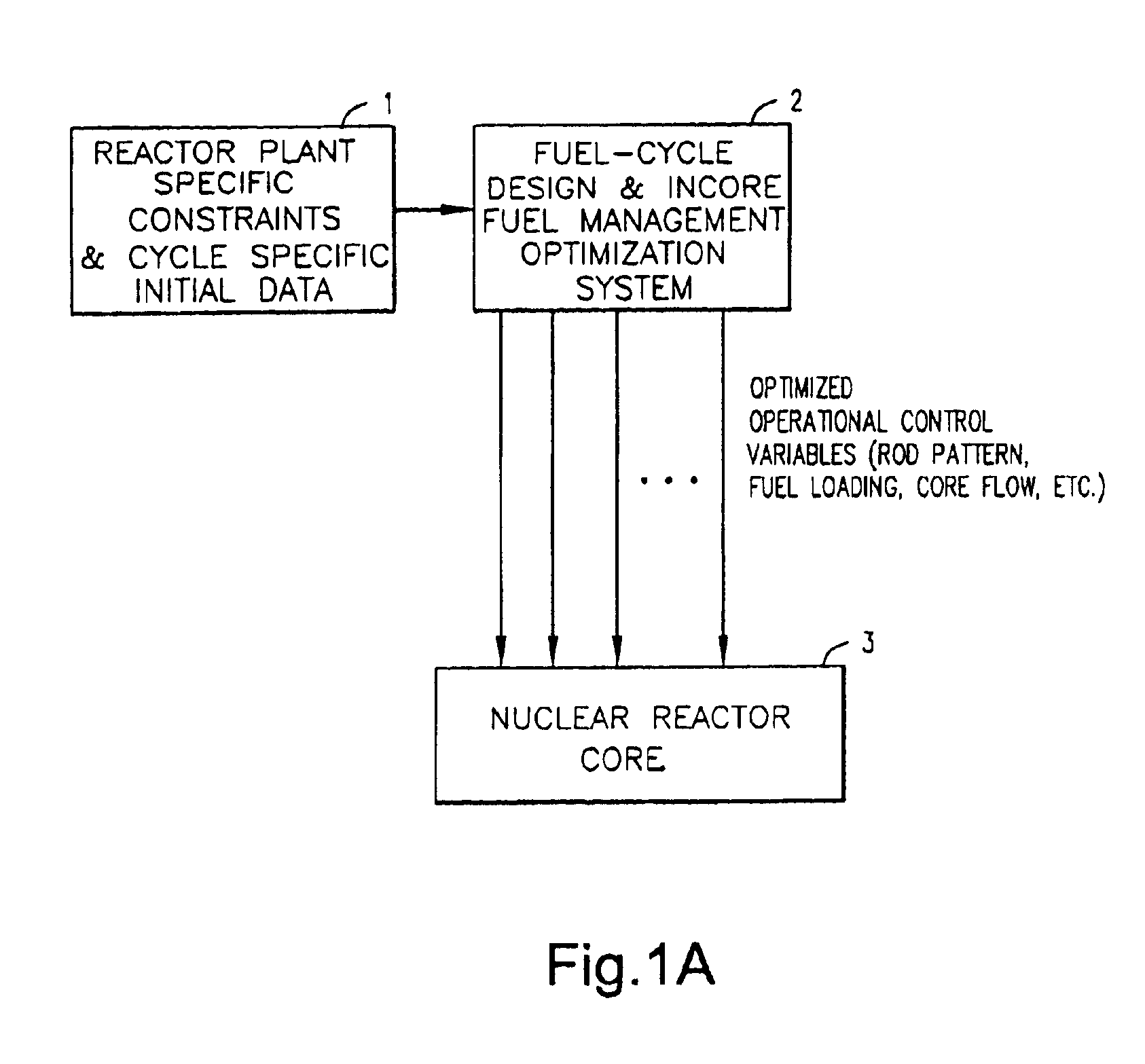

ActiveUS6862329B1Increase energy outputLimit thermal performanceNuclear energy generationNuclear monitoringNuclear engineeringTotal energy

According to the method, a reactor core is shut down during the operation cycle. One or more fuel bundles of the reactor core are then moved to new positions within the reactor core to increase a total energy, output of the reactor core as compared to continuing operation of the reactor core without the shutting down and moving steps.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

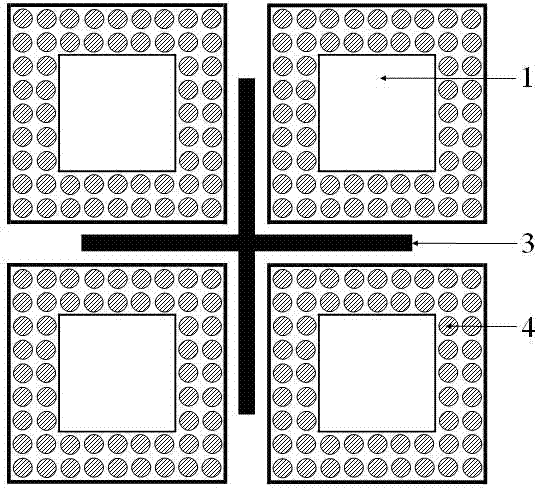

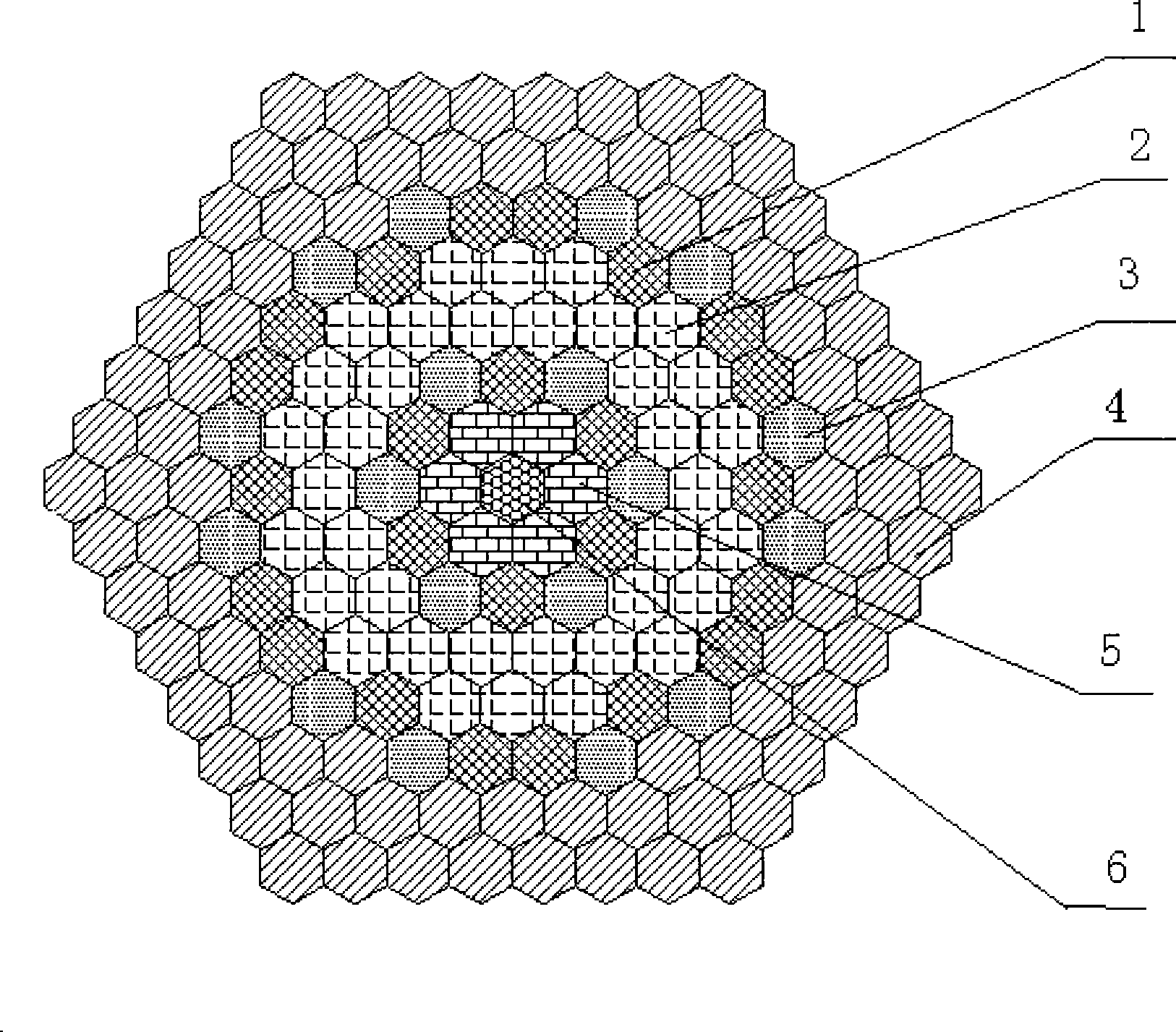

Combined square fuel assembly, reactor core and two-pass flowing method of super-critical water reactor

ActiveCN102737735AGuaranteed Moderation UniformitySlow down fully and evenlyNuclear energy generationFuel element assembliesNuclear engineeringCoolant flow

The invention provides a combined square fuel assembly, a reactor core and a two-pass flowing method of a moderator and a coolant, which are suitable for a super-critical water reactor. The fuel assembly consists of 4 same child components arranged in a 2*2 square form, wherein each child component consists of multiple fuel rods arranged in a square grid form, a water rod is arranged in a central area, and a guide tube of a crossed control rod and a conduit of the water rod are placed above the component and a conduit of the water rod and a moderator duct are placed below the component; the reactor core is divided into first and second pass areas; the moderator flows into the space between the water rod and the child component from top to bottom in both passes; the coolant flows into a first pass fuel area from top to bottom; and the moderator and the coolant flow into a second pass fuel area from bottom to top after being stirred and mixed below the reactor core and flow out of the reactor core. According to the combined square fuel assembly, the reactor core and the two-pass flowing method of the super-critical water reactor, the moderator and the coolant as well as the different pass coolants in the components and the reactor core can be effectively shunted when the fuel rod is fully and uniformly moderated, the structural materials are reduced and the feasibility and safety are high.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

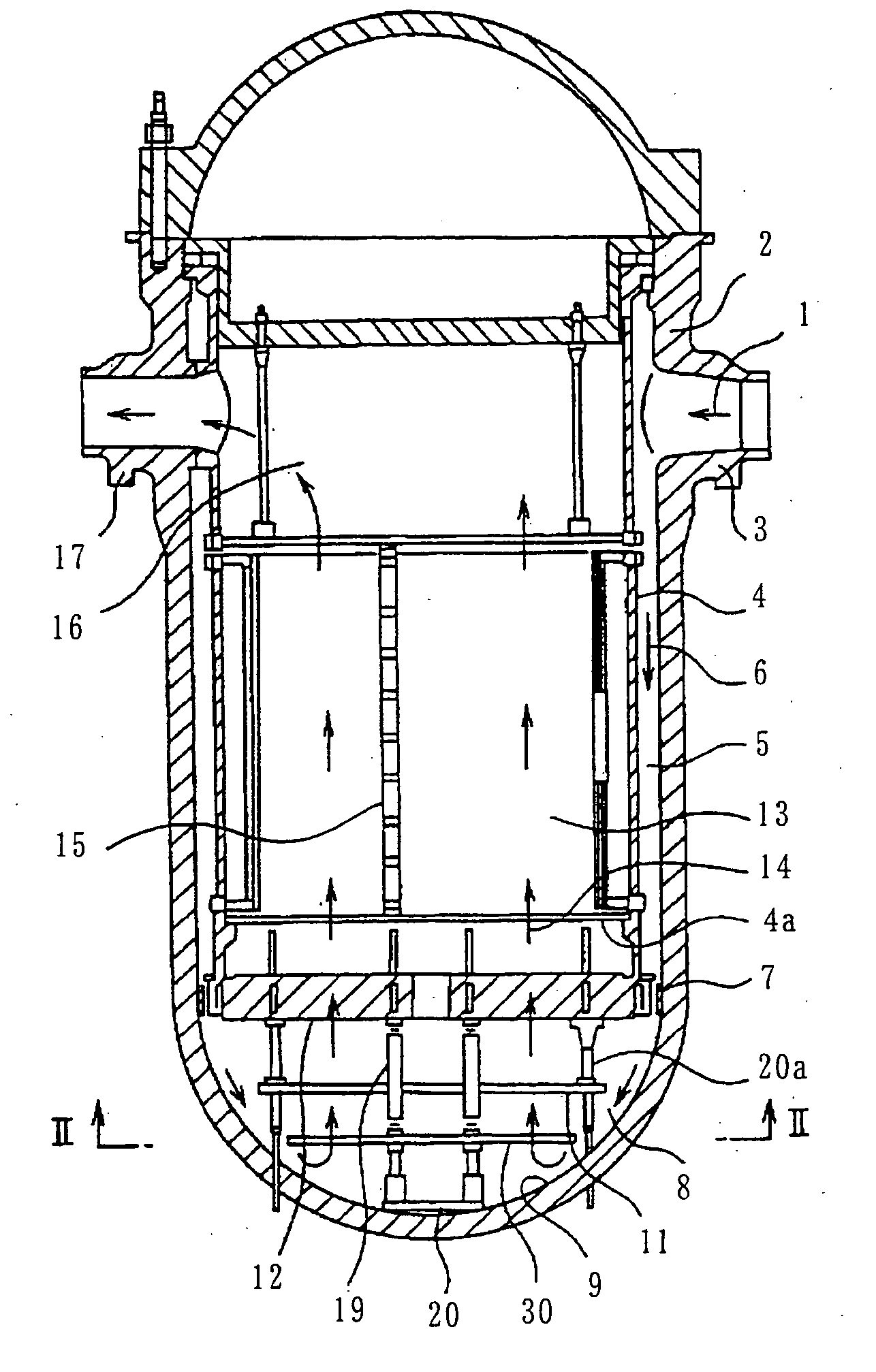

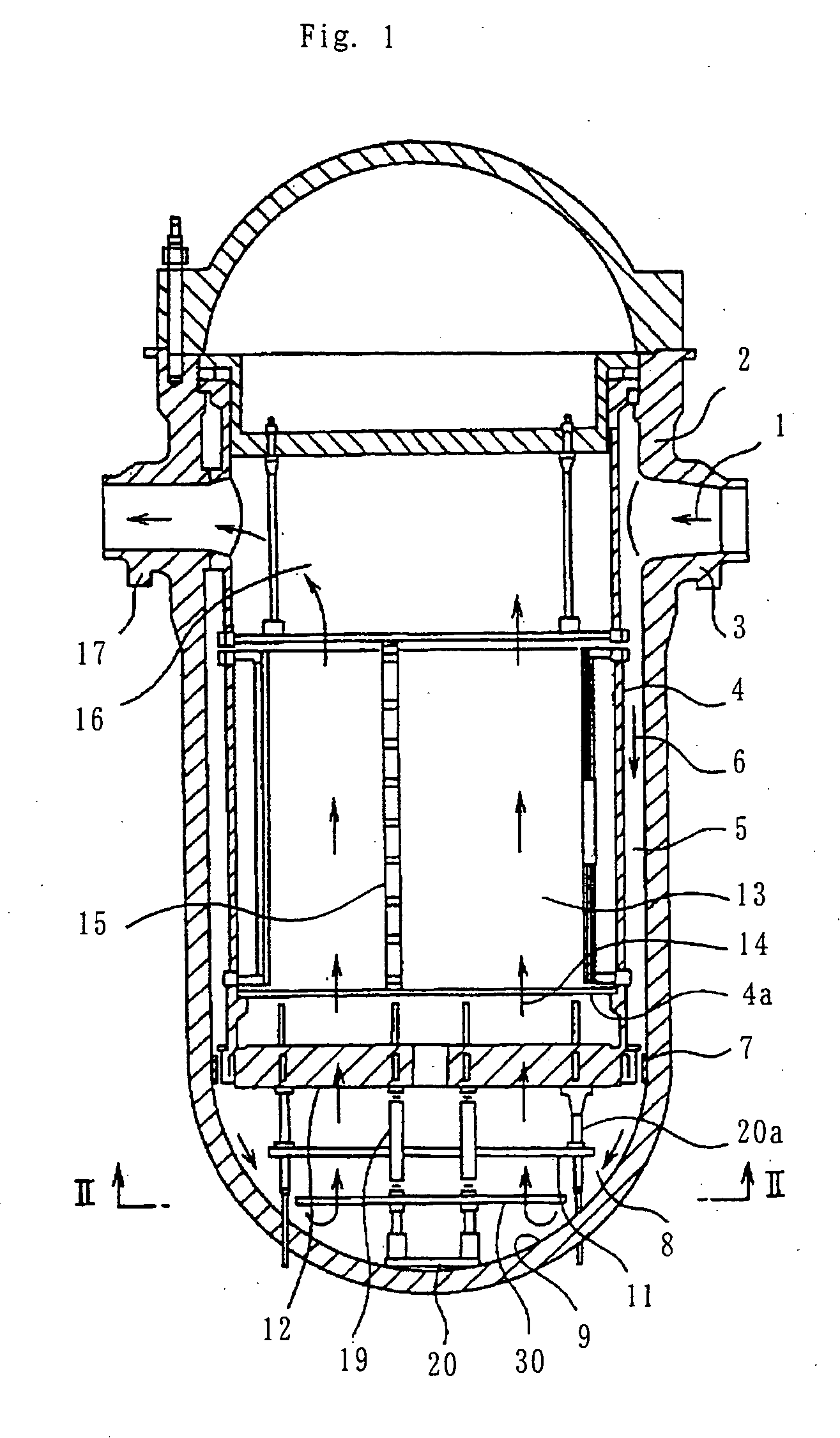

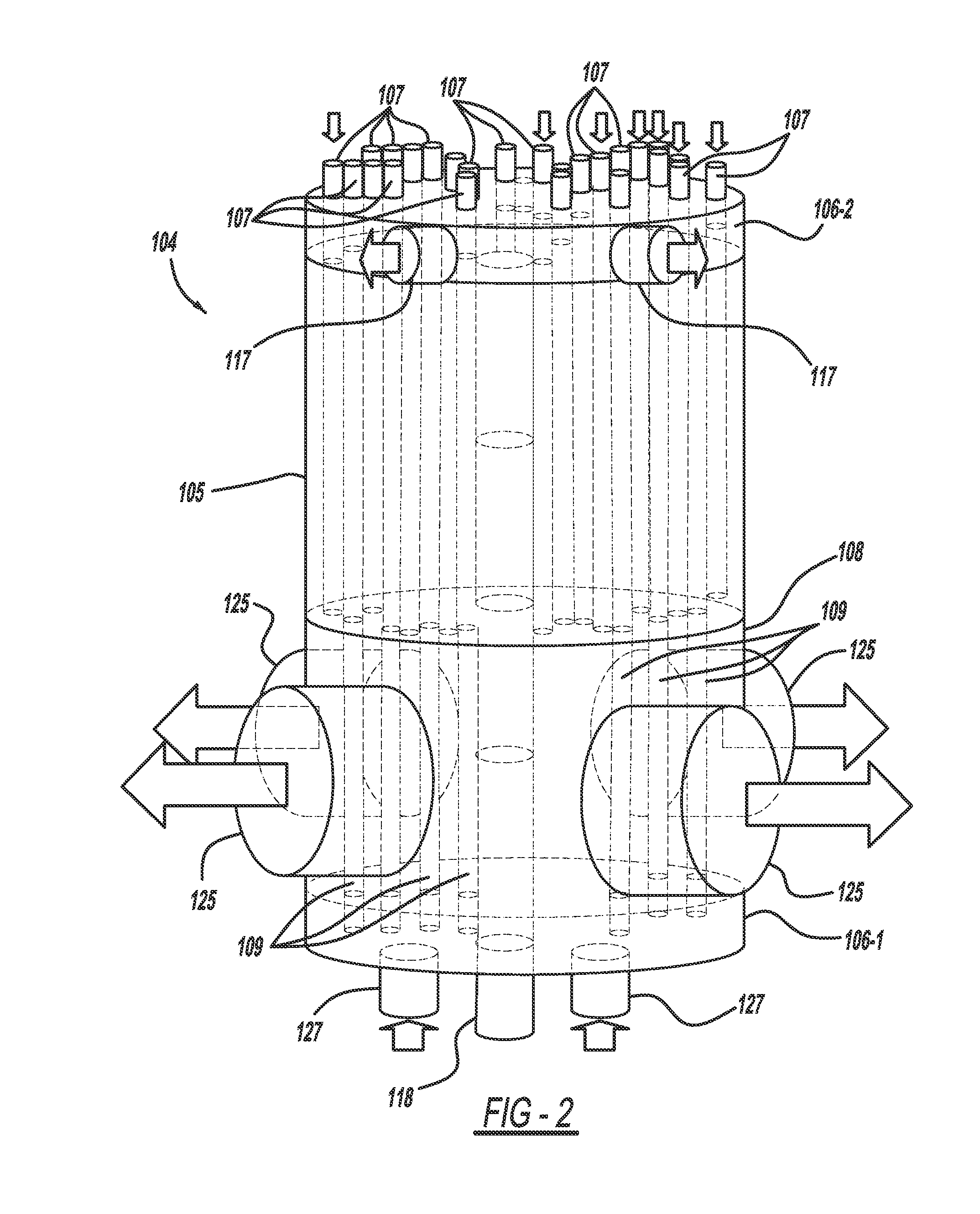

Nuclear reactor internal structure

ActiveUS20070133732A1Separating vortexReduce flow rateNuclear energy generationNuclear engineering problemsNuclear reactorEngineering

Owner:MITSUBISHI HEAVY IND LTD

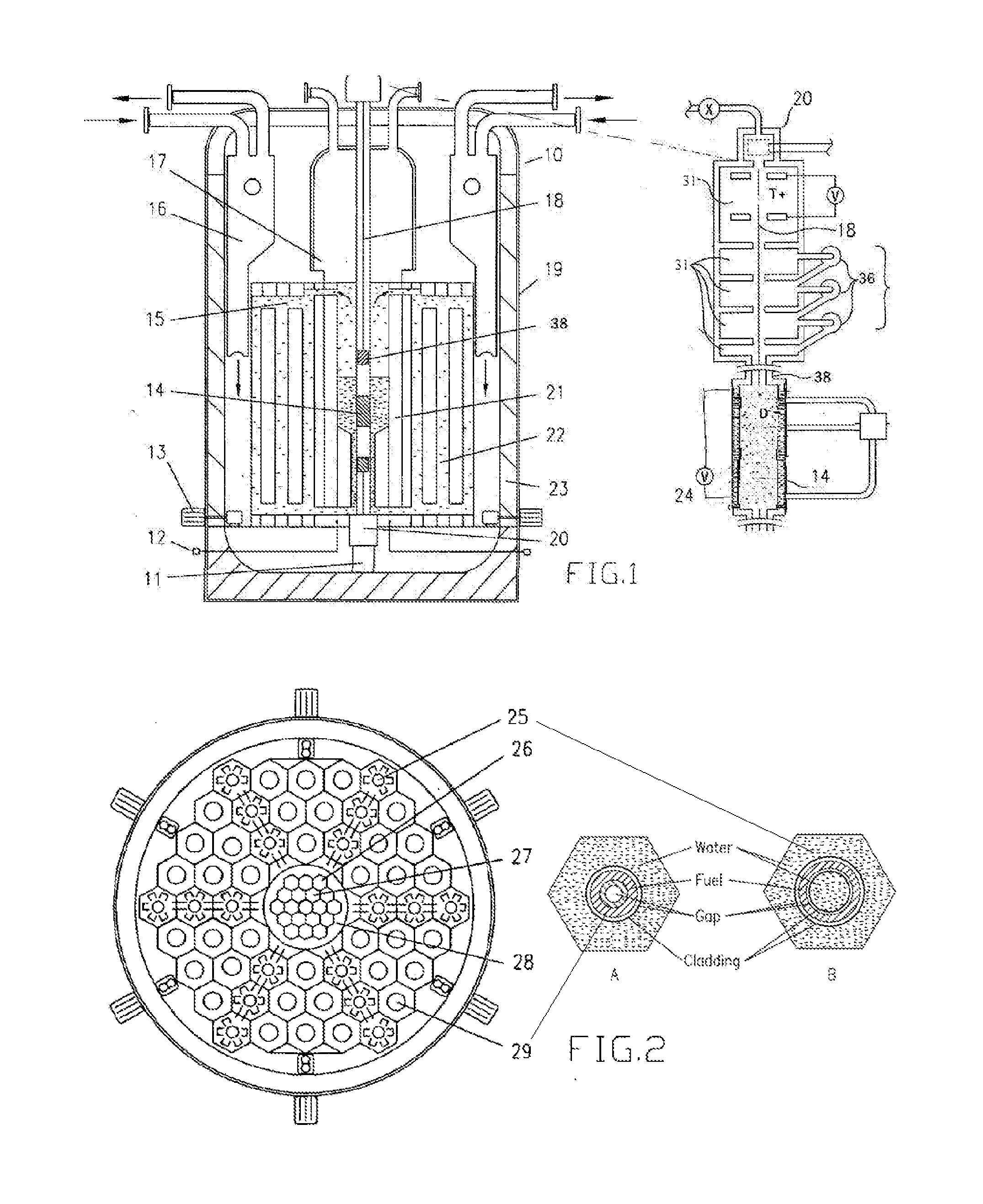

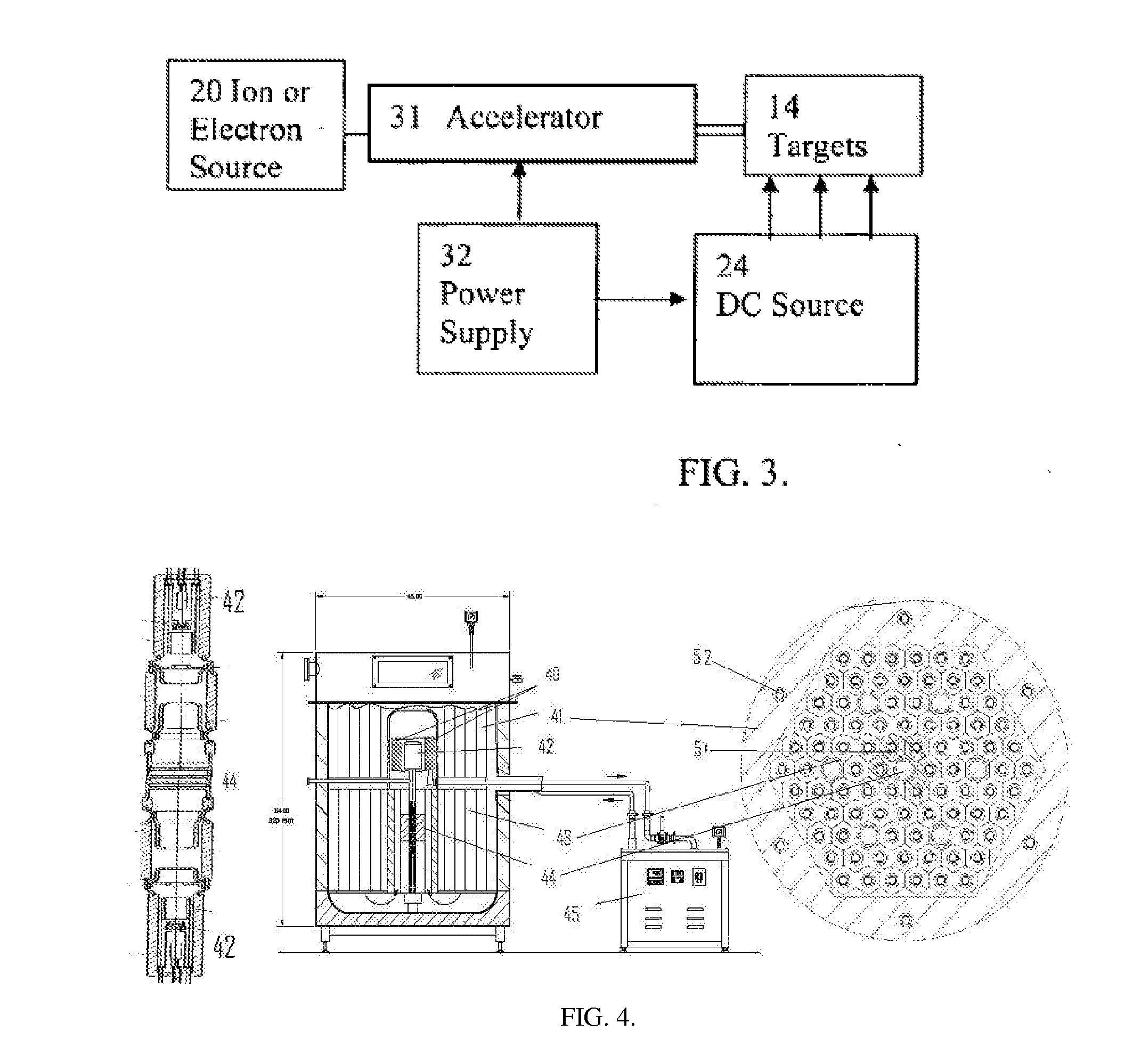

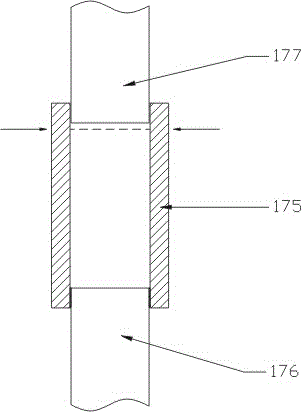

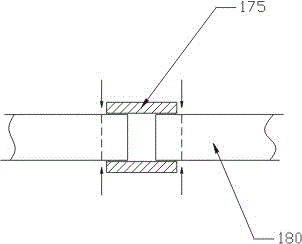

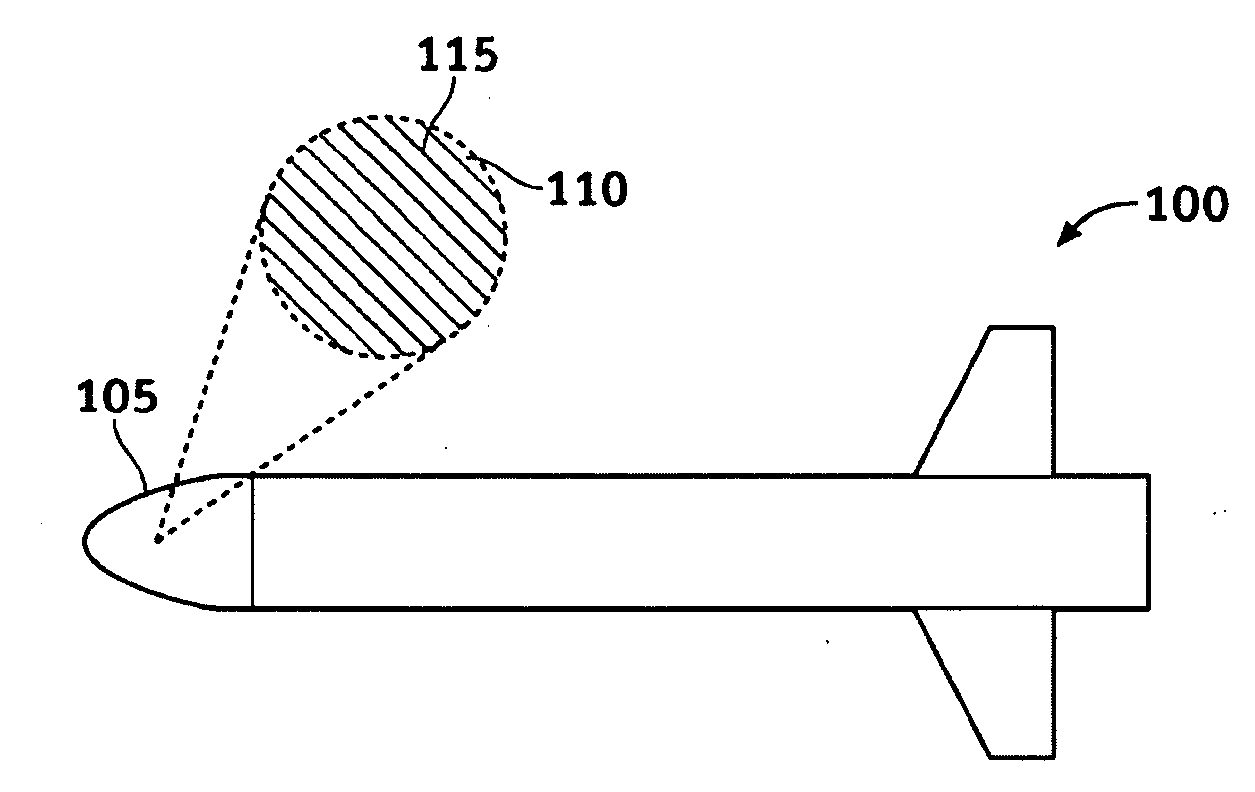

Sustainable Modular Transmutation Reactor

InactiveUS20150098544A1Improve distributionImprove economyIntegral reactorsConversion outside reactor/acceleratorsFission fusionDelayed neutron

A light water reactor to safely convert depleted uranium into a fuel source that could be used as a sustainable source of energy for centuries. The reactor is a type of breed-burn reactor uniquely combined with a proliferation-resistant fuel cycle with no uranium enrichment and no plutonium isolation. It is comprised of a compact factory-produced fast region and a thermal region that produces about 95% of the core power and contains the passageways for transports of delayed-neutron emitters to the fast region, where they can provide additional neutrons (source-based mode) or all the necessary excitation without an external neutron source (self-regulating mode). A second embodiment of the invention is a small unit driven by a neutron source with beam recycling for propulsion, electrical power or radioisotope production. It could also serve as a demonstration facility for the transmutation reactor with fission-fusion fuel.

Owner:BLANOVSKY ANATOLY

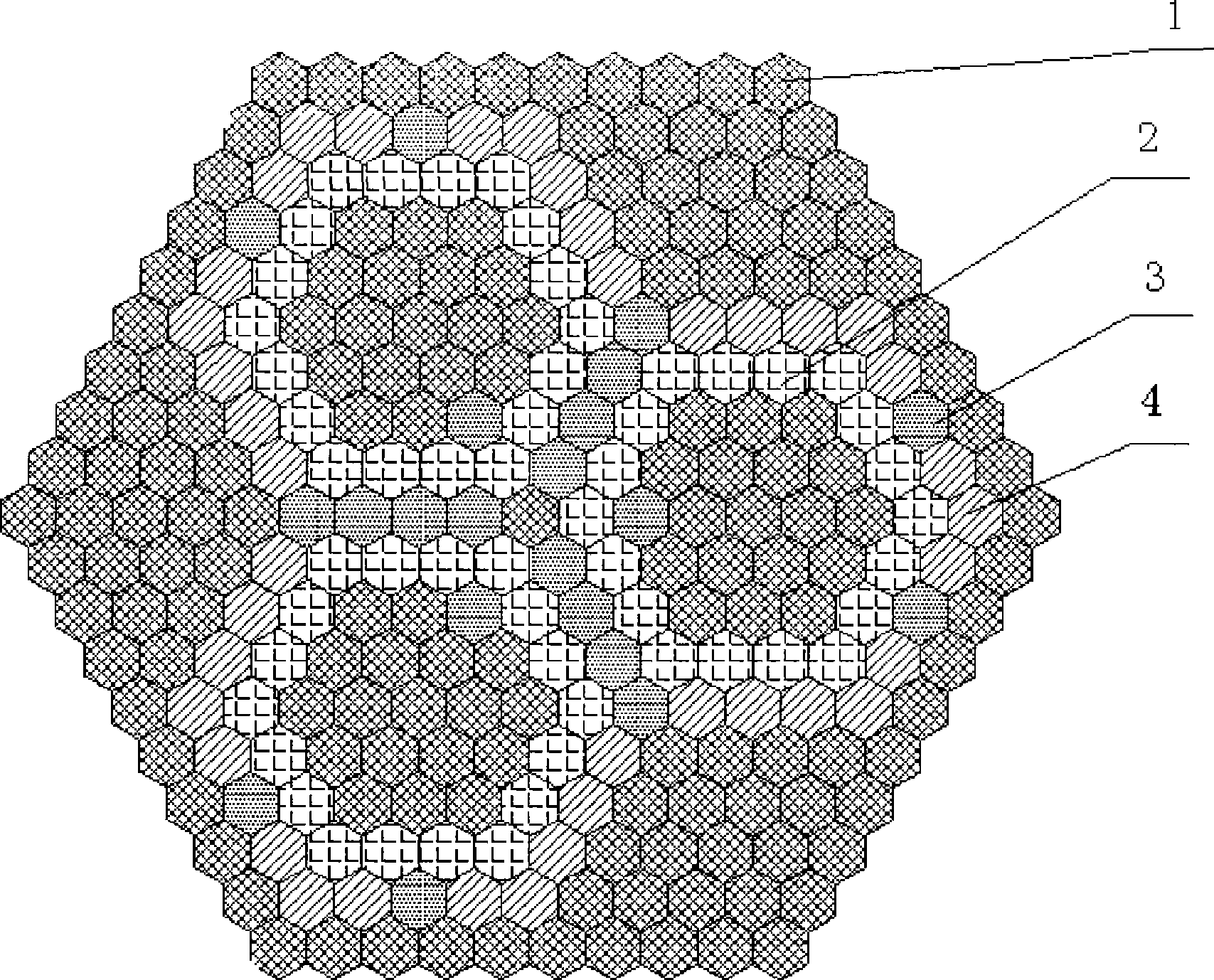

Fast reactor type coupling nuclear reaction implementation method and nuclear reactor for same

InactiveCN105023621AInherently safeReduce engineering difficultyFuel elementsNuclear energy generationNuclear reactor coreInherent safety

The present invention relates to a fast reactor type coupling nuclear reaction implementation method and a nuclear reactor for same. The main contents comprise: a fast reactor type coupling nuclear reaction implementation method, a reactor modular design approach, a fast reactor type coupling nuclear reactor, a reactor core, a fuel element, a nuclear control system, and a proliferation fuel system. The fast reactor type coupling nuclear reactor mainly combusts thorium and nuclear waste, and has inherent security. The reactor main container is composed of a fission pool and a moderating pool that are completely isolated from each other but coupling to each other. A primary coolant is separated from a moderator. A thermal insulation layer is disposed between the fission pool and the moderating pool so that both can perform neutron exchange but heat exchange is blocked. Fast neutrons produced by the fission pool and moderated neutrons reflected by the moderating pool may enable the reactor core to simultaneously perform coupling nuclear reaction of the two types of neutrons. The moderating pool may be provided with the nuclear control system, and ex-core coupling core control may be implemented. The moderating pool is provided with a thorium purification fuel system, and on-line extraction of the purification fuel can be performed, and separation of nuclide is safe and simple, thereby providing a solution to the technical bottleneck of "thorium reactor".

Owner:陈安海

Lead-free mixture as a radiation protection additive

The present invention provides a mixture containing a) at least 26 wt. % of gadolinium and b) one or more elements, alloys and / or compounds from the group consisting of barium, indium, tin, lanthanum, molybdenum, niobium, tantalum, zirconium and tungsten, a process for the preparation of this mixture, use of the mixture as radiation protection, use of the mixture to prepare polymeric radiation protection substances, a process for preparing radiation screening rubbers, thermoplastic materials and polyurethanes, a process for preparing products from the polymeric radiation protection substances and products made from these polymeric radiation protection substances.

Owner:LANXESS DEUTDCHLAND GMBH

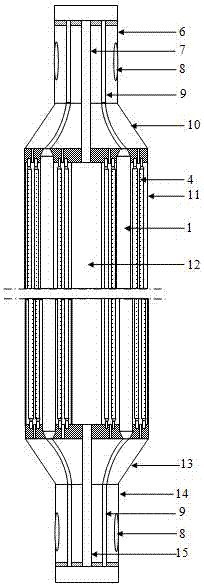

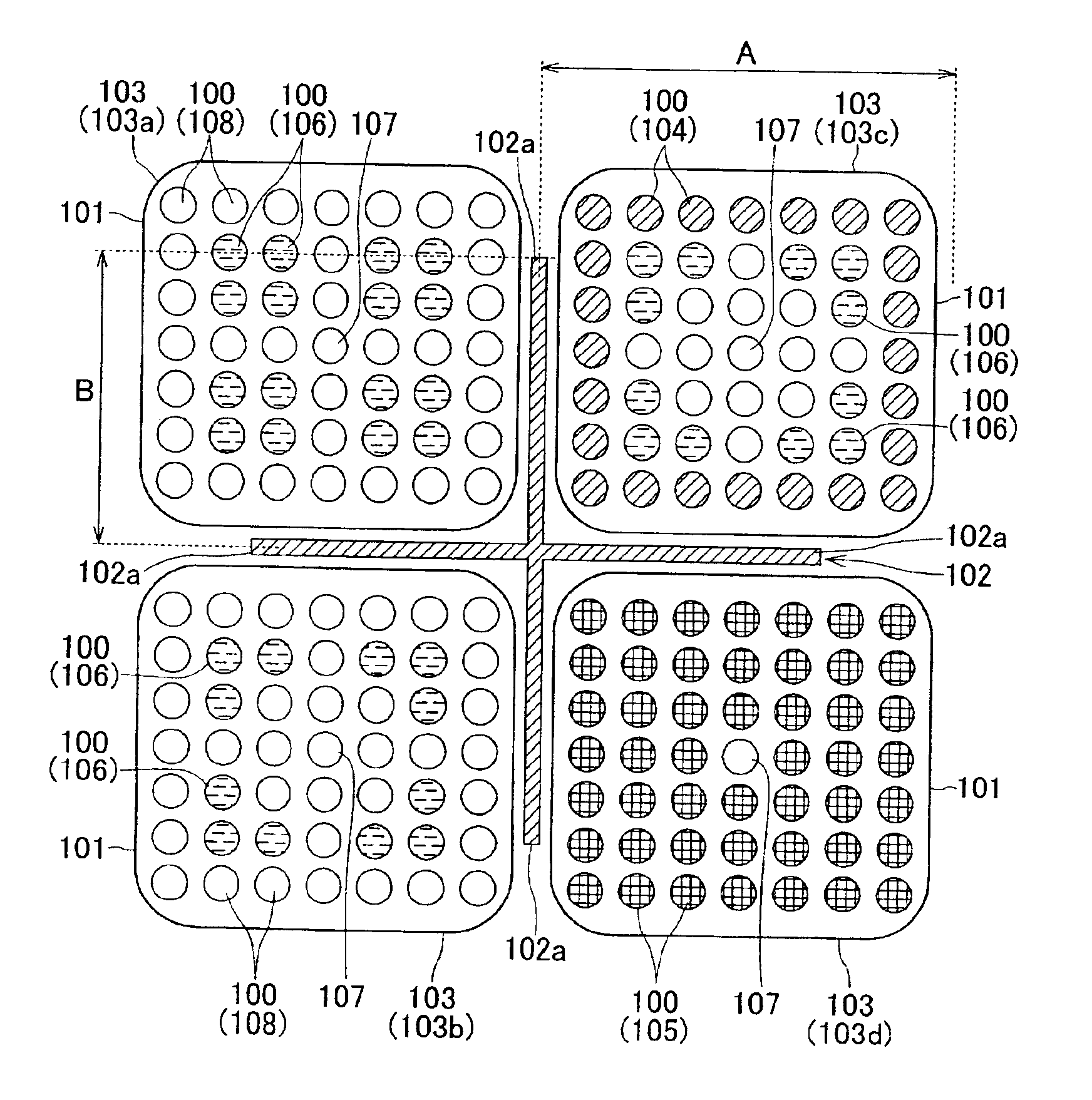

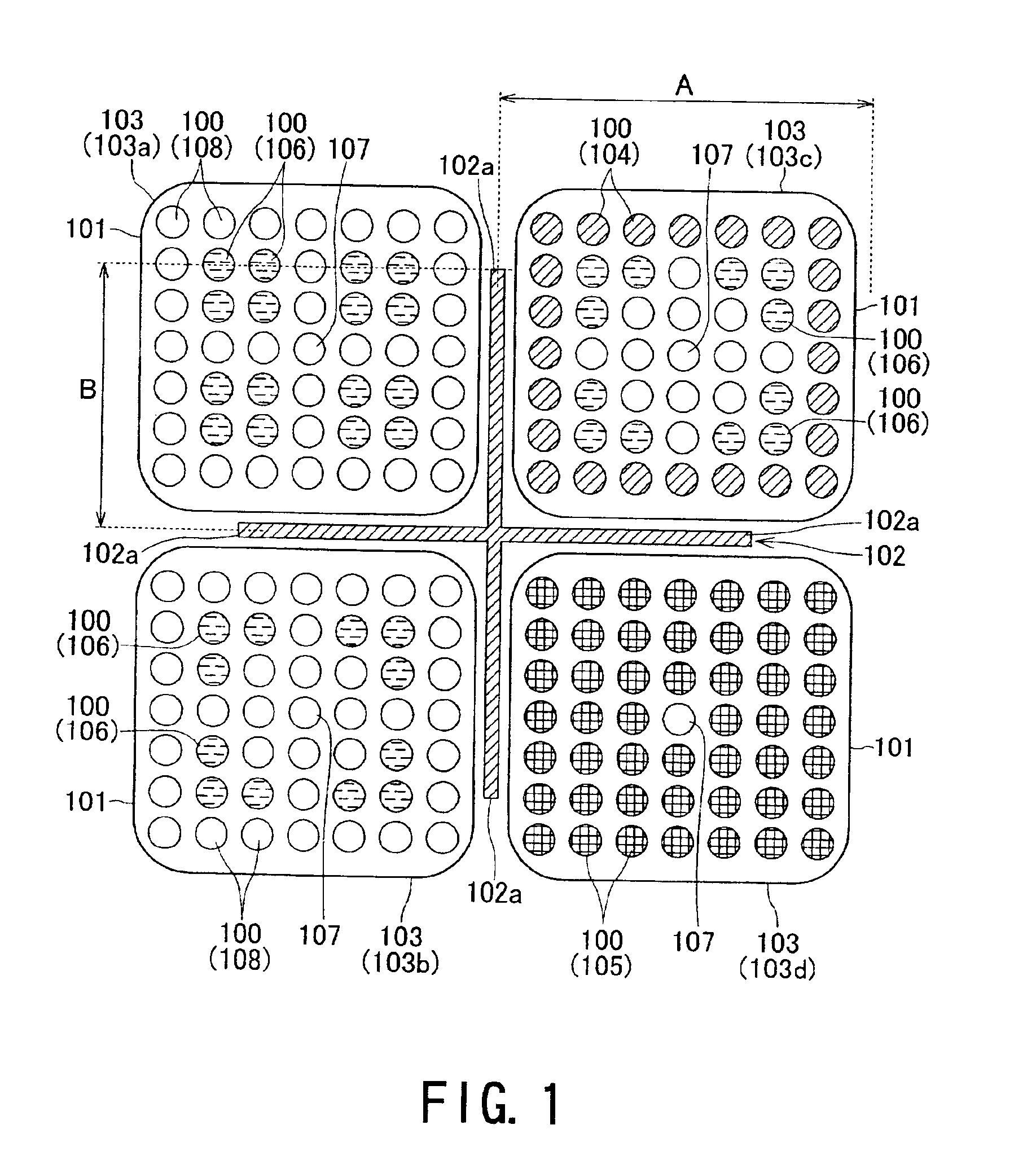

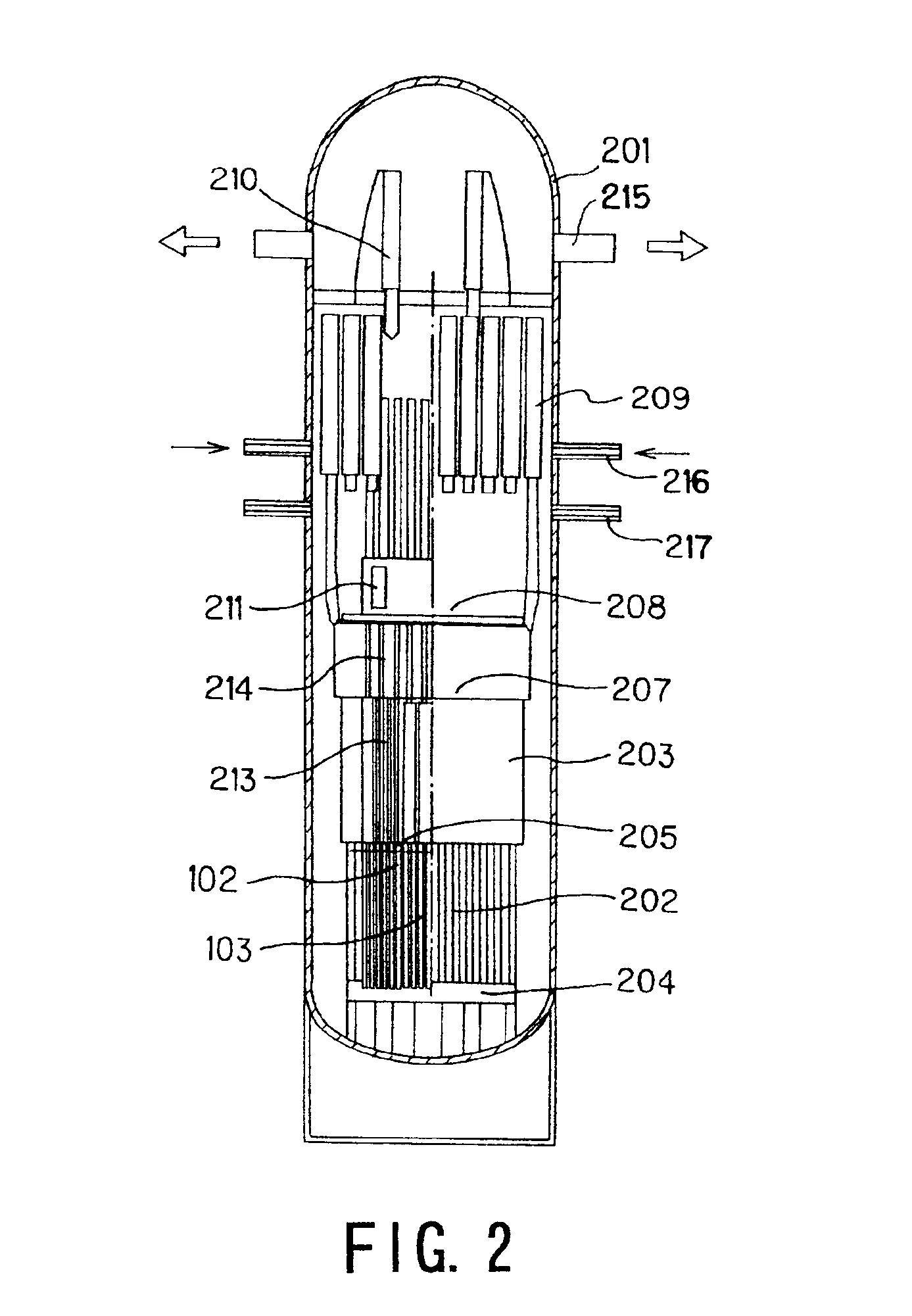

Reactor core and method for operating nuclear reactor

InactiveUS6925138B2Continuous operationShorten the durationConversion outside reactor/acceleratorsNuclear energy generationNuclear plantNuclear reactor core

The present invention is to provide a reactor core that allows a nuclear plant to continuously operate for a long term period, for example 15 years or longer, without requiring any fuel exchange, reduces the duration and number of maintenance steps involved in regular plant inspections, markedly improves plant availability and economic efficiency, and is effective in terms of nuclear nonproliferation.A plurality of fuel assemblies 103, themselves obtained by arranging fuel rods 100 and water rods 107 in square lattices, are arranged in a square lattice at a certain pitch. The blades 102a of a cross-shaped (cruciform) control rod 102 in a cross section are inserted into four adjacent spaces formed by four fuel assemblies 100 facing each other. A value of 0.06 cm−1 or greater is selected for the ratio (B / S) of the width (B) of each blade on the cruciform control rod 102 and the surface (S) of the fuel lattice defined by the surface area of a square whose side is equal to the pitch between the fuel assemblies 103.

Owner:KK TOSHIBA

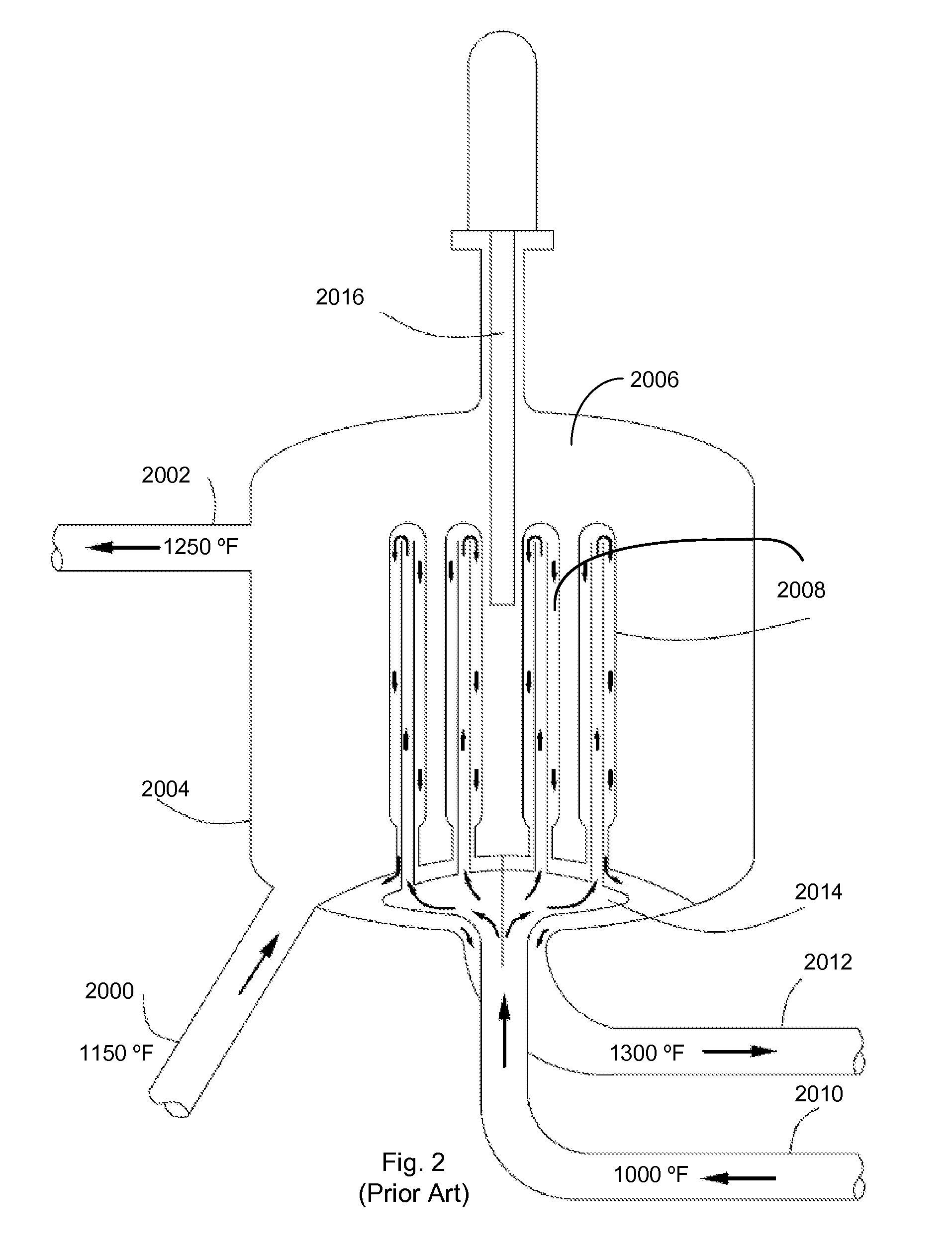

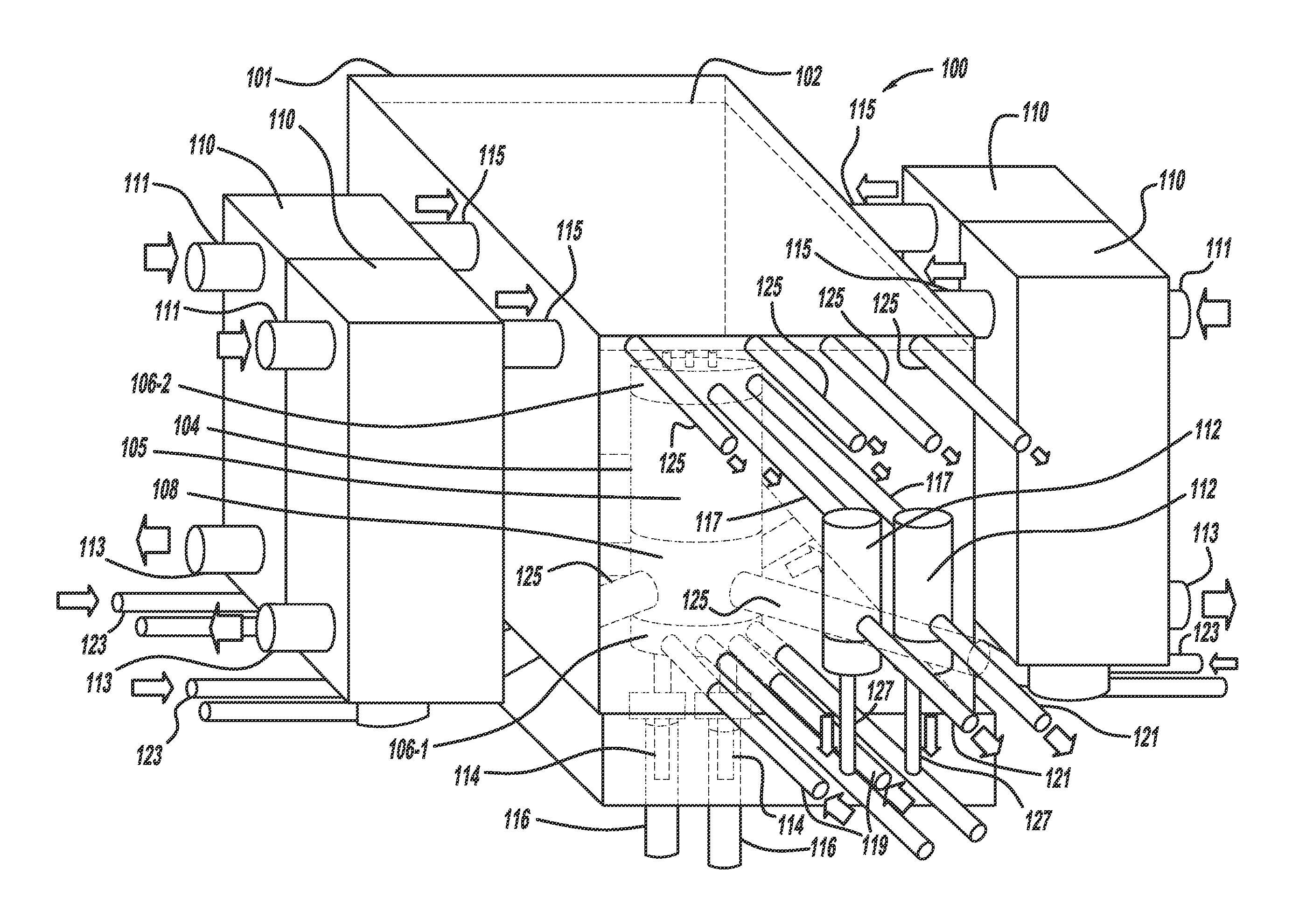

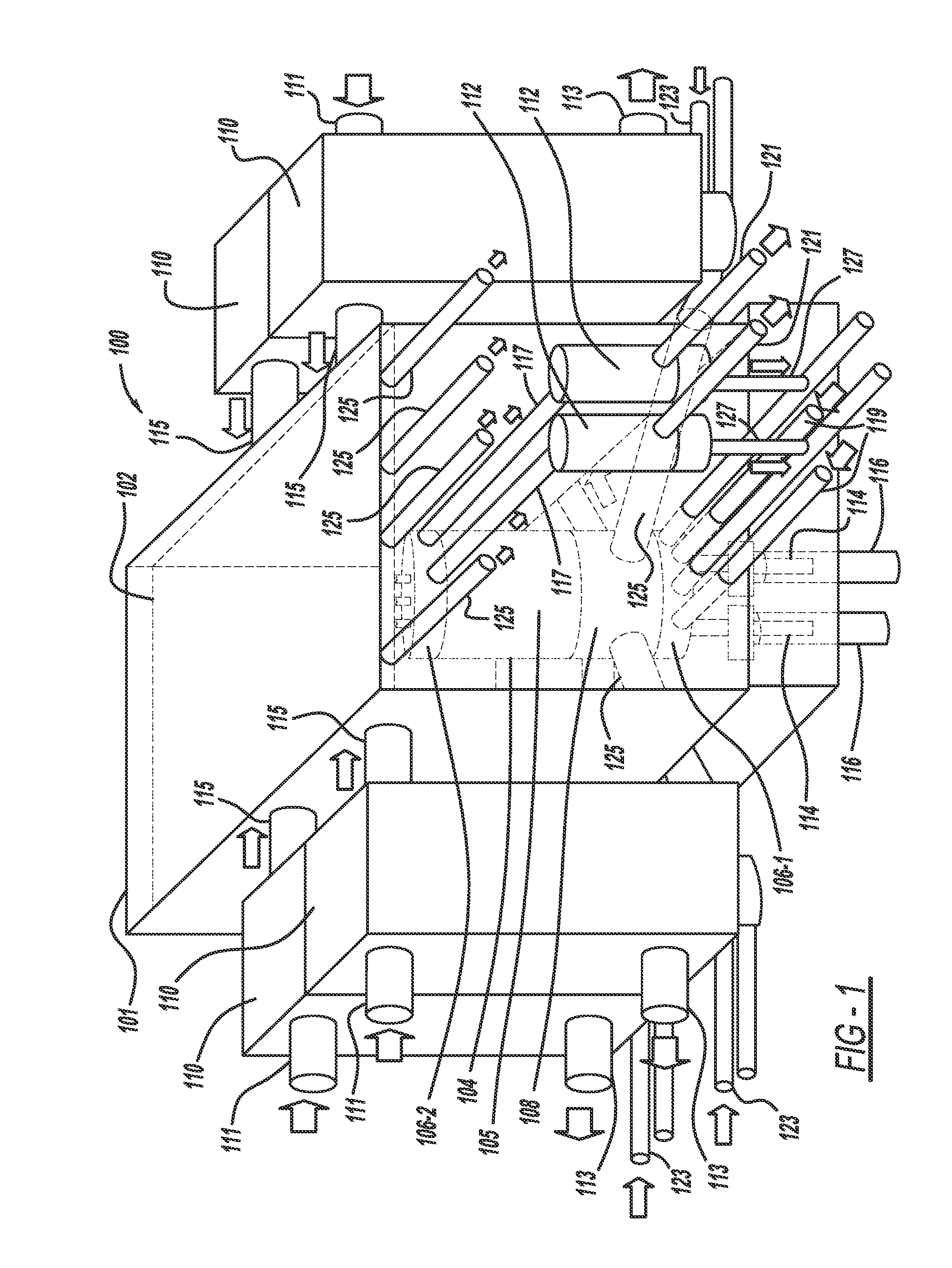

Heat pipe molten salt fast reactor with stagnant liquid core

A molten salt reactor is described that includes a containment vessel, a reactor core housed within the containment vessel, a neutron reflector spaced from the containment vessel and positioned between the core and the containment vessel, a liquid fuel comprised of a nuclear fission material dissolved in a molten salt enclosed within the core, a plurality of heat transfer pipes, each pipe having a first and a second end, wherein the first end is positioned within the reactor core for absorbing heat from the fuel, a heat exchanger external to the containment vessel for receiving the second end of each heat transfer pipe for transferring heat from the core to the heat exchanger, and at least one and preferably two or more reactor shut down systems, where at least one may be a passive system and at least one or both may be an active or a manually operated system. The liquid fuel in the core is kept within the core and heat pipes are used to carry only the heat from the liquid core to the heat exchanger.

Owner:WESTINGHOUSE ELECTRIC CORP

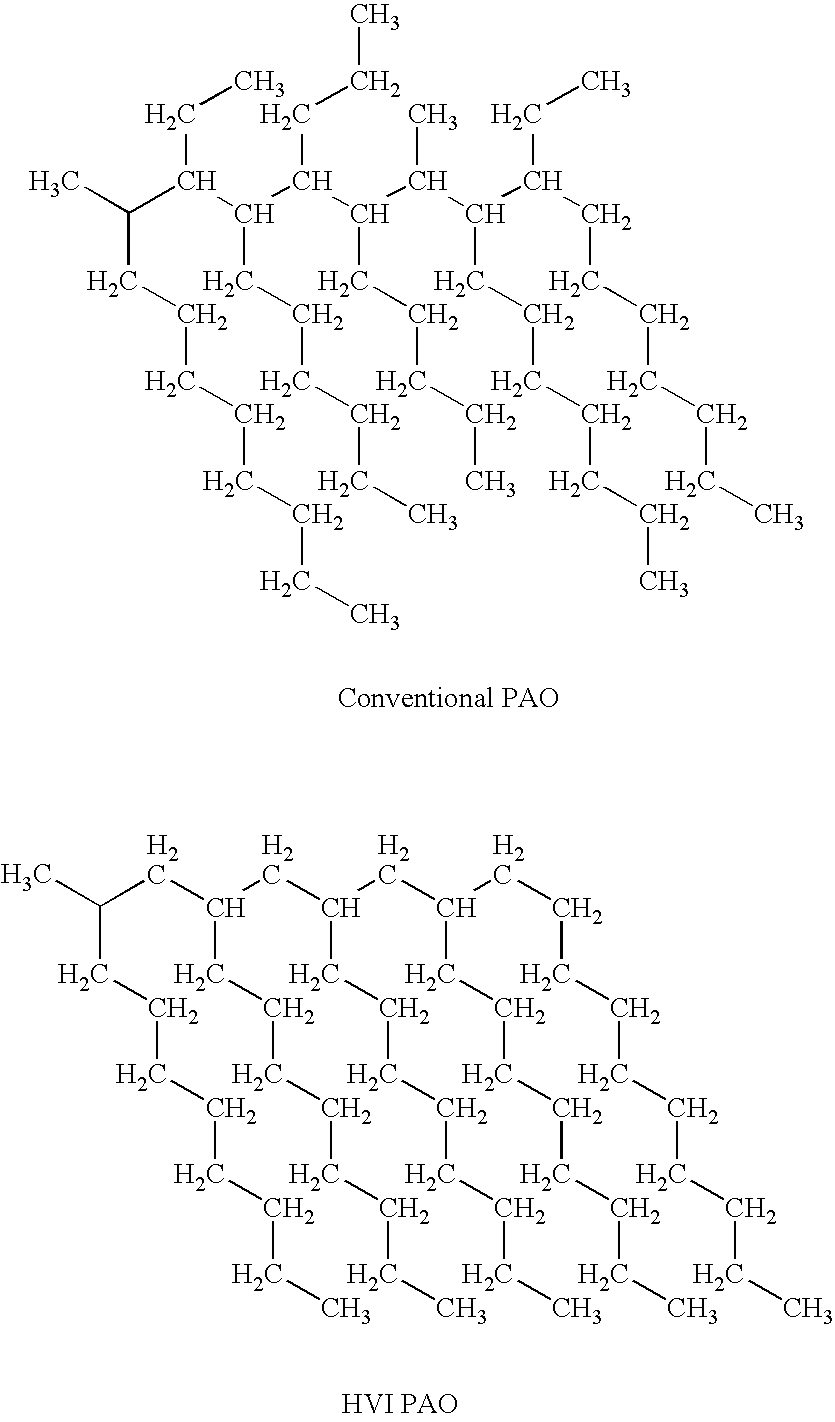

Rock bit grease composition

InactiveUS7312185B2Minimizes scoring and galling and wearGood thermal and oxidative stabilityTransportation and packagingHydrocarbon purification/separationViscosity indexLubrication

A grease for rock bit lubrication and other high temperature bearing applications is provided comprising a high viscosity index polyalphaolefin synthetic base fluid in combination with an alkylated naphthalene base fluid.

Owner:TOMLIN SCI

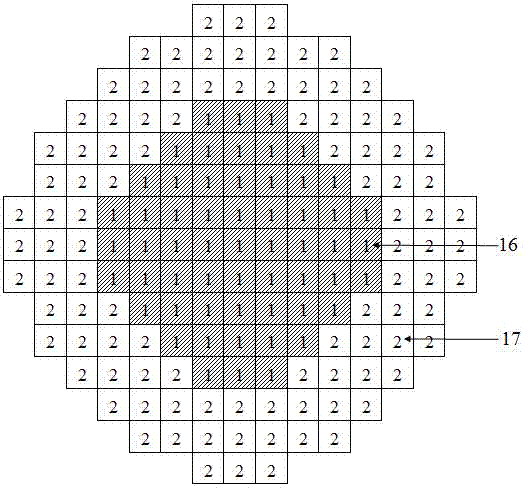

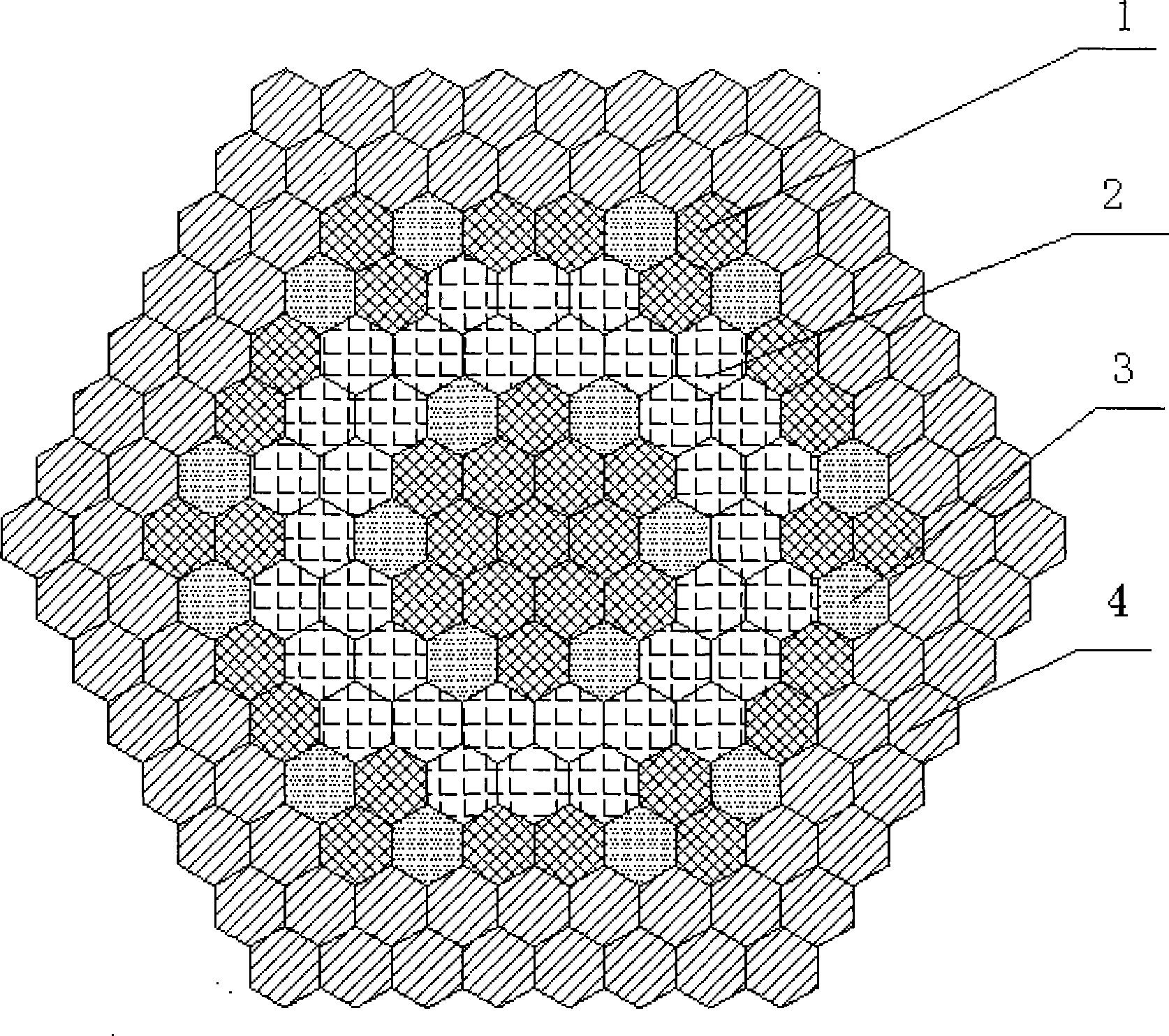

Nuclear reactor core capable of improving neutron flux rate

ActiveCN101447238AHigh fluence rateNuclear energy generationShieldingNuclear reactor coreNuclear reactor

The invention discloses a nuclear reactor core capable of improving neutron flux rate; the core is a circular structure; the center of the core is a Be thermal neutron well region, the circumference of which is a fuel component region, the circumference of which is a Be reflecting layer; the whole core is a circular structure. The maximum thermal neutron flux rate of the central Be thermal neutron well region can be over twice larger than that of the fuel region ; as the thermal neutron well region can be provided with fuel component with high uranium content, the fuel component center can form fast neutron region, therefore, the generated fission neutron has high flux rate.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

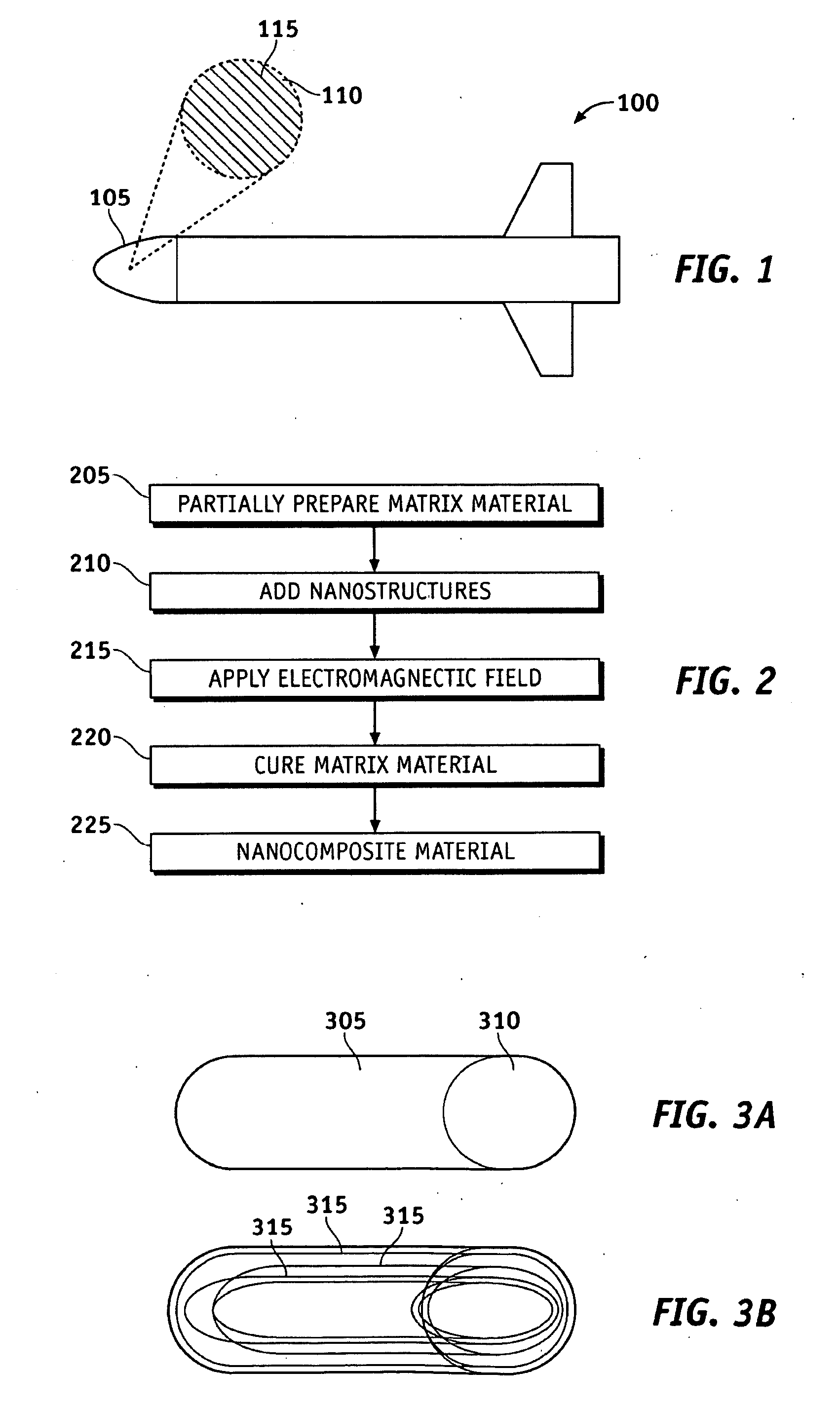

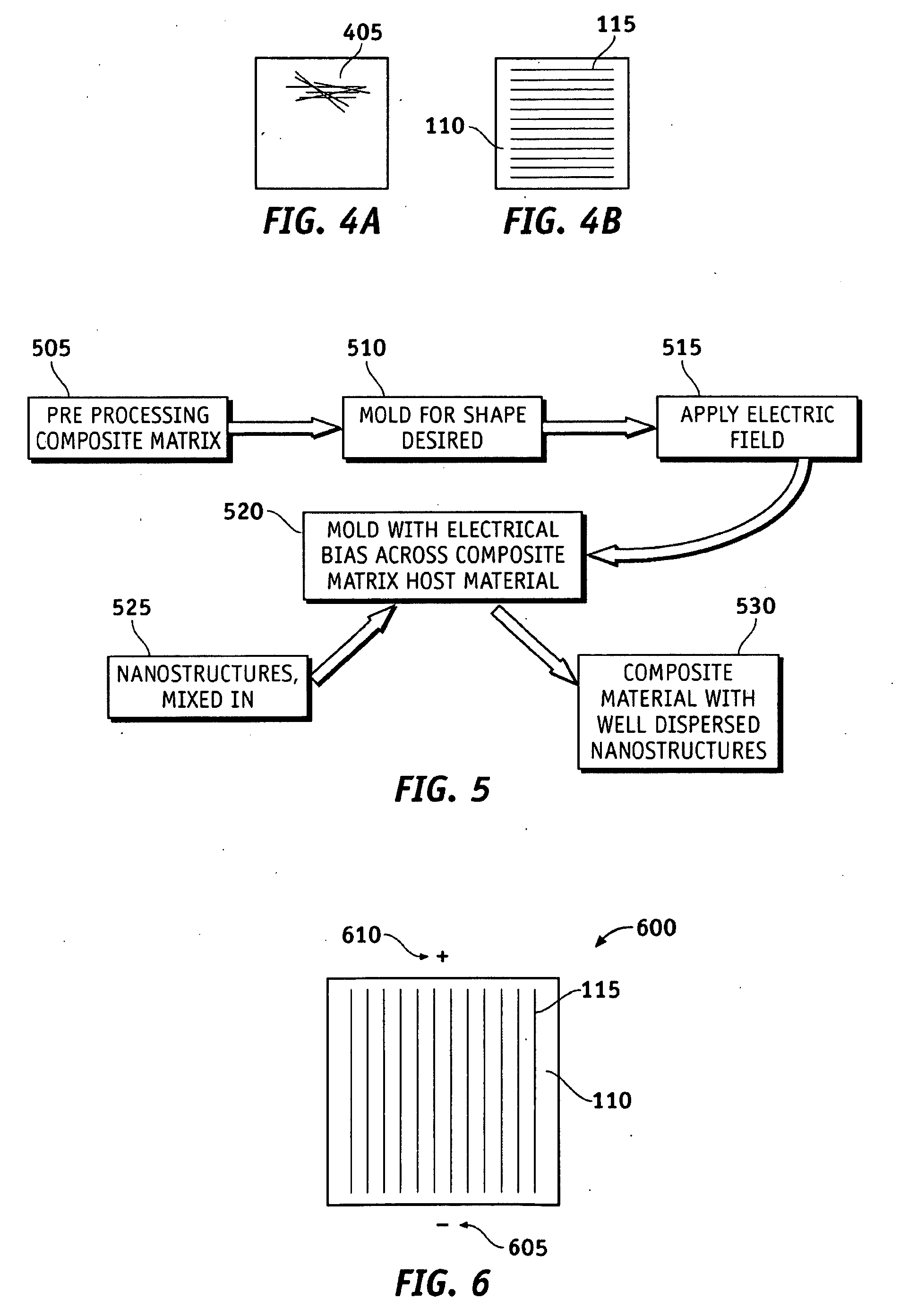

System and methods of dispersion of nanostructures in composite materials

Apparatus and methods according to various aspects of the present invention may operate in conjunction with composite matrix material and reinforcement material, such as nanostructures. The nanostructures may be evenly dispersed and / or aligned in the matrix material through application of an electromagnetic field, resulting in a nanocomposite material. In one embodiment, the nanocomposite material is suitable for large scale processing.

Owner:RAYTHEON CO

Two-fluid molten-salt reactor

ActiveUS20120051481A1Shut downConversion outside reactor/acceleratorsNuclear energy generationNuclear engineeringMolten salt reactor

A reactor vessel includes a plenum and a reactor core with first and second sets of channels. A blanket salt flows through the first set of channels, and a fuel salt flows through the second set of channels. The plenum receives the blanket salt from the first set of channels. The blanket salt provides a breed-stock for a fission reaction in the fuel salt and transfers heat generated by the fission reaction without mixing with the fuel salt.

Owner:ACAD SINIC +1

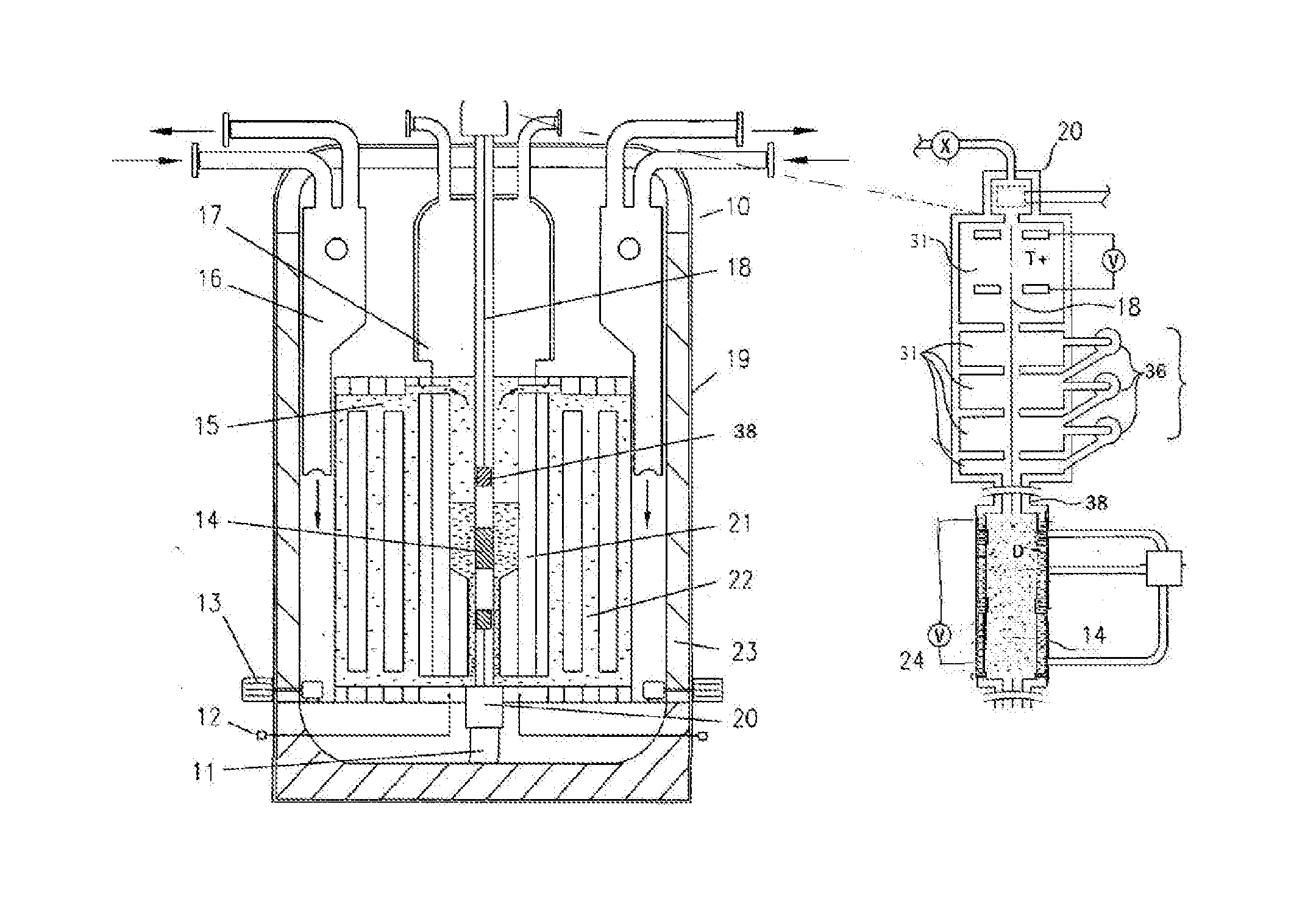

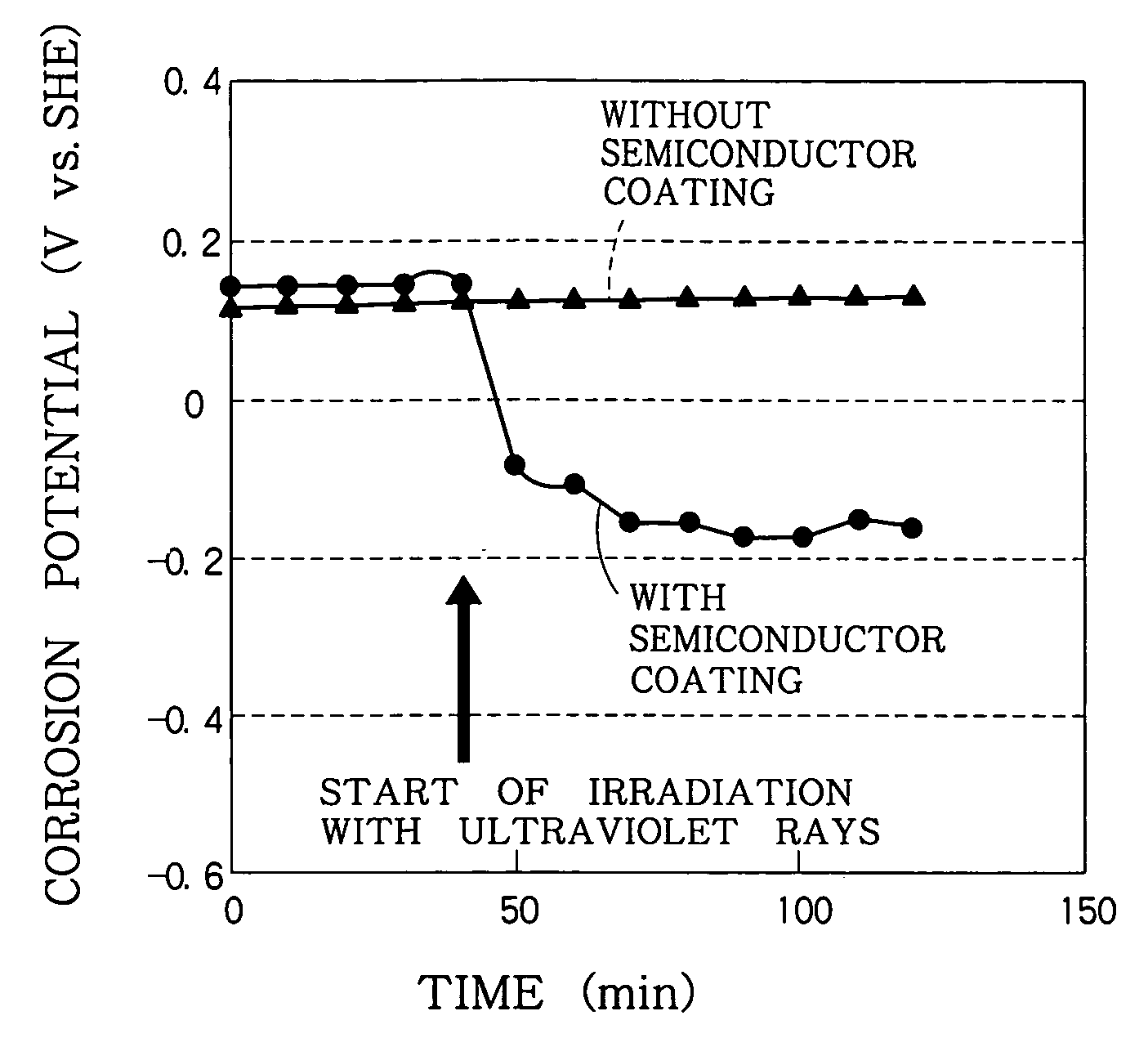

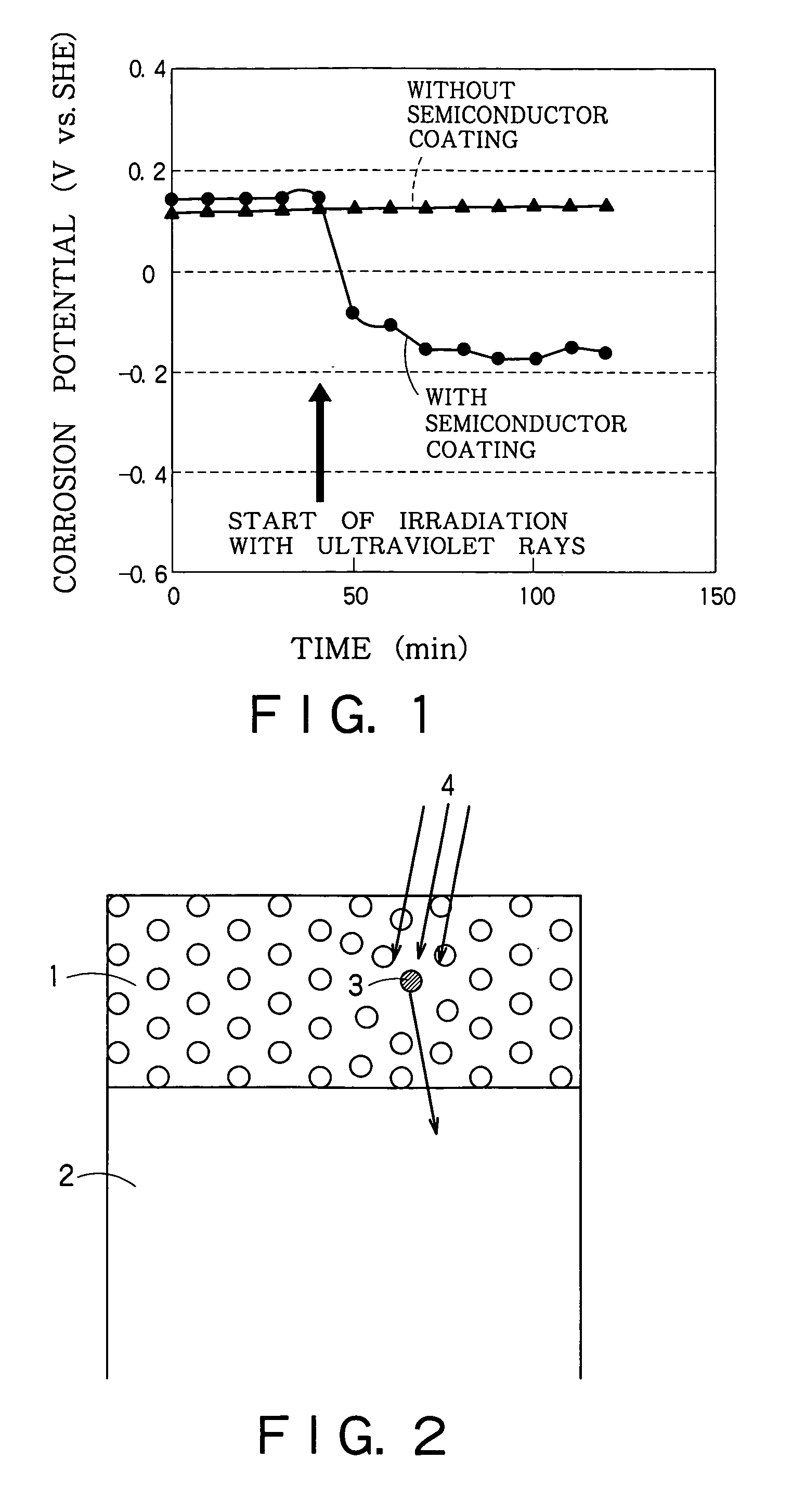

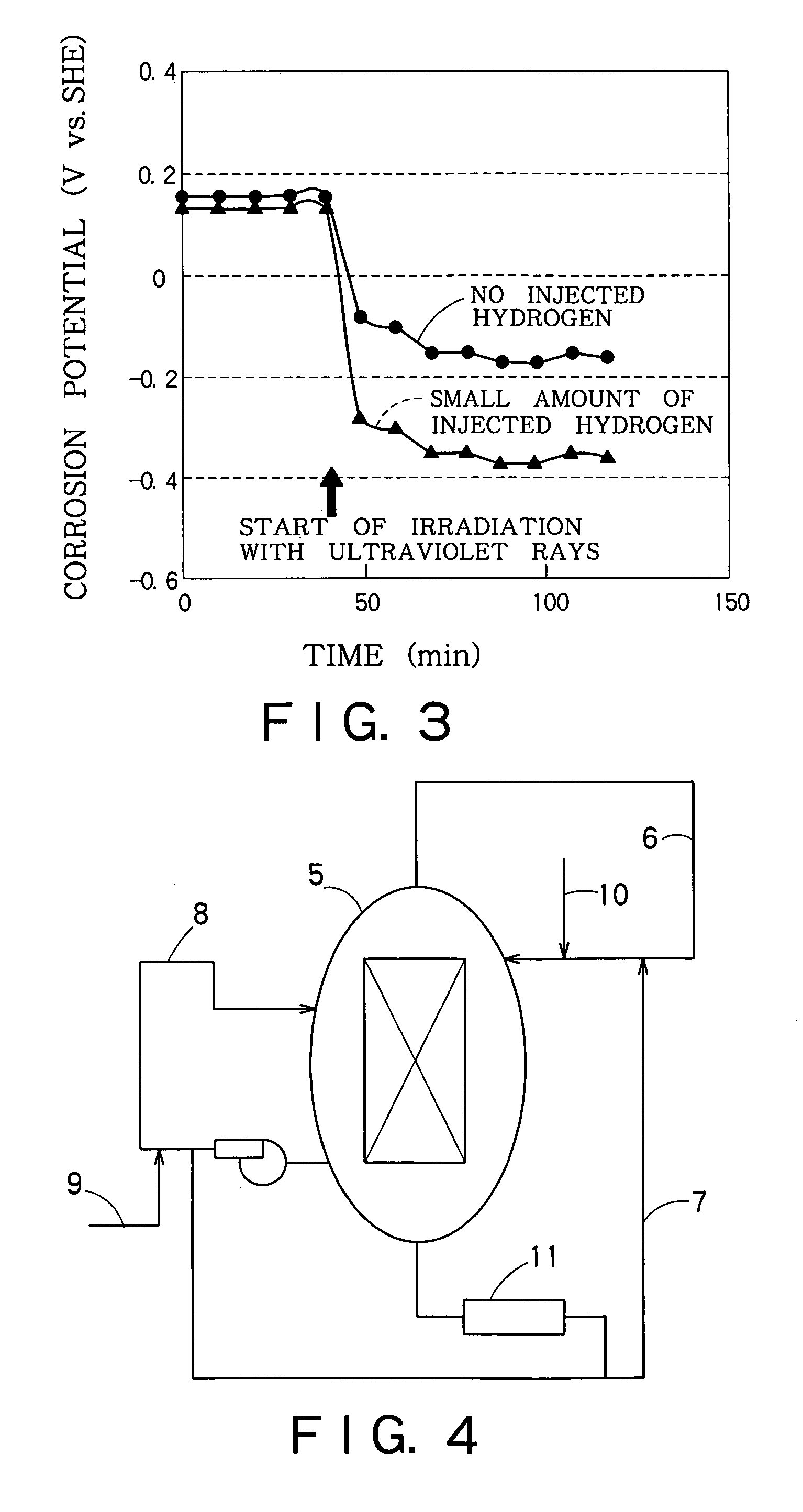

Reactor structural member and method of suppressing corrosion of the same

InactiveUS6940939B1Increase the concentration of hydrogenEffective preventionNuclear energy generationNuclear monitoringHydrogen concentrationNuclear reactor

A photocatalytic substance having the properties of an n-type semiconductor is deposited on a surface of a metal base made of a stainless steel or Inconel. When necessary, the hydrogen concentration of the reactor water is increased. A current produced by the photocatalytic substance when the same is irradiated with light or radioactive rays in a nuclear reactor flows through the metal base to reduce corrosion current. When necessary, the photocatalytic substance is provided on its surface with at least one of Pt, Rh, Ru and Pd.

Owner:KK TOSHIBA

Composite materials and techniques for neutron and gamma radiation shielding

ActiveUS7250119B2Increase volumeWaste loadingDiffusing elementsNuclear engineering solutionsPolymer modifiedCement grout

Owner:SAYALA DASHARATHAM

Ceramic radiation shielding material and method of preparation

InactiveUS20070102672A1Reduce solubilityReduce coefficient of frictionOther chemical processesMagnetic/electric field screeningPhosphateRadiation shield

Owner:CO OPERATIONS INC

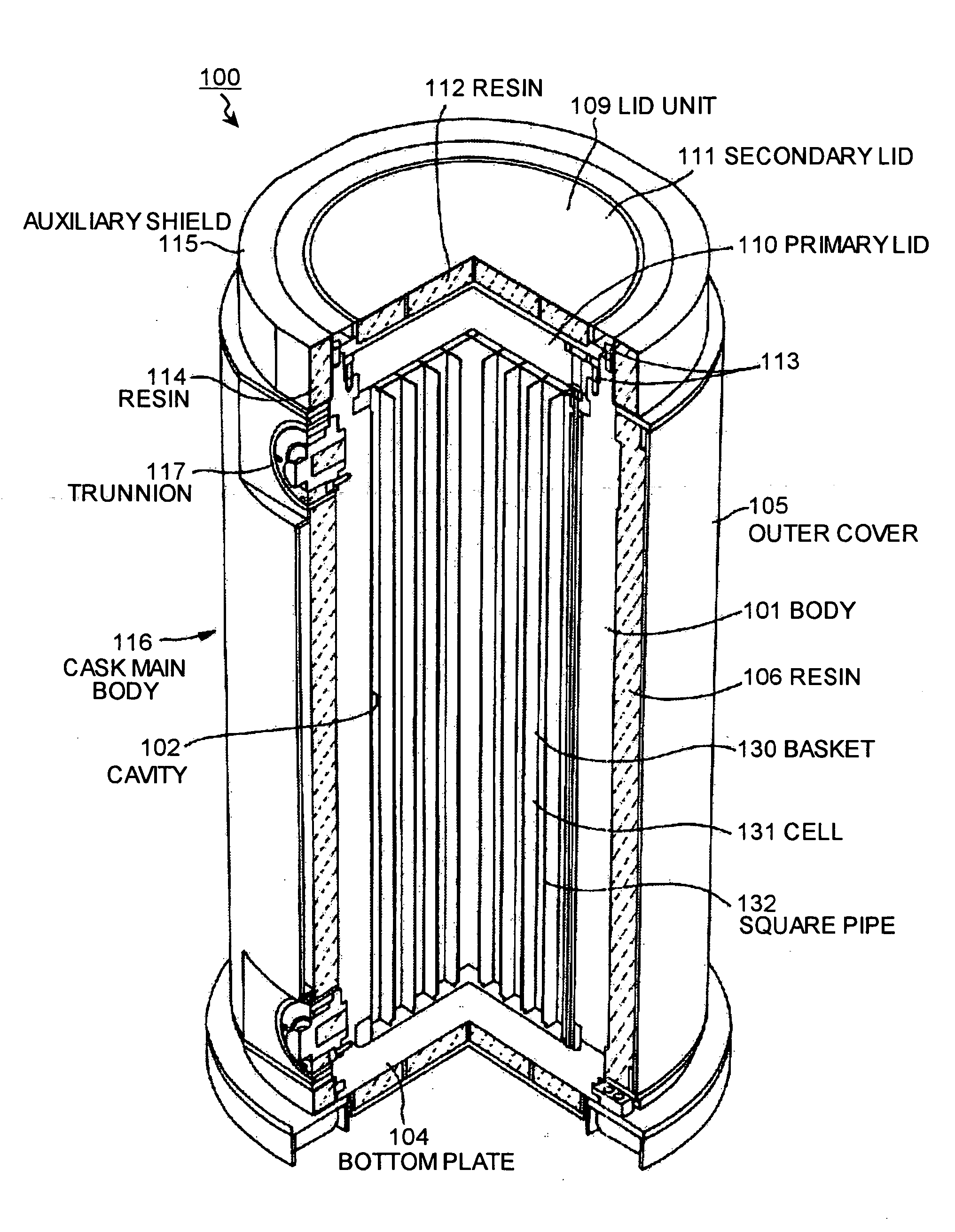

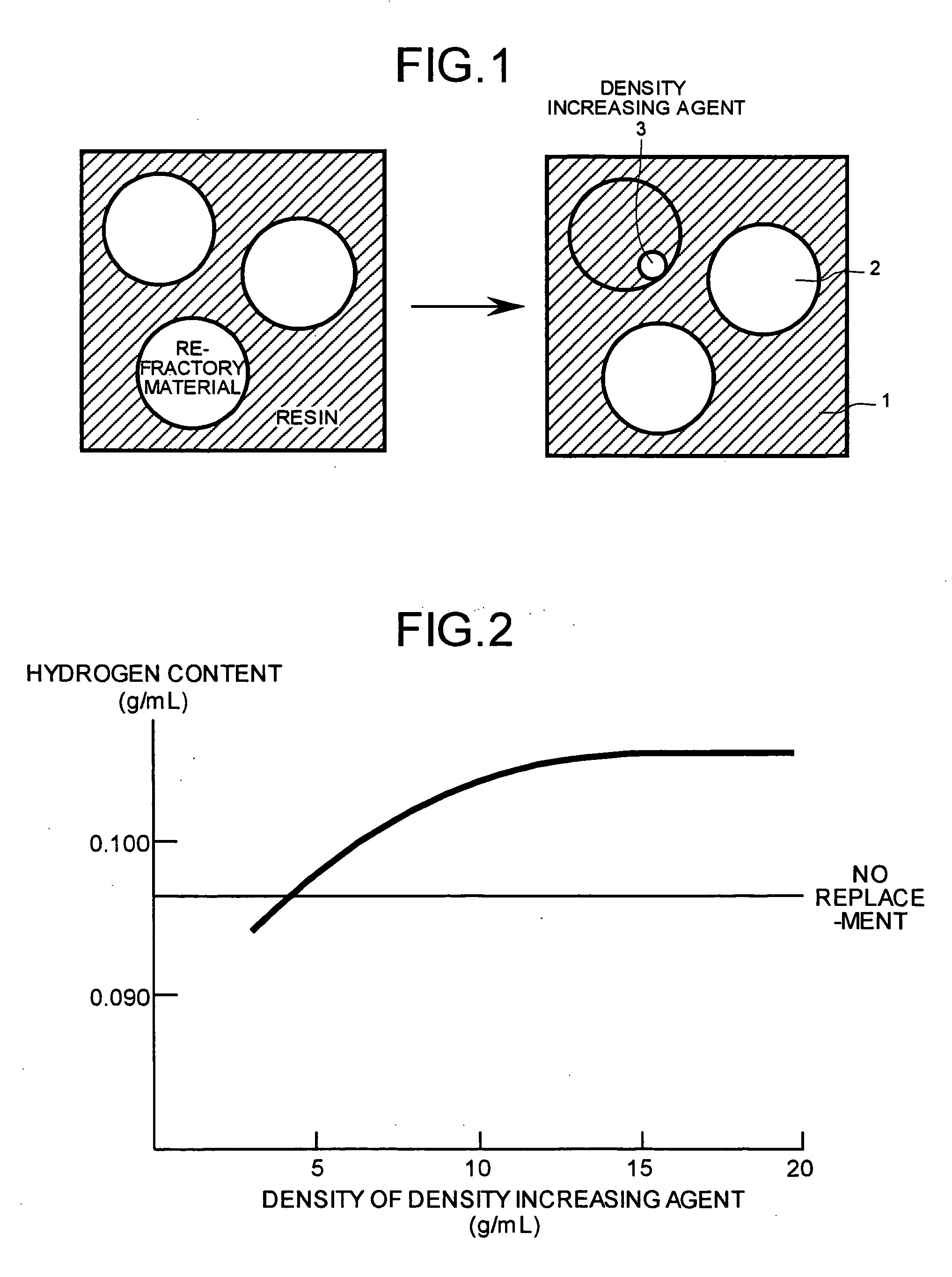

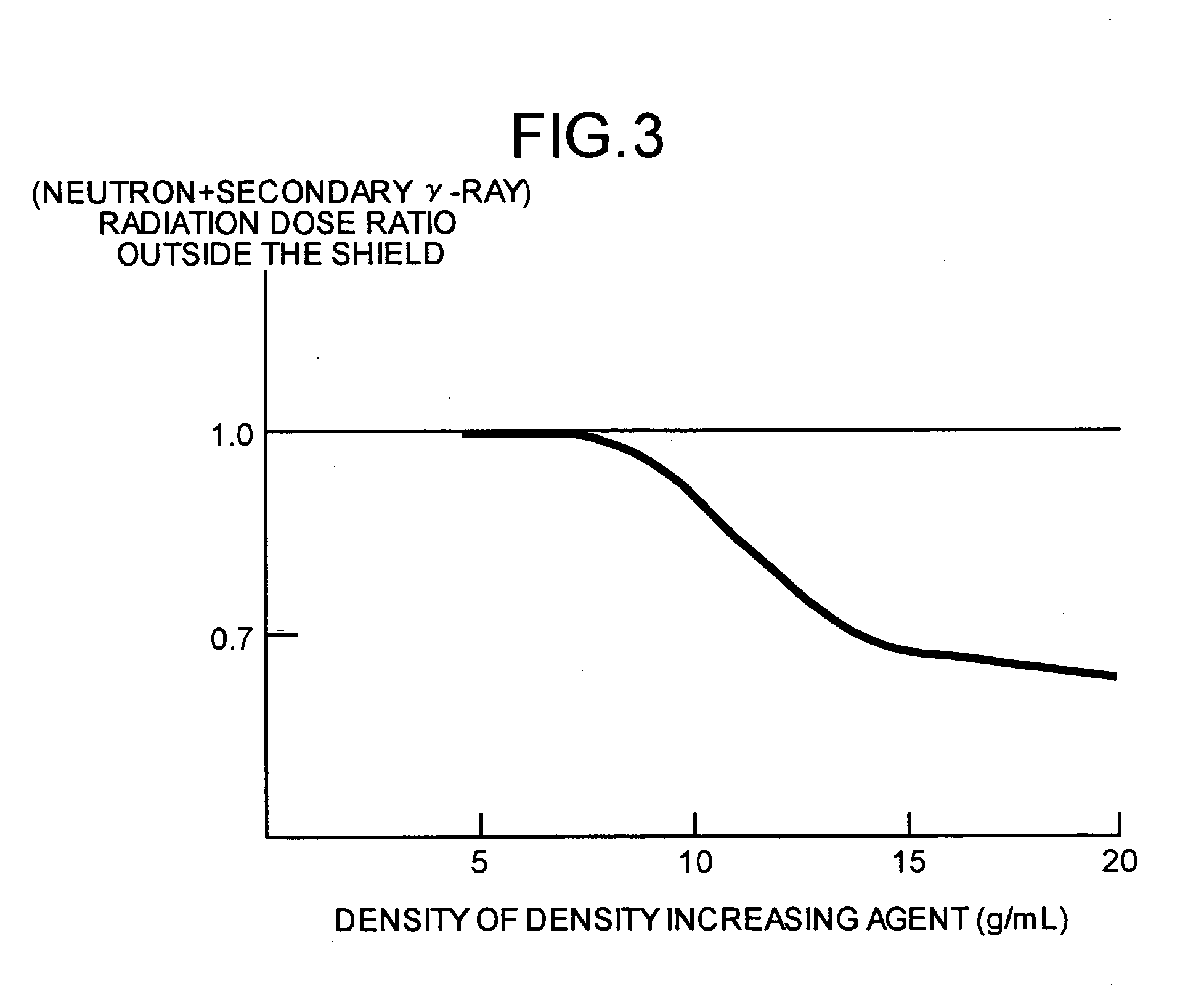

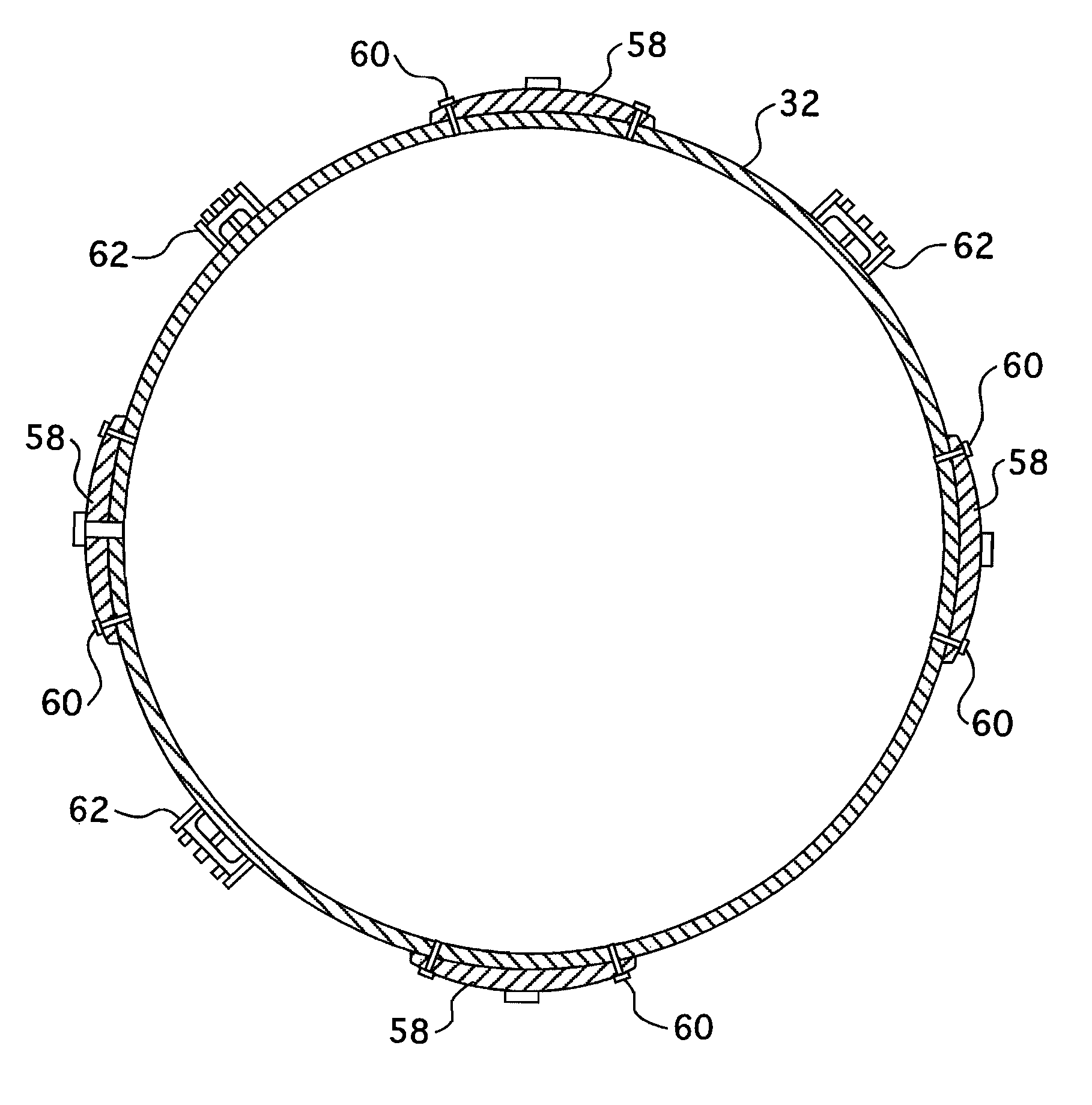

Cask, composition for neutron shielding body, and method of manufactruing the neutron shielding body

ActiveUS20050157833A1Enhancing neutron shielding effectMaintain performanceElectrode and associated part arrangementsDischarge tube/lamp detailsRefractoryEngineering

A cask includes a trunk body that includes a basket having a square pipe or a plate member forming a cell that contains a spent fuel assembly, and a neutron shield that is formed by filling a composition for neutron shielding between the trunk body and an outer cover surrounding the trunk body. The composition includes a refractory material, a density increasing agent, and a neutron shielding material composed mainly of a polymer.

Owner:MITSUBISHI HEAVY IND LTD

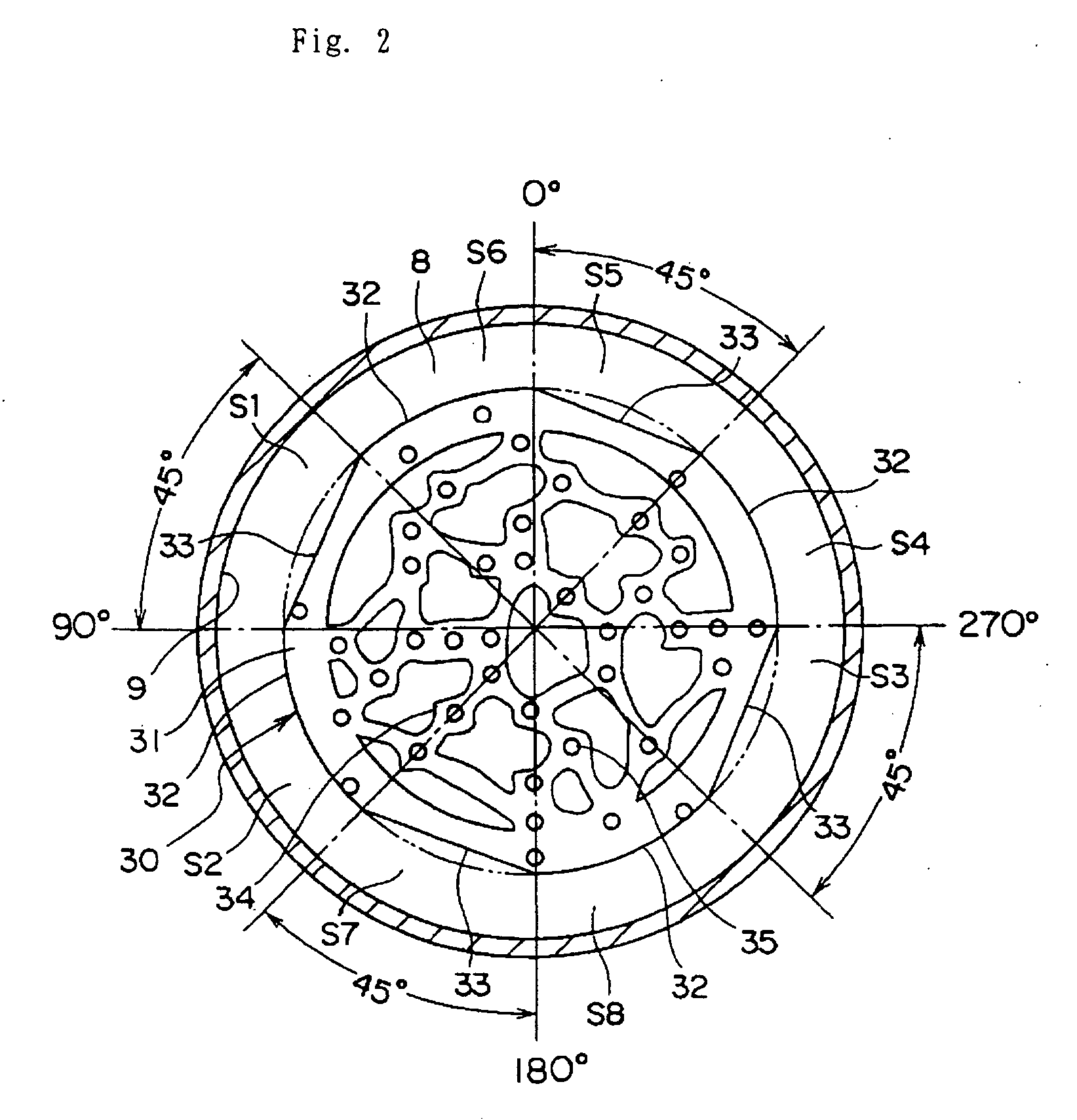

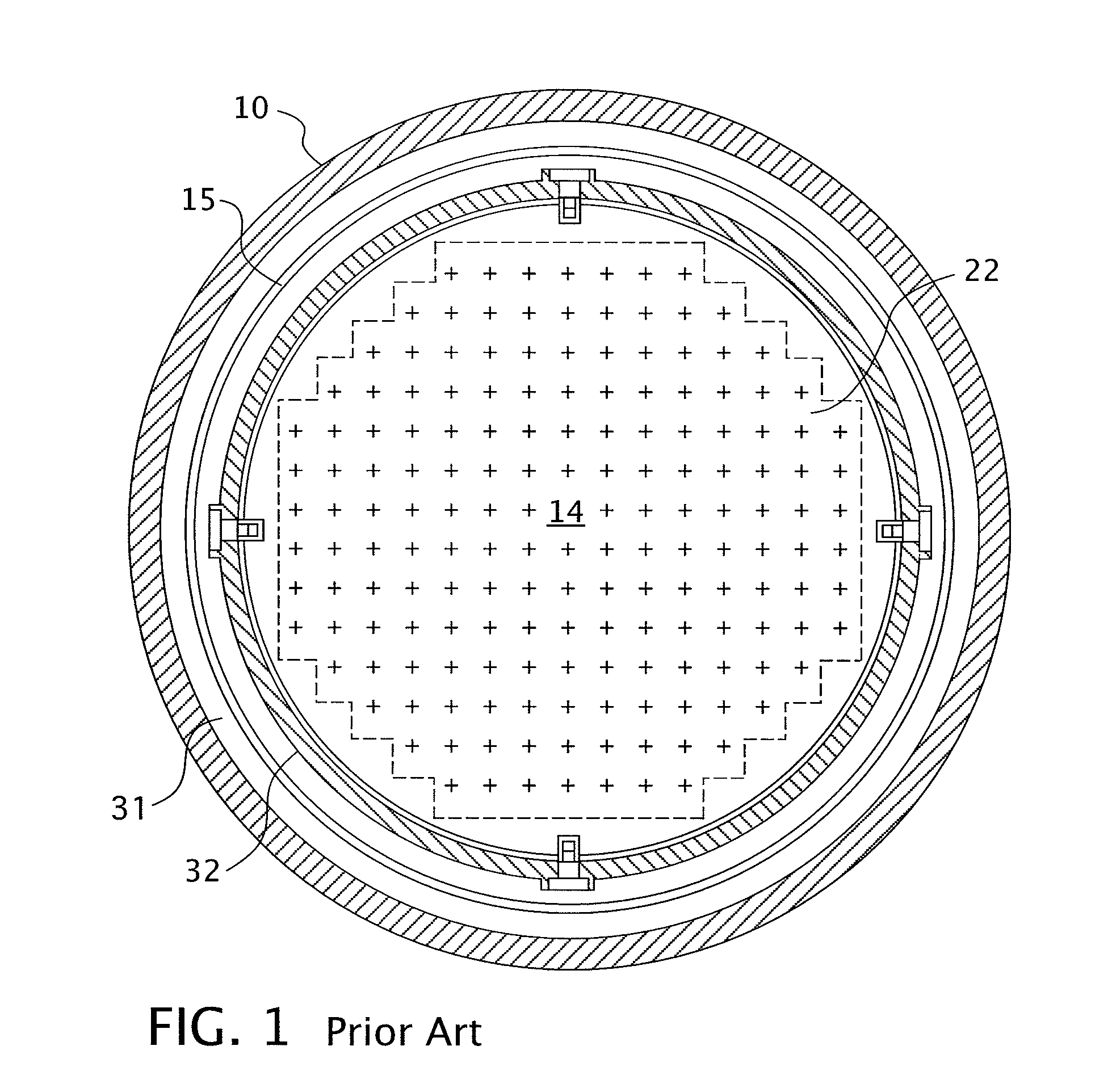

Neutron shielding panels for reactor pressure vessels

ActiveUS8064564B2Reduce passageNuclear energy generationShieldingReactor pressure vesselNuclear reactor

In a nuclear reactor neutron panels varying in thickness in the circumferential direction are disposed at spaced circumferential locations around the reactor core so that the greatest radial thickness is at the point of highest fluence with lesser thicknesses at adjacent locations where the fluence level is lower. The neutron panels are disposed between the core barrel and the interior of the reactor vessel to maintain radiation exposure to the vessel within acceptable limits.

Owner:WESTINGHOUSE ELECTRIC CORP

Hydrocarbon composition

InactiveUS20110178346A1Hydrocarbon purification/separationLiquid carbonaceous fuelsCarbon numberGram

A hydrocarbon composition is provided containing:at least 0.05 grams of hydrocarbons having boiling point in the range from an initial boiling point of the composition up to 204° C. (400° F.) per gram of the composition;at least 0.1 gram of hydrocarbons having a boiling point in the range from 204° C. up to 260° C. (500° F.) per gram of the composition;at least 0.25 gram of hydrocarbons having a boiling point in the range from 260° C. up to 343° C. per gram of the composition;at least 0.3 gram of hydrocarbons having a boiling point in the range from 343° C. to 538° C. per gram of the composition; andat most 0.03 gram of hydrocarbons having a boiling point of greater than 538° C. per gram of the composition;at least 0.0005 gram of sulfur per gram of the composition, wherein at least 40 wt. % of the sulfur is contained in hydrocarbon compounds having a carbon number of 17 or less as determined by GC-GC sulfur chemiluminescence, where at least 60 wt. % of the sulfur in the sulfur-containing hydrocarbon compounds having a carbon number of 17 or less is contained in benzothiophenic compounds as determined by GC-GC sulfur chemiluminescence.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com